Patents

Literature

157 results about "Galling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

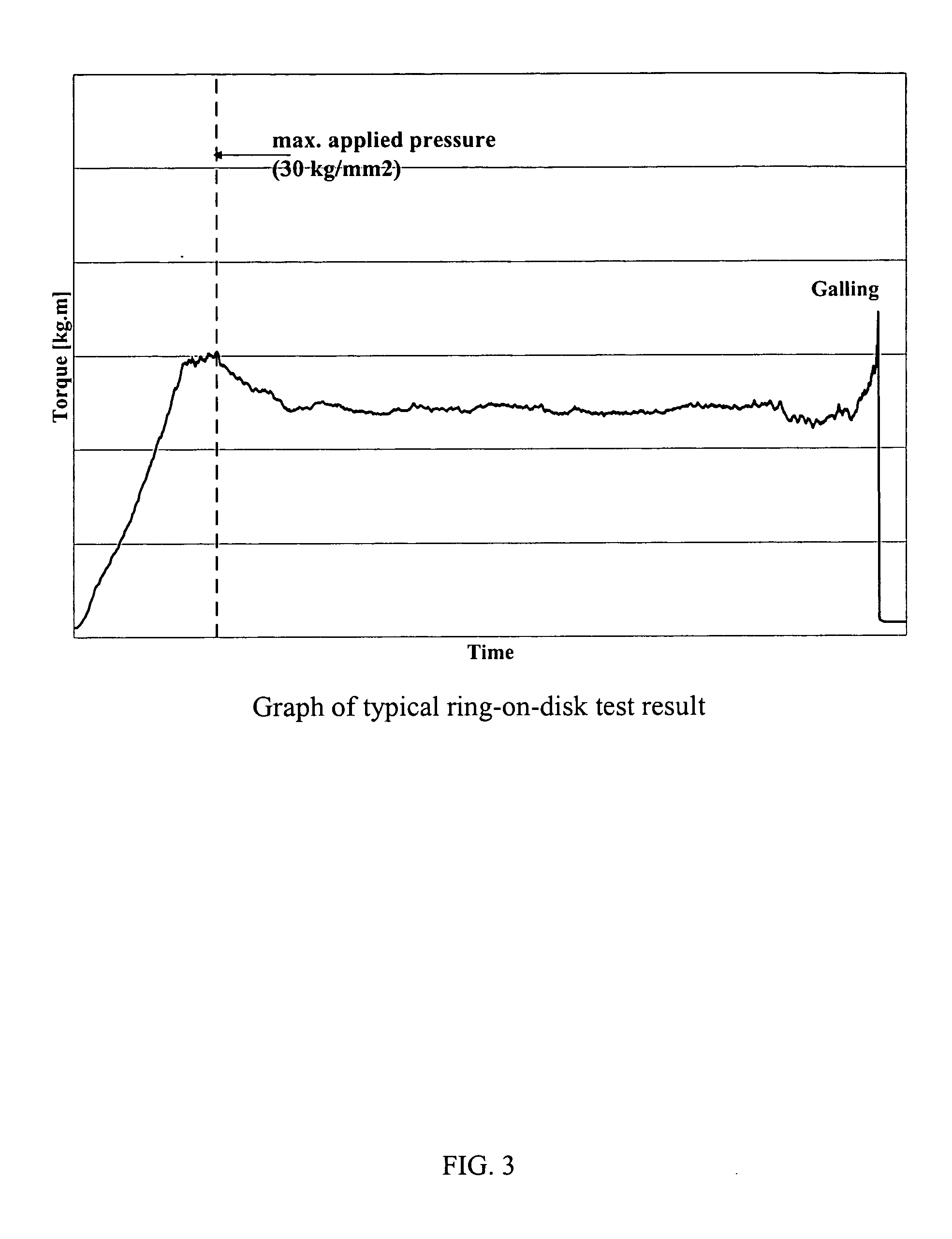

Galling is a form of wear caused by adhesion between sliding surfaces. When a material galls, some of it is pulled with the contacting surface, especially if there is a large amount of force compressing the surfaces together. Galling is caused by a combination of friction and adhesion between the surfaces, followed by slipping and tearing of crystal structure beneath the surface. This will generally leave some material stuck or even friction welded to the adjacent surface, whereas the galled material may appear gouged with balled-up or torn lumps of material stuck to its surface.

Anodized locking plate components

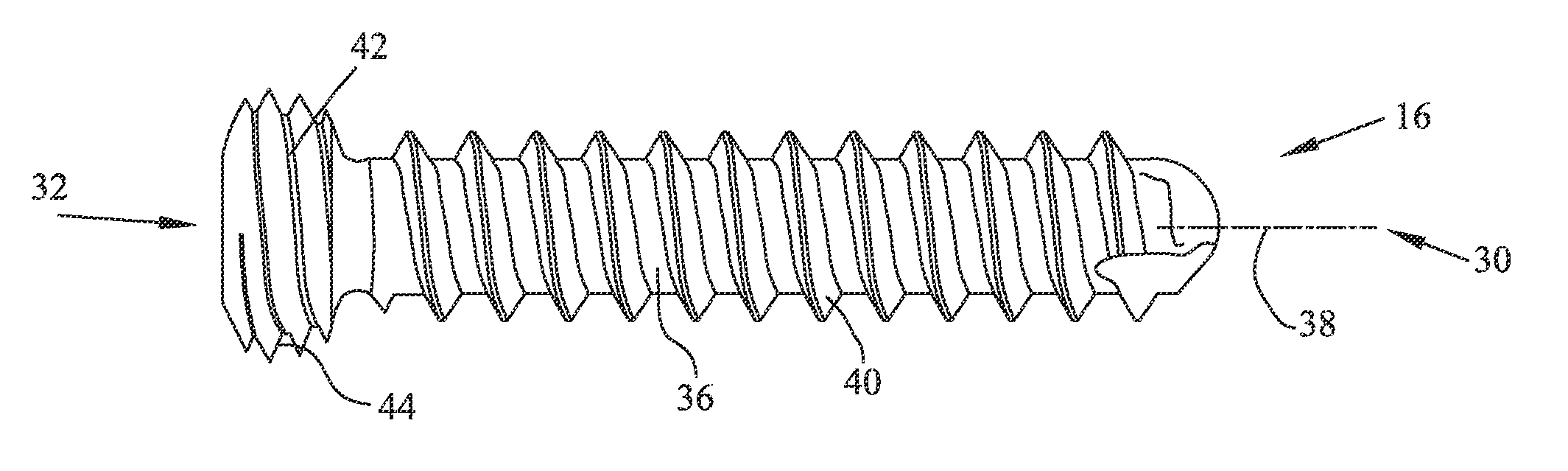

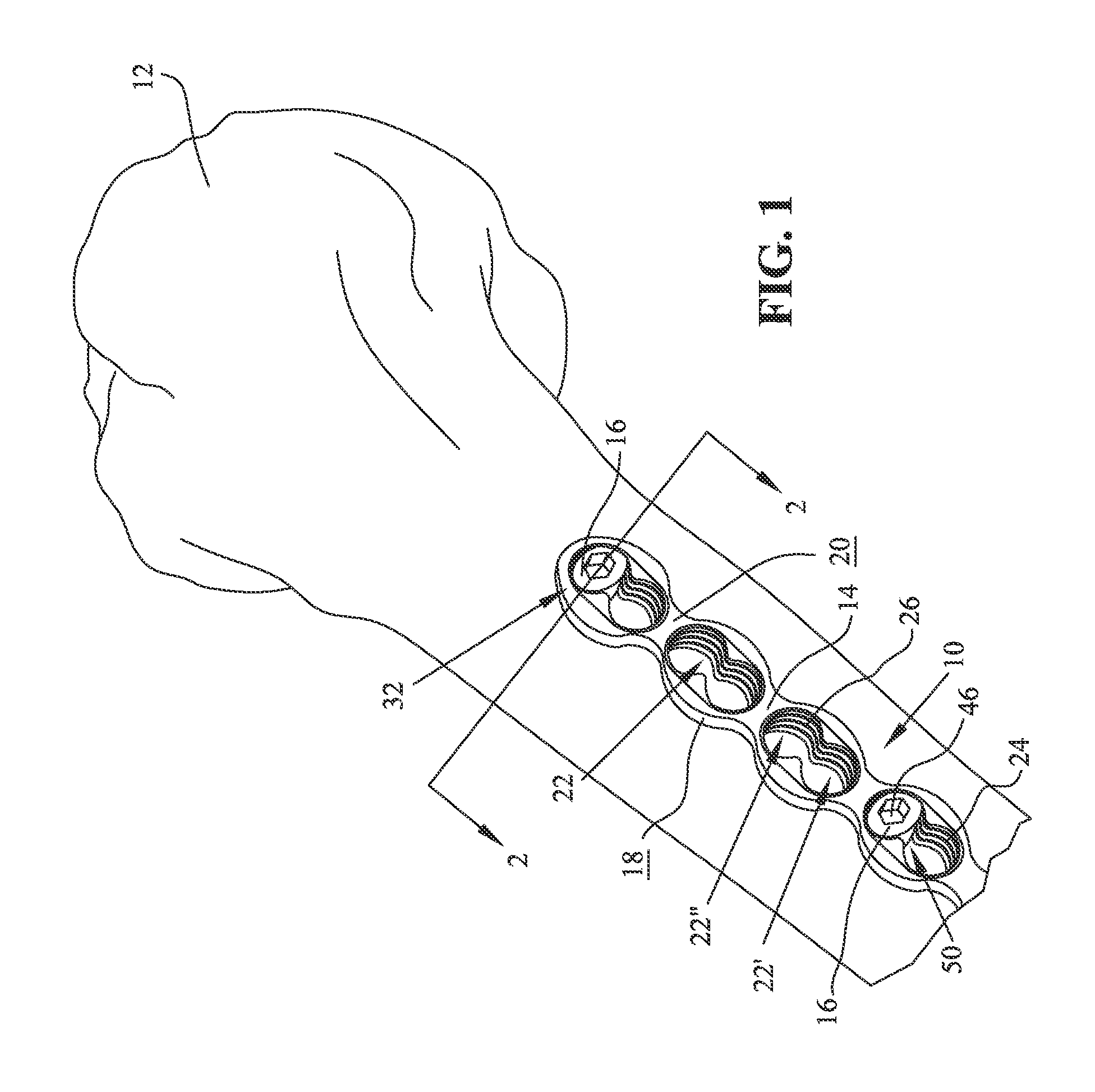

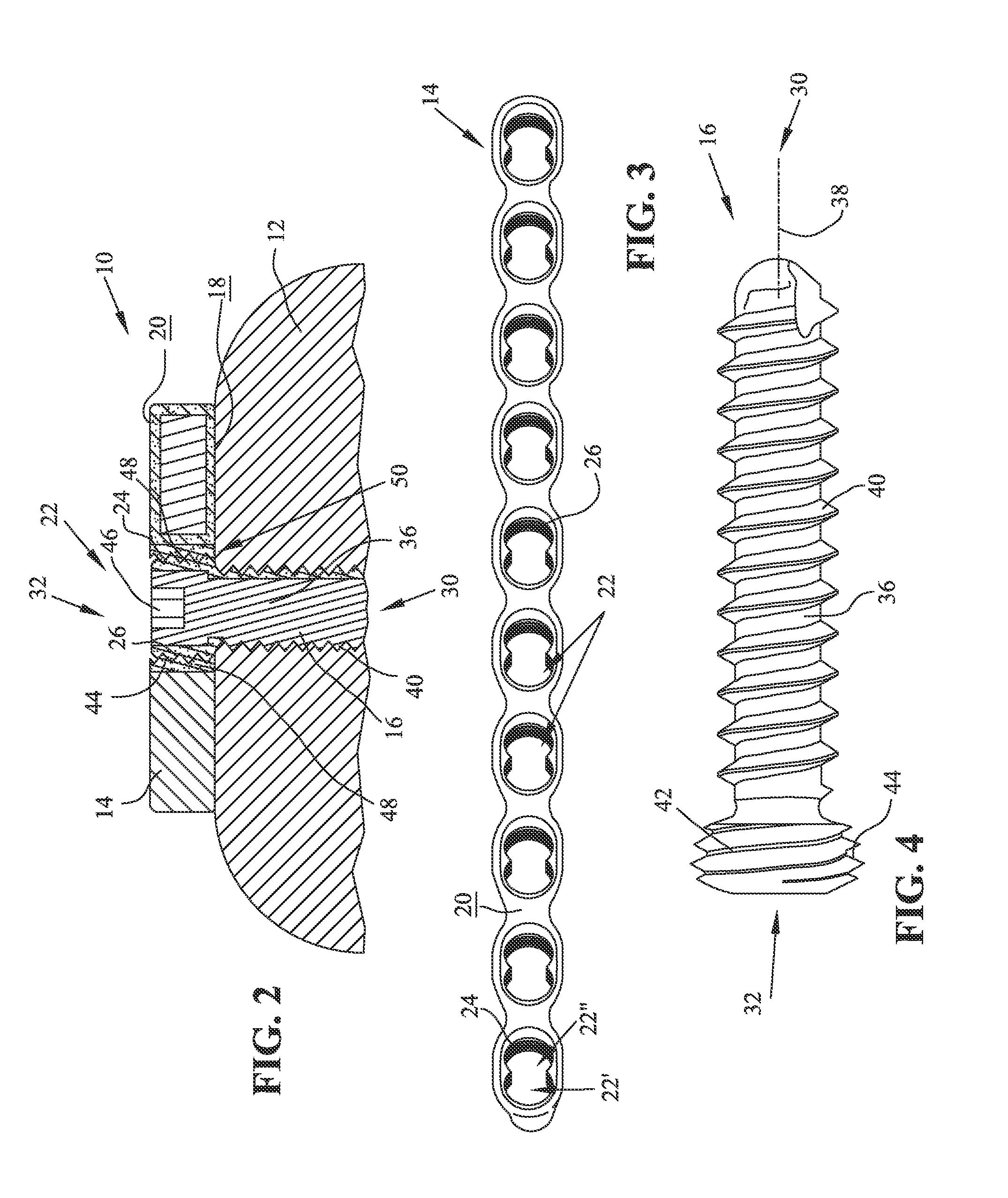

InactiveUS20100057086A1Minimize gallingMinimize cold weldingSuture equipmentsLigamentsGallingPlastic surgery

An orthopedic assembly including a plate and a locking screw that interlocks with the plate to secure the plate to a bone while the bone heals. To minimize galling or cold welding within an engagement region of the orthopedic assembly, an anodized coating, such as a Type II anodized coating, may be applied to both engaging surfaces of the engagement region. To avoid having to mask portions of the plate and the locking screw outside of the engagement region during the coating process, the anodized coating may be applied to the entire plate and the entire locking screw.

Owner:ZIMMER INC

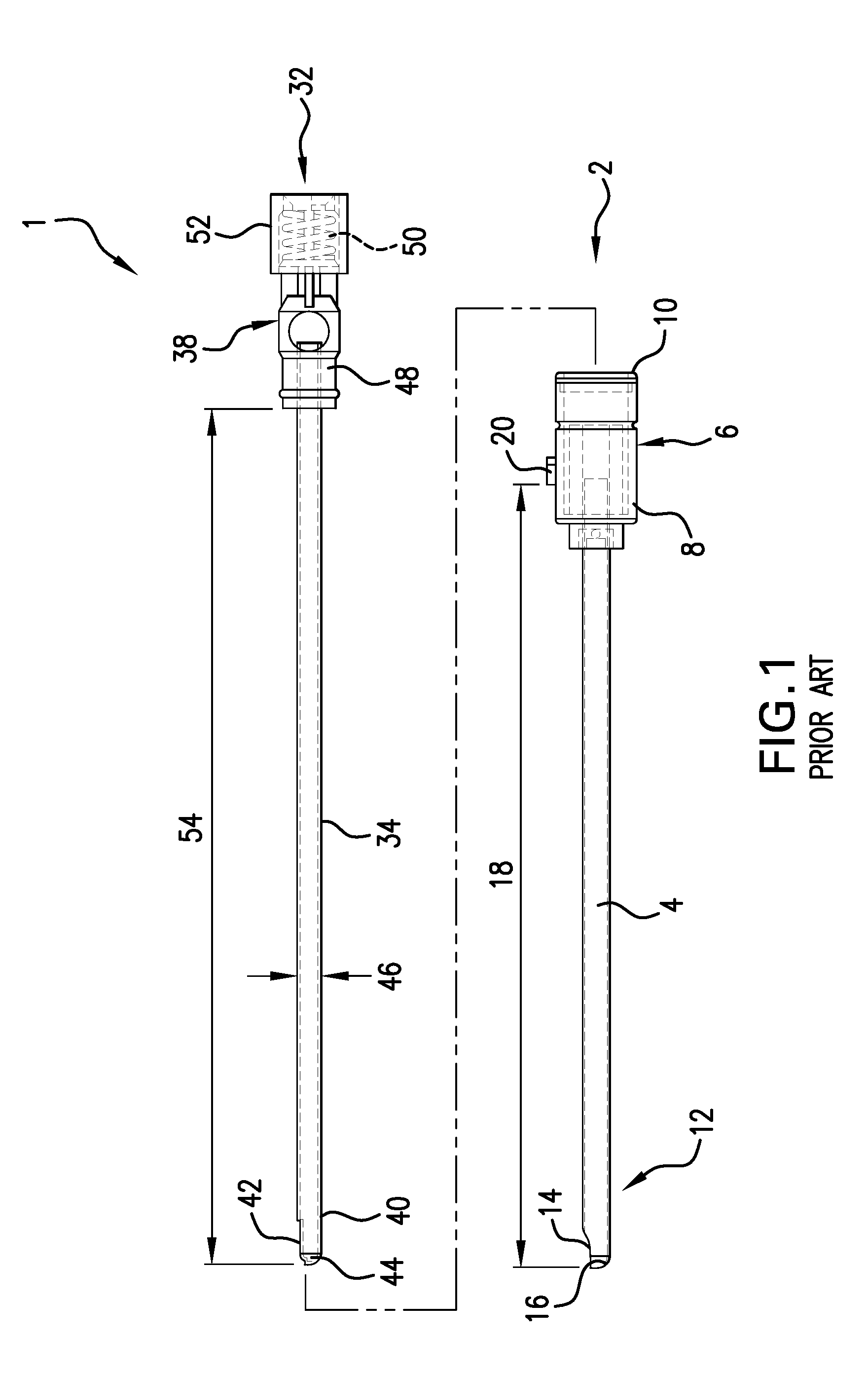

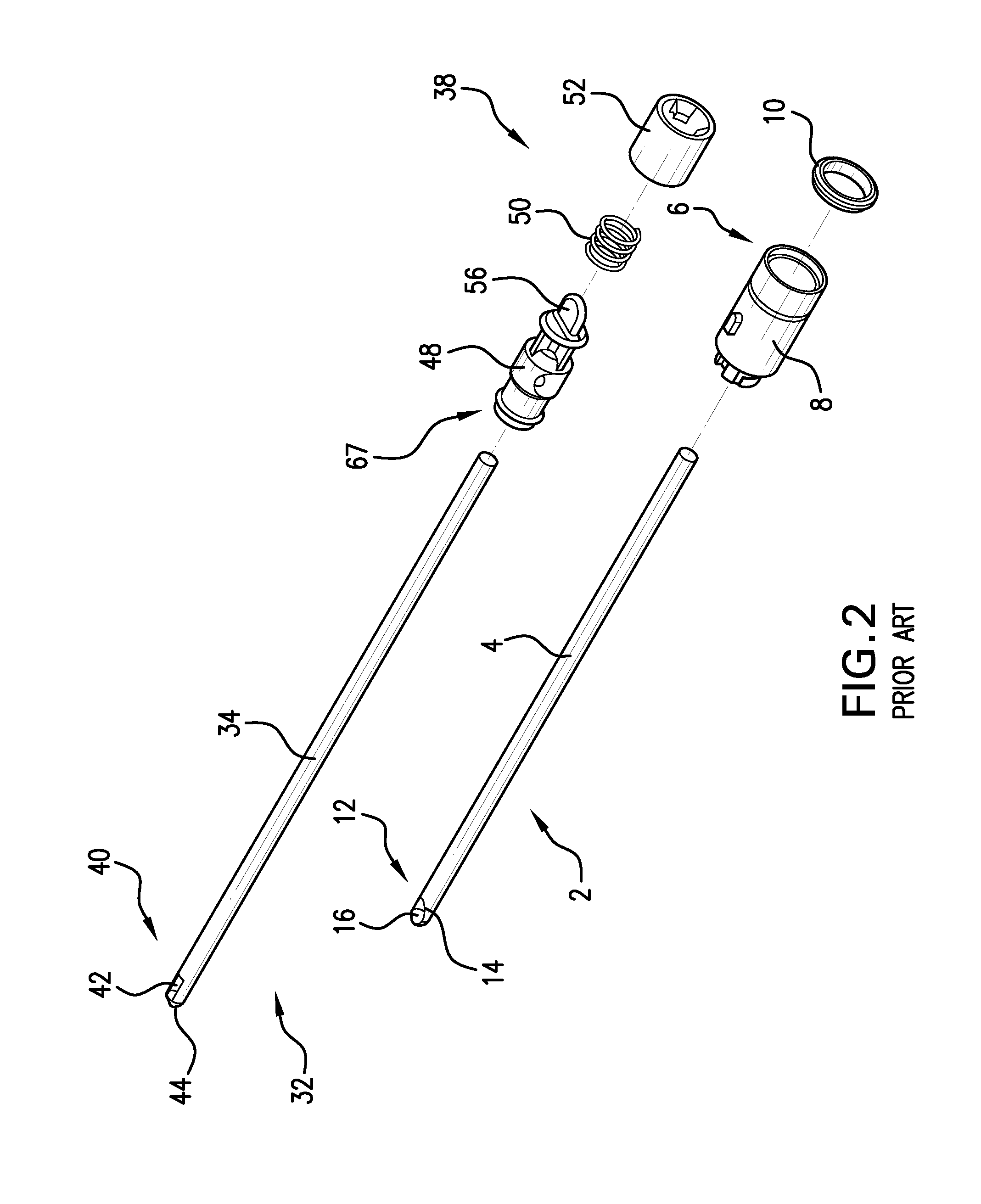

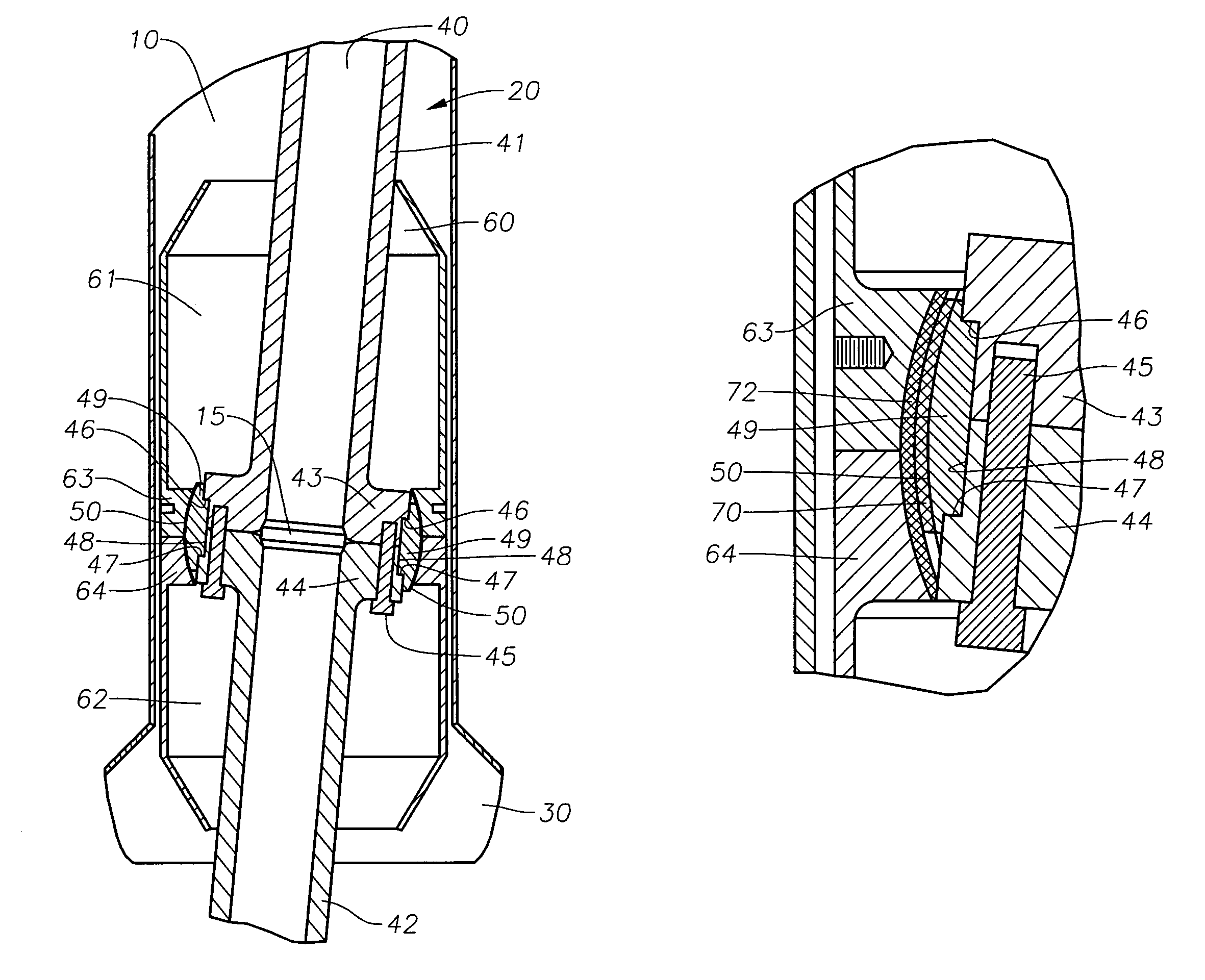

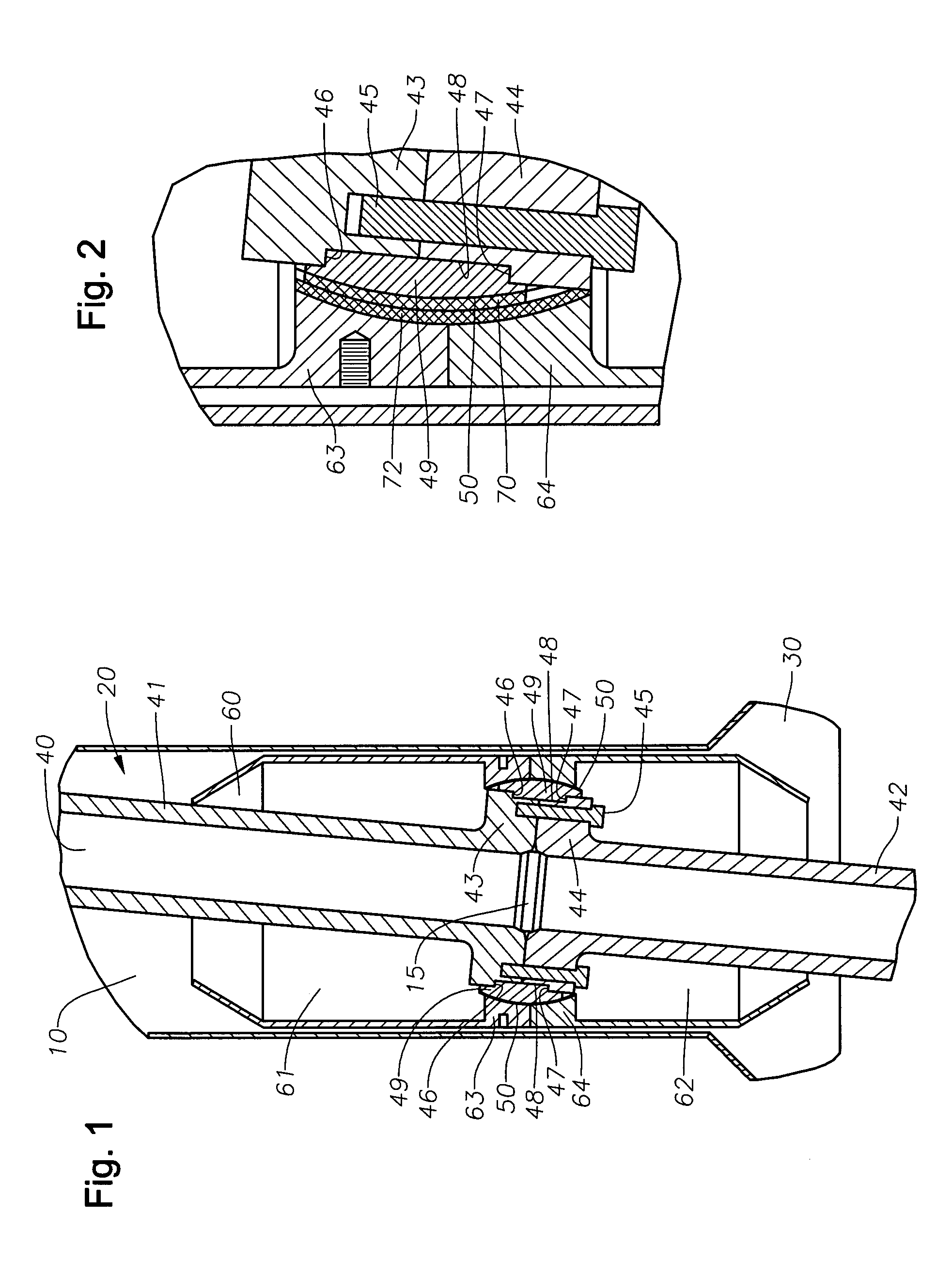

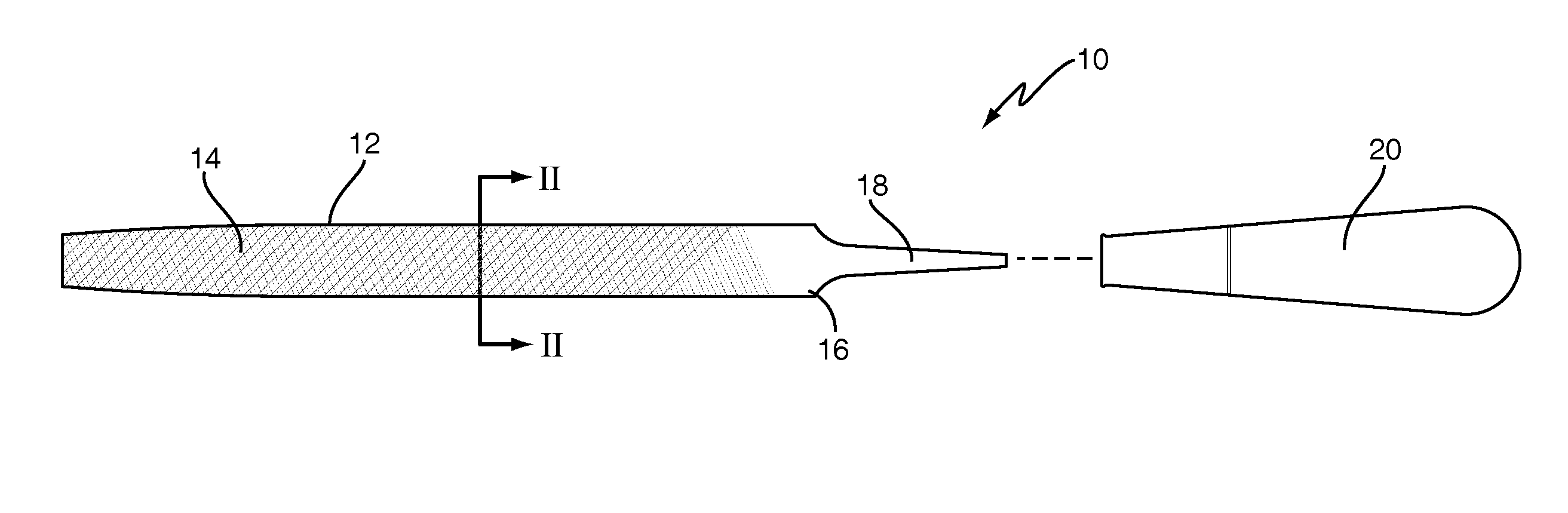

Endoscopic cutting instruments having improved cutting efficiency and reduced manufacturing costs

InactiveUS20090048485A1Improve cutting efficiencyReduce manufacturing costEndoscopesEndoscopic cutting instrumentsGallingEngineering

The present invention is directed to improving the cutting efficiency and reducing the manufacturing costs associated with endoscopic cutting instruments by eliminating the distal bearing surfaces or providing means for making the contact at the distal bearing intermittent so that surfaces do no undergo high localized heat and galling. In one embodiment, this goal is achieved by modifying or removing the axial constraints on the inner sliding member that are characteristic of conventional endoscopic shavers. In another embodiment, the improved cutting efficiency and reduced manufacturing cost is achieved by eliminating a closed end characteristic of conventional endoscopic shavers (e.g., removing the closed end of either the inner sliding member or the outer sliding member to thereby eliminate the associated bearing surface formed therebetween).

Owner:HANSHI

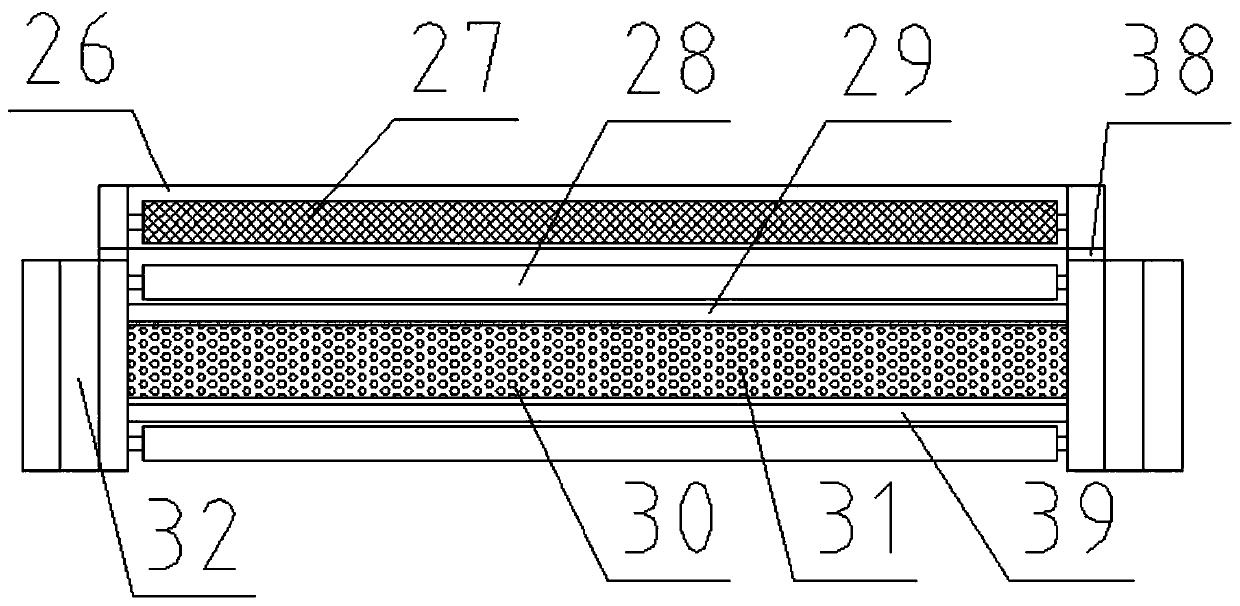

High-count smooth double-faced wool and production process thereof

The invention discloses high-count smooth double-faced wool which is double-layer texture structure cloth with upper portion and lower portion connected. The front texture of the high-count smooth double-faced wool is 2 / 2 twill, and the back texture of the cloth is 2 / 2 herringbone. A production process of the high-count smooth double-faced wool includes: respectively performing loose fiber dying on wool fibers, dacron fibers and modal fibers, then performing full sliver mixing, and spinning the mixed fibers into 20 / 1 and 24 / 1 yarns with an open-end spinning mode; weaving the high-count smooth double-faced wool cloth on a rapier loom through yarns; and performing blank checking, mending, reviewing, hemming, wool washing, dehydration, milling, wool jigging, dehydration, rotary width drying, wool steaming, fluffing, shearing, squeezing, burring galling, rolling, drying, polishing, polishing shearing, wool steaming and finish inspection on the weaved cloth to manufacture finished products. The high-count smooth double-faced wool is full in hand feeling, elastic, natural and gentle in gloss, and smooth and ordered in villus, cannot cause bottom explosion and depilation, and is rich and smooth in hand feeling and suitable for manufacturing high-grade clothing.

Owner:苏州优布纺织科技有限公司

Method of using intrinsically conductive polymers with inherent lubricating properties, and a composition having an intrinsically conductive polymer, for protecting metal surfaces from galling and corrosion

InactiveUS20050176592A1Increase pressureIncrease frictionLiquid surface applicatorsOrganic chemistryGallingConductive polymer

A method for protecting a metal surface from galling and corrosion includes a step of providing a protective dry film on the metal surface. The film includes a solid lubricant and a conducting polymer, the conducting polymer having lubricant properties and being capable of binding the solid lubricant to the metal surface. Threaded metal joint surfaces coated with the film are capable of resisting galling under high pressure and high torque conditions, even after several fastening and unfastening operations or over a long period of time. Protection from corrosion is also provided by the film. The method and film are economical in that only a single layer of protective compound need be applied in order to provide metal surfaces with both lubrication and protection against corrosion, and problems such as removal or leakage, which are associated with protective compounds that use oils, are avoided. Additionally, the dry film is advantageous because it does not contain heavy metals that are harmful to the environment.

Owner:TENARIS CONNECTIONS

Treating agent for forming a protective coating and metallic materials with a protective coating

InactiveUS7651556B2Maintain good propertiesReduce complicated treatment solution controlAlkali metal silicate coatingsPretreated surfacesGallingMetallic materials

A protective coating is formed on a metallic material surface by applying a treating agent comprising water, an alkali silicate, and, optionally, a lubricating component to the surface and drying the treating agent. The coating film thereby formed has excellent anti-galling and rust preventive properties. If a lubricating component is present, the coating film also has excellent self-lubricating properties.

Owner:HENKEL KGAA

Laser cladding repairing method of piston rod

InactiveCN102166702AExtended service lifeBalanced performanceMetallic material coating processesForeign matterGalling

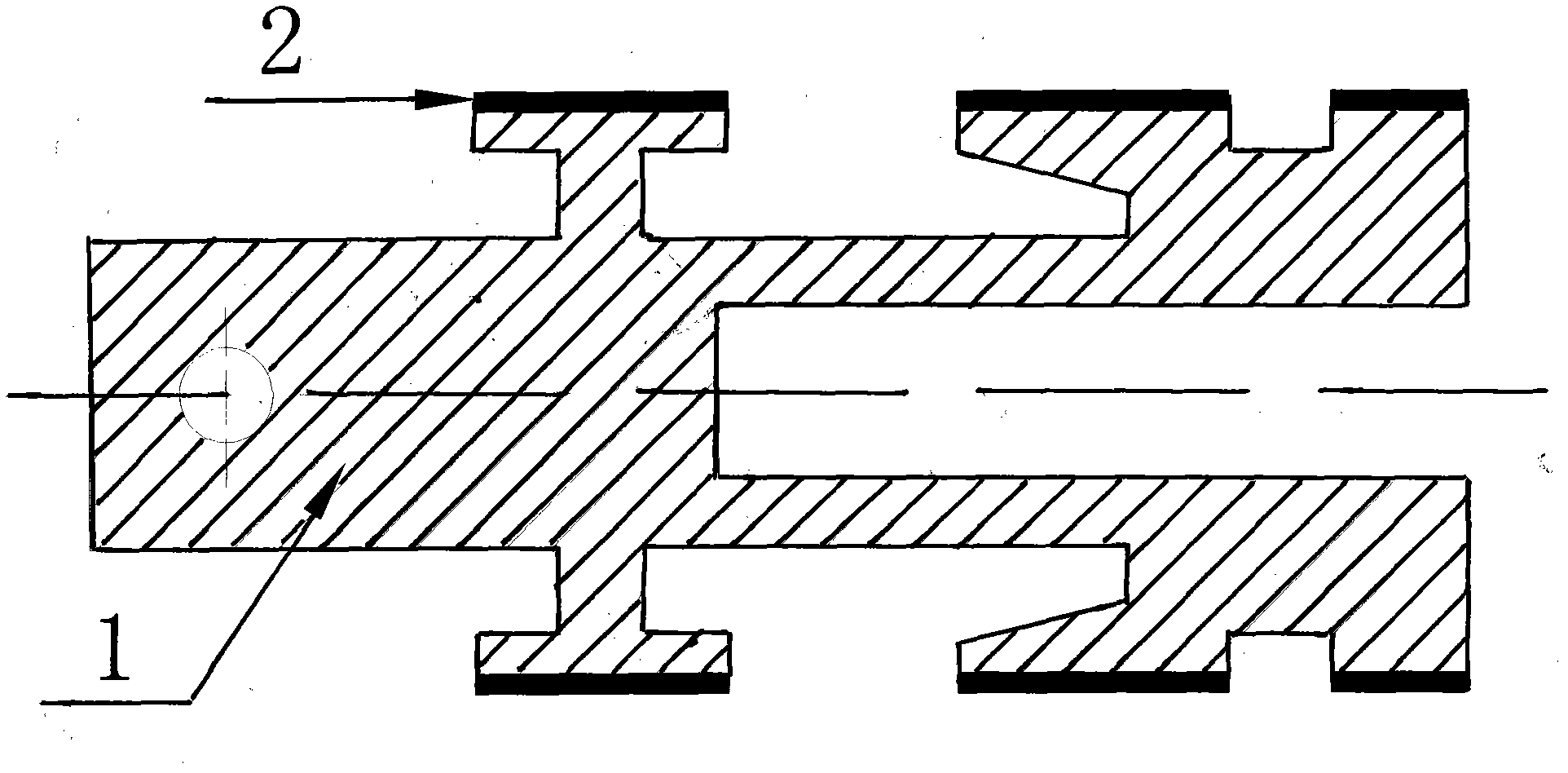

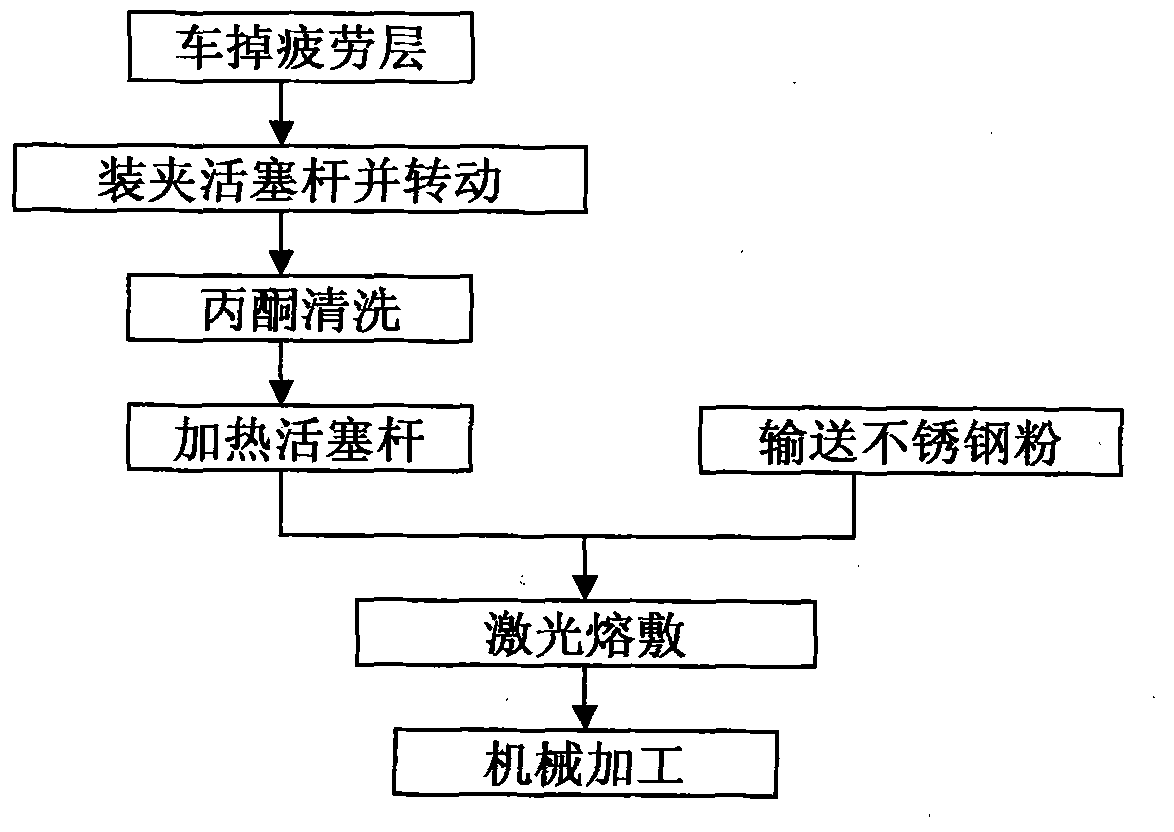

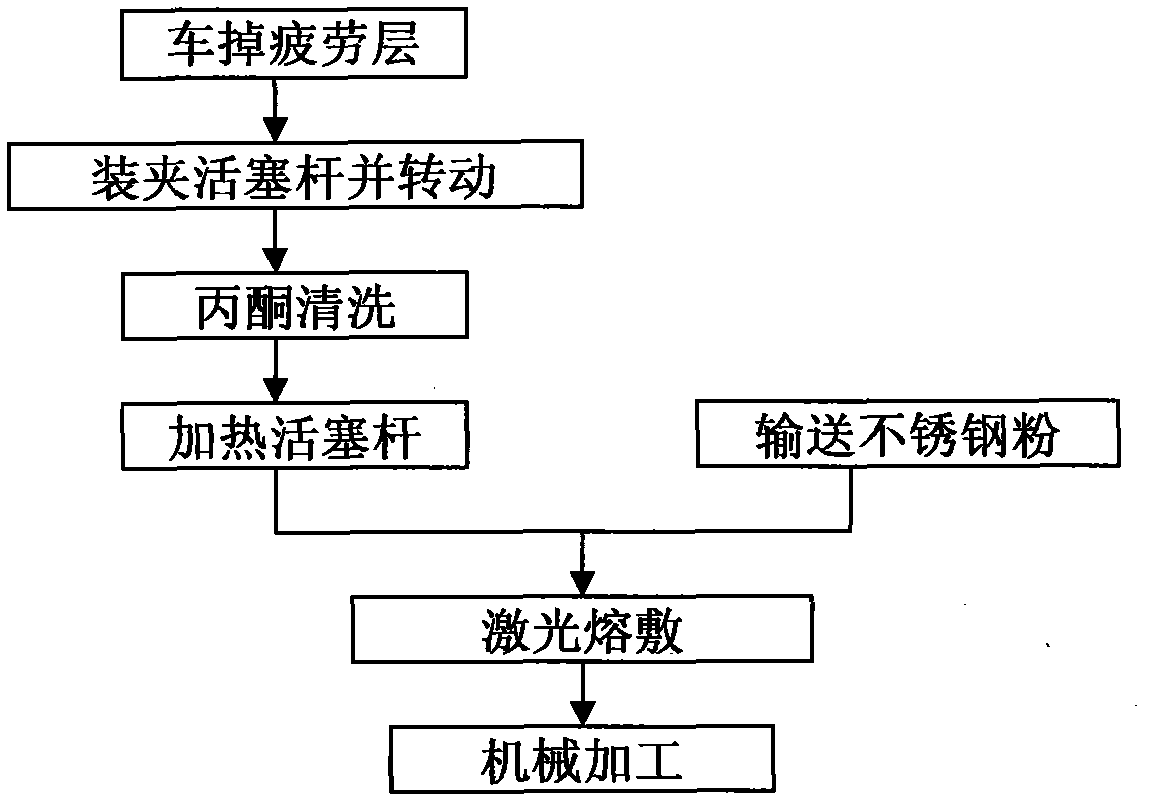

The invention discloses a laser cladding repairing method of a piston rod. The process is realized by the following steps: removing a 0.5-2mm body metal fatigue layer on the working surface of the piston rod by utilizing a lathe; clamping a workpiece; rotating the workpiece in the linear velocity of 400-700mm / min; cleaning grease stains and impurities on the surface by acetone; heating the workpiece to 40-100 DEG C; laser cladding a layer of stainless steel to be used as an antiwear anticorrosion surface layer in 3.5KW power and 3mm bandwidth; and finally mechanically processing the laser cladding layer to achieve the use size specification of the piston rod. The laser cladding repairing method has the advantages of not only realizing the repairing of the old hydrocylinder piston rod, reducing the rejection rate of spare parts and saving the production cost, but also leading the repaired hydrocylinder piston rod to have longer service life and balancer operation performance, and avoiding the use problems that the galling appears on the working surface of the piston rod caused by the reason that the cooling lubricating oil is insufficient or foreign matters enter the cylinder, and hydraulic oil leaks, and the like.

Owner:KUNMING UNIV OF SCI & TECH

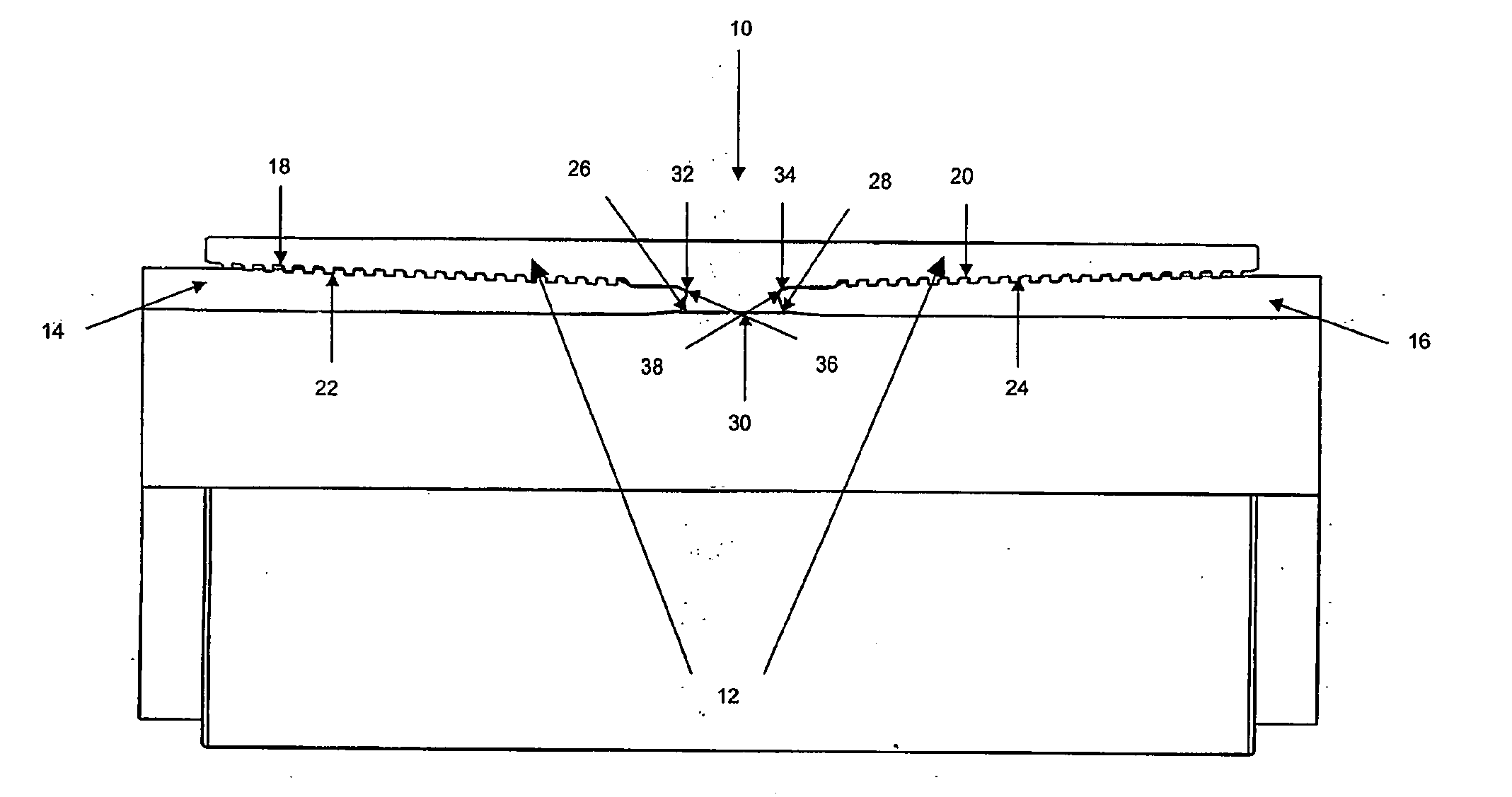

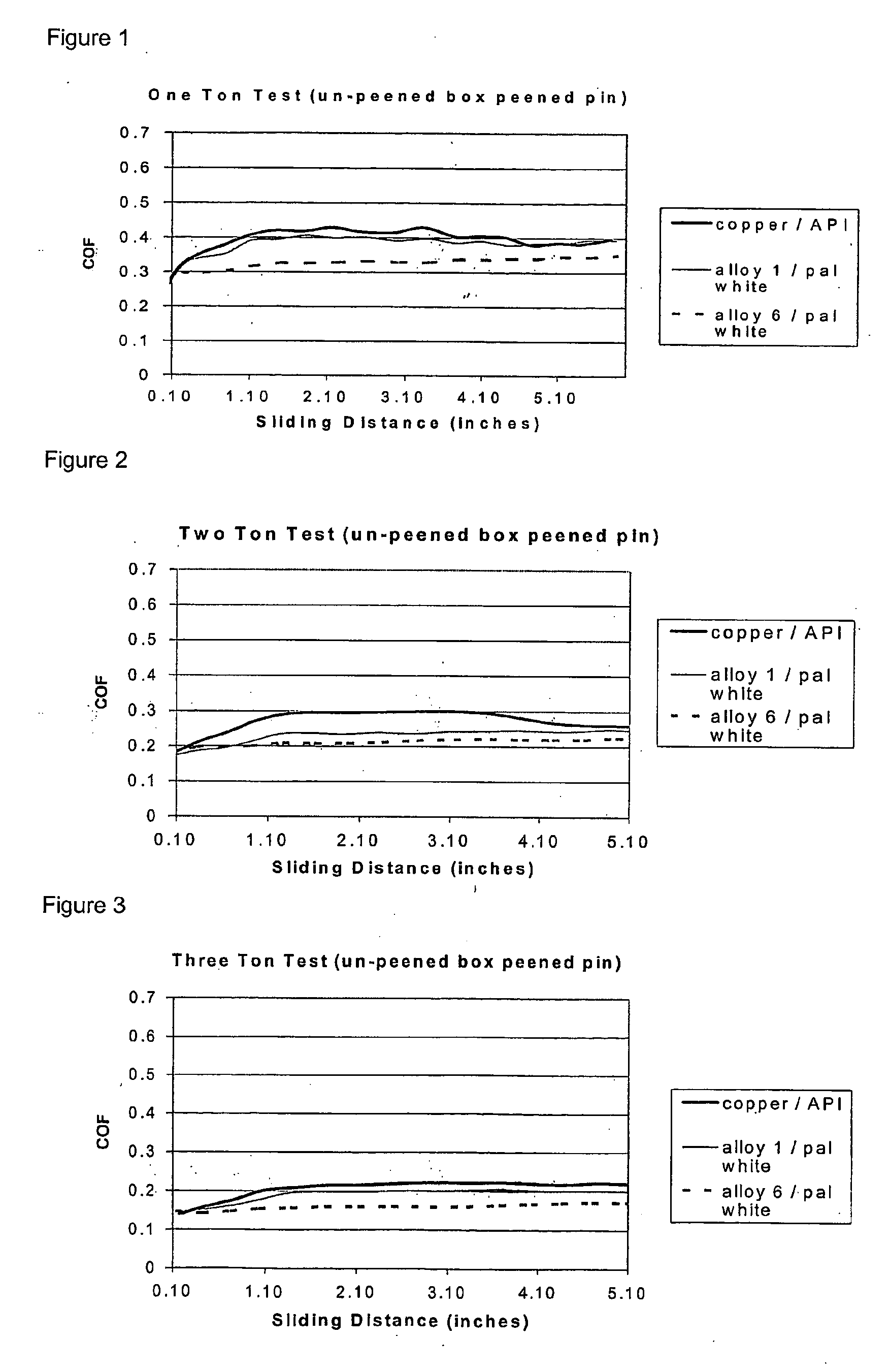

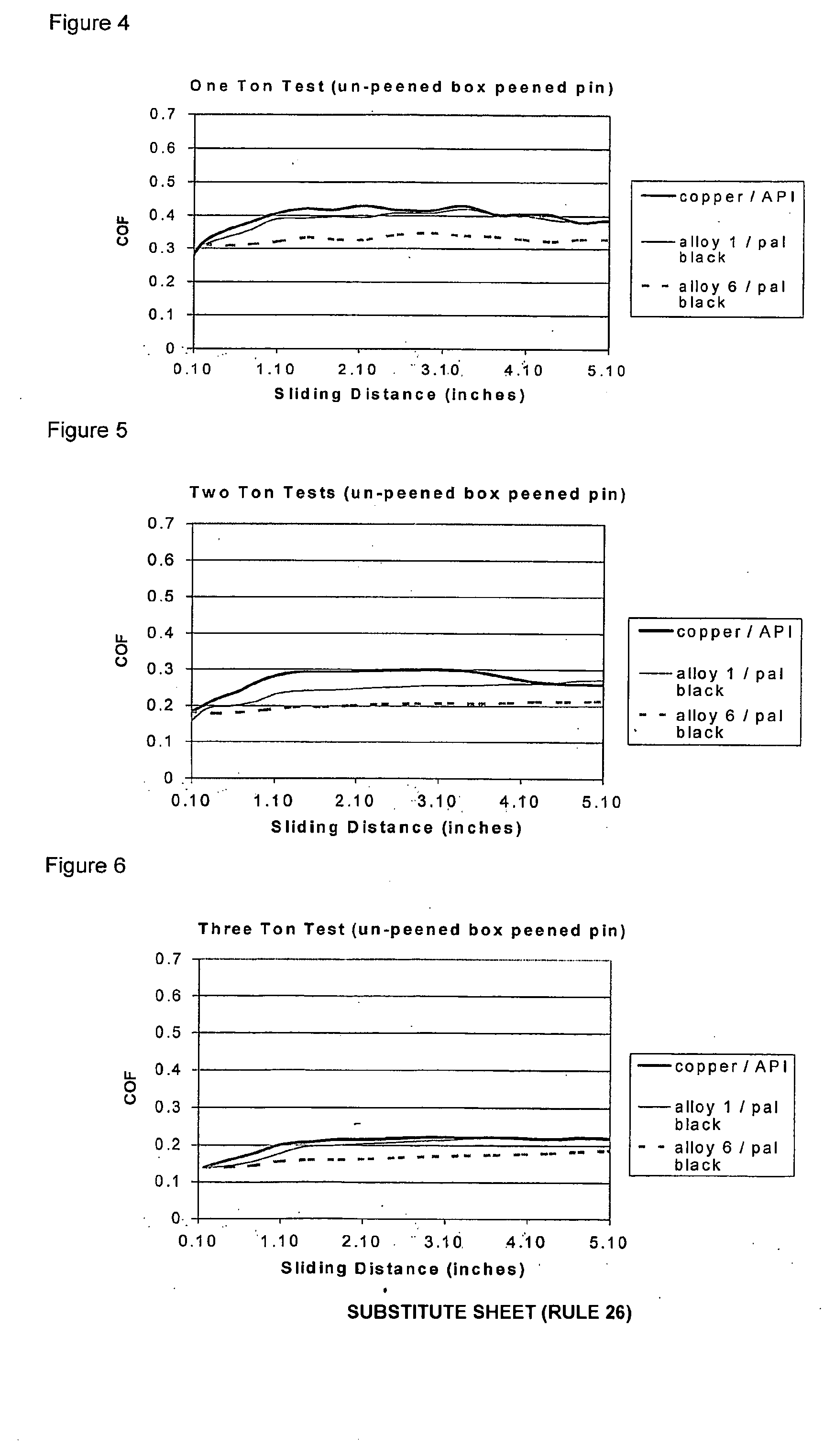

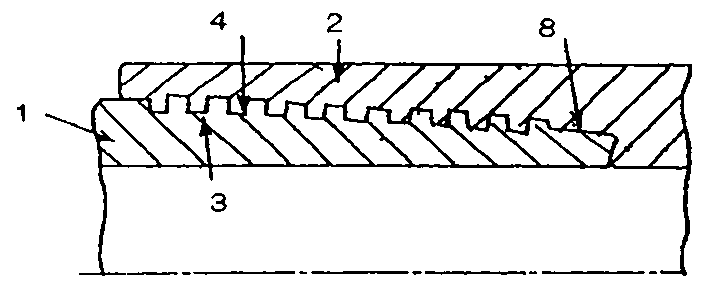

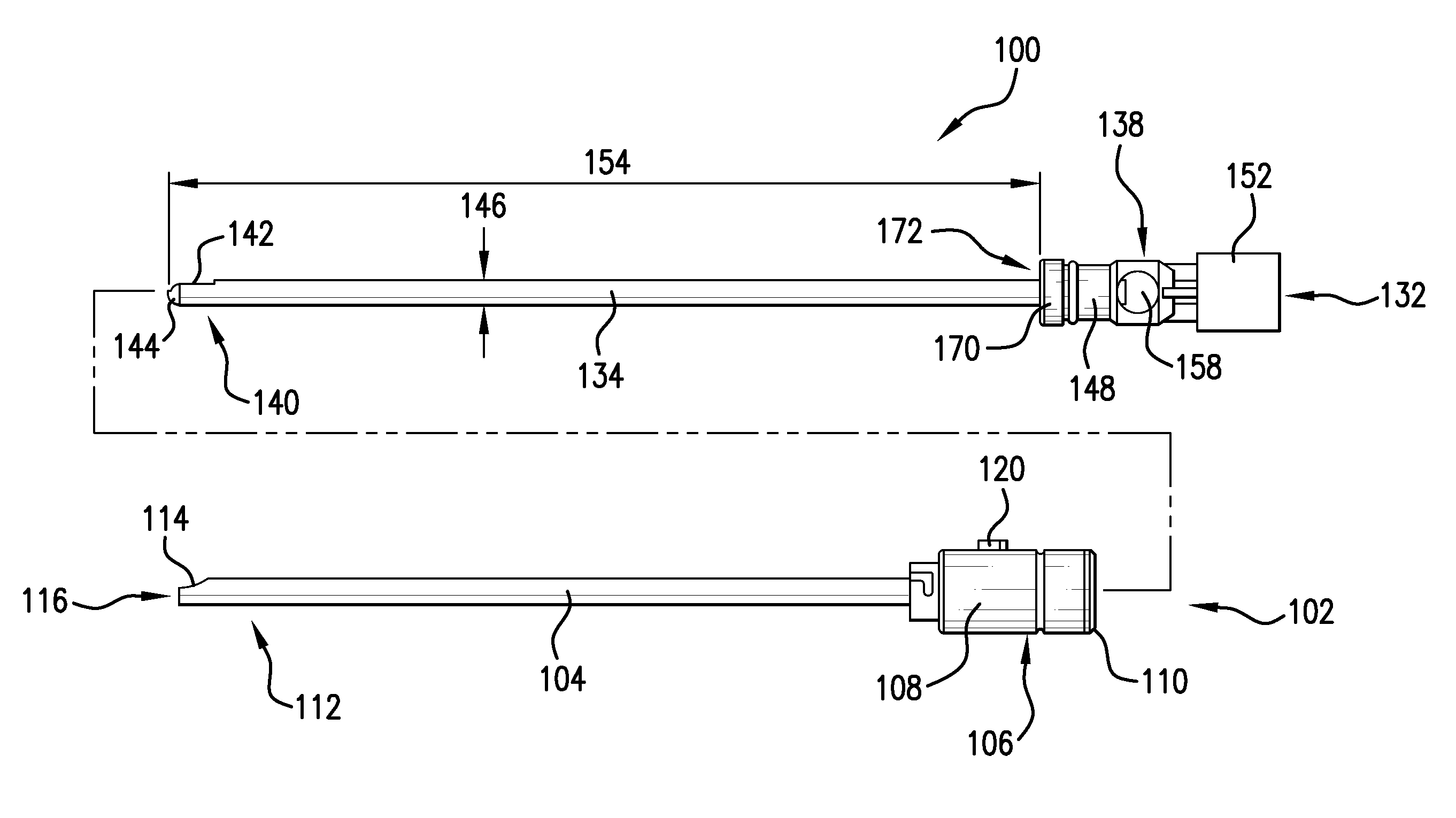

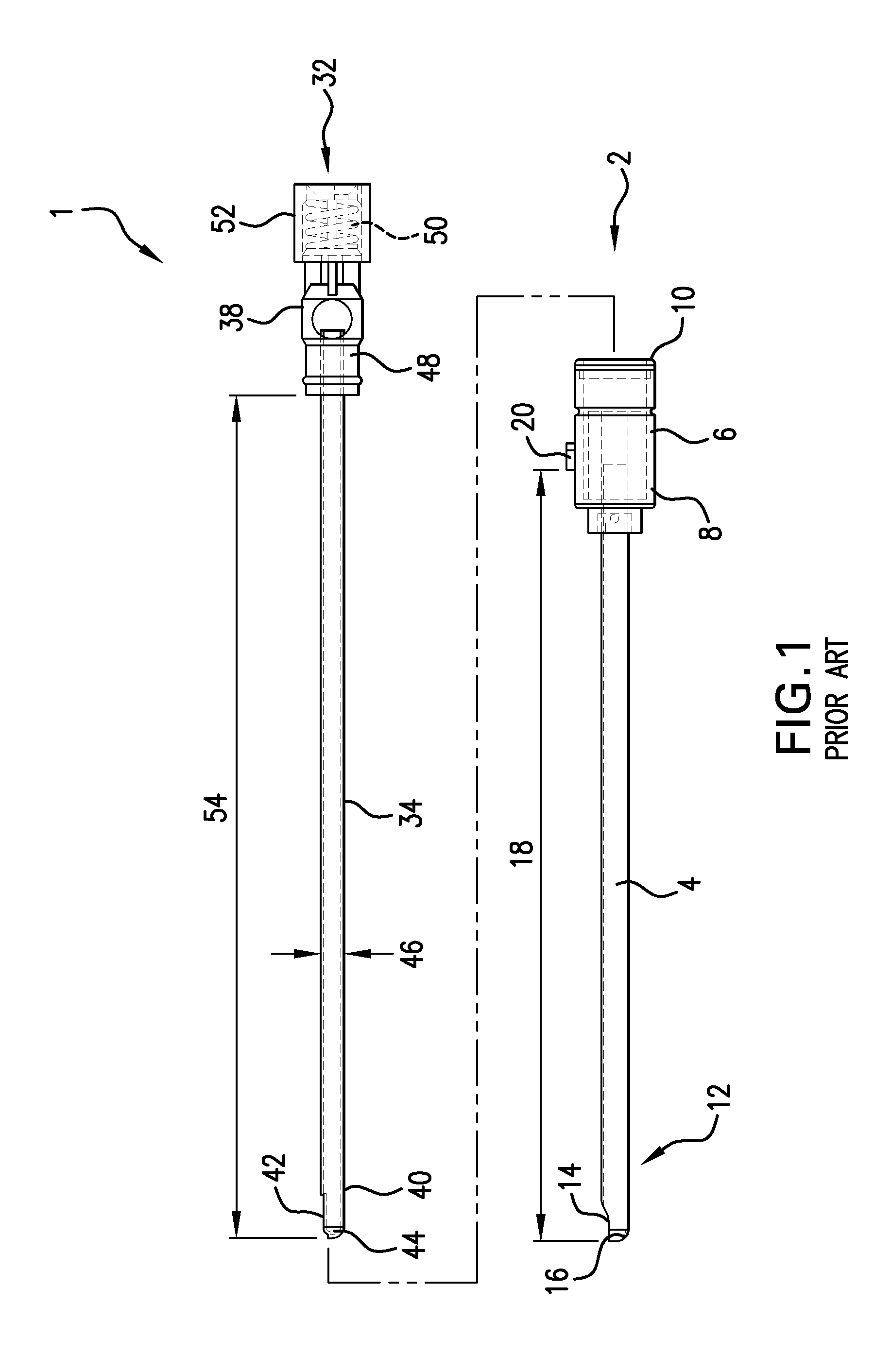

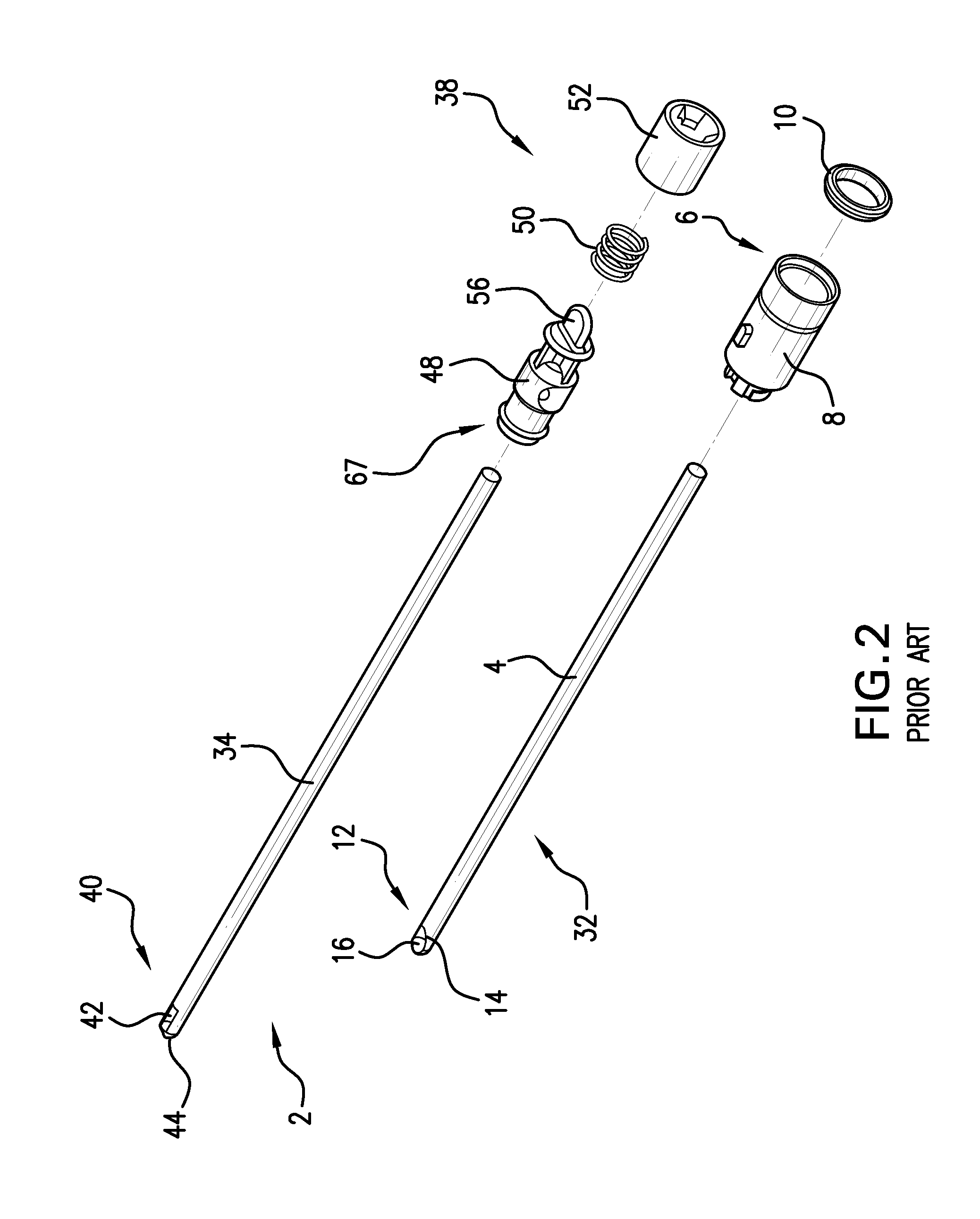

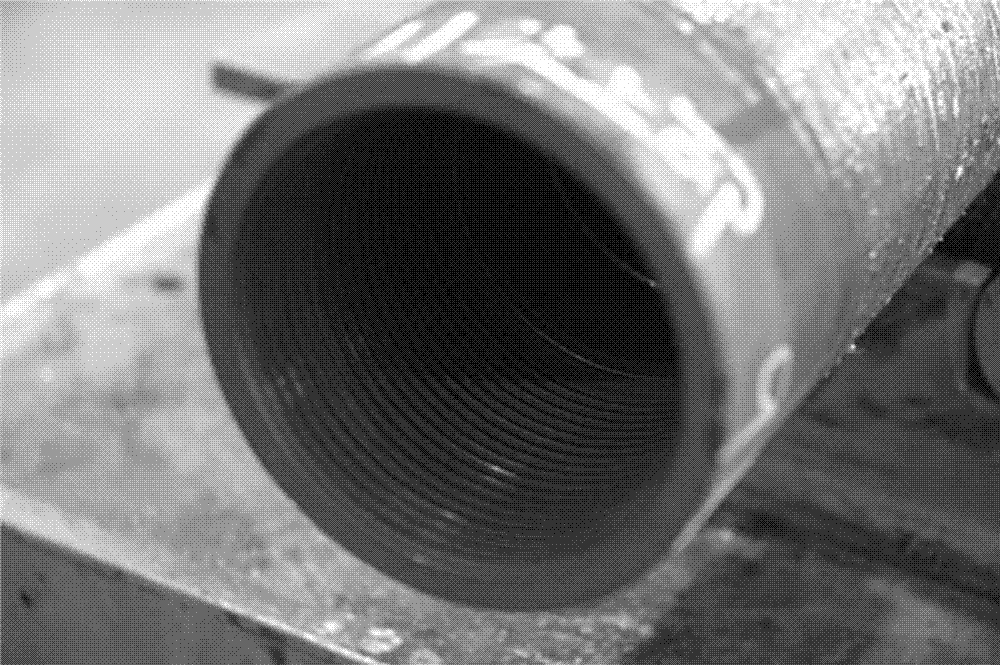

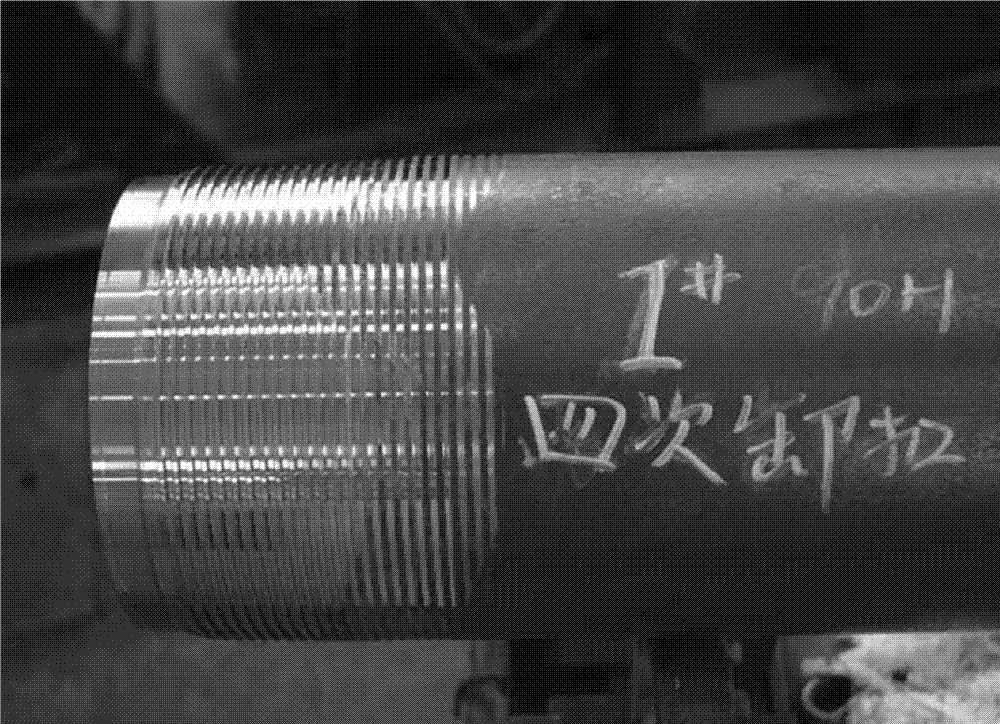

Tubular member having an anti-galling coating

ActiveUS20050118364A1Improved metal-metal seal connectionReinforced Sealed ConnectionRecord information storagePipe elementsGallingAlloy

A tubular member 12 having an internal and / or external metal thread 18, 20 at one end thereof, at least part of the thread 18, 20 being coated with an alloy of copper and tin, said alloy containing 5 wt % to 95 wt % copper. The tubular member 10 can be combined with another tubular member 14, 16 to provide a threaded connection 10 having improved galling resistance.

Owner:JFE STEEL CORP

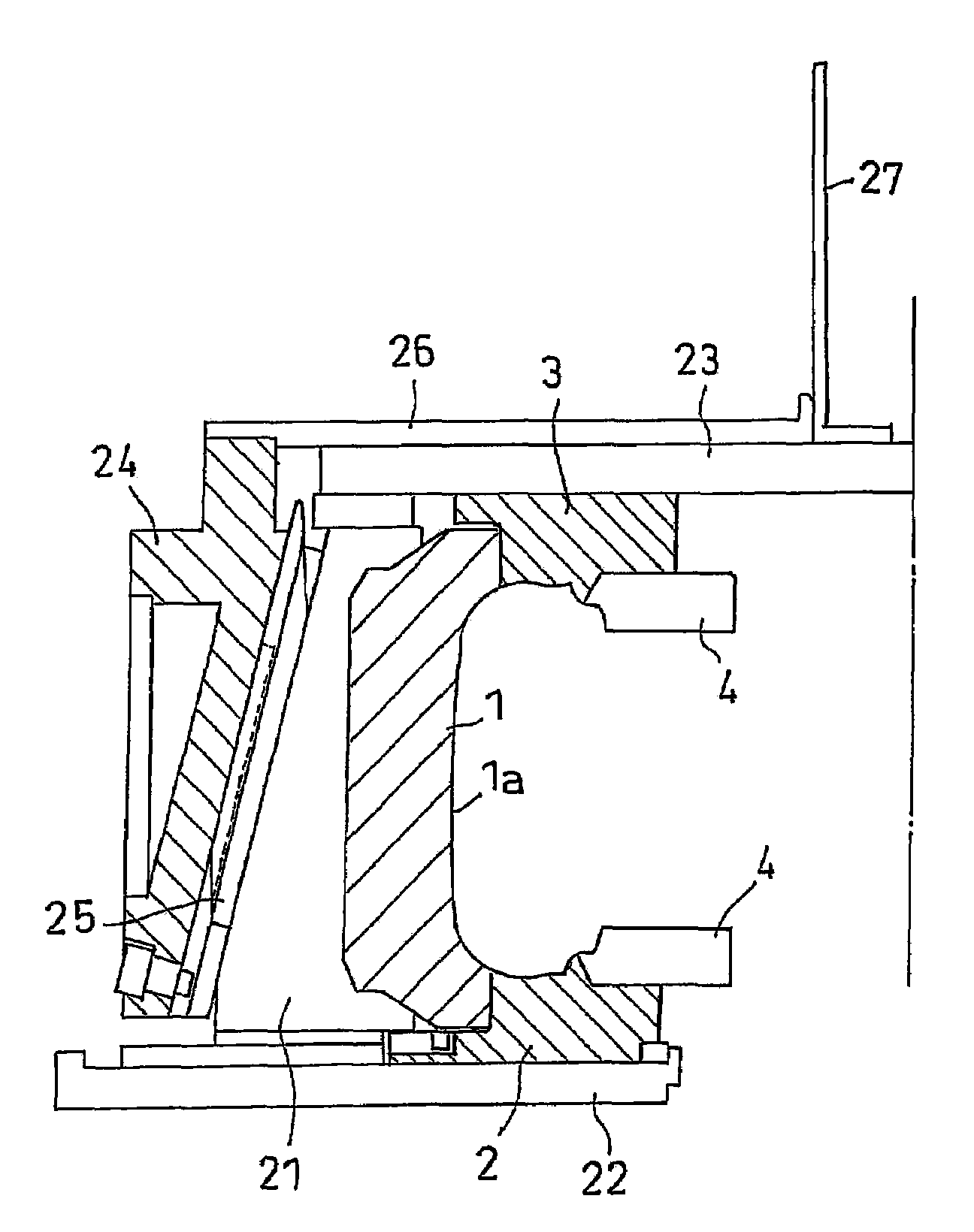

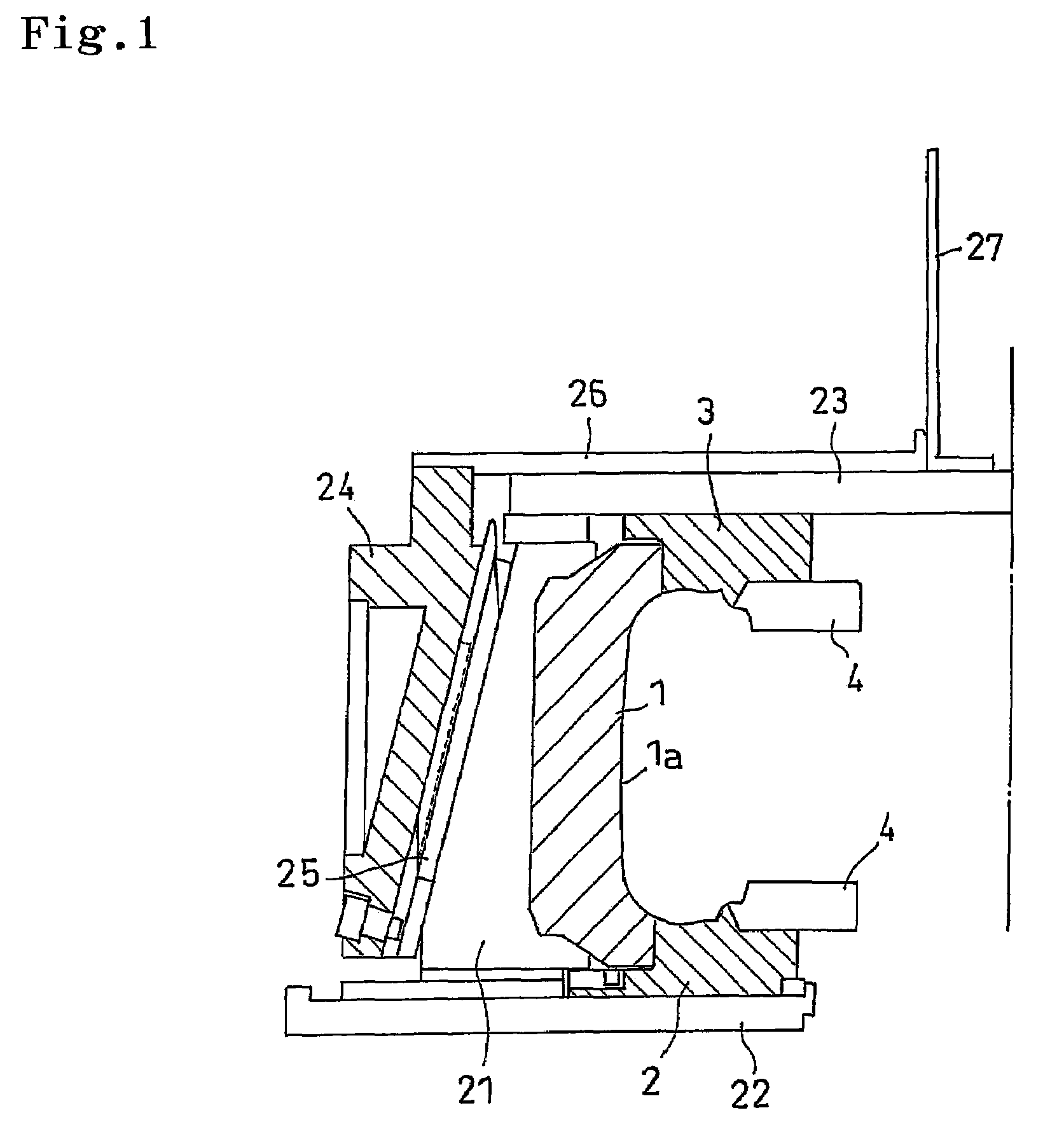

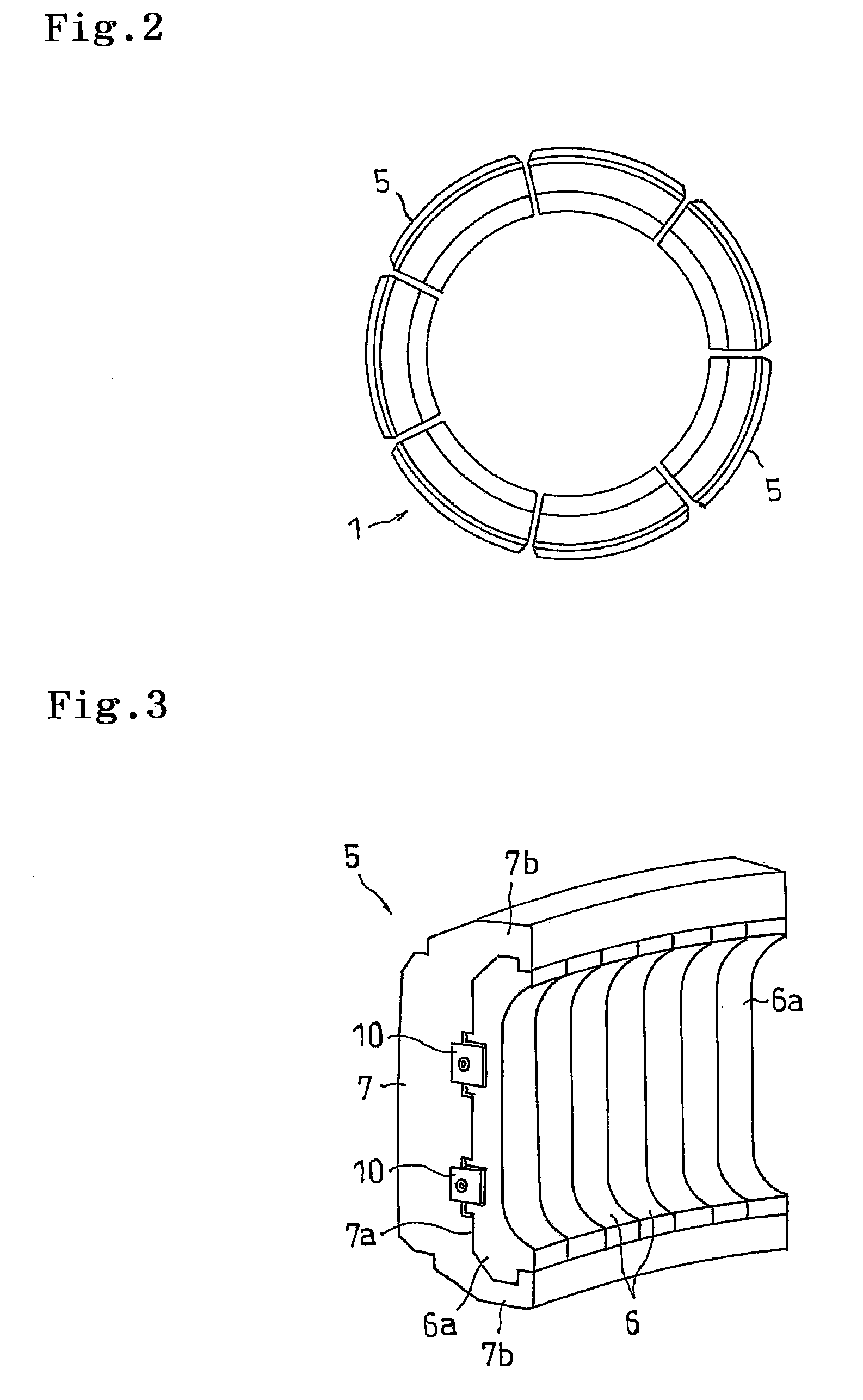

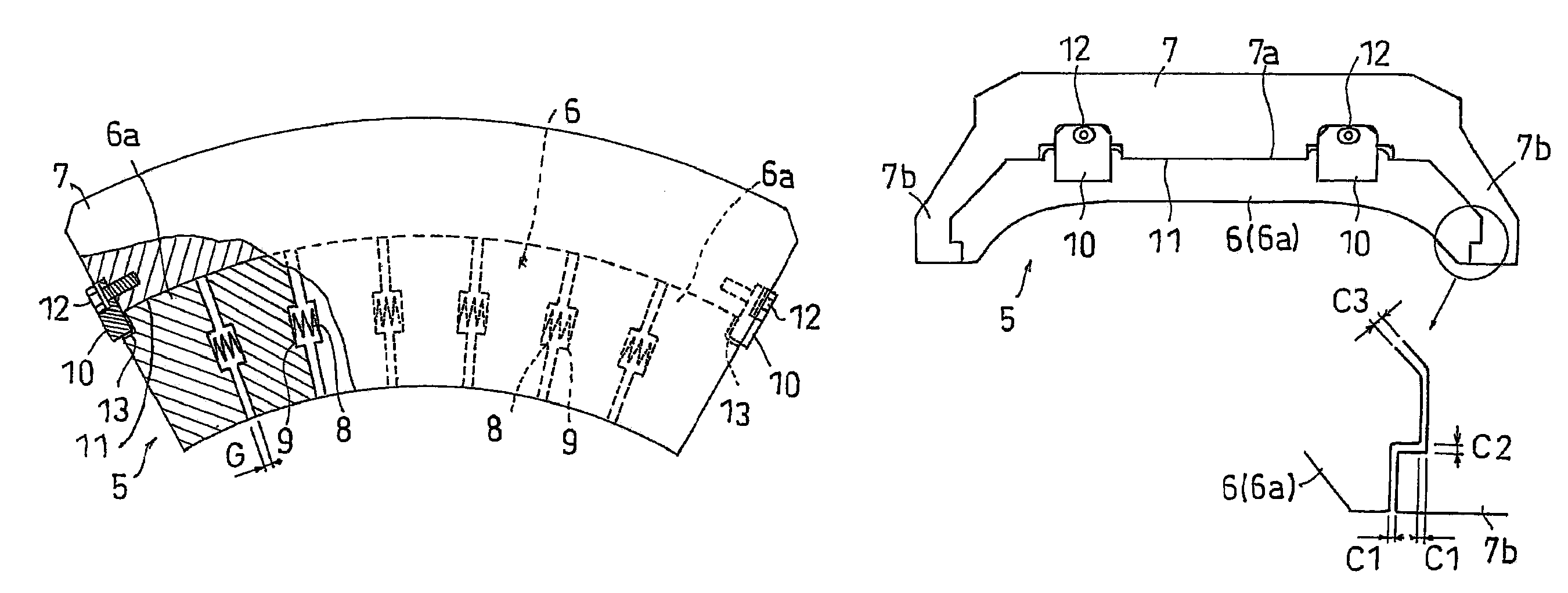

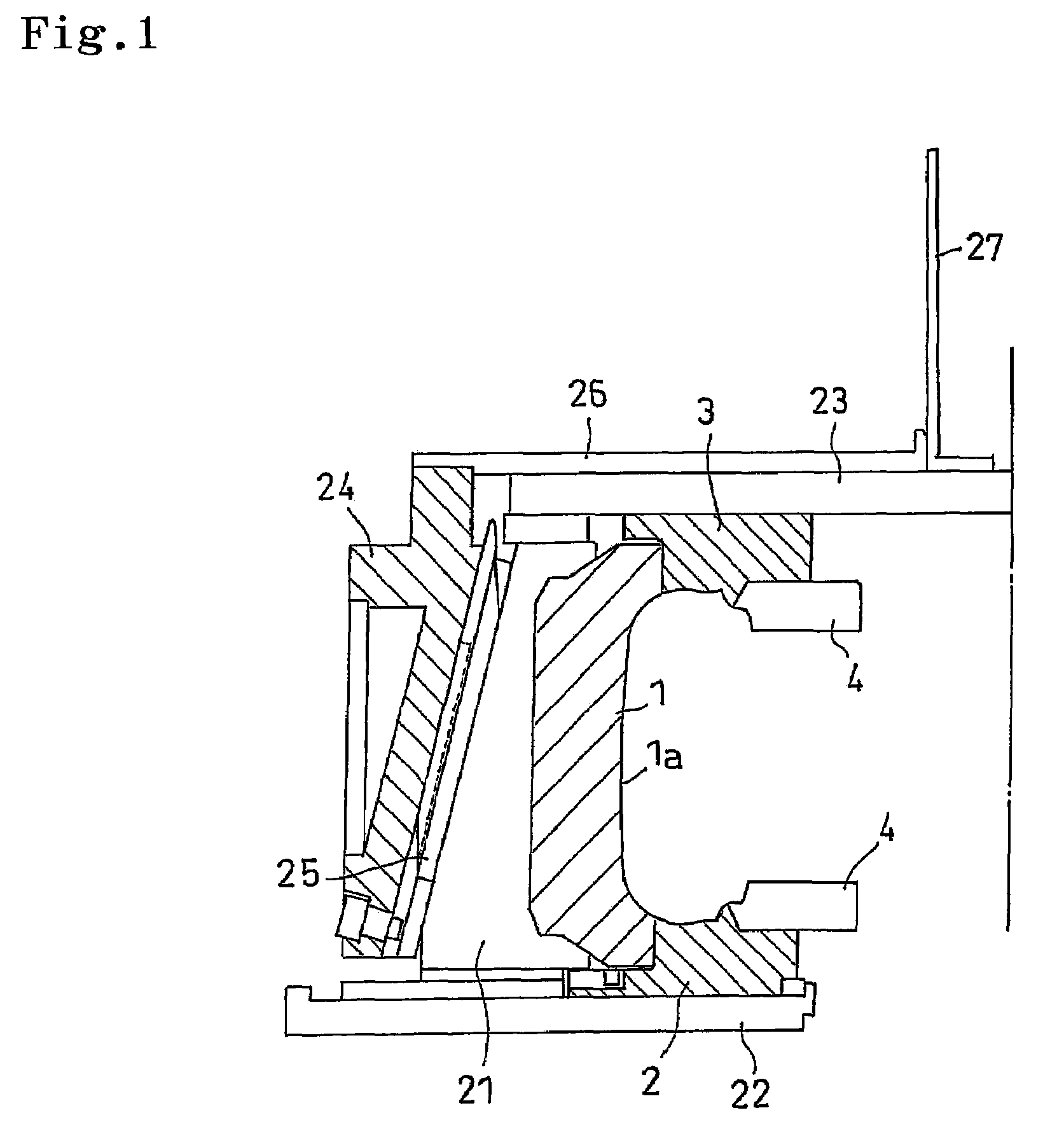

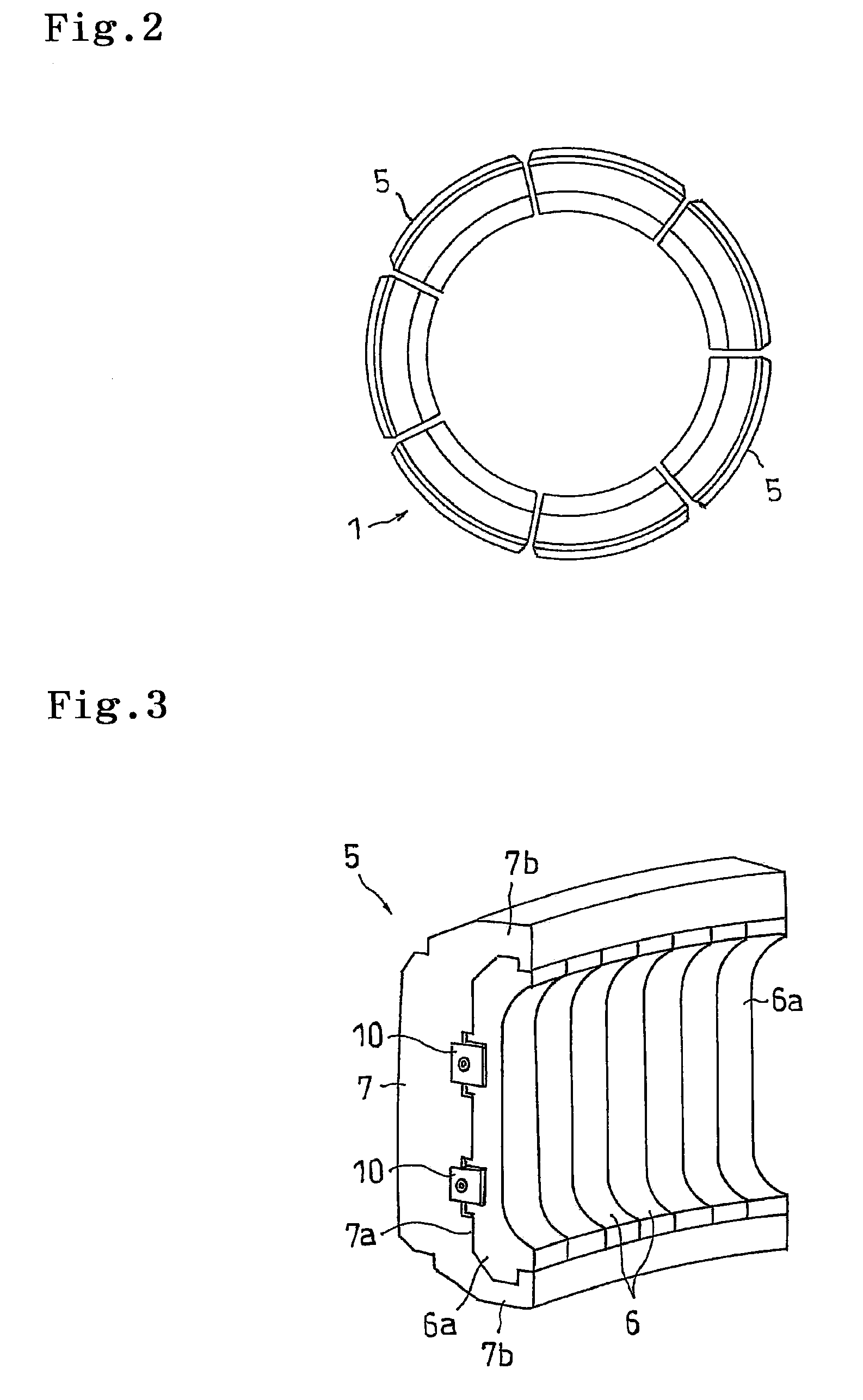

Tire curing metal mold and tire manufacturing method

A sector is provided with a plurality of pieces divided in a tire circumferential direction, a back segment supporting a plurality of pieces, and an elastic body interposed between end surfaces in the tire circumferential direction of the pieces. In an unheated state before curing, since clearances C1 to C3 are provided between the piece and the back segment, and the piece is slidable in the tire circumferential direction, it is possible to suitably adjust a gap between the pieces to a uniform state without any deviation. Further, in a heated state at a time of curing, since the clearances C1 to C3 are reduced by a thermal expansion of the piece, and the piece is fixed to the back segment, the piece does not slide in the tire circumferential direction, and it is possible to prevent an attrition and a galling of the piece from being generated early.

Owner:TOYO TIRE & RUBBER CO LTD

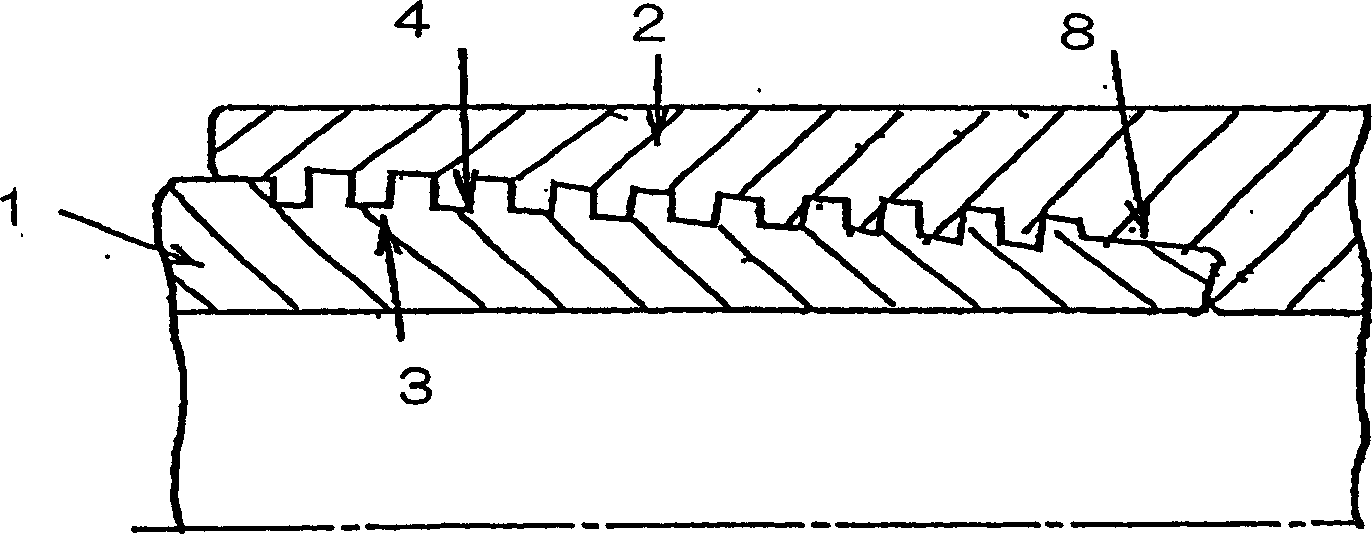

Threaded joint for steel pipes

InactiveCN1656334AImprove scratch resistanceAvoid scratchesDrilling rodsCorrosion preventionWaxGalling

A threaded joint for steel pipes comprising a pin 1 and a box 2 each having a contact surface comprising a threaded portion 3 or 4 and an unthreaded metal contact portion 8 is provided with improved anti-galling propertied by forming a lubricating coating on the contact surface of at least one of the pin and the box, the lubricating coating exhibiting a self-repairing function by liquid lubrication and having a decreased greasiness. The lubricating coating is (1) a coating which comprises a lower lubricant layer which is in liquid form in the temperature range of above 0 DEG C and below 40 DEG C and an upper lubricant layer which is in solid form at 40 DEG C, or (2) a coating which is semi-solid or solid at 40 DEG C and is formed of a mixture comprising a lubricating oil which is in liquid form in the temperature range of above 0 DEG C and below 40 DEG C and a wax which is in solid form at 40 DEG C, the mixture preferably having been heated so as to liquefy the wax and dissolve in each other the wax and lubricant oil.

Owner:NIPPON STEEL CORP +1

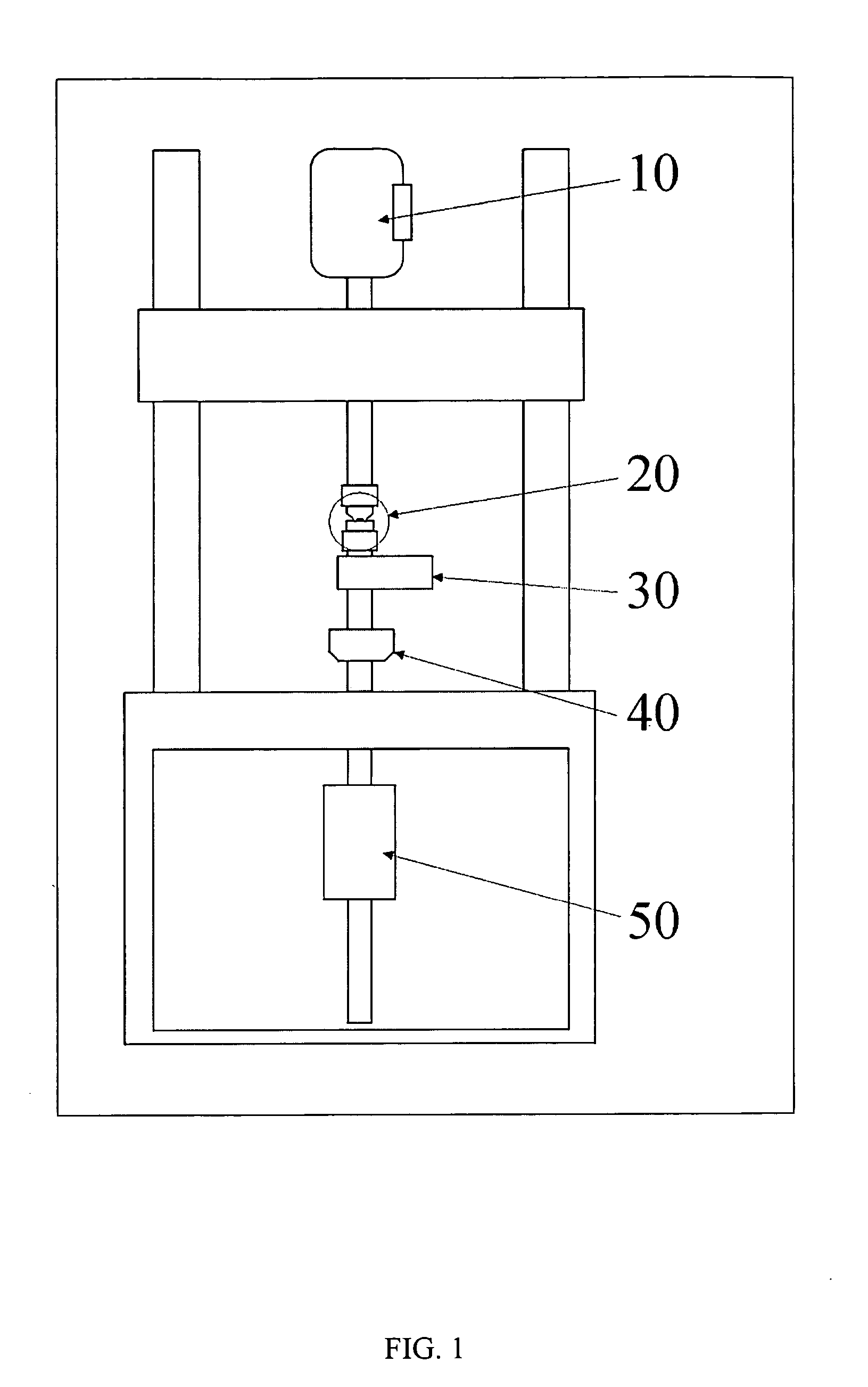

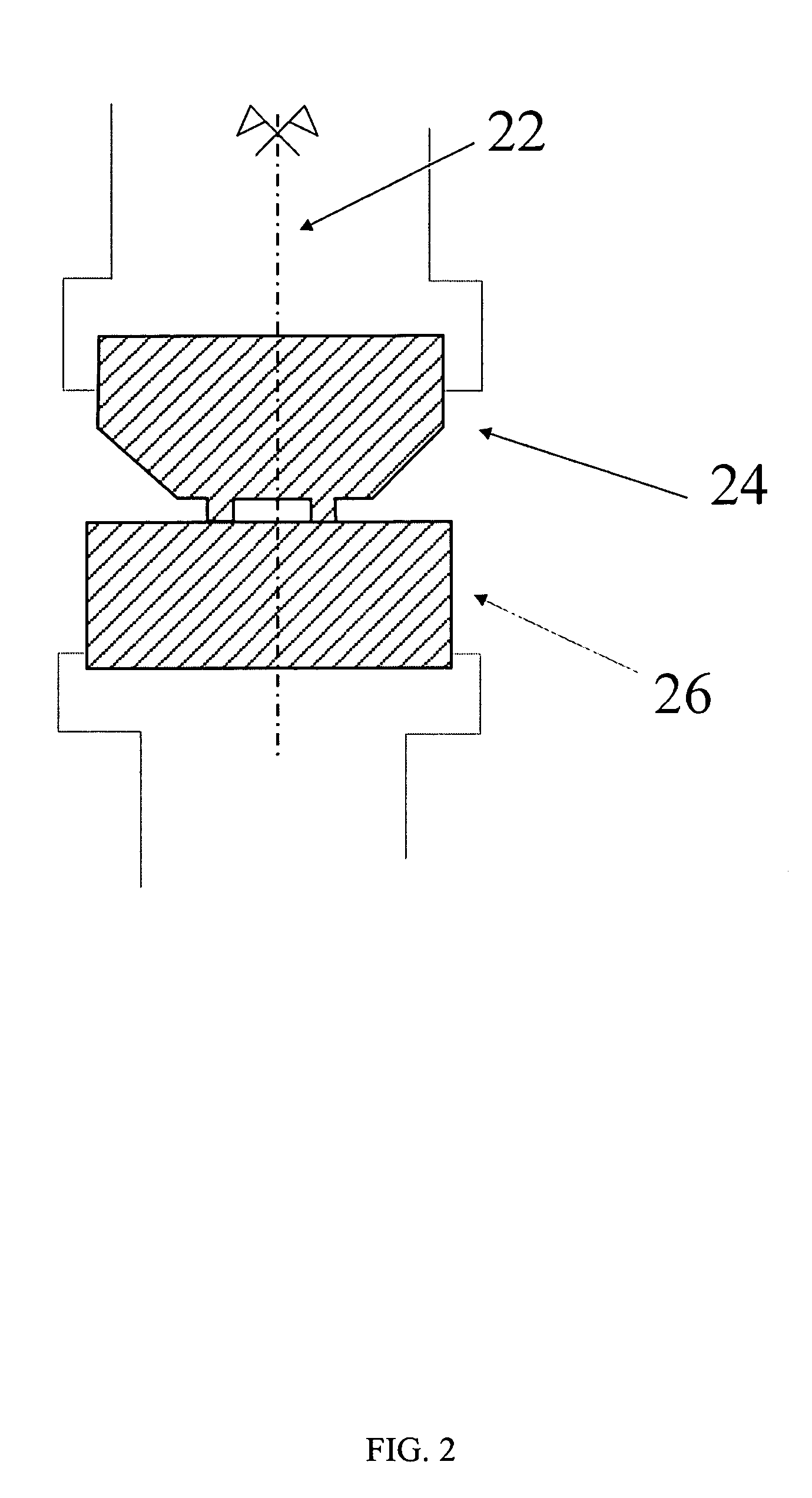

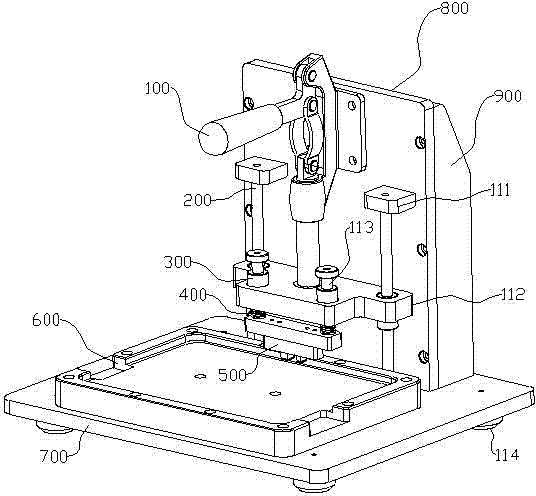

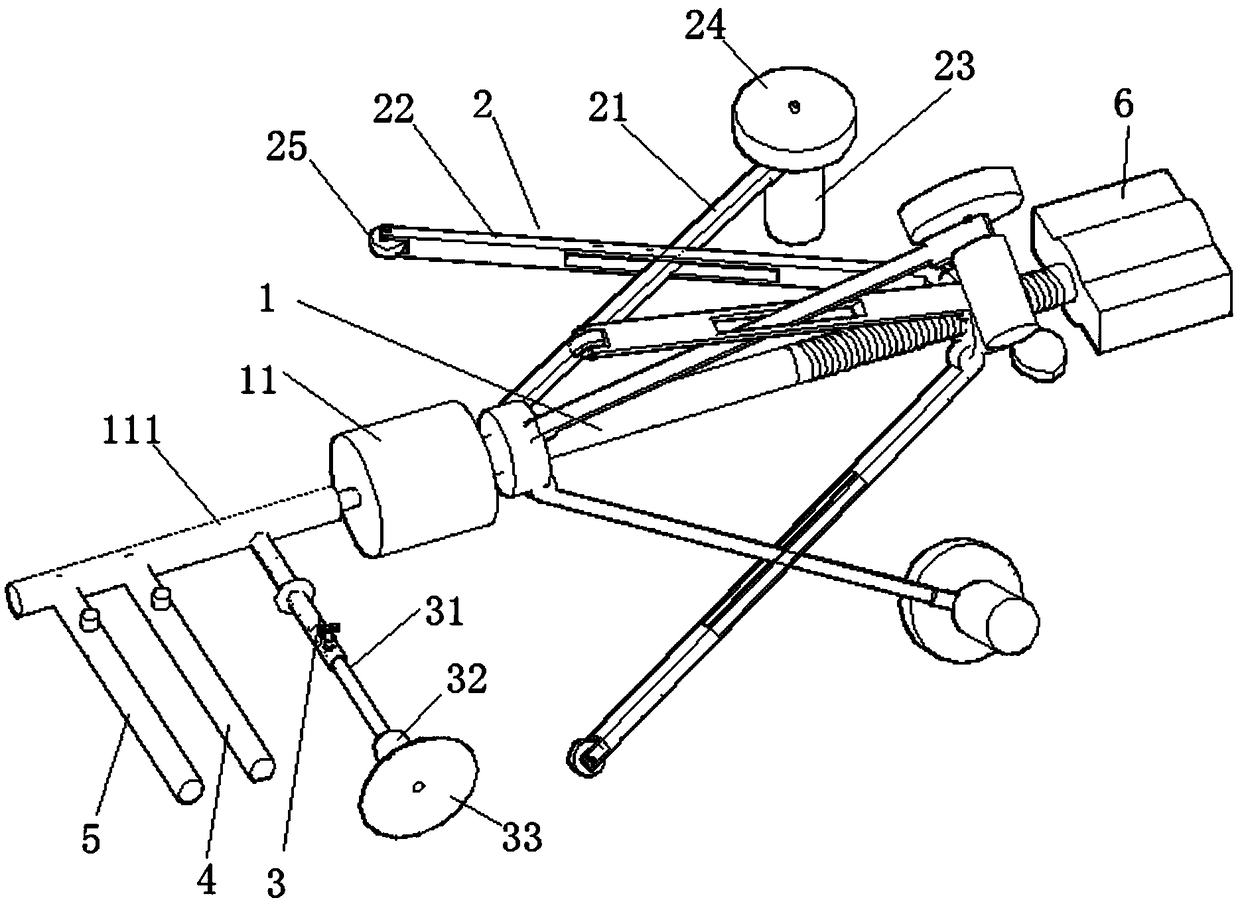

Camera module press fitting fixture

The invention discloses a camera module press fitting fixture comprising a base plate and a clamp fixing plate, wherein one side of the clamp fixing plate is provided with a fast clamp while the other side is provided with a reinforcement rib; two sides of the fast clamp are respectively provided with a vertical guide pillar, one side of each vertical guide pillar is provided with a guide pillar fixing plate while the other side is provided with a movable connection plate; two sides of the movable plate are respectively provided with a linear bearing, one end of each linear bearing is connected with a press fitting guide pillar while the other end is provided with a pressure spring. The camera module press fitting fixture has advantages that the automation degree is high, the situation of hand galling caused by hand press is avoided due to the fact that the force is exerted by the fast clamp, the pressure is controlled by adjusting the stroke of the spring, the pressure of each product is in a very small range, and thus badness caused by the pressure difference is improved greatly. The camera module press fitting fixture is capable of increasing the production efficiency, good in practical performance and novel in design so as to serve as an excellent innovation and have a very wide market promotion prospect.

Owner:KUSN MAIZHI FIXTURE TECH

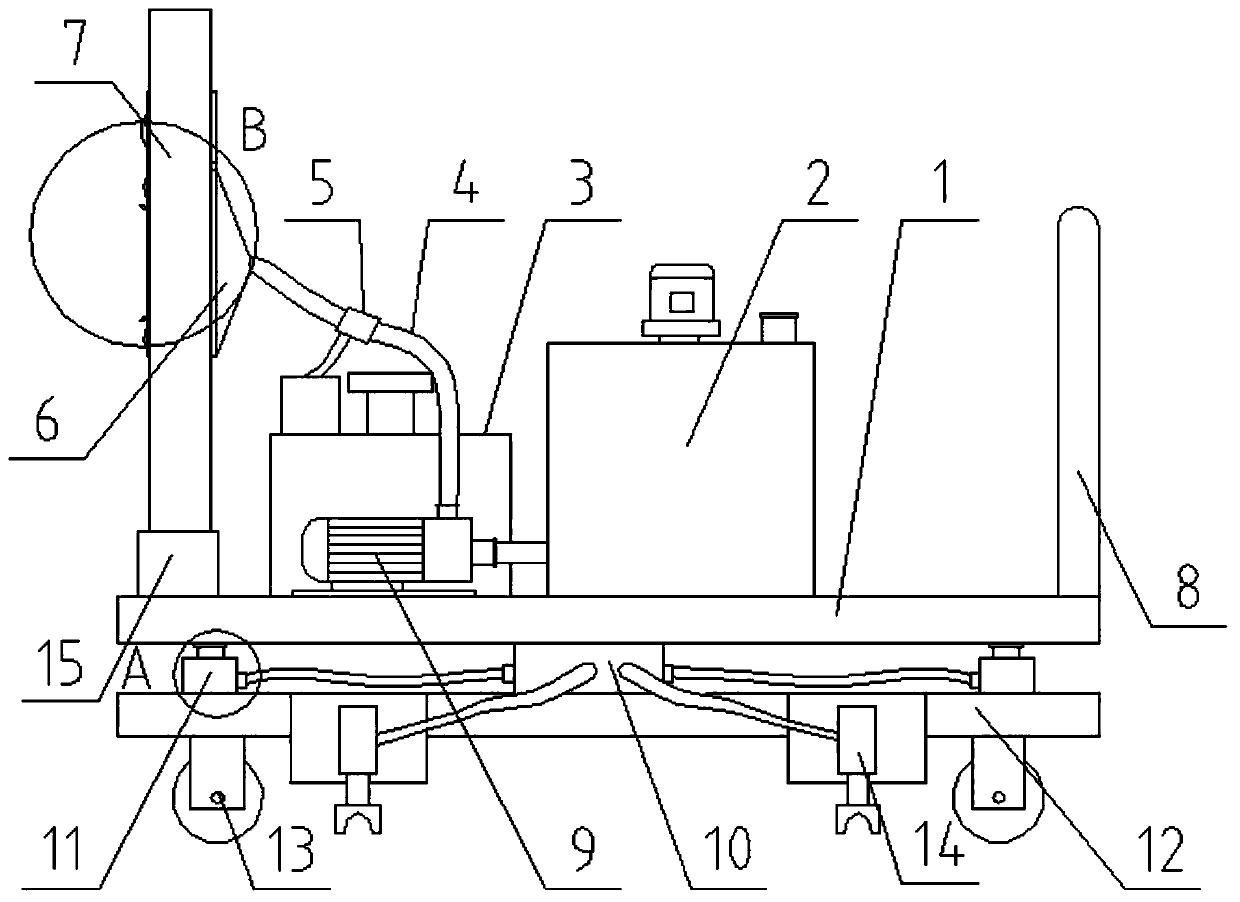

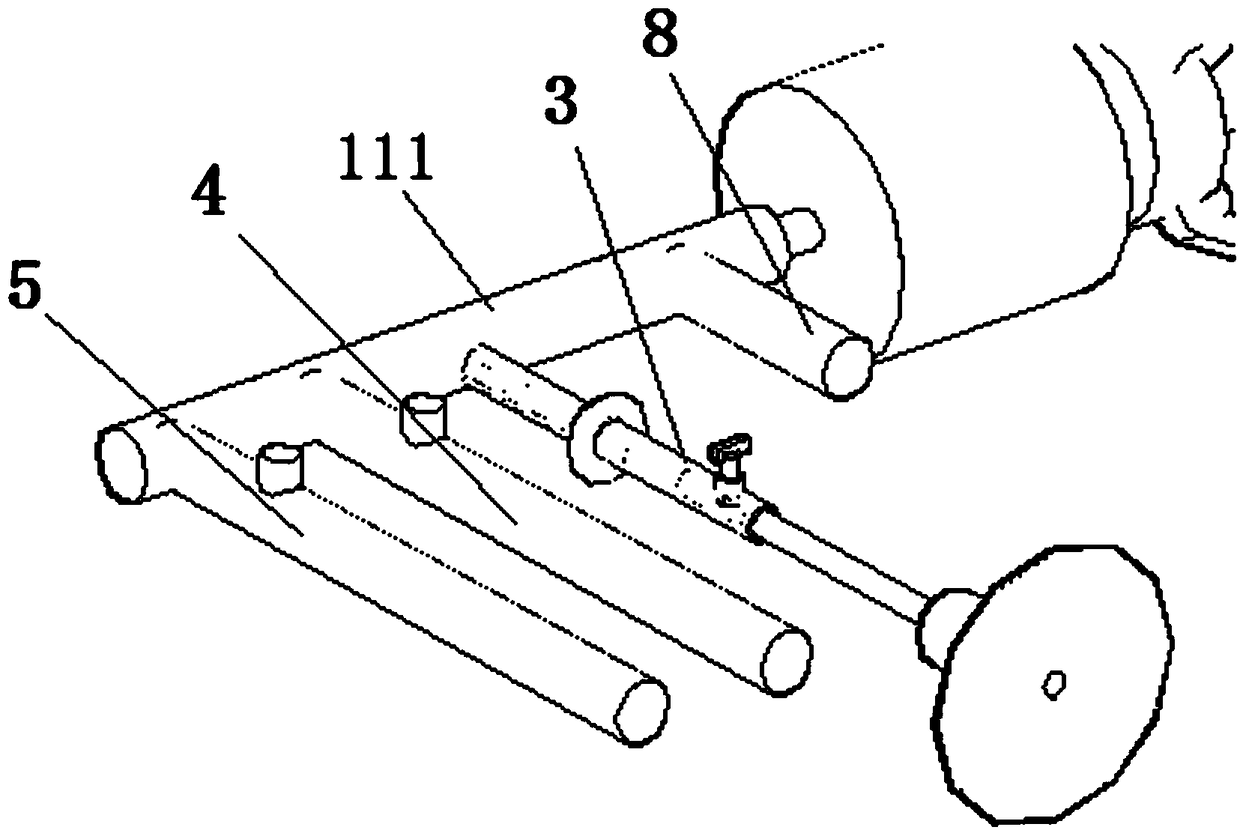

Plastering, galling and automatic mortar-spraying machine

ActiveCN109868977AImprove work efficiencyReduce the amount of manual laborBuilding constructionsGallingFuel tank

The invention discloses a plastering, galling and automatic mortar-spraying machine, which comprises a pedestal plate and a base plate located below the pedestal plate, a hydraulic oil tank and a plurality of hydraulic jacking devices located at the four corners of the base plate are fixedly mounted between the pedestal plate and the base plate, the pedestal plate and the base plate are connectedthrough the multiple hydraulic jacking devices, the multiple hydraulic jacking devices all communicate with the hydraulic oil tank through oil guiding pipes correspondingly, horizontal displacement mechanisms are symmetrically mounted on the side faces of the base plate and communicate with the hydraulic oil tank through oil guiding pipes, and idler wheels are mounted at the four corners of the lower end of the base plate. The plastering, galling and automatic mortar-spraying machine has the three functions of plastering, galling and mortar spraying and has the advantages of high mortar-outletefficiency and horizontal moving plastering, and the problem that the high wall surface cannot be painted is solved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Wear resistant coating for keel joint

ActiveUS7067201B2Reduce stressReduce wearMetallic material coating processesThin material handlingKeelWear resistant

Owner:VETCO GRAY LLC

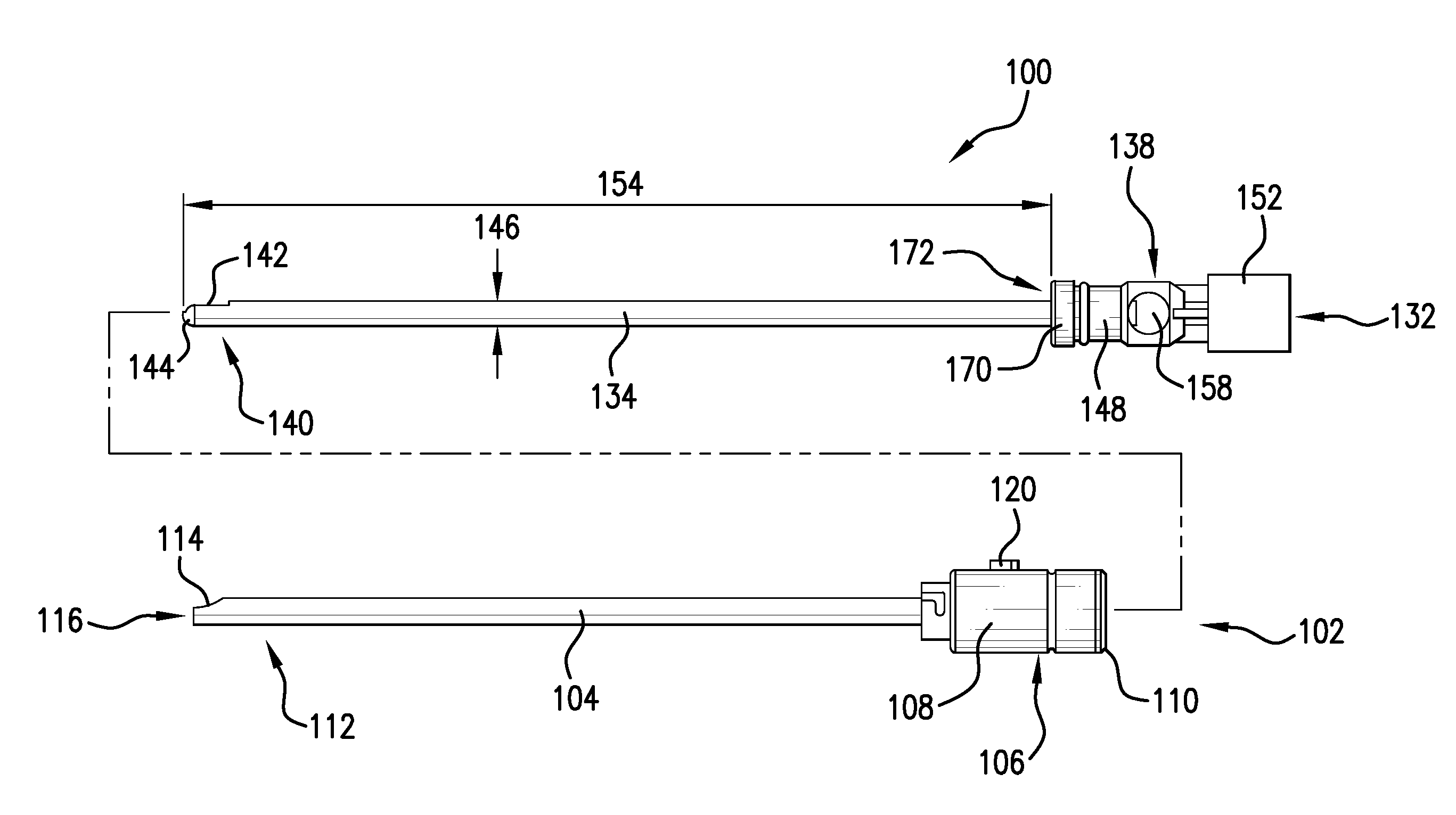

Endoscopic cutting instruments having improved cutting efficiency and reduced manufacturing costs

ActiveUS20120065658A1Improve cutting efficiencyReduce manufacturing costEndoscopic cutting instrumentsGallingEngineering

The present invention is directed to improving the cutting efficiency and reducing the manufacturing costs associated with endoscopic cutting instruments by eliminating the distal bearing surfaces or providing means for making the contact at the distal bearing intermittent so that surfaces do no undergo high localized heat and galling. In one embodiment, this goal is achieved by modifying or removing the axial constraints on the inner sliding member that are characteristic of conventional endoscopic shavers. In another embodiment, the improved cutting efficiency and reduced manufacturing cost is achieved by eliminating a closed end characteristic of conventional endoscopic shavers (e.g., removing the closed end of either the inner sliding member or the outer sliding member to thereby eliminate the associated bearing surface formed therebetween).

Owner:HANSHI

Oil casing pipe joint anti-thread-gluing coating and preparation method thereof

An anti-galling coating for a threaded joint of an oil casing. The mass percentages of the components of the coating are: organic binder 30-60 wt%, solid lubricant 30-60 wt%, anticorrosive agent 6-15 wt%, leveling agent 0.01-0.1 wt%, wetting agent 0.01-0.1 wt% and mixed solvent in addition. The organic binder is polyamide-imide liquid resin with a solid content of 38-42 wt%. The solid lubricant is any one of molybdenum disulphide and tungsten disulfide, or a combination of molybdenum disulfide or tungsten disulfide and polytetrafluoroethylene. Preferably the solid lubricant and the anticorrosive agent are surface modified with silane coupling agent. The anti-galling coating is obtained by spraying the coating on the surface of an oil casing joint processed with phosphate, and the environmental pollution caused by heavy metal powder in thread compounds is avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

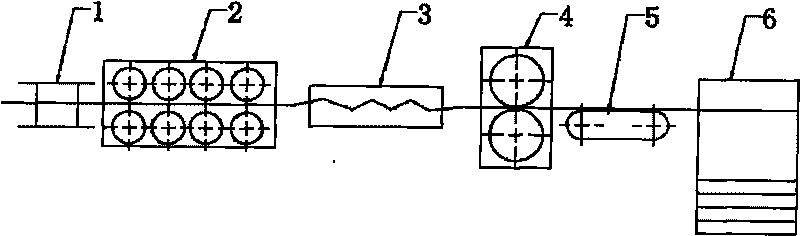

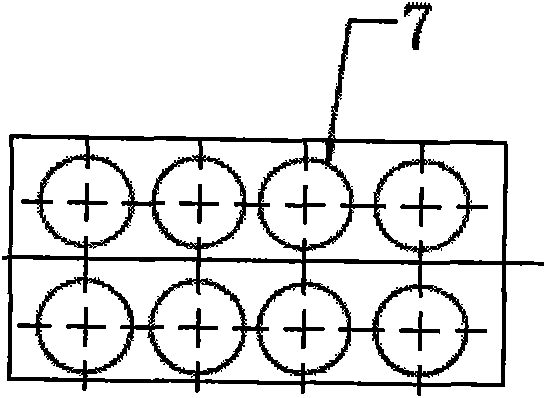

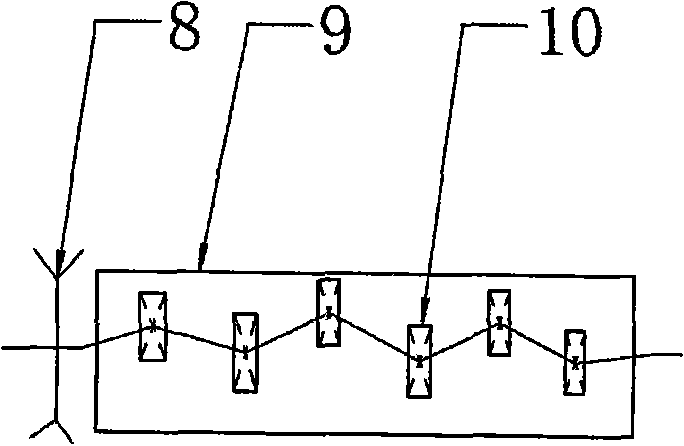

Flying shear type high-speed wire cutting device

The invention discloses a flying shear type high-speed wire cutting device, which consists of an auxiliary wire feeding mechanism, a high-speed wire cutting mechanism, a baiting machine and a storage tank, wherein the high-speed wire cutting mechanism comprises a wire feeder, a straightening machine and a fly-cutter shearer; the wire feeder consists of wire feeding wheels with the same rotating speed and opposite directions; the straightening machine consists of a rotating hub and a belt transmission mechanism, and a hole die is arranged in the rotating hub; and the fly-cutter shearer consists of an upper cutter head and a lower cutter head with the same rotating speed and opposite directions, and cut-off blades are arranged in cutter head grooves. The flying shear type high-speed wire cutting device has the advantages that: the operation is simple, the adjustment for the straightening machine is simple and easy, and the cut-off size of the fed wire does not need to be adjusted; the product has high quality, has no quality defects such as short head free, double cutters, surface galling and the like, and has high yield; the detachment is quick and the maintenance is convenient, so the maintenance downtime is reduced; the automation degree is high, and the processes of removing oxide skins from wire rods, drawing steel wires and straightening and cutting off the steel wires are finished once, so the labor production efficiency is improved; and the working condition is improved, and the noise is reduced.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

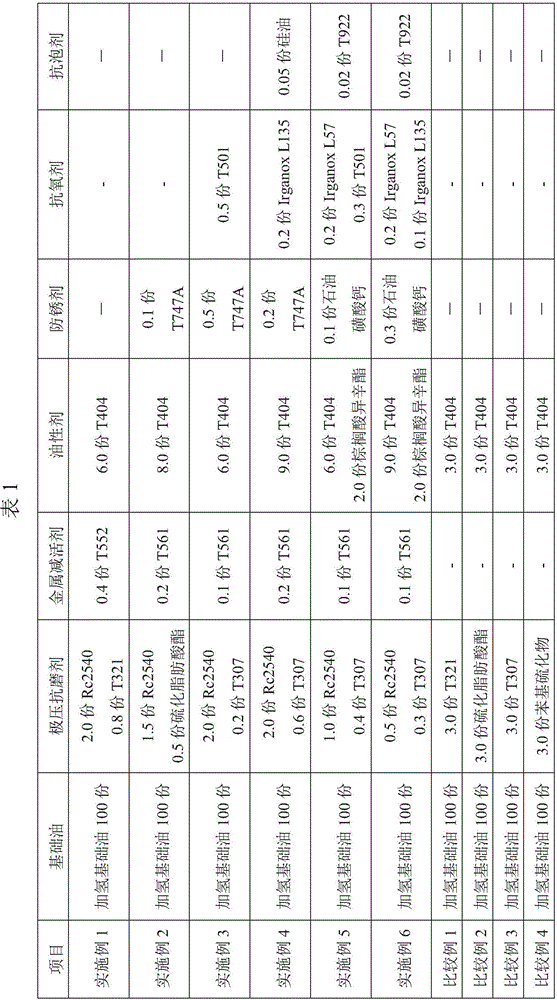

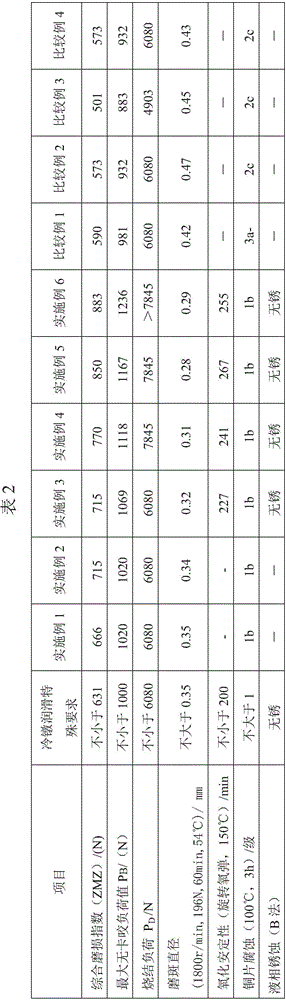

Cold heading oil composition and application thereof

ActiveCN106635285AImprove extreme pressure and anti-wear performanceAccelerated corrosionLubricant compositionGallingTriazole derivatives

The invention relates to a cold heading oil composition and an application thereof. The composition mainly solves the problems in the prior art that the extreme pressure anti-wear property and copper corrosion resistance of cold heading oil cannot satisfy usage requirements of partial cold heading equipment for lubrication unified oil supply for cold heading process and equipment, galling is generated on the surface of workpiece, or transmission gear shaft is corroded. The composition comprises the following components in parts by weight: a) 100 parts of mineral base oil; b) 0.1-5.0 parts of an anti-wear reagent at extreme pressure; c) 0.01-0.5 parts of a metal passivator; d) 1.0-15.0 parts of an oiliness agent; e) 0.005-0.5 parts of an anti-foaming agent. The anti-wear reagent at extreme pressure is a mixture of sulfurized olefin and at least one of sulfurized isobutylene, phenyl sulfide, sulfurized fatty acid ester or ammonium thiophsphonate. The metal passivator is selected from at least one of triazole derivatives or thiadiazole derivatives; the oiliness agent is a mixture of sulfurized plant oil and at least one selected from fatty acid ester or high-grade fatty alcohol. The technical scheme can better solve the problem, and is used for partial cold heading equipment for lubrication unified oil supply for cold heading process and equipment.

Owner:CHINA PETROLEUM & CHEM CORP

Wool-like knitted fabric and production method thereof

ActiveCN103556372ASolve hygroscopicitySolve problems such as poor pilling resistanceWeft knittingHeating/cooling textile fabricsYarnGalling

The invention relates to a wool-like knitted fabric and a production method thereof. The fabric is made of blended yarns of double-resistant superfine acrylic fiber and cotton and is in cotton-wool weave. The production method includes: 1, subjecting the blended yarns of double-resistant superfine acrylic fiber and cotton to cotton-cool weaving by a double circular knitting machine with 20-28G stitch length so as to obtain a blank; 2, subjecting the blank to after-finishes, such as pre-finishing, acrylic fiber dyeing, soaping, cotton dyeing, after-finishing, drying, galling, shearing, flat setting, and reeling. The advantages in the acrylic fiber and cotton are combined, the performances are complemented, and the wool-like fabric is developed; the acrylic fiber and cotton are cheap, the problem that the commercially available wool is expensive is solved, and the fabric has a great competitive advantage in the market; the production process is simple and low in cost and has promising market prospect.

Owner:NINGBO DAQIAN TEXTILE

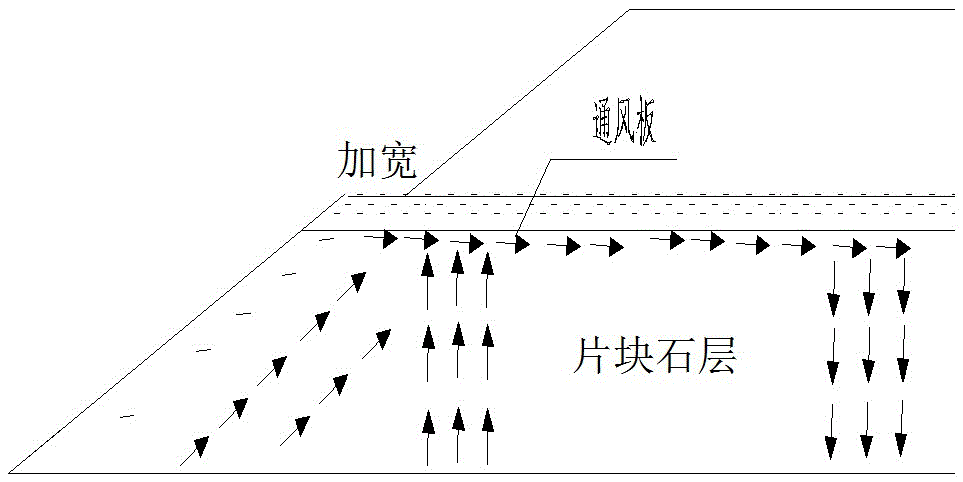

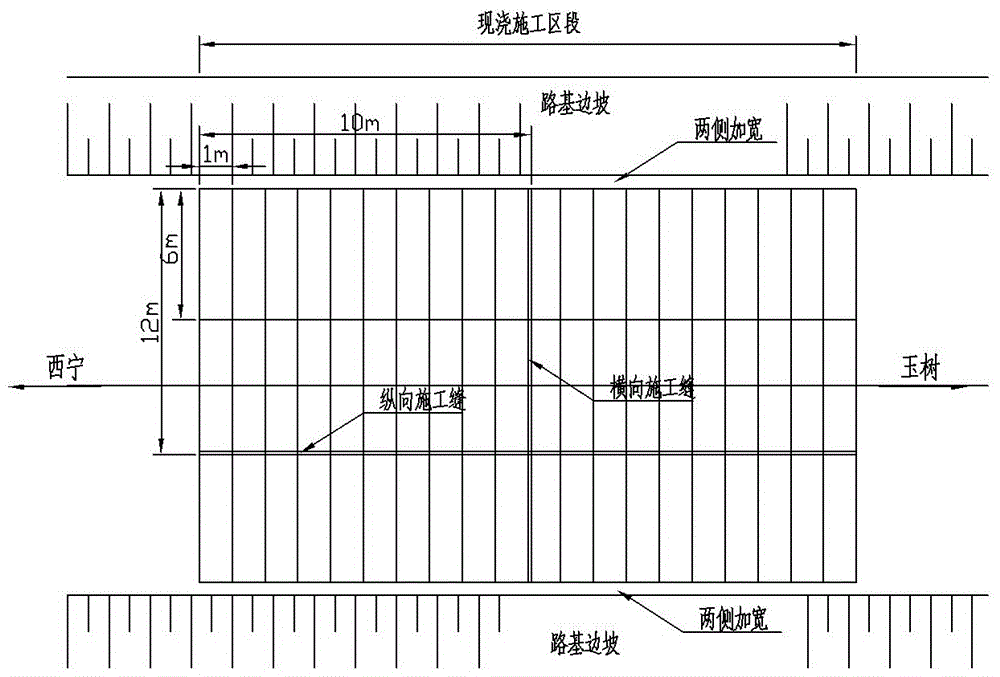

Construction method for rubble stone-ventilating board composite roadbed of expressway at permafrost area

InactiveCN106676987AReduce the temperatureStrengthen the internal convection heat transfer effectRoadwaysGallingCrushed stone

The invention relates to a construction method for a rubble stone-ventilating board composite roadbed of an expressway at a permafrost area. The method includes the steps that firstly, rubble stone is prepared, after a bottom cushion layer is detected to be qualified, the rubble stone is poured for filling at a time, and then filling shaping, leveling and padding, and static pressure rolling are conducted; gravels are poured on the rubble stone for filling, after leveling and static pressure rolling, a water-permeable geotextile is laid on a gravel layer, and a sand-gravel cushion and a geogrid are laid on the water-permeable geotextile, so that roadbed construction is completed; a high-strength waterproof film is laid on the top face of a roadbed, pouring formworks for ventilating boards are mounted, a reinforcement fabric is manufactured, transverse PVC ventilating pipes are arranged, pouring is completed, and after top galling, curing and demolding are conducted. By means of the construction method, the temperature of the top surface of the rubble stone roadbed can be lowered, and the convection heat exchange effect inside the roadbed is enhanced; after the ventilating boards are additionally arranged on the rubble stone layer, the upper temperature of the rubble stone layer is lowered through the ventilation effect, the temperature difference between the top and the bottom of the rubble stone layer is increased, and the convection heat exchange effect of the rubble stone layer is enhanced.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

Coating material and surface treated metal plate

The present invention provides a coating that includes a thermoplastic resin having a glass transition point of more than 100° C. and an acid value of from 20 to 350 mg-KOH / g, a metallic soap of metal stearate, an anti-galling agent, and a surface-treated metal sheet having a film of this coating. The coating according to the present invention has the superior durability of the film, in particular, wear resistance and peel resistance. The surface-treated metal sheet having the film of this coating has superior press formability, in particular, galling resistance and lubricity, and further, a temporary antirust property and alkaline solubility of the film even in a high temperature environment caused by severe ironing.

Owner:JFE STEEL CORP

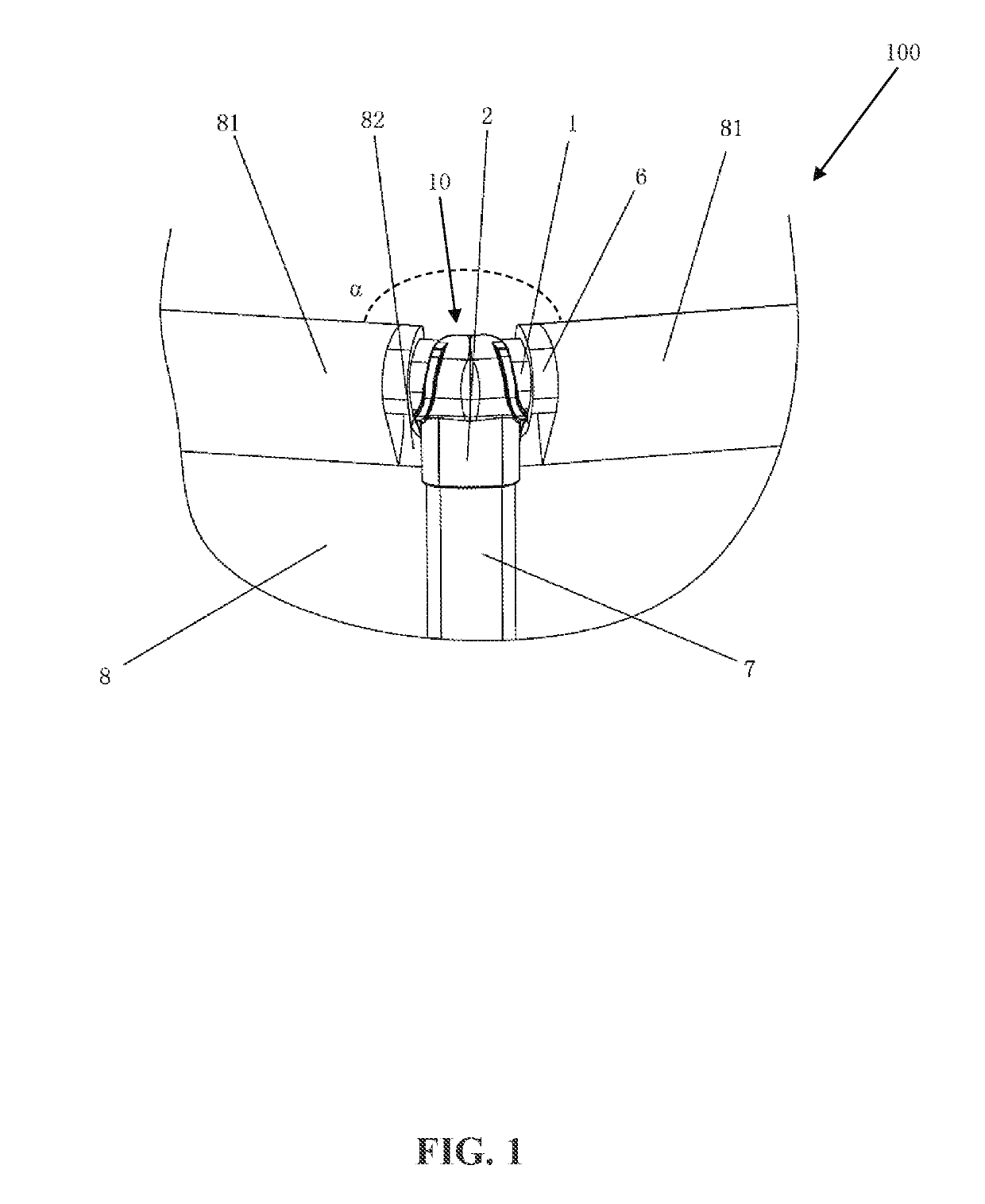

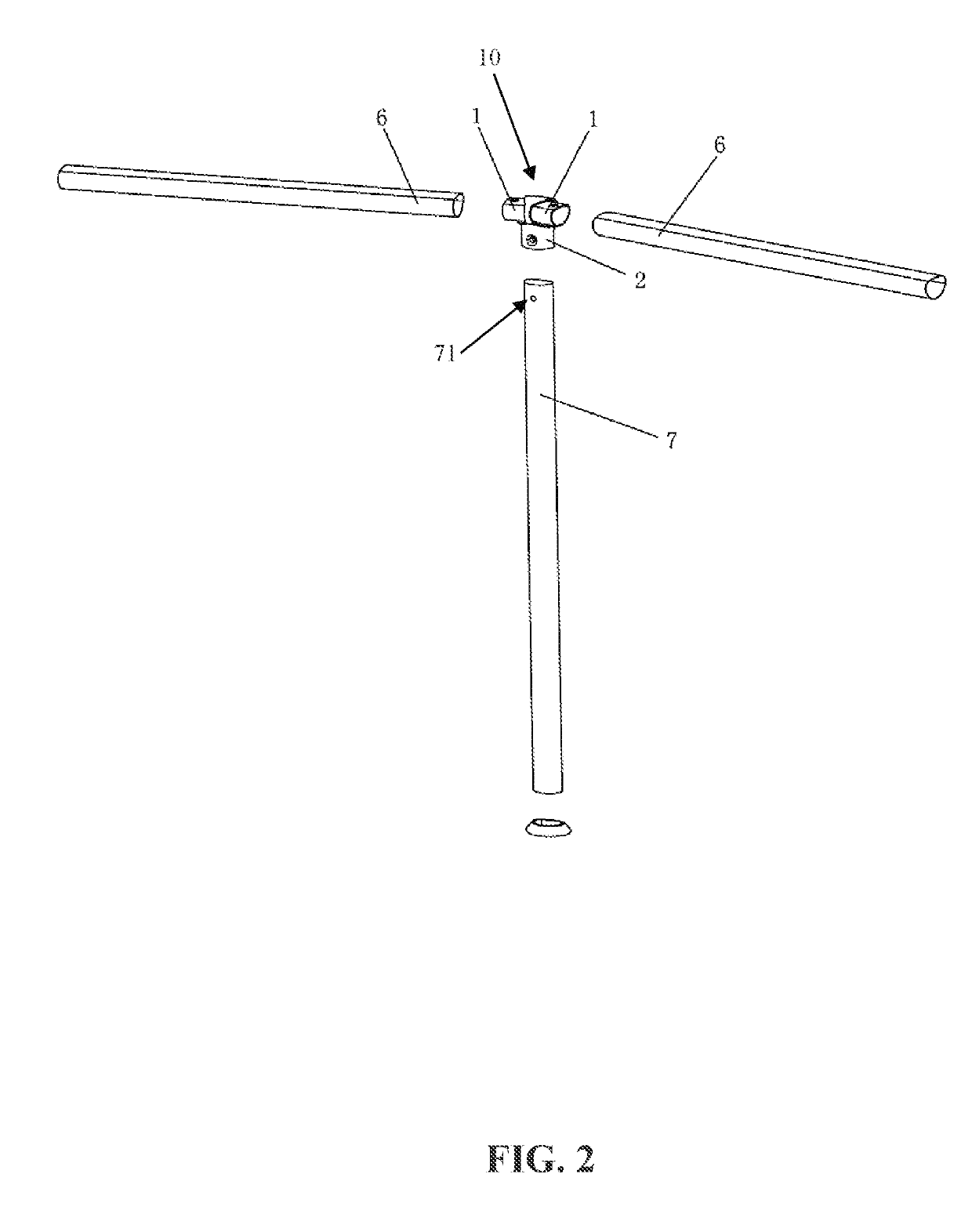

Joint for above ground pool frame

A frame pool is disclosed including a frame assembly and a pool liner, the frame assembly including horizontal frame members and a vertical frame member coupled together via a T-shaped joint. The T-shaped joint may be constructed of plastic to facilitate attachment and detachment to the adjacent frame members and to resist galling and corrosion. The T-shaped joint may also be relatively small to improve the appearance and water containment of the frame pool.

Owner:INTEX MARKETING

Tire curing metal mold

Owner:TOYO TIRE & RUBBER CO LTD

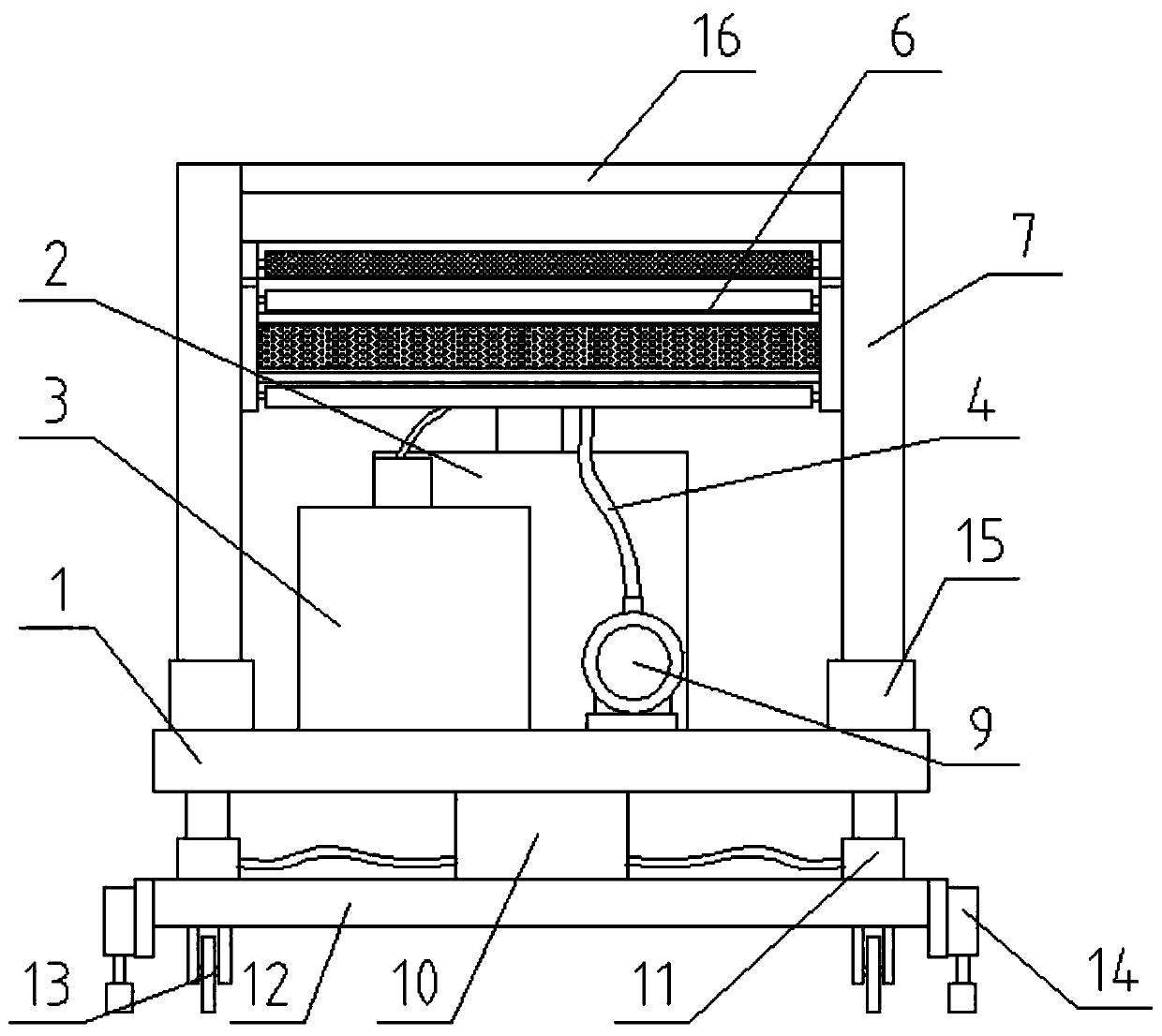

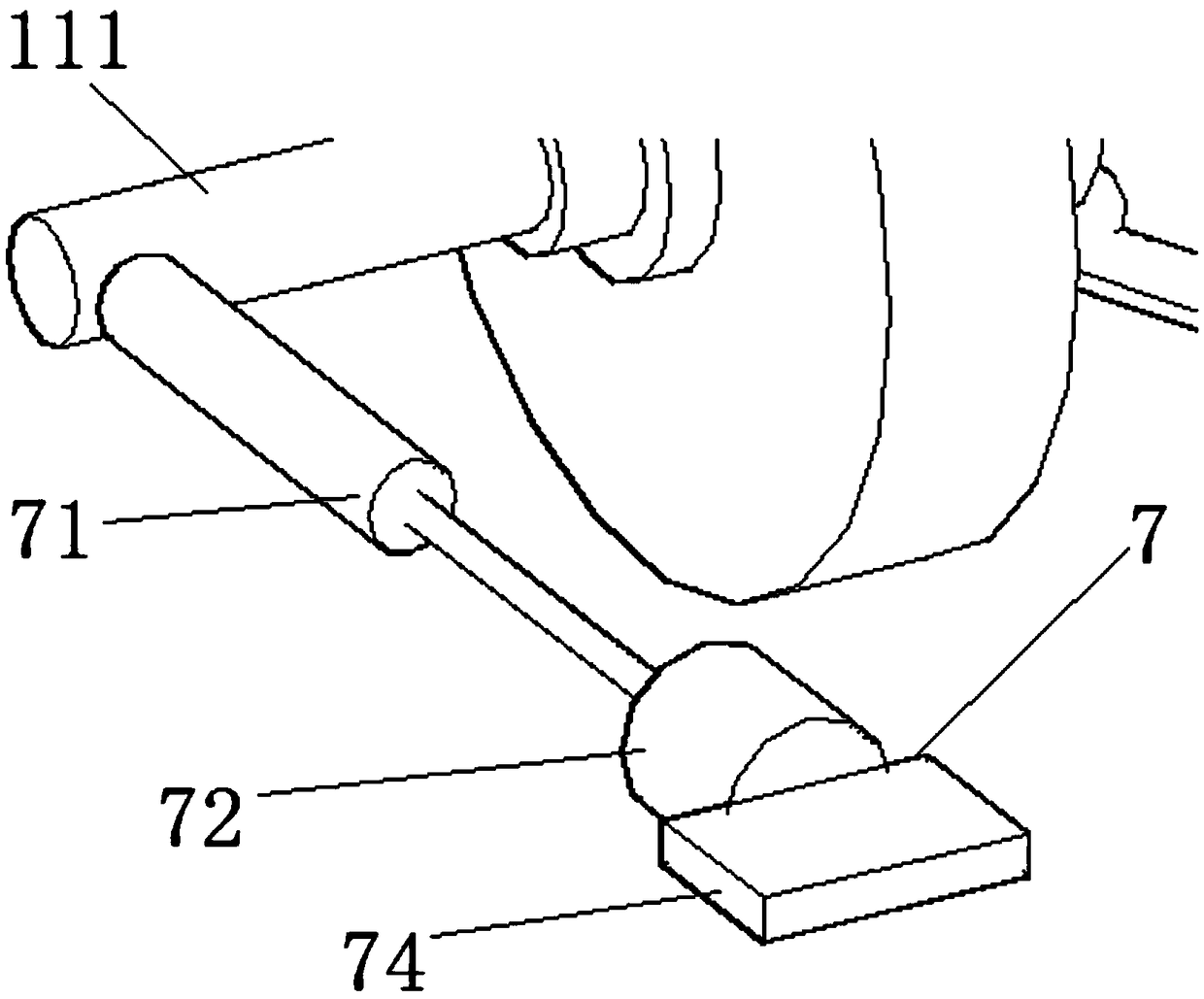

Galling and dust blowing and sucking device for coating of inner wall of pipeline

ActiveCN109365431AStable roughnessUniform roughnessRevolution surface grinding machinesGrinding drivesMotor driveGalling

The invention provides a galling and dust blowing and sucking device for a coating of the inner wall of a pipeline. The device comprises a main pipe body, a walking mechanism, a galling device, a dustblowing pipe, a dust sucking pipe, a cleaning device and a main controller. The walking mechanism drives the galling device, the dust blowing pipe and the dust sucking pipe to move on the inner wallof the pipeline along the axis, a main rotary motor drives the galling device, the dust blowing pipe and the dust sucking pipe to move on the inner wall of the pipeline along the circumference, the inner wall of the pipeline is stably galled through the galling device, intense blowing airflow is generated by the dust blowing pipe, abrasive dust left after galling is completed is blown up, the abrasive dust is sucked through the dust sucking pipe, cleaning liquid is sprayed on cotton cloth a wiping cloth single unit through a liquid sprayer, the cotton cloth makes contact with the inner wall ofthe pipeline for wiping, the abrasive dust left after galling is completed is effectively removed, the cleanliness of a grinding surface is greatly improved, the surface with the uniform and stable roughness is obtained on the inner wall of the pipeline, adhesive force between two coatings is improved, the spraying effect is improved, and the corrosion resistance of the inner wall of the pipelineis improved.

Owner:NANTONG INST OF TECH

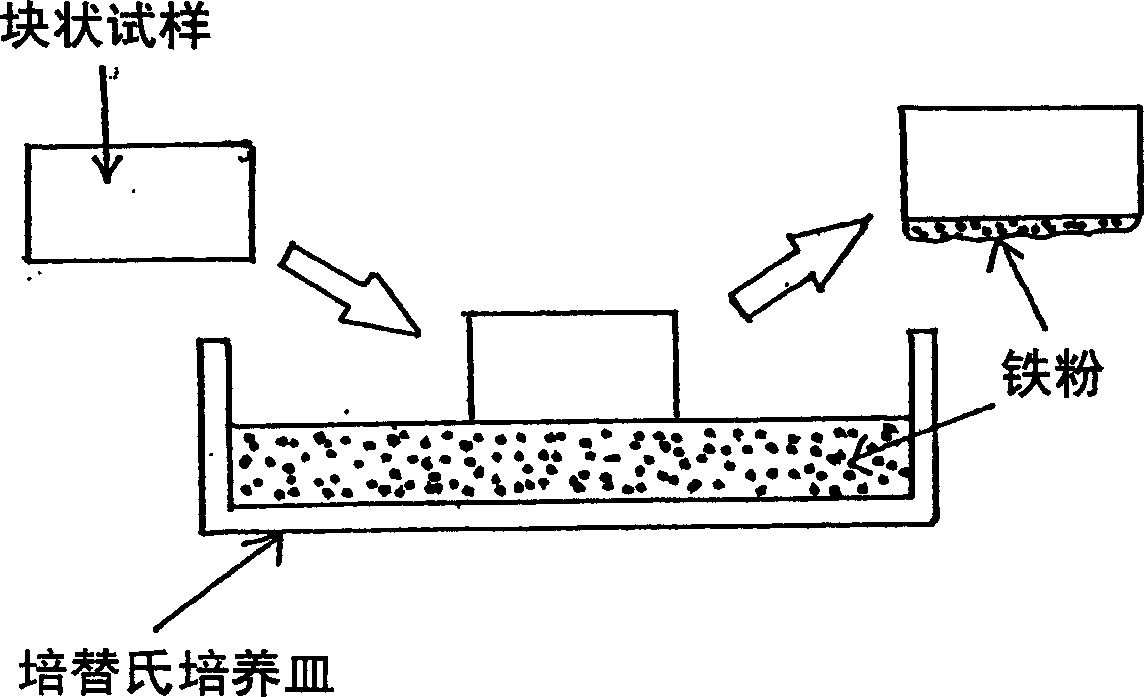

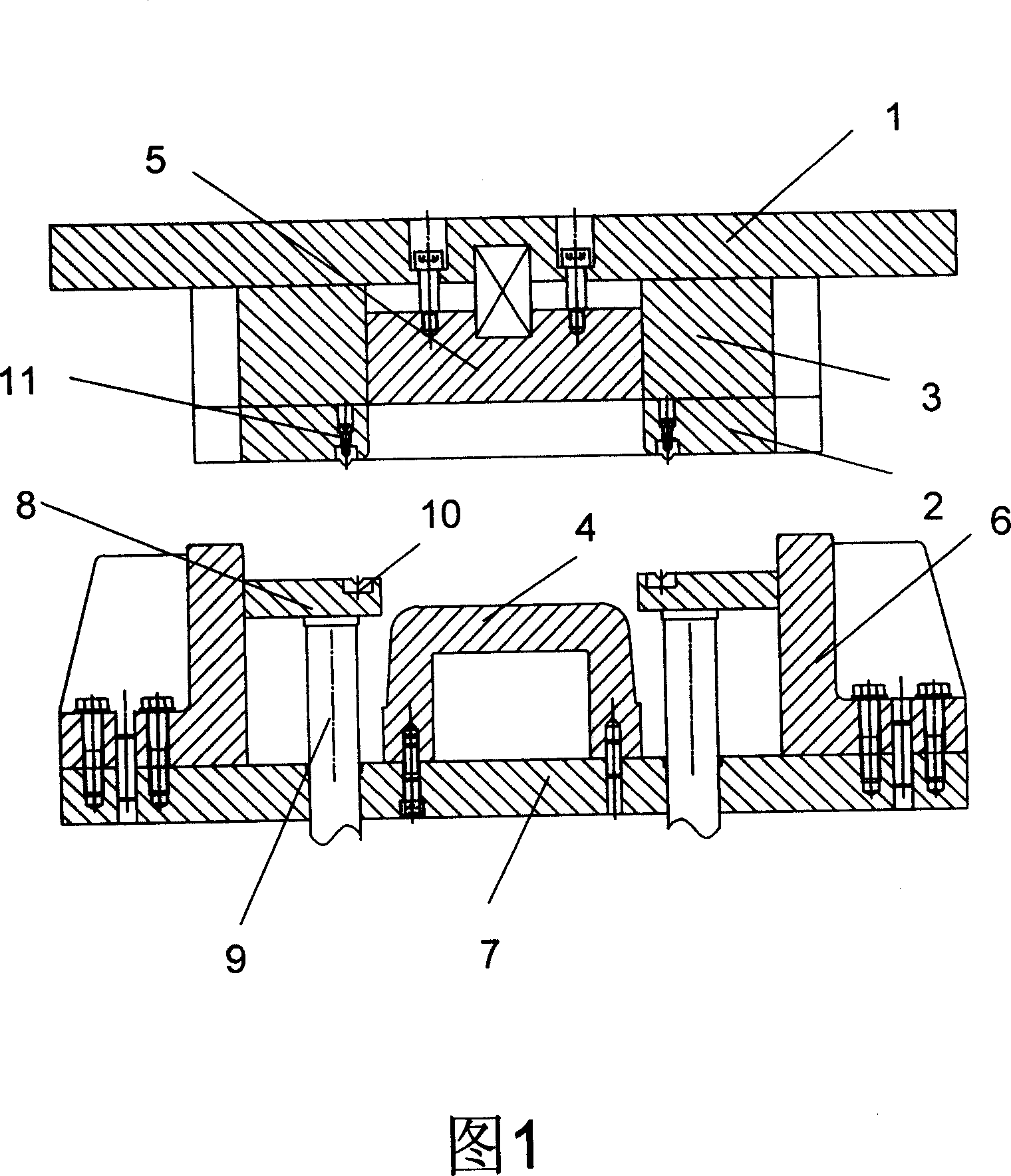

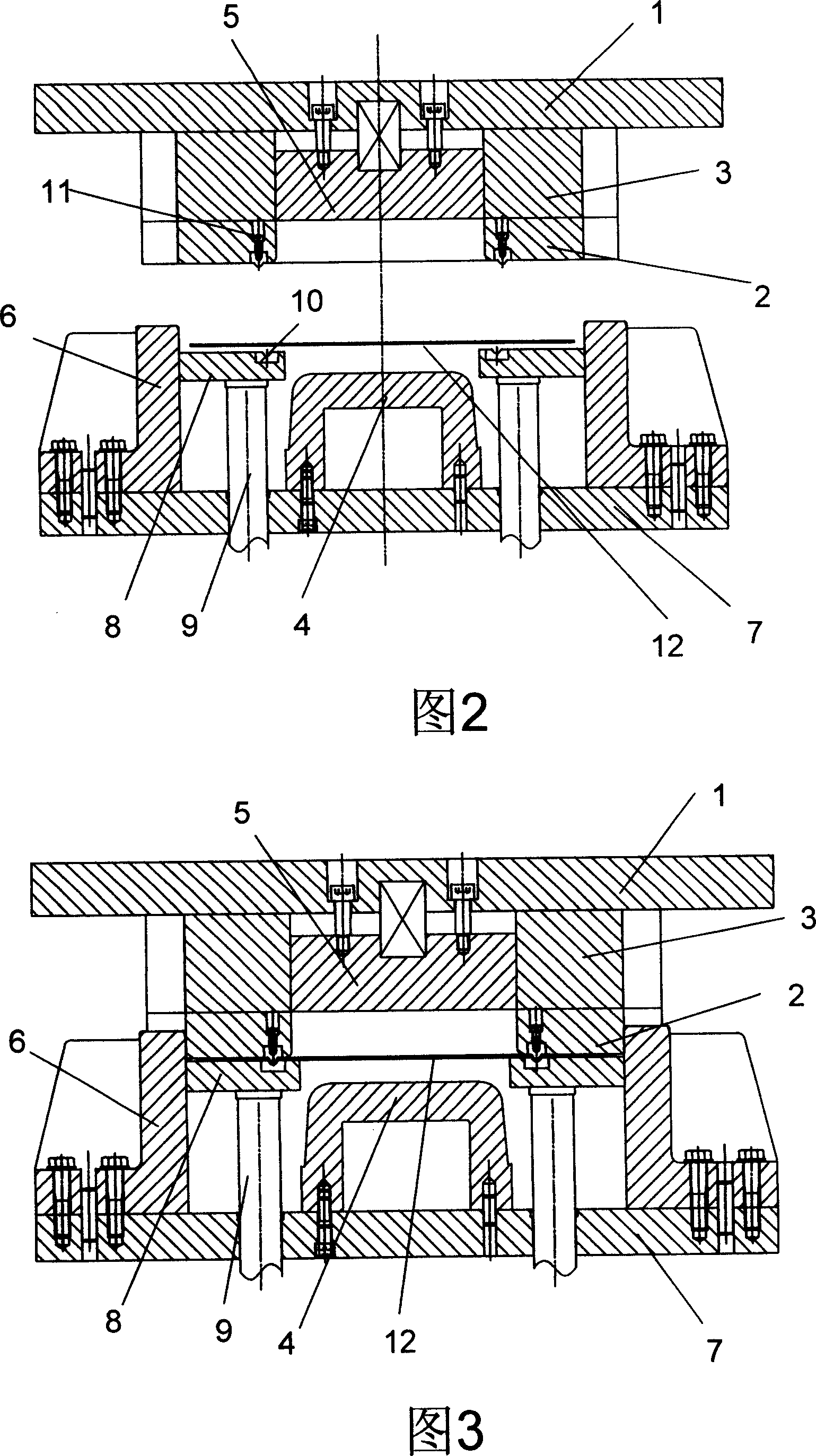

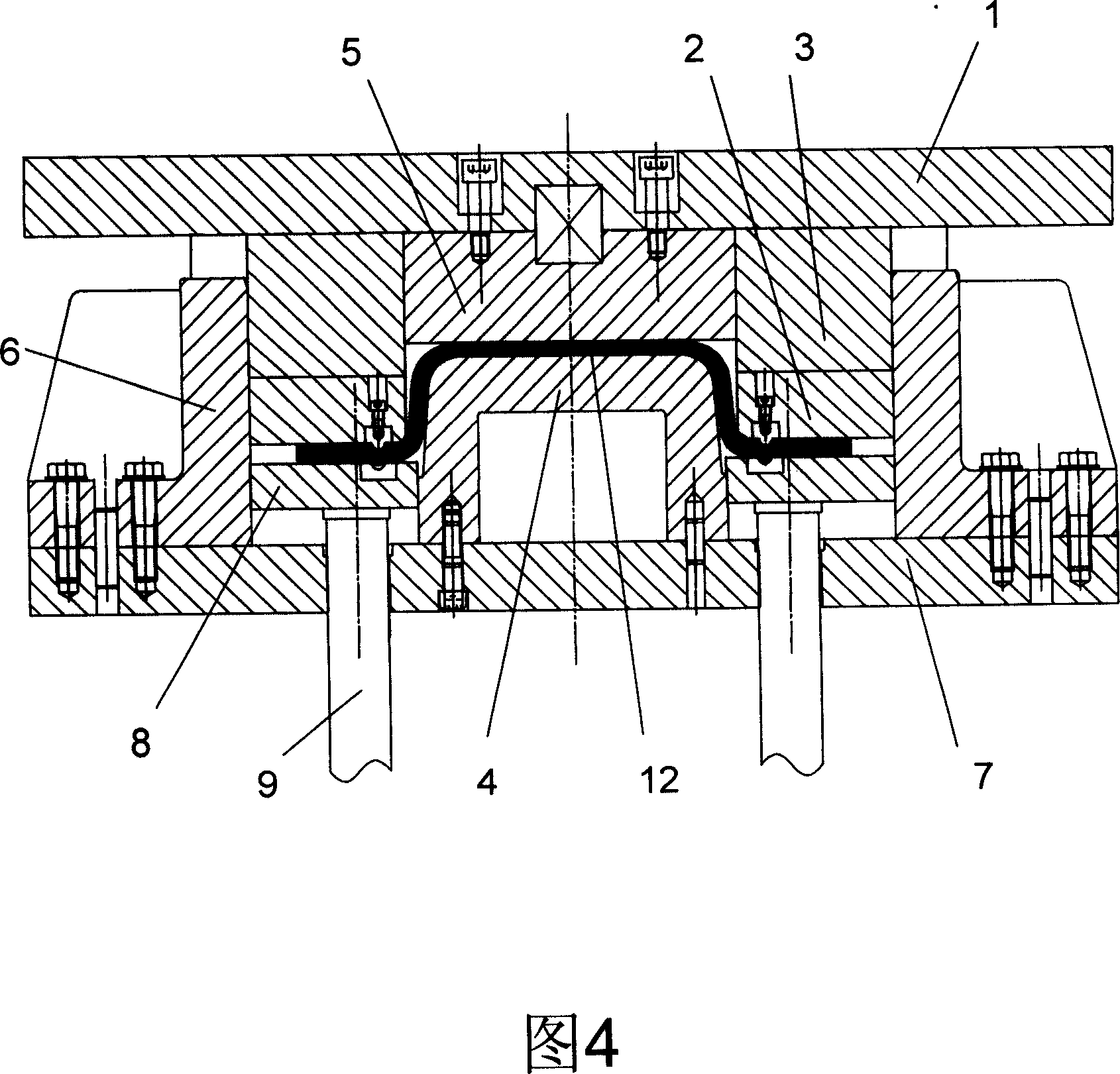

Vehicle plate surface galling defect inducing device

The invention discloses a kind of car board surface galling flaw induction equipment which includes the cavity die section and the male die section and the cavity section includes a top bottom board, a cavity, a cavity bearer supporting bracket and the male die section includes the down bottom board, male die, back guide block, pressure side board, active top bar, and the male die fixes on the down bottom board and corresponds with the cavity backup plate of the cavity die section and the active top bar lays on the down bottom board and lays at the two sides of the sale die and the back guide block fixes on the down bottom board and lays at the two sides of the top bar and the pressure side board lays on the top bar. When the nickelclad lays on the induction equipment on the pressure board and the cavity die moves downstream driving by the pressure machine and at the time of the cavity tie contacting the nickelclad the pressure side board moves downstream with the cavity die and forms the bonding knob on the surface of cavity die and pressure side board surface and during the process of press the bonding knob may fish tail the surface of the nickelclad generating the galling flaw and with the increasing of pressure times the degree of the galling becomes more and more seriously and it provides the technology support for the evaluation system of the galling flaw.

Owner:BAOSHAN IRON & STEEL CO LTD

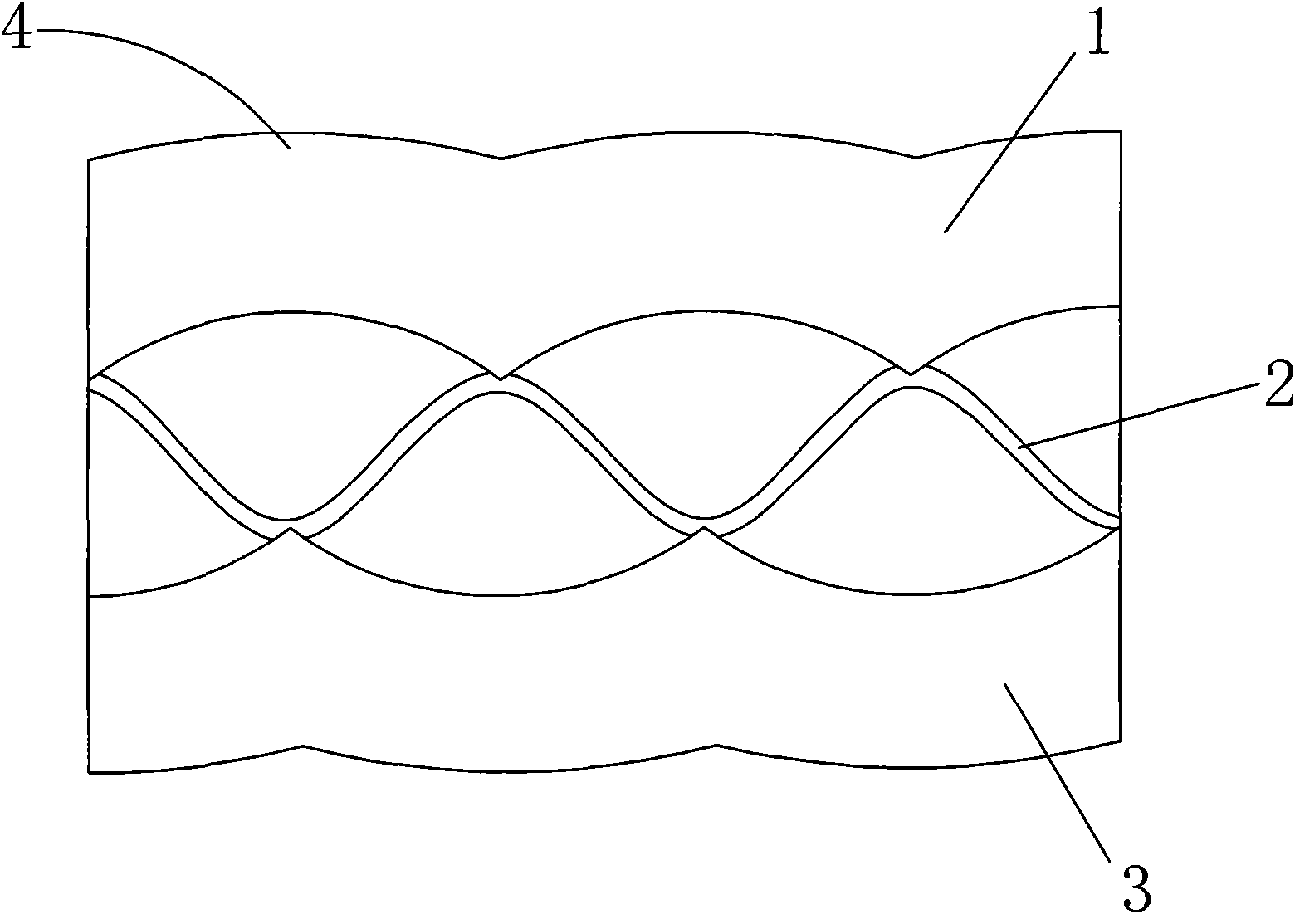

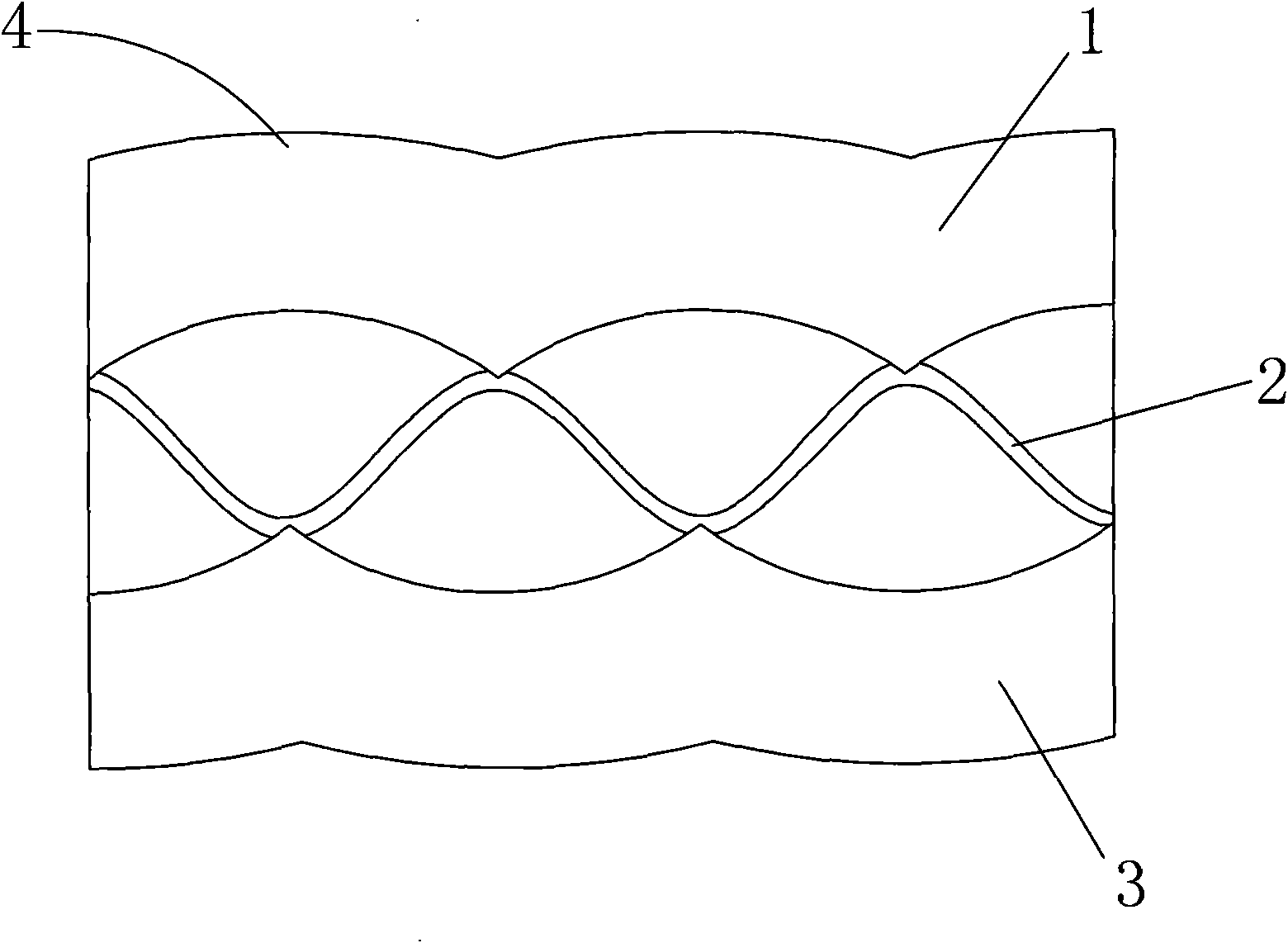

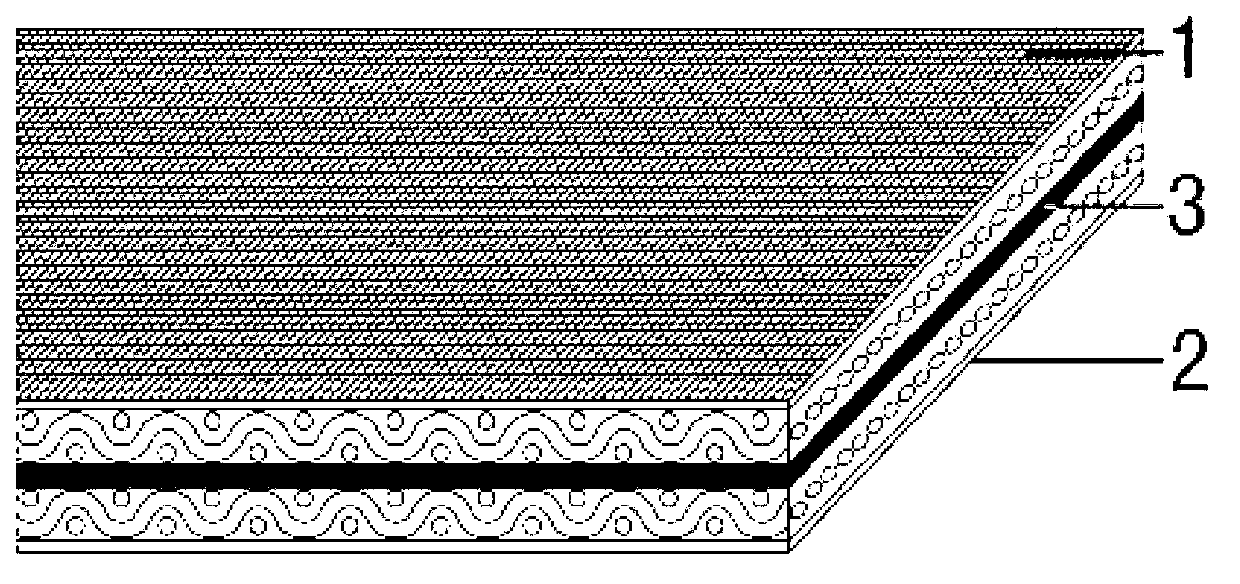

Improved structure of thermal insulation textile

The invention discloses an improved structure of a thermal insulation textile. The surface layer of the textile is a cotton weaving layer; the inner layer of the textile is a galling-trimmed super-fine denier terylene stretch yarn layer (fibers, the fiber number of which is below 0.55dtex, are super-fine denier yarns in industry, wherein dtex is decitex and refers to the gram of a fiber bundle which is 10000 meters long); the middle layer of the textile is a yarn layer with elastic traction; the fabric structures of the surface layer and the inner layer of the textile are plain knitting structures; the surface layer and the inner layer of the textile are weaved together through the middle layer of the textile; the surfaces of the surface layer and the inner layer of the textile are provided with a plurality of convex longitudinal strips at intervals under the elastic traction action of the terylene cladding yarns of the middle layer of the textile, thereby forming a thicker air layer; and moreover, the open air layer of the inner layer is formed after the galling trimming is carried out on the super-fine denier terylene stretch yarn of the inner layer of the textile, thereby greatly improving the thermal insulation rate.

Owner:JIANGSU

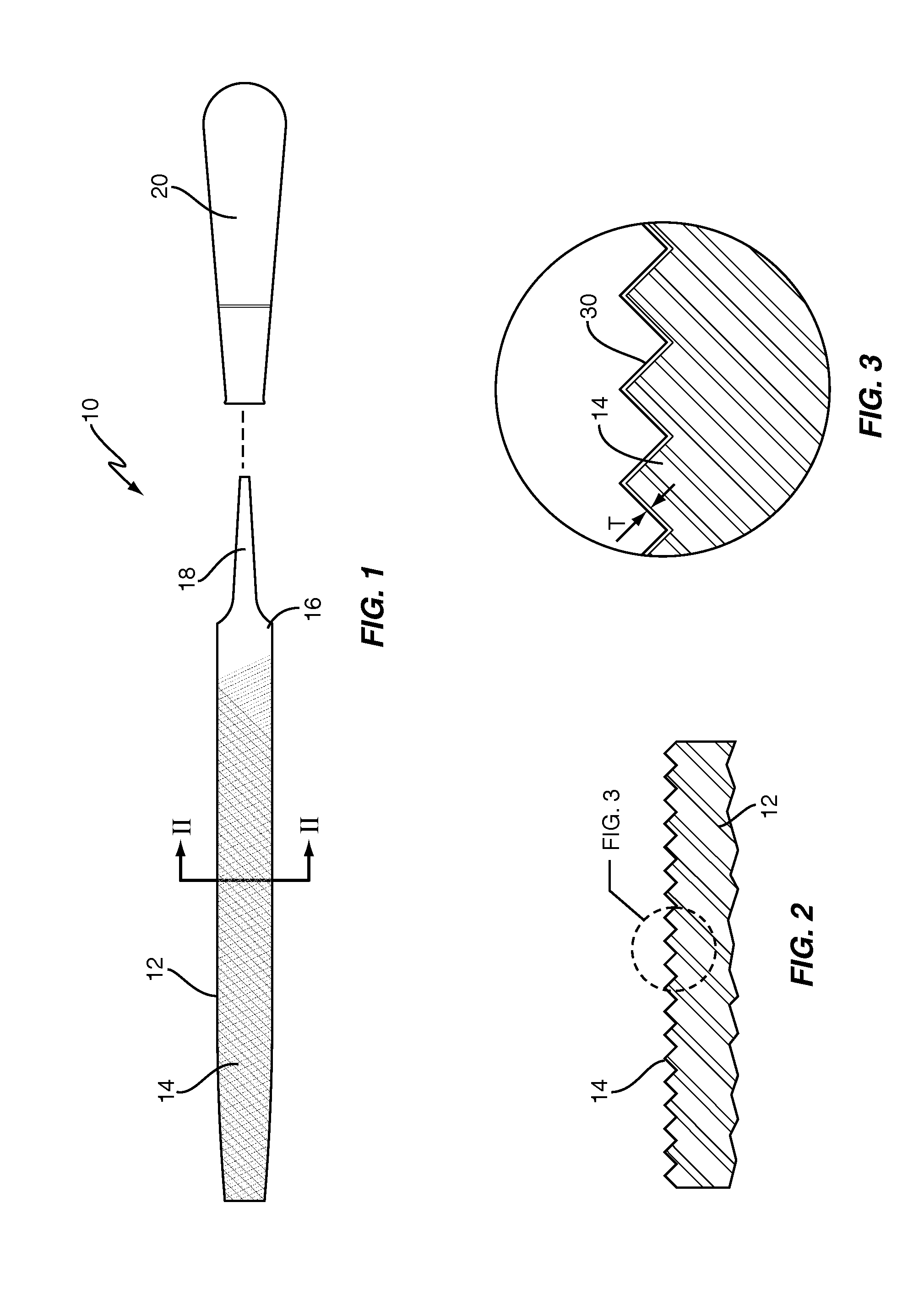

Transition Metal Nitride Coated File

InactiveUS20070147963A1Metallic material coating processesFiling/rasping toolsGallingCeramic coating

A hand operated file is provided with a thin ceramic coating of a transition metal nitride, such as vanadium nitride and / or zirconium nitride, on its teeth. The coating may be 20 um or less, thereby not altering the macro dimensions of the file. The coating may be applied using a vapor deposition process such as physical vapor deposition, and advantageously via a physical vapor deposition process where the file body does not exceed a temperature of about 300° F. The coating helps prevent galling, thereby increasing the useful life of the file.

Owner:COOPER BRANDS

Anti-galling coating for oil sleeve joint and coating method thereof

ActiveCN102453407AMeet the use requirementsHigh bonding strengthDrilling rodsPretreated surfacesGallingUltimate tensile strength

The invention relates to the technical field of oil sleeve joint surface treatment, and discloses an anti-galling coating for an oil sleeve joint. The coating is a composition, and comprises the following components in percentage by weight: 5 to 20 percent of polyphenylene sulfide, 10 to 40 percent of polytetrafluoroethylene, 2 to 15 percent of molybdenum disulfide, 1 to 10 percent of polyvinylpyrrolidone, 1 to 10 percent of octyl phenyl polyoxyethylene ether, and the balance of water, wherein the polyphenylene sulfide, the polytetrafluoroethylene, the molybdenum disulfide and the polyvinylpyrrolidone are powdery particles with the particle size of 0.01-5mu m; and the octyl phenyl polyoxyethylene ether is liquid. By the anti-galling coating and the coating method thereof, the bonding strength and anti-galling property of the coating can be convenient to control, and the coating process is simple, easy to operate and suitable industrial implementation.

Owner:BAOSHAN IRON & STEEL CO LTD

Conveying belt for paper conveyer and manufacturing method thereof

ActiveCN103342242ASmall diameterAvoid scratchesConveyorsArticle feedersElectrical resistance and conductanceAlcohol

The invention relates to a conveying belt for a paper conveyer and a manufacturing method of the conveying belt. The conveying belt comprises a middle layer, an upper surface and a lower surface, wherein the upper surface and the lower surface are adhered to the middle layer through an adhesion agent. Each of the upper surface and the lower surface comprises, by weight, 45%-55% of polyurethane, 45-55% of nylon, 0.3-0.5% of accelerant, 0.05-0.08% of colorant and 40-45% of methyl alcohol. According to the formulation, the manufacturing method of the conveying belt comprises the following steps of drying, mixing, roll manufacturing, galling, application of adhesive, combination of the upper surface, the lower surface and the middle layer and the like. A rubber hardness meter is used for testing the conveying belt manufactured according to the method, a testing result shows that the hardness of the conveying belt is 65-70 degrees, the hardness of the conveying belt manufactured according to the method is smaller than that of general rubber, and therefore the conveying belt manufactured according to the method meets the paper delivery requirement and will not scratch paper. A resistance test result shows that the resistance value of the conveying belt is 2.3*10^8 ohms. The conveying belt for the paper conveyer can well eliminate the electrostatic interaction between the paper and the conveying belt.

Owner:RIZHI TRANSMISSION OF POWER SYST SHANGHAI CO LTD

Aerated brick wall plastering construction method

The invention discloses an aerated brick wall plastering construction method. The method comprises the following steps that firstly, a wall is cleaned, crack filling is performed, and then, after the wall is showered and moistened by watering, slurry throwing and galling are performed on the wall; next, a steel wire mesh is hung at a junction part between an aerated brick and a concrete wall; then, fine cement mortar is uniformly sprayed and coated on the wall, and primary scraping and leveling is performed; before the primary solidification of the mortar of the first plastering, gridding cloth is fully hung on the whole wall; after the first plastering mortar is finally solidified, the wall is subjected to second plastering guniting; meanwhile, the wall is subjected to cleaning and polishing treatment; and finally, the wall maintenance is performed. The construction method has the advantages that the aerated brick wall is subjected to plastering construction, so that the perpendicularity and the flatness of the wall can be guaranteed; the gridding cloth is arranged between a plastering surface layer and a bottom layer, so that the tensile strength and the deformation resistance of the wall are greatly improved; the aerated brick wall can be effectively prevented from generating plastering cracks; and the construction quality of the plastering wall is improved.

Owner:CCFED THE FIRST CONSTR & ENG

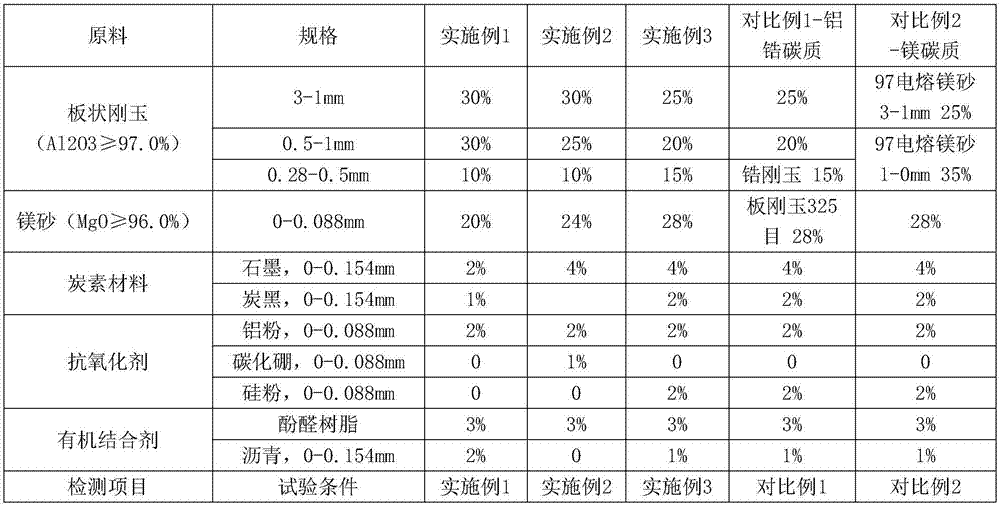

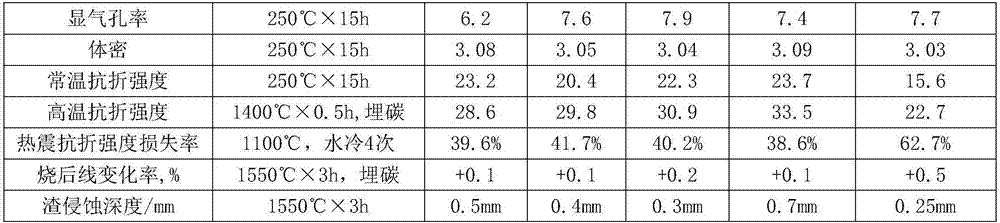

Aluminum-magnesium carbon sliding plate brick for converter slag stopping and production method thereof

The invention discloses an aluminum-magnesium carbon sliding plate brick for converter slag stopping and a production method thereof. The aluminum-magnesium carbon sliding plate brick is produced from the following components in percentage by weight: 60-70% of corundum, 20-28% of magnesia powder, 2-7% of a carbon material, 2-5% of an anti-oxidant, and 3-5% of an organic binding agent. The method comprises: pre-mixing; feeding and mixed milling; press molding; baking for curing; polishing green faces, metal hooping and solid lubricant coating on work surfaces; and thermal insulation and drying. The invention has the advantages that the corundum with high hardness ensures the abrasion strength of the sliding plate surface and avoids the problem of steel drilling galling caused by the low strength of the surface; the corundum aggregate reduces the thermal expansion coefficient of materials and the thermal shock resistance is also significantly better than that of the magnesium carbon sliding, basically the same with that of aluminum carbon; and a fine powder part use a magnesium carbon material, so that the material has more excellent erosion resistance, is small in hole broadening after using, and longer in service life compared with aluminum carbon or aluminum zirconium carbon materials.

Owner:ANHUI XINHAI ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

Composite particles which contain both cellulose and inorganic compound

ActiveUS20150174255A1Large apparent specific volume and pore volumeImprove retentionOrganic active ingredientsBiocideCelluloseGalling

Provided are composite particles which exhibit excellent fluidity and high liquid retentivity and which exhibit high fluidity even in a liquid-holding sate. Also provided are composite particles which permit direct compressing in an open feed manner and which suffer from little compressing trouble and exhibit high shapability. When shaped together with an active ingredient, the composite particles provide shaped bodies which have uniform weight, uniform active ingredient content, and high hardness and which suffer from less galling.

Owner:ASAHI KASEI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com