Wool-like knitted fabric and production method thereof

A wool knitted fabric and fabric technology, applied in the field of imitation wool knitted fabric and its preparation, can solve the problems of strong luster restricting development, hygroscopic performance of all acrylic fabrics, poor pilling resistance, low grade of all acrylic fabrics, etc. Competitive advantage, outstanding performance, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

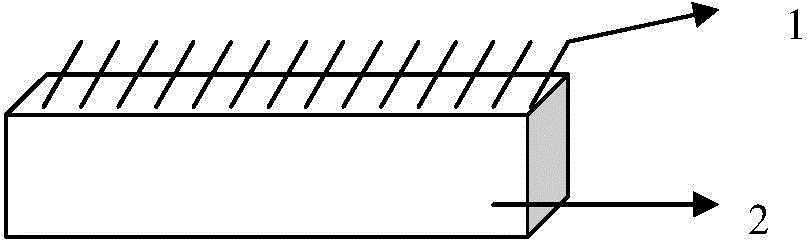

Image

Examples

Embodiment 1

[0028] (1) Raw material preparation: blended yarn of acrylic fiber and cotton, yarn count 38S, fiber content of acrylic fiber 70%, cotton 30%.

[0029] Weaving on the upper machine: choose a machine number of 24N large circular machine weaving, and the weight of the finished fabric is 200g / m 2 about.

[0030] Cutting and rolling on the machine to ensure the flatness of the cloth surface and avoid creases on the cloth surface.

[0031] (2) Finishing process:

[0032] Pre-treatment process: place the fabric in a solution with a bath ratio of 1:16 and a temperature of about 50-70°C; solution additives: penetrant 0.7-2g / l, silicon defoamer 0.04-0.1g / l , hydrogen peroxide 2~5g / l, trisodium phosphate 2~3g / l, soda ash 2~3g / l.

[0033] Dyeing process of acrylic fiber: Add additives and dyes at 40°C, heat up at 1-2°C / min to 95-100°C and run for 40-60min;

[0034] Soaping process: put the fabric into a solution with soaping agent 1-3g / L and run for 20 minutes;

[0035] Cotton dyein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com