Patents

Literature

2348results about How to "Good light fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printing liquids for improved print quality

InactiveUS6022908AImprove print qualityReduce bleedingDuplicating/marking methodsInksColoring agentsAnionic polymers

A set of printing liquids is disclosed comprising a first anionic printing liquid comprising an aqueous vehicle, at least one first colorant, and at least one first anionic polymer; a second anionic printing liquid comprising an aqueous vehicle at least one second colorant, at least one second anionic polymer, and an acid additive having a pKa up to the pKa of the at least first polymer of the first liquid; a third cationic printing liquid comprising an aqueous vehicle, at least one third colorant, at least one third cationic polymer, and a pH in the range from about 2 to about 5; and a fourth anionic printing liquid comprising an aqueous vehicle, at least one fourth anionic dye, and a precipitating agent. More specifically, the present set of printing liquids may find application in ink-jet printing. The set of ink-jet inks provides improved print quality, specifically, reduced bleed; improved edge-acuity, uniform area fills, and color quality; while maximizing lightfastness without sacrificing printing reliability.

Owner:HEWLETT PACKARD DEV CO LP

Radiation-curable liquid resin composition for coating optical fibers

InactiveUS6136880AConvenient coatingLow viscositySynthetic resin layered productsYarnPhotoinitiatorChemistry

Owner:DSM IP ASSETS BV

Method of manufacturing yarns and fabrics having a wash-durable non-electrically conductive topically applied metal-based finish

Durable non-electrically conductive metal treatments (such as coatings or finishes) for yarns and textile fabrics. Such treatments preferably comprise silver and / or silver ions; however, other metals, such as zinc, iron, copper, nickel, cobalt, aluminum, gold, manganese, magnesium, and the like, may also be present or alternatively utilized. Such a treatment provides, as one example, an antimicrobial fiber and / or textile fabric which remains on the surface and does not permit electrical conductivity over the surface. The treatment is extremely durable on such substrates; after a substantial number of standard launderings and dryings, the treatment does not wear away in any appreciable amount and thus the substrate retains its antimicrobial activity (or other property). The method of adherence to the target yarn and / or fabric may be performed any number of ways, most preferably through the utilization of a binder system or through a transfer method from a donor fabric to a target textile fabric in the presence of moisture and upon exposure to heat. The particular methods of adherence, as well as the treated textile fabrics and individual fibers are also encompassed within this invention.

Owner:MILLIKEN & CO

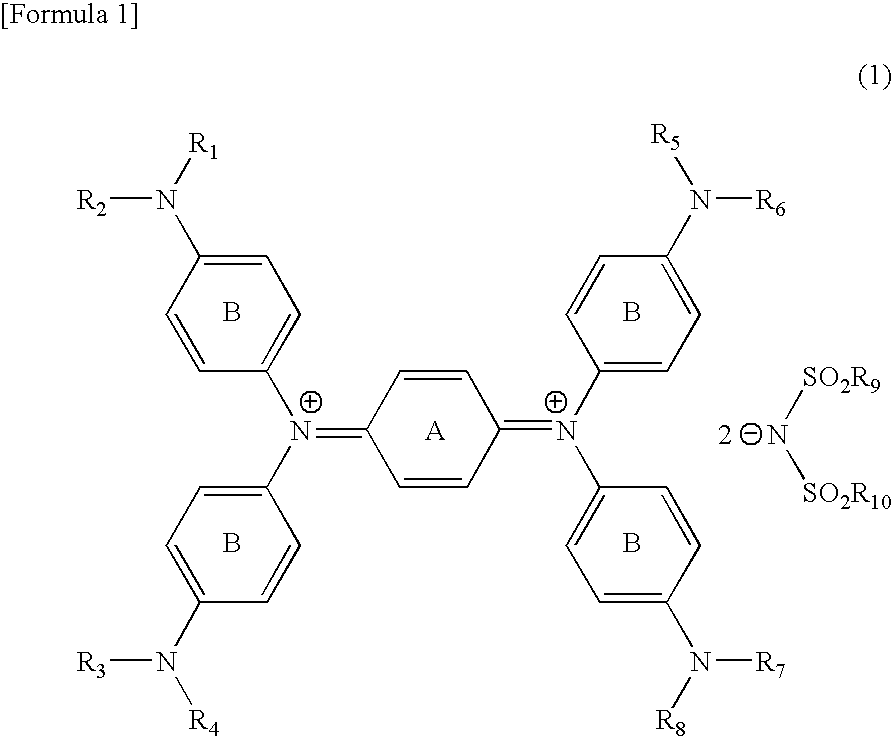

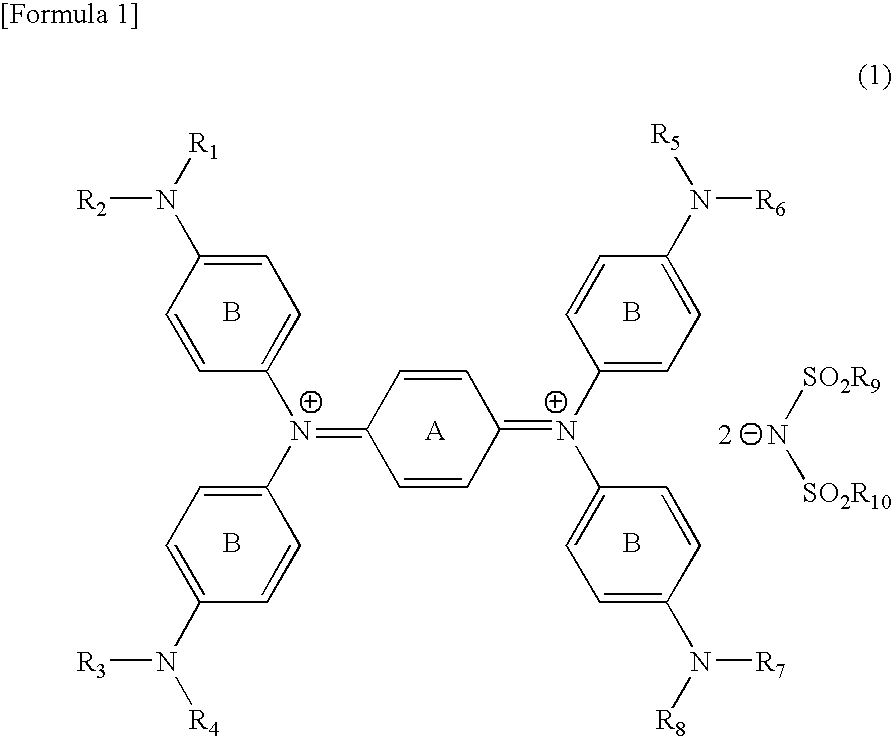

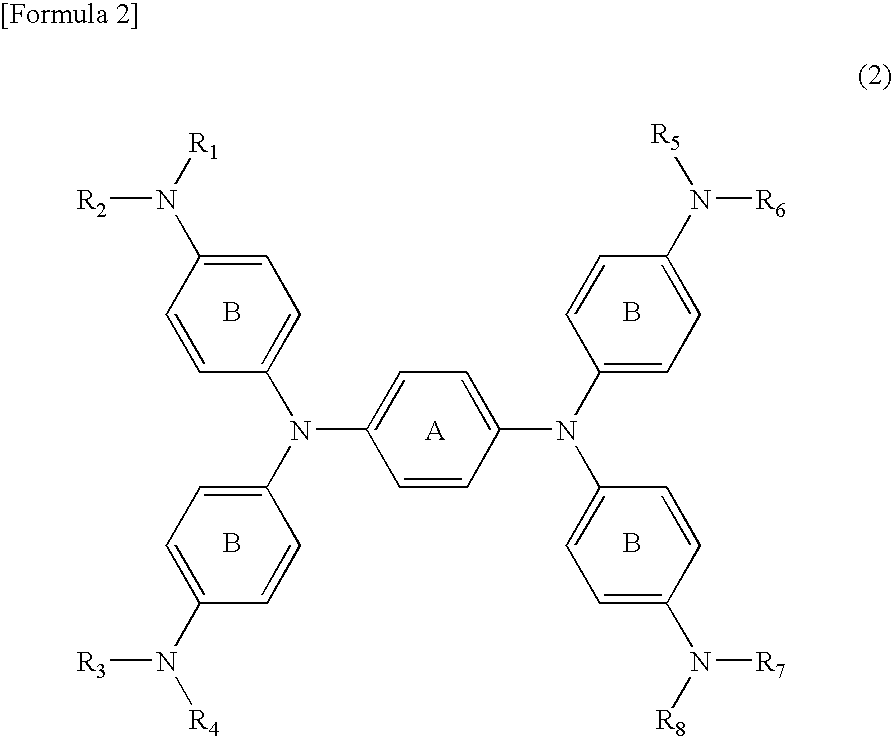

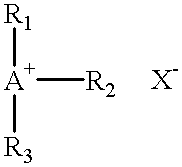

Diimmonium compound and use thereof

InactiveUS20050148786A1High visible light transmittanceHigh light transmittanceOrganic chemistryPhotomechanical apparatusInfraredAmmonium compounds

To provide a near-IR absorption compound free from antimony or arsenic and excellent in stability, especially, in heat resistance, light fastness, and moisture-and-heat resistance and also an IR absorption filter, an optical information recording medium, and a resin composition excellent in durability by using the near-IR absorption compound. The near-IR absorption compound is a diimmonium compound having the following structure and the resin composition contains the diimmonium compound: (wherein R1 to R8 independently denote hydrogen atom or an optionally substituted aliphatic hydrocarbon group; R9 and R10 independently denote an aliphatic hydrocarbon group optionally containing a halogen atom; and rings A and B may further have substituent groups.).

Owner:NIPPON KAYAKU CO LTD

Digital ink jet fabric-treating process

The present invention is digital ink jet fabric treating process, and belongs to the field of textile science and technology. The fabric pre-treating process for digital ink jetting and printing with water thinned pigment ink is suitable for fabric of cotton, hemp, silk, Dacron, polyester and cotton blend, acrylic fiber, etc.; and the treated fabric may be ink jetting printed with water thinned pigment ink in one digital ink jetting printer. After printing and proper heat treatment, may be produced printed product with clear pattern, bright color, and high fastness to resist water washing, friction and sunlight.

Owner:JIANGNAN UNIV

Topical application of solid antimicrobials to carpet pile fibers during carpet manufacture

InactiveUS6641829B1Good light fastnessShampoo durabilityBiocideBiochemical fibre treatmentFiberLiquid medium

Carpeted floor covering articles comprising carpet pile fibers to which a topical antimicrobial application of solid particles has been applied either during or after product manufacture (such as part of a cleaning or treatment process) are provided. Such a topical treatment includes specific inorganic antimicrobial metal ion-based solid compounds, such as silver ion-exchange compounds, silver zeolites, and / or silver glasses, which may or may not be dispersed within a liquid medium for ease in handling and application. Such treatments also optionally include compositions of stain resistant agents, anti soil-redeposition compounds and liquids, surfactants, antistatic agents, and the like, to impart other characteristics to the target carpeted products. Such carpeted products thus exhibit excellent antimicrobial characteristics at both the surface of the carpet pile, as well as within the pile itself. Furthermore, it has been found that application of such solid metal-ion based antimicrobials permits the ability to increase antimicrobial activity for the target carpet product after vacuuming.

Owner:SAGE AUTOMOTIVE INTERIORS INC

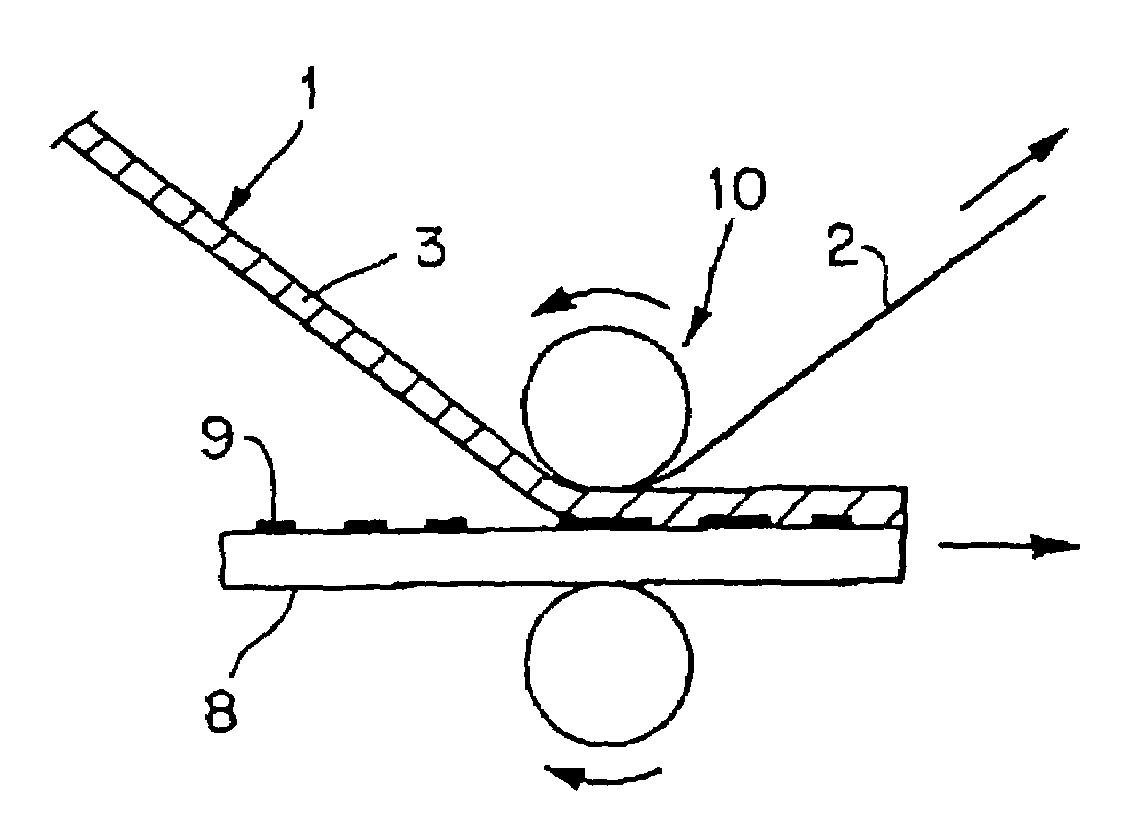

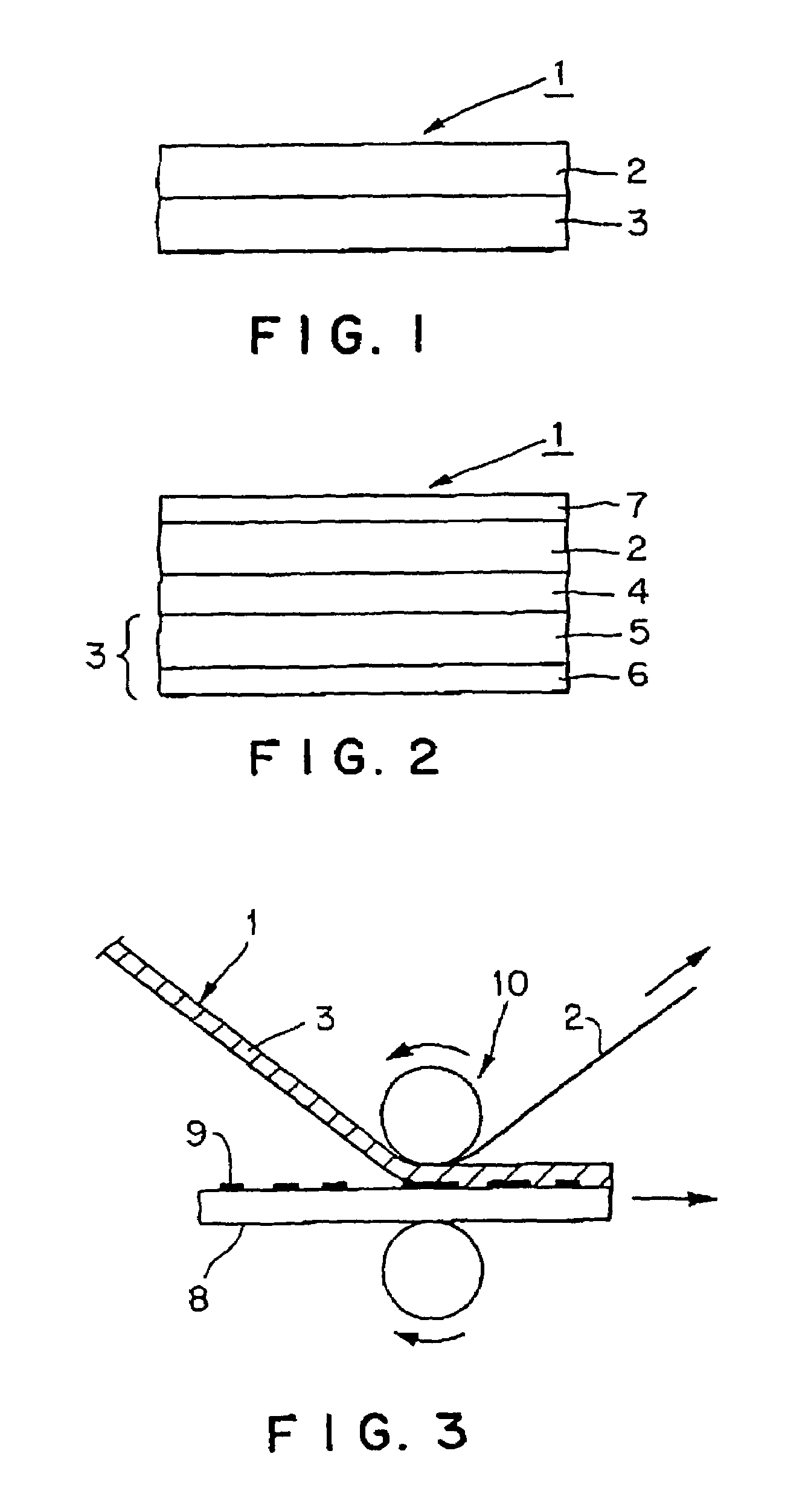

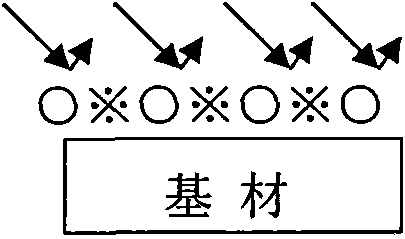

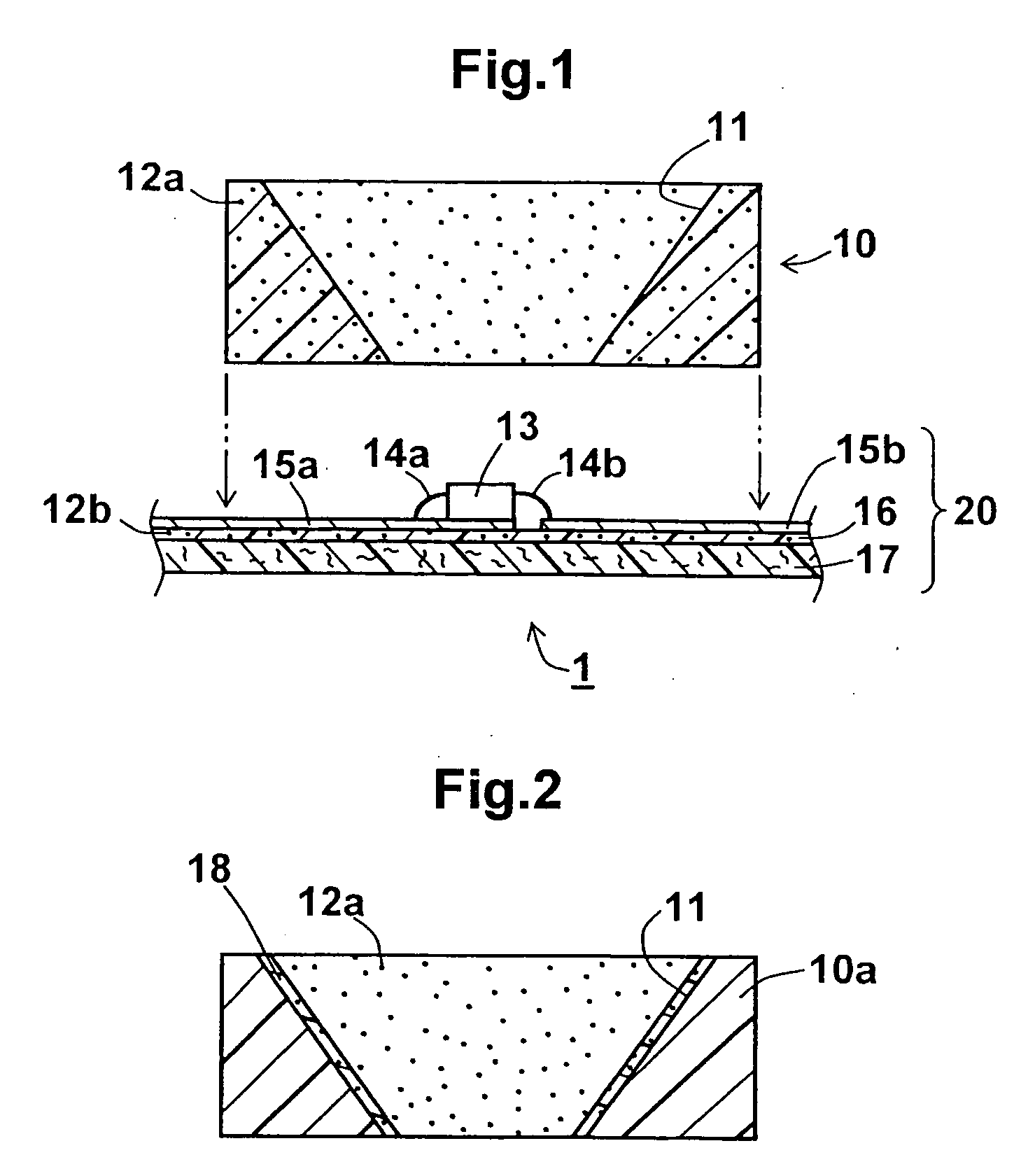

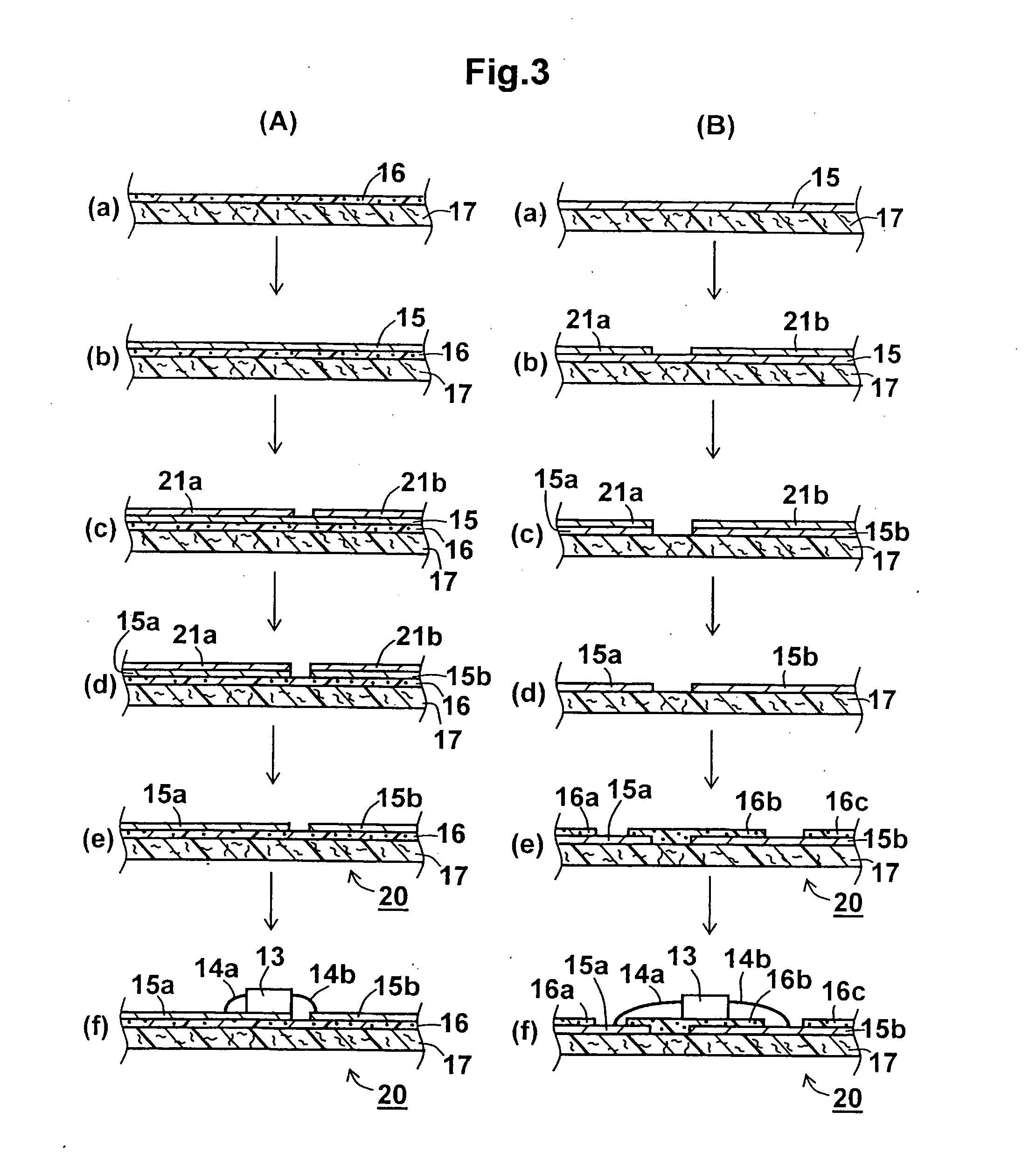

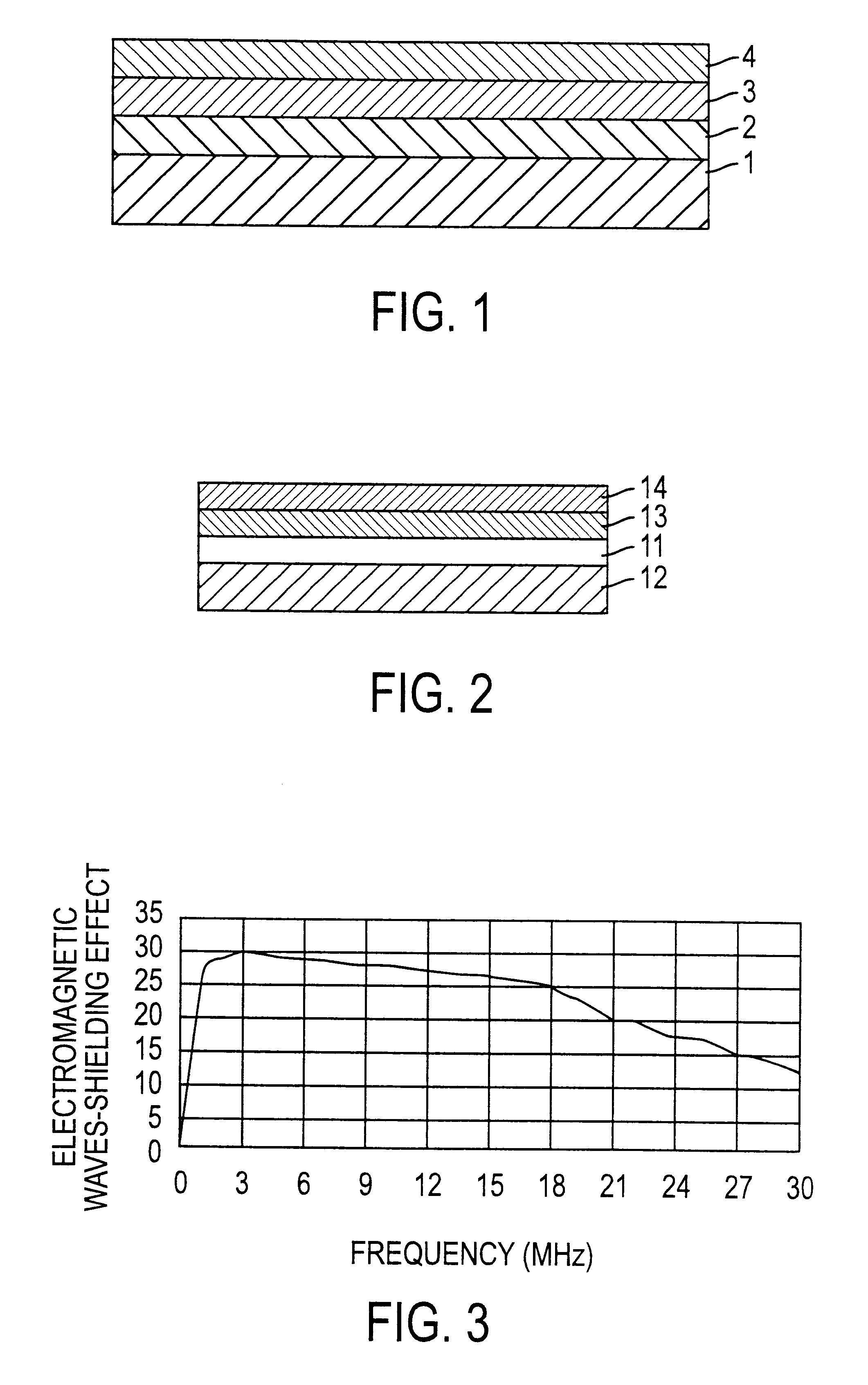

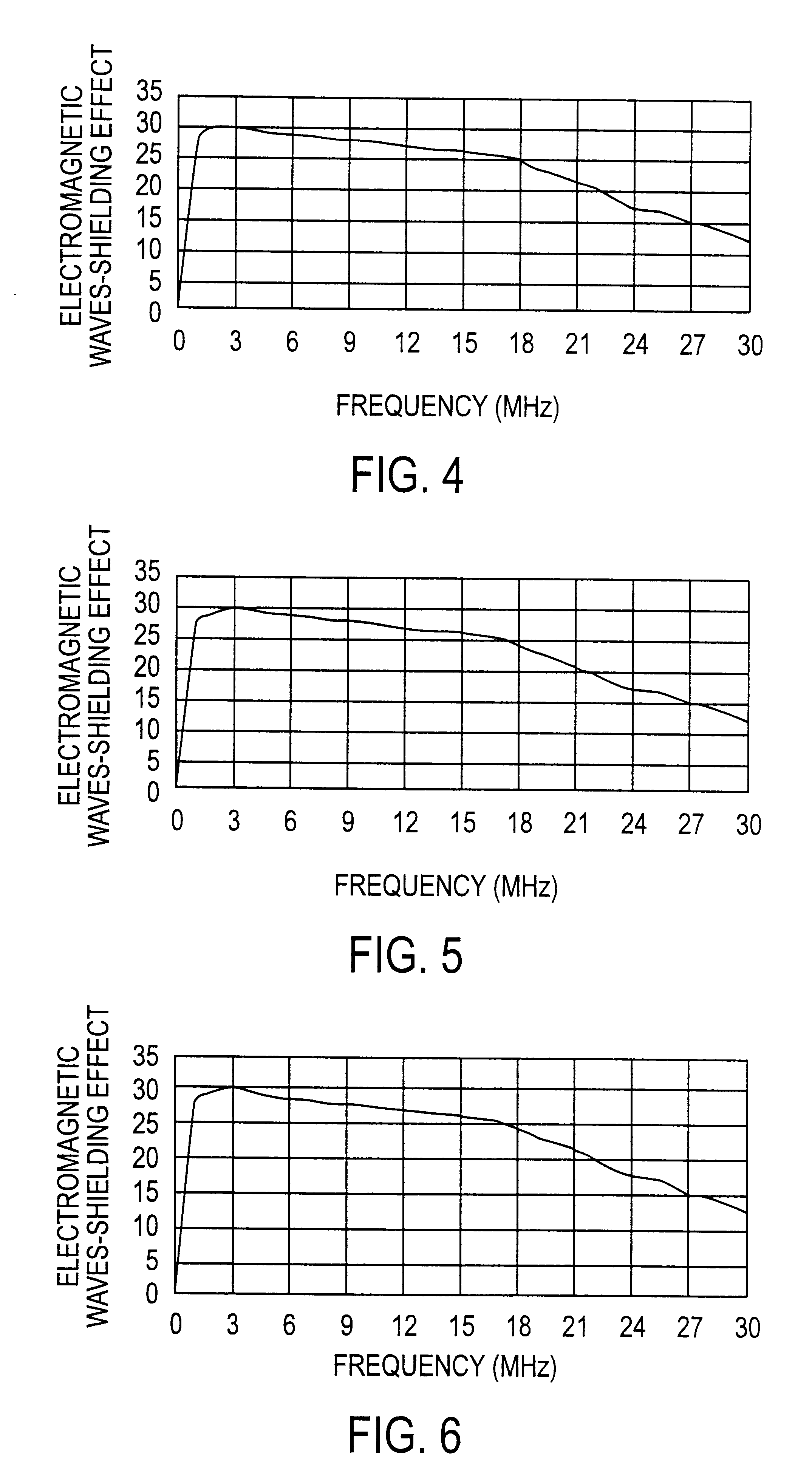

Thermally transferable image protective sheet, method for protective layer formation, and record produced by said method

InactiveUS7169546B2High fastnessIncrease resistancePhotography auxillary processesRadiation applicationsAngle of incidenceLightfastness

Disclosed are a thermally transferable image protective sheet and a method for protective layer formation that can provide a protective layer which can protect an image of a record produced by a nonsilver photographic color hard copy recording method, can impart lightfastness and other properties to the record, and can realize a record having a glossy impression comparable to silver salt photographs. The thermally transferable image protective sheet comprises a support and a thermally transferable resin layer having a single-layer or multilayer structure stacked on the support so as to be separable from the support. The thermally transferable image protective sheet has been constructed so that, when the thermally transferable image protective sheet is put on top of a print so as for the thermally transferable resin layer to be brought into contact with an image portion in the print and the thermally transferable resin layer is thermally transferred to cover at least the image portion of the print followed by the separation of the support from the thermally transferable image protective sheet to form a thermally transferred resin layer on the surface of the print, the surface of the thermally transferred resin layer on the print has a specular glossiness of not less than 60% as measured at an angle of incidence of 20 degrees according to JIS (Japanese Industrial Standards) Z 8741.

Owner:DAI NIPPON PRINTING CO LTD

Artificial suede-type leather and process for producing the same

InactiveUS20060035556A1Good light fastnessBrilliant colorationSynthetic resin layered productsWoven fabricsPolyesterLight irradiation

This invention relates to a suede-like artificial leather using ultra-fine polyester fibers and a polyurethane, and provides a suede-like artificial leather free from the occurrence of specking and having graceful surface appearance and high light fastness. The suede-like artificial leather comprising a fiber-entangled substrate mainly containing ultra-fine polyester fibers with a fiber fineness of 0.7 dtex or less and a polyurethane, and is dyed, and is wherein said polyurethane contains at least one each of yellow pigments, red pigments and blue pigments, and that said artificial leather satisfies all of the following properties (1) through (3) as measured by the methods described in the specification; (1) The infrared reflectance at 850 nm is 60% or more; (2) The surface temperature during light irradiation is 105° C or lower; (3) The light fastness is class 3 or better. Especially since the suede-like artificial leather of this invention has high light fastness, it can be most suitably used for car seats.

Owner:TORAY IND INC

Aquosity elastic heat preserving insulating paint and its preparing process

A water-base and elastic heat insulation coating and the preparation method are provided. The invention adopts the elastic pure emulsion and the silicone-acrylate emulsion as the film former and also adopts the materials such as insulating materials and rutile type titanium pigment talc. The preparation process is that water is added with a dispersant, an antifoamer A, a pH regulator with right amount, propylene glycol and titanium pigment in turns under the stirring speed of 500r / min; the rotary speed is adjusted to 1500r / min and the dispersive degree below 25Mum; then an antifoulant, a mildewproof agent, an antifoamer B, silicone-acrylate emulsion, elastic emulsion and a film forming additive are added to stirred for 10min under the rotary speed of 500r / min and then the rotary speed is adjusted to 300r / min, and two third of the insulating materials are added to stir for 20min; at last, the remaining insulating materials are added to stir for 20min under the rotary speed of 300r / min, and the thickeners A, B are added to stir for 15min; the pH value is adjusted to 7.5 to 9 and a preservative is added to stir for 10min to produce the coating of the invention.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Multiple reversible color change microcapsule anti-counterfeiting material and preparation method and application thereof

InactiveCN101724392AHigh-speed emulsification and dispersionGood weather resistanceOther chemical processesLuminescent/fluorescent substance additionInfraredWater based

The invention discloses a multiple reversible color change microcapsule anti-counterfeiting material and a preparation method and applications thereof. The preparation method comprises the following steps: dissolving at least one of temperature-sensitive material, humidity sensitive material, ultraviolet excited fluorescence material and infrared excited fluorescence material in high boiling point solvent containing UV resistant agent and antioxidant, then adding emulsifier and protective colloid to obtain emulsion solution, and adopting the in-situ polymerization method to obtain the anti-counterfeiting material with microcapsule structure. The microcapsule structure of the invention can isolate the air and the wall of the microcapsule can reduce the light transmission, thus improving the weather resistance and light resistance of the anti-counterfeiting material and prolonging the use validity of the product. The material is a microcapsule aqueous solution so that the material is completely applicable to the coating method of the currently existing water-based paint, removes apprehensions in areas of safety, health and environmental protection, thoroughly solves the defect of the complicated solvent-based (oily material) coating and processing method, satisfies the anti-counterfeiting demand and can be applied in papers, cloth and film materials in large.

Owner:张世智

White color reflecting material and process for production thereof

ActiveUS20120138997A1Improve heat resistanceImprove light resistanceDiffusing elementsSolid-state devicesUltravioletRutile

A general-use white color reflecting material, and a process for production thereof are provided. The white color reflecting material, without troublesome surface treatment such as formation of a reflective layer by plating, is capable of reflecting a near-ultraviolet ray of a wavelength region of 380 nm or longer or a near-infrared ray sufficiently without light leakage; does not become yellow even when exposed to near-ultraviolet rays; has excellent lightfastness, heat resistance, and weatherability; has high mechanical strength and chemical stability; is capable of maintaining a high degree of whiteness; and is easily moldable at a low cost. Further a white color reflecting material used as an ink composition for producing the white color reflecting material in a film shape is also provided. The white color reflecting material comprises; a silicone resin or silicone rubber formed from titanium oxide-containing silicone composition, in which anatase-type or rutile-type titanium oxide particles are dispersed.

Owner:ASAHI RUBBER

Transparent inorganic-oxide dispersion, resin composition containing inorganic oxide particles, composition for encapsulating luminescent element, luminescent element, hard coat, optical functional fi

ActiveCN101296982AHigh refractive indexExcellent mechanical propertiesInorganic pigment treatmentZirconium oxidesSilane couplingChemistry

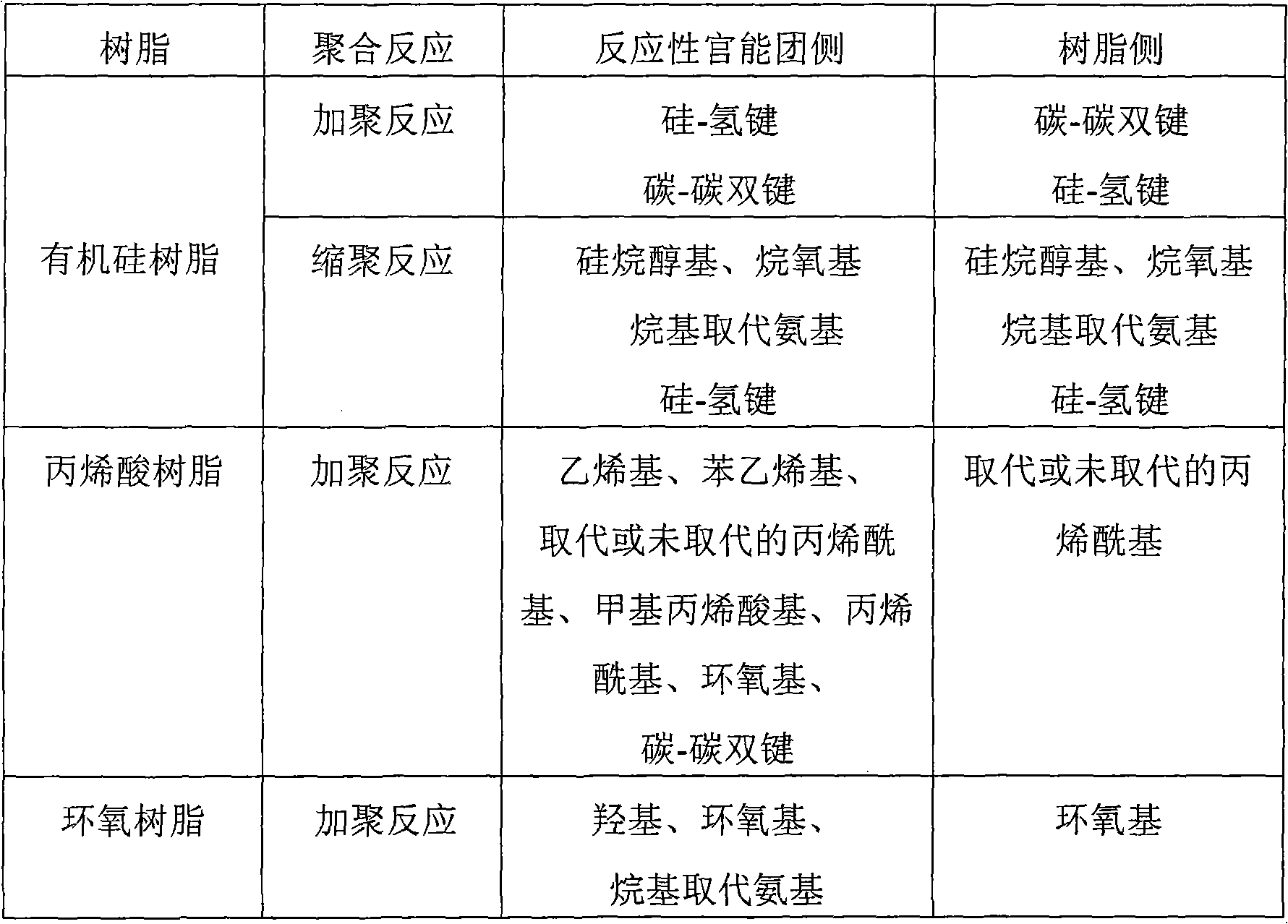

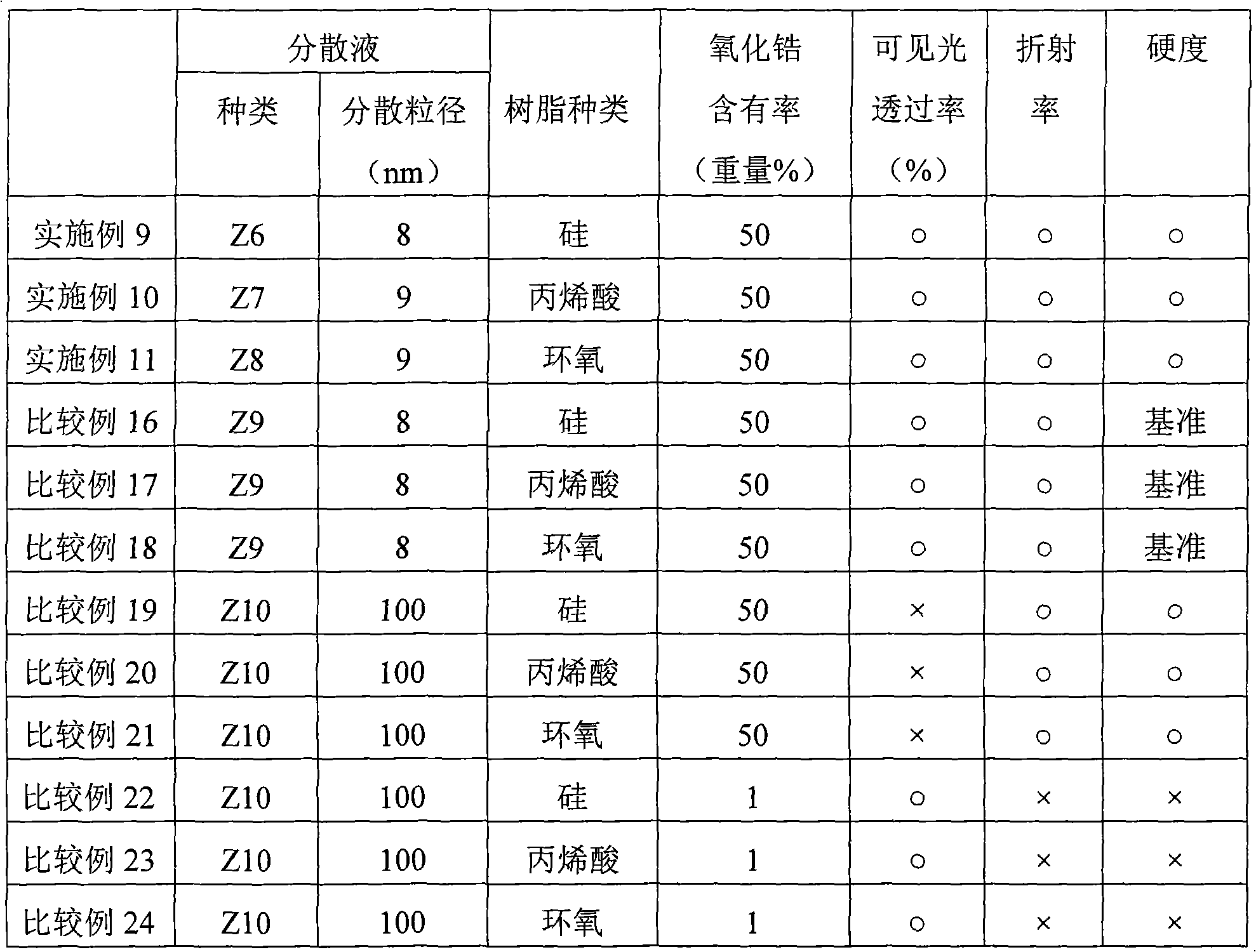

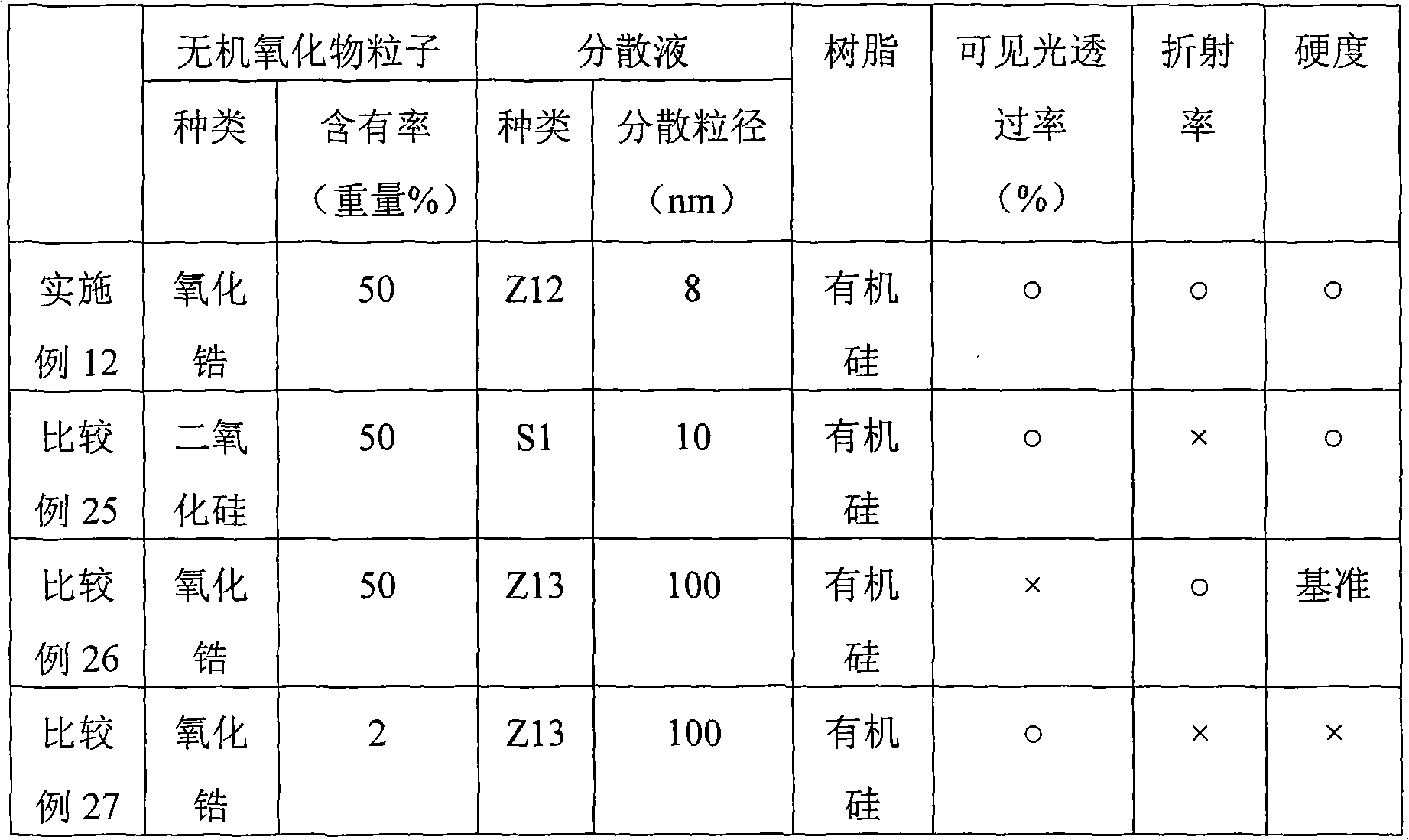

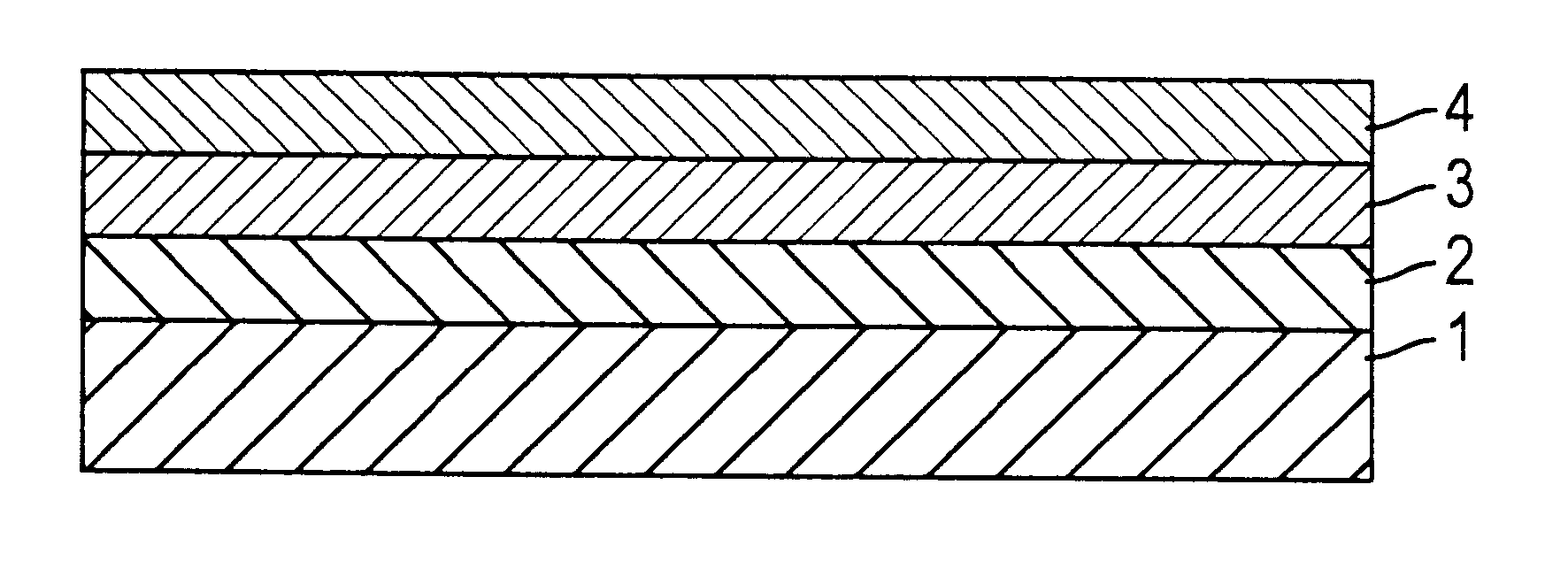

A transparent inorganic-oxide dispersion which contains inorganic oxide particles whose surface has been modified with a surface modifier having one or more reactive functional groups and, due to this, enables improvements in refractive index and mechanical properties and retention of transparency; and an inorganic-oxide-particle-containing resin composition obtained by combining and uniting this transparent inorganic-oxide dispersion with a resin through a polymerization reaction. Also provided are: a composition for encapsulating luminescent elements; a luminescent element; a process for producing the resin composition containing inorganic oxide particles; a hard coat and an optical functional film which have high transparency and can attain improvements in refractive index and toughness; an optical lens; and an optical part. The transparent inorganic-oxide dispersion is characterized by comprising a dispersion medium and inorganic oxide particles the surface of which has been modified with a surface modifier having one or more reactive functional groups and which have a dispersed-particle diameter of 1 to 20 nm. It is further characterized in that the surface modifier is one or more members selected from the group consisting of silane coupling agents, modified silicones, and surfactants.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Adhesive transparent resin and a composite including the same

InactiveUS6224976B1Improve coatabilityMaintain good propertiesSynthetic resin layered productsGlass/slag layered productsChemistryElectronic materials

To provide a transparent resin which is suitable in the process of producing a coating for electronic materials, a glass having both of the scattering-preventing function and the antireflective function, an adhesive agent, a shock-absorbing material, an ultraviolet-cutting sheet for televisions, a filter for VDTs and a high refractive index primer composition as well as the process for the production of primer-coated lenses using said primer composition, is excellent in a coatability, adhesive property, storage stability, durability, shock resistance and the like, and is particularly excellent in a transparency and adhesive property after curing of the same.A transparent resin having an adhesive property characterized by comprising a cured product of the polymerizing composition which comprises at least one of diallyl phthalate, diallyl isophthalate and diallyl terephthalate, and pentaerythritol tetra(3-mercaptopropionate).

Owner:ASAHI KOGAKU KOGYO KK

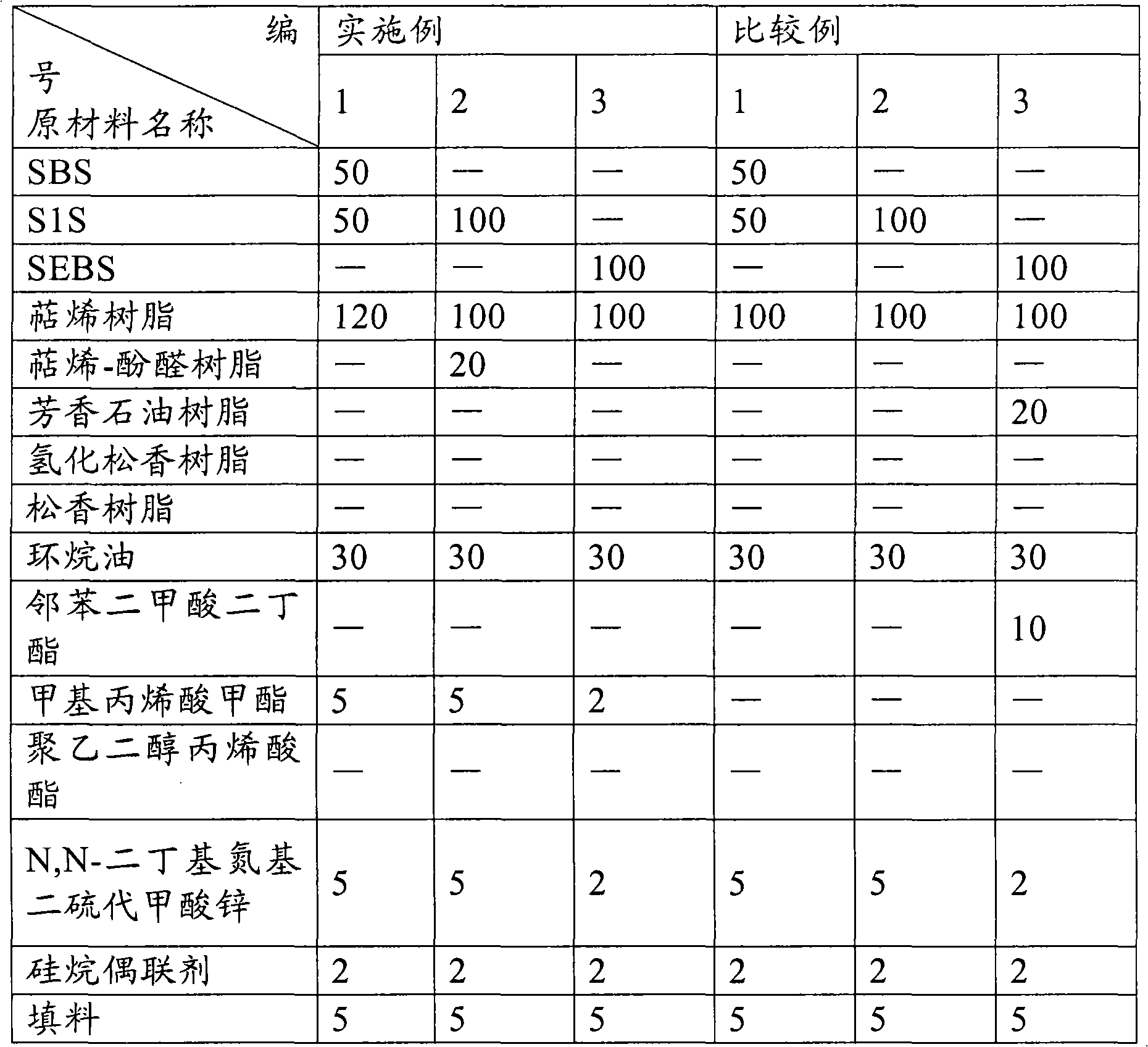

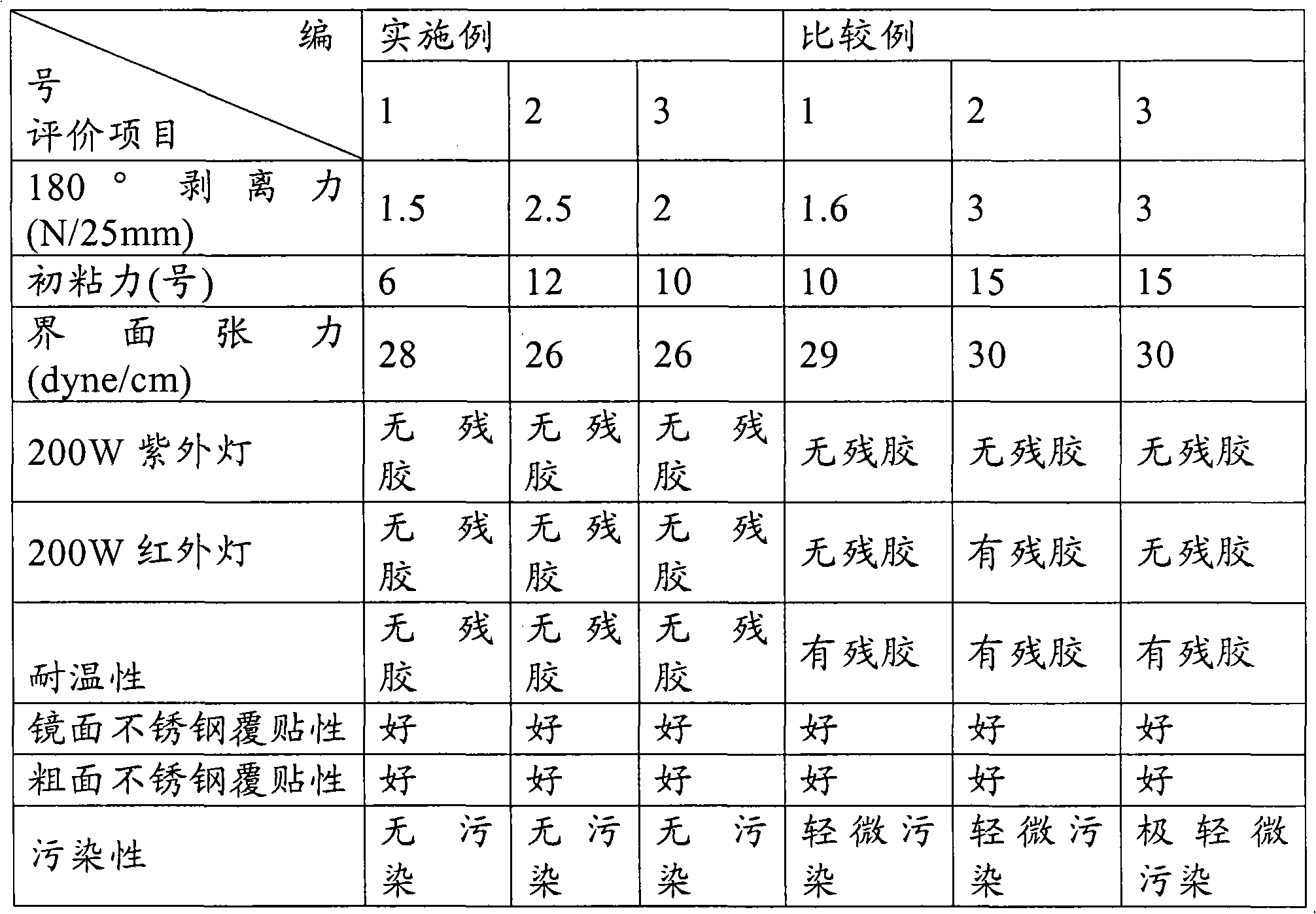

Preparation methods of hot melt pressure-sensitive adhesive and protective film as well as hot melt pressure-sensitive adhesive

ActiveCN102051149AImprove heat resistanceGood weather resistanceLiquid surface applicatorsNon-macromolecular adhesive additivesTectorial membranePolyolefin

The invention discloses preparation methods of a hot melt pressure-sensitive adhesive and a protective film as well as the hot melt pressure-sensitive adhesive. The preparation method of the hot melt pressure-sensitive adhesive comprises the following steps: adding thermoplastic elastomers, a tackifier, a plasticizer, an antiager, an antioxidant, a crosslinker, a filler and the like into a double-mixed column mixer, stirring, heating until the materials are melted down, and uniformly mixing to obtain the pressure-sensitive adhesive. The preparation method of the protective film comprises the following steps: directly pumping the melted and uniformly mixed pressure-sensitive adhesive into a coating roll of the a hot melt coating machine by a heat transfer pump, coating the pressure-sensitive adhesive onto one face of a polyolefin plastic film or thin plastic-coated paper, cooling, and rolling to obtain the protective film (paper). The hot melt pressure-sensitive adhesive disclosed by the invention can obtain good initial stickiness, cohesion and age stripping property by changing the different ratio of the thermoplastic elastomer as well as the variety and usage amount of the tackifier. The prepared polyethylene (PE) film substrate protective film has low interfacial tension, good initial stickiness, high cohesion and high temperature resistance, light resistance and weather resistance, and the comprehensive performance and product cost of the hot melt pressure-sensitive adhesive disclosed by the invention are better than those of the traditional solvent pressure-sensitive adhesive taking natural rubber as the main material.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

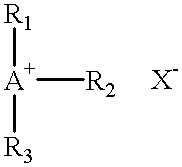

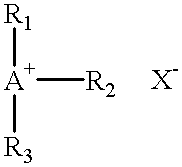

Optical recording material and optical recording medium

InactiveUS20050142490A1Reproduction deteriorationGood light fastnessPhotomechanical apparatusRecord information storageNitrogenNaphthalene

An optical recording material used in an optical recording medium which can record information by light irradiation, this optical recording material containing a dye compound obtained by salt formation between a chelate compound formed by coordination between one metal and one or two compounds represented by the following general formula (1): where A and B are groups of atoms which may be identical or different, and which respectively form aromatic rings, and X1 and X2 are respectively functional groups having one or more active hydrogen atoms which may contain a substituent group, and a cation represented by the following general formula (2): where C is a group of atoms forming a benzene ring or naphthalene ring which may have a substituent group, R1 and R2 are respectively five-membered rings or six-membered rings which may have a substituent group, Y1 is a substituent group, Q3 is a nitrogen-containing heterocyclic ring which may have a condensed ring, p and q are respectively integers from 1 to 4, and n is an integer from 0 to 3.

Owner:TKD CORP

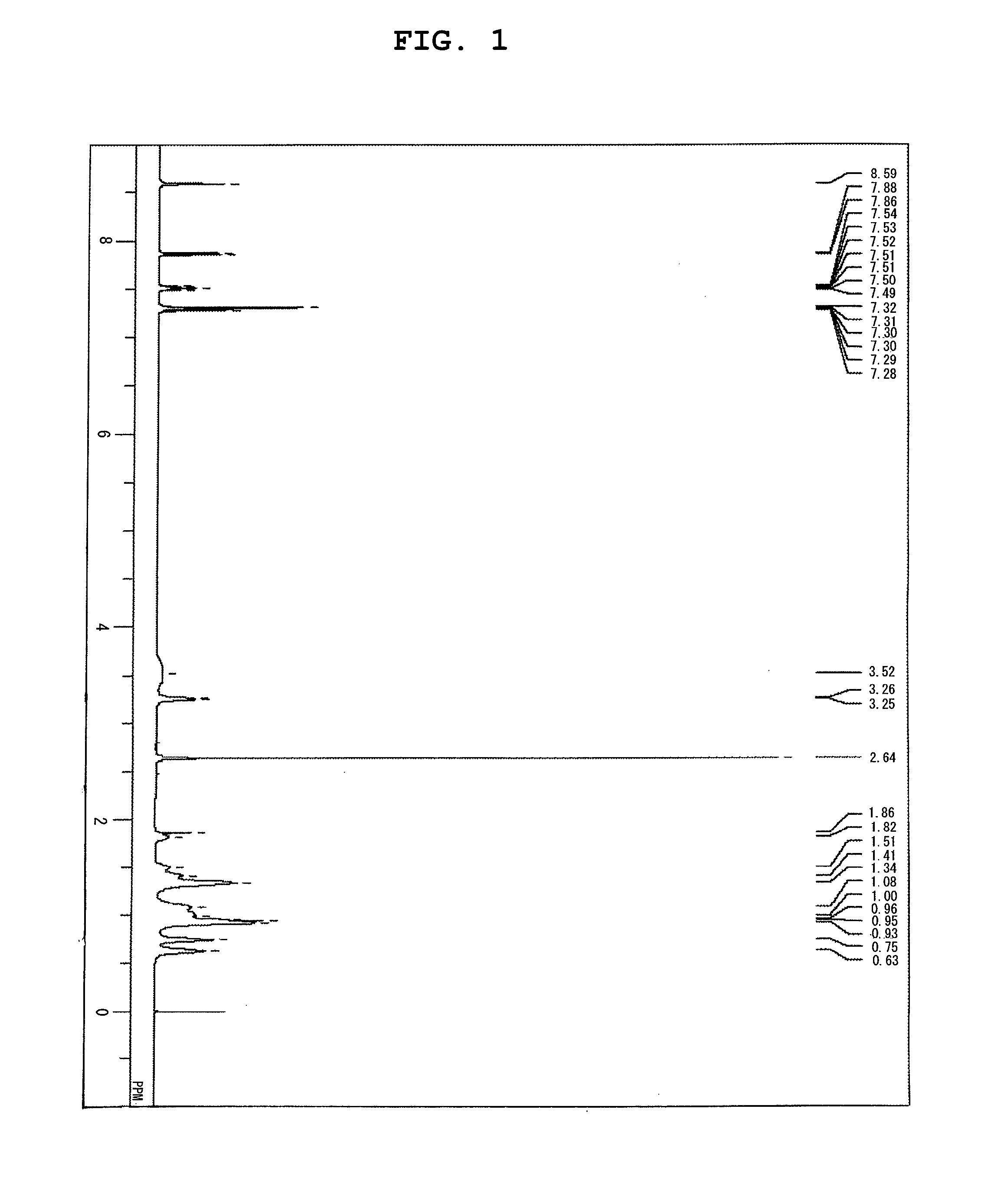

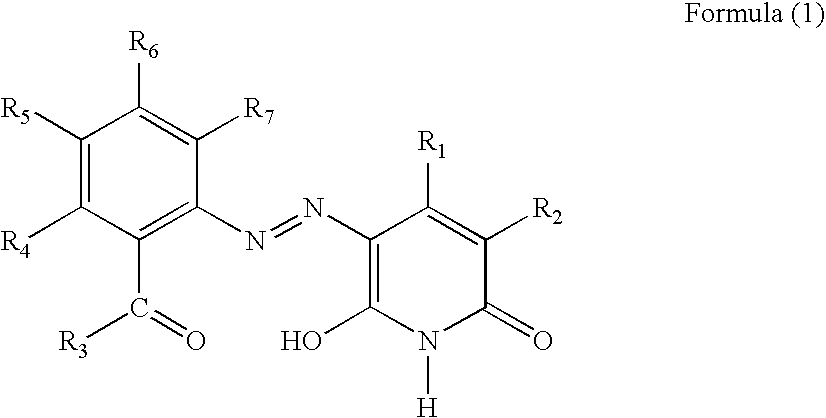

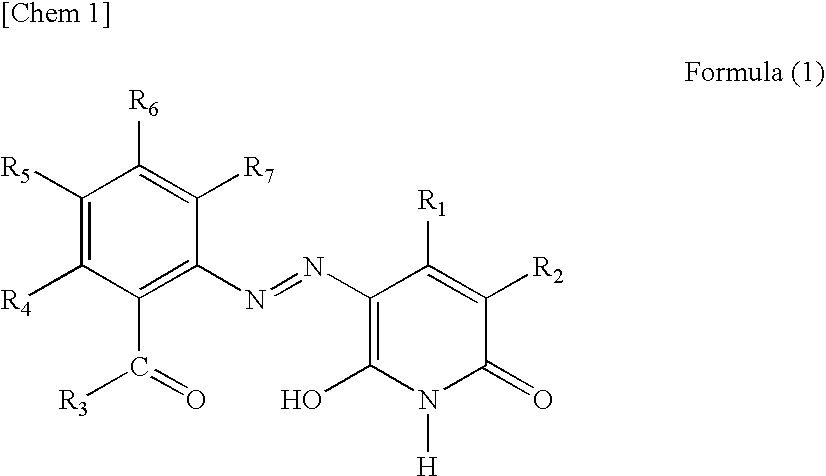

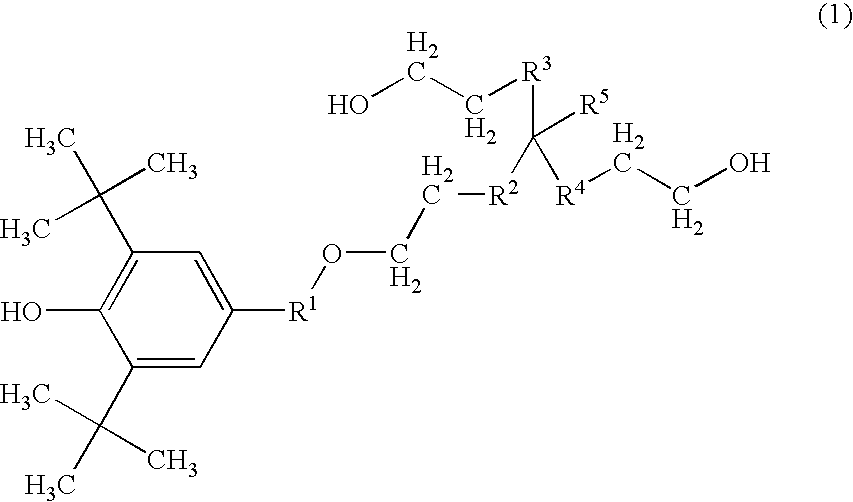

Coloring compound and yellow toner containing the coloring compound

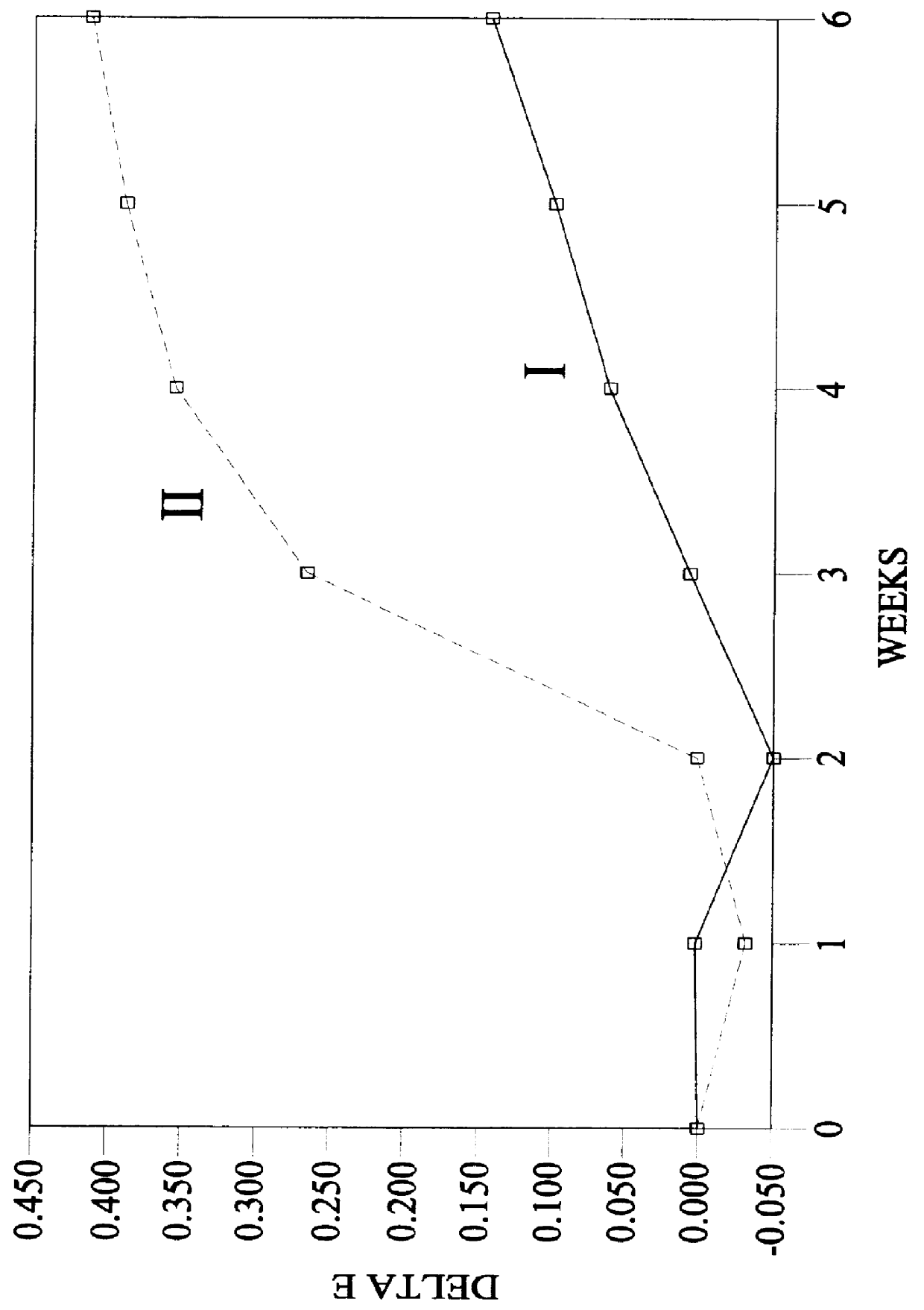

Provided are a coloring compound for color toner which satisfies all of solubility in an organic solvent, a color tone, and lightfastness, and does not inhibit the polymerization of a polymerizable monomer when used in a polymerized toner, and a yellow toner using the coloring compound and achieving compatibility between a good color tone and excellent lightfastness, in which, the coloring compound has a structure represented by the following formula (1).

Owner:CANON KK

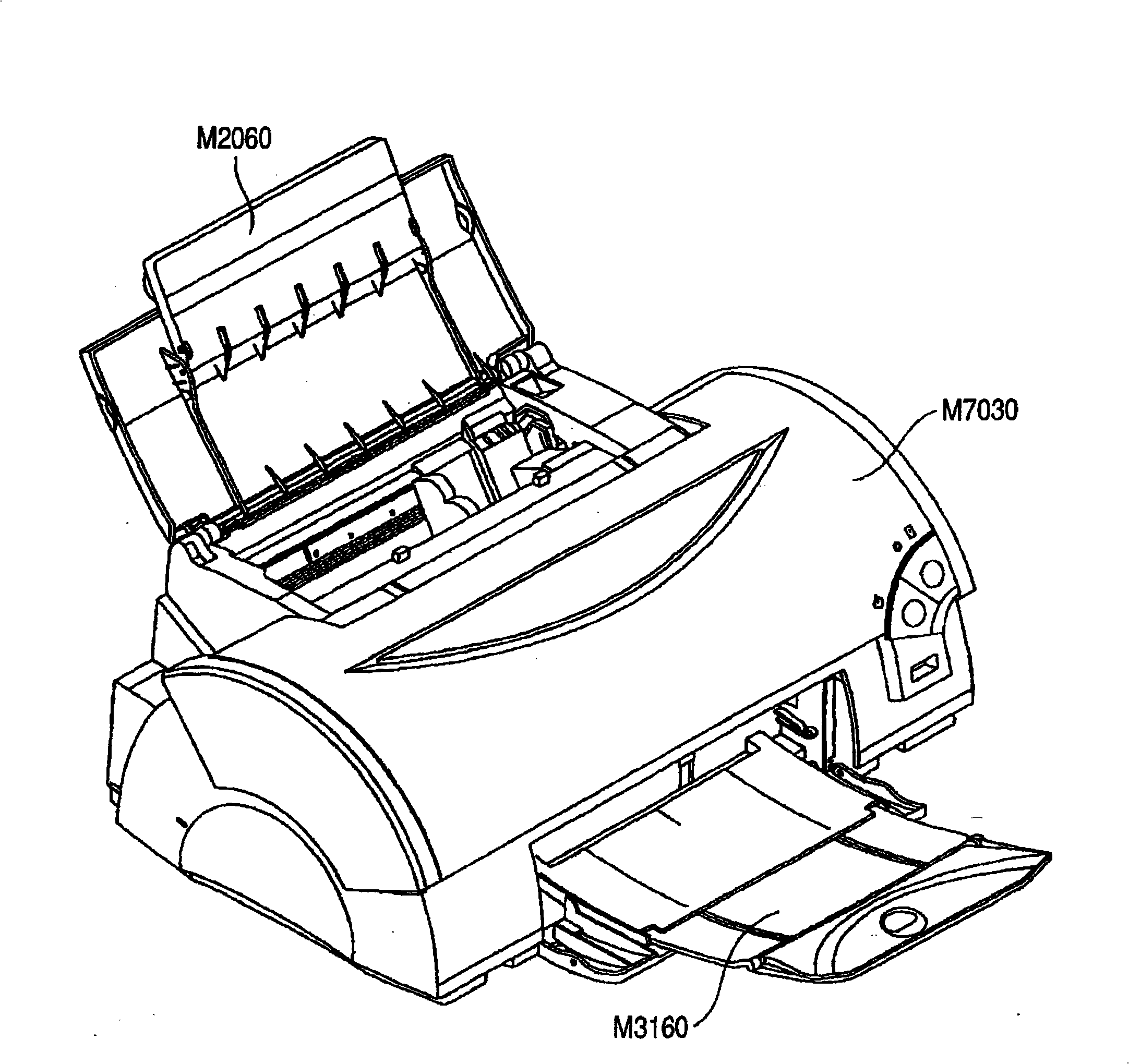

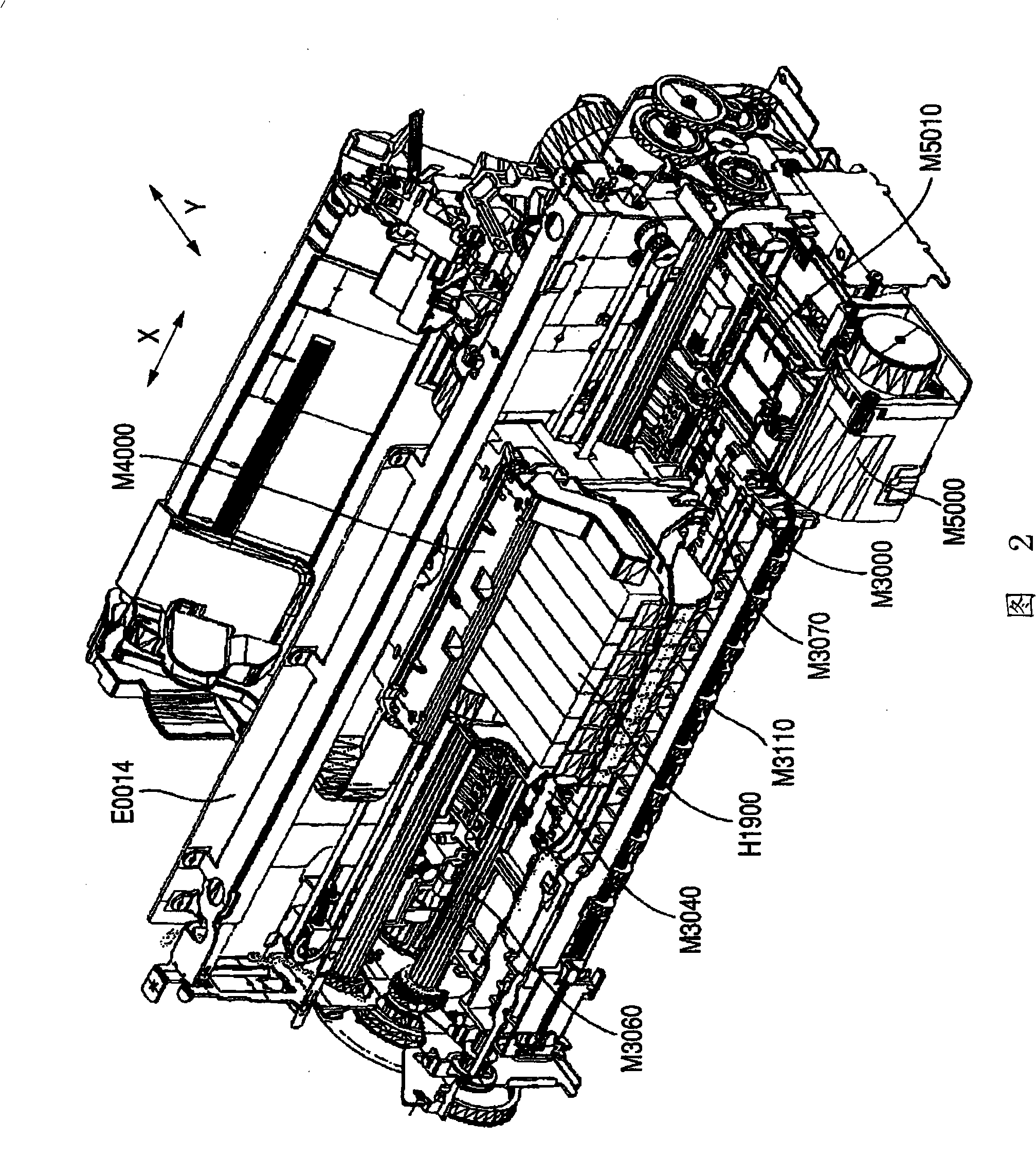

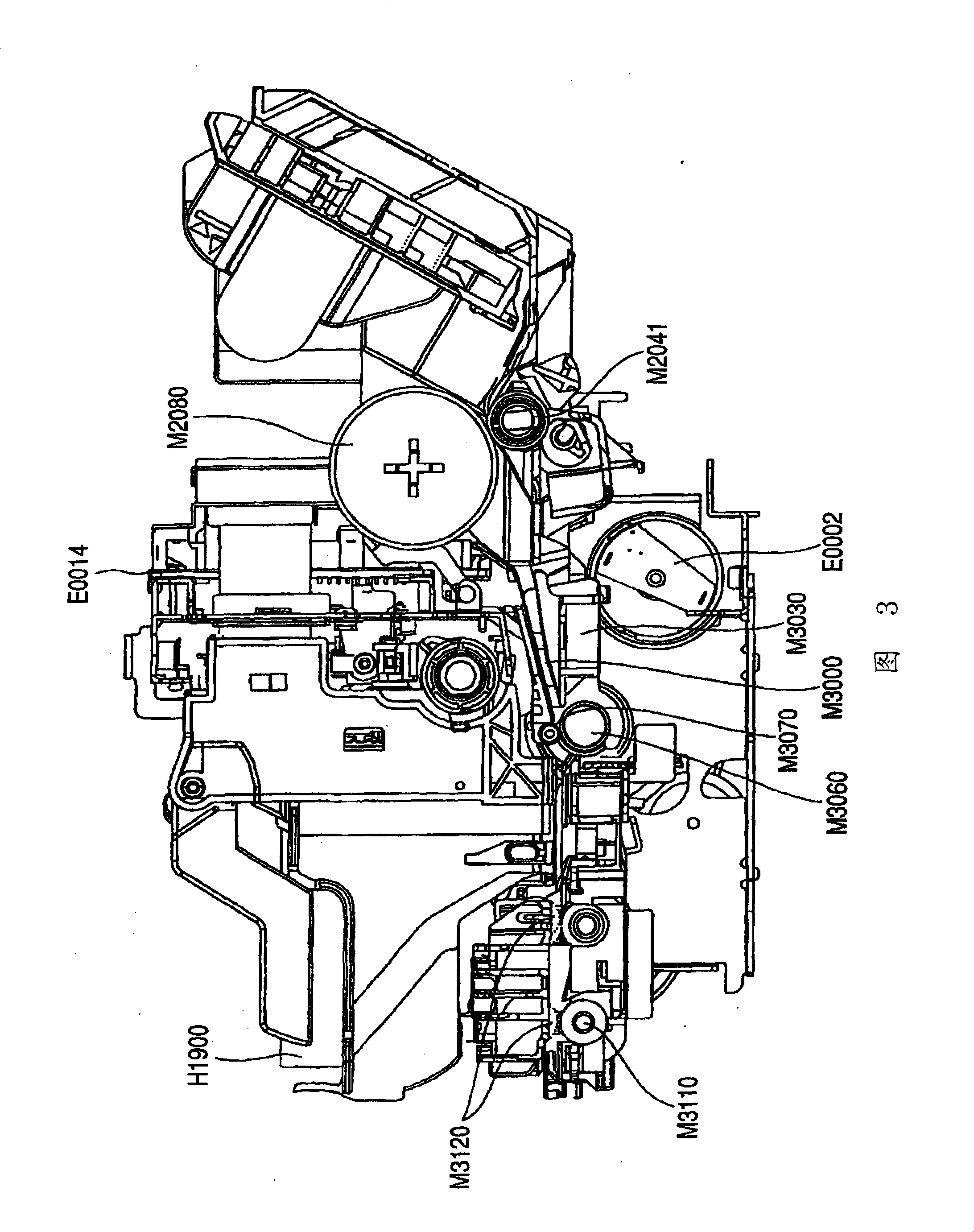

Ink-jet printing system for improved print quality

InactiveUS6247808B1Improve print qualityReduce bleedingMeasurement apparatus componentsDuplicating/marking methodsInkjet printingColoring agents

An ink-jet printing system is disclosed comprising a set of ink-jet inks comprising a first anionic ink comprising an aqueous vehicle, at least one first colorant, and at least one first anionic polymer; a second anionic ink comprising an aqueous vehicle; at least one second colorant, at least one second anionic polymer, and an acid additive having a pKa up to the pKa of the at least first polymer of the first ink; a third cationic ink comprising an aqueous vehicle, at least one third colorant, at least one third cationic polymer, and a pH in the range from about 2 to about 5; and a fourth anionic ink comprising an aqueous vehicle, at least one fourth anionic dye, and a precipitating agent. The printing system provides improved print quality, specifically, reduced bleed; improved edge-acuity, uniform area fills, and color quality; while maximizing lightfastness without sacrificing printing reliability.

Owner:HEWLETT PACKARD DEV CO LP

Yarns and fabrics having a wash-durable antimicrobial silver particulate finish

InactiveUS7232777B1Washing durabilityDurable finishOther chemical processesBiochemical fibre treatmentYarnEngineering

Durable silver particulate treatments for yarns and textile fabrics are provided. Such treatments provide, as one example, an antimicrobial fiber and / or textile fabric which remains on the surface and retains its antimicrobial characteristics after a substantial number of standard launderings and dryings. The method of adherence to the target yarn and / or fabric may be performed any number of ways, most preferably through the utilization of a binder system. The particular method of adherence, as well as the treated textile fabrics and individual fibers are also encompassed within this invention.

Owner:MILLIKEN & CO

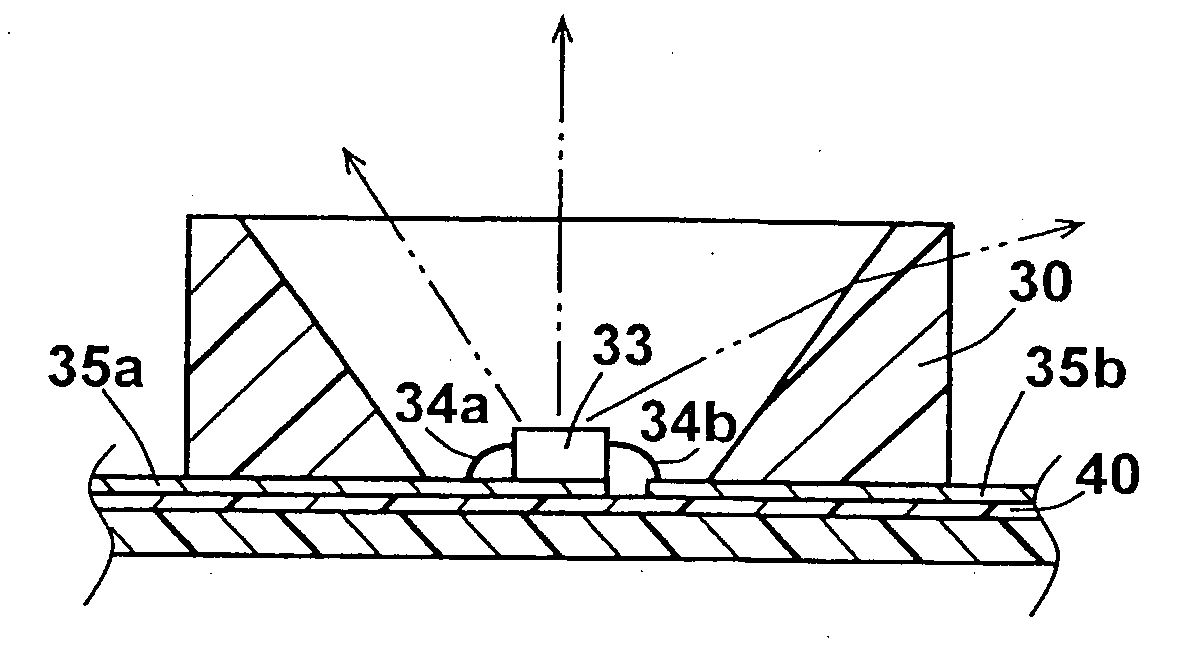

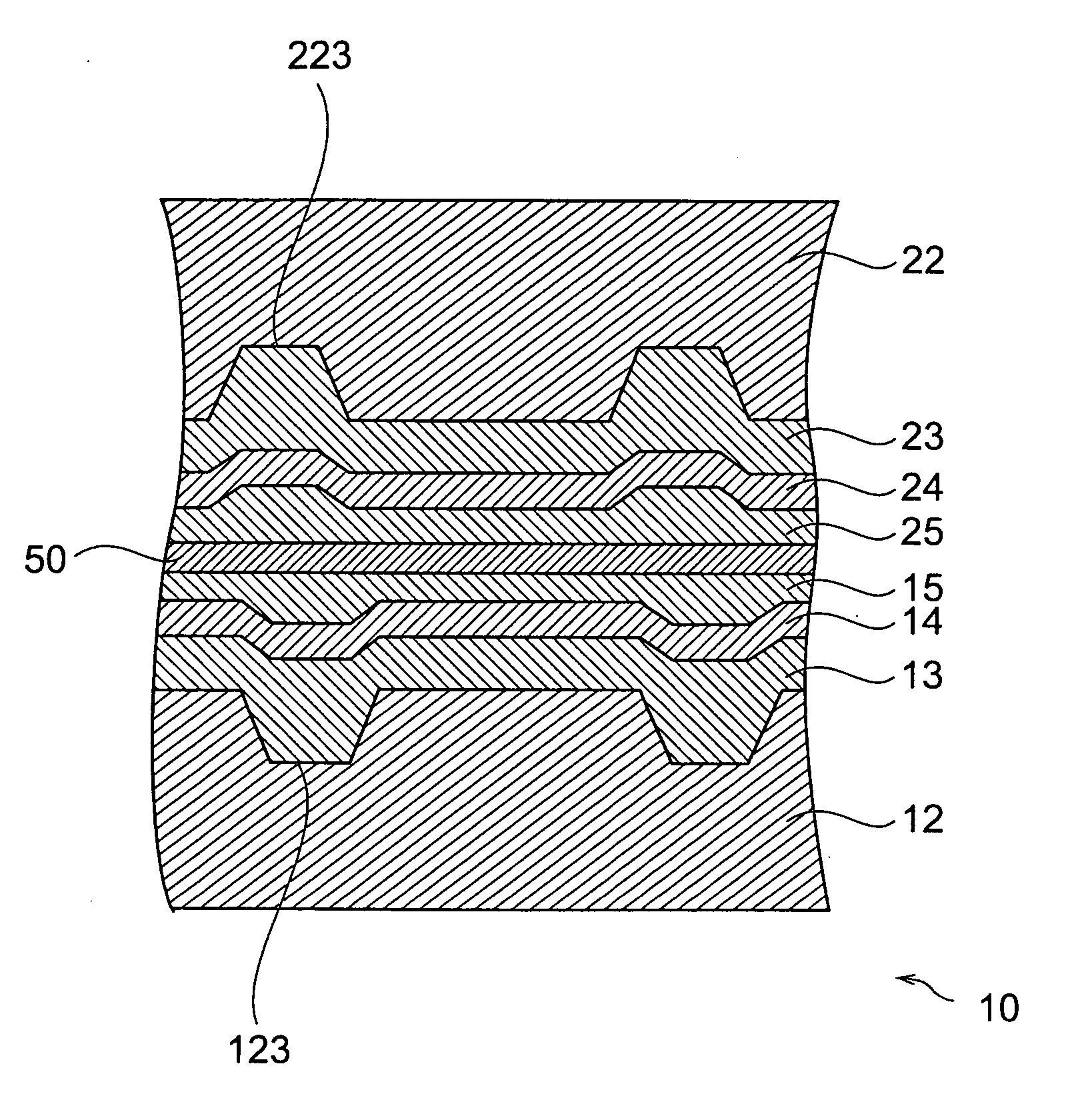

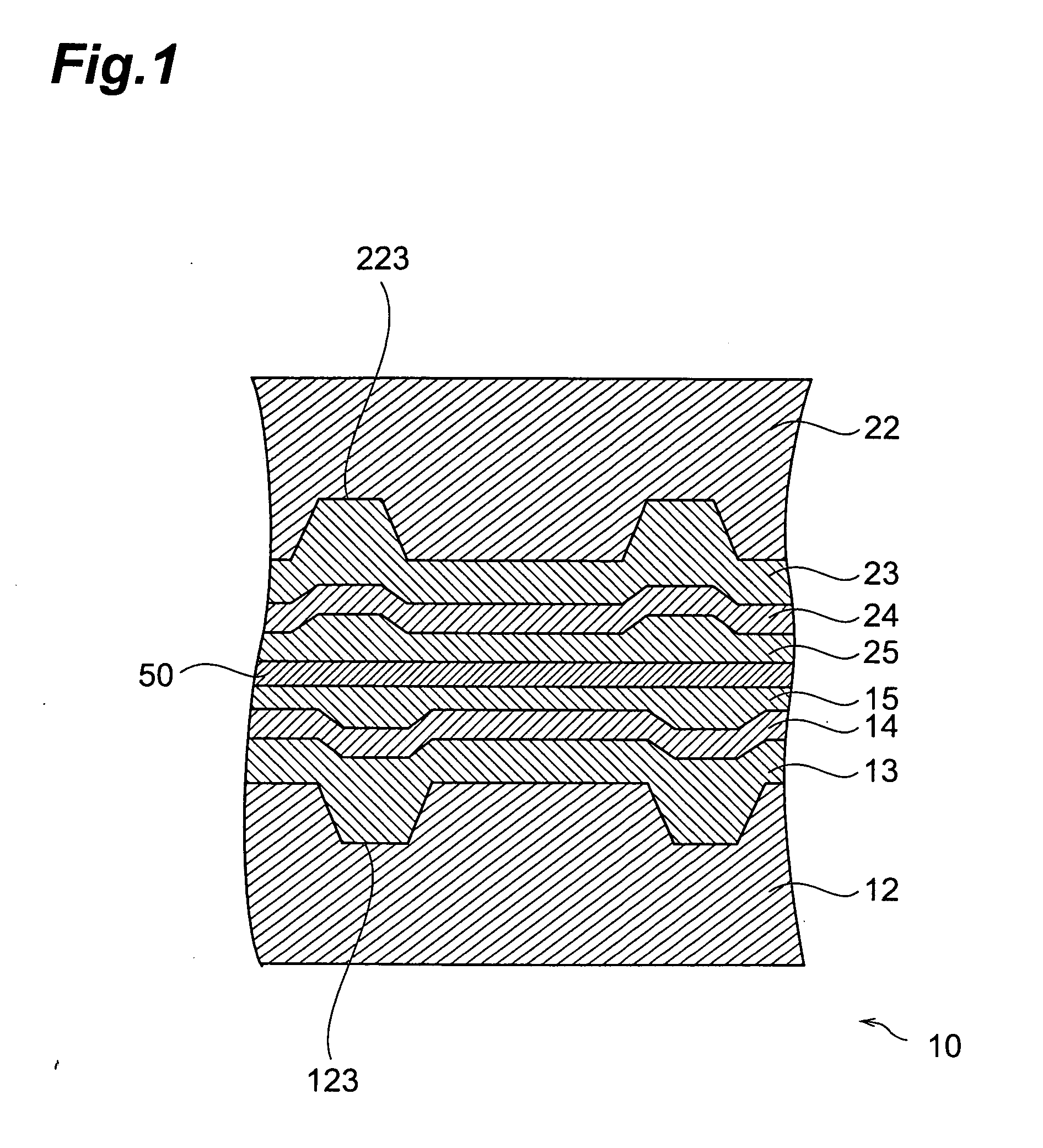

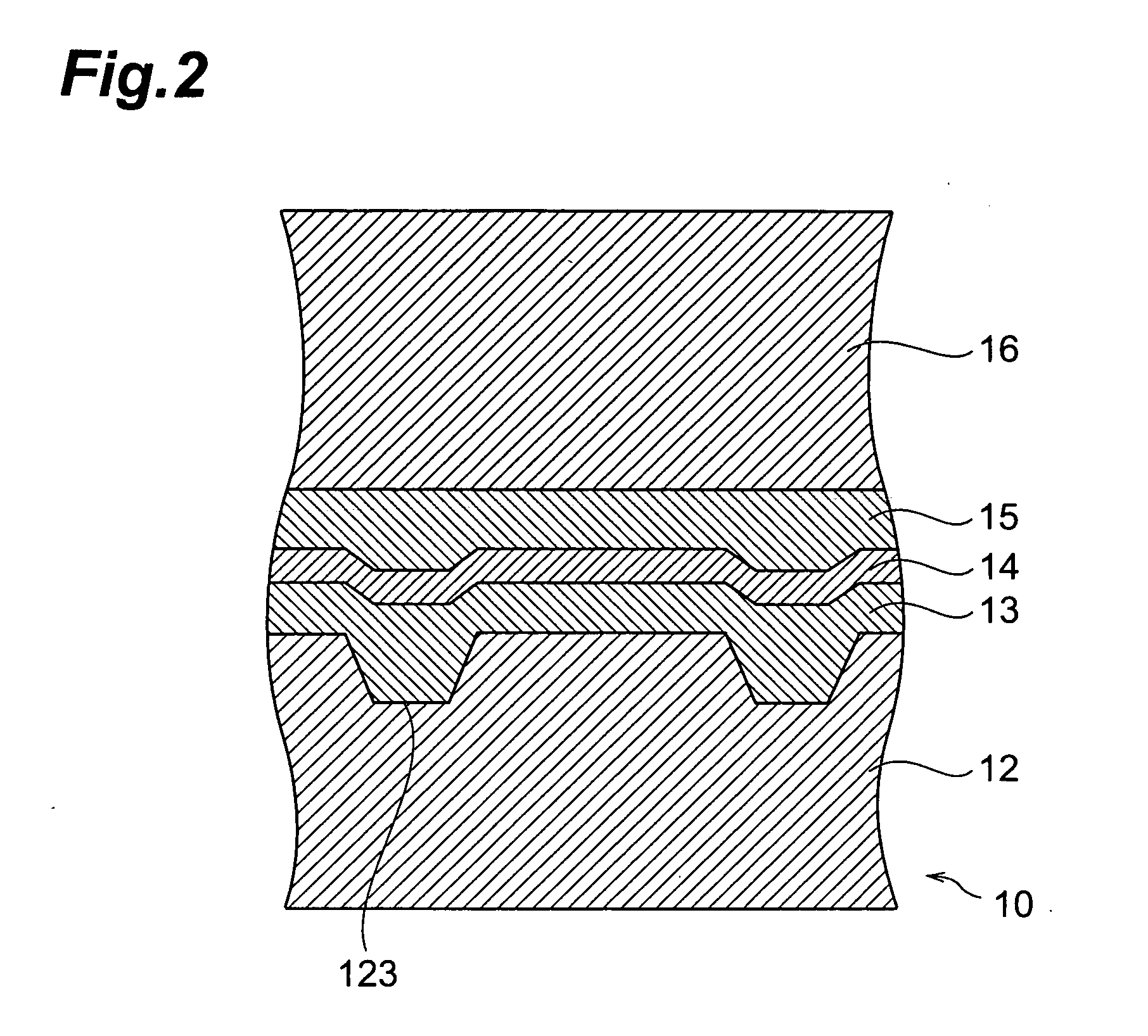

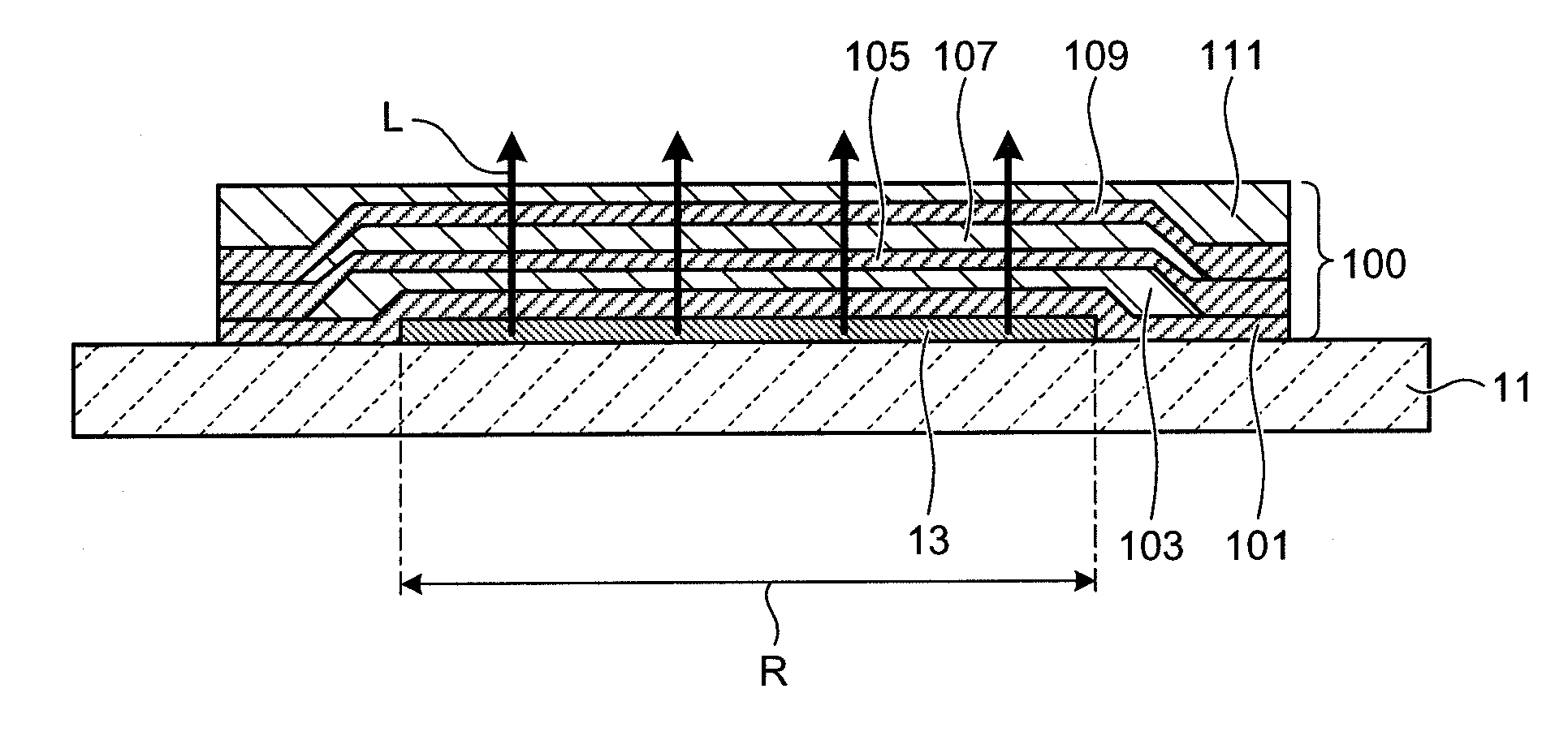

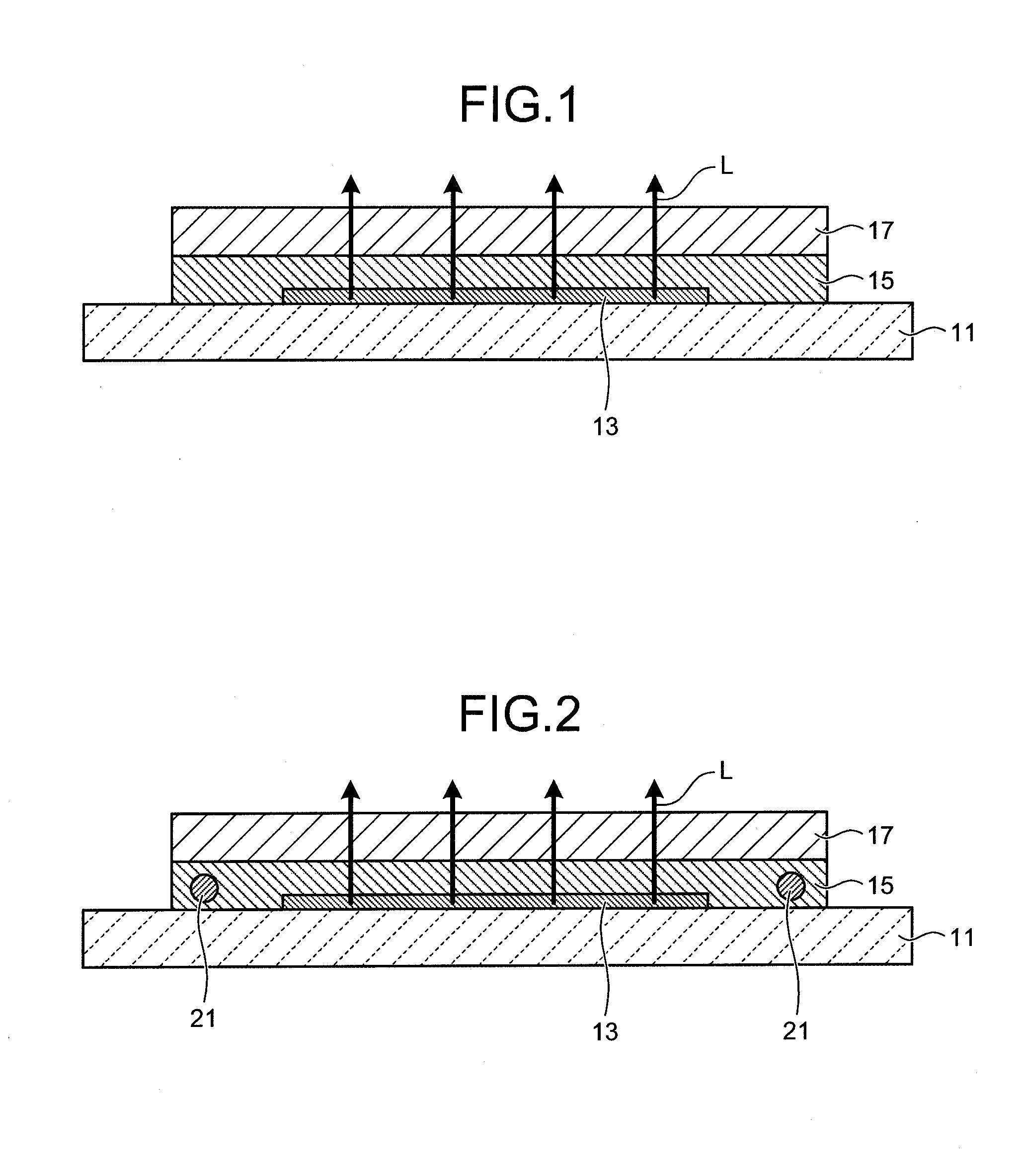

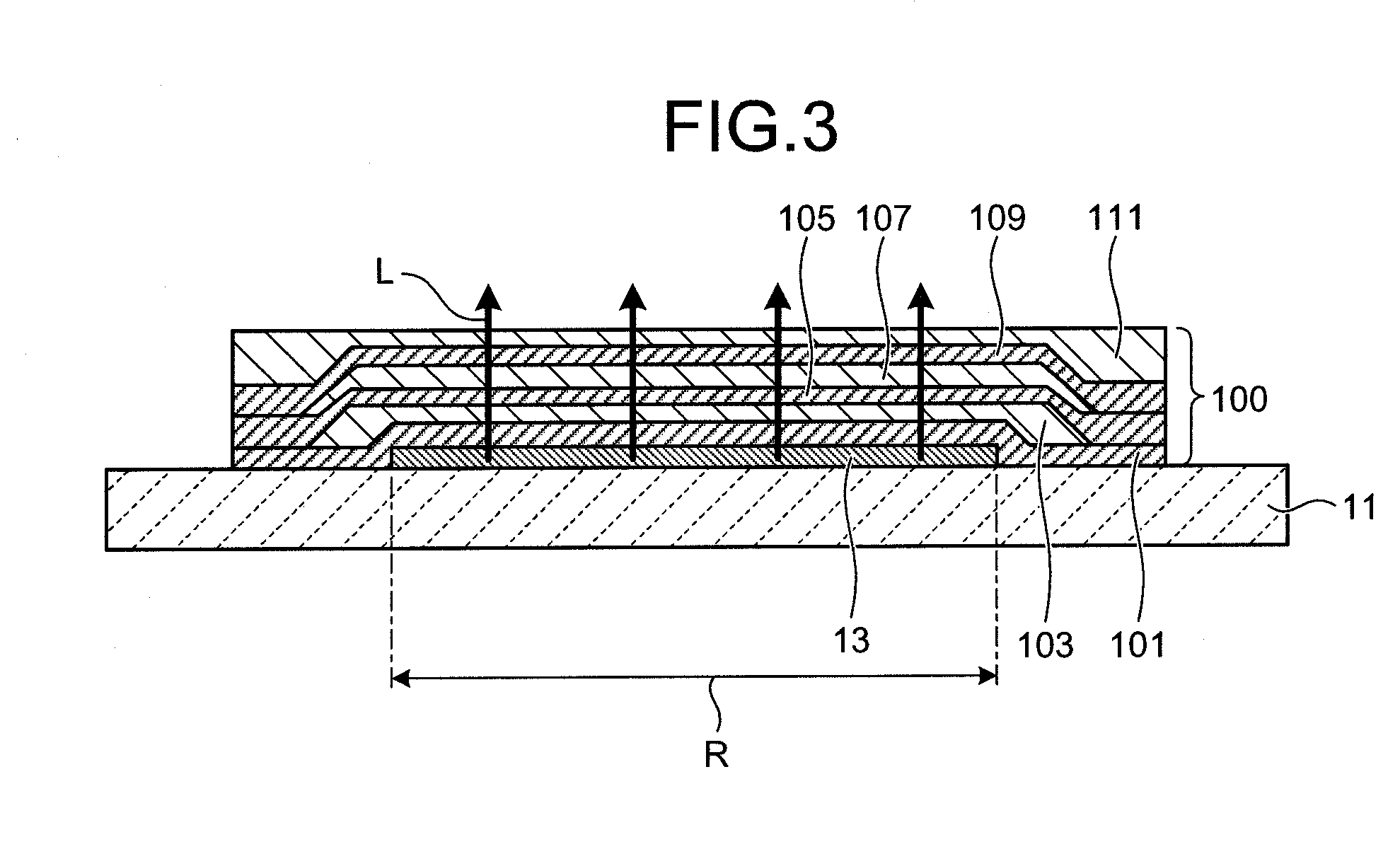

Organic electroluminescent device and method for manufacturing the same

InactiveUS20100244073A1Improve light resistanceGood light fastnessElectroluminescent light sourcesSolid-state devicesOrganic electroluminescenceUv absorber

An object of the present invention is to obtain an organic EL device having excellent light resistance and a method for manufacturing the same. An organic EL device comprises: a first substrate as a supporting substrate; a first electrode provided on the first substrate; an organic layer that is provided on the first electrode and includes at least an organic light-emitting layer; a second electrode provided on the organic layer; a resin layer provided to cover the first substrate and the second electrode thereon, the resin layer containing, at least in a region on the organic layer, an ultraviolet light absorber that absorbs ultraviolet light; and a second substrate arranged on the resin layer to block the organic layer from ambient air.

Owner:SUMITOMO CHEM CO LTD

Ink jet ink, ink jet recording method, ink cartridge, recording unit and ink jet recording apparatus

InactiveCN101298526AExcellent toneGood light fastnessDuplicating/marking methodsInksLightfastnessMagenta

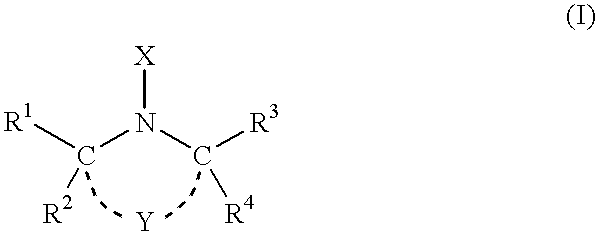

The present invention provides an ink jet ink having a magenta color which gives an image excellent in magenta color tone and also excellent in image fastness (lightfastness and gas resistance). The ink jet ink includes a first coloring material that is an anthrapyridone compound having a structure represented by general formula (I) and / or general formula (II) and a second coloring material that is an azo compound having a structure represented by general formula (III), wherein the mass ratio of the content of the first coloring material to the content of the second coloring material is from 2.5 or more to 10.0 or less.

Owner:CANON KK

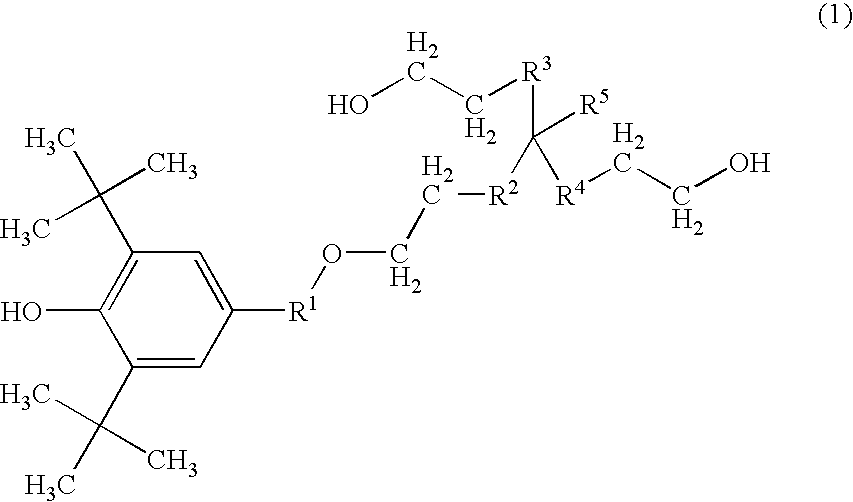

Resin with function of oxidation inhibition and emulsion thereof

InactiveUS7169844B2Good dispersionGood light fastnessPolyurea/polyurethane coatingsChemical inhibitorsEmulsionHydrogen

An emulsion of resin having a function of oxidation inhibition obtained by subjecting an antioxidant (A) having two or more alcoholic hydroxy groups, a polyol compounds (B) as an optical ingredient, a compound (C) having a carboxy group and an active-hydrogen group, and an organic polyisocyanate (D) to urethanation reaction in an organic solvent, neutralizing the resultant resin solution with a neutralizing agent (E), and then dispersing the solution in water. A resin having the function of oxidation inhibition is obtained from the emulsion.

Owner:DAICEL CHEM IND LTD

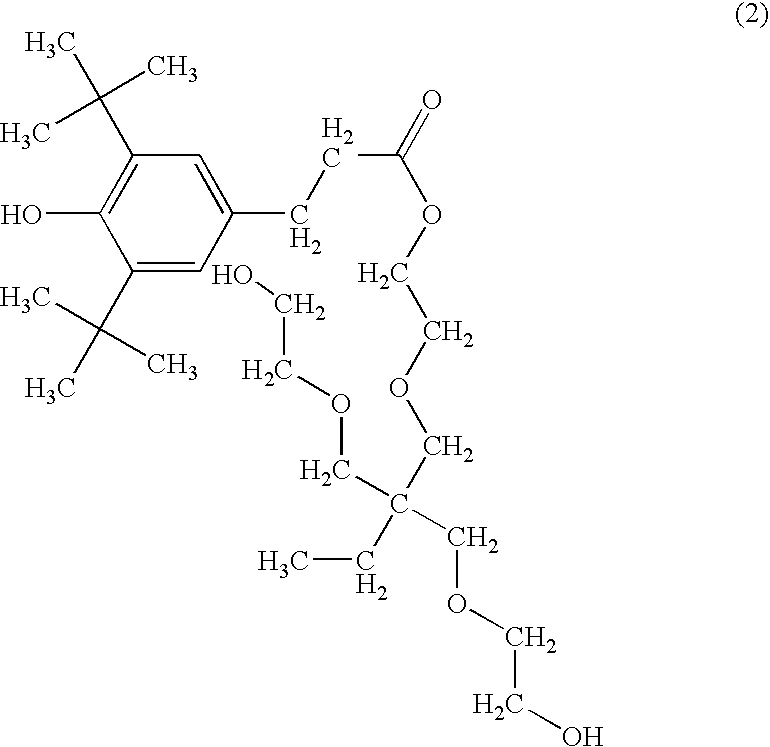

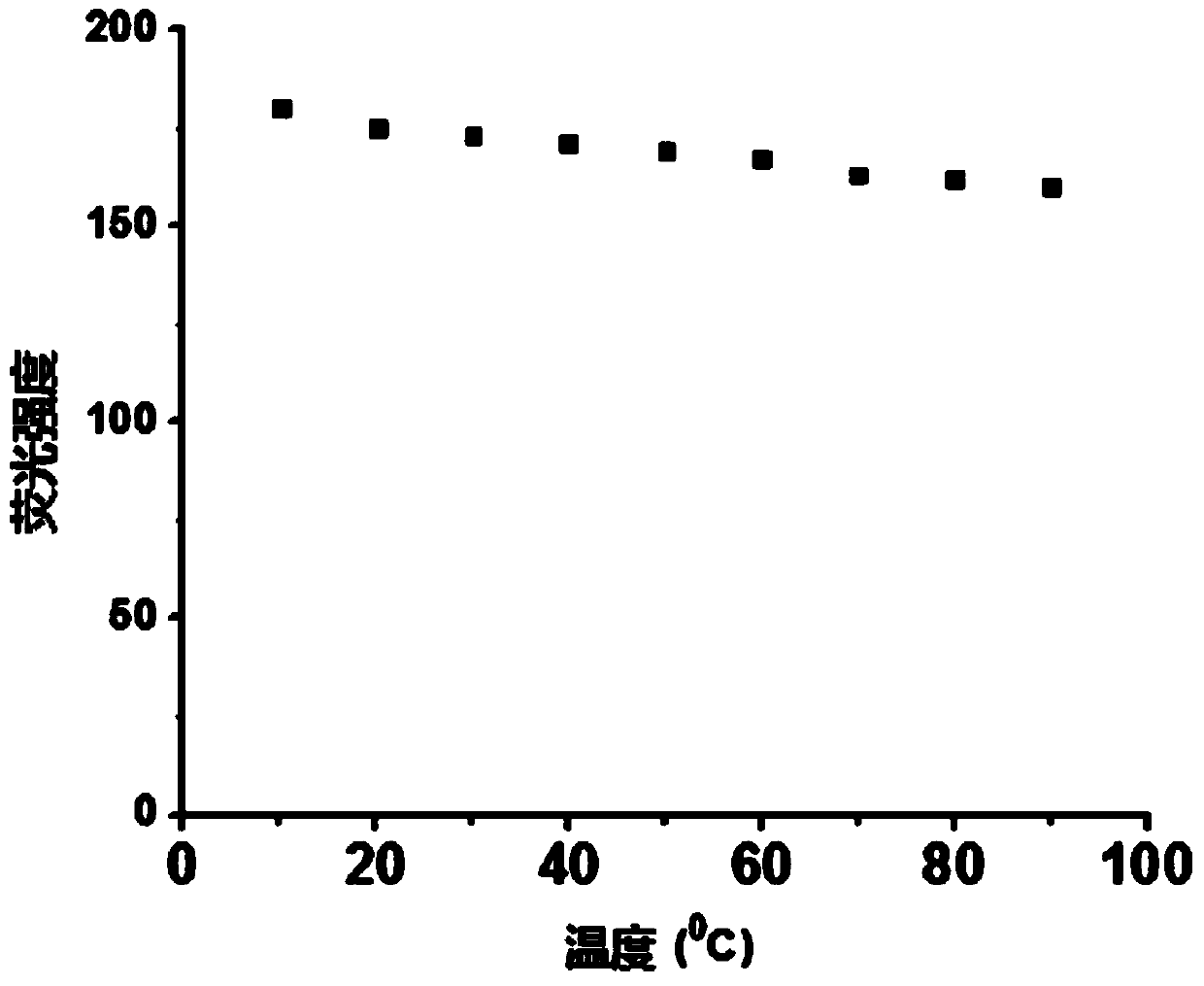

Application of multifunctional carbon quantum dot taken as fluorescent whitening agent

ActiveCN103993504AAvoid it happening againThe synthesis method is simpleLuminescent paintsFibre treatmentWhitening AgentsReactive oxygen radicals

The invention discloses application of a multifunctional carbon quantum dot taken as a fluorescent whitening agent in the fields of spinning printing and dyeing, washing agents, papermaking, plastics, leathers or coatings and the like. The carbon quantum dot disclosed by the invention has the advantages of wide application field, good whitening effect and good light resistance, is innoxious and environmentally friendly, can be applied to the fields of spinning printing and dyeing, washing agents, papermaking, plastics, leathers or coatings and the like, and can generate unforeseeable technical effect because the carbon quantum dot can generate active oxygen free radicals under the condition of illumination, wherein the unforeseeable technical effect is as follows: the bacteria attached to the surfaces of spinning printing and dyeing materials, the washing agents, paper sheets, the plastics, the leathers or the coatings and the like can be effectively killed after the spinning printing and dyeing materials, the washing agents, paper sheets, the plastics, the leathers or the coatings and the like which are doped with the carbon quantum dot absorb ultraviolet light.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

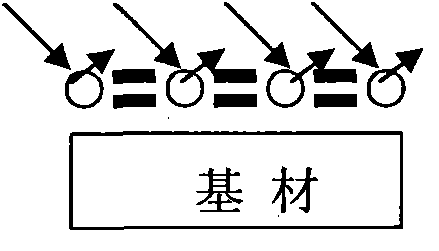

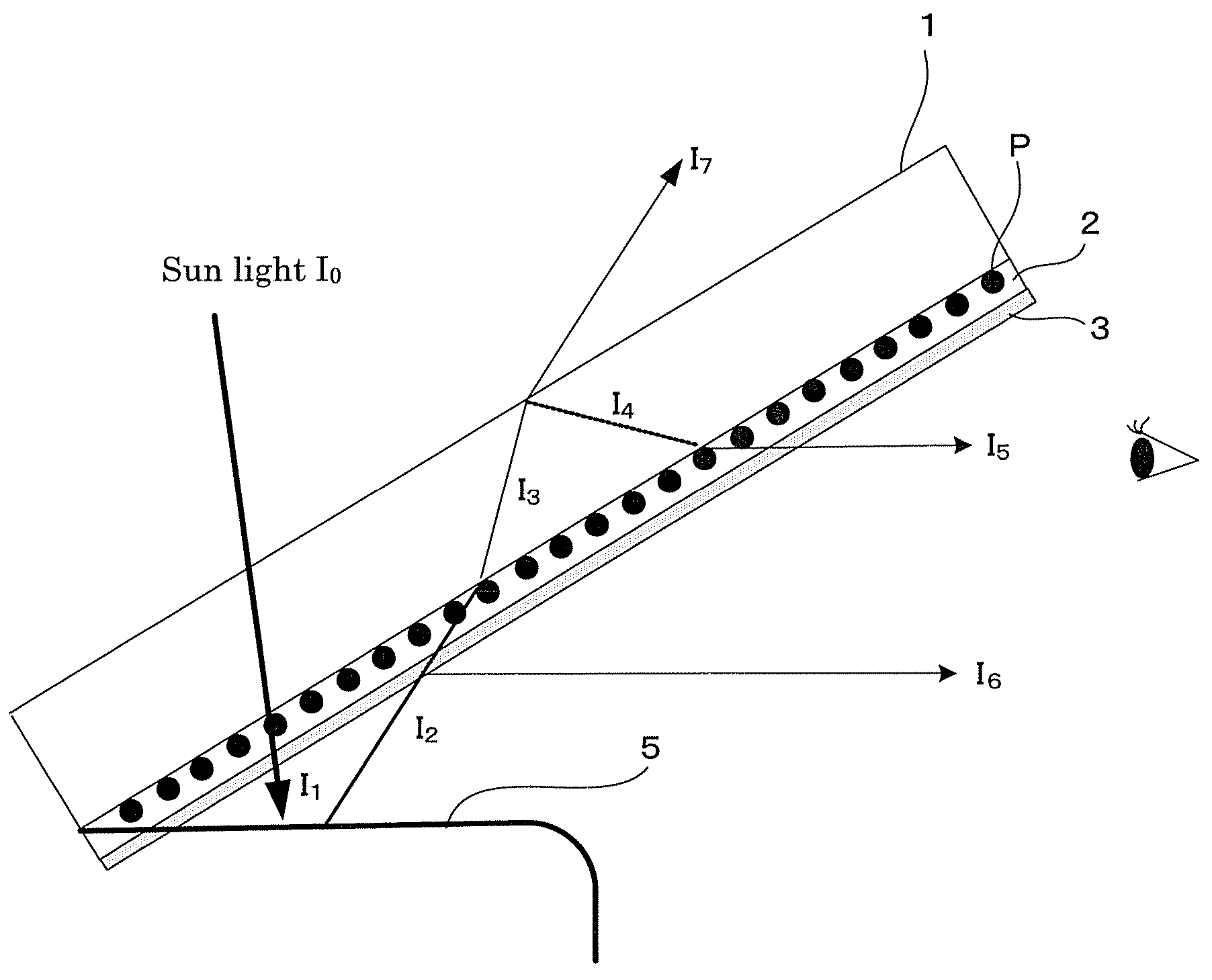

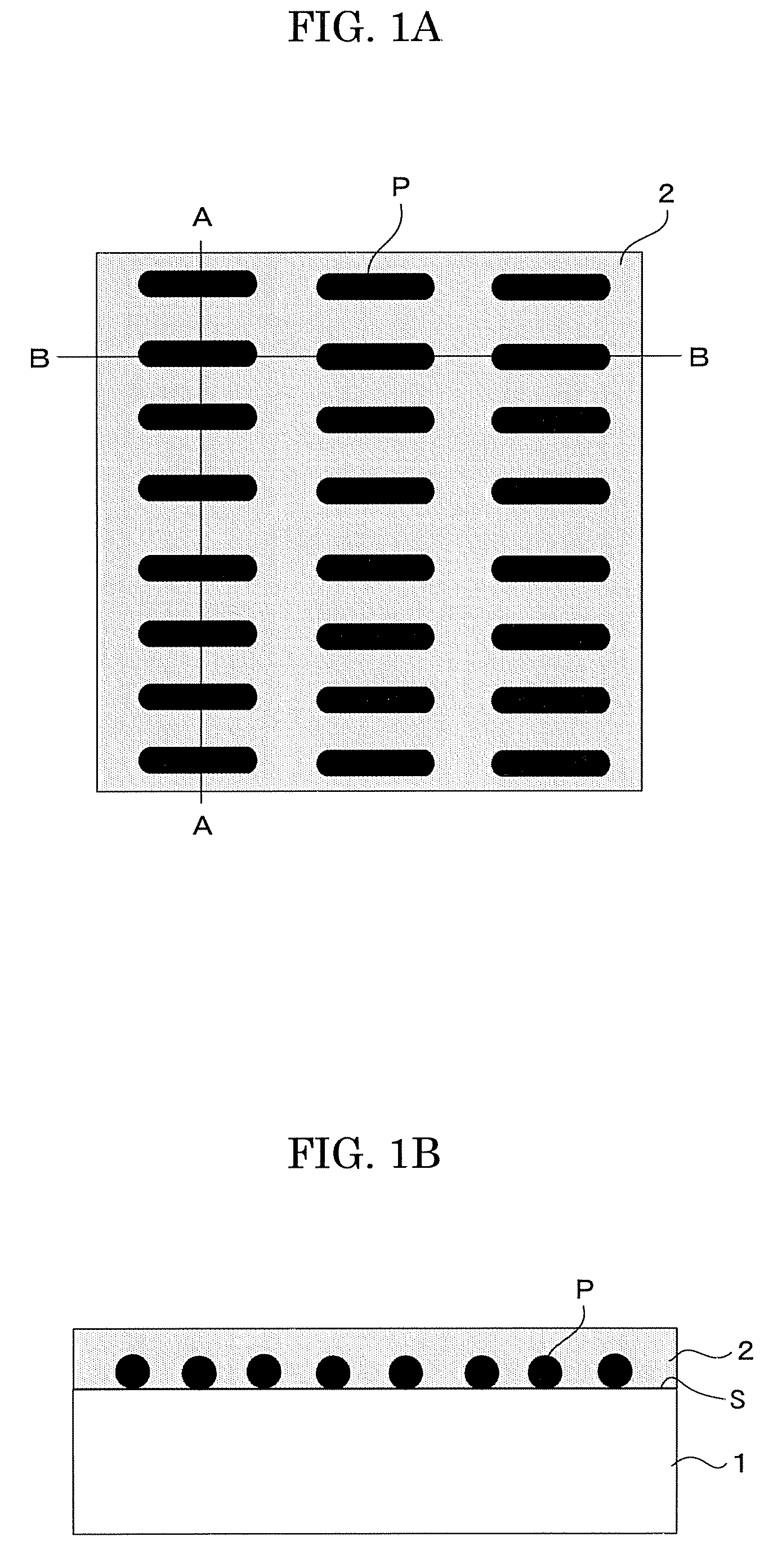

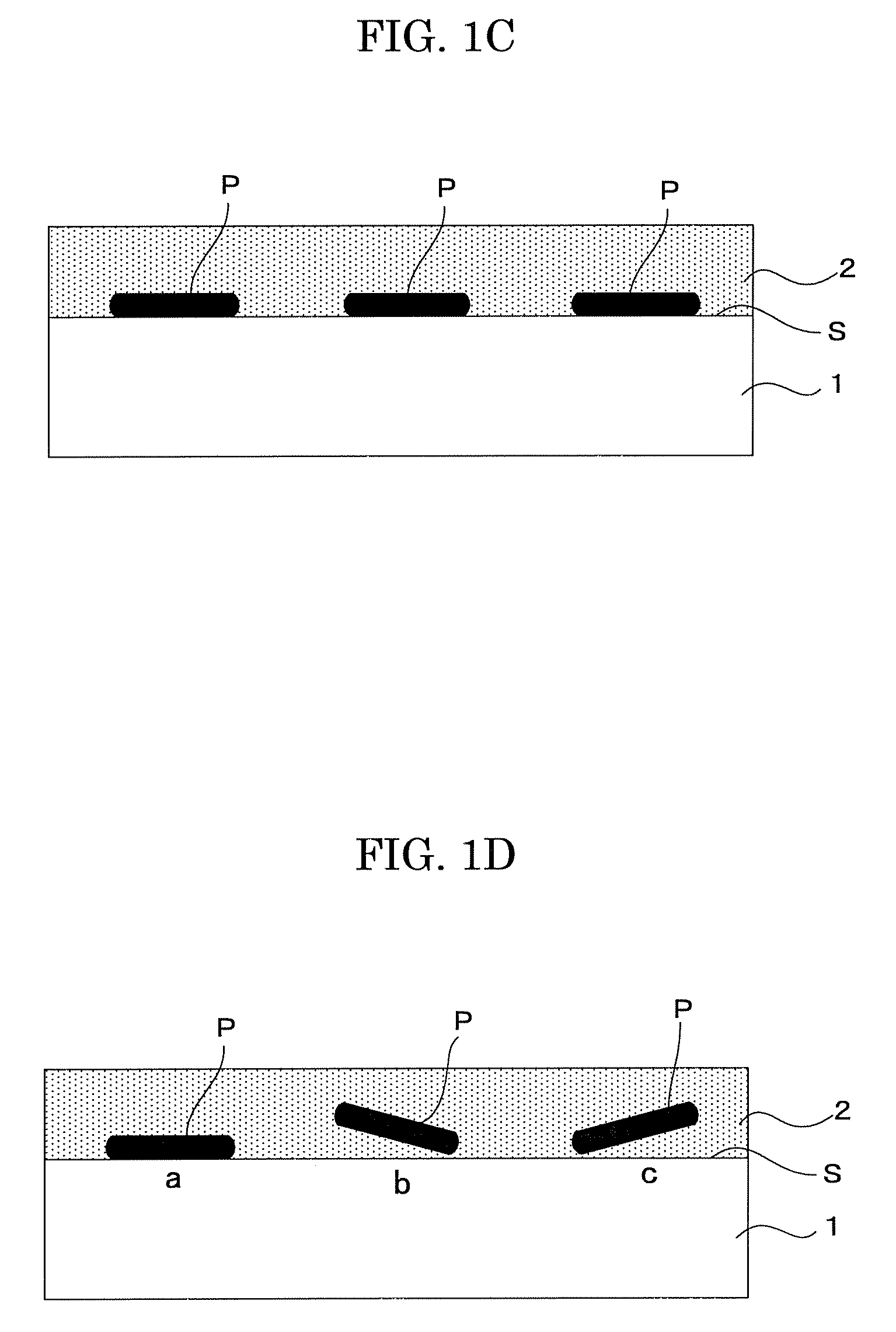

Polarizing film for window and front window for means of traveling

InactiveUS20090201583A1Improve securityGood light fastnessAntiglare equipmentPolarising elementsMechanical engineeringMaterials science

There is provided a front window for means of traveling, which contains at least a base, a polarizing film, and a anti-reflection film, wherein the polarizing film contains at least an anisotropic absorber, and the anisotropic absorber has a reduction ratio of a parallel polarized light (s-polarized light) included in incident light of 90% or less.

Owner:FUJIFILM CORP

Aqueous ink

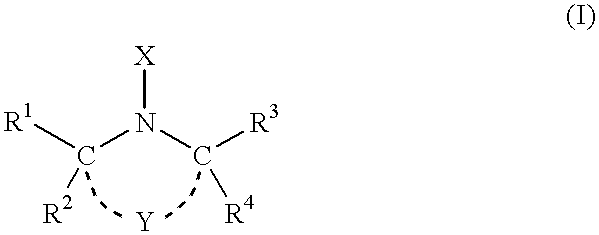

An aqueous ink comprising at least a colorant, a water-soluble organic solvent and a compound represented by general formula (I) shown below, wherein said water-soluble organic solvent stays liquid at a temperature of not higher than 40° C., exhibits a water solubility of not lower than 1% by weight at a temperature of 20° C. and a saturated vapor pressure of not higher than 1.7 Pa at a temperature of 20° C. and is contained in an amount of from 5 to 35% by weight: wherein Y represents a nonmetallic atom group required to form a 5 to 7-membered ring with C And N; X represents a hydrogen atom, oxyradical group, hydroxyl group, alkyl group, alkenyl group, alkinyl group, aryl group, acyl group, sulfonyl group, sulfinyl group, alkoxy group, aryloxy group or acyloxy group; and R1 to R4 may be the same or different and each represent a hydrogen atom or alkyl group, with the proviso that any two of R1 to R4 and Y may be connected to each other to form a 5- to 7-membered ring.

Owner:SEIKO EPSON CORP

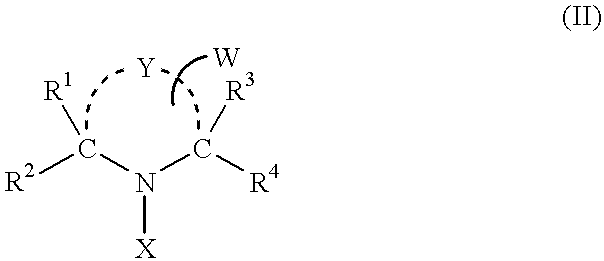

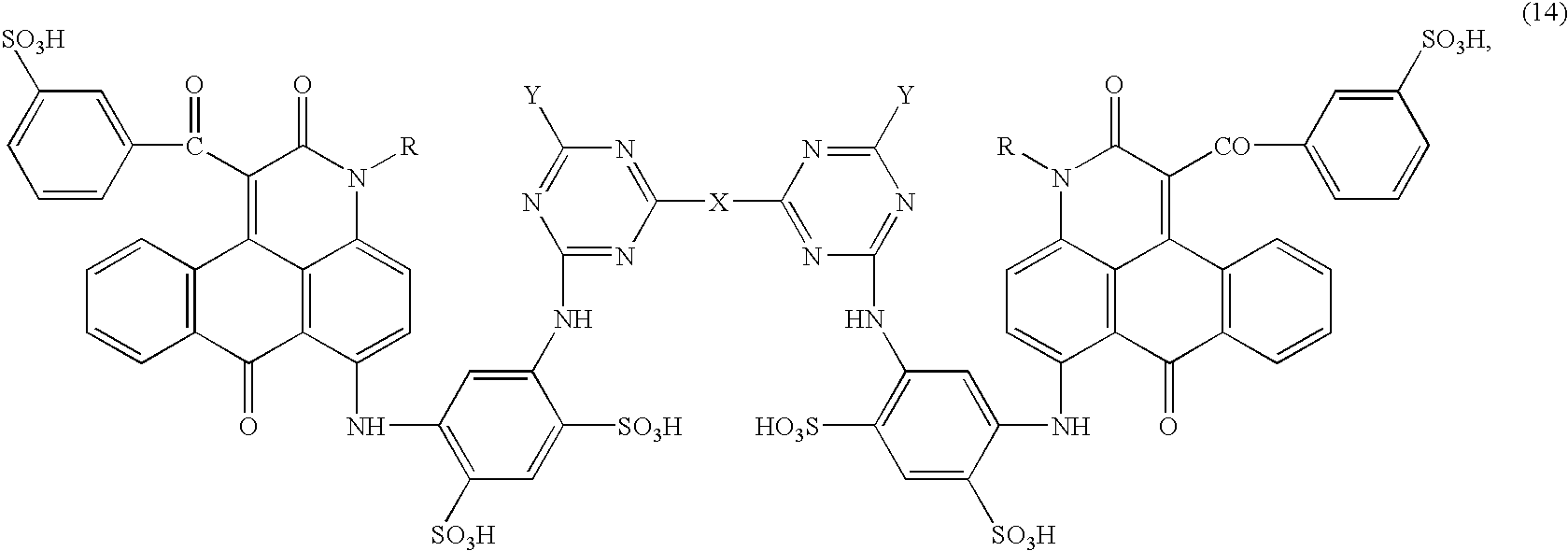

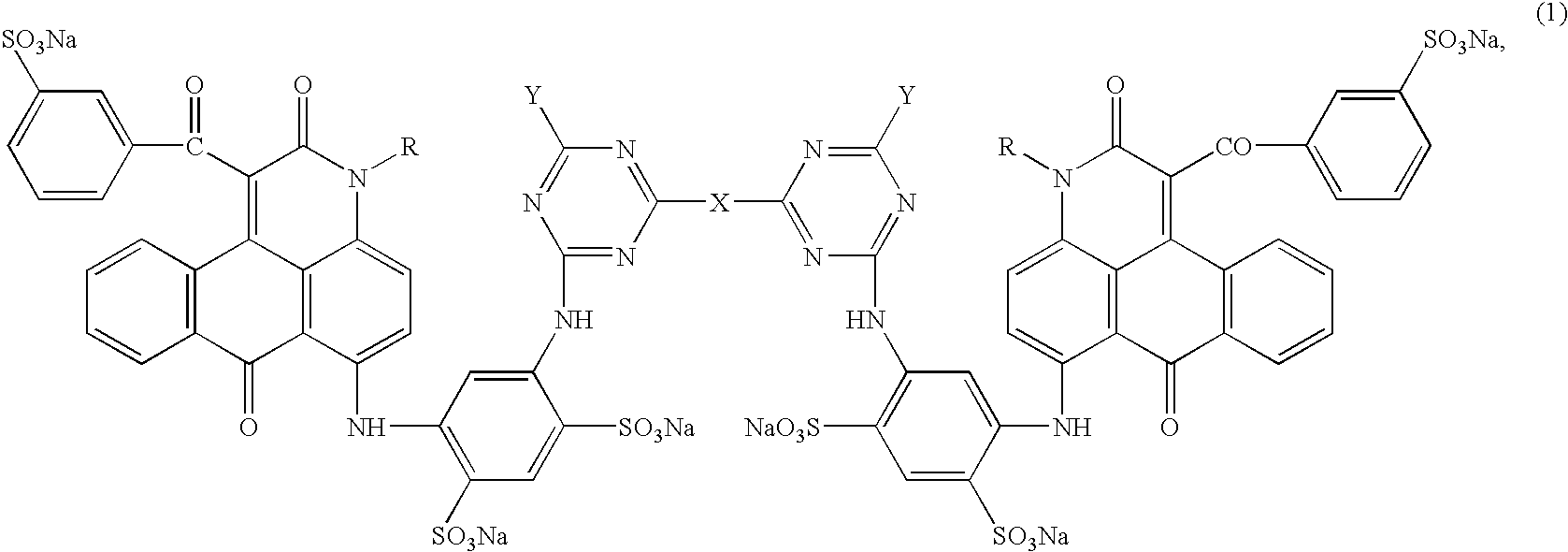

Anthrapyridone compounds, water-base magenta ink compositions and method of ink-jet recording

InactiveUS6929361B2Stable and high qualityEasy to useOrganic chemistryMeasurement apparatus componentsWater basedCarboxyl radical

New anthrapyridone compounds represented by the general formula (14): {wherein R represents a hydrogen atom, an alkyl group (optionally substituted with mono- or di-alkylamino group), a lower alkyl group (optionally substituted with a hydroxyl group or a cyano group), or a cyclohexyl group; Y represents a chlorine atom, a hydroxyl group, an amino group, mono- or di-alkylamino group (optionally substituted with a sulfonic acid group, a carboxy group, or a hydroxyl group), an aralkyl- or cycloalkyl-amino group, an alkoxy group, a phenoxy group (optionally substituted with a sulfonic acid group, a carboxy group, an acetylamino group, an amino group, or a hydroxyl group), an anilino group (optionally substituted with a sulfonic acid group or a carboxy group), or a naphthylamino group (optionally substituted with a sulfonic acid group); and X represents a bridging group}; or salts thereof and magenta inks containing the same, which have hues and vividness suitable for ink-jet recording and give records excellent in fastness to light, gas, water and so on.

Owner:NIPPON KAYAKU CO LTD

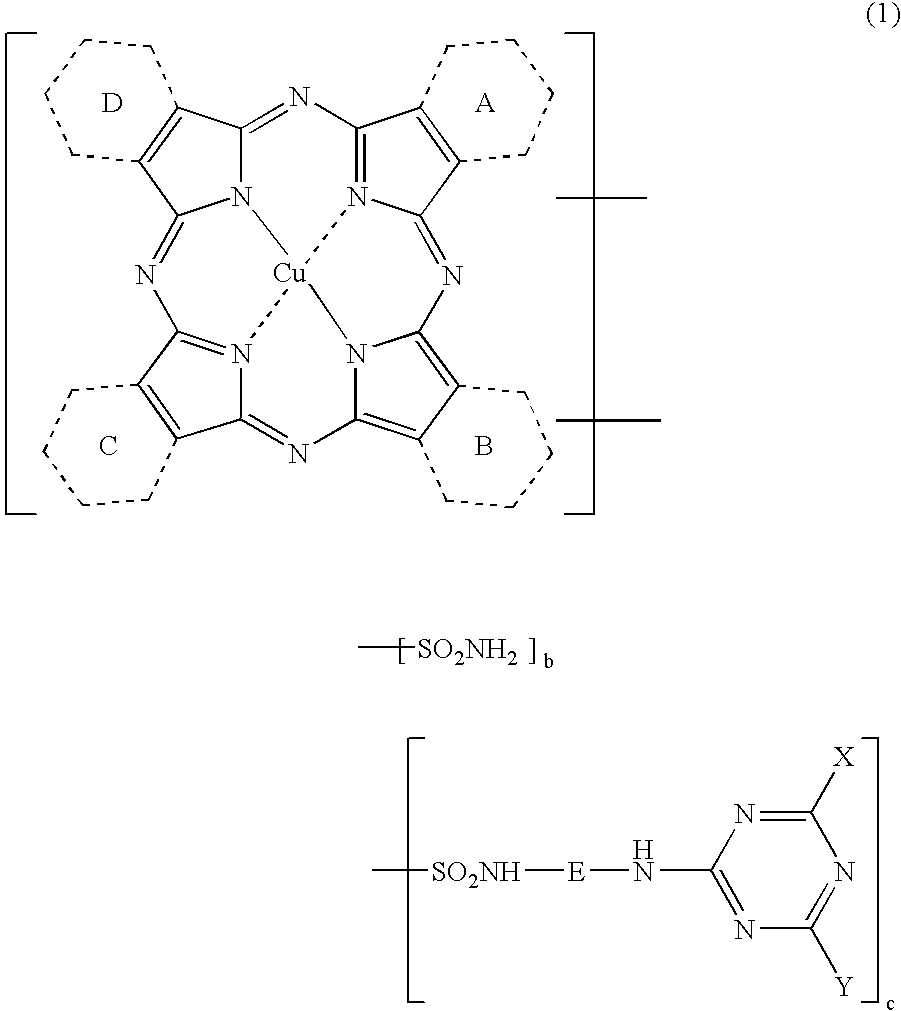

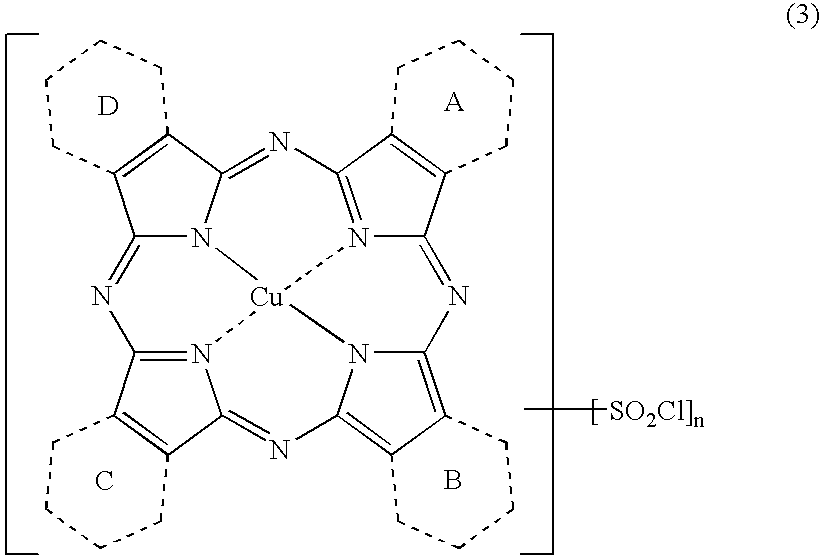

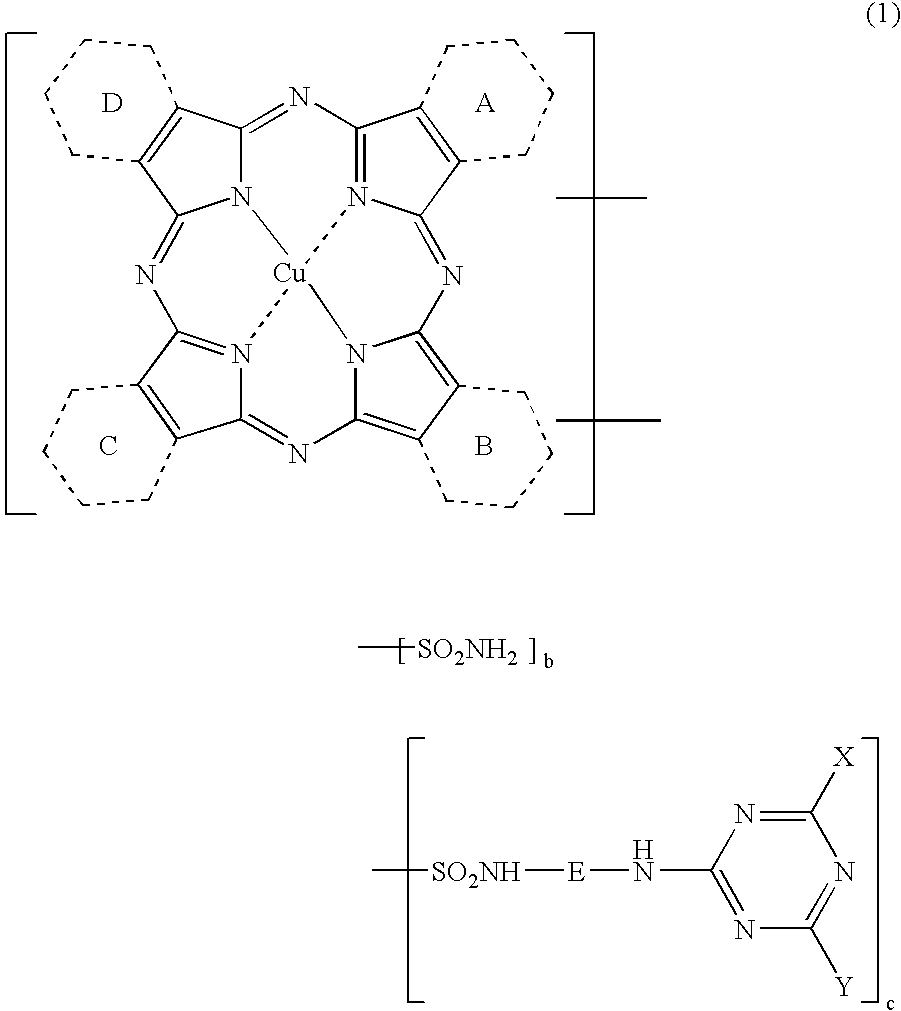

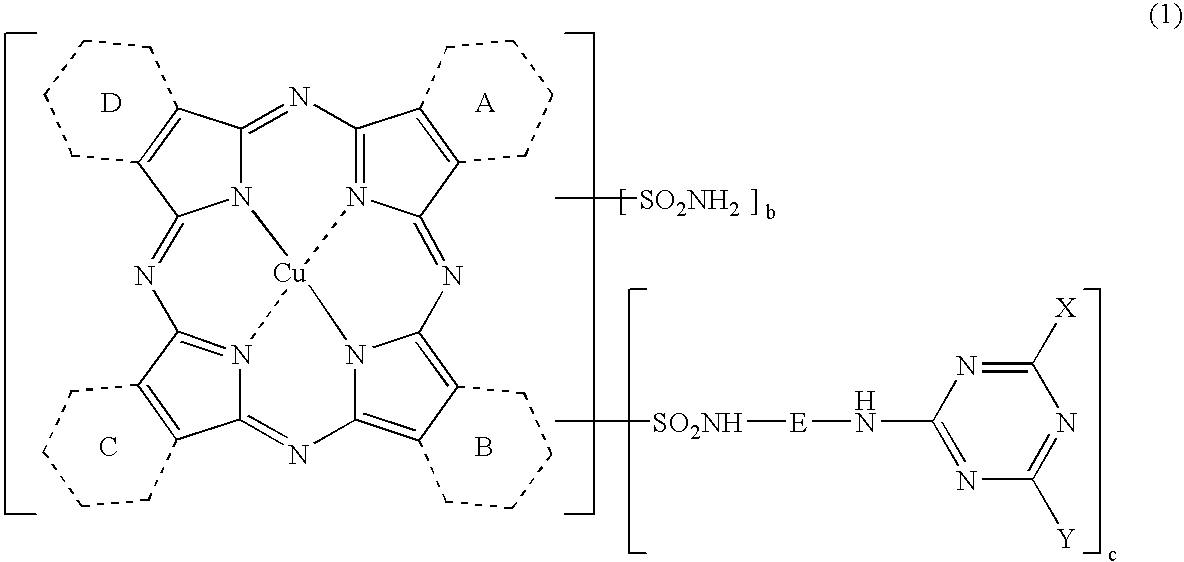

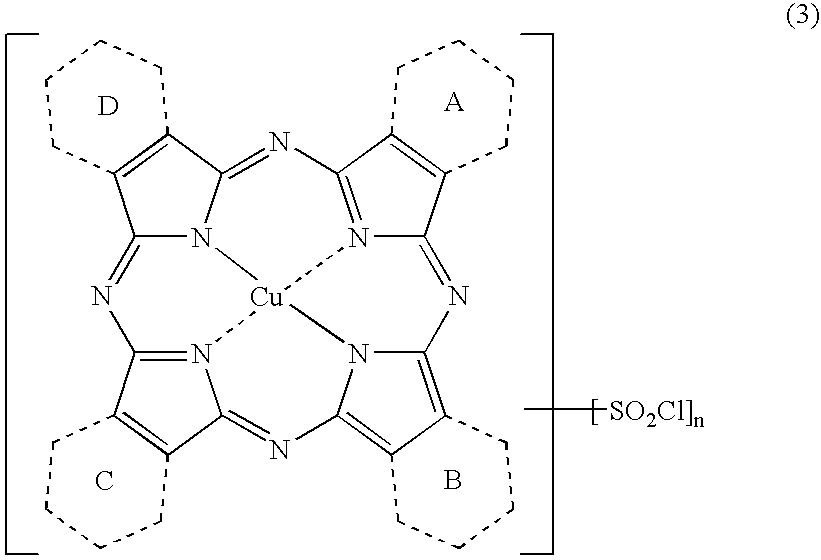

Porphyrazine coloring matter, ink, ink set and colored article

ActiveUS7591888B2Excellent toneGood light fastnessLiquid surface applicatorsOrganic chemistryPorphyrazineNitrogen

The present invention relates to a porphyrazine coloring matter represented by the following formula (1):(wherein, A, B, C and D independently represent a 6-membered ring having aromaticity, at least one or more of them are benzene rings and at least one or more of them contain nitrogen-containing heteroaromatic rings; E represents alkylene, X is a substituted anilino group and have at least one or more of sulfo group, carboxy group and phosphono group as a substituent, Y represents a hydroxy group or an amino group, b is respectively 0 to 2.9, c is 0.1 to 3, and the sum of b and c is 1 to 3) in free acid form, which is suitable for inkjet recording because it has good hue as a cyan ink, is excellent in light fastness, ozone fastness and moisture fastness, and does not cause bronzing phenomenon.

Owner:NIPPON KAYAKU CO LTD

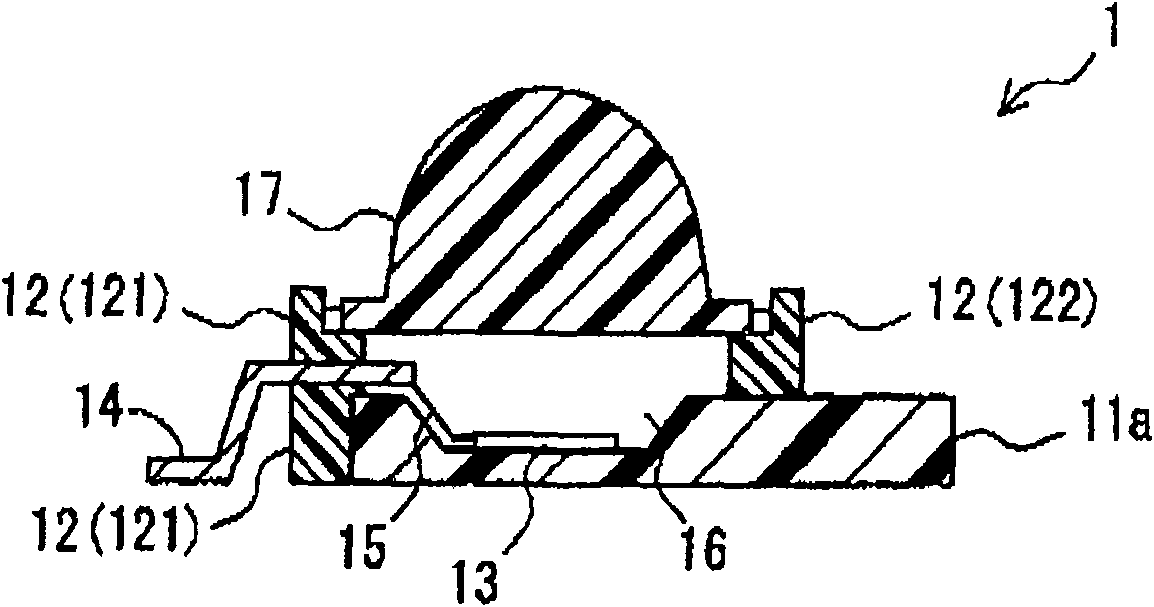

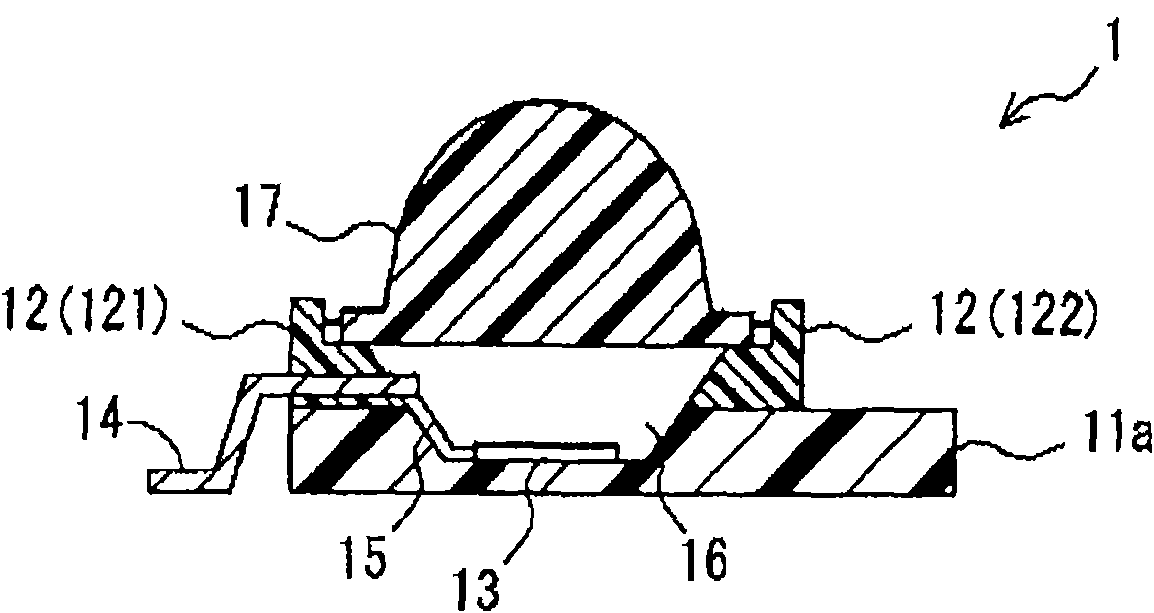

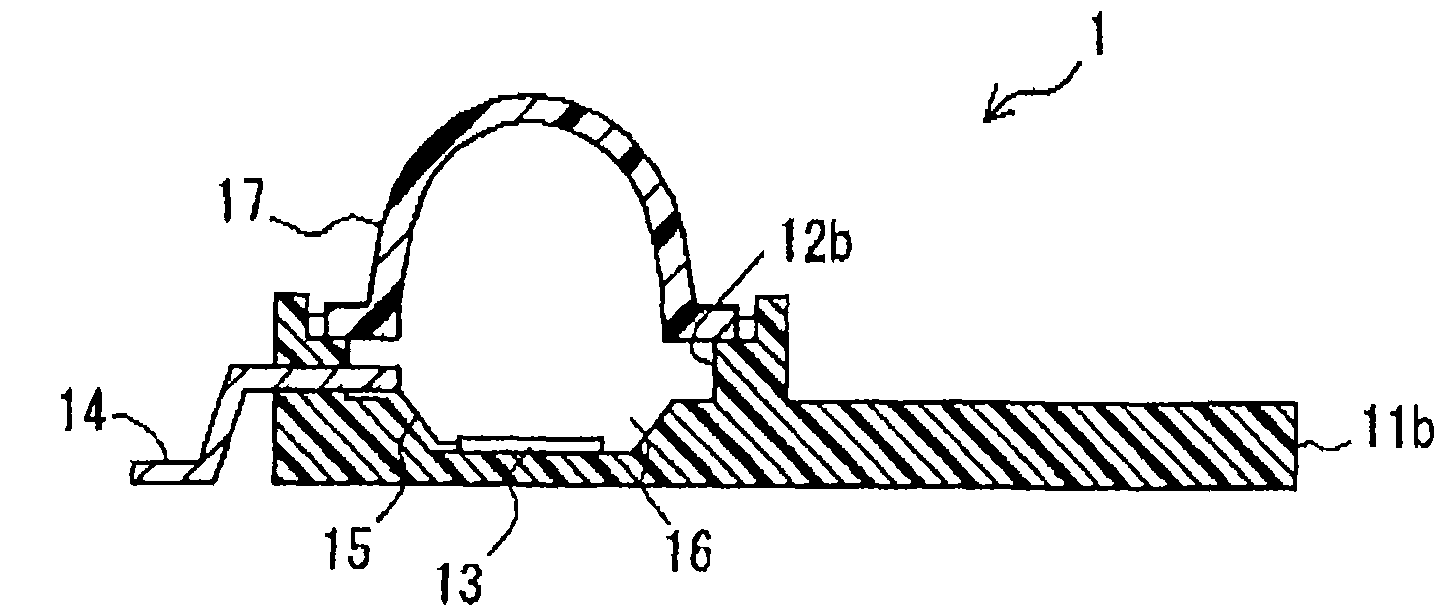

Heat-dissipating resin composition, substrate for LED mounting, reflector, and substrate for LED mounting having reflector portion

InactiveCN101583670AEasy to processImprove impact resistanceSolid-state devicesHeat exchange apparatusHeat deflection temperatureEmissivity

Disclosed is a heat-dissipating resin composition which is used for forming a substrate for LED mounting or a reflector provided on the substrate for LED mounting, and excellent in heat dissipation, electrical insulation, heat resistance and light resistance during the time when an LED element emits light. Also disclosed are a substrate for LED mounting and a reflector respectively containing such a heat-dissipating resin composition. Specifically disclosed is a composition containing a thermoplastic resin such as a modified PBT and a thermally conductive filler such as a flake boron nitride. The composition has a heat distortion temperature of not less than 120 DEG C, a thermal conductivity of not less than 2.0 W / (m K) and a thermal emissivity of not less than 0.7.

Owner:TECHNO POLYMER CO LTD

Antirust emulsion of self-crosslinked interpenetrating net polymer and its production

InactiveCN101029115AImprove stabilityExcellent calcium ion stabilityAnti-corrosive paintsCross-linkEpoxy

A self-cross-linked interpenetrating network polymer antirust emulsion and its production are disclosed. The emulsion consists of epoxy resin 2-50 proportion, unsaturated hydrocarbon monomer mixture 20-80 proportion, olefine hydroxyl-acid 0.5-8 proportion, functional organic silane 0.5-25 proportion, functional organic fluoride monomer 0.5-20 proportion, cross-linking agent 0.1-1.2 proportion, neutralizing agent 0.5-1.5 proportion, emulsifying agent 1-8 proportion, chain transfer agent 0.05-0.6 proportion, pH regulator 0.2-0.6 proportion, initiating agent 0.3-0.8 proportion, softened water 90-150 proportion and cross-linking curing agent 0.2-5 proportion. The process is carried out by dosing in the first, second and third reactors, mixing in the third reactor and discharging to obtain final product. It has excellent weather and water resistances, better anti-corrosive performance and storage stability.

Owner:HARBIN INST OF TECH

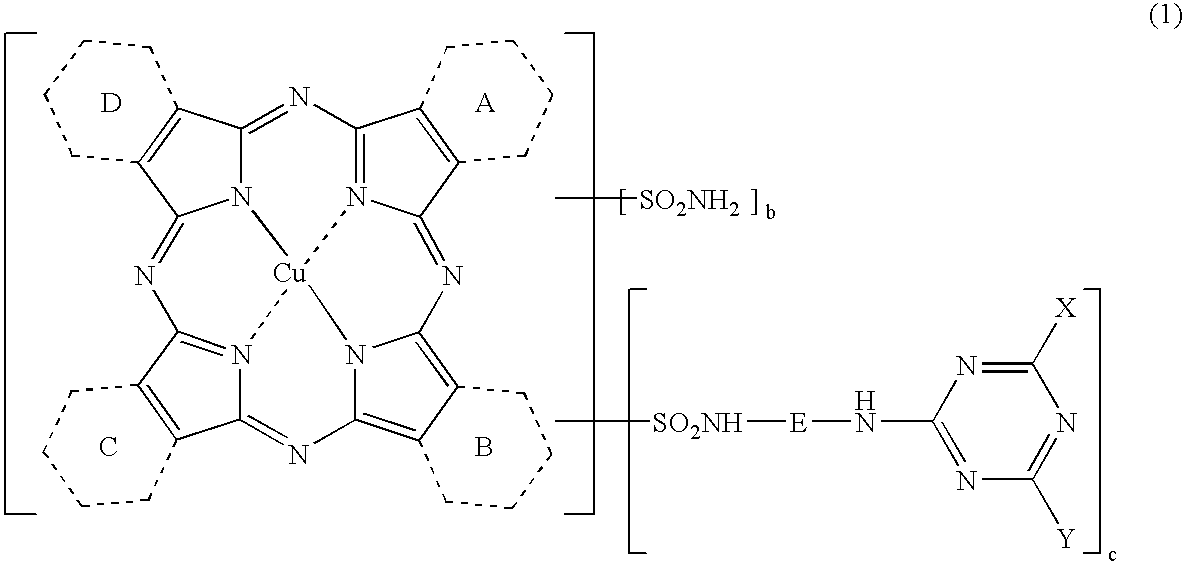

Novel Porphyrazine Coloring Matter, Ink, Ink Set and Colored Article

ActiveUS20090029120A1Excellent toneGood light fastnessLiquid surface applicatorsMeasurement apparatus componentsFree acidCarboxylic group

The present invention relates to a porphyrazine coloring matter represented by the following formula (1):(wherein, A, B, C and D independently represent a 6-membered ring having aromaticity, at least one or more of them are benzene rings and at least one or more of them contain nitrogen-containing heteroaromatic rings; E represents alkylene, X is a substituted anilino group and have at least one or more of sulfo group, carboxy group and phosphono group as a substituent, Y represents a hydroxy group or an amino group, b is respectively 0 to 2.9, c is 0.1 to 3, and the sum of b and c is 1 to 3) in free acid form, which is suitable for inkjet recording because it has good hue as a cyan ink, is excellent in light fastness, ozone fastness and moisture fastness, and does not cause bronzing phenomenon.

Owner:NIPPON KAYAKU CO LTD

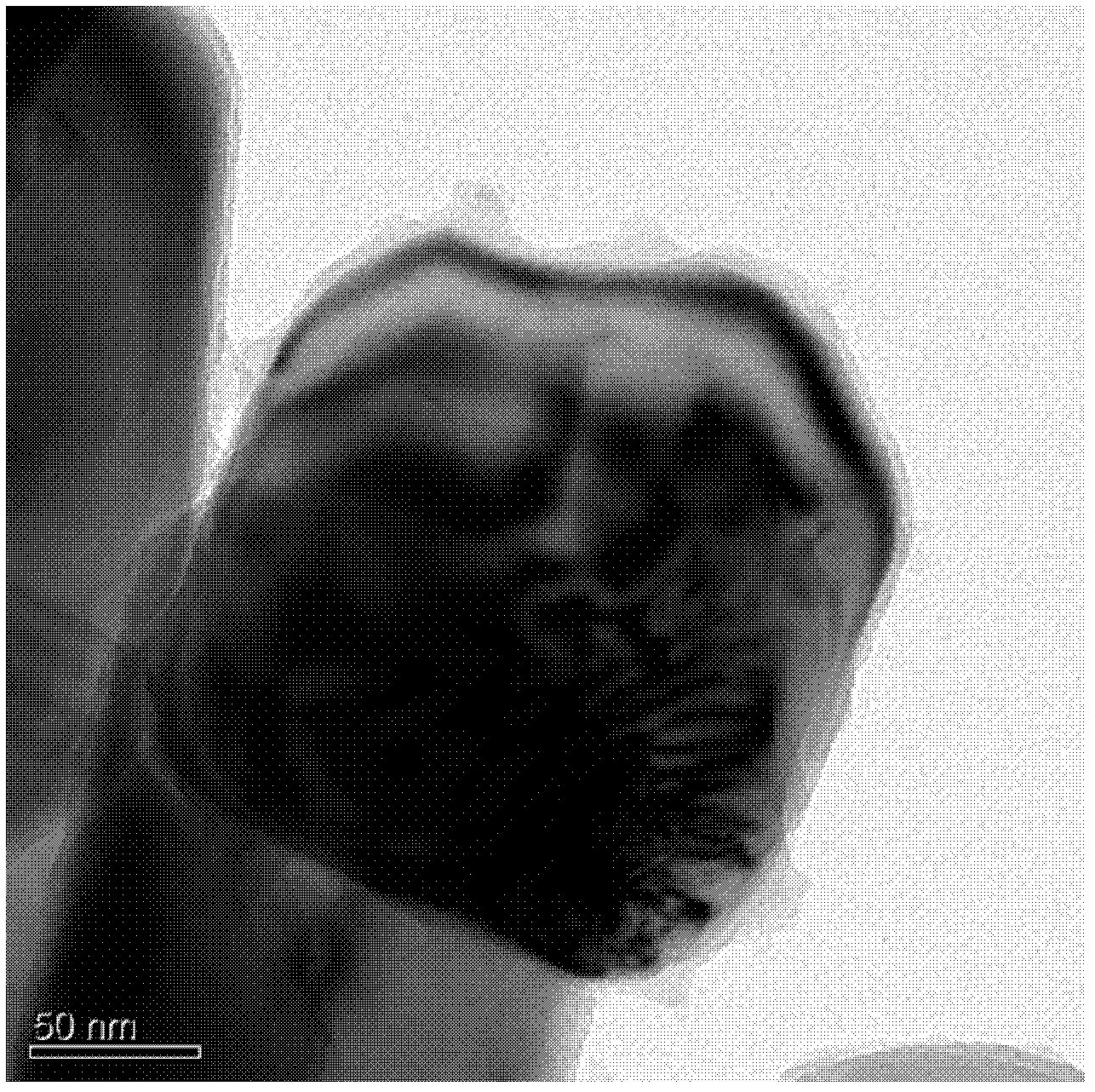

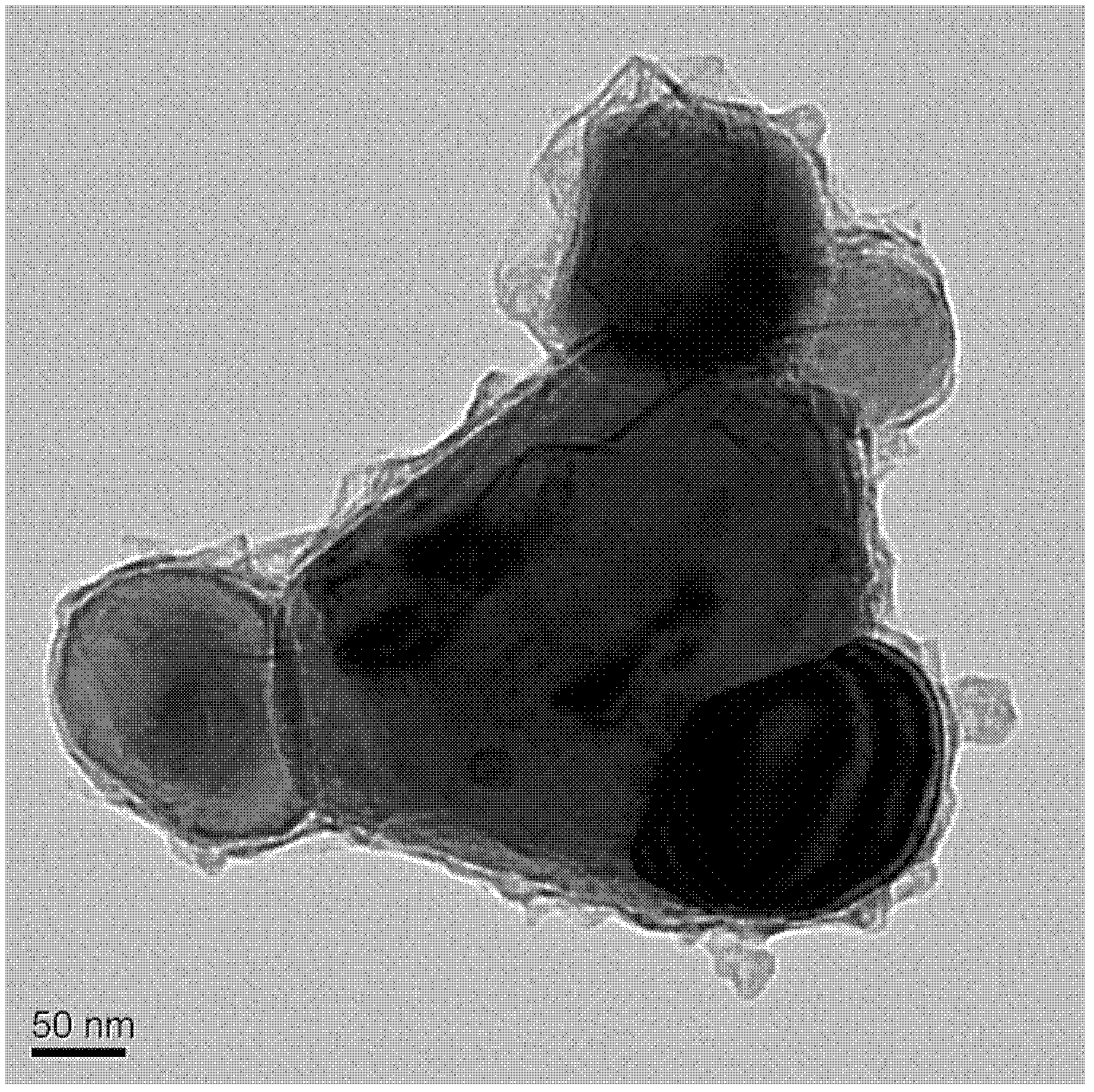

Preparation method for high-light fastness titanium dioxide pigment

ActiveCN102585559AImprove controllabilityGood reproducibilityInorganic pigment treatmentInorganic compound additionAluminium hydroxidePhosphoric acid

The invention discloses a preparation method for a high-light fastness titanium dioxide pigment. The preparation method comprises the following steps of: preparing aqueous suspension of a titanium dioxide initial product; depositing a layer of dense silicon dioxide cladding layer on a titanium dioxide pigment; depositing an aluminum phosphate compound on the silicon dioxide-coated titanium dioxide pigment; depositing aluminum hydroxide by using a parallel-flow method; after the aluminum hydroxide is coated, stirring and aging; and filtering, washing, drying, and performing fluid energy milling and organic treatment to obtain the high-light fastness titanium dioxide pigment. The method provided by the invention has the advantages of high controllability, reproducibility, high operability and the like, facilitates industrial production and has a good application prospect. The titanium dioxide pigment prepared by the method has the advantages of high light fastness, high light resistance, high non-transparency, high color-change resistance and the like, and can be used in decoration paper, laminated paper and coating and plastic products which have high requirements on the light resistance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com