Patents

Literature

55results about How to "Reliable printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printing liquids for improved print quality

InactiveUS6022908AImprove print qualityReduce bleedingDuplicating/marking methodsInksColoring agentsAnionic polymers

A set of printing liquids is disclosed comprising a first anionic printing liquid comprising an aqueous vehicle, at least one first colorant, and at least one first anionic polymer; a second anionic printing liquid comprising an aqueous vehicle at least one second colorant, at least one second anionic polymer, and an acid additive having a pKa up to the pKa of the at least first polymer of the first liquid; a third cationic printing liquid comprising an aqueous vehicle, at least one third colorant, at least one third cationic polymer, and a pH in the range from about 2 to about 5; and a fourth anionic printing liquid comprising an aqueous vehicle, at least one fourth anionic dye, and a precipitating agent. More specifically, the present set of printing liquids may find application in ink-jet printing. The set of ink-jet inks provides improved print quality, specifically, reduced bleed; improved edge-acuity, uniform area fills, and color quality; while maximizing lightfastness without sacrificing printing reliability.

Owner:HEWLETT PACKARD DEV CO LP

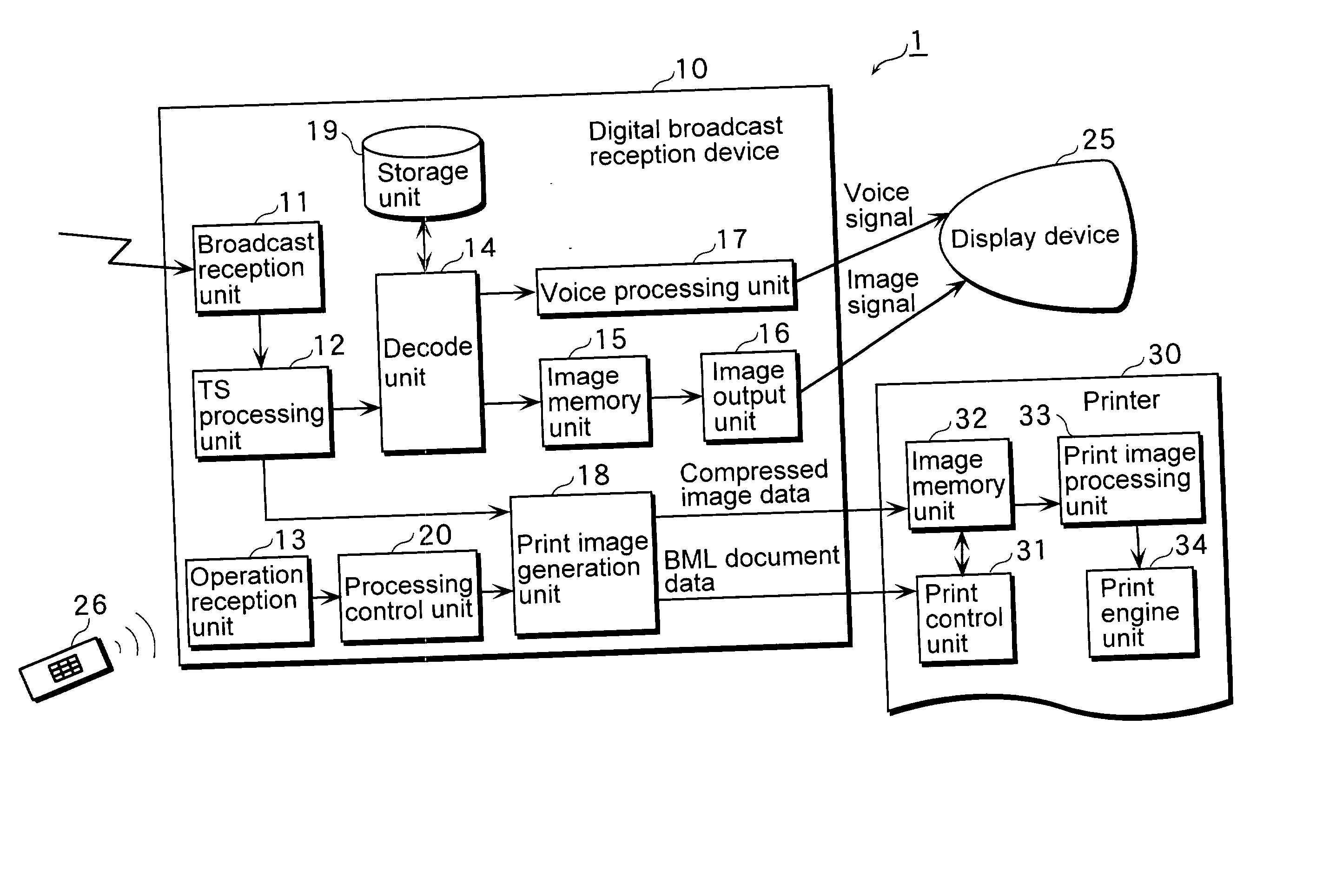

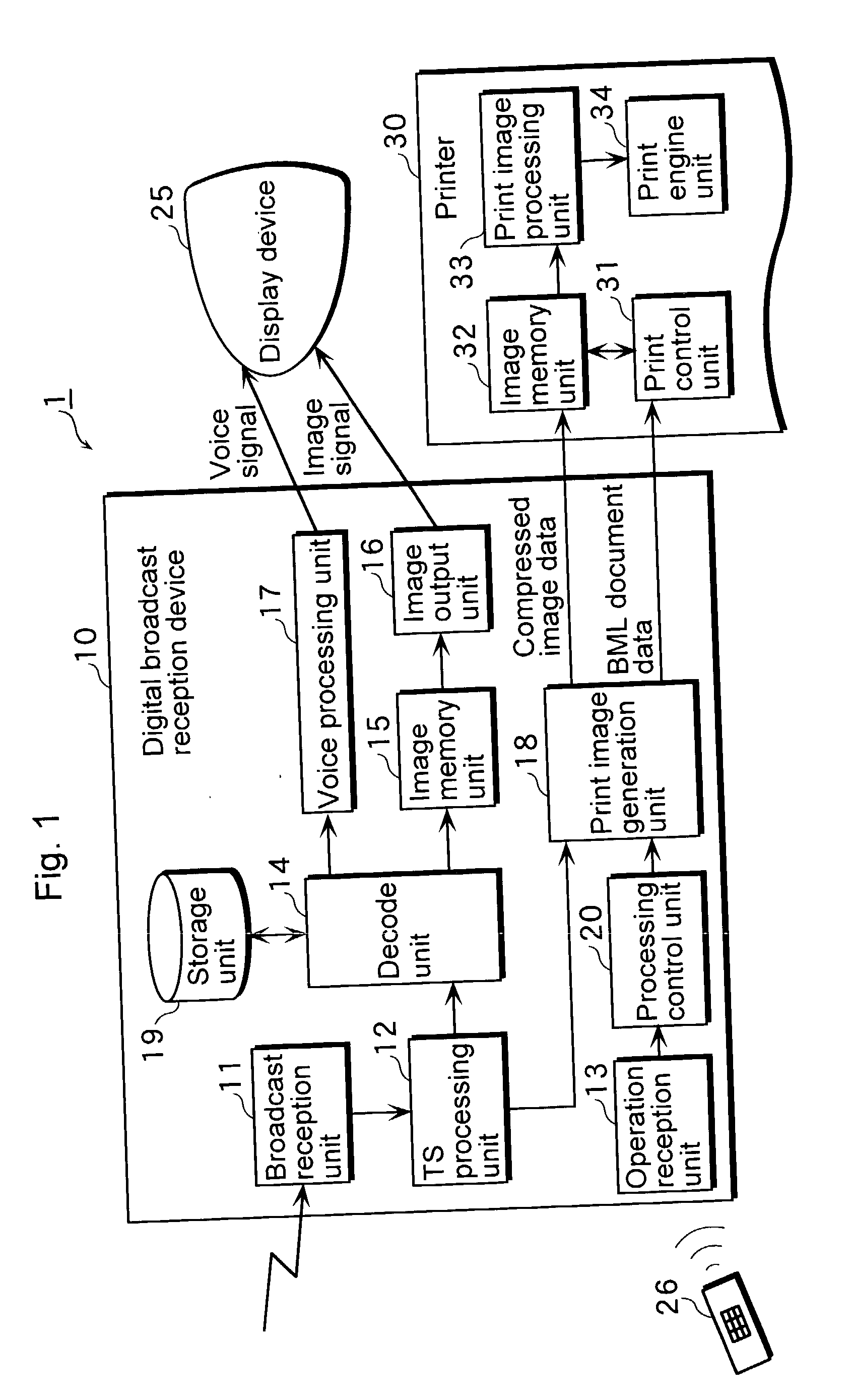

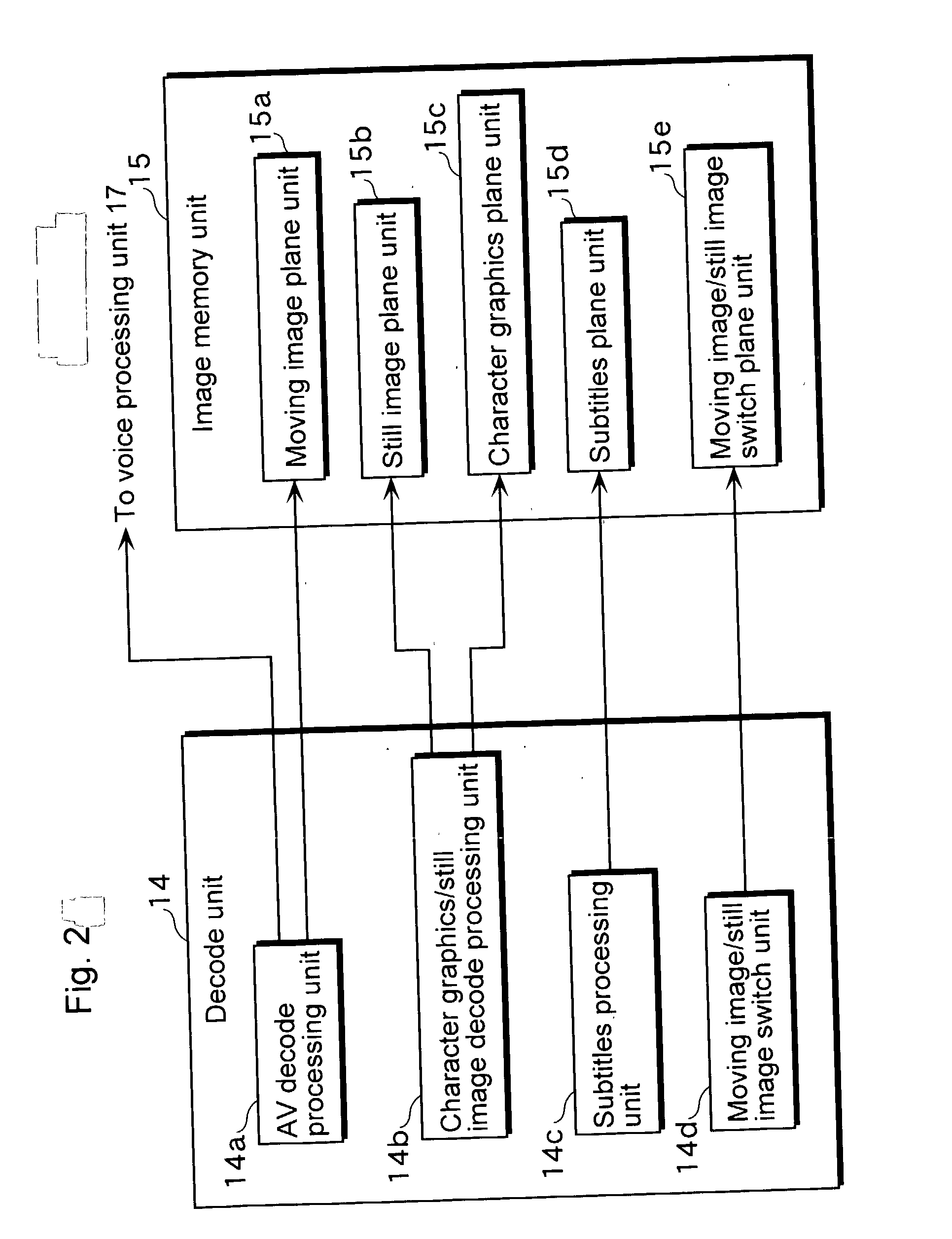

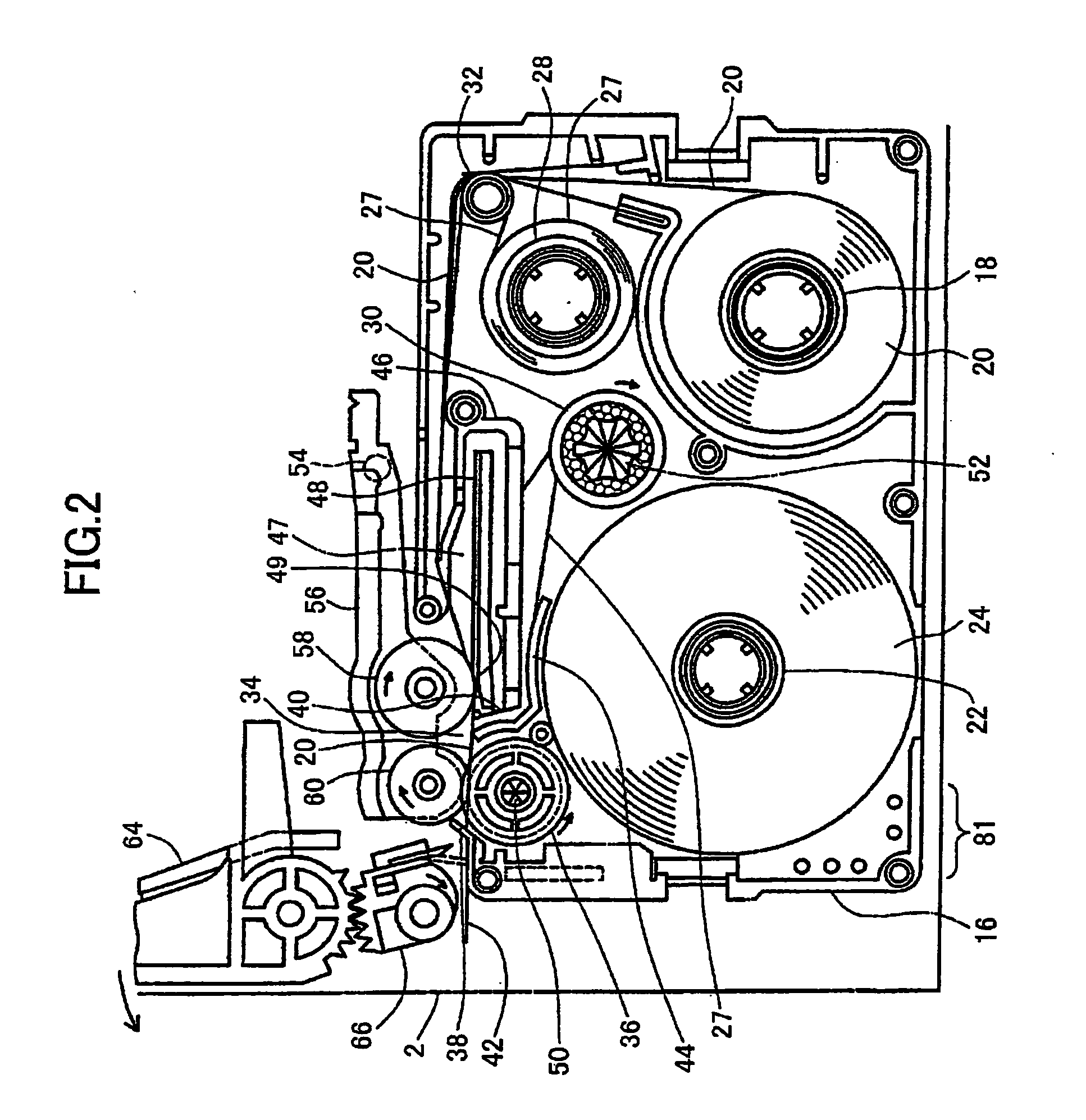

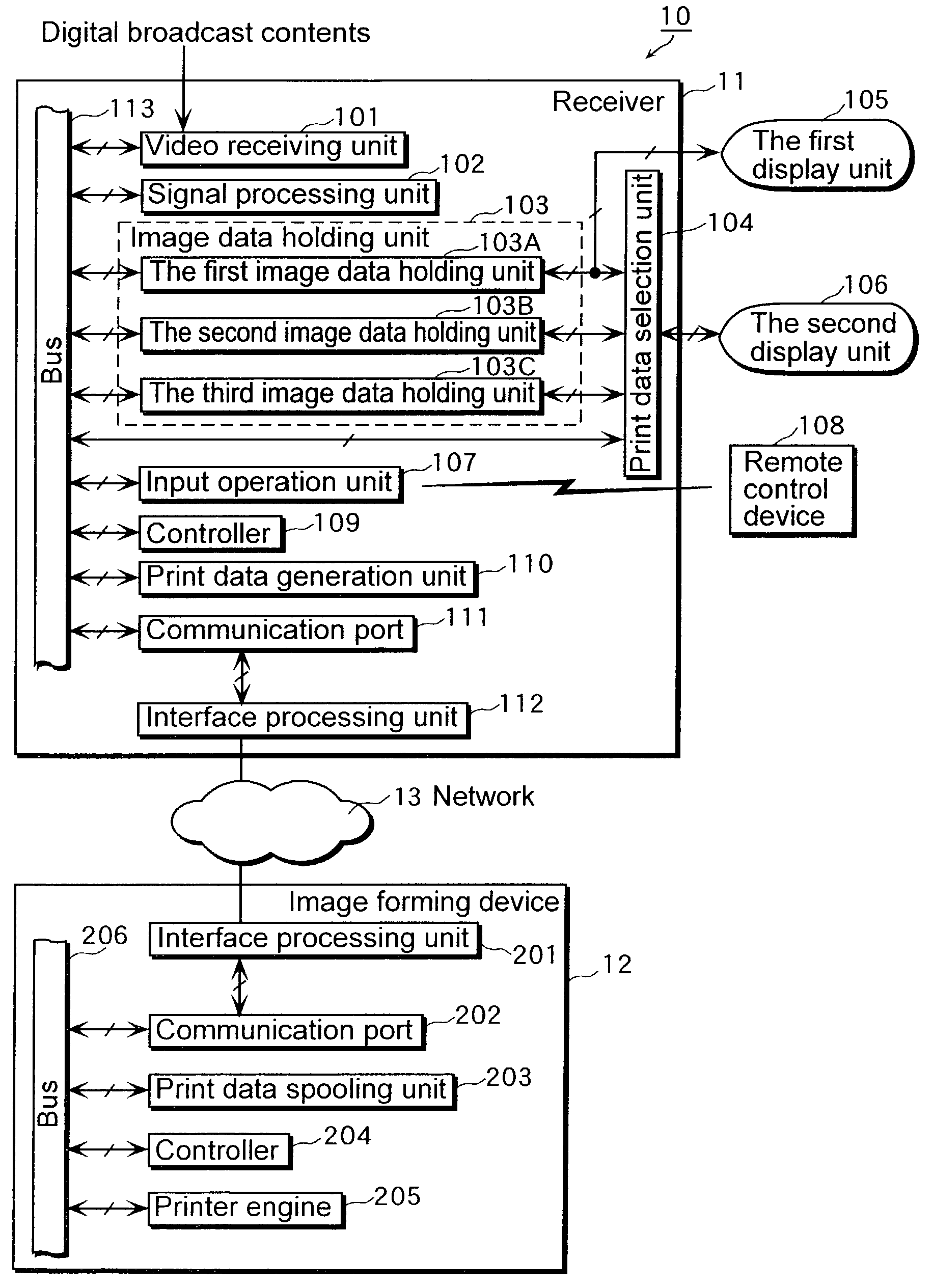

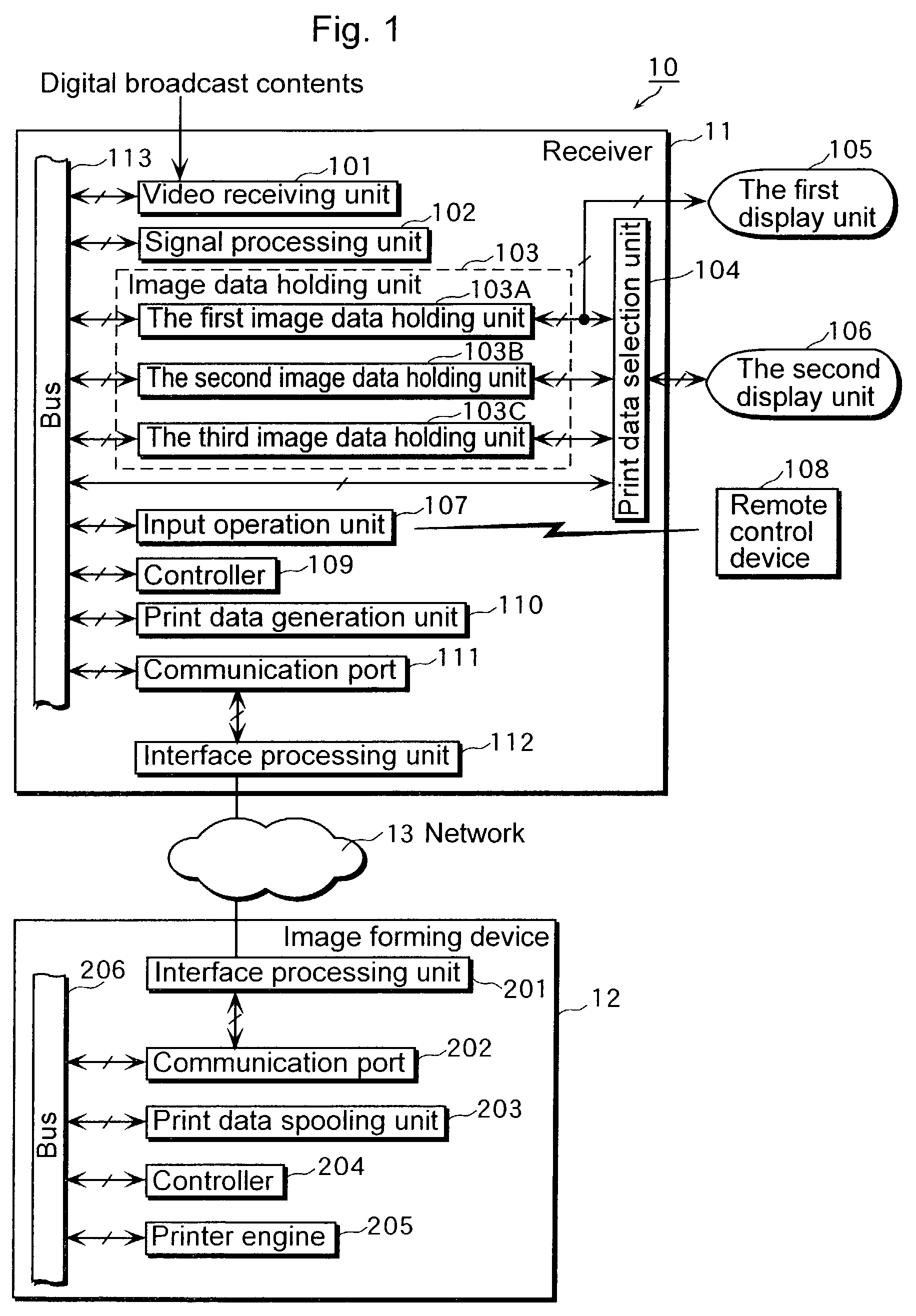

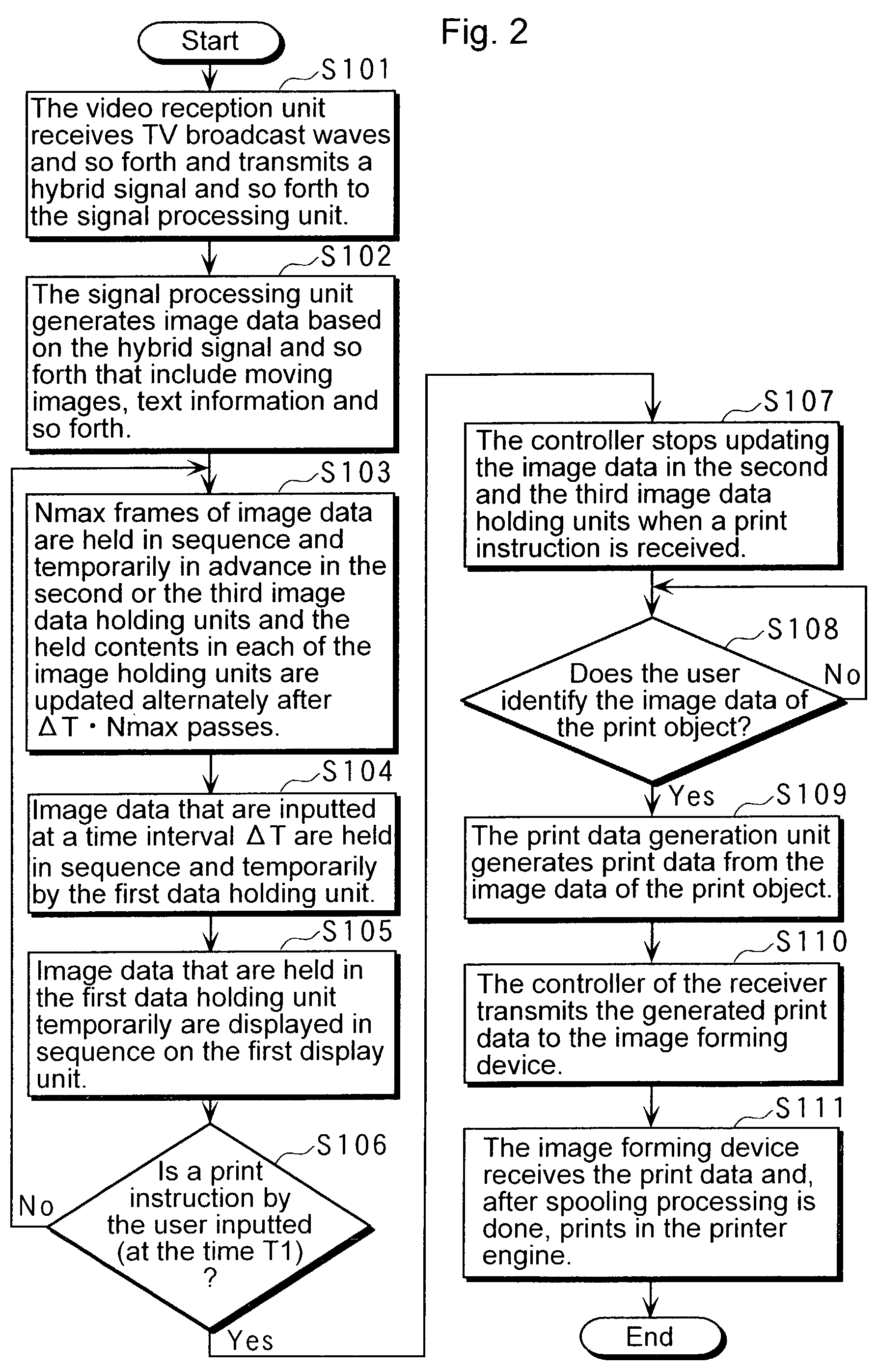

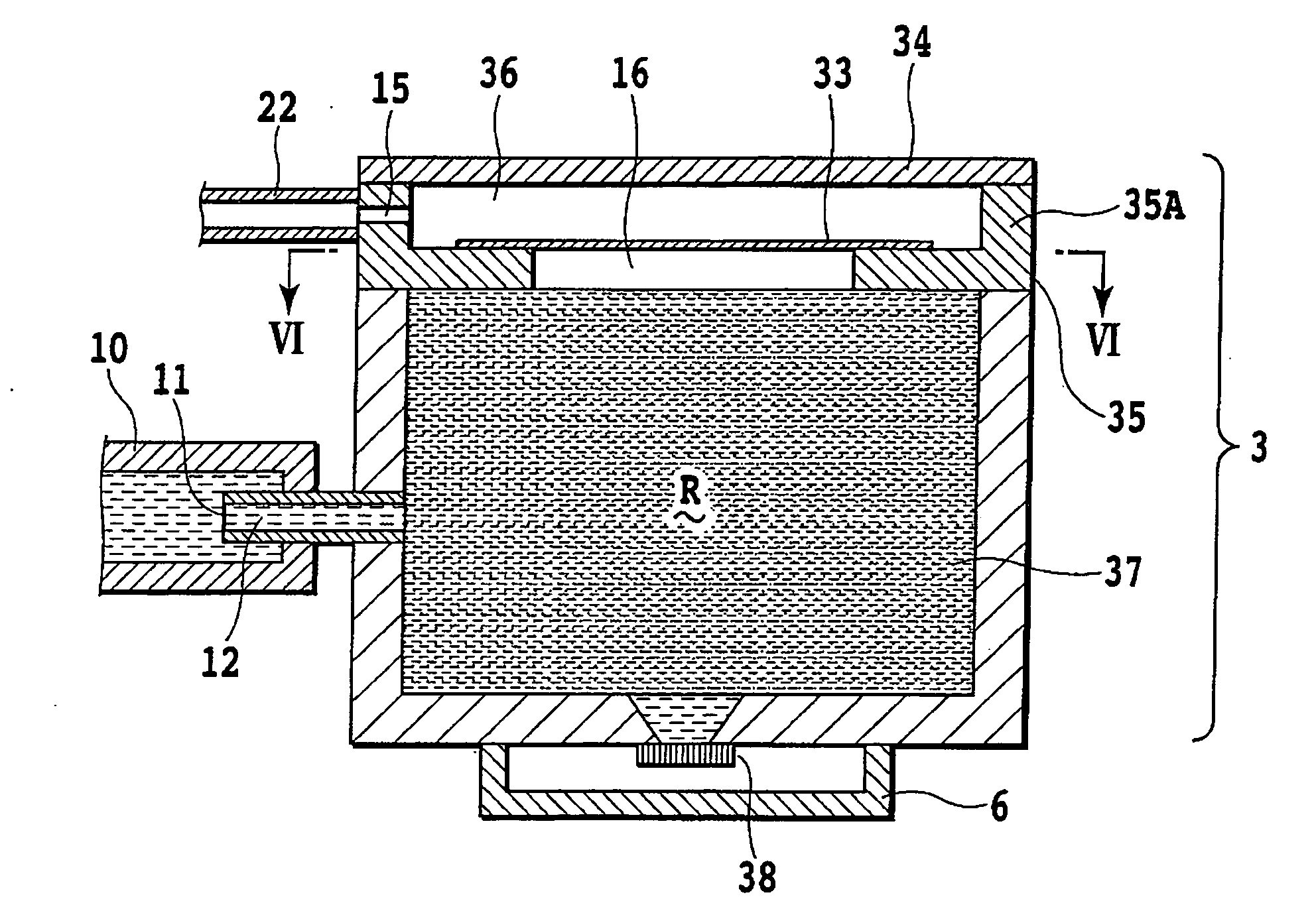

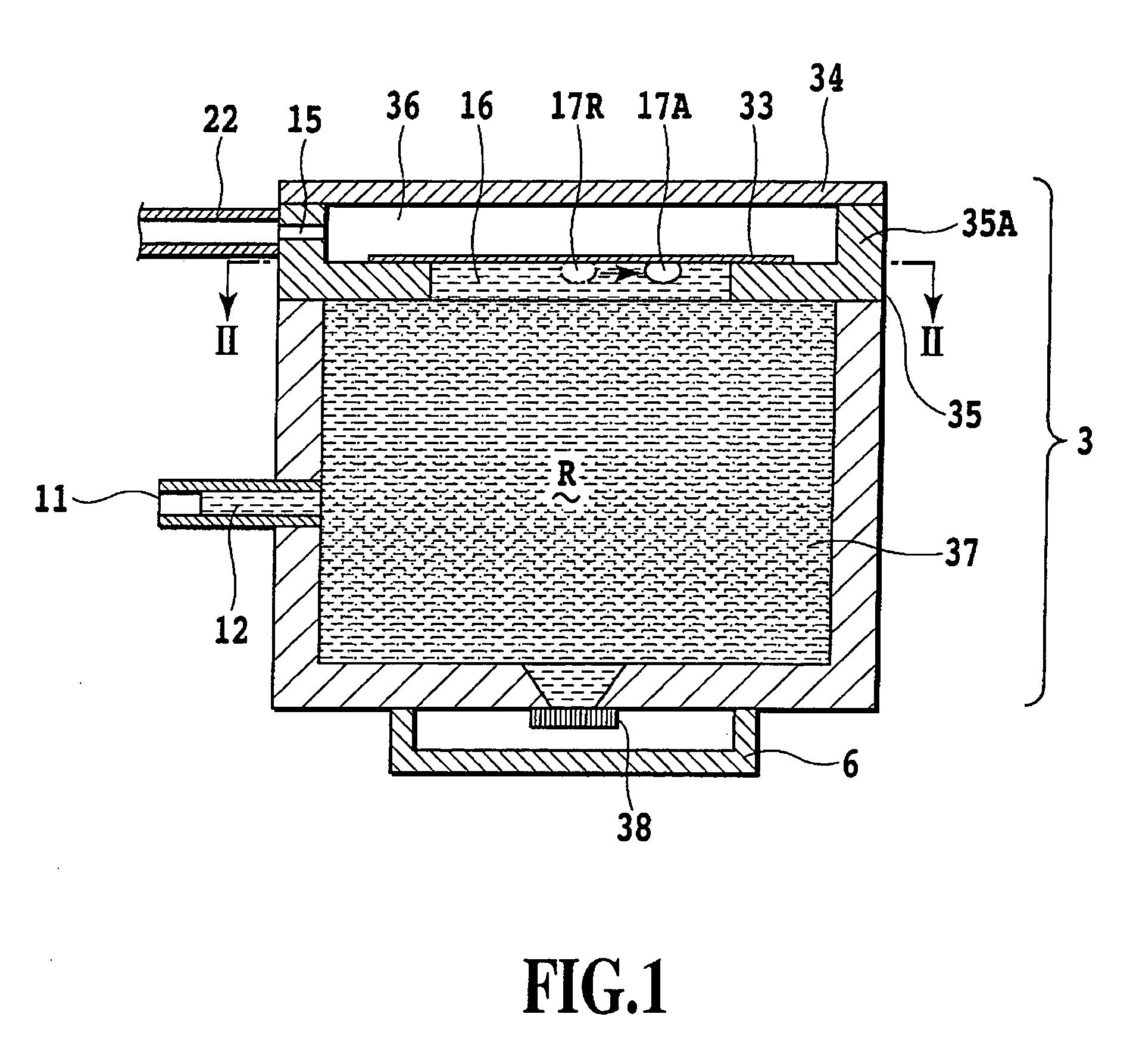

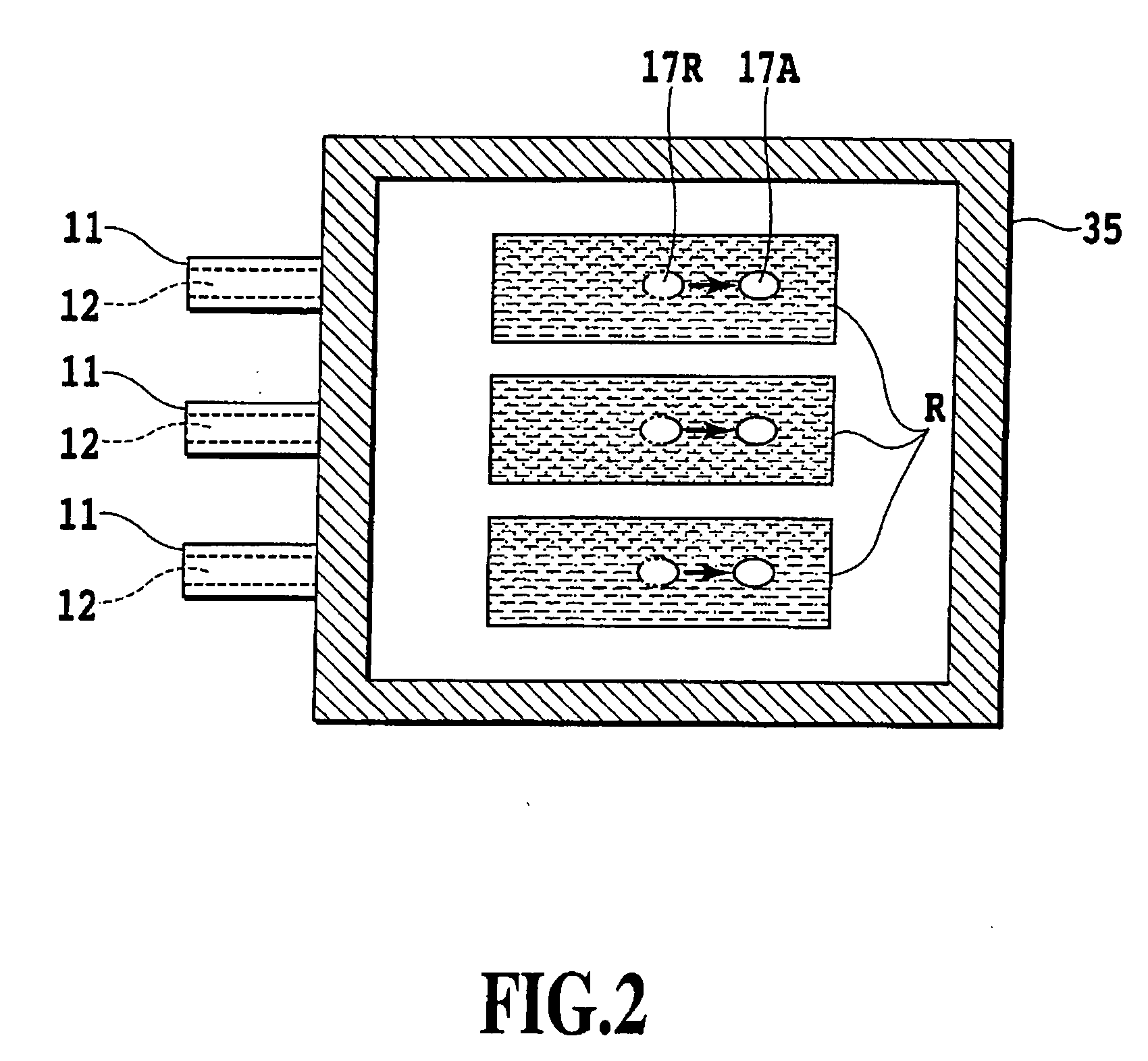

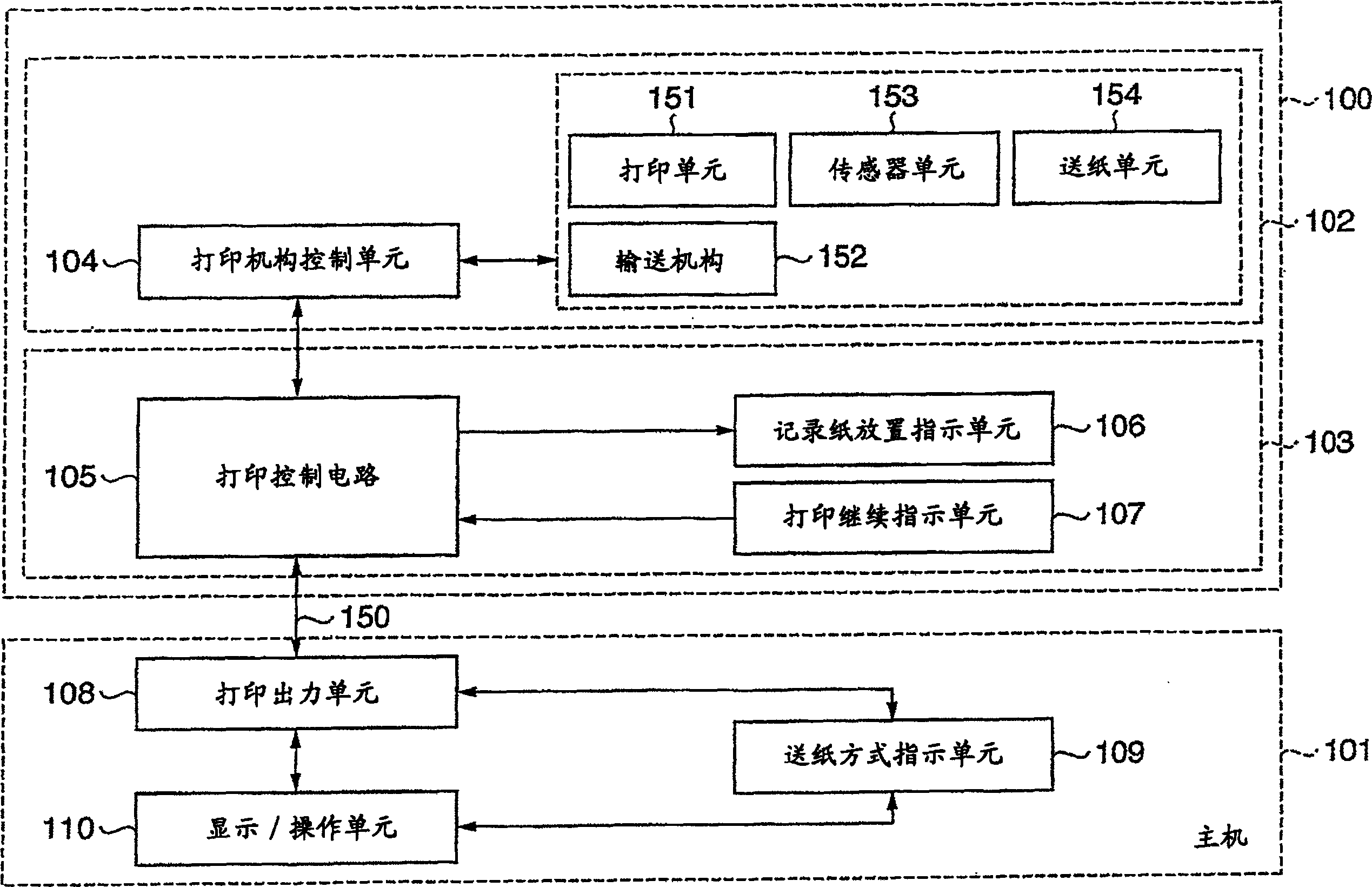

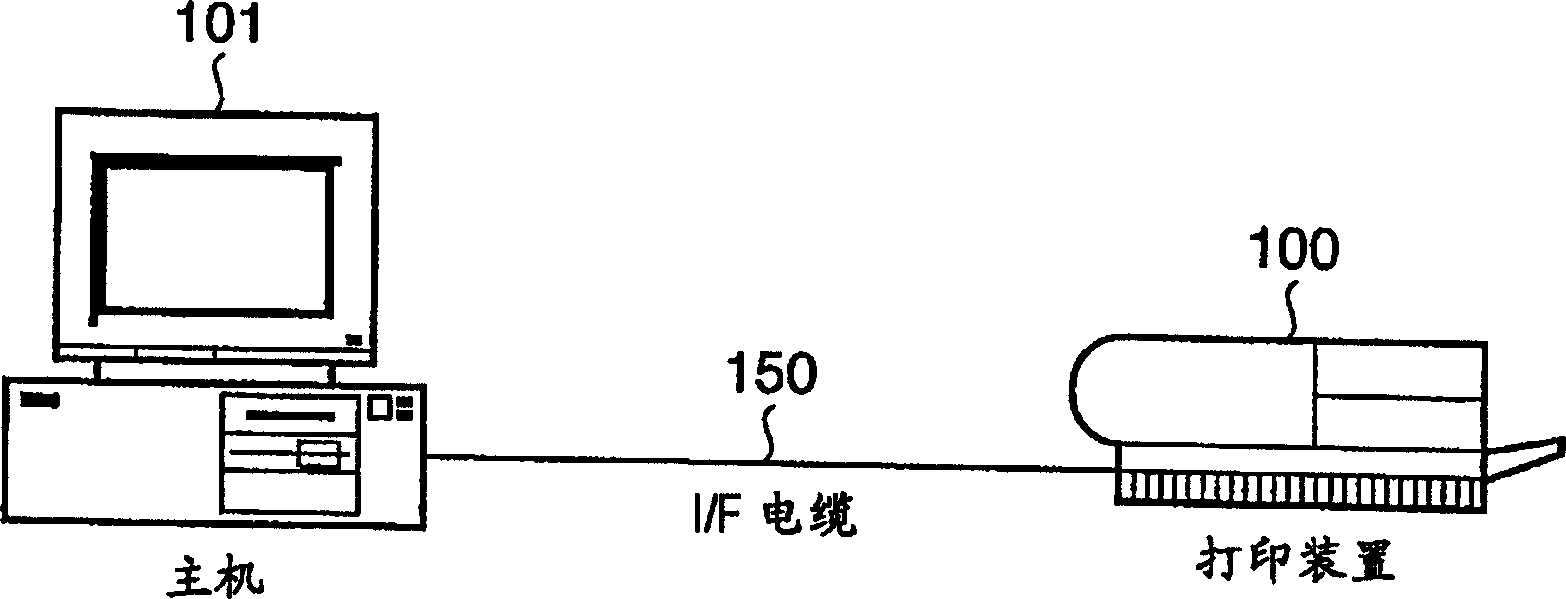

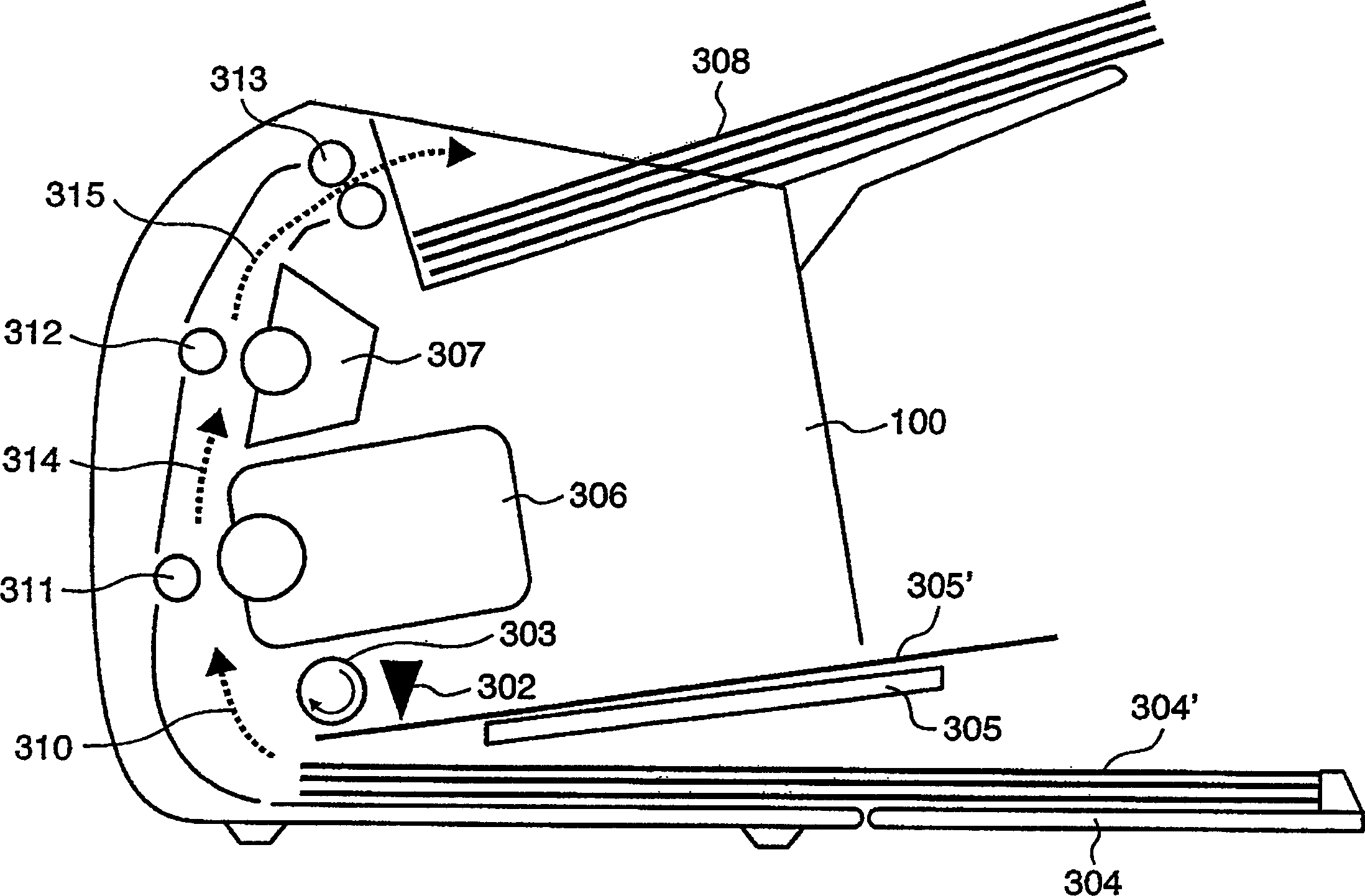

Digital boradcast reception device and method thereof, and printing device and method thereof

InactiveUS20030084462A1Easy to operateReliable printingTelevision system detailsAnalogue secracy/subscription systemsData contentComputer graphics (images)

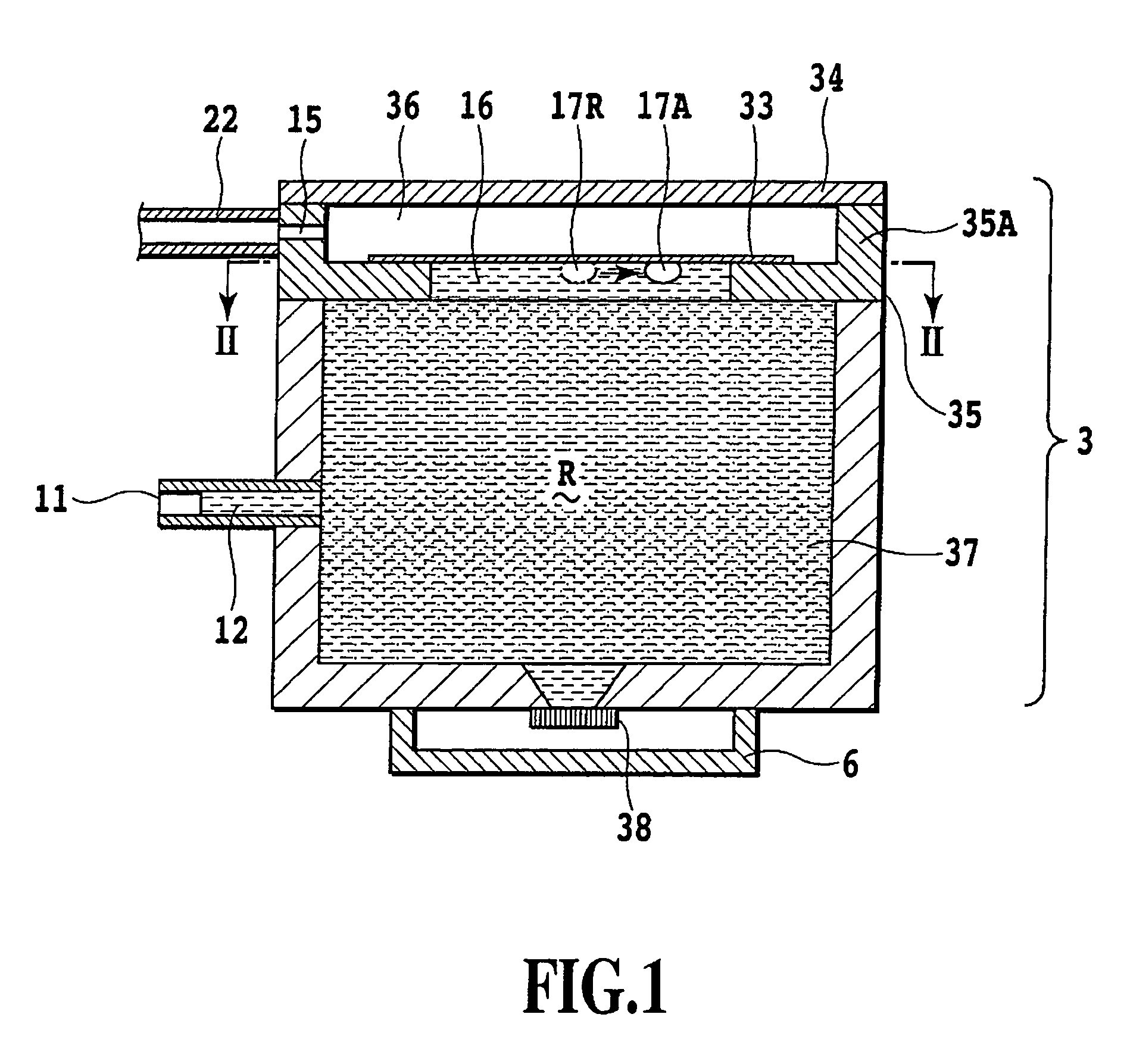

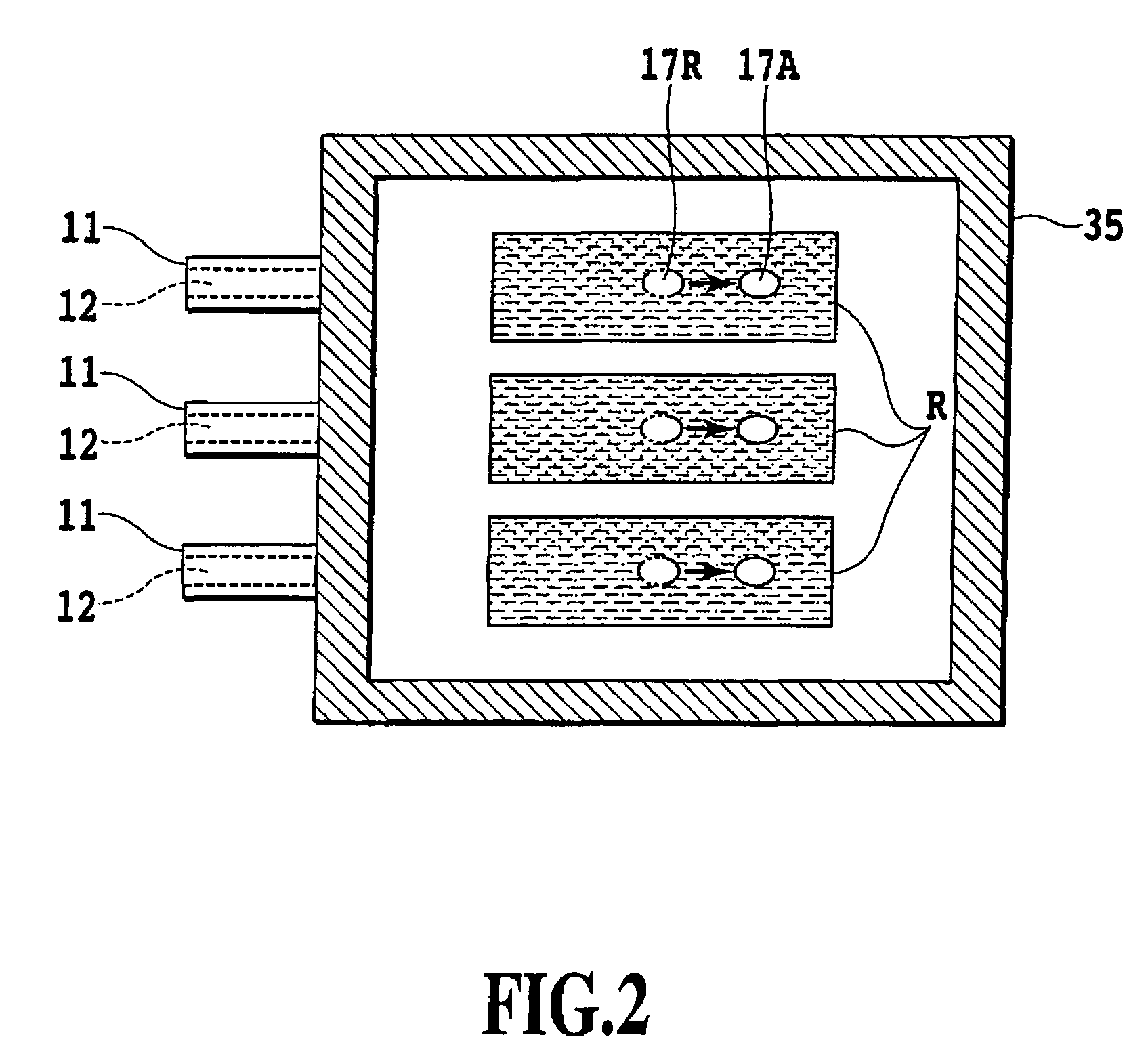

A digital broadcast reception device comprises: a broadcast receiving unit 11 that receives a digital broadcast; a TS processing unit 12 and a decode unit 14 that separate video contents and data contents from the received digital broadcast; a image memory unit 15 that stores the separated video contents and data contents in a special-purpose plane and memorizes the separated video contents and data contents temporarily; an image output unit 16 that synthesizes the video contents and data contents stored in the image memory unit 15, generates image data, and output the image data; a remote control 26, an operation reception unit 13, and a processing control unit 20 that acquire a print instruction from an operator; and a print image generation unit 18 that selects and synthesizes the video contents and data contents stored in the image memory unit 15, generates a print data, and outputs the generated print data to a printer 30 in response to the print instruction.

Owner:PANASONIC CORP

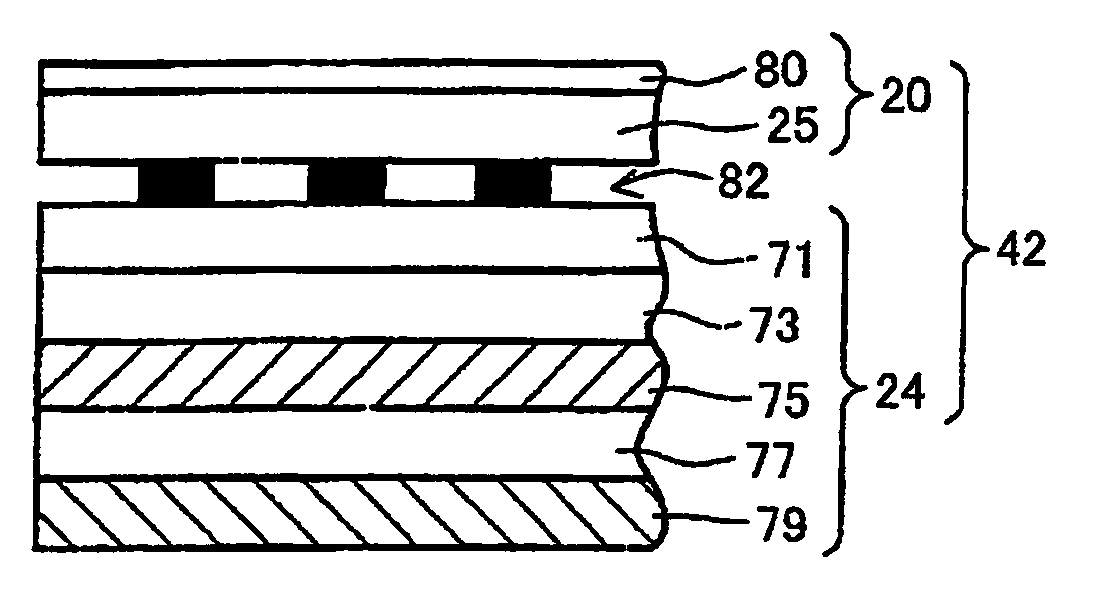

Ink-jet printing system for improved print quality

InactiveUS6247808B1Improve print qualityReduce bleedingMeasurement apparatus componentsDuplicating/marking methodsInkjet printingColoring agents

An ink-jet printing system is disclosed comprising a set of ink-jet inks comprising a first anionic ink comprising an aqueous vehicle, at least one first colorant, and at least one first anionic polymer; a second anionic ink comprising an aqueous vehicle; at least one second colorant, at least one second anionic polymer, and an acid additive having a pKa up to the pKa of the at least first polymer of the first ink; a third cationic ink comprising an aqueous vehicle, at least one third colorant, at least one third cationic polymer, and a pH in the range from about 2 to about 5; and a fourth anionic ink comprising an aqueous vehicle, at least one fourth anionic dye, and a precipitating agent. The printing system provides improved print quality, specifically, reduced bleed; improved edge-acuity, uniform area fills, and color quality; while maximizing lightfastness without sacrificing printing reliability.

Owner:HEWLETT PACKARD DEV CO LP

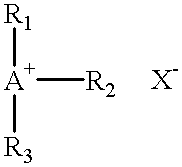

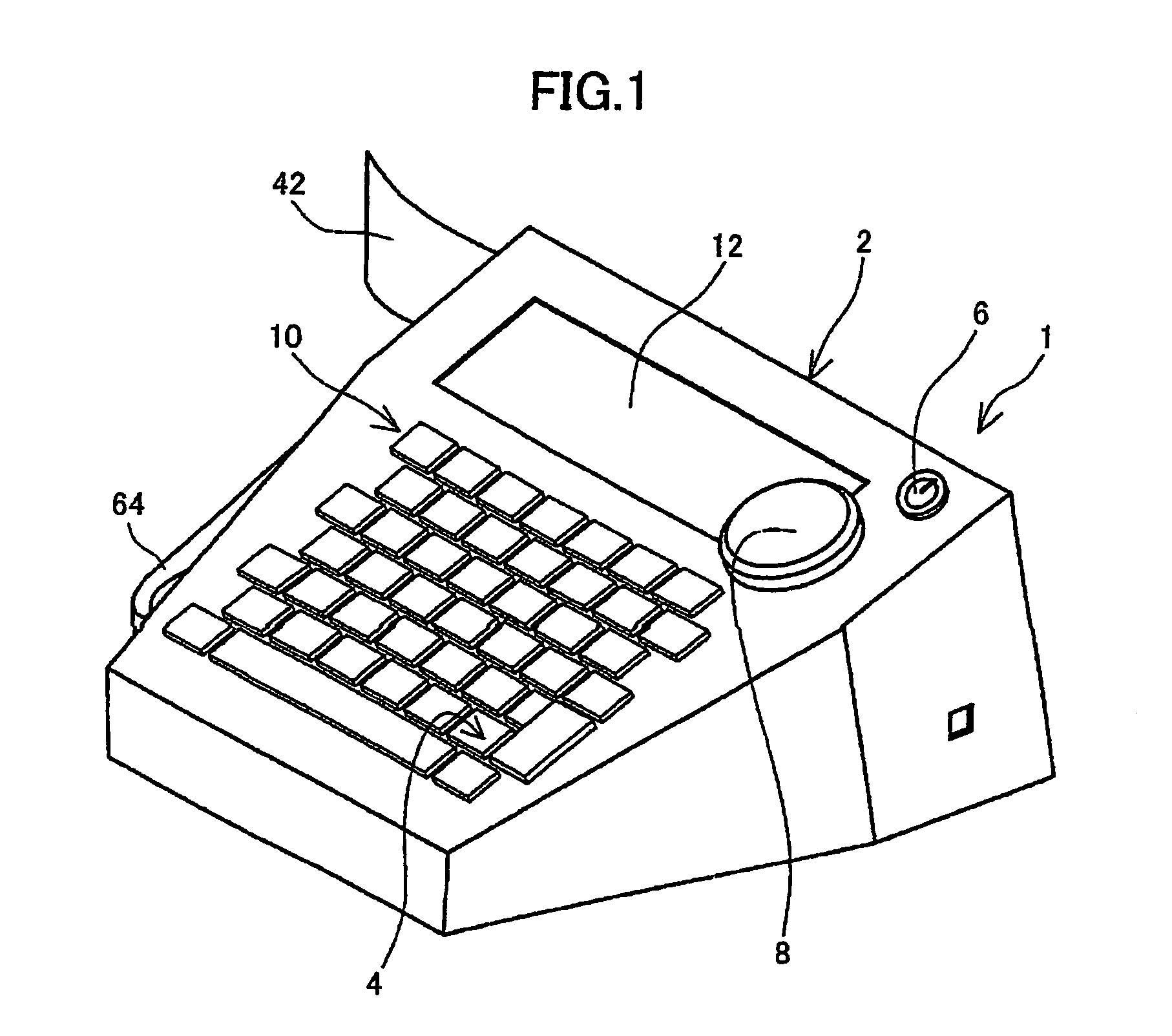

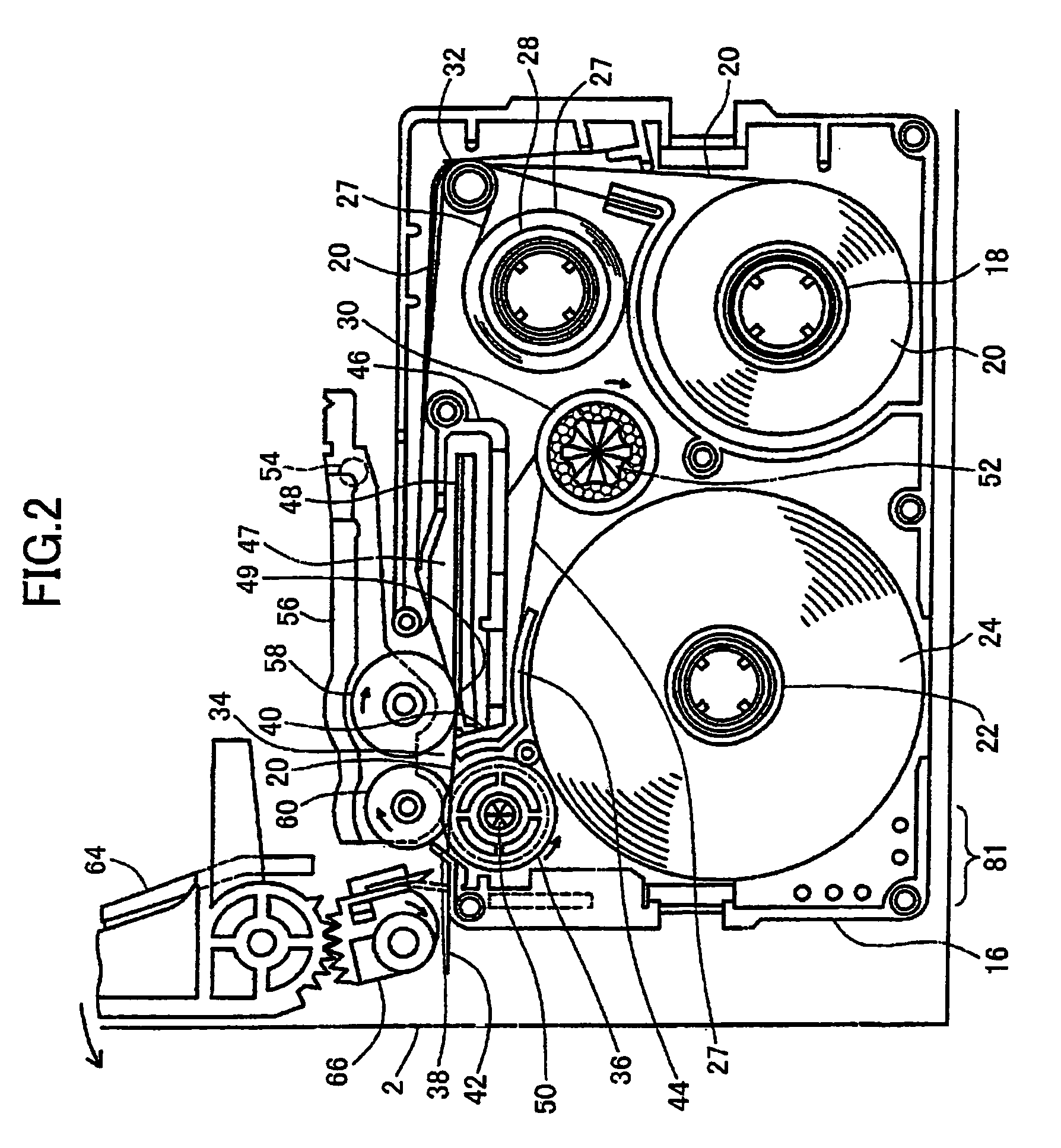

Temperature-indicating tape and device for creating labels using the same

InactiveUS20060121229A1Eliminate failureReliable printingLayered productsFilm/foil adhesivesEngineeringElectrical and Electronics engineering

A tape-like label forming device is capable of forming a label tape that is made up of a printing tape and a double-sided tape. A temperature-indicating material that changes color in response to changes in ambient temperature is applied to the surface of the printing tape. With this construction, since the color of the temperature-indicating material conceals the colors of the double-sided tape and characters such as letters and symbols printed on the underside of the printing tape, the colors of the characters and the double-sided tape can be freely selected and combined.

Owner:BROTHER KOGYO KK

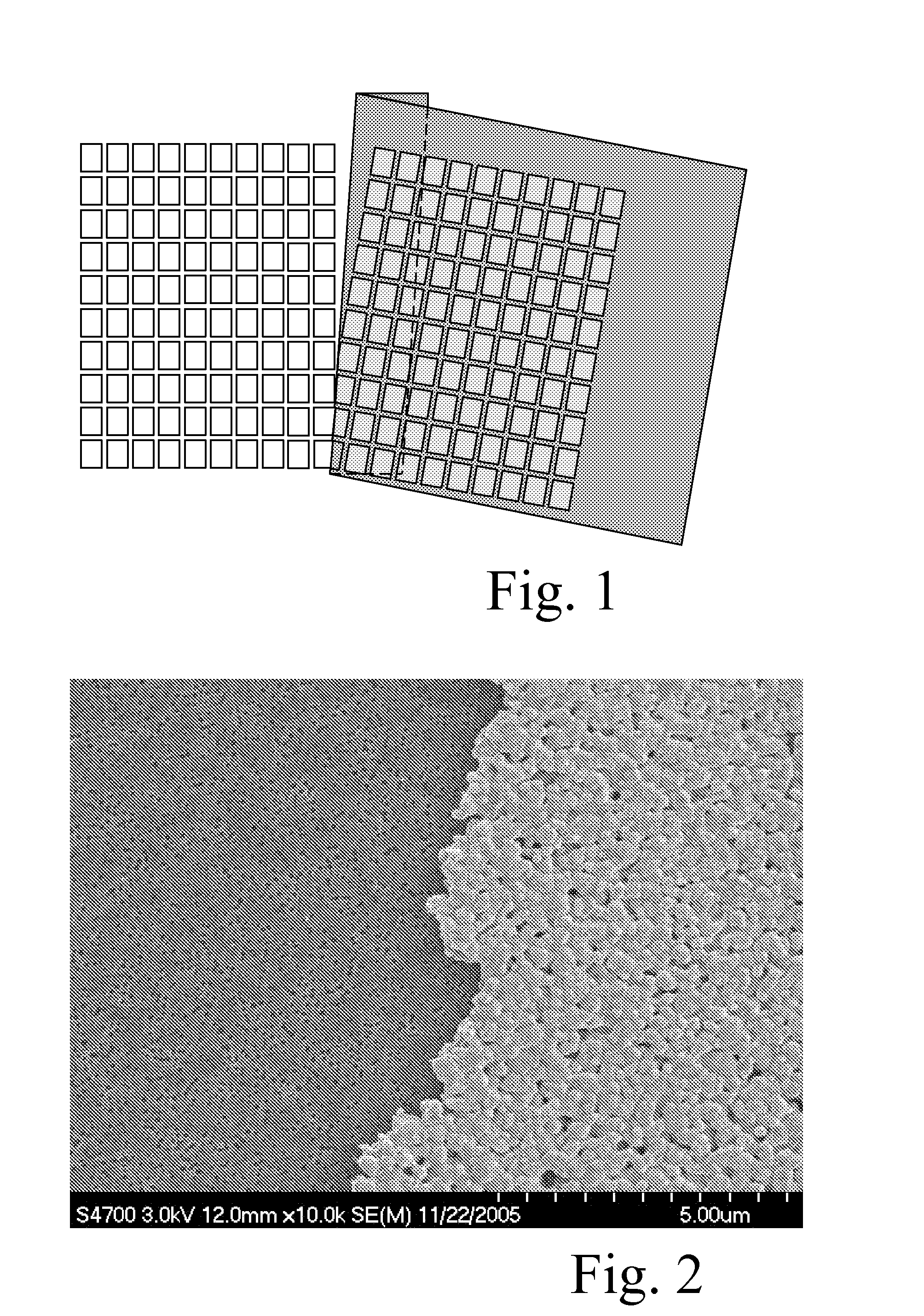

Silver Ink Compositions Containing An Additive For Inkjet Printing

ActiveUS20080236444A1Improve adhesionDesired conductivityConductive materialInksSilver inkSilver particles

The present invention provides an aqueous ink containing ≧3% silver particles having much improved adhesion. It has been found that the adhesion can be improved by adding an aqueous cationic dispersion of a styrene / acrylate copolymer, PEI (polyethyleneimine), or arabinogalactan as an additive to the ink. The advantage of using one of these materials to improve the adhesion of the silver ink is the stability of the ink is maintained and the resistivity goal is met when printed onto the specified media. In other words, this invention provides a silver ink with great adhesion properties while still able to meet the <0.1 Ω / square resistivity requirement and remain stable for up to 4 weeks at 60° C. at accelerated oven aging conditions.

Owner:LEXMARK INT INC

Image output device, image forming device and method for generating video hard copy

InactiveUS7221470B2Reliable printingClose in timeDigital computer detailsCharacter and pattern recognitionData selectionImage formation

Owner:PANASONIC CORP

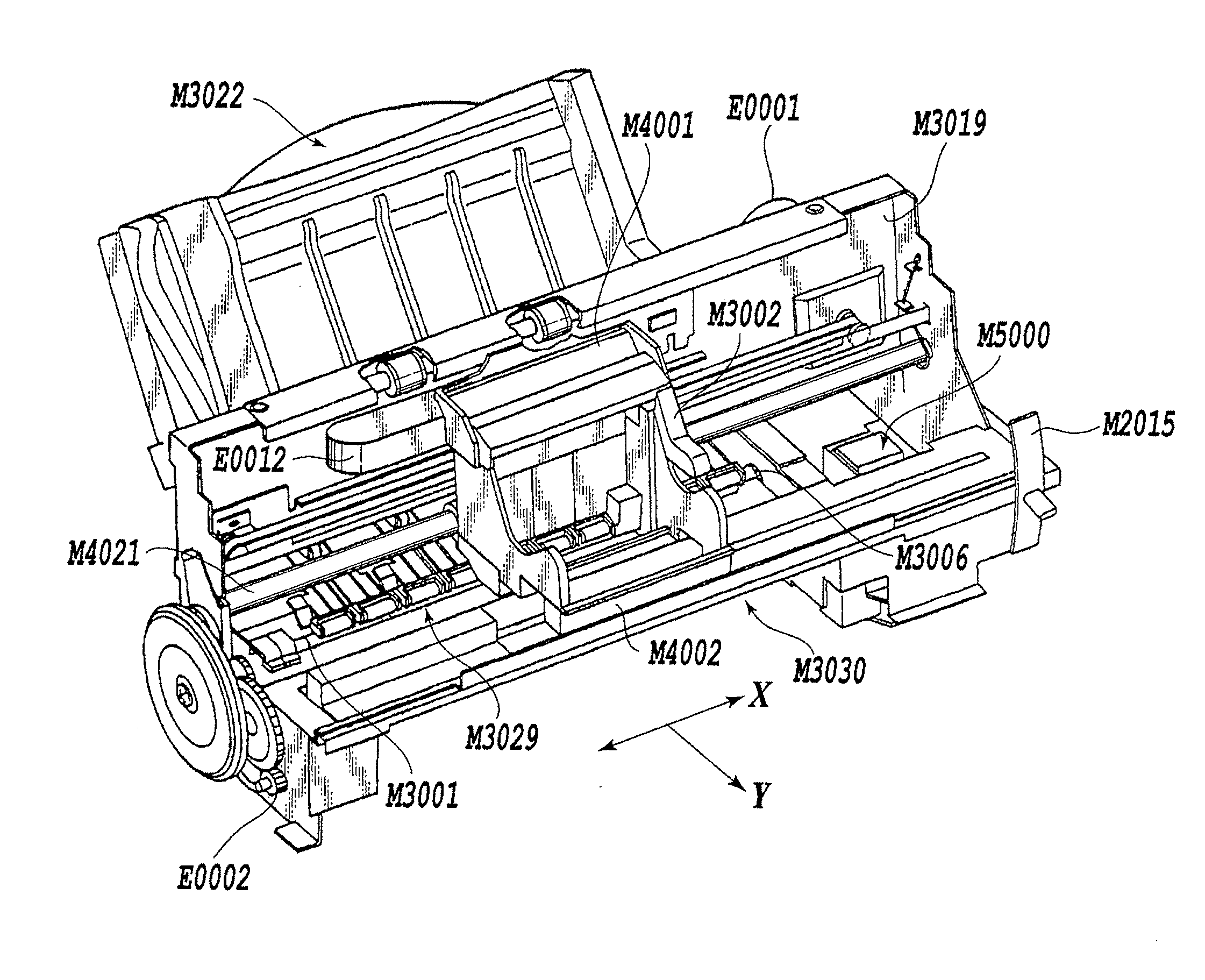

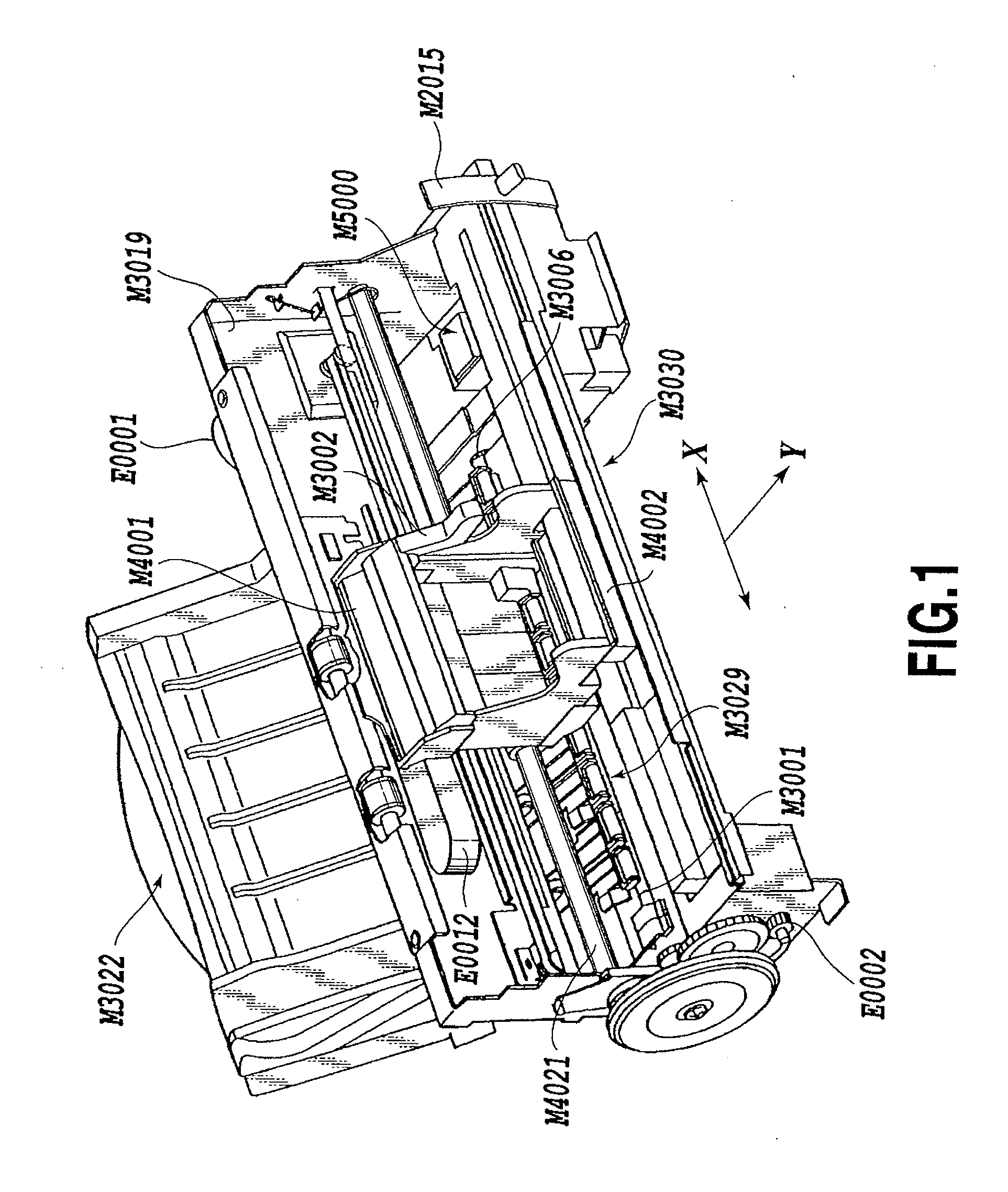

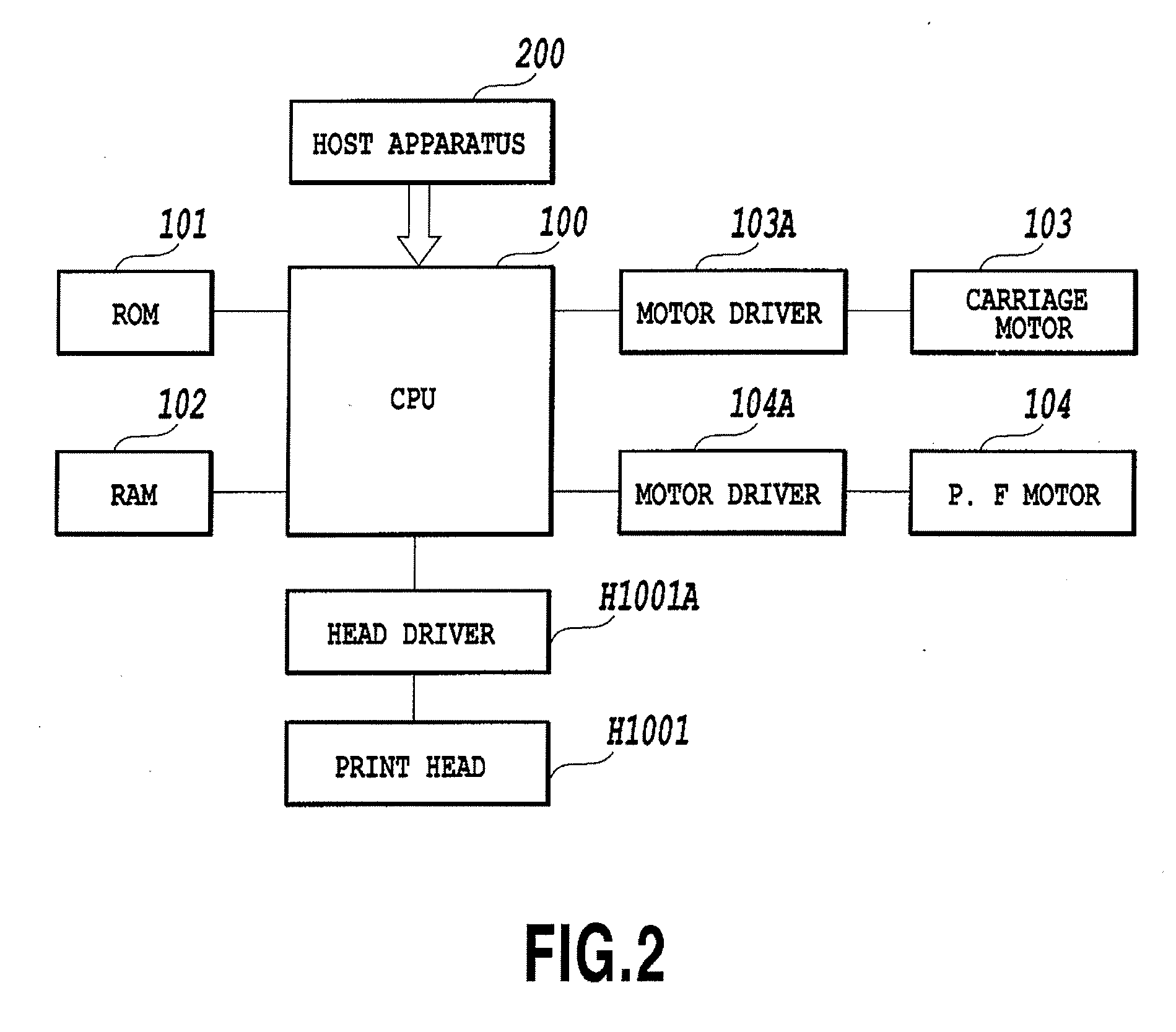

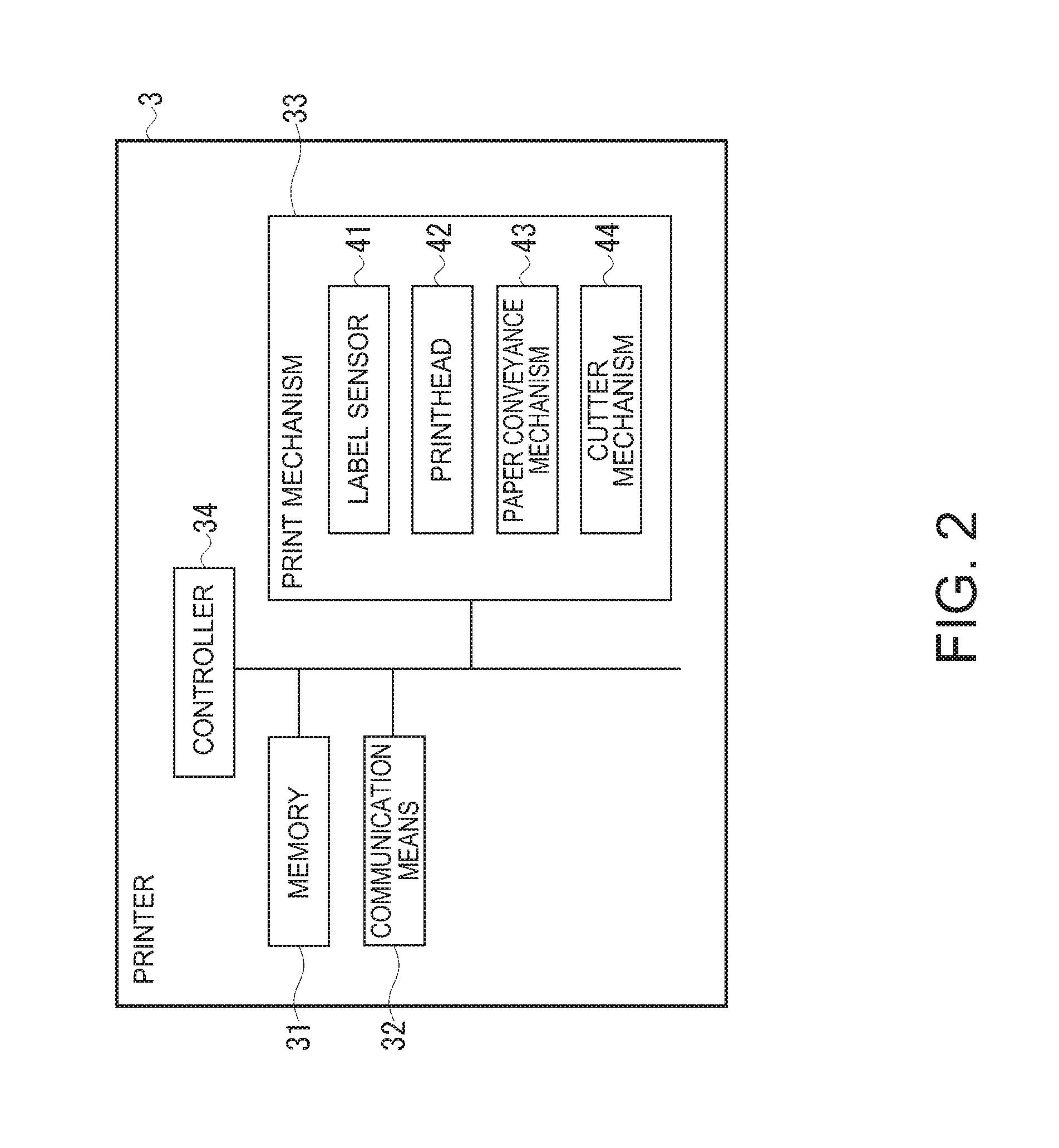

Inkjet printing apparatus

An ink jet printing apparatus including a suction recovery function performs suction recovery that that recovers the reliability of a print head while reducing the amount of ink sucked from the print head. An ink jet printing apparatus includes a print head having an ejection port surface with ejection ports formed therein from which ink is ejected, a cap covering the ejection port surface of the print head, and suction unit for allowing a pump to generate negative pressure in the cap to suck ink from the print head. The suction unit has a valve provided in a communication tube joining the pump and the cap together. The suction unit sucks ink under a relatively low negative pressure and then switches the valve to suck the ink under a relatively high negative pressure.

Owner:CANON KK

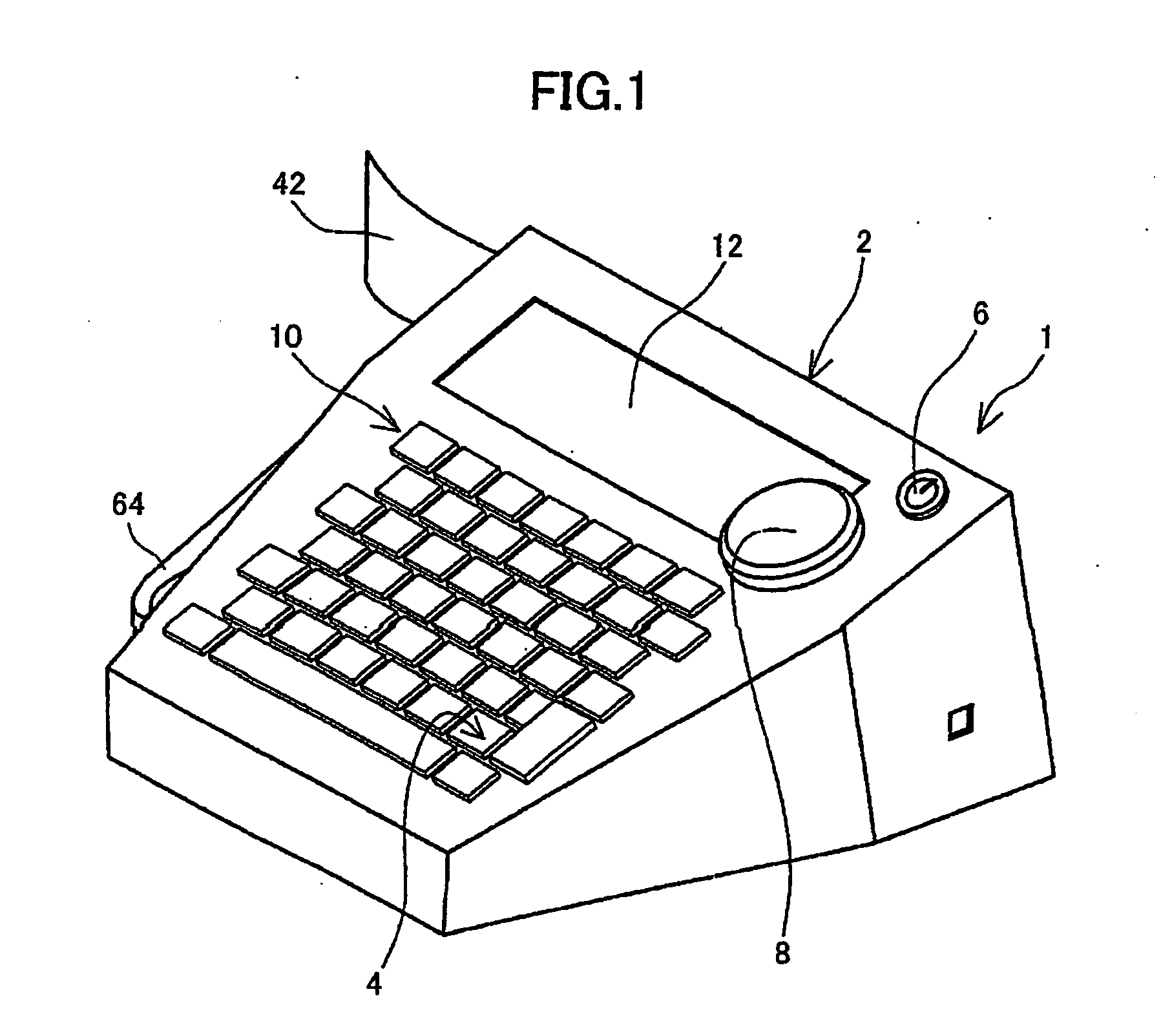

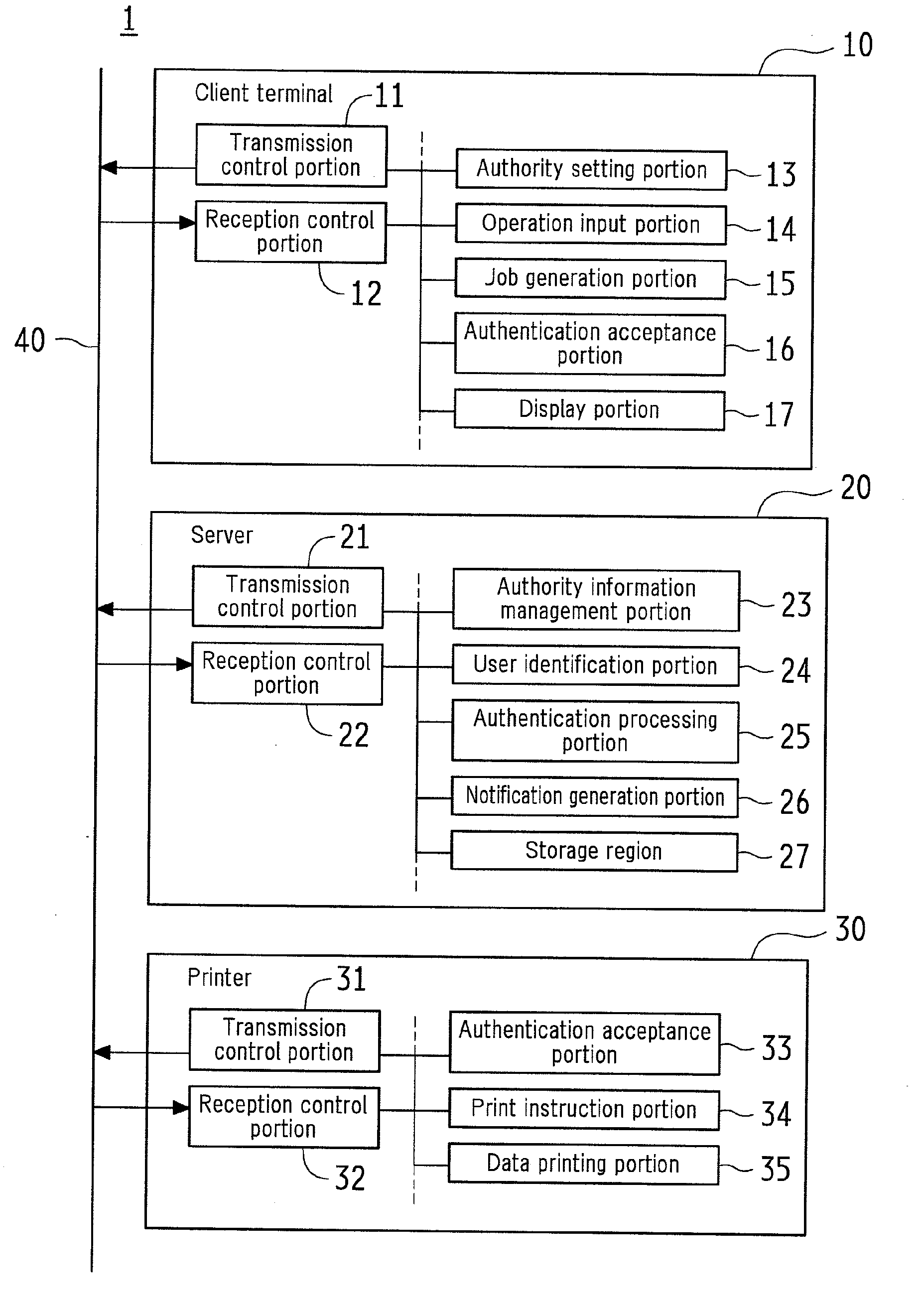

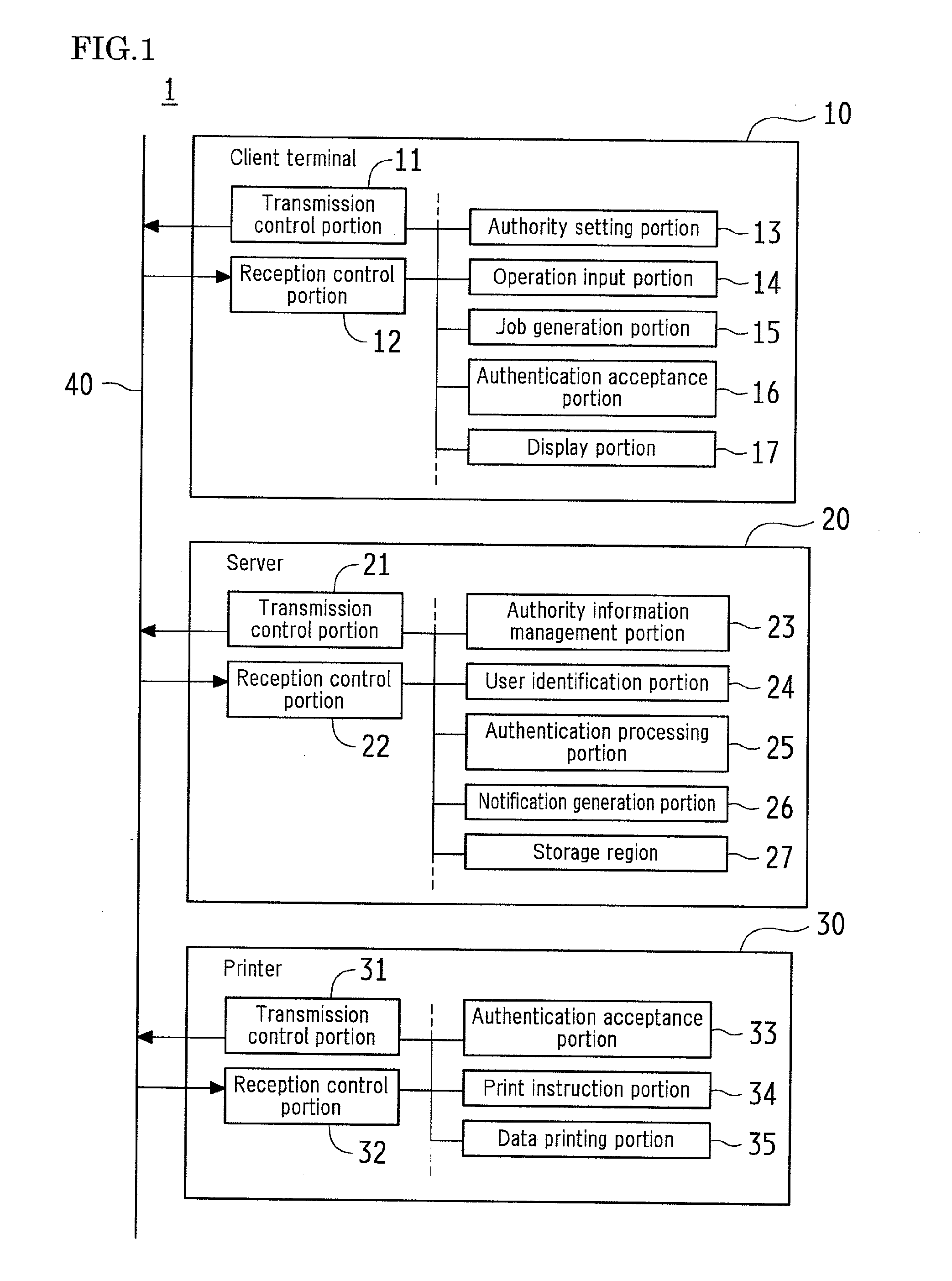

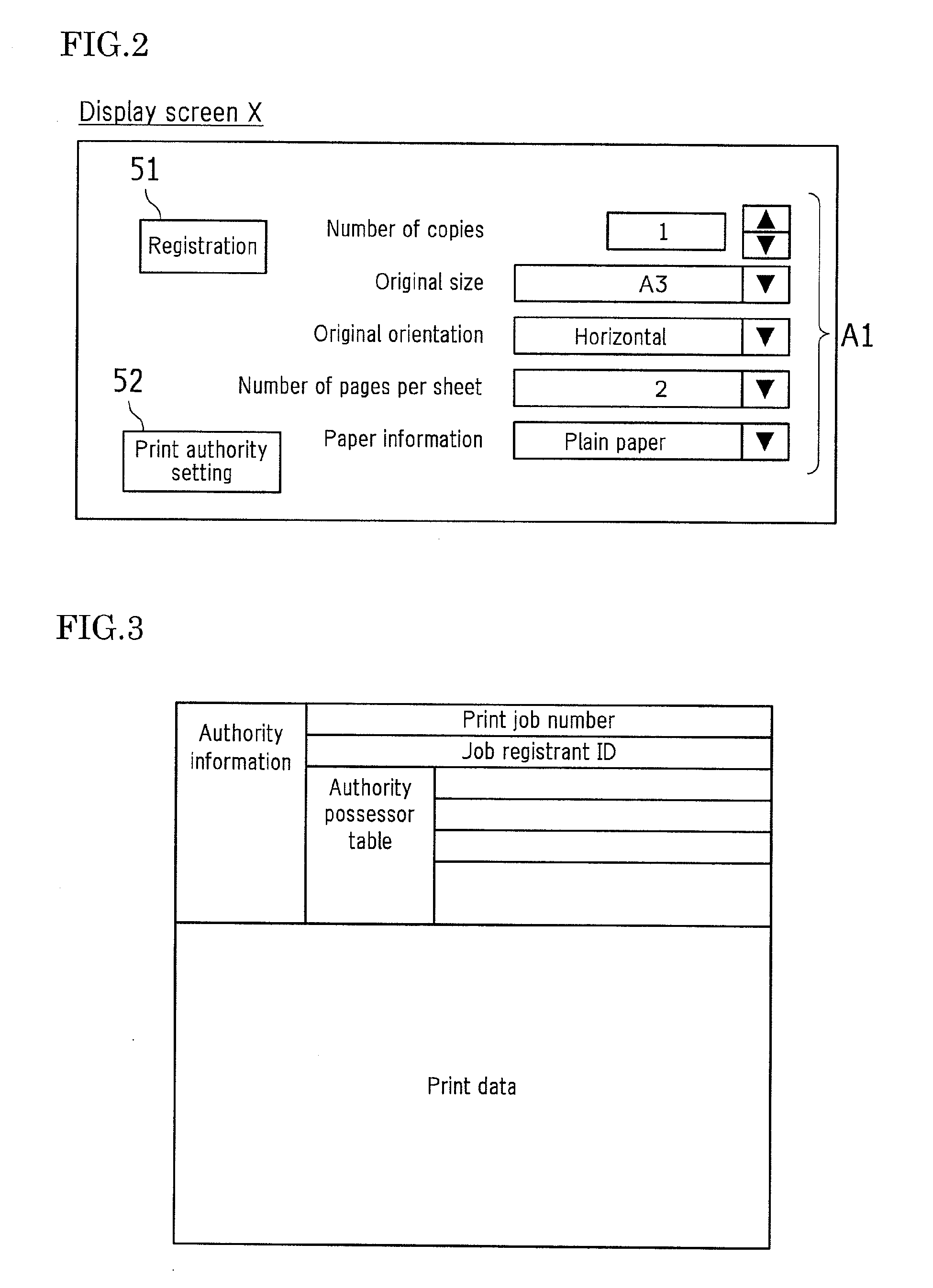

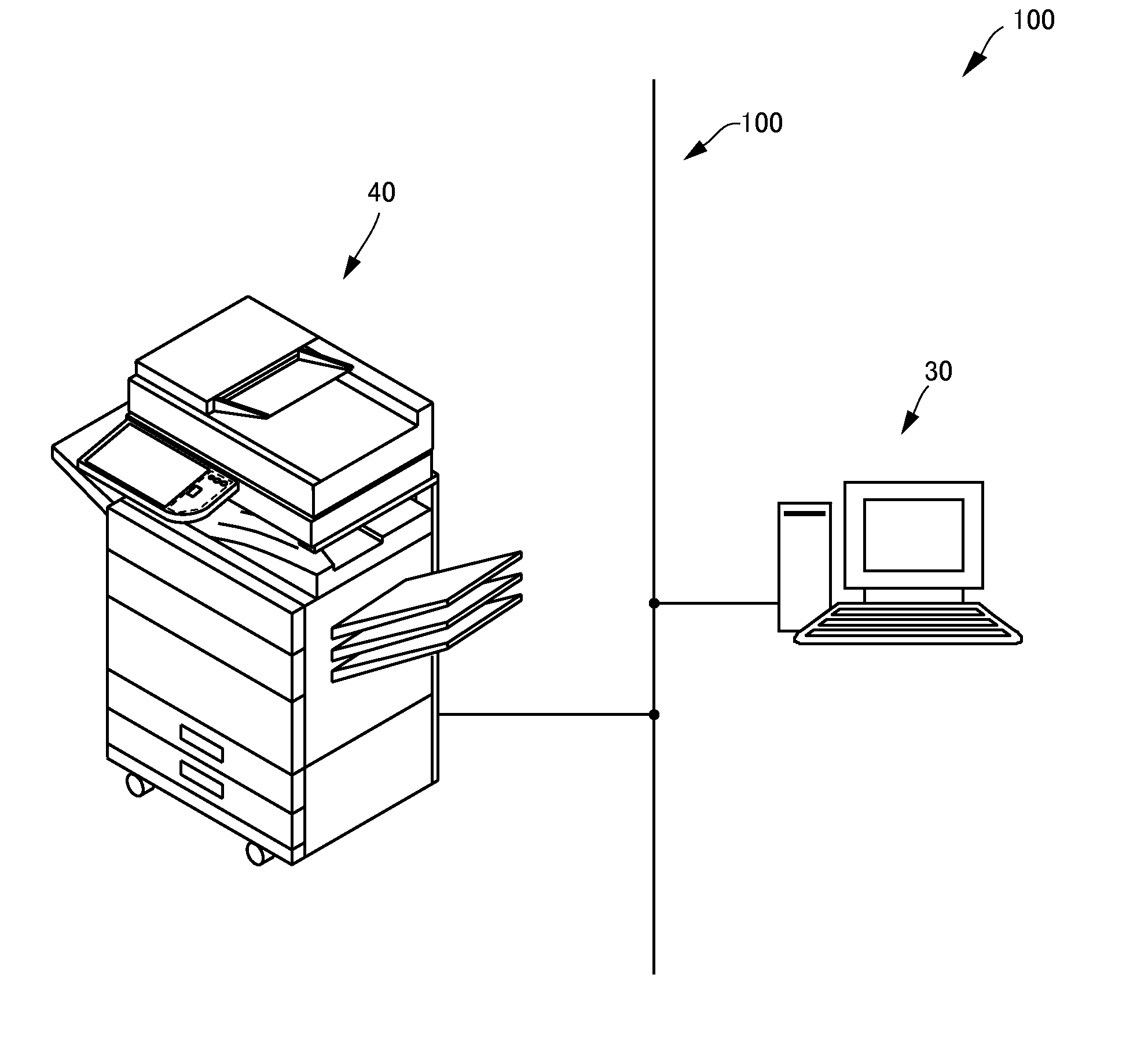

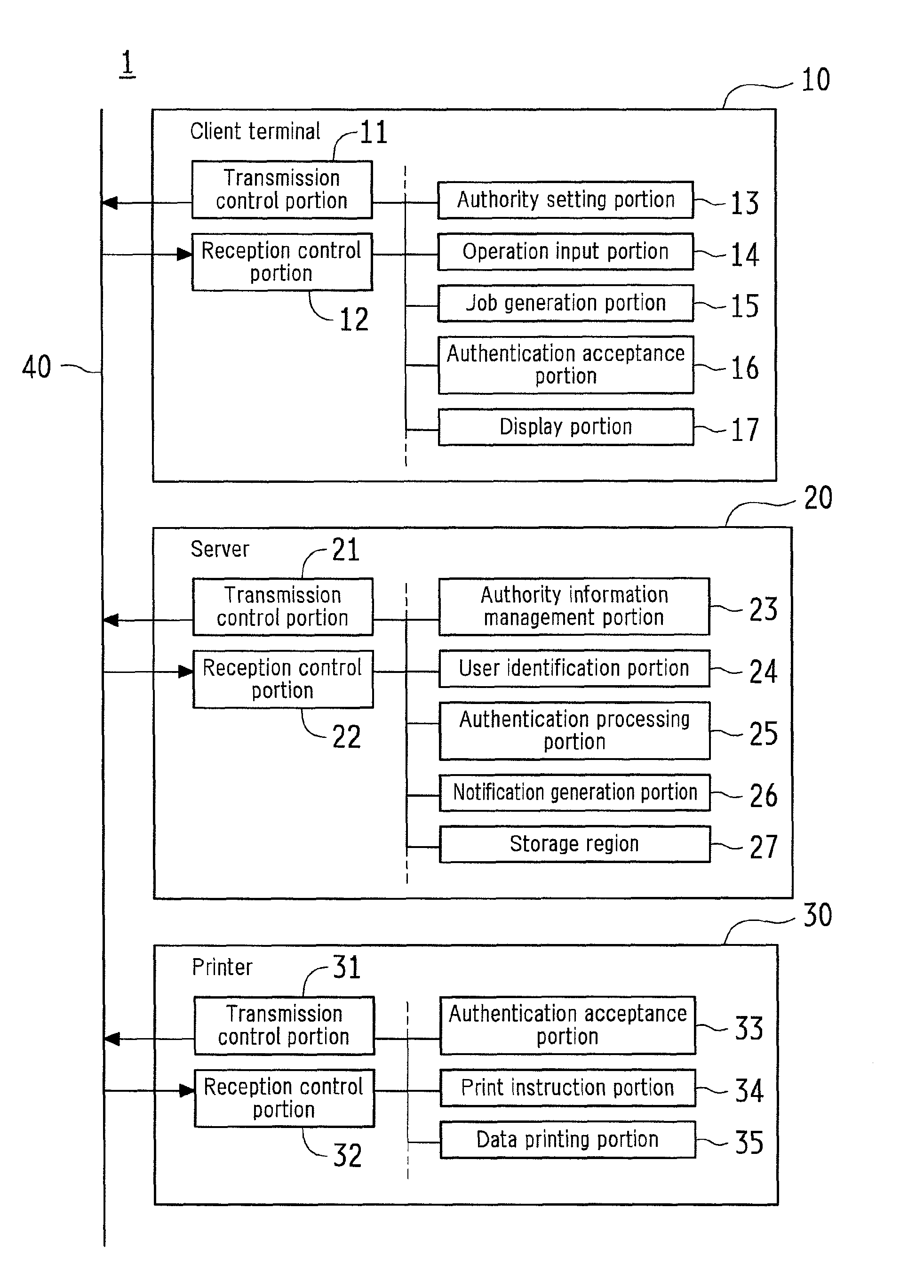

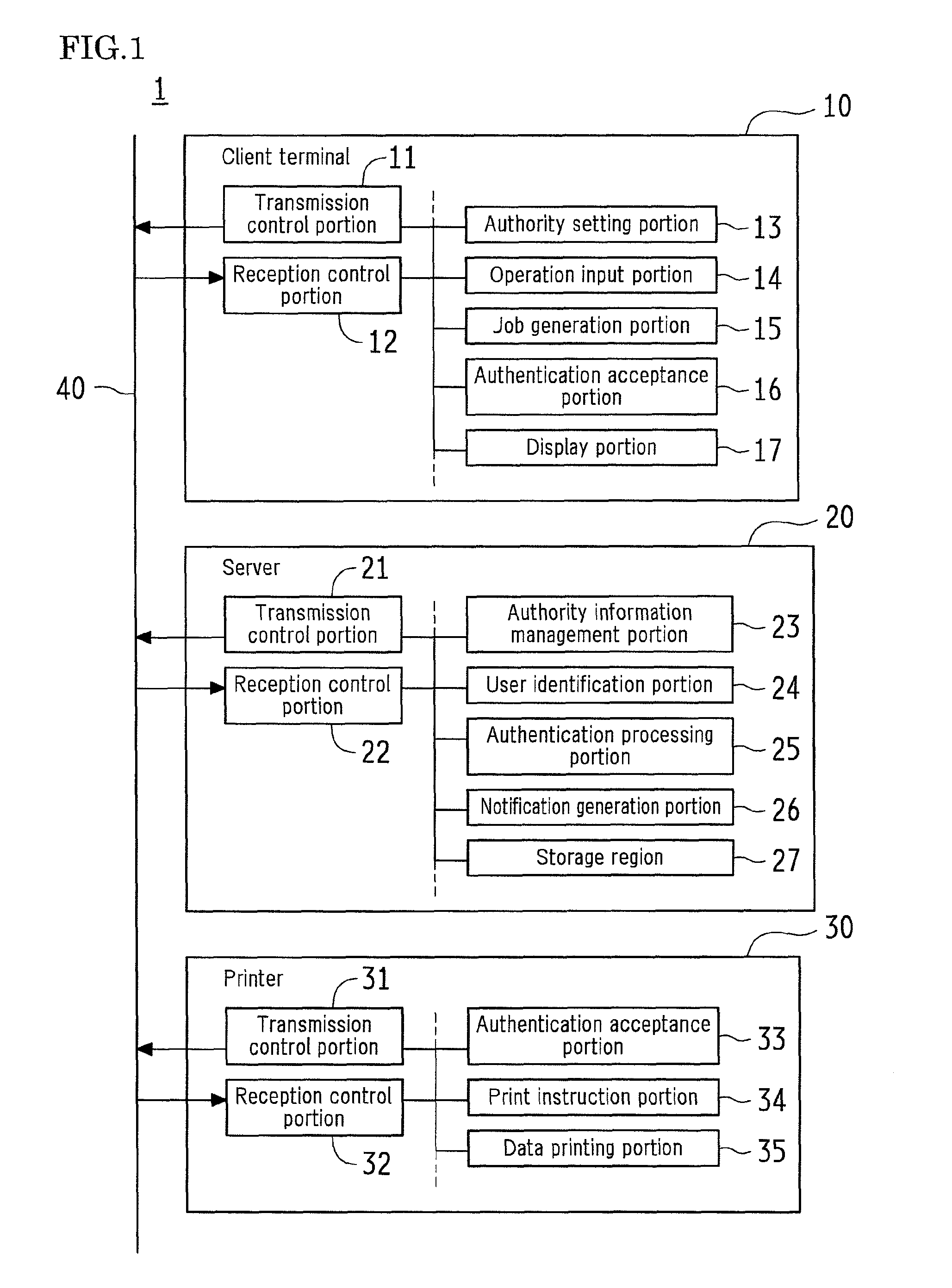

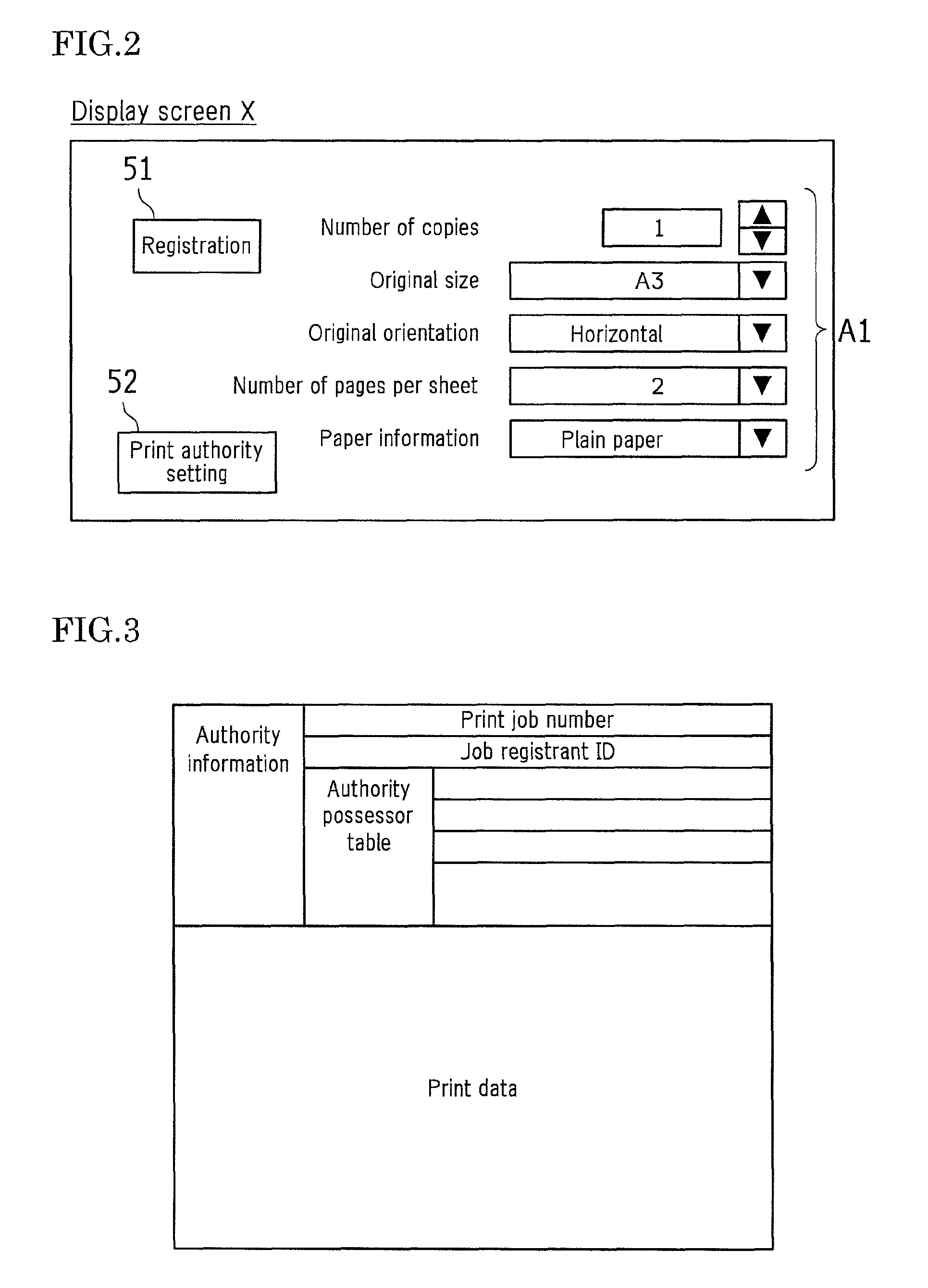

Print system

ActiveUS20110261402A1Reduce dataShorten the time periodComputer security arrangementsDigital output to print unitsIdentification deviceUser information

In one embodiment of a print system, a client terminal (10) that generates a print job, a server function portion that stores the print job, a printer (30) that performs pull printing of the print job are connected via the network (40). The print job holds print data and authority information including user information for specifying a user having print authority over the print data. The client terminal (10) is provided with an authority setting means for setting authority information. A server (20) is provided with the server function portion, and is configured to update authority information, identify a user, authenticate whether or not to permit printing based on the authority information and the identification result obtained by a user identification means, and transmit print data.

Owner:SHARP KK

Ink supply method and printing apparatus

Owner:CANON KK

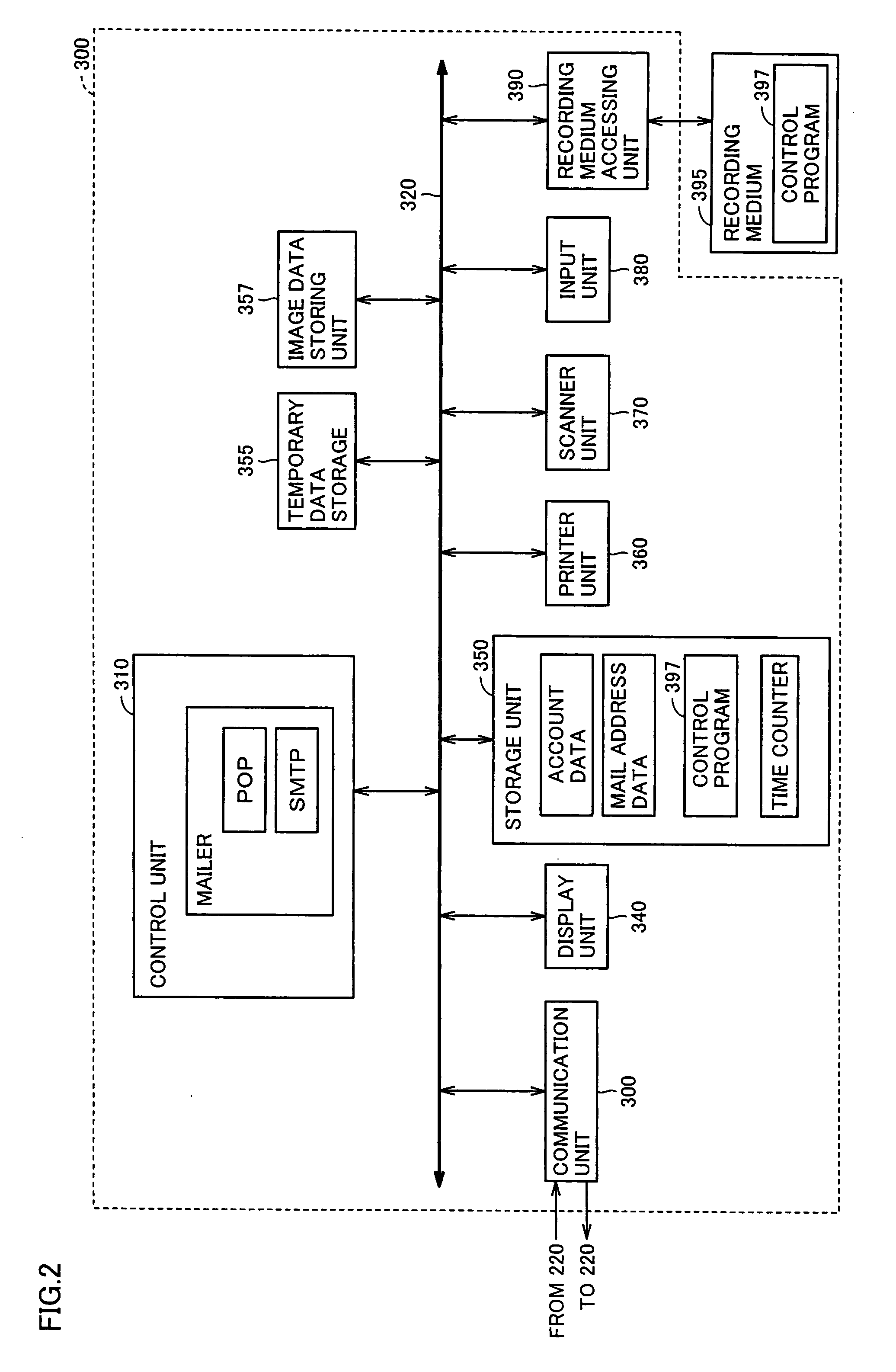

Image forming apparatus with improved convenience of Internet facsimile and program product causing computer controlling the image forming apparatus to execute print notifying function

InactiveUS20060066889A1Improve convenienceReliable printingData switching networksPictoral communicationThe InternetImage formation

Data type of data attached to a first e-mail received by using an account data is determined, and if the attached data is an image data of a prescribed format, the image data is printed, and a second e-mail notifying completion of printing is transmitted to the destination of the first e-mail.

Owner:KONICA MINOLTA BUSINESS TECH INC

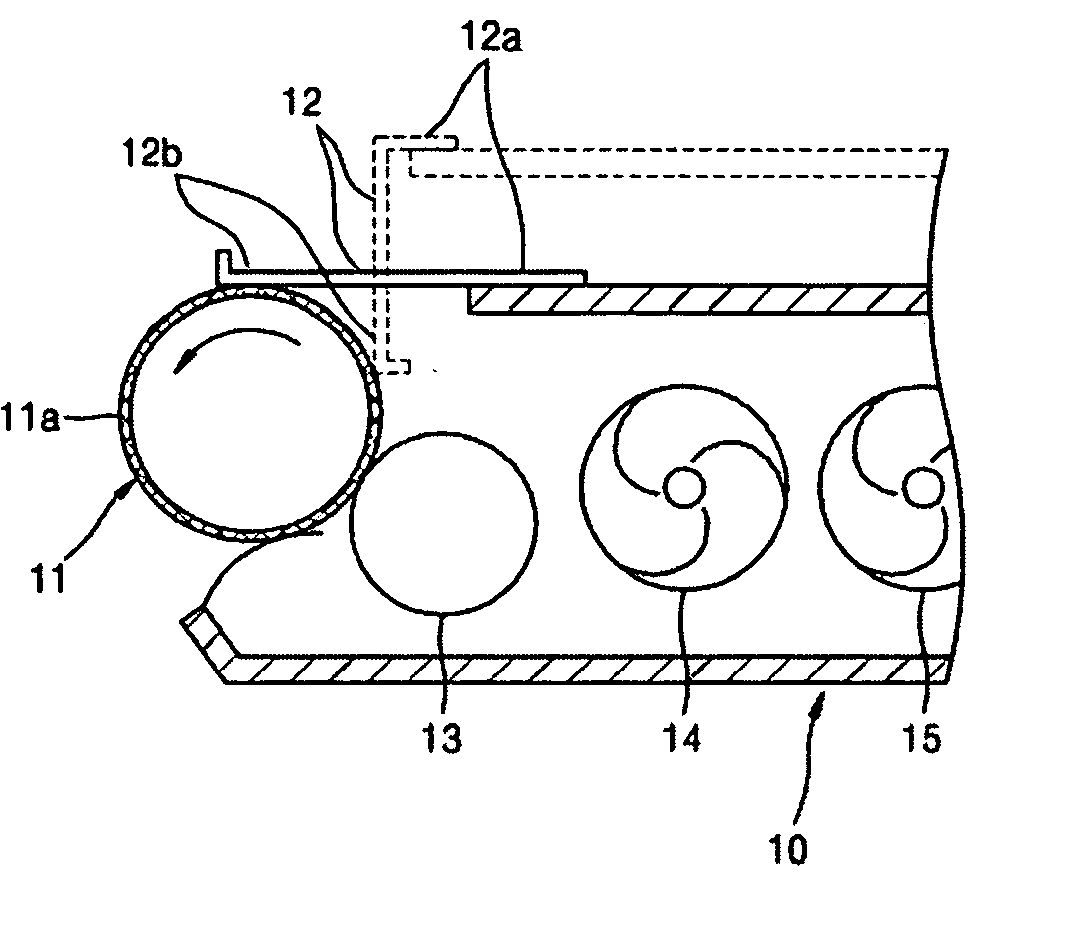

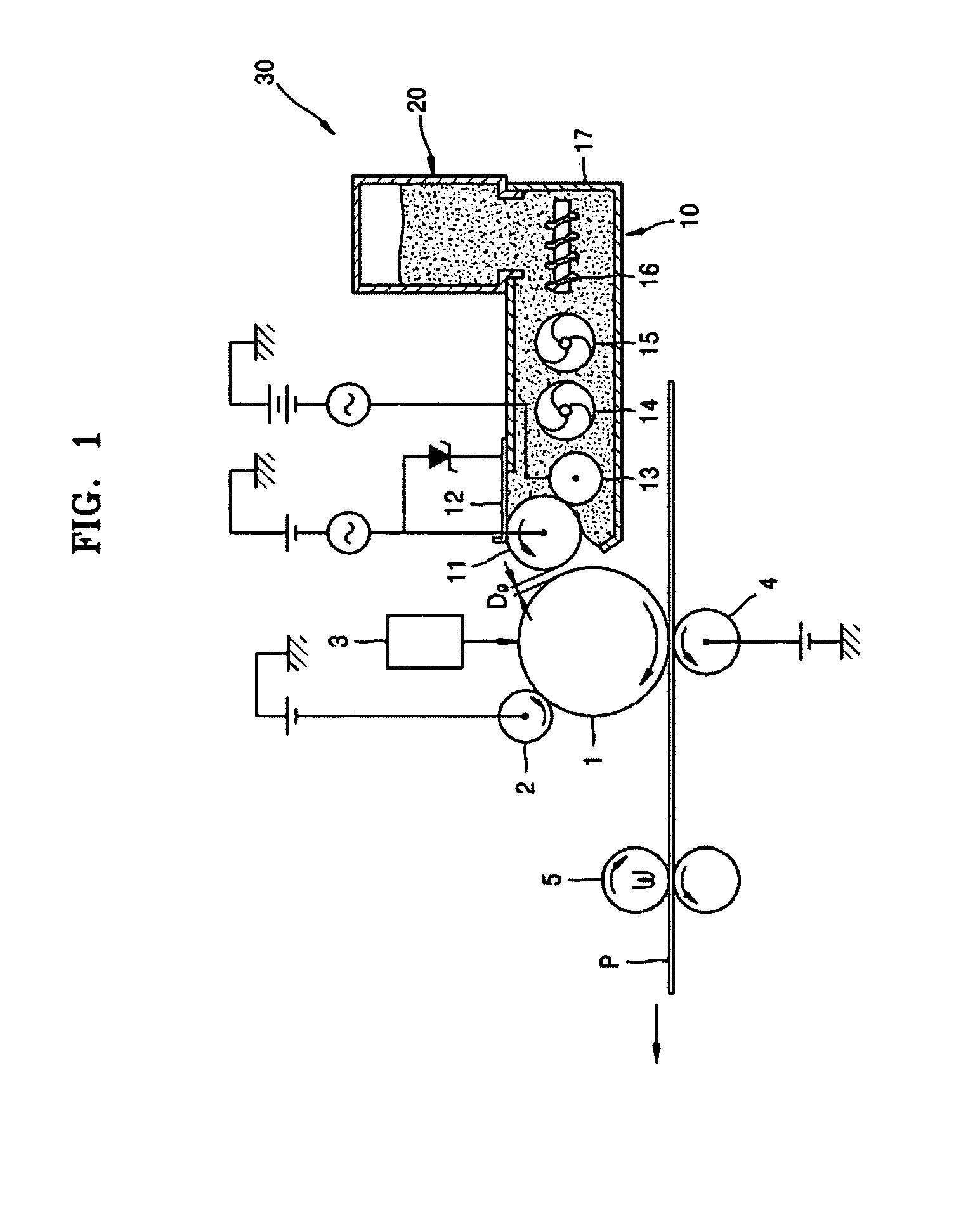

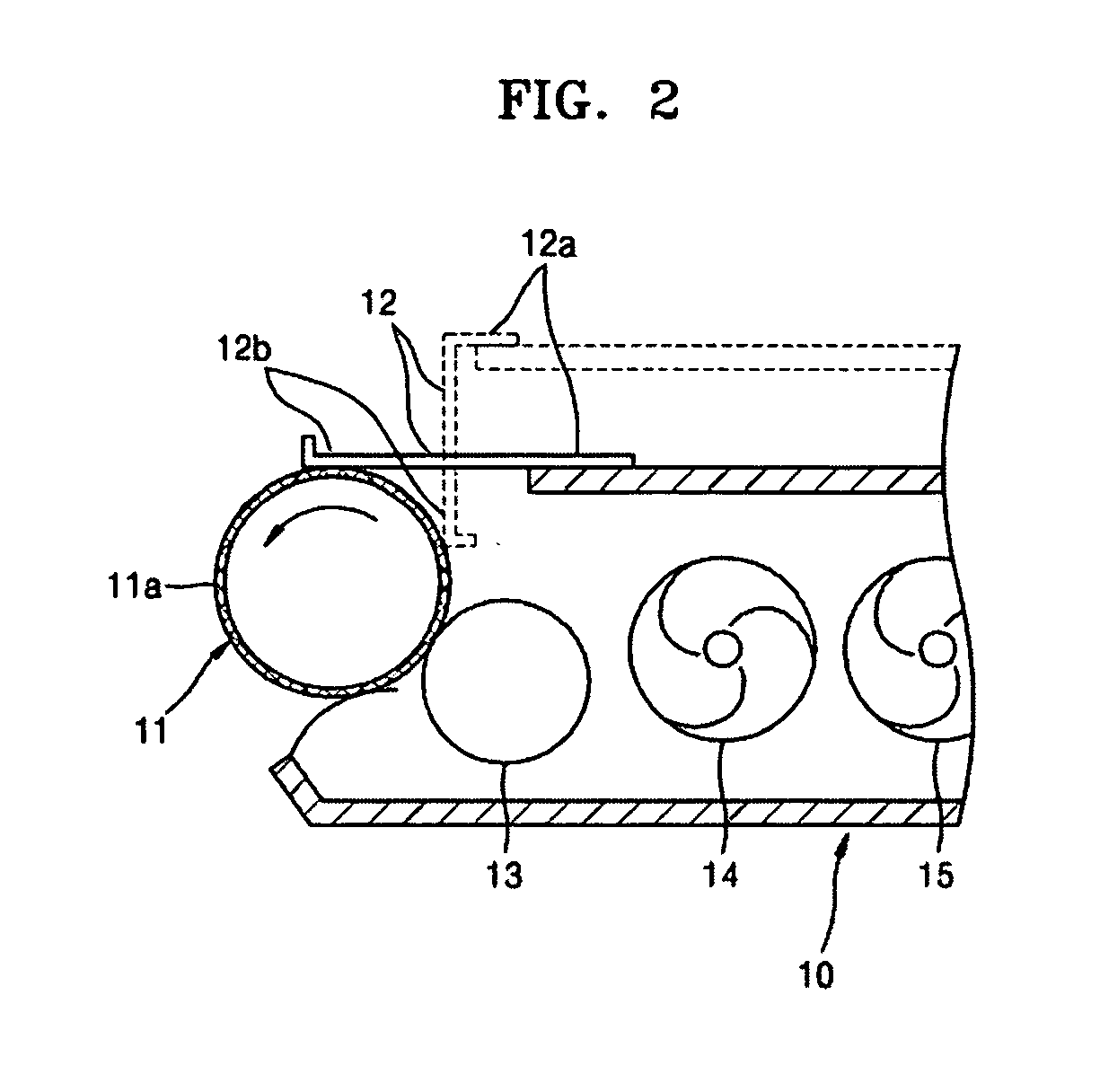

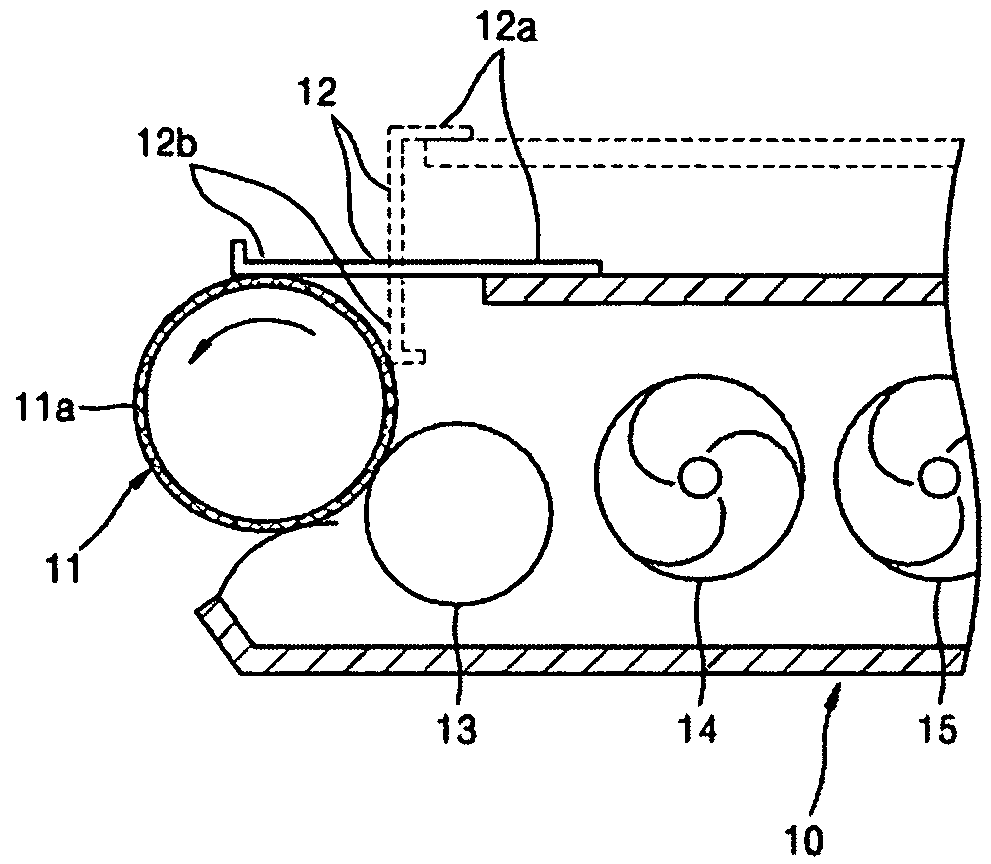

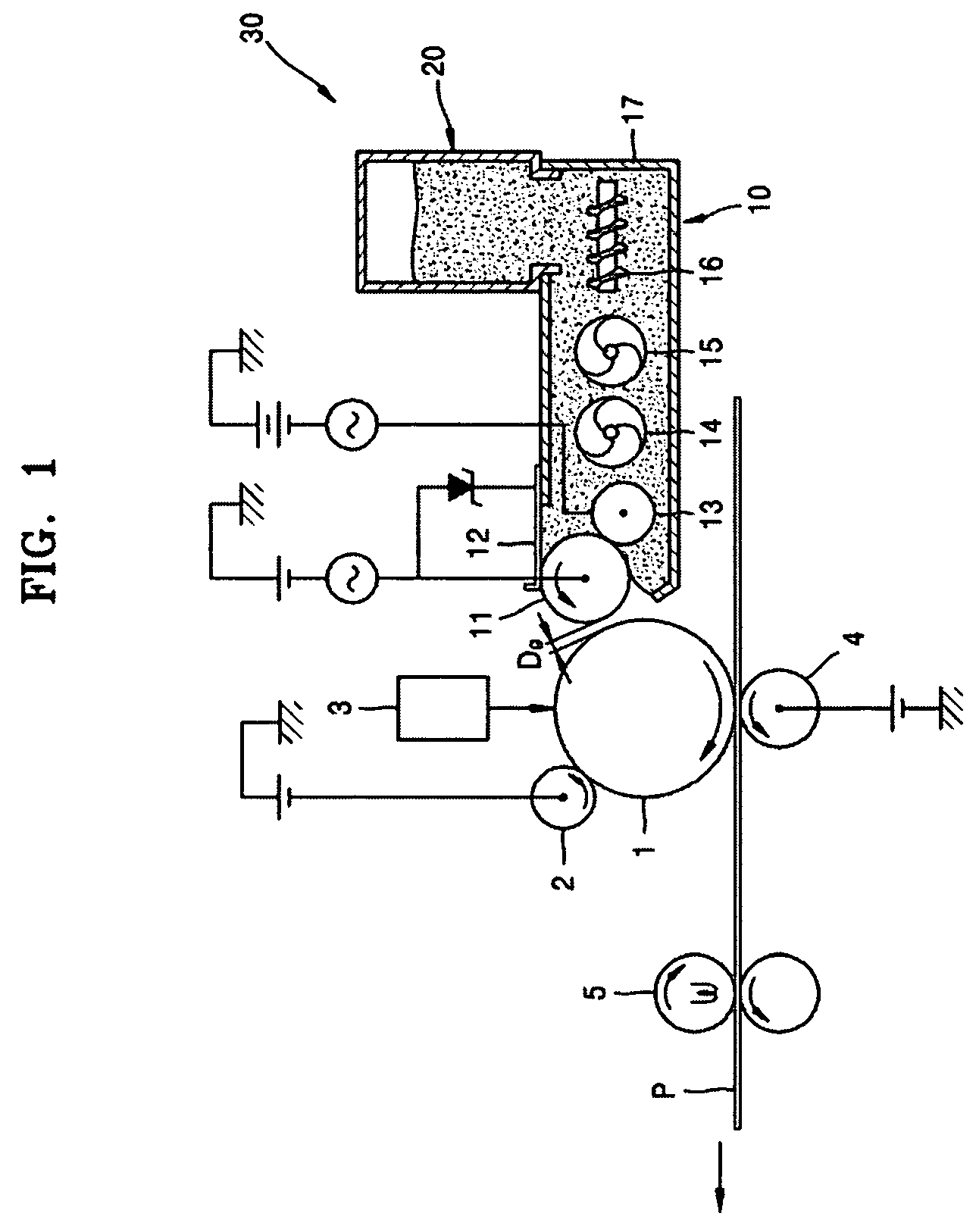

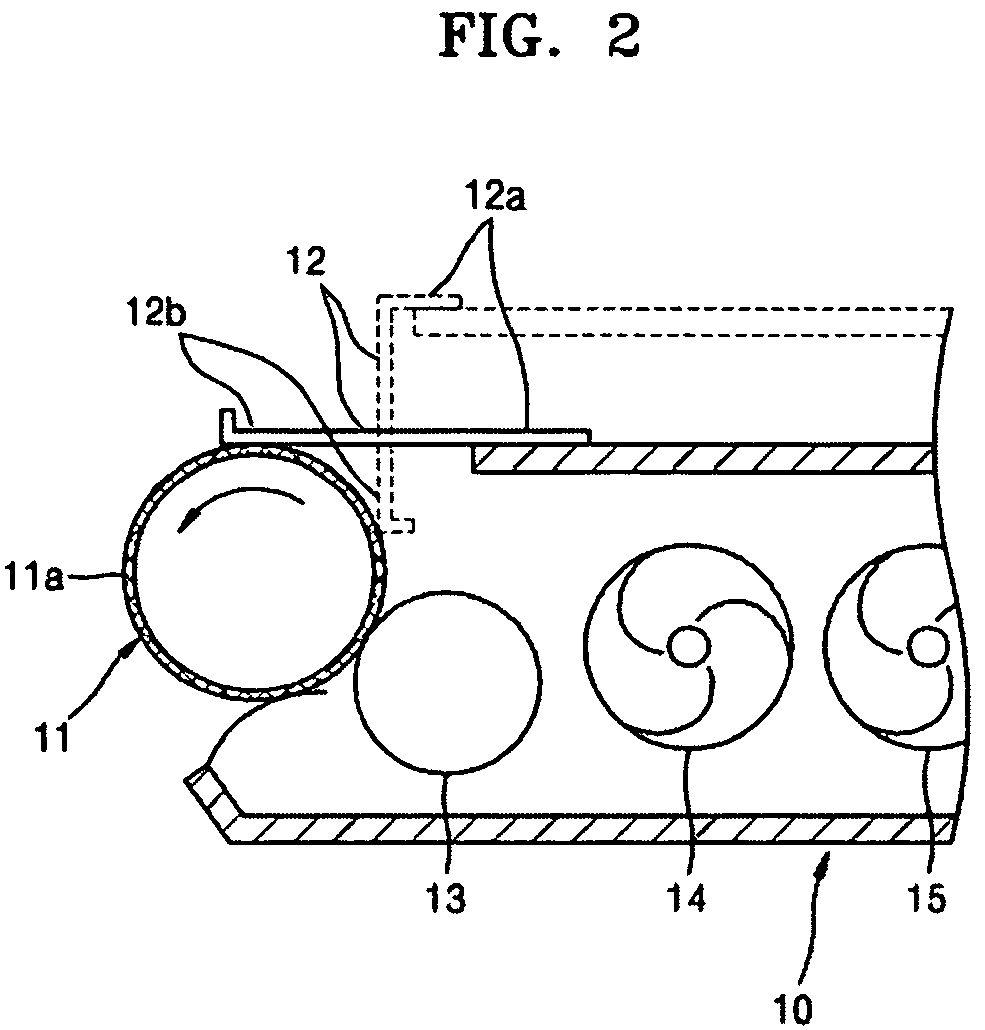

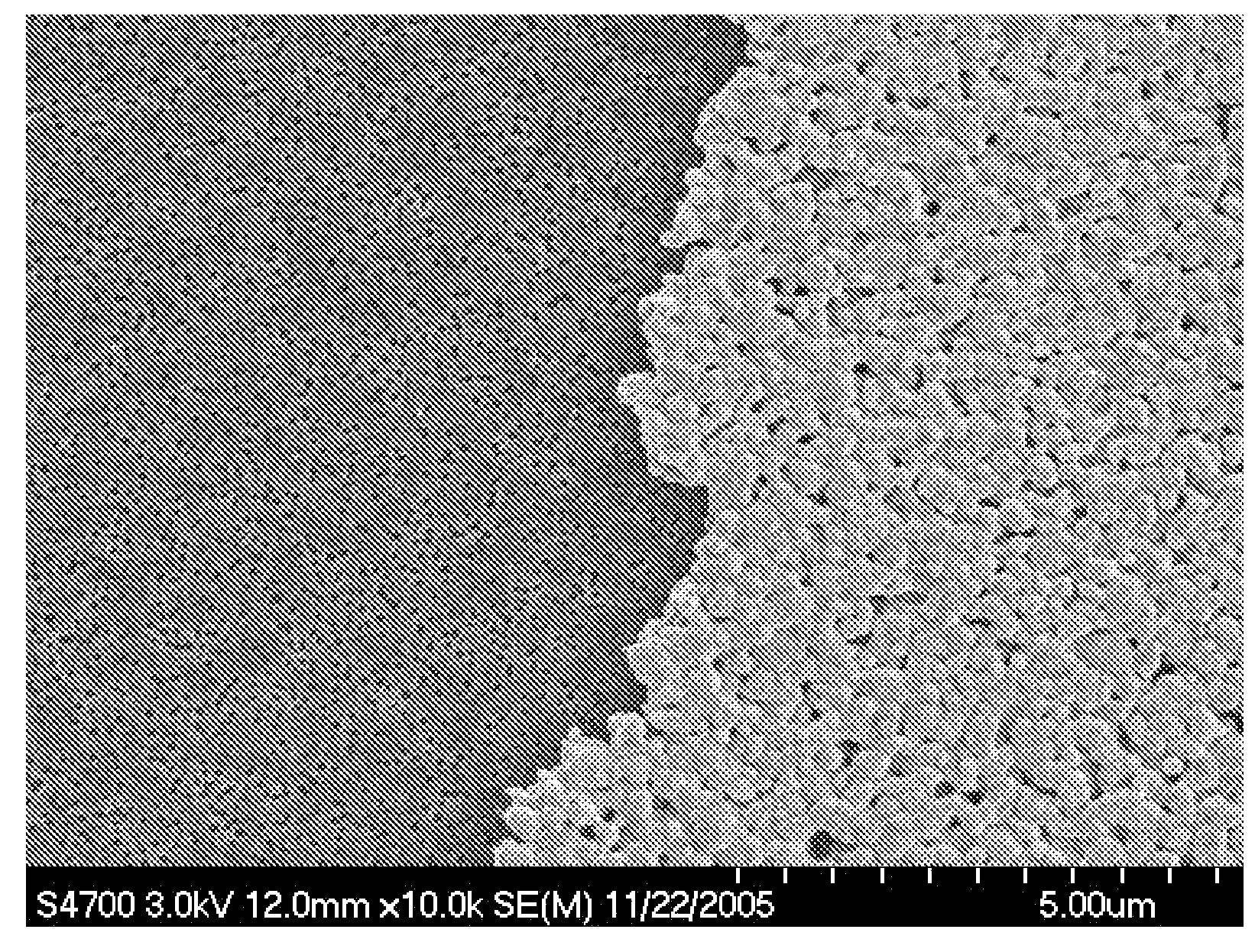

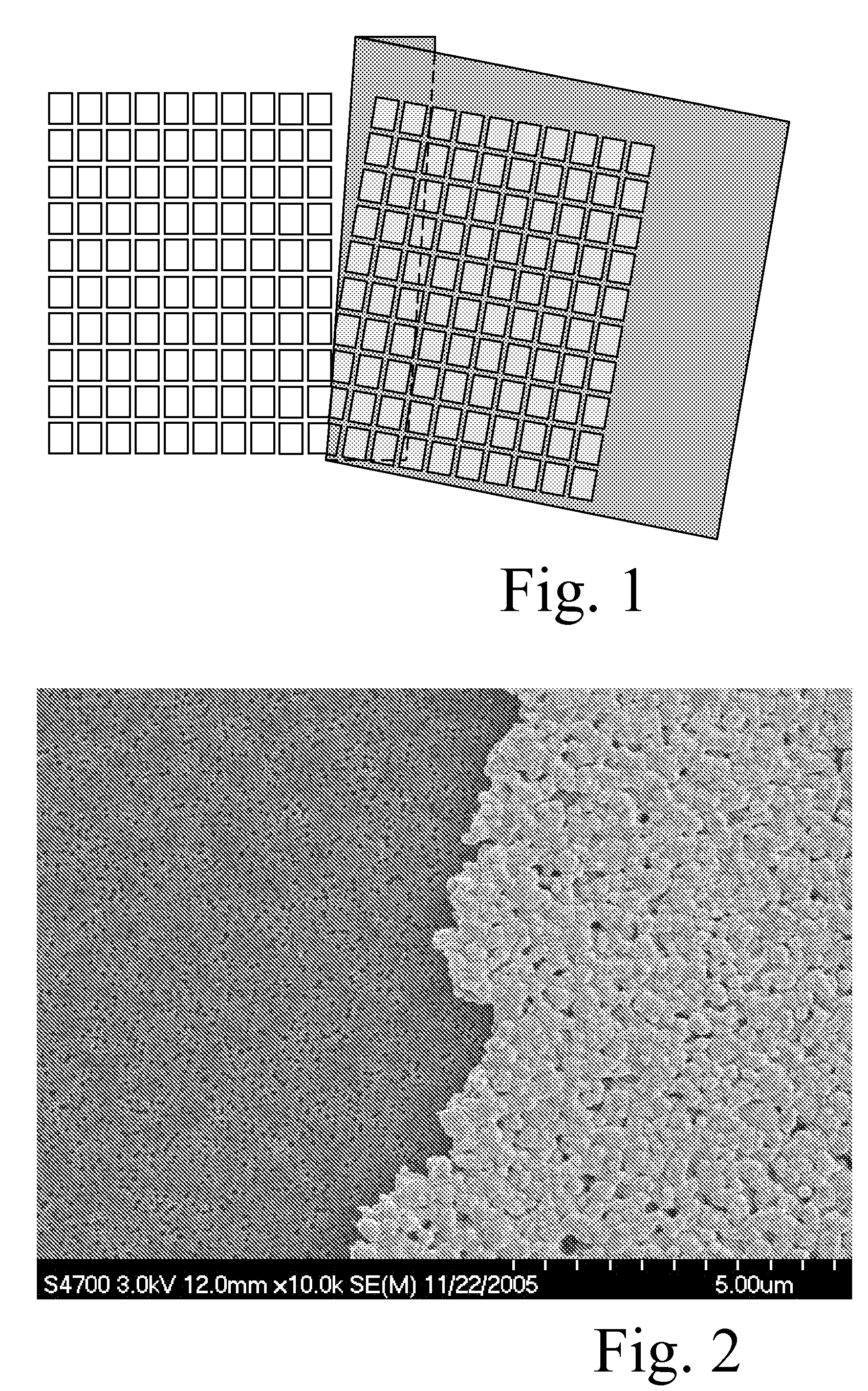

Electrophotographic image forming apparatus including a developing roller for a developing unit using non-magnetic mono-component toner, and developing method using the same

ActiveUS20060257174A1Extend your lifeReliable printingElectrographic process apparatusLatent imageEngineering

An electrophotographic image forming apparatus is provided which includes an image receptor on which an electrostatic latent image is formed. A developing unit develops the electrostatic latent image by supplying non-magnetic mono-component toner to the electrostatic latent image and includes a developing roller which faces the image receptor. A trail type regulating blade is installed to form a uniform toner layer on the developing roller. In the electrophotographic image forming apparatus, the rate of the amount of toner particles having a diameter of not more than about half of a median value of a volume-diameter distribution of the toner is not more than about 15% in a number-diameter distribution.

Owner:HEWLETT PACKARD DEV CO LP

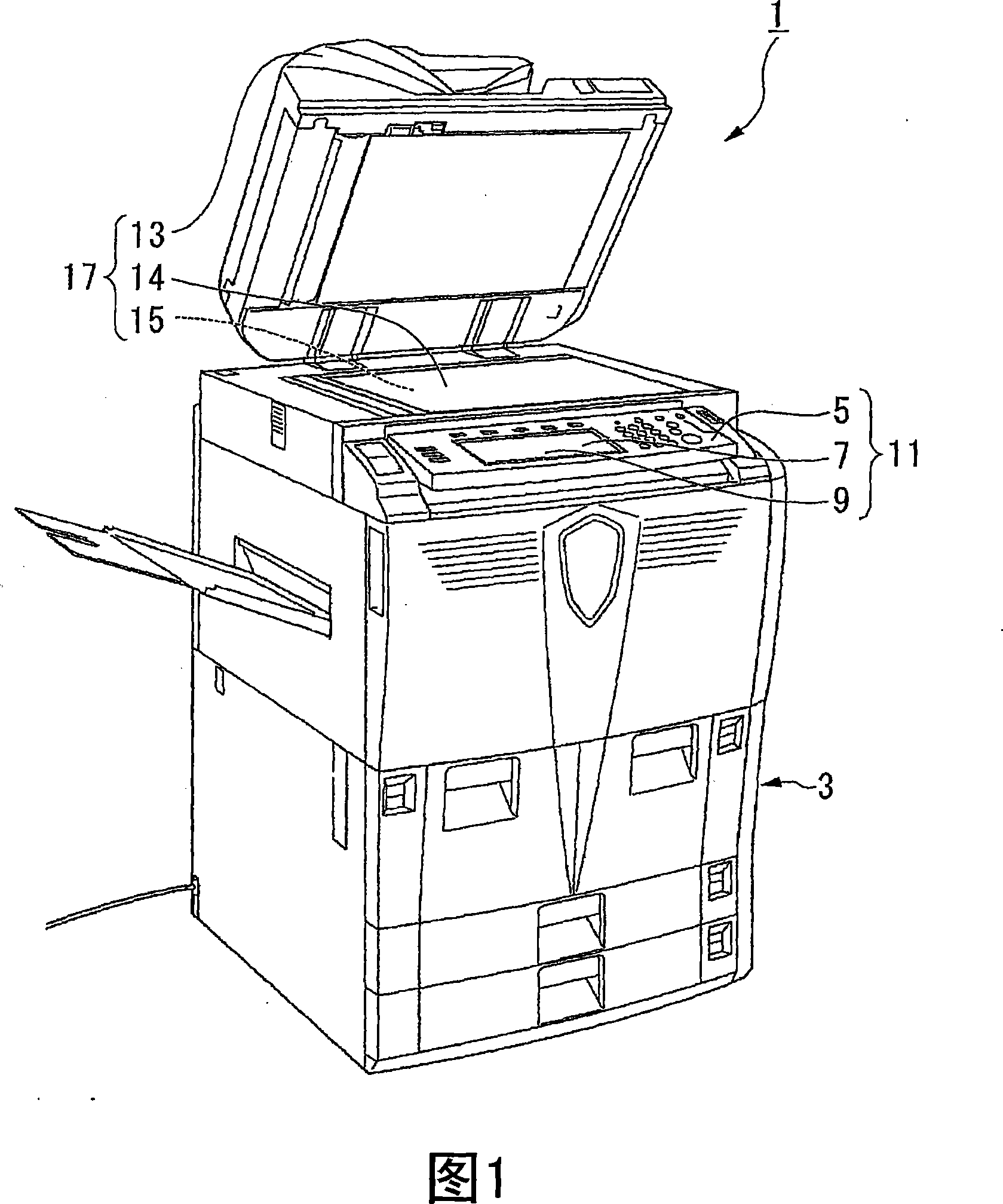

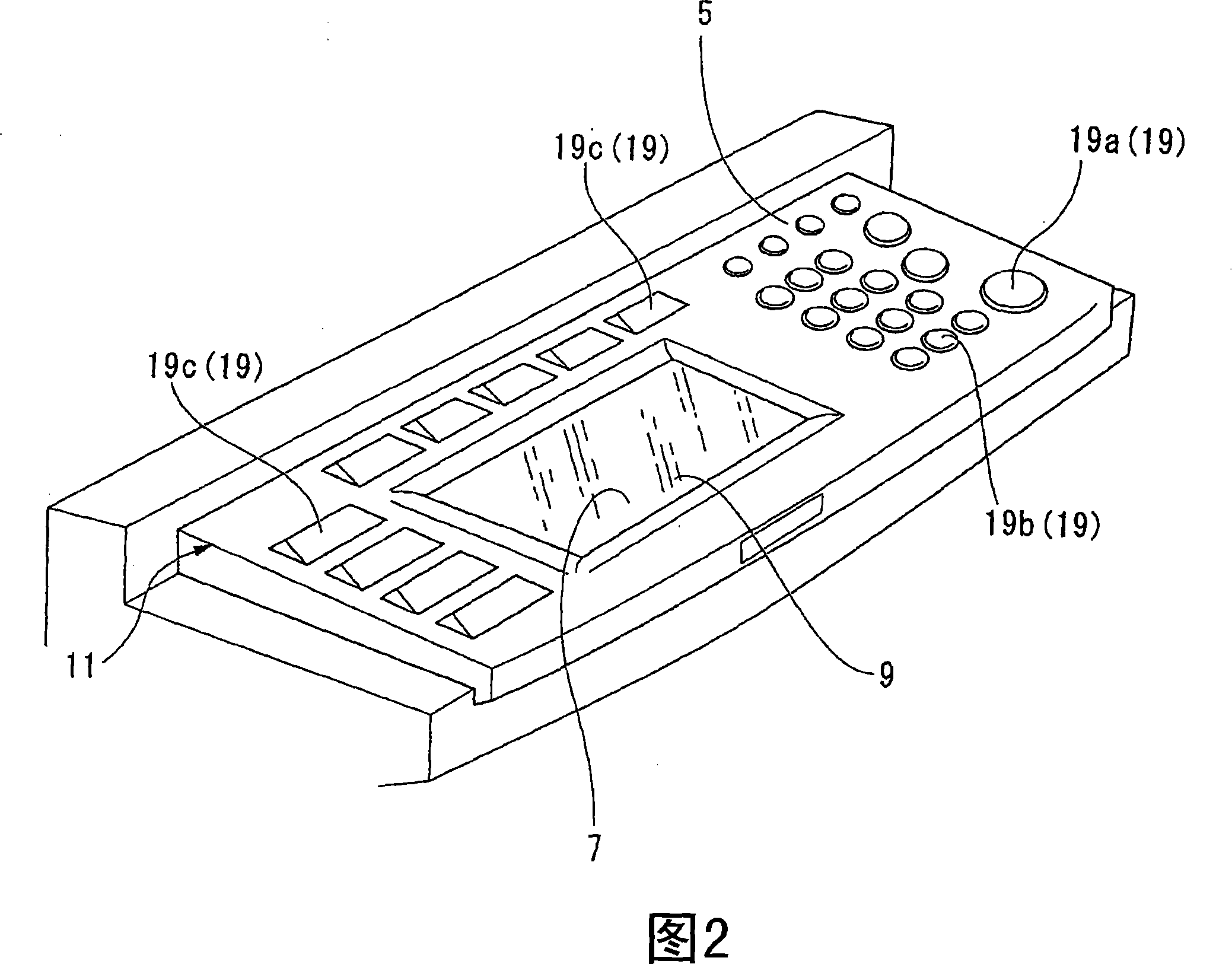

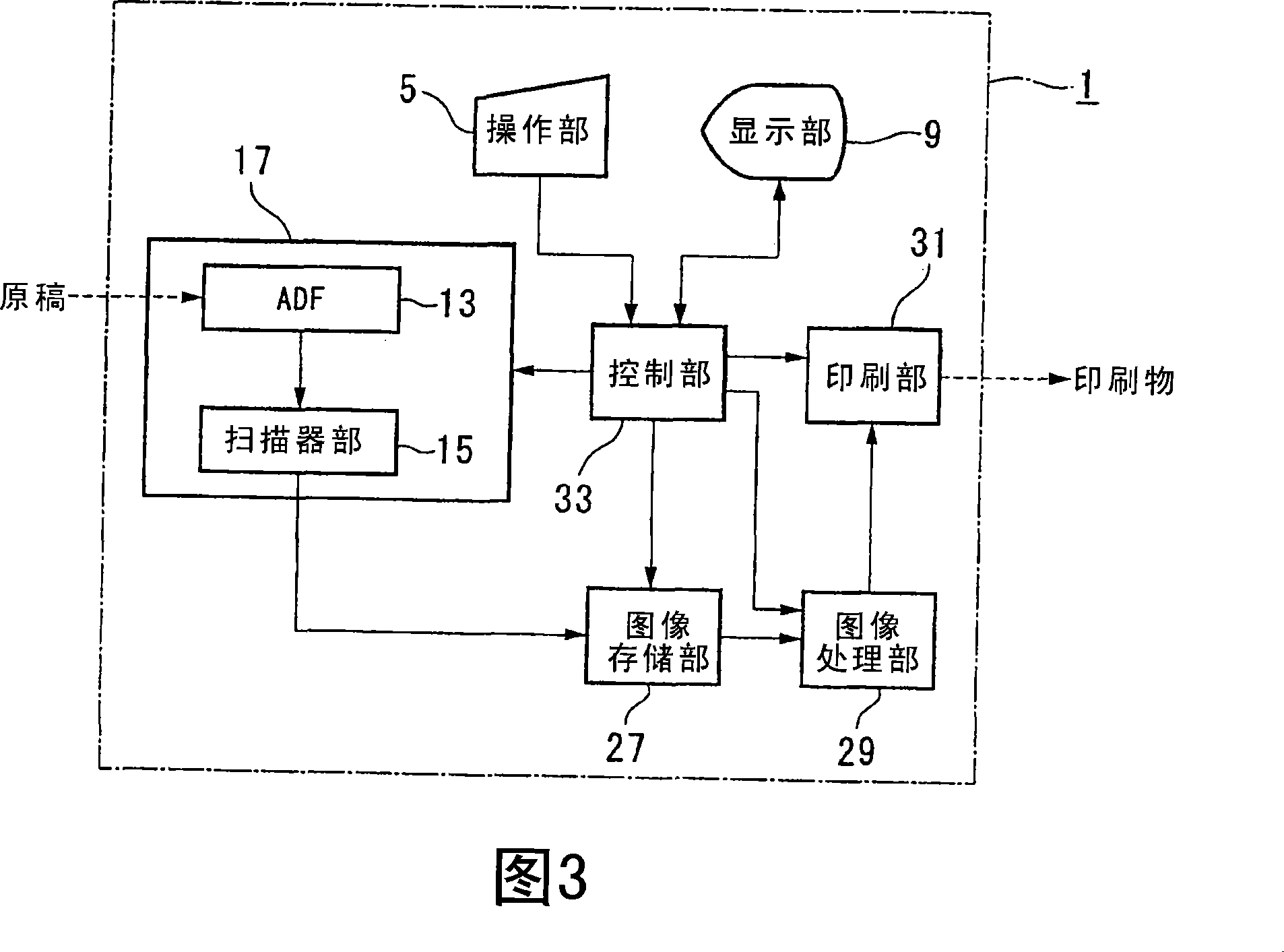

Image forming device

ActiveCN101237502ASimple and reliable determinationReliable printingPictoral communicationImage formationMagnification

The present invention provides an image forming apparatus having a double-sided copying function, characterized by comprising: a document detection unit for detecting the size of a document, and a document size setting unit for setting the size of the document according to requirements. At least one; the top position setting unit of the original, which sets the top position of the original according to the requirements; the printing mode setting unit, which sets from double-sided to double-sided, from single-sided to double-sided, from double-sided to single-sided One side, one printing mode from one side to one side; the binding direction setting unit is used to set the binding direction of the original document and the binding direction of the output paper according to the requirements; the output size setting unit is set according to the requirements The size of the output paper; the printing magnification setting unit, which sets the printing magnification according to the requirements; and the copy area determining unit, when the top position of the original is set as the upper, and the upper left corner of the original is used as a reference. Specify the copy area.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Print system

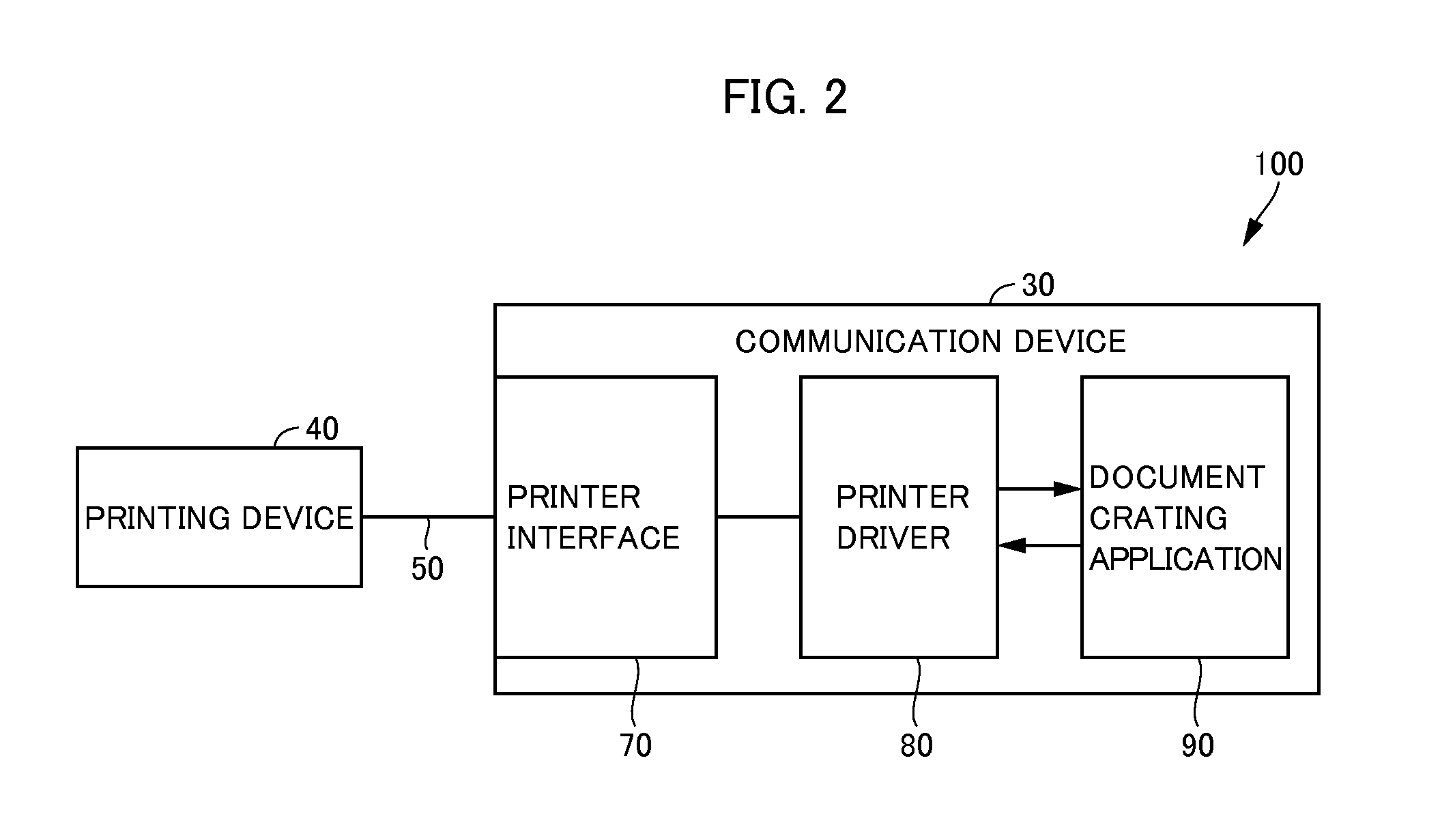

InactiveUS20120250045A1Possible to printArea minimizationDigitally marking record carriersVisual presentation using printersDocumentationData processing

A print controller sets, in response to reception of an inquiry related to dimensions of unprintable area as an area not allowing printing of a document from a document data creating unit, dimensions of the unprintable area to default values or values smaller than the default values. The set dimensions of the unprintable area are notified to a document data processing unit, print data is formed based on data received from the document data processing unit and the dimensions of the unprintable area, and a print instruction is given to a printing device.

Owner:SHARP KK

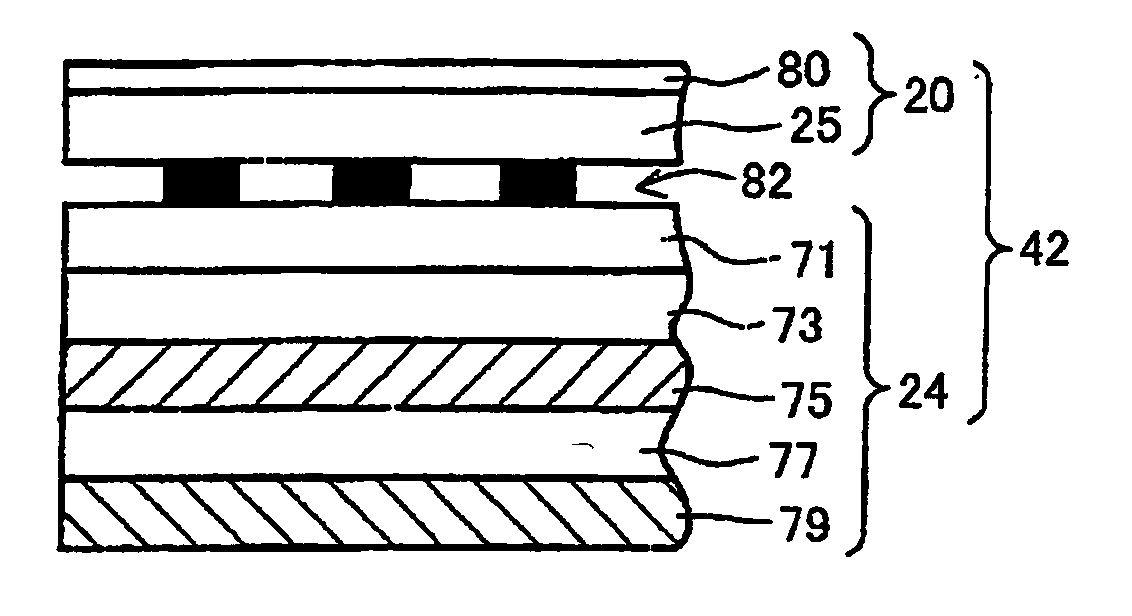

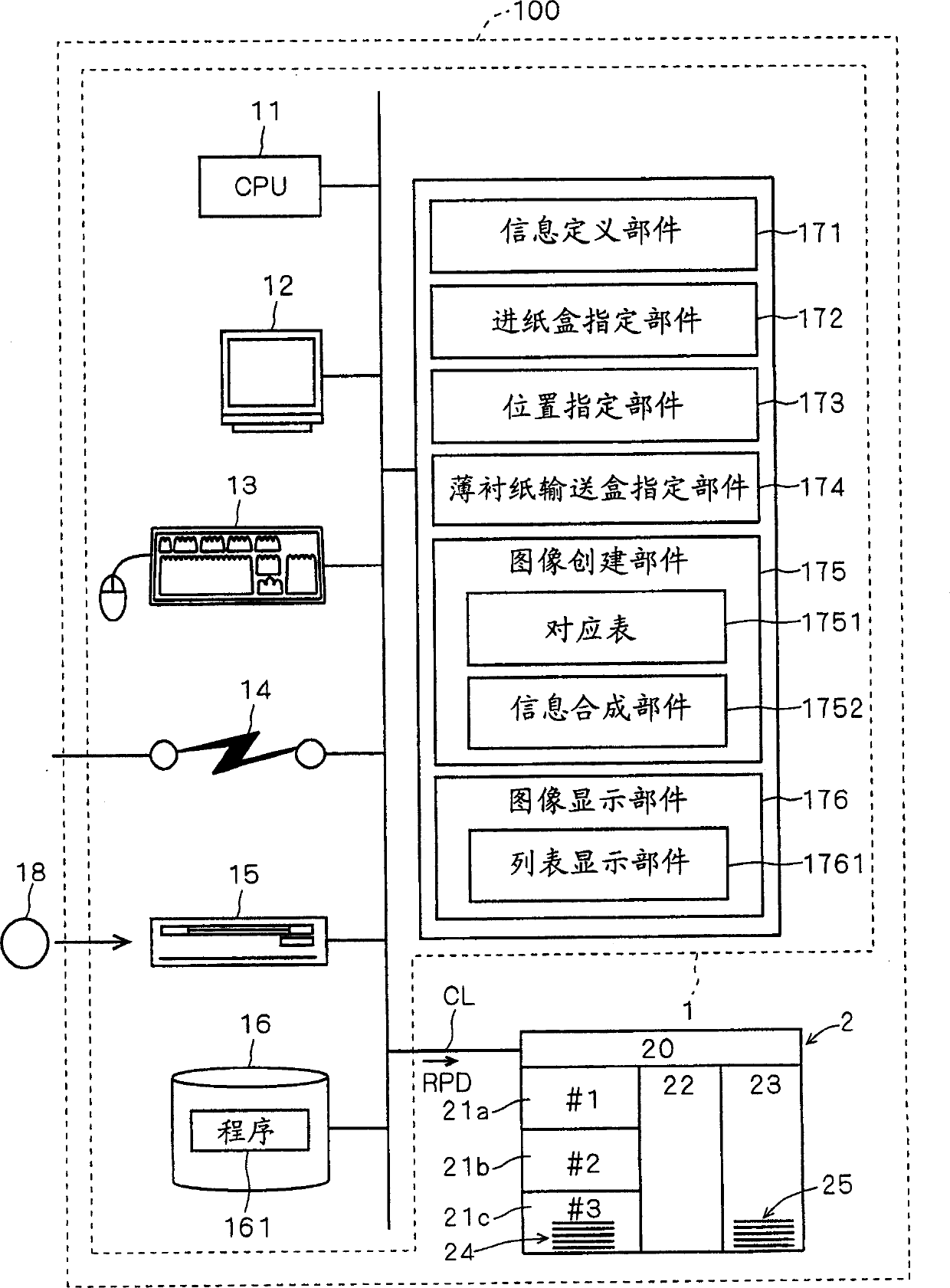

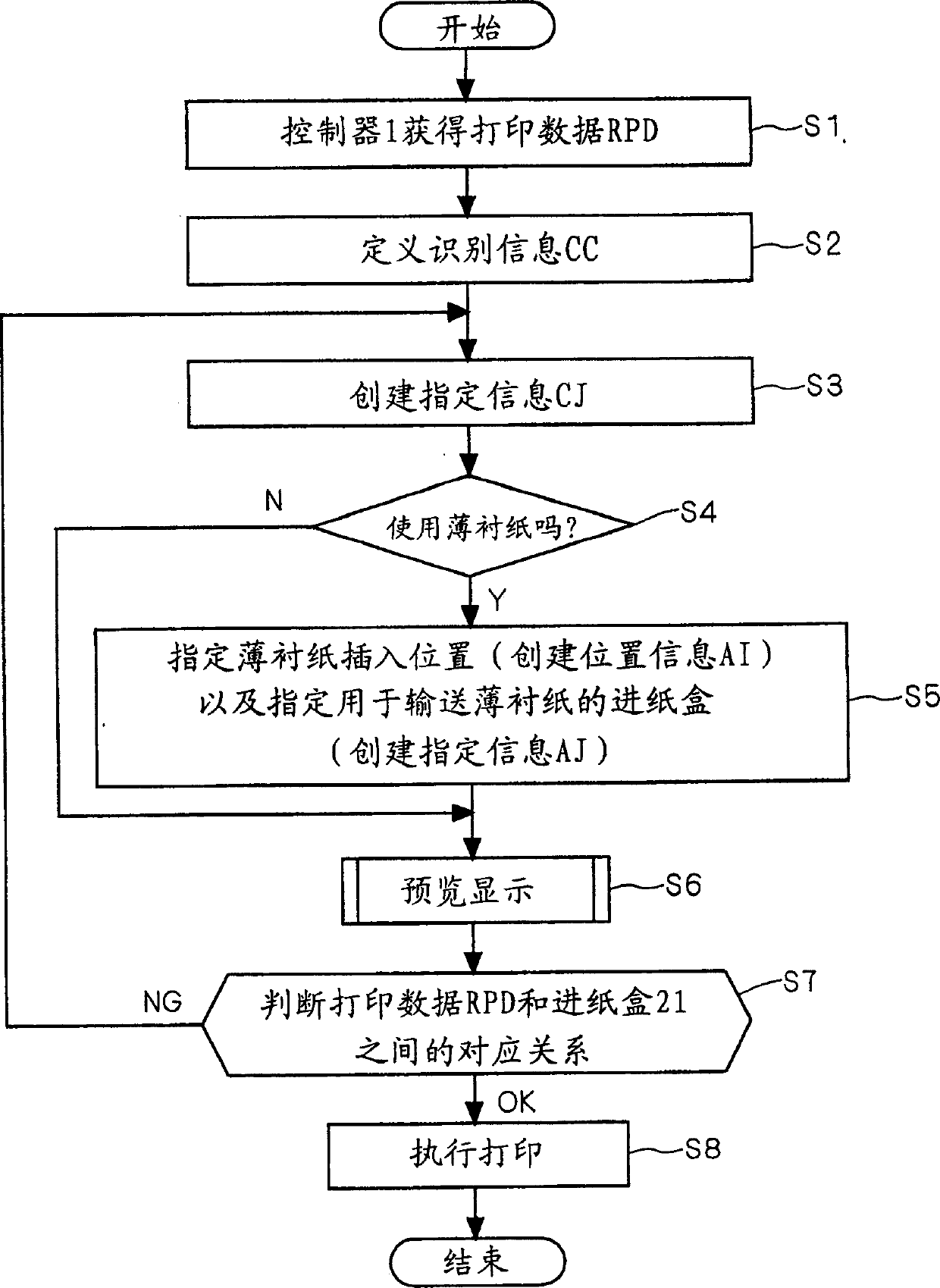

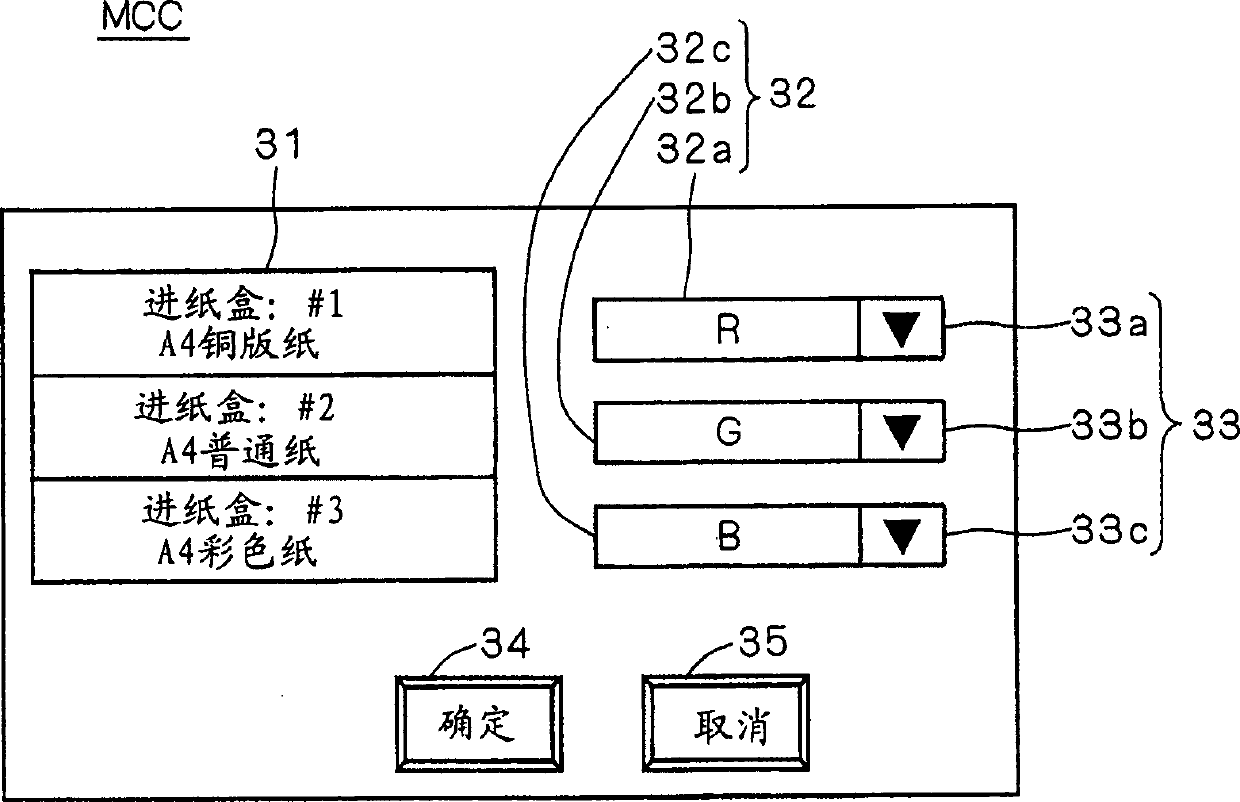

Printing system, controller and display method

InactiveCN1497421AReliable printingVisual presentation using printersTypewritersComputer printingComputer engineering

In a printing system, a controller defines identification information for identifying a plurality of paper feed cassettes provided in a printing machine for each of the paper feed cassettes. When an operator specifies a paper feed cassette for feeding a sheet for printing of an image represented by print data, the controller stores a correspondence between the print data and the specified paper feed cassette. Based on the correspondence, the controller combines the identification information assigned to the paper feed cassette corresponding to the print data with the image represented by the print data to create a preview image, and then displays the preview image. Prior to the execution of the printing, the operator can thereby easily recognize which paper feed cassette stores the sheet on which the image represented by the print data is to be printed.

Owner:DAINIPPON SCREEN MTG CO LTD

Electrophotographic image forming apparatus including a developing roller for a developing unit using non-magnetic mono-component toner, and developing method using the same

ActiveUS7542705B2Extend your lifeReliable printingElectrographic process apparatusLatent imageEngineering

An electrophotographic image forming apparatus is provided which includes an image receptor on which an electrostatic latent image is formed. A developing unit develops the electrostatic latent image by supplying non-magnetic mono-component toner to the electrostatic latent image and includes a developing roller which faces the image receptor. A trail type regulating blade is installed to form a uniform toner layer on the developing roller. In the electrophotographic image forming apparatus, the rate of the amount of toner particles having a diameter of not more than about half of a median value of a volume-diameter distribution of the toner is not more than about 15% in a number-diameter distribution.

Owner:HEWLETT PACKARD DEV CO LP

Generating 1-bit image data from multiple-bit image data for producing when printed a dot image with reduced dot gain and appearance of patterning caused by isolated diagonally adjacent pixels

ActiveUS8654400B2Reliable printingSmall appearanceImage enhancementVisual presentationDot gainOutput device

A computer program for, or method of, generating 1-bit image data from multiple-bit image data, by a process which comprises the steps of: receiving multiple-bit image data comprising multiple-bit pixel values; and deriving from the multiple-bit pixel values 1-bit image data comprising “on” and “off pixel values, each pixel value of the 1-bit image data corresponding to a pixel of an output medium, which pixel an output device would attempt to mark when printing the 1-bit image data if the pixel value were “on”, the 1-bit image data producing when printed an image constituted by dots, each dot corresponding to a plurality of pixel values of the 1-bit image data, which pixel values correspond to a block of M*N horizontally and / or vertically adjacent pixels of an output is medium, at least one of M and N being greater than one, wherein for at least some of the dots, where M or N is equal to one, a pixel value corresponding to a first or last pixel of a row of horizontally adjacent pixels, or to a first or last pixel of a column of vertically adjacent pixels, is “off, and where both M and N are greater than one, at least one pixel value corresponding to a pixel of a first or last row of horizontally adjacent pixels is “off and / or at least one pixel value 20 corresponding to a pixel of a first or last column of vertically adjacent pixels is “off.

Owner:HAMILLROAD SOFTWARE LTD

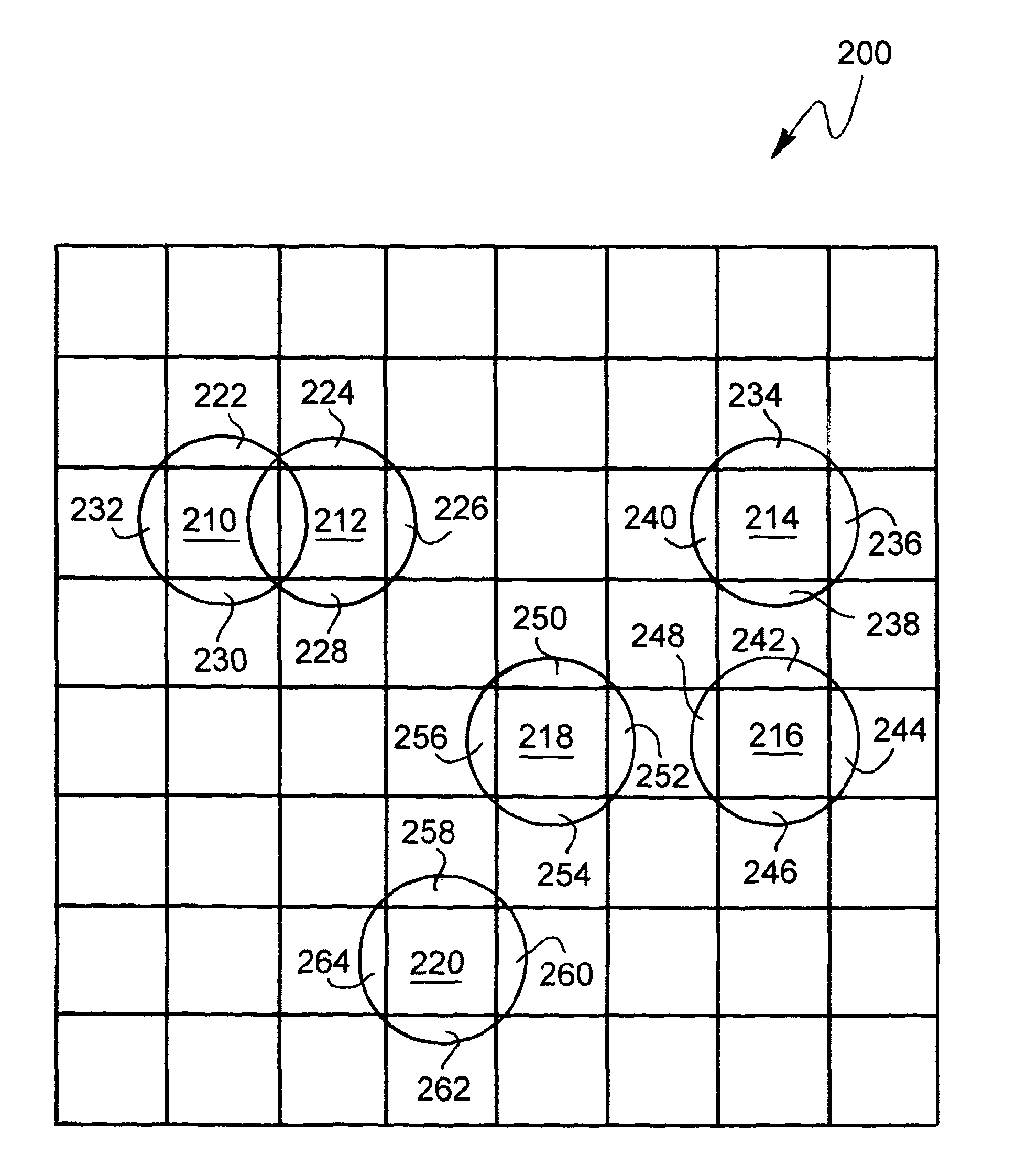

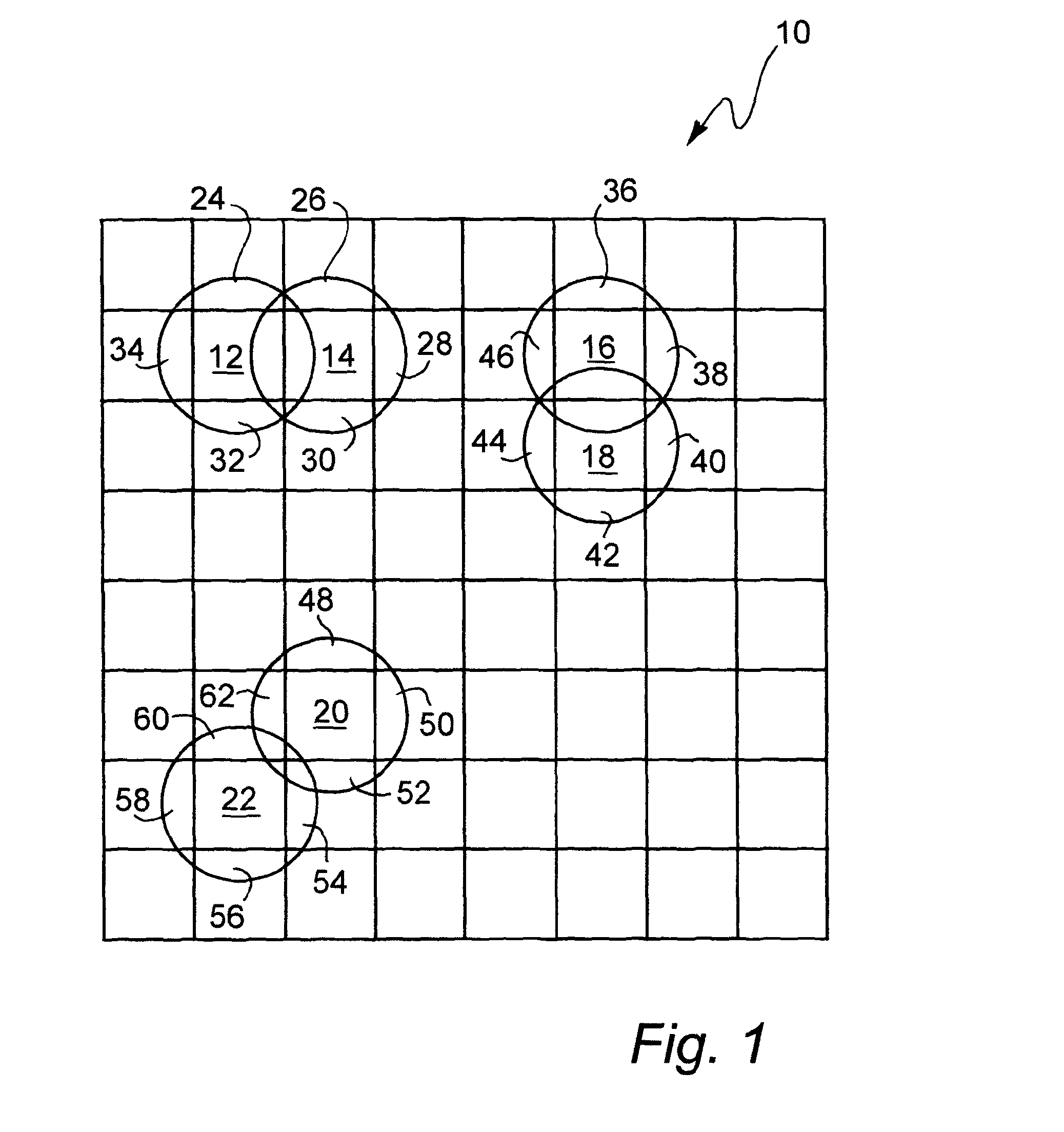

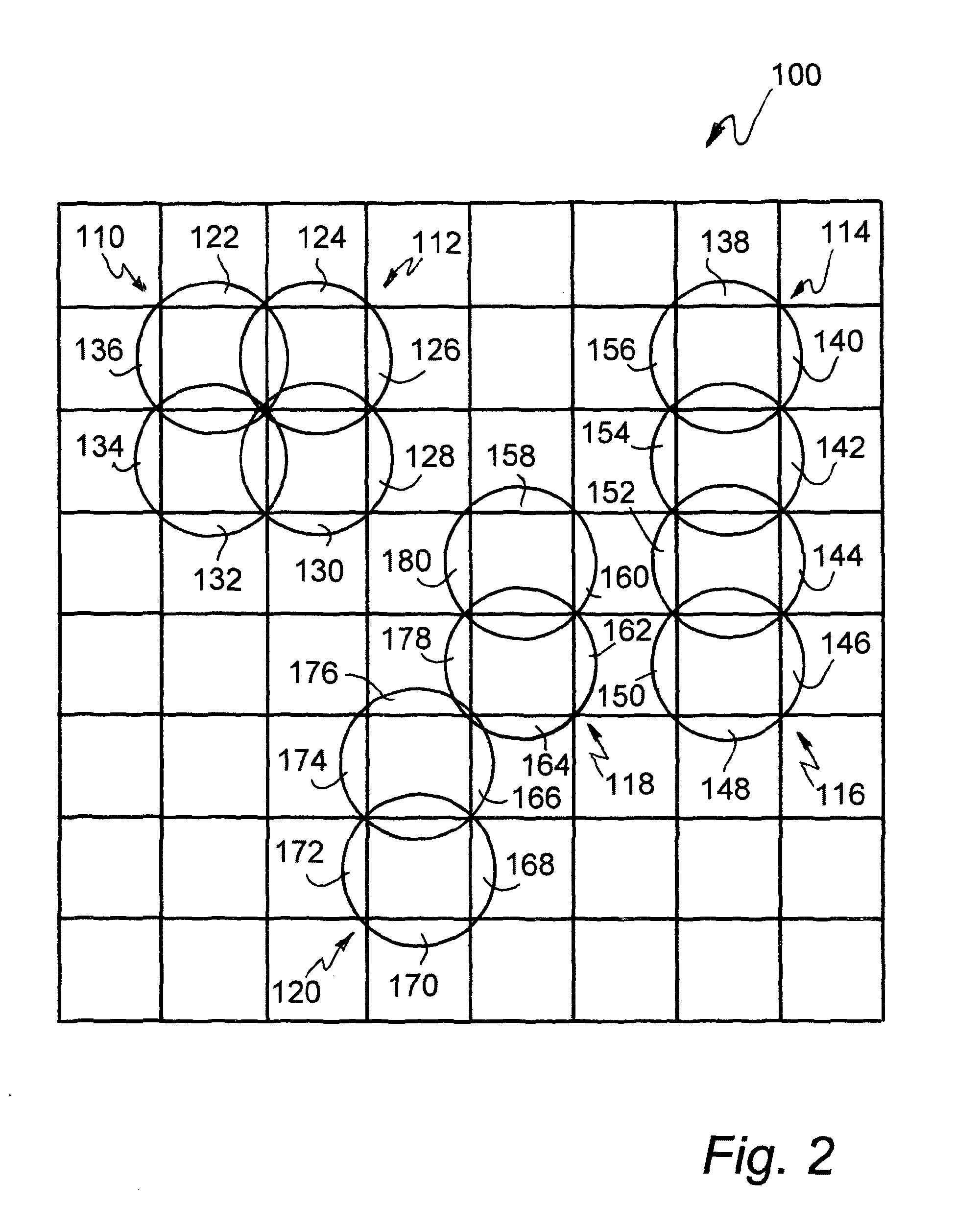

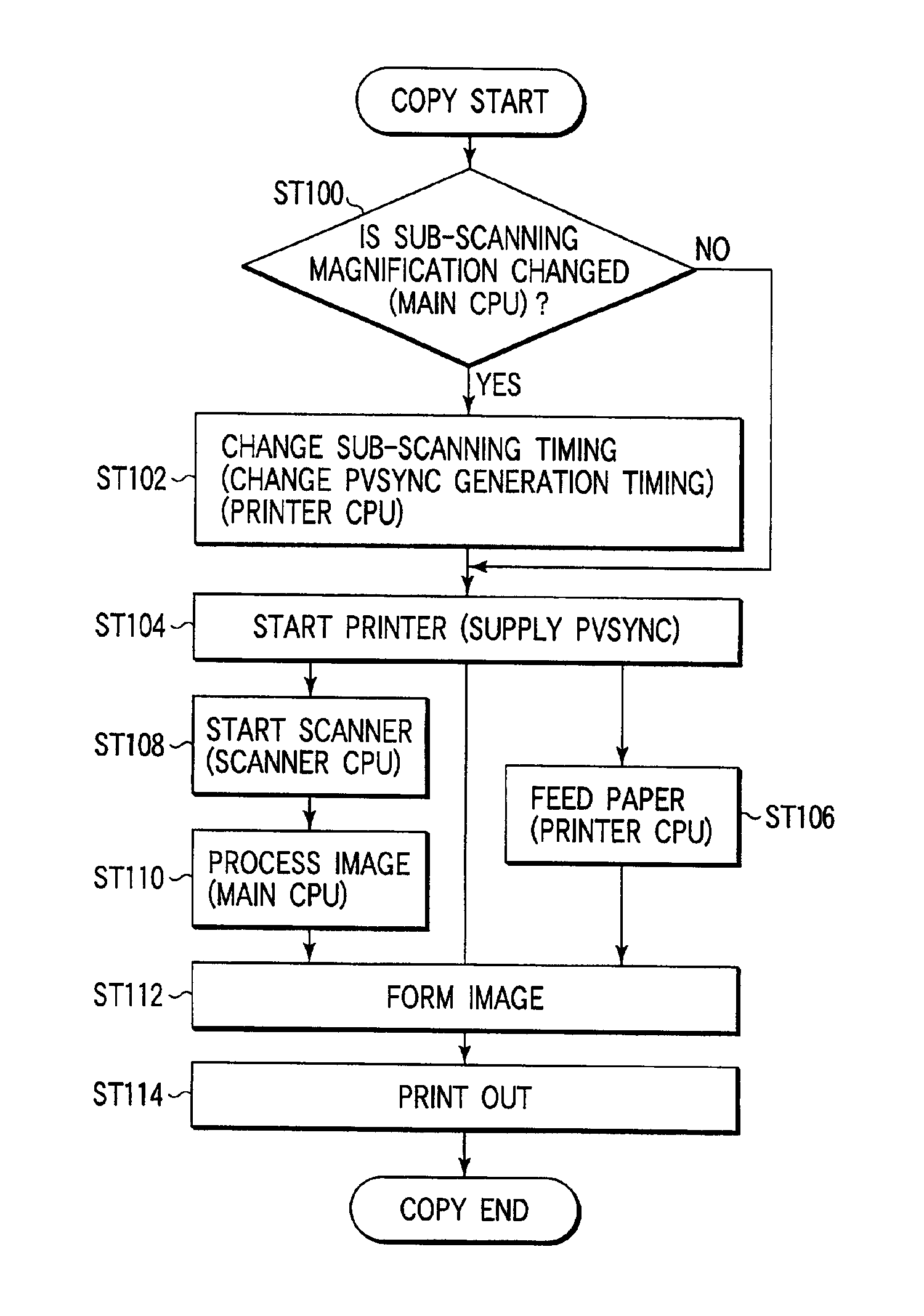

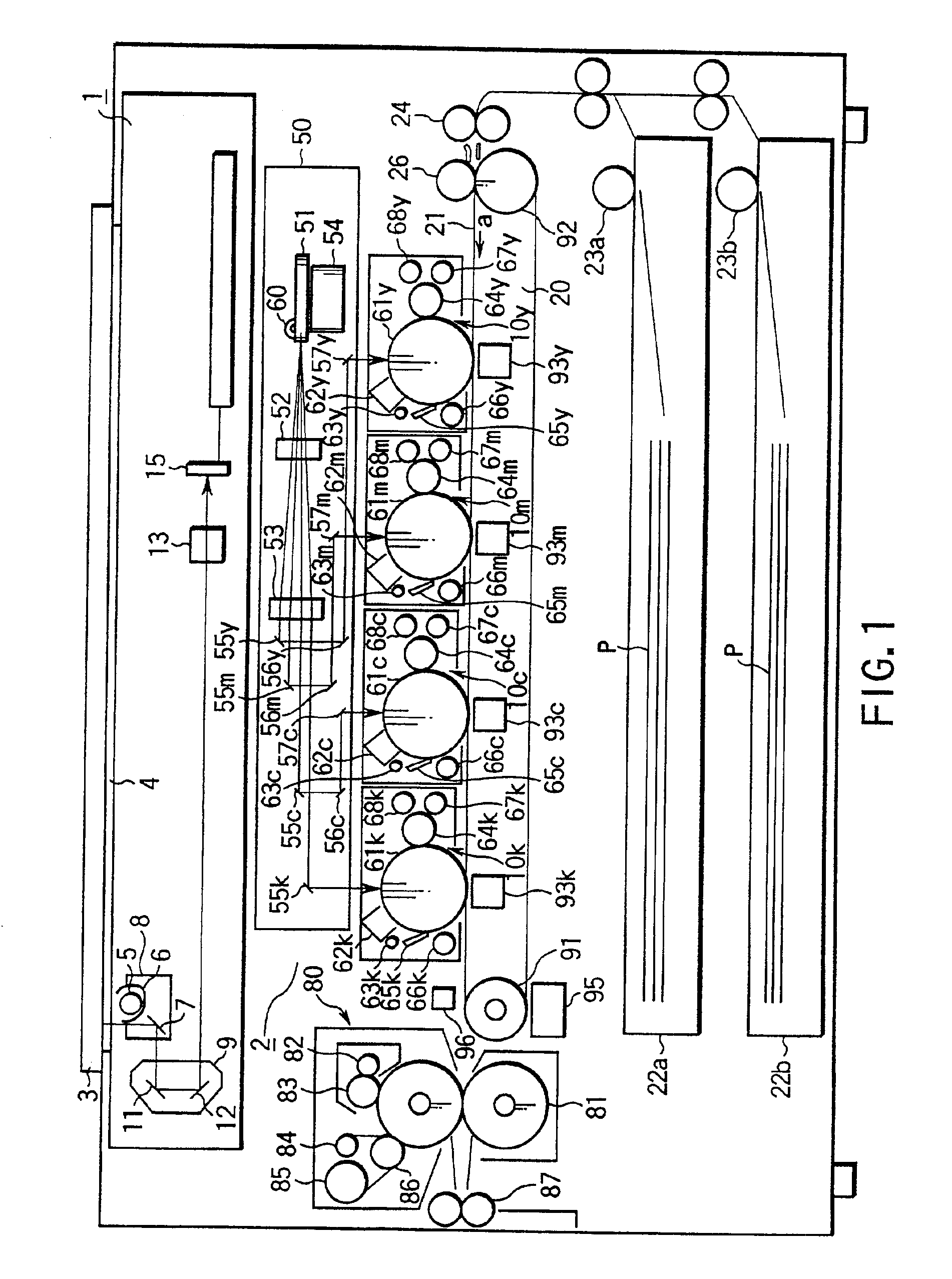

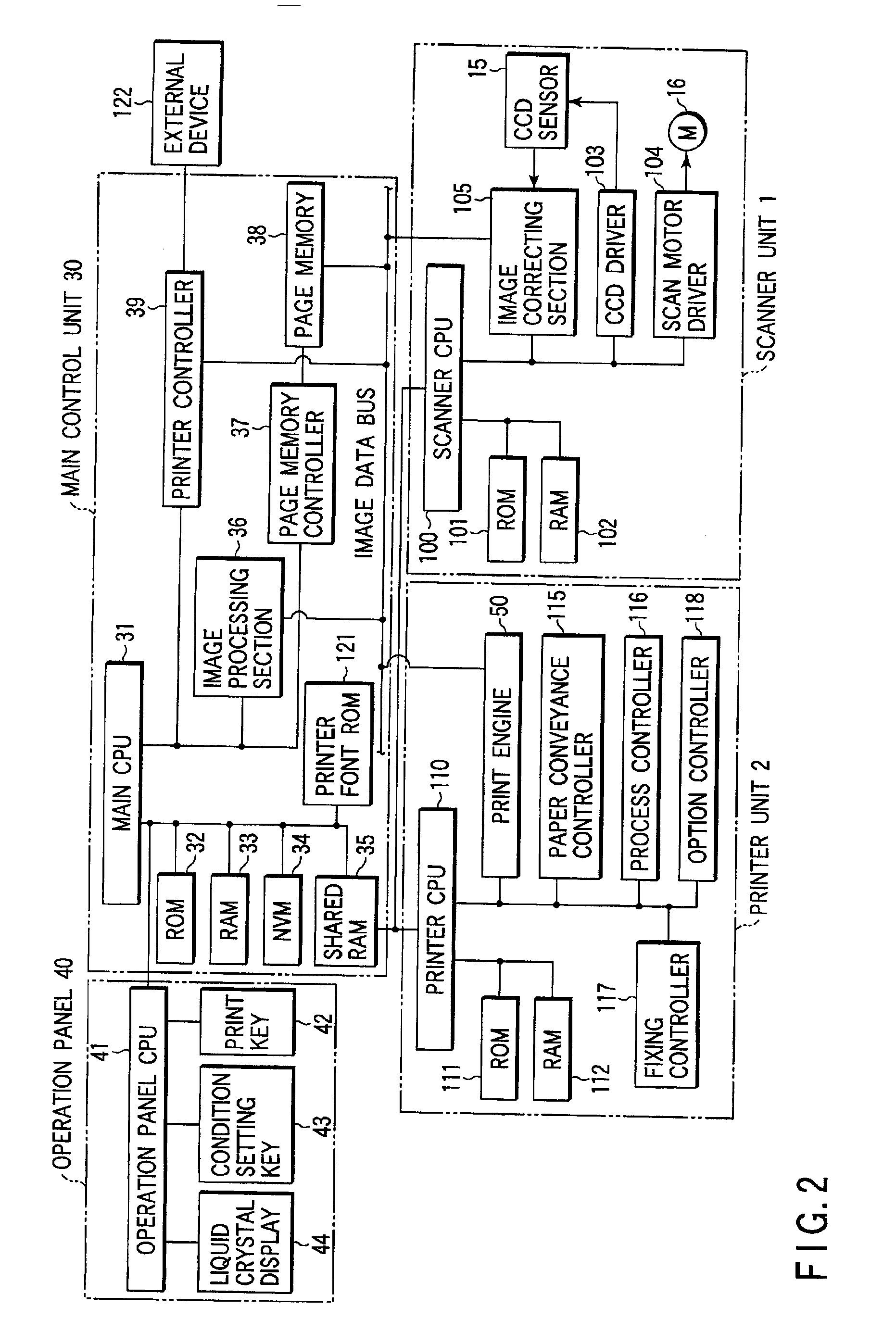

Image forming system with scanner capable of changing magnification of scanned image

InactiveUS6909521B1Reliable printingDigitally marking record carriersDigital computer detailsLeading edgeImage formation

The present invention provides an image forming system in which an image of a document can always be printed in an appropriate position of paper with reliability even when a scanning magnification of the image is changed. The system therefore includes a scanner for scanning a document image to generate an image signal, a printer for forming a copying image on paper in response to the image signal supplied from the scanner, a paper feeding section for feeding the paper to the printer, a magnification setting section for setting a scanning magnification when the scanner scans the document image, and a timing control section for controlling timing of supply of the image signal from the scanner to the printer and / or timing of supply of the paper from the paper feeding section to the printer such that the size of a margin between the leading edge of the paper and that of the copying image formed on the paper is fixed irrespective of the scanning magnification.

Owner:KK TOSHIBA +1

Silver ink compositions containing a cationic styrene/acrylate copolymer additive for inkjet printing

ActiveUS7560052B2Improve adhesionDesired conductivityConductive materialInksSilver inkSilver particles

The present invention provides an aqueous ink containing ≧3% silver particles having much improved adhesion. It has been found that the adhesion can be improved by adding an aqueous cationic dispersion of a styrene / acrylate copolymer, PEI (polyethyleneimine), or arabinogalactan as an additive to the ink. The advantage of using one of these materials to improve the adhesion of the silver ink is the stability of the ink is maintained and the resistivity goal is met when printed onto the specified media. In other words, this invention provides a silver ink with great adhesion properties while still able to meet the <0.1 Ω / square resistivity requirement and remain stable for up to 4 weeks at 60° C. at accelerated oven aging conditions.

Owner:LEXMARK INT INC

Inkjet ink composition and ink/receiver combination

InactiveUS7381755B2Good abrasionGood lightfastnessDuplicating/marking methodsFibre treatmentSURFACTANT BLENDPolymer chemistry

Owner:EASTMAN KODAK CO

Temperature-indicating tape and device for creating labels using the same

InactiveUS7429414B2Reliable printingEliminate failure problemsLayered productsFilm/foil adhesivesChange colorEngineering

A tape-like label forming device is capable of forming a label tape that is made up of a printing tape and a double-sided tape. A temperature-indicating material that changes color in response to changes in ambient temperature is applied to the surface of the printing tape. With this construction, since the color of the temperature-indicating material conceals the colors of the double-sided tape and characters such as letters and symbols printed on the underside of the printing tape, the colors of the characters and the double-sided tape can be freely selected and combined.

Owner:BROTHER KOGYO KK

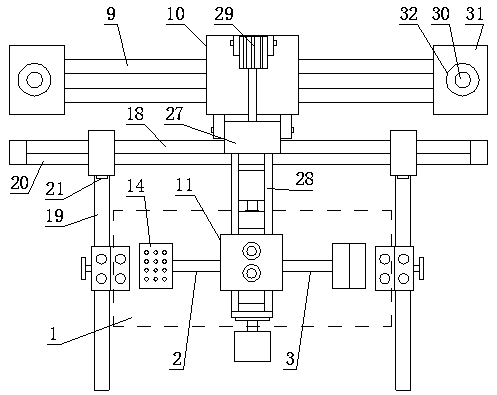

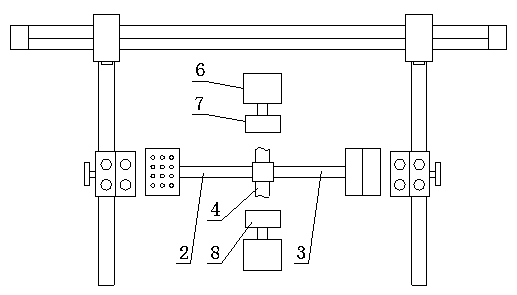

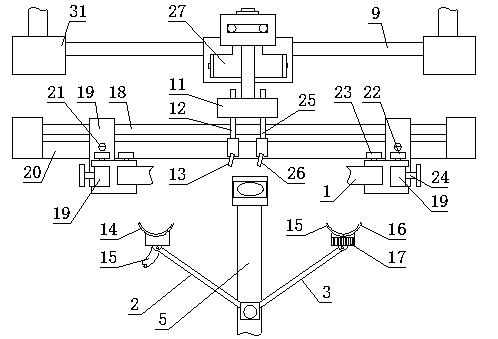

Printing unit of printing equipment of mouth-slanted wine bottle

InactiveCN103895330AReduce labor intensityIncrease productivityScreen printersWine bottleEngineering

The invention discloses a printing unit of printing equipment of a mouth-slanted wine bottle. The printing unit comprises a wine bottle printing transfer tool fixture and a printing mechanism. The wine bottle printing transfer tool fixture comprises a V-shaped bottle feeding rocking bar and a bottle discharging rocking bar. A bottle feeding fixing fixture is arranged at the upper end of the bottle feeding rocking bar, a bottle discharging fixing fixture is arranged at the upper end of the bottle discharging rocking bar, vertically-upward fixing supporting arms are arranged at the two ends of a rocking bar rotating shaft respectively, and a bottle bottom clamping plate an a bottle mouth clamping plate are arranged at the upper ends of the fixing supporting arms. A printing plate is fixed to a machine frame through a printing plate installing mechanism, and then the lower surface of the printing plate can be attached to the upper surface of the wine bottle, wherein the wine bottle is fixed by the bottle bottom clamping plate and the bottle mouth clamping plate. A printing scraping plate is arranged in the printing mechanism. The printing unit of the printing equipment of the mouth-slanted wine bottle can achieve automatic wine bottle printing and transfer, reduces labor intensity, improves production efficiency and has the advantages of being convenient to adjust, reliable in printing and the like.

Owner:CHONGQING ZHAOHUI GLASS CRYSTAL PROD

Ink supply method and printing apparatus

Owner:CANON KK

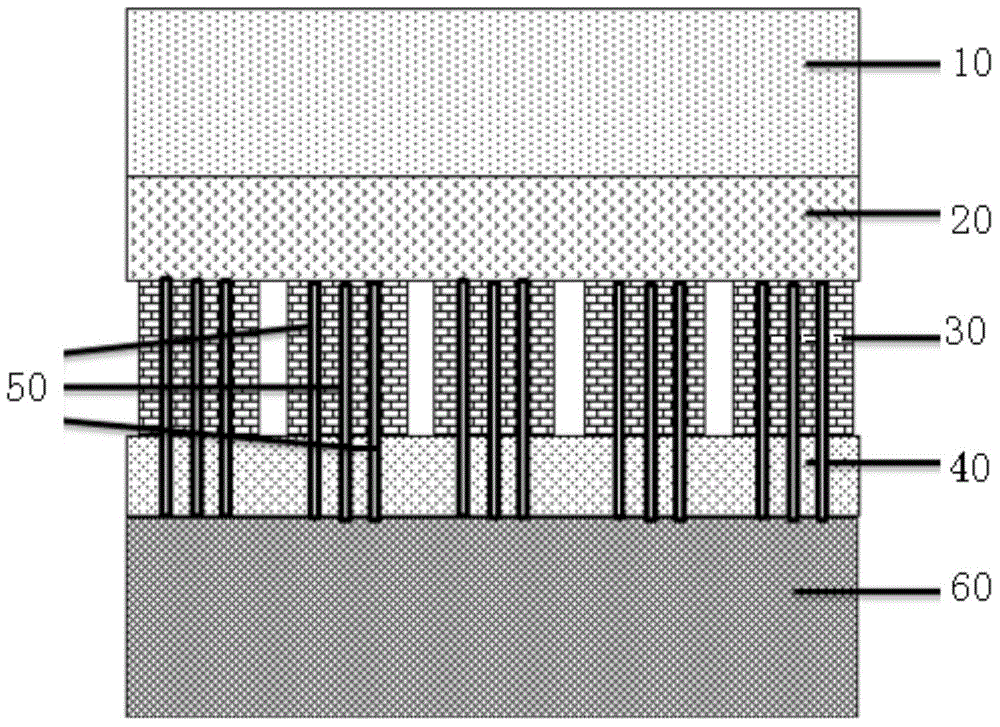

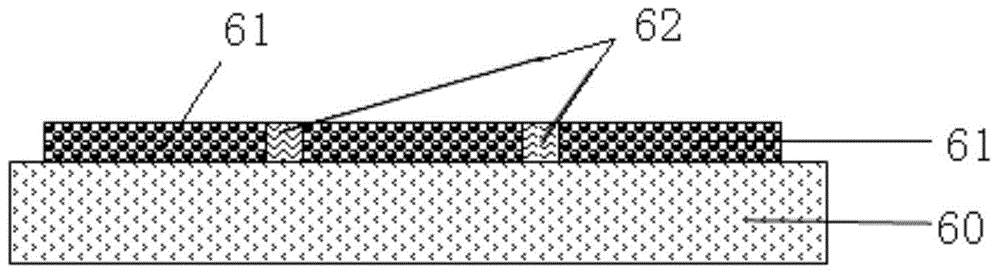

Back-contact solar cell assembly

InactiveCN103560154AGood heat resistanceHigh resistance to electrochemical corrosionPhotovoltaic energy generationSemiconductor devicesBackplaneEngineering

The invention provides a back-contact solar cell assembly which comprises an overlaid transparent layer (10), a first packing layer (20), a battery piece layer (30), a second packing layer (40) and a back plate layer (60). A first conductor and a second conductor are arranged between the back plate layer (60) and the second packing layer (40). The back-contact solar cell assembly further comprises a first hole channel and a second hole channel which are both formed in the battery piece layer (30) and the second packing layer (40). The first hole channel is communicated with a positive electrode of a battery piece of the battery piece layer (30) and the first conductor, the second hole channel is communicated with a negative electrode of the battery piece of the battery piece layer (30), the first hole channel and the second hole channel are filled with conductive slurry (50), and the back plate layer (6) is made of glass. The technical scheme of the back-contact solar cell assembly effectively solves the problems that a back-contact solar cell assembly in the prior art is complex in manufacturing process and high in rejection rate.

Owner:倪健雄

Printing missing word repairing method

The invention relates to a printing missing word repairing method. The printing missing word repairing method comprises the following steps of: (A) preparing a printing plate of words to be repaired, moving out a word missing part of a book, typesetting the word missing part and reserving an appropriate space convenient for operation in the future repairing; (B) making a repairing printing film according to four layers of a transparent film base material, a mold release agent, transfer printing ink and hot melt adhesive in sequence and printing the words needed to be transferred onto the transparent film by using a screen printing method; (C) making a transfer printing iron board according to the range of the repaired words; (D) heating a heating body to 180-200 DEG C and placing the transfer printing iron board on the heating body for 10-20 minutes; (E) placing the machined transfer printing film at a part needed to be repaired, aligning positions of the transfer printing film and the part needed to be repaired, impressing the heated transfer printing iron board onto the words needed to be thermoprinted, and moving out the transfer printing iron board after heated for 2-3 seconds; and (F) cooling the transfer printing film for 10-15 seconds and rapidly uncovering the thermoprinting film with heavy force. The method provided by the invention has the advantages of simplicity and convenience for operation, cost reduction, high repairing speed and the like.

Owner:南京爱德印刷有限公司

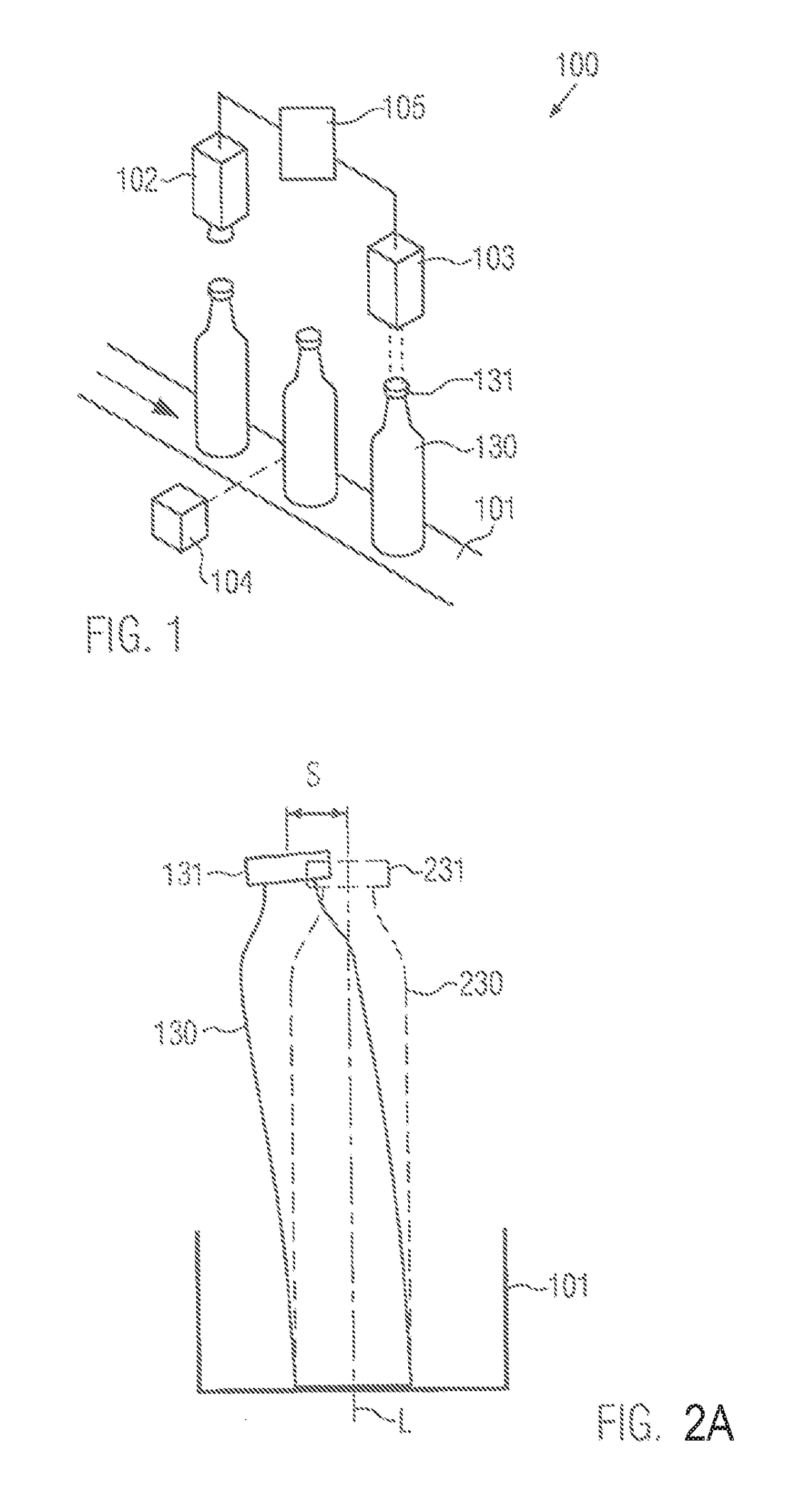

Device for printing closures of closed containers

InactiveUS20190084714A1Reliable printingCompensation deviationTypewritersApplying date marks/code marksPrinting inkControl unit

A device for printing closures of closed containers, comprising a transport section for transporting the containers, wherein a detection unit and a printing unit for printing the closure of a container are arranged behind one another in the transport direction and the detection unit can individually determine the position of the closure transversely with respect to the transport direction for each container and can transmit a signal which is indicative of the position to a control unit which is assigned to the detection unit and the printing unit. The control unit is designed to control the printing unit to apply printing ink to the closure in order to print the closure according to its position. Also disclosed is a corresponding method.

Owner:KRONES AG

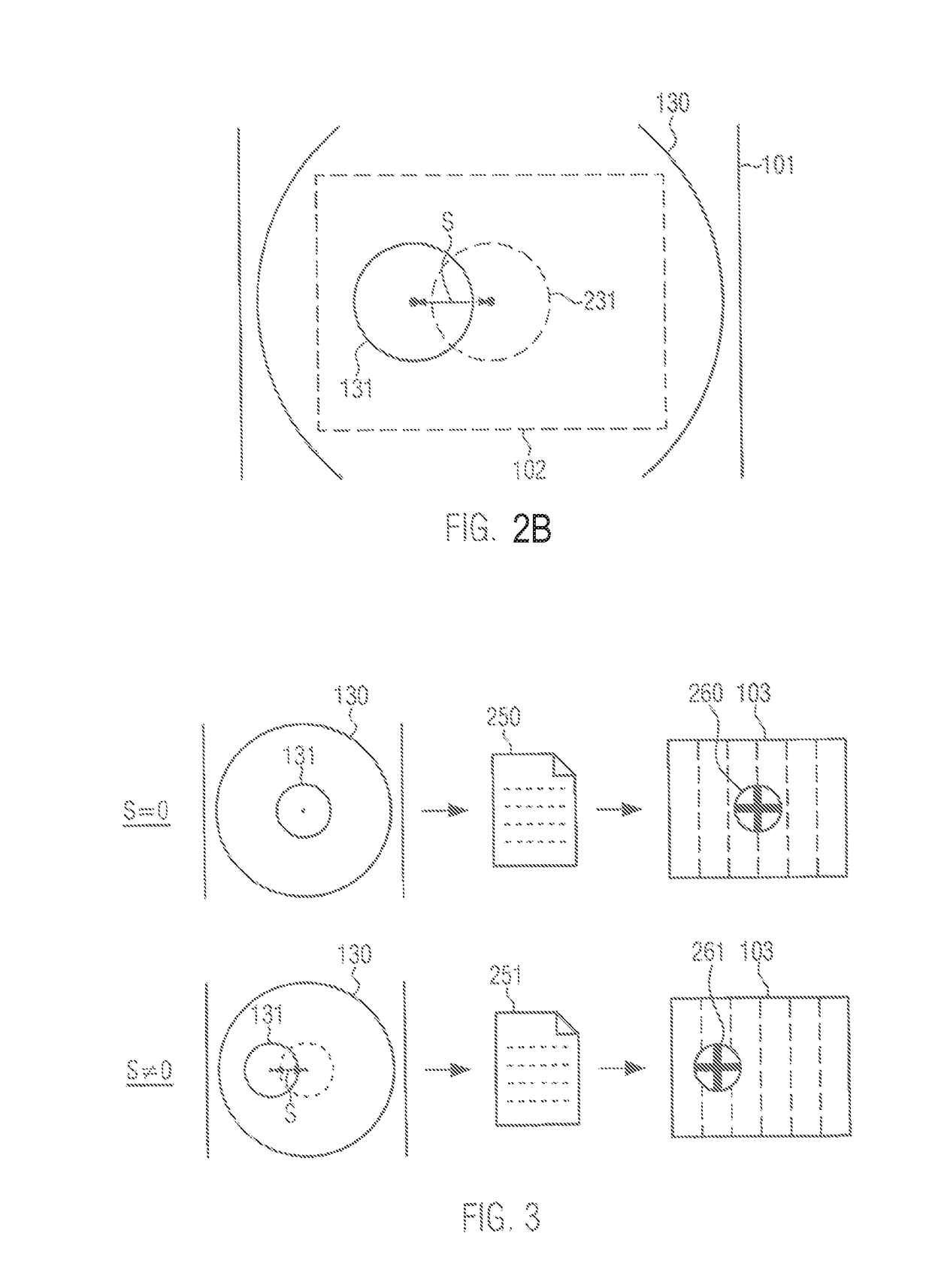

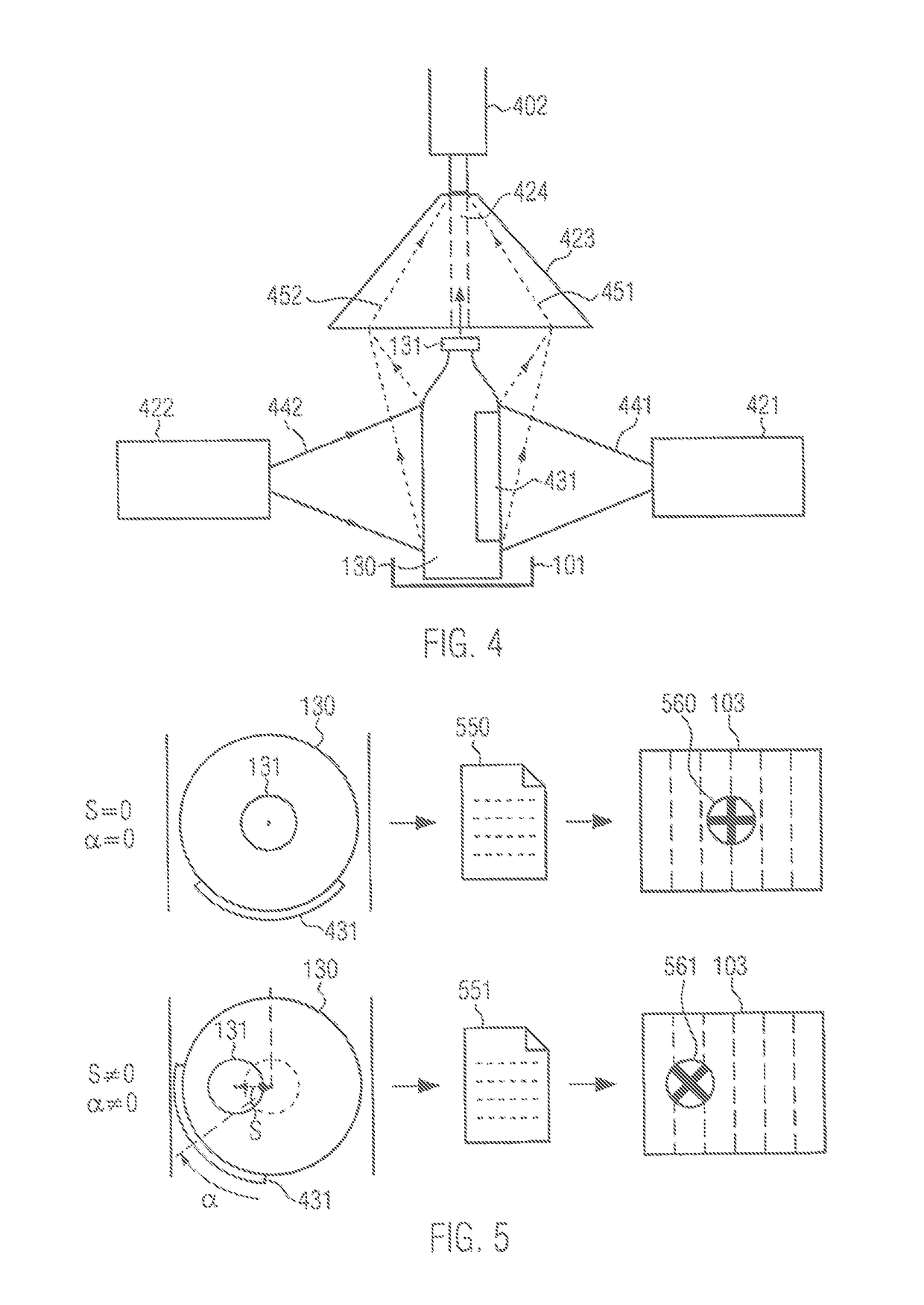

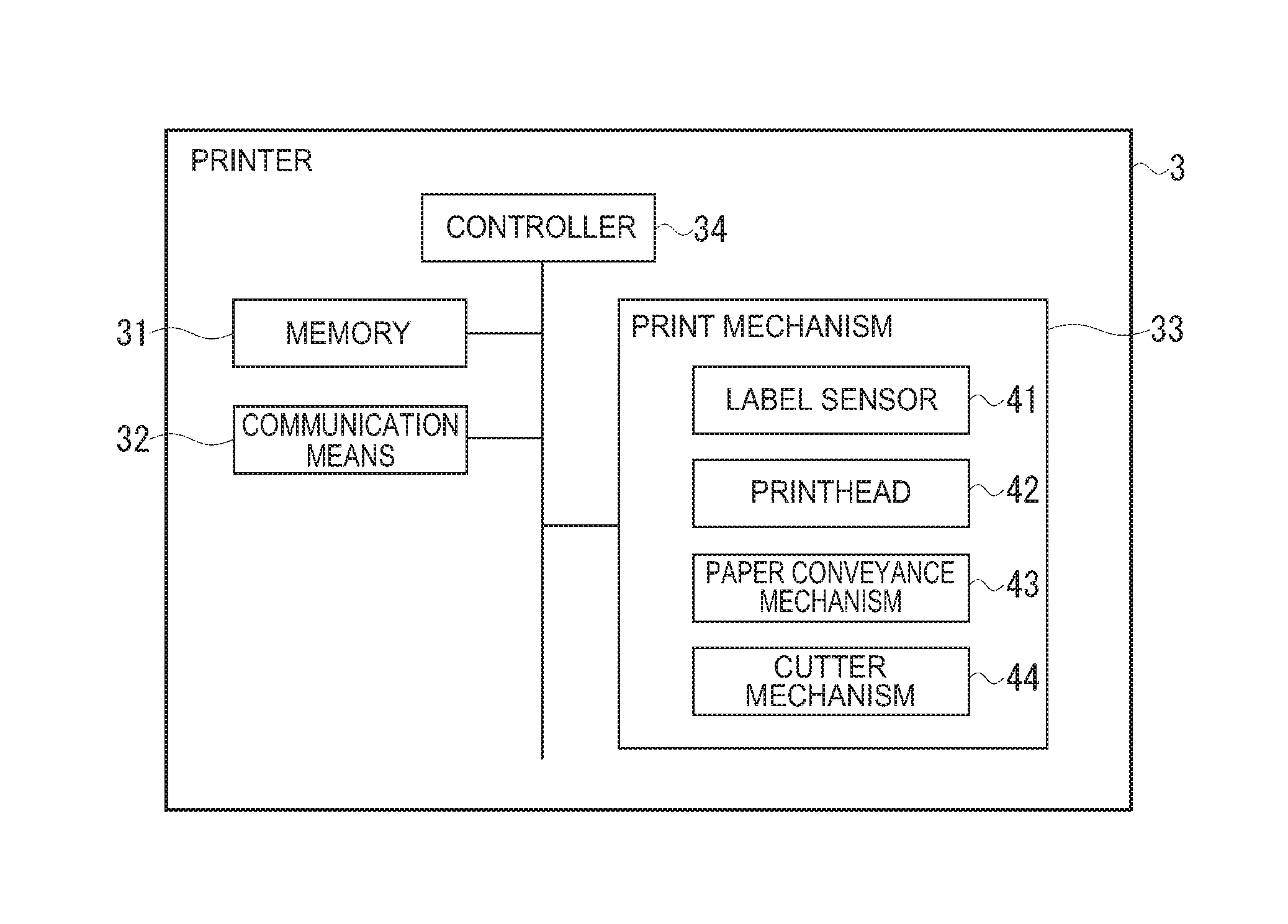

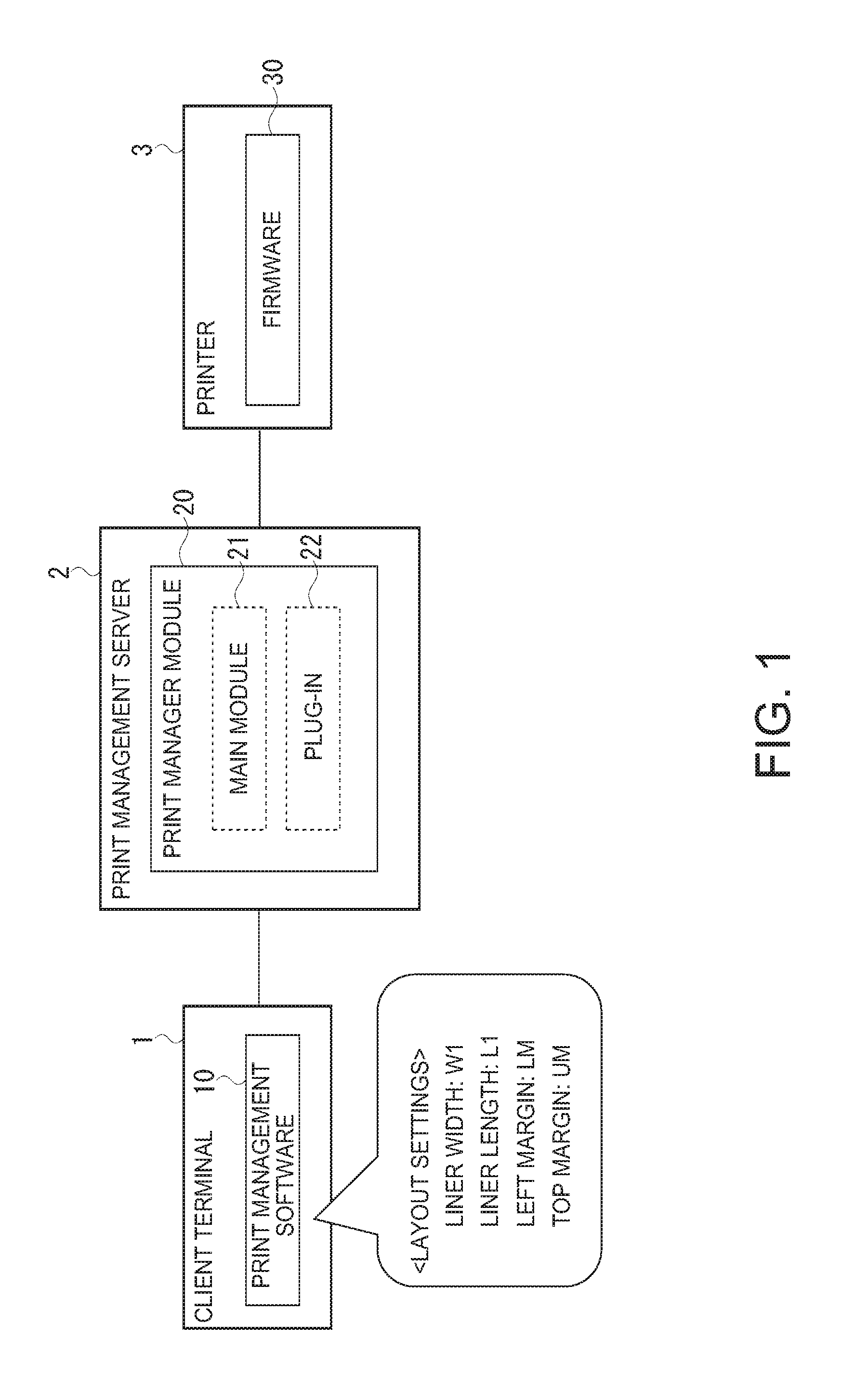

Control Method of a Printer, Program, and Recording medium

ActiveUS20170039459A1Preventing executionLayout generating process can be preventedVisual presentation using printersPattern selectionIndustrial engineering

The user can configure the print layout intuitively, and prevent needlessly executing a compensation process based on the printer mode. A plug-in 22 that controls a printer 3 that prints to a target print area in each unit print area disposed in the conveyance direction of a continuous print medium has: a mode selector 51 that determines if the printer 3 prints based detecting each unit print area of the print medium; a layout acquisition unit 53b that acquires first layout information representing the location of the target print area in the unit print area; and a layout generator 54b that generates second layout information which differs from the first layout information in the conveyance direction of the print medium when the printer determines to print based on the position detection.

Owner:SEIKO EPSON CORP

Information processing apparatus, information processing method, and host-based printer

The invention provides an information processing apparatus, an information processing method, and a host-based printer. An information processing apparatus which controls a host-based printer includes a determination portion which determines designation of feed from a feed unit or manual feed port, a display control portion which, when it is determined that feed from the manual feed port is designated, causes a display portion to display a display to prompt the operator to insert a print medium into the manual feed port, an identification portion which identifies compressed-image data transfer permission corresponding a user instruction, and a transfer portion which transfers compressed image data of one page to the host-based printer.

Owner:CANON KK

Fabric printing and washing process

InactiveCN105926330AReliable printingFine print graphicsDry-cleaning apparatus for textilesDyeing processSodium carbonatePre treatment

The invention provides a fabric printing and washing process which is simple and can improve printing quality and ensure beautiful colors. The process comprises the following steps: 1, selecting a fabric and performing dust removal treatment on the fabric; 2, performing primary printing treatment: performing printing treatment on the pre-treated fabric; 3, performing primary washing: adding sodium carbonate into a water tank to regulate the pH value to 10 to 11, adding 1 to 3 parts of a CD anti-staining agent, and performing washing with 30 to 45 DEG C water; 4, drying a semi-finished product fabric in a dryer at drying temperature of 120 to 130 DEG C; 5, performing secondary printing treatment: spraying a color fixing agent onto the surface of a pattern; 6, performing secondary washing: adding acetic acid into the water tank to regulate the pH value to 4 to 4.5, adding 5 to 7 parts of a KNR color fixing agent, and performing washing with 50 to 60 DEG C water; 7, performing washing with clear water and drying. According to the process, the printed pattern is delicate, beautiful in color, highly layered, fast in coloring and low in fading rate.

Owner:HUZHOU XINLONGLONG SILK PRINTING

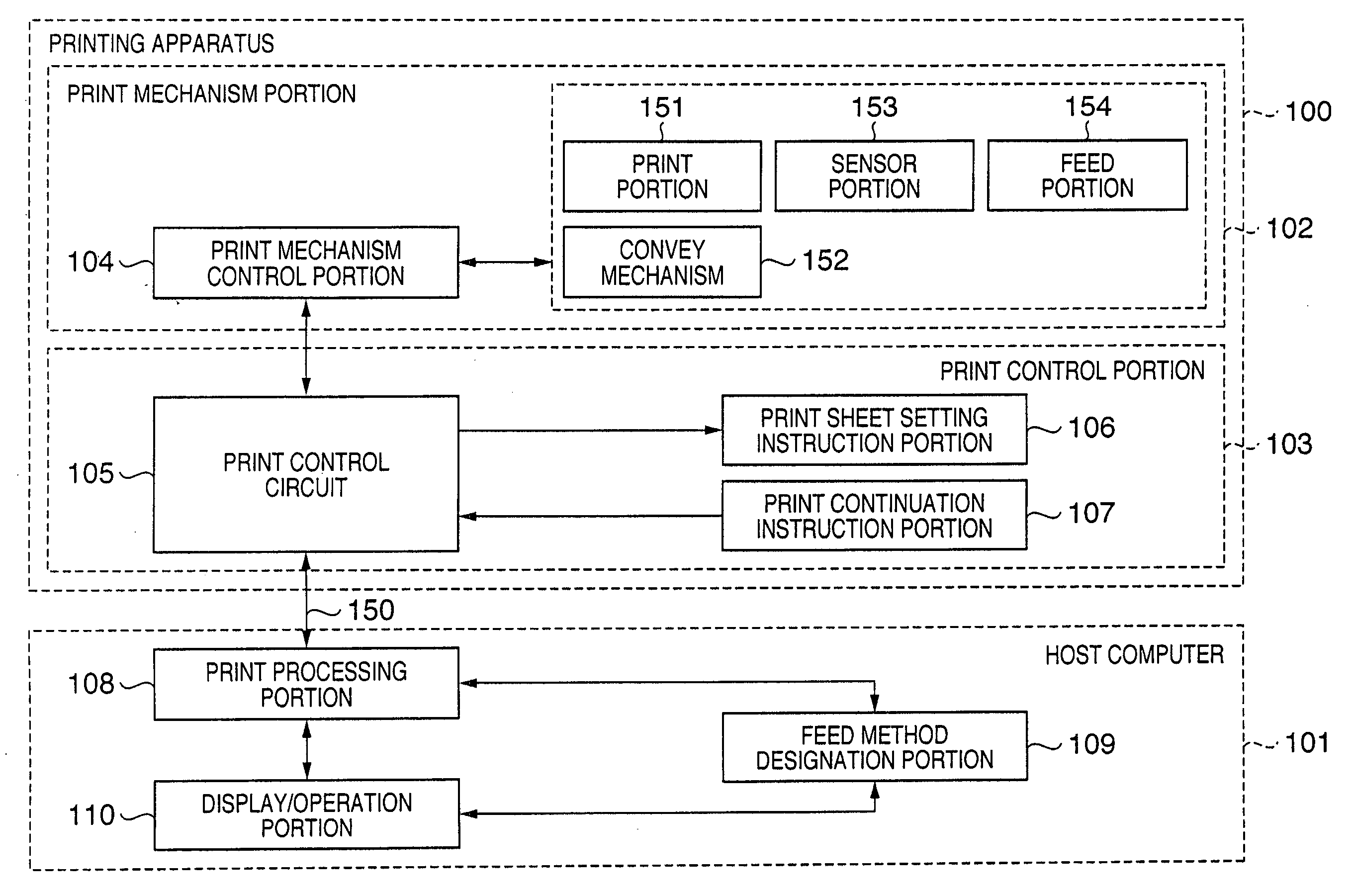

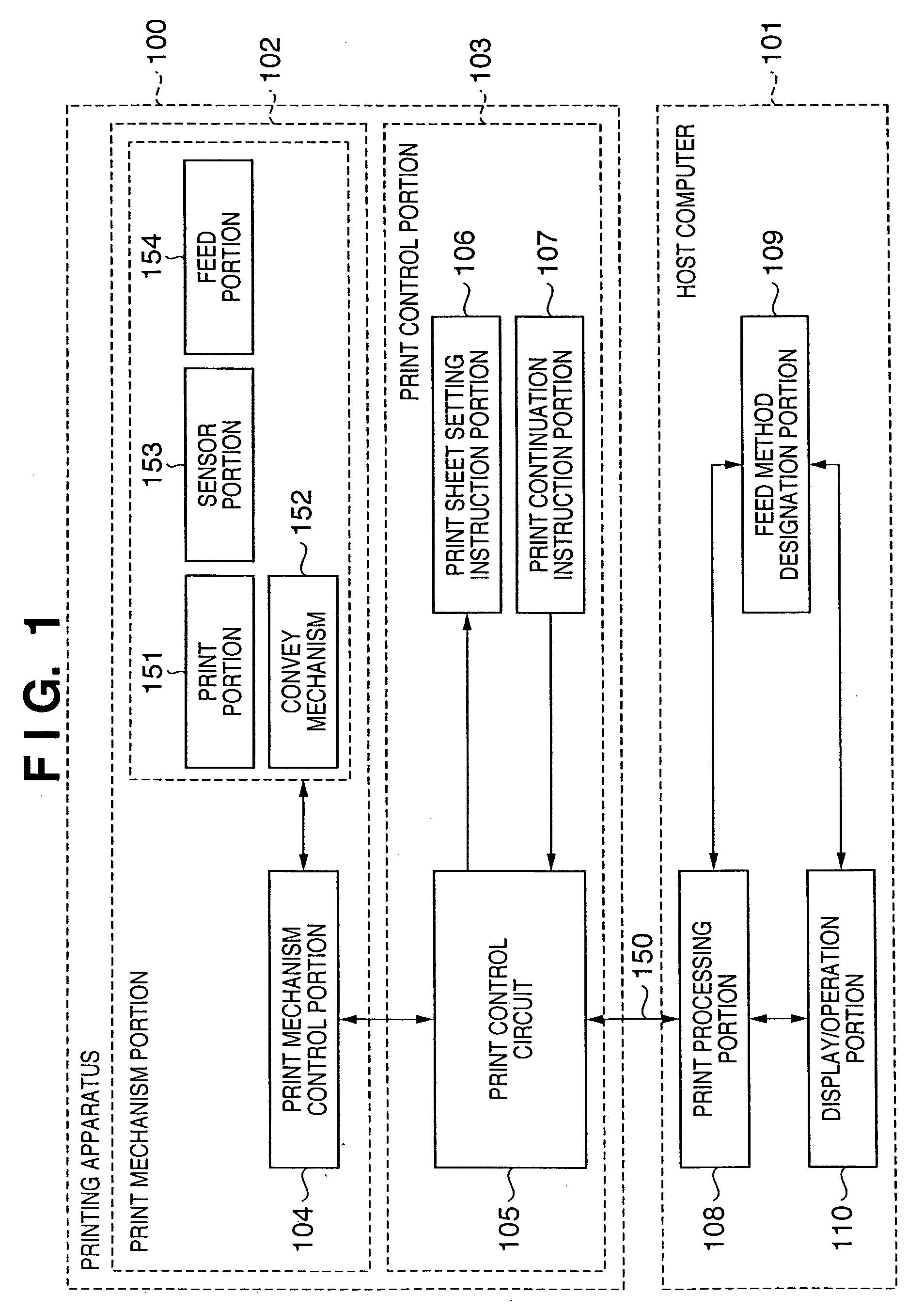

Information processing apparatus, information processing method, and host-based printer

InactiveUS20060275070A1Reliably be printLow costDigitally marking record carriersRegistering devicesData shippingComputer graphics (images)

An information processing apparatus which controls a host-based printer includes a determination portion which determines designation of feed from a feed unit or manual feed port, a display control portion which, when it is determined that feed from the manual feed port is designated, causes a display portion to display a display to prompt the operator to insert a print medium into the manual feed port, an identification portion which identifies compressed-image data transfer permission corresponding a user instruction, and a transfer portion which transfers compressed image data of one page to the host-based printer.

Owner:CANON KK

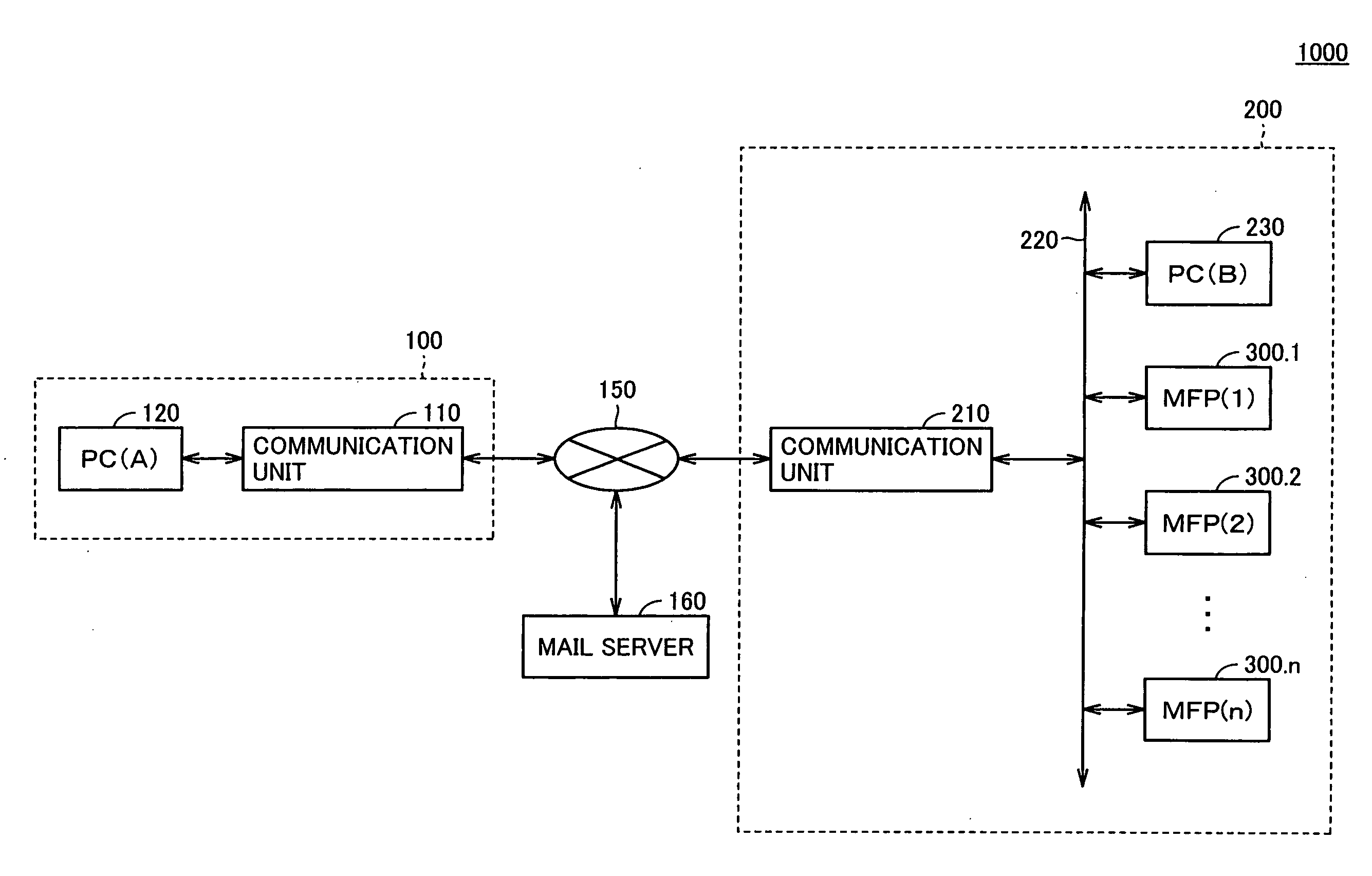

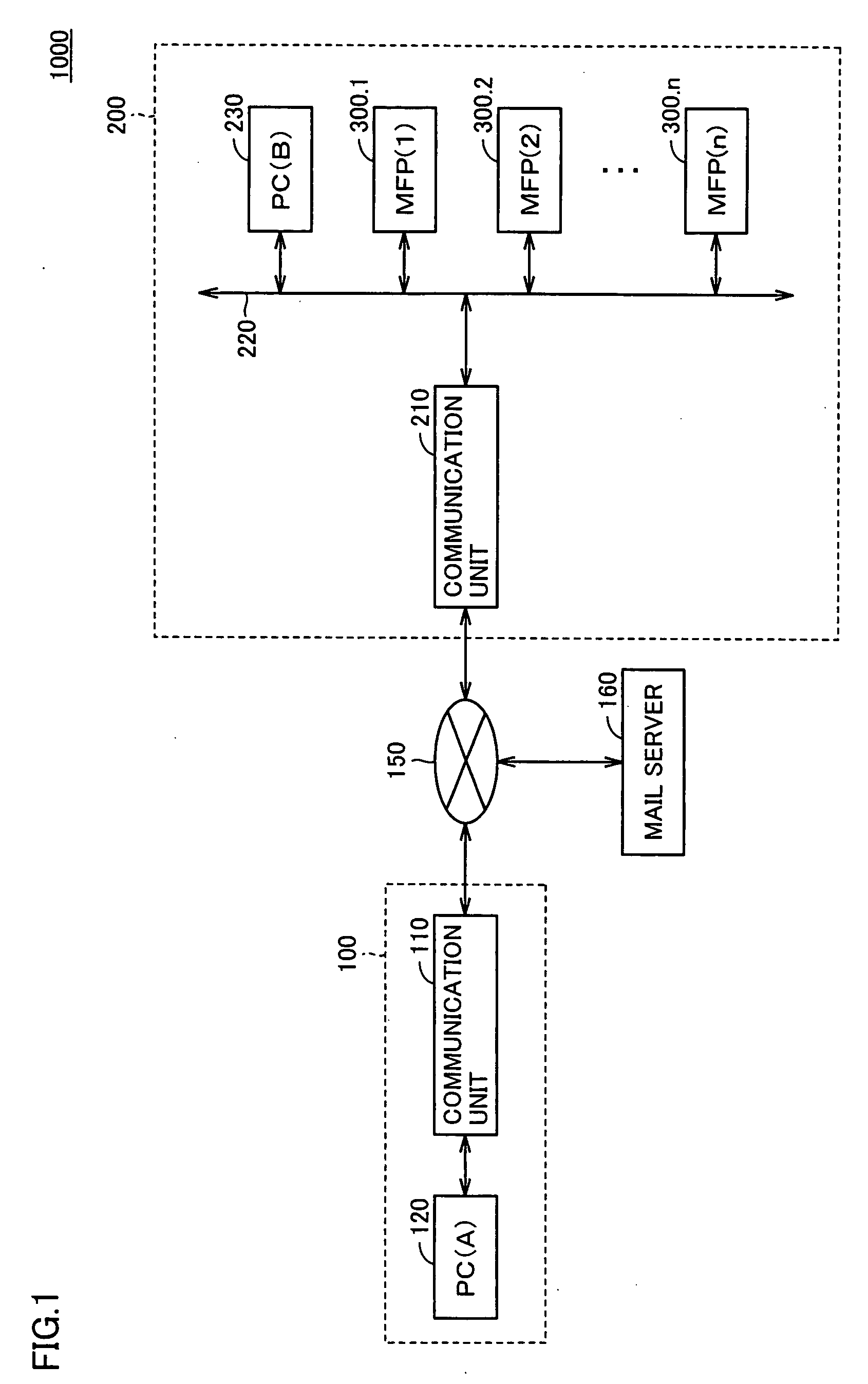

Print system

ActiveUS8711382B2Reliable printingEnsure confidentialityDigital data processing detailsAnalogue secracy/subscription systemsNetwork connectionComputer printing

In one embodiment of a print system, a client terminal (10) that generates a print job, a server function portion that stores the print job, a printer (30) that performs pull printing of the print job are connected via the network (40). The print job holds print data and authority information including user information for specifying a user having print authority over the print data. The client terminal (10) is provided with an authority setting means for setting authority information. A server (20) is provided with the server function portion, and is configured to update authority information, identify a user, authenticate whether or not to permit printing based on the authority information and the identification result obtained by a user identification means, and transmit print data.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com