Patents

Literature

406results about How to "Prevent flocculation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printing liquids for improved print quality

InactiveUS6022908AImprove print qualityReduce bleedingDuplicating/marking methodsInksColoring agentsAnionic polymers

A set of printing liquids is disclosed comprising a first anionic printing liquid comprising an aqueous vehicle, at least one first colorant, and at least one first anionic polymer; a second anionic printing liquid comprising an aqueous vehicle at least one second colorant, at least one second anionic polymer, and an acid additive having a pKa up to the pKa of the at least first polymer of the first liquid; a third cationic printing liquid comprising an aqueous vehicle, at least one third colorant, at least one third cationic polymer, and a pH in the range from about 2 to about 5; and a fourth anionic printing liquid comprising an aqueous vehicle, at least one fourth anionic dye, and a precipitating agent. More specifically, the present set of printing liquids may find application in ink-jet printing. The set of ink-jet inks provides improved print quality, specifically, reduced bleed; improved edge-acuity, uniform area fills, and color quality; while maximizing lightfastness without sacrificing printing reliability.

Owner:HEWLETT PACKARD DEV CO LP

Composite epoxy anticorrosive paint and preparation method thereof

ActiveCN104231857AHigh glass transition temperatureGood flexibilityConjugated diene hydrocarbon coatingsAnti-corrosive paintsEpoxyPolymer science

The invention discloses composite epoxy anticorrosive paint and a preparation method thereof. The composite epoxy anticorrosive paint is composited by a component A and a component B at a ratio of 2:1, wherein the component A comprises constituents as follows: organosilicon modified epoxy resin, a pigment, filler, a plasticizer, a dispersant, a coalescing agent and a antifoaming agent; the component B comprises constituents as follows: polyphenyl ether resin powder, styrene-butadiene rubber, toluene, a plasticizer, a coupling agent, auxiliary materials and a flame retardant; and the components A and B are mixed respectively for preparation, and B is sprayed on A to form the composite epoxy anticorrosive paint. The composite epoxy anticorrosive paint is prepared by two components, has superior high-temperature resistance and abrasion resistance as well as good adhesion and low shrinkage simultaneously, has good corrosion resistance and penetration resistance to water, medium acid, alkali and other solvents and further has superior flexibility and paint application simultaneously; and the preparation method of the composite epoxy anticorrosive paint is simple and low in cost.

Owner:JIANGSU MARINE VICTORY COATING

High-temperature (800 DEG C) wear-resistant paint and preparation method thereof

The invention discloses high-temperature (800 DEG C) wear-resistant paint and a preparation method thereof. The high-temperature wear-resistant paint comprises a component 1 and a component 2, wherein the component 1 is prepared by mixing a component A and a component B; the component A in the component 1 comprises the following components: black silicon carbide, fine-grain aluminum oxide, dispersing agent, zinc oxide, modified epoxy resin, flatting agent and an auxiliary material; the component B in the component 1 comprises the following components: organic silicon modified epoxy resin, a filler, antimony trioxide, film-forming assistant and thickener; and the component 2 is curing agent and coupling agent. The high-temperature (800 DEG C) wear-resistant paint is prepared by the following steps: mixing the component A and the component B in the component 1, and curing the component 1 with the component 2. The high-temperature wear-resistant paint is prepared by compounding the double components, has excellent high temperature resistance and wear resistance, and also has the fine properties of favorable hardness, high heat stability, ductility, workability and the like. The invention also designs the method for preparing the high-temperature wear-resistant paint. The preparation method is simple and low in cost.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

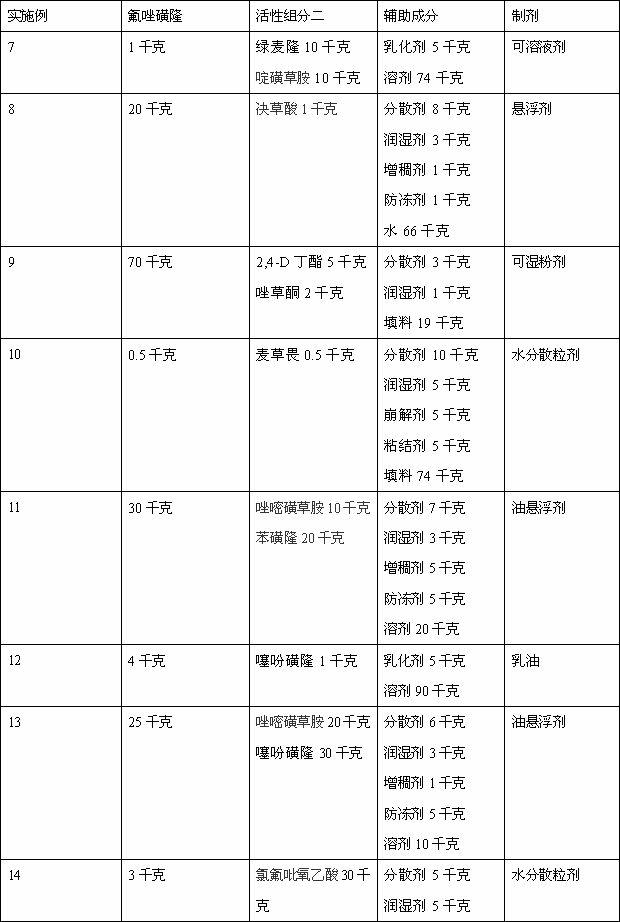

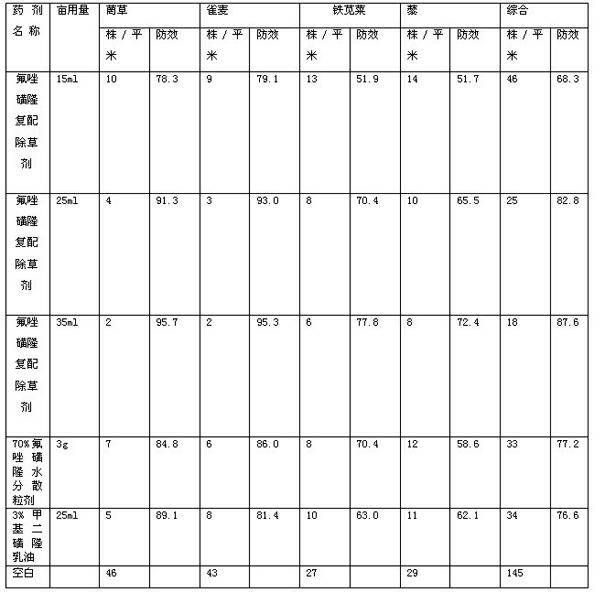

Flucarbazone-Na compounded herbicide

InactiveCN102428945APrevent flocculationAvoid layeringBiocideAnimal repellantsFluroxypyrFluoroglycofen-ethyl

The invention discloses a flucarbazone-Na compounded herbicide which comprises an active component I (flucarbazone-Na), an active component II and auxiliary components, wherein the active component II is one or a combination of several of mesosulfuron methyl, isoproturon, chlortoluron, pyroxsulam, Clodinafop-propargyl, carfentrazone-ethyl, tribenuron-methyl, fluroxypyr, methoxone, 2,4-D-butyl ester, dicamba, bromoxynil, thifensulfuron methyl, amidosulfuron, bensulfuron-methyl, flumetsulam, fluoroglycofen-ethyl and florasulam; the auxiliary components comprise an auxiliary agent and also comprise one of a filler and a solvent; the auxiliary agent is one or a combination of two of an emulsifying agent, a dispersant, a wetting agent, a disintegrant, an agglomerant, an antifreezing agent and a thickening agent; the mass sum of the active component I (flucarbazone-Na) and the active component II is 1%-85% of the total mass of the flucarbazone-Na compounded herbicide; and the mass ratio of the active component I to the active component II is (1:20)-(20:1). The flucarbazone-Na compounded herbicide disclosed by the invention is a novel herbicide for preventing and removing weeds in a wheatland.

Owner:河北博嘉农业有限公司

Method for preparing edible grease gel with Pickering emulsion as template

ActiveCN105994698AHigh strengthInhibition of oil-water phase separationEdible oils/fatsChemistryOil in water

The invention relates to a method for preparing edible grease gel with a Pickering emulsion as a template. Firstly, an oil-in-water type emulsion with soybean isolate protein nanoparticles as an emulsifier and xanthan gum as a gel enhancer is prepared, moisture in the emulsion is removed with a drying means, and the edible grease gel containing little water is obtained. By comparison with a traditional emulsion, particles can be adsorbed to an oil / water interface of the oil-in-water type emulsion irreversibly, accordingly, coalescence and flocculation of liquid drops and curing of Ostwald are effectively inhibited, and the emulsion can keep stable for months or years. With the adoption of the preparation method, grease which does not contain trans-fatty acids and low-content saturated fatty acids can be obtained and can replace part of solid or semi-solid fat in food. The method has the advantages that operation is simple and convenient, raw materials are safe and environment-friendly and the like.

Owner:河南福美生物科技有限公司

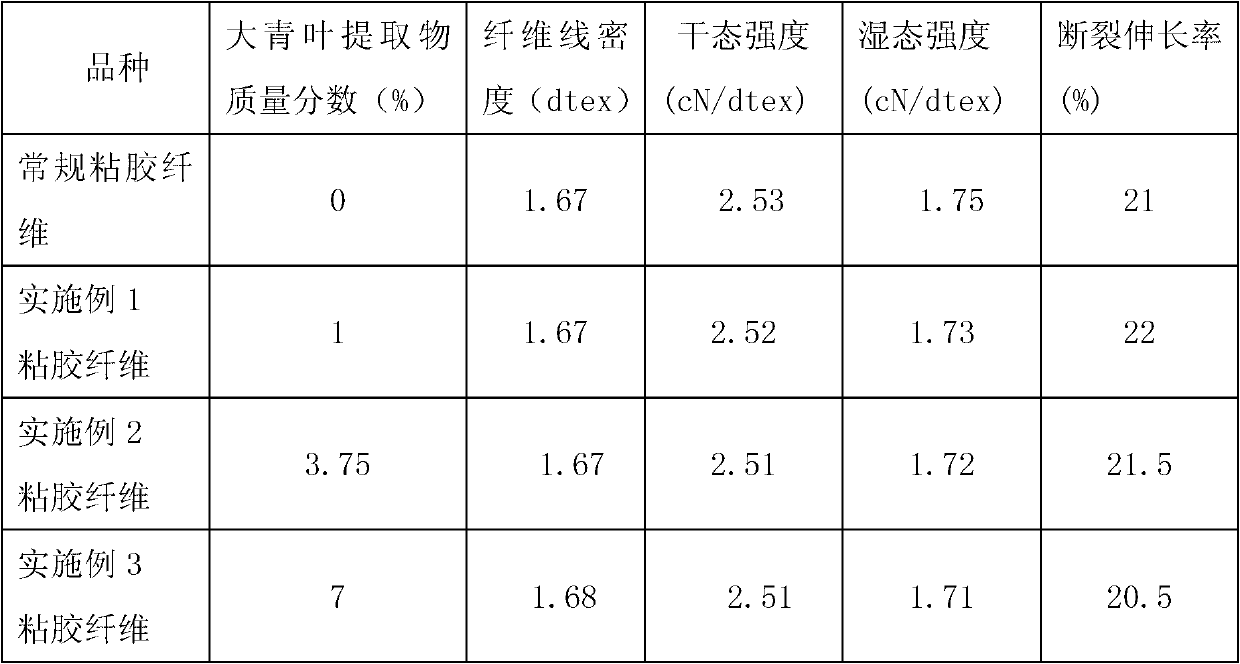

Viscose containing natural antimicrobials and preparation method thereof

InactiveCN102926013AImprove antibacterial functionNo side effectsArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentViscose fiberStock solution

The invention provides viscose containing natural antimicrobials. The viscose containing the natural antimicrobials comprises the viscose and the antimicrobials contained in the viscose. The viscose containing the natural antimicrobials is characterized in that the antimicrobials is natural indigowoad leaf extract powder, a natural indigowoad leaf extract powder solution added with dispersing agent is added into a viscose filature stock solution, the additive amount of the natural indigowoad leaf extract powder is 1%-7% of the quality of the viscose filature stock solution, the additive amount of the dispersing agent in the natural indigowoad leaf extract powder solution is 0.1%-1.0% of the quality of water in the natural indigowoad leaf extract powder solution. The preparation method of the viscose comprises the steps of dissolving the indigowoad leaf extract powder into water and adding the dispersing agent to obtain the indigowoad leaf extract powder solution, adding the indigowoad leaf extract powder solution to the viscose filature stock solution according to a ratio of 10%-14% of the quality of the viscose filature stock solution, and then shaping a obtained solution according to conventional wet spinning jet process to obtain the viscose. The viscose has a durable antibacterial function and has no side effect on human bodies. The preparation method has reasonable and simple technology, and is suitable for industrialized production.

Owner:单修铎

Ink-jet printing system for improved print quality

InactiveUS6247808B1Improve print qualityReduce bleedingMeasurement apparatus componentsDuplicating/marking methodsInkjet printingColoring agents

An ink-jet printing system is disclosed comprising a set of ink-jet inks comprising a first anionic ink comprising an aqueous vehicle, at least one first colorant, and at least one first anionic polymer; a second anionic ink comprising an aqueous vehicle; at least one second colorant, at least one second anionic polymer, and an acid additive having a pKa up to the pKa of the at least first polymer of the first ink; a third cationic ink comprising an aqueous vehicle, at least one third colorant, at least one third cationic polymer, and a pH in the range from about 2 to about 5; and a fourth anionic ink comprising an aqueous vehicle, at least one fourth anionic dye, and a precipitating agent. The printing system provides improved print quality, specifically, reduced bleed; improved edge-acuity, uniform area fills, and color quality; while maximizing lightfastness without sacrificing printing reliability.

Owner:HEWLETT PACKARD DEV CO LP

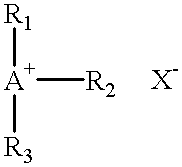

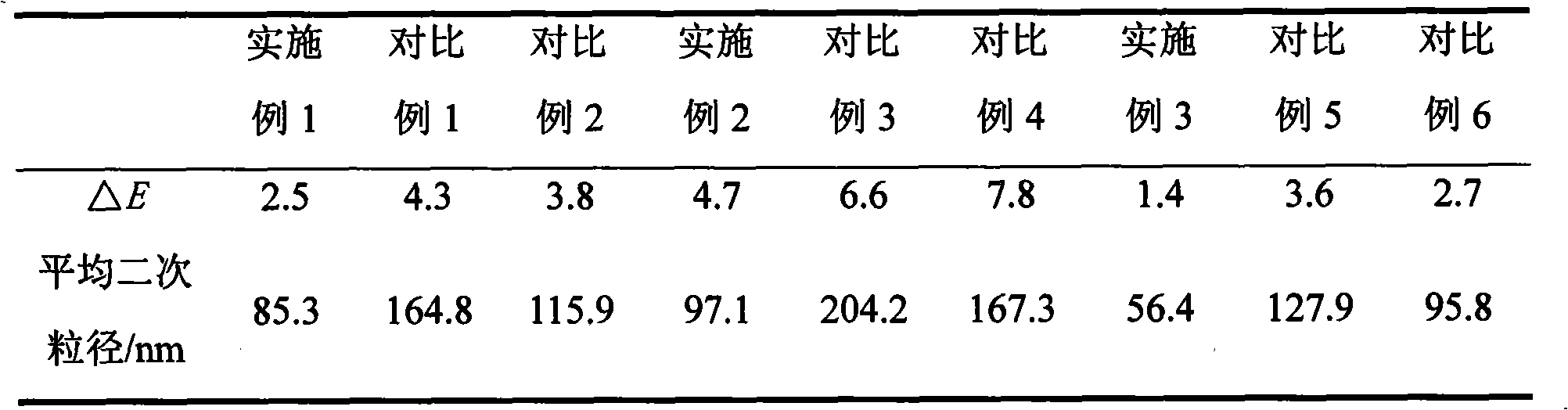

Nano titanium oxide inorganic surface treatment method

ActiveCN101255288AAvoid flocculationReduce clumpingInorganic pigment treatmentNanometreTitanium dioxide

The invention discloses a nm titanium dioxide inorganic surface treating method. The inorganic surface treating is performed when the nm titanium dioxide is in good dispersed state and the inorganic surface treatment effect is increased using the said method. The invention solves the flocculation and dispersion problem of nm titanium dioxide using ultrasonic field, mechanical agitation and film separation and phase integrating. During the process of treating the inorganic surface, on the one hand the nm titanium dioxide dispersion liquid is always under the action of mechanical agitation and ultrasonic, on the other hand, the impurity ions are continuously removed using membrane separation device, so as to make sure the inorganic surface coating reaction under the full dispersed state of the nm titanium dioxide.

Owner:江苏河海纳米科技股份有限公司 +1

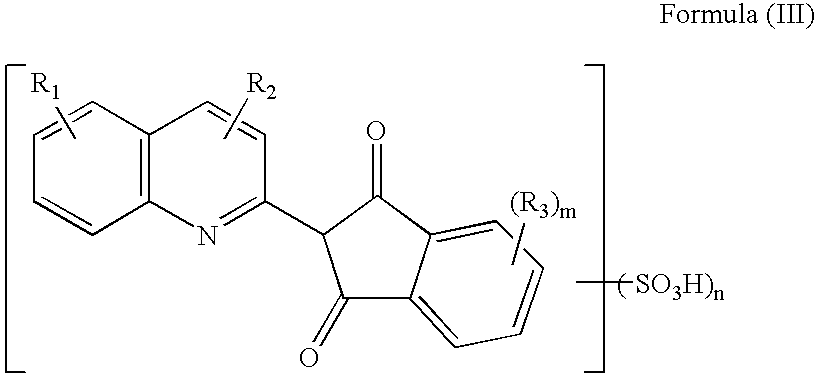

Pigment dispersants and their use

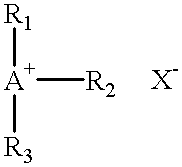

ActiveUS20060185558A1Prevent flocculationExcellent spectral curve characteristicOrganic chemistryProjectorsAmmoniumSulfonic acid

A pigment dispersant contains the following component (a) alone or the following components (a) and (b) in combination: Component (a): a composite pigment formed of a diketopyrrolopyrrole pigment having a sulfonic group and another diketopyrrolopyrrole pigment having no sulfonic group, wherein the number of sulfonic group per molecule of the diketopyrrolopyrrole pigments in the composite pigment is from 0.05 to 0.5; and Component (b): a pigment other than the component (a), wherein the pigment has a sulfonic group or its metal salt, ammonium salt or amine salt. Also disclosed are a colored composition for color filters, a process for the fabrication of a color filter, the color filter fabricated by the process, an image display device including the color filter, and an information communication equipment including the image display device. These colored composition, process, color filter, image display device and information communication equipment all make either direct or indirect use of the pigment dispersant.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

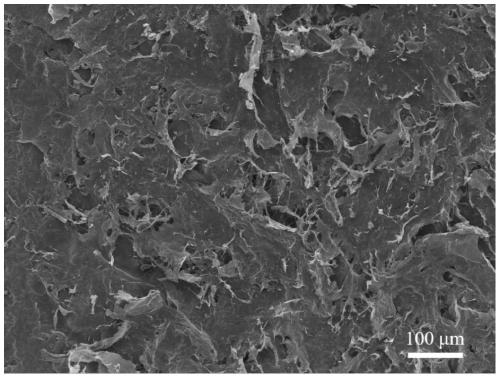

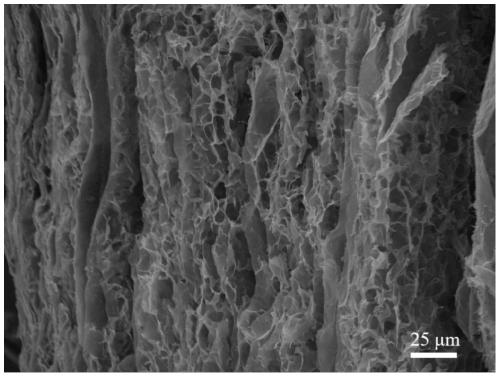

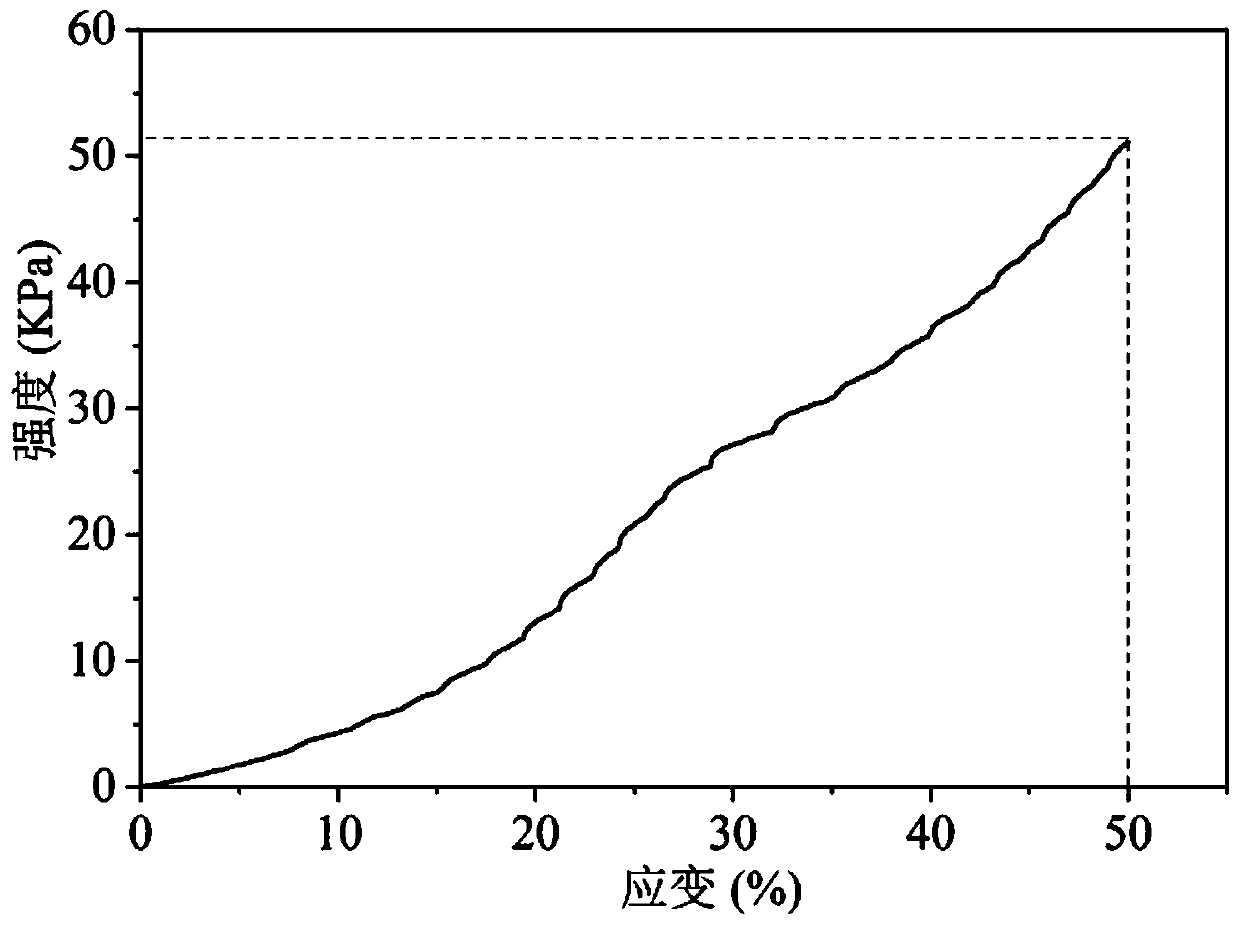

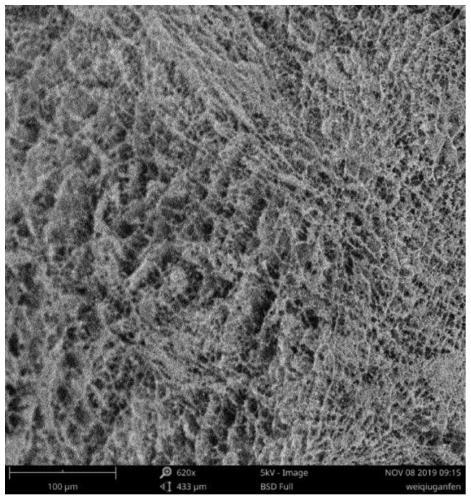

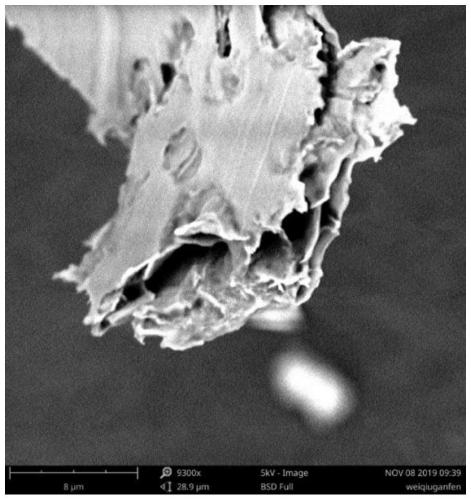

Aramid nanofiber/MXene composite conductive aerogel and preparation method thereof

ActiveCN111040238ALarge aspect ratioImprove temperature resistanceForce measurementElectrically conductiveFibrous composites

The invention discloses aramid nanofiber / MXene composite conductive aerogel and a preparation method thereof. By using aramid nanofibers with a nano-scale structure, high strength, a large length-diameter ratio and high temperature resistance as a matrix and using MXene with excellent conductivity, good chemical stability and a unique two-dimensional nano-film structure as a conductive and fillingcoating material, the aramid nanofiber / MXene composite conductive aerogel with low density, high strength and high compression resilience is prepared. The preparation method specifically comprises the following steps: preparing an aramid nanofiber dispersion liquid, preparing an MXene dispersion liquid, preparing an aramid nanofiber / MXene composite dispersion liquid, preparing a gelatinous aramidnanofiber / MXene composite material and the like, thereby obtaining the aramid nanofiber / MXene composite conductive aerogel. The preparation process is simple and easy to implement, and the obtained aramid nanofiber / MXene composite conductive aerogel has wide application prospects in the fields of pressure sensing, intelligent sensors, wearable equipment and the like.

Owner:SHAANXI UNIV OF SCI & TECH

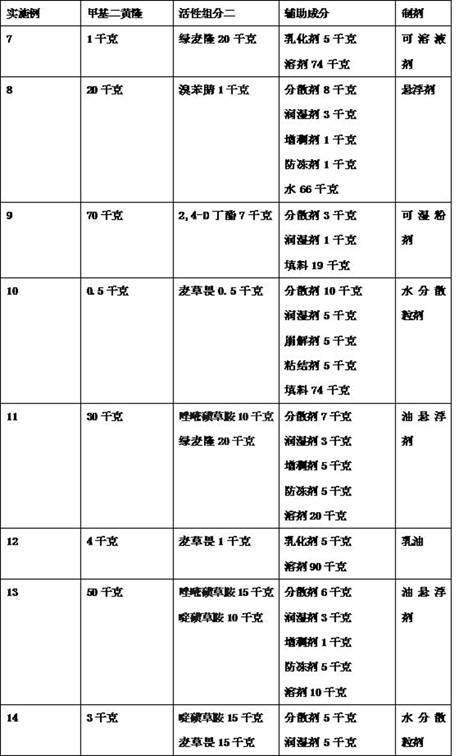

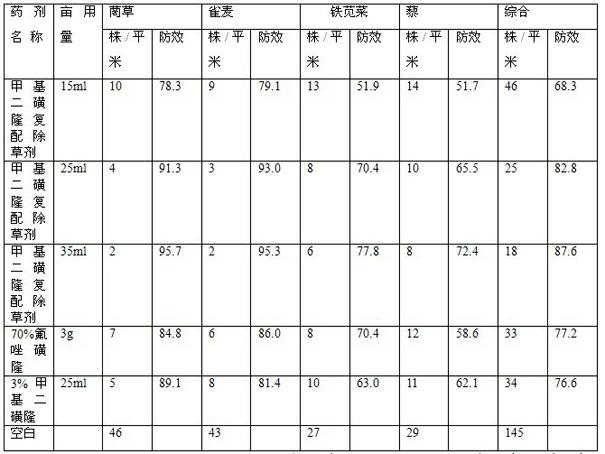

Mesosulfuron-methyl compound herbicide

InactiveCN102550585APrevent flocculationAvoid layeringBiocideAnimal repellantsAdjuvantAdditive ingredient

The invention discloses a mesosulfuron-methyl compound herbicide which consists of mesosulfuron-methyl as active ingredient I, active ingredient II and auxiliary ingredients; the active ingredient II is the combination of one or more of flucarbazone-Na, isoproturon, chlortoluron, pyroxsulam, 2-methyl-4-chlorophenoxy acetic acid, 2,4-D butyl ester, dicamba, bromoxynil, amidosulfuron, bensulfuron-methyl, flumetsulam, fluoroglycofen-ethyl and florasulam; the auxiliary ingredients consists of adjuvant and one of filler and solvent, and the adjuvant is the combination of one or more of emulsifying agent, dispersing agent, wetting agent, disintegrant, binding agent, antifreezing agent and thickening agent; the sum of the weight of the mesosulfuron-methyl as the active ingredient I and the weight of the active ingredient II is 1 to 85 percent of the total weight of the mesosulfuron-methyl compound herbicide; and the weight ratio of the active ingredient I to the active ingredient II is 1:20 to 20:1. The mesosulfuron-methyl mixed herbicide is novel herbicide for wheatlands.

Owner:河北博嘉农业有限公司

Method for forming a glittering coating film and glittering coated object

InactiveUS20060057363A1Less feelingUnprecedented variationLayered productsPretreated surfacesWeather resistanceVarnish

Disclosed is a method for forming a glittering coating film in which after a glittering base coating film is formed on a substrate to be coated by applying thereto a glittering base coating material containing a colloid particle liquid containing noble metal or copper colloid particles, said glittering base coating film is heated or set, and then a clear coating film is formed by executing any one of the following processes (A) to (F). By the method, a glittering coating film is provided which has weathering resistance and high gloss, and develops a metal feeling or a coloring metal feeling giving rise to a less feeling of metal particles than by the plating-tone coating film, and superior in design property. (A) a process of forming and heating a top clear coating film by applying a clear coating material thereto, and heating the formed top clear coating film; (B) a process of forming and heating a glittering clear coating film by applying thereto a glittering clear coating material containing a glittering material, which is different from said noble metal or copper colloid particles; (C) a process of forming and heating a glittering clear coating film by applying thereto a glittering clear coating material containing a glittering material, which is different from said noble metal or copper colloid particles, and then forming and heating a top clear coating film by applying a clear coating material thereto; (D) a process of forming and heating a matting clear coating film by applying thereto a matting clear coating material; (E) a process of forming and heating a top color clear coating film by applying thereto a color clear coating material; and (F) a process of forming and heating a glittering clear coating film by applying thereto a glittering clear coating material containing a glittering material, which is different from said noble metal or copper colloid particles, and then applying a color clear coating material to form a top color clear coating film, and heating the resultant.

Owner:NIPPON PAINT AUTOMOTIVE COATINGS

Method for forming a glittering coating film

InactiveUS7166330B2Less feelingUnprecedented variationLayered productsPretreated surfacesWeather resistanceMetal particle

A method for forming a glittering coating film in which after a glittering base coating film is formed on a substrate to be coated by applying thereto a glittering base coating material containing a colloid particle liquid containing noble metal or copper colloid particles, the glittering base coating film is heated or set, and then a clear coating film is formed. By the method, a glittering coating film is provided which has weathering resistance and high gloss, and develops a metal feeling or a coloring metal feeling giving rise to a less feeling of metal particles than by the plating-tone coating film, and superior in design property.

Owner:NIPPON PAINT AUTOMOTIVE COATINGS

Enzymatically hydrolyzed cereal beverage and method for preparing same

The invention relates to a comprehensive development and utilization technology of cereals, especially oats and particularly relates to a whole-oat dietary beverage and a method for preparing the whole-oat dietary beverage by virtue of an enzyme preparation. The whole-oat dietary beverage is a beverage prepared by mixing oat grains or oat powder with water to obtain oat pulp and hydrolyzing the oat pulp through amylase and protease. The process of hydrolyzing the oat pulp through the amylase and the protease is finished in one step. The beverage is good in flavor and the production method of the beverage is easy to implement industrially.

Owner:DSM IP ASSETS BV

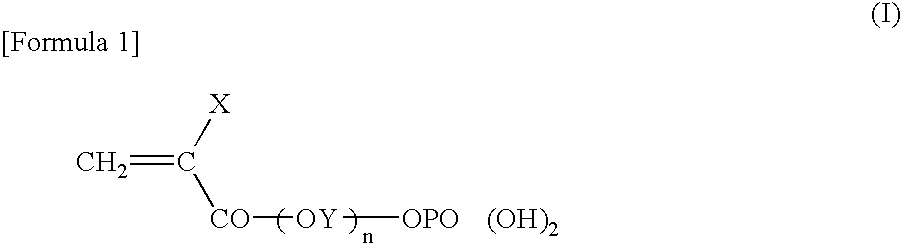

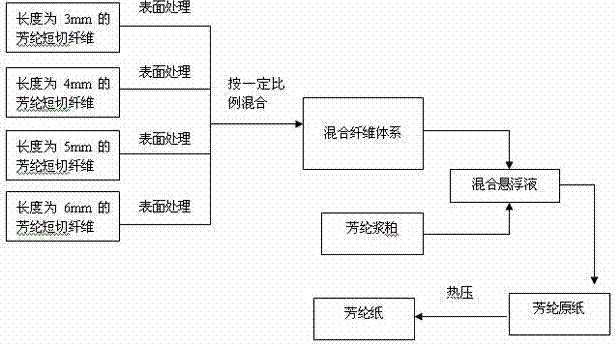

Preparation method of mixed fiber system aramid paper

ActiveCN103485234AReduce the ratioPrevent flocculationSynthetic cellulose/non-cellulose material pulp/paperPolymer scienceAramid

The invention discloses a preparation method of mixed fiber system aramid paper. The mixed fiber system aramid paper comprises the following components in parts by mass: (1) 30-50 parts of aramid chopped fiber with different average lengths, which is compounded by the aramid chopped fiber with the lengths of 3mm, 4mm, 5mm and 6mm; and (2) 50-70 parts of aramid pulp. The preparation method of the aramid paper comprises the following steps: (1) performing surface treatment on the aramid chopped fiber with the different lengths; (2) mixing the aramid chopped fiber with the different lengths according to different proportions to obtain a mixed aramid chopped fiber system; (3) mixing the aramid chopped fiber system with the aramid pulp; (4) preparing wet-formed aramid raw paper; and (5) performing hot-pressing on the aramid raw paper. The preparation method disclosed by the invention can solve the problems of fiber flocculation, poor evenness of the formed paper and poor paper strength in an existing aramid preparation process.

Owner:SHAANXI UNIV OF SCI & TECH

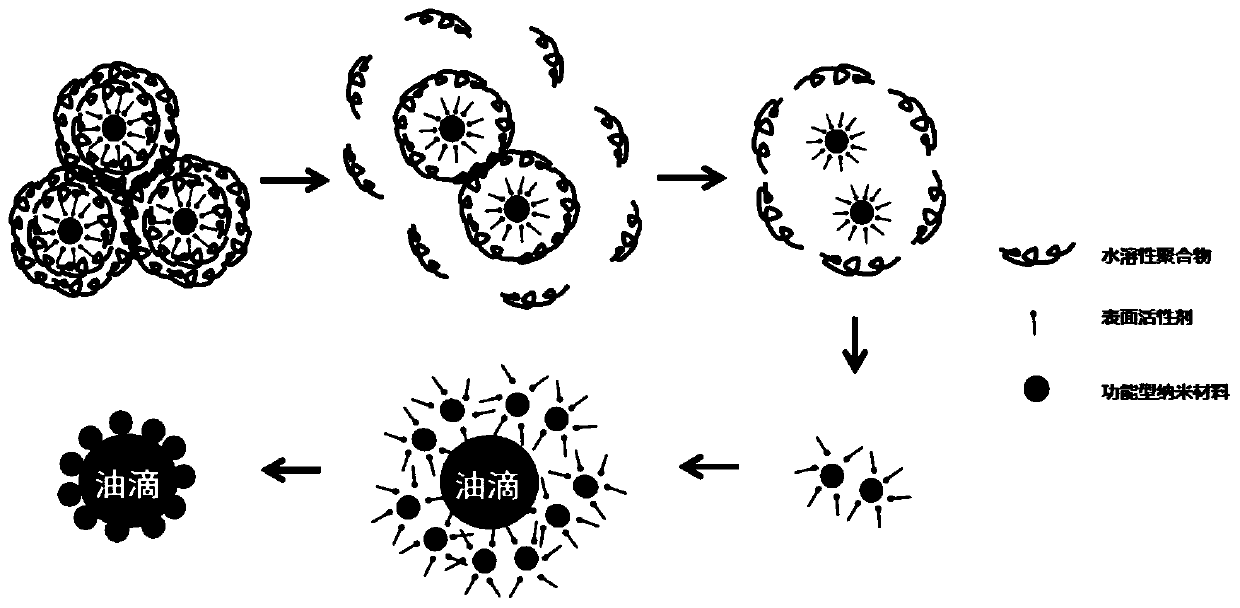

Nano oil displacement agent and preparation method and application thereof

InactiveCN111423866AGuaranteed no flocculationPrevent flocculationFluid removalDrilling compositionActive agentSoluble polymer

The invention discloses a nano oil displacement agent and a preparation method and application thereof. The nano oil displacement agent is characterized by comprising a nanometer material, a surfactant, a water-soluble polymer and water, and the water-soluble polymer is coated at the periphery of the nano material. The nano oil displacement agent is a temperature-resistant and salt-resistant oil-displacing agent, and ensures that a functional nano dispersion liquid does not flocculate or precipitate within a certain temperature and salinity range, the water-soluble polymer can be slowly decomposed under the conditions of high temperature and high salt, and meanwhile, the nano material is released, so that the functional nano material plays a role.

Owner:NINGBO FENGCHENG NANOTECHNOLOGY CO LTD

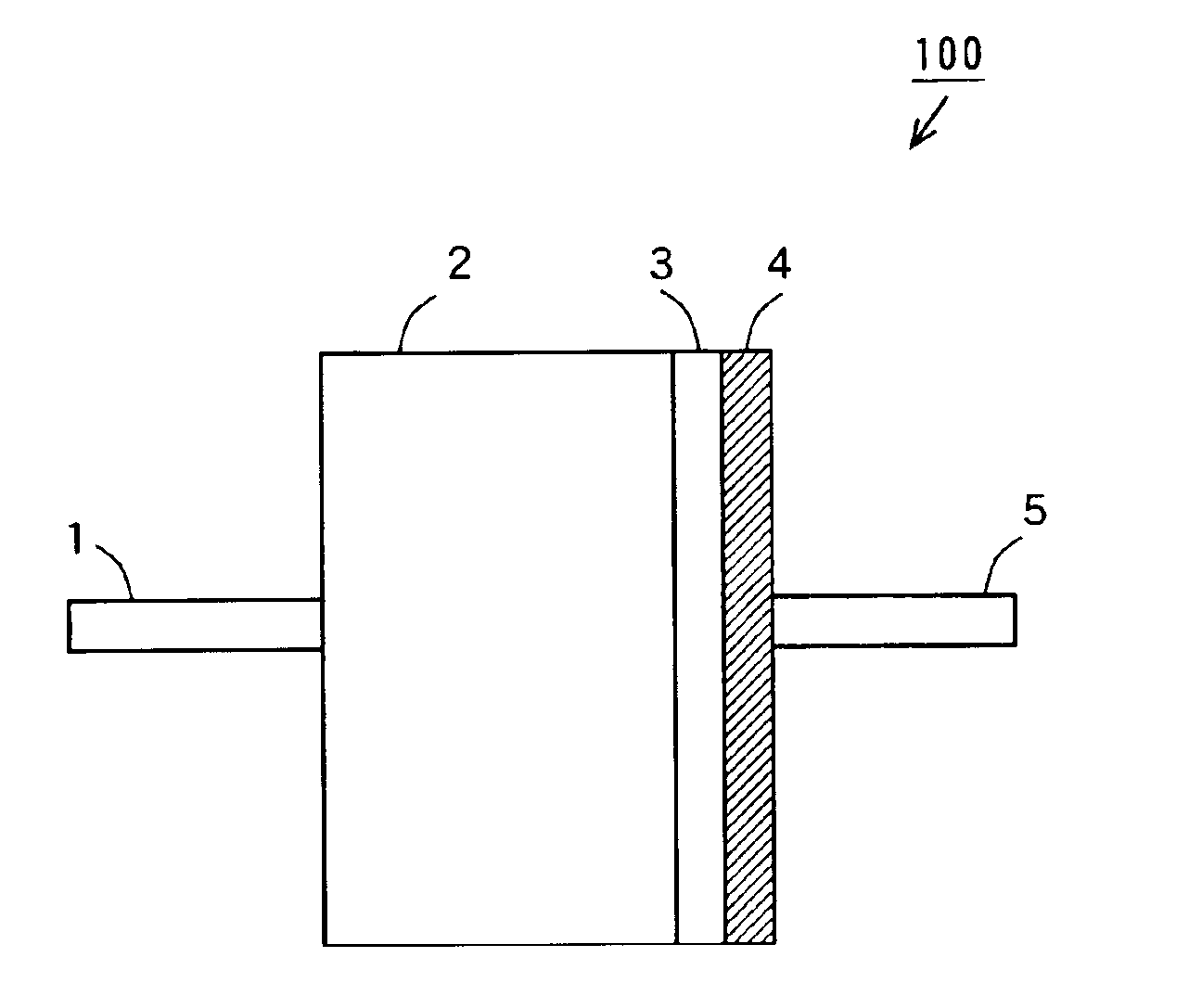

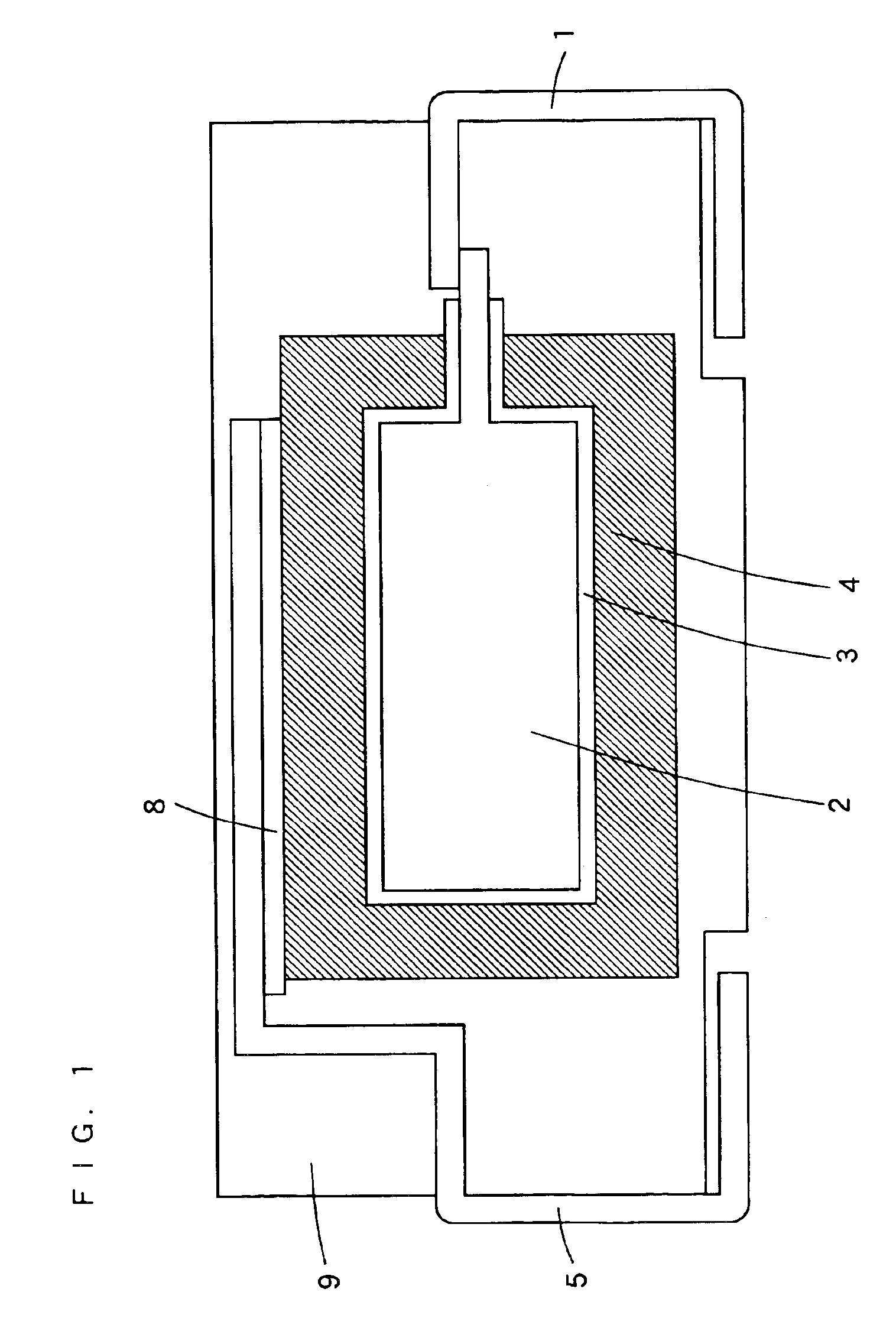

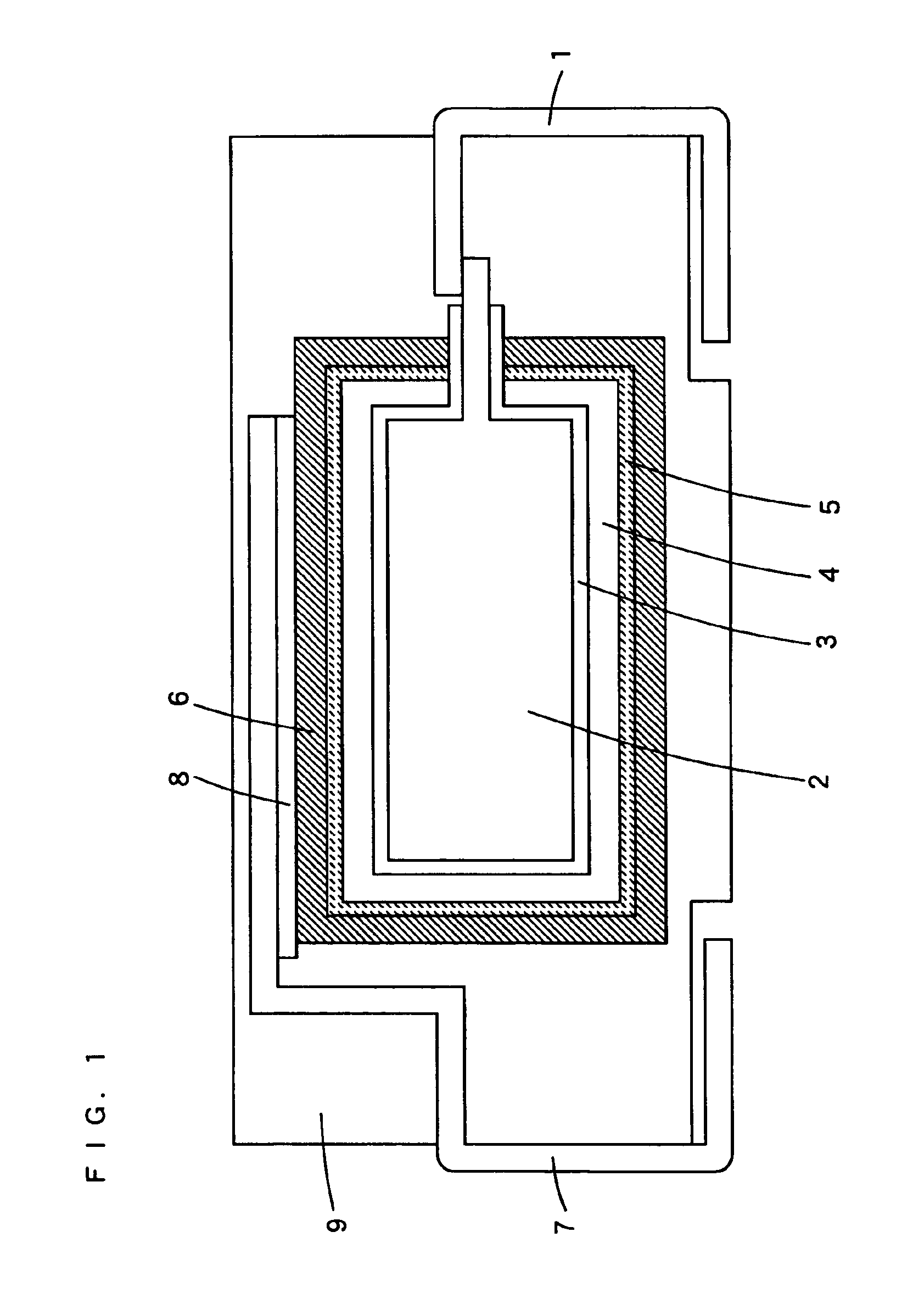

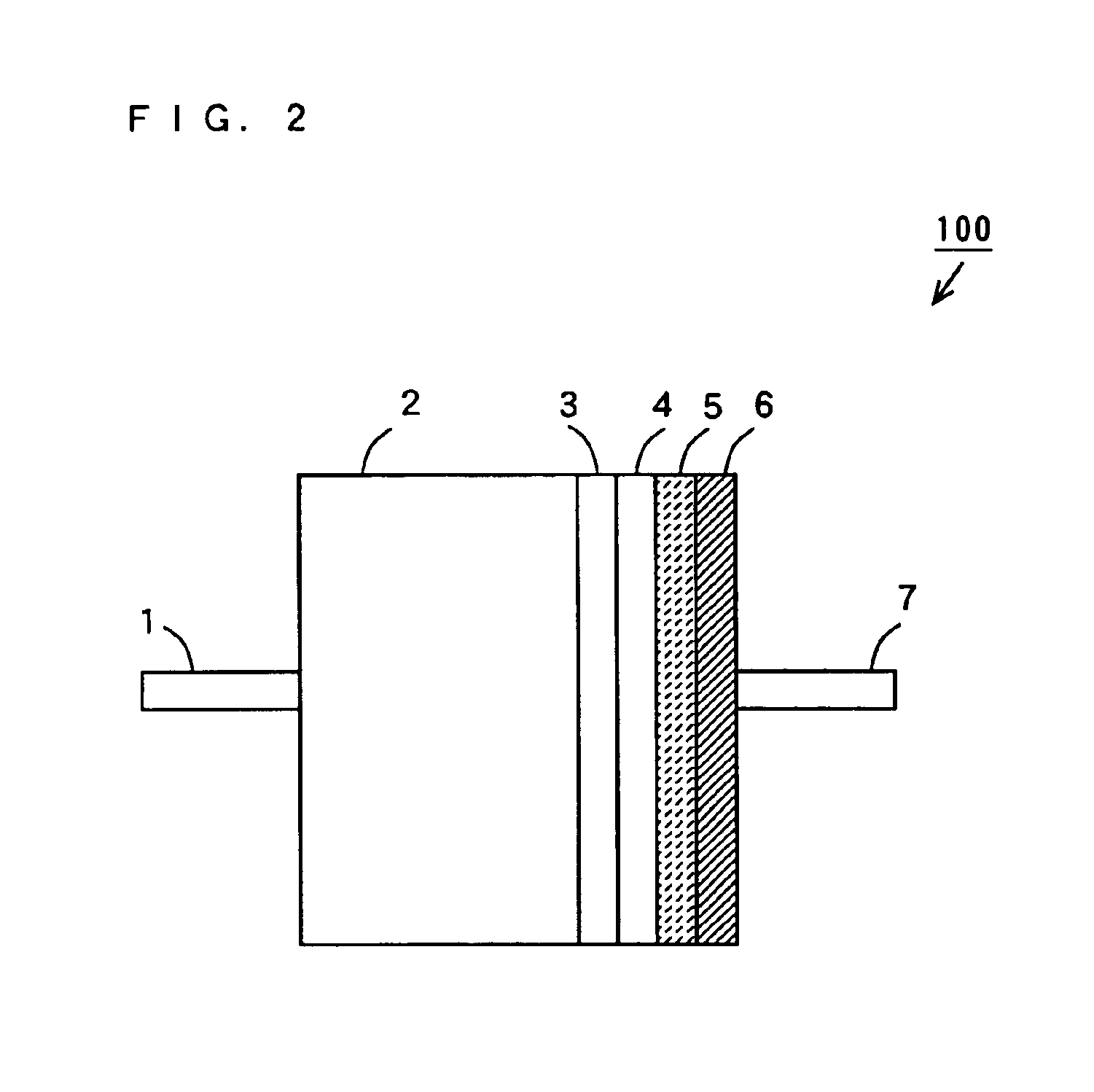

Solid electrolytic capacitor and manufacturing method thereof

InactiveUS6965508B2Prevent flocculationEquivalent serial resistance is reducedSolid electrolytic capacitorsClosuresElectrolysisAdhesive

A solid electrolytic capacitor has a structure in which a dielectric layer and a metal layer are formed in this order on the surface of an anode. The anode is composed of a porous sinter of tantalum particles. The dielectric layer is composed of a dielectric oxide film formed by anodizing the surface of the anode in an aqueous solution consisting of phosphoric acid, for example. The metal layer is formed by preparing a silver paste by mixing silver particles having an average particle diameter of not larger than 0.05 μm, a protective colloid, and an organic solvent, and applying the silver paste on the surface of the dielectric layer, and drying the silver paste at a temperature of 150° C. or higher. Further, the anode is connected with an anode terminal, and the metal layer is connected with a cathode terminal through a conductive adhesive.

Owner:SANYO ELECTRIC CO LTD

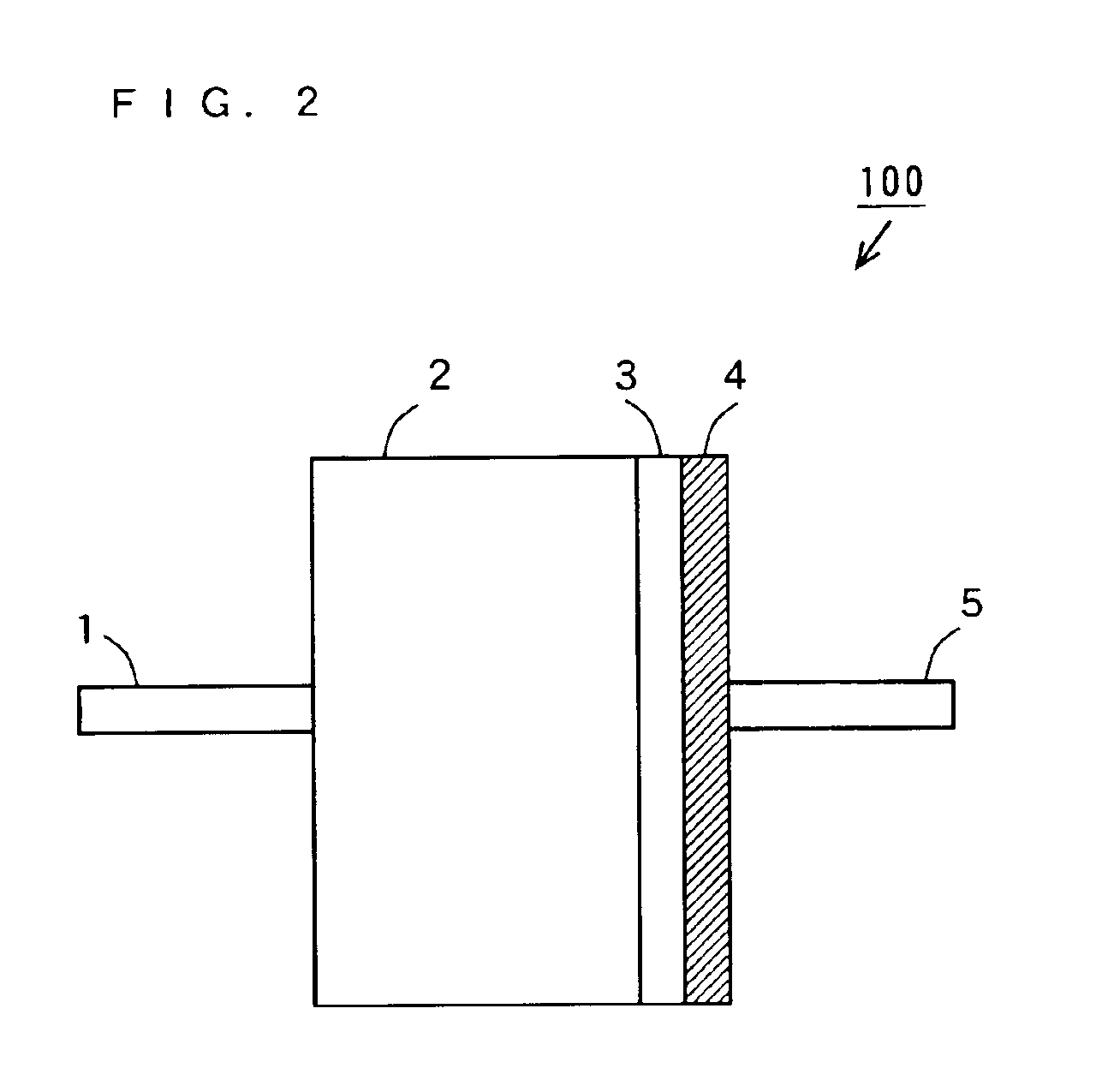

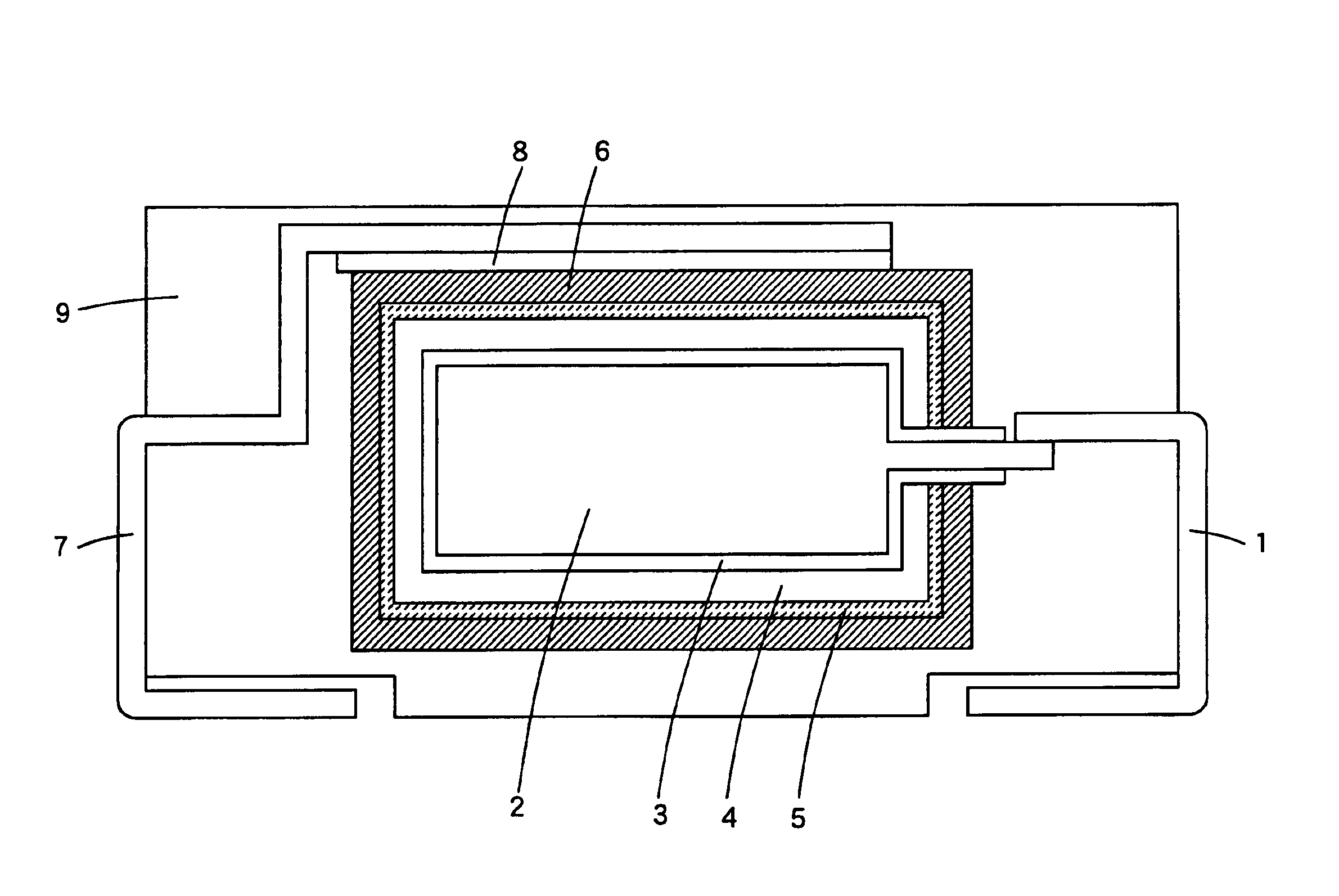

Solid electrolytic capacitor and manufacturing method thereof

ActiveUS6894890B2Improve conductivitySmall contact resistanceHybrid capacitor electrolytesSolid electrolytic capacitorsCarbon layerElectrolysis

A solid electrolytic capacitor has a structure in which a dielectric layer, an electrolyte, a carbon layer, and a metal layer are formed in this order on the surface of an anode. The anode is composed of a porous sinter of tantalum particles. The dielectric layer is composed of a dielectric oxide film formed by anodizing the surface of the anode in an aqueous solution of phosphoric acid, for example. The electrolyte is composed of a conductive polymer, such as polypyrrole or polythiophene. The metal layer is formed by preparing a silver paste by mixing silver particles having an average particle diameter of not larger than 0.05 μm, a protective colloid, and an organic solvent, and applying the silver paste on the surface of the carbon layer, and drying the silver paste at approximately 150° C. or higher.

Owner:SANYO ELECTRIC CO LTD

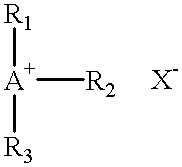

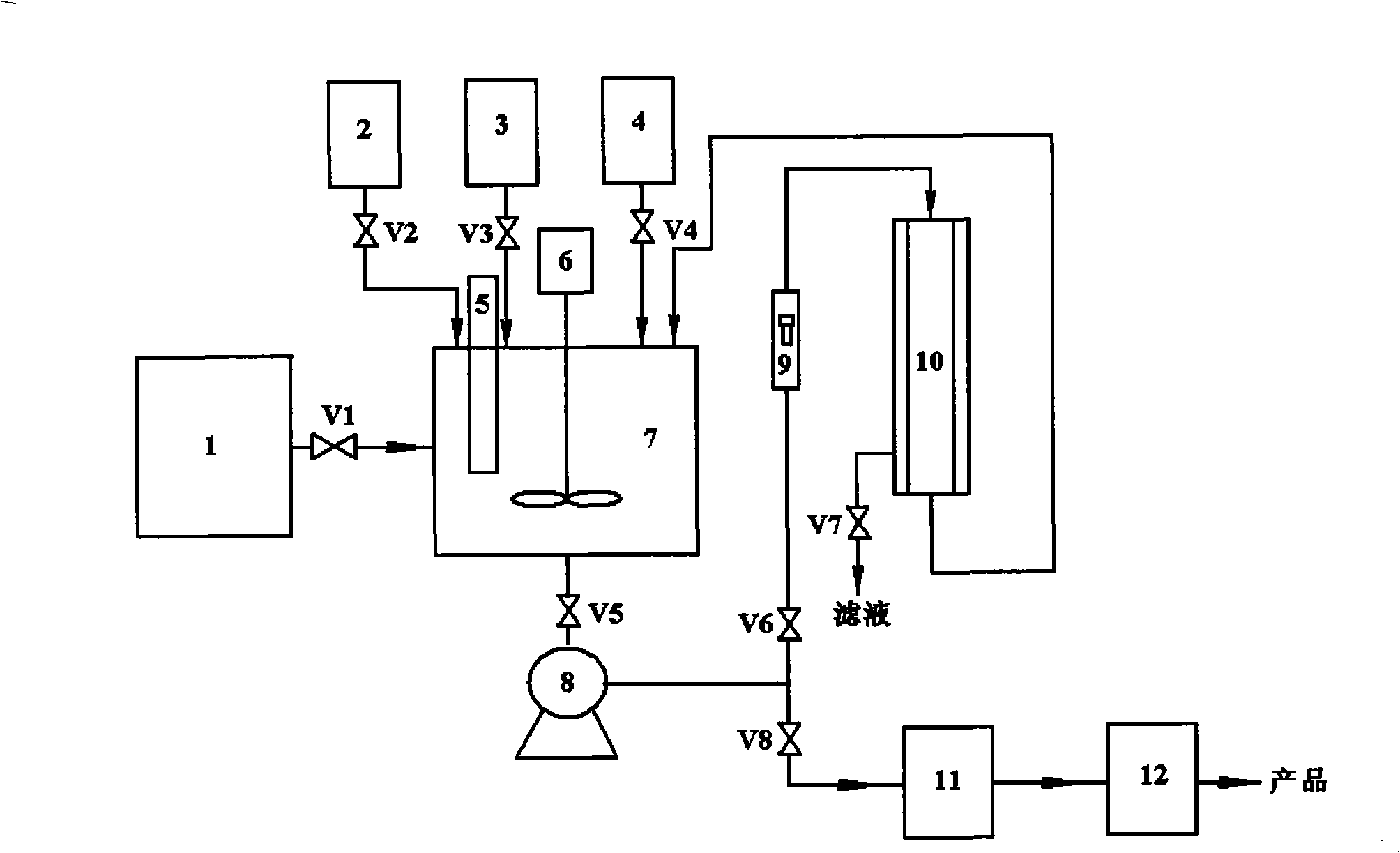

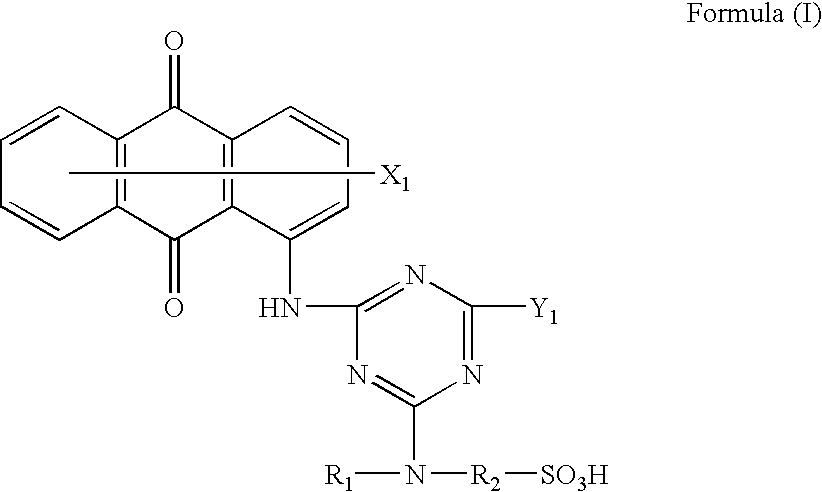

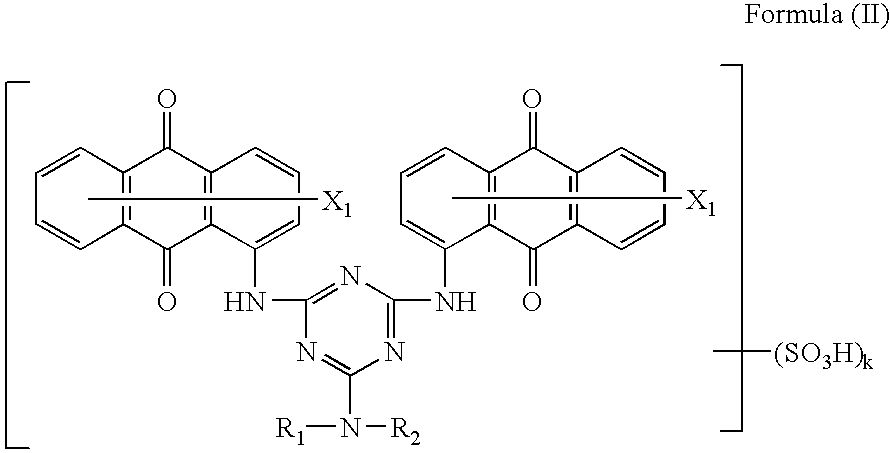

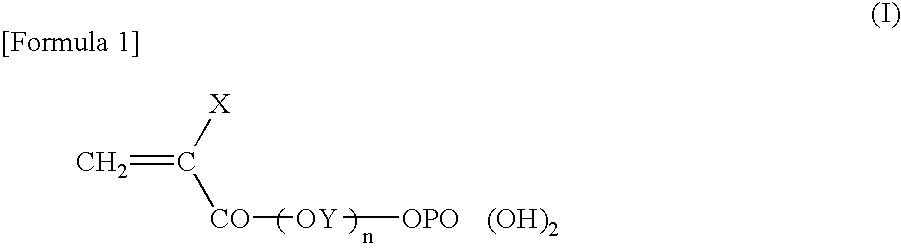

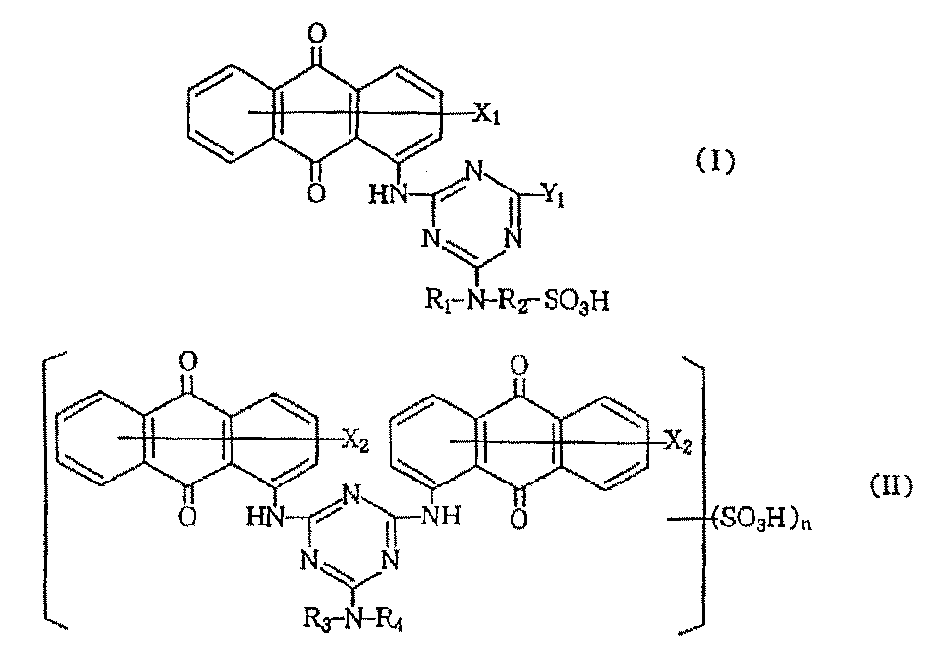

Pigment dispersing agent and pigment composition containing the same dispersing agent

InactiveCN1310205AImprove liquidityPrevent flocculationTransportation and packagingOrganic dyesHydrogen atomHydrogen

Pigment dispersants comprise compounds represented by the following formula (I) or (II) or metal, ammonium or amine salts thereof wherein X1 is a hydrogen or halogen atom or an alkyl or acylamino group, Y1 is an anthraquinonylamino, phenylamino, naphthylamino or phenoxy group, each of R1 and R3 is a hydrogen atom or a substituted or unsubstituted alkyl or phenyl group, R2 is a substituted or unsubstituted alkylene, phenylene or naphthylene group, X2 is a hydrogen or halogen atom or a substituted or unsubstituted alkyl group, R4 is a substituted or unsubstituted phenyl or naphthyl group, and n means an average number of sulfonic acid groups introduced in said compound and stands for a number of from 0.5 to 2. Pigment compositions, such as colorants for gravure inks, paints or color filters, comprise pigments and the pigment dispersants.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

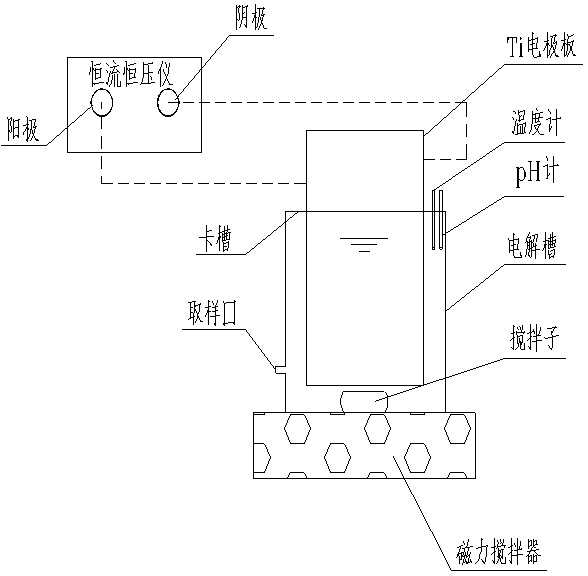

Method for removing harmful algae in water body by adopting electro-Fenton

InactiveCN101962216AStable in natureNo electrocoagulationWater/sewage treatment by oxidationFerric hydroxideElectrolysis

The invention belongs to the technical field of environmental protection and in particular relates to a method for removing harmful algae pollution in water body by adopting electro-Fenton. Hydrogen peroxide and ferrous ions in a reactor react to generate hydroxyl radicals, at the same time, the ferrous ions are regenerated from iron ions and iron hydroxide in the cathode region for electrolysis through reduction, thus continuously generating vast hydroxyl radicals, efficiently inactivating algae cells, simultaneously rapidly carrying out oxidation degradation on the microcystins and effectively avoiding secondary pollution. The body part of the reactor comprises a power source, electrodes, an electrolytic bath and a magnetic stirrer. After the algae liquid to be treated is introduced to the electrolytic bath, the magnetic stirrer at the bottom of the electrolytic bath is used for ensuring the algae liquid to be uniformly distributed in the whole reactor. Under the set process parameters, the method can realize rapid inactivation of the harmful algae and simultaneously realize efficient degradation of the microcystins.

Owner:FUDAN UNIV

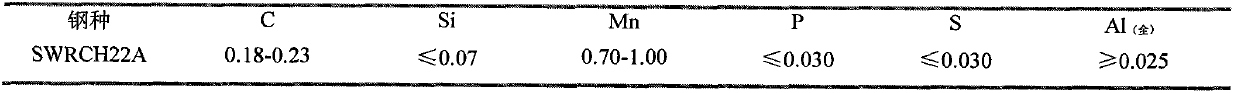

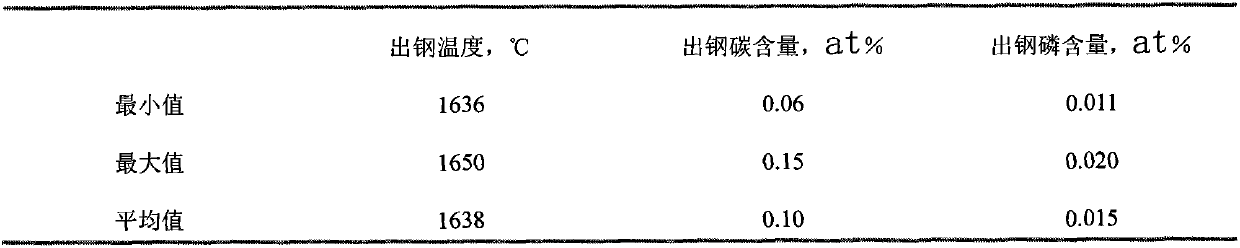

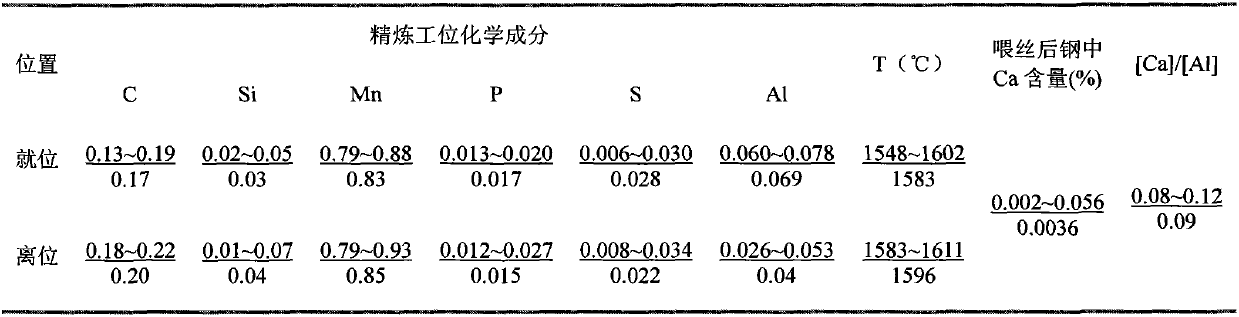

Low-silicon aluminum-containing steel and production method thereof

InactiveCN102747269AAvoid flocculationMeeting control targets for low silicon contentFlocculationHigh carbon

The invention relates to a production method of low-silicon aluminum-containing steel. The method is characterized in that: in converter terminal-point molten steel, the content of C is no lower than 0.05at%, the content of P is no lower than 0.020at%, and a tapping temperature is 1630-1670 DEG C. High-carbon ferromanganese and aluminum-manganese-titanium deoxidizing agents are added, and a refining target is that [Al]=0.060-0.080at%. In the LF refining furnace, component fine tuning is carried out, wherein addition amounts of medium-carbon ferromanganese and aluminum wires are determined according to alloy elements of the converter molten steel. Wire feeding treatment is carried out by using Ca-Fe wires, wherein a requirement on molten steel before calcium treatment is that [Al]=0.045-0.060at%. The Ca-Fe wires are vertically fed, wherein a feeding speed is no lower than 2.1m / s, and a [Ca] / [Al] mass ratio is 0.08-0.12. During continuous casting production, a superheat degree is controlled at 25-35 DEG C, and a casting speed is controlled within a range of 2.2-2.6m / min. When casting is started, 10 Ca-Fe wires are added in a middle-ladle T-port. When a large ladle begins casting, 3-5 Ca-Fe wires are added into the middle-ladle at the 1 and 6 flow stoppers. The method provided by the invention is advantaged in that: under a premise that a technical route is not changed, outlet flocculation blocking during continuous casting of the steel is avoided with a specific technology, and a control target of low silicon content is satisfied.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

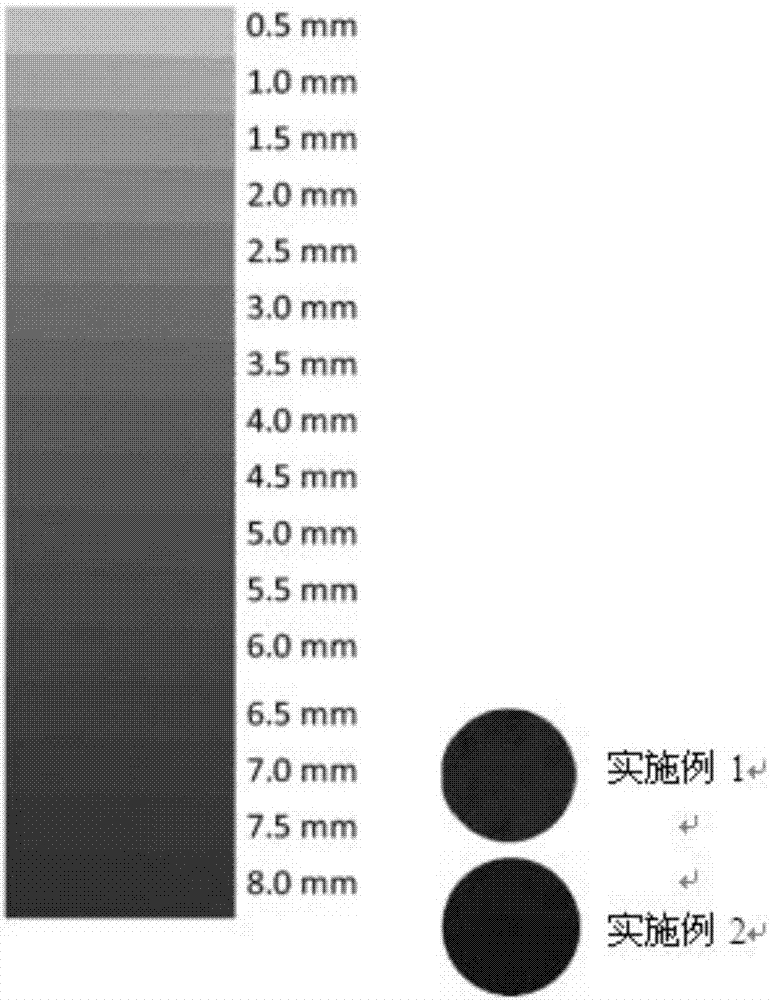

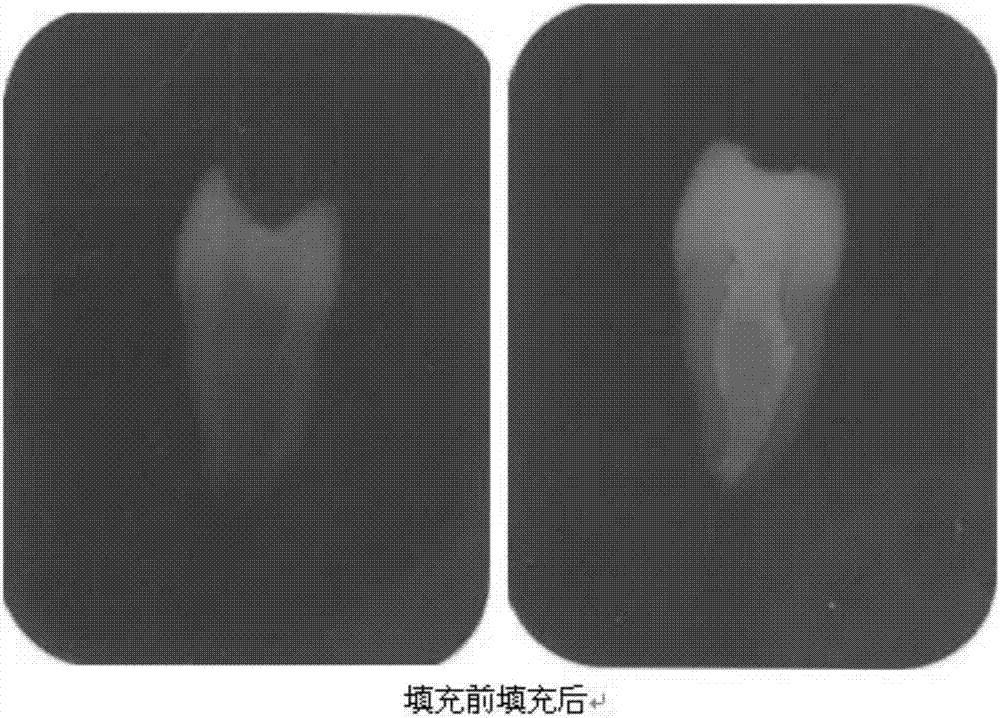

Premixed calcium silicate based root canal filling material with suspension stability as well as preparation method and application thereof

ActiveCN107080697APrevent precipitationPrevent flocculationImpression capsDentistry preparationsDispersion stabilityFlocculation

The invention provides a premixed calcium silicate based root canal filling material with suspension stability as well as a preparation method and an application thereof. At least one calcium silicate compound is used as a main phase, and at least a second phase for improving solidification performance, at least one nonaqueous phase solvent which can be mixed with water, at least one suspension stabilizing agent and at least one radiopaque material are added in order to prepare the root canal filling material with excellent injectable performance. An inorganic dispersant with suspension stabilizing effect is added into the premixed type calcium silicate based root canal filling material system, based on reservation of excellent biological compatibility, biological activity, marginal sealability, and the like of the calcium silicate material, layering, deposition or flocculation of the premixed system are effectively prevented, long-term dispersion stability of the premixed paste is improved, and the material can be used as a filling material for dental pulp capping, root canal therapy, and other dental restoration fields.

Owner:YANTAI ZHENGHAI BIO TECH

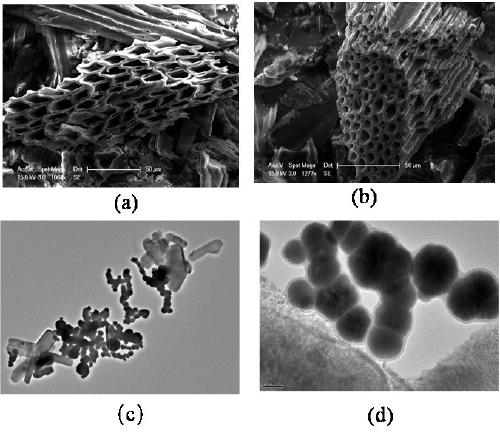

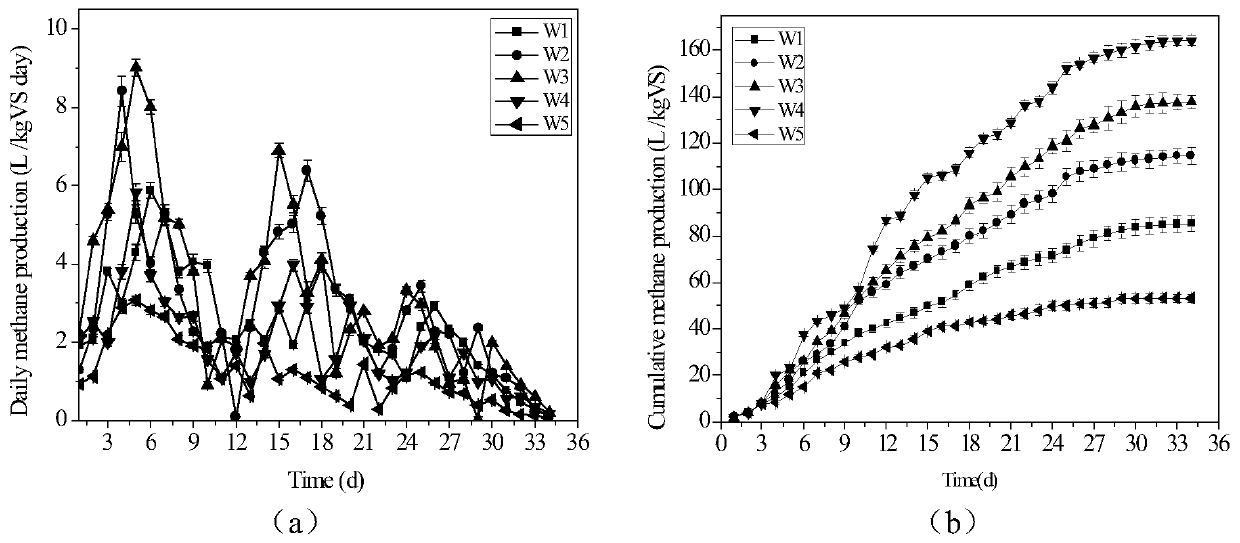

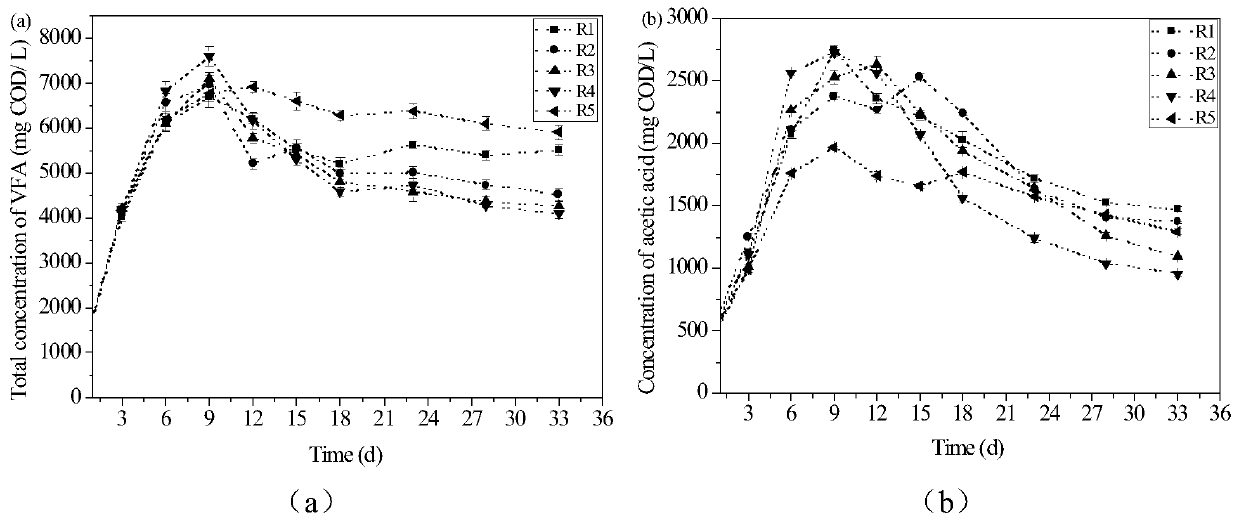

Method for simultaneously improving sludge anaerobic digestion efficiency and reducing ecotoxicity of heavy metals

ActiveCN110127972ALower pHIncrease productionWater contaminantsBiological sludge treatmentChemical reactionMicrowave

The invention relates to a method for simultaneously improving sludge anaerobic digestion efficiency and reducing the ecotoxicity of heavy metals. According to the method, after straws are activated with a ZnCl2 solution, straw biochar is prepared under a 550 DEG C high-temperature anaerobic condition, and further modification is performed by using an HCl solution and microwave; and by using modified biochar as carrier, a zero-valent nano-iron loaded modified biochar composite material HCl-FBC is prepared through a chemical reaction. According to the present invention, by adding the modified biochar composite HCl-FBC to the anaerobic digestion reactor at the initial stage of sludge anaerobic digestion, the organic matter conversion rate of sludge can be significantly increased, and the cumulative gas production of methane can be increased; HCl-FBC can easily increase the microbial diversity and the activity of the digested sludge and change the microbial community structure; and with the method, the sludge anaerobic digestion efficiency can be significant increased, the biogas production can be increased, the biological toxicity of the heavy metal in the digested sludge is effectively reduced, and the great significance is provided in the resource utilization of sludge and the reduction of the risk of sludge land use.

Owner:TONGJI UNIV

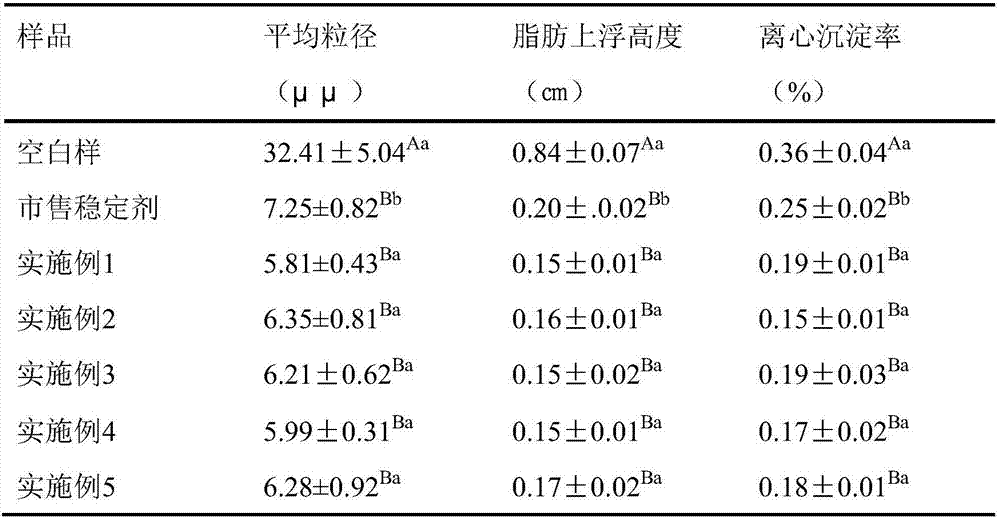

Stabilizer combination for dairy food and uses thereof

InactiveCN101253889APrevent flocculationDelicate and smooth tasteOther dairy technologyFood preparationFlocculationCarrageenan

The invention relates to a stabilizer composite and the application thereof, in particular to a stabilizer composite for dairy food and the application thereof, which belongs to the food technology field. The stabilizer composite comprises the following components by the weight proportion as follows: carrageenan 0.5-2, pectin 0.5-2, and carob bean gum 0.1-1. The stabilizer composite has the advantages that milk proteins can be stabilized efficiently, protein flocculation and precipitation can be prevented efficiently; the product containing up to more than 1% protein tastes soft and smooth and can be directly eaten with spoons or straws. Hot filling means or cold filling means at moderate temperature can be adopted when filling, and the product for sale can be stored at normal or cold temperature.

Owner:丹尼斯克(中国)有限公司

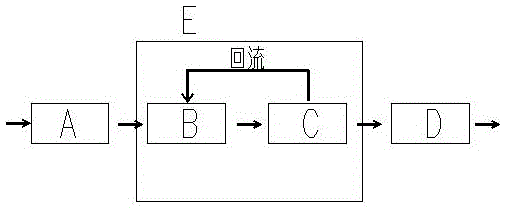

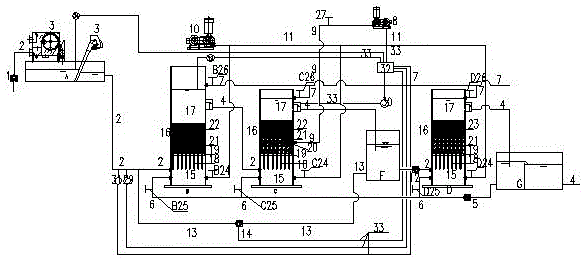

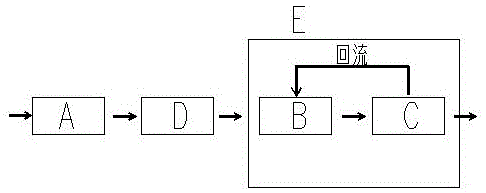

Process and device for sewage nitrogen and phosphorus removal integrating physical and biochemical filtration

The invention discloses a process and device for sewage nitrogen and phosphorus removal integrating physical and biochemical filtration. The device is formed by a physical filtering tank, a hypoxia denitrification biological filter / an aerobic nitrification biological filter denitrification system, a phosphorus removal adsorption filtration reaction system and a PLC control system. Sewage enters the physical filtering tank, outflow water of the physical filtering tank can first enter the hypoxia denitrification biological filter / the aerobic nitrification biological filter denitrification system to be denitrified, and outflow water enters the phosphorus removal adsorption filtration reaction system to be dephosphorized thoroughly; or outflow water first enters the phosphorus removal adsorption filtration reaction system to be dephosphorized and then enters the hypoxia denitrification biological filter / the aerobic nitrification biological filter denitrification system to be denitrified; sewage having been denitrification and dephosphorized enters a clear water area and finally flows into a disinfecting tank, and the sewage is disinfected and discharged. According to the process and device, a phosphorus removal chemical does not need to be added, phosphorus in the sewage can be removed, the process is short, the investment cost is reduced, the operation cost is low, and sludge is treated easily.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

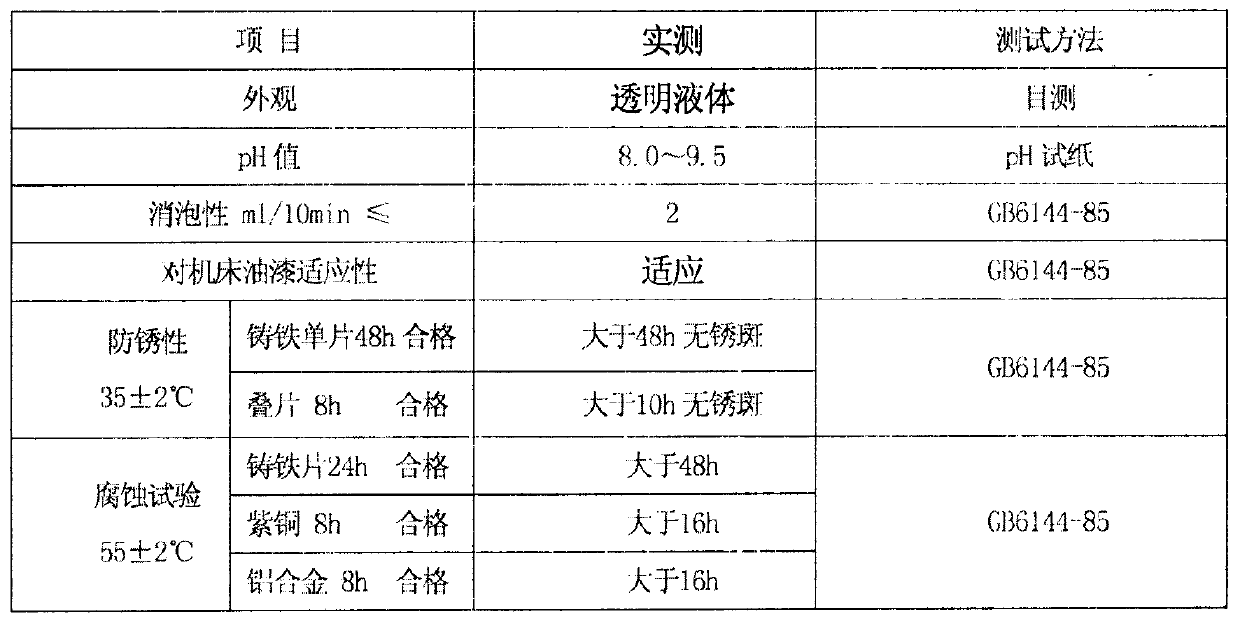

Water-based cutting fluid for metal processing and preparation method of water-based cutting fluid

The invention discloses water-based cutting fluid for metal processing and a preparation method of the water-based cutting fluid. The cutting fluid mainly consists of a lubricating agent, a metal antirust agent, an anti-wear reagent at extreme pressure, a nonionic surfactant, a dispersing agent, an antifoaming agent and water, and the cutting fluid comprises the following components in percentage by weight: 8-12 percent of oleic acid, 1.8-2.5 percent of triethanolamine, 0.3-0.6 percent of boric acid, 0.2-0.5 percent of benzotriazole, 5-8 percent of sodium carbonate, 10-12 percent of polyethylene glycol, 0.2-0.5 percent of dodecylphenol polyoxyethylene ether (OP-10), 0.7-1 percent of glycine betaine, 0.5-0.8 percent of glycerin polyoxypropylene ether and the balance of water. According to the water-based cutting fluid disclosed by the invention, the problems that the conventional water-based cutting fluid is poor in antirust and lubricating performances, low in recycling period and harmful to the human and environment are solved, and the aims of improving the lubricating effect and the antirust performance, realizing harmlessness to the environment and a human body and reducing the production cost of metal processing are achieved by virtue of synthesis of polybasic esters.

Owner:中钢集团郑州金属制品研究院股份有限公司

Emulsion stabilizer for coconut juice beverage and preparation method of emulsion stabilizer

ActiveCN107950853AIncrease viscosityThick tasteFood ingredient as emulsifierFood additiveFlocculation

The invention provides an emulsion stabilizer for a coconut juice beverage and a preparation method of the emulsion stabilizer, and relates to food additives. The emulsion stabilizer for a coconut juice beverage consists of the following components in percentage by mass of 10%-45% of glyceryl monostearate, 5%-25% of sucrose fatty acid esters, 1%-10% of agar, 1%-20% of xanthan gum, 10%-45% of sodium caseinate and 5%-15% of sodium tripolyphosphate. The preparation method comprises the following steps of mixing the glyceryl monostearate with the sucrose fatty acid esters, the agar, the xanthan gum, the sodium caseinate and the sodium tripolyphosphate so as to obtain the powdery emulsion stabilizer for the coconut juice beverage. The emulsion stabilizer is used for producing the coconut juicebeverage, products are free from precipitate, flocculation or floating oil within the quality guarantee period, and the quality and the mouth feel of the products are improved.

Owner:厦门唯康食品科技有限公司

Filtration method of nanometer molecular screen

InactiveCN1541765ALife expectancyPromote flocculationMolecular sieve catalystsLoose filtering material filtersMolecular sieveFlocculation

The filtering method for nano molecular sieve features that the method includes adding alkali medium, non-electrolyte and water into molecular sieve slurry. The added amount of the alkali medium is such that the mixture has pH not lower than 12; and the volume ratio among molecular sieve slurry, non-electrolyte and water is 1 to 1-5 to 0-2. The said method can inhibit flocculation of un-crystallized SiO2 effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

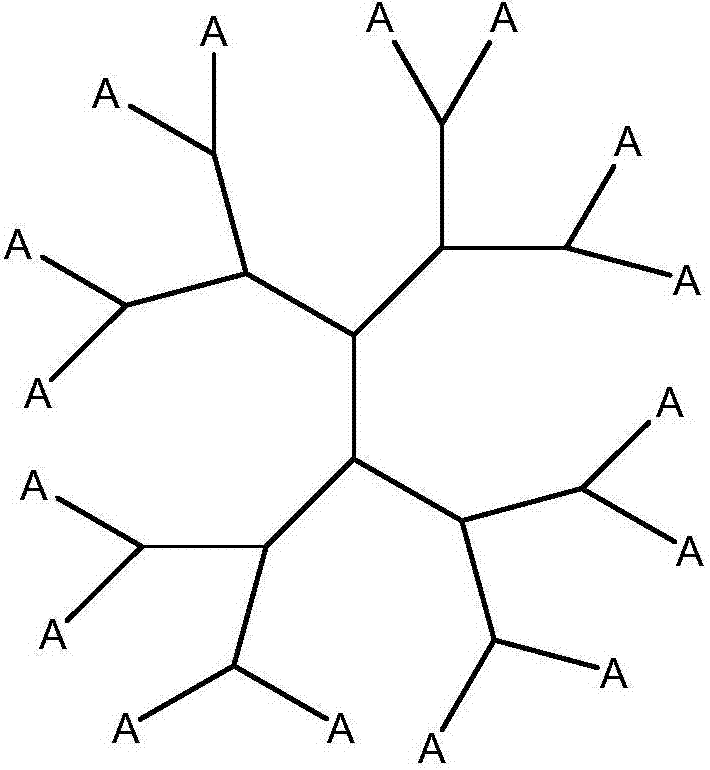

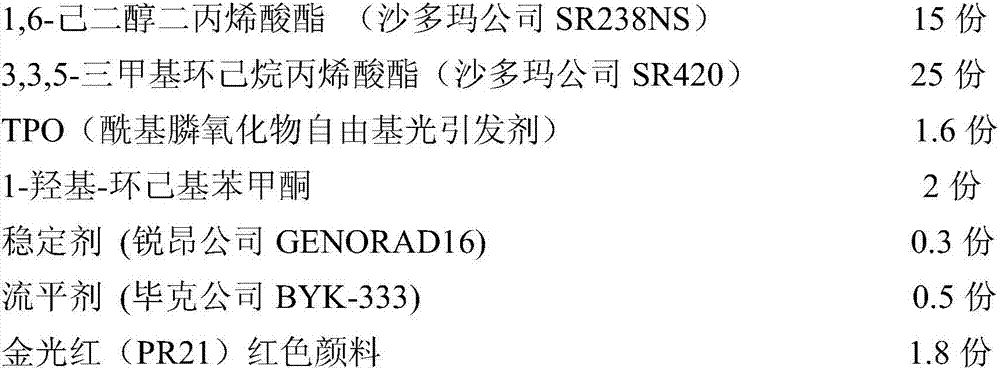

Ink composition for 3D ink-jet printing, ink kit and preparation method thereof

The invention provides an ink composition for 3D ink-jet printing, an ink kit and a preparation method thereof. The ink composition comprises the following components in parts by weight: 45-75 parts of an acrylic acid oligomer, 20-45 parts of an acrylic monomer, 1-9 parts of an ultraviolet photoinitiator, 0.2-10 parts of aids and 0-4 parts of a coloring agent, wherein the acrylic acid oligomer is selected from one or more of polyurethane acrylate, polyester acrylate and polyether acrylate. At the temperature of 25 DEG C, the viscosity of the ink composition is 25-70cps; at the temperature of 40-60 DEG C, the surface tension of the ink composition is 20-35dyn; and under at least one temperature of 40-60 DEG C, the viscosity of the ink composition is 9-14.5cps. The ink composition disclosed by the invention is simple in constitution, and the service life of a printing head can be prolonged. Moreover, the curing process is simple, emission of VOCs (Volatile Organic Compounds) is avoided, pollution is eliminated, and buckling deformation is avoided in the preparation.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

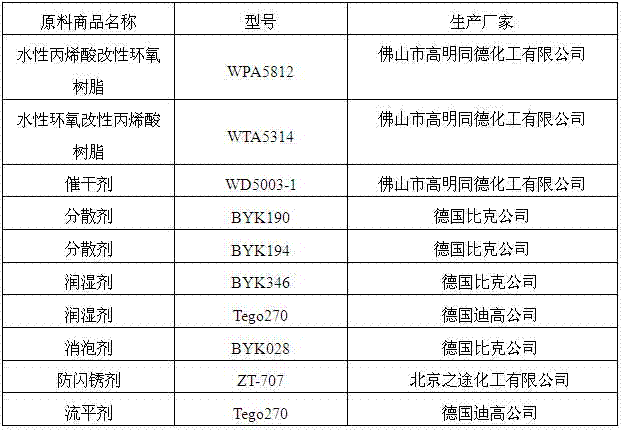

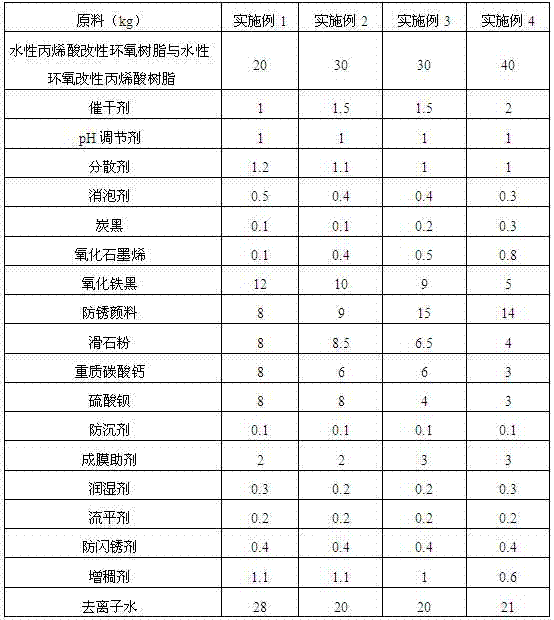

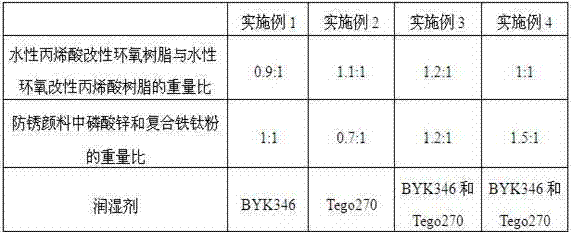

Dip-coating water-based paint for transmission shaft and preparation method thereof

InactiveCN106867368AWith cleanQuick-drying at room temperatureAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses dip-coating water-based paint for a transmission shaft and a preparation method thereof and relates to the technical field of metal water-based paint. The dip-coating water-based paint is prepared from the following raw materials in parts by weight: 20 to 40 parts of waterborne acrylic modified epoxy resin and epoxy modified acrylic resin, 0.3 to 3 parts of a drier, 0.4 to 1.5 parts of a pH (Potential of Hydrogen) regulator, 0.6 to 1.5 parts of a dispersant, 0.3 to 0.5 part of a de-foaming agent, 0.05 to 3 parts of carbon black, 0.01 to 1 part of graphene oxide, 4 to 12 parts of iron oxide black, 2 to 20 parts of antirust pigment, 3 to 8 parts of talcum powder, 0.5 to 8 parts of heavy calcium carbonate, 3 to 8 parts of barium sulfate, 0.05 to 0.15 part of an anti-sedimentation agent, 2 to 3 parts of a film forming auxiliary agent, 0.1 to 0.5 part of a wetting agent, 0.1 to 0.5 part of a leveling agent, 0.1 to 0.5 part of a flash-rust resisting agent, 0.1 to 1.2 parts of a thickener and 10 to 28 parts of water. The water-based paint has the advantages of easiness of improving a film thickness, high rigidity, good wear-resisting and corrosion-preventing effects, capability of being rapidly dried at room temperature and extremely low VOC (Volatile Organic Compounds) content.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com