Nano oil displacement agent and preparation method and application thereof

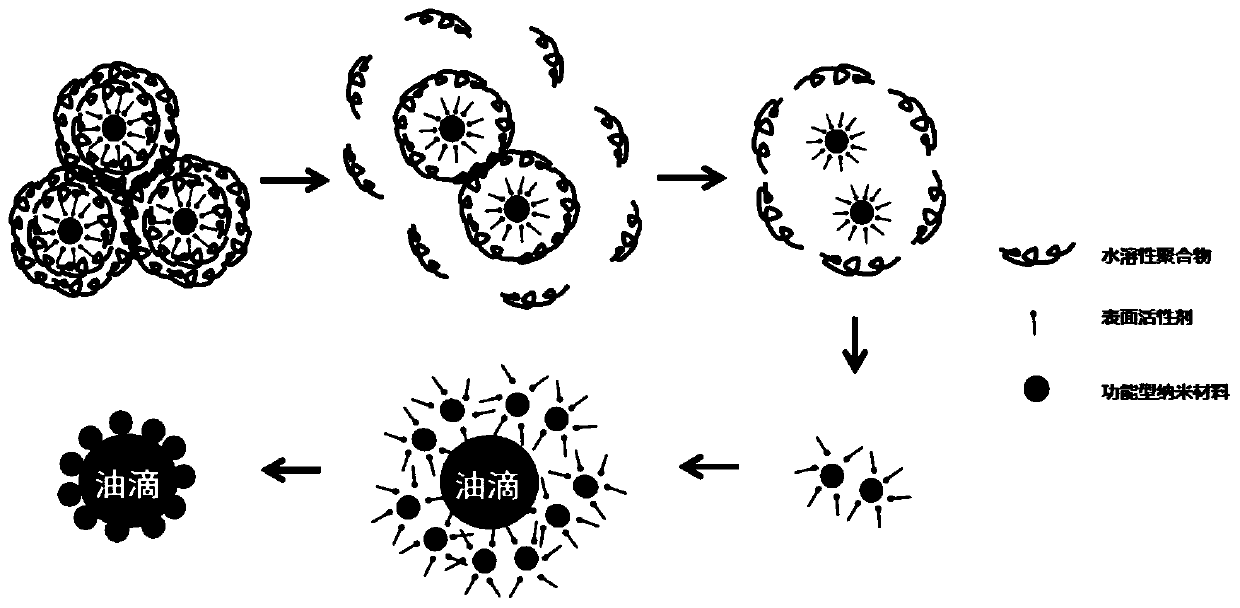

An oil-displacing method and oil-displacing agent technology, which are applied in chemical instruments and methods, earth-moving drilling, and fluid production, etc., can solve the problems of unknown effect, difficulty in stabilizing nano-materials, and large dosage, and achieve flocculation prevention, easy action, The effect of expanding the affected area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] Introduce the preparation method of the modified nanomaterial in this application below:

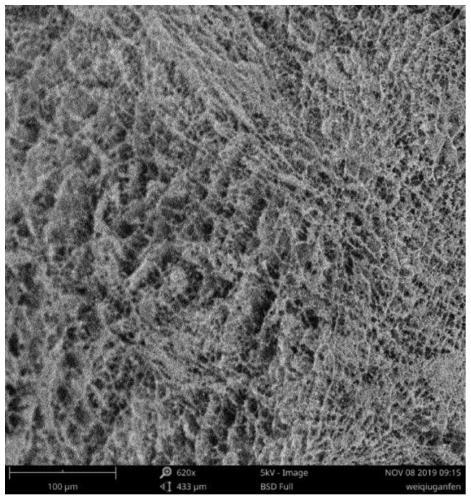

[0074] The preparation method of the modified graphene oxide nanosheet adopts the preparation method commonly used in the prior art, and a common preparation method is introduced below: See references: Luo D, Zhang F, Zheng H, et al.Electrostatic-attraction-induced high internal phase emulsion for large-scale synthesis of amphiphilic Janus nanosheets[J].Chemical Communications,2019.;

[0075] The preparation method of modified titanium dioxide adopts the commonly used preparation method in the prior art, and a common preparation method is introduced below: See references: Feng Xiaoyu, Hou Jirui, Cheng Tingting, et al. Preparation of oleic acid modified nano-TiO2 and its flooding Oil performance evaluation [J]. Oilfield Chemistry, 2019.

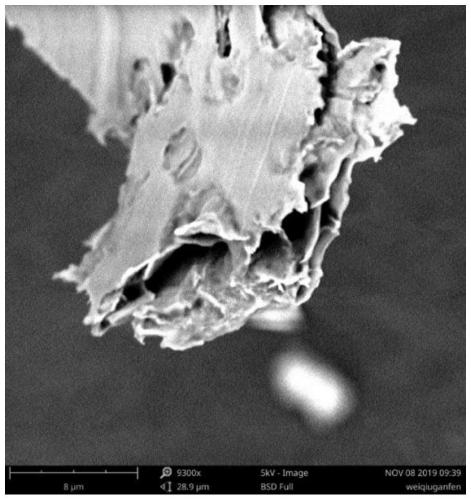

[0076] The preparation method of modified silicon dioxide, adopts the preparation method commonly used in the prior art, introduces a kind of co...

Embodiment 1

[0081] 1. Take the nanometer amphiphilic graphene oxide dispersion (converted to 1 part of dry powder mass), add 5 parts of anionic surfactant (specifically sodium lauryl sulfate), stir and mix for 30 minutes (rotating speed 100 rpm), and get mixture.

[0082] 2. Dissolve polyacrylamide (anionic, molecular weight: 16 million) in pure water to prepare a mother liquor with a concentration of 10,000 mg / L.

[0083] 3. Add 1000 parts by mass of the polymer mother liquor obtained in step 2 to 1 part by mass of the mixed solution in step 1, rotate at a speed of 500 rpm, and stir for 30 minutes to obtain a high-temperature salt-resistant nano-oil displacing agent, which is recorded as a sample 1#.

[0084] In sample 1#, the ratio of the mass fractions of the nanomaterial nano-amphiphilic graphene oxide, the anionic surfactant sodium dodecyl sulfate, and polyacrylamide is 1:5:10.

Embodiment 2

[0086] 1. Take the modified nano-silica dispersion (1 part converted into dry powder), add 10 parts of cationic surfactant (specifically hexadecyltrimethylammonium bromide), stir and mix for 20 minutes (300 rpm / min) to obtain a mixed solution.

[0087] 2. Dissolve hydroxyethyl cellulose (purchased from Aladdin, with a molecular weight of 250,000) in pure water to prepare a mother liquor with a concentration of 6000 mg / L.

[0088] 3. Add 2000 parts by mass of the polymer mother liquor obtained in step 2 to 1 part by mass of the mixed solution in step 1, rotate at a speed of 500 rpm, and stir for 30 minutes to obtain a high-temperature salt-resistant nano-oil displacing agent, which is recorded as a sample 2#.

[0089] In sample 2#, the mass fraction ratio of nanomaterial-modified nano-silica, cationic surfactant cetyltrimethylammonium bromide, and water-soluble sodium polystyrene sulfonate is 1:10:12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com