Dip-coating water-based paint for transmission shaft and preparation method thereof

A drive shaft and dip coating technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of insufficient paint film hardness, poor chemical resistance, easy scratches, etc., to improve film thickness, application Wide-ranging, full-bodied effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

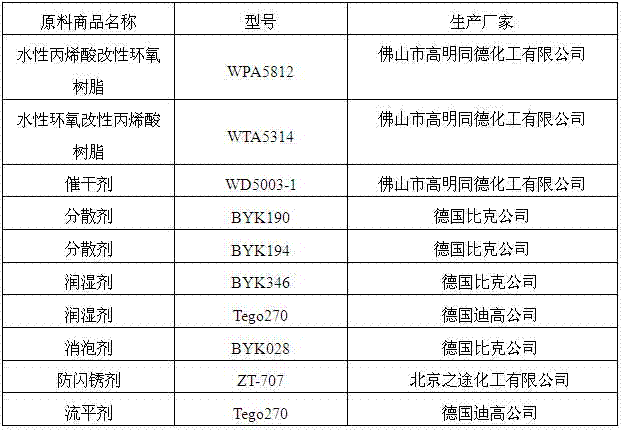

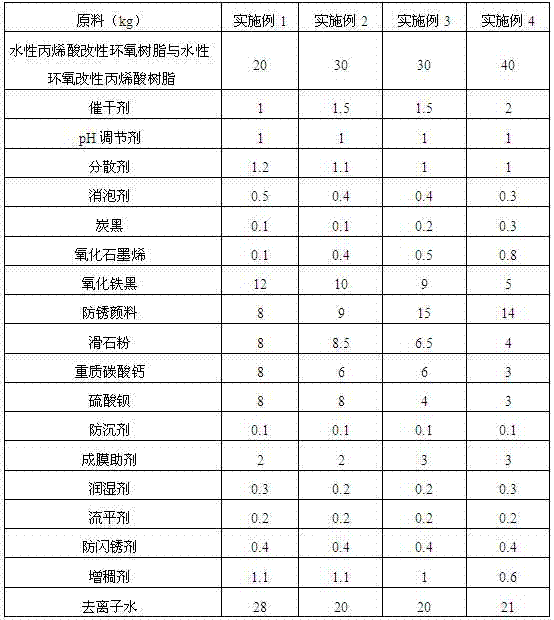

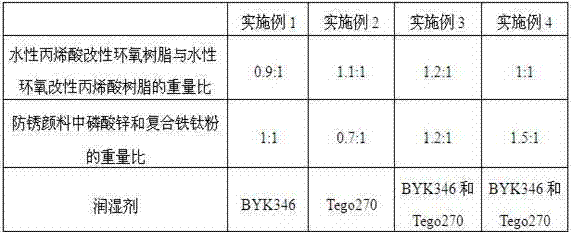

Method used

Image

Examples

Embodiment 1

[0053] Example 1: Lowest cost, good performance, for example, use tin plate, film thickness is 20μm, pencil hardness 2H-3H, adhesion ≤ grade 1, flexibility 0.5mm (r=0.5mm), impact > 50cm, anti-corrosion performance It is mainly reflected in the neutral salt spray performance, the film thickness is 60μm, and the salt spray test can reach 5 days without blistering and rust.

Embodiment 2

[0054] Embodiment 2: The cost is relatively low, the performance is good, and the antirust performance is improved compared with Example 1. For example, a tinplate plate is used, the film thickness is 20 μm, the pencil hardness is 2H, the adhesion is ≤ grade 1, and the flexibility is 0.5mm (r=0.5mm) , impact > 55cm, anti-corrosion performance is mainly reflected in the neutral salt spray performance, the film thickness is 60μm, and the salt spray test can reach 6 days without blistering and rust.

Embodiment 3

[0055] Example 3: The performance is good, and the anti-rust performance is improved compared with Example 2. For example, a tin plate is used, the film thickness is 20 μm, the pencil hardness is 2H, the adhesion is ≤ grade 1, the flexibility is 0.5mm (r=0.5mm), and the impact is > 55cm , The anti-corrosion performance is mainly reflected in the neutral salt spray performance, the film thickness is 60μm, and the salt spray test can reach 7 days without blistering and rust.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Pencil hardness | aaaaa | aaaaa |

| Shock | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com