Preparation method of straw-plastic composite plate

A composite type and composite material technology, applied in the field of preparation of straw-plastic composite boards, can solve problems such as inability to eliminate damage, poor operability, complex process, etc., achieve strong mechanical properties and waterproof performance, save straw and plastic, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

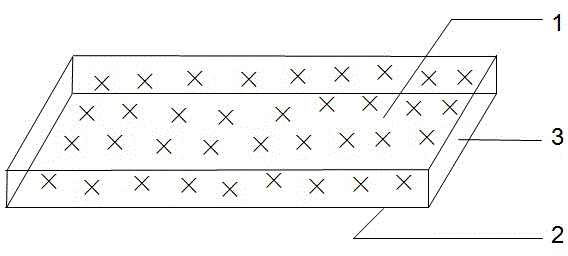

Image

Examples

Embodiment 1

[0022] Embodiment 1: choose poplar wood flour to be straw raw material;

[0023] The preparation method of this straw-plastic composite board comprises the following steps:

[0024] (1) Grinding raw materials: crush and grind poplar wood powder with mechanical equipment into a powder with a particle size of 80 mesh; dry to a water content of 4%; crush and grind calcium carbonate powder with a mechanical device into a powder with a particle size of 400 mesh; dry to a water content of 2%;

[0025] (2) Preparation of modified straw powder:

[0026] Weigh 2000g of the poplar wood powder obtained in the step (1) according to the proportion by weight, put it into a high-speed mixer, heat up to 130°C, then add 2000g of calcium carbonate powder and 100g of preservative chromium copper arsenate, at a speed of 360 Mix under rpm, the mixing time is 15 minutes, to obtain modified straw powder;

[0027] (3) Preparation of straw-plastic composite material: Weigh 4000g of the modified str...

Embodiment 2

[0029] Embodiment 2: choose wheat straw powder as straw raw material;

[0030] The preparation method of this straw-plastic composite board comprises the following steps:

[0031] (1) Grinding raw materials: crush and grind wheat straw powder with mechanical equipment into a powder with a particle size of 60 mesh; 3%;

[0032] (2) Preparation of modified straw powder:

[0033] Weigh 2200g of the wheat straw powder obtained in step (1) according to the proportion by weight, put it into a high-speed mixer, heat up to 90°C, then add 2200g of calcium carbonate powder and 60g of preservative chromium copper arsenate, at a speed of 400 Mix under rpm, and the mixing time is 25 minutes to obtain modified straw powder;

[0034] (3) Preparation of straw-plastic composite material: Weigh 4400g of the modified straw powder obtained in step (2) and 4000g of the plastic masterbatch according to the weight ratio, and plasticize and compound the modified straw powder and the plastic master...

Embodiment 3

[0036] Embodiment 3: choose rice straw powder as straw raw material;

[0037] The preparation method of this straw-plastic composite board comprises the following steps:

[0038] (1) Grinding raw materials: crush and grind the rice straw powder into a powder with a particle size of 100 mesh with mechanical equipment; 2%;

[0039] (2) Preparation of modified straw powder:

[0040] Weigh 1800g of the rice straw powder obtained in step (1) according to the proportion by weight, put it into a high-speed mixer, heat up to 150°C, then add 1600g of wollastonite powder and 200g of preservative chromium copper arsenate, at a speed of 450 Mix under rpm, and the mixing time is 30 minutes to obtain modified straw powder;

[0041] (3) Preparation of straw-plastic composite material: Weigh 3600g of the modified straw powder obtained in step (2) and 5000g of the plastic masterbatch according to the weight ratio, and plasticize and compound the modified straw powder and the plastic masterb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com