High-strength high-toughness ultrafine-grained high-entropy alloy and preparation method thereof

A technology of high-entropy alloy and ultra-fine grain, which is applied in the field of high-strength ultra-fine-grain high-entropy alloy and its preparation, to achieve the effects of controllable grain size, high yield and clean interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

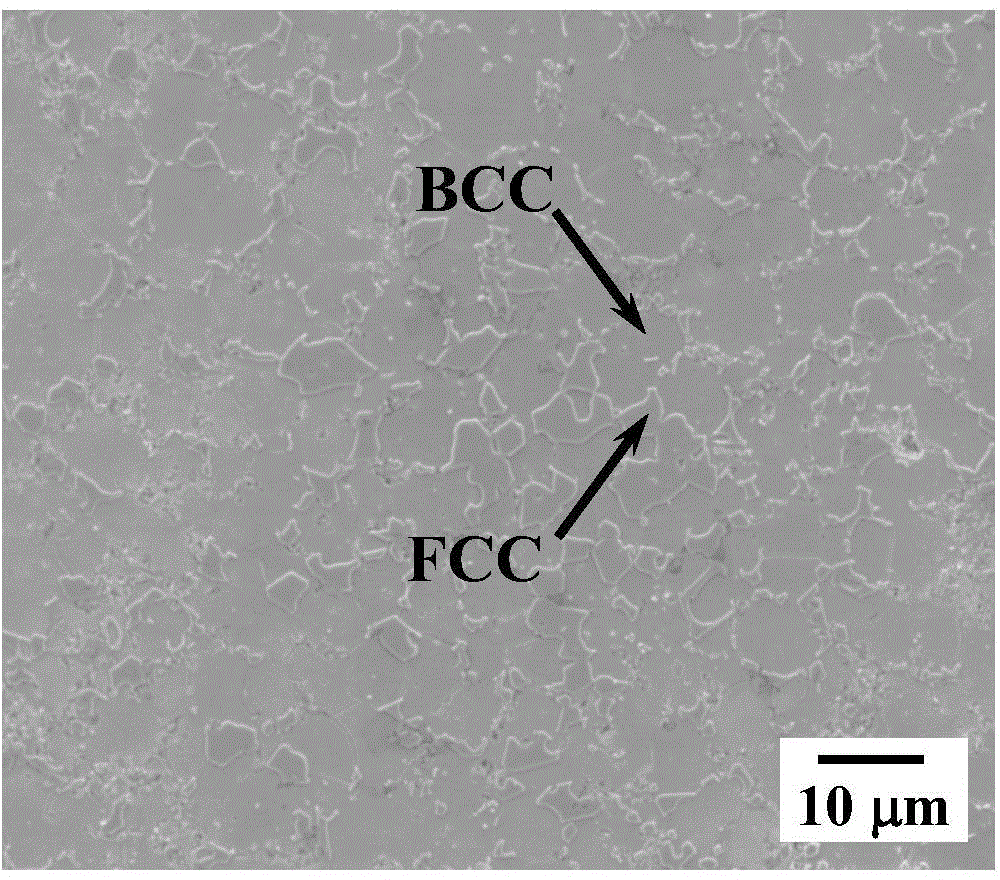

[0034] A high-strength and tough ultrafine-grained high-entropy alloy in this embodiment is prepared from the following atomic percentage components: 20% Ni, 20% Fe, 20% Co, 20% Cr, and 20% Al.

[0035] The preparation method of the above-mentioned high-strength and tough ultra-fine-grained high-entropy alloy, the specific operation steps are as follows:

[0036] (1) mixed powder

[0037] The elemental powders with atomic percentages of Ni 20%, Fe 20%, Co 20%, Cr 20%, and Al 20% were dry-blended in a V-0.002 type powder mixer for 24 hours until uniform, and the average particle size of each elemental powder Both are about 50 μm, the purity of aluminum is 99.0wt.%, and the purity of other elemental powders is higher than 99.9wt.%.

[0038] (2) Preparation of amorphous composite powder by high energy ball milling

[0039] The high-energy ball mill is completed by QM-2SP20 planetary ball mill. The material of the ball and the inner wall of the ball mill is made of stainless ste...

Embodiment 2

[0050] A high-strength and tough ultrafine-grained high-entropy alloy in this embodiment is prepared from the following atomic percentage components: 25% Ni, 18% Fe, 18% Co, 18% Cr, and 21% Al.

[0051] The preparation method of the above-mentioned high-strength and tough ultra-fine-grained high-entropy alloy, the specific operation steps are as follows:

[0052] (1) mixed powder

[0053] The elemental powders with atomic percentages of Ni 25%, Fe 18%, Co18%, Cr 18%, and Al 21% were dry-blended in a V-0.002 type powder mixer for 24 hours until uniform, and the average particle size of each elemental powder was uniform. About 50 μm, the purity of aluminum is 99.0wt.%, and the purity of other elemental powders is higher than 99.9wt.%.

[0054] (2) Preparation of amorphous composite powder by high energy ball milling

[0055] The high-energy ball mill is completed by QM-2SP20 planetary ball mill. The material of the ball and the inner wall of the ball mill is made of stainless ...

Embodiment 3

[0066] A high-strength and tough ultrafine-grained high-entropy alloy in this embodiment is prepared from the following atomic percentage components: 20% Ni, 20% Fe, 18% Co, 18% Cr, and 24% Al.

[0067] The preparation method of the above-mentioned high-strength and tough ultra-fine-grained high-entropy alloy, the specific operation steps are as follows:

[0068] (1) mixed powder

[0069] The elemental powders with atomic percentages of Ni 20%, Fe 20%, Co18%, Cr 18%, and Al 24% were dry-blended in a V-0.002 type powder mixer for 24 hours until uniform, and the average particle size of each elemental powder was uniform. About 50 μm, the purity of aluminum is 99.0wt.%, and the purity of other elemental powders is higher than 99.9wt.%.

[0070] (2) Preparation of amorphous composite powder by high energy ball milling

[0071] The high-energy ball mill is completed by QM-2SP20 planetary ball mill. The material of the ball and the inner wall of the ball mill is made of stainless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com