Patents

Literature

172results about How to "Control grain size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength high-toughness ultrafine-grained high-entropy alloy and preparation method thereof

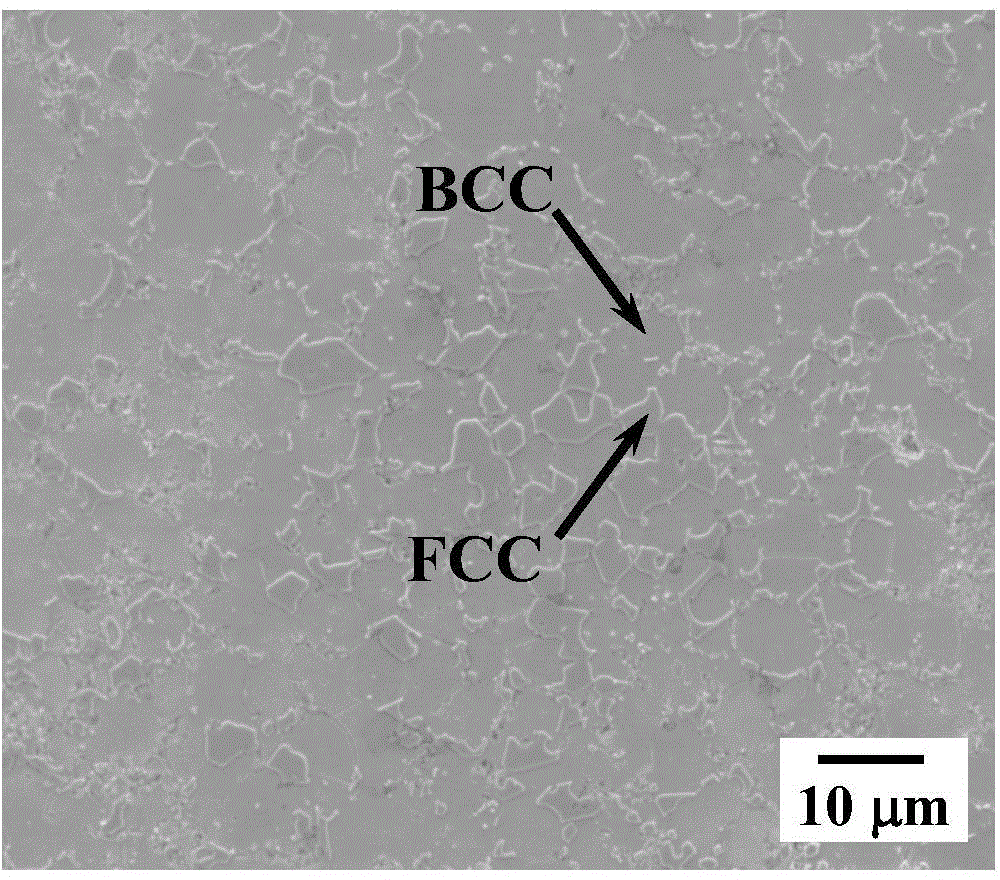

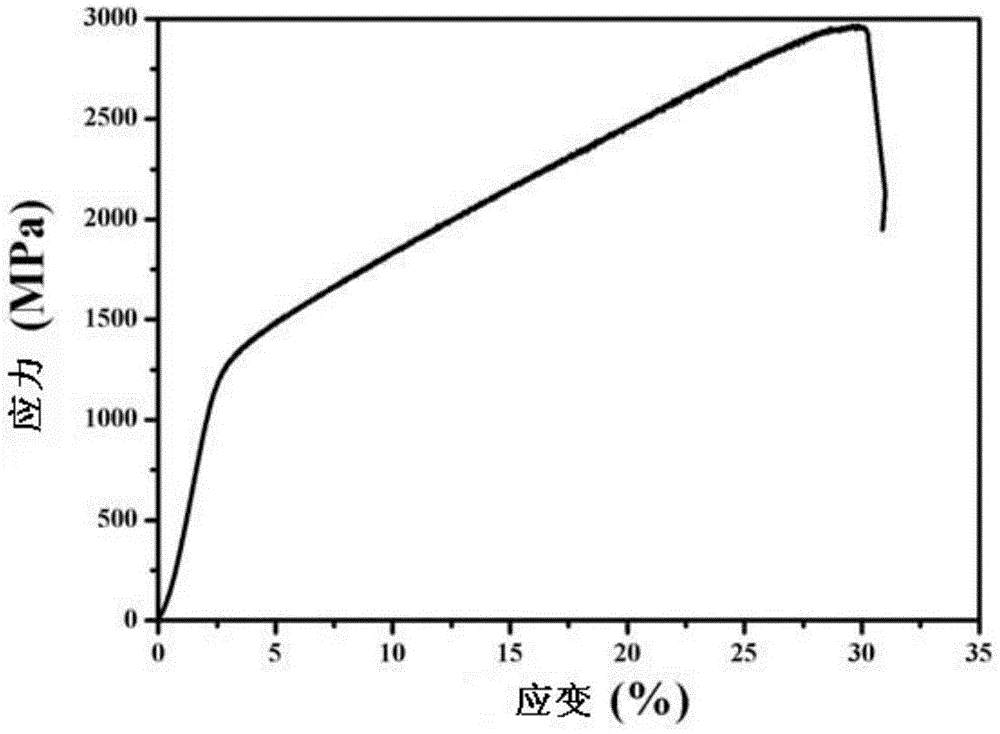

The invention belongs to the technical field of alloy material, and discloses a high-strength high-toughness ultrafine-grained high-entropy alloy and a preparation method thereof. The high-strength high-toughness ultrafine-grained high-entropy alloy is composed of the following elements according to the atomic percentage: 20%-25% of Ni, 18%-20% of Fe, 18%-22% of Co, 18%-20% of Cr, and 20%-24% of Al; the microstructure takes a body-centered cubic disordered solid solution phase rich in Ni and Al elements as a matrix phase, and takes a face-centered cubic disordered solid solution phase rich in Fe and Cr elements as a reinforcing phase. The preparation method of the alloy comprises the steps: elemental powders with the atomic percentages are subjected to powder mixing and high-energy ball milling to prepare an amorphous composite powder, and the amorphous composite powder is sintered to obtain the high-strength high-toughness ultrafine-grained high-entropy alloy. The prepared high-entropy alloy has the advantages of large size and good comprehensive mechanical properties, and can be used in the fields of aeronautics and astronautics, military industry, electrons, instruments and apparatuses and the like.

Owner:SOUTH CHINA UNIV OF TECH

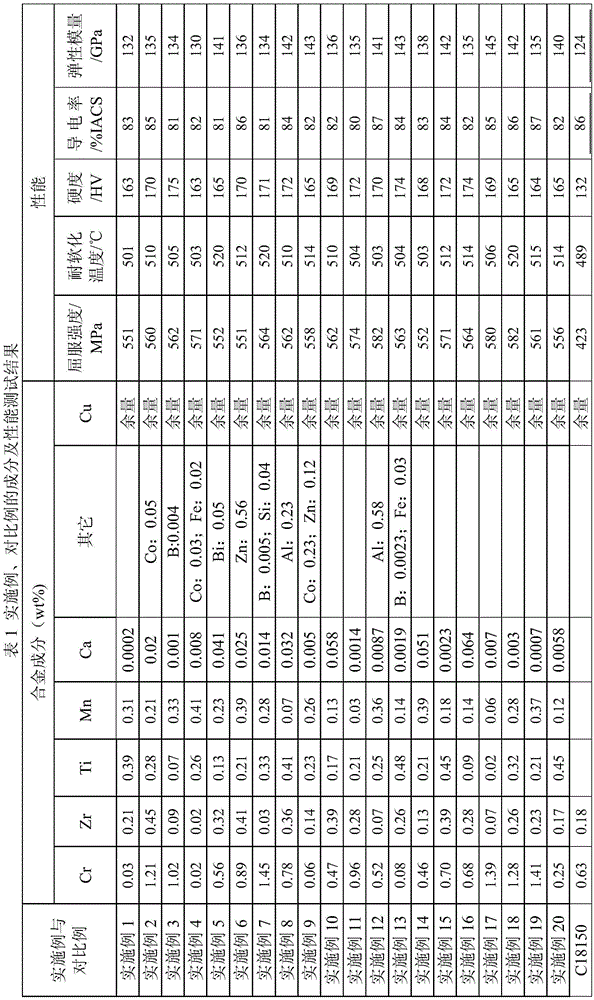

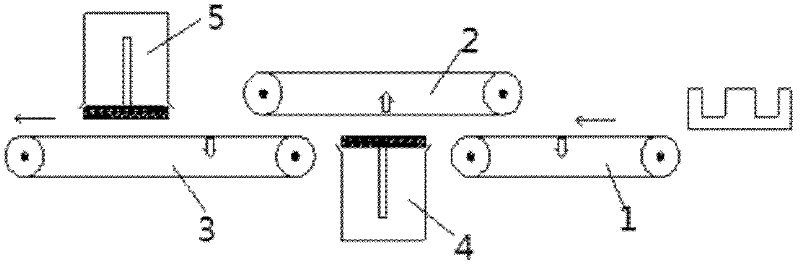

High-strength high-conductivity copper-chromium-zirconium alloy and preparation method of plate/strip thereof

The invention discloses a high-strength high-conductivity copper-chromium-zirconium alloy and a preparation method of a plate / strip thereof. This alloy comprises the chemical composition: 0.01-1.5 wt% of Cr, 0.01-0.5 wt% of Zr, 0.001-0.5 wt% of Ti, 0.01-0.5 wt% of Mn, 0.0001-0.07 wt% of Ca, and the balance of copper and unavoidable impurities; the position and process of the Cu-Cr-Zr alloy are optimized, the provided high-strength high-conductivity copper-chromium-zirconium alloy retains high conductivity (above 80% IACS), elastic modulus up to higher than 130 GPa, softening temperature resistance up to higher than 500 DEG C, yield strength up to higher than 550 MPa and hardness up to 160 HV, the copper-chromium-zirconium plate / strip is imparted high strength, high conductivity and excellent comprehensive performance, this comprehensive performance meets the requirements of products such as a lead frame and a connector upon base material stamping and machining performances, and this plate / strip material is mainly applied to electronic components such as connectors and lead frames.

Owner:NINGBO POWERWAY ALLOY PLATE & STRIP CO LTD

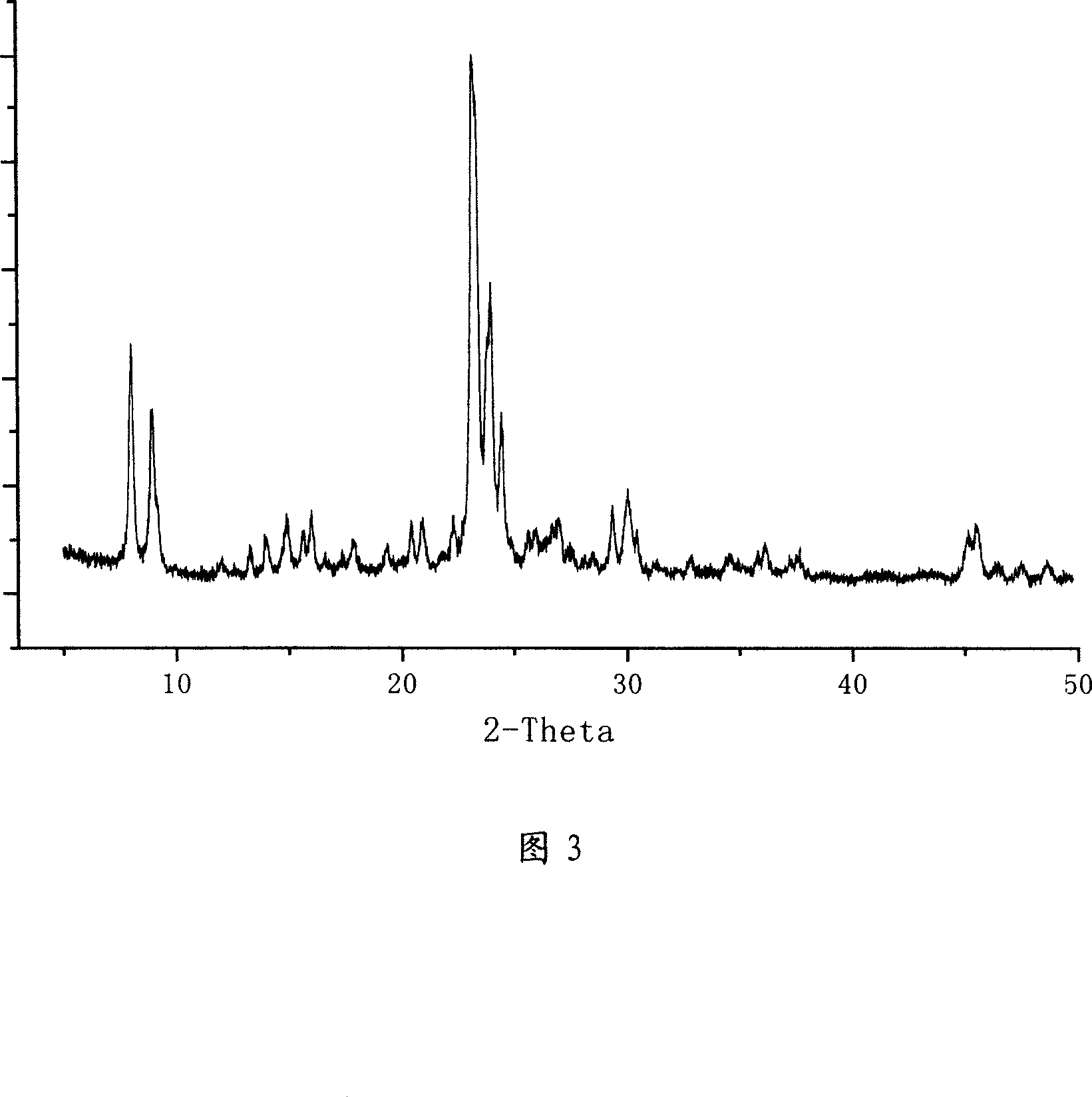

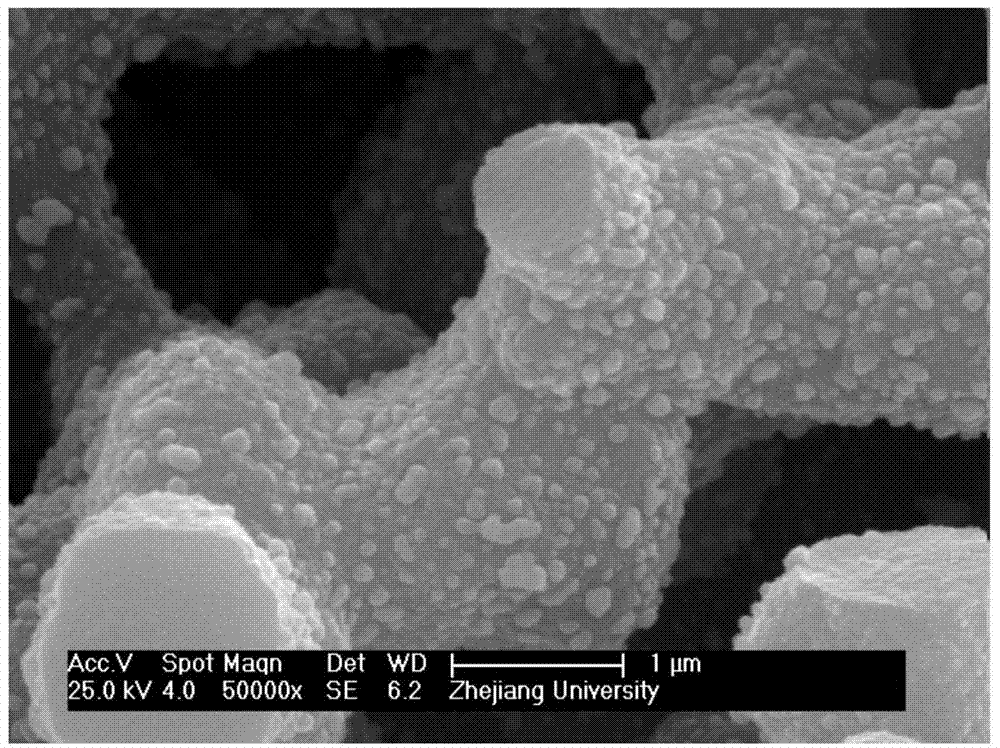

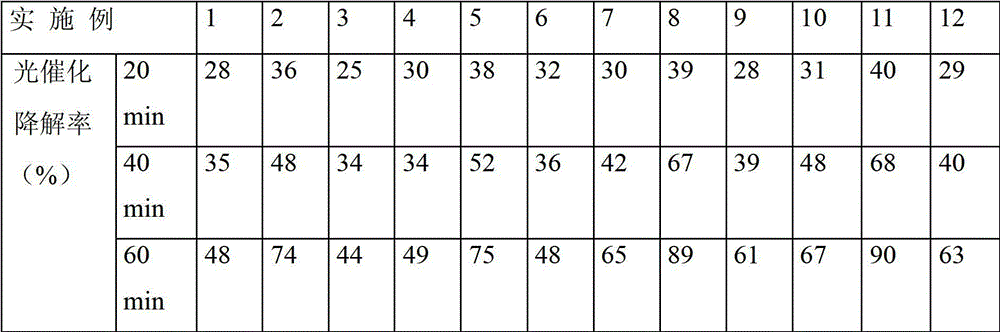

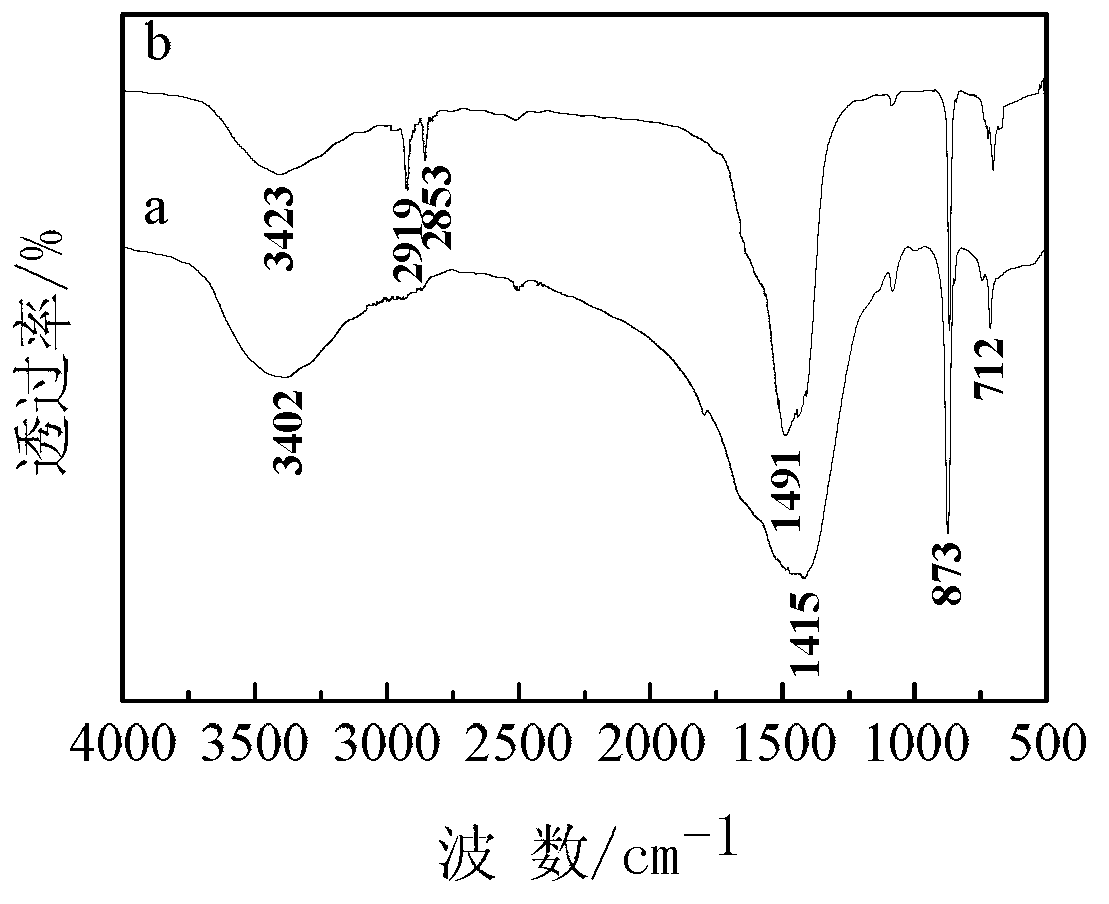

Sulfur doped titanium dioxide photocatalyst with anatase structure water-heating preparation method

InactiveCN101053839AAvoid obstructionEnter fullyPhysical/chemical process catalystsThioureaVacuum drying

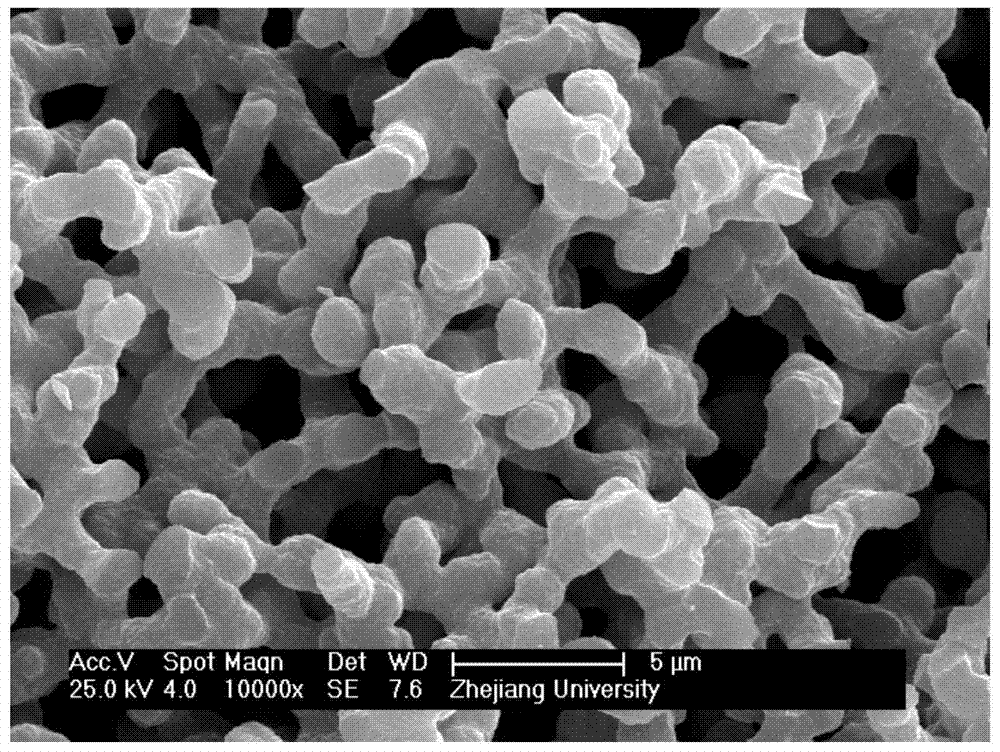

The invention discloses a hydrothermal preparation method for a sulfur doping titanium dioxide photocatalyst with an anatase structure, comprising the following steps: 1)preparing a nano powder precursor solution by agitating and mixing 8-12ml butyl titanate, 55-65ml deionized water, 15-25ml absolute ethyl alcohol, 5-10ml trolamine and 0.38-4.56 gthiourea at a temperature of 10-40 DEG C; 2) preparing a nano powder in a hydrothermal condition by placing the nano powder precursor solution into a reaction kettle, rising temperature at a speed of 1-5 DEG C / min to 150-240 DEG C and keeping the temperature to perform the hydrothermal reaction, stopping heating after 2-5 hours, when the reaction kettle is naturally cooled to room temperature, taking out the reactants, washing with the deionized water and the absolute ethyl alcohol for 3-4 times, and finally drying the reactants in a vacuum drying oven at 50-80 DEG C. The invention is capable of synchronous achieving processes both of the preparation of TiO2 nano particle and sulfur doping, which makes the preparation technical line of the catalyst more reasonable, be suitable to product quantity control with low energy consumption.

Owner:ZHEJIANG UNIV

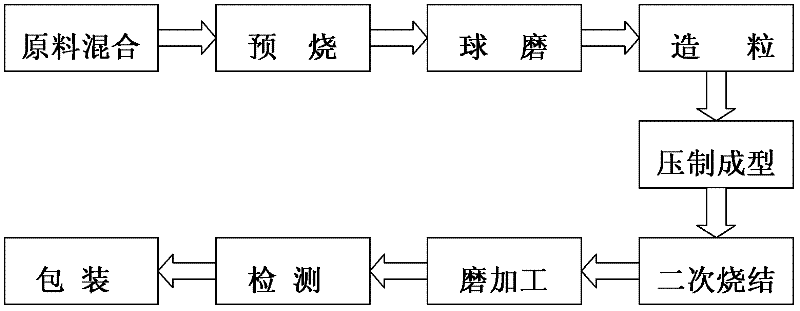

Method for producing soft magnetic ferrite core

InactiveCN102643083AImprove permeabilityLow dissipation factorEdge grinding machinesPolishing machinesInitial permeabilitySoft magnet

The invention discloses a method for producing a soft magnetic ferrite core. The method comprises the following steps of: mixing of raw materials, pre-sintering, ball milling, compression moulding, secondary sintering, grinding and detection, wherein an integral magnetic-attraction double-sided grinding machine is adopted in the grinding process. The magnetic core produced by the method has high magnetic conductivity and low loss factor, and energy sources can be saved; the magnetic core has uniform color, flat end surface and bright and clean surface; the ball milling as well as the uniformity and sphericity of the mixed material are improved; a low-temperature sintering technology is adopted, the heating rate and cooling rate of each stage are adjusted, the ferrite transformation of the material is promoted, and the grain size can be effectively controlled; and the initial permeability and temperature characteristic are improved.

Owner:ANHUI TAIDE ELECTRONICS TECH

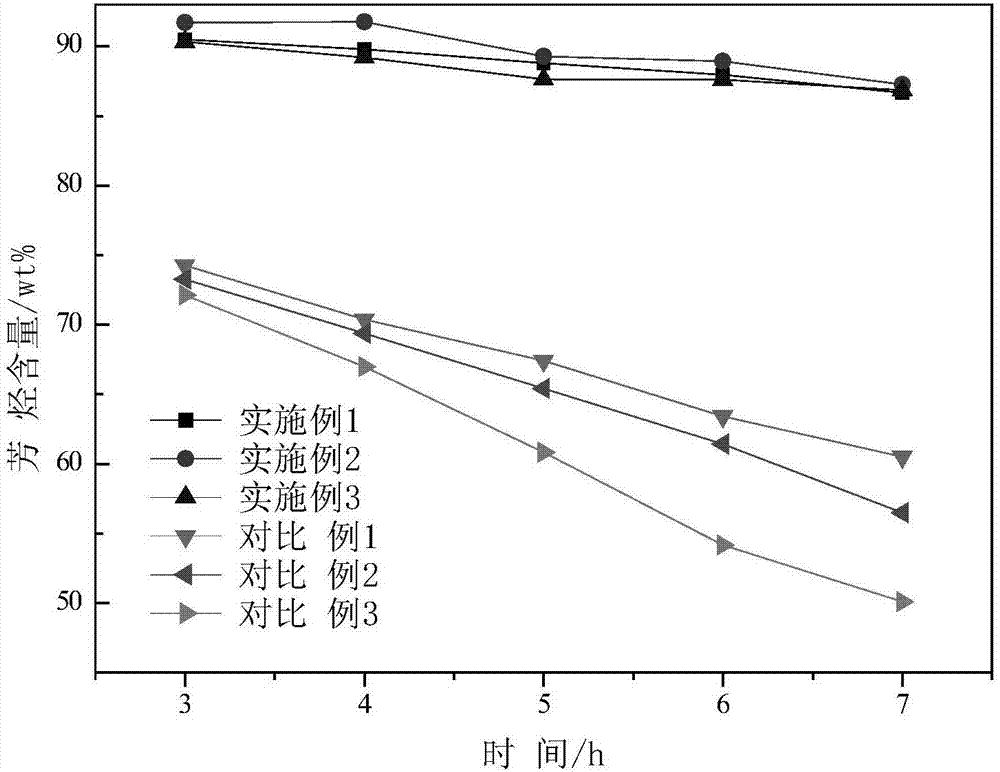

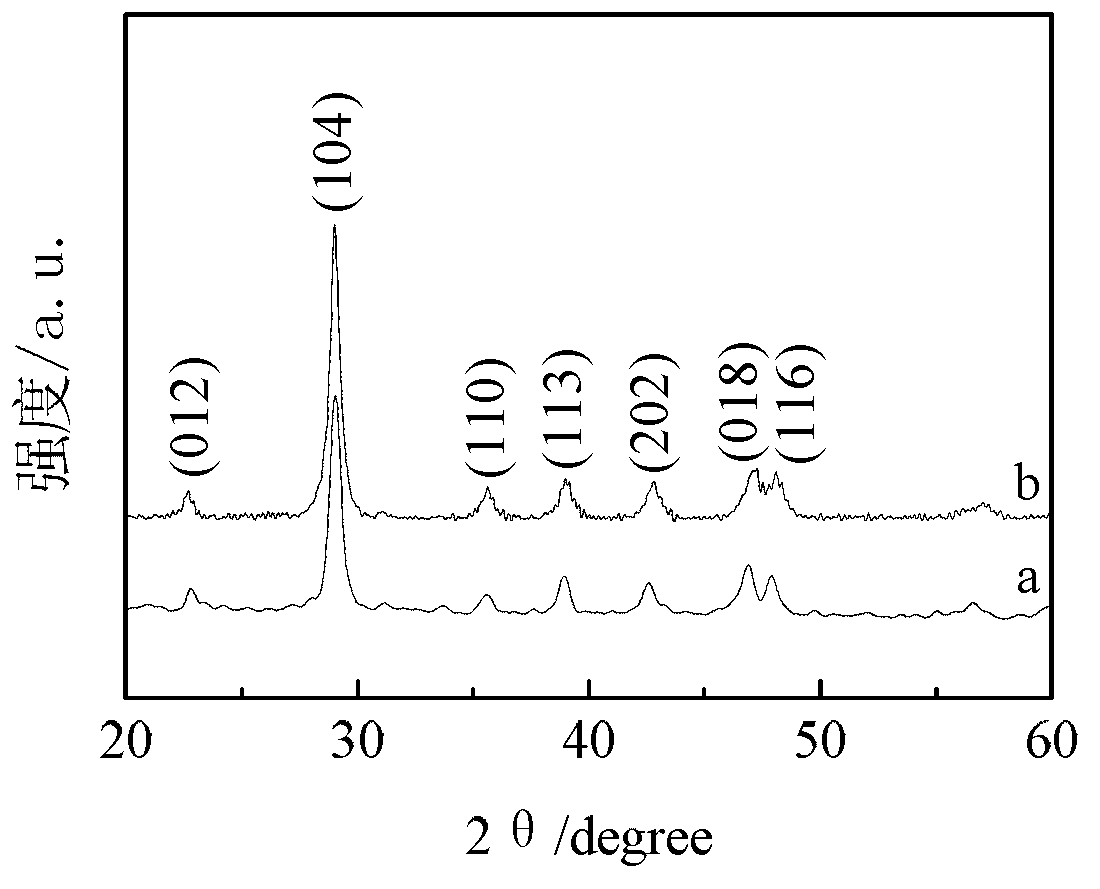

Lithium ion battery positive electrode material with adjustable crystalline grain size and preparation method thereof

InactiveCN105118985AControl grain sizeEasy to realize industrial productionCell electrodesSecondary cellsIonChemistry

The invention discloses a lithium ion battery positive electrode material with an adjustable crystalline grain size and a preparation method thereof as well as a lithium ion battery containing the positive electrode material. The crystalline grain size of the positive electrode material can be adjusted more conveniently by selecting proper doping ions through a certain preparation technology; the lithium ion battery containing the positive electrode material is excellent in normal-temperature and high-temperature circulating performance by adjusting the crystalline grain size of the positive electrode material, so that the aim that the lithium ion battery can be applied to different application fields is fulfilled. The preparation technology for the positive electrode material is simple and convenient and is favorable for industrial production. The lithium ion battery adopting the positive electrode material provided by the invention is high in circulating performance.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

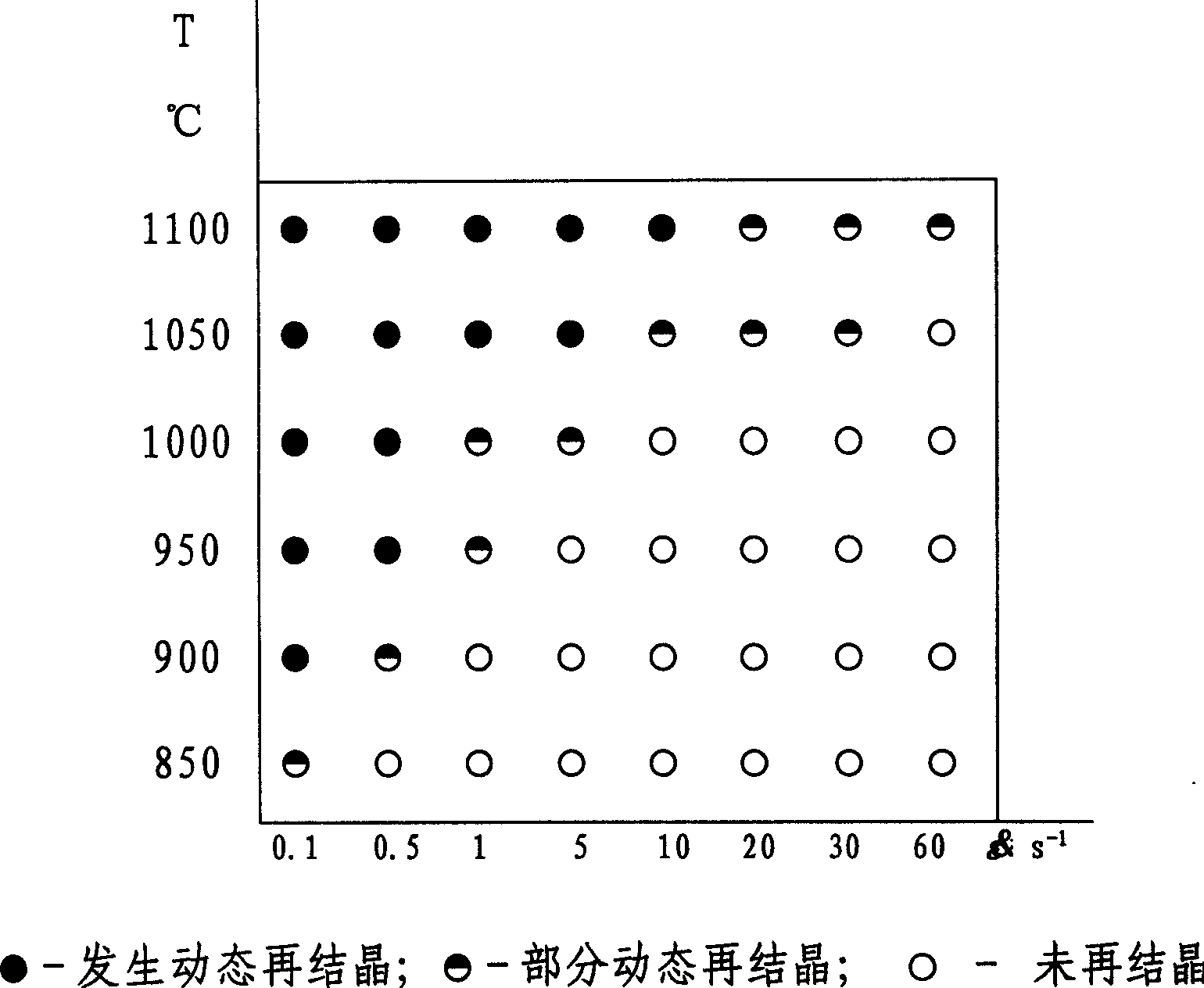

Rolling method for low carbon twisted steel bar

InactiveCN1586750AControl yield strengthRefine the grain sizeScrew-threads articlesMetal rolling arrangementsCarbon steelSteel bar

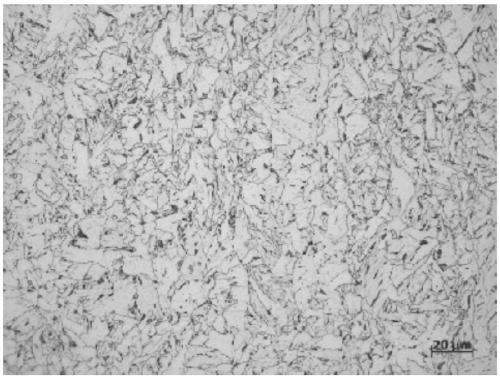

The present invention relates to metal rolling technology, and especially the rolling process of twisted low carbon steel bar. The twisted low carbon steel bar has the chemical components of: C 0.17-0.23 wt%, Si 0.20-0.80 wt%, Mn 0.50-1.50 wt%, S not more than 0.035 wt% and P not more than 0.035 wt%. The rolling process with complete or patial temperature control includes the following steps: initial rolling with low temperature cogging at 850-950 deg.c, middle rolling at 750-850 deg.c with accumulated deformation over 50 %, finish rolling at 750-900 deg.c, and subsequent water cooling at lower than 600 deg.c with cooling speed greater than 10 deg.c / sec. Compared with available technology, the present invention has superfine crystal grain structure and high steel bar performance.

Owner:CENT IRON & STEEL RES INST

Alkali-modified ZSM-5 molecular sieve, preparation method and application thereof

InactiveCN107876082AReduced Diffusion ResistanceExtend your lifeMolecular sieve catalystsHydrocarbonsAromatizationOrganic chemistry

The invention relates to a preparation method of an alkali-modified ZSM-5 molecular sieve, which includes the steps of: mixing ZSM-5 molecular sieve with an alkali solution, performing a reaction andperforming post-treatment, wherein the reaction is carried out at 150-200 DEG C. The invention also relates to an application of the alkali-modified ZSM-5 molecular sieve in an aromatization reactionof hexene. The alkali-modified ZSM-5 molecular sieve is low in micropore ratio, wherein the micropores are enlarged into the range of mesopores and macropores (5-110 nm); the molecular sieve also is higher in crystalline degree, can effectively delay deactivation due to coking, thus increasing service life of a catalyst; without damage on the appearance of the ZSM-5 molecular sieve, grain size canbe controlled and acidity of the ZSM-5 molecular sieve can be regulated; in addition, pore structure in the molecular sieve is regulated, so that catalytic performance and service life of the catalyst are improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

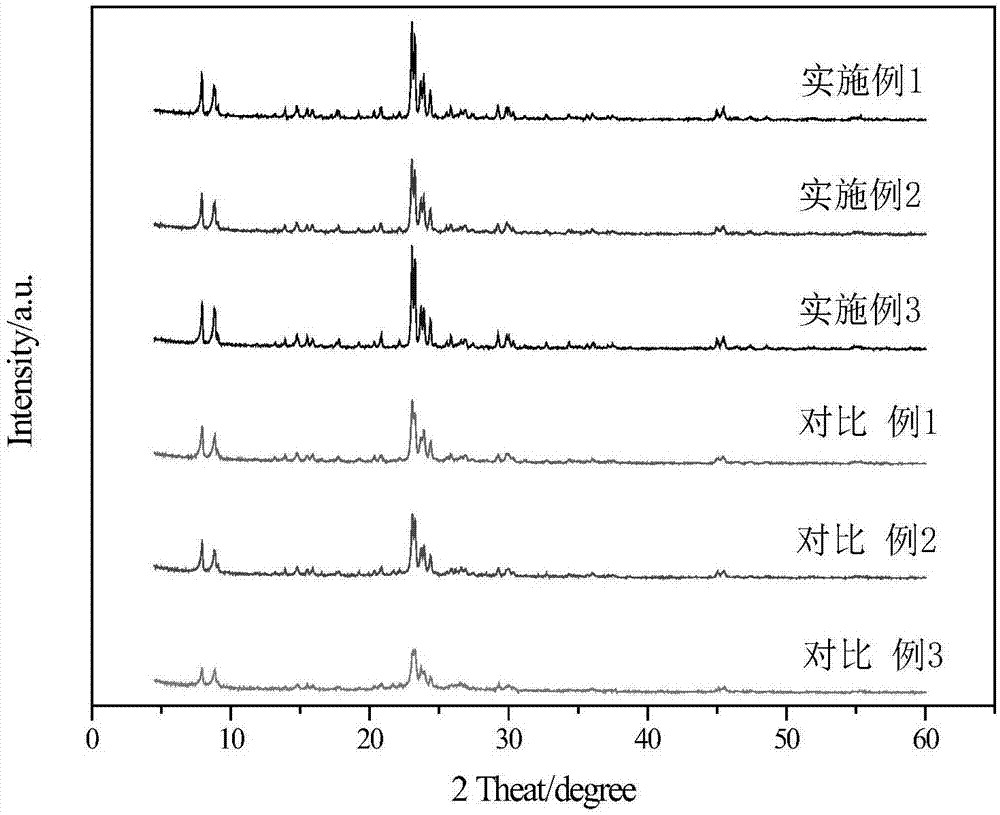

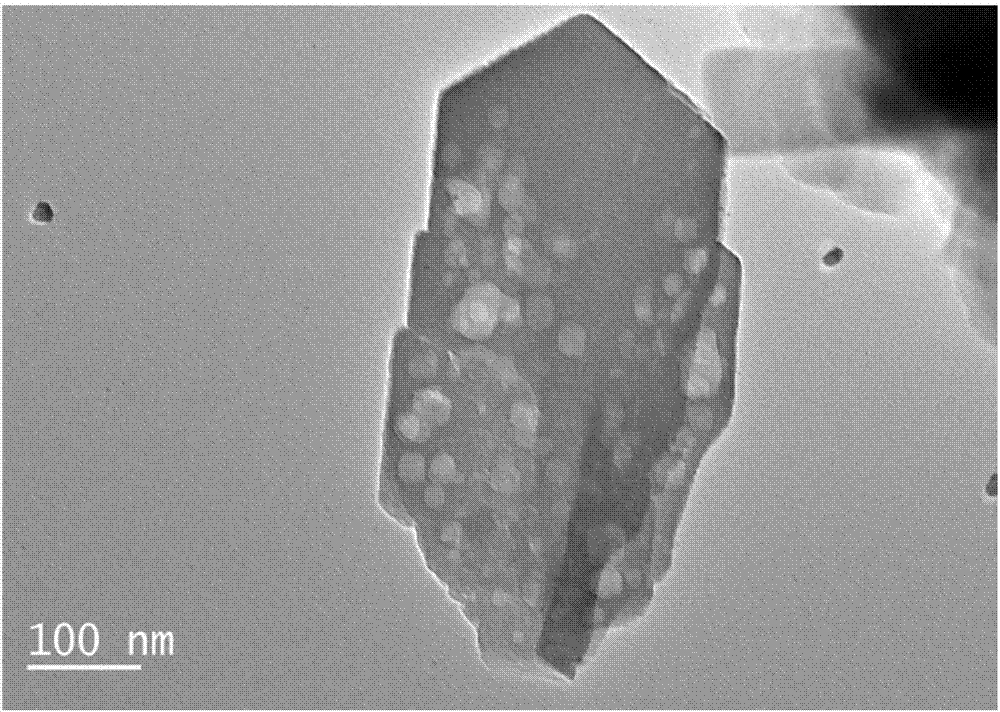

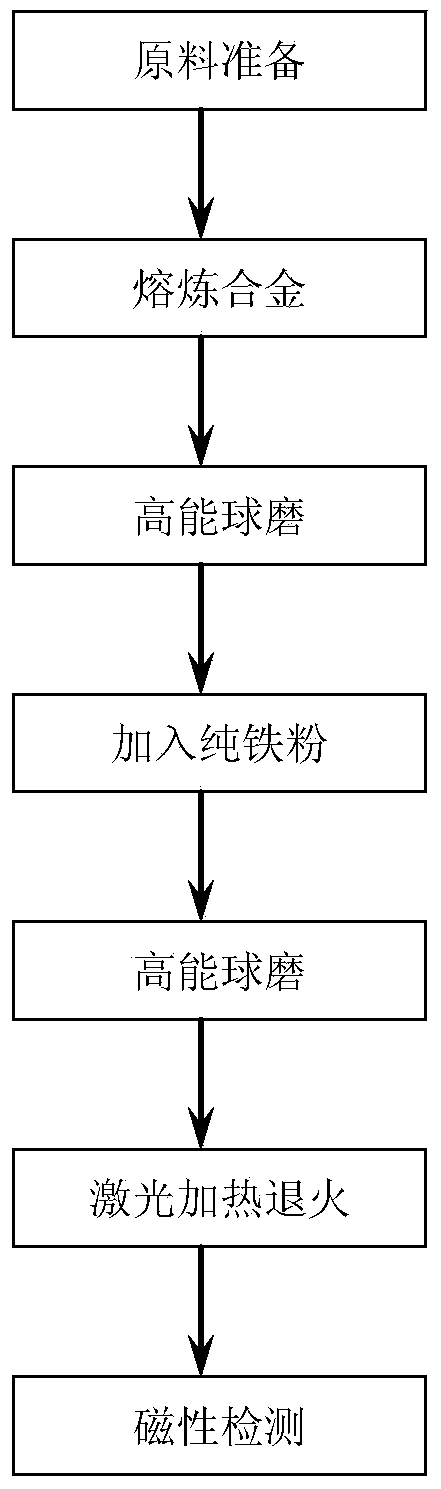

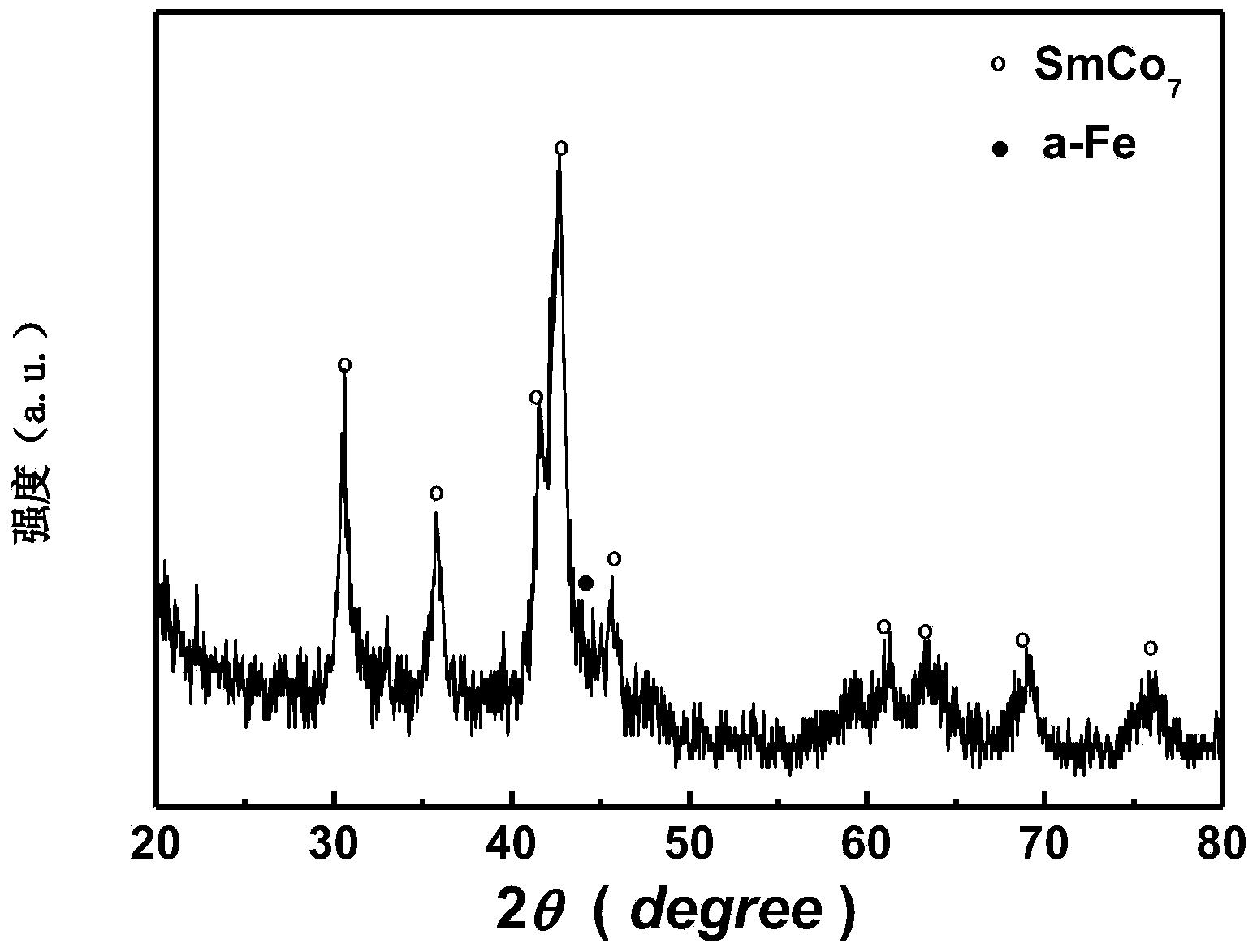

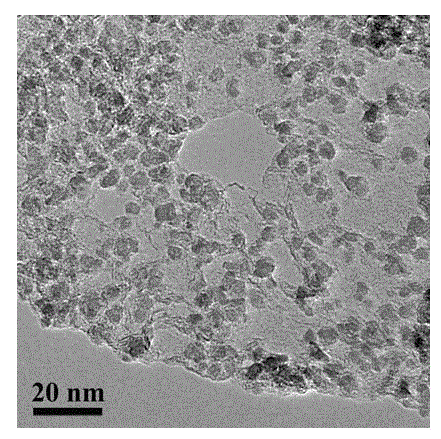

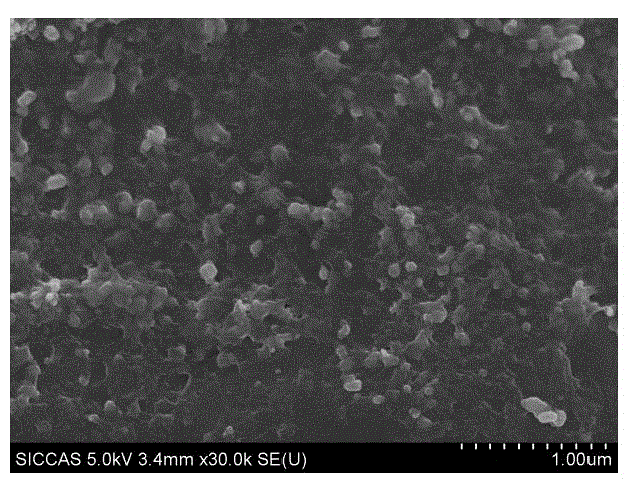

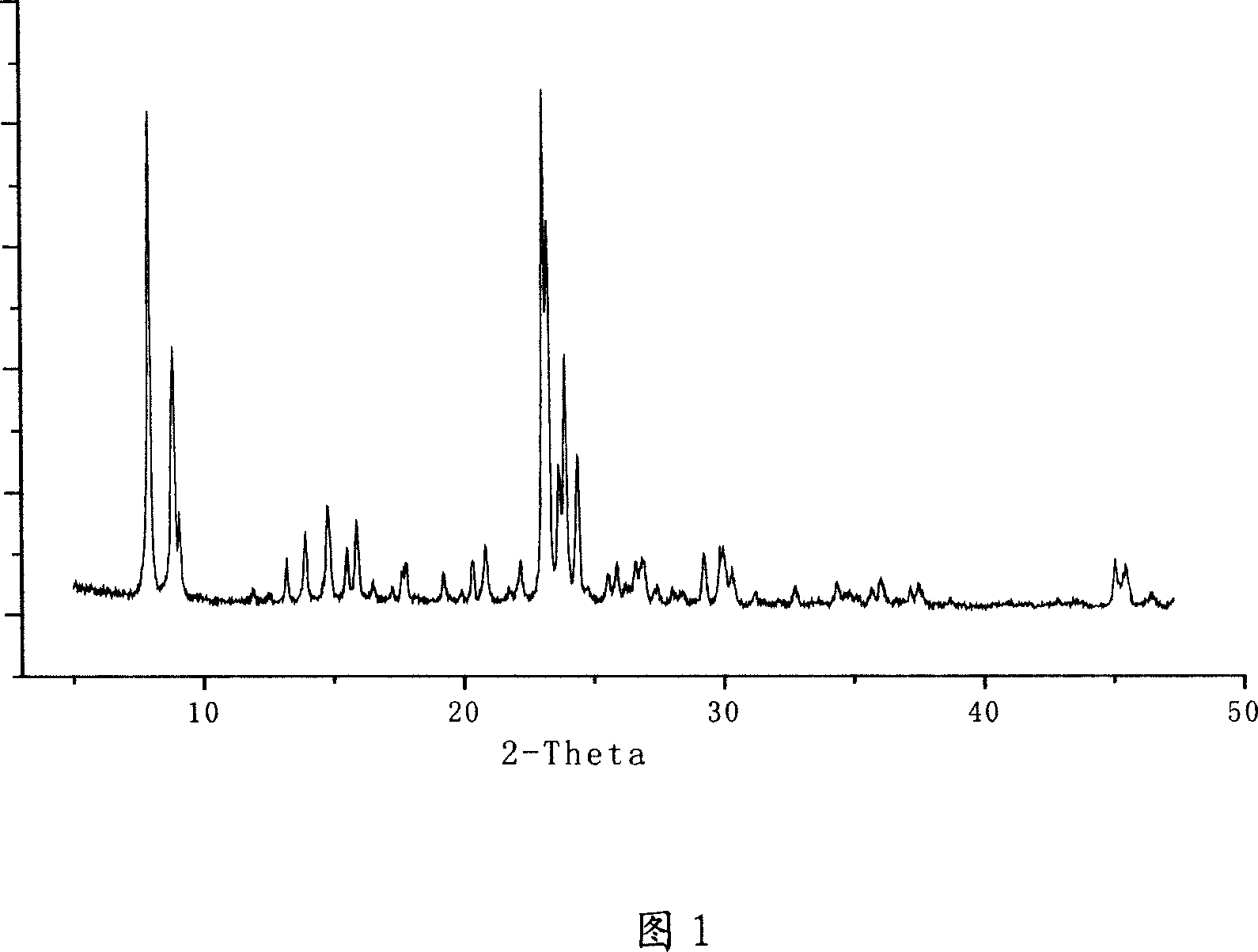

Samarium-cobalt-base nanocrystalline permanent magnet material and preparation method thereof

The invention relates to the metallurgy field and discloses novel samarium-cobalt-base nano-composite permanent magnetic material. The samarium cobalt base is (Sm, R)1(Co, Fe, Cu, Zr)7 in type and comprises a TbCu7 type structure, and Co is partially replaced by Fe, Cu and Zr; Re is any one of heavy rare earth Lu, Dy and Tb and partially replaces Sm. The preparation method includes steps that 1) mixing raw materials of the samarium cobalt base according to proportion, and smelting to obtain a 1: 7 type samarium cobalt base alloy ingot; 2) ball milling the alloy ingot through a high-energy ball milling technique, mixing with Fe powder according to proportion, and performing high-energy ball milling to obtain nanocrystalline composite magnetic powder; 3) carrying out annealing heat treatment on the nanocrystalline composite magnetic powder. According to the samarium-cobalt-base nanocrystalline permanent magnet material and the preparation method thereof, the soft / hard-magnetic phase composite magnetic powder is prepared through the high-energy ball milling, laser heat treatment and other techniques, a high magnetic energy product is obtained through exchange coupling between the nanocrystalline hard magnetic phase and nanocrystalline soft magnetic phase, and meanwhile, because rare-earth Fe phase is not used, the cost is lowered, and the operation technique is simplified.

Owner:嘉兴市鹏程磁钢有限公司 +1

Preparation method of lithium iron phosphate/graphene nano composite material

InactiveCN102751496AGood dispersionUniform dispersionCell electrodesNano compositesGraphene nanocomposites

The invention relates to a preparation method of lithium iron phosphate / graphene nano composite material. The preparation method comprises the steps of dispersing iron trioxide / graphene composite into a solvent, and adding ascorbic acid, lithium hydrate and phosphoric acid to obtain a precursor dispersing agent; and arranging the precursor dispersing agent into a reactor, and conducting solvent thermal reaction for 1-48h at 90-350 DEG C.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Fine grain strong acid type molecular sieve and method for synthesizing same

ActiveCN101041442ASolve pollutionShort synthesis cycleMolecular sieve catalystsPentasil aluminosilicate zeoliteSupersonic wavesStrong acids

The invention discloses a synthetic method of fine grain strong acid type ZSM-5 molecular sieve, which comprises the following steps: fetching silica dioxide and aluminum oxide; allocating mole ratio at 15-100, junior particle diameter at 0.01-0.5 mu m and surface area at 300-550m2 / g; making silica source, aluminium source and inorganic acid as raw material; fore-treating through supersonic wave; hydrothermal blooming; filtering; exchanging; washing; filtering and drying under exciting seed or non-exciting seed condition; getting the product. The molecular sieve possess higher active, which can product cyclohexanol effectively.

Owner:天津南化催化剂有限公司

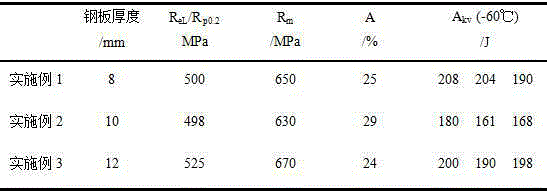

Method for producing thin-specification and high-strength atmosphere corrosion resistance structural steel plate

InactiveCN105256246AHigh strengthImprove toughness and plasticityLaminar coolingUltimate tensile strength

The invention discloses a method for producing a thin-specification and high-strength atmosphere corrosion resistance structural steel plate. The heating temperature of a continuous casting before rolling ranges from 1,150 DEG C to 1,250 DEG C; the finishing temperature of rough rolling ranges from 1,020 DEG C to 1,080 DEG C, and the accumulated rolling reduction of rough rolling is larger than or equal to 60%; the thickness of a hold-temperature blank is larger than or equal to 3.0 h, the fine rolling finishing temperature is larger than or equal to 830 DEG C, and the reduction rate of fine rolling tail pass is smaller than or equal to 12.5%; after fine rolling is finished, high-speed steel throwing is carried out, the steel throwing speed is 4 m / s, and it is guaranteed that the water entry temperature of a rolled piece is larger than or equal to 770 DEG C; and laminar cooling is carried out, the finished cooling temperature ranges from 550 DEG C to 650 DEG C, and the cooling speed ranges from 5 DEG C / s to 30 DEG C / s. The steel is delivered in the hot rolling state; and by means of the low-carbon and alloy components, it is guaranteed that the atmosphere corrosion resistance index I of the steel is larger than or equal to 6.5, the yield strength of the steel is larger than or equal to 450 MPa, the tensile strength of the steel is larger than or equal to 550 MPa, the yield ratio of the steel is smaller than or equal to 0.85, the ductility of the steel is larger than or equal to 20%, and the ballistic work of the steel at the temperature being minus 60 DEG C is larger than or equal to 100 J.

Owner:NANJING IRON & STEEL CO LTD

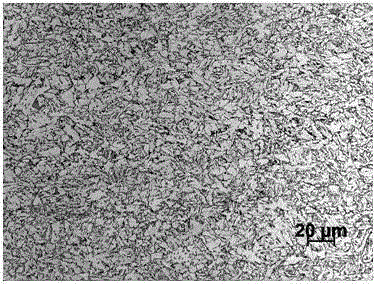

EH47 crack arrest steel for large container ship and manufacture method thereof

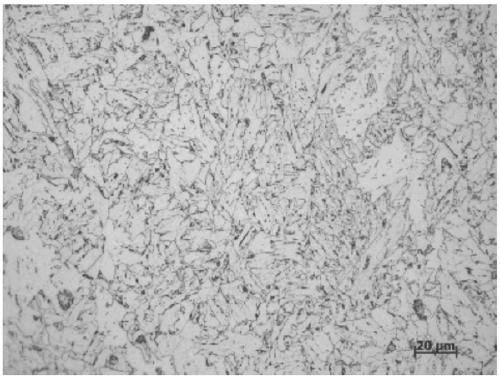

ActiveCN109576585AImprove corrosion resistanceAvoid negative effectsProcess efficiency improvementManufacturing technologySmallerThan

The invention relates to EH47 crack arrest steel for a large container ship. The chemical components of a steel plate comprise, by mass, 0.03%-0.06% of C, 0.15%-0.50% of Si, 1.50%-2.00% of Mn, smallerthan or equal to 0.008% of P, smaller than or equal to 0.0050% of S, 0.050%-0.080% of Nb, 0.020%-0.050% of V, 0.008%-0.020% of Ti, 0.80%-1.30% of Ni, 0.10%-0.30% of Cr and 0.10%-0.30% of Cu. The manufacture technology process of the steel plate comprises the steps of smelting, continuous casting, reheating, TMCP rolling and controlled cooling. The steel plate obtains fine and uniform acicular ferrite in the whole thickness, the strength is moderate, the toughness is excellent, the good brittle fracture resistance is achieved, namely, the CTOD characteristic value delta is larger than or equal to 0.15 mm at -60 DEG C, and the crack arrest performance is excellent, namely, Kca is larger than or equal to 6,500 N / mm<3 / 2>.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Preparation method of nano-silver loaded porous silicon dioxide

ActiveCN103861657ALarge specific surface areaPore structure can be adjustedCatalyst carriersSilicaSolventCooking & baking

The invention discloses a preparation method of nano-silver loaded porous silicon dioxide. The preparation method of nano-silver supported porous silicon dioxide comprises the step of preparing hierarchy porous silicon dioxide by polyoxyethylene, and also comprises the following steps: 1) modifying the hierarchy porous silicon dioxide by taking amino propyl triethoxy silicane as a modifying agent and by adopting absolute ethyl alcohol as a modifying solvent; 2) loading: dissolving silver nitrate into glycol as a reducing agent, and carrying out magnetic stirring so as to obtain a glycol solution of silver nitrate; firstly, cleaning the modified hierarchy porous silicon dioxide obtained in the step 2) with deionized water, and then putting into the glycol solution of silver nitrate, and loading for 48-72 hours in a baking oven at 35-45 DEG C; forming nanoscale silver particles by taking glycol as a reducing agent to reduce silver nitrate; loading the nano silver particles to the modified hierarchy porous silicon dioxide; 3) drying the obtained material in the step 2) after cleaning, thereby obtaining the nano silver loaded porous silicon dioxide.

Owner:ZHEJIANG UNIV

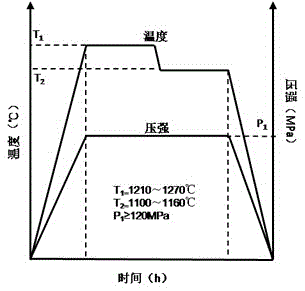

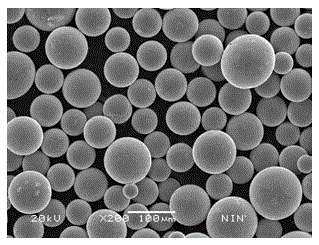

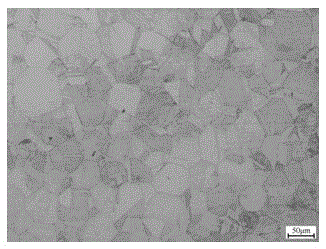

Powder metallurgical method for IN718 alloy

InactiveCN105603259ANarrow particle size distributionAchieve tissue homogenizationPowder metallurgyHot isostatic pressing

The invention provides a powder metallurgical method for IN718 alloy. The powder metallurgical method for the IN718 alloy comprises the following steps: firstly, preparing spherical powder of the IN718 alloy by adopting a plasma rotating electrode process; secondly, putting the spherical powder into a stainless sheath, carrying out vacuum degassing for 4-8 hours at the temperature of 400-800 DEG C, and soldering and sealing the opening of the sheath; and thirdly, carrying out hot isostatic pressure treatment on the sheath after being soldered and sealed, namely firstly carrying out heat and pressure preservation for 2-4 hours at the temperature of 1210-1270 DEG C and the pressure more than 120 MPa, lowering the temperature to be 1100-1160 DEG C while the pressure condition is not changed, continuously carrying out heat and pressure preservation for 2-4 hours, and finally cooling to room temperature at a cooling rate more than 50 DEG per minute. The powder metallurgical method for the IN718 alloy is simple in technology, only hot isostatic pressure temperature is changed, an extra working process does not need to be added, adverse effect of carbon and oxides on particle surfaces can be effectively eliminated without increasing cost, and mechanical properties of the alloy are obviously improved.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

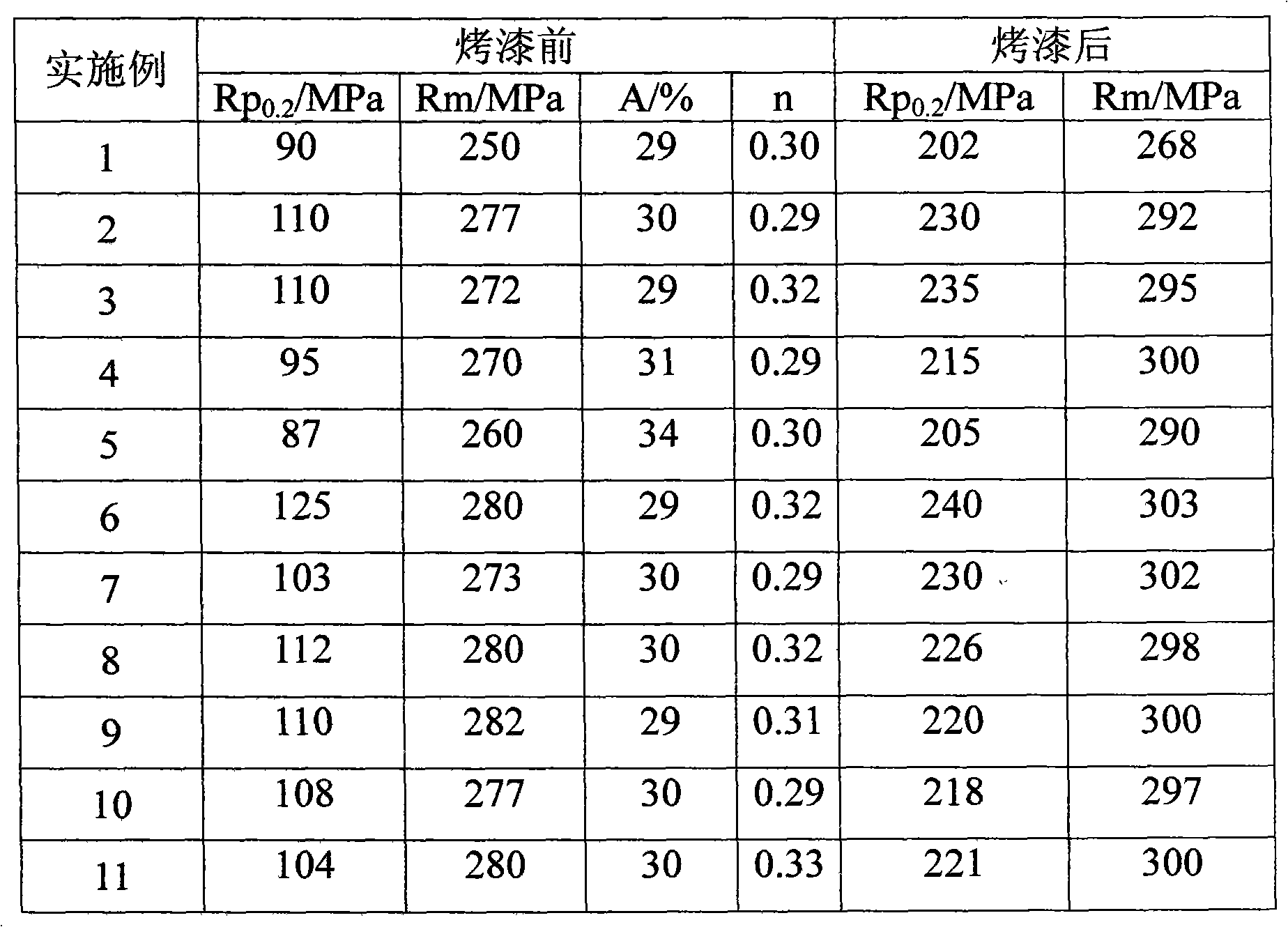

Aluminium alloy with high forming property for automobile body plate

The invention discloses an aluminium alloy with high forming property for an automobile body plate, comprising the following chemical constituents in percentage by weight: 0.50-1.20wt% of Si, 0.35-0.70wt% of Mg, 0.01-0.20wt% of Cu, 0.05-0.20wt% of Mn, less than or equal to 0.10wt% of Cr, 0.01-0.25wt% of Zn, less than or equal to 0.15wt% of Ti, 0.05-0.15wt% of Fe and the balance of Al. The aluminium alloy material of the invention has lower yield strength before baking finish, which is favourable for stamping shaping; and after baking finish, the yield strength is improved. The material has higher forming property and simultaneously satisfies the requirements of the impact resistance of the automobile body plate.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Method for preparing macroporous hollow-sphere titanium oxide photocatalytic material

InactiveCN103752299AControl Hollow ApertureControl areaPhysical/chemical process catalystsPhotocatalytic degradationHigh activity

The invention discloses a method for preparing a macroporous hollow-sphere titanium oxide photocatalytic material for photocatalytic degradation of pollutants. The method aims to provide a macroporous hollow-sphere titanium oxide preparation technique to obtain a material with optimal degradation capacity. The method comprises the following steps: by using a glucose solution as a raw material, preparing colloid carbon spheres under hydrothermal conditions; and by using tetra-n-butyl titanate as a precursor, preparing a uniform-particle high-activity high stability macroporous hollow-sphere titanium oxide photocatalyst by sol-gel and calcination processes. The keys of the preparation process are synthesis of the colloid carbon spheres and the sol-gel technique. The method has the advantages of simple technique, mild conditions and favorable repetitiveness, can be widely used for photocatalytic degradation of organic pollutants, and has wide application prospects in the aspect of environmental treatment.

Owner:SHENYANG LIGONG UNIV

Boron modified HZSM-5 molecular sieve, preparation method and application thereof

InactiveCN106745049ASmall grain sizeSimple method and operationMaterial nanotechnologyMolecular sieve catalystsIon exchangeSeed crystal

The invention discloses a method for preparing nanoscale boron modified HZSM-5 by seed crystal directing. The method comprises the steps as follows: (1) mixing an aluminum source, a silicon source, an alkali source, a boron source, ZSM-5 molecular sieve seed crystals and water, adjusting the pH of an obtained mixture to 10-12 and mixing the mixture uniformly to form gel; (2) crystallizing the gel in a reactor, and performing solid-liquid separation, washing and drying on a crystallized product to obtain a dried crystallized product; (3) adding the dried crystallized product in an ammonium salt solution for ion exchange to obtain an ammonia type ZSM-5 molecular sieve; (4) roasting the ammonia type ZSM-5 molecular sieve to obtain HZSM-5. The invention further discloses a molecular sieve prepared by the method and application of the molecular sieve in a reaction of methanol to propylene. The boron modified HZSM-5 requires no roasting of a template agent and is environment-friendly, the propylene yield and the service life are greatly increased, the selectivity of propylene reaches 44.0wt% or higher, and the service life reaches 500 h or longer.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

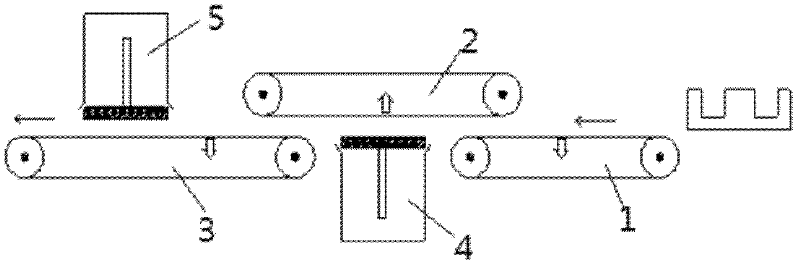

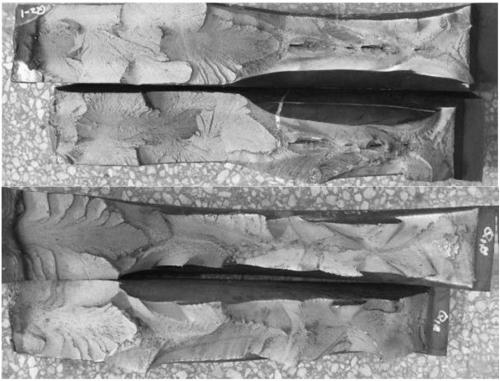

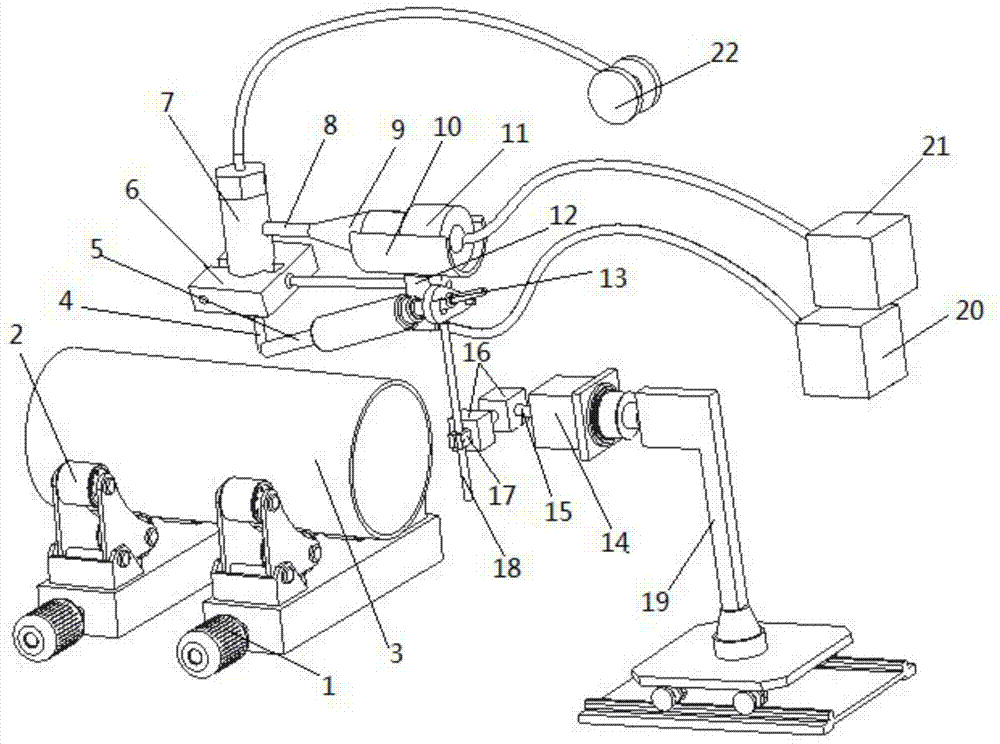

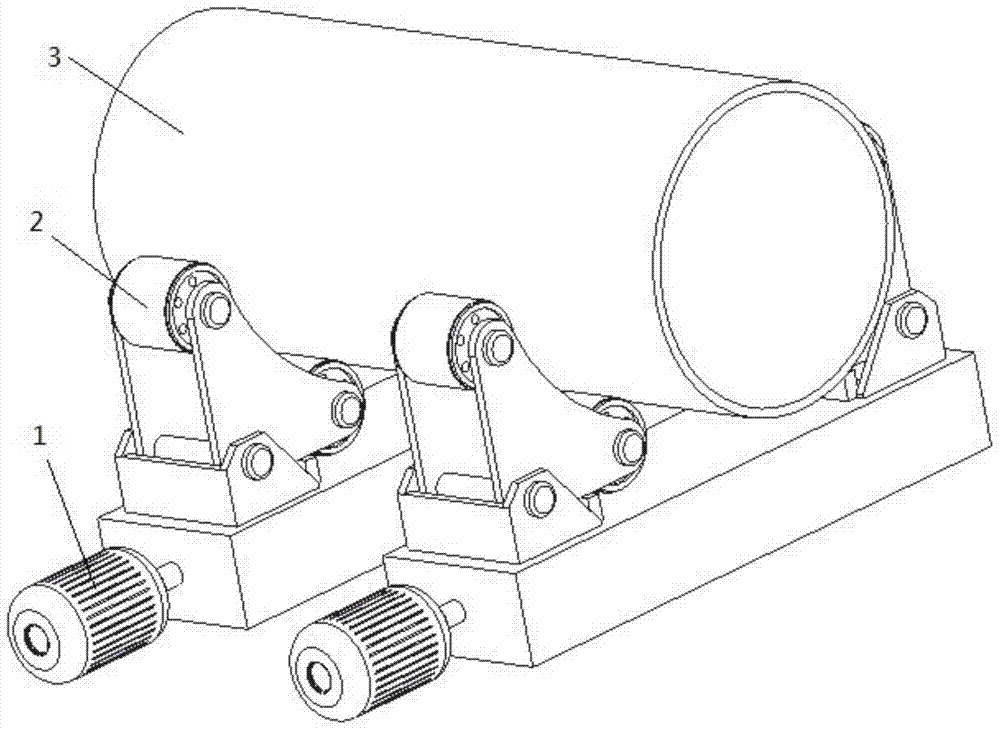

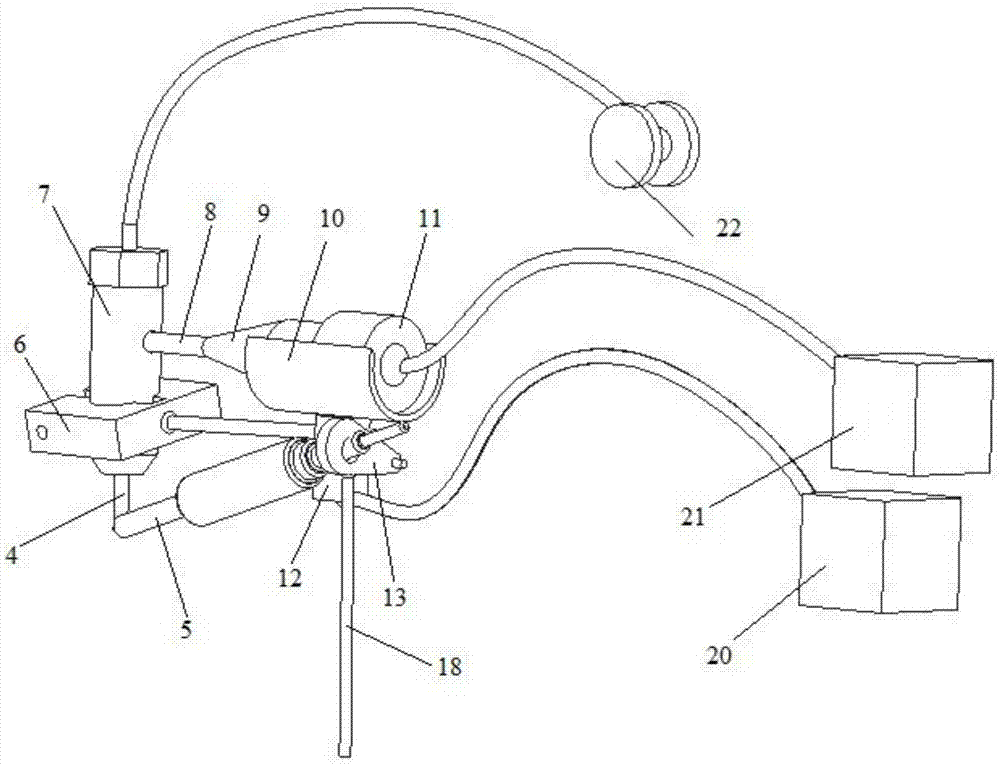

Device and method for welding high steel grade and large wall thickness pipeline steel

The invention discloses a device and a method for welding high steel grade and large wall thickness pipeline steel. The device for welding the high steel grade and large wall thickness pipeline steel is mainly composed of a work platform controller 1, an idler wheel support 2, a work piece 3, a welding gun 5, a wire feeding nozzle 7, an ultrasonic tool head 8, an amplitude variation pole 9, an ultrasonic transducer 11, a welding power source 20, an ultrasonic generator 21, a wire feeding mechanism 22, an oscillator 14, a transmission shaft 15, an angle adjustor 16 and the like. The method for welding the high steel grade and large wall thickness pipeline steel includes: (1) placing the work piece on the idler wheel support, and starting the work platform controller; (2) setting welding voltage and a welding current, turning on the welding power source, and starting the ultrasonic generator after an electric arc is stabilized; (3) adjusting angles of the welding gun through the angle adjustor; (4) starting the oscillator, and driving the welding gun to swing back and forth through entrance and exiting movements of the transmission shaft; (5) starting the wire feeding mechanism, and staring automatic welding. The device and the method for welding the high steel grade and large wall thickness pipeline steel achieve high welding quality, good weld joint formation, and a high welding joint microstructure constituent homogenization degree, and have a broad market application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Non-annealed cold forging steel hot-rolled wire rod and production method thereof

The invention discloses a non-annealed cold forging steel hot-rolled wire rod and a production method thereof. The method comprises the steps of continuous casting, heating, rolling, spinning and cooling. The non-annealed cold forging steel hot-rolled wire rod comprises 0.29-0.38wt% of C, 0.15-0.30wt% of Si, 0.70-0.90wt% of Mn, 0.03wt% or less of P, 0.03wt% or less of S, 0.30wt% or less of Cr, 0.0008-0.0050wt% of B, and the balance of Fe and residual elements. In the heating step, continuous cast billets are heated to 1100-1190DEG C; in the rolling step, the initial finish rolling temperature is 965-995DEG C; in the spinning step, the spinning temperature is 960-990DEG C; and in the cooling step, the cooling speed is 0.5-1.5DEG C / s. The method realizes production of the non-annealed cold forging steel hot-rolled wire rod through optimally designing chemical components, controlling the heating temperature, the initial finish rolling temperature, the spinning temperature and the cooling speed and controlling the amount and the grain size of ferrite by using present devices and technologies without increasing investment or production cost, so the non-annealing production and cost reduction demands of downstream users are met, and pollution of annealing to environment is avoided.

Owner:XINGTAI IRON & STEEL

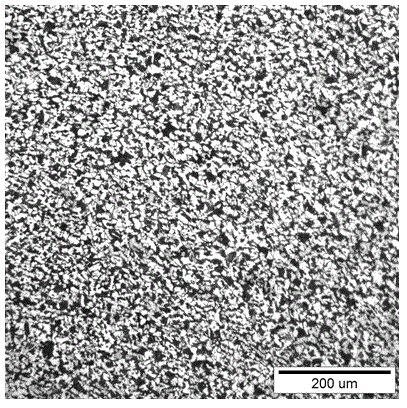

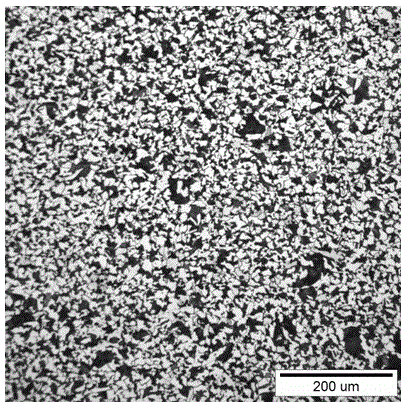

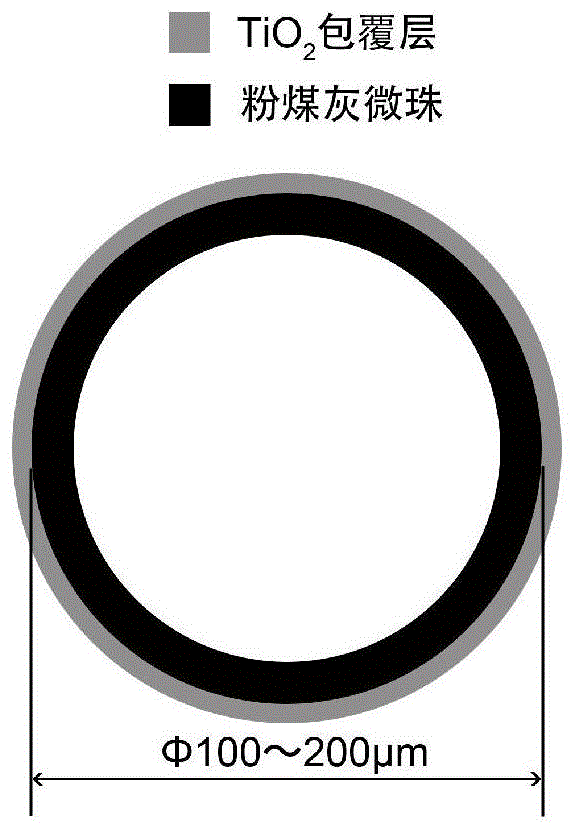

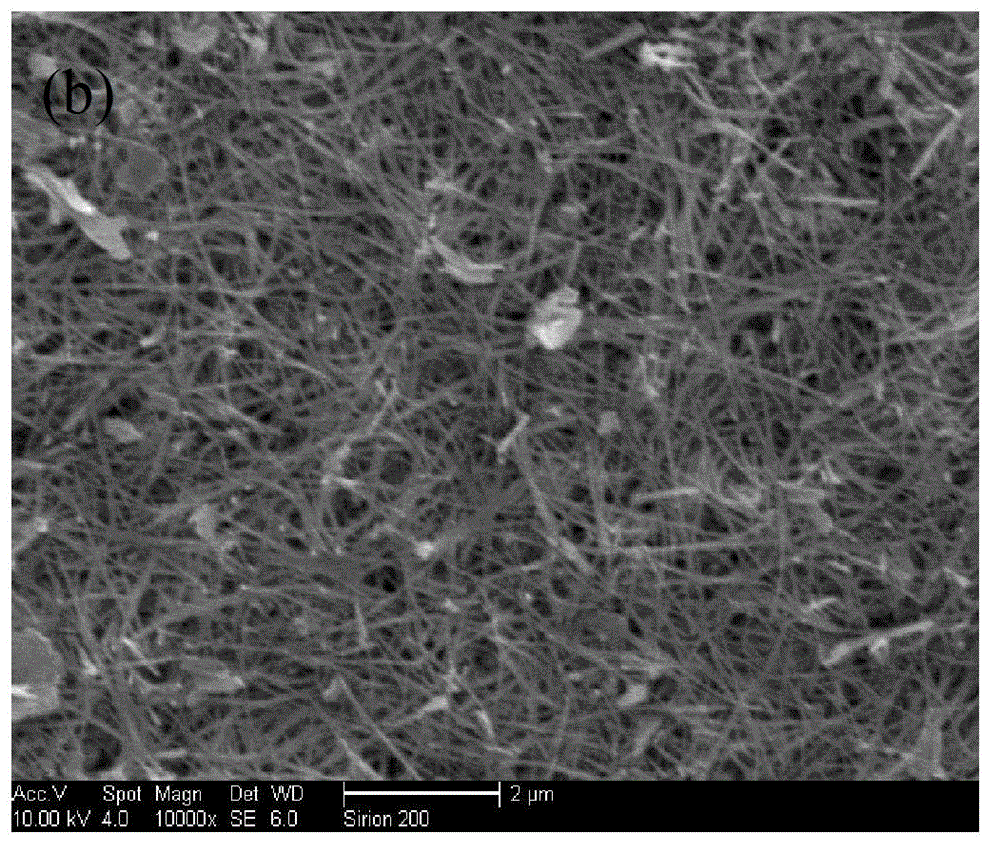

Coal ash microsphere loaded one-dimensional nanometer titanium dioxide (TiO2) composite photocatalyst and preparation method thereof

InactiveCN102872846AFully irradiatedWith heat insulationWater/sewage treatment by irradiationCatalyst activation/preparationLiquid mediumMicrosphere

The invention discloses coal ash microsphere loaded one-dimensional nanometer titanium dioxide (TiO2) composite photocatalyst and a preparation method thereof. The coal ash microsphere loaded one-dimensional nanometer TiO2 composite photocatalyst consists of a coal ash microsphere and a one-dimensional nanometer TiO2 film covered on the surface of the coal ash microsphere, wherein the coal ash microsphere is in a thin-wall hollow structure; the external diameter of the coal ash microsphere is 100-200 micrometers; the thickness of the wall is 2-6 micrometers; the thickness of the one-dimensional nanometer TiO2 film is about 0.5-3 micrometers; and the TiO2 is in the one-dimensional nanometer structure. The composite photocatalyst disclosed by the invention is easy to disperse, recover and use in liquid medium, has a higher reaction activity and has a wide application prospect on the water body purification aspect, and a purpose of effectively removing organic pollutants in the water body can be achieved.

Owner:HEFEI UNIV OF TECH

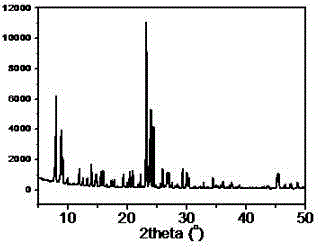

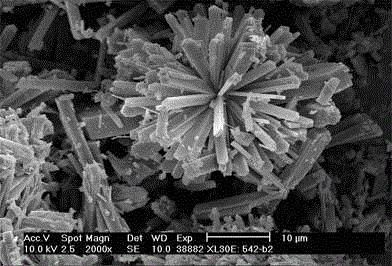

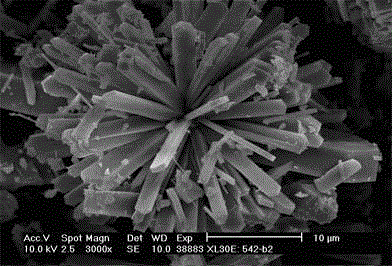

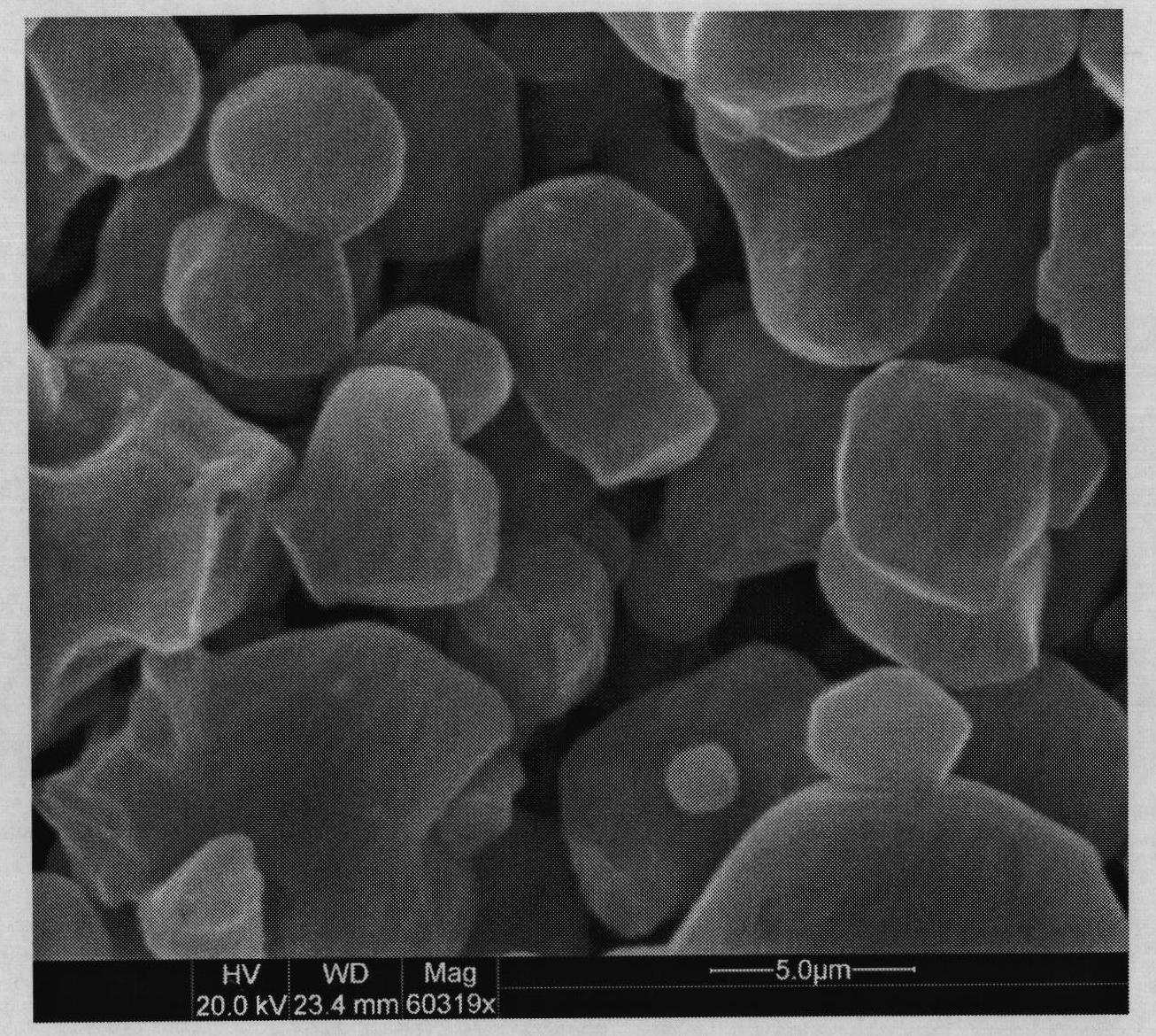

Synthesis method for ZSM-5 molecular sieve of special morphology

ActiveCN105293520AAdjust grain sizeControl shapePentasil aluminosilicate zeoliteMolecular sieveCrystal morphology

The invention belongs to the technical field of zeolite molecular sieve synthesis, in particular to a synthesis method for a ZSM-5 zeolite molecular sieve of a petaloid morphology. According to the synthesis method, morphology control is an important aspect in the field of molecular sieve synthesis; when MFI zeolite molecular sieve catalysts of different crystal morphologies are adopted in a catalytic reaction, all of the product selectivity, the reaction activity, the reaction stability and the like can be changed obviously along with the morphology difference. The invention further relates to a preparation method for ZSM-5 zeolite. The synthesis method provided by the invention has the advantages that the synthesis process is simple and convenient, and industrialization is easy to realize; meanwhile, a plurality of templates are applied, so as to effectively control the product crystallinity and the final morphology; sample XRD shows that the obtained product is the ZSM-5 molecular sieve of which the product crystallinity is high; sample SEM shows that zeolite has a special petaloid morphology, and thus can be utilized for industrial production of ZSM-5 zeolite of the special petaloid morphology.

Owner:CHINA PETROLEUM & CHEM CORP +1

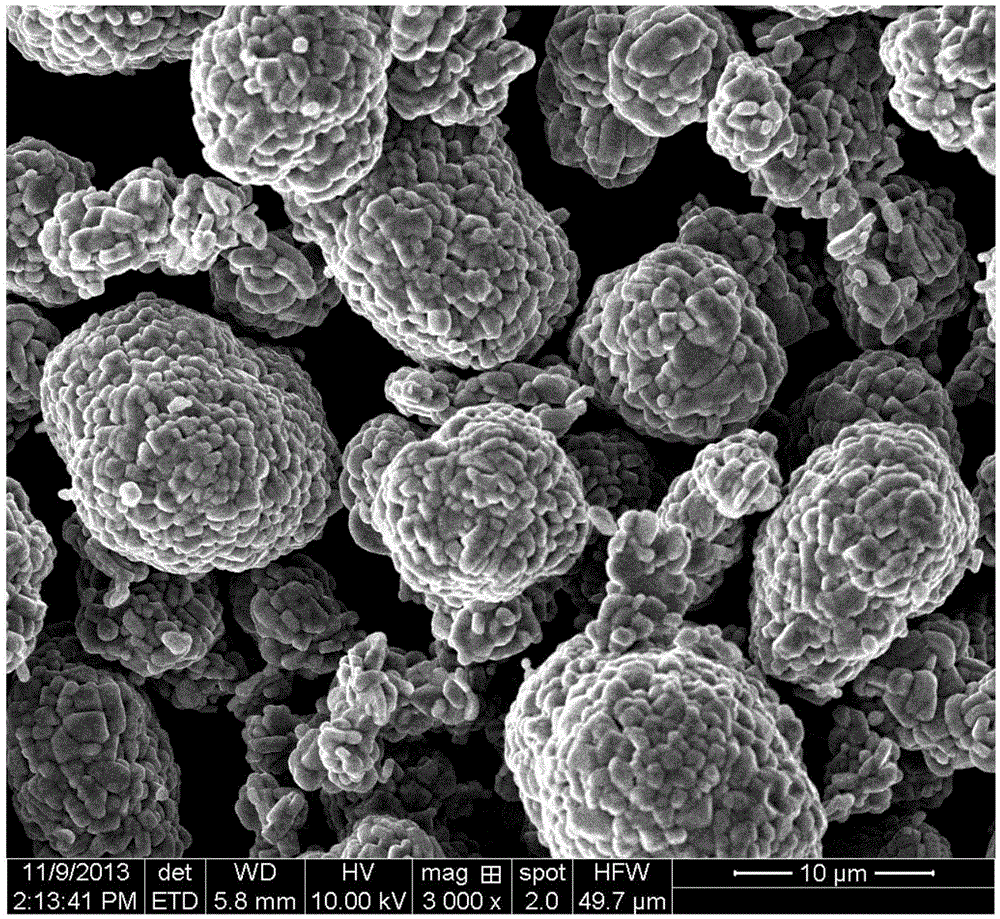

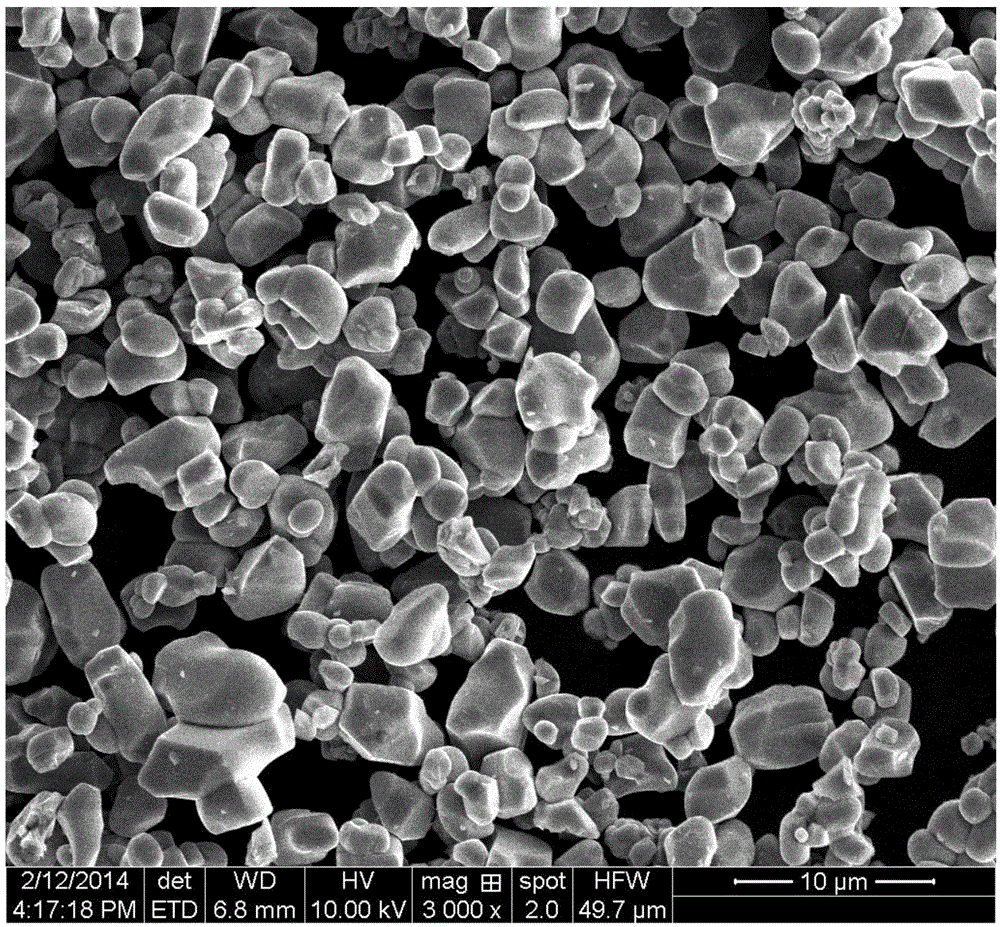

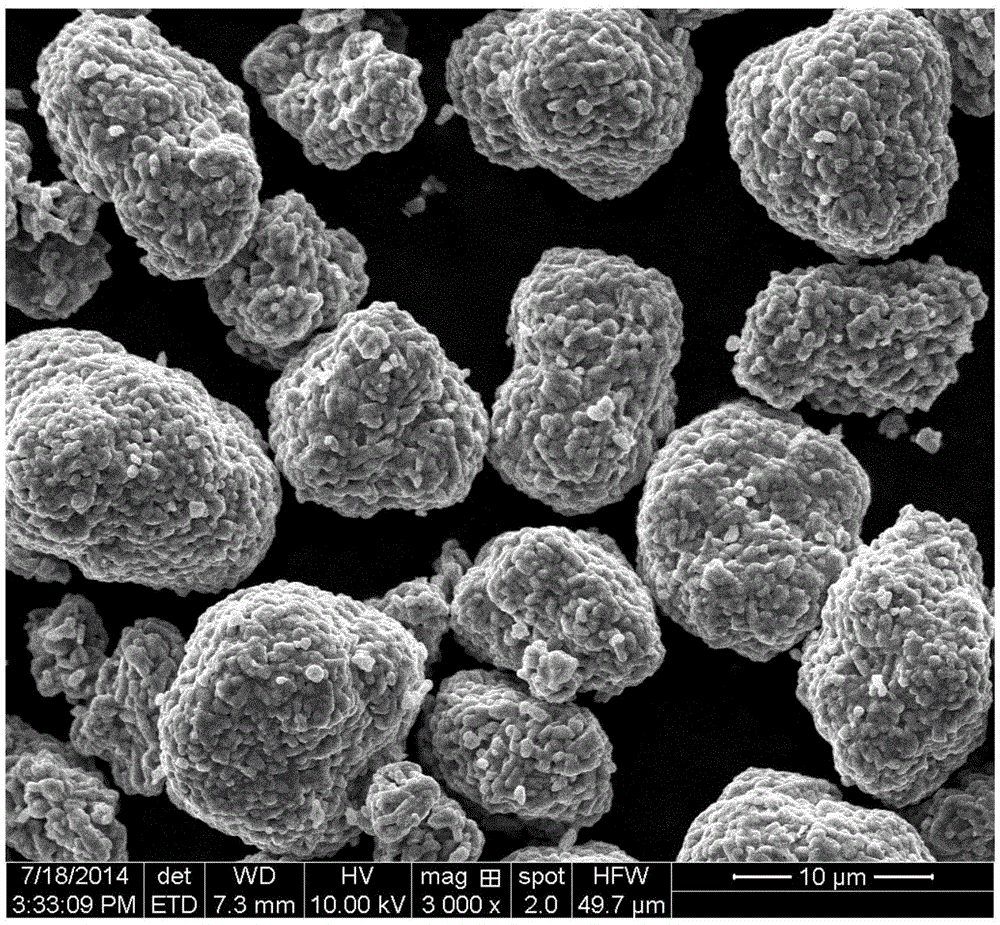

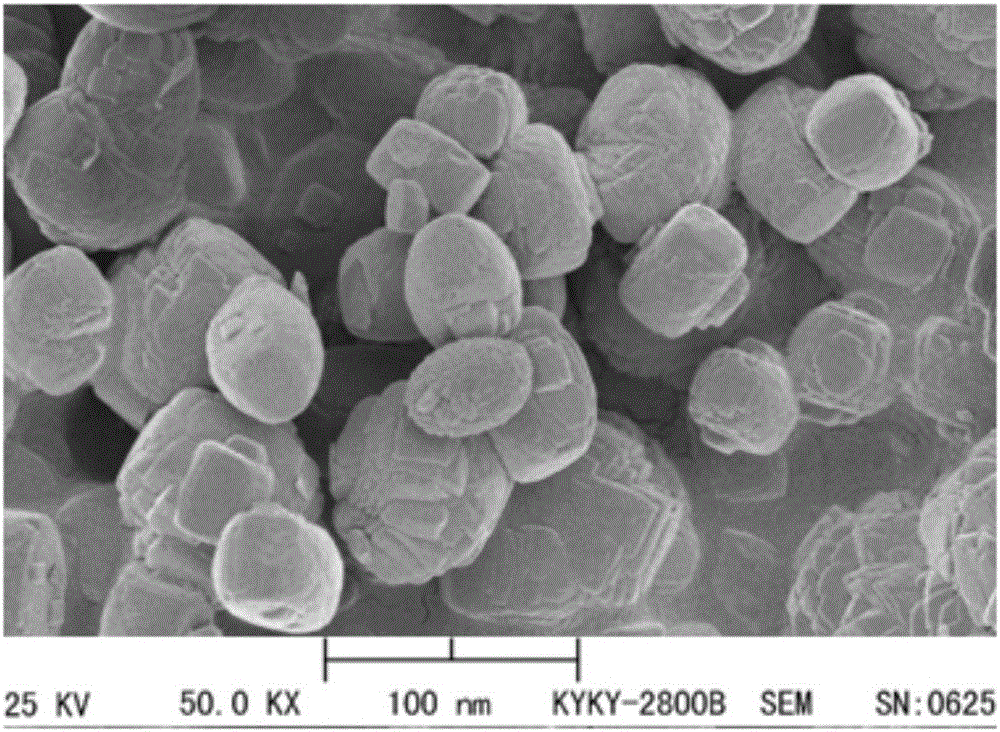

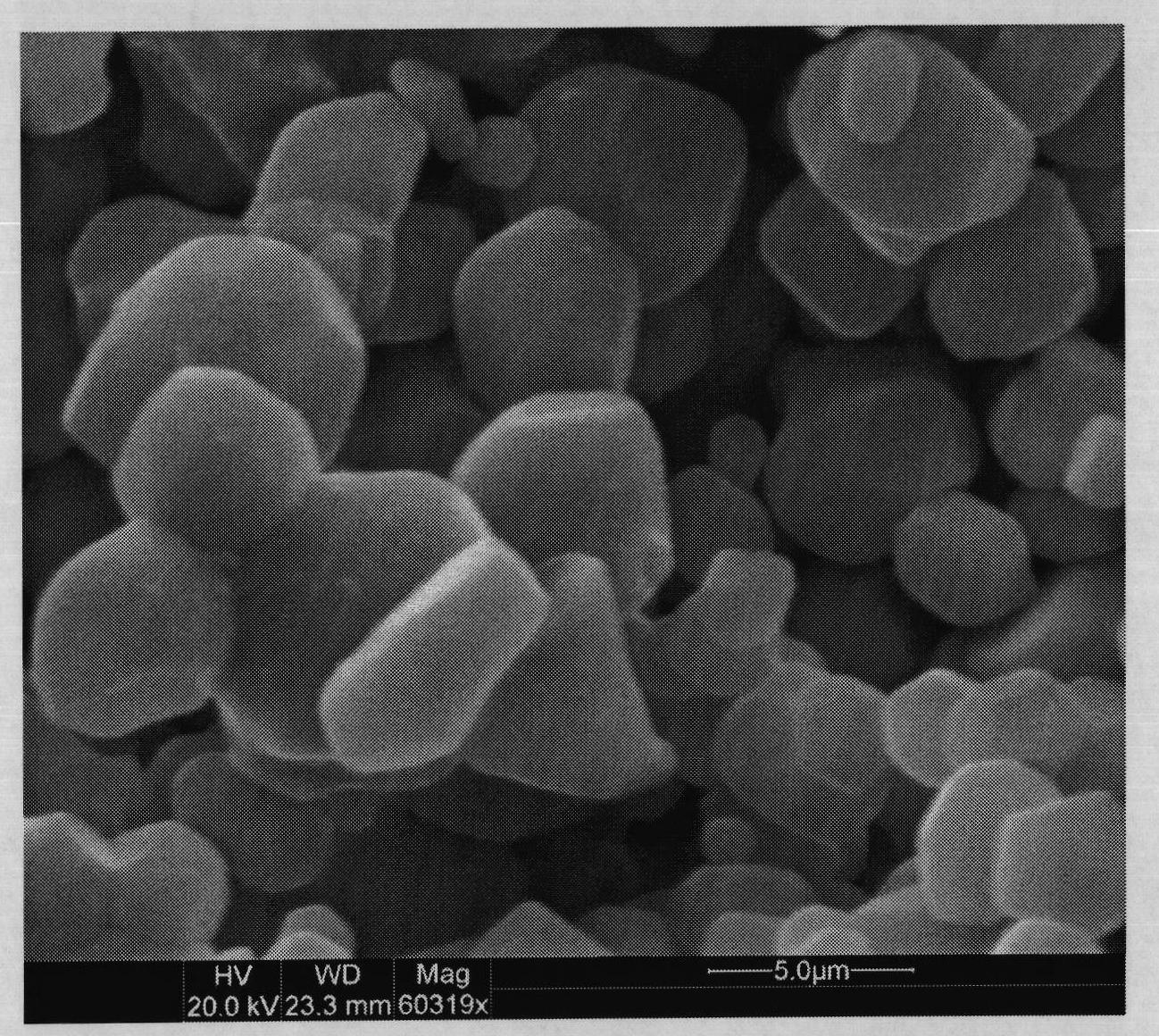

Method for preparing cobaltosic oxide with large grain size and high safety

InactiveCN101982422ARefined grain sizeGrain Size ControlCobalt oxides/hydroxidesCrystal morphologyForeign matter

The invention provides a method for preparing cobaltosic oxide with large grain size and high safety, comprising the following steps: preparing the raw material cobalt and a precipitant into cobalt solution and precipitant solution with deionized water, adding the cobalt solution and the precipitant solution which are prepared to certain concentration to a reaction vessel by the charging methods including cocurrent charging according to certain molar ratio, preparing the cobalt salt precursor by controlling the reaction temperature, charging speed, PH value and stirring speed, washing and dehydrating the precursor, directly putting the water-containing filter cake into a pot, spheroidizing and calcining the pot at high temperature, carrying out mechanical grinding, grading and activating, controlling the grain size and the crystal morphology and finally removing the magnetic metal foreign bodies, thus finally obtaining the high quality battery grade cobaltosic oxide. The method is simple in process, easy to operate, low in cost, energy-saving, environment-friendly and suitable for industrial production. The prepared cobaltosic oxide looks like spheroid and has large grain size, good powder flowability and uniform granularity.

Owner:JIANGSU DONGXIN ENERGY TECH

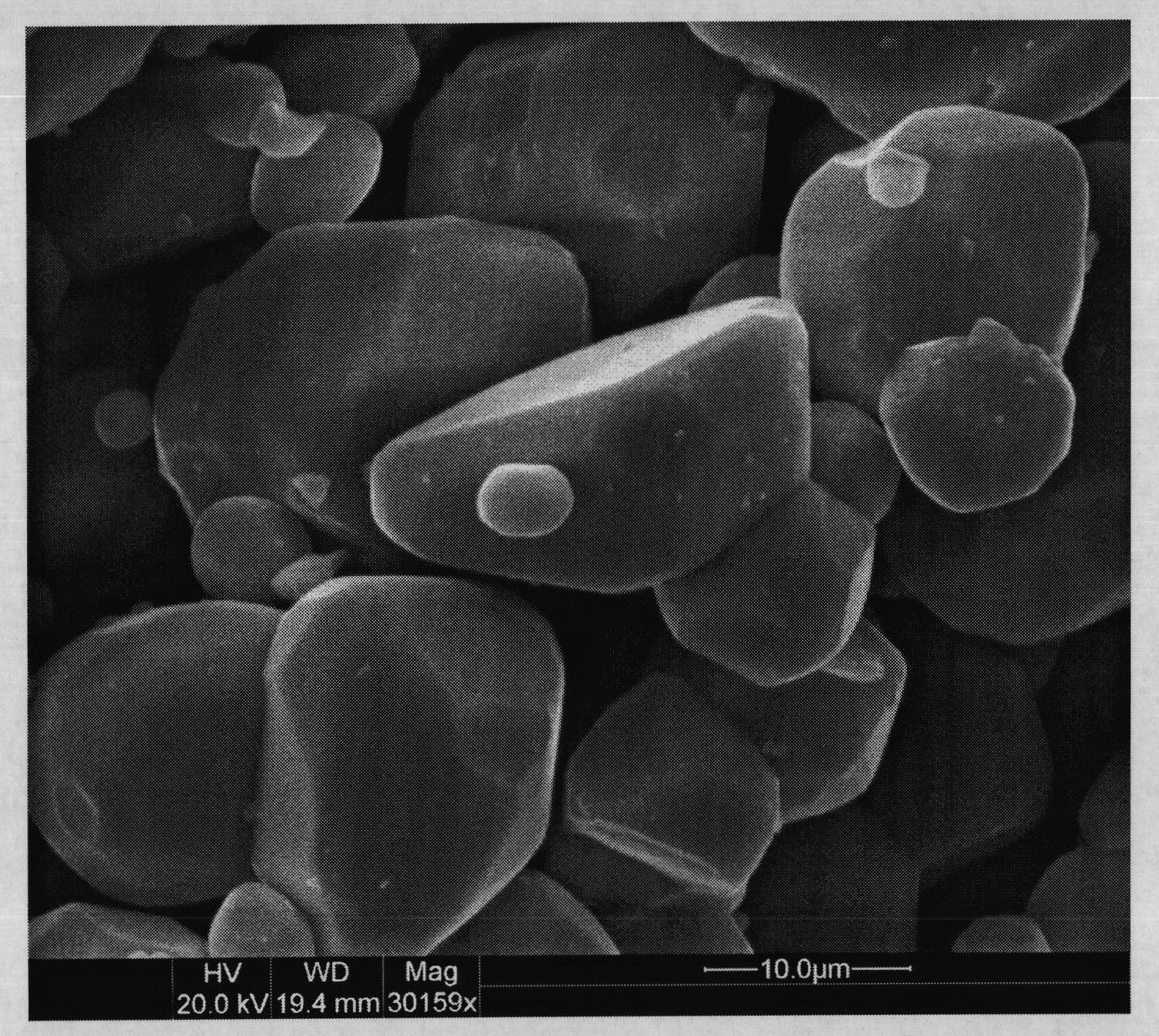

Preparation method of rod-like calcite type calcium carbonate crystals

InactiveCN103253693AControl grain sizeImprove controllabilityCalcium/strontium/barium carbonatesWater bathsAlcohol

The invention discloses a preparation method of rod-like calcite type calcium carbonate crystals, relating to a preparation method for calcium carbonate crystals and aiming at solving the technical problems that an existing preparation method of the rod-like calcite type calcium carbonate crystals is complicated, and high in cost, and the sizes of crystal particles cannot be well controlled. The preparation method disclosed by the invention comprises the steps of: I. placing a Ca(OH)2 solution into a thermostatic water bath cauldron, and introducing CO2 gas under the stirring condition; II. adding a PASP (Sodium of Polyaspartic Acid) solution with certain concentration into the solution, reacting for certain time, and then stopping the introduction of the CO2 gas; and III. washing the obtain samples respectively with deionized water and absolute ethyl alcohol, leaching, and carrying out vacuum drying for certain time under certain thermostatic condition to obtain the calcium carbonate crystals. The rod-like calcite type calcium carbonate crystals can be produced into plastics absorbed by the environment when being applied to plastic materials.

Owner:HEILONGJIANG UNIV

Method for making 17-7PH thick wall seamless pipe

InactiveCN101733303ALarge amount of deformationReduce the number of cold processing passesRoll mill control devicesFurnace typesDistortionReduction rate

The invention relates to a method for making a 17-7PH thick wall seamless pipe, which comprises the steps of: 1, cold deformation, wherein cold-rolling and cold-drawing integrated production process is adopted, the external diameter dereduction factor is controlled to be 25-32 percent, the wall thickness reduction rate is controlled to be 16-20 percent, the distortion is controlled to be 38-50 percent; 2, baking at low temperature after drawing the external diameter, wherein the baking temperature is 200-300 DEG C and the baking time is 20-30min; 3, heat treatment, wherein a continuous roller hearth furnace is adopted in a middle heat treatment process, the solid solution temperature is 1050-1080 DEG C, and the heat preservation time is controlled to be 35-60min; and the heat treatment for a finished product adopts a continuous type roller hearth furnace, the heat treatment process is a solid solution and aging integrated treatment process, the solid solution temperature is 1040-1060 DEG C, and the heat preservation time is 20-30min; 4, scouring, wherein the scouring temperature is controlled to be 40-60 DEG C and the scouring time is controlled to be 15-20min; and 5, straightening, deoiling, degreasing, cutting and hammering. The invention reduces cold machining pass, prevents the pipe from longitudinally cracking, meets the requirement on magnetic conductivity of the finished product, provides surface quality, and controls the size of the finished product.

Owner:宝钢特钢有限公司

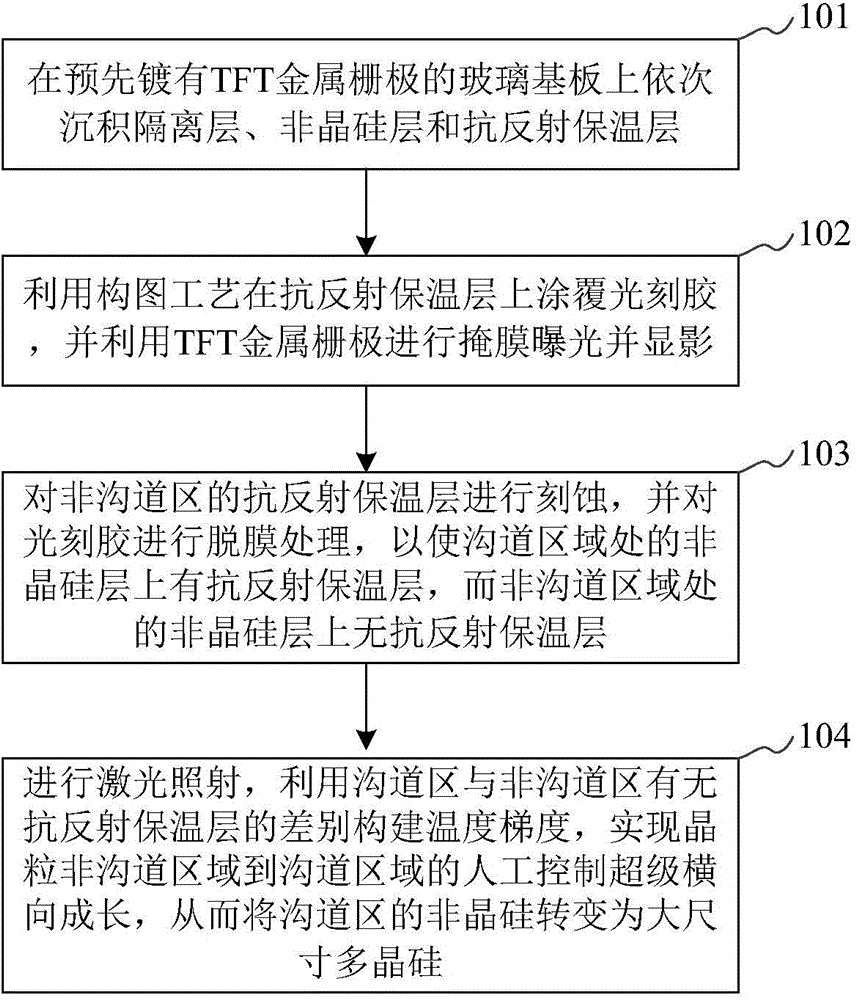

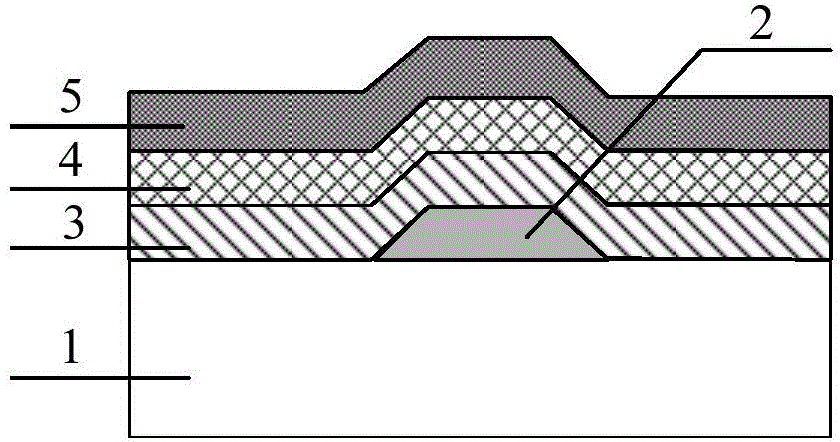

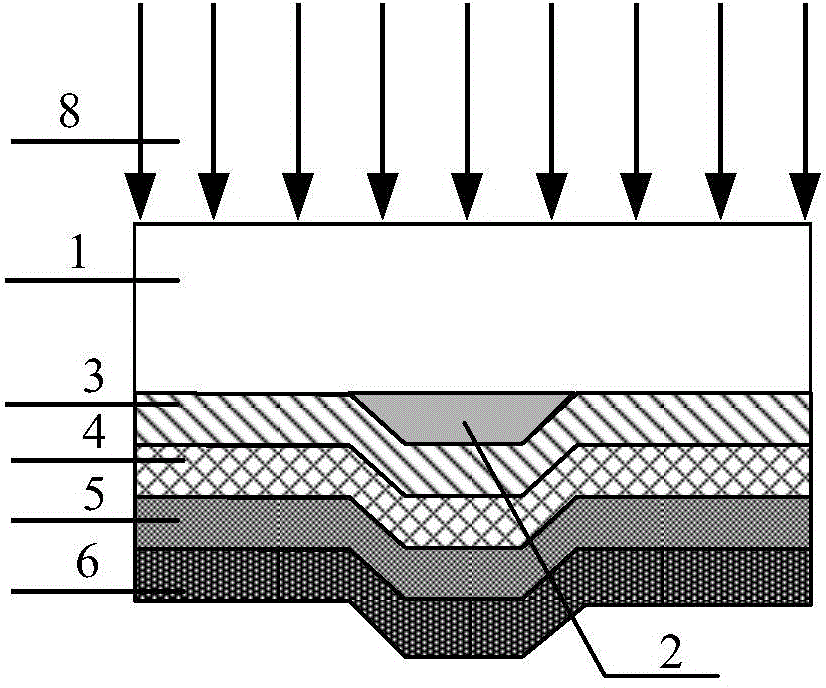

Thin film transistor low-temperature polycrystalline silicon thin film manufacturing method

InactiveCN104465401AControl grain sizeImprove mobilityTransistorSemiconductor/solid-state device manufacturingComposition processCharge carrier mobility

The invention discloses a thin film transistor low-temperature polycrystalline silicon thin film manufacturing method. The method includes the steps of firstly, sequentially depositing an isolation layer, a non-crystalline silicon layer and an anti-reflection heat preservation layer on a glass substrate where a TFT metal grid is plated in advance; secondly, coating the anti-reflection heat preservation layer with photoresist through a picture composition process, and conducting mask exposure and developing through the TFT metal grid; thirdly, etching the portion, in a non-channel area, of the anti-reflection heat preservation layer, and conducting demolding on the photoresist; fourthly, conducting laser radiation so that the non-crystalline silicon of a channel area can be converted into large-size polycrystalline silicon. By means of the technical scheme, the temperature gradient of the TFT channel area and the non-channel area can be formed, the manual-control super transverse growth of crystalline grain from the non-channel area to the channel area can be achieved, the TFT channel area has only one grain boundary, and therefore the carrier migration rate is increased, and the performance of a device in a channel is uniform.

Owner:TRULY HUIZHOU SMART DISPLAY

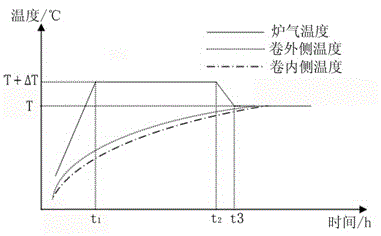

Annealing process of aluminum alloy coiled material

ActiveCN104087879AEffective monitoring of annealing temperatureMonitor annealing temperatureHeating furnaceToughness

The invention provides an annealing process of an aluminum alloy coiled material. According to the annealing process provided by the invention, the annealing time is greatly shortened,the problem of poor finished material coil head-tail structure property difference generated when annealing treatment is carried out on an aluminum-magnesium alloy coiled material is solved by adopting an existing aluminum alloy annealing process, the size of a crystal grain can be effectively controlled and the plasticity and toughness of a finished product state coiled material are improved. The annealing process is characterized by comprising the following steps: placing the aluminum alloy coiled material into an annealing heating furnace; fast heating the aluminum alloy coiled material by setting the furnace gas temperature of the annealing heating furnace as T+delta T, and monitoring the temperature of the aluminum alloy coiled material; when the outer side temperature of the aluminum alloy coiled material, namely the high-point temperature of the aluminum alloy coiled material, reaches T-delta t, reducing the furnace gas temperature of the annealing heating furnace to T, wherein the temperature reduction time is 60-90 minutes; and when the inner side temperature of the aluminum alloy coiled material, namely the low-point temperature of the aluminum alloy coiled material, is monitored to reach T-(5-30 DEG C), preserving heat for 60-120 minutes, and then taking out of the furnace for air-cooling, wherein the temperature T is the predetermined target temperature of the annealing of the aluminum alloy material, the delta T is 20-150 DEG C, and the delta t is 10-70 DEG C.

Owner:YINBANG CLAD MATERIAL

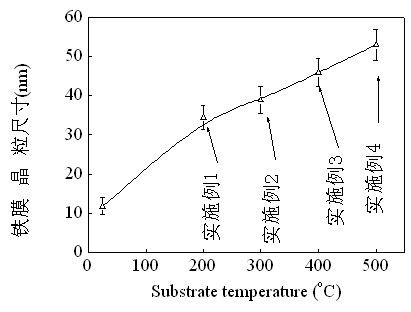

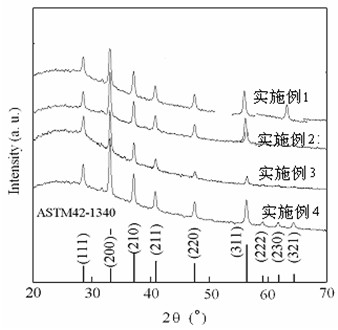

Method used for preparing FeS2 film and capable of controlling precursor grain size

InactiveCN102560374ARefined grain sizeControl grain sizeFinal product manufactureVacuum evaporation coatingAlcoholControl quality

The invention discloses a method used for preparing a FeS2 film and capable of controlling precursor grain size. A coating substrate is boiled in saturation chromic acid solution, washed with deionized water, and washed and dried through ultrasonic oscillation in acetone, absolute ethyl alcohol and deionized water sequentially. A pure Fe film is sputtered, and temperature and thickness of the substrate are controlled. The pure Fe film and sulphur powder are packaged in a glass tube to be processed through sulfidizing. The method can obtain fine and even precursor ferrum film grain size, and the grain size can be controlled conveniently. The method can use optimization of different technology of optimizing precursor film sputtering and following sulfidizing and flexibly controls quality and state of the finally obtained FeS2 film. A control means and a control process are flexible, optimization of preparation technology is facilitated, and more choices for industrial production of the FeS2 film are also provided.

Owner:ZHEJIANG UNIV

Method for preparing rare earth titanate nanocrystalline with controllable size through self-propagating combustion

ActiveCN103332733AShort reaction timeSimple preparation processMaterial nanotechnologyTitanium compoundsMagnetic stirrerMetal

The invention discloses a method for preparing rare earth titanate nanocrystalline with the controllable size through self-propagating combustion. The method comprises the following steps of: hydrolyzing titanic alkoxide to obtain oxygen titanium hydroxide, and dissolving the oxygen titanium hydroxide in a salpeter solution to obtain nitric acid oxygen titanium; placing rare earth nitrate, the nitric acid oxygen titanium and glycine in an evaporating dish, and placing the evaporating dish on a magnetic stirring apparatus so as to volatilize liquid; continuously heating under the stirring condition, stopping stirring when sparkle occurs, wherein the sparkle rapidly spread and burns, and obtaining fluffy rare earth titanate powder on the evaporating dish in the end. According to the method, the glycine is taken as a fuel and is subjected to self-propagating combustion by using heat generated by the oxidation-reduction reaction happening between the rare earth metal titanate and the glycine, so that the rare earth titanate nanocrystalline is rapidly synthesized. The regulation and control of crystalline size of the rare earth titanate can be realized by adjusting and controlling the molar ratio of nitrate ions to the glycine. The method disclosed by the invention has the advantages of being short in reaction time, simple in technology and environment-friendly; equipment is simple; and the production cycle is short.

Owner:FUJIAN NORMAL UNIV

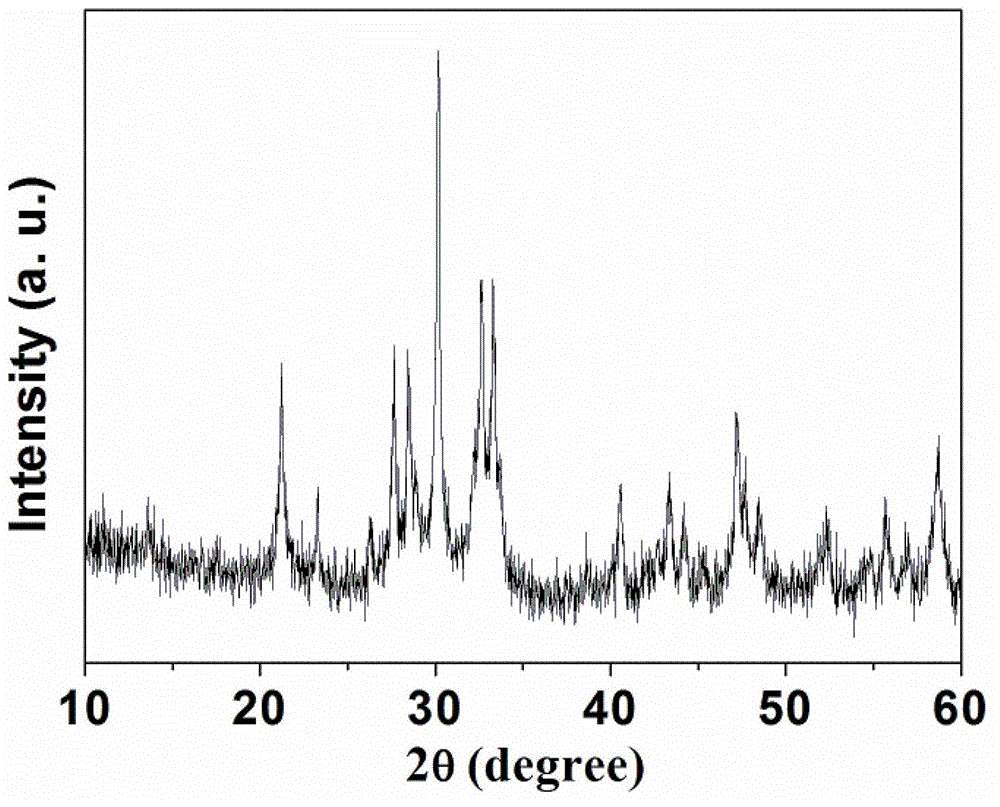

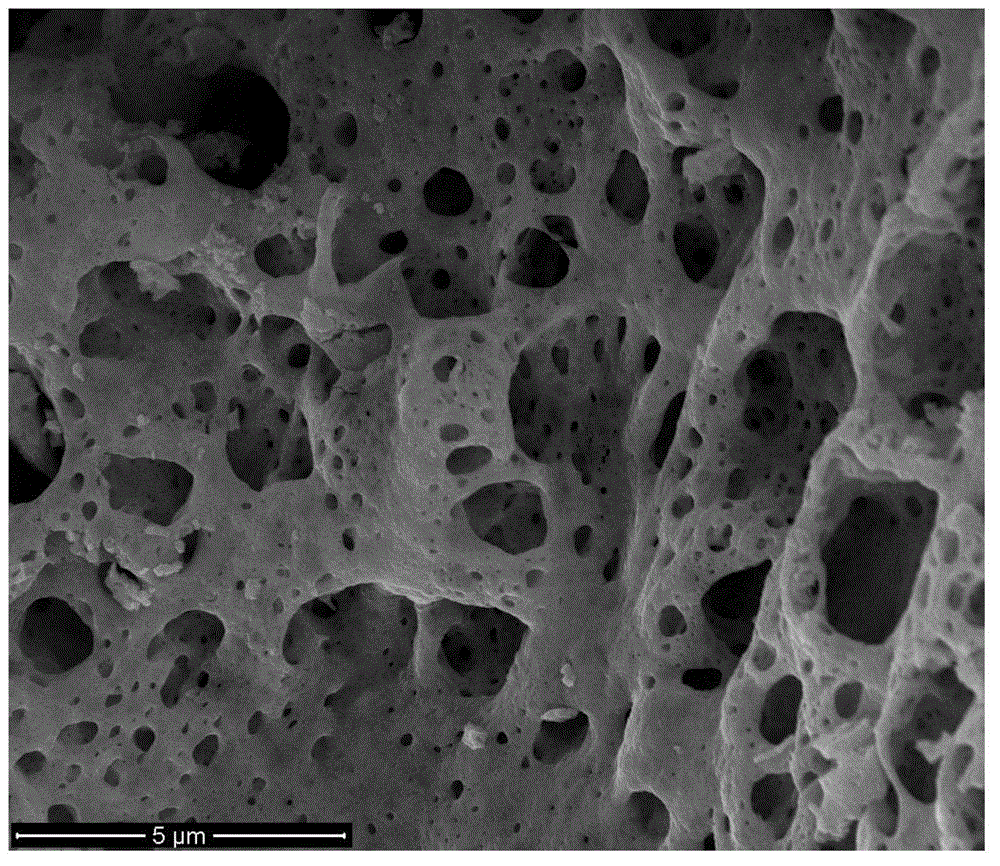

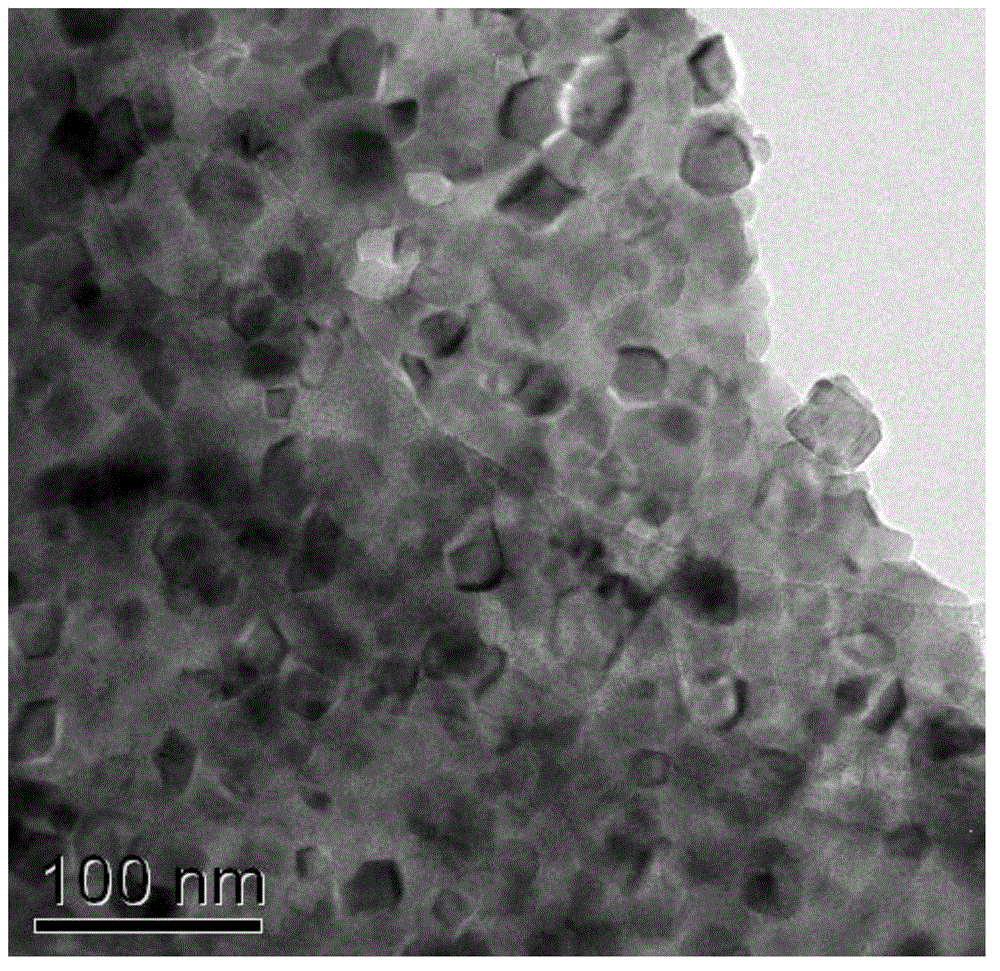

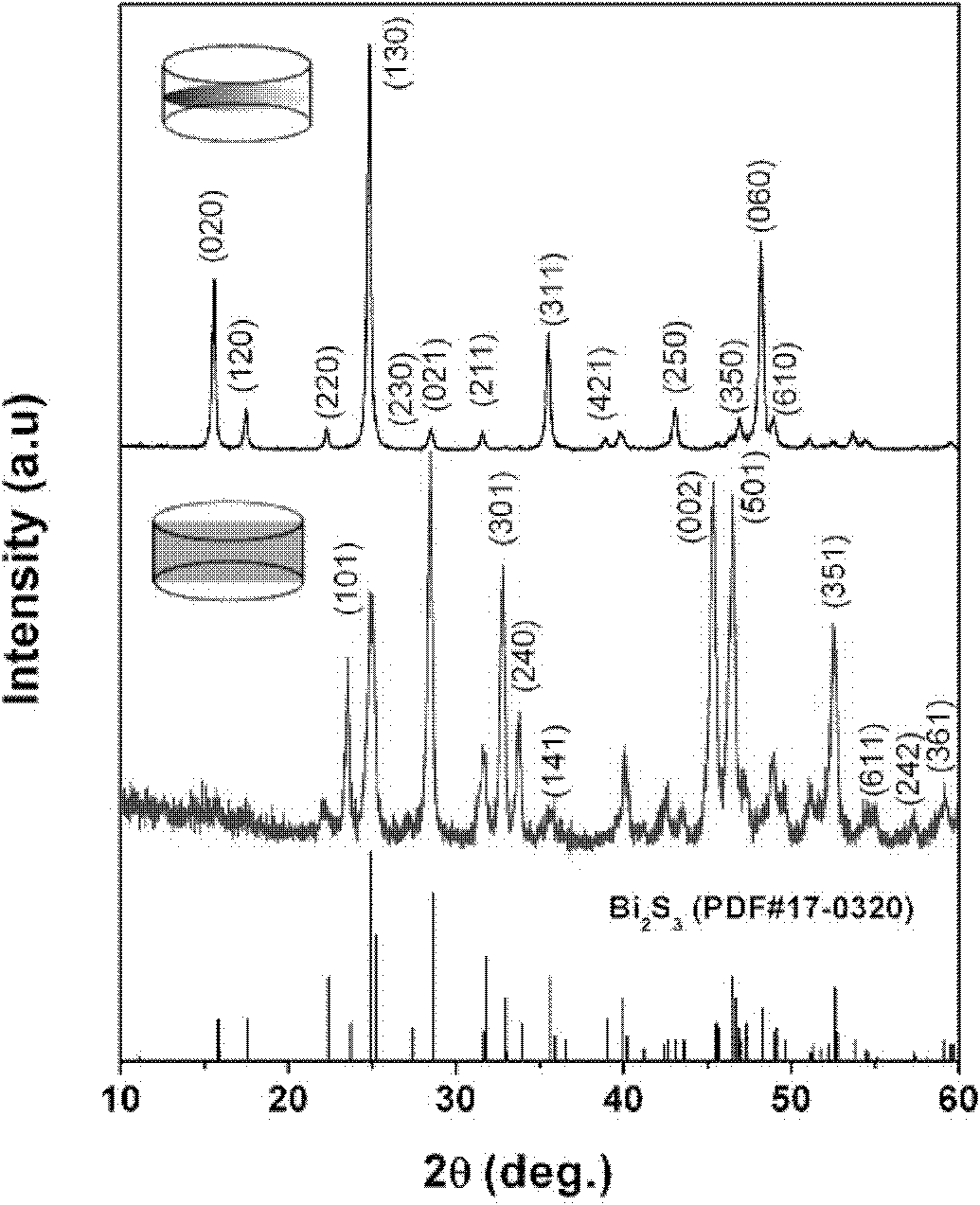

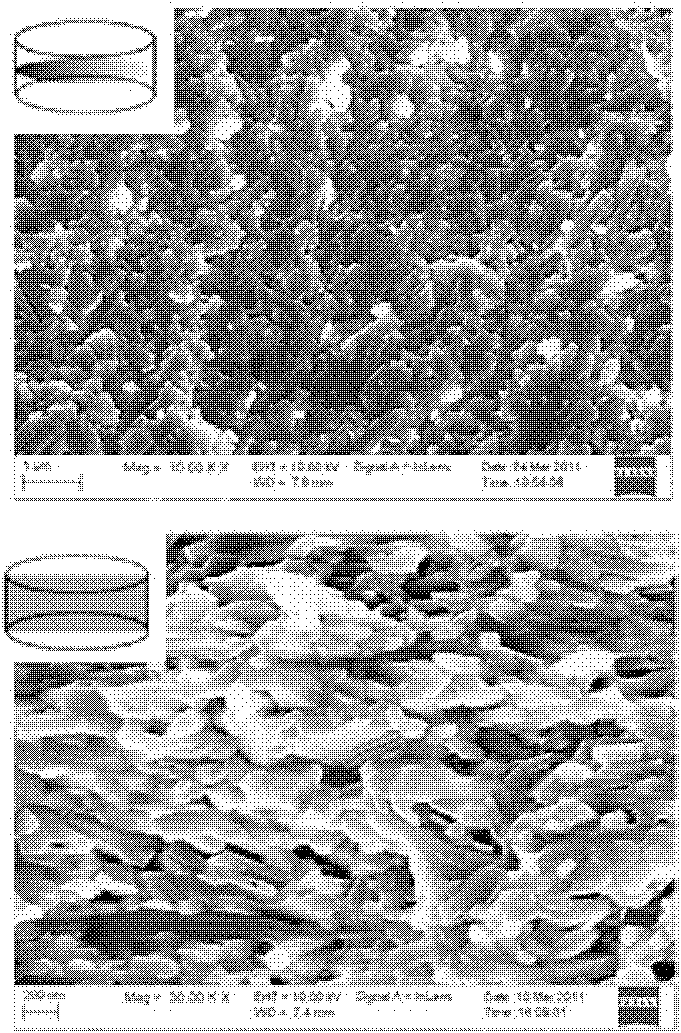

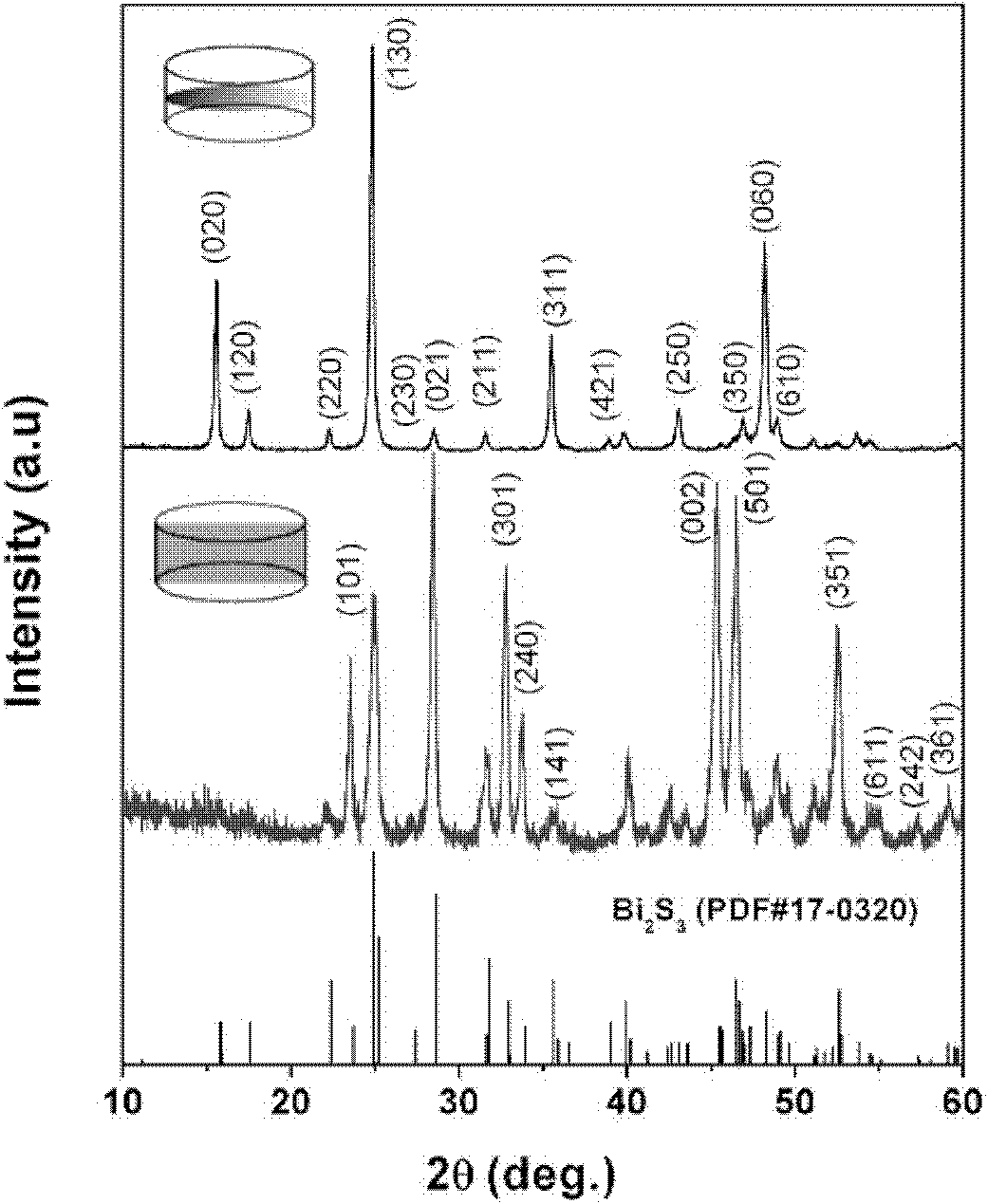

Method for preparing polycrystalline textured thermoelectric material from single-crystal bismuth sulfide precursor powder

InactiveCN102161507AControl textureControl grain sizeBismuth compoundsBismuth sulfideThermoelectric materials

The invention belongs to the technical field of energy materials, in particular relates to a method for preparing polycrystalline textured thermoelectric materials from single-crystal bismuth sulfide precursor powder. Specifically, the method comprises the following steps of: selecting uniformly-orientated single-crystal bismuth sulfide [Bi2S(3-x), 0<=x<=0.5] powder (including nanoflakes, nanotubes and nanowires) as precursor powder; performing rapid sintering under increased pressure by using a spark plasma sintering technique so that the single-crystal powder trends to be arranged in the direction perpendicular to the pressure and freeze to form highly-textured dense polycrystalline bulk thermoelectric materials; and controlling the texture degree, the crystal grain degree and the density of the bulk materials by adjusting the applied pressure, the sintering temperature and the heat retention time. Owing to the texture, the polycrystalline materials show strong anisotropy, so that the power transmission performance is greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

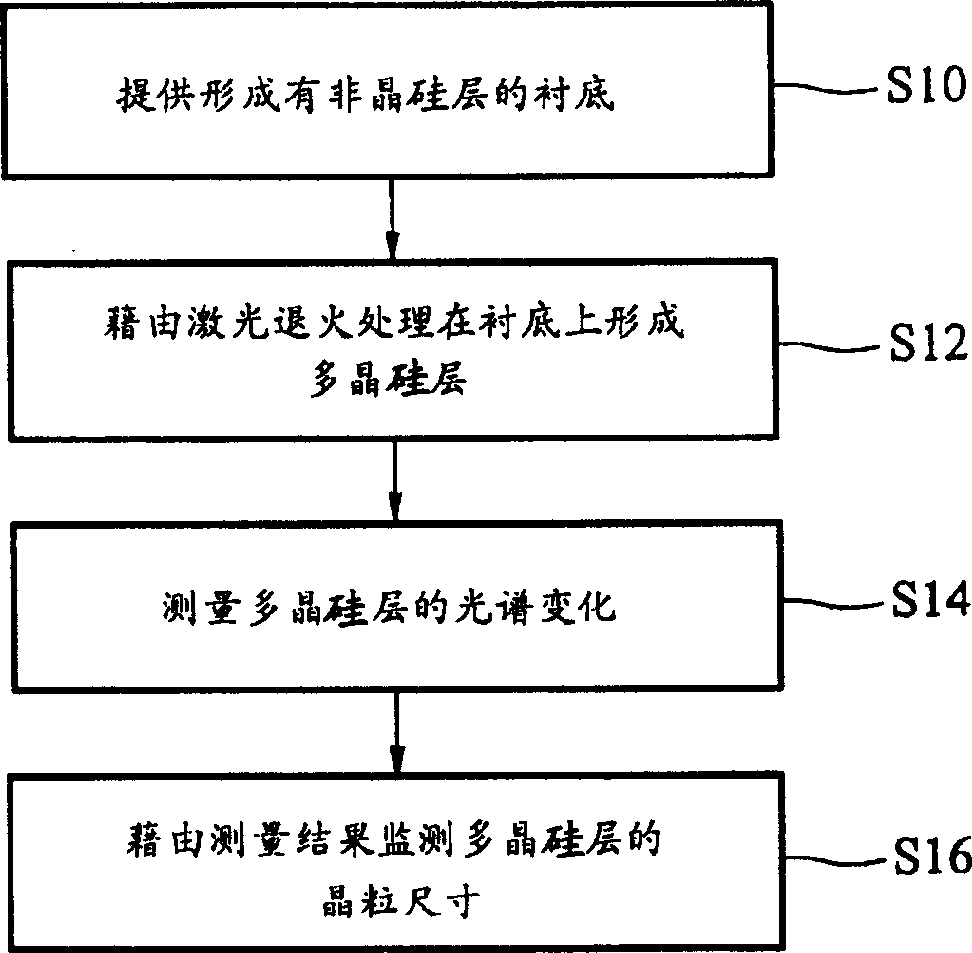

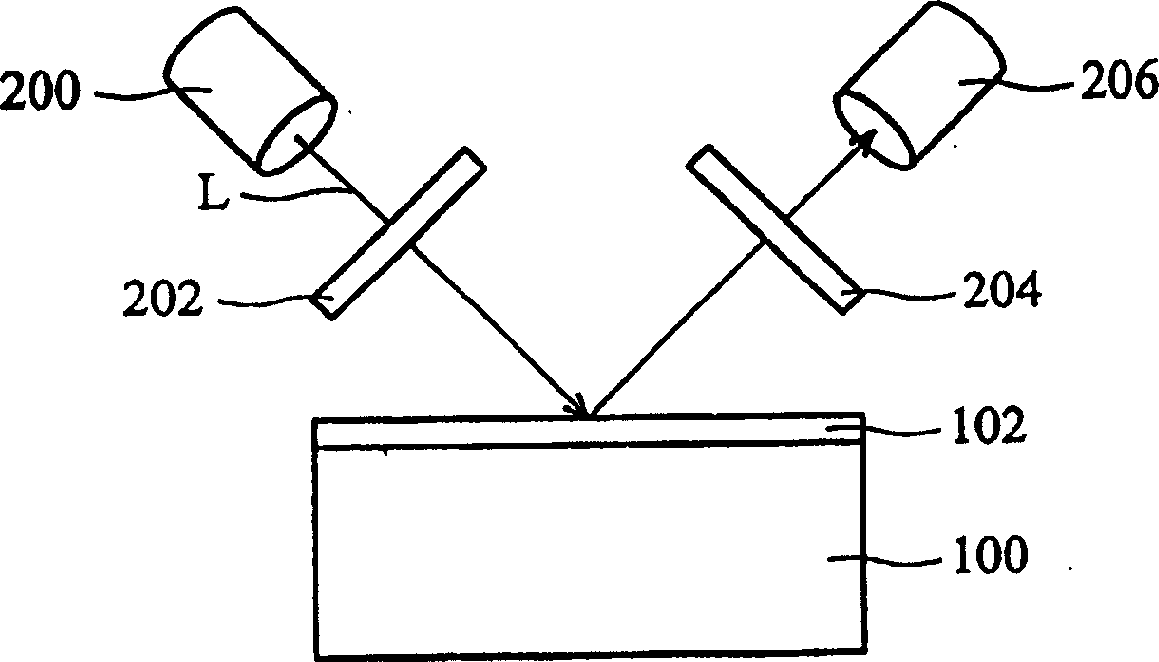

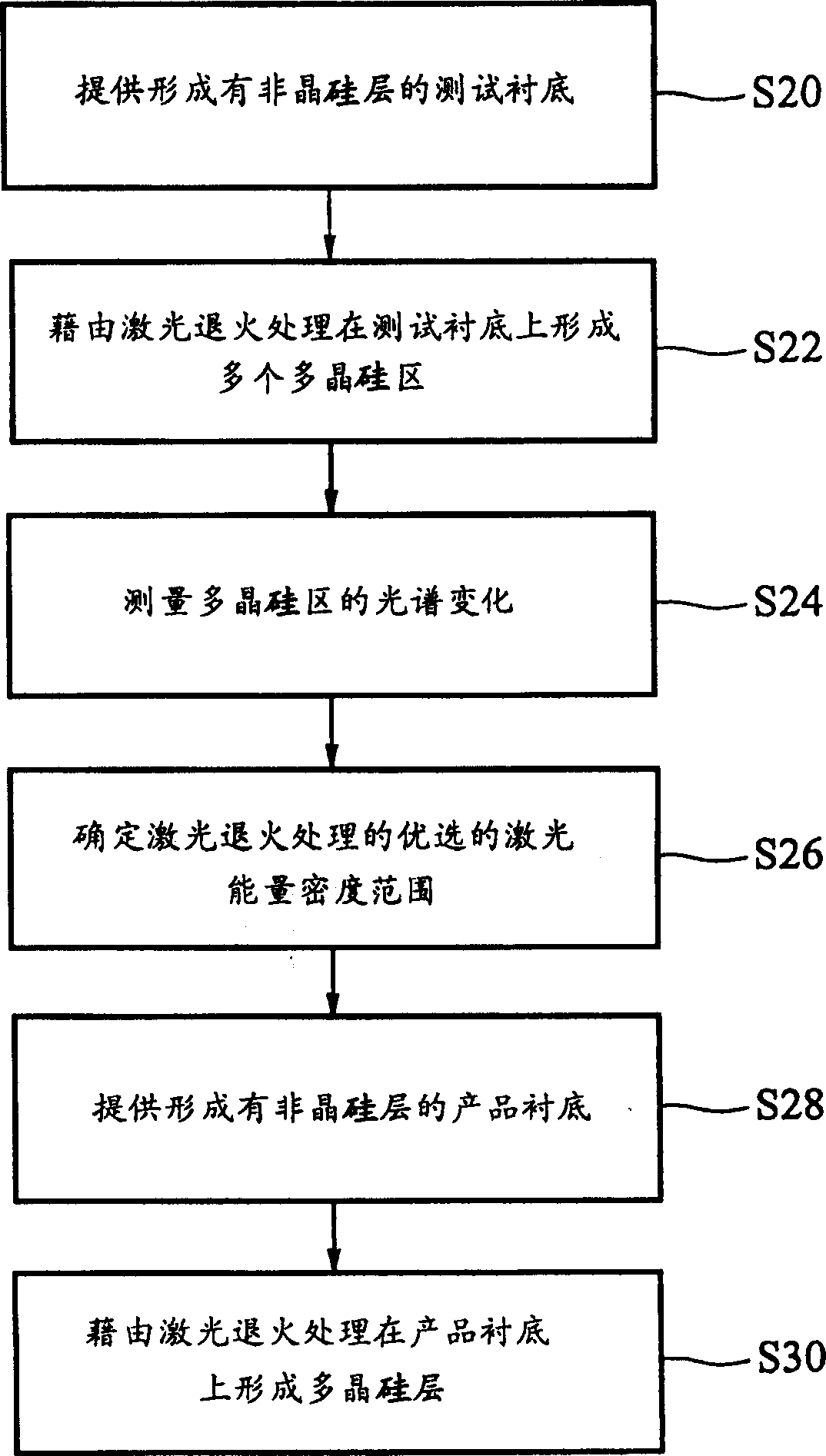

Control of crystal grain size of polysilicon film and detecting method thereof

InactiveCN1501465AAccurate detectionQuick checkSemiconductor/solid-state device testing/measurementMaterial analysis by optical meansLighting spectrumCrystalline silicon

The invention discloses a polycrystalline silicon thin film crystal particle size control and detecting method comprising, providing a first substrate covered by a first non-crystalline silicon layer, implementing annealing treatment to the first non-crystalline silicon layer using laser rays of dissimilar energy density to form a plurality of first polycrystalline silicon areas, measuring the light spectrum change of each first polycrystalline silicon area with a finite photon energy range, providing a second substrate covered by a second non-crystalline silicon layer, implementing annealing treatment to the first non-crystalline silicon layer using the above laser energy density to obtain largest polycrystalline silicon crystal particle dimension, and detecting its crystal particle dimension using an elliptical instrument.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com