Preparation method of rod-like calcite type calcium carbonate crystals

A calcite type, calcium carbonate technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of complex preparation methods, poor control of grain size, and high price, and achieve simple preparation methods, low prices, and wide sources of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

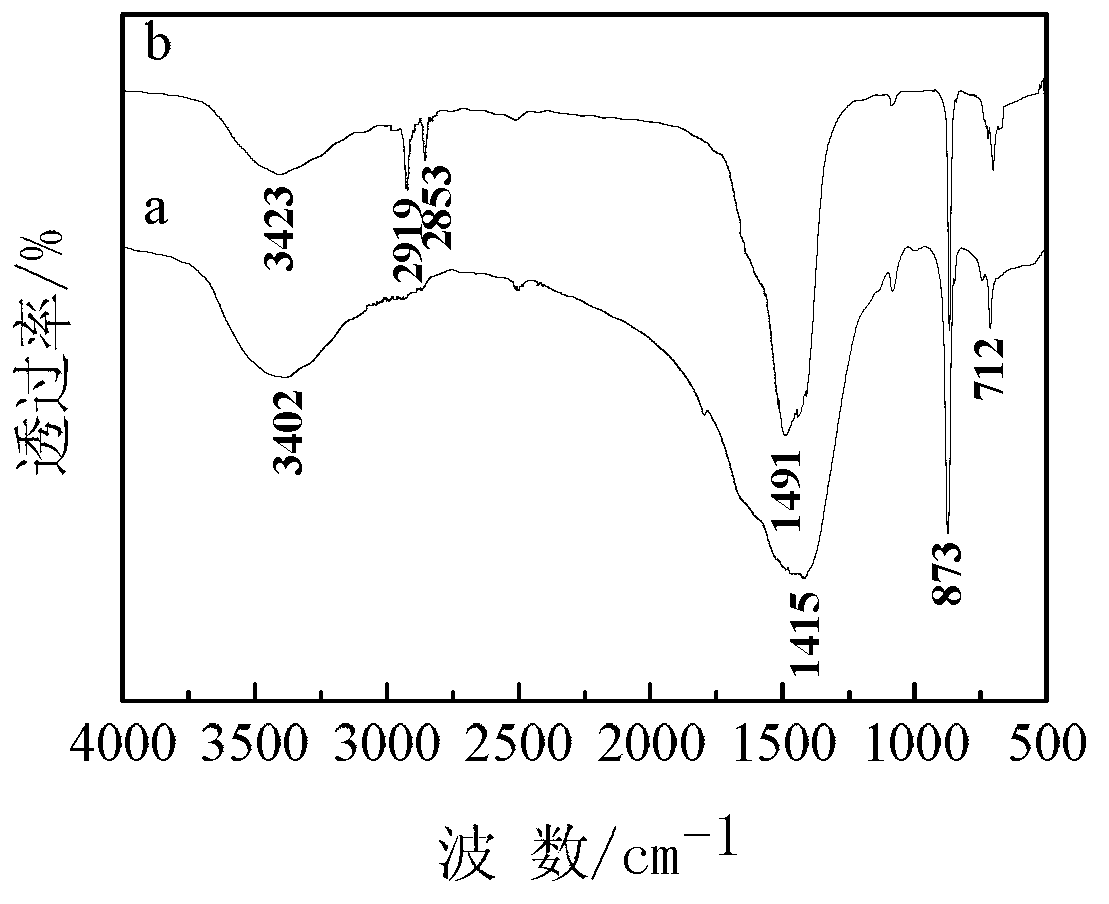

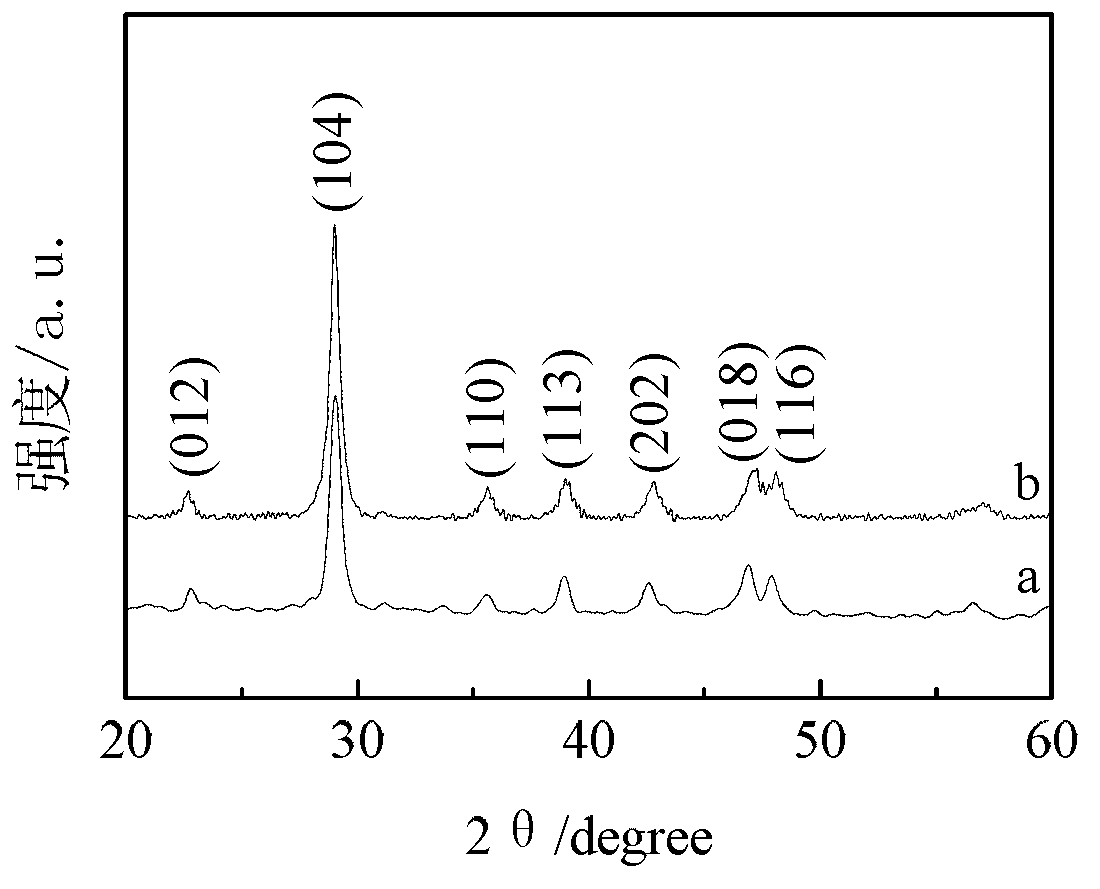

[0024] The specific embodiment one: the preparation method of a kind of rod-shaped calcite type calcium carbonate crystal is carried out in the following steps in the present embodiment:

[0025] 1. Add Ca(OH) 2 It is configured into an aqueous solution with a mass concentration of 6% to 10%, and then placed in a constant temperature water bath at 20°C to 60°C, at 50r·min -1 ~300r·min -1 While stirring at 0.2L·min -1 ~0.8L·min -1 into CO at a rate of 2 Gas for 10min to 20min to obtain a mixed solution;

[0026] 2. First configure PASP into a PASP aqueous solution with a mass concentration of 4%, and then add it to the mixed solution obtained in step 1. After reacting for 1.5h to 2h, stop feeding CO 2 , the gas gets a suspension;

[0027] 3. Wash the suspension obtained in step 2 with deionized water for 2 to 4 times, and then wash with absolute ethanol for 2 to 4 times. Dry under vacuum for 12h to 36h to obtain calcium carbonate crystals.

[0028] The rod-shaped calcit...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, Ca(OH) 2 The mass concentration of the solution is 7%-9%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: This embodiment is different from Embodiment 1 to Embodiment 2 in that: the temperature of the water bath in step 1 is 25°C-45°C. Others are the same as one of the specific embodiments 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com