Patents

Literature

242 results about "Bismuth sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bismuth (III) sulfide can also be prepared by the reaction of elemental bismuth and elemental sulfur in an evacuated silica tube at 500 °C for 96 hours.

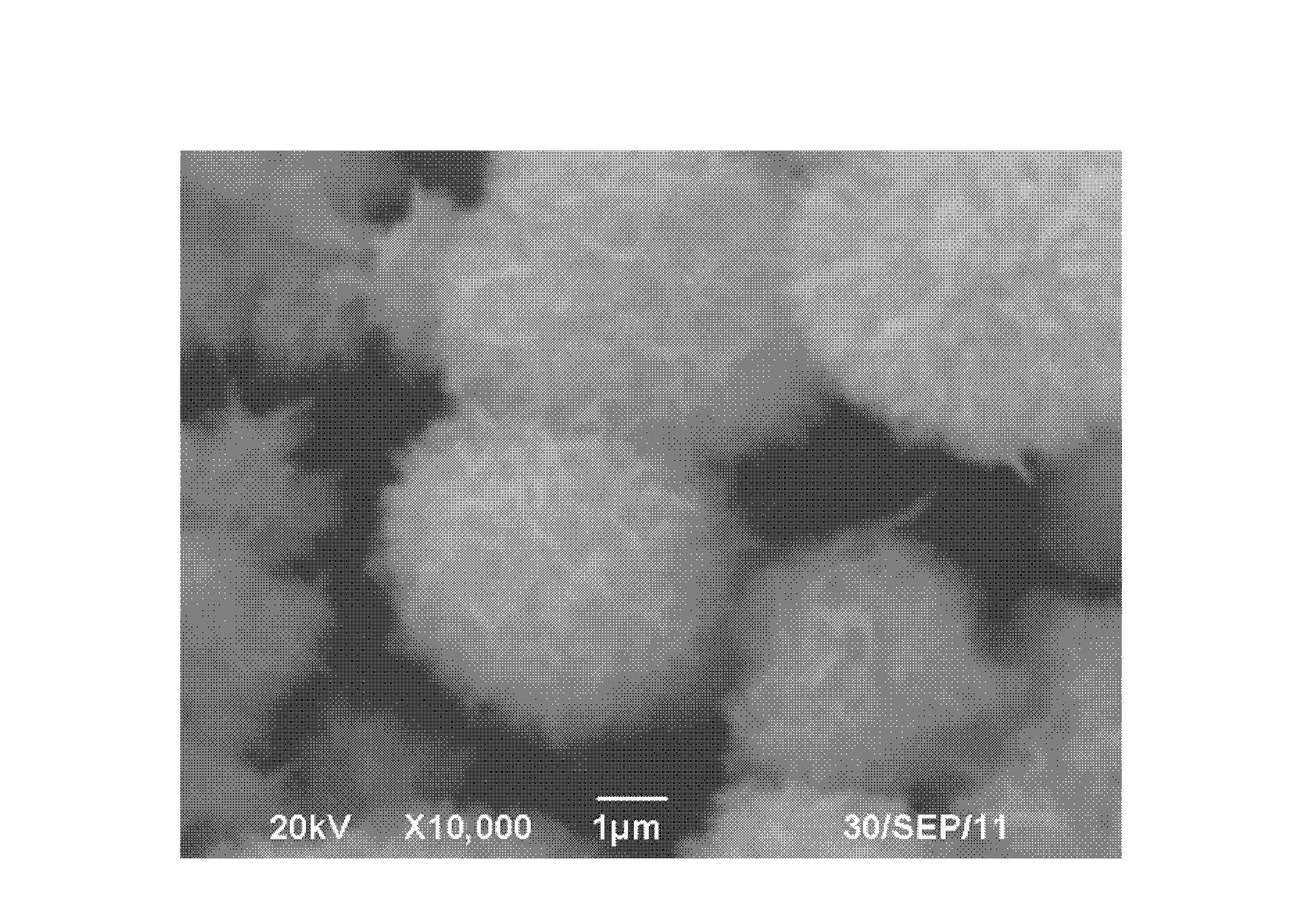

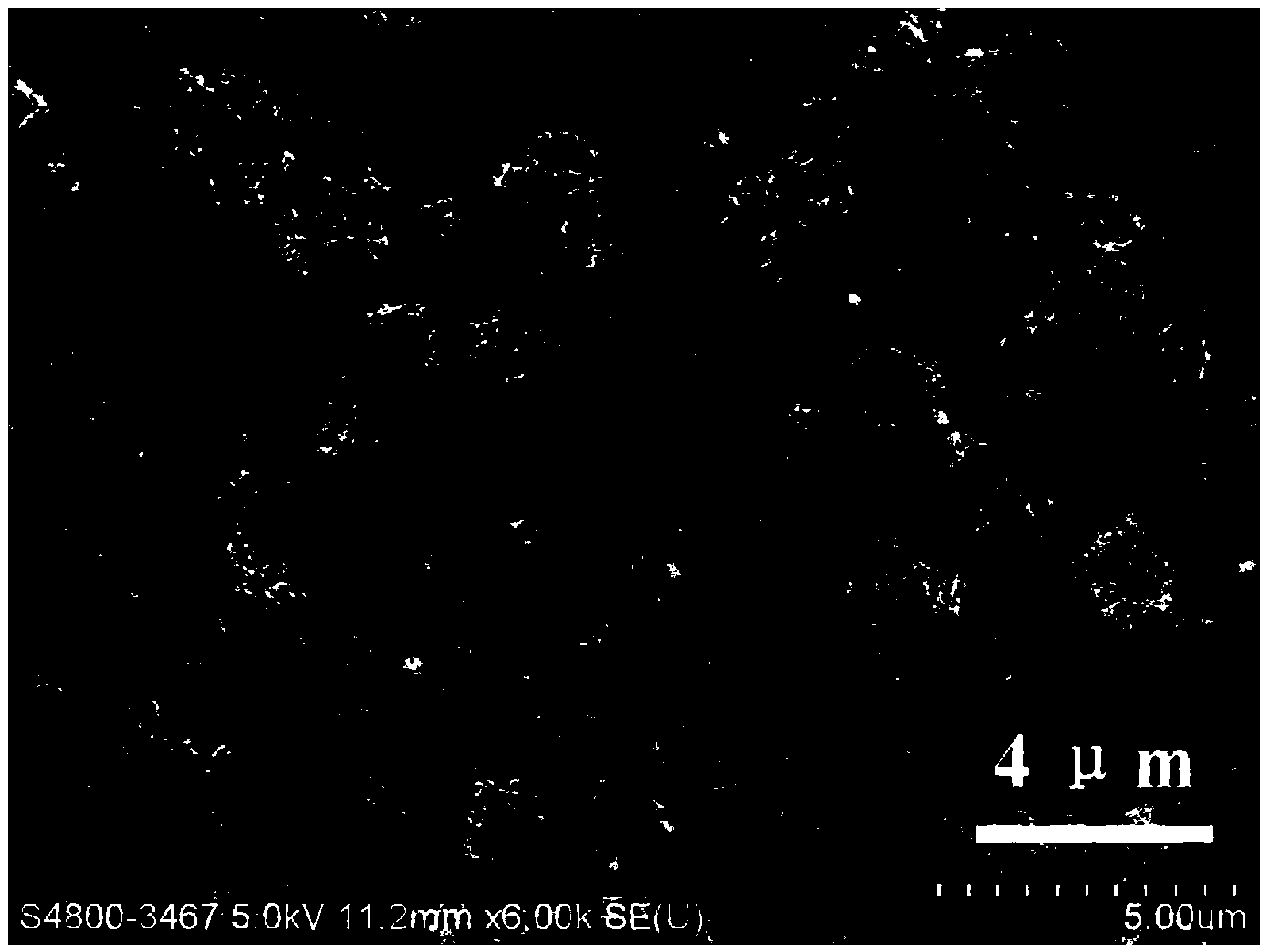

Compound photocatalysis material with bismuth sulfide nano particles/bismuth oxychloride and preparation method thereof

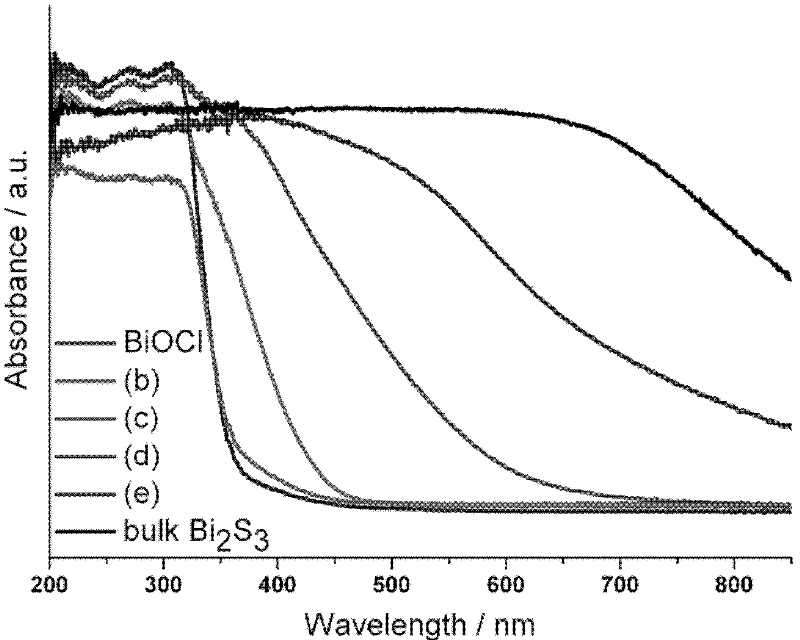

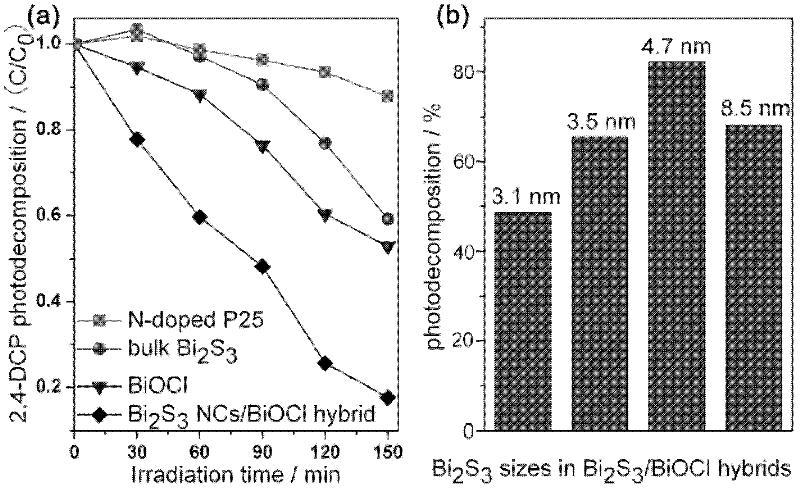

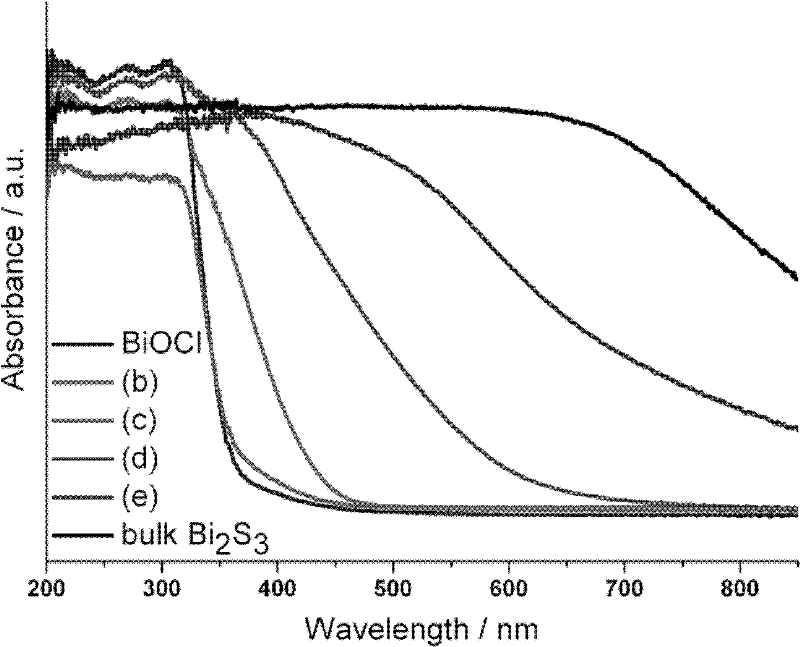

InactiveCN102513134AEfficient light absorptionLight absorption regulationPhysical/chemical process catalystsBismuth sulfideSolvothermal reaction

The invention relates to a compound photocatalysis material with bismuth-sulfide nano particles / bismuth oxychloride and a preparation method thereof. The preparation method comprises the following steps of: firstly, dissolving bismuth nitrate and chlorinated 1-dodecyl-3-methyl glyoxaline into ethylene glycol monomethyl ether respectively, afterwards carrying out a thermal reaction by a solvent soas to prepare bismuth-oxychloride micron balls, then adding the bismuth-oxychloride micron balls into a water solution containing a sulfur source and exchanging parts of ions so as to prepare a compound photocatalysis material containing bismuth-sulfide nano particles and bismuth oxychloride. The method disclosed by the invention can be executed at room temperature and normal pressure, the cost is low, and equipment is simple and is easy to operate; and moreover, the compound photocatalysis material with the bismuth-sulfide nano particles / bismuth oxychloride can be produced at a large scale and has important potential application in the aspect of industrial production. The prepared compound photocatalysis material with the bismuth sulfide / bismuth oxychloride has favorable absorption of visible light, the separation of a photon-generated carrier is obviously improved, and the photocatalysis performance of the material is greatly enhanced.

Owner:SHANDONG UNIV

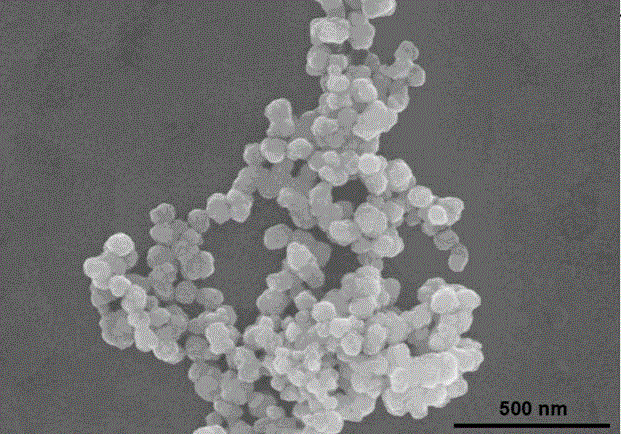

One-step process of preparing monodispersive nanometer bismuth sulfide particle

InactiveCN1974406AParticle size controllableGood biocompatibilityNanostructure manufactureBismuth compoundsBismuth sulfideBiocompatibility Testing

The present invention relates to process of preparing monodispersive nanometer bismuth sulfide particle. The process includes the following steps: 1. preparing bismuth containing precursor solution; 2. preparing sulfur containing precursor solution; 3 adding the bismuth containing precursor solution into the sulfur containing precursor solution quickly based on the volume ratio between the bismuth containing precursor solution and the sulfur containing precursor solution of 1 to 5-2 to 5 at constant temperature of 45-130 deg.c and through high speed stirring, and reacting for 1-4 hr while controlling the pH value of the reaction system in 5.0-10.0 to control the growth of crystal nucleus, so as to obtain nanometer product particle with homogeneous particle size distribution. The present invention has the advantages of environment friendly dispersing medium deionized water or alcohol, short reaction period, high yield, the biocompatibility of the dispersing stabilizer, etc.

Owner:TIANJIN UNIV

Preparation method and application of non-molybdenum sulfide mineral flotation and separation inhibitor

The invention discloses a preparation method and application of a non-molybdenum sulfide mineral flotation and separation inhibitor. The preparation method for the flotation and separation inhibitor comprises the step of enabling phosphorus pentasulfide and alkaline compounds to react with water-soluble macromolecules, and thus the flotation and separation inhibitor can be obtained. According to the preparation method for the non-molybdenum sulfide mineral flotation and separation inhibitor, operation is easy, the process conditions are mild, the raw material cost is low, and the industrial production requirements are met; and moreover, the prepared product directly serves as the non-molybdenum sulfide mineral inhibitor applied to flotation and separation of molybdenum sulfide minerals and non-molybdenum sulfide minerals, the molybdenum sulfide minerals and the non-molybdenum sulfide minerals can be effectively separated, the grade of molybdenum concentrates is improved, and the flotation and separation inhibitor is particularly suitable for flotation and separation of molybdenite, copper sulfide ore, galena, pyrite, jamesonite, arsenopyrite, bismuth sulfide ore and the like.

Owner:CENT SOUTH UNIV

Preparation and application of hollow tree-like bismuth oxide-bismuth sulfide complex

ActiveCN103447052AShape is easy to controlCrystal phase controllablePhysical/chemical process catalystsBismuth sulfideWater soluble

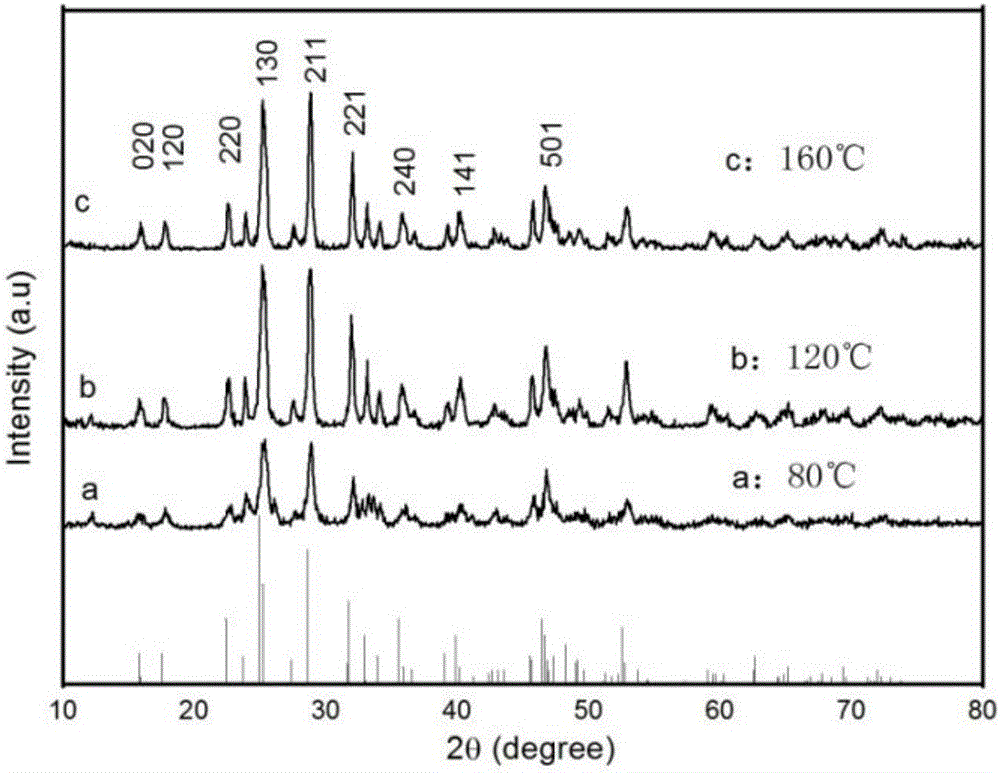

The invention provides a preparation method of a hollow tree-like bismuth oxide-bismuth sulfide complex. The preparation method comprises the following steps: (1) taking bismuth nitrate pentahydrate, stirring and dissolving in dilute nitric acid, and then regulating the pH value of a bismuth nitrate solution to 9-14 with a fixed quantity of alkaline solution; then transferring the solution into a crystallization reaction kettle, reacting at the temperature of 80-200 DEG C for 0.5-12h, cooling, filtering, separating, washing with deionized water, washing with anhydrous ethanol, drying and calcining to obtain hollow tubular bismuth oxide; and (2) dispersing the prepared hollow tubular bismuth oxide in the deionized water, adding a water-soluble sulfide while stirring, controlling the molar ratio of the bismuth oxide to the sulfide to be 1: (1-8), then transferring the obtained solution into the crystallization reaction kettle, reacting at 40-180 DEG C for 0.5-36h, cooling, filtering, separating, washing with the deionized water for three times, washing with the anhydrous ethanol and drying to obtain the hollow tree-like bismuth oxide-bismuth sulfide complex. The invention further relates to an application of the hollow tree-like bismuth oxide-bismuth sulfide complex as a photocatalyst.

Owner:HUNAN UNIV

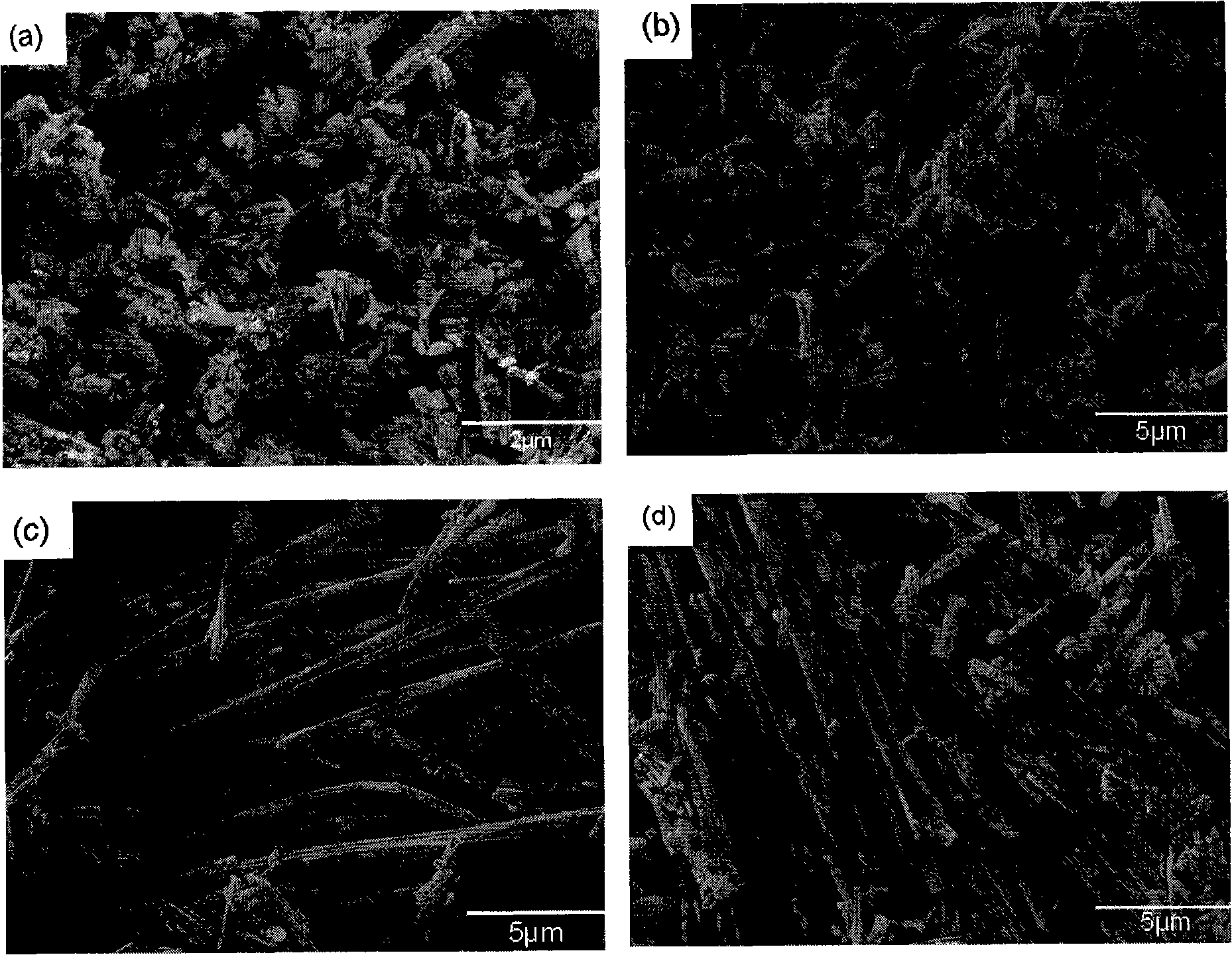

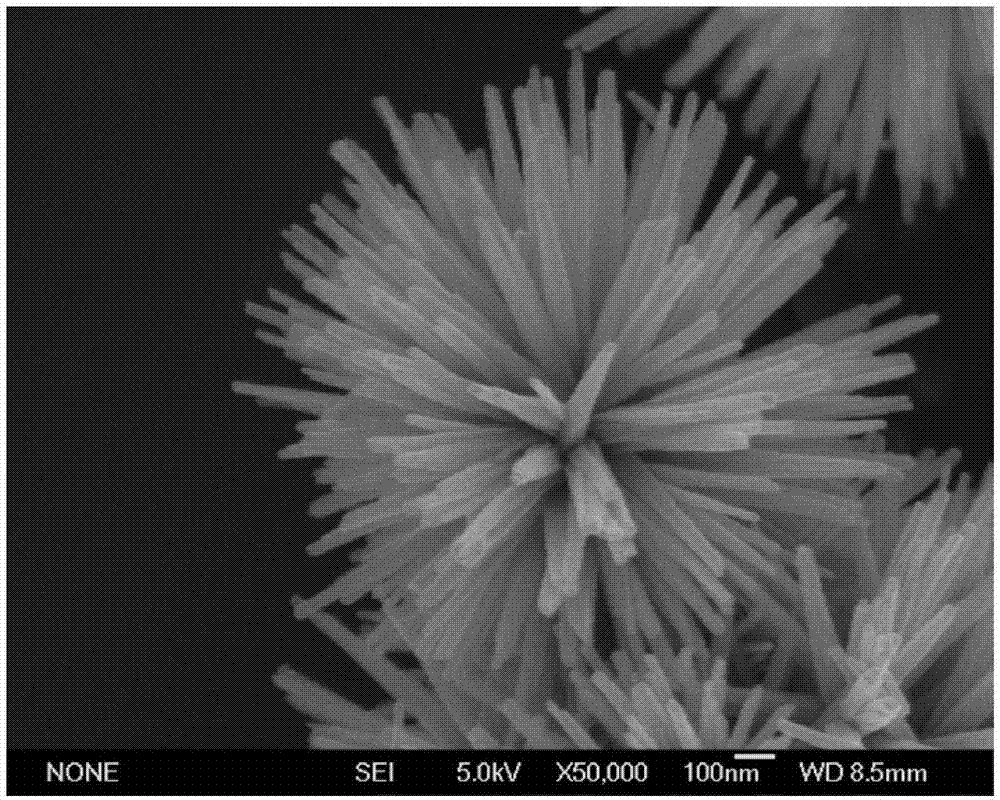

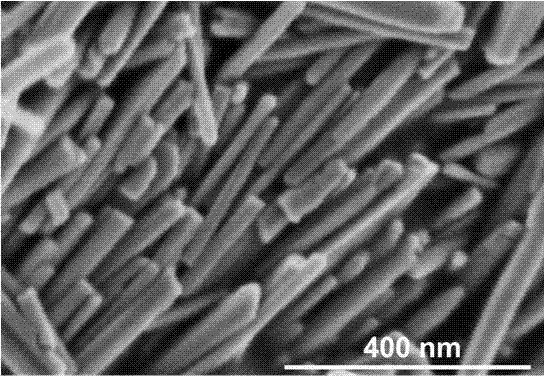

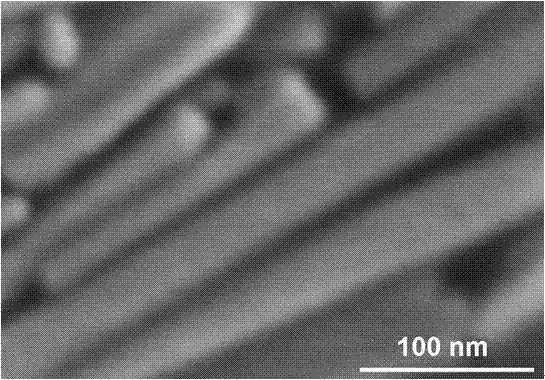

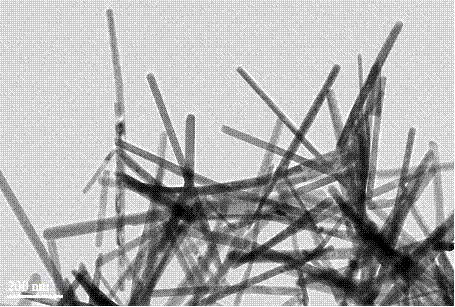

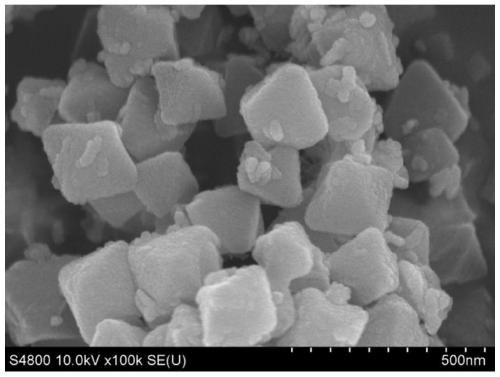

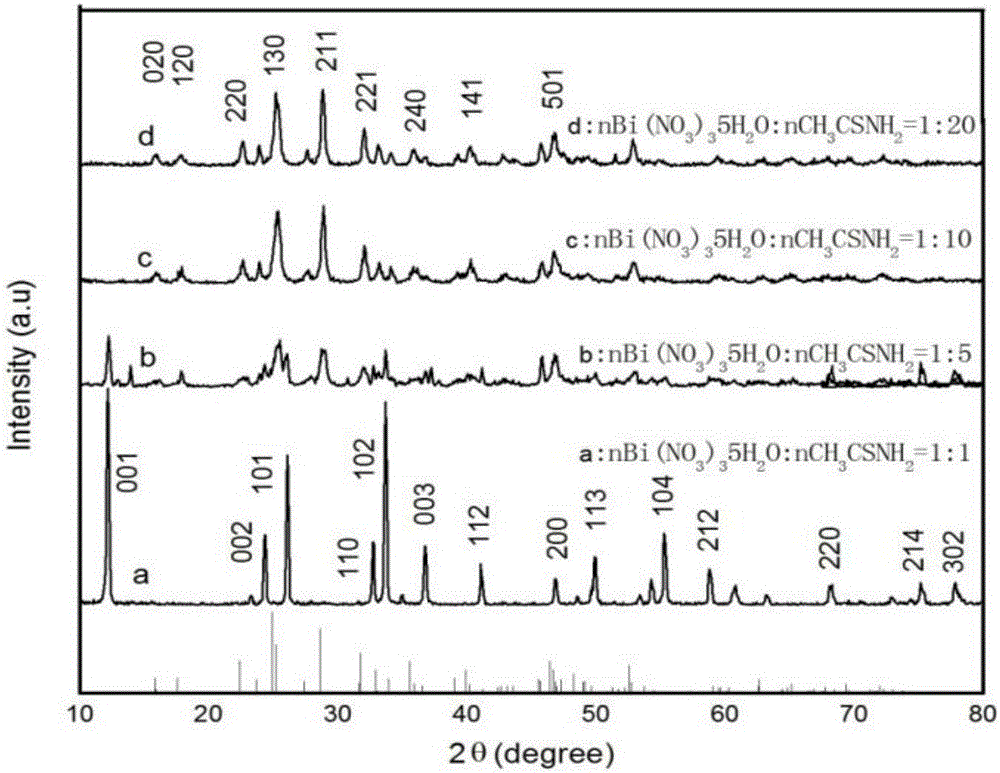

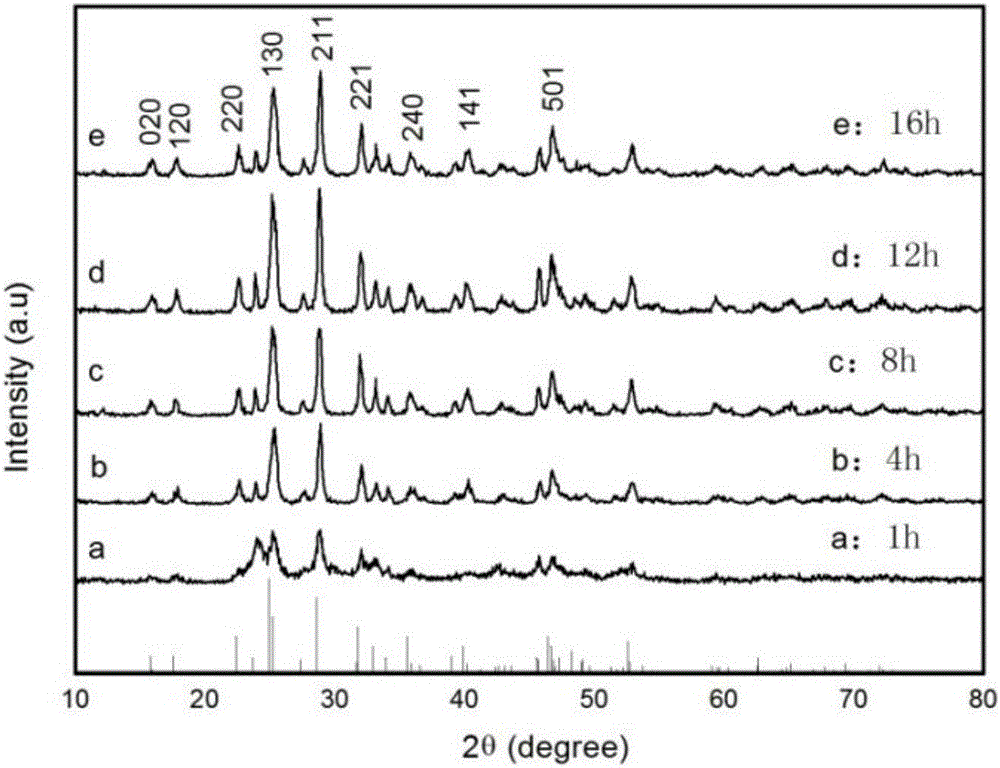

Method for preparing bismuth sulfide whiskers and the bismuth sulfide whiskers

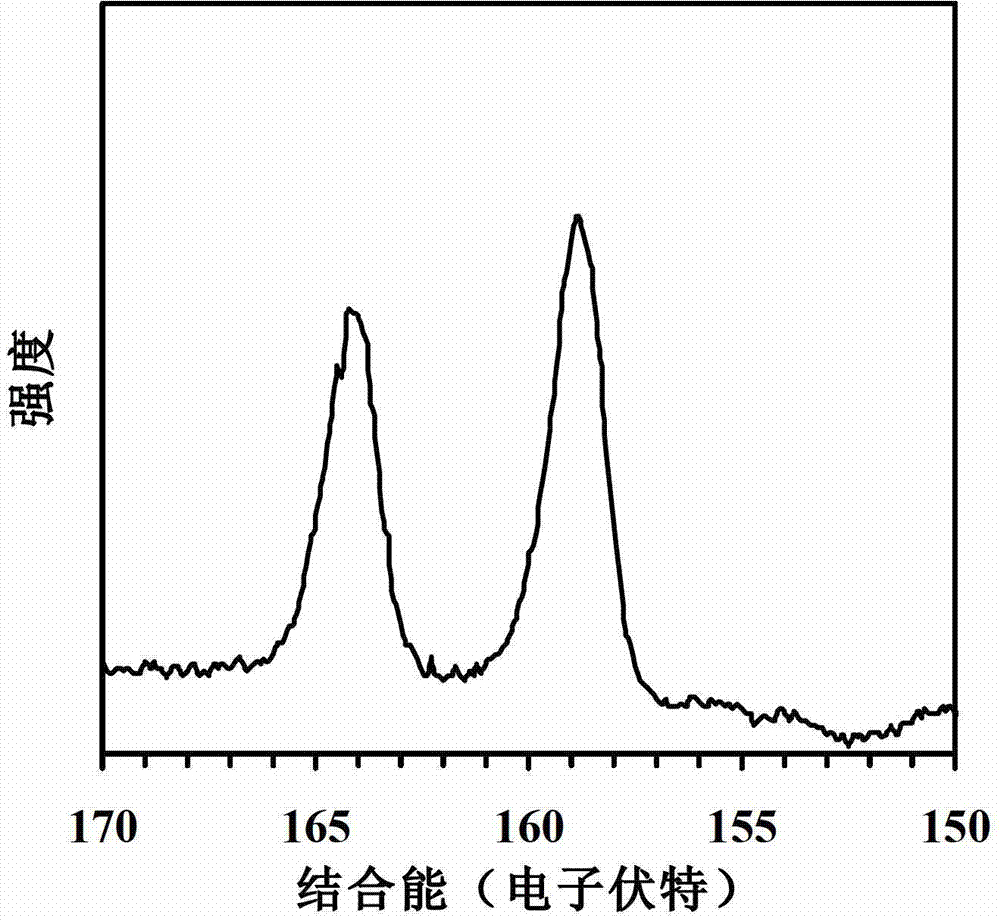

InactiveCN101311385AEvenly dispersedEasy to adjust the concentrationPolycrystalline material growthFrom normal temperature solutionsBismuth sulfideHydrothermal synthesis

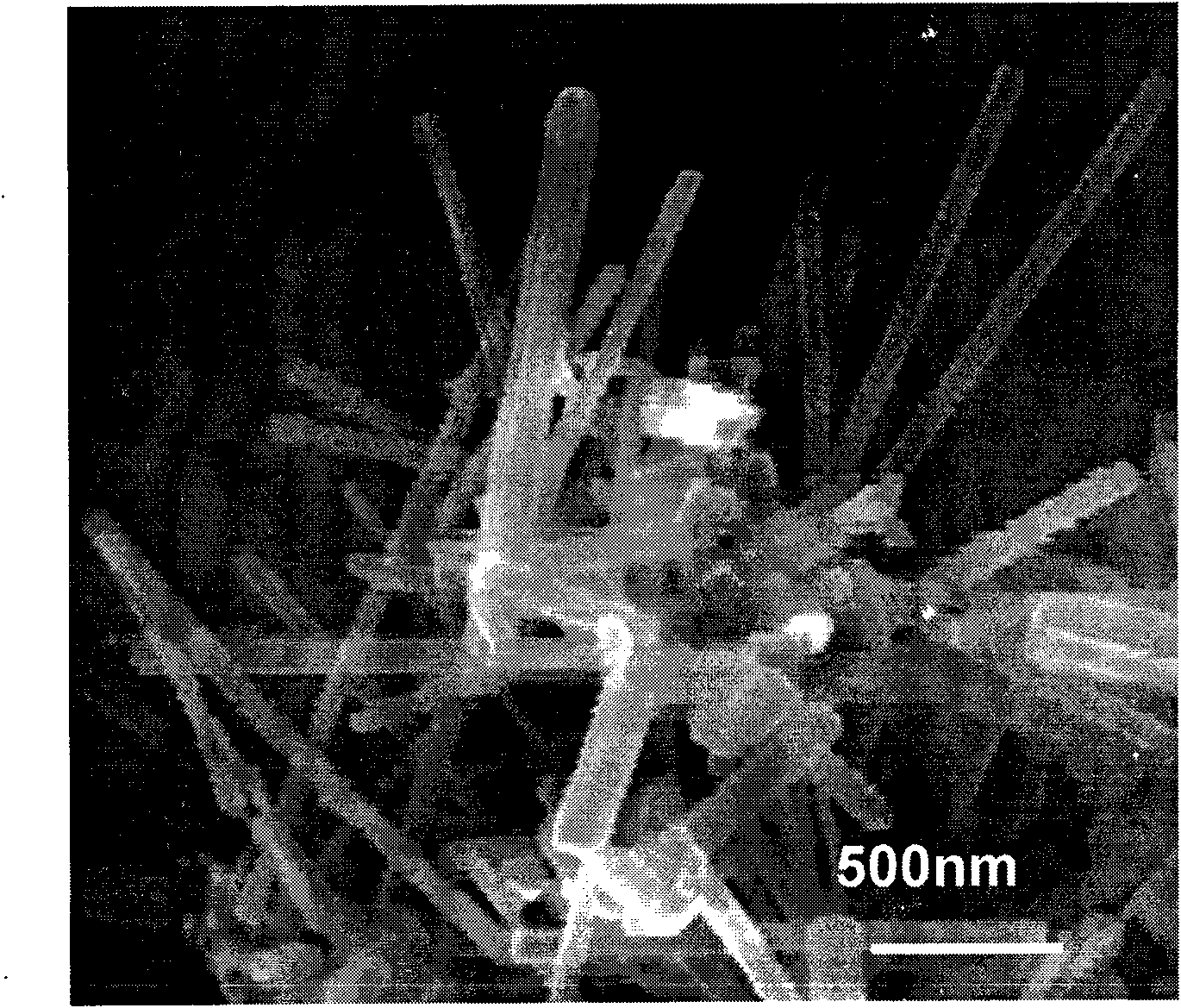

The invention relates to a preparation method of bismuth sulfide whisker, which applies hydrothermal synthesis method, and chooses Bi(NO3)3.5H2O, CS(NH2)2 and LiOH as raw materials and H2O as a hydrothermal reaction medium. The method applies LiOH of 1.0 to 1.5M as a mineralizing agent, and the bismuth sulfide whisker can be got by the hydrothermal reaction for 16 hours at a temperature of 200 DEG C. The preparation method provided by the invention can get the bismuth sulfide whisker with an average diameter of 200 to 300nm and the length equals to or above 20Mum, which has wide application prospect in the research fields of thermoelectricity, photoelectricity and infrared spectrum, etc.

Owner:BEIJING HANGBO NEW MATERIAL TECH

Preparation method of photoelectrochemical sensor for detecting dexamethasone based on in-situ generation of cadmium sulfide

ActiveCN105259236AEvenly groomedLow costMaterial analysis by electric/magnetic meansBismuth sulfideCarboxyl radical

The invention relates to a preparation method of a photoelectrochemical sensor for detecting dexamethasone based on in-situ generation of cadmium sulfide. The method specifically comprises the following steps: as carboxylated carbon nitride and bismuth sulfide are taken as substrate materials, and labeling a dexamethasone antibody by using titanium dioxide subjected to cadmium ion functionalization. Sodium sulfide is directly dropwise added to the electrode surface, a narrow band-gap cadmium sulfide semiconductor nanometer material with the high photoelectric conversion efficiency is generated in situ, and a photocurrent signal is generated under light source irradiation with visible wavelength. A porous titanium dioxide carrier and a cadmium sulfide energy band are well matched, so that the photoelectric conversion efficiency of the cadmium sulfide is improved, the high-sensitivity detection of dexamethasone is realized, and the detection limit is 2pg / mL.

Owner:UNIV OF JINAN

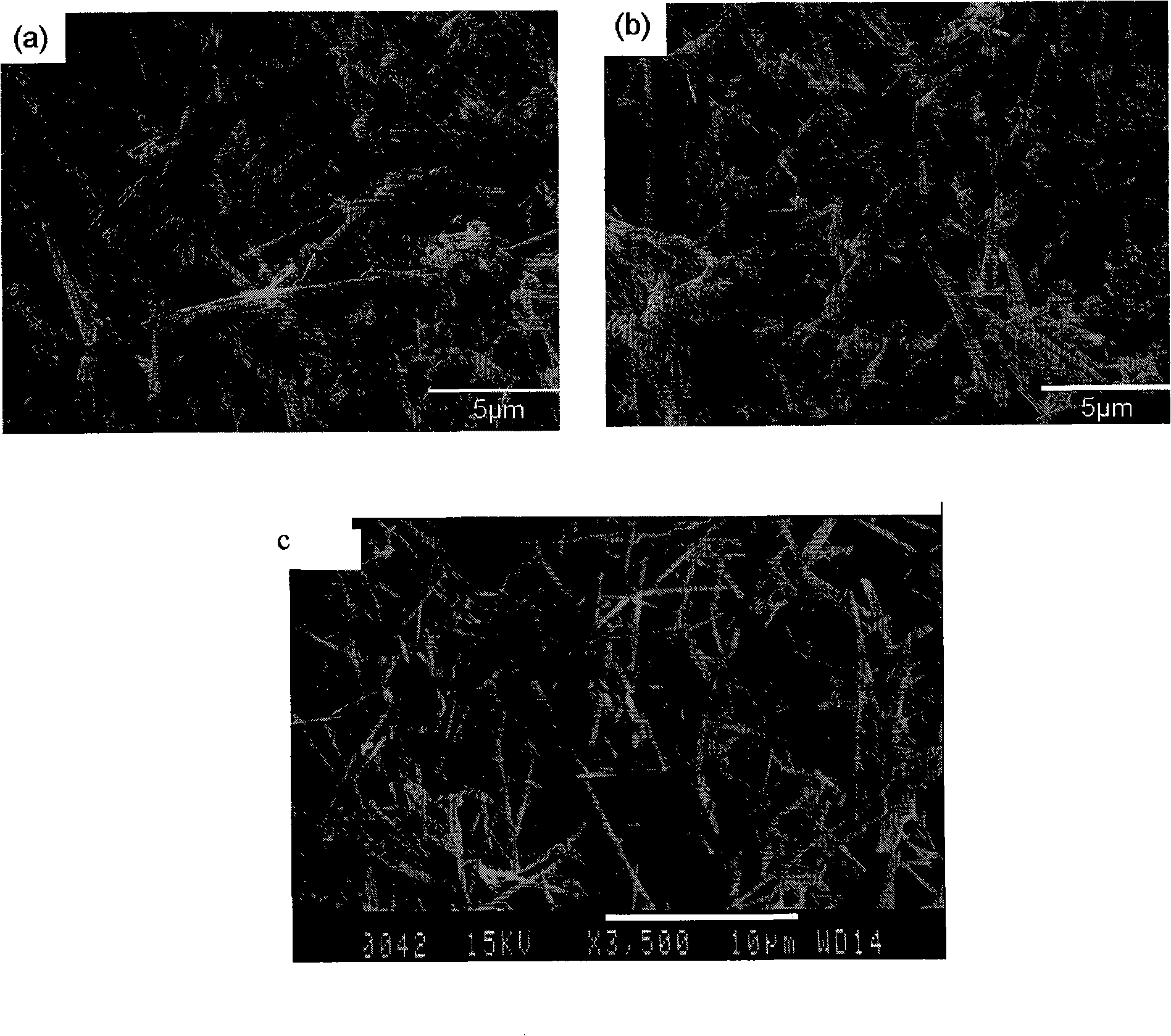

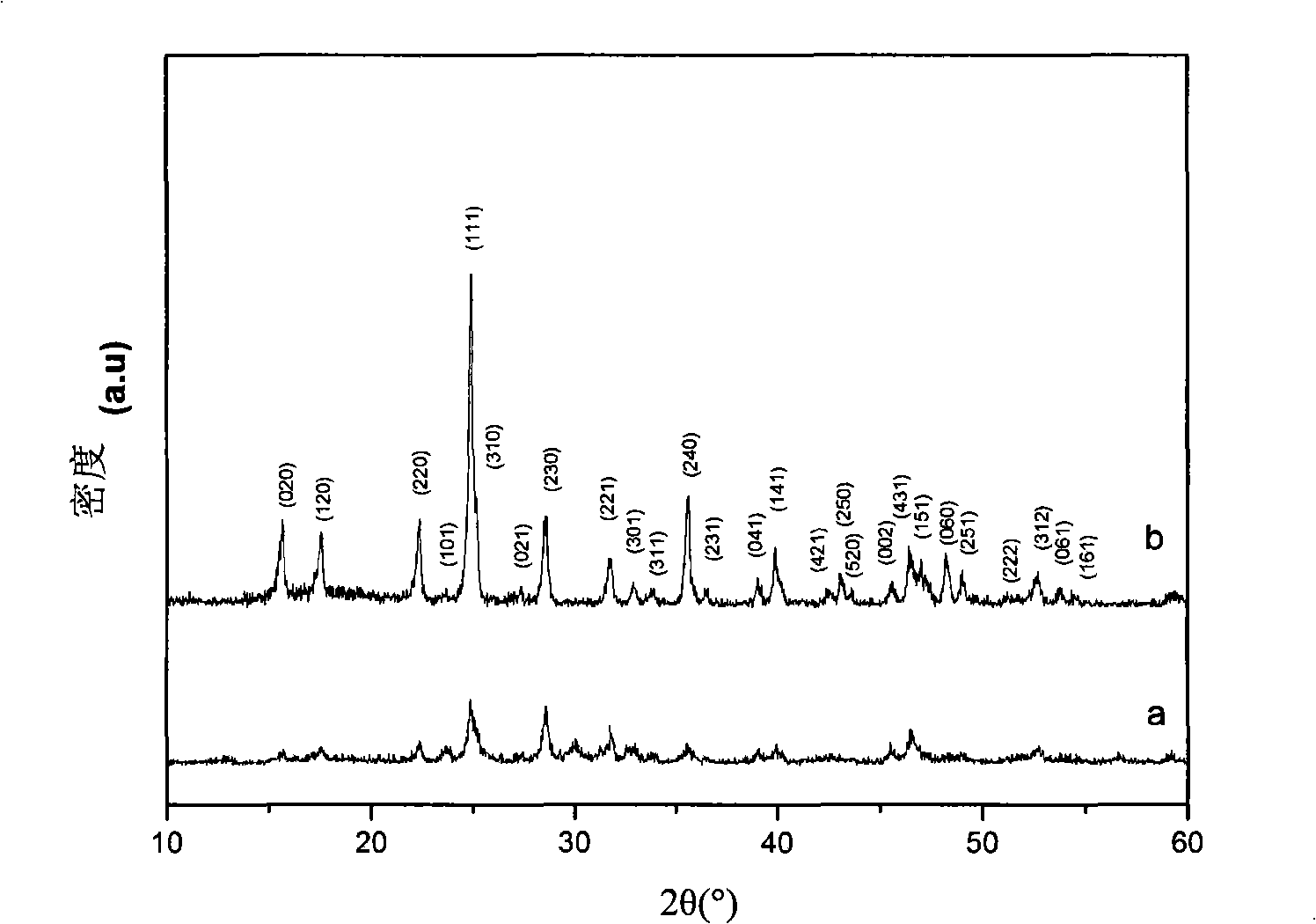

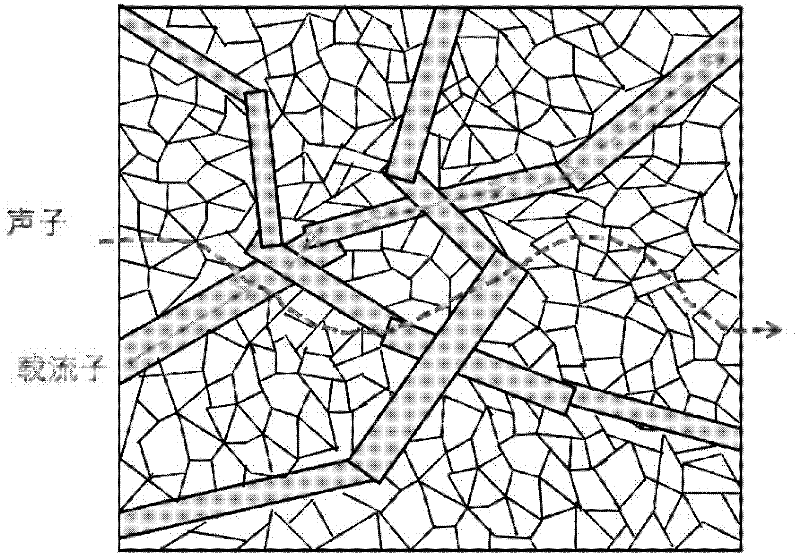

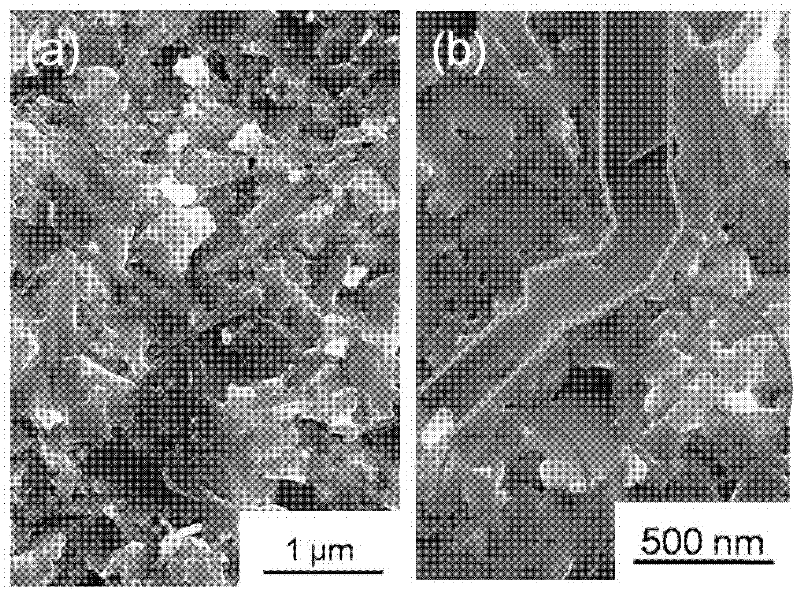

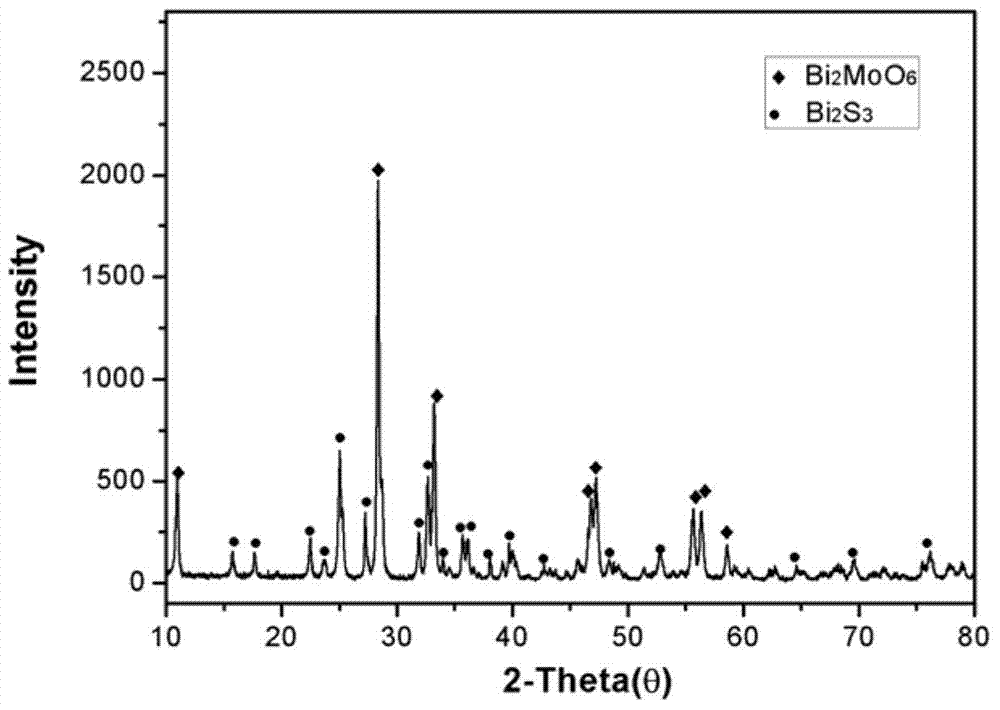

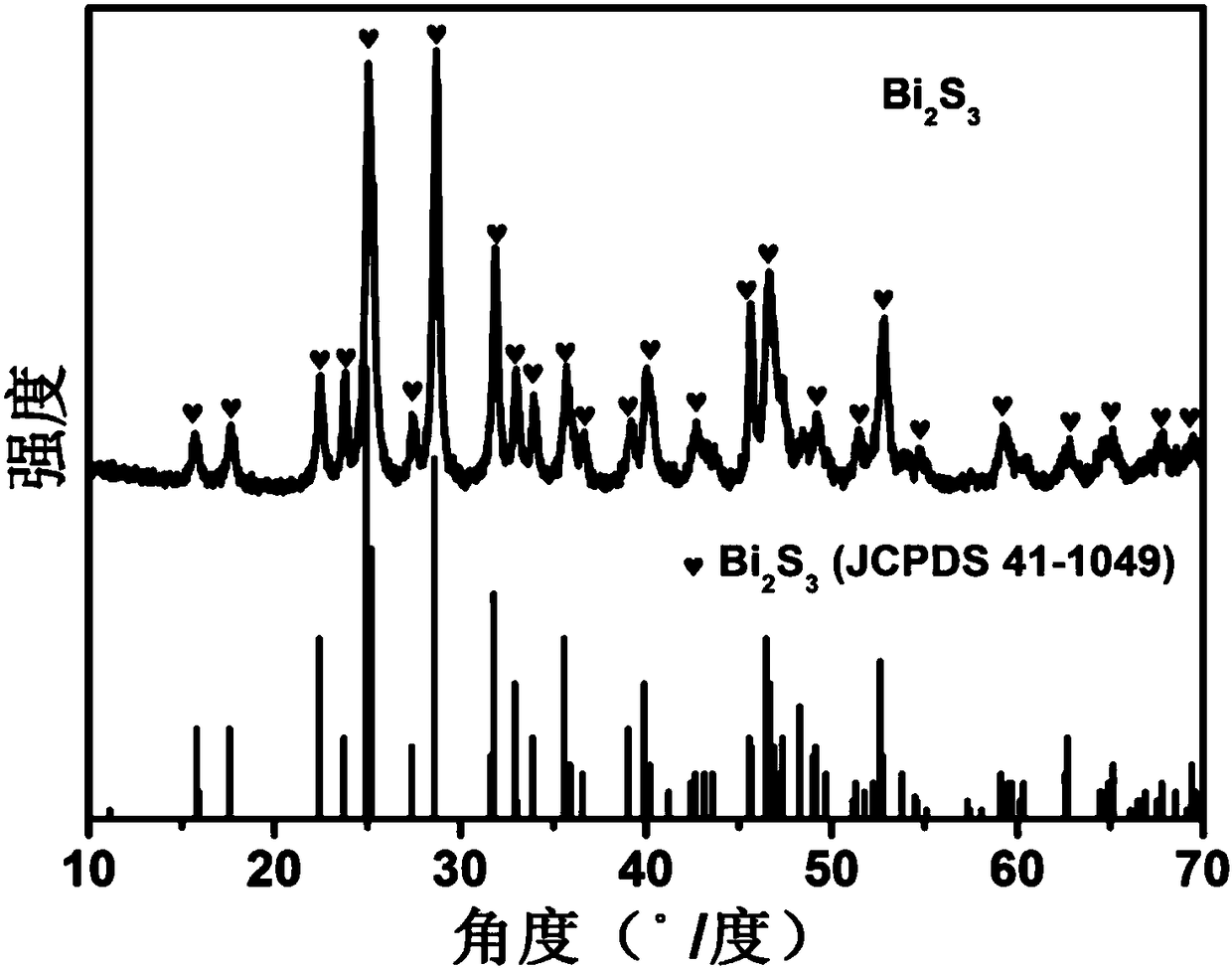

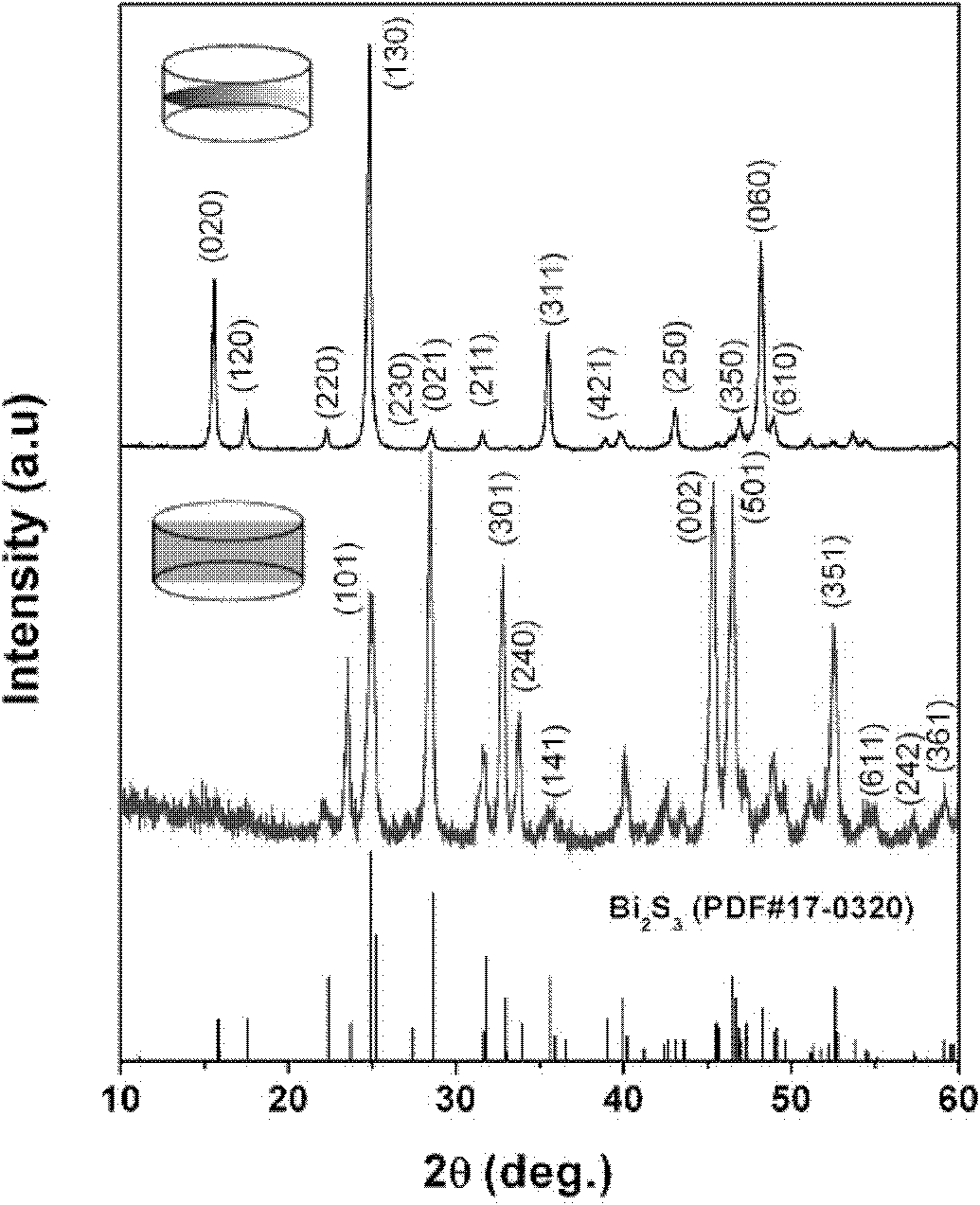

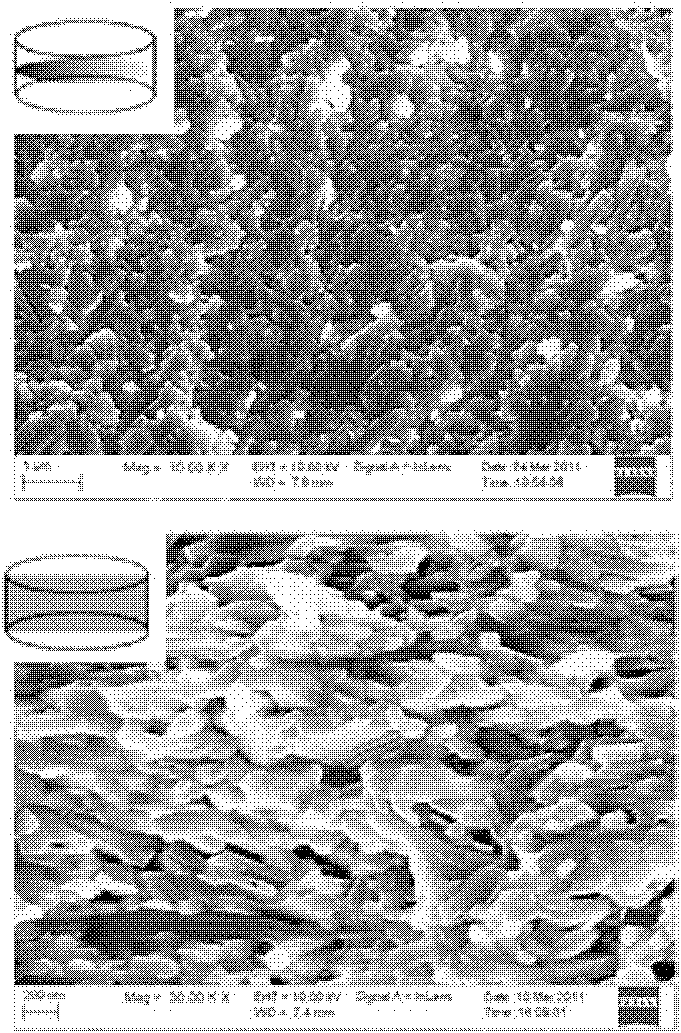

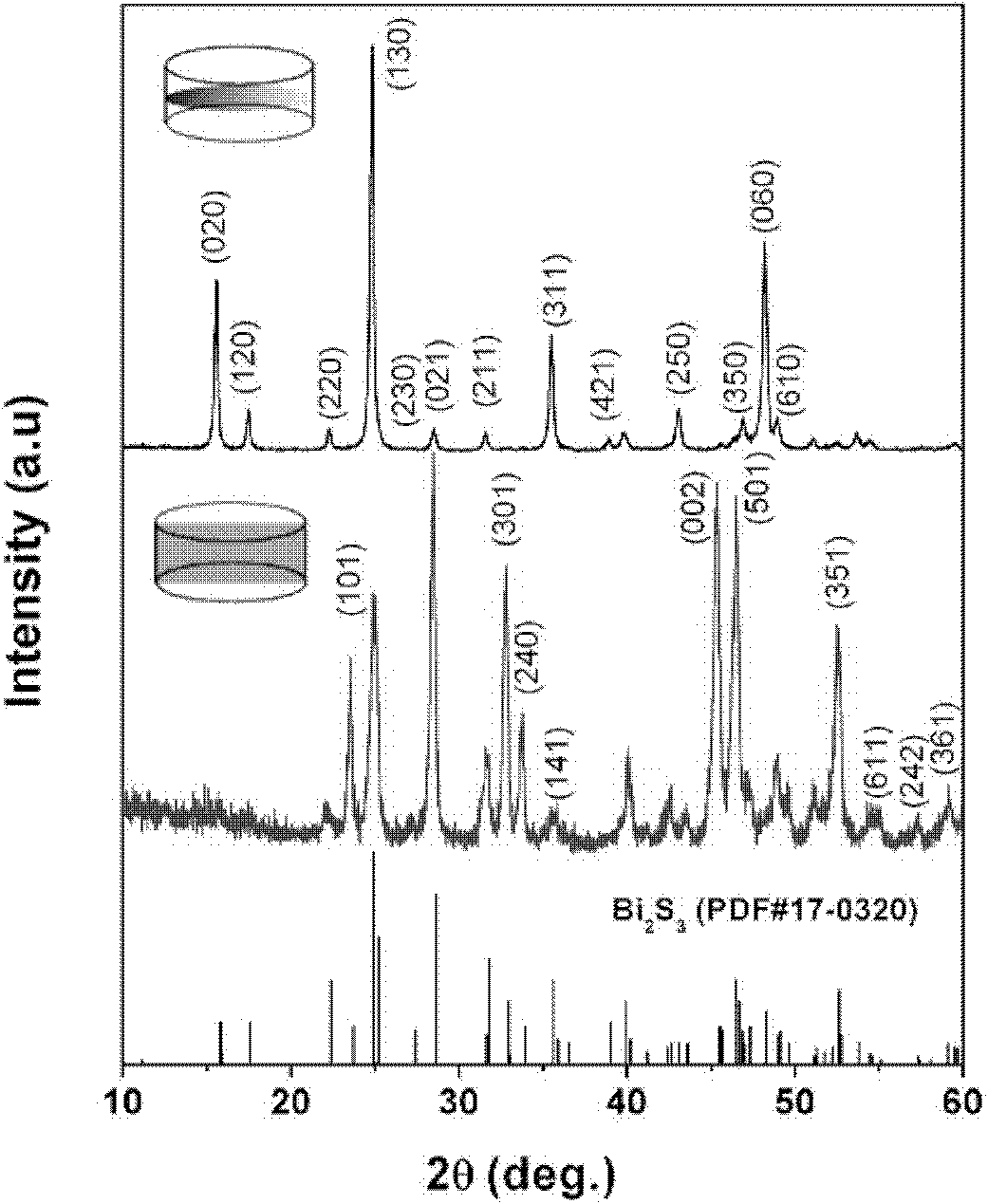

Method for improving thermoelectric properties of bismuth sulfide polycrystal

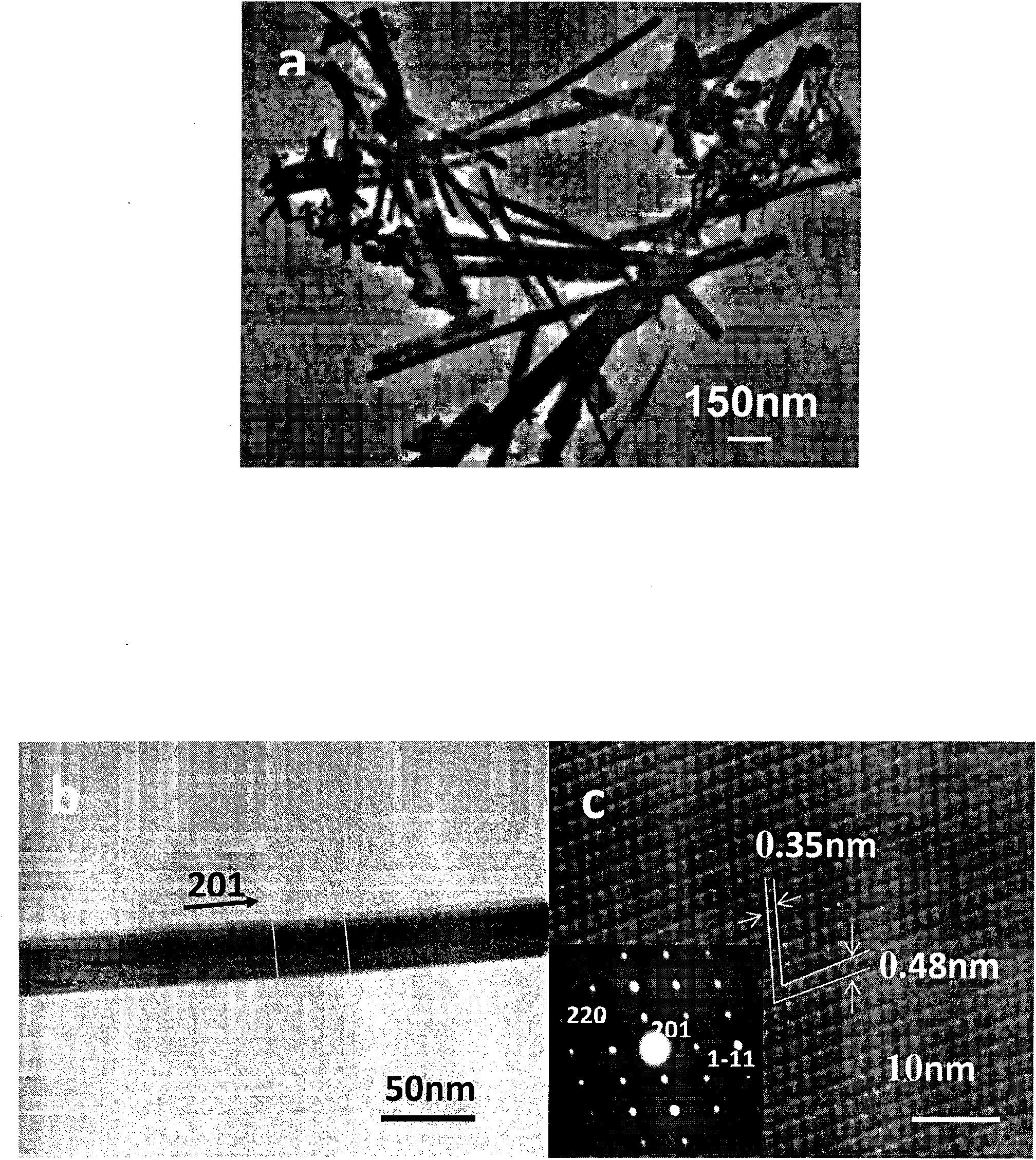

ActiveCN102443848AKeep shapeMaintain conductive propertiesPolycrystalline material growthSingle crystal growth detailsBismuth sulfideSingle crystal

The invention relates to a method for improving thermoelectric properties of bismuth sulfide polycrystal and belongs to the technical field of energy materials. The method is characterized by comprising the following steps of: mixing bismuth sulfide nano powder prepared by a mechanical alloying method with (001)-oriented monocrystal bismuth sulfide nanorod powder synthesized by a hydrothermal method, ultrasonically dispersing in absolute ethanol for 10-200 minutes, drying and then manually grinding in an agate mortar for 10-100 minutes; and placing ground powder in a graphite mold, sintering at 300-500 DEG C by adopting a spark plasma sintering process, and maintaining the temperature for 0-30 minutes to prepare a bismuth sulfide polycrystal block. Because the spark plasma sintering process has high heating rate, thus the growth and fusion of crystals are inhibited, the monocrystal nanorod structure is retained in the polycrystal block to form a fast channel for carrier migration, and the electric transmission performance and thermoelectric property of the bismuth sulfide polycrystal are greatly improved; and the method has the advantages of simplicity in required equipment, easiness in operation, low cost, significant effect and the like.

Owner:香河汇文节能科技有限公司

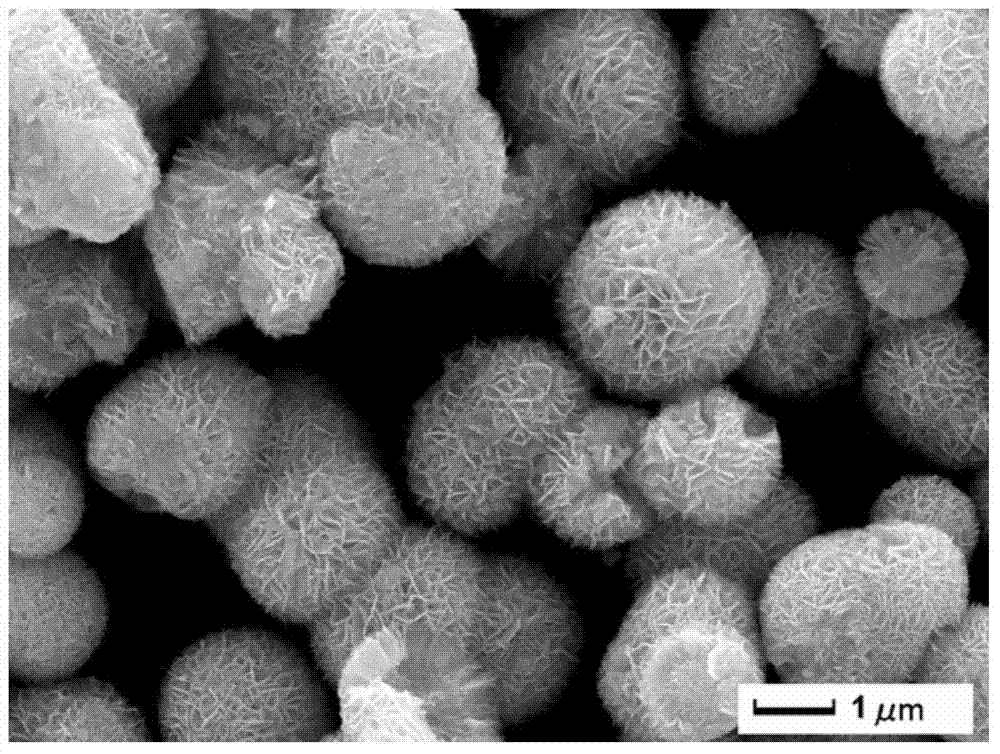

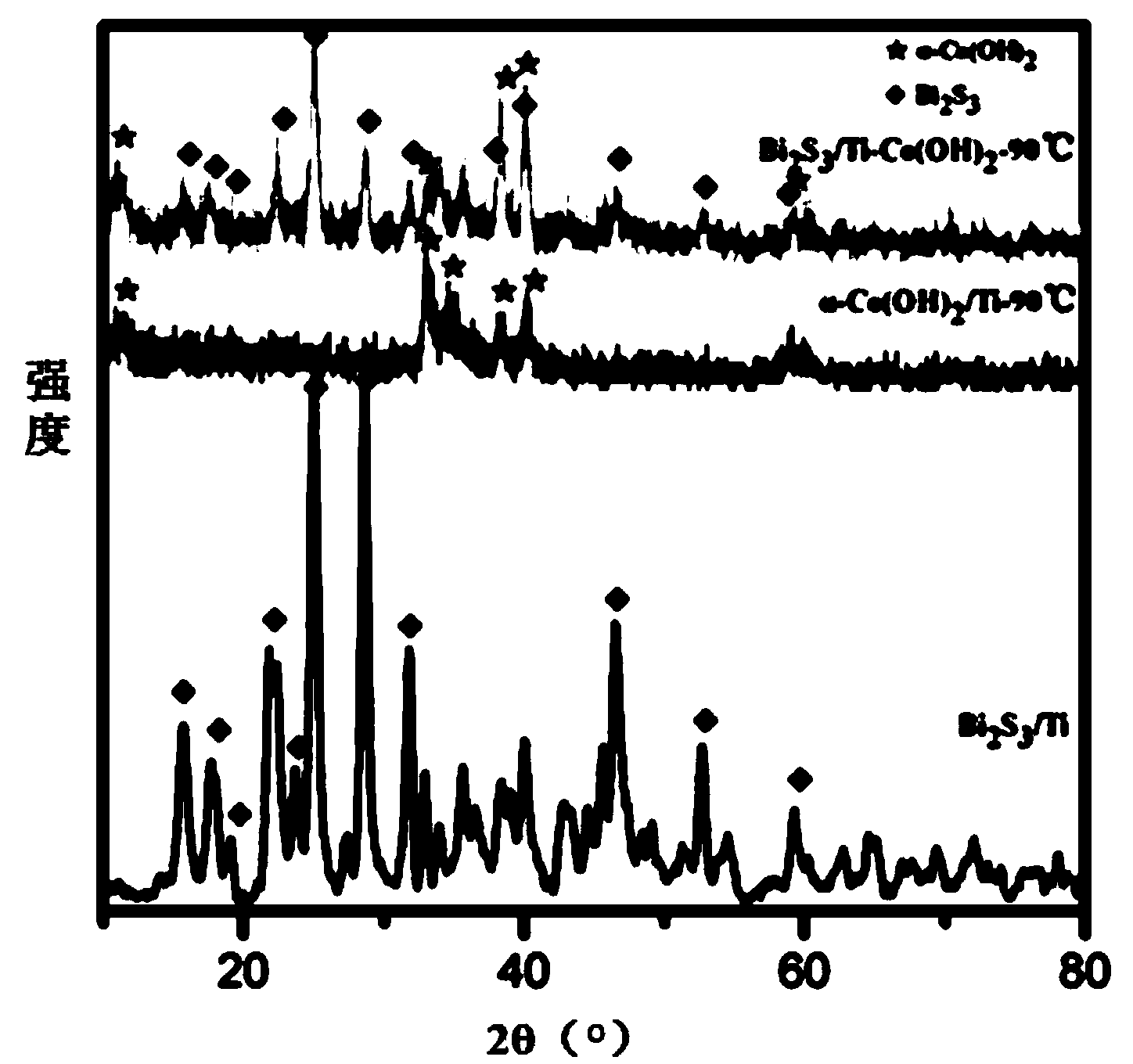

Preparation method of bismuth sulfide/bismuth molybdenum oxide heterojunction photocatalytic composite material

ActiveCN103611551ASimple processHigh crystallinityPhysical/chemical process catalystsHeterojunctionBismuth sulfide

The invention relates to a preparation method of a bismuth sulfide / bismuth molybdenum oxide heterojunction photocatalytic composite material. The preparation method is characterized by comprising the steps of dispersing BiOBr micro-sphere particles in de-ionized water in a proportion of 7.7g / L, and uniformly stirring; adding a molybdenum source: sodium molybdate, sodium chloride, sodium thiocyanate and a surfactant to a solution (1) and stirring for 30-60min; regulating pH value of the solution to be acid through hydrochloric acid; pouring the mixed solution into a stainless steel reaction kettle, and reacting for 24-48 hours at 150-200 DEG C; after reaction, naturally cooling, centrifuging and washing a reaction product for times through de-ionized water and ethanol, and drying the product to obtain the Bi2S3 / Bi2MoO6 heterojunction composite material. The preparation method is simple and convenient to operate and is low in reaction temperature, and the prepared composite material is excellent in photocatalytic performance.

Owner:ZHENJIANG COLLEGE

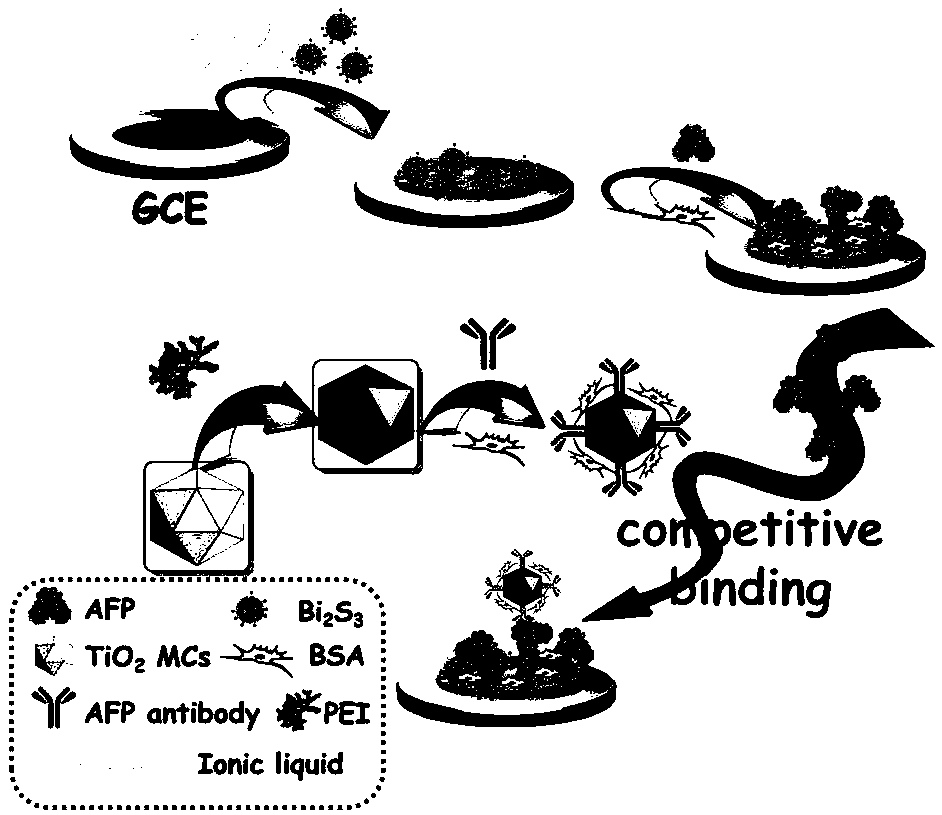

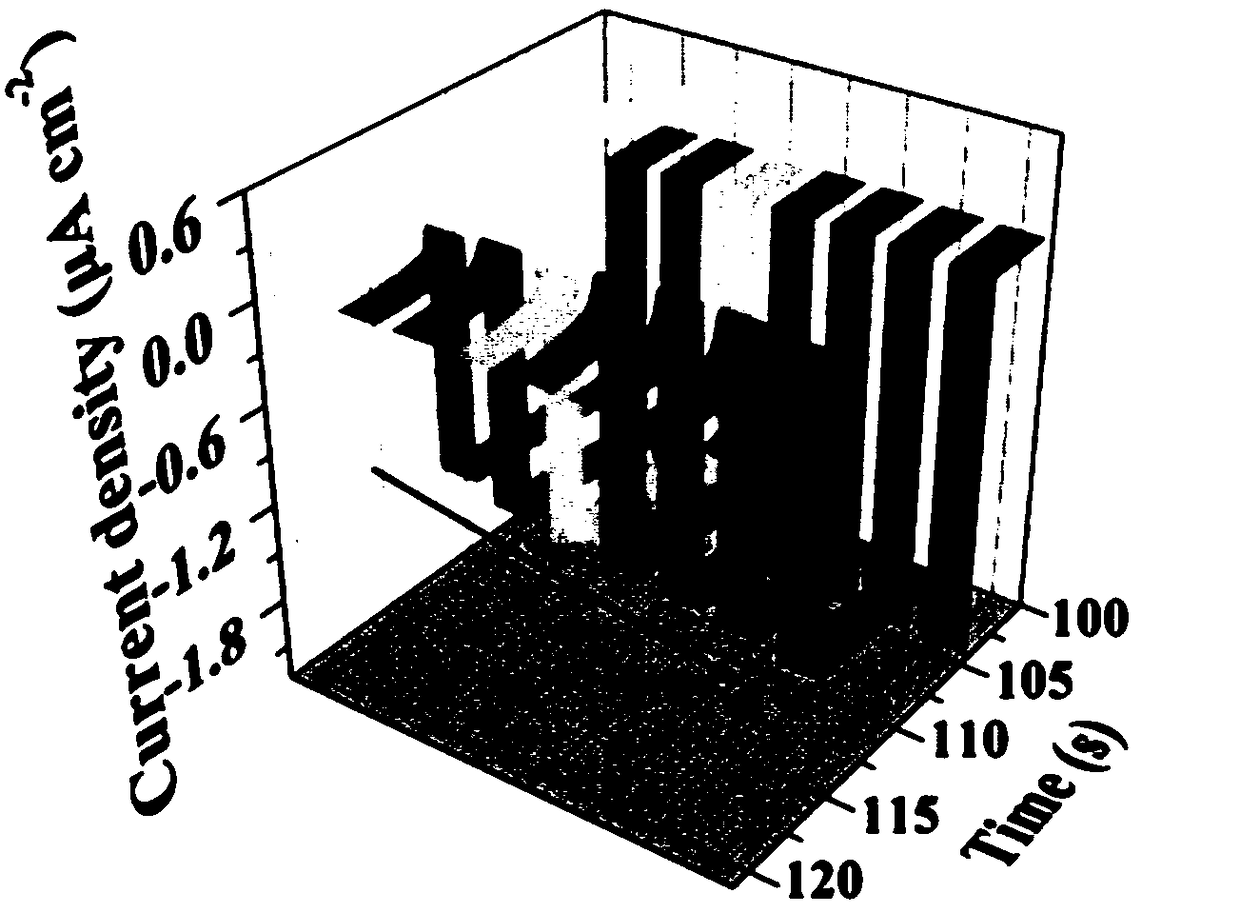

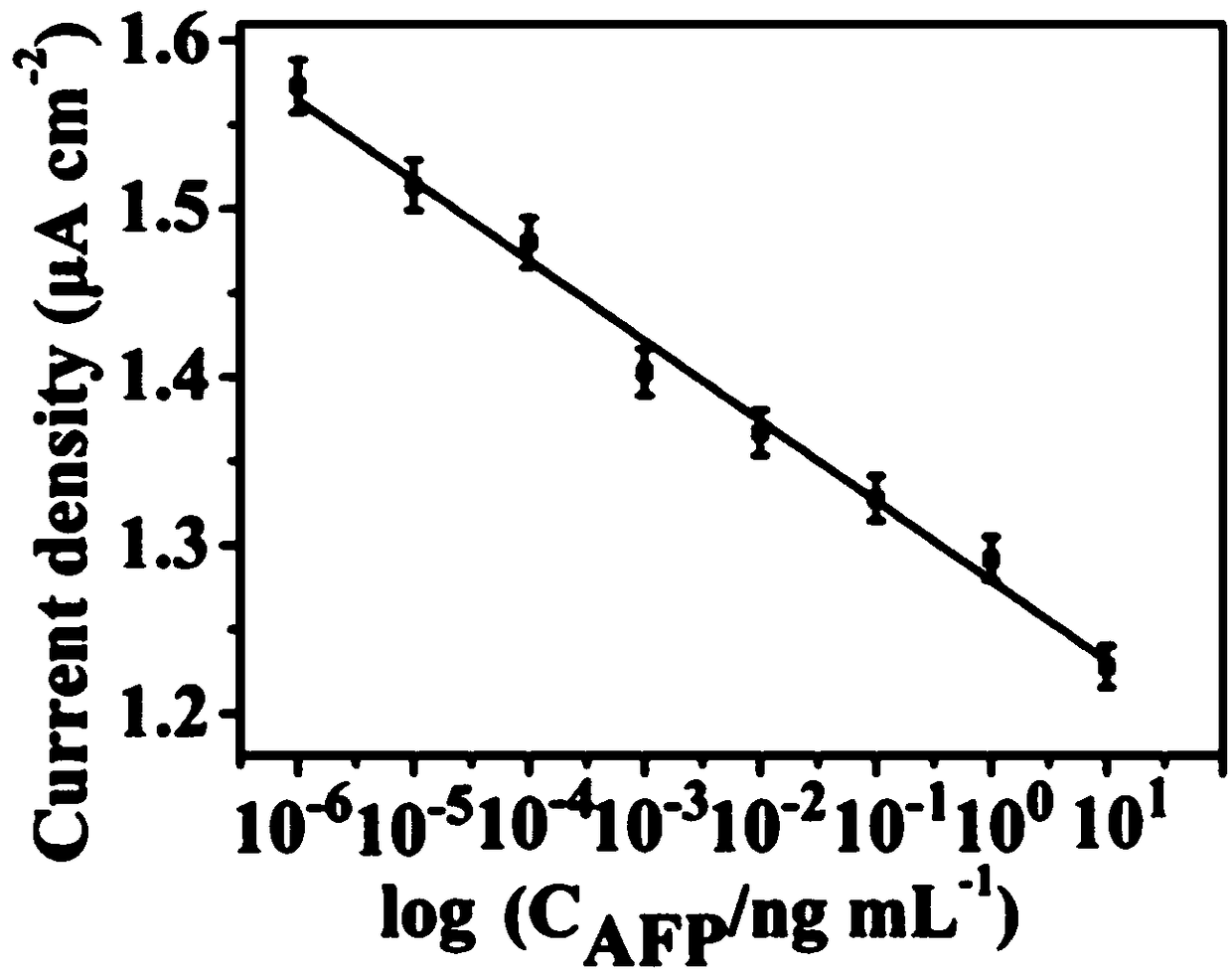

Preparation and application of alpha-fetoprotein photoelectrochemical competitive immunosensor based on double-sensitized structure

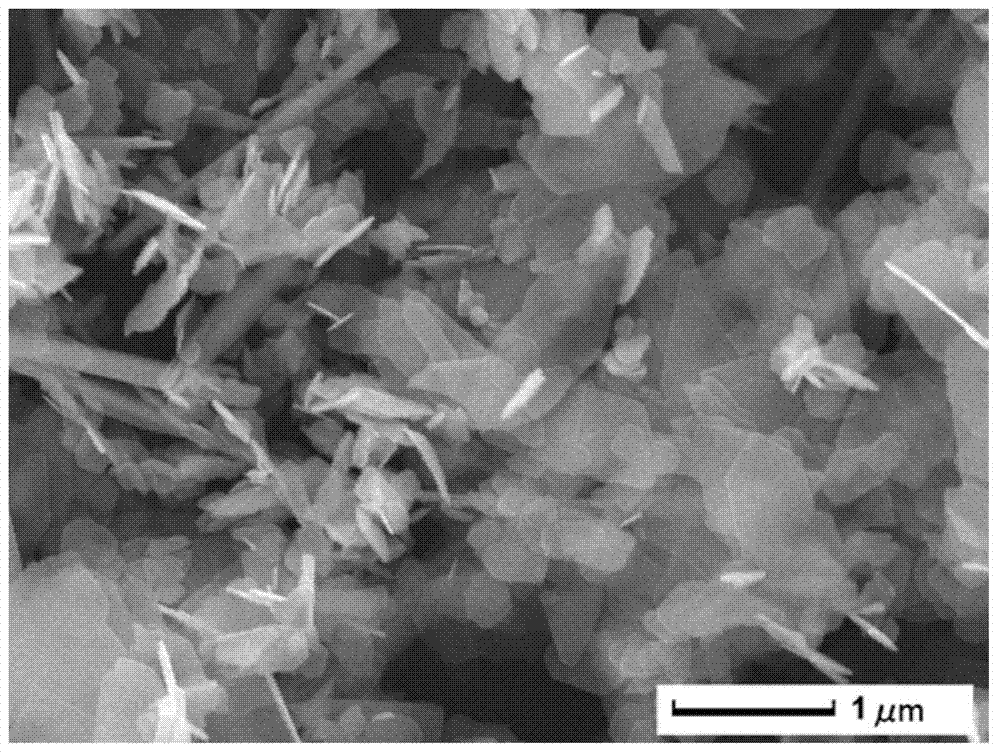

InactiveCN108872341ALarge specific surface areaImplement multiple reflectionsMaterial electrochemical variablesBismuth sulfideMesocrystal

The invention discloses preparation and application of an alpha-fetoprotein photoelectrochemical competitive immunosensor based on a double-sensitized structure. A sensing interface is constructed byusing titanium dioxide mesocrystals as a probe substrate and immobilizing an alpha-fetoprotein antibody (Ab), and using bismuth sulfide as an electrode substrate and immobilizing an alpha-fetoproteinantigen; the sensor with the double-sensitized structure is constructed by means of specific binding between an antigen and the antibody. An electrode modified with the alpha-fetoprotein antigen is placed in a mixed solution containing different concentrations of free antigen and a certain amount of labeled probes, and the free target antigen competes with the immobilized antigen for bonding to the labeled probes. Under the illumination condition, the electrode bonded with the probes can generate photocurrent with certain intensity, and the amplification of a current signal is realized by means of the double-sensitized structure. Furthermore, as the concentration of the free target material increases, the number of the probes bonded to the immobilized antigen decreases, and the photocurrent intensity is also reduced. Based on the phenomenon, a photoelectric analysis method for alpha-fetoprotein can be established.

Owner:FUJIAN NORMAL UNIV

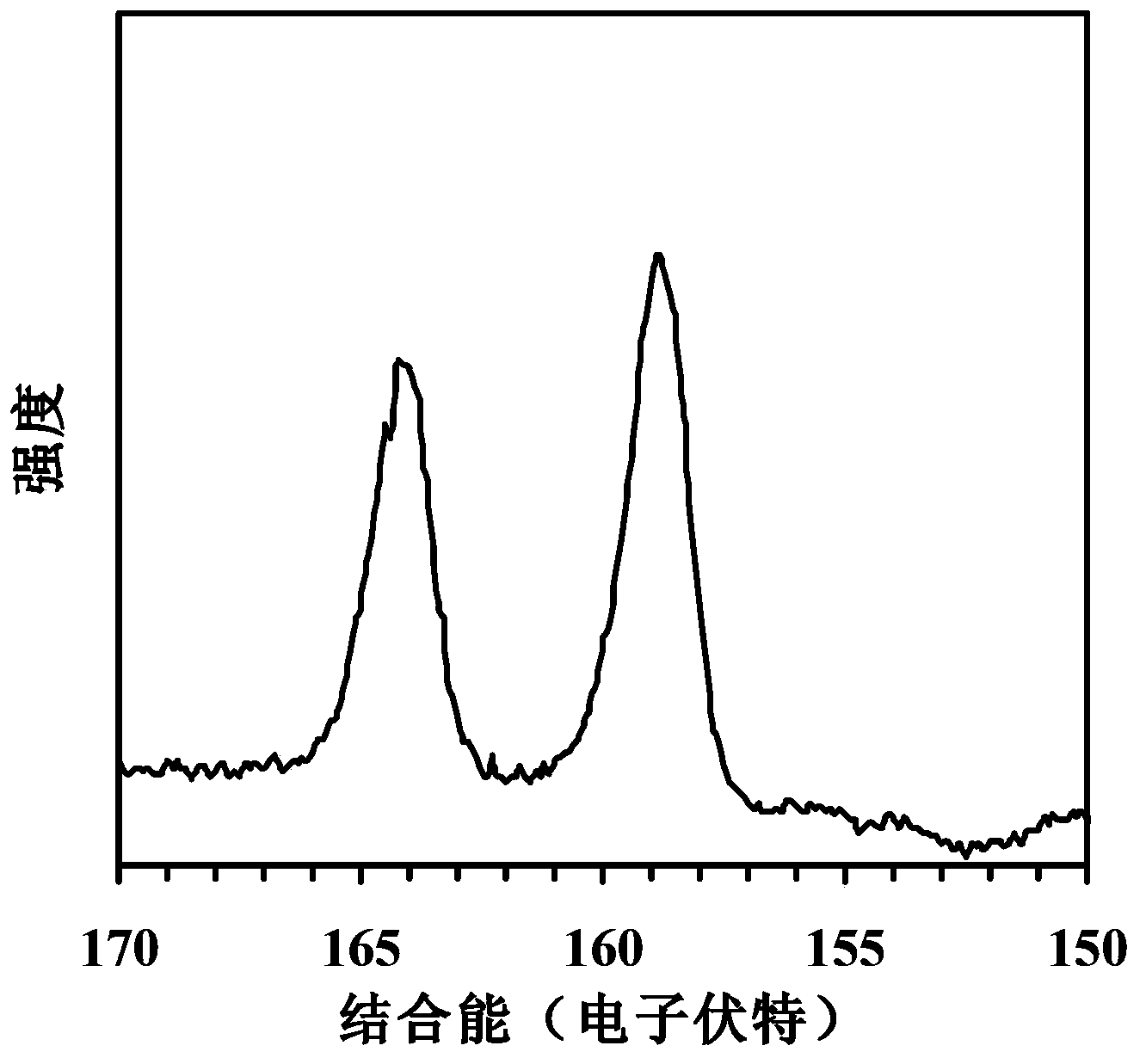

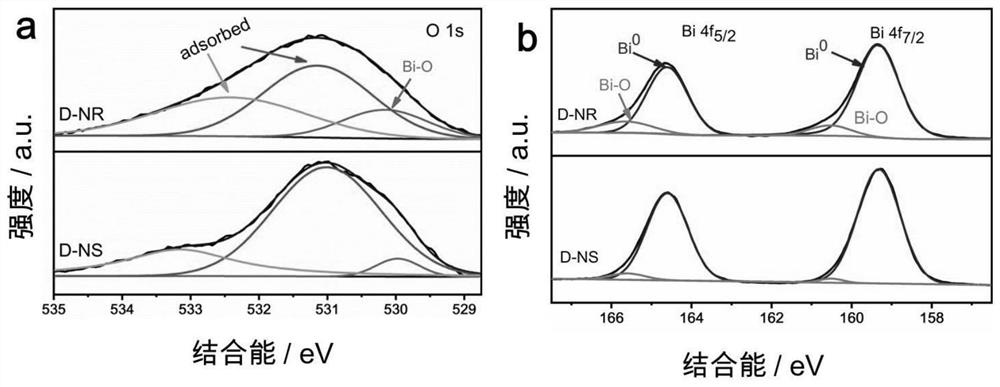

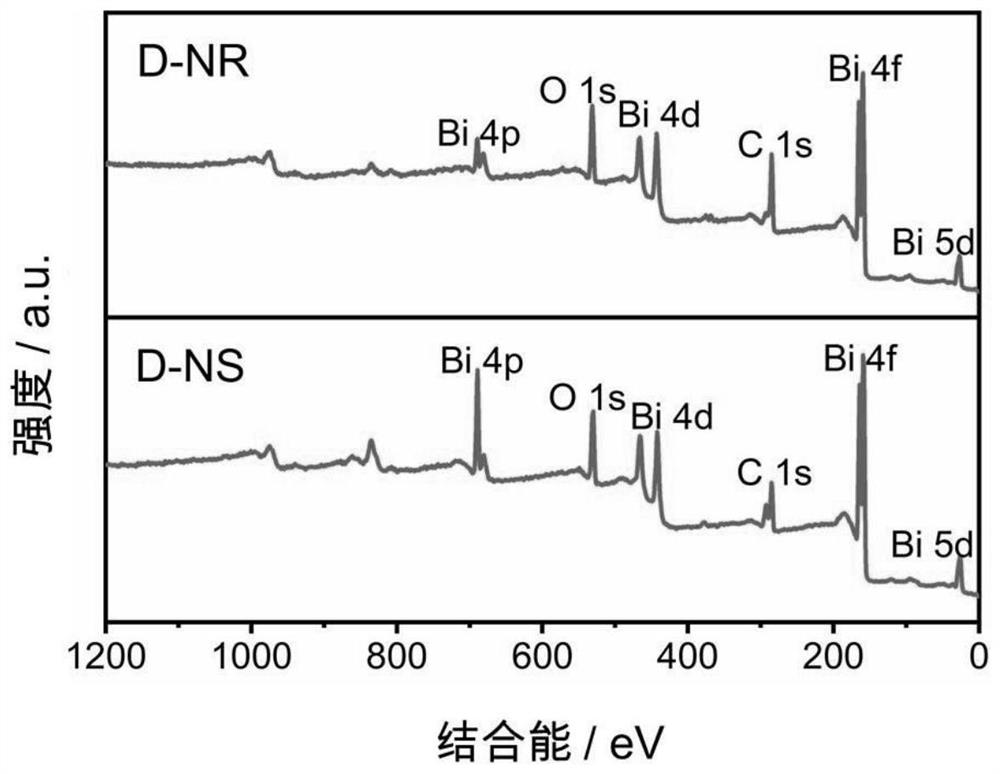

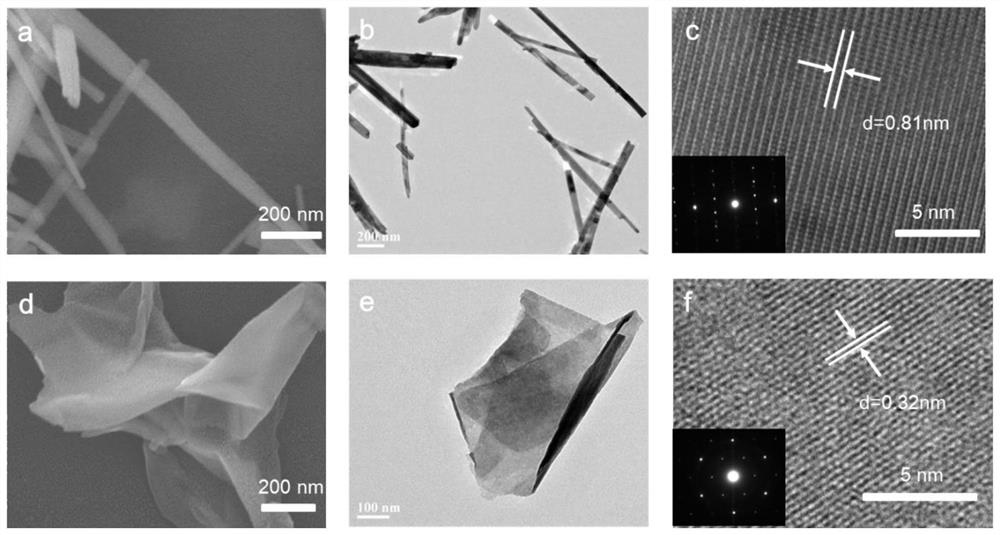

Bismuth-based nano material as well as preparation method and application thereof

ActiveCN111604046AImprove reducibilityImprove stabilityMaterial nanotechnologyCarbon compoundsBismuth sulfidePhysical chemistry

The invention discloses a bismuth-based nano material as well as a preparation method and application thereof. The preparation method disclosed by the invention comprises the step of preparing a nano-sheet-shaped bismuth-based material from nano-rod-shaped bismuth sulfide by an electrochemical reduction method, wherein the nano-rod-shaped bismuth sulfide is prepared from Bi (S2CNEt2) 3 through a hydrothermal method. The bismuth-based nano material solves the problem of low concentration of subsurface solvent oxygen active components, and realizes high CO2 electrocatalytic reduction efficiency.

Owner:EAST CHINA UNIV OF SCI & TECH

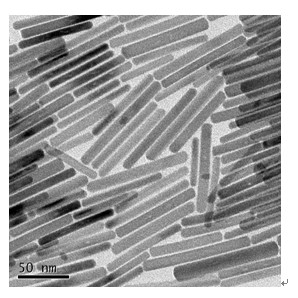

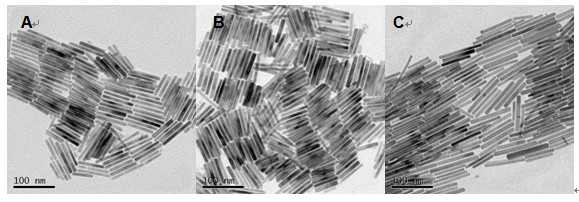

Bismuth sulfide nanorod with CT (computed tomography) angiography function, nano-composite material and preparation thereof

InactiveCN102633304AShape is easy to controlUniform sizeX-ray constrast preparationsNanotechnologyBismuth sulfideSolvent

The invention discloses a bismuth sulfide nanorod with a CT (computed tomography) angiography function, a nano-composite material and preparation thereof. The preparation method of the bismuth sulfide nanorod comprises the following steps of: (1) dissolving bismuth chloride in a solvent in an ultrasonic manner to get a solution A; (2) dissolving sulfur powder or thiacetamide in the solvent in the ultrasonic manner to get a solution B; and (3) increasing the temperature of the solvent to 80-180 DEG C under the protection of argon, sequentially adding the solution A and the solution B, stirring to realize complete reaction, cooling, and then adding ethanol for centrifugation so as to get the bismuth sulfide nanorod, wherein the solvent is selected from oleyl amine, ethylene glycol and glycerin. The oleyl amine and a metal salt type compound are added into a toluene solution of the bismuth sulfide nanorod, stirring is performed at room temperature, and the ethanol is added for centrifugation so as to get the nano-composite material. The method disclosed by the invention is fast, simple and convenient, and the prepared bismuth sulfide nanorod and the nano-composite material thereof have the advantages of controllable appearance, uniform size and low cost and have excellent CT signals.

Owner:SUZHOU UNIV

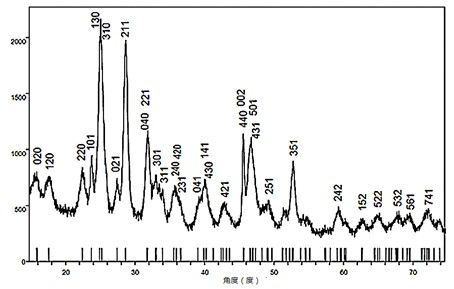

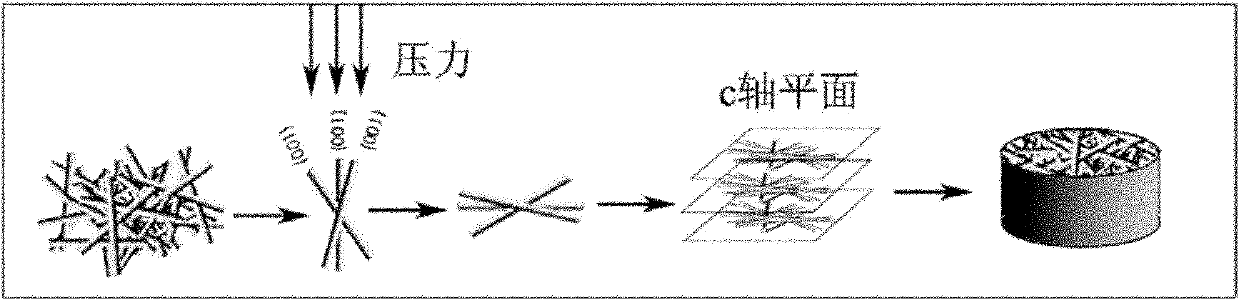

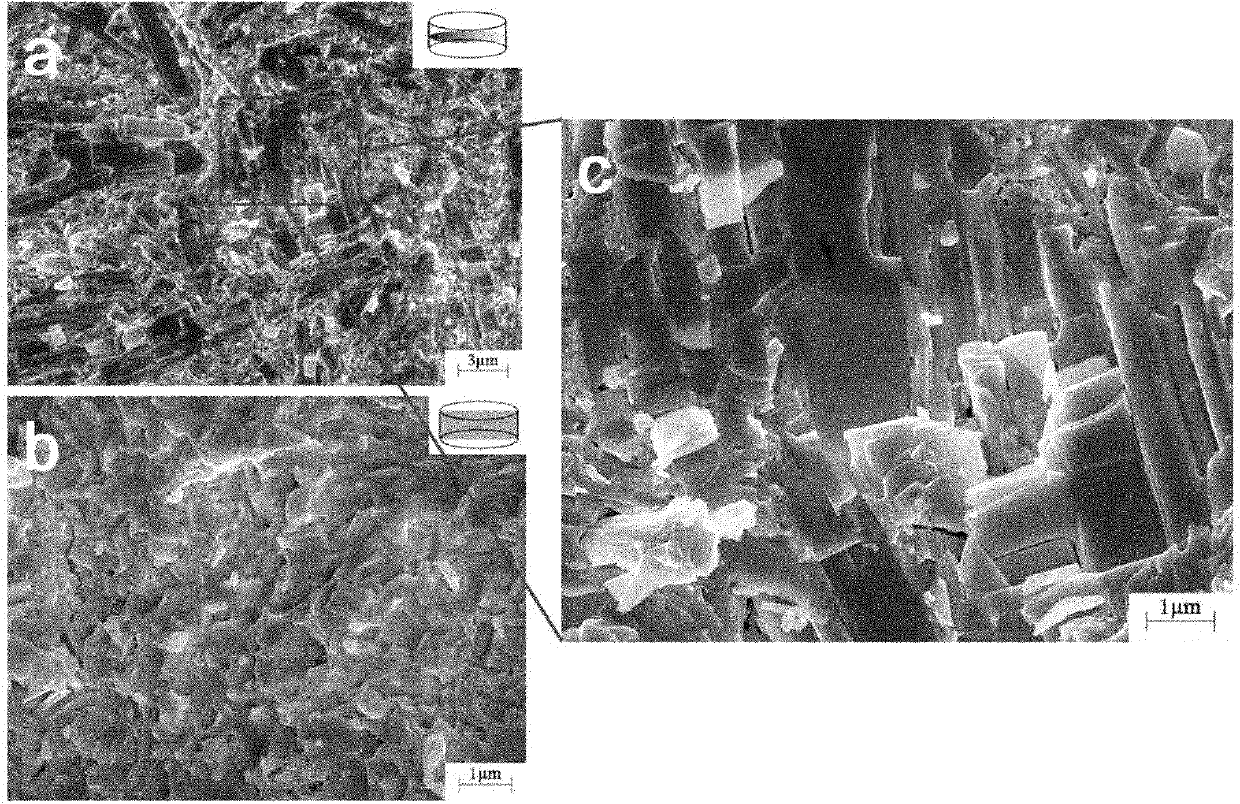

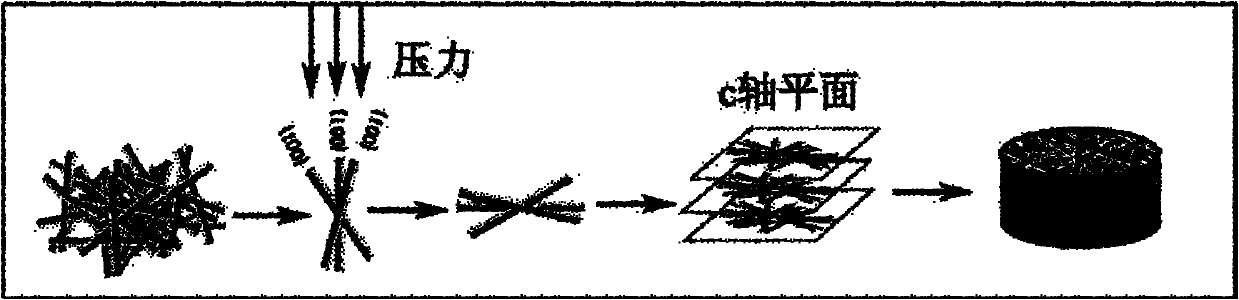

Method for controlling bismuth-sulfide polycrystalline thermoelectric material texture

InactiveCN102002757AEasy to makeEasy to manufacturePolycrystalline material growthFrom normal temperature solutionsBismuth sulfideEthylenediamine

The invention relates to a method for controlling bismuth-sulfide polycrystalline thermoelectric material texture, belonging to the technical field of energy materials. The method is characterized by comprising the following steps of: with bismuth nitrate and sodium thiosulfate as raw materials, quadrol as a pH value regulating agent and deionized water and absolute ethyl alcohol as solvents, carrying out hydro-thermal reaction for 6-72 hours at the temperature of 160-200 DEG C to prepare a monocrystal bismuth sulfide nano rod along an orientation (001), wherein the monocrystal bismuth sulfide nano rod has a diameter of 50-400nm and a length of 500-5 microns; then, sintering nano rod powder by using a spark plasma sintering technology at the pressutre of 10-80MPa and the temperature of 250-550 DEG C without holding time; retaining a monocrystal nano rod structure in a block body; arraying the monocrystal nano rod structure along a horizontal direction; and preparing a bismuth-sulfide block material with a high texture degree, wherein the texture degree is controllable. The method can simply and conveniently prepare the bismuth-sulfide block thermoelectric material with the controllable texture degree, thereby optimizing the carrier mobility of the material and increasing electrical transmission performance and the thermal stability of thermoelectric property.

Owner:UNIV OF SCI & TECH BEIJING

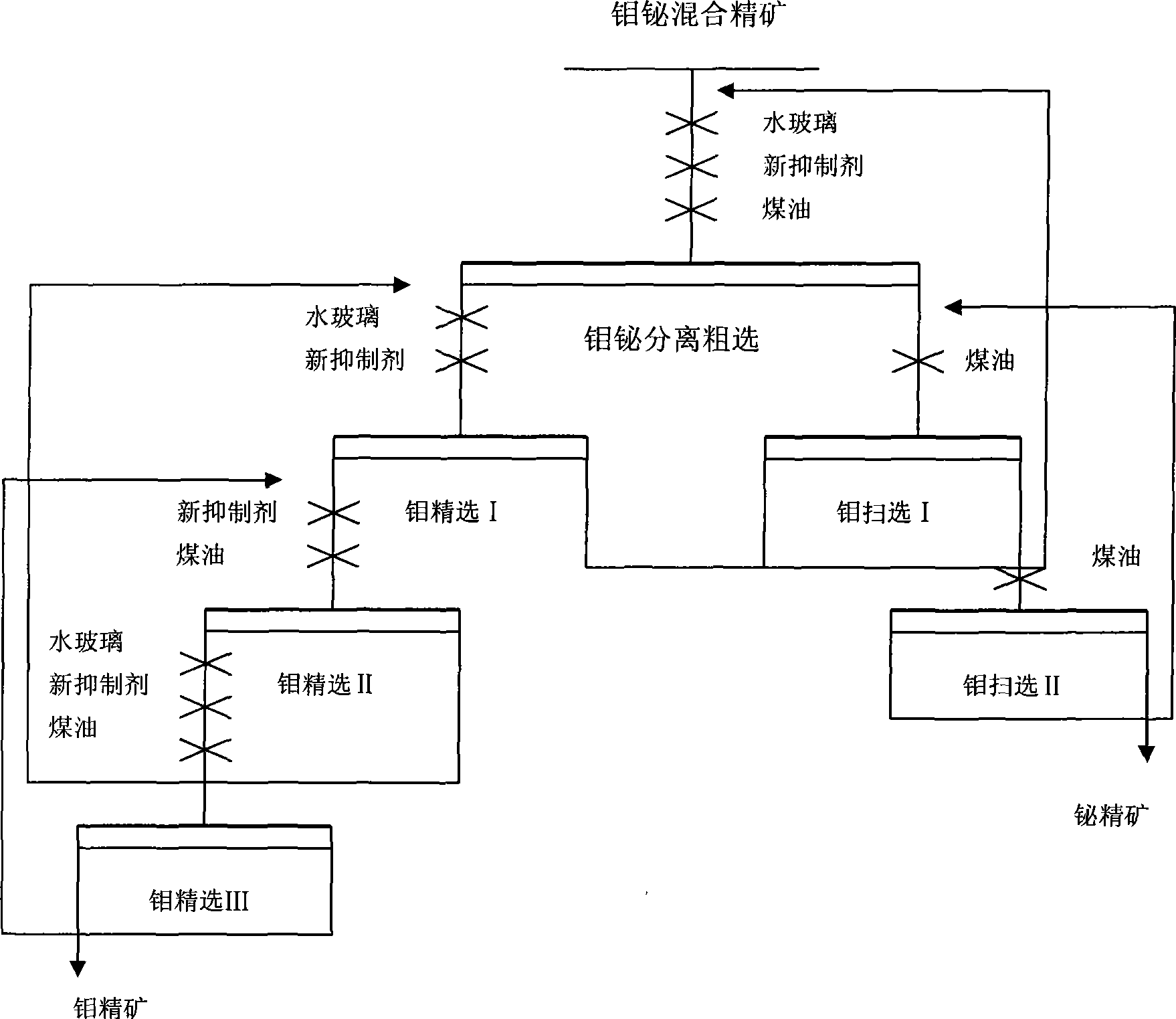

Method for separating molybdenum and bismuth sulfide minerals

A method for separating molybdenum and bismuth sulfide collective concentrate minerals relates to a mineral separation process, in particular to a method for separating the molybdenum and bismuth sulfide collective concentrate minerals to obtain molybdenum concentrate and bismuth concentrate. The invention is characterized in that the floatation separation process adopts bi-hydroxyethyl group amino sodium formate or bi-hydroxyethyl group amino potassium formate as the inhibitor of the bismuth sulfide mineral. The method of the invention efficiently overcomes the defects of large use amount ofcommon sodium sulfide, bad operation environment and heavy pollution, and has the characteristics of convenient adding, safe usage and the like. The invention provides an effective method featuring small medicament use amount, convenient usage and little environment pollution for the separation of molybdenum and bismuth sulfide minerals.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

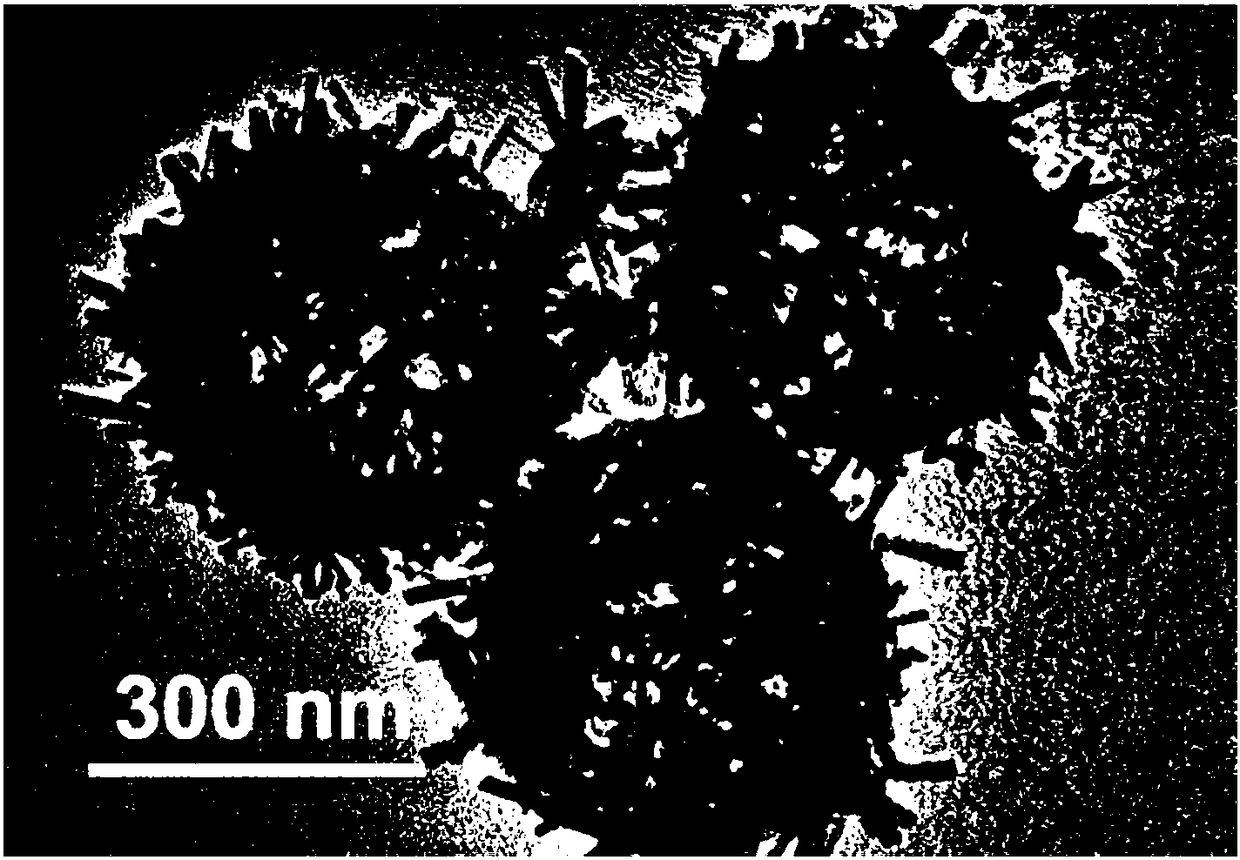

Rodlike bismuth sulfide hollow nanoscale balloon and preparation method thereof

ActiveCN108529675AUniform shapeReduce manufacturing costEnergy modified materialsInorganic non-active ingredientsBismuth sulfideAlcohol

The invention discloses a rodlike bismuth sulfide hollow nanoscale balloon and a preparation method thereof. The preparation method of the rodlike bismuth sulfide hollow nanoscale balloon comprises dispersing monodispersed hierarchical porous structured ZnS nanoscale balloons and thiourea into alcohol solution, stirring and heat-preserving the mixture at 80-130 DEG C for 10 min, then rapidly filling in bismuth salt fully dissolved inside alcohol solution for exposed reaction for 10-30 min, naturally cooling down to room temperature, performing centrifugal washing to obtain the target product of the rodlike Bi2S3 hollow nanoscale balloon. The preparation method for the first time achieves synthesis of the rodlike Bi2S3 hollow nanoscale balloon in solution phase in an exposed system and accordingly is simple in synthesizing method and mild in reaction conditions; the prepared rodlike Bi2S3 hollow nanoscale balloon is uniform in morphology, low in product cost and applicable scaled industrial production.

Owner:HEFEI UNIV OF TECH

Method for preparing bismuth sulfide nano-rod crystalline material

InactiveCN101613882ALow costSimplify operating proceduresPolycrystalline material growthFrom melt solutionsChemical reactionSolvent

The invention discloses a method for preparing a bismuth sulfide nano-rod crystalline material, wherein the method is suitable for preparing nano-crystalline materials of bismuth sulfide and other sulfides. The method is characterized in that molten compound nitrate solvent is utilized; the crystalline material is synthesized through chemical reaction under normal pressure and at a temperature of 100-300 DEG C; raw materials used in the method include soluble inorganic metal bismuth salt and sodium sulfide or sulfur powder; the cost during the synthesis is simple; various parameters in the reaction process are easy to monitor and control; little environment pollution is caused; a reaction system has good uniformity; the process is simple and the production can be easily expanded; obtained bismuth sulfide realizes good crystallization, clean surface and uniform size and is suitable for conducting researches on intrinsic properties thereof and bringing the functions of nano-crystalline materials into maximum play.

Owner:CHONGQING UNIV

Preparation method of highly sensitive photoelectrochemical sensor for detecting microRNA

ActiveCN110412097AIncrease surface areaEnhance photoelectric signalMaterial electrochemical variablesBismuth sulfideBismuth vanadate

The invention discloses a highly sensitive paper-based photoelectrochemical sensor for detecting microRNA. A paper chip is prepared by means of a wax printing technology, gold nano-particles are grownin situ in a hydrophilic working area to achieve functionalization of the paper chip, a cuprous oxide / bismuth sulfide / bismuth vanadate tertiary sensitizer is modified subsequently, and microRNA is captured through a fixed hairpin DNA chain; by means of identification of specificity and digestion effect of duplex-specific nuclease, signal amplification on microRNA is achieved, and then by means ofa multibranched hybrid chain, platinum nanoparticles are embedded into a main part of the chain, branch parts form a chlorhematin / G-tetrad structure, and a DNA concatemer with catalase bological characteristics is formed; signal amplification is further achieved, thus preparation of the photoelectrochemical sensor is completed, and highly sensitive and accurate detection on microRNA is achieved.

Owner:UNIV OF JINAN

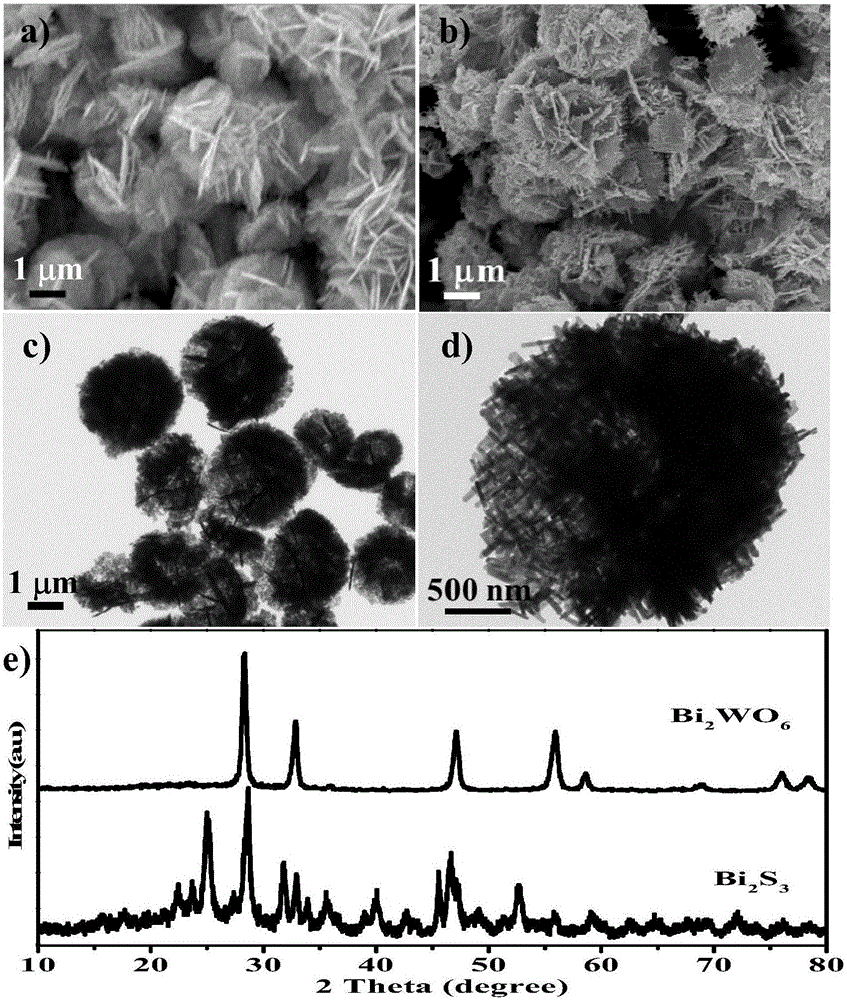

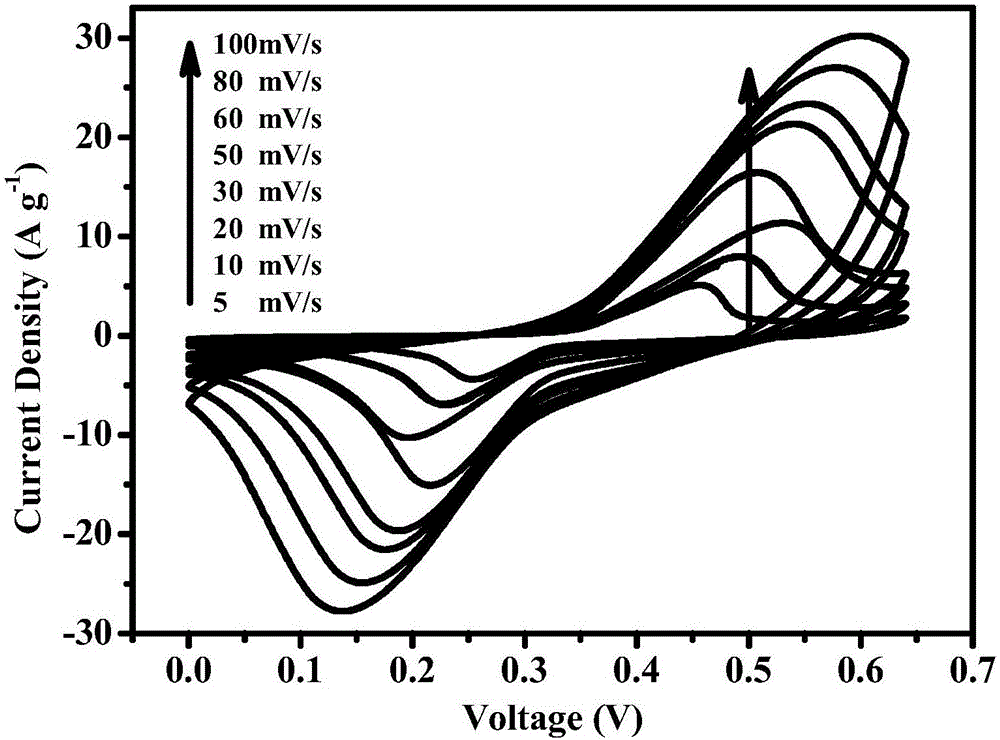

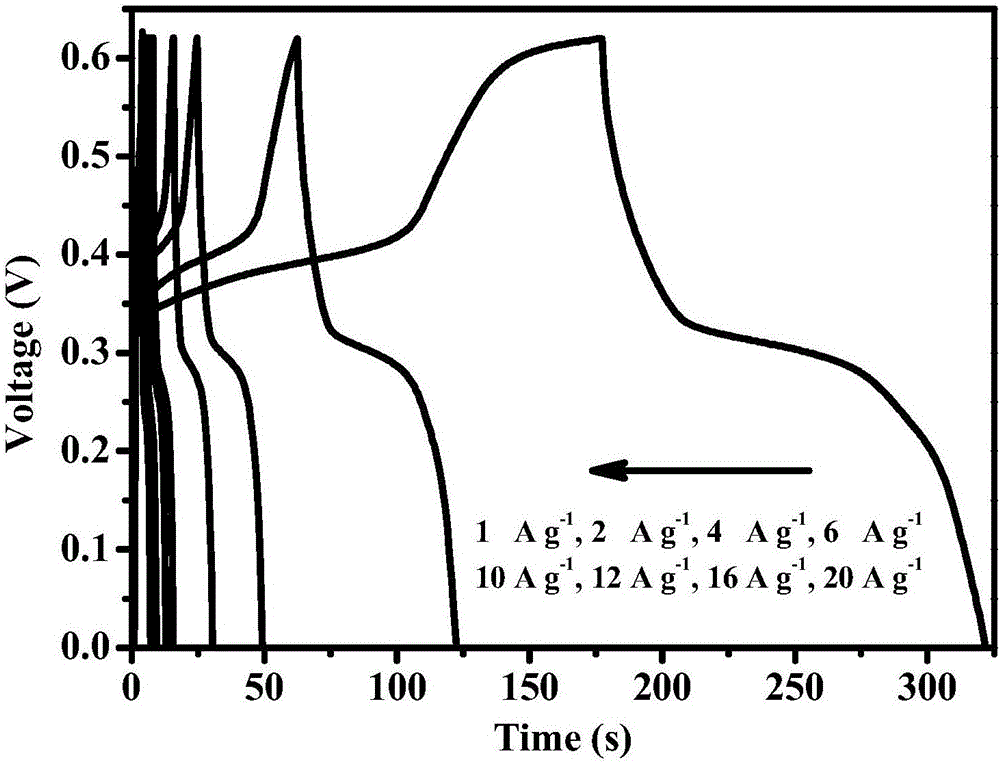

Bismuth sulfide graded nanoflower supercapacitor electrode material and preparation method

InactiveCN106477629AMorphological rulesSize rulesHybrid capacitor electrodesNanotechnologyBismuth sulfideElectric capacity

The invention relates to a bismuth sulfide (Bi2S3) graded nanoflower supercapacitor electrode material and a preparation method. Bi2WO6 graded nanoflowers are dispersed into a thioacetamide solution; after the stirring, the materials are put into a hydrothermal reaction kettle to perform hydrothermal reaction; after the reaction is completed, the materials are naturally cooled to room temperature; precipitates are collected; water and ethyl alcohol are respectively used for alternate washing for three times; centrifugation and drying are performed. The Bi2S3 nanoflowers obtained through in situ topological synthesis by a hydrothermal method have regular appearance, uniform dimension and good dispersibility; compared with a conventional Bi2S3 nanometer material, a Bi2S3 graded structure has the advantages that a greater specific surface area is realized, so that the electric capacity can be effectively improved.

Owner:JIANGSU UNIV

Sulfur group hetero-structure nano material, preparation method and application thereof

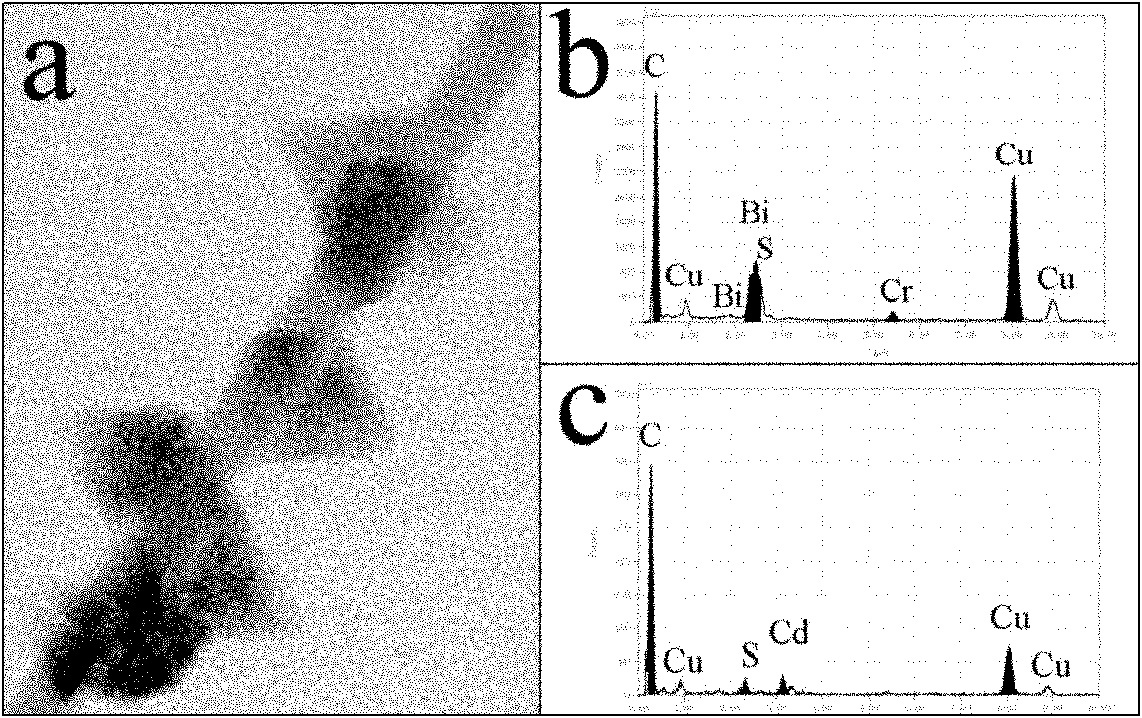

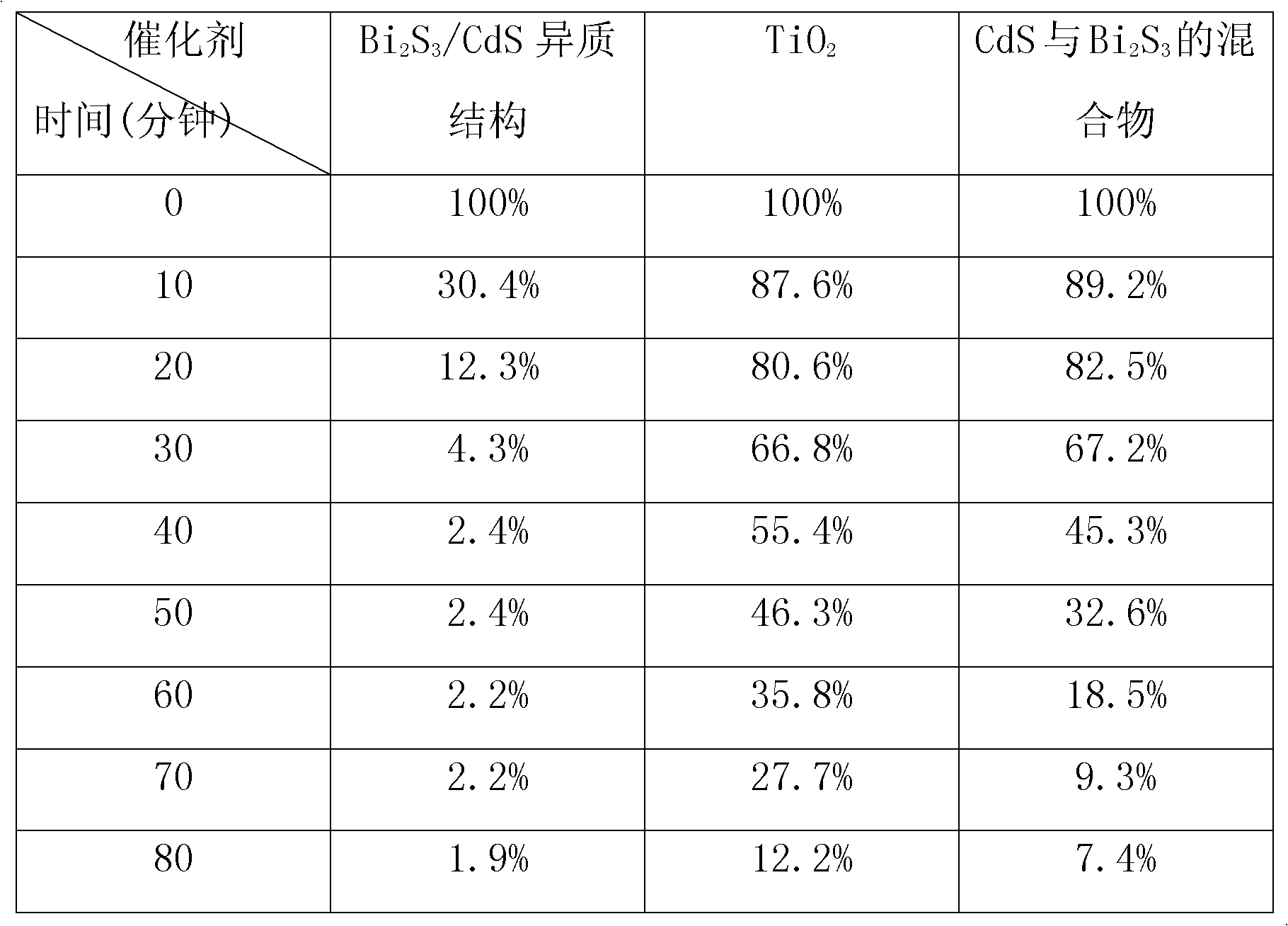

InactiveCN102008966AEasy to prepareRaw materials are easy to getNanostructure manufacturePhysical/chemical process catalystsBismuth sulfideSulfur

The invention discloses a sulfur group hetero-structure nano material, a preparation method and application thereof. The nano material is Bi2S3 / CdS, and the molar ratio of a bismuth source to a cadmium source is 1:1. Compared with the prior art, bismuth sulfide nano wires can be mutually combined with cadmium sulfide nano granules by simple one-step solvent heat, the raw materials are easily obtained, the preparation method is simple, and the yield is 88 percent; and when the material prepared by the method is applied to photocatalytic degradation of organic pollutants such as methyl red dye, the organic pollutants can be basically completely degraded in 20 minutes.

Owner:ANHUI NORMAL UNIV

Preparation and application of core-shell-structure bismuth sulfide@bismuth oxide composite microspheres

ActiveCN103480395ARegular and controllable shapeCrystal phase controllablePhysical/chemical process catalystsBismuth sulfideMicrosphere

The invention provides core-shell-structure bismuth sulfide@bismuth oxide composite microspheres and a preparation method thereof. The preparation method comprises the following steps: (1) dissolving bismuth nitrate pentahydrate and lysine in a glycol solution, dissolving water-soluble sulfide and lysine in a glycol solution, dropwisely adding the glycol solution containing water-soluble sulfide and lysine into the glycol solution containing bismuth nitrate pentahydrate and lysine, transferring the prepared solution into a crystallization reaction kettle, reacting at 60-160 DEG C in a thermostatic oven for 1-12 hours, cooling, filtering, separating, washing with deionized water, washing with anhydrous ethanol, and drying to obtain bismuth sulfide; and (2) dispersing the prepared bismuth sulfide powder into an alkali solution, transferring the solution into a crystallization reaction kettle, reacting at 60-160 DEG C in a thermostatic oven for 1-24 hours, cooling, filtering, separating, washing with deionized water, washing with anhydrous ethanol, and drying to obtain the core-shell-structure bismuth sulfide@bismuth oxide composite. The invention also provides application of the core-shell-structure bismuth sulfide@bismuth oxide composite microspheres as a photocatalyst.

Owner:HUNAN UNIV

Preparation method of novel bismuth sulfide nanorods

InactiveCN103086429ASimple preparation processRaw materials are cheap and easy to getMaterial nanotechnologyPhysical/chemical process catalystsBismuth sulfidePhoto catalytic

The invention discloses a preparation method of novel bismuth sulfide nanorods. The preparation method comprises the following steps of: taking bismuth nitrate and glutathione as starting reactants, adopting an alcohol with smaller molecular weight, such as methanol or ethanol as a reaction reagent, performing complete reaction under supercritical conditions of the solvent, then directly discharging the solvent and drying products, namely performing one-step synthesis to obtain bismuth sulfide semiconductor nanorods through a hydro-thermal synthesis method. The method has the advantages of high yield and low cost, the photocatalytic activity of the obtained products is high, and the method has great industrialized application prospects.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

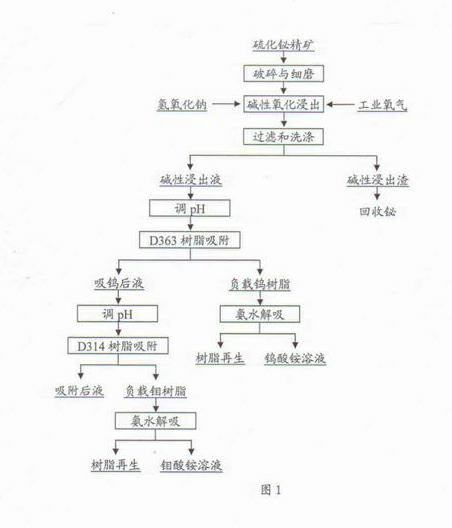

A method for separating tungsten, molybdenum and bismuth in bismuth sulfide concentrate

InactiveCN102296180AEfficient separationComprehensive recycling benefits are goodProcess efficiency improvementBismuth sulfideMaterials science

The invention discloses a method capable of effectively separating tungsten, molybdenum and bismuth in bismuth sulfide ore concentrate. The method comprises the following steps of: performing pressure oxidation leaching on the bismuth sulfide ore concentrate containing tungsten and molybdenum in sodium hydroxide solution, wherein the tungsten and the molybdenum enter the alkali leachate, and the bismuth and other heavy metals enter the alkali leached residue in an oxide form, so that effective separation of the tungsten, the molybdenum and the bismuth in the bismuth sulfide ore concentrate isrealized; adsorbing the tungsten and the molybdenum in the alkali leachate by using macroporous weak alkali acrylic series anion exchange resin D363 and D314 respectively; and finally, desorbing the tungsten and the molybdenum by using aqueous ammonia respectively, so that effective reclamation of the tungsten and the molybdenum in the leachate is realized. By the method, effective separation of the tungsten, the molybdenum and the bismuth in the bismuth sulfide ore concentrate is realized, the leaching rate of the tungsten and the molybdenum is over 99 percent, and the bismuth, copper and the like enter the alkali leached residue after being oxidized; the tungsten and the molybdenum in the alkali pressure leachate are adsorbed by adopting resin, and the recovery rate of the tungsten and the molybdenum is over 99 percent; and the method is low in labor intensity, short in treatment time and good in operating environment.

Owner:CENT SOUTH UNIV

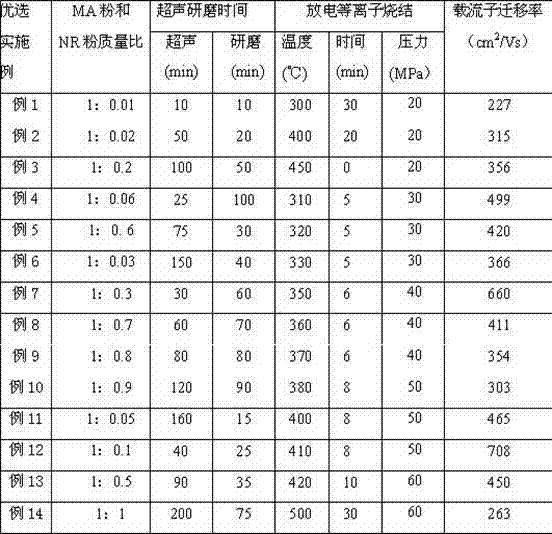

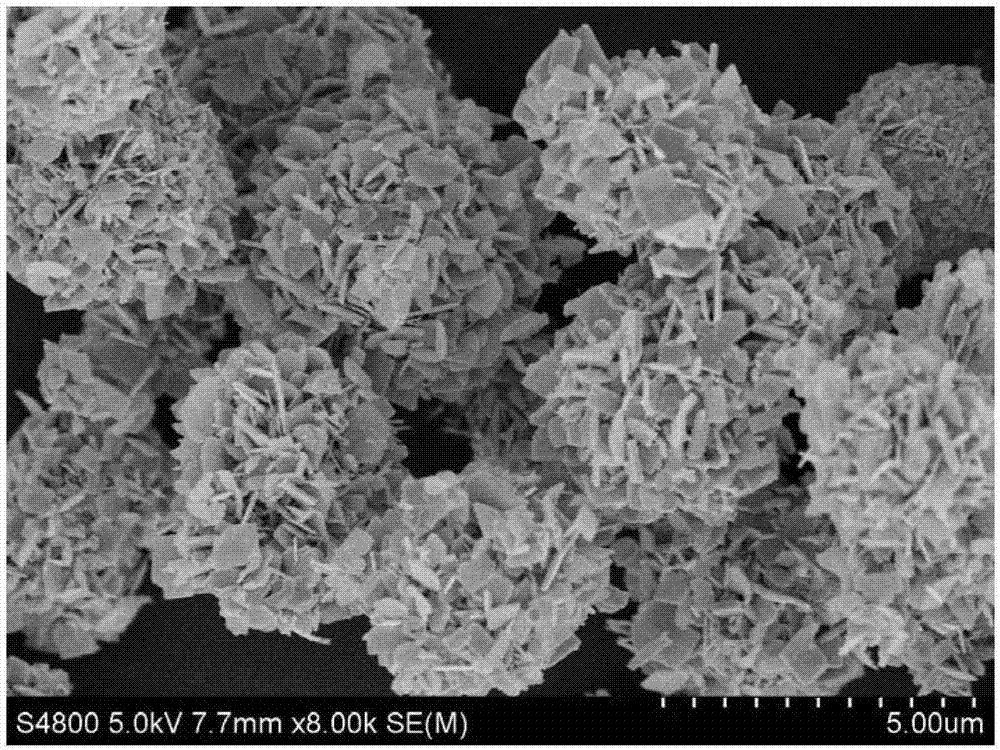

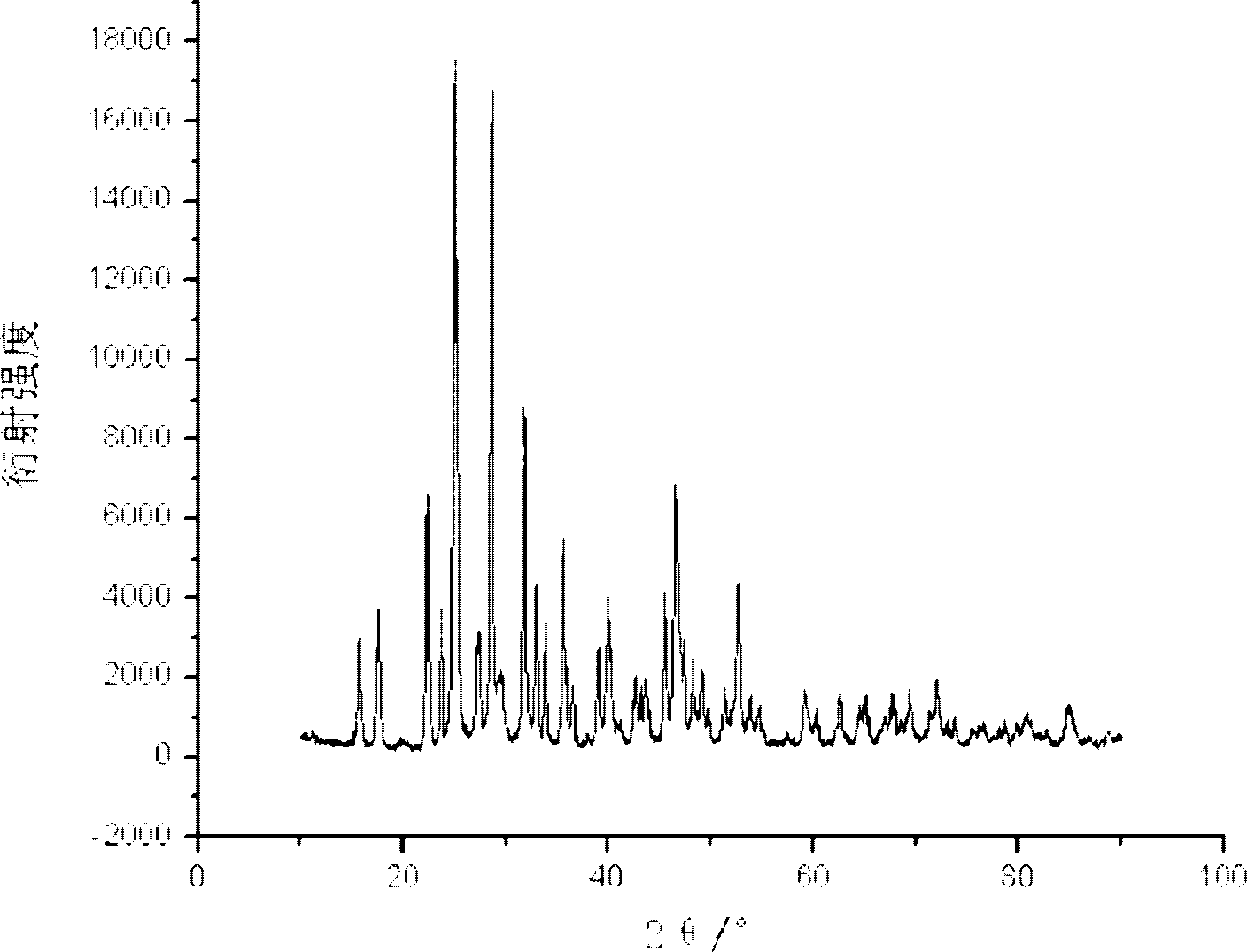

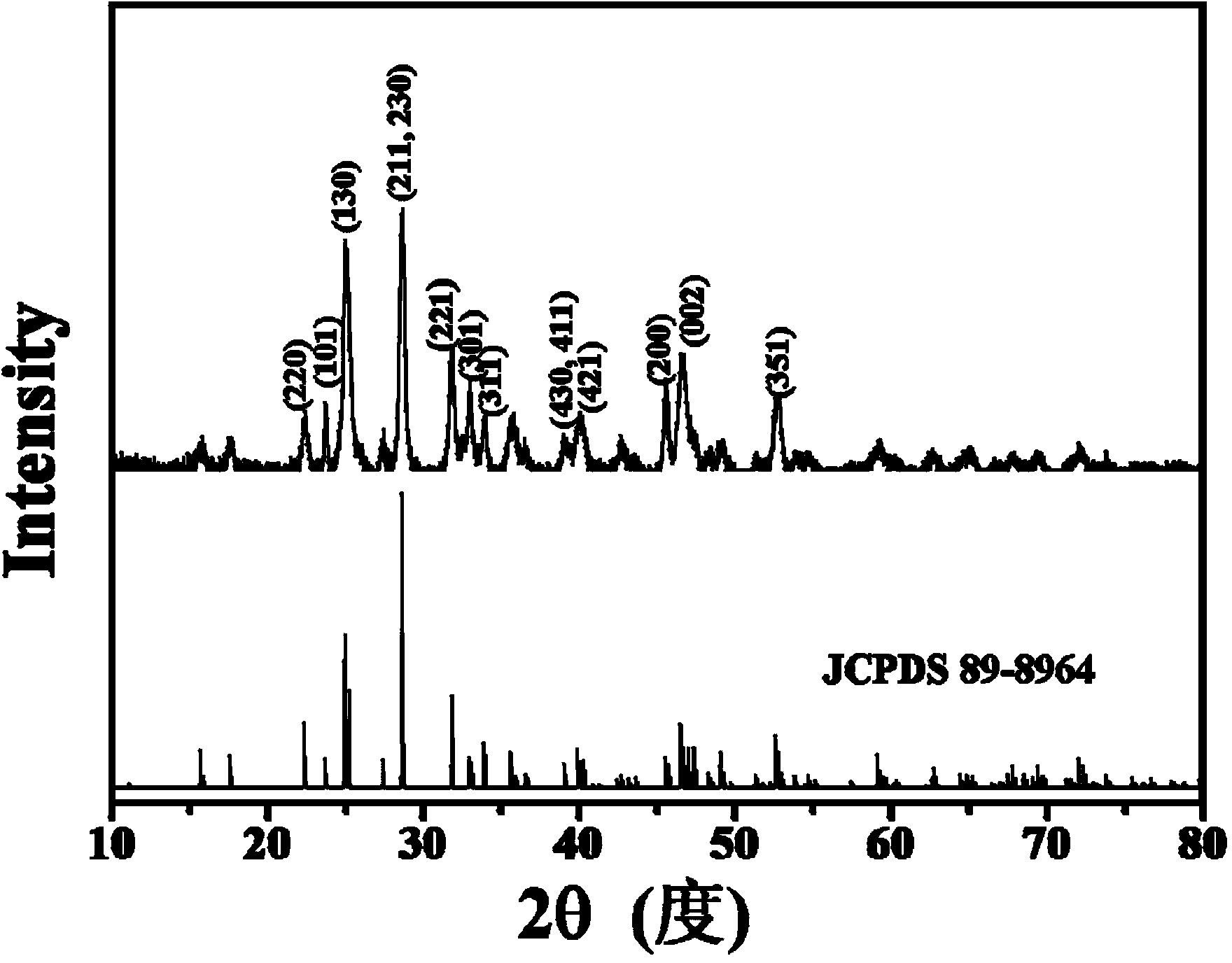

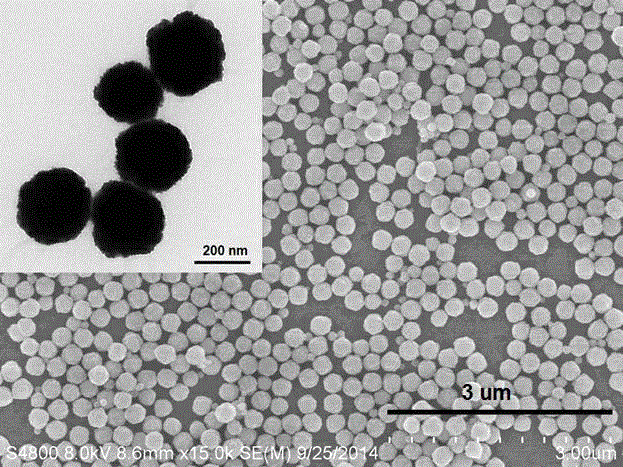

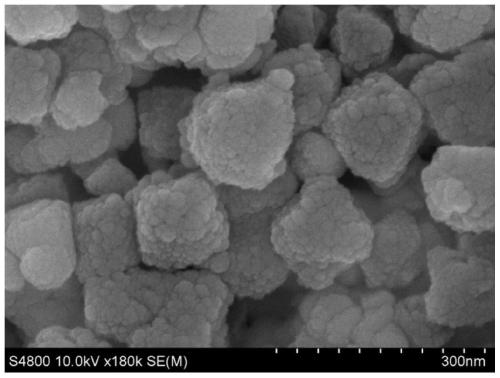

Pompon bismuthous sulfide and preparation method thereof

InactiveCN102616844AHigh activityHigh selectivityNanotechnologyBismuth compoundsBismuth sulfideThiourea

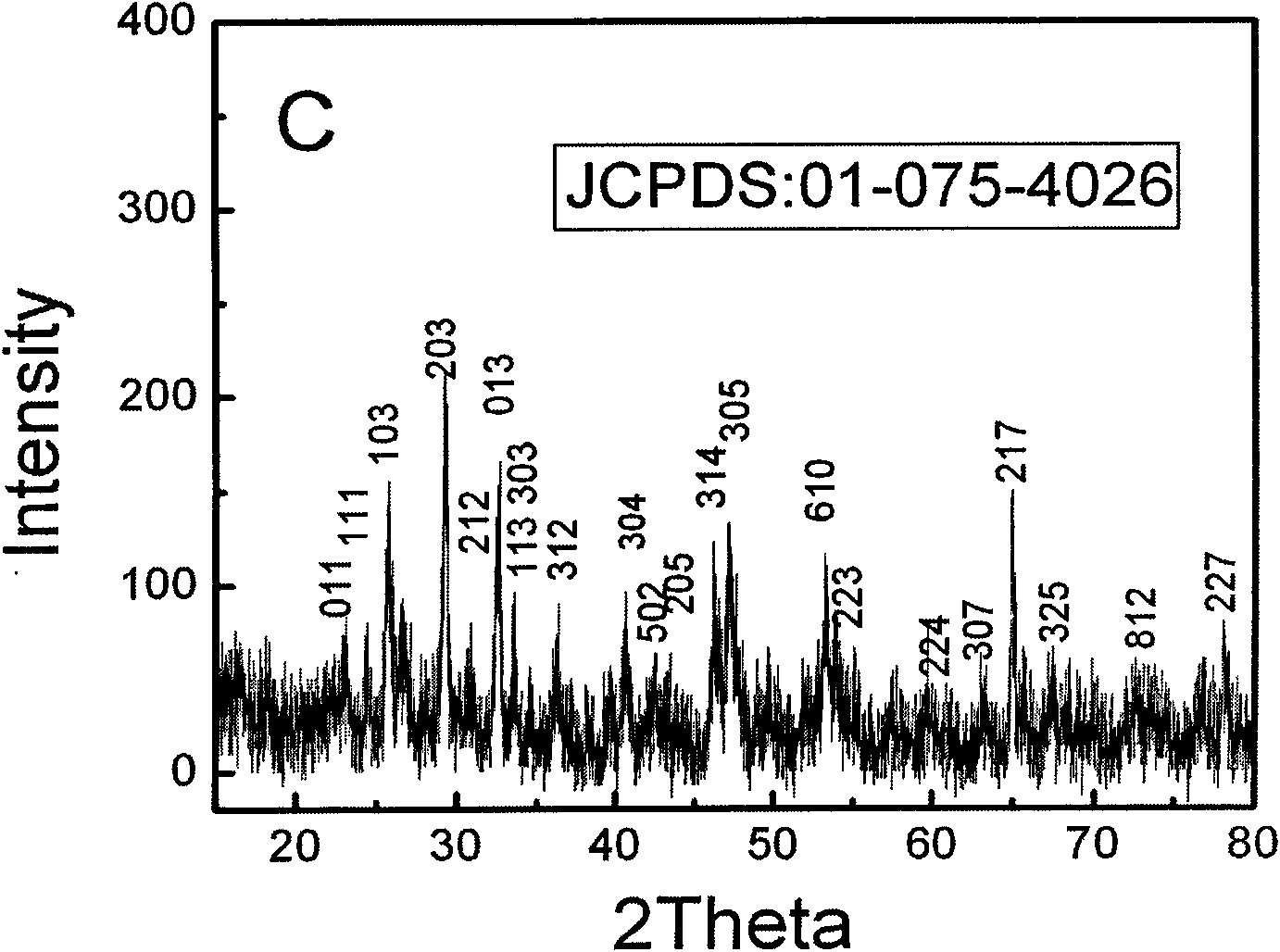

The invention discloses pompon bismuthous sulfide and a preparation method thereof. The preparation method is characterized in that bismuth nitrate serves as a bismuth source, thiourea or thioacetamide serves as a sulfur source, and hydrothermal / solvothermal reaction is preformed on the bismuth source and the sulfur source under the action of carboxylated polyphenylvinylene surfactant. Prepared bismuth sulfide pompon has an orthorhombic system structure, and cell parameters of crystals in the directions of coordinate axes X, Y and Z are respectively 11.149nm, 11.304nm and 3.981nm; and nanoribbon sliver-shaped pompon formed by the crystals of the bismuthous sulfide is subjected to agglomeration to generate bismuthous sulfide pompon, the diameter of the bismuthous sulfide pompon is 2 plus / minus 0.3 mu m, the length of the single nanoribbon sliver-shaped pompon is 0.3 plus / minus 0.1 mu m, the width of the pompon sliver is 300 plus / minus 10 nm, and the thickness of the pompon sliver is 100 plus / minus 10 nm. Compared with bismuth sulfide materials prepared by the convention method, the bismuth sulfide material prepared by the method disclosed by the invention has larger specific surface area and is good in crystallization and uniform in size, thus having better application prospect in the fields of catalysis and sensing.

Owner:HEFEI UNIV OF TECH

Self-lubricating wear-resistant ceramic for cutting tools and preparation method thereof

ActiveCN104387071AImprove high temperature resistanceImprove carrying capacityPolyoxyethylene castor oilWear resistant

The invention relates to a self-lubricating wear-resistant ceramic for cutting tools, which is prepared from the following raw materials in parts by weight: 2-3 parts of bismuth sulfide, 2-3 parts of diethanolamine, 2-3 parts of ammonium sulfate, 2-3 parts of magnesium chloride, 2-3 parts of calcium carbide sludge, 2-3 parts of graphene oxide, 0.6-0.8 part of KOH, 0.2-0.3 part of polyoxyethylene castor oil, 3-4 parts of magnesium oxide, 36-40 parts of titanium boride, 4-5 parts of nano tungsten trioxide, 30-35 parts of titanium carbide, 3-5 parts of beryllium oxide, 1-2 parts of silver powder, a right amount of ethanol, a right amount of deionized water, 1-1.5 parts of polyacrylic acid, 1.2-1.6 parts of polyethyleneglycol and 4-5 parts of antiwear assistant. The added nano tungsten trioxide enhances the high temperature resistance of the ceramic. The ceramic has the characteristics of high temperature resistance, high carrying capacity, self lubrication, thermal shock resistance, high wear resistance and the like, and is suitable for manufacturing cutting tools. The antiwear assistant can enhance the wear resistance and heat resistance of the ceramic.

Owner:枣庄科顺数码有限公司

Method for preparing polycrystalline textured thermoelectric material from single-crystal bismuth sulfide precursor powder

InactiveCN102161507AControl textureControl grain sizeBismuth compoundsBismuth sulfideThermoelectric materials

The invention belongs to the technical field of energy materials, in particular relates to a method for preparing polycrystalline textured thermoelectric materials from single-crystal bismuth sulfide precursor powder. Specifically, the method comprises the following steps of: selecting uniformly-orientated single-crystal bismuth sulfide [Bi2S(3-x), 0<=x<=0.5] powder (including nanoflakes, nanotubes and nanowires) as precursor powder; performing rapid sintering under increased pressure by using a spark plasma sintering technique so that the single-crystal powder trends to be arranged in the direction perpendicular to the pressure and freeze to form highly-textured dense polycrystalline bulk thermoelectric materials; and controlling the texture degree, the crystal grain degree and the density of the bulk materials by adjusting the applied pressure, the sintering temperature and the heat retention time. Owing to the texture, the polycrystalline materials show strong anisotropy, so that the power transmission performance is greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

Multilevel structure bismuth sulfide, preparation method and application thereof

InactiveCN104226335ARegular shapeUniform sizePhysical/chemical process catalystsWater/sewage treatment by irradiationBismuth sulfideReaction rate

The invention relates to a preparation method of a multilevel structure bismuth-containing nanometer material with a sonochemical method to obtain the multilevel structure bismuth sulfide with high specific surface area and wide light adsorption range. The preparation method comprises the following steps: adding bismuth nitrate pentahydrate and chlorine-containing ionic liquid to an organic solvent, conducting ultrasonic until all the compounds are uniformly dispersed, placing the obtained dispersion liquid in a microwave-ultrasonic wave combined reactor to take a reaction, adding thiourea in the reaction system to continue reaction, after reaction, centrifugally washing the product to remove the solvent remained on the surface and excessive organic matters, and drying the product to obtain the multilevel structure bismuth sulfide nanometer material. The preparation method of the multilevel structure bismuth-containing nanometer material has the benefits as follows: 1) the preparation method is quick in reaction rate, short in reaction time, high in product output and low in energy consumption; 2) the bismuth sulfide has the characteristics of regular morphology, uniform size, large specific surface area, wide light absorption range and the like; 3) the multilevel structure bismuth sulfide nanometer material obtained by the method disclosed by the invention has visible light response photocatalytic performance, and has better chromium photocatalytic degradation efficiency than the product titanium dioxide.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

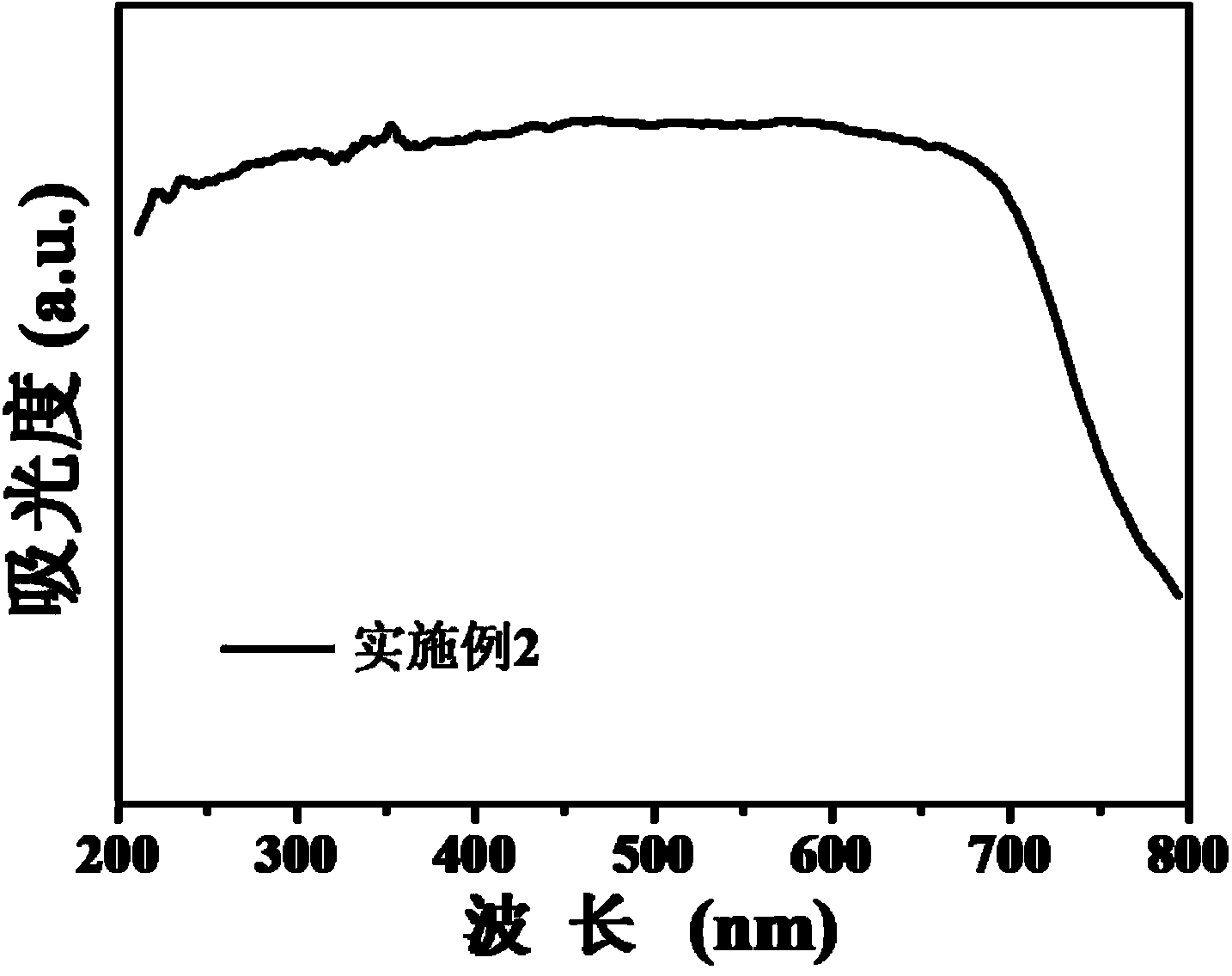

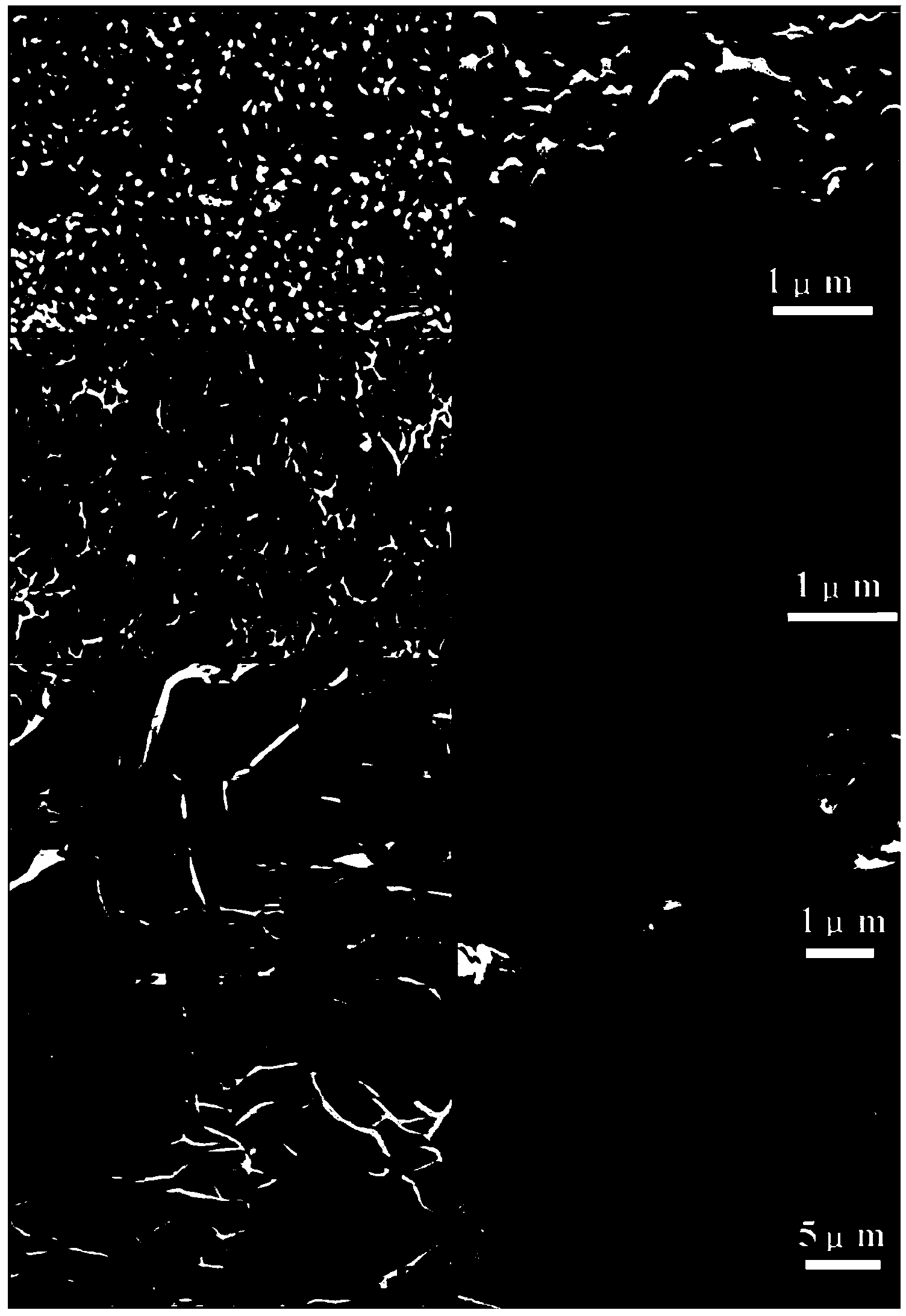

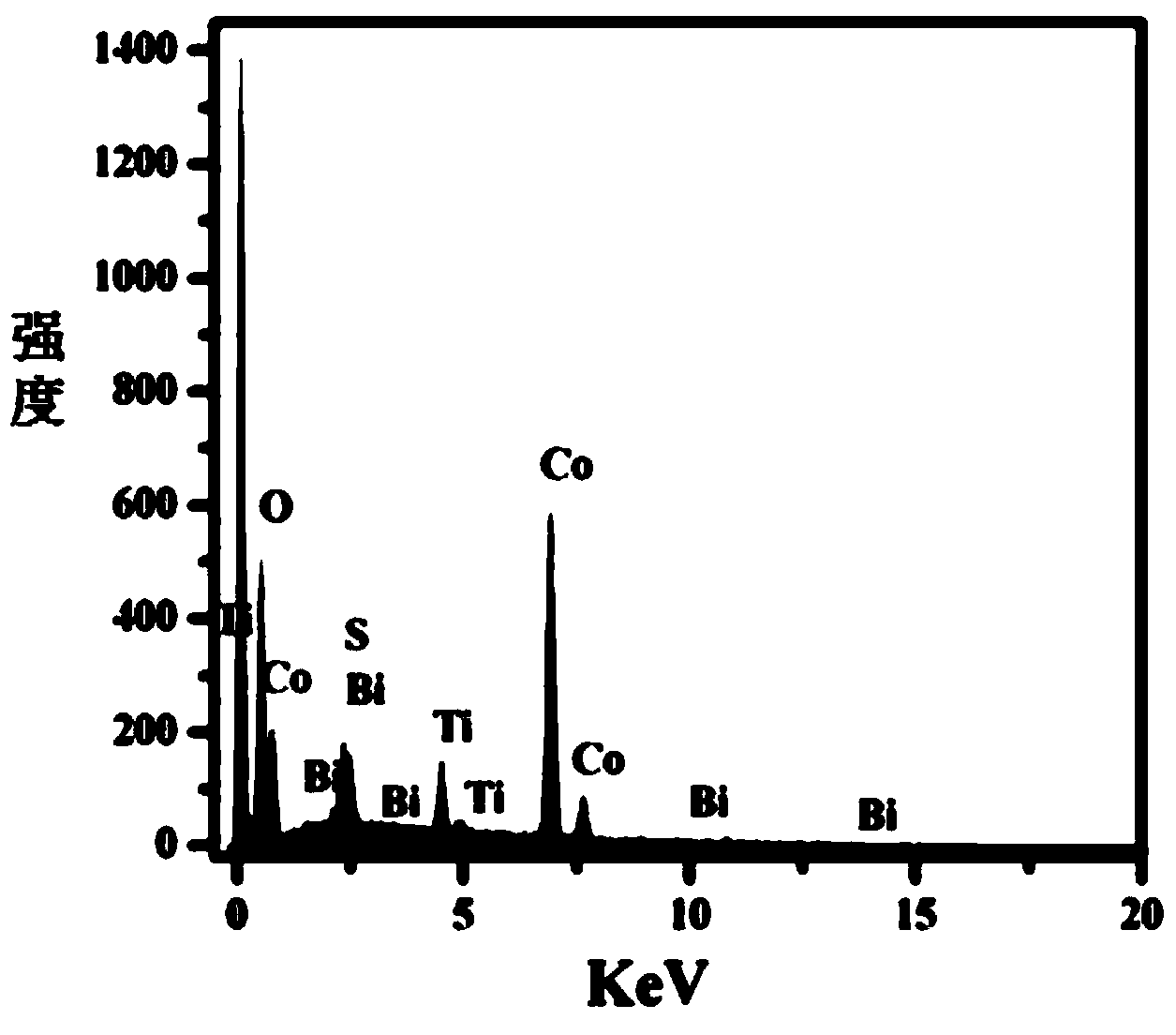

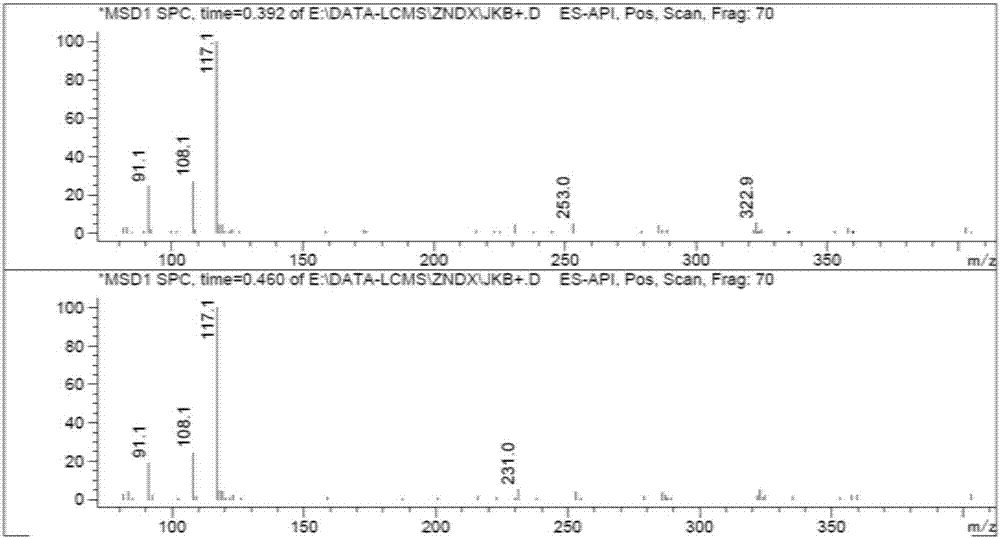

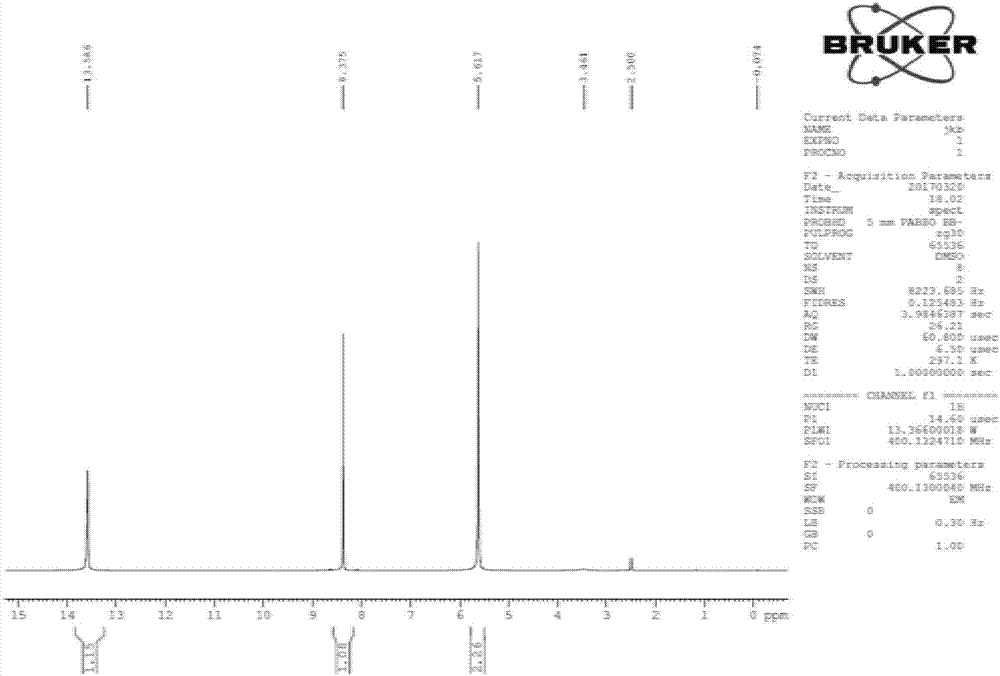

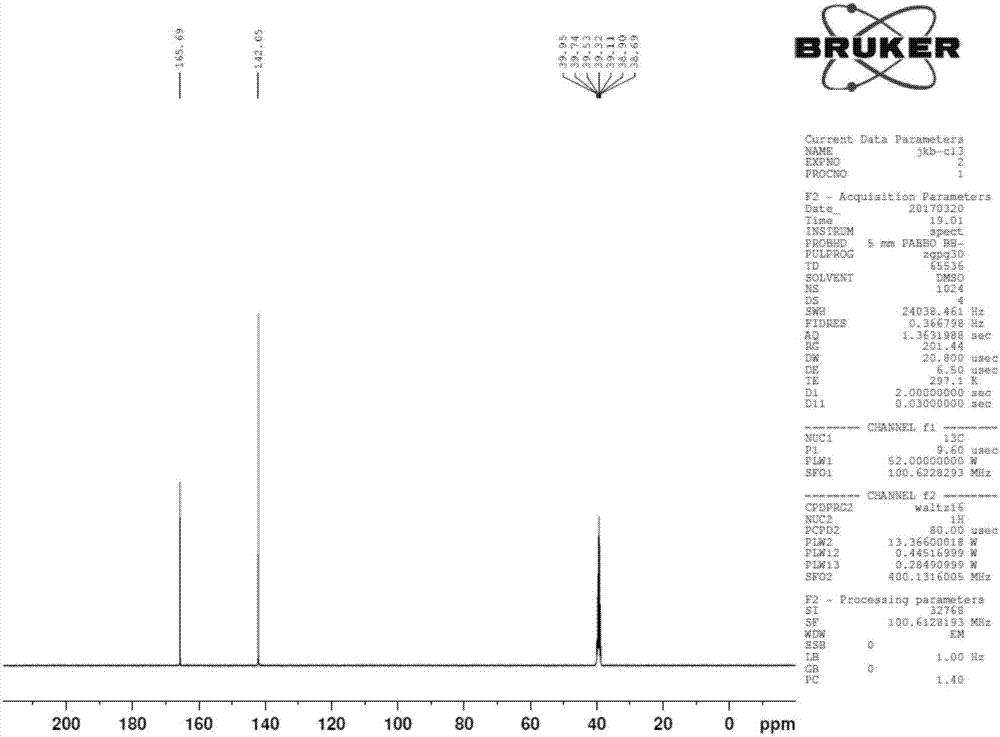

Method for preparing cobaltous hydroxide/bismuth sulfide composite nanowire electrode material of super-capacitor

ActiveCN103456521AIncrease capacityImprove cycle stabilityMaterial nanotechnologyHybrid capacitor electrodesBismuth sulfideCapacitance

The invention discloses a method for preparing a cobaltous hydroxide / bismuth sulfide composite nanowire electrode material of a super-capacitor. The method for preparing the cobaltous hydroxide / bismuth sulfide composite nanowire super-capacitor electrode material of the super-capacitor includes the steps of (1) preparing a bismuth sulfide crystal seed layer on an electrode substrate, (2) carrying out annealing treatment on the electrode substrate with the crystal seed layer obtained in the step (1) in air, (3) growing a layer of bismuth sulfide nanowire on the annealed electrode substrate obtained in the step (2) through a hydrothermal reaction to obtain the electrode substrate with the bismuth sulfide nanowire, and (4) using the electrode substrate with the bismuth sulfide nanowire obtained in the step (3) as a work electrode and embellishing a cobaltous hydroxide nanosheet on the bismuth sulfide nanowire by means of an electrodeposition method to obtain the cobaltous hydroxide / bismuth sulfide composite nanowire super-capacitor electrode material of the super-capacitor. The cobaltous hydroxide / bismuth sulfide omposite nanowire material has a high capacity and good cycling stability when serving as the super-capacitor electrode material.

Owner:SOUTHWEST UNIVERSITY

Application of aminotriazolethione compound serving as metal sulfide mineral surface modification agent

ActiveCN107029893ASpecial molecular structureSuppression of floatingFlotationBismuth sulfideChemical compound

The invention discloses application of an aminotriazolethione compound serving as a metal sulfide mineral surface modification agent. The aminotriazolethione compound comprises a hydrophilic modification perssad and an aminotriazolethione perssad at the same time. The aminotriazolethione compound mainly serves as the non-molybdenum sulfide mineral surface modification agent for flotation separation of the molybdenum sulfide mineral and the non-molybdenum sulfide mineral, the hydrophilia of the surfaces of the sulfide minerals with the natural hydrophobicity can be enhanced, especially, the hydrophilia of the surfaces of copper pyrites, chalcocite, galena, blende, brasses, the bismuth sulfide mineral and other non-molybdenum sulfide minerals can be effectively improved, and efficient flotation separation of the molybdenum sulfide mineral and the non-molybdenum sulfide mineral is achieved.

Owner:CENT SOUTH UNIV

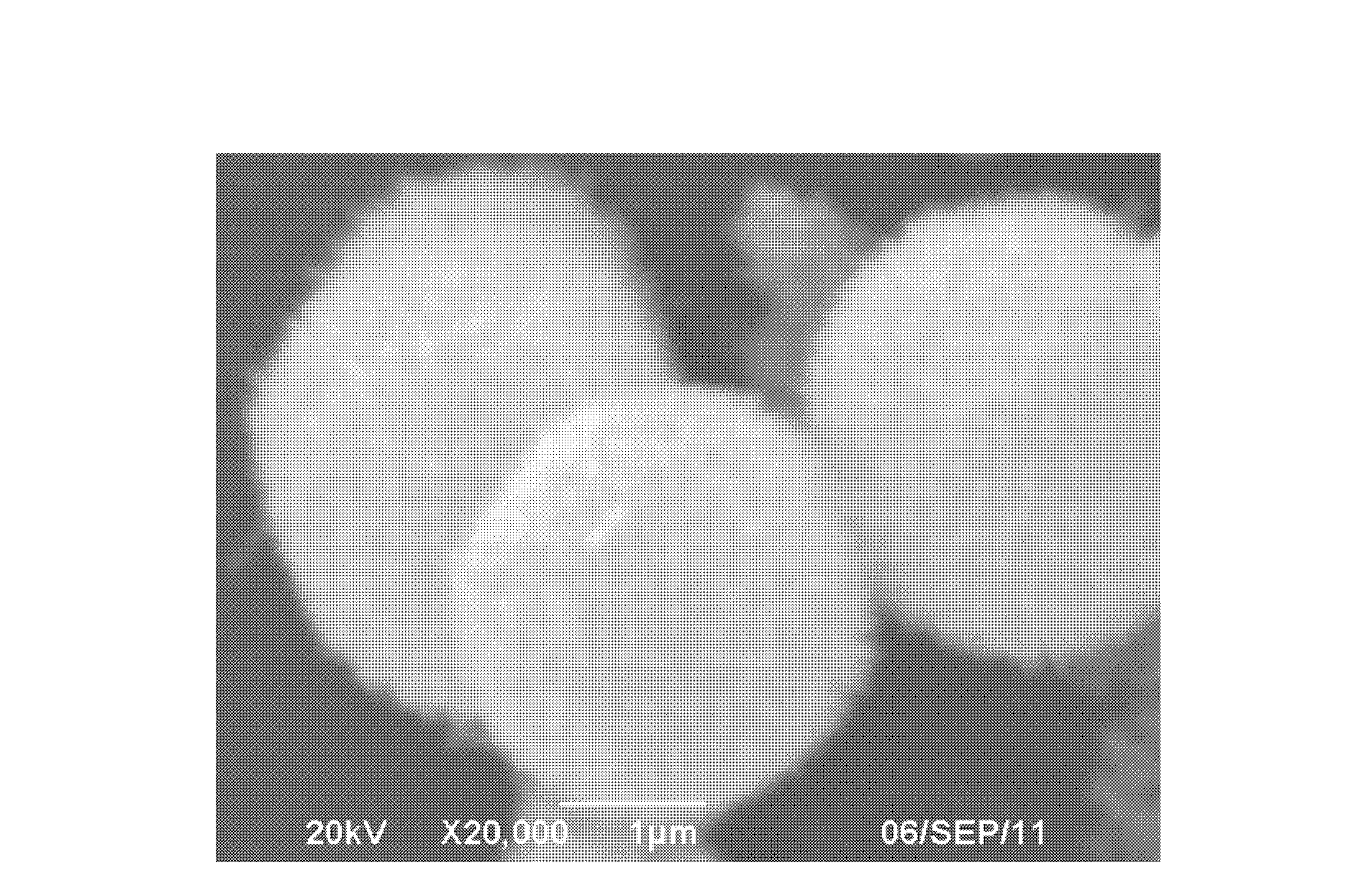

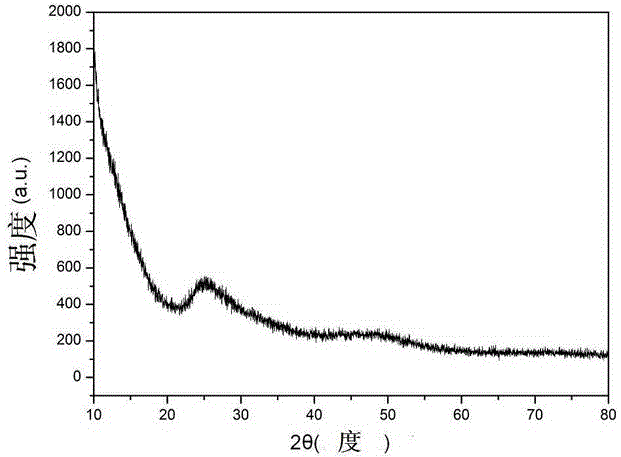

Room-temperature water phase preparation method of bismuth sulfide nanospheres

InactiveCN104817111AGood lookingUniform sizeMaterial nanotechnologyBismuth compoundsBismuth sulfideActive agent

The invention discloses a room-temperature water phase preparation method of bismuth sulfide nanospheres. A surfactant is dissolved in de-ionized water, then a chelating agent is added, next bismuth nitrate pentahydrate is added, the materials are stirred at room temperature, sulfur-containing solution is slowly dropwise added into bismuth iron solution, and the materials are uniformly mixed and then react for 2 h at room temperature to obtain the bismuth sulfide nanospheres. The bismuth sulfide nanometer material prepared by the method has good shape and uniform size, and has a potential application value in the fields such as thermoelectricity, electronics and photo-electronic devices; the method has the advantages of simple equipment, mild condition, low energy consumption, short preparation period and easiness in implementation and is an ideal method for preparing the bismuth sulfide nanometer material.

Owner:NANJING UNIV OF POSTS & TELECOMM

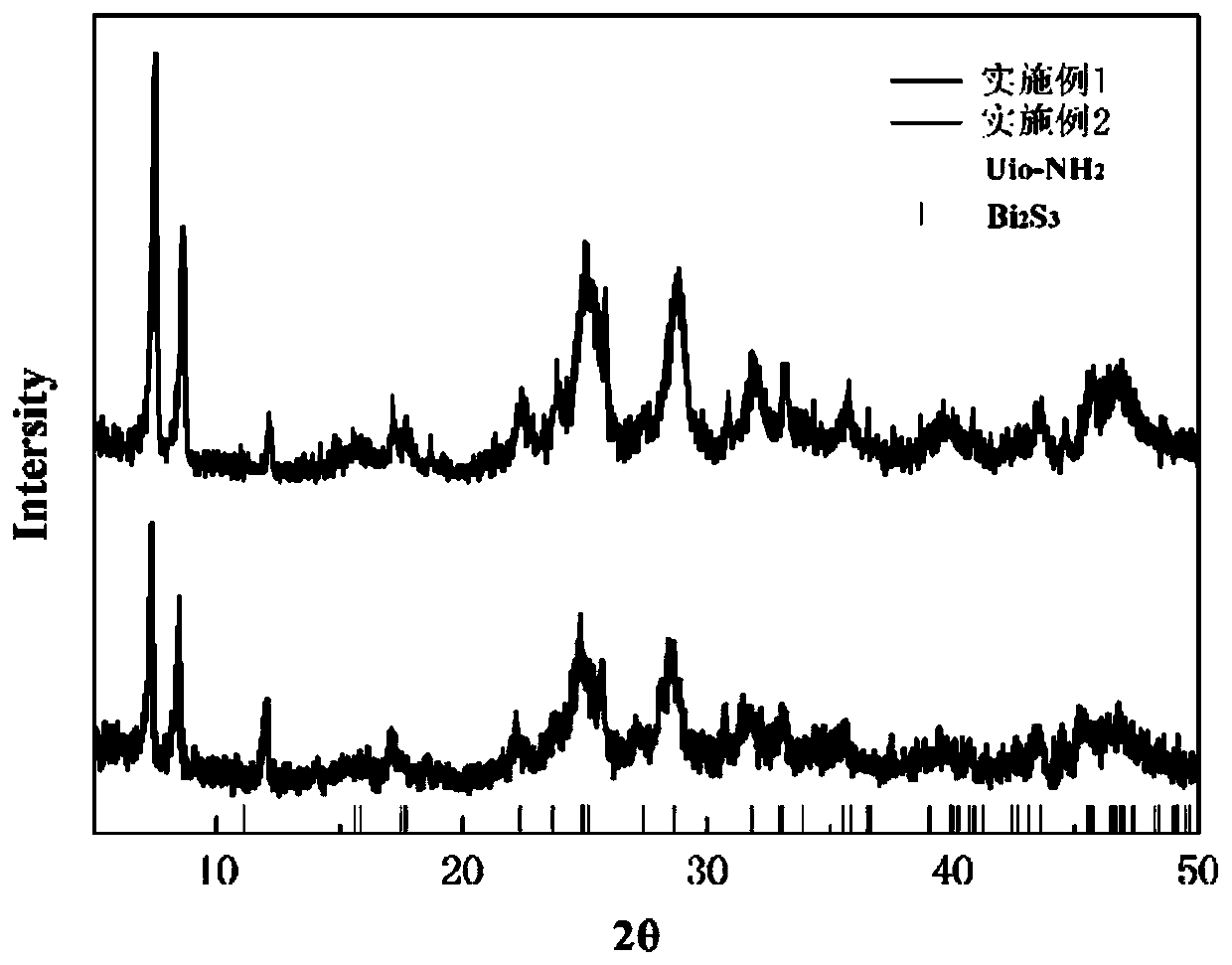

Bismuth sulfide based composite visible-light-induced photocatalyst and preparation method thereof

InactiveCN111359666AImprove interface tightnessIncrease profitWater/sewage treatment by irradiationWater treatment compoundsBismuth sulfideOrganic dye

The invention discloses a preparation method of a Bi2S3@UiO-66-NH2-SH based visible-light-induced photocatalyst with a core-shell structure and a preparation method thereof. The ratio of Bi: Zr of Bi2S3 and UiO-66-NH2 is 1-4:2. The preparation method comprises the following steps: preparing UiO-NH2 with a regular octahedron morphology by adopting a solvothermal method, and then modifying UiO-NH2 by mercapto-acetic acid to uniformly load bismuth sulfide nano particles on the surface of UiO-NH2, thereby obtaining the composite visible-light-induced photocatalyst taking UiO-NH2 as a core and Bi2S3 as a shell. The preparation method of the composite visible-light-induced photocatalyst is simple; the composite visible-light-induced photocatalyst has high visible-light response and better photocatalytic effect than that of pure bismuth sulfide, methyl orange can be degraded by 95% within 90 min under visible-light irradiation, and the composite visible-light-induced photocatalyst is expectedto be applied to the fields of photocatalytic degradation of organic dyes, antibiotics and the like on a large scale.

Owner:SHANGHAI INST OF TECH

Bismuth sulfide electrode material with specific morphologic structure and application thereof

ActiveCN106299357AImprove the shortcomings of small specific capacity and large impedanceSmall specific surface areaCell electrodesSecondary cellsBismuth sulfideState form

The invention belongs to the technical field of a material and particularly relates to a nanometer bismuth sulfide electrode material with specific morphologic structure, a preparation method thereof and application of nanometer bismuth sulfide electrode material in a lithium ion battery. The bismuth sulfide electrode material provided by the invention is under a spherical or similar spherical secondary particle state formed by clustering the first particles with bar-shaped structures, wherein a gap is arranged between the first particles; the bar lengths of the first particles are 300-500nm; the diameter is 40-80nm; the secondary particles have microcellular structures; the aperture is 1.8-2nm; the specific area is 20-21cm<3> / g. The bismuth sulfide electrode material provided by the invention has relatively small specific area, small impedance and certain rate discharge characteristic. When the bismuth sulfide electrode material is applied to the lithium ion battery, the specific capacity of the lithium ion battery is increased.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com