Method for controlling bismuth-sulfide polycrystalline thermoelectric material texture

A technology of thermoelectric materials and polycrystalline materials, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and single crystal growth, and can solve problems such as increased thermal conductivity, complex processes, and easy growth of crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

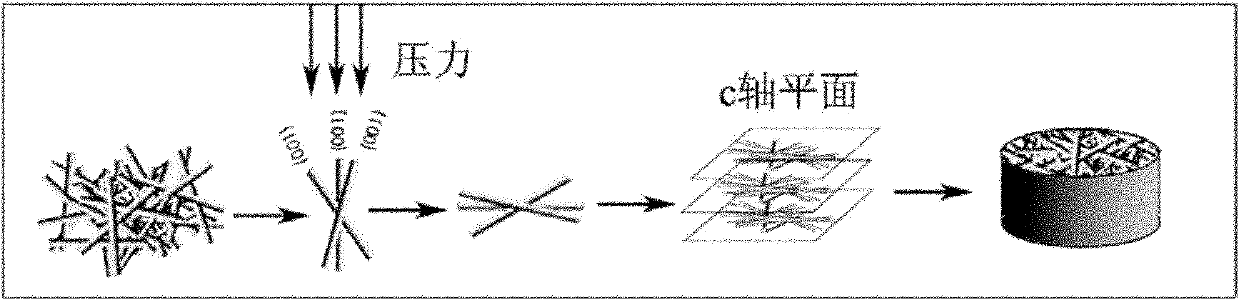

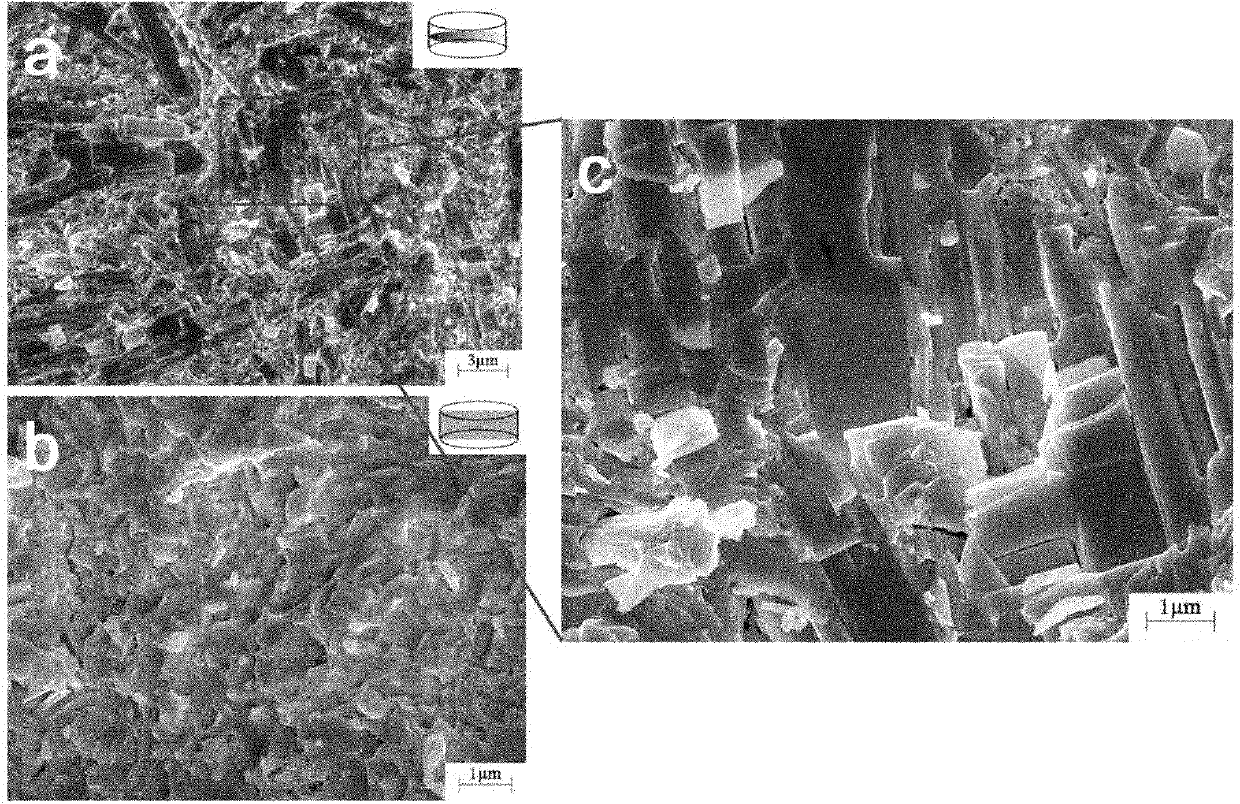

[0014] According to the molar ratio: bismuth nitrate / sodium thiosulfate=3:2 configuration, weigh the corresponding mass of bismuth nitrate and sodium thiosulfate, use ethanol and deionized water as solvent, and ethylenediamine as pH regulator to adjust pH value to 11~12, hydrothermal reaction at 160°C for 6 hours, and bismuth sulfide nanorods with a length of 500~800 nm and a diameter of 50~100 nm grown along the [001] plane were prepared.

[0015] Using the prepared nanorods as the precursor powder, spark plasma sintering was used to sinter at 250°C under a pressure of 80 MPa without holding time, and a bismuth sulfide bulk material with a high degree of texture was obtained. According to the XRD test and quantitative calculation, in the direction perpendicular to the c-axis, the texture degree of the [h k 0] plane is F=0.47. The thermoelectric performance test has good temperature stability, and the power factor in the test range from room temperature to 300 °C is 50~60μWm ...

example 2

[0017] According to the molar ratio: bismuth nitrate / sodium thiosulfate=3:2 configuration, weigh the corresponding mass of bismuth nitrate and sodium thiosulfate, use ethanol and deionized water as solvent, and ethylenediamine as pH regulator to adjust pH The bismuth sulfide nanorods with a length of 500 nm-2 μm and a diameter of 200-500 nm grown along the [001] plane were prepared by hydrothermal reaction at 180 °C for 36 hours.

[0018] Using the prepared nanorods as the precursor powder, spark plasma sintering was used to sinter at 550°C under a pressure of 40 MPa without holding time to obtain a bismuth sulfide bulk material with a high degree of texture. According to XRD test and quantitative calculation, in the direction perpendicular to the c-axis, the texture degree of [h k 0] plane is F=0.65. It has good temperature stability in thermoelectric performance test, and the power factor in the test range from room temperature to 300°C is 85~95μWm -1 K -2 .

example 3

[0020] According to the molar ratio: bismuth nitrate / sodium thiosulfate=3:2 configuration, weigh the corresponding mass of bismuth nitrate and sodium thiosulfate, use ethanol and deionized water as solvent, and ethylenediamine as pH regulator to adjust pH value to 11~12, hydrothermal reaction at 200°C for 48 hours, and bismuth sulfide nanorods with a length of 1~5 μm and a diameter of 100~300nm grown along the [001] plane were prepared.

[0021] Using the prepared nanorods as the precursor powder, spark plasma sintering was used to sinter at 450°C under a pressure of 10 MPa without holding time, and a bismuth sulfide bulk material with a high degree of texture was obtained. According to the XRD test and quantitative calculation, the texture degree of the [h k 0] plane is F=0.72 perpendicular to the c-axis direction. It has good temperature stability in the thermoelectric performance test, and the power factor in the test range from room temperature to 300°C is 110~120μWm -1 K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com