Patents

Literature

8787 results about "Thermal reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thermal reaction is a form of chemical reaction in which the reactants get energy as heat. We name these reactions as “thermolysis” or “thermal decomposition reactions”. It mainly involves the chemical decomposition of a substance when we apply heat energy.

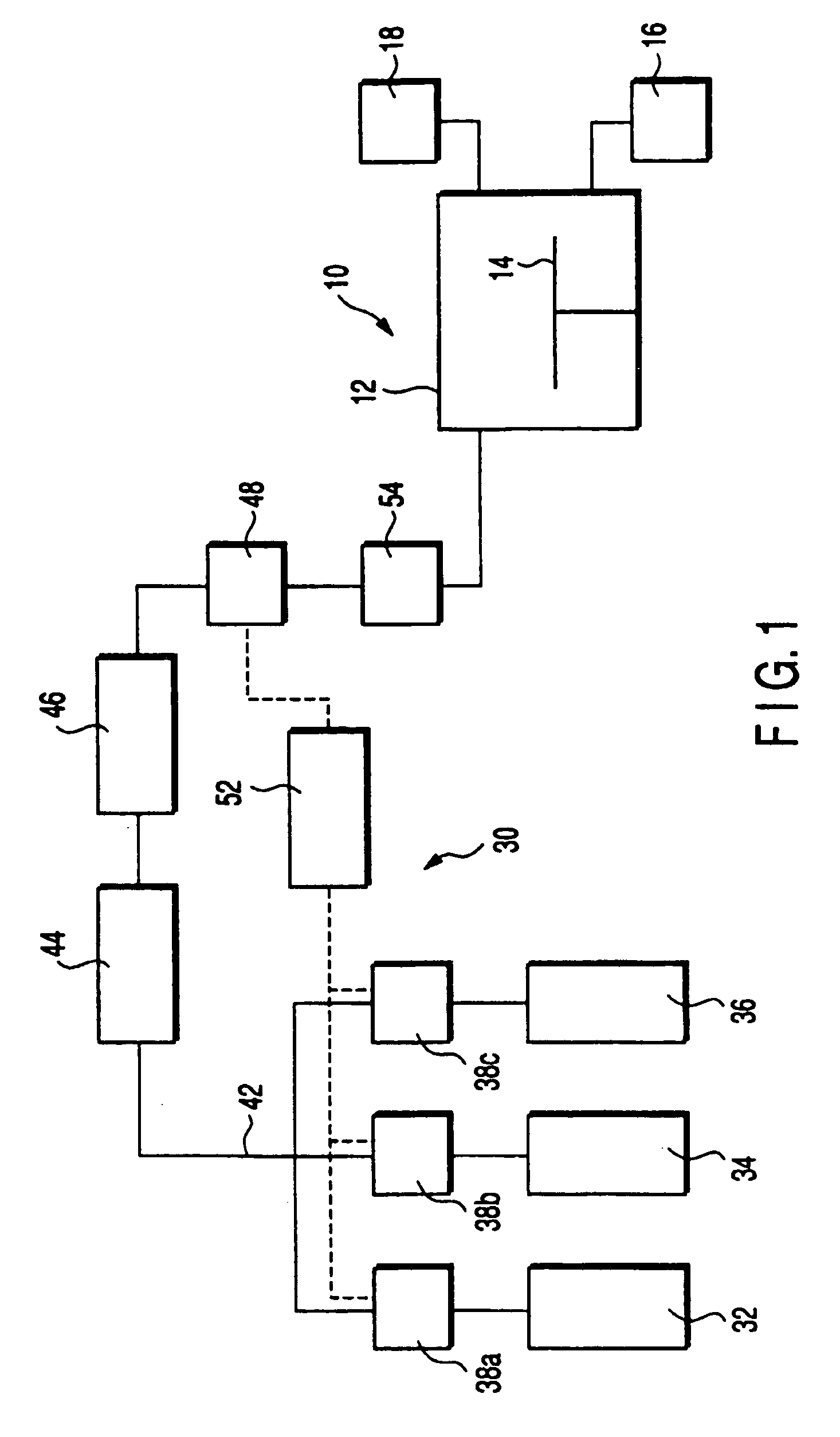

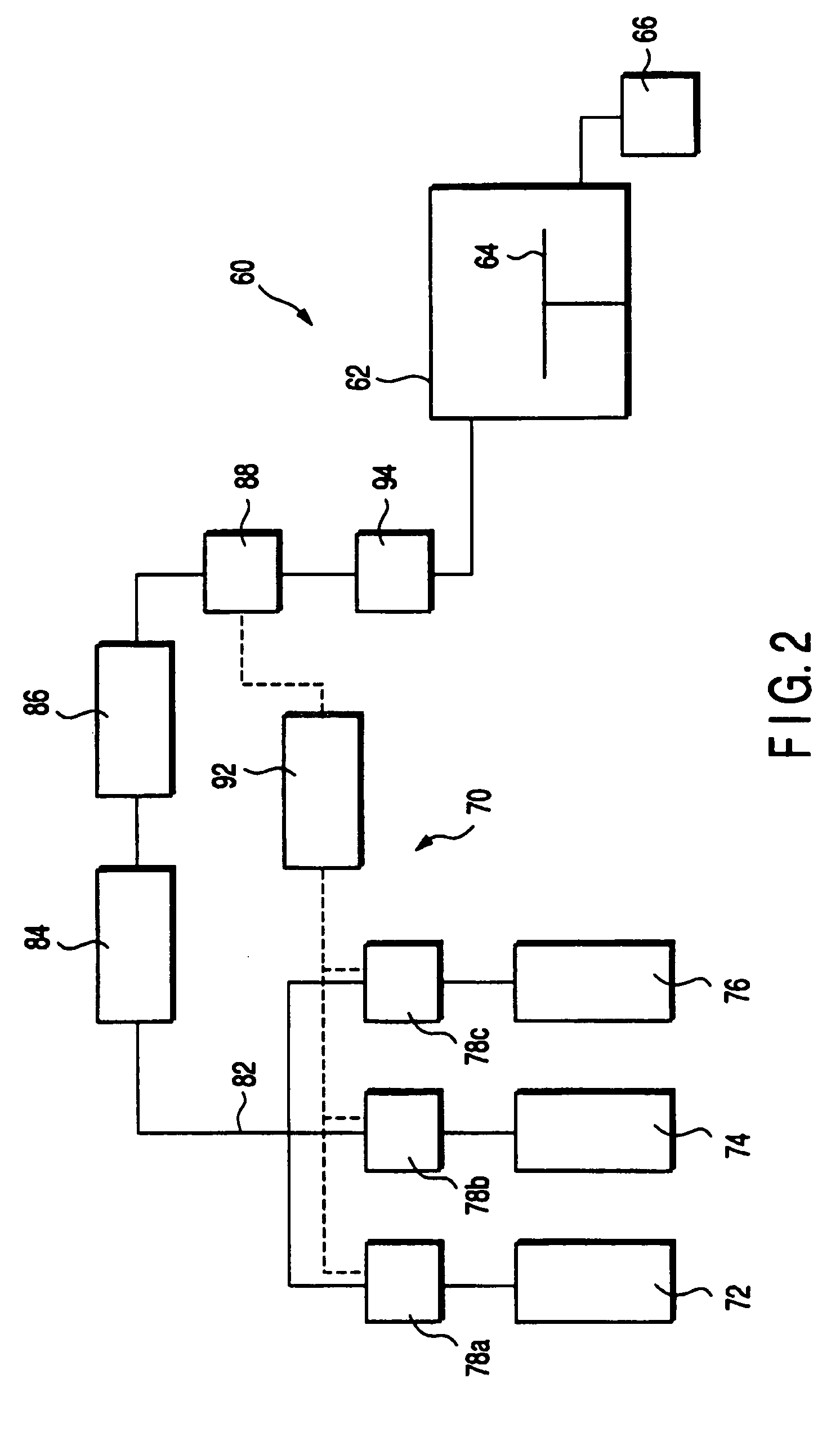

Method and apparatus for cleaning and method and apparatus for etching

InactiveUS20050020071A1Increase flexibilityImprove securitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringForming gas

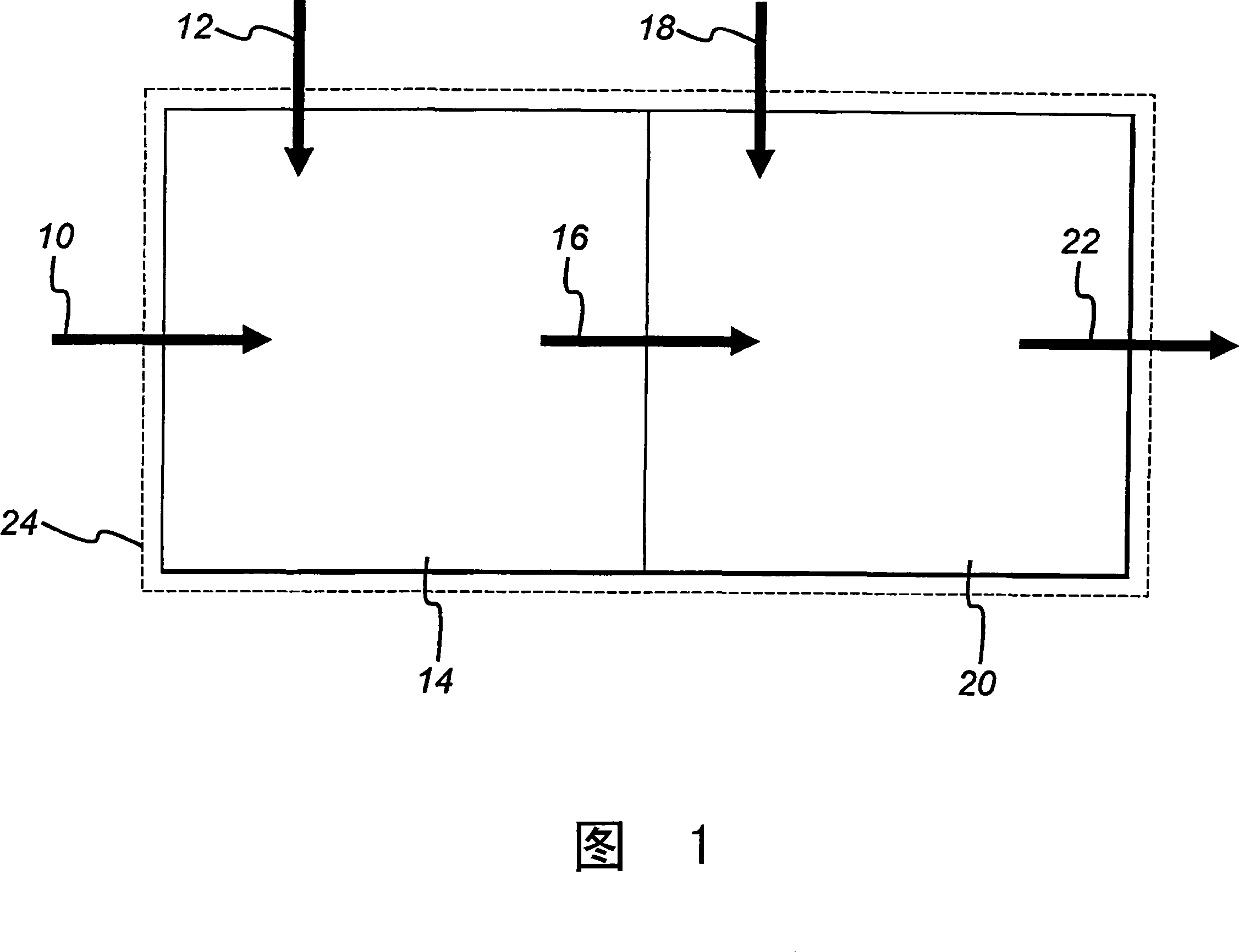

A cleaning apparatus (30) is connected to a treating chamber (12) of a CVD apparatus (10) for forming a silicon film. The cleaning apparatus (30) has a first, a second, and a third gas sources (32, 34, 36) and a chlorine gas, a fluorine gas, and an inert gas are introduced from the gas sources through FMC (38a, 38b, 38c), respectively, with flow rates controlled independently from one another. Those gases are gathered at a pipe (42) and mixed into a mixed gas. The mixed gas is passed through a heated reactor (44) such as a heat exchanger to thereby react the chlorine gas with the fluorine gas and form a formed gas containing fluorinated chlorine gas such as CIF3. The formed gas is supplied to the treating chamber (12) through a cooler (46), an analyzer (48) and a buffer (54).

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

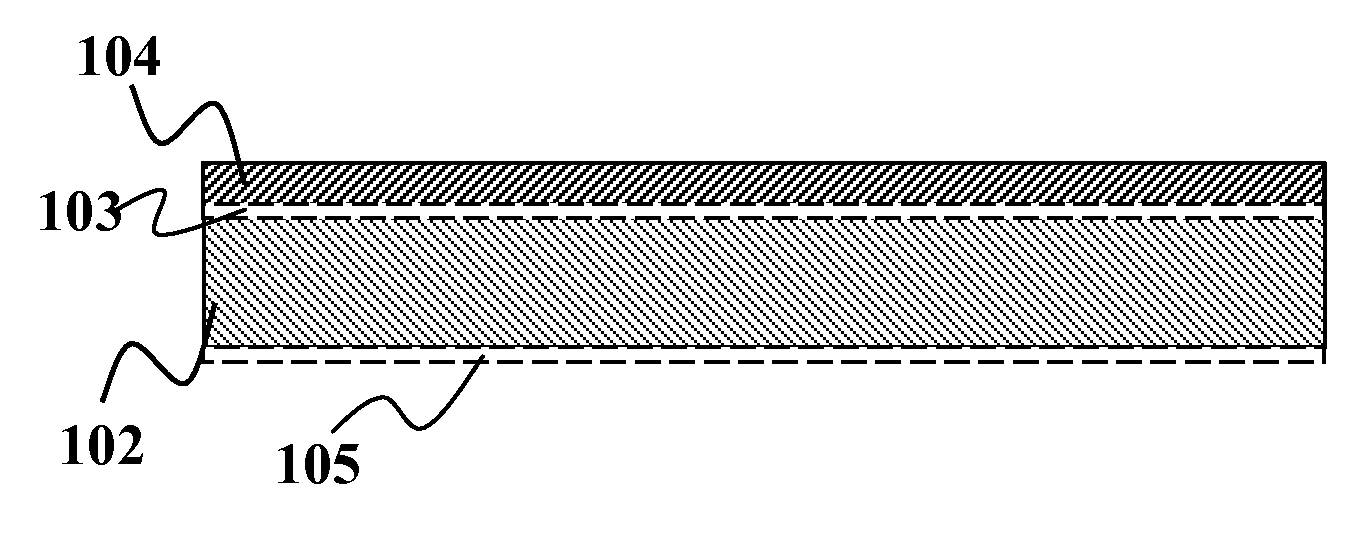

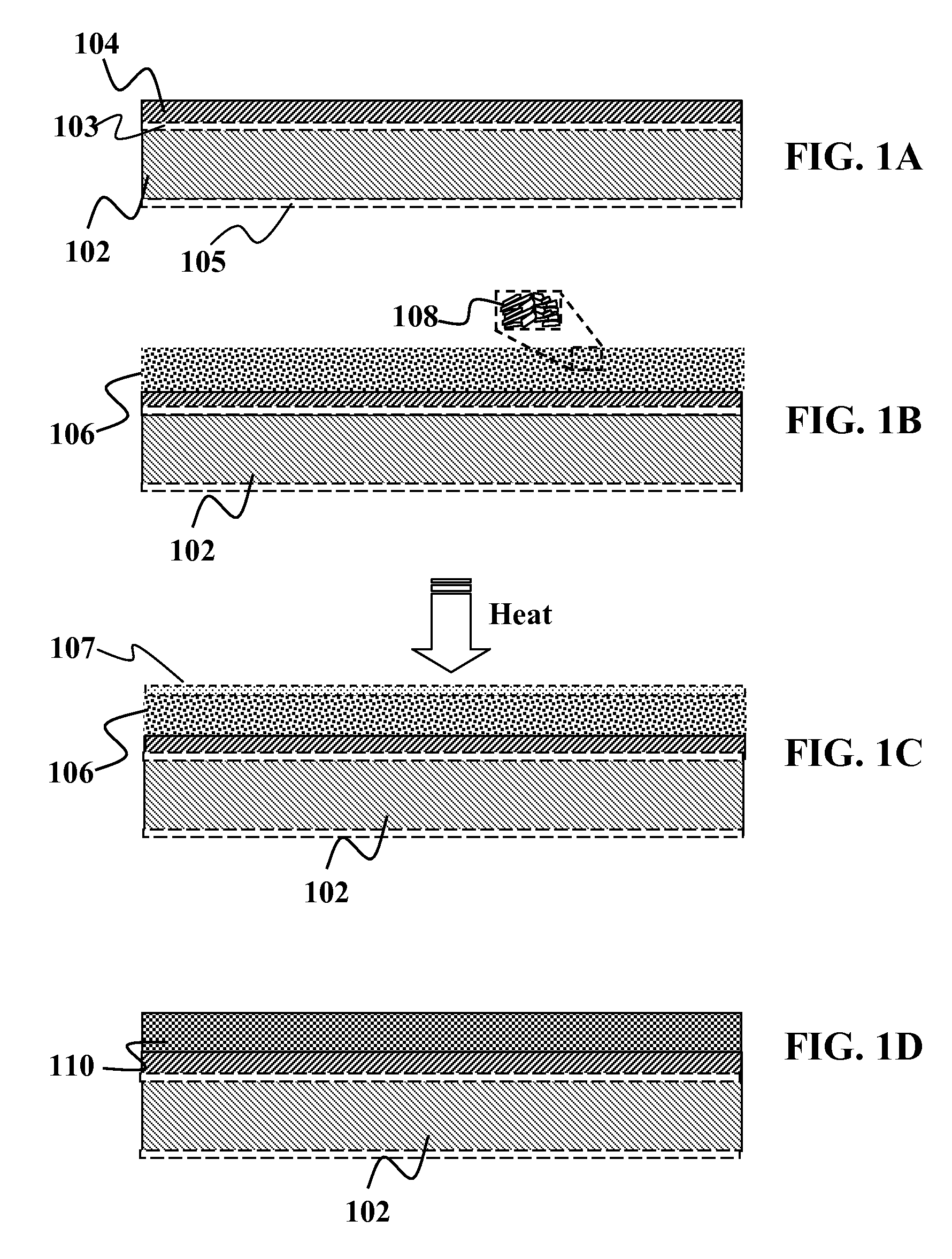

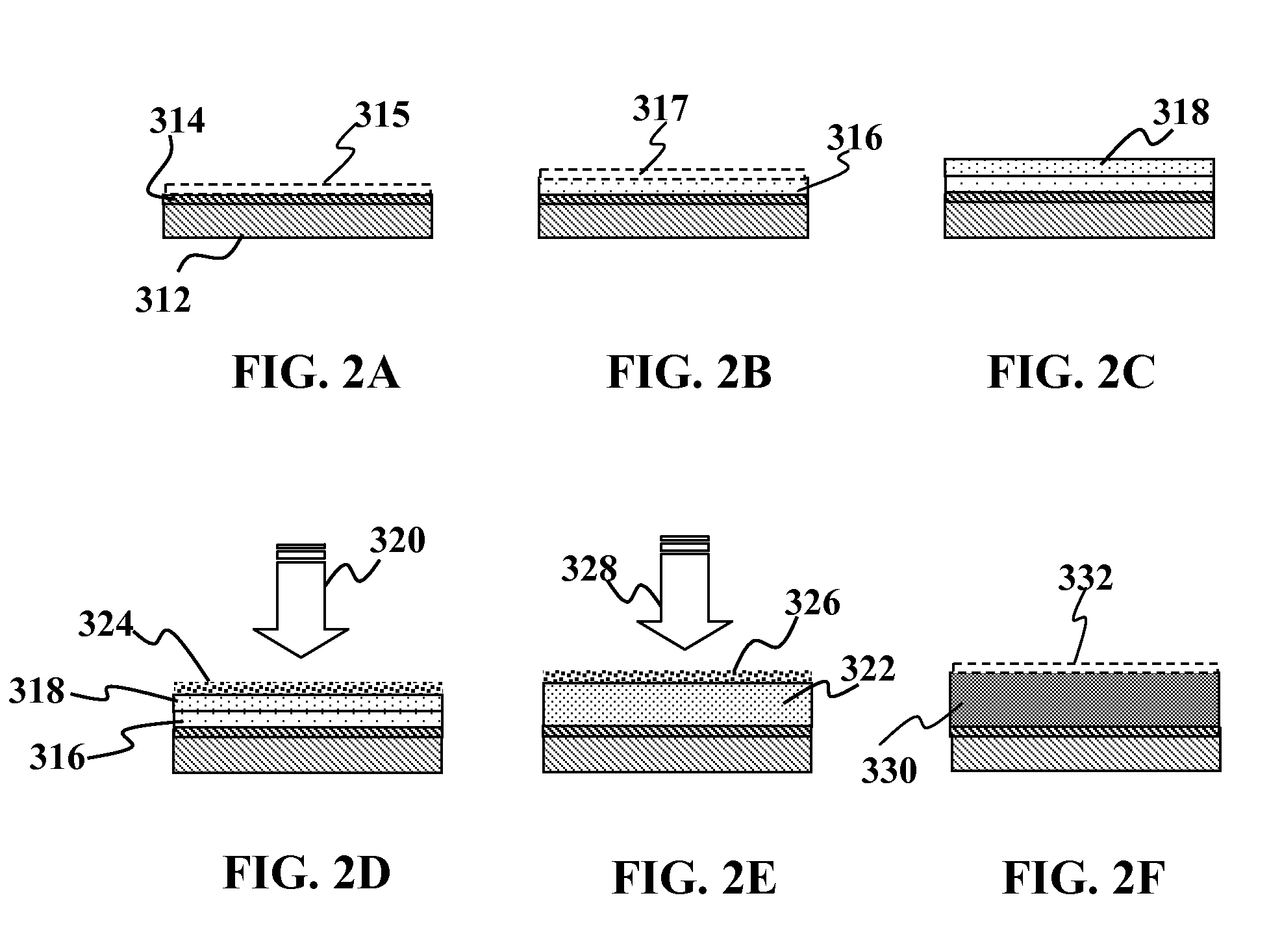

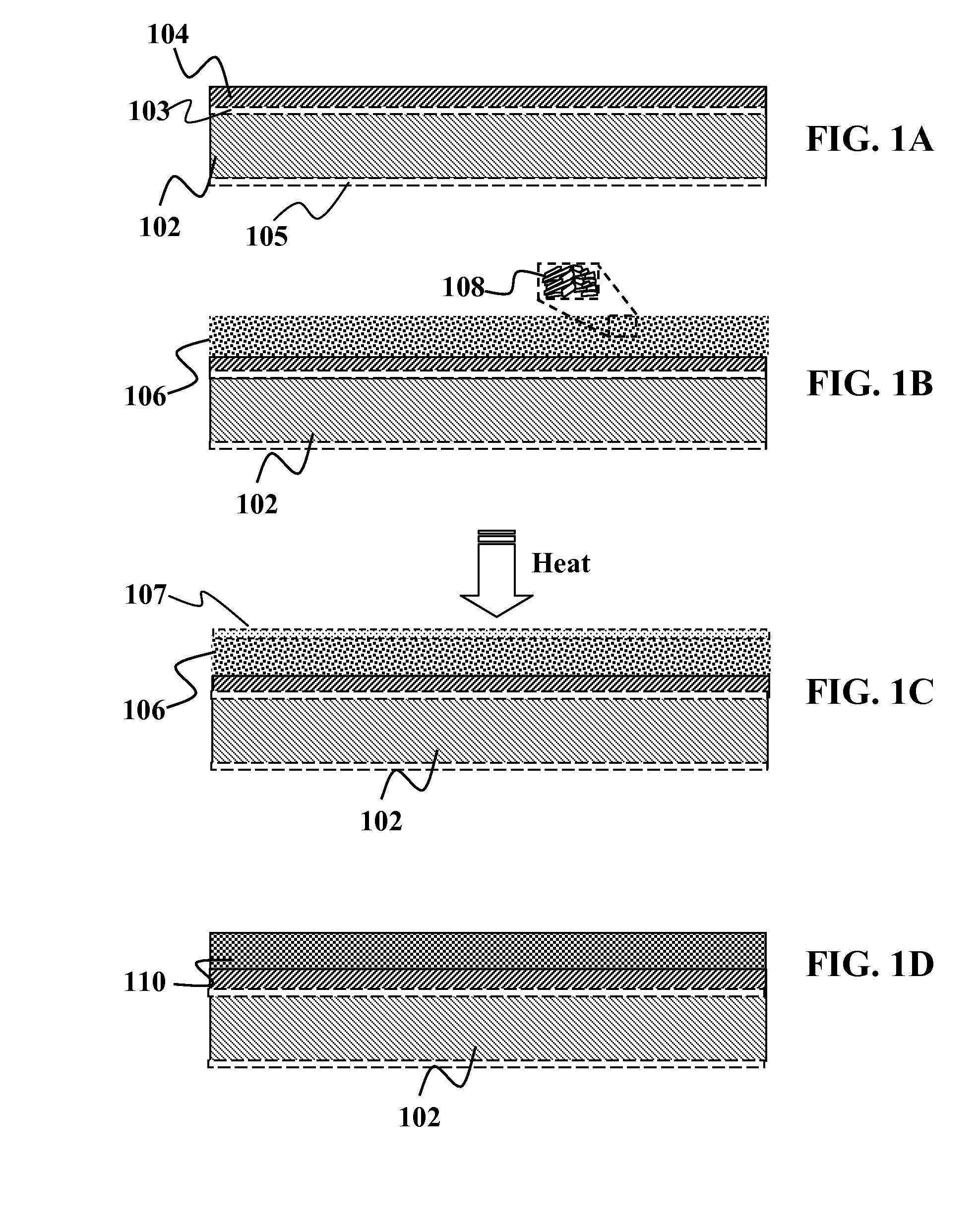

Solar cell absorber layer formed from metal ion precursors

Methods and devices are provided for forming an absorber layer. In one embodiment, a method is provided comprising of depositing a solution on a substrate to form a precursor layer. The solution comprises of at least one polar solvent, at least one binder, and at least one Group IB and / or IIIA hydroxide. The precursor layer is processed in one or more steps to form a photovoltaic absorber layer. In one embodiment, the absorber layer may be created by processing the precursor layer into a solid film and then thermally reacting the solid film in an atmosphere containing at least an element of Group VIA of the Periodic Table to form the photovoltaic absorber layer. Optionally, the absorber layer may be processed by thermal reaction of the precursor layer in an atmosphere containing at least an element of Group VIA of the Periodic Table to form the photovoltaic absorber layer.

Owner:AERIS CAPITAL SUSTAINABLE IP

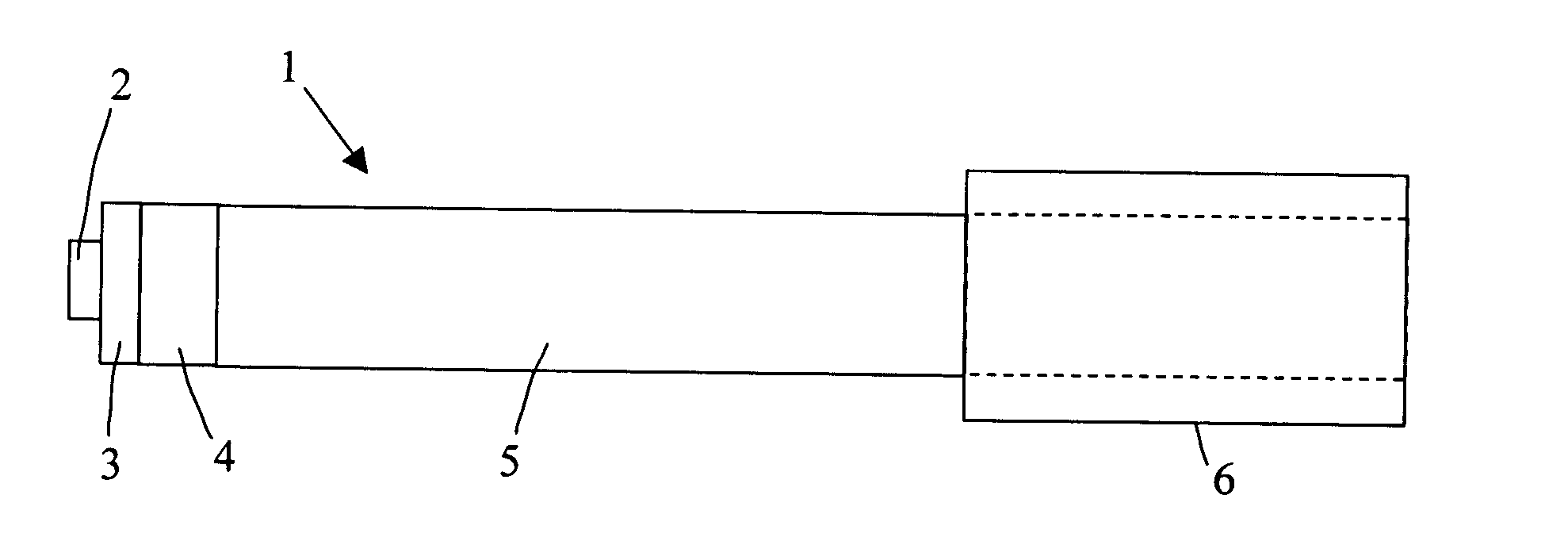

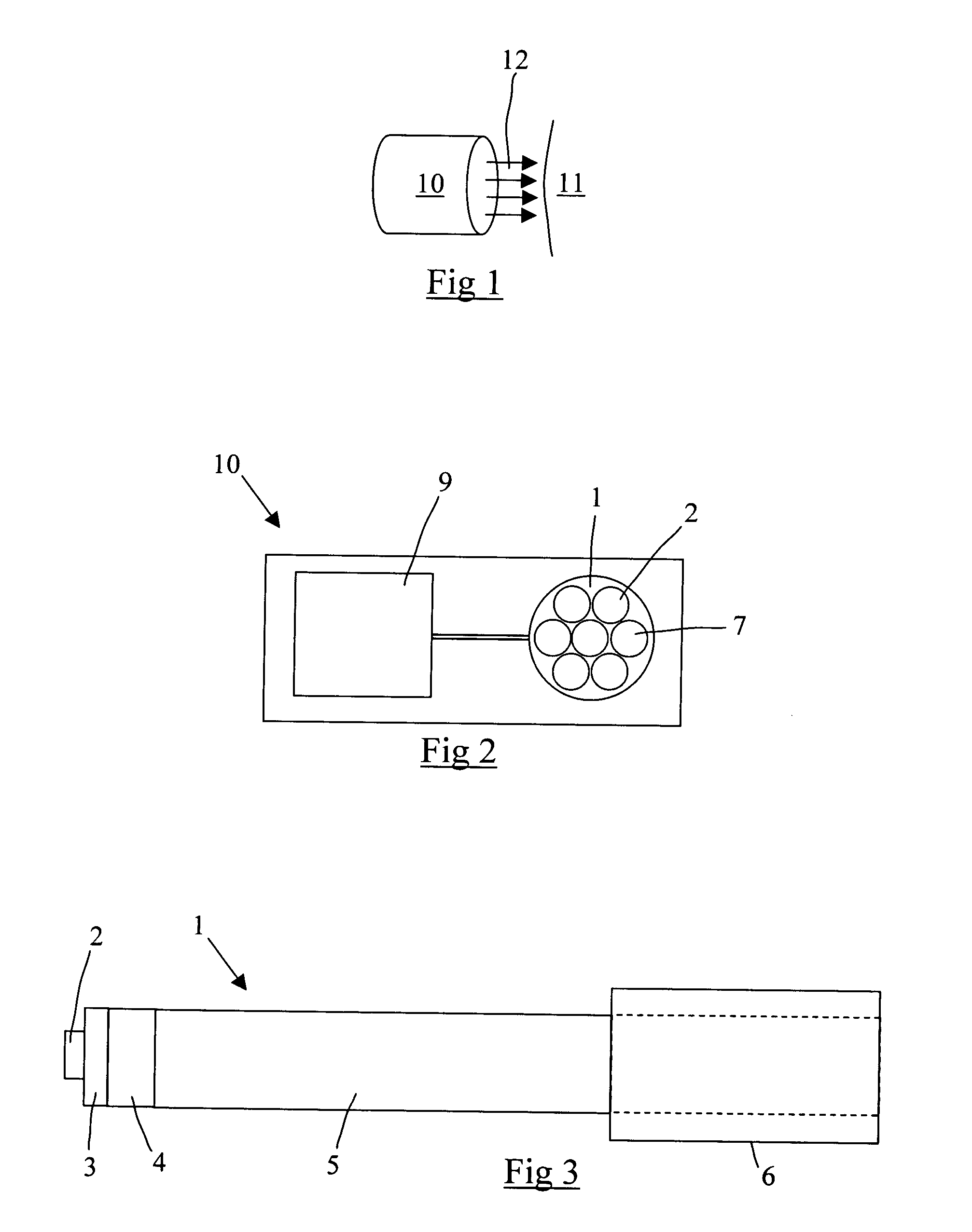

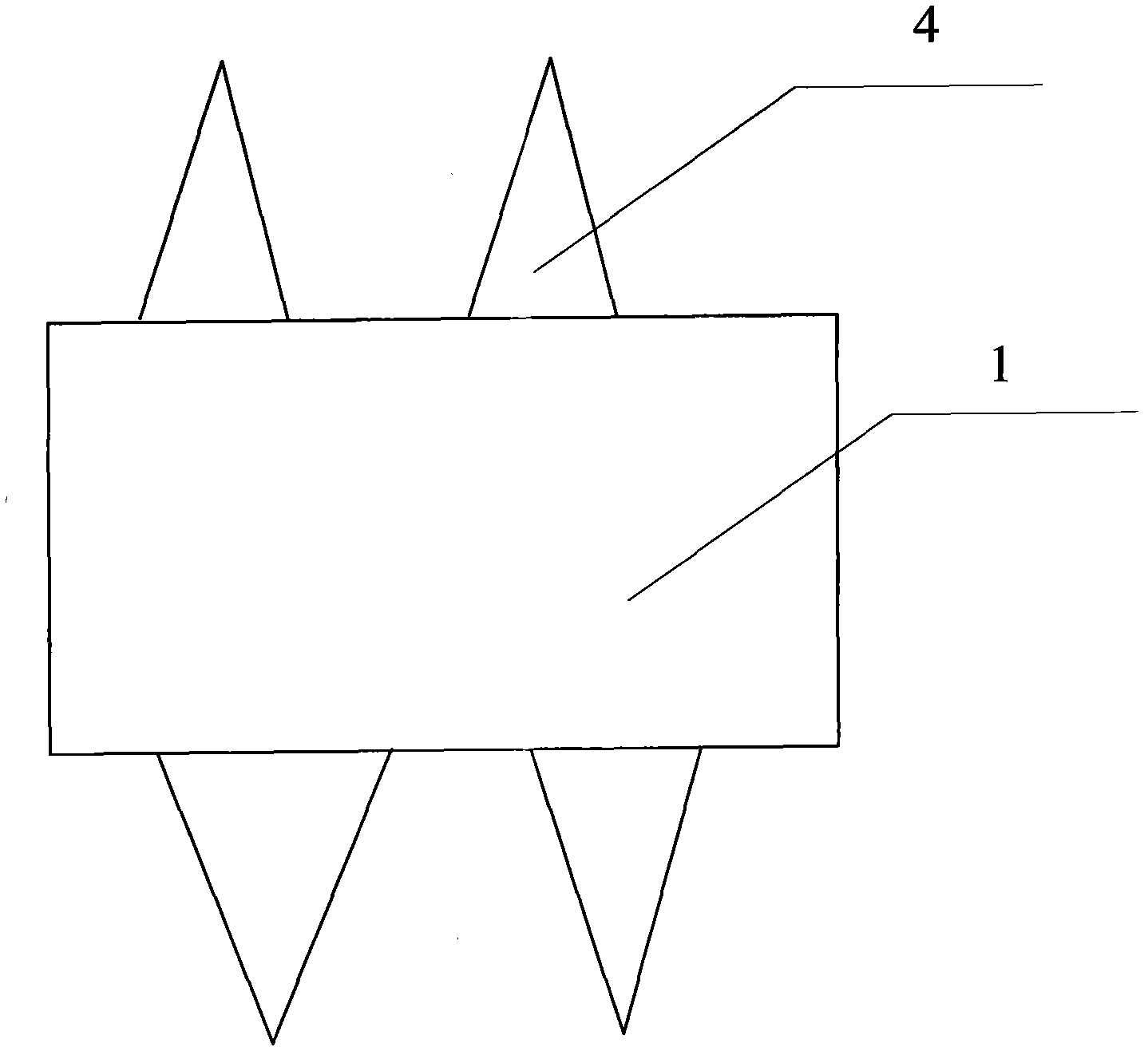

Method and device for treatment of skin conditions

InactiveUS20050055070A1Simple and inexpensive to carry-outSimple and inexpensiveLight therapyChemical reactionLight equipment

Method and device for treatment of skin conditions A method and apparatus for improving the cosmetic appearance of a region of skin 11 affected by Acne Vulgaris, Rosacea or similar skin condition by means of directing light radiation 12 from an illuminating device 1 on to the skin 11. The apparatus 10 comprises a control unit 9 that operates one or more LEDs 7 (light emitting diodes) of the illuminating device 1. Each dose of light radiation 12 lasts for at least 100 ms, during which time the skin 11 receives light energy from the LED(s) 7, which causes a photochemical reaction that stimulates the production of free radicals (singlet oxygen) that react with, and at least partially disable or destroy, bacteria that contribute to the symptoms of the skin condition. The light energy directed on to the skin 11 during any given period of 10 μs is less than 0.5 Jcm−2, and during any given period of 100 ms is less than 5 Jcm−2. Substantially no beneficial photo-thermal reaction occurs within the skin 11. Light having wavelengths around 405 nm and / or 585 nm is used. The duration of a single dose may be much longer than 100 ms and can last up to 10 hours (for overnight treatment).

Owner:ENFIS

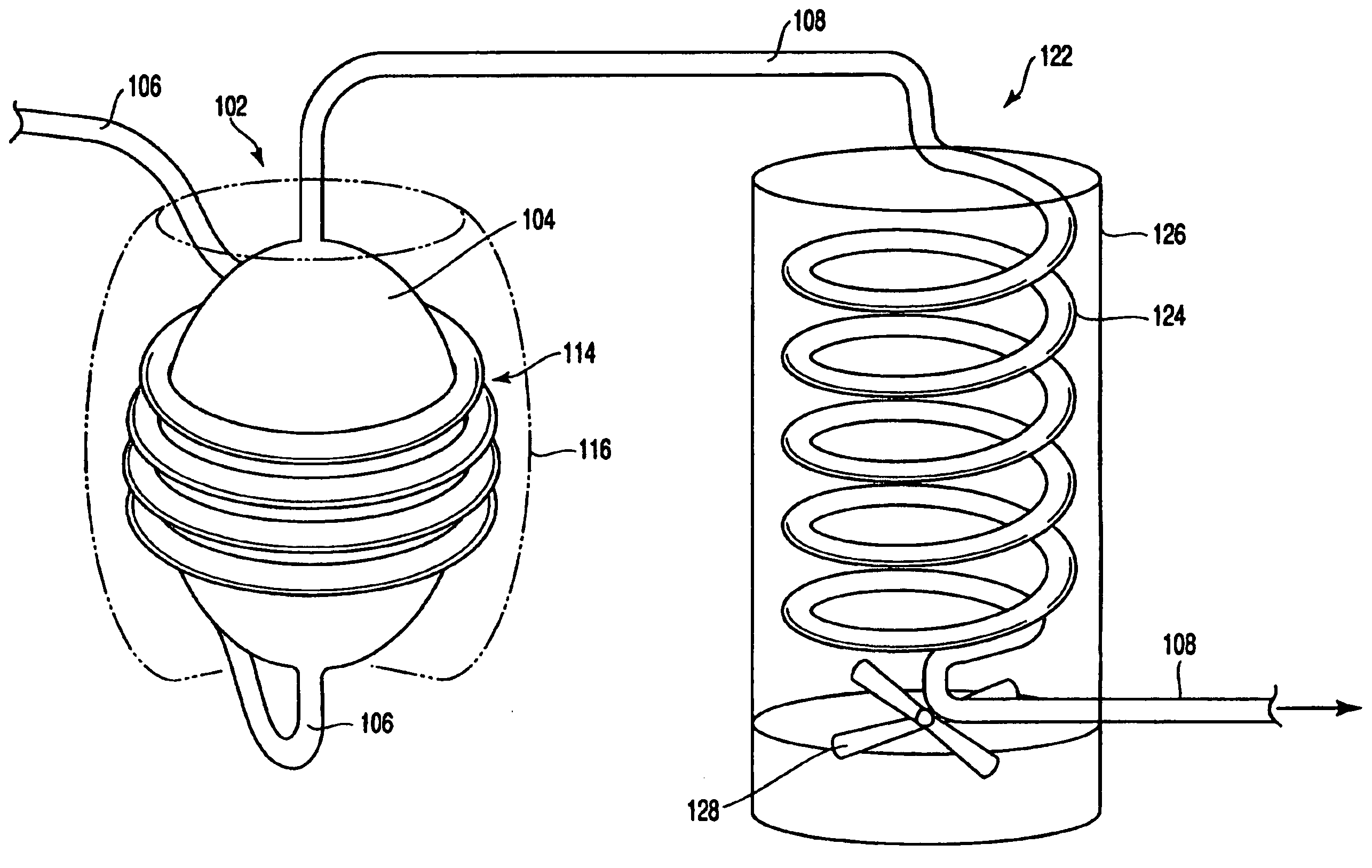

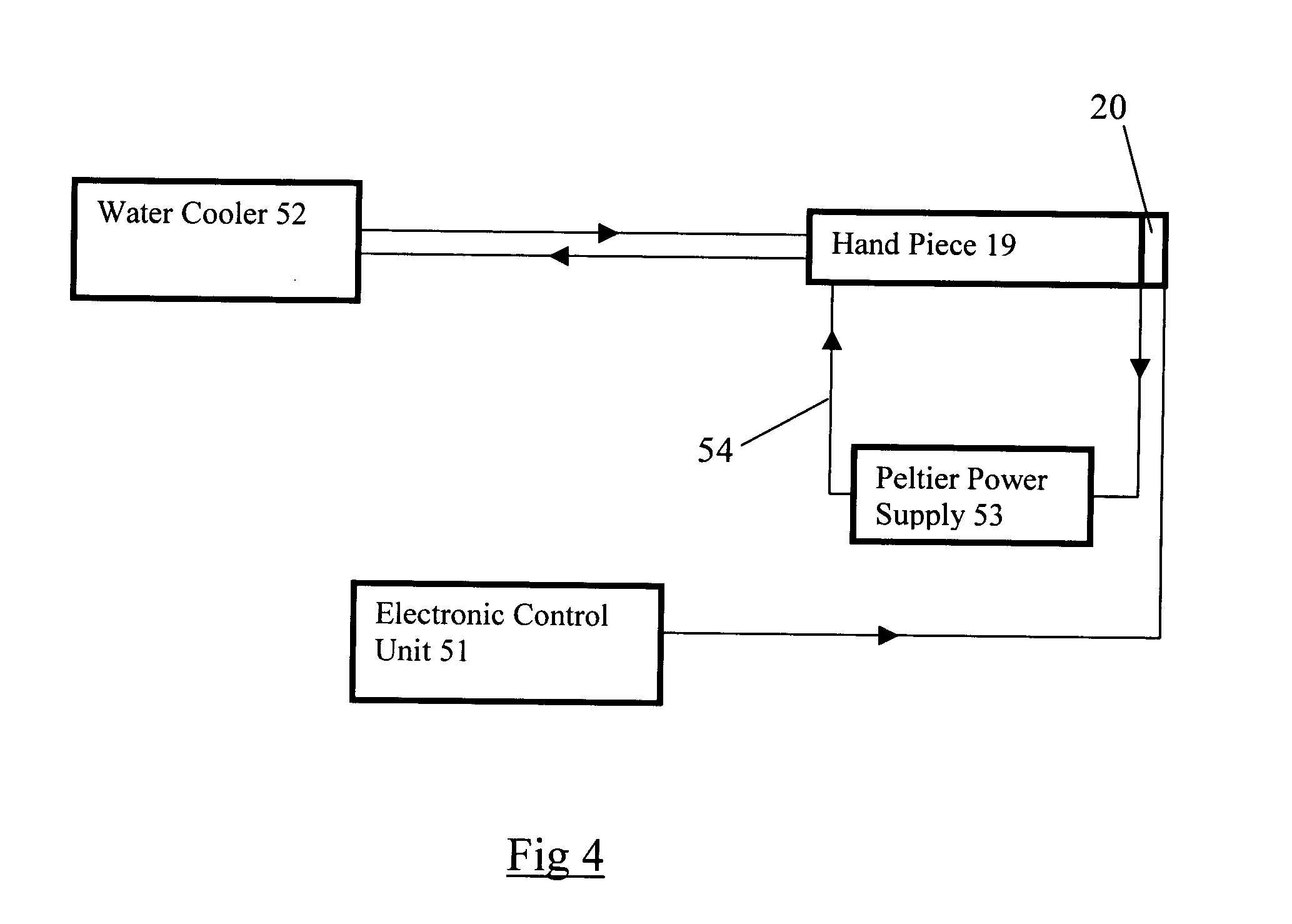

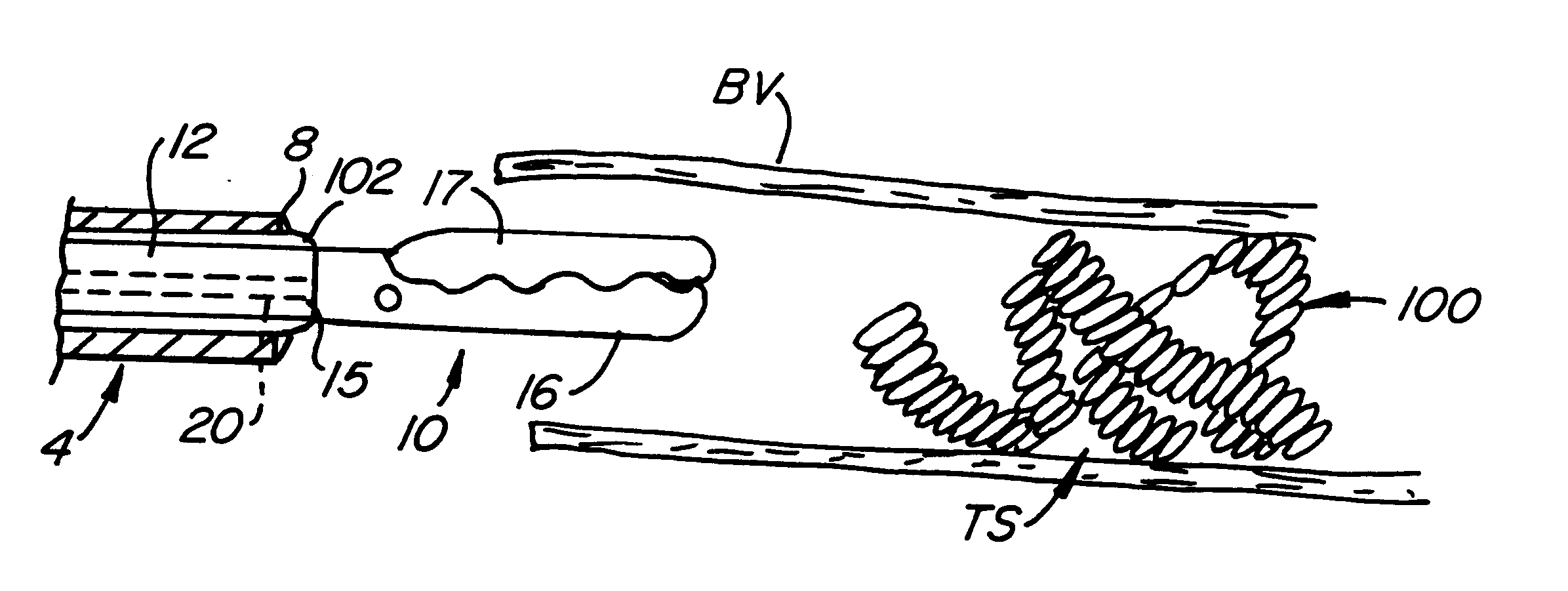

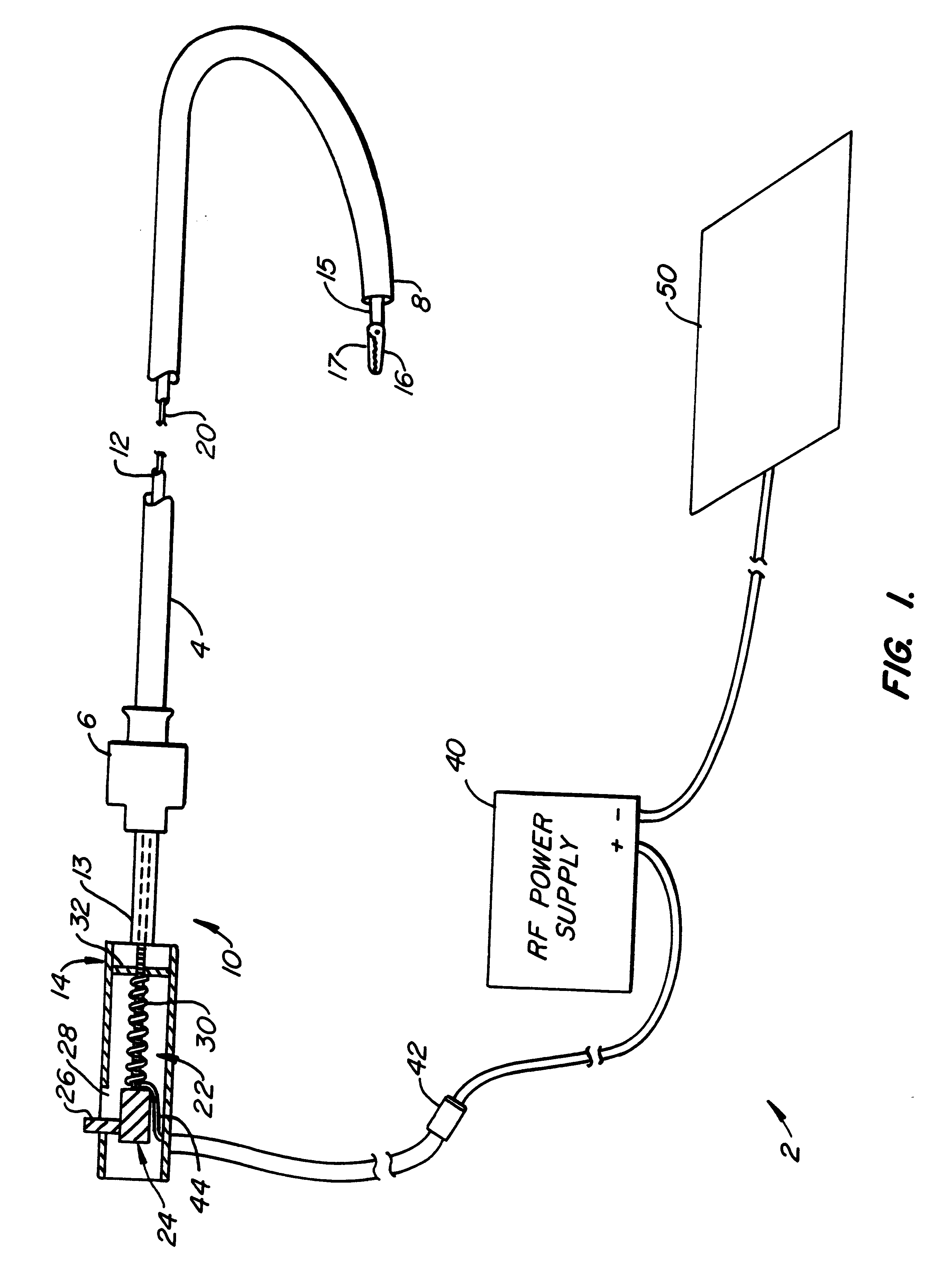

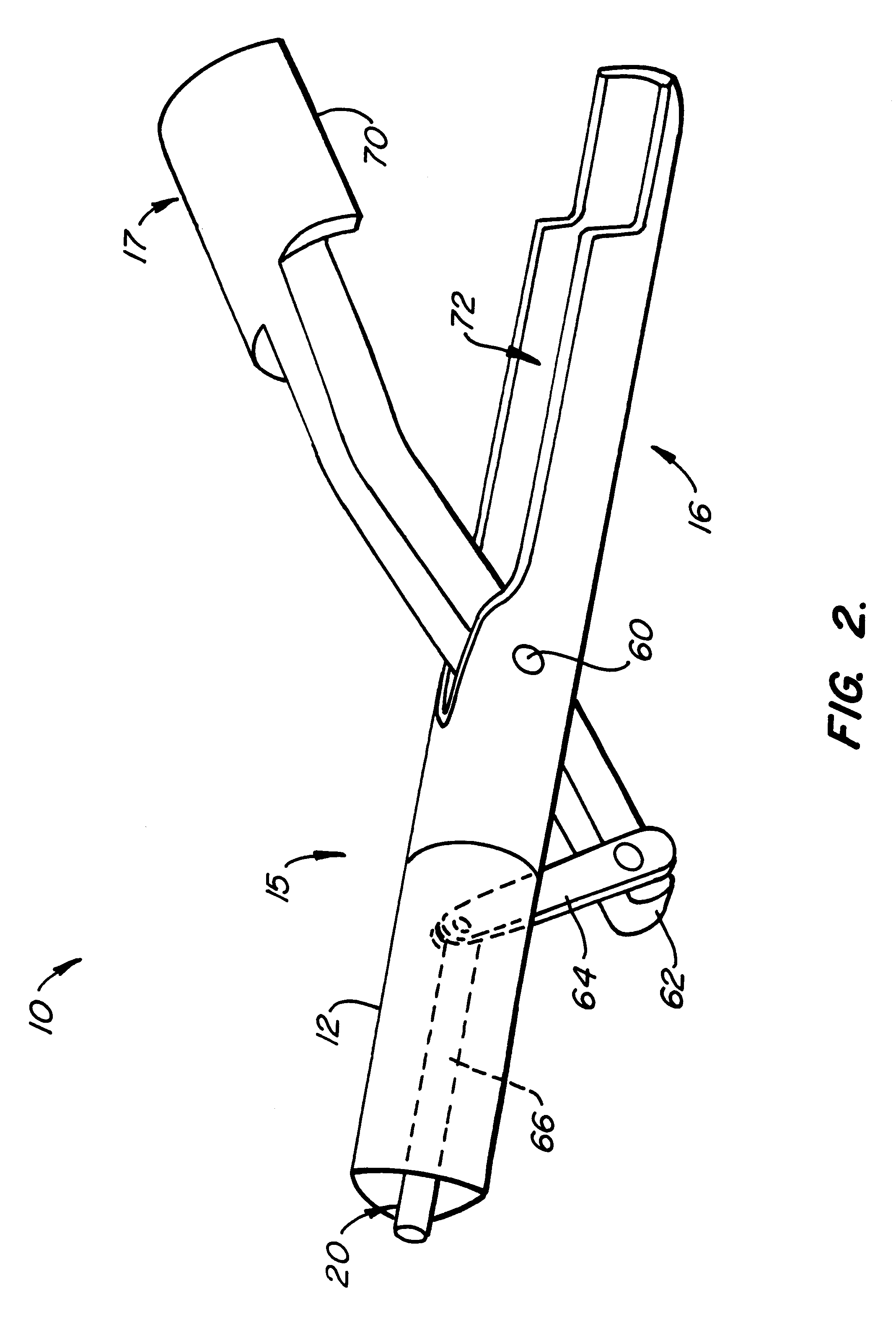

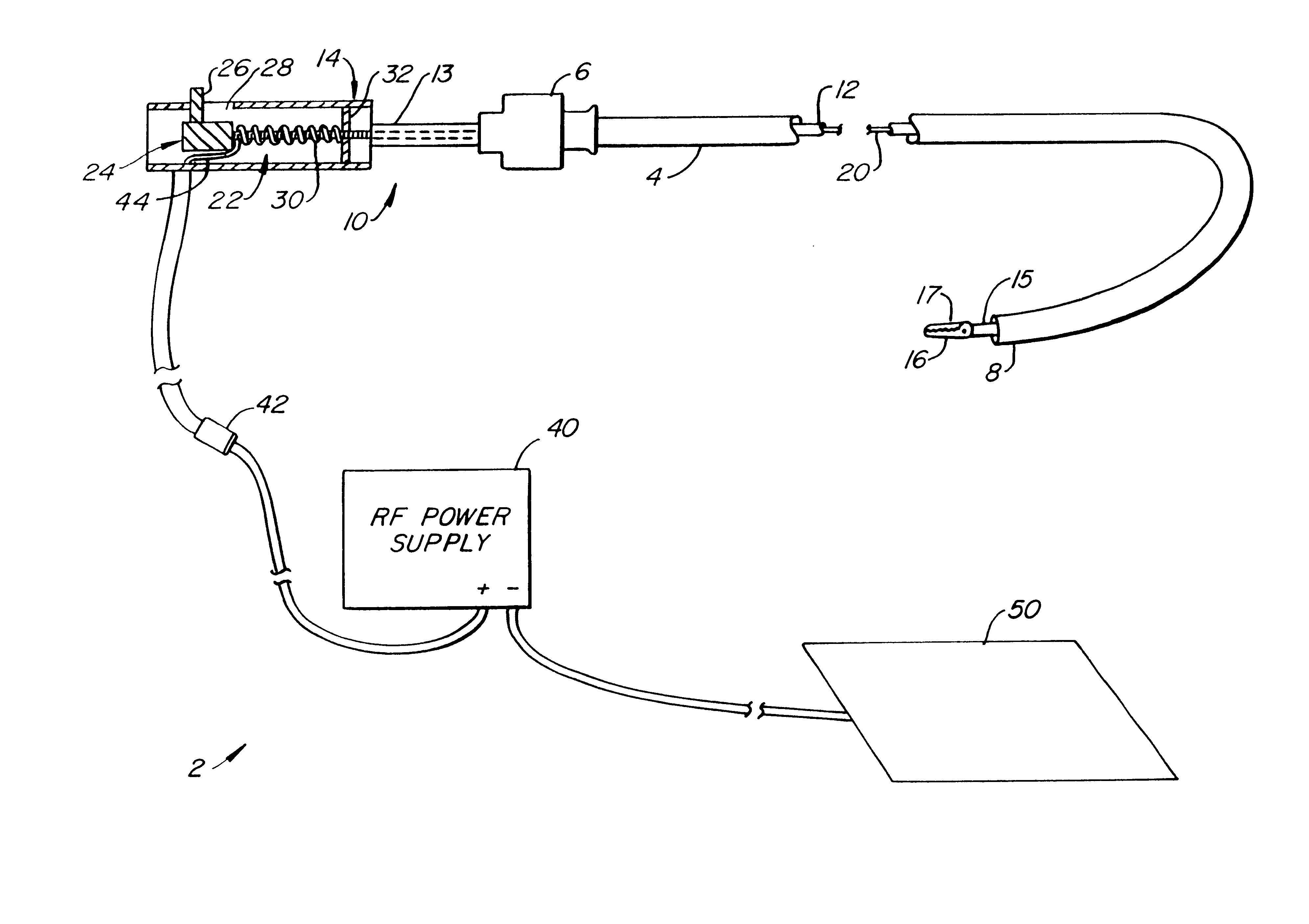

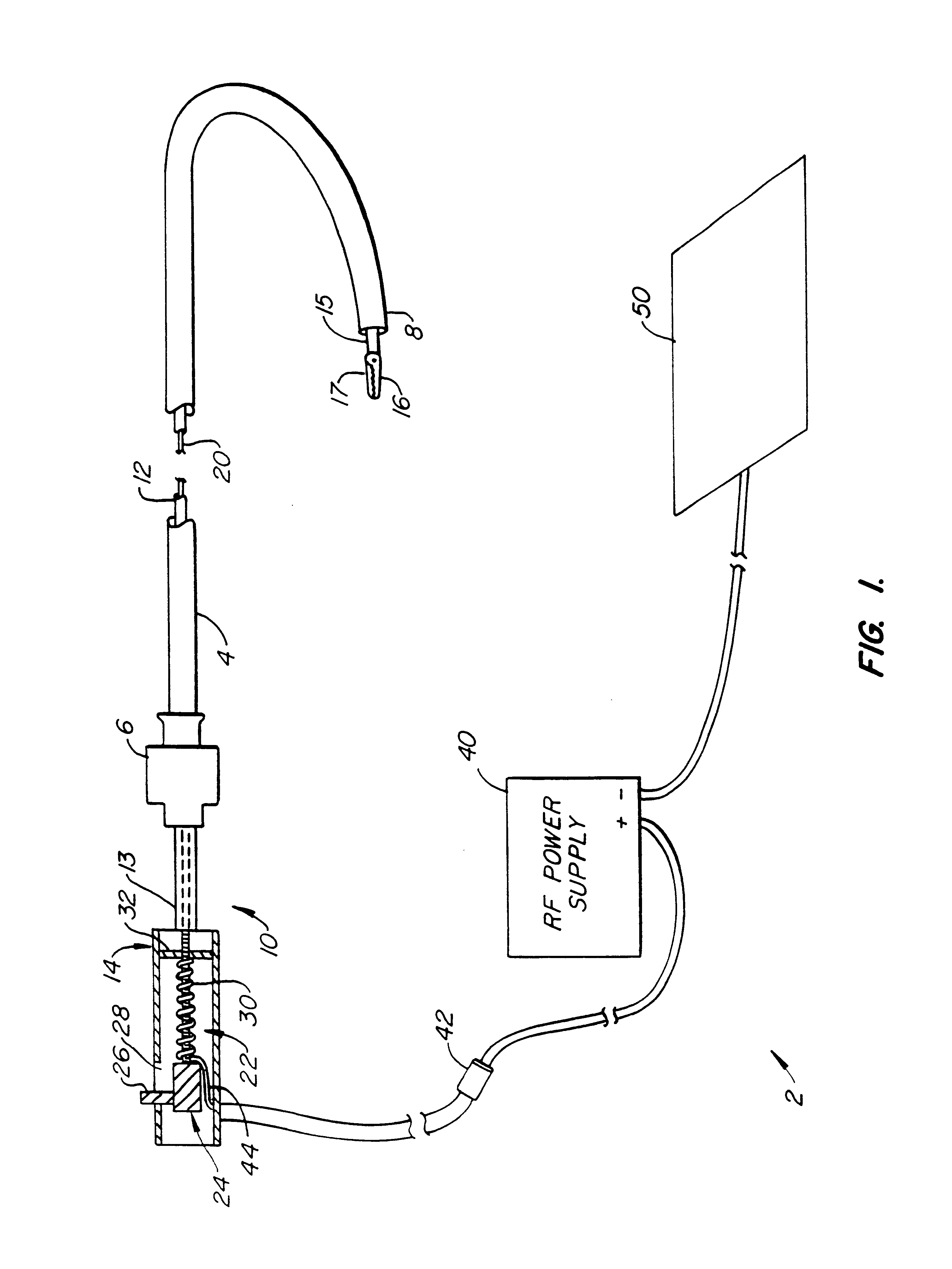

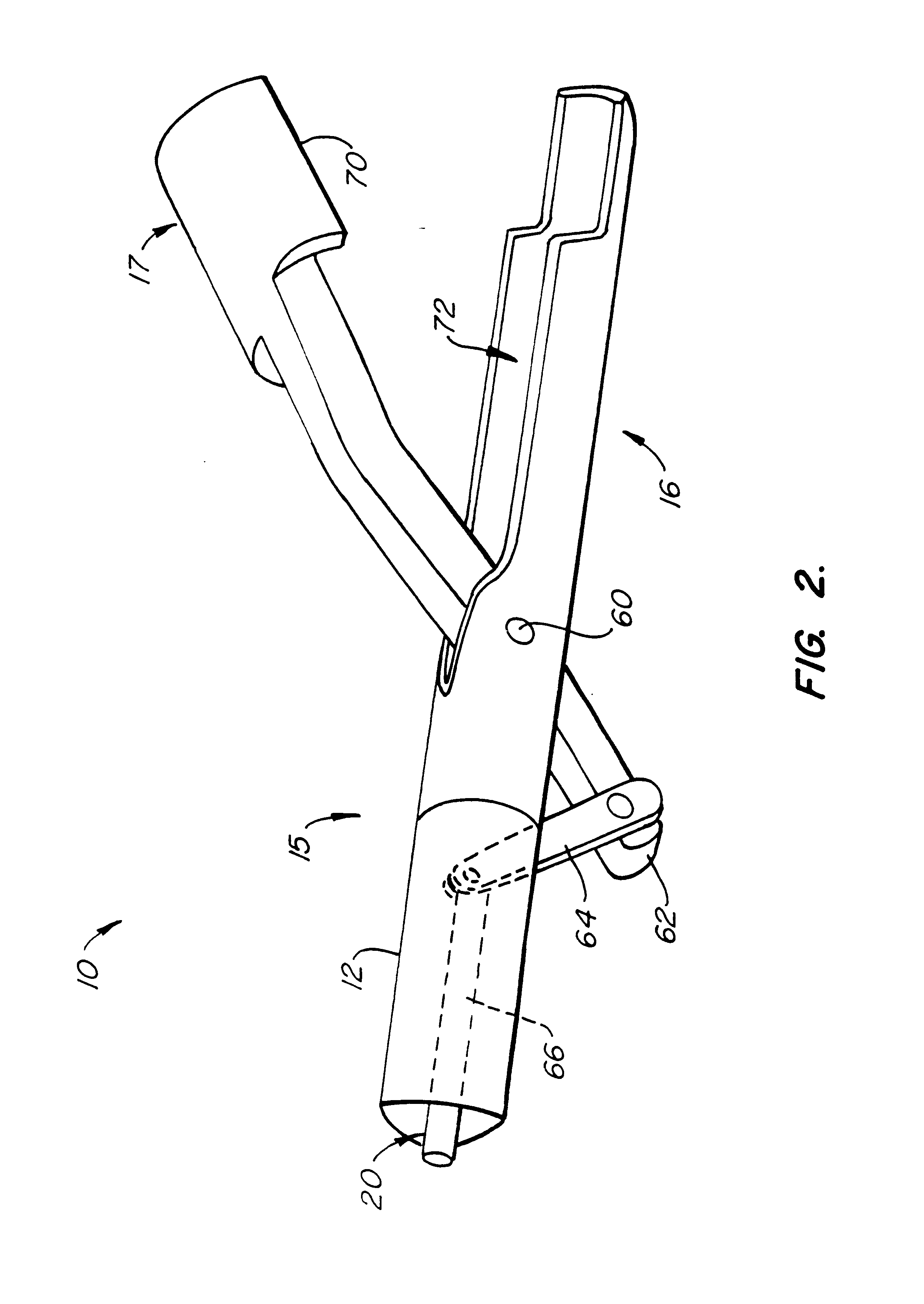

Method and device for enhancing vessel occlusion

Body lumens such as blood vessels are selectively occluded by applying radiofrequency voltage to a vaso-occlusive coil (100) at the target site (TS) and generating a thermal reaction to induce fibrogenic occlusion of the blood vessel (BV) around the vaso-occlusive coil. The radiofrequency current is usually sufficient to induce thermal damage to the luminal wall and to coagulate the surrounding blood, thereby initiating clotting and subsequent fibrosis to permanently occlude the lumen. The invention also includes a method for endoluminally deploying the vaso-occlusive coil and preventing migration of the coil from of the target site.

Owner:BOSTON SCI SCIMED INC

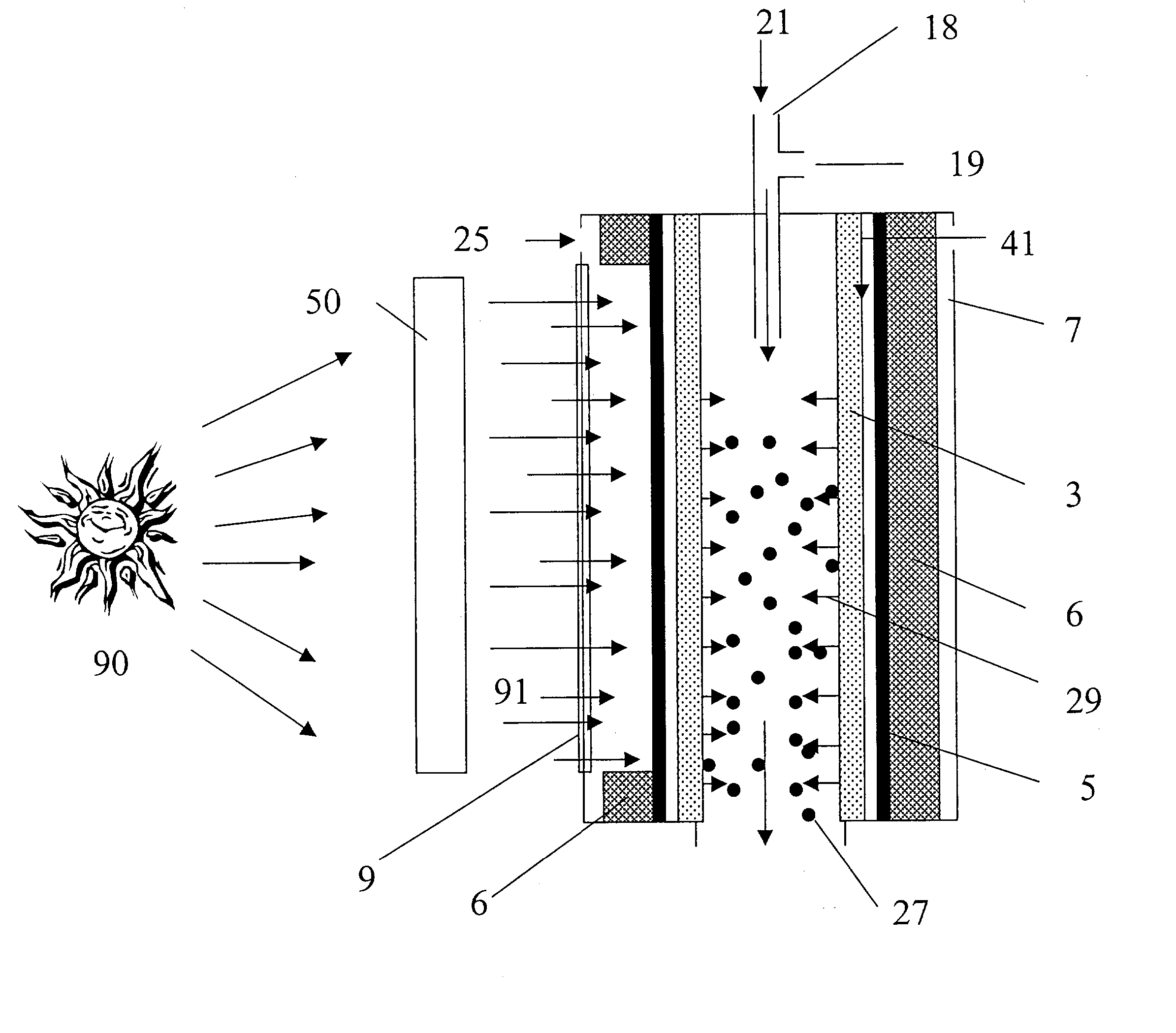

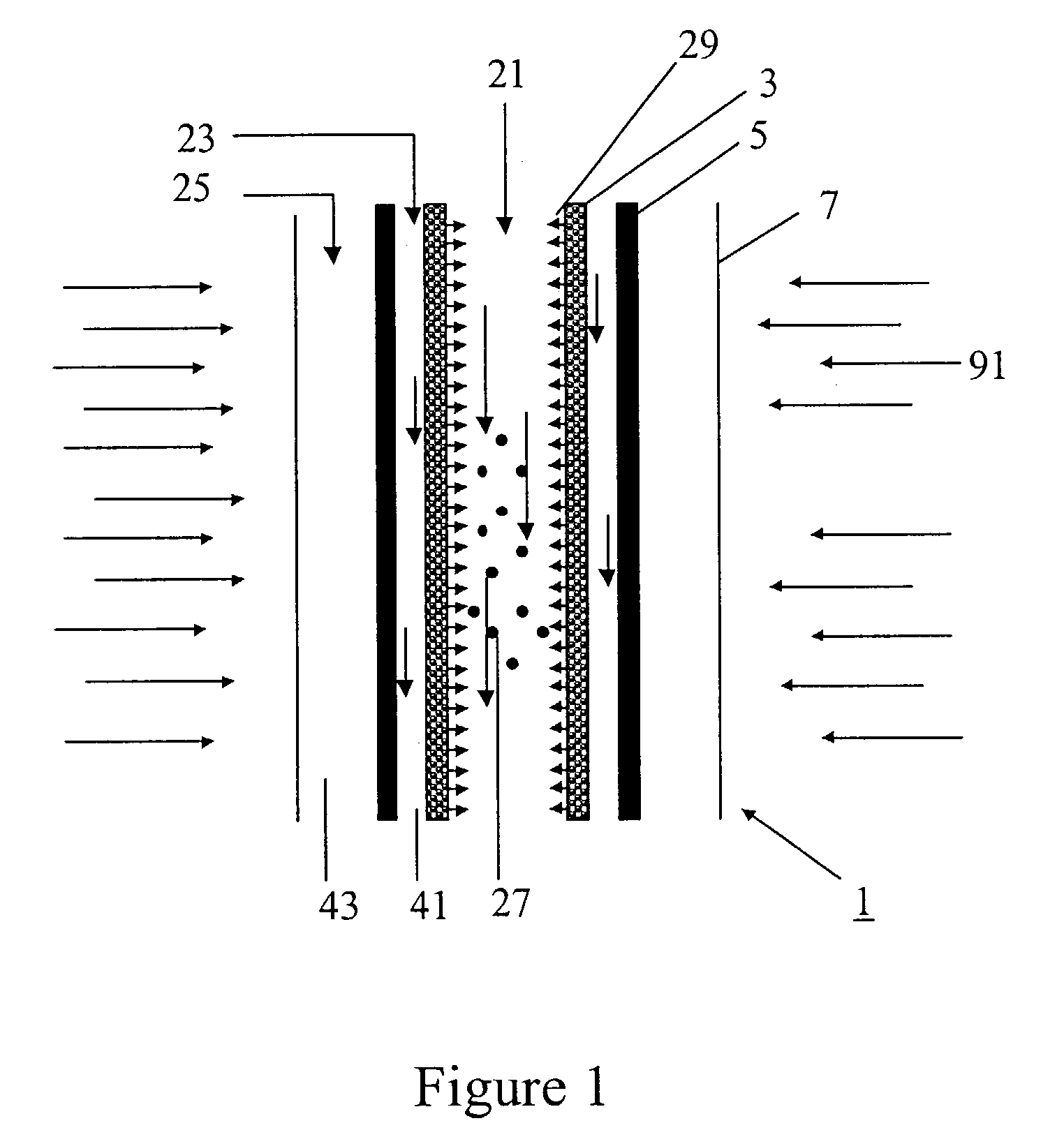

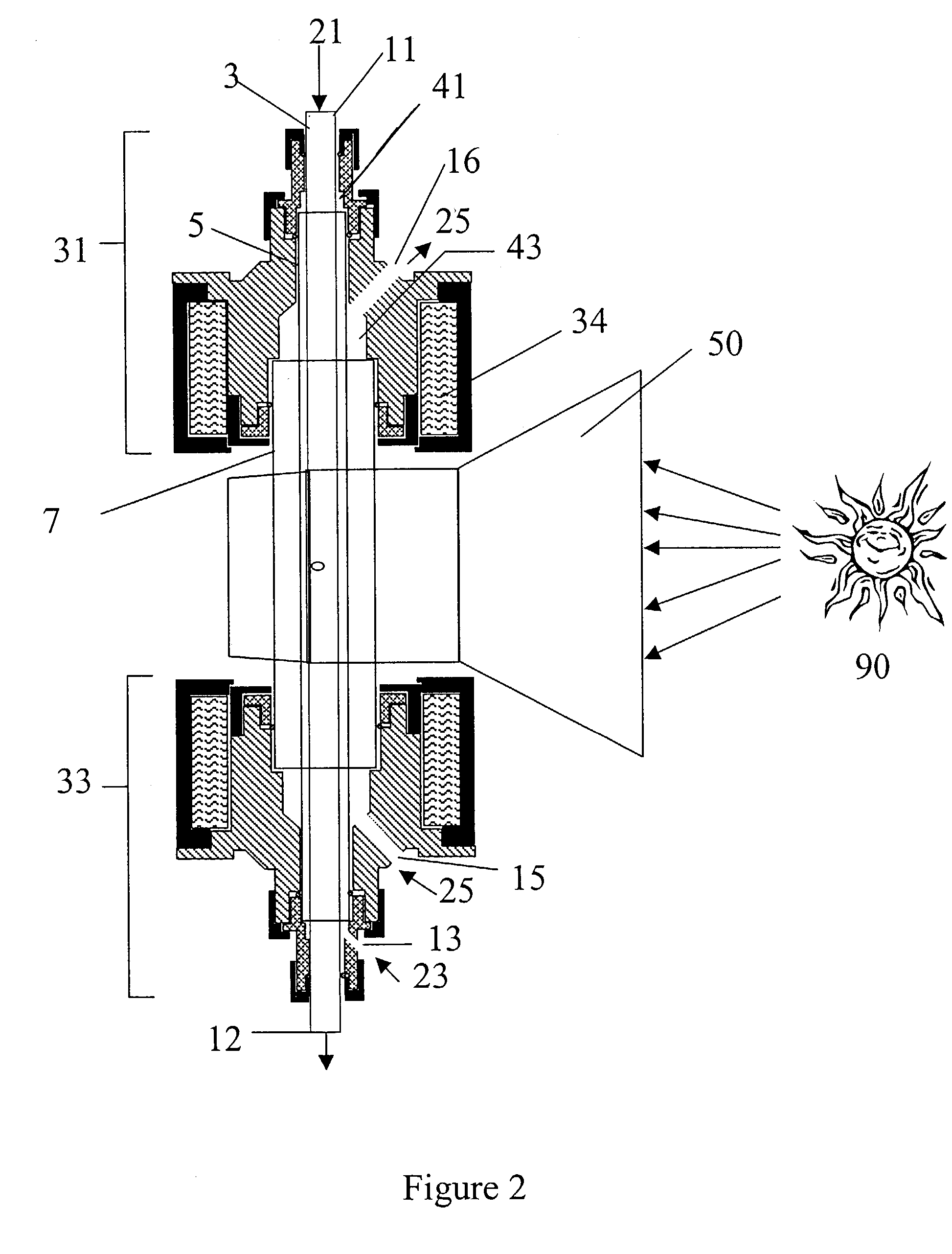

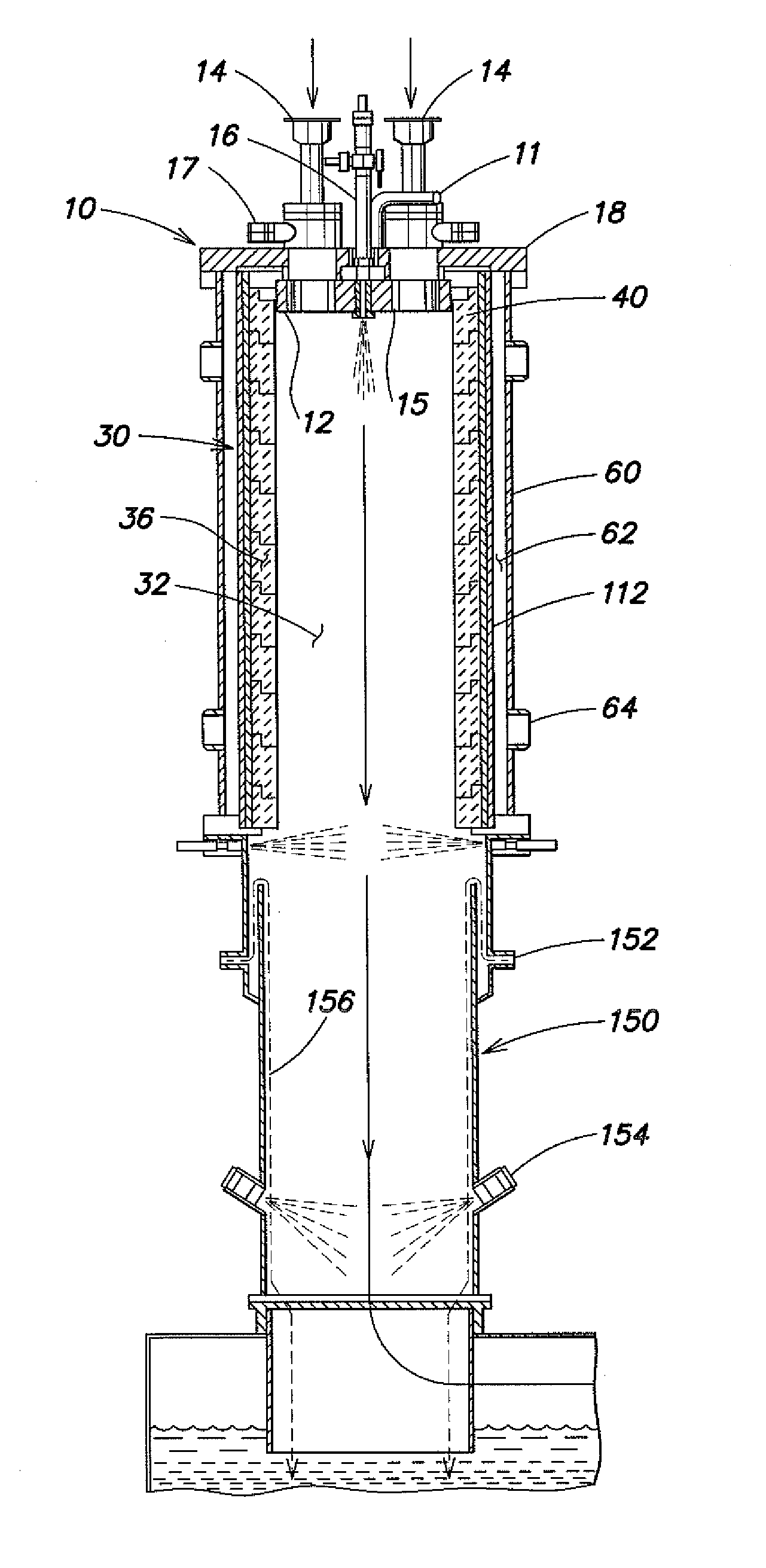

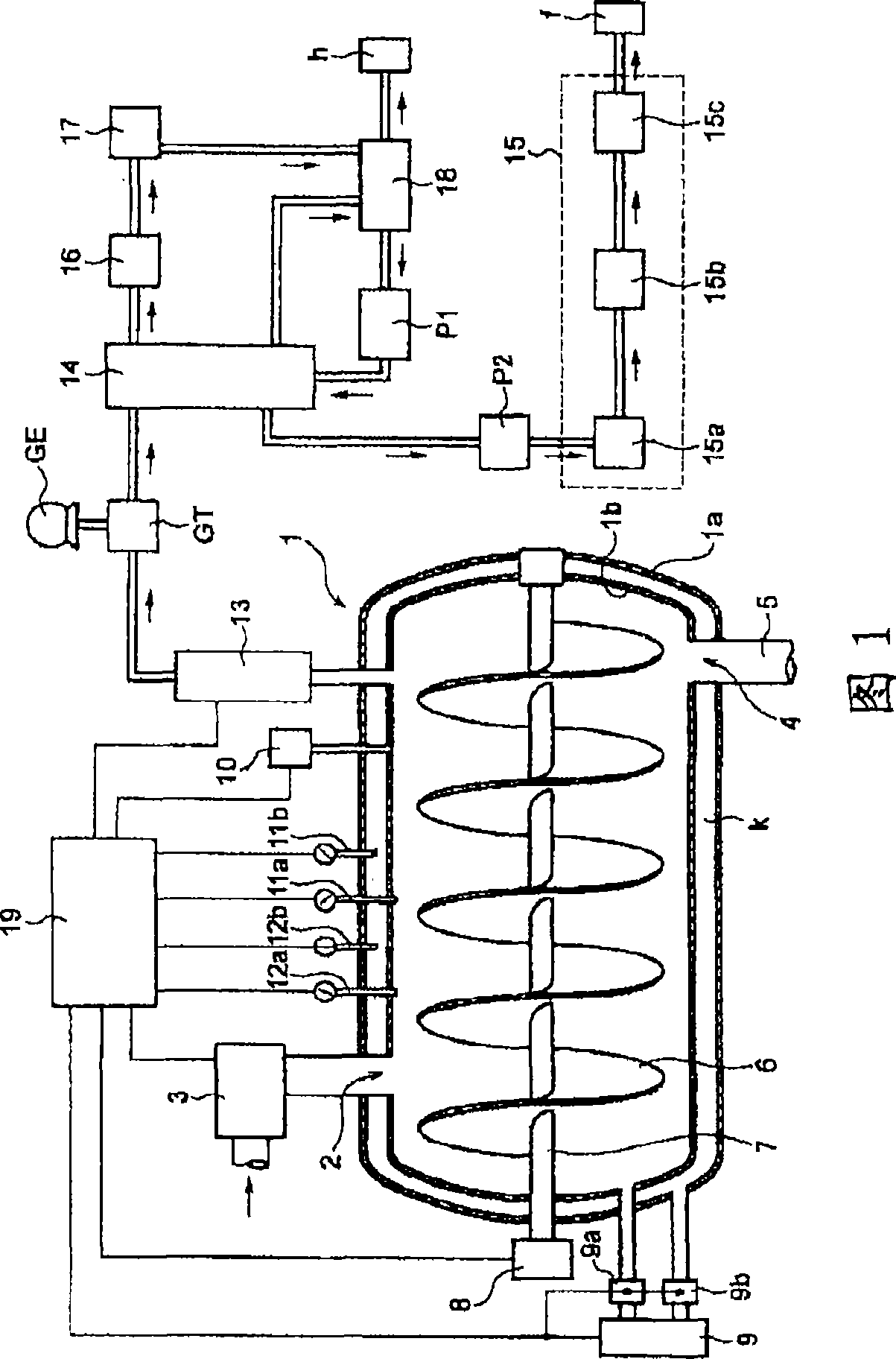

Solar-thermal fluid-wall reaction processing

InactiveUS7033570B2Reduce and preventShort stayThermal non-catalytic crackingSolar heating energyHydrogenReactor system

The present invention provides a method for carrying out high temperature thermal dissociation reactions requiring rapid-heating and short residence times using solar energy. In particular, the present invention provides a method for carrying out high temperature thermal reactions such as dissociation of hydrocarbon containing gases and hydrogen sulfide to produce hydrogen and dry reforming of hydrocarbon containing gases with carbon dioxide. In the methods of the invention where hydrocarbon containing gases are dissociated, fine carbon black particles are also produced. The present invention also provides solar-thermal reactors and solar-thermal reactor systems.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

Method and device for enhancing vessel occlusion

Body lumens such as blood vessels are selectively occluded by applying radiofrequency voltage to a vaso-occlusive coil (100) at the target site (TS) and generating a thermal reaction to induce fibrogenic occlusion of the blood vessel (BV) around the vaso-occlusive coil. The radiofrequency current is usually sufficient to induce thermal damage to the luminal wall and to coagulate the surrounding blood, thereby initiating clotting and subsequent fibrosis to permanently occlude the lumen. The invention also includes a method for endoluminally deploying the vaso-occlusive coil and preventing migration of the coil from of the target site.

Owner:BOSTON SCI SCIMED INC

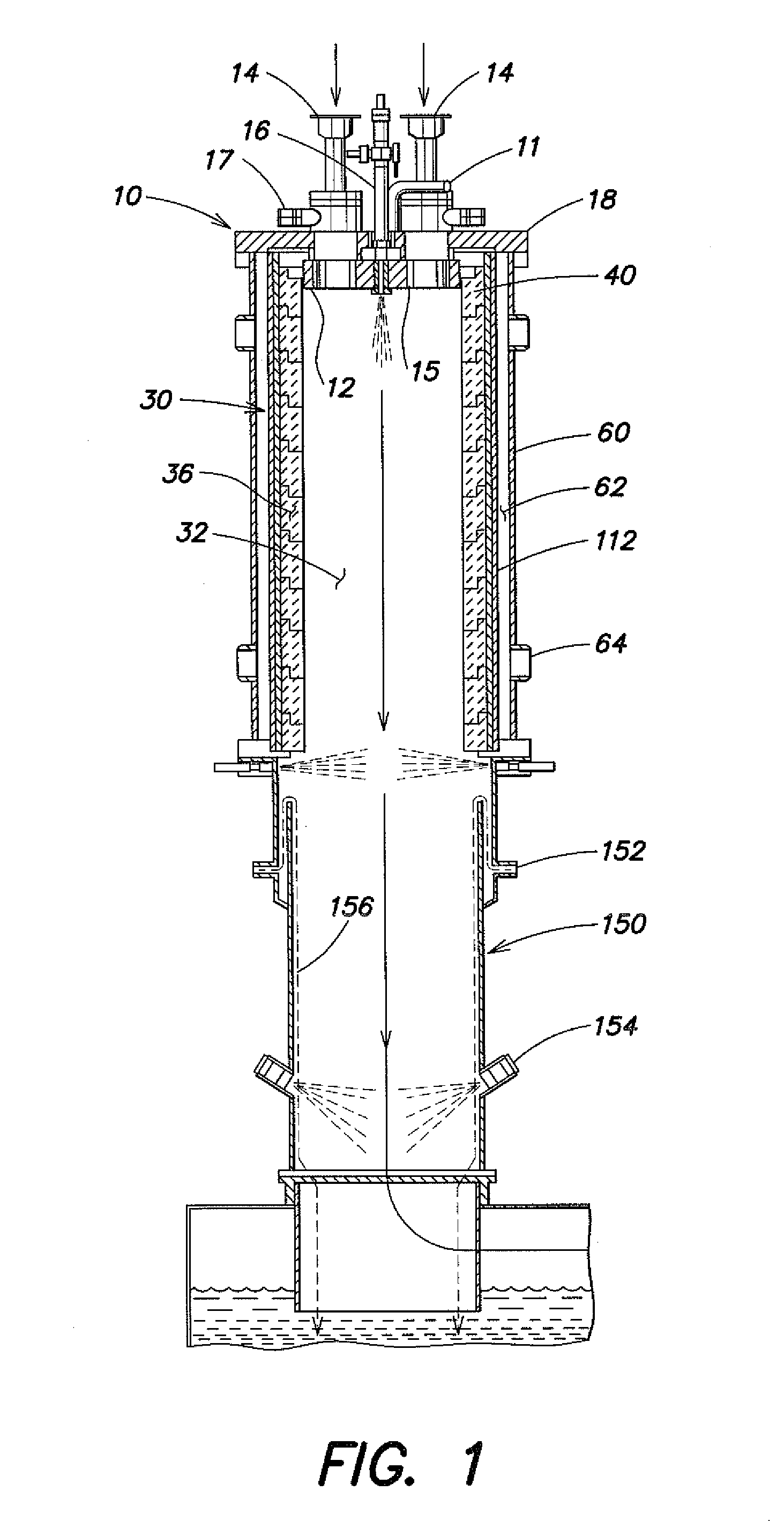

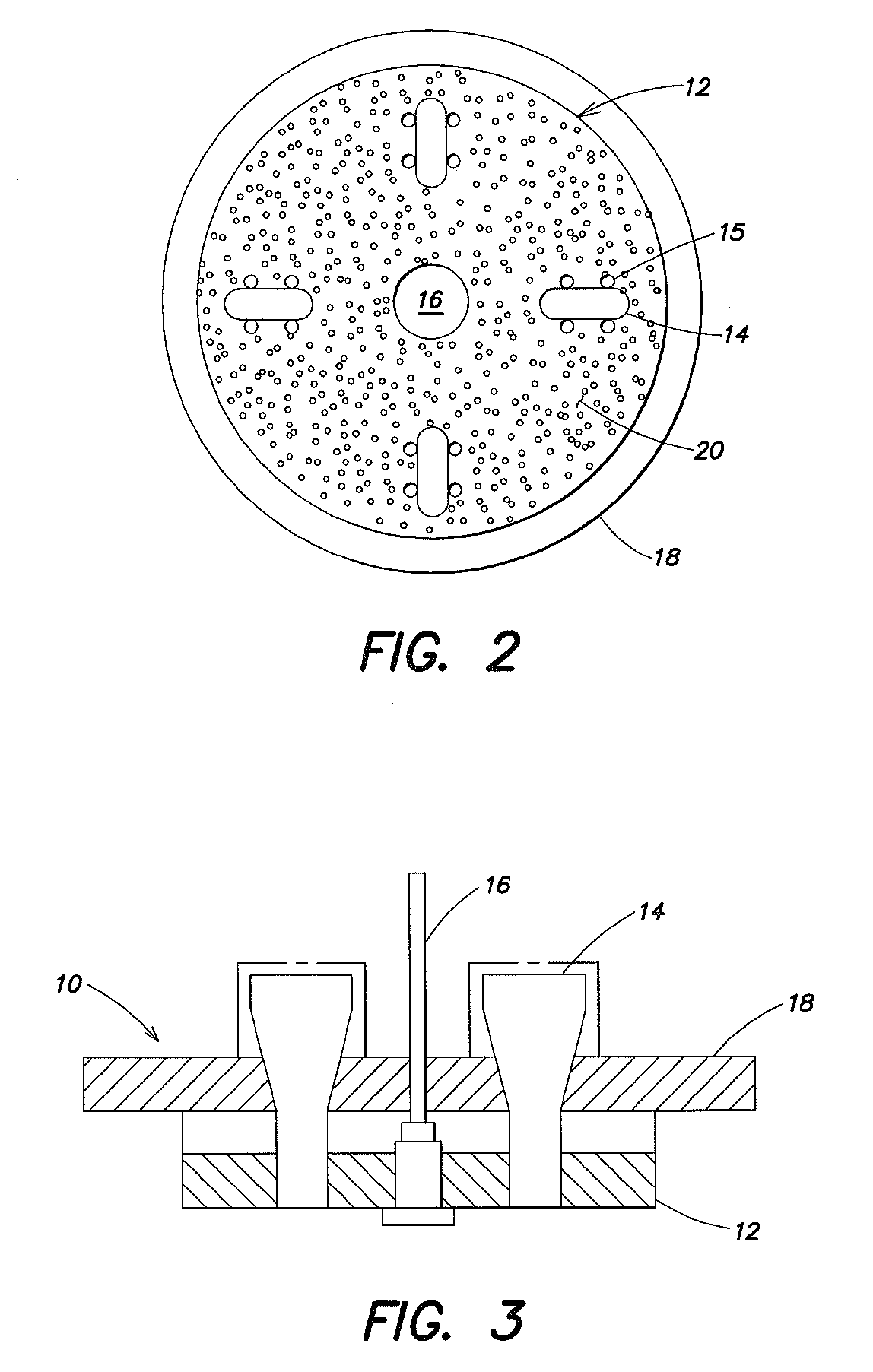

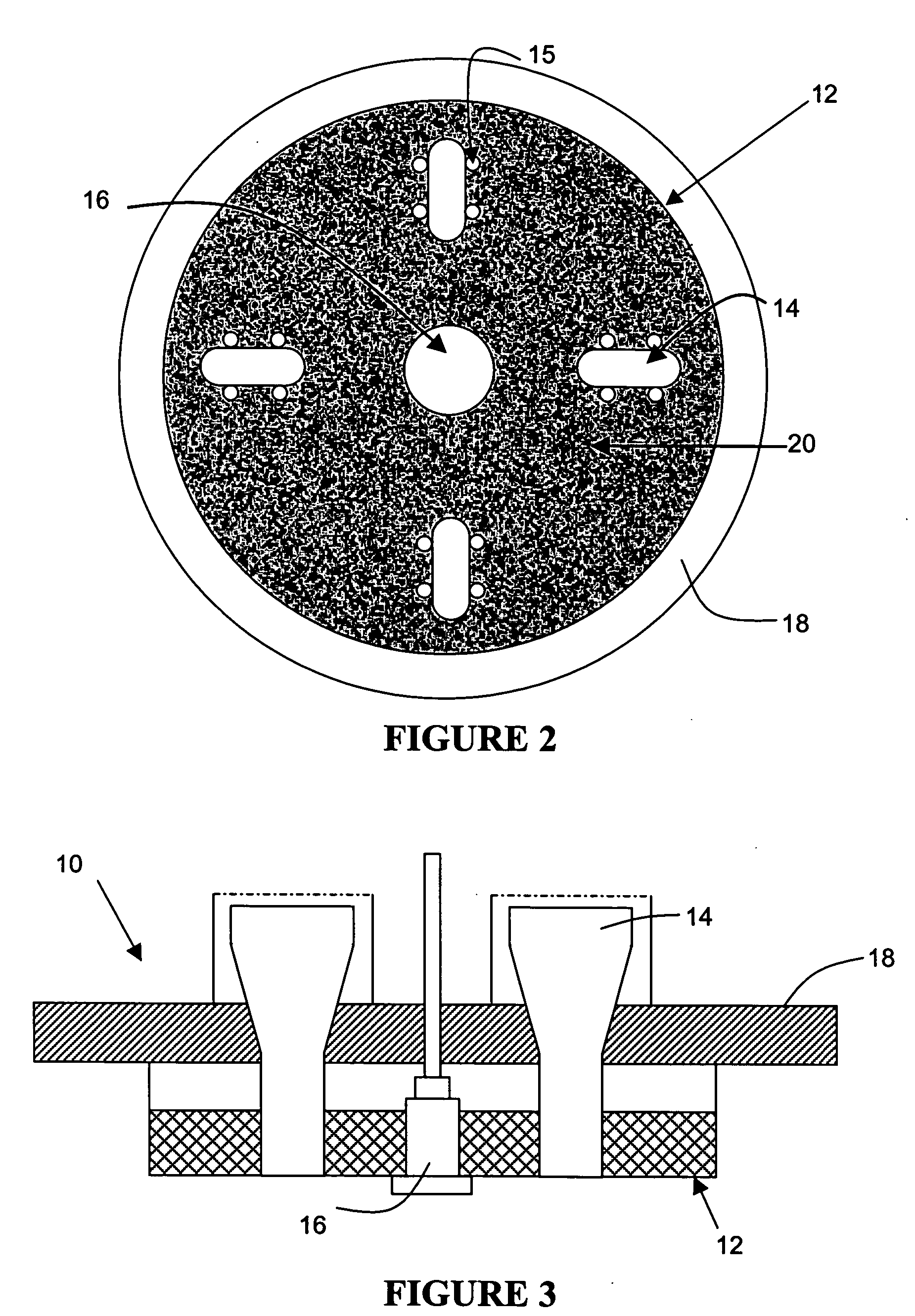

Reactor design to reduce particle deposition during process abatement

InactiveUS20070274876A1Reduce accumulationReduce crackingCombination devicesBurnersCombustionDecomposition

The present invention relates to systems and methods for controlled combustion and decomposition of gaseous pollutants while reducing deposition of unwanted reaction products from within the treatment systems. The systems include a novel thermal reaction chamber design having stacked reticulated ceramic rings through which fluid, e.g., gases, may be directed to form a boundary layer along the interior wall of the thermal reaction chamber, thereby reducing particulate matter buildup thereon. The systems further include the introduction of fluids from the center pilot jet to alter the aerodynamics of the interior of the thermal reaction chamber.

Owner:APPLIED MATERIALS INC

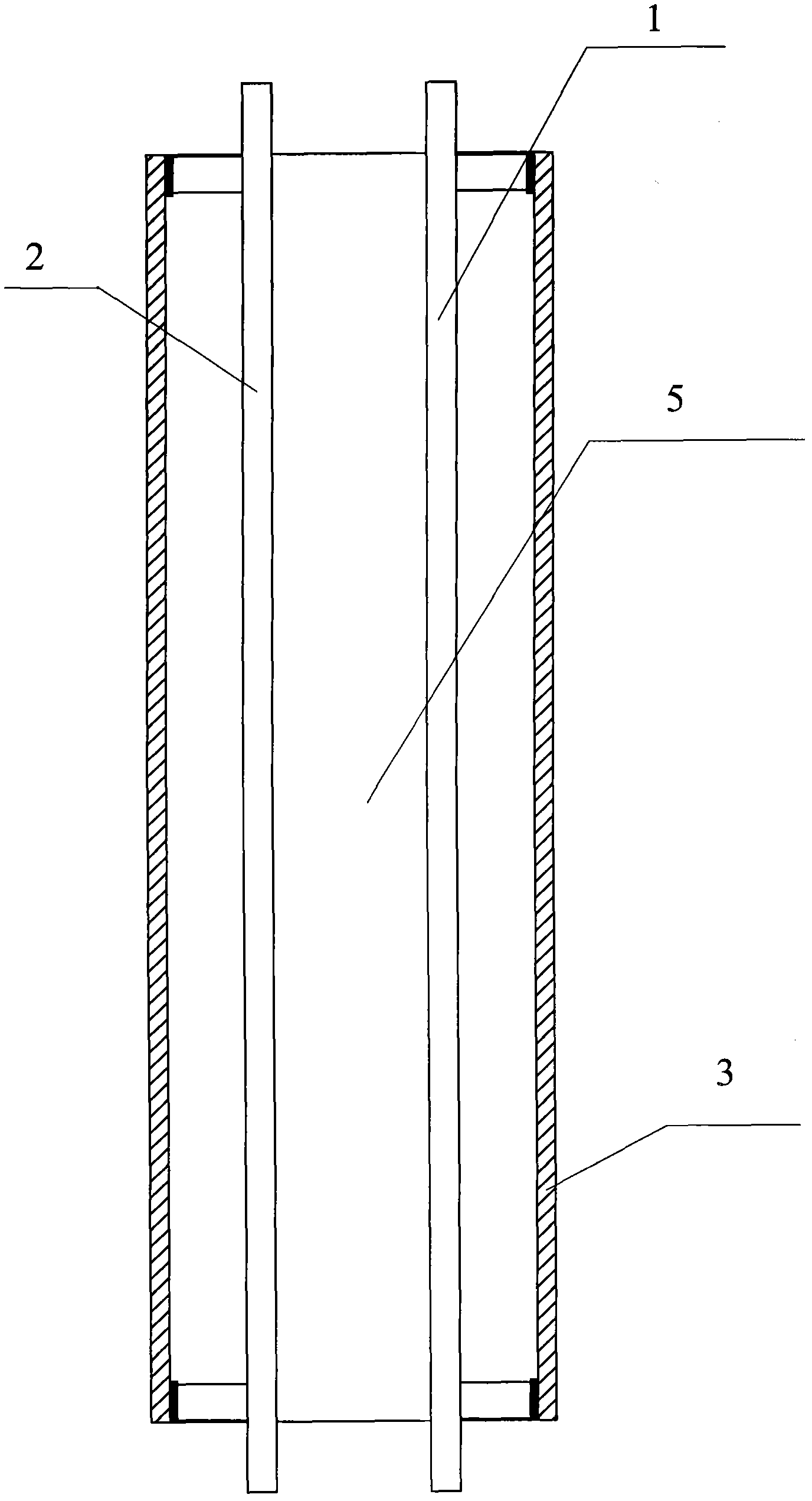

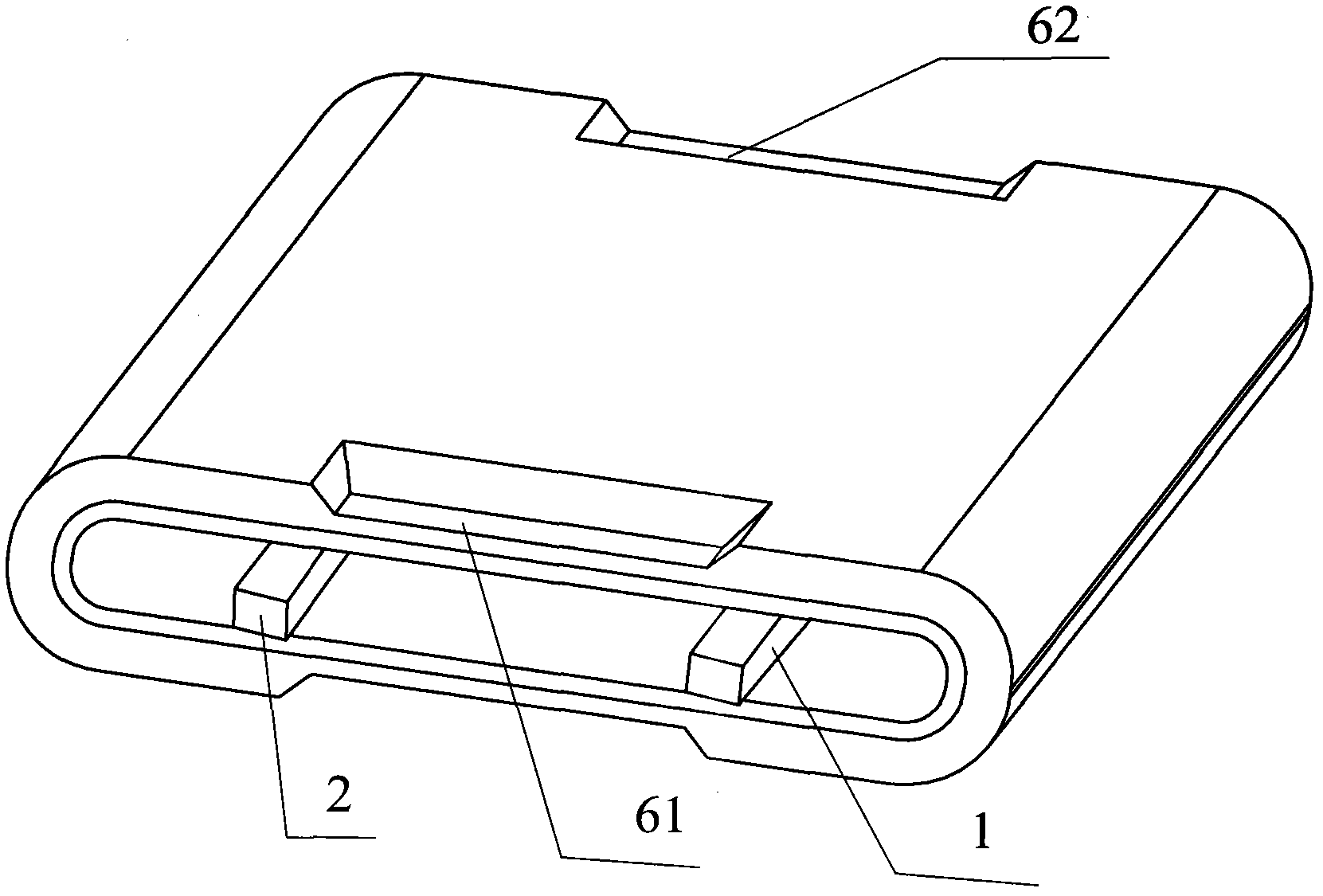

Battery

InactiveCN102569866AStable temperatureConsistent temperatureFinal product manufactureCell temperature controlHeat conductingReaction temperature

The invention provides a battery, comprising a cover plate, a shell, a battery cell and electrolyte. The battery cell and the electrolyte are sealed in the shell of the battery, and the cover plate is hermetically connected with the shell. The battery cell comprises a positive polar plate, a negative polar plate and a diaphragm arranged between the positive polar plate and the negative polar plate. A positive polar lug is arranged on the positive polar plate, and a negative polar lug is arranged on the negative polar plate. The battery cell is further internally provided with a positive polar current and heat conducting member and a negative polar current and heat conducting member, and the positive polar current and heat conducting member and the negative polar current and heat conducting member are mutually insulated. The positive polar current and heat conducting member and the positive polar lug are conducted; the negative polar current and heat conducting member and the negative polar lug are conducted; the positive polar current and heat conducting member and / or the negative polar current and heat conducting member penetrate(s) through the cover plate to leading out current. According to the invention, the internal heat of the battery cell can be reduced rapidly, substances on the polar plates can be prevented from further thermal reaction, and thus, the safety performance of the battery is increased. Meanwhile, the stability of the internal temperature of the battery cell is guaranteed, the cyclic performance and the like of the battery are improved. In addition, the temperature at all parts in the battery cell can be ensured to be consistent so as to eliminate temperature differences and make the reaction temperature of all parts of the polar plates consistent. Meanwhile, the current and heat conducting members can play roles of backbone and support to support the battery cell, and is beneficial to not only assembly but also winding of the battery cell.

Owner:BYD CO LTD

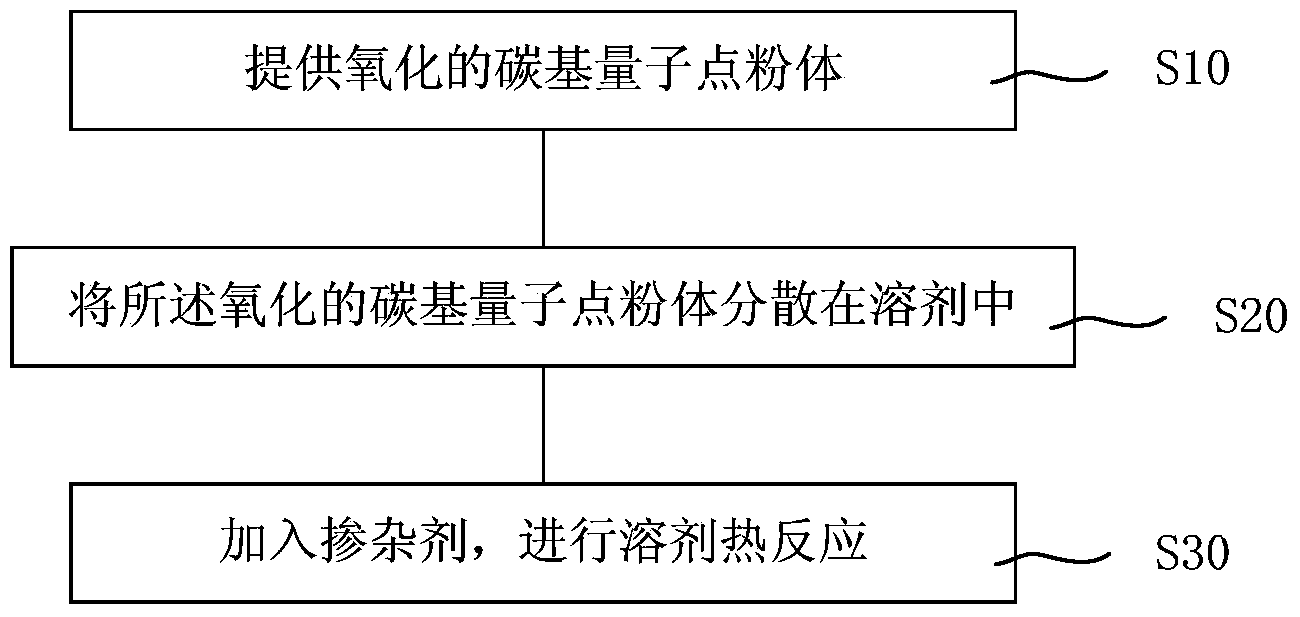

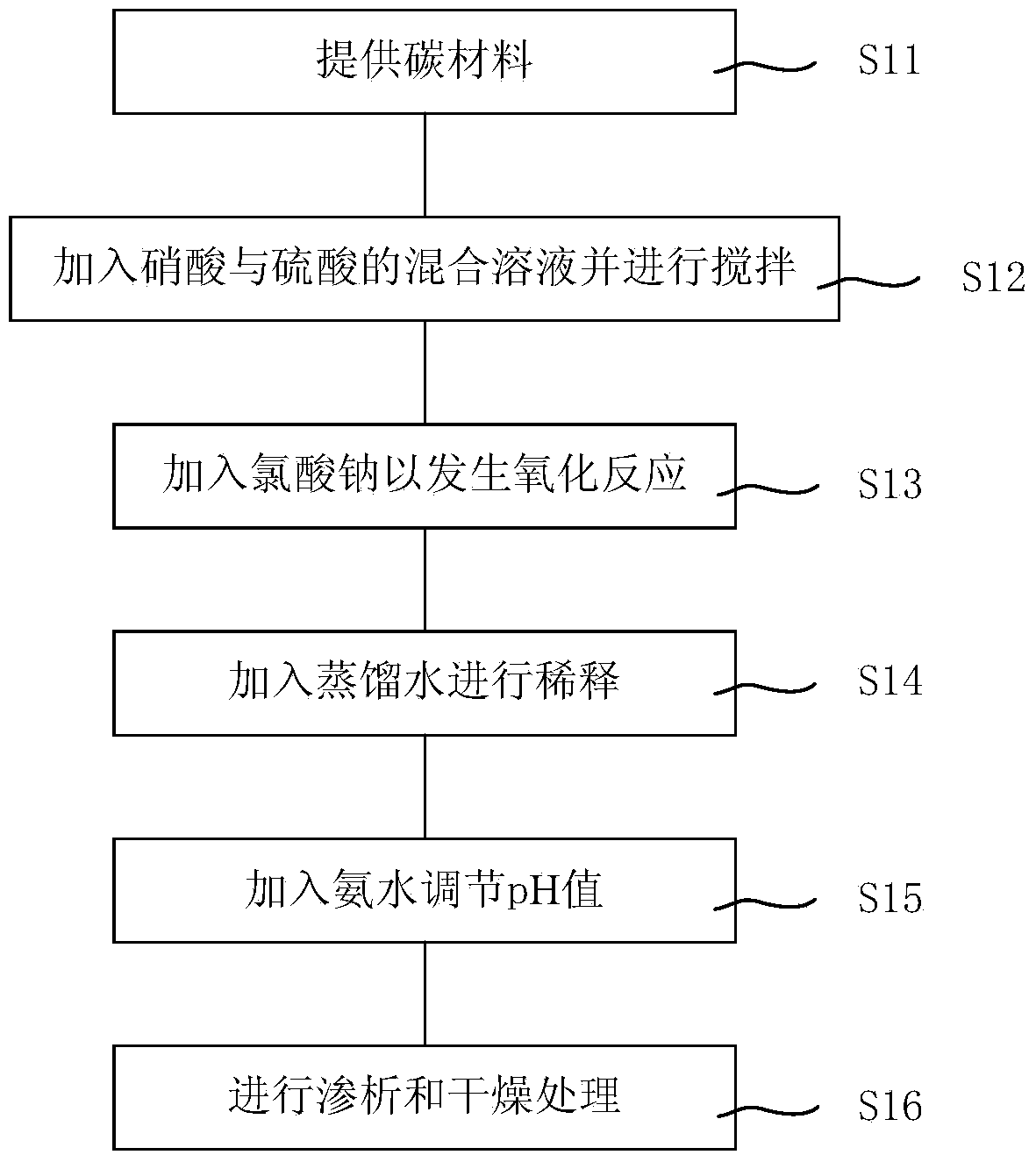

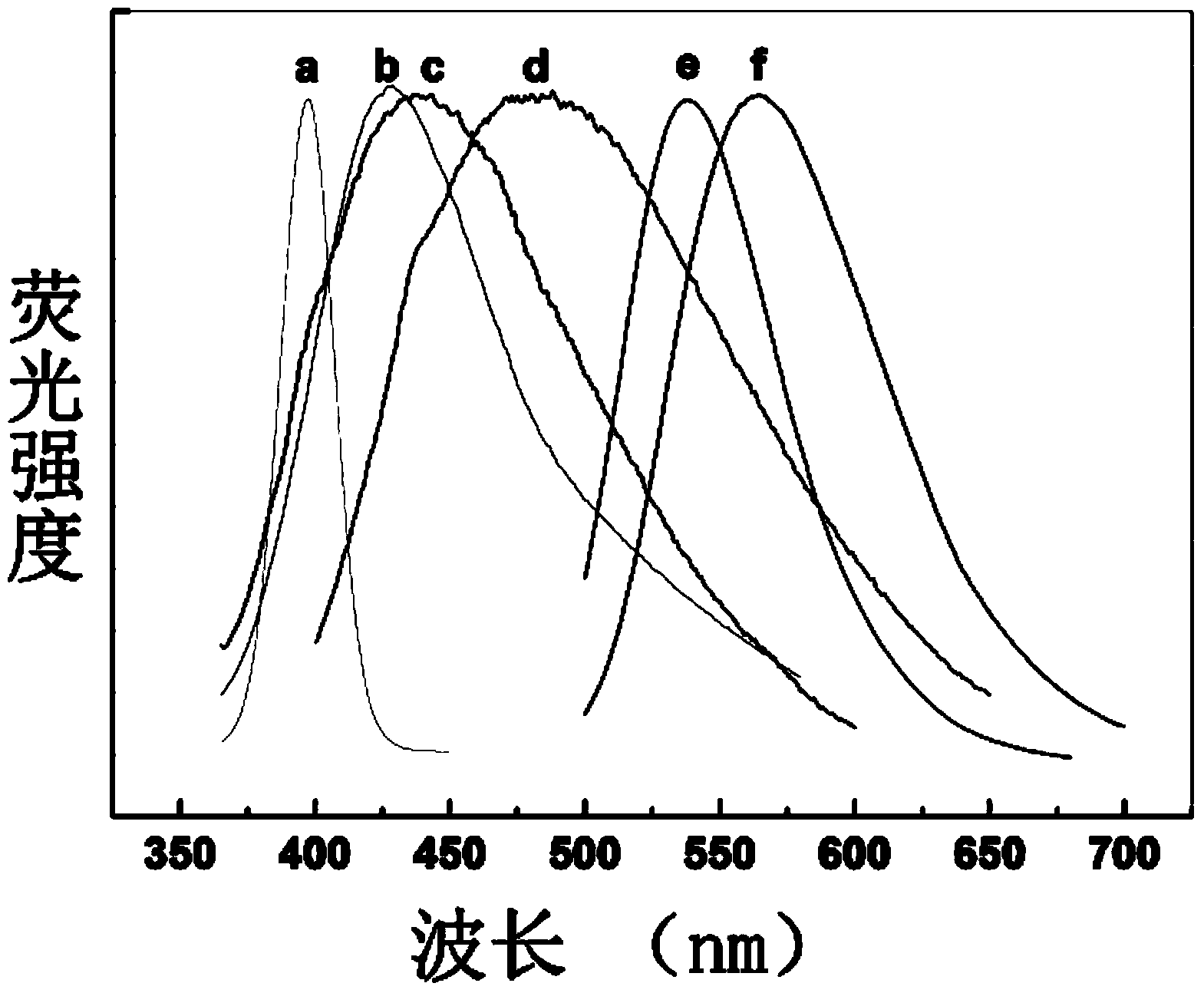

Preparation method for fluorescence carbon-based quantum dot

The invention provides a preparation method for a fluorescence carbon-based quantum dot. The preparation method for the fluorescence carbon-based quantum dot at least comprises the steps of providing oxidized carbon-based quantum dot powder; providing a solvent, and dispersing the oxidized carbon-based quantum dot powder into the solvent to obtain the oxidized carbon-based quantum dot solution; adding a doping agent into the oxidized carbon-based quantum dot solution, reducing the oxidized carbon-based quantum dot by utilizing the solvent thermal reaction so as to obtain the doped carbon-based quantum dot. According to the invention, the technical scheme that oxidized carbon-based quantum dot is taken as a raw material and the solvent thermal reduction and doping are synchronously carried out is adopted, the carbon-based quantum dot represented by graphene quantum dot and carbon quantum dot can be reduced and doped by adopting various easily available nonmetal compounds or metal compounds through the solvent thermal reaction, the yield of a product is high, the regulation on the fluorescent spectrum of the carbon-based quantum dot can be realized, and the yield of quantum can be improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

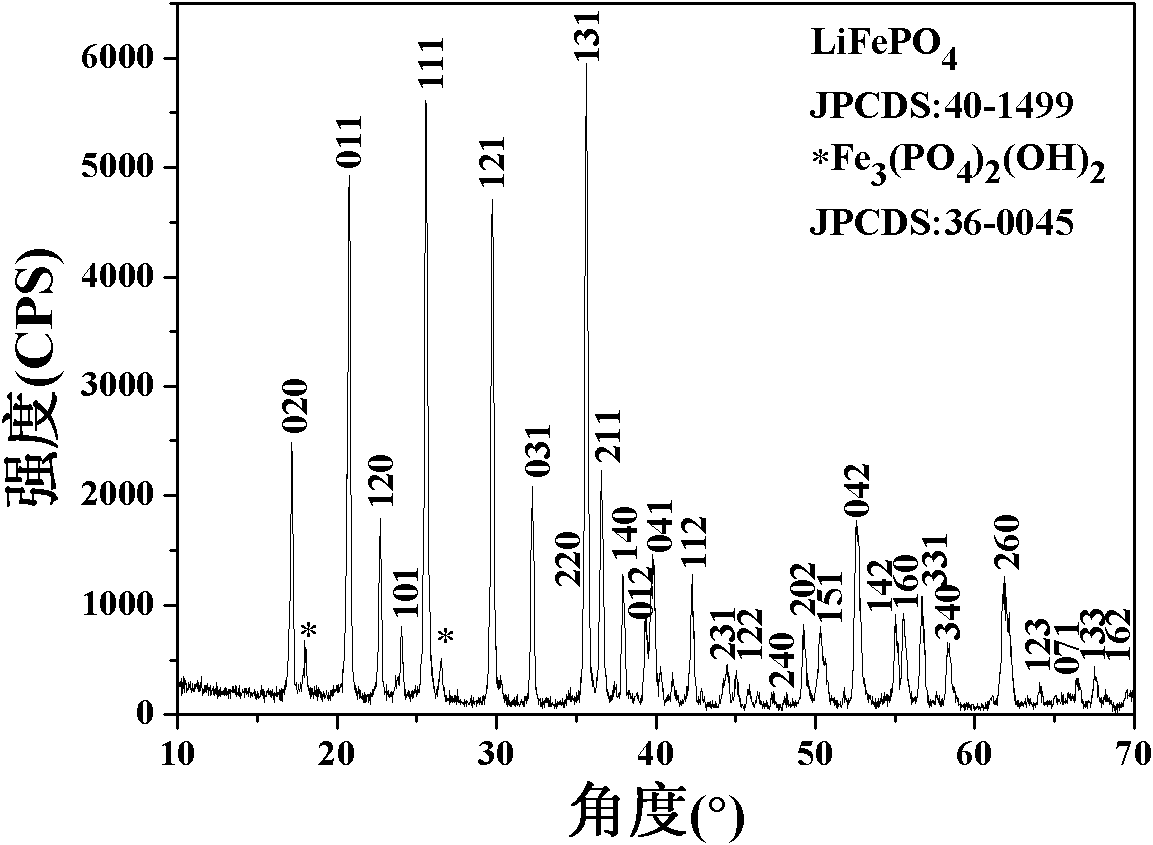

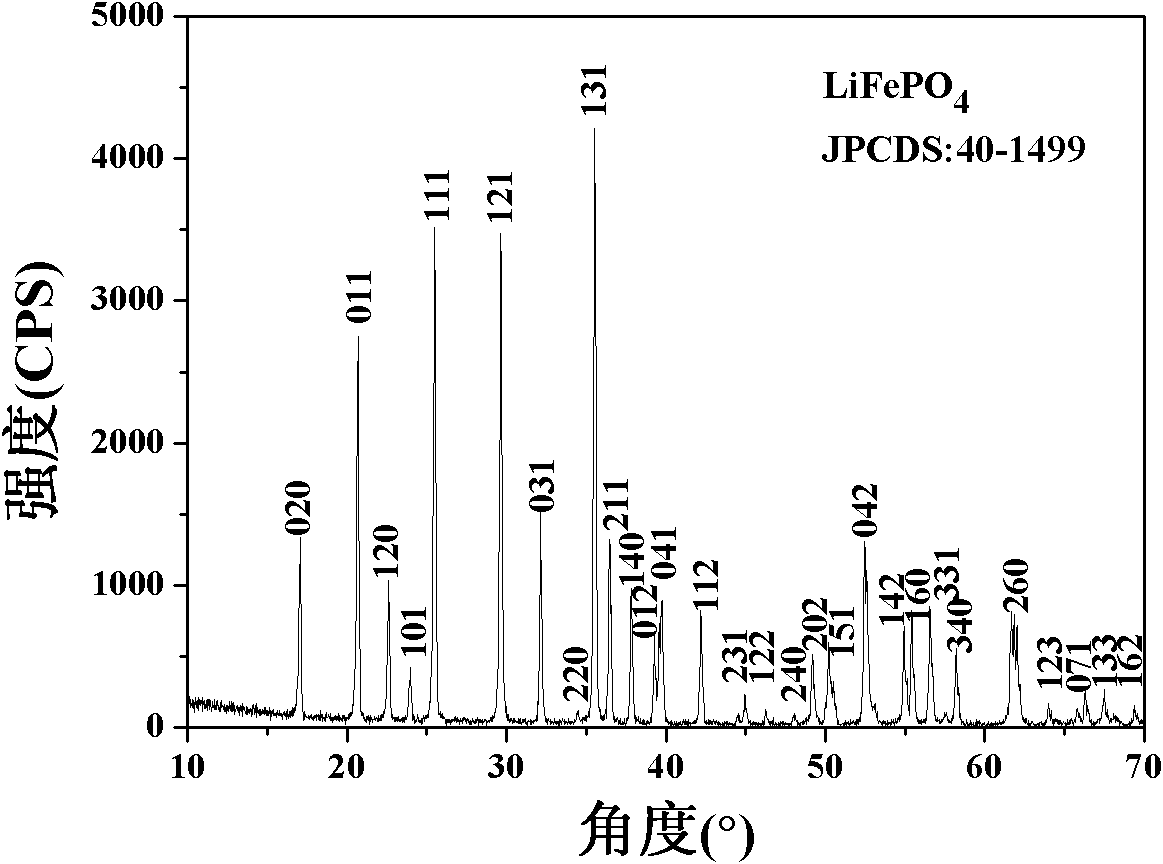

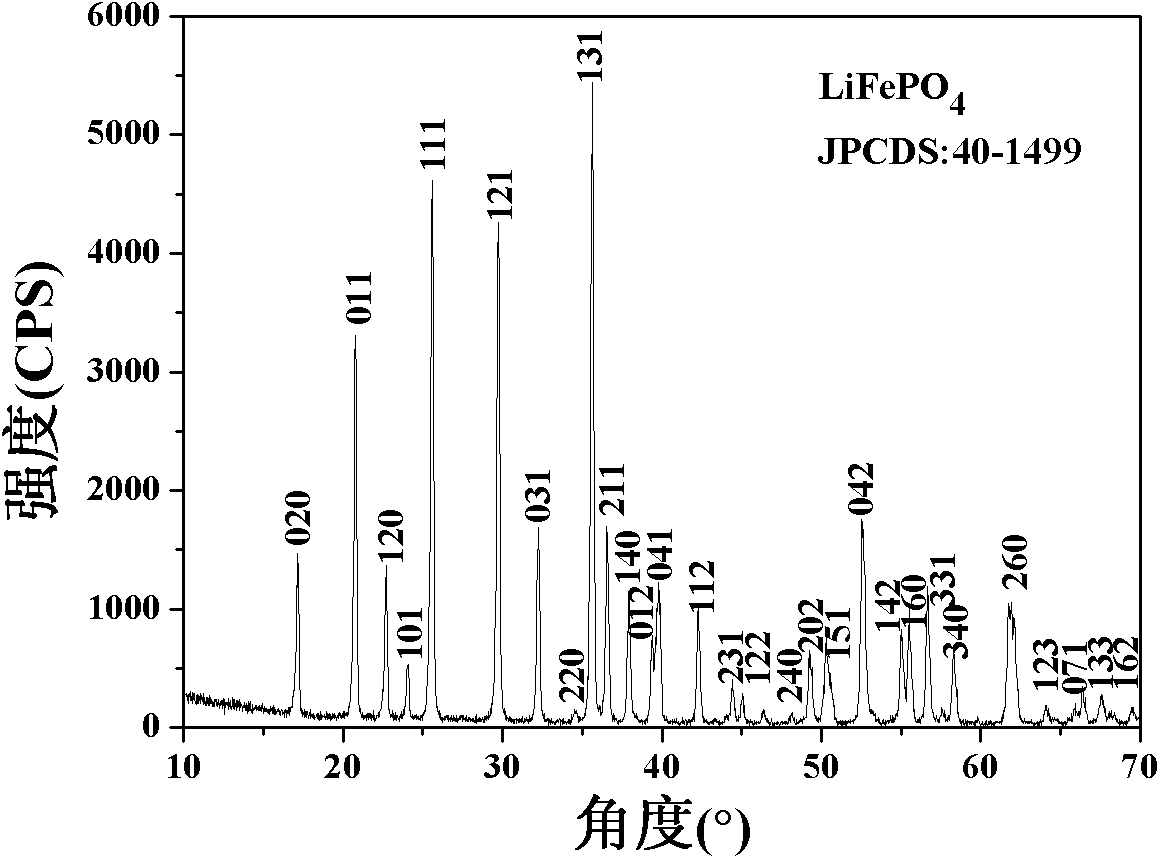

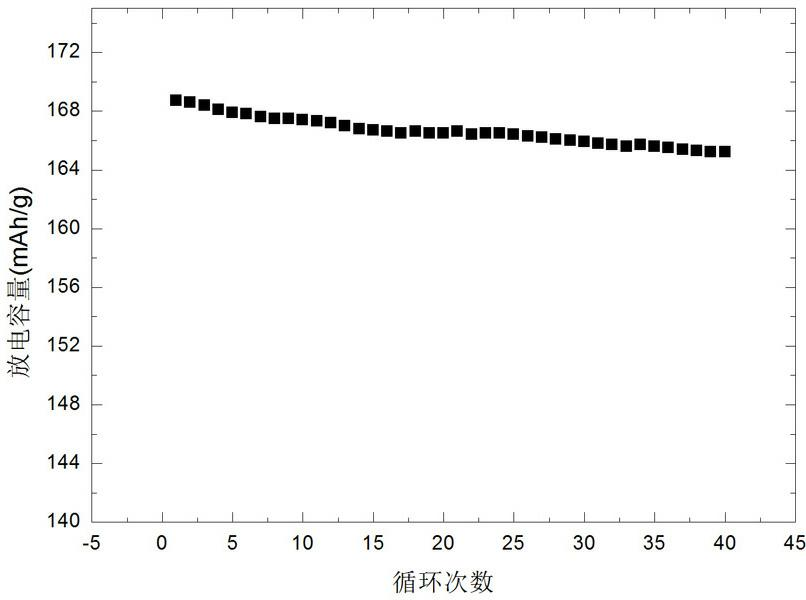

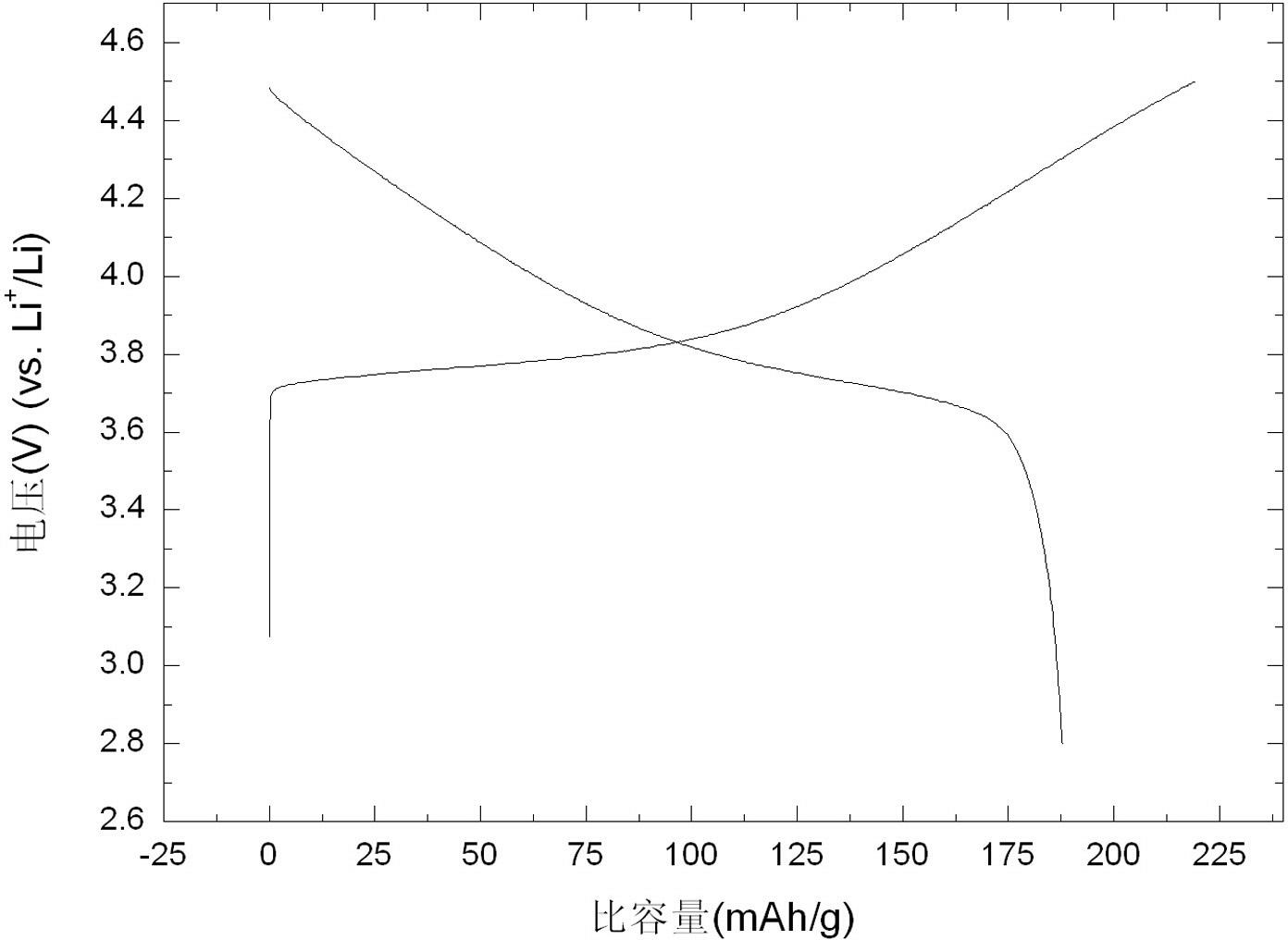

Method for repair and regeneration of waste lithium iron phosphate battery cathode material

ActiveCN102208707AReduce pollutionSave resourcesSolid waste disposalWaste accumulators reclaimingLithium iron phosphateEngineering

The invention discloses a method for repair and regeneration of waste lithium iron phosphate battery cathode materials, which allows a lithium-source solution or a suspension to react with a recovered waste lithium iron phosphate battery material by a hydrothermal reaction or a solvent-thermal reaction, or allows the recovered waste lithium iron phosphate battery material to be processed by solid-phase ball-milling and calcination with the lithium source, performs liquid-phase or solid-phase direct lithium-supplementing repair of delithiated waste lithium iron phosphate, and then performs pertinent repair and regeneration by coating conductive agents or coating conductive agents and doping metal ions. The invention adopts a direct repair and regeneration method; the repaired waste lithium iron phosphate battery cathode material has excellent performance, and the specific capacity can reach above 90% of the specific capacity before discard; the method not only can effectively reduce environmental pollution of waste batteries, but also can make full use of waste resources and changes waste into valuables.

Owner:HEFEI UNIV OF TECH

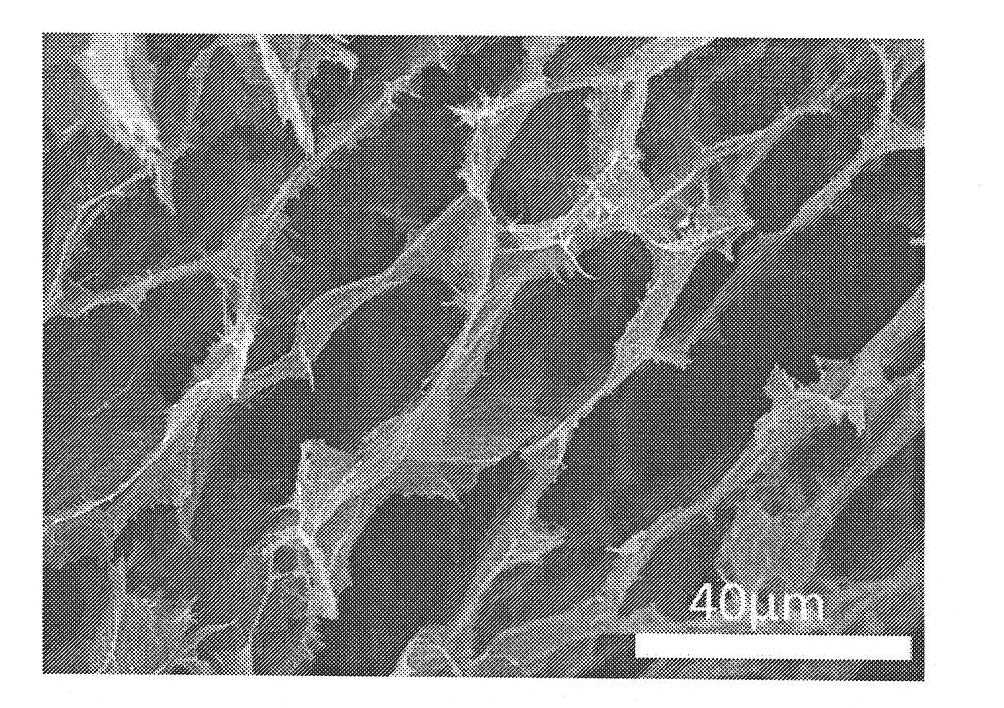

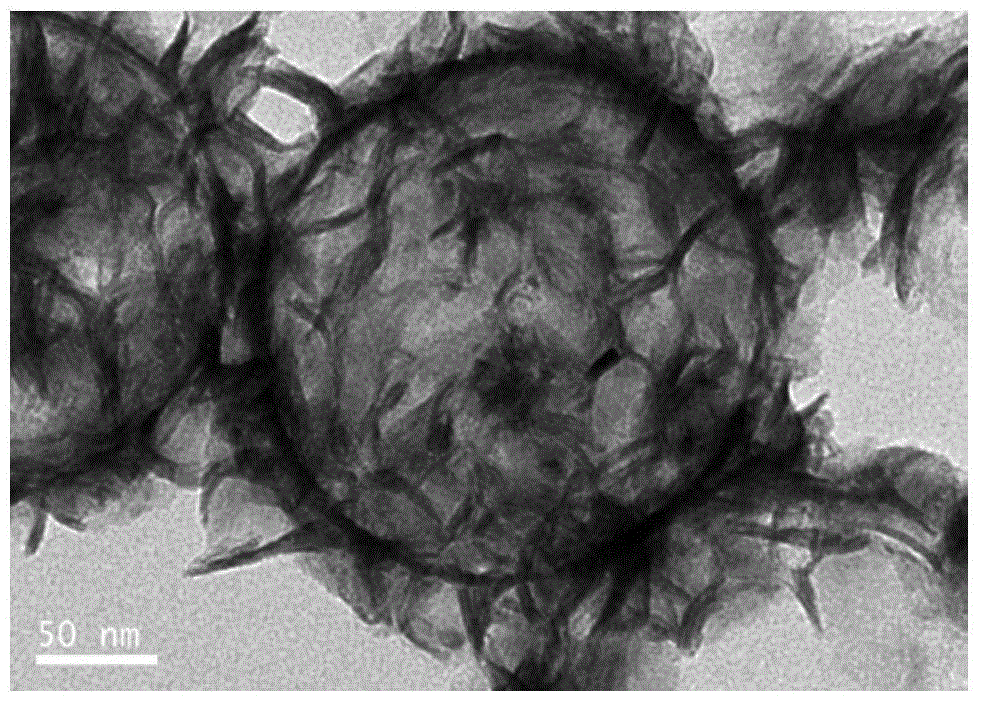

Graphene three-dimensional material as well as preparation method and application thereof

The invention discloses a graphene three-dimensional material as well as a preparation method and an application thereof. The material consists of 10 to 99% of graphene and 1 to 90% of the oxide of manganese, nickel, iron or cobalt. The preparation method comprises the following steps: performing ultrasonic dispersion on graphite oxide to prepare a graphite oxide solution; adding a metal salt solution while stirring or under ultrasonic conditions, and adding a hydrazine hydrate solution; conducting reaction in a drying oven or a hydro-thermal reaction kettle; and then drying to obtain the graphene three-dimensional material. The graphene three-dimensional material is applied to a super capacitor with the capacity of 200 to 800 F / g, or used for making the cathode of a lithium ion battery with the capacity of 300 to 1,400 mAh / g. According to the invention, the preparation process is simple; the prepared graphene three-dimensional macroscopic material has high conductivity and strength; and when being used for the cathode of the lithium ion battery and the super capacitor, the material has high performance.

Owner:TIANJIN UNIV

Nitrogen doped carbon quantum dot as well as preparation method and application thereof

InactiveCN103756675AHigh quantum yieldEasy to adjustBiological testingLuminescent compositionsFluoProbesBiological imaging

The invention discloses a nitrogen doped carbon quantum dot as well as a preparation method and an application thereof, belonging to the technical field of material science. The preparation method comprises the steps: after mixing organic acid and organic amine, directly performing a hydrothermal reaction to prepare a nitrogen doped carbon quantum dot water dispersion solution, and extracting and drying the nitrogen doped carbon quantum dot water dispersion solution to obtain a nitrogen doped carbon quantum dot solid. The size of the nitrogen doped carbon quantum dot is not more than 10 nm, the nitrogen content is not more than 50 percent, the surface of the nitrogen doped carbon quantum dot contains amino, carboxyl and hydroxyl; and the quantum efficiency is 39.8-50 percent. The preparation method is simple to operate, environment-friendly, low in equipment requirement; and the prepared nitrogen doped carbon quantum dot has excellent light emitting property, and can be widely applied to fields such as photoelectric materials, biological imaging and fluorescence probe.

Owner:XIAN YABO BIOTECH

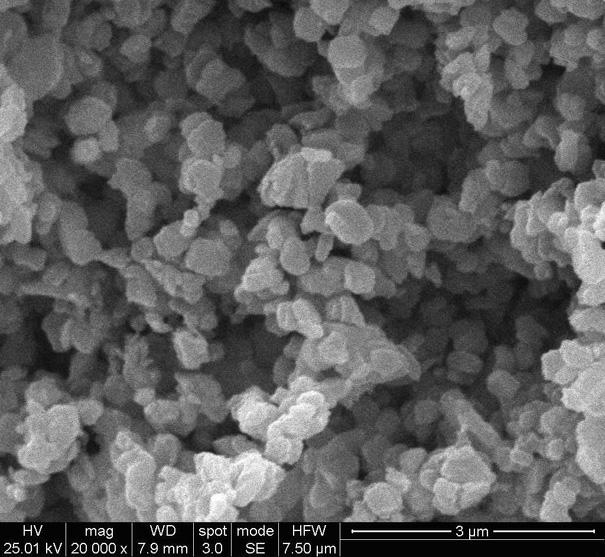

Preparation method of nano positive material for lithium ion battery

InactiveCN102386381AShort heat treatment timeReduce energy consumptionNanostructure manufactureCell electrodesNickel saltElectrical battery

The invention belongs to the field of preparation techniques of nanophase materials and green energy resources, and relates to a preparation method of a nano positive material LiNi1 / 3Mn1 / 3Co1 / 3O2 applied to a lithium ion battery. By using the method, the defects that the calcining temperature needed by a current synthetic material is high, the calcining time is long, the particle sizes of a product are not uniform, and the like, are mainly solved. The preparation method comprises the following steps: adding a certain amount of template agent in a mixed aqueous solution of a nickel salt, a manganese salt and a cobalt salt, and then, dripping a precipitant and a complexing agent into the obtained mixture to form a precipitate; subjecting the precipitate and the mixed aqueous solution to a high-pressure thermal reaction in a hydrothermal kettle, cleaning and baking the obtained product to be dry, so as to obtain a nickel manganese cobalt oxide; and finally, uniformly mixing the nickel manganese cobalt oxide with the lithium salt to prepare a final product by calcining and cooling. By using the preparation method, the product with favorable electrochemical performance can be obtained within a shorter calcining time; the energy consumption is decreased; and the preparation method has obvious economic benefit in the large-scale application of industrial synthesis.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

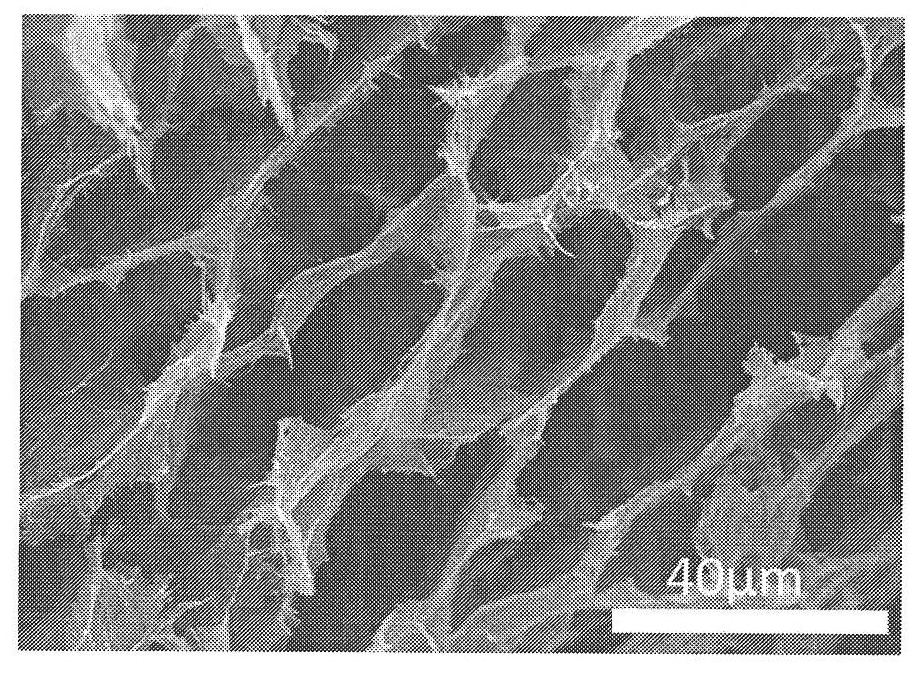

Graphene-based porous macroscopic carbon material and preparation method thereof

The invention relates to a graphene-based porous macroscopic carbon material and a preparation method thereof, belonging to the technical field of porous macroscopic carbon materials. The material comprises graphene and carbon from polyvinyl alcohol and has large specific surface area. The preparation method comprises the following processes of: mixing a graphene oxide water solution and a polyvinyl alcohol solution, and placing the uniformly mixed solution into a hydro-thermal reaction kettle to obtain a graphene-based hydrogel; freezing and drying the hydrogel to obtain a graphene-based aerosol; and carrying out thermal treatment on the aerosol under the protection of an argon gas atmosphere to obtain the graphene-based porous macroscopic carbon material. The invention has the following advantages of simple preparation process and wide raw material source scope; and the prepared porous macroscopic carbon material has the following advantages of well-developed pore structure, extra-large specific surface area, favorable structural stability and wide application range.

Owner:深圳清研紫光科技有限公司

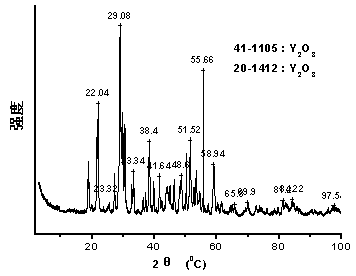

Grapheme/rare earth oxide nanometer composite material and preparation method and application thereof

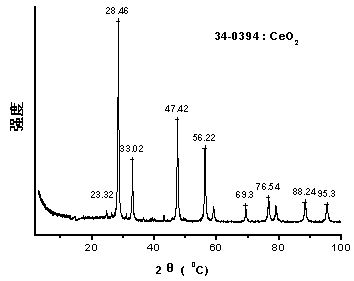

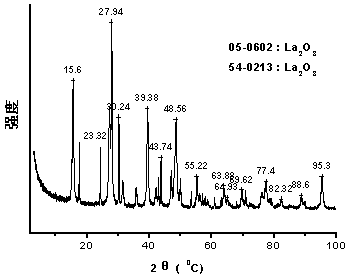

InactiveCN103066292ANot easy to reuniteHigh specific surface areaMaterial nanotechnologyCell electrodesLithium-ion batteryNanocomposite

The invention relates to a graphene / rare earth oxide nanometer composite material and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly mixing oxidized graphene dispersion liquid and a soluble rare earth compound at the weight ratio of (1:1)-(1:10), regulating a pH value to alkalescence, and carrying out hydrothermal reaction to obtain the graphene-rare earth oxide nanometer composite material; and uniformly mixing the oxidized graphene dispersion liquid and the soluble rare earth compound at the weight ratio of (1:1)-(1:10), adding a reducer, and carrying out reflux reaction at certain temperature to obtain the graphene-rare earth oxide nanometer composite material. According to the invention, rare earth oxides are successfully loaded to the surface of graphene, the rare earth oxides can be connected in a physical loading or chemical bonding way because of the electrostatic action of the surface of the oxidized graphene and uniformly dispersed to the surface of a nanometer graphene sheet by being formed into nanometer level particles, the particle size is 5-50 nanometers, and the sheet thickness is 1-5 layers, so that the agglomeration phenomena of the graphene is obviously improved, and the electrochemical property of the graphene nanometer composite material as a cathode material and the circulation stability of the graphene nanometer composite material in the charge-discharge process are effectively enhanced and superior to those the cathode of the traditional commercial lithium ion battery. The preparation method disclosed by the invention has the advantages of simple process, low cost, short period, and the like.

Owner:TONGJI UNIV

Integrated catalytic process for converting alkanes to alkenes and catalysts useful for same

InactiveCN101165031AHydrocarbon by hydrogenationHeterogenous catalyst chemical elementsAlkanePtru catalyst

The present invention relates to an integrated multi-zone process for the conversion of alkanes to their corresponding alkenes comprising the exothermic conversion of a portion of the alkanes by oxidative dehydrogenation in an exothermic reaction zone in the presence of oxygen and a suitable catalyst to its corresponding alkenes, the product of said exothermic reaction zone is then passed to an endothermic reactor in which at least a portion of the remaining unconverted alkanes are absorbed in the presence of carbon dioxide and other suitable catalysts Thermal dehydrogenation.

Owner:ROHM & HAAS CO

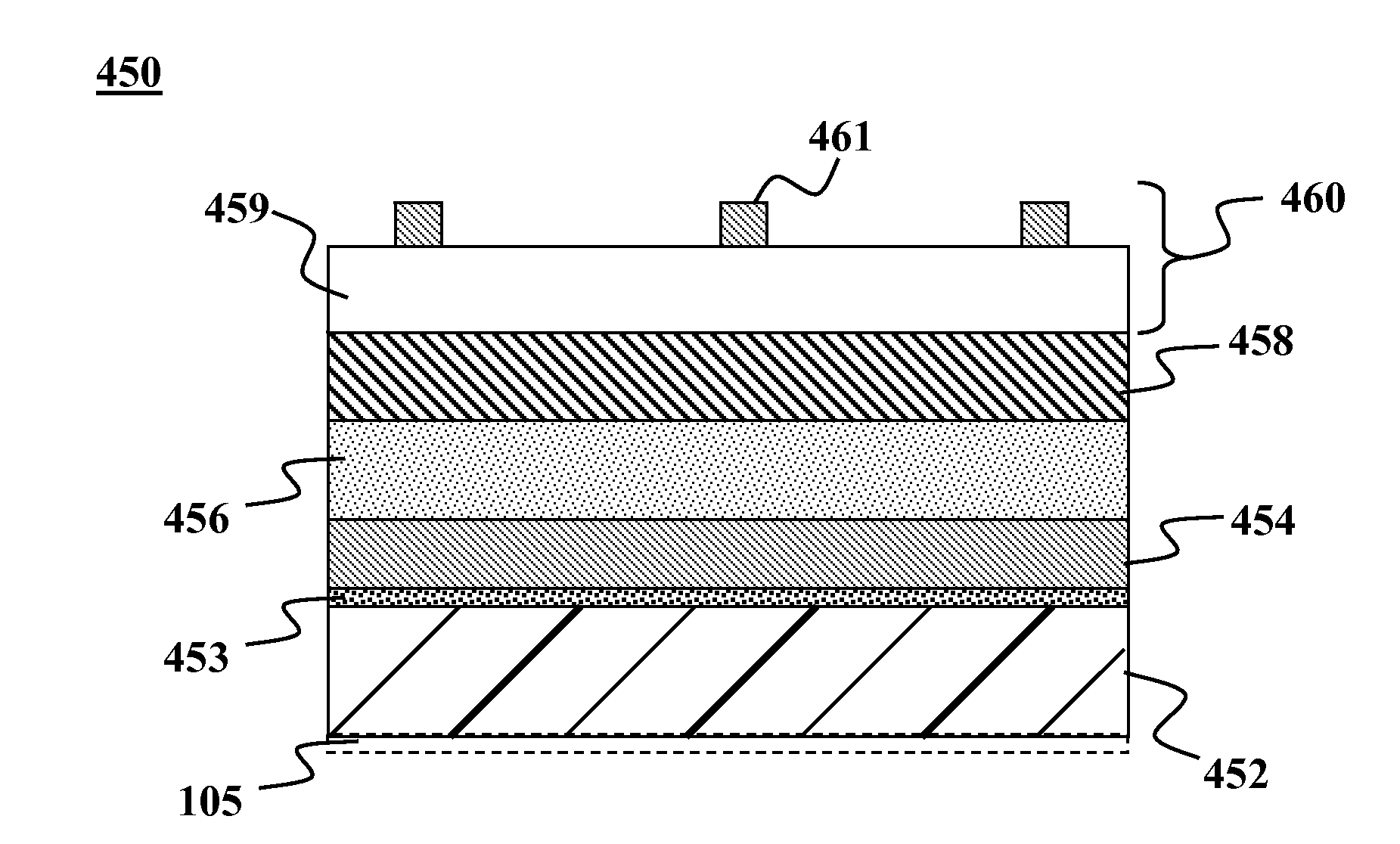

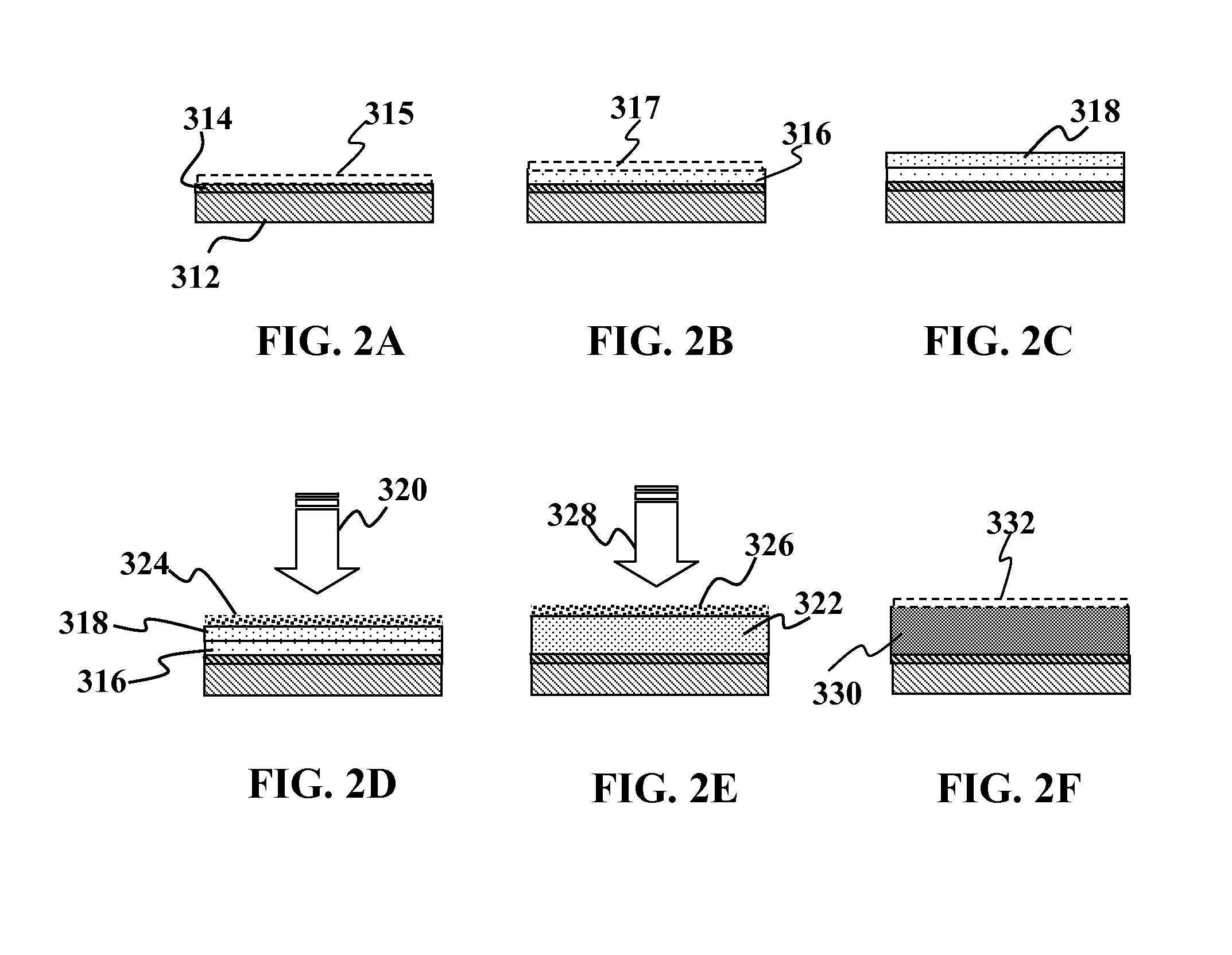

Solar cell absorber layer formed from equilibrium precursor(s)

InactiveUS20100248419A1Promote wettingMinimize ballingFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellSolid film

Methods and devices are provided for forming an absorber layer. In one embodiment, a method is provided comprising of depositing a solution on a substrate to form a precursor layer. The solution comprises of at least one equilibrium and / or near equilibrium material. The precursor layer is processed in one or more steps to form a photovoltaic absorber layer. In one embodiment, the absorber layer may be created by processing the precursor layer into a solid film and then thermally reacting the solid film in an atmosphere containing at least an element of Group VIA of the Periodic Table to form the photovoltaic absorber layer. Optionally, the absorber layer may be processed by thermal reaction of the precursor layer in an atmosphere containing at least an element of Group VIA of the Periodic Table to form the photovoltaic absorber layer.

Owner:WOODRUFF JACOB +3

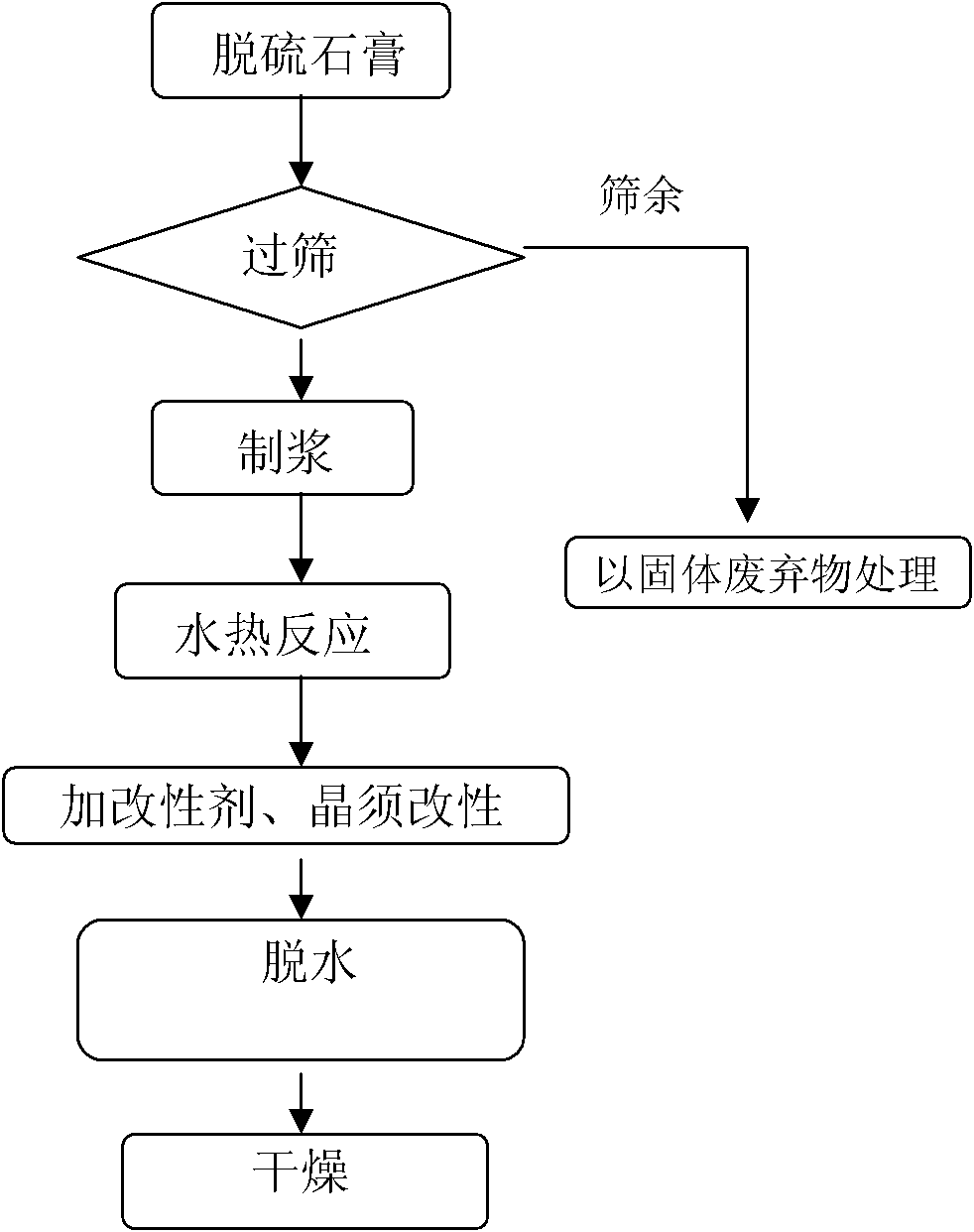

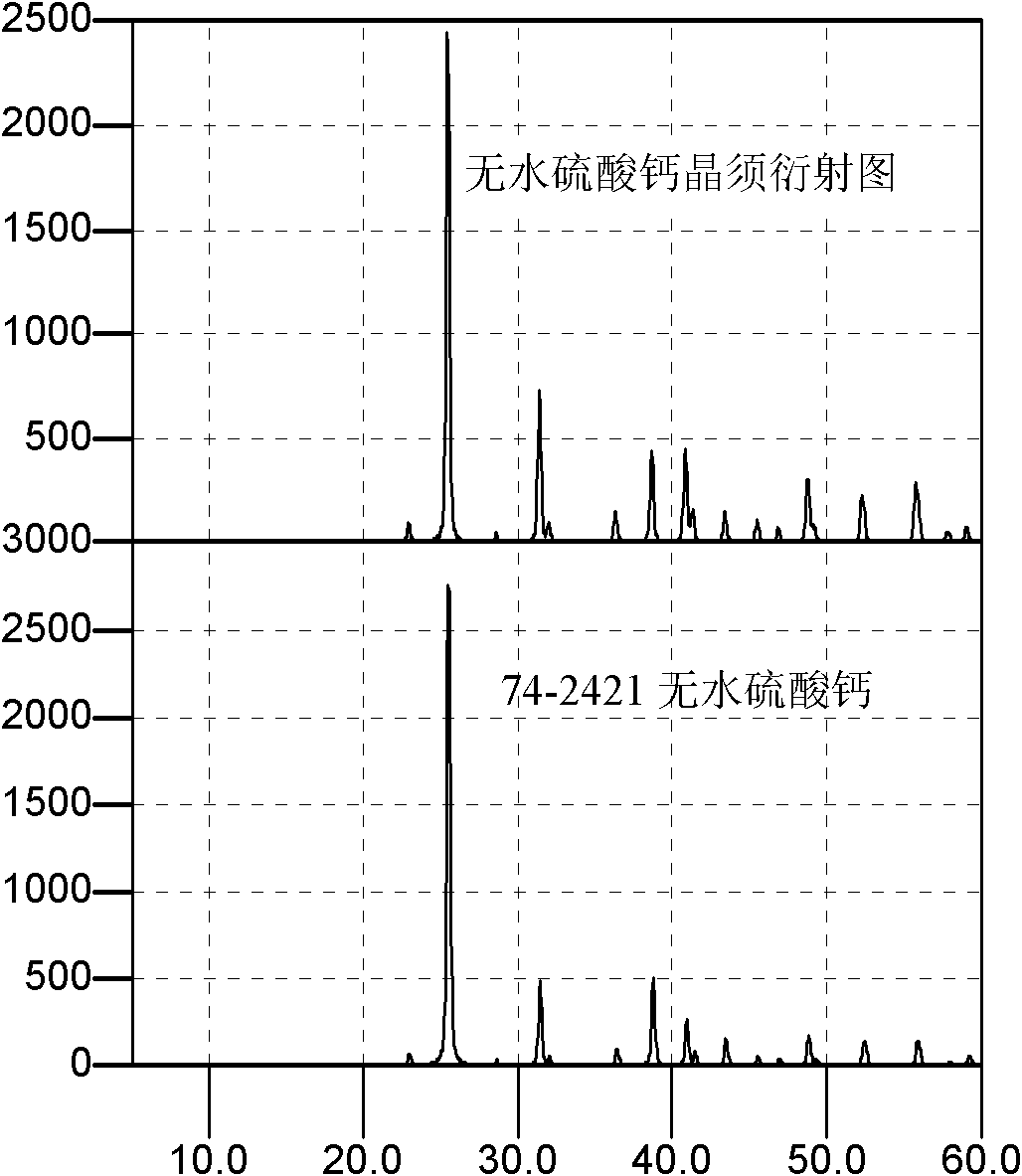

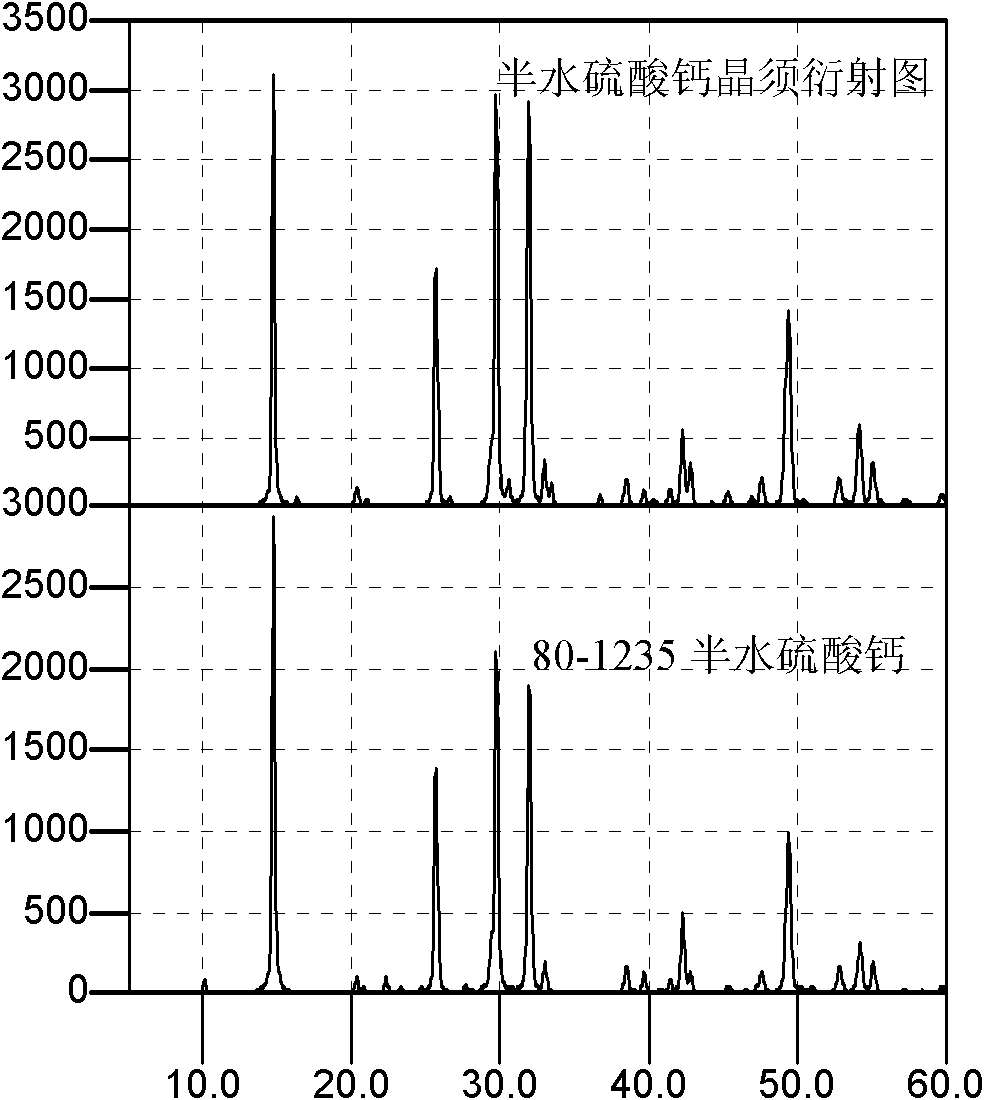

Method for preparing modified calcium sulfate whisker by using desulfurization gypsum

ActiveCN101994153AGood compatibilitySolve the problem of prone to hydration leading to whisker breakagePolycrystalline material growthFrom normal temperature solutionsSulfateMicrometer

The invention discloses a method for preparing a modified calcium sulfate whisker by using desulfurization gypsum, comprising the following steps of sieving, pulping, performing hydro-thermal reaction and whisker surface modification, dewatering and drying, wherein the reaction temperature ranges from 107 DEG C to 180 DEG C, the concentration of desulfurization gypsum and water is 5-33wt% and the drying temperature ranges from 100 DEG C to 300 DEG C, and a modifier which is 0.05-5% of the weight of desulfurization gypsum in the calcium sulfate whisker suspension formed in hydro-thermal reaction. The invention solves the problem that CaSO4.0.5H2O whisker is easy to hydrate in the drying process tocause fracture of the whisker and enhances the compatibility of the calcium sulfate whisker and the high polymer materials. The prepared modified calcium sulfate whisker has a diameter of 0.5-6 micrometers, a length of 30-300 micrometers and a diameter ratio of 15-115 and the contact angle of water on the surface of the modified calcium sulfate whisker ranges from 12 to 140 degrees. The invention has the advantages of good modified effect, simple process, low production cost, the use of the non-toxic modifier and environmental-friendly preparation process.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

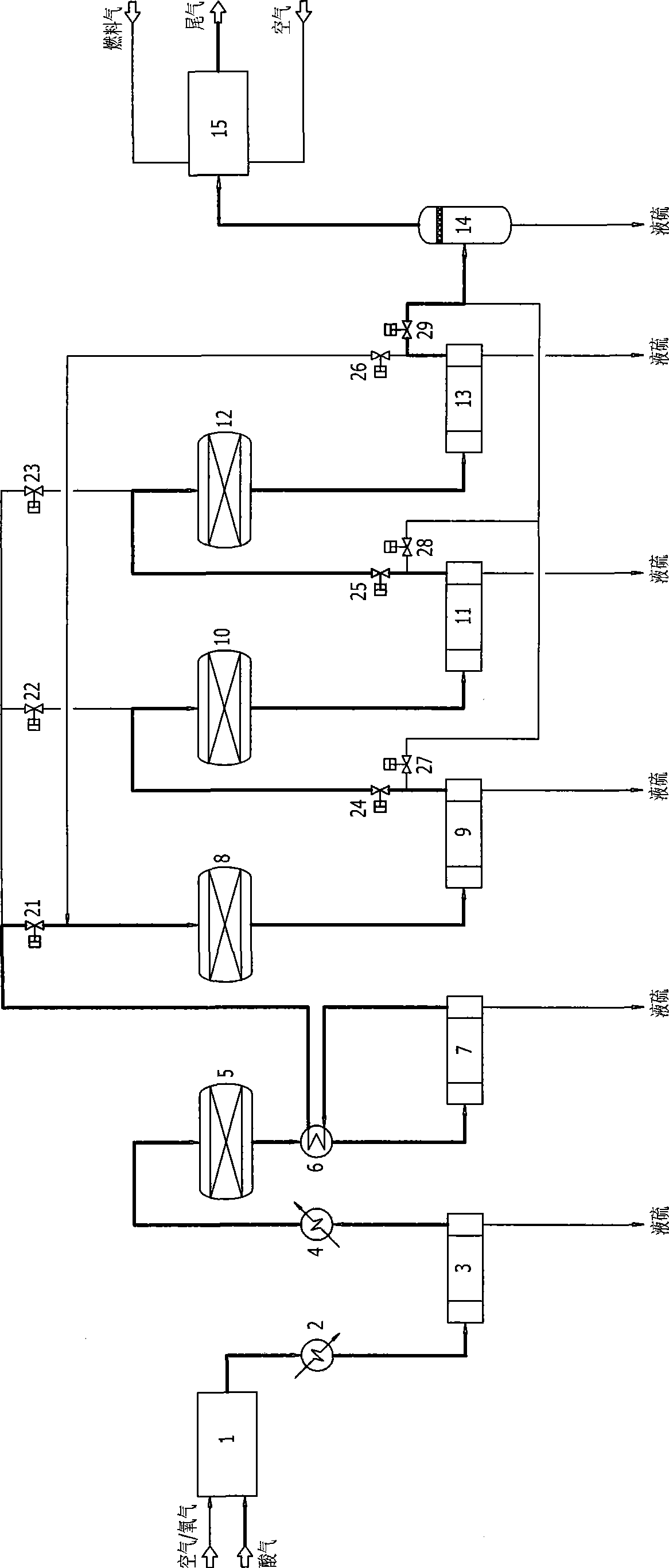

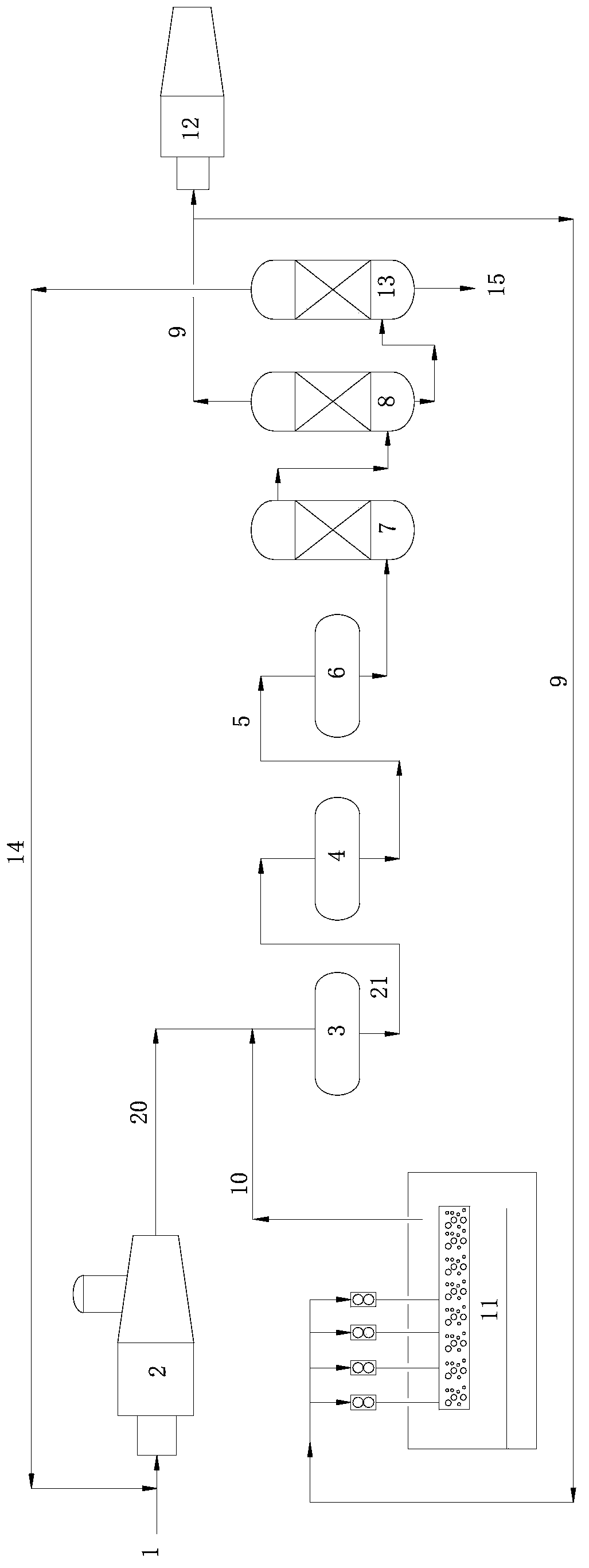

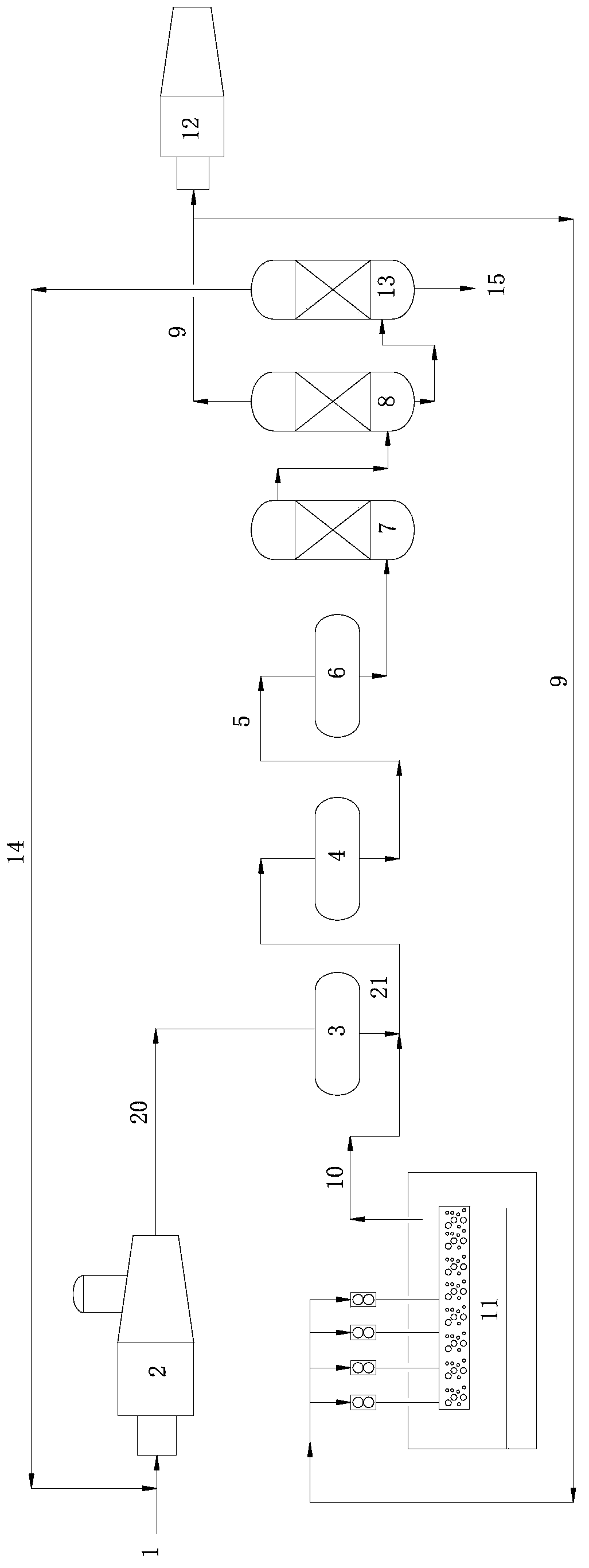

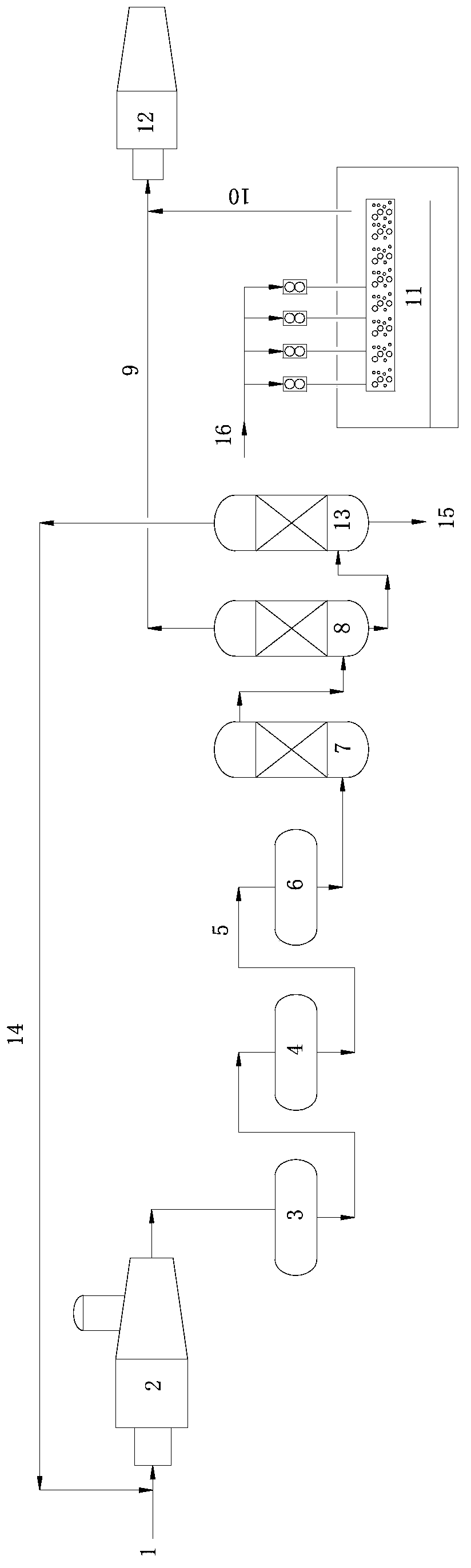

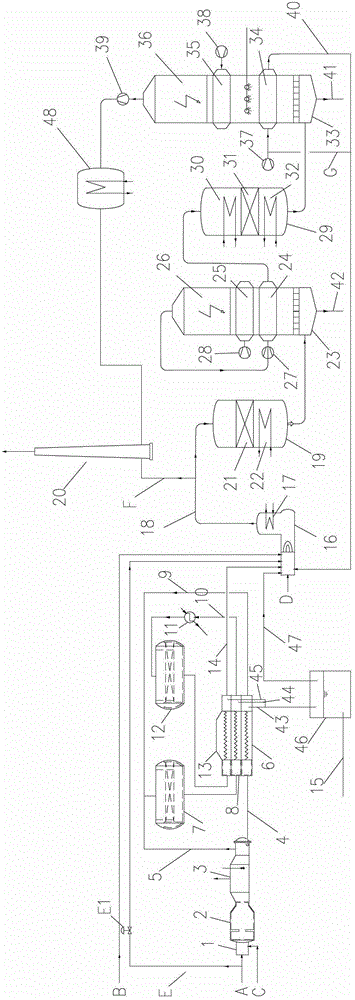

Low temperature Claus sulfur recovery process and device therefor

InactiveCN101519192AAchieve regenerationImprove conversion rateEnergy inputSulfur preparation/purificationReaction temperatureOxygen

Owner:CHENGDU SEPMEM SCI & TECH

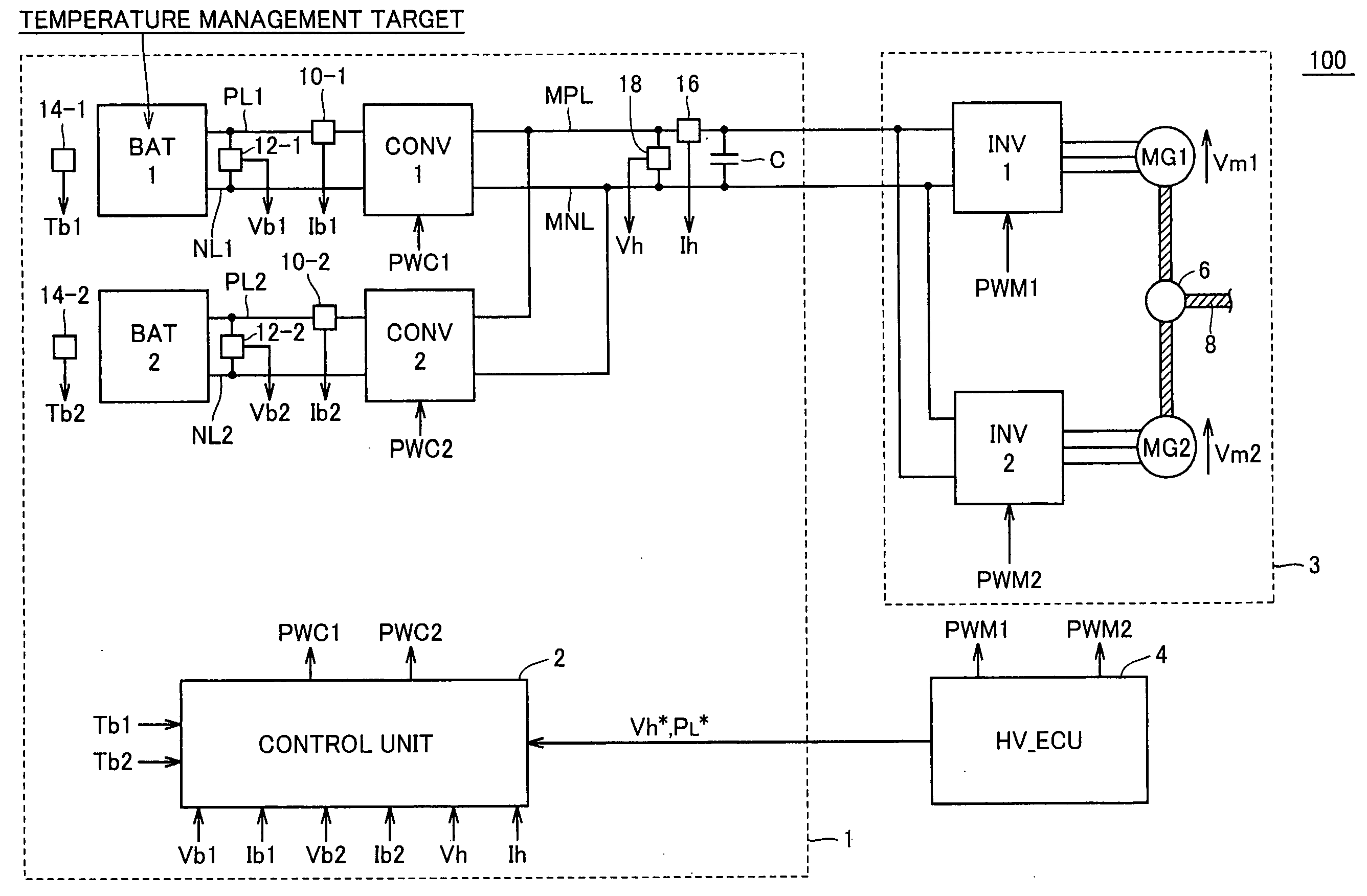

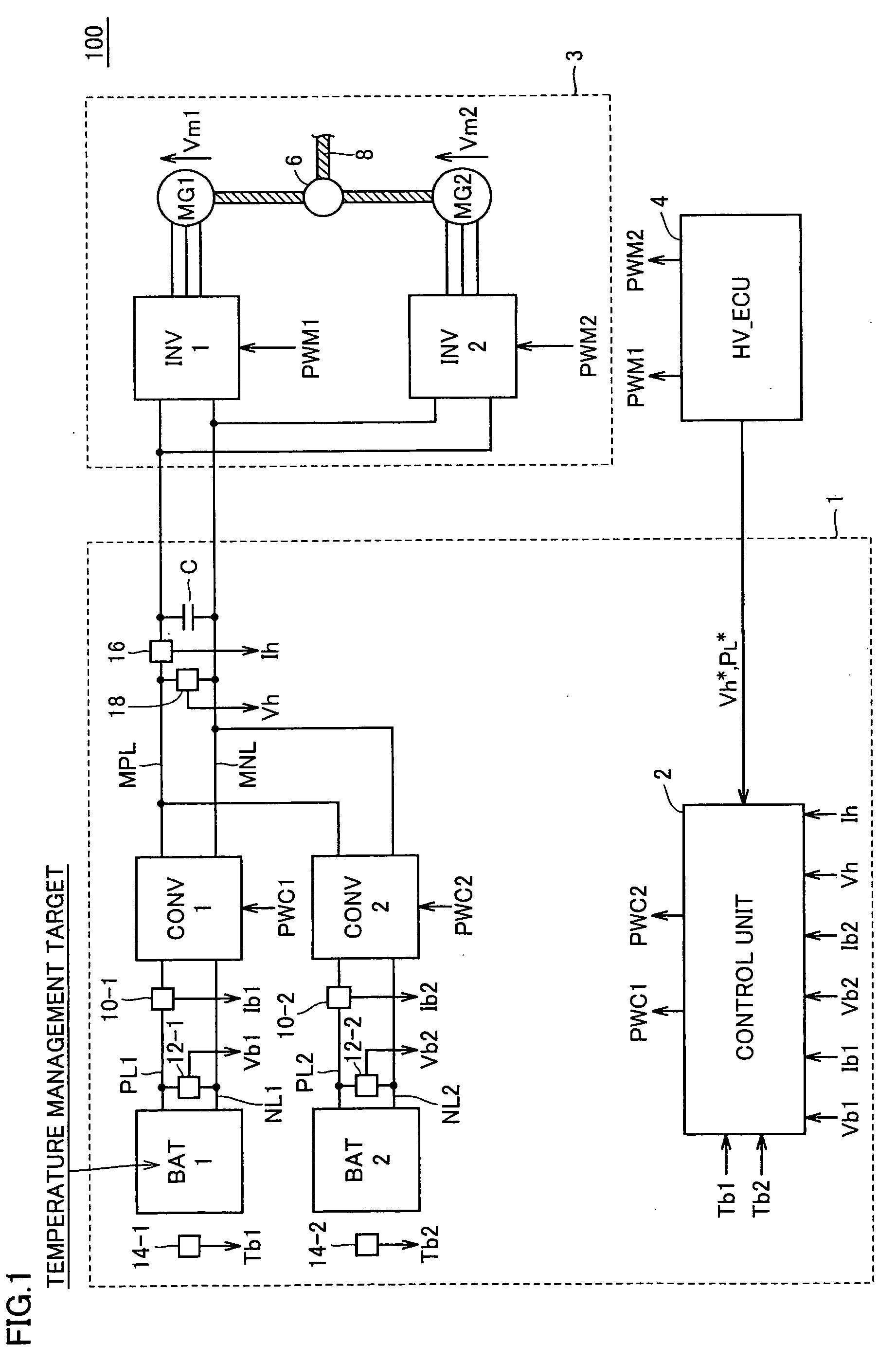

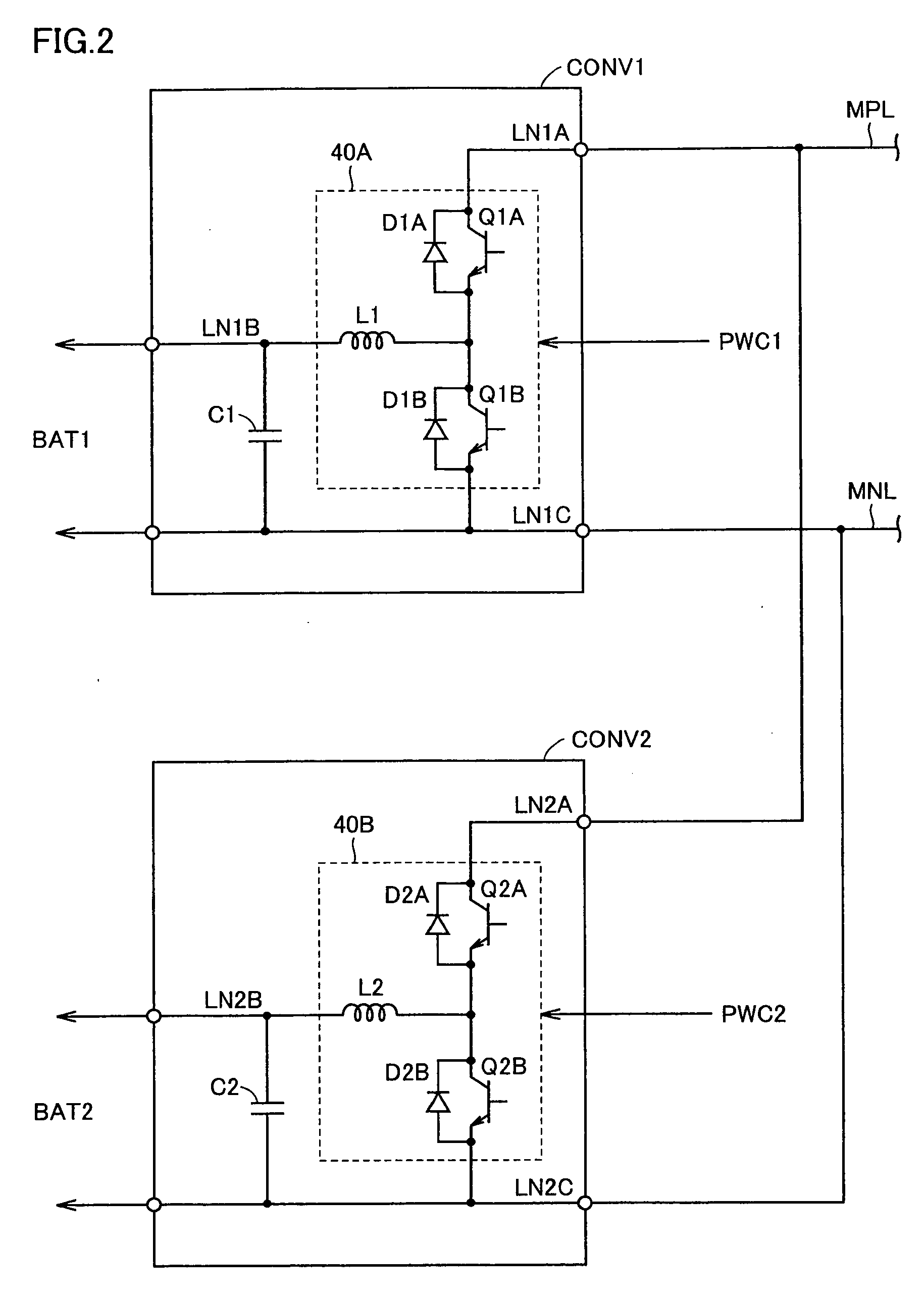

Power Supply System, Vehicle with the Same and Temperature Managing Method

ActiveUS20090179616A1Precise managementInhibition effectBatteries circuit arrangementsCell temperature controlElectrical batteryControl unit

A request determining unit compares a battery temperature of a battery unit with a predetermined temperature management value, and produces a heating request or a cooling request when a temperature deviation of a predetermined threshold is present between them. A current direction determining unit determines, based on thermal reaction characteristics of the battery unit, in which one of a direction on a charge side and a direction on a discharge side a current is to be passed for responding to the heating request or the cooling request. A target current value determining unit determines a target current value related to the charge / discharge determined by the current direction determining unit. A current control unit produces a switching instruction for matching a battery current of the battery unit with the target current value provided from a selecting unit.

Owner:TOYOTA JIDOSHA KK

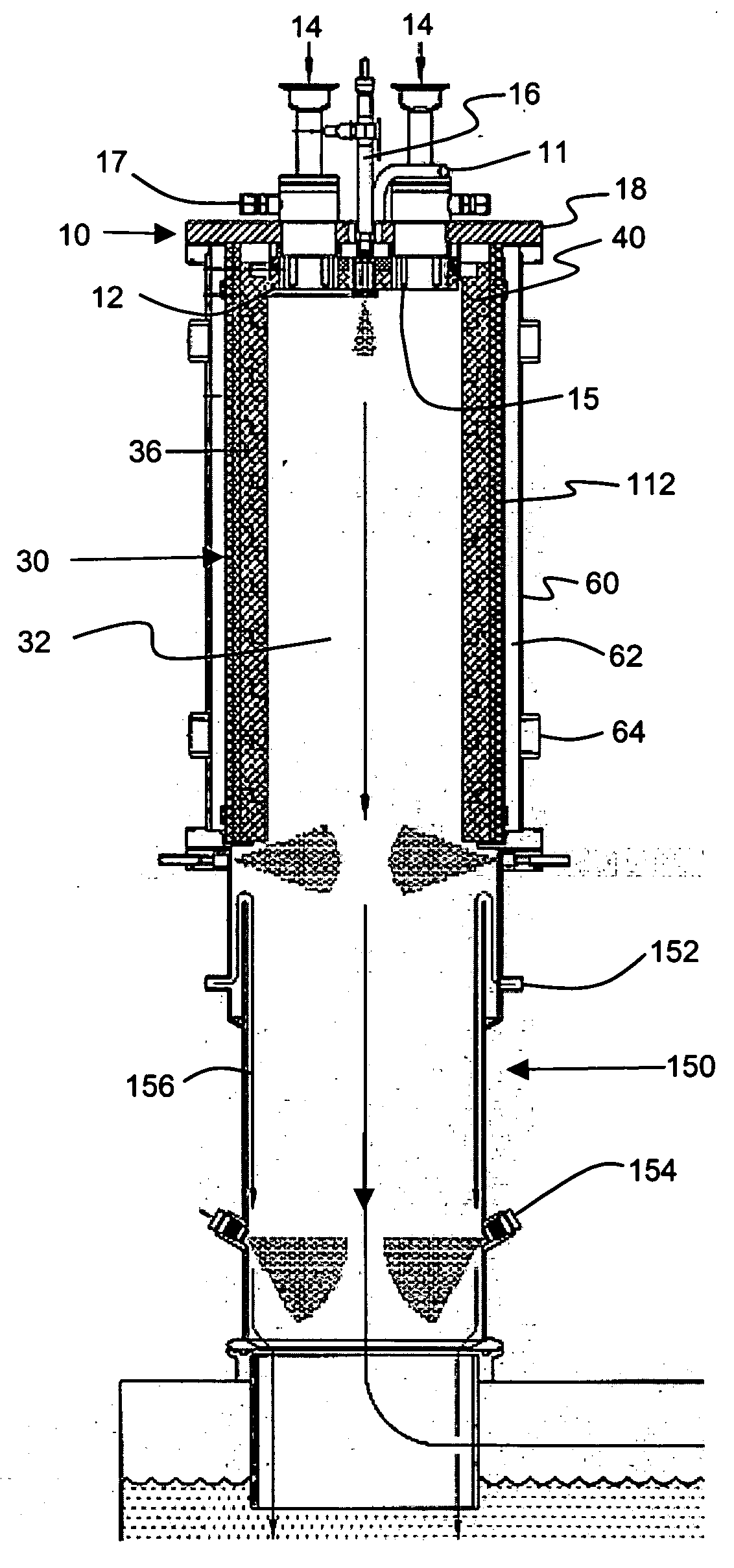

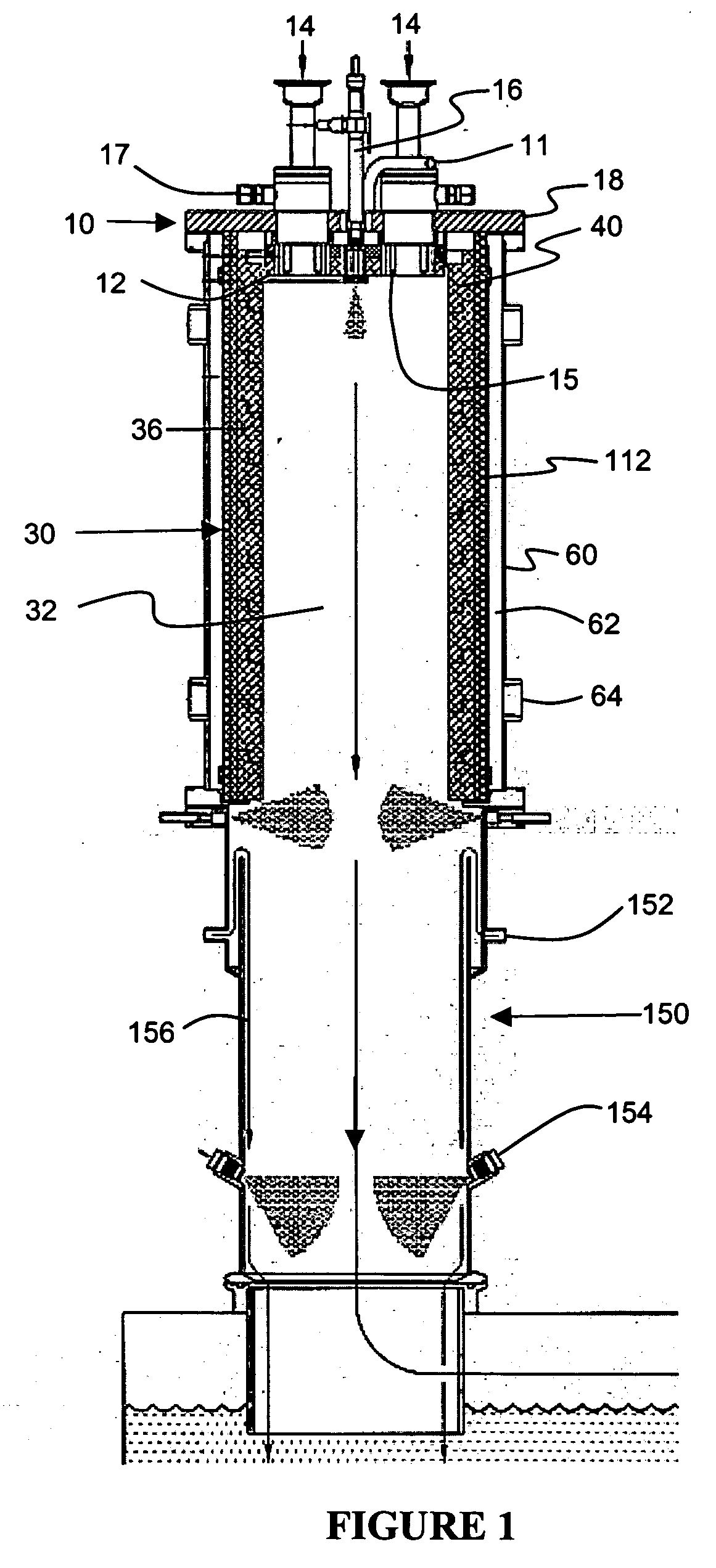

Reactor design to reduce particle deposition during process abatement

InactiveUS20060104879A1Reduce accumulationReduce reactor chamber crackingCombination devicesBurnersCombustionDecomposition

The present invention relates to systems and methods for controlled combustion and decomposition of gaseous pollutants while reducing deposition of unwanted reaction products from within the treatment systems. The systems include a novel thermal reaction chamber design having stacked reticulated ceramic rings through which fluid, e.g., gases, may be directed to form a boundary layer along the interior wall of the thermal reaction chamber, thereby reducing particulate matter buildup thereon. The systems further include the introduction of fluids from the center pilot jet to alter the aerodynamics of the interior of the thermal reaction chamber.

Owner:APPLIED MATERIALS INC

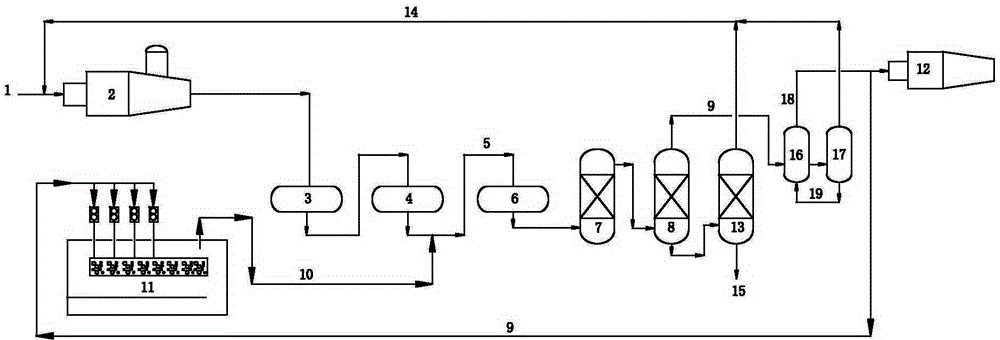

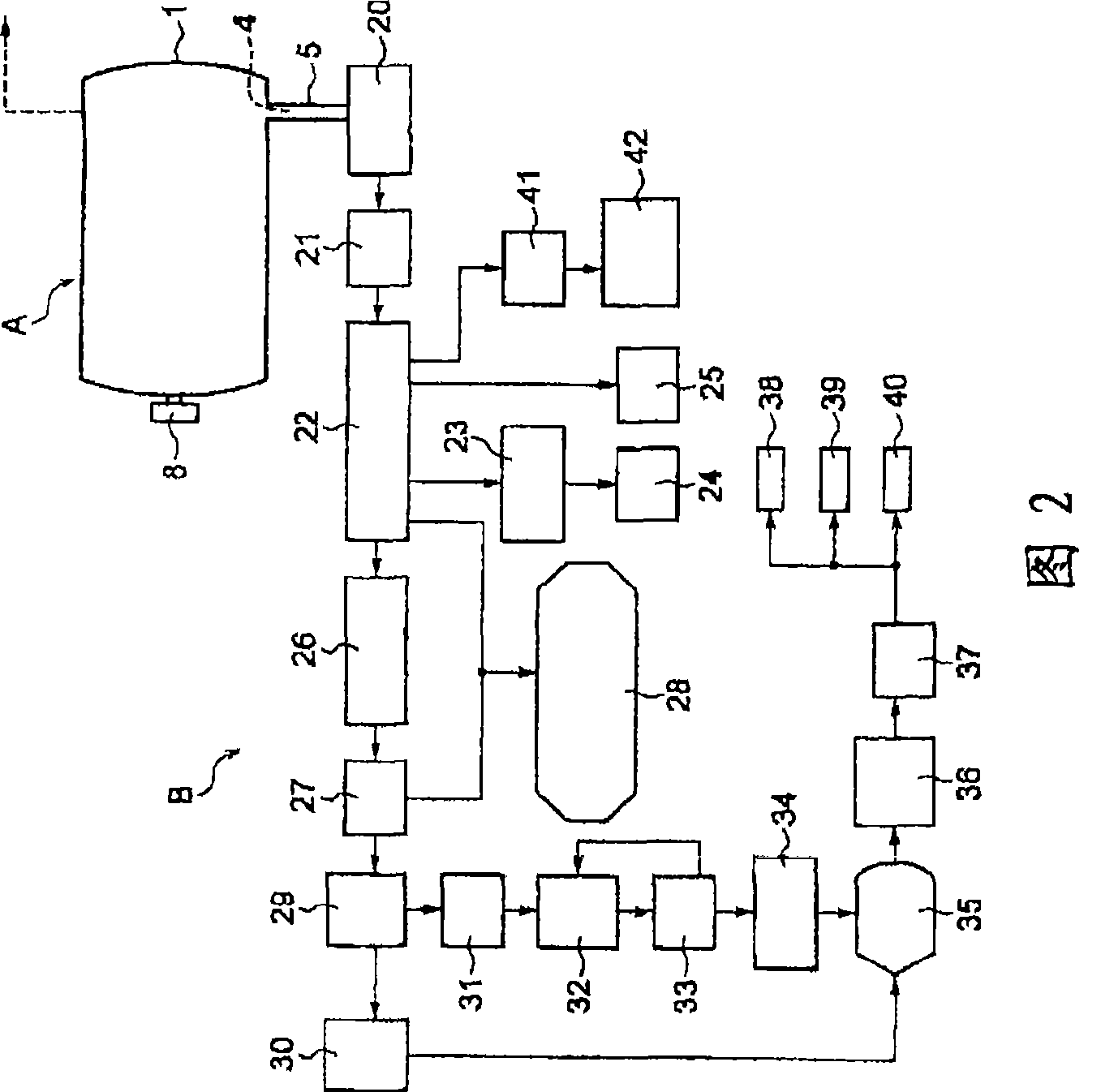

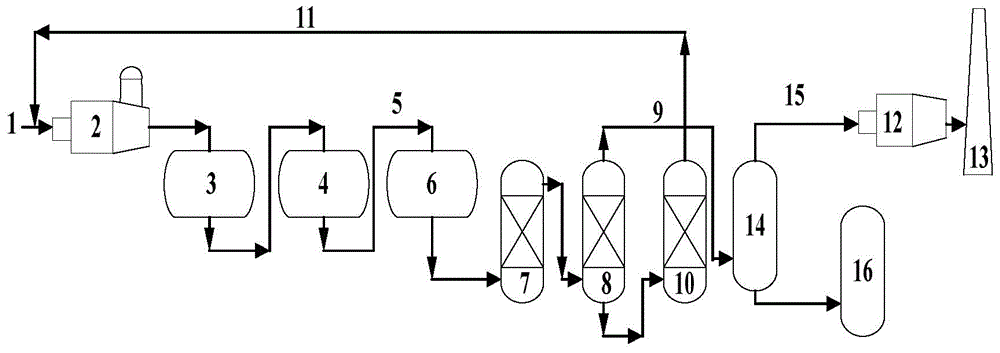

Sulfur recovery process for reducing SO2 emission

ActiveCN104555940APromote absorptionWith savingsDispersed particle separationSulfur preparation/purificationFlue gasSulfur

The invention belongs to the technical field of sulfur recovery, and particularly relates to a sulfur recovery process for reducing SO2 emission. According to the sulfur recovery process, a thermal reaction unit, a catalytic reaction unit and a tail gas purification unit are utilized; based on the traditional Claus and SCOT tail gas treatment process, an ammonia water absorption tank is additionally arranged for removing H2S from purified tail gas, so as to ensure that the H2S content in the purified tail gas is lower than 5 mg / m<3>; waste ammonia water is sent to a sewage stripping unit for treating; through the adoption of the sewage stripping device, H2S and ammonia can be respectively extracted; the extracted H2S is returned to a sulfur recovery device for sulfur recovery, and the extracted ammonia is returned to the ammonia water absorption tank for cyclic utilization; finally, the flue-gas SO2 emission concentration for the sulfur recovery device can be reduced below 100 mg / m<3>, the new environmental protection standard to be executed is satisfied, and a novel method for building a new sulfur recovery device with a small investment and low operating cost is provided. The sulfur recovery process is excellent in absorption effect, simple to operate, low in expense, environment-friendly, and economical.

Owner:CHINA PETROLEUM & CHEM CORP

Chemical reactor

InactiveUS6921518B2Significant changeAvoid mixingLiquid surface applicatorsVapor condensationChemical reactorProcess engineering

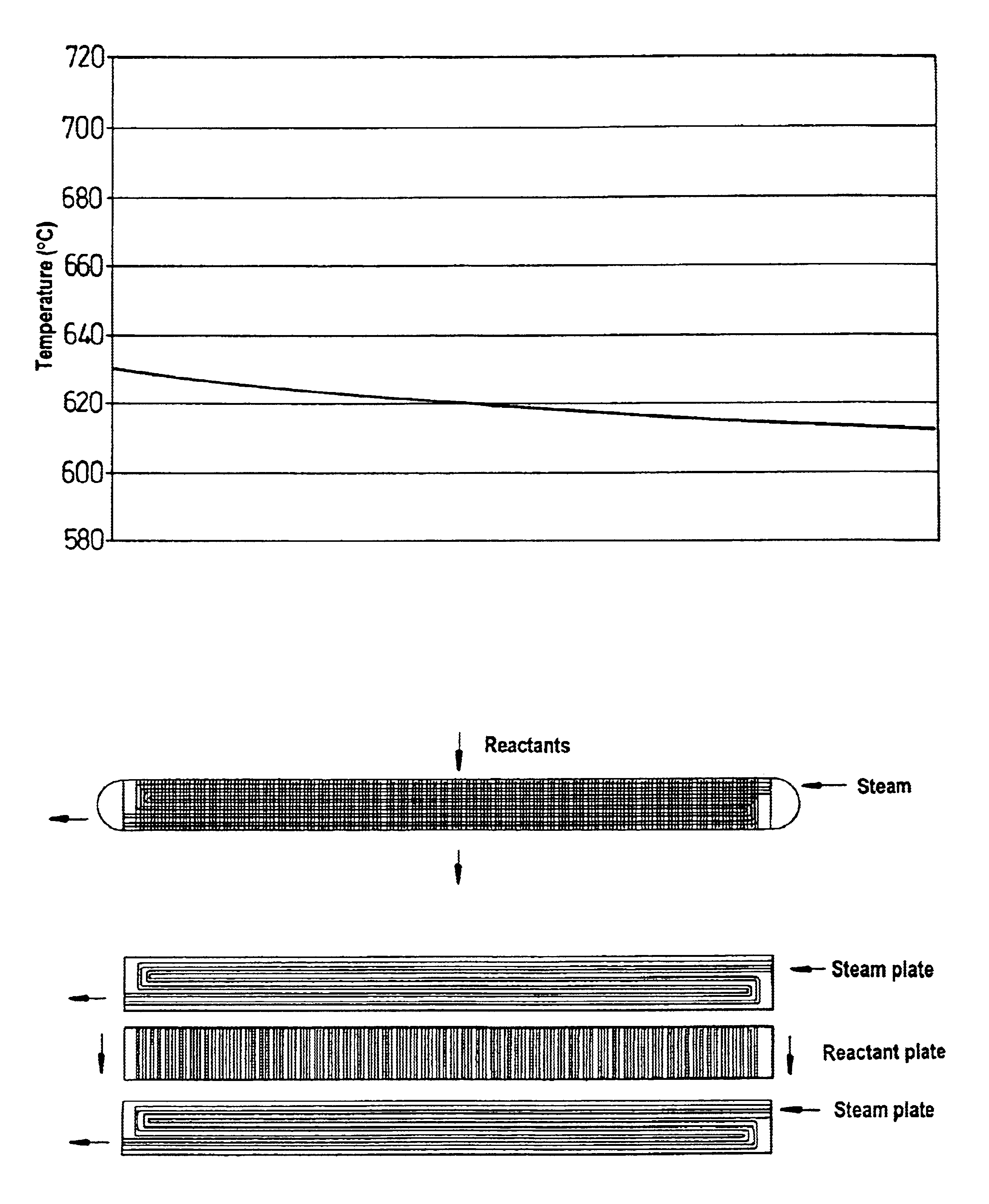

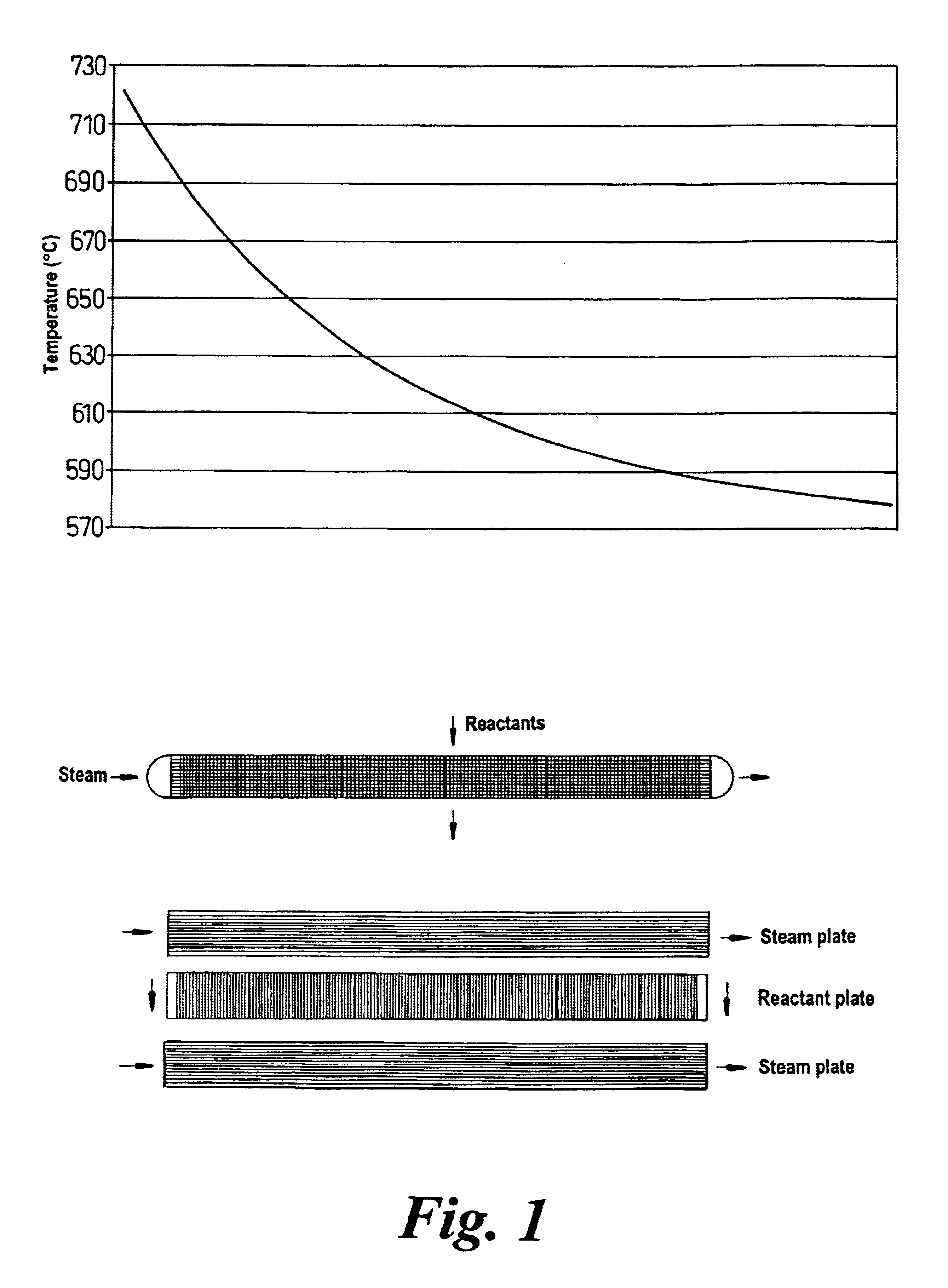

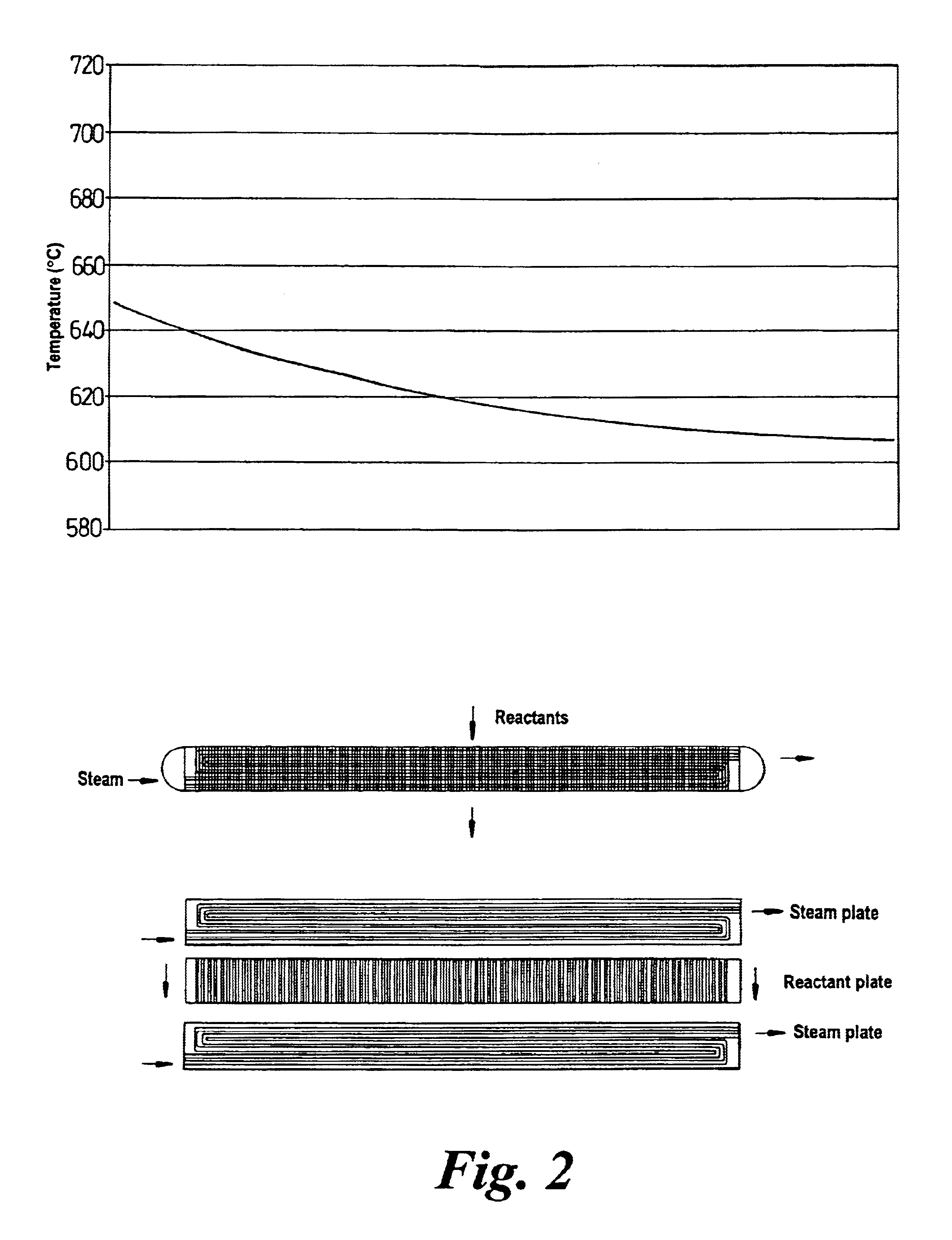

A reactor of the staged adiabatic reactor type, comprises at least one heat exchanger panel, preferably a printed circuit heat exchange (PCHE) panel, interposes between adiabatic beds of catalyst, wherein the facial area of the panels and the superficial facial area of the corresponding catalyst are substantially similar, and the panels include means defining discrete passages for handling of reactants and heat transfer media, wherein the means defining passages for heat transfer media provide for at least two differing flow path directions for the heat transfer media through the heat exchanger panel whereby the occurrence of temperature bias or differentials is reduced.

Owner:MEGGIT (UK) LTD

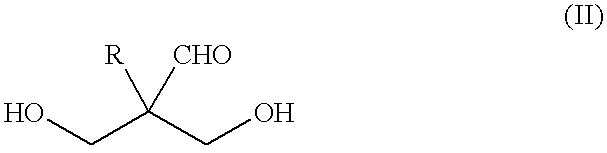

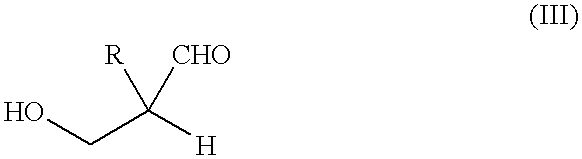

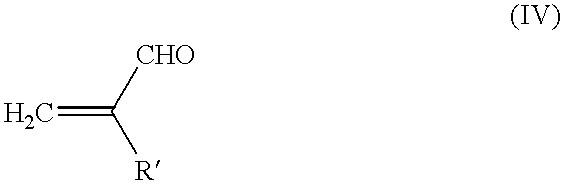

Method for producing polyalcohols

Methylolalkanal of the formula II(R=CH2OH, C1-C22-alkyl, aryl or C6-C22-aralkyl) is prepared spe-wise bya) reacting a C2-C24-aldehyde with formaldehyde in the presence of a tertiary amine,b) separating the reaction mixturei) into a bottom fraction comprising the compound of formula II and an incompletely methylolated compound of the formula IIIand a distillate stream comprising unconverted or partially converted starting materials, orii) into an aqueous phase and an organic phase, and recycling the distillate stream or the organic phase to a), andc) subjecting the bottom fraction or the aqueous phasei) to a catalytic or thermal reaction to convert the compound of formula III to the compound of formula II and to a corresponding methylene compound of formula IV(R'=H or R) andii) separating the reaction product into an overhead stream comprising the compound of formula IV and unconverted formaldehyde which is recycled to a), and a bottom fraction comprising the compound of formula II.

Owner:BASF AG

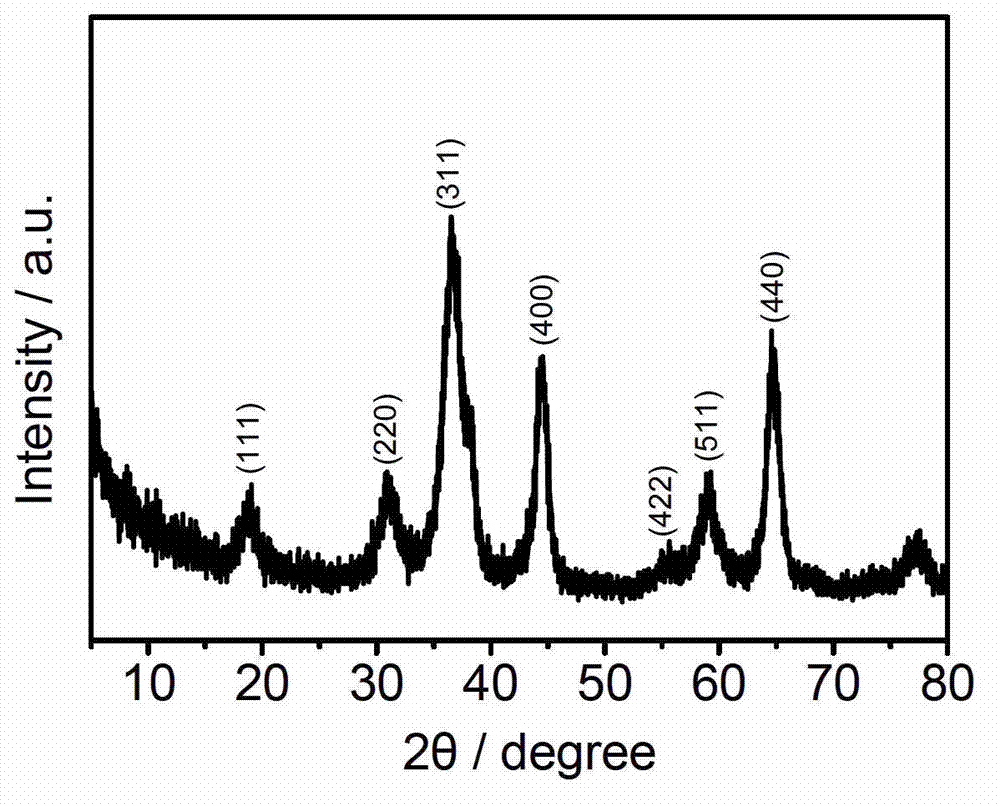

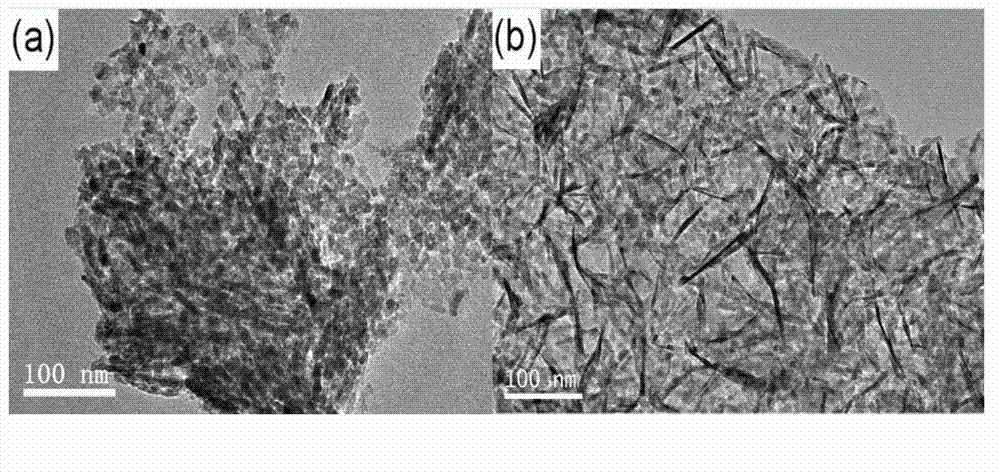

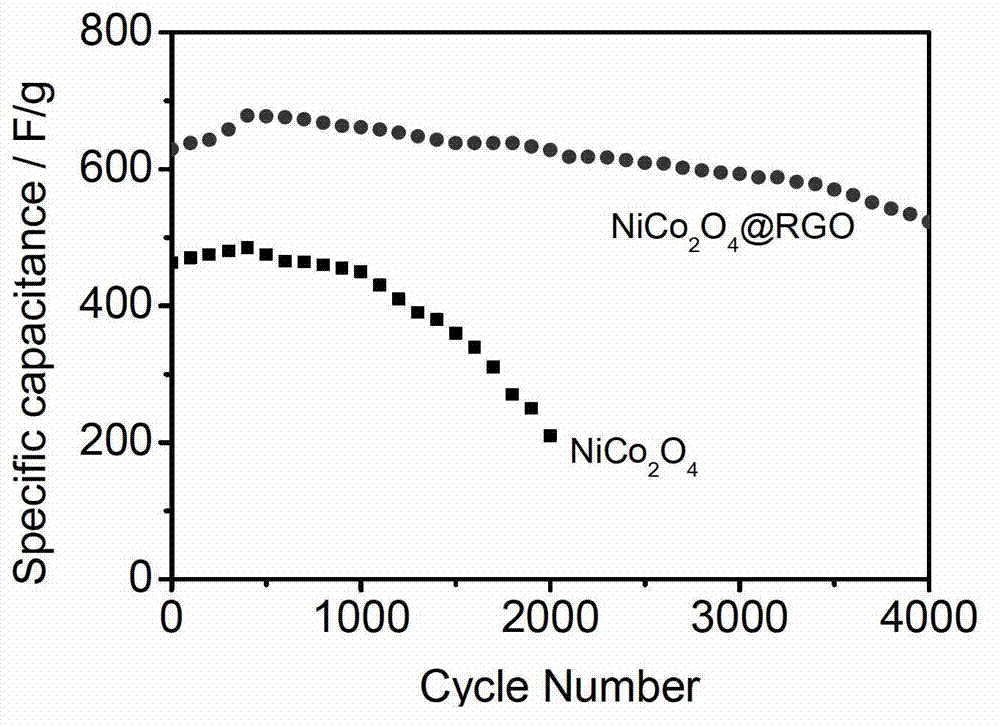

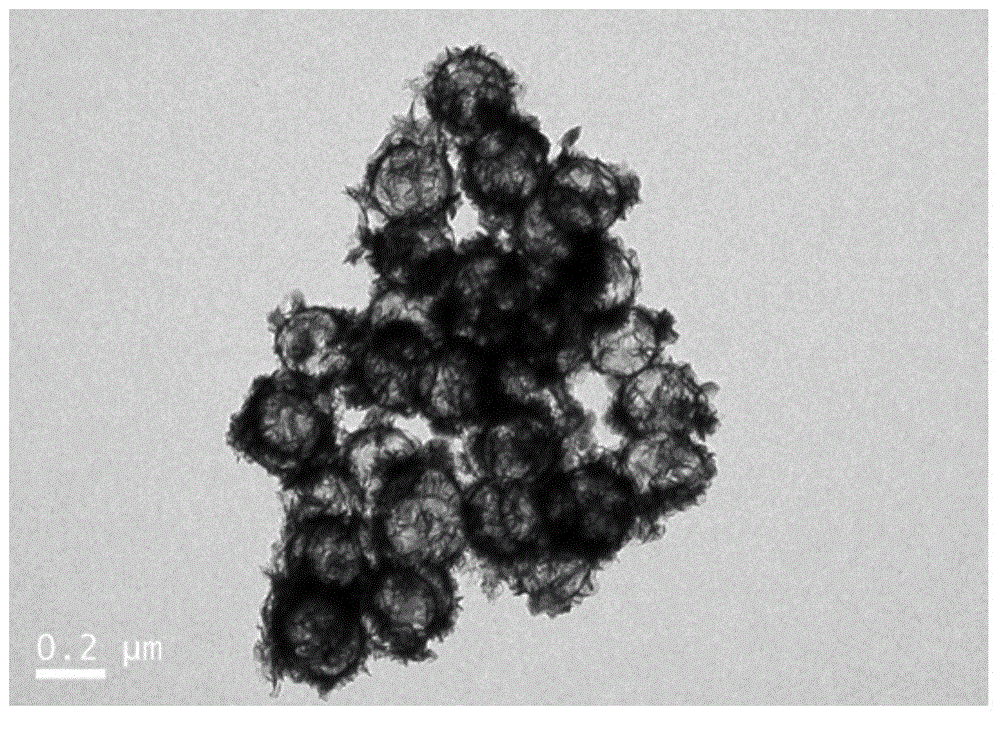

Nickel cobaltate-graphene composite material and application and preparation method thereof

InactiveCN102891016ASmall sizeLarge specific surface areaElectrolytic capacitorsCapacitanceNickel salt

The invention relates to a nickel cobaltate-graphene composite material and a preparation method thereof. The composite material comprises graphene and nickel cobaltate, wherein nickel cobaltate nanowires are uniformly grown on a graphene sheet, the wire length of the nickel cobaltate nanowires is 50-300nm, and the wire width is 5-30nm. The preparation method comprises the following steps of: taking a graphene oxide water solution and a cobalt salt and nickel salt water solution which are dispersed in an ultrasonic manner, mixing, further adding a precipitator, uniformly stirring and mixing, transferring into a high-temperature reaction kettle, performing hydro-thermal reaction for a certain period of time, filtering, washing and drying an obtained product, and further performing thermal treatment so as to obtain the nickel cobaltate nanowire-graphene composite material. The nickel cobaltate nanowire-graphene composite material prepared by the method disclosed by the invention has the advantages of high single-electrode capacitance and good cycle performance, and is suitable for being used as an electrode material of a super-capacitor.

Owner:CHANGZHOU UNIV

Processing system for organic waste

InactiveCN101448581AReduce processing costsEasy to handleBio-organic fraction processingSolid waste disposalSludgeHigh pressure

The invention relates to a processing system for organic waste. The processing system for organic waste can deal with industrial waster like mud and plastic scraps, and also can stirring municipal waste from household and general public service in a two-wall structural pressure container at high temperature and pressure. After the treatment for recomposing waster by using hydro-thermal reaction under thermal conditions, the treated dry water can be recycled after classification.

Owner:ECO MATERIAL +1

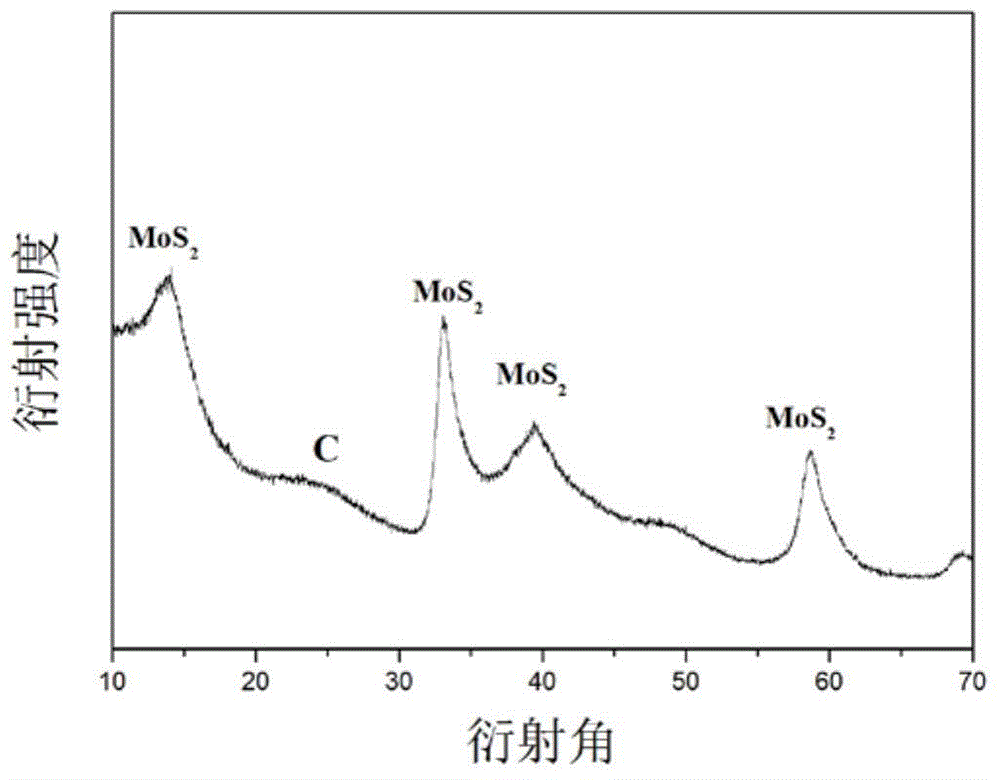

Molybdenum disulfide/carbon composite material and preparation method thereof

InactiveCN104934602AImprove poor conductivityNot easy to reuniteCell electrodesSecondary cellsCarbon compositesCarbonization

The invention discloses a molybdenum disulfide / carbon composite material. The molybdenum disulfide / carbon composite material comprises a molybdenum disulfide layer and a carbon hollow ball, wherein the molybdenum disulfide layer is positioned outside the carbon hollow ball; and the carbon hollow ball has a hollow structure. The invention also discloses a preparation method of the molybdenum disulfide / carbon composite material. The preparation method comprises the following steps of using amino modified silica spheres as a template; wrapping the template by pyrolyzation of an organic carbon source; performing thermal reaction on the template and ammonium tetrathiomolybdate through solvent; performing high-temperature carbonization in an inert atmosphere; and removing the silicon oxide template to obtain the molybdenum disulfide / carbon composite material. The lithium-intercalation capacity of the molybdenum disulfide / carbon composite material is 1467mAh / g for the first time, and the specific capacity of the molybdenum disulfide / carbon composite material can be kept at 733mAh / g after 30 times of repeated charging and discharging cycles.

Owner:SHANGHAI JIAO TONG UNIV

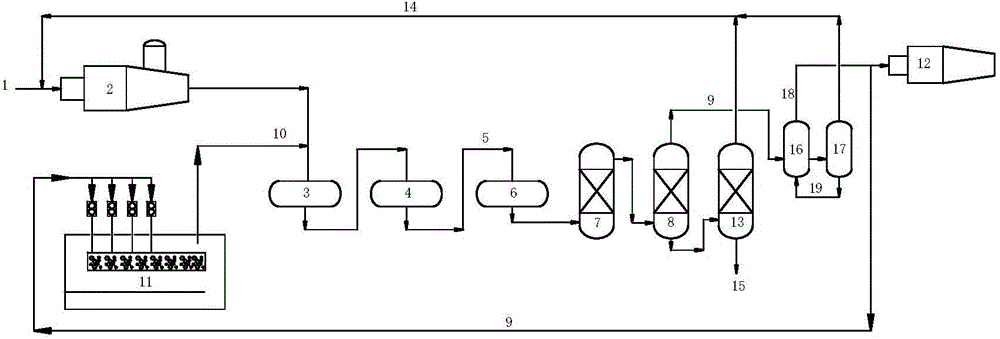

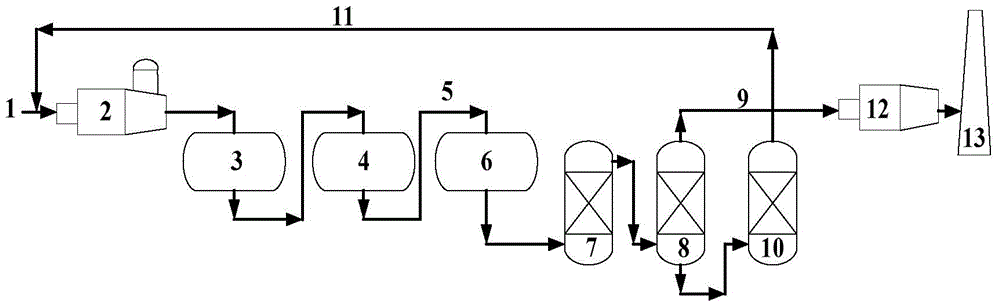

Purified gas treatment process of sulfur recovery device

InactiveCN104555939AReduce contentDispersed particle separationSulfur preparation/purificationHydrogenation reactionSulfur

The invention relates to a purified gas treatment process of a sulfur recovery device. The purified gas treatment process comprises a thermal reaction phase, a catalytic reaction phase and a tail gas purifying treatment phase, wherein in the tail gas purifying treatment phase, the Claus tail gas generated in the catalytic reaction phase is sequentially subjected to a hydrogenation reaction, cooling in a rapid quenching tower and amine liquid absorption, then the purified tail gas is fed to alkali liquor to be subjected to H2S removal treatment, and the tail gas removed from H2S is combusted and then discharged; the amine liquid amine-rich liquid absorbing H2S is fed to a regeneration tower to be regenerated, the regenerated acid gas is mixed with the acid gas, and then returned to the thermal reaction phase to further recover elemental sulfur; the exhausted lye removed from H2S is subjected to caustic dross biological treatment or acidic water stripping treatment. With adoption of the purified gas treatment process disclosed by the invention, H2S in the purified gas can be removed to 5 mg / m<3> below, the SO2 content in the smoke is obviously reduced within the reduction range of 100-1000 mg / m<3>; the exhausted lye treatment method is further provided, and the exhausted lye is subjected to the caustic dross biological treatment or the acidic water stripping treatment, so that pollution can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP

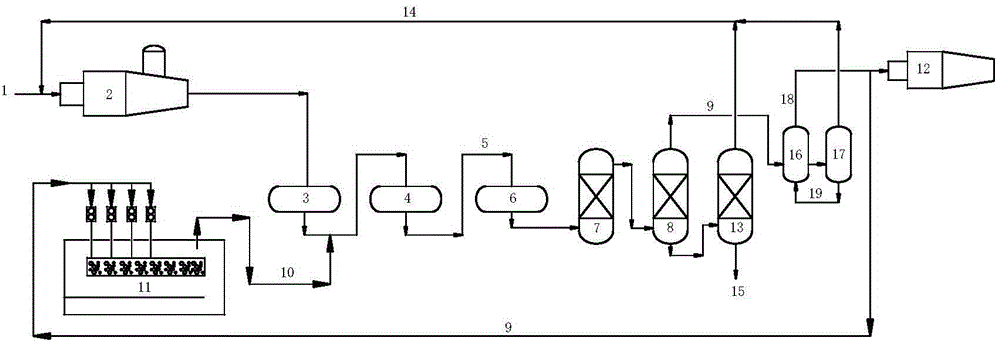

Method for reducing SO2 emission concentration of sulfur recovery device

ActiveCN104249995ASmall volumeReduce dosageChemical industryDispersed particle separationHydrogenation reactionExhaust fumes

The invention relates to a method for reducing the SO2 emission concentration of a sulfur recovery device. The method includes: at a tail gas purification processing stage, subjecting Claus tail gas to hydrogenation reaction, quench tower cooling and amine liquid absorption in turn, then taking part of purification tail gas as the stripping gas for liquid sulfur degassing, leading the residual purification tail gas into an incinerator to incinerate, letting the exhaust gas of liquid sulfur degassing enter a catalytic reaction stage, making the amine liquid absorbing hydrogen sulfide enter a regeneration tower to undergo regeneration, mixing a regenerated acidic gas with a raw material acidic gas, and returning the mixture to the thermal reaction section again for further recovery of elemental sulfur. The method for reducing the SO2 emission concentration of the sulfur recovery device provided by the invention is efficient, energy saving and economical, and greatly reduces the SO2 emission concentration.

Owner:CHINA PETROLEUM & CHEM CORP

System and method for treating waste acid gas

ActiveCN102910593ANo emissionsLower requirementEnergy inputSulfur preparation/purificationLiquid wasteSulfur

Owner:美景(北京)环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com