Processing system for organic waste

A technology for processing system and waste, which is applied in the treatment of biological organic parts, preparation of organic fertilizer, removal of solid waste, etc., can solve the problems of complicated equipment, difficult to take out, and rising cost, and achieve the effect of realizing processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

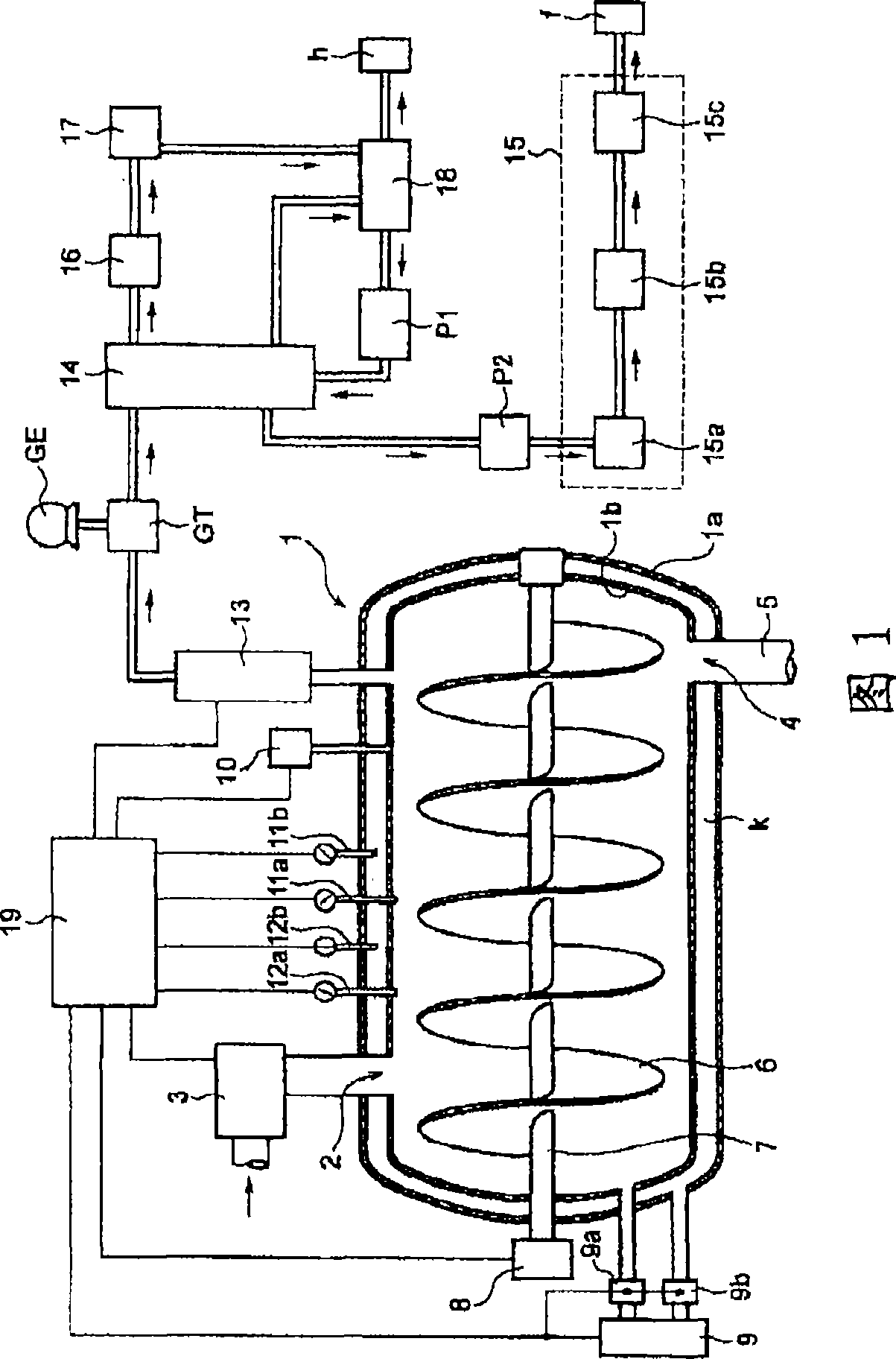

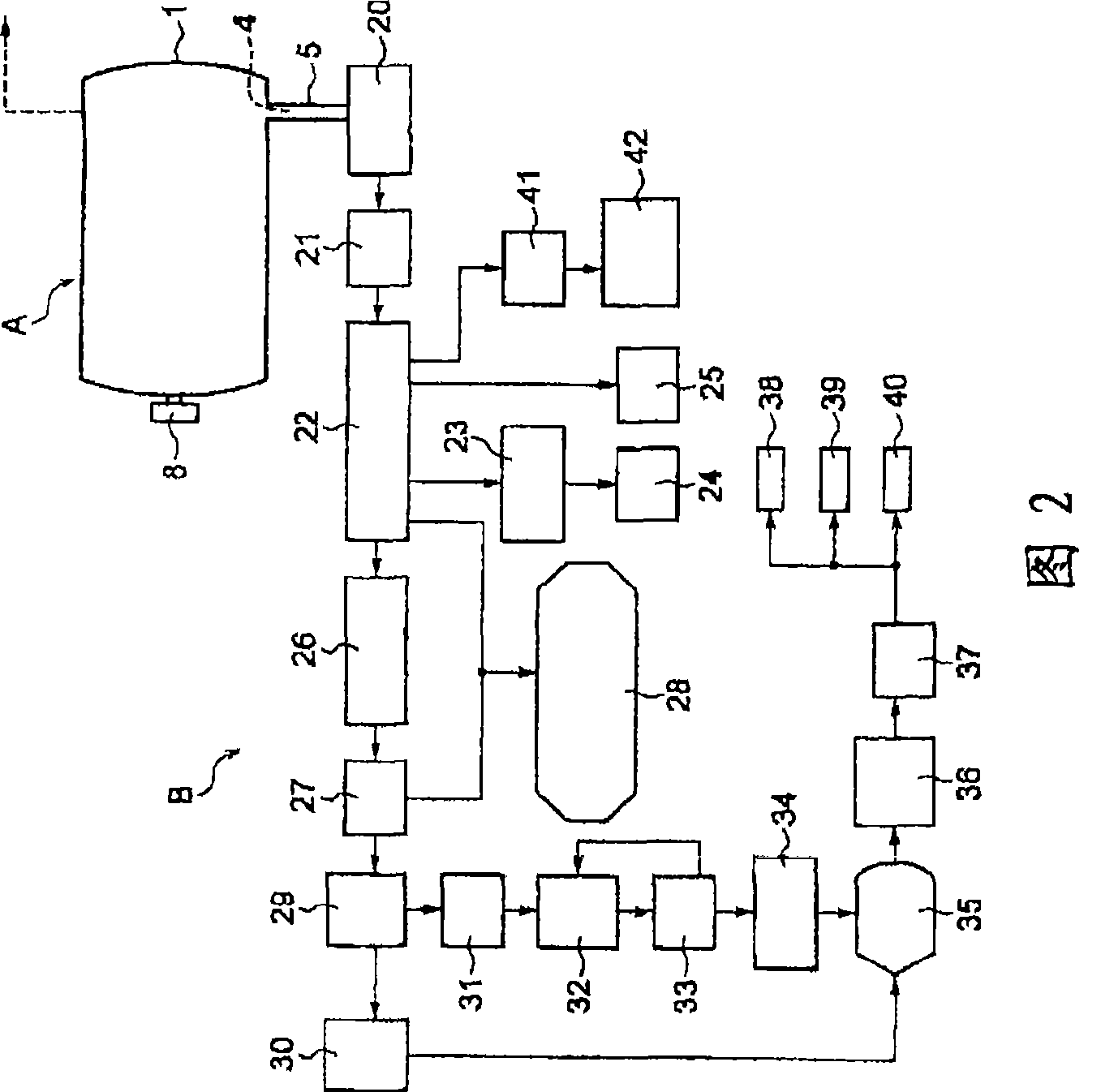

[0065] The embodiments of the present invention will be described below based on the drawings. FIG. 1 is a cross-sectional view of an example of an organic waste treatment device A in the waste treatment system of the present invention, and FIG. 2 is a block diagram of an example of the waste treatment system of the present invention in which the treatment device A of FIG. 1 is assembled.

[0066] In Figure 1, A is an organic waste treatment device that becomes the main part of the waste treatment system of the present invention, 1 is a heat-resistant and pressure-resistant container with a two-layer wall structure that constitutes the organic waste treatment device A, and 1a is a heat-resistant and pressure-resistant container. The outer wall of the heat-resistant and pressure-resistant container 1, and 1 b is the inner wall of the heat-resistant and pressure-resistant container 1. An appropriate gap k is opened between the outer wall 1a and the inner wall 1b, and high-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com