Patents

Literature

195 results about "Dry water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry water , an unusual form of "powdered liquid", is a water–air emulsion in which tiny water droplets, each the size of a grain of sand, are surrounded by a sandy silica coating. Dry water actually consists of 95% liquid water, but the silica coating prevents the water droplets from combining and turning back into a bulk liquid. The result is a white powder that looks very similar to table salt. It is also more commonly known among researchers as empty water.

Method for removing residues formed during the manufacture of MEMS devices

ActiveUS20070134927A1Overcome problemsSatisfy cleanlinessSemiconductor/solid-state device manufacturingCleaning using liquidsWater vaporEnvironmental engineering

A method of removing residues from an integrated device, in particular residues resulting from processing in HF vapor, is disclosed wherein the fabricated device is exposed to dry water vapor for a period of time sufficient to dissolve the residues in the dry water vapor.

Owner:TELEDYNE DIGITAL IMAGING INC

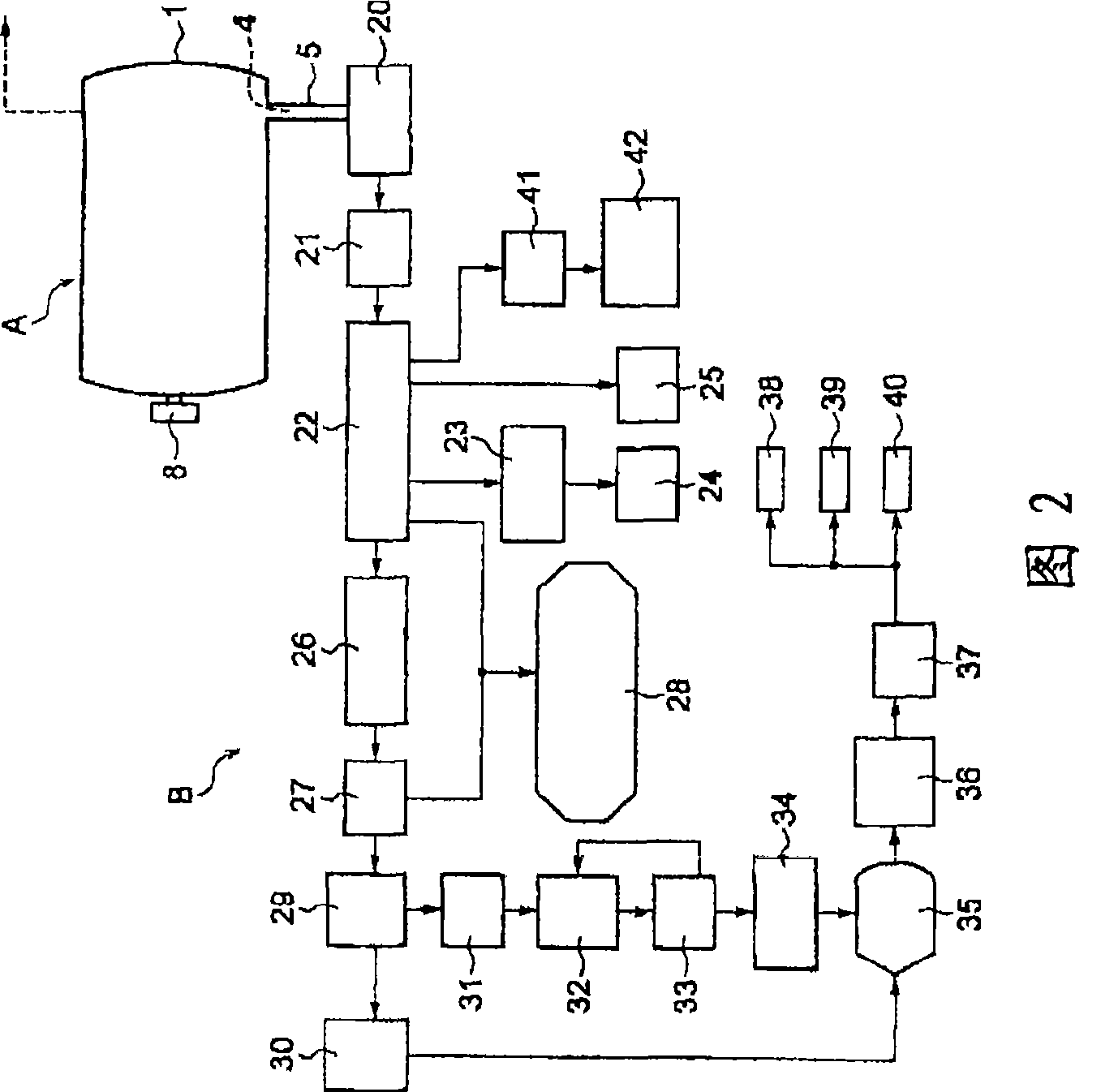

Processing system for organic waste

InactiveCN101448581AReduce processing costsEasy to handleBio-organic fraction processingSolid waste disposalSludgeHigh pressure

The invention relates to a processing system for organic waste. The processing system for organic waste can deal with industrial waster like mud and plastic scraps, and also can stirring municipal waste from household and general public service in a two-wall structural pressure container at high temperature and pressure. After the treatment for recomposing waster by using hydro-thermal reaction under thermal conditions, the treated dry water can be recycled after classification.

Owner:ECO MATERIAL +1

Process for producing catalyst for methacrylic acid production

InactiveUS20070010394A1High yieldHigh selectivityOrganic compound preparationHeterogenous catalyst chemical elementsGas phaseWater insoluble

The object of the present invention is to provide a method for preparing a catalyst for producing methacrylic acid by subjecting methacrolein, isobutyl aldehyde or isobutyric acid to gas phase catalytic oxidation with high yield and high selectivity. A method for preparing a catalyst for producing methacrylic acid by subjecting methacrolein, isobutyl aldehyde or isobutyric acid to gas phase catalytic oxidation, the method comprising: (a) a step of blending compounds each containing any one of Mo, V, P, Cu, Cs or NH4 with water to prepare an aqueous solution or dispersion of the compounds (hereinafter referred to, both included, as a slurry); (b) a step of drying the slurry obtained in the step (a) to obtain a dried slurry; (c) a step of calcining the dried slurry obtained in..the step (b) to obtain a calcined body; (d) a step of filtering a mixture obtained by blending the calcined body obtained in the step (c) with water to separate an aqueous solution and water-insoluble matter; and (e) a step of drying the water-insoluble matter obtained in the step (d) to obtain a dried water-insoluble body.

Owner:NIPPON KAYAKU CO LTD

Dry-peelable temporary protective coatings

InactiveUS6991851B2Improve adhesionImprove clarityWax coatingsSynthetic resin layered productsPolyurethane dispersionPolymer science

A dry-strippable coating composition can be incorporated into a composite article and comprises a dried water-borne polyurethane dispersion including a release additive comprising a releasing co-solvent or other selected release material. When water is removed from the polyurethane dispersion of the composite article and when the article comprises a thermoformable substrate, the article can be thermoformed to provide a shaped article. Dry-stripping the coating composition from the substrate provides a thermoformed substrate and a thermoformed protective layer. The dry-strippable coatings provide temporary protection for the surface of various products and components during manufacture, assembly, shipping, installation, painting, and refinishing operations.

Owner:3M INNOVATIVE PROPERTIES CO

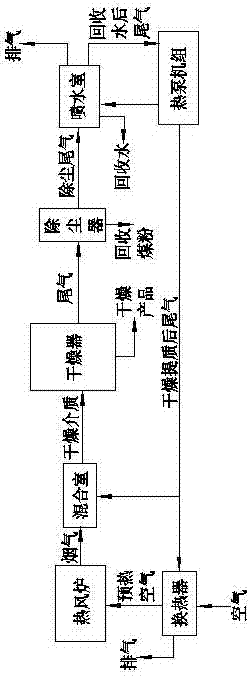

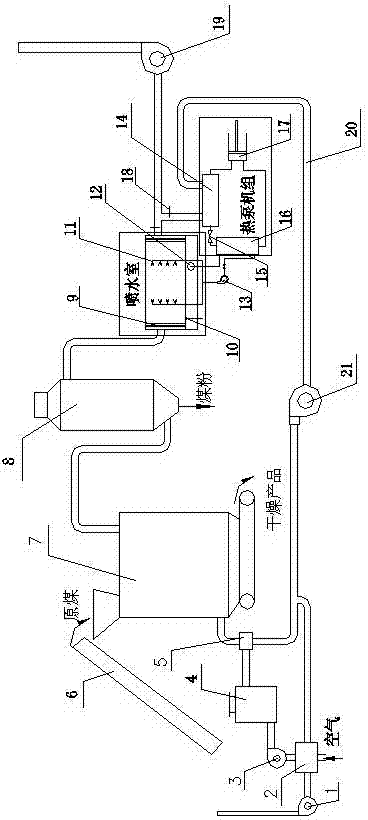

Lignite drying water recycling and drying tail gas recycling system

InactiveCN103575068AImprove recycling efficiencyPromote circulationDrying solid materials with heatDispersed particle filtrationWater useVolatiles

The invention relates to a lignite drying water recycling and drying tail gas recycling system which comprises a hot blast heater, a drier, a dry type deduster, a heat pump machine set, a mixing chamber and a water spraying chamber, wherein the mixing chamber is used for mixing fume of the hot blast heater and a recycled tail gas heated by the heat pump machine set into low-temperature hot fume to be used as a drying medium of the drier; the dried tail gas and the cold water sprayed out from a nozzle of the water spraying chamber are sufficiently mixed and subjected to heat-humidity exchange in the water spraying chamber; part of steam in the dried tail gas is condensed into water to be recycled; at the same time, visible heat and latent heat of vaporization are released; the cold water used in the water spraying chamber is supplied by the heat pump machine set; the water recycled in the water spraying chamber flows out through an overflowing tube and is collected. The fume discharged from the water spraying chamber is heated by an air cooling condenser of the heat pump machine set, is subsequently fed into the mixing chamber, is mixed with the fume generated from the hot blast furnace, and is subsequently used as the drying medium of the drier. The system is at a low temperature and is dry, and the oxygen content of the drying medium is low, so that volatiles in coal are prevented from being lost, and precious water resource is recycled.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Methods to reduce organic impurity levels in polymers and products made therefrom

InactiveUS20070106061A1Reduce moisture contentReduce water contentPharmaceutical non-active ingredientsSynthetic polymeric active ingredientsWater solubleImpurity

Owner:BUCKMAN LAB INT INC

Dry water plant powder preparing method

InactiveCN101116986AMild operating conditionsReduce energy consumptionAnimal feeding stuffWood working apparatusPermeationLivestock

Owner:ZHEJIANG UNIV

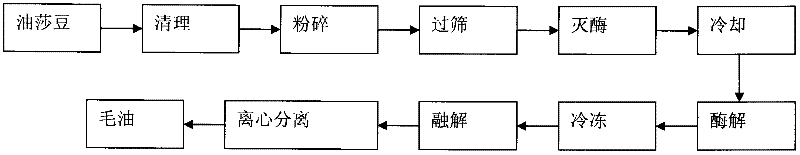

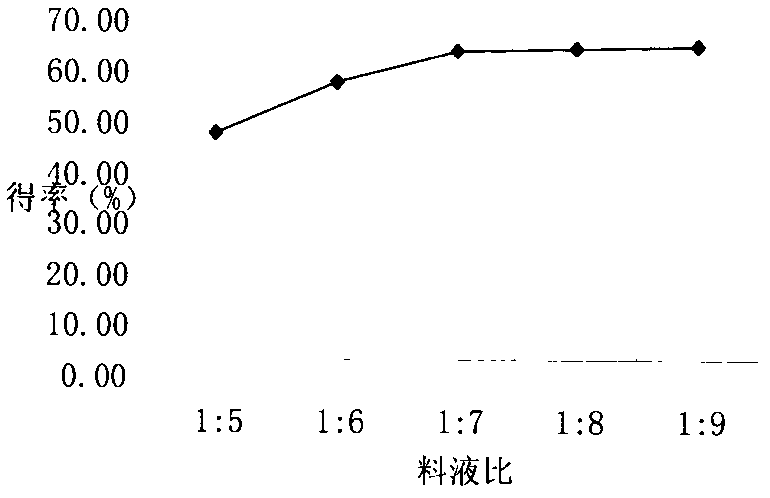

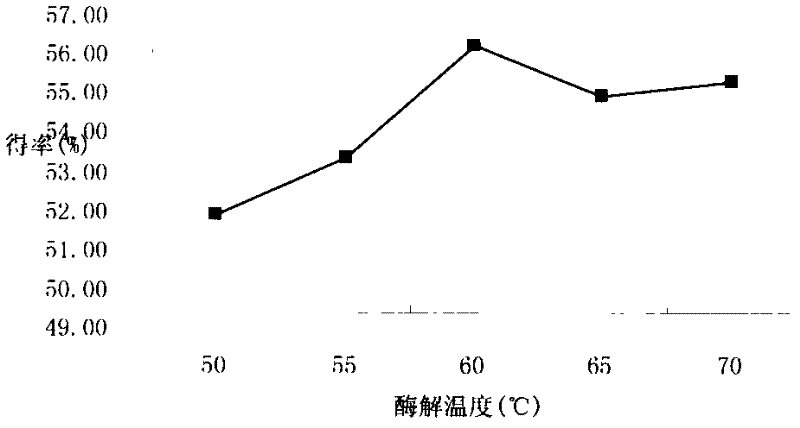

Method for extracting Cyperus esculentus oil by aqueous enzymatic extraction-freeze-thaw coupling technology

InactiveCN102311867AEasy to operateOperational securityFatty-oils/fats productionSodium bicarbonateUltra Low Temperature Freezer

The invention discloses a method for extracting Cyperus esculentus oil by the combination of aqueous enzymatic extraction and freeze-thaw, selecting plump Cyperus esculentus without insect diseases, removing impurities on the surface by washing with the use of water, and drying water on the surface; crushing, weighing 500kg of a Cyperus esculentus powder, adding a mixed buffer solution of sodium carbonate and sodium bicarbonate at the solid-liquid ratio of 1:7 (m / v), adjusting pH value to 7, immersing for 1 hour at the temperature of 50 DEG C, killing enzyme for 10 min at the temperature of 90 DEG C; adopting a compound enzyme of alkali protease and cellulase mixed at the mass ratio of 2:1 (m / m) while the solid-liquid ratio is 1:6, the enzymatic hydrolysis time is 6 hours, the enzyme addition is 2.5% and the enzymatic hydrolysis temperature is 70 DEG C; placing the enzymatic hydrolysis solution into an ultralow temperature refrigerator at the temperature of minus 30 DEG C for 30 min after enzymatic hydrolysis, followed by thawing at room temperature; centrifuging for 20 min at the rotating speed of 4000r / min, carrying out secondary centrifugation, and separating crude oil to obtain the product. According to the invention, the oil extraction rate is raised, and good grease quality is also maintained.

Owner:XINJIANG UNIVERSITY +1

Method for deeply drying gas

The invention discloses a method for deeply drying water vapor-containing mixed gas, relating to the method using multilayer sectionalized adsorption. The water vapor-containing mixed gas is feed gas. The method for deeply reducing the content of water vapor is characterized by using the pressure variation and temperature swing adsorption gas separation process and having at least two adsorbers, wherein, purified gas with low water vapor content is obtained after the feed gas passes through one adsorber, at least two kinds of adsorbents are arranged in the adsorber, the front section is provided with the adsorbent with low vapor drying capability and easy deabsorption, the rear section is provided with the adsorbent with high vapor drying capability and hard deabsorption, and the adsorbent of the front section can desorb most adsorbed water by the process of pressure reduction; and meanwhile, gas which flows out during the regeneration of the adsorbent of the rear section has the function of regenration on the adsorbent of the front section. The feed gas can be hydrogen, carbon dioxide, carbon monoxide, methane, ethane, propane, butane, ethylene, acetylene, nitrogen, oxygen, argon, helium and other raw materials which are applicable to the industries of chemical engineering, metallurgy, aviation, etc.

Owner:杨皓

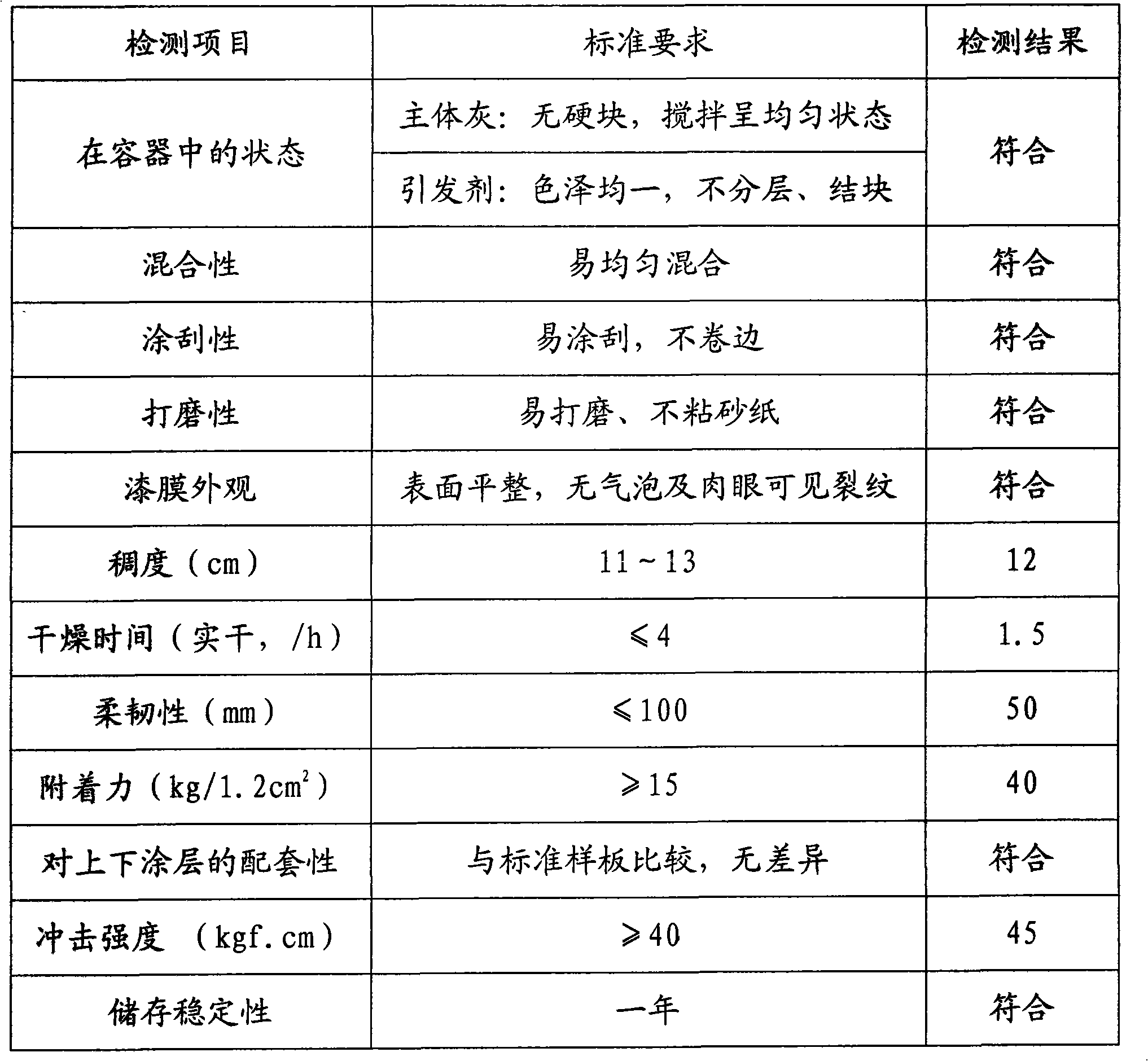

Environment-friendly aqueous putty

An environment-friendly aqueous putty consists of main putty and an initiator. The putty is obtained by evenly mixing the main putty and the initiator at required weight ratio. The main putty consists of the following components: an air-drying water-born unsaturated polyester resin, deionized water, an anti-shrinking agent, a promoter, a wetting dispersant, an anti-skinning agent, an anti-settling agent, an adhesion promoter, an anti-mildew agent, a structure reinforcing agent and packing. The initiator consists of the following components: benzoyl peroxide, dibutyl phthalate and silicon dioxide. The putty has the advantages that air-drying performance of a product is hardly affected by temperature of construction environment; the product has high environmental protection performance, good service performance in construction, special structure reinforcing agent and high overcoatability for use.

Owner:GUANGDONG SANVO CHEM IND TECH

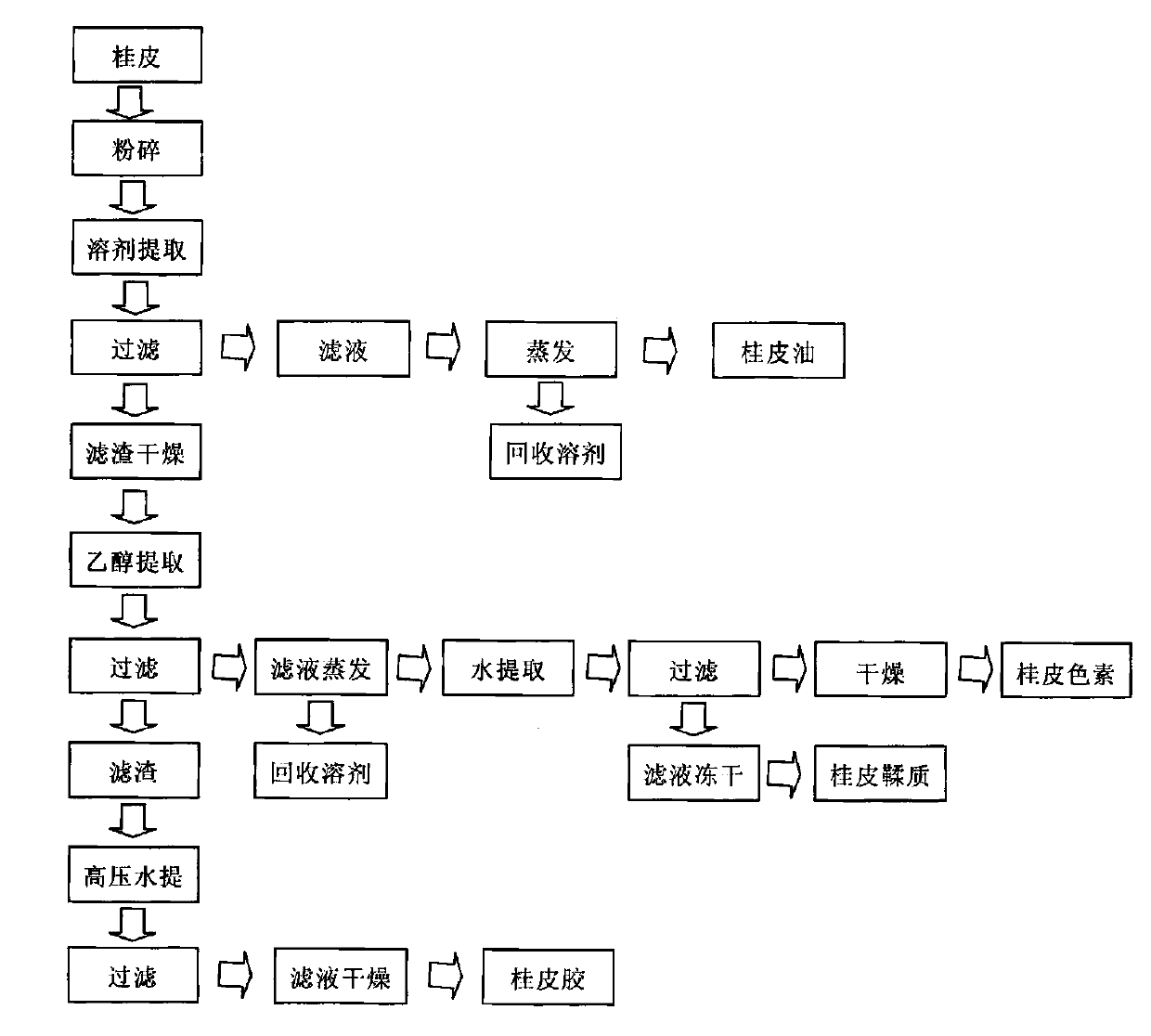

Extraction method of cinnamon bark extract

The invention discloses an extraction method of a cinnamon bark extract. The extraction method comprises the following steps: (1) extracting volatile oil in cinnamon bark by utilizing an organic solvent; (2) extracting degreased cinnamon bark powder after extraction of cinnamon bark oil by utilizing a certain concentration of ethanol, concentrating and drying an extract solution to obtain an ethanol extract, performing further extraction on the ethanol extract with water, performing vacuum concentration on a water solution, freeze-drying to obtain tannins, and drying water-insoluble substances to obtain a cinnamon bark pigment; (3) drying cinnamon bark residue after ethanol extraction, adding water, heating, pressurizing, and evaporating and drying filtrate after filtration to obtain cinnamon bark gum. All useful substances in cinnamon bark are separated by the extraction method disclosed by the invention, and final products after separation comprise four major products including the cinnamon bark oil, the cinnamon bark tannins, the cinnamon bark pigment and the cinnamon bark gum, so that the utilization rate of cinnamon bark can achieve 20-50%.

Owner:BEIJING UNIV OF AGRI

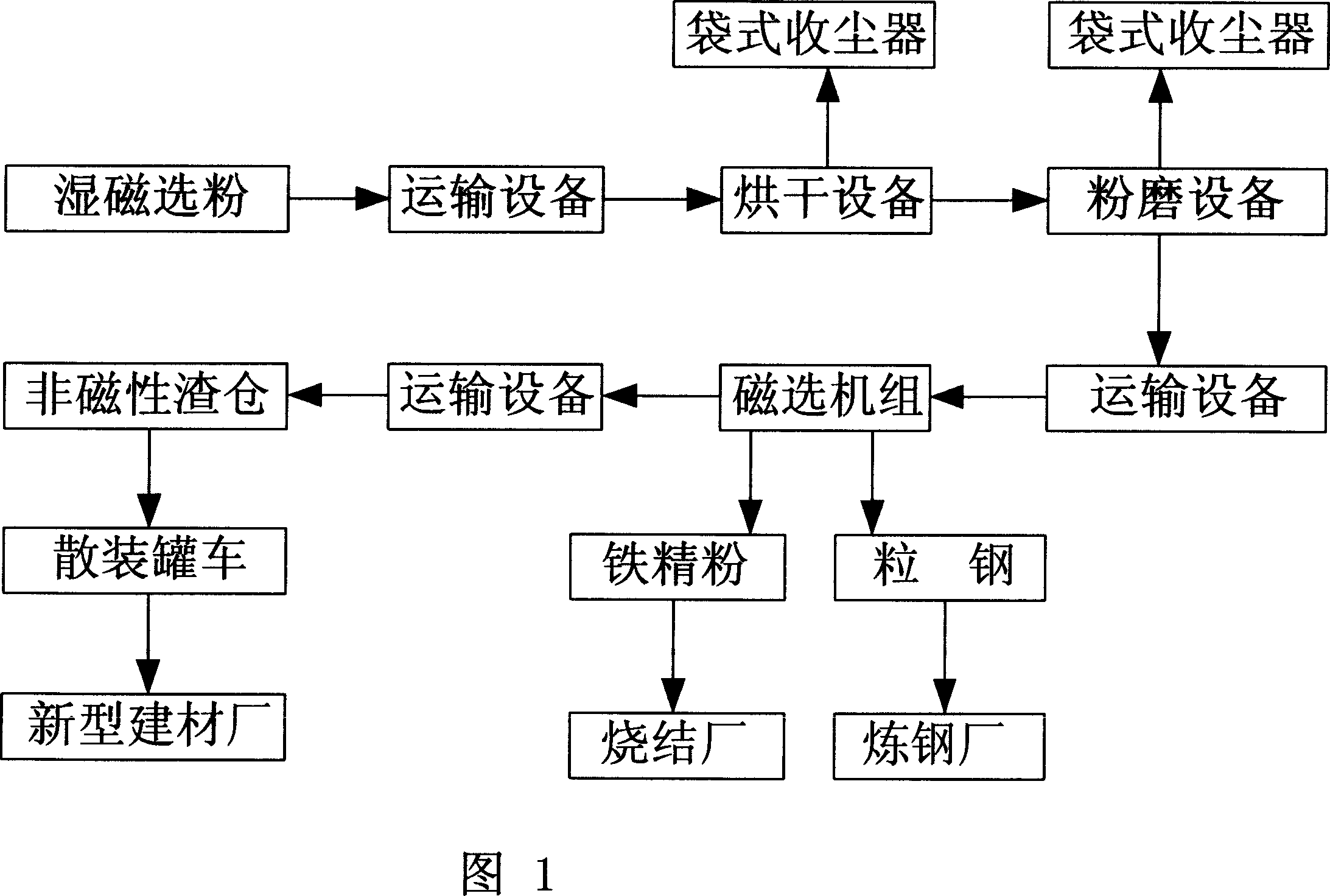

Magnetic separation concentration method

The invention involves a method of select enriched magnetic powder which includes pre-drying, grinding and magnetic separation. A, sending wet magnetic powder which particle size is 0-30mm and TFe<=40% into drying equipment to pre-drying, temperature should be controlled below 950 degree C, the initial water content should decrease from <=20% to <=5% through pre-drying;B, cooling the pre-dried magnetic powder in step A until the temperature below 100 degree C, sending it into a mill equipments to grinding until the size <= 6mm, while using waste heat of magnetic powder and the friction heat when grinding further drying water content <=2%; C, using magnet separator to magnetic select and enrich the magnetic powder treated in step B, then preparing Fe fine powder which TFe>=55%, clean granule steel which TFe>=90% and non-magnetic tailings powder. The invention can separate slag and steel completely and increase magnetic slag TFe significantly; The production process do not discharge wastewater and waste slag, and no dust emissions, it achieves completely effective use of steel slag resources and clean production of steel slag processing and treatment.

Owner:郭心岭

Preparation method of biological carbon particles

InactiveCN107364842AGap developedLarge specific surface areaOther chemical processesWater contaminantsParticulatesSludge

The invention discloses a preparation method of biological carbon particles, comprising the steps of 1, washing water hyacinth; 2, air-drying the water hyacinth; 3, drying the water hyacinth; 4, crushing the dried water hyacinth, and screening; 5, preparing sludge that has a water content of 65-75%; 6, mixing the sludge of step 5 and the water hyacinth powder of step 4; 7, making the mixture into particulate sludge; 8, pyrolyzing the particulate sludge into biological carbon particles; 9, soaking the biological carbon particles in dilute hydrochloric acid; 10, washing the biological carbon particles with deionized water until neutrality; 11, baking the biological carbon particles. Biological carbon that has highly-developed pores, large specific surface area and rich active surface functional groups and having significant adsorbing property for heavy metals can be used as an adsorbent to adsorb pollutants in soil or water so as to arrive at environmental restoration.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

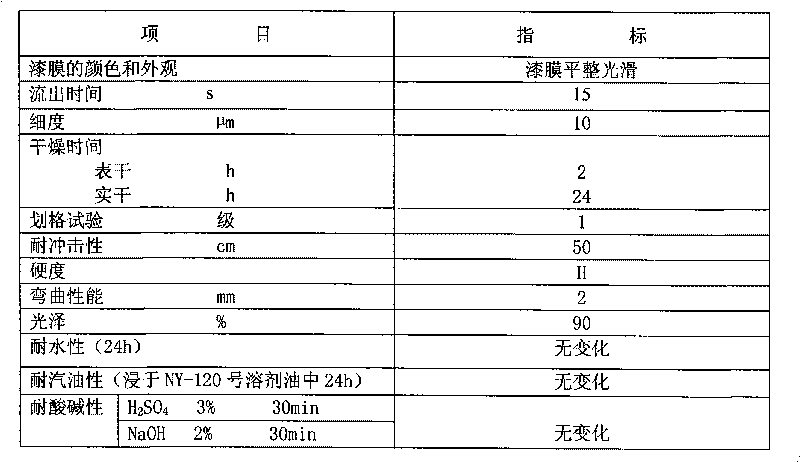

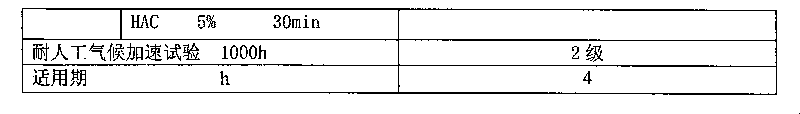

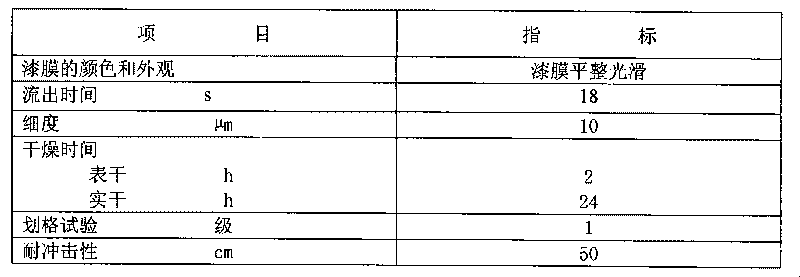

Two-component air-dry water-based finishing varnish

InactiveCN101701122ANo pollutionImprove mechanical propertiesCoatingsMechanical propertyPolymer chemistry

A two-component air-dry water-based finishing varnish relates to the chemical technology field. The finishing varnish comprises the following raw materials by weight percent: 45-55 of polyacrylate emulsion containing hydroxyl groups, 30-35 of hydrophilic aliphatic polyisocyanate curing agents, 15-20 of deionized water and 1.1-1.9 of auxiliaries. The finishing varnish has the following beneficial effects: (1) the product is characterized by being non-combustible, non-toxic and environmentally friendly and saving energy, etc, thus being best suitable for coating on the inner and outer surfaces of the transportation such as various trains, cars, aircrafts and the like; (2) the films formed by the paint have high mechanical properties, and each property approaches or reaches the level of that of the solvent-based two-component paint; (3) the product can be cured under normal temperature and has excellent water resistance, solvent resistance and chemical reagent resistance; and (4) the product has strong decorative effect and simple and convenient construction.

Owner:CHANGCHUN HUARI PAINT

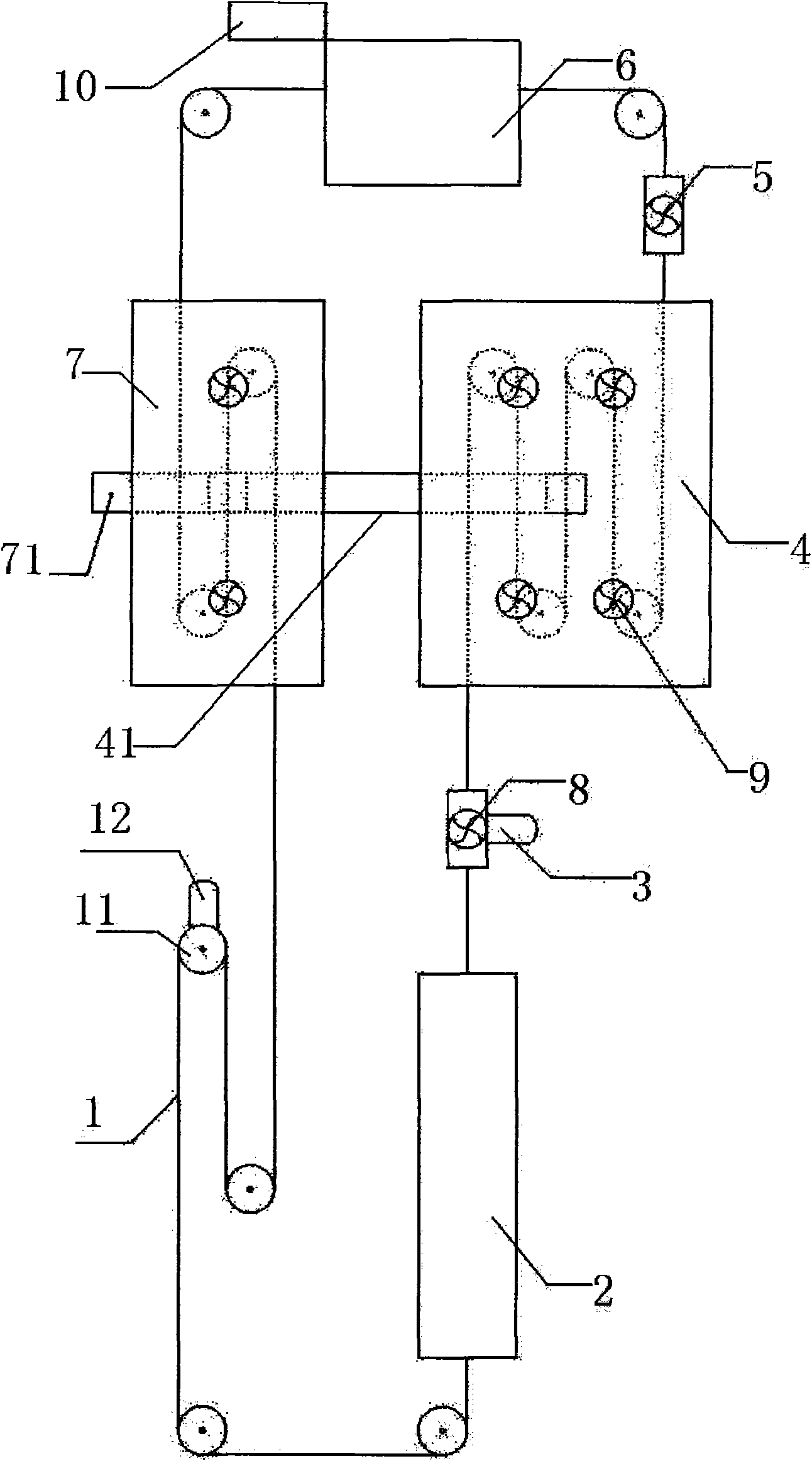

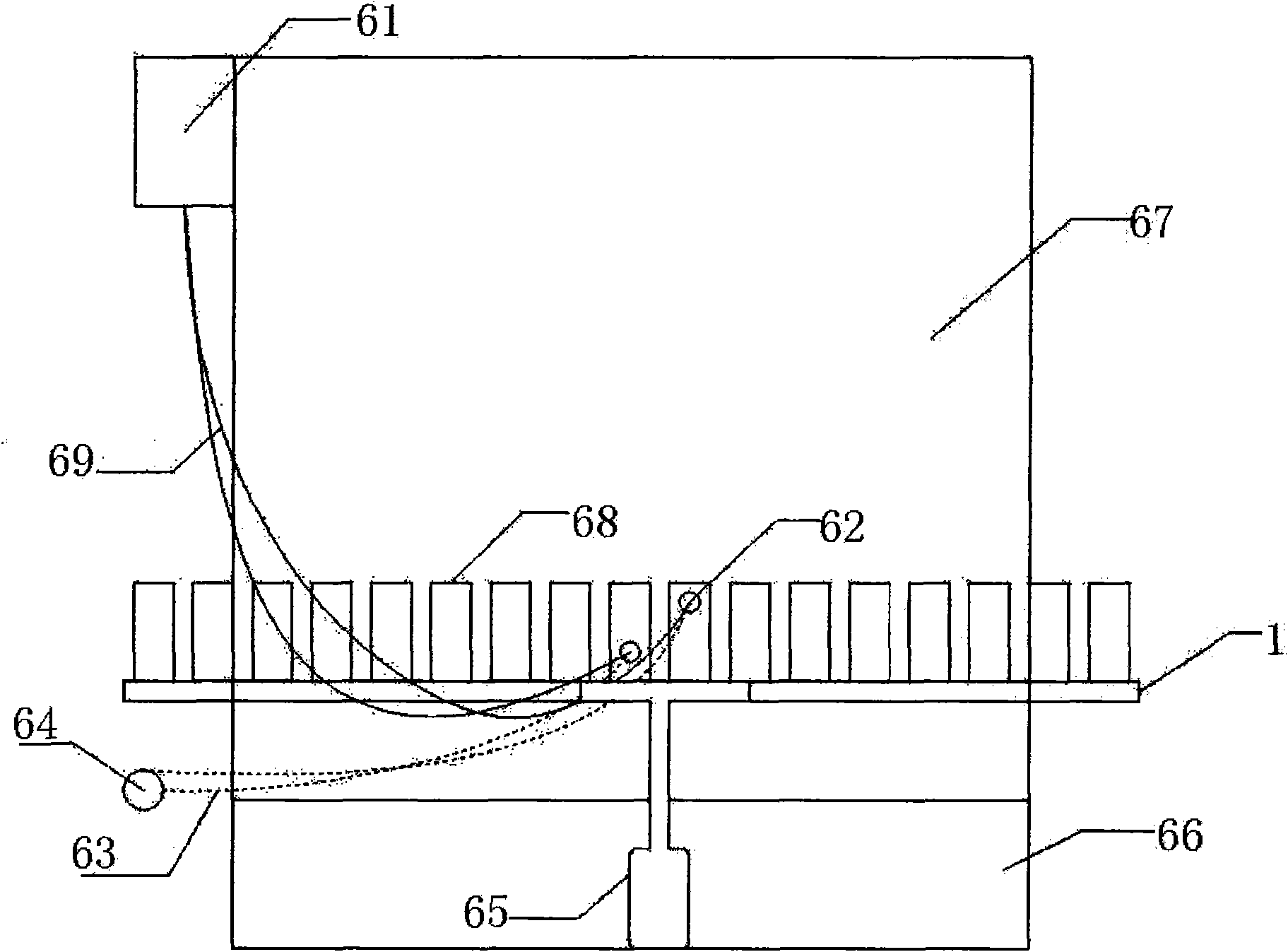

Full-automatic glazing production line and full-automatic glazing process

The invention discloses a full-automatic glazing production line and a full-automatic glazing process. The full-automatic glazing production line comprises a product conveyer belt; and an automatic cleaning cabinet, a water throwing device driven by a motor, a numerical control drying water furnace, an automatic glazing spray cabinet and a numerical control curing furnace are arranged in turn along the conveying direction of the product conveyer belt. The full-automatic glazing process comprises the following processes of: assembling fittings, cleaning with automatic circulating water, automatic water throwing and drying, drying water with waste heat and self-heating, automatic rotation and spraying, curing with waste heat and self-heating, and off-line framing. The full-automatic glazing production line finishes the processes of cleaning, water drying, glazing, glaze curing and the like through a streamline production line so as to eliminate the intervals of the processes, reduce product stacking and improve the production efficiency and quality. The full-automatic glazing process does not place intermediate products, saves the production field, has high production efficiency, and only needs manual monitoring during glazing so as to reduce the labor intensity of workers.

Owner:广东强盛陶瓷玻璃有限公司

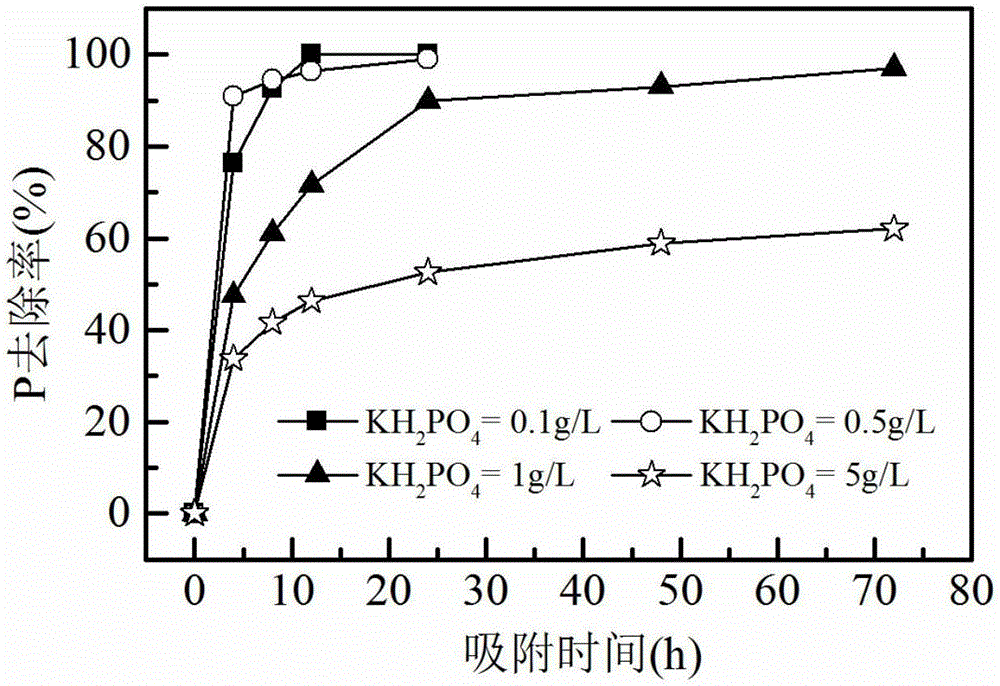

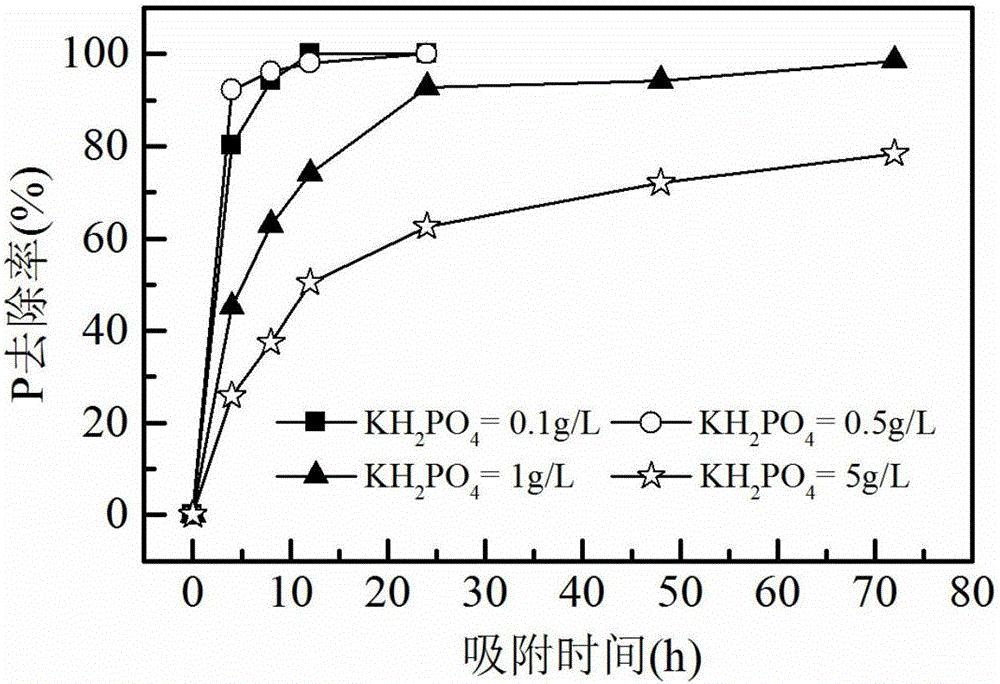

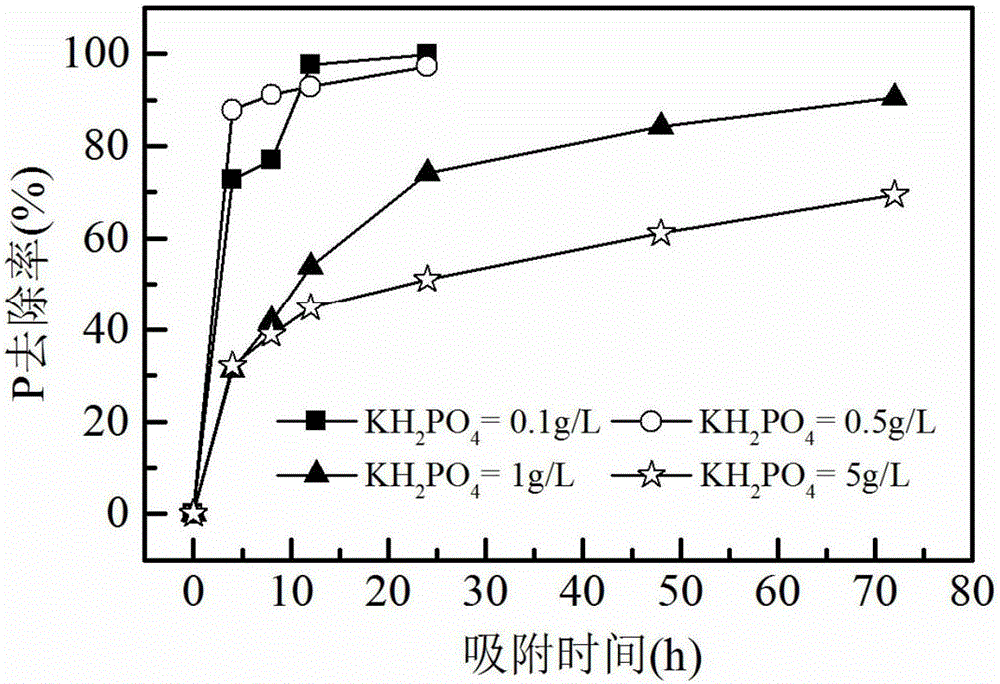

Water supply plant sludge-based phosphorus removal particle adsorbent preparation method

InactiveCN106540650AWide variety of sourcesEasy to prepareOther chemical processesAlkali metal oxides/hydroxidesSludgeSorbent

The present invention belongs to the field of water treatment, and particularly relates to a water supply plant sludge-based phosphorus removal particle adsorbent preparation method, which specifically comprises: drying water supply plant sludge, breaking, screening, uniformly mixing the screened sludge and a sodium alginate solution, adding to a calcium chloride solution in a dropwise manner to form small balls, and carrying out curing drying to form the water supply plant sludge particles, wherein the phosphorus in wastewater can be effectively removed by using the water supply plant sludge particles in phosphorus-containing wastewater treatment, and the adsorption capacity is up to 44 mg / g. According to the present invention, the water supply plant sludge adsorption capacity is maintained while the water supply plant sludge particles having the good performance are produced, such that the resource of the waste is achieved, and the good economic and environmental benefits are provided.

Owner:BEIJING NORMAL UNIVERSITY

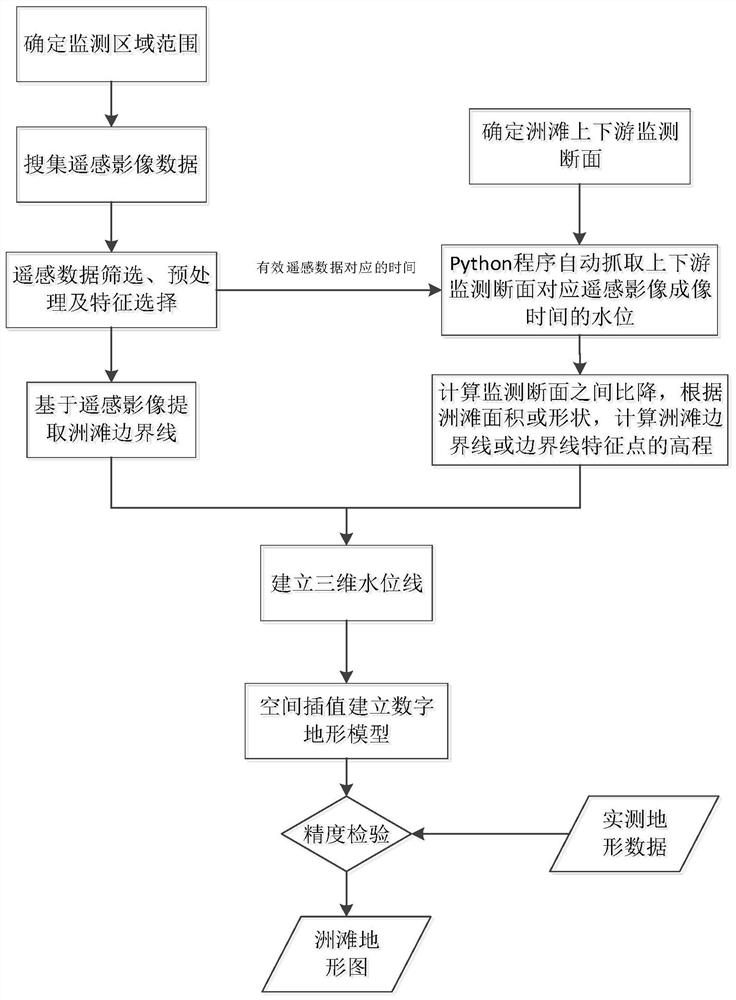

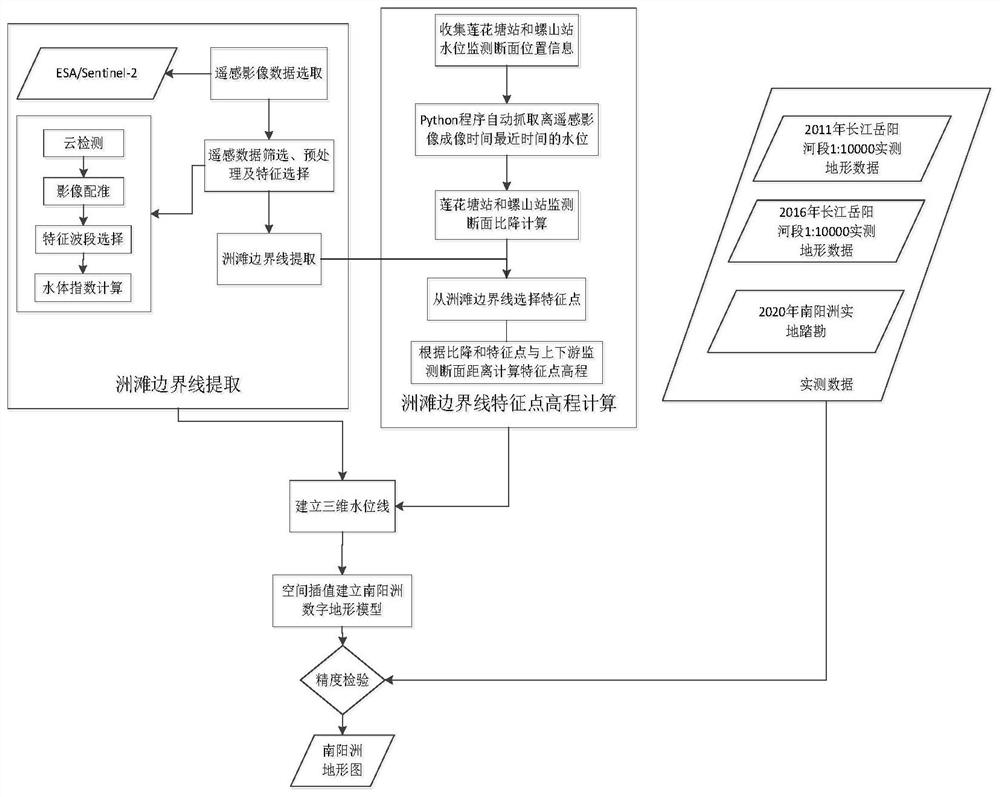

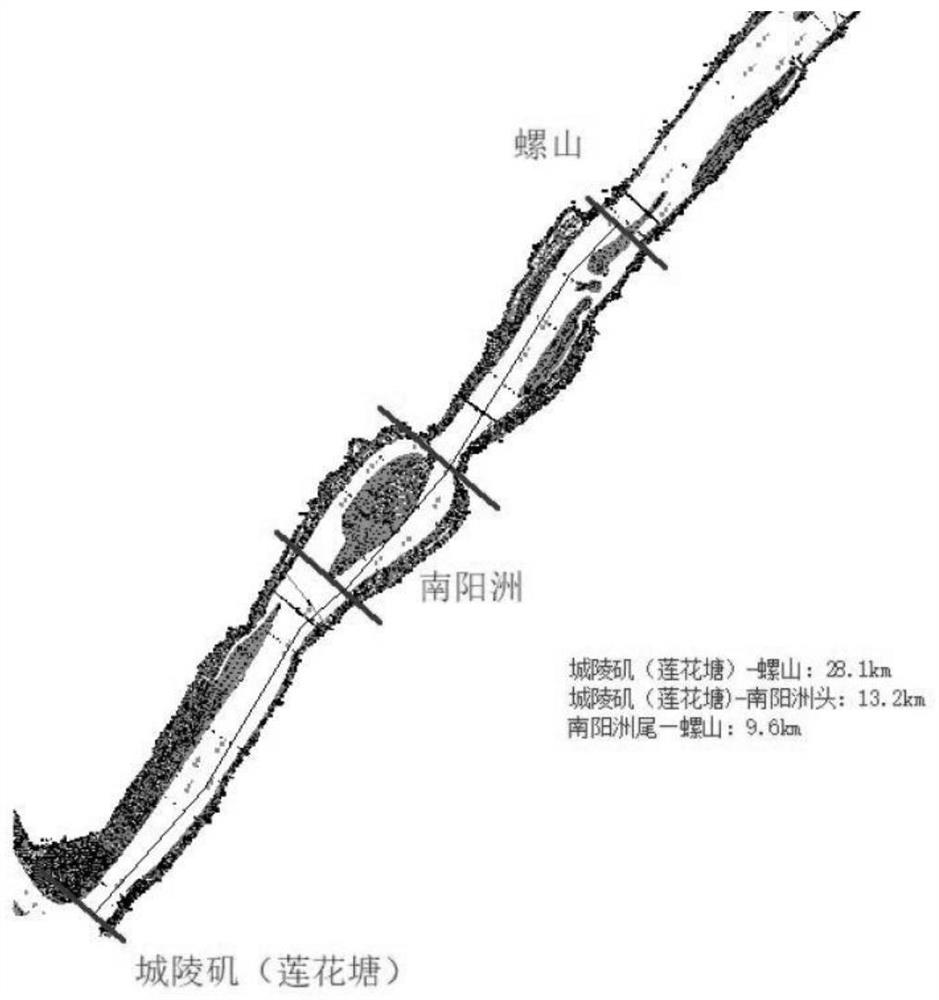

Method for reconstructing terrains above dry water level of beach based on time sequence remote sensing images and water level monitoring data

ActiveCN111951392AOvercome measurements affected by weatherOvercome the limitations of air traffic control and other problemsWater resource protectionSurveying instrumentsTerrainLandform

The invention provides a method for reconstructing terrains above a dry water level of a beach based on time sequence satellite remote sensing data and water level monitoring data, mainly aiming at the river beach of which the area is greatly changed along with the water level in the year. A river beach boundary line of a time sequence is extracted from an ESA / Sentinel2 remote sensing image, waterlevel observation data of nearest hydrological stations at the upstream and the downstream of the beach at corresponding time are automatically captured, the elevation of a beach water line or elevation information of each feature point of the beach water line is obtained, and terrains above the self-dry water line of the beach are established through spatial interpolation. Under the condition that field measurement is not carried out, existing satellite remote sensing data and water level monitoring data are fully utilized, the invention is suitable for the beach with the area obviously changed due to the influence of water level changes, the beach terrains above the dry water line are established, and the invention has great significance in scour silting analysis, protection, development and utilization of the beach.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

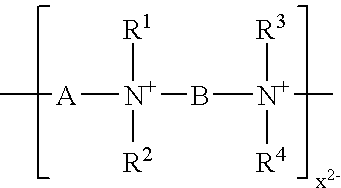

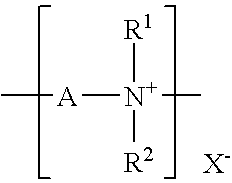

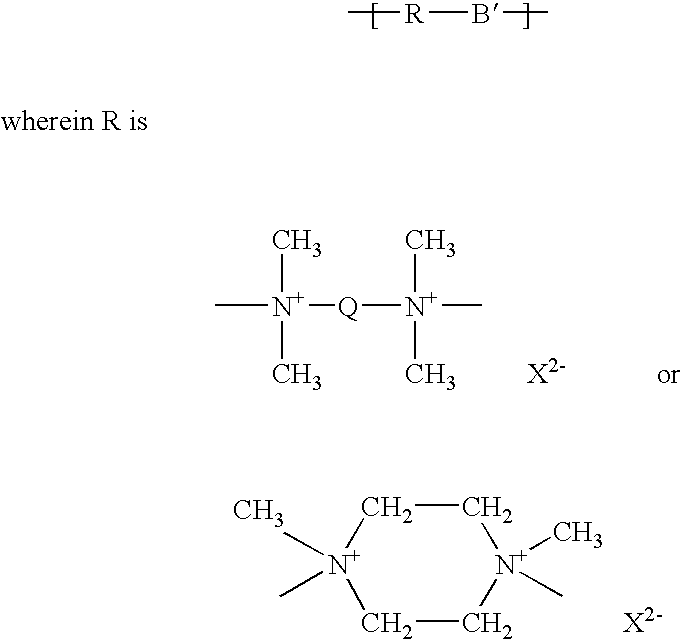

Dry water soluble polymer particles

ActiveUS20160369068A1Sludge treatment by de-watering/drying/thickeningAluminates/aluminium-oxide/aluminium-hydroxide purificationInorganic saltsWater soluble

A method of forming a micronized dry water soluble polymer particles is disclosed herein. In some embodiments, the method includes reducing a particle size of dry water soluble polymer (DWSP) particles; and forming micronized DWSP particles by mixing an additive with the DWSP particles at least one of prior to, during, or after the reduction of the particle size of the DWSP particles, wherein the DWSP is selected from the group consisting of a dry anionic, a dry cationic, a dry nonionic water soluble polymer, and mixtures thereof, wherein the additive is selected from the group consisting of an inorganic oxide, an inorganic hydroxide, an inorganic salt, an organic salt, an insoluble water absorbing material, and mixtures thereof, and wherein a mean particle size of the micronized DWSP particles ranges from about 1 to about 300 microns.

Owner:WATERMARK TECH

Method for extracting pigment and polyphenol from water chestnut peels

ActiveCN103589185AFacilitate decomposition and utilizationAvoid damageNatural dyesPlant ingredientsWater ChestnutsPolyphenol

A method for extracting pigment and polyphenol from water chestnut peels comprises the following steps: crushing dried water chestnut peels by a pulverizer, sieving by a sieve with 20 meshes; adding proper amount of water into the water chestnut peel powder to adjust water content of the powder to 15%; processing the wetted powder by a twin-screw extruder with an extrusion temperature of 120 DEG C; adding proper amount of cold boiled water into the extruded material to make the water content of the material be 30-50%; inoculating a mixed animalcule bacteria accounting for 0.1% by weight of the material, fermenting at 20-40 DEG C for 2-10 days; adding alcohol accounting for one third by weight of the material, fully stirring at room temperature, filtering out alcohol extract under pressure, repeating for 3 times, and merging three time alcohol extracts; distilling the alcohol filtrate under pressure to recover alcohol and obtain water chestnut peel pigment and polyphenol.

Owner:NANCHANG UNIV

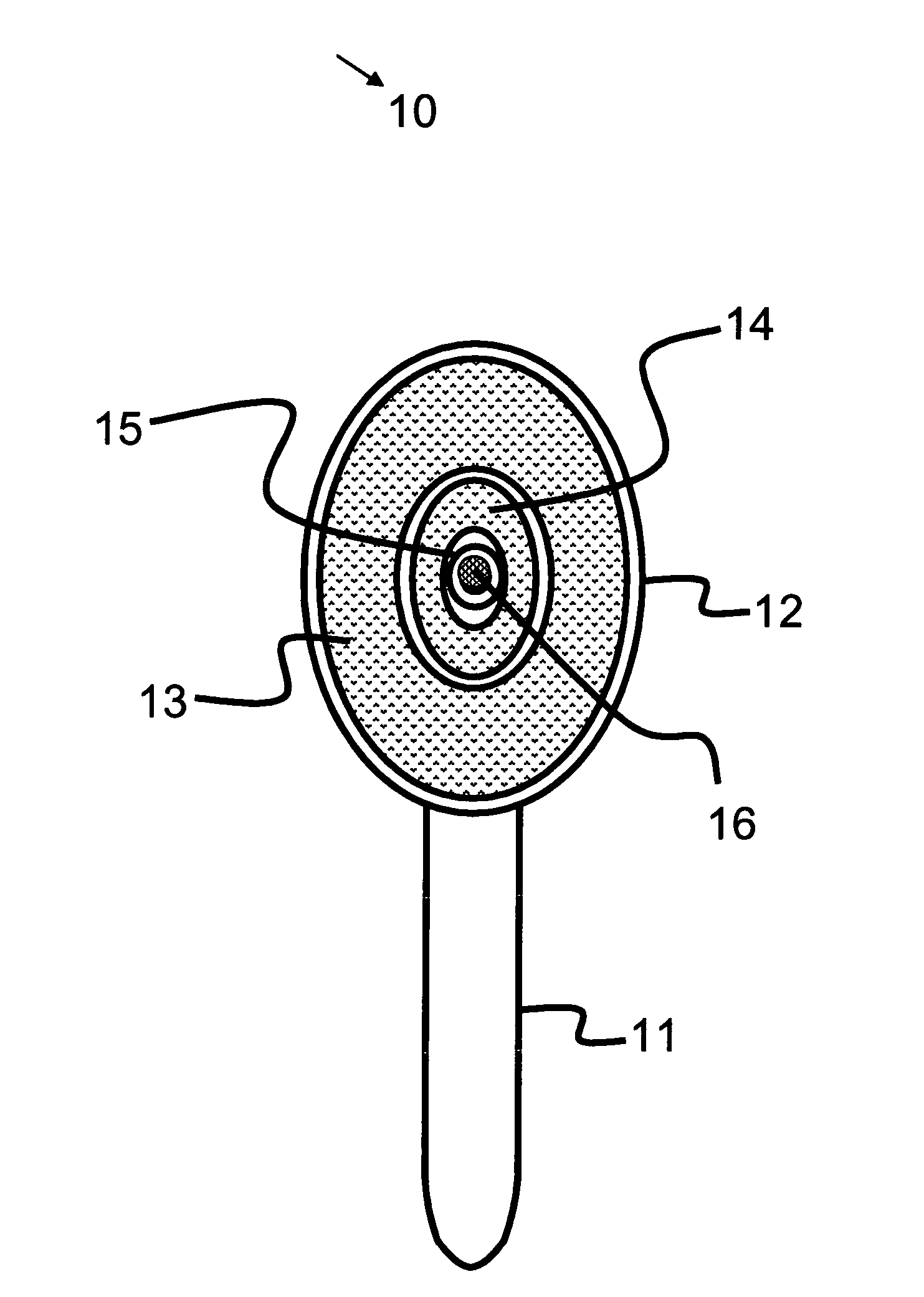

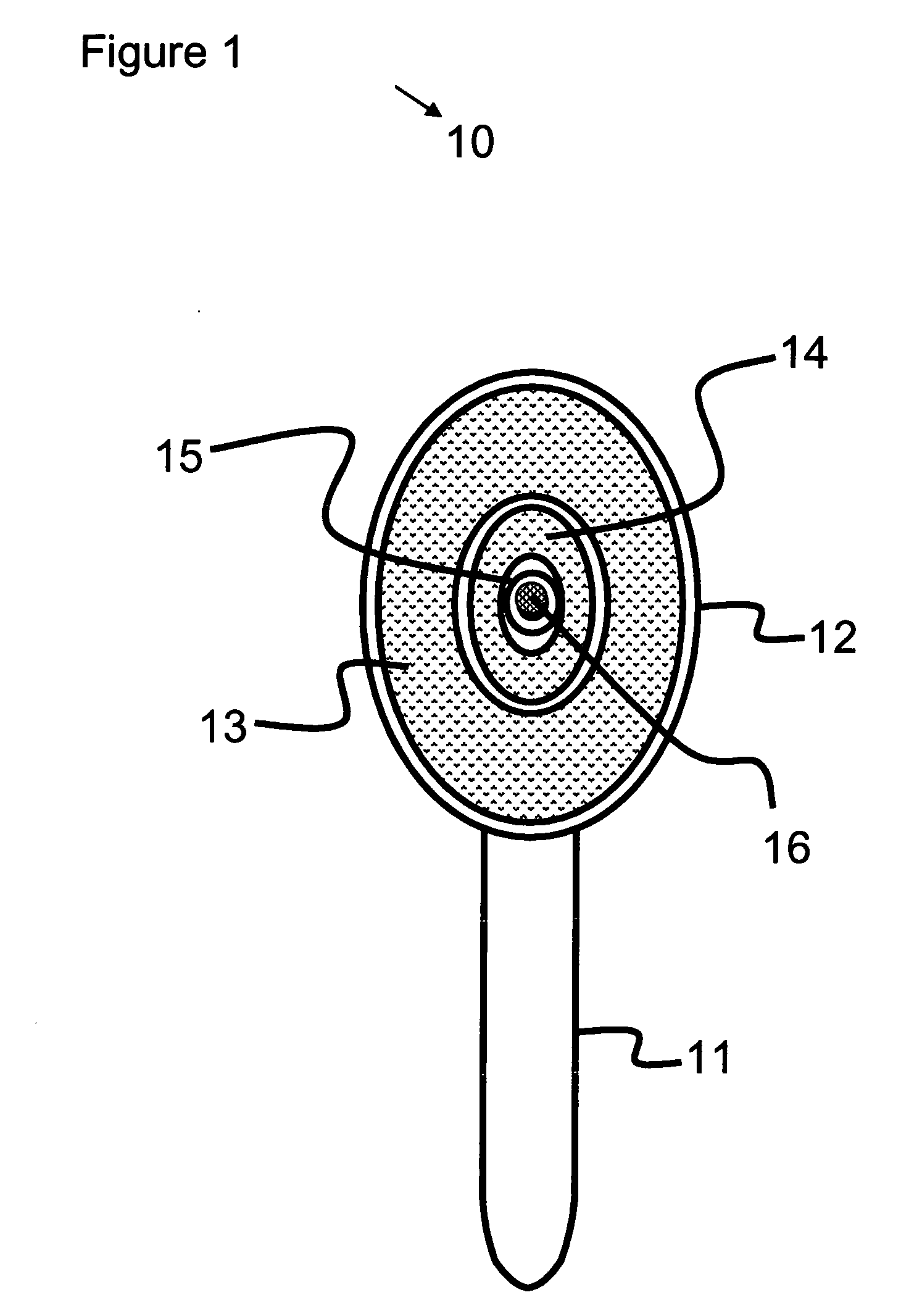

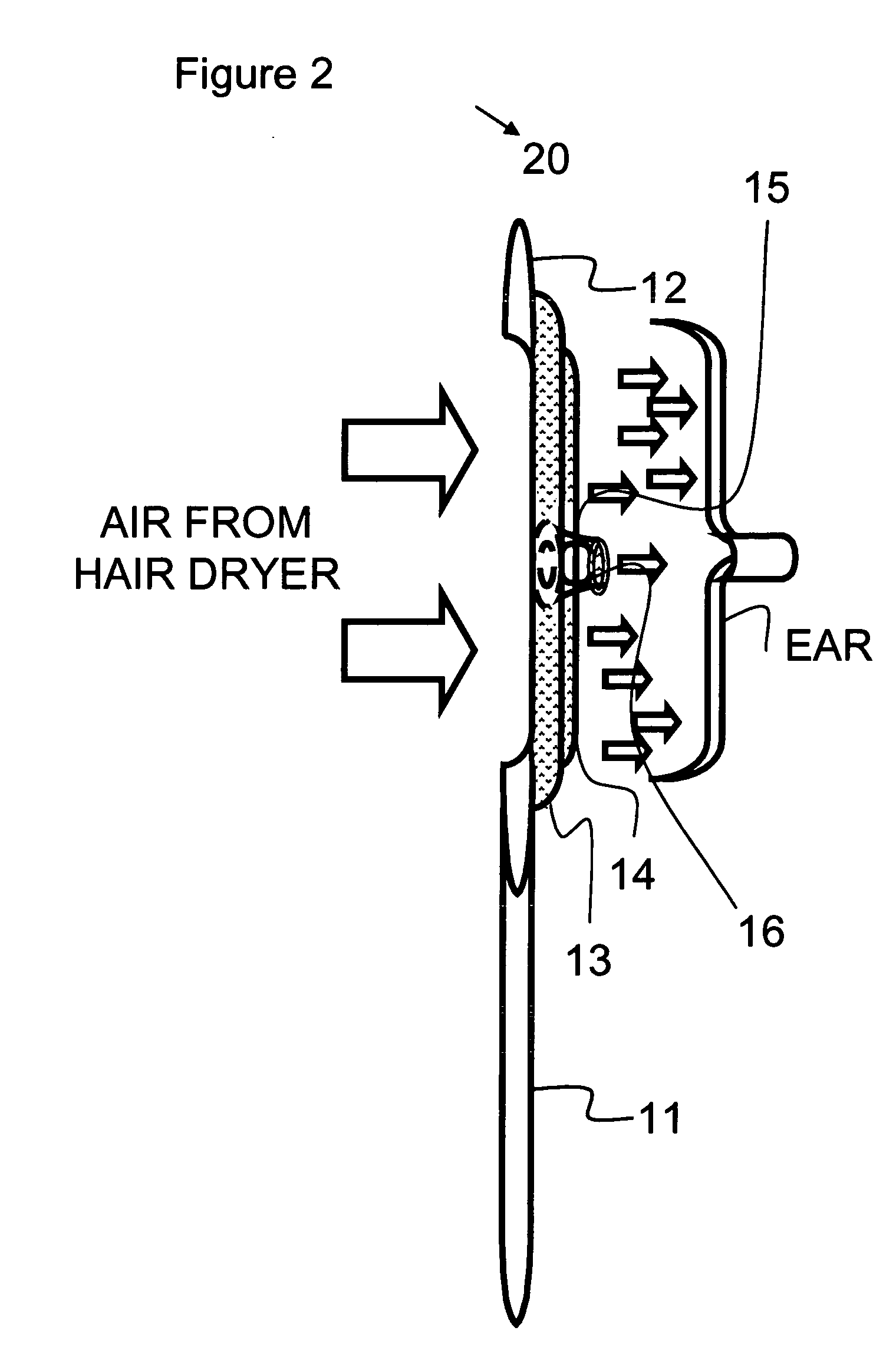

Outer and inner ear drying system

InactiveUS20070051008A1Reduce the average velocityIncrease speedDrying solid materials with heatDrying gas arrangementsExternal earsAir velocity

A system dries water droplets within a person's outer and inner ear. The presence of the droplets is typically caused by swimming, showering, bathing, and other activities associated with water sports such as diving, water polo and the like. A hair dryer blows warm air at a distance into a handheld drying apparatus. One or more diffusion chambers containing a plurality of apertures deliver warm air from the hair dryer into the outer ear. An integral central tubular element forming part of the diffusion chamber delivers warm air from the hair dryer into the inner canal. The diffusion chamber has a handle to help position the central tubular element within the inner ear canal. The distance between the hair dryer and the handheld drying apparatus may be varied to select a comfortable warmth level and warm air velocity.

Owner:DONOVAN STEPHEN

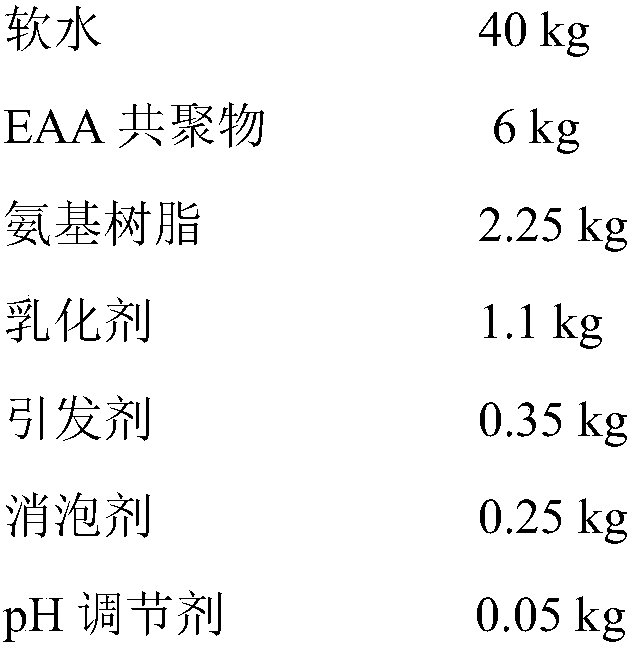

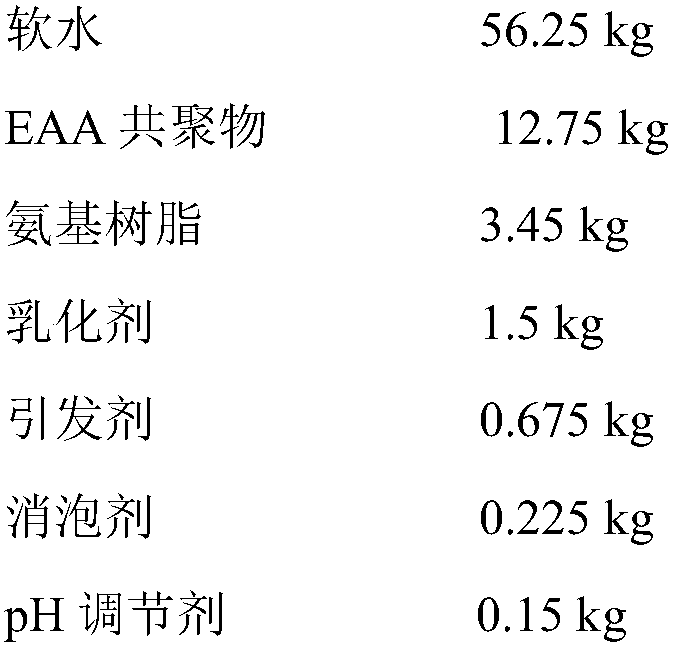

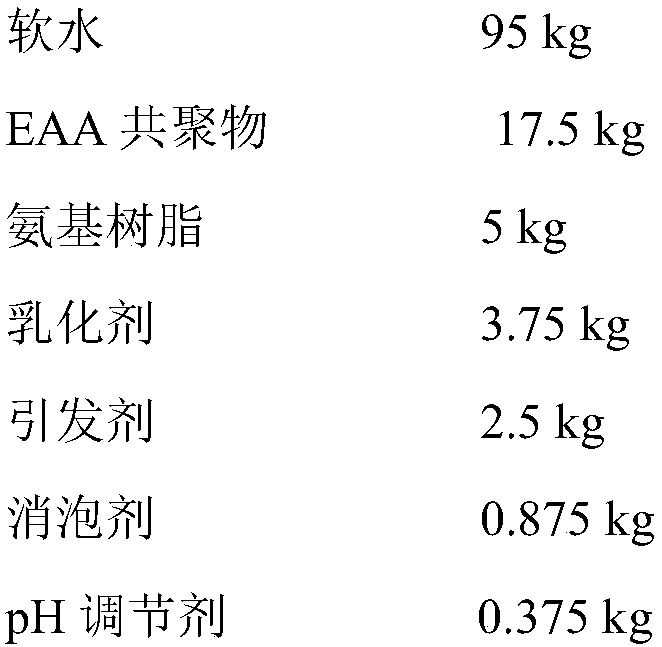

Low-temperature hot-sealed coating film and manufacturing method thereof

ActiveCN108176573AHigh glass transition temperatureAvoid sticky situationsPretreated surfacesCoatingsSoft waterCopolymer

The invention relates to a low-temperature hot-sealed coating film and a manufacturing method thereof. The coating film comprises a base material, and a paint layer on the surface of the base material; a bottom glue layer is arranged between the paint layer and the base material, and is a coating layer formed by drying water polyurethane paint; the paint layer is the coating layer formed after drying of low-temperature hot sealing paint which is prepared through polymerization and emulsification and coated on the bottom glue layer through a coating process; the low-temperature hot sealing paint is prepared by the following raw materials in percentage by weight: 75-80% of soft water, 12-17% of ethylene-acrylic copolymer, 4-8% of amino resin, 2-5% of emulsifying agent, 0.5-2% of initiator, 0.3-1% of defoaming agent, and 0.1-0.3% of pH adjusting agent; the base material is a BOPP film with a thickness of 20-35 microns; when the sealing temperature of the coating film is low, the hot sealing strength at 70 DEG C is not lower than 3 N / 15 mm; and the manufacturing process is simple.

Owner:HAINAN SHINER IND

Gum leakage method of bamboo-wood rods with high water content

InactiveCN101637932ASolve the problem of uneven dippingEliminate the drying processPressure impregnationDomestic articlesVacuum pressureEvaporation

The invention discloses a gum leakage process technology of bamboo-wood rods with high water content. The method comprises the following steps: 1) taking the bamboo-wood rods with high water content for carbonizing, bleaching and the like, putting the bamboo-wood rods into a pressure vessel, and separating bamboo-wood bundles with partition bars to assure a certain space, thus guaranteeing gum solution flowing; 2) carrying out vacuum bulking treatment at a vacuum pressure of 0.070-0.09MPa, wherein, a preferred pressure is 0.078MPa and system vacuum time is 20-60min, and determining specific vacuum time combined with thickness of the bamboo-wood rods; 3) carrying out gum leakage by diffusion; 4) carrying out vacuum drainage treatment; and 5) taking out the bamboo rods after gum leakage. Theprocess in the invention helps avoid the procedure for drying the bamboo-wood rods before gumming, and only the drying process after gumming is required, thus simplifying the process, solving the problem of conventional dry bamboo-wood rods such as uneven gumming, realizing stable and even product performance, and saving production cost of the drying procedure before gumming including labor wage,electric energy and dried water evaporation heat energy unit about ** / m<3>.

Owner:YUNNAN MENGXIANG BAMBOO IND

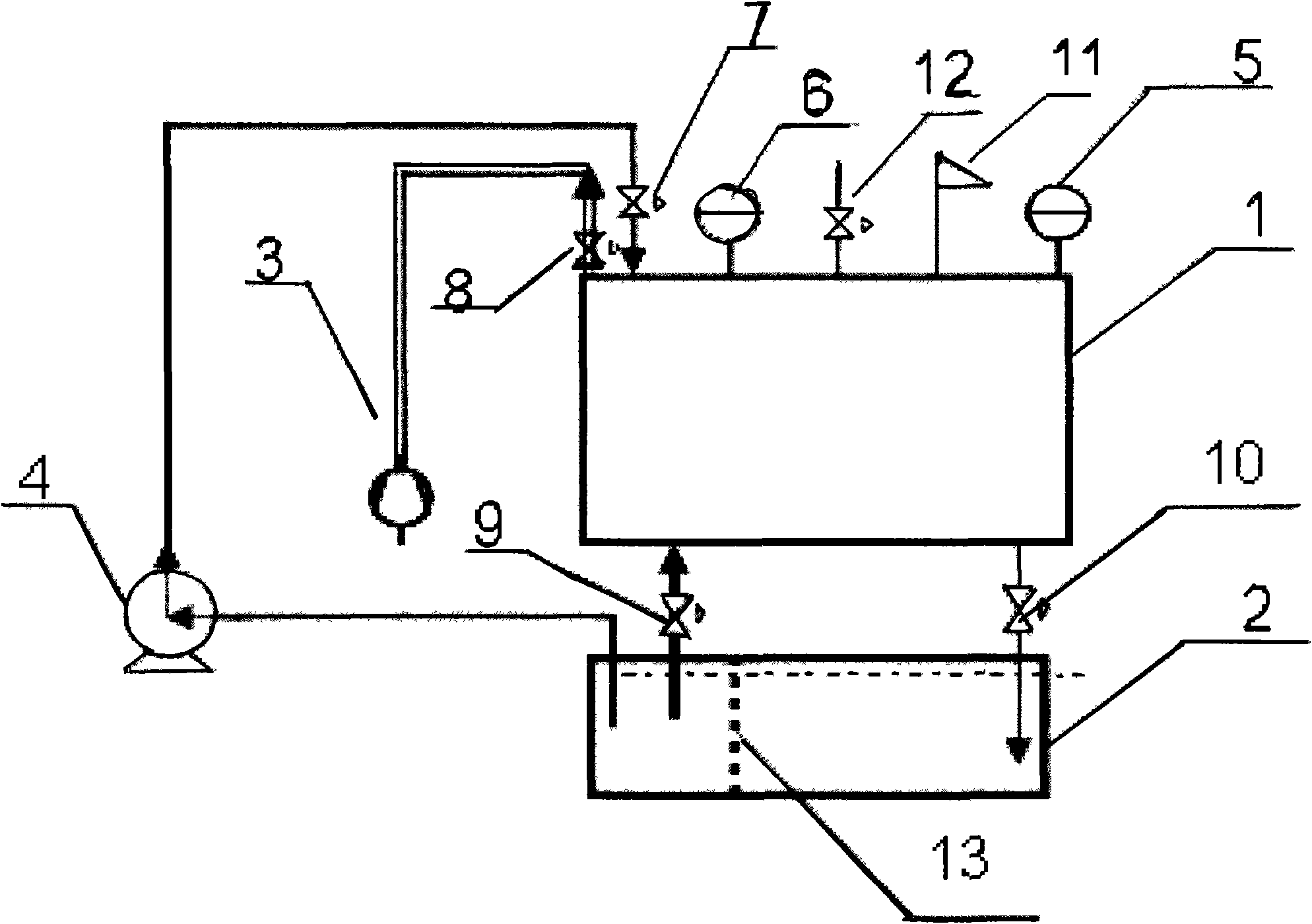

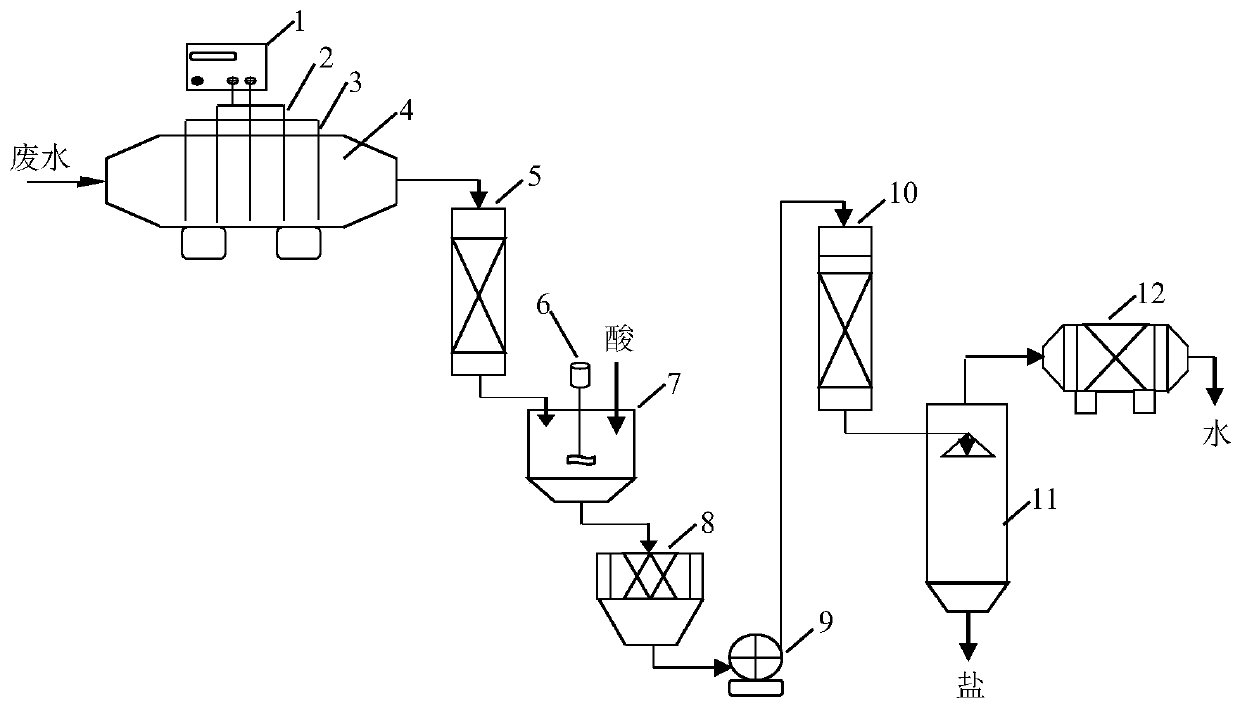

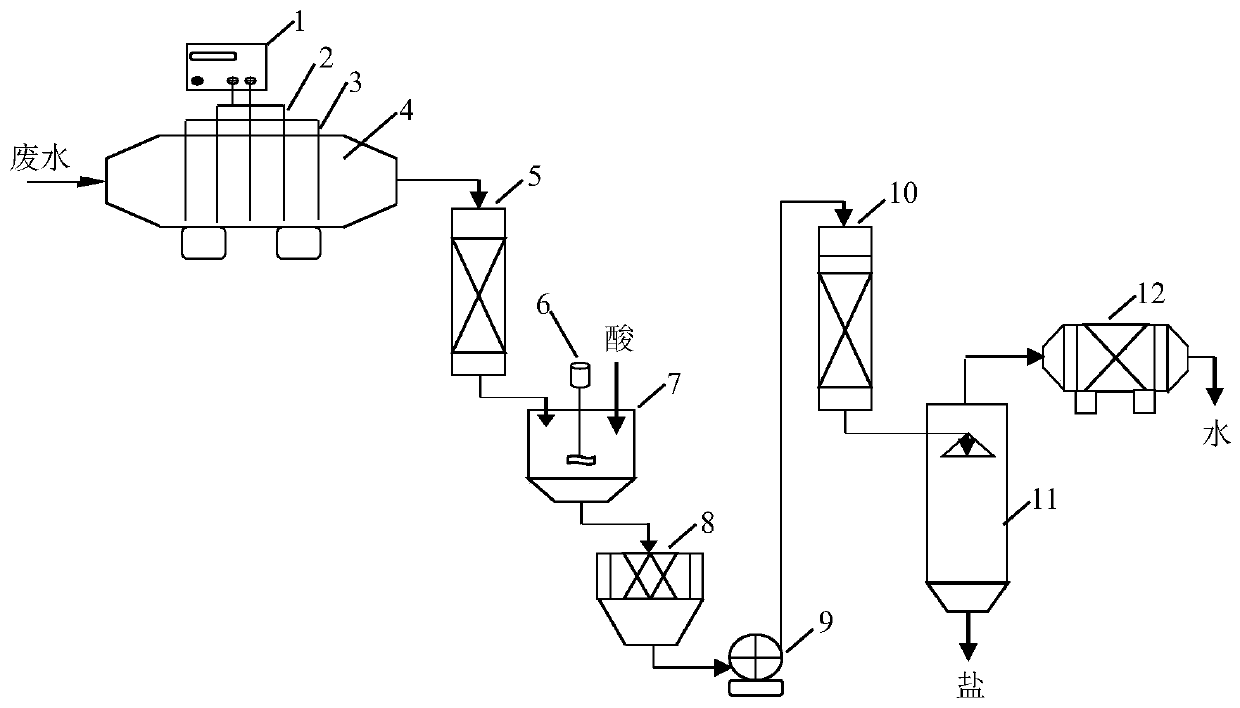

Treatment system and method for recycling and zero emission of binary high-salt complex-system nickel hydrometallurgy wastewater

ActiveCN110015795AClear ingredientsRecycling process is simpleWater contaminantsTreatment involving filtrationHigh concentrationFiltration

The invention discloses a treatment system and method for recycling and zero emission of binary high-salt complex-system nickel hydrometallurgy wastewater. Firstly, organic matter is removed by electro-catalytic oxidation and activated carbon adsorption; then the pH value of the wastewater is adjusted, so that carbonates are completely converted into sulfates; precision filtration is carried out,and then heavy metals which are mainly nickel is recycled through ion exchange and enrichment, so that a sodium sulfate water solution subjected to organic matter removal and heavy metal removal is obtained; finally, anhydrous sodium sulfate in salt water is recycled through spray drying; and meanwhile, dried water vapor is condensed and recycled and is returned to a production system. The invention effectively solves the treatment problem of the complex-system nickel hydrometallurgy wastewater containing heavy metals, high-concentration composite salts and a small amount of macromolecular organic matter, recycling of heavy metal nickel and salt in the wastewater is realized at the same time, and meanwhile, the condensed water can be recycled to the production system, so that comprehensiveutilization and zero emission of resources in the wastewater are truly realized.

Owner:HOHAI UNIV

Preparation method of ceramisite filter material for water treatment

ActiveCN105541372AReduce the risk of secondary pollutionLow costCeramic materials productionCeramicwareChemical compositionSludge

The invention provides a preparation method of a ceramisite filter material for water treatment, comprising the following steps: naturally air-drying sewage sludge and water supply sludge; respectively grinding and smashing clay and the air-dried water supply sludge and sewage sludge, and filtering by using a sieve after smashing; detecting the percentage contents of SiO2, Al2O3, Fe2O3, CaO, MgO, K2O, Na2O and organic matters in the clay, the water supply sludge and the sewage sludge: detecting the following chemical components in powder after mixing, and if a following ratio is not reached, adding absent substances, so that a mixture meets a certain ratio as follows; adding water in the mixture, stirring until a sticky state is formed, and then putting into a ball forming mill for ball forming, wherein the addition amount of the water is 36-44 percent of the weight of the mixture; putting a pellet at a cool and ventilated place, and naturally drying for 24h; putting the pellet into a muffle furnace, adjusting the temperature to 395-405 DEG C, and preheating for 10min; heating up for firing, and keeping a constant temperature for 20min after the in-furnace temperature of the muffle furnace is increased to 1200 DEG C; after completely firing the ceramisite filter material, taking out the ceramisite filter material, and naturally cooling to room temperature.

Owner:浙江绿治环保技术有限公司

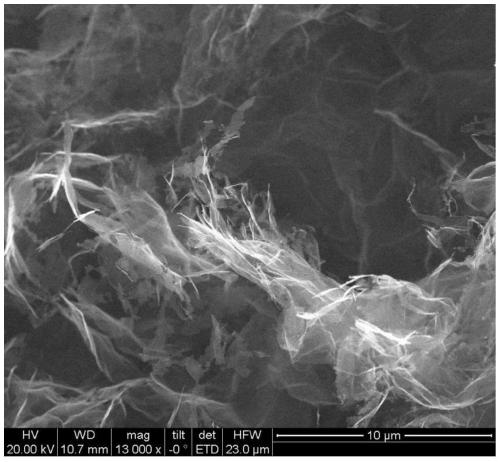

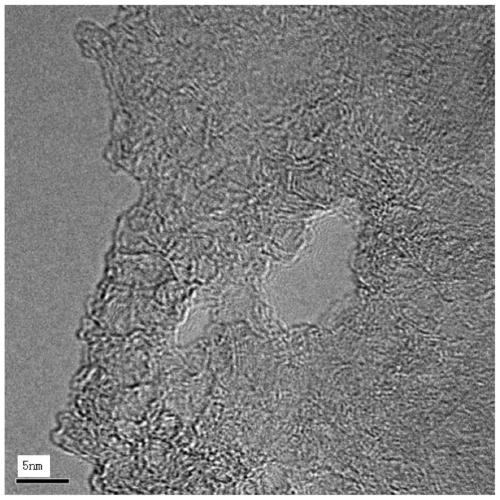

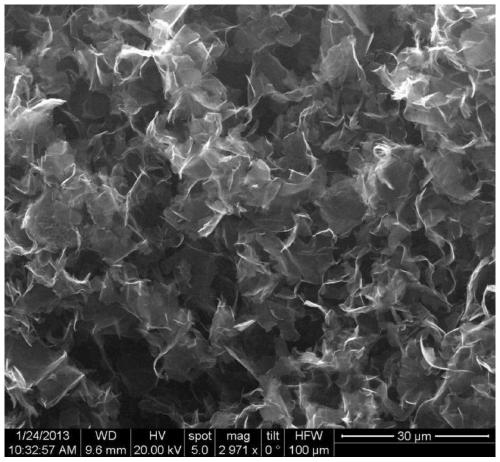

Porous ultra-thin graphene suitable for lubricating oils and preparation method and application thereof

The invention embodiment relates to a porous ultra-thin graphene suitable for lubricating oils and a preparation method and application thereof. The preparation method comprises the following steps: opening graphite edges by a weak oxidation or halogenation manner; inserting water molecules into the graphite subjected to weak oxidation or halogenation to obtain a water intercalated graphite; washing and drying the water intercalated graphite; performing microwave treatment on the dried water intercalated graphite, performing ultrasonic dispersion in a solvent, and performing drying after ultrasound dispersion. The graphene prepared by the method has a layer number fewer than four layers, the size distribution is uniform, the interior of the graphene surface has no defects, the graphene edges are suitable for grafting long carbon chains, and the grafted graphene is suitable for being added in the lubricating oils to improve lubricating oil performances.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

Water-based paint spraying process

InactiveCN110302945AInhibition releaseAvoid potential damagePretreated surfacesCoatingsWater basedLacquer

The invention discloses a water-based paint spraying process. The water-based paint spraying process comprises the following steps that coating of water-based closed primer is performed for the firsttime, wherein the coating amount is 80-100 g / m<2>, after coating, drying is performed, the dried water-based closed primer undergoes sanding, then water-based paint color wiping is performed, the wiping amount is 80-100 g / m<2>, and air-drying is performed after color wiping; coating of water-based primer is performed, wherein the coating amount is 90-120 g / m<2>, and the dried water-based primer undergoes sanding; coating of water-based color paint is performed, wherein the coating amount is 80-100 g / m<2>, and air-drying and sanding are performed after coating; coating of water-based finish paint is performed, wherein the coating amount is 90-120 g / m<2>. According to the water-based paint spraying process, the water-based closed primer is sprayed, so that the phenomenon of outward volatilization of veneer tannic acid in the water-based finish paint spraying process is effectively avoided, then the phenomenon of spot-like yellowing due to outward volatilization of the veneer tannic acidis effectively avoided, and the product quality is improved; and according to the water-based paint spraying process, sanding is performed after spraying of each time, the adhesive force of the water-based paint is increased through sanding, then the phenomenon of layering of the water-based paint in the spraying process is effectively avoided, and the quality of spraying is effectively guaranteed.

Owner:安徽志邦全屋定制有限公司

Cleaning method of target material

PendingCN110670083APrevent oxidationReduce usageVacuum evaporation coatingSputtering coatingMegasonic cleaningHigh pressure water

The invention provides a cleaning method of a target material. The cleaning method of the target material comprises the following steps that (1), a cleaning agent is coated on the surface of the target material, and brushing is carried out; (2), the brushed target material is ultrasonically cleaned; and (3), inert gas is used to blow-dry water on the surface of the target material after ultrasoniccleaning, and then vacuum drying treatment is carried out to obtain the cleaned target material. According to the cleaning method of the target material, the target material does not need to be cleaned by using a high-pressure water gun, the cleaning method is simple, the consumption of the cleaning agent is low, the cleaning cost is reduced, moreover, the amount of waste liquid generated throughthe cleaning method is small, and the pressure of waste liquid treatment is favorably reduced.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

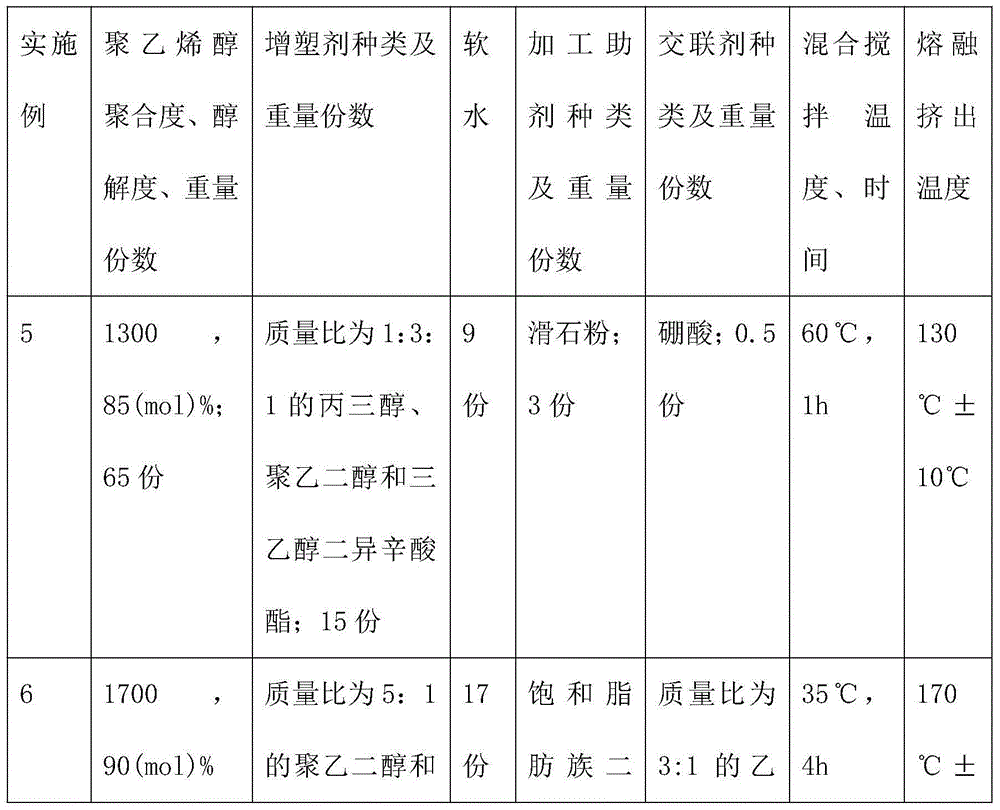

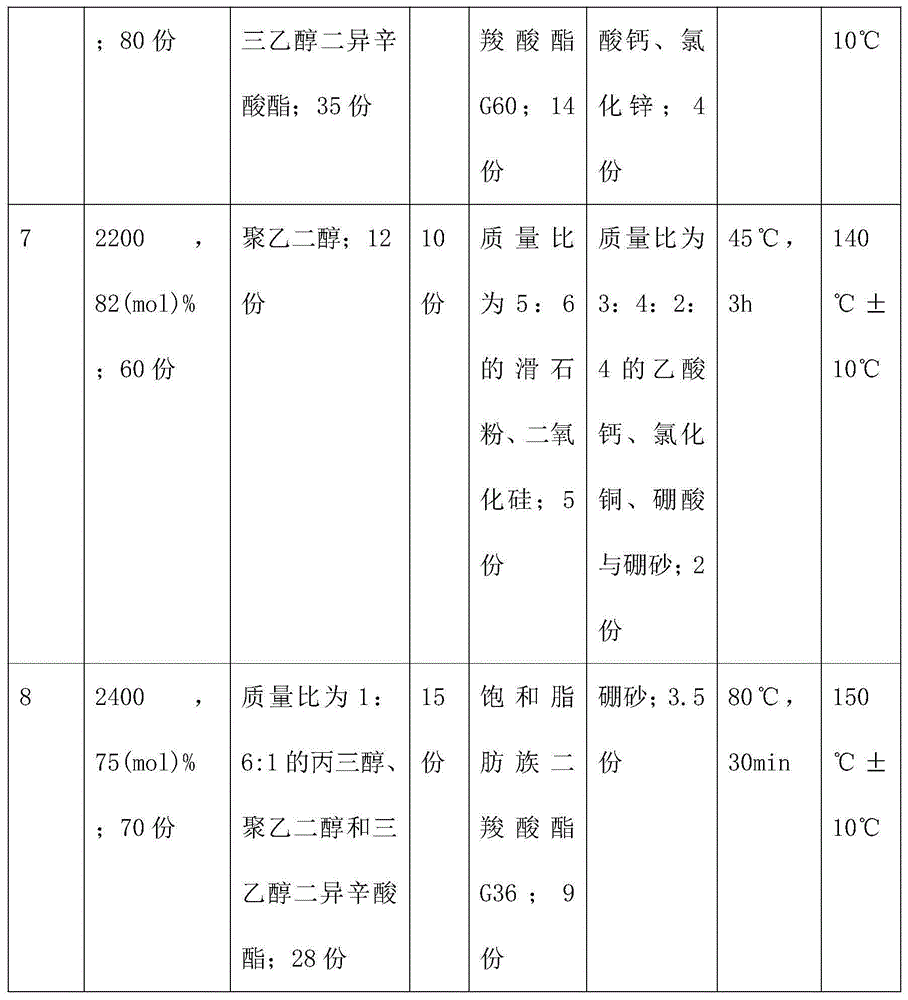

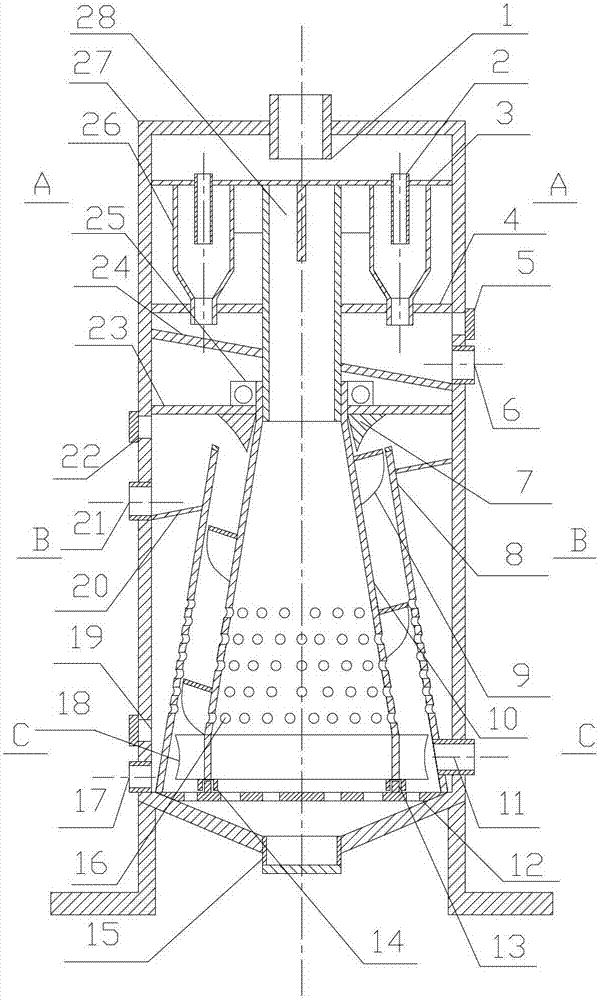

Room-temperature water-soluble 3D printing consumptive material

ActiveCN106189011AHigh decomposition temperatureImprove protectionAdditive manufacturing apparatusPolymer scienceProcedure Agents

The invention relates to a room-temperature water-soluble 3D printing consumptive material. The room-temperature water-soluble 3D printing consumptive material is prepared by drying water-soluble polyvinyl alcohol resin under the condition of 40-120 DEG C, wherein the water-soluble polyvinyl alcohol resin is prepared from polyvinyl alcohol, a plastifier, soft water and a processing aid in effective quantity; the polymerization degree of the polyvinyl alcohol is 1000-2400, and the alcoholysis degree of the polyvinyl alcohol is 72mol%-92.0mol%; the plastifier is one or the combination of several kinds of glycerin, polyethylene glycol and triethylene glycol di-2-ethylhexoate(triglycol dioctate); the processing aid is one or the combination of several kinds of talcum powder, silicon dioxide and saturated aliphatic dicarboxylic ester; and the drying time is 1-24h. After the manufactured 3D printing consumptive material is used for 3D printing, the 3D printing consumptive material can dissolve in water of 20-40 DEG C, so that three-dimensional products with hollowed-out patterns can be manufactured.

Owner:CHINA PETROCHEMICAL CORP +1

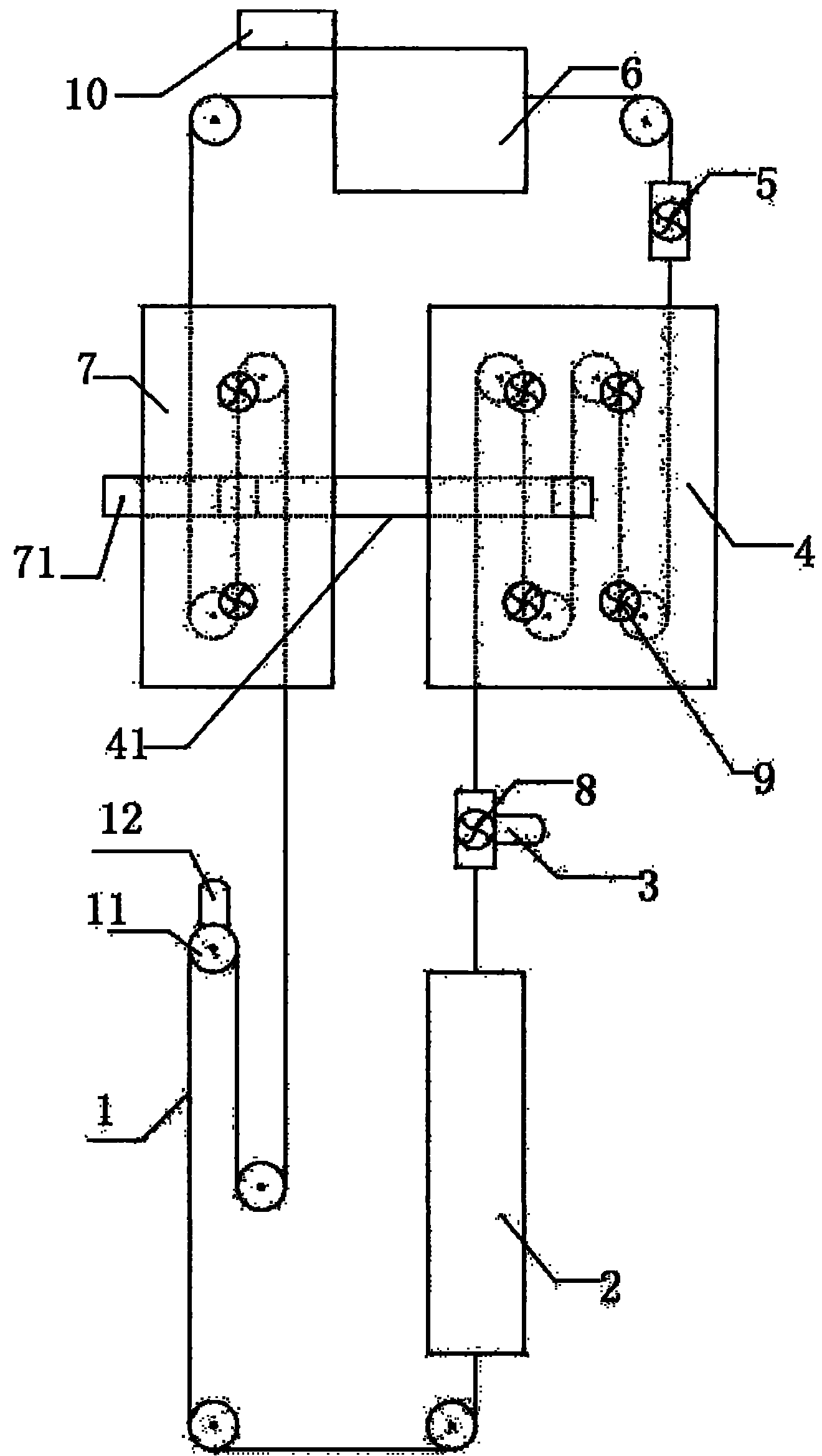

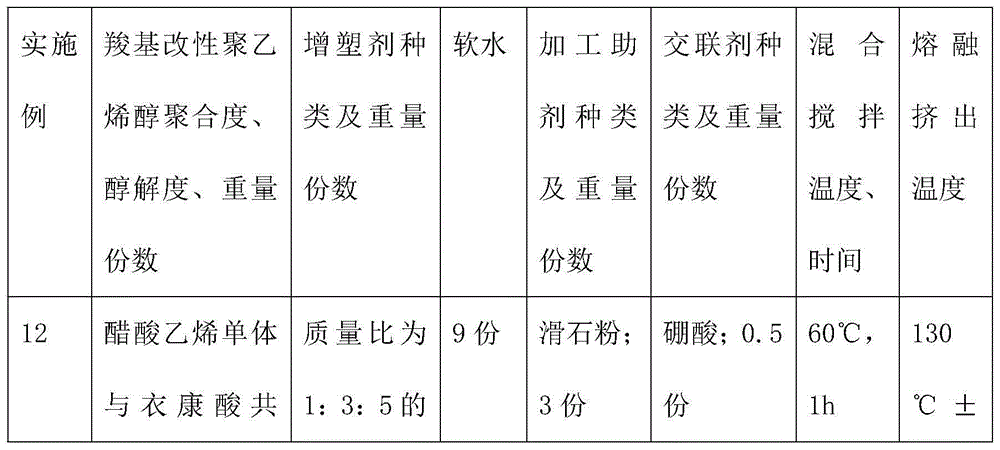

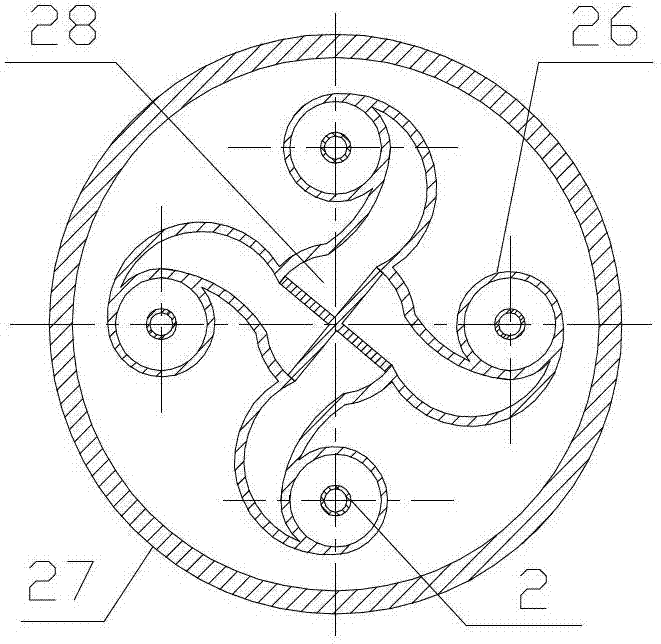

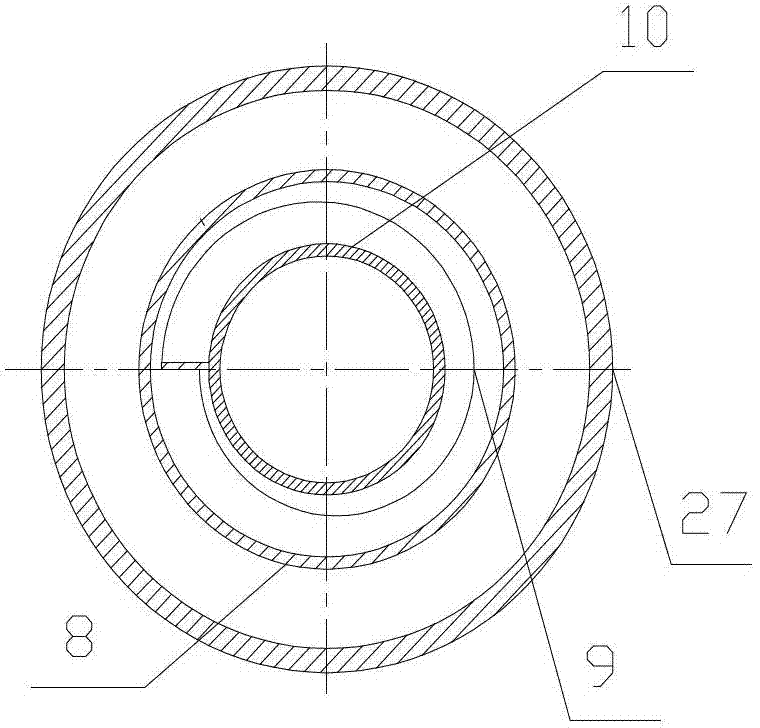

Self-drive centrifugal cyclone wet/dry water-powder-air separator

The invention discloses a self-drive centrifugal cyclone wet / dry water-powder-air separator, comprising a cylindrical outer barrel, an air outlet arranged on the outer barrel, a liquid outlet, a central collecting port, a wet powder outlet, a dry powder outlet and a wet powder collecting plate in the inner cavity, a lower separator, a dry powder collecting plate, a middle separator, an upper separator and a lower support plate, wherein a self-drive rotary scraping cone connected with a bearing is arranged above the lower support plate, a water filtration cone connected with the wet powder collecting plate and the central hole of the self-drive rotary scraping cone is arranged below the lower separator, a spiral channel is formed between the self-drive rotary scraping cone and the water filtration cone, four inverted cone cyclone separators and a round distributor with an X-shaped guide plate are arranged between the middle separator and the upper separator, the lower end of the round distributor is provided with the dry powder collecting plate, and the centers of the upper ends of the four cyclone separators are respectively provided with exhaust pipes. The invention is suitable for separating wet / dry water-powder-air mixtures with high separation efficiency.

Owner:JIANGSU UNIV OF SCI & TECH

Carbon-free gas hydrate fire extinguishing agent and preparation method thereof

InactiveCN104826263AReduce the temperatureSignificant technological progressFire extinguisherNitrogenHigh pressure

The invention relates to a carbon-free gas hydrate fire extinguishing agent. The fire extinguishing agent is a solid hydrate powder generated from an inert gas and a water mixture at a low temperature under a high pressure, the inert gas is anyone of nitrogen and argon, or a gas obtained by mixing nitrogen with argon according to an arbitrary ratio, and the water mixture can be water or an aqueous solution or dry water or a dry solution or ice. The invention also provides a preparation method of the fire extinguishing agent. The method comprises the following steps: reacting the inert gas with water or the aqueous solution or the dry water or the dry solution or ice at -10-10DEG C under 7-20MPa to generate a gas hydrate, crushing in below -10DEG C environment, and screening to form the hydrate powder with the particle size of below 1.0mm. The carbon-free gas hydrate fire extinguishing agent has the advantages of realization of zero carbon discharge, simple preparation process, low price, and rapid fire extinguishing, and is a clean and efficient fire extinguishing agent.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com