Patents

Literature

462results about "Aluminates/aluminium-oxide/aluminium-hydroxide purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for definition of DICOM header values

InactiveUS20060239589A1Aluminates/aluminium-oxide/aluminium-hydroxide purificationCharacter and pattern recognitionDICOMComputer vision

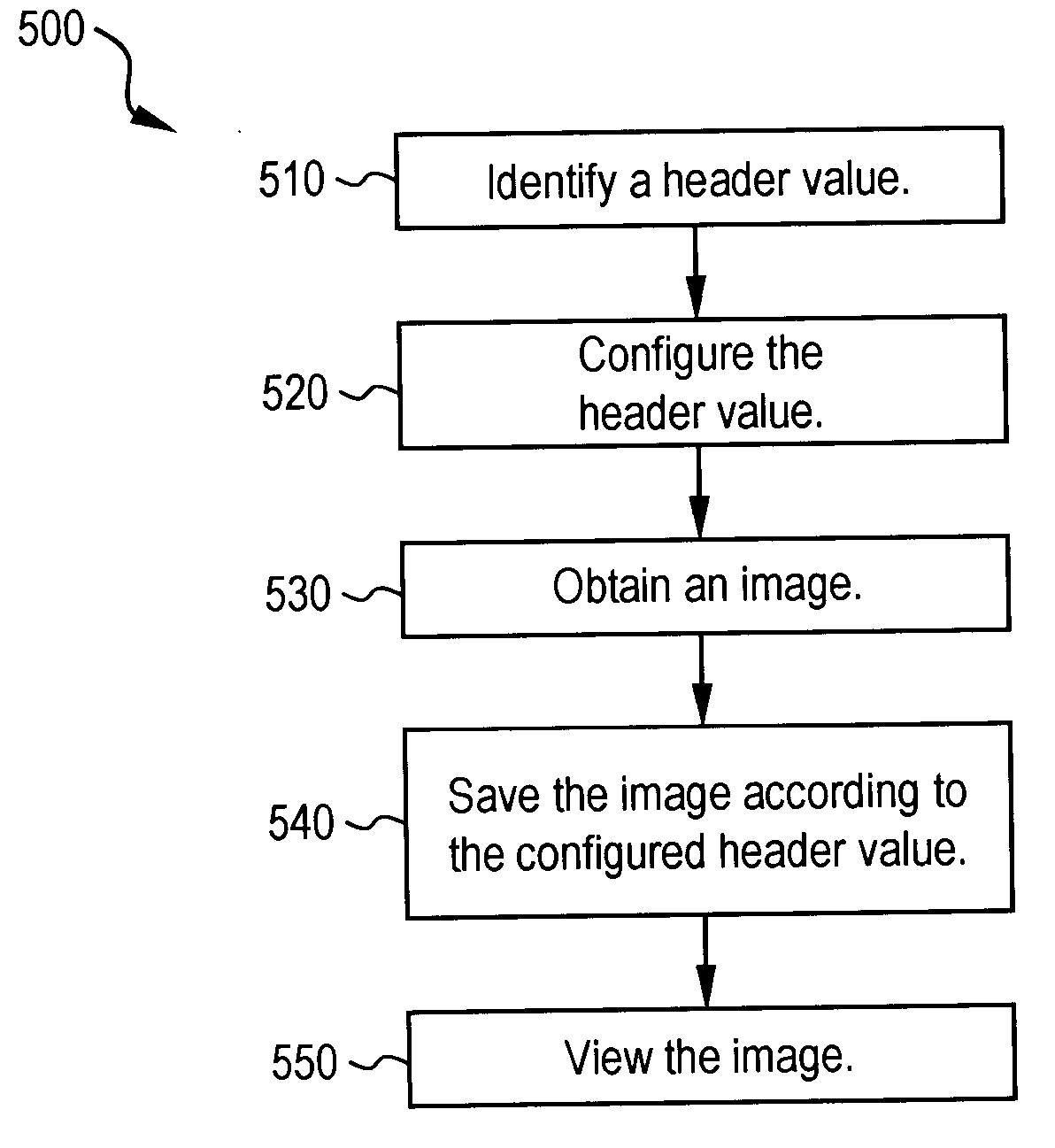

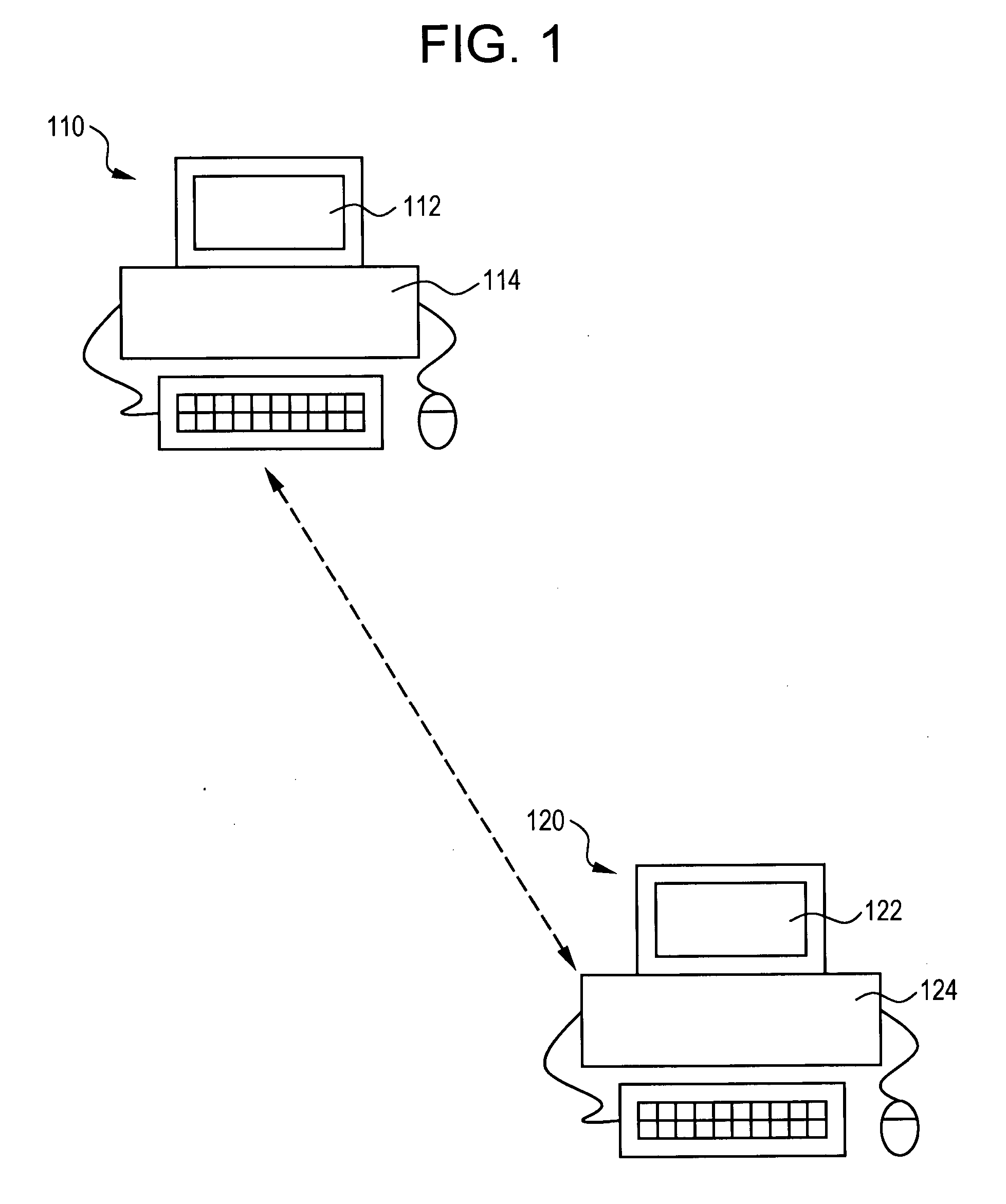

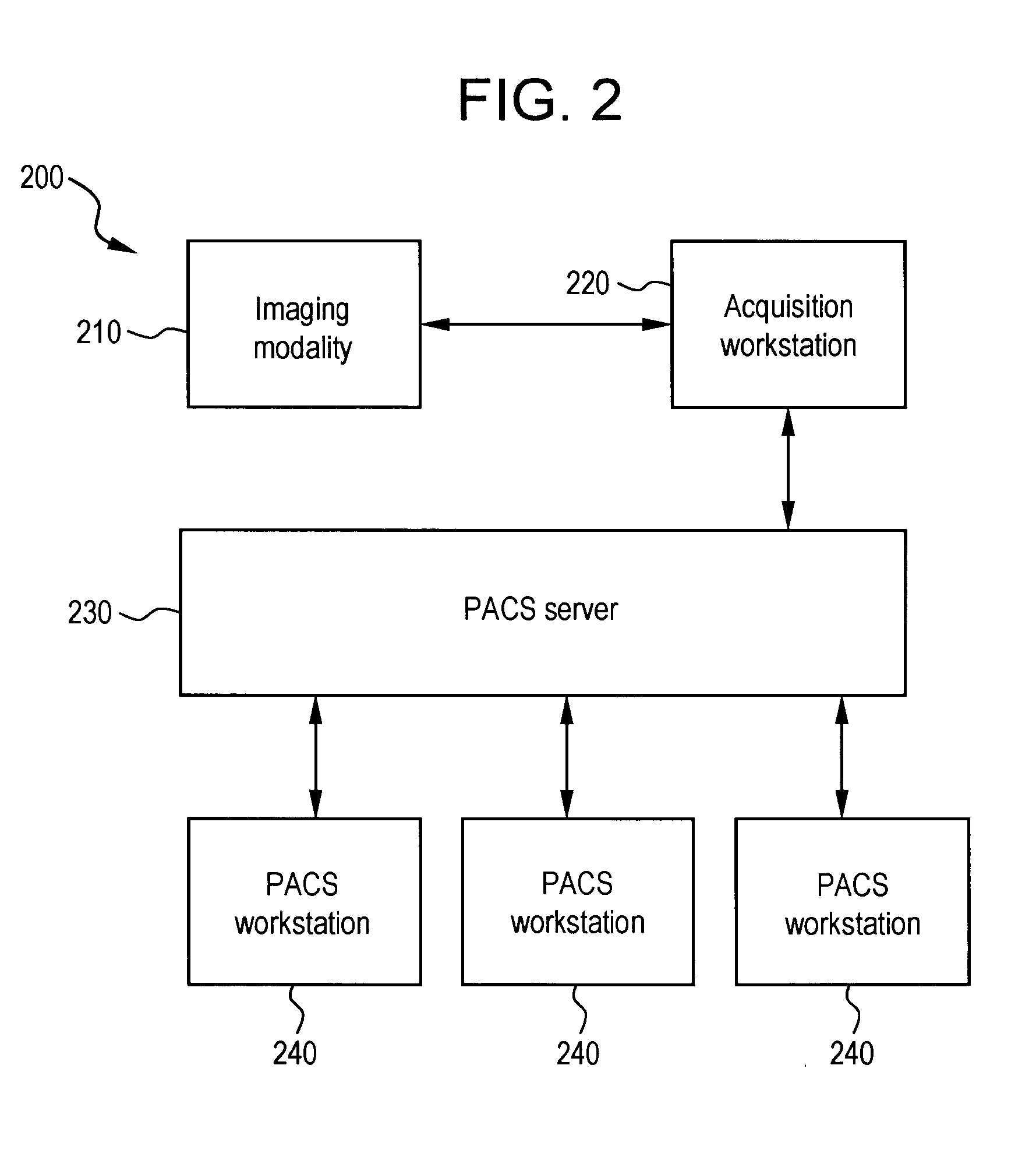

Certain embodiments of the present invention provide an improved system and method for image file header configuration. Certain embodiments of the method include retrieving one or more criterion for configuration of an image orientation parameter, configuring the image orientation parameter based on the one or more criterion, obtaining image data, and storing the image data in an image file. The image file has a header portion including the image orientation parameter. In an embodiment, the image orientation parameter may be modified from a default configuration. The one or more criterion may include user preference, modality restriction, system preference, and / or rule, for example. The method may further include saving the image file with the configured image orientation parameter. Additionally, the method may include displaying an image according to the configured image orientation parameter. The image may be automatically oriented for display based on the configured image orientation parameter.

Owner:GENERAL ELECTRIC CO

Method for making high purity and free flowing metal oxides powder

InactiveUS7931836B2Improve physical and chemical propertyImprove purification effectBurnersOxide/hydroxide preparationApparent densityFree falling

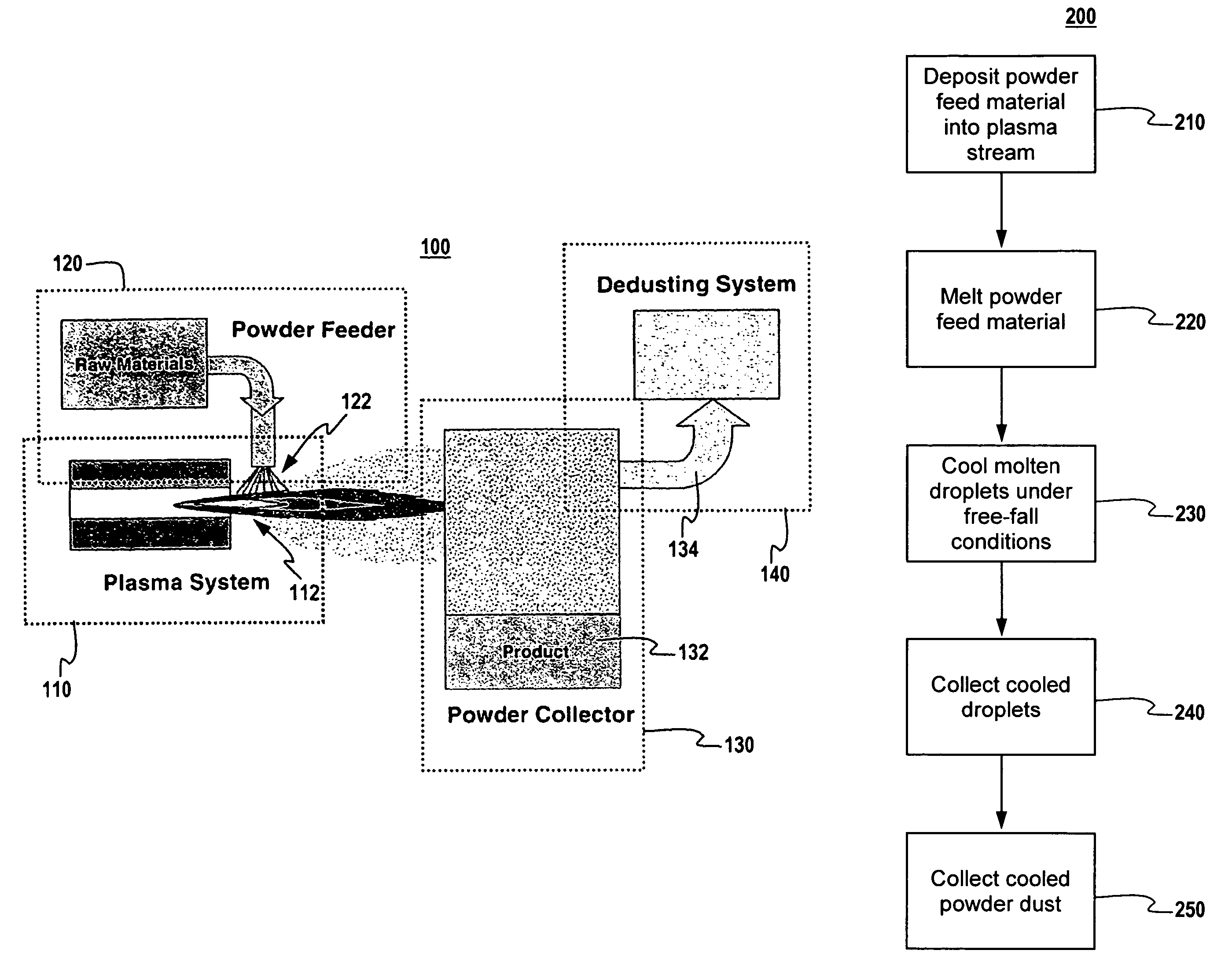

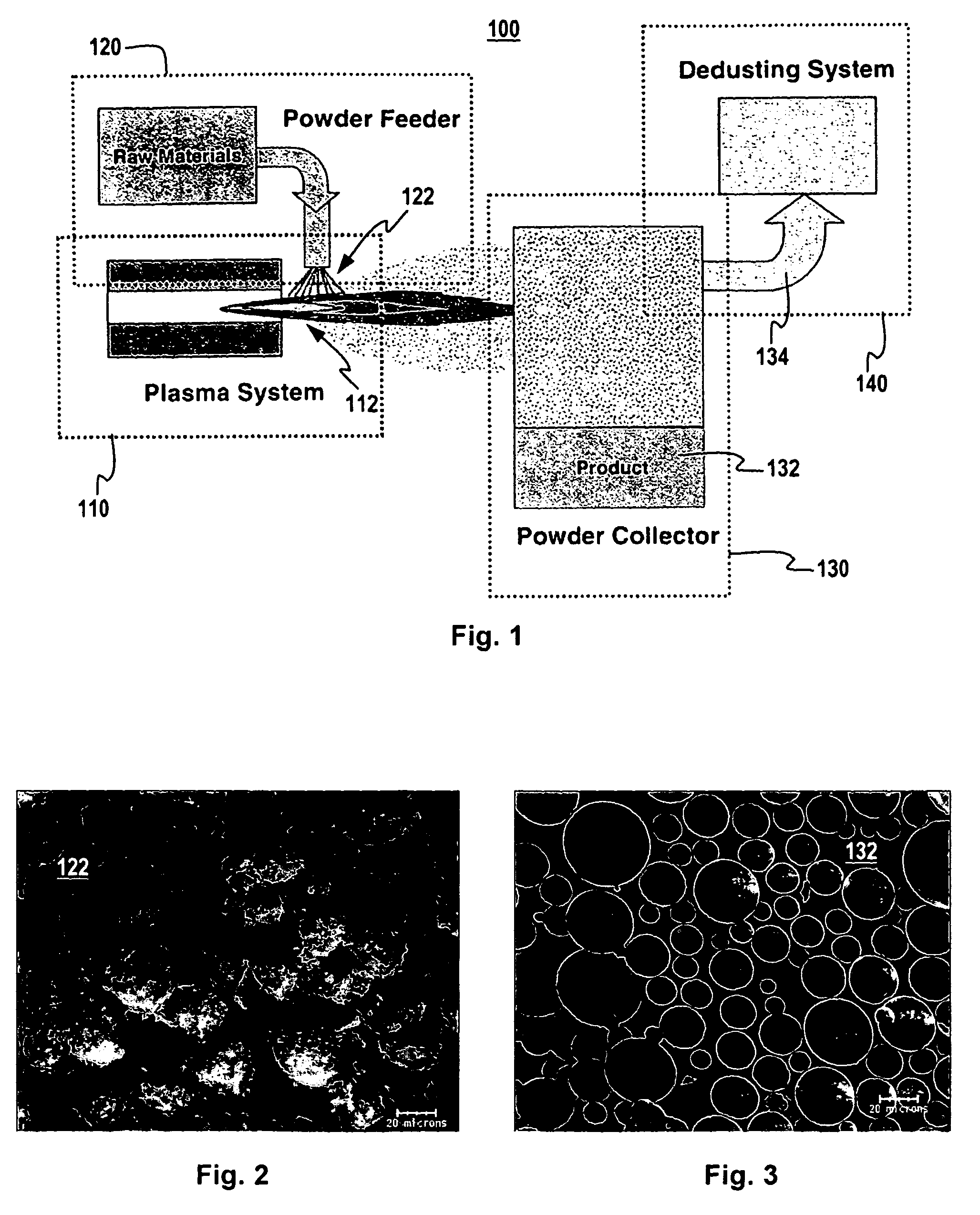

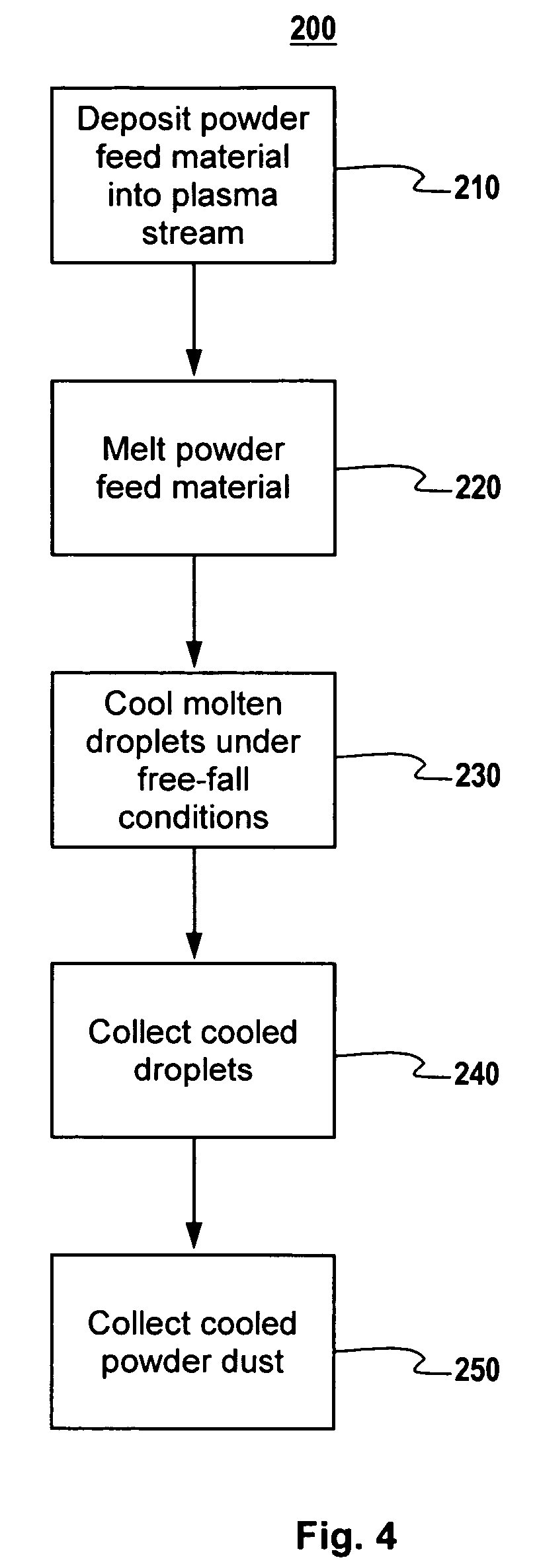

According to aspects of the present invention, metal oxide powder, such as yttria and alumina powder (feed material), is processed using a plasma apparatus. The process generally consists of in-flight heating and melting of the feed material by the plasma apparatus. The plasma apparatus contains a plasma torch with required power supply and cooling systems, a powder feeder, a chamber to collect the powder and a dedusting system. The heated powder forms molten spherical droplets that are rapidly cooled under free fall conditions. The plasma densification process removes some impurity oxides, modifies the morphology of the particle and increases the apparent density of the powder.

Owner:SULZER METCO (US) INC

Method for preparing high-pruity alumina powder

ActiveCN1579941ALow costNo pollution in the processAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxide/hydroxide preparationAluminium hydroxideFluorescence

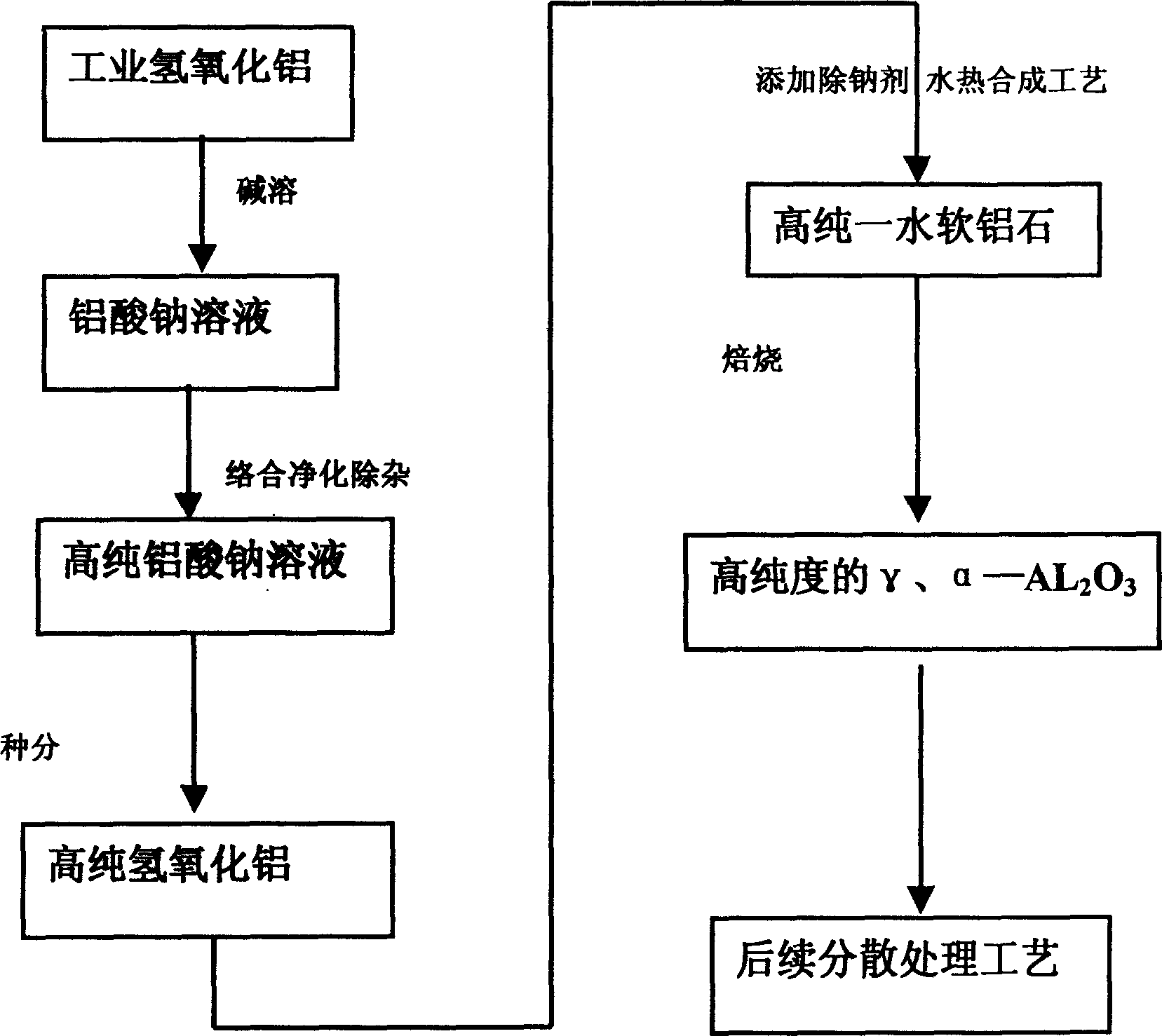

The invention discloses a method to produce highly pure Alumina powder. The steps are as follows: deploying Aluminium hydroxide which is produced in the process of manufacturing alumina using sintering process to be solution, disposing of impurity, adding seed crystal to prepare highly pure aluminium hydroxide; removing Na in the solution, getting highly pure bodhmite after hydrothermal synthesis; and after washing and baking, highly pure Alumina can be obtained. The cost is about 15 thousand per ton, which is far less than current market price, 40-60 thousand per ton. It can put into production in a large scale and it is easy to reach 1-5 thousand ton per year. With a low cost, no pollution and high purity (over 99.99 percent), the production is widely used in rare earth fluorescence materials, high voltage Na lamp and other relative special Alumina fine ceramics field.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

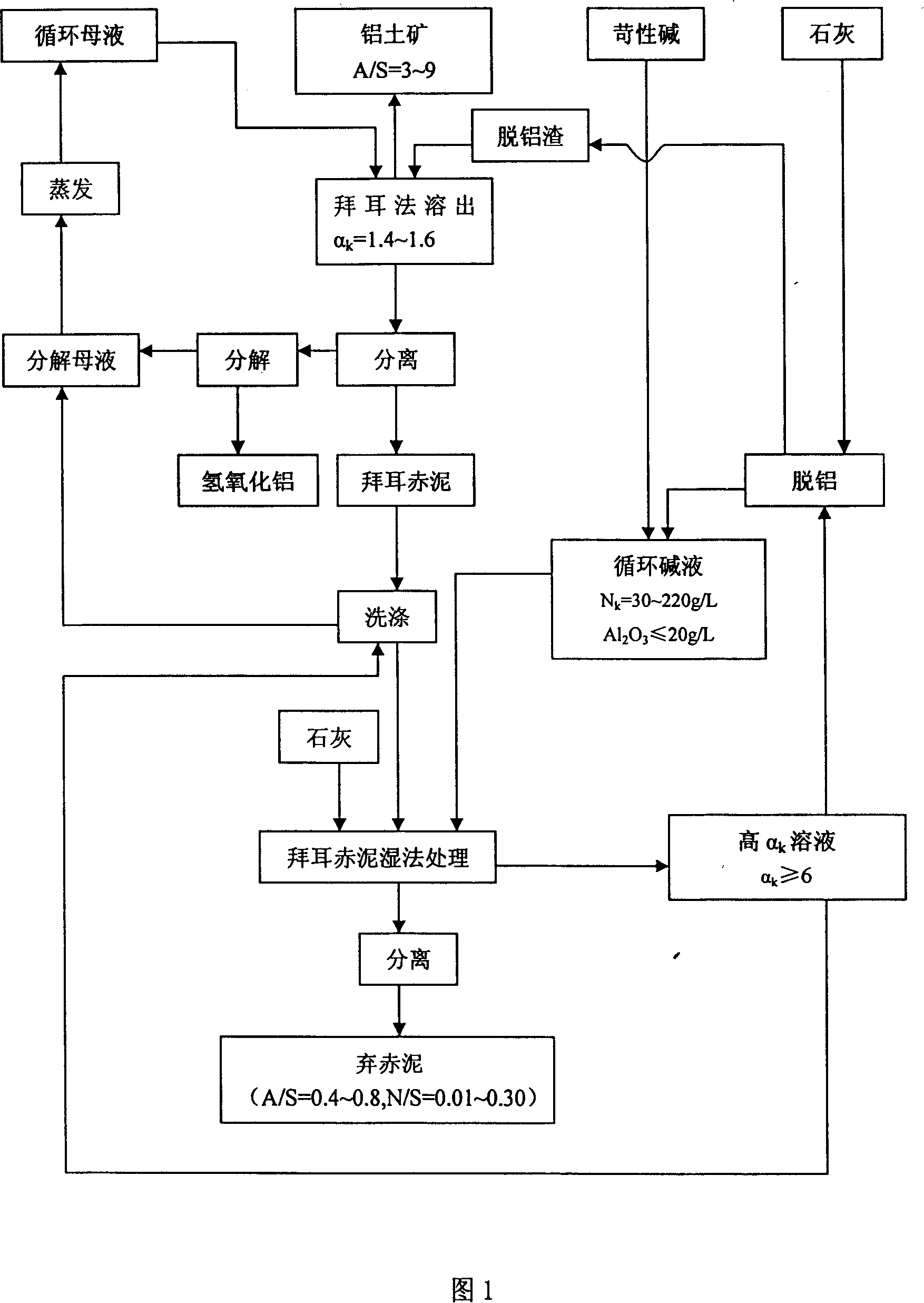

Red mud dealkalization method at normal pressure by Bayer process

InactiveCN1594093ASatisfy evacuation requirementsIncrease productivityAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxides/hydroxidesDealkalizationPetroleum engineering

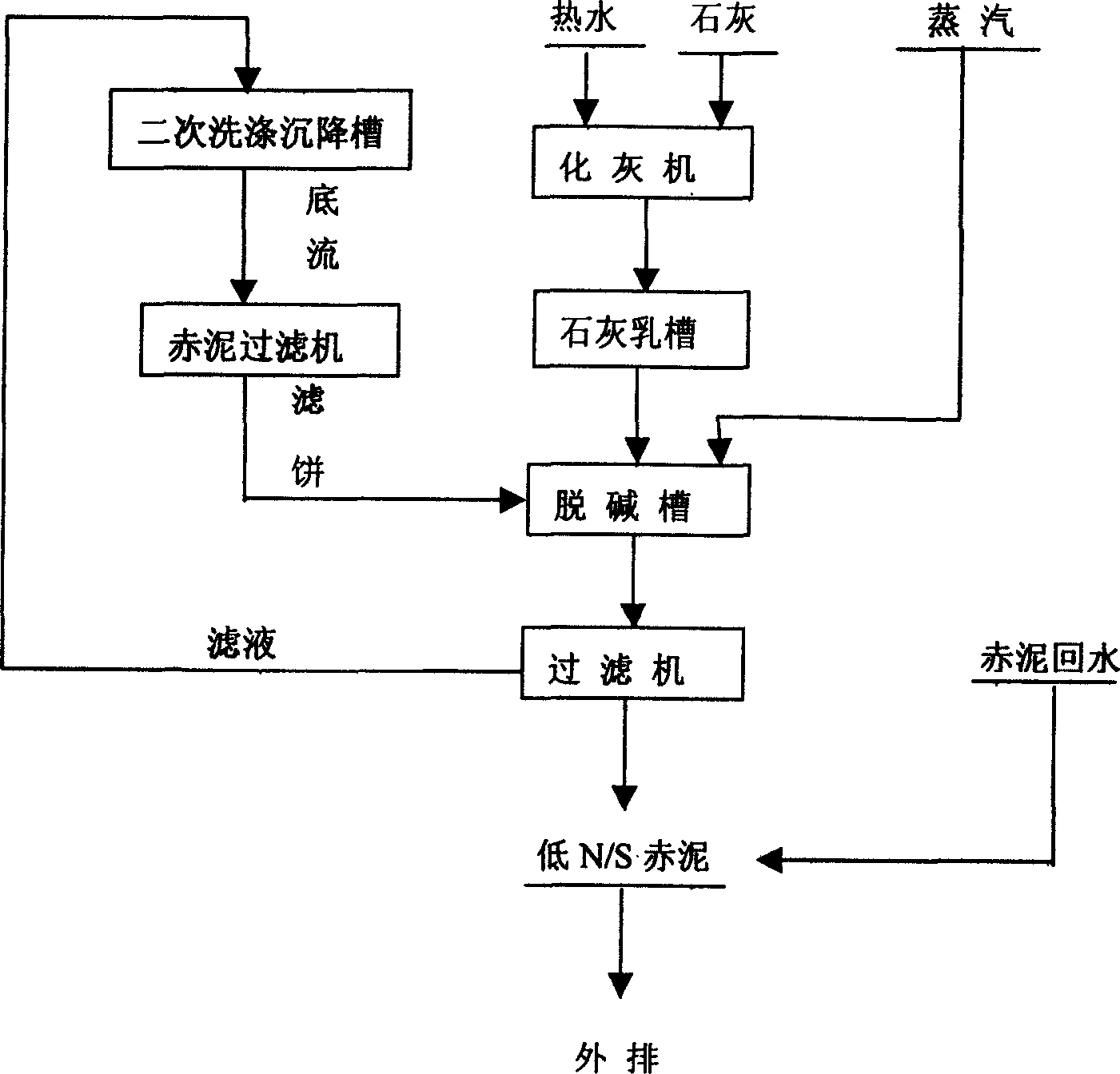

The invention discloses a red mud dealkalization method at normal pressure by Bayer process, wherein the dealkalizing step consists of, washing and filtering the red mud, charging lime cream into the red mud filter cake, mixing for dealkalizing reaction, subjecting the reaction slip to washing, filtering, drying and discharging.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

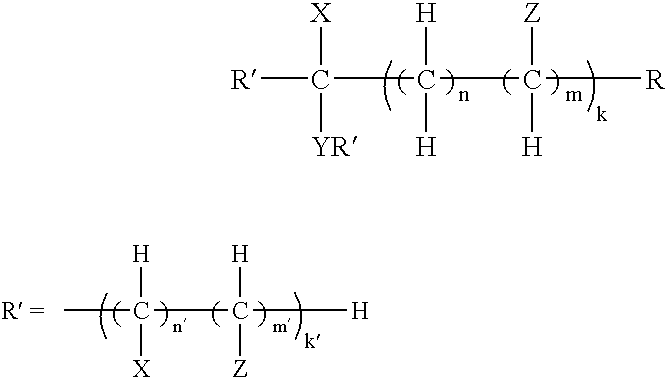

Recovery of alumina trihydrate during the bayer process using cross-linked polysaccharides

ActiveUS8298508B2Accelerated settlementEnhanced inhibitory effectGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationCross-linkCellulose

The invention provides methods and compositions for improving the production of alumina hydrate. The invention involves adding one or more polysaccharides to liquor or slurry in the fluid circuit of the production process. The one or more polysaccharides can be a cross-linked polysaccharide (such as cross-linked dextran or cross-linked dihydroxypropyl cellulose). The various polysaccharides can impart a number of advantages including at least some of: greater flocculation effectiveness, increasing the maximum effective dosage, faster settling rate. The production process can be a Bayer process.

Owner:NALCO CO

Recovery of alumina trihydrate during the bayer process using cross-linked polysaccharides

ActiveUS20120034142A1Accelerated settlementEnhanced inhibitory effectGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationCross-linkCellulose

The invention provides methods and compositions for improving the production of alumina hydrate. The invention involves adding one or more polysaccharides to liquor or slurry in the fluid circuit of the production process. The one or more polysaccharides can be a cross-linked polysaccharide (such as cross-linked dextran or cross-linked dihydroxypropyl cellulose). The various polysaccharides can impart a number of advantages including at least some of: greater flocculation effectiveness, increasing the maximum effective dosage, faster settling rate. The production process can be a Bayer process.

Owner:NALCO CO

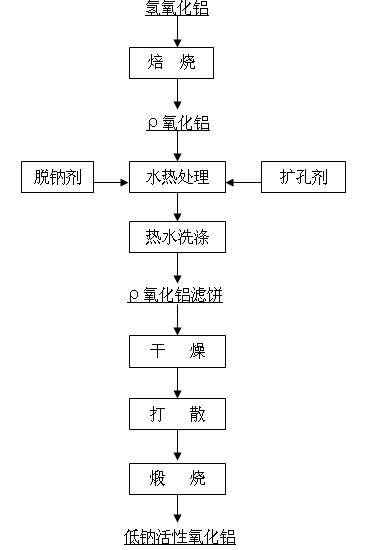

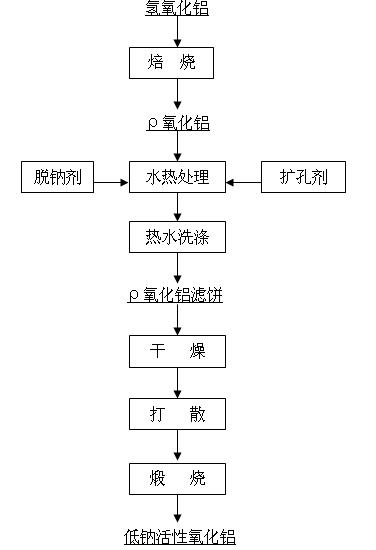

Preparation method of low-sodium active aluminum oxide

InactiveCN102070169AReduce manufacturing costLarger than surfaceCatalyst carriersAluminates/aluminium-oxide/aluminium-hydroxide purificationSlurryHeat treating

The invention relates to a preparation method of low-sodium active aluminum oxide, in particular to a preparation method of active aluminum oxide used as catalyst carrier for cleaning automobile tail gas. The method is characterized by comprising the following steps: roasting aluminum hydroxide to obtain an intermediate product rho aluminum oxide, adding a sodium removal agent and a pore expanding agent to carry out hydrothermal treatment, filtering the treated slurry, washing with hot pure water, drying, dispersing the dried product with a dispersion machine, and calcining to obtain active aluminum oxide. In the method provided by the invention, any one or more than two of nitric acid, acetic acid and citric acid is / are used as the sodium removal agent to wash the intermediate product after the roasting of aluminum hydroxide, thereby lowering the sodium content. The low-sodium active aluminum oxide prepared from aluminum hydroxide has the advantages of larger specific surface, multiple pores, high pore volume, simple preparation method and lower production cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Processing method for aluminum electrolysis waste cathode carbon block

ActiveCN107662913AAchieve recyclingElectrolytic realizationCalcium/strontium/barium sulfatesAluminates/aluminium-oxide/aluminium-hydroxide purificationElectrolysisAluminium hydroxide

The invention belongs to the technical field of recycling of electrolytic aluminum industrial wastes and specifically discloses a processing method for an aluminum electrolysis waste cathode carbon block. The processing method comprises the following steps: breaking the waste cathode carbon block and then adding water for ball-milling, performing decyanation treatment, leaching with hot water, leaching with concentrated sulfuric acid, washing and performing flotation, thereby acquiring a first-level carbon powder product and a second-level carbon powder product; reacting a primary acid leaching solution with a sodium hydroxide solution and filtering, thereby acquiring solid aluminum hydroxide; mixing the reaction filtrate with lime and filtering, thereby acquiring calcium sulfate; using water for absorbing the mixed gas formed by the primary washing gas and the acid leaching gas, thereby acquiring a hydrofluoric acid solution; mixing the prepared hydrofluoric acid solution with a ball-milling separating liquor and a hot water leaching separating liquor; adding aluminum hydroxide into the mixed liquor; filtering and separating the reactants; filtering, thereby acquiring the liquid phase of reusable water and the solid phase of fluorine-containing aluminum hydroxide; and roasting, thereby acquiring a fluorine-containing aluminum hydroxide product. According to the method providedby the invention, the harmless comprehensive recycling of the aluminum electrolysis waste cathode carbon block is realized.

Owner:山东绿脉铝业科技有限公司

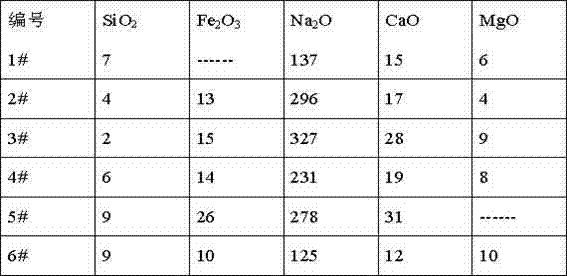

Treated Geothermal Brine Compositions With Reduced Concentrations of Silica, Iron and Lithium

This invention relates to treated geothermal brine compositions containing reduced concentrations of lithium, iron and silica compared to the untreated brines. Exemplary compositions contain concentration of lithium ranges from 0 to 200 mg / kg, concentration of silica ranges from 0 to 30 mg / kg, concentration of iron ranges from 0 to 300 mg / kg. Exemplary compositions also contain reduced concentrations of elements like arsenic, barium, and lead.

Owner:TERRALITHIUM LLC

Method of flotation desulfur desilicon in bauxite

ActiveCN1868599AAdvanced technologyIncrease production capacityAluminates/aluminium-oxide/aluminium-hydroxide purificationFlotationResource utilizationFatty acid

A floatation process for bauxite to remove S and Si includes such steps as grinding the crude bauxite, adding the yellow catching agent B, reverse floatation for removing S, grinding, adding the match of saponified fatty acid and naphthenic acid, and forward floatation. The resultant bauxite concentrate can be used to prepare aluminum oxide by Bayer method.

Owner:中铝郑州有色金属研究院有限公司

Method for producing aluminium oxide by middle-low grade alumyte

ActiveCN101113001AReduce energy consumptionReasonable processAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateResource utilization

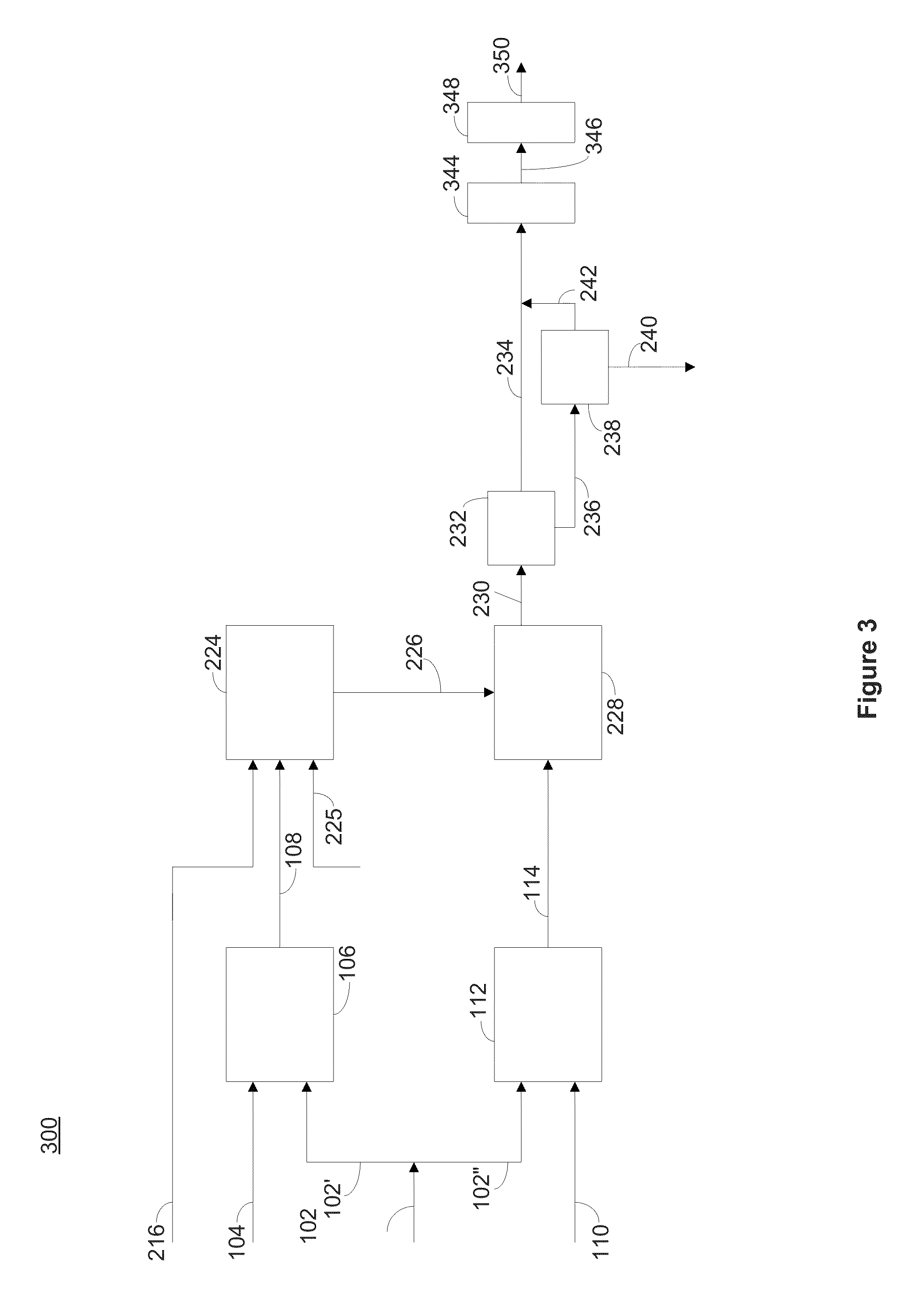

A method to produce aluminum oxide with middle-low bauxite relates to a method to produce aluminum oxide with middle-low bauxite by the means of Bayer-method. The invention is characterized in that: during the Bayer-method process, digestion process is to add dealuminization slag instead of lime as additive in middle-low bauxite to do Bayer process digestion; after digestion and backward washing of red mud, the red mud is mixed with recycle alkaline liquor, the lime is added, the digestion reaction is done, the red mud is separated from the slurry and discharged outside, the solution part obtained oppositely washes with Bayer-method, is sent to Bayer-method system to supplement alkali after digesting the red mud, the lime is added partly and is reacted, then, dealuminization slag and recycle alkaline liquor that goes through Bayer-method red mud wet treatment are gotten and dealuminization slag calcium aluminate hydrate instead of lime is added into the Bayer process digestion. The method of the invention belongs to all wet treatment, has simple process, low energy consumption, low alkali consumption and high recovery rate of aluminum oxide and is suitable for treating Chinese bauxite that is mainly middle-low bauxite; besides, the resource utilization is high, the amount of discharged red mud is low and the red mud is easy to be utilized comprehensively.

Owner:中铝郑州有色金属研究院有限公司

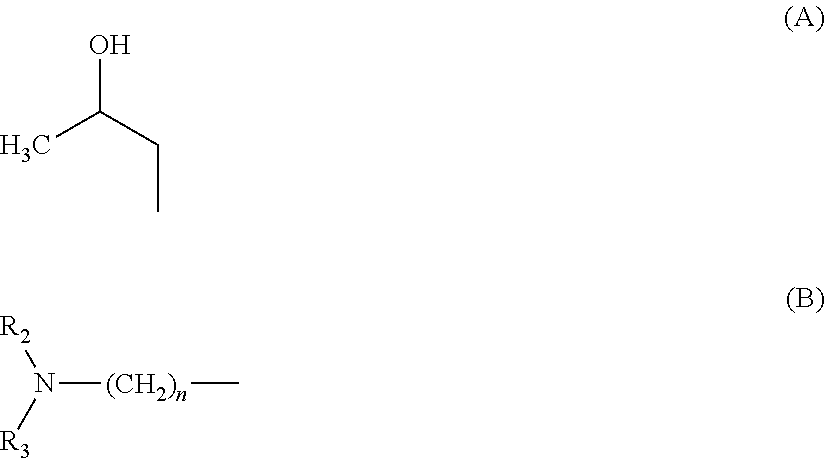

Use of polyols as scale control reagents in the mining processes

ActiveUS20090130006A1Improve stabilityReduce precipitationGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationPolyolAqueous solution

In the mining process, linear, branched, hyperbranched or dendrimeric polyols or mixtures thereof are employed as process stabilization aids for aqueous solutions and, or suspensions of metal salts. A specific application area of the polyols is the stabilization of bauxite liquor in the Bayer process of producing alumina from bauxite.

Owner:ECOLAB USA INC

Method for preparing aluminum oxide from low aluminum-silicon ratio aluminum-containing mineral

InactiveCN101100304ANo emissionsRealize refined utilizationSulfur compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationDecompositionSesquioxide

This invention discloses a method for producing aluminium oxide by using aluminium-containg are with low aluminium / silicon ratio. The method comprises procedures of: (1), atomizing raw material ore; (2), dressing by magnetic separation; (3), acid treatment; (4), filtering and separation; (5), heating for dehydration decomposition; (6), recovering sulfur trioxide. After that, produced is the inventive product aluminium sesquioxide with high pureness upto 99.5%, meeting the standard of Non-Ferrous Metals Industries SY / T274-1998. The advantages of this invention are; full reutilization of materials, simple process, simple equipment, no discharge of wastes of solid, liquid and gas, no secondary pollution.

Owner:NORTHEASTERN UNIV

Method for reducing content of sodium in aluminum hydroxide

InactiveCN102020302AReduce sodiumGood application effectAluminates/aluminium-oxide/aluminium-hydroxide purificationFire retardantLow sodium

The invention relates to a method for reducing the content of sodium in aluminum hydroxide, in particular to a method for preparing low-sodium aluminum hydroxide (Na2O is less than 0.1 percent) serving as a fire retardant or a raw material for calcining low-sodium aluminum oxide. The method is characterized by comprising the following steps of: after homogenizing the aluminum hydroxide by using pure water, performing hydro-thermal treatment, and filtering, washing and drying to obtain low-sodium aluminum hydroxide powder. In the method, the aluminum hydroxide prepared by a Bayer process or a sintering process is subjected to the hydro-thermal treatment, so that adherent alkali and lattice alkali in the aluminum hydroxide are dissolved in the water, and the low-sodium aluminum hydroxide powder is obtained by processes of solid-liquid separation, washing, drying and the like, wherein the powder can be used as the fire retardant or the raw material for calcining the low-sodium aluminum oxide. The method has the advantages that a process is simple, industrialization is easy to realize and the like, so the using performance of the aluminum hydroxide fire retardant can be improved effectively, and the low-sodium aluminum hydroxide can be used as the raw material for calcining low-sodium alpha-aluminum oxide.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

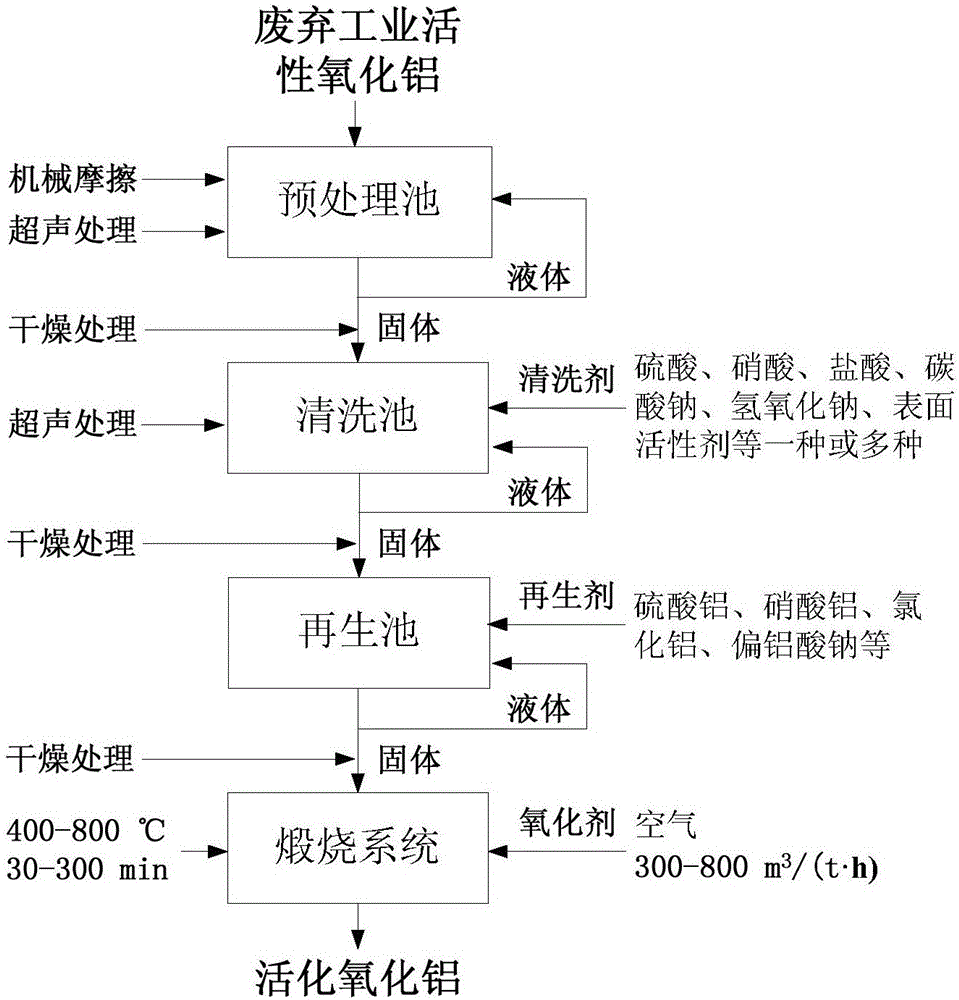

Method for activating and regenerating waste industrial activated aluminum oxide

ActiveCN106629796AHigh pore volumeRealize resource utilizationOther chemical processesAluminates/aluminium-oxide/aluminium-hydroxide purificationAir atmosphereActivated Aluminum Oxide

The invention discloses a method for activating and regenerating waste industrial activated aluminum oxide. The method comprises pretreatment, cleaning liquid impregnation treatment and regeneration treatment; adopted cleaning liquid is selected from at least one of acid liquor and alkali liquor and surfactant solution; the regeneration treatment comprises regenerated liquid impregnation and calcination treatment, and adopted regenerated liquid is selected from aluminum-contained solution; the calcination treatment is performed under air atmosphere, and air inlet amount is 300 to 800 m<3> / (h.t). According to the method for activating and regenerating the waste industrial activated aluminum oxide provided by the invention, an original pore structure channel is dredged through a physical and chemical method, and a new pore structure is regenerated on the basis of the existing pore structure to obtain activated aluminum oxide with high specific surface area and high pore volume.

Owner:杭州贝采催化剂有限公司 +1

Method of purifying organic substance in solution by Bayer method

InactiveCN101058433AAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSodium aluminateSodium sulfate

The invention discloses a purifying method of sodium aluminate through Baeyer method, which comprises the following steps: evaporating the solution of Baeyer method to condense; adding the crystal additive of one or two composition of sodium carbonate, sodium sulfate, sodium oxalate, calciumaluminate and alumina in the sintering kiln; cooling; crystallizing; evolving organics with additive, sodium carbonate and sodium sulfate; separating the sintering material to obtain the product; combining the evaporating crystal and seed organically; reducing bad influence for organics in the manufacturing course.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

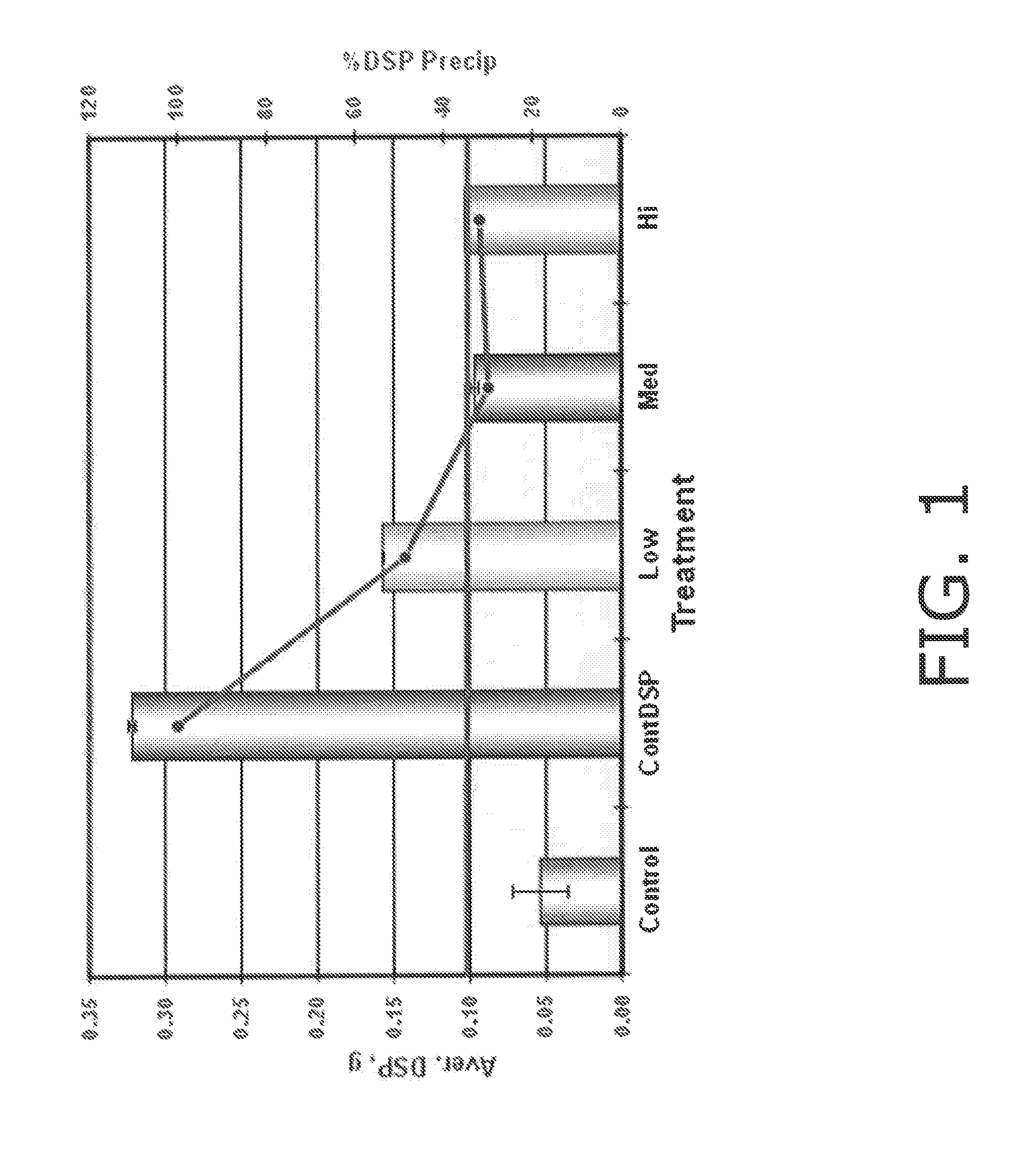

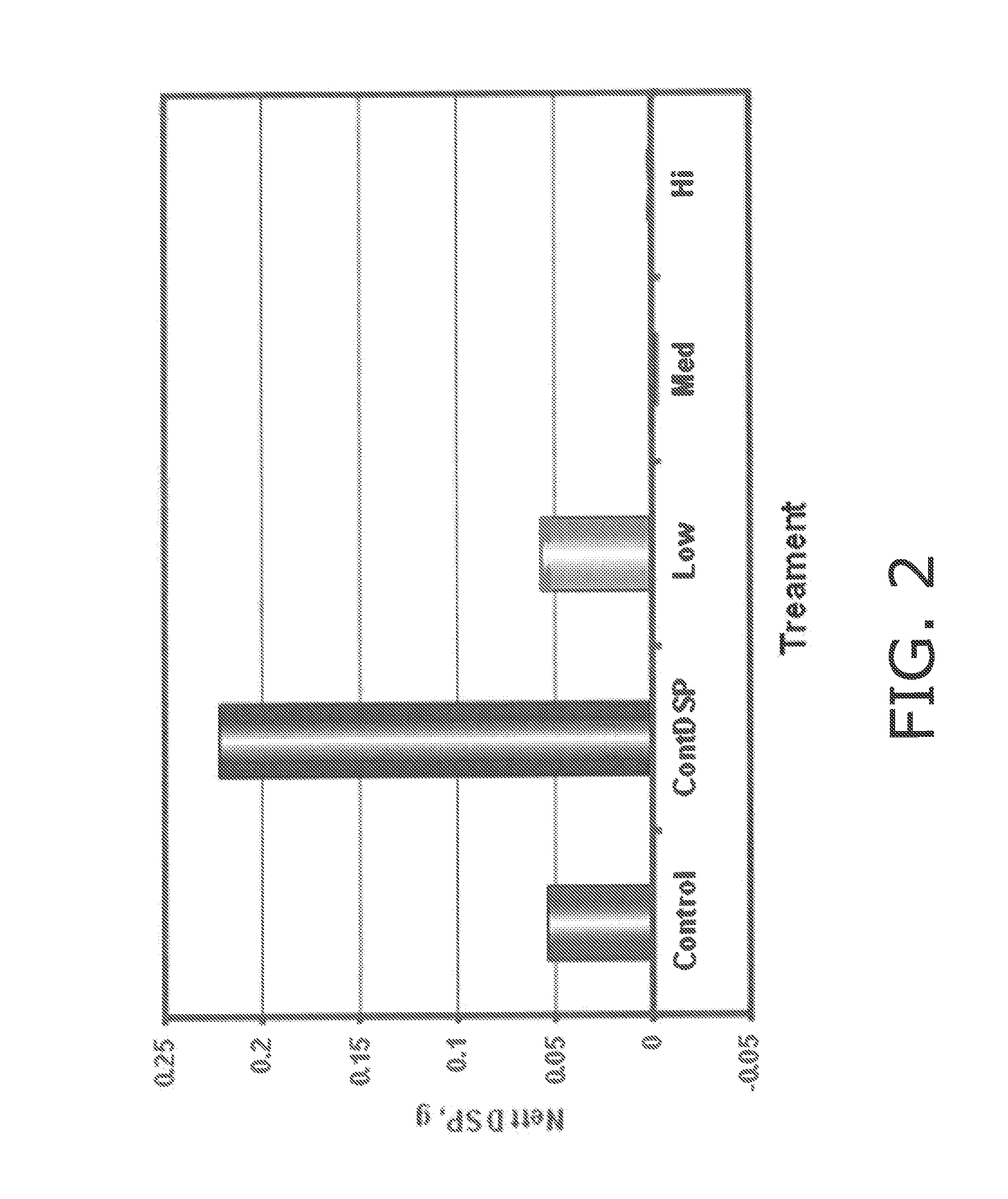

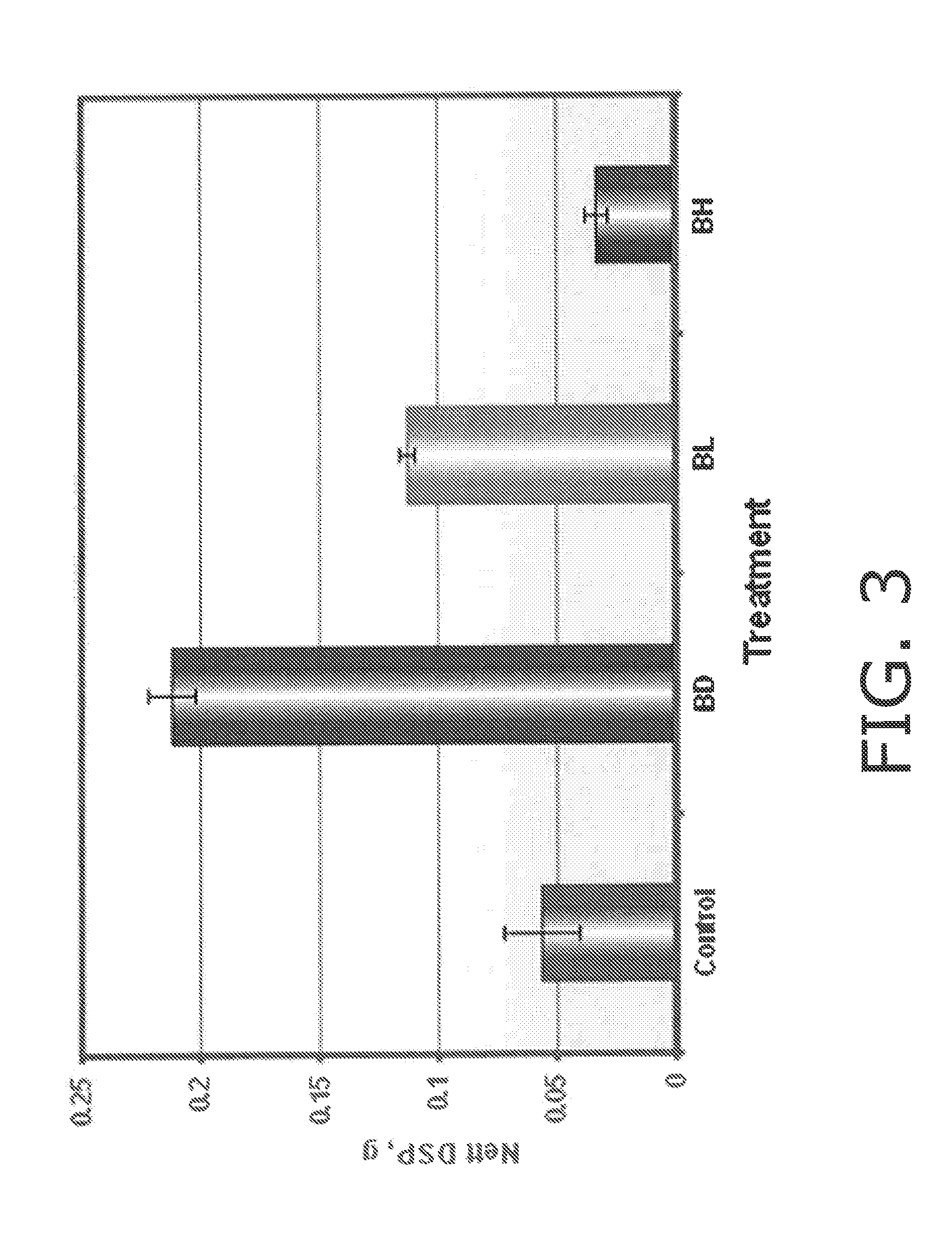

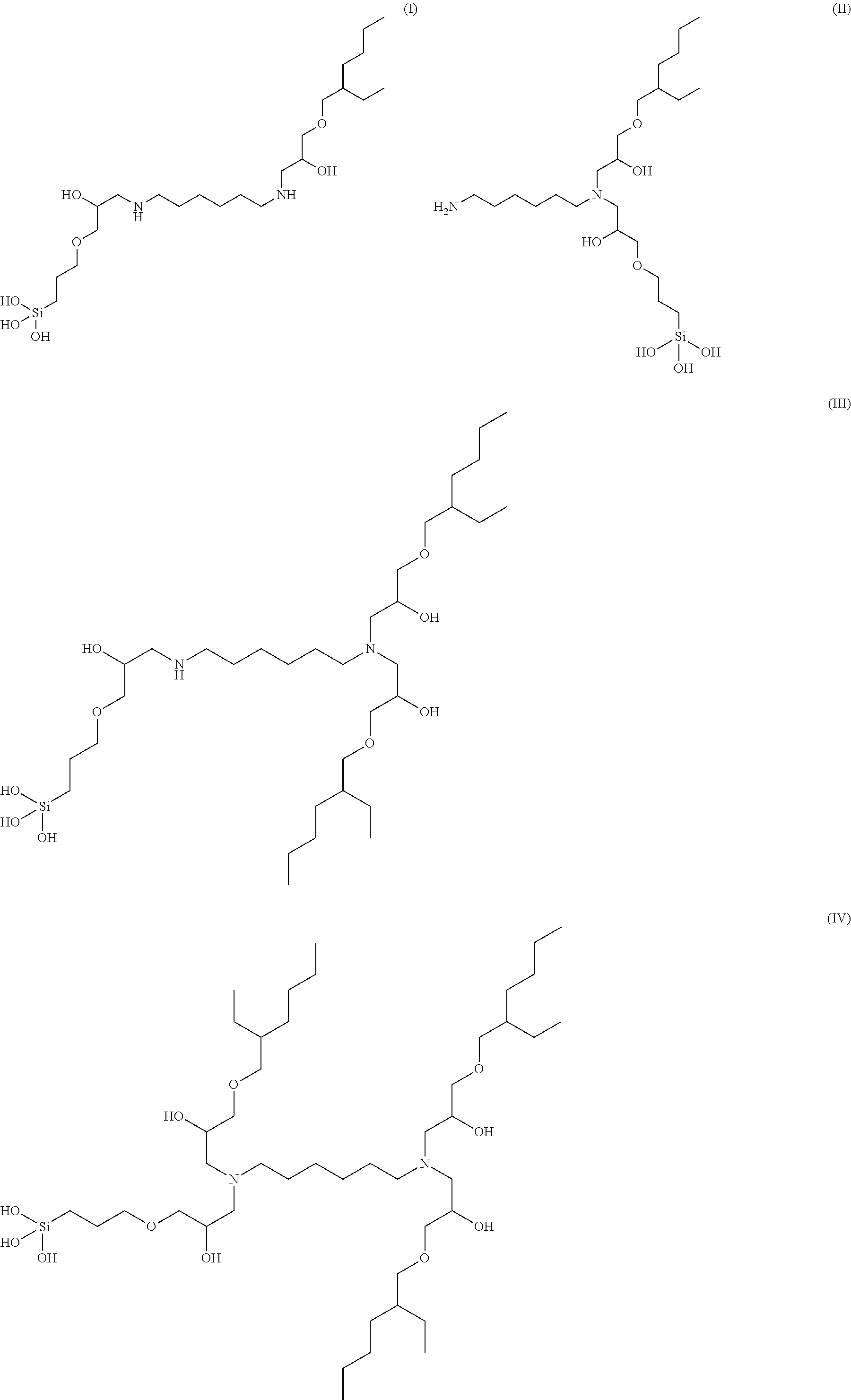

Mitigation and control of aluminosilicate scale through a novel feeding strategy of the inhibitor

InactiveUS20130189529A1Reducing siliceous scaleAluminates/aluminium-oxide/aluminium-hydroxide purificationWater-setting substance layered productProcess equipmentPre treatment

The invention provides a method of inhibiting the accumulation of DSP scale in the liquor circuit of Bayer process equipment. The method includes pre-treating surfaces of the process equipment with one or more particular silane based small molecules. These scale inhibitors reduce DSP scale formation and thereby increase fluid throughput, increase the amount of time Bayer process equipment can be operational and reduce the need for expensive and dangerous acid washes of Bayer process equipment. As a result, the invention provides a significant reduction in the total cost of operating a Bayer process.

Owner:NALCO CO

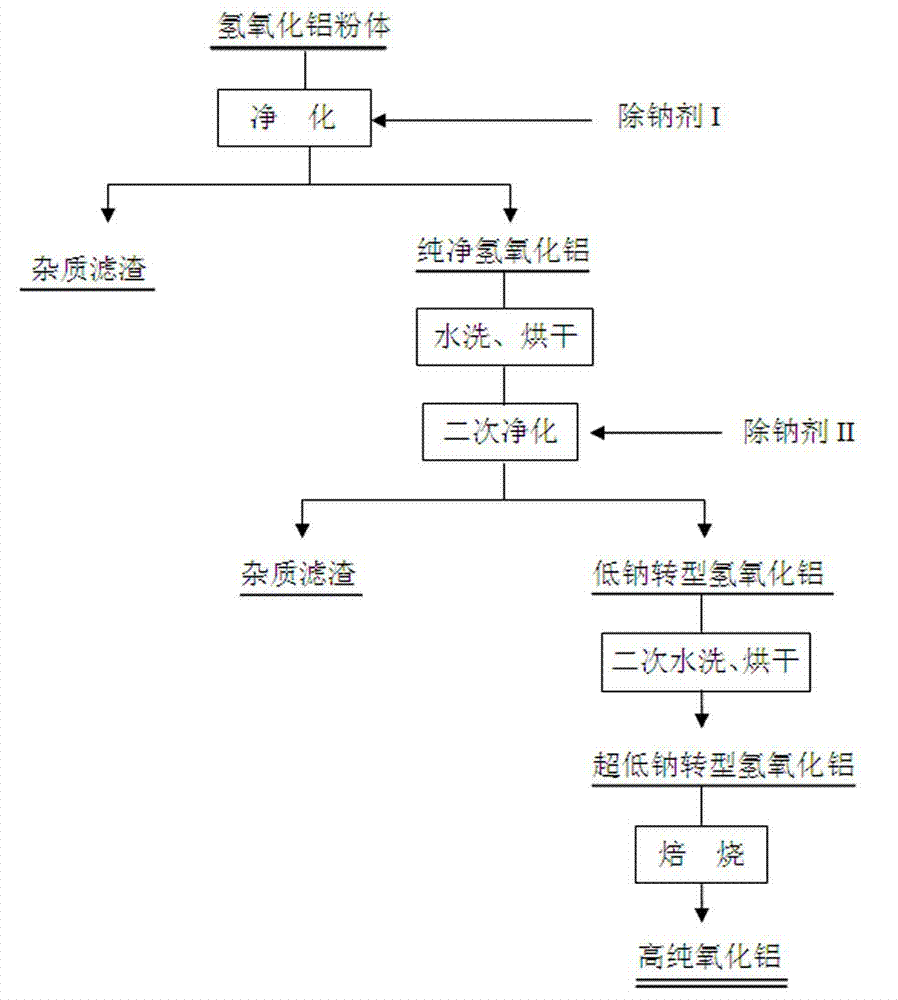

Method for removing sodium in preparation of high-purity alumina

ActiveCN103204530ATo achieve the purpose of removing sodiumSodium removal effect is obviousAluminates/aluminium-oxide/aluminium-hydroxide purificationWater bathsHigh sodium

The invention discloses a method for removing sodium in a preparation of high-purity alumina. The method comprises the steps of purifying, secondary purifying, washing, drying, secondary washing and drying again. The method specifically comprises the following steps of: grinding aluminium hydroxide with high sodium content to be less than or equal to 500mu m, stirring and washing for 2-3 times in thermostatic water bath with temperature being 50-55 DEG C by utilizing a sodium removing agent I to obtain pure aluminium hydroxide; washing the purified pure aluminium hydroxide with water till pH value is 7.0-7.5, drying and dehydrating; adding a sodium removing agent II to the washed and dried aluminium hydroxide, and stirring and washing for 2-3 times in the thermostatic water bath with temperature being 30-50 DEG C; and washing the aluminium hydroxide which is purified for the second time by utilizing pure water with temperature being 30-50 DEG C, drying, dehydrating and transforming the washed aluminium hydroxide to fluffy ultralow sodium aluminium hydroxide. The method has the advantages of convenience, conciseness, no pollution and good sodium-removing effect.

Owner:KUNMING METALLURGY INST

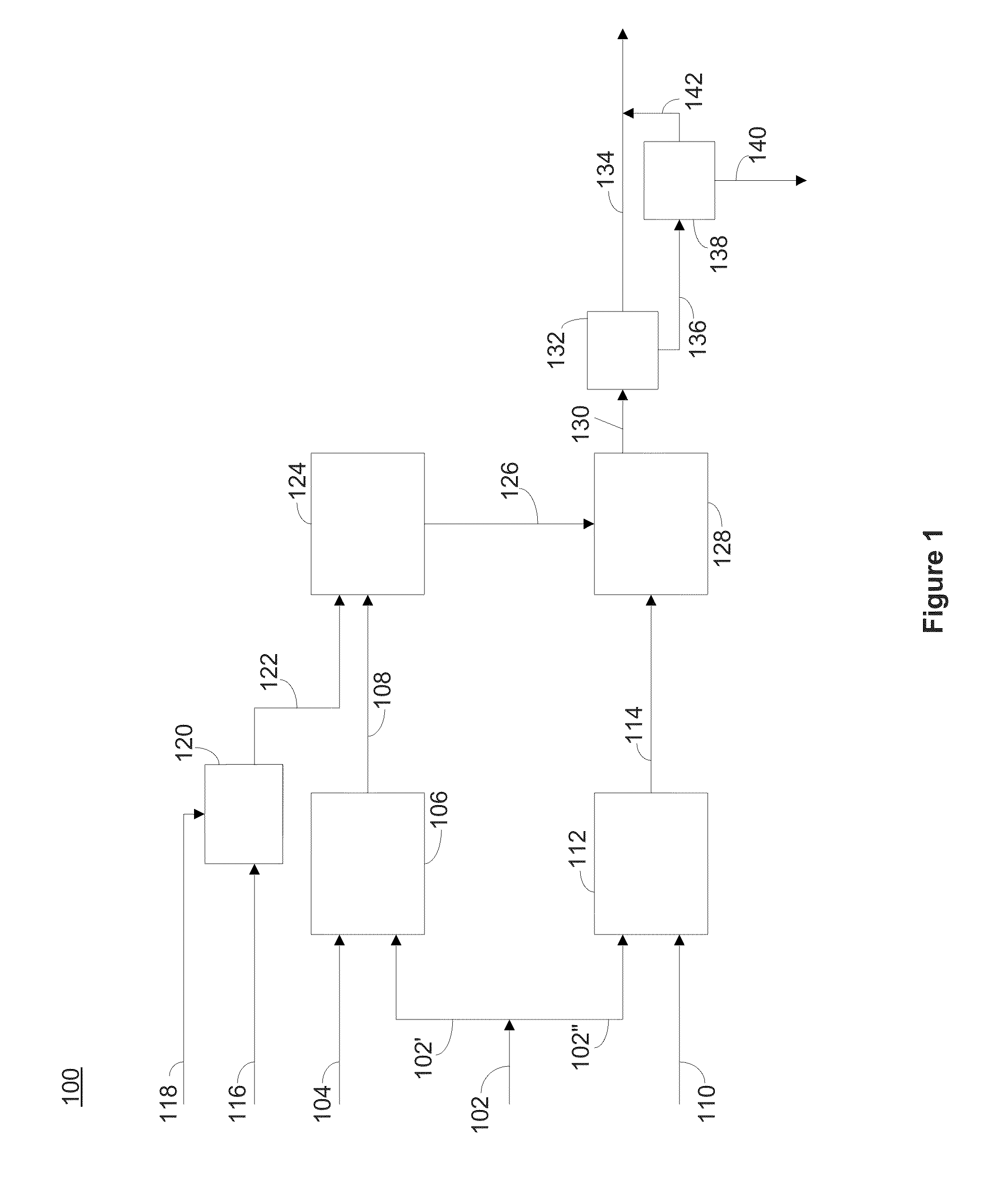

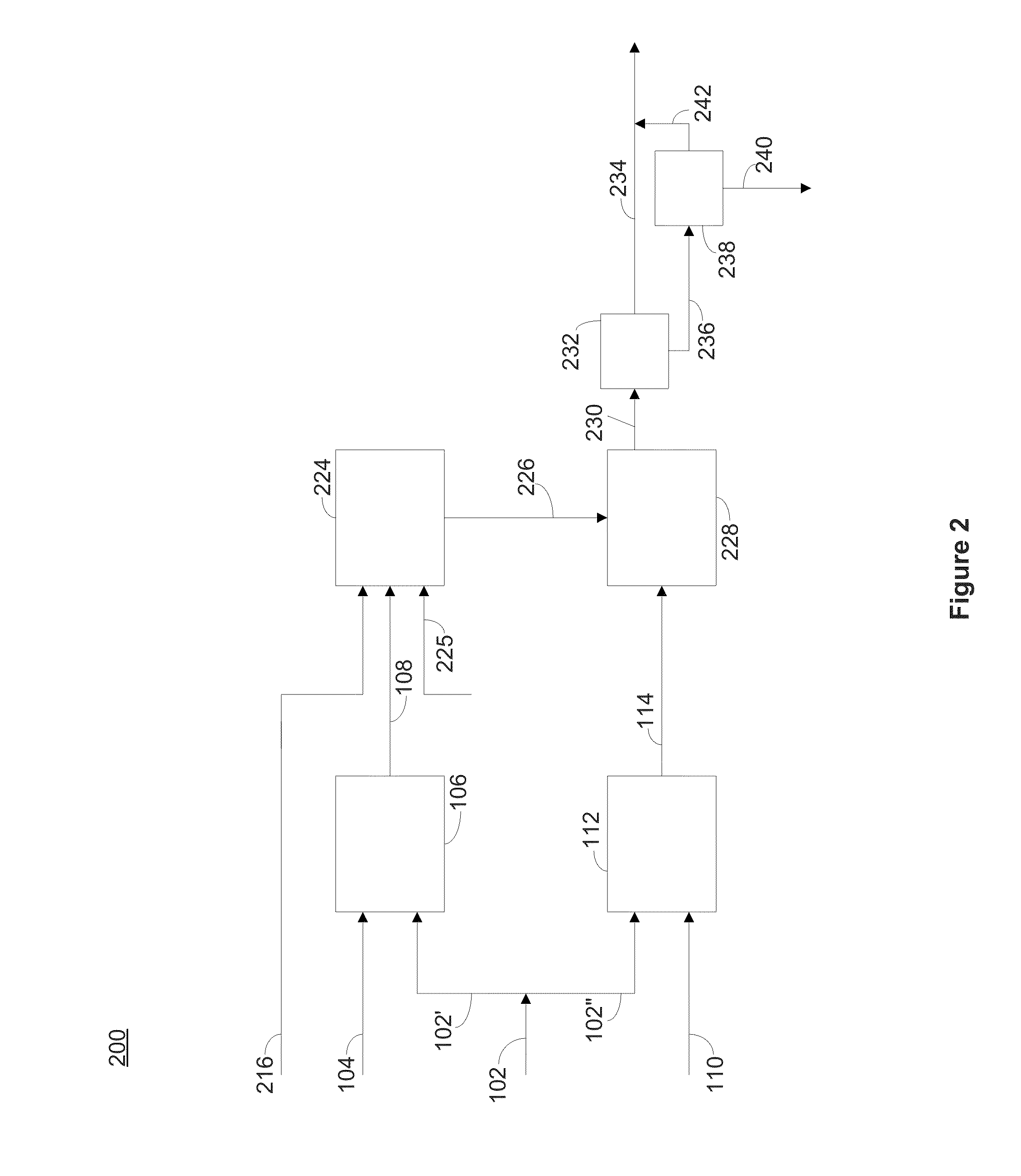

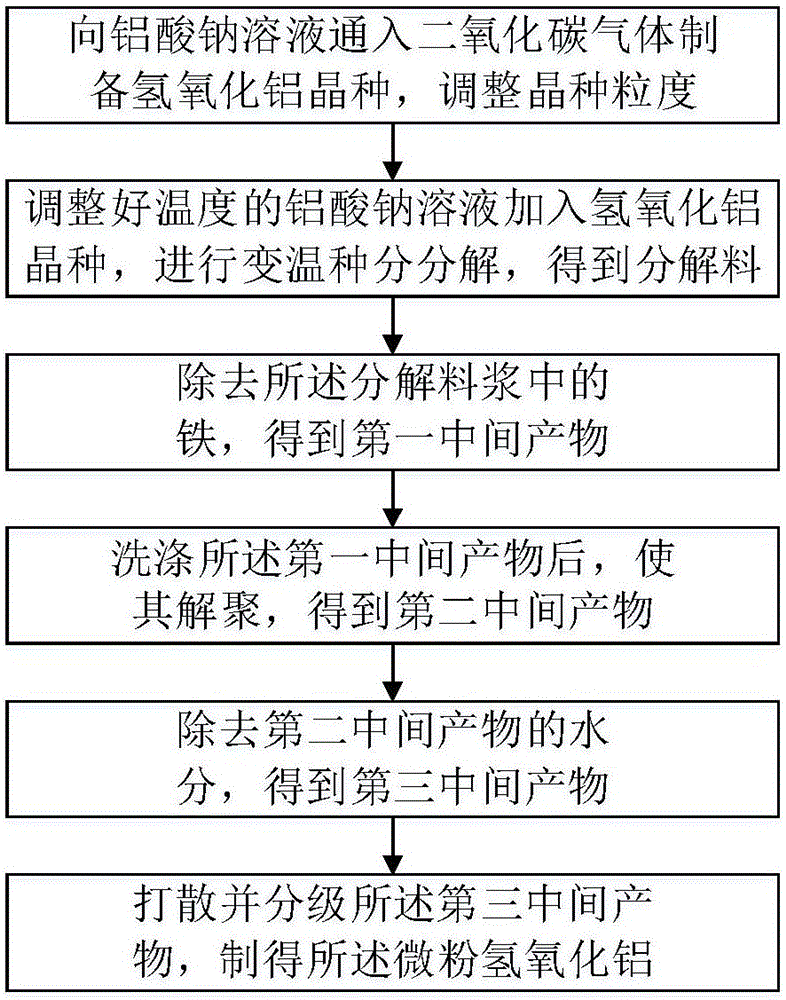

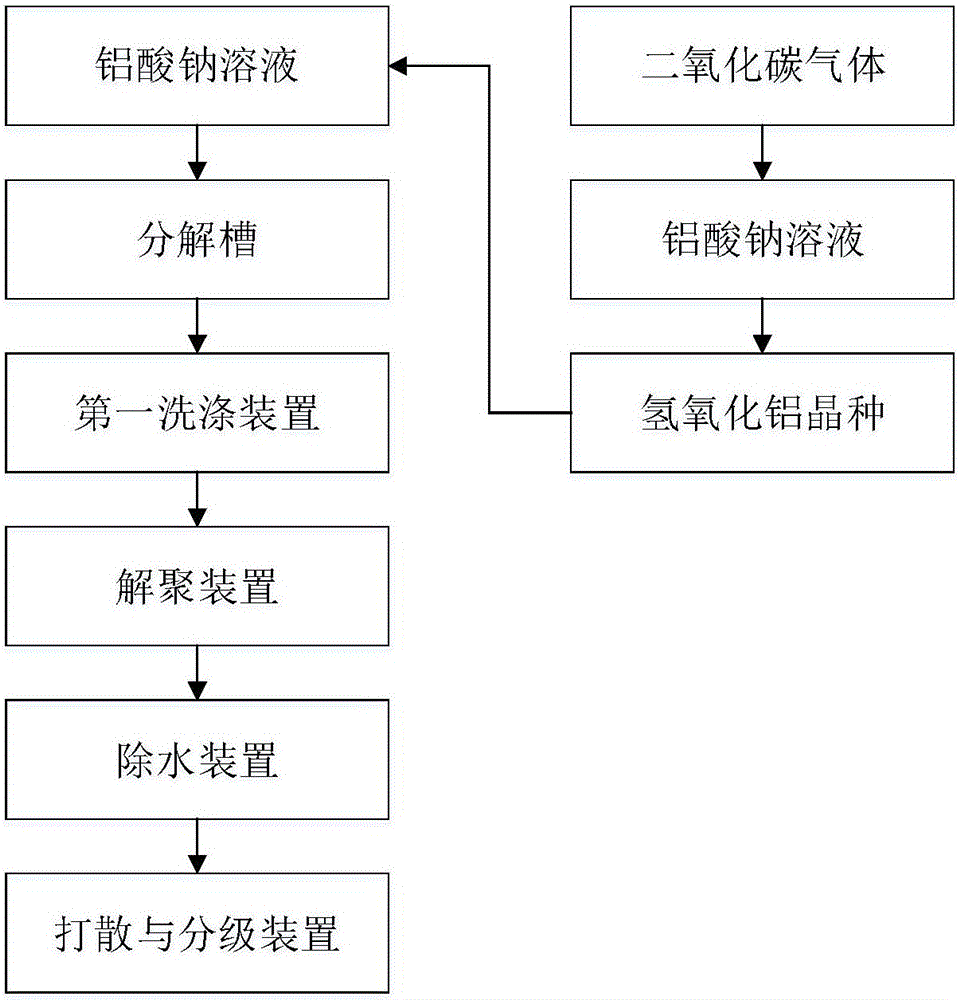

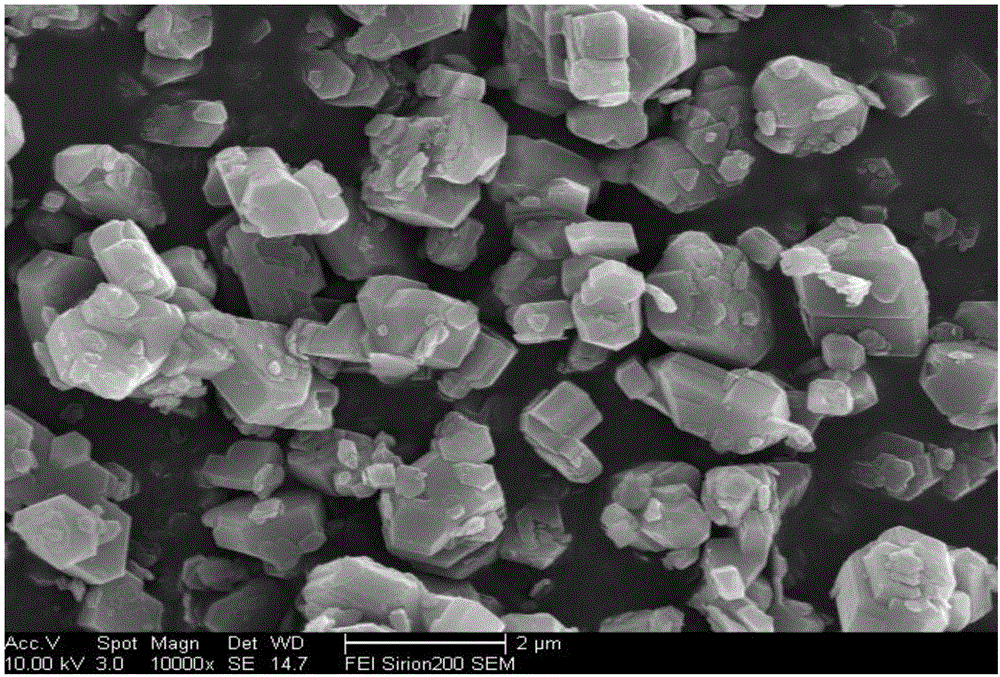

Micro-powder aluminum hydroxide preparation method and device and micro-powder aluminum hydroxide

ActiveCN105776269AAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDepolymerizationDecomposition

The invention discloses a micro-powder aluminum hydroxide preparation method and device and micro-powder aluminum hydroxide. The preparation method comprises the steps of adding aluminum hydroxide seed crystals obtained through carbonation decomposition of a sodium aluminate solution into the sodium aluminate solution to perform variable-temperature seed decomposition to obtain decomposition slurry; removing iron in the decomposition slurry to obtain a first intermediate product; washing the first intermediate product to depolymerize the first intermediate product to obtain a second intermediate product; removing water in the second intermediate product to obtain a third intermediate product; scattering and grading the third intermediate product to obtain micro-powder aluminum hydroxide. The preparation device comprises a decomposition tank, an iron removing device, a first washing device, a depolymerization device, a water removing device, and a scattering and grading device. The micro-powder aluminum hydroxide is prepared by using the preparation device according to the preparation method, such that the grain distribution of the micro-powder aluminum hydroxide product with a median particle diameter of 1mu m is even, the oil absorption is reduced to 30mL / 100g to 35mL / 100g, the impurity content of the obtained product is low, the whiteness is high and the product quality is stable.

Owner:中铝山东新材料有限公司

Synthesis and Use of AEI Structure-Type Molecular Sieves

InactiveUS20090238745A1Increase temperaturePhosphatesAluminium silicatesMolecular sieveCrystallization temperature

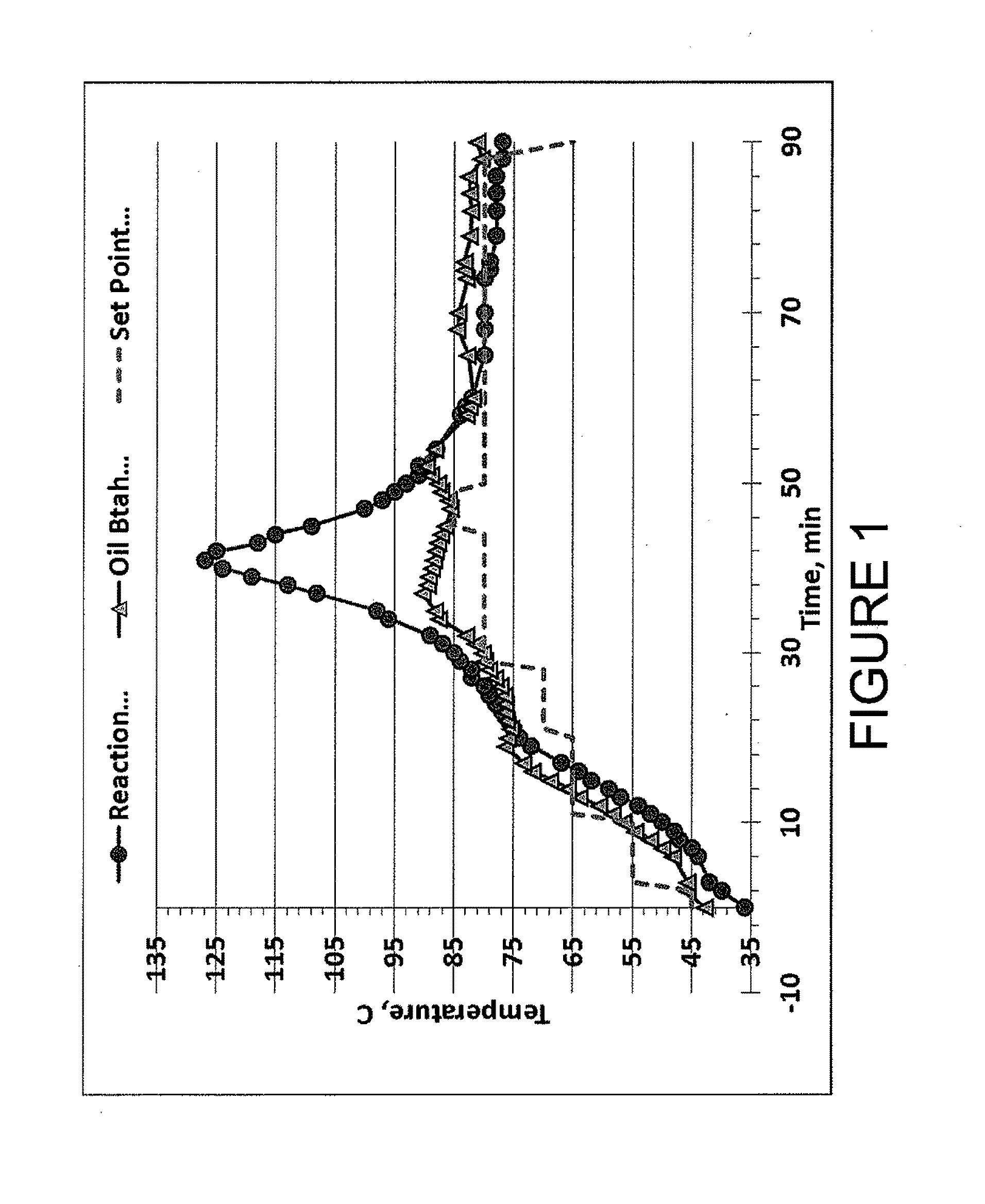

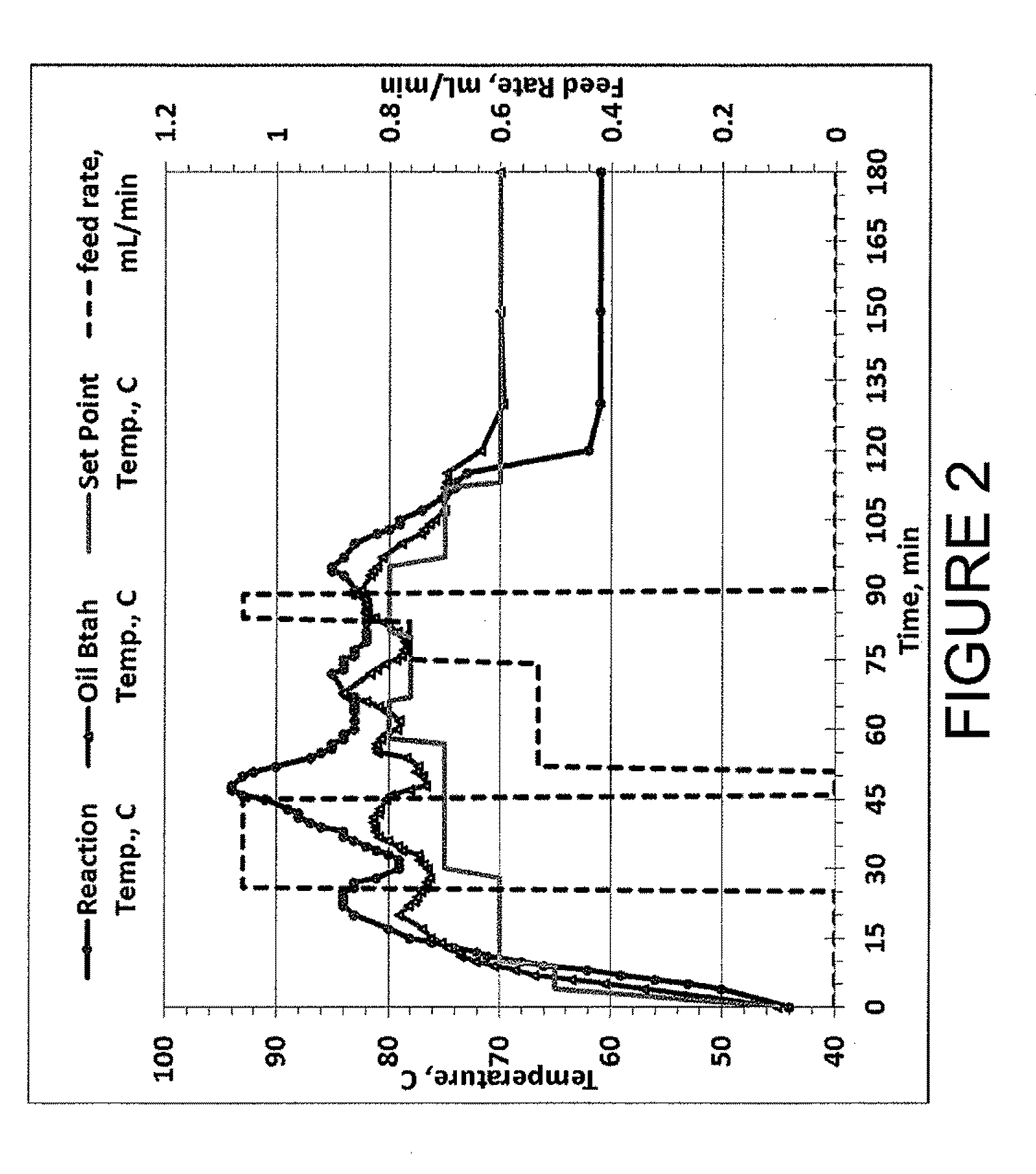

A method is disclosed of synthesizing an aluminophosphate or metalloaluminophosphate molecular sieve comprising an AEI structure type material, in which the rate of heating to the crystallization temperature is controlled, either alone or in combination with the H2O:A12O3 molar ratio of the synthesis mixture, so as to enhance the yield of the desired molecular sieve product.

Owner:EXXONMOBIL CHEM PAT INC

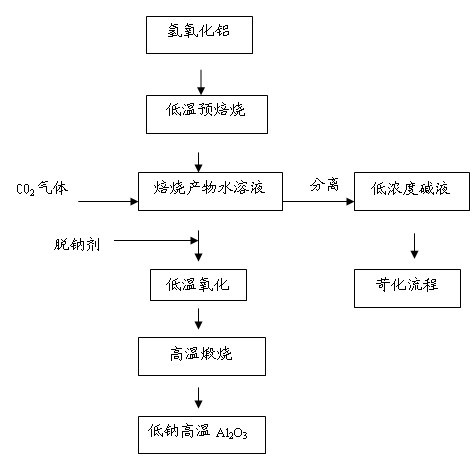

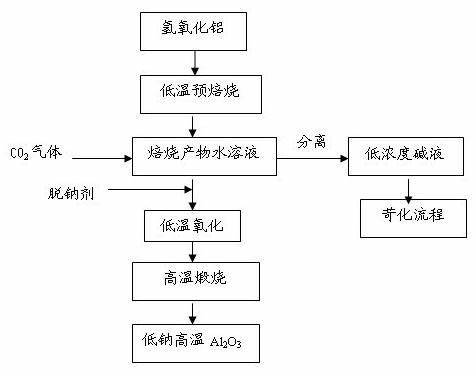

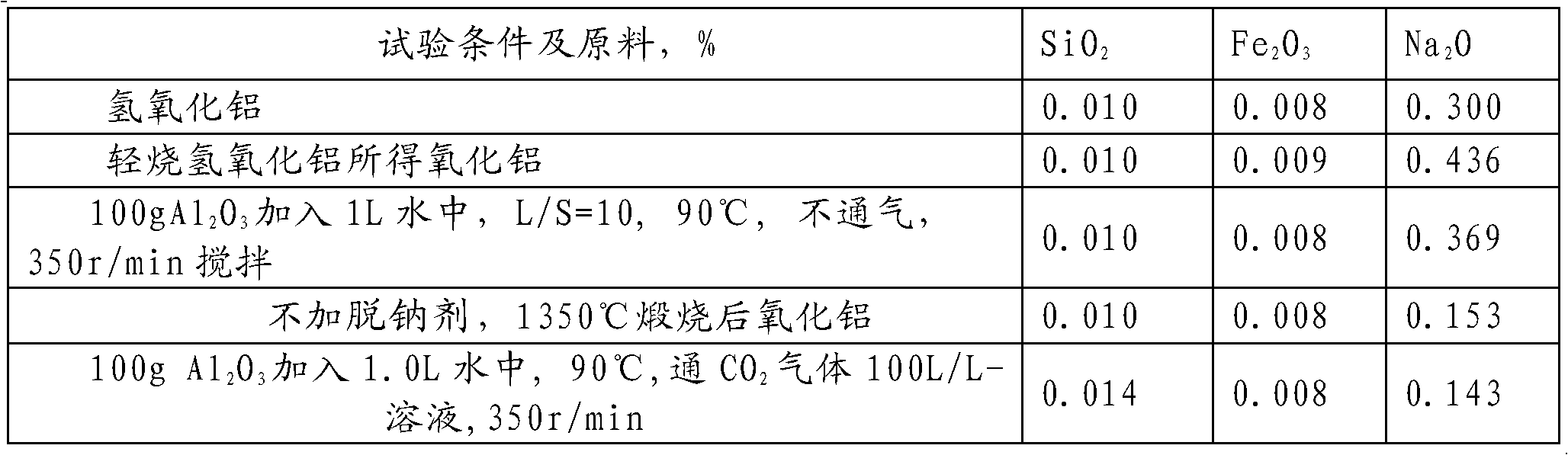

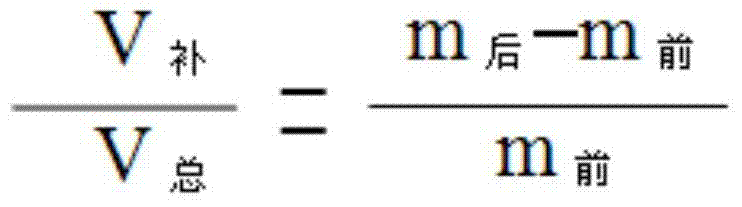

Method for reducing sodium oxide in aluminum oxide by using carbon dioxide

ActiveCN102070168AReduce sodium oxide contentLow costAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxide/hydroxide preparationCooking & bakingFree cooling

The invention discloses a method for reducing sodium oxide in aluminum oxide by using carbon dioxide. The method comprises the following steps of: pre-baking aluminum hydroxide and adding a baked product into water to prepare baked product aqueous solution for later use; introducing CO2 gas into the baked product aqueous solution and fully stirring; adding a small number of sodium removing agents into the baked product aqueous solution into which the CO2 gas is introduced; performing liquid-solid separation; drying to obtain a solid; calcining the solid at a high temperature; and naturally cooling to obtain low-sodium aluminum oxide. By the method, the cost for manufacturing the high-temperature low-sodium aluminum oxide can be reduced, the variation in product performance caused by the sodium removing agent can be reduced, and a new approach is discovered for utilization of the carbon dioxide.

Owner:中铝山东有限公司

Method for recycling alkali and aluminum in process of treating bayer red mud by calcification-carbonization method

ActiveCN103934258APromote incomeReduce energy consumptionSolid waste disposalContaminated soil reclamationHigh concentrationRecovery method

The invention relates to the field of environment protection, and in particular relates to a method for recycling alkali and aluminum in a process of treating bayer red mud by a calcification-carbonization method. The method comprises the steps of mixing the bayer red mud with calcium aluminate or lime and the calcium aluminate to obtain a mixture, performing calcification dealkalization transformation on the mixture in high-concentration alkali liquid with the caustic alkali concentration being 100-300g / L, totally converting silicon-containing phases in the red mud into calcified slag generated in a dealkalization process in the form of hydrate garnet, carbonizing the calcified slag to obtain carbonized slag, then o carrying out low-temperature aluminum smelting and aluminum precipitation to obtain a calcium aluminate product, and recycling the calcium aluminate product in the red mud calcification dealkalization transformation process. Part of alkali and aluminum-containing liquid phases subjected to calcification dealkalization transformation can be reused as supplement alkali in a bayer production process. The method disclosed by the invention can realize recycling of alkali and aluminum in the red mud and harmless treatment of the bayer red mud, and is an energy-saving and environment-friendly red mud utilization method.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

Method for selectively leaching nitric acid from lithium element in aluminum electrolyte

ActiveCN107974565AAchieve separationEfficient extractionAluminates/aluminium-oxide/aluminium-hydroxide purificationProcess efficiency improvementLithiumElectrolysis

The invention discloses a method for selectively leaching nitric acid from lithium element in aluminum electrolyte, and relates to the technical field of aluminum electrolyte extraction recycling. Themethod comprises the following steps that 1, aluminum electrolyte containing the lithium element is smashed and screened; 2, nitric acid and water are mixed, the pH value of the acid solution is adjusted to be smaller than 4, and the electric potential is adjusted to be between 0.015V and 0.8V; 3, the aluminum electrolyte is added into the acid solution, stirred, heated and leached, the reactiontemperature is 20-85 DEG C, the adding amount of aluminum electrolyte is controlled according to the concentration and acidity of fluorinion in the solution, the acidity pH value is smaller than 4, and the fluorinion concentration is larger than 1g / L; 4, the mixed solution is filtered and washed to obtain filtrate and filter matter; and 5, the filtrate is used for extracting the lithium element, the filter matter is washed, dried and returned to an aluminum electrolyte plant to produce aluminum electrolyte and / or retuned to a leaching process. Lithium salt is selectively leached, high-additional-value lithium salt is recycled, industrial aluminum electrolyte high in purity and applicable to aluminum electrolyte production is obtained, and the energy consumption and extraction cost for aluminum electrolyte production are low.

Owner:NORTHEASTERN UNIV

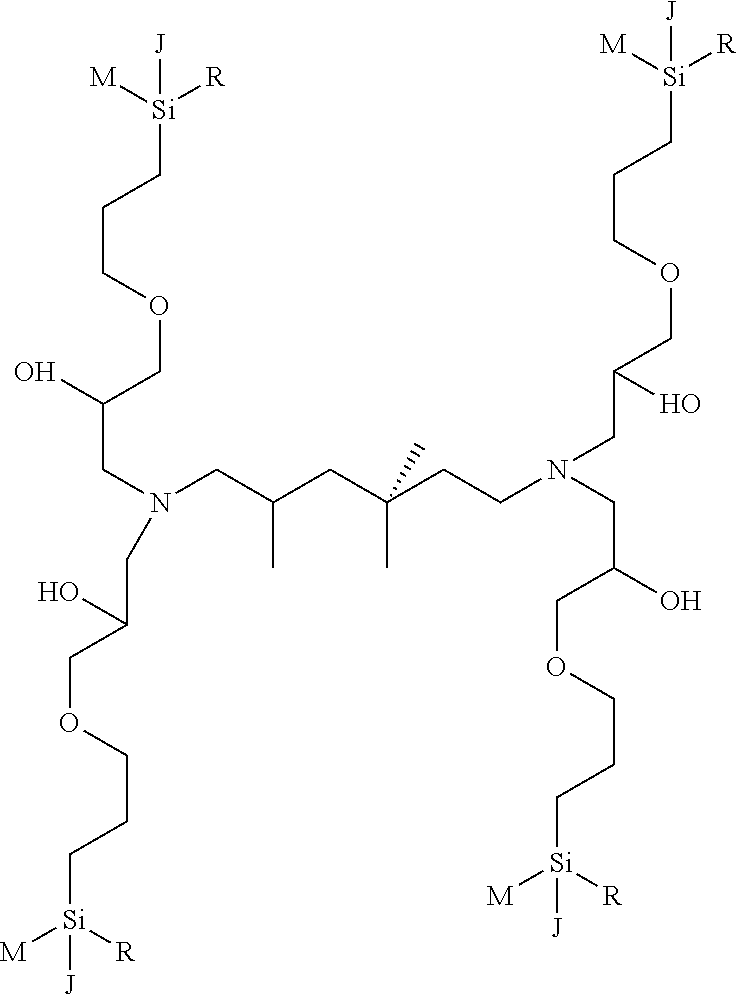

Reducing aluminosilicate scale in the bayer process

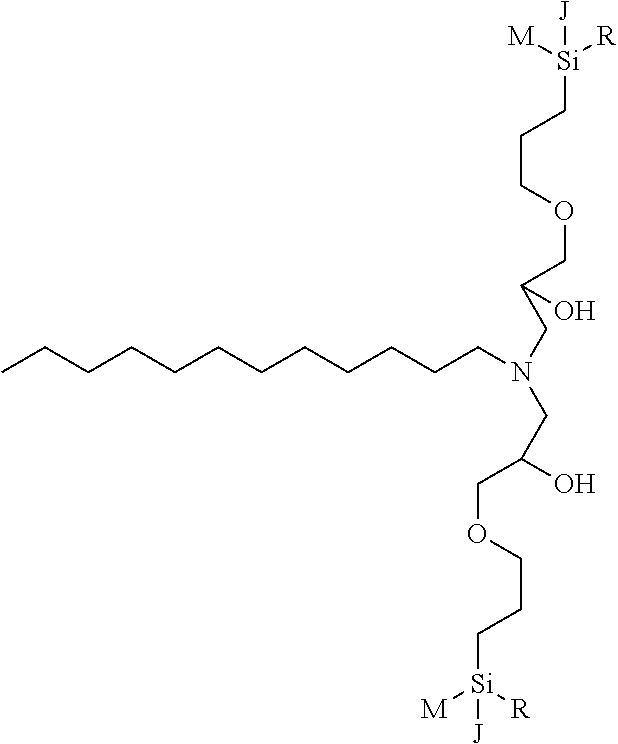

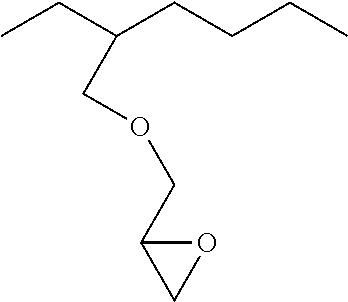

ActiveUS20120148462A1Group 4/14 element organic compoundsGallium/indium/thallium compoundsSilanesSmall molecule

The invention provides a method of inhibiting the accumulation of DSP scale in the liquor circuit of Bayer process equipment. The method includes adding one or more particular silane based small molecules to the liquor fluid circuit. These scale inhibitors reduce DSP scale formation and thereby increase fluid throughput, increase the amount of time Bayer process equipment can be operational and reduce the need for expensive and dangerous acid washes of Bayer process equipment. As a result, the invention provides a significant reduction in the total cost of operating a Bayer process.

Owner:ECOLAB USA INC

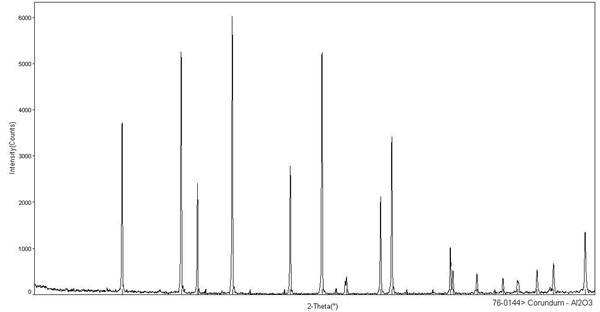

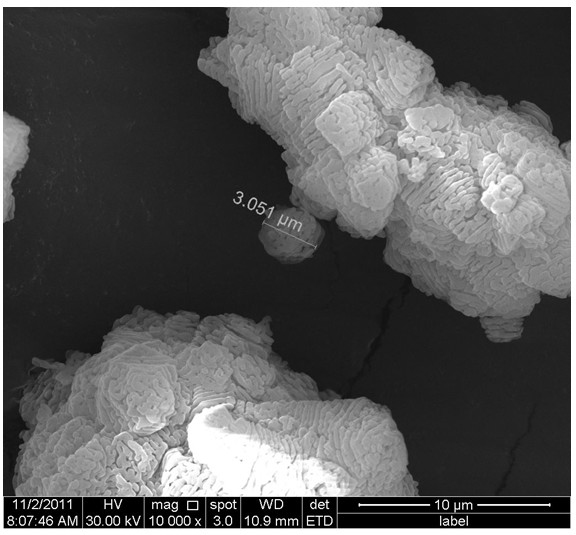

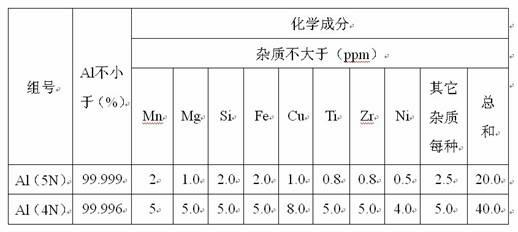

Method for preparing high-purity ultrafine Al2O3 powder

InactiveCN102491393ASpeed up digestionFacilitate chemical reactionsAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxide/hydroxide preparationSocial benefitsHydrogen

The invention provides a method for preparing high-purity ultrafine Al2O3 powder. The method comprises the following steps of: uniformly mixing metal aluminum, water and a catalyst in a certain ratio, performing microwave heating, cooling to room temperature, obtaining an aluminum hydroxide precipitate, and discharging hydrogen; and washing the aluminum hydroxide precipitate through high-purity water, and performing suction filtration, dehydration and calcination to obtain 4 to 5N high-purity ultrafine Al2O3 powder. In the whole preparation process, a flow is short, a process is simple, the reaction speed is high, energy consumption and cost are low, the purity is easy to control, toxic and harmful gases and liquid are not generated, high-efficiency large-scale production can be performed, and obvious economic benefits and social benefits can be produced.

Owner:NANTONG TADE ELECTRONICS MATERIAL TECH

Reducing aluminosilicate scale in the bayer process

The invention provides a method of inhibiting the accumulation of DSP scale in the liquor circuit of Bayer process equipment. The method includes adding one or more particular silane based small molecules to the liquor fluid circuit. These scale inhibitors reduce DSP scale formation and thereby increase fluid throughput, increase the amount of time Bayer process equipment can be operational and reduce the need for expensive and dangerous acid washes of Bayer process equipment. As a result, the invention provides a significant reduction in the total cost of operating a Bayer process.

Owner:ECOLAB USA INC

A method for recovering alkali and aluminum in course of treatment of bayer red mud by using calcification-carbonation method

ActiveUS20170036920A1Comprehensive utilization of valuable elementLow costSolid waste disposalContaminated soil reclamationHigh concentrationRecovery method

A method for recovering alkali and aluminum during treatment of Bayer red mud using a calcification-carbonation method, including steps of mixing the Bayer red mud with calcium aluminate or with calcium aluminate and lime, performing calcification dealkalization conversion in a high-concentration alkaline liquor, and carbonizing the calcified residues produced during dealkalization to obtain carbonized residues; and then performing low-temperature aluminum dissolution, aluminum precipitation and the like to obtain calcium aluminate products, which is returned to the calcification dealkalization conversion of the red mud for recycling. Part of an alkali-containing and aluminum-containing liquid phase after calcification dealkalization conversion can be used as supplementary alkali in the Bayer production course for recycling. The method is energy-saving and environmentally-friendly, and allows recovering alkali and aluminum from the red mud and harmless treatment of the Bayer red mud.

Owner:NORTHEASTERN UNIV

Reducing aluminosilicate scale in the bayer process

ActiveUS20110212006A1Reducing siliceous scaleGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationProcess equipmentAluminosilicate

The invention provides a method of inhibiting the accumulation of DSP scale in the liquor circuit of Bayer process equipment. The method includes adding one or more particular silane based small molecules to the liquor fluid circuit. These scale inhibitors reduce DSP scale formation and thereby increase fluid throughput, increase the amount of time Bayer process equipment can be operational and reduce the need for expensive and dangerous acid washes of Bayer process equipment. As a result, the invention provides a significant reduction in the total cost of operating a Bayer process.

Owner:ECOLAB USA INC

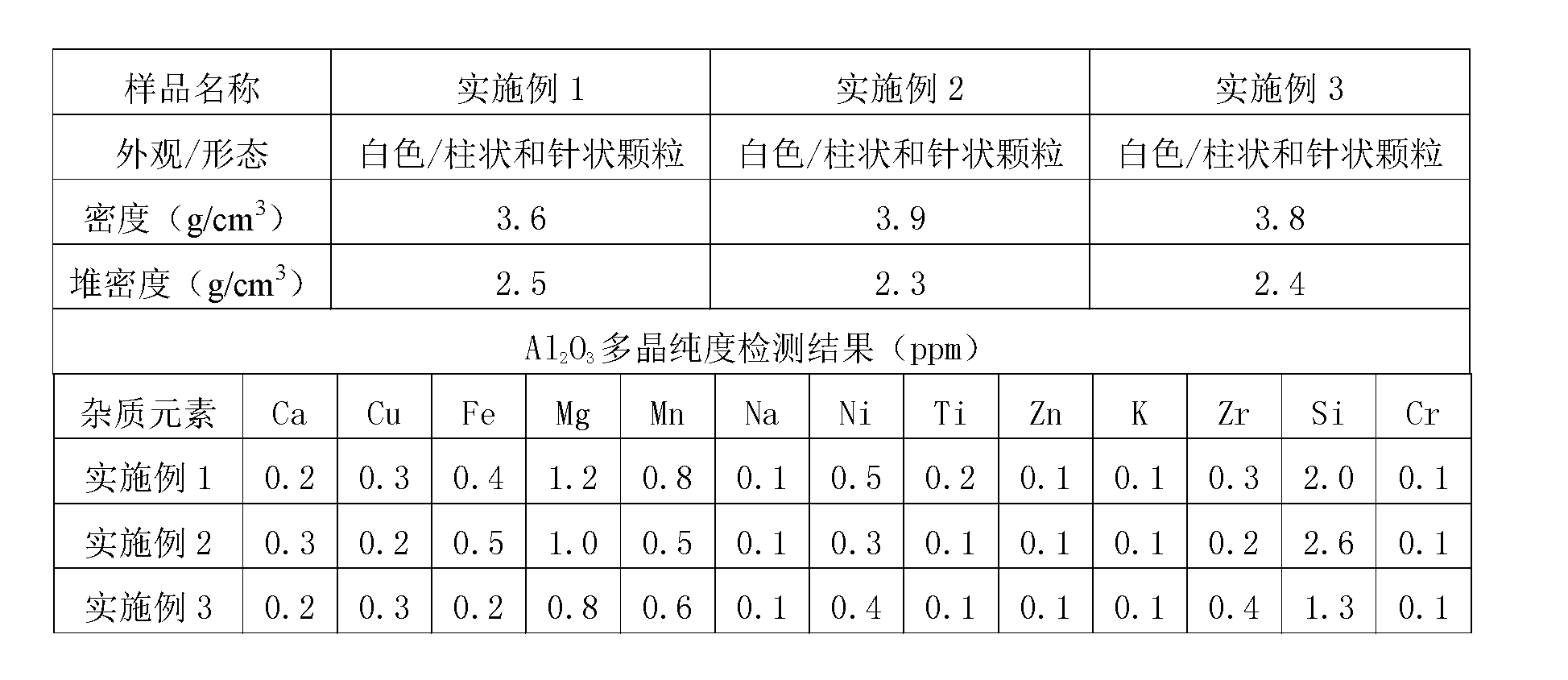

Production method of 5N high-purity aluminum oxide polycrystal material

InactiveCN103011220AAvoid pollutionLow costAluminates/aluminium-oxide/aluminium-hydroxide purificationCrucibleCost savings

The invention discloses a production method of a 5N high-purity aluminum oxide polycrystal material, which is characterized by comprising the following steps: adding a 5N high-purity aluminum oxide powder material into a cold crucible defined by a copper tube coated with a high-temperature-resistant coating, using a 5N high-purity metal aluminum sheet as an igniter, and adopting a high-frequency cold crucible technology to produce the 5N high-purity aluminum oxide polycrystal material product, wherein the appearance and shape of the product is a white columnar and acicular particle, the density is 3.5-3.9 g / cm<3>, the bulk density is 2.2-2.6 g / cm<3>, and the purity is greater than 5N. The production method disclosed by the invention is simple and easy to implement, and has the advantages of cost saving, energy saving, environment friendliness and the like.

Owner:SICHUAN XINJU MINERAL RESOURCE DEV CO LTD

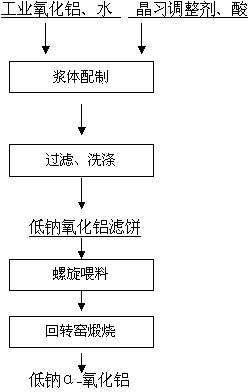

Method for preparing alpha-aluminum oxide

ActiveCN104386719ALarge specific surface areaLow impurity contentAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxides/hydroxidesPotassiumSlurry

The invention discloses a method for preparing an alpha-aluminum oxide, and relates to a method for preparing a low-sodium alpha-aluminum oxide which is used for producing electronic ceramics, glass substrates and finely polished and refractory materials. The method is characterized by comprising the following preparation processes: by adopting an industrial aluminum oxide as a raw material, carrying out hydrothermal reaction on industrial aluminum oxide slurry, carrying out liquid-solid separation and washing the slurry; and finally calcining to obtain a low-sodium alpha-aluminum oxide product. According to the method disclosed by the invention, soluble impurities such as sodium oxide and potassium oxide in the aluminum oxide raw material can be effectively removed; a crystal shape modifier is added in the wet treatment process; a trace crystal shape modifier can be fully mixed with the aluminum oxide by virtue of the adsorptive property of the aluminum oxide; the aluminum oxide of which the sodium oxide content is smaller than 0.15% is obtained after filtering and washing; and the low-sodium alpha-aluminum oxide product is obtained in a calcining manner in a high-temperature kiln. The method disclosed by the invention has the advantages of being simple in process, environment-friendly, high in production efficiency and the like, and the alpha-aluminum oxide is uniform in crystal particle.

Owner:ZHENGZHOU HICER HIGH TECH CERAMICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com