Method for preparing alpha-aluminum oxide

A technology of alumina and industrial alumina, which is applied in the field of preparation of low-sodium α-alumina, can solve the problems of complex process, high energy consumption, and low production efficiency, and achieve uniform product grains, large specific surface area, and high production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

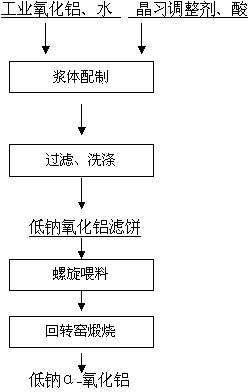

[0019] A preparation method of α-alumina, which uses industrial alumina as raw material, adopts wet pretreatment method to remove soluble impurities such as sodium oxide and potassium oxide in the alumina raw material, and adds a crystal habit regulator during the wet treatment process , relying on the adsorption performance of alumina to fully mix a small amount of crystal habit modifier with alumina, filter and wash to obtain alumina with a sodium oxide content of less than 0.15%, and then calcined in a high-temperature kiln to obtain low-sodium α-alumina product.

[0020] The industrial alumina used is aluminum hydroxide produced by the Bayer process, and the industrial alumina produced by roasting in a suspension roaster has a specific surface area (BET) greater than 40m 2 / g, the sodium oxide content is less than 0.5%.

[0021] The operation process first prepares industrial alumina and tap water or pure water to make a slurry of 100-600g / l. In order to further improve t...

Embodiment 1

[0026] Add 10 tons of industrial alumina to the batching tank, add 50 cubic meters of tap water, and add oxalic acid to adjust the initial pH value of the slurry to 6. After stirring, the slurry is fully mixed, and then the slurry is transported to the pipeline by a diaphragm pump In the chemical plant, after the slurry is gradually preheated to 150°C in the pipeline, it enters the high-pressure reactor for hydrothermal impurity removal treatment. The slurry stays in the high-pressure reactor for 60 minutes, and then the slurry is flashed. Tank flash cooling to below 95°C. After the hydrothermal treatment, the slurry enters the buffer tank, and the slurry is transported to the vacuum belt filter by the slurry pump for filtration and washing to obtain low-sodium alumina with a sodium oxide content of 0.12%, and the alumina filter cake is passed through the screw feeding equipment Send it into a rotary kiln and calcinate at 1350°C in the rotary kiln to obtain a high-temperature ...

Embodiment 2

[0028] Add 15 tons of industrial alumina to the stirring tank, add 30 cubic meters of tap water at 90°C, add dilute sulfuric acid to make the initial pH of the slurry 5, add aluminum fluoride at 0.1% by mass of alumina, and stir for 2 hours , the alumina slurry is filtered and washed with a flat disc filter to obtain an alumina filter cake with a sodium oxide content of 0.15%, which is calcined at 1400°C in a rotary kiln to obtain a high-temperature alumina with an α-phase conversion rate greater than 95%. Observed by scanning electron microscope, the primary grain size is about 2.6 microns, and the sodium oxide content is 350ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com