Patents

Literature

854 results about "Bayer process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

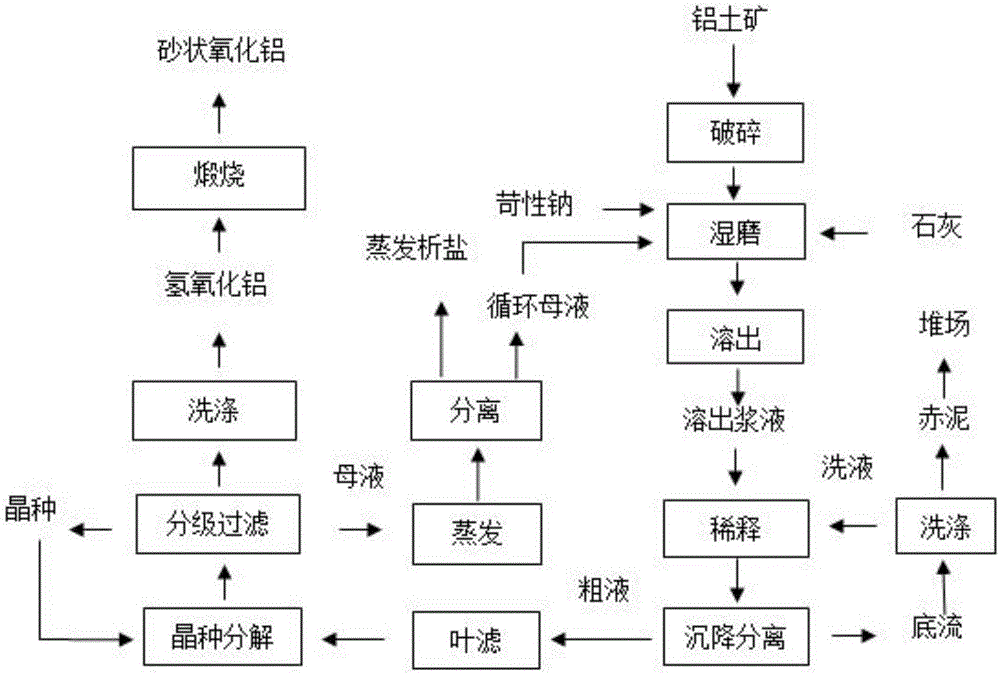

The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Josef Bayer. Bauxite, the most important ore of aluminium, contains only 30–60% aluminium oxide (Al₂O₃), the rest being a mixture of silica, various iron oxides, and titanium dioxide. The aluminium oxide must be purified before it can be refined to aluminium metal.

Method of preventing or reducing aluminosilicate scale in a bayer process

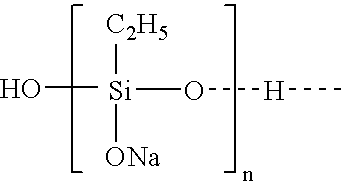

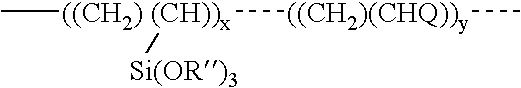

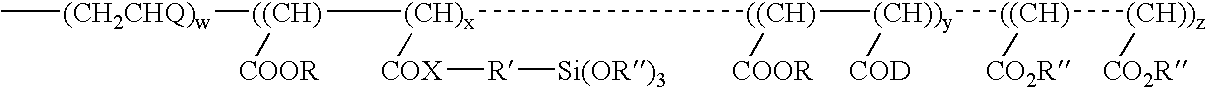

ActiveUS20050010008A2Reduce and eliminate aluminosilicate scalingReduce and even completely prevent formationSilicon organic compoundsAluminium compoundsPlate heat exchangerEnd-group

Abstract of the DisclosureMaterials and a process are provided whereby polymers with the pendant group or end group containing --Si(OR")3 (where R" is H, an alkyl group, Na, K, or NH4) are used to control aluminosilicate scaling in a Bayer process. When materials of the present invention are added to the Bayer liquor before the heat exchangers, they reduce and even completely prevent formation of aluminosilicate scale on heat exchanger walls. The present materials are effective at treatment concentrations that make them economically practical.

Owner:CYTEC TECH CORP

Method for dissolving Bayer process red mud

ActiveCN102757060AMeet industrial requirementsReduce sodiumCalcium/strontium/barium carbonatesSludge treatmentCalcium silicateAluminium hydroxide

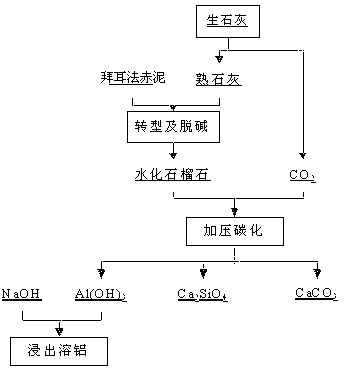

The invention discloses a method for dissolving red mud. The method comprises the following specific steps of: mixing Bayer process red mud with white lime in the mass ratio of 1:(0.3-0.9); stirring at the temperature of 80-140 DEG C for reacting for 1-15 hours for calcifying, transforming and dealkalizing; mixing calcified, deformed and dealkalized Bayer process red mud with clear water or a low-concentration sodium aluminate solution in an enclosed container; introducing CO2 into the container to obtain calcified slag containing calcium silicate, calcium carbonate and aluminum hydroxide serving as main components; and extracting aluminum hydroxide from the calcified slag by using a sodium hydroxide solution or an aluminum hydroxide solution. In the method disclosed by the invention, the structure and composition of red mud are changed by adopting calcification transformation and pressurizing calcification transformation methods, so that dealkalization and extraction of aluminum can be realized; and iron is extracted properly, so that the structure and the composition of red mud can meet the requirements of cement production, and the aim of dissolving red mud on a large scale at low cost is fulfilled.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

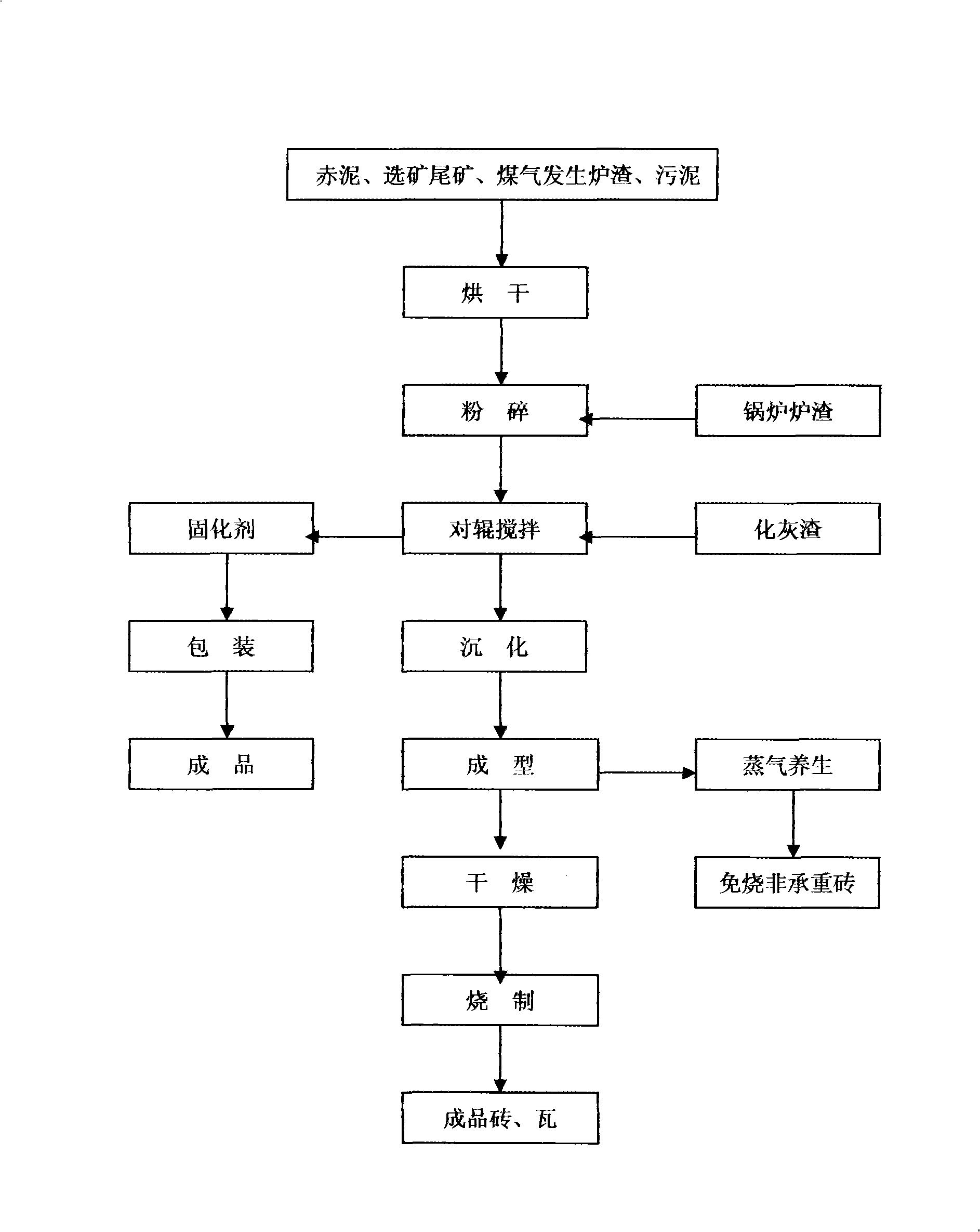

Process and method for converting waste slag wholly of aluminum industry into ecological building material

The invention belongs to a method for utilizing resources. The method utilizes the matter characteristics of solid wastes (six kinds of waste residues) such as red mud(the sintered method and the Bayer method), boiler slag, ore dressing tailings, ash and gas generation slag, which are generated during the manufacturing process in aluminum industry, and converts the solid wastes into a novel road material and construction walling material by the processes such as drying, crushing, reasonable proportioning, machine shaping(grinding and extrusion) and consolidation or sintering. The method is characterized in that the utilization ratio of the waste residues is 100 percent. The waste residues comprise the following compositions: (1) the produced road material-curing agent, which can be used to reinforce a highway subgrade and bases of road surface substrates(substrate and subbase) and buildings and completely replace cement, lime and sandstone materials, and the road material can meet prior national(industrial) standards and environmental protection standards in performance; and (2) the produced construction walling materials-non supporting brick, supporting brick, air brick, hollow building block, common tile, glazed roof tile and andorful tile, which are superior to the prior national standards in performance. The material obtained by the invention has the characteristics of energy conservation, thermal insulation, high strength, corrosion resistance, efflorescence resistance and no pollution.

Owner:王文举

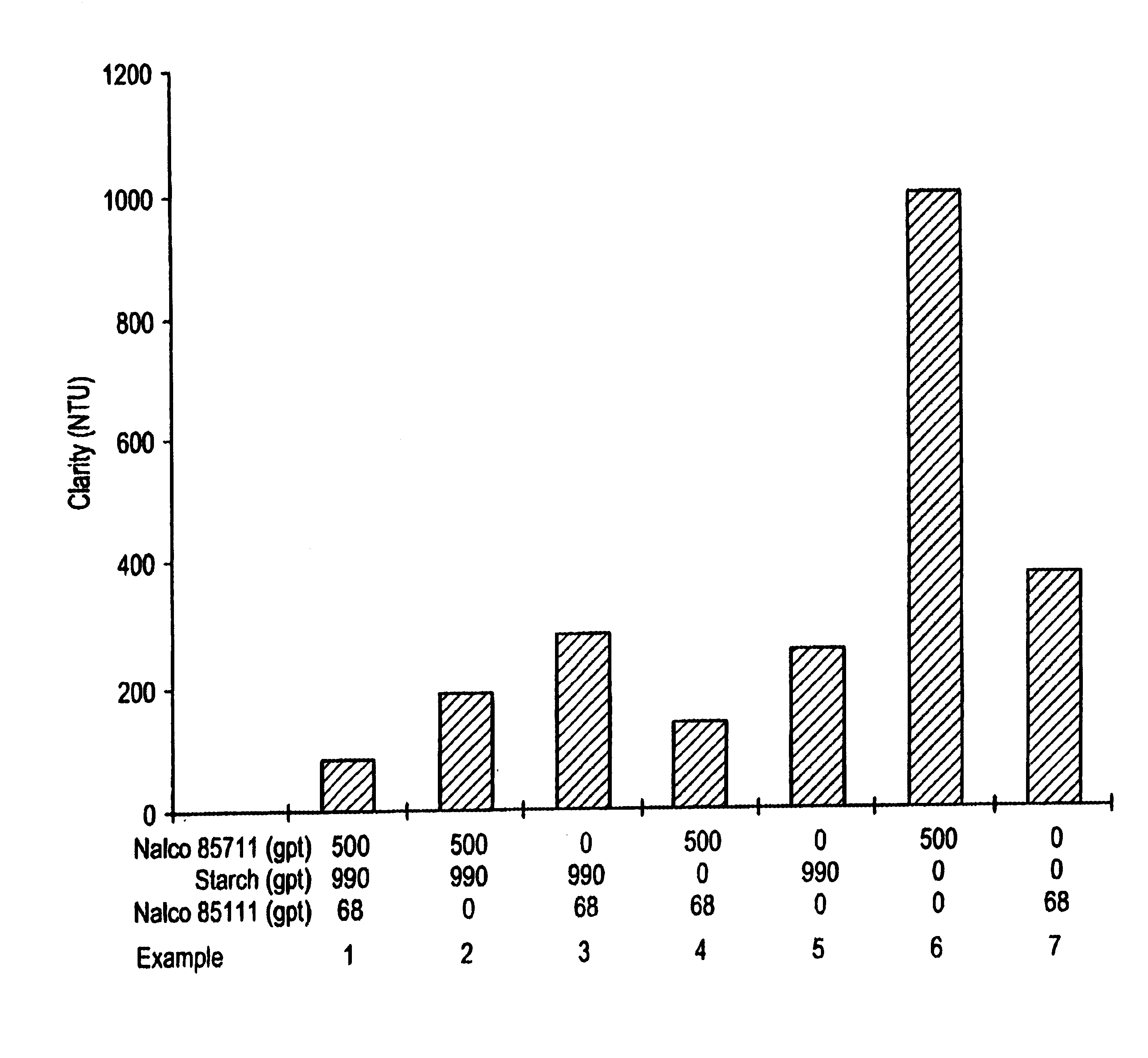

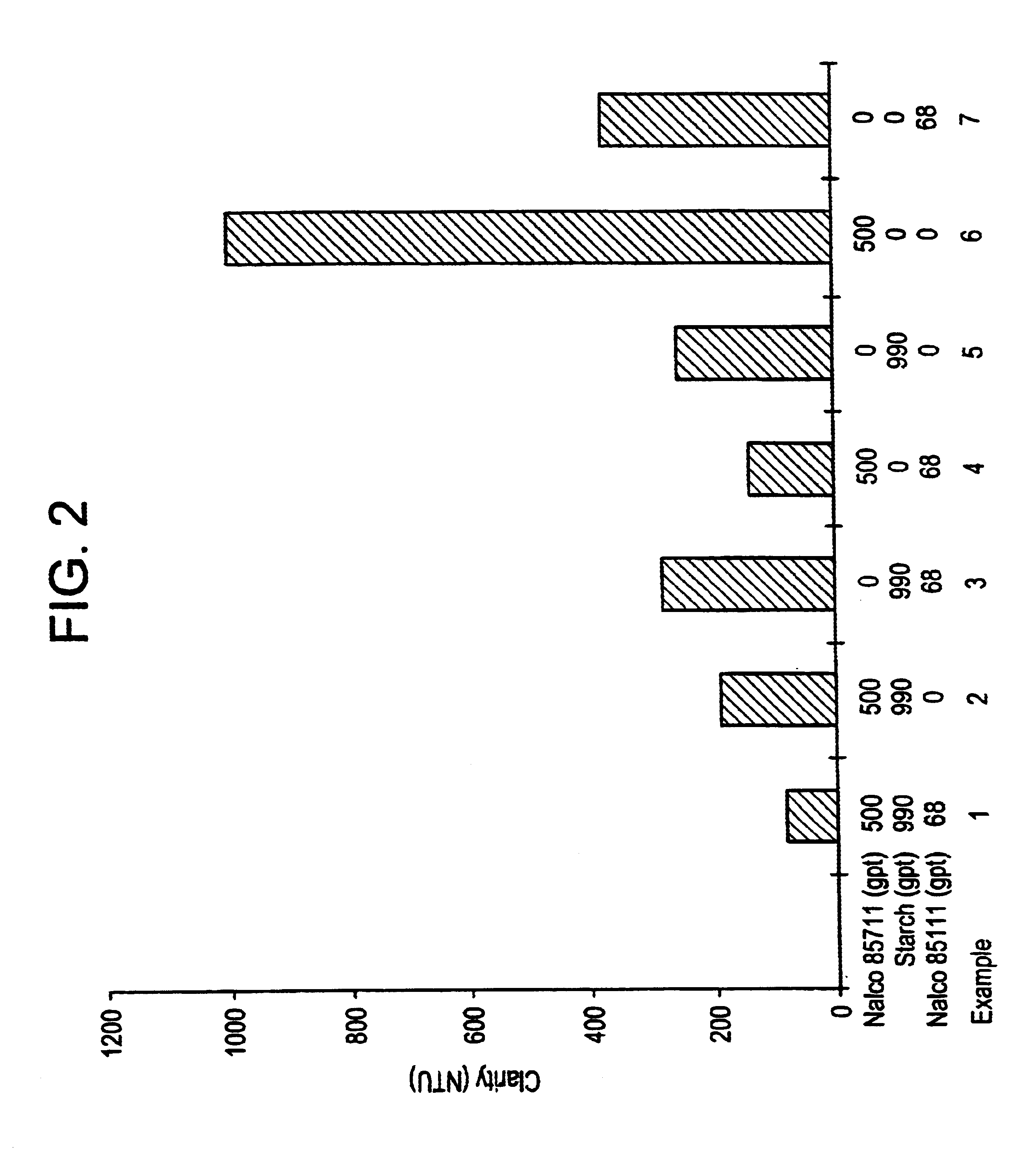

Dextran starch and flocculant combination for improving red mud clarification

InactiveUS6726845B1Easy to separateGallium/indium/thallium compoundsCentrifugal force sediment separationFiltrationCentrifugation

The claimed invention is a method for separating Bayer process red mud from a Bayer process liquor which comprises adding to a Bayer process liquor containing red mud an effective amount of a water soluble synthetic flocculant, dextran and starch combination. The flocculant is added anywhere in the slurry containing the red mud suspended in Bayer process liquor, or in a liquor slurry containing bauxite prior to or during digestion. Once the flocculant combination is added, it is mixed sequentially with the Bayer process liquor and the red mud contained in the Bayer process liquor is removed by sedimentation, centrifugation or filtration.

Owner:ECOLAB USA INC

Method for preparing magnetic sludge-based biochar material from sludge and application of magnetic sludge-based biochar material

ActiveCN112354516AEasy to separateLarge specific surface areaOther chemical processesSludge treatment by pyrolysisSludgeRed mud

The invention discloses a method for preparing a magnetic sludge-based biochar material from sludge and the application of the magnetic sludge-based biochar material, and belongs to the technical field of sludge resource utilization. The invention aims to fully utilize municipal and industrial wastes such as sewage sludge, hematite, rust, Bayer process red mud, high-iron-content fly ash, picklingwastewater and the like, and prepare magnetic sludge-based biochar from a solid waste iron source: dried sludge with the water content of less than 15% and a solid iron source are mechanically crushedand uniformly mixed; continuous pyrolysis is carried out, the pyrolysis temperature is 400-800 DEG C, the solid material stays in the device for 20-120 min, and fine ball milling and smashing are carried out until the particle size is 100 [mu] m or below; in the nano Fe3O4 / magnetic sludge-based biochar core-shell material prepared by the method, both the material core and the shell have magnetism, so that efficient recycling can be realized.

Owner:SHANGHAI FUTING TECH CO LTD

Method for producing high-performance haydite from red mud

The invention discloses a method for producing high-performance haydite from red mud, which comprises the following steps: taking 40-70 parts by weight of Bayer-process red mud, 0-30 parts by weight of sintering-process red mud, 5-20 parts by weight of fly ash and 5-30 parts by weight of clay material on dry basis as raw materials; evenly mixing the raw materials with 5-20 parts by weight of water, and putting the mixture on a pelletization plate to carry out pelletization, thereby obtaining the haydite fresh pellets; sintering the haydite fresh pellets, of which the diameters are 0.5-20mm, in a rotary kiln or sintering machine at 1050-1200 DEG C for 15-60 minutes; and quenching the sintered haydite to obtain the high-performance haydite product, of which the density level is 600-900, the water absorptivity is lower than 12%, the cylindrical compressive strength is higher than 7.5MPa and the strength grade is higher than 50MPa. The invention can effectively and massively utilize red mud as the raw material to produce the high-performance haydite, has the advantages of simple manufacturing technique and high product quality, and changes wastes into valuable substances.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +1

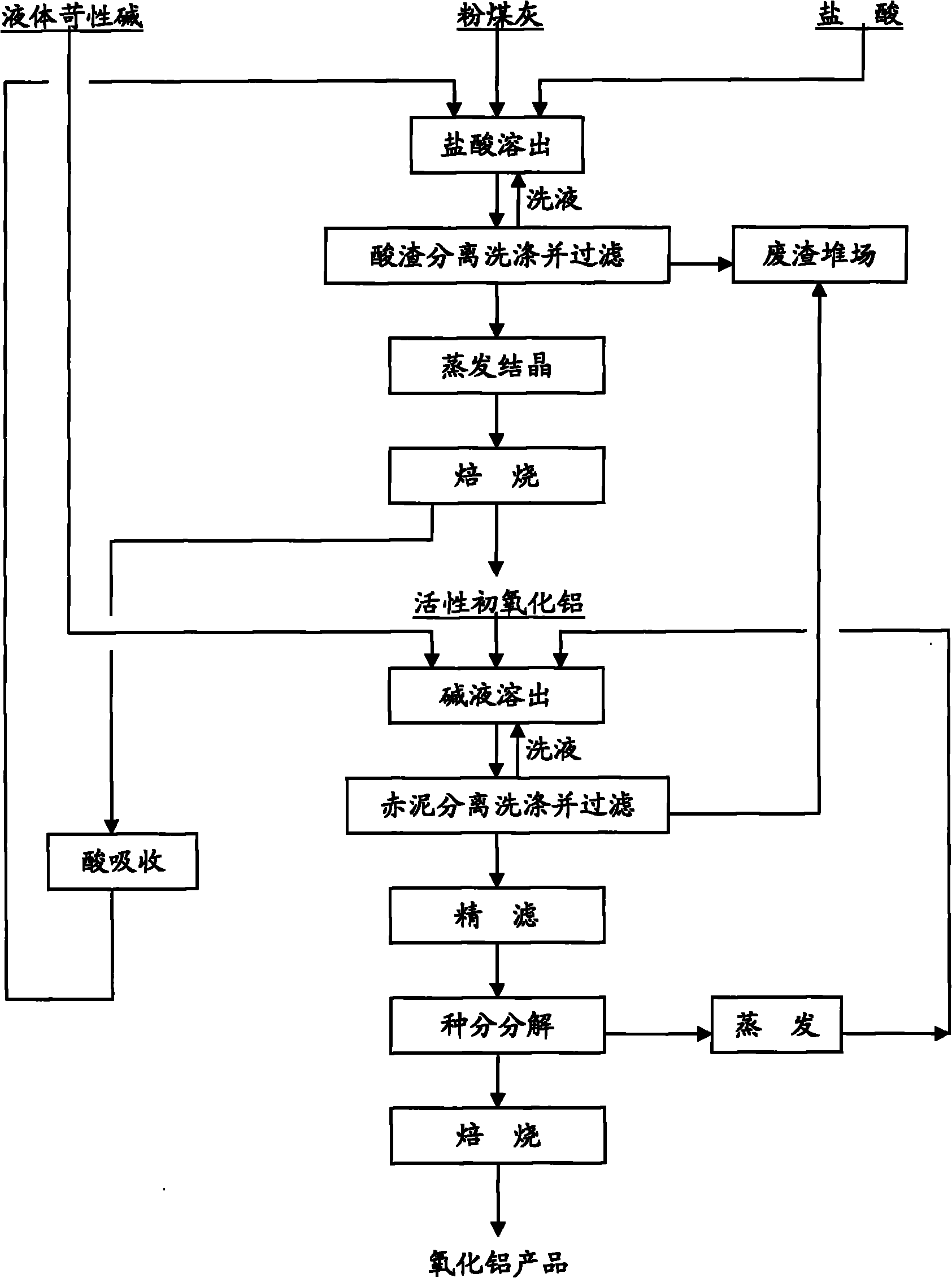

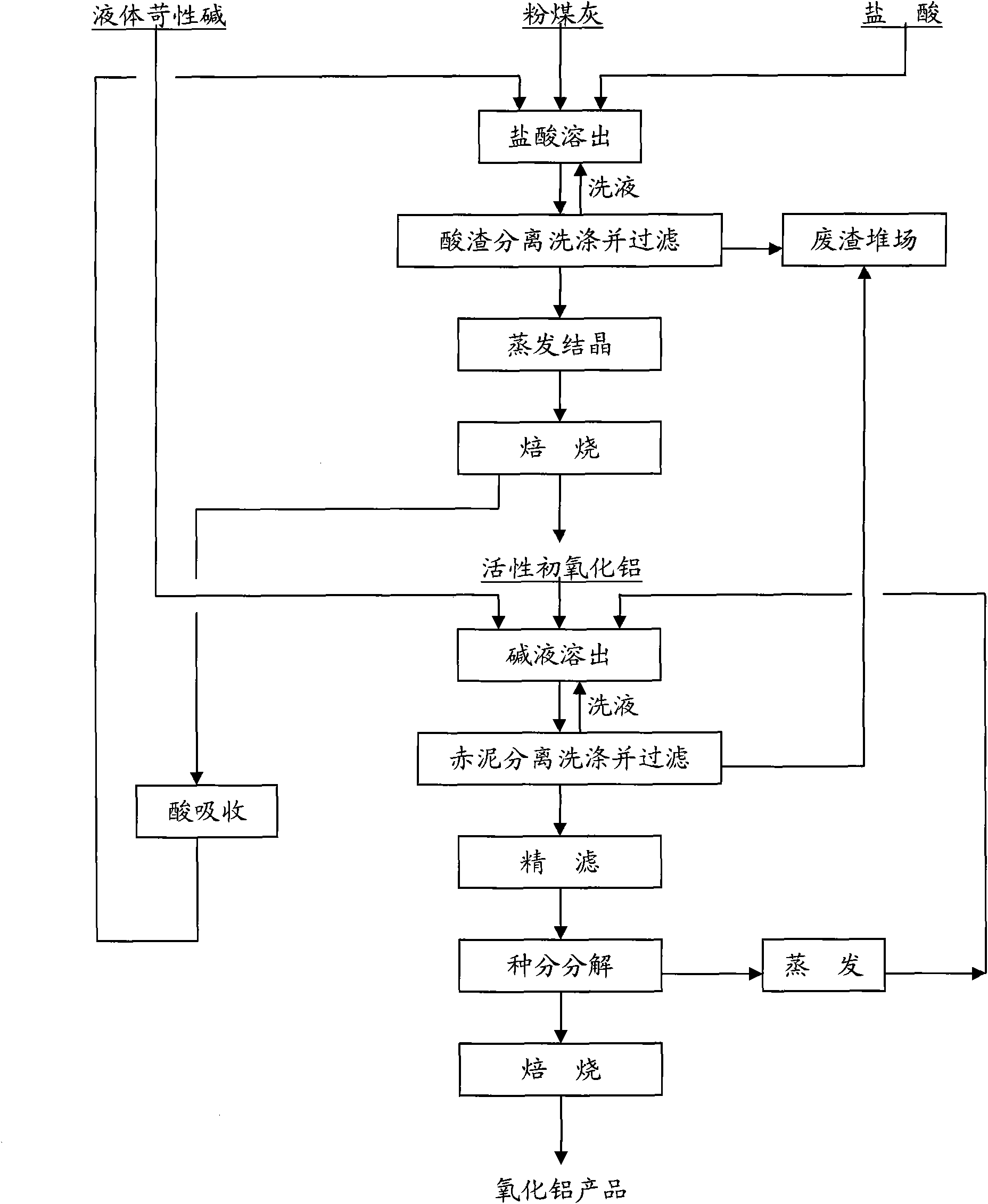

Method for extracting aluminum oxide from fly ash

InactiveCN101811711AOvercoming technical defects of alumina extraction processOvercoming technical deficienciesSolid waste disposalAluminium oxides/hydroxidesAluminium hydroxideFiltration

The invention discloses a method for extracting aluminum oxide from fly ash. The method comprises the following steps of: a, acid-method treatment: mixing hydrochloric acid and fly ash, and transferring the mixture in a digester, of which the lining is made of polytetrafluoroethylene materials, for digestion, performing the separation of the pulp digested in a settling tank, evaporating and crystallizing upper-part overflow, baking the crystals to decompose the crystals into active coarse aluminum oxide and hydrogen chloride gas, wherein the hydrogen chloride gas is recovered to make acid and the acid is returned to the fly ash settling step; and b, bayer method treatment: mixing the active coarse aluminum oxide and circulating mother liquor, transferring the mixture in the digester for digestion, separating the pulp digested by settlement, performing refined filtration of the upper-part overflow to obtain refined solution, mixing the refined solution and aluminum hydroxide crystal seeds, decomposing the crystal seeds to obtain decomposed mother liquor and aluminum hydroxide, and filtering, washing and baking the aluminum hydroxide to obtain the aluminum oxide product, wherein the decomposed mother liquor is evaporated and then returned to the step of digesting the active coarse aluminum oxide. By adopting the method of the invention, the metallurgical-grade aluminum oxide meeting the requirements on national standards can be prepared.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Process for recovery of gallium

InactiveUS20040042945A1High yieldHigh purityAluminium compoundsPhotography auxillary processesGallium alloyChemistry

The present invention relates to a process for the recovery of gallium from Bayer process liquors. Bayer process liquor is obtained from alumina industries and contains 450 g / L Na2O, 80 g / L Al2O3 and 190±20 ppm of gallium. The present invention utilizes an organic and inorganic phase for a two stage separation process to recover gallium with high purity.

Owner:COUNCIL OF SCI & IND RES

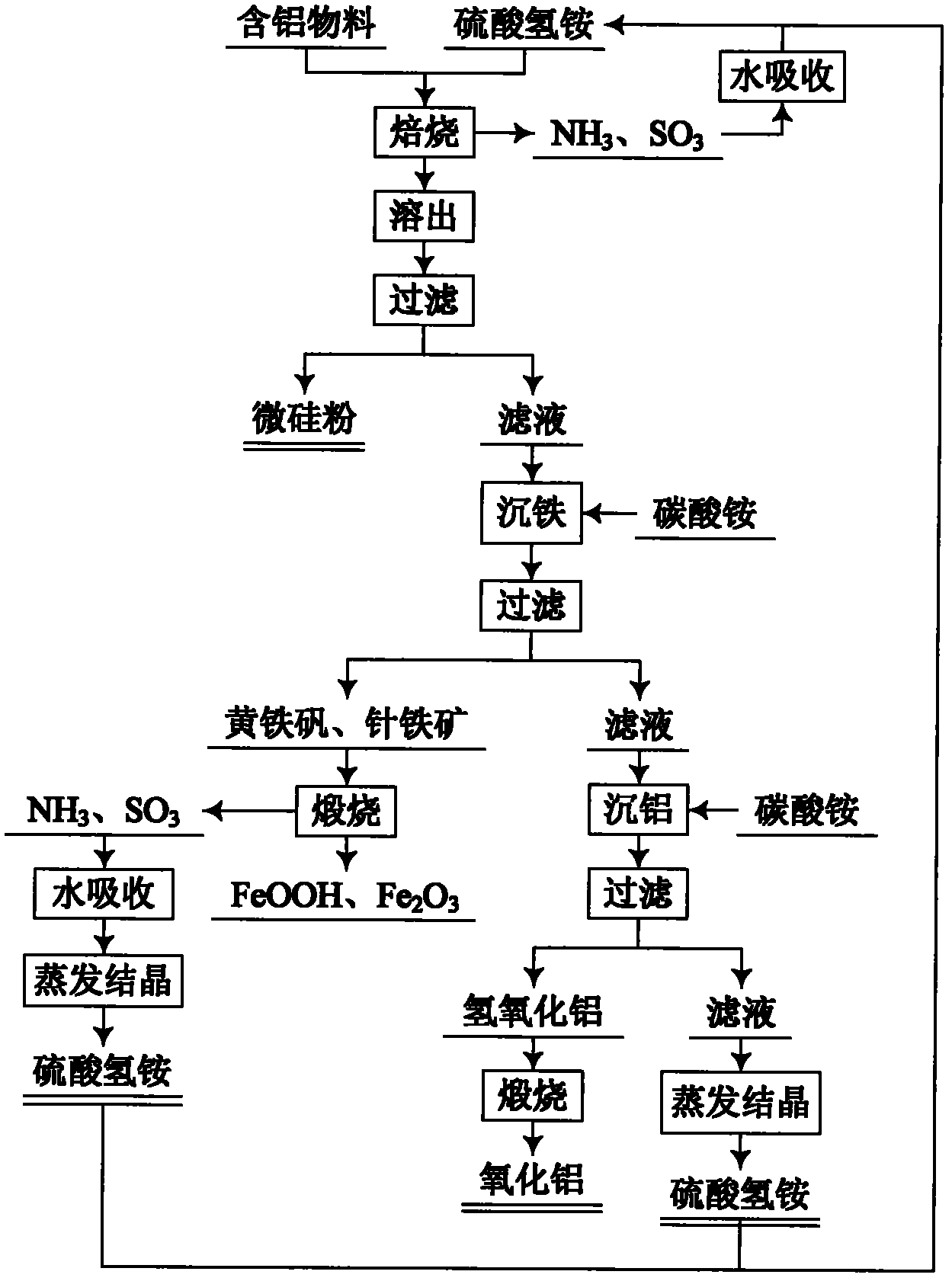

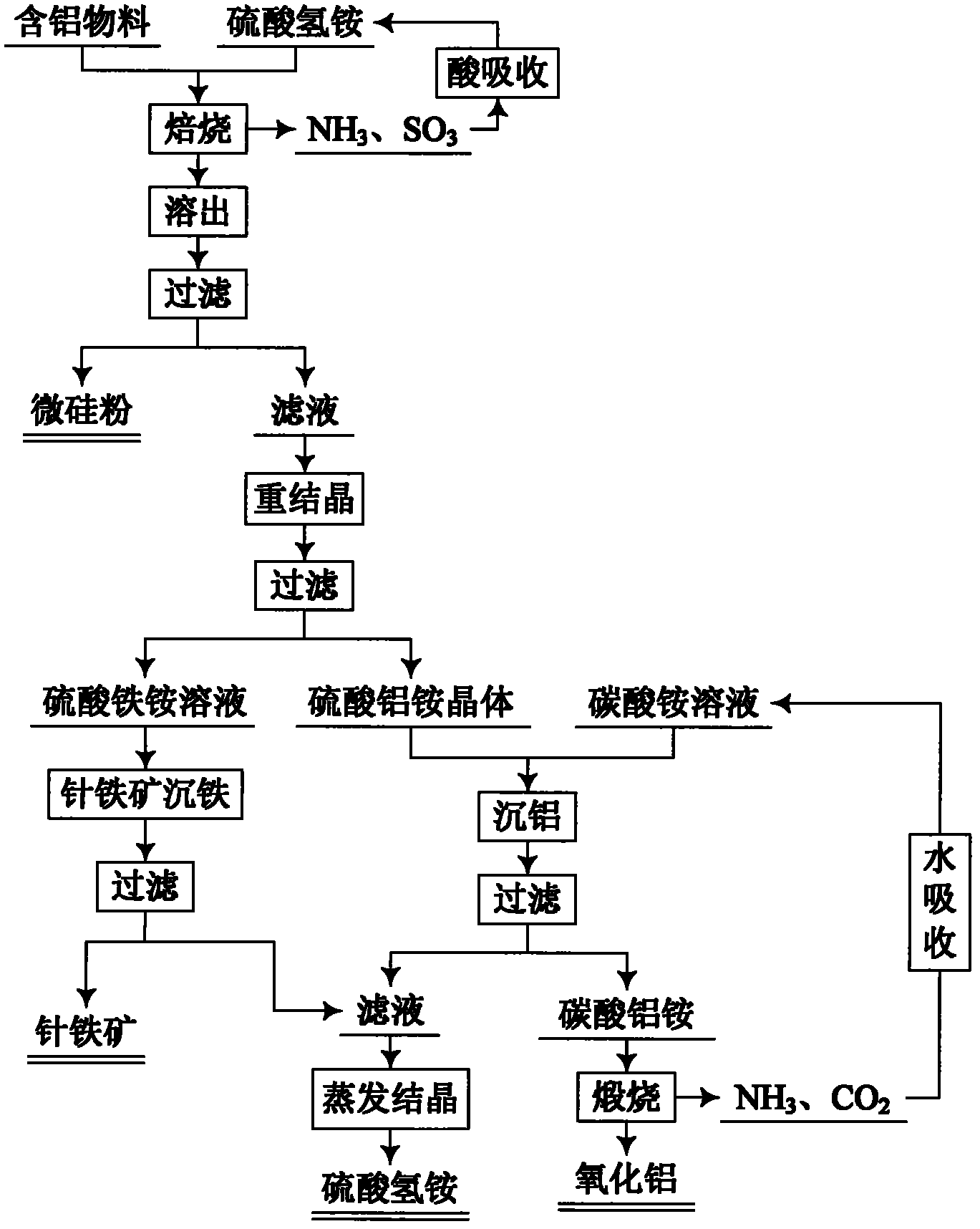

Method for comprehensive utilization of aluminum-containing material

The invention relates to a method for preparing aluminum oxide and other products by aluminum-containing materials of bauxite, alunite, nepheline, fly ash, kaolin, coal gangue and clay. The method comprises the following steps: (1) crushing and grinding an aluminum-containing material, carrying out mixing and baking for the treated aluminum-containing material and ammonium bisulfate; (2) carryingout dissolution and filtering for the baked clinker to obtain a crude ammonium aluminum sulfate solution and aluminum extracting residue; (3) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration more than 1 g / L by adopting a jarosite method, then carrying out an iron precipitating treatment by a goethite method, carrying out an aluminum precipitating treatment for the resulting solution, carrying out calcination for the resulting aluminium hydroxide to prepare aluminum oxide; (4) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration less than 1 g / L by adopting the goethite method, and carrying out an aluminum precipitating treatment to prepare aluminum oxide, or adopting a recrystallization method to carry out purification, adopting a reaction of the ammonium aluminum sulfate crystal and a ammonium carbonate solution to precipitate the aluminum to obtain ammonium aluminumcarbonate, carrying out calcination for the ammonium aluminum carbonate, and adopting a Bayer method to treat the calcined ammonium aluminum carbonate to prepare sandy aluminum oxide; (5) washing anddrying the aluminum extracting residue, wherein the dried aluminum extracting residue is adopted as the silicon dioxide product.

Owner:NORTHEASTERN UNIV

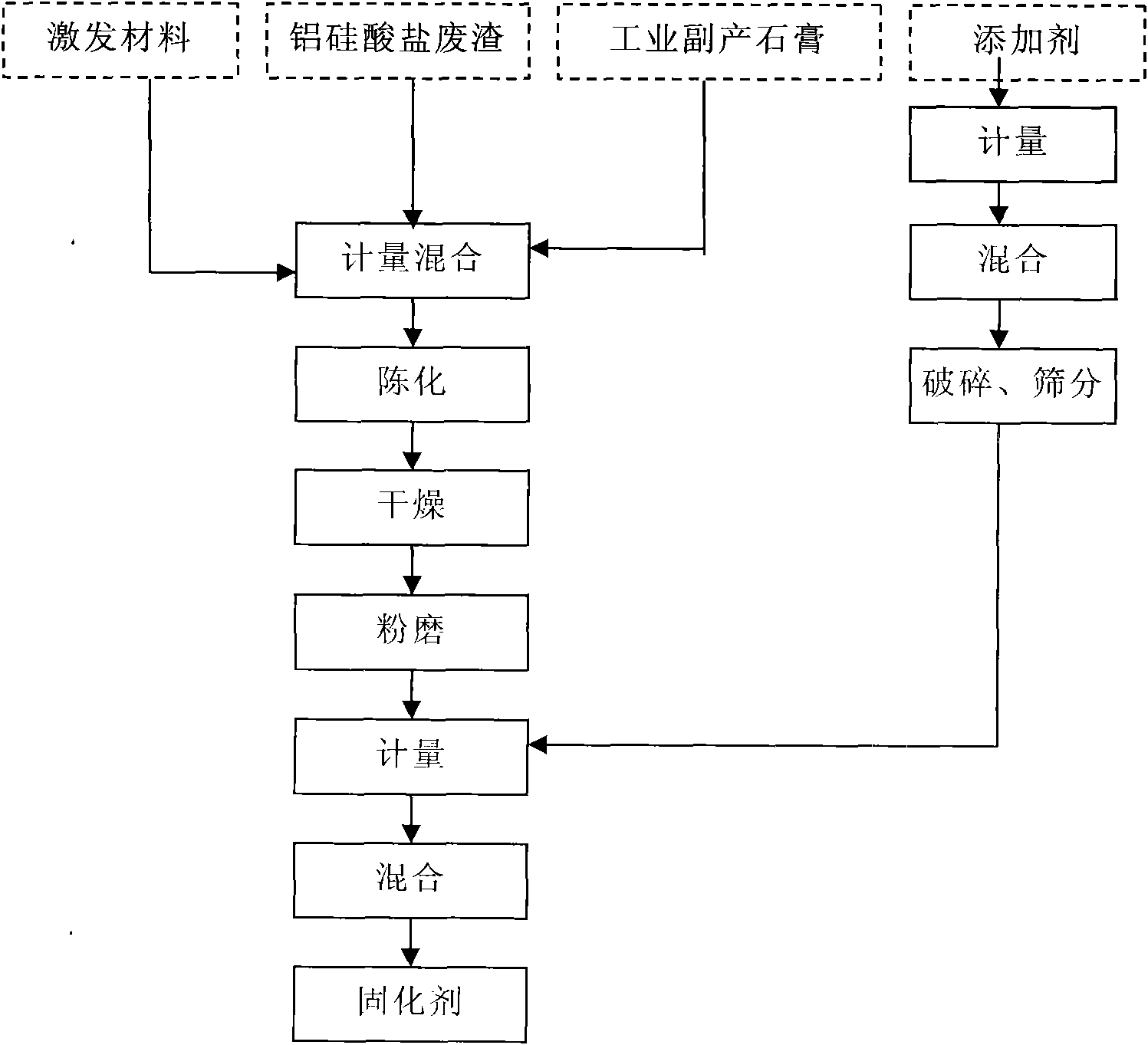

Low-temperature ceramic curing agent of red mud from Bayer process

The invention relates to a low-temperature ceramic curing agent of red mud from a Bayer process. The low-temperature ceramic curing agent is prepared by the following raw materials by weight parts: 100 aluminosilicate residues, 20-150 industrial by-product gypsum, 50-200 excited materials, 0-3.0 water-reducing agent, 0-5.0 flocculating agent and 0-5.0 retarder. The production method thereof comprises the following steps: (1) processing main raw materials; (2) preparing additives; and (3) preparing a curing agent. The invention has the beneficial effects that (1) all components of the curing agent can irreversibly react with the red mud; compared with the prior gelled material, the invention does not use cement, base excited materials and expensive high molecular polymers, thereby achieving low cost; (2) the invention uses the industrial residues as the raw materials to cure the red mud so as to achieve the aim of treating a waste with another waste; no secondary waste is exhausted in a production process and an application process so as to benefit environmental protection; and (3) the invention can thoroughly solve the safety problem of a red mud library after curing the red mud.

Owner:山西鑫秀工矿废渣利用有限公司 +1

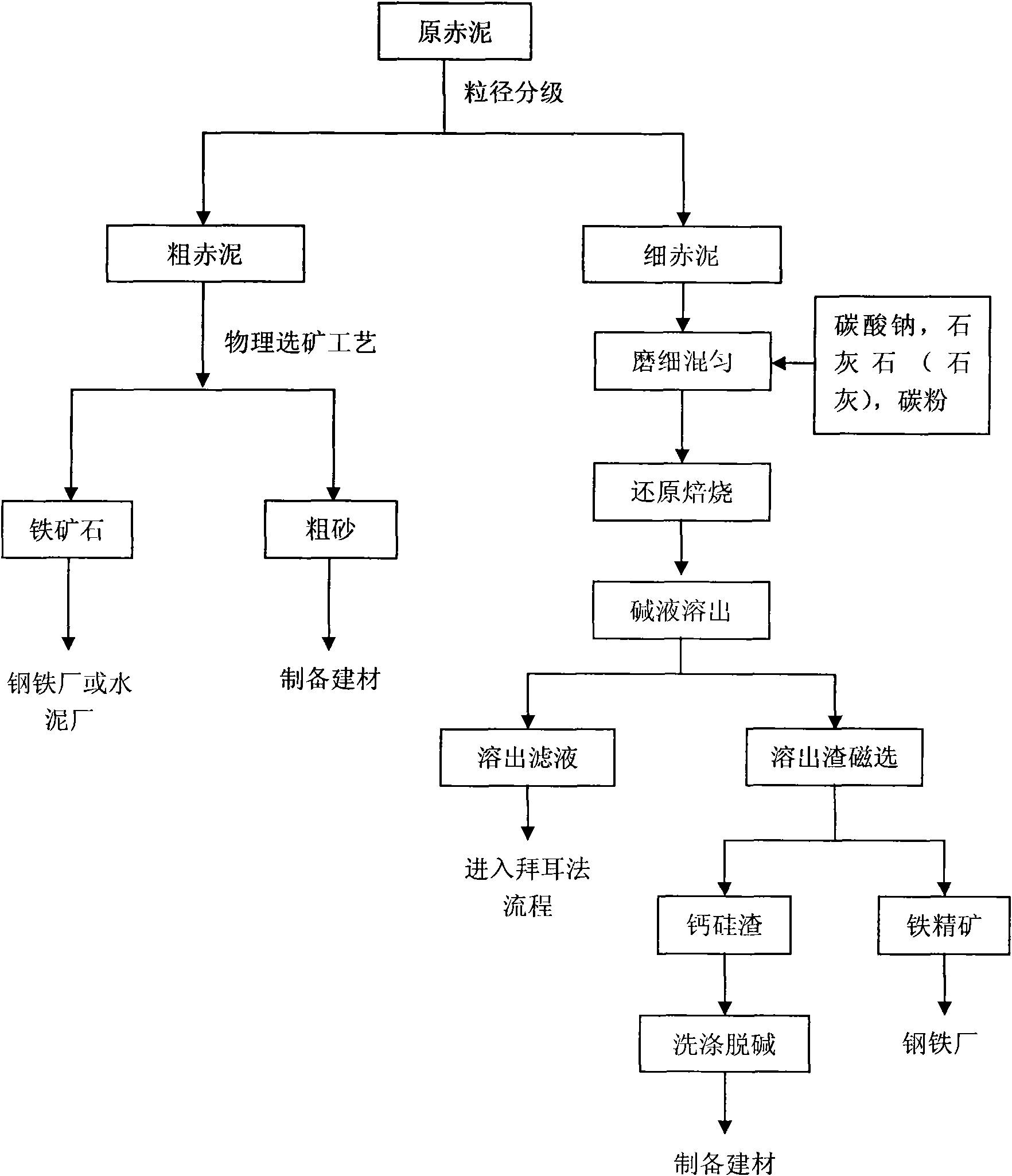

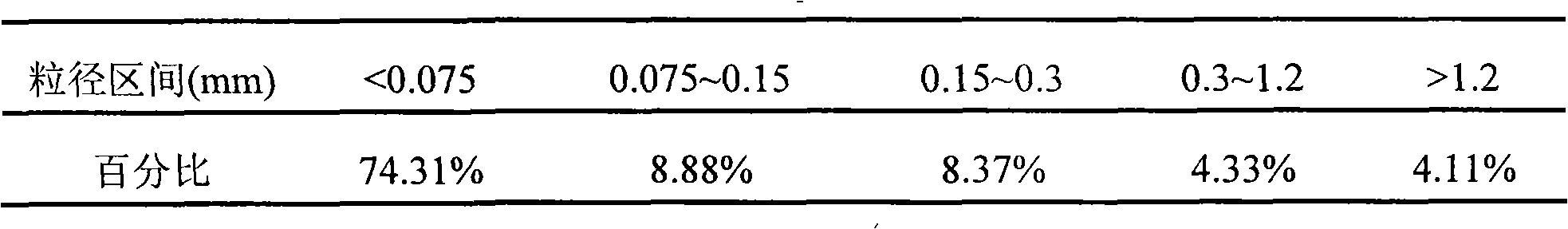

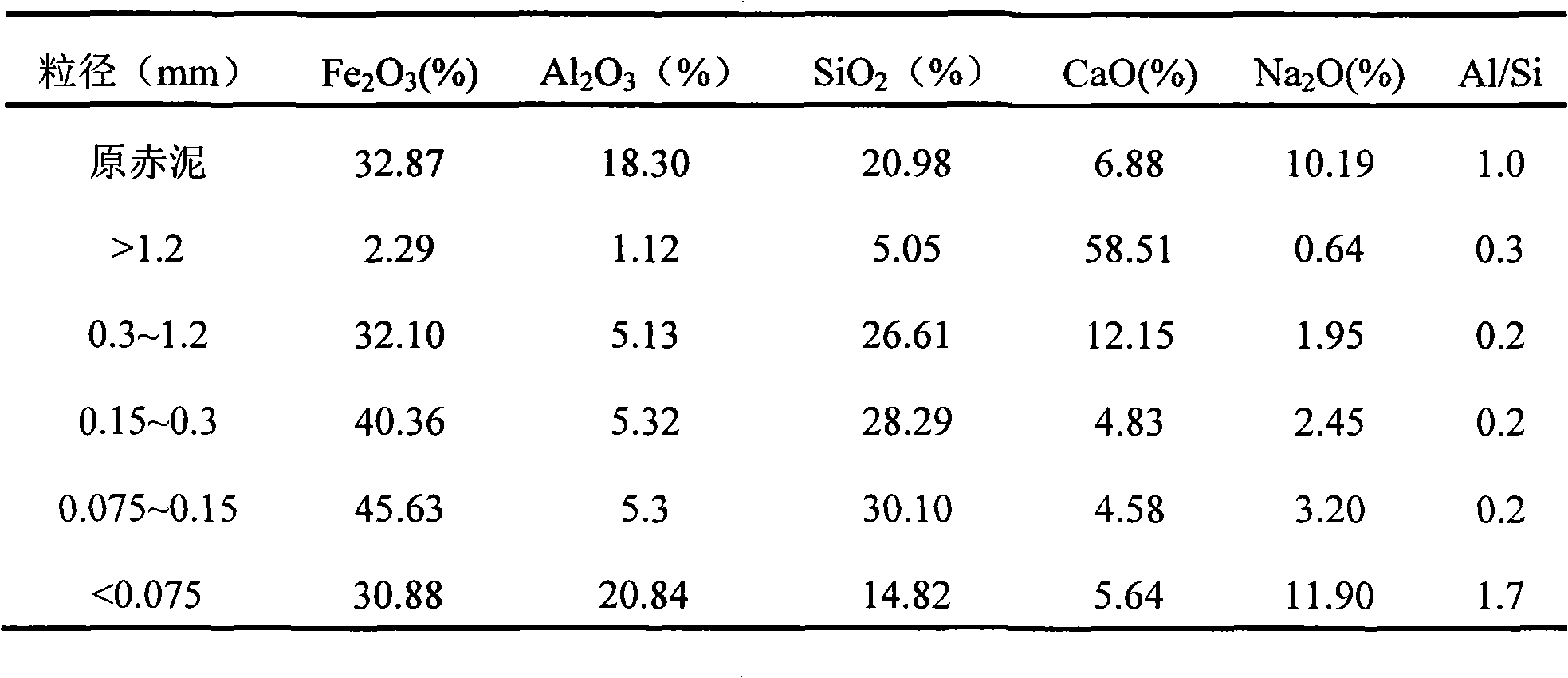

Method for recycling iron and aluminum by particle size grading pretreatment of Bayer process red mud

InactiveCN101624654AReduce difficultyReduce energy consumptionProcess efficiency improvementSlagRed mud

The invention relates to a method for recycling iron and aluminum by particle size grading pretreatment of Bayer process red mud, belonging to the technology for recycling red mud resources. The method comprises the following steps: firstly, Bayer process red mud is graded in terms of the particle size by using a physical method into coarse red mud and refined red mud; the coarse red mud is processed using physical mineral dressing processes, such as magnetic separation, gravity separation and the like, in order to obtain iron ore having high iron quality and coarse-grained sand, which are made use of respectively; the refined red mud is mixed with sodium carbonate, limestone and carbon power and is then subjected to reduction sintering, and two processes of magnetizing reduction roasting of iron and soda lime sintering of aluminum are implemented synchronously by means of the control of sintering conditions; sodium aluminate is dissolved out of clinker through dilute alkali solution, dissolved slag is subjected to magnetic separation to recover iron ore concentrate, and after being subjected to dealkalized cleaning, the residual calcium silicon slag is applied to building material industry. The method realizes combined recovery of iron, aluminum and other elements, magnificently achieves the comprehensive utilization of the Bayer process red mud, is capable of effectively relieving environment pollution resulting from the accumulation of the Bayer process red mud, and has excellent economic and social benefits.

Owner:HUAZHONG UNIV OF SCI & TECH

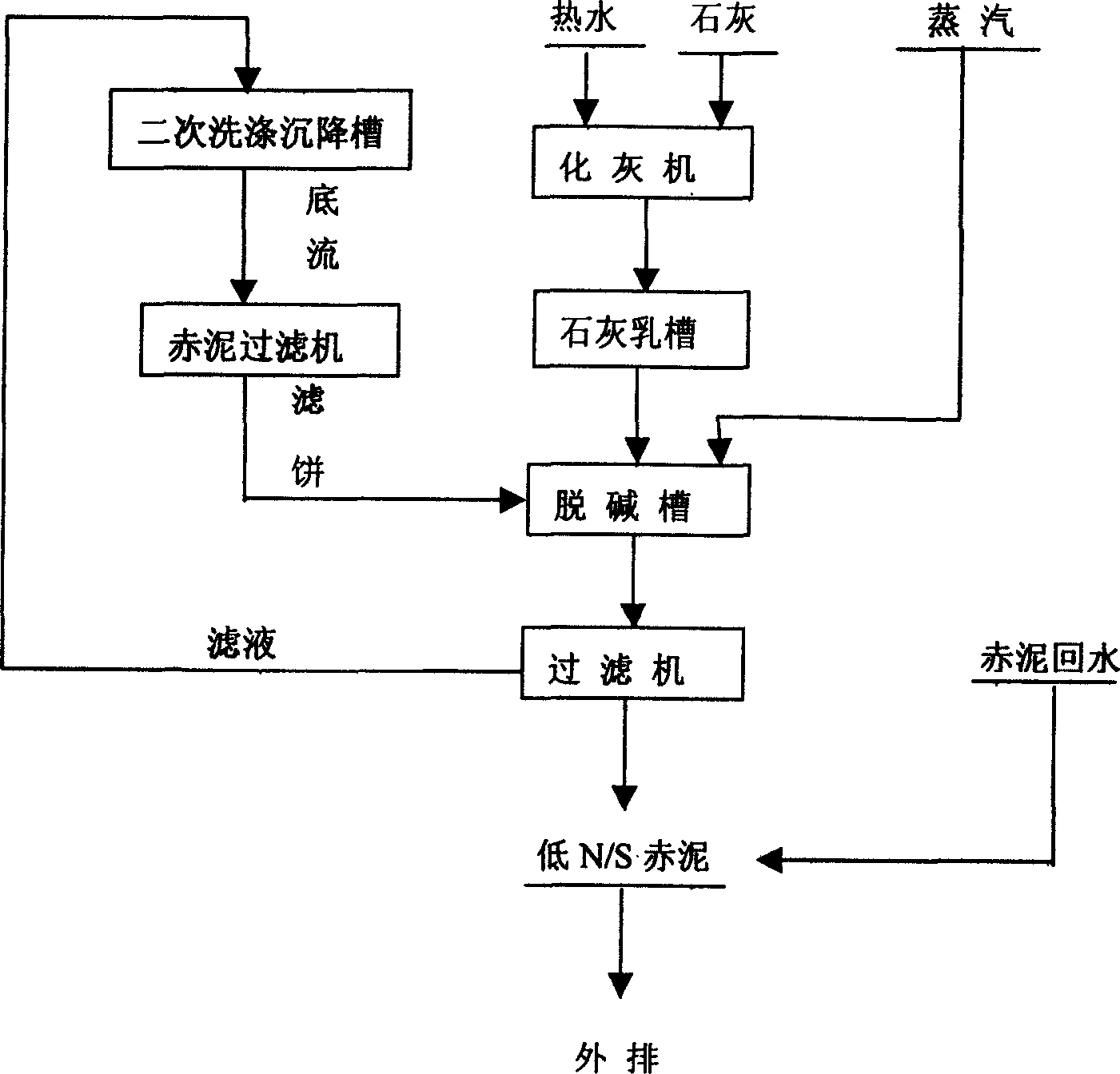

Red mud dealkalization method at normal pressure by Bayer process

InactiveCN1594093ASatisfy evacuation requirementsIncrease productivityAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxides/hydroxidesDealkalizationPetroleum engineering

The invention discloses a red mud dealkalization method at normal pressure by Bayer process, wherein the dealkalizing step consists of, washing and filtering the red mud, charging lime cream into the red mud filter cake, mixing for dealkalizing reaction, subjecting the reaction slip to washing, filtering, drying and discharging.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for producing alumina by using high sulphur bauxite

ActiveCN101456572AImprove energy efficiencyPromote dissolutionAluminium oxides/hydroxidesFluidized bedSulfur

The invention relates to a method for producing alumina by utilization of high-aluminum alumyte, which belongs to the technical field of metallurgy. The method comprises: firstly, grinding alumyte ores, and adopting a fluidized bed to perform roasting and desulfurization pretreatment; secondly, treating obtained roasted ores by a Bayer process, and obtaining Al2O3 products after stripping, crystal seed decomposition and calcining treatment; and thirdly, introducing roasted tail gas generated by roasting into red mud under the stirring condition, and absorbing SO2 in the tail gas. The method has low stripping temperature, can effectively remove sulfur element in the ores, has great significance in developing and using the ores for alumina industrial production practice, uses the red mud during industrial production of alumina as an absorbent of the low concentration SO2 tail gas during roasting, and realizes dealkalization and modification treatment and comprehensive utilization of the red mud.

Owner:NORTHEASTERN UNIV

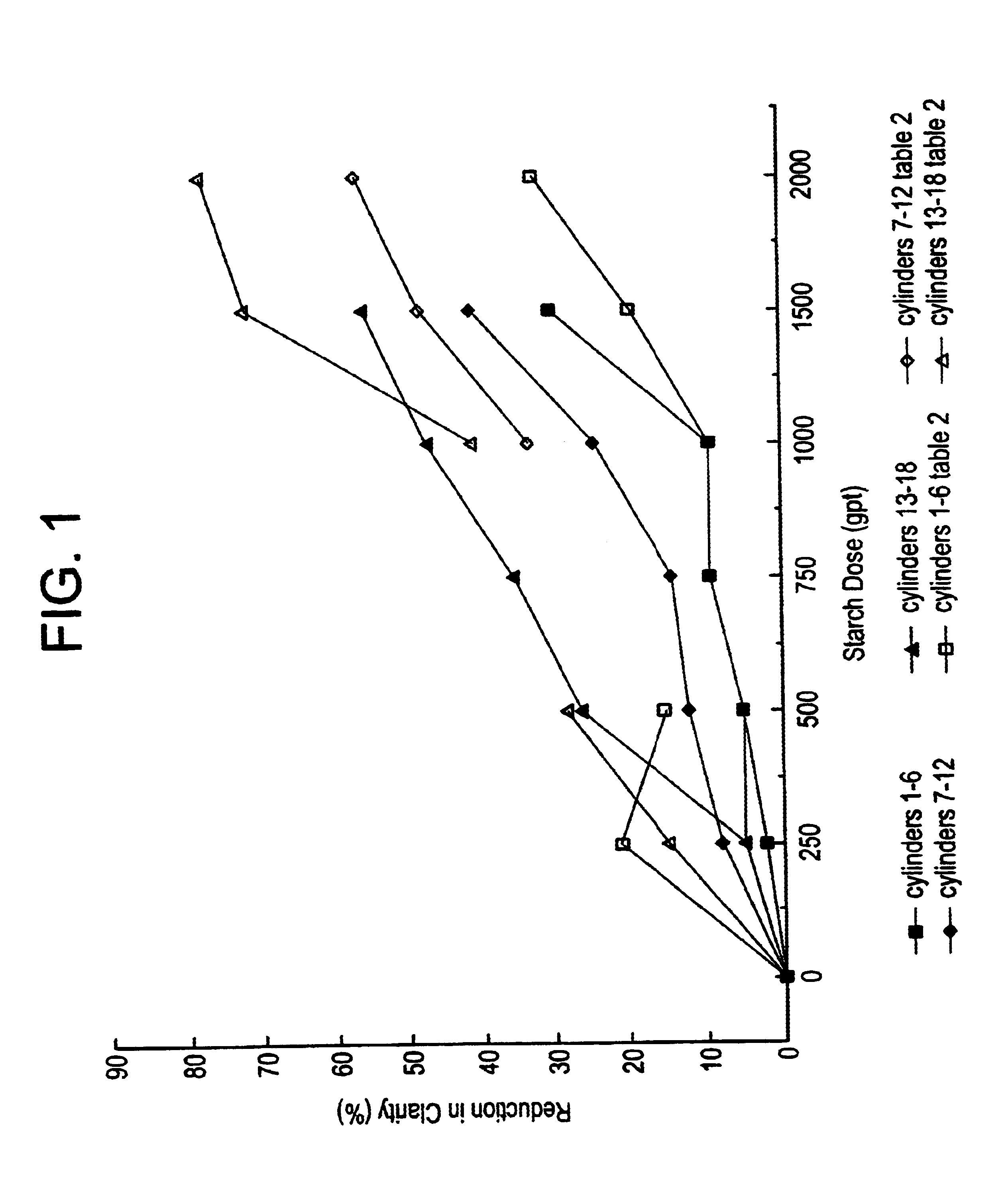

Recovery of alumina trihydrate during the bayer process using cross-linked polysaccharides

ActiveUS8298508B2Accelerated settlementEnhanced inhibitory effectGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationCross-linkCellulose

The invention provides methods and compositions for improving the production of alumina hydrate. The invention involves adding one or more polysaccharides to liquor or slurry in the fluid circuit of the production process. The one or more polysaccharides can be a cross-linked polysaccharide (such as cross-linked dextran or cross-linked dihydroxypropyl cellulose). The various polysaccharides can impart a number of advantages including at least some of: greater flocculation effectiveness, increasing the maximum effective dosage, faster settling rate. The production process can be a Bayer process.

Owner:NALCO CO

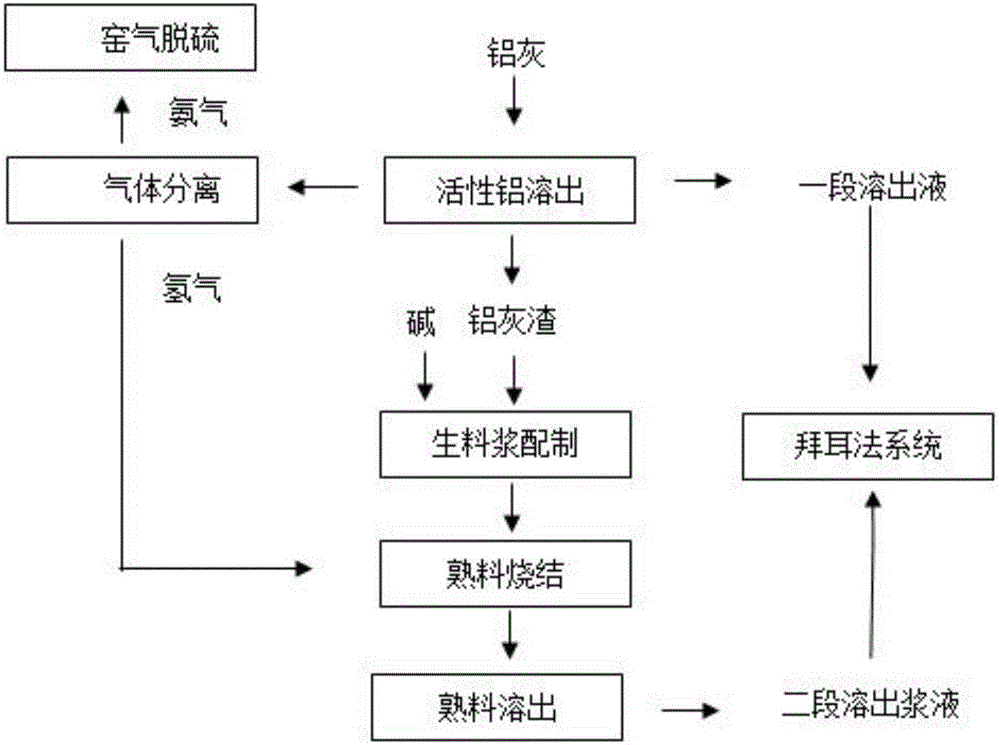

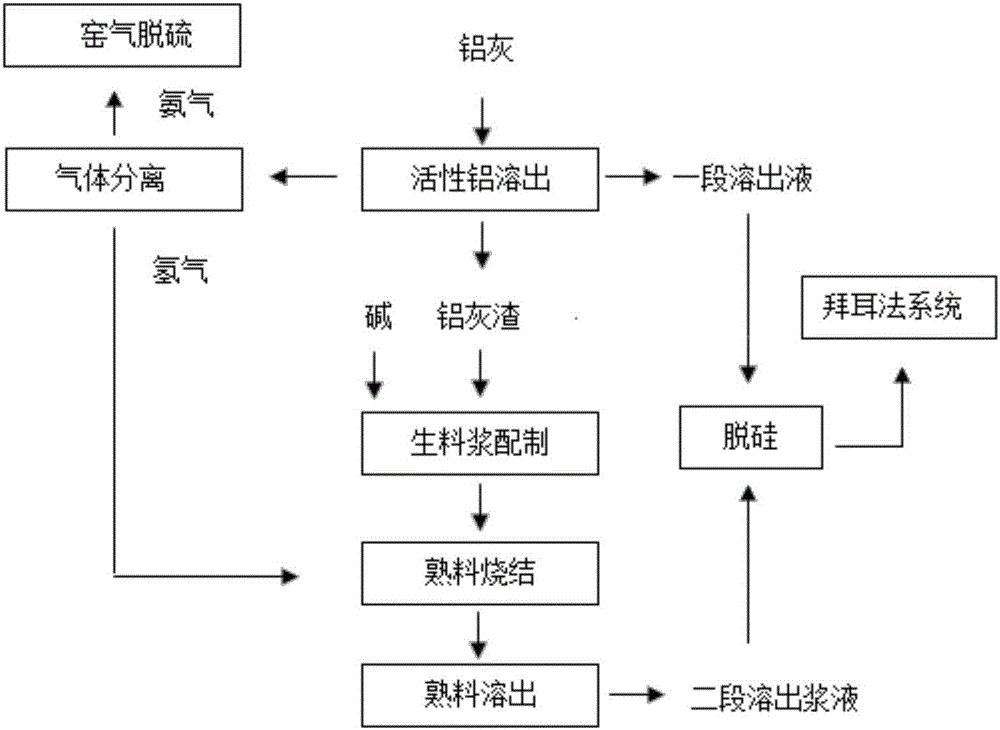

Method for safely and efficiently producing sand-like alumina from aluminum ash

ActiveCN106830030AReduce processingImprove economyChemical industryHydrogen productionHydrogenSodium aluminate

The invention provides a method for safely and efficiently producing sand-like alumina from aluminum ash. The method comprises the steps as follows: 1) aluminum ash is added to a sodium aluminate to react with the sodium aluminate solution, then solid-liquid separation is performed, a first-section digestion liquid and aluminum ash residues are obtained, and hydrogen and ammonia gas are comprehensively utilized; 2) alkali and an additive are added to the aluminum ash residues, raw slurry is obtained, and thus chlorine and fluorine elements are prevented from entering tail gas; 3) the raw slurry is sintered and clinker is obtained; 4) the clinker is added to an adjustment liquid for digestion, and second-section digestion slurry is obtained; 5) the first-section digestion liquid and the second-section digestion slurry are mixed in a Bayer process digestion slurry dilution system for production of the sand-like alumina by the Bayer process system. Nitrogen, fluorine, chlorine, hydrogen and other harmful elements in the aluminum ash are disposed safely, the concentration of organic matter in a Bayer process solution is decreased, and aluminum components are recovered efficiently and economically; for the aluminum ash, the method has the characteristics of safety, high efficiency, low cost and the like; for the Bayer process system, the yield is increased, the solution is purified, and the production efficiency is significantly improved.

Owner:CENT SOUTH UNIV +1

Method for preparing sintering-expanded haydite by taking red mud of Bayer process as main raw material

InactiveCN101538131AGood vitrificationUniform porositySolid waste managementSolid waste disposalCooking & bakingRed mud

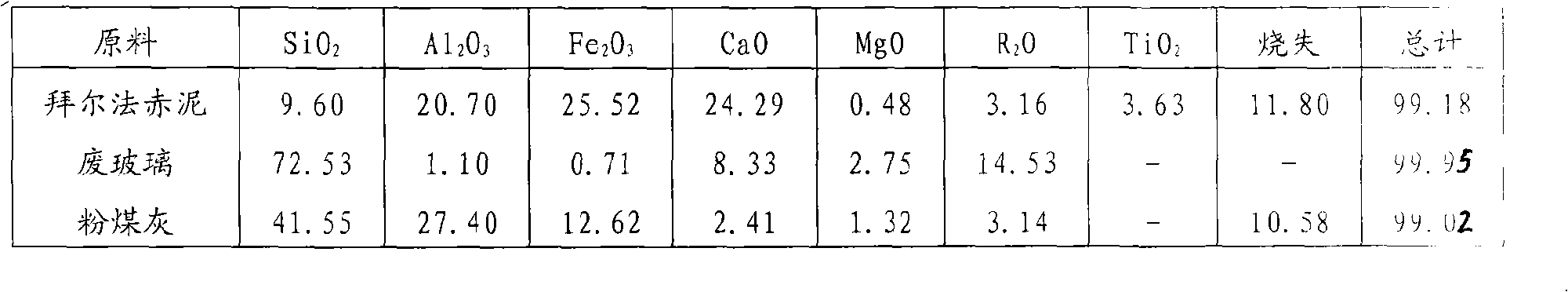

The invention discloses a method for preparing a sintering-expanded haydite by taking red mud of Bayer process as a main raw material, comprising the following steps of by taking the red mud of Bayer process, fly ash, wasted glass, starch, carbon powder and sodium hexametaphosphate as raw materials, respectively grinding the red mud of Bayer process, the fly ash and the wasted glass by a sieve of 160 meshes; proportioning and uniformly mixing the sieved raw materials by the following mass ratio: (50-60):(20-25):(15-20):2:2;1 for Bayer process, fly ash, wasted glass, starch, carbon powder and sodium hexametaphosphate respectively; adding the water of 5-10% by mass in the raw material, mixing the mixture for 5-10min, decaying the mixture for 20-30min and forming balls; baking the formed balls in an oven for 2-5h at the temperature of 105 DEG C; drying the balls and preheating the balls in a muffle for 10-30min at the temperature of 600 DEG C; after preheating, quickly moving and baking the balls in a high-temperature Si-Mo furnace for 10-30min at the temperature of 1100-1200 DEG C; and after finishing baking, opening the furnace door, taking out the balls and forcibly cooling the balls. The sintering-expanded haydite prepared by the method has fine vitrification degree on the external surface and uniform internal aperture and takes closed holes as main ones.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Recovery of alumina trihydrate during the bayer process using cross-linked polysaccharides

ActiveUS20120034142A1Accelerated settlementEnhanced inhibitory effectGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationCross-linkCellulose

The invention provides methods and compositions for improving the production of alumina hydrate. The invention involves adding one or more polysaccharides to liquor or slurry in the fluid circuit of the production process. The one or more polysaccharides can be a cross-linked polysaccharide (such as cross-linked dextran or cross-linked dihydroxypropyl cellulose). The various polysaccharides can impart a number of advantages including at least some of: greater flocculation effectiveness, increasing the maximum effective dosage, faster settling rate. The production process can be a Bayer process.

Owner:NALCO CO

Treatment or remediation of natural or waste water

ActiveUS20120228229A1Protect the surfaceWater contaminantsSolid sorbent liquid separationAluminateAluminium hydroxide

A process for treating a natural or wastewater containing dissolved Mg or dissolved Al comprising the steps of adding at least one Mg-containing compound or at least one Al-containing compound to the natural or wastewater to thereby form a layered double hydroxide (LDH) containing Mg and Al as predominant metal species in a lattice of the LDH. The LDH may comprise hydrotalcite. The AL-containing compound may be aluminate or aluminium hydroxide derived from the Bayer process or from an alumina refinery.

Owner:COMMONWEALTH SCI & IND RES ORG

Method for reclaiming alumina and sodium oxide in red mud of Bayer process

InactiveCN101607725AReduce energy consumptionOvercome the disadvantages of large investment, short service life and difficult operationAlkali metal oxidesAluminium oxides/hydroxidesFiltrationRed mud

The invention relates to a method for reclaiming alumina and sodium oxide in red mud of Bayer process. The method comprises the following steps: carrying out leaching reaction of the red mud in 30 to 70 weight percent NaOH solution for 0.2 to 5 hours, according to the weight ratio of alkali solution to red mud being 4:1-8:1, at a leaching temperature between 180 and 250 DEG C, and under a pressure between 0.3 and 1.8MPa; obtaining alkali solution containing sodium aluminate and dealuminized red mud by filtration; crystallizing the alkali solution containing sodium aluminate at a temperature between 50 and 100 DEG C to obtain hydrated sodium aluminate macrocrystal and crystallized mother solution, and applying the crystallized mother solution in leaching reaction circularly; dissolving the hydrated sodium aluminate macrocrystal by water to return to Bayer process production, and obtaining alumina through desiliconization, seed separation and calcination; adding water and calcium oxide with the weight accounting for 5 to 20 percent of that of the dealuminized red mud in the dealuminized red mud to eliminate sodium at a temperature between 100 and 180 DEG C and a liquid-solid ratio ranging from 6:1 to 10:1; and after sodium elimination, the red mud is used for cement production, while the NaOH solution is used for leaching reaction. The method has the advantages of lower dissolution temperature and pressure and 90 percent dissolution rate of alumina.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

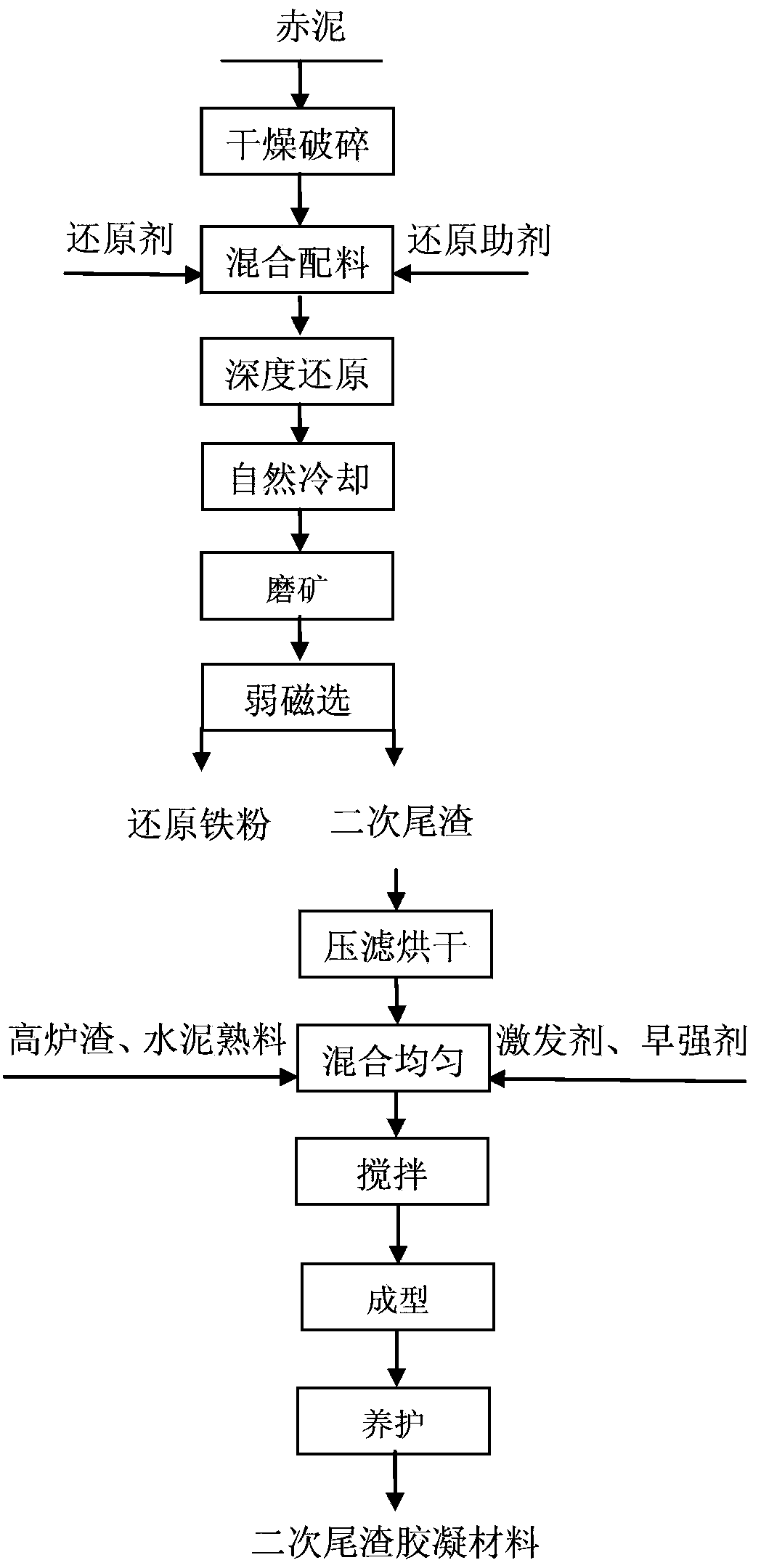

Method used for extracting iron from red mud by drastic reduction and method used for preparing gel material from secondary tailings

ActiveCN103397128ASolve storage problemsAchieve recyclingCement productionMagnetic separationSlagRed mud

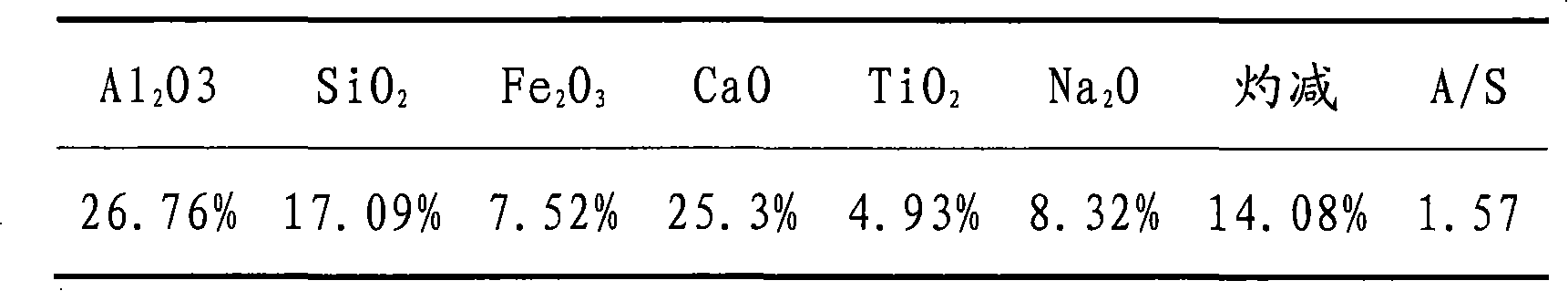

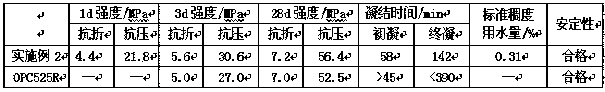

The invention discloses a method used for extracting iron from red mud by drastic reduction and a method used for preparing a gel material from secondary tailings, and belongs to the field of comprehensive utilization of resources. The method used for extracting iron from red mud by drastic reduction comprises following steps: Bayer process red mud is dried and crushed; the crushed red mud is mixed uniformly with a reducing agent and an auxiliary agent; the mixture is subjected to drastic reduction in a sealed container in a kiln with oxidizing atmosphere or reducing atmosphere; and the cooled material prepared by reduction reaction is subjected to wet milling and magnetic separation so as to obtain the iron powder of drastic reduction with iron grade of 90% or more, and iron recovery rate of 90% or more. The method used for preparing the gel material from secondary tailings comprises following step: the secondary tailings obtained after magnetic separation is dried, and are mixed uniformly with blast furnace slag, cement clinker, an exciting agent and an early strength agent; and then the secondary tailing gel material is prepared, wherein compressive strength and breaking strength of the secondary tailing gel material both meet the requirements of composite Portland cement 325 standard. According to the methods of the invention, the large amount of residual iron is recycled from the red mud, and the secondary tailings are used for preparation of the gel material, so that waste is transformed into valuables, the recovery of red mud iron resource is realized, and a problem of accumulation of red mud is solved.

Owner:UNIV OF SCI & TECH BEIJING +1

Bayer process red mud composite brick and producing method thereof

InactiveCN101215142AEliminate pollutionComprehensive Utilization of Effective ResourcesSolid waste managementRed mudSlag

The invention discloses bayer process red mud composite bricks and the production method thereof. The composite bricks are mixed and produced the following raw materials, bayer process red mud 20 -35 parts, fly ash 15-34 parts, carbide slag 5-15 parts, slag 30-40 parts, cement 5-12 parts and gypsum 0-5 parts. The preparation process of the composite bricks is that after the bayer process red mud is dewatered, mixing and stirring the bayer process red mud with other raw materials, controlling the moisture content of wet base in the range of 12%-20%, the mixture is shaped under the pressure of 15-40MPa, the shaped bricks are produced into products in steam with 0.1-1.3MPa keeping pressure for 5-8h. The product can reach the requirement of the strength grade of fly ash bricks reaching to 10 or more. The total amount of use of industrial waste residue of the technology nearly reaches 90%, the technology has the advantages of no sintering, low energy consumption, no emission of exhaust gas, meeting the country policy of energy saving and emission reduction, having distinctive effects on environmental benefit, social benefit and economic benefit.

Owner:HUAZHONG UNIV OF SCI & TECH

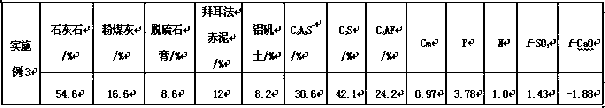

Method for preparing belite-sulphate aluminium cement by using coal ashes and bayer-process red mud

The invention discloses a method for preparing belite-sulphate aluminium cement by using coal ashes and bayer-process red mud. The method comprises the following steps: separately crushing and grinding limestone, coal ashes, bayer-process red mud, flue gas desulfurization gypsum and bauxite and sieving; preparing raw materials according to the rate value of the clinker in which Cm is 0.95-1.0, P is 3.50-3.82 and N is 0.8-1.1, wherein the f-(SO3) content in a clinker controlled to be 1-1.5% and f-(CaO) content is controlled to be greater than -2.0%; mixing and tabletting the prepared raw materials; carrying out heat preservation at 1250-1300 DEG C for 0.5-1 hour, and then quenching to obtain the clinker; crushing the clinker and grinding the crushed clinker, gypsum and portland cement clinker together into the specification of 400+ / -10m<2> / kg and preparing into cement. The mechanical property and the setting time of the cement disclosed by the invention can meet the requirements of 425 early-strength sulphoaluminate cement, and the belite-sulphate aluminium cement is good in grindability, and has good anti-freezing and anti-permeability performances. The resource utilization rate of the coal ashes and the flue gas desulfurization gypsum can be improved by application of the technology, and especially, a new way is provided for solving comprehensive control problems of the bayer-process red mud.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for preparing high-whiteness aluminium hydroxide micropowder from Bayer process sodium aluminate solution

ActiveCN102502742AAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideSodium aluminate

A method for preparing high-whiteness aluminium hydroxide micropowder from Bayer process sodium aluminate solution is disclosed, which comprises the following steps of: (1) performing purification and decoloration on Bayer process high-concentration sodium aluminate solution at first; (2) preparing high-whiteness seed crystal by the purified and decoloured sodium aluminate solution; (3) adding the high-whiteness seed crystal slurry prepared in the step (2) in the high-concentration sodium aluminate solution purified and decoloured in the step (1), and performing seed precipitation to prepare high-whiteness aluminium hydroxide micropowder; and (4) performing surface modification on the filtered and washed high-whiteness aluminium hydroxide micropowder, so as to prevent the agglomeration of the aluminium hydroxide micropowder during drying process. In the method for preparing high-whiteness aluminium hydroxide micropowder from Bayer process sodium aluminate solution disclosed by the invention, the high-whiteness aluminium hydroxide micropowder is prepared by using high-concentration sodium aluminate solution during production process for alumina using Bayer process, leading out the high-concentration sodium aluminate solution via a lateral line, and performing the processes of purification and decoloration for solution, preparation for active seed crystal, seed precipitation for the high-concentration sodium aluminate solution and the like, and seed precipitation mother solution is returned to the present production process for alumina simultaneously.

Owner:河南能源集团研究总院有限公司 +1

The recovery of alumina trihydrate during the bayer process using a water continuous polymer

InactiveUS20080107578A1Increase floccule sizeIncrease the amount addedAluminium compoundsGallium/indium/thallium compoundsBayer processAluminium oxide

A method for increasing the floccule size and volume of alumina trihydrate during the Bayer processing of bauxite ore using a flocculant in conjunction with a water continuous polymer. The addition of the flocculant and the water continuous polymer to the alumina trihydrate slurry following the security filtration and settling producing trihydrate that is put through the calcination process to produce purified alumina or used as seed for the precipitation process.

Owner:ECOLAB USA INC

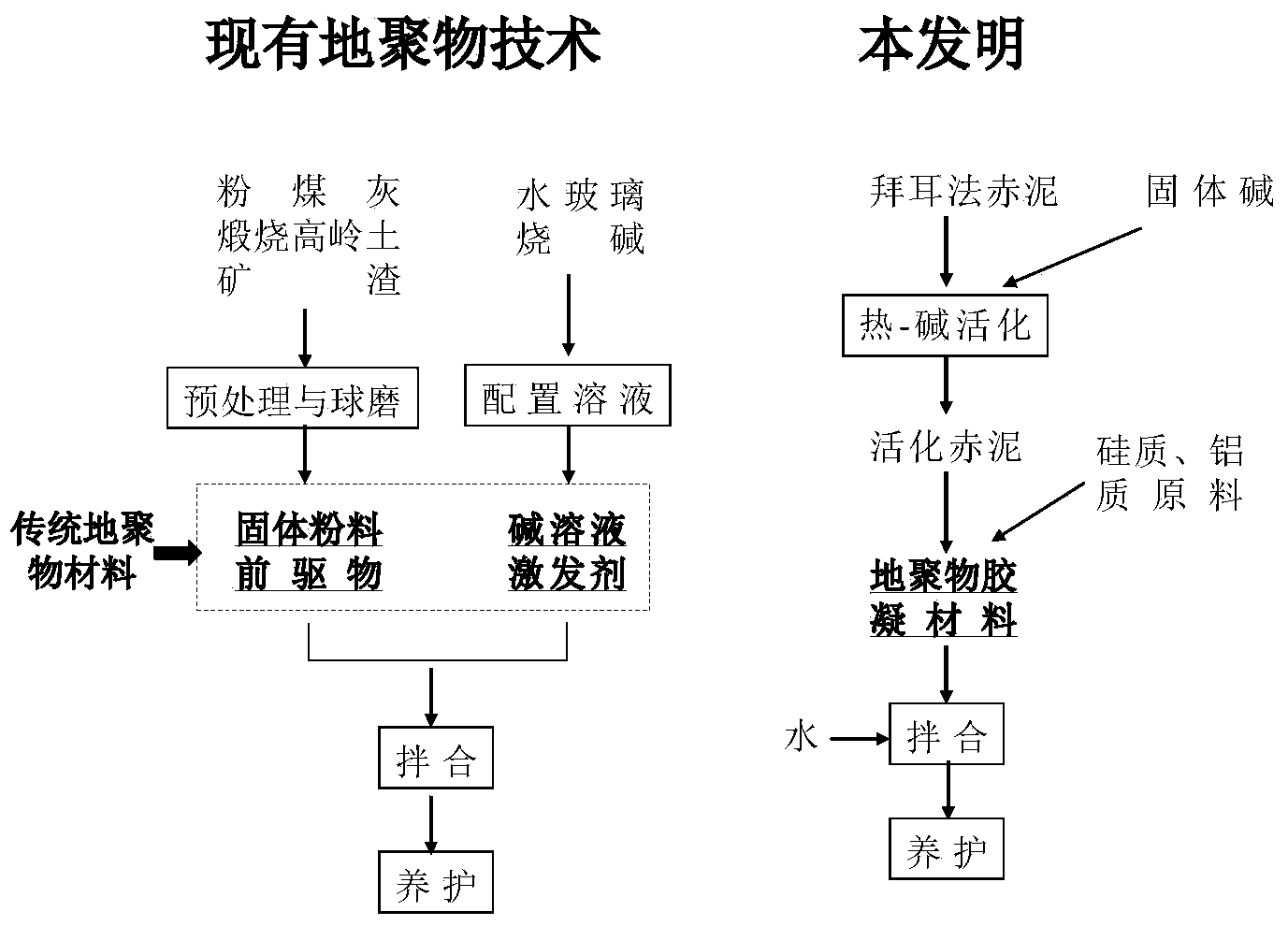

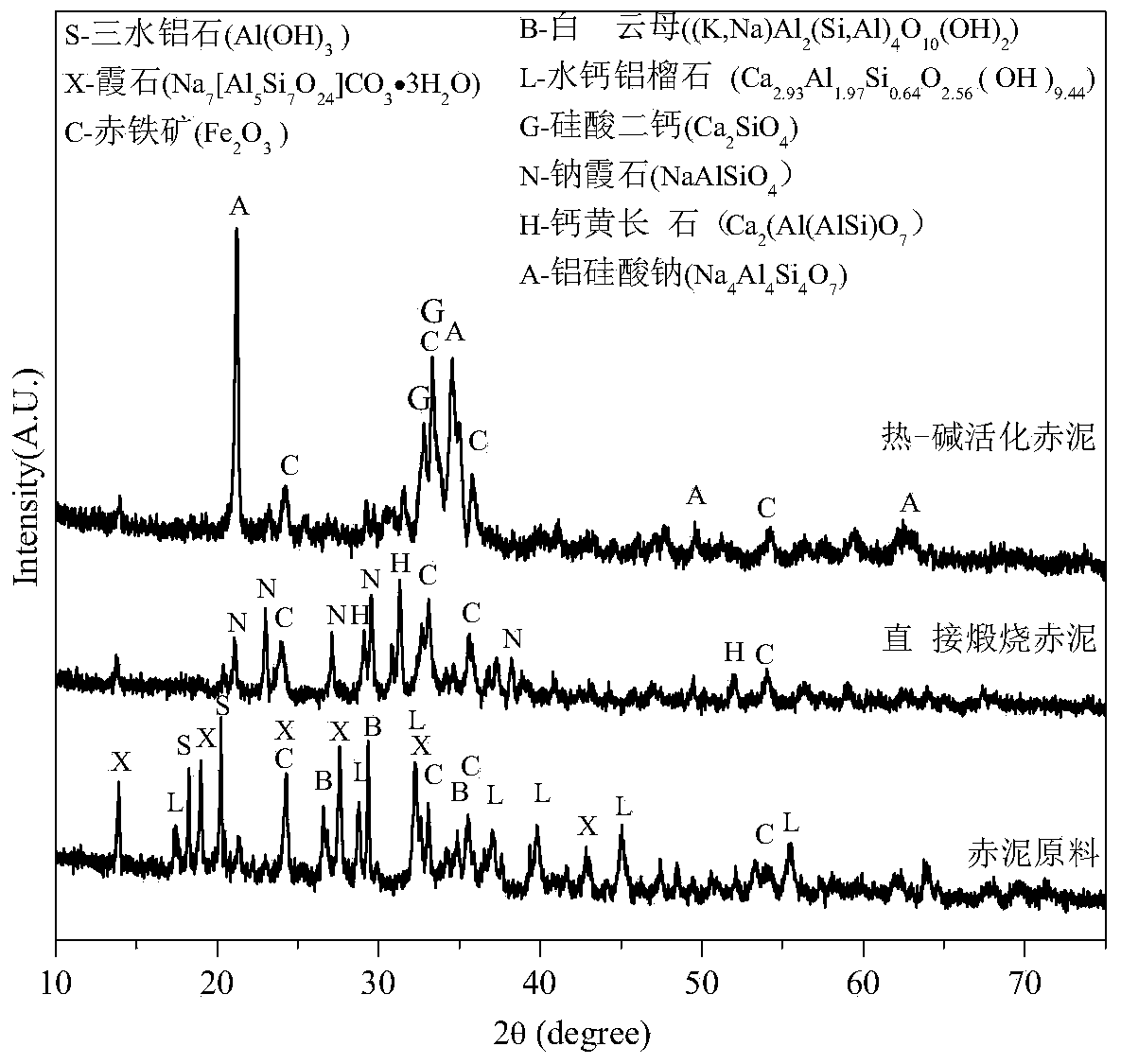

Method for producing geopolymer binding material by red mud and geopolymer binding material

The invention discloses a method for producing a geopolymer binding material by red mud and the geopolymer binding material. The method comprises the following steps: (1), the red mud is evenly mixed with hydroxide of alkali metal or carbonate, and 3 to 5 mol of alkali metal is contained in the hydroxide of alkali metal or the carbonate, which is added into the red mud per kilogram; (2), the mixture is calcined for 1 to 3 hours at the temperature of 700 DEG C to 900 DEG C, and a heat-alkali activated red mud is obtained after cooling; (3), the activated red mud is mixed with granulated blast-furnace slag powder according to the mass ratio of (1.5:1):(4:1). When being used, the geopolymer binding material produced according to the method is evenly mixed with water with the mass ratio of 60 percent to 70 percent so as to achieve maintenance formation. According to the invention, waste material red mud produced by using Bayer processes largely is environmentally friendly and low in cost. The geopolymer binding material can be directly added with water to stir during the use, alkaline boosters such as water glass and the like are not required to be added, steaming and pressing or dried formation are not required, the use is convenient, and the adaptability is good.

Owner:HUAZHONG UNIV OF SCI & TECH

A comprehensive utilization method of red mud

ActiveCN104340995AEfficient separationAchieve cycleChlorine/hydrogen-chlorideSolid waste disposalFerric hydroxideAluminium hydroxide

The invention relates to a comprehensive utilization method of bauxite and particularly relates to a comprehensive utilization method of red mud. The method includes: a step of mixing the red mud with hydrochloric acid, adding the mixture into a hydrochloric acid-resistant reactor, and reacting; a step of cooling after the reaction is finished, performing solid liquid separation and washing; a step of adding the obtained solution into a sodium hydroxide solution to obtain an aluminium hydroxide precipitate, an iron hydroxide precipitate and a sodium chloride solution, performing solid liquid separation, and washing; a step of preparing the aluminium hydroxide and iron hydroxide solid into metallurgy-level aluminum oxide and high-iron slag through a simple Bayer process; a step of subjecting the sodium chloride solution to electrolysis by an ionic exchange membrane electrolytic cell to obtain hydrogen, chlorine and a sodium hydroxide solution; a step of returning the sodium hydroxide solution discharged from an ionic membrane cathode zone and recycling; and a step of returning and recycling the obtained hydrogen and the obtained chlorine. The method is obvious in environment protection effects, effectively separates aluminum, iron and silicon in the red mud, and recovers the aluminum, the iron, sodium and other useful elements, thus achieving comprehensive utilization.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

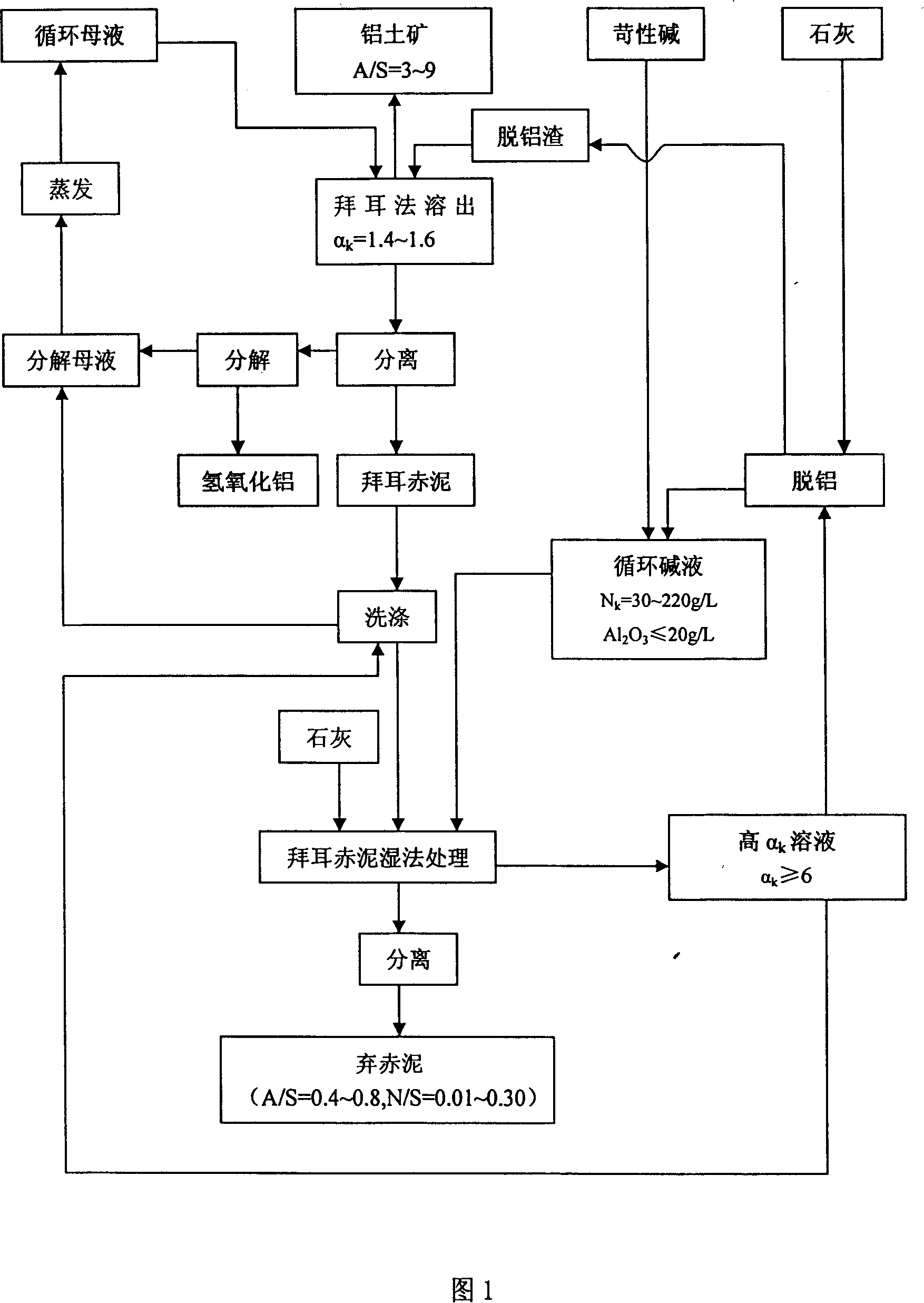

Method for producing aluminium oxide by middle-low grade alumyte

ActiveCN101113001AReduce energy consumptionReasonable processAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateResource utilization

A method to produce aluminum oxide with middle-low bauxite relates to a method to produce aluminum oxide with middle-low bauxite by the means of Bayer-method. The invention is characterized in that: during the Bayer-method process, digestion process is to add dealuminization slag instead of lime as additive in middle-low bauxite to do Bayer process digestion; after digestion and backward washing of red mud, the red mud is mixed with recycle alkaline liquor, the lime is added, the digestion reaction is done, the red mud is separated from the slurry and discharged outside, the solution part obtained oppositely washes with Bayer-method, is sent to Bayer-method system to supplement alkali after digesting the red mud, the lime is added partly and is reacted, then, dealuminization slag and recycle alkaline liquor that goes through Bayer-method red mud wet treatment are gotten and dealuminization slag calcium aluminate hydrate instead of lime is added into the Bayer process digestion. The method of the invention belongs to all wet treatment, has simple process, low energy consumption, low alkali consumption and high recovery rate of aluminum oxide and is suitable for treating Chinese bauxite that is mainly middle-low bauxite; besides, the resource utilization is high, the amount of discharged red mud is low and the red mud is easy to be utilized comprehensively.

Owner:中铝郑州有色金属研究院有限公司

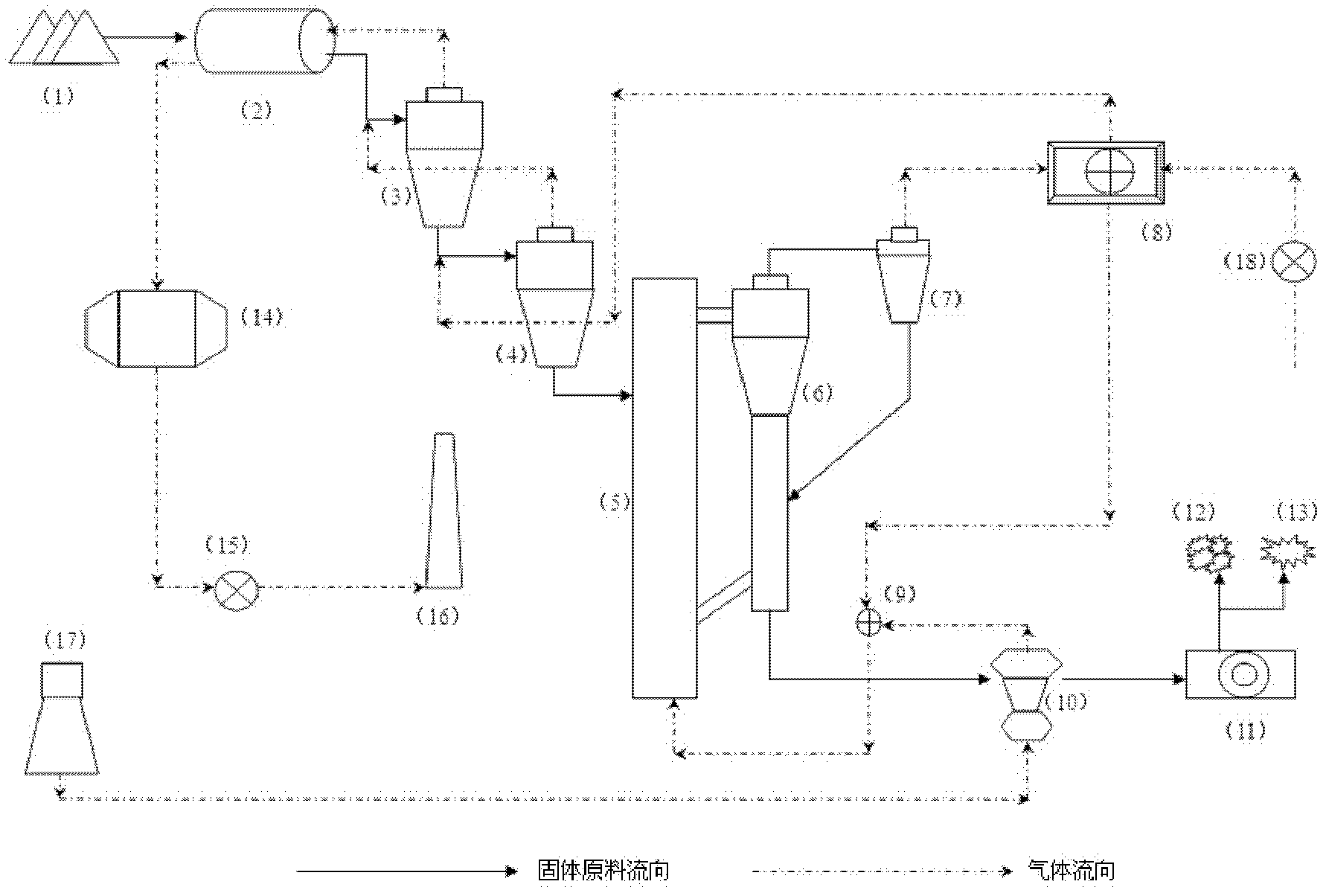

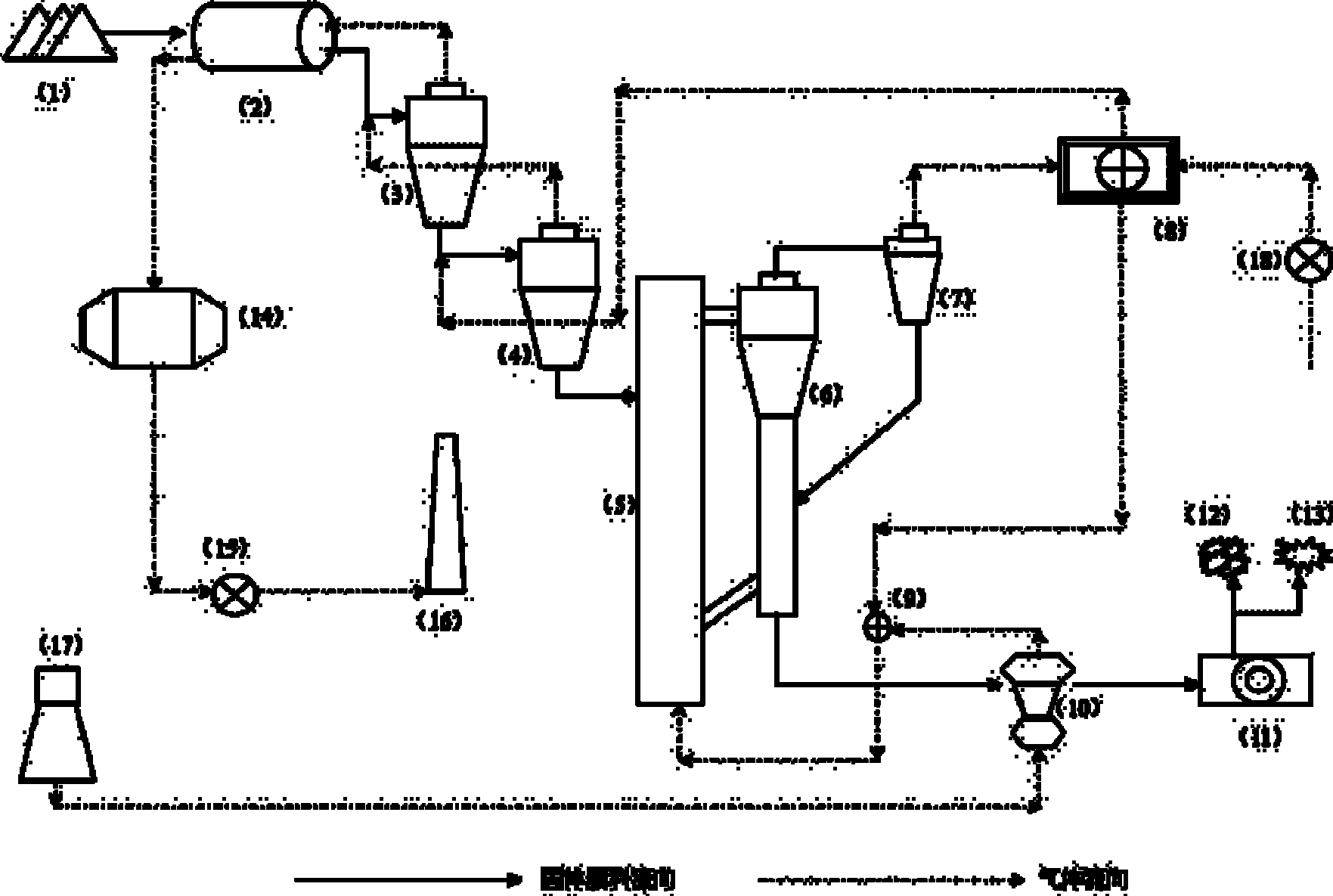

Method for preparing iron concentrate powder by reducing and magnetizing red mud in fluidized bed

InactiveCN102628097AReduce energy consumptionImprove economyProcess efficiency improvementCombustion chamberRed mud

The invention discloses a method for preparing iron concentrate powder by reducing and magnetizing red mud in a fluidized bed. The method comprises the following steps of: magnetizing, reducing and baking dried and pre-heated red mud powder by an efficient circulating fluidized bed technology; burning exhaust gas in a combustion chamber, wherein the exhaust gas is generated after reducing and baking, a part of burned exhaust gas pre-heats the red mud powder through a multistage cyclone preheater, and the other part of burned exhaust gas is mixed with gas of a gas generating furnace; after adjusting the components of the gas, allowing the mixed gas to get into a circulating fluidized bed, wherein the mixed gas entering the fluidized bed reduces over 90 percent of Fe2O3 in the red mud into Fe3O4; after the reduced and magnetized red mud departs the fluidized bed, cooling the reduced and magnetized red mud in a cooler, wherein a cooling medium is the gas generated in the gas generating furnace; and after cooling the reduced red mud, performing magnetic separation on the red mud to obtain iron concentrate of which the grade is 61 to 65 percent. The iron concentrate is prepared from Bayer process red mud, the recovery rate of ferrum is more than 90 percent, the energy consumption in a baking process is reduced, and the environment is also protected.

Owner:UNIV OF SCI & TECH BEIJING

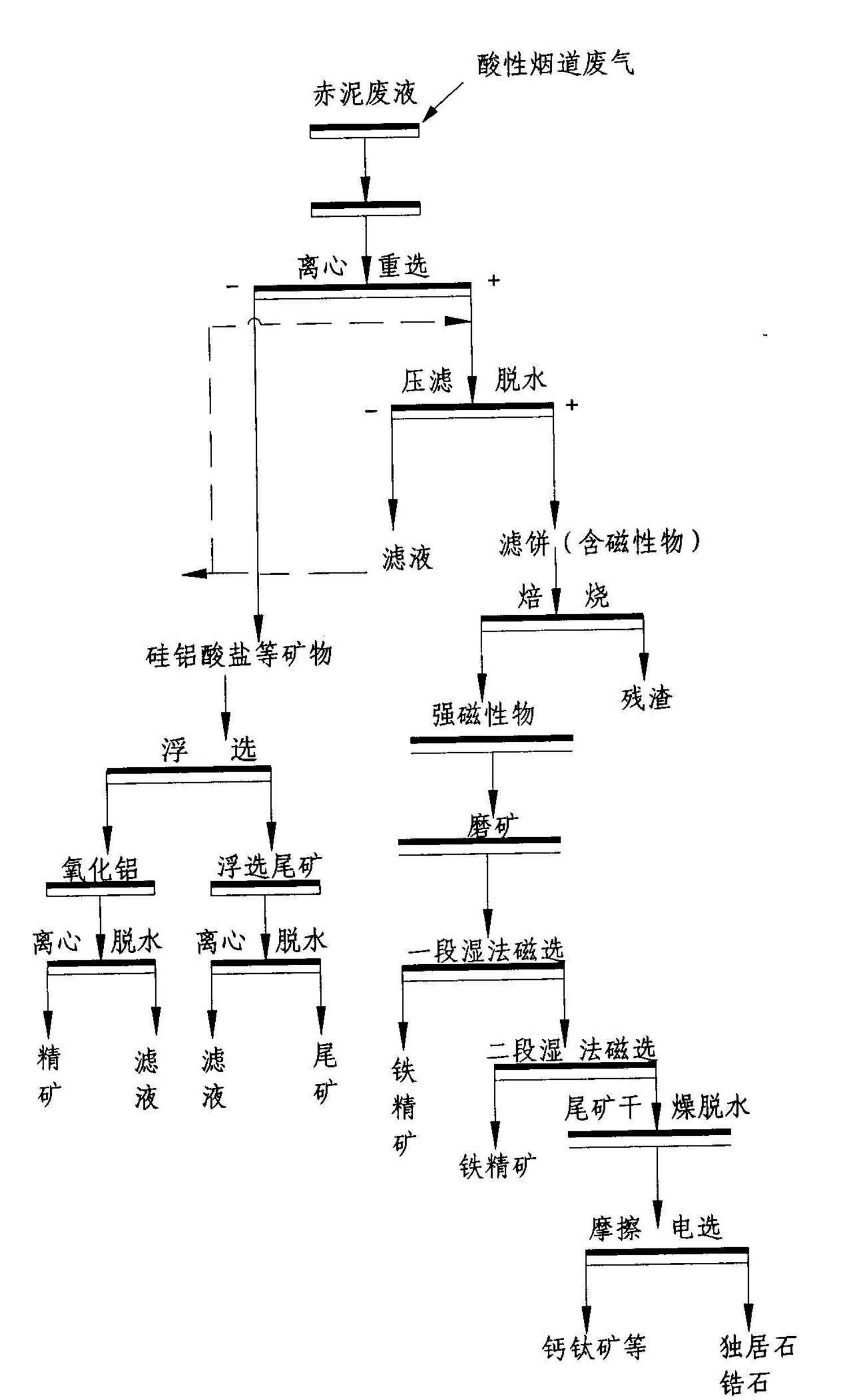

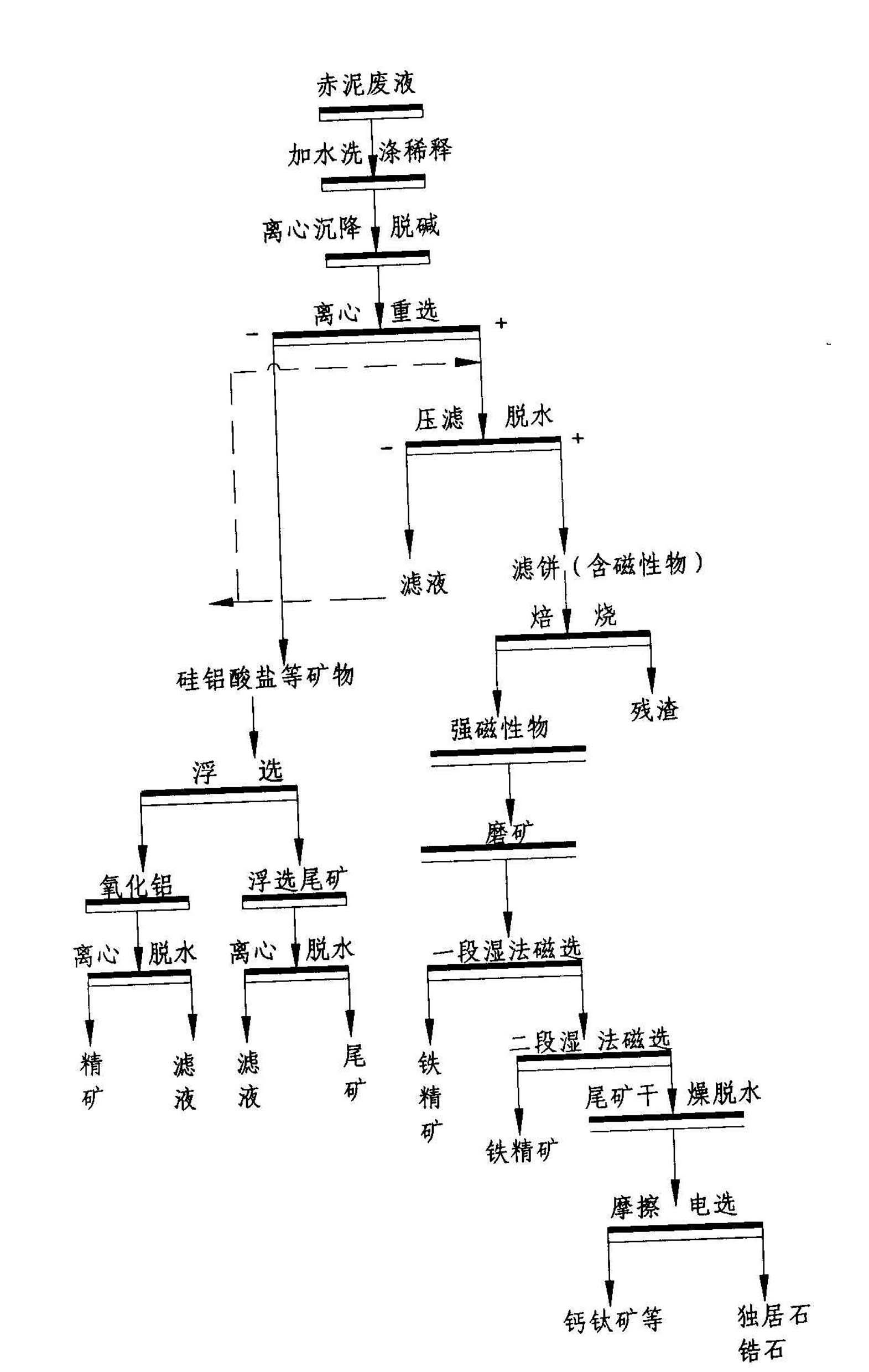

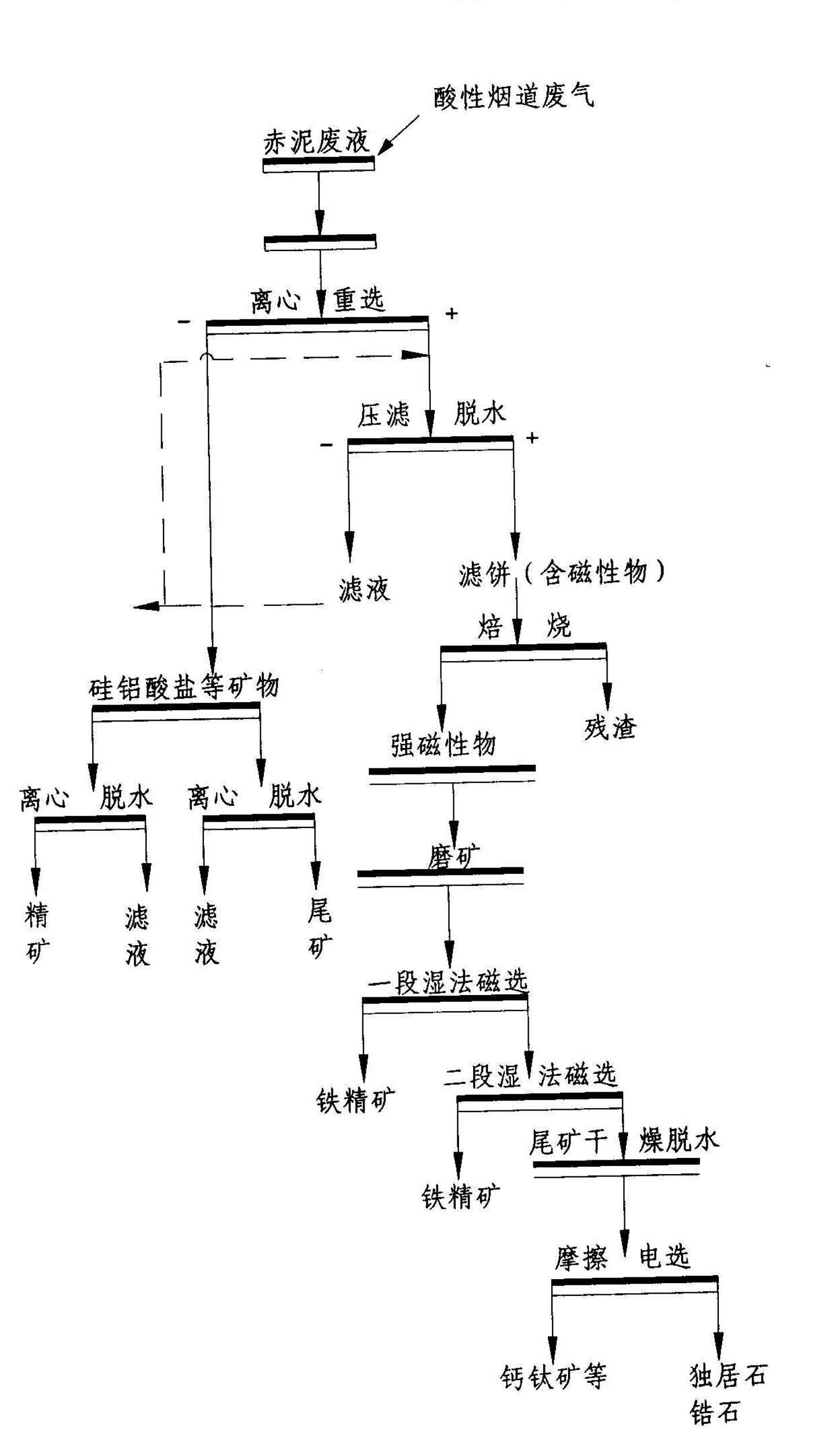

Red mud harmless comprehensive recycling technology suitable for Bayer process

The invention discloses a red mud harmless comprehensive recycling technology suitable for a Bayer process. The technology is mainly used for removing alkaline matters in the red mud and selecting a great quantity of iron minerals in the red mud through technical means while separating the radioactive minerals such as zircon, monazite and the like from the red mud at the same time; the separated red mud tailings are used as a large quantity of raw materials for cement processing, brick / tile firing, road building and the like, or used as mine filling materials and the like; the red mud minerals are turned into wealth and sufficiently used; large-scale resource utilization of red mud is realized; and a series of problems in resources and environment and potential safety hazard caused by red mud damming and stacking are fundamentally solved.

Owner:ANHUI UNIV OF SCI & TECH

Baking-free brick prepared from red mud

ActiveCN103641402ATo overcome the shortage of low dosageImprove performanceSolid waste managementCement productionBrickRed mud

The invention discloses a baking-free brick prepared from red mud. Bayer process red mud is high in alkali content, and the problem of efflorescence can be easily caused during the production of a building material. A geopolymer synthesis technology is used for converting alkali in the red mud into an activator in an activation way, so that problems caused by the alkali during the utilization of the red mud are solved. The baking-free brick is mainly prepared from the following raw materials in parts by weight: 3 to 8 parts of water glass, 15 to 20 parts of active initiator, 70 to 80 parts of red mud and 0.5 to 1 part of micro silicon powder. The baking-free brick is prepared by the following steps of sequentially adding the red mud, the active initiator, the water glass and the micro silicon powder into a forced mixer, performing extrusion forming by using a brick making machine after uniform mixing, standing a brick blank for 1 to 2 hours under natural conditions to endow certain hardness to the brick blank, feeding the brick blank to an autoclave, and performing autoclaved curing for 2 to 4 hours under pressure of 0.8 to 1.2MPa to obtain a finished product. The baking-free brick prepared from red mud is low in cost, stable in product performance, strong in compressive strength and high in freezing and thawing cycle resistance, a production process is simple, the production site is small, and efflorescence after building is avoided.

Owner:广东新立晟环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com