Method for comprehensive utilization of aluminum-containing material

A material and scheme technology, applied in ammonium sulfate, alumina/aluminum hydroxide, silica and other directions, can solve problems such as environmental pollution, and achieve the effects of low equipment requirements, simple process flow and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

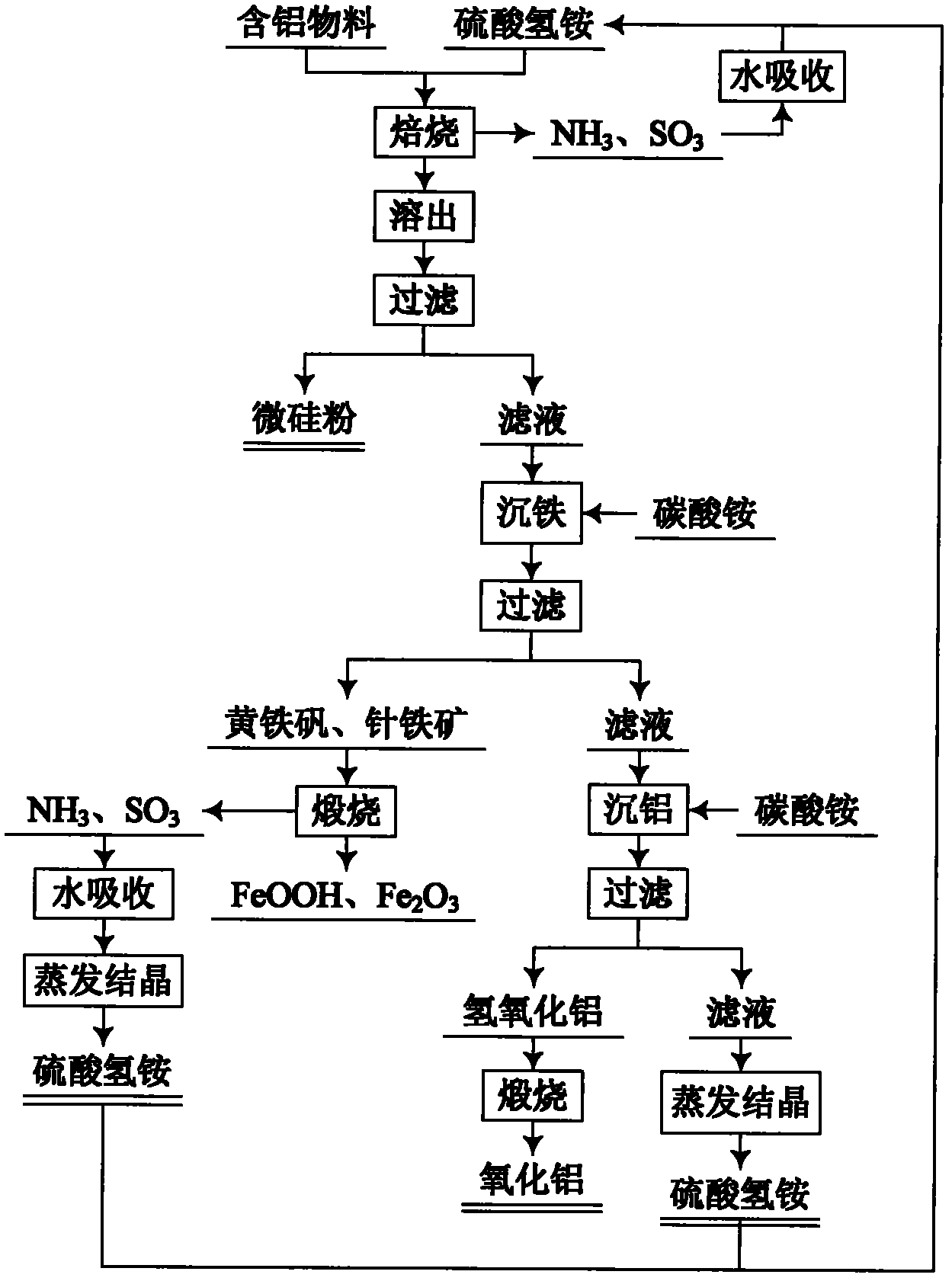

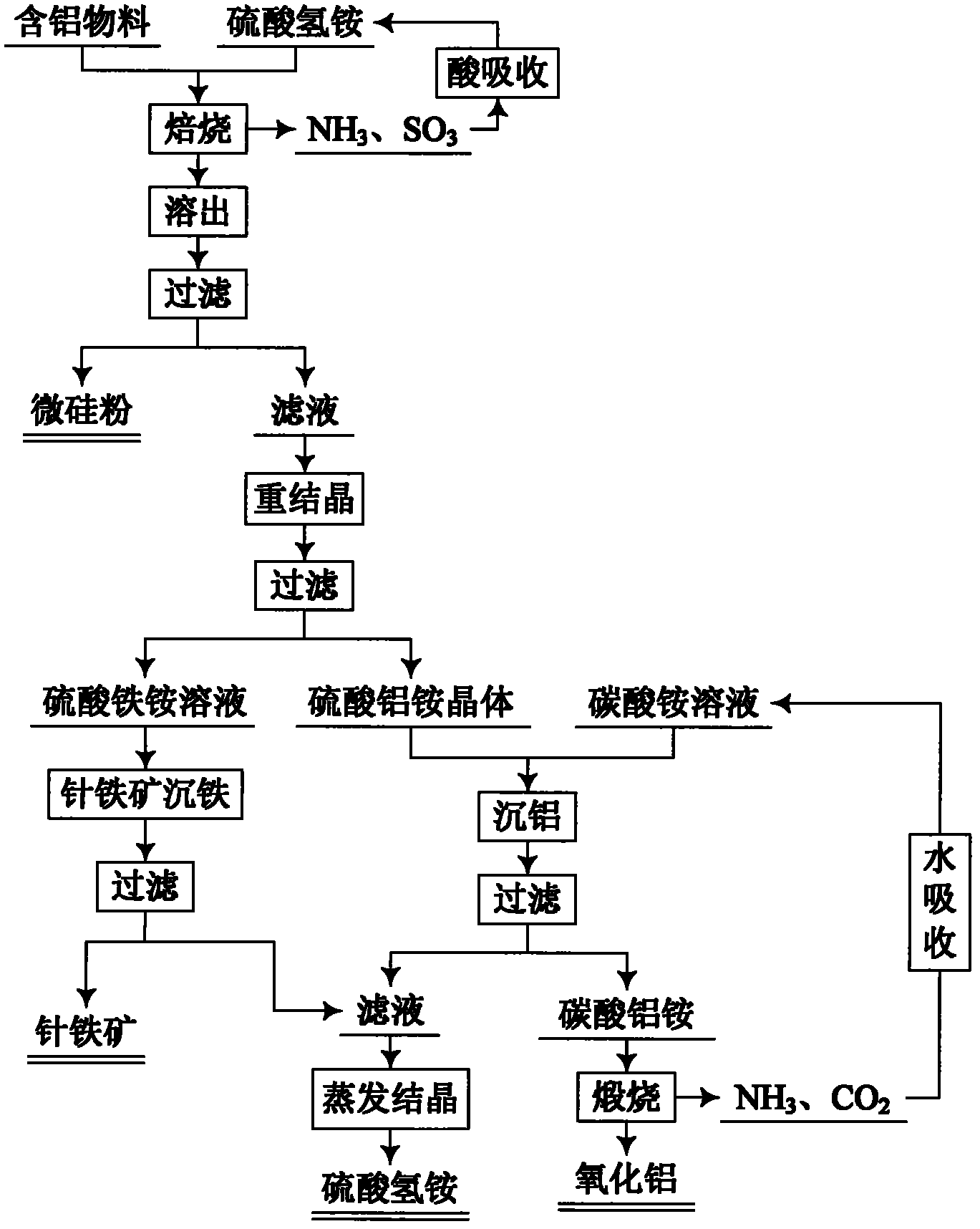

Image

Examples

Embodiment 1

[0048] The main composition of fly ash used is: Al 2 O 3 41.4%, SiO 2 46.3%, Fe 2 O 3 5.1%, CaO 2.9%, TiO 2 1.1%, MgO 0.3%, others 2.9%.

[0049] After the fly ash, which has been crushed and ground down to 80μm or less, is magnetically separated for iron removal, it is mixed with ammonium bisulfate at a mass ratio of 1:1.6. The material is roasted and reacted at 350°C for 4 hours. Ammonia and trioxide generated during the reaction The sulfur is absorbed by dilute sulfuric acid to obtain an ammonium aluminum sulfate solution, which is evaporated and crystallized and returned for roasting.

[0050] The roasting clinker is dissolved with water, the mass ratio of water to clinker is 6:1, and the solution is dissolved at 95°C for 30 minutes, and filtered to obtain aluminum extraction slag and aluminum ammonium sulfate solution. After washing and drying, the aluminum extraction slag is directly used as a micro-silica powder product.

[0051] The ammonium aluminum sulfate solution is ...

Embodiment 2

[0053] The main composition of bauxite used is: Al 2 O 3 38.9%, SiO 2 33.9%, Fe 2 O 3 14.9%, CaO 3.6%, MgO 2.4%, TiO 2 1.4%, K 2 O 0.9%, others 4.0%.

[0054] The crushed and ground high-iron bauxite and ammonium bisulfate with a mass ratio of 1:2.2 are uniformly mixed, and the material is roasted at 375°C for 3.5 hours. The gas released during the reaction is absorbed by dilute sulfuric acid to obtain ammonium aluminum sulfate. The solution, evaporation and crystallization are returned for roasting.

[0055] The roasted clinker is cooled and dissolved by adding water, the mass ratio of water to clinker is 5:1, and dissolved at 90°C for 40 minutes, and filtered to obtain aluminum extraction slag and crude aluminum ammonium sulfate solution. After washing and drying, the aluminum extraction slag becomes a micro silicon powder product.

[0056] The crude aluminum ammonium sulfate solution was oxidized by adding hydrogen peroxide at 35°C. After 0.5h of reaction, the yellow ammonium...

Embodiment 3

[0058] The main composition of alunite used is: Al 2 O 3 31.82%, SiO 2 23.48%, Fe 2 O 3 0.44%, SO 3 24.61%, K 2 O6.18%, TiO 2 0.1%, Na 2 O 0.59%, others 12.78%.

[0059] The alunite that has been crushed and ground to below 80μm is calcined and dehydrated at 700°C for 4 hours, then mixed with ammonium bisulfate at a mass ratio of 1:1.7, and kept at 400°C for 3 hours. The gas released during the reaction is absorbed by sulfuric acid to obtain The ammonium aluminum sulfate solution is evaporated and crystallized back for roasting.

[0060] The calcined clinker is dissolved with water, the mass ratio of water to clinker is 4:1, and the mixture is dissolved at 85°C for 50 minutes, filtered, and the filter residue is washed and dried as a microsilica product; the filtrate is an ammonium aluminum sulfate solution for further extraction of aluminum.

[0061] Add saturated ammonium bicarbonate solution to the ammonium aluminum sulfate solution at 60°C, control the pH value of the ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com