Patents

Literature

241results about How to "Coating stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixing and dispersion of nanotubes by gas or vapor expansion

InactiveUS6908572B1Coating stabilityImprove mechanical propertiesMaterial nanotechnologyNanoinformaticsTarget surfaceSulfur

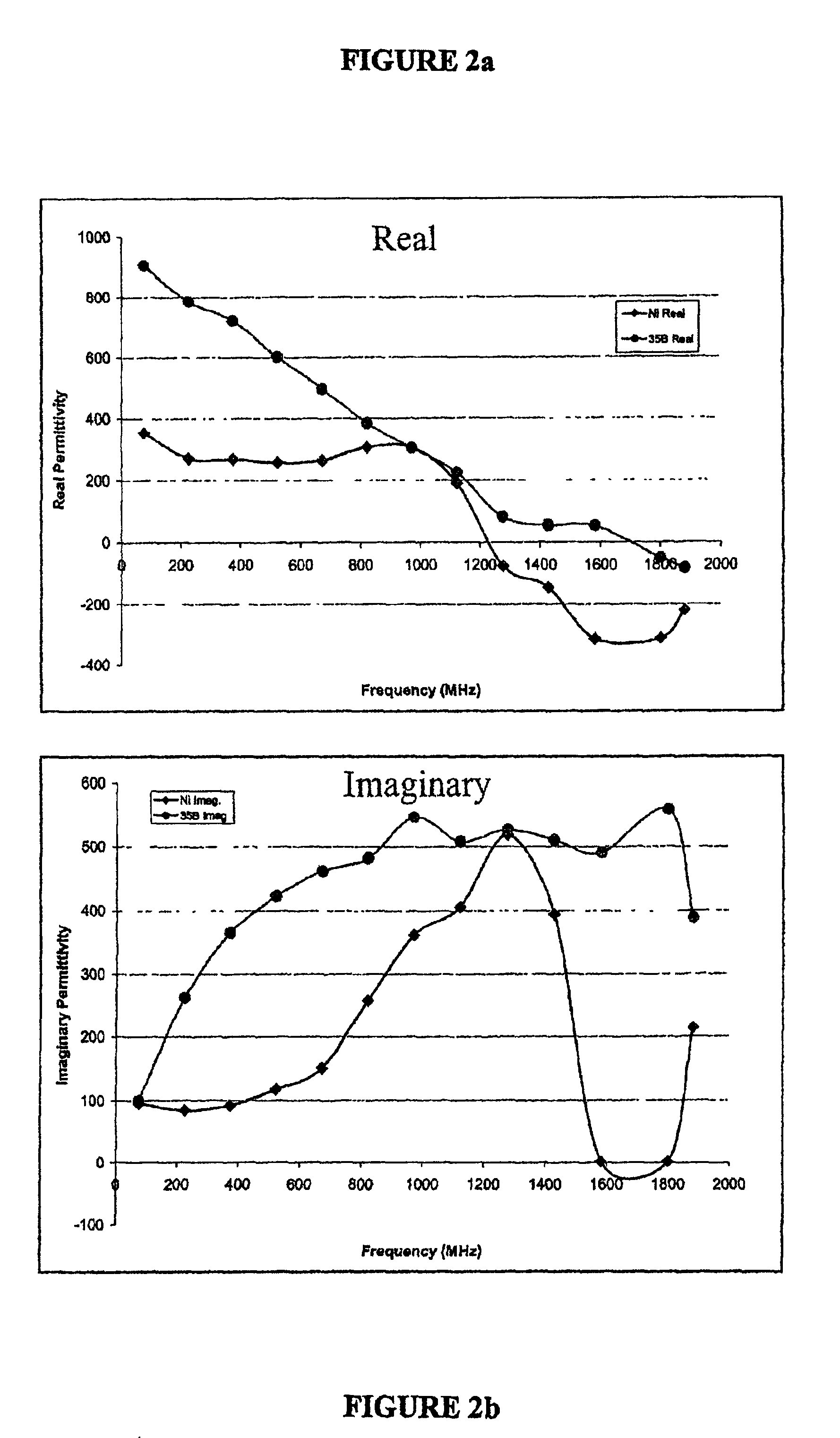

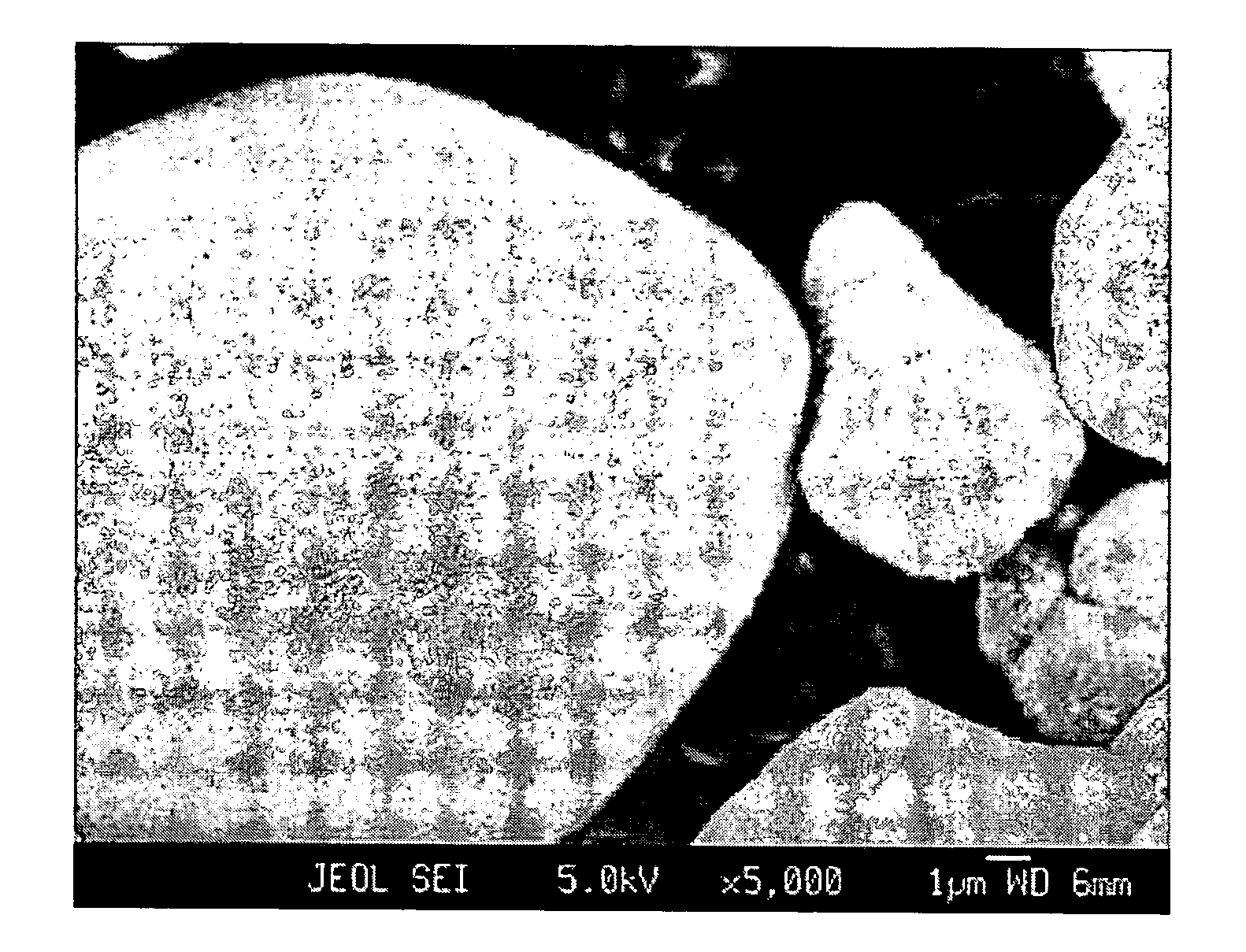

Novel methods and compositions for coating target surfaces with non-entangled multi-wall carbon nanotubes are disclosed. In one aspect, the methods and compositions of the invention comprise dispersion of non-entangled multi-wall carbon nanotubes in solvent, and application of the non-entangled multi-wall carbon nanotube / solvent mixture to a surface by spraying. In another aspect, the methods and compositions of the invention comprise dispersion of non-entangled multi-wall carbon nanotubes in solvent, and applying the nanotube / solvent mixture to a suitable matrix by spraying to form a surface coating which is substantially contiguous with the surface of the matrix. The compositions of the invention are substantially free of metal oxides and sulfur, and do not require harsh oxidative treatments.

Owner:UNIV OF KENTUCHY RES FOUND

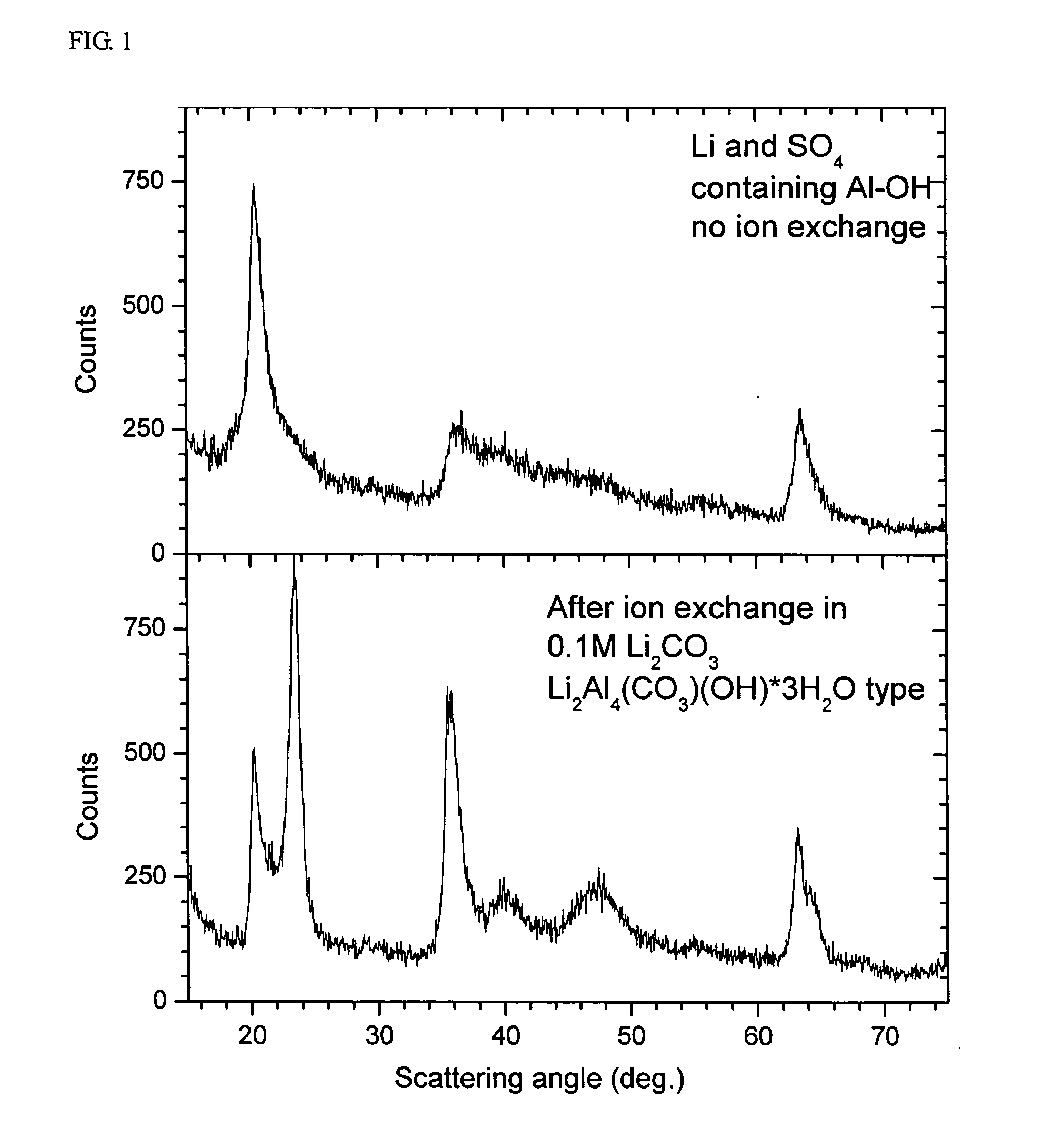

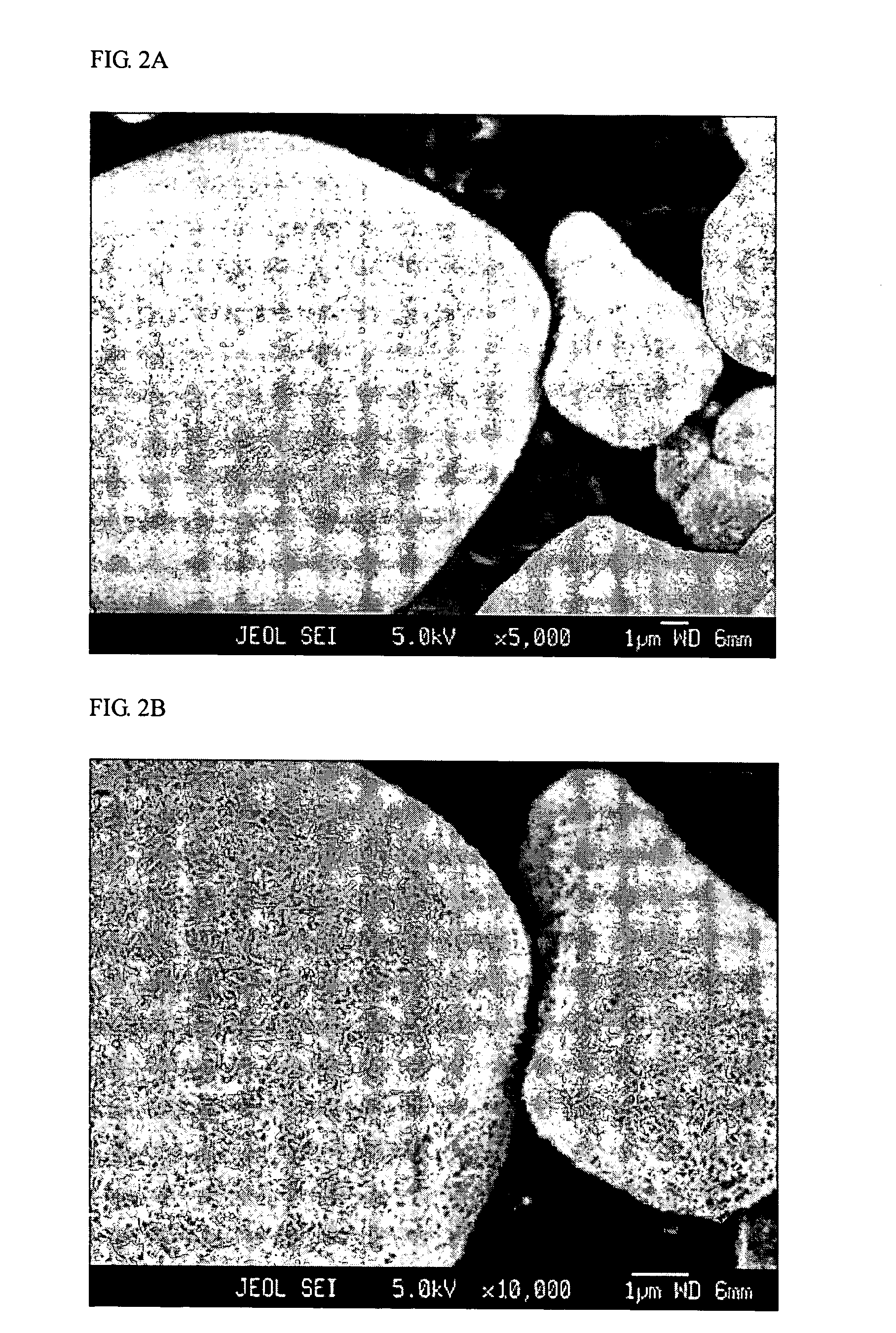

Composite precursor for aluminum-containing lithium transition metal oxide and process for preparation of the same

ActiveUS20060068289A1Coating stabilityEasy to replaceElectrode manufacturing processesConductive materialWater basedAluminium hydroxide

The present invention provides a powdery composite precursor, which comprises a core of a lithium transition metal oxide, and an aluminum hydroxide-based precipitate layer coated on the surface of the core, and a process to prepare the composite precursor. The preparation process comprises the formation of a water based slurry by dispersing lithium transition metal oxide powder in water, and a precipitation reaction of an aluminum salt solution with a base solution where the lithium transition metal particles act as seed particles, whereby a mechanically stable precipitate layer of homogeneous thickness can be achieved. The composite precursor can be converted into aluminum-containing, e.g., aluminum-doped, lithium transition metal oxide suitable for a cathode active material of lithium rechargeable battery by heat treatment.

Owner:LG ENERGY SOLUTION LTD

Method for preparing medicine sustained-releasing bracket

ActiveCN101185779ANo oxidative decompositionThickness is easy to controlStentsSurgeryDrug release rateSustained release drug

A preparation method of a drug sustained-release stent includes a preparation stent, a drug sustained-release stent constituted by drug coating on the stent, and the drug coating of the stent is composed of the following steps sequentially: (1) the preparation of a sustained-release drug coating layer; (2) the coating of the sustained-release drug coating layer; (3) drying. The dosages of the drug components on the sustained-release drug stent of the invention are in line with the designed dosages, and the drug can be released according to the stipulated dosages in the stipulated time of the design requirements completely in vitro tests. The invention has good biocompatibility, low cost of spraying process, high yield, controllable thickness of the coating layer, and slow and stable drug release rate.

Owner:上海赢生医疗科技有限公司

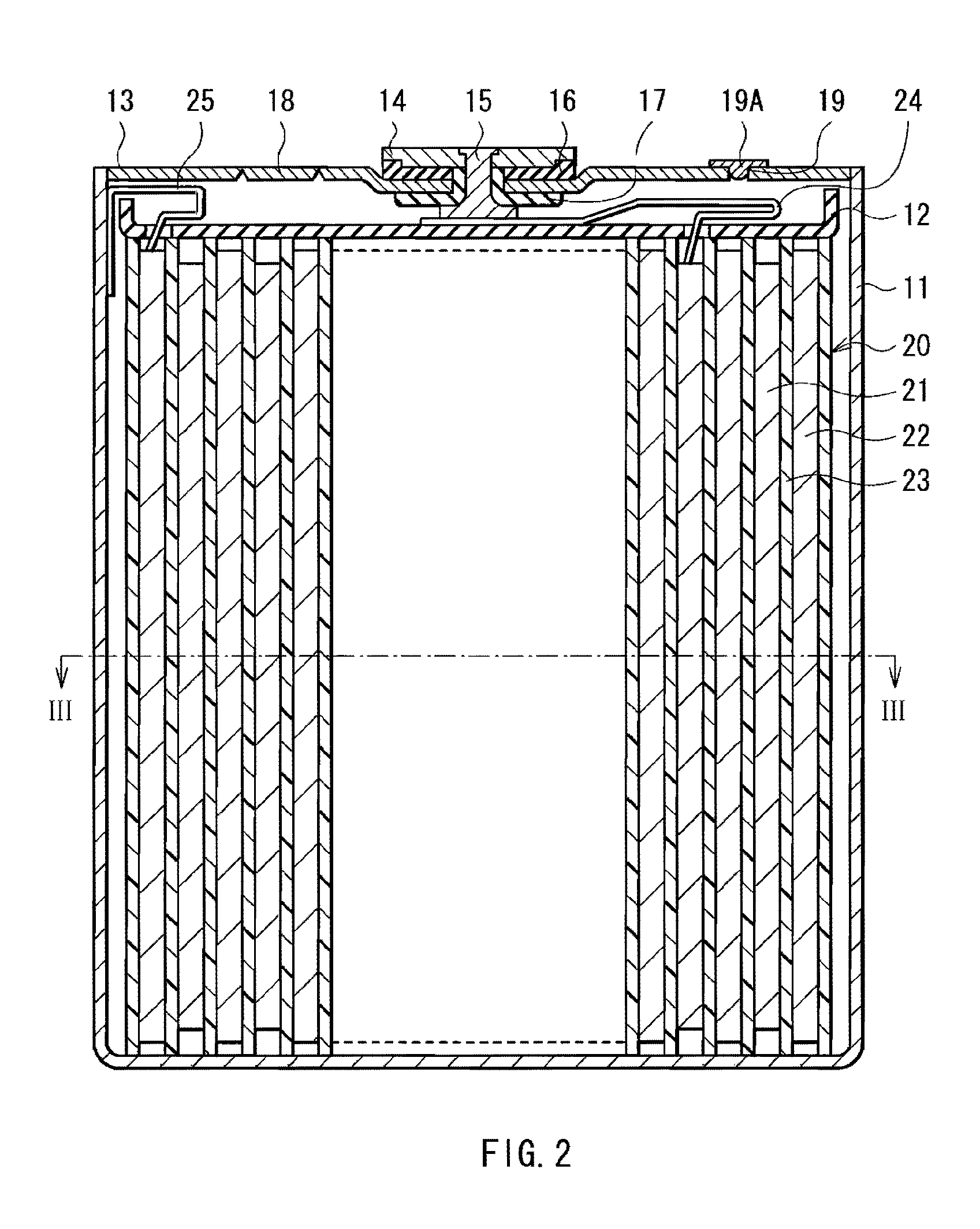

Anode active material, anode, and battery

ActiveUS20090111031A1Improve performanceExcellent cycle characteristicsFinal product manufactureElectrode carriers/collectorsX-rayPeak intensity

A battery capable of improving the cycle characteristics is provided. The battery includes a cathode, an anode, and an electrolytic solution. The anode has an anode active material layer that contains an anode active material containing silicon on an anode current collector, and intensity ratio I1 / I2 between peak intensity I1 originated in (220) crystalline plane of silicon obtained by X-ray diffraction and peak intensity I2 originated in (111) crystalline plane of silicon obtained by X-ray diffraction is 0.05 or more.

Owner:MURATA MFG CO LTD

Aqueous PU fog face rubbing surface treatment agent for synthetic leather and preparation method thereof

The invention discloses an aqueous PU fog face rubbing surface treatment agent for synthetic leather, comprising the following components by weight percentage: 40-50% of aqueous polyurethane resin, 30-40% of water, 3-6% of matting agent, 1-5% of organic silicon antifoaming agent, 0.5-5% of organic silicon flatting agent and 0.5-5% of aqueous polyurethane thickener. The surface treatment agent provided by the invention takes water as solvent which replaces poisonous solvents such as dimethylformamide and butanone and has the performances of non-combustion, safety, environmental protection and less cost; after being treated by the surface treatment agent provided by the invention in a wiping manner, the prepared leather has good fog face rubbing effect, sharp contrast between colours of a surface layer and a rubbing layer, good visual effect and excellent general effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Aqueous PU velvet resin used for synthetic leather

InactiveCN101634109ALow costThe ratio is scientific and reasonableFibre treatmentDimethyl formamideChemistry

The invention discloses an aqueous PU velvet resin used for synthetic leather, which comprises the following raw materials by weight percent: 40-50% of aqueous polyurethane resin, 40-50% of water, 2-5% of low-temperature sheep bar powder, 2-4% of silicon dioxide velvet powder, 1-3% of organic silicone oil smoothing agent, 1-4% of extinction powder, 0.5-1% of organic silicon flatting agent, 2-5% of organic silicon antifoaming agent and 0.5-2% of aqueous polyurethane thickening agent. The aqueous PU velvet resin used for synthetic leather of the invention takes water as solvent to replace toxic solvent, such as dimethyl fomamide, butanone and the like and has the advantages of being non-combustible, safe and environment-friendly, saving cost and the like. The aqueous PU velvet resin also has the advantages of good film-forming resistance, firm bonding, coating solvent resistance, cold resistance, hydrolysis resistance and heat-proof aging. Products fabricated by using the resin have the characteristics of plump feel, unique velvet effect, strong real leather quality, fine and smooth texture, good air permeability and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Photocuring resinoid compsn. and printed circuit board using same

ActiveCN1661475ACoating stabilityLow priceTelevision system detailsDigital media broadcastingEpoxyScreen printing

To provide a photosetting / thermosetting resin composition for a printed wiring board which exhibits temporally stable coating properties in screen printing, curtain coating, spray coating, roll coating and in other methods and is superior in heat resistance, adhesion and electrical insulation, and to provide a printed wiring board which uses the same. The photosetting / thermosetting resin composition comprises (A) a carboxylic resin, having one or more carboxyl groups in one molecule, (B) a photopolymerization initiator, (C) a polyhydroxycarboxylic ester additive, (D) a diluent, (E) a filler and (F) an epoxy resin, wherein the polyhydroxycarboxylic ester additive (C) is preferably xylene-free.

Owner:TAIYO HLDG CO LTD

Stabilized tin-oxide-based oxidation/reduction catalysts

InactiveUS7390768B2Improve thermal stabilityExpand the scope of operationOrganic chemistryInternal combustion piston enginesActive componentCerium

The invention described herein involves a novel approach to the production of oxidation / reduction catalytic systems. The present invention serves to stabilize the tin oxide reducible metal-oxide coating by co-incorporating at least another metal-oxide species, such as zirconium. In one embodiment, a third metal-oxide species is incorporated, selected from the group consisting of cerium, lanthanum, hafnium, and ruthenium. The incorporation of the additional metal oxide components serves to stabilize the active tin-oxide layer in the catalytic process during high-temperature operation in a reducing environment (e.g., automobile exhaust). Moreover, the additional metal oxides are active components due to their oxygen-retention capabilities. Together, these features provide a mechanism to extend the range of operation of the tin-oxide-based catalyst system for automotive applications, while maintaining the existing advantages.

Owner:NASA

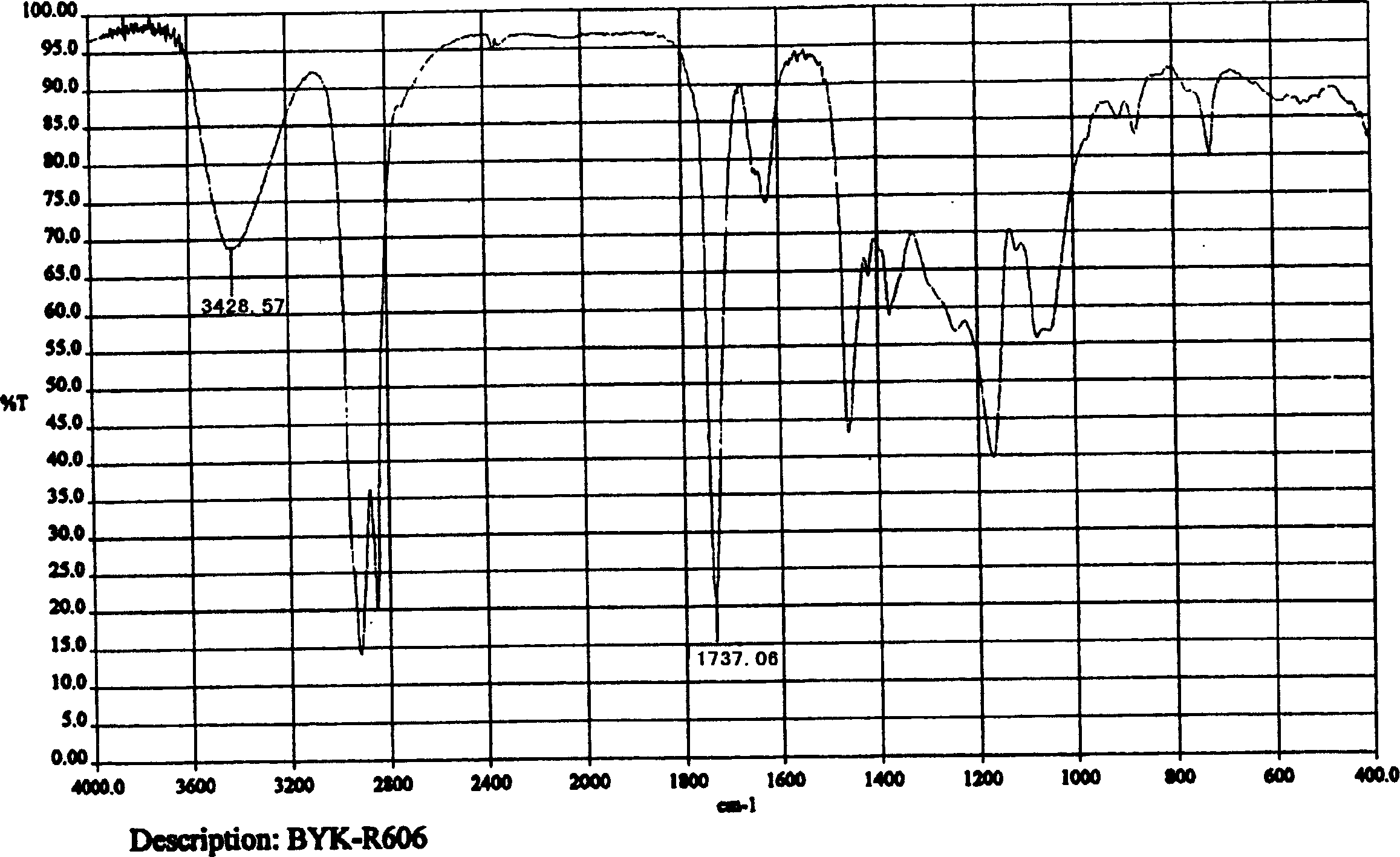

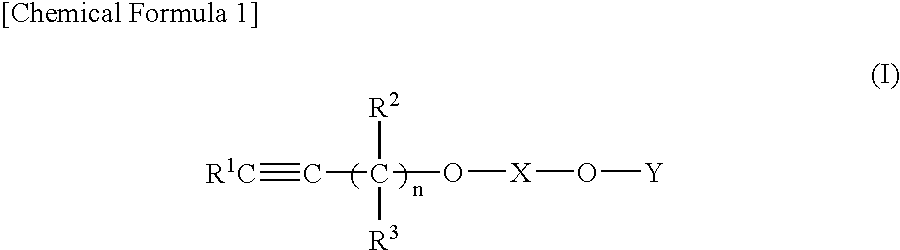

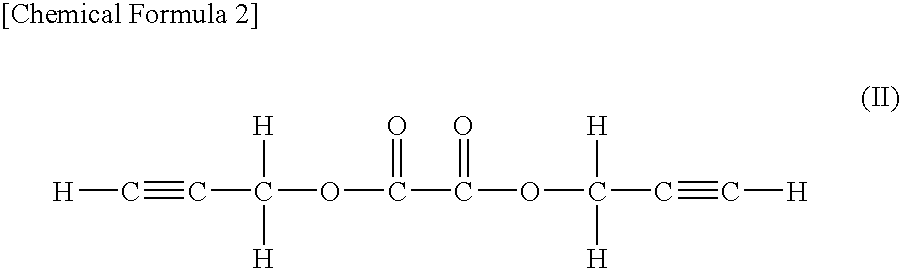

Nonaqueous electrolyte secondary battery

InactiveUS20070178380A1Excels in cycling characteristicLarge capacityNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsOxalateOrganic solvent

A nonaqueous electrolyte secondary battery comprising a negative electrode constituted of a carbonaceous material permitting reversible insertion and desorption of lithium, a positive electrode permitting reversible insertion and desorption of lithium, a separator separating these positive electrode and negative electrode from each other and a nonaqueous electrolyte composed of an organic solvent and, dissolved therein, a solute of lithium salt, wherein the nonaqueous electrolyte contains vinylene carbonate and di(2-propynyl) oxalate, these vinylene carbonate and di(2-propynyl) oxalate added in an amount of 0.1 to 3.0% by mass and 0.1 to 2.0% by mass, respectively, based on the mass of the nonaqueous electrolyte. Thus, there can be provided a nonaqueous electrolyte secondary battery wherein a stable SEI surface coating is formed to thereby exhibit a large initial capacity and excel in cycle characteristics at high temperature and wherein any cell swelling is slight.

Owner:SANYO ELECTRIC CO LTD

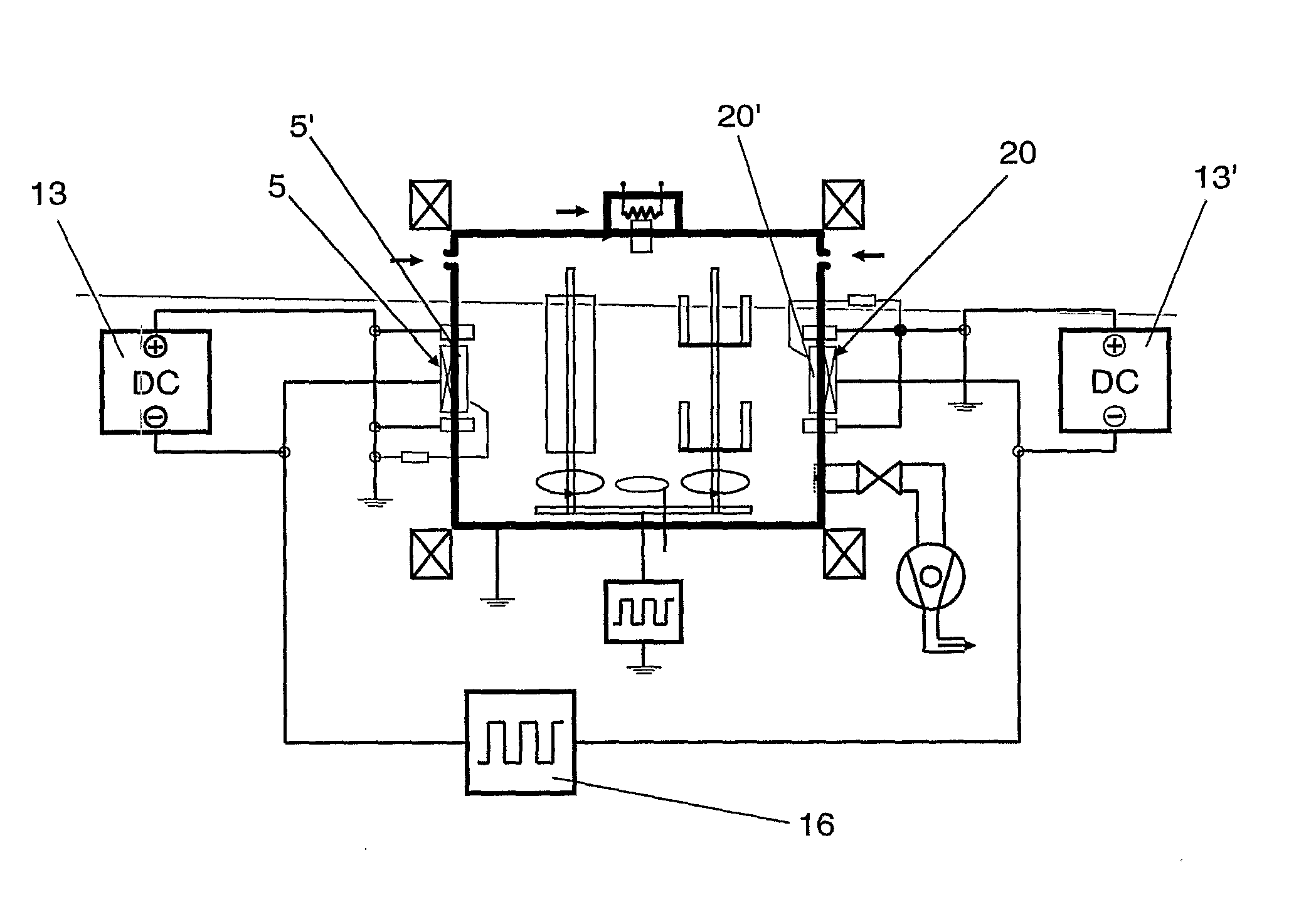

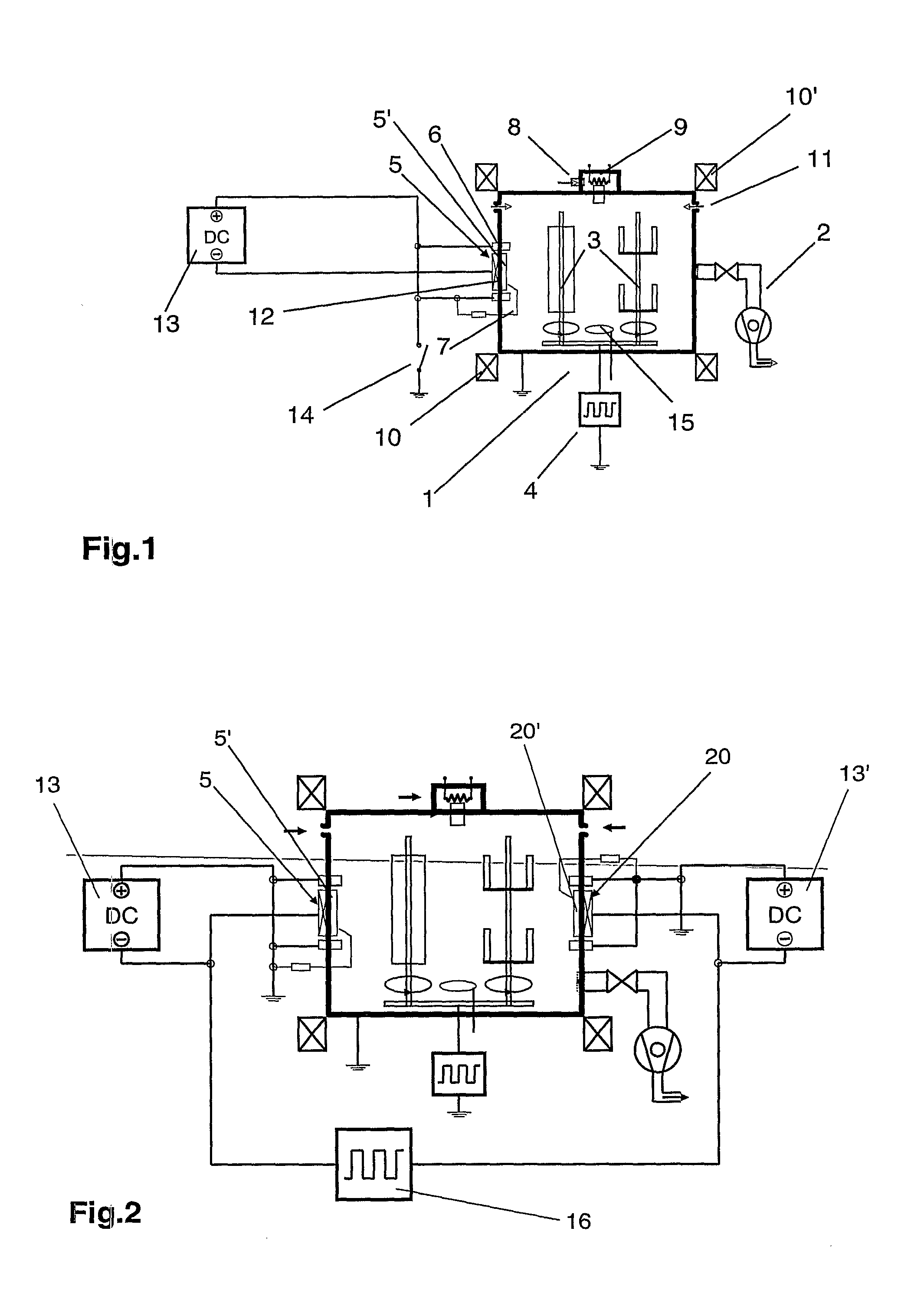

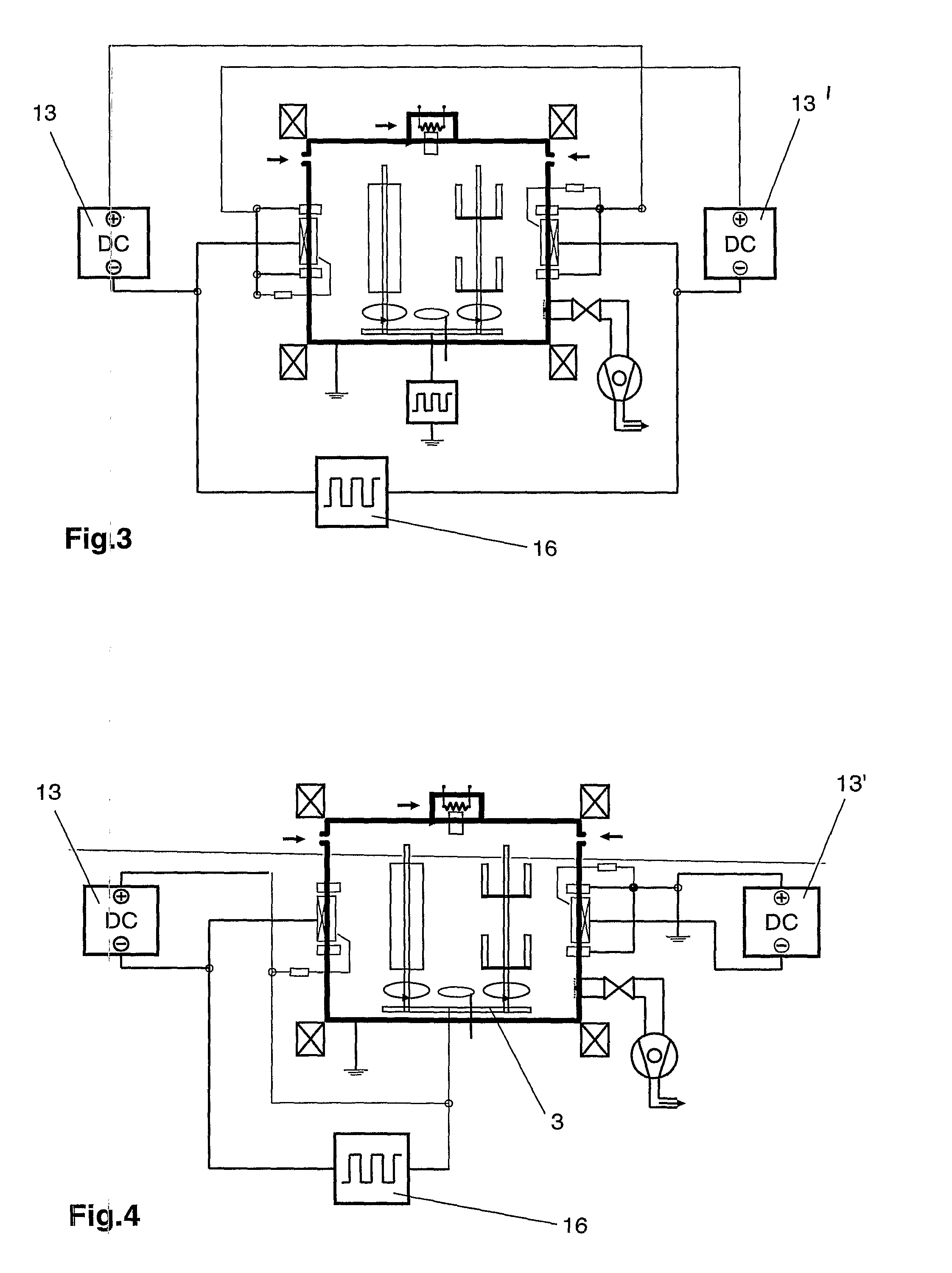

Method For Operating a Pulsed Arc Evaporation Source and Vacuum Process System Comprising Said Pulsed Arc Evaporation Source

ActiveUS20080173536A1High degree of ionizationImprove controllabilityCellsElectric discharge tubesProcess systemsEvaporation

A vacuum process system for surface-treating work pieces uses an arc evaporation source. The system has a first electrode connected to a DC power source and a second electrode, disposed separately from the arc evaporation source. The two electrodes are operated while being connected to a single pulsed power supply.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

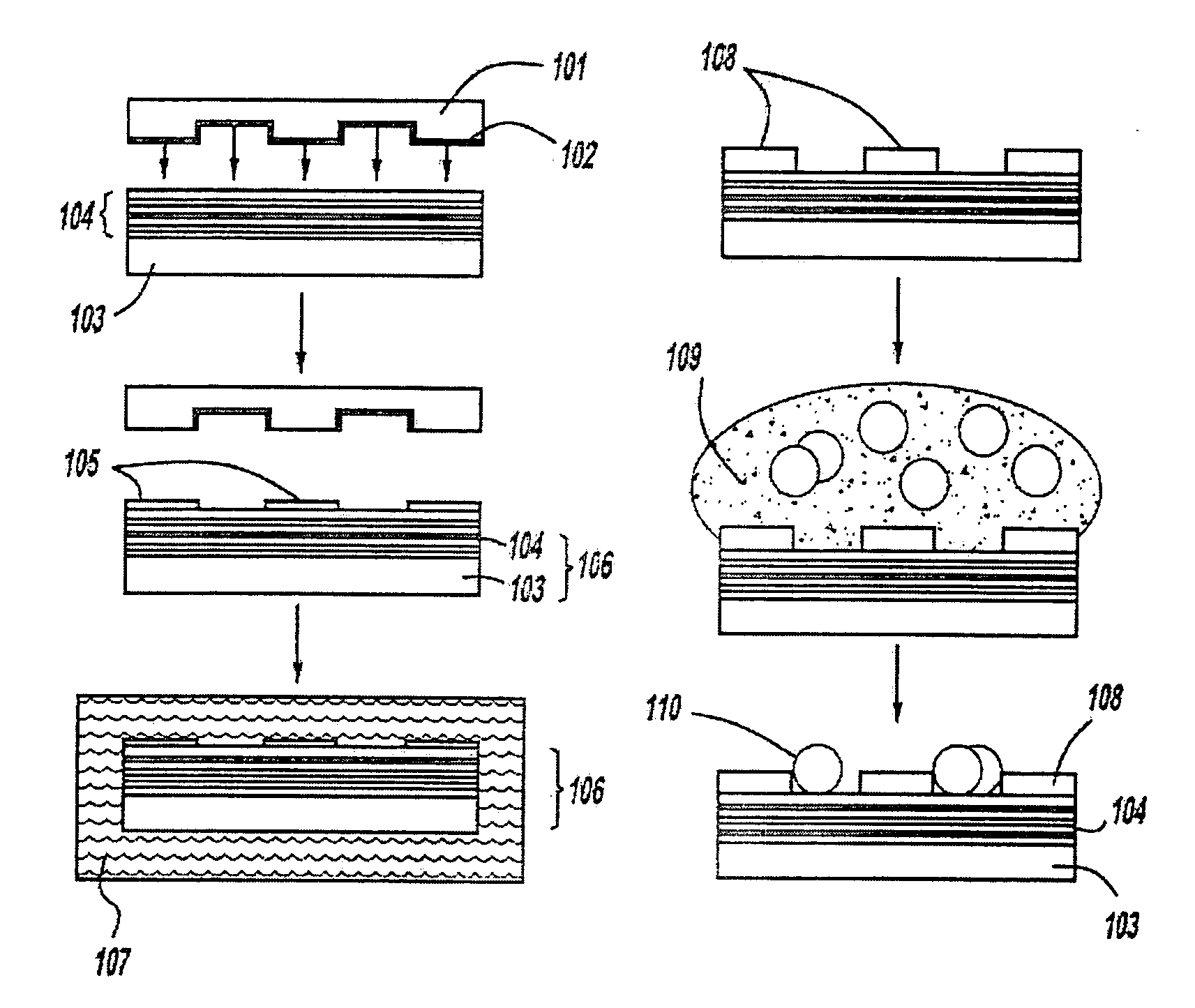

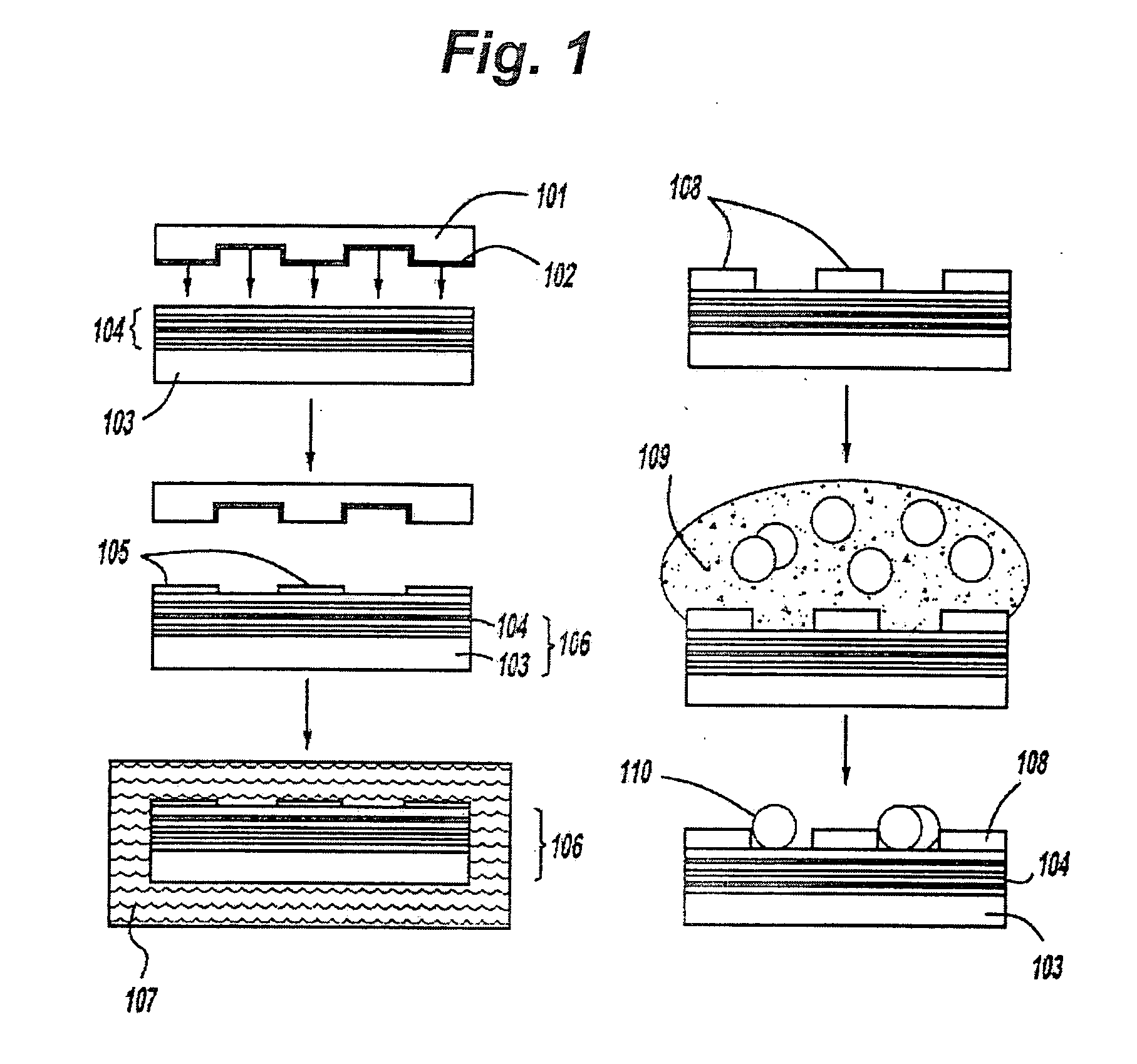

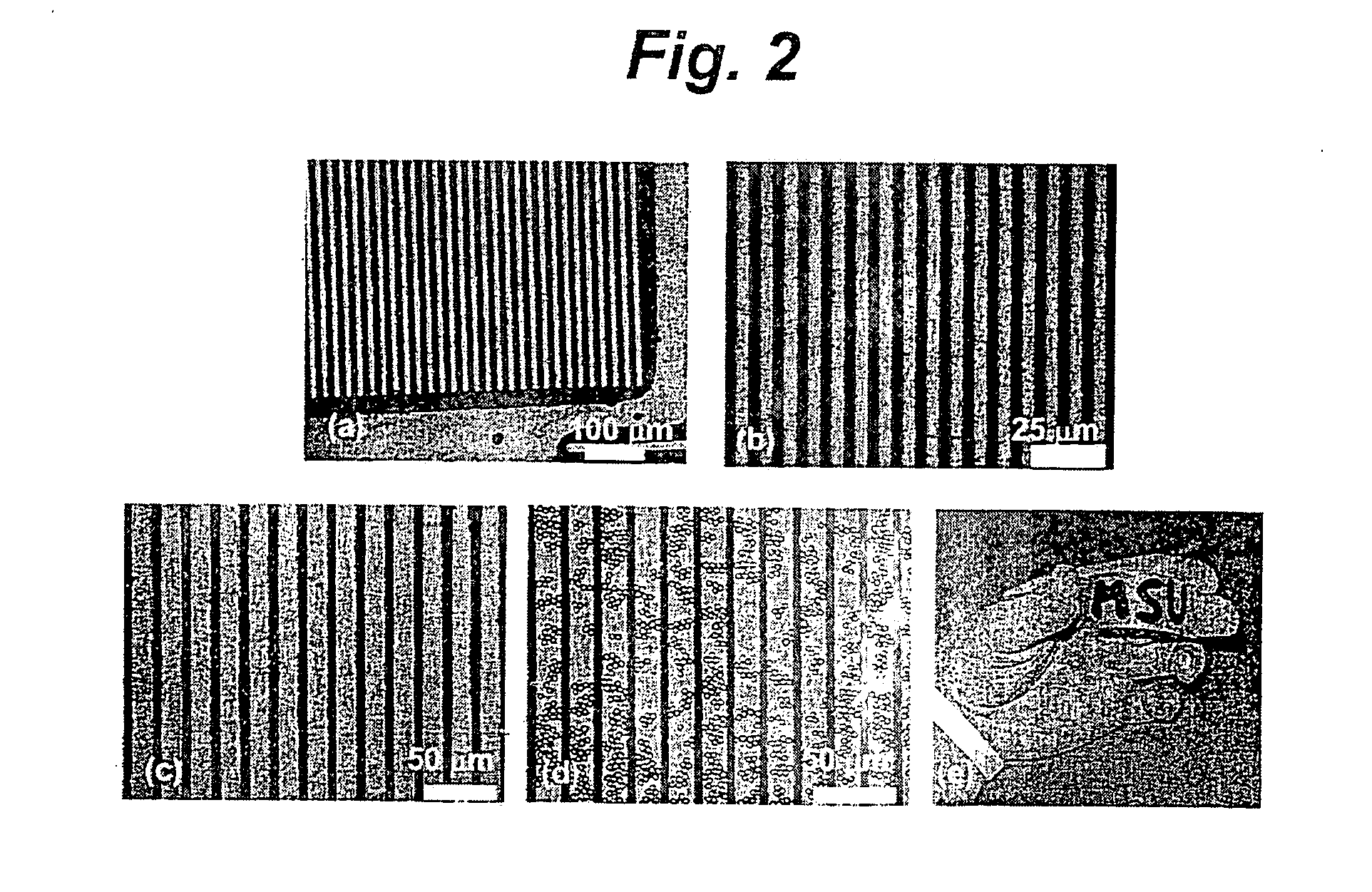

Selective metal patterns using polyelect rolyte multilayer coatings

InactiveUS20080014356A1Coating stabilityProcess economyMaterial nanotechnologyPretreated surfacesMicrocontact printingElectroless deposition

Processes for creating versatile and selective metal patterns (such as copper and nickel) combine the use of PEM coatings, microcontact printing (MCP), and electroless deposition. MCP is used to pattern a charged catalyst (such as palladium and stannous ions) onto oppositely charged PEM coated substrates. The substrate is then placed into an electroless deposition bath where a metal selectively plates at the catalyzed regions.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

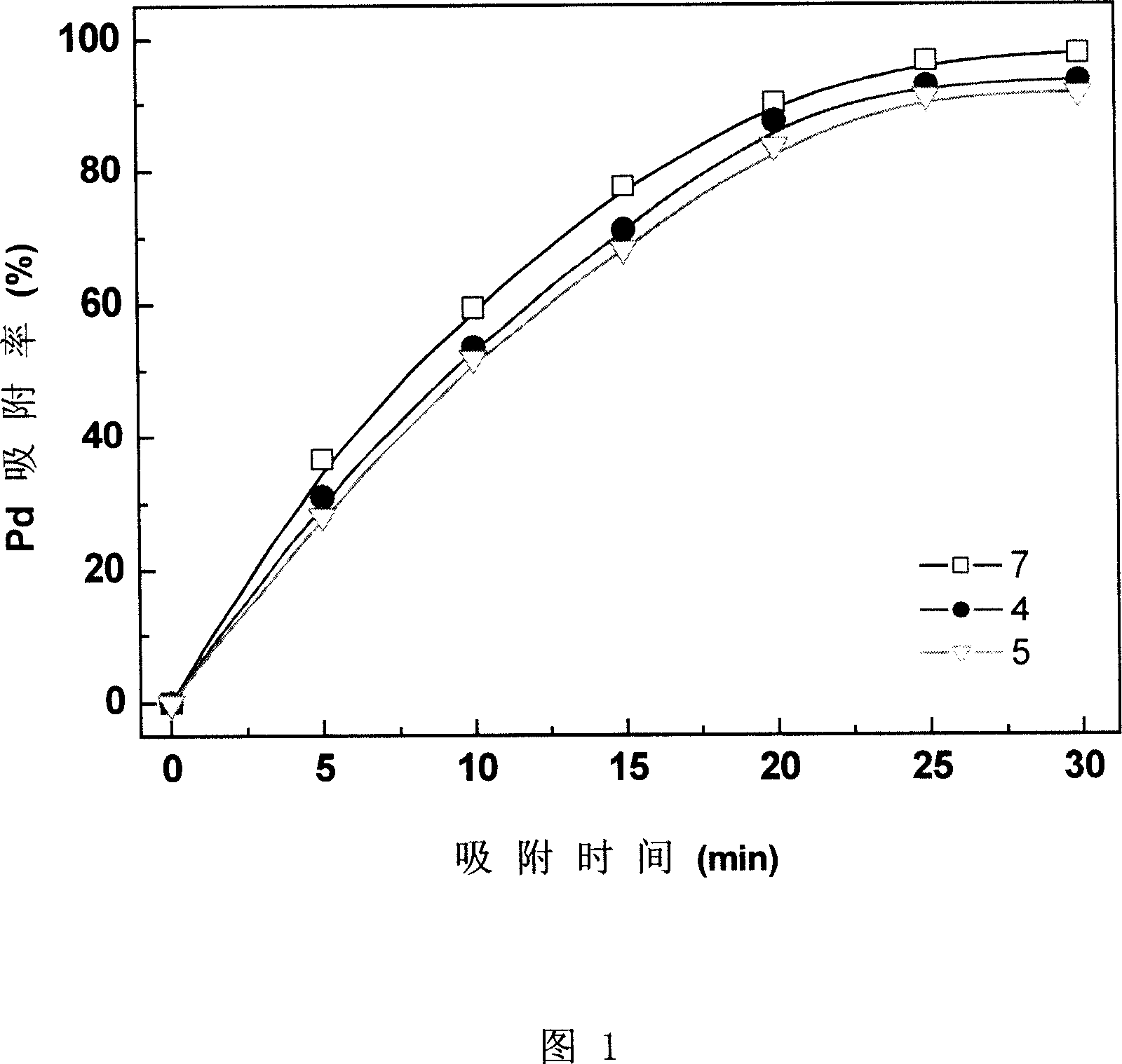

Preparation method of rare earth composite oxides coating Pt-supported catalyst

InactiveCN101007274AThe preparation process is environmentally friendlySimple processDispersed particle separationCatalyst activation/preparationOrganic acidHazardous substance

The invention involves environmental protect technology field, particularly a rare earth compound oxide covering load Pd catalyst preparation method used for organic waste gas treatment. The invention aims at: because the covering of the existing honeycomb ceramics carrier catalyst is easy to reacting with carrier or adjuvant and generating spinel compounds and the covering is easy to drop, the method provides a preparation method which preparation art is simple, does not generate harmful substances in the preparation process, covering has strong adsorption capacity to Pd and is combine with honeycomb ceramics carrier firmly. The preparation method is: adding organic acid or ethandiol or mixture of said both into certain amount of the third and fourth subgroup metal oxide or hydroxide and mixing uniformly and preparing the covering liquid, immersing the honeycomb ceramics carrier into covering liquid and getting it out, then airing, drying and roasting it to preparing the carrier with covering; then immersing the carrier with covering into prepared H2PdCl4 solution, preparing the accelerant after drying and roasting.

Owner:ZHEJIANG NORMAL UNIVERSITY

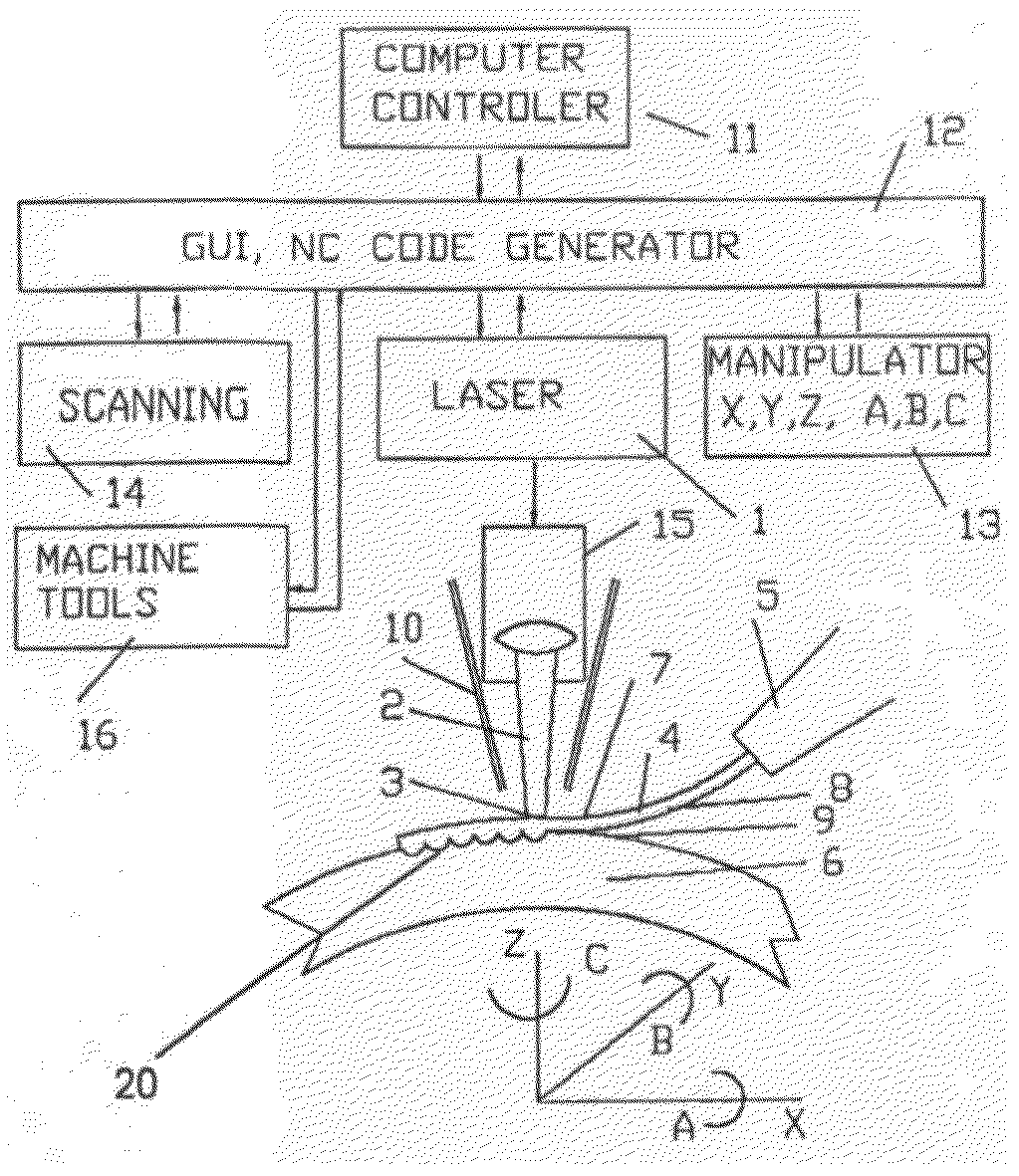

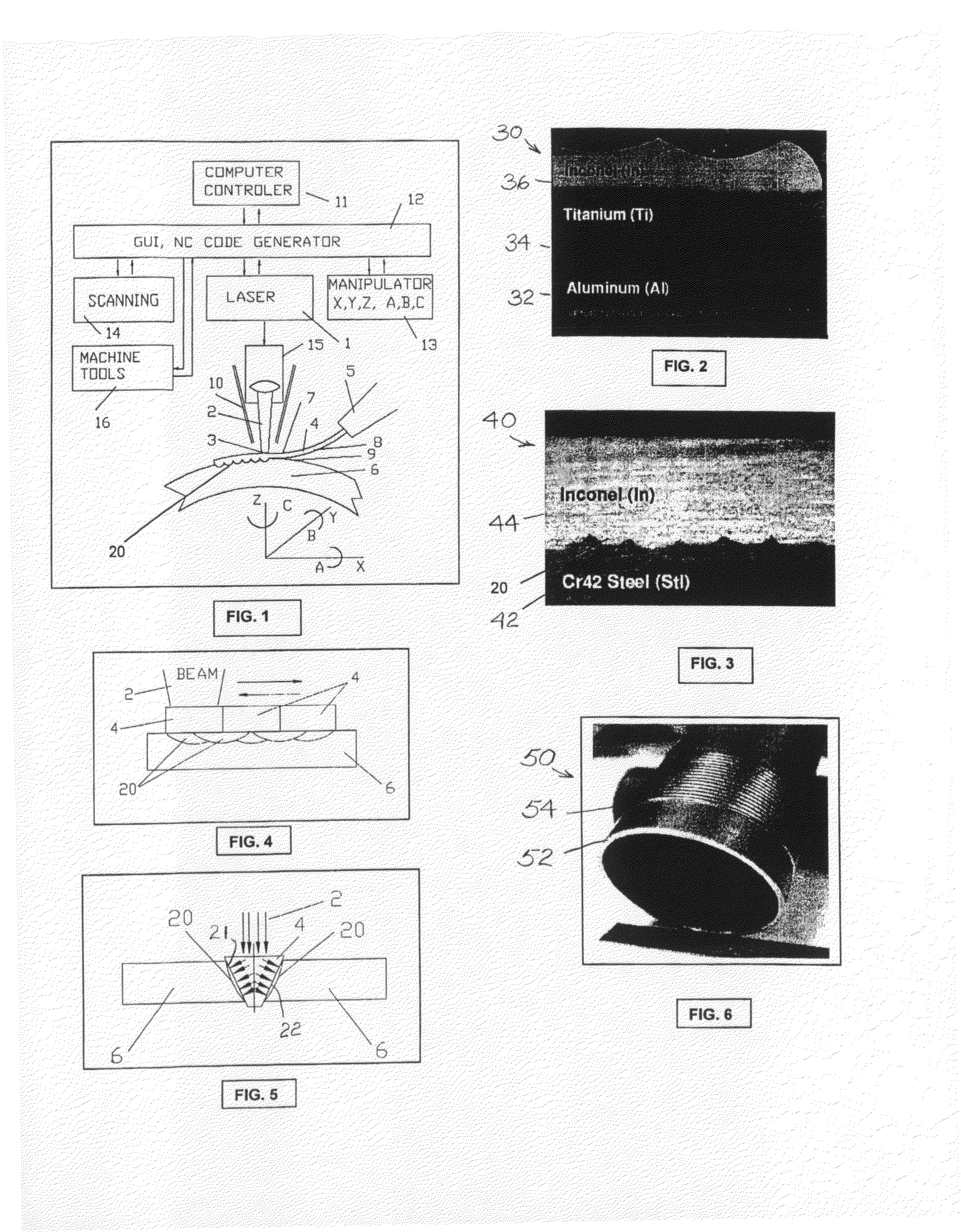

Process for energy beam solid-state metallurgical bonding of wires having two or more flat surfaces

InactiveUS20100155374A1Strong wave-shape interface morphologyLow costAdditive manufacturing apparatusElectron beam welding apparatusWire rodBeam energy

An energy beam assisted solid-state welding welds a wire material to a substrate. A wire of coating or repairing material is placed in contact with a surface or surfaces of a substrate. A beam is directed into an outer flat surface of the wire, which heats the wire through flat outer surface of the wire with beam energy. Beam energy produces compression stress-waves that drive molecules of the material flat wire into a surface of the substrate, joining the material and the substrate with strong wave shaped interfaces.

Owner:RABINOVICH JOSHUA E

Electrically conductive coatings and method of their use

InactiveUS20070029307A1Maintain coating propertyReadily apparentHeating element materialsConductive coatingSolvent

It has been discovered that finely ground elemental graphite enhances the electrical conductivity of a coating when added to conductive amorphous carbon, using any one of several different binders in formulating the coating. The coating can be energized with electrical energy creating an electrical resistance heat element. Such combination of amorphous carbon and elemental graphite particles, ranging in size from about 0.001 to less than 1 micron, creates a more uniform conductive coating compared to use of larger sized particles, where the amount of conductive particles ranges from about 5 to about 80 weight-% based on the non-volatile solids content of the coating formulation (e.g., without solvent and other components that evolve (are driven off) from the coating during drying).

Owner:PROGRESSIVE COATINGS TECH

Preparation method for SCR catalyst for purifying oxynitride in motor vehicle exhaust

InactiveCN105833899ASmooth coating processImprove stabilityGas treatmentInternal combustion piston enginesCrystallizationSSZ-13

The invention discloses a preparation method for an SCR catalyst for purifying oxynitride in motor vehicle exhaust .The preparation method includes the steps of preparation of an SSZ-13 molecular sieve, preparation of a Cu-SSZ-13 catalyst and preparation of an integrated SCR catalyst .The preparation method is simple, production cost is lowered, SSZ-13 crystallization time is short, crystallization is relatively pure, HN3-SCR catalytic activity is high, and the purification rate of oxynitride in motor vehicle exhaust is high.

Owner:ZHEJIANG FORSOL ENERGY

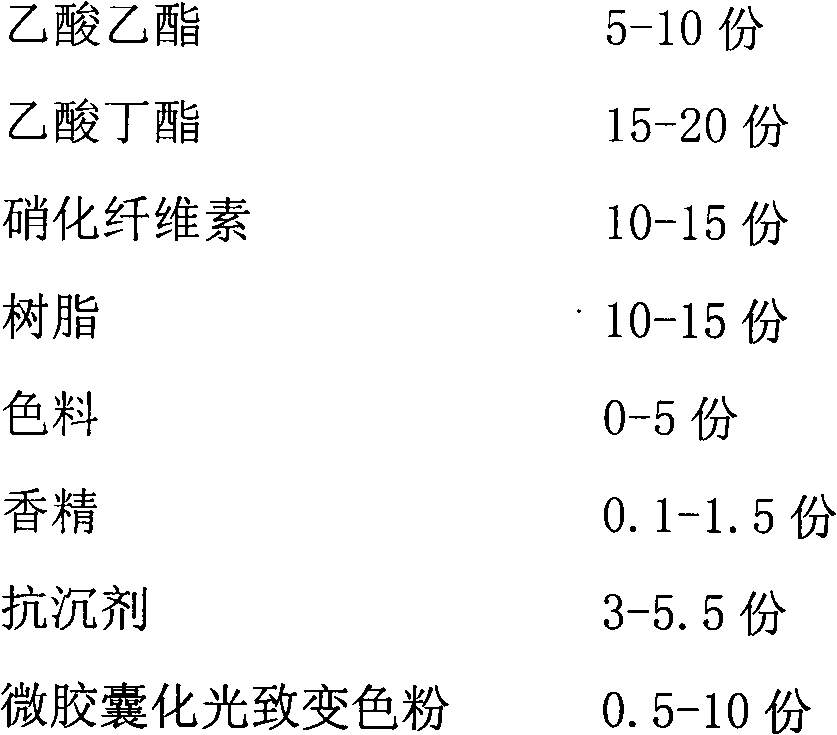

Photochromic nail polish

InactiveCN103099741AGood dispersionUniform toneCosmetic preparationsToilet preparationsDispersityNitrocellulose

The invention provides a photochromic nail polish which comprises the following components in parts by weight: 5-10 parts of ethyl acetate, 15-20 parts of butyl acetate, 10-15 parts of nitrocellulose, 3-5 parts of resins, 0-5 parts of pigment, 0.1-1.5 parts of essence, 3-5.5 parts of anti-settling agent, and 0.5-10 parts of microencapsulated photochromic powder. The photochromic nail polish provided by the invention has the advantages and beneficial effects that because a photochromic compound is added, the photochromic nail polish can be changed into different colors in the sun so as to generate a novel and peculiar effect; and a photochromic material is processed by using a microencapsulated processing method, so that the photochromic nail polish is better in dispersity, the obtained color is more uniform, and the photochromic nail polish is firmer after being coated on nails; and the essence in the photochromic nail polish provided by the invention is selected from plant essence, and the other materials are all benzene-free, methanol-free and formaldehyde-free materials, therefore, the photochromic nail polish is non-toxic, environment-friendly and healthful.

Owner:TIANJIN FORESEEN TECH

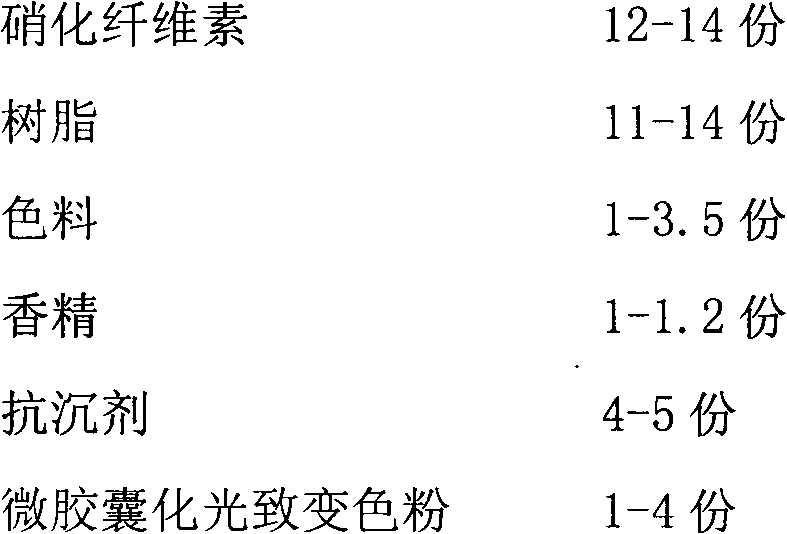

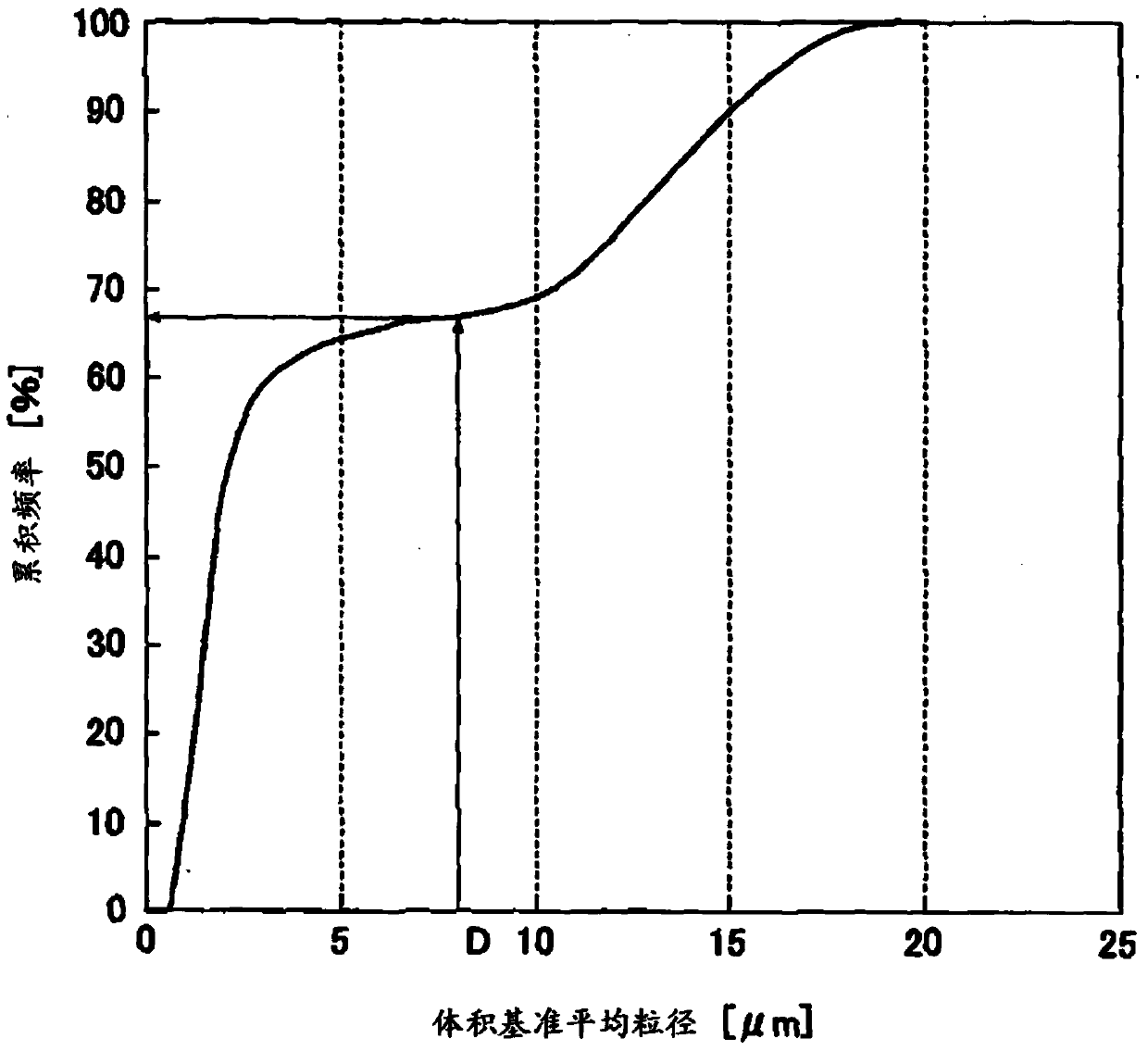

Oxidized starch adhesive and preparation method thereof

InactiveCN104861892AReduce usageFast oxidationNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesivePapermaking

The invention discloses an oxidized starch adhesive and a preparation method thereof. The oxidized starch adhesive is mainly prepared from the raw materials of, by weight, 100 parts of starch, 3-5 parts of hydrogen peroxide, 0.1-0.5 parts of a potassium permanganate solution, 0.4-1 part of s catalyst, 9-11 parts of sodium hydroxide, 1-3 parts of a crosslinking agent, 300-500 parts of water, and 0-0.5 parts of a defoaming agent. According to the invention, hydrogen peroxide and the potassium permanganate solution are both used as oxidizing agents, and cooperates to provide a synergistic effect in carrying out oxidization treatment upon the starch material. The oxidization speed is high, and the dose of oxidizing agent is low. The obtained oxidized adhesive has the advantages of high bonding strength, good stability, good gelling resistance, long storage time, short drying time, good environment friendliness, and low cost. The adhesive is nontoxic and harmless, and can be widely applied in the fields of papermaking, trademark, textile, and the like.

Owner:HENAN UNIV OF URBAN CONSTR

Suspension type rape seed coating agent

InactiveCN102197821ACoating stabilityIncrease water permeability and breathabilityBiocidePlant growth regulatorsDisinfectantMass ratio

The invention relates to a suspension type rape seed coating agent formulation. The suspension type rape seed coating agent is prepared by carrying out wet grinding on a film-forming agent, an emulsifier, an anti-freezing agent, a warning color material and insecticide, disinfectant, a plant growth regulator, a trace-element fertilizer and water; and the suspension type rape seed coating agent issuitable for carrying out coating treatment on all sorts of seeds. The rape seed coating agent provided by the invention has the advantages of simple manufacturing technique, convenience for coating and low cost and can be used for mechanical coating or manual coating, and the mass ratio of the rape seed coating agent to the seeds can reach up to 1 to 200-300; when the seeds are coated, a film with dense film pore channels is formed on the surface of each seed; and then the active components can be slowly released through the film pore channels and the lasting period is 55-day-long to 70-day-long; the prevention and cure rate of the coating agent on the rape seedling stage sclerotiniose is up to 86-97% and the prevention and cure rate on the aphid and the subterranean pest-insect is up to82-95%; a rape seedling has the developed roots, is neat and stocky and has strong stress resistance; the rate of emergence of the seedlings is improved by 8-18% and the planting percent is improved by 7-15% so that the yield is obviously increased. The suspension type rape seed coating agent has good economic benefits, social benefits and ecological benefits.

Owner:HUNAN YINGCHENG MODERN AGRI SCI & TECH DEV

Coating for color roof tile and its use method

The present invention discloses one kind of paint for color roof tile and its usage. The paint consists of silicon / fluorine modified acrylic acid emulsion, pigment, stuffing, assistant and water in proper proportion. It has the features of high weather resistance, high wash resistance, good antibiotic property, high endurance, high hardness, high brightness, no toxicity, stable coating, etc.

Owner:陈敬福

Water-based PU brush surface conditioning agent for synthetic leather

InactiveCN101705623AExcellent crosslink hardnessGood recoatabilityFibre treatmentWater basedSilicon dioxide

The invention discloses a water-based PU brush surface conditioning agent for synthetic leather, which comprises the following materials by weight percent: 10 to 20 percent of water-based stoving varnish resin, 1 to 6 percent of water-based polyurethane, 60 to 70 percent of water, 5 to 13 percent of silicon dioxide matting agent, 0.5 to 2 percent of organic silicon flatting agent, 1 to 5 percent of organic silicon foam killer and 2 to 6 percent of water-based modified polyethylene wax emulsion. In the water-based PU brush surface conditioning agent for synthetic leather, water is taken as solvent to replace noxious solvents, such as dimethyl formamide and butanone, so that the water-based PU brush surface conditioning agent has the performances of non-inflammation, safety, environmental protection and cost saving, and resin has the advantages of good film reforming property, firm bonding, solvent resistance, cold resistance, hydrolysis resistance and thermosenescence resistance of coating, and the finished product made of the surface conditioning agent has unique brush effect, strong dermis effect, water resistance and good air permeability.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Preparation method for magnesium alloy cast paint

InactiveCN101342570AReduced hot cracking tendencyImprove insulation effectFoundry mouldsFoundry coresWrinkle skinPhosphoric acid

The present invention relates to a method for preparing magnesium casting coating; 0.7 percent of paligorskite clay that is configured with 17 percent of water is milled for 3 hours to be made into solution A; secondly 5 percent of talcum powder, 3 percent of diatomite, 0.5 percent of KBF4 and 1 percent of aluminium phosphate are put into a spherical mill, and is respectively mixed with solution A, 3 percent of silica sol and 67.6 percent of water to be milled for 3 hours to obtain the magnesium alloy metal-typed casting coating; metal mould is heated to be about 200 DEG C, and then is sprayed with a layer of magnesium alloy casting coating on the surface, and is dried finally. The method of the present invention has the advantages of strong heat preservation, flame retardant performance, sticking performance and coating performance, favorable suspension performance and less heat fracture of the casting piece. Oxidation is prevented, so the surface is bright and smooth and is free from oxidized wrinkle.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

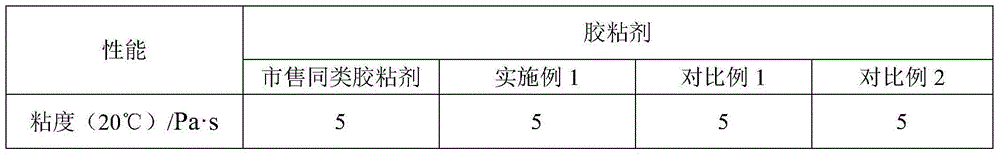

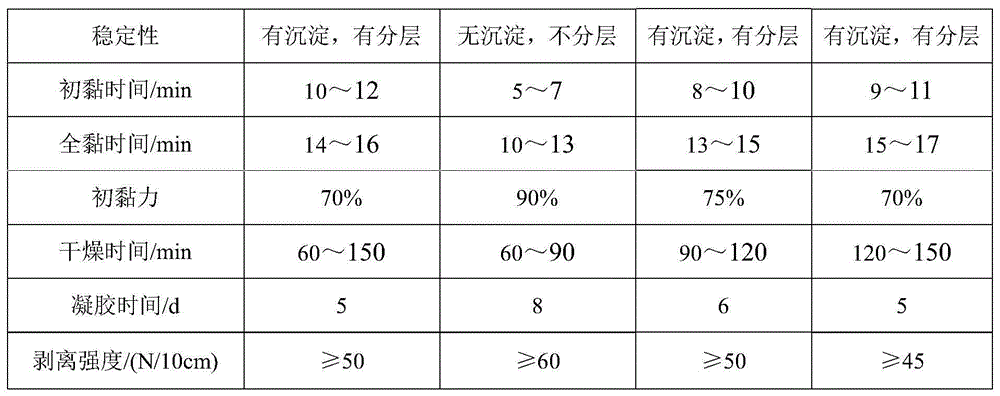

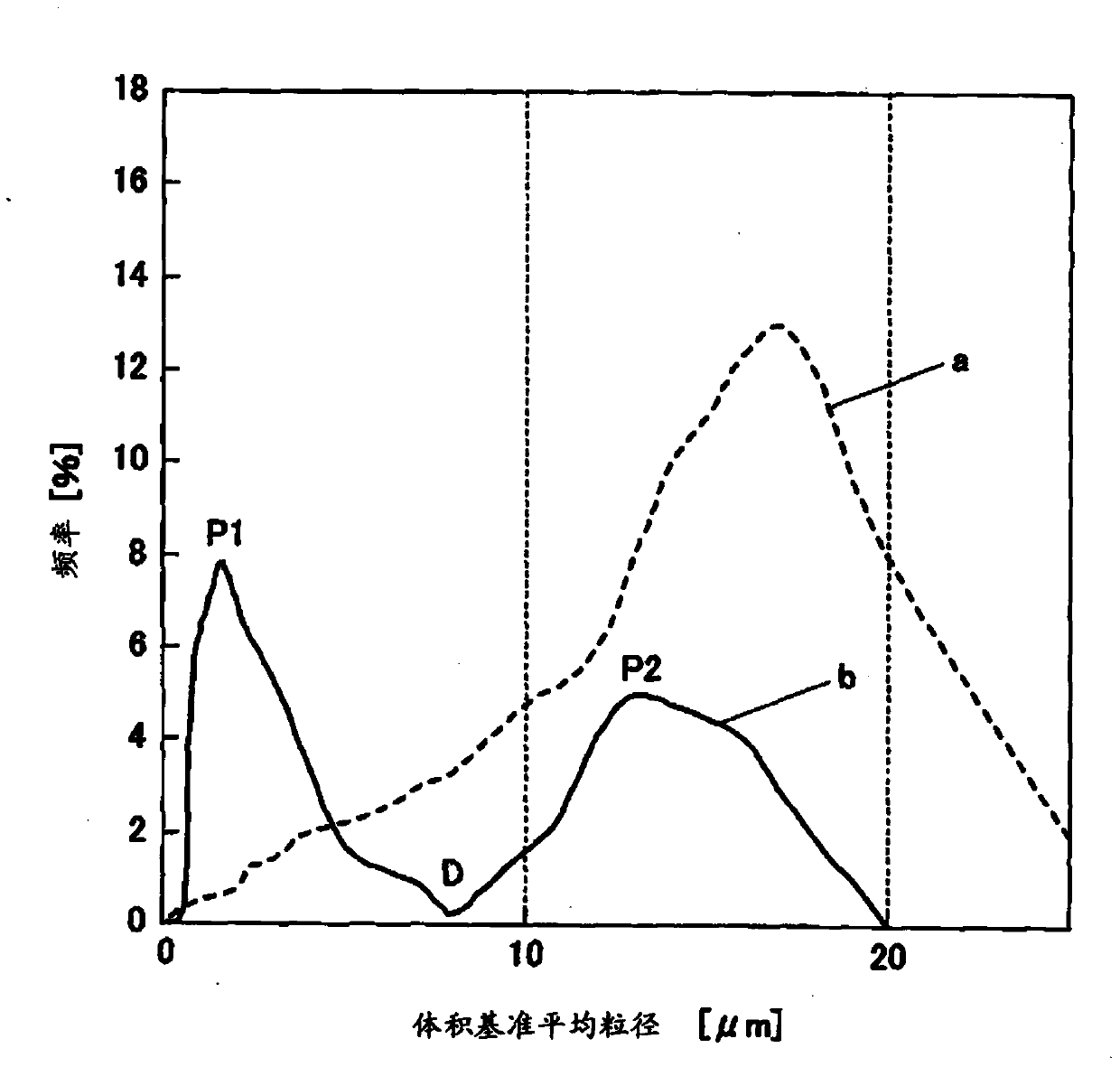

Electrostatic latent image developing toner, production method of the toner for electrostatic latent image development and electrophotographic image formation method

ActiveCN104181786AShort lifeCoating stabilityDevelopersElectrographic processes using charge patternLatent imagePhysical chemistry

A toner for electrostatic latent image development of the present invention includes toner particles containing toner mother particles and an external additive. The external additive contains fatty acid metal salt particles, and a volume based particle diameter (size) distribution of the fatty acid metal salt particles has two peaks on a side of smaller size and a side of larger size, respectively. A volume based mean particle diameter of the fatty acid metal salt particles having the peak on the side of smaller size is 3.0 μm or smaller and a volume based mean particle diameter of the fatty acid metal salt particles having the peak on the side of larger size is larger than a volume based mean particle diameter of the toner mother particles.

Owner:KONICA MINOLTA INC

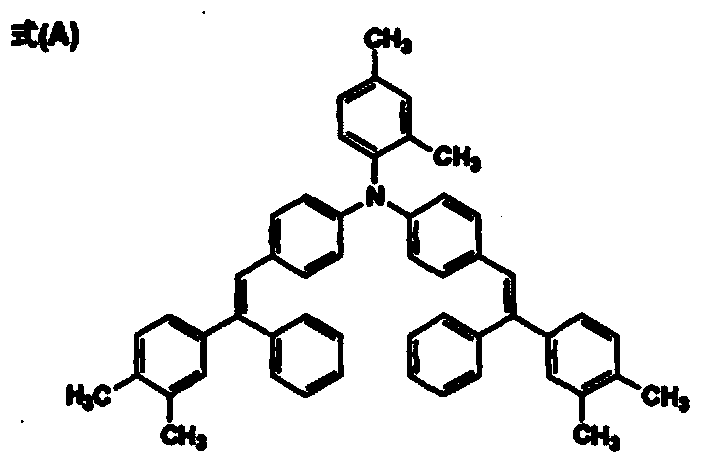

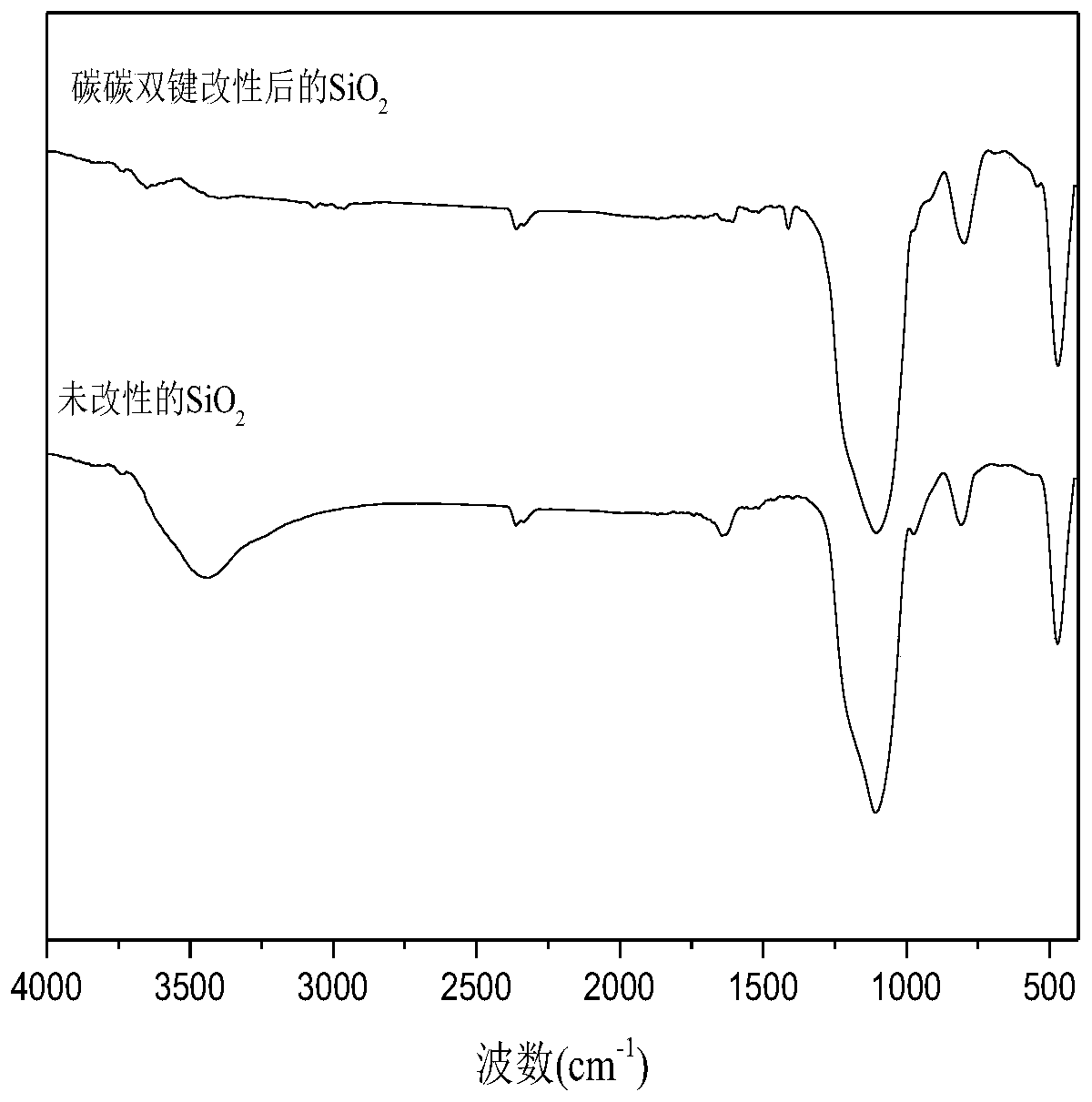

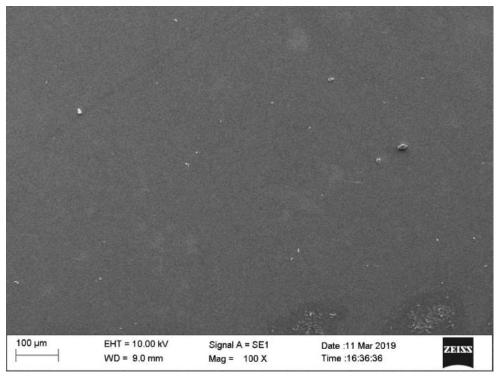

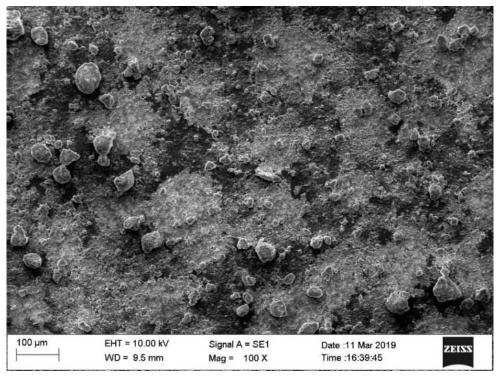

Super-hydrophilic coating using organic polysilazane as anchor molecule and preparation method thereof

ActiveCN110205025AImprove mechanical stabilityGood chemical stabilitySpecial surfacesCoatingsHydrophilic coatingPolysilazane

The invention discloses a super-hydrophilic coating using organic polysilazane as an anchor molecule and a preparation method thereof. The preparation method includes the steps that a preliminarily prepared organic polysilazane solution is adopted to coat the surface of a base material to form an organic polysilazane coating through a coating method; after a solvent evaporates, modified inorganicnanoparticles with reactive carbon-carbon double bonds on the surfaces are used for coating the surface, on which organic polysilazane is attached, of the base material, and through heat treatment, anorganic polysilazane / inorganic nanoparticle composite coating with reaction activity is obtained; betaine-type zwitterionic compounds with carbon-carbon double bonds are grafted onto the inorganic nanoparticles on the surface of the composite coating, and then hydrophilic modification is achieved. The water contact angle of the surface of the prepared hydrophilic modified coating is smaller than10 degrees, so that the super-hydrophilic coating has super-hydrophilic characteristics, and the coating and the surface of the base material have excellent attachment characteristics. The super-hydrophilic coating has good application effects of frogging prevention, self-cleaning, adhesion resistance of ships and underwater facility and the like.

Owner:SOUTH CHINA UNIV OF TECH

Sputter target, method for manufacturing a layer, particularly a tco (transparent conductive oxide) layer, and method for manufacturing a thin layer solar cell

InactiveUS20090272641A1Increase sputtering rateLow oxygen bombardmentCellsVacuum evaporation coatingThin layerOxygen ions

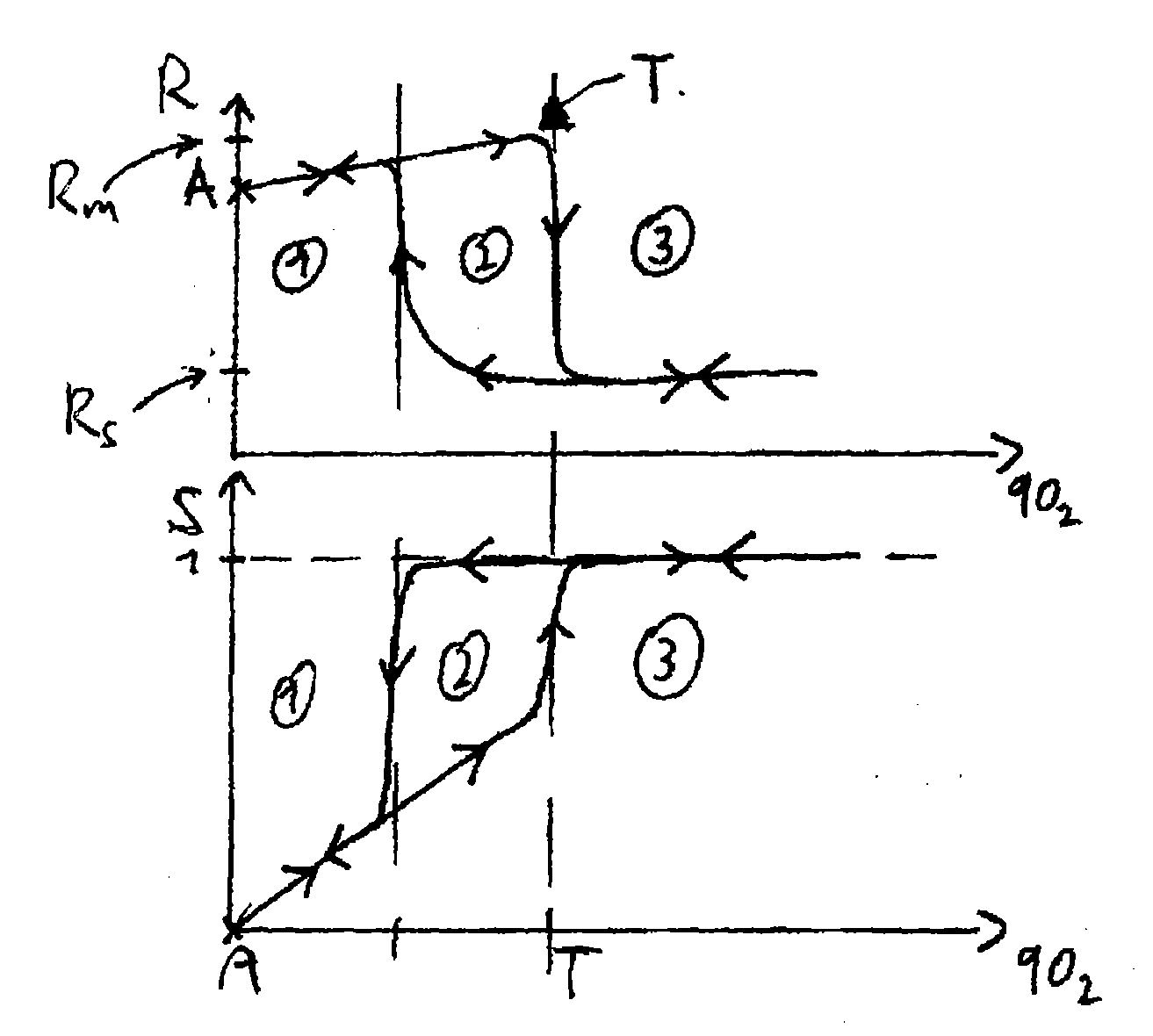

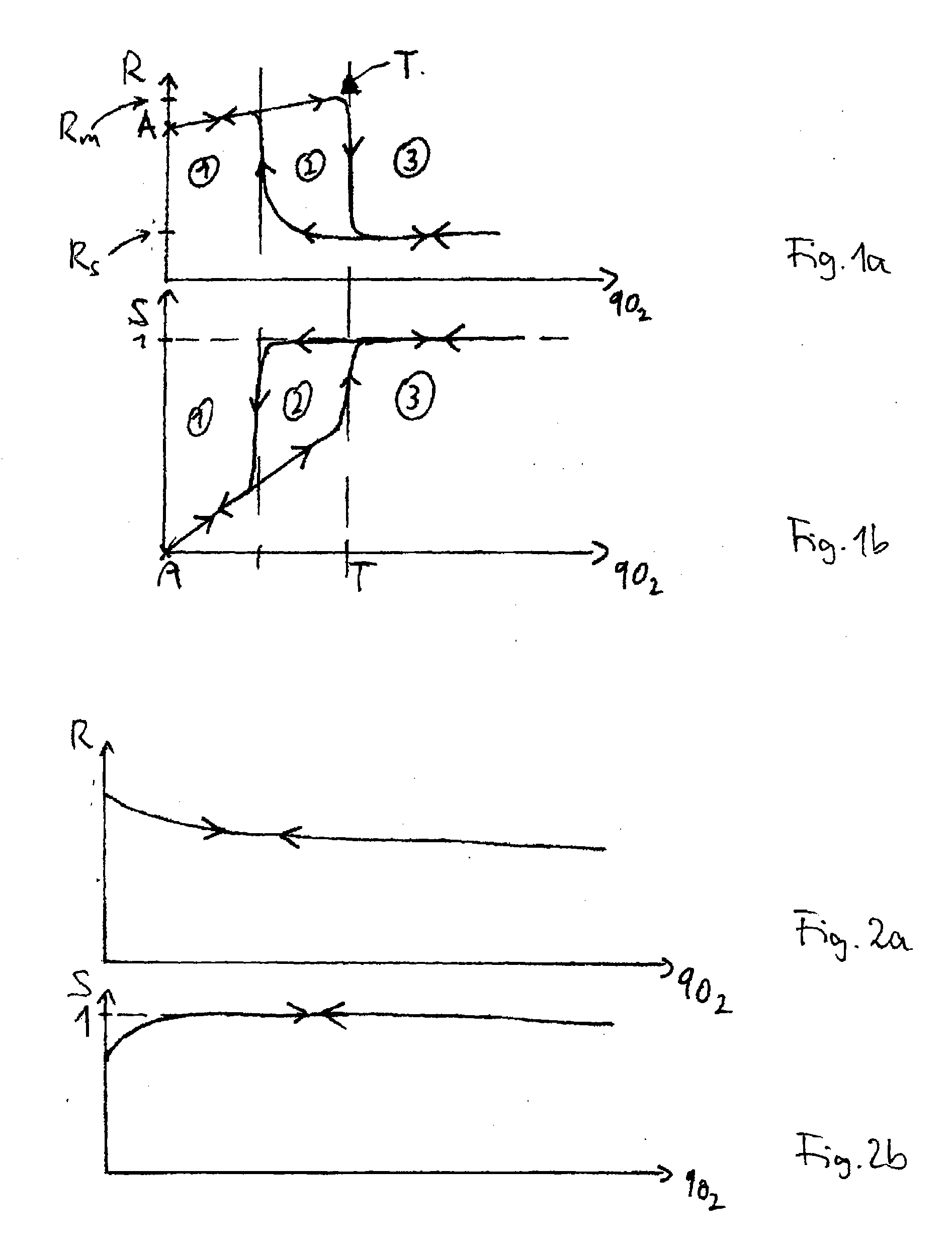

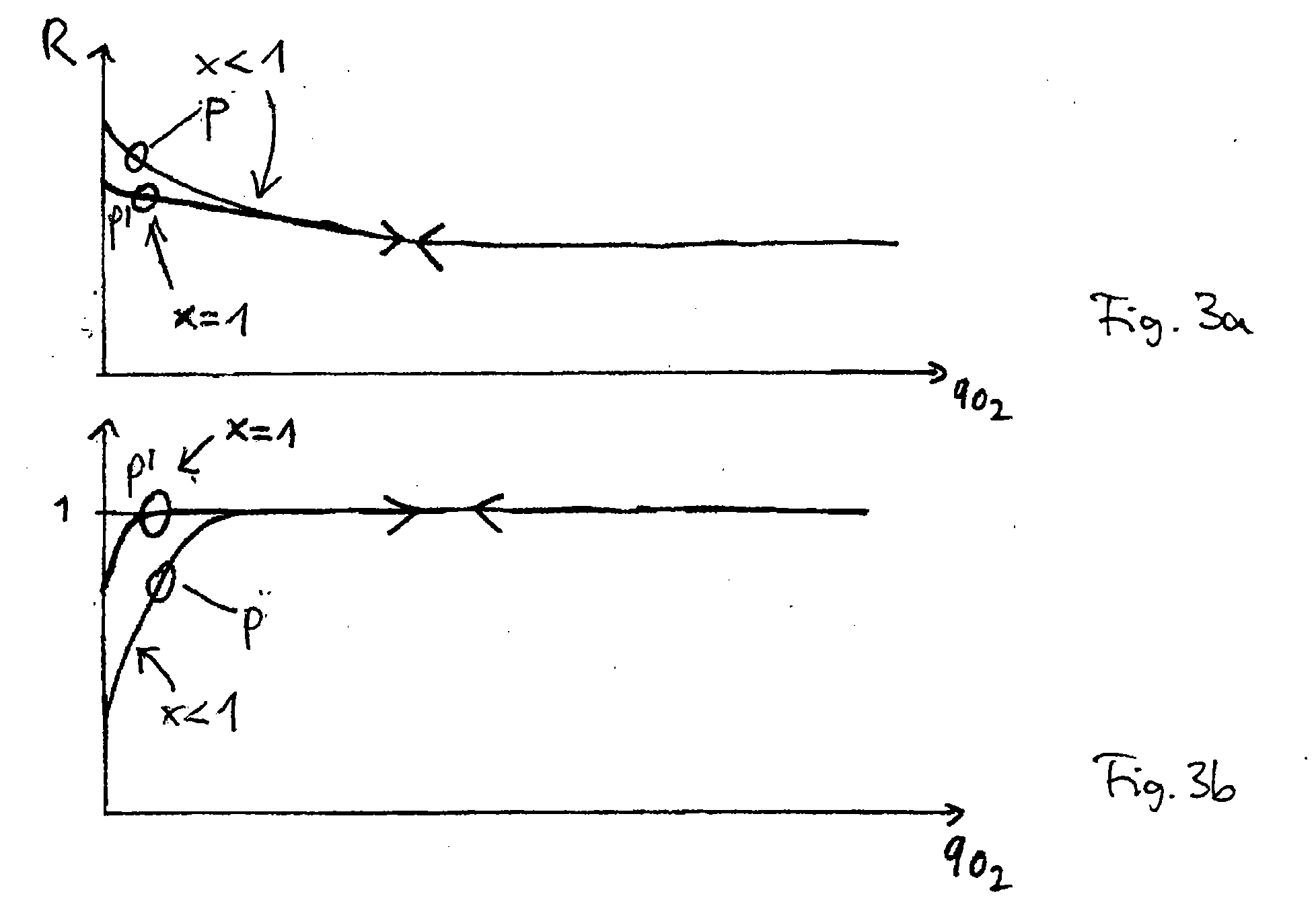

In the present invention a sub-stoichiometric ceramic ZnOx:Al target, with 0.3<x<1, is used for depositing a ZnO:Al layer in a reactive sputtering process. The process is carried out in an Ar / O2 atmosphere. The diagram depicts the deposition rate R depending on the oxygen flow in a sputtering process according to the present invention compared with a conventional sputter process using a stoichiometric ZnO target. The upper line x<1 indicates the deposition rate R when using the inventive target and process. The lower line x=1, for comparison only, indicates the deposition rate R when using a stoichiometric ceramic ZnO target. It can be seen from the diagram that both processes are quite stable as there are no steep slopes when varying the oxygen flow. However, the line x<1 is above the line x=1. Therefore, a working point P may be selected which has a higher deposition rate R than a corresponding working point P of a corresponding ceramic target. A higher deposition rate, however, entails a lower bombardment of the deposited layer with oxygen ions. Therefore, the quality of the ZnO:Al layer is improved as far as the conductivity and the etchability of the layer are concerned.

Owner:APPLIED MATERIALS INC

Microcoating Comprising Siloxanes

ActiveUS20080234417A1Easy to installSimple wayFilm/foil adhesivesConductive materialChemistryCoating

Owner:EWALD DORKEN

Superfine powder type rape seed coating agent

ActiveCN103342616ACoating stabilityImprove permeabilityFertilizer mixturesAdditive ingredientCoated drugs

The invention relates to a superfine powder type rape seed coating agent. The superfine powder type rape seed coating agent is prepared by ultrasonically crushing active ingredients including bactericide hymexazol, insecticide imidacloprid, plant growth regulator compound sodium nitrophenolate, trace element fertilizer boric acid and the like, and inactive ingredients including film-forming agent carboxymethyl chitin, pigment, auxiliaries and the like. The superfine powder type rape seed coating agent is suitable for coating treatment of various rape seeds under different ecological conditions; the mass ratio of coated drug to seeds is as high as 1 to 150-180; a coated film with a film pore path is formed on the surface of the seed during a coating process; the active ingredients can be slowly released by the film pore path, so that the prevention and treatment agent for stalk break at the rape seedling period is 83%-97%, and the prevention and treatment rate for aphids and soil insects is 85%-96%; a rape root system is developed and strong in stress resistance, so that the emergence rate is improved by 10%-19%, the seedling emergency percentage is improved by 8%-17% and a yield-increasing effect is obvious. Besides, the superfine powder type rape seed coating agent is simple and convenient to produce, low in cost and convenient to use.

Owner:HUNAN AGRICULTURAL UNIV

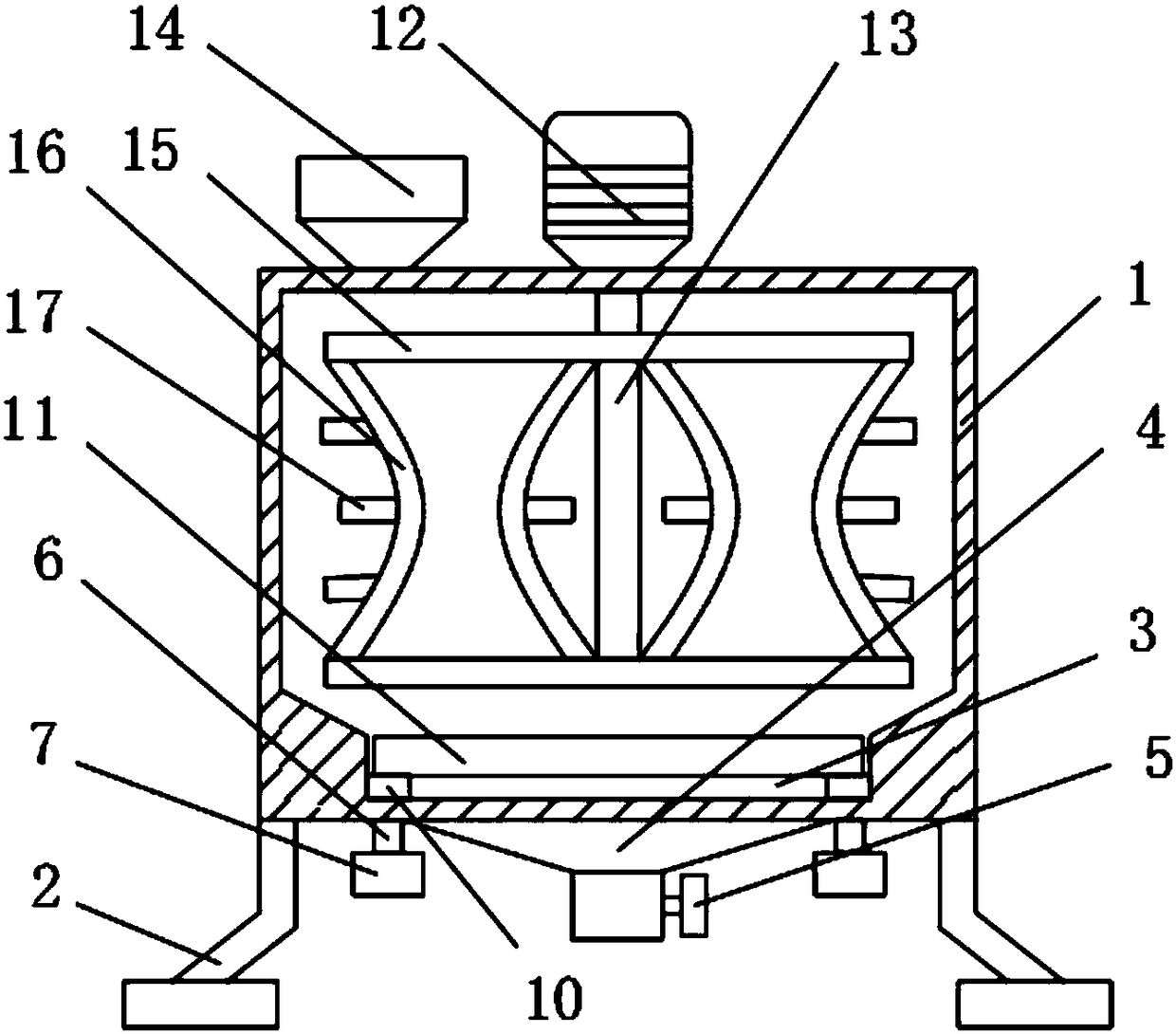

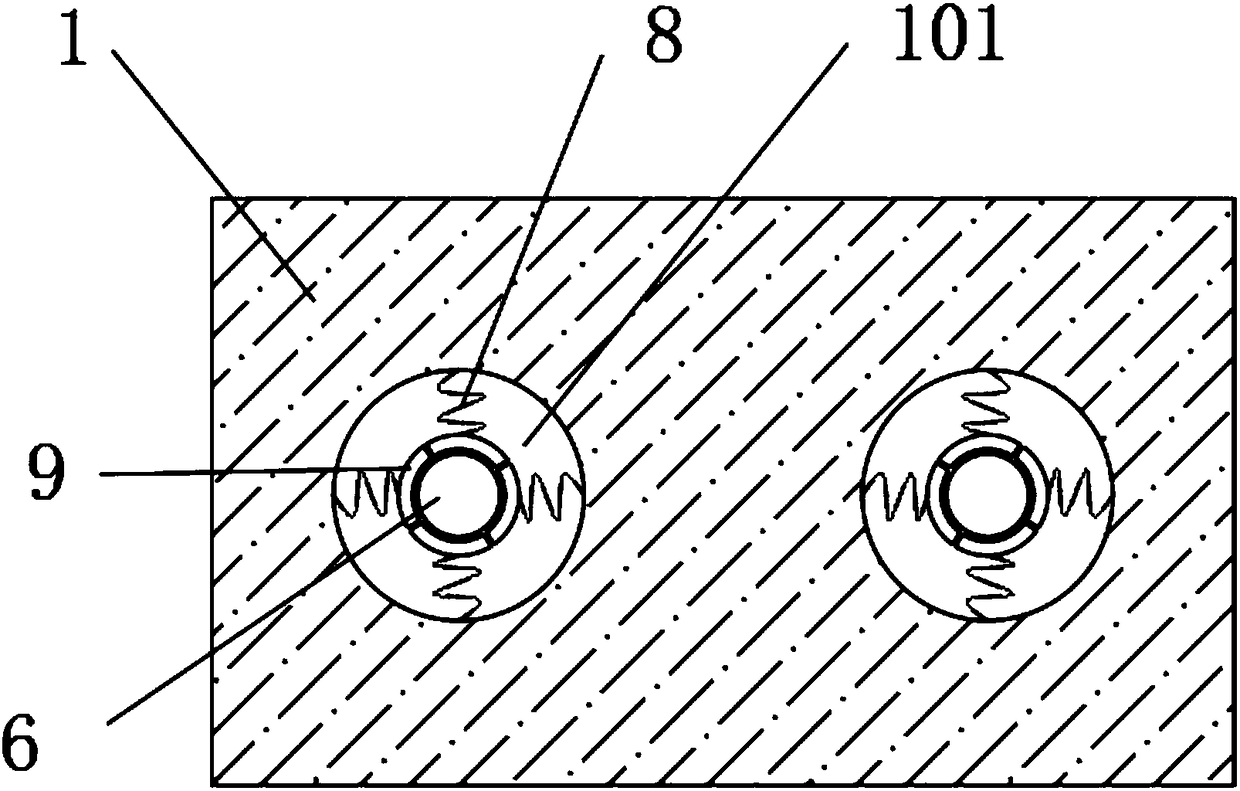

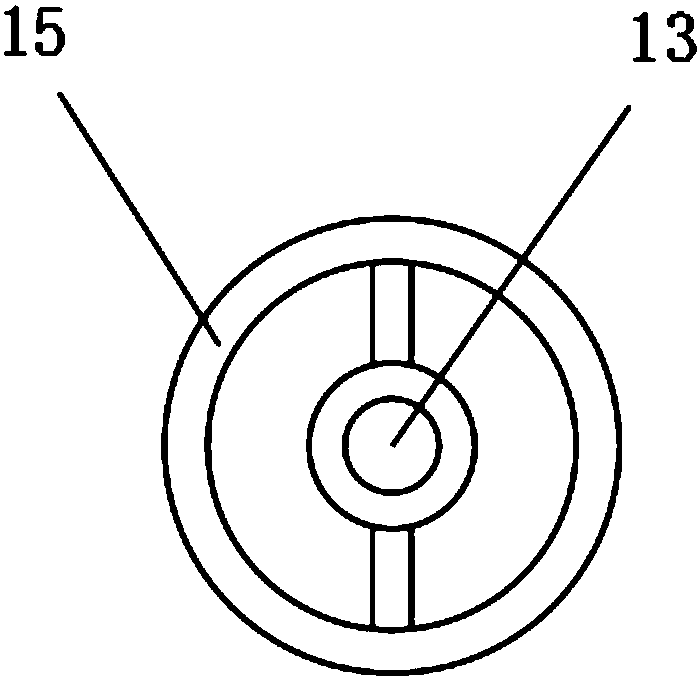

Stirring and filtering device for lithium battery paste

InactiveCN108159765AEvenly dispersedReasonable structureMoving filtering element filtersSlurryEngineering

The invention discloses a stirring and filtering device for lithium battery paste. The stirring and filtering device comprises a main casing, through holes, supporting legs, a putting groove, a discharging pipe, a discharging valve, sliding rods, vibration motors, elastic springs, circular arc clamping plates, sealing blocks, a filtering plate, filtering holes, filtering screens, an electric motor, a rotating shaft, a discharging pipe, fixed frames, stirring rods and stirring blades. The stirring and filtering device for the lithium battery paste has the advantages of reasonable structure, novel design and convenience in discharging; dispersion uniformity of the lithium battery paste is improved; during discharging, the lithium battery paste is filtered so as to remove particles and impurities in the slurry, ensure uniform dispersion of the lithium battery paste and stable subsequent coating and improve the quality of a product; automatic stirring of the lithium battery paste is realized and better dispersion of the lithium battery paste is ensured; moreover, the sealing property of the bottom of the main casing is ensured, and the discharging of the lithium battery paste in the main casing is favorably controlled; the stirring and filtering device has higher practical value and is suitable for popularization and use.

Owner:NANJING TAOTESI SOFTWARE TECH CO LTD

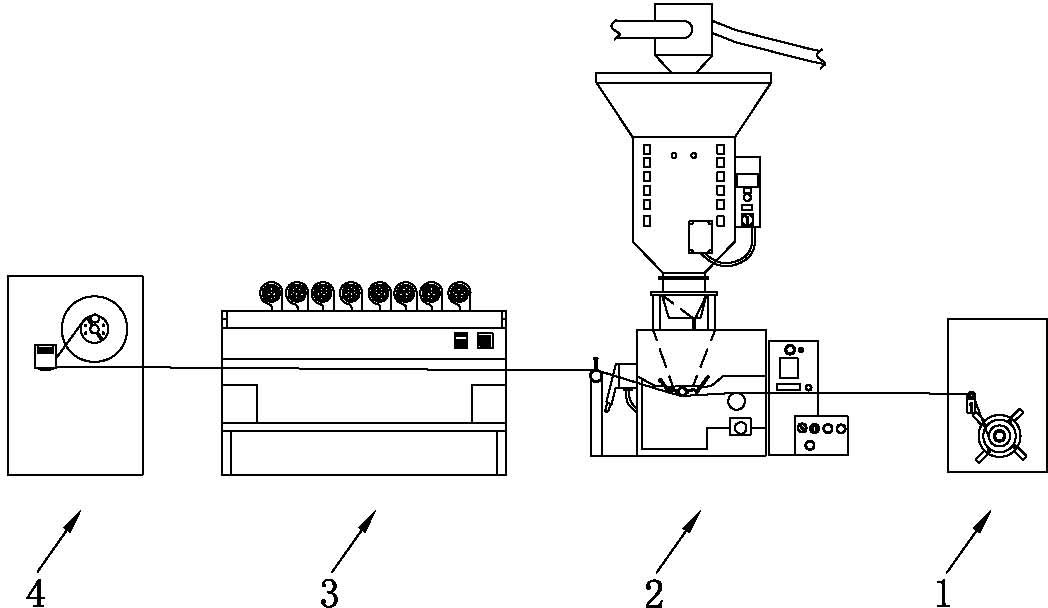

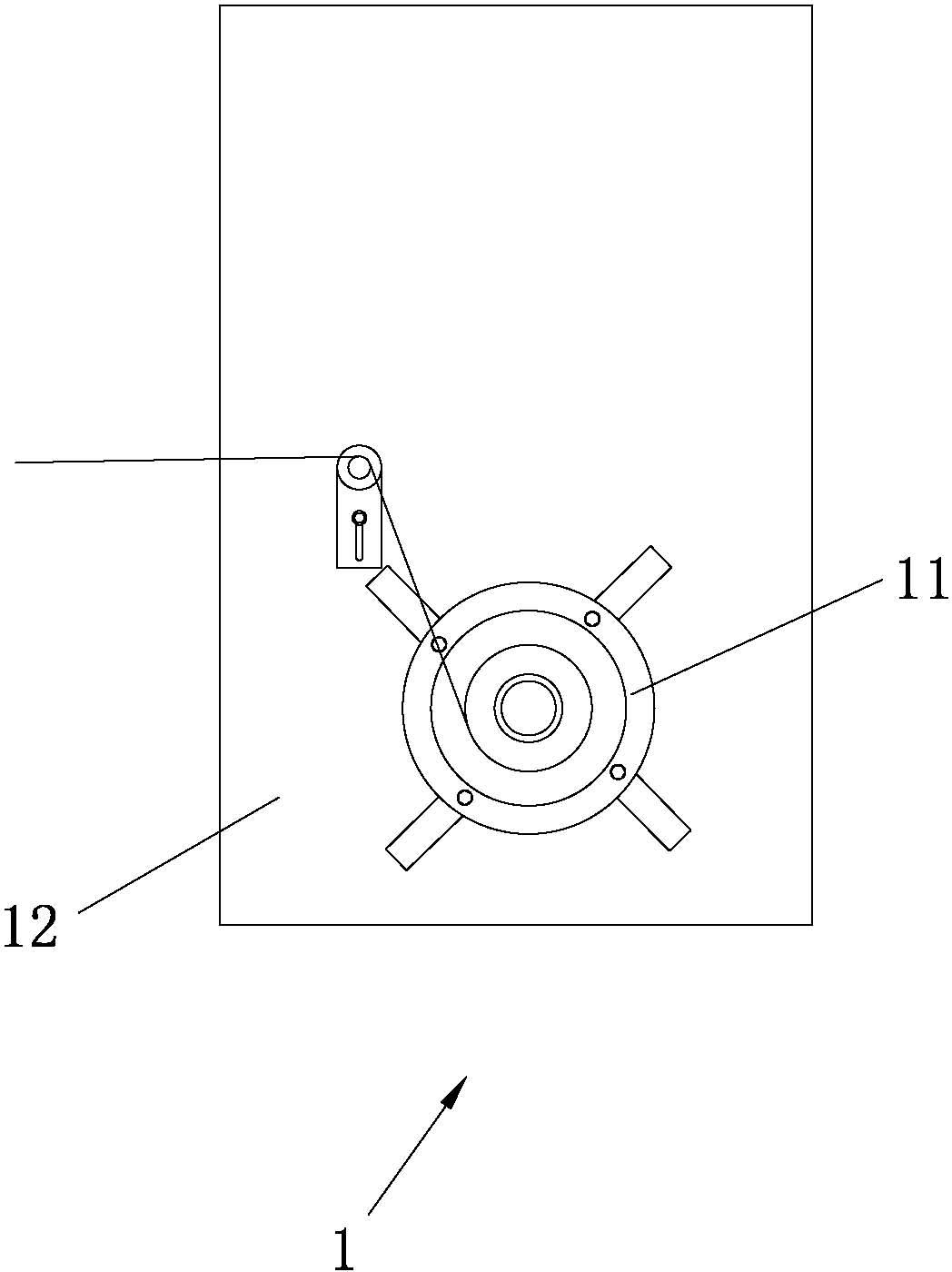

Edge banding back-coating hot melt adhesive device

ActiveCN102671829AEasy to processIncrease productivityLiquid surface applicatorsCoatingsCoatingEdge banding

The invention relates to the technical field of production equipment of edge bandings, in particular to an edge banding back-coating hot melt adhesive device, which comprises an unreeling device for giving off edge bandings, a melt adhesive coating device, a cooling device and a rolling device, wherein the back surfaces of the edge bandings are coated with hot melt adhesive through the melt adhesive coating device to made gummed edge bandings, the gummed edge bandings are cooled and solidified by the cooling device, the gummed edge bandings after being cooled and solidified are rolled by the rolling device, and the unreeling device, the melt adhesive coating device, the cooling device and the rolling device are orderly arranged. The edge banding back-coating hot melt adhesive device is an automatic device integrated with unreeling, melt adhesive coating, cooling, solidifying and rolling, is particularly suitable for thin edge bandings, the thickness of the thin edge bandings is between 0.2mm and 0.8mm, and is convenient to process the made gummed edge bandings. The coating speed is between 20m / s and 30m / s, the coating amount is from 130g / square meter to 140g / square meter, more than two edge bandings can be coated for one time, and the production efficiency is high.

Owner:东莞市华富立装饰建材有限公司

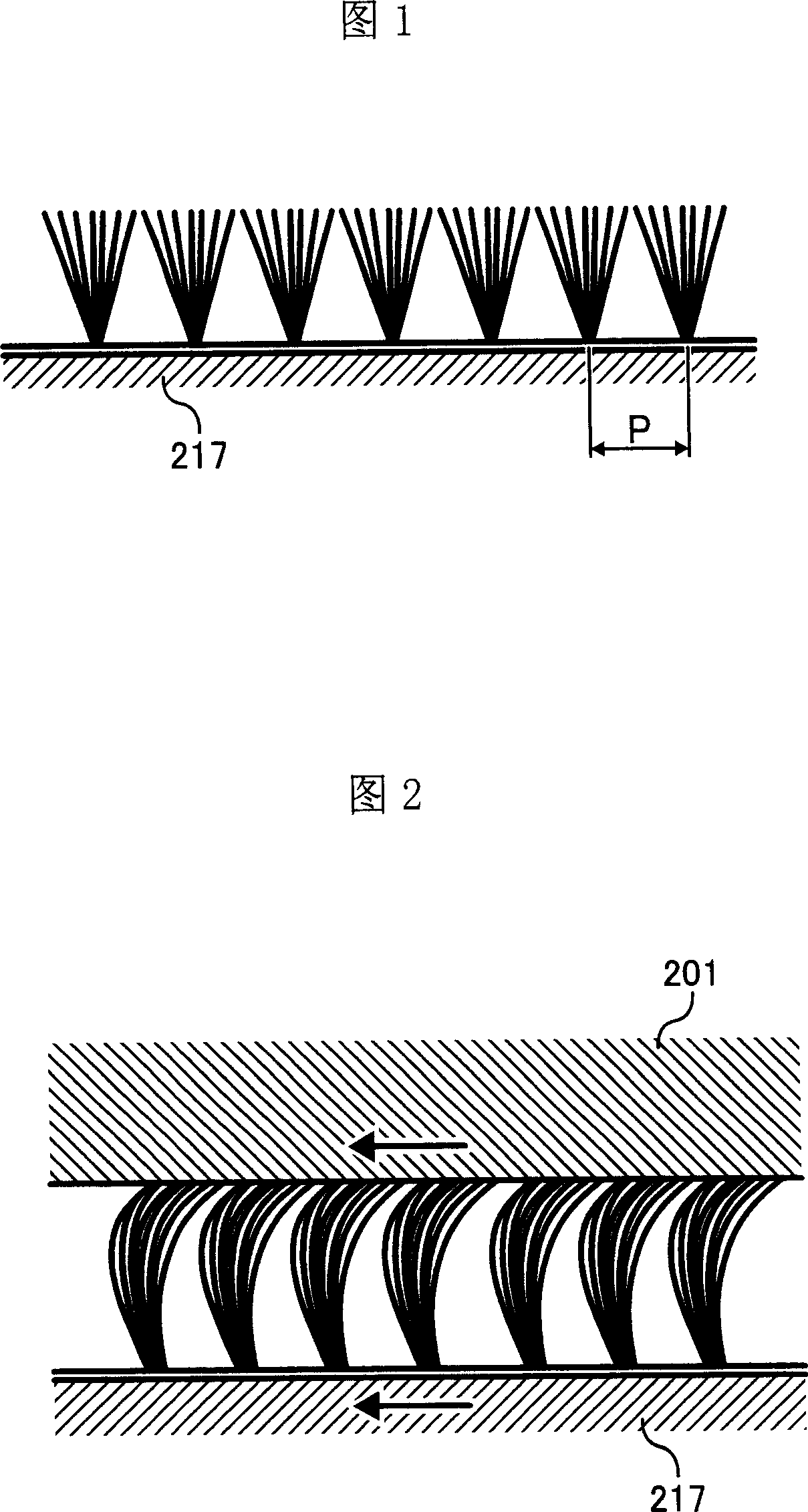

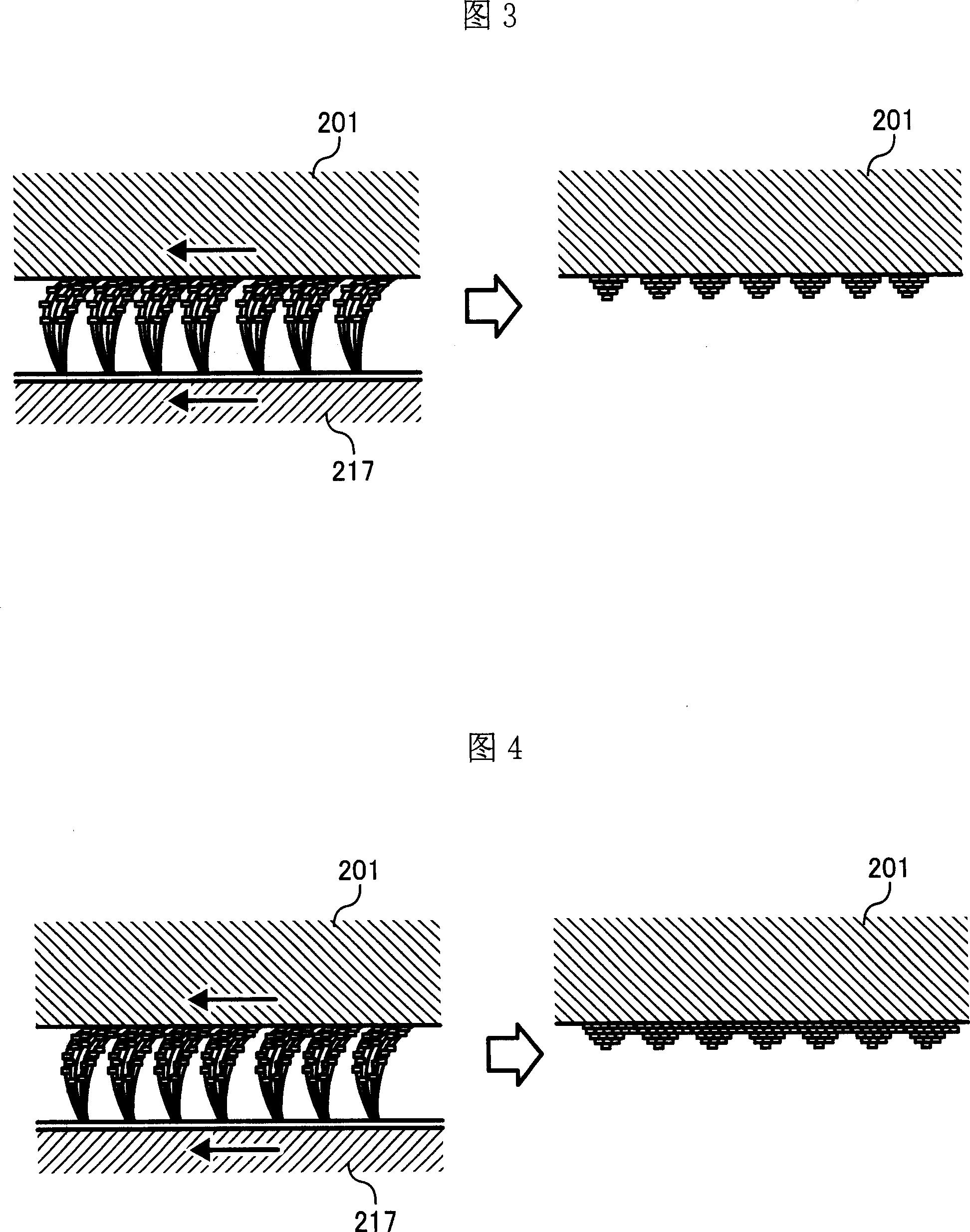

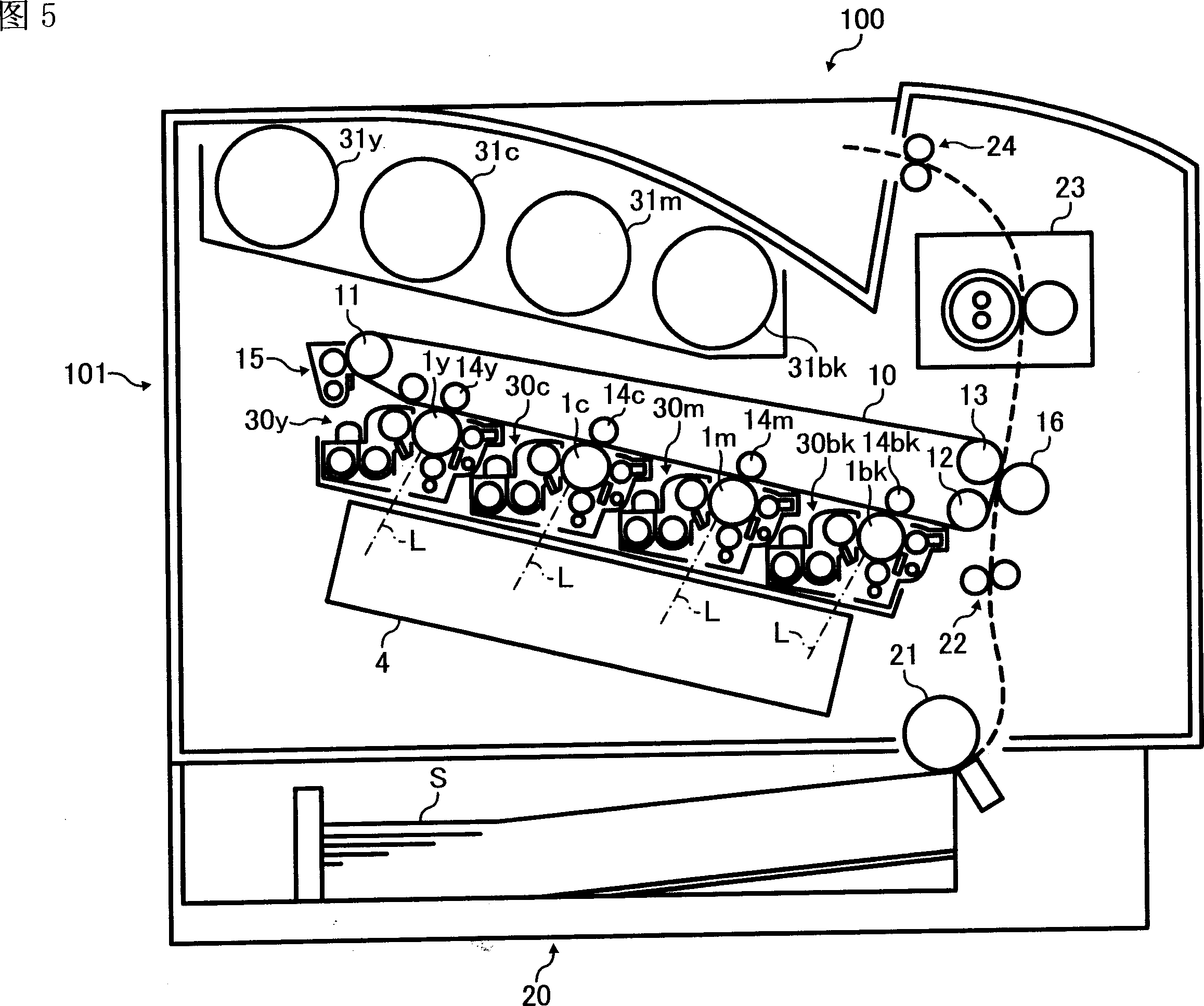

Processing cassette, image forming method and apparatus

InactiveCN1979357AQuality improvementUneven suppressionElectrographic processes using charge patternBand shapeImage formation

The invention relates to a processing box, an image forming device using thereof and an image forming method. A image carrier gyres at prtermined speed to connect with the lubricant coating brush 17a of cleaning apparatus 17, which gyring with the same direction of the image carrier at the contacted location, lubricant is coated on surface of the image carrier. Speed of the lubricant coating brush 17a is set higher than photo-conductor drum 1 as the image carrier, comparing with the situation of the image carrier and ubricant coated parts gyre with the same speed, lubricant amounts of lubricant coated parts is less. The invention prevents increasing torque, generating banded stripe images, enables coated lubricant 17b uniformly on the photo-conductor drum 1, and avoid brush injuries and conjunctiva.

Owner:RICOH KK

Antique paint and manufacturing technique thereof

The invention provides an antique paint and a manufacturing technique thereof, relating to the field of paints. The antique paint is composed of the following components in parts by weight: 5-25 parts of epoxy resin, 2-6 parts of phthalic anhydride, 10-15 parts of polyacrylamide, 8-20 parts of isopropanol, 4-10 parts of titanium white, 2-5 parts of nano silver oxide, 0.1-0.4 part of sodium soap, 5-8 parts of light calcium carbonate powder, 3-5 parts of kaolin, 0.7-2 parts of coupling agent, 0.5-6 parts of dispersing agent, 4-8 parts of defoaming agent, 3-10 parts of anti-settling agent, 3-8 parts of thickener, 1-3 parts of pigment, 5-25 parts of thinner, 5-15 parts of metal powder, 5-8 parts of alkyd resin and 55-75 parts of turpentine. The coated antique paint provided by the invention has the advantages of low cracking tendency, favorable glossiness and favorable decorative effect.

Owner:DONGGUAN LIUHUA ART

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com