Photocuring resinoid compsn. and printed circuit board using same

A resin composition, photocurable technology, applied in printed circuits, secondary treatment of printed circuits, epoxy resin coatings, etc., can solve problems such as reduced thixotropy, increased affinity, and xylene content, and achieves a defective rate. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

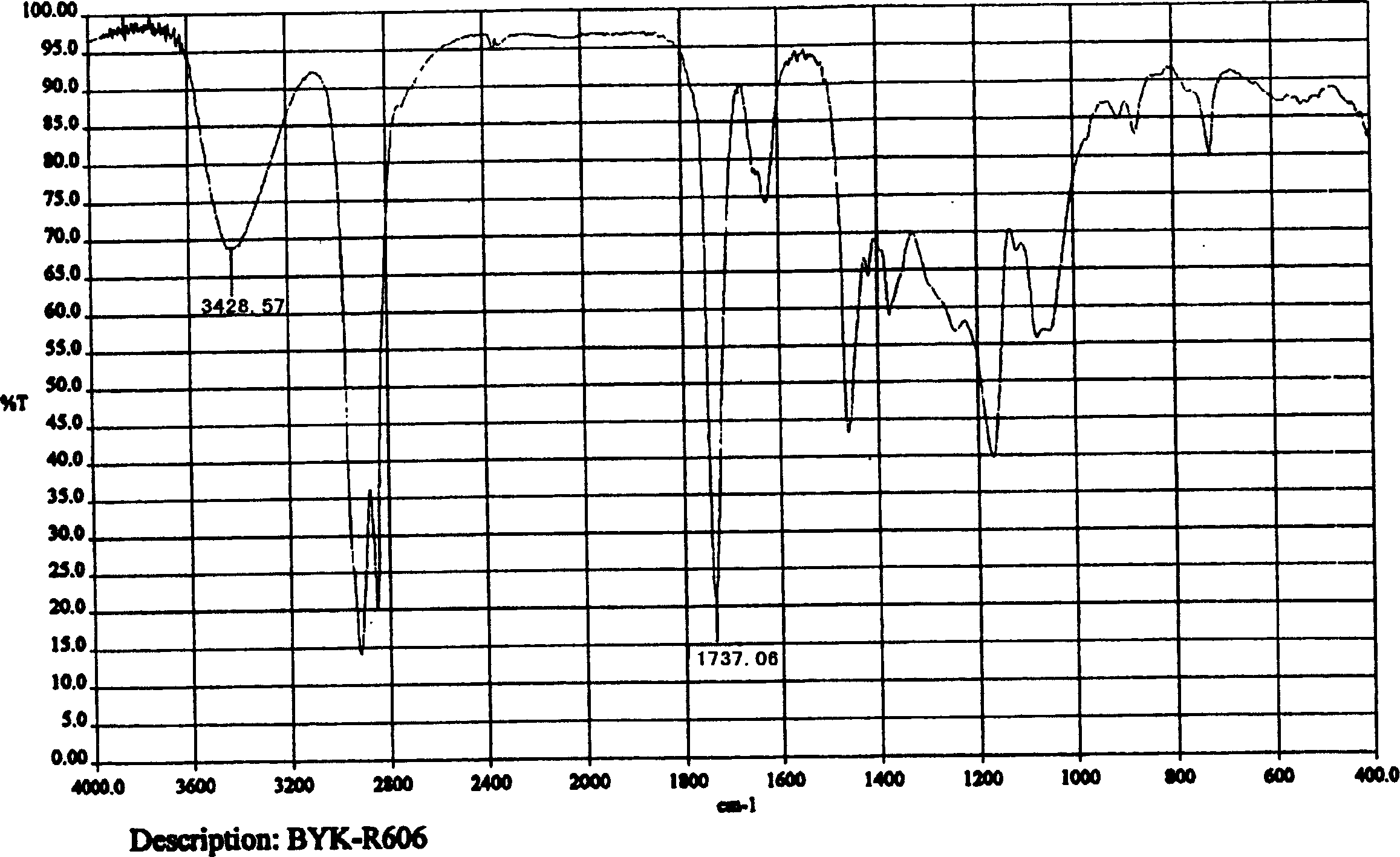

Image

Examples

Embodiment

[0058] The following examples and comparative examples are given to describe the present invention in detail, but the present invention is not limited to the following examples. The following "parts" mean "parts by mass" unless otherwise specified.

Synthetic example

[0060] 215 parts of cresol novolac type epoxy resin N-680 (manufactured by Dainippon Ink Chemical Industry Co., Ltd., epoxy equivalent=215) are packed into a four-necked flask with a stirrer and a reflux cooler, and propylene glycol monomethyl ether ethyl ether is added. 196 parts of acid ester, dissolved by heating. Then, 0.46 parts of methylhydroquinone as a polymerization inhibitor and 1.38 parts of triphenylphosphine as a reaction catalyst were added. This mixture was heated to 95-105 degreeC, and 72.0 parts (1.0 equivalent) of acrylic acid was dripped gradually, and it was made to react for about 32 hours, and the reaction product with an acid value of 0.9 mgKOH / g was obtained. The reaction product (hydroxyl group: 1 equivalent) was cooled to 80-90° C., 76.0 parts (0.5 equivalent) of tetrahydrophthalic anhydride was added, reacted for about 8 hours, and taken out after cooling. The carboxyl group-containing resin (A) prepared in this way had a non-volatile content of 65%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com