Edge banding back-coating hot melt adhesive device

An edge banding and hot melt adhesive technology, which is applied to devices and coatings for coating liquids on the surface, can solve the problems of low coating efficiency, low production efficiency, and difficulty in dispensing glue, and achieve good coating quality, The effect of high production efficiency and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

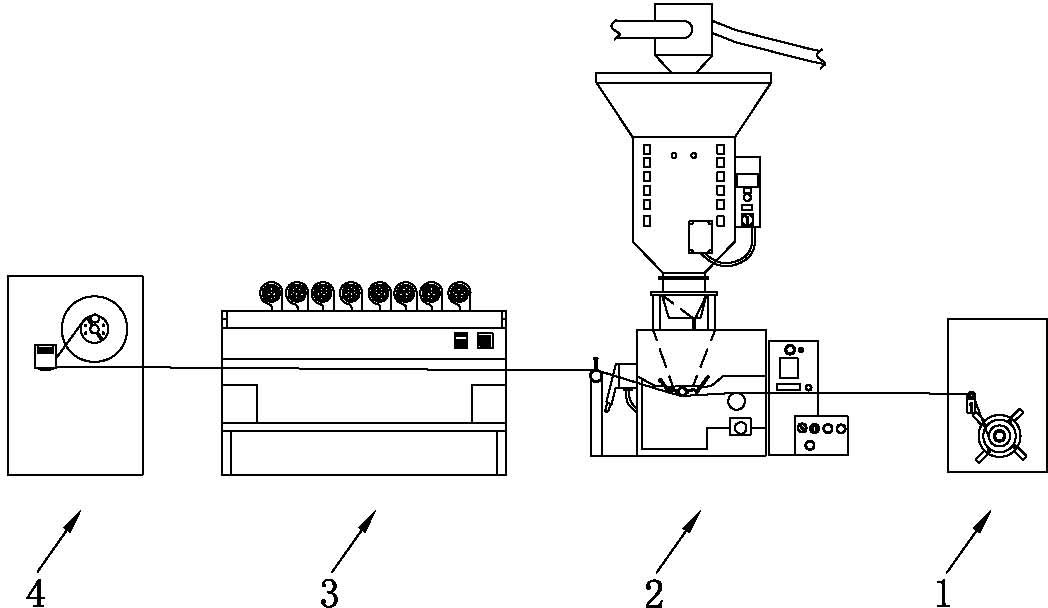

[0049] Such as Figure 1~7 As shown, the edge banding back coated hot melt adhesive device, it includes the unwinding device 1 for releasing the edge banding, coating hot melt adhesive on the back side of the edge banding to obtain the melt glue coating of the glued edge banding Device 2, a cooling device 3 for cooling and solidifying the glued edge banding strip and a winding device 4 for winding the glued edge banding strip after cooling and solidification, the unwinding device 1, the coating device, and the cooling device 3 And winding device 4 is arranged in sequence.

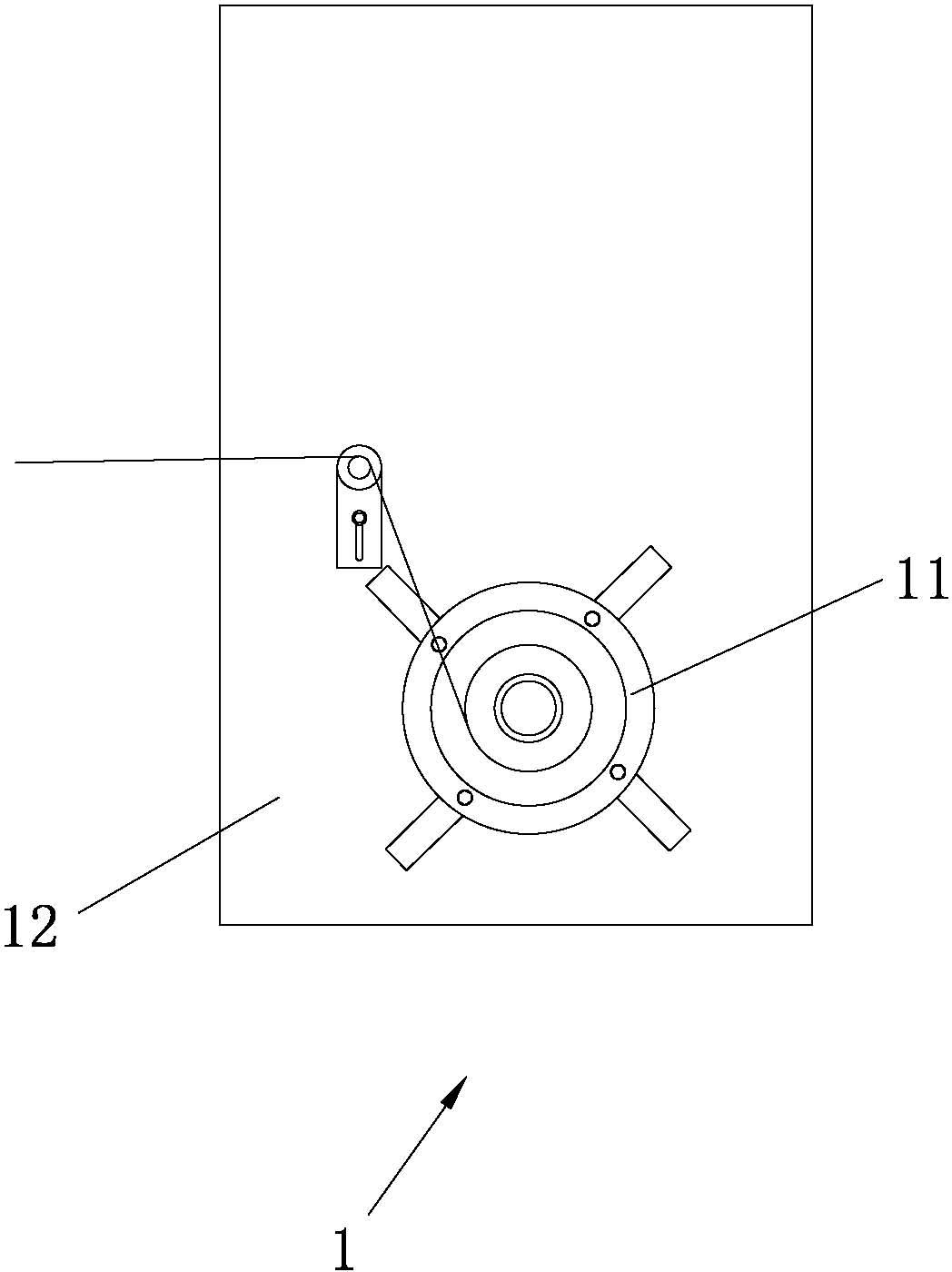

[0050] Such as figure 2 As shown, the unwinding device 1 includes an unwinding stand 12, and an unwinding reel 11 is arranged on the unwinding stand 12, and one unwinding reel 11 unwinds one roll of edge banding to be coated each time. The unwinding device 1 also includes a clutch and an automatic switch. The automatic switch is controlled by the clutch, and then the start or stop of unwinding is control...

Embodiment 2

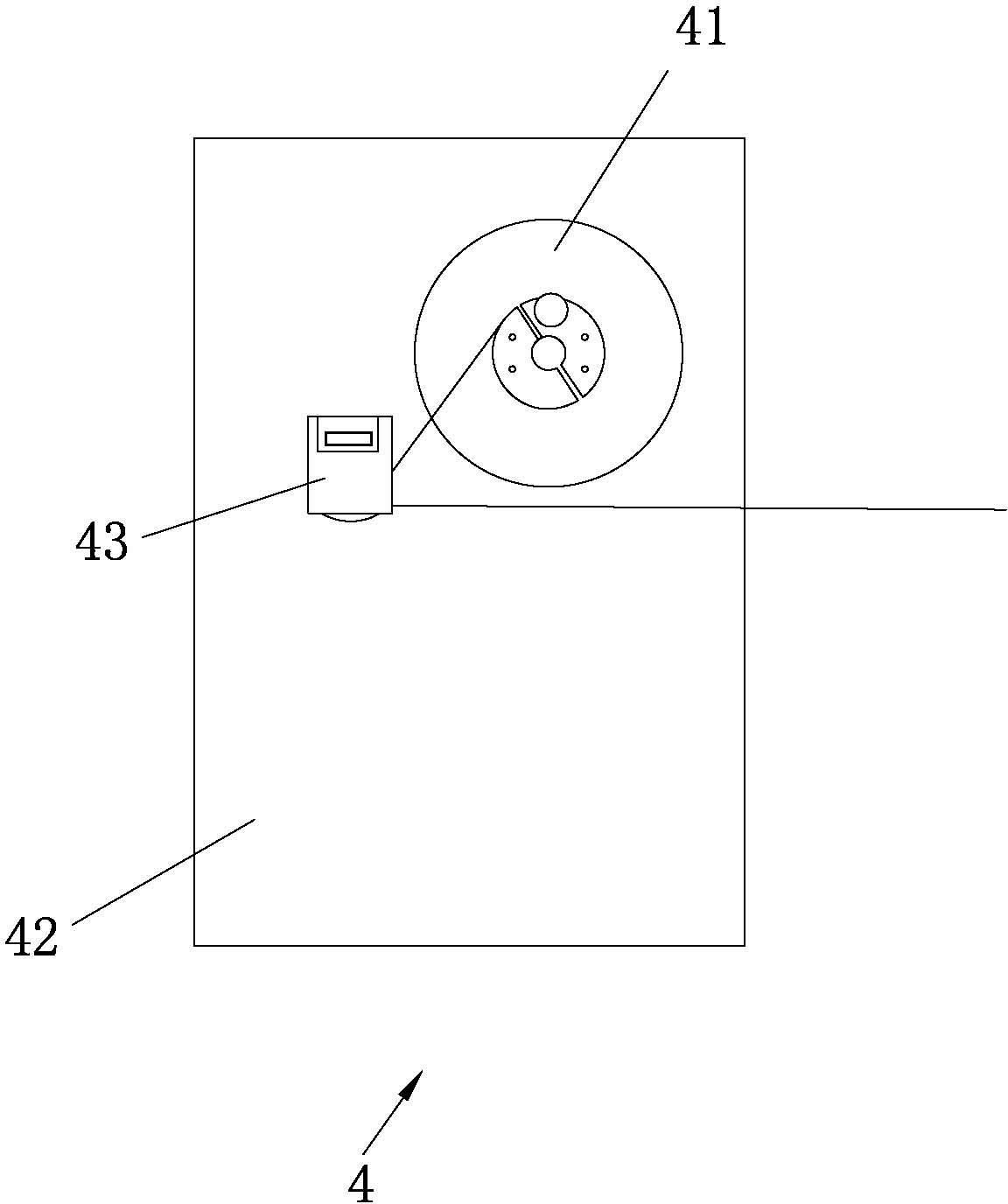

[0072] Such as Figure 8 , Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that: the unwinding device 1 described in this embodiment is provided with more than two unwinding reels 11, and the rewinding device 4 is provided with a connection with the unwinding reels 11. Equal number of winding reels 41. More than two unwinding reels 11 are arranged on the unwinding rack 12, and each unwinding reel 11 unwinds one roll of the edge banding strip to be coated at a time. More than two reels 41 are arranged on the reel 42, and each reel 41 rewinds a roll of glued edge banding at a time, and the number of reels 41 is equal to the number of unwinding reels 11 .

[0073] The width of the edge banding strip is smaller than the length of the glue-coating roller 231, and the glue-coating roller 231 is coated on the whole edge banding strip. Coating roller 231 can coat more than two edge bands at the same time, and more than two edge bands are arranged sid...

Embodiment 3

[0077] Such as Figure 10 , Figure 11 As shown, the difference between this embodiment and Embodiment 2 is that this embodiment also includes a tension adjustment device 5, and the tension adjustment device 5 is arranged between the unwinding device 1 and the melt glue coating device 2 between. The tension adjustment device 5 is provided with a guide wheel 51. The edge banding strip released from the unwinding reel 11 is guided by the guide wheel 51, flattened and tightened, and then sent to the coating device for coating hot melt adhesive to avoid loose edge banding. The phenomenon of missing coating caused by stretching, so that the hot melt adhesive can be coated evenly and the coating quality is good.

[0078] The quantity of the guide wheels 51 is set according to the quantity of the unwinding reel 11, and one guide wheel 51 is arranged for each roll of edge banding.

[0079]The tension adjusting device 5 is also provided with an exhaust fan, which washes and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com