Patents

Literature

63results about How to "Smooth coating process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

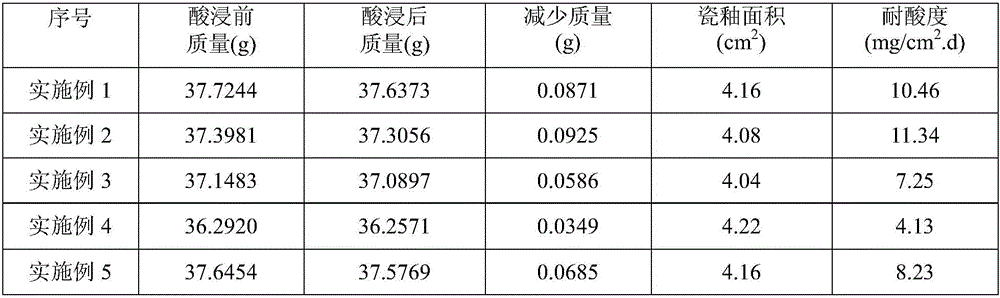

Enamel glaze material, enamel slurry, and preparation method and application thereof

The invention specifically relates to an enamel glaze material, an enamel slurry, and a preparation method and an application thereof. The invention relates to the technical field of enamel materials. The invention aims at solving a technical problem of providing an enamel glaze material. The enamel glaze material is prepared by uniformly mixing the following raw materials, by weight: 40-45 parts of quartz sand, 9.5-10 parts of feldspar powder, 24-26 parts of borax, 2.5-3 parts of cryolite, 5.5-7.5 parts of sodium nitrate, 3.5-4 parts of lithium carbonate, 3.5-4.5 parts of fluorite powder, 2-4 parts of calcium carbonate, 3-4 parts of cobalt nitrate, 0.8-1.2 parts of nickel nitrate, 2-2.2 parts of manganese oxide, and 3.4-3.8 parts of zirconium dioxide. The enamel glaze material can be combined well with glass powder to produce the enamel slurry. The enamel slurry can be coated on the surface of a metal substrate to form an enamel coating. The coating has the advantages of smooth glaze surface, good gloss, no bubble, and no scaling. The coating can be firmly combined with a carbon steel substrate, and has good acid resistance.

Owner:PANZHIHUA UNIV

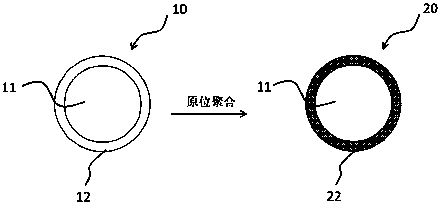

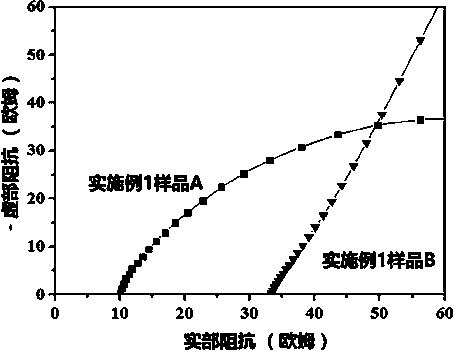

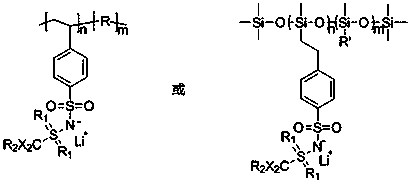

Positive electrode material with low internal resistance for solid state lithium battery and preparation method of positive electrode material

InactiveCN108232138ALower internal resistancePrevent interdiffusionCell electrodesSecondary cellsInternal resistanceConductive materials

The invention provides a positive electrode material with low internal resistance and particularly relates to a positive electrode material with low internal resistance for a solid state lithium battery and a preparation method of the positive electrode material. The positive electrode material with low internal resistance is prepared from a positive electrode active material core and a surface composite material layer covering the positive electrode active material core, wherein the surface composite material layer is mainly prepared from a nano long-range conducting material and a single ionconductor polymer material. The positive electrode material with low internal resistance, provided by the invention, has higher electronic conductivity and lithium ion conductivity and can effectively reduce the internal resistance of the solid state lithium battery; because the positive electrode active material core and the surface composite material layer have strong interaction, the phenomenaof granule cracking and grinding caused by volume deformation of the positive electrode active material core in repeated charging and discharging process can be effectively inhibited so as to ensurethe structural integrity of the positive electrode active material core and good interface stability; and furthermore, the technical scheme provided by the invention is simple and easy, low in production cost and suitable for performing large-scale production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Preparation method for SCR catalyst for purifying oxynitride in motor vehicle exhaust

InactiveCN105833899ASmooth coating processImprove stabilityGas treatmentInternal combustion piston enginesCrystallizationSSZ-13

The invention discloses a preparation method for an SCR catalyst for purifying oxynitride in motor vehicle exhaust .The preparation method includes the steps of preparation of an SSZ-13 molecular sieve, preparation of a Cu-SSZ-13 catalyst and preparation of an integrated SCR catalyst .The preparation method is simple, production cost is lowered, SSZ-13 crystallization time is short, crystallization is relatively pure, HN3-SCR catalytic activity is high, and the purification rate of oxynitride in motor vehicle exhaust is high.

Owner:ZHEJIANG FORSOL ENERGY

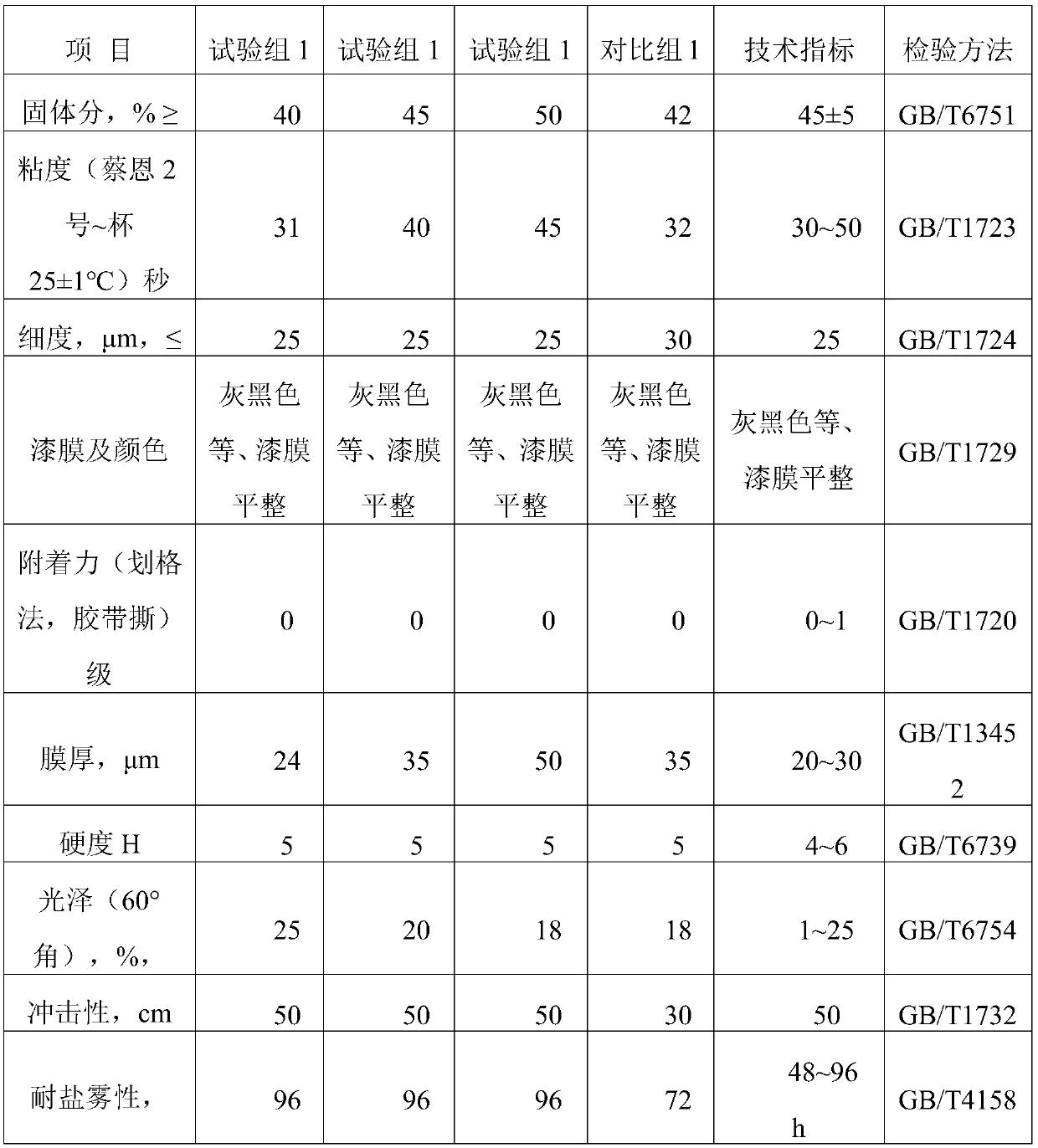

Processing technology for lubricating wear-resistant coating of bearing bush of engine

ActiveCN109248843ASolve environmental problemsImprove operational reliabilityPretreated surfacesEpoxy resin coatingsThermal sprayingWear resistant

The invention discloses a processing technology for a lubricating wear-resistant coating of a bearing bush of an engine. The processing technology comprises the steps of (1) pretreatment, wherein thesurface of the bearing bush is cleaned, after sand blasting treatment, the bearing bush is placed in a passivation pond for passivation treatment, and after passivation, the bearing bush is cleaned and dried; (2) pre-heating treatment, wherein after pretreatment, the bearing bush is placed in a drying oven and hated to 40-60 DEG C, and the temperature is preserved for 10-30 min; (3) spraying treatment, wherein the bearing bush is taken from the drying oven, and thermal spraying is conducted on the surface of the bearing bush by adopting the wear-resistant lubricating coating; (4) solidifying treatment, wherein the bearing bush is placed in the drying oven and heated to 120-160 DEG C for solidifying, and the solidifying time is 20-30 min; (5) packaging checking. According to the processingtechnology, a spraying mode is adopted for replacing a bearing bush electroplating mode, the environmentally friendly problem is solved, and the production cost is reduced; the processed lubricating wear-resistant coating of the bearing bush of the engine greatly improves the running reliability of the bearing bush of the engine, and the service life is long.

Owner:在邦润滑材料(上海)有限公司

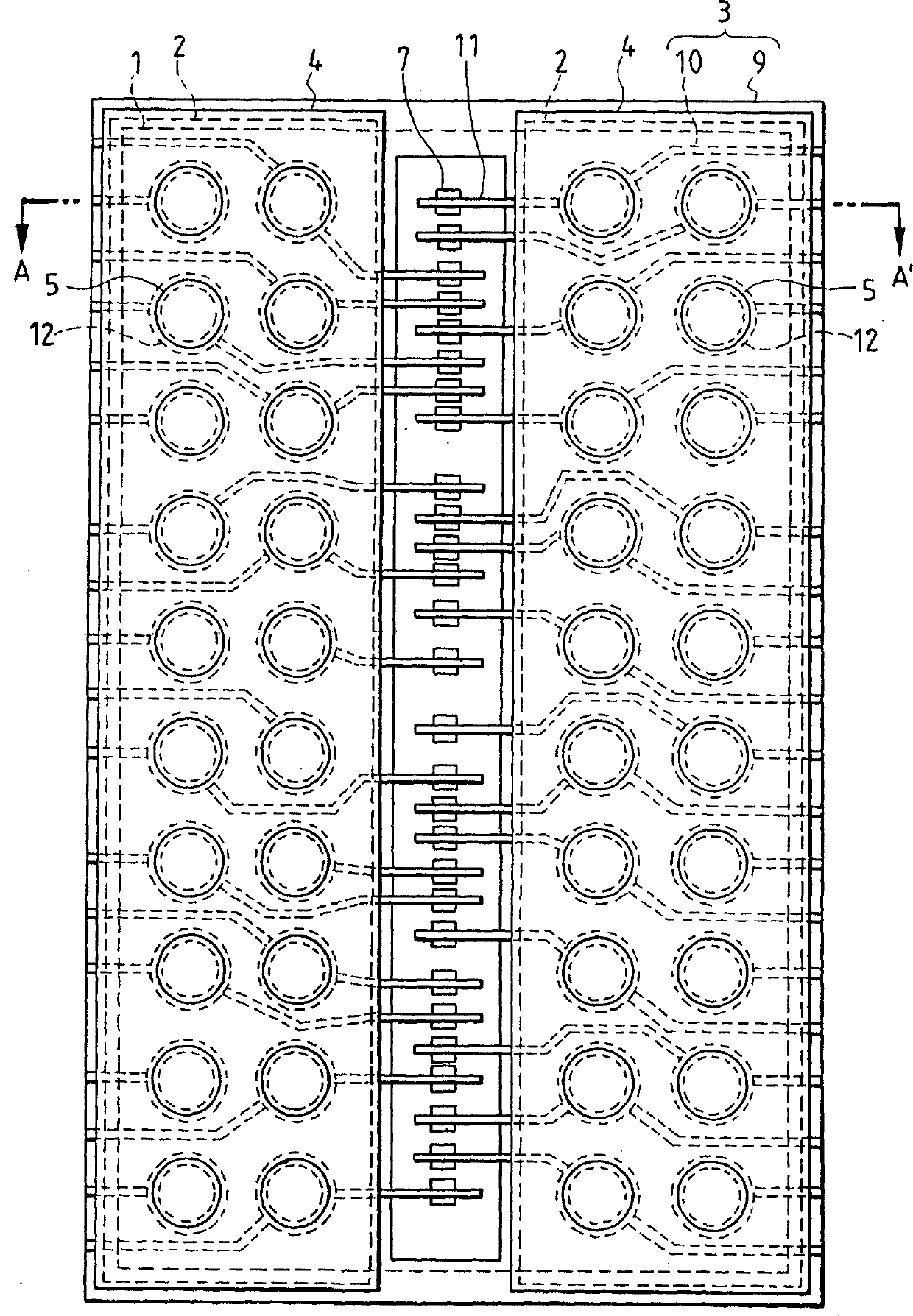

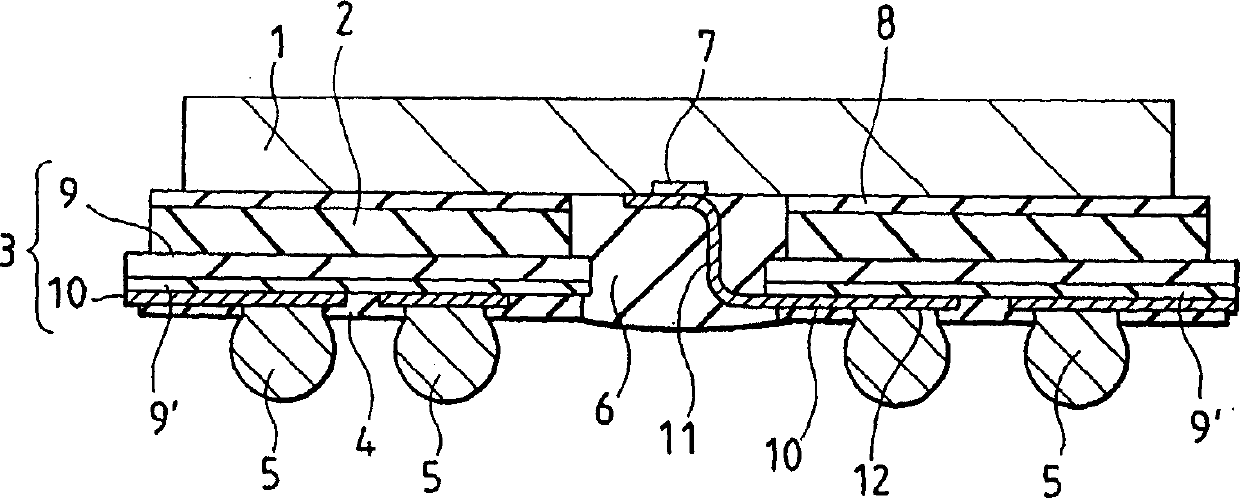

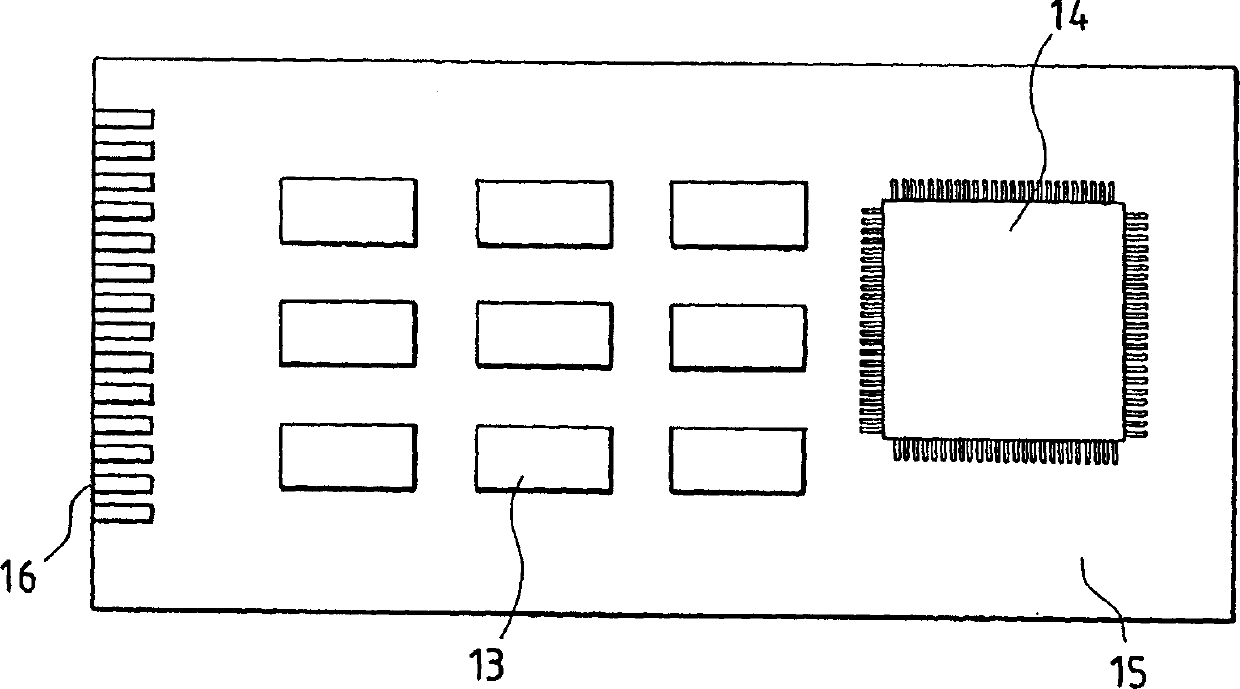

Semiconductor device

InactiveCN1728372AReduce flatnessReduce crackingSemiconductor/solid-state device detailsSolid-state devicesResistElastomer

A ball grid array type semiconductor package includes a semiconductor chip formed with bonding pads, an elastomer bonded to the semiconductor chip, a flexible wiring substrate bonded to the elastomer and formed with wirings connected at one end of the bonding pads of the semiconductor chip, a solder resist formed on the main surface of the flexible wiring substrate and solder bump electrodes connected to the other ends of the wirings. The elastomer is bonded to the flexible wiring substrate on the side of the tape, the solder resist is formed on the side of the wirings, and the solder bump electrodes are connected with the wirings by way of through holes formed in the solder resist.

Owner:HITACHI LTD +1

Solvent-free polyurethane dispersoid with controllable particle size and waterborne polyurethane coating solution

ActiveCN111019077ANo pollution in the processNo stimulationGlovesCoatingsPolyurethane dispersionPolymer science

The invention discloses a solvent-free polyurethane dispersoid with particle size controllable and a waterborne polyurethane coating liquid, and particularly relates to the technical field of dispersoids and coating liquids; the average particle size of the solvent-free polyurethane dispersoid is 400-1500 [mu]m, and the solid content of the solvent-free polyurethane dispersoid is 10%-45%; the solvent-free polyurethane dispersoid can be made into the waterborne polyurethane coating liquid with the solid content of 9%-25%, and the waterborne polyurethane coating liquid is composed of the raw materials in parts by weight: 100 parts of the solvent-free polyurethane dispersoid, 0.1-3 parts of a thickening agent, 0.1-4 parts of a wetting agent, 0.1-5 parts of a defoaming agent and the balance being water. The invention aims to control the particle size of the waterborne polyurethane dispersoid particles, so that the waterborne polyurethane dispersoid is only coated on the outer surface of gloves and does not permeate into a glove fabric, and the gloves have good flexibility. The waterborne polyurethane coating liquid provided by the invention can ensure smooth film formation, is environment-friendly, and is non-toxic even after long-term use.

Owner:HONGBAOLI GRP CO LTD

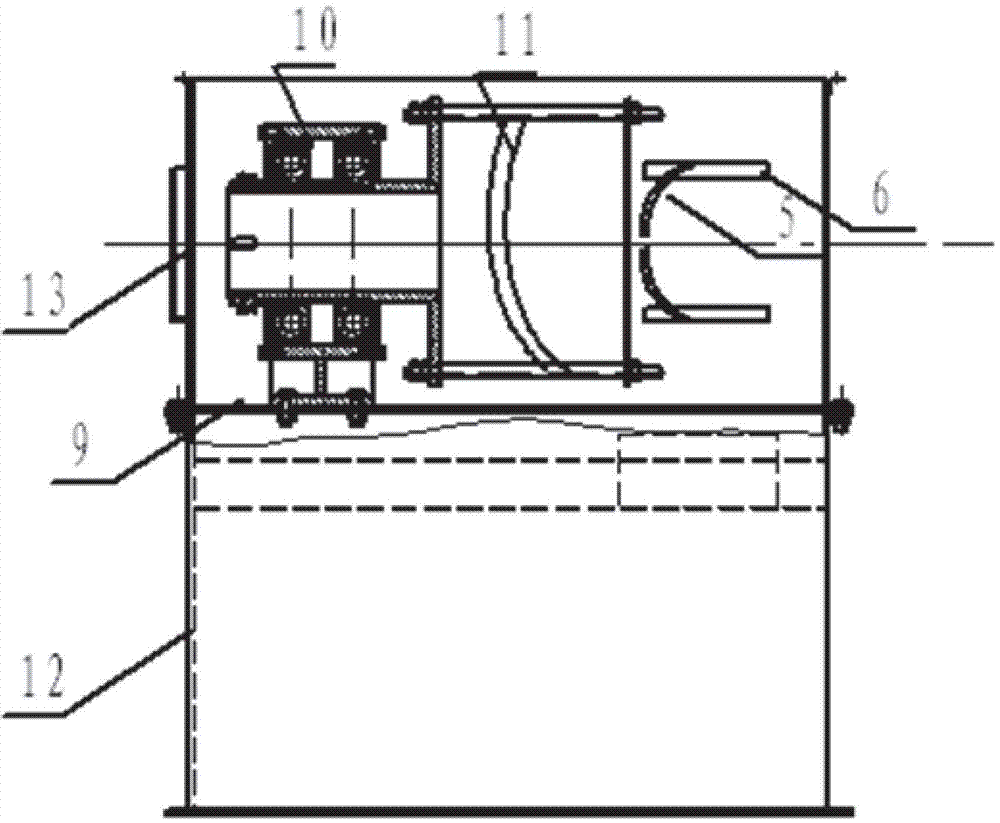

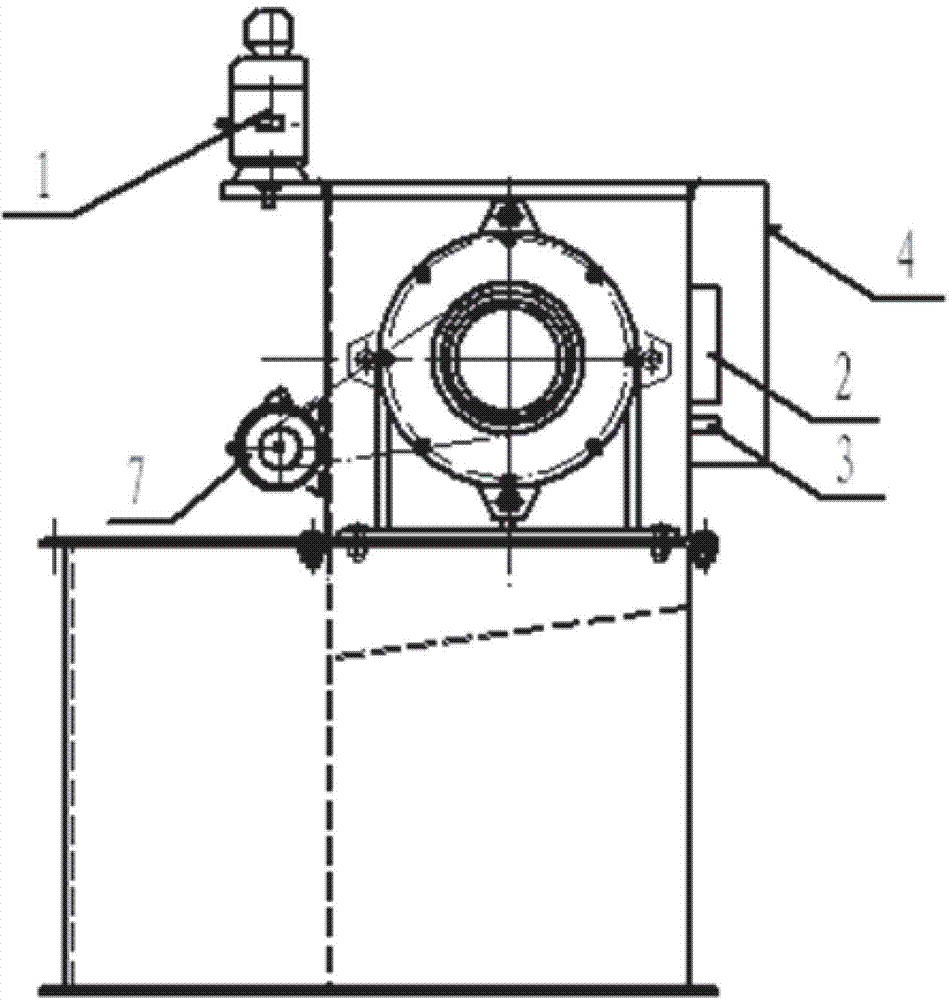

Adjustable scrapable high-voltage cable pitch coating device

ActiveCN102820107ASolve the problem of uneven sprayingSolve quality problemsCable/conductor manufactureFrequency changerLow speed

The invention discloses an adjustable scrapable high-voltage cable pitch coating device which comprises a sprayer (5) for painting pitch, a scraping belt (11) for performing scraped finishing on the surface of the cable painted with pitch, a variable frequency motor (1), a frequency converter (2), a programmable logic controller (3) and a potentiometer (4), wherein the potentiometer (4) presets analog quantity for flow of the pitch, signals of the potentiometer (4) are transmitted to the PLC (3) and then transmitted to the frequency converter (2) through digital operation of the PLC (3), the frequency converter (2) is provided with low-speed vectors for controlling actions of the variable frequency motor (1), and flow of a pitch pump is controlled by rotating speed of the variable frequency motor (1), so that the sprayer (5) is controlled to spray pitch with proper flow. The adjustable scrapable high-voltage cable pitch coating device effectively controls the flow of the pitch by adopting an electric automatic closed loop, solves the problem of even coating of the pitch and achieves stable coating during production of high-voltage cables.

Owner:HENGTONG SUBMARINE POWER CABLE CO LTD +1

Coating composition for ceramic matrix surface metallization

The invention provides a coating composition for ceramic matrix surface metallization. The coating composition for ceramic matrix surface metallization comprises a component A and a component B, wherein the component A is selected from two or more than two of Cu, Al, Fe, Ni, Co, Zn, Ag, Au, Cd, Ti, Zr or Mg; the component B is selected from one or a plurality of ceramic, W, Mo or Cr. After the coating composition is used for carrying out metallization on a ceramic matrix, a formed metallization layer is excellent in thermal shock resistance, the surface is still good after 500 times, damage orfalling does not appear, whereas a current metallization layer falls off after dozens of times or two hundred times at most, and the binding force of a material and the ceramic matrix is strong.

Owner:JIANGSU TIANZIGE NEW MATERIAL TECH CO LTD

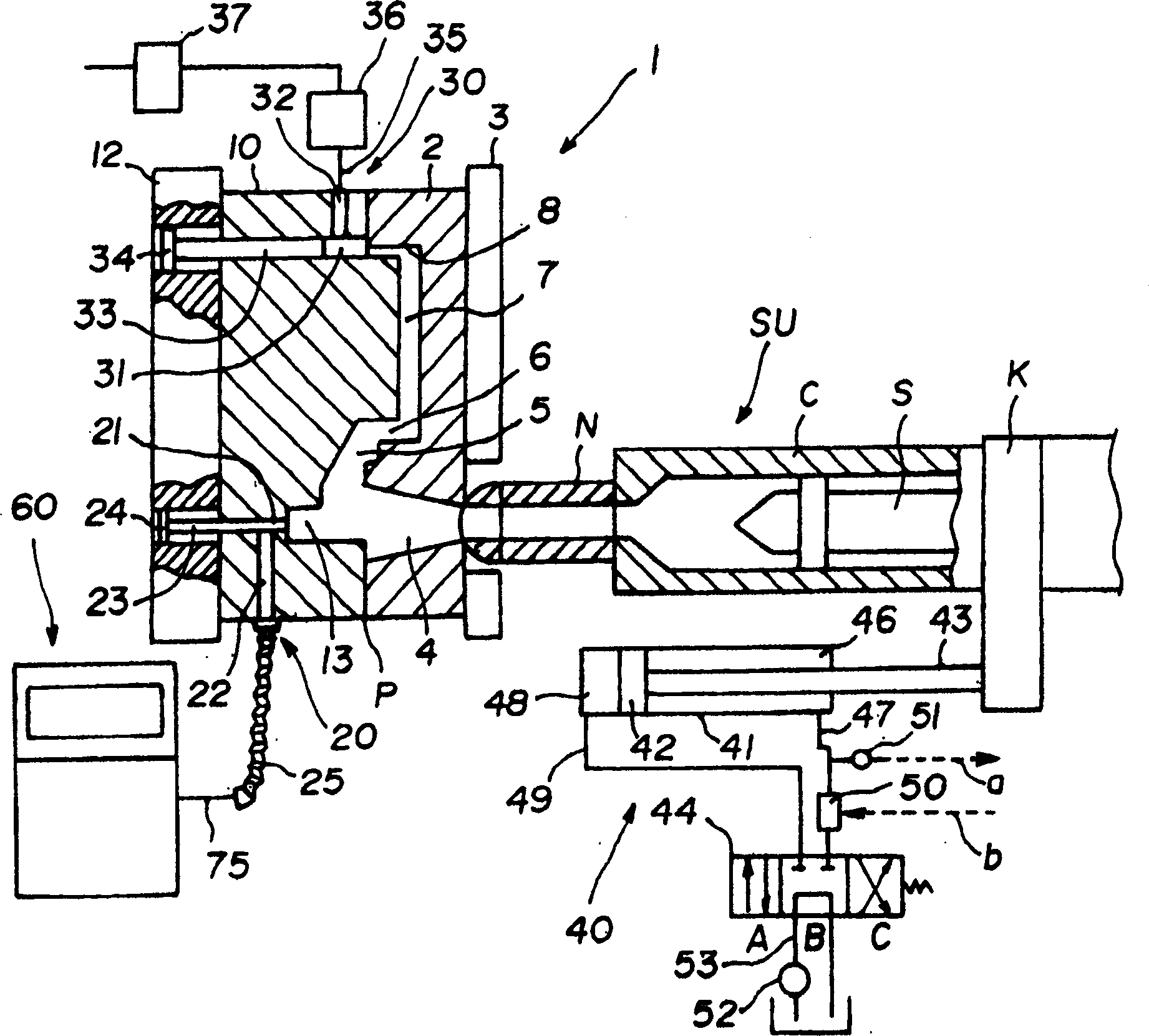

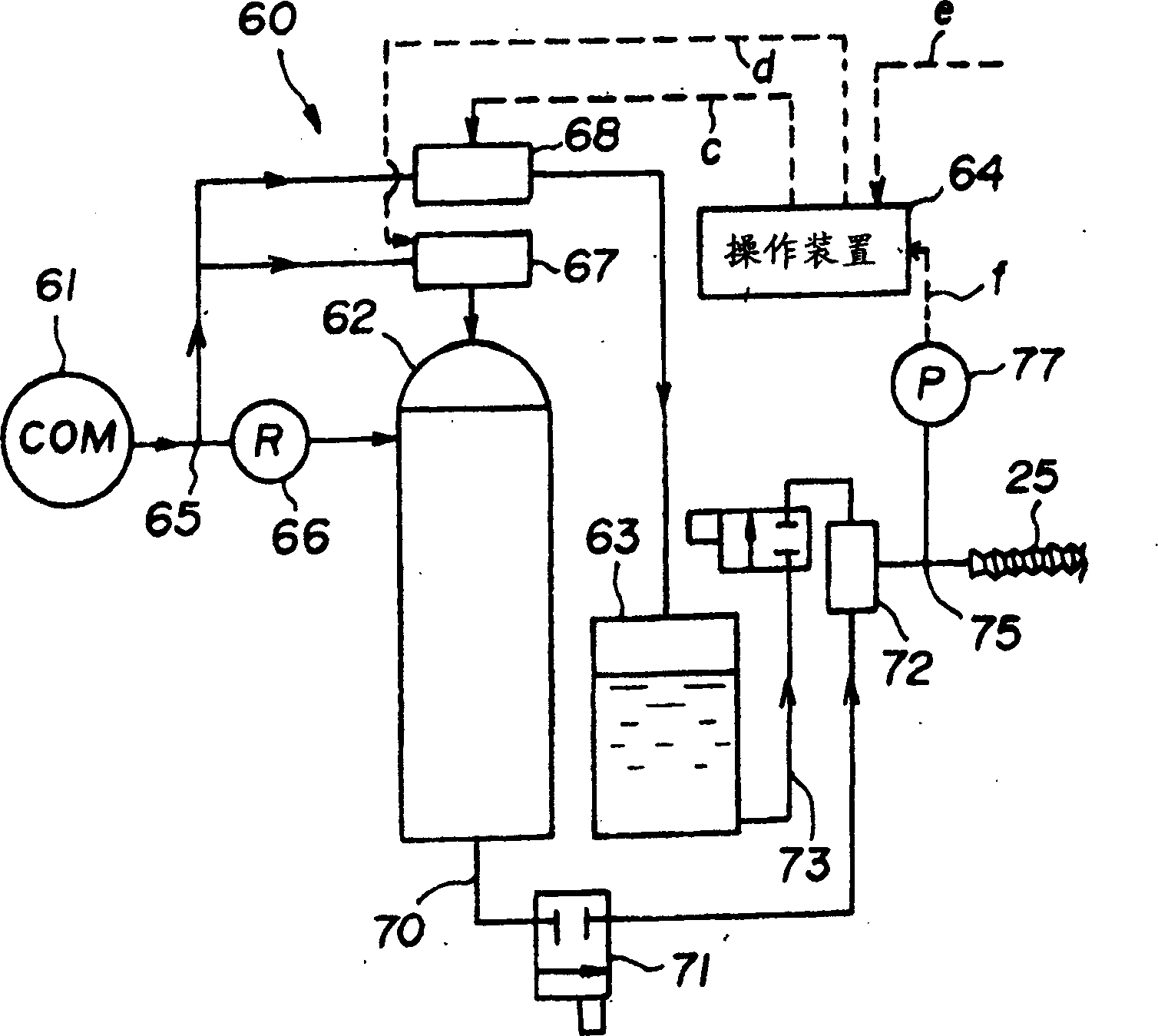

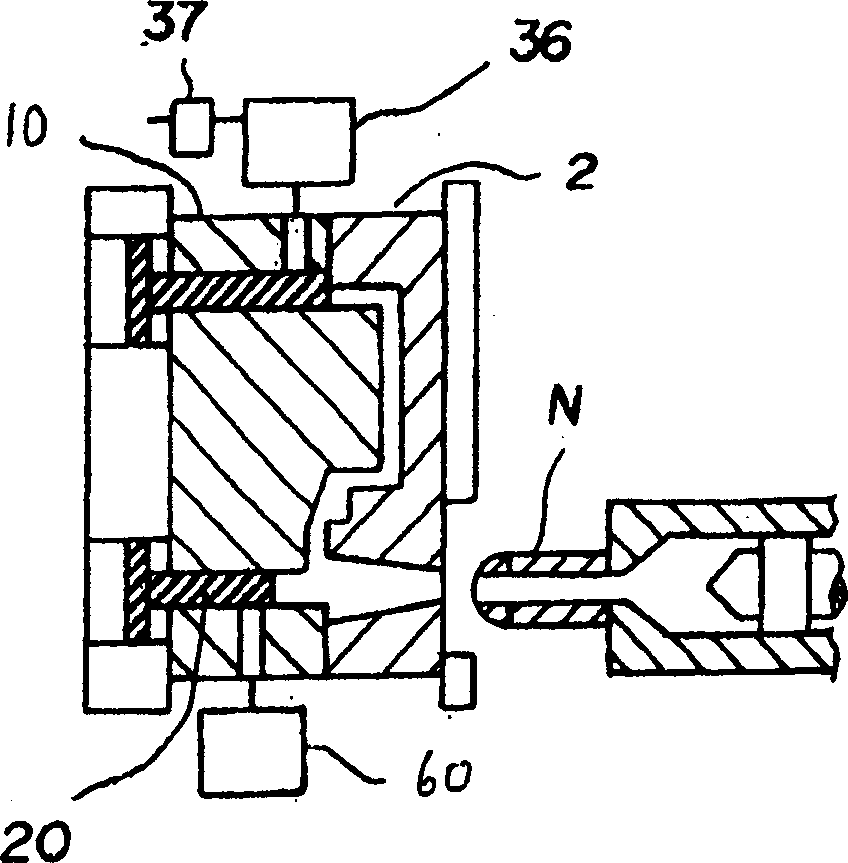

Method of coating lubricant in metallic injection machine

The movable mold is fastened to the fixed mold, and the relationship between the contact force and the tightness of the injection nozzle and the injection hole of the fixed mold is investigated. Through the contact force, the injection nozzle and the injection hole of the fixed mold are brought into pressure contact to achieve a predetermined tightness , and apply the release agent by predetermined pressure. In this case, one end of the cavity is open or the air is vented from this end, as required. The release agent is applied as a mist by mixing with compressed air. In addition, the release agent is applied by keeping constant the pressure difference between the pressure applied to the release agent and the internal pressure of the cavity and the pressure difference between the pressure of the compressed gas and the internal pressure of the cavity.

Owner:THE JAPAN STEEL WORKS LTD

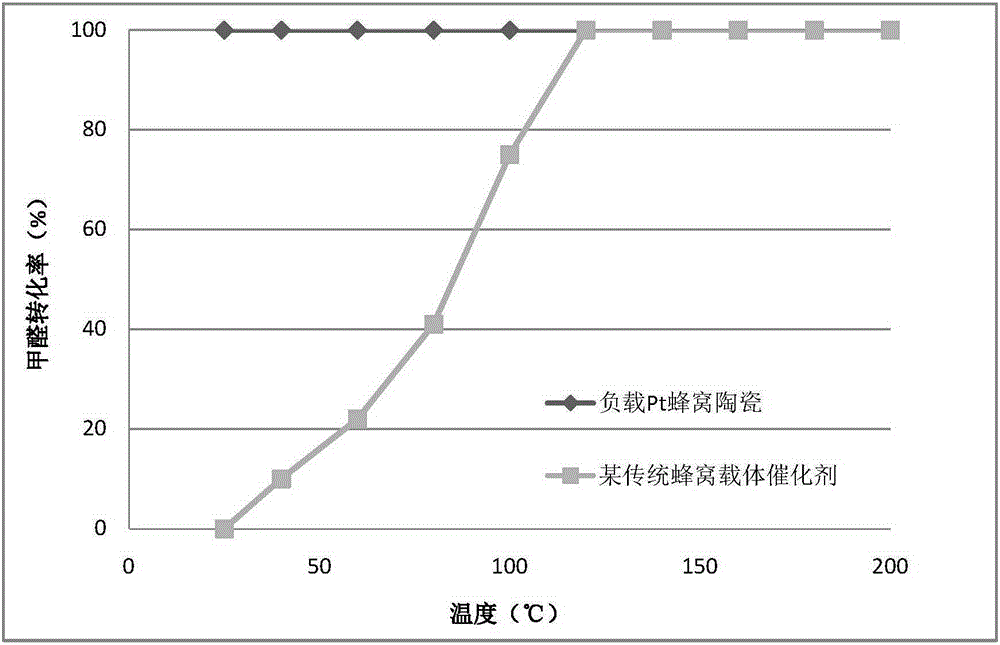

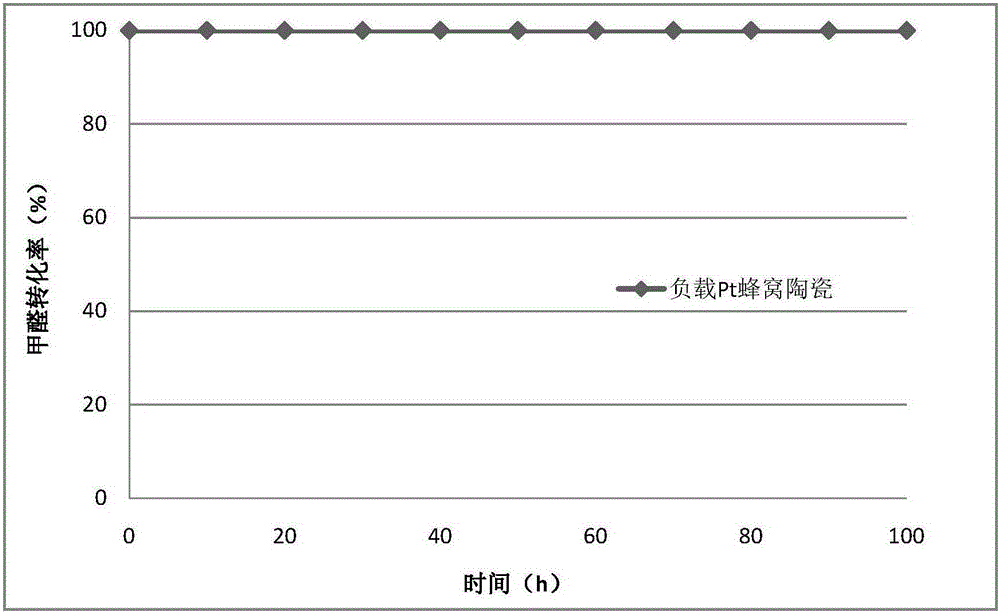

Honeycomb ceramic catalyst, preparation method therefor and application thereof

InactiveCN105233847ALow costReduce contentPhysical/chemical process catalystsDispersed particle separationCalcium biphosphateRoom temperature

The invention provides a honeycomb ceramic catalyst, a preparation method therefor and an application thereof. The honeycomb ceramic catalyst comprises: a honeycomb ceramic; a coating layer which is formed on the surface of the honeycomb ceramic, and comprises a binder and active ingredients; and noble metal which is loaded on the surface of the coating layer, wherein an active ingredient of the noble metal is calcium phosphate oxide. According to the embodiment of the invention, the honey ceramic catalyst has relatively high activity under a room temperature condition, and can remove formaldehyde in a long-acting manner without losing efficacy; and meanwhile, the coating layer and the honey ceramic are firmly combined, so that the problem that a conventional catalyst active ingredient is easy to drop can be effectively overcome; and the honeycomb ceramic catalyst is low in cost and beneficial for realizing industrial production.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

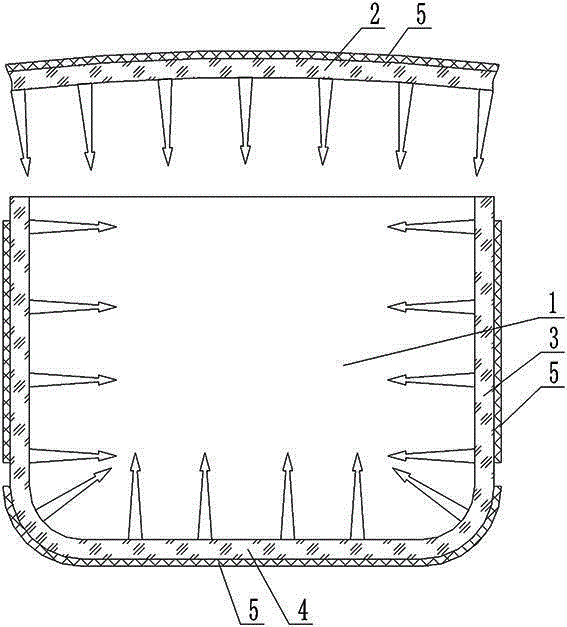

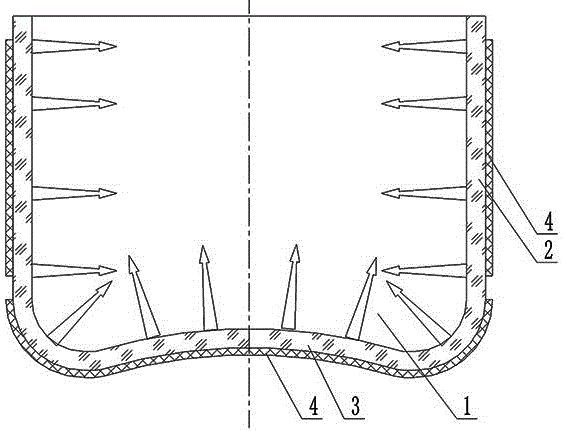

Heating device with bottom part, lateral part and top part being heated simultaneously and heating method

InactiveCN105007640AFast heatingHigh infrared emissivityOhmic-resistance heatingPower densityCalcium

The invention discloses a heating device with the bottom part, the lateral part and the top part being heated simultaneously, which comprises a lower base body (1) and an upper base body (2), and is characterized in that the upper surface of the upper base body (2), the outer surface of a side wall (3) of the lower base body (1) and the lower surface of a bottom plate (4) of the lower base body (1) are provided with an electrothermal film (5), and the electrothermal film is formed by such components as stannic chloride, titanium trichloride, antimony trichloride, calcium chloride, chromium oxide, manganese dioxide, nickel oxide, isopropyl alcohol, ethanol and water; the components are mixed and prepared into an electrothermal film treatment solution, then the electrothermal film treatment solution is sprayed to the surface of the heated base bodies, annealing is carried out, and then a finished product of the electrothermal film is acquired after electrode processing. The invention further discloses a heating method of the device. The heating device and the heating method have the beneficial effects that the electrothermal film is not easy to fall, the upper temperature limit of the electrothermal film is improved, and the temperature of the heated base bodies is enabled to rise quickly; the highest surface operating temperature can reach 800 DEG C, the power density can reach 30W / cm2, and the service life can reach up to 20000 hours.

Owner:CHENGDU LONGXIN TECH CO LTD

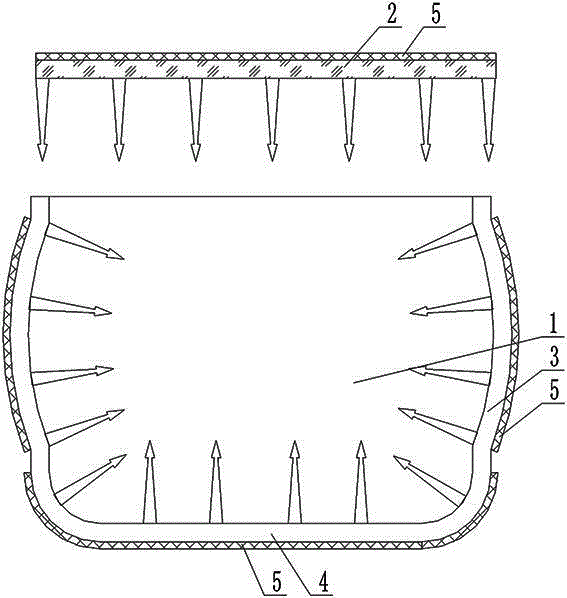

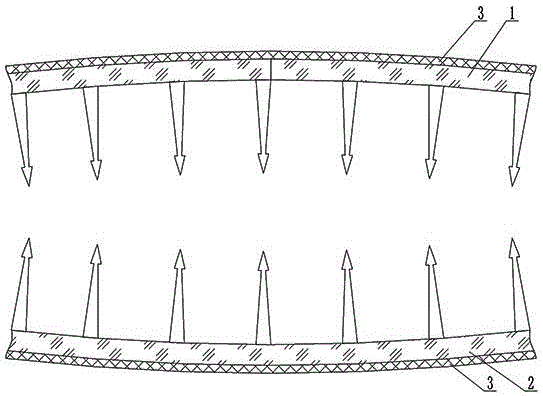

Heating apparatus for heating bottom and top simultaneously and heating method thereof

InactiveCN105050212ARaise the upper surface temperature limitHeating up fastHeating element materialsWorking temperatureEngineering

The invention discloses a heating apparatus for heating a bottom and a top simultaneously. The heating apparatus comprises an upper base body (1) and a lower base body (2), wherein the upper base body and the lower base body are arranged oppositely in an up-down mode; and electrothermal films (3) are arranged at the upper surface of the upper base body (1) and the lower surface of the lower base body (2). The electrothermal films are formed by the components of stannic chloride, titanium trichloride, antimony trichloride, calcium chloride, chromic oxide, manganese dioxide, nickelic trioxide, isopropanol, ethanol, and water. After the components are mixed to prepare electrothermal film treating fluid, the electrothermal film treating fluid is sprayed and coated on the surfaces of the heated base bodies; annealing is carried out; and then electrode processing is carried out to obtain electrothermal film finished products. In addition, the invention also discloses a method for carrying out heating by using the heating apparatus. The apparatus and method have the following beneficial effects: shedding is prevented; the upper limit of the temperature of the electrothermal film is enhanced, so that the temperature of the heating base body can rise rapidly; and the maximum surface working temperature can reach 800 to 1000 DEG C, the highest power density can reach 40W / cm<2>, and the service life can reach over 30000 hours.

Owner:CHENGDU LONGXIN TECH CO LTD

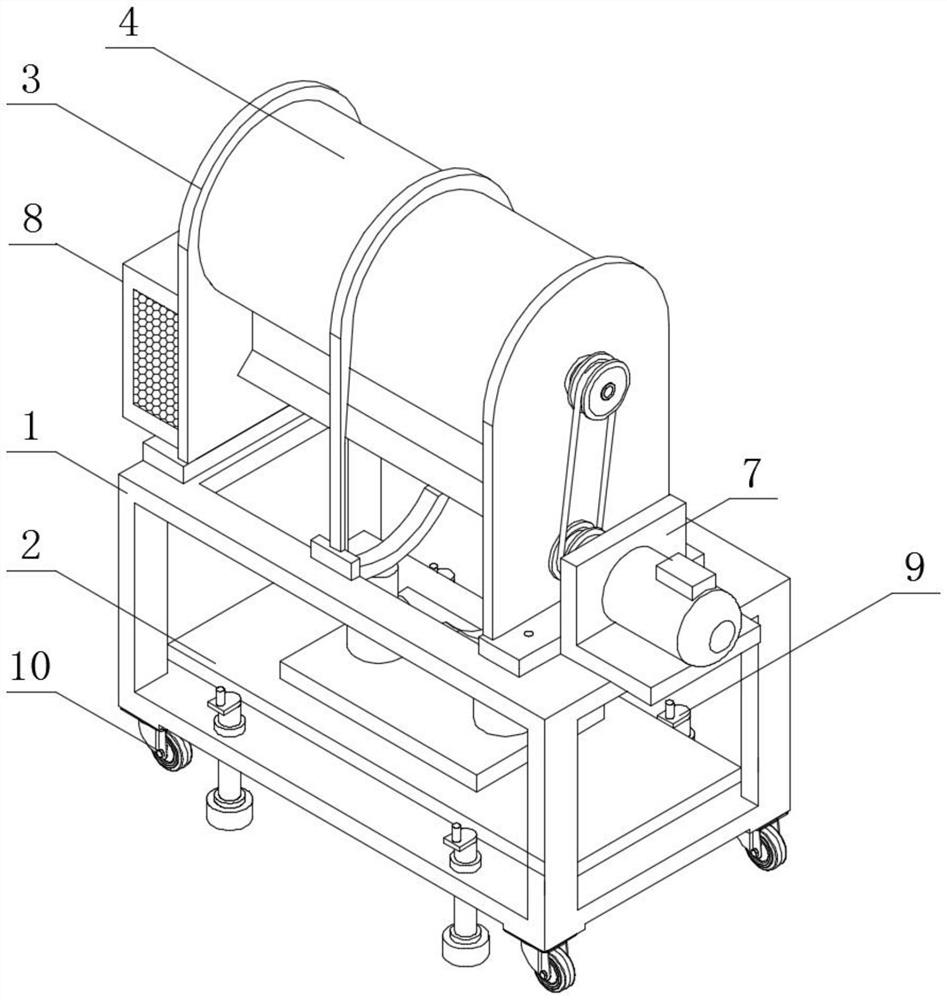

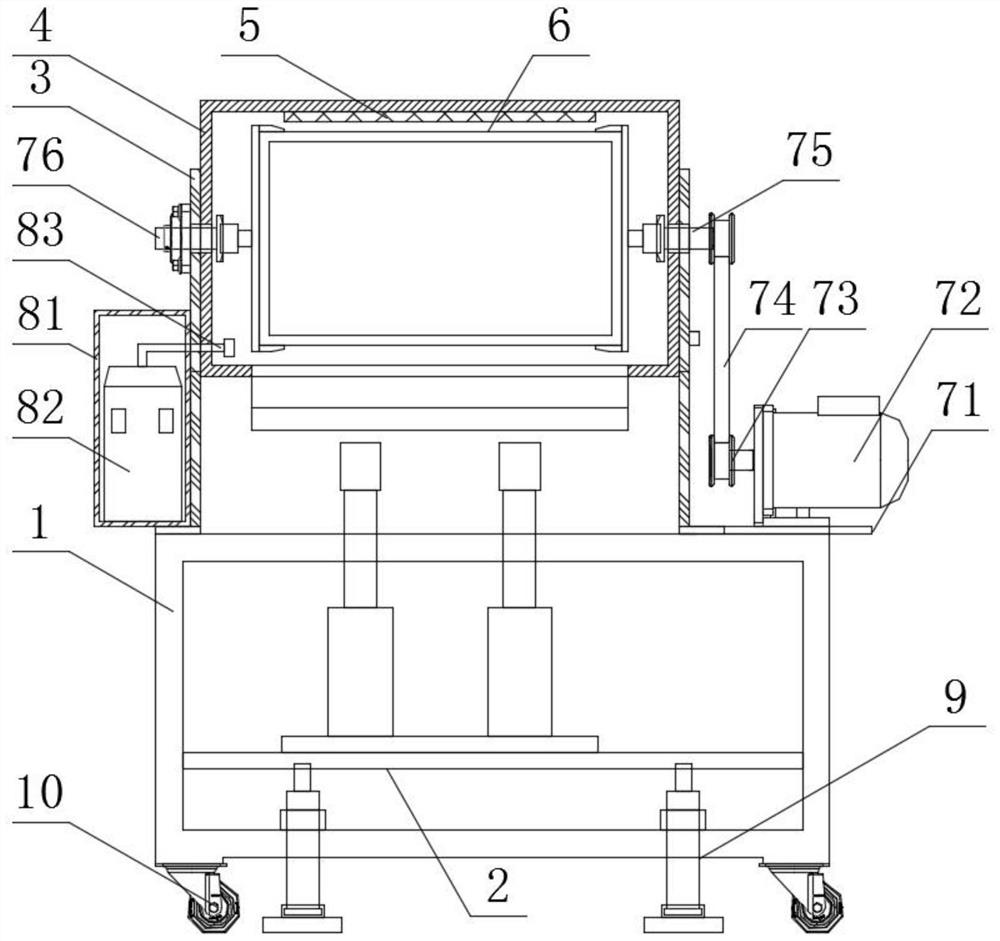

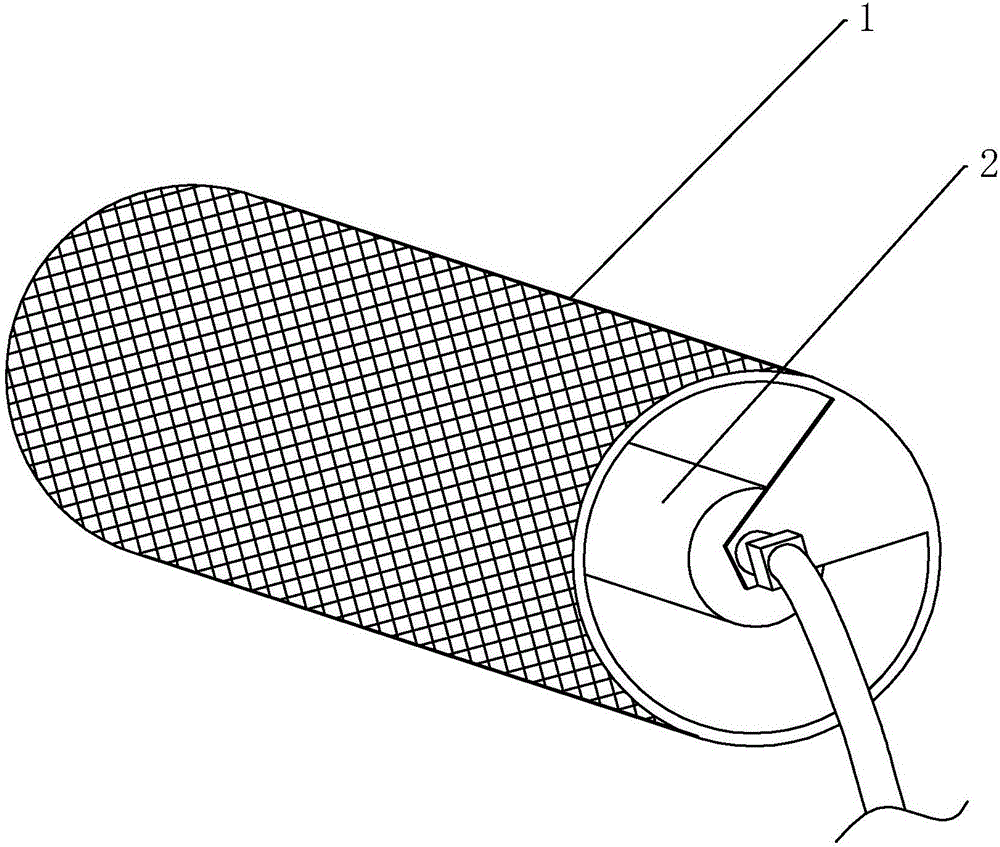

Full-automatic rotational molding machine for electronic product production and working method thereof

The invention discloses a full-automatic rotational molding machine for electronic product production and a working method thereof. The full-automatic rotational molding machine comprises a rack, a feeding assembly, mounting vertical plates, a rotational molding roller, first electric heating plates, a machining assembly, a power assembly, a smoke removal assembly, a positioning assembly and moving wheels, wherein the mounting vertical plates are fixedly mounted on two sides of the top end surface of the rack through welding, the rotational molding roller is fixedly mounted between the mounting vertical plates, the first electric heating plates are fixedly mounted on the top and the two sides of the inner wall of the rotational molding roller, the machining assembly is arranged in the rotational molding roller, the power assembly is arranged on one side of the outer portion of the rotational molding roller, and the feeding assembly is arranged below the bottom of the rotational molding roller. The full-automatic rotational molding machine is firm in structure, stable in transmission, the rotational molding mold is firm in fixation and good in rotation stability during use, the rotational molding effect can be improved, and the molding quality of electronic products can be improved; and meanwhile, the full-automatic rotational molding machine also has a smoke removal function and can reduce smoke pollution effectively.

Owner:马鞍山安慧智电子科技有限公司

Extrusion type lamination process for preparing composite film

InactiveCN105584191AGood firmnessImprove firmnessLamination ancillary operationsLaminationPrinting inkEngineering

The invention discloses an extrusion type lamination process for preparing a composite film, which comprises the following steps of: (1) film preparation; (2) dry lamination: coating a film A with an adhesive under the action of a roller, drying, curing, and forming a composite film with a film B under the action of the roller; (3) composite film printing: printing print ink on the composite film through a printing machine; (4) irradiating the print ink with ultraviolet rays emitted by a first group of ultraviolet lamps of the printing machine to have crosslinking reaction between the print ink and a printing layer; (5) irradiating the print ink with ultraviolet rays emitted by a second group of ultraviolet lamps of the printing machine to cure the printing layer on the composite film; (6) drying the printing layer with an infrared ray dryer arranged on the printing machine; and (7) carrying out UV glazing on the dried printing layer with an UV glazing device arranged on the printing machine. By adopting the extrusion type lamination process, the problem that the composite film prepared by adopting the existing composite film preparation process is low in fastness is solved.

Owner:SICHUAN HUILI IND

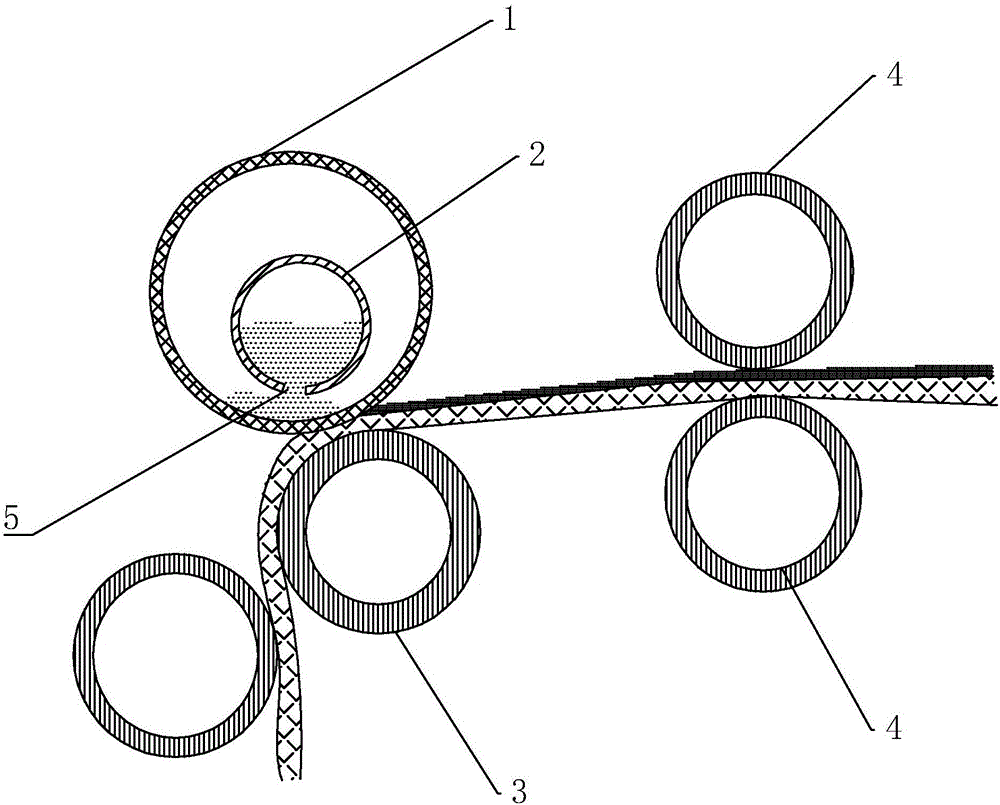

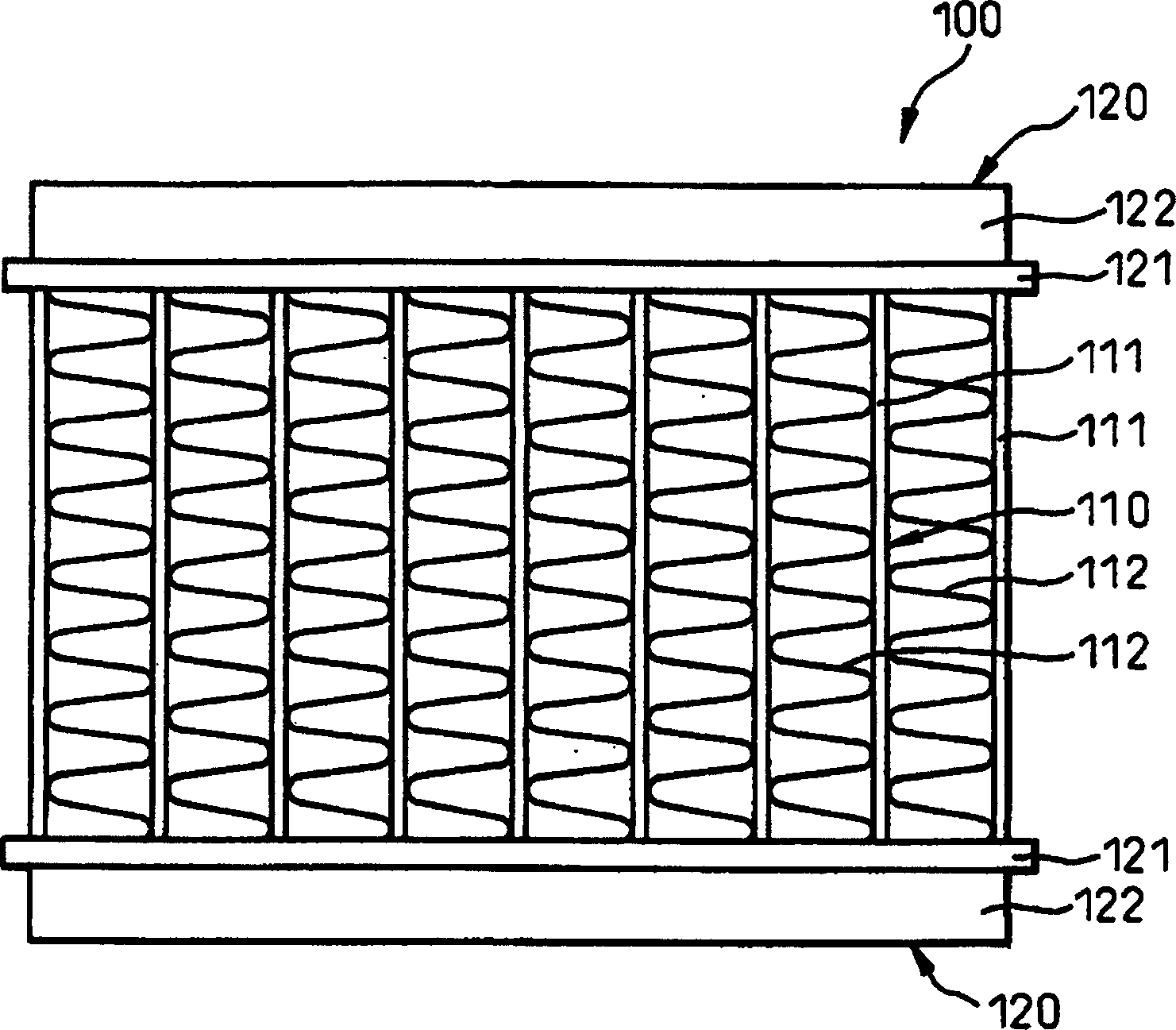

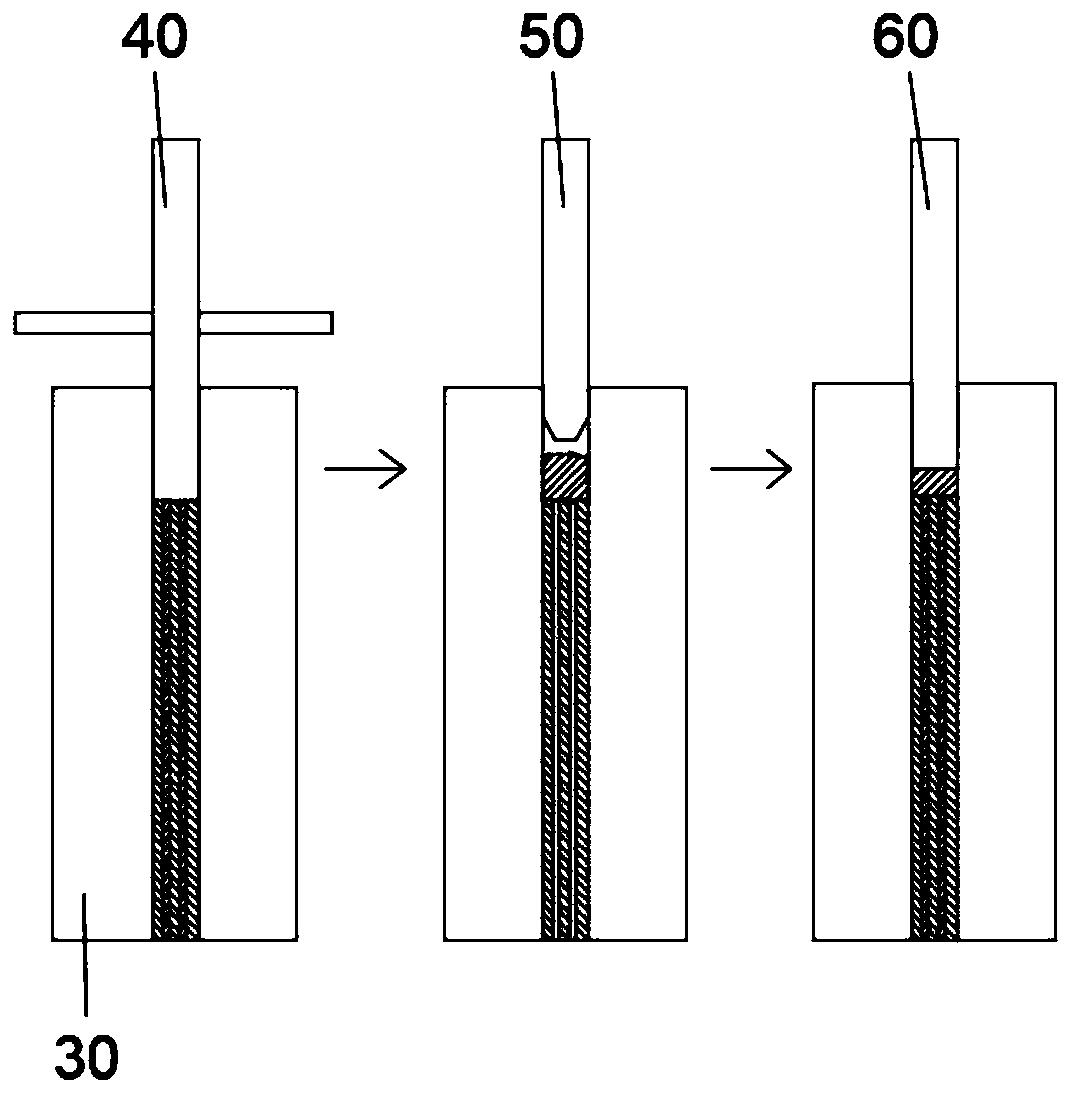

Coating equipment for cylinder mould and coating process applying equipment

InactiveCN106638011ASmooth coating processImprove uniformityScreen printersDyeing processSlurryMaterials science

The invention discloses coating equipment of a cylinder mould and a coating process applying the equipment. The key point in the technical scheme is that the coating equipment comprises a coating device and an extruding device through which a non-woven fabric sequentially passes, wherein the coating device comprises a cylinder mould roller and a first press roller matched with the cylinder mould roller; a discharging roller is arranged in the cylinder mould roller; a material slurry outlet is formed in the discharging roller in the axial direction; two ends of the discharging roller are connected with a pumping device; the extruding device comprises two parallel second press rollers; and the non-woven fabric passes through a crack of the two second press rollers. Through the adoption of the coating equipment disclosed by the invention, the surface coating of the non-woven fabric can be uniform in distribution, the coating effect is favorable, and the bonding fastness is high.

Owner:JIAXING HUALI NON WOVEN FABRIC CO LTD

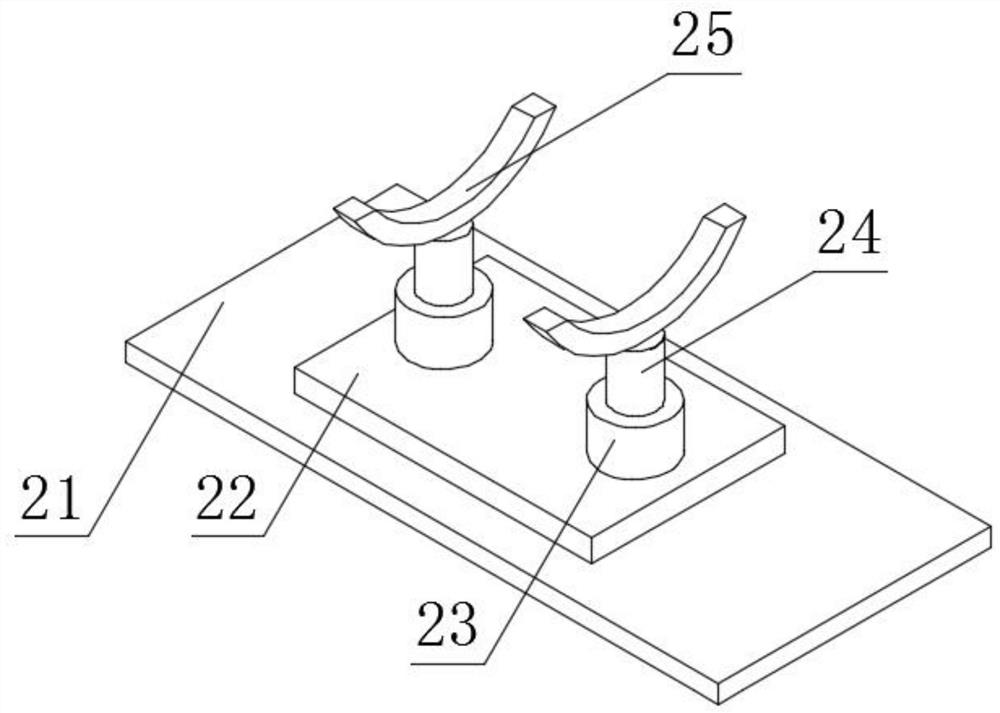

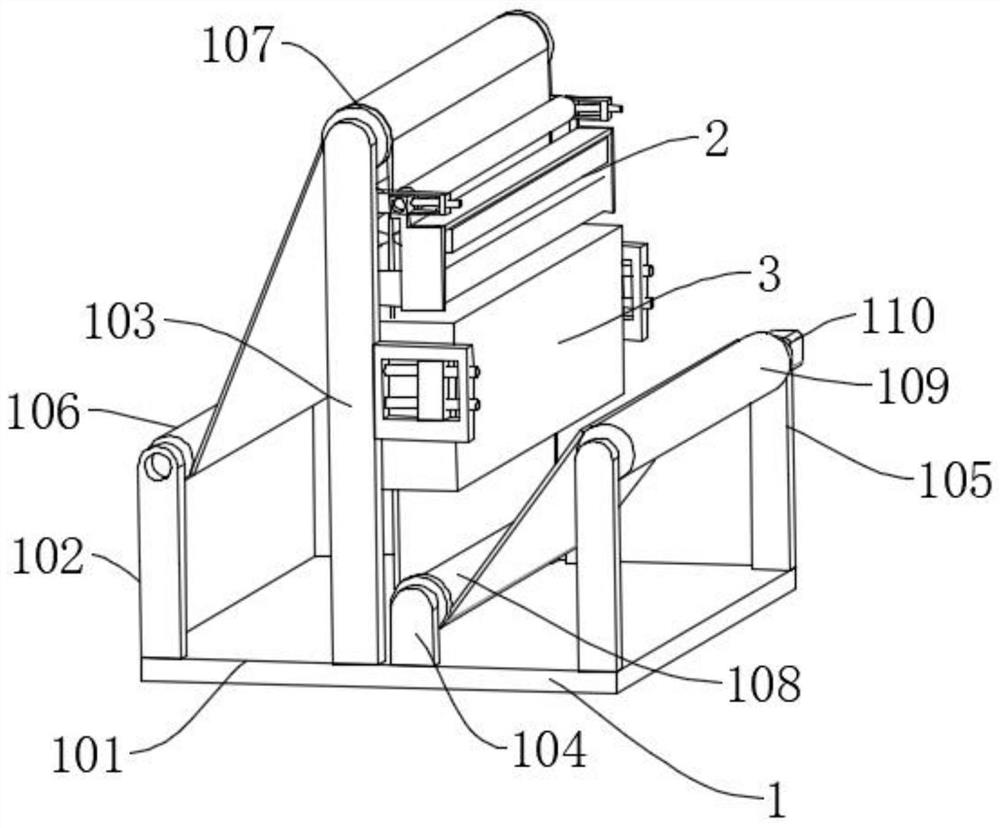

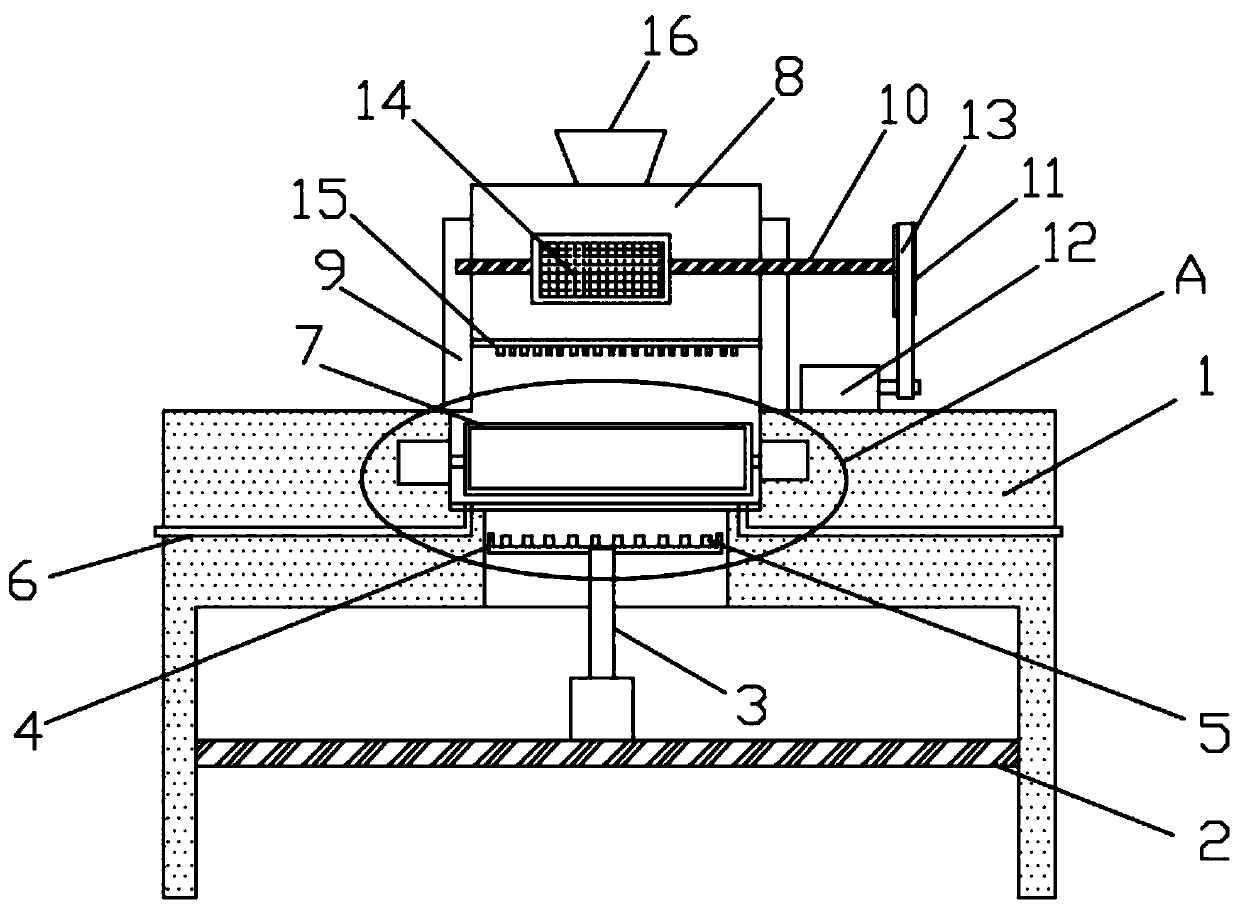

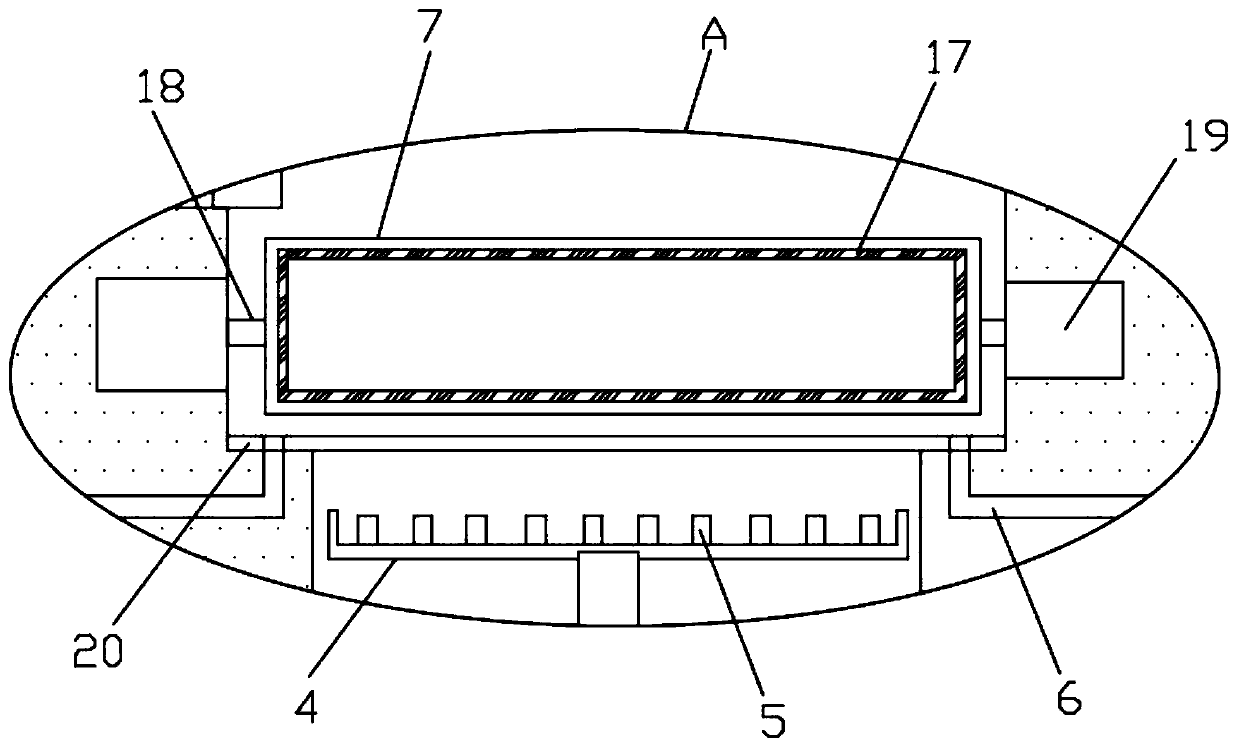

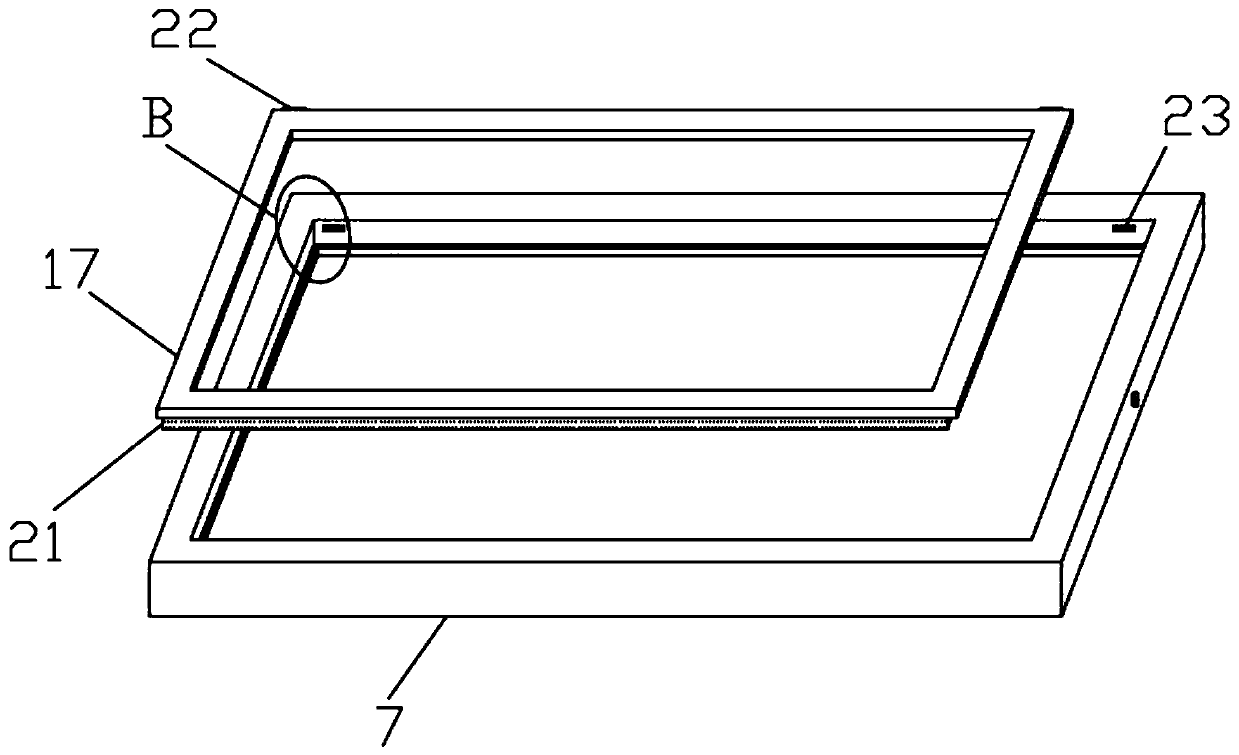

Slurry coating device for battery pole piece in new energy battery production

InactiveCN113663861ASmooth coating processImprove uniformityLiquid surface applicatorsElectrode collector coatingNew energyControl engineering

The invention discloses a slurry coating device for a battery pole piece in new energy battery production. The device comprises a transmission mechanism, the transmission mechanism is mainly composed of a bottom plate, first vertical plates, second vertical plates, third vertical plates, fourth vertical plates, a discharging roller, a first positioning roller, a second positioning roller, a winding roller and a winding motor, a coating mechanism and a drying mechanism are further arranged between the second vertical plates, the coating mechanism is located above the drying mechanism, and material passing openings are formed in the top and the bottom of the drying mechanism correspondingly. With the device, the pole piece is relatively stable during slurry coating, so that the slurry coating uniformity is facilitated, meanwhile, slurry on the pole piece can be controlled through a fixed scraper and a movable scraper, so that the non-uniformity of the slurry on the pole piece caused by the non-uniformity of the slurry discharged from a movable coating machine head is prevented, and the slurry coating uniformity is further ensured; and when the pole piece is conveyed, the pole piece can pass through a first driving assembly and a second driving assembly conveniently, and thus a large amount of preparation time before production is saved.

Owner:王国川

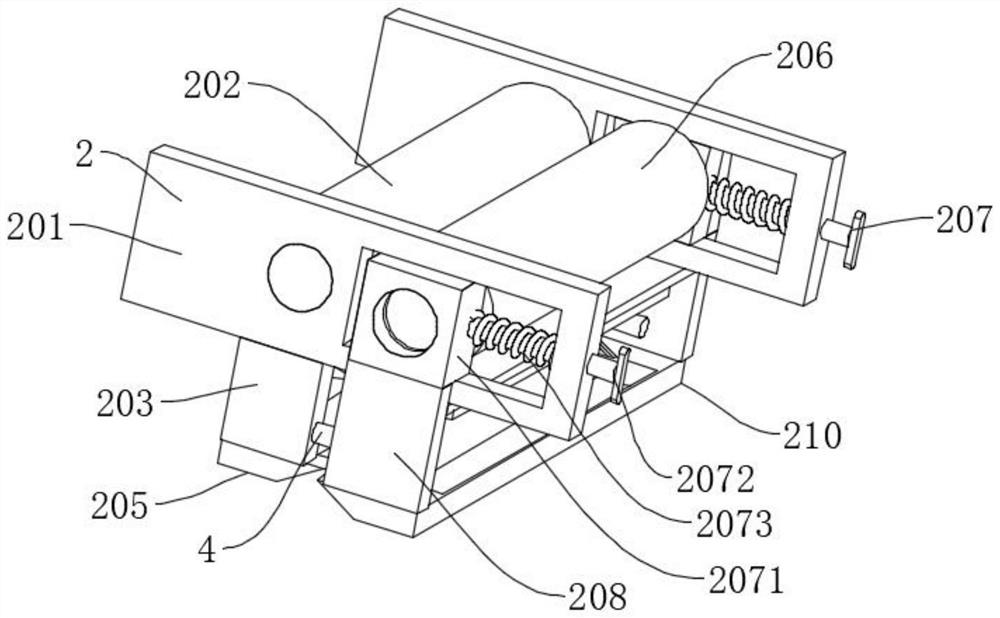

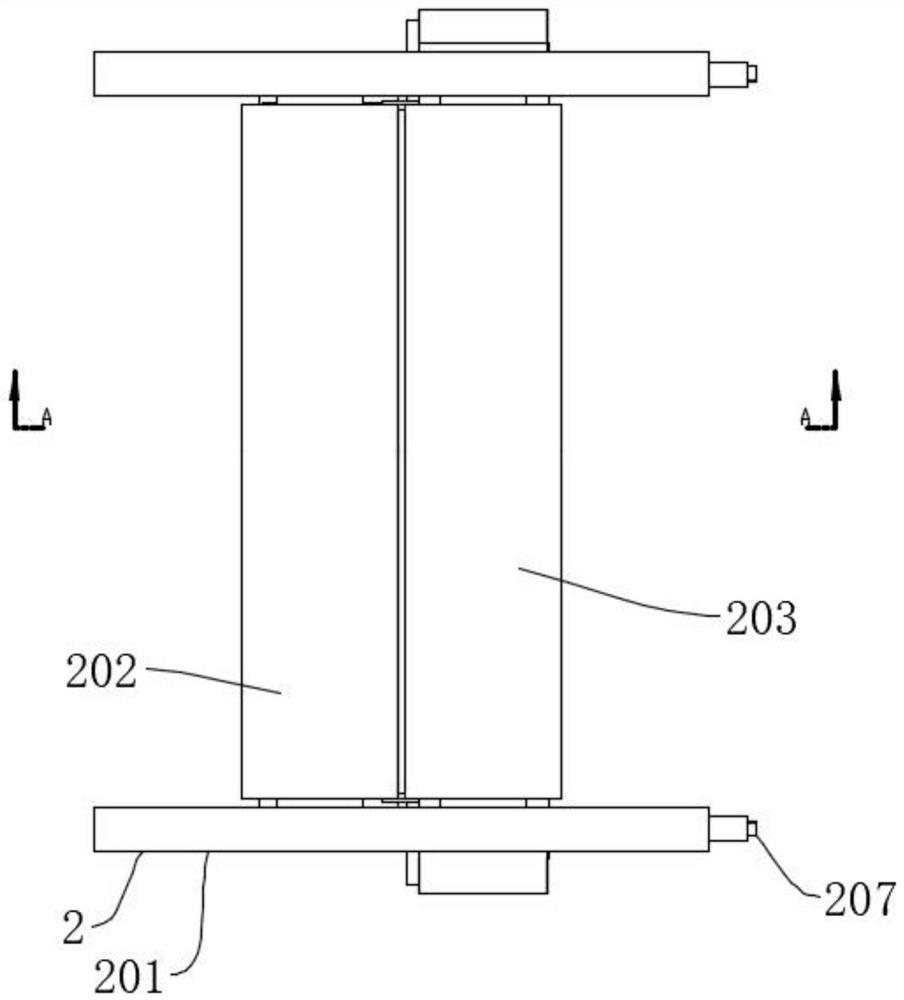

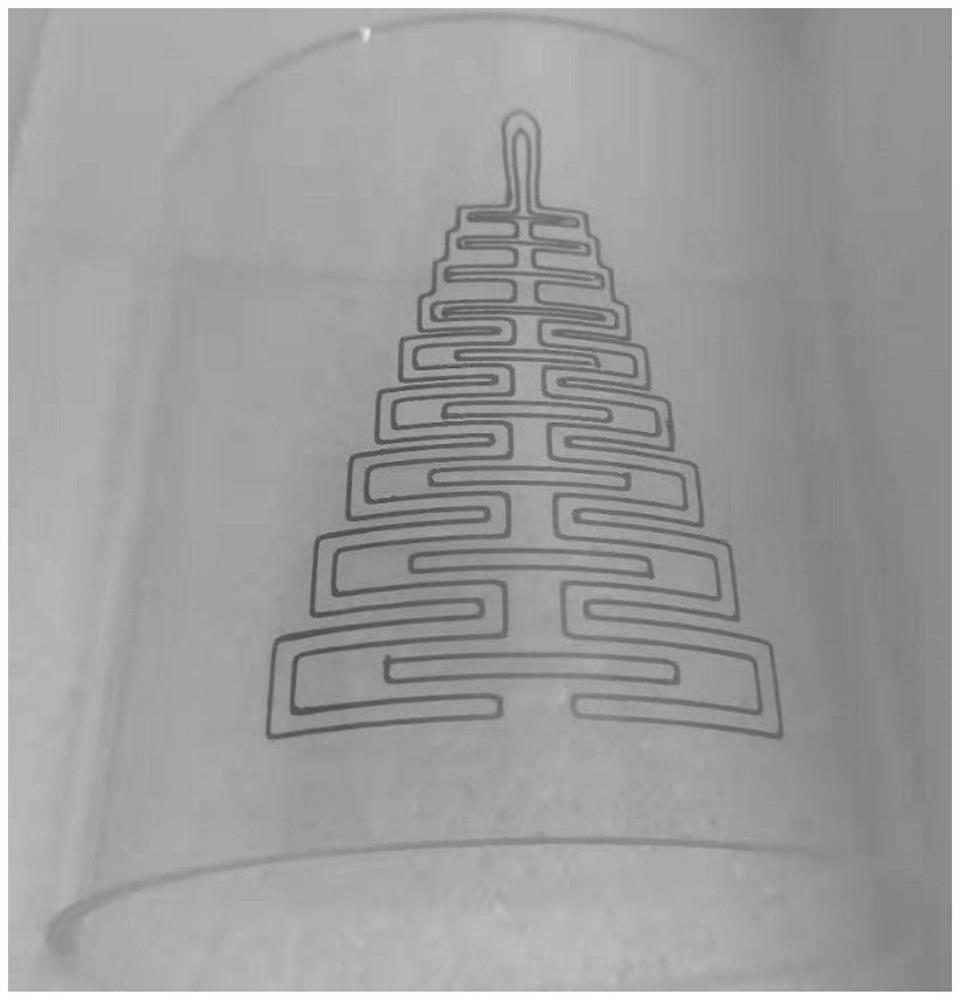

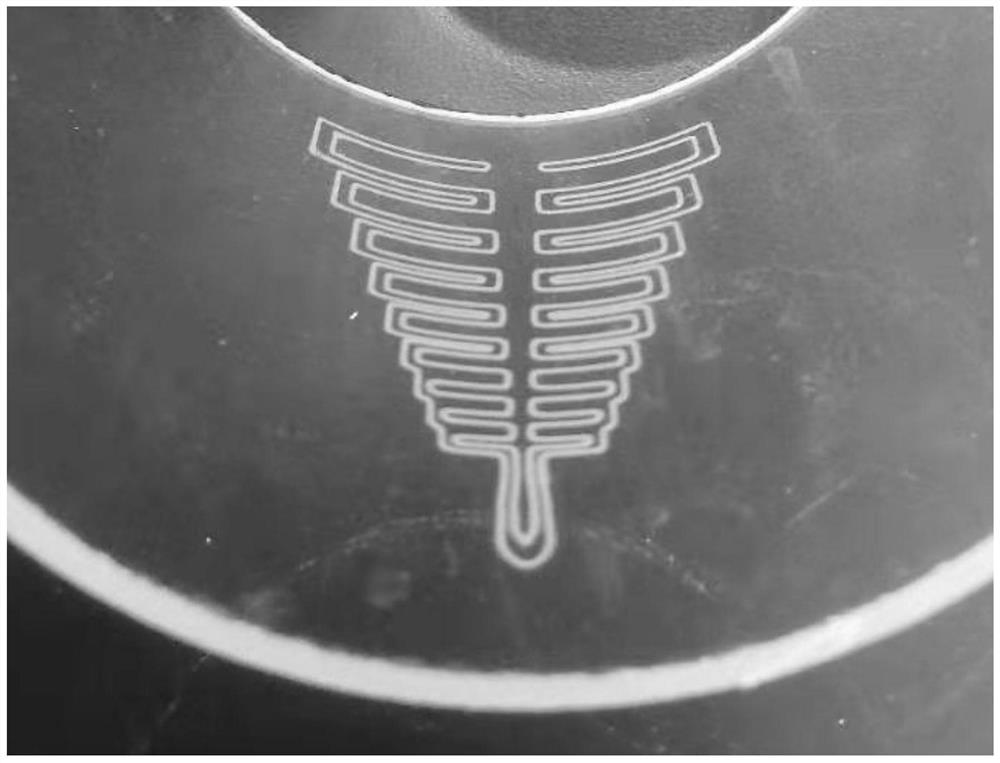

Laser-assisted conformal 3D printing method for complex curved surface special-shaped structure

ActiveCN112958765AStrong bondNo complexityAdditive manufacturing apparatusTransportation and packagingLaser assistedErbium lasers

The invention discloses a laser-assisted conformal 3D printing method for a complex curved surface special-shaped structure, and relates to a conformal 3D printing method for a curved surface special-shaped structure. The problems that conformal manufacturing of the surface of a complex non-unfolded curved surface structure is difficult to achieve and the printing line width precision is low in an existing direct writing type and other contact type 3D printing technologies are solved. The laser-assisted conformal 3D printing method comprises the following steps that 1, weighing is carried out; 2, laser curing slurry is prepared; 3, coating is carried out; 4, a laser and a base plate are fixed; 5, 3D laser printing is carried out; 6, cleaning is carried out; and 7, sintering is carried out. The laser-assisted conformal 3D printing method is used for laser-assisted conformal 3D printing of the complex curved surface special-shaped structure.

Owner:HARBIN INST OF TECH

One-component polyurethane adhesive for furniture and preparation method of one-component polyurethane adhesive

InactiveCN108219734AGood weather resistanceSmooth coating processNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDiphenylmethanePolymer science

The invention discloses a one-component polyurethane adhesive for furniture and a preparation method of the one-component polyurethane adhesive. The preparation method comprises the following steps ofadding a function system in a modification system, adding 4,4-diphenylmethane and maleic anhydride under stirring at 60 DEG C, performing stirring for 35mins, then adding a foundational system, performing stirring for 85mins at the temperature of 110 DEG C, adding ethanol while performing natural cooling to obtain a system with the solid content being 65-70 percent, i.e., the one-component polyurethane adhesive for the furniture. The obtain product can be used in the furniture industry, has excellent peeling strength, fairly excellent flame retardancy and toughness and particularly good antibacterial property.

Owner:昆山市冠宝化学有限公司

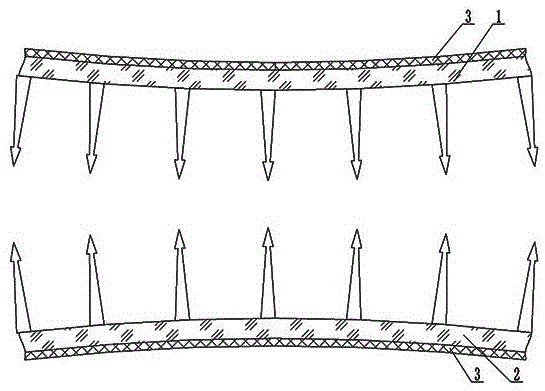

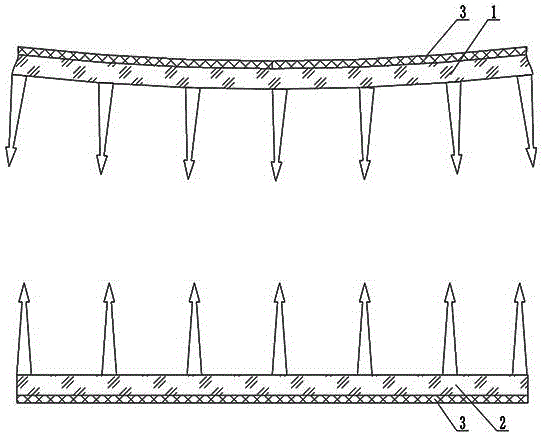

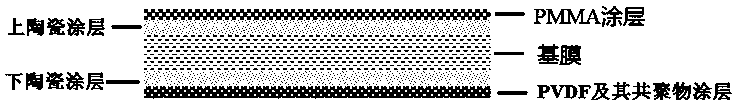

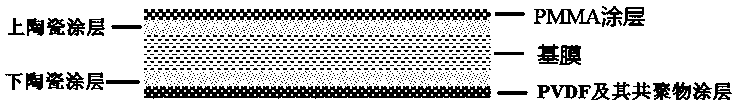

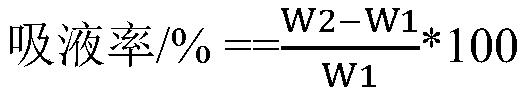

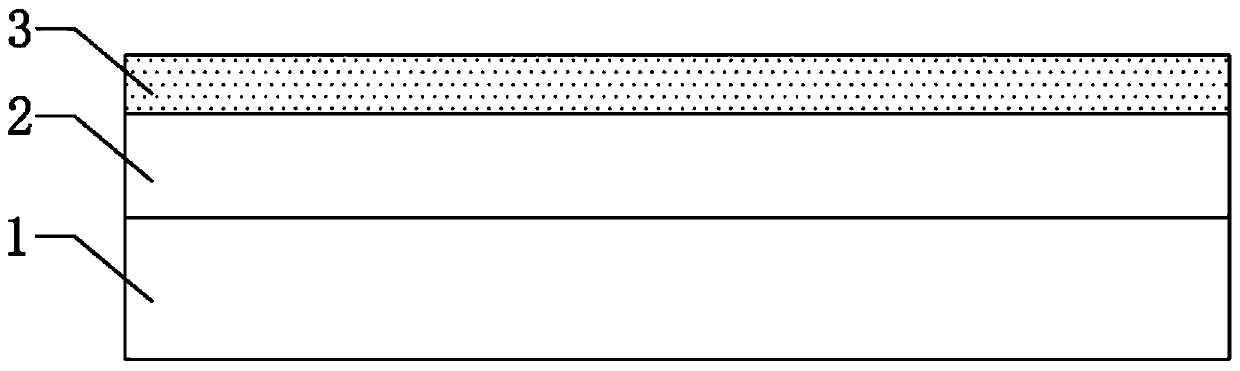

Preparation method of composite diaphragm

InactiveCN109713197ASmooth coating processLower requirementCell component detailsAbsorption ratePolyvinylidene fluoride

The invention discloses a preparation method of a composite diaphragm. The method comprises the steps: preparing ceramic slurry, polymethyl methacrylate (PMMA) slurry, polyvinylidene fluoride (PVDF) slurry and copolymer slurry thereof; coating the upper layer and the lower layer of a base membrane with the ceramic slurry, wherein the PMMA slurry is coated on the upper ceramic coating, and the PVDFand the copolymer slurry are coated on the lower ceramic coating, i.e., forming the composite diaphragm composed of the PMMA coating / the upper ceramic coating / a base layer / the lower ceramic coating / the PVDF and the copolymer coating thereof. The diaphragm has higher liquid absorption rate, peel strength and thermal stability.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

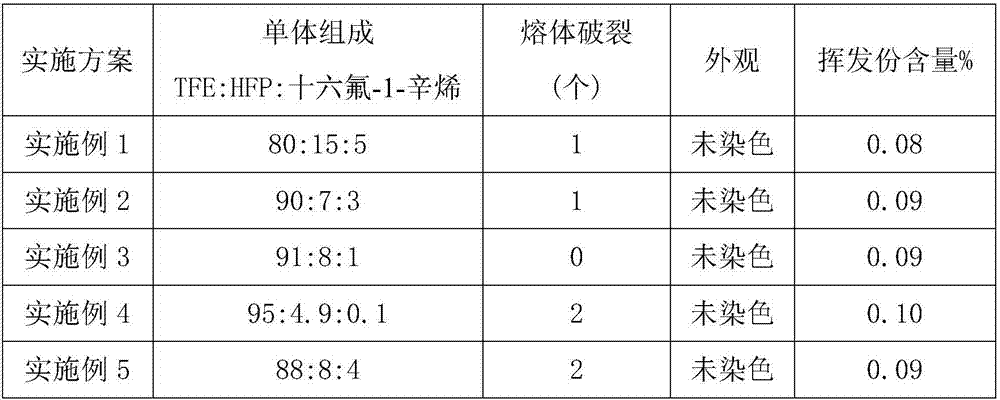

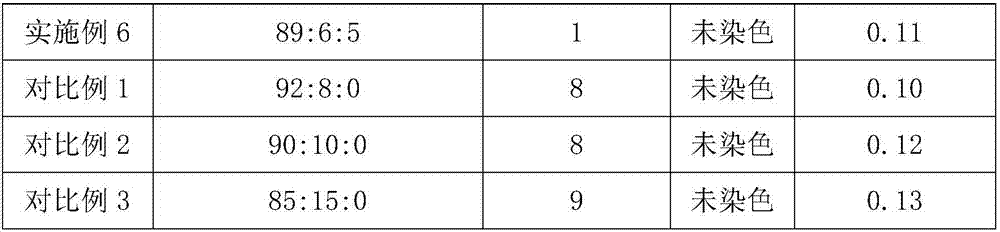

Hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and solution polymerization preparation method thereof

The invention discloses a hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and a solution polymerization preparation method thereof. According to the solution polymerization preparation method, tetrafluoroethylene, hexafluoropropylene and hexadecafluoro-1-octene serve as copolymerizable monomers, wherein a molar fraction of the tetrafluoroethylene to hexafluoropropylene to hexadecafluoro-1-octene is (80-95):(4.9-15):(0.1-5). The preparation process comprises the following steps: adding a fluorine-containing solvent and copolymerizable monomers into a reactor at a certain temperature, raising the temperature to 20-60 DEG C, adding a perfluoro initiator to initiate a polymerization reaction under the pressure of 1.1-1.5MPa, supplementing the copolymerizable monomers in the reaction process, and finally preparing the modified polyperfluoro ethylene-propylene. The modified monomers are taken as polyperfluoro monomers, so that the prepared modified polyperfluoro ethylene-propylene resin is excellent in heat resistance, causes no aggregate dyeing phenomenon, can serve as a high-speed extrusion grade product and can be stably coated on a cable surface at a high speed of 300-500m / min.

Owner:JUHUA GROUP TECH CENT

Anti-scratch wear-resistant glass fiber fabric and production technique thereof

ActiveCN110344260AImprove performanceImproved interlaminar shear performanceTextiles and paperPorosityWear resistant

The invention discloses an anti-scratch wear-resistant glass fiber fabric and a production technique thereof. The anti-scratch wear-resistant glass fiber fabric is made from, by weight, 90-125 parts of glass fiber monofilaments, 15-24 parts of a slurry and 3-5 parts of an adhesive. Superfine mica powder is added into the slurry, so that porosity can be improved, and improved interlayer shear performance, improved impact resistance and longer fatigue life can be provided for the glass fiber fabric. Dibutyl phthalate helps improve watertightness of the glass fiber fabric. Polyethylene glycol, guar gum and sodium carboxymethyl starch can coordinatively improve viscosity of the slurry and enhance bonding of contact faces of glass fiber and synthetic ring, wear resistance of the glass fiber fabric is improved effectively, and good scratch resistance is produced. The slurry can be scattered and cleaned during coating, and the stability is high. Ultraviolet curing helps impart better coatingeffect to a base; the prepared glass fiber fabric has better scratch resistance.

Owner:安徽弋尚纺织科技有限公司

High tenacity dicyclopentadiene phenol type epoxy resin decontaminating coating

InactiveCN104861818ALarge specific surface areaImprove adsorption capacityAntifouling/underwater paintsEpoxy resin coatingsEpoxyPhenol

The invention discloses a high tenacity dicyclopentadiene phenol type epoxy resin decontaminating coating. The high tenacity dicyclopentadiene phenol type epoxy resin decontaminating coating is composed of the raw materials in parts by weight as follows: 52-55 parts of dicyclopentadiene phenol type epoxy resin, 36-40 parts of macroporous resin loaded with bismuth ferrite, 14-18 parts of glycerin alkyd resin, 6-9 parts of nanometer titania, 6-9 parts of nanometer sea-foam stone powder, 2.2-2.5 parts of silane coupling agent WD, 1.5-1.8 parts of defoamer, 1.8-2.2 parts of advection agent, 0.5-0.8 parts of mildew preventive, 1.5-1.8 parts of pigment, 3.4-6.8 parts of flexibilizer, 1.3-1.7 parts of curing agent, and 48-52 parts of organic solvent. The high tenacity dicyclopentadiene phenol type epoxy resin decontaminating coating is high in tenacity and good in decontaminating effect.

Owner:TONGCHENG XINFENG COLOR PRINTING PACKAGING

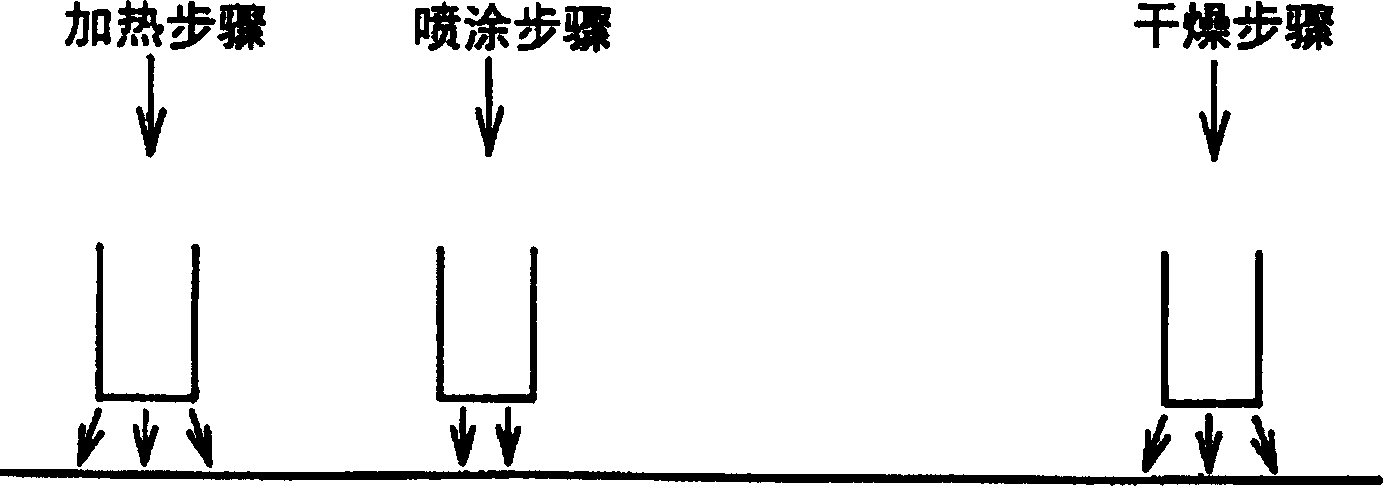

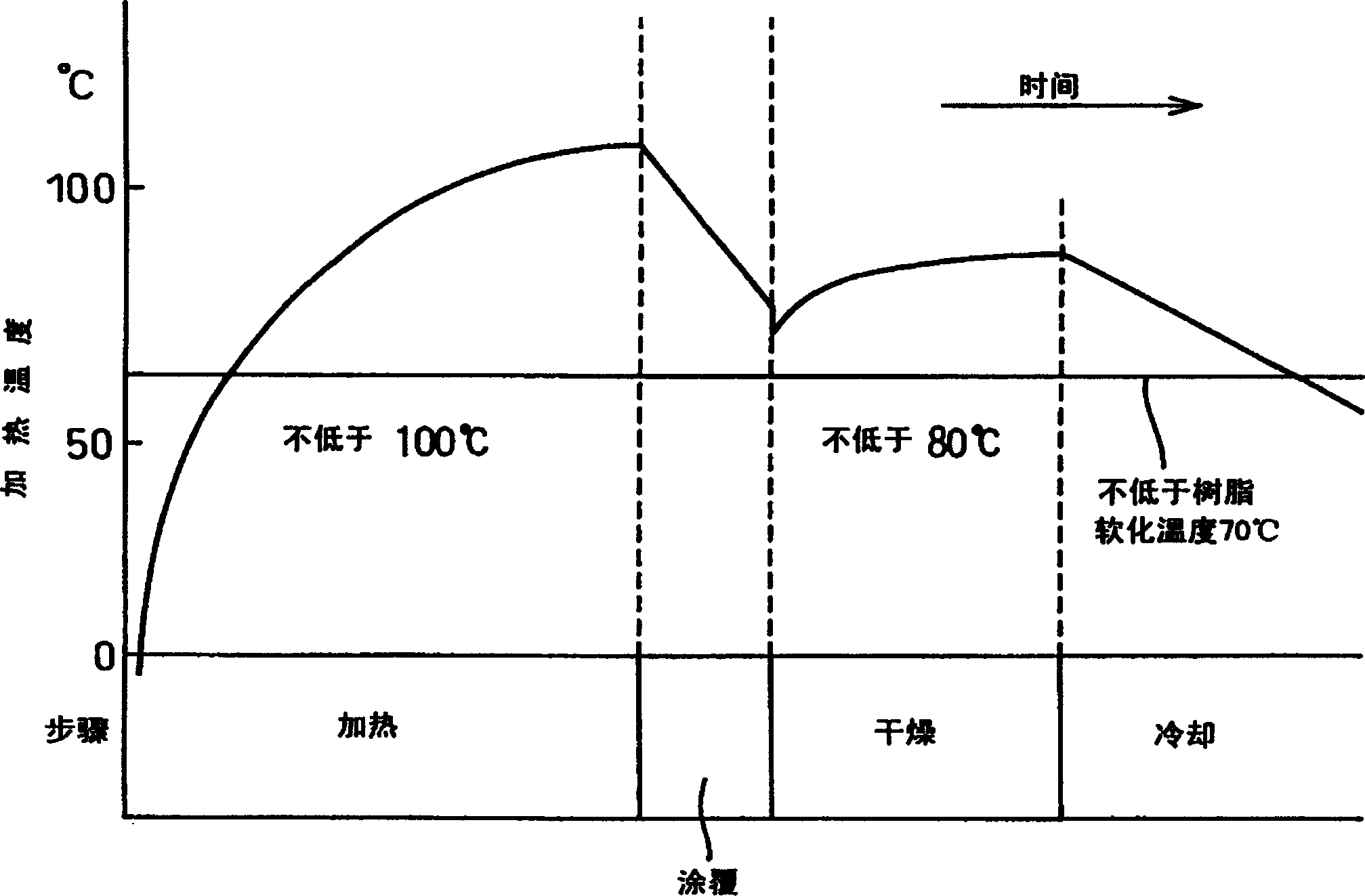

Method for brazed joint of metal workpieces

InactiveCN1192843CSmooth coating processHeat exchanger casingsWelding/cutting media/materialsForeign matterMetal working

A method of brazing a metal work is disclosed, in which the work is heated to at least the softening temperature of resin and coated with a suspension constituted of a mixture of a flux and a binder, after which the work is brazed by being heated and dried. As a result, the binder (resin) attached to the surface of the work is softened and increases in stickiness. Even if foreign matter becomes attached to the work surface, therefore, the binder causes the flux to be firmly attached to (coupled with) the work surface together with the foreign matter. Thus, the flux can be securely coated (attached) on the work surface. The temperature of the work is not lower than the evaporation temperature of water. Even if oil becomes attached to the work surface, therefore, the water in the suspension is evaporated before it can be repelled by the oil, thus making it possible to prevent the flux from being repelled along with the water. In this way, the flux can be securely coated (attached) on the work surface.

Owner:DENSO CORP

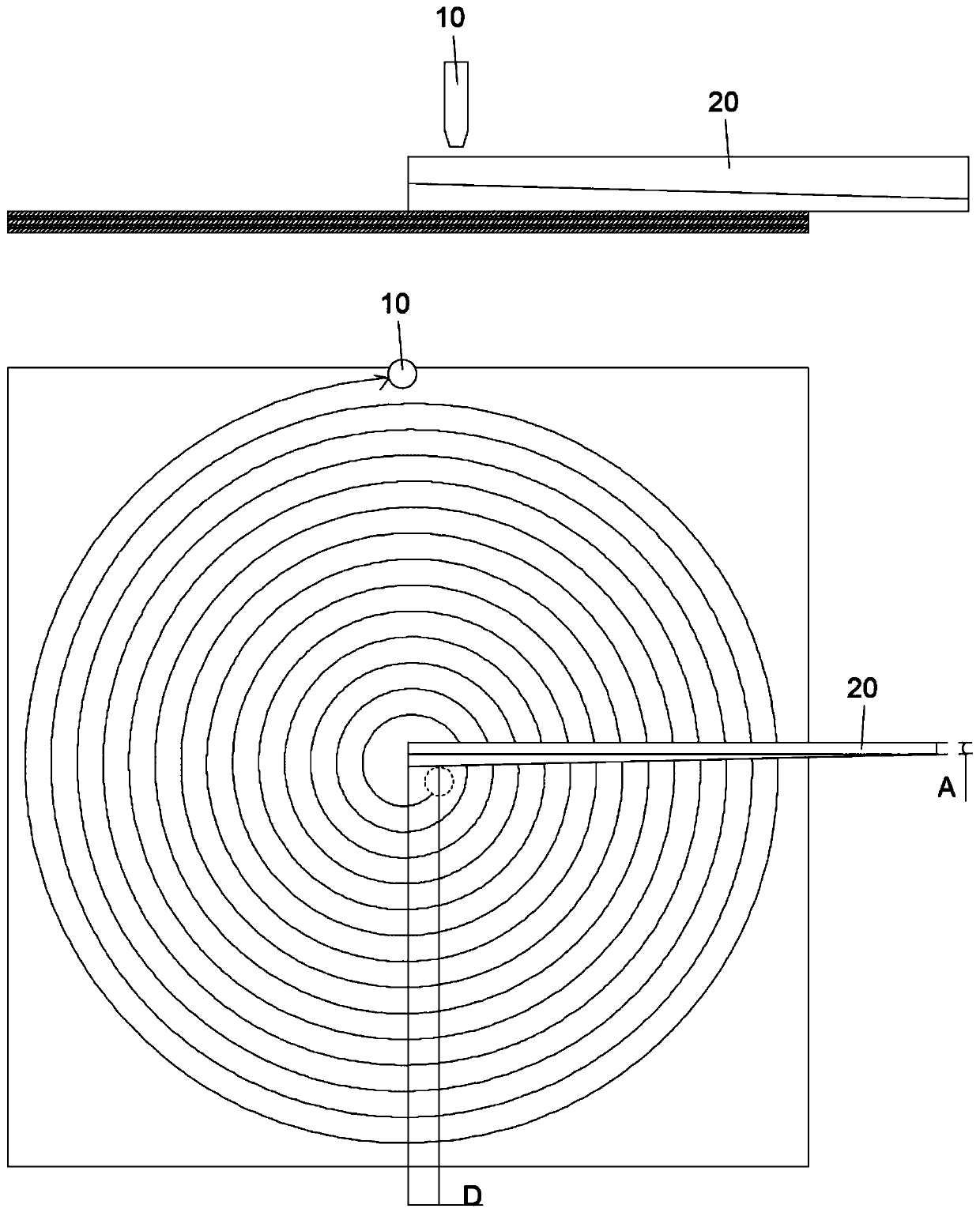

Coating process of Oxford fabric polyurethane coating fabric

InactiveCN110685172ASmooth coating processFit closelyTextiles and paperCoated surfacePolymer science

The invention discloses a coating process of an Oxford fabric polyurethane coating fabric. The method includes the steps: S1 flatly laying an Oxford fabric, and leaning the Oxford fabric by hot air; S2 spirally spraying tackifiers onto the surface of the Oxford fabric by a sprayer from inside to outside, and enabling an oblique plane scraper to rotate along with the sprayer to flat the tackifiersin a scraped manner; S3 melting polyurethane, spirally spraying the melted polyurethane onto the surface of the Oxford fabric by the sprayer from inside to outside, and enabling the oblique plane scraper to rotate along with the sprayer to scrape the polyurethane; S4 performing standing, drying and solidifying after the polyurethane is scraped; S5 turning over the Oxford fabric, and repeating thesteps S2 to S4; S6 erecting the Oxford fabric; S7 heating the edge of the Oxford fabric, spraying the polyurethane, and scraping the polyurethane; S8 rotating the Oxford fabric, repeating the step S7,enabling the edge of the Oxford fabric to be uniformly sprayed by the polyurethane; S9 performing standing, drying and solidifying. The method is simple in process, the coated surface is smooth, combination is firm, waterproof effects and surface elasticity are good, and shapes are stable.

Owner:苏州市千玺成纺织有限公司

Macroporous adsorption resin modified decontamination coating

InactiveCN104861820AGood compatibilityLarge specific surface areaAntifouling/underwater paintsPaints with biocidesEpoxyKetone

The invention discloses macroporous adsorption resin modified decontamination coating. The macroporous adsorption resin modified decontamination coating comprises raw materials of, by weight, 45 to 48 parts of epoxy resin, 41 to 44 parts of bismuth ferric loaded macroporous adsorption resin, 5 to 8 parts of terpene resin, 8 to 11 parts of aldehyde ketone resin, 6 to 9 parts of nano titanium dioxide, 5 to 8 parts of zeolite powder, 8 to 11 parts of superfine calcium carbonate, 5 to 8 parts of organic montmorillonite, 2.2 to 2.5 parts of titanate coupling agent KR-TTS, 1.2 to 1.5 parts of calcium stearate, 0.8 to 1.1 parts of sodium oleate, 2.1 to 2.4 parts of defoaming agent, 1.5 to 1.8 parts of smoothing agent, 0.8 to 1.1 parts of mould inhibitor, 10 to 13 parts of pigment, 2.6 to 2.9 parts of flexibilizer and 1.8 to 2.1 parts of curing agent. The macroporous adsorption resin modified decontamination coating is excellent in adhesion and toughness and high in decontamination capability.

Owner:TONGCHENG XINFENG COLOR PRINTING PACKAGING

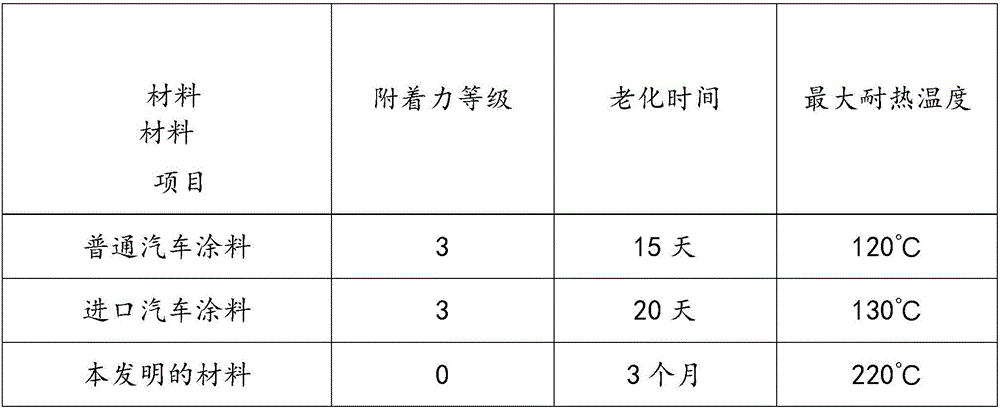

Automobile high-temperature-resistant paint and preparation method thereof

InactiveCN106810980AHigh temperature resistanceHas anti-aging effectFireproof paintsMonomagnesium phosphateMelamine formaldehyde resin

The invention discloses an automobile high-temperature-resistant paint which is prepared from the following materials in parts by weight: 16-20 parts of magnesium biphosphate, 35-40 parts of nano aluminum powder, 10-15 parts of titanium dioxide, 9-16 parts of sodium silicate, 20-22 parts of silicon carbide, 7-12 parts of silica sol, 63-68 parts of pure acrylic emulsion, 5-8 parts of silicone oil, 10-11 parts of talcum powder, 4-8 parts of butyl acetate, 9-15 parts of n-butanol, 3-7 parts of magnesium chloride, 11-14 parts of sodium borate, 13-16 parts of titanate coupling agent, 6-8 parts of polyoxyethylene ether, 13-18 parts of white latex, 7-9 parts of zinc phosphate, 6-12 parts of paraffin and 14-16 parts of melamine formaldehyde resin. The automobile high-temperature-resistant paint has the advantages of aging resistance, long service life, high adhesion and favorable high-temperature-resistant effect.

Owner:芜湖天鸿汽车零部件有限公司

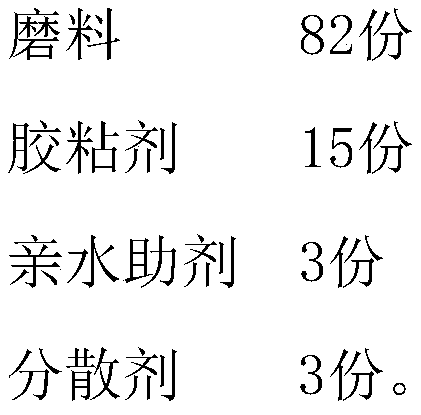

Abrasive paper hydrophilic coating

InactiveCN110885622AReduce roughnessHydrophilic hasPolyurea/polyurethane coatingsEpoxy resin coatingsHydrophilic coatingPolymer science

The invention relates to the technical field of grinding tool materials, in particular to an abrasive paper hydrophilic coating. The abrasive paper hydrophilic coating is prepared from the following raw materials in parts by weight: 80-90 parts of grinding materials, 10-20 parts of an adhesive and 1-5 parts of a hydrophilic auxiliary agent. According to the hydrophilic coating disclosed by the invention, the hydrophilic auxiliary agent is adopted to improve the hydrophilicity of the coating layer, is matched with the adhesive to stably coat the surface of the abrasive paper with the coating, the formed hydrophilic coating can enable water to be uniformly infiltrated on the surface of the hydrophilic coating to ensure the uniform wetting of abrasive paper and increase the initial sharpnessof the abrasive paper, an adhesive film on the surface of a mortar layer is polished, the adhesive film on the surface of the mortar layer is removed, so that the polishing effect of the abrasive paper is improved; and moreover, the abrasive material in the hydrophilic coating can pre-polish a workpiece, the overall polishing effect of the abrasive paper is improved, the roughness of the polishedsurface of the workpiece is reduced, and the manufactured abrasive paper product has the hydrophilic, grinding-assisting and anti-blocking effects.

Owner:DONGGUAN GOLDEN SUN ABRASIVES

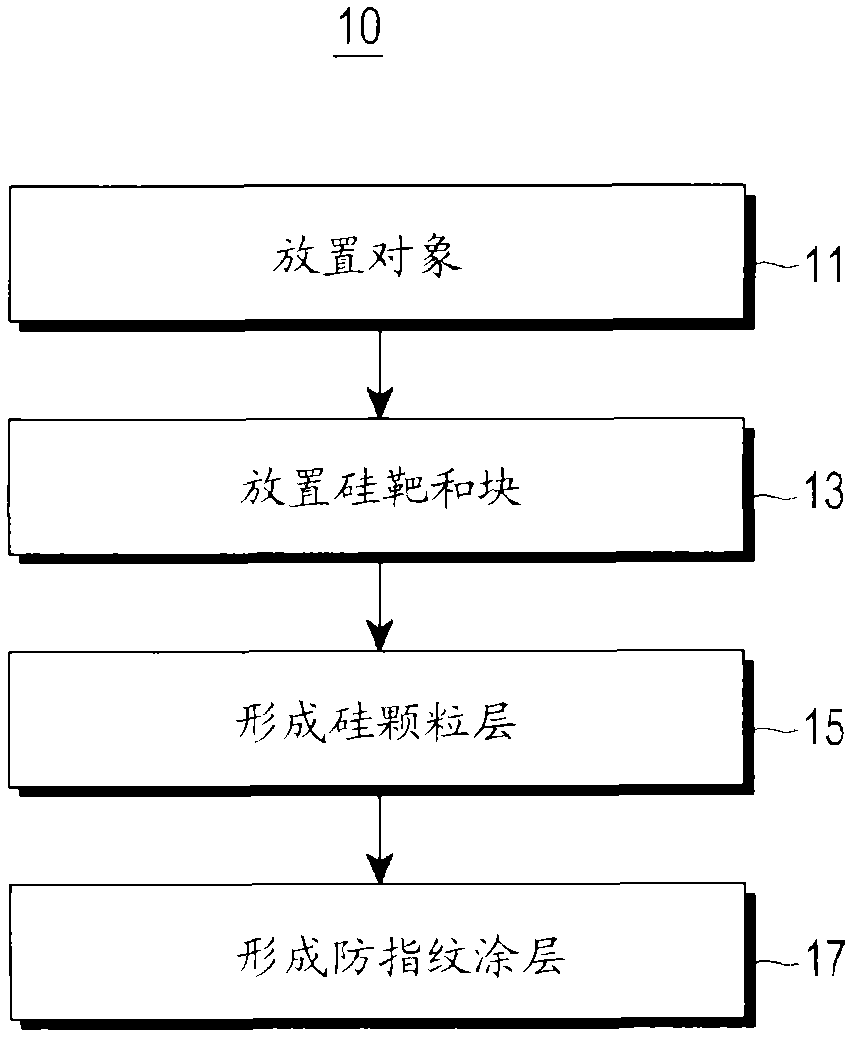

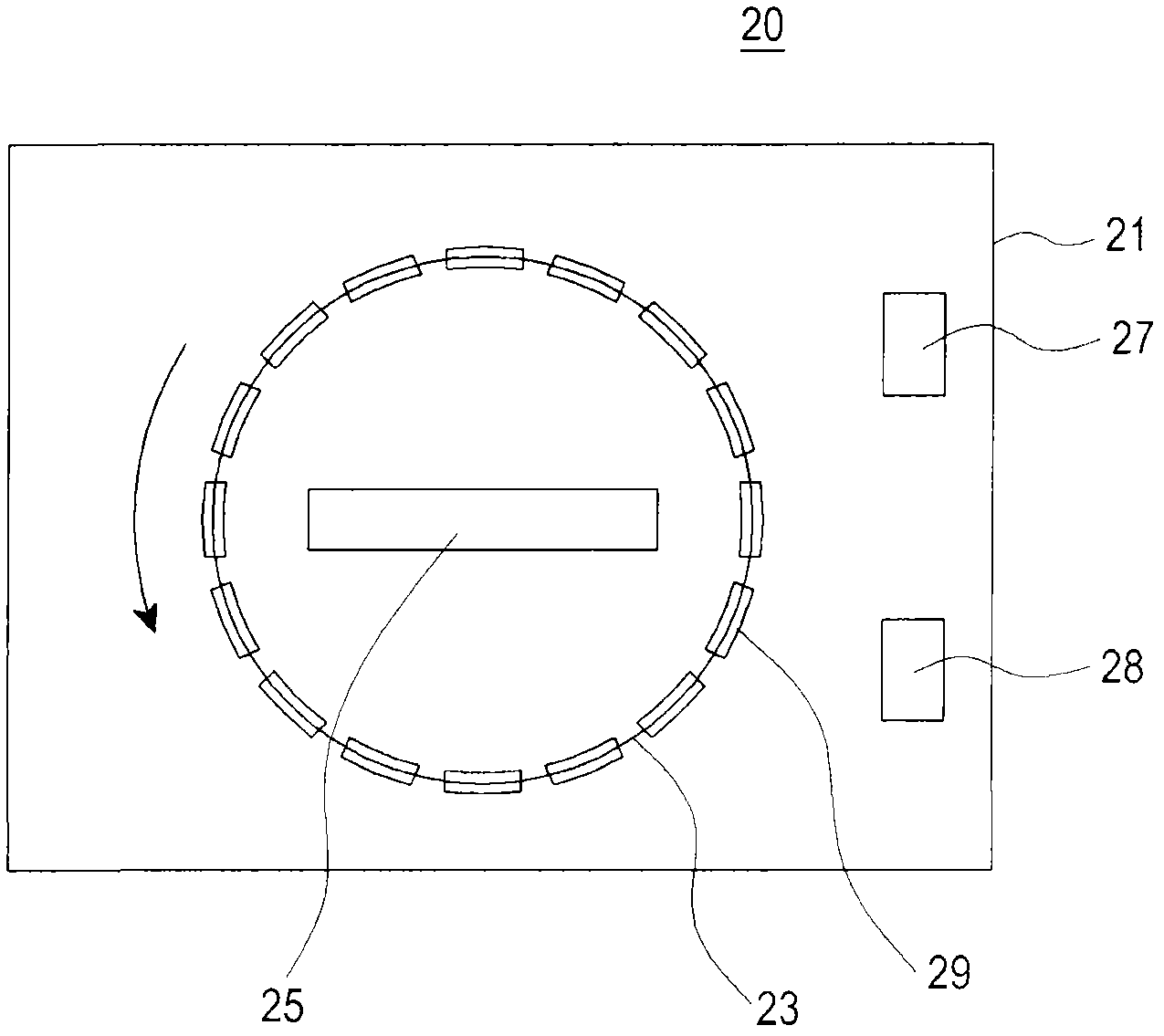

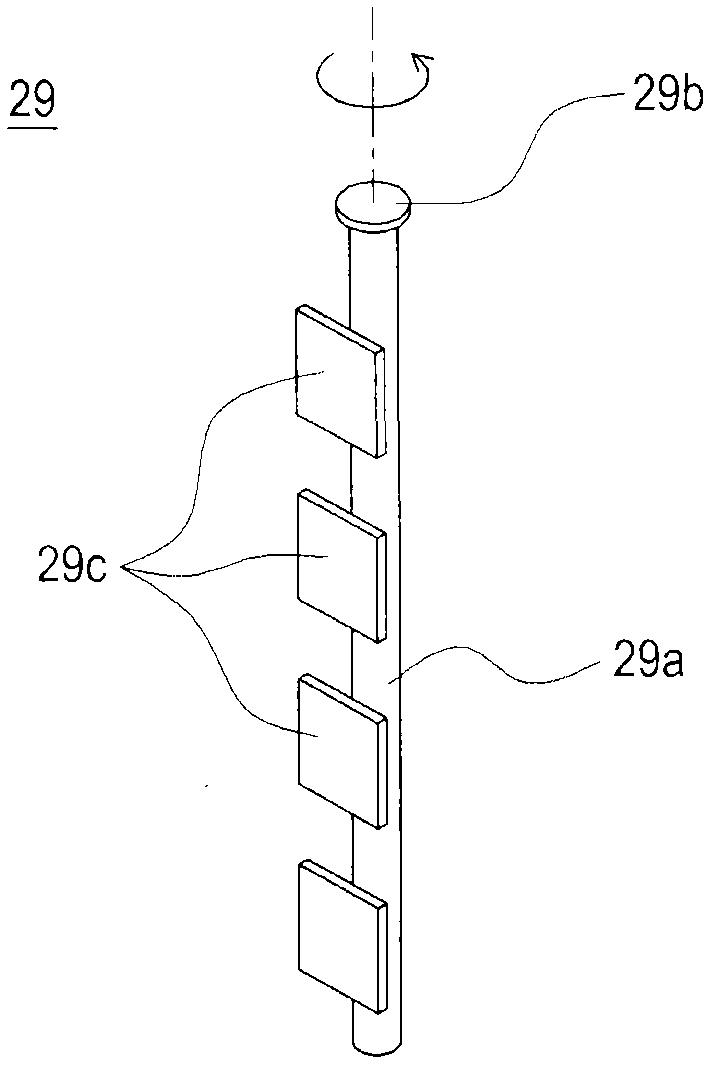

Surface coating method and device for exterior part

InactiveCN102650040ASpread evenlyUniform qualityVacuum evaporation coatingSputtering coatingEvaporationBiomedical engineering

The invention provides a surface coating method and a device for an exterior part. The surface coating method for an exterior part includes positioning one or more exterior part preforms, which are objects to be surface-coated, within a deposition chamber capable of revolution and rotation; positioning one or more tablets containing a coating component on an evaporation device installed within an area surrounded by the revolution trace of the exterior part preforms; and depositing a coating layer to a surface of each of the exterior part preforms by evaporating the tablets while revolving and rotating the exterior part preforms. The surface coating method and device conduct the rotation and revolution of objects to be coated in while proceeding with a coating step, whereby an evaporated coating component can be uniformly diffused over the entire deposition chamber, and a uniform coating layer can be formed on the entire surface of each of the objects to be coated.

Owner:SAMSUNG ELECTRONICS CO LTD

Coating process for European window production line

InactiveCN102824992AImprove textureSmooth coating processLiquid surface applicatorsCoatingsProduction linePulp and paper industry

The invention discloses a coating process for a European window production line. The coating process includes the steps of firstly, selecting laminated pine wood or catalpa wood 1m<2>; secondly, spraying mixed liquor (3) composed of 80wt% of water and 20wt% of basecoat by intermediate spraying; thirdly, using No.240 abrasive paper for sanding so as to flatten and remove burrs and wood ribs; fourthly, using a curtain coater to curtain at an oblique angle of 45 DEG with the coating amount of 20L / m<2>; fifthly, using No.320 abrasive paper to smooth the surface with penetrating; sixthly, coloring the surface, namely embellishing according to a finish reference color board with the coating amount of 0.3-0.4L / m<2>; seventhly, using No.400 abrasive paper to smooth the surface without penetrating; and eighthly, performing electrostatic spraying with 0.6-0.7L / m<2> finish. The intermediately sprayed mixed liquor is antiseptic. The wood ribs and burrs are removed for smoothing. Surface mild damage is subjected to puffing. After the intermediate spraying mixed liquor is used, two workers are omitted, labor cost is reduced by one fifth, efficiency is improved by 20%, and repair amount is lowered by 50%. The coating process is simple in process, and the coating effect is lasting.

Owner:QINGDAO HAIYAN PROPERTY GRP

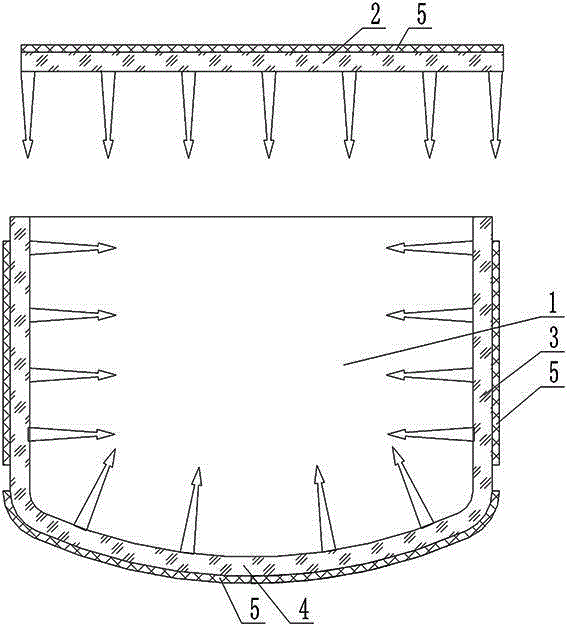

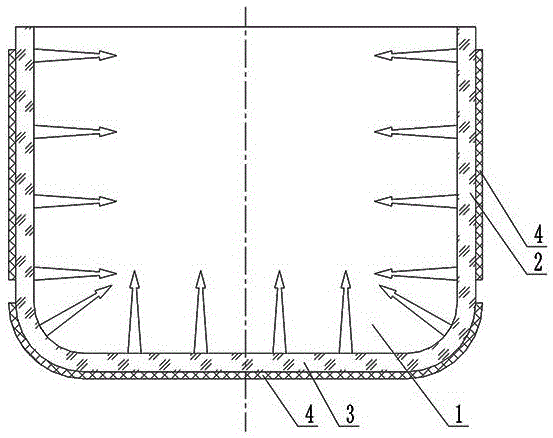

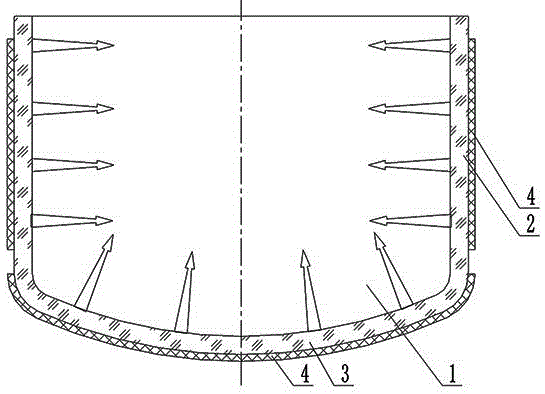

Heating device capable of simultaneously heating from bottom part and lateral parts and heating method

InactiveCN105142247ARaise the upper surface temperature limitHeating up fastHeating element materialsNickel sesquioxideWorking temperature

The invention discloses a heating device capable of simultaneously heating from a bottom part and lateral parts. The heating device comprises a base body (1), wherein the base body (1) comprises a cylindrical lateral wall (2) and a bottom plate (3), wherein electrothermal films (4) are arranged on the outer surface of the lateral wall (2) and the lower surface of the bottom plate (3); each electrothermal film is prepared from the following components: stannic chloride, titanium trichloride, antimony trichloride, calcium dichloride, dichromium trioxide, manganese dioxide, nickel sesquioxide, isopropyl alcohol, ethanol and 20-30 parts of water; the components are mixed to prepare electrothermal film treating liquid; and the electrothermal film treating liquid is sprayed on the surface of the heated base body, and is annealed and processed into an electrode to obtain an electrothermal film product. The invention further discloses a heating method of the device. The heating device has the beneficial effects that the heating device is not easy to fall off; the upper temperature limit of the electrothermal film is improved; the heating base body rapidly heats; the highest surface working temperature can reach 800-1,000 DEG C; the highest power density can reach 40W / cm<2>; and the service life is greater than 30,000 hours.

Owner:CHENGDU LONGXIN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com