Honeycomb ceramic catalyst, preparation method therefor and application thereof

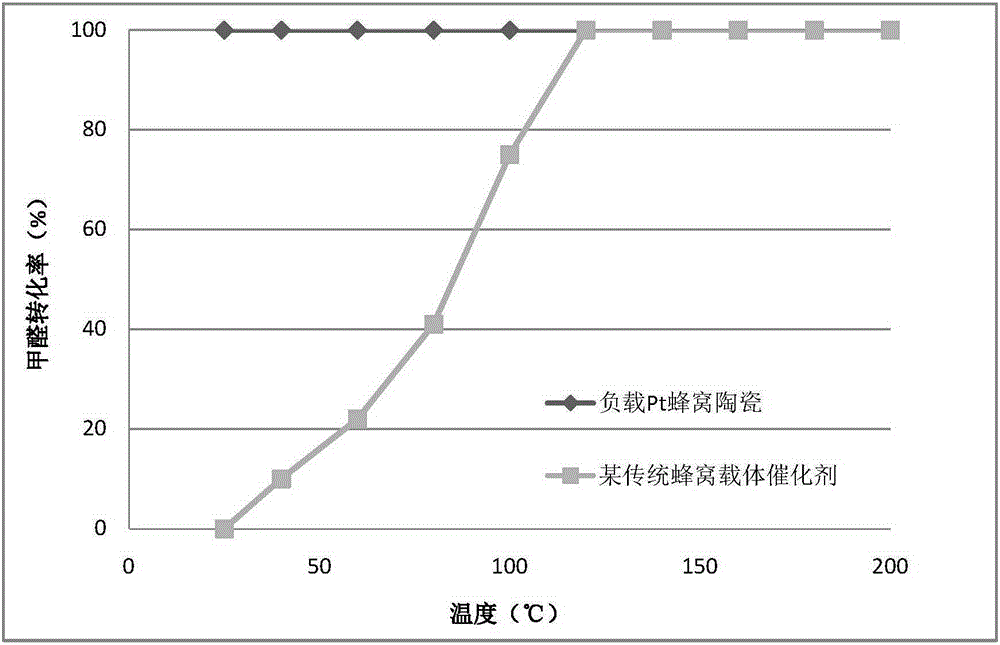

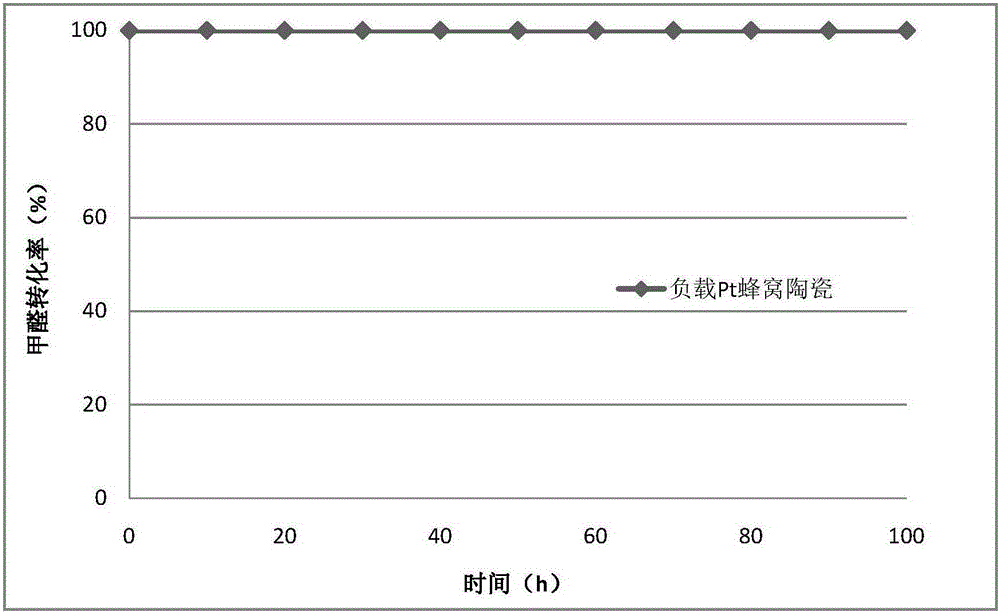

A honeycomb ceramic and catalyst technology, which is applied in the field of indoor air purification, can solve the problems of enrichment coating amount, catalytic activity reduction, unfavorable catalytic reaction, etc., and achieve strong formaldehyde removal ability, good catalytic effect, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1: Preparation of honeycomb ceramic catalyst

[0060] In this embodiment, the honeycomb ceramic catalyst is prepared according to the following steps:

[0061] Step 1: Soak the cordierite honeycomb ceramic carrier in absolute ethanol solution for 8 hours for pretreatment to remove surface impurities, wash with deionized water, dry in an oven at 110°C for 2 hours, and then bake at 500°C to obtain pretreated (surface treated) carrier;

[0062] Step 2: Add 10g of butyl silicate and 10g of butyl acetate into the reaction kettle, add 1000mL of water and stir, and then add surfactant sodium benzenesulfonate, thickener hydroxyethyl cellulose, disperse Sodium hexametaphosphate; then slowly add silica sol, wherein the mass ratio of sodium benzenesulfonate: hydroxyethyl cellulose: sodium hexametaphosphate: silica sol is 50:10:0.5:100, grind with a sand mill Grind finely to obtain the binder coating, and control the pH of the binder coating to be 9;

[0063] Step 3: ...

Embodiment 2

[0068] In this embodiment, the honeycomb ceramic catalyst is prepared according to the following steps:

[0069] Step 1: Soak the cordierite honeycomb ceramic carrier in absolute ethanol solution for 8 hours for pretreatment to remove surface impurities, wash with deionized water, dry in an oven at 110°C for 2 hours, and then bake at 500°C to obtain pretreated (surface treated) carrier;

[0070] Step 2: Add 10g of butyl silicate and 10g of butyl acetate into the reaction kettle, add 1000mL of water and stir, and then add surfactant sodium benzenesulfonate, thickener hydroxyethyl cellulose, disperse Sodium hexametaphosphate; then slowly add silica sol, wherein the mass ratio of sodium benzenesulfonate: hydroxyethyl cellulose: sodium hexametaphosphate: silica sol is 50:10:0.5:100, grind with a sand mill Grind finely to obtain the binder coating, and control the pH of the binder coating to be 9;

[0071] Step 3: Dissolve 12.6g of calcium nitrate hydrate in a mixed solution of 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com