Patents

Literature

48results about How to "Improved interlaminar shear performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

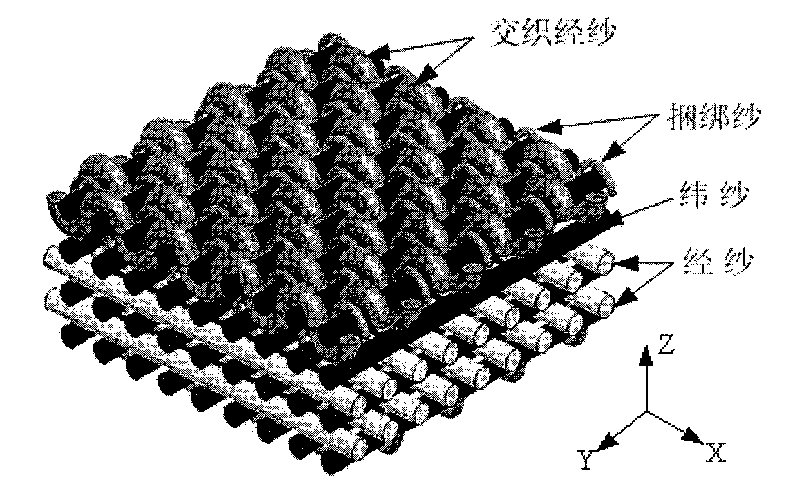

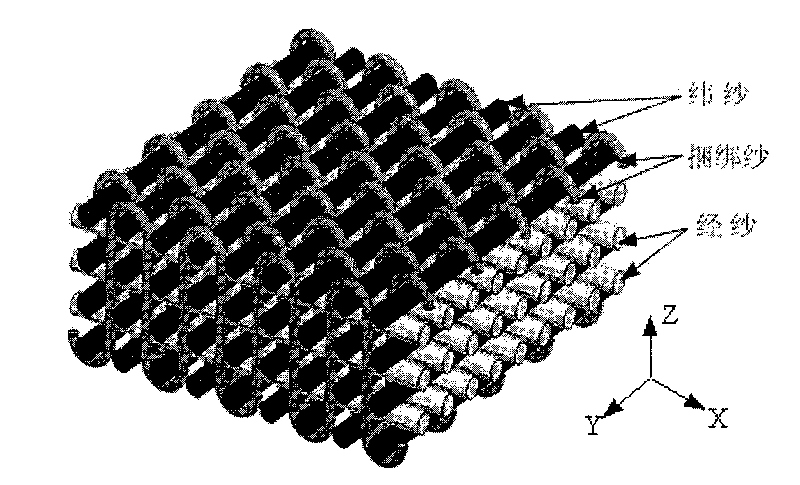

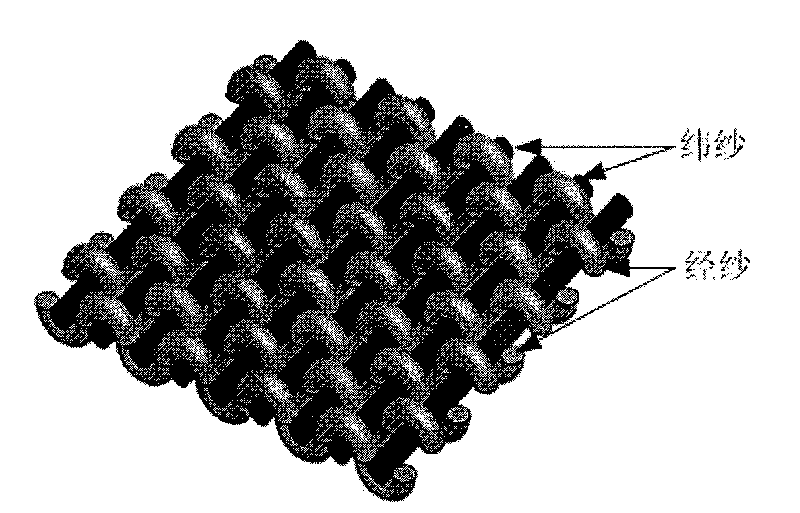

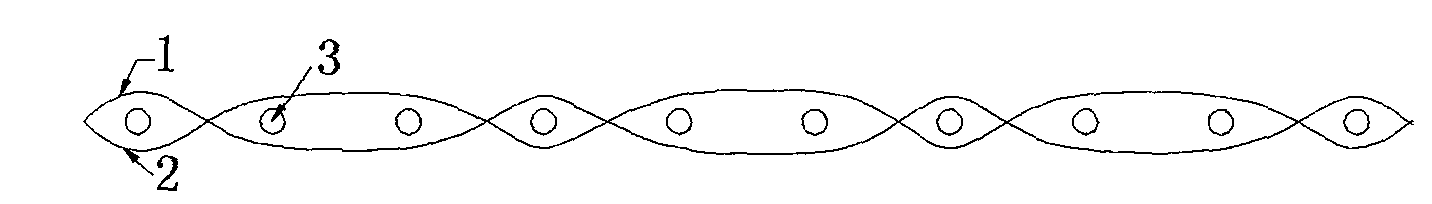

Manufacturing method for three-dimensional textile having orthogonal structure and plain weave structure

InactiveCN101718020AExpand the scope of applicationCompact structureLayered productsWoven fabricsPlain weaveEngineering

The inventions relates to a manufacturing method for three-dimensional textile having orthogonal structure and plain weave structure, comprising the steps of threading the odd yarns in the longitude yarns through a harness wire hole of one harness frame, threading even yarns through a harness wire hole of another harness frame, interweaving the two harness frames up and down in order to acquire the plain weave structure, respectively threading the odd yarns and the even yarns of binding yarns through a harness wire hole of another two harness frames, interweaving the two harness frames up and down in order to acquire the orthogonal structure of the longitude and latitude yarns of the orthogonal structure layer of the three-dimensional textile, and then integrating the longitude and latitude yarns of the plain weave structure and the yarns of the orthogonal structure layer via vertical binding yarns in order to acquire the three-dimensional textile having orthogonal structure and plain weave structure. The method of the invention is simple and is fit for commercial process. The acquired textile has excellent integrality and interlayer cutting property, meeting the demand for the embedding form of intelligent fiber.

Owner:DONGHUA UNIV

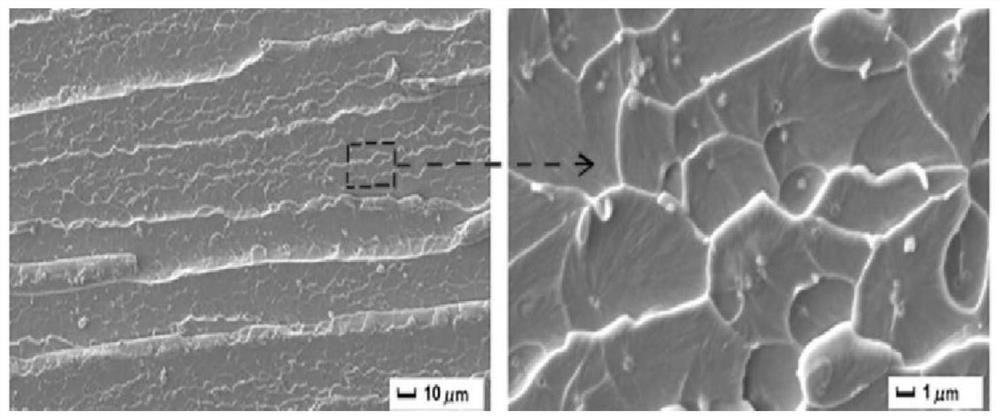

Super hybrid carbon nano material modified carbon fiber/epoxy matrix composite material and preparation method thereof

InactiveCN103552325AImproved interlaminar shear performanceThe interface is firmly bondedSynthetic resin layered productsModified carbonResin matrix

The invention relates to a super hybrid carbon nano material modified carbon fiber / epoxy matrix composite material and a preparation method thereof. The composite material an epoxy resin matrix material and an inorganic nano filler which is uniformly dispersed in the epoxy resin matrix material, wherein the composite nano inorganic filler is composed of graphene and carbon nanotubes. The excellent mechanical properties of the graphene and carbon nanotubes and the active functional groups on the surface are utilized to effectively enhance the mechanical properties of the epoxy resin matrix and the interface bonding strength between the matrix and the carbon fibers. The prepared composite material has excellent interlaminar shear property, and the interlaminar shear strength is enhanced from 50 MPa to 68 MPa.

Owner:JIAXING UNIV

Graphene oxide/carbon nano-tube collaboration-modified glass fiber reinforced epoxy composite material and preparation method thereof

The invention relates to a graphene / carbon nano-tube collaboration-modified glass fiber reinforced epoxy composite material and a preparation method thereof. The composite material comprises an epoxy resin base material and inorganic nanometer filler which is uniformly dispersed in the epoxy resin base material, wherein the composite nanometer inorganic filler is composed of graphene oxide with thickness of 0.35nm-20nm and diameter of 5 microns-100microns and the carbon nano-tube with the diameter of 30nm-50nm and length of 10 microns-20 microns. The graphene / carbon nano-tube collaboration-modified glass fiber reinforced epoxy composite material can be used for effectively improving the mechanical performances of epoxy resin matrix and interface bonding strength between the matrix and the glass fiber by utilizing the excellent mechanical performances and the surface active functional groups of the graphene oxide and the carbon nano-tube, so that the interlayer shearing strength of the glass fiber composite material is effectively improved.

Owner:JIAXING UNIV

Basalt fiber and carbon fiber hybrid composite compressed natural gas cylinder and preparation method thereof

The invention aims to provide a basalt fiber and carbon fiber hybrid composite compressed natural gas cylinder and preparation method thereof. The compressed natural gas cylinder is characterized in that a composite layer of the compressed natural gas cylinder is composed of an epoxy resin matrix, a basalt fiber, a carbon fiber and fiberglass. Epoxy resin doped with a carbon nano tube is composited with the fibers, so that the adhesive property and shear strength of a single-bundle fiber and interlamination are effectively improved, and the service life of the compressed natural gas cylinder which is collided is prolonged; the mechanical property of the basalt fiber is superior to that of the common fiberglass, the basalt fiber has a favorable anti-humid heat characteristic; compared with the carbon fiber, and the basalt fiber has an obvious cost advantage and more extensive applicability. The natural compressed gas cylinder prepared by a basalt fiber and carbon fiber hybrid composite has the advantages that the cost is effectively lowered while the product performance is ensured; the working pressure of the compressed natural gas cylinder reaches 35MPa; according to a 1.8m high-altitude falling experiment, the burst pressure still exceeds 130MPa, and the safety coefficient is increased by 3.4 times; the compressed natural gas cylinder has favorable use performance and cost advantages.

Owner:沈阳中复科金压力容器有限公司

Composite component curing process and composite workpiece

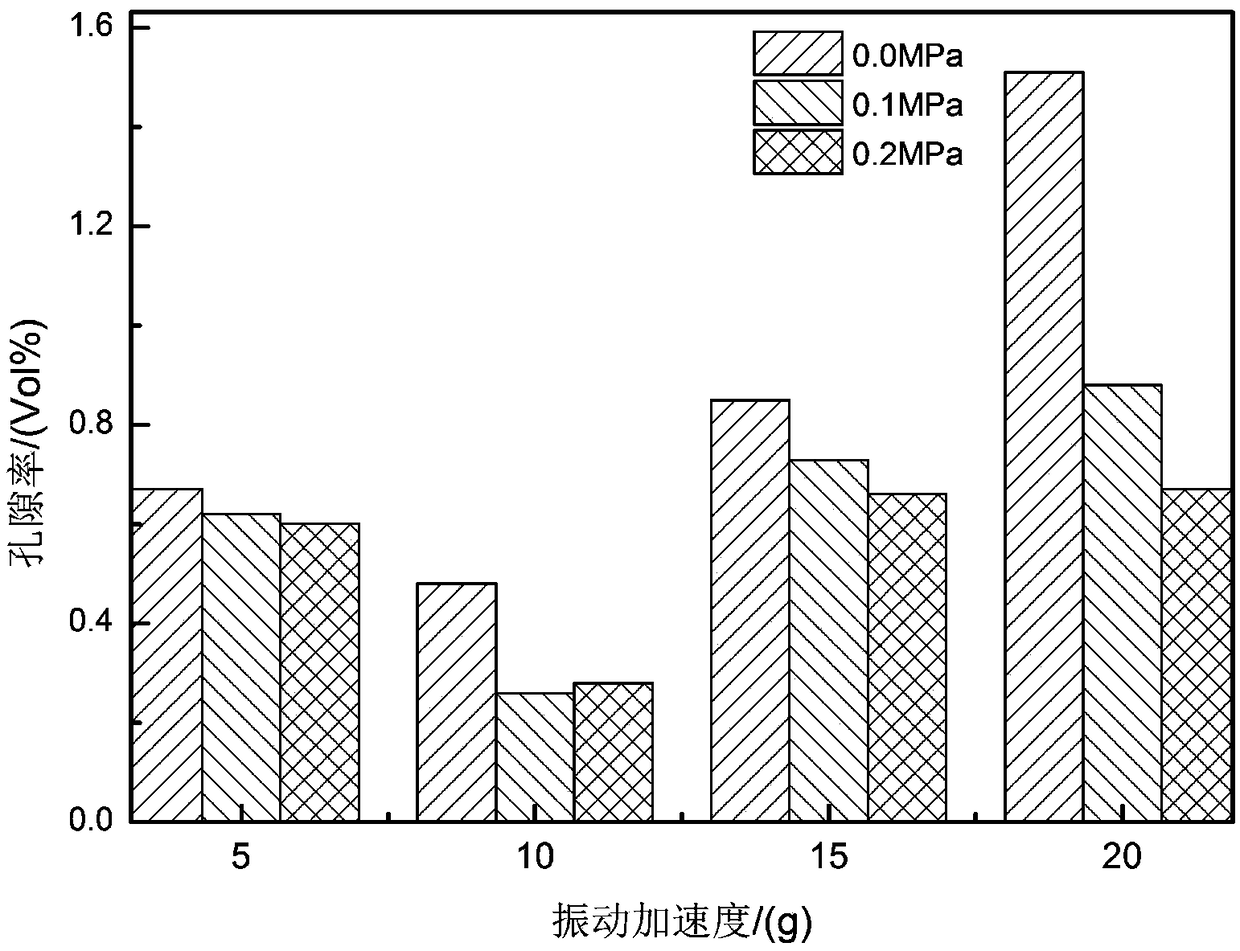

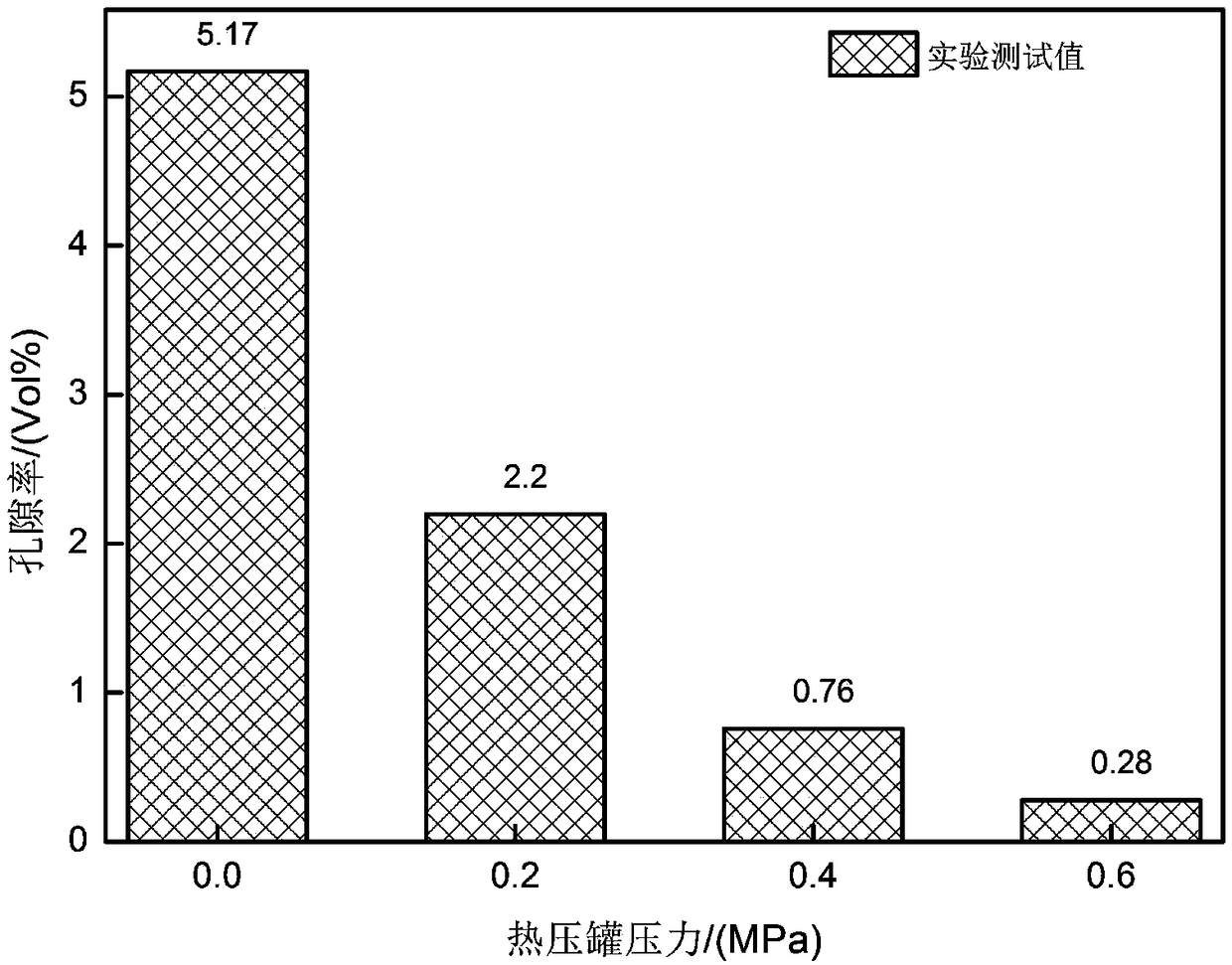

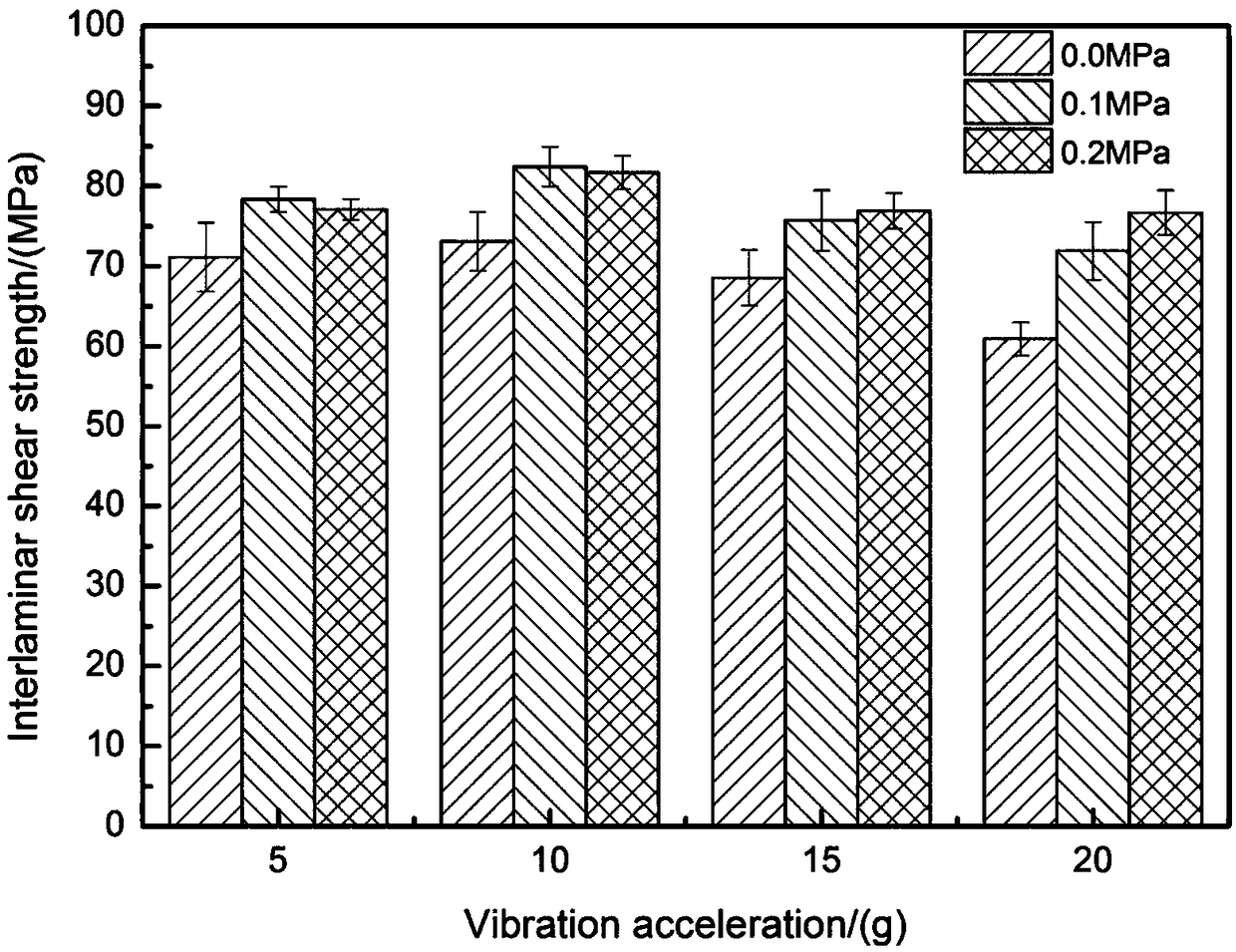

ActiveCN108839359AEliminate delaminationDecreased interlaminar shear performancePorosityEnergy analysis

The invention belongs to the field of materials, and relates to a composite component curing process and a composite workpiece. The composite component curing process comprises the following steps that (1) the to-be-processed composite workpiece is heated and subjected to heat preservation in a vibration experimental platform; (2) in the heating and heat preservation processes, the to-be-processedcomposite workpiece is vibrated through the vibration experimental platform; (3) after vibration is finished, the low pressure is applied to the to-be-processed composite workpiece through the vibration experimental platform; and (4) in the process of applying the low pressure, the to-be-processed composite workpiece is subjected to secondary temperature rise, and subsequent curing of the to-be-processed composite workpiece is completed. According to the composite component curing process, under the low curing pressure, the porosity of the composite workpiece can be significantly decreased, the performance of the composite workpiece can be significantly improved, and safe, efficient and energy-saving forming curing of the large composite workpiece can be achieved.

Owner:CENT SOUTH UNIV

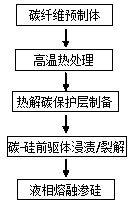

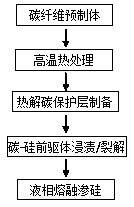

Carbon-silicon carbide double-ingredient substrate carbon fiber composite material as well as preparation method and application thereof

ActiveCN108516852AEvenly distributedImprove frictional stabilityBraking discsAdditive ingredientPorous carbon

The invention discloses a carbon-silicon carbide double-ingredient substrate carbon fiber composite material as well as a preparation method and application thereof. The method comprises the followingsteps of (1) performing weaving and high-temperature heat treatment on a carbon fiber prefabricated body; (2) preparing a porous carbon / carbon blank body; (3) introducing carbon elements and siliconelements into the carbon / carbon blank body in an impregnating mode; after the soaking and pyrolysis circulation period, obtaining a Cf / Cm-Sim porous intermediate; (4) performing embedded fusion Si seeping on the Cf / Cm-Sim porous intermediate to obtain a Cf / Cm-SiCm composite material. The inside SiC distribution of the composite is uniform; the residue Si content is 1.2 to 3.3 percent; the bendingintensity is 236 to 275MPa; the compression intensity is 322 to 364MPa; the dynamic friction coefficient is 0.32 to 0.48; the mechanical / friction performance is excellent; the thermal stability and the environment applicability are high; the material is applicable to the manufacturing of automobile braking discs / sheets.

Owner:湖南金羽先进材料有限公司

Preparation method of transparent self-toughening dicyandiamide/epoxy resin-based composite material

The invention belongs to the technical field of application of high performance epoxy resin and particularly relates to a preparation method of a transparent self-toughening dicyandiamide / epoxy resin-based composite material, in particular to a preparation method of a transparent self-toughening epoxy resin composition with low heat release, a heavy-thickness prepreg unidirectional tape and a composite material. The composition comprises the following raw materials in parts by weight: 60-100 parts of liquid epoxy resin, 0-40 parts of solid epoxy resin, 1.0-12 parts of a dicyandiamide curing agent and 0.5-6 parts of an accelerant. The epoxy resin is prepared by adopting a solution reaction manner; compared with a general dicyandiamide / epoxy resin system, a system in the invention has the advantages that the peak heat flux is decreased by 48% or higher, the heat release is decreased by 38% or higher, and the reaction heat is low; moreover, a resin casting body has 3.5% or more of breaking elongation, 80MPa or higher of tensile strength and 24kJ / m<2> of higher impact strength and has good toughness without adding a toughening agent; 130-DEG C medium temperature curing can be realized, and a cured product is transparent.

Owner:AVIC BASIC TECH RES INST

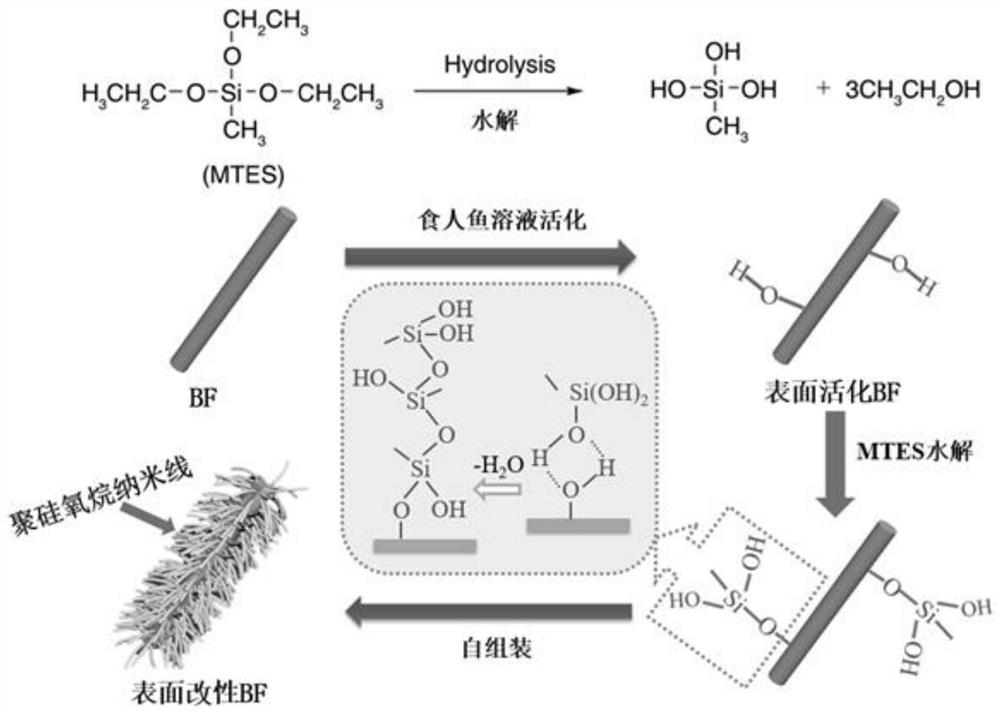

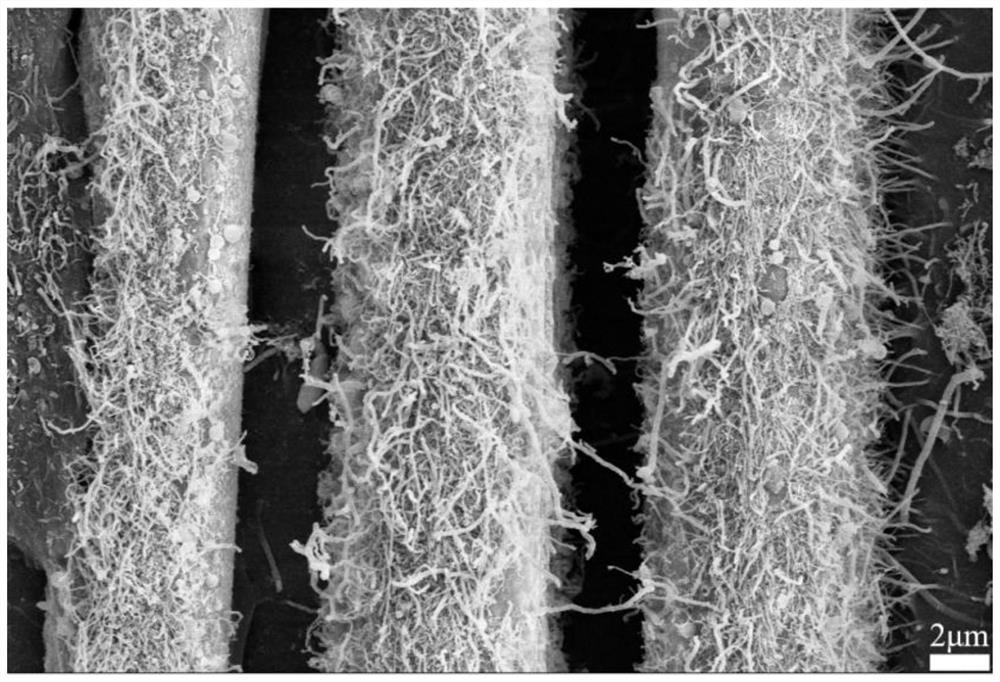

Method for optimizing interface of basalt reinforced resin-based composite material

ActiveCN111690158ASolve the problem of poor interface performanceImprove interface performanceTriethoxysilanePiranha solution

The invention discloses a method for optimizing an interface of a basalt reinforced resin-based composite material, wherein the method mainly comprises the steps: soaking basalt fibers in a piranha solution for activation to obtain surface-activated basalt fibers; putting the activated basalt fiber into dehydrated and deoxygenated toluene, then adding methyltriethoxysilane, then adding hydrochloric acid to keep the solution acidic, carrying out a reaction for 6-10 h, cleaning and drying to obtain modified basalt fibers; fixing the modified basalt fibers on a mold, making the length of the fibers equivalent to that of the mold, then pouring the resin and curing agent mixed solution into the mold, and carrying out mold pressing to obtain the composite material. According to the method, silicon nanowires grow on the surfaces of the basalt fibers, the surface roughness of the fibers is improved, meanwhile, a large number of active groups such as hydroxyl exist on the silicon nanowires, themechanical meshing and chemical bonding effects between the fibers and resin are enhanced, and the interface performance of the basalt reinforced resin-based composite material is effectively optimized.

Owner:SOUTHWEST PETROLEUM UNIV

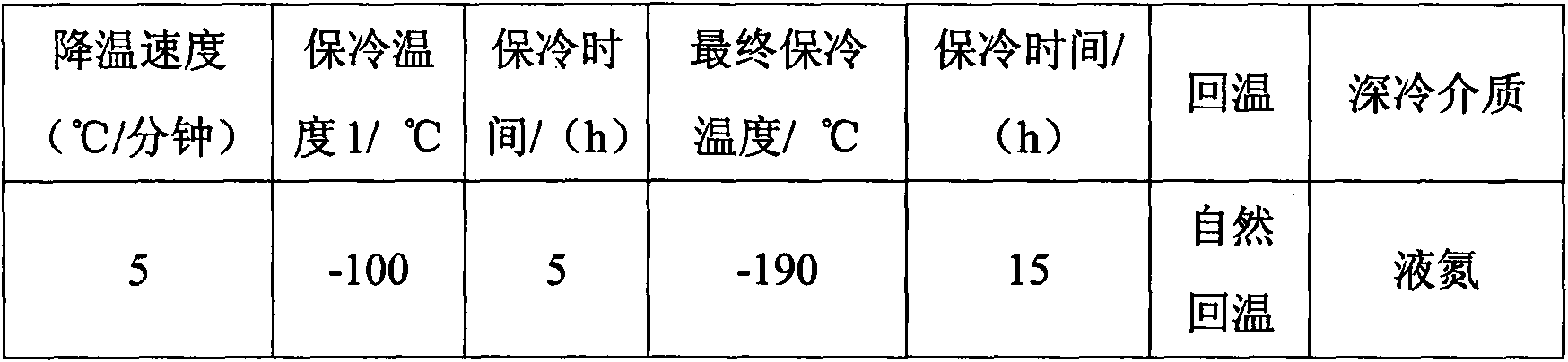

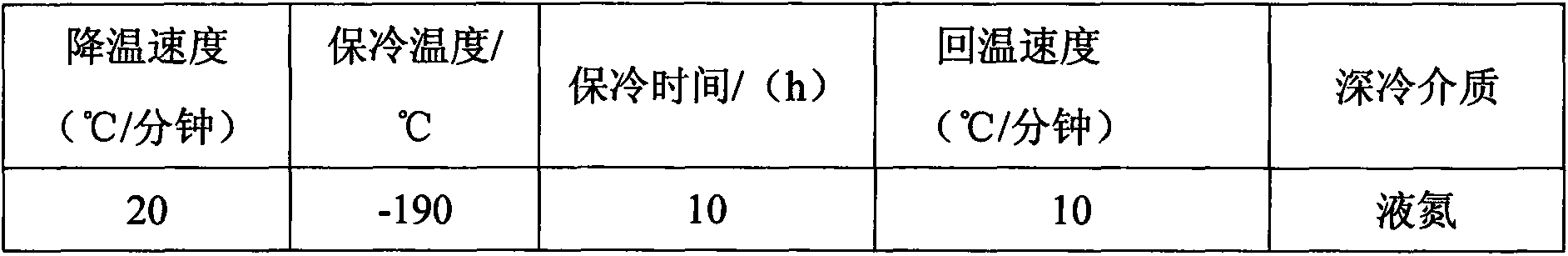

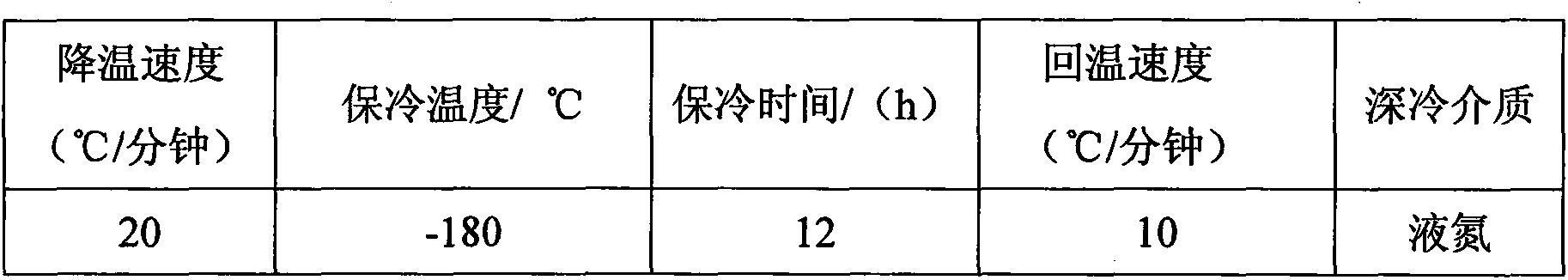

Method for modifying carbon fiber composite material by cryogenic treatment

The invention provides a method for modifying a carbon fiber composite material by cryogenic treatment. The method is characterized by comprising the following specific steps: putting a carbon fiber composite material sample into a cryogenic treatment device with a cryogenic medium, closing a container and performing cryogenic treatment, wherein the treatment temperature is constant temperature and at -100 DEG C to -200 DEG C and the treatment time is 1h-15h; and increasing the temperature through a program for temperature returning or taking the sample out of the cryogenic treatment device for natural temperature returning after cryogenic treatment. As resin has a larger shrinkage rate than carbon fiber under cryogenic conditions, the cohesion pressure between the resin and fiber is increased and an interfacial effect is strengthened. Thus, the carbon fiber composite material has high tensile property, bending property, interlaminar shear property, wear resistance property and other comprehensive properties. The process method provided by the invention is simple, convenient to operate and pollution-free and has important practical significance and industrial application prospects.

Owner:DONGHUA UNIV

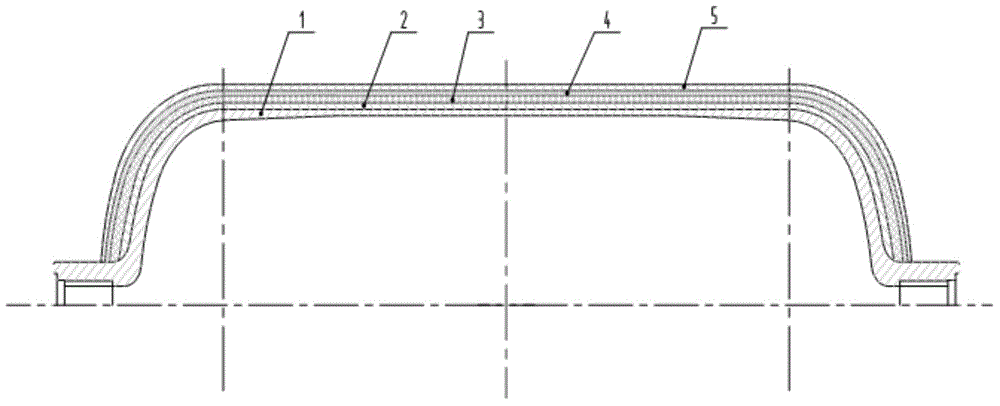

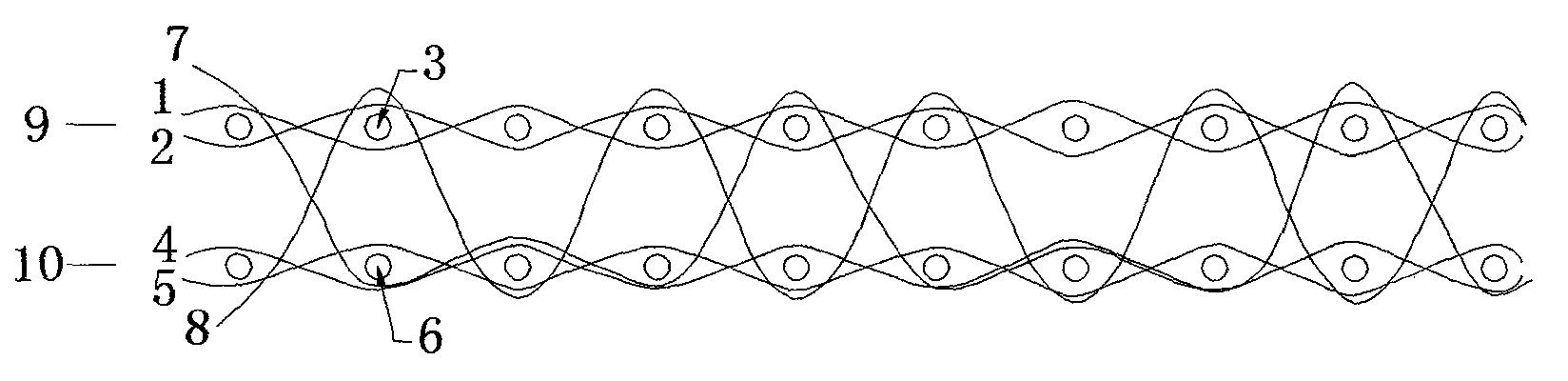

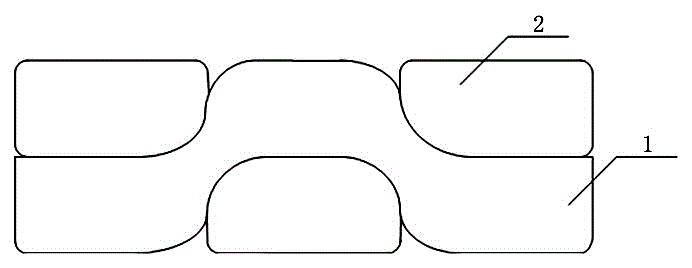

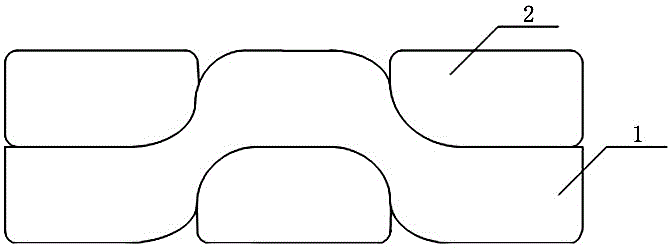

Loop fabric

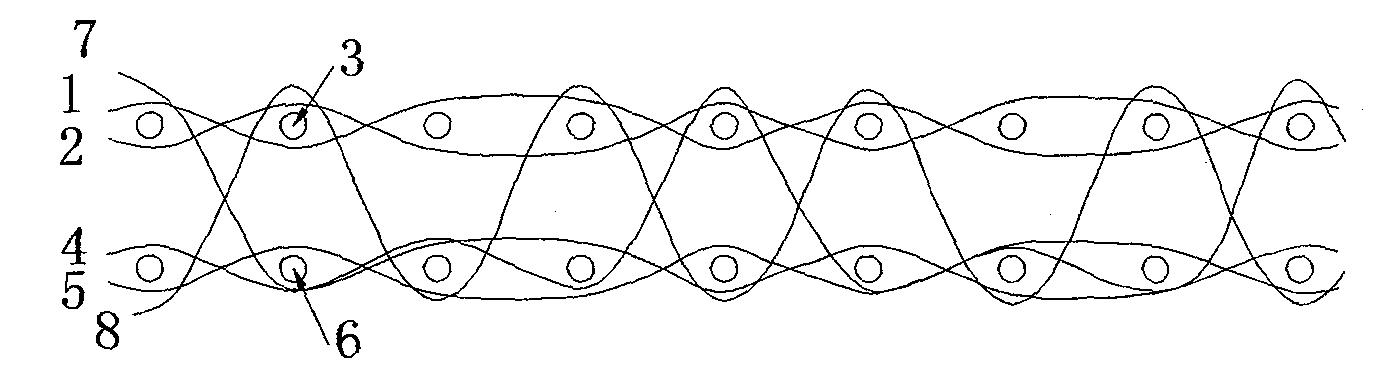

The invention relates to a loop fabric, comprising an upper layer (9) formed by interweaving upper layer body warps (1) and (2) and an upper layer weft (3) and a lower layer (10) formed by interweaving lower layer body warps (4) and (5) and a weft (6); the number the upper layer and the lower layer is at least one. The loop fabric is characterized in that the wefts (3) and (6) on the upper layer and the lower layer of the fabric are respectively interweaved with a binder yarn (7) and a loop yarn (8) besides being interweaved with the body warps (1) and (2) and the body warps (4) and (5) on the same layers. The invention has the advantages of strong designability and suitability for scale weaving. Vast pile loops are attached to the surface of the invention, thereby effectively increasing the contact area among interfaces and reaching the aim of improving interlaminar shear property and delamination resistance of materials. Therefore, the loop fabric can be widely used as a wear-resistant material of bonding materials and composite materials among interfaces.

Owner:SINOMA SCI & TECH

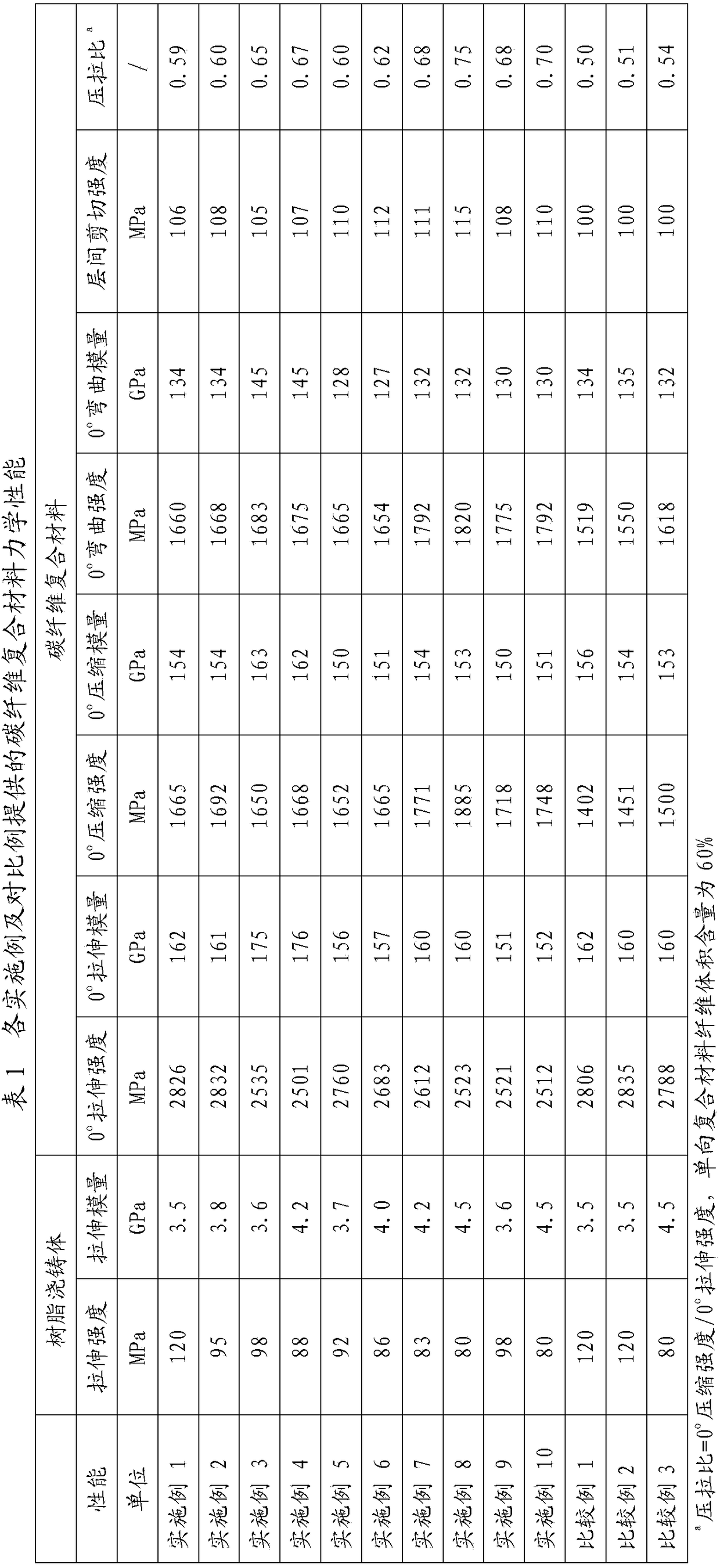

Carbon fiber composite material with high compressive strength and high-pressure draw ratio and preparation method thereof

The invention discloses a carbon fiber composite material with high compressive strength and a high-pressure draw ratio and a preparation method of the carbon fiber composite material with the high compressive strength and the high-pressure draw ratio, and belongs to the field of composite materials. The composite material comprises a resin matrix and reinforced fibers, wherein the reinforced fibers are carbon fibers of which the fiber monofilament diameters are 5.4 to 7.0 microns, the resin matrix comprises the following components in parts by mass: 100 parts of resin, 30 to 60 parts of a curing agent, 0.5 to 2 parts of an accelerator and 0.1 to 3 parts of inorganic nanoparticles. The composite material disclosed by the invention has excellent mechanical properties, especially the characteristics of high compressive strength and good pressure-tension balance, can be used for preparing main force-bearing structural parts of aerospace vehicles, and further can meet demands for the composite material with light weight, high strength, compressive strength and high-pressure draw ratio in the fields of high-speed rails, automotives and other industrial equipment.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

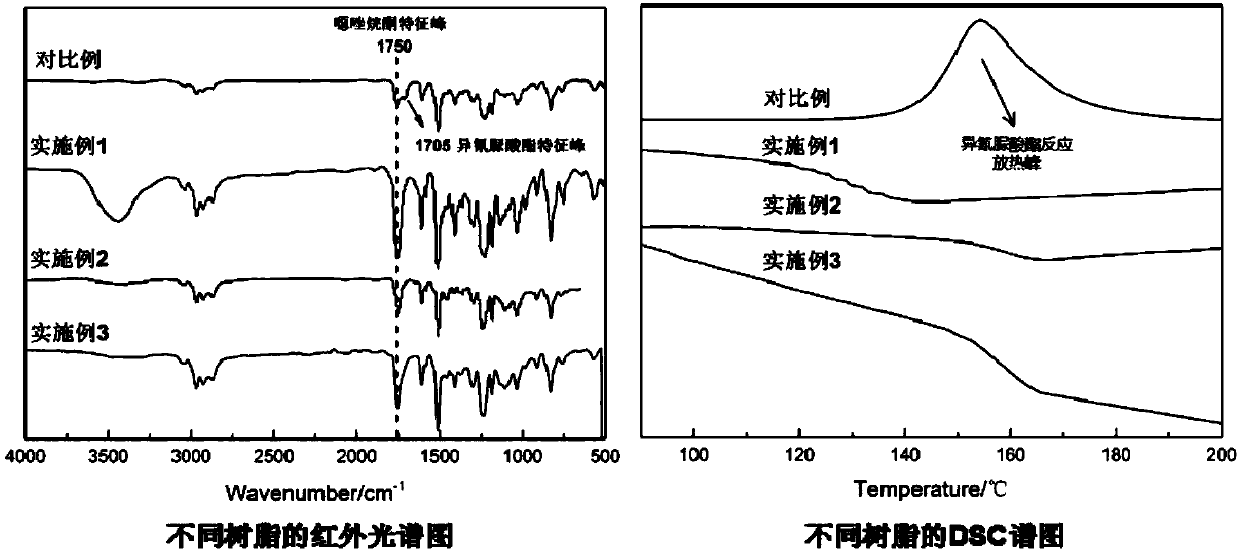

Interface bonding-enhanced aramid fiber composite material preparation method

The invention discloses an interface bonding-enhanced aramid fiber composite material preparation method. The method is characterized in that isocyanate and epoxy resin are used for preparing modifiedepoxy resin having a molecule main chain containing a five-membered ring structure according to controllable proportion and technical reaction; liquid epoxy resin and a curing agent are added for kneading to obtain a pre-dip material resin system with synchronously increased bonding property and toughness; a resin glue membrane is prepared, then is composited with aramid fiber or fabric to obtaina pre-dip material, and finally moulding preparation is carried out to obtain the interface bonding-enhanced aramid fiber composite material. The toughness of the modified epoxy resin system is increased, the bonding property of a resin matrix and aramid fiber are enhanced, the technical performance of the pre-dip material is good, a processing moulding window is wide, the interlayer shearing intensity of the composite material is obviously increased, and the modified epoxy resin system can be used for the composite material having the aramid fiber structure.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of reactive liquid nanometer additive for carbon fiber wet winding

InactiveCN101624484AImprove heat resistanceImproved interlaminar shear performancePigment treatment with non-polymer organic compoundsEpoxyFiber

The invention relates to a reactive liquid nanometer additive suitable for a wet winding forming technology of carbon fiber composite materials, belonging to the field of carbon fiber composite material preparation. The reactive liquid nanometer additive comprises the following materials: material 1: a multiwalled carbon nano tube; material 2: mixed acid of concentrated sulfuric acid and concentrated nitric acid; material 3, a mixed solution of thionyl chloride and N, N-dimethylformamide; material 4, i.e. a mixed solution of the N, N-dimethylformamide and liquid aliphatic series polyamine, and a material 5, i.e. liquid ethoxyline resin, wherein the in the mixed acid of the concentrated sulfuric acid and the concentrated nitric acid, the mole ratio of a sulfate radical to a nitrate radical is 2 / 1 to 4 / 1; the volume ratio of the thionyl chloride to the N, N-dimethylformamide is 30 / 1 to 50 / 1; the volume ratio of the N, N-dimethylformamide to the aliphatic series polyamine is 0.8 / 1 to 1.2 / 1; and the viscosity of the liquid ethoxyline resin is less than 500 mPas under room temperature. The reactive liquid nanometer additive can be directly used as a thinner of the an ethoxyline resin matrix and can enhance the heat resistance and the interlayer shearing property of the carbon fiber composite materials when a very little using amount is used.

Owner:BEIJING UNIV OF CHEM TECH

Graphene-modified polyester glass fiber reinforced plastic material and preparation method thereof

InactiveCN105504733AImprove bending abilityImprove tensile propertiesBuilding insulationsPolyesterDecomposition

The invention discloses a graphene-modified polyester glass fiber reinforced plastic material. After low-temperature pretreatment is carried out on glass fibers through a physical method, the bending property, tensile property and interlaminar shear property of the glass fibers are improved. Through high-temperature treatment, oxidative decomposition of original gel on the surfaces of the glass fibers is achieved, and thus moisture stored and adsorbed by the glass fibers is removed. Graft modification is carried out on the surfaces of the glass fibers with materials such as porous carbon nanotubes through a chemical method, hole structures are formed, chain segments of some high polymers enter the holes when the glass fibers are compounded with a matrix, and an effect like anchoring is achieved. Thus, the bonding force between interfaces of the glass fibers and the polymers is increased, the impact resistance of the product is increased, and the obtained glass fiber reinforced plastic material has the advantages of being low in brittleness, large in toughness, low in formaldehyde content, large in tensile strength and the like.

Owner:WUHU EDISON AUTOMATION EQUIP

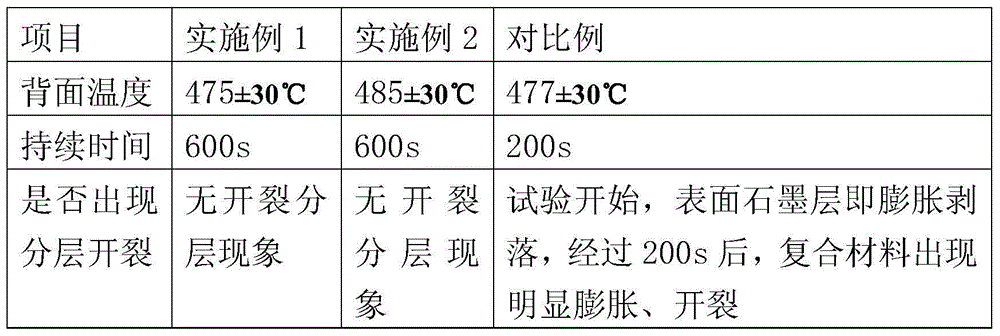

Stitched laminar flexible heat insulation material and preparation method thereof

ActiveCN104589724AGood high temperature insulation performanceImprove volume fraction and interlaminar shear performanceLayered productsGraphite compositeBonding strength

The invention discloses a stitched laminar flexible heat insulation material and a preparation method thereof, wherein the stitched laminar flexible heat insulation material comprises an aluminum oxide fiber-graphite composite layer and two pieces of carbon fiber cloth, wherein the aluminum oxide fiber-graphite composite layer is formed by sticking a plurality of pieces of aluminum oxide fiber paper and a plurality of pieces of graphite paper which are alternately arranged; the two pieces of carbon fiber cloth are respectively arranged on the two sides of the aluminum oxide fiber-graphite composite layer; the carbon fiber cloth and the aluminum oxide fiber-graphite composite layer are stitched into a whole by a carbon fiber rope. The stitched laminar flexible heat insulation material is good in high temperature oxidation resistance and heat-insulating property, and all the layers have higher bonding strength.

Owner:CHINA BUILDING MATERIALS ACAD

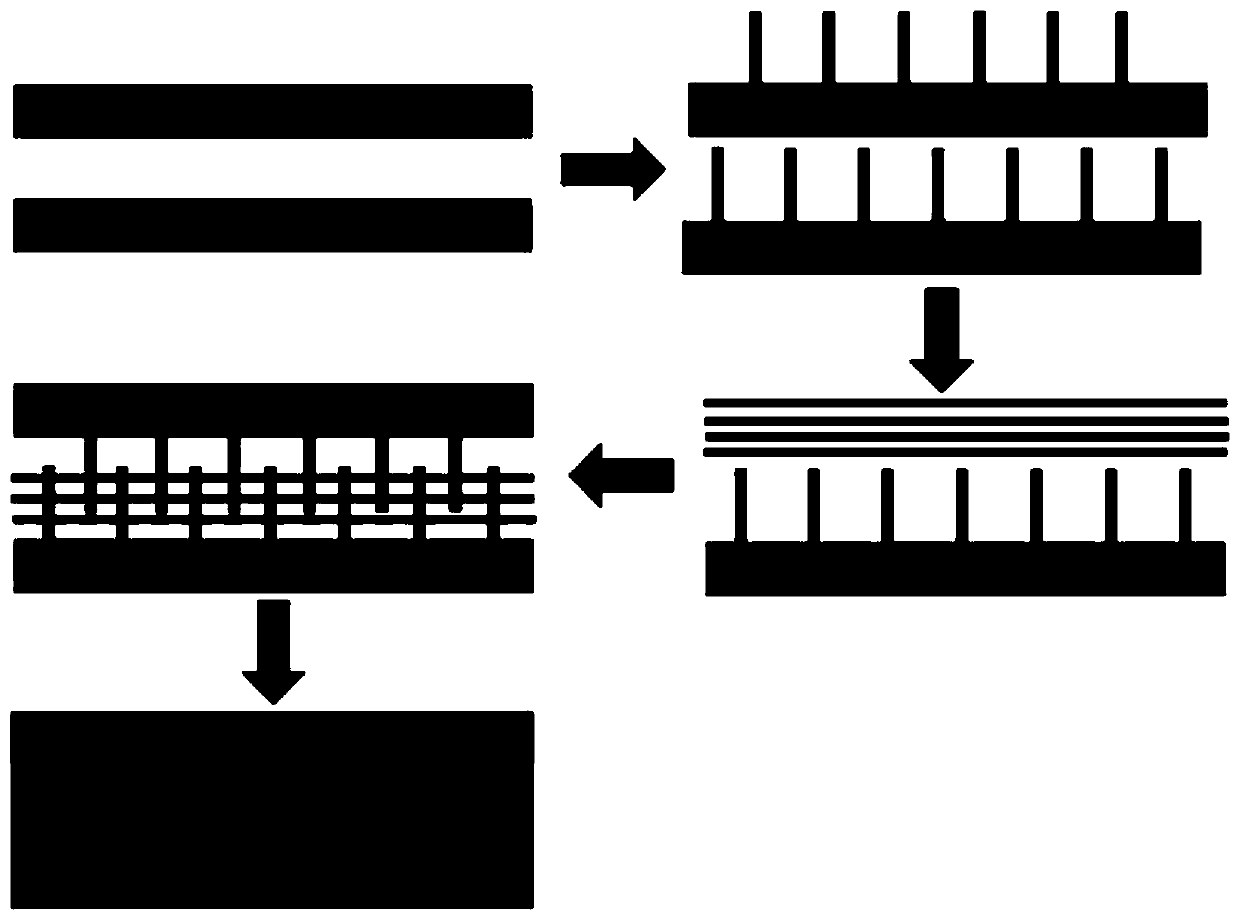

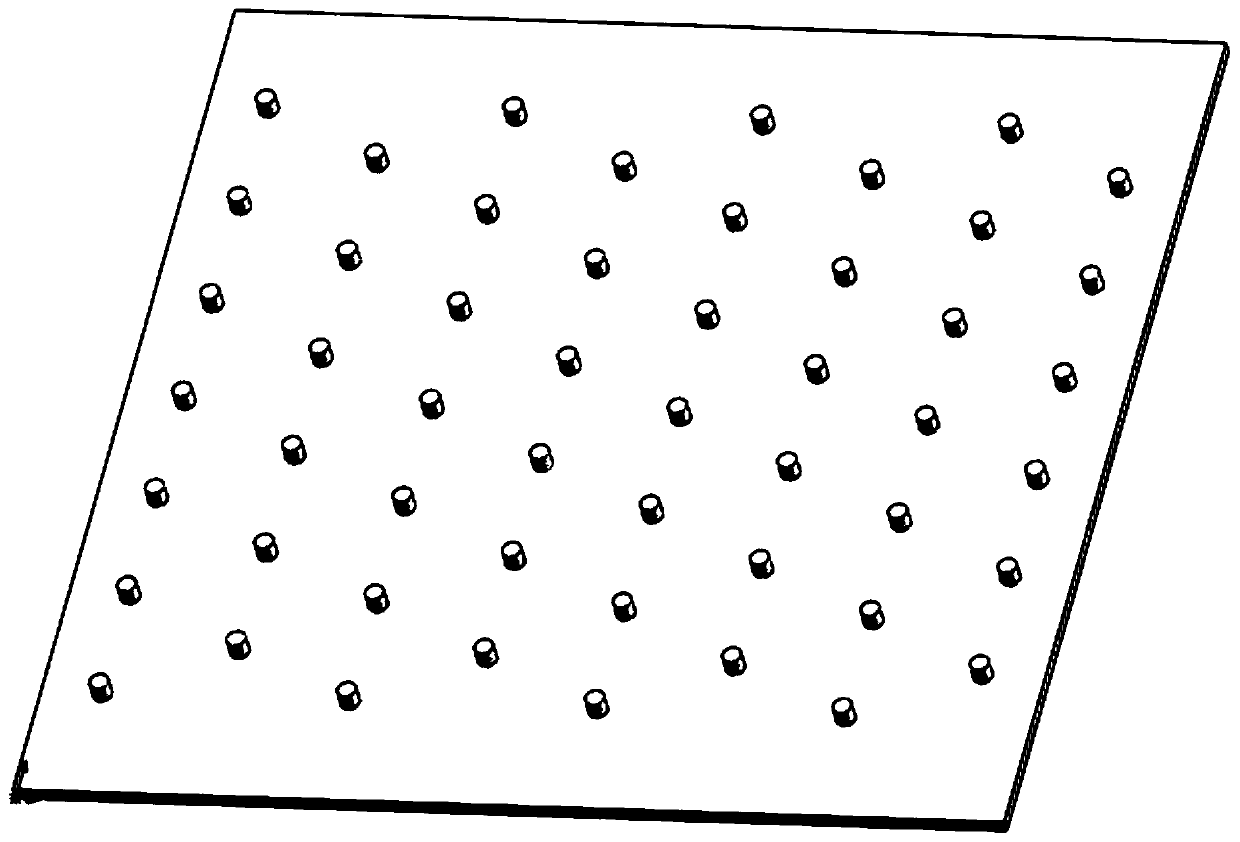

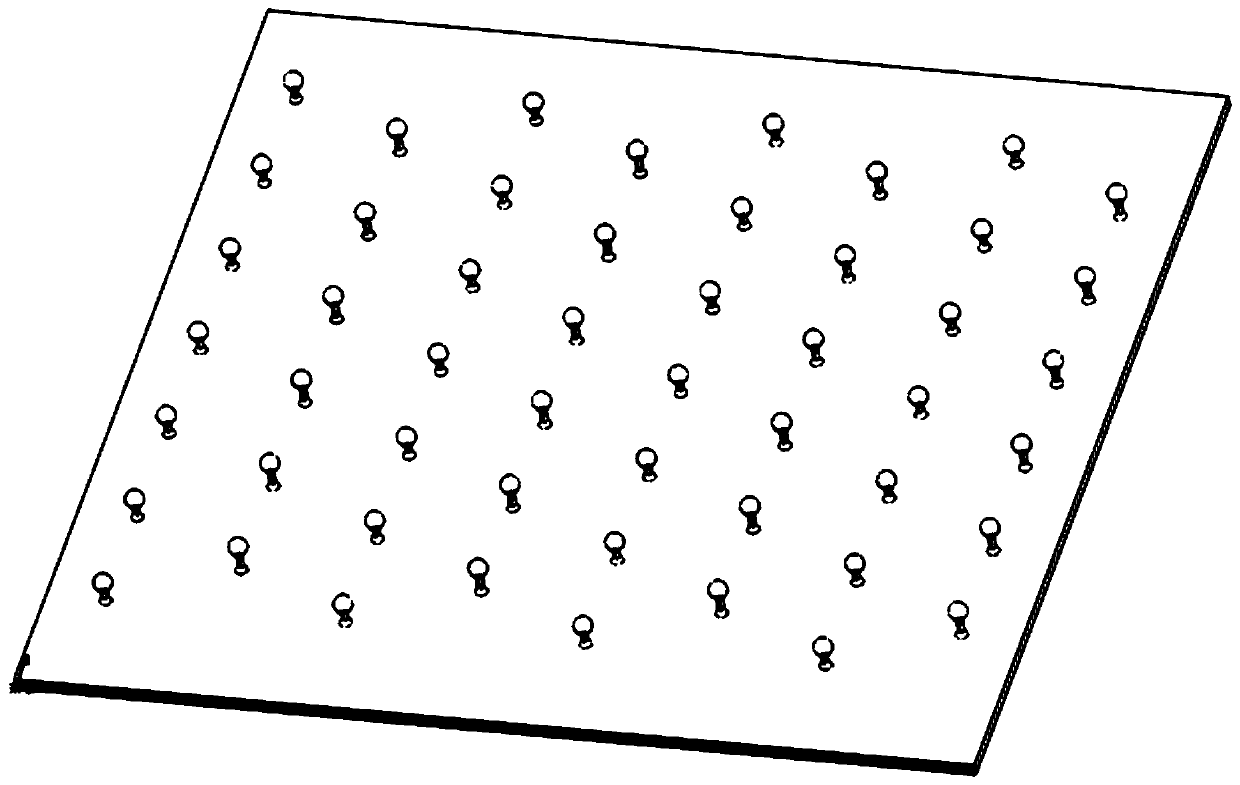

Novel fiber metal laminate and preparation method thereof

ActiveCN110466217AEnhanced interface bindingImprove performanceLamination ancillary operationsLaminationMaterials preparationManufacturing technology

The invention provides a novel fiber metal laminate and a preparation method thereof, and belongs to the technical field of composite material preparation, wherein a metal plate and a prepreg are laminated, and curing is performed at a certain temperature under a certain pressure to form an ultra-hybrid composite material, ie., the novel fiber metal laminate. The preparation method comprises: (1)preparing a projection structure with a certain height on the surface of a metal plate by using an additive manufacturing technology, and pre-treating the surface of the metal plate; (2) cutting a prepreg, and laying in a mold; (3) pre-pressing the prepreg layer, carrying out surface piercing, and carrying out secondary cutting; and (4) carrying out laminating paving and hot pressing molding on the metal layer and the prepreg layer. According to the present invention, the novel fiber metal laminate prepared by the method can increase the interface connection strength between the metal and thecomposite material, inhibit the delamination, improve the interlayer performance of fiber metal laminates, and increase the interlaminar shear strength and the damage tolerance.

Owner:DALIAN UNIV OF TECH

Janus particle/epoxy resin composite material

InactiveCN112210190AImprove flame retardant propertiesImprove matrix toughnessEpoxy resin compositeResin composite

The invention discloses a Janus particle / epoxy resin composite material which is prepared by the following steps: adding mixed powder of polystyrene and polydivinylbenzene into deionized water, then adding aluminum oxide, conducting ultrasonic dispersing, then adding azodiisobutyronitrile, conducting ultrasonic stirring, then adding a formed solution into a sodium dodecyl benzene sulfonate aqueoussolution, conducting ultrasonic dispersing, adding gamma-methacryloyloxypropyltrimethoxysilane into epoxy resin, dropwise adding an alkaline substance to adjust the pH value to 9, conducting heatingfor reaction, conducting cooling and centrifuging, conducting washing with an absolute ethyl alcohol solution for three times to obtain Janus microsphere particles, adding the Janus microsphere particles into epoxy resin, adding a curing agent, conducting heating and stirring, pouring a formed mixture into a preheated mold, conducting curing for a period of time, and conducting cooling to obtain the Janus particle / epoxy resin composite material. The Janus particle / epoxy resin composite material effectively prevents crack development on an interface, so that the mechanical property of the prepared composite material is improved.

Owner:董燕飞

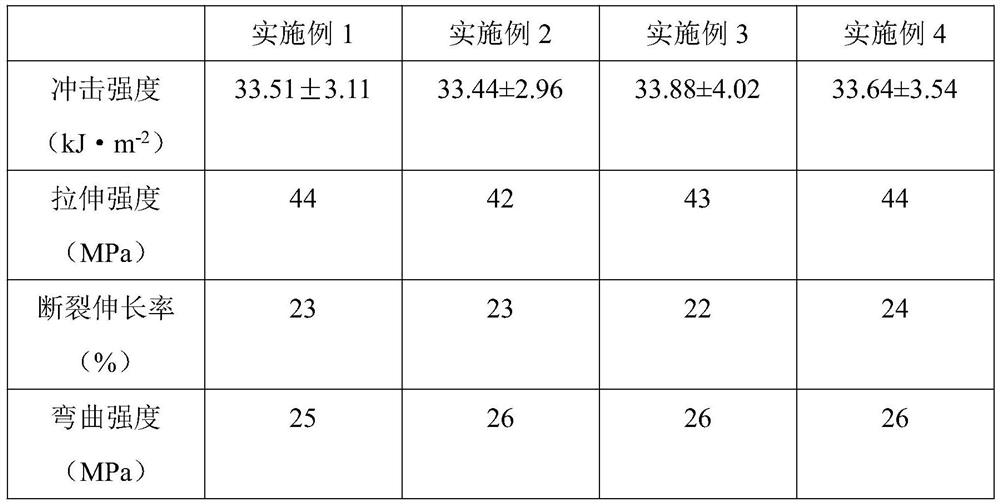

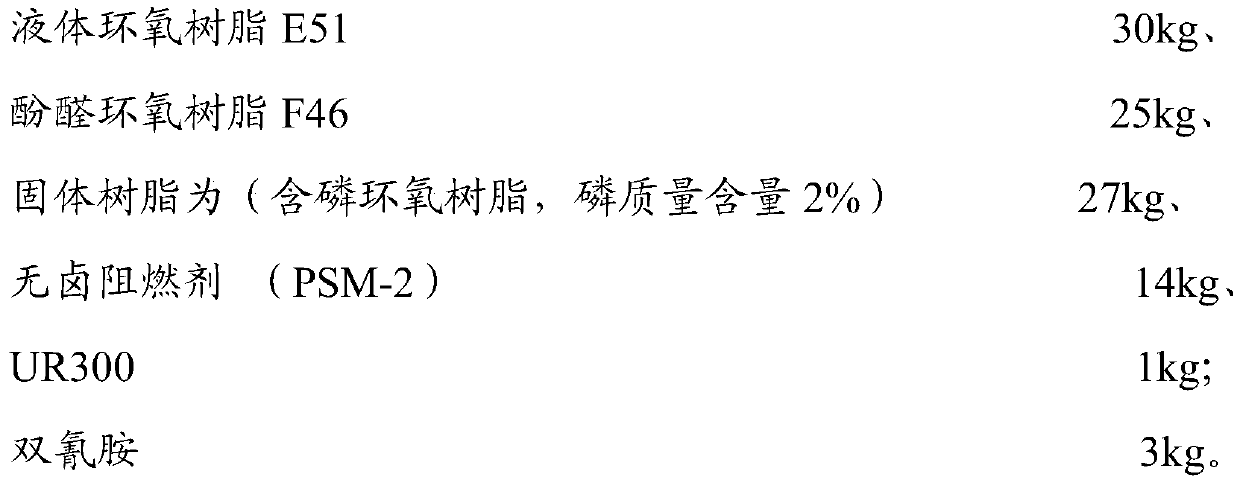

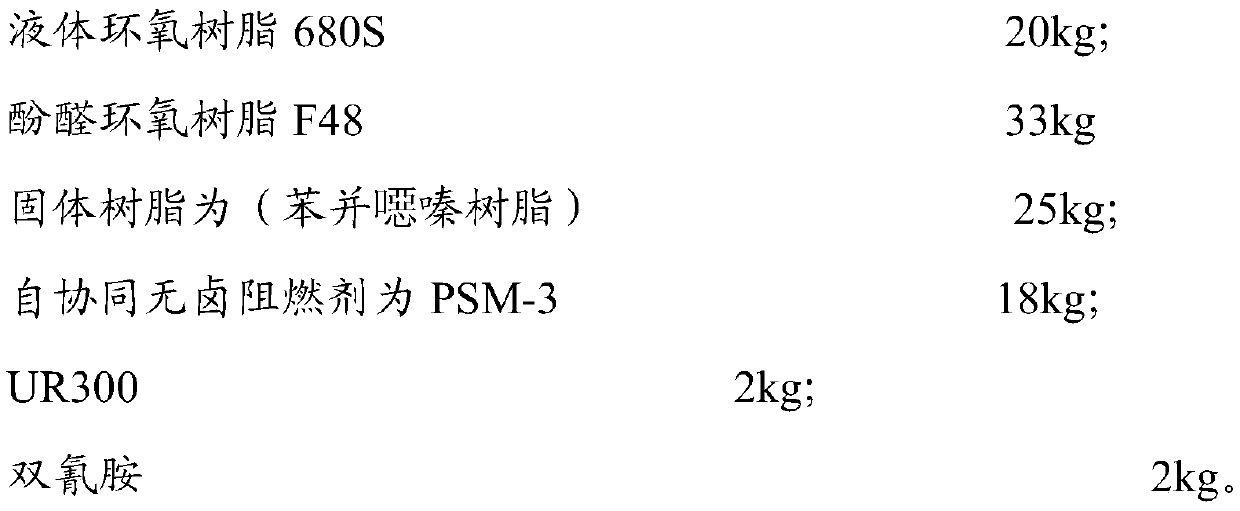

Halogen-free flame-retardant epoxy resin based composite material and preparation method and application thereof

The invention provides a halogen-free flame-retardant epoxy resin based composite material and a preparation method and application thereof. The composite material comprises a resin matrix and reinforced fiber, the resin matrix comprises, by mass, 30-70% of liquid-state epoxy resin, 5-30% of solid resin, 12-32% of solid halogen-free flame retardant and 2-8% of epoxy curing agent, the solid resin is at least one of phosphorus epoxy resin, phenolic resin or benzoxazine resin, and the solid halogen-free flame retardant is at least one of halogen-free organic reaction type phosphorus, silicon or nitrogen flame retardant. The composite material has high-flame-retardant and smoke suppression effect, meets highest-grade flame-retardant requirements required in standards like DIN5510 and EN45545,has strong interlayer shearing force and can be used as a force-bearing structure material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Forming technique for large-curvature composite foam sandwich structure

InactiveCN107081917AImproved interlaminar shear performanceImprove performanceUltimate tensile strengthPolyresin

The invention discloses a forming technique for a large-curvature composite foam sandwich structure. According to the forming technique for the large-curvature composite foam sandwich structure, PVC foam provided with array reinforced holes is used as a core material, a sandwich preform is prepared under the heating auxiliary vacuum condition, fiber reinforced materials and the preform are laid in a mold, a resin system is poured into the forming mold through the vacuum auxiliary forming technique, demolding is conducted after curing, and thus the large-curvature composite foam sandwich structure is obtained. The large-curvature composite foam sandwich structure obtained through the method has good overall performance, high stripping strength and high forming precision.

Owner:南京辰茂新材料科技有限公司

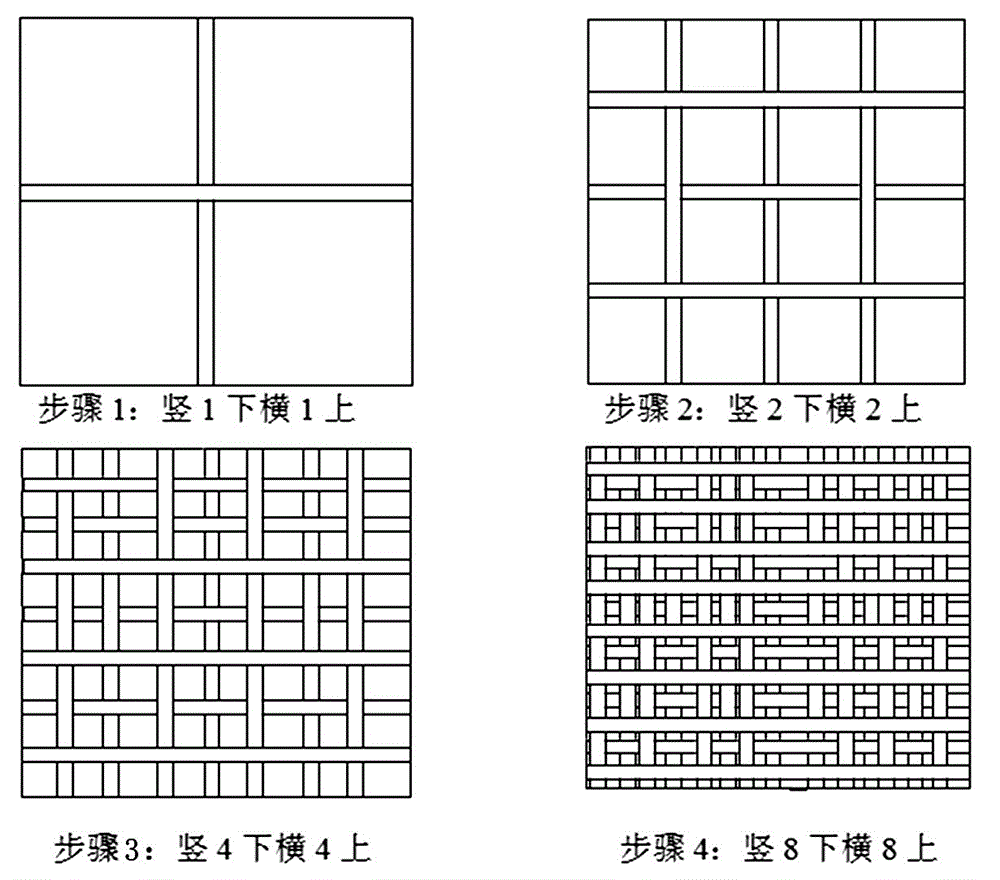

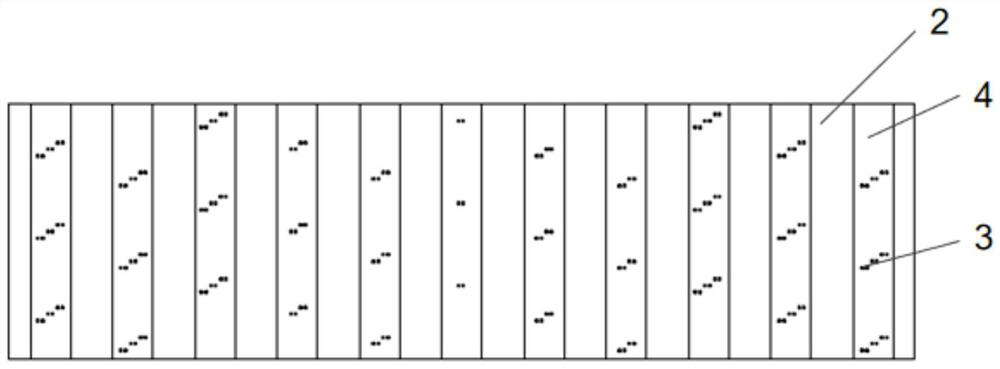

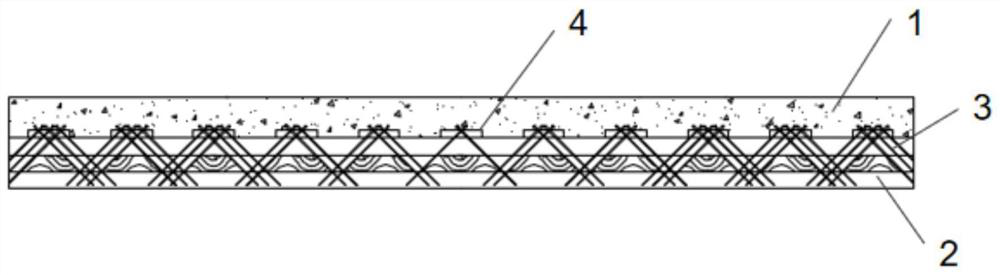

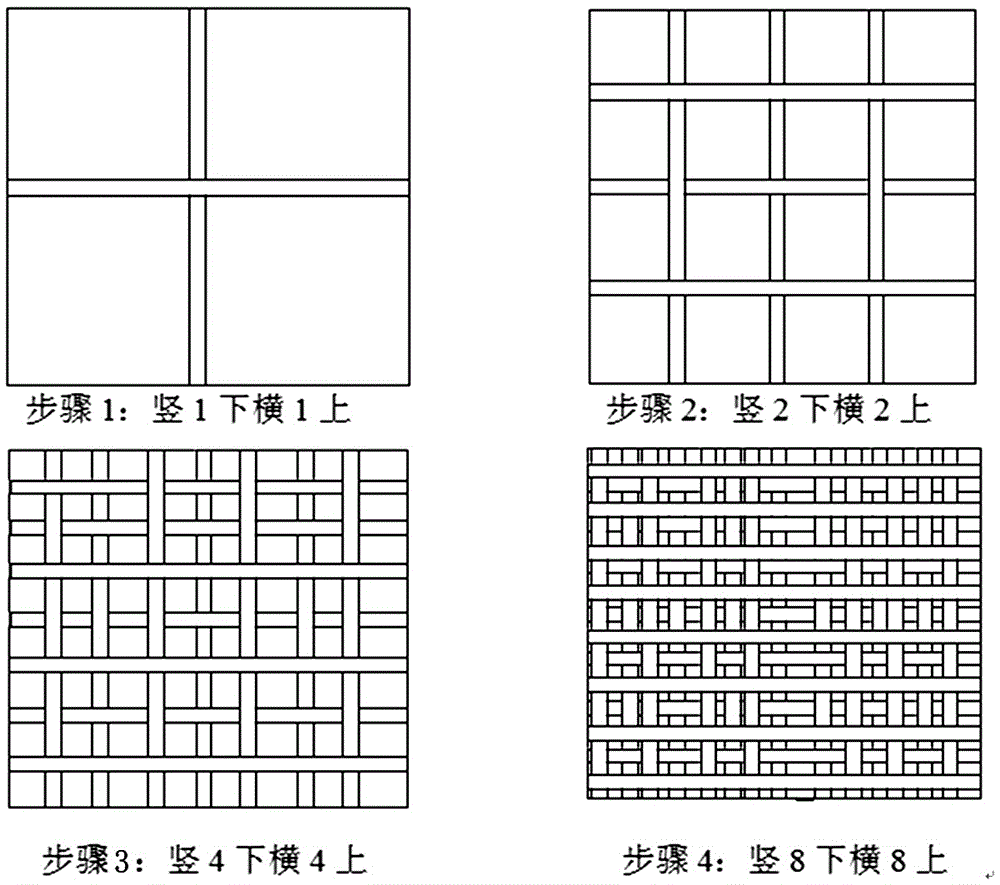

Grid stacking structure capable of optimizing performances of composite material laminated plate and production method

The invention discloses a grid stacking structure capable of optimizing the performances of a composite material laminated plate and a production method. The stacking structure is characterized by being composed of a plurality of perpendicular longitudinal prepreg strips and transversal prepreg strips in a crossing manner, wherein the length of the stacking structure is 2<m>-1 times of the width of rectangular strips, the width of the stacking structure is 2<n>-1 times of the width of the rectangular strips, and m and n are natural numbers. According to the stacking structure and the production method disclosed by the invention, the feature of structure designability of composite materials is ingeniously utilized, and a reasonable stacking design is carried out in a new stacking manner, so as to design a structure which is approximately three-dimensionally weaved, and on the premise of using the same prepreg, the tensile strength, flexural strength, shear strength and the like of the stacking structure can be obviously improved compared with the existing stacking structure after being subjected to curing formation; and the tensile, flexural and interlayer shear performances of the laminated plate obtained in the weaving manner are improved to a certain extent relative to conventional laminated plates, thus achieving great promotion significance on development of a three-dimensional enhancement technology for the composite materials.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Impact-resistant glass fiber reinforced polyester material and preparing method thereof

The invention discloses an impact-resistant glass fiber reinforced polyester material. After glass fibers are pretreated at the ultralow temperature with a physical method, the bending resistance, the tensile performance and the inter-layer shear performance of the glass fibers are improved; original sizing materials on the surfaces of the glass fibers are oxidized and decomposed through high-temperature treatment, and water stored and adsorbed by the glass fibers is removed accordingly; then modification porosity carbon-nano-tube materials are grafted on the surfaces of the glass fibers with a chemical method, and a hole structure is formed; when the glass fibers and a matrix are compounded, some chain segments of high polymers enter holes to achieve the anchoring-similar effect. In this way, binding force between interfaces of the glass fibers and the polymers is increased, and the impact resistance of a product is improved; meanwhile, nylon 12 is creatively compounded into unsaturated polyester, and the prepared glass fiber reinforced polyester material has the advantages of being resistant to impact, high in intensity, excellent in fire resistance and resistant to corrosion.

Owner:WUHU EDISON AUTOMATION EQUIP

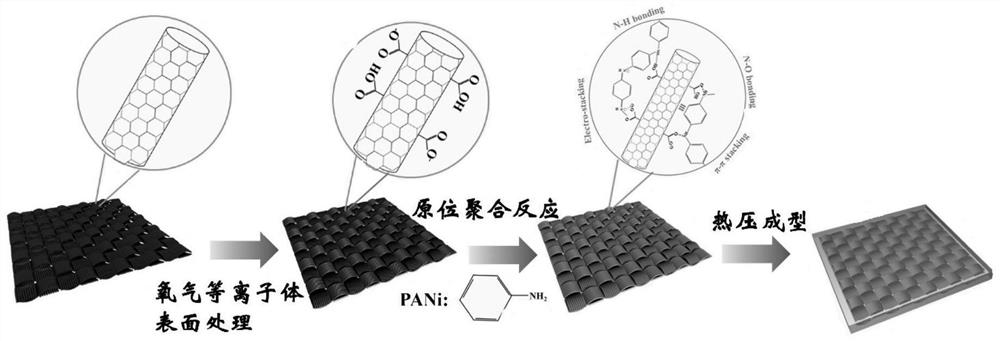

Polyaniline modified carbon fiber composite material as well as preparation method and application thereof

The invention discloses a polyaniline modified carbon fiber composite material with excellent interface performance and electromagnetic shielding performance, and a preparation method and application thereof. The preparation method comprises the steps: carrying out oxygen plasma surface treatment on desized carbon fiber, adding the oxidized carbon fiber into an aniline monomer solution for soaking, adding an initiator, and coating the surface of the carbon fiber with polyaniline nanoparticles by an in-situ chemical oxidation polymerization method; and pre-impregnating the polyaniline-coated carbon fibers with a composite solution of epoxy resin, a curing agent and an accelerant, and carrying out hot press molding to obtain the polyaniline nanoparticle-modified carbon fiber composite material. The polyaniline modified carbon fiber composite material has excellent interface bonding performance and electromagnetic shielding performance, has important significance for improving the use stability and diversity of the carbon fiber composite material, does not need to add any strong acid or other strong oxidants in the preparation process, has small damage to the fiber, is non-toxic and harmless in the whole in-situ polymerization process, and has wide application prospects and huge application advantages.

Owner:SICHUAN UNIV

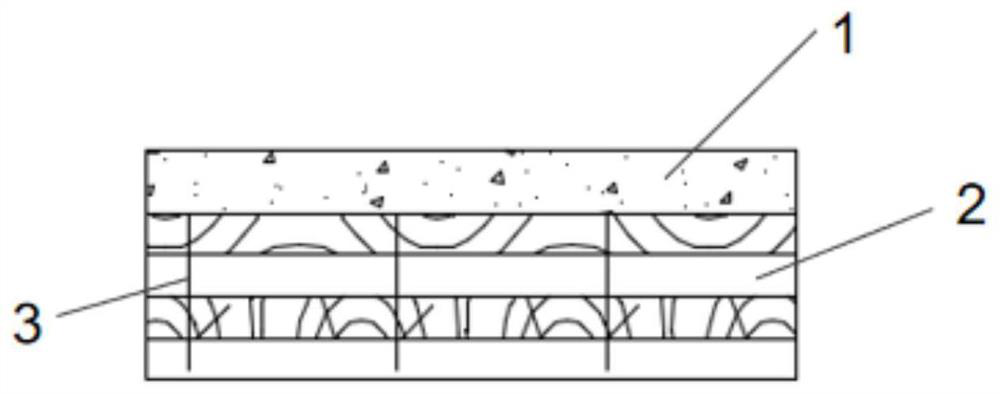

Orthogonal laminated wood-concrete composite floor and reinforcing method

InactiveCN113187139AImprove ultimate carrying capacityImproved interlaminar shear performanceFloorsBuilding repairsFloor slabInterlaminar shear

The invention discloses an orthogonal laminated wood-concrete composite floor. The orthogonal laminated wood-concrete composite floor comprises a concrete plate, a CLT plate, a plurality of pneumatic strip nails and a plurality of wood cushion blocks; the plurality of wood cushion blocks are arranged on the first surface of the CLT plate, the plurality of pneumatic strip nails penetrate through the wood cushion blocks from the upper surfaces of the wood cushion blocks and are inserted into the CLT plate, and an included angle exists between the insertion direction of the pneumatic strip nails and the vertical direction; and the concrete plate is poured on the first surface of the CLT plate, the wood cushion blocks and the pneumatic strip nails. The pneumatic strip nails are driven into the wood cushion blocks and the CLT plate so that the interlayer shearing capacity of concrete and the CLT plate can be remarkably improved, the interlayer shearing capacity of all layers of the CLT plate and the rolling shearing capacity of the CLT plate are improved, the application range of the orthogonal laminated wood-concrete composite floor is convenient to popularize and expand, and the development of a multi-story and high-rise wood structure is promoted; and meanwhile, according to the orthogonal laminated wood-concrete composite floor, the ultimate bearing capacity, the structural rigidity and the stability of the CLT-concrete composite floor can be effectively improved, and the ultimate bearing capacity of the CLT-concrete composite floor can be improved by about 60%.

Owner:SHANGHAI INST OF TECH

Halogen-free flame retardant epoxy resin system, prepreg and preparing methods thereof

The invention provides a halogen-free flame retardant epoxy resin system, prepreg and preparing methods thereof. The resin system is prepared from, by mass, 30-70% of liquid epoxy resin, 5-30% of solid resin, 12-32% of a solid halogen-free flame retardant and 2-8% of an epoxy curing agent, wherein the solid resin is at least one of phosphorus-containing epoxy resin, phenolic resin or benzoxazine resin, and the solid halogen-free flame retardant is at least one of organic-reaction-type phosphorus-series, silicon-series or nitrogen-series flame retardants which do not contain halogen. The resinsystem has high flame retardance and smoke suppression effects, and the highest-level flame retardance requirement in DIN5510, EN45545 and other standard requirements is met; meanwhile, the system hasstrong interlayer shearing force, and can be used as a load-carrying structure material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

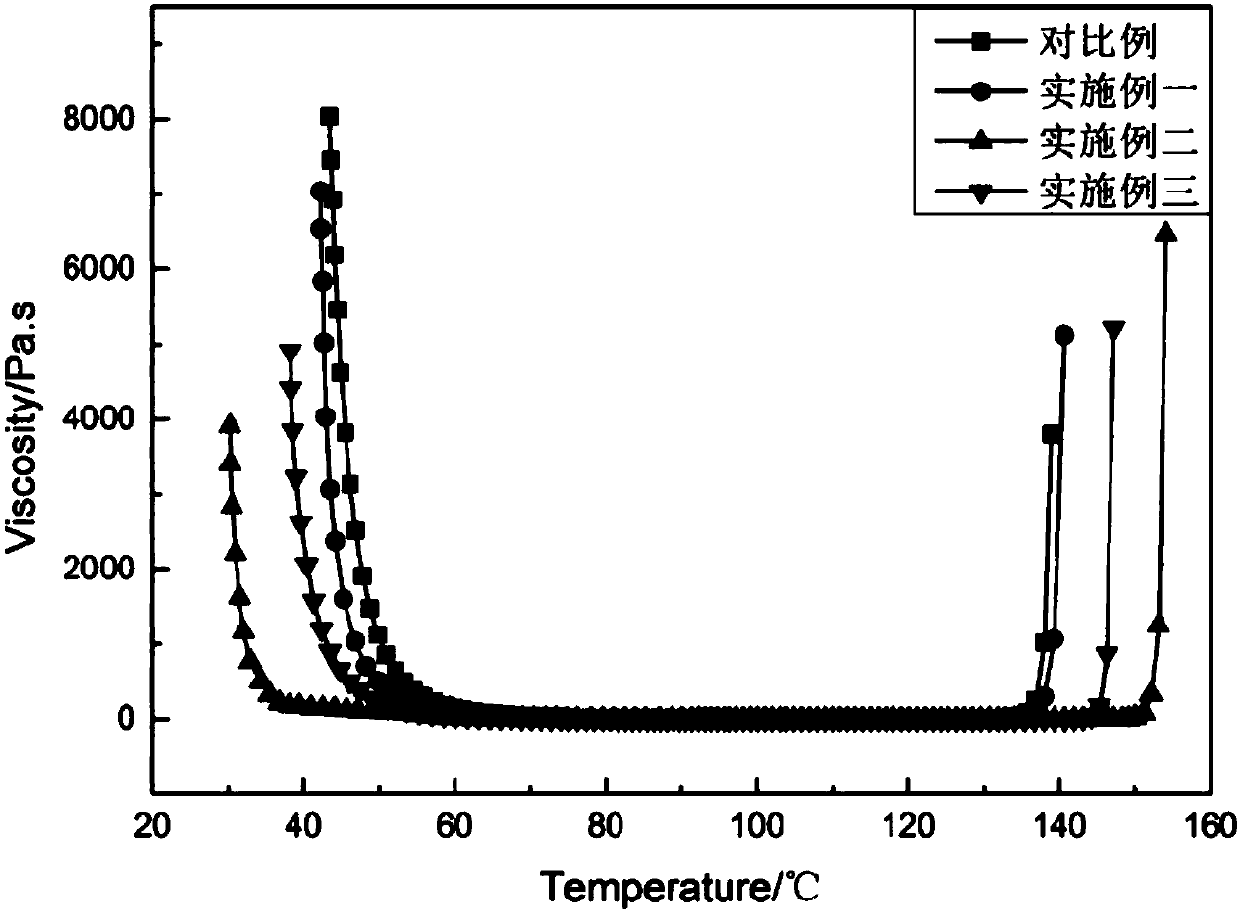

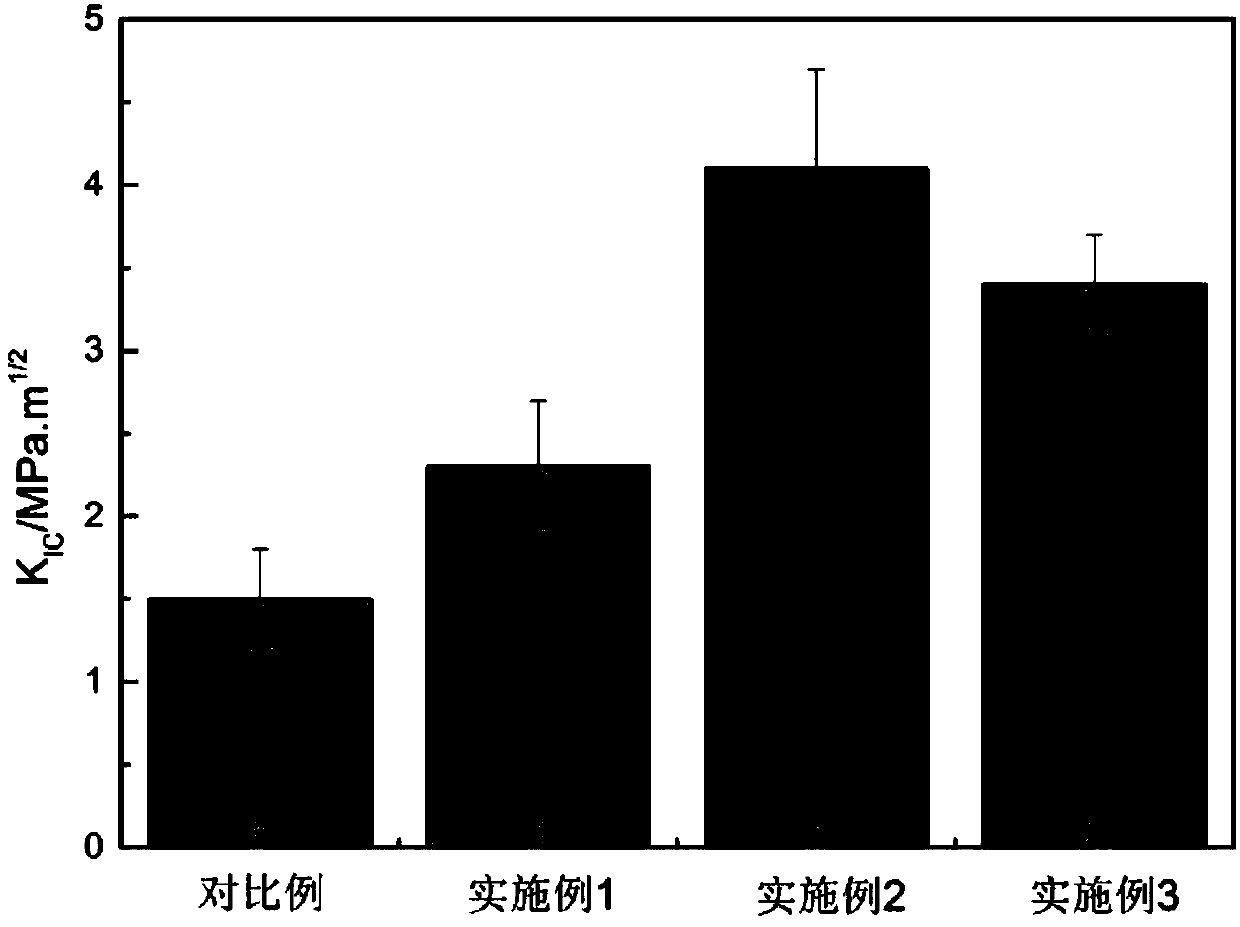

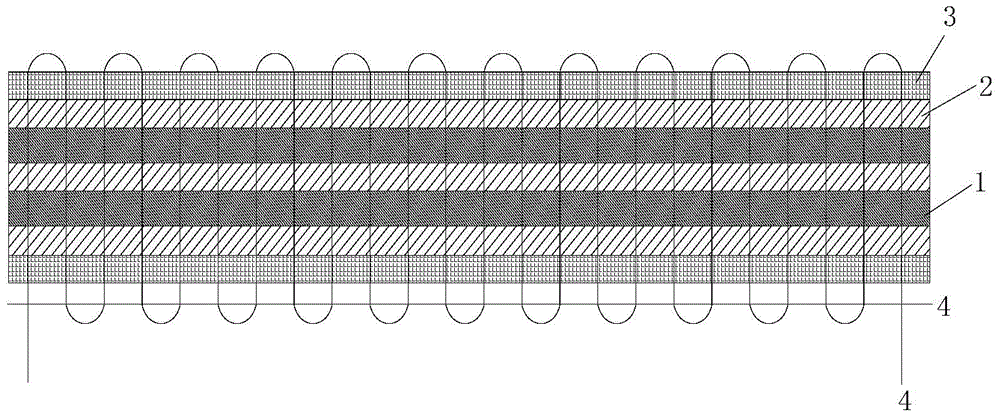

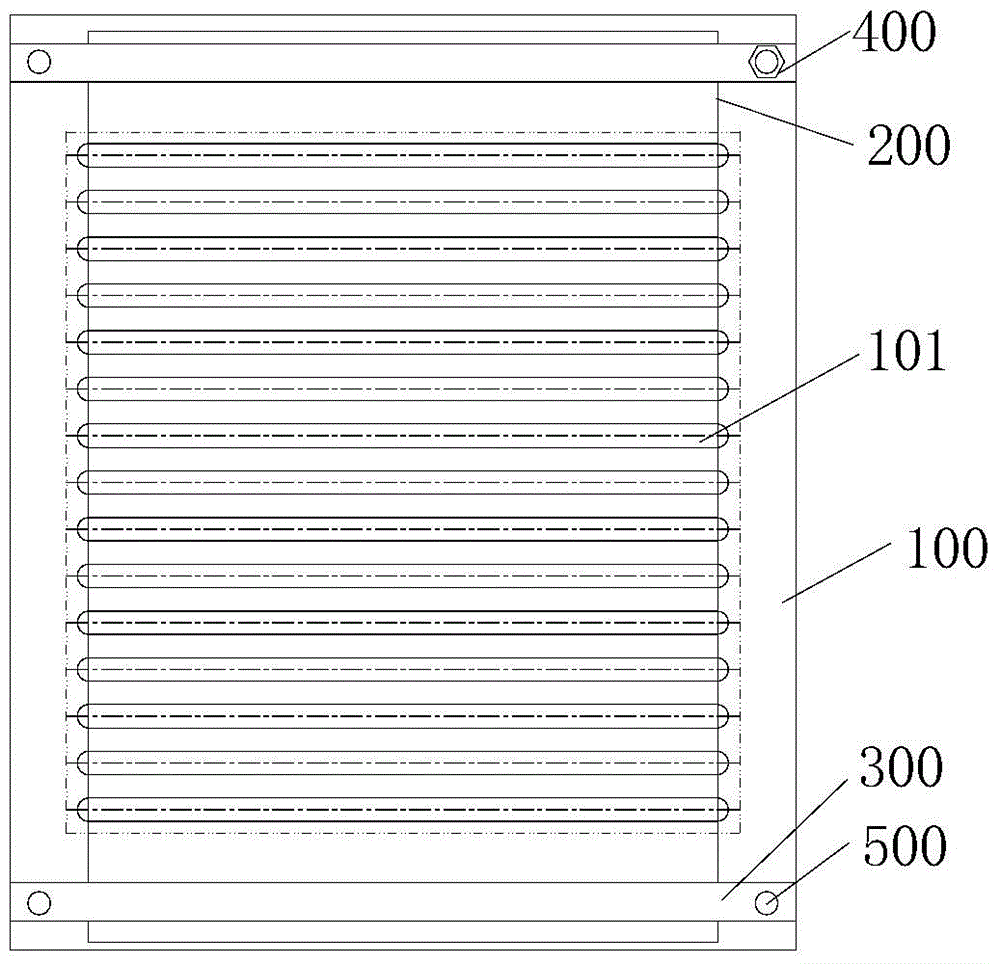

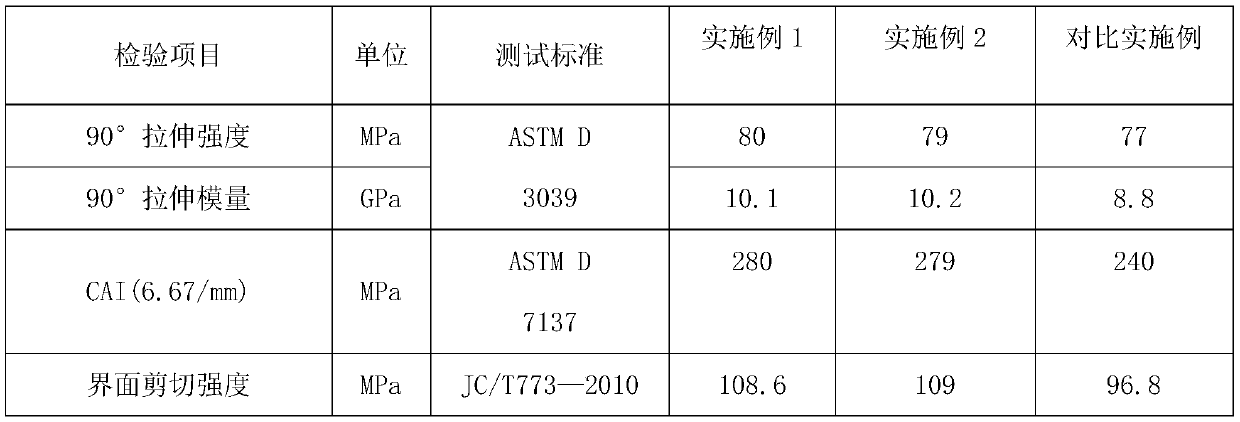

High-interlaminar-shear-performance high-toughness carbon fiber/epoxy resin composite material and preparation method thereof

ActiveCN111187488AIncrease stiffnessImproved interlaminar shear performanceInterlaminar shearEpoxy resin composite

The invention discloses a high-interlaminar-shear-performance high-toughness carbon fiber / epoxy resin composite material and a preparation method thereof. The composite material comprises carbon fibers, epoxy resin and modified SiO2@PDVB Janus particles dispersed in the epoxy resin, wherein the mass ratio of the carbon fibers, the epoxy resin and the modified SiO2@PDVB Janus particles is 20:100:4;and the modified SiO2@PDVB Janus particles are particles obtained by modifying SiO2@PDVB Janus particles by using TETA or KH570. The modified SiO2@PDVB Janus particles enable the carbon fiber composite material to obtain good toughness, and also enable the interface bonding of the matrix resin and the carbon fibers to be firmer, so that the prepared nanofiber composite material has excellent interlaminar shear performance and good toughness.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Anti-scratch wear-resistant glass fiber fabric and production technique thereof

ActiveCN110344260AImprove performanceImproved interlaminar shear performanceTextiles and paperPorosityWear resistant

The invention discloses an anti-scratch wear-resistant glass fiber fabric and a production technique thereof. The anti-scratch wear-resistant glass fiber fabric is made from, by weight, 90-125 parts of glass fiber monofilaments, 15-24 parts of a slurry and 3-5 parts of an adhesive. Superfine mica powder is added into the slurry, so that porosity can be improved, and improved interlayer shear performance, improved impact resistance and longer fatigue life can be provided for the glass fiber fabric. Dibutyl phthalate helps improve watertightness of the glass fiber fabric. Polyethylene glycol, guar gum and sodium carboxymethyl starch can coordinatively improve viscosity of the slurry and enhance bonding of contact faces of glass fiber and synthetic ring, wear resistance of the glass fiber fabric is improved effectively, and good scratch resistance is produced. The slurry can be scattered and cleaned during coating, and the stability is high. Ultraviolet curing helps impart better coatingeffect to a base; the prepared glass fiber fabric has better scratch resistance.

Owner:安徽弋尚纺织科技有限公司

A grid layup structure and manufacturing method for optimizing the performance of composite material laminates

ActiveCN105082552BHigh tensile strengthImprove flexural strengthComposite laminatesFlexural strength

The invention discloses a grid stacking structure capable of optimizing the performances of a composite material laminated plate and a production method. The stacking structure is characterized by being composed of a plurality of perpendicular longitudinal prepreg strips and transversal prepreg strips in a crossing manner, wherein the length of the stacking structure is 2<m>-1 times of the width of rectangular strips, the width of the stacking structure is 2<n>-1 times of the width of the rectangular strips, and m and n are natural numbers. According to the stacking structure and the production method disclosed by the invention, the feature of structure designability of composite materials is ingeniously utilized, and a reasonable stacking design is carried out in a new stacking manner, so as to design a structure which is approximately three-dimensionally weaved, and on the premise of using the same prepreg, the tensile strength, flexural strength, shear strength and the like of the stacking structure can be obviously improved compared with the existing stacking structure after being subjected to curing formation; and the tensile, flexural and interlayer shear performances of the laminated plate obtained in the weaving manner are improved to a certain extent relative to conventional laminated plates, thus achieving great promotion significance on development of a three-dimensional enhancement technology for the composite materials.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A carbon-silicon carbide dual matrix carbon fiber composite material, its preparation method and application

ActiveCN108516852BEvenly distributedImprove frictional stabilityBraking discsCarbide siliconPorous carbon

The invention discloses a carbon-silicon carbide double-ingredient substrate carbon fiber composite material as well as a preparation method and application thereof. The method comprises the followingsteps of (1) performing weaving and high-temperature heat treatment on a carbon fiber prefabricated body; (2) preparing a porous carbon / carbon blank body; (3) introducing carbon elements and siliconelements into the carbon / carbon blank body in an impregnating mode; after the soaking and pyrolysis circulation period, obtaining a Cf / Cm-Sim porous intermediate; (4) performing embedded fusion Si seeping on the Cf / Cm-Sim porous intermediate to obtain a Cf / Cm-SiCm composite material. The inside SiC distribution of the composite is uniform; the residue Si content is 1.2 to 3.3 percent; the bendingintensity is 236 to 275MPa; the compression intensity is 322 to 364MPa; the dynamic friction coefficient is 0.32 to 0.48; the mechanical / friction performance is excellent; the thermal stability and the environment applicability are high; the material is applicable to the manufacturing of automobile braking discs / sheets.

Owner:湖南金羽先进材料有限公司

A kind of high-rise inter-shear performance carbon fiber composite material and its preparation method

ActiveCN104356600BImproved interlaminar shear performanceThe interface is firmly bondedPigment physical treatmentPigment treatment with non-polymer organic compoundsMicro nanoInterlaminar shear

The invention relates to a carbon fiber composite material with interlayer shear performance and a preparation method thereof. The composite material includes carbon fibers, an epoxy resin matrix material and micro-nano materials dispersed in the epoxy resin matrix material in an orientation; the micro-nano materials are Refers to graphene oxide surface modified with magnetic nanoparticles. The invention uses graphene oxide modified by magnetic field orientation magnetic particles to enhance the interlayer shear performance of the carbon fiber composite material, while strengthening the matrix resin, the interface between the matrix resin and the carbon fiber is combined more firmly, so that the prepared composite material has Excellent interlaminar shear properties.

Owner:JIAXING LONGSHINE CARBON FIBER PROD

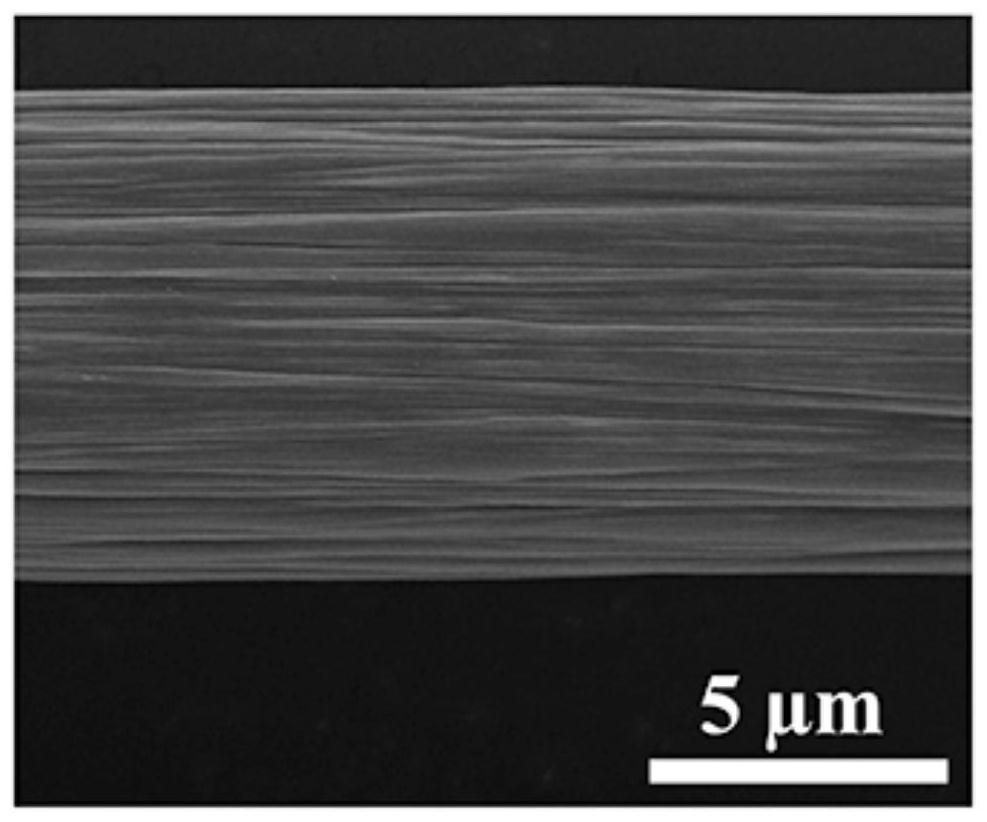

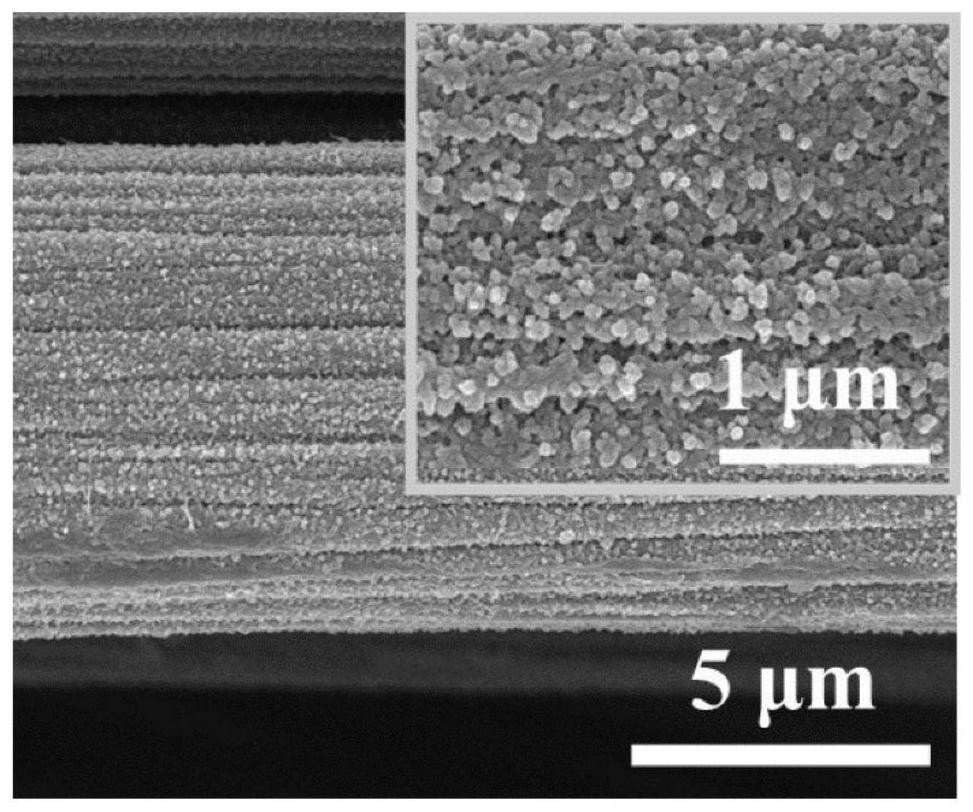

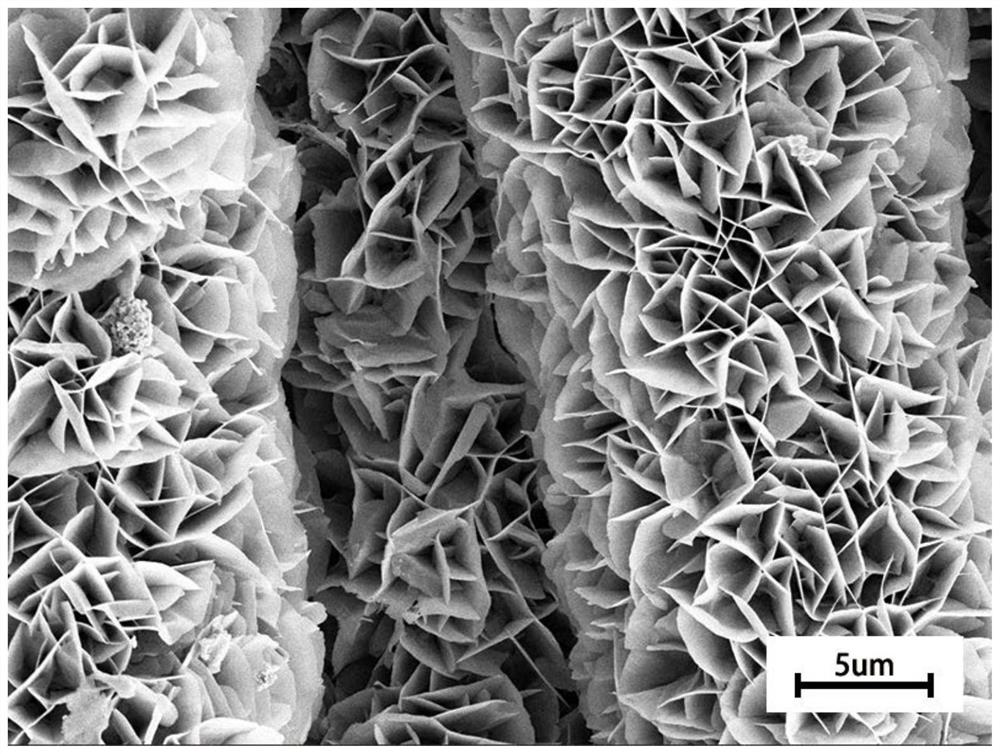

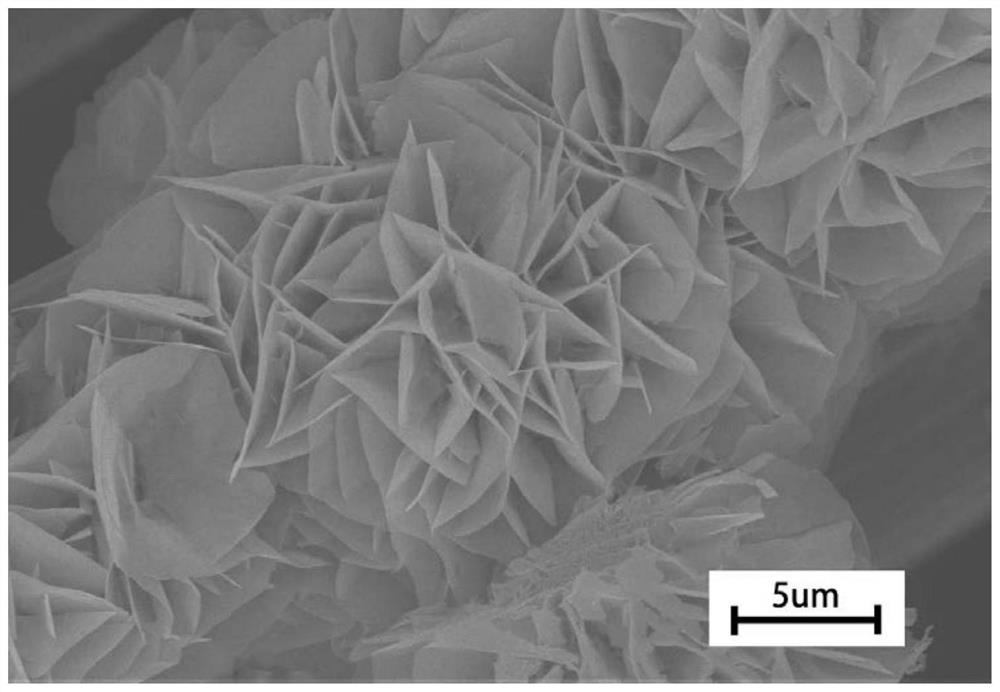

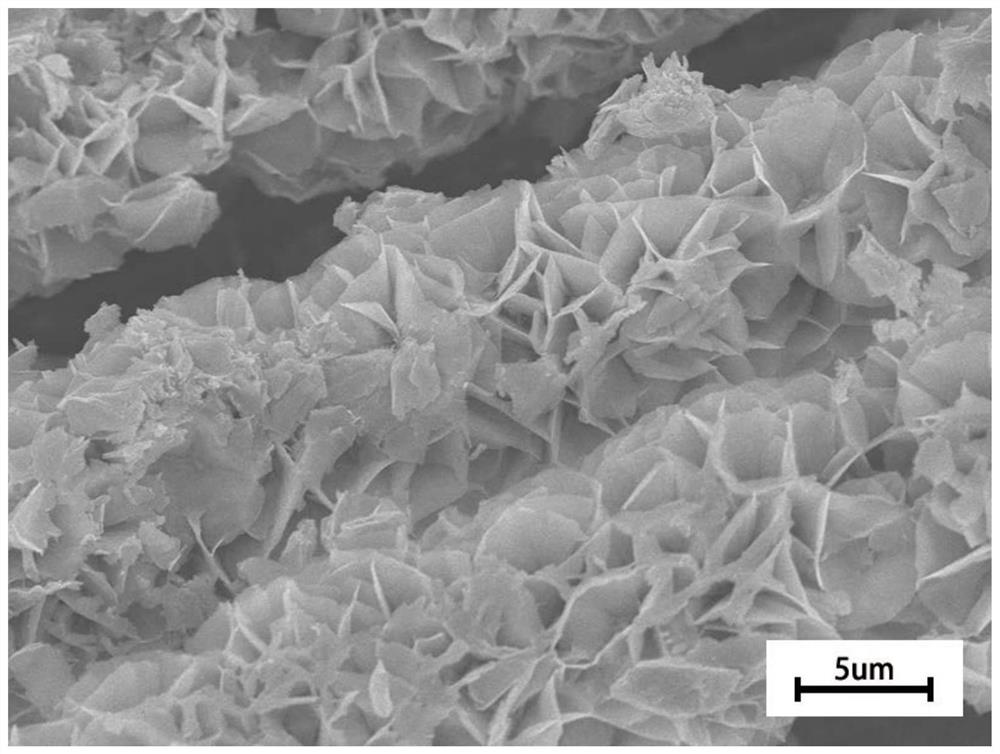

Structure and function integrated carbon fiber/epoxy composite material and preparation method thereof

ActiveCN113999495AIncrease contact areaThe interface is tightly combinedInterlaminar shearResin matrix

The invention relates to a structure and function integrated carbon fiber / epoxy composite material and a preparation method thereof. The composite material comprises a carbon fiber fabric reinforcing material, an epoxy resin matrix material and functional nanoscale transition metal sulfide modified on the surface of carbon fiber. The transition metal sulfide is petal-shaped tungsten sulfide synthesized by a hydrothermal method. According to the invention, dense nanoflower microstructures are introduced on the surfaces of the carbon fibers through the compounded surfactant by adopting a hydrothermal method, so that the contact area of the fibers and an epoxy resin matrix is increased, and the interface bonding of the matrix resin and the carbon fibers is tighter, so that the composite material shows excellent interlaminar shear performance. And due to the introduction of the tungsten sulfide nanoflowers, the composite material is endowed with a certain electromagnetic absorption function.

Owner:JIAXING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com