Structure and function integrated carbon fiber/epoxy composite material and preparation method thereof

A composite material and carbon fiber technology, applied in the field of structural-function integrated carbon fiber/epoxy composite material and its preparation, can solve the problems of increasing electromagnetic wave attenuation ability, poor phase affinity, etc., achieve excellent mechanical properties, reduce electromagnetic pollution, excellent Effect of interlaminar shear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

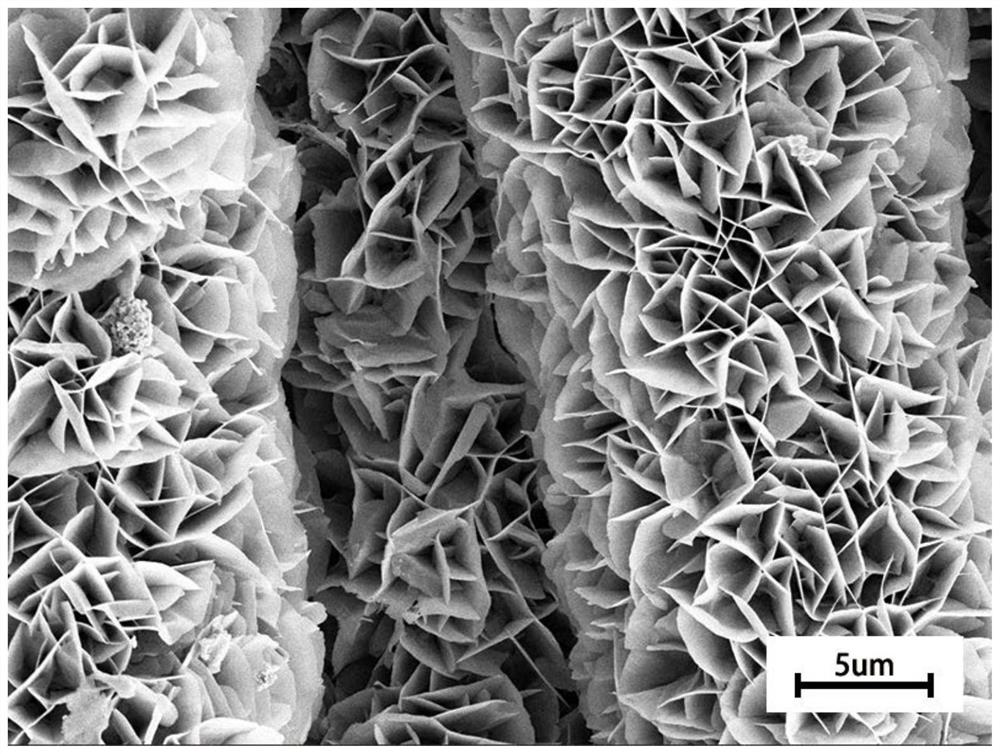

[0036] 1) Soak a carbon fiber cloth cut into a size of 7×3cm in an acetone solution, keep it at room temperature for 48 hours for desizing treatment, and then repeatedly rinse the desized carbon fiber cloth with ethanol and deionized water to remove The residual slurry and acetone on the surface were dried to obtain a desized carbon fiber cloth; the desized carbon fiber cloth was soaked in an ethanol solution, and the carbon fiber cloth was ultrasonically cleaned for 1 hour with an ultrasonic device with a power of 600W, and then, using ethanol, Rinse repeatedly with deionized water to remove residual impurities and dust on the surface and dry; weigh 10mmol, 40mmol and 20mmol of sodium tungstate hexahydrate, thiourea and hydroxylamine hydrochloride and dissolve them in 40mL of deionized water to prepare mixed solution A , then weighed 0.375g of cetyltrimethylammonium bromide (CTAB) and 0.125g of fatty alcohol sodium isethionate dissolved in 40mL of deionized water to configure ...

Embodiment 2

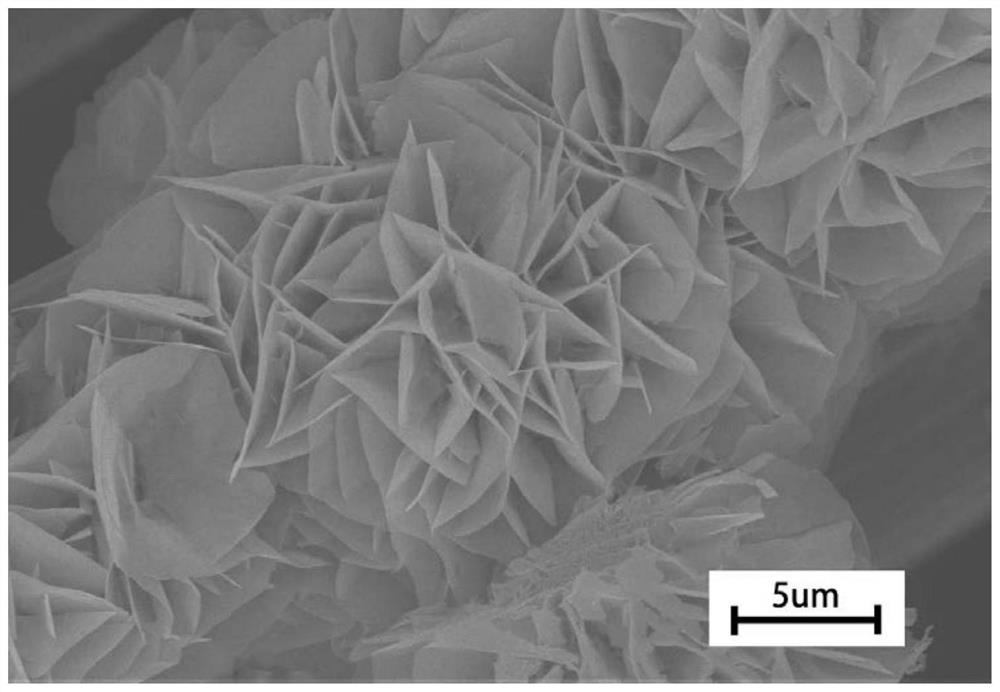

[0040] Other conditions and operations are the same as in Example 1, except that in step 1), the amount of surfactant is changed to 0.42g cetyltrimethylammonium bromide and 0.08g fatty alcohol sodium isethionate. The interlaminar shear strength of the carbon fiber composite material obtained in this example is 52.4 MPa, and the minimum reflection loss value of electromagnetic absorption at 4 GHz reaches -22 dB.

Embodiment 3

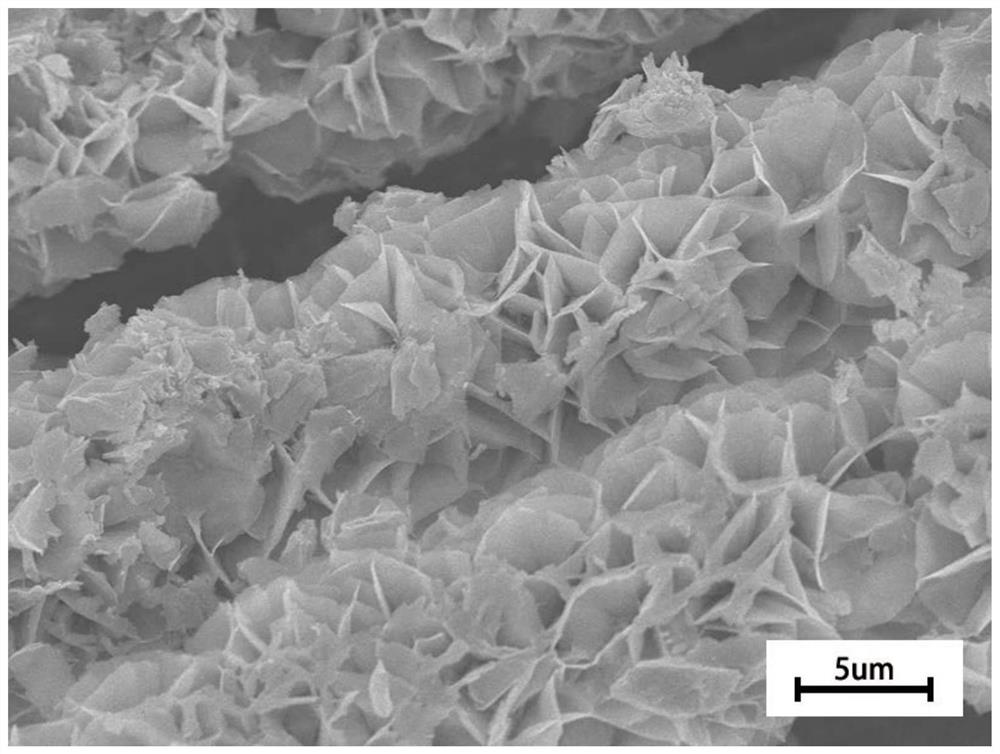

[0042] Other conditions and operation are identical with embodiment 1, difference is that in step 1), the consumption of surfactant is changed into 0.25g cetyltrimethylammonium bromide and 0.25g fatty alcohol sodium isethionate.

[0043] The interlaminar shear strength of the carbon fiber composite material obtained in this example is 48.2 MPa, and the minimum reflection loss value of electromagnetic absorption at 4 GHz reaches -21 dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com