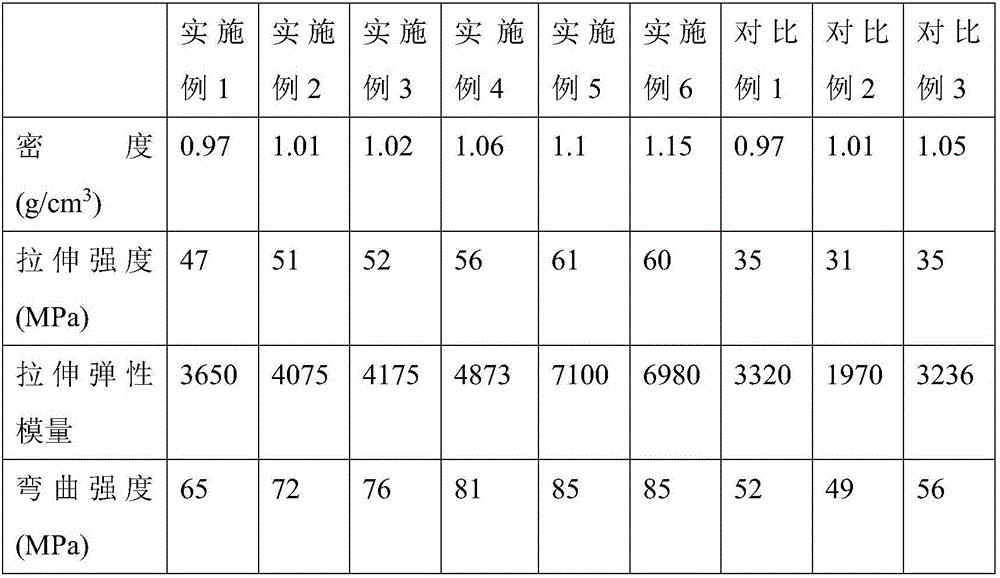

Patents

Literature

234 results about "Specific modulus" patented technology

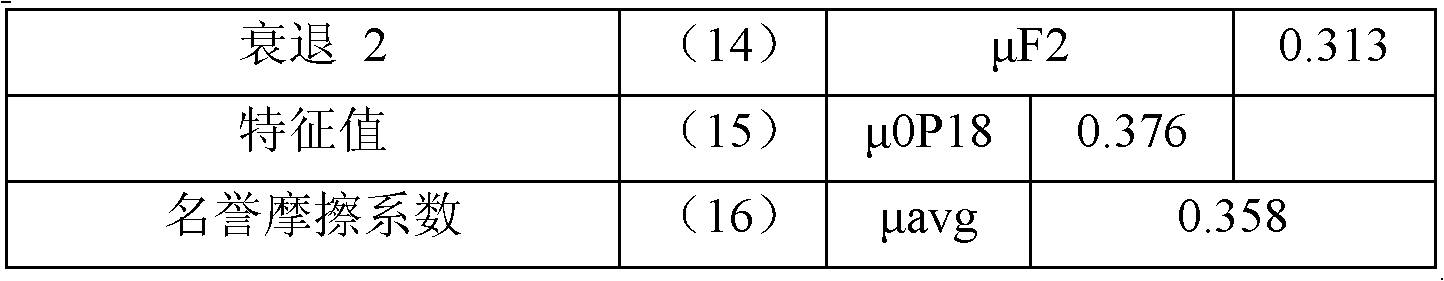

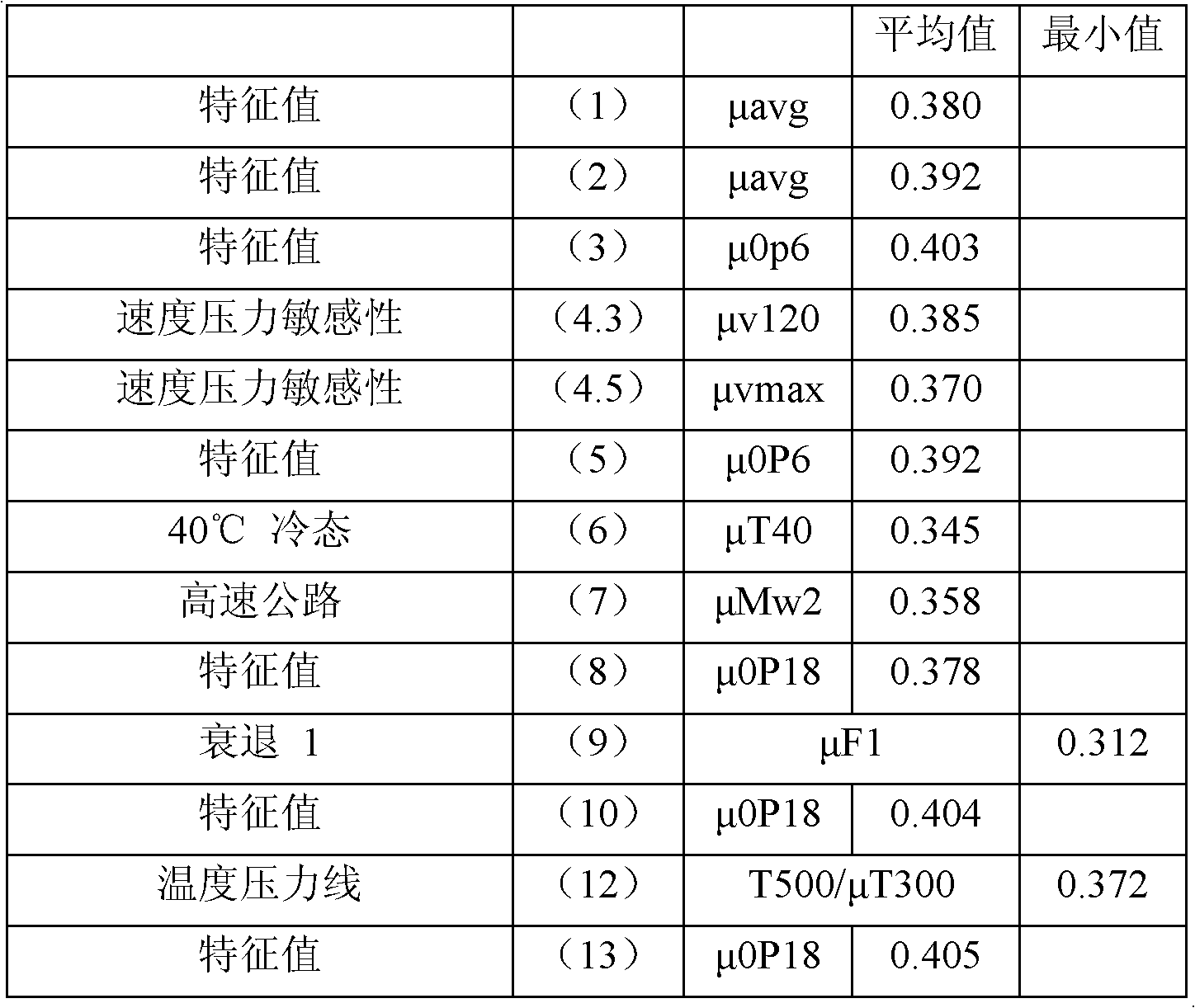

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

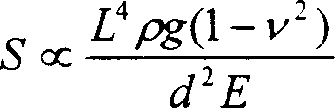

Specific modulus is a materials property consisting of the elastic modulus per mass density of a material. It is also known as the stiffness to weight ratio or specific stiffness. High specific modulus materials find wide application in aerospace applications where minimum structural weight is required. The dimensional analysis yields units of distance squared per time squared.

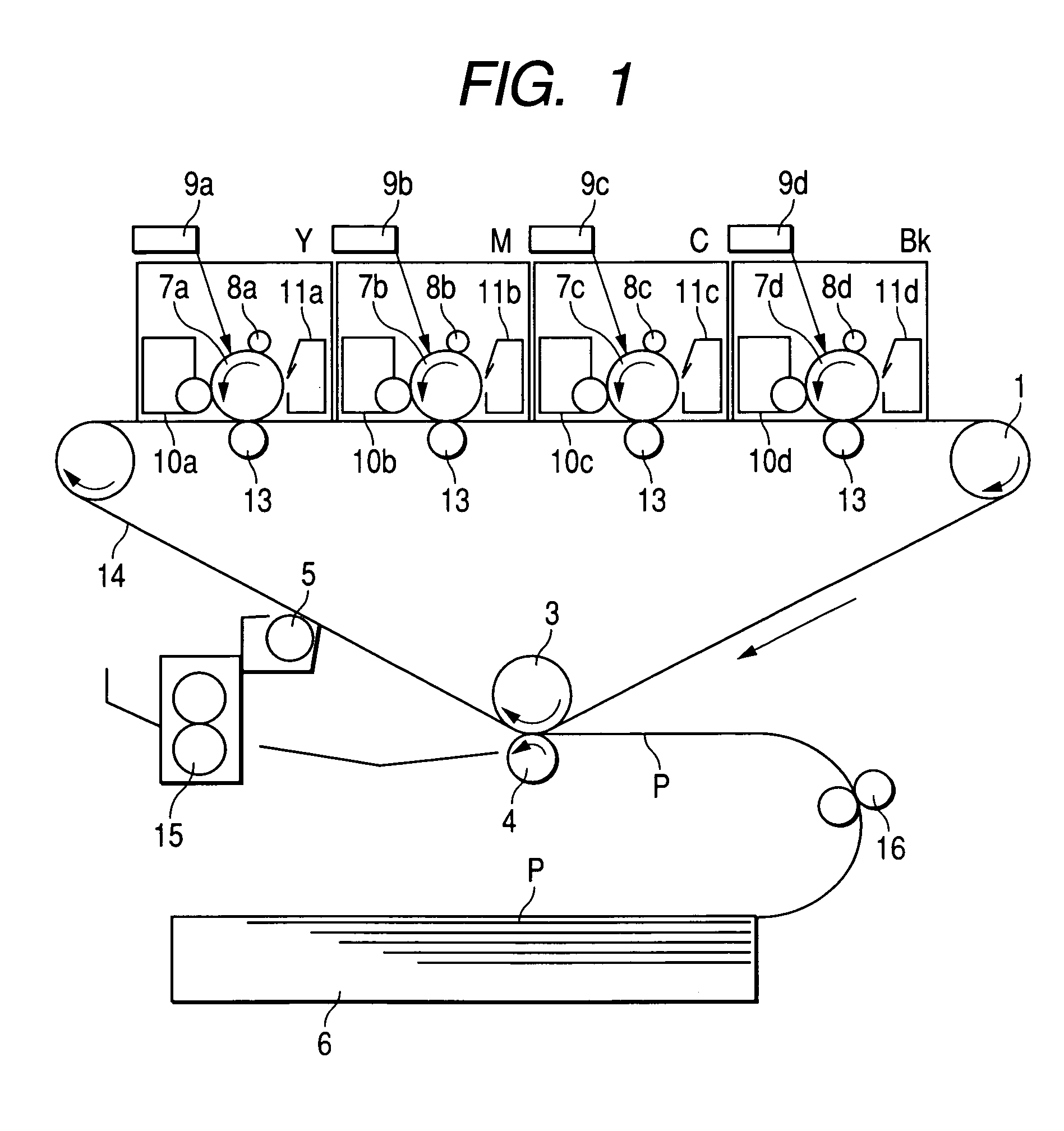

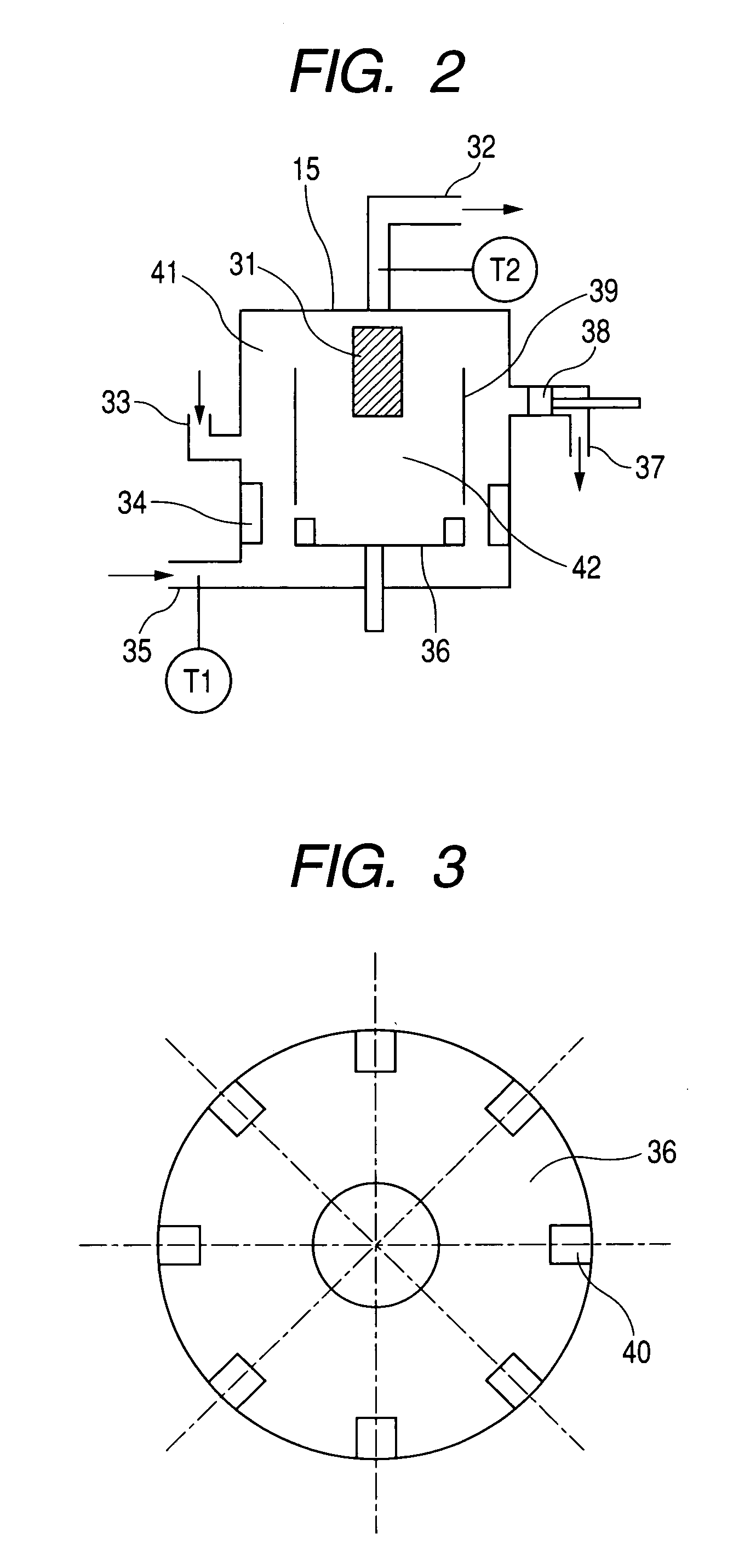

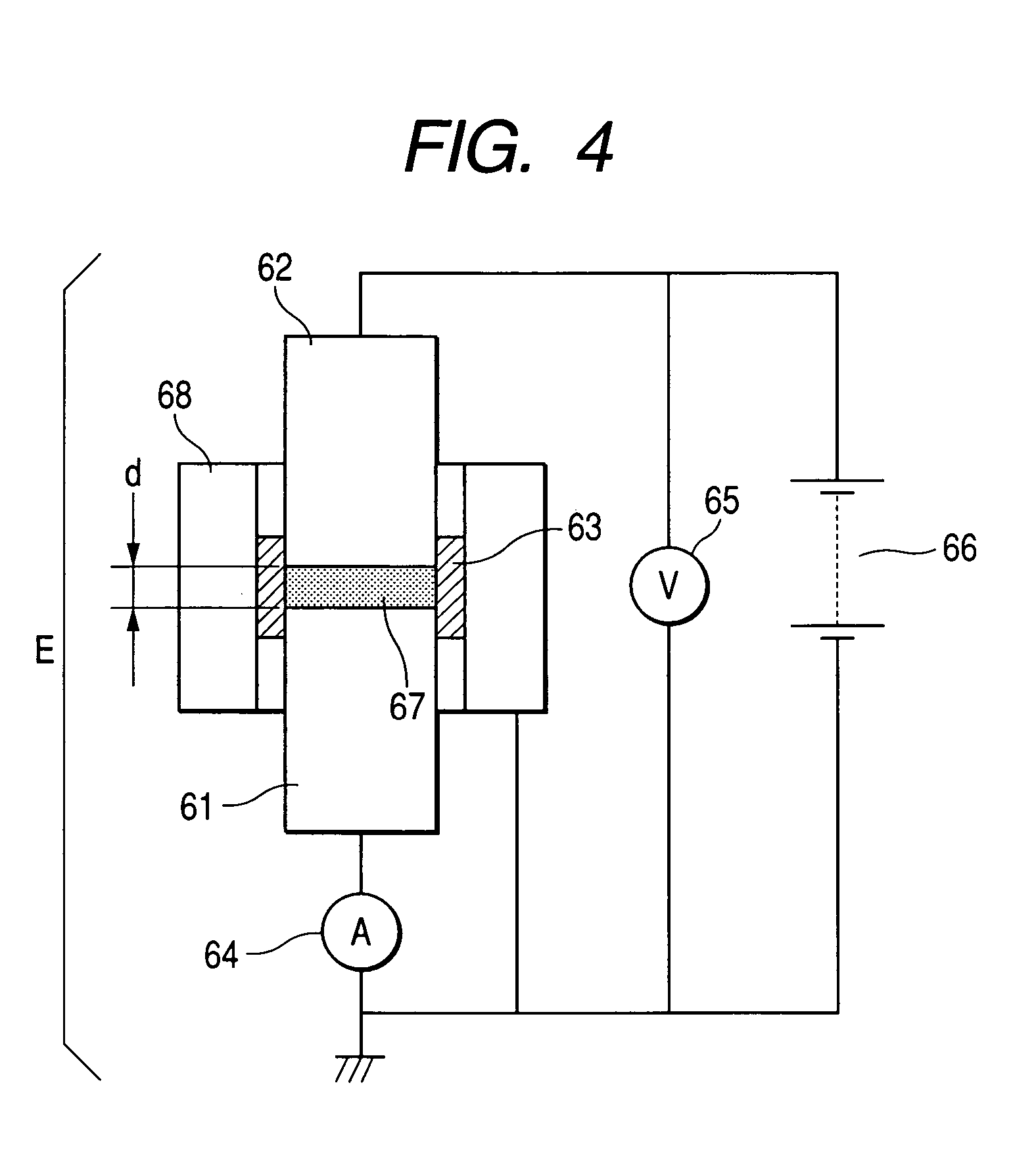

Image forming method and image forming apparatus

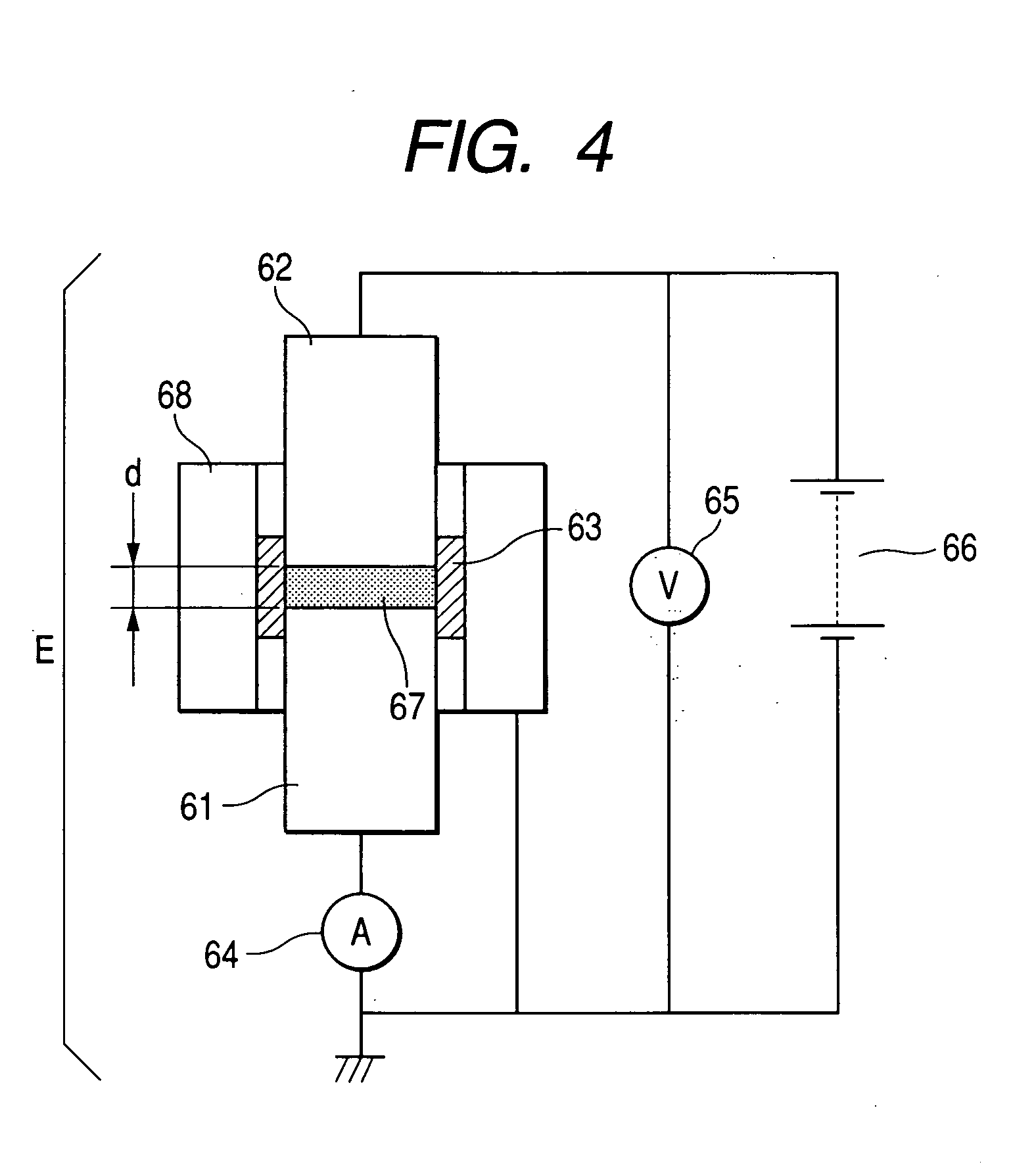

ActiveUS7396629B2Improve the level ofIncrease contrastElectrographic process apparatusElectrographic processes using charge patternLatent imageImage formation

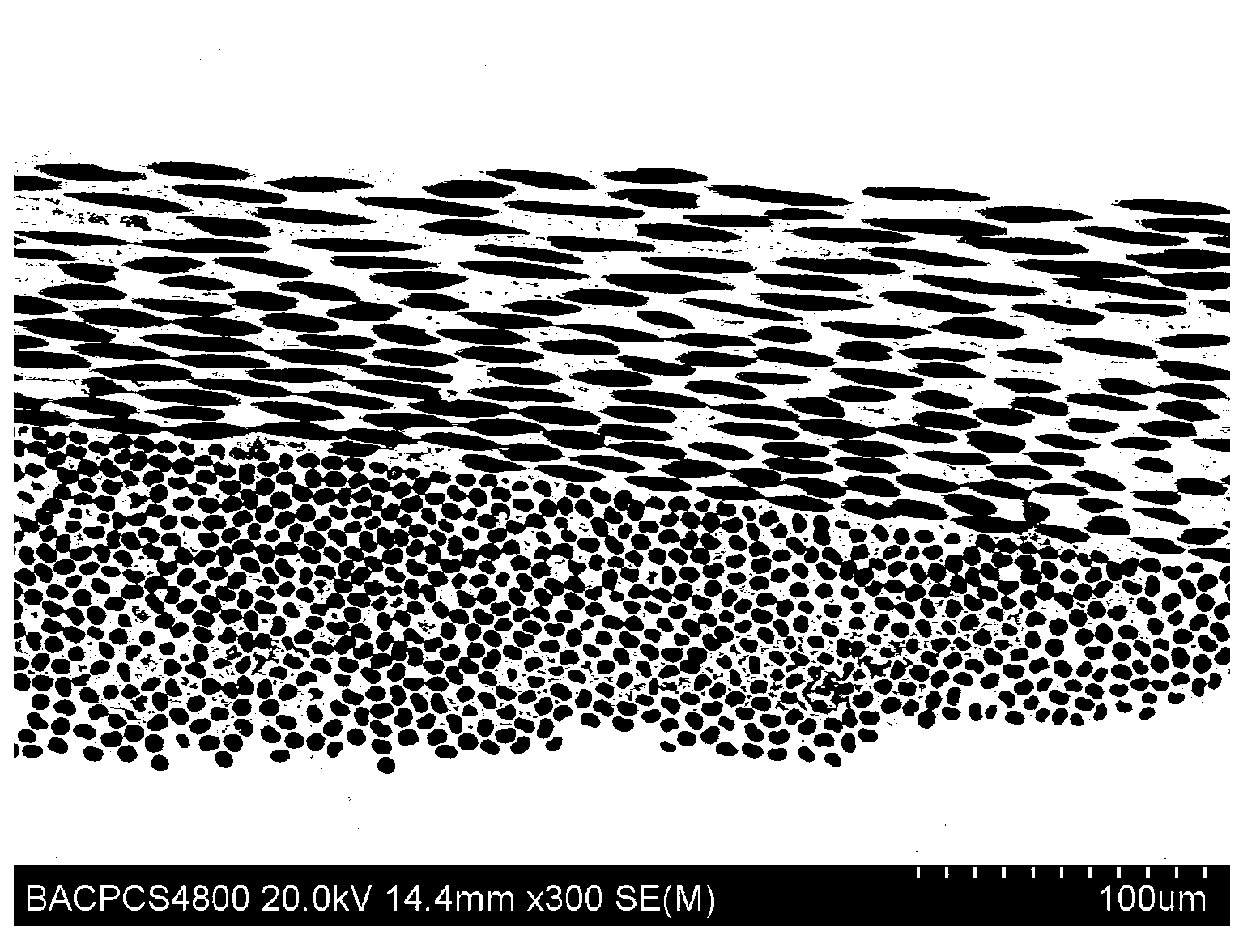

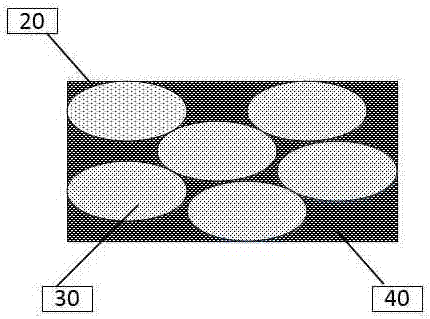

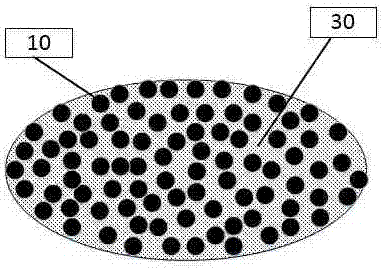

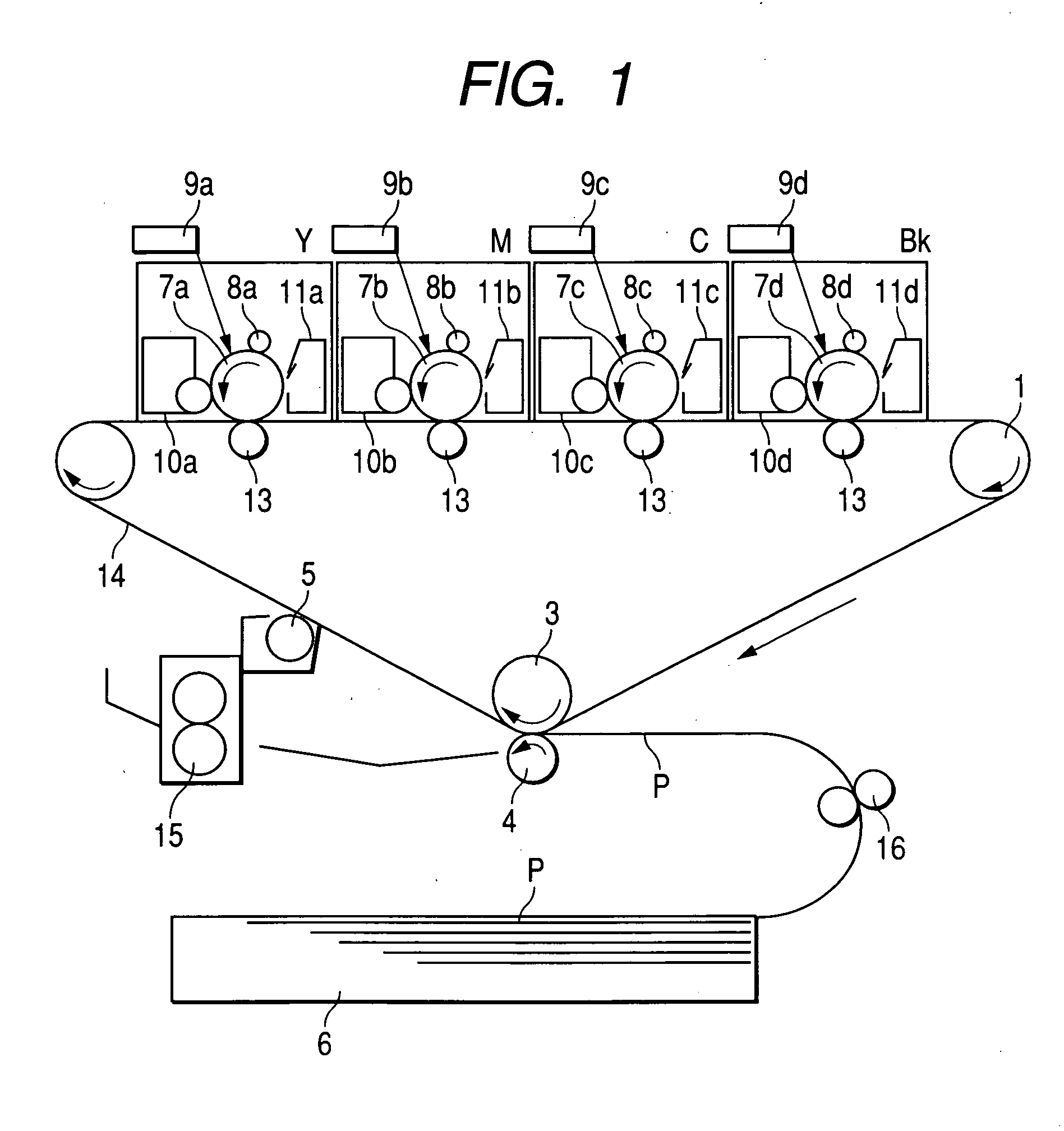

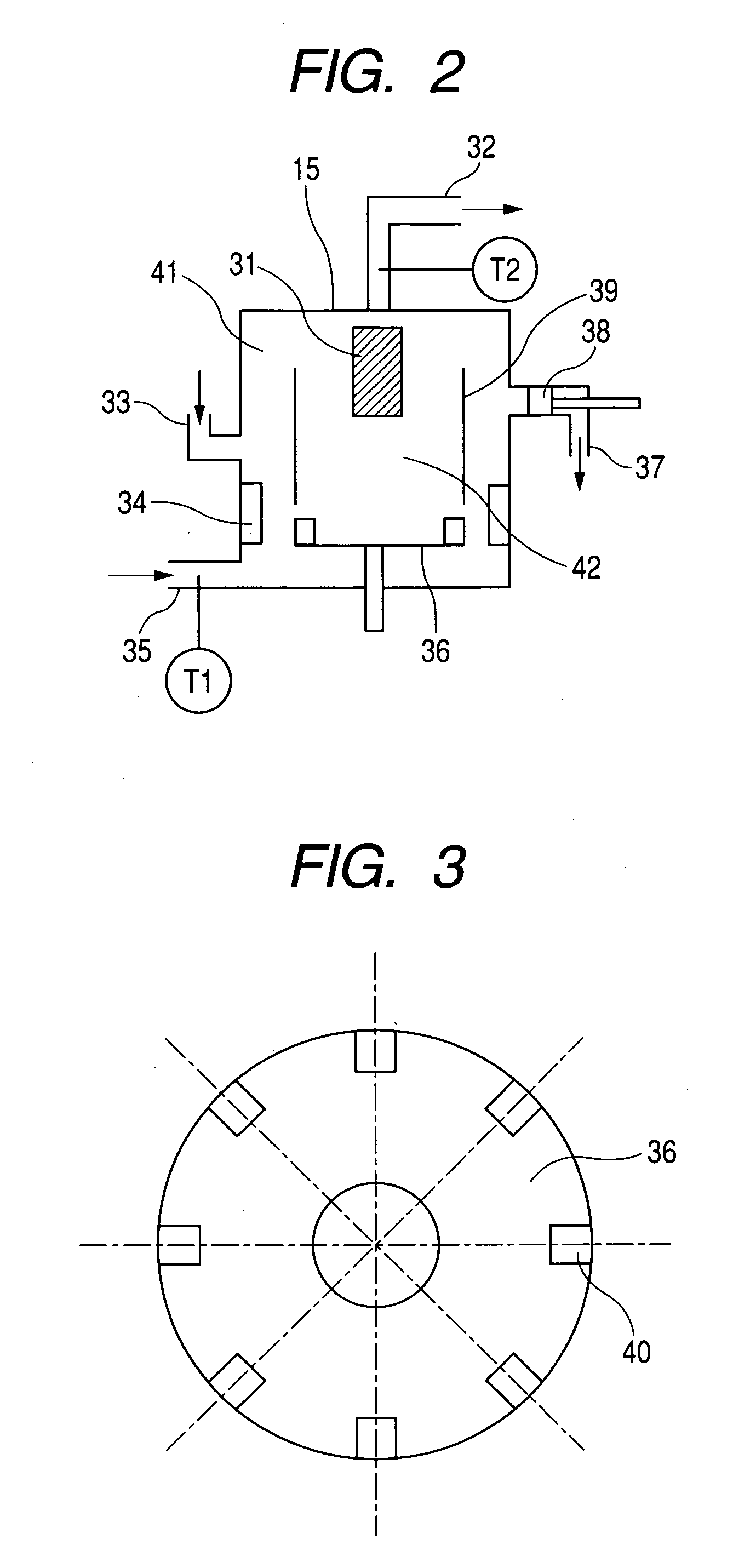

An image forming method and an image forming apparatus are disclosed in which an electrostatic latent image is formed on a photosensitive member surface by using a two-component developer including a toner and carrier. The photosensitive member surface has a specific modulus of elastic deformation and includes a charge transport layer with a specific thickness. The toner has a specific weight-average particle diameter. The carrier has a specific volume-average particle diameter and a specific circularity, and contains 20% by number or less of particles having a value of “average circularity−2σ” where σ is standard deviation of carrier circularity.

Owner:CANON KK

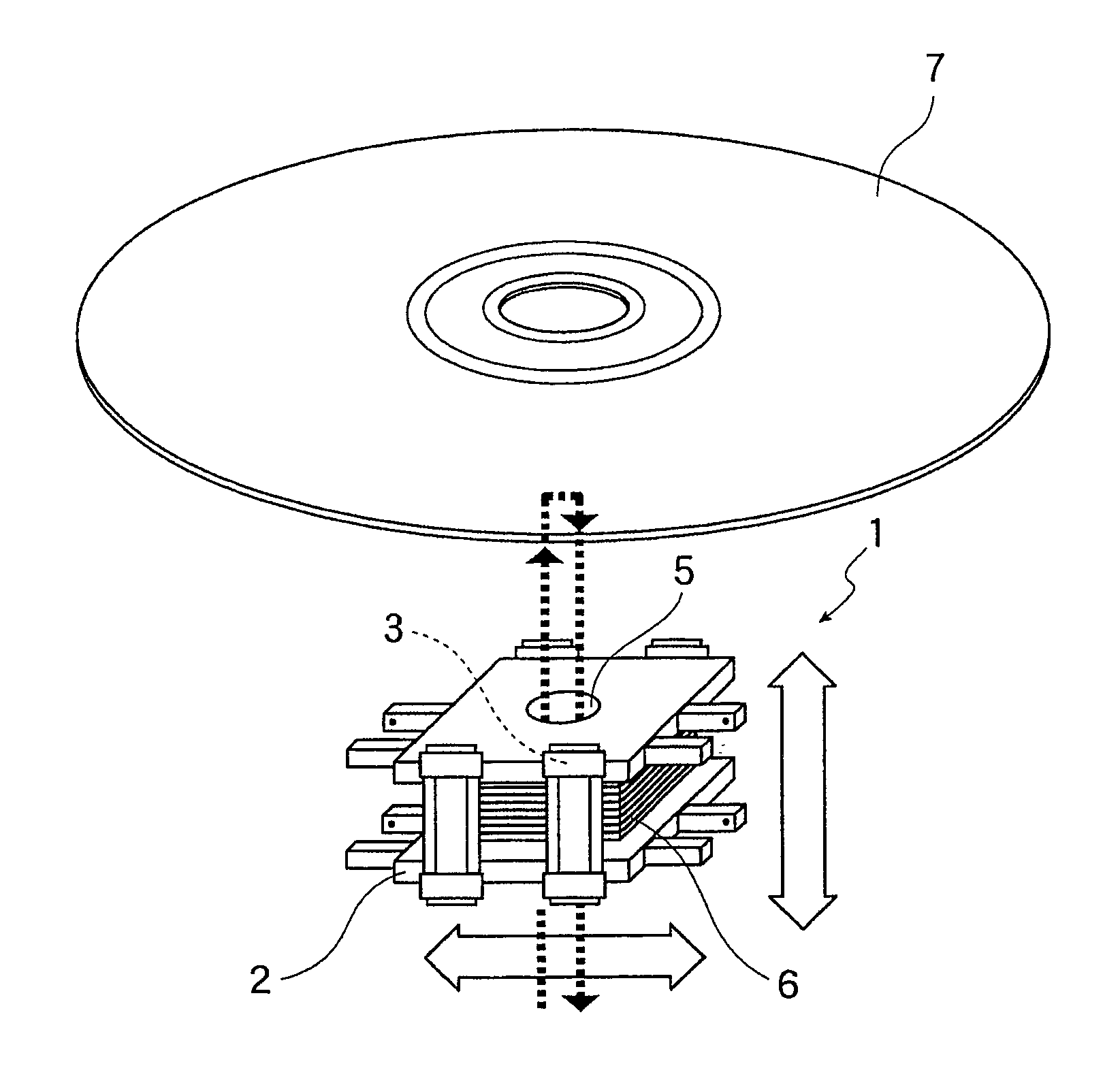

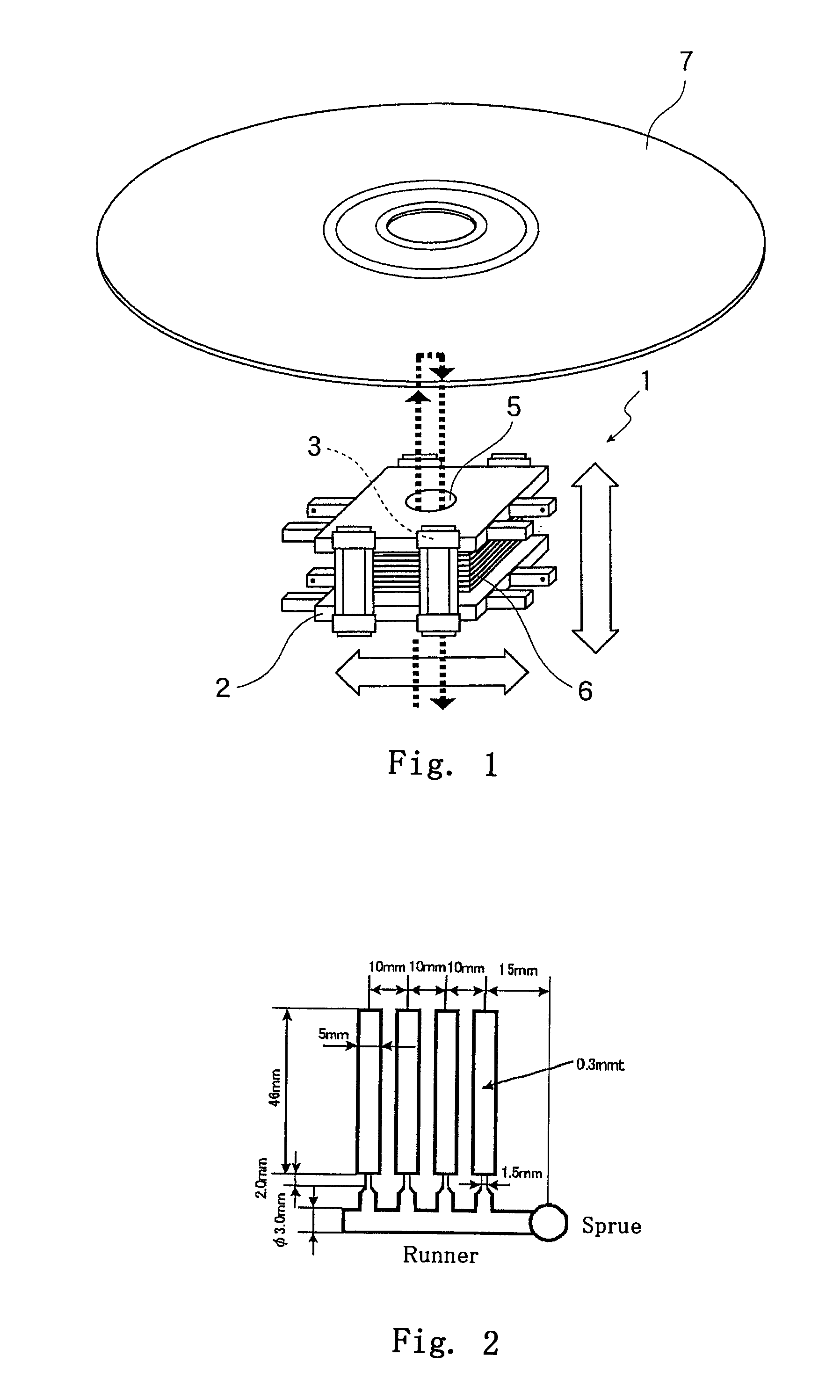

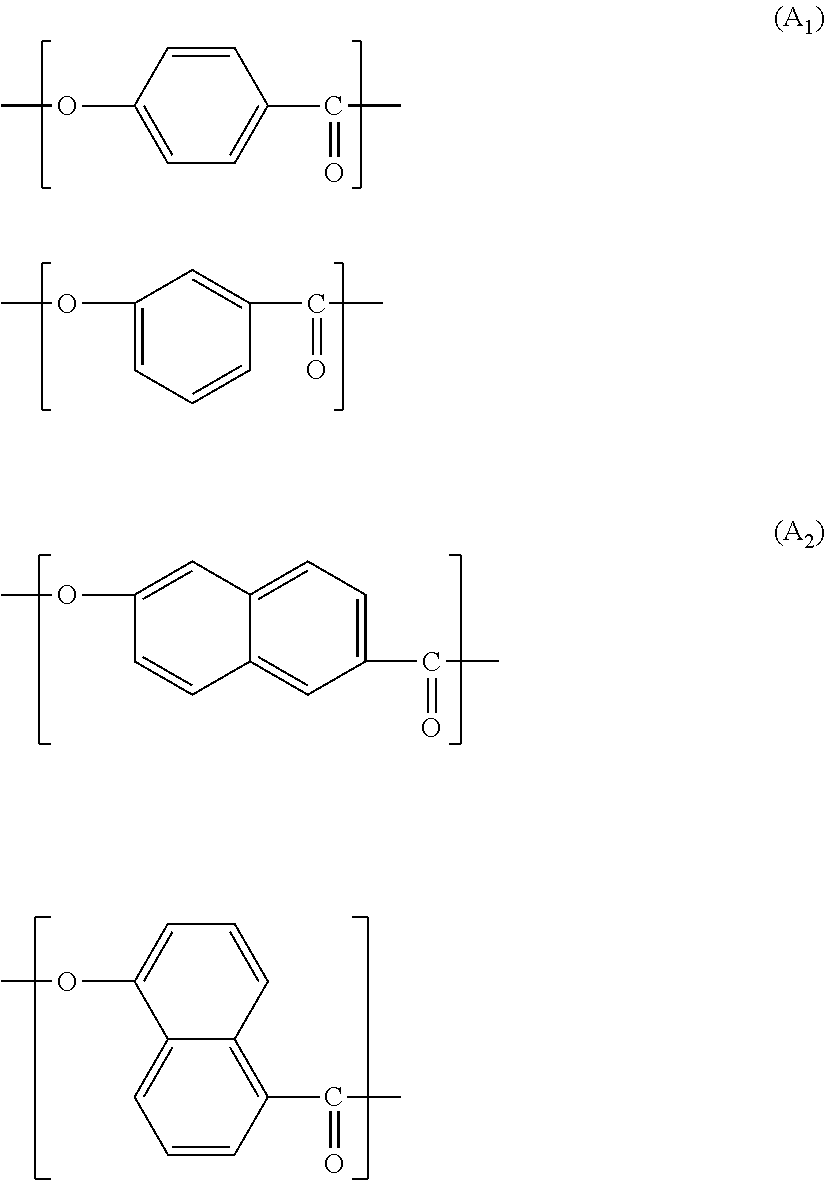

Liquid crystalline polyester resin composition, molded article and holder for optical pickup lenses

A liquid crystalline polyester resin composition is provided, by which a molded article with an enhanced specific modulus can be produced. The liquid crystalline polyester resin composition comprises mica fillers in an amount of 15 to 30 parts by mass and carbon fibers with specific volume resistance of 108 Ωcm or more in an amount of 5 to 20 parts by mass with respect to 100 parts by mass of the liquid crystalline polyester.

Owner:SUMITOMO CHEM CO LTD

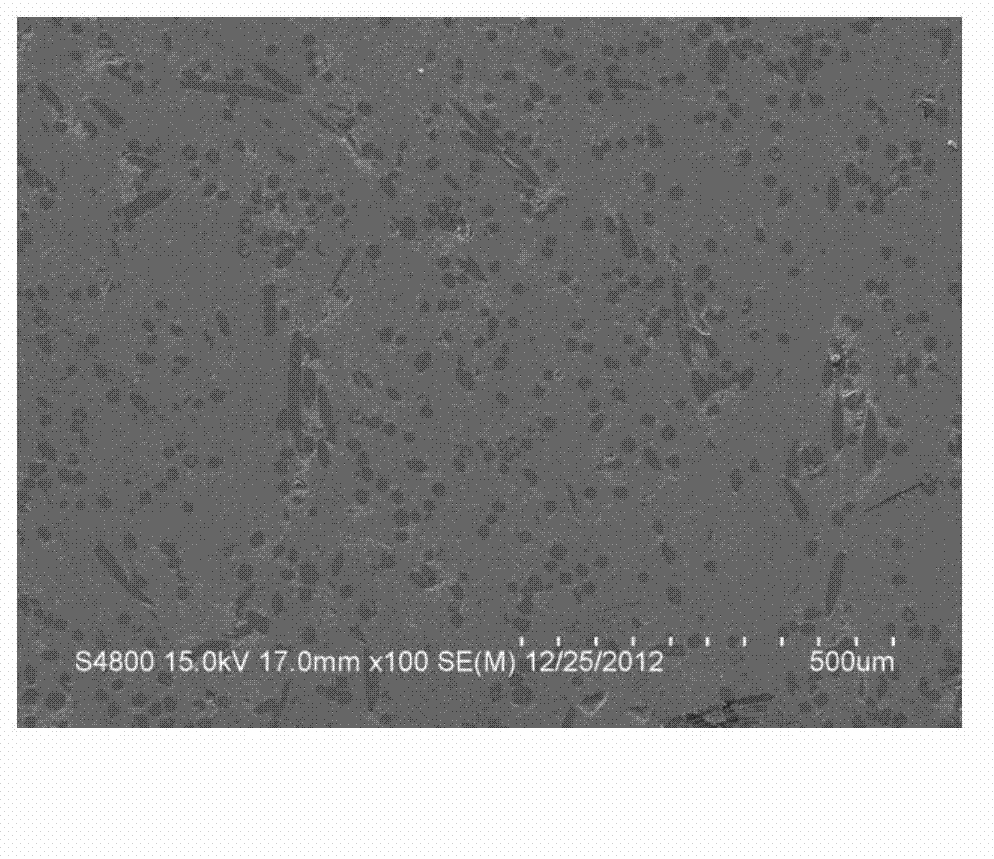

Preparation method for short carbon fiber/silicon carbide composites

The invention discloses a preparation method for short carbon fiber / silicon carbide composites by means of spark plasma sintering (SPS). The preparation method includes the steps: (1), pre-treating the short carbon fiber by placing the same in a heat-treatment furnace for heat preservation for 30 minutes under the temperature of 400 DEG C prior to soaking and coarsening the short carbon fibers in coarsening liquid composed of nitric acid, potassium dichromate, hydrogen peroxide and ammonium persulfate to be washed with deionized water and dried for standby; (2), placing the short carbon fiber, silicon carbide powder and sintering aids in a ball-milling pot to be ball-milled; (3), drying the materials in the step (2) through rotary evaporation prior to grinding the same to sieve the mixed powder; and (4), placing the mixed powder into a graphite mould and subjecting the mixed powder to the spark plasma sintering. The short carbon fiber / silicon carbide composites prepared by the method are good in performance, and volume content of the short carbon fibers can be controllable; and the short carbon fiber / silicon carbide composites have high specific modulus, high specific strength and excellent toughness, and can hopefully be applied to light weight armor field.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Synthetic fiber paper containing polyphenyl sulfide and aromid fiber and producing method thereof

InactiveCN1974925AHigher than strongHigher than the moldNon-fibrous pulp additionCalendersPolymer scienceThermal expansion

The present invention belongs to the field of synthetic fibre paper. In particular, it relates to a kind of synthetic fibre paper made up by using aramid fiber as structural fiber and utilizing polyphenylene sulfide fiber or granules through the processes of adhesive bonding and finalization. Said synthetic fiber paper possesses the excellent properties of light weight, high strength, resisting high temperature, resisting fatigue, resisting chemical corrosion, resisting radiation, high specific modulus, low thermal-expansion coefficient and good biological compatibility, and can be extensively used in the fields of electromechanical technology and aerospace industry. Besides, said invention also provides a wet preparation method for producing said synthetic fiber paper.

Owner:陶世毅 +3

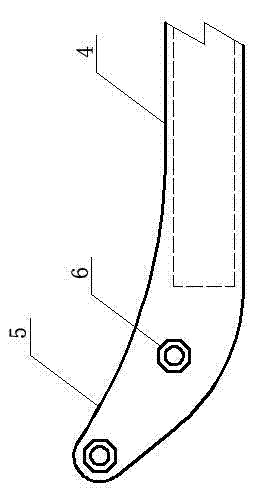

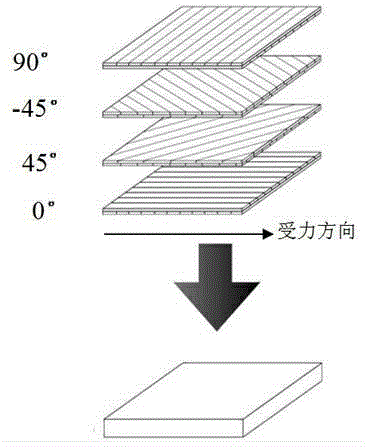

Carbon-fibre composite boom for concrete pump truck

InactiveCN102454299AHigh specific strengthHigh specific modulusBuilding material handlingEpoxyEngineering

The invention relates to a carbon-fibre composite boom for a concrete pump truck, belonging to the field of composites. A main body box girder is arranged, wherein a 90-degree angled carbon fiber cloth pre-impregnation material is laid on the inner layer of the main body box girder, and a 45-degree angled carbon fiber cloth pre-impregnation material is laid on the middle layer of the main body box girder, and a 0-degree angled carbon fiber cloth pre-impregnation material is laid on the outer layer of the main body box girder; the root of the main body box girder is provided with a plywood connected in an integrated way. The beneficial effects of the invention are as follows: the carbon-fibre composite boom gives full play of the higher specific strength, bigger specific modulus, fatigue resistance and corrosion resistance of the carbon-fibre reinforced epoxy resin composite so as to obtain a boom of a pump truck with excellent performances and reduce weight of the boom by 40-60%. At the same time, the carbon-fibre composite boom can also be applied in fields like fire engine booms, lifting arms of lifting appliances and power transmission and communication poles.

Owner:WEIHAI GUANGWEI COMPOSITES

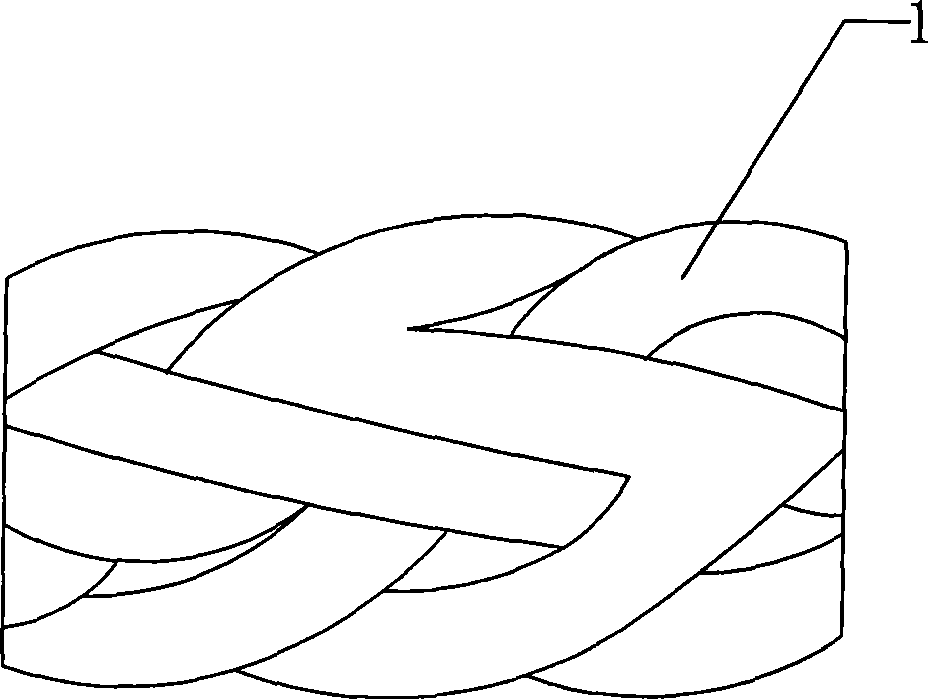

Super-macromolecule polyethylene rope and preparation technology thereof

The invention relates to an ultra high molecular weight polyethylene rope and a preparation process thereof. The ultra high molecular weight polyethylene rope comprises twelve strands which are braided into a unity. Six strands are left stranding and the other six strands are right stranding. The strands comprise twisted threads of an outer layer, a middle layer, an inner layer, a core layer, and the like which are formed in a twisting way. The twisted threads are high molecular weight polyethylene fiber twisted threads which are twisted according to the diameter of the rope. The preparation process comprises the following steps: 1) raw materials selection; 2) threads twisting; 3) strand preparation; 4) rope preparation; 5) surface treatment. The ultra high molecular weight polyethylene rope has the beneficial effects of corrosion resistance, fatigue resistance, wear resistance, ultraviolet resistance, cable insulation, and the like; besides, the common properties of similar products including small density less than 1, light weight, high strength, good specific modulus and impact resistance strength. The wear resistance is higher than similar products by about 8 percent. The fracture strength is higher than the similar products by 10 percent. And the ultra high molecular weight polyethylene rope has the advantages of reasonable structure, beauty and practicality.

Owner:浙江四兄绳业有限公司

Automobile anticollision structure part and preparation method thereof

The invention provides an automobile anticollision structure part and a preparation method thereof. The preparation method comprises the following steps: paving and superposing a carbon fiber material and performing thermocompression combination on the carbon fiber material and a resin material so as to form a resin-fiber composite material component; then fixedly connecting the resin-fiber composite material component with a metal material component so as to obtain the automobile anticollision structure part which not only comprises the carbon fibre material, but also comprises a metal base layer, not only preserves the advantages such as high strength and high tenacity of the metal anticollision component and meets the welding connection requirements of the anticollision structure part and body structure part, but also fully utilizes the advantages such as low density, light weight, excellent specific modulus and specific strength, high corrosion resistance and high modality of the carbon fiber material. The obtained automobile anticollision structure part has the unique advantages of light weight, high strength, corrosion resistance, excellent energy absorption capability and no possibility of falling from an automobile body when collided at a middle-low speed, is more beneficial to NVH control in an automobile running process, can be used for promoting extensive application of the carbon fiber material in automobile parts and has wide market prospect.

Owner:CHERY AUTOMOBILE CO LTD

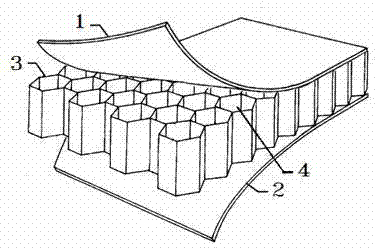

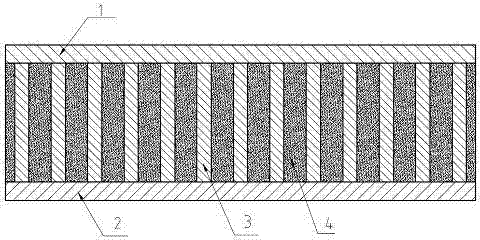

Continuous-fiber reinforced thermoplastic polymer temperature-adjusting plate

A continuous-fiber reinforced thermoplastic polymer temperature-adjusting plate comprises a surface plate, a bottom plate, a honeycomb core layer and a phase-change energy-storage material packed in the honeycomb core layer. The surface plate, the bottom plate and the honeycomb core layer are prepared from a sheet of a continuous-fiber reinforced thermoplastic polymer composite material filled with a modified heat-conduction filler, the honeycomb-core-layer phase-change energy-storage material is packed in multiple mutually-independent chambers in the honeycomb core layer, and the surface plate and the bottom plate are respectively combined with the upper surface and the lower surface of the honeycomb core layer through heat fusion. By blending a high-heat-conductivity substance with the polymer, the high-heat-conductivity continuous-fiber reinforced thermoplastic polymer plate, which is prepared by employing a double-face film coating method, has high specific modulus and specific strength. The honeycomb core layer employs a material same to that of the surface plate, and the honeycomb core layer and the surface plate are firmly bonded through fusion. Honeycomb holes are filled with the phase-change material, the addition amount is large and the problem that the phase-change material precipitates is effectively avoided. The continuous-fiber reinforced thermoplastic polymer temperature-adjusting plate has an expanded application field and is especially applicable to decoration of indoor decoration furred ceilings and wall surfaces.

Owner:BEIJING UNIV OF CHEM TECH

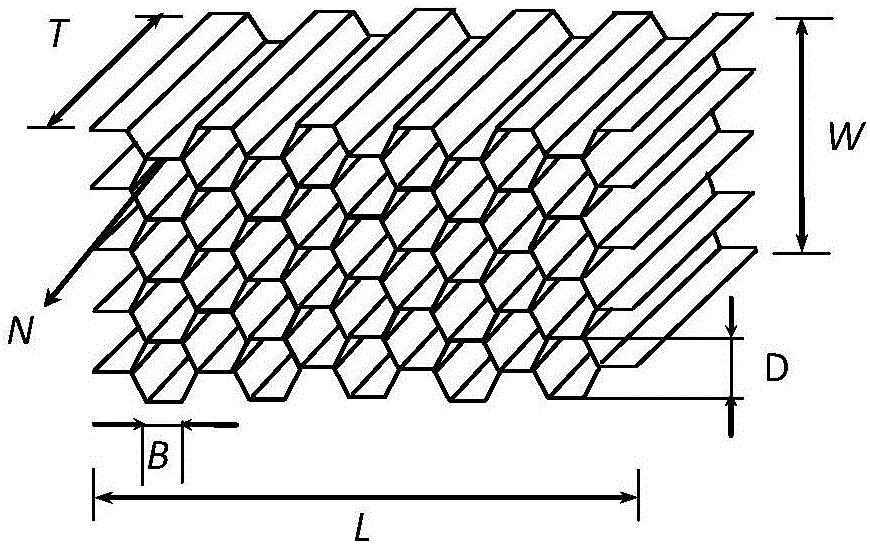

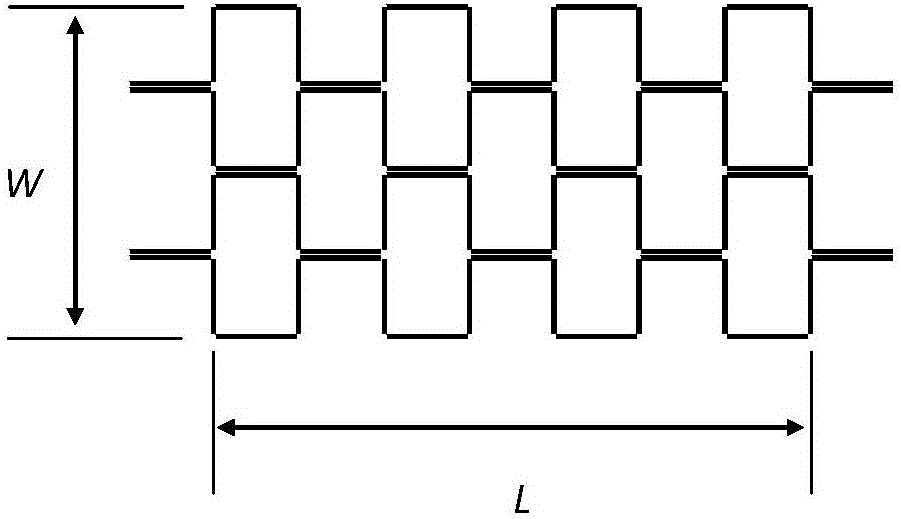

Preparation method of para-aramid paper honeycomb core

InactiveCN106696360AHigh specific strengthHigh specific modulusPaper/cardboard articlesMaterials preparationHoneycomb

The invention belongs to the technical field of composite material preparation, and relates to a preparation method of a para-aramid paper honeycomb core. The preparation method of the para-aramid paper honeycomb core is used for preparing a sandwich-structure composite material, and comprises the four treatment process steps of sequentially gluing and pressing para-aramid paper, stretching and setting the para-aramid paper, glue dipping and solidifying the para-aramid paper, and slicing processing the para-aramid paper. A para-aramid paper honeycomb prepared through the preparation method provided by the invention has higher specific strength and specific modulus, and a more excellent heat-resisting property; and under the same design requirement, the weight of a composite material component can be further reduced. The para-aramid paper honeycomb core prepared by adopting the method provided by the invention has higher strength and modulus, under the same mechanical property design requirement, the weight of the high-performance para-aramid paper honeycomb is reduced greatly, and the para-aramid paper honeycomb core can be widely applied in high-end fields such as aerospace.

Owner:AVIC COMPOSITES

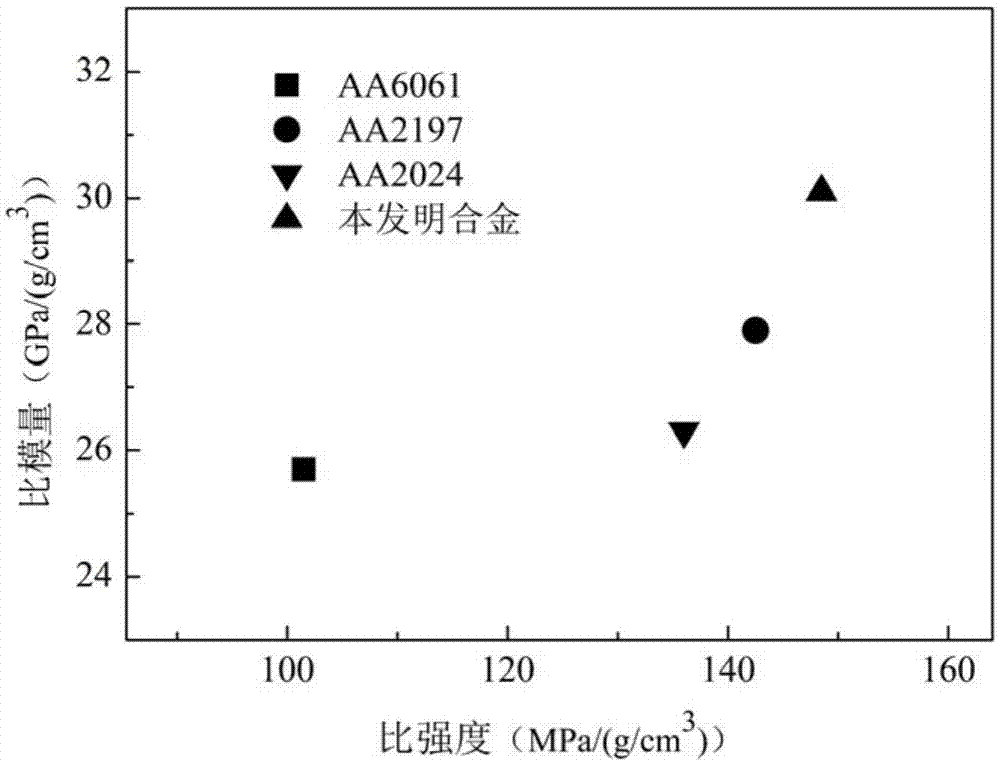

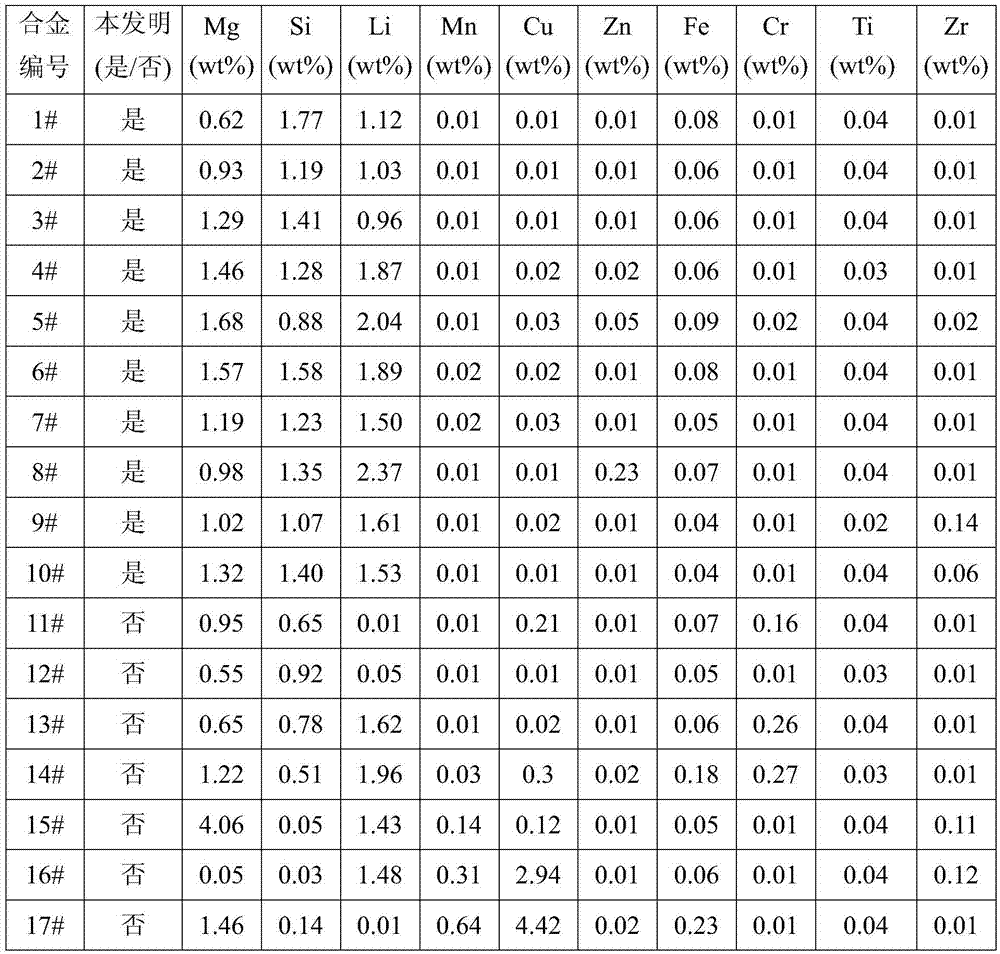

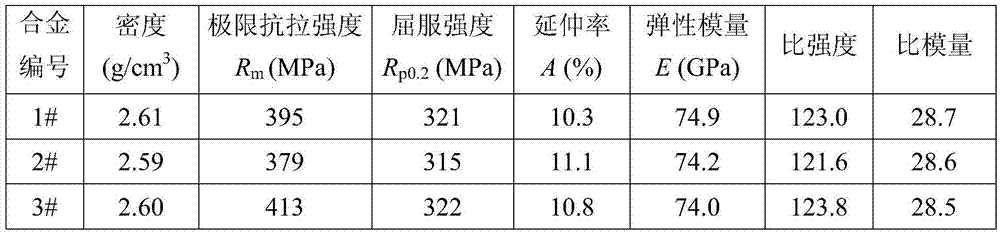

High-specific-strength and high-specific-modulus aluminum alloy material, preparation method thereof and component machined by material

The invention discloses a high-specific-strength and high-specific-modulus aluminum alloy material, a preparation method thereof and a component machined by the material. The aluminum alloy is prepared from, by weight, 0.60-1.70% of Mg, 0.85-1.80% of Si, 0.80-2.40% of Li, no more than 0.50% of Mn, no more than 0.50% of Cu, no more than 0.50% of Zn, 0.50% of Fe, no more than 0.50% of Cr, no more than 0.25% of Ti, no more than 0.25% of Zr, no more than 0.05% of each of other elements, and the balance Al, and the total content of the other elements is no more than 0.15%. The preparation method comprises the steps that an alloy ingot is manufactured, the alloy ingot is subjected to homogenizing heat treatment, deformation machining is conducted on the alloy ingot after the homogenizing heat treatment to obtain the alloy material of a required specification, the alloy material is subjected to solution heat treatment and cooled to the room temperature quickly, and the alloy material is subjected to aging heat treatment to obtain good performance matching. The high-specific-strength and high-specific-modulus aluminum alloy material has excellent specific strength and specific modulus performance and is an ideal material of modern manufacturing structure lightweight components.

Owner:GRIMAT ENG INST CO LTD

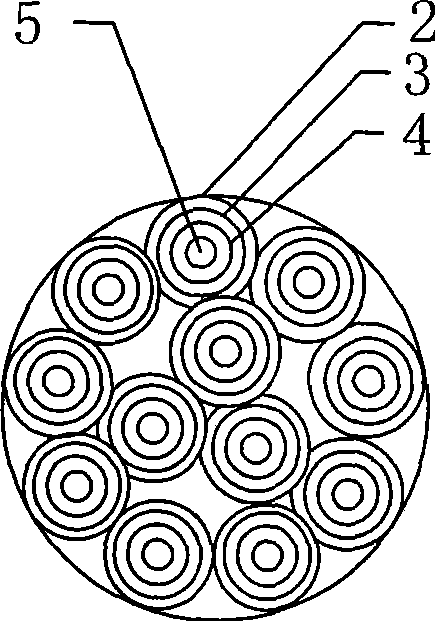

Nanometer silicon carbide particle reinforced aluminum matrix composite and preparation method thereof

The invention relates to the technical field of particle reinforced aluminum matrix composites and discloses a nanometer silicon carbide particle reinforced aluminum matrix composite and a preparation method thereof. The composite is prepared by uniformly distributing nanometer silicon carbide particles with the volume percentage of 6-16% into aluminum alloy with the volume percentage of 84-94%. The preparation method comprises the steps of firstly, proportioning, ball milling, premolding and carrying out hot pressing molding to prepare 1-5% of nanometer silicon carbide particle reinforced aluminum matrix composite; next, carrying out vacuum concentration on the 1-5% of nanometer silicon carbide particle reinforced aluminum matrix composite to evaporate parts of aluminum alloy matrixes; and finally, carrying out solid solution and aging treatment to prepare the nanometer silicon carbide particle reinforced aluminum matrix composite disclosed by the invention. Experiment data proves that the reinforced aluminum matrix composite with high nanometer silicon carbide particle content, prepared by using the preparation method not only has the functional properties of high heat conductivity, electrical conductivity, specific modulus, wear resistance and the like due to the high nanometer silicon carbide particle content, but also has strength as well as plasticity and toughness.

Owner:HENAN UNIV OF SCI & TECH

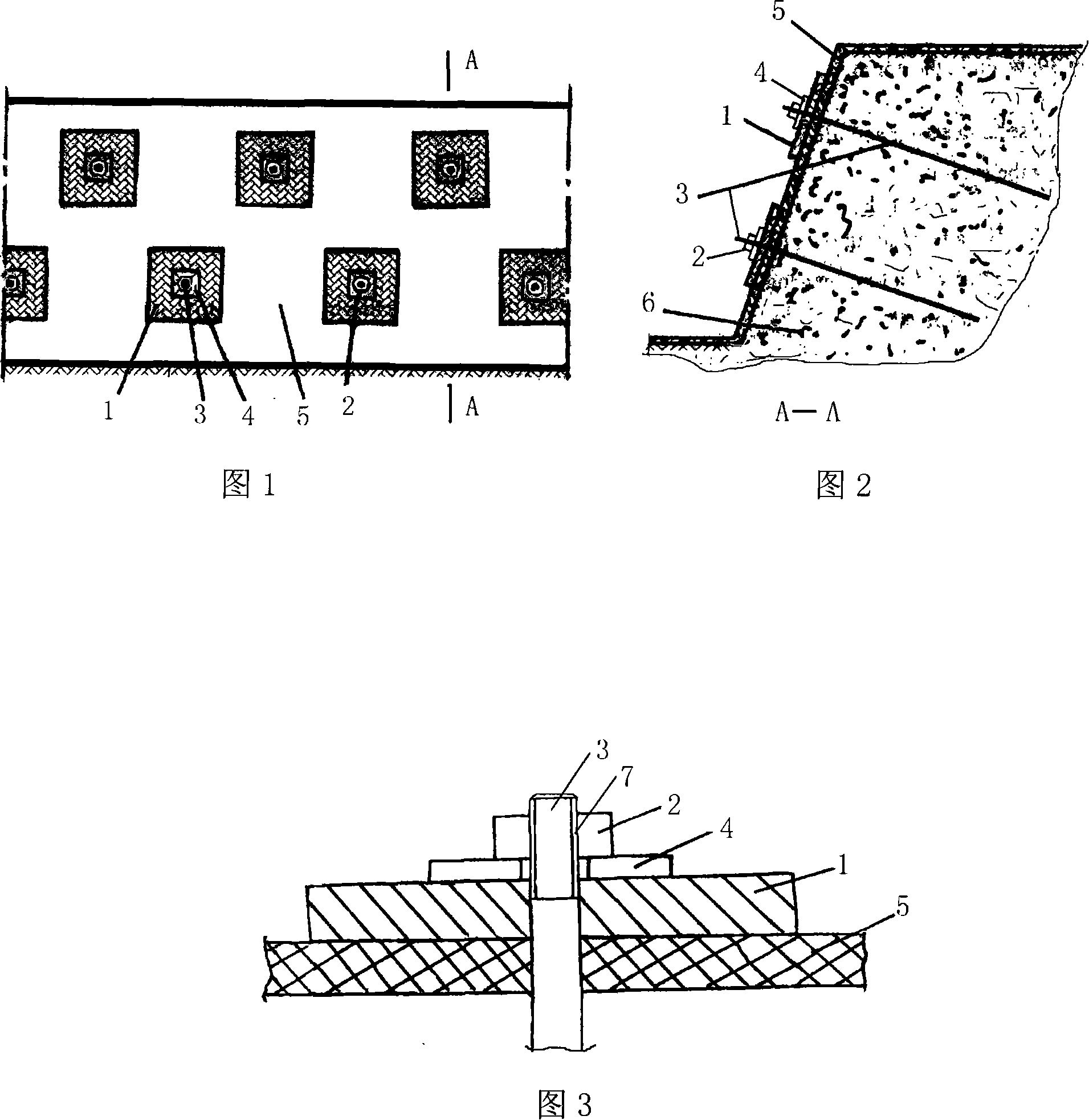

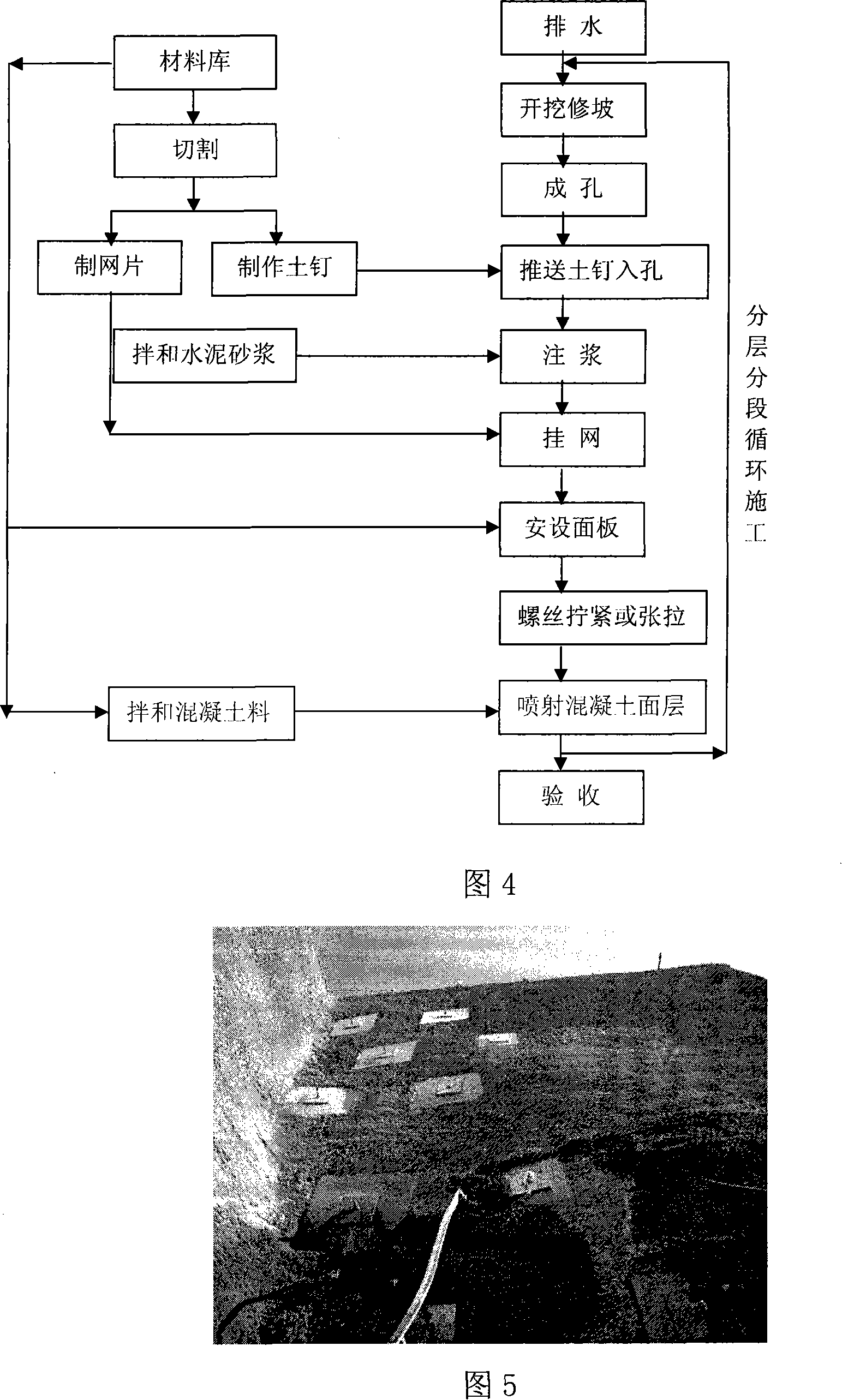

Demountable composite material face plate brad supporting system

ActiveCN101122132AEasy constructionFast and convenient construction speedExcavationsBulkheads/pilesResin matrixEngineering

The invention discloses a detachable composite material panel soil nail support system, which belongs to the technical field of building auxiliary engineering. The soil nails are fixed on the wall of the foundation pit, and the detachable composite panels are fixed on the wall of the wall foundation pit by detachable anchors and soil nails, and are connected by waterproof devices between the panels. After the service period is over, the composite panel can be disassembled to continue serving for the next project. The detachable composite panel is made of resin-based fiber composite material, mainly because of its light weight, high specific strength, large specific modulus, and good fatigue resistance. Compared with the traditional soil nail wall construction, the construction speed of the detachable composite panel support system is fast and saves time: the detachable composite panel soil nail support system is better than the traditional one in controlling the distribution of the plastic zone of the foundation pit and the deformation of the foundation pit. Soil nailed wall, good safety.

Owner:CHINA RAILWAY CONSTR GROUP +1

Glass composition for producing high strength and high modulus fibers

PendingUS20130225025A1Reduce manufacturing costHigh strengthGlass making apparatusGlass/slag layered productsGlass fiberFiber

A glass composition including Si02 in an amount from about 70.6 to about 79.6% by weight, AI2O3 in an amount from about 10.0 to 18.5% by weight, MgO m an amount from about 10.0 to about 19.0% by weight, CaO in an amount from about 0.1 to about 5.0% by weight, Li20 in an amount from 0.0 to about 3.0% by weight, and Na20 in an amount from 0.0 to about 3.0% by weight is provided. In exemplary embodiments, the glass composition is free or substantially free of B2O3 and fluorine. The glass fibers have a specific modulus between about 3.40×107 J / kg and 3.6×107 J / kg. Glass fibers formed from the inventive composition possess exceptionally an exceptionally high modulus and a low density, which make them particularly suitable in applications that require high strength, high stiffness, and low weight, such as wind blades and aerospace structures.

Owner:OCV INTELLECTUAL CAPITAL LLC

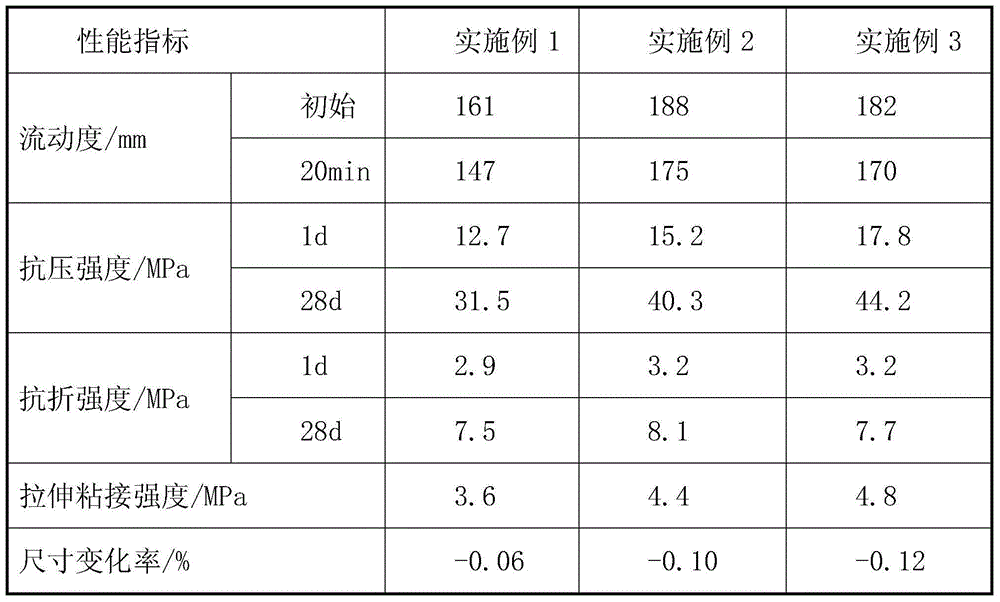

Inorganic mineral polymer self-leveling mortar and preparation method thereof

The invention relates to inorganic mineral polymer self-leveling mortar and a preparation method thereof. The mortar mainly comprises the raw materials in parts by weight: 64-72 parts of mine residues, 18-22 parts of kaolin, 10-14 parts of fly ash, 20-25 parts of water glass, 8-12 parts of sodium hydroxide, 25-30 parts of water, and 190-260 parts of fine sand, wherein additives are a water reducing agent, a stabilizing agent and an antifoaming agent; gelating materials adopt inorganic mineral polymers which are made from the mine residues, the kaolin and the fly ash and stimulated by the water glass with a specific modulus of 1.4-1.5; because of a dimensional net structure in the inorganic mineral polymers, the self-leveling mortar disclosed by the invention has higher compressive strength, higher rupture strength and durable and abrasion-proof performance. The 28d compressive strength is 45MPa, the 28d rupture strength is 9MPa, and the cohering strength is 4.5MPa. The mortar disclosed by the invention also solves the problems that the surface is not smooth after the mortar is hardened, the surface is cracked after being retracted, the surface is hollow and peeled; moreover, the utilization rates of industrial by-products are also improved.

Owner:SHENYANG JIANZHU UNIVERSITY

Multielement resin base carbon compound disc-type braking pad and preparation method thereof

ActiveCN102635653AImprove wear resistanceImprove high temperature resistanceFriction liningLow noiseSulfide

The invention discloses a multielement resin base carbon compound disc-type braking pad and a preparation method thereof. The braking pad is obtained by carrying out mould pressing and forming once on the following raw materials: unmodified phenolic resin, organosilicone modified phenolic resin, polyacrylate modified phenolic resin, polyacrylonitrile carbon fiber, artificial granular graphite, natural crystalline flake graphite, granular coke, silicon carbide, aramid pulp, compound mineral fiber, steel fiber, red copper powder, ferrous sulfide and barium sulfate. The product disclosed by the invention has the advantages of high temperature resistance, ablation resistance, small heat expansion coefficient, high specific strength, high specific modulus, good abrasion resistance, low noise, excellent initial performance, short breaking-in period, small heat fade, long service life, excellent pedal comfort degree, excellent high temperature and high speed performance and stable abrasion grade under different braking conditions, the effect on considering the good abrasion resistance and low noise is achieved, no dust is generated during braking, and various materials are all environment-friendly environment-protection materials. The multielement resin base carbon compound disc-type braking pad also has the function of automatically cleaning the braking disc.

Owner:JINAN GOLD PHOENIX BRAKE SYST

Preparation method of continuous fiber-toughened silicon carbide ceramic bullet-proof plate

ActiveCN108253843AHigh hardnessReduce hardnessLamination ancillary operationsLaminationShock resistanceHigh pressure

The invention relates to a preparation method of a bullet-proof plate, particularly to a preparation method of a continuous fiber-toughened silicon carbide ceramic bullet-proof plate. The preparationmethod has the beneficial effects that the continuous fiber-toughened silicon carbide ceramic provided by the invention inherits high hardness and abrasion resistance advantages of a silicon carbide ceramic material, exerts the continuous fiber reinforcing and toughening principle, and overcomes the inherent defects, of pure silicon carbide ceramic, that inherent toughness is poor and external shock load resistance performance is poor, so that the continuous fiber-toughened silicon carbide ceramic has the characteristics like low density, high specific strength, high specific modulus, high hardness and shock resistance, and bullet-proof performance, particularly multi-bullet-proof performance, of the bullet-proof plate can be effectively improved; a continuous fiber-toughened silicon carbide ceramic material is prepared through a polymer high-pressure impregnation pyrolysis technology, the technology is simple, and preparation cost is low; and a setting method provided by the inventionis simple and flexible, and size customization of the bullet-proof plate is facilitated.

Owner:AVIC BASIC TECH RES INST

Three-phase nanocomposite

ActiveUS7288133B1High strengthIncrease stiffnessMaterial nanotechnologyCeramic particleSpecific modulus

A three-phase nanocomposite that comprises about 0.5 to 10 vol % nano-scale aluminum oxide particles and about 1 to 45% high modulus ceramic particles and an aluminum alloy matrix. The nano phase is to enhance nanocomposite strength and the modulus phase is to enhance the specific modulus of the resulting nanocomposite.

Owner:YCT IND

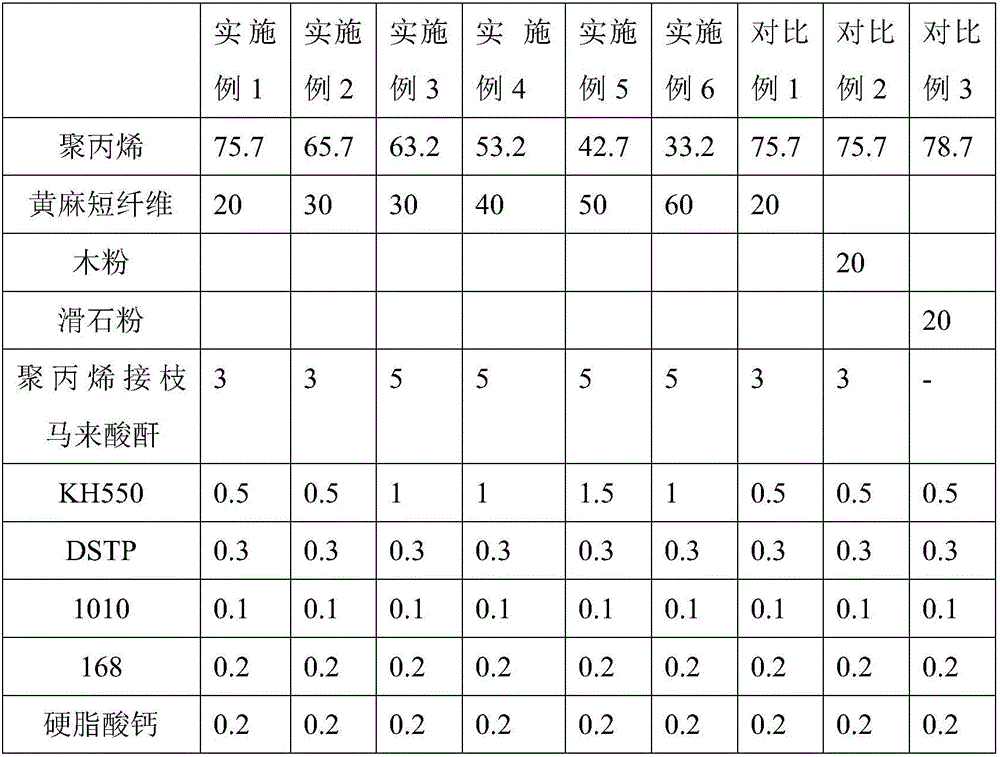

High heat-resistant, halogen-free and flame-retardant type jute fiber-reinforced polypropylene composite material and preparation method thereof

InactiveCN106674741AImprove flame retardant performanceAbundant resourcesPolypropylene compositesPolymer science

The invention discloses a high heat-resistant, halogen-free and flame-retardant type jute fiber-reinforced polypropylene composite material and a preparation method thereof. The jute fiber-reinforced polypropylene composite material is prepared from the following raw materials in parts by weight: 30 to 80 parts of polypropylene, 10 to 40 parts of jute fiber, 1 to 5 parts of whisker, 1 to 10 parts of halogen-free flame-retardant agent, 1 to 10 parts of compatilizer, 1 to 2 parts of coupling agent, 0.1 to 2 parts of antioxidant, and 0.2 to 1 part of lubricating agent. The jute fiber-reinforced polypropylene composite material has the advantages that the jute fiber with low cost, rich resource, high specific modulus and low density is used for preparing the vehicle reinforced polypropylene composite material, so that the production cost is reduced; by adding a certain amount of alkaline type magnesium sulfate whiskers into the polymer composite material on the basis of original basic formula, the high temperature-resistant property is improved; by adding a smaller amount of novel phosphor-containing organosilsesquioxane halogen-free flame-retardant agent, the flame-retardant property of the jute fiber-reinforced polypropylene composite material is improved.

Owner:CHONGQNG PRET NEW MATERIAL +4

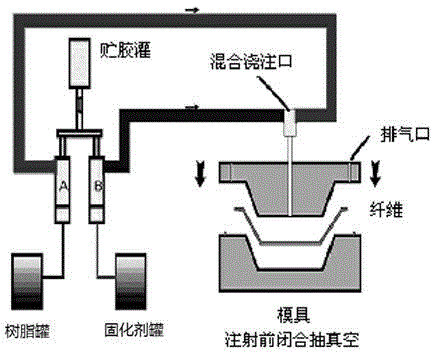

Method for manufacturing carbon fiber arm support for concrete pump truck

The invention relates to a method for manufacturing a carbon fiber arm support for a concrete pump truck, which comprises the following steps of: arranging a hollow core mold, laying a raw material for manufacturing the carbon fiber arm on the external surface of the core mold, coating the exterior of the raw material by using a vacuum film, sealing both ends of the vacuum film on both ends of the core mold, arranging air exhaust holes on the vacuum film, putting the entire mold in an autoclave, pressurizing by using compression air, and curing to form by using an electric heating tube to heat. The carbon fiber arm support for a concrete pump truck, processed by using the method, fully exerts the advantages of high specific strength, large specific modulus, fatigue resistance and corrosion resistance of a carbon fiber reinforced epoxy resin composite material, so that the pump truck arm support has excellent performance, and the weight of the arm support can be reduced by 40-60%. Meanwhile, because no outer mold is used in the invention, the investment to molds, tooling and equipment is greatly reduced, and the product design can be changed conveniently. Meanwhile, the method can also be applied to the fields of fire truck arm supports, suspension arms of hoisting equipment, transmission poles, communication poles and the like.

Owner:WEIHAI GUANGWEI COMPOSITES +1

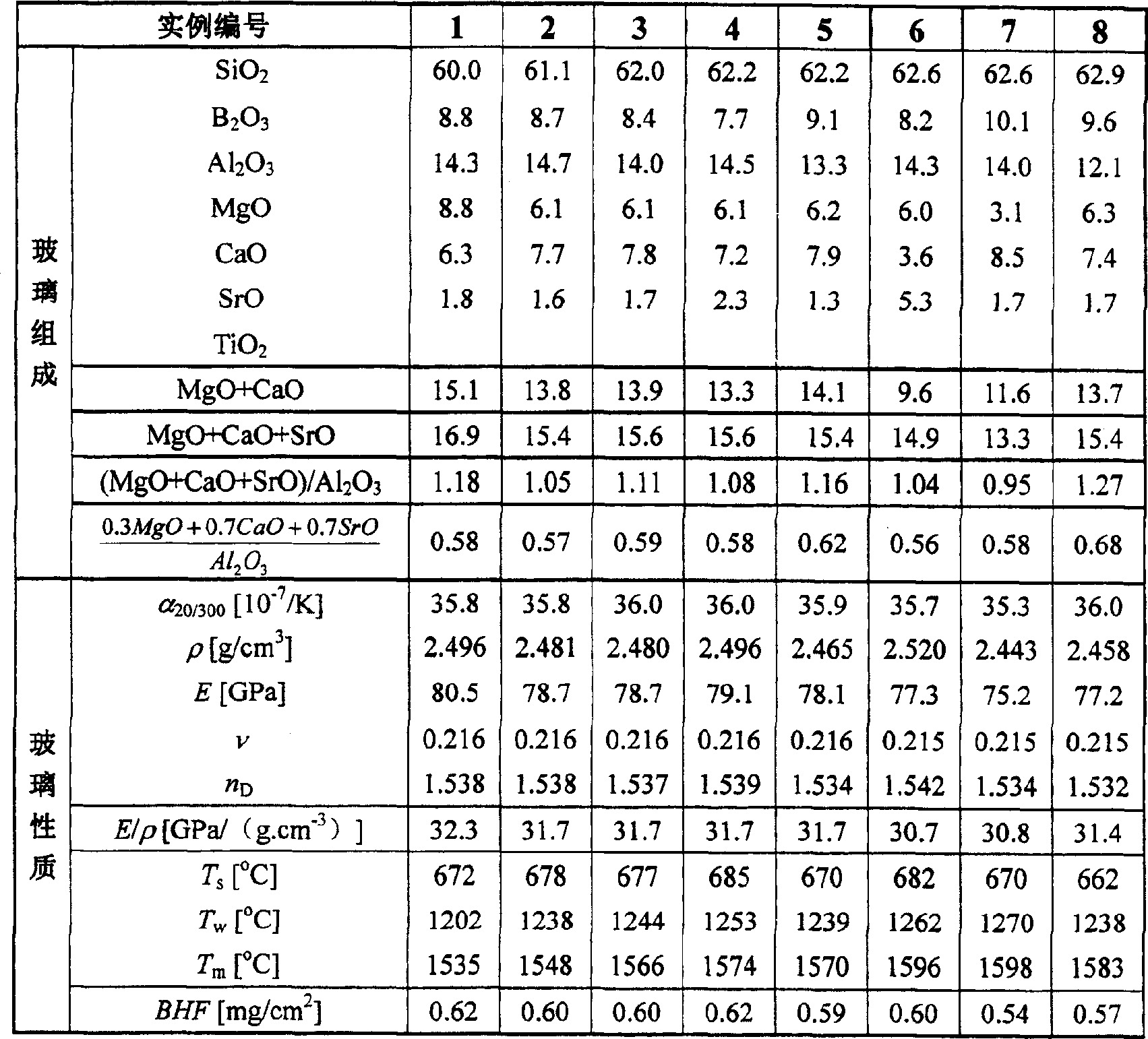

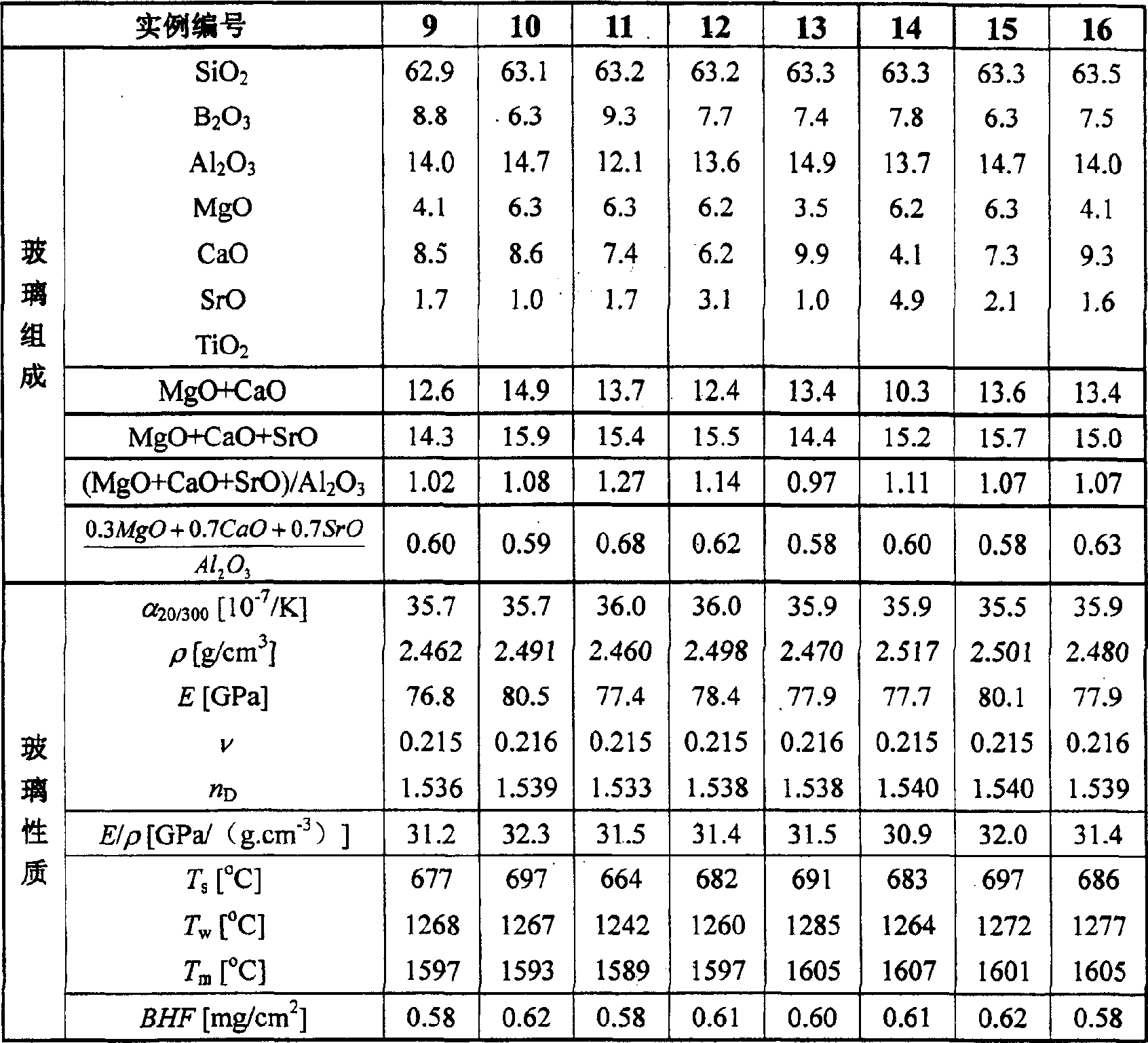

Non-alkali glass composition of high specific modulus value and its use

Owner:HENAN ANCAI HI-TECH

High-performance jute fiber reinforced polypropylene composite and preparation method thereof

The invention discloses a high-performance jute fiber reinforced polypropylene composite and a prepration method thereof. The high-performance jute fiber reinforced polypropylene composite comprises the following raw materials of, by weight, 20-60 parts of jute fibers, 30-80 parts of polypropylene, 1-10 parts of a compatilizer, 0.5-2 parts of a coupling agent, 0.1-1 part of antioxidants, and 0.2-1 part of lubricants. The polypropylene composite used for vehicles is prepared by adoption of the jute fibers which are low in price, rich in source, high in specific modulus, low in density and small in effect on the environment, the production cost can be lowered, and the composite accords with the development trend of low-weight, environment-friendly and recyclable automobiles; and meanwhile, the natural fibers are treated by adoption of an alkaline solution, the coupling agent and the compatilizer, the hygroscopicity of the jute fibers is reduced, and the bonding force between the jute fibers and polypropylene particles is increased at the same time.

Owner:CHONGQNG PRET NEW MATERIAL +4

Carbon fiber cloth-titanium alloy composite material and preparation method thereof

The invention discloses a carbon fiber cloth-titanium alloy composite material and a preparation method thereof. The method comprises the steps of Step 1, pretreating a carbon fiber cloth; Step 2, electroplating copper on the surface of the carbon fiber cloth, wherein the surface of the carbon fiber cloth is coated with the copper through an electroplating method; Step 3, placing the copper-plated carbon fiber cloth and a titanium alloy piece into a die in a certain sequence; and Step 4, obtaining the carbon fiber cloth-titanium alloy composite material in the required shape finally through a spark plasma sintering (SPS) method. The carbon fiber cloth-titanium alloy material prepared by the method is good in composition, the copper has the good interface wetting effect and effectively prevents the interface reaction of titanium and carbon, constituents of the titanium alloy are adjustable, the distribution of the carbon fiber cloth is controllable, and carbon fibers are firmly combined with a substrate. The composite material is high in specific modulus and interface bonding strength, simultaneously, compared with the titanium alloy, the composite material is low in density and high in static and dynamic compression strength, and the composite material is a high-performance structure material.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

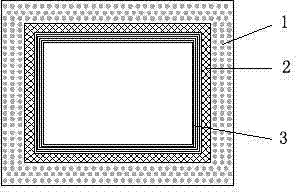

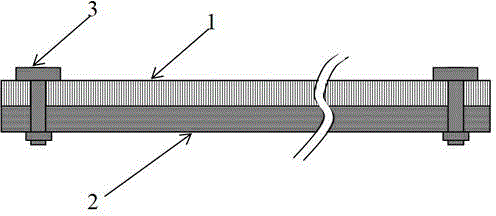

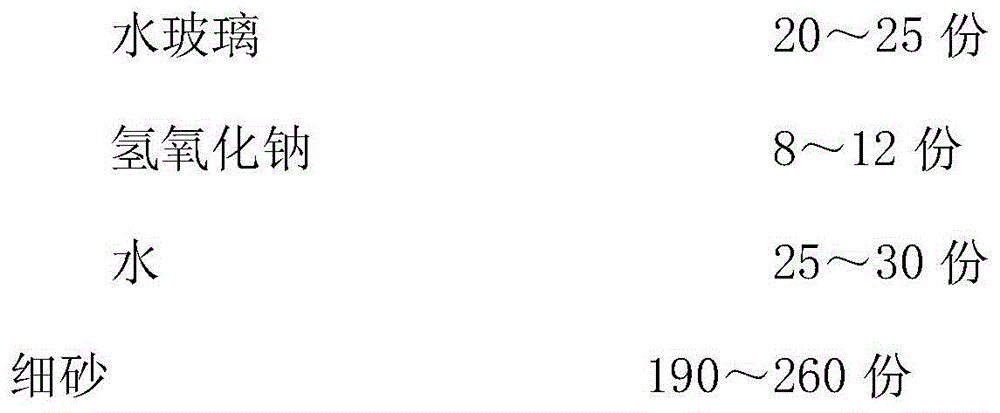

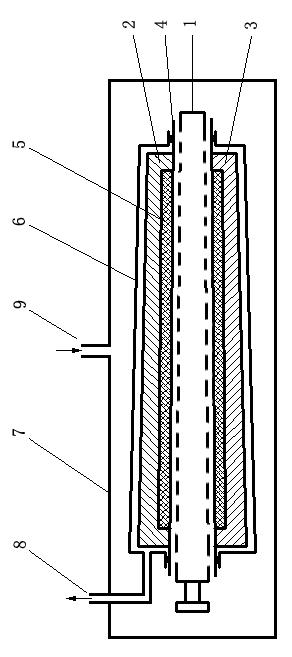

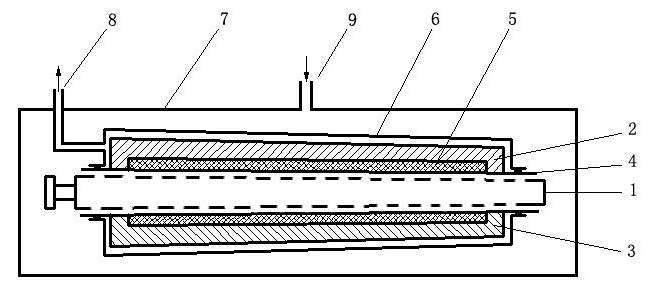

Collapsing and unfolding support tubes for space membrane facilities

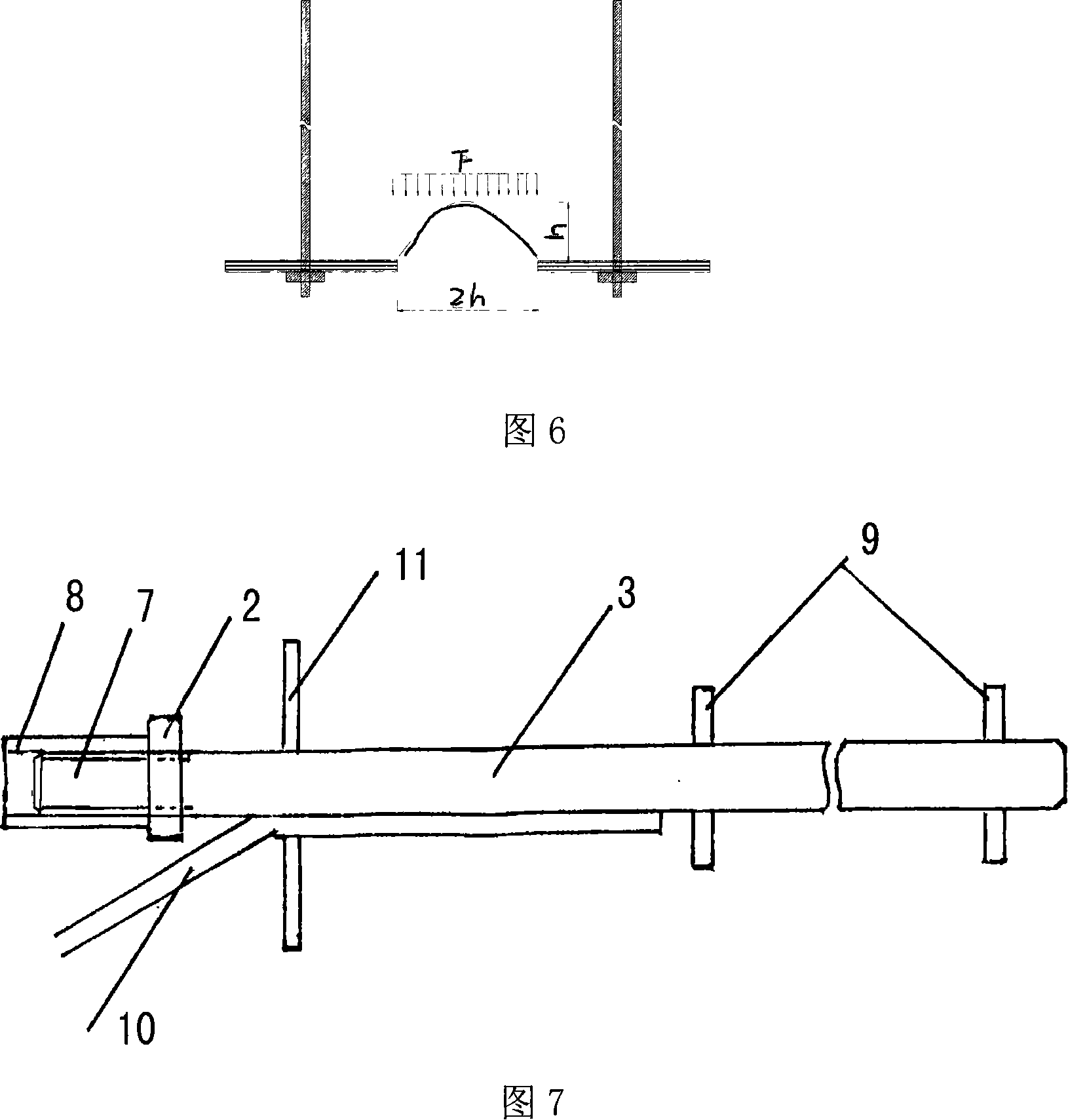

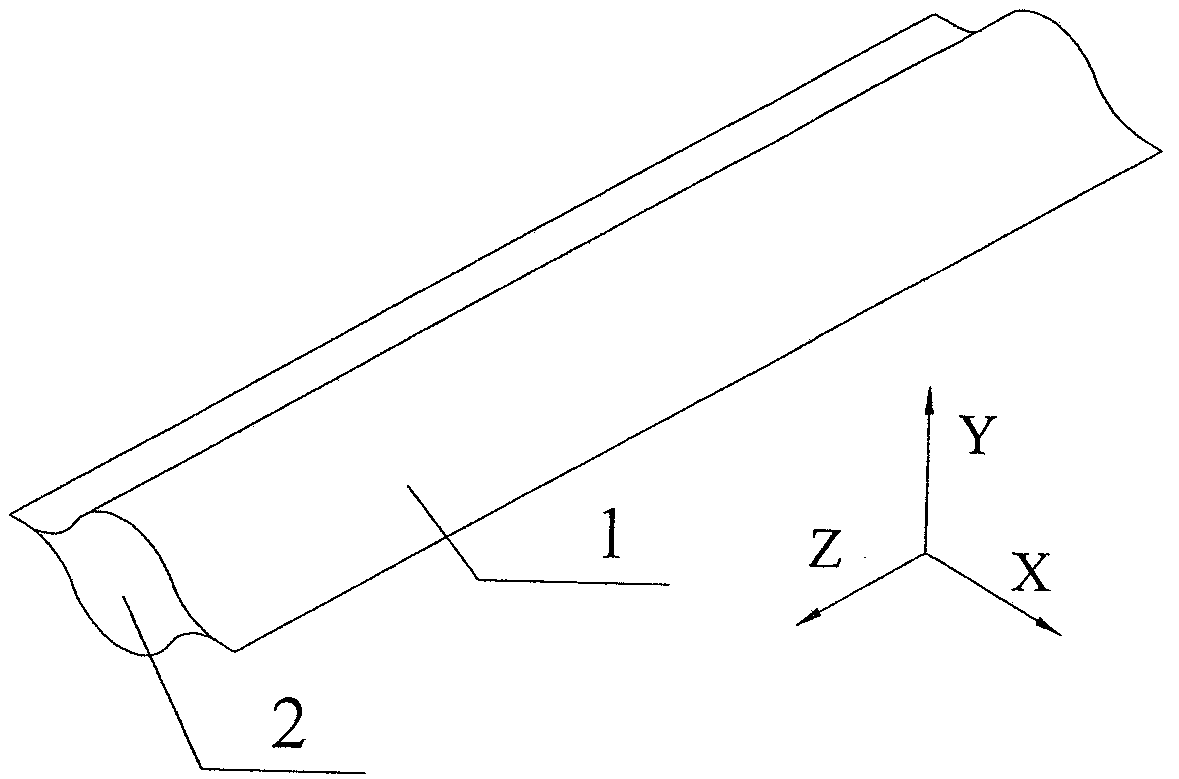

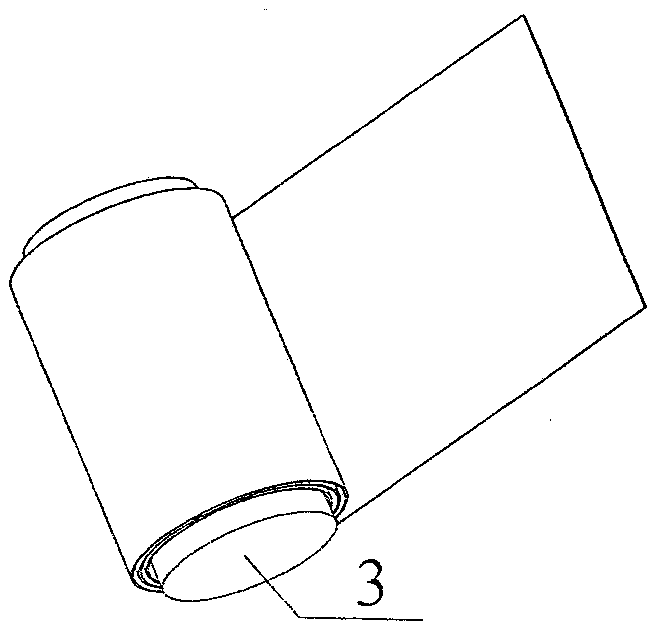

InactiveCN105474780BImprove mechanical propertiesGood dimensional stabilityCosmonautic vehiclesLayered productsResin-Based CompositeLow density

The invention relates to aerospace vehicle equipment, and discloses a retractable and unfolded support tube for a space film facility, comprising: an upper thin-walled shell [1] and a lower thin-walled shell [2] with a cross-section in the shape of "Ω". The semicircular concave surfaces are opposite to each other, and the flat edges on both sides are glued to each other to form a pod-shaped thin-walled support tube. During the launch stage of the spacecraft, the thin-walled support tube is flattened into a flat strip and curled around itself or a drum. After the spacecraft is launched to the predetermined orbit, the thin-walled support tube unfolds and returns from the flat roll state to the long tube state. The above-mentioned upper thin-walled shell [1] and lower thin-walled shell [2] are prepared from high specific modulus fiber-reinforced resin matrix composite materials. The invention solves the problems of large volume, complex structure, low deployment stability and reliability of the original structure, and has the advantages of large elastic recovery force, high elastic recovery rate, good elastic recovery reliability, low density, high strength, high rigidity and low cost. inferior advantages.

Owner:SHANGHAI AEROSPACE SYST ENG INST

Composite material of carbon/carbon/copper and production technology thereof

The invention discloses carbon / carbon / copper composite material which has the advantages that the production process is easy to be controlled, the isotropy of the product is good, and the combined property is good. The invention is characterized in that the carbon / carbon / copper composite material is calculated according to the weight percentage, and the weight ratio of the carbon / carbon composite material to copper or copper alloy is 15 to 75: 85 to 25; the production process comprises the following steps: a prepared web and carbon cloth are compounded into a precasting part through needling, the carbon, the copper or the copper alloy with different morphologies is compounded into a whole through densification (or vacuum pressure copper cementation) to form the carbon / carbon / copper composite material; the production process of the invention is simple and easy to be controlled, and the made composite material has good abrasive resistance and feasible electrical conductivity, and also has the advantages of high specific strength, high specific modulus, high temperature resistance and ablation resistance, and can be applied to the high conductivity and abrasive resistance field; the abrasion loss of an electric brush made of carbon / carbon / copper composite material is lower than 0.18 mm / 50 hours, and the abrasion loss of the prior electric brush is generally higher than 0.20 mm / 50 hours.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

Car brake block mixed with piemarker fiber and preparing method of car brake block

InactiveCN103836098AHigh melting pointModerate hardnessOther chemical processesFriction liningRare earthRenewable resource

The invention discloses a car brake block with a piemarker fiber and a preparing method of the car brake block. The car brake block comprises the natural piemarker fiber, aramid fiber pulp, rare-earth modified phenolic resin, a friction performance modifier, padding and the like, and comprises, by weight, 30-35 parts of reinforced fiber, 13-16 parts of binding agent, 9-12 parts of friction performance modifier and 40-45 parts of padding. The piemarker fiber on which the alkali treatment and ultrasonic treatment are carried out is low in price, light, high in specific strength, specific modulus and tensile strength and good in abrasion resistance and has other superior properties, and belongs to renewable resources. The car brake block prepared under the optimal technological condition and mixed with the piemarker fiber has a stable friction coefficient, a good brake effect and brake smoothness, is low in noise, good in comfort and friendly to the environment and is an ideal environment-friendly friction material.

Owner:QINGDAO UNIV

Method for manufacturing carbon fiber arm support for concrete pump truck

The invention relates to a method for manufacturing a carbon fiber arm support for a concrete pump truck. The carbon fiber arm support is provided with a hollow mandrel; the surface of the mandrel is hollowed out; a layer of vacuum film is covered on the surface of the mandrel; raw materials for manufacturing the carbon fiber arm support are laid on the surface of the vacuum film; an upper die and a lower die are combined on the mandrel; the combined position of the upper die and the lower die is fastened by bolts; the upper die and the lower die are coated by a vacuum film, and both ends of the vacuum film are sealed with both ends of the vacuum film on the mandrel; an air exhaust hole is formed on the vacuum film; and the whole die is put into a hot-press tank, is pressurized by compressing air and is heated, cured and molded by an electric heating tube. The carbon fiber arm support for the concrete pump truck processed by the method can fully exert the advantages of high specific strength, high specific modulus, fatigue resistance and corrosion resistance of carbon fiber reinforced epoxy resin composite materials so as to obtain superior-performance arm supports for the concrete pump truck and reduce 40 to 60 percent of weight of the arm support. Meanwhile, the method can be used in the fields of arm supports for fire trucks, suspension arms for hoisting equipment, power transmission, communication wires and poles and the like.

Owner:WEIHAI GUANGWEI COMPOSITES

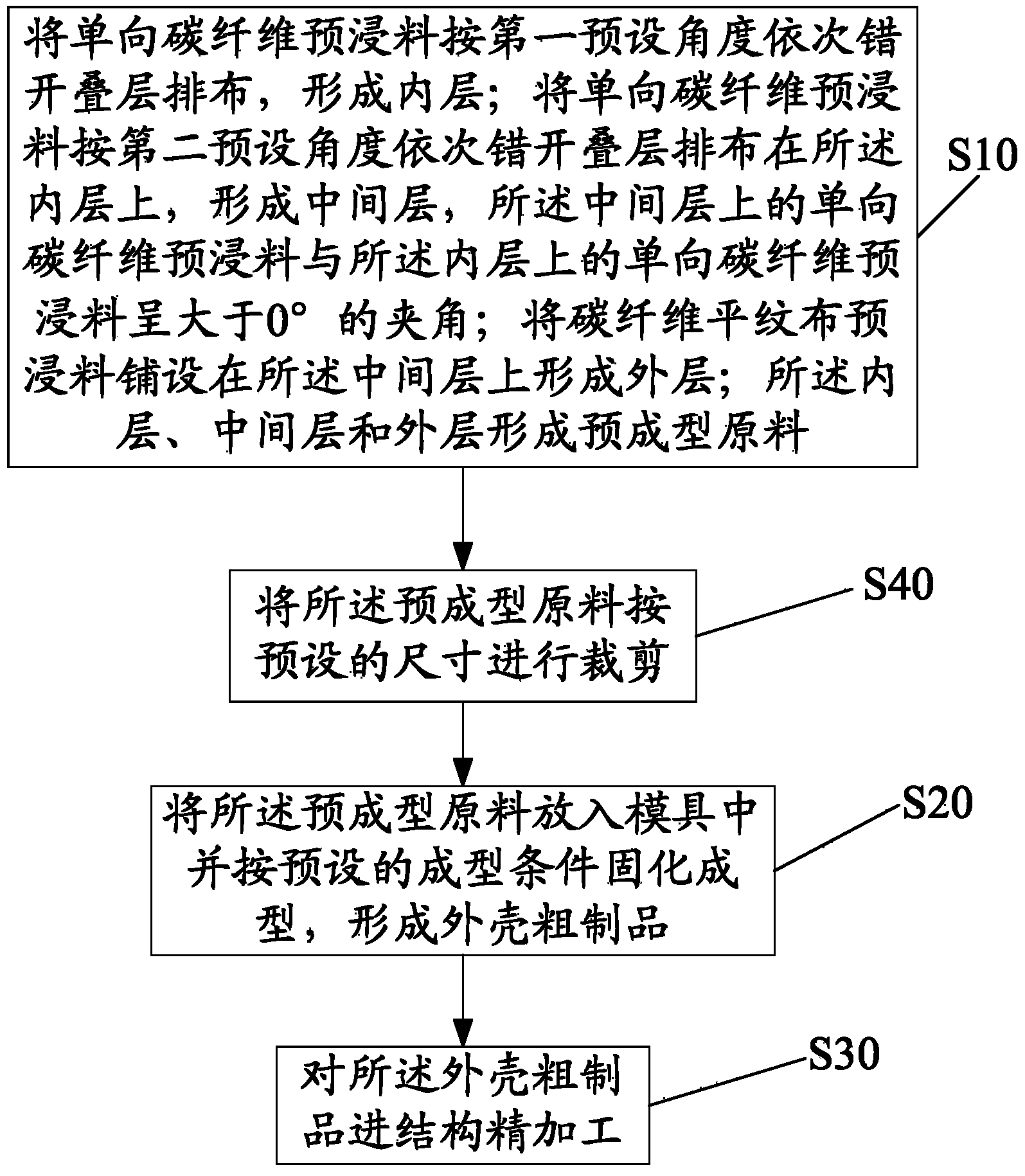

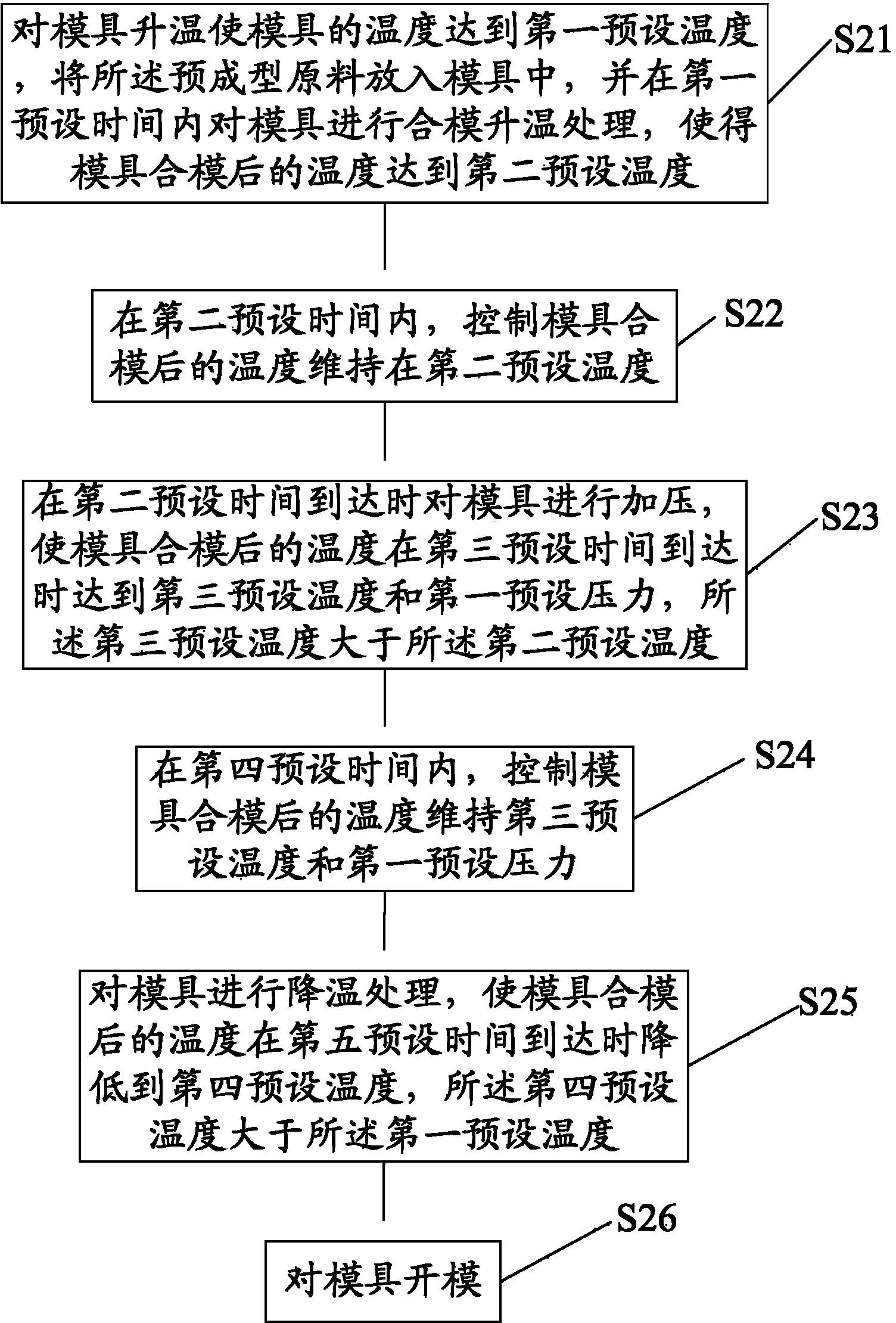

Carbon fiber housing making method

The invention discloses a carbon fiber housing making method which comprises the following steps: forming an inner layer and an intermediate layer by laminated arrangement of a uni-directional carbon fiber prepreg with an included angle of the uni-directional carbon fiber prepreg on the intermediate layer and the inner layer uni-directional carbon fiber prepreg on the inner layer being greater than 0 degree; laying a carbon fiber plain cloth prepreg on the intermediate layer to form an outer layer; forming a pre molding raw material on the inner layer, the intermediate layer and the outer layer; putting the pre molding raw material into a mold for curing molding according to preset curing molding conditions to form a rough housing product; and performing structural finish machining on the rough housing product. The material of a carbon fiber housing prepared by the carbon fiber housing making method is a carbon fiber epoxy resin composite, so that the carbon fiber housing is high in specific strength, light in self weight, beneficial for the lightweight design of a display device, high in specific modulus, large in stiffness, strong in falling resistance, good in corrosion resistance, good in high temperature resistance, good in anti fatigue performance and not easy to deform.

Owner:SHENZHEN TCL NEW-TECH CO LTD

Preparation method of compact C/C composite material

The invention discloses a preparation method of a compact C / C composite material. The method includes: firstly preparing a 3D or 2.5D braided carbon fiber preform; then putting the preform into a vacuum chemical vapor deposition furnace, introducing methane and hydrogen, letting pyrolytic carbon produced by methane decomposition infiltrate the preform by chemical vapor infiltration to realize compaction of carbon fiber filaments within the preform, thus turning the preform into a C / C composite material skeleton; then infiltrating the obtained C / C composite material skeleton with a thermosetting resin solution by precursor infiltration and pyrolysis method, and conducting high temperature pyrolysis in a vacuum furnace to obtain a glass carbon matrix; and finally cycling the step (3) repeatedly, and stopping the operation when the weight gain rate of the material is lower than 1%, and finally conducting pyrolysis to obtain pyrolytic glass carbon filled among fiber bundles, thus realizing compaction of fiber bundles, and obtaining the compact C / C composite material. The material has the advantages of high density, low porosity, high specific strength, specific modulus, and good toughness, high compactness, wear resistance and long service life.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

Image forming method and iamge forming apparatus

ActiveUS20050244737A1Prevent carrier adhesionImage stabilizationElectrographic process apparatusElectrographic processes using charge patternLatent imageImage formation

An image forming method and an image forming apparatus are disclosed in which an electrostatic latent image is formed on a photosensitive member surface by using a two-component developer including a toner and carrier. The photosensitive member surface has a specific modulus of elastic deformation and includes a charge transport layer with a specific thickness. The toner has a specific weight-average particle diameter. The carrier has a specific volume-average particle diameter and a specific circularity, and contains 20% by number or less of particles having a value of “average circularity−2 σ” where σ is standard deviation of carrier circularity.

Owner:CANON KK

Composite material of carbon fibers or carbon fiber powder, and processing process thereof

InactiveCN103333473AHigh specific strengthHigh specific modulusGlass ballElectrical resistance and conductance

The invention provides a composite material of carbon fibers or carbon fiber powder, and a processing process thereof. The composite material comprises, by mass, (1) 35-55% of a matrix, wherein an unsaturated polyester resin or an epoxy resin is adopted as the matrix, (2) 2-20% of carbon fibers or boron fibers, (3) 5-15% of micro glass balls or silicon carbide balls, (4) 35-55% of carbon fiber powder, and (5) 2-20% of copper powder or copper alloy powder. The composite material of carbon fibers or carbon fiber powder has high specific strength and high specific modulus, wherein the structure member formed from the composite material has characteristics of low density, fine surface burnishing effect, impact resistance, low resistivity, and good electrical conductivity.

Owner:邱献腾

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com