Preparation method of para-aramid paper honeycomb core

A technology of para-aramid paper and honeycomb core material, which is applied to cardboard articles and other directions, can solve the problems of low specific strength of meta-aramid paper honeycomb, electrochemical corrosion, poor wave transmission performance, etc., to improve the overall performance of the structure, High temperature resistance grade, excellent heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

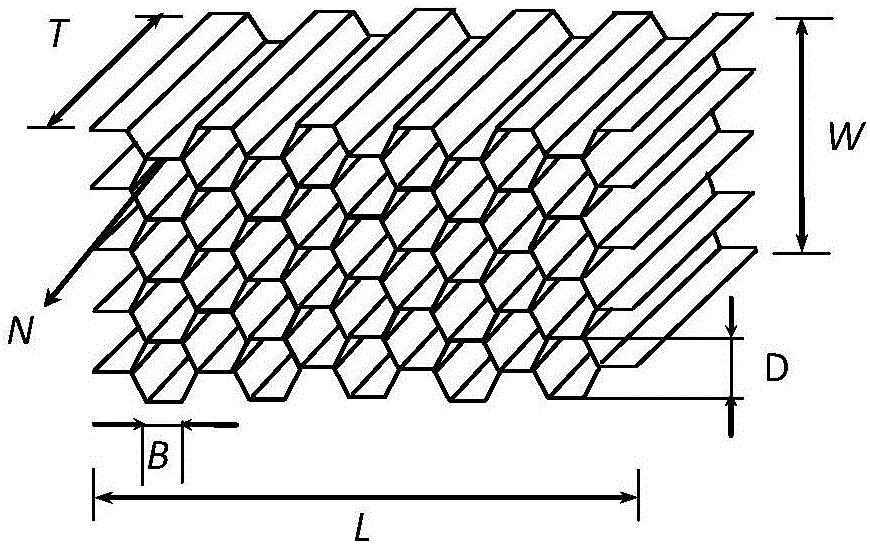

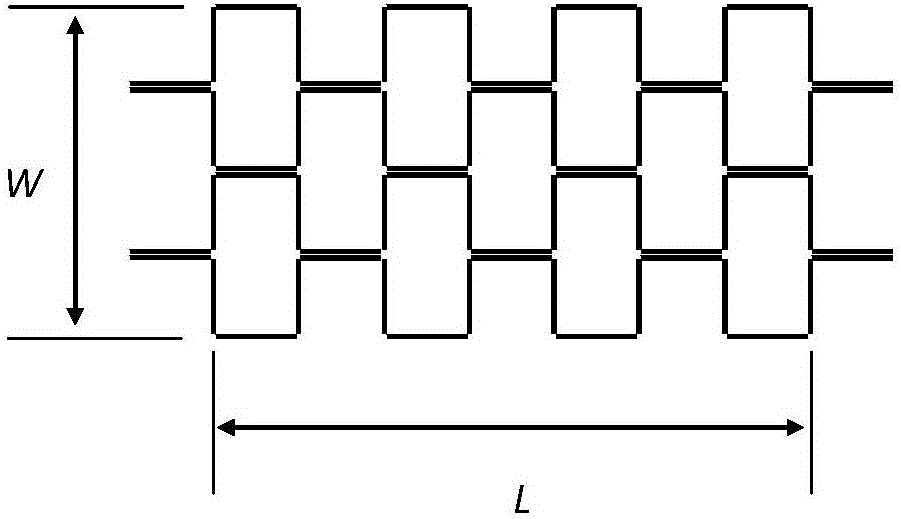

[0039] A regular hexagonal para-aramid paper honeycomb core with cell side length B of 1.83 mm was prepared. Specific steps are as follows:

[0040] (1) Using para-aramid paper with a thickness of 0.05mm as the raw material, first apply epoxy resin core strip glue to the aramid paper on the glue applicator, and then cut the aramid paper according to the target length after coating, and the multi-layer The glued para-aramid paper is stacked in dislocation to obtain a para-aramid paper laminate. After the lamination is completed, use a hot press machine to heat press the prepared laminate according to the curing process of the core strip glue, and then cure it to make a honeycomb laminate. The core strip glue is a modified phenolic epoxy resin liquid glue, which is made of special nitrile rubber as a toughening material, mixed with aromatic amine as a curing agent, and dissolved with an appropriate solvent. The glue viscosity is 30s / ml. When curing by hot pressing, first preh...

Embodiment 2

[0046] A regular hexagonal para-aramid paper honeycomb core with cell side length B of 2.75 mm was prepared. Specific steps are as follows:

[0047] (1) Using para-aramid paper with a thickness of 0.05mm as the raw material, firstly glue the aramid paper on the gluing machine, cut the aramid paper according to the required size after gluing, and cut the aramid paper after multi-layer gluing The para-aramid paper is stacked in dislocation. After the stacking is completed, the laminated board is hot-pressed with a hot press, and it is cured according to the curing process of the core strip glue to make a honeycomb laminated board. The core strip glue is a modified phenolic epoxy resin, which is a liquid glue made of special nitrile rubber as a toughening material, mixed with aromatic amine as a curing agent, and dissolved in an appropriate solvent. The viscosity of the glue is 25s / ml. When curing by hot pressing, first preheat at 70°C for 30 minutes, then cure at 180°C for 6 ho...

Embodiment 3

[0053] An overstretched para-aramid paper honeycomb core with cell side length B of 2.75 mm was prepared. Specific steps are as follows:

[0054] (1) Using para-aramid paper with a thickness of 0.05mm as the raw material, firstly glue the aramid paper on the gluing machine, cut the aramid paper according to the required size after gluing, and cut the aramid paper after multi-layer gluing The para-aramid paper is stacked in dislocation. After the stacking is completed, the laminated board is hot-pressed with a hot press, and it is cured according to the curing process of the core strip glue to make a honeycomb laminated board. The core strip glue is a modified phenolic epoxy resin, which is a liquid glue made of special nitrile rubber as a toughening material, mixed with aromatic amine as a curing agent, and dissolved in an appropriate solvent. The viscosity of the glue is 25s / ml. When curing by hot pressing, first preheat at 70°C for 30 minutes, then cure at 180°C for 6 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com