Patents

Literature

708 results about "Aluminum honeycomb" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

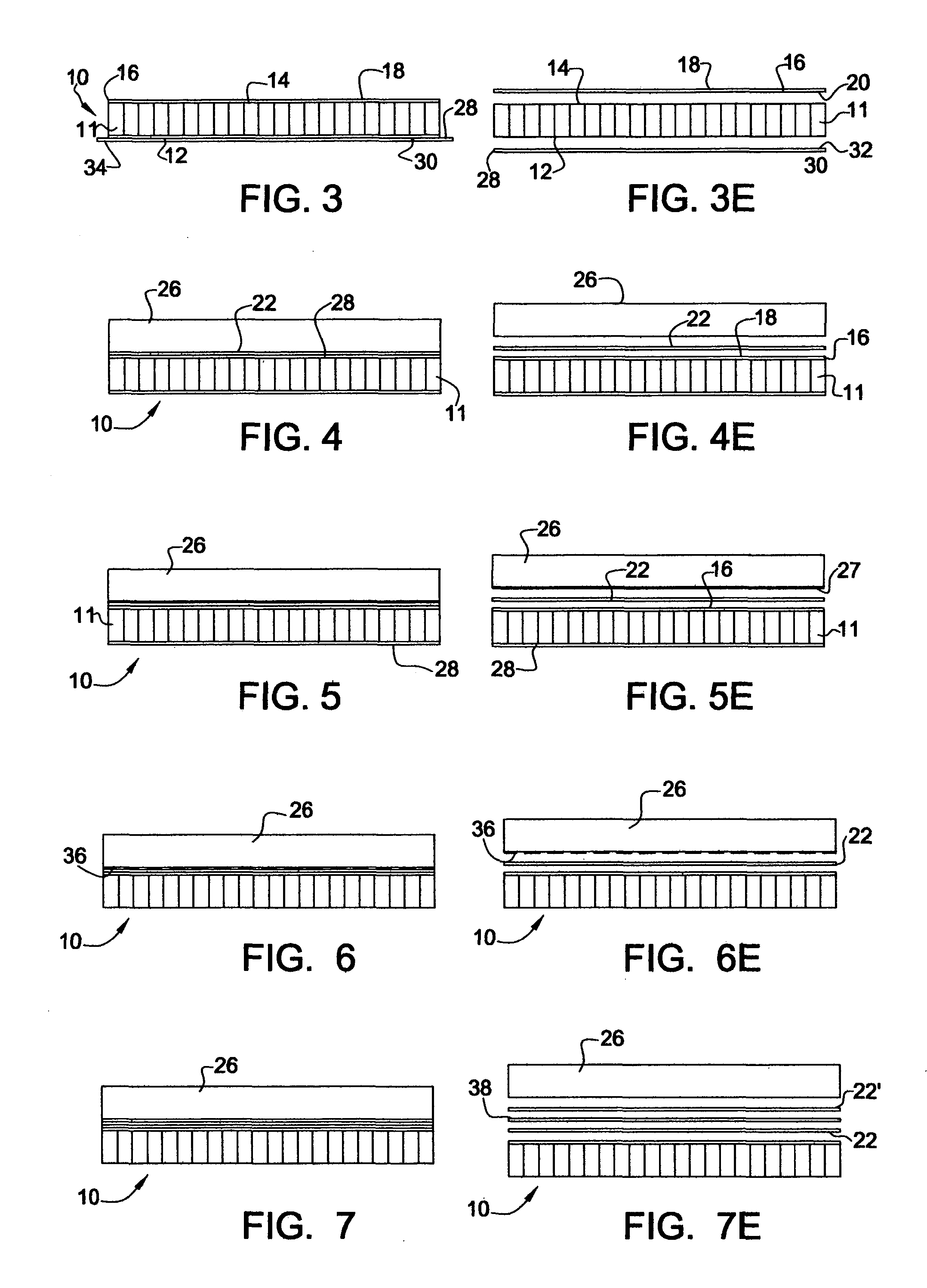

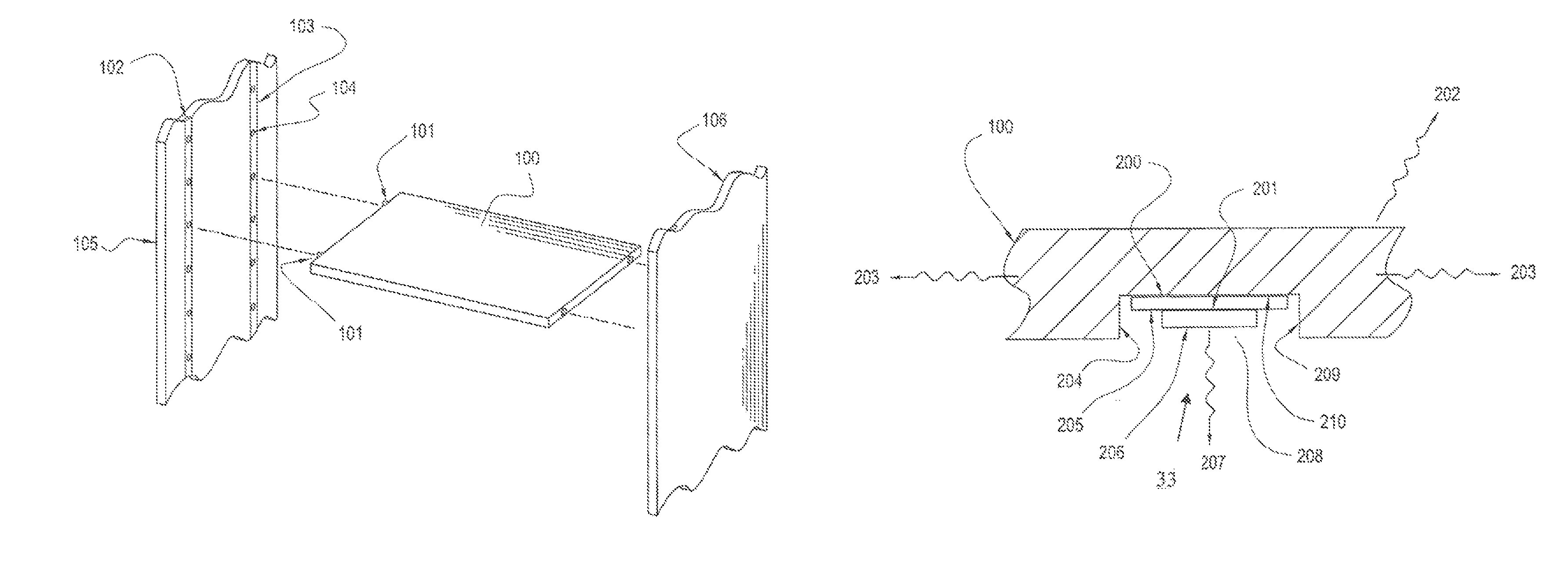

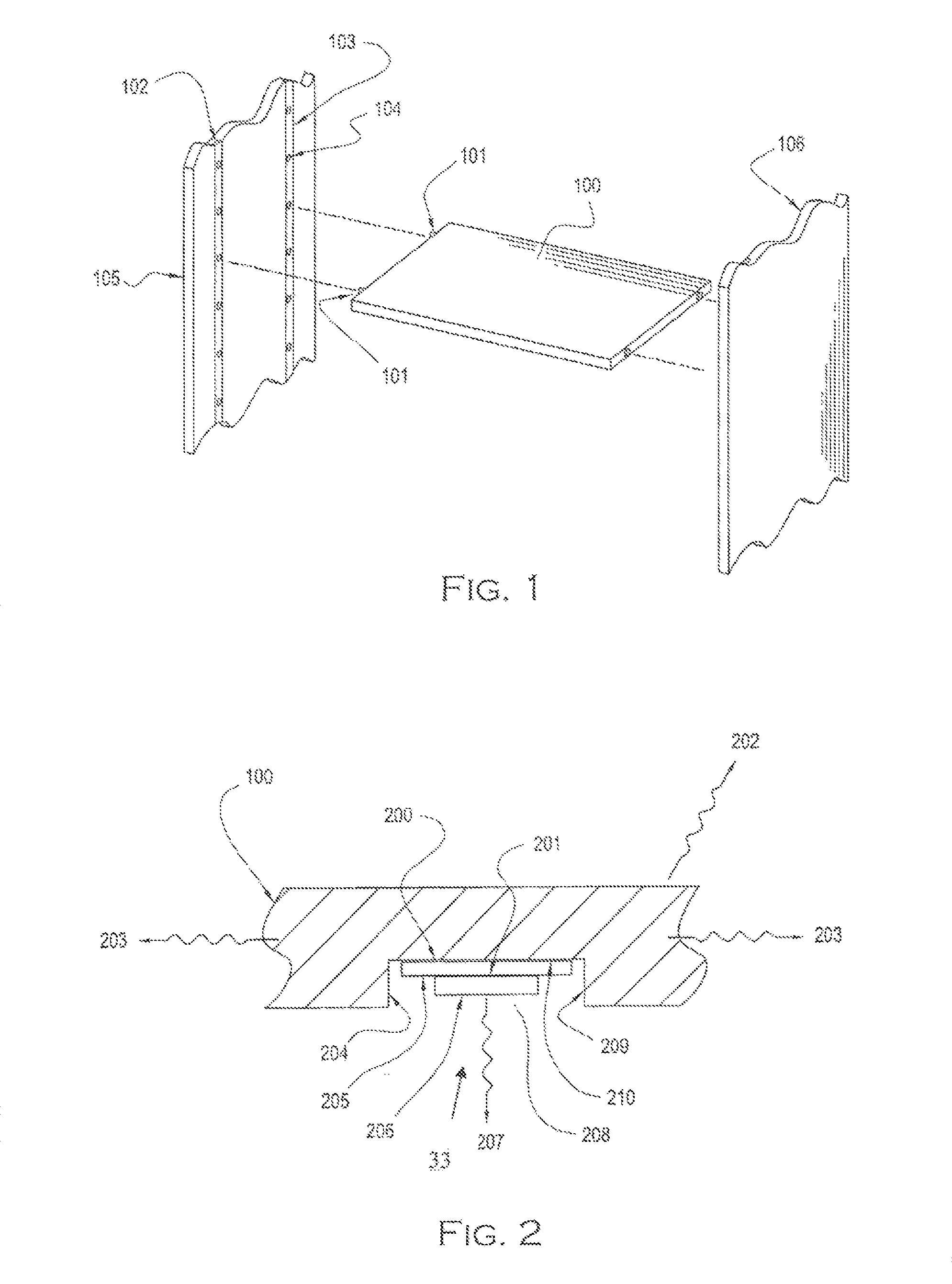

Methods and apparatus for EMI shielding

InactiveUS6870092B2Increased durabilityIncrease airflowVentilation panels with screening provisionsElectrically conductive connectionsDielectric substrateAluminum honeycomb

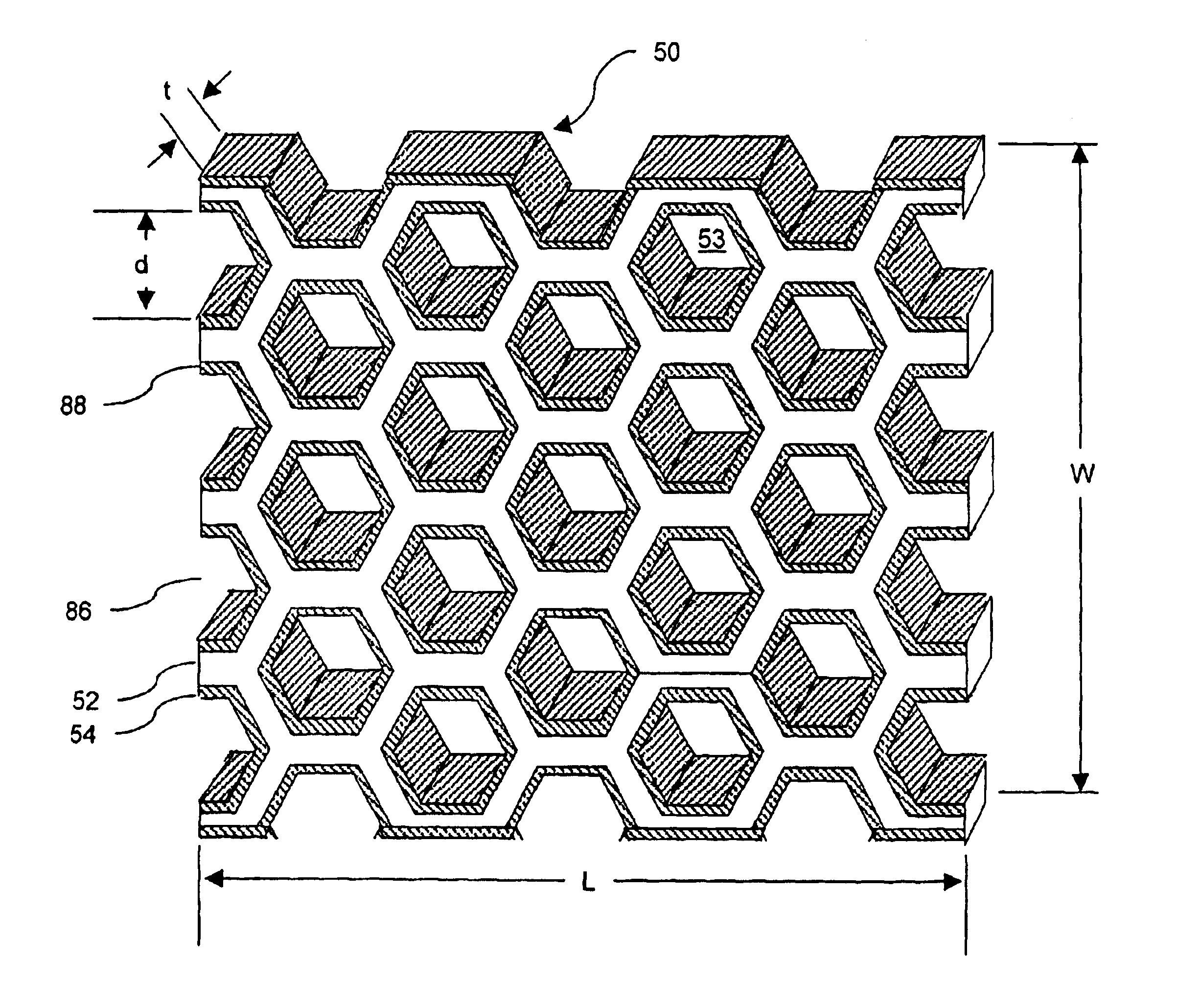

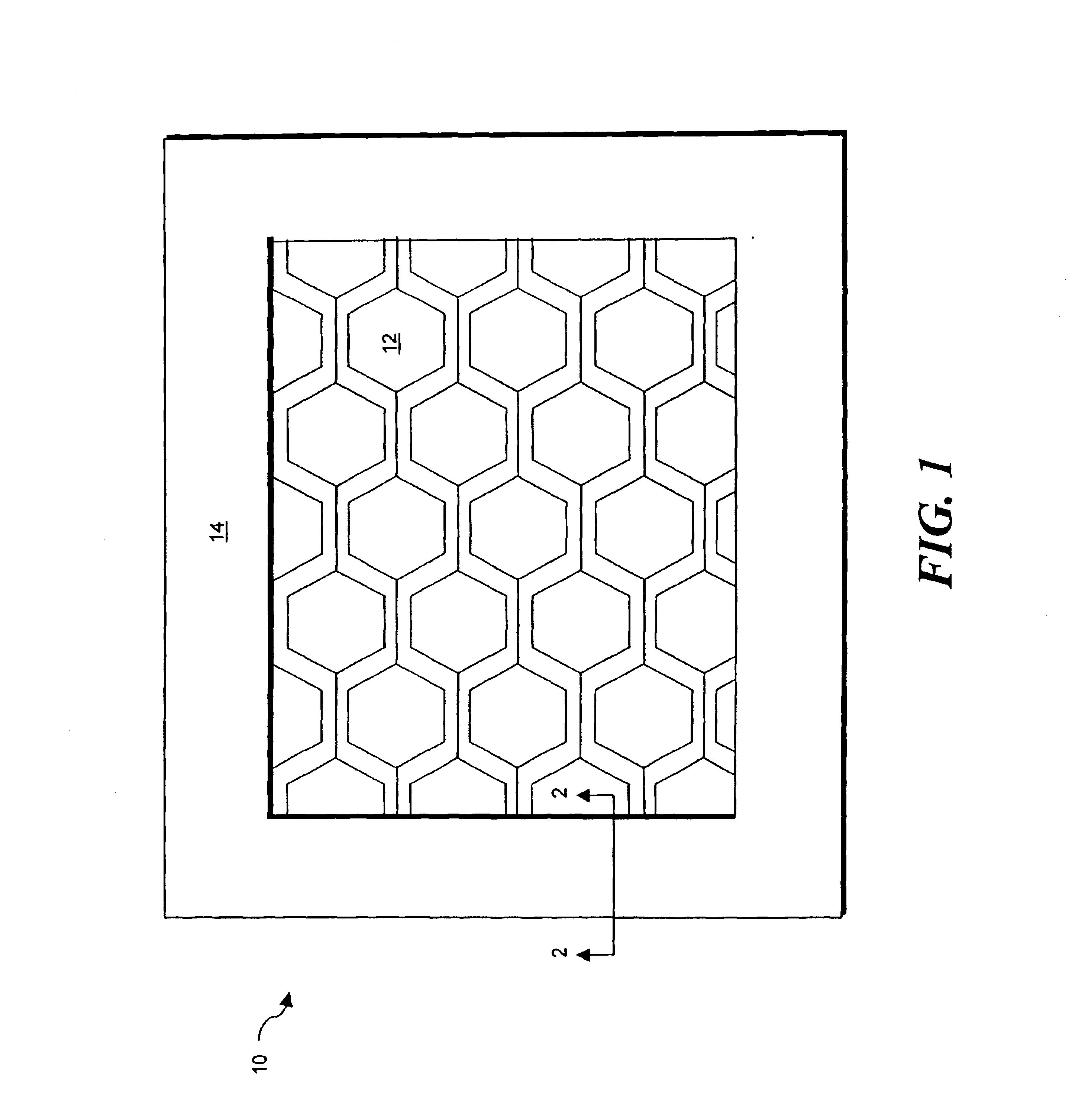

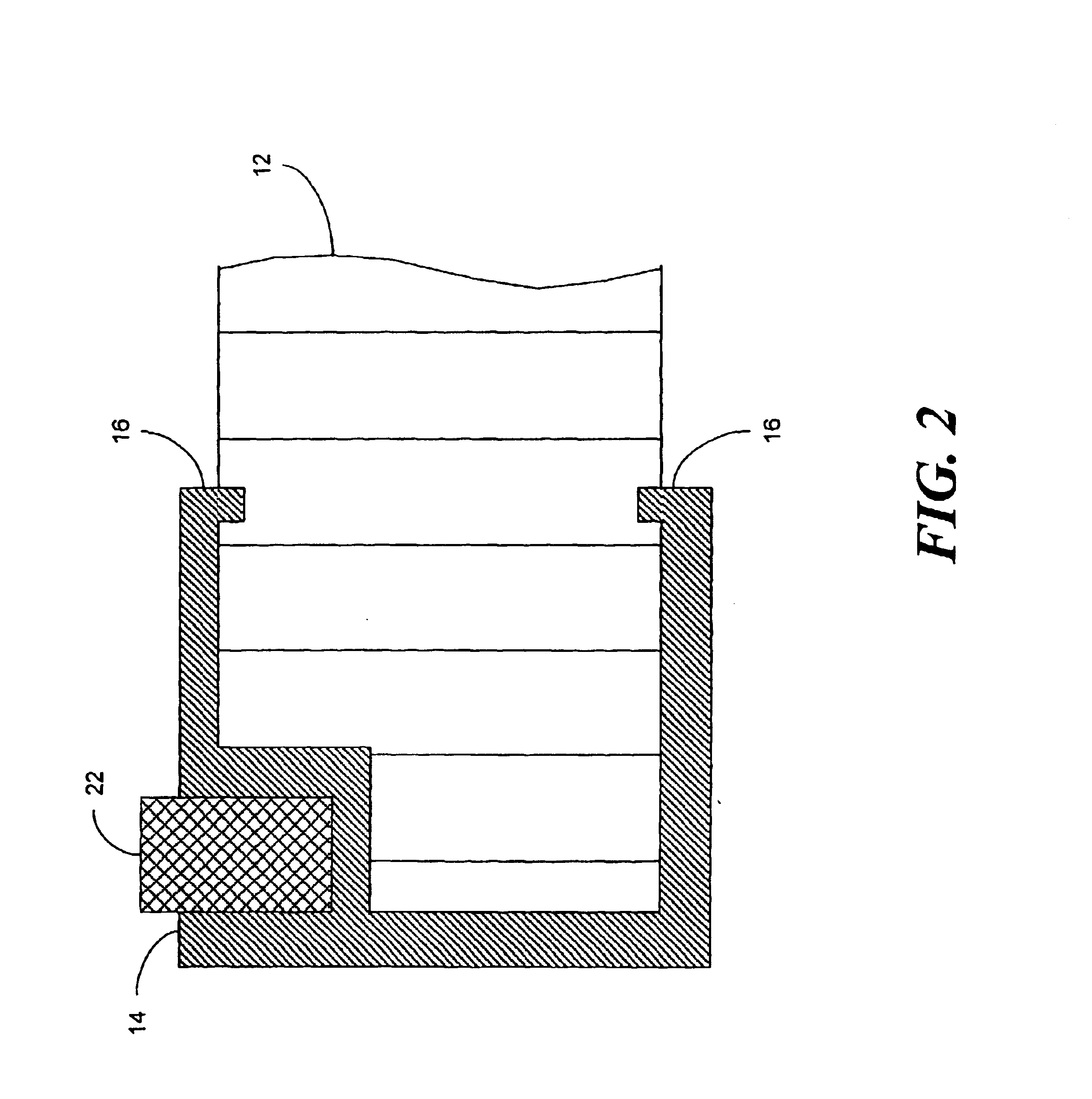

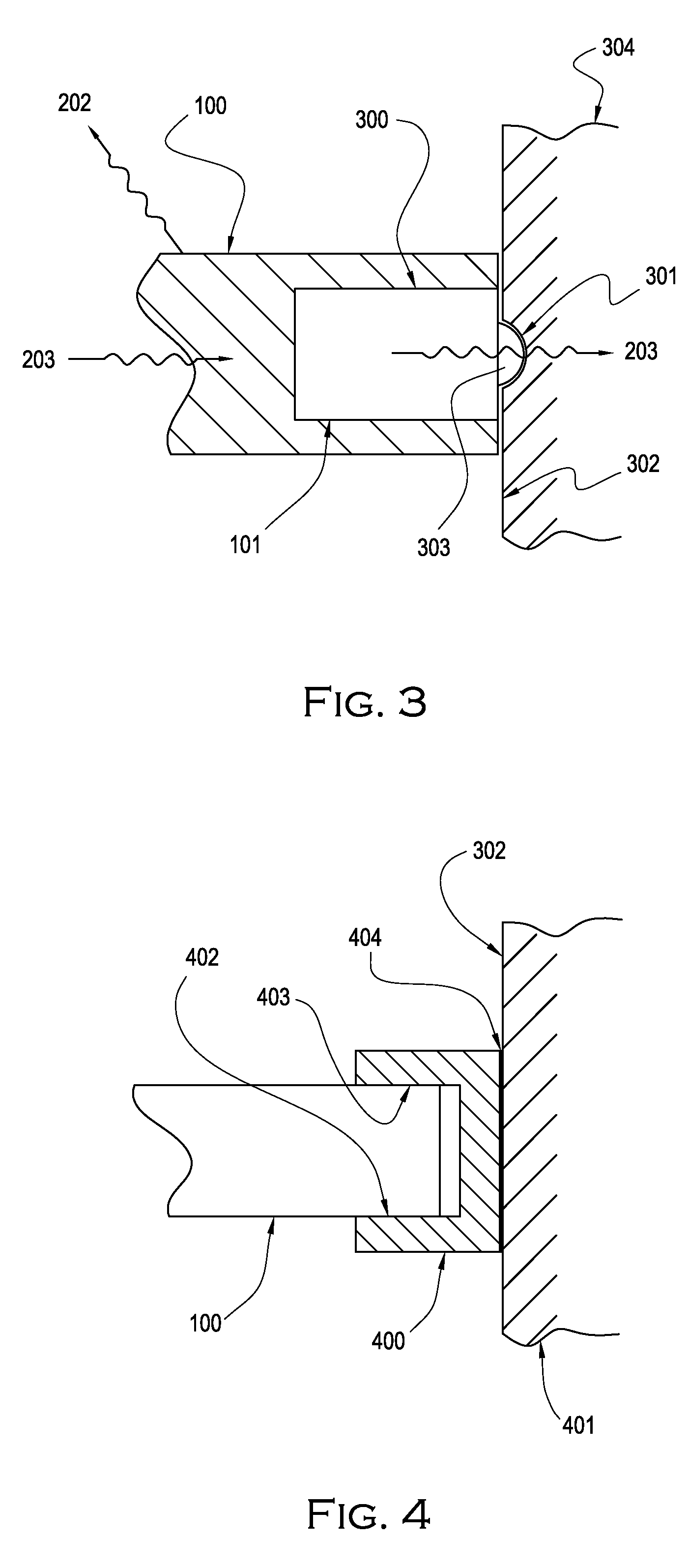

Disclosed are methods and apparatus for improving the resiliency and airflow through a honeycomb air vent filter while providing EMI shielding. In one embodiment, the honeycomb can be manufactured from a dielectric (e.g., plastic) substrate to provide improved resistance to deformation as compared to conventional aluminum honeycomb. The dielectric honeycomb substrate is metallized to provide EMI shielding capability. The metallized honeycomb substrate is cut slightly oversize to fit an opening in an electronic enclosure, which results in elastic deformation of resilient perimeter spring fingers that are used to hold the metallized dielectric honeycomb in place and provide electrical conductivity between the metallized dielectric substrate and the enclosure, thereby eliminating the use of a frame. In another embodiment, additional conductive layers can be added to the metallized dielectric honeycomb. In yet another embodiment, the metallized dielectric honeycomb substrate can be utilized in a framed configuration to provide improved durability.

Owner:LAIRD TECH INC

High-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards, and preparation method thereof

ActiveCN103205210AHigh bonding strengthImprove heat resistanceFilm/foil adhesivesPolyureas/polyurethane adhesivesElastomerPolyester

The invention discloses a high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards, and a preparation method thereof. The high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards is made from, by weight percent, 30-50% of polyester elastomer with above 180 DEG C of melting point, 10-40% of polyolefin copolymer modified by maleic anhydride, 0-40% of polyolefin copolymer, 10-30% of tackifying resin, 0-15% of filler, and 1-3% of functional aid. The components add up to 100%. The high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards has the advantages of high adhesion strength, instantaneous resistance to the temperature up to 170-190 DEG C, and long-term resistance to the temperature up to 130 DEG C.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +1

Panel-form loudspeaker

InactiveUS6247551B1Easy to operateImprove conversion efficiencyLoudspeaker transducer fixingThermometer applicationsHoneycomb PatternAluminum honeycomb

A panel-form loudspeaker has a resonant multi-mode radiator panel which is excited at frequencies above the fundamental frequency and the coincidence frequency of the panel to provide high radiation efficiency through multi-modal motions within the panel, in contrast to the pistonic motions required of conventional loudspeakers. The radiator panel is skinned composite with a honeycomb or similar core and must be such that it has a ratio of bending stiffness to the third power of panel mass per unit area (in mks units) of at least 10 and preferably at least 100. An aluminum skinned, aluminum honeycomb cored composite can meet this more severe criterion easily.

Owner:QINETIQ LTD

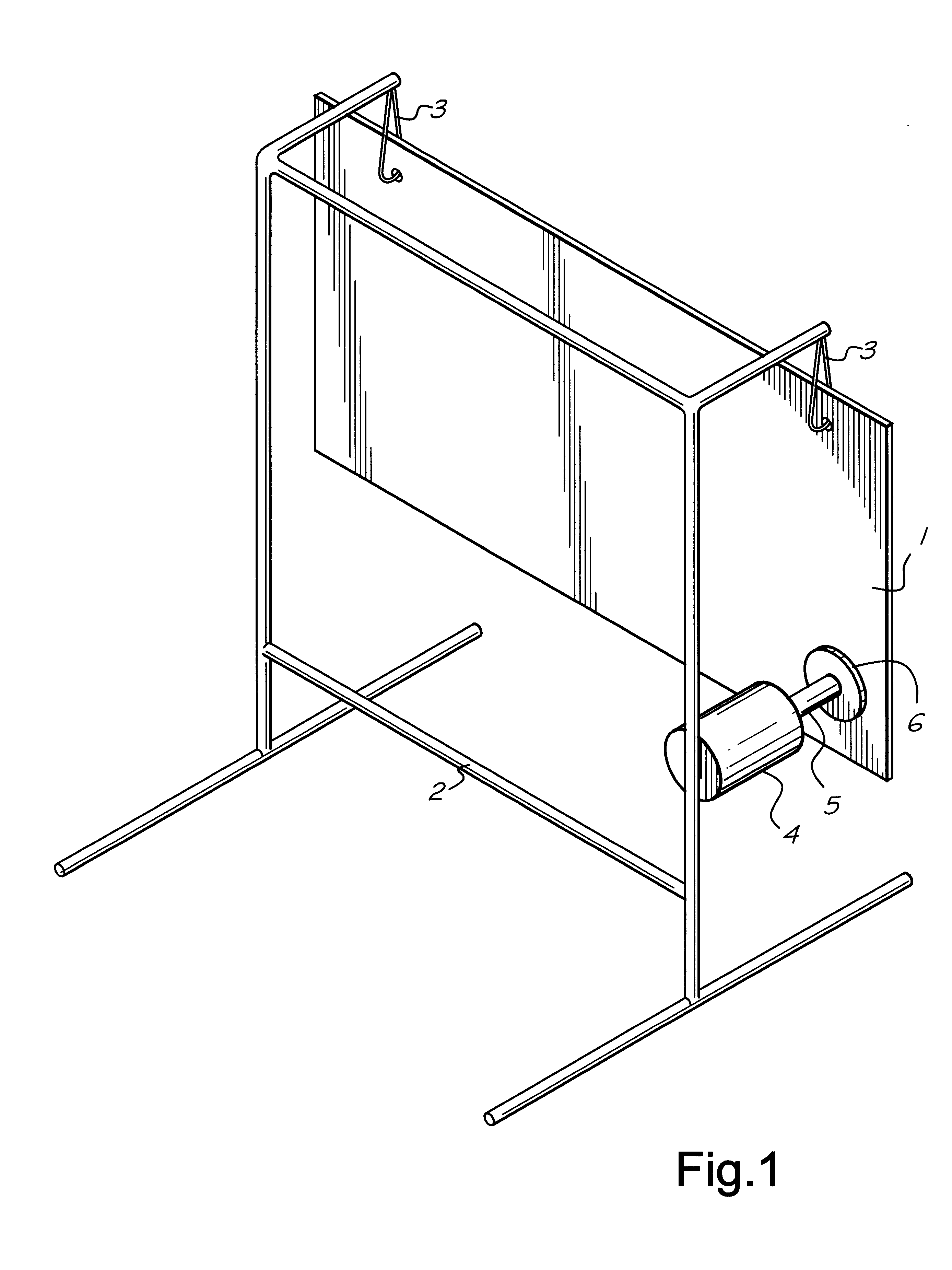

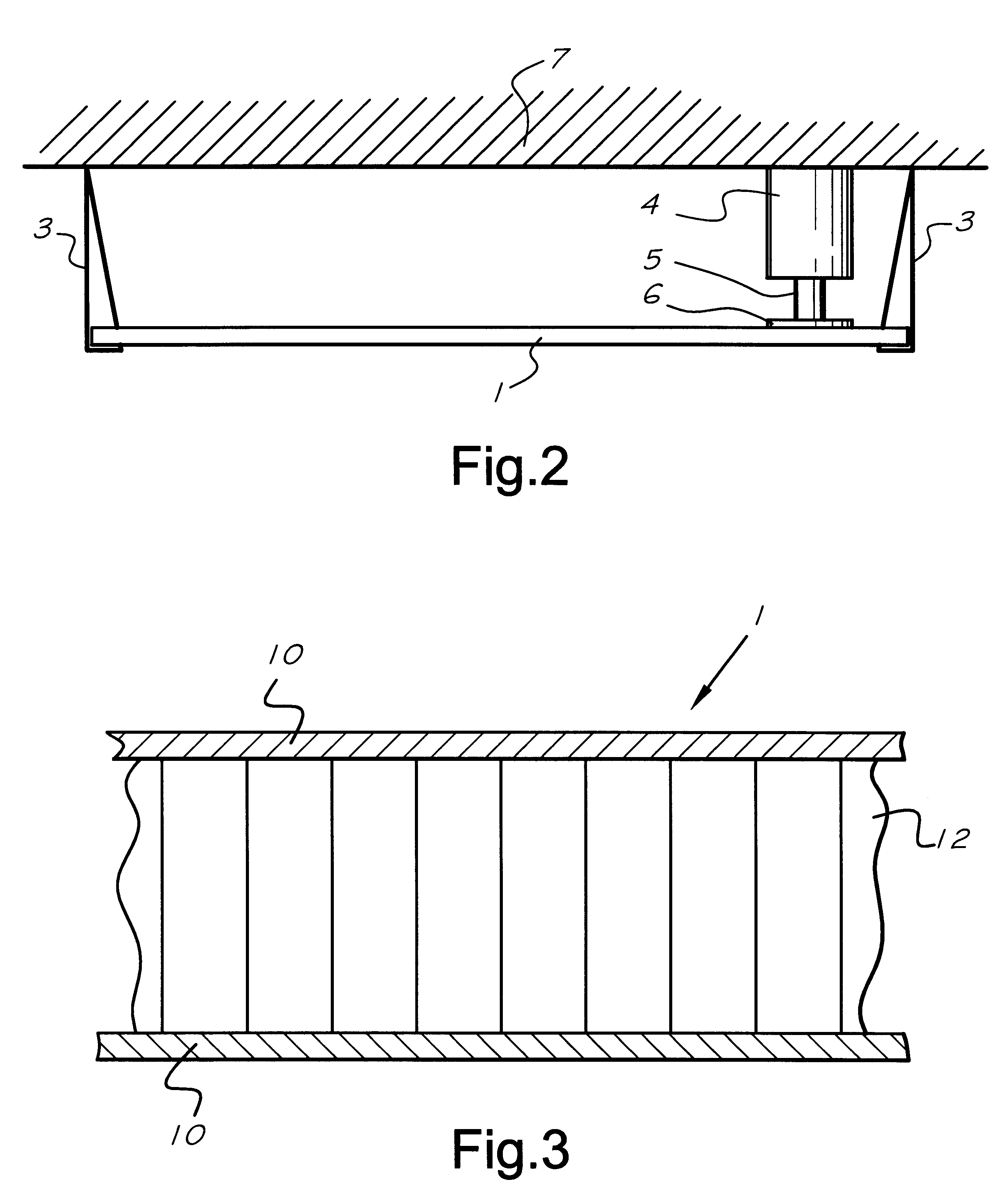

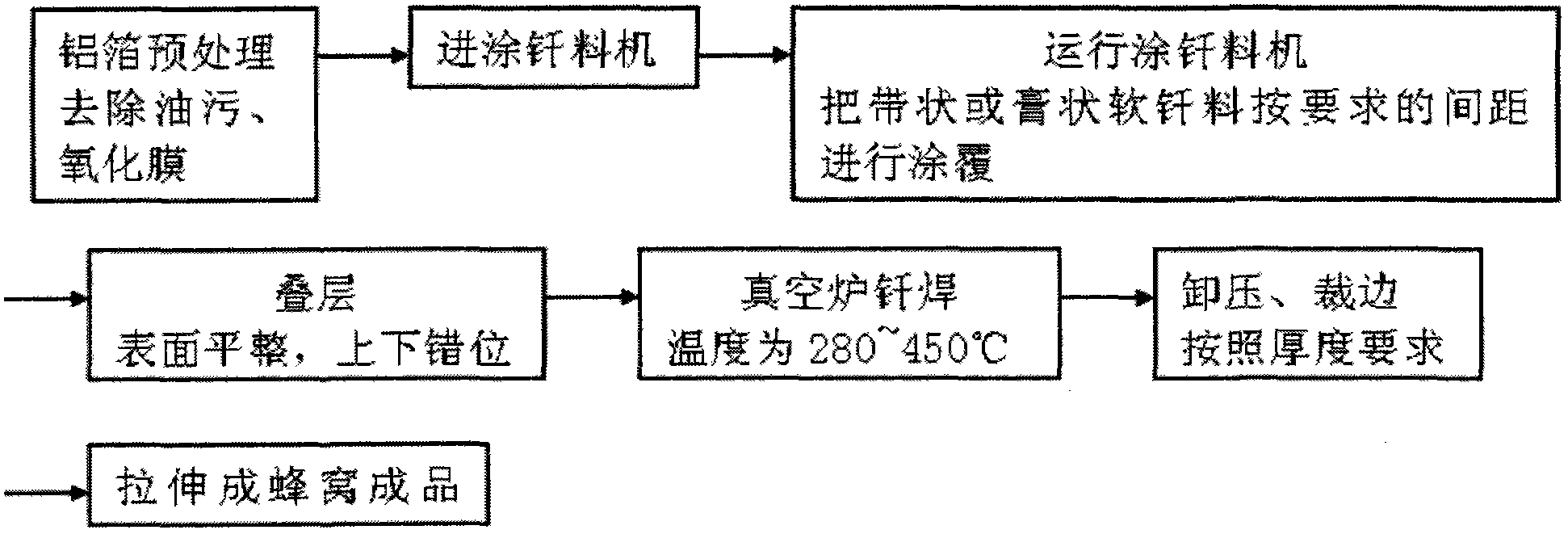

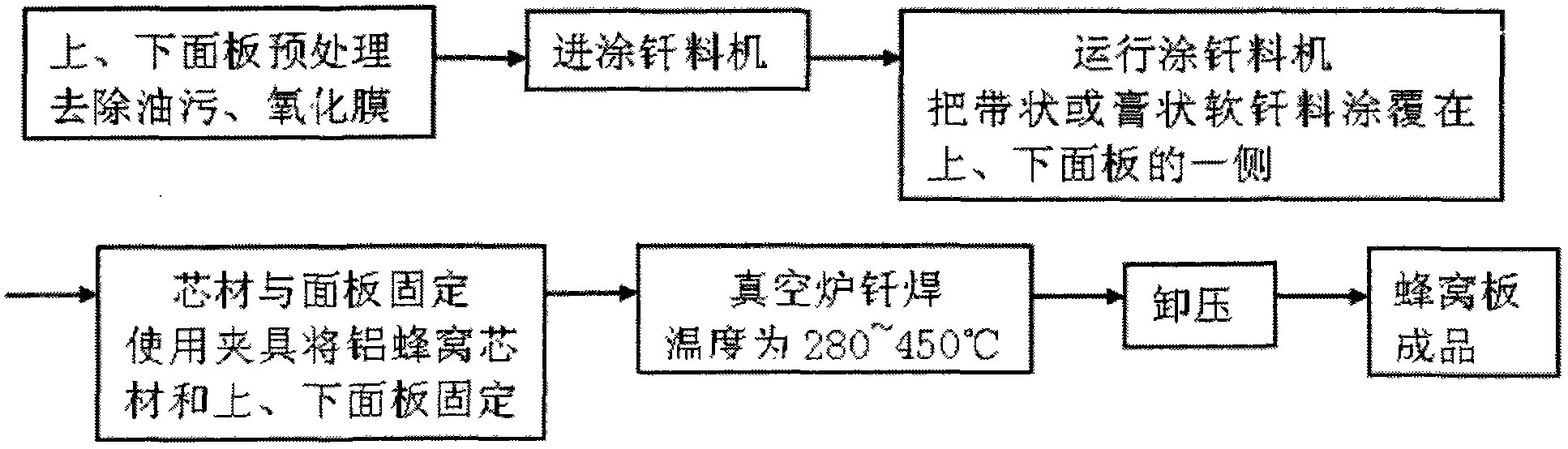

Preparation method of aluminum honeycomb core materials and honey comb plates

InactiveCN102689066AOvercome irregularitiesOvercome the shortcomings of being greatly affected by the performance of the adhesiveWelding/cutting media/materialsSoldering mediaAluminum honeycombAdhesive materials

The invention discloses a preparation method of aluminum honeycomb core materials and honey comb plates. According to the method, soft solder is used for preparing the aluminum honeycomb core materials and honey comb plates in a brazing manner. A product connector prepared by the invention can form a metallurgical structure, can be welded, and has light weight, strong strength, large rigidity, good stability, thermal and acoustical insulation and no pollution, so that the defect is overcome that a conventional adhesive type honey comb plate has an irregular honey comb core, and is greatly influenced by the property of adhesives; and the mechanical property of the honey comb plate is far higher than that of adhesive materials; moreover, the preparation process and the operation means are simpler, all performances are improved remarkably, and the preparation method is suitable for industrial production.

Owner:QINGDAO TAIHONG TRACK EQUIP

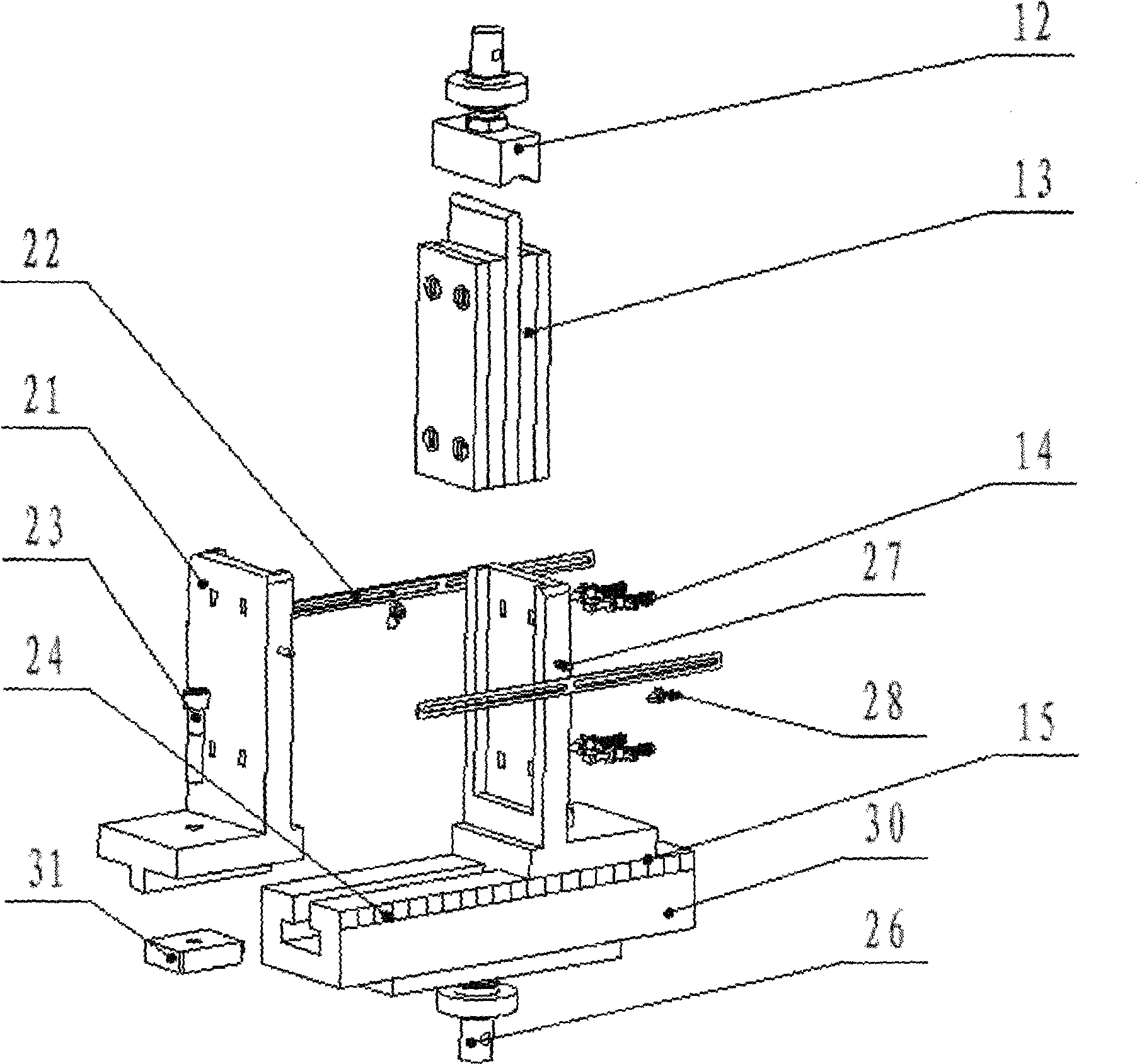

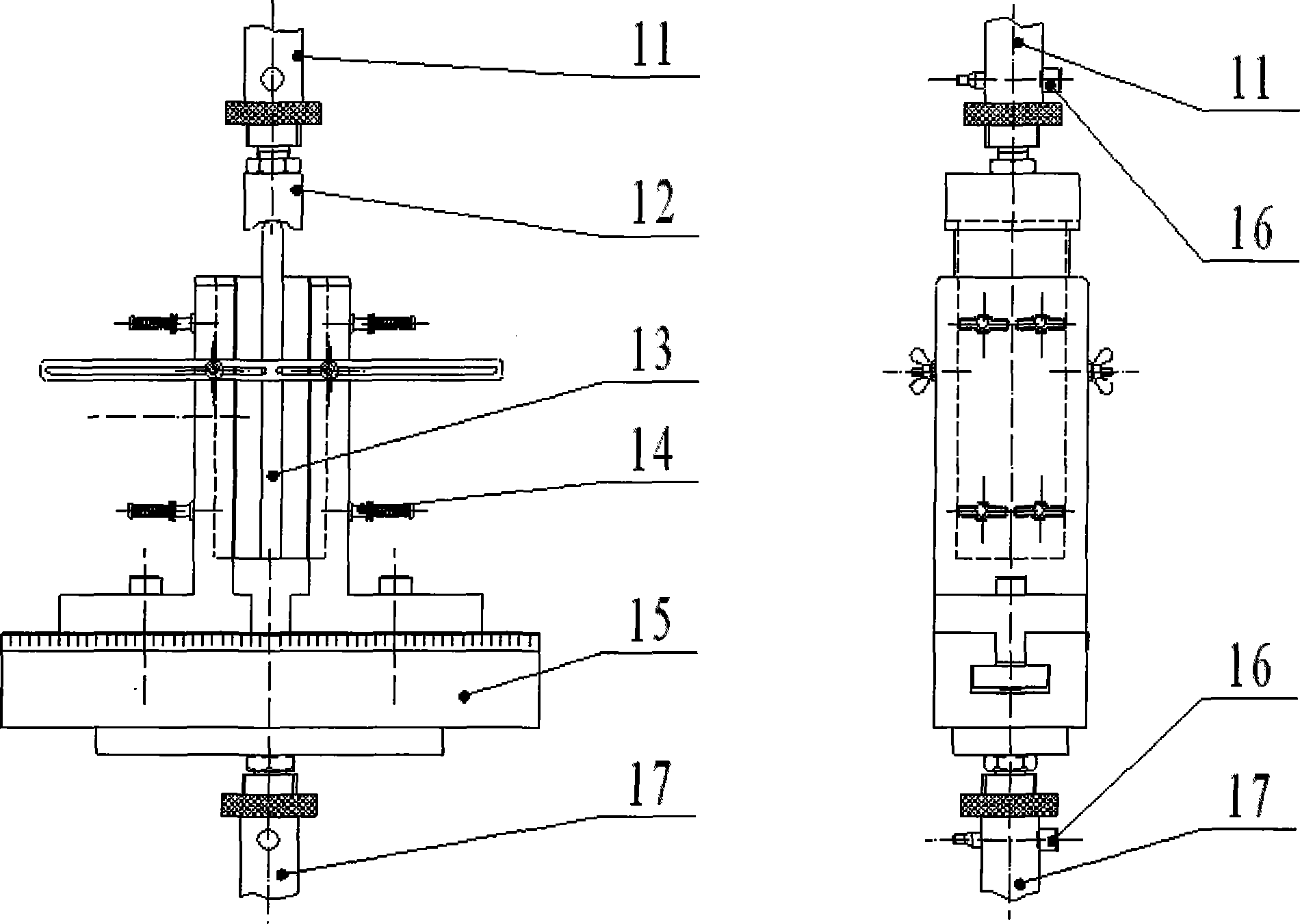

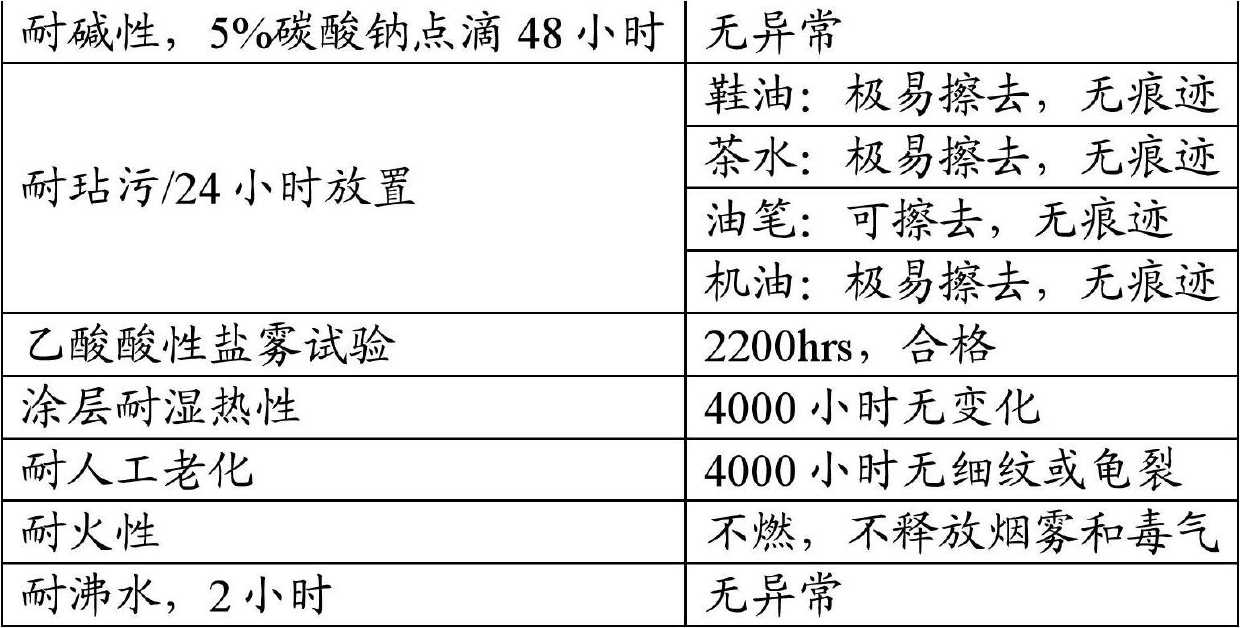

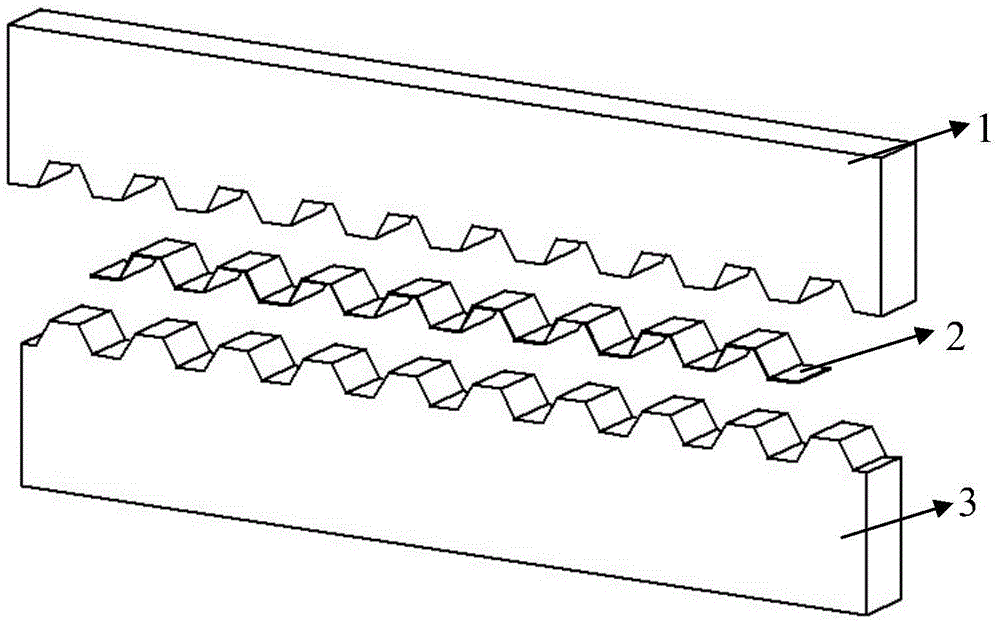

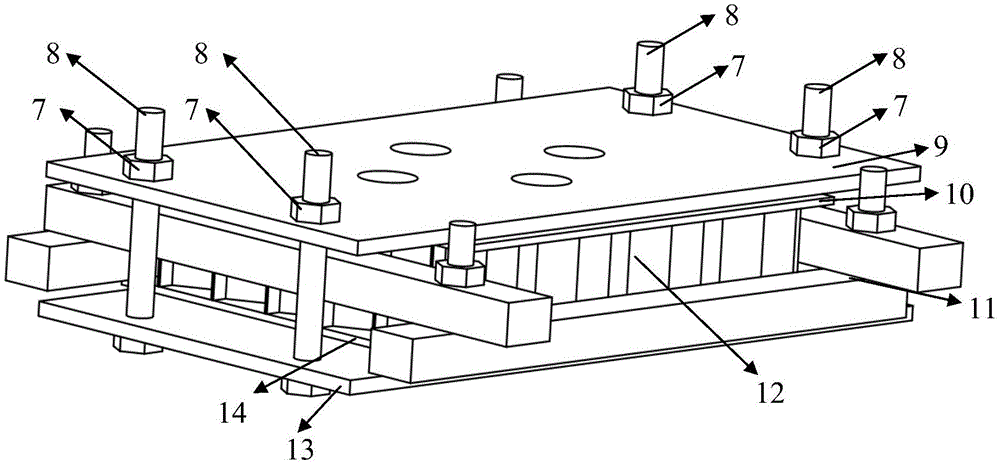

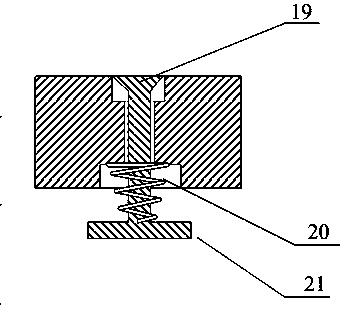

Test fixture for compression shear of symmetric sandwich structure

The invention provides a test fixture for compression shear of a symmetric sandwich structure, which belongs to the field of sandwich structure material test fixtures and aims to solve the problems of asynchronous manual indication of a deformation gauge and compression shear force value data and to-be-converted testing machine values in current standards and patents as well as poor stability and inconvenient alignment of a simple symmetric fixture. The test fixture disclosed by the invention is mainly composed of a compression shear pressure head component, a testing sample component, a connecting and locking device and a base component; the testing sample component is formed in a method that a pair of testing samples are symmetrically bonded to a sample group middle bonding board and a pair of sample sticking boards; the connecting and locking device is used for connecting the testing sample component with the base component; a locking head can be moved horizontally in a compression shear test process; the position of a base fixing sample component device of the base component can be regulated through an inner hexagon bolt; stability of the base fixing sample component device is ensured; and the testfixture is suitably used for compression shear tests of the sandwich structure materials such as honeycomb paperboards and aluminum honeycomb boards.

Owner:邳州市城洁保洁有限公司

Adhesion agent for aluminum cellular composite board and method of producing the same

ActiveCN101402839AHigh bonding strengthImprove heat resistanceEpoxy resin adhesivesAdhesiveGas phase

The invention relates to a glue adhesive used for an aluminum beehive composite board and a preparation method thereof; wherein, the glue adhesive consists of a component A and a component B; the weight percentage composition of the materials of the component A is as follows: 45 to 55 percent of epoxide resin, 2 to 5 percent of thinner, 30 to 42 percent of functional pigment filler, 1.5 to 2.5 percent of KH-560 coupling agent, 6 to 20 percent of kiss toughening agent and 2 to 3 percent of thickening and anti-sinking agent of gas phased silicon dioxide; the weight percentage composition of the materials of the component B is as follows: 60 to 80 percent of phenolic aldehyde modified amine curing agent, 8 to 15 percent of curing accelerator and 10 to 20 percent of plasticizer; and both the weight percentage sum of the materials of the component A and the weight percentage sum of the materials of the component B are 100 percent. The glue adhesive used for the aluminum beehive composite board has the advantages of normal temperature curing, good acid and alkaline resistance, low curing retraction rate, no pollution, high sticking intensity after curing, higher temperature resistance and lower price.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

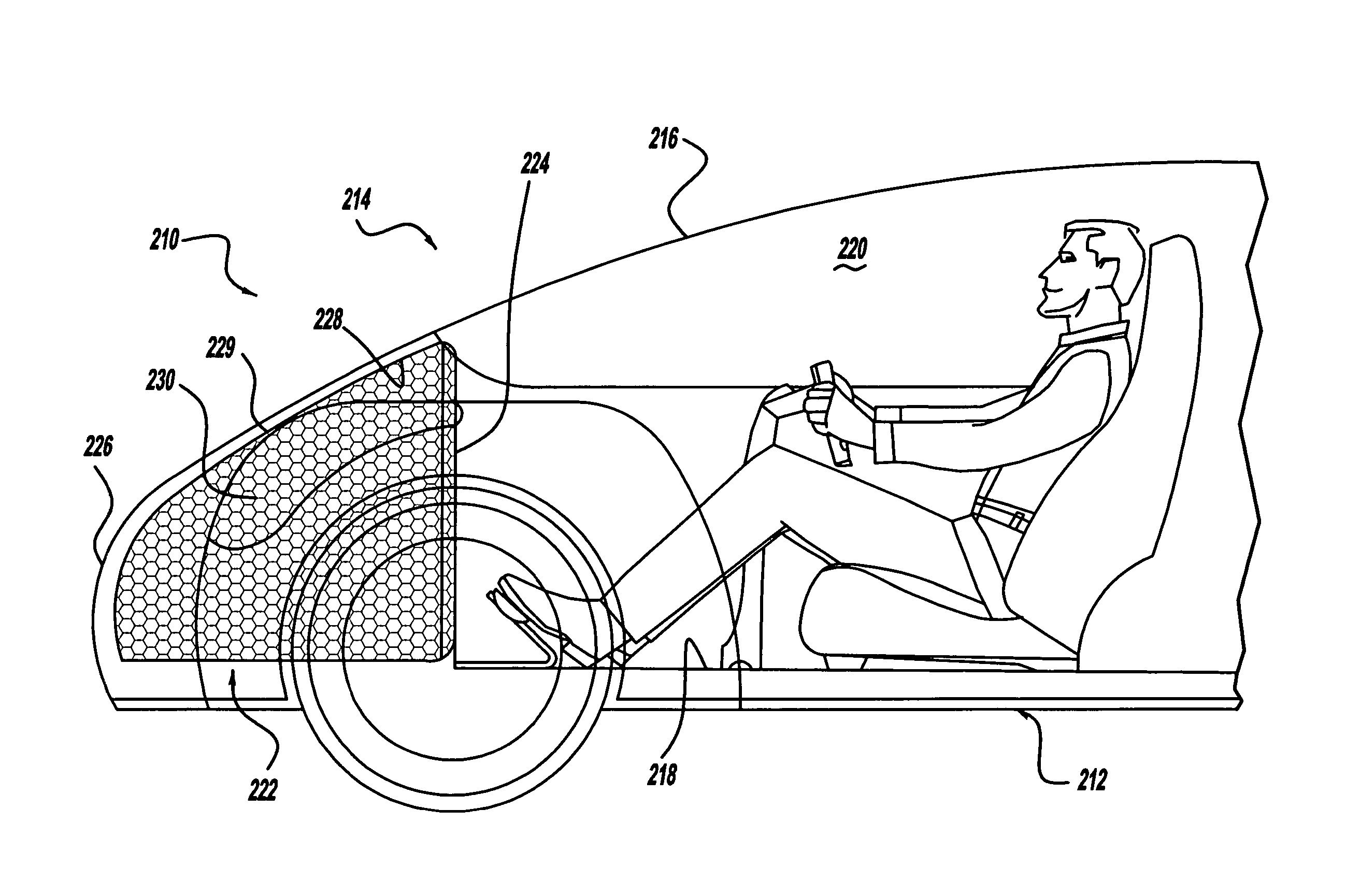

Frontal impact energy dissipation zone

InactiveUS7004502B2Simple interfaceEliminateVehicle seatsVehicle body-frame connectionsEnergy absorptionAluminum honeycomb

The invention capitalizes upon the absence of an engine compartment forward of the passenger compartment in the vehicle body and provides a frontal impact energy dissipation compartment forward of the passenger compartment. The frontal impact energy dissipation compartment is filled with an energy absorption structure, such as an aluminum honeycomb structure. Alternatively, a bulkhead member extends across the vehicle at the forward end of the passenger compartment to enhance structural integrity of the forward end of the vehicle. The bulkhead member may be integrated with air flow systems, cross-car structural support, safety airbags, slidable driver interface, speakers, etc.

Owner:GM GLOBAL TECH OPERATIONS LLC

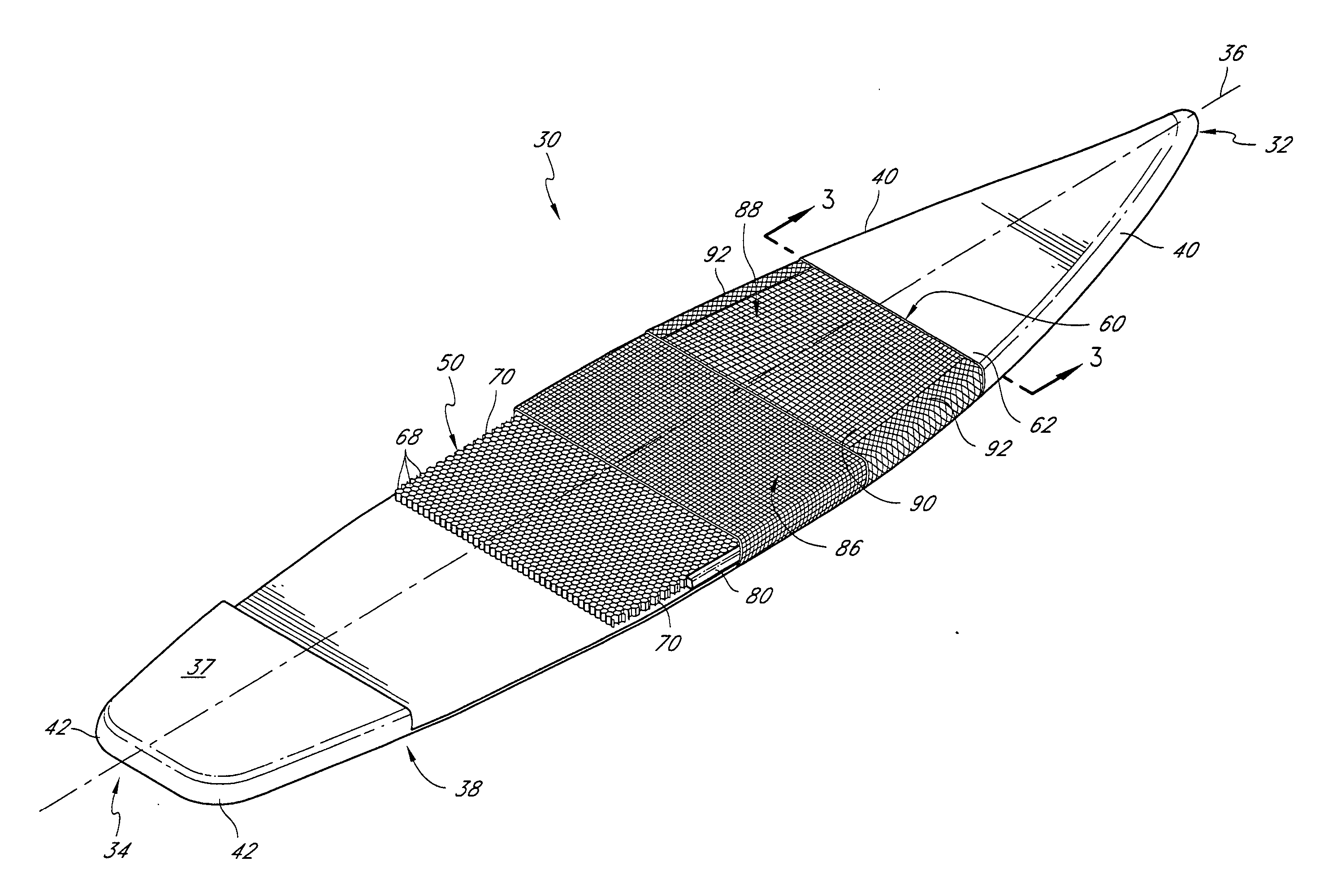

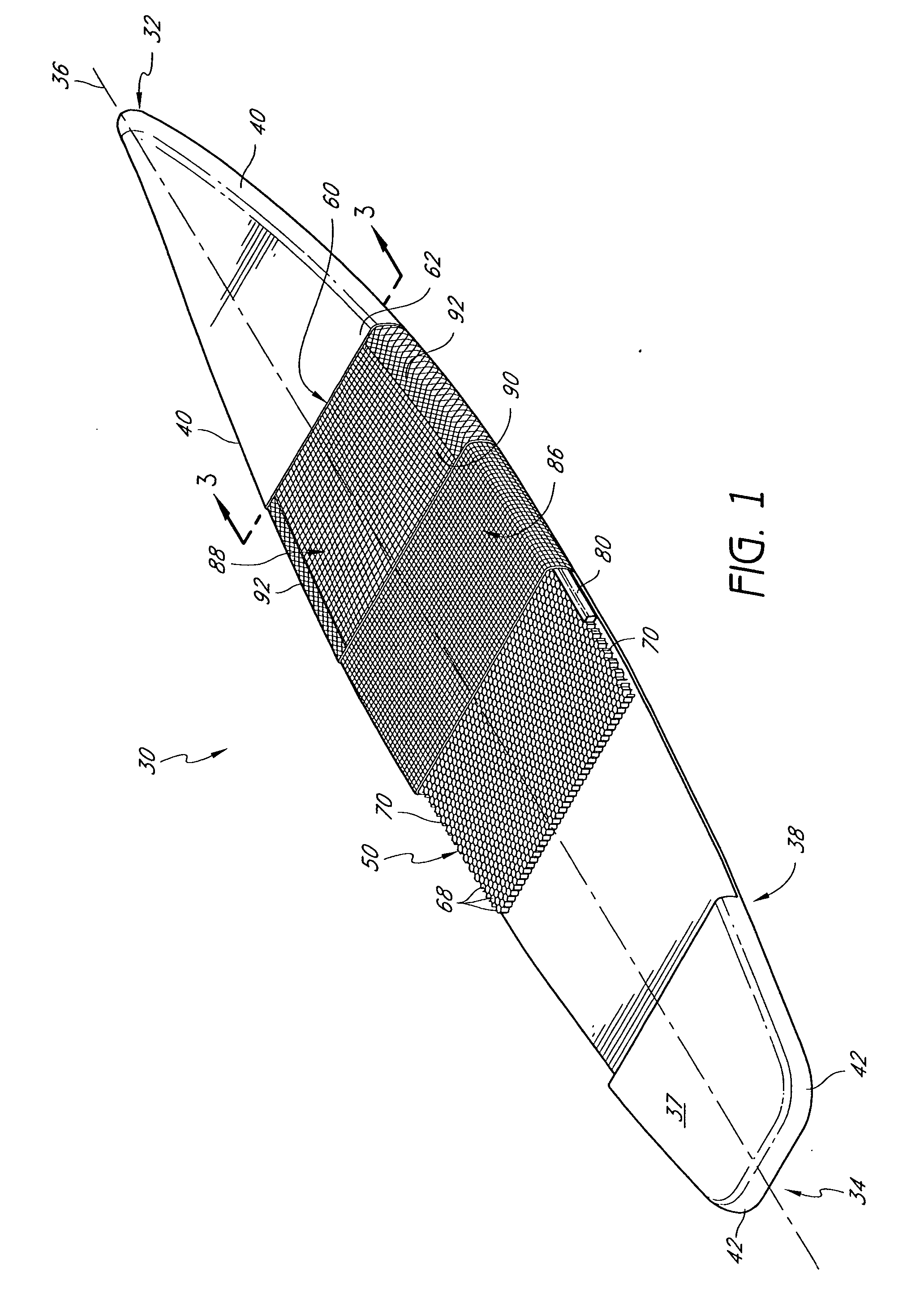

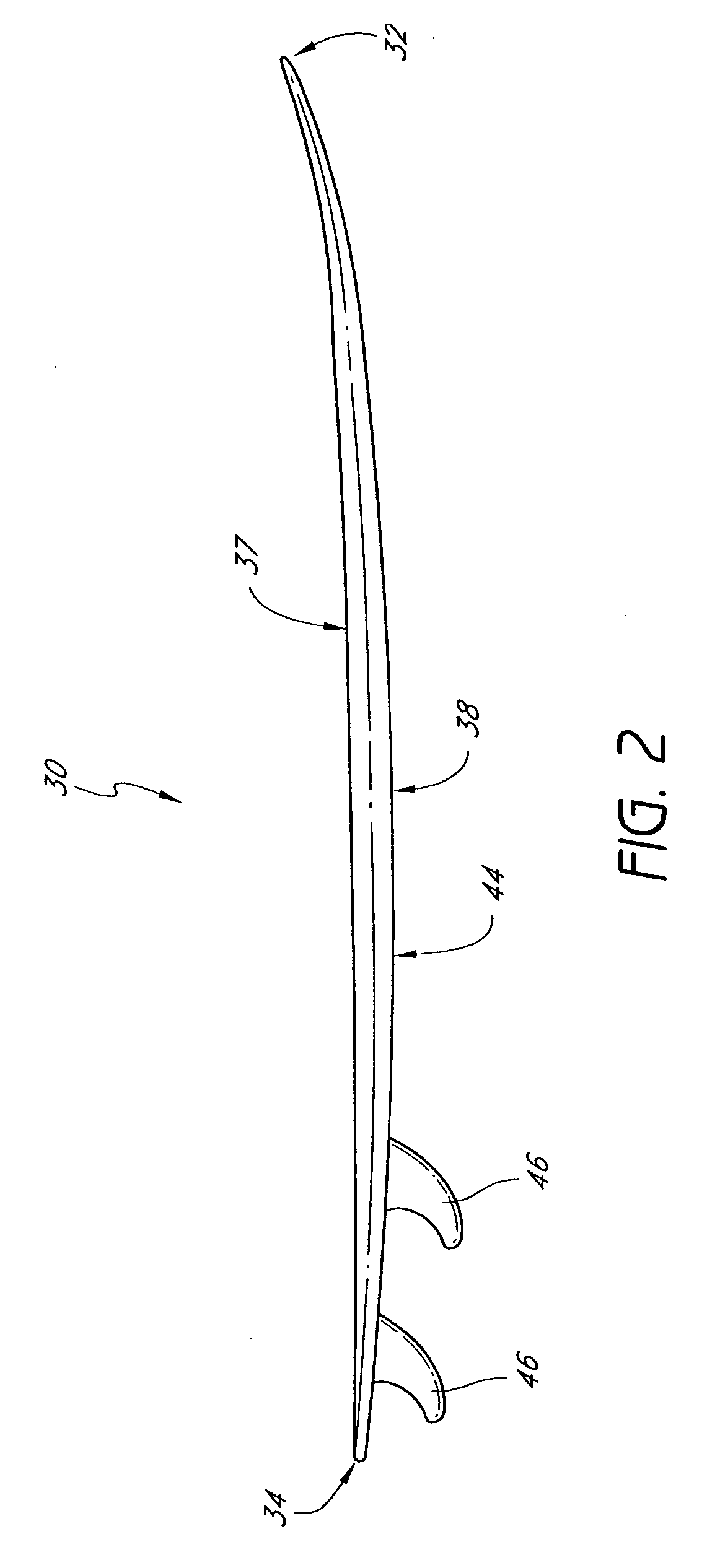

Surfboard having a honeycomb core

InactiveUS20060276087A1Maintaining flexibility characteristicStrong lightWaterborne vesselsWater sport boardsGlass fiberDecrease weight

An aquatic gliding board such as a surfboard is constructed using a honeycomb material for the core. The composite outer skin of the surfboard is constructed of materials having similar flexibility properties as found in a traditional foam / fiberglass surfboard. In a particularly preferred embodiment an aluminum honeycomb core is employed along with a fiberglass skin in order to achieve a surfboard with decreased weight and increased strength to resist failure in bending relative to a traditional foam / fiberglass surfboard, but having similar flexibility characteristics to such a traditional surfboard, or having increased flexibility relative to such a traditional surfboard.

Owner:VARIAL SURFING TECH

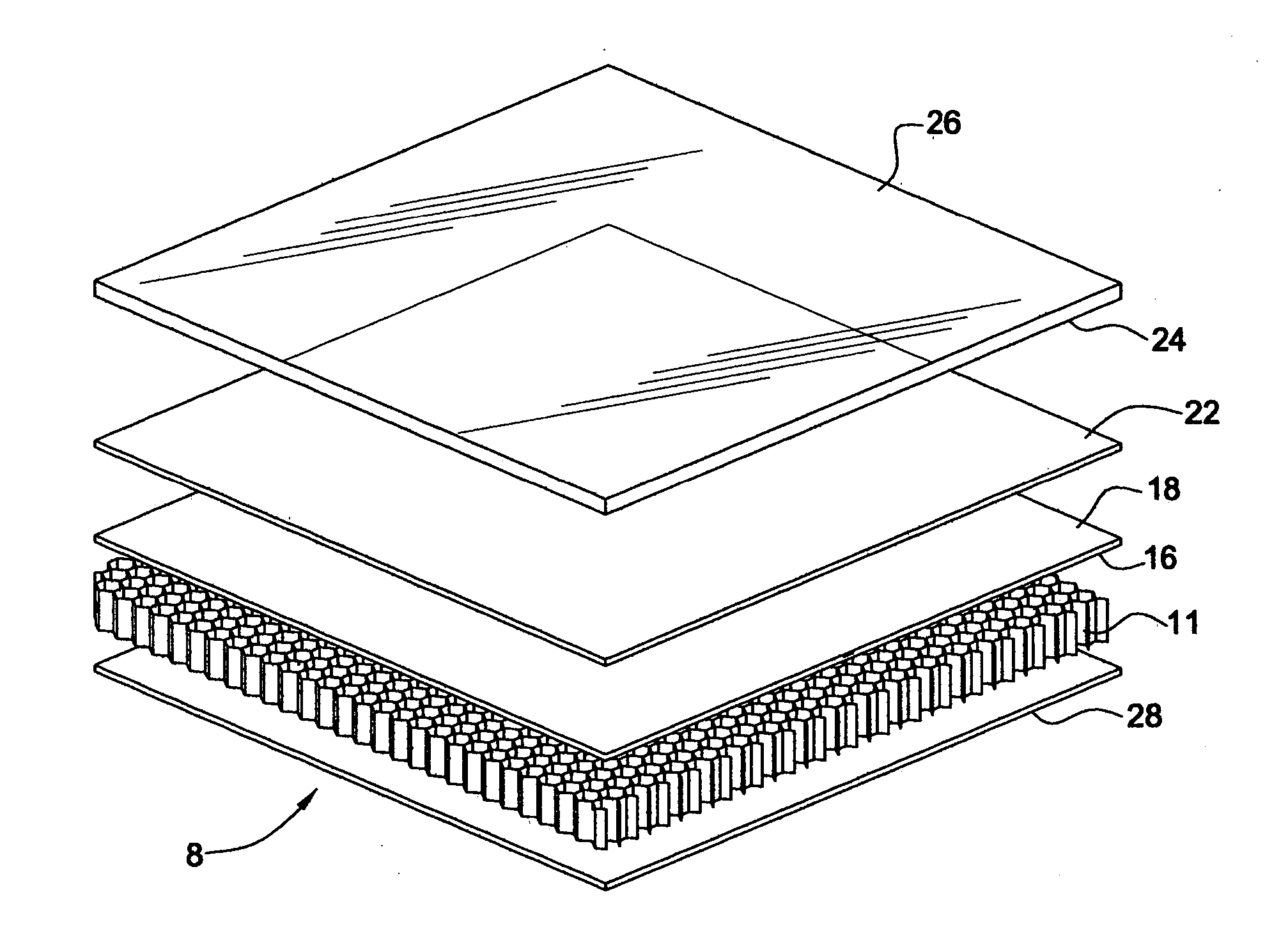

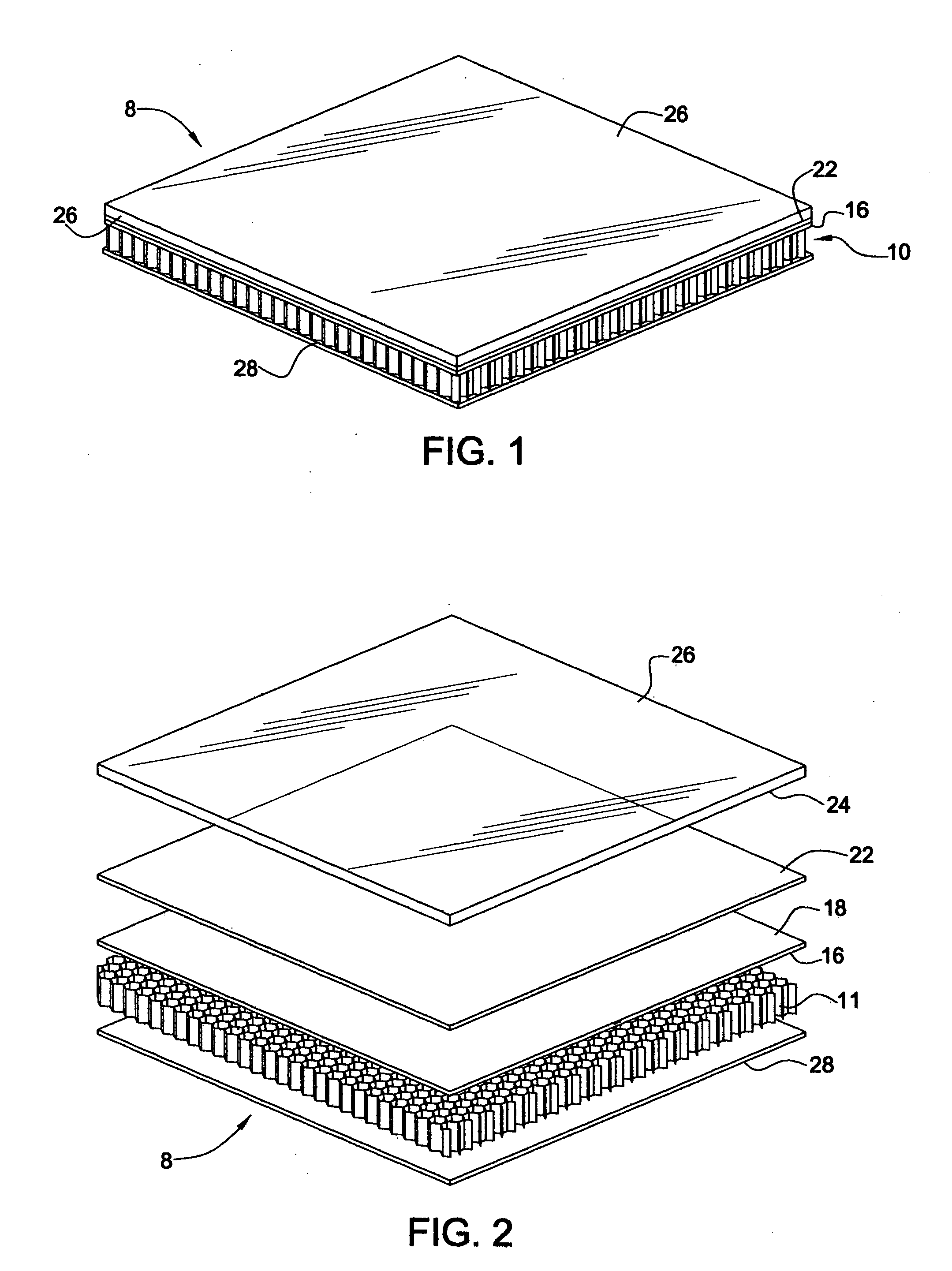

Single panel glass structural panel and method of making same

InactiveUS20050003148A1Improve rigidityHigh strengthGlass/slag layered productsThin material handlingColor effectGlass fiber

A window-type structural panel has a glass outer panel bonded to a core panel consisting of an aluminum honeycomb core having outer and inner skin surfaces of resin impregnated fiberglass having substantially the same coefficient of thermal expansion as the aluminum honeycomb core. Design and color effects are imparted to the glass panel by film sheets, printing on adhesive layers, physical insertion of wire, cloth or other solid materials bonded in position by heat and pressure to form a uniform rigid structure of great strength and a light weight.

Owner:CUNNINGHAM BETH KAY EKLAND +1

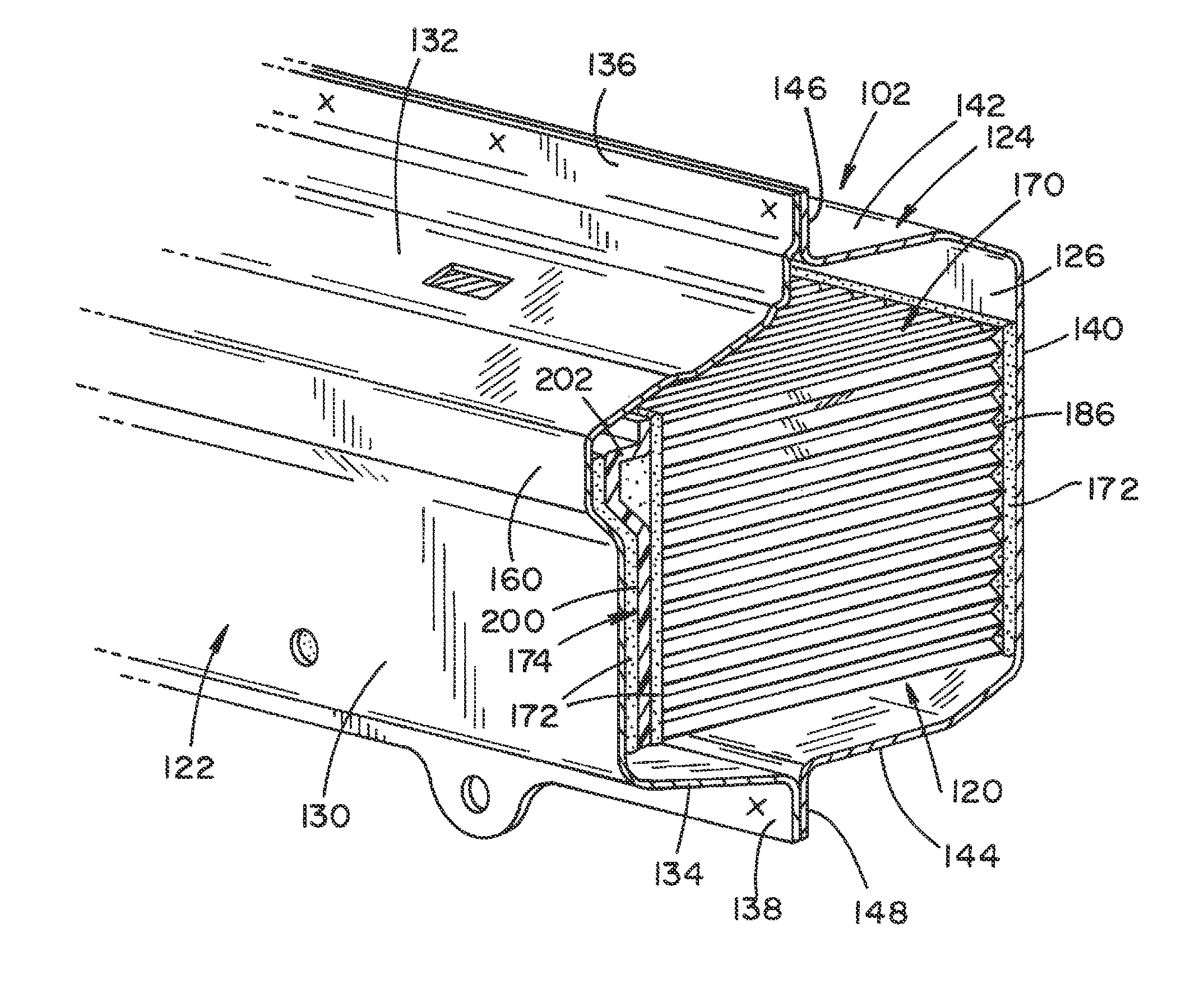

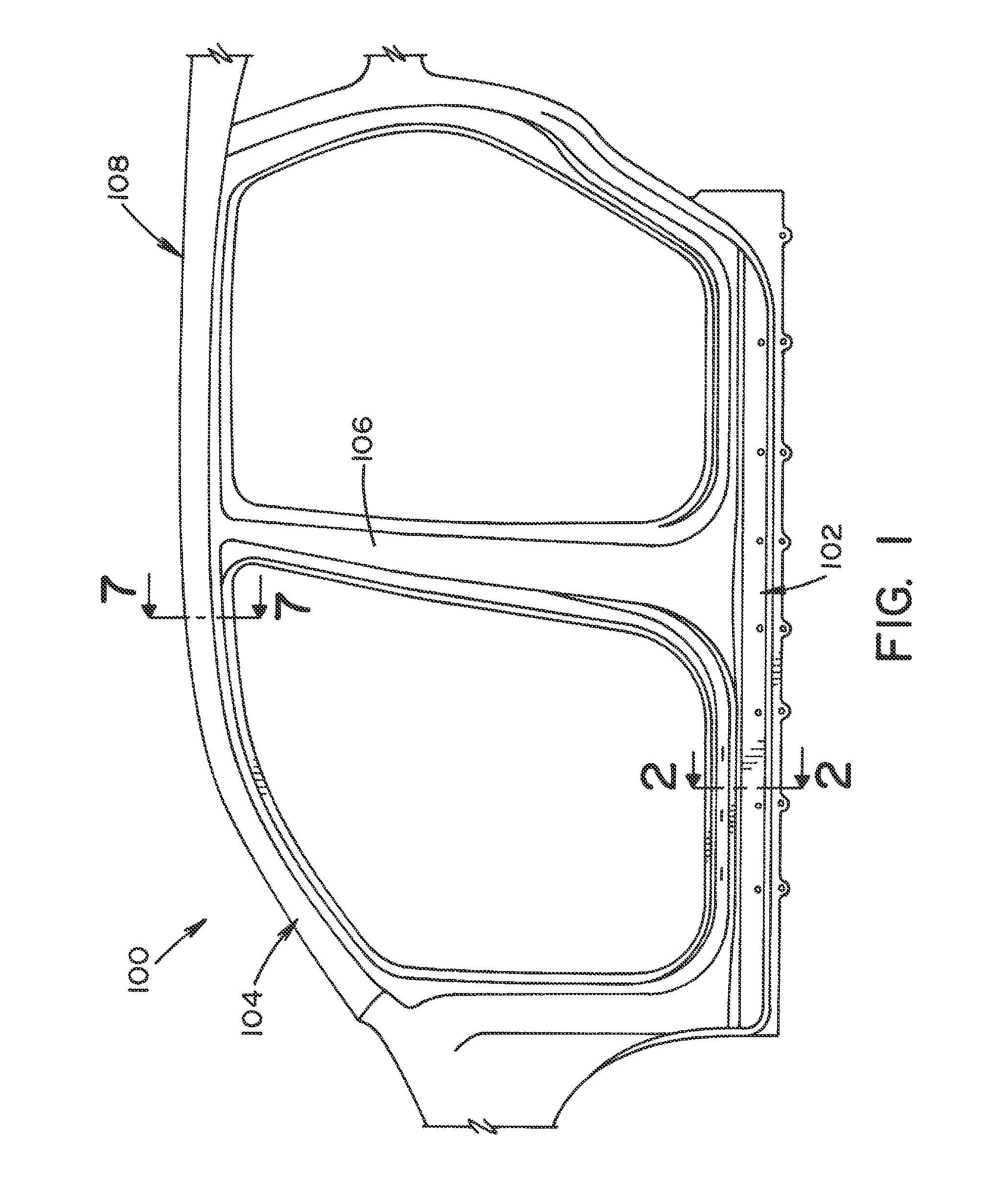

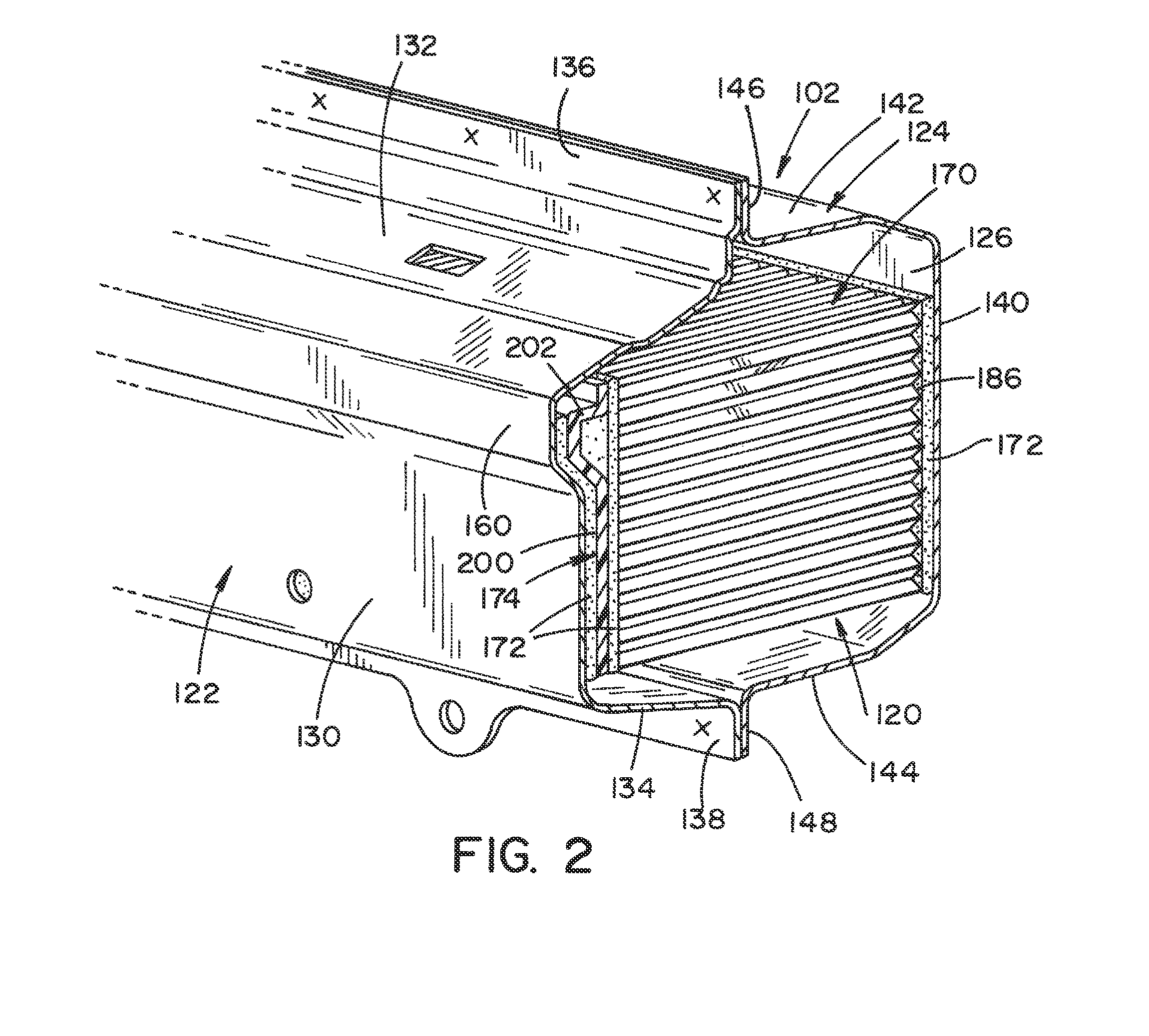

Encapsulated aluminum honeycomb structural stiffener

A vehicle body includes a hollow structural member having an inner surface. The hollow structural member includes a first metal or metal alloy. A structural reinforcement member is positioned in the hollow structural member and includes a stiffener including a second metal or metal alloy different from the first metal or metal alloy. A gap is provided between the stiffener and the inner surface of the structural member. An adhesive is secured to the stiffener. The adhesive is substantially dry to the touch prior to activation and is activatable to expand toward the inner surface to fill at least a portion of the gap. A frame is secured to the stiffener and is positioned between the stiffener and the inner surface of the structural member to maintain the gap prior to expansion of the adhesive. The frame is adapted to insulate the stiffener from the hollow structural member.

Owner:HONDA MOTOR CO LTD

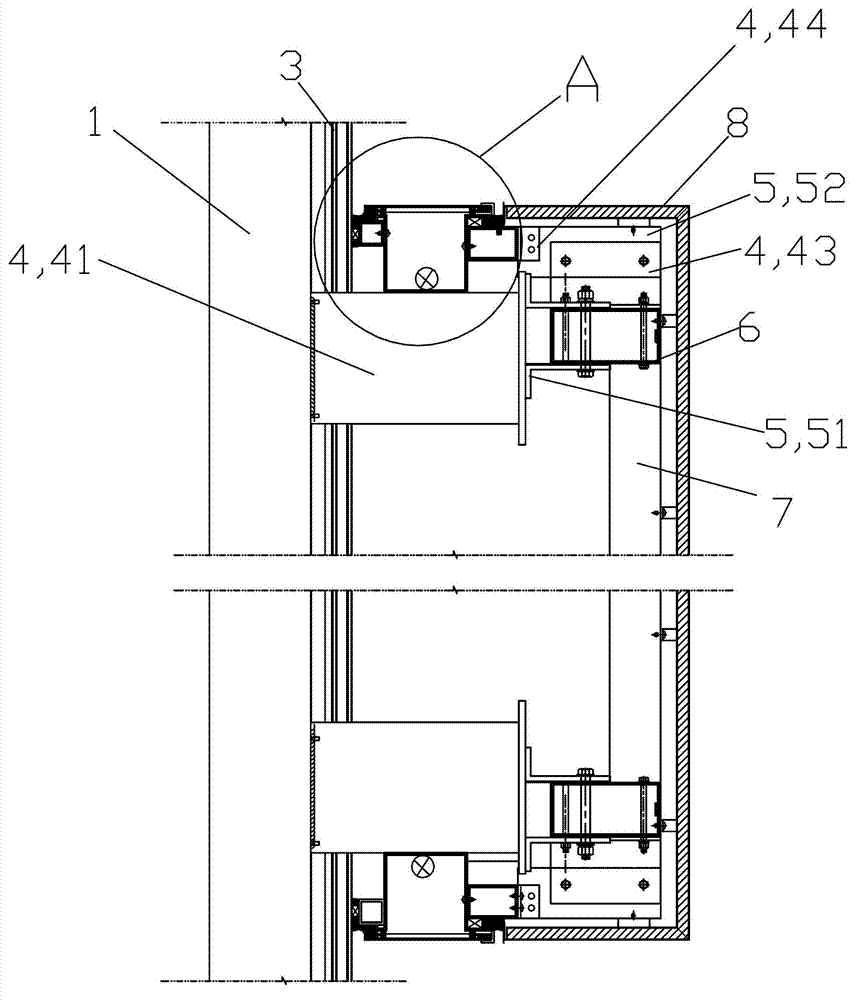

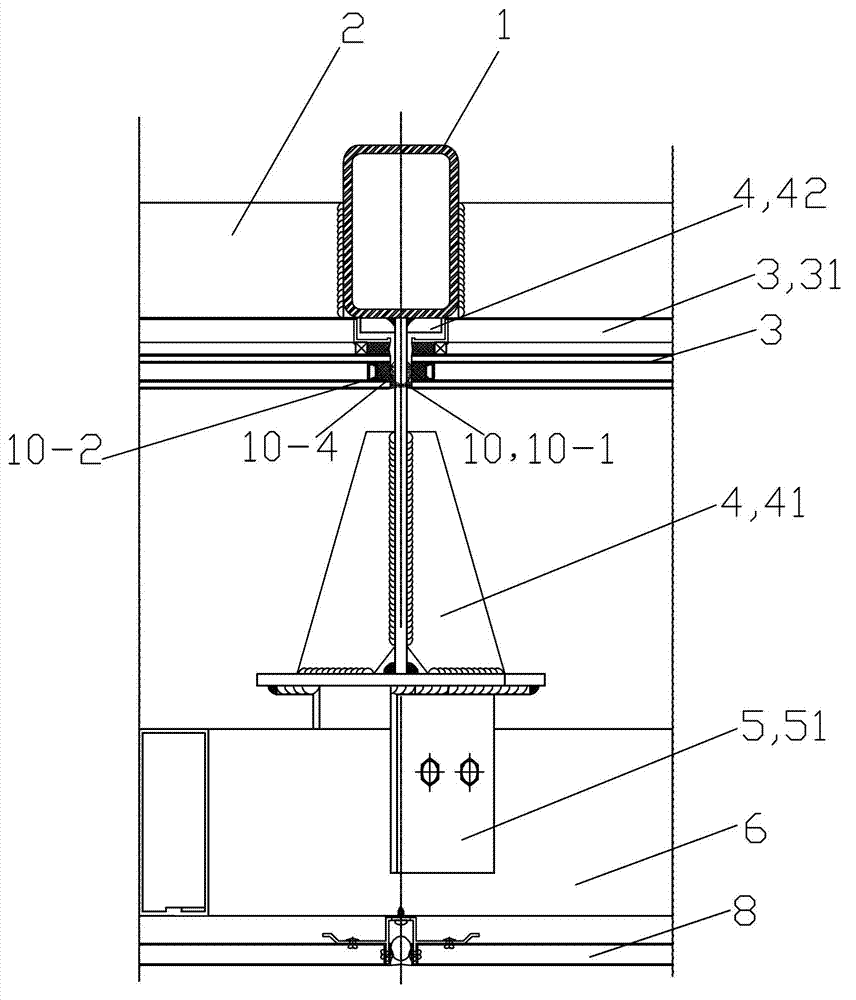

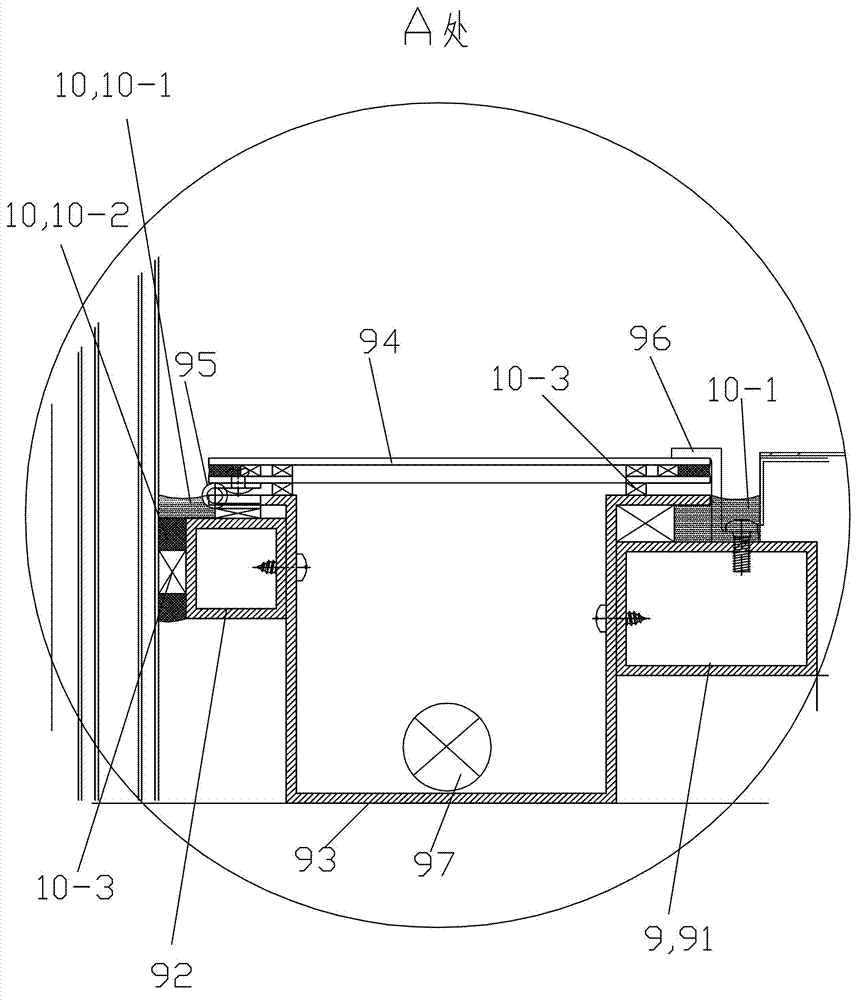

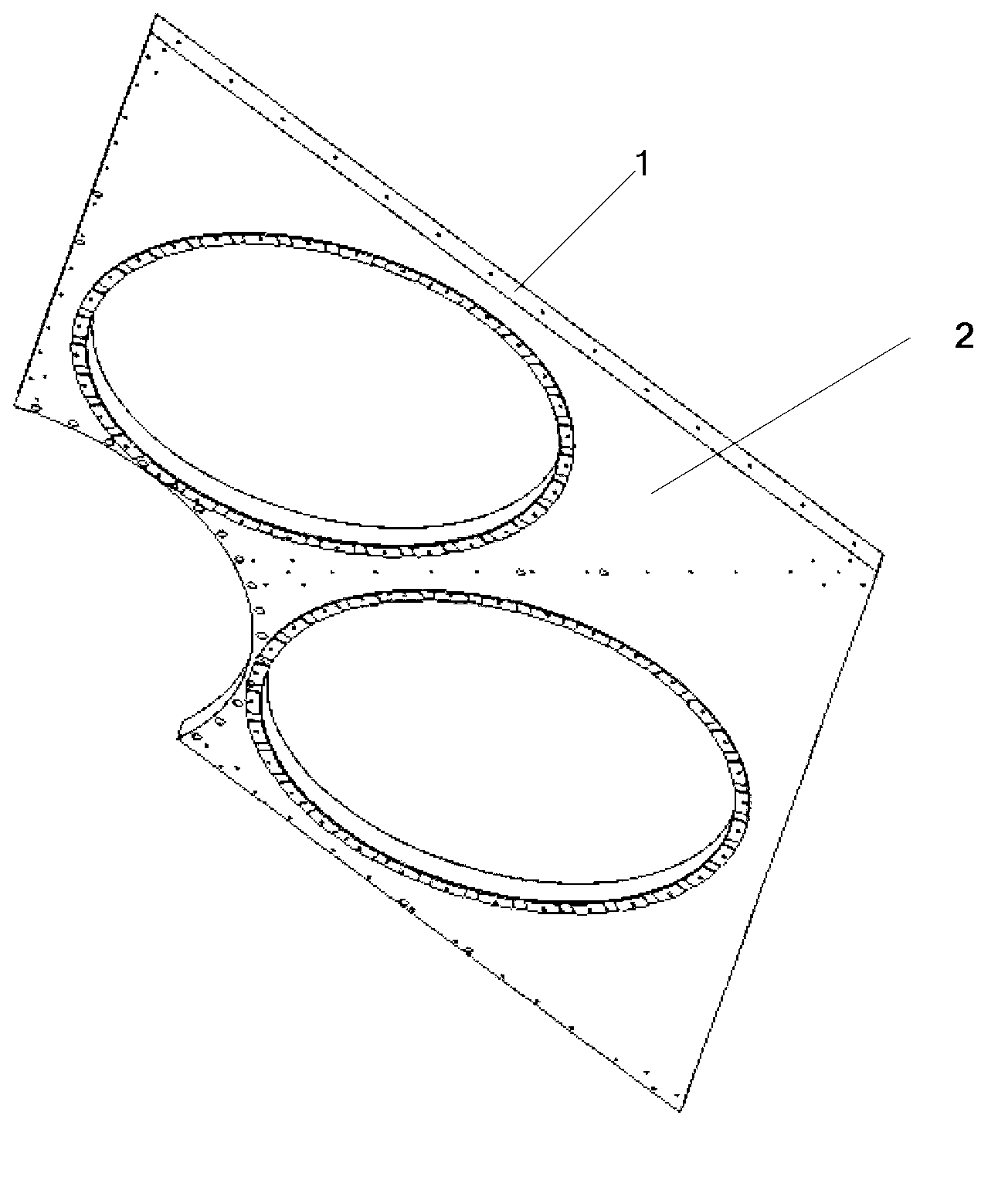

Curtain wall with glass and aluminum honeycomb plate bilayer structure and construction method thereof

ActiveCN102953484ADoes not affect large area constructionWithout destroying the integrityWallsBuilding material handlingAluminum honeycombStructural engineering

The invention provides a curtain wall with a glass and aluminum honeycomb plate bilayer structure, which comprises a main keel, a secondary keel, glass, a connecting assembly, a built-up connecting assembly, an aluminum honeycomb curtain wall main keel, an aluminum honeycomb curtain wall secondary keel, an aluminum honeycomb plate, a lamp assembly and a sealing and adhering assembly, wherein the main keel, the secondary keel and the glass form a hidden-frame glass curtain wall, and the aluminum honeycomb curtain wall main keel, the aluminum honeycomb curtain wall secondary keel, the aluminum honeycomb plate and the lamp assembly form an aluminum honeycomb plate curtain wall for decoration; and a main connecting piece of the connecting assembly penetrates through a gap between adjacent glass and is welded with the main keel, and an aluminum honeycomb plate curtain wall keel system is fixedly connected with the main keel of the glass curtain wall through the built-up connecting assembly. The construction method mainly comprises ten steps of installation of the glass curtain wall keel, installation of the main connecting piece, installation of the aluminum honeycomb plate curtain wall keel and the like. The curtain wall provided by the invention has the advantages of firm and stable structure, strong wind resistance, convenience in modeling and good decorative effect, and the construction method of such decoration project is expanded.

Owner:CHANGZHOU NO 1 CONSTR GRP

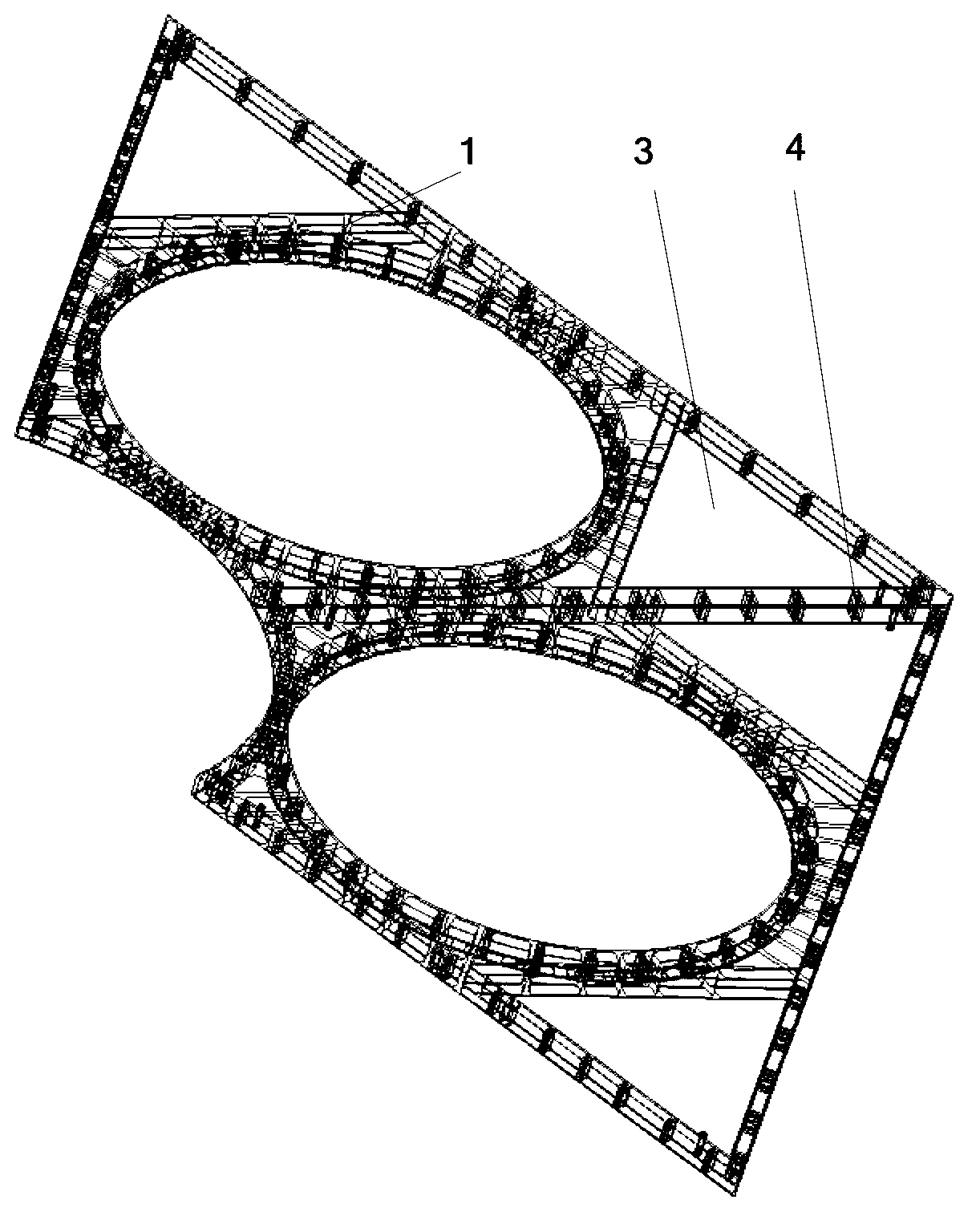

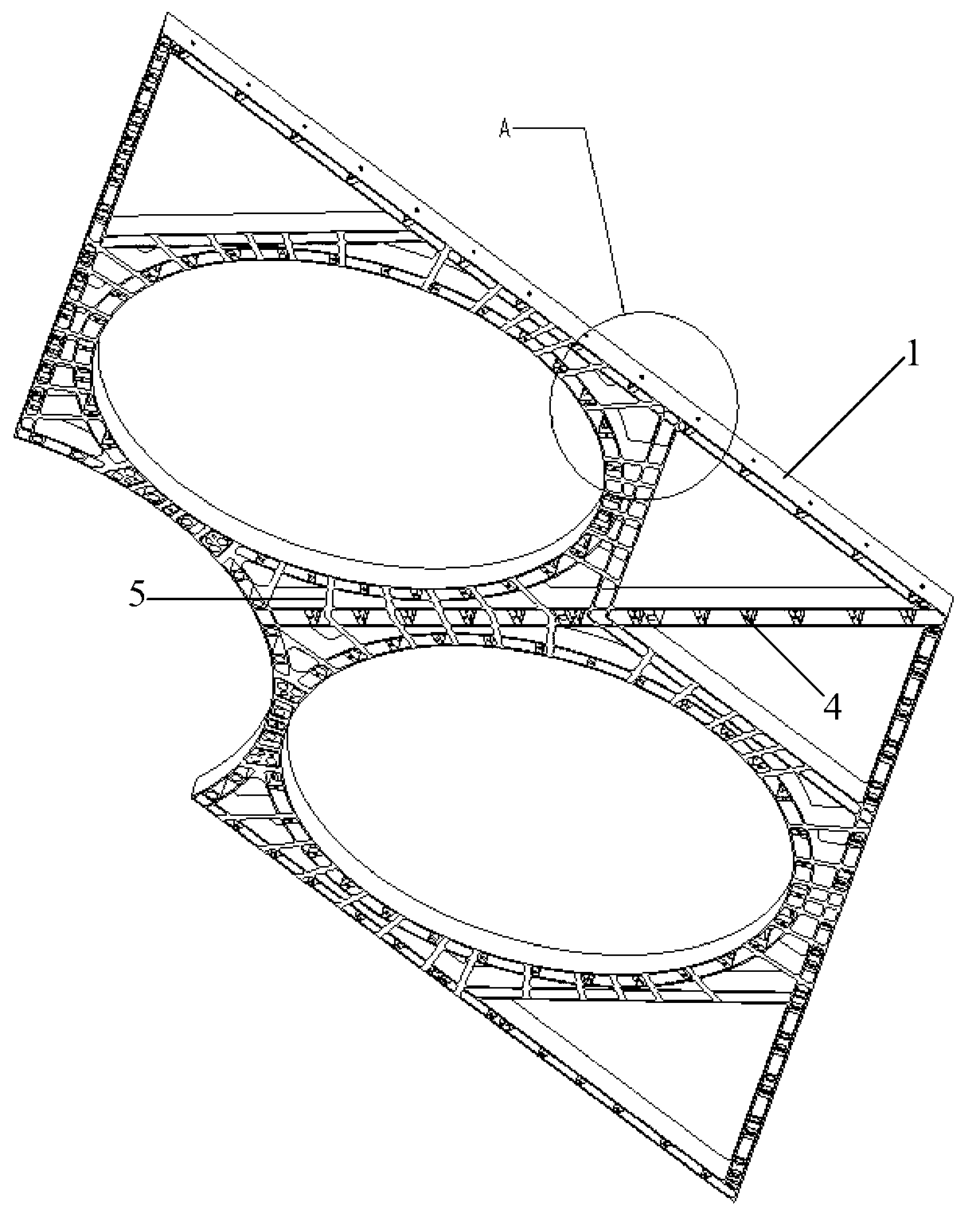

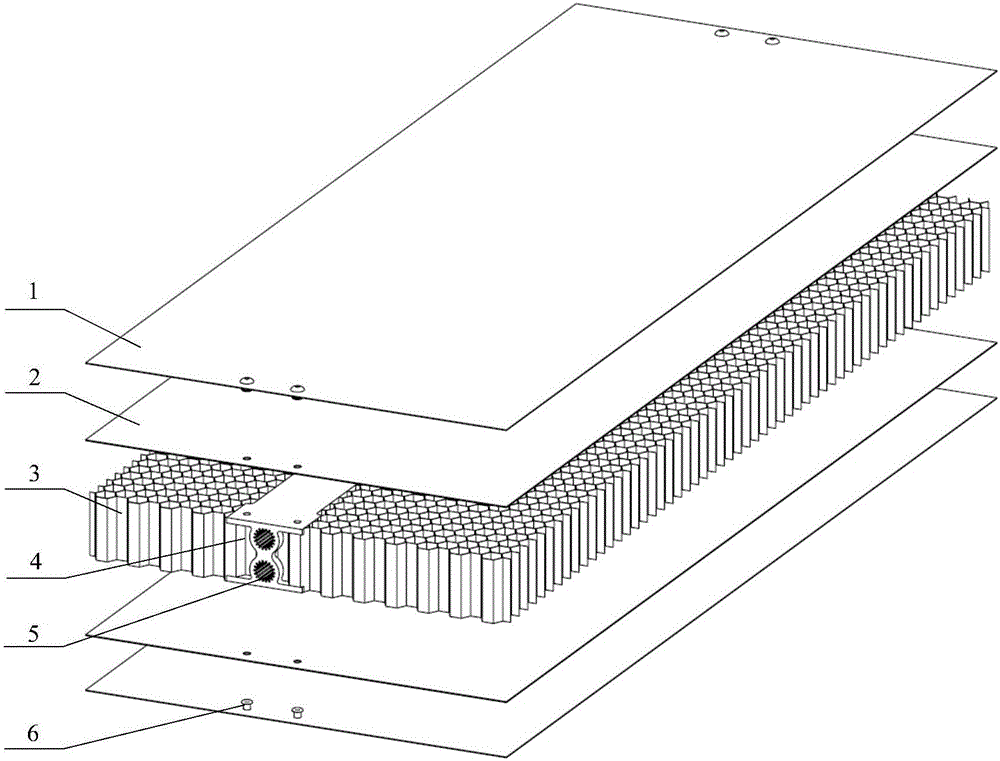

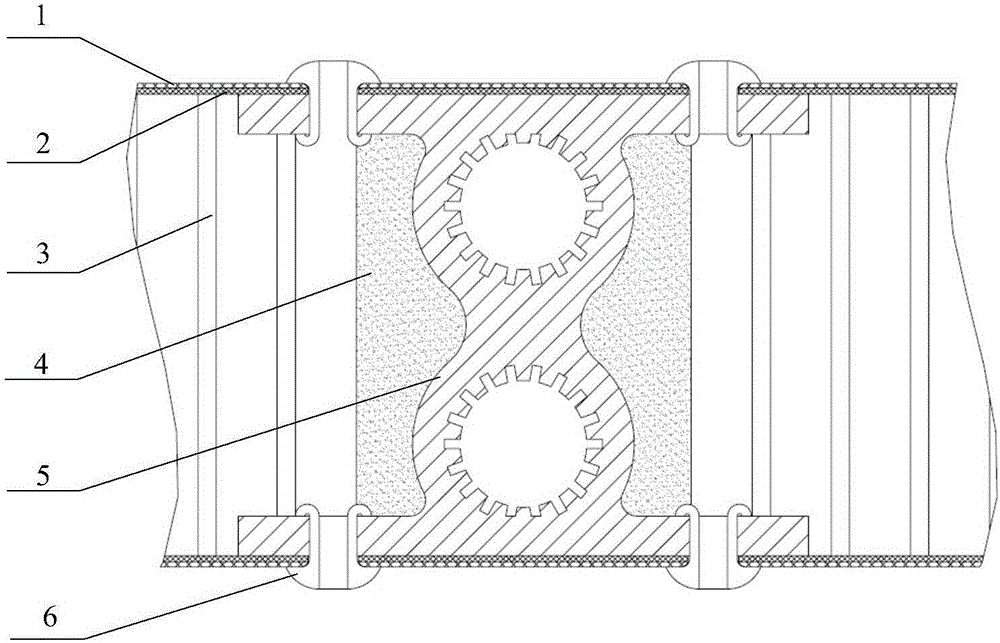

High-carrying-capacity embedded frame composite material structural slab

ActiveCN103287588AOvercome the problem that is difficult to form as a wholeHigh specific stiffnessCosmonautic vehiclesCosmonautic partsFiberCarbon fibers

The invention provides a high-carrying-capacity embedded frame composite material structural slab which comprises a carbon fiber embedded frame, outer stressed skins, an aluminum honeycomb core and metal embedded parts, wherein the carbon fiber embedded frame comprises a hollow part, a frame with a U-shaped groove section and reinforcing ribs; the reinforcing ribs are connected with the frame with the U-shaped groove section; the aluminum honeycomb core is connected with the hollow part; the metal embedded parts are embedded in the U-shaped groove; and the outer stressed skins are arranged above and below the carbon fiber embedded frame respectively and are in cementation connection with the carbon fiber embedded frame. The high-carrying-capacity embedded frame composite material structural slab has the advantages of light weight and high carrying capacity; and the wide application of the structural slab provides the following benefits: the launching cost is reduced, the capability of a spacecraft for carrying high-capacity conduit heads is improved, and the perform of the spacecraft is improved.

Owner:SHANGHAI SATELLITE ENG INST

Sustainably constructed heat dissipating integrated lighting surface

ActiveUS7744252B2Reduce the burden onReduce carbon footprintMechanical apparatusPoint-like light sourceFiberGlass fiber

A lighted heat dissipating panel made of sustainable renewable materials such as recycled aluminum and soy-based urethane, for use in architectural or shelving applications. The panel may be flat, rectangular, curvilinear, or of varying cross section so as to include any three-dimensional shape as desired. Lightweight materials such as carbon fiber, fiberglass, resin, soy-based urethane, and similar materials are used in combination with thermally conductive structural materials, such as expanded aluminum honeycomb, preferably fabricated from recycled aluminum, to provide a stiff, lightweight, machinable, moldable, and thermally conductive panel for use with lighting elements. Lighting elements are housed within the panel, providing illumination as desired. Heat is transferred from the lighting elements through the panel to the supporting structure and radiated from the panel itself, providing cooling effect for the lighting elements, reducing the temperature in the immediate vicinity of the lighting elements and providing for longer lighting element life.

Owner:LIGHTING SCI GROUP

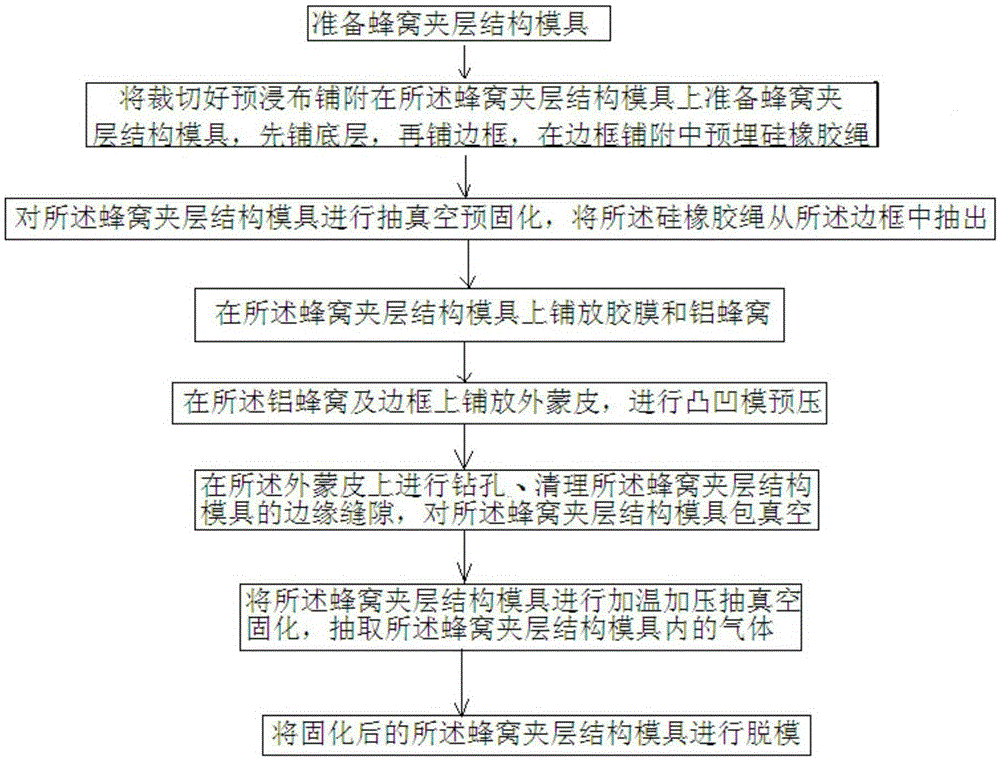

Method for designing and manufacturing ventilation channel of honeycomb sandwich structure

The invention discloses a method for designing and manufacturing a ventilation channel of a honeycomb sandwich structure, and belongs to the technical field of composite materials. The method for designing and manufacturing the ventilation channel of the honeycomb sandwich structure includes the following steps of preparing a honeycomb sandwich structure mold; laying cut pre-immersed cloth on the honeycomb sandwich structure mold in an attached manner, and embedding a silicon rubber rope in a laid and attached part of a frame; carrying out vacuumized procuring on the honeycomb sandwich structure mold, and pulling the silicon rubber rope out of the frame; laying a rubber film and an aluminum honeycomb on the honeycomb sandwich structure mold; laying outer skin on the aluminum honeycomb and the frame; drilling holes in the outer skin, clearing edge gaps of the honeycomb sandwich structure mold, and carrying out vacuum packaging on the honeycomb sandwich structure mold; and carrying out heating, pressurizing and vacuumizing curing on the honeycomb sandwich structure mold, and pumping out gas in the honeycomb sandwich structure mold. By means of the method for designing and manufacturing the ventilation channel of the honeycomb sandwich structure, the gas in the honeycomb is finally and smoothly pumped out, and the structural stability is achieved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

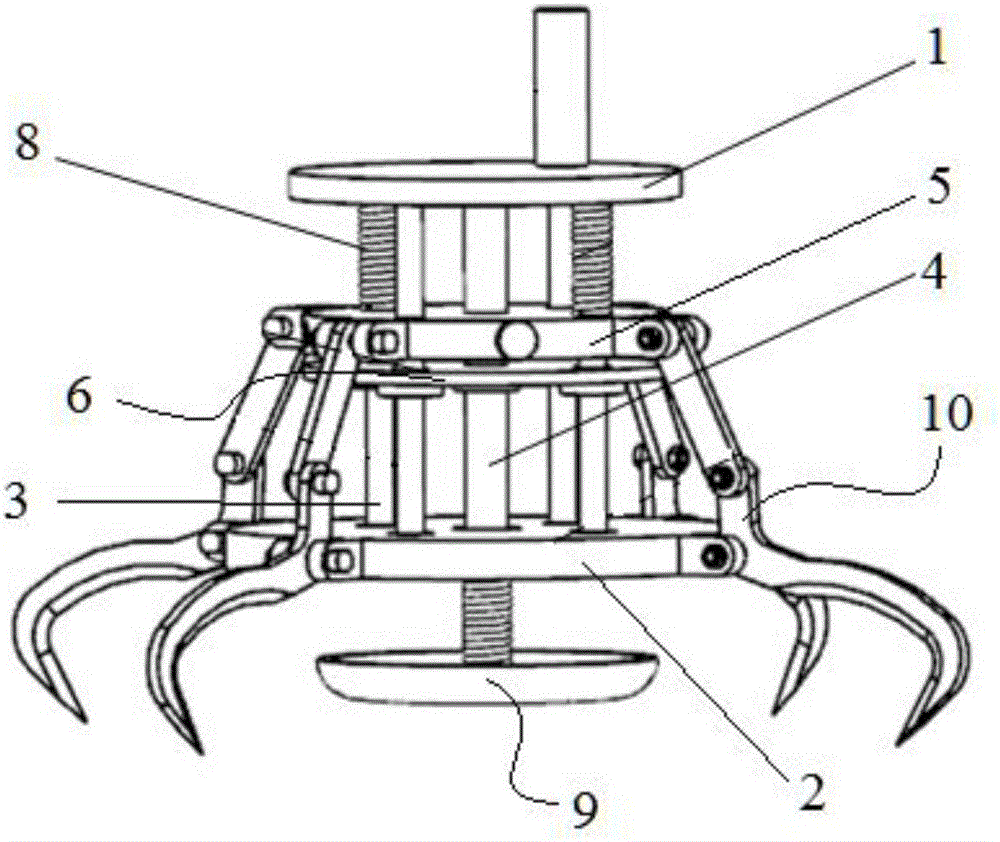

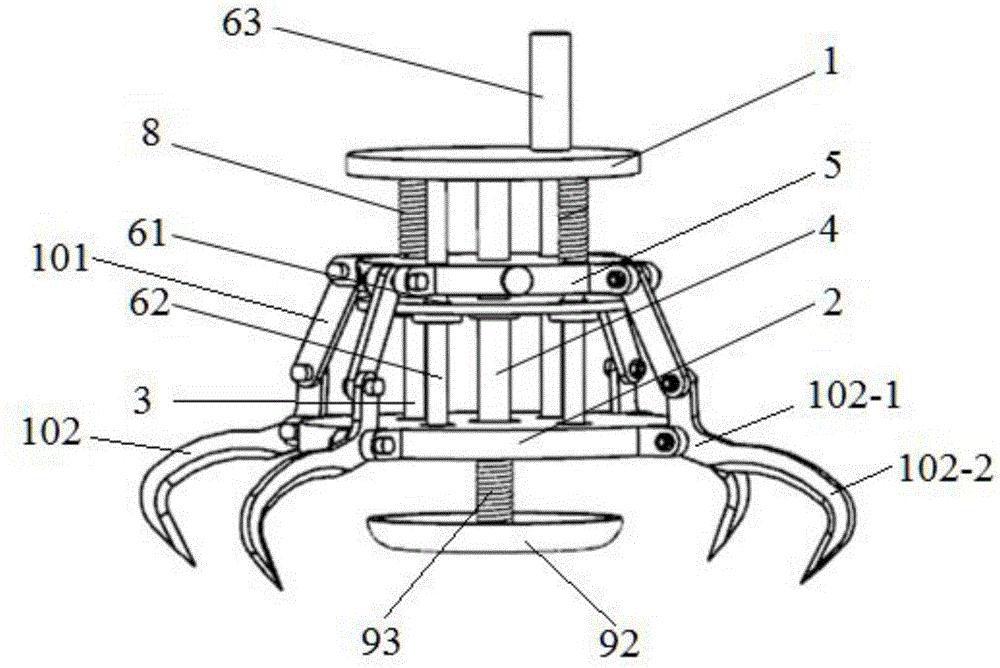

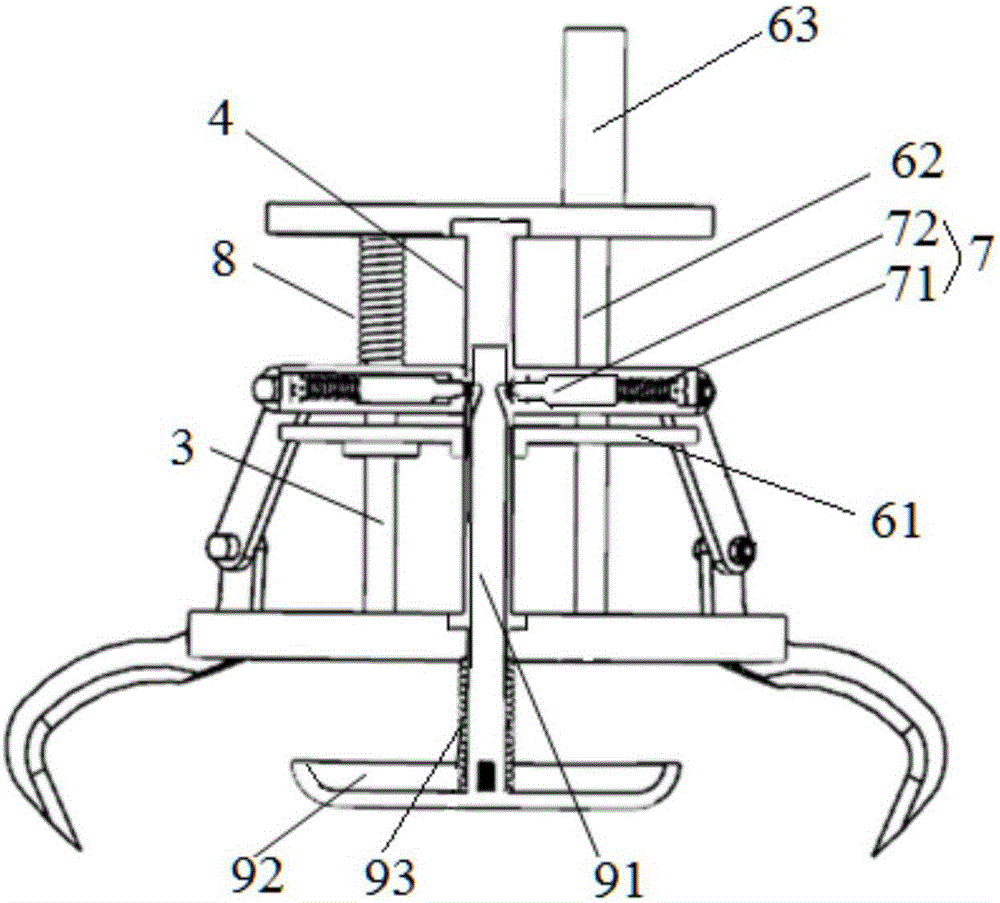

Interconnected elastic mechanical gripper

ActiveCN106826888ASimple structureFast, reliable and stable grip releaseGripping headsRobot handClassical mechanics

The invention relates to the technical field of industrial automation, in particular to an interconnected elastic mechanical gripper which comprises an upper support and a lower support. A moving push plate and a push component are arranged between the upper support and the lower support, the push component is used for pushing the moving push plate to move upwards, the top end of an outer sleeve is connected to the upper support, the bottom end of the outer sleeve penetrates the moving push plate and is connected with the lower support, a locking component is arranged in the moving push plate and matched with a hole in the outer wall of the outer sleeve, the top end of a supporting rod is connected to the upper support, the bottom end of the supporting rod penetrates the moving push plate and is connected with the lower support, an ejection elastic part is arranged on the outer wall of the supporting rod between the upper support and the moving push plate, a buffer component is arranged at the bottom of the lower support, the bottom end of the buffer component penetrates the lower support and extends into the outer sleeve, the outer wall of the moving push plate is rotatably connected with a push rod, the push rod is rotatably connected with a claw provided with a connecting portion, and the connecting portion is rotatably connected with the lower support. The surfaces of an aluminum honeycomb panel, a thin aluminum panel, a wood panel and the like can be rapidly, stably and reliably gripped and released.

Owner:BEIJING FORESTRY UNIVERSITY

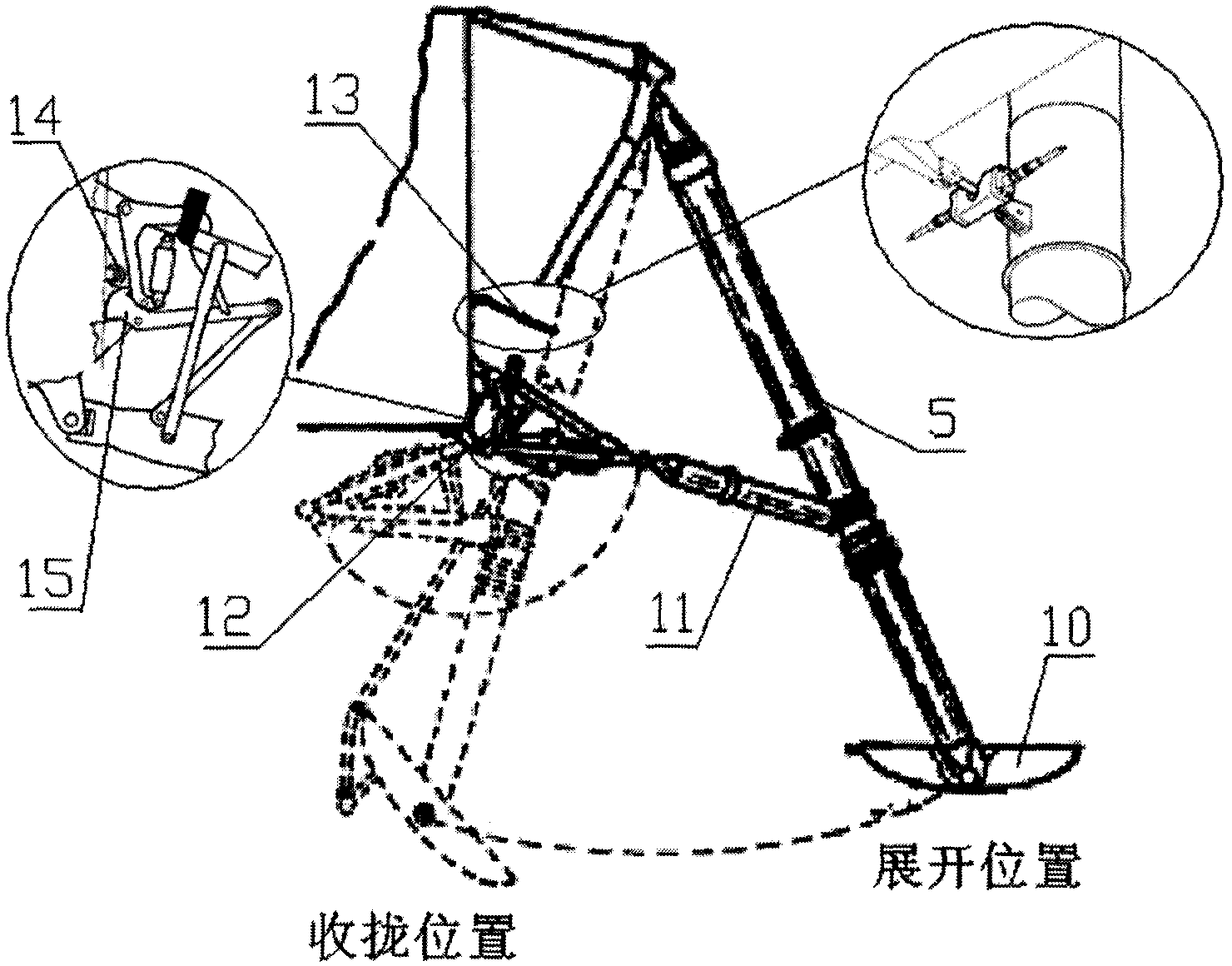

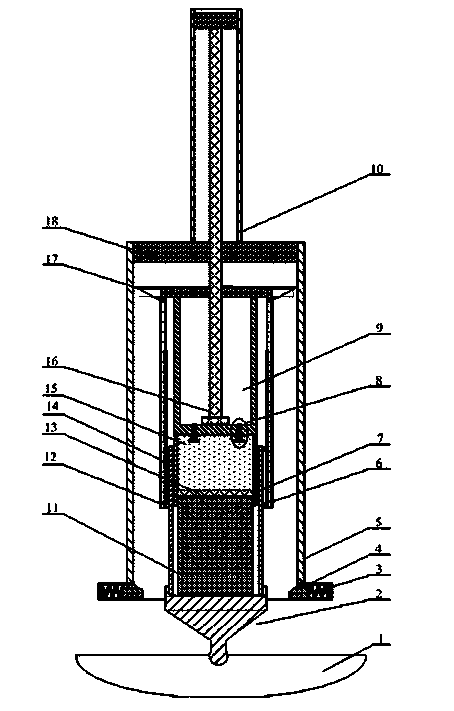

A detector landing buffer mechanism

ActiveCN105659758BEliminate independent compression linkReduce structural weightCosmonautic vehiclesSystems for re-entry to earthAluminum honeycombEngineering

A detector landing buffer mechanism is mainly composed of a main pillar, a multi-functional auxiliary pillar, a single-function auxiliary pillar, foot pads and the like. The multi-functional auxiliary pillar can not only buffer tensile and compressive impact loads, but also realize the functions of compression, release, deployment, and locking. There is no need to set a separate compression point when the landing buffer mechanism is assembled with the lander, which reduces the impact of the landing buffer mechanism. The interface with the landing detector is easy to install and operate. The deployment of the landing buffer mechanism is realized by the compression spring located inside the multifunctional auxiliary pillar. Even if the compression spring breaks, the deployment power will not be lost, and reliable deployment can still be guaranteed, greatly improving the reliability of deployment. In the multi-functional auxiliary pillar and the single-function auxiliary pillar, the compressive impact load is buffered through the compression deformation of the aluminum honeycomb material, and the tensile impact load is buffered through the tensile deformation of the tie rod, which not only makes the buffer more reliable, but also makes the structure simpler.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

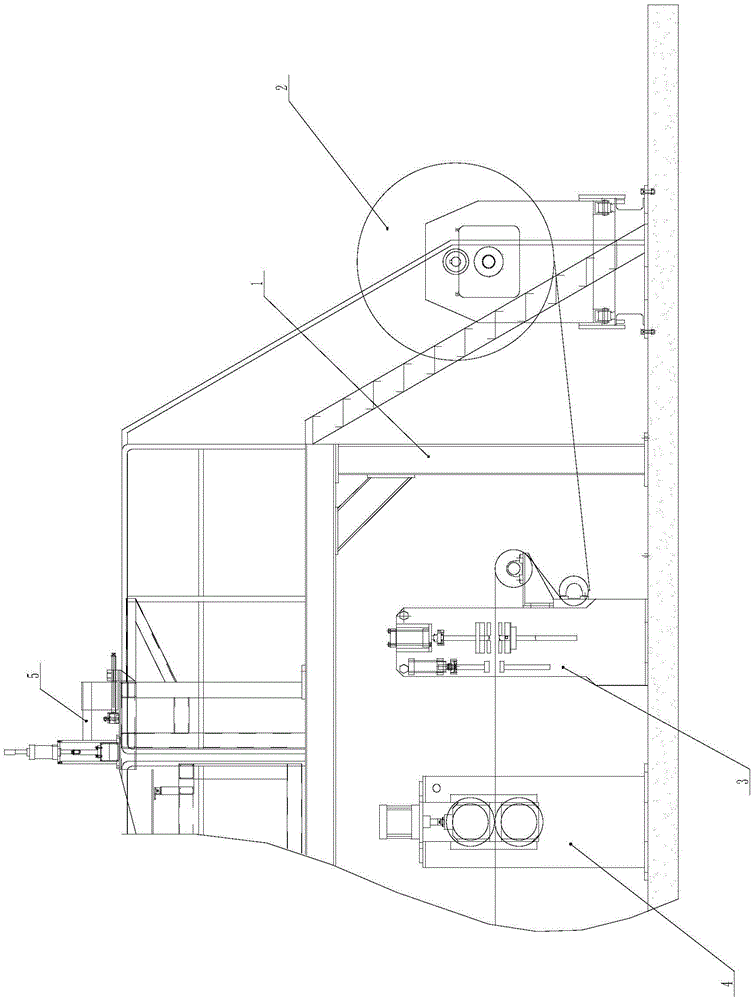

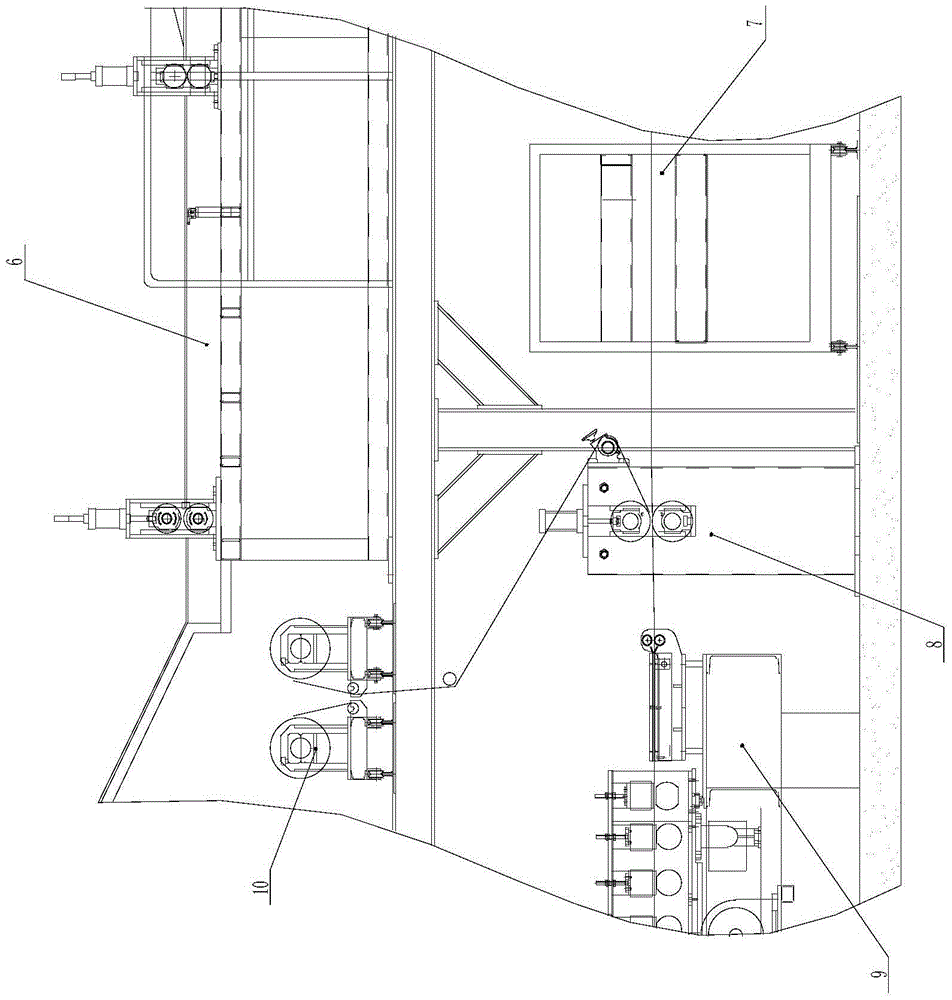

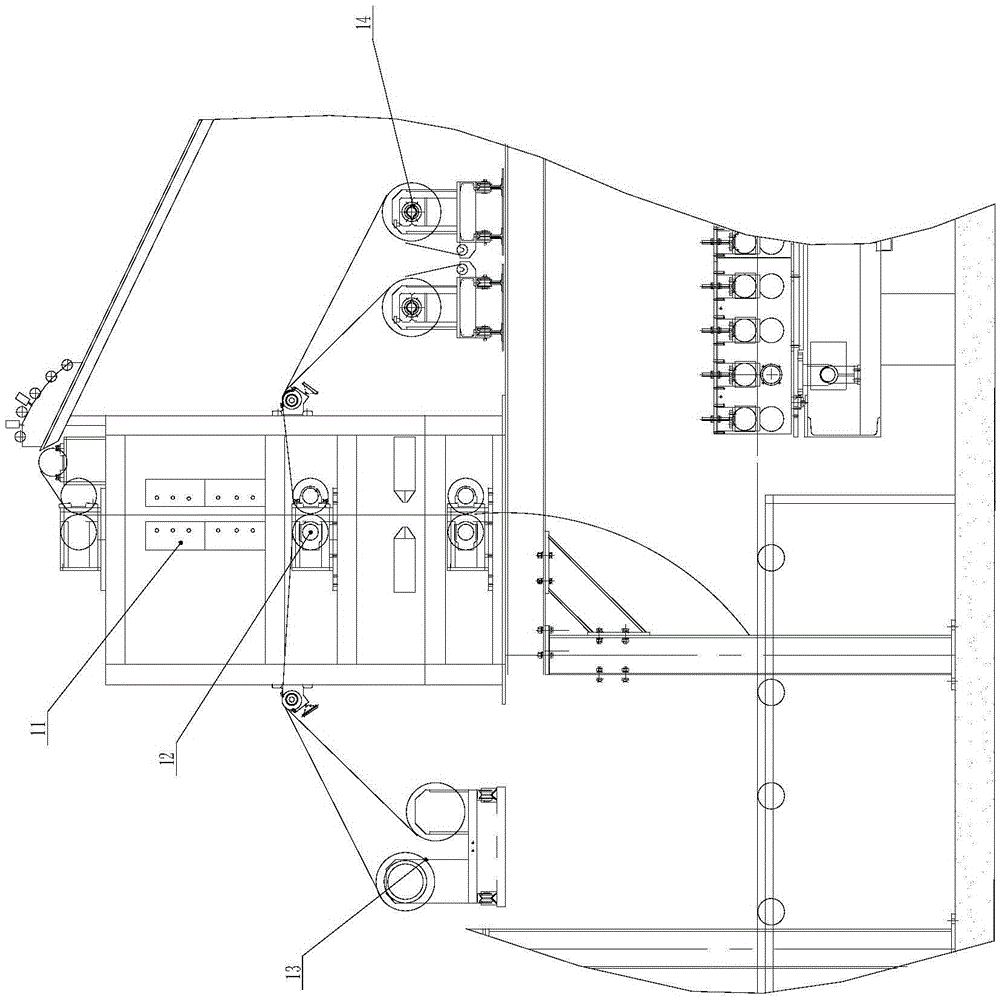

Continuous and automatic production line for aluminum honeycomb composite boards and continuous production process

InactiveCN105538870AFit tightlyReduce manual involvementLamination plant layoutLaminationProduction lineAluminum honeycomb

The invention discloses a continuous and automatic production line for aluminum honeycomb composite boards. The continuous and automatic production line comprises a rack, an aluminum honeycomb core layer forming unit, an upper-layer board forming unit, a lower-layer board forming unit and a composite forming unit. The aluminum honeycomb core layer forming unit achieves automation of splicing, stretching and unfolding aluminum honeycomb core strips into aluminum honeycomb core layers and coating the aluminum honeycomb core layers with polymeric membranes in advance, the upper-layer board forming unit and the lower-layer board forming unit are used for unreeling upper-layer boards and lower-layer boards and coating the upper-layer boards and the lower-layer boards with polymeric membranes in advance respectively, and finally the three layers are compounded on the composite forming unit. The aluminum honeycomb composite boards can be continuously produced through the continuous production line, capacity is improved, the quality of the formed aluminum honeycomb composite boards is consistent, and the thickness is uniform.

Owner:张家港市弘扬机械设备有限公司

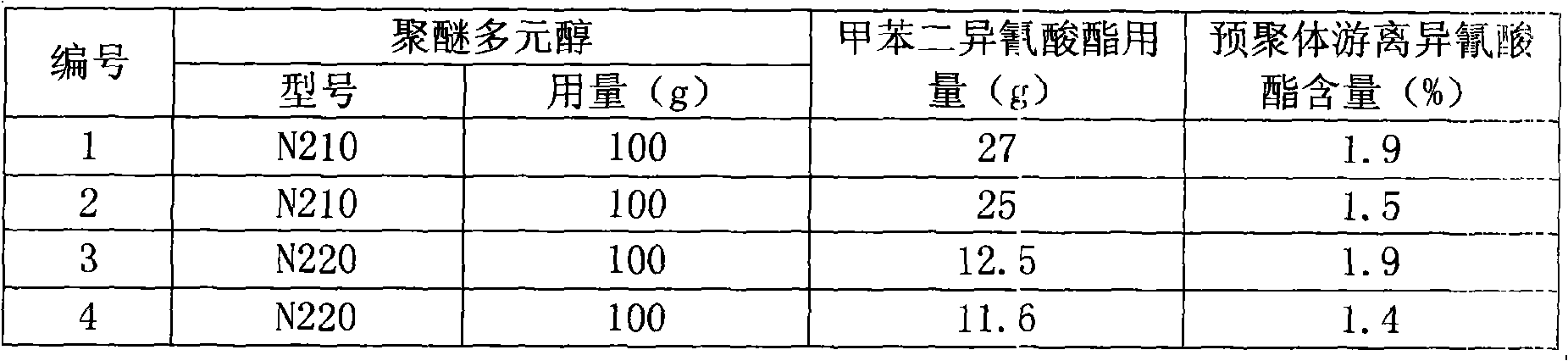

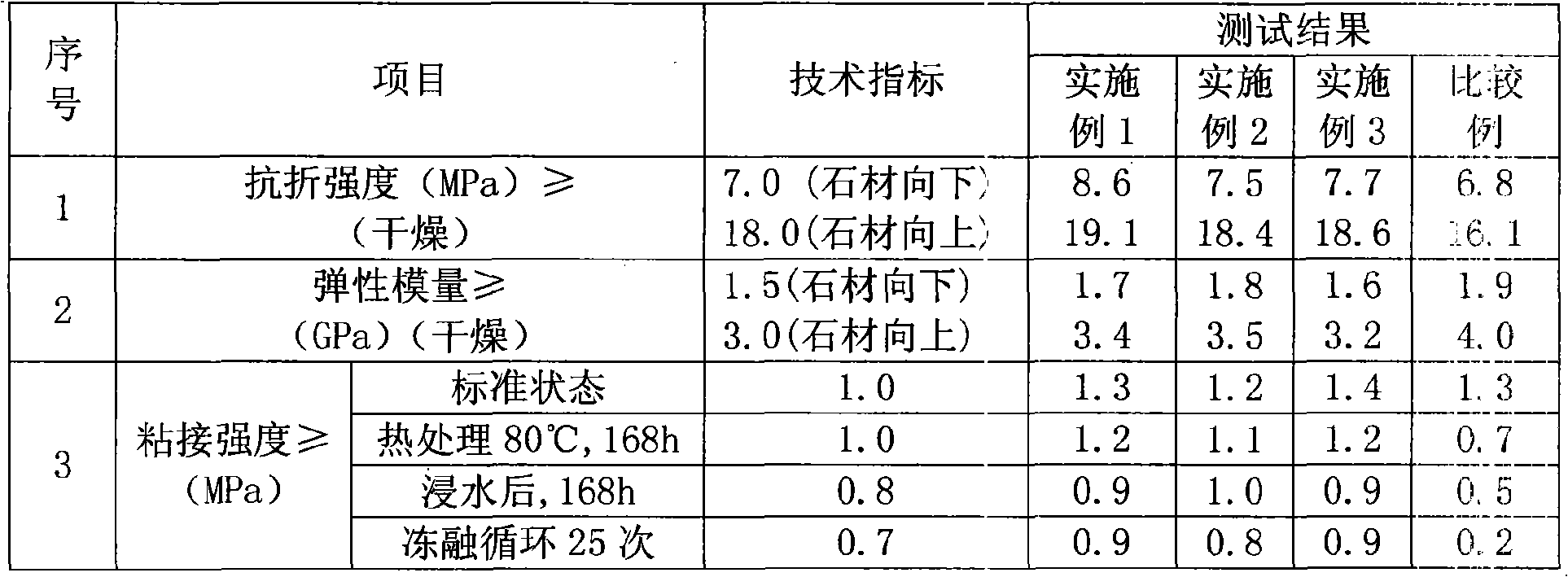

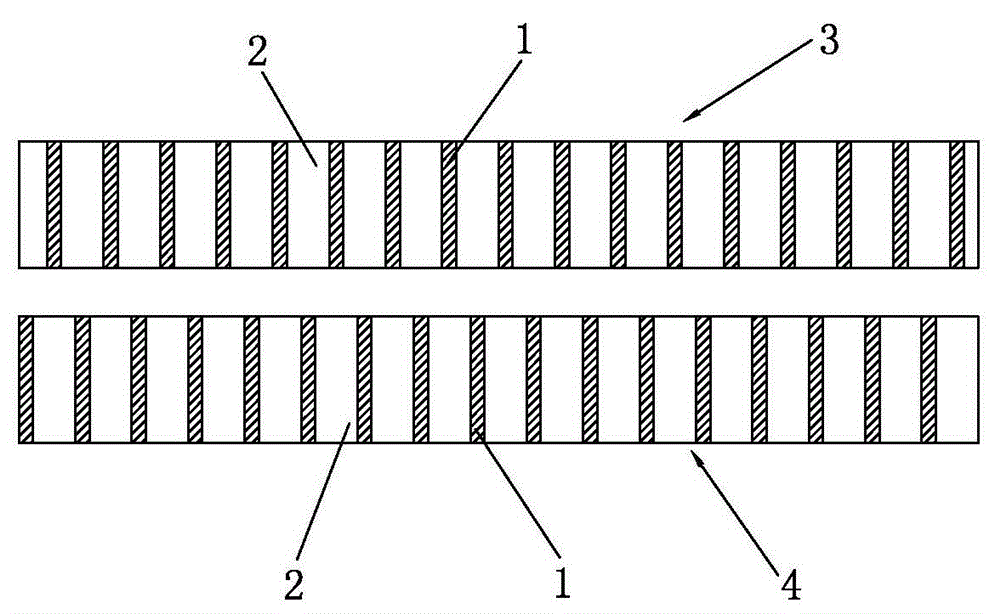

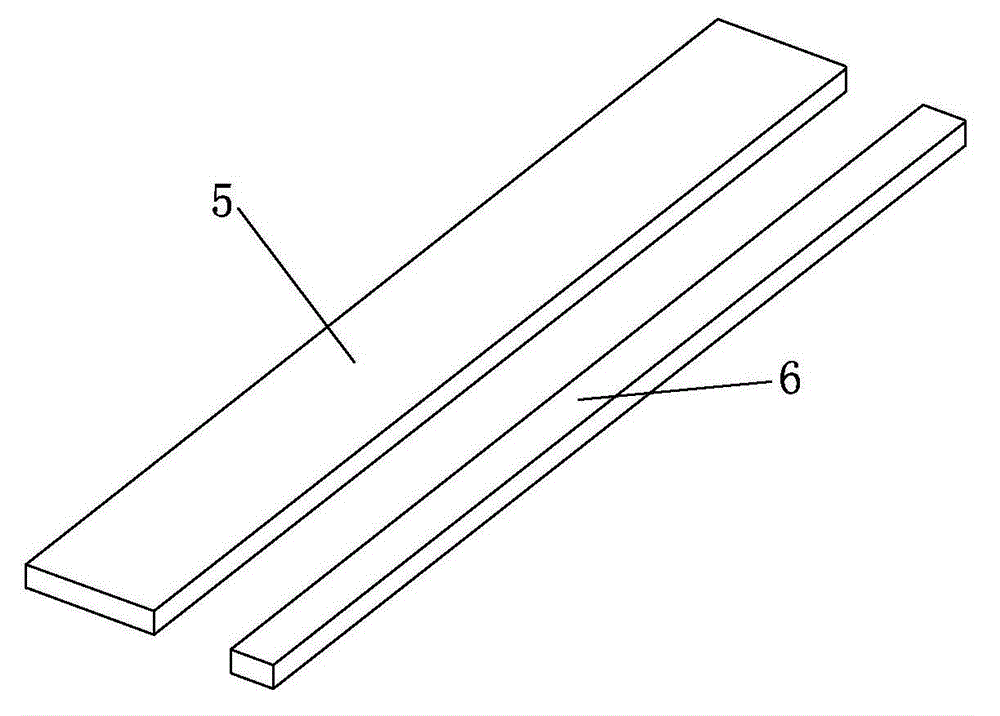

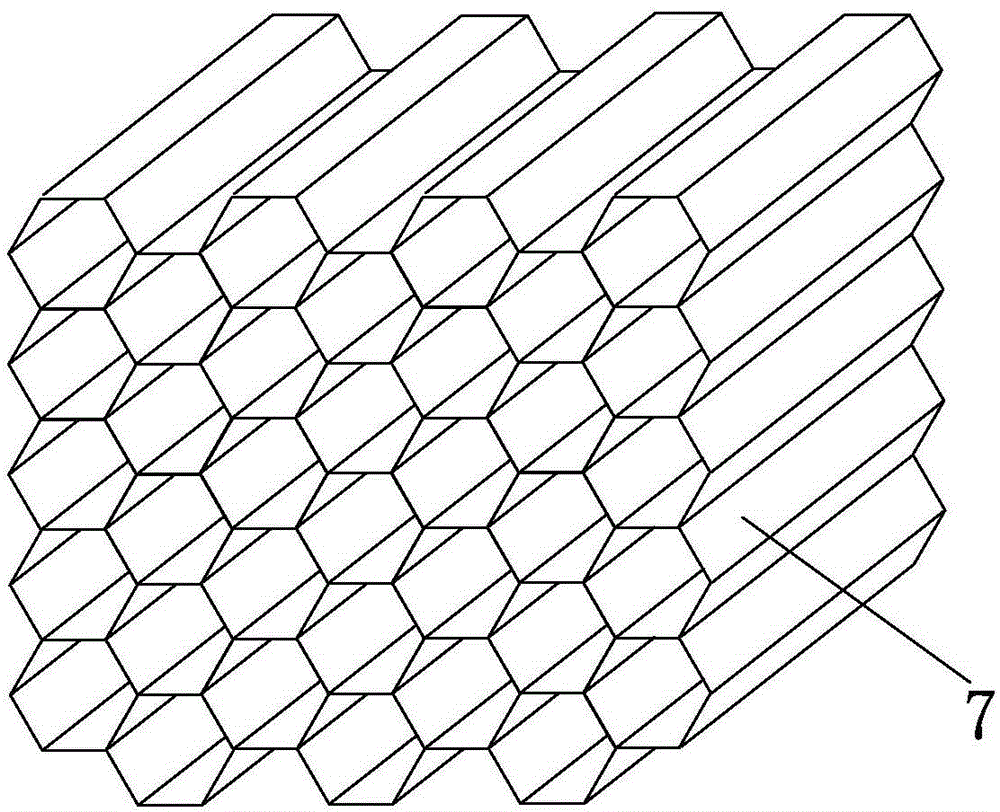

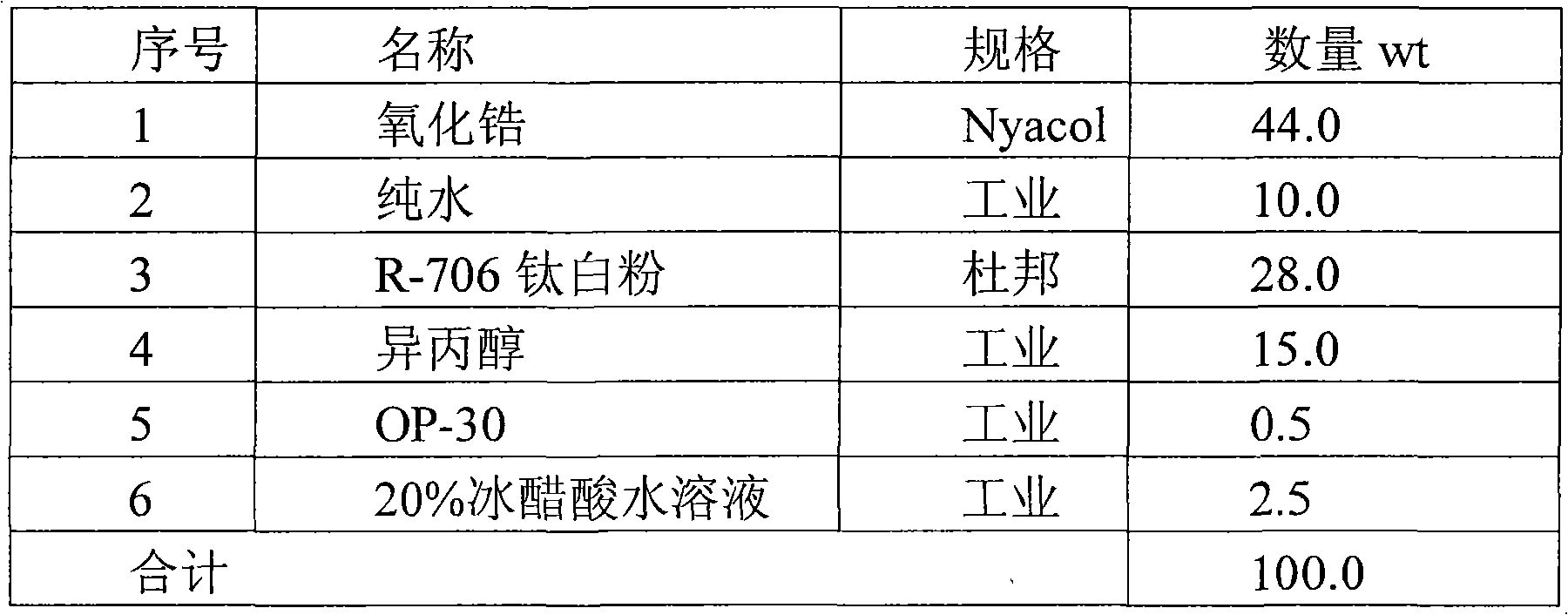

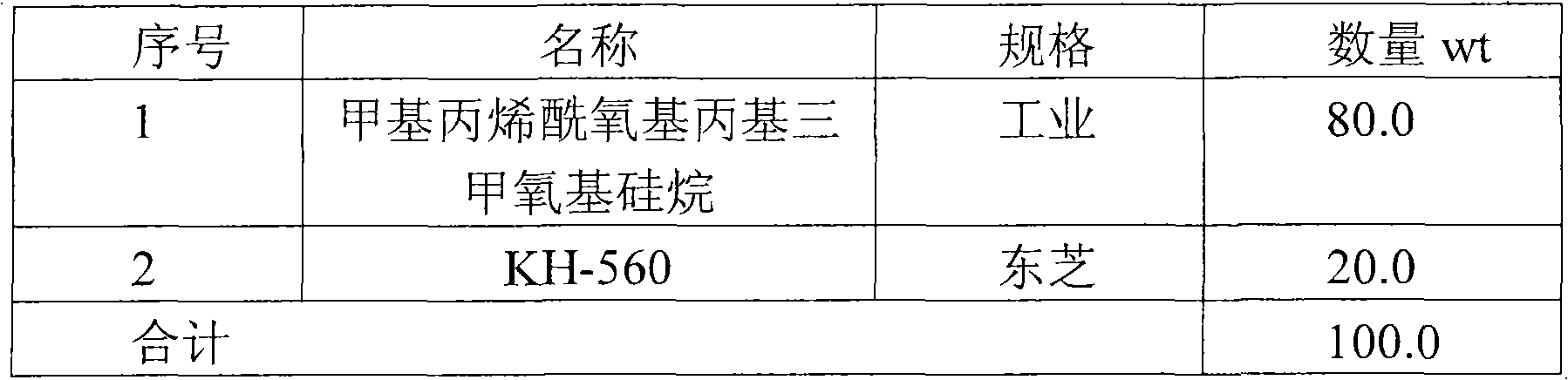

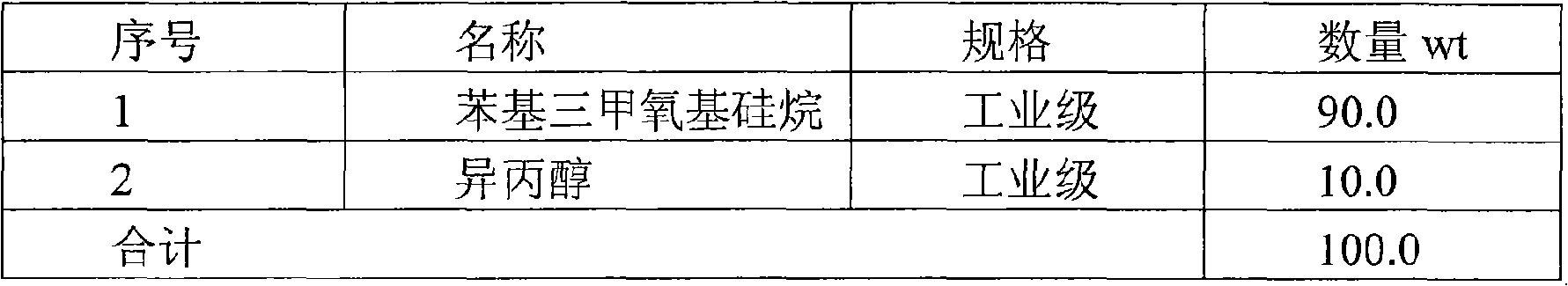

Ultra-thin stone and aluminum honeycomb composite modified epoxy adhesive and preparation thereof

ActiveCN101323772ALayered productsPolyureas/polyurethane adhesivesAluminum honeycombReactive diluent

The invention relates to a modified epoxy adhesive, in particular to a modified epoxy adhesive used in composite preparation of ornamental stone materials by ultra-thin stone materials and aluminum honeycombs. A component A of the adhesive is made from 20 percent to 40 percent of epoxy resin, 5 percent to 15 percent of reactive diluent, 1 percent to 5 percent of nanometer powder material, 10 percent to 30 percent of polyurethane prepolymer and 40 percent to 60 percent of inorganic powdery filler, while a component B is made from 20 percent to 30 percent of modified amine curing agent, 1 percent to 5 percent of accelerant, 1 percent to 5 percent of organic silicon coupling agent, 5 percent to 10 percent of glass flake and 40 percent to 60 percent of inorganic powdery filler; the proportion by weight between the component A and the component B is 2.5 to 3.5: 1. The modified epoxy adhesive is applied to composition of the ultra-thin stone materials and aluminum honeycombs, the key technical indexes of which meet the national building material industry standards of ultra-thin natural stone composite boards.

Owner:HUNAN SHENLI IND

Method for manufacturing aluminum honeycomb core

ActiveCN104527205AClose contactAvoid easy separationLaminationLamination apparatusAluminum honeycombAluminum foil

The invention provides a method for manufacturing an aluminum honeycomb core and relates to the technical field of honeycomb cores. The method comprises the following steps: (1) cleaning a strip-shaped aluminum foil by using ultrasonic waves; (2) coating one side of the strip-shaped aluminum foil with glue; (3) cutting the strip-shaped aluminum foil into aluminum foil sections; (4) overlapping the aluminum foil sections; (5) performing hot-pressing on the overlapped aluminum foil sections in a hot press for forming overlap blocks; (6) cutting the overlap blocks into cutting strips; and (7) stretching the cutting strips by using a hydraulic drawing mill, so that the cutting strips are unfolded to form the aluminum honeycomb core. According to the method disclosed by the invention, adhesion among the aluminum foil sections can be tight, the position of a gluing area is aligned in the overlapping process, and the cutting strips are stably unfolded.

Owner:FOSHAN CITY HUARUI CELLULAR TECH CO LTD

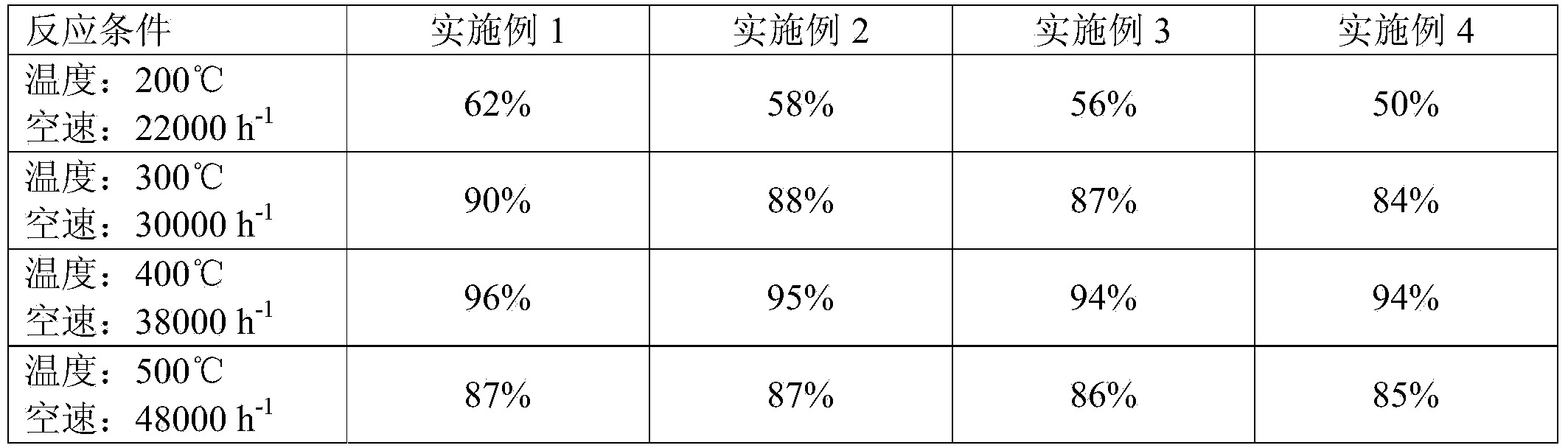

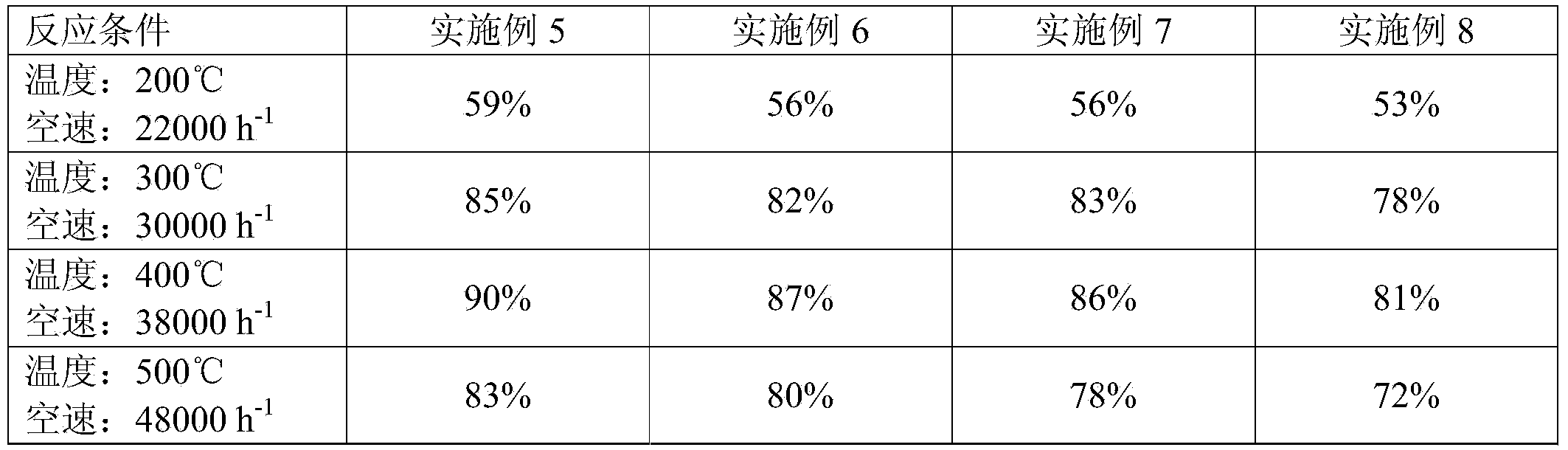

Effective SCR (selective catalytic reduction) catalyst applied to purification of nitrogen oxide in tail gas of diesel engine

ActiveCN104338545AReduce loss rateImprove thermal stabilityInternal combustion piston enginesDispersed particle separationClose couplingManganese oxide

The invention relates to an effective SCR catalyst applied to purification of nitrogen oxide in tail gas of a diesel engine, and belongs to the technical field of motor vehicle exhaust emission purification by a catalysis method. According to the catalyst, two or more of titanium, tungsten, silicon and zirconium oxide are used as a base coating, and one or more of vanadium oxide, manganese oxide and copper oxide are used as an active ingredient. The catalyst is coated on a cordierite honeycomb ceramic or iron-chrome-aluminum honeycomb metal carrier to be applied to post treatment of nitrogen oxide of tail gas of the diesel engine in a mode of a honeycomb catalyst. The catalyst has the advantages that the loss rate of the specific surface area of the coating under a high temperature reaction condition can be reduced by utilizing the close coupling structure among the oxides in the base coating, the heat stability and durability of the catalyst can be improved, and the service life of the catalyst can be prolonged; the low-temperature reaction cavity of the catalyst can be remarkably improved by adding manganese, copper and other active ingredients, so that nitrogen oxide can be effectively eliminated at a low exhaust temperature of the diesel engine.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

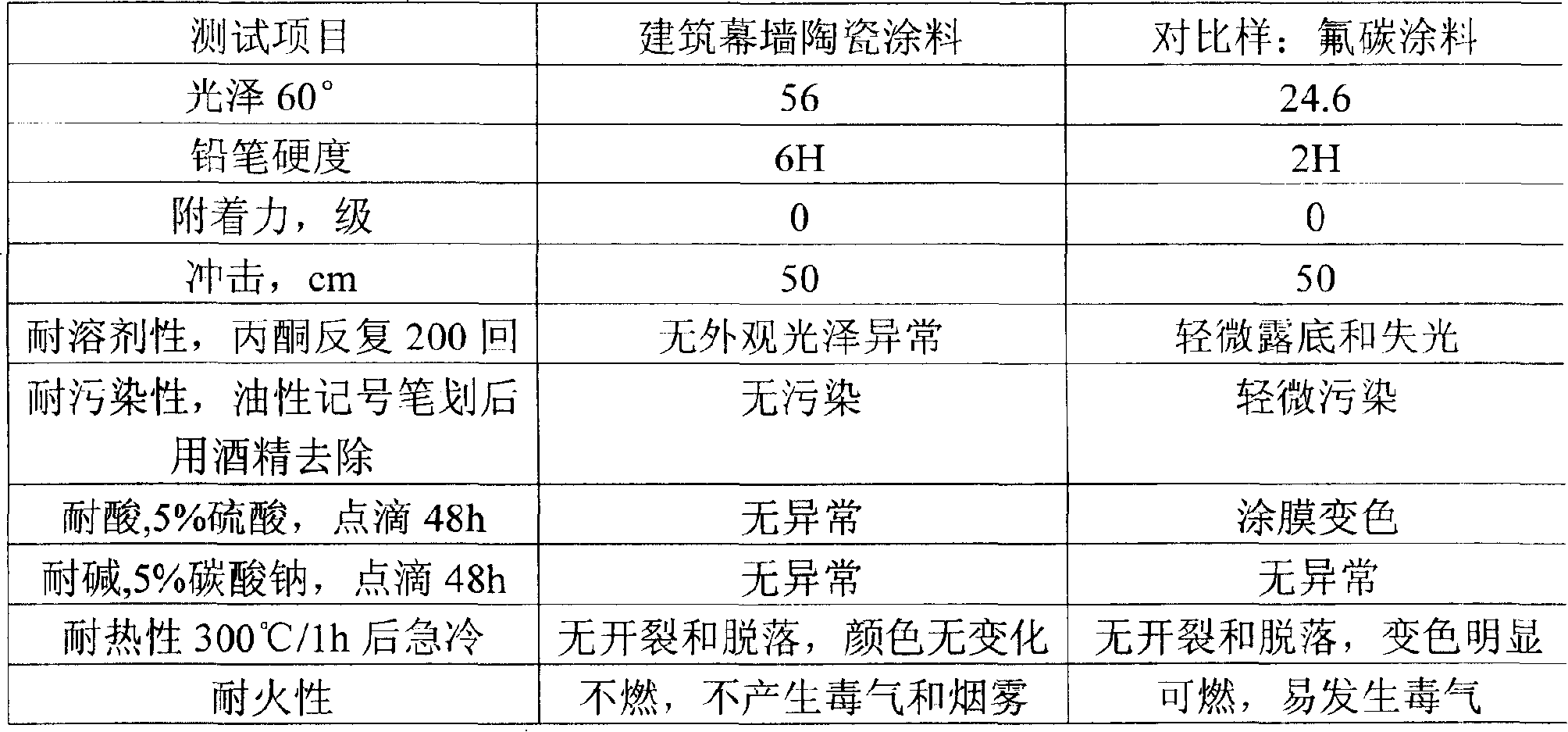

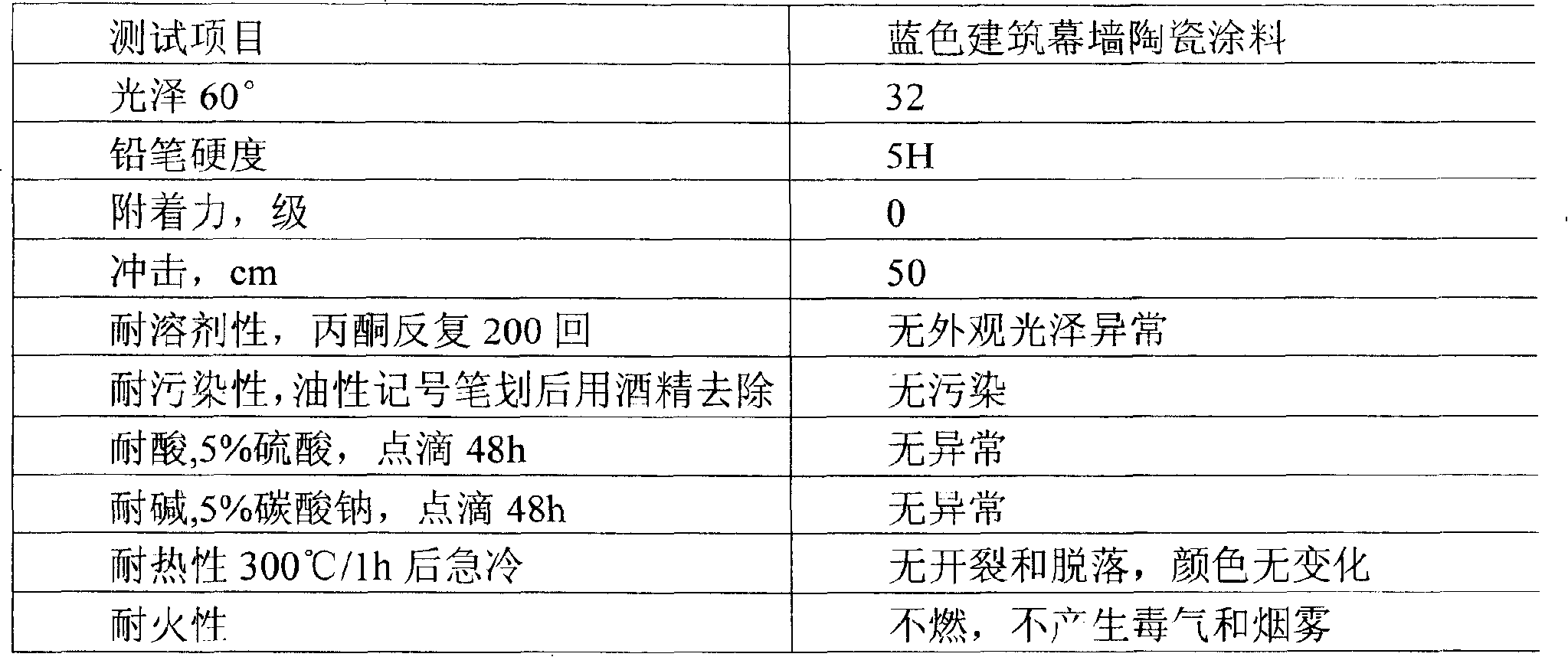

Paint for building curtain wall

The invention discloses a nanometer ceramics building curtain wall coating which consists of nanometer metallic oxide, tinting pigment, organic silicon curing agent and accessory ingredient, etc. The coating has the advantages of super weather resistance, anti-scratch property, fireproof and self-cleaning property, etc. The coating can be used for the coating of aluminum curtain walls, aluminum plates of subway engineering and aluminum honeycomb panels.

Owner:上海金力泰化工股份有限公司

Ceramic crystal coating for metal surfaces and preparation method thereof

The invention discloses a ceramic crystal coating for metal surfaces and a preparation method thereof. The ceramic crystal coating for metal surfaces is composed of nano-oxides or nano silicate colloids, high-temperature-resistant pigments and fillers, organic modifiers and additives, has the characteristics of high temperature resistance, no stain sticking, super weather resistance, super wear resistance, non combustion, fire prevention and high hardness, can be used on the surfaces of iron and steel or aluminum alloys required to be high-temperature-resistant and wear-resisting, and also can be applied to the coating of aluminum sheets, aluminum honeycomb panels or other metal plates for outdoor and indoor decoration.

Owner:ZHUHAI FUTE TECH

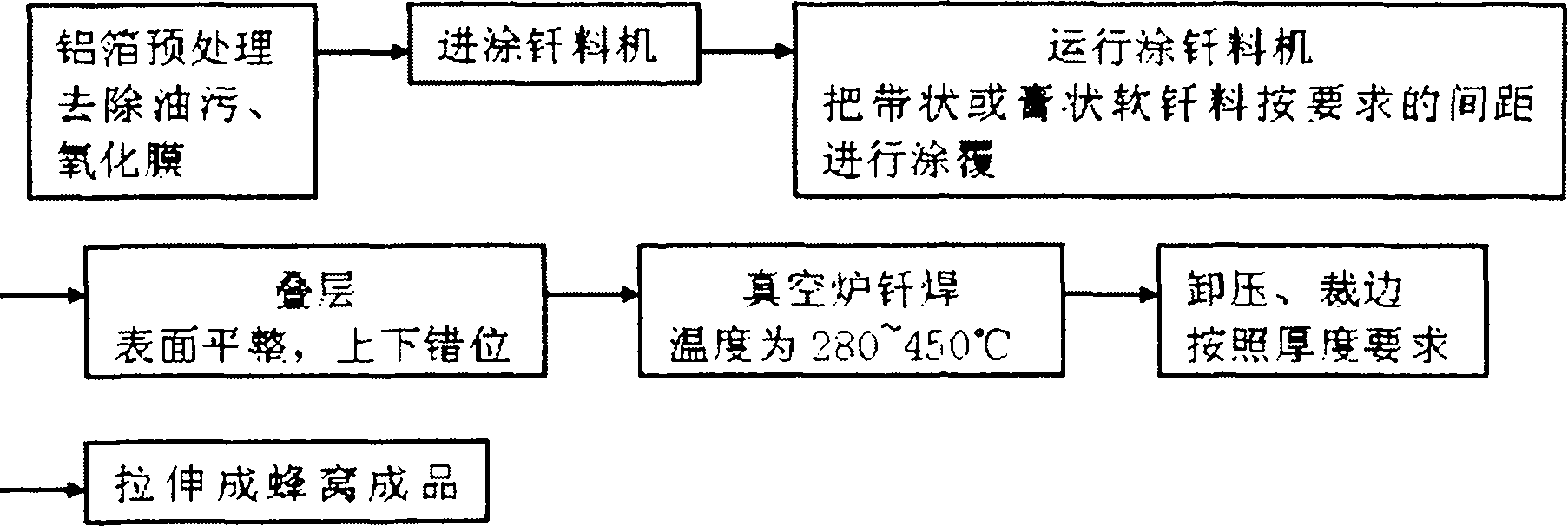

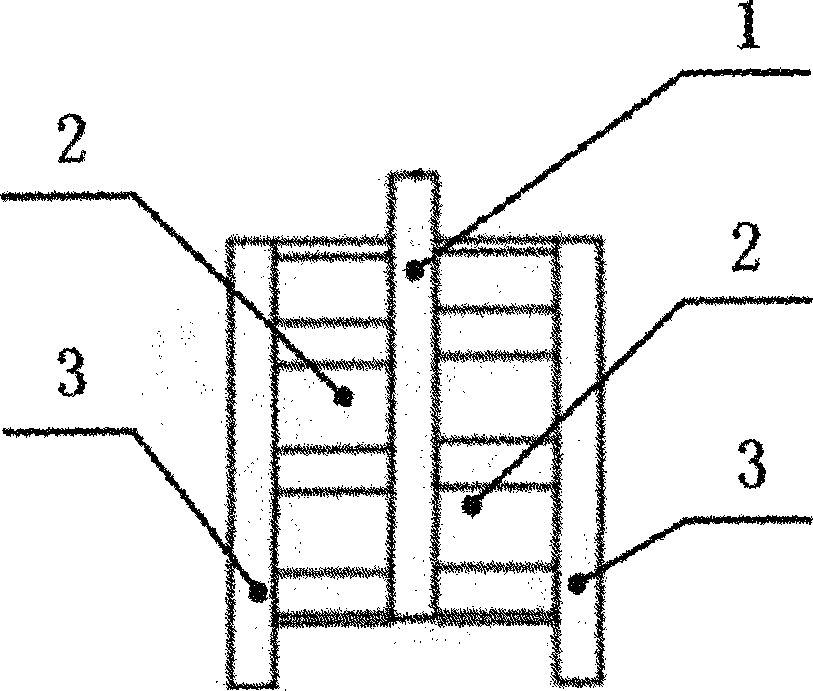

Intermediate temperature self-reaction brazing method for aluminum honeycomb boards

InactiveCN105562862AImprove performancePerformance constraints, its tensile strength increasesWelding/cutting auxillary devicesAuxillary welding devicesAluminum honeycombFiller metal

The invention discloses an intermediate temperature self-reaction brazing method for aluminum honeycomb boards. According to the brazing method, no alloy brazing filler metal is used, gas protection or vacuum protection is not adopted, a honeycomb core strip and an aluminum alloy panel which are coated with self-reaction brazing fluxes are assembled and fixed into an aluminum honeycomb board structure through a self-manufactured clamp, then insulating is conducted for 30 min in a box type atmosphere furnace heated to 570 DEG C, brazing is carried out, and the aluminum honeycomb boards good in connection are obtained. The method has the beneficial effects that the metallurgy connection of the aluminum honeycomb boards is successfully achieved in the intermediate temperature section, the problems of base metal overburning, brazing filler metal corrosion and the like caused by the too high brazing temperature are avoided, the limitation on the aluminum honeycomb boards due to the adhesive performance is avoided, and a foundation is laid for the later wide application of the intermediate temperature aluminum honeycomb board brazing technology.

Owner:TIANJIN UNIV

Construction curtain wall ceramic

The invention discloses a nanometer ceramic building curtain wall paint which comprises a nanometer oxide, a coloring pigment, an organosilicon curing agent and an auxiliary agent. The paint is characterized by super weathering resistance, scratch resistance, fireproofness, non-inflammability and self-cleaning, etc. The products of the invention are applicable to the hull painting of an outdoor aluminum curtain wall, and an aluminum veneer and an aluminum honeycomb panel which are used for indoor decoration.

Owner:上海金力泰化工股份有限公司

Aluminum honeycomb sandwich plate of high thermal conductivity carbon fiber panel pre-embedded heat pipe and preparation method thereof

ActiveCN106515091ASolve the problem of insufficient shear resistanceImprove cooling effectLaminationLamination apparatusFiberBond interface

The invention provides an aluminum honeycomb sandwich plate of a high thermal conductivity carbon fiber panel pre-embedded heat pipe and a preparation method thereof. The aluminum honeycomb sandwich plate includes high thermal conductivity carbon fiber panels, room temperature cured structural adhesive layers, an aluminum honeycomb core, a foam adhesive, a heat pipe and positioning rivets. The aluminum honeycomb core is internally provided with the heat pipe, the foam adhesive is arranged around the heat pipe, and the high thermal conductivity carbon fiber panels are laid on the upper surface and lower surface of the aluminum honeycomb core respectively through the room temperature cured structural adhesive layers. The invention solves the problem of insufficient shearing resistance of bonding interface caused by thermal expansion coefficient mismatch between an aluminum alloy material heat pipe and a carbon fiber panel material. By utilizing the high rigidity, micro-deformation and high thermal conductivity properties of the material, the application range of the spacecraft carbon fiber material panel aluminum honeycomb plate is further expanded, and the problems of spacecraft on-orbit deformation and high power consumption single-machine heat dissipation are solved.

Owner:SHANGHAI SATELLITE ENG INST

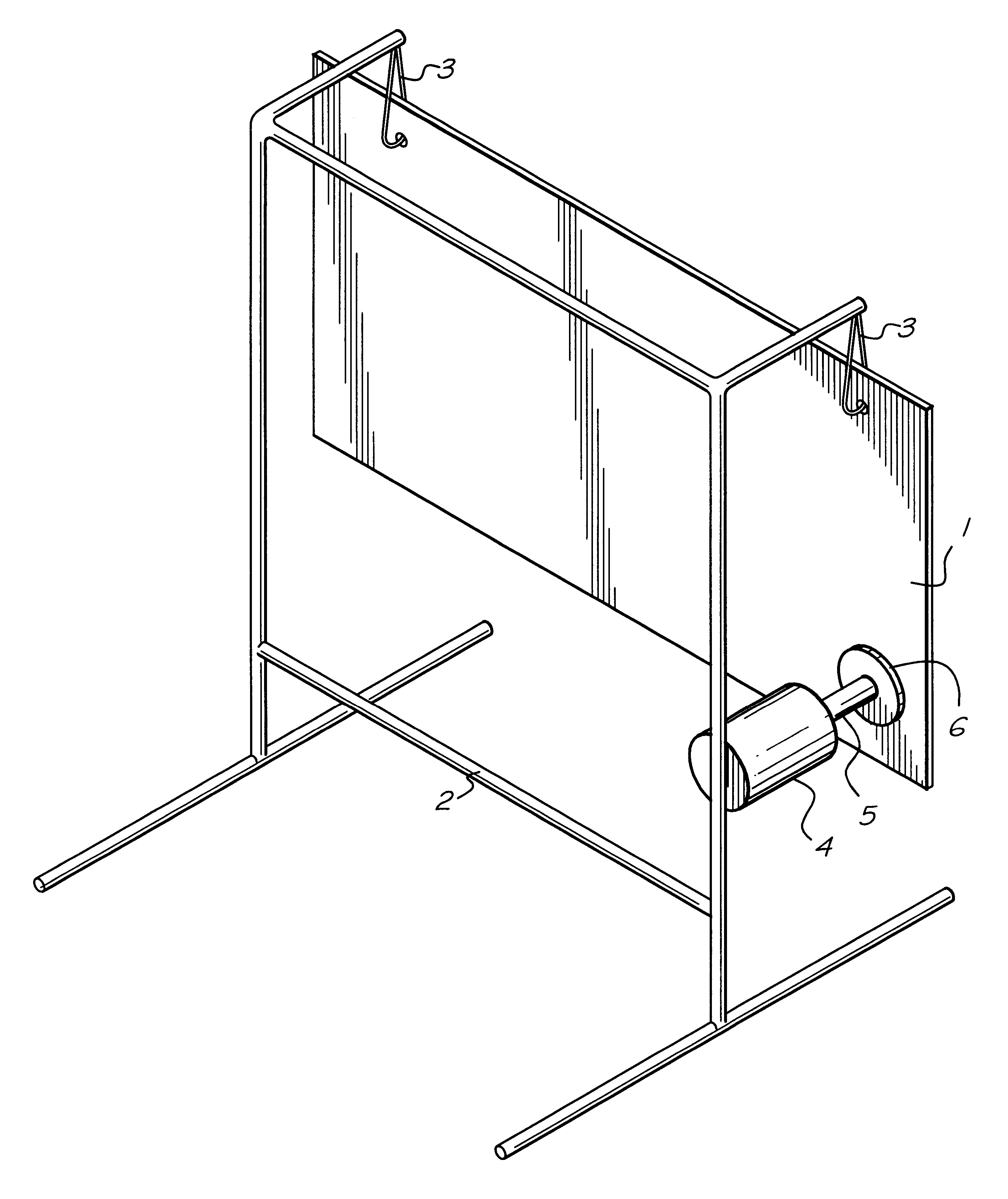

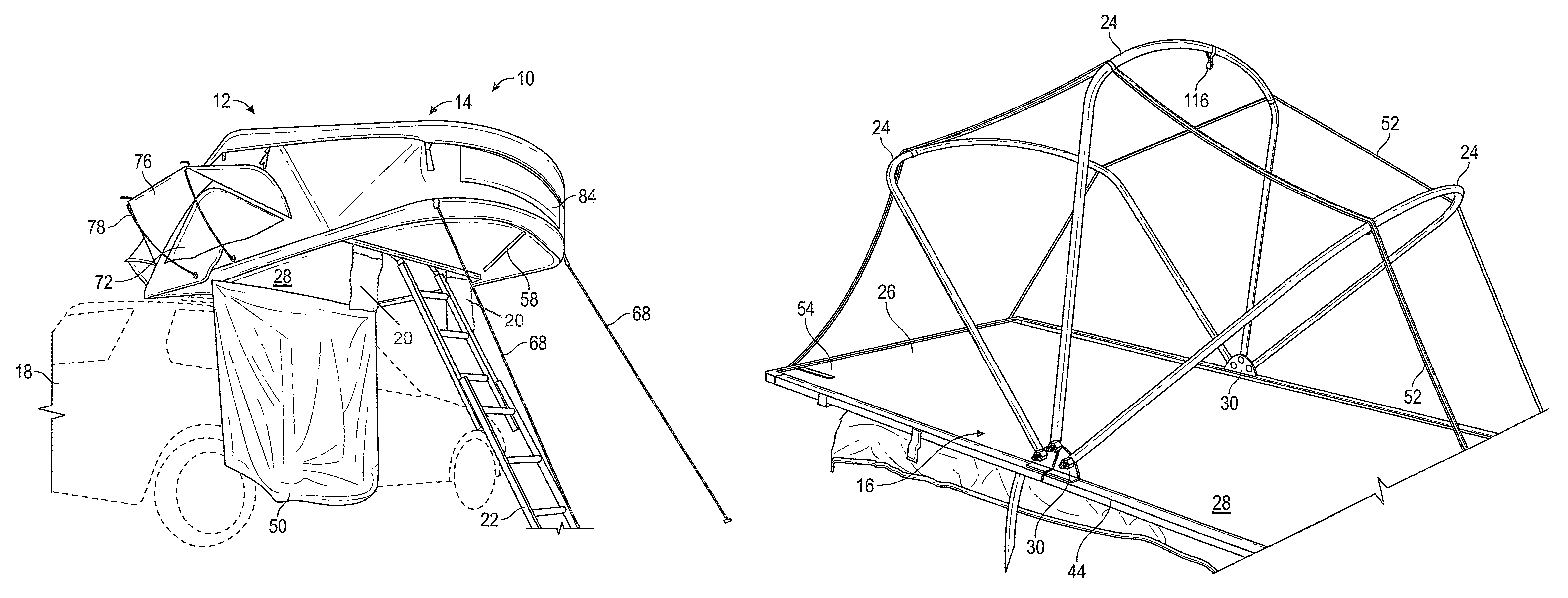

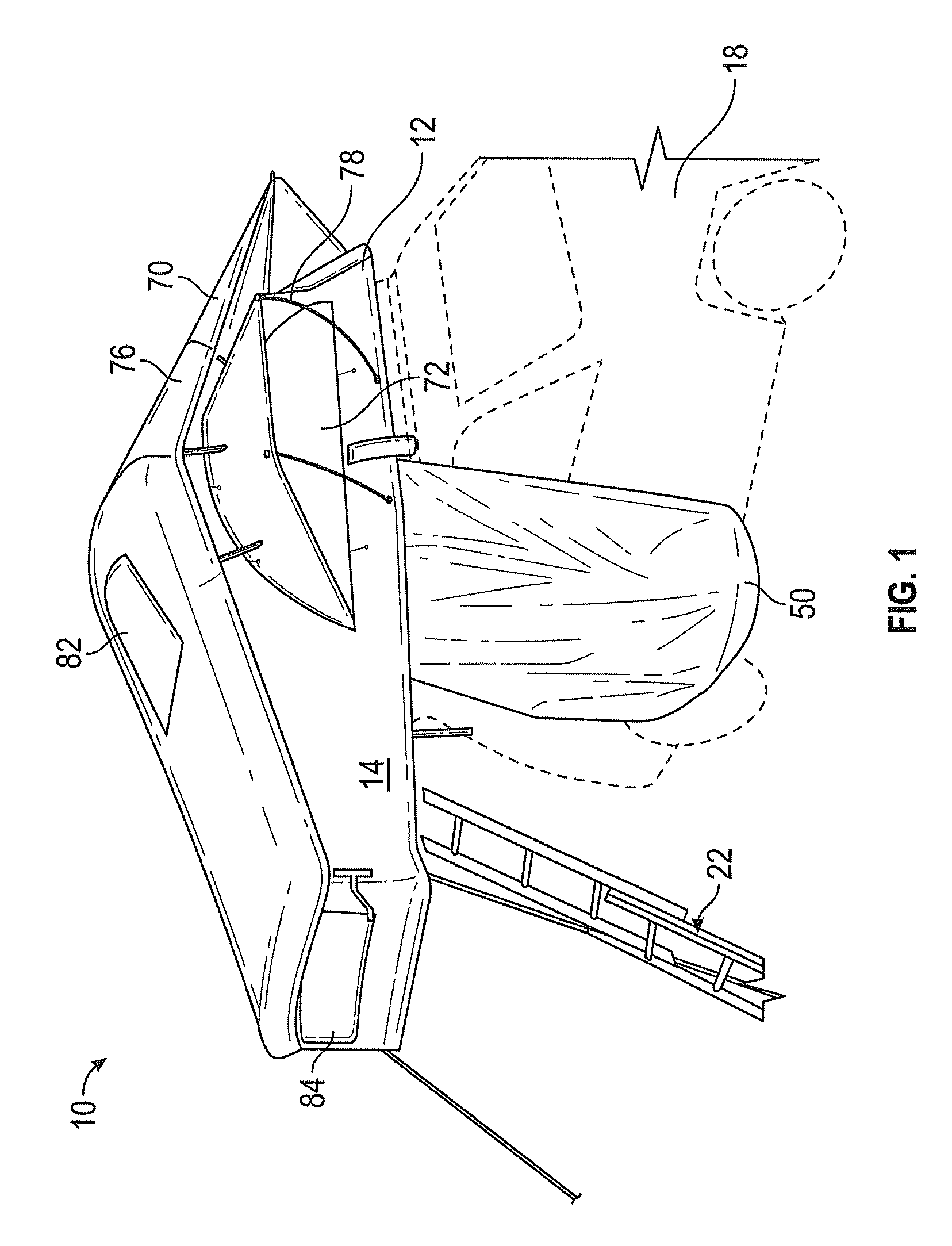

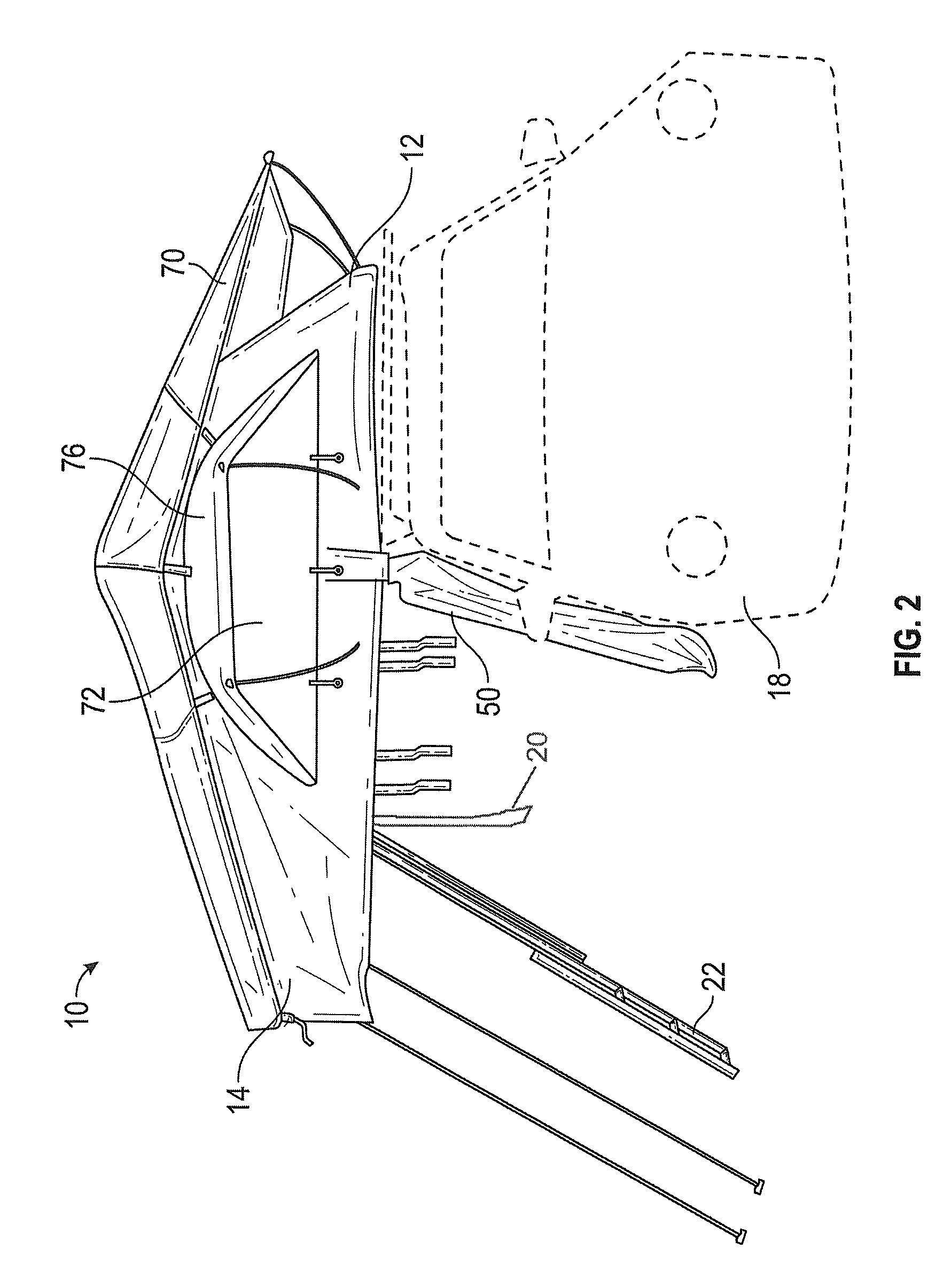

Vehicle roof-top tent

The present invention relates tents, and in particular, relates to various features and accessories for vehicle roof-top tents. The claimed inventions provide many advantages over tents in the prior art. For example, the roof-top design frees up space inside your vehicle, and height acts as a secondary safety defense against wildlife and ground-related elements. Other advantageous aspects of the claimed inventions include a superior curved frame, removable shoe bags, a roll up window awning, semicircular windows, a canopy PVC window, an aluminum honeycomb tent base, an advantageous stowing arrangement for the canopy pole, bungee cord pockets, dual PVC skylights and a quick release mounting for the vehicle roof rack. Other systems, methods, features and advantages of the invention are also described and presented in the figures and detailed description.

Owner:TREELINE OUTDOORS

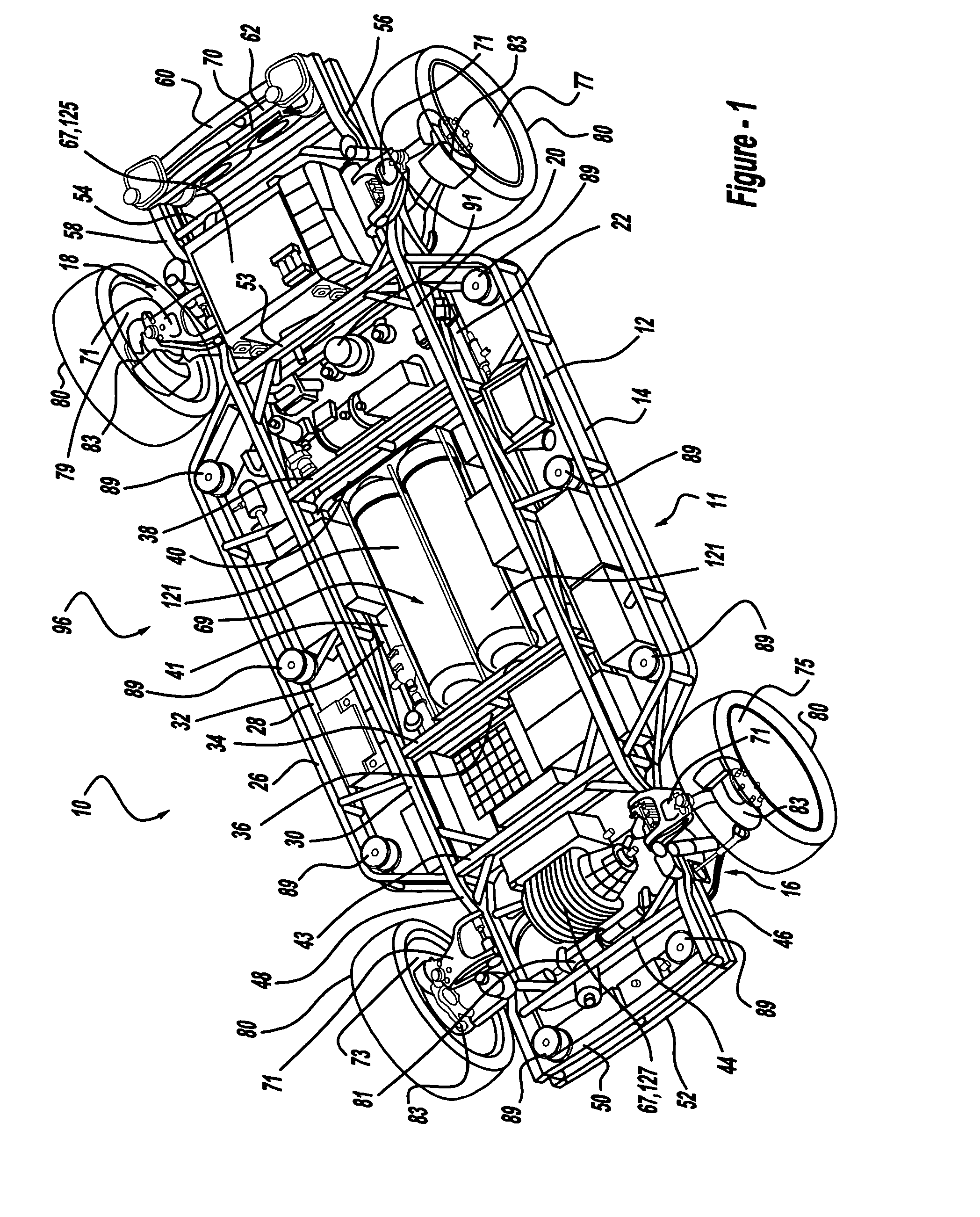

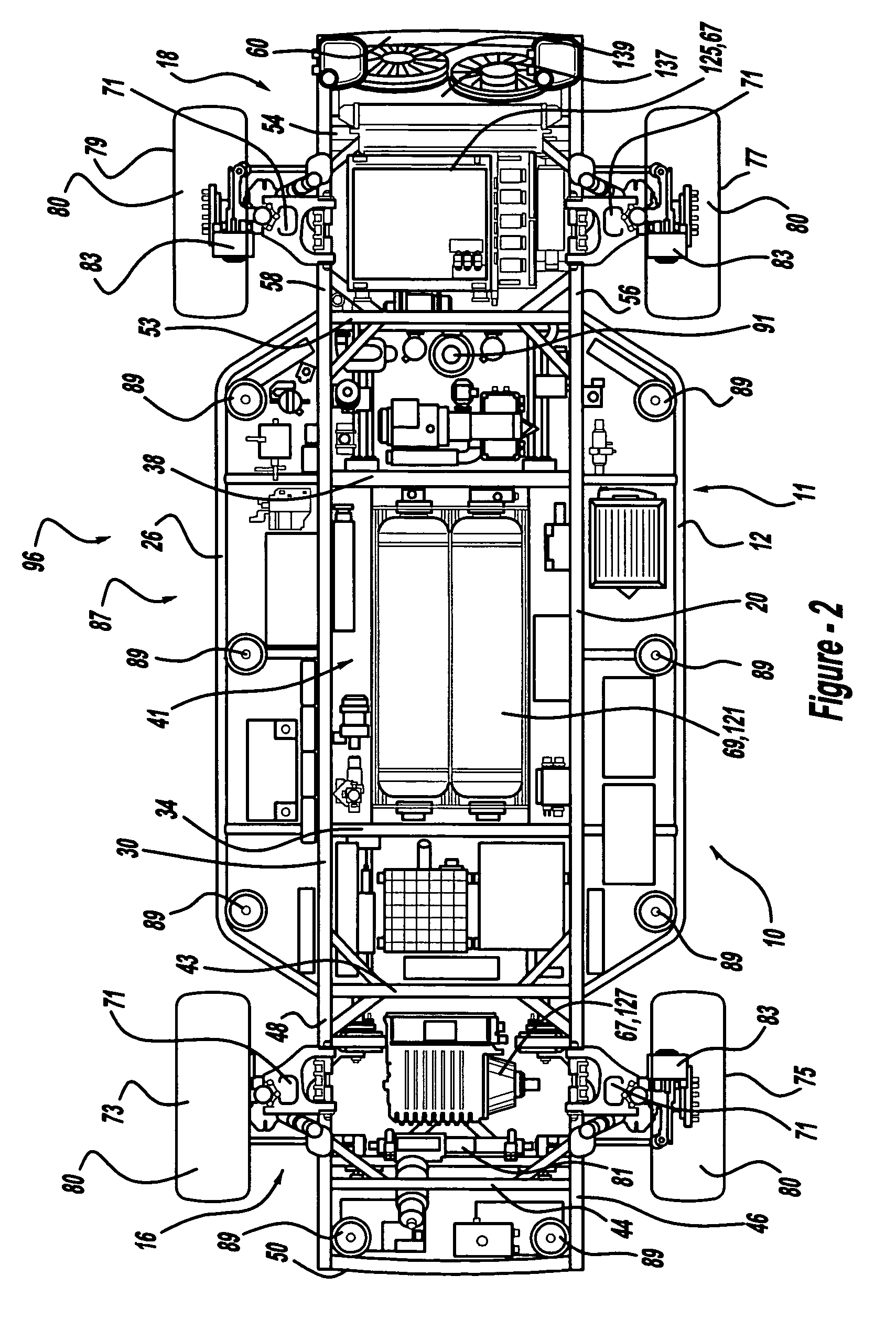

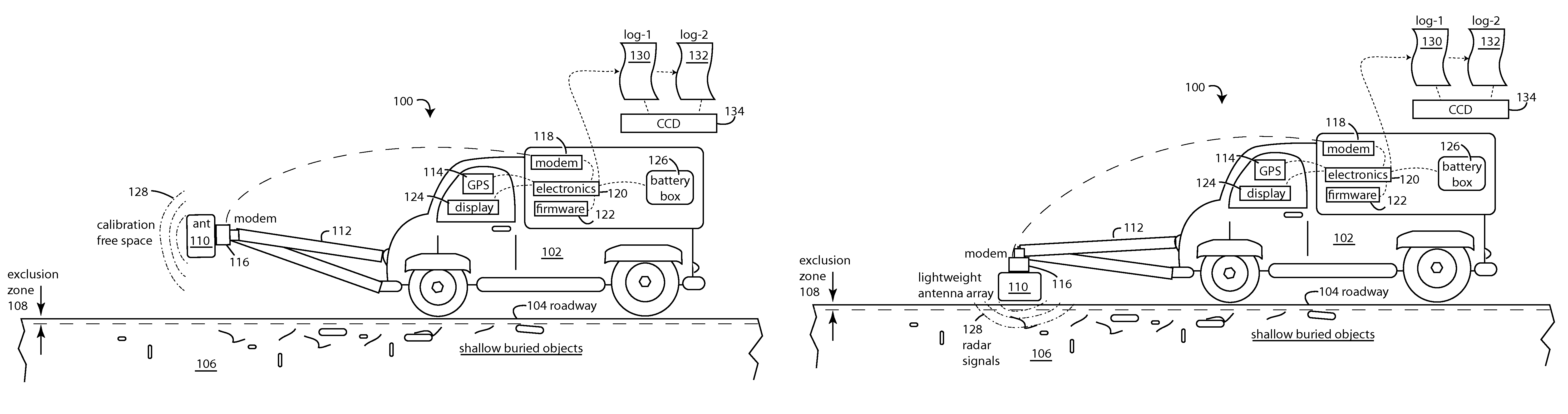

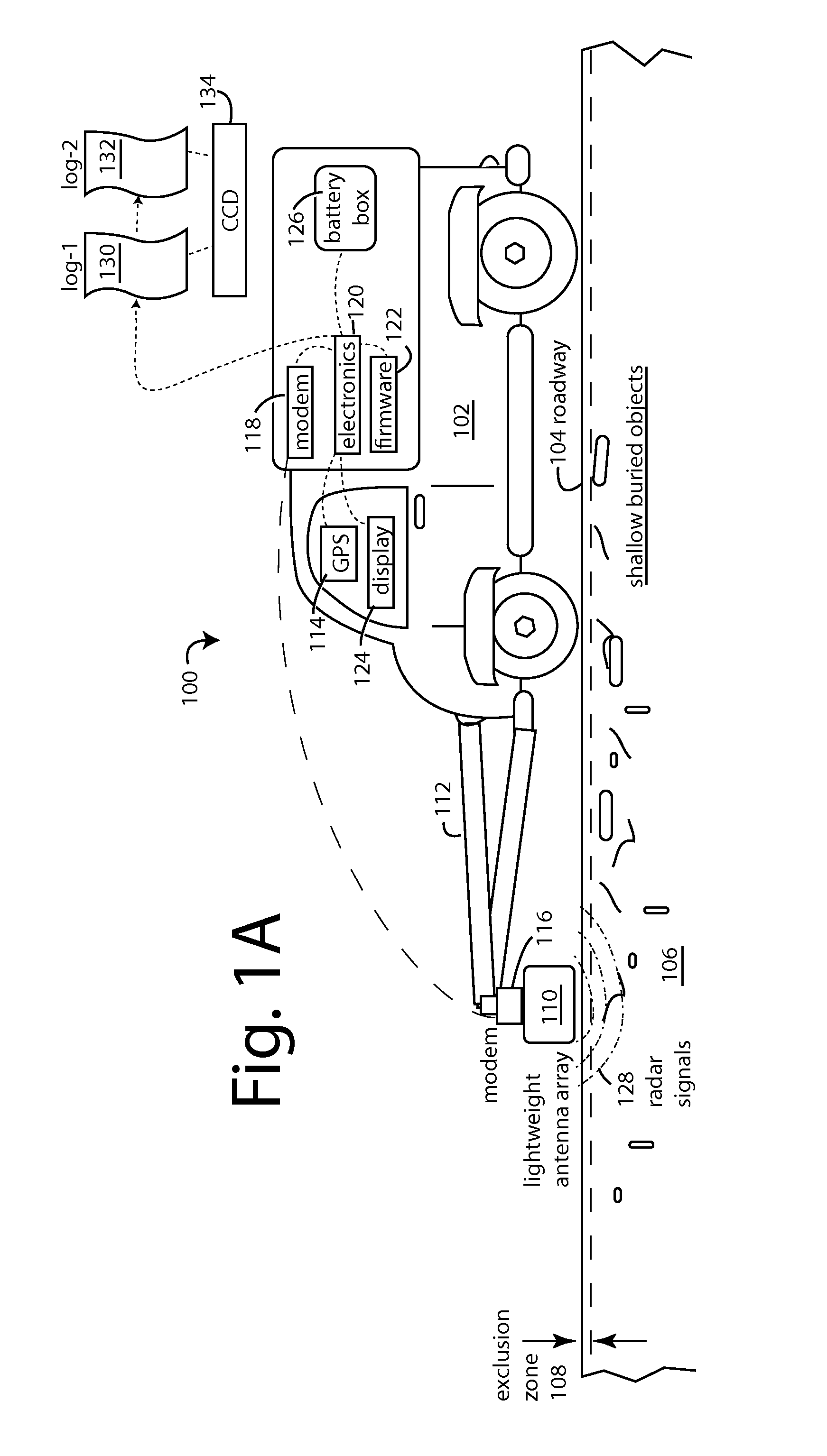

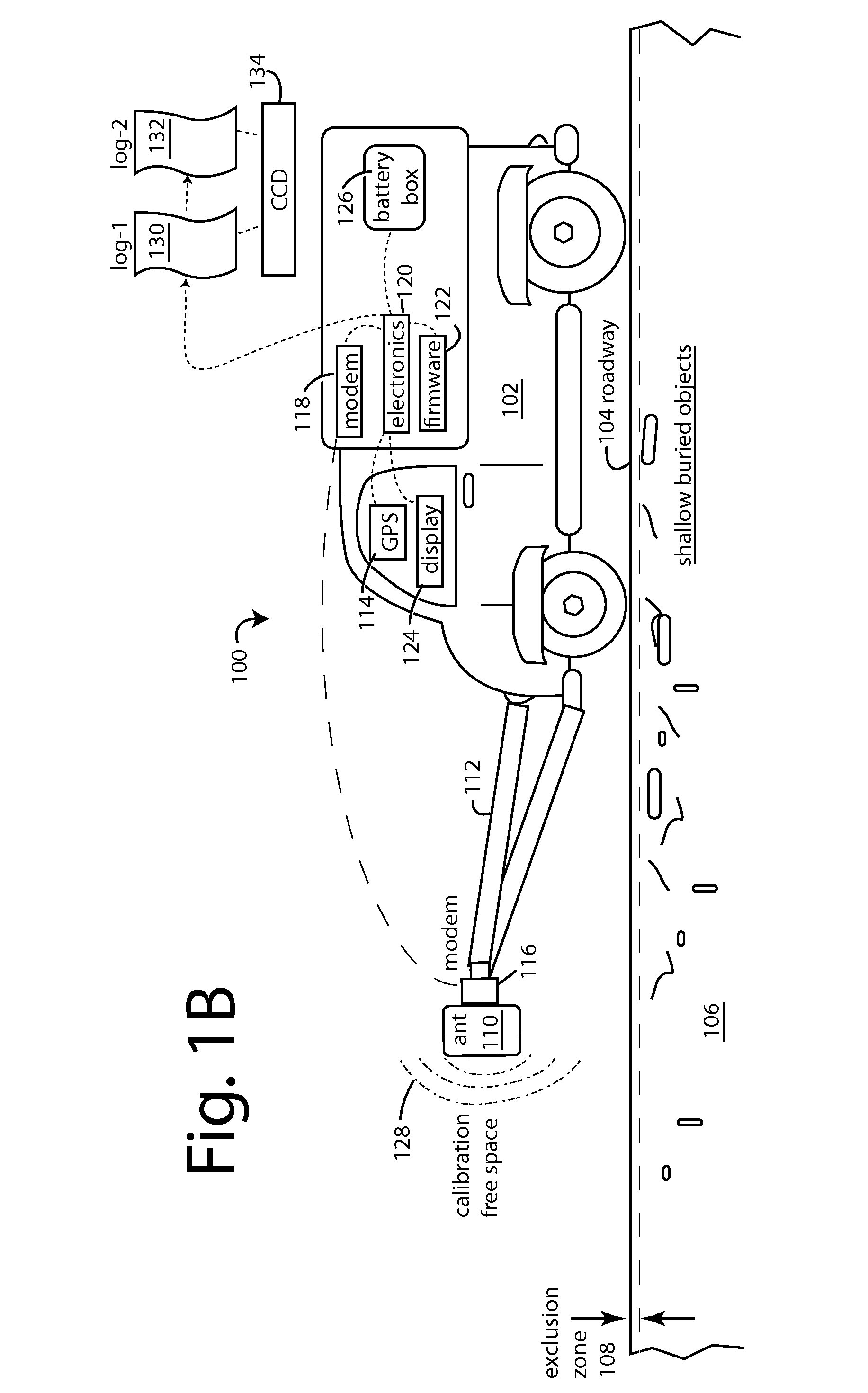

Large area ground monitoring

InactiveUS20140125508A1Improving false positive performanceImprove performanceAntenna arraysAntenna detailsAluminum honeycombGround vehicles

A municipal infrastructure maintenance system uses a ground vehicle to move an antenna array in back-and-forth sweeps over large areas or distances. The antenna array comprises dozens of compartmentalized radio dipole antennas arranged laterally, shoulder-to-shoulder across the width of each sweep. An antenna switch matrix is connected between the antenna array and a ground-penetrating-radar (GPR) set and provides electronic aperture switching and selection, and the ability to laterally register one sweep to the next. The antenna array is extended out in front of the ground vehicle on a pivotable boom, and the cantilevered weight is a primary concern. The antenna array is constructed with aluminum-on-aluminum honeycomb panels slotted and folded around dozens of resistive-card compartment separators. Printed circuit boards with matching baluns are also slotted to receive tabs on the resistive cards, and their dipole elements are resistive loaded to quench crosstalk and near field effects.

Owner:STOLAR

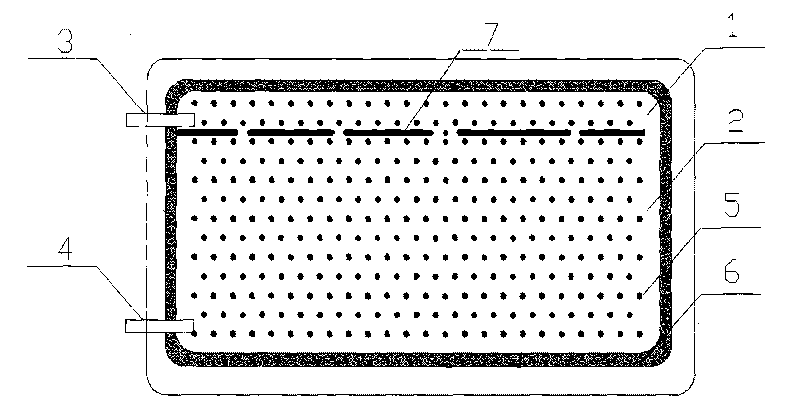

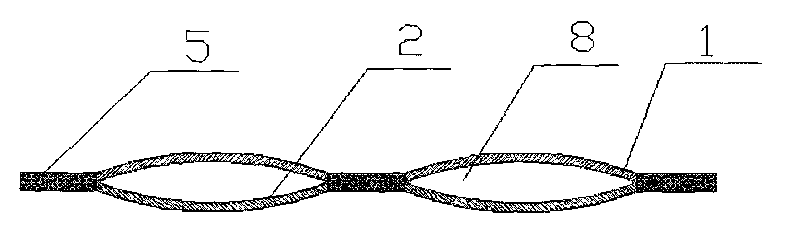

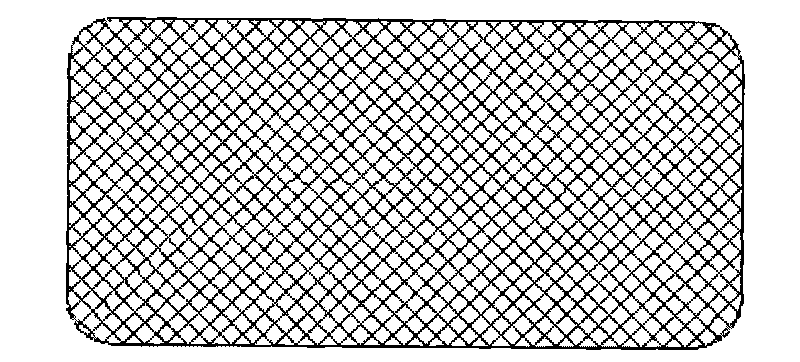

Aluminum honeycomb type evaporation plate and processing molding method thereof

InactiveCN101691978ANot easy to form dead angleLow flow resistanceShaping toolsArc welding apparatusAluminum honeycombEvaporation

The invention discloses an aluminum honeycomb type evaporation plate and a processing molding method thereof. The evaporation plate adopts a high strength aluminum alloy plate and consists of an upper plate, a lower plate, an inlet pipe and an outlet pipe, wherein the two high strength aluminum alloy plates are overlapped and welded together by a solid-phase stir friction connecting method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two high strength aluminum alloy plates and are connected with the high strength aluminum alloy evaporation plate body by using an electric arc welding method; and then the evaporation plate is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

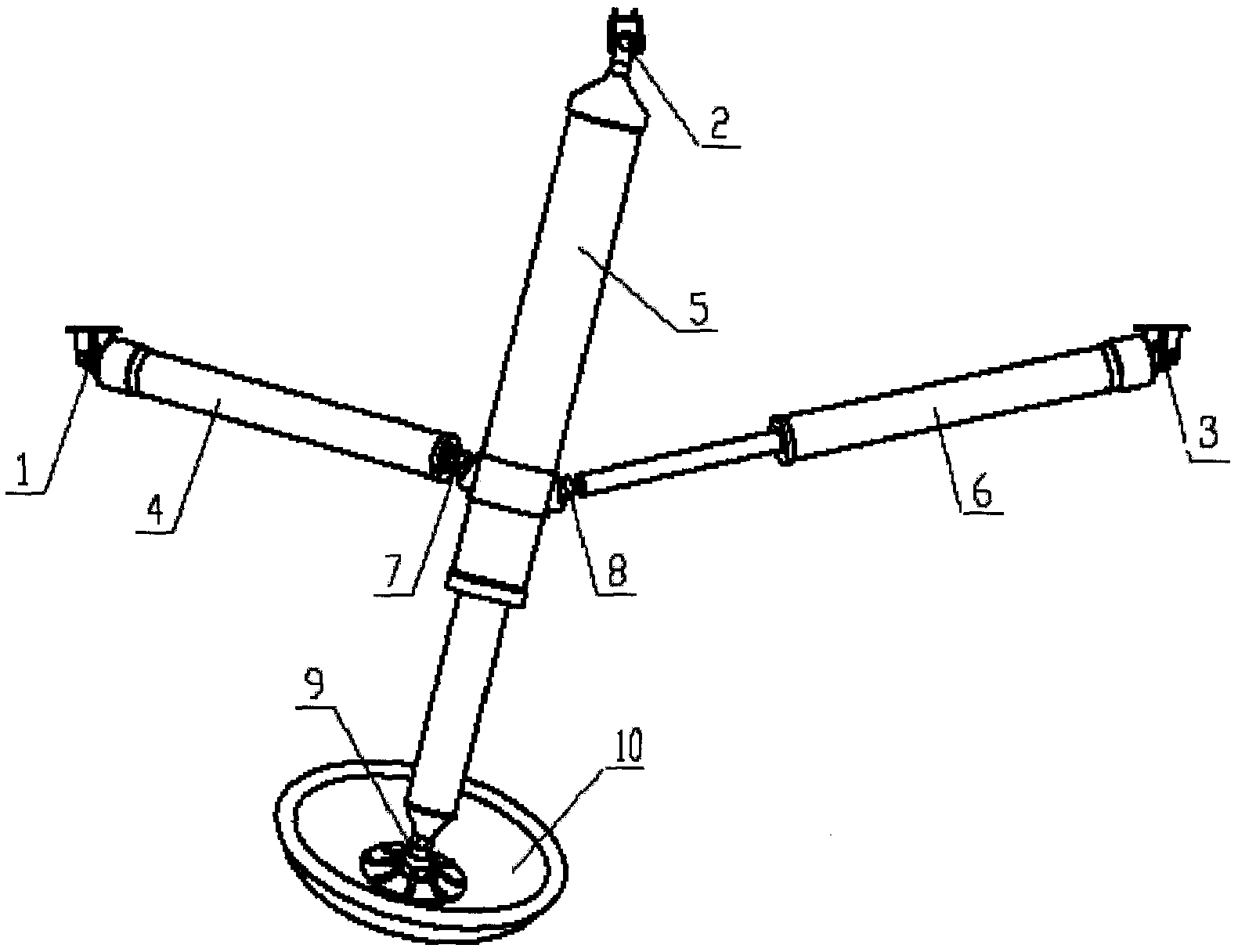

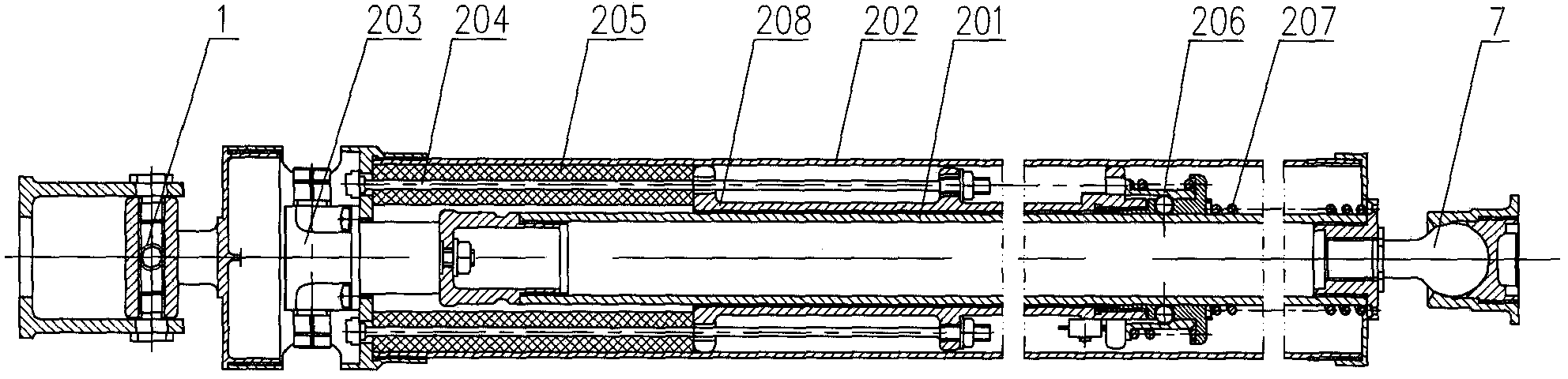

Built-in extension-type landing buffering mechanism

ActiveCN103661965AImprove reliabilitySimple structureAircraft landing aidsEnergy absorptionAluminum honeycomb

The invention provides a built-in extension-type landing buffering mechanism which comprises a first stage piston cylinder, a second stage piston cylinder, a third stage piston cylinder and a fourth stage piston cylinder. An air cavity connected with the top of the first stage piston cylinder is formed in the first stage piston cylinder, an oil cavity is formed in the lower end of the air cavity, and an overflow valve is arranged between the air cavity and the oil cavity. An opening is formed in the upper end of the second stage piston cylinder, the second stage piston cylinder is arranged in the first stage piston cylinder, the lower end of the second stage piston cylinder is connected to a buffering component, and a first buffering material is arranged in the second stage piston cylinder. The first stage piston cylinder and the second stage piston cylinder are located in the third stage piston cylinder, and can move up and down and be locked inside the third stage piston cylinder. The fourth stage piston cylinder is connected to the top of the third stage piston cylinder, a push rod is arranged in the fourth stage piston cylinder, and the lower end of the push rod is arranged on the bottom of the inner portion of the air cavity. According to the built-in extension-type landing buffering mechanism, an oil-air buffering mode is adopted, quite high impact energy can be absorbed, the built-in extension-type landing buffering mechanism can be matched with aluminum honeycomb crushing energy absorption at the same time, and the buffering effect is more efficient. In addition, the built-in extension-type landing buffering mechanism further has the function of unfolding and locking, and can be used repeatedly.

Owner:SHANGHAI AEROSPACE SYST ENG INST

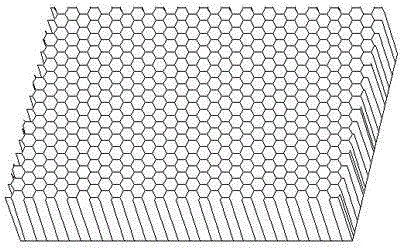

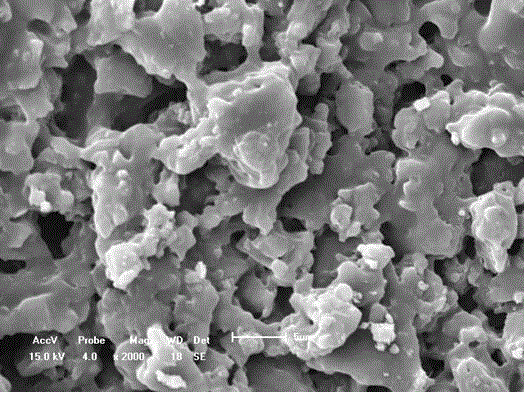

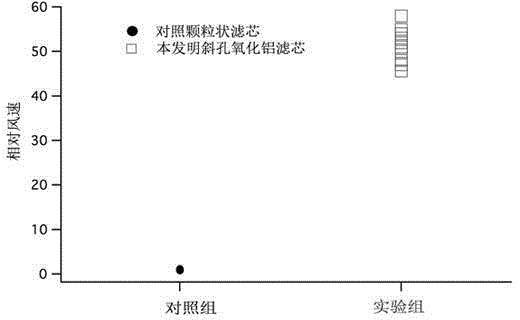

Formaldehyde-removing and air-purifying filter core based on inclined-hole aluminum honeycomb plate and preparation method thereof

ActiveCN104689708AReduce wind resistanceFast removalDispersed particle separationCoatingsActivated carbonAdhesive

The invention discloses a formaldehyde-removing and air-purifying filter core based on an inclined-hole aluminum honeycomb plate. The formaldehyde-removing and air-purifying filter core based on the inclined-hole aluminum honeycomb plate comprises a formaldehyde-removing coating and an aluminum honeycomb plate. The aluminum honeycomb plate is a plate-like body consisting of hexagonal pore passages; and an included angle between each of the hexagonal pore passages and a vertical direction of the front side of the plate-like body is 5-20 degrees. The formaldehyde-removing coating is prepared by coating, drying and solidifying a formaldehyde-removing dope onto inner surfaces of the hexagonal pore passages. The formaldehyde-removing dope is a mixture. Ingredients of the mixture comprise active carbon, calcium peroxide, calcium oxide, manganese dioxide, potassium carbonate, and an adhesive. The invention further discloses a preparation method of the formaldehyde-removing and air-purifying filter core based on the inclined-hole aluminum honeycomb plate. The provided formaldehyde-removing and air-purifying filter core based on the inclined-hole aluminum honeycomb plate is able to achieve a formaldehyde-removing rate of up to 93% within 2.5 minutes, and a formaldehyde-removing rate in the air of up to 100% within 10 minutes. Comparing to grained formaldehyde-removing fillers, the windage resistance is reduced by 98%. The formaldehyde-removing and air-purifying filter core based on the inclined-hole aluminum honeycomb plate is characterized in a high formaldehyde-removing efficiency, a high-temperature resistance, a low air resistance, anti-corrosion property, a long service life, and the like.

Owner:陶猛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com