Method for manufacturing aluminum honeycomb core

A manufacturing method and technology of aluminum honeycomb, applied in chemical instruments and methods, lamination devices, lamination and other directions, can solve the problems of easy separation, easy loosening, and take a long time, and achieve the effect of firm bonding and difficult separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

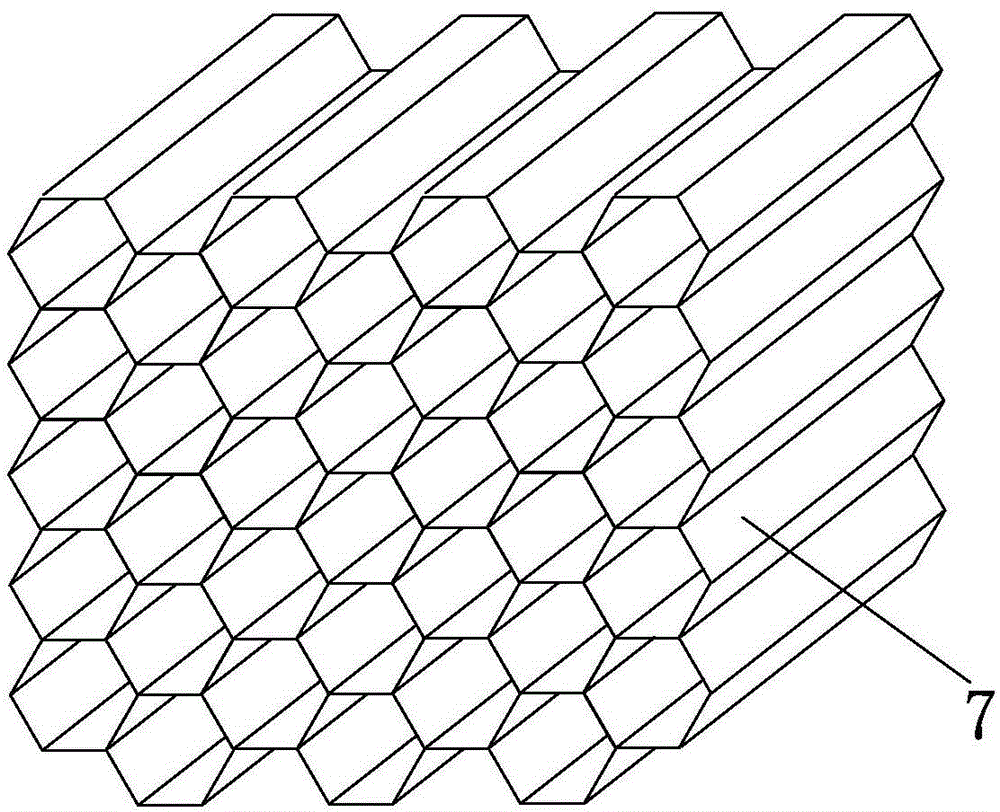

[0026] The following combination Figure 1 to Figure 3 To further illustrate the present invention, the following examples only represent one or several best implementation modes, and should not be construed as limiting the present invention.

[0027] The steps of the aluminum honeycomb core manufacturing process provided by the invention are as follows:

[0028] (1) Clean the strip-shaped aluminum foil used to make the aluminum honeycomb core with ultrasonic waves, wherein the ultrasonic power is 0.75KW, the frequency is 50Mz, and the cleaning speed is 23m / min.

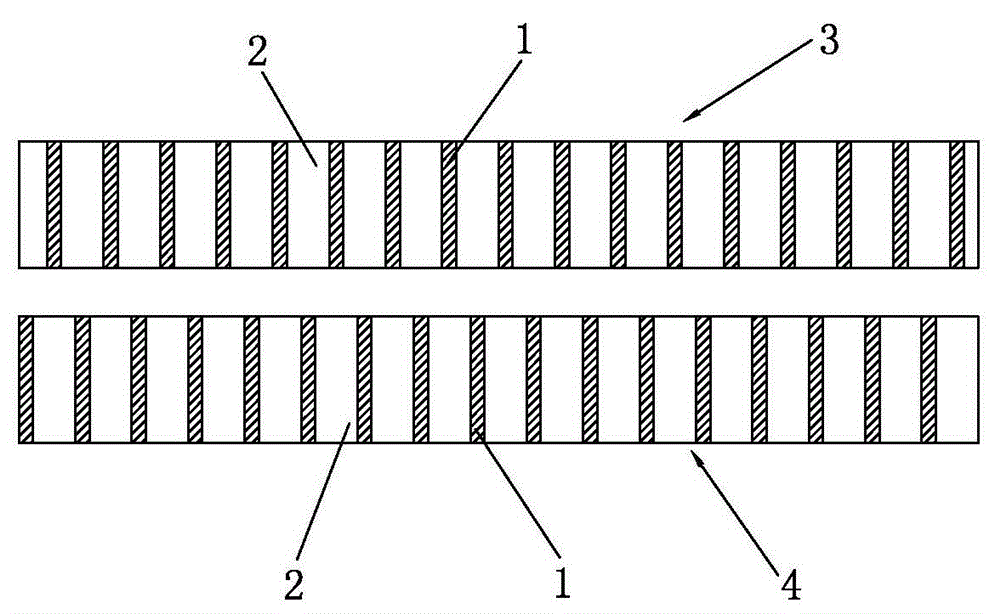

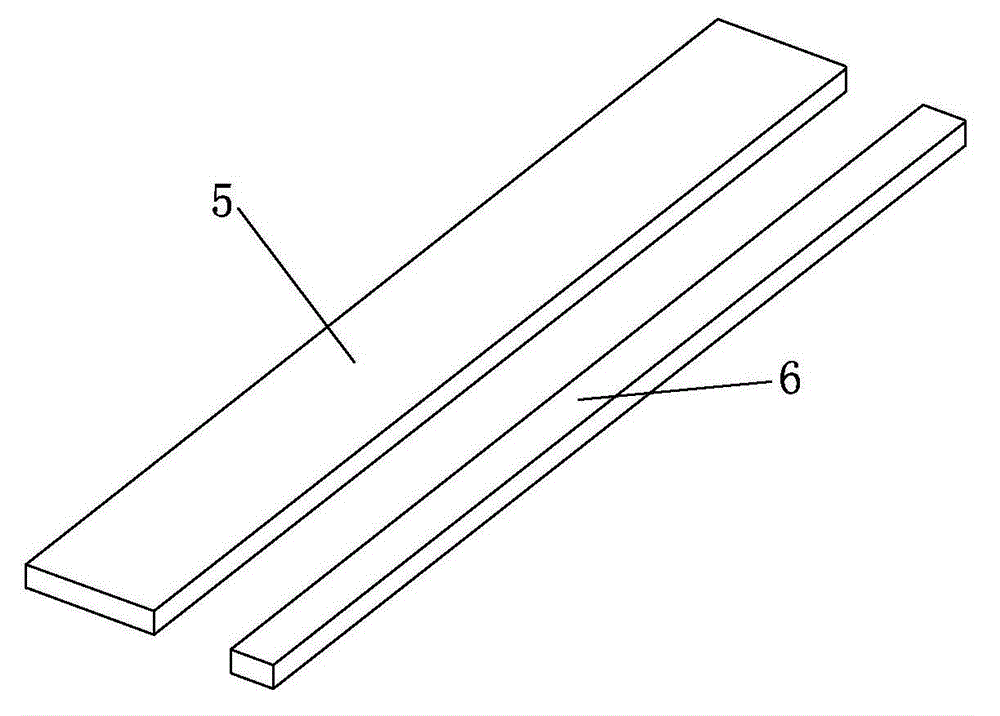

[0029] (2) Apply glue to one side of the strip-shaped aluminum foil, and form multiple glue-coated areas 1 with equal areas on the surface of the strip-shaped aluminum foil. These glue-coated areas 1 are long strips and parallel to each other. The area without glue between them is the non-glue area 2, the width direction of the glue-coated area 1 and the non-glue area 2 is the same and parallel to the length directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com