Macro/micro driven large travel high-speed nano-precision plane positioning system

A plane positioning, large stroke technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of insufficient stroke, speed/acceleration and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

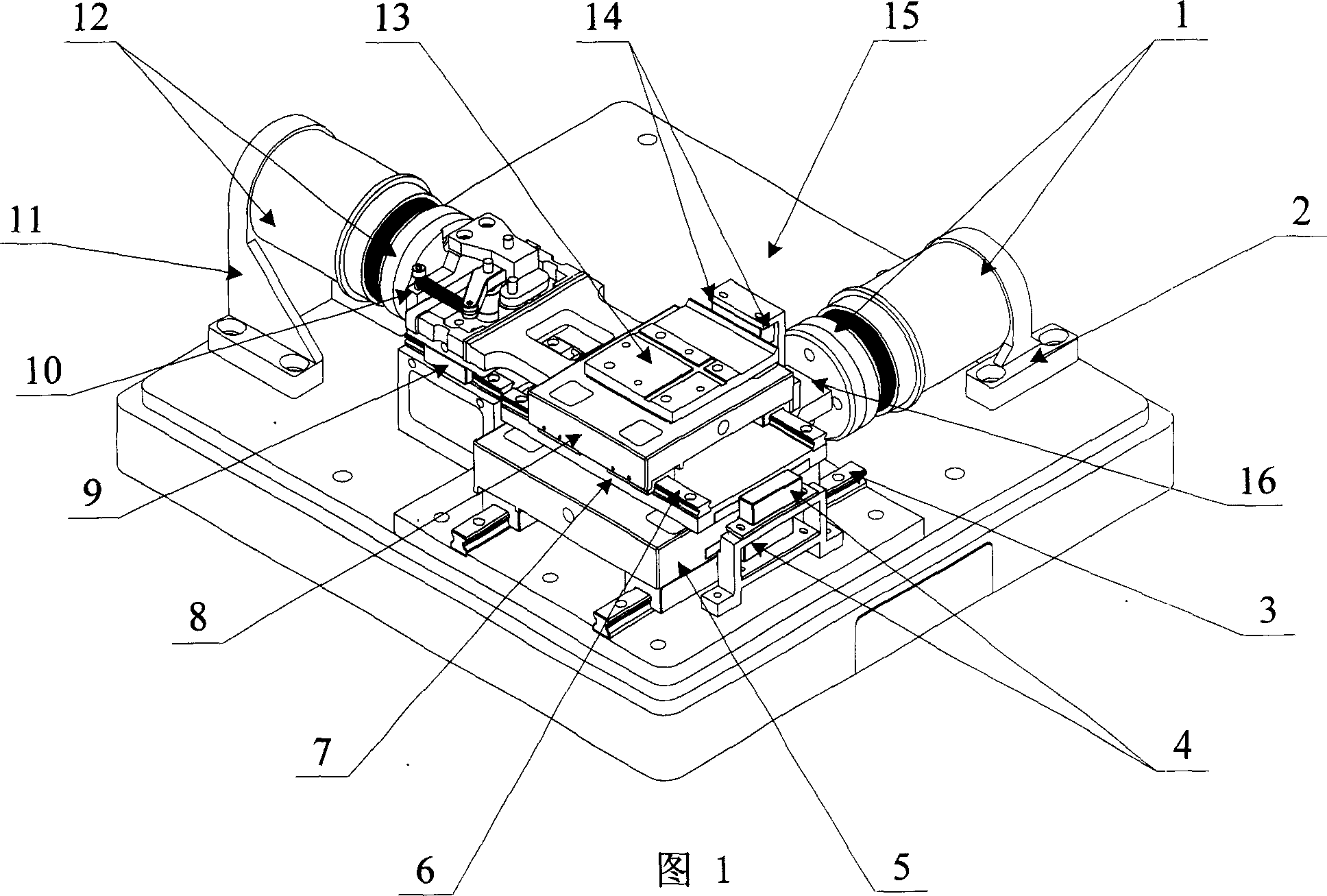

[0005] Specific embodiment one: (see Figure 1- Figure 6 ) This embodiment consists of X-axis linear voice coil motor (mover / stator) 1, X-axis motor base 2, X-axis guide rail 3, X-axis dual linear grating 4, X-axis macro / micro motion platform 5, Y-axis guide rail 6. Y-bearing bearing stage 7, Y-axis macro / micro-motion stage 8, XY-axis decoupling guide rail 9, XY-axis decoupling mechanism 10, Y-axis motor base 11, Y-axis linear voice coil motor (mover / stator) 12. The working platform 13, the Y-axis double linear grating 14 and the base 15, the stator of the X-axis linear voice coil motor 1 is fixed on the X-axis motor base 2, and the X-axis motor base 2 is fixed on the base 15. The stator of the Y-axis linear voice coil motor 12 is fixed on the Y-axis motor base 11, the Y-axis motor base 11 is fixed on the base 15, the mover of the X-axis linear voice coil motor 1 and the X-axis macro / micro motion platform 5Fixed connection, the mover of the Y-axis linear voice coil motor 12 is fix...

specific Embodiment approach 2

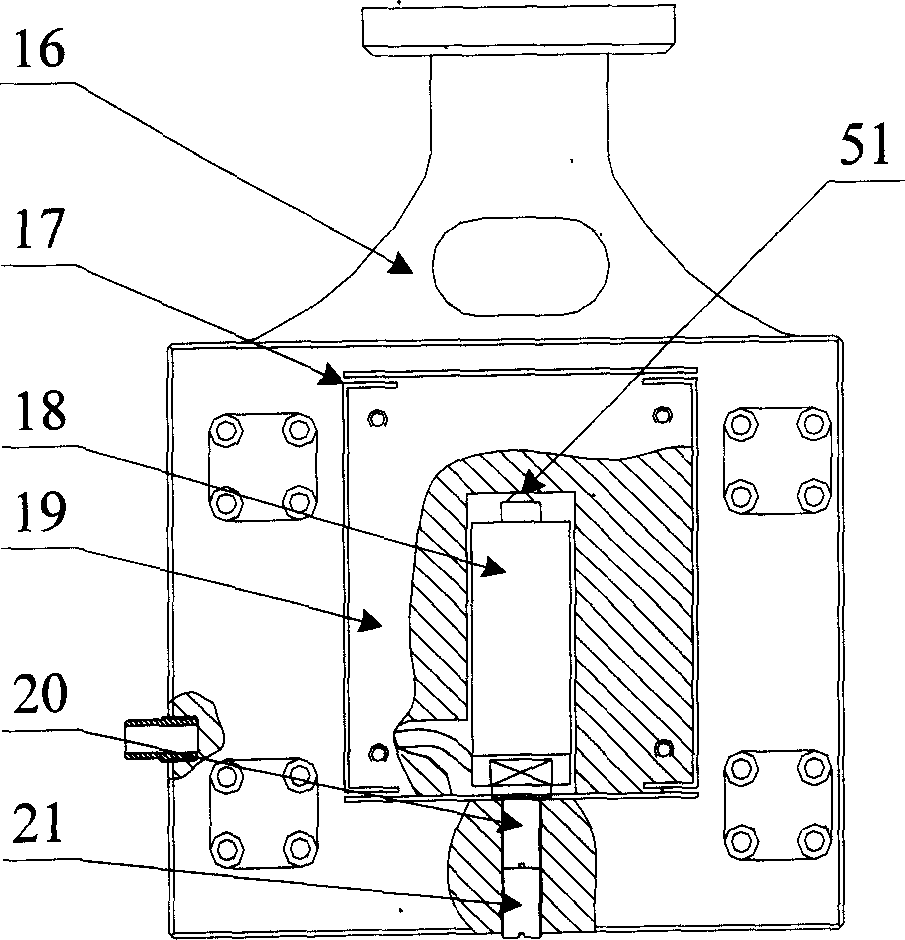

[0006] Specific implementation manner two: (see figure 2 ) In this embodiment, the end of the X-axis piezoelectric ceramic 18 connected to the X-axis micro-motion platform 19 is a spherical shape 51. The other composition and connection relationship are the same as in the first embodiment.

specific Embodiment approach 3

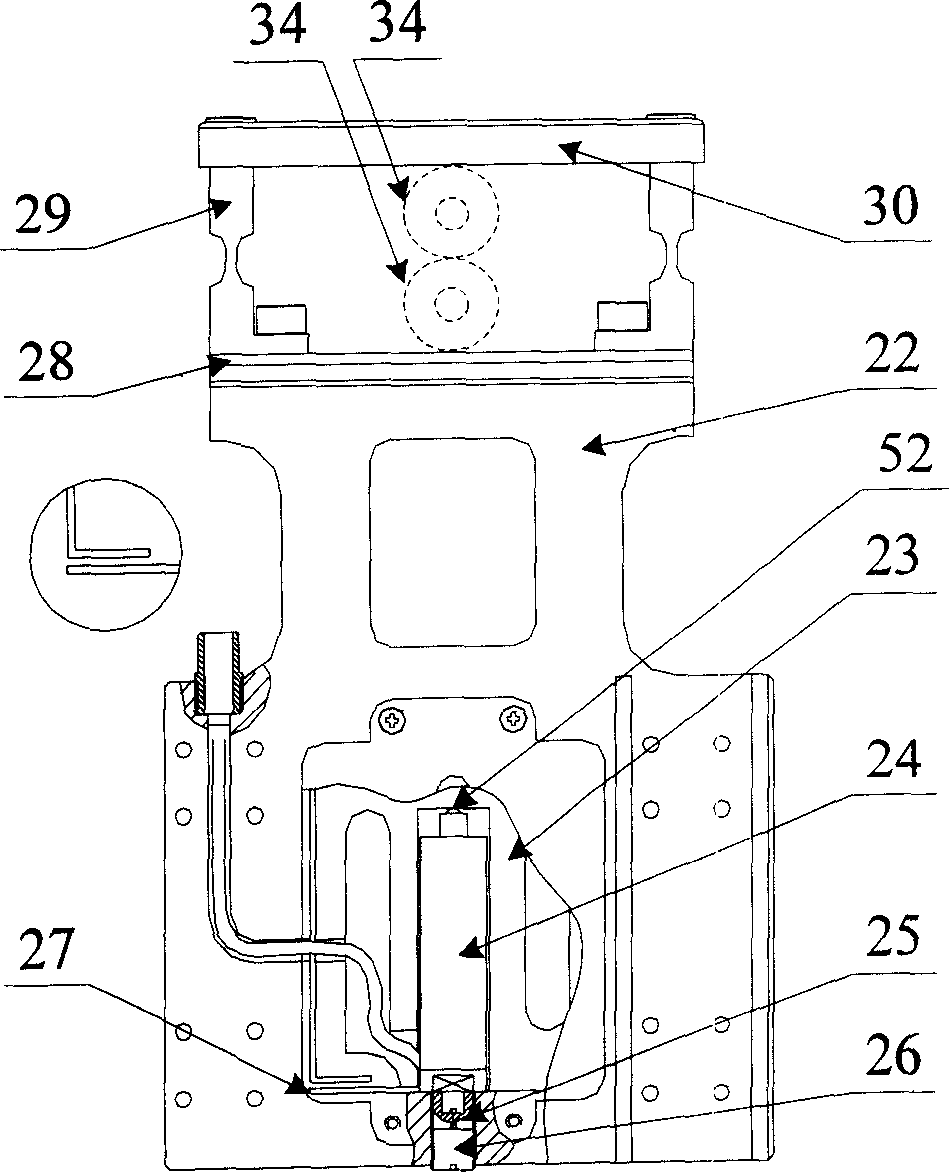

[0007] Specific implementation manner three: (see image 3 ) In this embodiment, the end of the Y-axis piezoelectric ceramic 24 connected to the Y-axis micro-motion platform 23 is a spherical 52. The other composition and connection relationship are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com