Calibration device of laser alignment device and method for measuring indication errors of laser alignment device through calibration device

A technology for calibrating equipment and indication errors, which is applied to measuring devices, instruments, and optical devices, can solve the problems of inability to measure indication errors, unreliable evaluation of measurement values, and poor operability, so as to avoid loss of precision and prevent Accidental crash, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

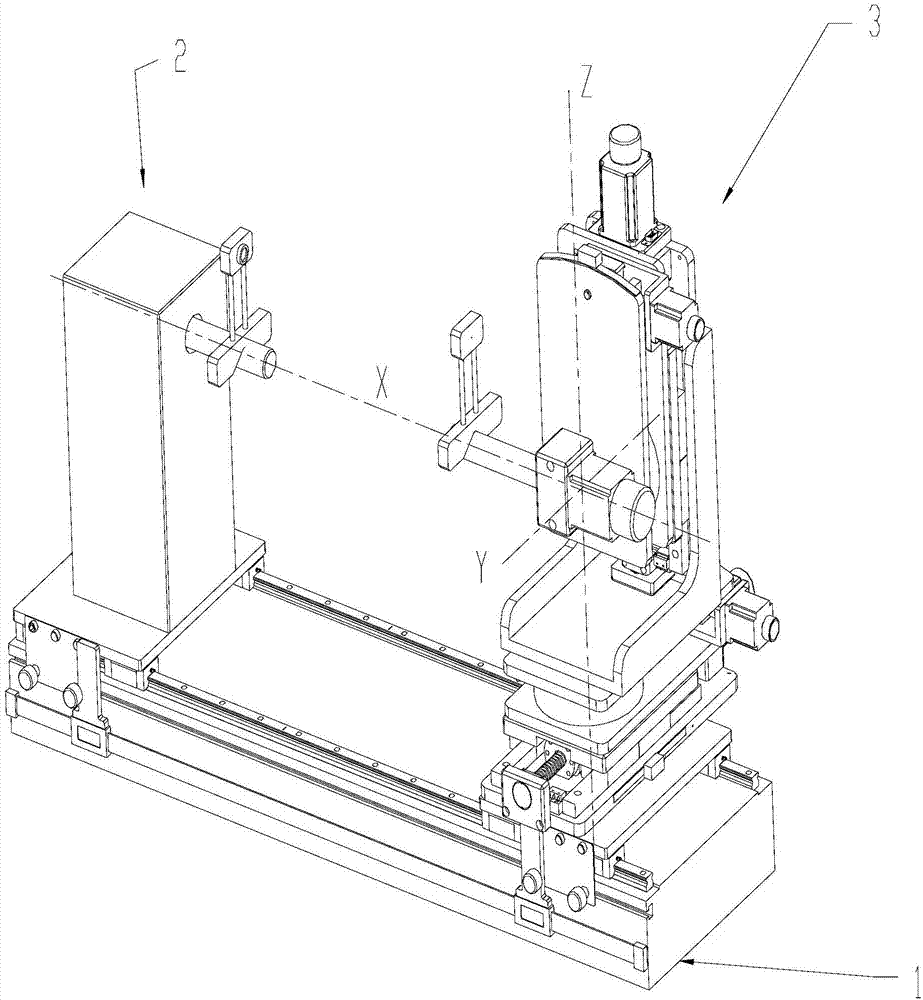

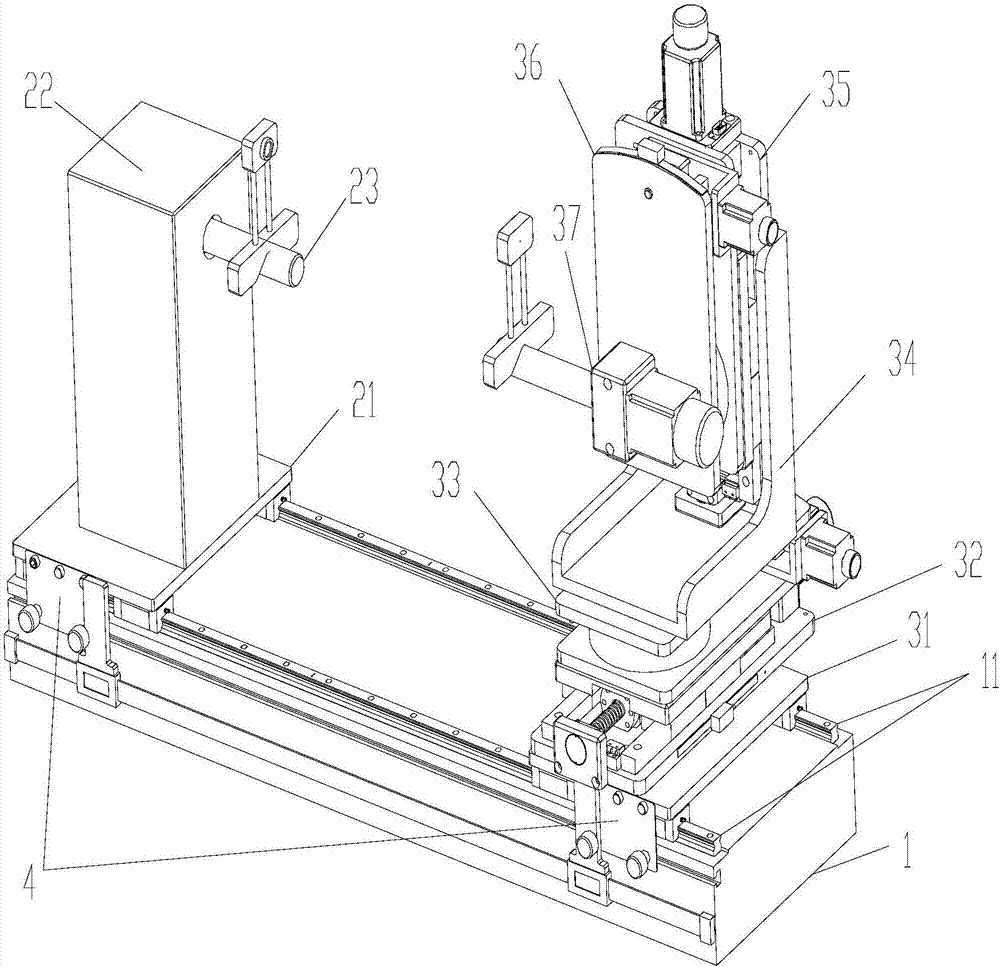

[0037] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

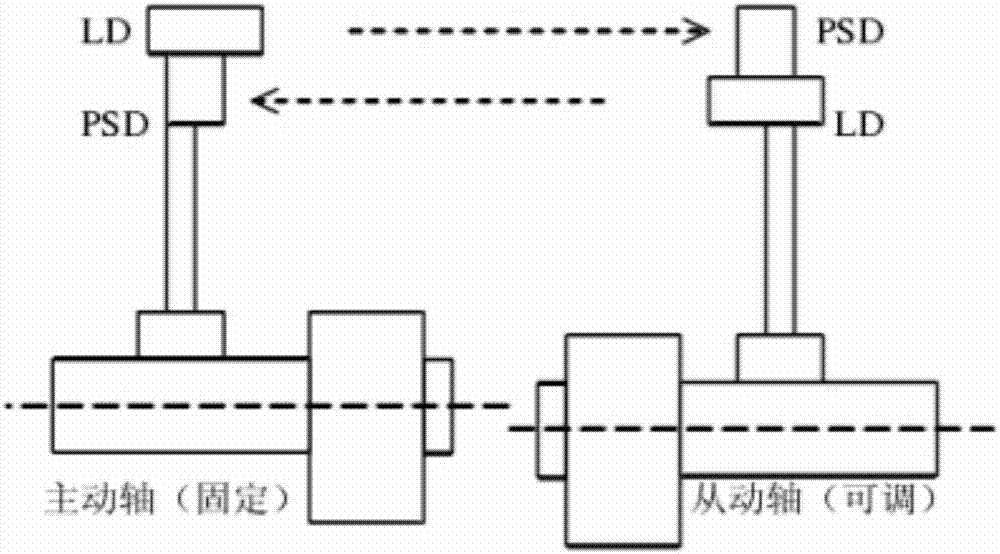

[0038] The laser alignment instrument can realize functions such as automatic collection of data, automatic processing of data, and real-time display of the adjustment value. CCD) and inclinometer, its working principle is: the beam emitted by the laser forms a track on the position sensitive sensor, if the relative position of the measured object changes, the position of the position sensitive sensor (coordinate value of PSD or CCD) will change, The display system of the laser alignment instrument automatically performs data processing and compensation according to the coordinates collected by the position sensitive sensor, the angle of inclinometer, the distance from the manually input laser transmitter to the receiving surface of the position sensitive sensor, and the mathematical relationship model of the centering deviation. , and then get the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com