Biological seedling growing matrix

A seedling-raising substrate and biological technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of difficult realization and immature earthworm breeding technology, and achieve the effect of less disease, reduced dosage, and good growth of seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

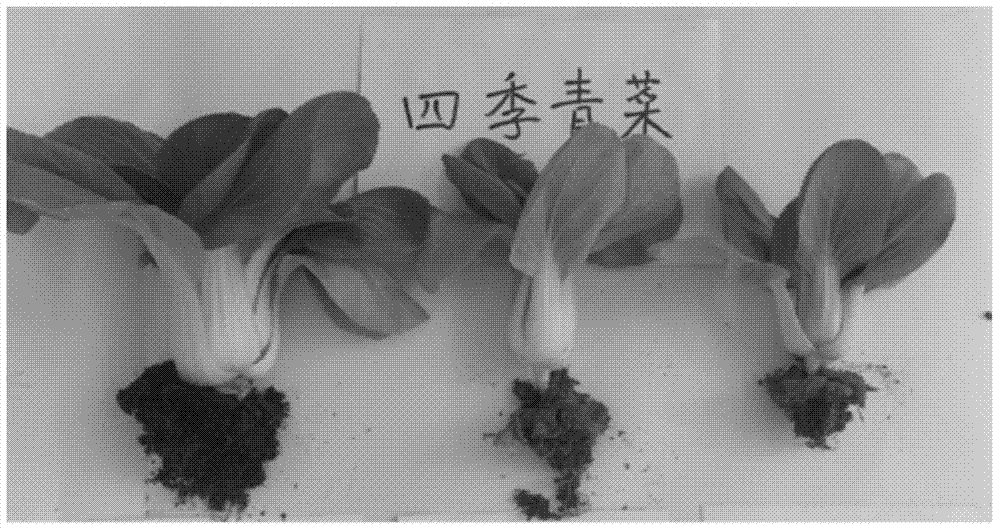

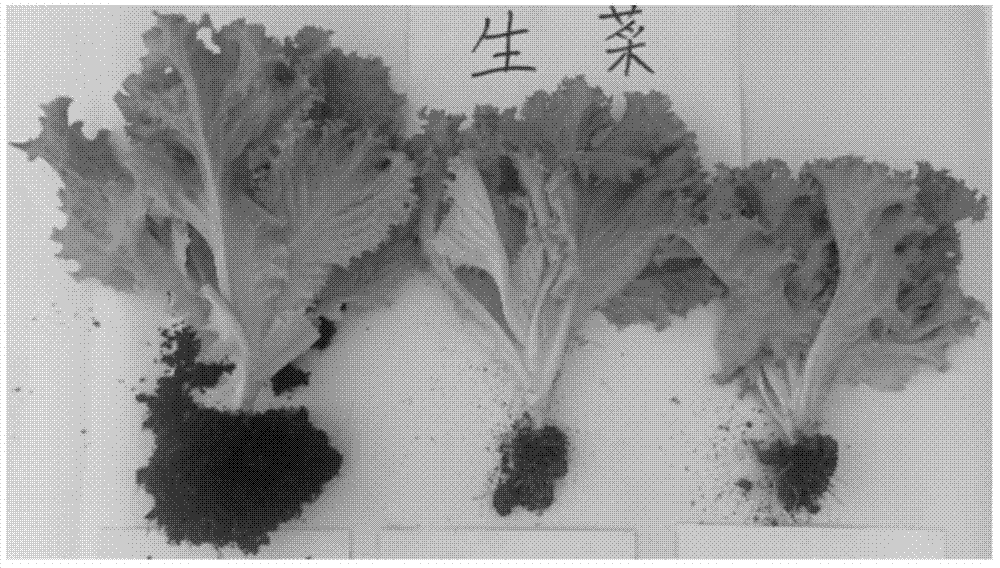

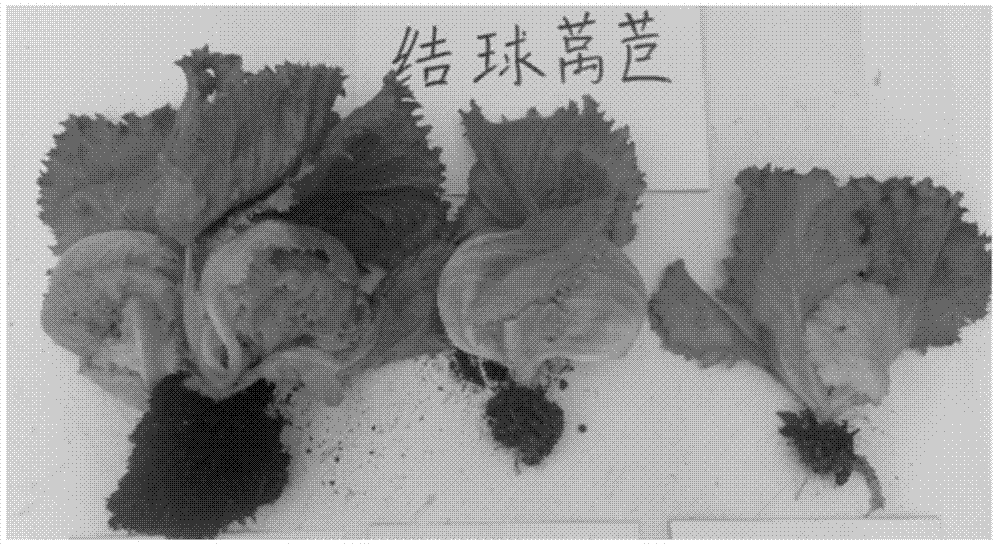

Image

Examples

Embodiment 1

[0053] Mix cow manure and pig manure at a ratio of 1:1, adjust the water content to 55wt%, accumulate and decompose, control the temperature of the fermentation heap at 50-55°C until the temperature of the fermentation heap drops to ambient temperature, air-dry and pulverize the fermented product .

[0054] Take 65kg of the above-mentioned fermentation product, mix it with 22kg of peat, 18kg of plant ash, and 10kg of sargassum to obtain 115kg of organic substrate.

[0055] 100kg of vermiculite, 100kg of perlite, 20kg of slag, 20kg of ceramsite, and 20kg of polystyrene particles were mixed, and then divided into five parts for grinding, and the average particle sizes were 0.5mm, 0.75mm, 1.4mm, 2.26mm, and 2.51mm respectively. Inorganic substrate, the above five substrates are mixed according to the weight ratio of 1:3:2:1.5:2 to obtain an inorganic substrate, 50kg is taken for later use.

[0056] 40g of ammonium chloride, 20g of potassium sulfate, and 15g of superphosphate are...

Embodiment 2

[0058] Get 65kg of the fermentation product described in Example 1, mix with 22kg of peat, 18kg of plant ash, 10kg of sargassum, and 10kg of bagasse to obtain 125kg of organic substrate.

[0059] Get 50kg of the inorganic matrix described in Example 1 for subsequent use.

[0060] 40g of ammonium chloride, 20g of potassium sulfate, and 15g of superphosphate are mixed with the above-mentioned inorganic matrix and organic matrix materials, pulverized and dried.

Embodiment 3

[0075] Get 80kg of the fermentation product described in Example 1, mix it with 25kg of peat charcoal, 20kg of plant ash, and 5kg of humic acid to obtain 130kg of organic substrate.

[0076] 100kg of vermiculite, 120kg of perlite, 30kg of slag, 20kg of ceramsite, 25kg of polystyrene particles, mixed, and then divided into five parts for grinding to obtain average particle sizes of 0.5mm, 0.7mm, 1.25mm, 2.25mm, 2.53mm The above five kinds of substrates were mixed according to the weight ratio of 1:3:2:1.6:1.6 to obtain the inorganic substrate, and 60kg was taken for later use.

[0077] 40g of ammonium chloride, 20g of potassium sulfate, and 15g of superphosphate are mixed with the above-mentioned inorganic matrix and organic matrix materials, pulverized and dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com