Patents

Literature

237 results about "Inorganic matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic matrix. The inorganic matrix of bone consists of a calcium hydroxyapatite, which is in a crystalline structure. This serves to: Mineralize the osteoid produced by osteoblasts, Provide strength and hardness to the bone,

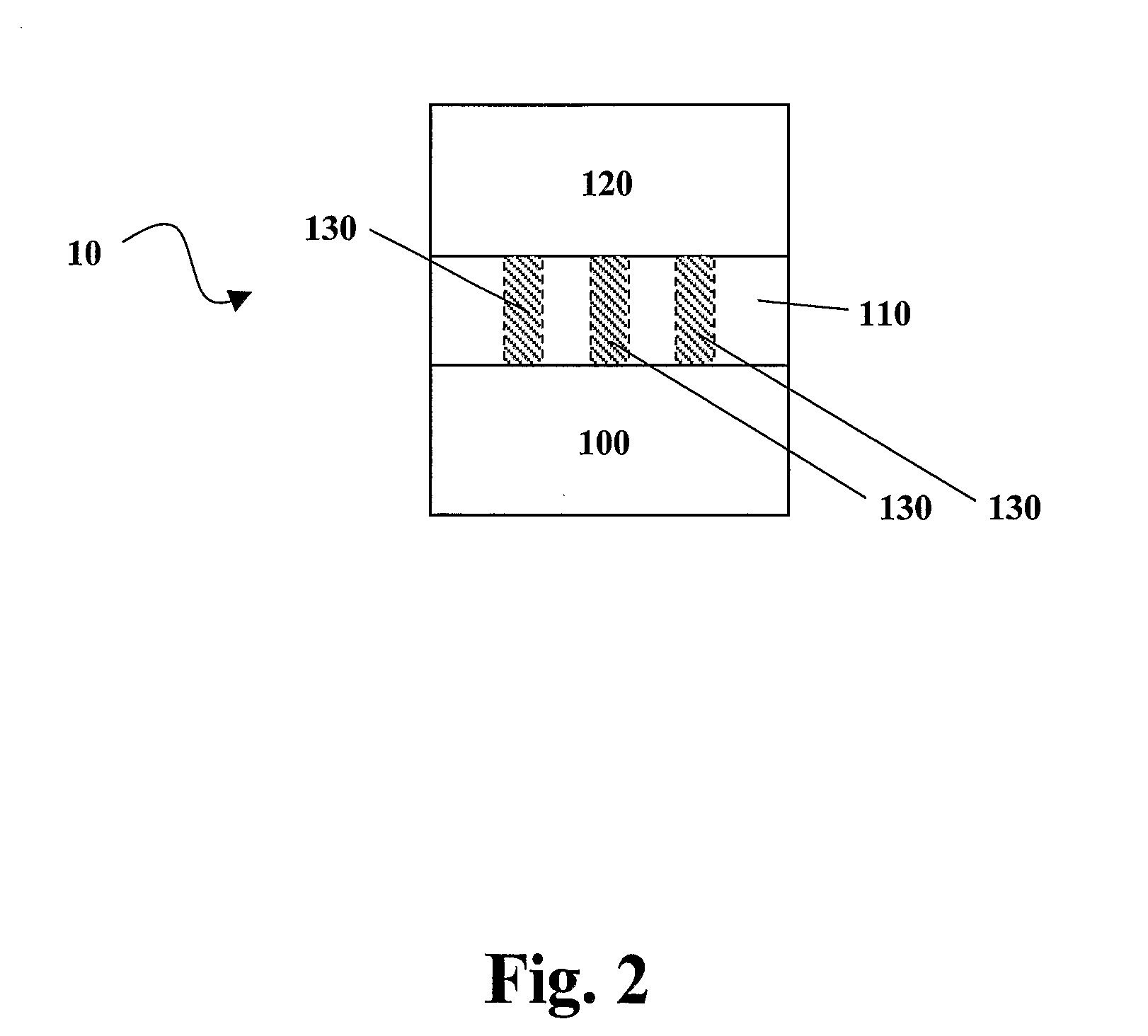

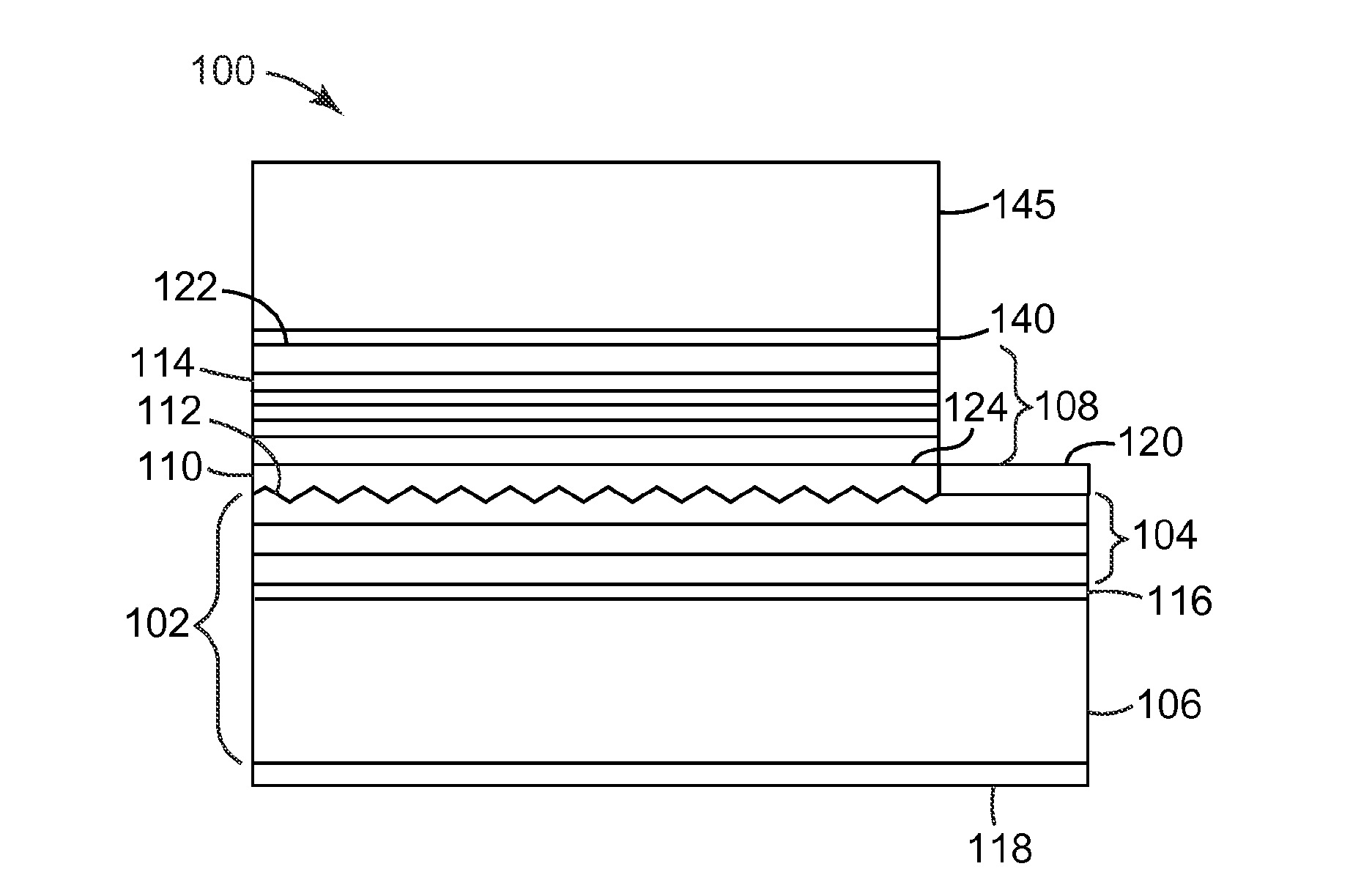

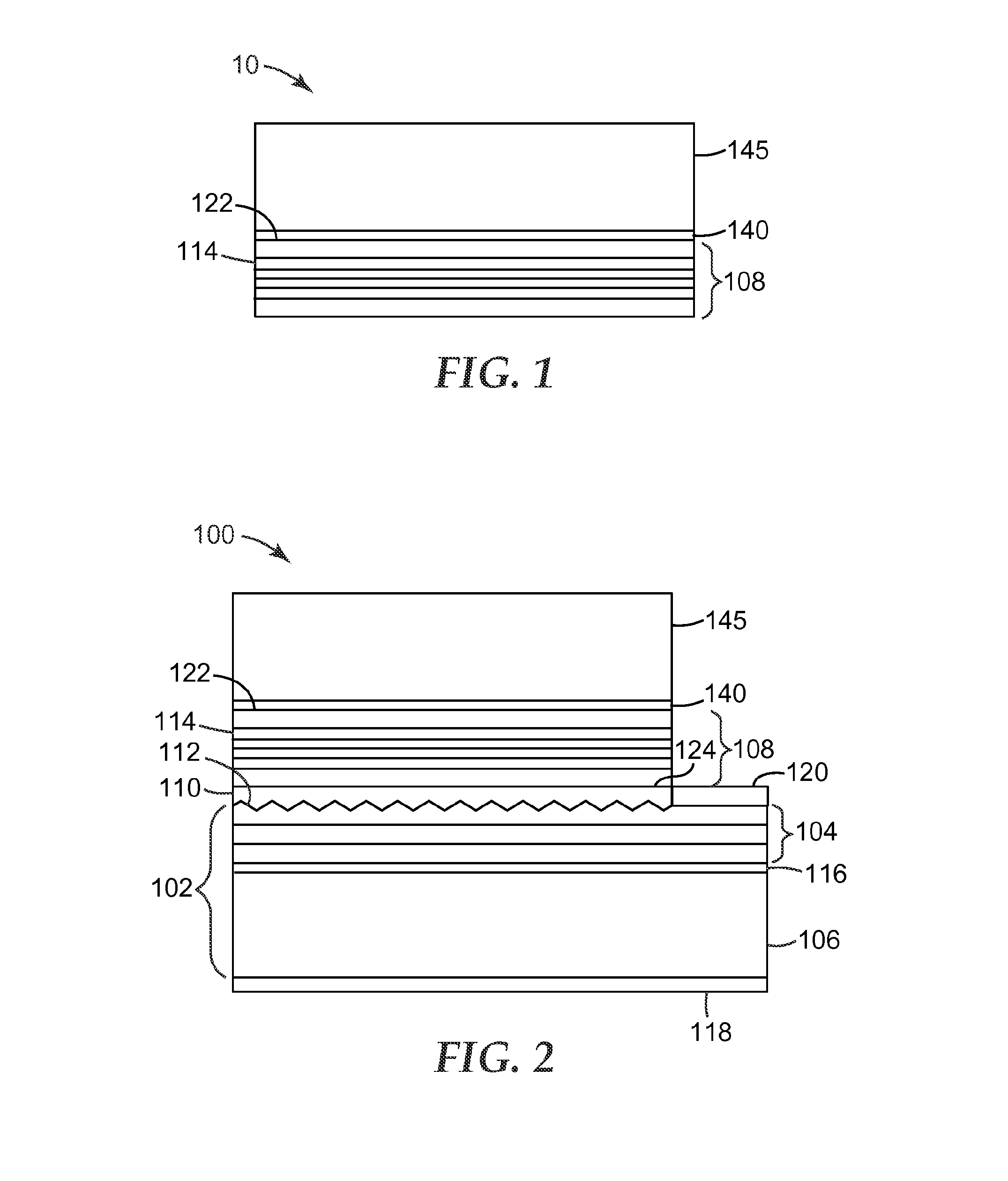

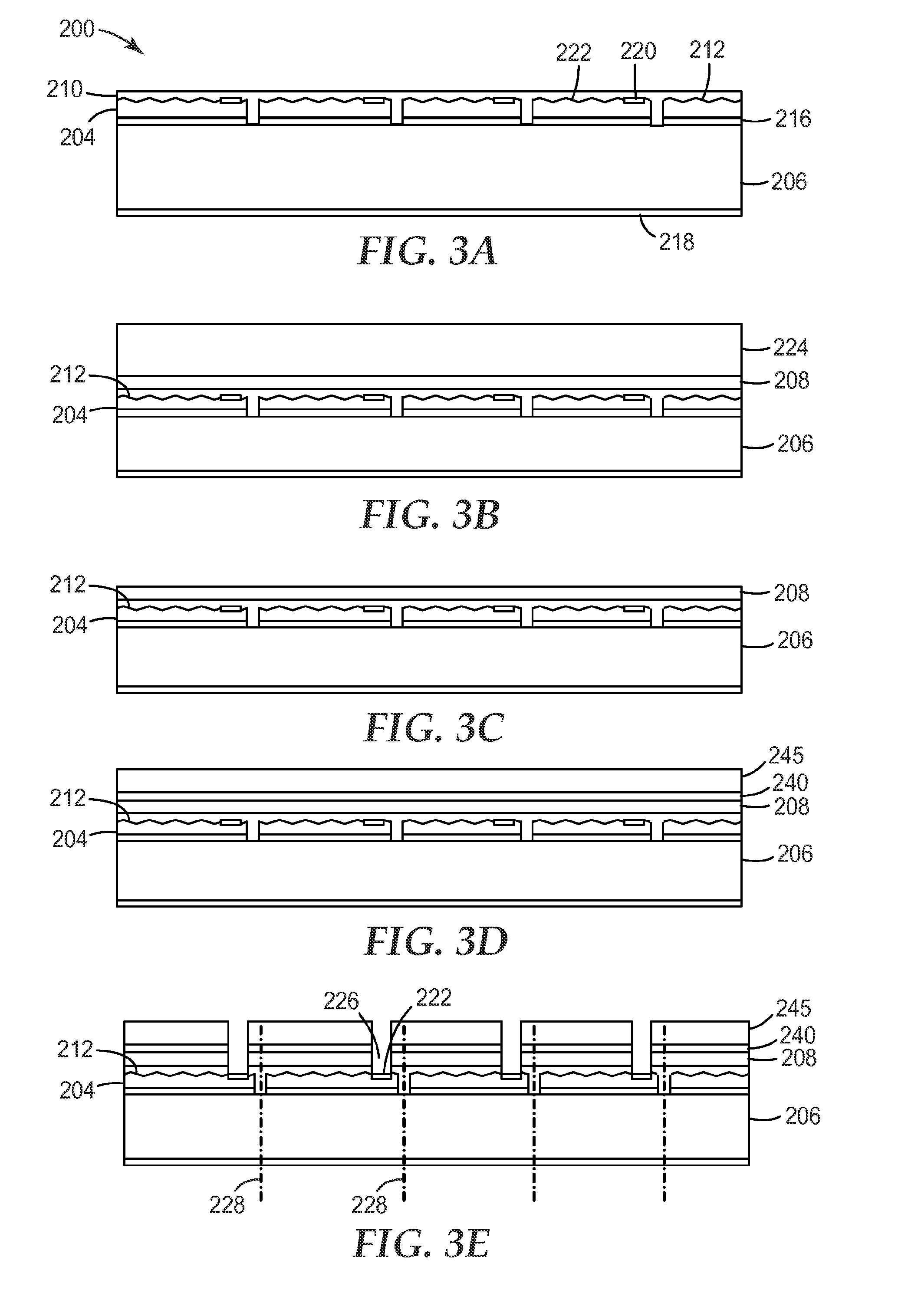

Nanostructured material comprising semiconductor nanocrystal complexes for use in solar cell and method of making a solar cell comprising nanostructured material

InactiveUS20070012355A1Improve performanceLow costNanoopticsPhotovoltaic energy generationNanostructured materialsSolar cell

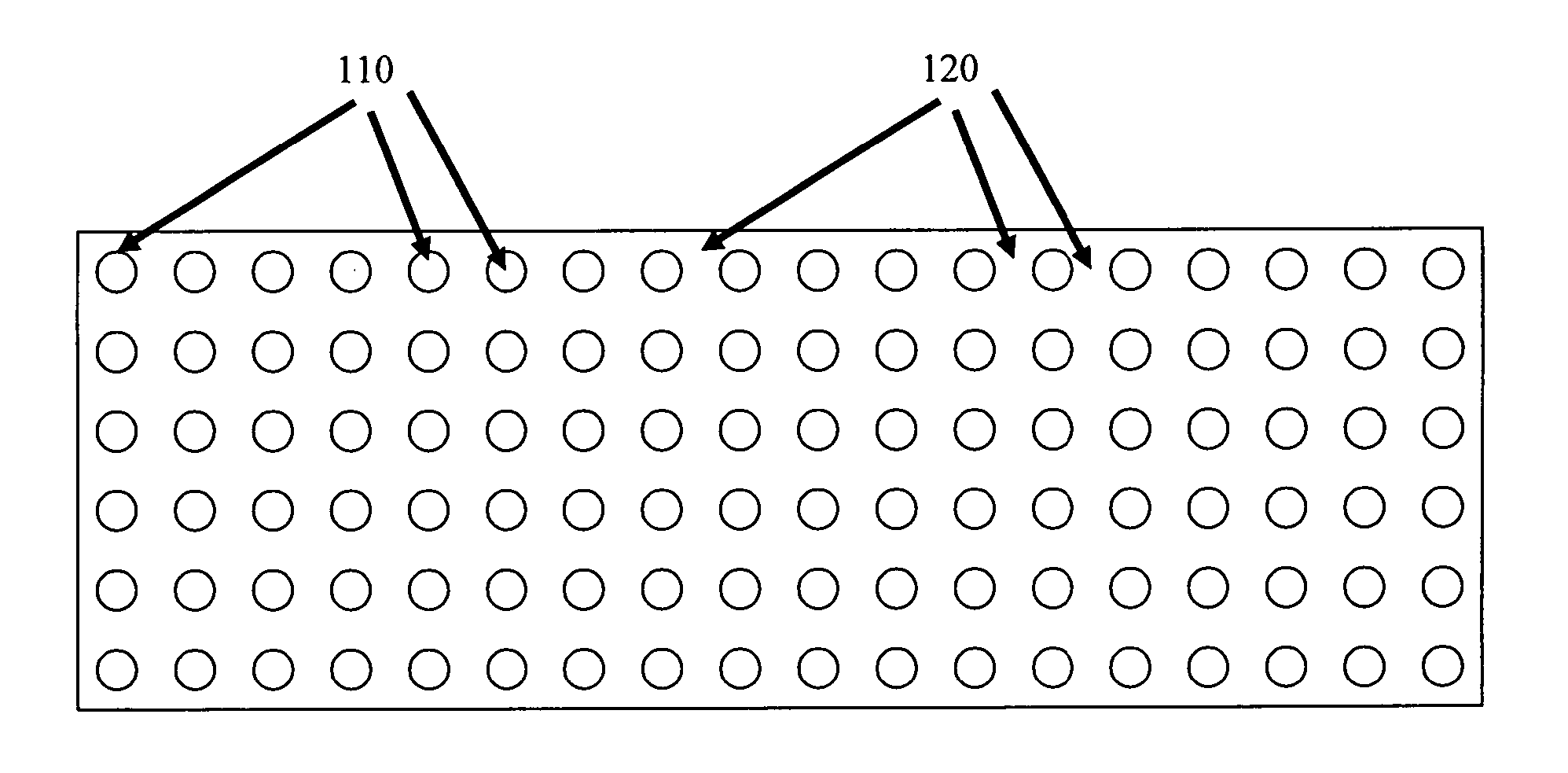

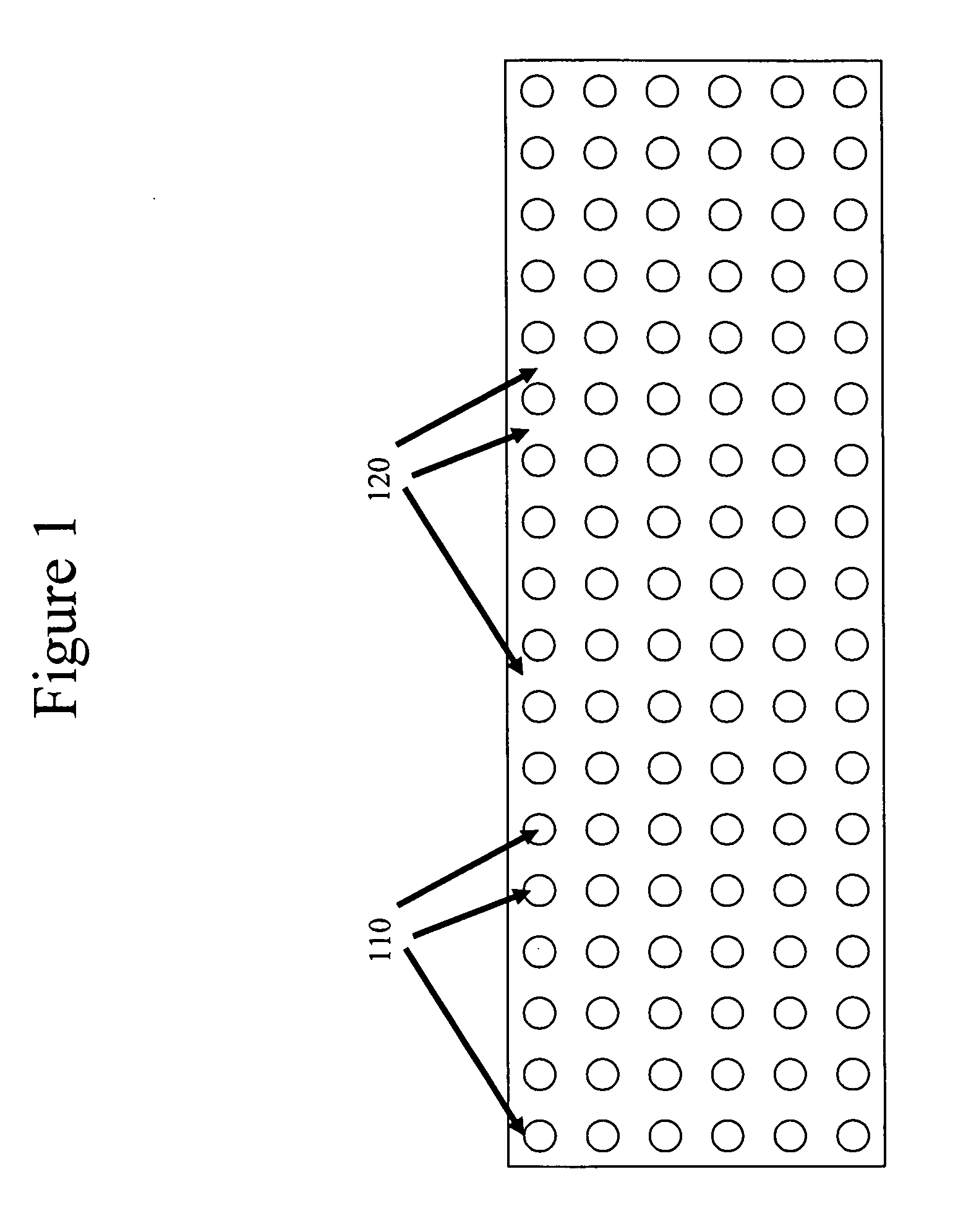

A solar cell includes a semiconductor base layer, a semiconductor nanocrystal complex over the semiconductor base layer, and a semiconductor emitter layer formed over the semiconductor nanocrystal complex. The semiconductor nanocrystal complex includes nanocrystal cores dispersed in an inorganic matrix material. A corresponding method is also disclosed.

Owner:EVIDENT TECH

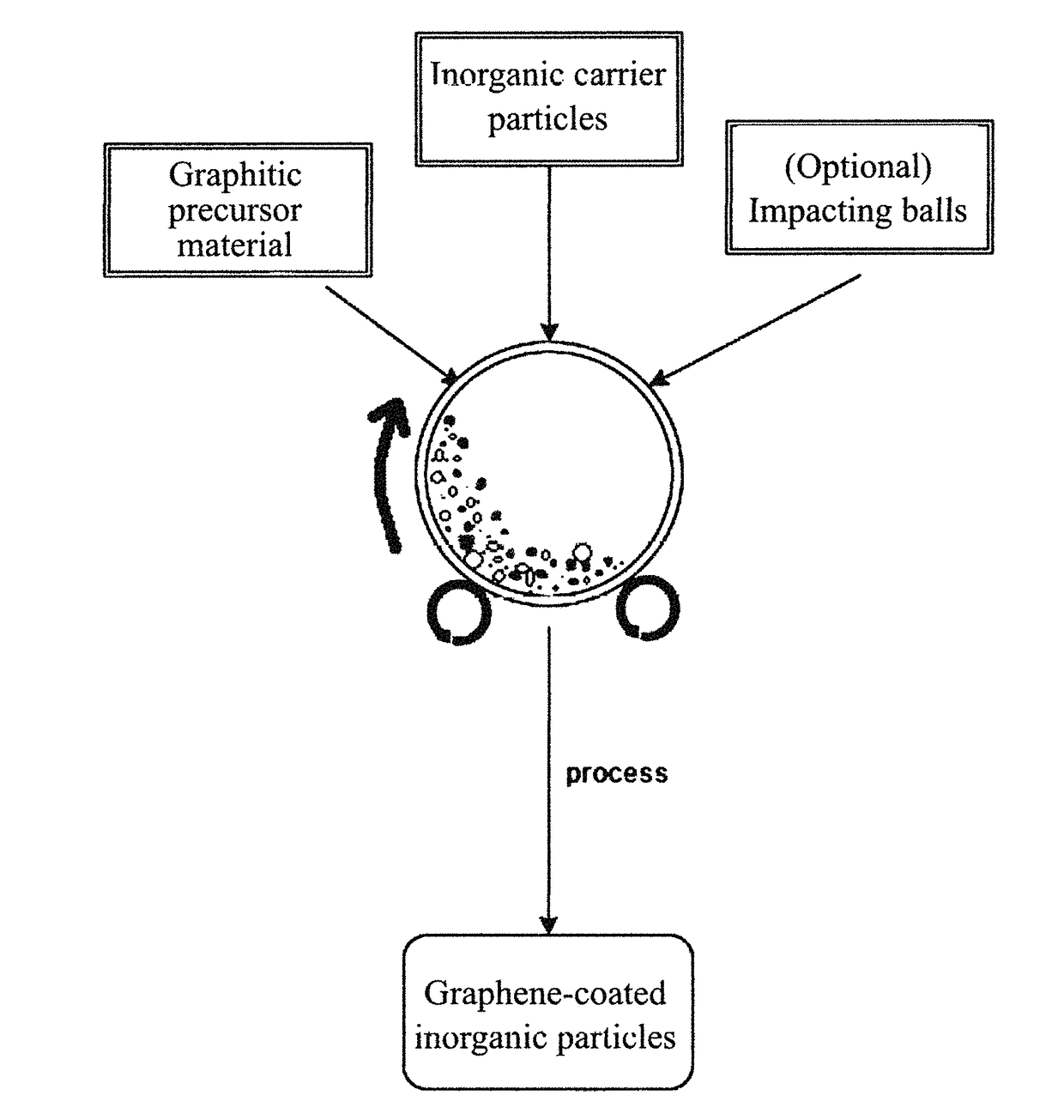

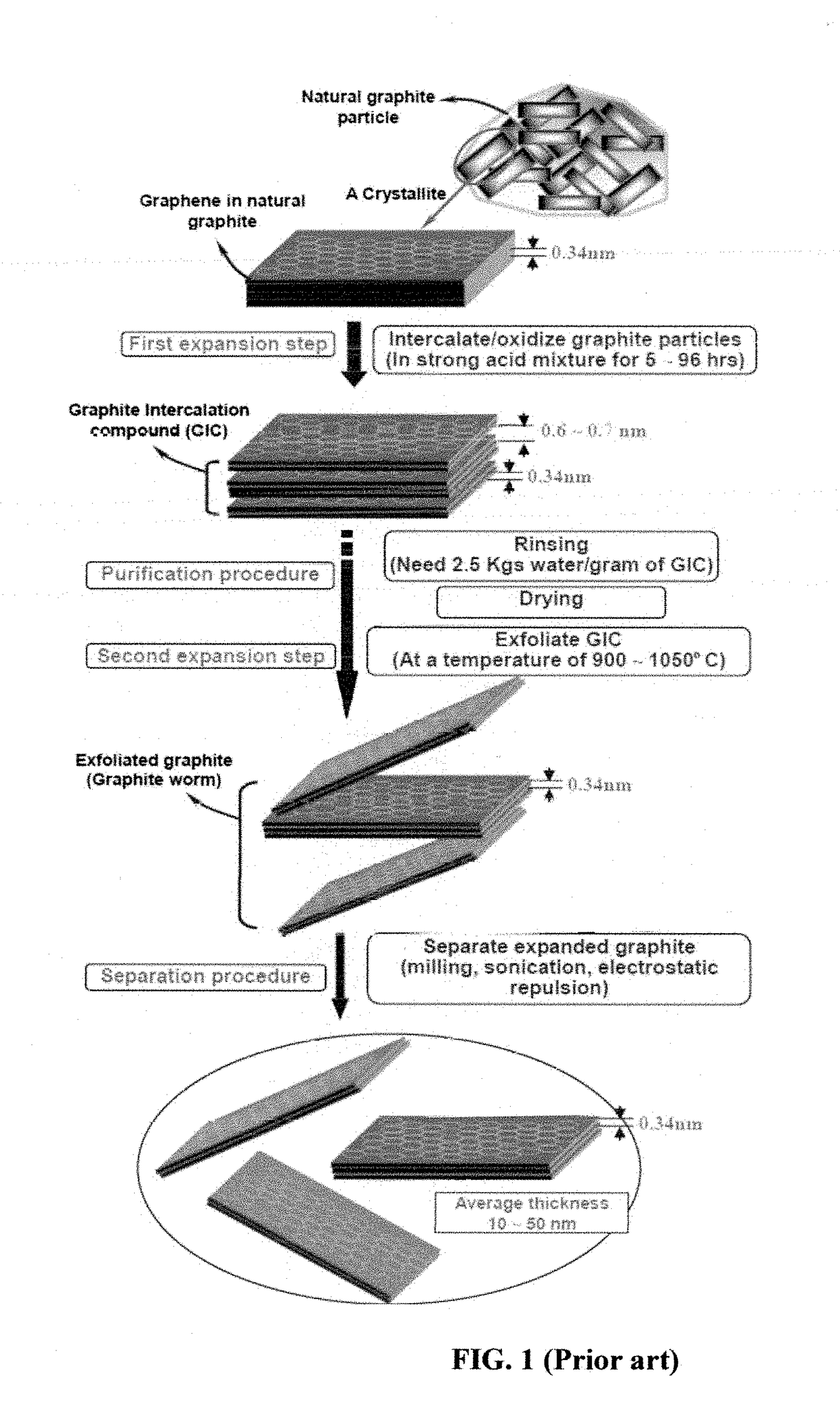

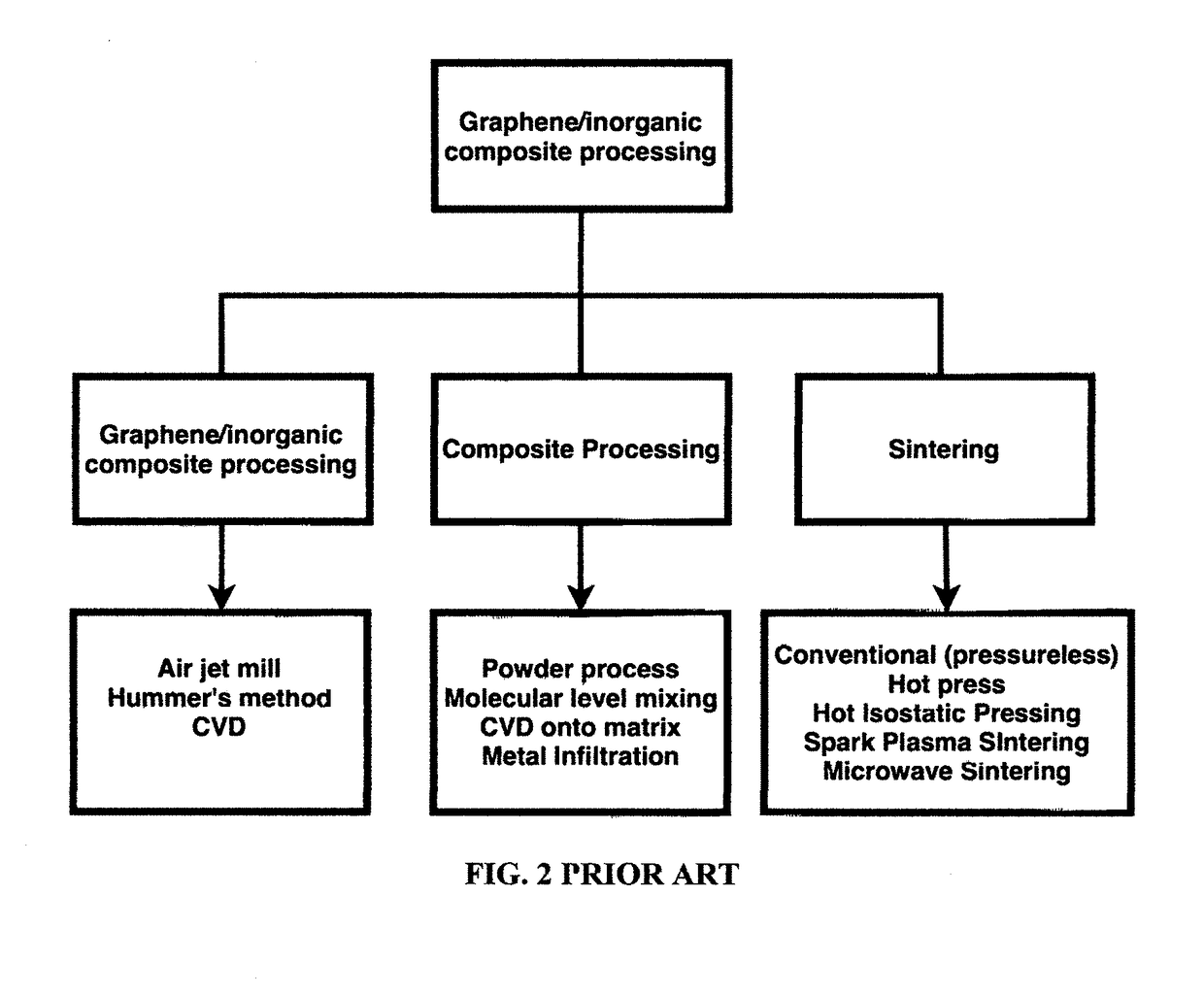

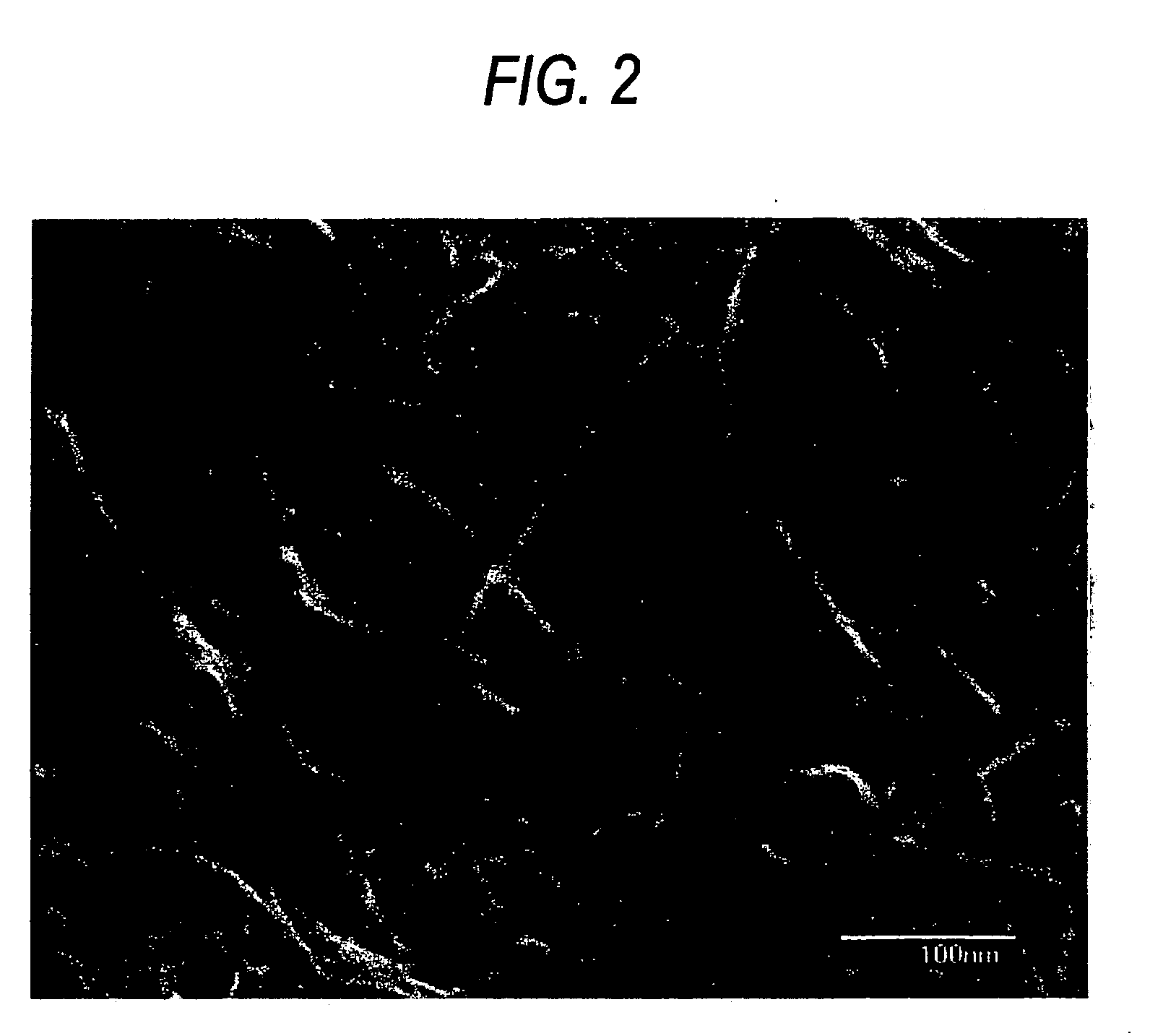

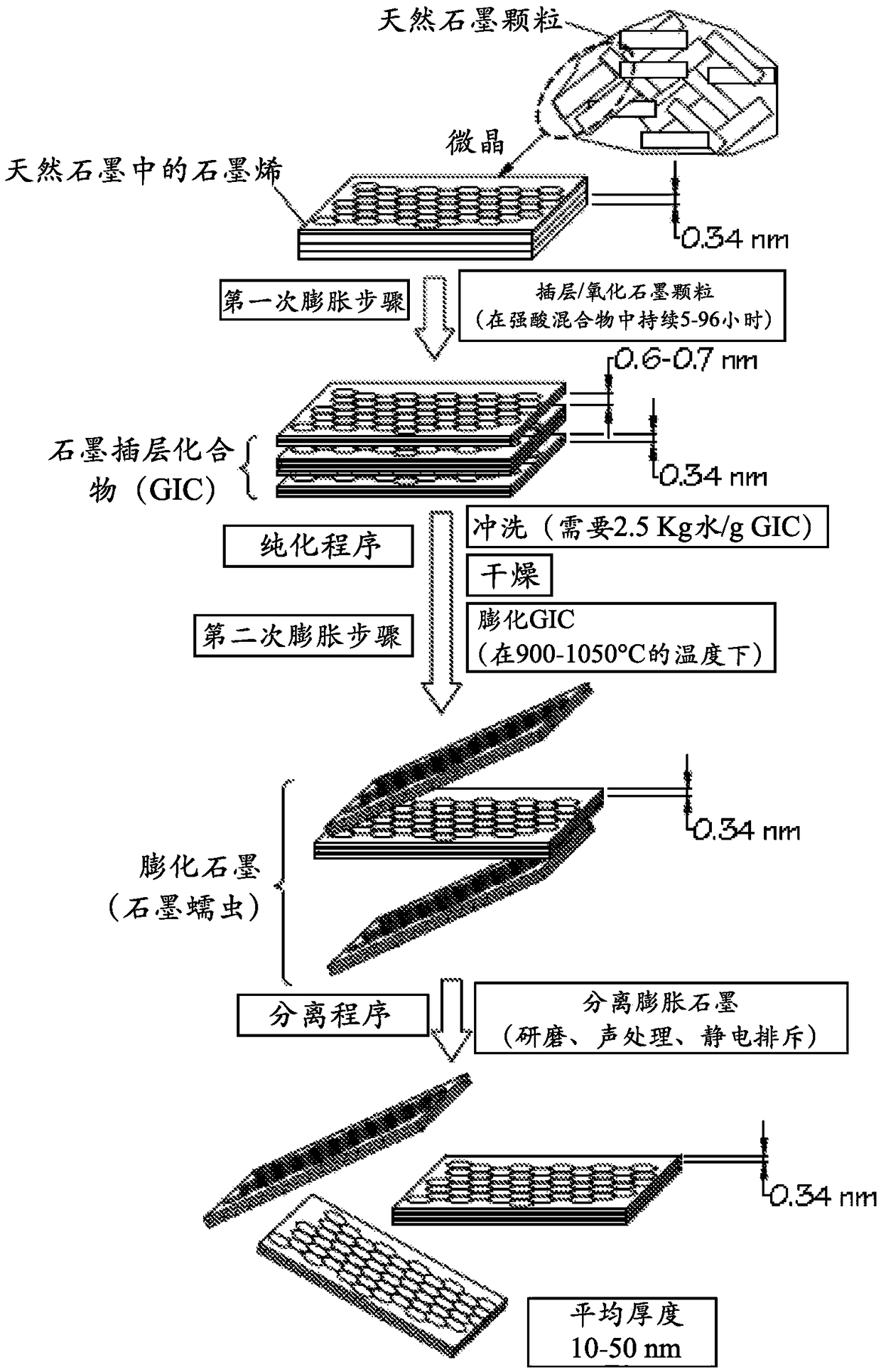

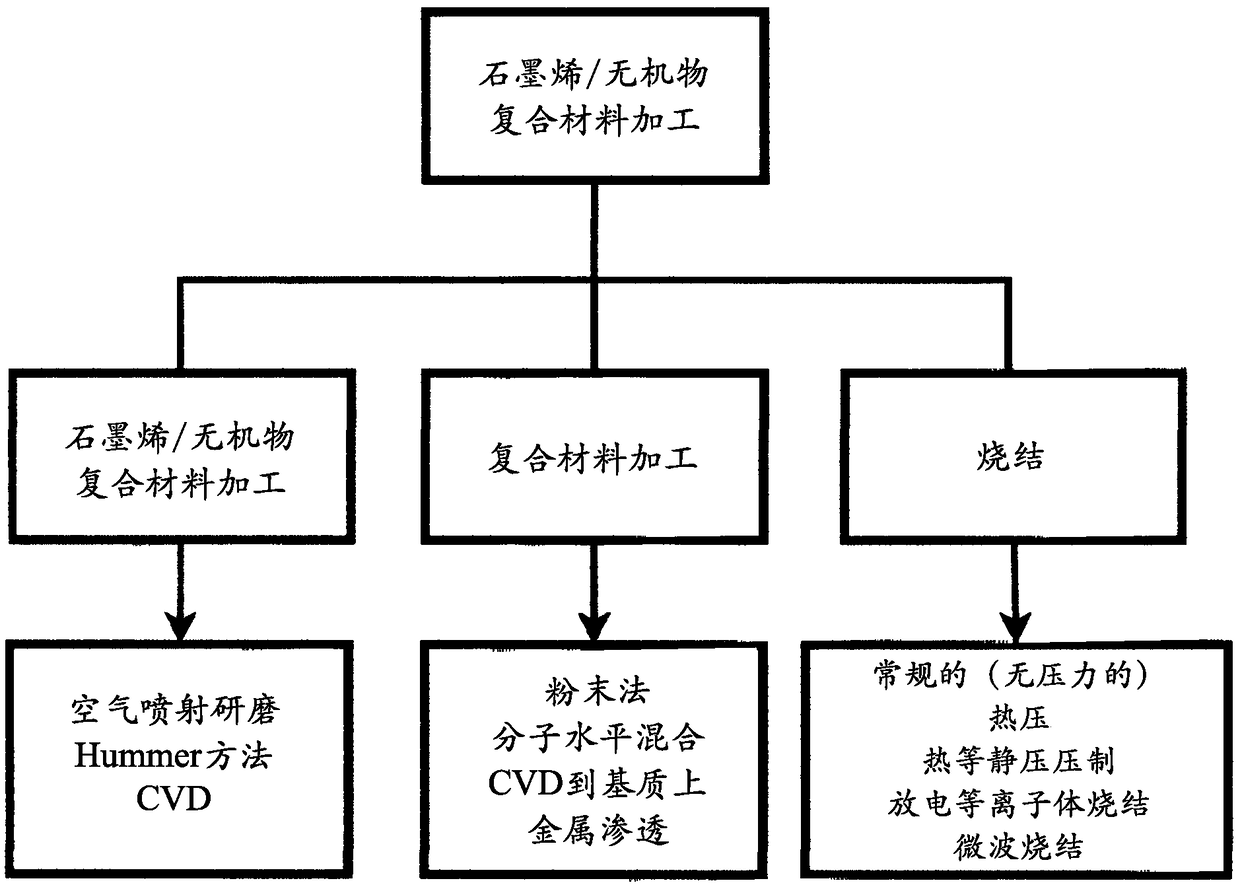

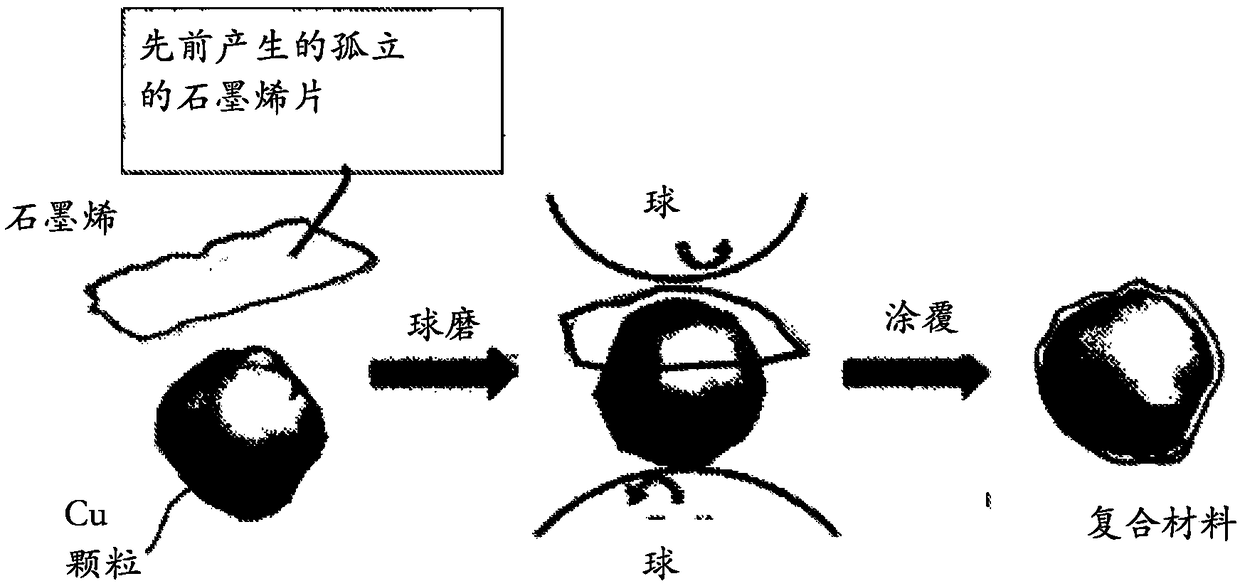

Chemical-free production of graphene-reinforced inorganic matrix composites

ActiveUS20170225233A1Low costAdditive manufacturing apparatusTransportation and packagingInorganic particleGraphene flake

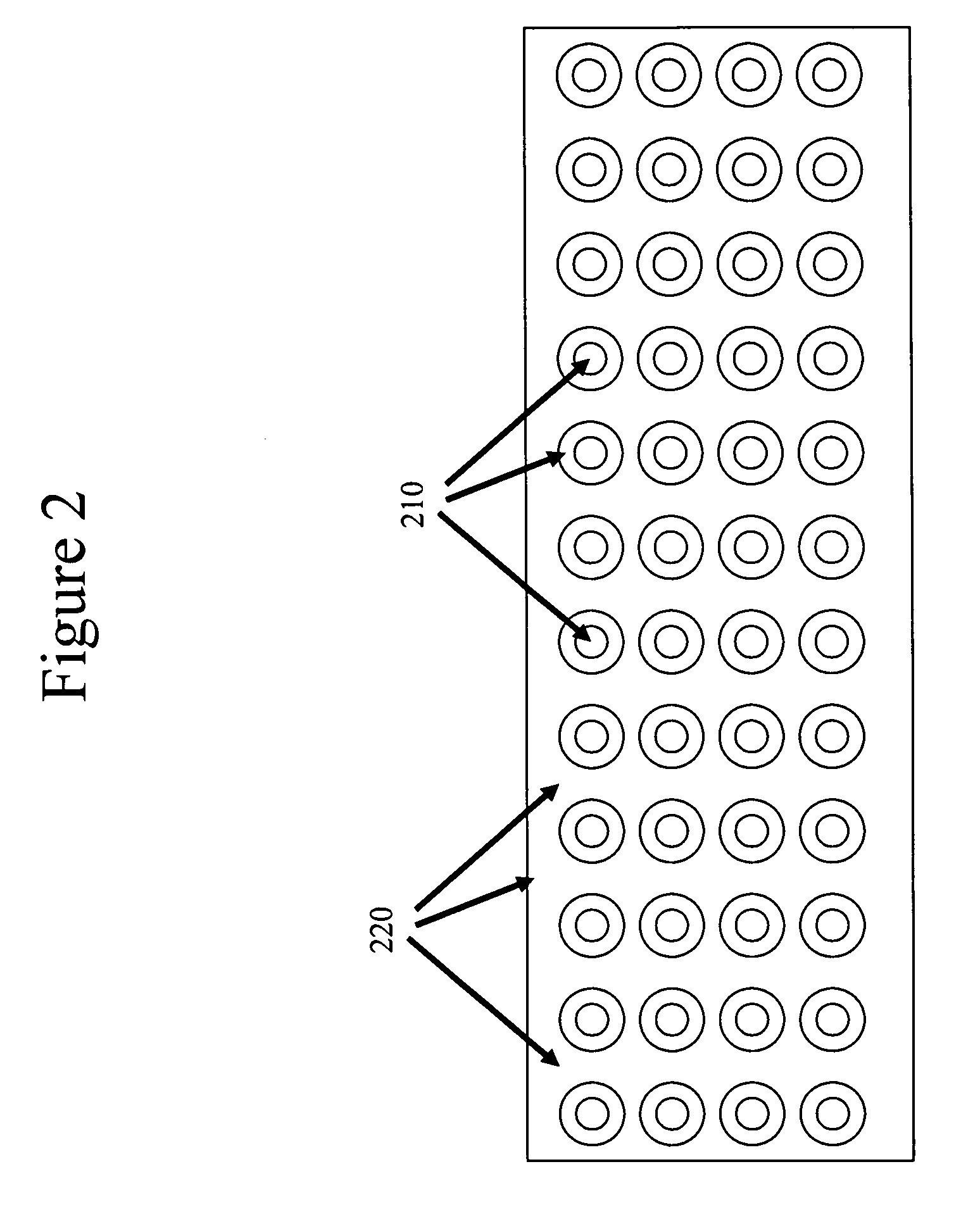

Provided is a simple, fast, scalable, and environmentally benign method of producing a graphene-reinforced inorganic matrix composite directly from a graphitic material, the method comprising: (a) mixing multiple particles of a graphitic material and multiple particles of an inorganic solid carrier material to form a mixture in an impacting chamber of an energy impacting apparatus; (b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for peeling off graphene sheets from the graphitic material and transferring the graphene sheets to surfaces of solid inorganic carrier material particles to produce graphene coated or graphene-embedded inorganic particles inside the impacting chamber; and (c) forming graphene-coated or graphene-embedded inorganic particles into the graphene-reinforced inorganic matrix composite. Also provided is a mass of the graphene-coated or graphene-embedded inorganic particles produced by this method.

Owner:GLOBAL GRAPHENE GRP INC

Biological seedling growing matrix

The invention provides a new crop seedling growing matrix, wherein the pH value of the seedling growing matrix is 6.0-6.5. The seedling growing matrix comprises the components by the weight percentage: 50%-80% of an inorganic matrix, and 15-30% of an organic matrix, wherein the organic matrix includes a composition of peat, fermented cattle manure, fermented pig manure, plant ash and an additional organic matrix, and the inorganic matrix includes a composition of vermiculite, perlite and an additional inorganic matrix and is composed of inorganic matrix particles with different particle sizes. The seedling growing matrix provided by the invention has relatively high total porosity and maximum water holding capacity, and is higher in aeration porosity ratio, more reasonable in water-gas ratio, small in bulk density and convenient to transport and use. The seedling growing matrix provided by the invention has the advantages of wide range and many types of applicable crops, high germination rate, less morbidity and good seedling growth vigor.

Owner:上海宇强品牌策划有限公司 +1

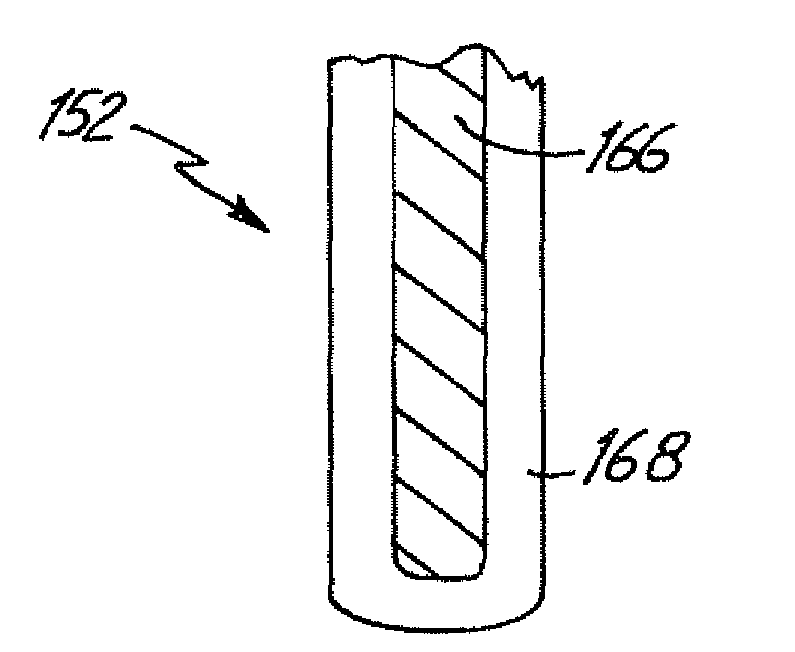

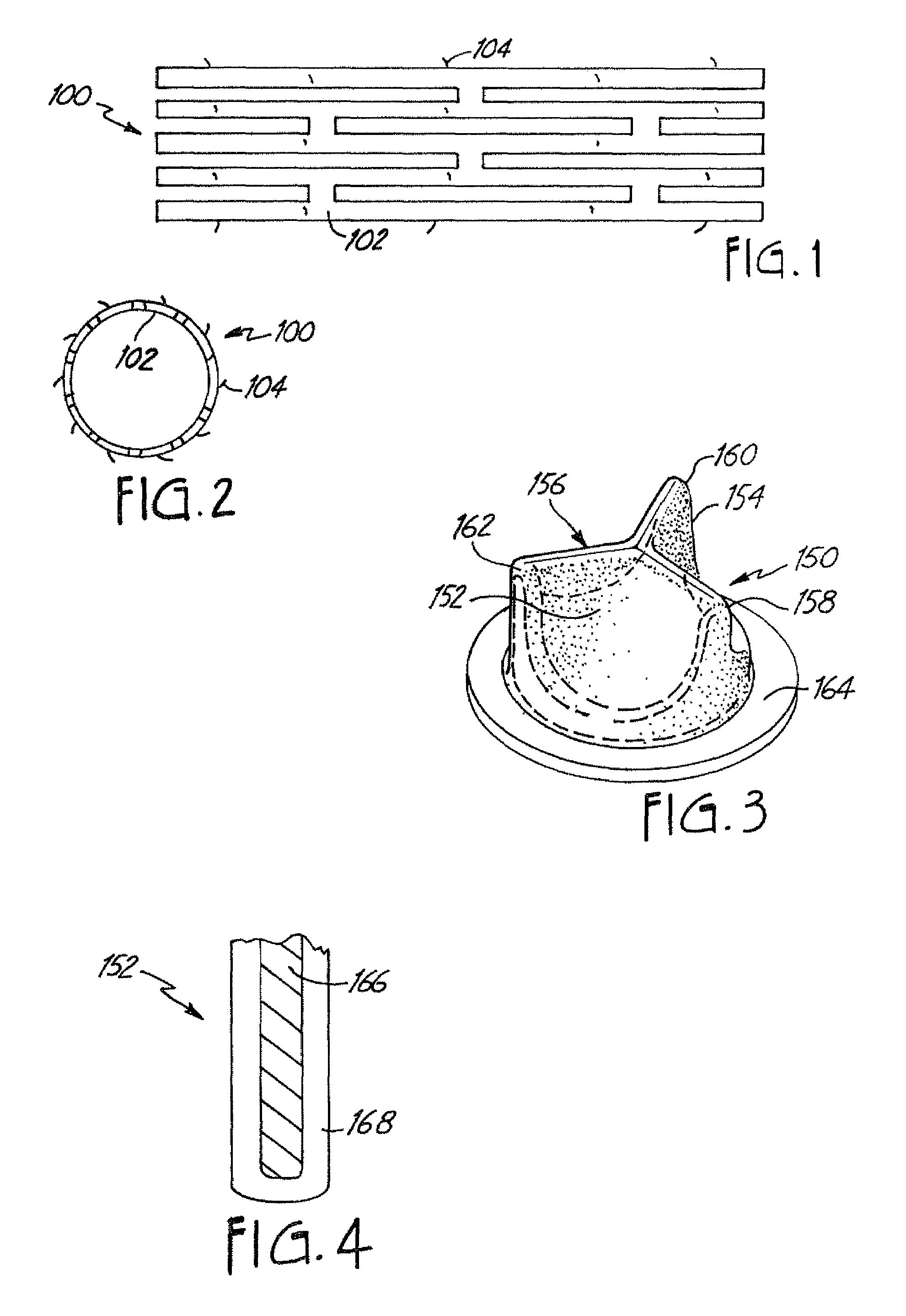

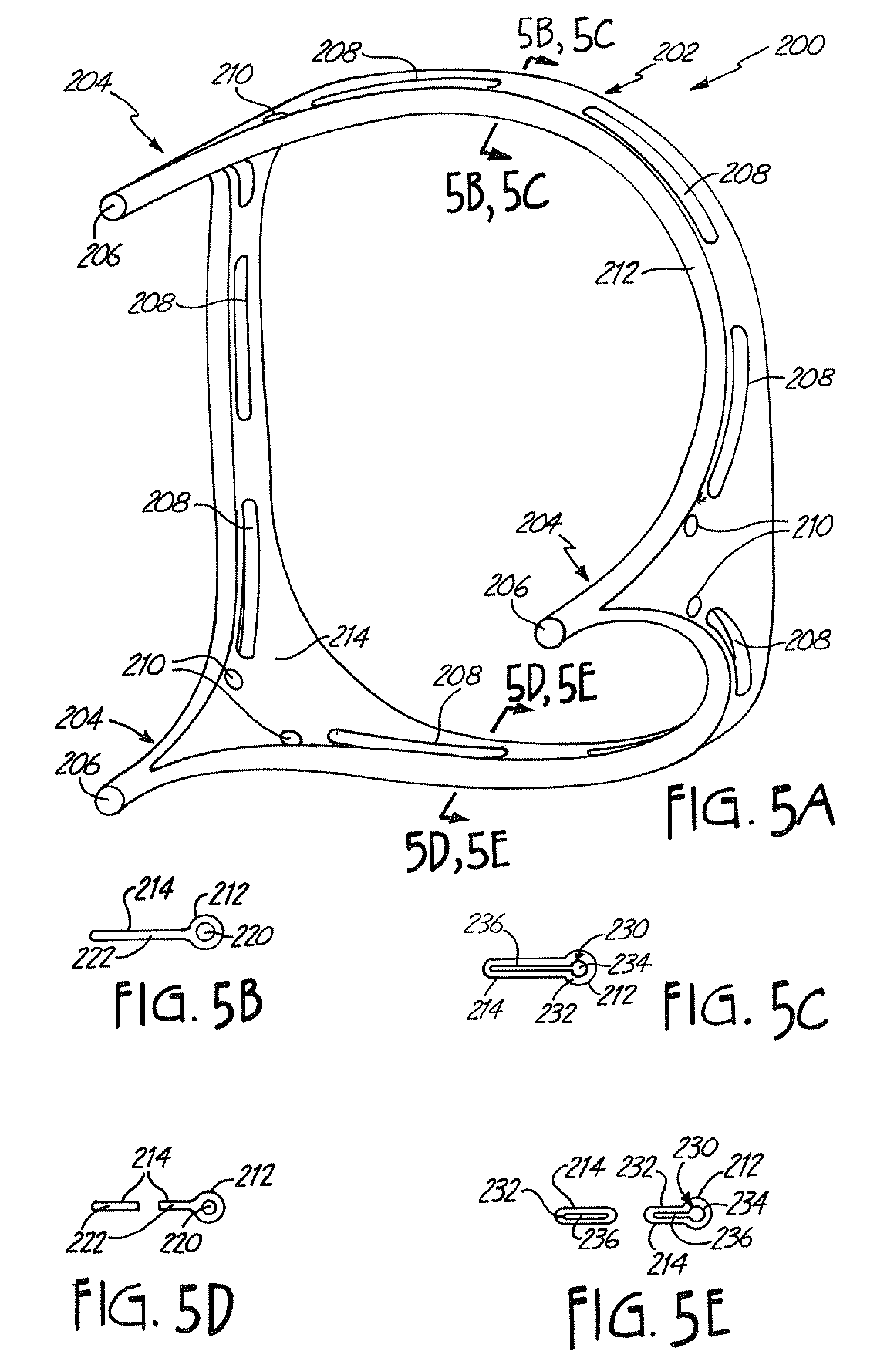

Medical devices with polymer/inorganic substrate composites

Improved medical device have an inorganic substrate and a polymer covering at least a portion of the substrate, in which the polymer forms a structure substantially different from the structure of the substrate. Other medical devices include a flexible composite component with an inorganic substrate and a polymer covering at least over a portion of the substrate. The flexible composite component can be bent, at least, about 100 degrees without extending the material beyond its elastic limit. Corresponding methods include applying a polymer onto an inorganic substrate, such that the polymer does not conform to the shape of the substrate.

Owner:ST JUDE MEDICAL

Inorganic matrix composition and composites incorporating the matrix composition

InactiveUS6969422B2Good physical and mechanical propertiesIncrease loadAlkali metal silicate coatingsCement productionSlurryOragene

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

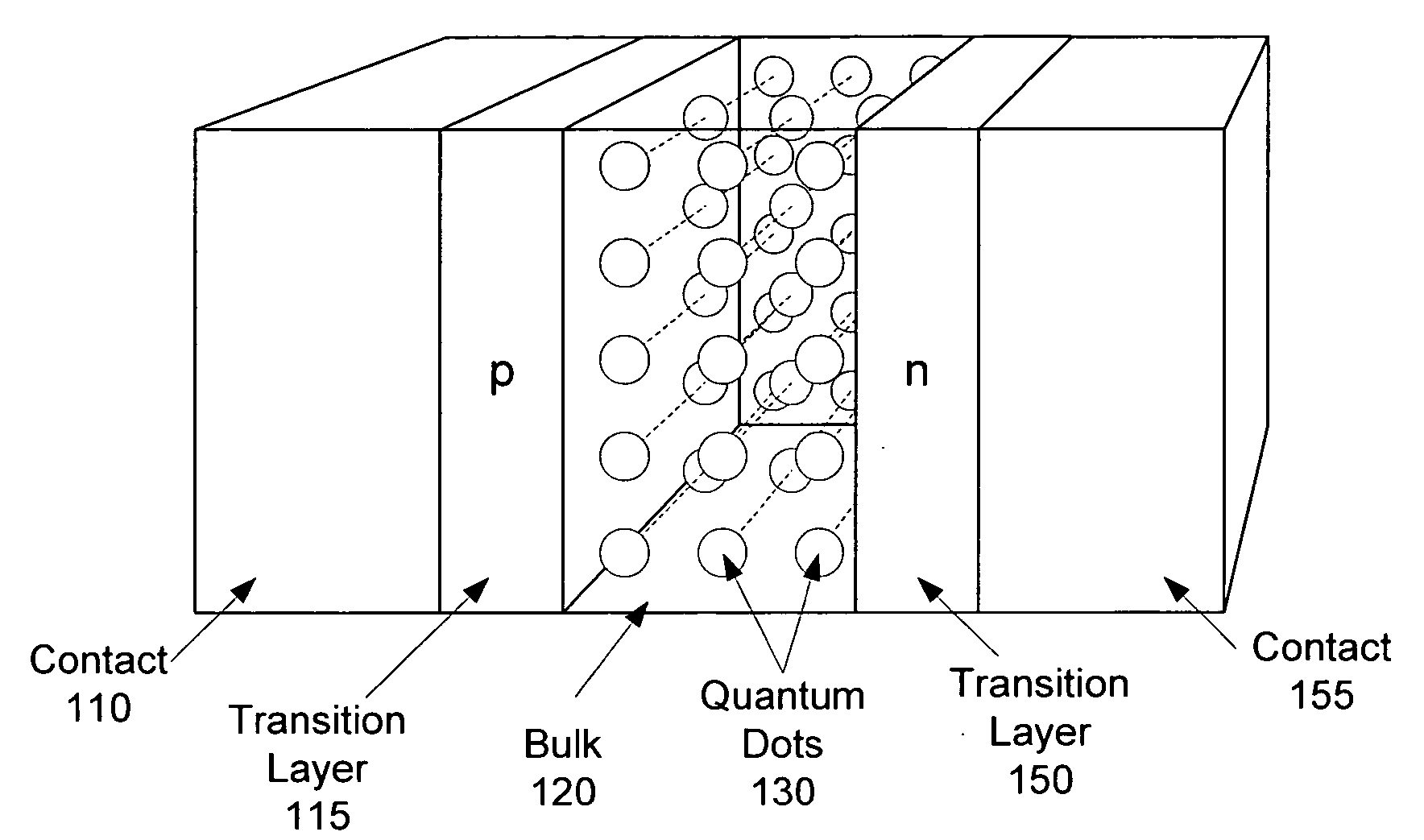

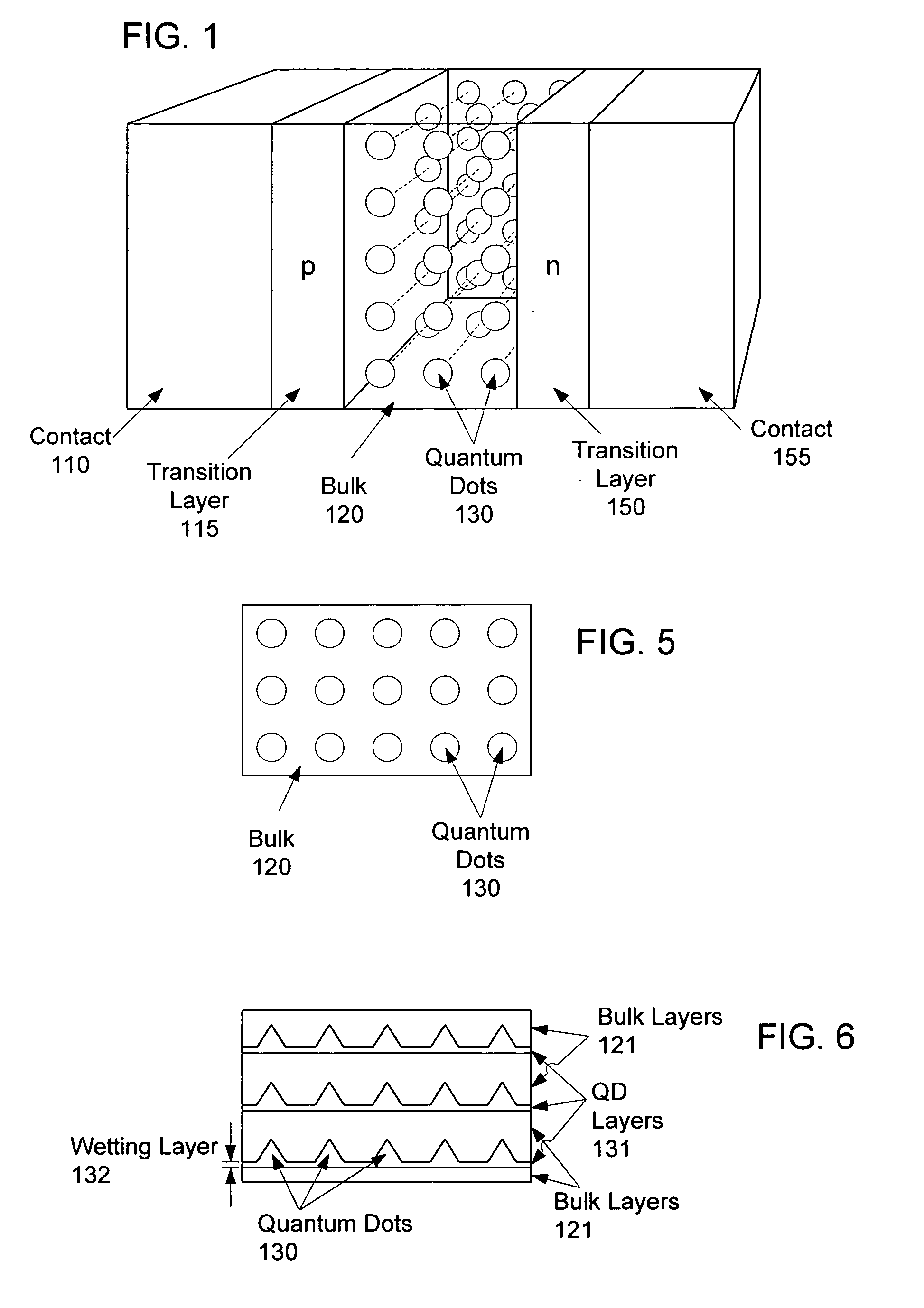

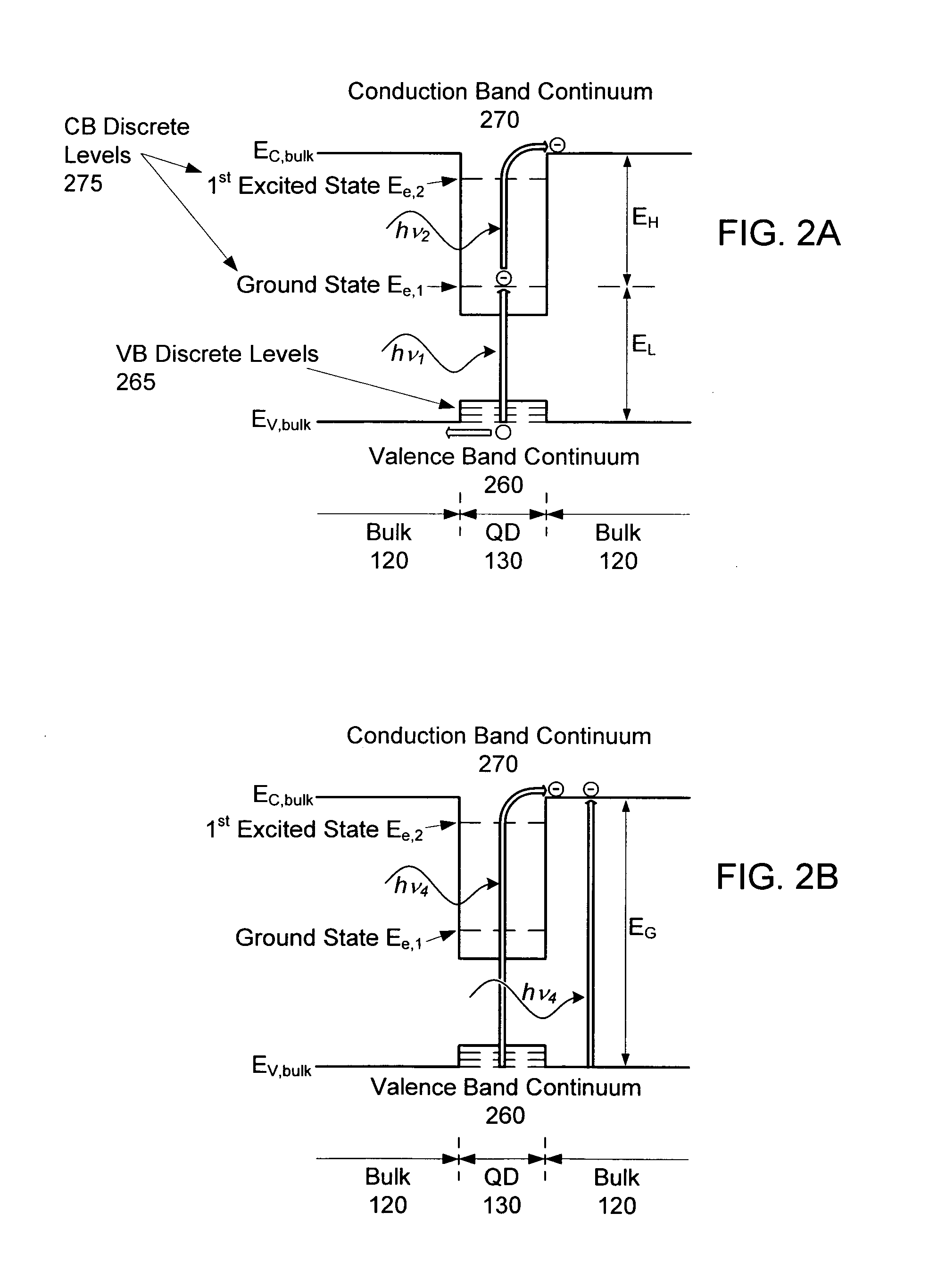

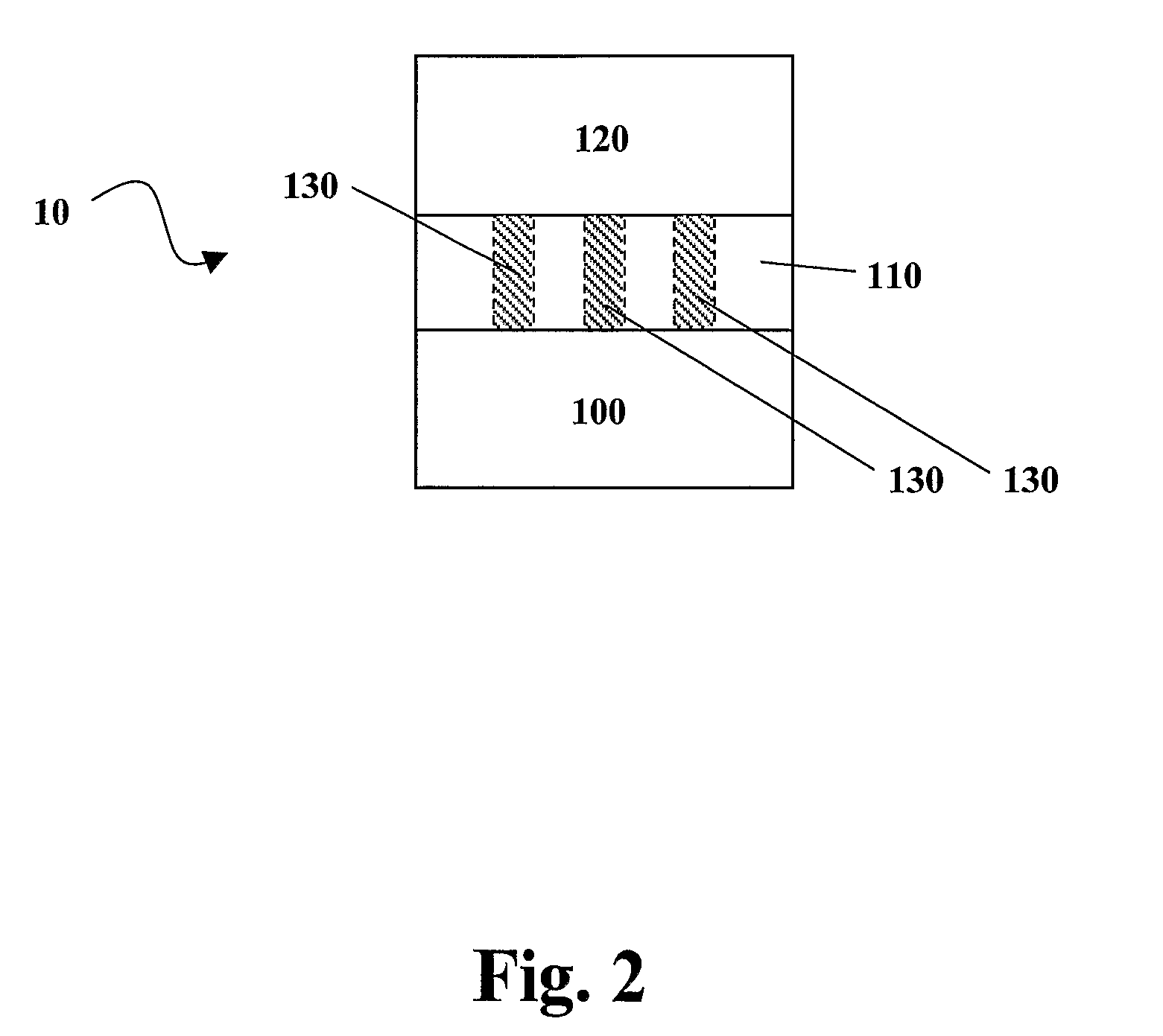

Intermediate-band photosensitive device with quantum dots having tunneling barrier embedded in inorganic matrix

A plurality of quantum dots comprise a first inorganic material, and each quantum dot is coated with a second inorganic material. The coated quantum dots being are in a matrix of a third inorganic material. At least the first and third materials are photoconductive semiconductors. The second material is arranged as a tunneling barrier to require a charge carrier (an electron or a hole) at a base of the tunneling barrier in the third material to perform quantum mechanical tunneling to reach the first material within a respective quantum dot. A first quantum state in each quantum dot is between a conduction band edge and a valence band edge of the third material in which the coated quantum dots are embedded. Wave functions of the first quantum state of the plurality of quantum dots may overlap to form an intermediate band.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Inorganic matrix compositions and composites incorporating the matrix composition

InactiveUS20050022698A1Maintain good propertiesExcellent thermalAlkali metal silicate coatingsCement productionCompression moldingInorganic composition

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

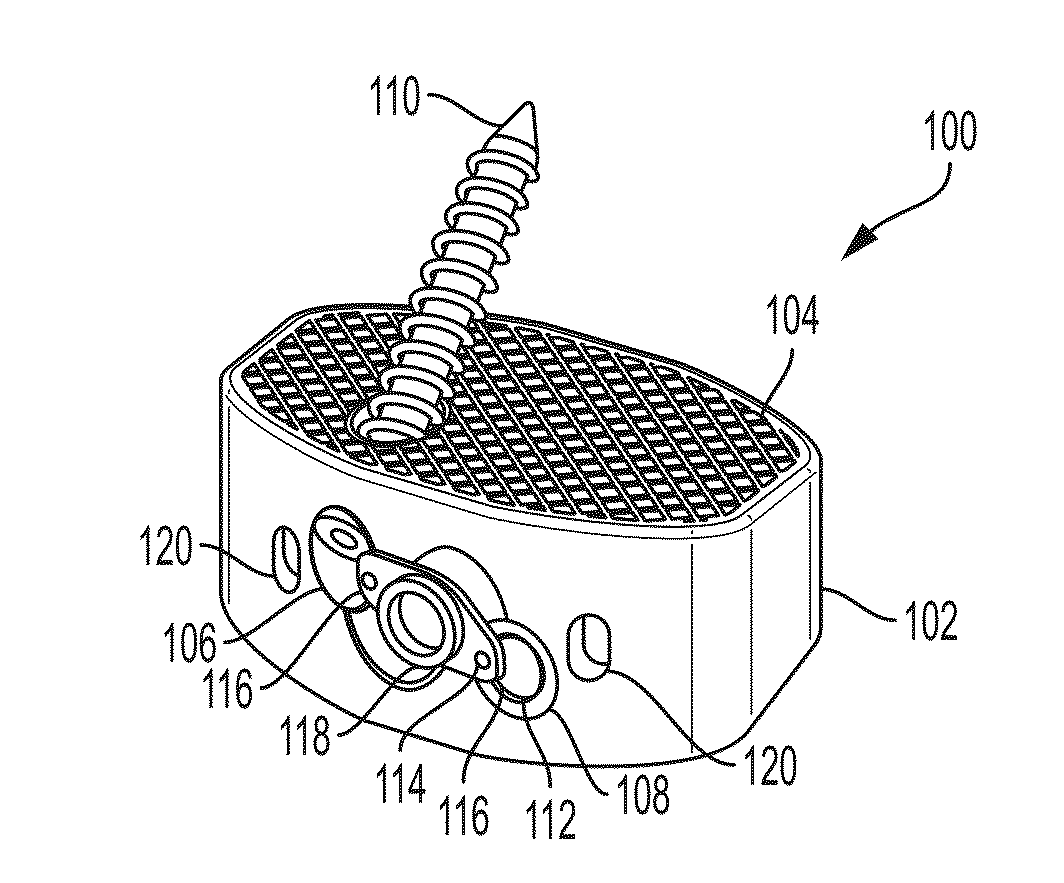

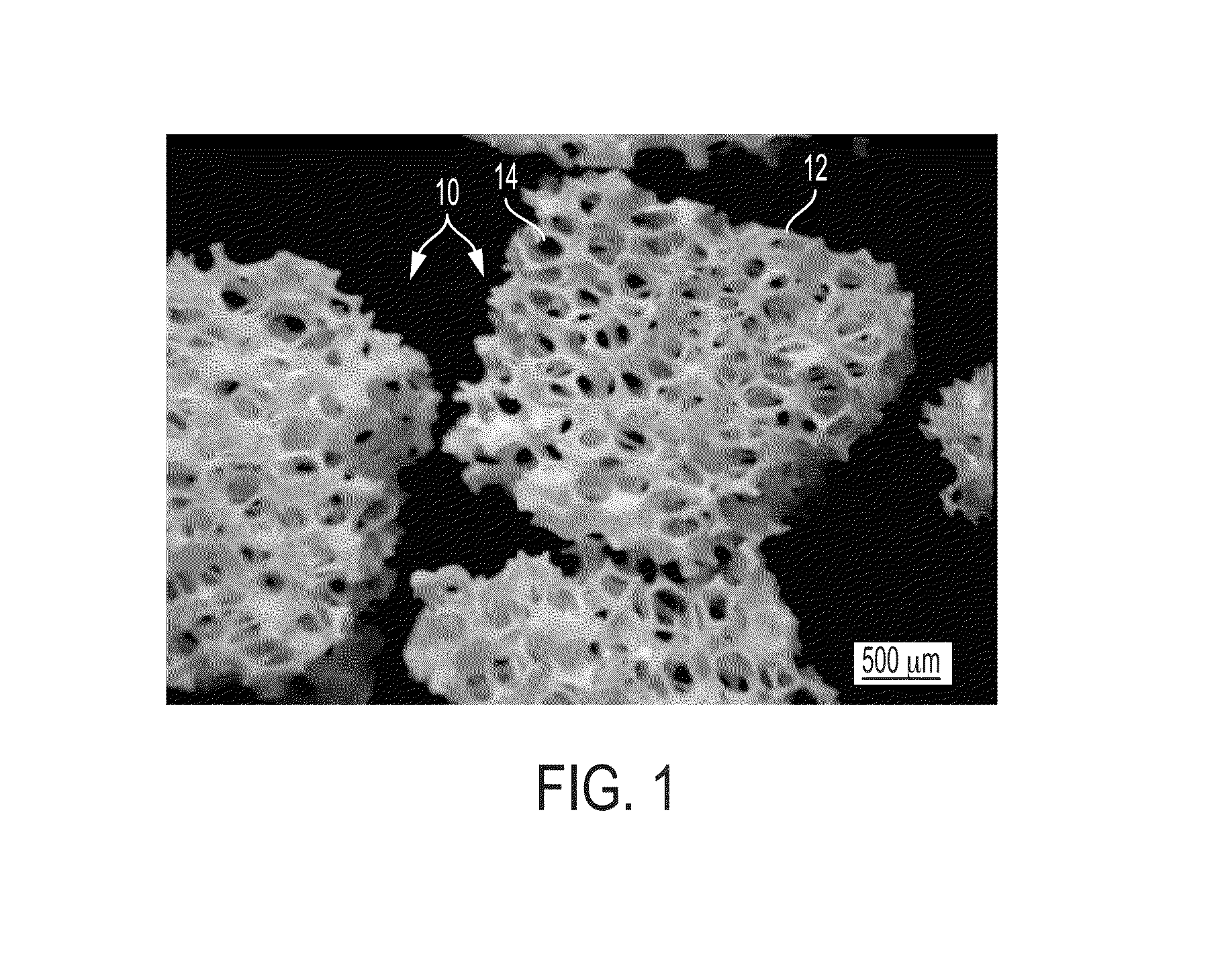

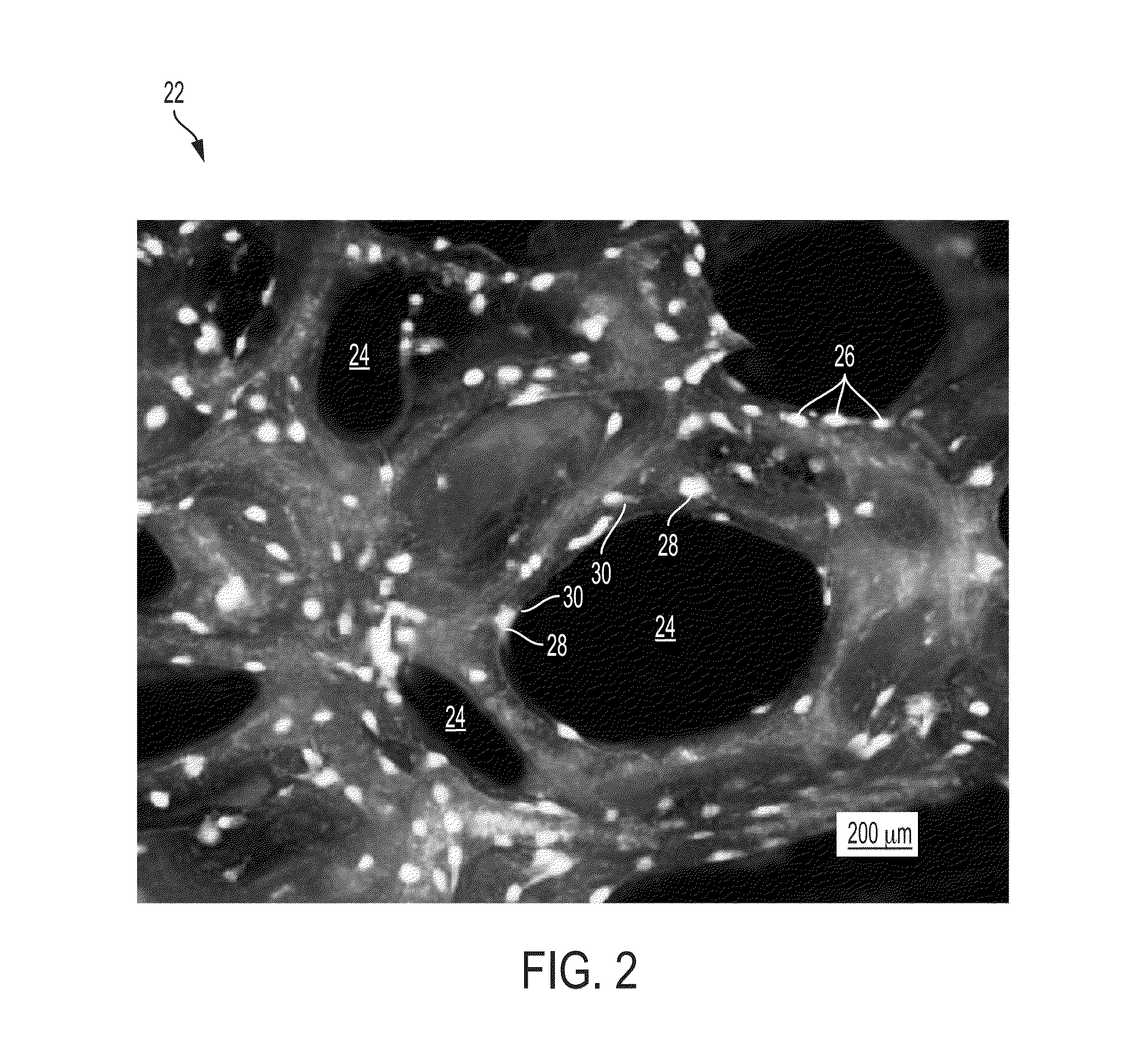

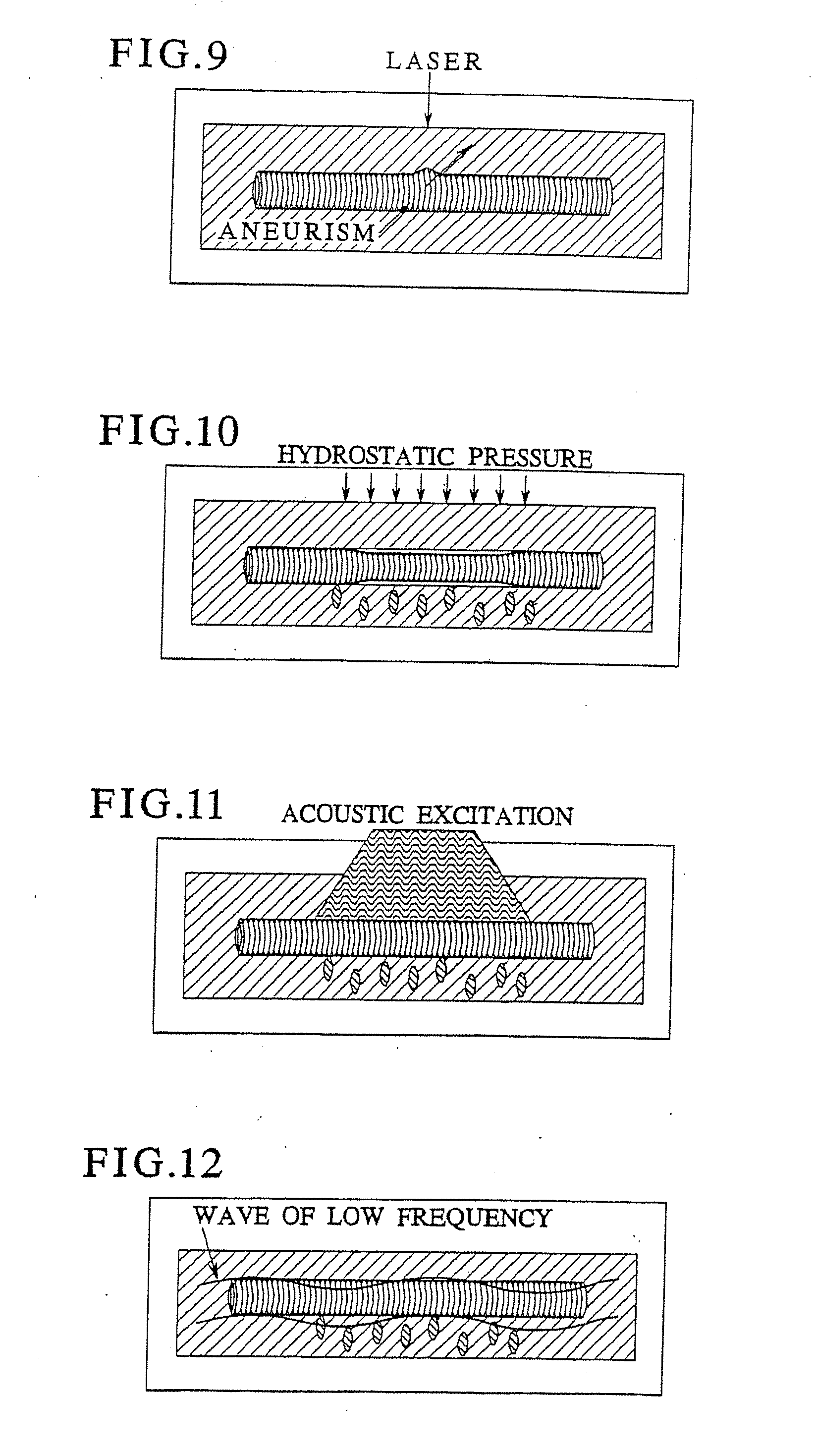

Treatment of skeletal voids with implantable substrate hydrated with bone marrow concentrate

ActiveUS20160270920A1Good adhesionContinued viability of cellJoint implantsSpinal implantsCellular componentCell-Extracellular Matrix

The invention is directed to a bone void filler comprising a scaffold or matrix. The scaffold or matrix may include a porous inorganic matrix component and / or a 3D-printed implantable device. The bone void filler may include a cellular component containing cells, some of which are capable of making extracellular matrix resembling native bone tissue. The bone void filler may include an organic matrix, such as, an organic biopolymer that aids in cell retention and renders the scaffold or matrix moldable. The bone void filler may include growth factors and / or cytokines. The bone void filler may include a clotting agent.

Owner:SPINESMITH PARTNERS

Drug delivery systems using mesoporous oxide films

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

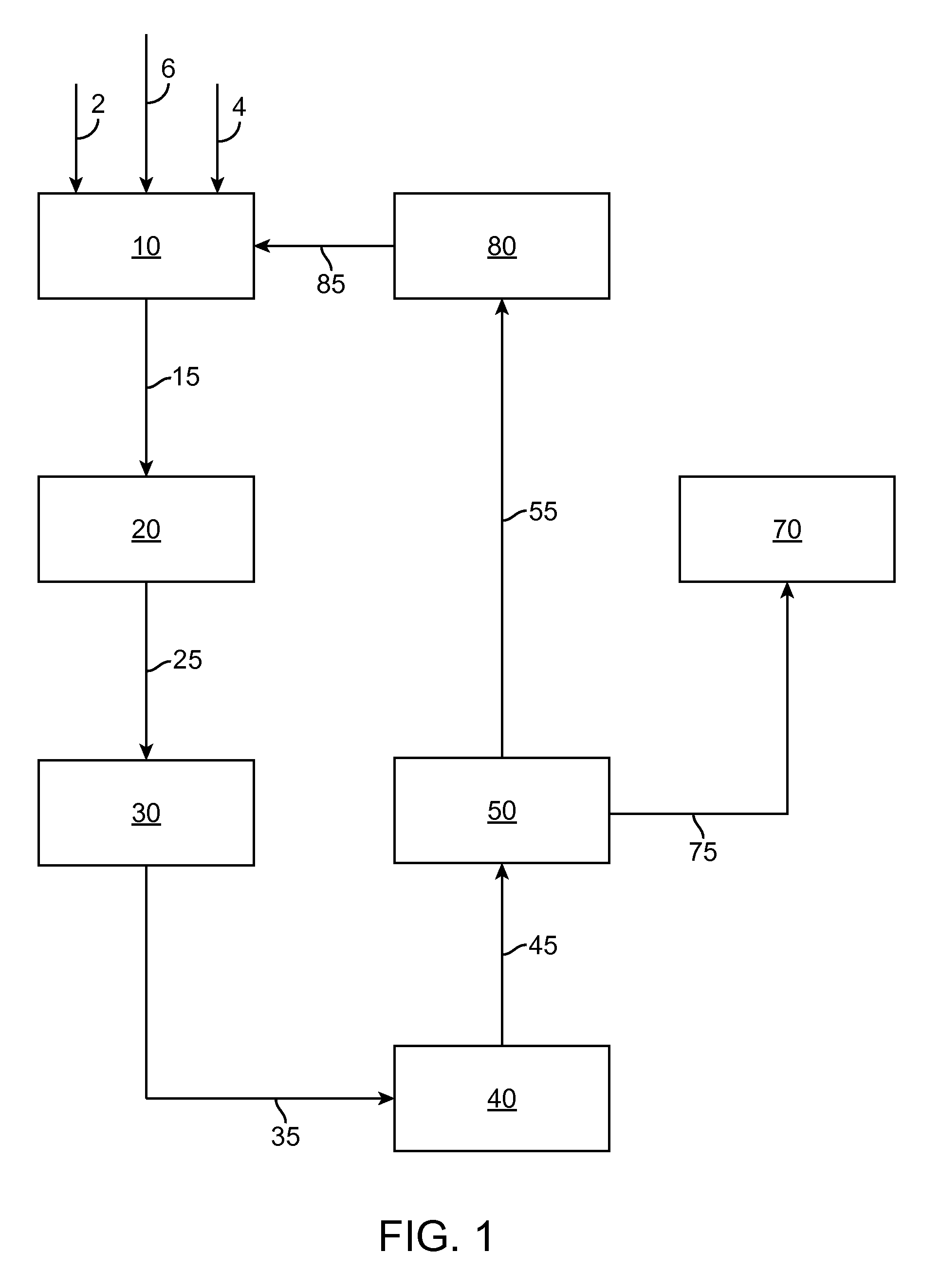

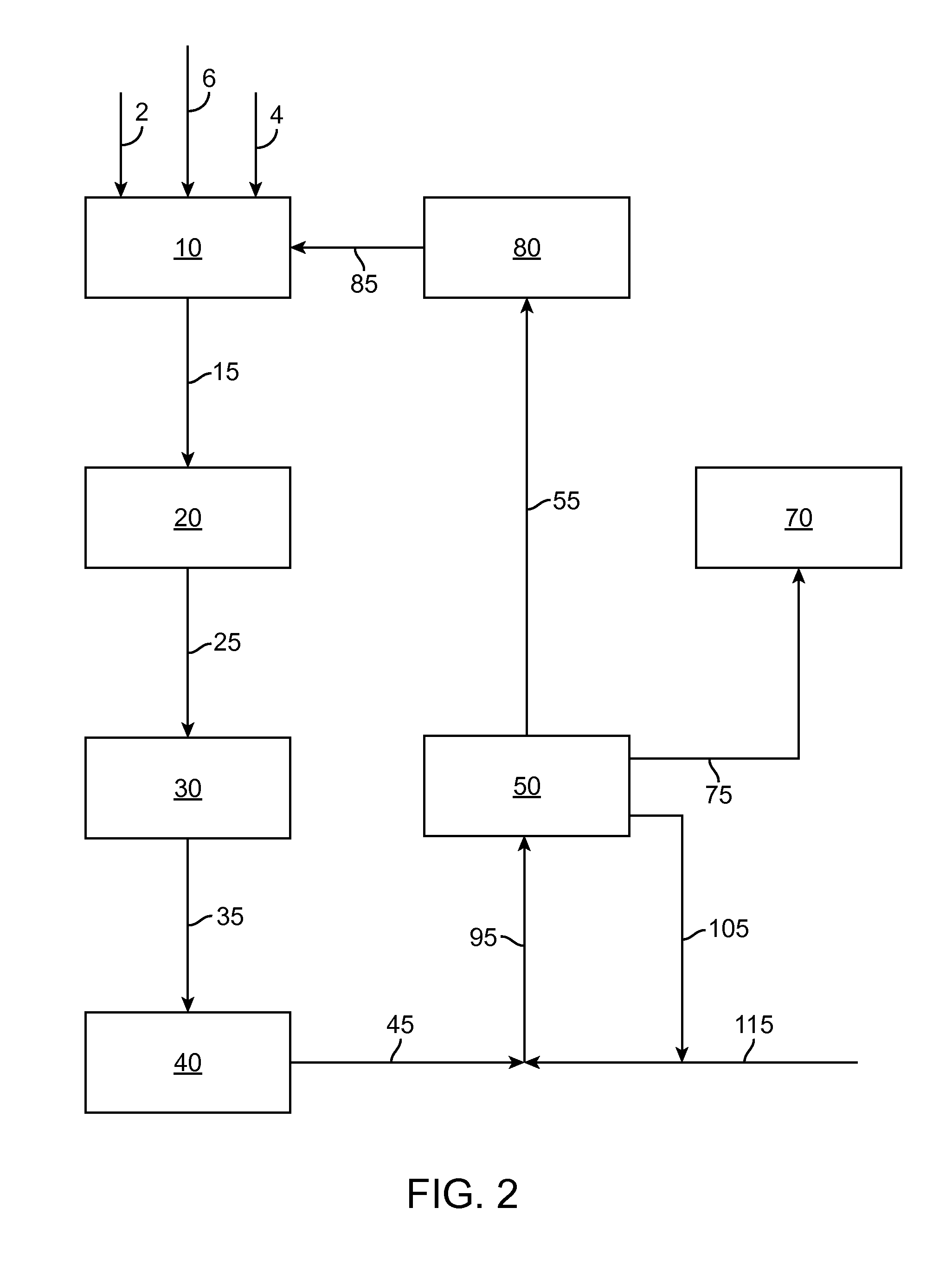

In-Situ Kerogen Conversion and Oxidant Regeneration

InactiveUS20130161002A1Process economyEfficient productionFluid removalDrilling compositionOrganic acidKerogen

Disclosed herein are methods for extracting a kerogen-based product from subsurface shale formations. The methods utilize in-situ reactions of kerogen involving liquid phase chemistry at formation temperatures and pressures. These methods rely on chemically modifying the shale-bound kerogen to render it mobile, using chemical oxidants. In the methods disclosed herein an oxidant is provided to the subsurface shale formation comprising kerogen in an inorganic matrix, the oxidant converting the kerogen to form organic acids, and forming a mobile kerogen-based product. The spent oxidant is regenerated in-situ to restore at least some of the original oxidation activity. At least a portion of the mobile kerogen-based product is recovered. The kerogen-derived product can be upgraded to provide commercial products.

Owner:CHEVROU USA INC

In-situ kerogen conversion and oxidant regeneration

InactiveUS8851177B2More environmentally benignProcess economyFluid removalDrilling compositionKerogenOrganic acid

The invention relates to methods for extracting a kerogen-based product from subsurface shale formations. The methods utilize in-situ reactions of kerogen involving liquid phase chemistry at formation temperatures and pressures. These methods rely on chemically modifying the shale-bound kerogen to render it mobile, using chemical oxidants. In one embodiment, an oxidant is provided to the subsurface shale formation comprising kerogen in an inorganic matrix, the oxidant converting the kerogen to form organic acids, and forming a mobile kerogen-based product. The spent oxidant is regenerated in-situ to restore at least some of the original oxidation activity. At least a portion of the mobile kerogen-based product is recovered. The kerogen-derived product can be upgraded to provide commercial products.

Owner:CHEVROU USA INC

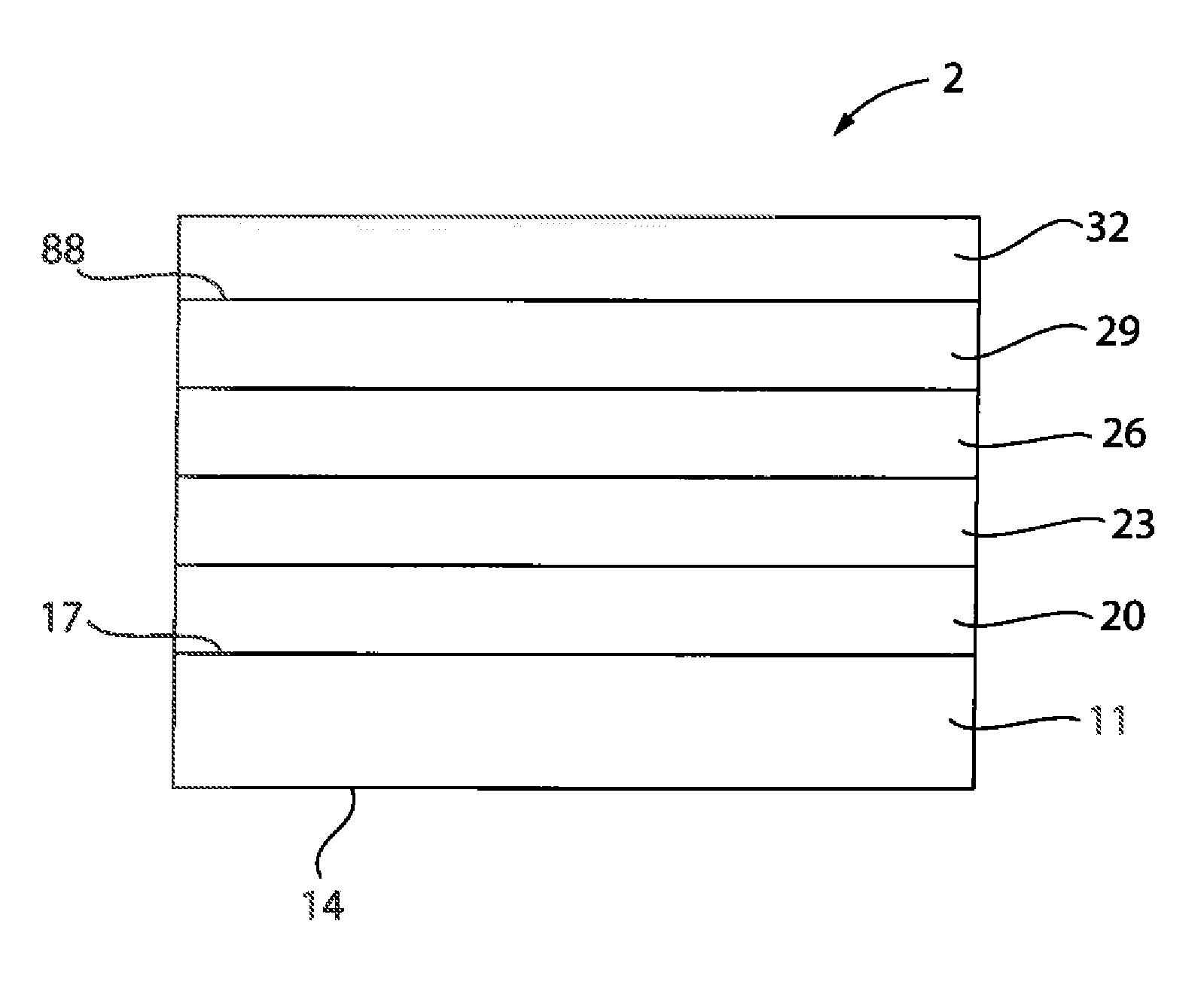

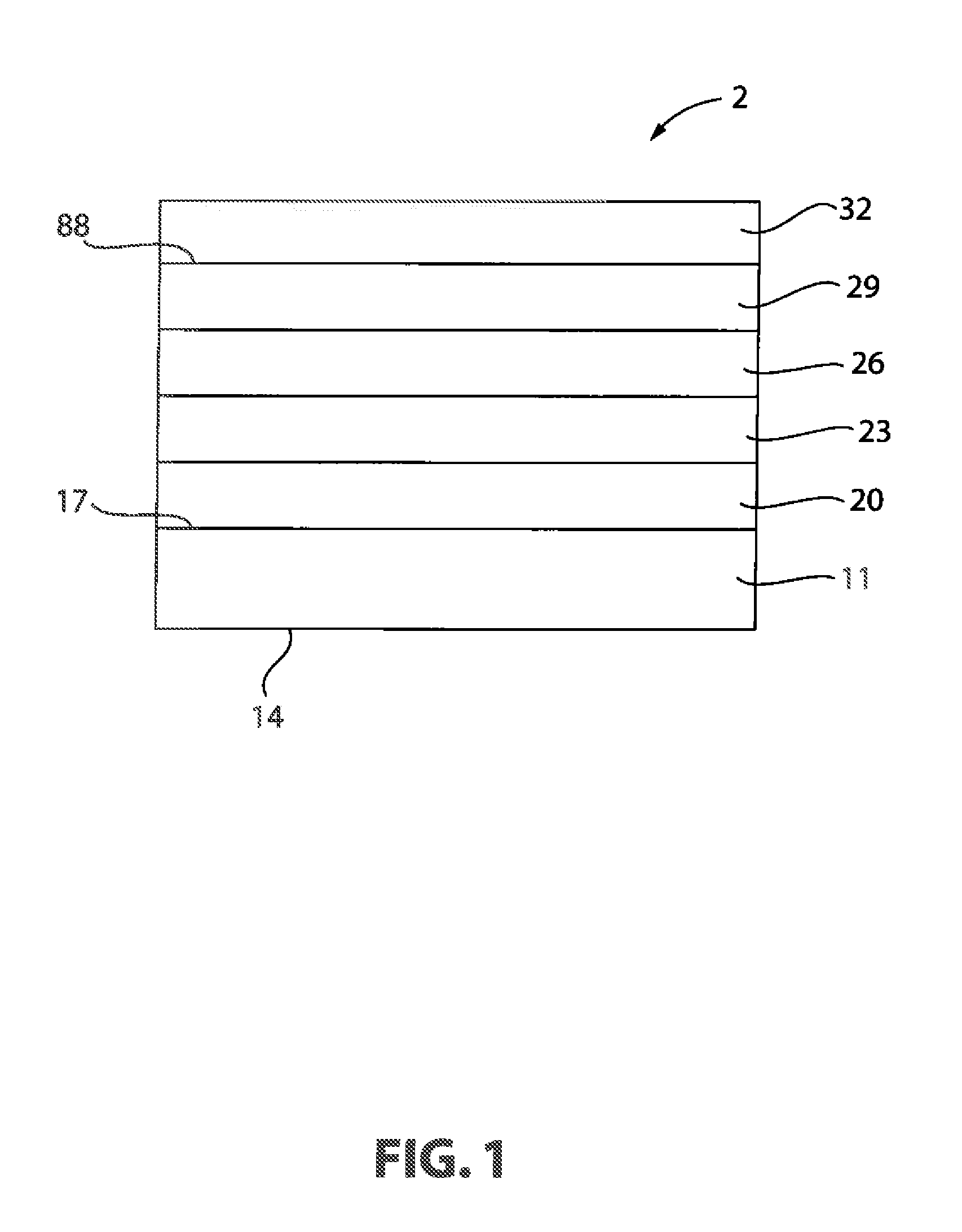

Multilayer tissue regeneration system

ActiveUS20080095817A1Facilitated releaseMaintain activityBiocideOrganic active ingredientsDissolutionBiology

A system for growing tissue based upon layers of an inorganic matrix, wherein each layer of the inorganic matrix is designed to dissolve at a separate rate and result in sequential growth factor delivery upon its dissolution.

Owner:WISCONSIN ALUMNI RES FOUND

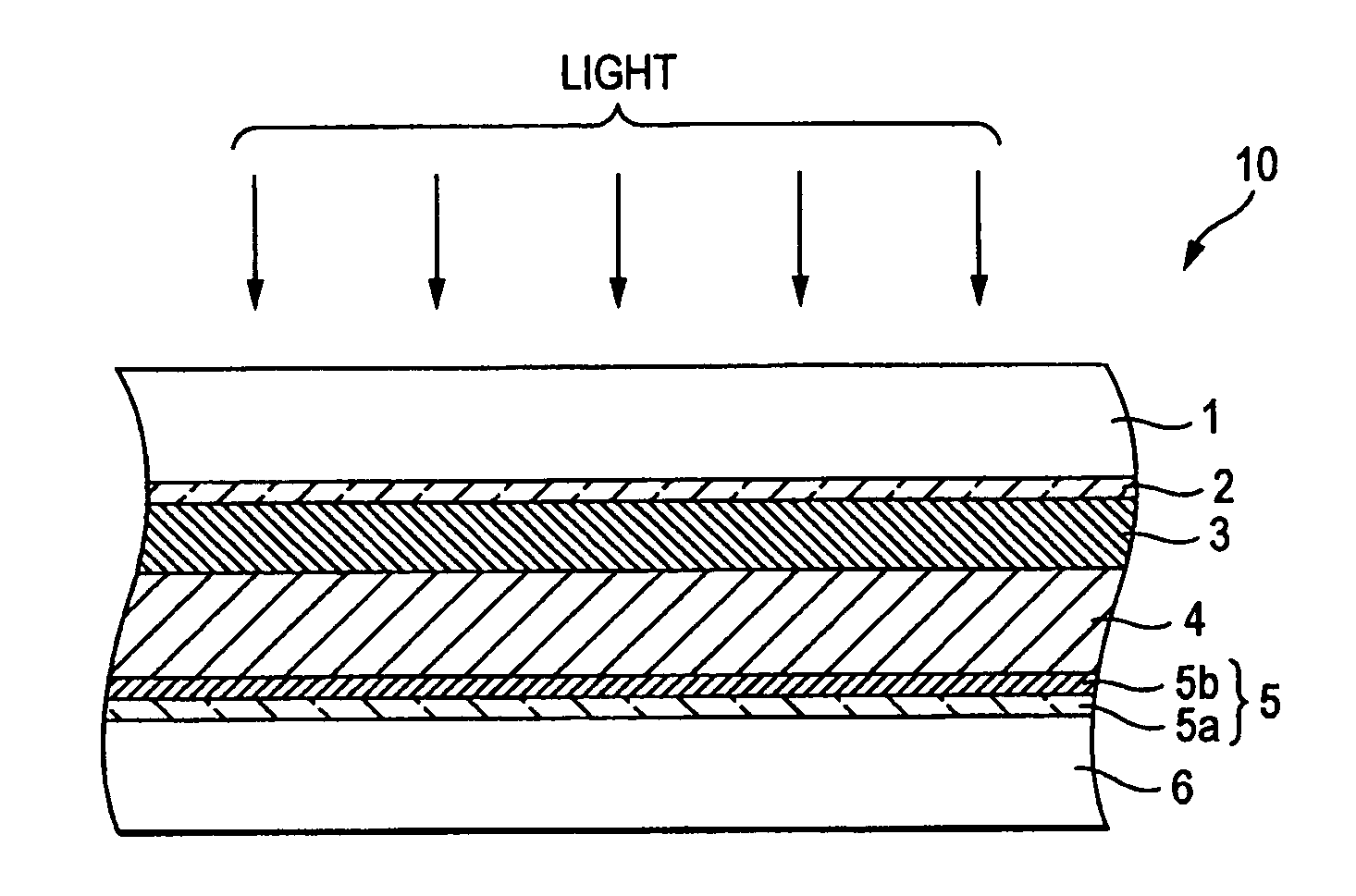

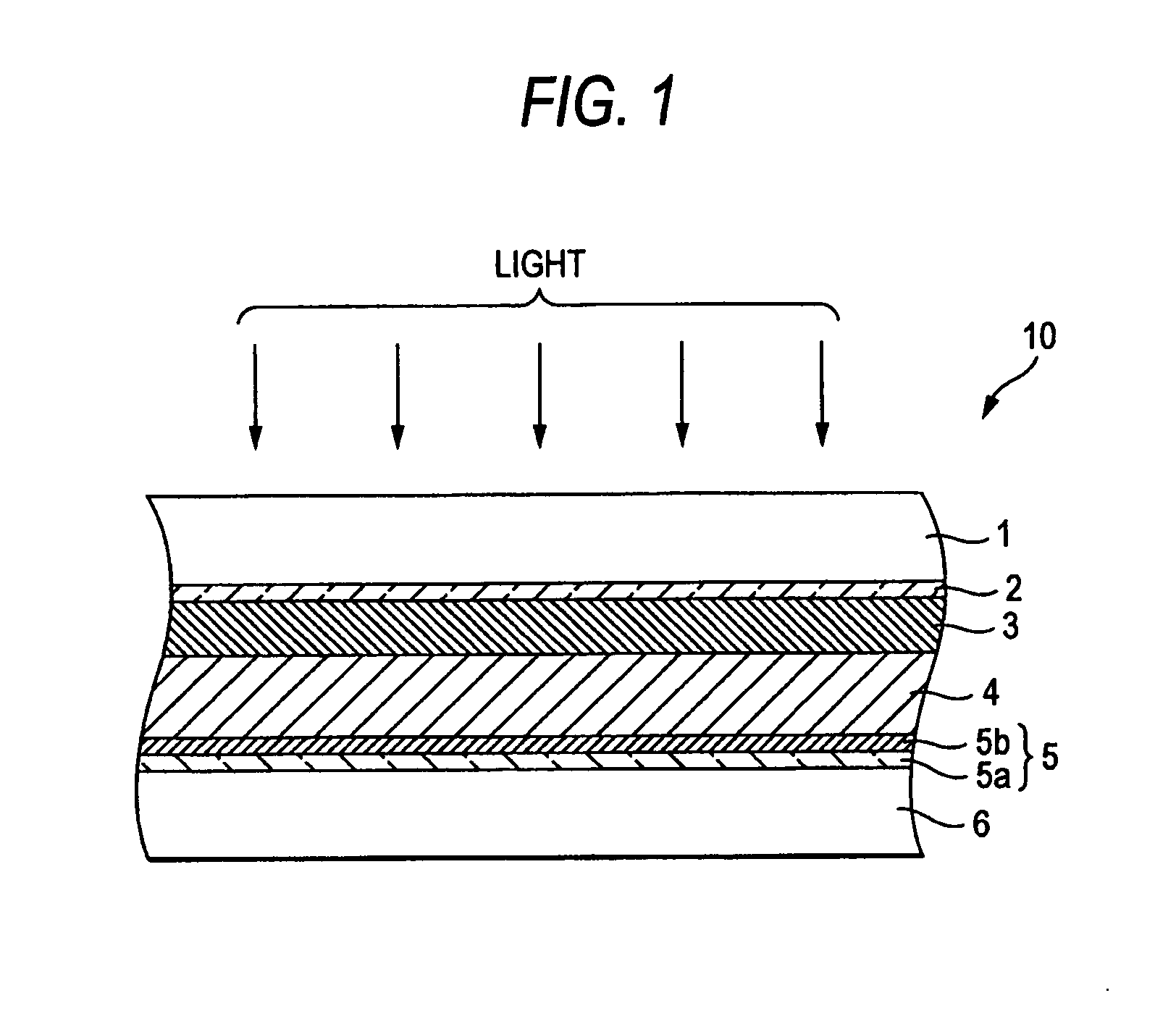

Photoelectric conversion apparatus and gelling agent

InactiveUS20070175510A1Large specific surface areaImprove performanceElectrolytic capacitorsPhotovoltaic energy generationPhotoelectric conversionSemiconductor

A photoelectric conversion apparatus is provided. The photoelectric conversion apparatus includes an electrolyte layer interposed between a semiconductor layer and a counter electrode. The electrolyte layer includes an electrolyte solution retained in a fibrous inorganic matrix in a gel state.

Owner:SONY CORP

Light emitting diode component comprising polysilazane bonding layer

ActiveUS20130221393A1Good optical clarityImprove thermal stabilitySolid-state devicesSemiconductor devicesPhosphorPolysilazane

In one embodiment, a semiconductor component, such as a wavelength converter wafer, is described wherein the wavelength converter is bonded to an adjacent inorganic component with a cured bonding layer comprising polysilazane polymer. The wavelength converter may be a multilayer semiconductor wavelength converter or an inorganic matrix comprising embedded phosphor particles. In another embodiment, the semiconductor component is a pump LED component bonded to an adjacent component with a cured bonding layer comprising polysilazane polymer. The adjacent component may the described wavelength converter(s) or another component comprised of inorganic material(s) such as a lens or a prism. Also described are methods of making semiconductor components such as wavelength converters and LED's.

Owner:3M INNOVATIVE PROPERTIES CO

Drug delivery systems using mesoporous oxide films

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Reflective article having a sacrificial cathodic layer

The present invention relates to reflective articles, such as solar mirrors, that include a sacrificial cathodic layer. The reflective article, more particularly includes a substrate, such as glass, having a multi-layered coating thereon that includes a lead-free sacrificial cathodic layer. The sacrificial cathodic layer includes at least one transition metal, such as a particulate transition metal, which can be in the form of flakes (e.g., zinc flakes). The sacrificial cathodic layer can include an inorganic matrix formed from one or more organo-titanates. Alternatively, the sacrificial cathodic layer can include an organic polymer matrix (e.g., a crosslinked organic polymer matrix formed from an organic polymer and an aminoplast crosslinking agent). The reflective article also includes an outer organic polymer coating, that can be electrodeposited over the sacrificial cathodic layer.

Owner:VITRO FLAT GLASS LLC

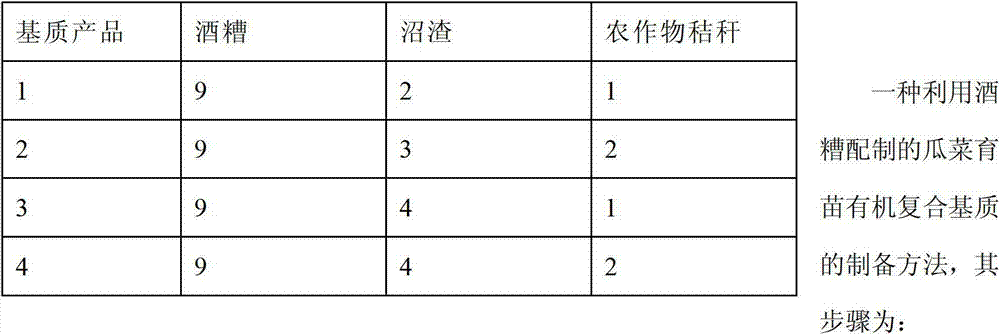

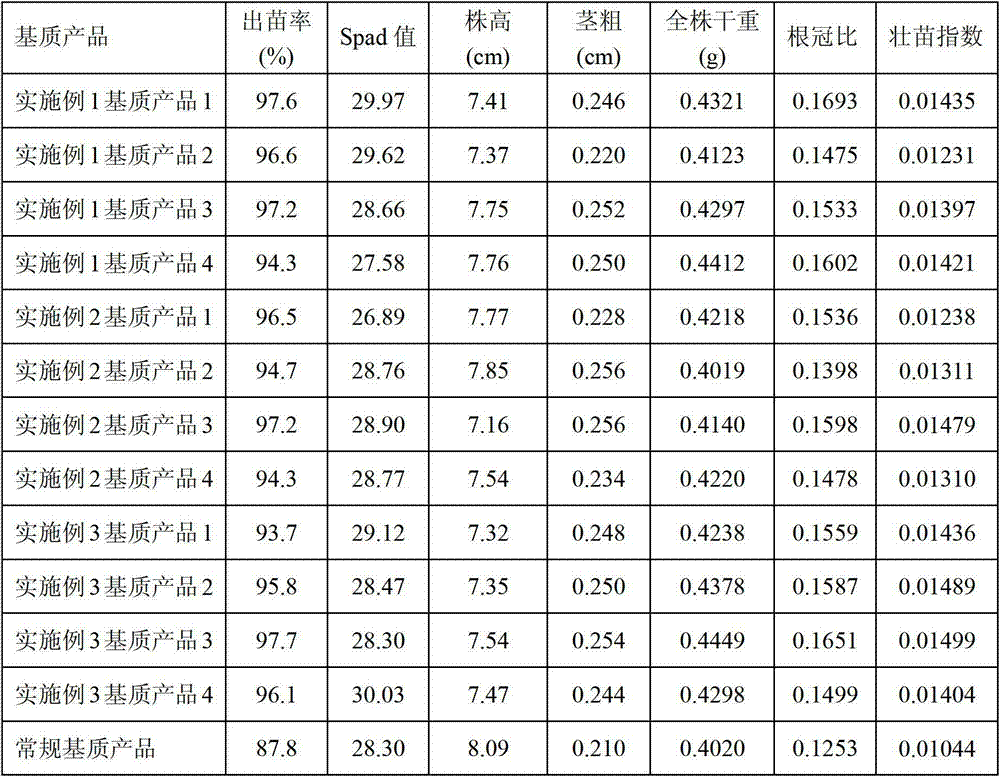

Melon/vegetable seedling raising organic compound substrate prepared from vinasse and production method thereof

ActiveCN103086755AImprove water retentionImprove breathabilityBio-organic fraction processingClimate change adaptationSlagMushroom

The invention discloses a melon / vegetable seedling raising organic compound substrate prepared from vinasse and a production method thereof. The volume ratio of components is vinasse:mushroom residue or vinasse:cattle manure or vinasse:marsh slag:crop straw. The production method comprises the following steps: collecting the raw materials, pulverizing, pretreating, rotting, preparing the substrate and carrying out quality inspection to obtain the melon / vegetable seedling raising organic compound substrate prepared from vinasse. The substrate disclosed by the invention has the advantages of high water retention property, favorable air permeability, abundant nutrient content and no inorganic substrate; the substrate can promote melon / vegetable seedlings to absorb and utilize water, fertilizer and air, and enhance the stress tolerance of the seedlings, thereby being beneficial to sound and full seedlings; and the substrate can completely substitute the substrate product mainly composed of grass carbon in the market. At present, the grass carbon is nonrenewable resources, and has the defects of high price and nonuniform distribution. The substrate disclosed by the invention can protect the resources and lower the seedling raising cost.

Owner:武汉维尔福生物科技股份有限公司

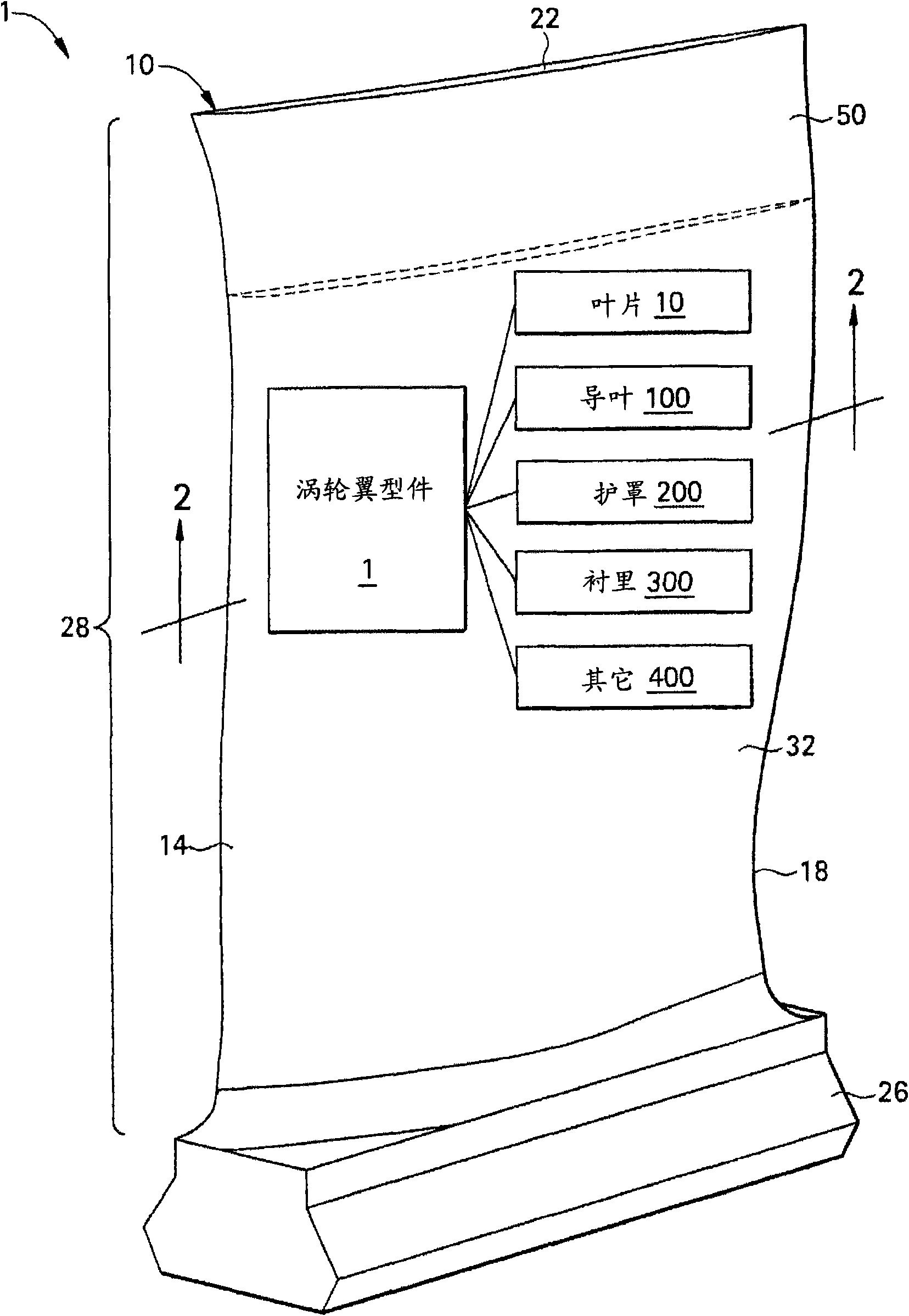

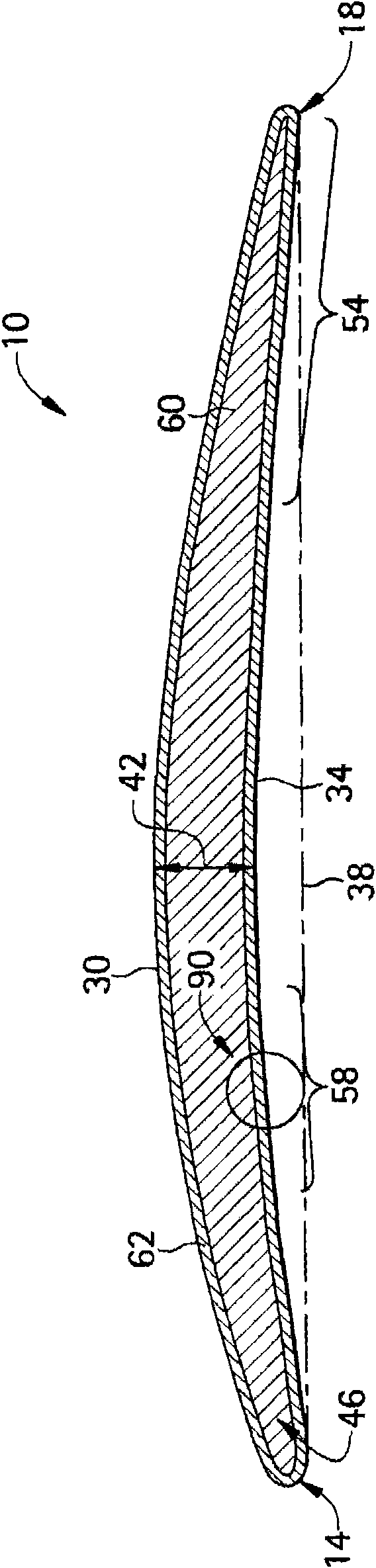

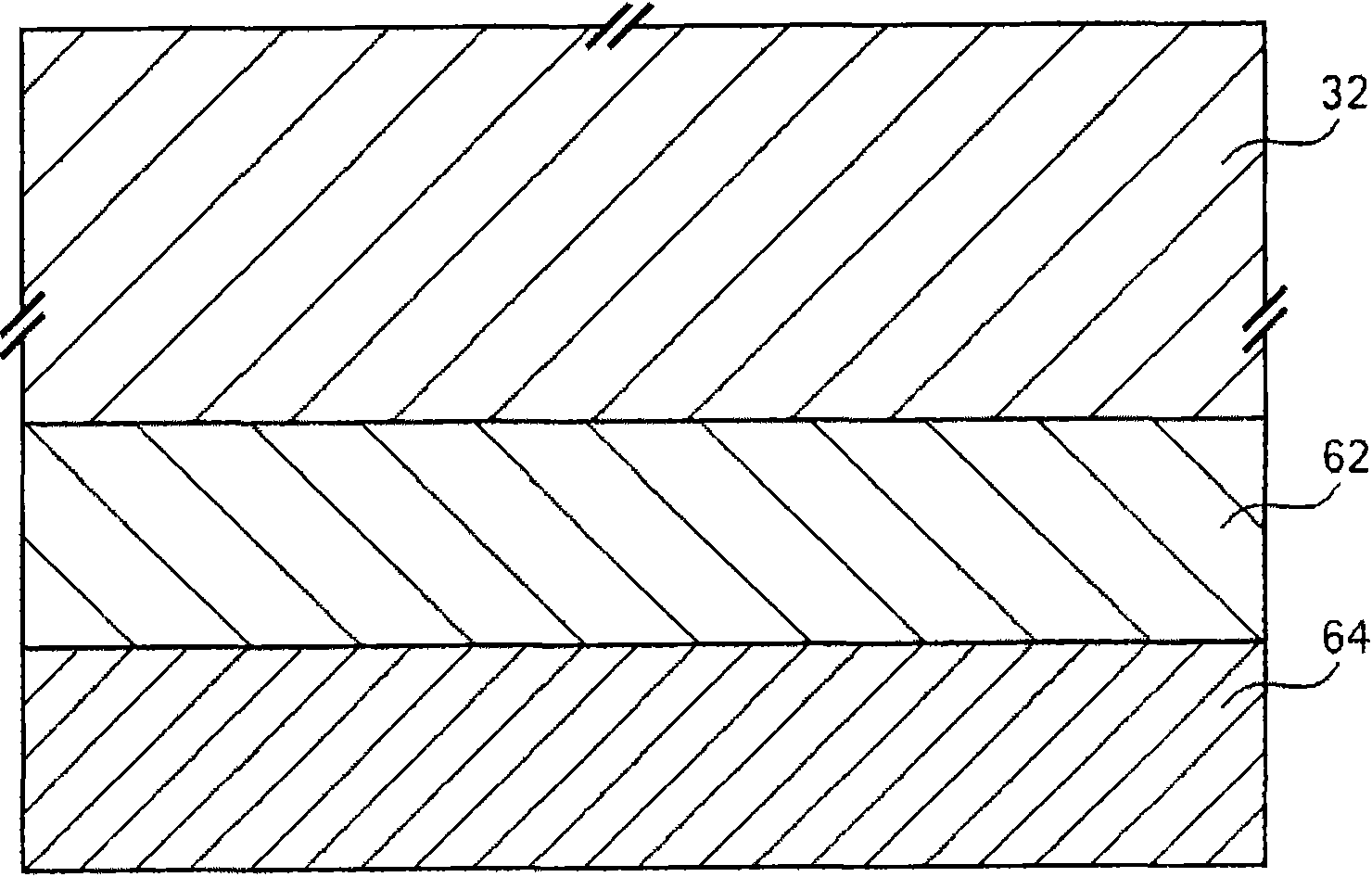

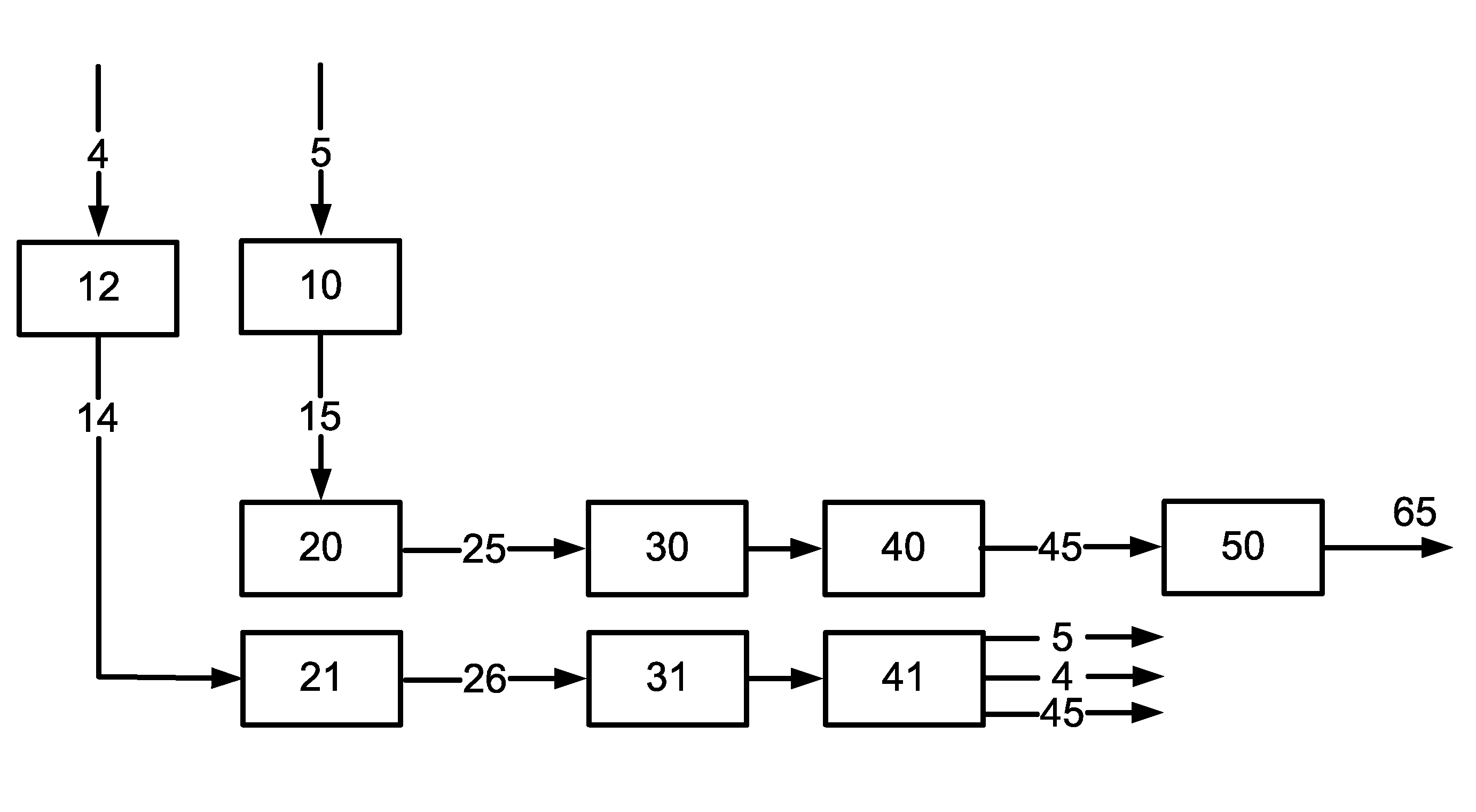

Erosion and corrosion resistant turbine compressor airfoil and method of making the same

The invention relates to an erosion and corrosion resistant turbine compressor airfoil and a method of making the same. A sacrificial and erosion-resistant turbine compressor airfoil includes a turbine compressor airfoil having a modified airfoil surface. The airfoil surface has an airfoil coating that includes a sacrificial coating comprising a layer of Al, Cr, Zn, an Ni-Al alloy, an Al-Si alloy, an Al-based alloy, a Cr-based alloy or a Zn-based alloy, an Al polymer composite, or a combination thereof, or a layer of a conductive undercoat and an overcoat of an inorganic matrix binder having a plurality of ceramic particles and conductive particles embedded therein disposed on the undercoat. The airfoil coating also includes an sacrificial coating, wherein one of the sacrificial coating or the erosion-resistant coating is disposed on the airfoil surface and the other of the corrosion-resistant coating or the erosion-resistant coating is disposed on the respective one, and wherein the sacrificial coating is more anodic than the airfoil surface or the erosion-resistant coating.

Owner:GENERAL ELECTRIC CO

Preconditioning a subsurface shale formation by removing extractible organics

InactiveUS8701788B2Easy accessMore environmentally benignFluid removalLiquid hydrocarbon mixture productionHydrocarbon solventsKerogen

The invention relates to methods for extracting an organics component from subsurface shale formations comprising kerogen and an extractible organics component in an inorganic matrix. Among other factors, these processes are based on the discovery that to more easily access the kerogen in oil shale, it is helpful to first remove the extractible organics component from the subsurface shale formation. The methods utilize a hydrocarbon solvent to at least partially solubilize the extractible organics component. The extractible organics component can be isolated and upgraded to produce useful products. The processes are more environmentally benign, more economical, and more efficient in producing commercial products and in providing access to kerogen.

Owner:CHEVROU USA INC

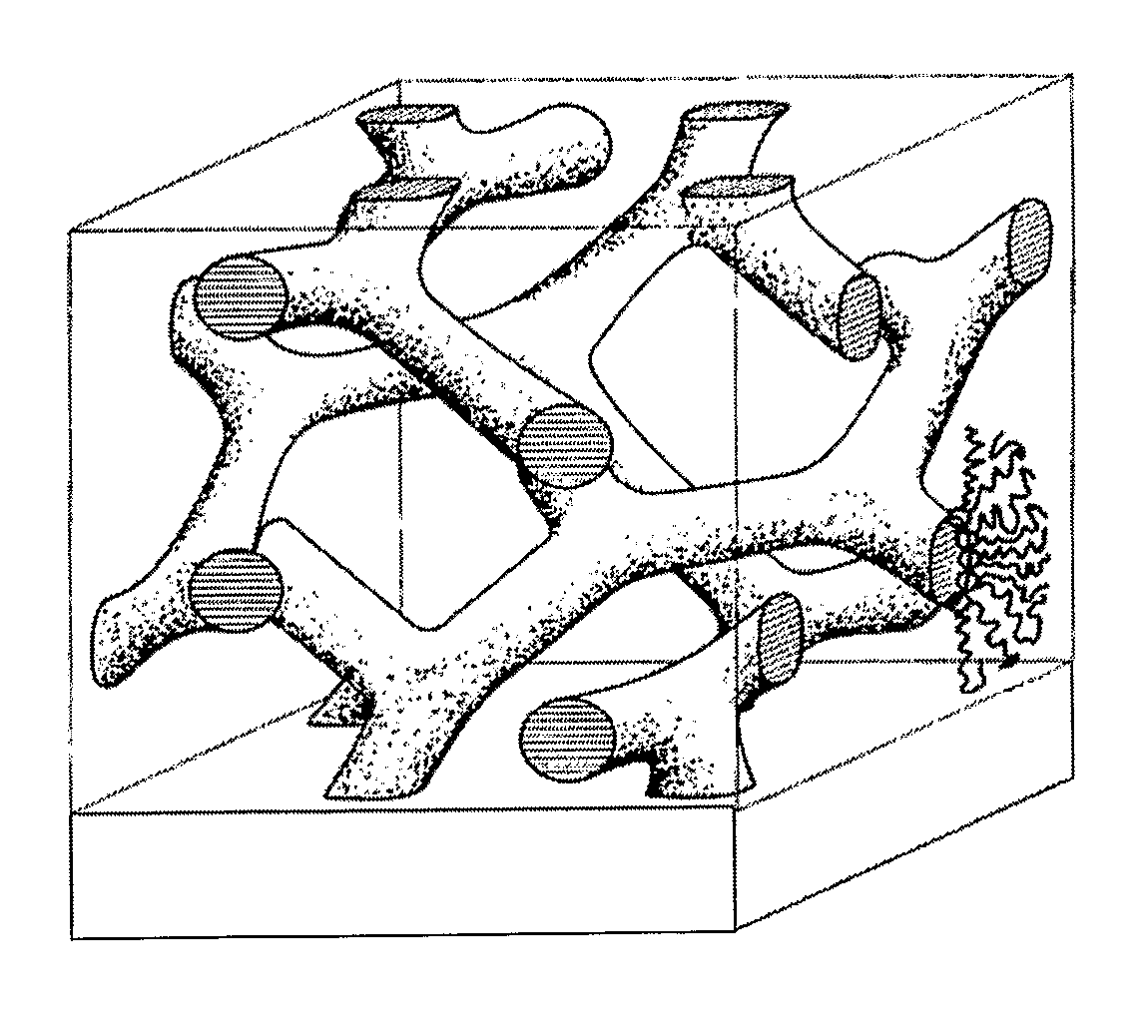

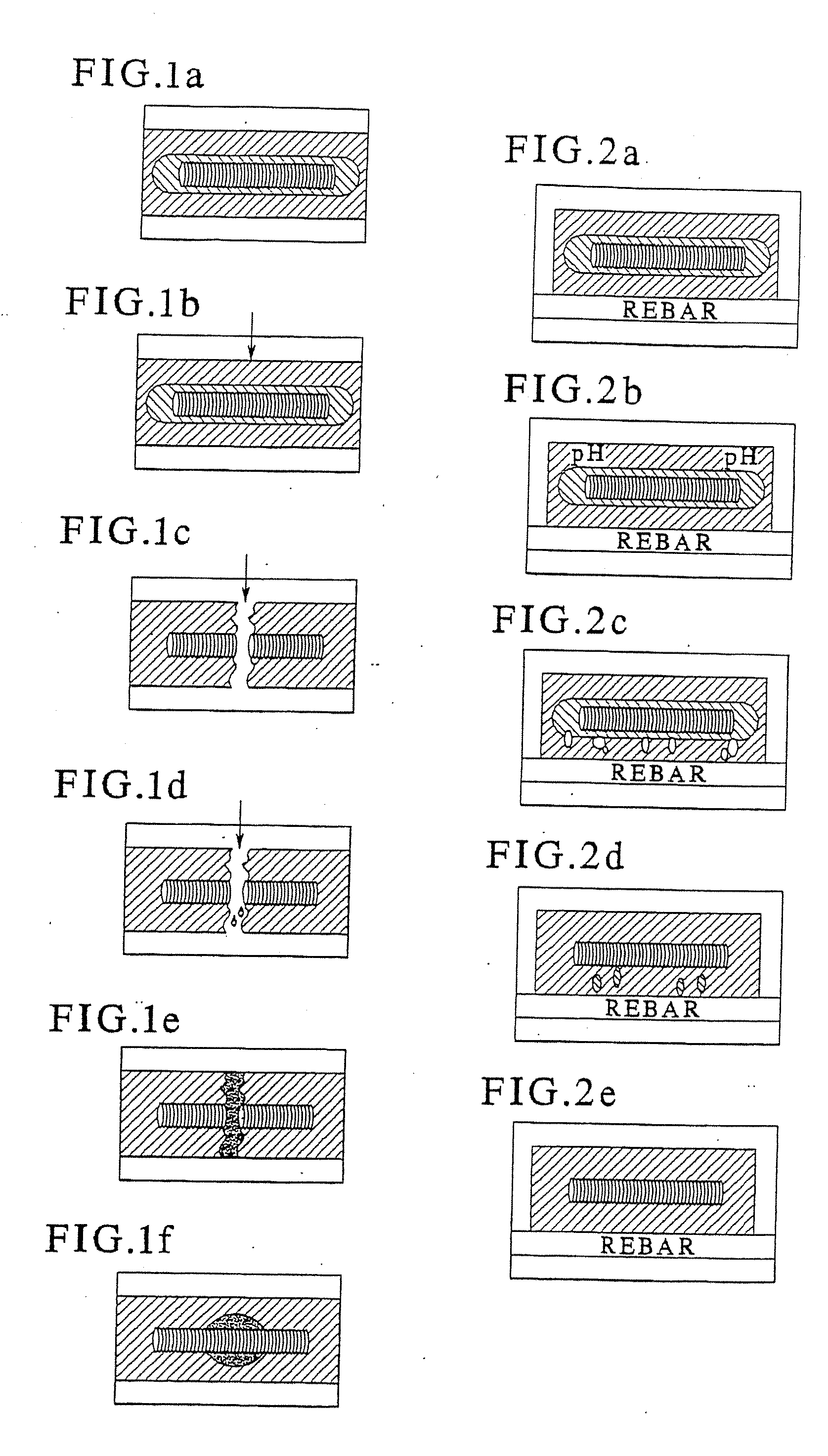

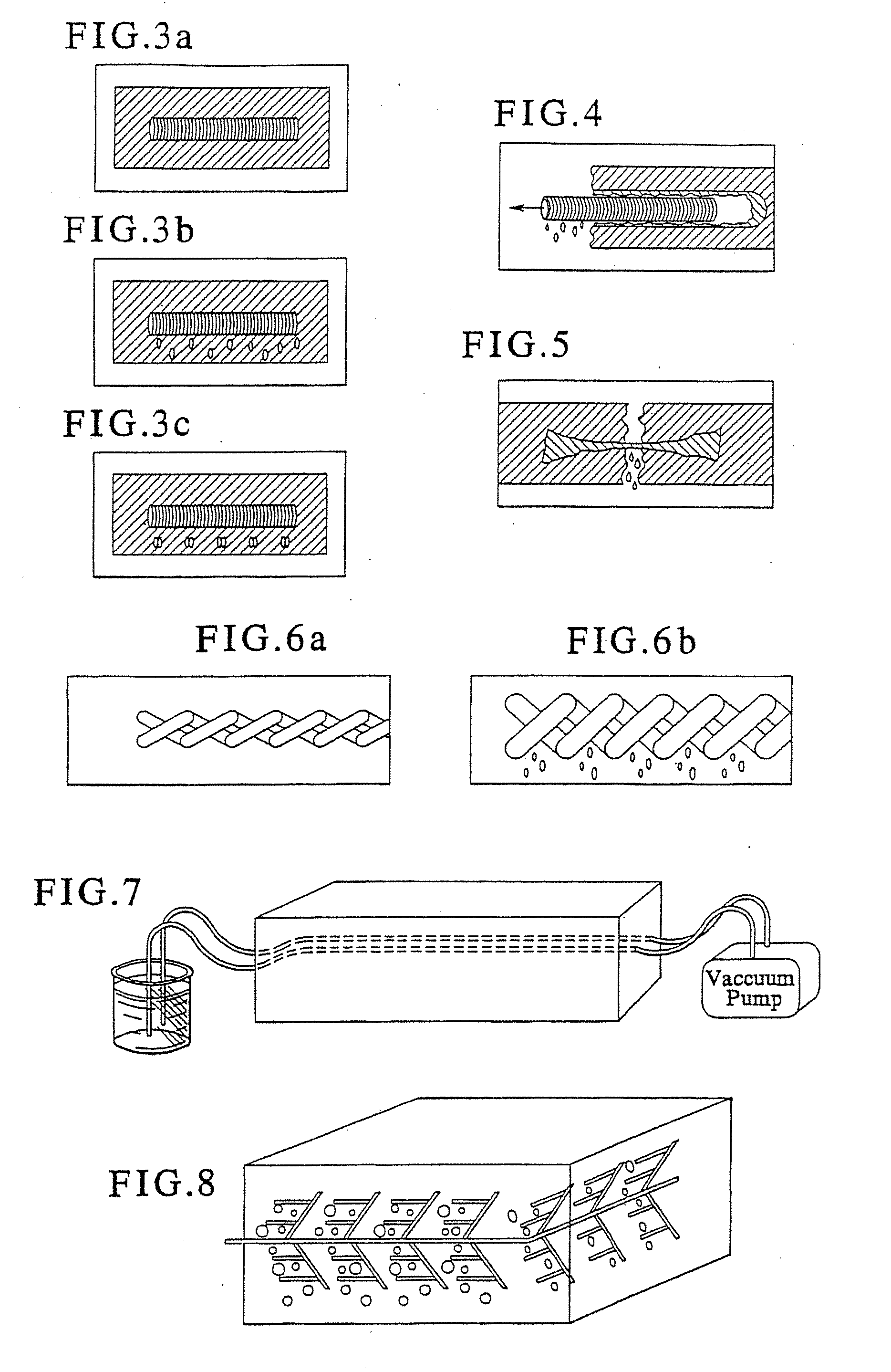

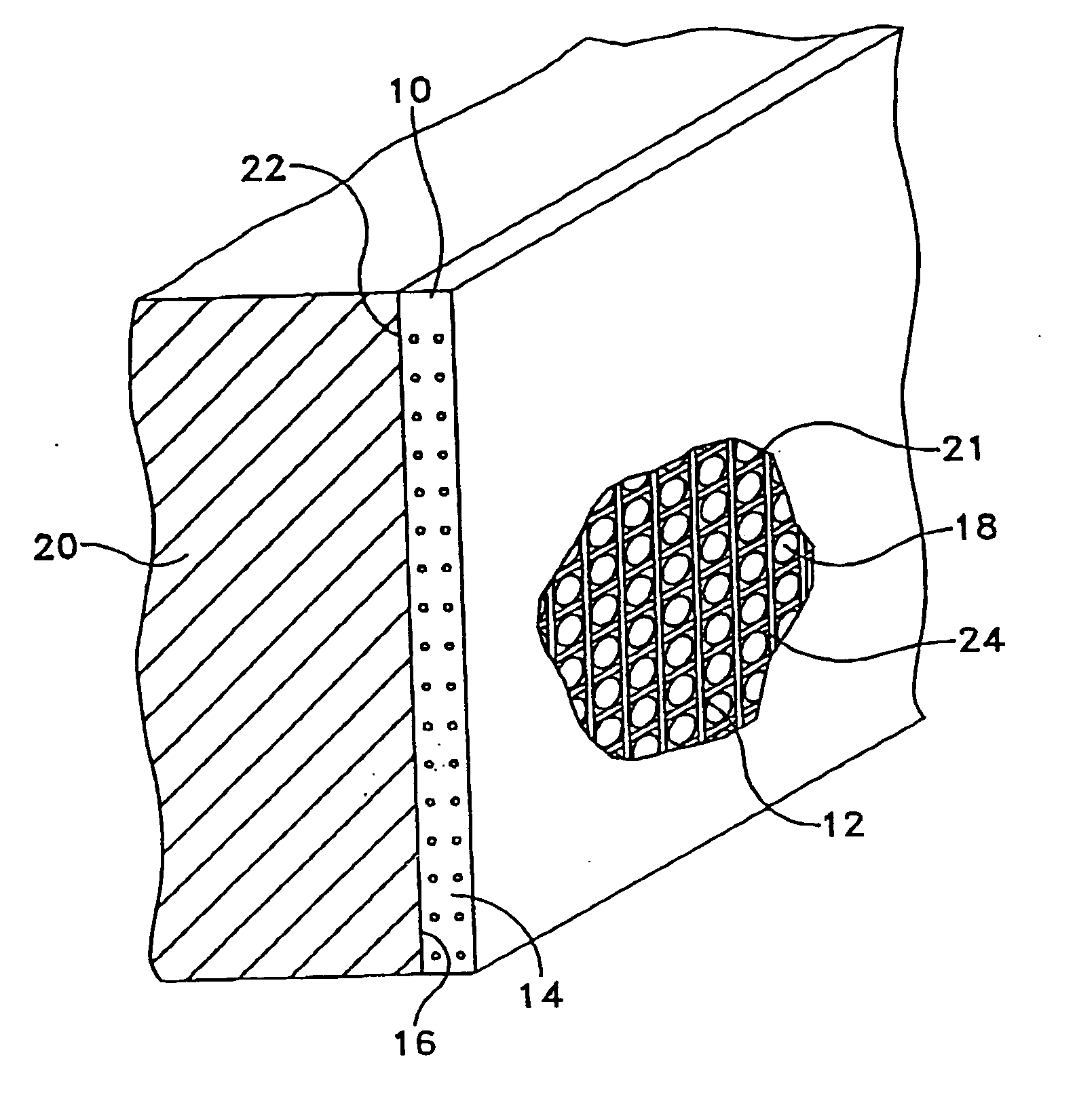

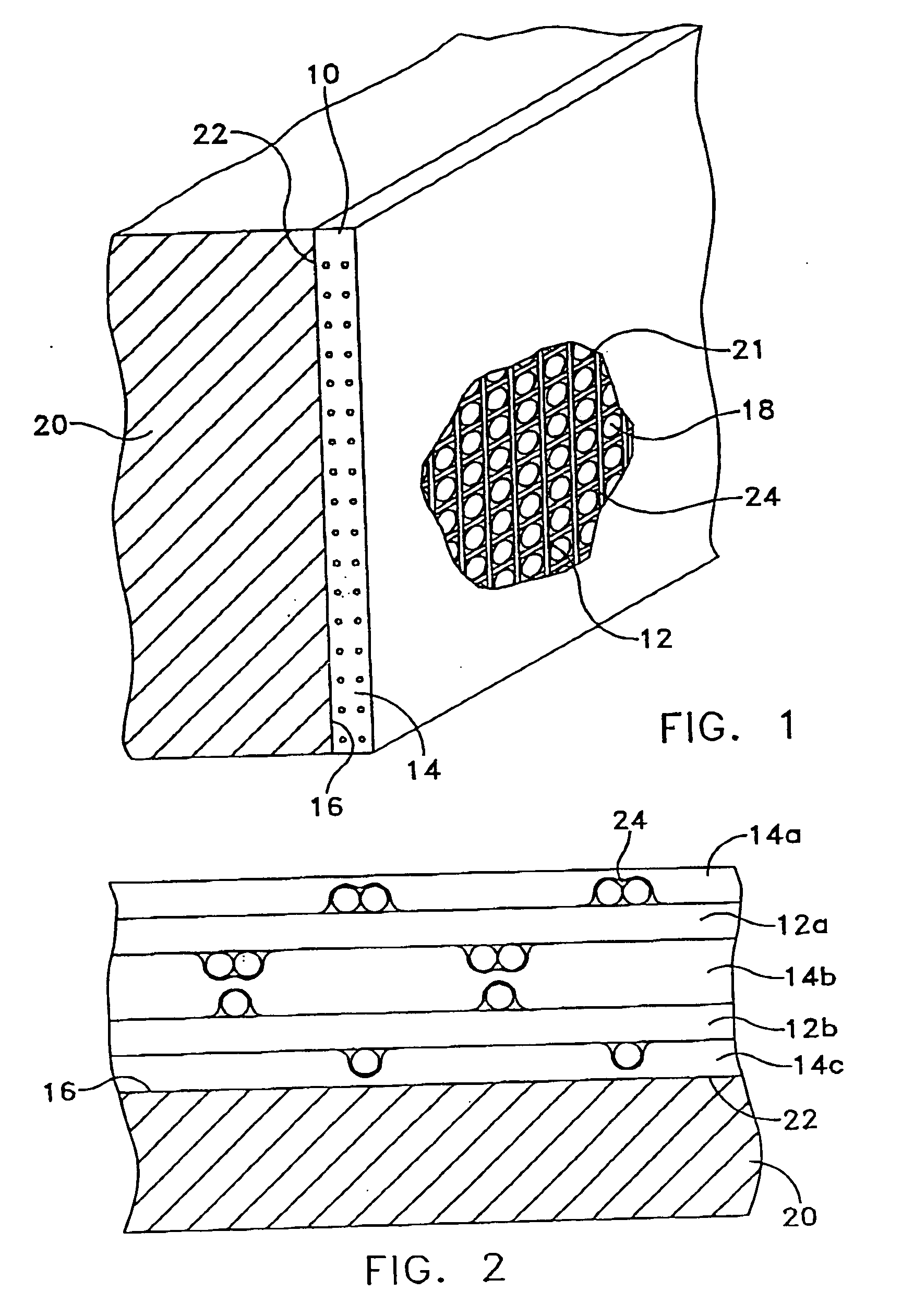

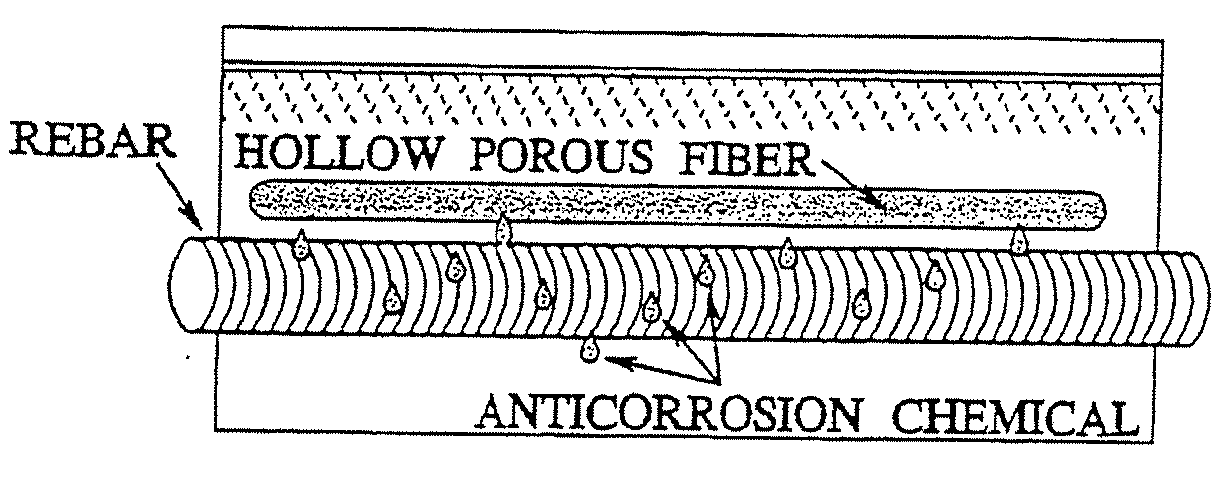

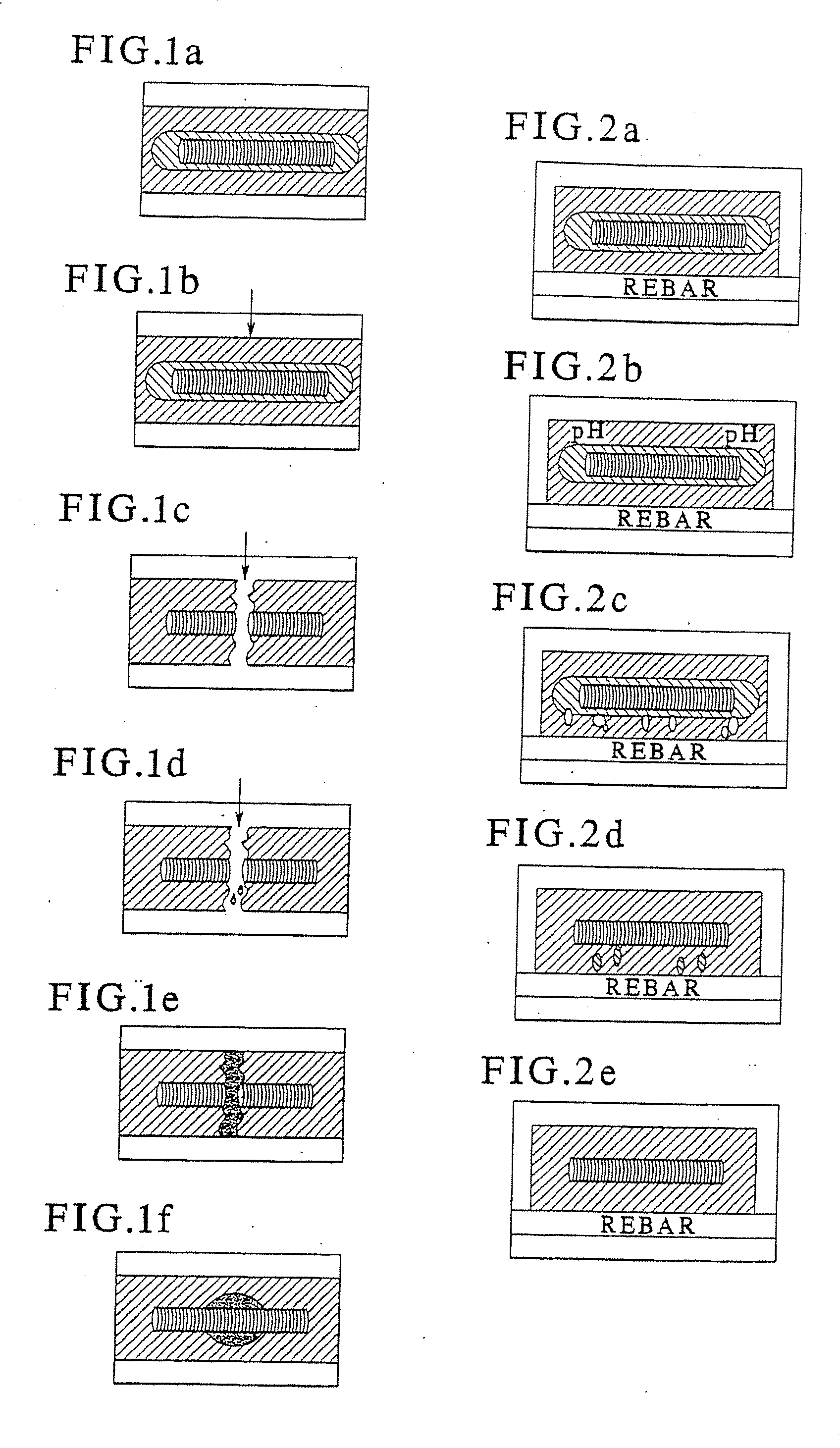

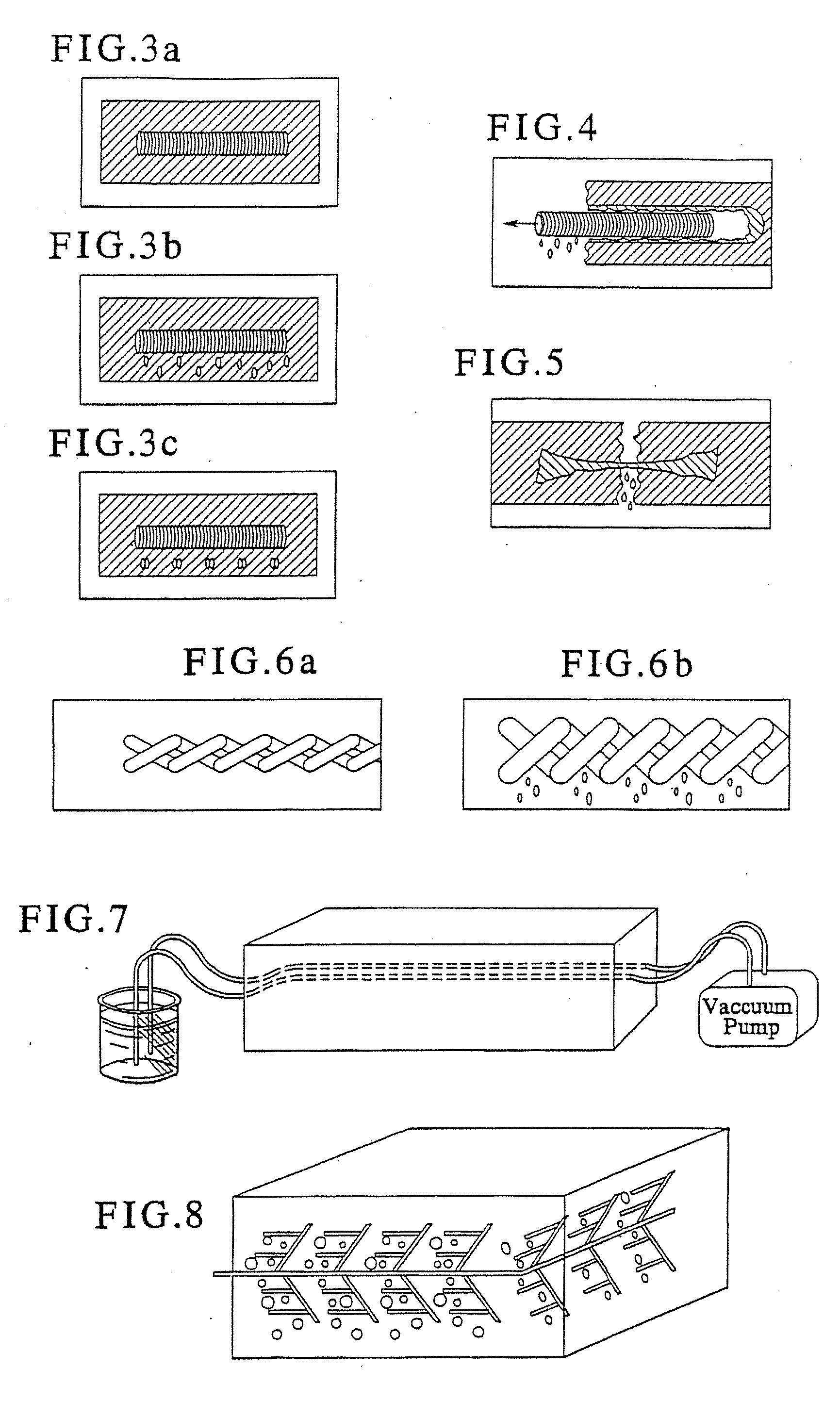

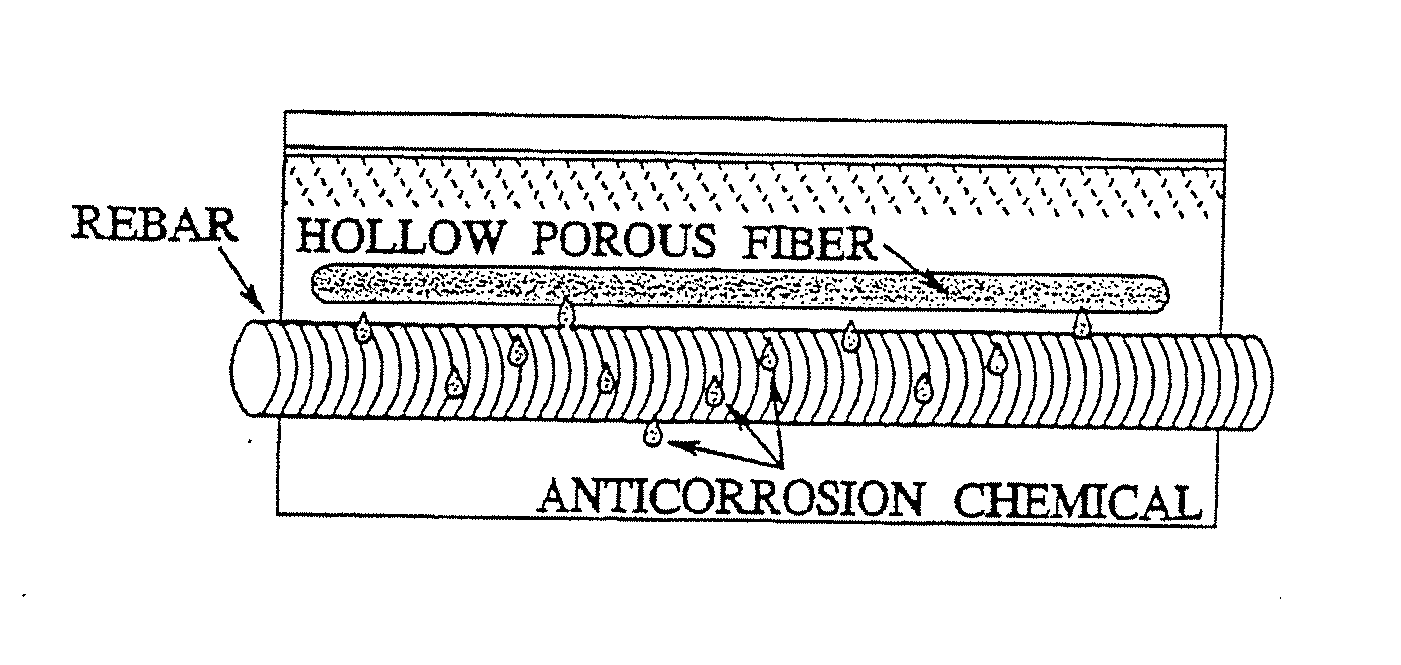

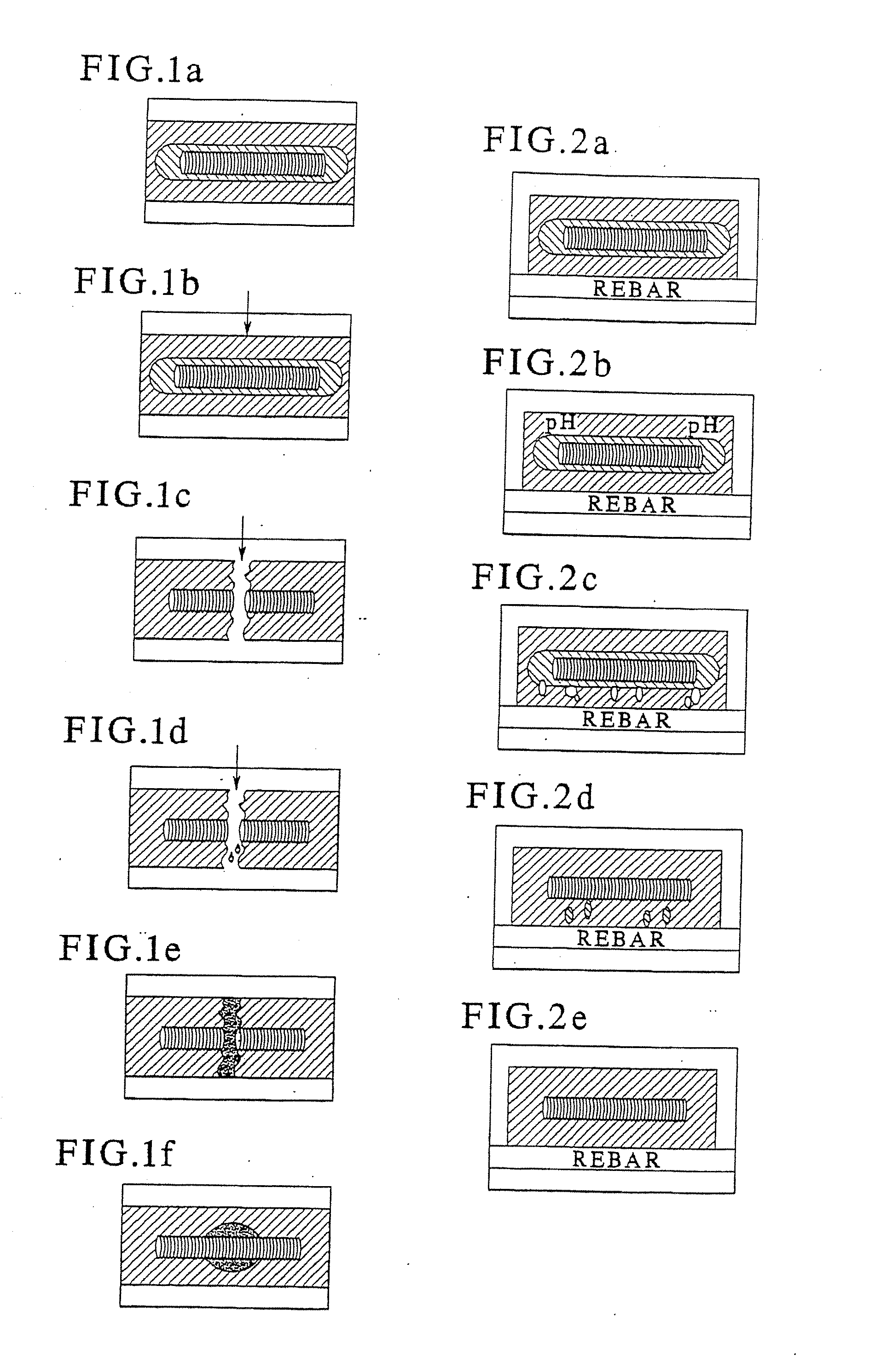

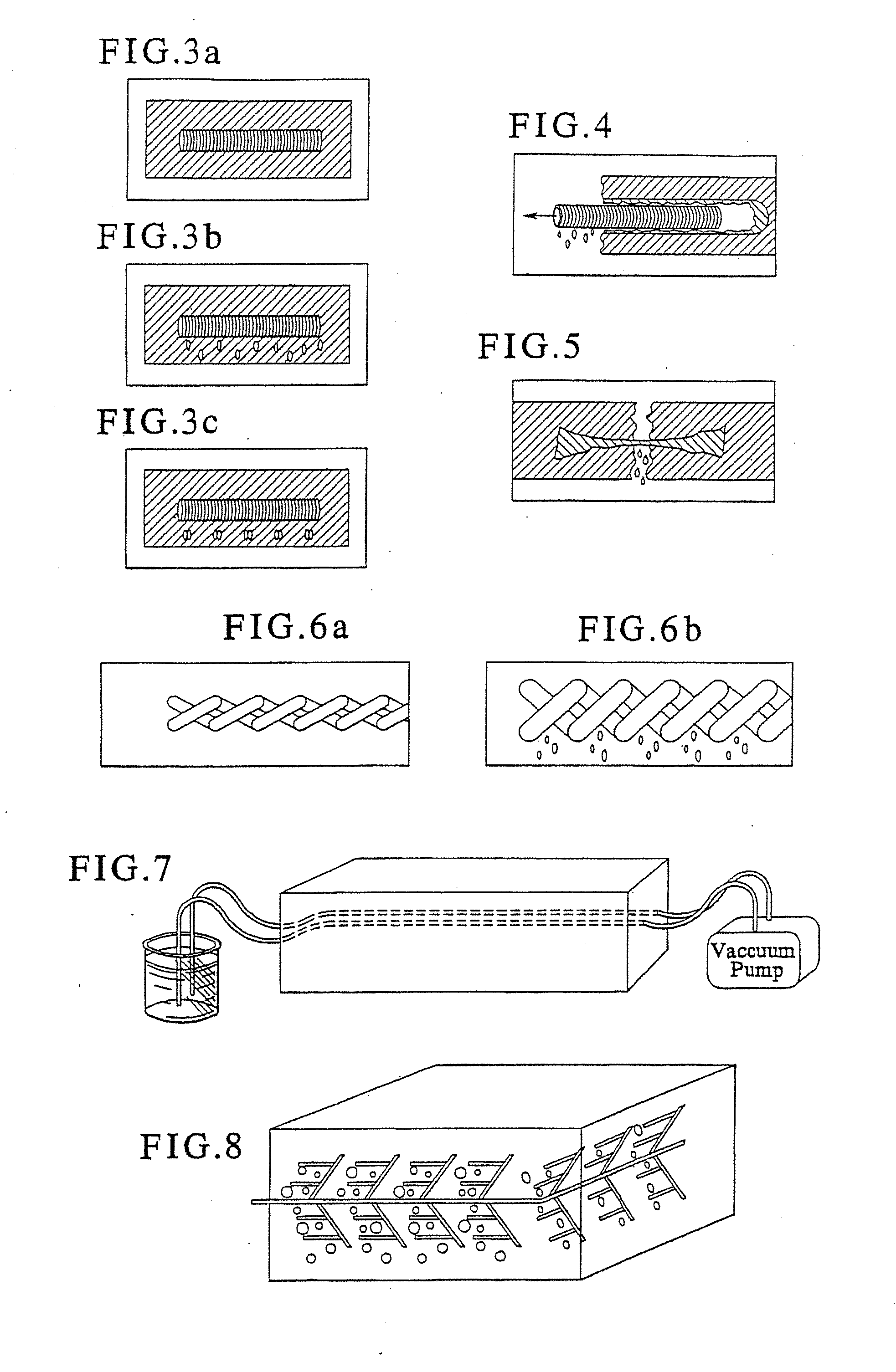

Self-repairing, reinforced matrix materials

InactiveUS20060169180A1Long-term durabilityIncreased durabilityMaterial nanotechnologyAuxillary shaping apparatusMaterials sciencePolymer

Self-repairing, fiber reinforced matrix materials include a matrix material including inorganic as well as organic matrices. Disposed within the matrix are hollow fibers having a selectively releasable modifying agent contained therein. The hollow fibers may be inorganic or organic and of any desired length, wall thickness or cross-sectional configuration. The modifying agent is selected from materials capable of beneficially modifying the matrix fiber composite after curing. The modifying agents are selectively released into the surrounding matrix in use in response to a predetermined stimulus be it internal or externally applied. The hollow fibers may be closed off or even coated to provide a way to keep the modifying agent in the fibers until the appropriate time for selective release occurs. Self-repair, smart fiber matrix composite materials capable of repairing microcracks, releasing corrosion inhibitors or permeability modifiers are described as preferred embodiments in concrete and polymer based shaped articles.

Owner:DRY CAROLYN M

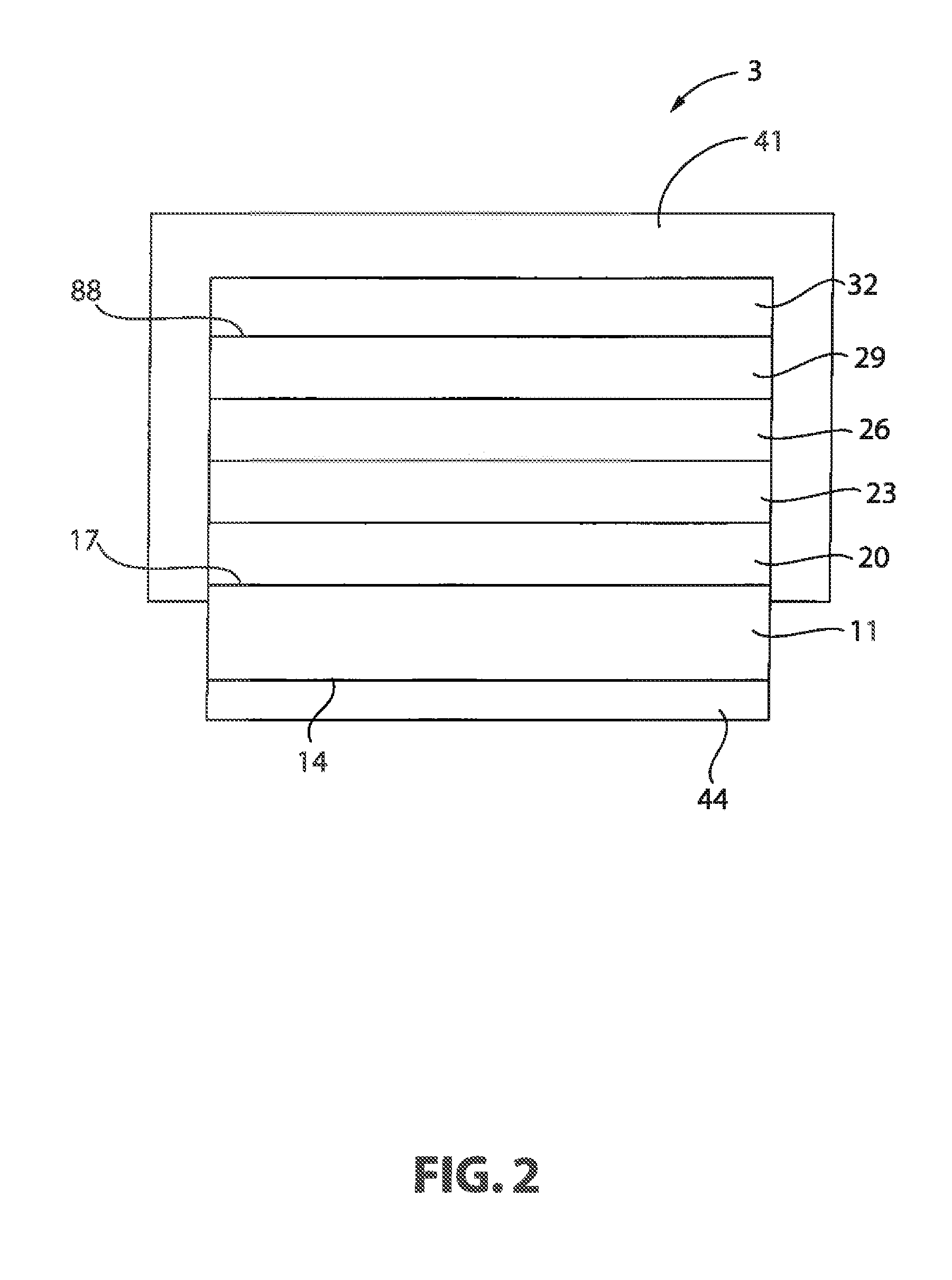

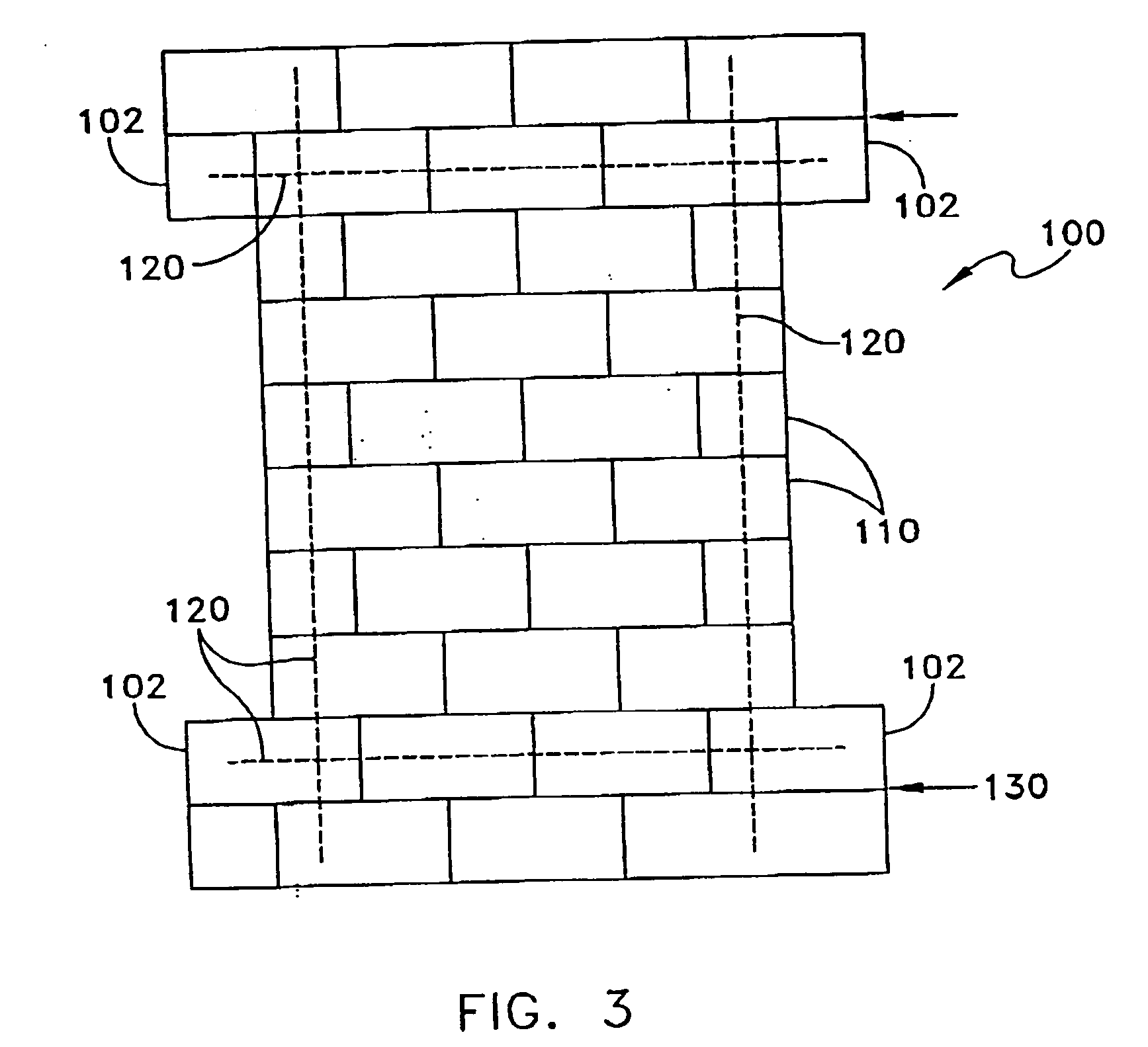

Inorganic matrix-fabric system and method

InactiveUS20050139308A1Improve the immunityHigh strength retentionCovering/liningsUnderground chambersSizingMaterials science

A method of reinforcing a structural support, includes applying a reinforcement system comprising an AR-glass fibrous layer embedded in an inorganic matrix to the structural support. The AR-glass fibrous layer has a sizing applied thereon, and a resinous coating applied is applied over the sizing. The inorganic matrix is adherent to the resinous coating and the resinous coating is adherent to the sizing.

Owner:ALDEA CORINA MARIA +1

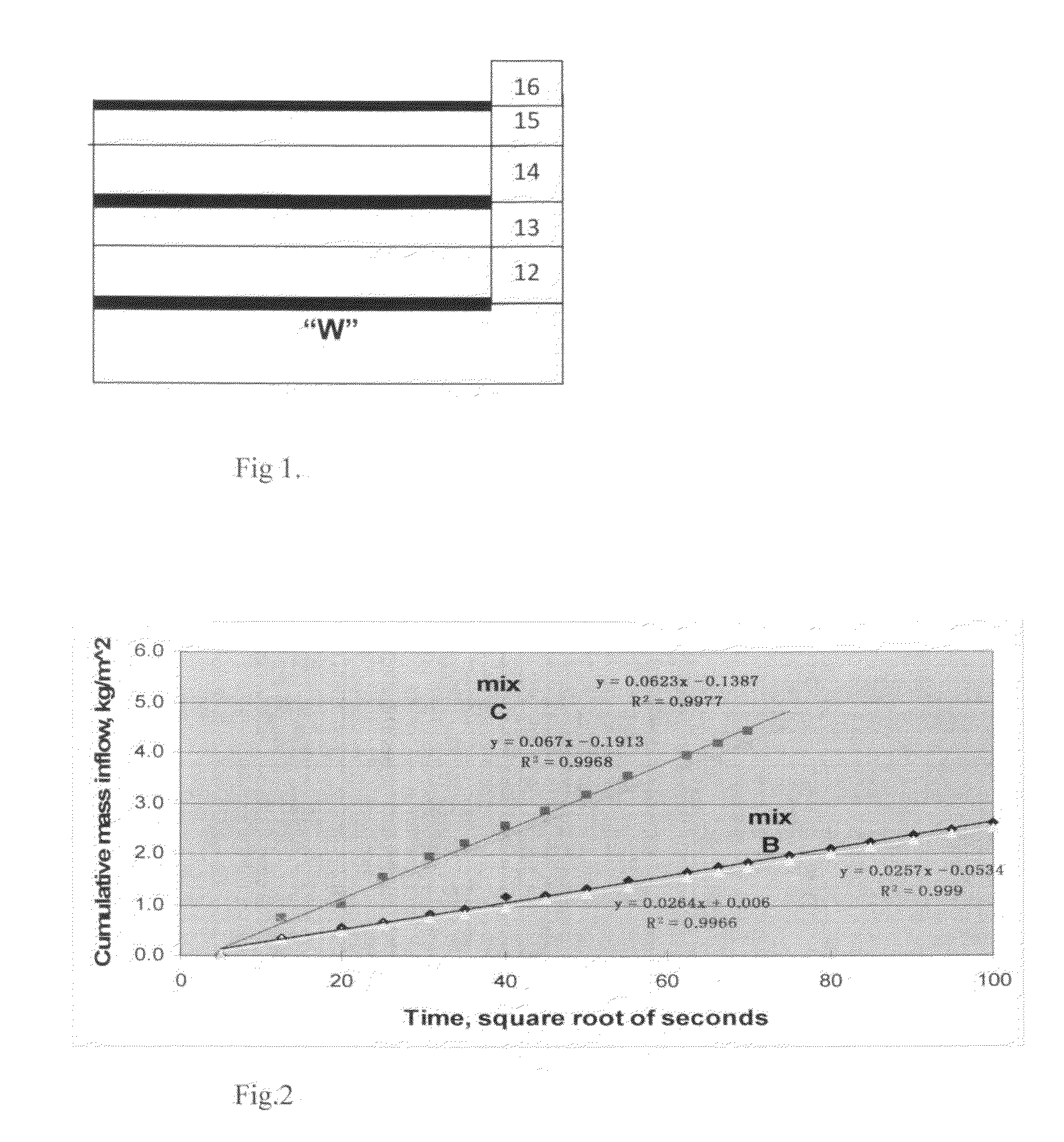

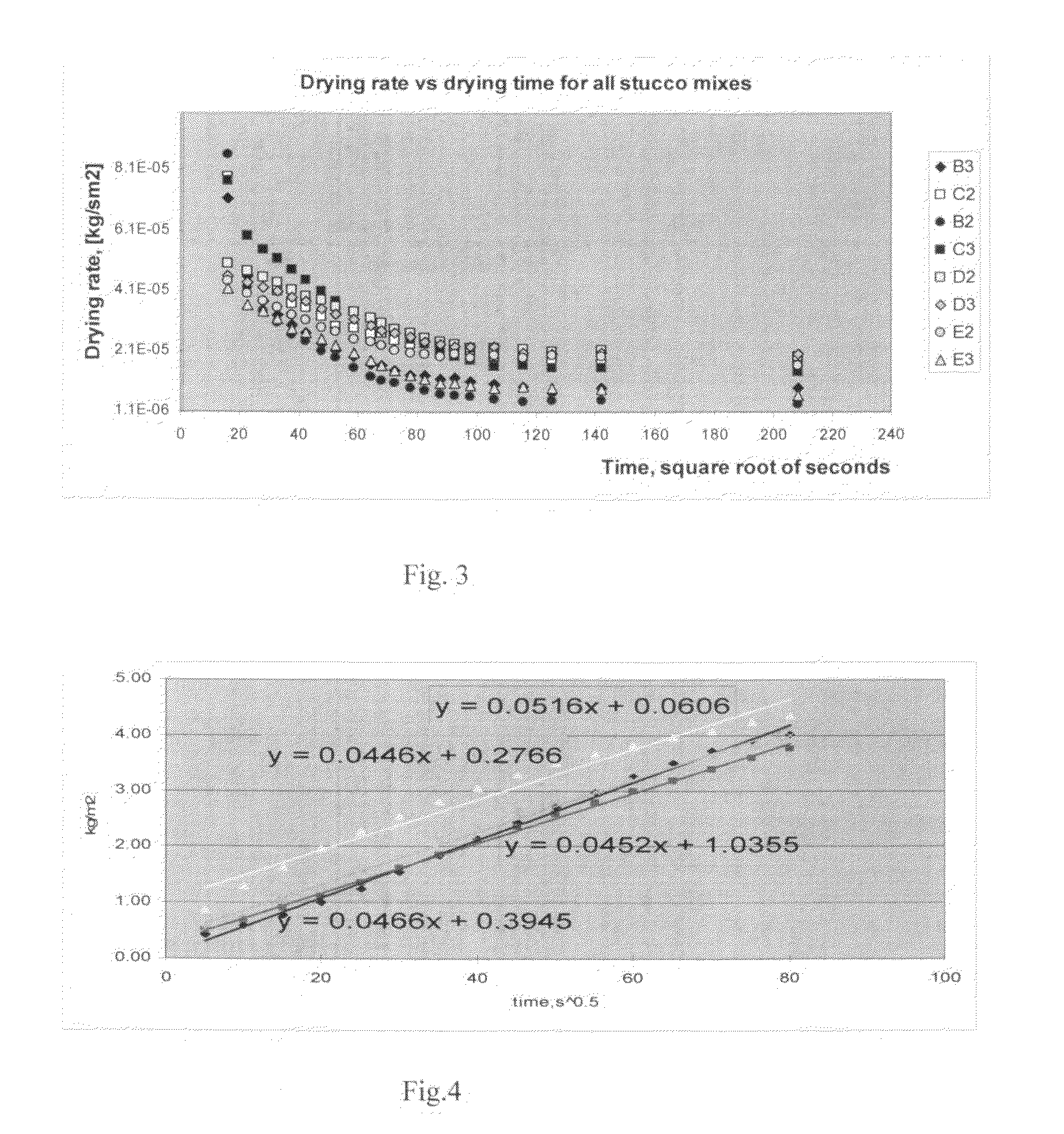

Exterior building wall insulation systems with hygro thermal wrap

InactiveUS20110256786A1Accelerated dryingRaise transfer toWeft knittingLayered productsFreeze thawingWater vapor

A composite, layered, thermal insulation and cladding system and method to construct a hygro thermal (HT) wrap. The external insulation system controls the passage of heat, air, liquid water, water vapor, and moisture permeability of the system with the change of the moisture content in some materials. The HT wrap comprises at a material mix applied in two layers, with or without additional surface treatments. The inventive method includes the material combinations and their fiber diameter or particle size in such a manner that the microstructure of HT wrap will provide pore space for retention of the initially added water, permit expansion of the freezing water (thereby improving freeze-thaw durability), provide the interruption in the crack propagation (because the brittle inorganic matrix of the binders is prone to cracking), and provide a degree of elasticity needed to accommodate movements caused by the polyurethane foam or other substrates.

Owner:BOMBERG MARK

Self-Repairing, Reinforced Matrix Materials

Self-repairing, fiber reinforced matrix materials include a matrix material including inorganic as well as organic matrices. Disposed within the matrix are hollow fibers having a selectively releasable modifying agent contained therein. The hollow fibers may be inorganic or organic and of any desired length, wall thickness or cross-sectional configuration. The modifying agent is selected from materials capable of beneficially modifying the matrix fiber composite after curing. The modifying agents are selectively released into the surrounding matrix in use in response to a predetermined stimulus be it internal or externally applied. The hollow fibers may be closed off or even coated to provide a way to keep the modifying agent in the fibers until the appropriate time for selective release occurs. Self-repair, smart fiber matrix composite materials capable of repairing microcracks, releasing corrosion inhibitors or permeability modifiers are described as preferred embodiments in concrete and polymer based shaped articles.

Owner:DRY CAROLYN

Chemical-free production of graphene-reinforced inorganic matrix composites

Provided is a simple, fast, scalable, and environmentally benign method of producing a graphene-reinforced inorganic matrix composite directly from a graphitic material, the method comprising: (a) mixing multiple particles of a graphitic material and multiple particles of an inorganic solid carrier material to form a mixture in an impacting chamber of an energy impacting apparatus; (b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for peeling off graphene sheets from the graphitic material and transferring the graphene sheets to surfaces of solid inorganic material particles to produce graphene coated or graphene-embedded inorganic particles inside the impacting chamber; and (c) forming graphene-coated or graphene-embedded inorganic particles into the graphene-reinforced inorganic matrix composite. Also provided is a mass of the graphene-coated or graphene-embedded inorganic particles produced by this method.

Owner:NANOTEK INSTR

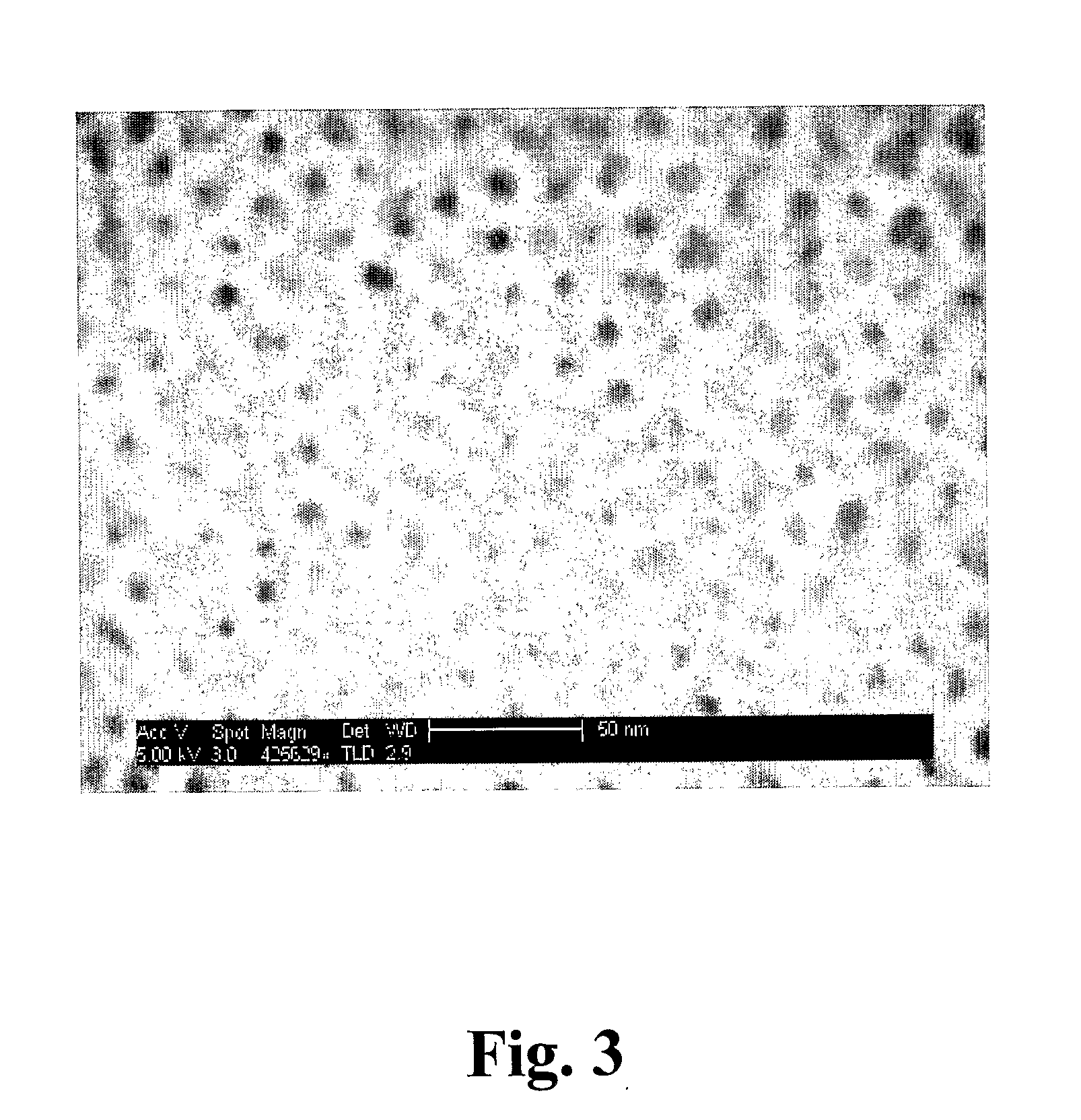

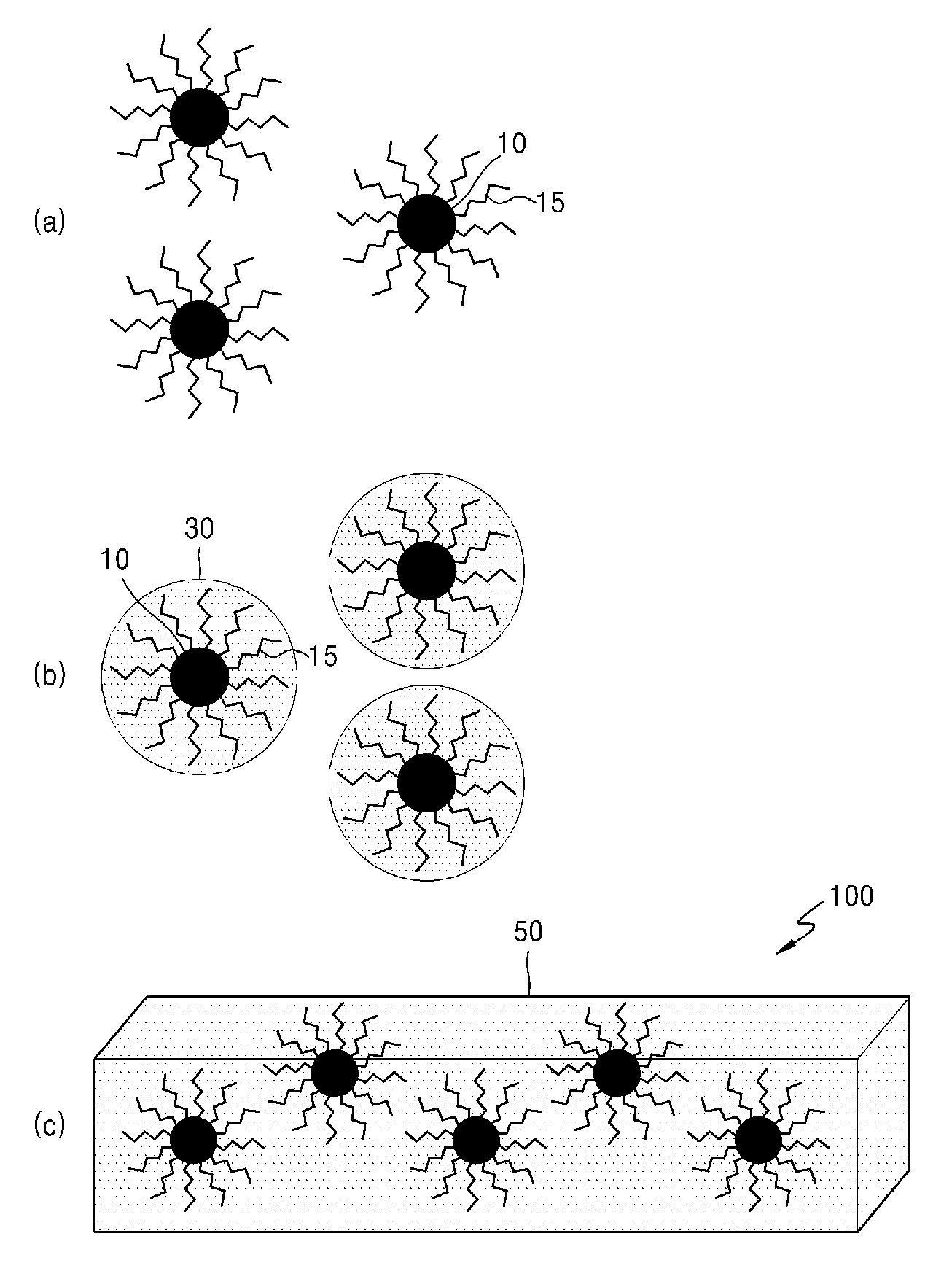

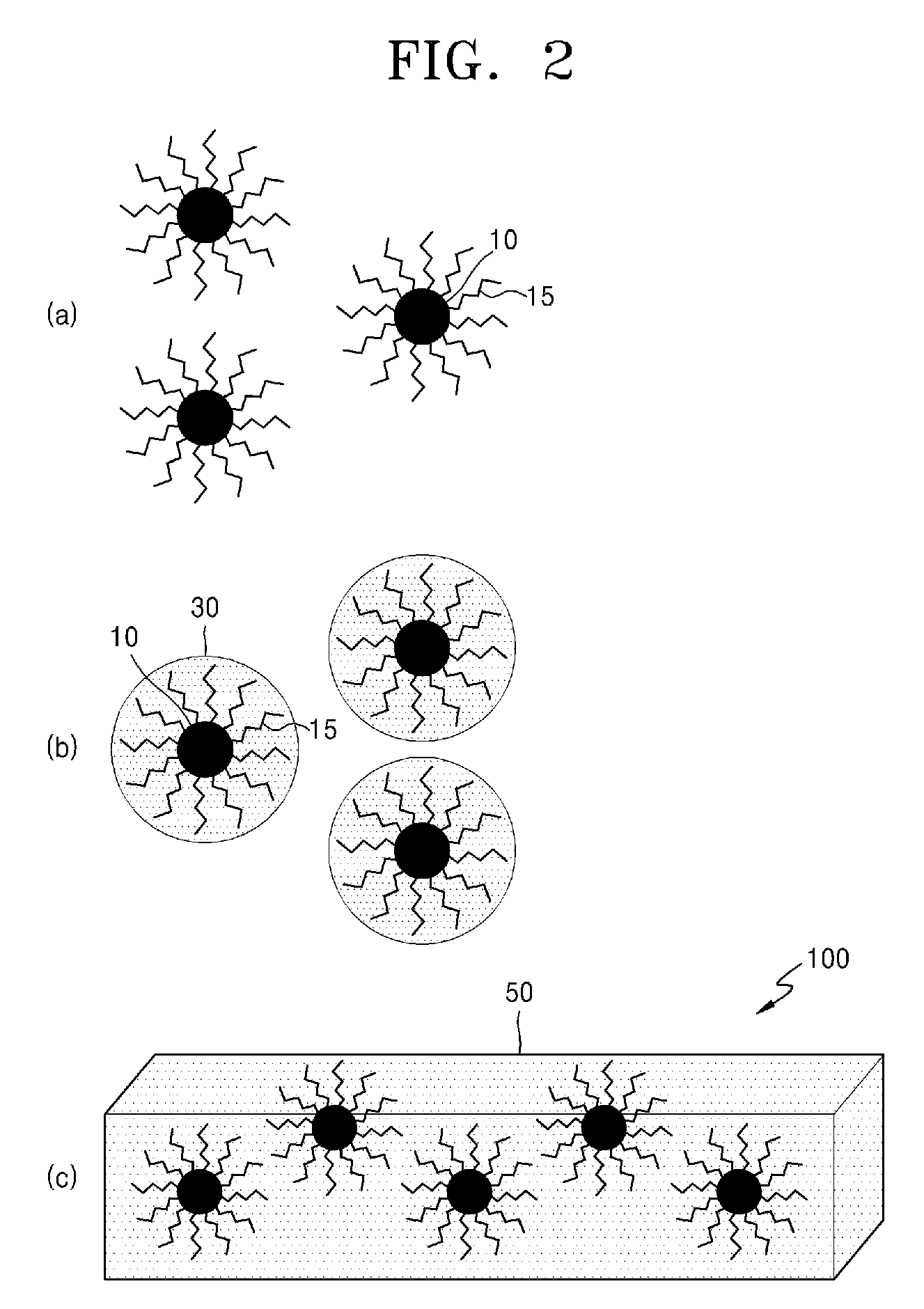

Nanocomposite material and method of manufacturing the same comprising forming an inorganic matrix by sol-gel reaction

InactiveUS7611750B2Improve stabilityMaterial nanotechnologyMetal-working apparatusNanoparticleNanometre

A nanocomposite material and a method of manufacturing the same are disclosed. The nanocomposite material includes a plurality of nanoparticles coated with a metal oxide, and a matrix of the metal oxide immobilizing the nanoparticles that are dispersed therein. The nanocomposite material is manufactured such that macro- or macro-scale cracks are prevented or effectively prevented, light stability is enhanced over a light-emitting period, and light brightness is improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

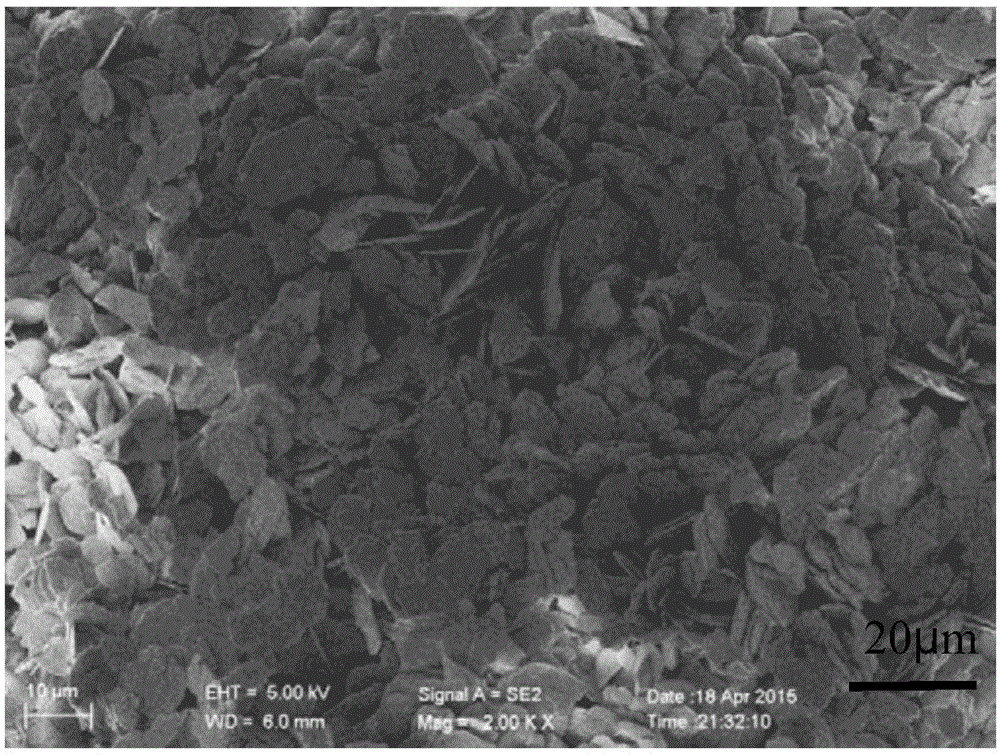

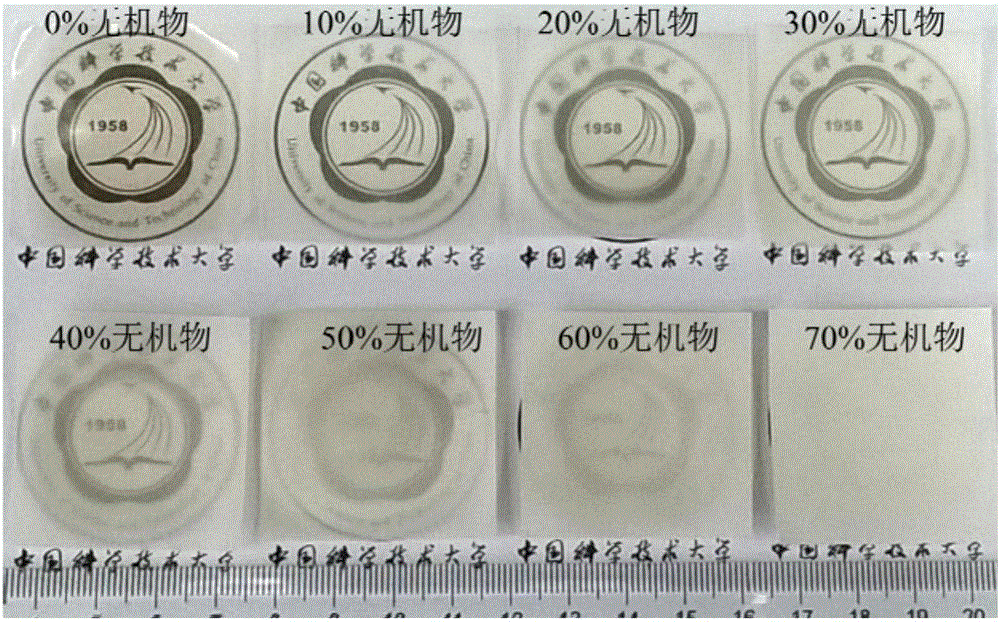

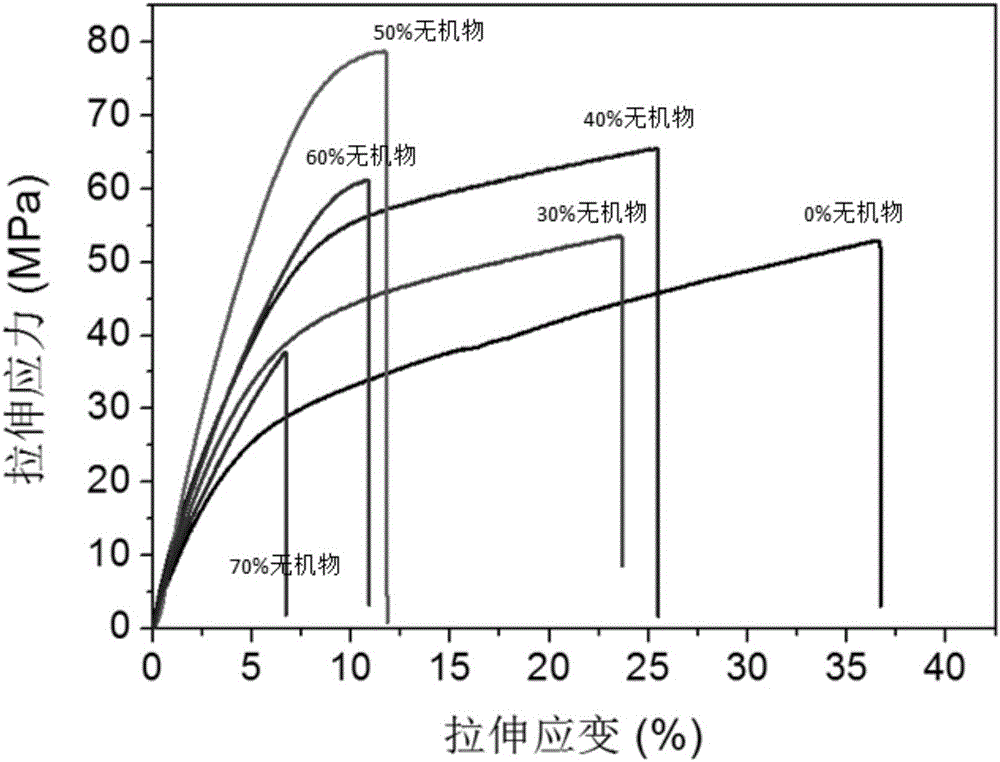

Blocky bionic material, method for manufacturing same and application of blocky bionic material

ActiveCN105079887AAchieve light weight and high strengthRealize that the prepared bulk biomimetic material has light weight and high strengthSynthetic resin layered productsProsthesisExperimental methodsStrong interaction

The invention provides a blocky bionic material, a method for manufacturing the same and application of the blocky bionic material. The method includes mixing platy or fibrous inorganic matrix materials and first polymers with one another and then assembling the platy or fibrous inorganic matrix materials and the first polymers to obtain bionic structure films; carrying out hot-pressing on the multiple layers of bionic structure films by the aid of second polymers to obtain the three-dimensional blocky bionic material. The second polymers are used as adhesion layers between the multiple layers of bionic structure films. The blocky bionic material, the method and the application have the advantages that the different inorganic matrix materials, the different first polymers and the different second polymers can be selected, high interaction force can be generated among various raw materials, and accordingly the blocky bionic material manufactured by the aid of the method is light and is high in strength; complicated experimental equipment can be omitted in manufacturing procedures, the experimental method is simple and feasible and is good in economical efficiency, the time and labor can be saved, and industrial production can be facilitated.

Owner:UNIV OF SCI & TECH OF CHINA

Self-Repairing, Reinforced Matrix Materials

Self-repairing, fiber reinforced matrix materials include a matrix material including inorganic as well as organic matrices. Disposed within the matrix are hollow fibers having a selectively releasable modifying agent contained therein. The hollow fibers may be inorganic or organic and of any desired length, wall thickness or cross-sectional configuration. The modifying agent is selected from materials capable of beneficially modifying the matrix fiber composite after curing. The modifying agents are selectively released into the surrounding matrix in use in response to a predetermined stimulus be it internal or externally applied. The hollow fibers may be closed off or even coated to provide a way to keep the modifying agent in the fibers until the appropriate time for selective release occurs. Self-repair, smart fiber matrix composite materials capable of repairing microcracks, releasing corrosion inhibitors or permeability modifiers are described as preferred embodiments in concrete and polymer based shaped articles.

Owner:DRY CAROLYN M

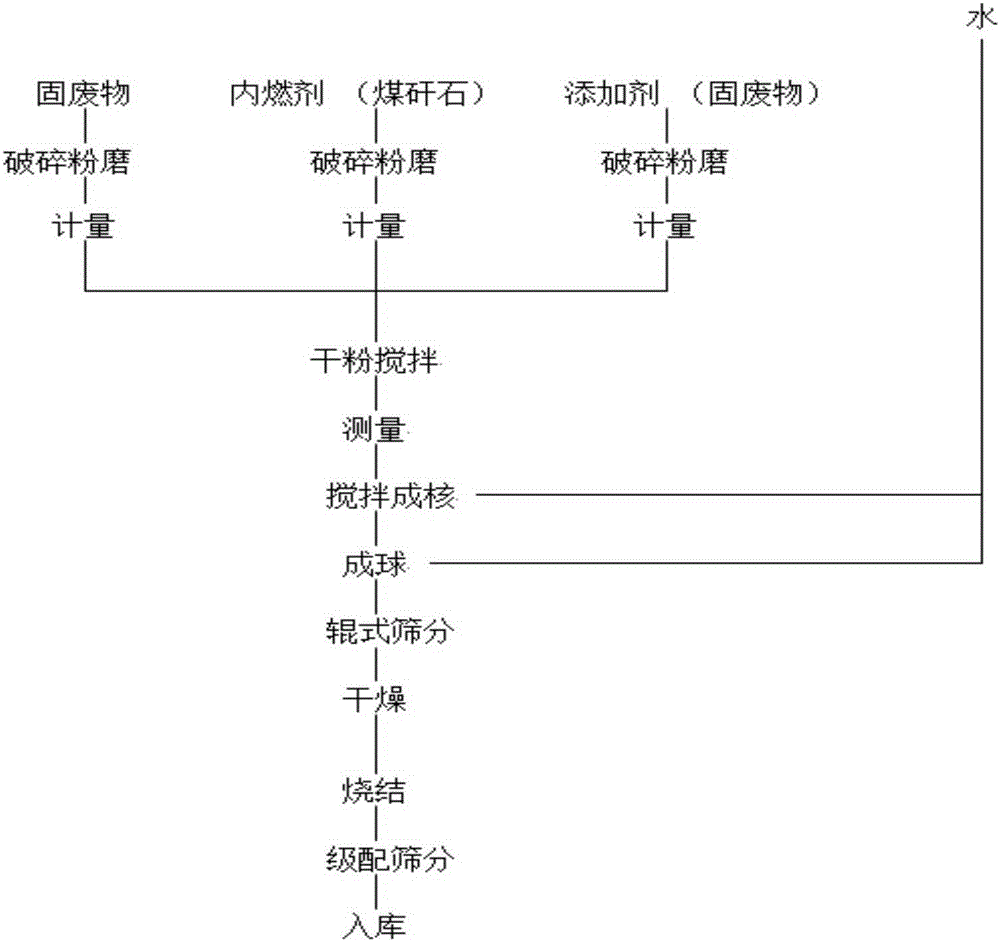

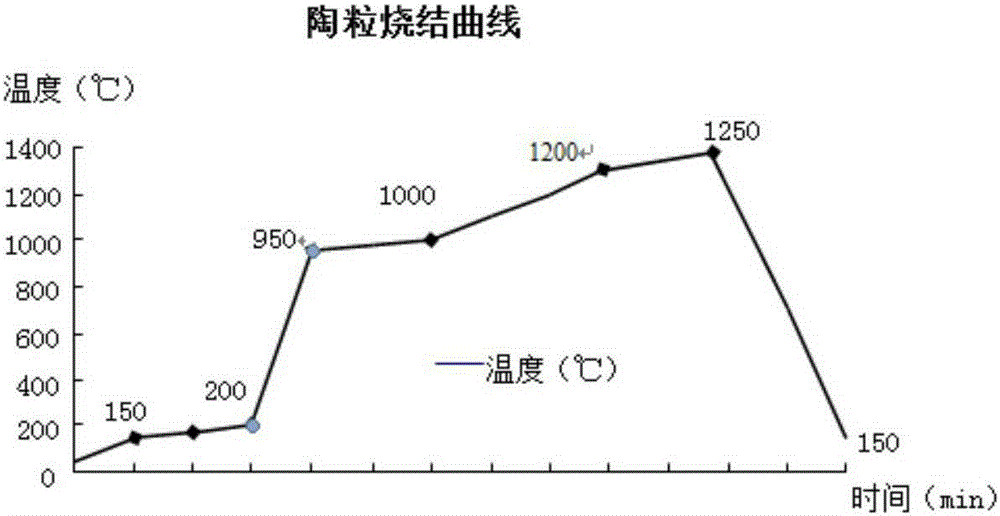

Technology utilizing waste solids to prepare ceramic particles used as soilless culture substrates

InactiveCN105174915ARestore ecologyEnsure chemical stabilityAgriculture gas emission reductionCultivating equipmentsSludgeRed mud

The invention relates to a technology utilizing waste solids to prepare ceramic particles used as the soilless culture substrates. The technology comprises the following steps: (1) grinding main raw materials and internal combustion agent into powder with a particle size of 60 to 80 [mu]m, and maintaining a dry state, wherein the main raw material is one or more of fly ash, city sludge, lake / river mud, industrial slag, electrolytic ash, tailings, and red mud, and the internal combustion agent is one or more of coal gangue, agricultural straw, and saw dust; (2) weighing 80 to 95 parts by weight of waste solid powder and 5 to 10 parts by weight of internal combustion agent powder, evenly mixing the powder, adding water into the evenly-mixed powder, keeping on stirring to form crystal nucleus accounting for 10 to 12% of the total weight, balling, performing roll-screening, and sintering to obtain the ceramic particles. Waste solids are taken as the raw material, then the components are scientifically and reasonably compounded, and finally inorganic substrate (ceramic particle) for soilless culture is produced by a sintering technology. The provided technology can save the energy and reduce the discharge, and is capable of replacing the conventional technical scheme using non-renewable resources to produce ceramic particles.

Owner:BAOTOU ZHENGTANG ENVIRONMENTAL PROTECTION IND

Building materials incorporated with hydrophobic silicone resin(s)

InactiveUS7875674B2Improve the immunityComposition and simple and economicalLayered productsCeramic shaping apparatusParticulatesPolymer chemistry

An inorganic matrix building material with enhanced water impermeability is prepared by curing an inorganic curable matrix and at least one particulate hydrophobic silicone resin substantially uniformly incorporated within the matrix, the at least one hydrophobic silicone resin being selected from the group consisting of a TD resin, an MQ resin, an MT resin, an MQT resin, and combinations thereof. In certain particular instances, the at least one hydrophobic silicone resin is a TD resin. The curing takes place at elevated temperature, optionally at elevated pressure.

Owner:WACKER CHEM CORP

Composite material of organic/inorganic multi-phase induction nano-hydroxyapatite

InactiveCN106075590AGood biocompatibilityAchieve nanoscale dispersionTissue regenerationProsthesisPhosphateApatite

The invention discloses a composite material of organic / inorganic multi-phase induction nano-hydroxyapatite. The composite material is characterized in that on the basis of the effect that graphene oxide can enhance adhesion of stem cells, and stem cells are induced to be differentiated into bone cells and adsorb organic and inorganic nanoparticles, chitosan and bovine collagen are adopted as organic matrixes, a graphene oxide water solution is adopted as an inorganic matrix, a soluble calcium salt and a soluble phosphate are adopted as a precursor of inorganic phase nano-hydroxyapatite, a biological mechanism and an in-situ composite preparation technology are adopted, and the composite material of organic / inorganic multi-phase induction nano-hydroxyapatite is prepared bionically. The preparation conditions are mild, the composite material is uniform in pore diameter, the hole forming performance is good, the biocompatibility and biodegradability are good, and the composite material is expected to be the novel composite material for treating osteoporosis.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com