Patents

Literature

2760 results about "Gangue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mining, gangue (/ɡæŋ/) is the commercially worthless material that surrounds, or is closely mixed with, a wanted mineral in an ore deposit. It is thus distinct from overburden, which is the waste rock or materials overlying an ore or mineral body that are displaced during mining without being processed, and from tailings, which is rock already stripped of valuable minerals; a worthless rock containing valuable material.

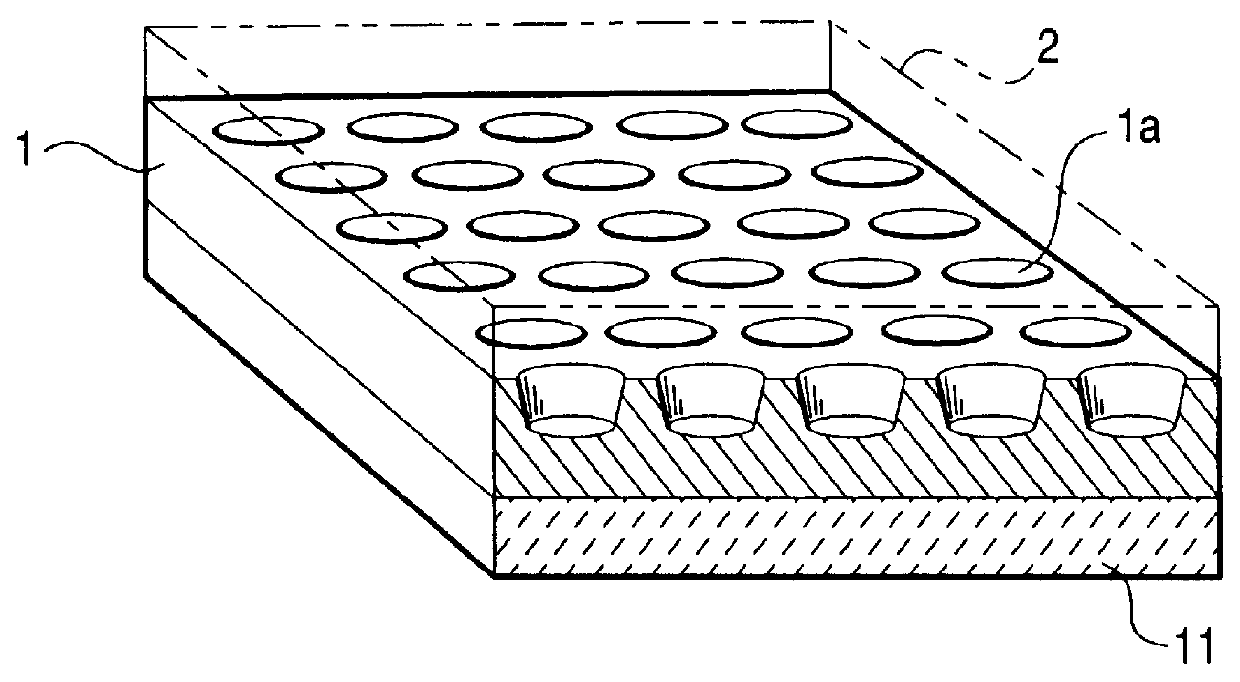

Method of producing a reduced metal, and traveling hearth furnace for producing same

InactiveUS6126718ALow gangue and ash contentSmall amountProcess efficiency improvementGas emission reductionHearthMetal

Producing reduced metal by charging and stacking a raw material containing a metal-containing material and a solid reducing material on a horizontally moving hearth of a traveling hearth furnace, by disposing a solid reducing material layer on the hearth, forming concave portions at the solid reducing material surface, stacking the raw material on the surface of the solid reducing material layer, reducing raw material by at least once heating and melting the material on the hearth to separate metal and gangue and ash ingredients, and discharging metal from the hearth.

Owner:KAWASAKI STEEL CORP

Divided solid composition composed of grains provided with continuous metal deposition, method for the production and use thereof in the form of a catalyst

This invention relates to a solid divided composition comprising grains whose mean size is greater than 25 μm and less than 2.5 mm, wherein each grain is provided with a solid porous core and a homogeneous continuous metal layer consisting of at least one type of transition non-oxidised metal and extending along a gangue coating the core in such a way that pores are inaccessible. A method for the production of said composition and for the use thereof in the form of a solid catalyst is also disclosed.

Owner:INST NAT POLYTECHNIQUE DE TOU LOUSE +1

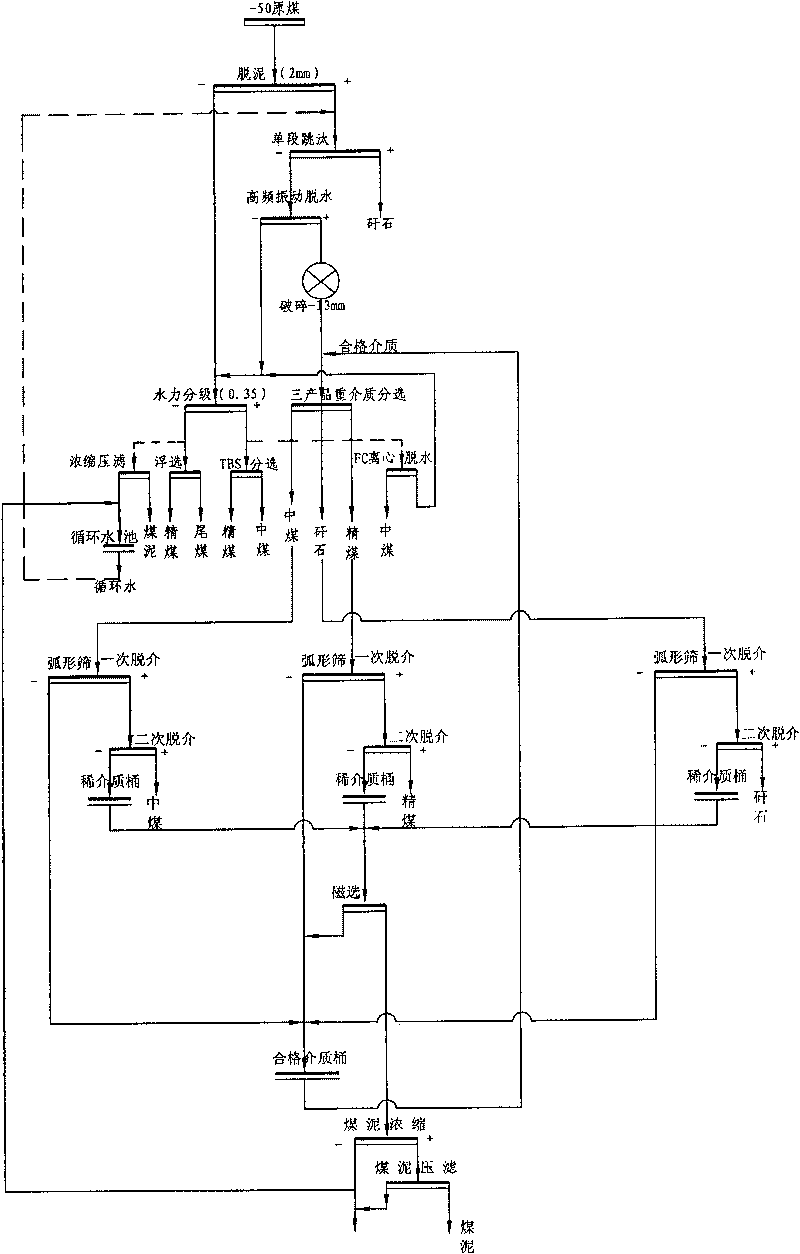

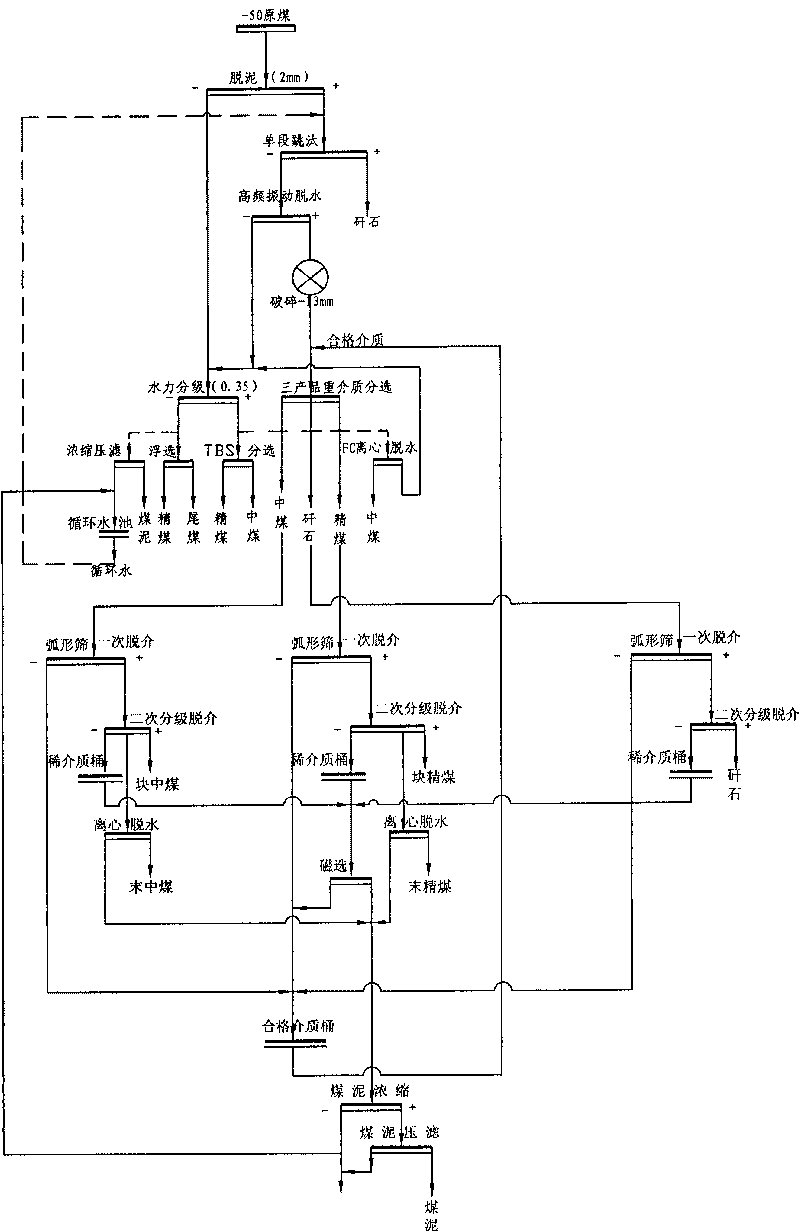

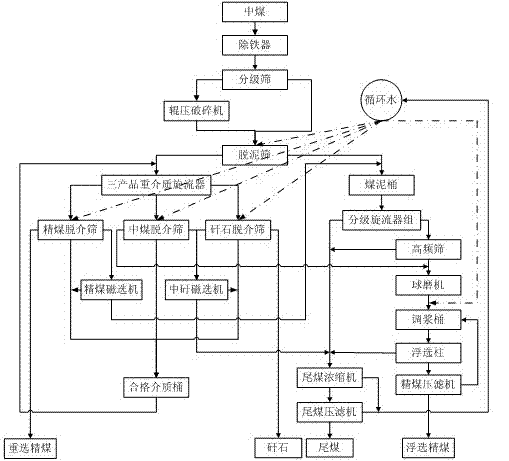

Raw coal washing process capable of realizing non-polar ash conditioning

InactiveCN101716552AReduce the amount of re-insertionReduce manufacturing costWet separationCycloneSingle stage

The invention provides a raw coal washing process capable of realizing non-polar ash conditioning. The process comprises the following steps: a, desliming and screening the part of raw coal with granularity less than 50 to 100mm; b, carrying out single stage jigging separation on screen products on a desliming screen; c, crushing lump coal obtained from the step b, namely screen products on an oscillating screen, by a crushing machine; d, feeding the crushed products from the step c into a three-product heavy medium cyclone for separation; e, respectively treating underflows and overflows obtained from a hydroclone in the step c; f, carrying out TBS separation or centrifugal dehydration treatment on the underflows of the hydroclone from the step e; g, respectively carrying out primary medium removal on clean coal, middlings coal and gangue obtained from the step d; h, respectively carrying out secondary medium removal and dehydration on the three products from the step g; and i, carrying out magnetic separation on undersize dilute medium obtained by secondary medium removal on the coal gangue in the clean coal in the step h, feeding the separated magnetite powder into a qualified medium tank, collecting residues, and carrying out coal slurry concentration.

Owner:HENAN POLYTECHNIC UNIV

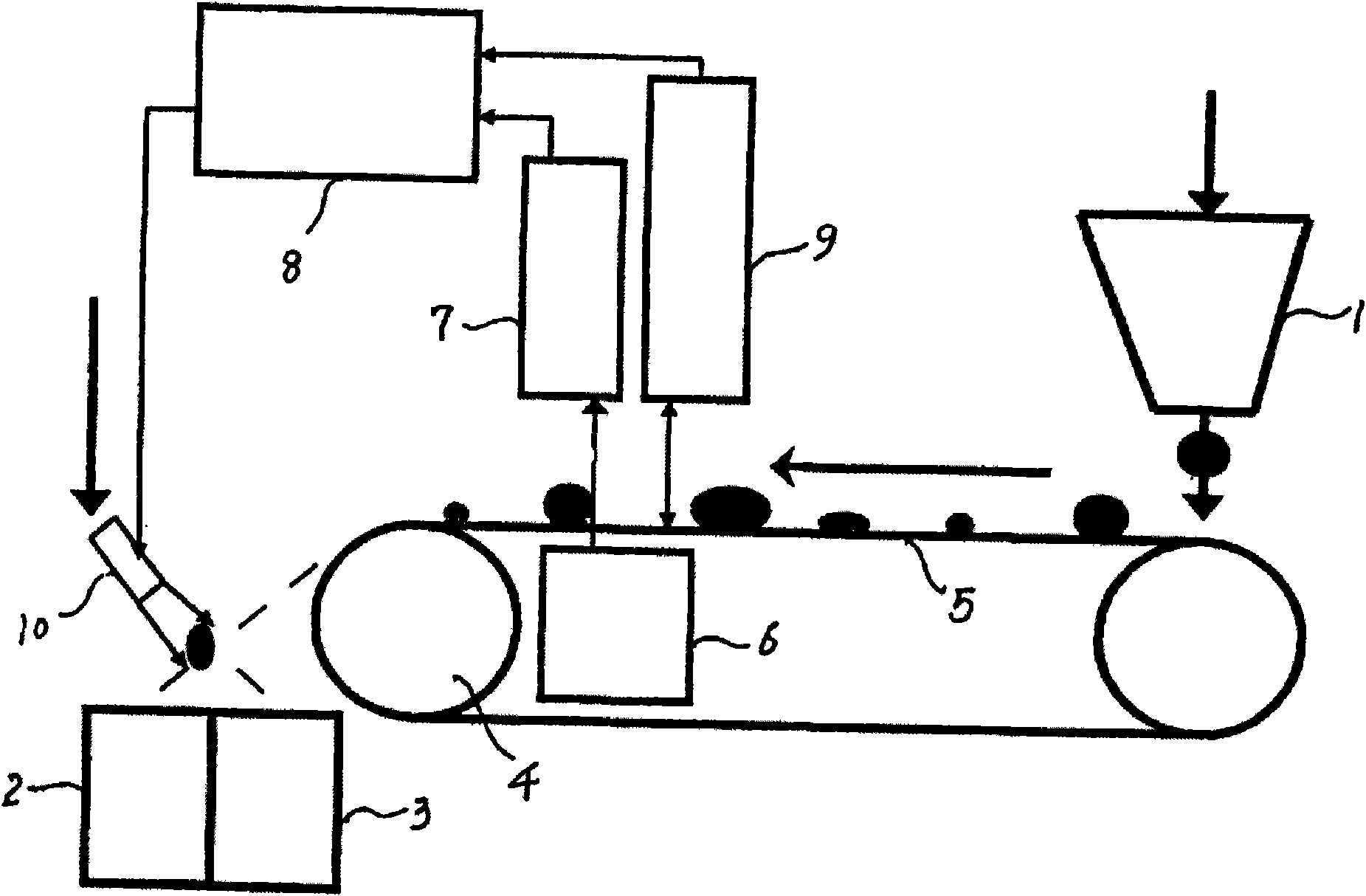

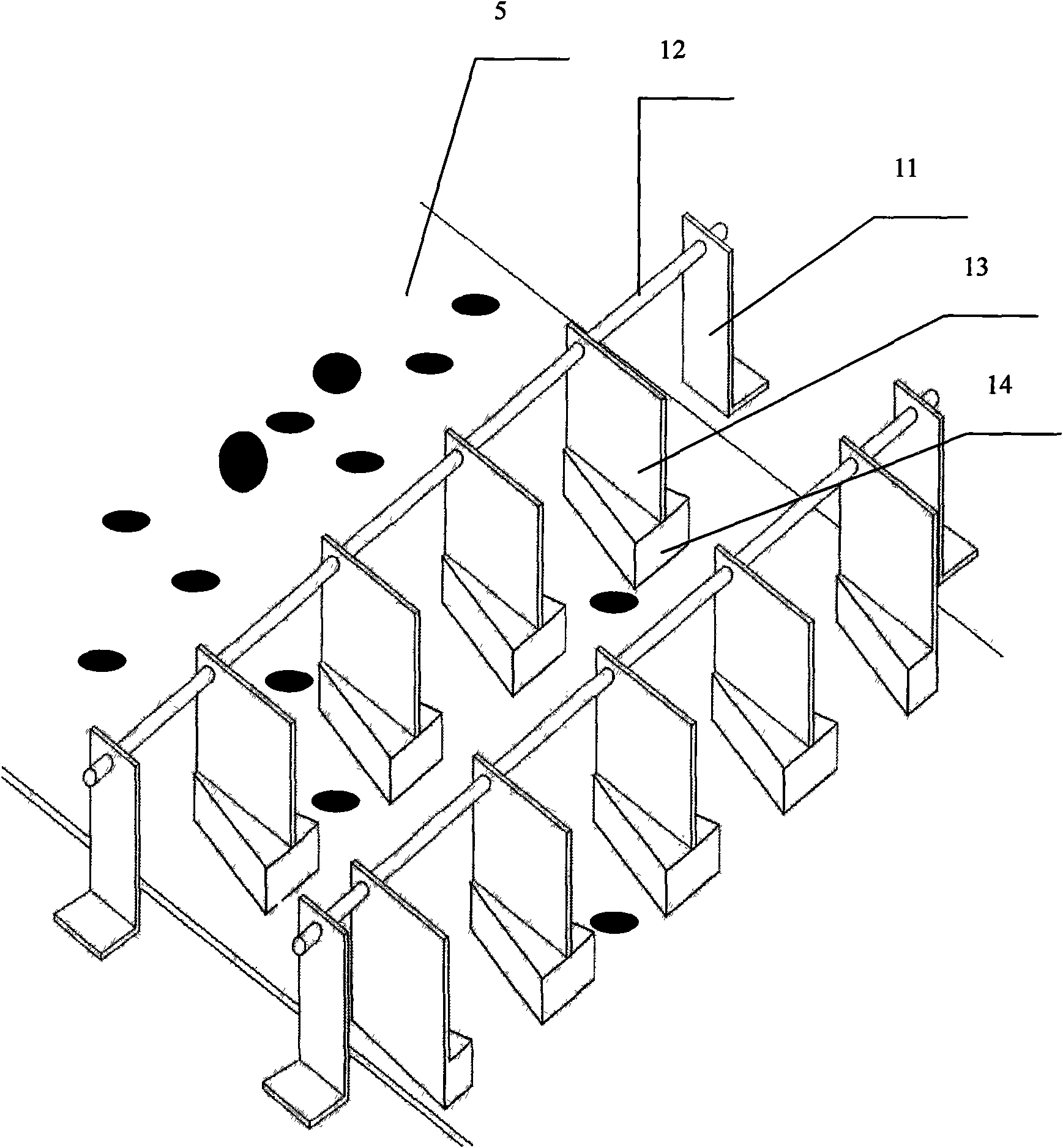

Automatic separator of coal gangue

ActiveCN101637765ANo mutual interferenceSolve the technical problems of poor sorting effectSortingConveyor partsX-rayGamma ray

The invention relates to an automatic separator of coal gangue, which comprises a raw material feeding copper, a coal receiving copper, a gangue receiving copper, a conveying-belt conveyor, an identification and separation controlling mechanism and an executing mechanism, wherein the conveying-belt conveyer is arranged among the raw material feeding copper, the coal receiving copper and the gangue receiving copper; the identification and separation controlling mechanism comprises a single-energy gamma ray source, an X-ray sensor, a measure and control instrument and an ultrasonic transmitter-receiver; the single-energy gamma ray source is arranged below a conveying belt, the X-ray sensor is arranged above the conveying belt and corresponds to the single-energy gamma ray source, the measure and control instrument is electrically connected with the X-ray sensor, and the ultrasonic transmitter-receiver is arranged above the conveying belt and electrically connected with the measure and control instrument; the executing mechanism is a high-frequency air valve arranged above the coal receiving copper and the gangue receiving copper; and the valve port of the high-frequency air valve isarranged towards a throwing track of coal and gangue. As the single-energy gamma ray source is adopted, only one nuclear radiation material exists, and only one spectral line is radiated, the mutualinterference among a plurality of spectral lines can not be generated; and the invention has accurate measurement and good separation effect.

Owner:GREAT DRAGON RISING ELECTROMECHANICAL TECH BEIJING

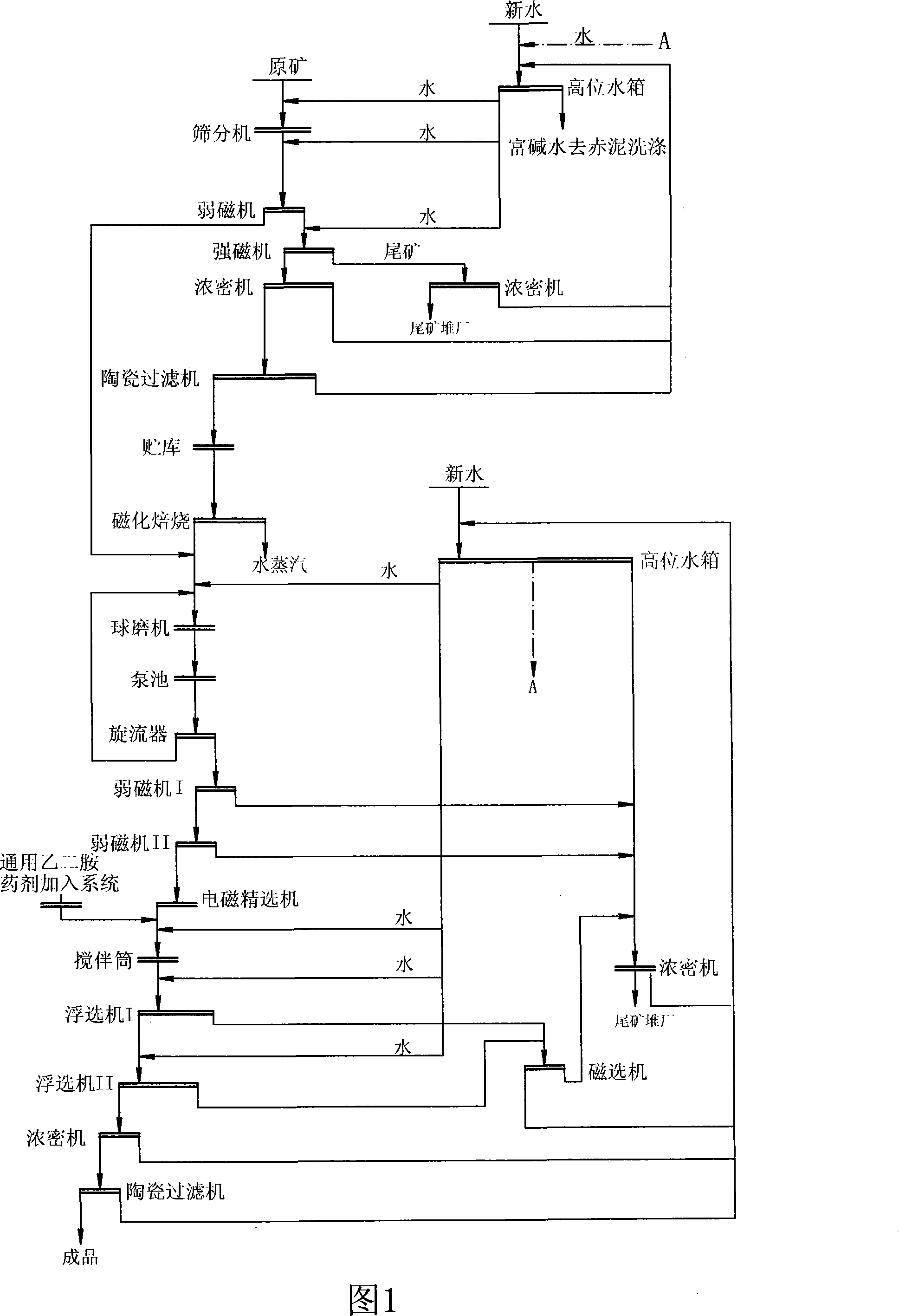

Method of refining iron ore from alkaline red mud and making gangue neutral

The invention relates to a method to select refined iron ore from alkaline red mud and neutralize mine tailings. The method consists of red mud pretreatment and technological process of preparing refined iron ore. The red mud pretreatment is that water is added into the red mud slurry discharged from aluminum factory; the red mud slurry is diluted to the solid concentration of 30 to 40 percent and then is screened and put into a low intensity magnetic separator for selecting ferromagnetic substance. The ferromagnetic substance is dehydrated and directly selected as the product. The remaining red mud is watered down to 30 percent solid concentration and put into a high intensity magnetic separator for magnetic separation and desliming. The obtained coarse ore is washed to a coarse ore settling tank or a thickener to be concentrated while the undercurrent is sent into a vacuum ceramic filter and a filter cake is roasted in a suspended magnetic roasting furnace. The roasted materials are crushed into a ball mill and then are milled. The water is overflown until 95 percent of the solid material granularities are less than 75m and then is treated by the third stage magnetic separation and the second flotation. The undercurrent is filtered by the ceramic filter, and then the refined iron ore with a purity of 58 to 65 percent is obtained. The refined iron ore is recycled from the red mud by the invention so as to fully employ aluminum ore, save resources and energy consumption and neutralize the whole red mud. The invention reduces environmental pollution and has good economic and social benefits.

Owner:SHENYANG XINBO IND TECH

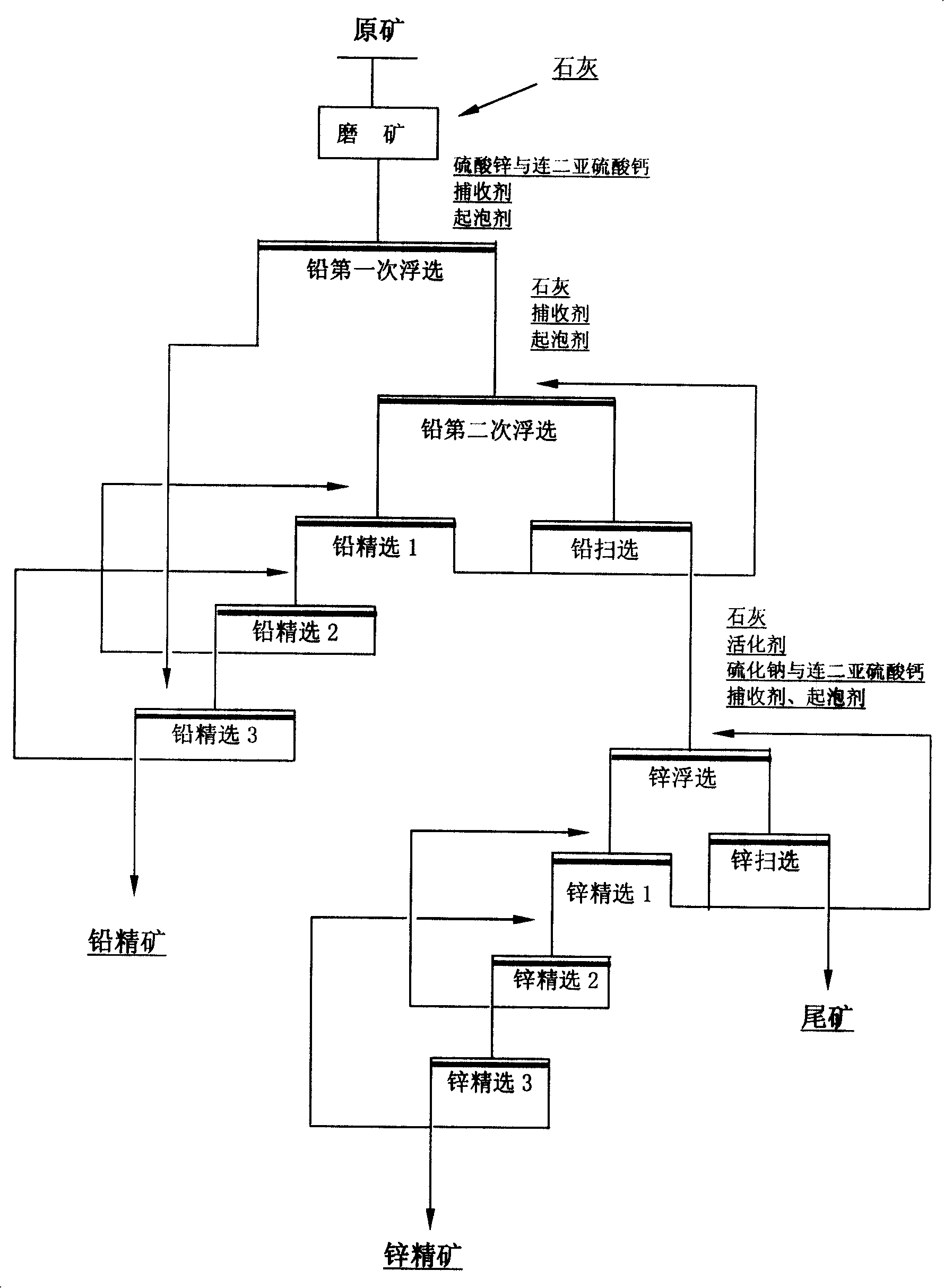

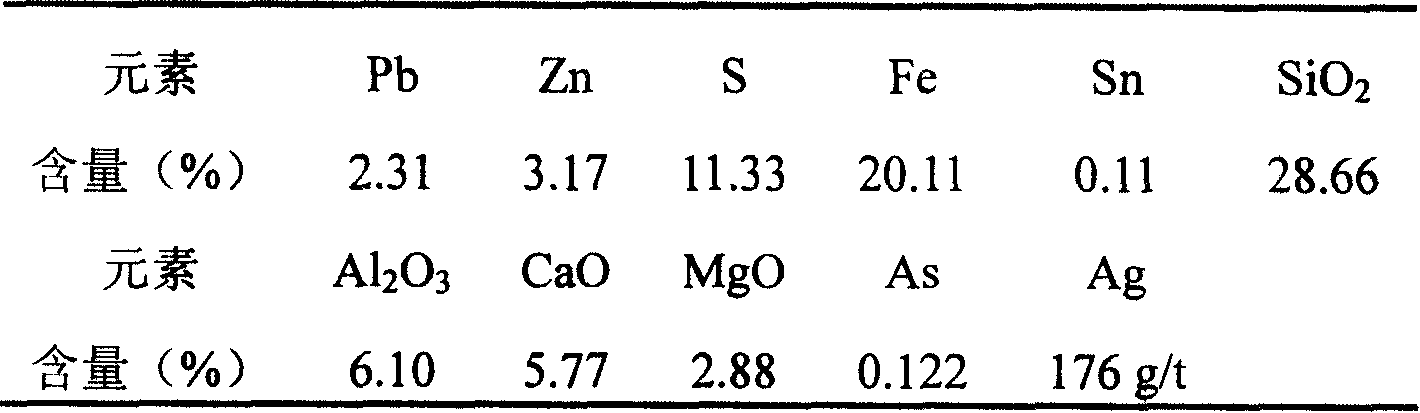

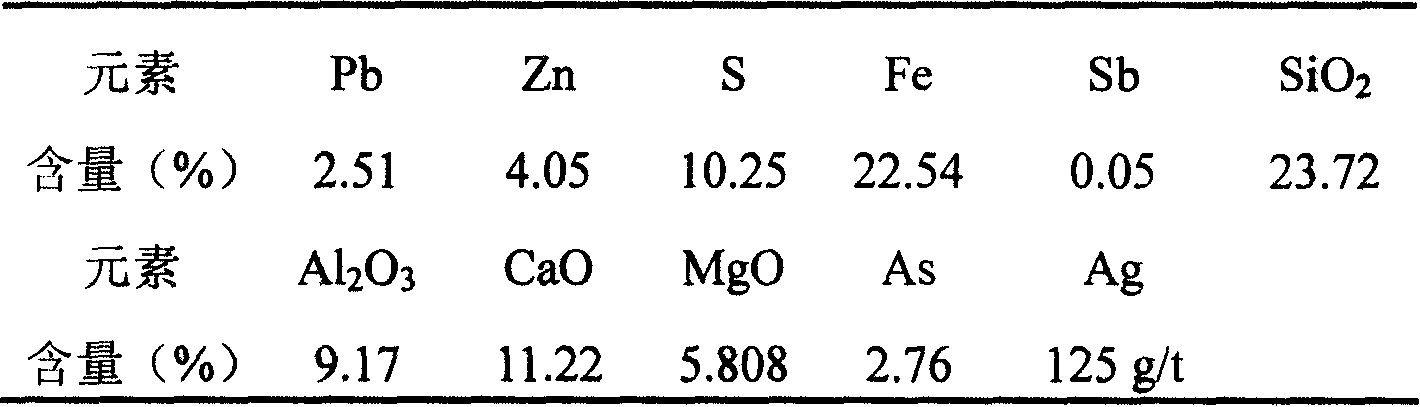

Complex plumbum, zinc, silver vulcanizing ore containing newboldite and pyrrhotite floatation method

The invention discloses a lead and zinc flotation method to ferreous blende and pyrrhotite typed complex lead zinc silver sulphide ore, mainly comprising lead ore branch flotation which controls the electrochemical conditions of the flotation and the zinc and sulfur flotation separation which controls the electrochemical conditions of the flotation. The invention has the advantages of implementing the lead-zinc sulfur separation by adopting twice branch flotation, carrying out fast flotation to the lead ore by using a novel composite catching agent to the galena and silver ore with easy floating coarse grains under the conditions of higher ore pulp potential and low pH; the normal flotation of the lead ore with difficultly floated fine grains is carried out under the conditions of lower ore pulp potential and high pH. The pH of the ore pulp is adjusted to more than 12 by lime for the gangue after the lead is floated; the iron blende is activated by bluestone; the iron blende is recovered by the catching agent with the same type of the lead sulfide floatation, thus leading the property of the lead flotation waste water to be basically consistent with that of the zinc flotation waste water and being beneficial for the circular application of floatation waste water.

Owner:CENT SOUTH UNIV

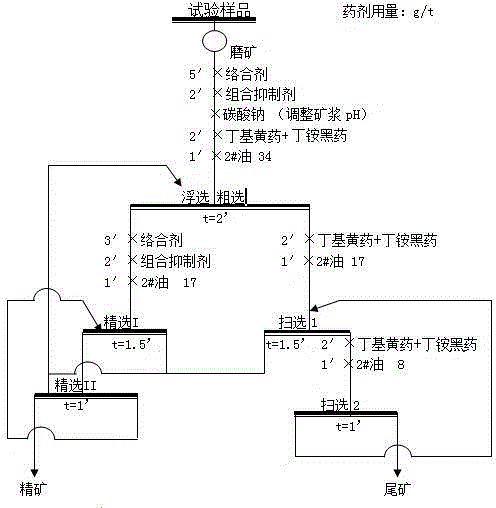

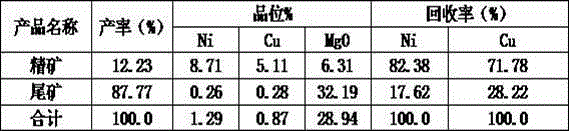

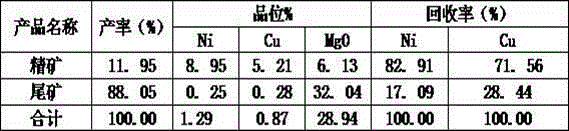

Method for reducing concentrate magnesium oxide content in copper-nickel sulfide ore flotation

The invention relates to a method for reducing concentrate magnesium oxide content in copper-nickel sulfide ore flotation. The method includes steps of firstly adding complexing agent oxalic acid, citric acid, tartaric acid, quadrol and EDTA (ethylene diamine tetraacetic acid), cleaning active ions of copper and nickel on the surface of magnesium-contained gangue mineral such as serpentine, removing flotation activity of sulfide ore collector such as xanthogenate, and adding composition agent to suppress gangue mineral. Ore pulp is treated by complexing agent, the flotation environment is improved, and floatability difference between copper-nickel sulfide mineral and magnesium-contained gangue mineral is increased. By combined inhibitor, serpentine and talc gangue mineral are suppressed, and magnesium-reducing effect is better; nickel recovery rate is increased to some extent as compared with that of actual production. Meanwhile, content of magnesium oxide in concentrate is reduced, and melting cost is lowered.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

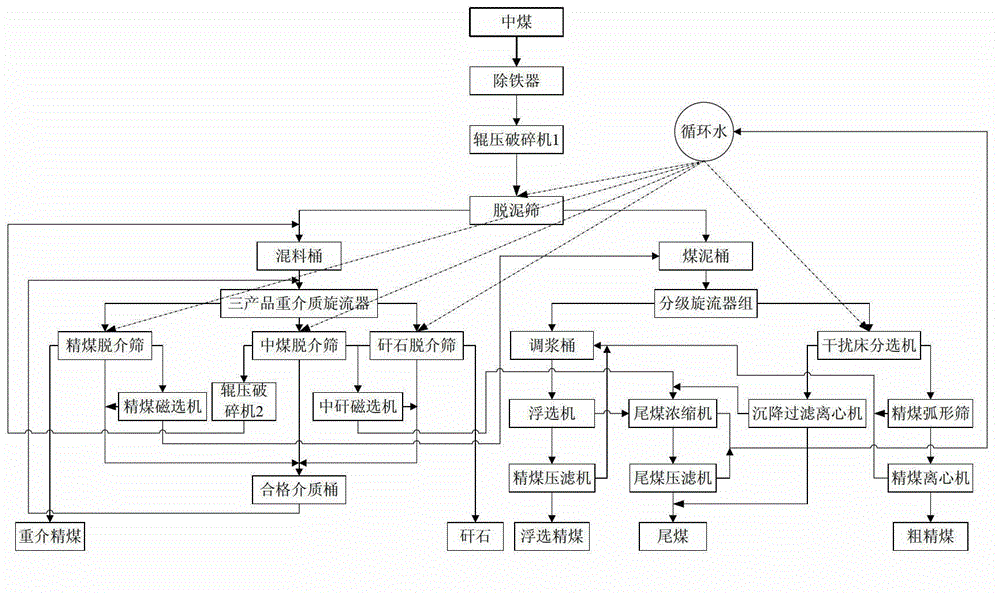

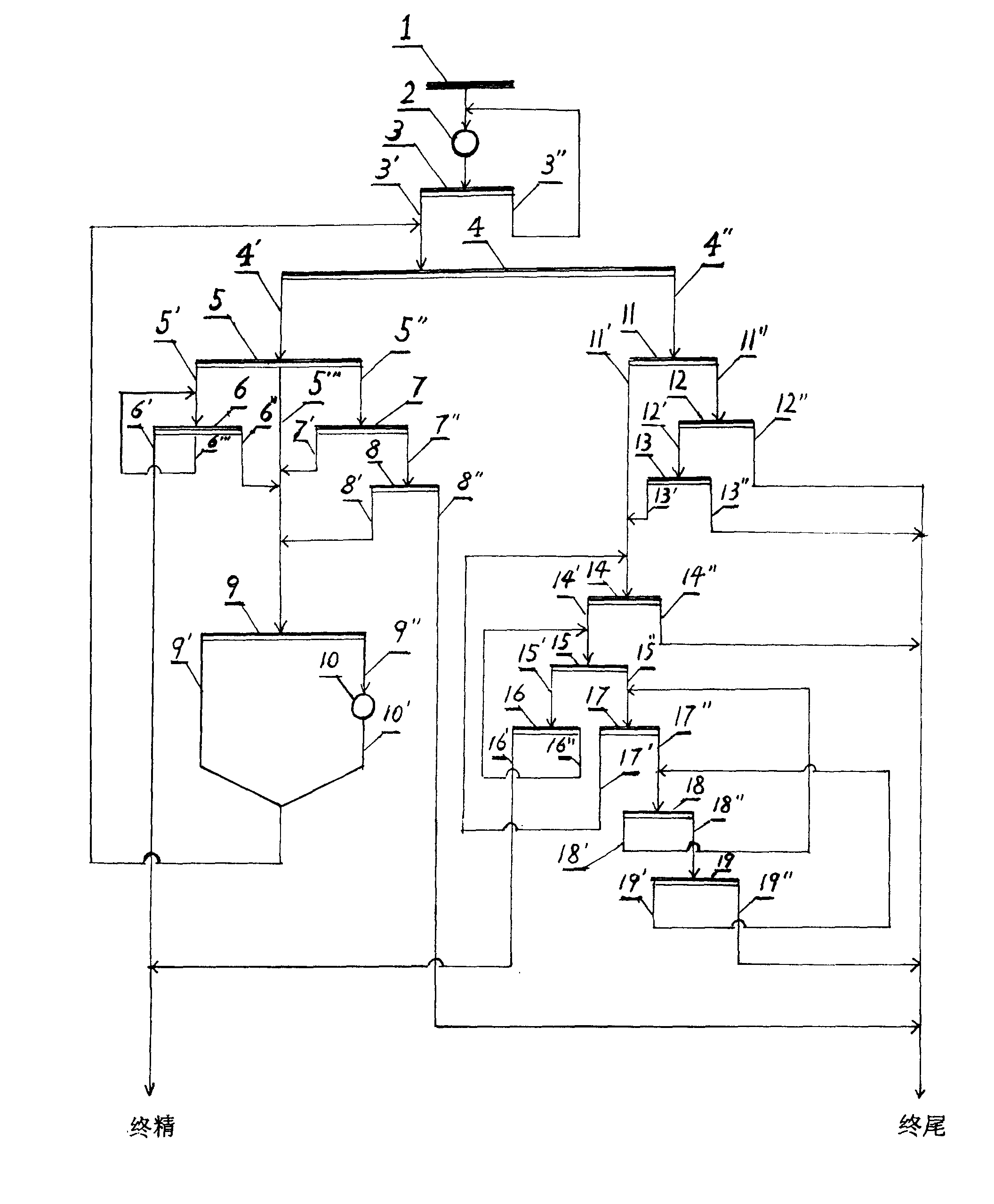

Efficient crushing and three-section type screening method of coking coal gravity middings

An efficient crushing and three-section type screening method of coking coal gravity middings belongs to coal crushing, dissociating and screening processes. Gravity middings in a coking coal preparation plant are taken as a raw material to be crushed through rolling to the fraction being below 6 mm or 3 mm; a desliming screen is used to deslime a material with the fraction being 1 mm, a material with the fraction being 6 to 1 mm or 3 to 1 mm enters into a three-product dense medium cyclone, and clean coal, middings and gangues are respectively obtained after two sections are subjected to medium drainage; the material with the fraction being 1 mm is mixed with tailings in a clean coal magnetic separator, fine coal slimes with the fraction being 0.25 mm are deslimed by a classifying cyclone; coarse coal slimes with the fractions being 1 to 0.25 mm enter into a teetered bed separator for screening, light products are dewatered by a sieve bend and a coal slime centrifuge to obtain coarse clean coal, and heavy products are dewatered by a screen bowl centrifuge to obtain tailings; the fine coal slimes with the fractions being 0.25 mm enter into a flotation machine for flotation, and foamed clean coal and the tailings are sequentially subjected to concentration and pressure filtration dewatering to obtain flotation clean coal and the tailing product; and after the gravity middings are crushed through rolling, the product returns to a mixing barrel. The method has the advantages that the graded screening is carried out on the preselected coal slimes with coarse fraction and fine fraction, and the equipment screening precision is improved.

Owner:CHINA UNIV OF MINING & TECH

High-performance sand-soil consolidation material, as well as preparation method and using method thereof

The invention relates to a high-performance sand-soil consolidation material, as well as a preparation method and a using method thereof. The high-performance sand-soil consolidation material belongs to a mortar composition and is characterized by comprising the following raw materials in parts by weight: 5-40 parts of cement clinker, 3-6 parts of gypsum, 4-10 parts of alkali additive, 0.5-6 parts of compound activating agent, 1-4 parts of early strength agent, 2-10 parts of mineral activating agent, 3-8 parts of expansion agent and 22-77 parts of micro-powder formed by fine grinding of blast furnace water-quenched slag. The invention provides the high-performance sand-soil consolidation material which has the advantages of simple operation, convenient construction, good water resistance, fast consolidation, high early strength, stable improvement of post-strength, resistance to erosion of underground inorganic salt water, excellent anti-seepage performance and low production cost, as well as the preparation method and the using method thereof. The high-performance sand-soil consolidation material is suitable for consolidating mine tailings, natural weathered sand, fly ash, gravel, stone chips, stone powder, soil, sludge, construction waste, coal gangue and phosphorus slag into a solid material, and can be used for laying a subgrade, constructing a wall body and constructing a site foundation.

Owner:淄博乾耀固结材料有限公司

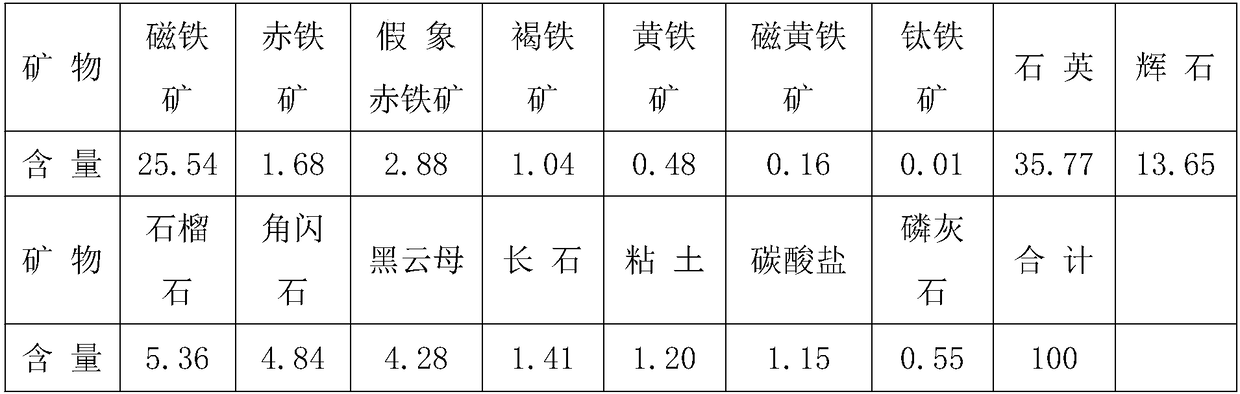

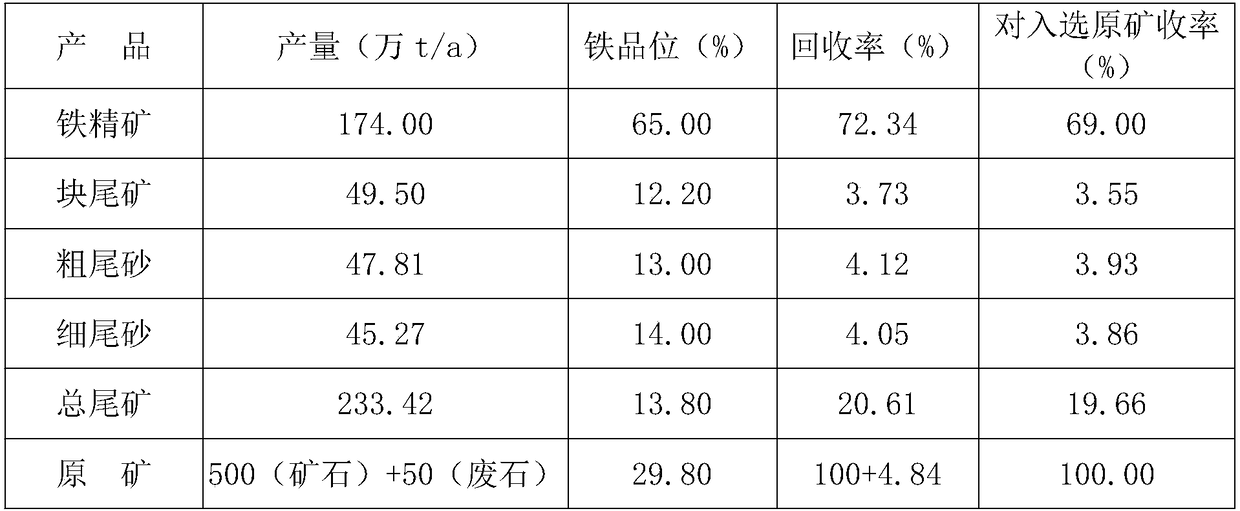

Ore dressing process of treating poor hematite

The ore dressing process of treating poor hematite includes staged ore milling, size separating, gravitational dressing, strong magnetic dressing and inverse floating. By means of staged ore milling, early separation between iron containing mineral and gangue, returning the intergrowth to next ore milling for further separation, separating milled material based on size, gravitational dressing of coarse grains, strong magnetic dressing and inverse floating of fine grains, the raw ore of 30 % grade is enriched into high grade concentrated ore up to 67 % in the metal recovering rate over 76 % and SiO2 content lowered from 8-10 % to below 4.5 %.

Owner:鞍钢集团矿业公司研究所

Breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking

A breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking belongs to a coal breaking dissociation flotation process. (1) coal products in a coal preparation plant serve as raw materials, and the coal which is larger than 6mm is rolled and broke into size smaller than 6mm; (2) a desliming screen is used for desliming on middings smaller than 6mm, middings which is 6-0.5mm enters a three-product dense medium cyclone, and dense medium, middings and gangue are obtained after two-stage medium separation is carried out; (3) the middings smaller than 0.5mm is mixed with clean coal magnetic separation gangue, a grading hydrocyclones group is adopted to conduct high frequency screening to obtain high ash fine silt contained slurry water, and coarse particle are mixed with middings on the midding sculping screen to enter a ball mill for wet grinding; and (4) products after grinding enter a flotation column to conduct flotation, foam clean coal and tailing are respectively concentrated, filtered and dewatered to obtain flotation clean coal and tailing products. The breaking grinding dissociation and re-flotation two-stage recovery process has the advantages that the high ash fine silt in fine fraction is pre-selected, pollution of the high ash fine silt is reduced, equipment separation particle size range is reduced, separation accuracy of equipment is improved, and scarce coking coal resources are recovered as far as possible.

Owner:CHINA UNIV OF MINING & TECH

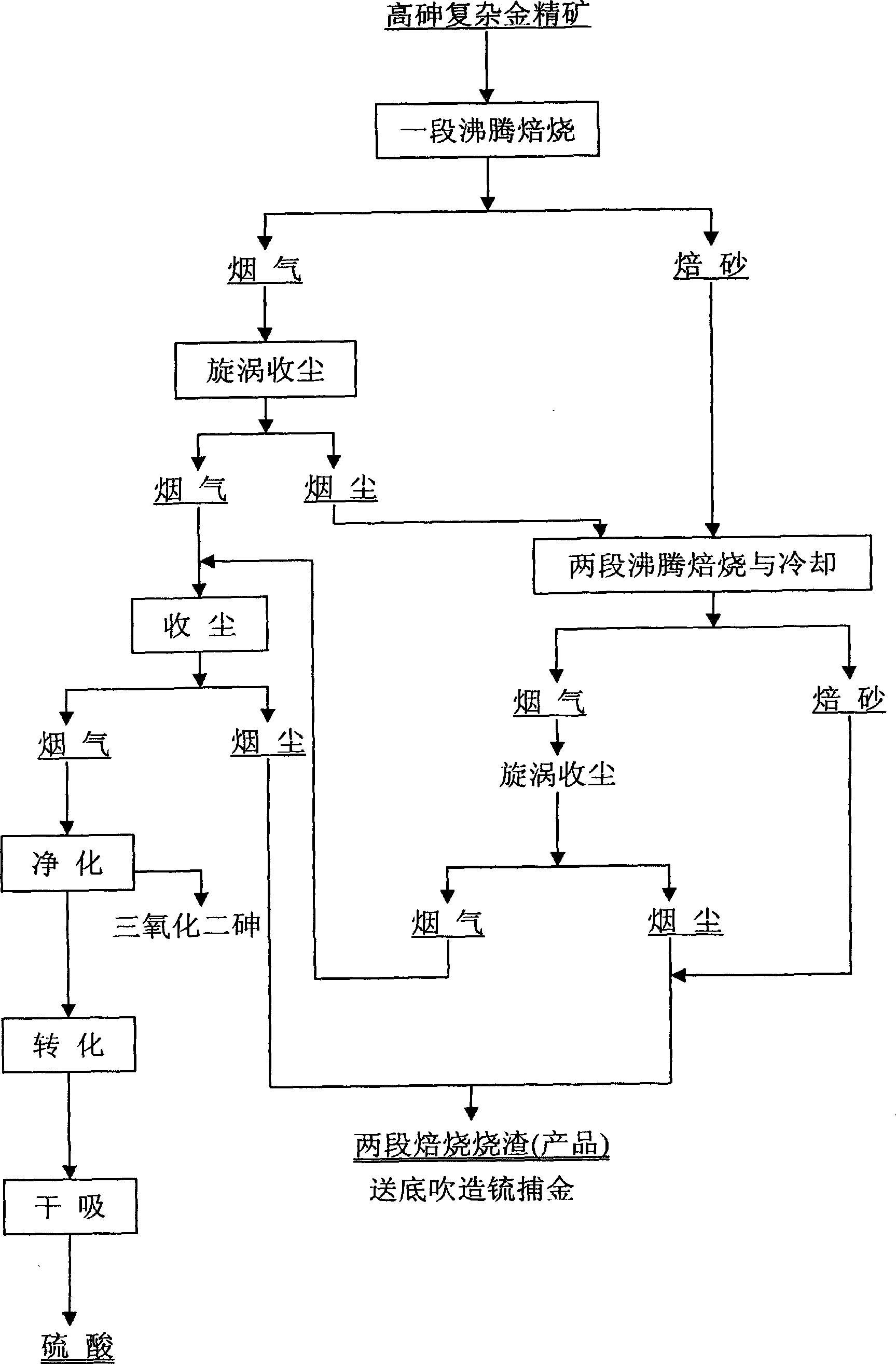

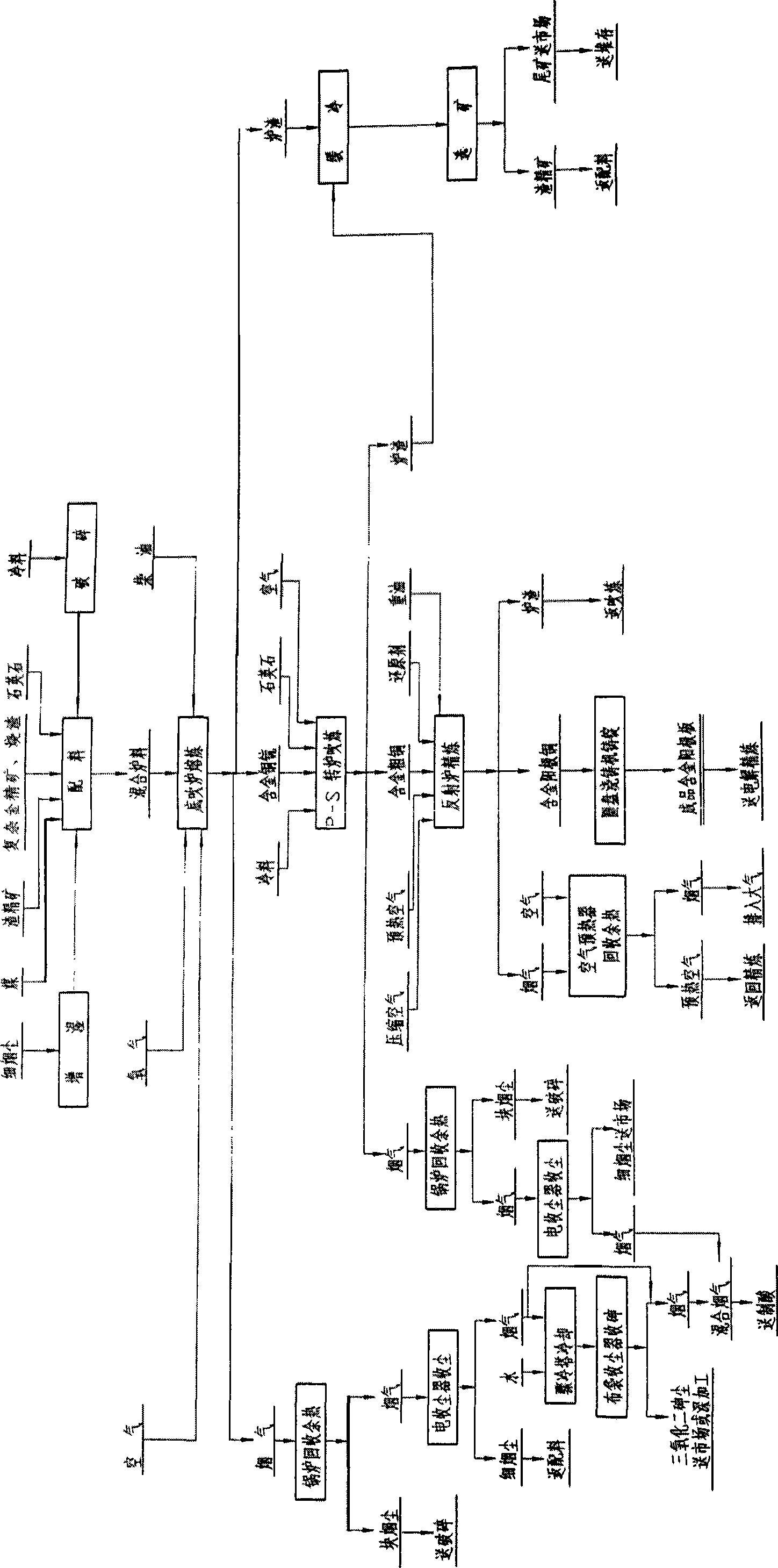

Method for extracting high arsenic complicated golden ore concentrate multielement

ActiveCN101519731AImprove recycling efficiencyReduce low altitude pollutionPhotography auxillary processesReverberatory furnaceElectrolysisMaterials science

The invention discloses a method for extracting high arsenic complicated golden ore concentrate multielement. The method comprises the following steps that: the multielement complicated golden ore concentrate with extra-high arsenic is subjected to the roast dearsenification technique treatment, part of sulfur in the multielement high arsenic golden ore concentrate converted into sulfur dioxide and the arsenic converted into arsenic trioxide enter flue gas which is subjected to dust and arsenic collection, and then enter an acid making system to produce sulphuric acid; the multielement smelting slag and multielement low arsenic golden ore concentrate obtained by roast dearsenification, return products and flux are mixed to obtain copper matte regulus, and the like by adopting oxygen enrichment bottom blowing matte smelting gold collecting process to carry out the smelting process; the copper matte regulus is subjected to converting and refining to cast an anode plate which is sent to an electrolysis system to obtain an electrolytic copper product by refining; anode mud generated through electrolysis is sent to a noble metal refine system to produce gold and sliver, and the like; smelting slag and converting slag are subjected to floatation treatment to obtain copper and iron ore concentrate; and the generated gangue belongs to harmless slag and can be used. The method has the characteristics of wide range of the raw material application, high synthesized recovery efficiency of valuable element, and obvious economic and environment benefits.

Owner:SHANDONG HUMON SMELTING

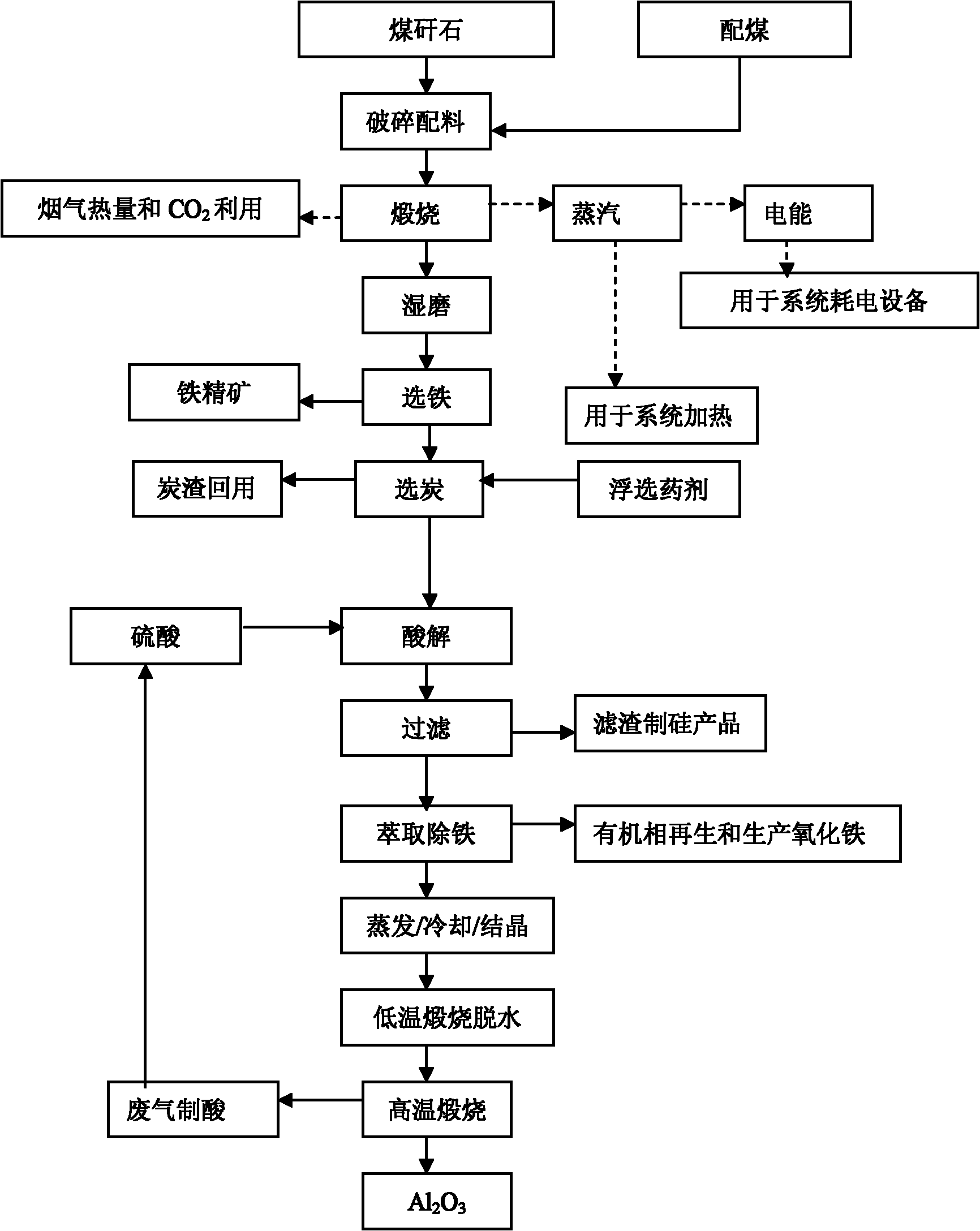

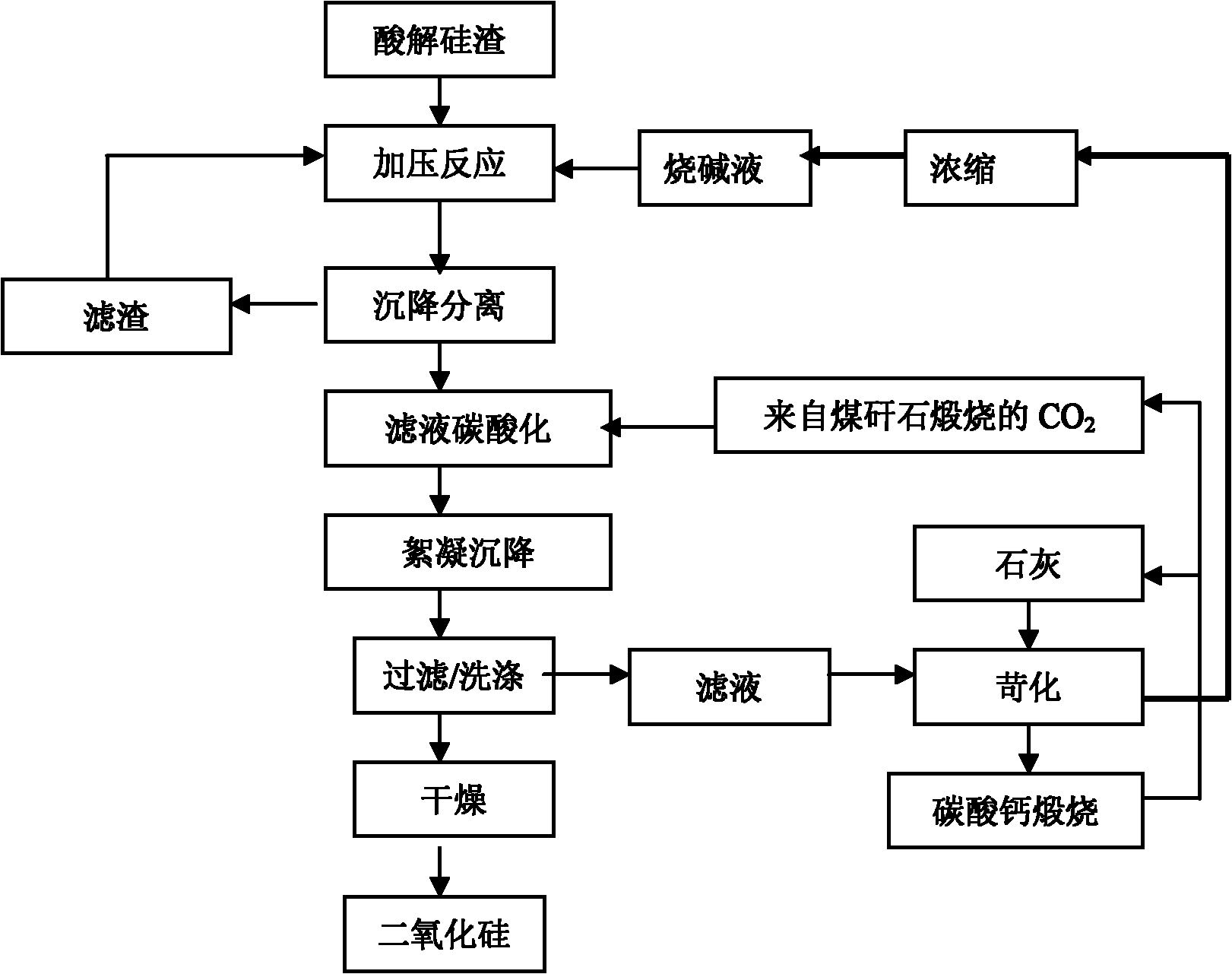

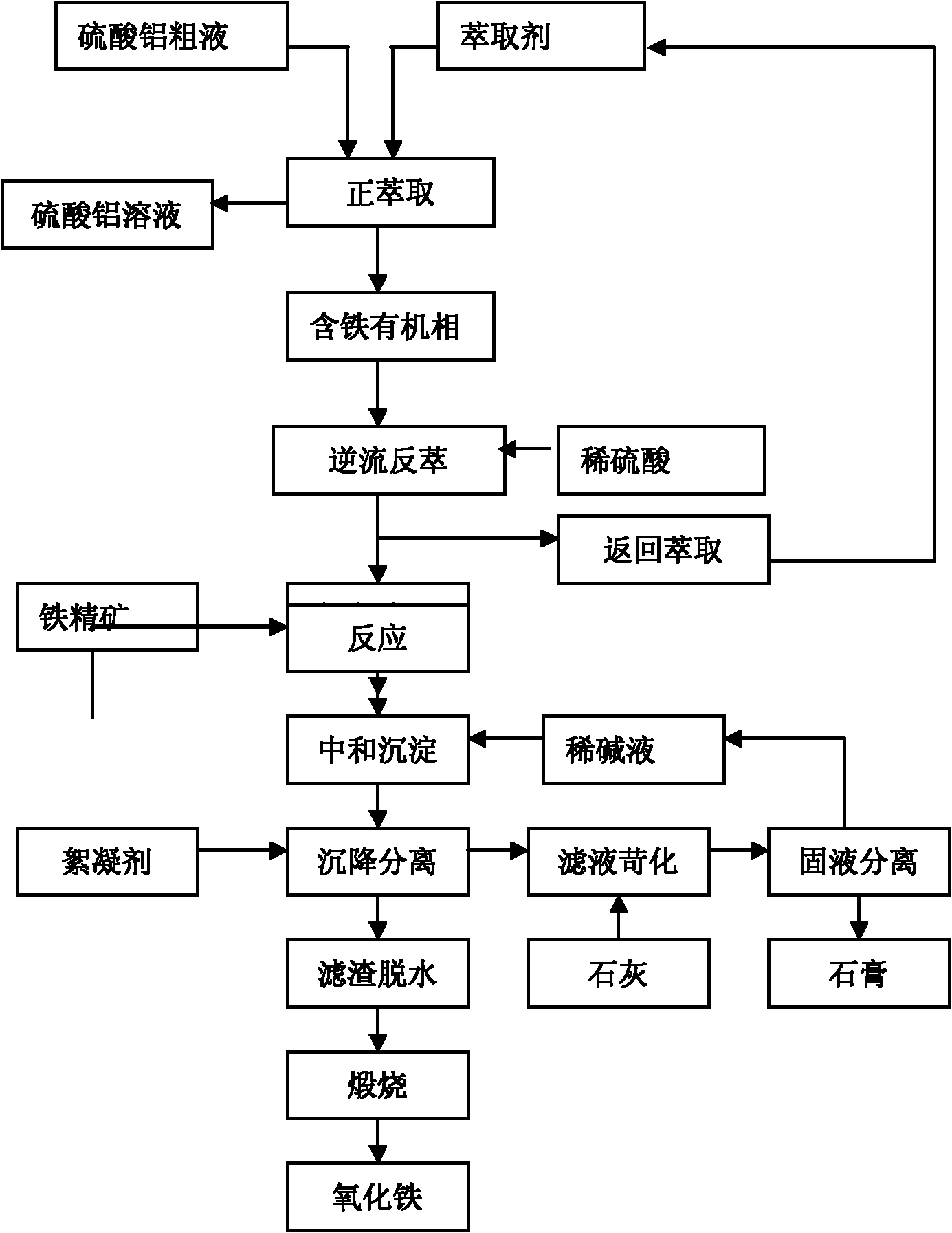

Method for extracting aluminum oxide, monox and ferric oxide from gangue combustion ashes

InactiveCN101913632AEfficient use ofMeet steamSilicaCalcium/strontium/barium sulfatesBiological activationCoal blending

The invention relates to a method for extracting aluminum oxide, monox and ferric oxide from gangue combustion ashes. Coal blending is carried out according to heating value conditions after the gangue is pretreated, gangue activation is achieved while calcination generation is carried out, and the produced electricity and steam are supplied for a system to use; the aluminum oxide is extracted from the ashes by an acid method, the monox is extracted by an alkaline method, and the ferric oxide is extracted by comprehensive utilization of by-products; and acid, alkaline, lime, an extractant andCO2 which are required by each craft link are recycled inside the system. The invention has the beneficial effects that gangue reclamation is implemented by using the method; the energy and the chemical components in the gangue are fully utilized; the discharge amounts of greenhouse gases and waste ashes are greatly reduced, and the economic benefit of the system is improved; and the method is a novel technology of gangue greening and high added-value utilization, and has obvious competitive advantage.

Owner:KUNMING UNIV OF SCI & TECH +1

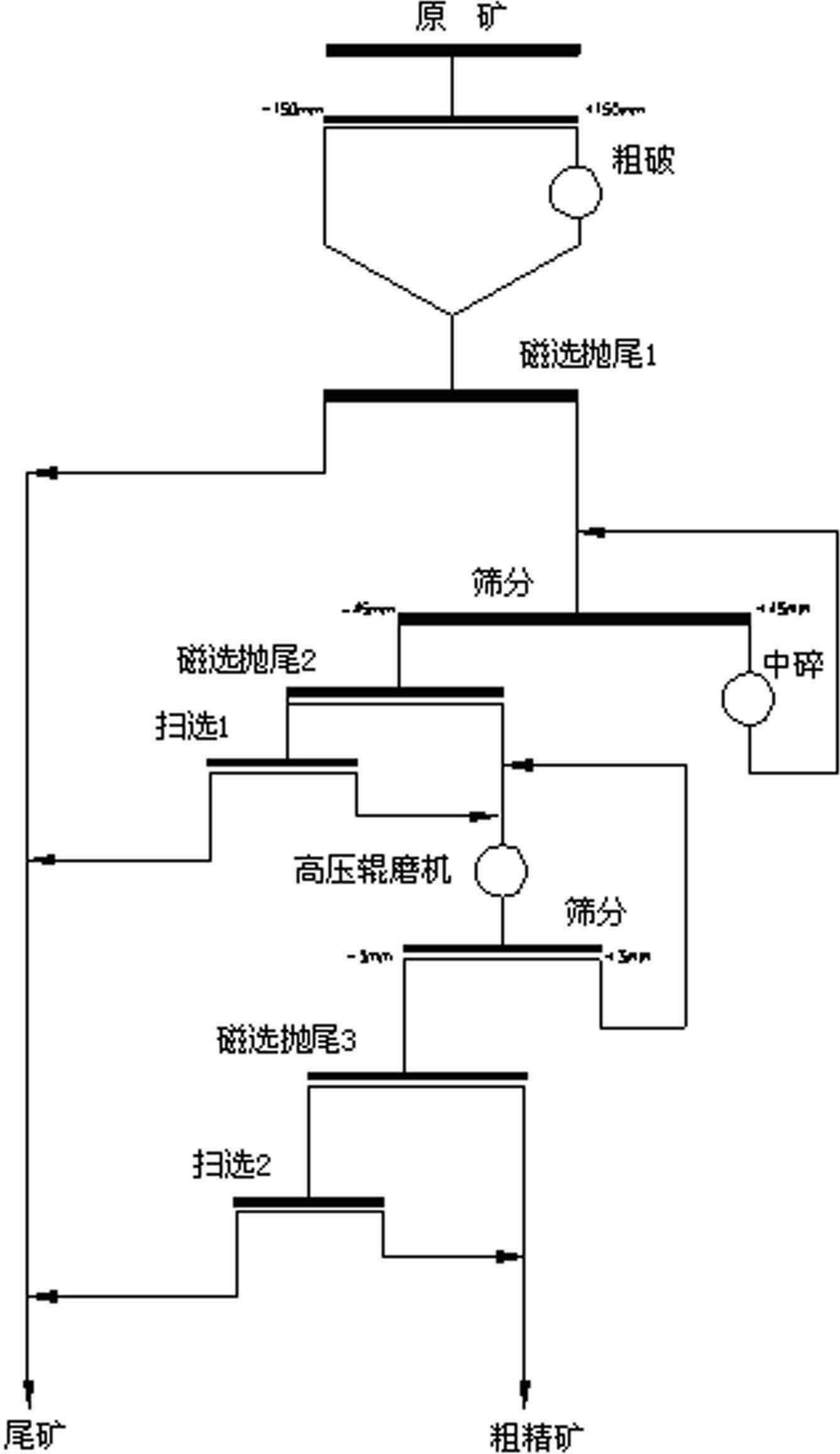

Mineral separation process of magnetic iron ore

ActiveCN101480632AReduce energy consumptionFine Concentrate SizeSievingScreeningMagnetiteMaterials science

The invention discloses a beneficiation method for a pure magnetic iron ore. A crude ore is sequentially treated according to the steps such as first crushing, first-stage dry-type magnetic dressing, medium crushing, second-stage dry-type magnetic dressing, fine crushing and third-stage dry-type magnetic dressing, fine ore is obtained after a great amount of gangues are thrown by the third-stage dry-type magnetic dressing and sent to a grinding head sieve to be griddled and separated, granules griddled by the grinding head sieve are treated in a first-section magnetic dressing process, rough ore griddled by the grinding head sieve is treated in a first-section ball grinding and then enters the first-section magnetic dressing process; ore aggregates obtained from the first-section magnetic dressing process are treated in a second-section ball grinding after discharging gangue sands till the granularity of ore powder is -200meshes being more than or equal to 60 percent, ore powder generated from the second-section ball grinder are treated in second-section magnetic dressing, ore aggregates generated from the second-section magnetic dressing are treated in a high-frequency sieve after discharging gangue sands, products positioned on the high-frequency sieve are filtered to obtain ore concentrate, and products positioned below the high-frequency sieve are treated with desliming and then treated with floatation. The invention adopts two sections of grinding ore open-way processes and distinguishes the ore aggregates during the ore dressing process, thereby greatly reducing the energy consumption of a system, lowering the production cost and enhancing the utility ratio of equipment.

Owner:安徽大昌矿业集团有限公司

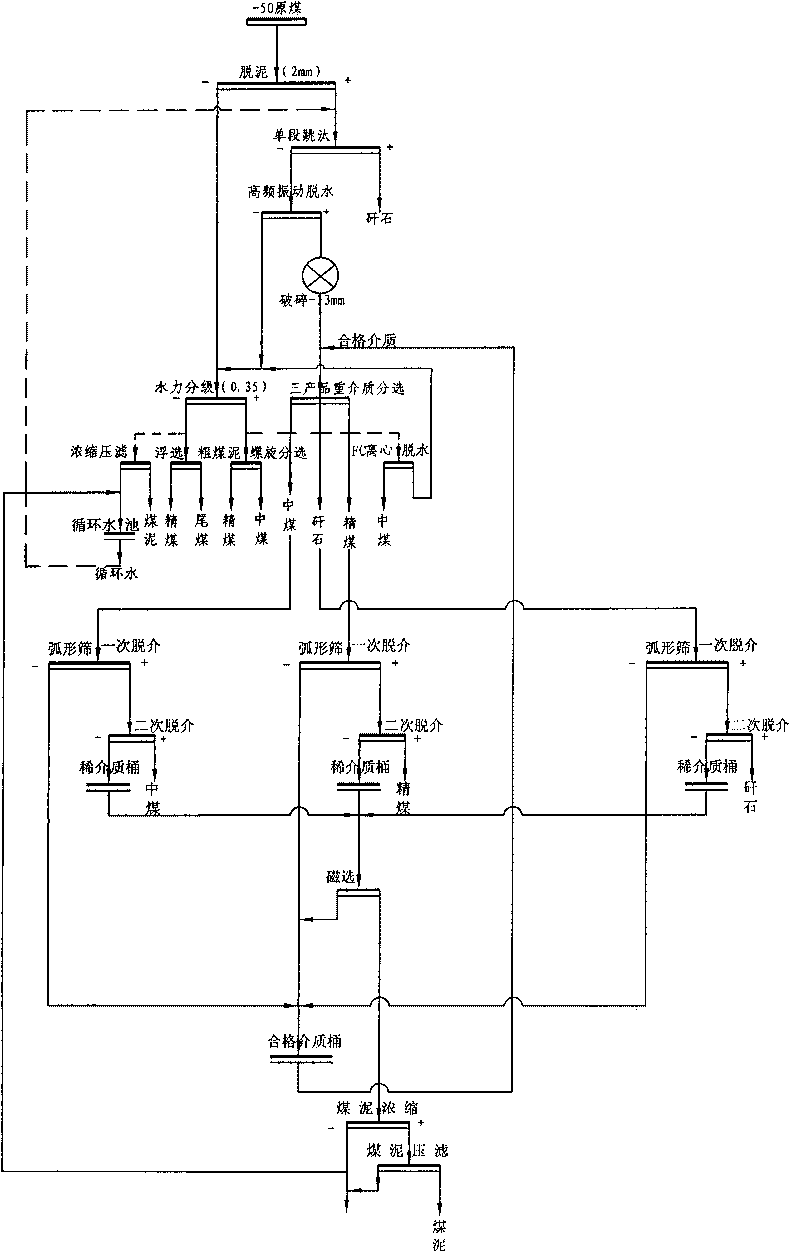

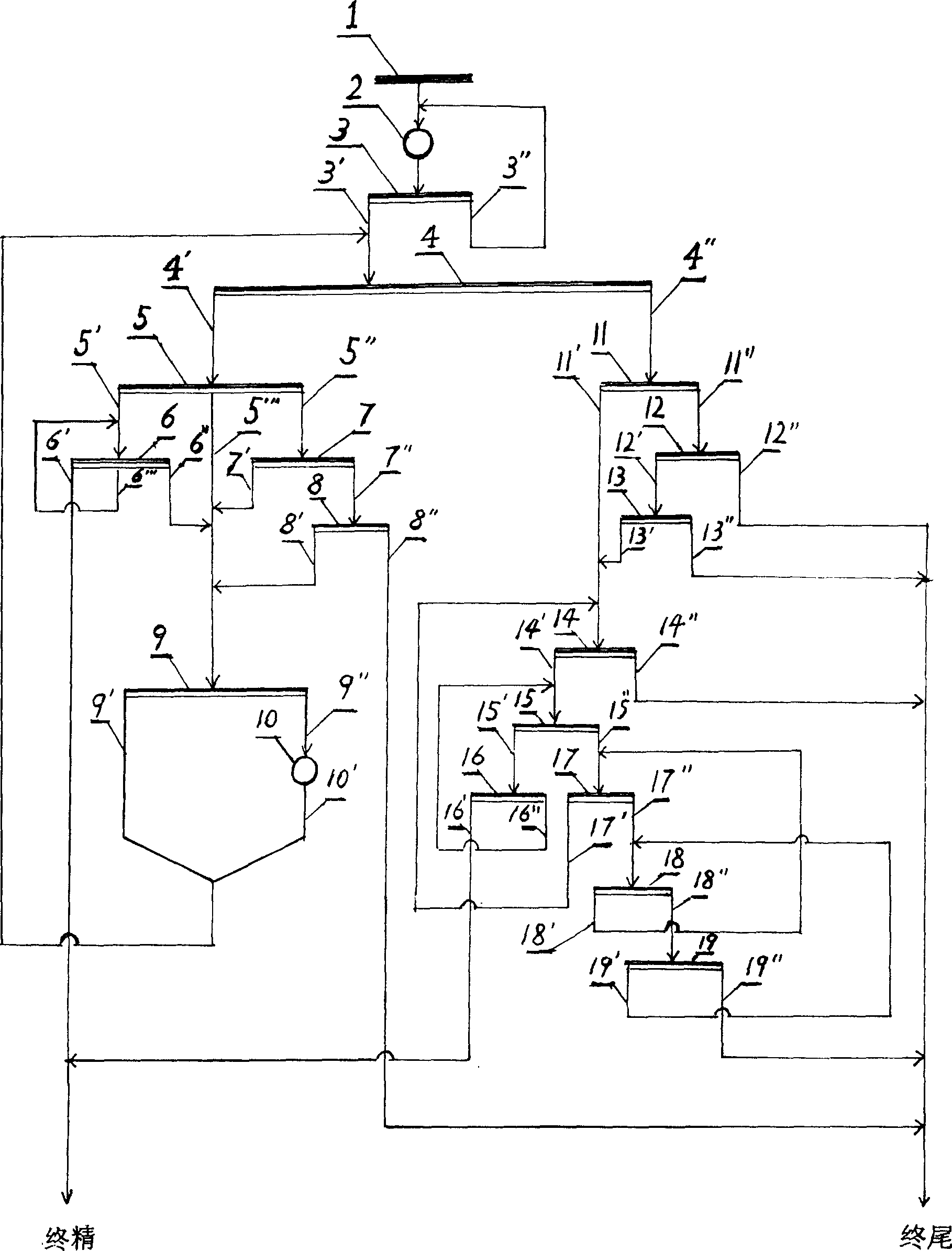

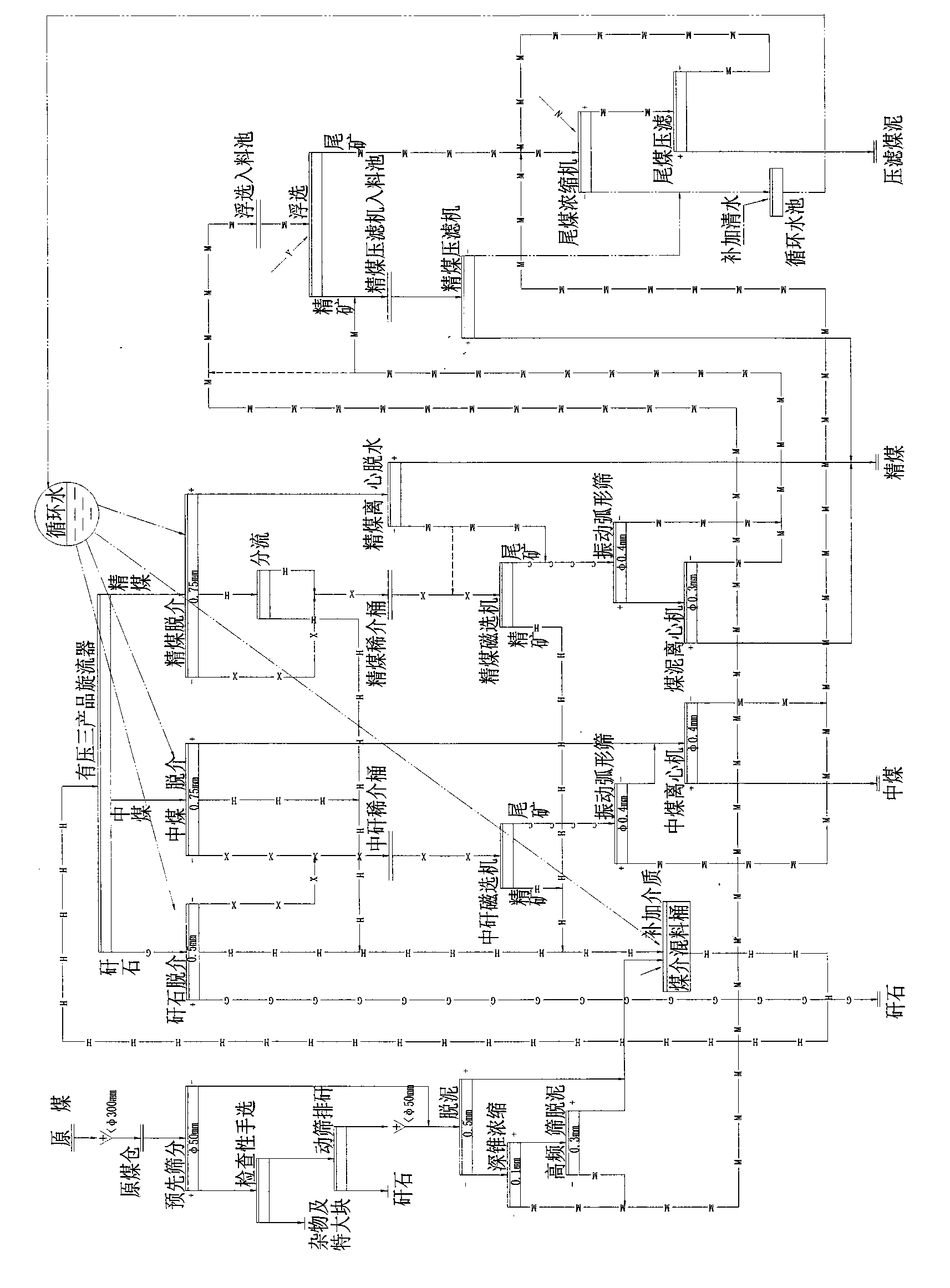

Classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process

InactiveCN103350027AImprove sorting efficiencyFlexible structureWet separationThermodynamicsMagnetic separator

Provided is a classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process. The process comprises the steps that wet classification and primary desliming are carried out on raw coal after prescreening, gangue predischarging and breaking are carried out on the raw coal, secondary desliming is carried out on the screen underflow of the raw coal after the screen underflow is concentrated, the oversize products of the secondary desliming and the screen underflow of the primary desliming are together fed in a pressurized three-product cyclone, three products are obtained after separation, and clean coal, middle coal and gangue are obtained after medium separation and dehydration are carried out on the three products. Part of qualified suspension liquid and dilute suspension liquid are obtained when the medium separation is carried out on the three products, magnetic concentrate is obtained after the dilute suspension liquid is recovered by a magnetic separator, and the magnetic concentrate and the qualified suspension liquid are directly fed in a medium blending barrel. The magnetic tailings of the dilute suspension liquid and the undersize mixtures of pre-desliming, the overflow of concentration classifying equipment and a secondary desliming screen enter a coal slime recovery processing system together. The process is high in separation efficiency, flexible in product structure, low in producing and operating cost and prone to achieving the large-scale single system, the modularization and the integrating intellectualization of plant layout.

Owner:煤炭科学研究总院唐山研究院

Ceramsite prepared by using smelting wastes, and preparation method thereof

ActiveCN103922698AHarmlessAchieve reductionCeramic materials productionClaywaresSocial benefitsSludge

The invention relates to the technical field of harmlessness treatment of smelting wastes, and especially relates to a ceramsite prepared by using smelting wastes, and a preparation method thereof. The ceramsite comprises 10-90% of smelting waste powder, 5-40% of municipal sludge, 4-20% of fly ash, 0-20% of gangue and 0.1-10% of a curing agent. The preparation method of the ceramsite comprises the following steps: 1, crushing the smelting wastes by using a crusher to prepare the smelting waste powder; 2, weighing the smelting waste powder, the municipal sludge, the fly ash, gangue and the curing agent, mixing, and uniformly stirring to prepare ceramsite powder; 3, conveying the ceramsite powder to a ball forming granulation machine, and carrying out granulation molding to prepare ceramsite balls; 4, drying the ceramsite balls; and 5, calcining he dried ceramsite balls to prepare the finished ceramsite. The ceramsite prepared in the invention has the advantages of light weight, environmental protection and wide uses; and the preparation method recycles the smelting wastes, and has good economic and social benefits.

Owner:DONGGUAN YICHENG ENVIRONMENTAL TECH

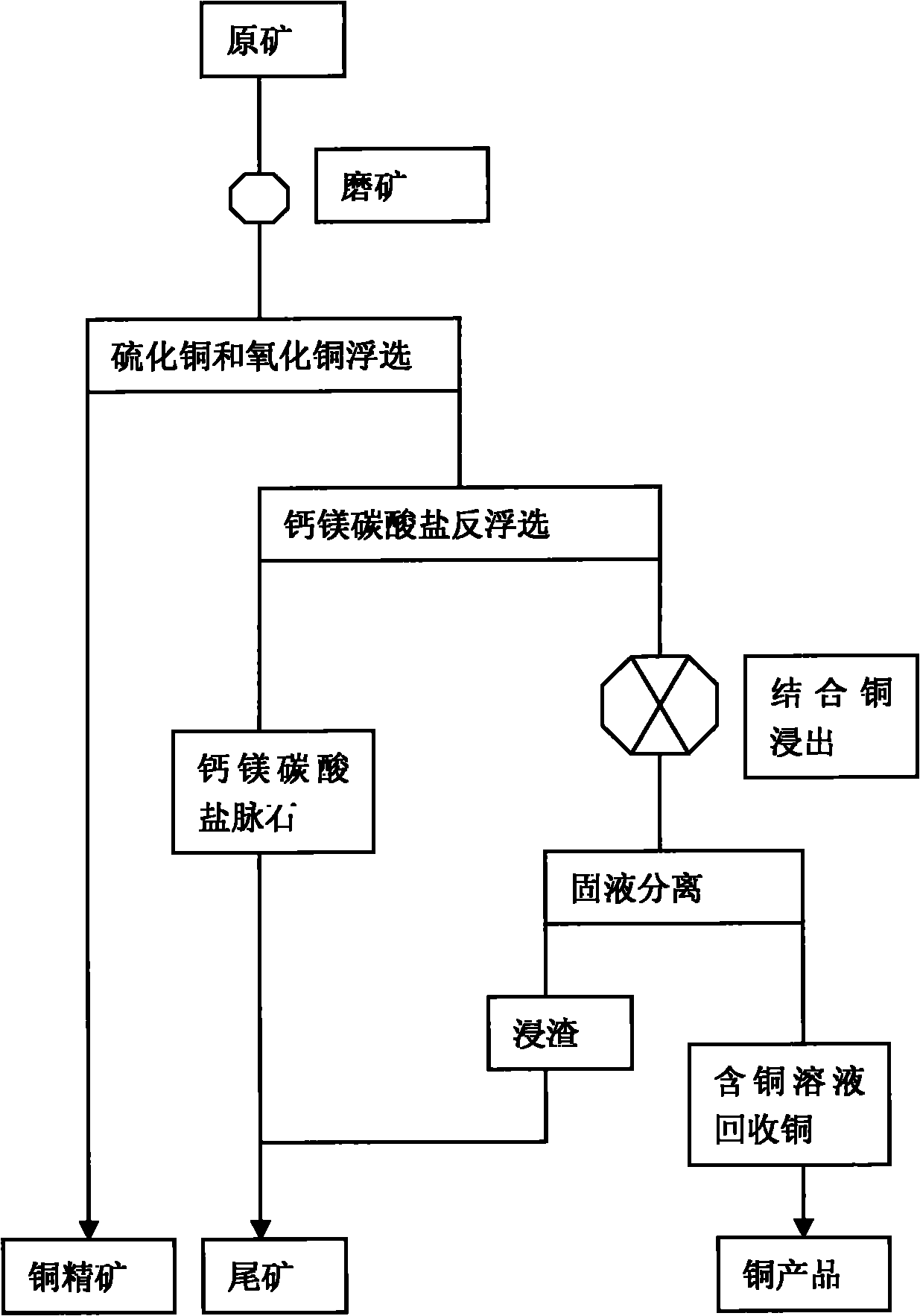

Flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore

ActiveCN101831559AAvoid lostReduce consumptionFlotationProcess efficiency improvementCopper oxideOxygen

The invention relates to a flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore. The flotation and metallurgy method comprises the following steps of: firstly, recovering copper sulfide minerals and free copper oxide minerals in the high-bonding-ratio oxygen-sulfur mixed copper ore with high calcium-magnesium carbonate gangue mineral content by flotation; carrying out reverse flotation on calcium-magnesium carbonate ore in tailings obtained after floatation with fatty acid to obtain middlings containing combined copper and less calcium-magnesium carbonate minerals; then, adding sulphuric acid and stirring to leach out combined copper; and processing a copper-contained solution obtained after solid-liquid separation to obtain a copper product by a metallurgy method. The method combines the flotation and the metallurgy for complementary advantages, efficiently recovers and utilizes high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore resources incapable of being processed at present, lessens the emission of castoff, such as carbon dioxide, magnesium calcium sulfate, and the like and has favorable economic benefits and environmental benefits.

Owner:YUNNAN TIEFENG MINING CHEM NEW TECH CO LTD

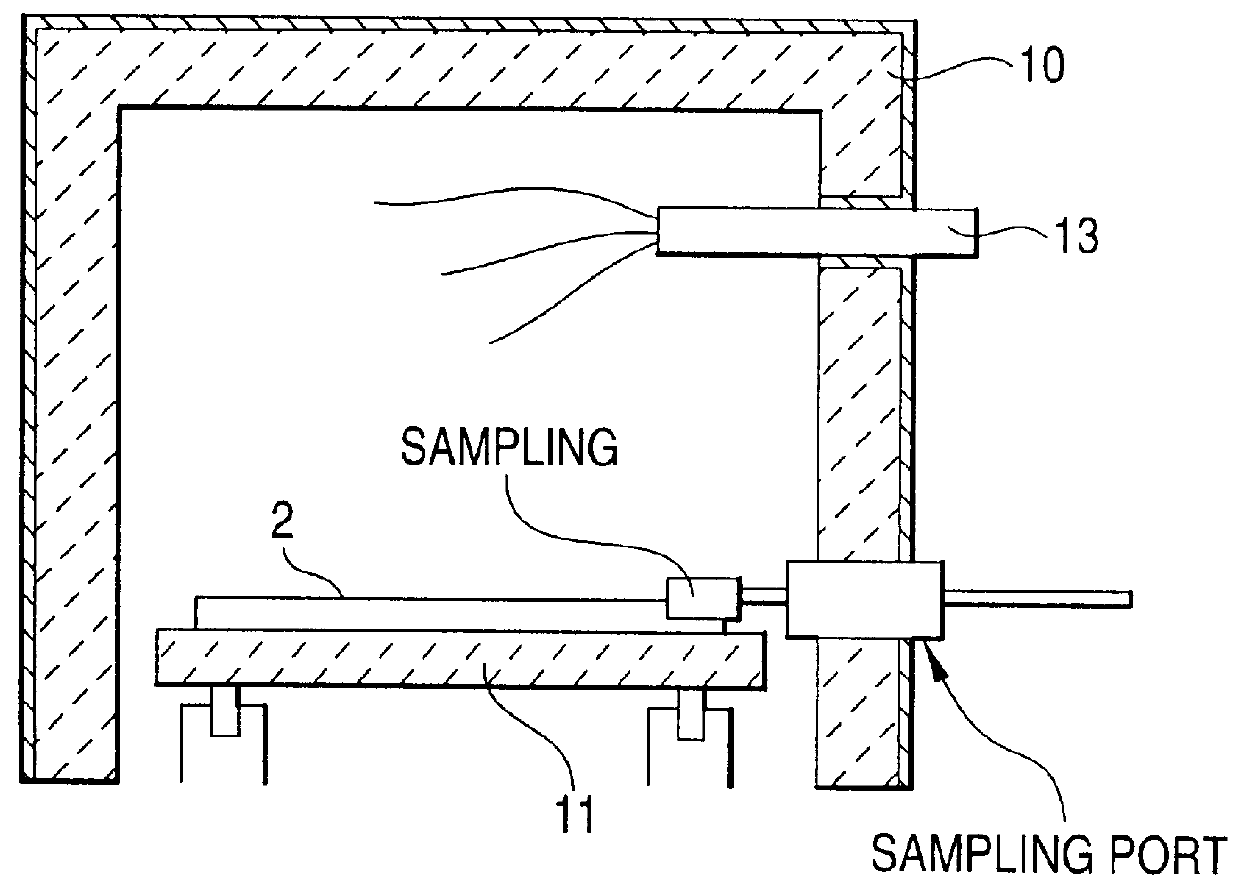

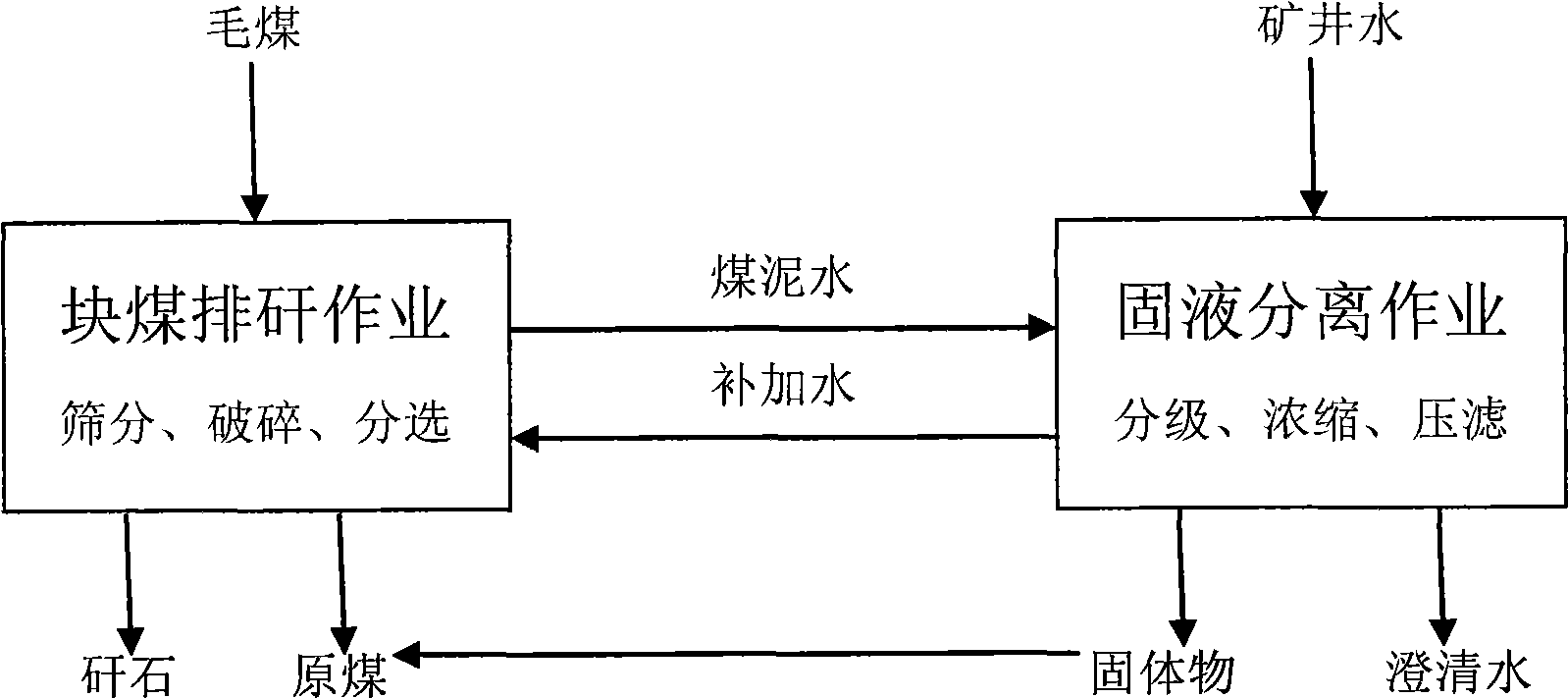

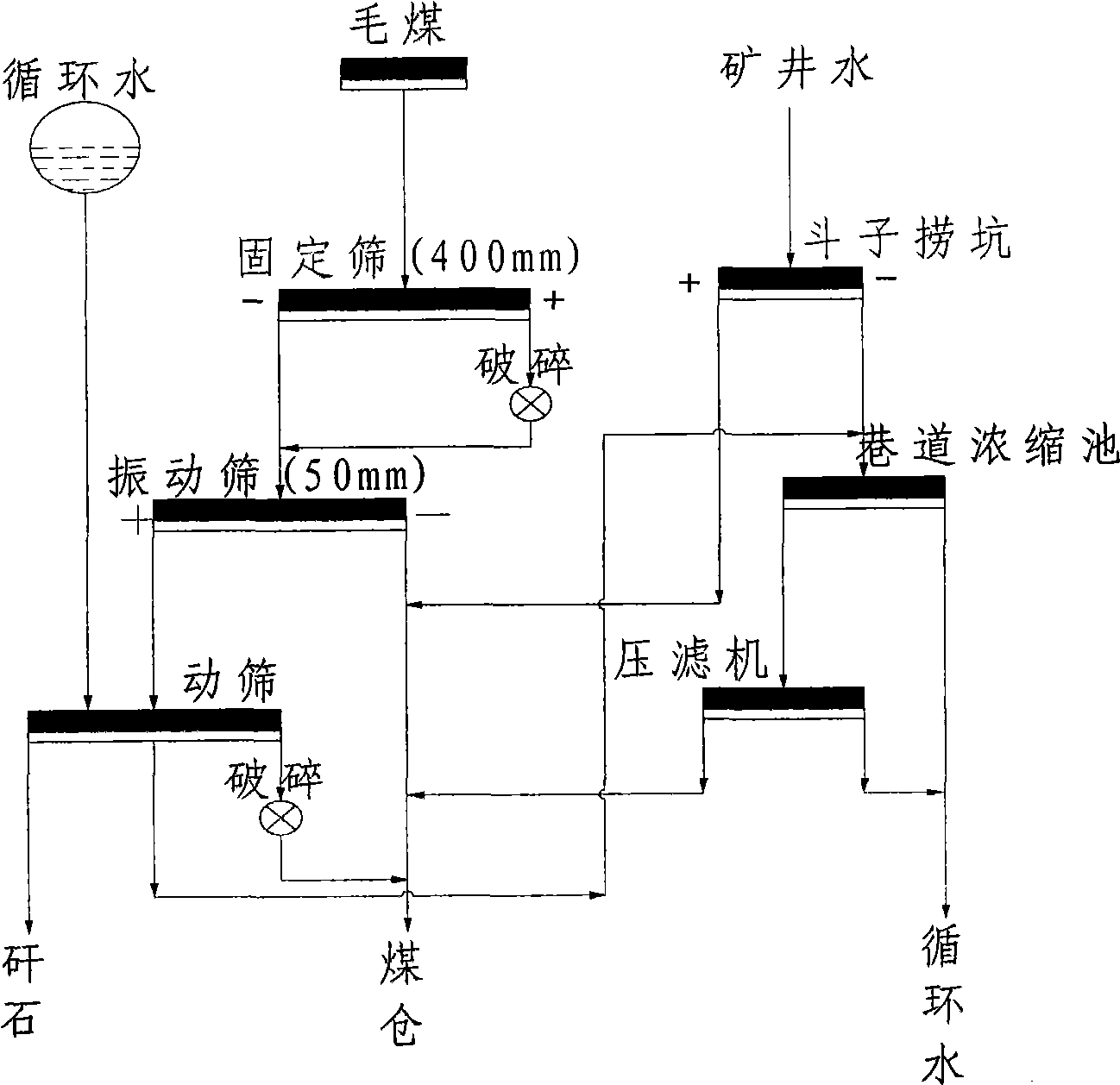

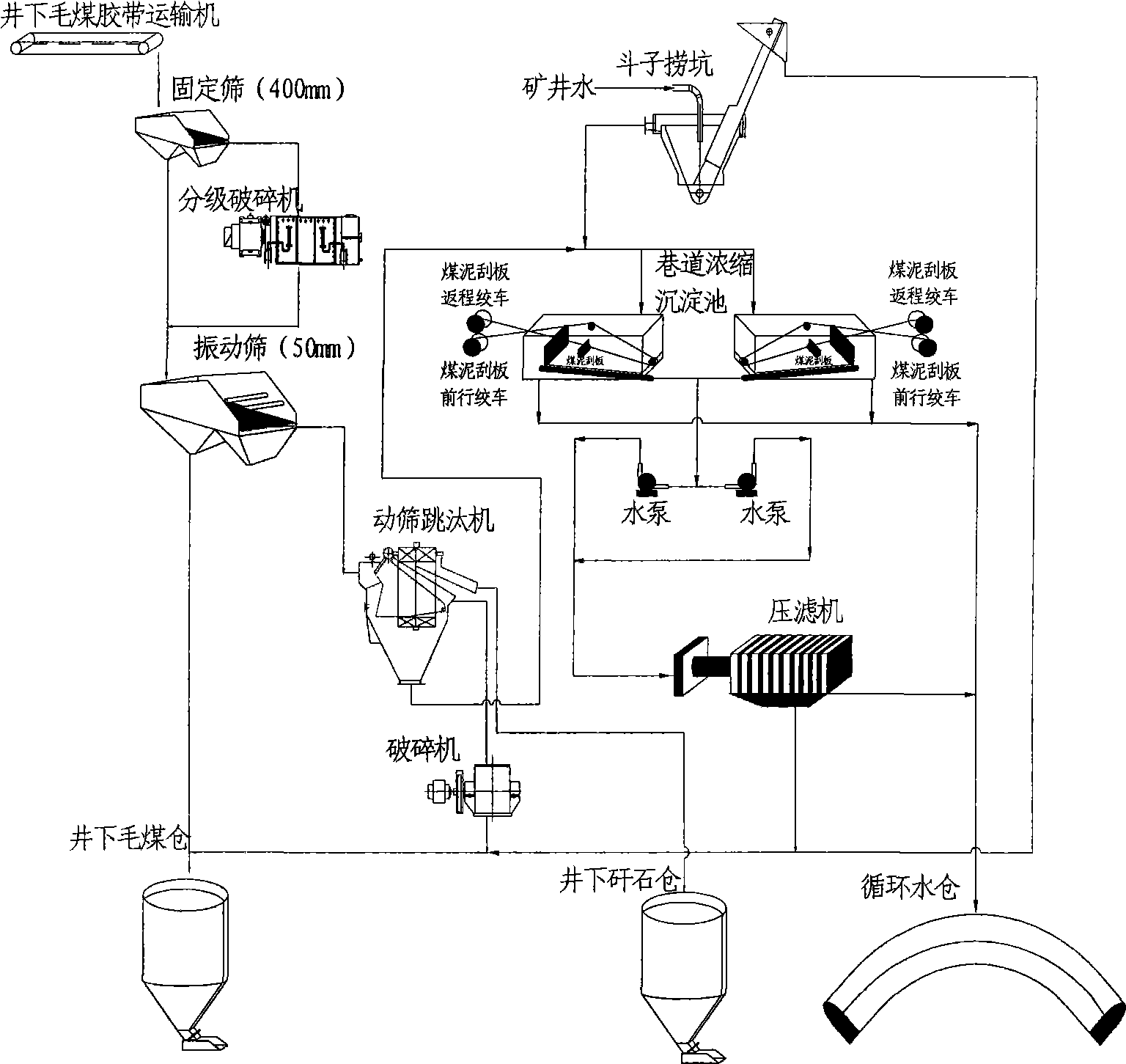

Down-hole gross coal dirt-discharging and mine water treating combined process

An underground gross coal gangue removal and mine water treatment combined process is characterized in that the process comprises two parts: gangue removal operation from lump coal and mine water solid-liquid separation operation, wherein, the gangue removal operation from lump coal comprises screening, crushing and separation steps, and the mine water solid-liquid separation operation comprises hydraulic classification, concentration and pressure filtration steps; by the gangue removal operation from lump coal, chunks of gangues in the gross coal are removed, and simultaneously the large particles thereof are crushed into appropriate size; by the mine water solid-liquid separation operation, the solid substances in the mine water are recycled to a coal streamline, and simultaneously the clear overflow water is delivered to a underground water sump; the coal muddy water generated by the gangue removal operation from lump coal is delivered to a mine water solid-liquid separation system for treatment and the mine water solid-liquid separation system provides water for washing and selection for the gangue removal operation from lump coal, so the coal muddy water and the water for washing and selection are combined into an organic whole.

Owner:HENAN POLYTECHNIC UNIV

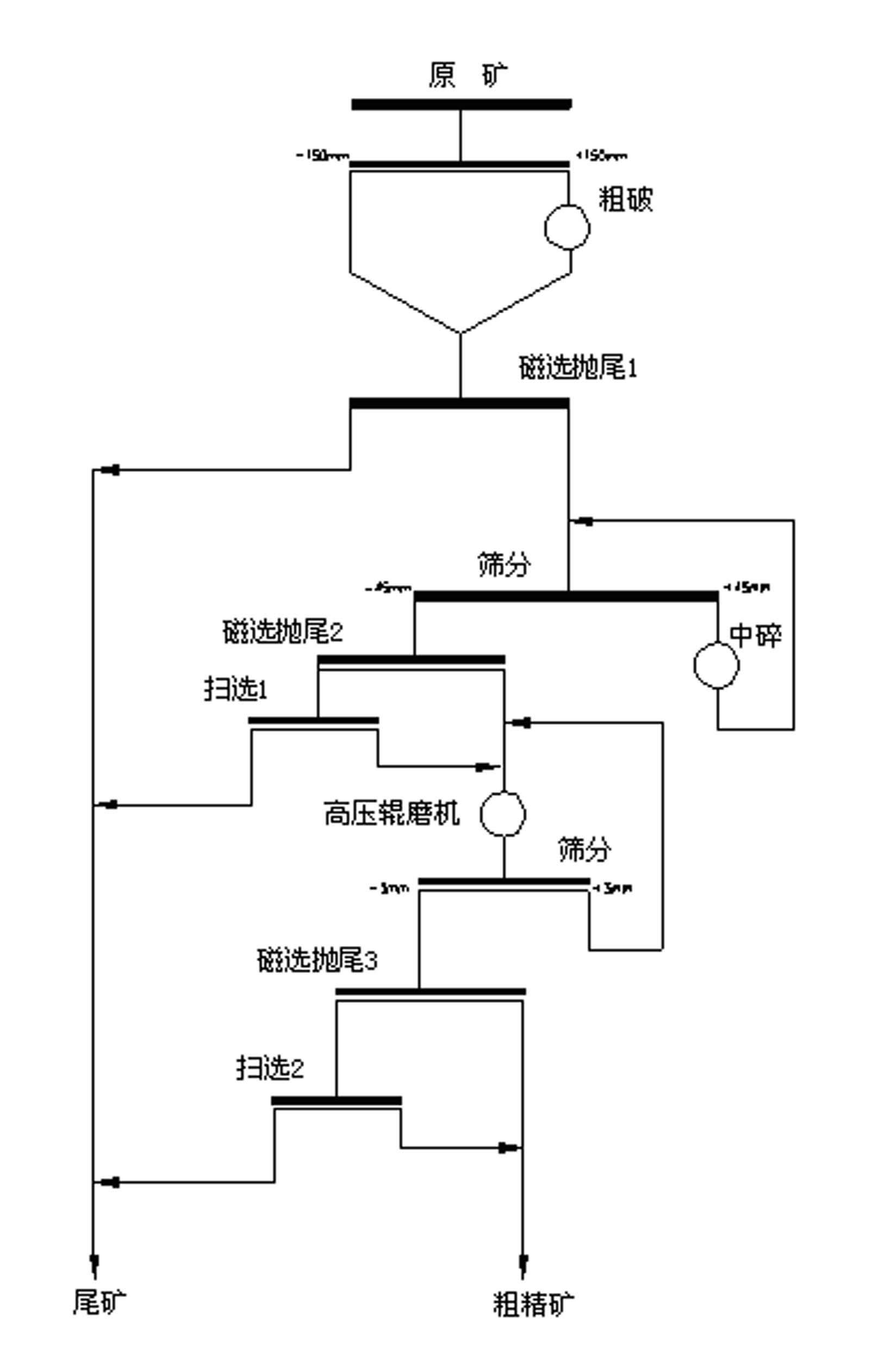

Pre-selecting and tailings discarding process of lean magnetite ores

InactiveCN102430473AImprove the grade of iron for grindingImprove efficiencyMagnetic separationGrain treatmentsMagnetiteMagnetic separator

The invention discloses a pre-selecting and tailings discarding process of lean magnetite ores, comprising three stages: a coarse crushing stage, an intermediate crushing stage and an ultra-fine crushing stage, wherein fine crushing operation stage can be increased before the ultra-fine crushing stage and after the intermediate crushing stage. The staged magnetic pre-separation and tailings discarding work can be executed by different types of magnetic separators according to the difference of granularity of each crushing stage. Surrounding rocks and partial dissociatve gangue which drop in the tailings are removed in the first discarding work; waste stones which are not removed in the first tailings discarding work and the gangue which is further dissociated after the intermediate crushing stage are removed in the secondary tailings discarding work; and the third tailings discarding work is to discard the tailings after the tailings are ultra-finely crushed by a high-pressure roller mill. After the lean magnetite ores in which the fine particles are embedded are ultra-finely crushed by the high-pressure roller mill, the dissociation degree is further improved, and the magnetic separating and tailings discarding effects are good. The tailings discarding work is designed to reduce the loss of ferrous metal. The complete process can effectively improve the grade of grinding ferrous, can ensure the TFe recovery rate of the work, can improve the grinding characteristics of the material in the grinder, can reduce the quantity of the ore to be grinded, and can reduce the energy consumption of grinding the ores and the cost of separating the ores.

Owner:ANHUI UNIV OF SCI & TECH

Near infrared spectral recognizing coal gangue and gangue content control method

ActiveCN101798927AIncrease release rateRealize automatic coal dischargeMining devicesUnderground miningInfraredDischarge rate

The invention relates to a near infrared spectral recognizing coal gangue and a gangue content control method. The method comprises the following steps of: mounting a plurality of transmitting light wave probes and receiving light wave probes on a scraper conveyor under top caving coal liquid; receiving the signal conversion of the transmitting light wave probes and the receiving light wave probes by a near infrared analyzing device to recognize the coal gangue content; setting a threshold value of the gangue content for the near infrared analyzing device before detection; then carrying out multidirectional detection on a coal gangue mixture on the conveyer by the probes; acquiring data in real time; analyzing and processing the gangue content in the coal gangue mixture and comparing the gangue content with the set threshold value; when the detected gangue content reaches or exceeds the set gangue content threshold value, controlling the automatic closing of a coal discharge opening by an electrohydraulic valve controller and realizing automated coal discharge. The invention improves the discharge rate of comprehensive top coal caving, reduces labor, improves the efficiency, enables a coal miner to be far away from the severe environment of the underground working surface and has simple method, convenient operation, good controllability, safety and reliability.

Owner:CHINA UNIV OF MINING & TECH

Beneficiation method for separating fluorite and tungsten through flotation

ActiveCN104084315AAvoid the problem of poor floatability and difficult flotation recoveryAvoid lostFlotationSulfidationTungsten

The invention discloses a beneficiation method for separating fluorite, white tungsten (black tungsten) and gangue minerals in complex polymetallic ore through flotation. Non-magnetic products of tailings subjected to sulphide ore flotation or tailings subjected to sulphide ore flotation and then subjected to strong magnetic separation for recycling black tungsten serve as two kinds of samples. The pH value is controlled by adding regulators, white tungsten, black tungsten, other gangue combined inhibitors and collectors are added, fluorite is subjected to differential flotation, then, tungsten minerals are subjected to flotation, and therefore fluorite and tungsten can be efficiently recycled. Loss of fluorite in tungsten flotation concentrate is avoided when tungsten minerals are subjected to differential flotation, and the defect that when tungsten flotation is performed, fluorite is difficult to recycle through flotation because the inhibitors have strong inhibition on fluorite, and beneficiation efficiency is low is avoided. Compared with a current beneficiation situation, the fluorite recycling rates of tests on the two different samples are increased by 39% to 48 % and 9% respectively, and the tungsten recycling efficiency is improved by 3%.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL +1

Method for comprehensive utilization of red mud, phosphogypsum and coal gangue

A method for comprehensive utilization of red mud, phosphogypsum and coal gangue comprises the following steps: red mud, phosphogypsum and coal gangue are used as main original burning materials, a correction material is taken as a secondary original burning material, a homogeneous moisture material is prepared through two-stage batching process and is shaped or dried and crushed, and then a clinker product including main ingredients of dicalcium silicate, calcium sulphoaluminate and calcium sulphoferrite is prepared through calcination. The clinker produced by the method can be not only directly sold as a product but also further processed into a cementing material or product for sale by utilizing the prior art. The method provided by the invention is simple in process and low in investment, the production scale can be either big or small, a rapid hardening early strength clinker produced by the method is wide in use and relatively higher in value, not only are lots of clay resources and non-renewable burning coal saved, but also environmental pollution caused by waste pollutants are effectively reduced, secondary disasters is prevented, and high industrial competitiveness and favorable investment economical efficiency are realized.

Owner:长沙紫宸科技开发有限公司

Reverse/direct flotation technology of collophanite

The invention discloses a reverse / direct flotation technology of collophanite. The technology comprises the following steps of: performing ore reduction, ore grinding and size mixing on the silicon calcium type collophanite; adding a carbonate gangue mineral flotation regulator and fatty-acid soap respectively to perform size mixing; performing reverse flotation on the material after the size mixing, wherein the product in the tank is reverse flotation concentrate; dehydrating the reverse flotation concentrate and adding sodium carbonate so as to adjust the pH value to 8-10; performing closed-loop ore grinding and grading on the base flow; enabling the grading overflow to enter a direct flotation stirring tank, and adding water glass and fatty acid soap into the tank respectively to perform size mixing; performing direct flotation on the material subjected to the size mixing, wherein the direct flotation foam product is direct flotation concentrate; and performing concentration, filtration and drying to obtain the finished product of phosphate concentrate. After dehydration (reagent removal), the technology disclosed by the invention can be used for remarkably reducing the amount of sodium carbonate for neutralizing acid water; the sodium carbonate has a dispersion and grinding aid function, and the over-grinding of the material of direct flotation can be reduced; and the fresh surface and proper size composition generated by the ore grinding are favorable for improving the sorted behavior of the direct flotation and improving the sorting efficiency.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

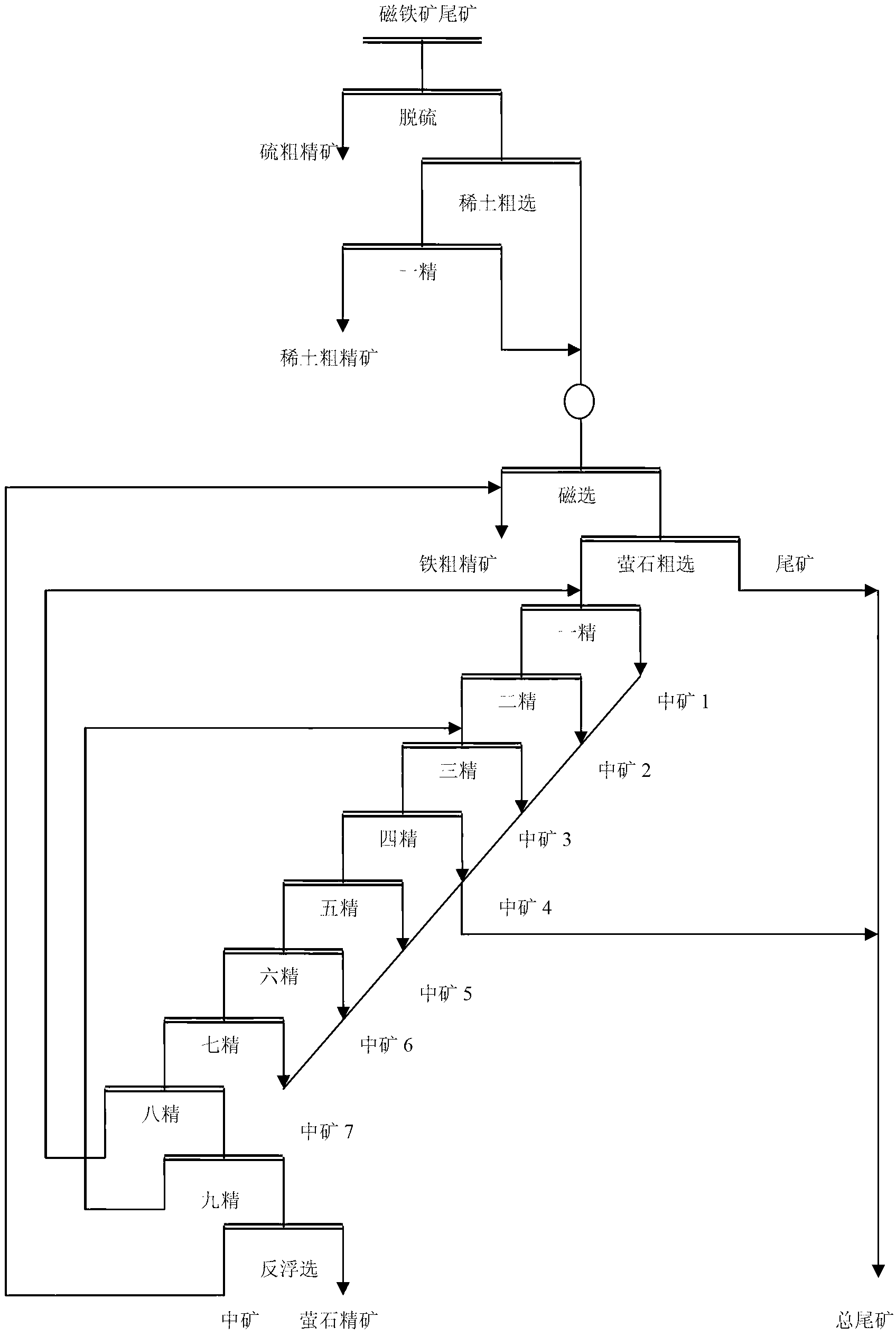

Mineral processing technology for recycling fluorite from baotite, magnetite and tailing

The invention belongs to the technical field of mineral engineering and provides a mineral processing technology for recycling fluorite from baotite, magnetite and tailing. In the tailing, mineral particle size of the fluorite is thin, iron-bearing mineral, rare-earth mineral, gangue mineral and the fluorite mineral are closely symbiotic and floatability of minerals such as rear earth, barite, apatite, calcite and dolomite is close to the fluorite mineral, so that separation of the fluorite mineral is difficult. According to the mineral processing technology for recycling the fluorite from the baotite, the magnetite and the tailing, priority desulfuration, rear earth flotation, ore grinding, iron selection through magnetic separation, fluorite selection through direct flotation and a reverse flotation sorting technology are performed on the magnetite and the tailing to enable pyrite, the rare earth, the iron-bearing mineral and the fluorite to be picked out in sections, efficient, high selective, easy-to-operate inhibitor and collecting agent combination is utilized in sorting of fluorite which is mostly performed monomer separation, so that fine fluorite of high grade and high recovery rate is obtained, a purpose of synthetically recycling valuable minerals is achieved, and effective separation of the fluorite mineral and the gangue mineral is achieved.

Owner:包钢集团矿山研究院(有限责任公司)

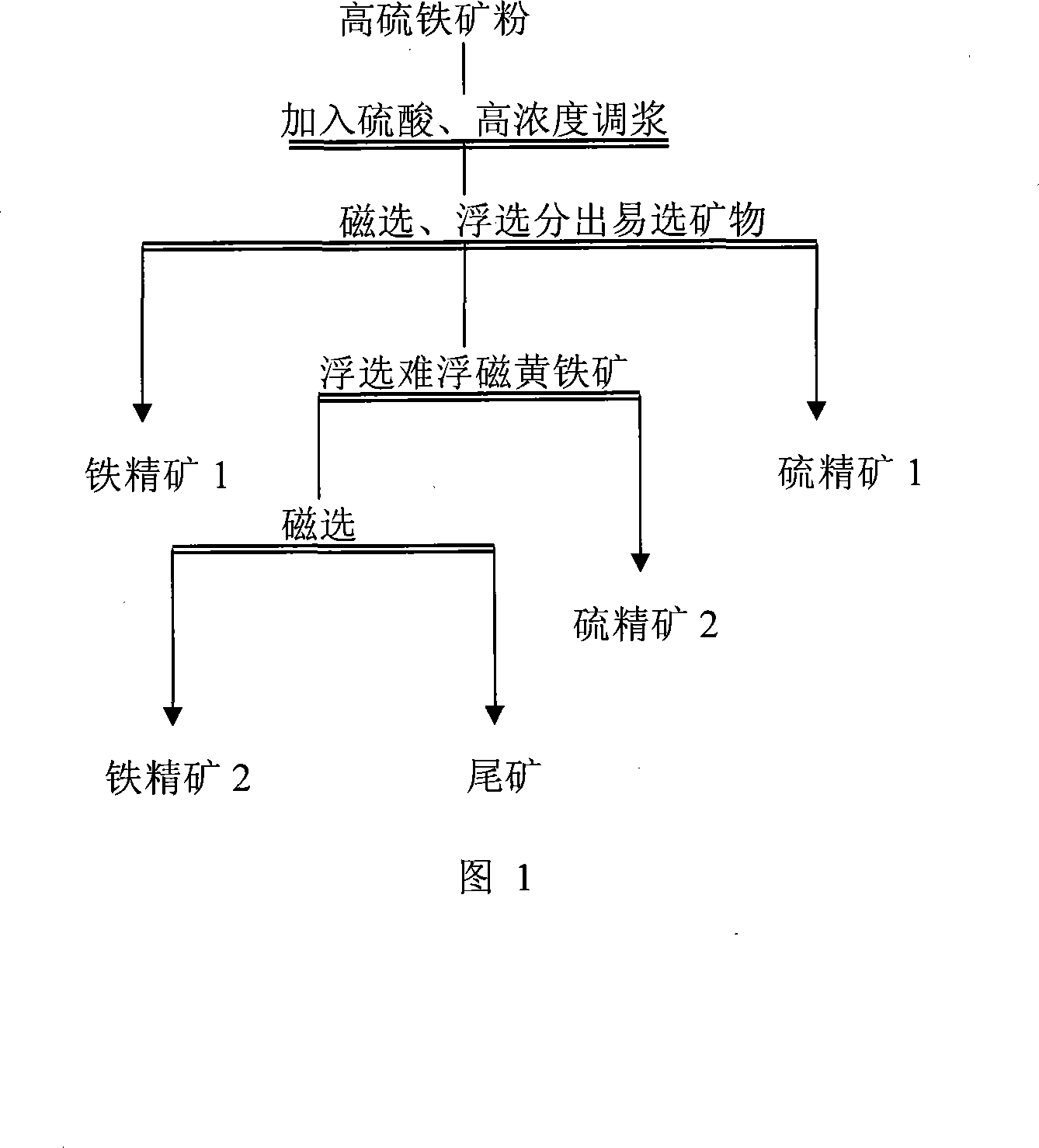

Desulfuration method for high sulfide pyrite powder

ActiveCN101157979ASimple process structureLow costFlotationProcess efficiency improvementIronstoneSulfur

The invention relates to the desulfurizing method of high-sulphur iron ore power, in particular to the iron ore power recycled by using sulfurous iron ore, pyrites and floatation gangue. When the content of sulphur of the iron ore concentrate, which is mostly magnetite, reaches over 15 percent, by adopting the principle of asynchronous size classification, the iron ore concentrate can reach over 65 percent, wherein the content of sulphur is reduced to less than 0.3 percent, and the rate of desulphurization reaches more than 90 percent. The method has the advantages of the simple system of medicament, slight acid-causticity for equipment, and low cost of operation.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

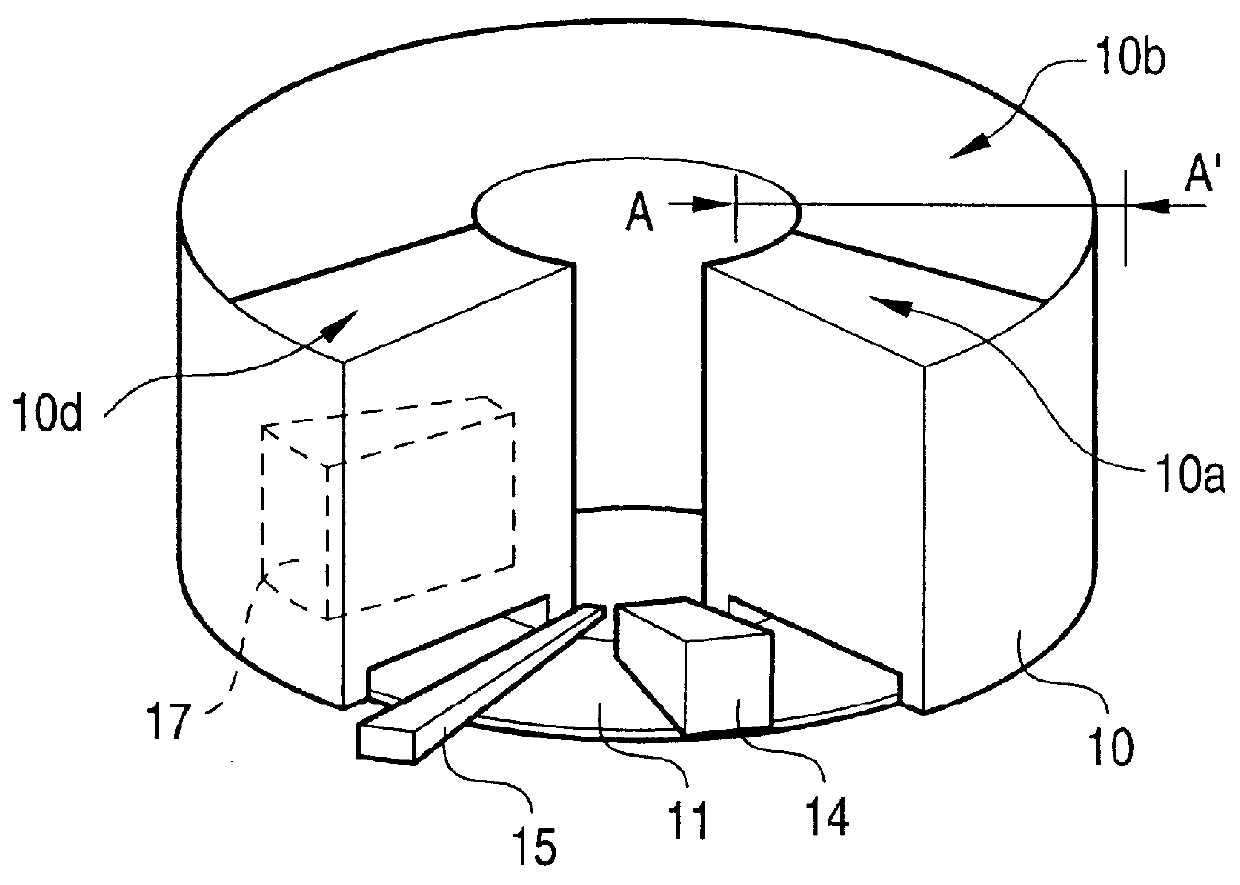

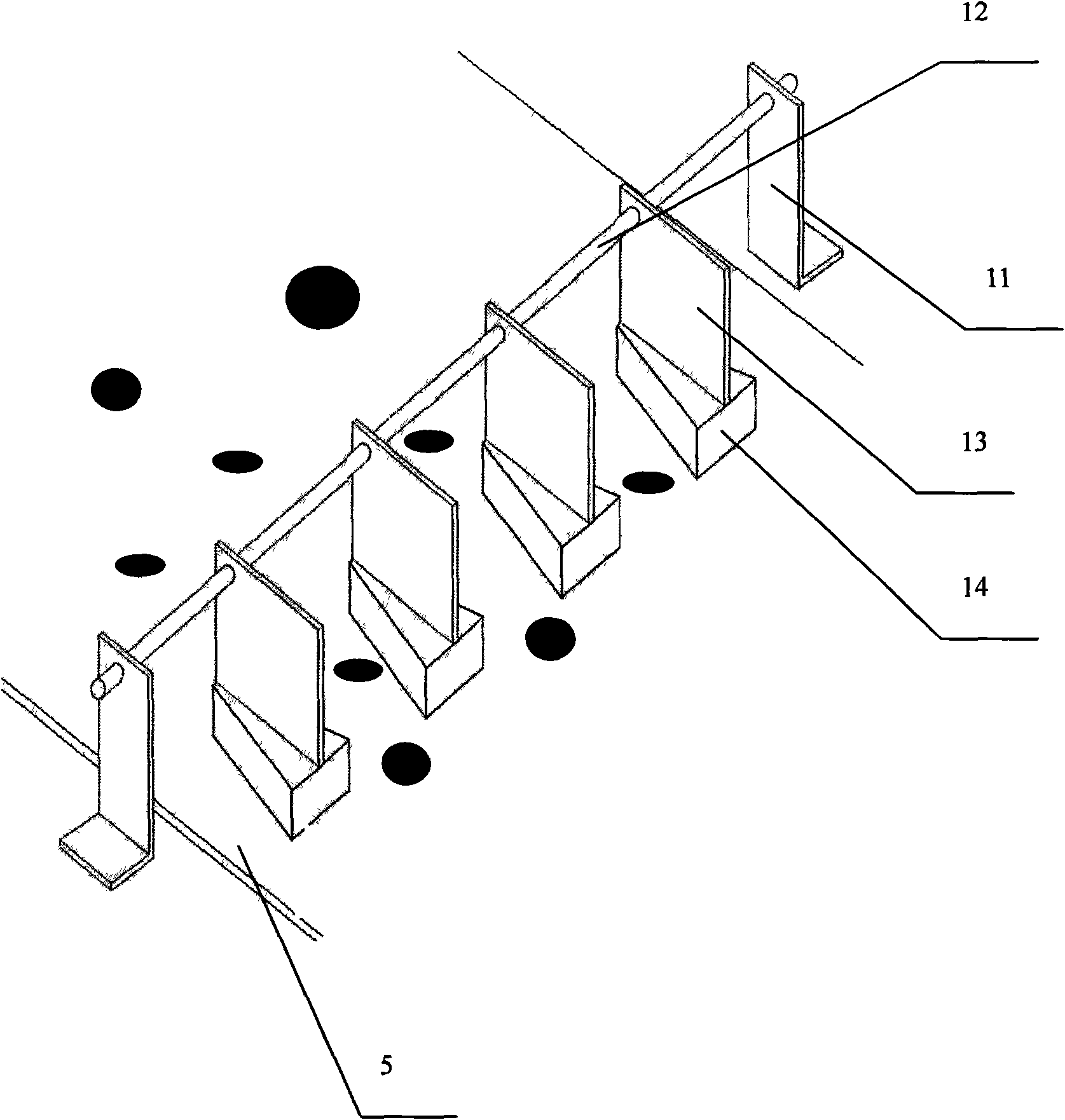

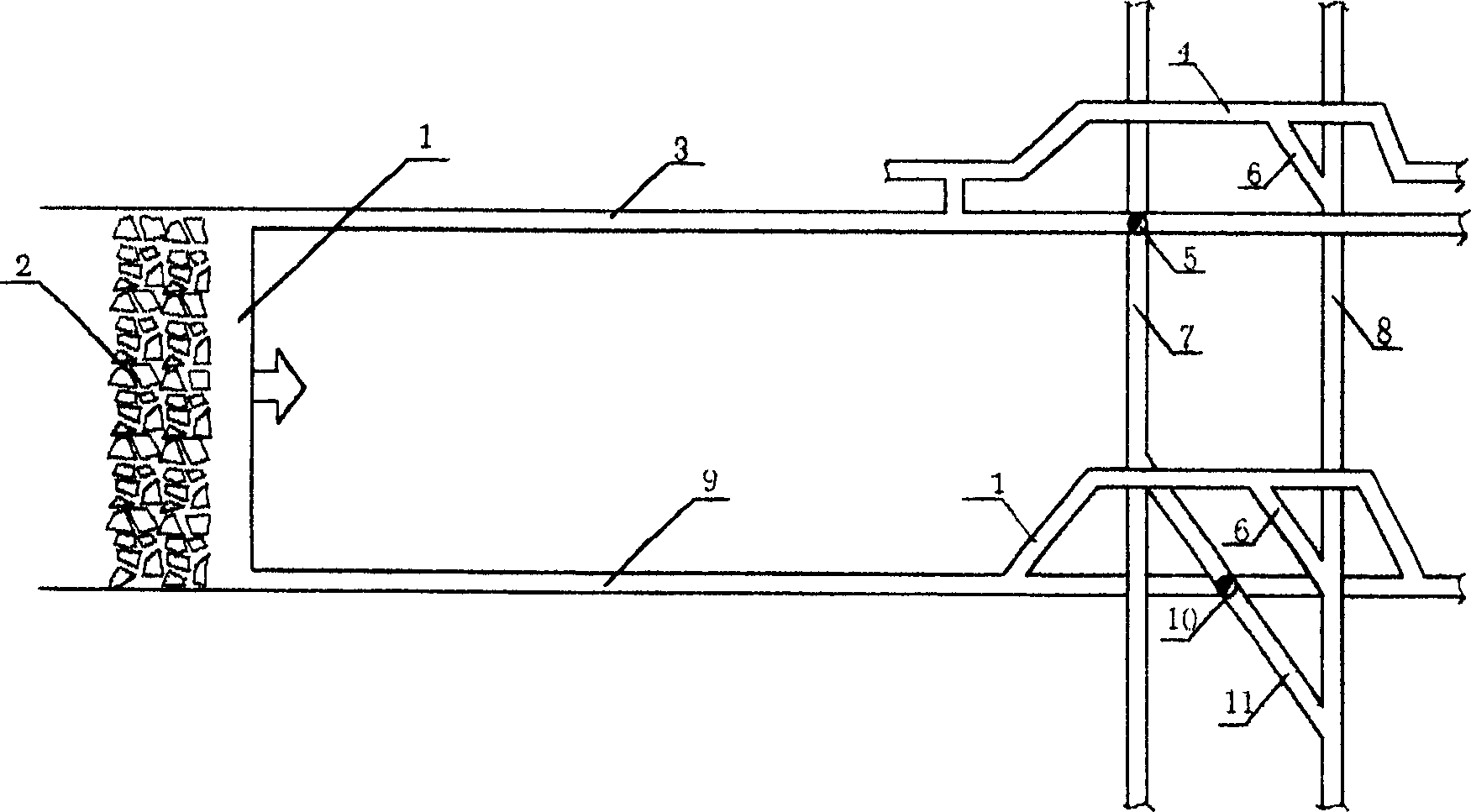

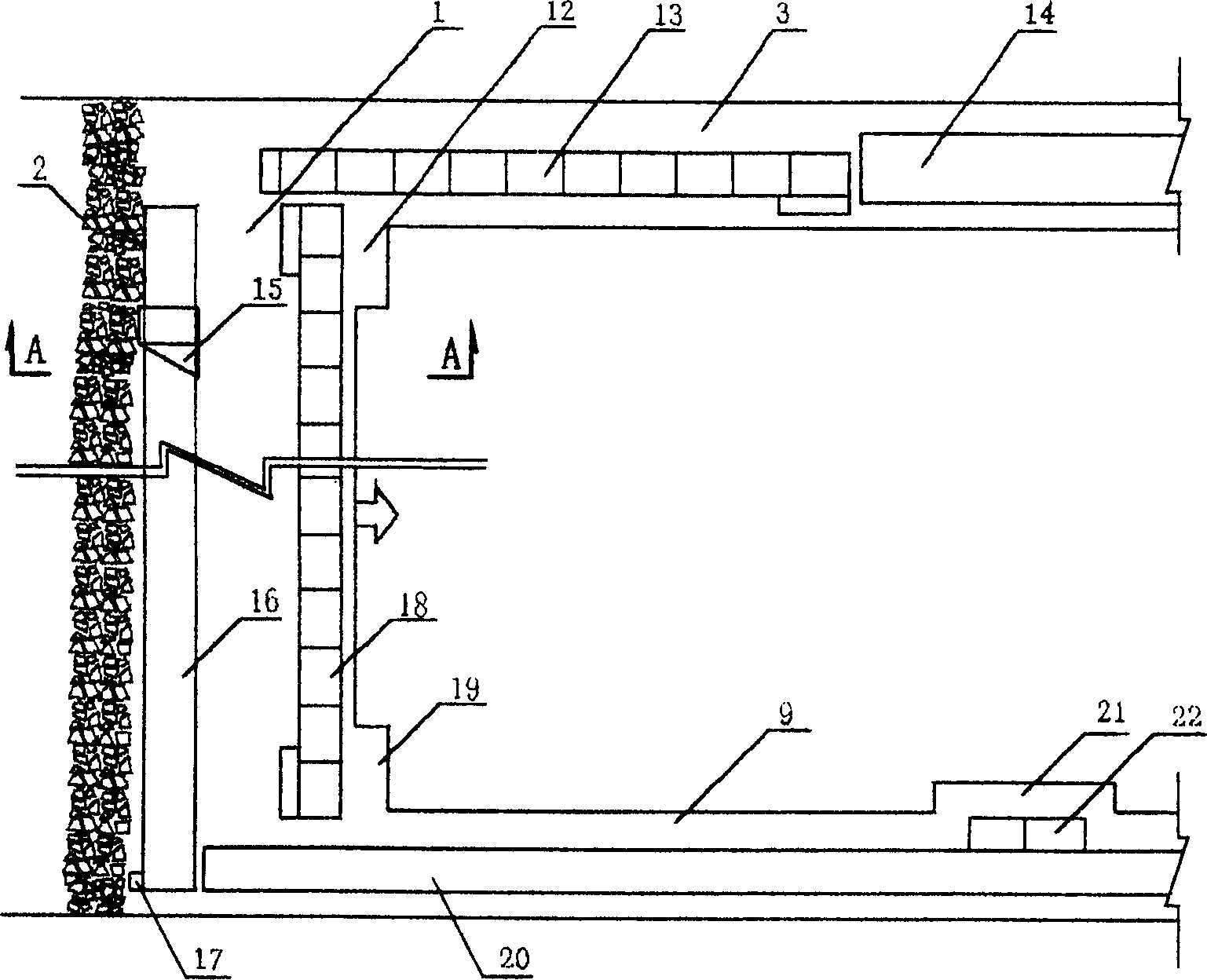

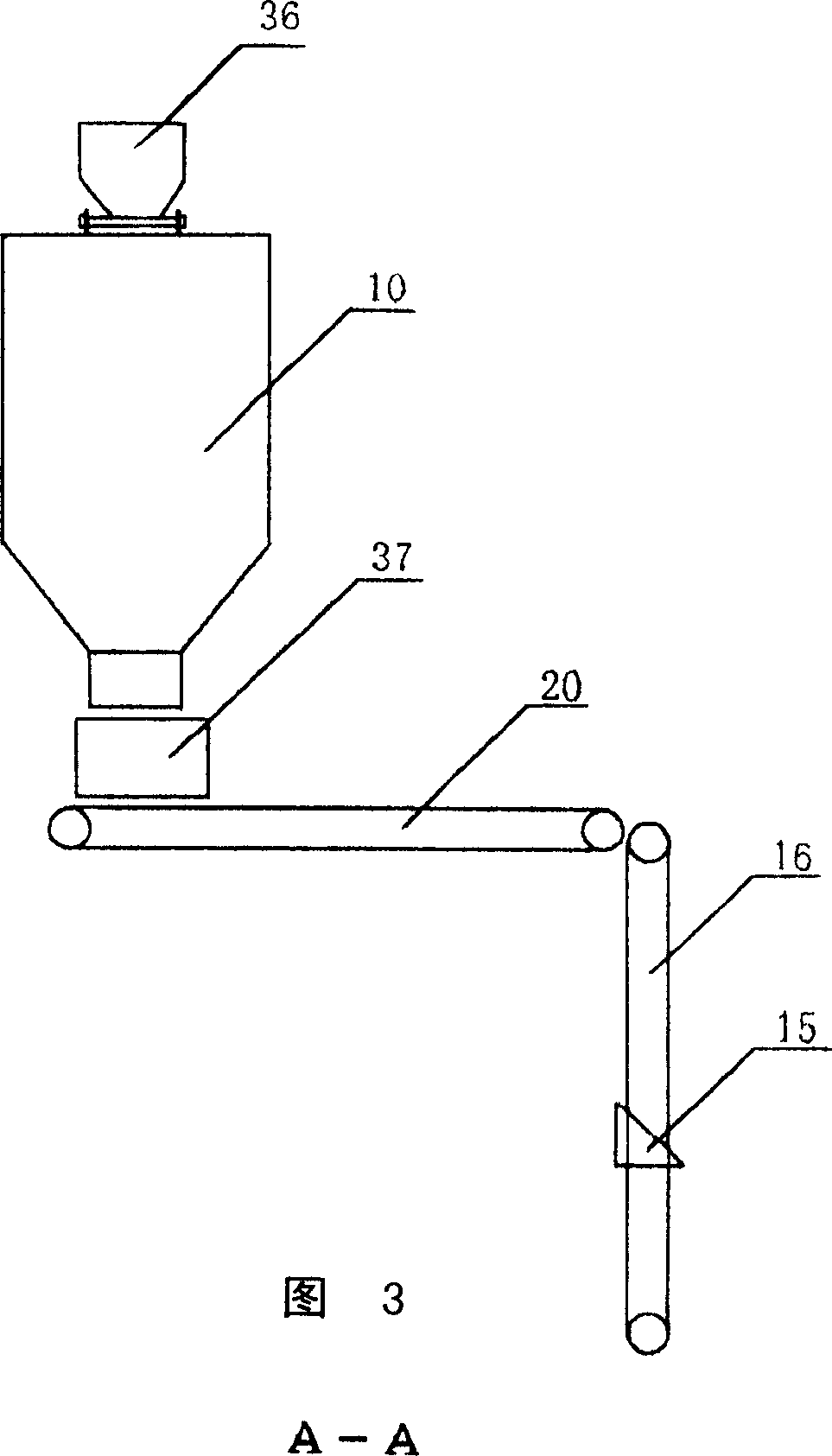

Method for filling goaf by gangue

The invention relates to a method for using stone to fill the worked-out section under the coal well, which arranges a stone bin (10) outside the working surface to transfer the under-well stone or the ground stone to the stone bin (10) to be broken by the breaker; and using the stone belt machine (20) on the producing surface to transfer them to the upper end of producing surface (1); the producing surface (1) is supported by the filling brackets or the brackets whose back have extending beams; when the bracket is self-motion type, suspending a small belt device (16) on the extending beam and moving ahead with the bracket; when the bracket is not self-motion type, the small belt device (15) is arranged at the bottom plate under the extending beam and using slide device to move ahead; the small belt device (16) is mounted with a self-motion stone unload cart (15); transferring the small belt device (16) to the upper end of producing surface to unload the stone to the worked-out section. The invention can reduce the earth sink, effectively treat the stone, and reduce the accommodation area of stone and the pollution, with simple device and lower cost.

Owner:新汶矿业集团汶南煤矿有限责任公司

Method for the floatation of cuprum, plumbi, zincium ore concentrate from tailings for extracting gold

The invention relates to a method for extracting copper, lead and zinc concentrates through flotation from tailings from gold extraction of direct cyanidation, belonging to the technical field of methods for extracting copper, lead and zinc concentrates through flotation in industries of gold smelting and chemical engineering. The invention is applicable to tailings from gold extraction of sulfide ores, which is characterized in that: copper, lead and zinc in the tailings from gold extraction are blended adopting the floatation technology; the mixed concentrates of copper, lead and zinc as well as gangue containing sulfur are obtained, and copper concentrate, lead concentrate and zinc concentrate are obtained after separating the mixed concentrates of copper, lead and zinc through floatation. The invention has the advantages of improved integrated resources utilization, reduced environmental pollution and improved economic benefit of the enterprise.

Owner:SHANDONG GUODA GOLD

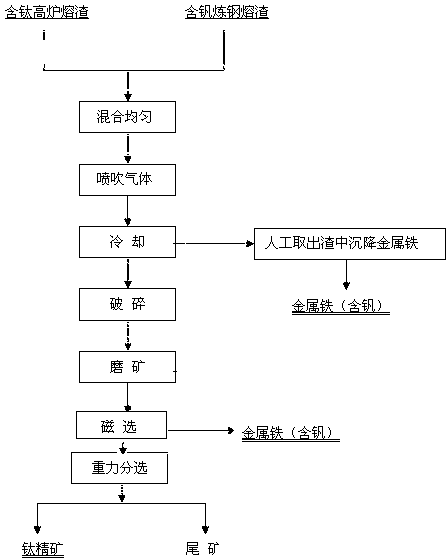

Method for separating titanium, iron, vanadium and calcium from mixed titaniferous slag

ActiveCN103343174ATake advantage ofIncrease temperatureRecycling and recovery technologiesProcess efficiency improvementMolten slagGravity separation

The invention belongs to the field of metallurgy, and in particular relates to a method for separating titanium, iron, vanadium and calcium from mixed titaniferous slag. The method comprises the following steps of: sufficiently mixing blast furnace liquid molten titaniferous blast furnace slag and converter vanadium-containing steel slag flowing out from slag discharge holes, so as to form mixed molten slag, blowing an oxidization gas into a mixed molten body, after the gas blowing is accomplished, naturally cooling down the molten slag, manually taking out the vanadium-containing metal iron which is settled to the bottom of the molten slag, further separating the rest vanadium-containing metal iron in a magnetic separation mode, and finally separating titaniferous ingredients in the molten slag from gangue phase by using a gravity separation method so as to obtain titanium concentrate and tailings the main phases which are perovskite phases, wherein the mass percentage of TiO2 in the titanium concentrate is 35-50%. According to the method, the physical thermal resource of the molten slag is sufficiently utilized, the efficiency is high, the energy is saved, and meanwhile the titanium ingredient, the iron ingredient, the vanadium ingredient and the free calcium oxide ingredient in the mixed molten slag are recycled, so that the purpose of comprehensive high-efficiency recycling on secondary resource is achieved.

Owner:NORTHEASTERN UNIV

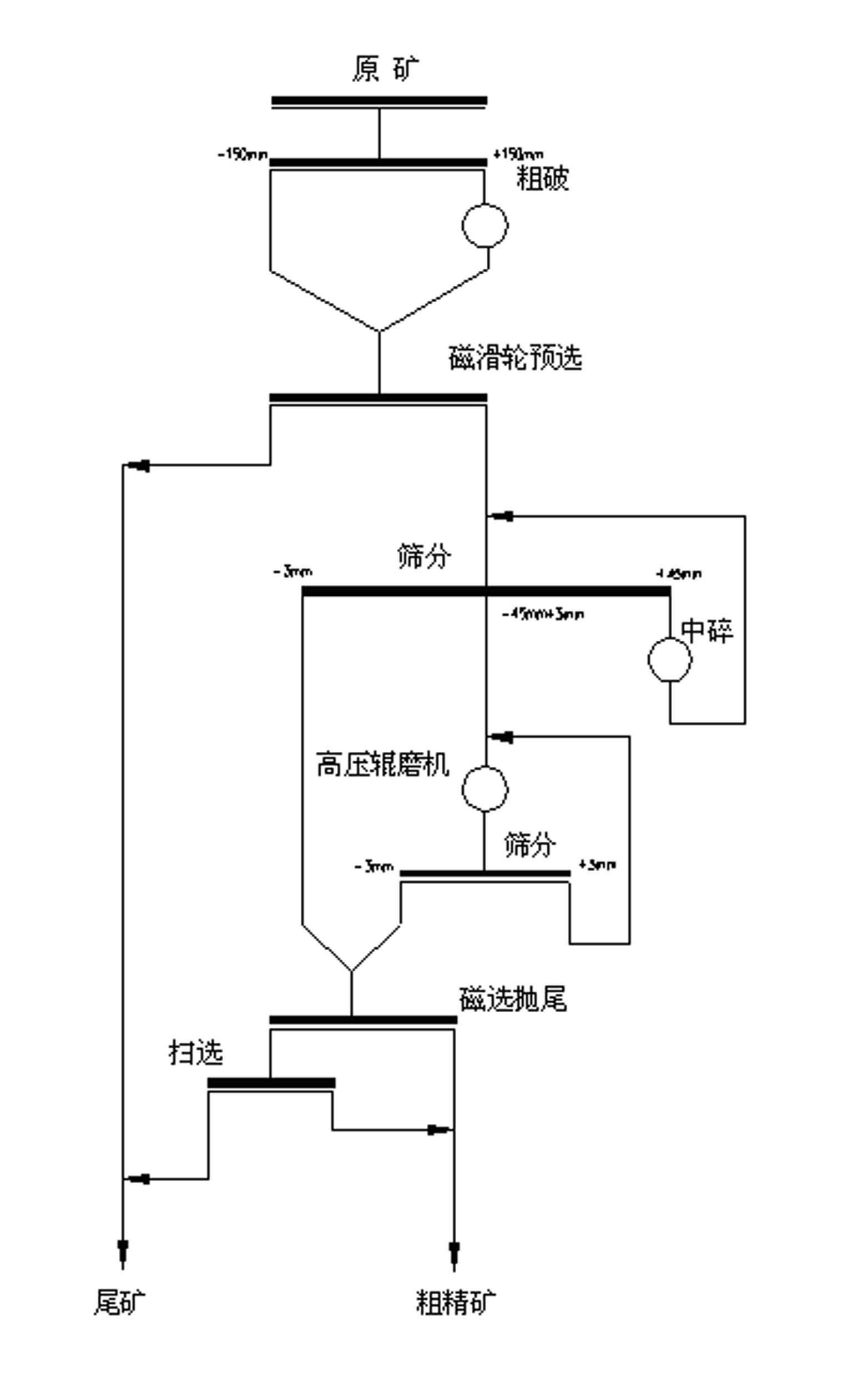

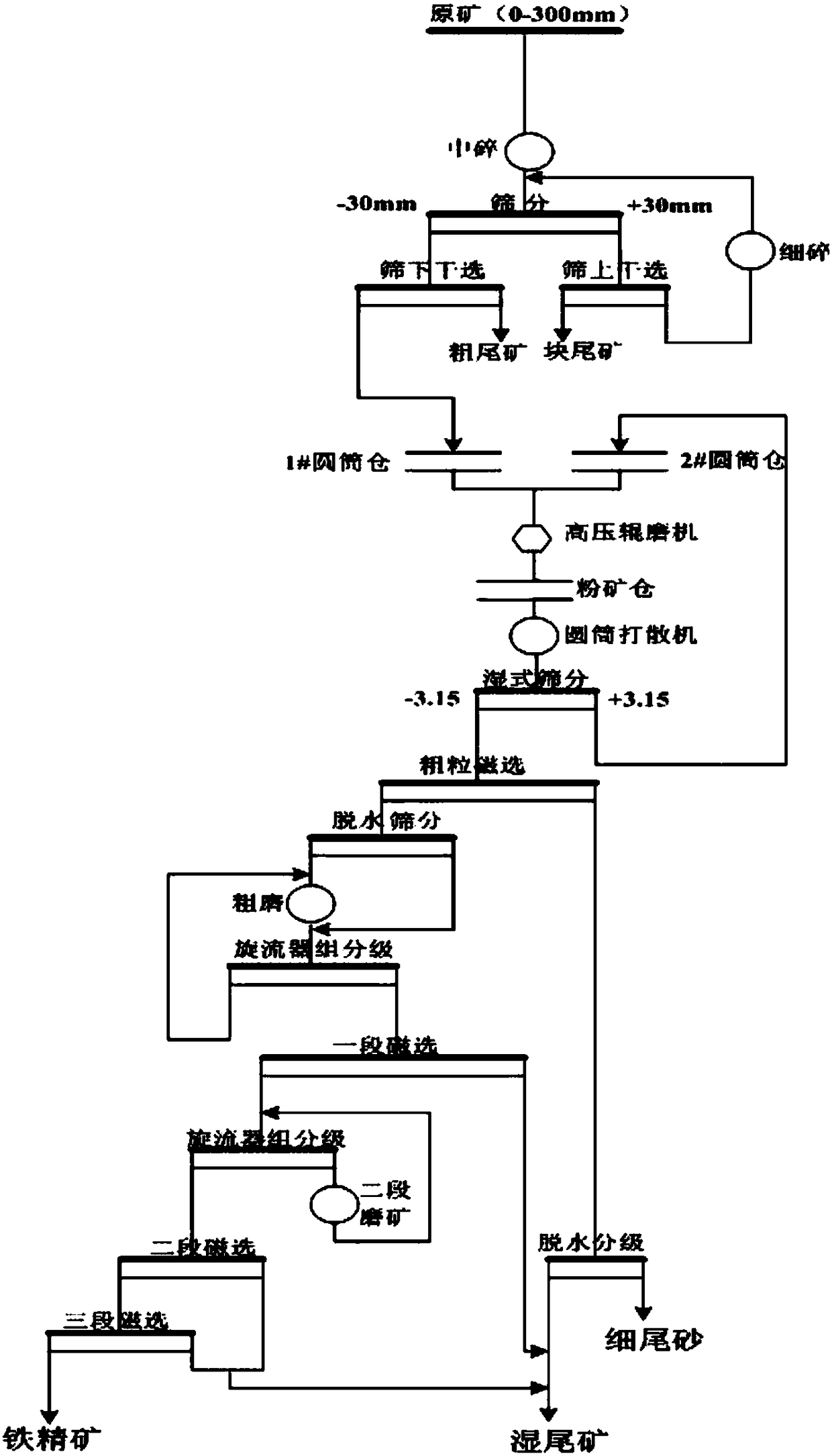

Iron improvement and silicon reduction beneficiation method of high ferrosilite and lean magnet iron ore

ActiveCN108246490AEasy to transportReasonable layoutMagnetic separationWet separationHigh pressureMaterials science

The invention discloses an iron improvement and silicon reduction beneficiation method of high ferrosilite and lean magnet iron ore, the method comprises the following processes of crushing-screening,fine crushing, dry-type preconcentration tailings discardinghigh-pressure roller milling, coarse particle magnetic separation, and coarse particle magnetic separation concentrate rough grinding-low intensity magnetic separation, wherein coarse crushing is arranged underground, medium and fine crushing are arranged on the ground, the placement is reasonable and orderly, reducing of occupied spaceis facilitated, and transporting and lifting of ore from the downhole is convenient. The dry-type preconcentration tailings discarding is carried out on sieve residue and through product after intermediate crushing and fine crushing, mixed barren rock is thrown out, throwing out is carried out and rough gangue and block gangue used as building products are recovered in advance, the iron grade of follow-up separating operations is recovered and improved, the ore content given to the follow-up operations is greatly reduced, " receiving early and losing early" is realized. The feeding grain sizeof high-pressure roller milling is up to 30mm, a precedent is broken, characteristics of low energy consumption and high processing capacity of a high-pressure roller milling machine is fully played,a product stock heap is not arranged in design, and occupied space and dust pollution are reduced.

Owner:安徽马钢张庄矿业有限责任公司

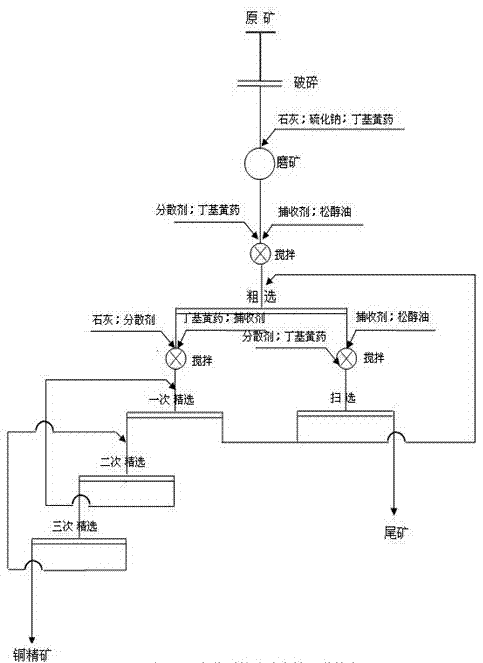

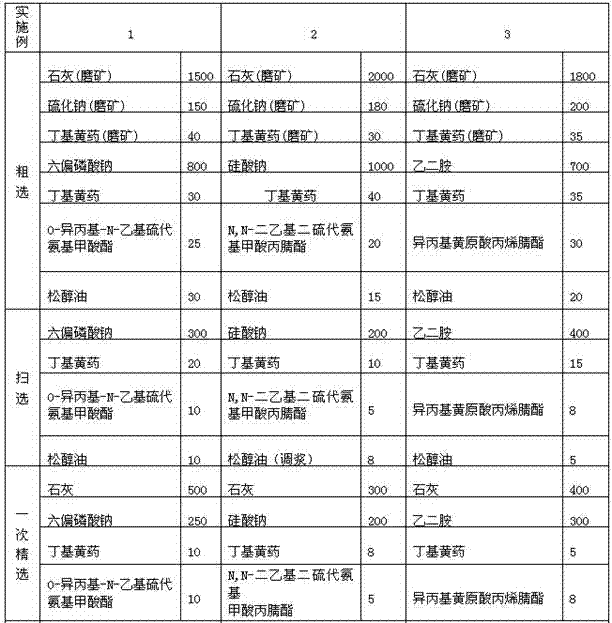

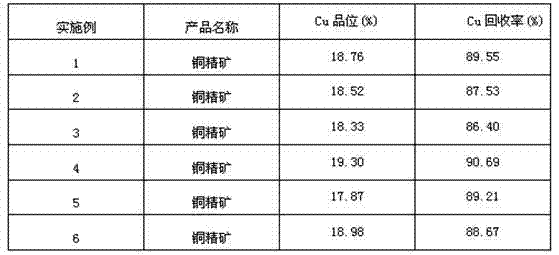

Beneficiation method for copper sulfide ore containing easily-sliming gangue minerals

The invention relates to a beneficiation method for copper sulfide ore containing easily-sliming gangue minerals. According to the method, lime is adopted as pH regulator and pyrite depressant of flotation pulp of the copper sulfide ore containing the easily-sliming gangue minerals; sodium sulfide serves as activator of a small number of copper oxide minerals in the ore; sodium hexametaphosphate, sodium silicate or ethylenediamine serves as gangue slurry dispersant; a combination of butyl xanthate and other collectors serves as a collector of copper sulfide minerals; terpernic oil serves as foaming agent. The ore is subjected to primary grinding, primary roughing, primary scavenging and three-time concentration; the ore pulp is subjected to strong stirring and pulp mixing before starting to be subjected to primary roughing, primary scavenging and primary concentration, so that copper contained in the ore is efficiently recovered. According to the method, through reasonable combination and addition of chemicals, the ore grinding and pulp mixing process is strengthened, the adverse influence of gangue slurry on copper sulfide mineral floatation is eliminated, the surface characteristics of copper sulfide minerals are improved, the preferential adsorption of the collector on the surfaces of the copper sulfide minerals is enhanced, and accordingly, compared with a conventional method, the copper grade and the copper recovery rate of copper concentrate are substantially increased.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com