Raw coal washing process capable of realizing non-polar ash conditioning

A technology for stepless conditioning and raw coal, which is applied in solid separation, wet separation, chemical instruments and methods, etc., can solve problems such as reducing the pressure of coal slime water system, and achieve the effect of reducing coal washing cost, easy realization, and extending the lower limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

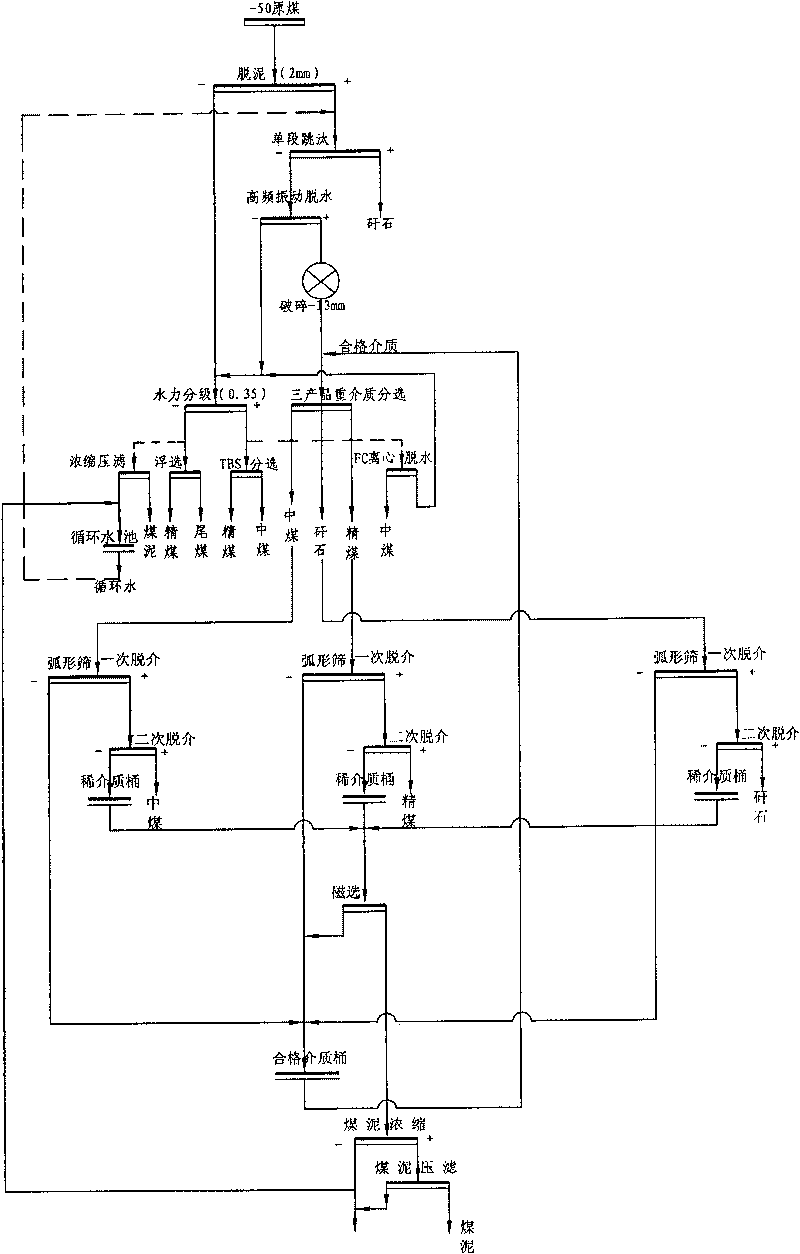

[0038] Such as figure 1 Shown, the technological process of the present embodiment is as follows:

[0039] a. After the raw coal enters the coal preparation system, the part smaller than 50mm is deslimed in advance through the coal feeding system. The lower limit of the sieve hole of the desliming vibrating screen is 2mm, and the upper and lower coarse coal slime products are obtained;

[0040] b. Jig separation: the sieve top product of the desliming screen in step a is subjected to single-stage jigging separation through a jig machine to produce two products of gangue and clean coal, and the gangue directly enters the gangue bin; the clean coal is vibrated through the clean coal The sieve enters high-frequency vibration dehydration, and after dehydration, lump coal and fine coal are separated;

[0041] c. Lump coal dense medium separation: the dehydrated lump coal is crushed through a crusher to make the particle size less than 13mm, and then this part of lump coal is subje...

Embodiment 2

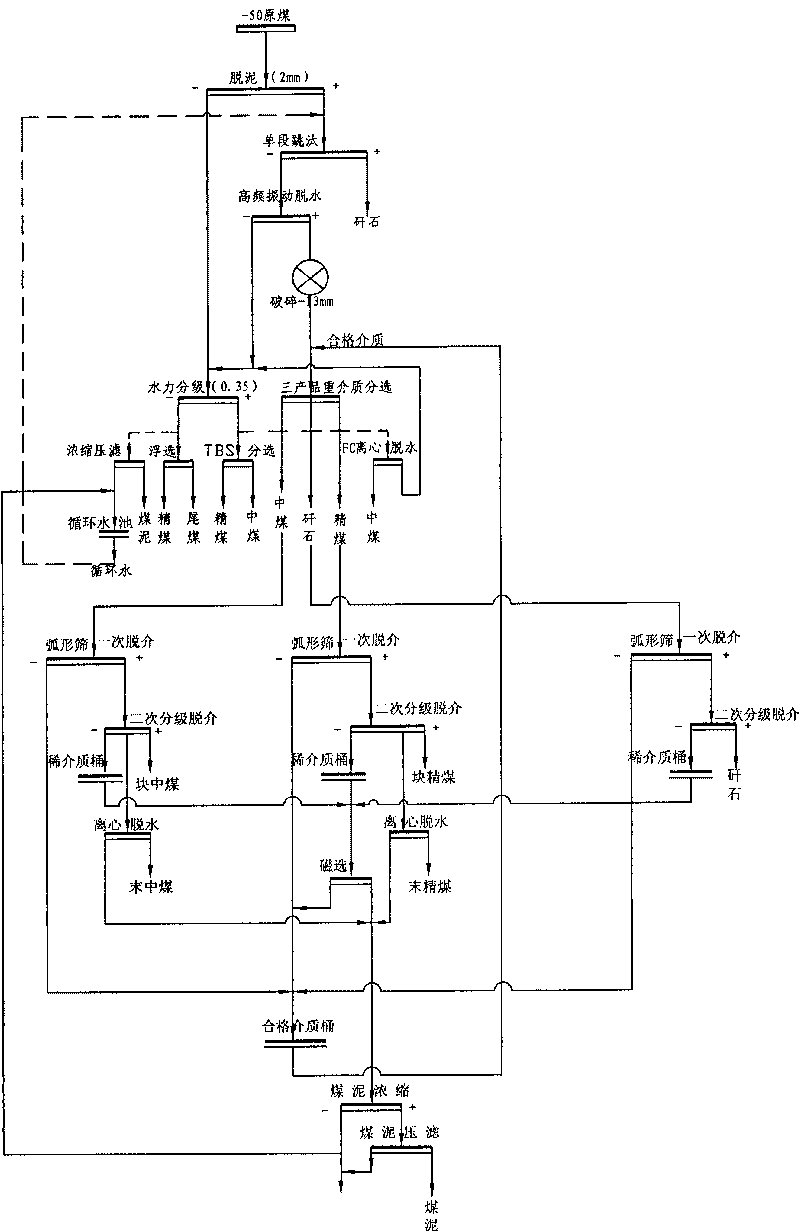

[0051] Based on the same principle and method, for the fine coal separation system, the present invention can replace the fine coal separation system in the process of embodiment 1 with the following process system:

[0052] The fine coal obtained after dehydration is subjected to hydraulic classification through a hydrocyclone, and the classification particle size is 0.35mm. Through classification, underflow and overflow can be obtained; the underflow of hydraulic classification is collected and sent to TBS for interference settlement separation, and medium coal and clean coal are obtained Two kinds of products; the clean coal directly enters the clean coal bunker to become a product, and the medium coal directly enters the medium coal bunker to become a product; the overflow obtained by hydraulic classification directly enters the thickener for concentration and pressure filtration, and the obtained overflow is directly circulated in the pool as circulating water It is used f...

Embodiment 3

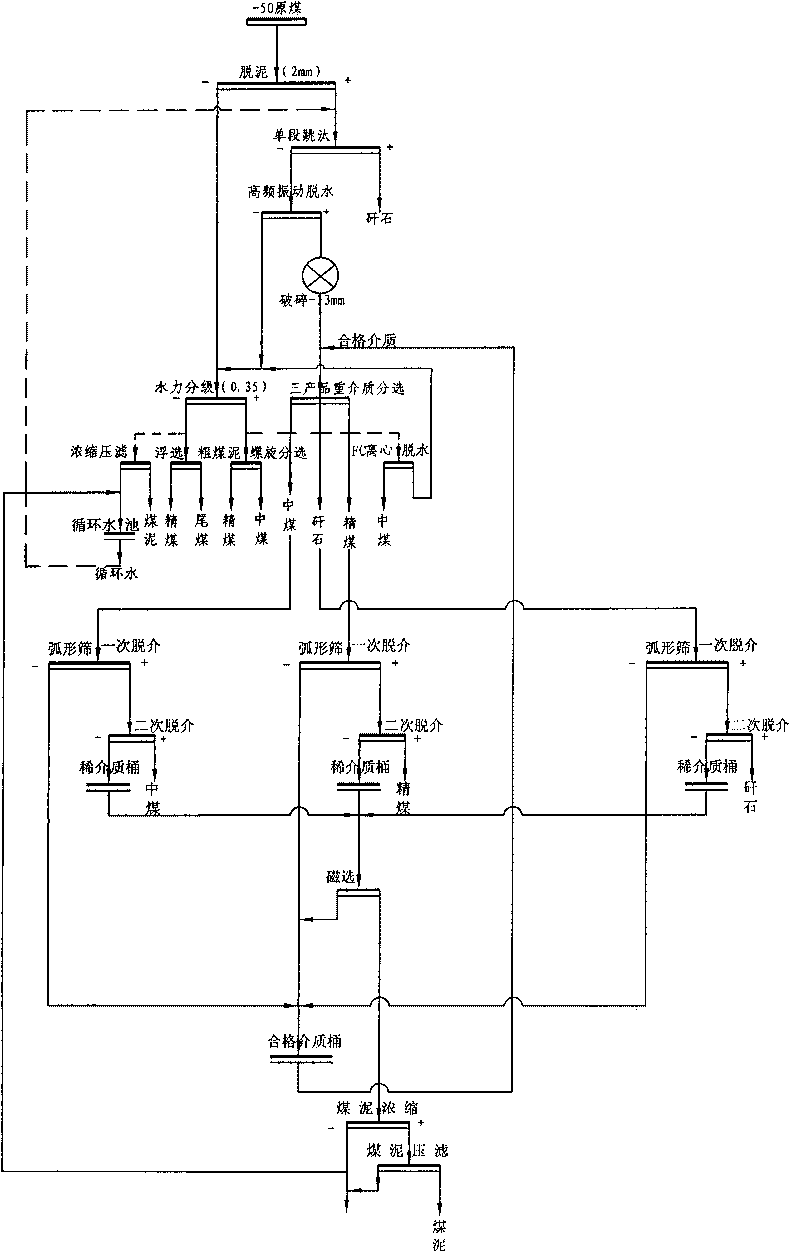

[0054] Based on the same principle and method, for the fine coal separation system, the present invention can replace the fine coal separation system in the process of embodiment 1 with the following process system:

[0055] The fine coal obtained after dehydration is subjected to hydraulic classification through a hydrocyclone, and the classification particle size is 0.35mm. Through classification, the underflow and overflow can be obtained; the underflow of the hydraulic classification is collected and sent to the FC centrifugal dehydrator for centrifugal dehydration to obtain medium coal and centrifugal dehydration. The medium coal directly enters the medium coal bunker as a medium coal product, and the centrifuge re-enters the hydrocyclone for circular separation; the overflow obtained by hydraulic classification directly enters the thickener for concentrated filtration, and the obtained overflow is directly circulated in the pool Used as circulating water for coal washing,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com