Patents

Literature

4899 results about "Coal gangue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gangue, also called coal gangue, is the solid waste discharged in coal mining process and coal washing process, black rock harder than coal. Its carbon content is low and exists along with coal seam. Gangue could be found in roof, bottom board, inter-layer, and it could be selected in washing process.

Coal gangue lightweight through-hole ceramsite

The invention discloses coal gangue lightweight through-hole ceramsite. The technical scheme has the essentials that the coal gangue lightweight through-hole ceramsite is composed of coal gangues, attapulgite clay, a powdery coal gangue foaming agent, active carclazyte waste dreg, hollow microspheres, lightweight magnesium oxide, expanded perlite, expanded vermiculite, ferrous sulfate and quick lime. The materials of the coal gangue lightweight through-hole ceramsite are stirred and mixed, extruded and granulated, dried, roasted, subjected to heat insulation, sieved, sealed and packaged to prepare the coal gangue lightweight through-hole ceramsite. The coal gangue lightweight through-hole ceramsite has the characteristics of large specific surface area, small bulk density, high water absorption rate, excellent ventilation performance, beautiful appearance and shape and no odors, no harmful bacteria, good lightweight strength, and consistent micro-pores and macro-pores. When the coal gangue lightweight through-hole ceramsite is used for culturing or planting various types of nursery stocks, flowers and vegetables, the roots of the plants can absorb nutrition constituents of water or a liquid fertilizer from the coal gangue lightweight through-hole ceramsite, so that good growth and development and the survival rate of the plants are ensured and the coal gangue lightweight through-hole ceramsite is suitable for preparing a soilless culture substrate and nutrient soil.

Owner:平凉华晨非金属应用科技有限公司

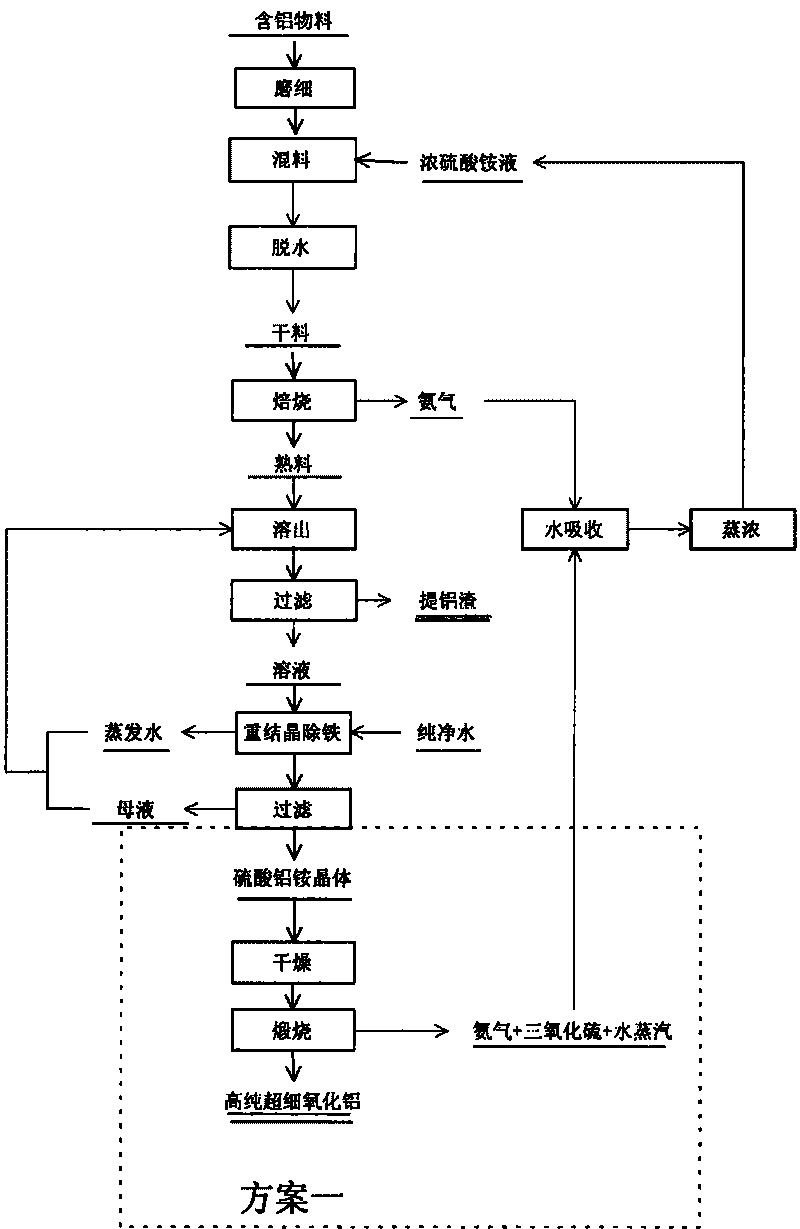

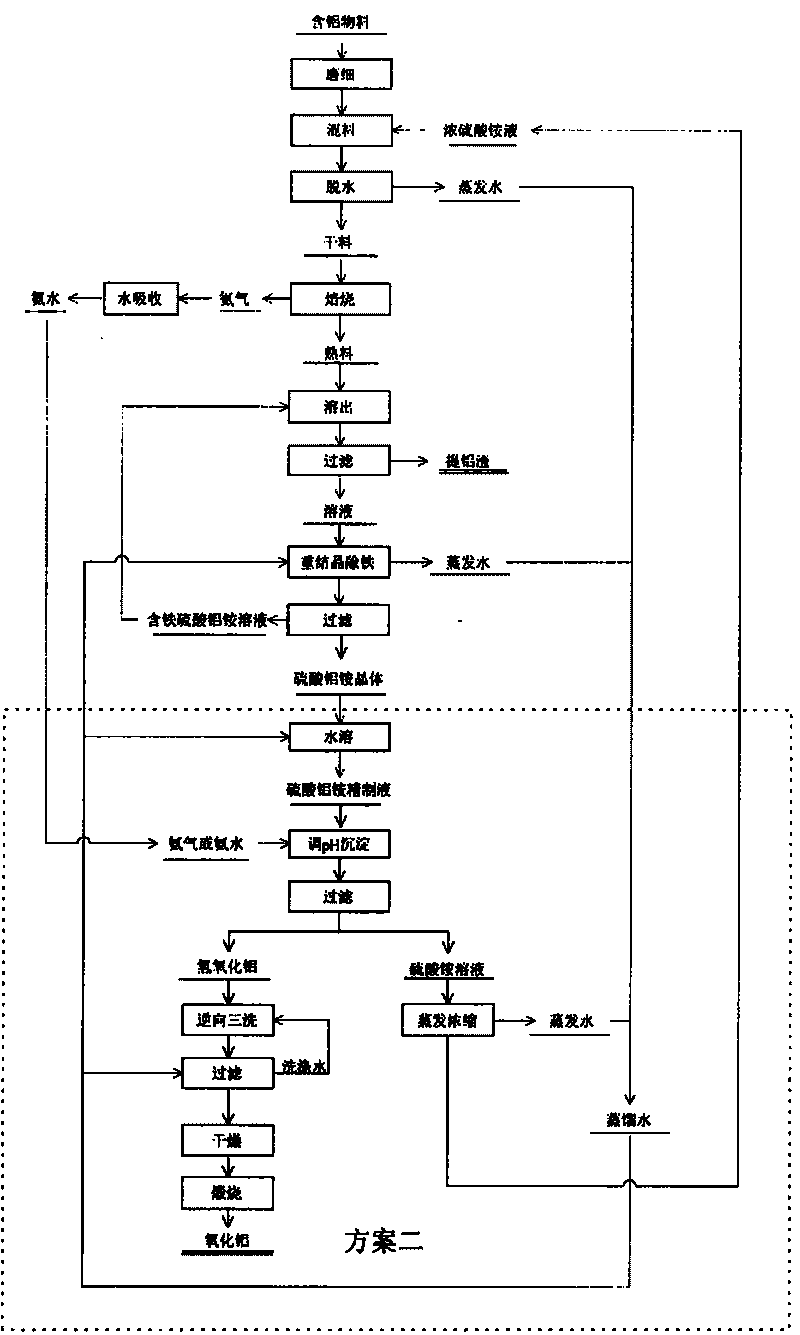

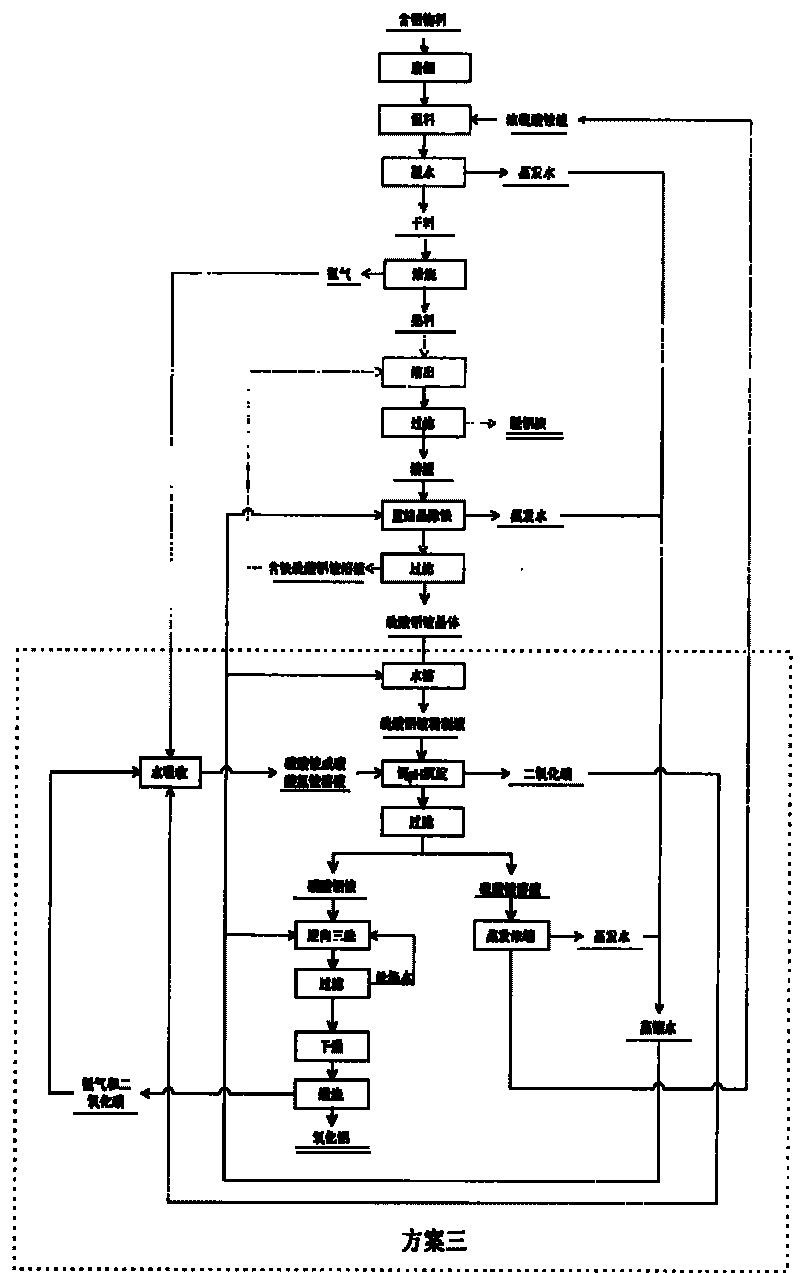

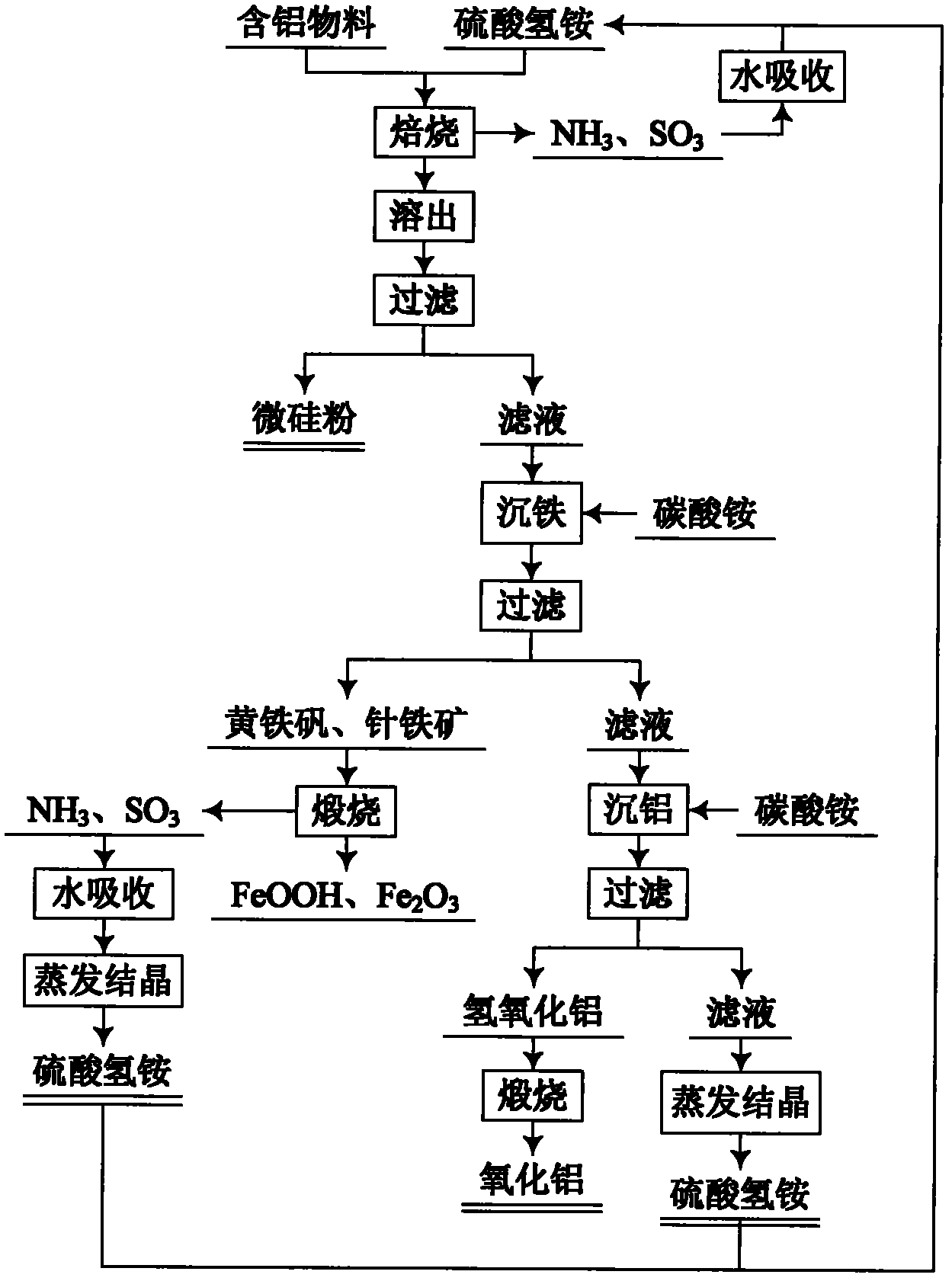

Method for preparing aluminum oxide from aluminiferous material

InactiveCN101734698AHigh value-added comprehensive utilizationCause secondary pollutionAluminium oxide/hydroxide preparationAluminium hydroxide preparationAluminum ammonium sulfateAlunite

The invention provides a method for preparing aluminum oxide and other products from aluminiferous materials such as bauxite, high iron bauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like. The method comprises the following steps: (1) crushing, grinding and mixing the aluminiferous materials with ammonium sulfate and then roasting; (2) dissolving the roasted product (clinker aggregate) in water, and filtering to obtain aluminum ammonium sulfate solution and filter residues; (3) carrying out deferrization, aluminum deposition or recrystallization on the aluminium ammonum sulfate solution with ammonia to prepare aluminum oxide, and meanwhile, recycling the ammonium sulfate; (4) preparing silicon dioxide from the filter residues, and taking the remaining residues containing ferrum as the raw material for ironmaking. The method is suitable for treating various aluminiferous materials, has the advantages of simple technical process, simple equipment, no emission of solid, liquid and gas wastes, and no secondary pollution, and realizes the high-added-value green complex utilization of the aluminiferous materials such as bauxite, high ironbauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like.

Owner:NORTHEASTERN UNIV

Composite tailing non-fired and non-steamed building block brick and preparation method thereof

InactiveCN102093004AHigh waste rateSolve the problem of excessive dosageSolid waste managementBrickSlag

The invention discloses a composite tailing non-fired and non-steamed building block brick and a preparation method thereof. The brick comprises the following raw materials in parts by weight or volume: 50-300 parts of tailing and 3-30 parts of cement; and at least two components are selected from the active wastes such as fly ash, coal gangue, shale slag, alkaline residue, carbide slag, chemical gypsum and the waste residue of metallurgical industry to be mixed with the raw materials. The preparation method comprises the following steps: mixing to stir, compressing and shaping, performing natural curing or utilizing the solar heaing hydrating maintenance to prepare the composite tailing building block brick. By adopting the preparation method of the invention, the single performances of the tailings and slags can be changed, thus the product can have higher strength and quality owning to the interaction of materials; the technology does not adopt firing and steaming, the cost is low; different sizes of solid bricks, perforated bricks, hollow blocks, floor tiles, grass planting bricks, roadside bricks and artistic rails can be prepared by changing the mould; and various harmful slags such as tailings can become good, the Chinese development direction of the comprehensive utilization of resources is satisfied and the brick of the invention has development and application prospect.

Owner:郭东京 +2

Burning-free block brick prepared from bulky industrial waste residues

The invention relates to a burning-free block brick prepared from bulky industrial waste residues. The burning-free block brick is characterized in that the block brick comprises the following raw materials in parts by weight or volume: 10-80 parts of at least one of tailing, magnesium slag, basic slag, mountain flour, cinder, fly ash, coal gangue, oil shale waste and sulfuric acid slag, 0-80 parts of at least one of gravel, waste sand, construction waste, garbage to be burnt, steel slag, mineral slag, copper slag, iron slag with gold, ardealite, phosphorous slag and carbide slag, 0-50 parts of active cementing material, 0-30 parts of cement clinker, 2-15 parts of cement and a defined amount of water. The preparation method of all types of burning-free and steaming-free standard bricks, perforated bricks, hollow blocks, paving tiles, road edge bricks and fence railings which have low cost and high strength, is as follows: proportioning, stirring for 1-6 minutes, adding a defined amount of water to stir, placing in moulds to form in a machine and performing natural curing for 7-28 days. The burning-free block brick has high raw material selectability, simple technology and wide development and application prospects, and is environmental-friendly.

Owner:司密花 +2

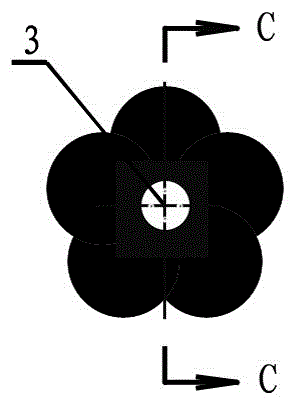

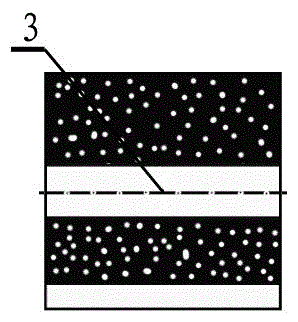

Production method of concave convex stick ceramic grain filter

InactiveCN100423808CGood film-hanging performanceImprove stabilityFiltration separationClaywaresRough surfaceWater quality

The invention discloses a produce method for concavo-convex bar ceramsite filtering material. Wherein, the said filter material comprises concavo-convex bar clay, coal gangue and volcanic ash, and is produced by burdening, milling, granulating, baking, screening and packaging. The filter material has rough surface, well bonding film property, small flow resistance, and well stability and adsorption properties. This invention needs low cost and baking temperature, can save much energy, has no secondary pollution and fit to water purification treatment.

Owner:许盛英

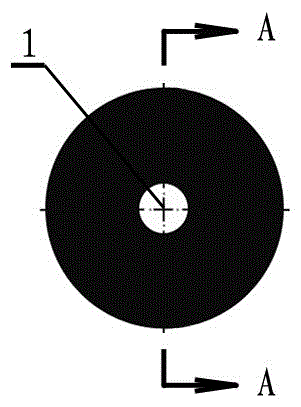

Low-density ceramic proppant and preparation method thereof

The invention relates to a low-density ceramic proppant and a preparation method thereof, which belong to the field of exploring petroleum and natural gas. The preparation method of the low-density ceramic proppant comprises the steps of forming an inner core made of bauxite and coal gangue and a shell made of bauxite and trimanganese tetroxide into a ball and sintering to obtain low-density ceramic. The ceramic has higher strength and low density and is applicable to a ceramic proppant for fracturing a deep-level oil-gas well with high closed pressure and low permeability; the sintering temperature is relatively reduced in the range of 1,300-1,380DEG C, so that thus the energy consumption is effectively reduced and the energy can be saved by 20 percent; and meanwhile, the effect with low crushing rate can be achieved.

Owner:阳泉市长青石油压裂支撑剂有限公司

Lightweight heat insulating material and method for making same

InactiveCN101182168ASimple preparation processImprove performanceSolid waste managementCement productionCoal gangueAluminium

The invention discloses a light isolated material and a preparation method thereof, including an aluminates polymer, the molar ratio of silicon (Si) and aluminum (Al) in which is more than or equal to one and less than or equal to three and which includes solid raw materials containing silicon and aluminum of 50-85 weight percent of fly ash, kaolin, coal gangue, coal slag, etc.; 14.5-48 percent of liquid alkaline activator; 0.5-2 percent of foaming agent. The liquid alkaline activator includes caustic solution and water glass, which are mixed and stirred with the solid raw materials and the foaming agent to produce a roof heat insulation plate, which is applied to both the direct pouring and the die molding prefabrication and can be used both for the heat insulation or the cold insulation of cold or heat equipment and for making large size building wallboards for heat insulation, deafening and fireproofing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

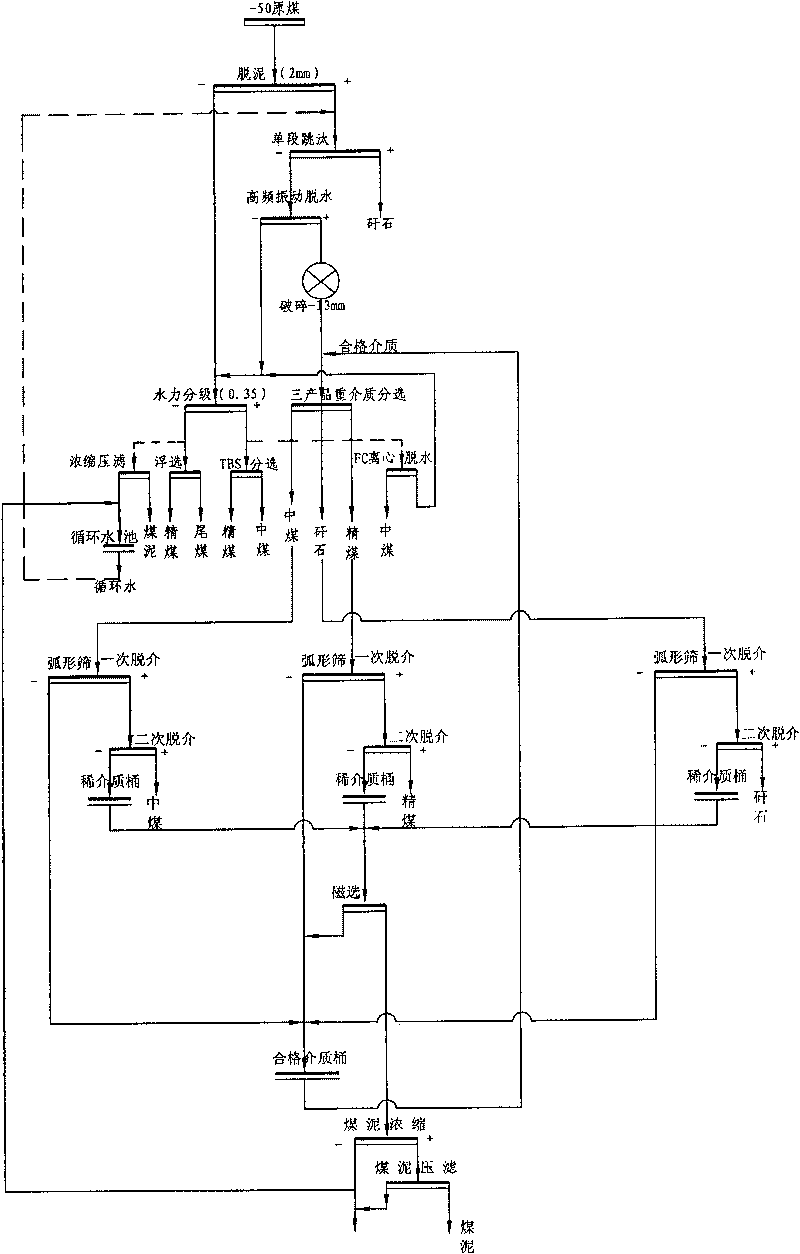

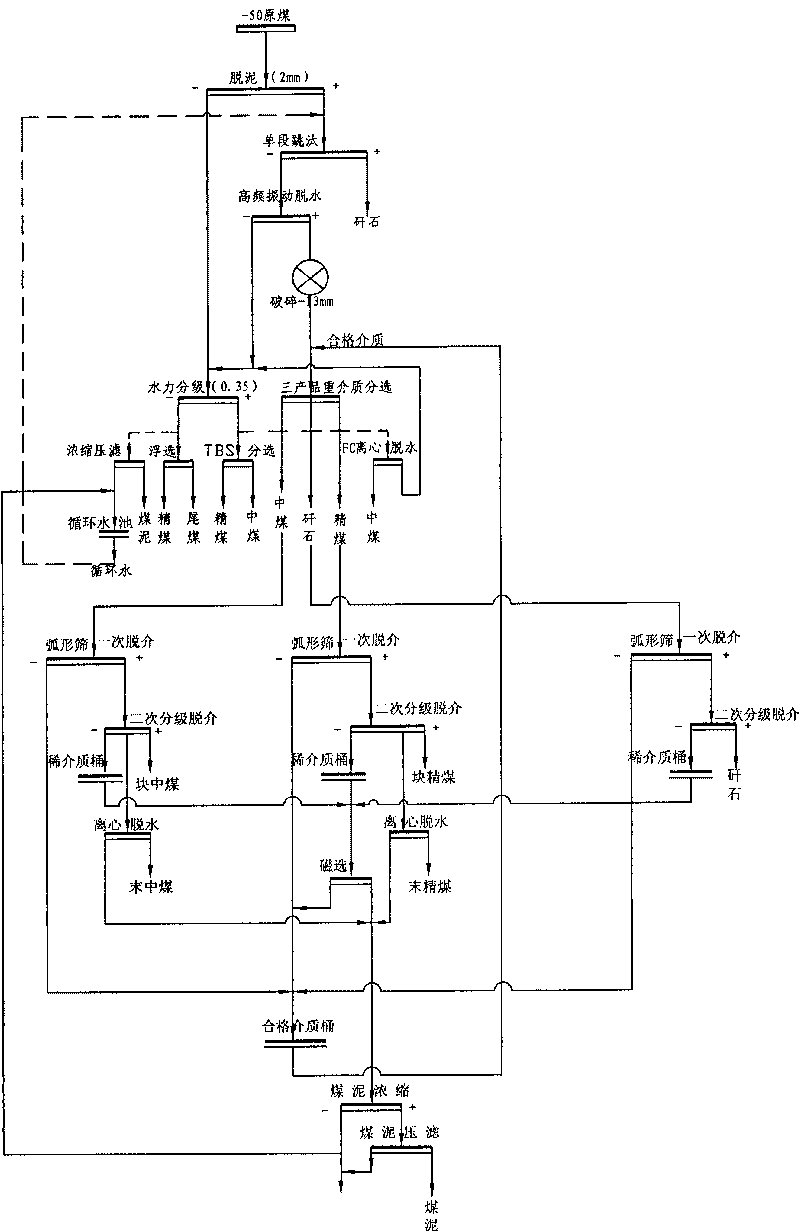

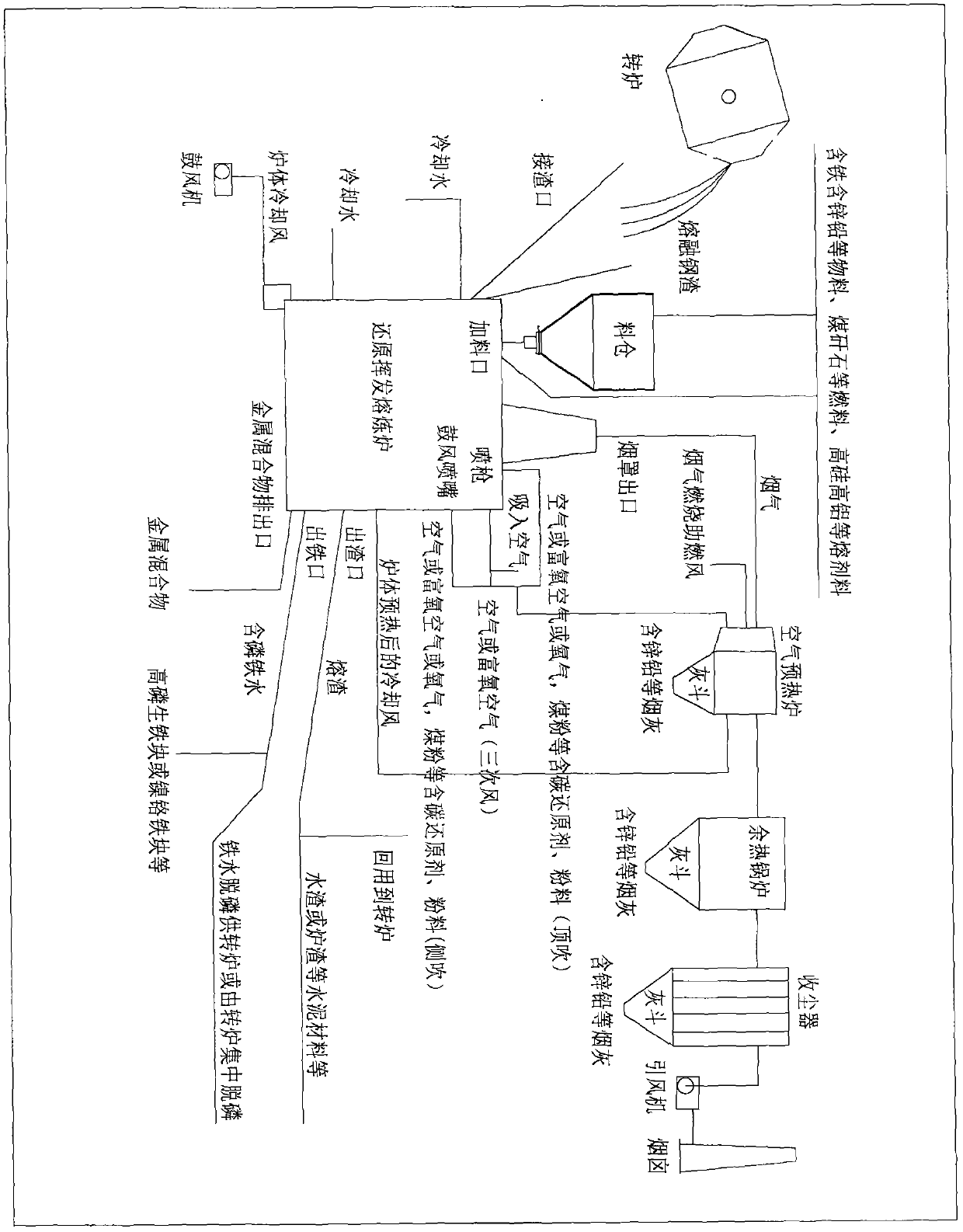

Raw coal washing process capable of realizing non-polar ash conditioning

InactiveCN101716552AReduce the amount of re-insertionReduce manufacturing costWet separationCycloneSingle stage

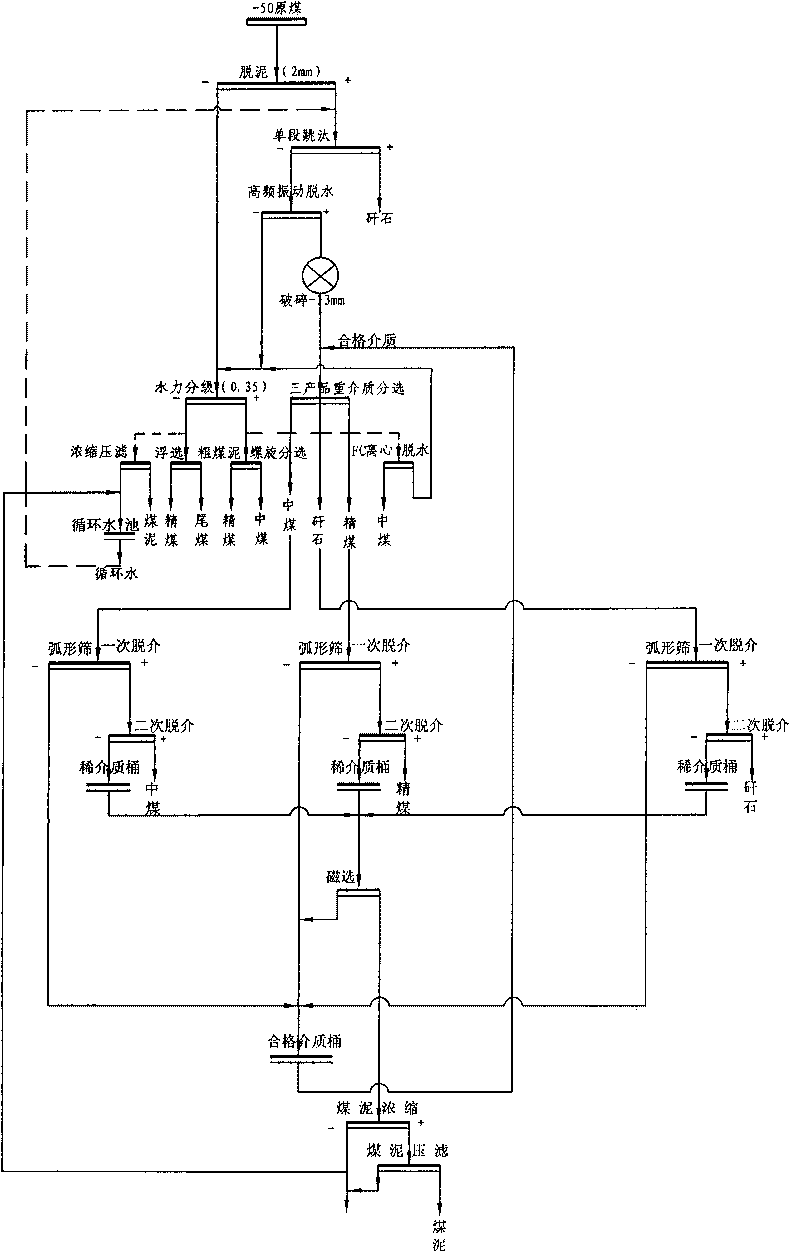

The invention provides a raw coal washing process capable of realizing non-polar ash conditioning. The process comprises the following steps: a, desliming and screening the part of raw coal with granularity less than 50 to 100mm; b, carrying out single stage jigging separation on screen products on a desliming screen; c, crushing lump coal obtained from the step b, namely screen products on an oscillating screen, by a crushing machine; d, feeding the crushed products from the step c into a three-product heavy medium cyclone for separation; e, respectively treating underflows and overflows obtained from a hydroclone in the step c; f, carrying out TBS separation or centrifugal dehydration treatment on the underflows of the hydroclone from the step e; g, respectively carrying out primary medium removal on clean coal, middlings coal and gangue obtained from the step d; h, respectively carrying out secondary medium removal and dehydration on the three products from the step g; and i, carrying out magnetic separation on undersize dilute medium obtained by secondary medium removal on the coal gangue in the clean coal in the step h, feeding the separated magnetite powder into a qualified medium tank, collecting residues, and carrying out coal slurry concentration.

Owner:HENAN POLYTECHNIC UNIV

Sintered heat insulating hollow building block

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

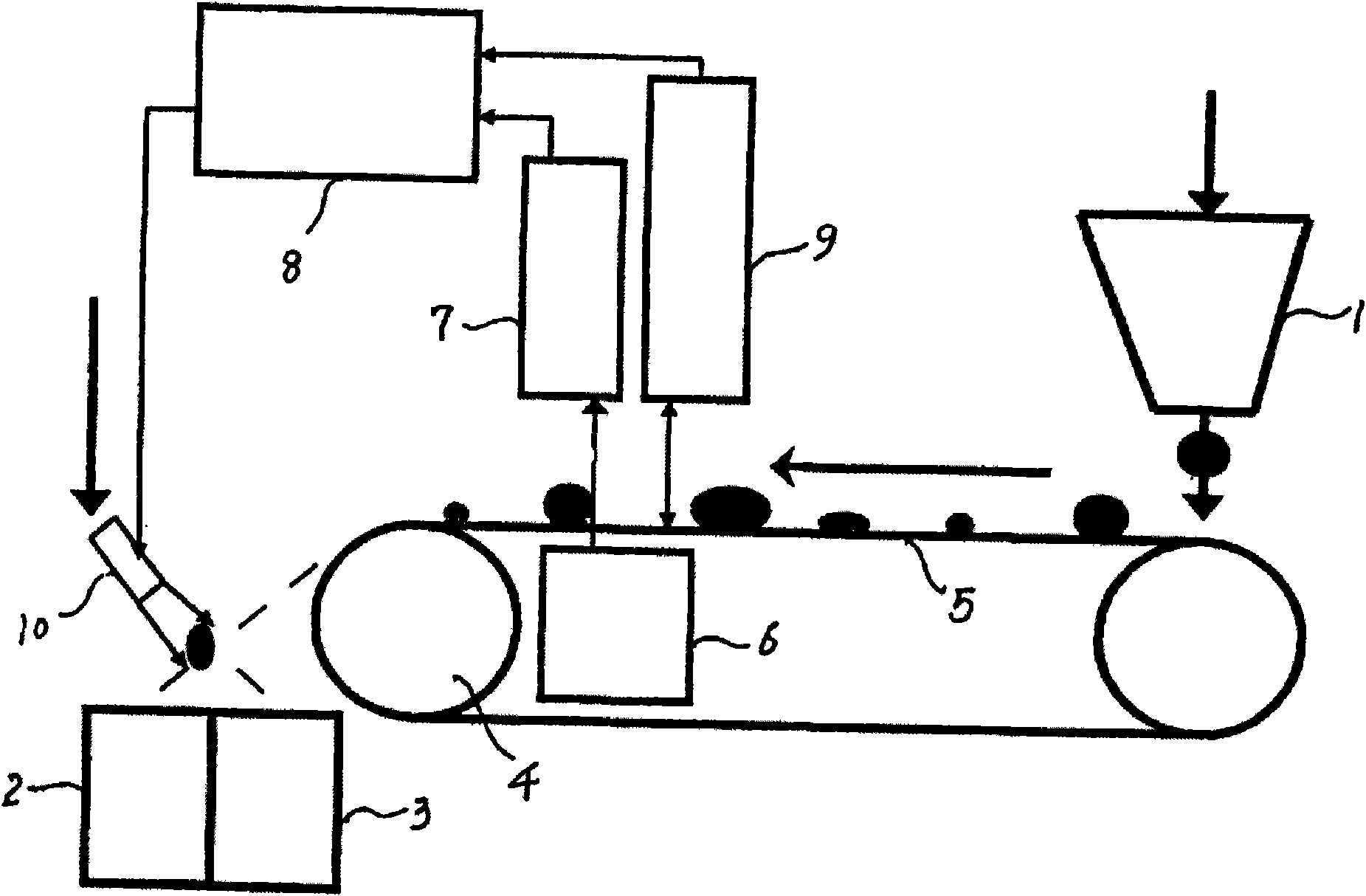

Automatic separator of coal gangue

ActiveCN101637765ANo mutual interferenceSolve the technical problems of poor sorting effectSortingConveyor partsX-rayGamma ray

The invention relates to an automatic separator of coal gangue, which comprises a raw material feeding copper, a coal receiving copper, a gangue receiving copper, a conveying-belt conveyor, an identification and separation controlling mechanism and an executing mechanism, wherein the conveying-belt conveyer is arranged among the raw material feeding copper, the coal receiving copper and the gangue receiving copper; the identification and separation controlling mechanism comprises a single-energy gamma ray source, an X-ray sensor, a measure and control instrument and an ultrasonic transmitter-receiver; the single-energy gamma ray source is arranged below a conveying belt, the X-ray sensor is arranged above the conveying belt and corresponds to the single-energy gamma ray source, the measure and control instrument is electrically connected with the X-ray sensor, and the ultrasonic transmitter-receiver is arranged above the conveying belt and electrically connected with the measure and control instrument; the executing mechanism is a high-frequency air valve arranged above the coal receiving copper and the gangue receiving copper; and the valve port of the high-frequency air valve isarranged towards a throwing track of coal and gangue. As the single-energy gamma ray source is adopted, only one nuclear radiation material exists, and only one spectral line is radiated, the mutualinterference among a plurality of spectral lines can not be generated; and the invention has accurate measurement and good separation effect.

Owner:GREAT DRAGON RISING ELECTROMECHANICAL TECH BEIJING

Geopolymer gel material for rush repairs and rush constructions

ActiveCN101628791AGood mechanical propertiesEasy constructionSolid waste managementCement productionSlagMetakaolin

The invention provides a geopolymer gel material for rush repairs and rush constructions, which is prepared by adding water to 13-17 percent by weight of exciting agent and 82-87 percent by weight of slag containing aluminosilicate. The slag comprises one or the combination of more of blast furnace slag, steel slag, coal ash and coal gangue, and the exciting agent comprises the following components in percentage by weight: 35-75 percent of SiO2, 0-55 percent of Na2O, 0-65 percent of K2O, 0-1 percent of CaO and 0-1 percent of SO3. The geopolymer gel material which has the characteristic of quick setting and hardening is prepared by using the industrial waste slag as a main raw material and matching the exciting agent, and the geopolymer gel material has excellent mechanical property and controllable setting time and can replace gel materials such as fast setting and hardening cement, and the like in the processes of rush repairs and rush constructions. The industrial solid wastes such as the blast furnace slag, the steel slag, the coal ash, the coal gangue, and the like containing the aluminosilicate series are used as main raw materials, metakaolin is not added and the raw materials do not need to be calcined, thus the invention has low energy consumption, less pollution, simple process, low cost, environmental protection and energy saving.

Owner:深圳市航天新材科技有限公司

Self-compaction filling paste body and preparation process thereof

The invention discloses a self-compaction filling paste body and a preparation process thereof, relates to a filling material with self-compaction performance for coal mine cut and fill mining and a corresponding proportion stirring process, and belongs to the field of construction materials. The self-compaction filling paste body is characterized by being prepared by uniformly mixing coal gangue, coal ash, cements, high-efficiency water reducing agent and water according to proper proportion, wherein the slurry concentration of the paste body is 75-85 percent; and in terms of mass percentage, the proportion of the coal gangue to the coal ash to the cements to the water reducing agent to the water is 45-55 percent to 15-20 percent to 10-15 percent to 3-5 percent to 15-25 percent. The paste body is high in flowability, stability and filling performance, low in bleeding rate and uniform and consistent in quality, and fully fills every corner of a worked-out section; the bleeding and the segregation of the aggregates are avoided; the convenience in transportation and control is achieved; a pipeline is not blocked during transportation; and original mine wastes are adopted for the paste body for realizing the filling so as to protect the environment.

Owner:TAIYUAN UNIV OF TECH

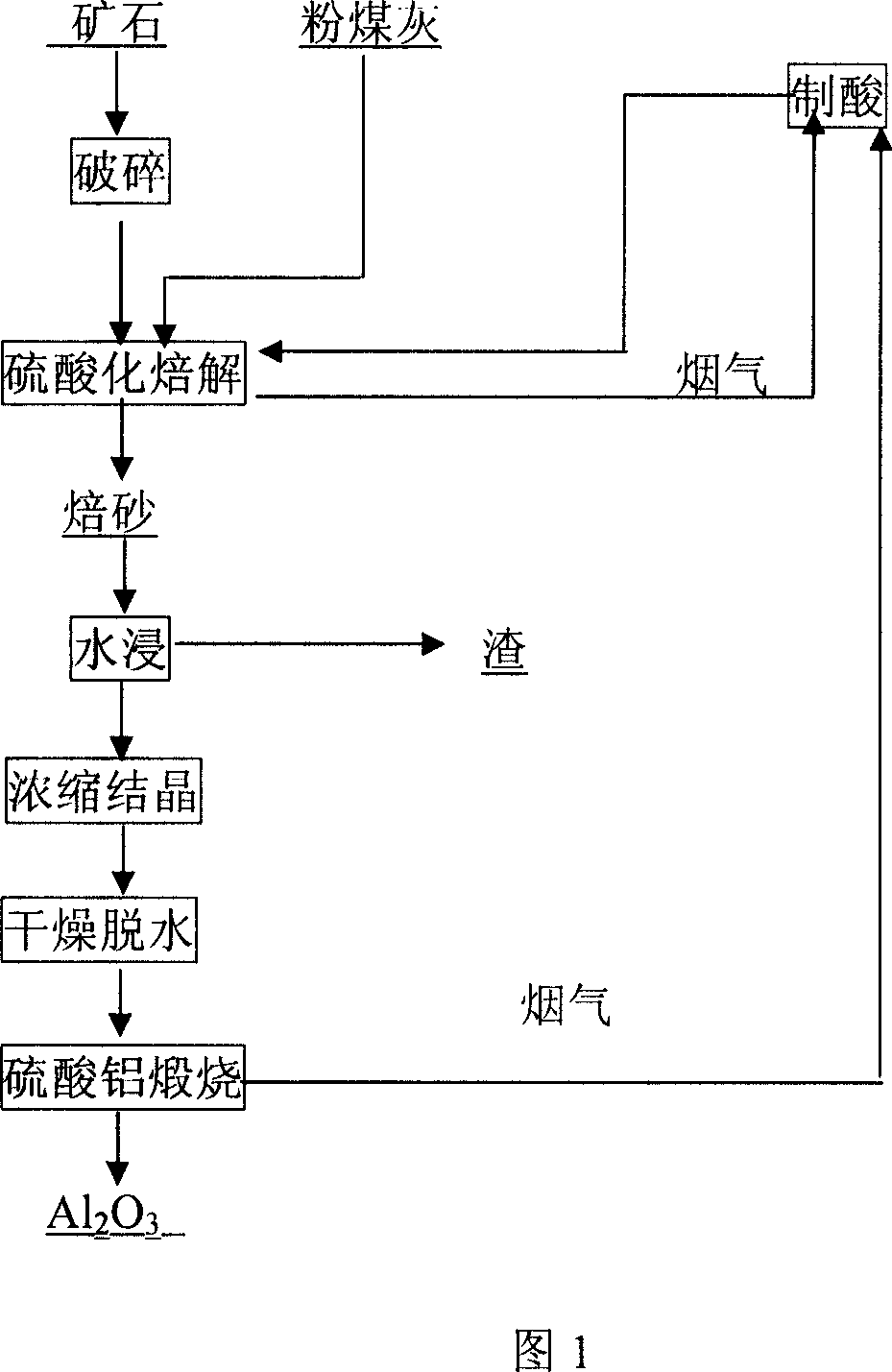

Method of acid extracting aluminium from high-silicon alumina-containing raw mineral materials

The invention relates the method of extracting aluminium from high-silicon siliceous mineral. The method comprises the following steps: mixing the aluminous ore and sulfuric acid, baking, leaching with water, filtering leachate, getting aluminium sulphate solvent, thickening filter liquor, separating out aluminium sulphate, drying, dewatering, getting anhydrous aluminium sulphate; calcining aluminium sulphate, and getting Al2O3. The invention can extracte aluminium from high-silicon siliceous mineral, coal gangue, coal ash, China clay, andalusite, feldspath, ganister, nepheline and vermiculite without baking. The method has the advantages of simple technology, little corrosion, easy operation and high recovery ratio.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Expendable pattern casting (EPC) molding shell paint for casting steel and preparation method thereof

InactiveCN102407275AHigh strengthImprove breathabilityFoundry mouldsFoundry coresFiberPolyvinyl alcohol

The invention relates to an expendable pattern casting (EPC) molding shell paint for casting steel, and the EPC molding shell paint comprises surface a layer fireproof paint and a back layer reinforcing paint, wherein the surface layer fireproof paint comprises the following components in parts by weight: 80-90 parts of high-chromium alundum powder, 10-20 parts of calcined kaolinite, 6-8 parts ofcalcium rectorite powder, 1-3 parts of sodium tripolyphosphate, 3-5 parts of polyvinyl formal solution, 0.3-0.5 part of ethoxylated alkyl sodium sulfate, 0.6-1.0 part of polyether type modified polydimethylsiloxane and 60-75 parts of water; and the back layer reinforcing paint comprises the following components in parts by weight: 75-85 parts of coal gangue sand, 15-25 parts of kaolinite, 3-6 parts of feldspar powder, 8-13 parts of calcium rectorite powder, 8-10 parts of sodium tripolyphosphate, 1.5-2.0 parts of wood fiber and 30-45 parts of water. A molding shell manufactured by the surface layer fireproof paint and the back layer reinforcing paint has the characteristics of high strength and refractoriness, good air permeability and the like.

Owner:HUBEI UNIV OF TECH

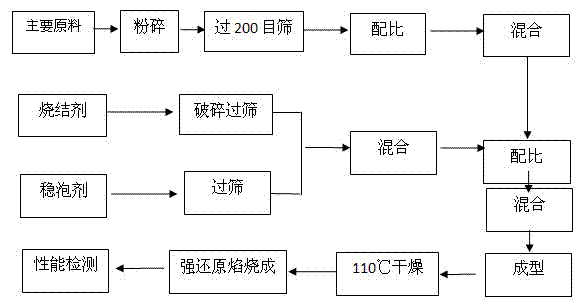

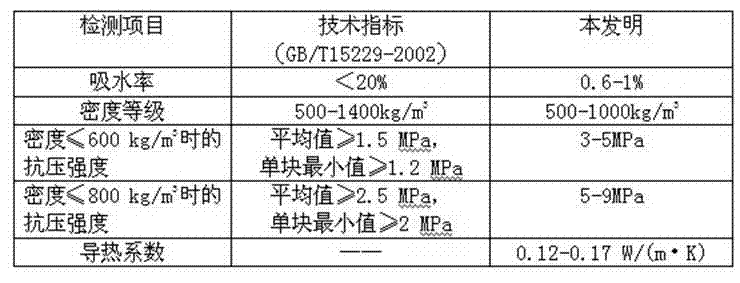

Method for preparing foam ceramic self-insulation wall material by utilizing solid wastes

InactiveCN103396150AReduce manufacturing costRealize comprehensive utilizationSolid waste disposalCeramicwareChromium sesquioxideInsulation layer

The invention relates to a method for preparing a foam ceramic self-insulation wall material by utilizing solid wastes. The wall material comprises a main material and an admixture. The main material is prepared from the following components in proportion: 25% to 35% of chromium slags, 19% to 27% of coal gangue, 20% to 26% of waste ceramic polishing residues, 17% to 25% of albite and 1% to 6% of bentonite. The method comprises the following steps of: adding 16 to 20g of the admixture into every 200g of the main material; evenly mixing and screening the mixture; putting the mixture into a die; molding the mixture in a pressing manner and drying; sintering the mixture under a strong reducing atmosphere at the temperature of 1120-1180 DEG C, thereby obtaining the foam ceramic self-insulation wall material. The carbon in the coal gangue can serve as a foaming agent or a reducing agent, so that hexavalent chromium is reduced into chromium sesquioxide at the high temperature and under the strong reducing atmosphere. Thus, the toxicity of the chromium slags is eliminated. The prepared foam ceramic self-insulation wall material is low in pyroconductivity, small in density and low in water absorption rate; the usage temperature can reach 900 DEG C. In addition, the foam ceramic self-insulation wall material is complete in fire resistance, high in strength and long in service life, and can be used for replacing the existing wall materials and flammable insulation materials. The wall material integrates protection and thermal insulation functions; an exterior wall insulating layer is not required. Thus, the construction cost is lowered.

Owner:HENAN COAL CHEM IND GROUP INST +1

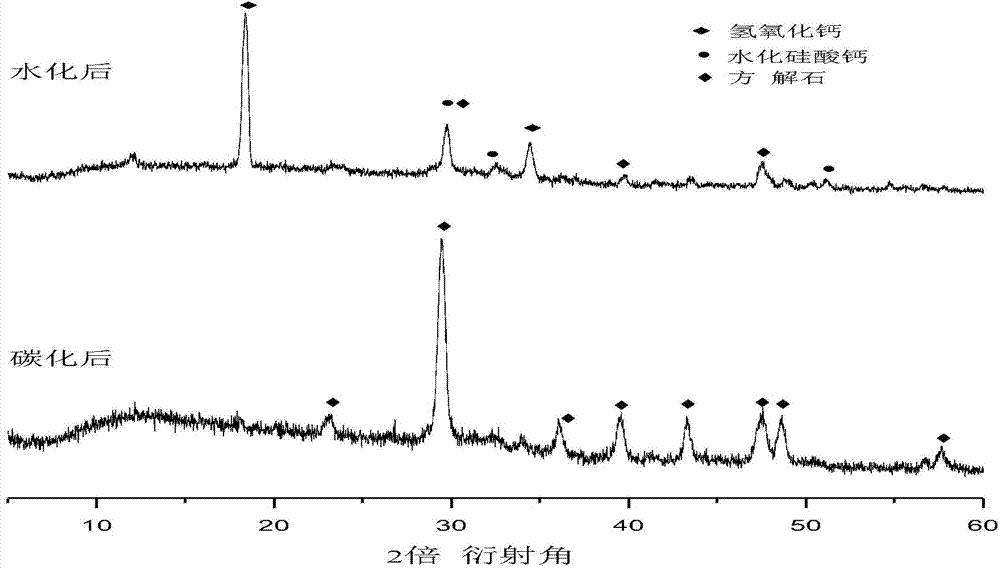

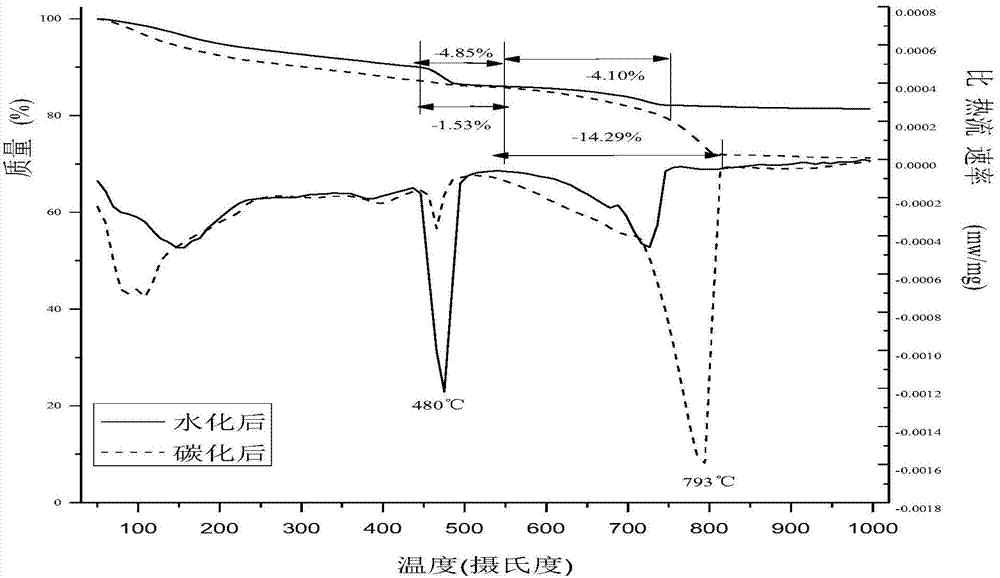

Method for preparing building material products through hydration-carbonation coupling technique

The invention belongs to the technical field of building materials, and provides a method for preparing building material products through processing industrial solid waste by hydration-carbonation coupling technique. The method comprises steps of uniformly mixing the industrial waste comprising at least one of calcium oxide, calcium hydroxide, dicalcium silicate, tricalcium silicate and tobermorite with alkaline excitation material and proper amount of water so as to prepare the blank of the building material product, wherein the industrial waste comprises steel slag, mineral waste residue, furnace slag, coal ash or coal gangue, the alkaline excitation material comprises carbide slag, lime, Portland cement or waste cement; maintaining for a period through hydration, then maintaining through carbonation so as to obtain the carbonate-based building material product. The coupling technique can effectively use the industrial solid wastes such as steel slag, mineral waste residue, furnace slag, coal ash, coal gangue, carbide slag and the like, so that emission of greenhouse gases is reduced, the greenhouse effect is relieved, furthermore, the method can be used for producing the building material products with good properties, effectively uses the waste and is environmentally friendly.

Owner:DALIAN UNIV OF TECH

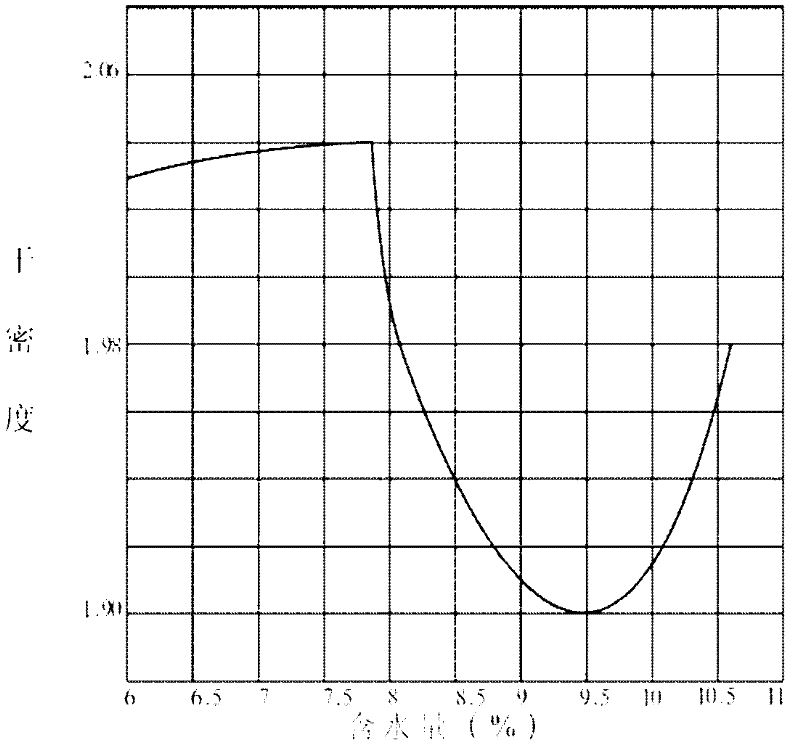

High-performance sand-soil consolidation material, as well as preparation method and using method thereof

The invention relates to a high-performance sand-soil consolidation material, as well as a preparation method and a using method thereof. The high-performance sand-soil consolidation material belongs to a mortar composition and is characterized by comprising the following raw materials in parts by weight: 5-40 parts of cement clinker, 3-6 parts of gypsum, 4-10 parts of alkali additive, 0.5-6 parts of compound activating agent, 1-4 parts of early strength agent, 2-10 parts of mineral activating agent, 3-8 parts of expansion agent and 22-77 parts of micro-powder formed by fine grinding of blast furnace water-quenched slag. The invention provides the high-performance sand-soil consolidation material which has the advantages of simple operation, convenient construction, good water resistance, fast consolidation, high early strength, stable improvement of post-strength, resistance to erosion of underground inorganic salt water, excellent anti-seepage performance and low production cost, as well as the preparation method and the using method thereof. The high-performance sand-soil consolidation material is suitable for consolidating mine tailings, natural weathered sand, fly ash, gravel, stone chips, stone powder, soil, sludge, construction waste, coal gangue and phosphorus slag into a solid material, and can be used for laying a subgrade, constructing a wall body and constructing a site foundation.

Owner:淄博乾耀固结材料有限公司

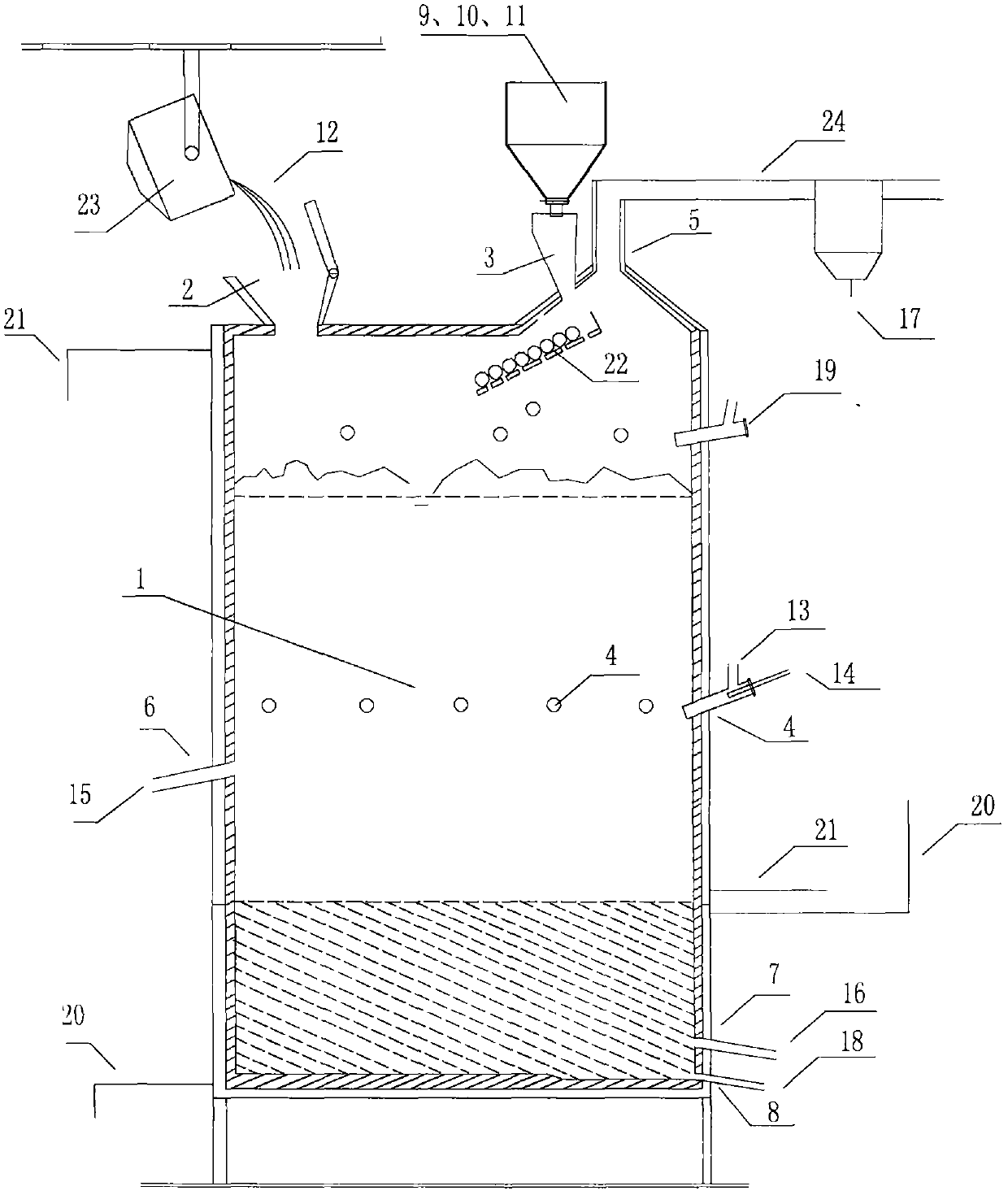

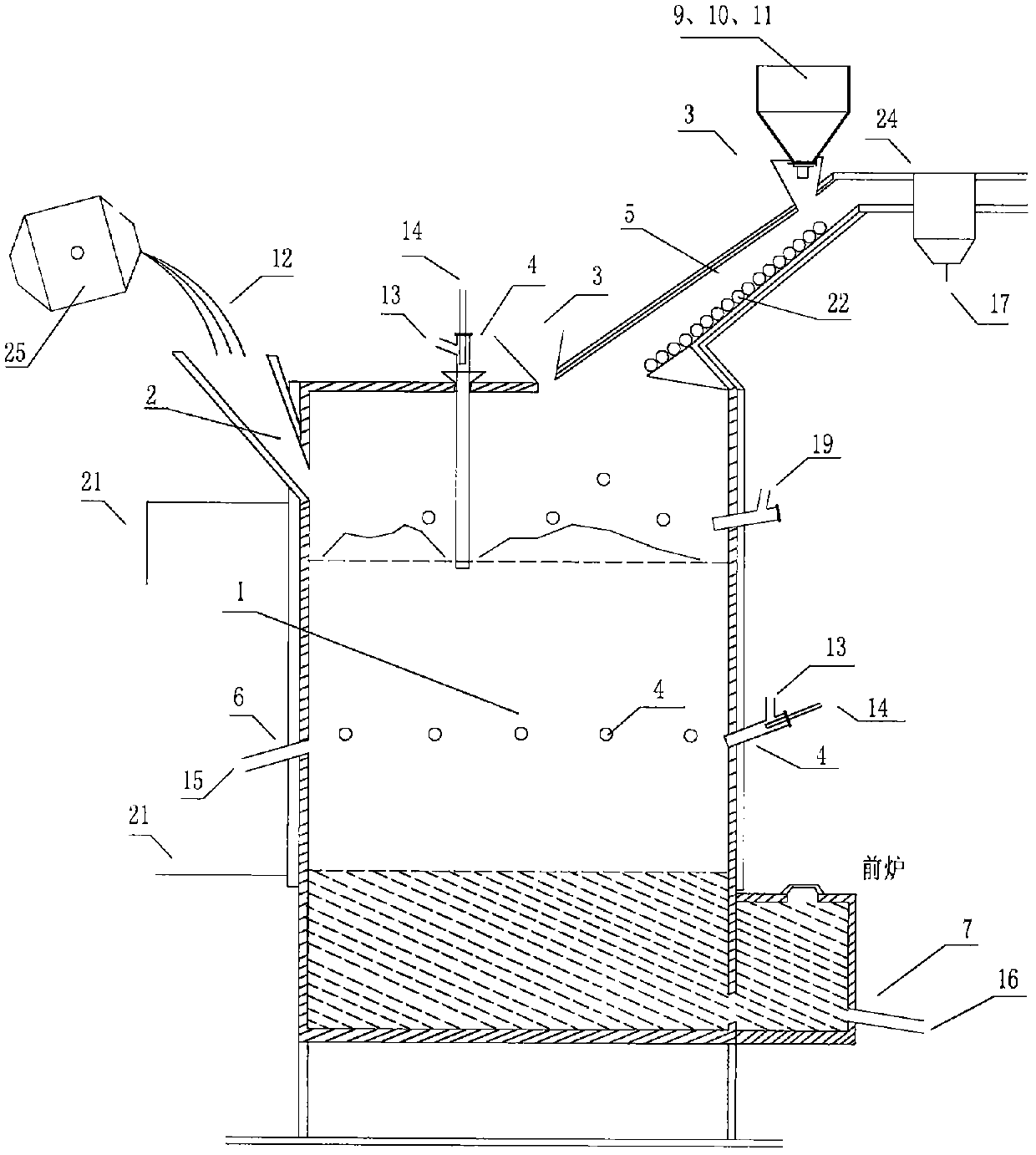

Cooperative processing and recycling method for material containing iron and/or zinc, lead, copper and tin, and the like and molten steel slag

PendingCN108676942AReduce outputEfficient recyclingRecycling and recovery technologiesProcess efficiency improvementMolten slagMaterials science

The invention discloses a process method for cooperatively and continuously processing waste containing iron and / or zinc, lead, copper and tin, and the like and molten steel slag on line, separating and recycling metal such as iron, zinc, lead, copper and tin as well as molten slag. The cooperative processing and recycling method is characterized in that pellets prepared from waste containing iron, zinc, lead, copper, tin and the like, particles, a blocky material containing iron, zinc, lead, copper, tin and the like and high-temperature molten steel slag are added into a reducing, volatilizing and smelting furnace, molten iron, which is obtained by air-blowing, adding of fuels such as coal gangues and flux such as high silicon and high aluminum, high-temperature reducing and volatilizingtreatment, is discharged from an iron outlet of the reducing, volatilizing and smelting furnace; volatilized substances such as zinc and lead and smoke gas are sucked into a dust collector for being collected and utilized; enriched metal such as gold, silver, copper, tin and lead is discharged from a discharge hole in the bottommost part of the reducing, volatilizing and smelting furnace for beingrecycled; and molten slag is discharged through a slag outlet, water slag and the like or the molten slag is returned into a converter for being recycled. Waste containing iron, zinc, lead, copper, tin and the like, molten steel slag and coal gangue waste slag and the like are cooperatively and continuously treated to separate and recycle useful metal, so that remarkable energy-saving environment-friendly social benefits and economic benefits are achieved.

Owner:湖南建鑫冶金科技有限公司

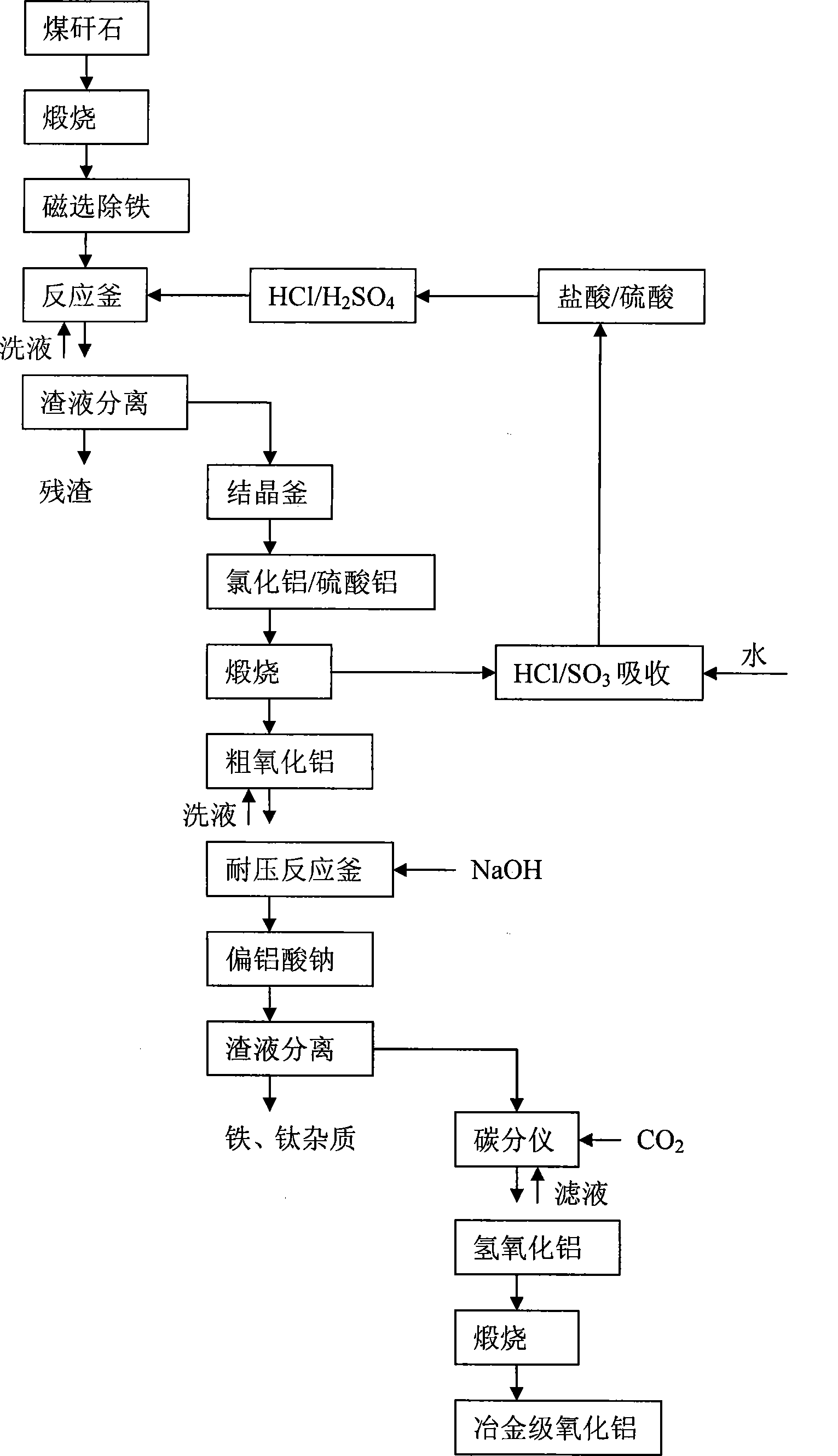

Method for extracting alumina from coal gangue

InactiveCN101450811AAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideSodium aluminate

The invention mainly relates to a method for extracting alumina from coal gangue. The coal gangue is ground, and then is calcined through a fluidized furnace and iron is removed through a magnetic separator, the coal gangue with the iron removal reacts with an acid to obtain an aluminum chloride solution without silicon impurities, the solution containing the aluminum is concentrated and crystallized and then is subjected to low-temperature calcination to obtain crude aluminum oxide, then the crude aluminum oxide reacts with sodium hydroxide to obtain a sodium aluminate mother solution, impurities such as iron and titanium are removed, an aluminum hydroxide crystal seed is added to the mother solution, and carbon dioxide gas is introduced for seed precipitation to obtain an aluminum hydroxide precipitate, and metallurgical grade alumina can be obtained through the calcinations. The method does not use any auxiliary agent at normal pressure, and uses hydrochloric acid and sulfuric acid to directly leach and extract alumina; the content of the alumina prepared by the method can reach more than 99 percent; and the method has the advantages of simple process flow, adequate raw material sources, less energy consumption, low cost, and high utilization value of the coal gangue.

Owner:CHANGCHUN CHAOWEI NEW MATERIALS TECH

Concrete cement foaming insulation brick and manufacturing method thereof

The present invention discloses a concrete cement foaming insulation brick, taking a concrete perforated brick as a main body. The concrete perforated brick is injected with a cement foam material, so that the cement foam material and the concrete perforated brick are fully combined. By adjusting the formulation and improving the process, the present invention makes full use of industrial wastes such as fly ash and coal gangue, does not need autoclaved curing, and is small in investment and simple in process. The foaming brick produced by the present invention has excellent heat insulation and sound insulation properties, and is high in strength, good in impact resistance, low in moisture absorption, light in weight, compression resistant, good in weather resistance, environmental-friendly and energy-saving, and non-toxic. The brick has great market space and development prospects in the application field of building energy efficiency.

Owner:嵊州市万顺新型墙体材料有限公司

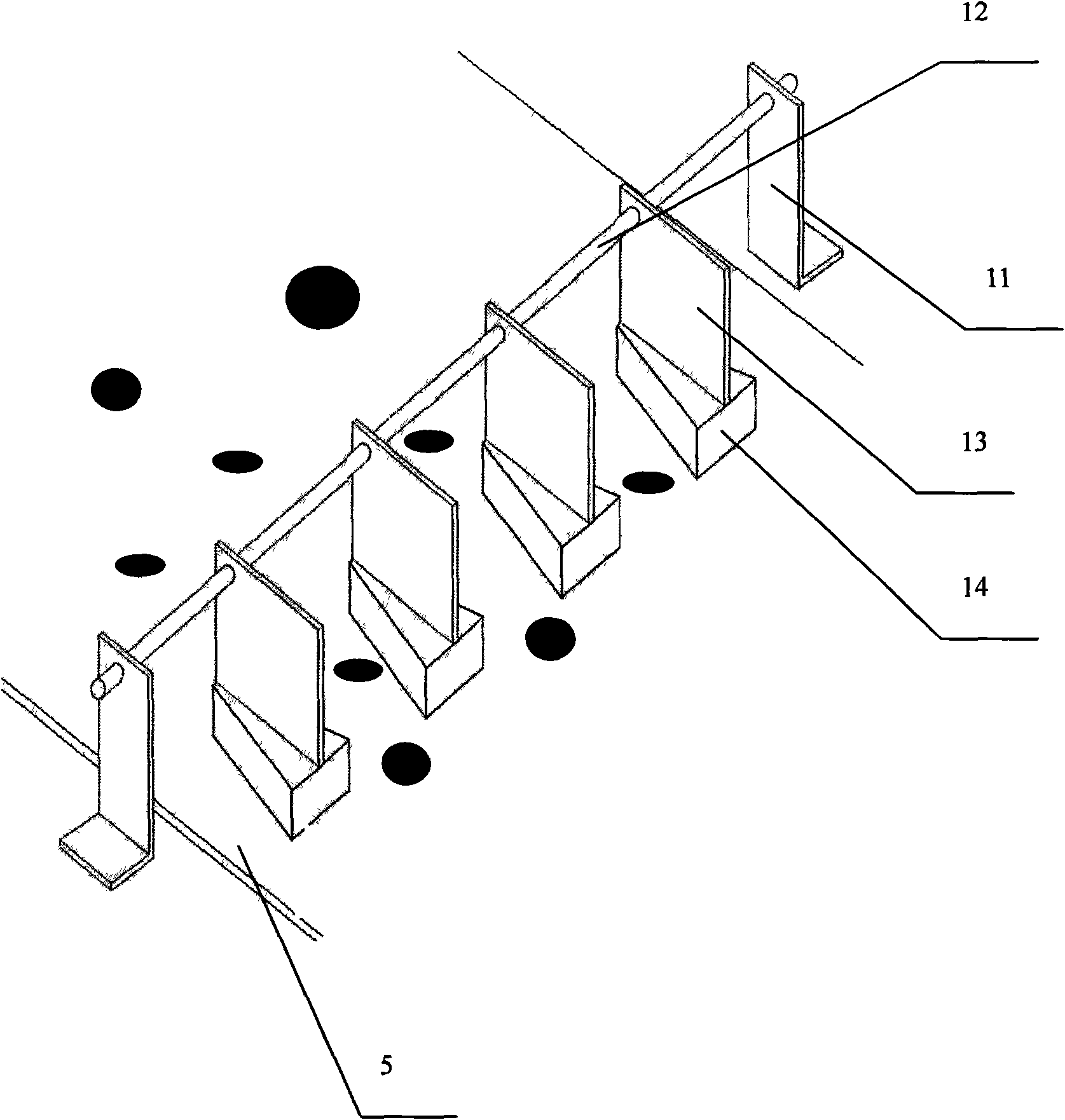

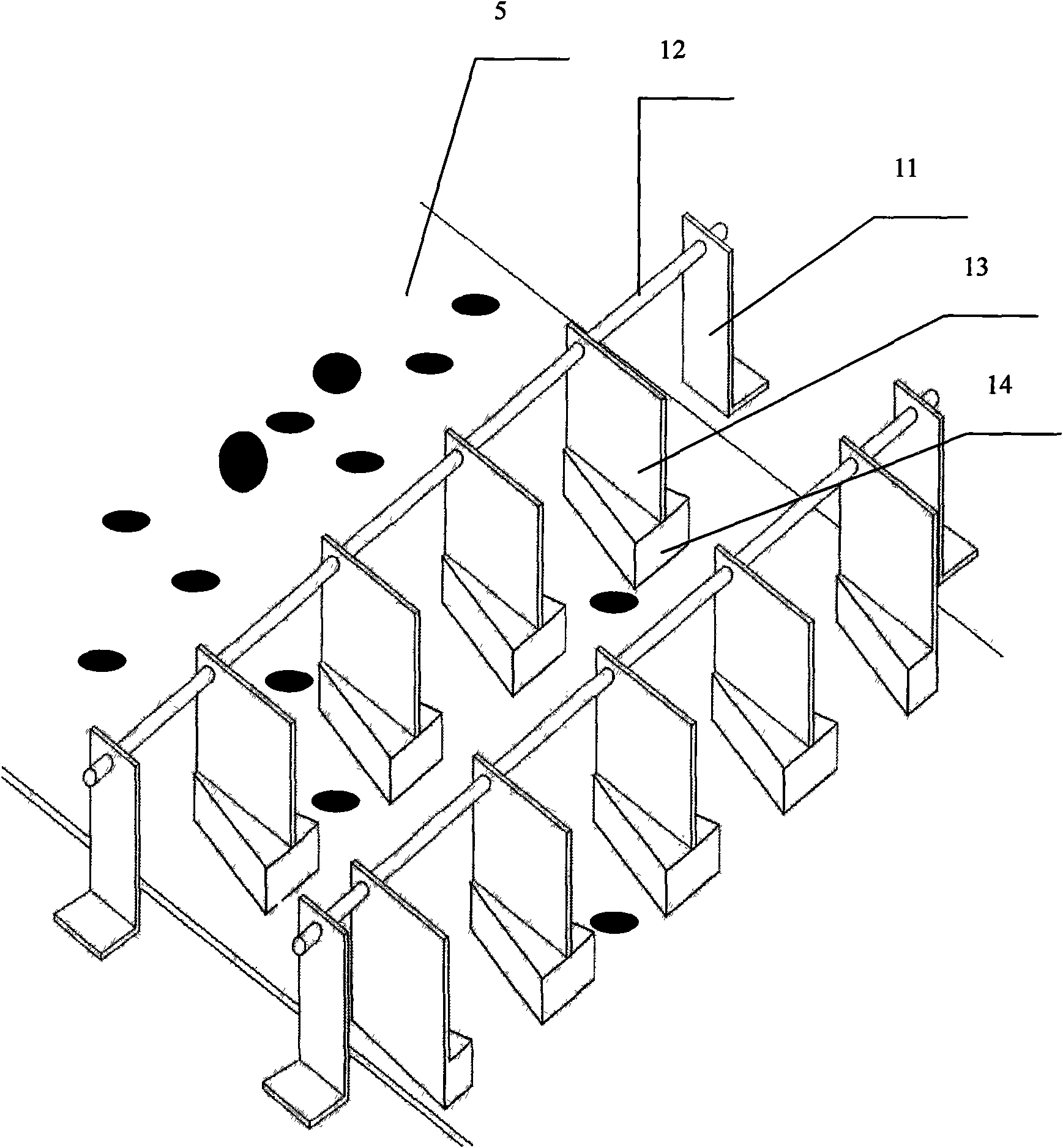

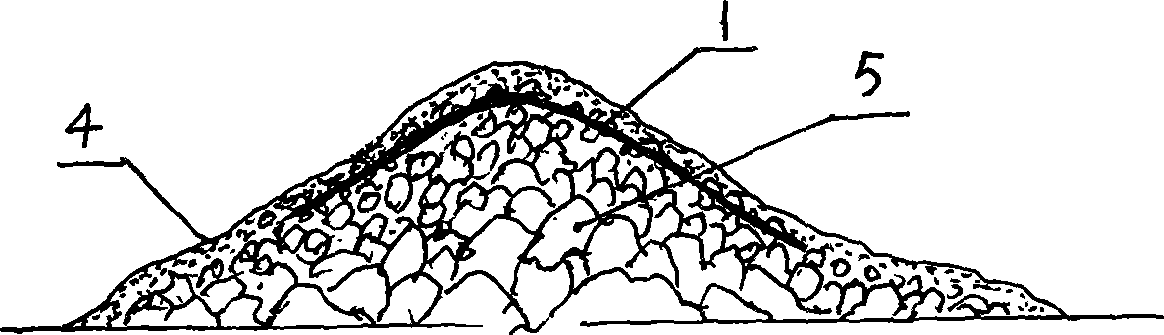

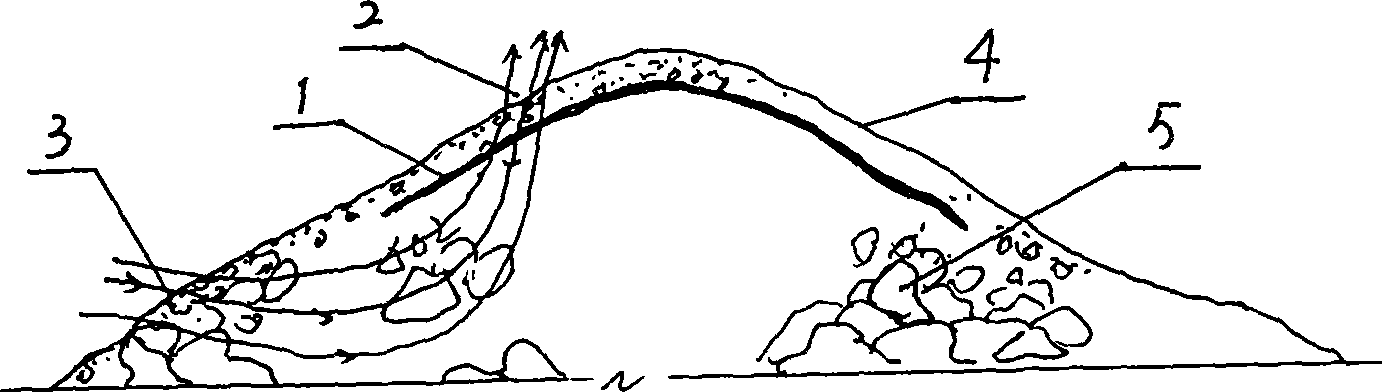

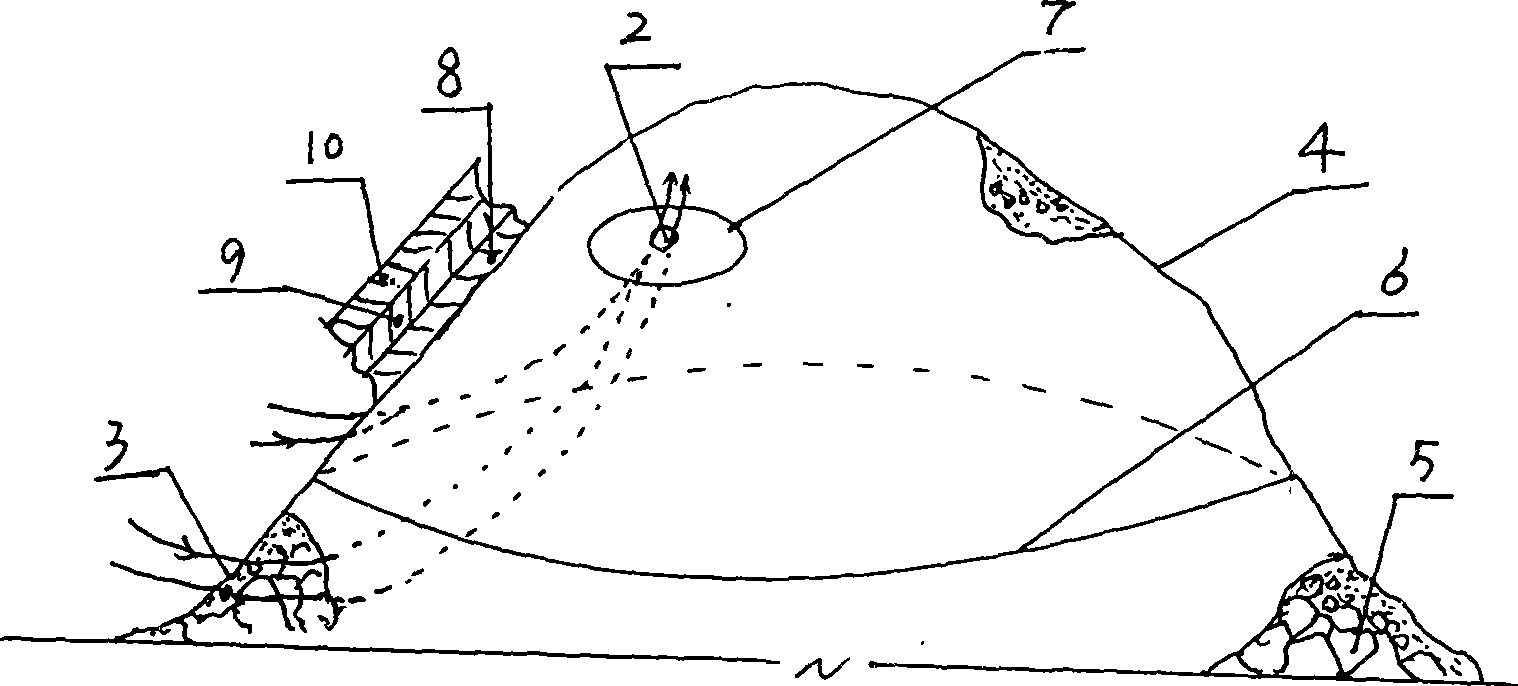

Method for comprehensively treating ecological environment of coal gangue hill

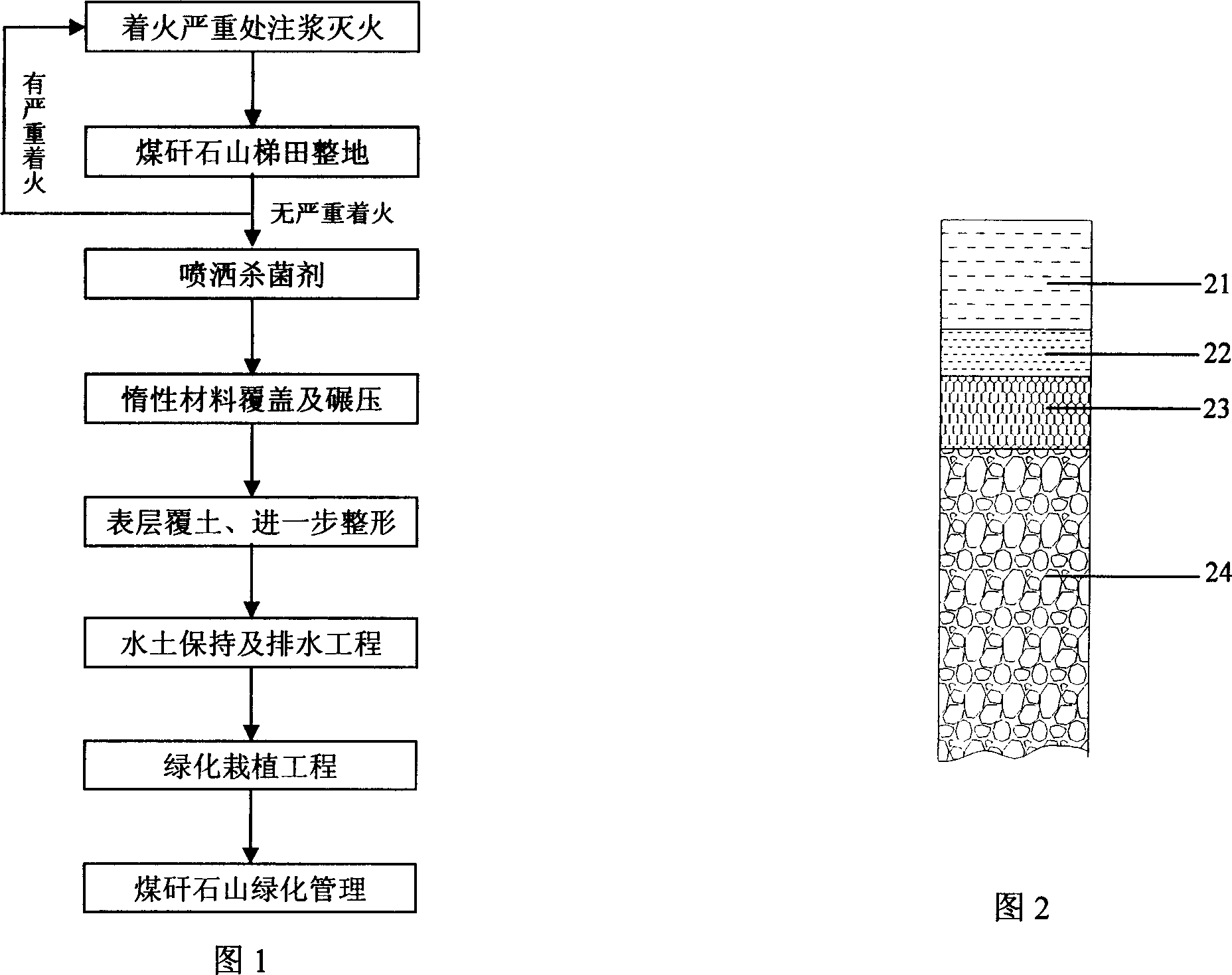

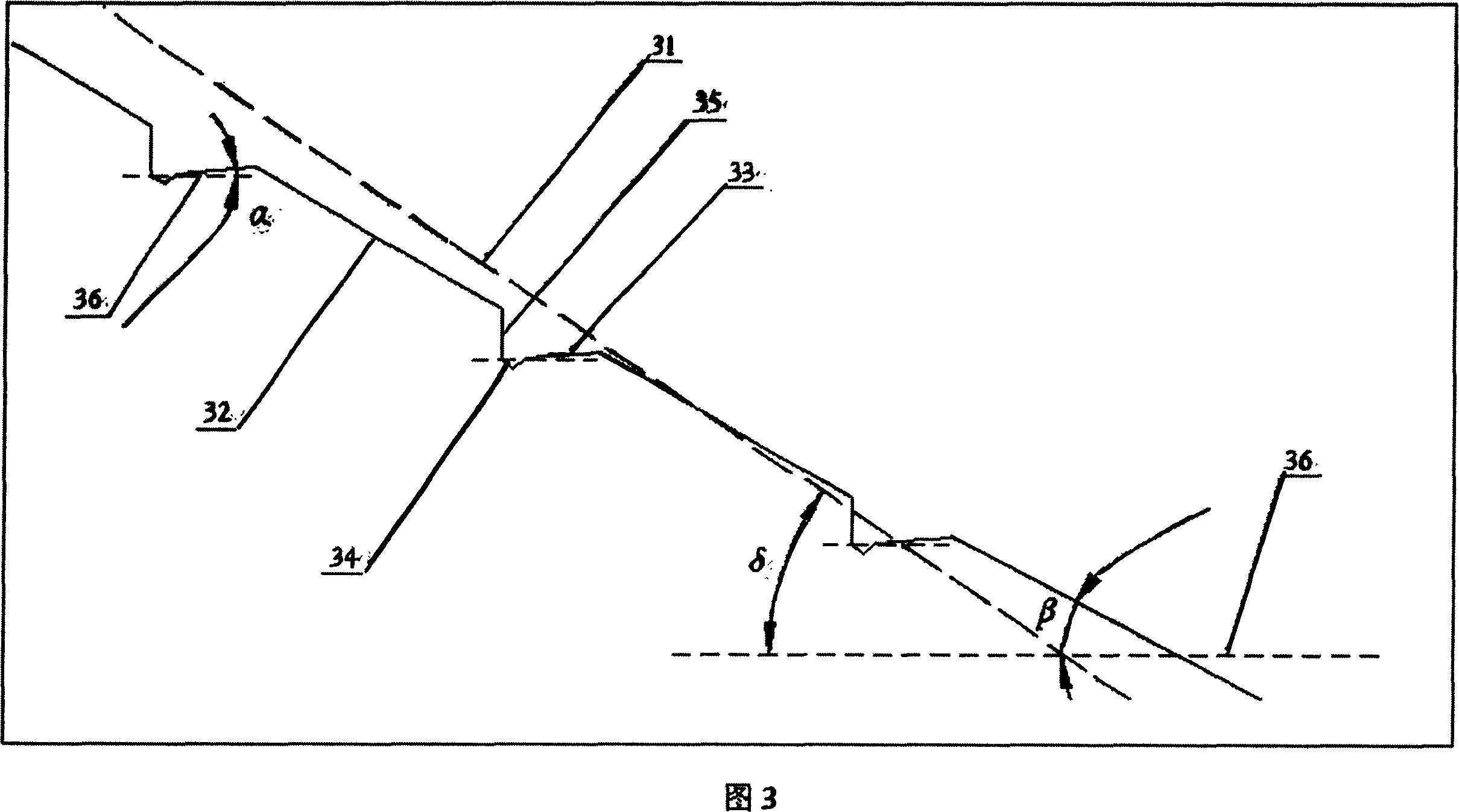

InactiveCN101519966AReduce flowAvoid formingUnderground miningSurface miningRevegetationEcological environment

The invention relates to a method for comprehensively treating the ecological environment of a coal gangue hill, which belongs to the field of mineral waste treatment and ecological environment restoration. The method mainly solves the problems of fire extinction, fire prevention and vegetation construction of the coal gangue hill. The method comprises the steps: the on-site reconnaissance of the coal gangue hill is carried out, and a construction operation plan is established; with fire prevention as principal and the combination of fire prevention and fire extinction, the fire prevention is crucial and is combined with the fire extinction, a thin layer of slurry is firstly sprayed on the coal gangue hill by a mechanical method to completely seal to form a sealing layer (8), transition slurry is sprayed on the sealing layer (8) to completely cover the sealing layer (8) to form a transition layer (9), slurry containing grass-shrub vegetation is spayed on the transition layer (9) to completely cover the transition layer (9) to form a planting layer (10); the contour line girdle band type operation in the spraying process is carried out from bottom to top to gradually and completely cover the hill, and different operating modes are selected according to practical conditions. The invention can not disturb the structure of the coal gangue hill, takes the fire prevention as the principal, combines the fire prevention with the fire extinction, has good and durable fire prevention effect, uses reliable and effective fire prevention and fire extinction measures as guarantee conditions to construct the planting layer, adopts grass-shrub plants, carries out hill sealing management and ensures vegetation restoration; in addition, the method uses the prior specialized mechanical devices to carry out construction operation, is easy to implement, has little difficulty, high efficiency and low investment and can ensure treatment effect.

Owner:赵平 +1

Green organic agronomic crop microorganism bacterial manure and method of producing the same

The invention relates to a fertilizer and a process for preparing the same, in particular to a green organic crop microorganism fertilizer. The microorganism fertilizer is characterized in that the microorganism fertilizer is prepared by the mix-fermentation of eight bacterial communities of photosynthetic bacteria, azotobacter, actinomycete, lactobacillus, yeast, root fixing bacteria, potassium bacteria and phosphorus bacteria, a plurality of beneficial microbial agents, coal gangue powder, lignite, straw carbon, humic acid, crop straw powder and excrement. Tests show that the microorganism fertilizer has obvious effect on the growth of corn, broomcorn, cereal, legume, paddy rice, fruits, flowers, pasture and the like, the production increasing rate is between 15 and 30 percent, and the microorganism fertilizer has obvious function on resisting diseases, lodging and insects, and can replace pesticide, fertilizer and hormone, avoid chemical pollution, improve soil fertility and product quality, and make the product become green or organic standards; and particularly, various crop straw and excrement are used as a carrier, thereby further lowering cost of the microorganism fertilizer and opening up a new path for the popularization and application of the microorganism fertilizer.

Owner:张庆国

Method for preparing phosphoric acid and byproduct building brick by using phosphatic ore tailings after phosphate ore dressing

InactiveCN1837129AReduce consumptionReduce energy consumptionSolid waste managementPhosphoric acidBrickPhosphoric acid

The invention discloses a preparing phosphoric acid and by-product building brick method by debris with phosphor after phosphorus ore dressing ore, which comprises the following steps: adding in dinas rock powder, coking carbon powder (coal gangue powder), caoline to mix up; adding in water; ageing the mixture; modeling by vacuum extrusion machine or brick press; dipping after drying; putting mixture in kiln vehicle and entering tunnel oven; getting phosphor vapour and carbon monoxide after preheating and heating-up; getting concentrated phosphoric acid through hydrated tower; getting carrying brick production through heat transferring and cooling. The invention uses the mine and ore dressing fag-end to prepar acid and brick. We can use the ore when the P2O5 is not smaller than 6%.

Owner:HUBEI SANXIN PHOSPHORIC ACID

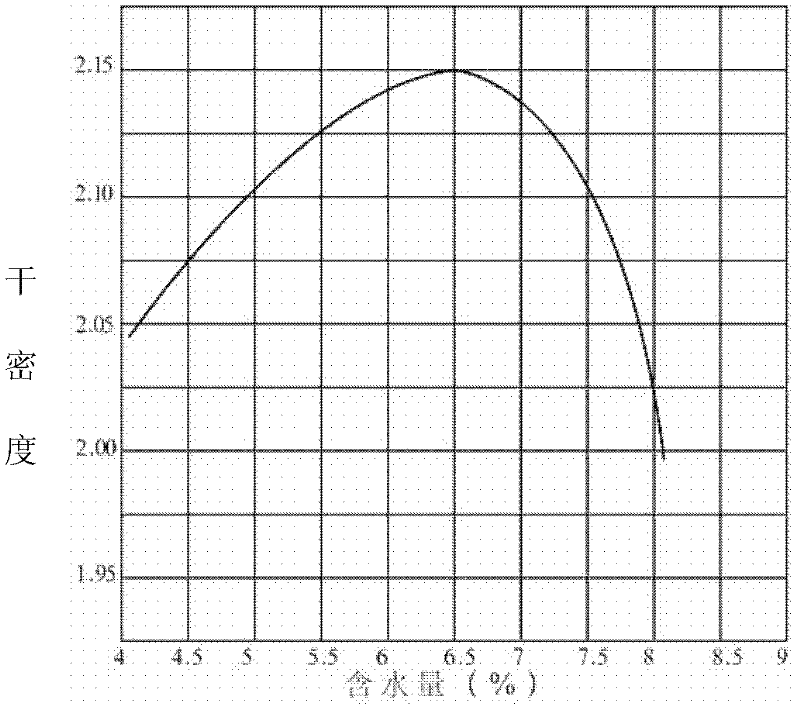

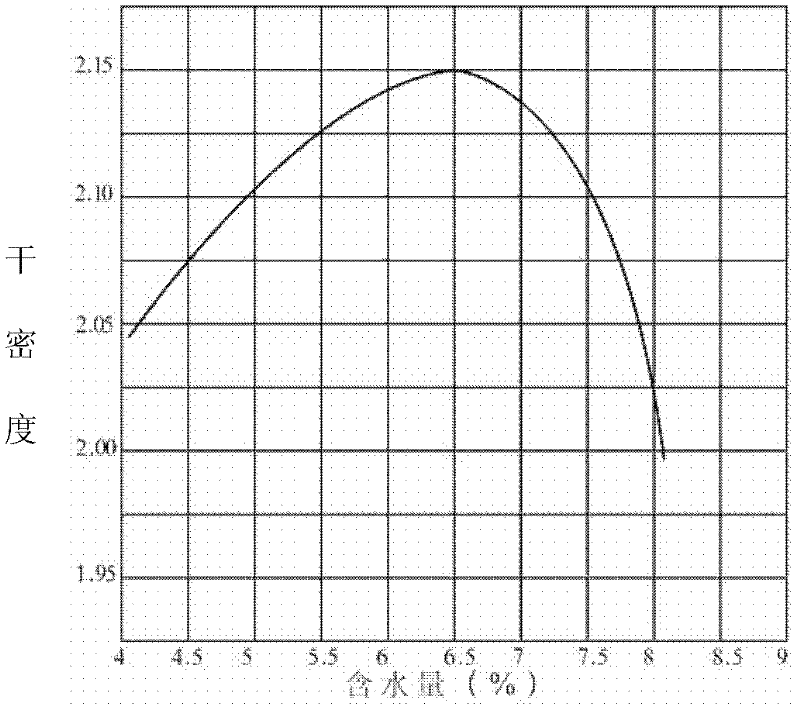

Composite cement with large amount of coal gangue and its preparation method

InactiveCN1546410AImprove performanceFull play of water activity and hardnessSolid waste managementHigh intensityMaceral

The invention discloses a large mixing amount coal gangue composite cement comprising coal gangue, silicate cement clinker aggregate, exciting agent, gypsum coagulation regulating agent, mineral admixture by right weight portion through a finite process, wherein the content of coal gangue is 20-80% wt. The composite cement according to the invention can be used for making various concrete structure, in particular mass concrete structure.

Owner:TONGJI UNIV

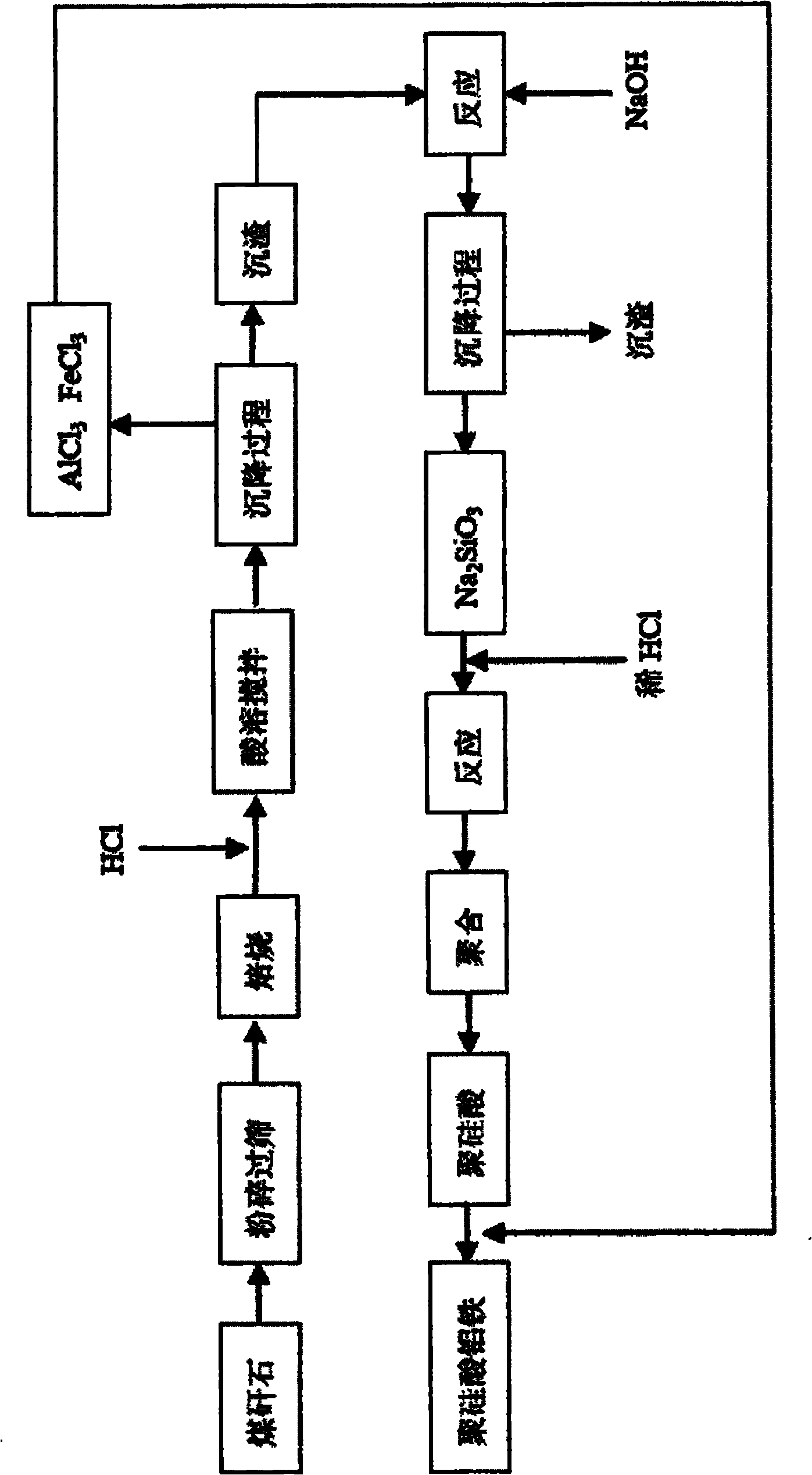

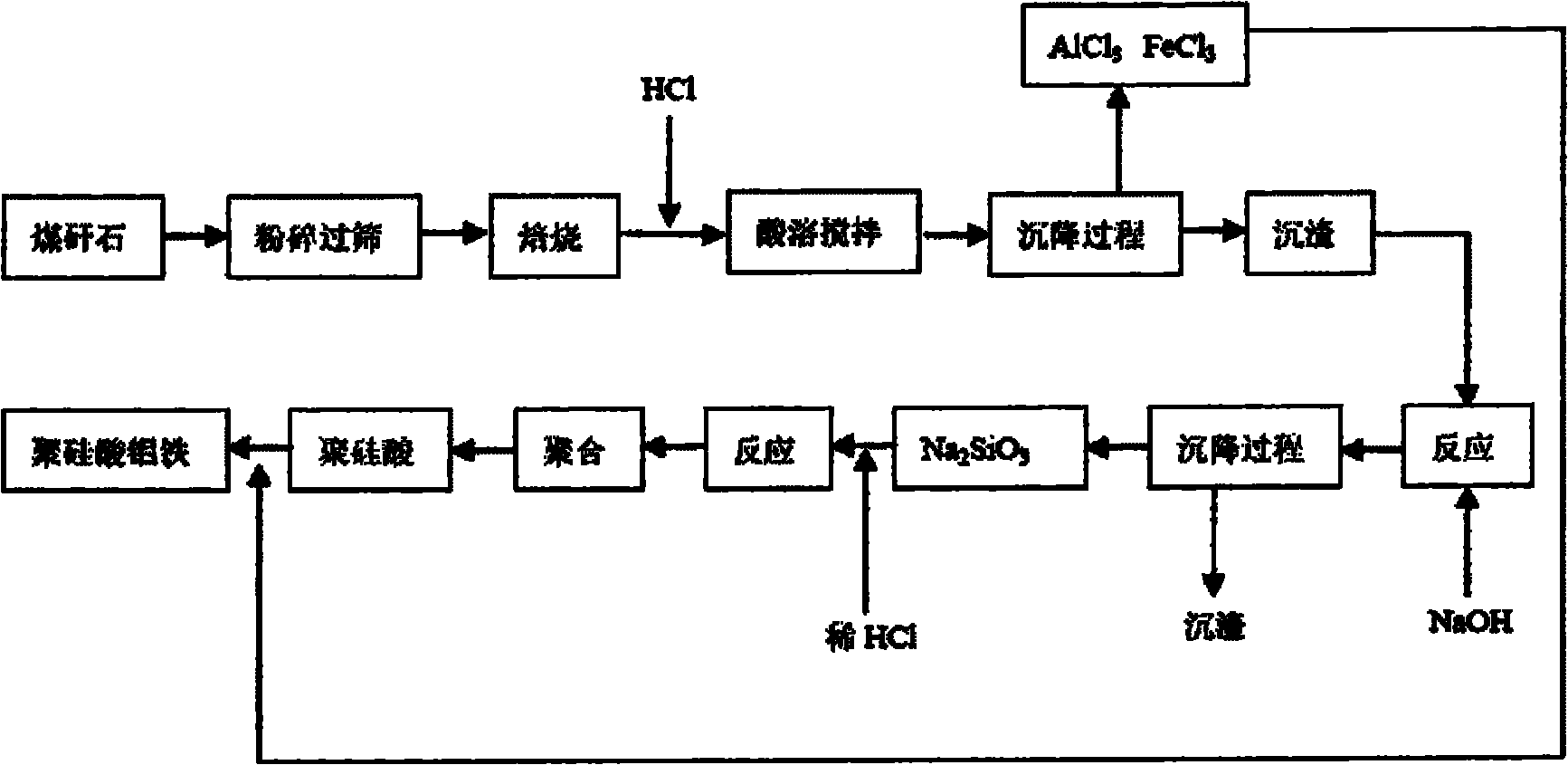

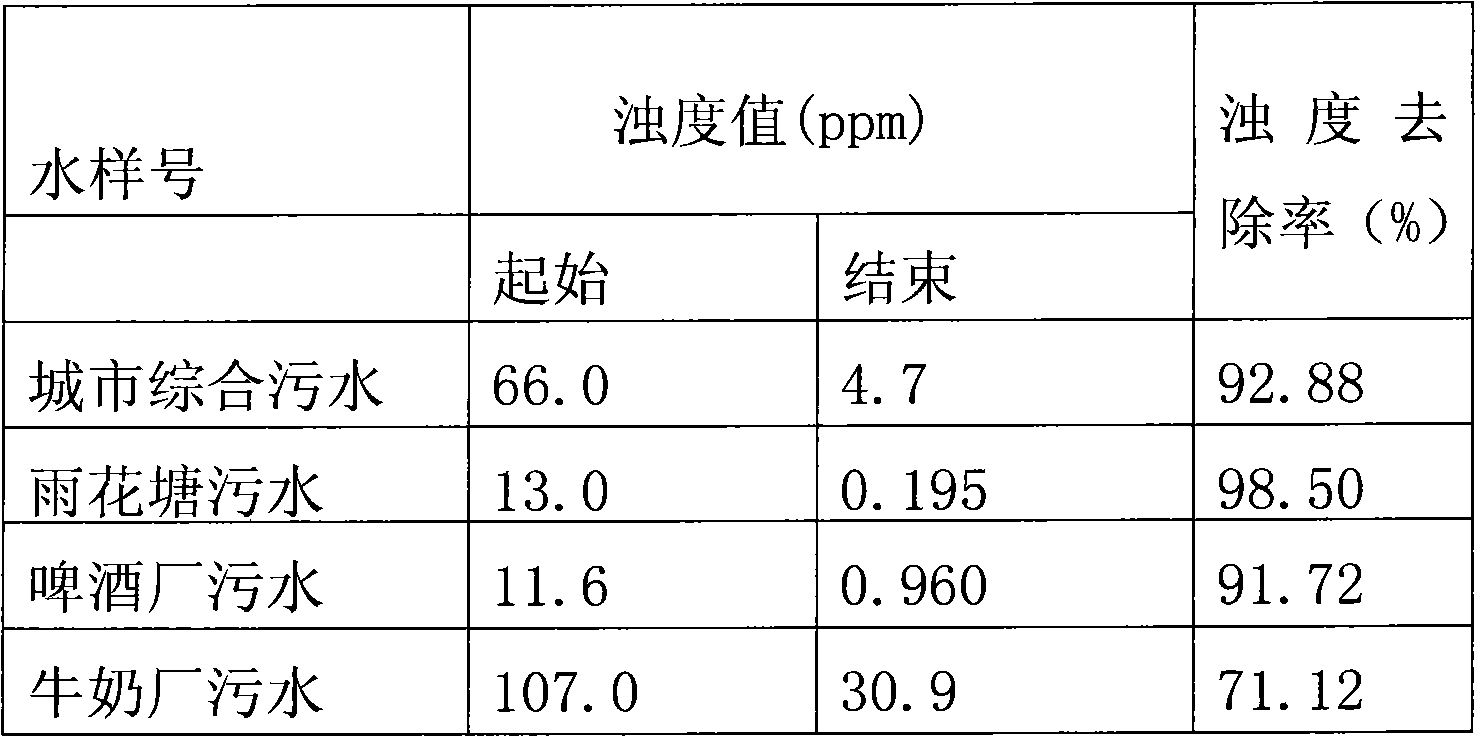

Method for producing poly silicate aluminium ferric flocculating agent by utilizing coal gangue

InactiveCN101823721ASolve the problem of stockpiling and polluting the environmentScientific and streamlined processAluminium silicatesSolid waste disposalSilicic acidMass ratio

The invention relates to the inorganic macromolecule flocculating agent technical field, in particular to a method for producing poly silicate aluminium ferric flocculating agent by utilizing coal gangue. The method includes the following steps: firstly coal gangue is smashed, roasted and mixed with hydrochloric acid by solid-liquid volume ratio of 1:4-6, reaction is carried out, then the obtained reaction liquid is filtered, the obtained residue is for spare use, and the pH value of the obtained filtrate is regulated to be 3-3.5, thus obtaining the poly aluminium ferric solution; then the obtained residue and sodium hydroxide are mixed for reaction by mass ratio of 2-4:1, and the filtrate obtained by filtration of reaction liquid is sodium silicate solution namely; the prepared sodium silicate solution is added with acid for carrying out activation treatment; then the prepared poly aluminium ferric solution and the activated sodium silicate solution are mixed for reaction by mass ratio of 1:1, thus obtaining the poly silicate aluminium ferric flocculating agent. The invention adopts coal gangue as raw material, cost is low, and meanwhile the poly silicate aluminium ferric flocculating agent prepared by the invention has better stability and flocculation effect.

Owner:HEFEI UNIV

Method for preparing foamed ceramic insulation board by waste glass ceramic wafer

The invention discloses a method for preparing a foamed ceramic insulation board by a waste glass ceramic wafer, belonging to the field of preparation technology of the foamed ceramic insulation board. The method comprises the steps of: washing the waste glass ceramic wafer with clear water, drying and grinding by ball milling to obtain waste glass ceramic powder with the fineness less than or equal to 100mu m; mixing the waste glass ceramic powder, pulverized fuel ash, furnace slag, coal gangue, ceramic tailings, foaming agent and modifying agent according to the mass ratio of (30-40):(10-15):(5-7):(10-18):(25-35):(1.8-2.2):(1.1-1.5); putting the mixture into a ball grinding mill, carrying out wet grinding and evenly mixing to form mixed slurry; drying by a pressure type spray granulation dryer and putting the dried product into a foaming refractory mould coated with aluminum oxide; heating to 1120-1150 DEG C in a heating furnace; and finally, annealing, cooling and cutting to obtain the foamed ceramic insulation board. The method is low in production cost and simple in technology, and can be used for continuously preparing the porous foamed ceramic insulation board with large size; and the product is good in performances.

Owner:ANSHENG SCI & TECH DEP

Building external wall thermal insulation foamed ceramic material and production method thereof

InactiveCN102584326AEfficient use ofLow costSolid waste disposalCeramicwareThermal insulationEnergy conservation

The invention belongs to the field of building materials, and in particular relates to a building external wall thermal insulation foamed ceramic material and a production method thereof. The building external wall thermal insulation foamed ceramic material is prepared from the following raw materials in part by weight: 60 to 80 parts of industrial solid waste, 15 to 35 parts of fluxing material and 2 to 5 parts of foaming agent, wherein the industrial solid waste is a mixture of two or three of coal gangue, metal tailing and polishing waste in any ratio; the fluxing material is one or a mixture of two of albite and bottle waste glass in any ratio; and the foaming agent is silicon carbide powder. The method comprises the following steps of: mixing the raw materials, grinding, filling in a recrystallized silicon carbide die, feeding into a kiln, firing, naturally cooling, cutting, and inspecting to obtain the foamed ceramic material which meets the building external wall thermal insulation requirement. The building external wall thermal insulation foamed ceramic material has the characteristics of A-level non-inflammability, high thermal insulation and heat preservation performance, energy conservation, environment friendliness and low cost.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

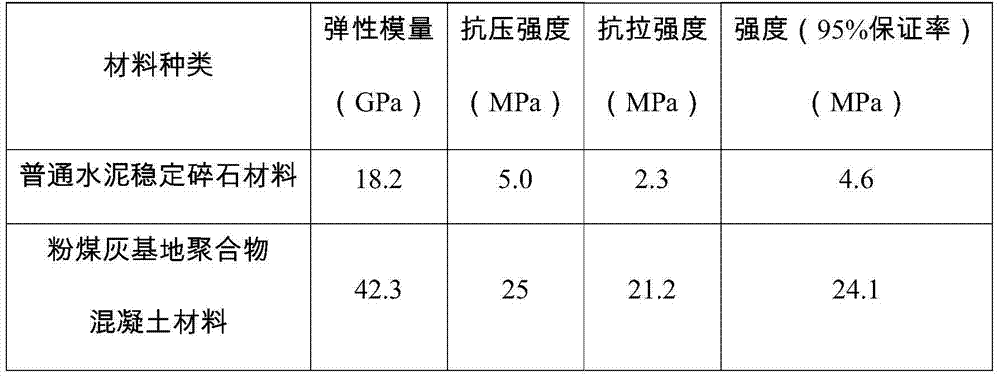

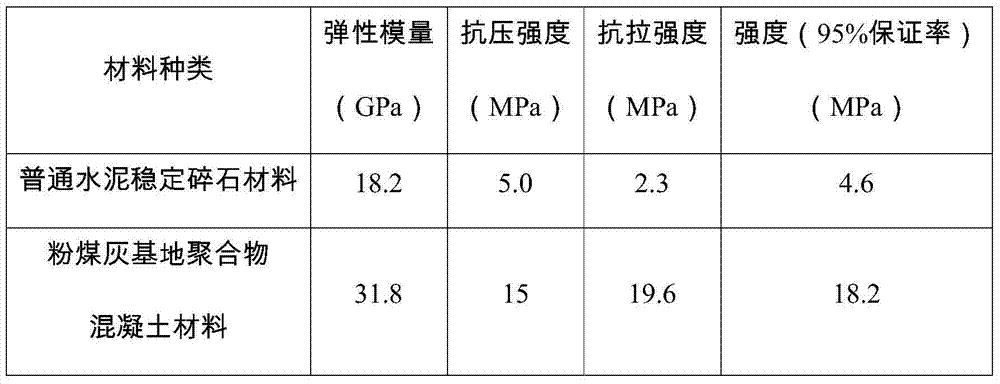

Flyash-based polymer concrete material and preparation method thereof

ActiveCN104496333APromote environmental protectionImprove mechanical propertiesPolymer sciencePolymer concrete

The invention discloses a flyash-based polymer concrete material and a preparation method and an application thereof. The flyash-based polymer concrete material comprises the following components in percentage by mass: 25%-45% of flyash, 0-15% of metakaolin, 10%-15% of cement, 0-5% of coal gangue and slag, 25%-35% of an alkali activator, 0.5%-1% of a retarder and 1%-5% of deionized water. An alkali-activated flyash-based polymer is adopted as a main gel material, so as to prepare an inorganic polymer concrete material; the polymer concrete material has the characteristics of high environmental protection property, good mechanical property and high early strength.

Owner:SHANGHAI PUDONG NEW AREA CONSTR GRP CO LTD

Greening method of self-ignition coal gangue hill

ActiveCN101011009AAvoid pollutionImprove the ecological environmentSolid waste disposalLandfill technologiesEcological environmentGreening

The invention relates to a method for greening the mine, comprising that based on the competition of mine, furnishing the slope into reverse-slope inclined terrace, using slurry method to extinguish fire and reducing temperature, plating disinfector on the face of mine, using inertia material to cover and roll the face of mine, covering soil and building soil and water conservation, greening and managing. The invention can combine the fire extinguish and green techniques.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

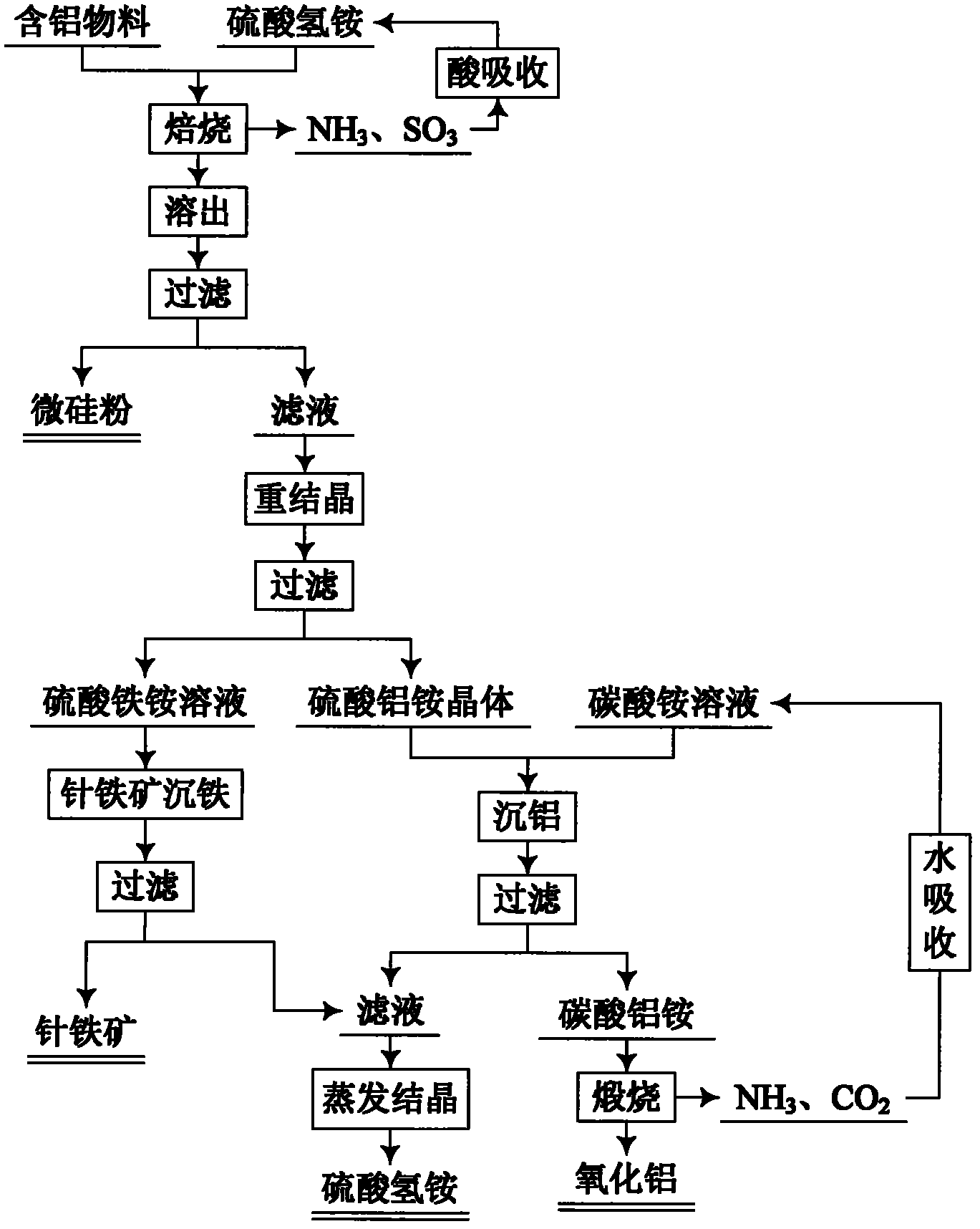

Method for comprehensive utilization of aluminum-containing material

The invention relates to a method for preparing aluminum oxide and other products by aluminum-containing materials of bauxite, alunite, nepheline, fly ash, kaolin, coal gangue and clay. The method comprises the following steps: (1) crushing and grinding an aluminum-containing material, carrying out mixing and baking for the treated aluminum-containing material and ammonium bisulfate; (2) carryingout dissolution and filtering for the baked clinker to obtain a crude ammonium aluminum sulfate solution and aluminum extracting residue; (3) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration more than 1 g / L by adopting a jarosite method, then carrying out an iron precipitating treatment by a goethite method, carrying out an aluminum precipitating treatment for the resulting solution, carrying out calcination for the resulting aluminium hydroxide to prepare aluminum oxide; (4) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration less than 1 g / L by adopting the goethite method, and carrying out an aluminum precipitating treatment to prepare aluminum oxide, or adopting a recrystallization method to carry out purification, adopting a reaction of the ammonium aluminum sulfate crystal and a ammonium carbonate solution to precipitate the aluminum to obtain ammonium aluminumcarbonate, carrying out calcination for the ammonium aluminum carbonate, and adopting a Bayer method to treat the calcined ammonium aluminum carbonate to prepare sandy aluminum oxide; (5) washing anddrying the aluminum extracting residue, wherein the dried aluminum extracting residue is adopted as the silicon dioxide product.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com