Coal gangue lightweight through-hole ceramsite

A technology of lightweight through-hole ceramsite and coal gangue, which is applied in the field of ceramsite, which can solve the problems of accumulation, land occupation, air pollution, and easy generation of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with embodiment the present invention will be further described:

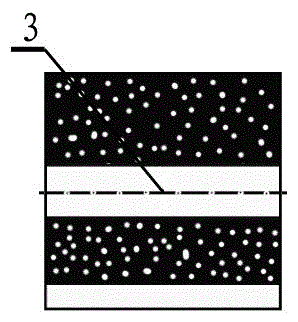

[0050] 1. The ingredients of gangue light through-hole ceramsite are composed of the following components by weight percentage: 32% of gangue, 25% of high-viscosity attapulgite clay, 8% of powdered gangue foaming agent, and 3% of activated clay waste residue , floating beads 4%, light magnesium oxide 3%, expanded perlite 1%, expanded vermiculite 1%, ferrous sulfate 1%, quicklime 0% and water 22%.

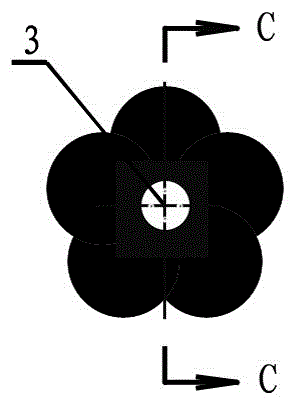

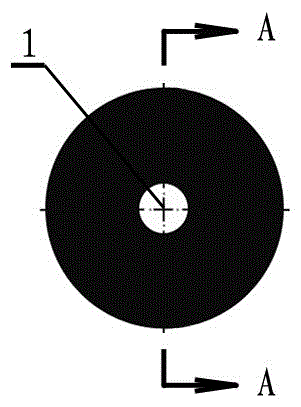

[0051] 2. The production method of coal gangue light through-hole ceramsite: (1) Input the ingredients of coal gangue light through-hole ceramsite into the stirring mixer that has been running, and stir and mix it into a mixture of coal gangue light through-hole ceramsite; (2) Transport the mixture of gangue light through-hole ceramsite to the extrusion granulator, and extrude and granulate into different shapes of coal gangue light through-hole ceramsite semi-finished products; (3) Coal g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com