Patents

Literature

15902results about "Agriculture gas emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

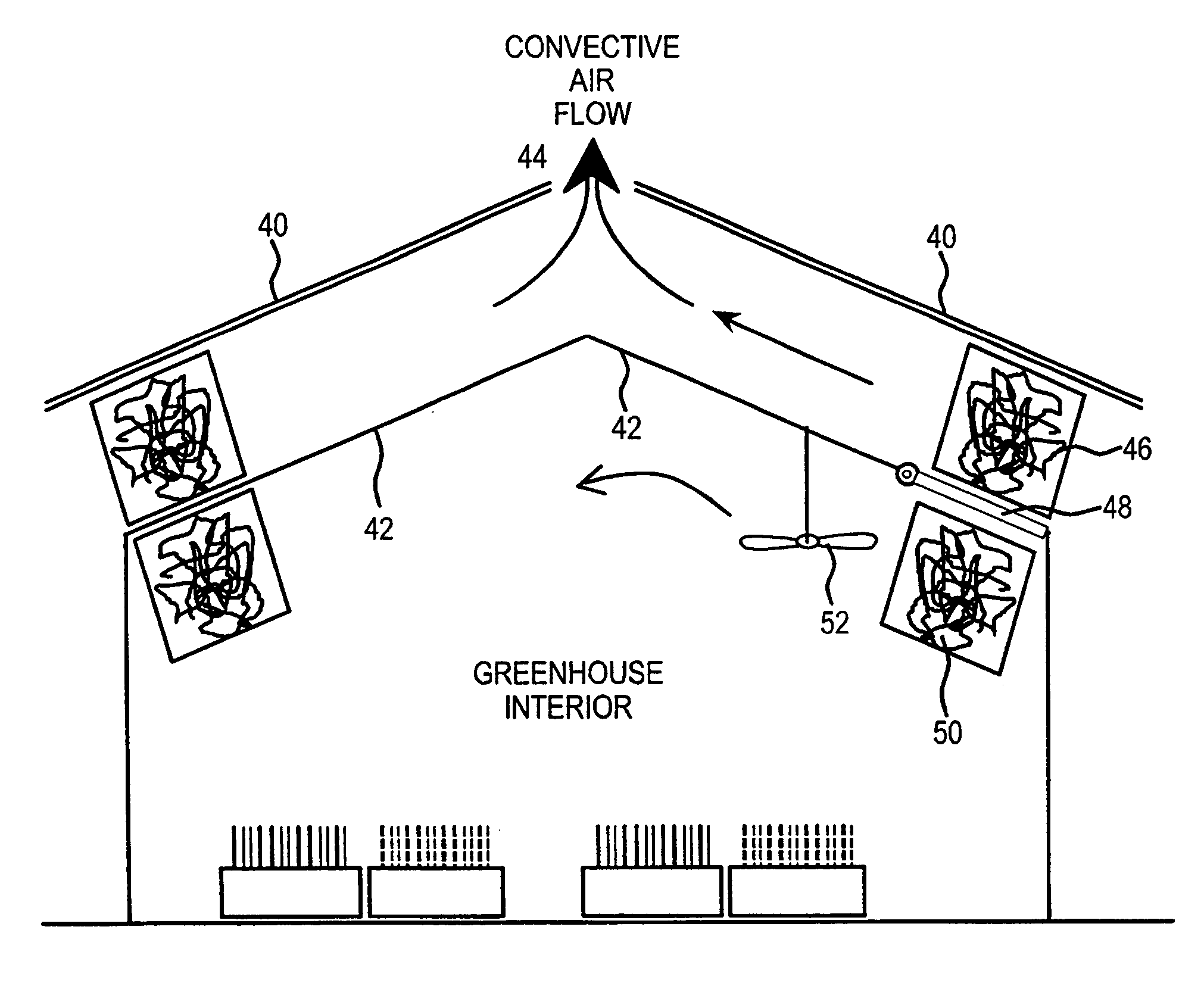

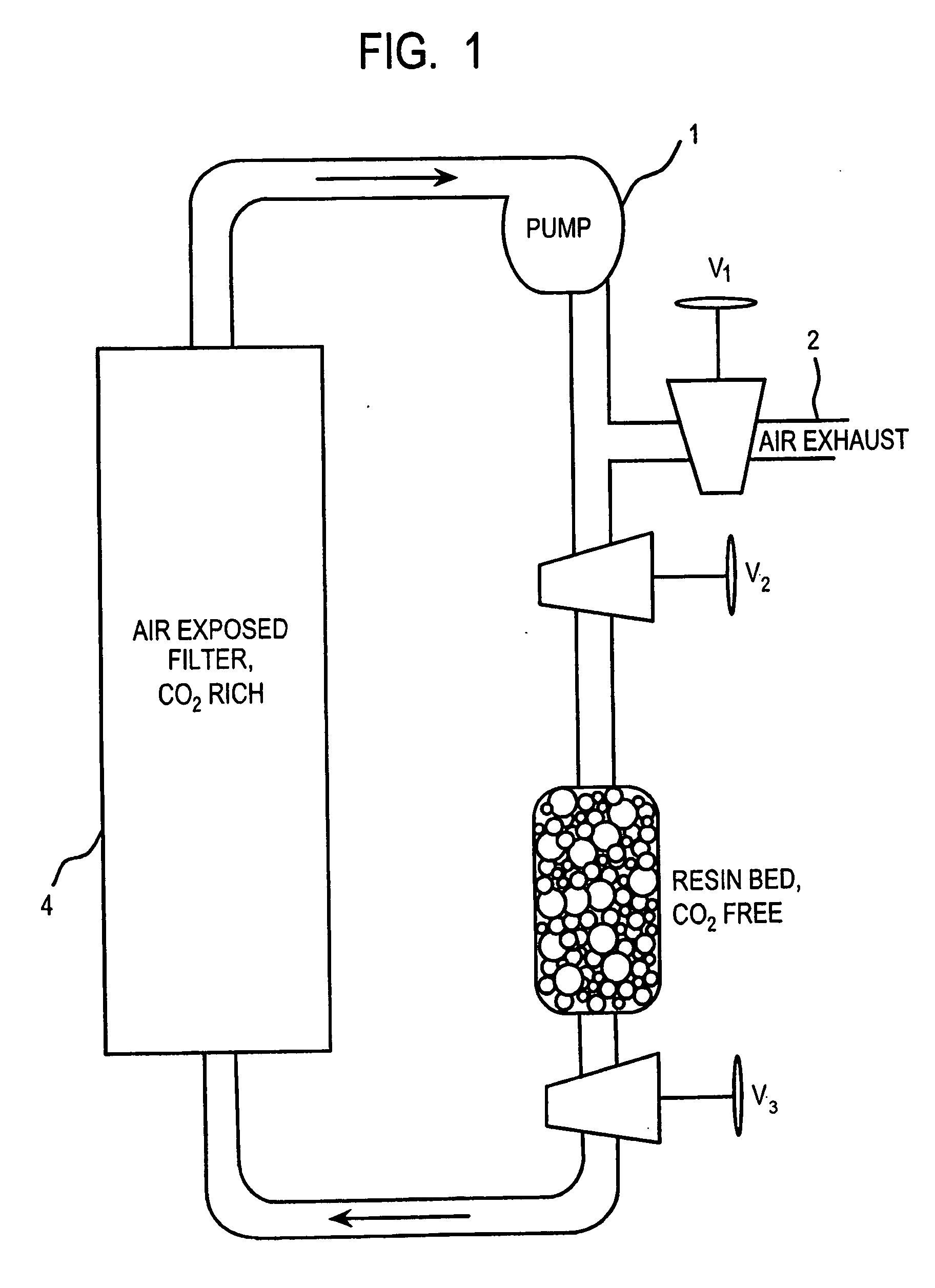

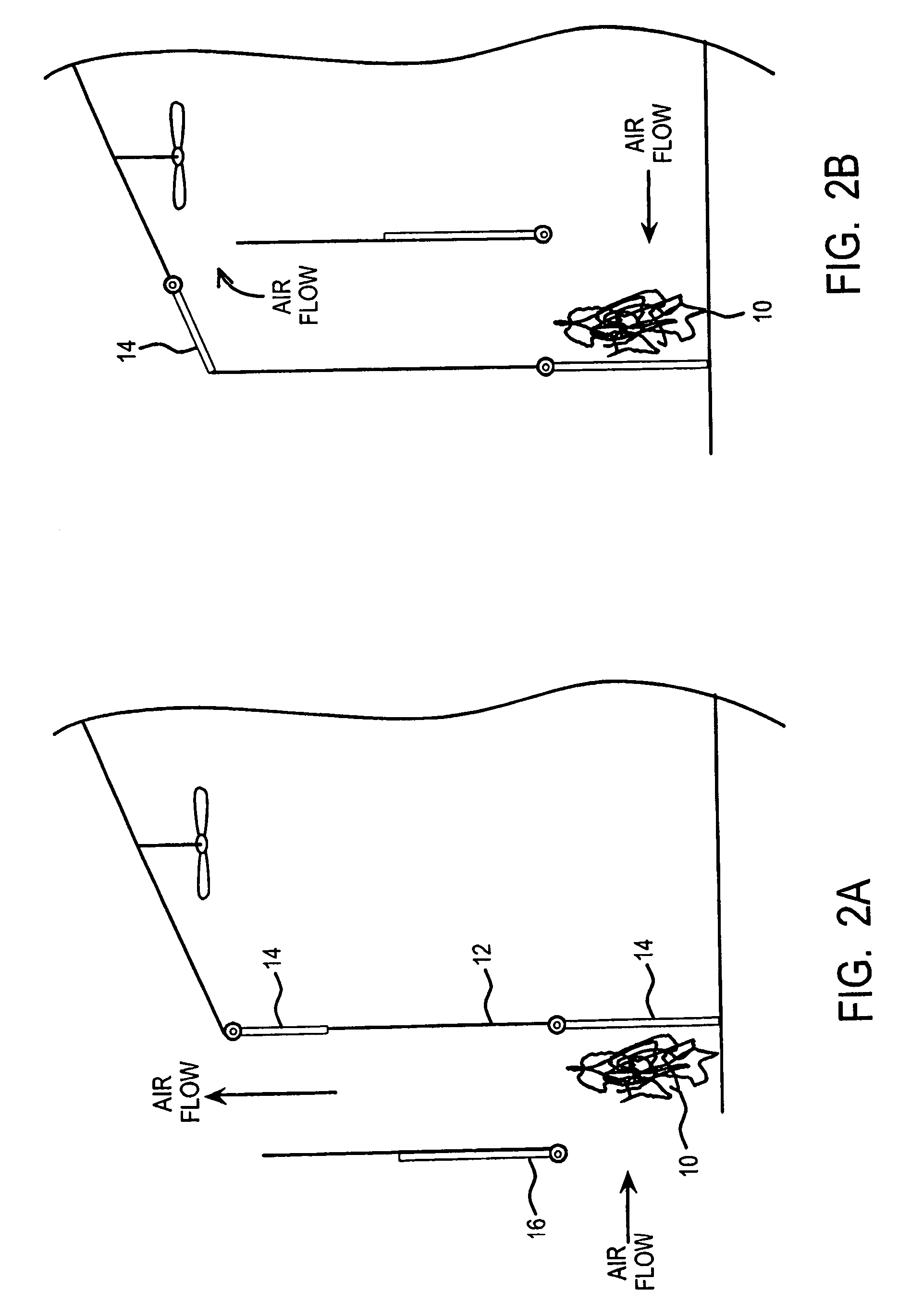

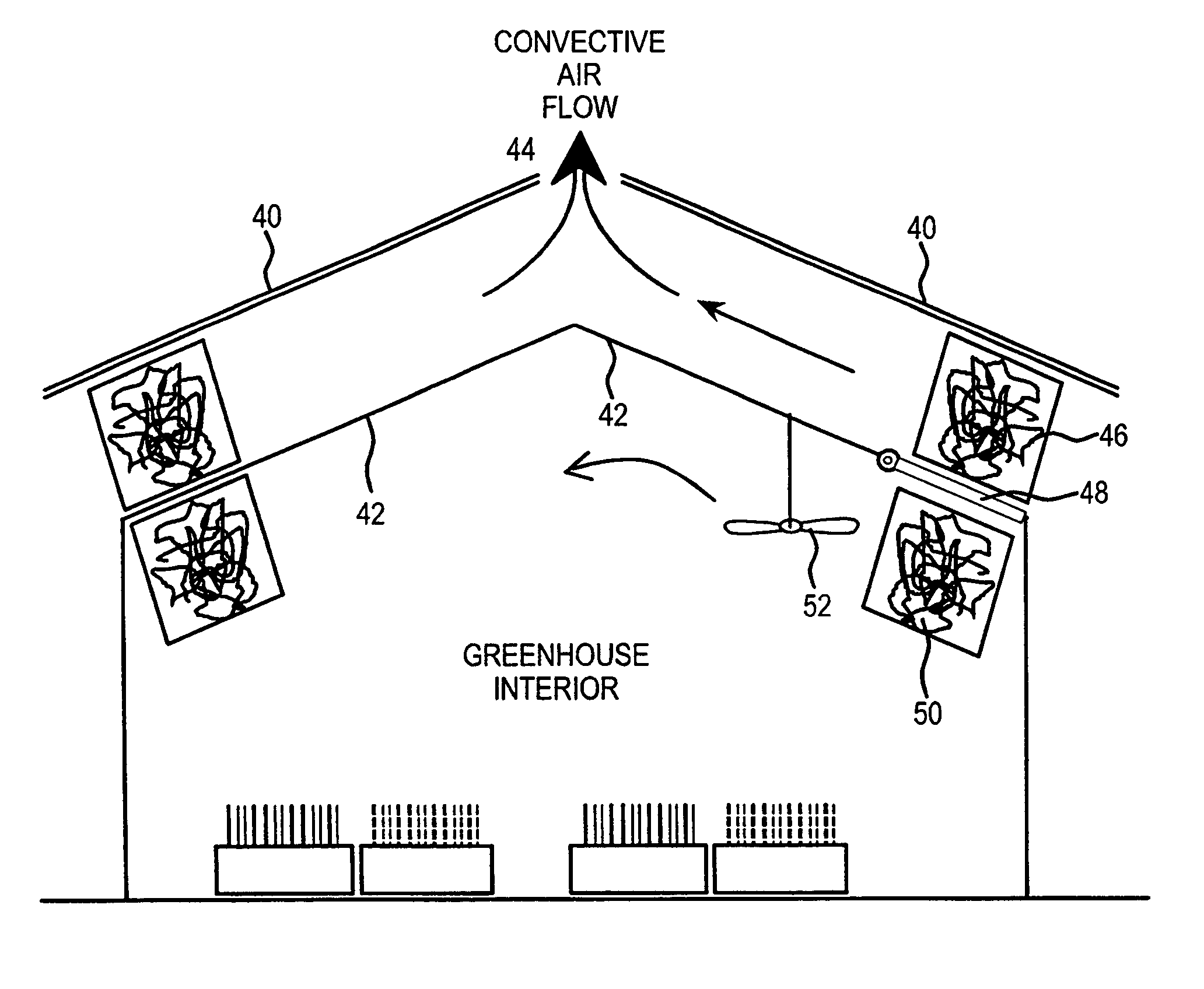

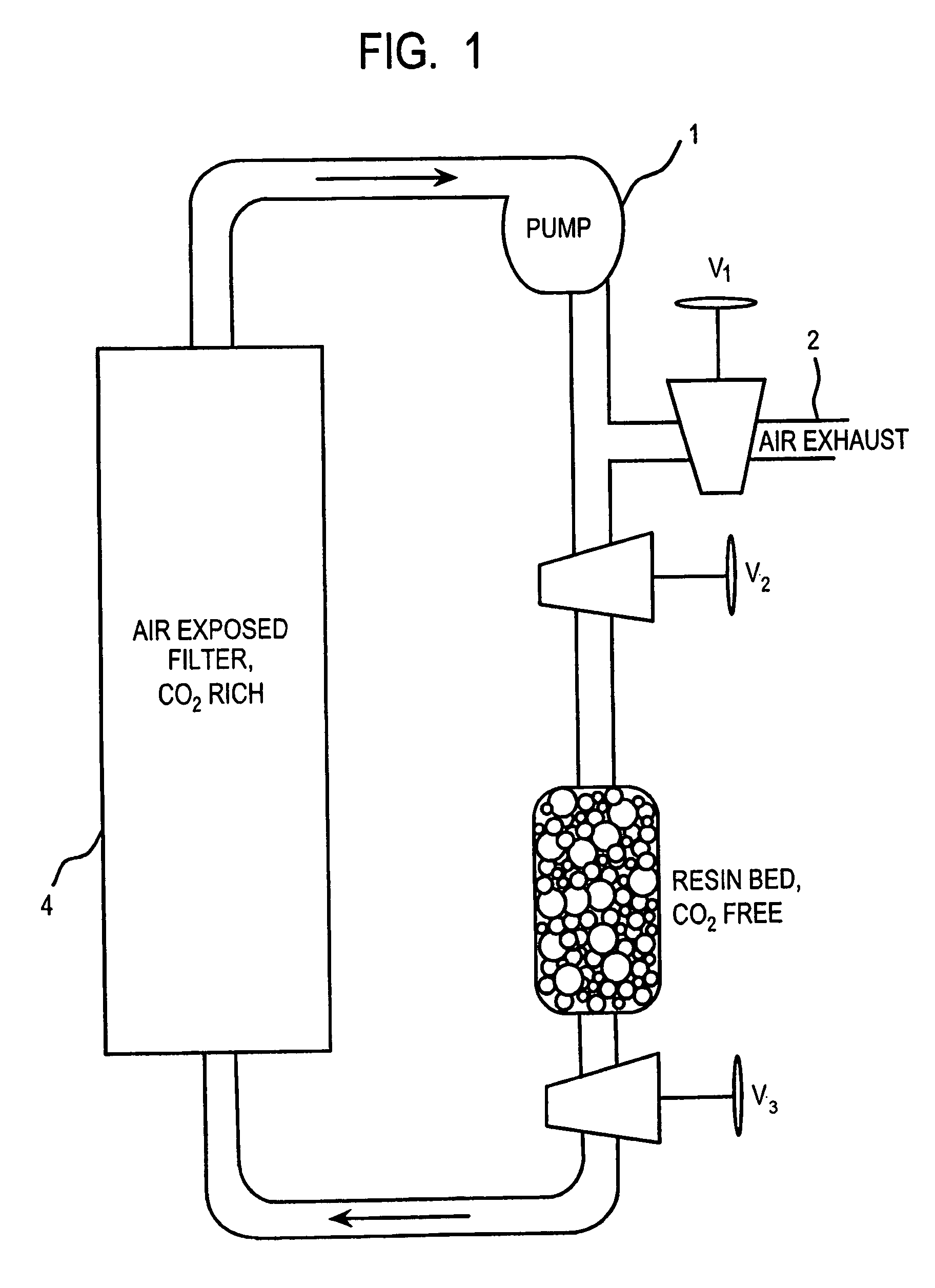

Method and apparatus for extracting carbon dioxide from air

A method and apparatus for extracting CO2 from air comprising an anion exchange material formed in a matrix exposed to a flow of the air, and for delivering that extracted CO2 to controlled environments. The present invention contemplates the extraction of CO2 from air using conventional extraction methods or by using one of the extraction methods disclosed; e.g., humidity swing or electro dialysis. The present invention also provides delivery of the CO2 to greenhouses where increased levels of CO2 will improve conditions for growth. Alternatively, the CO2 is fed to an algae culture.

Owner:CARBON SINK

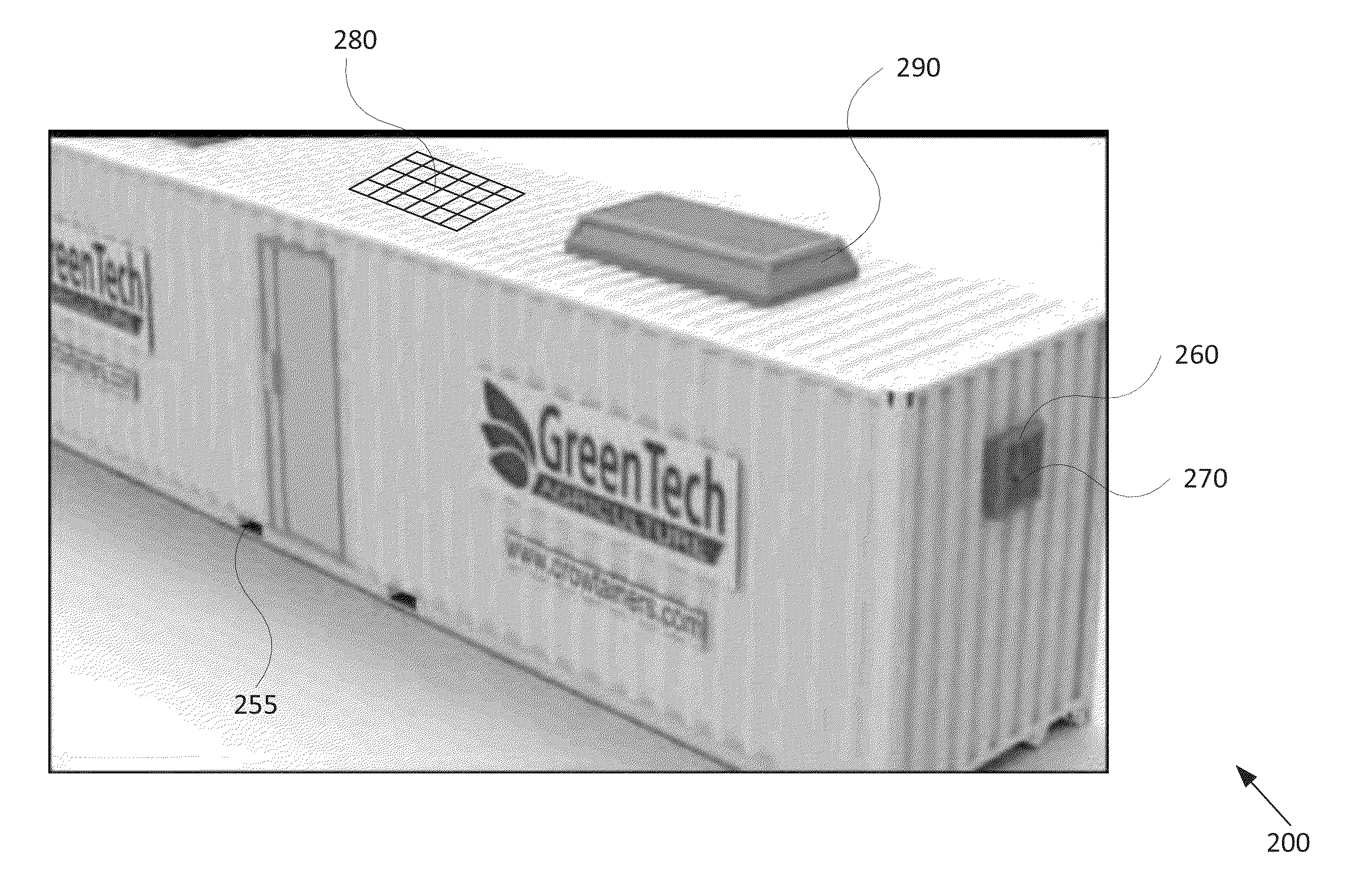

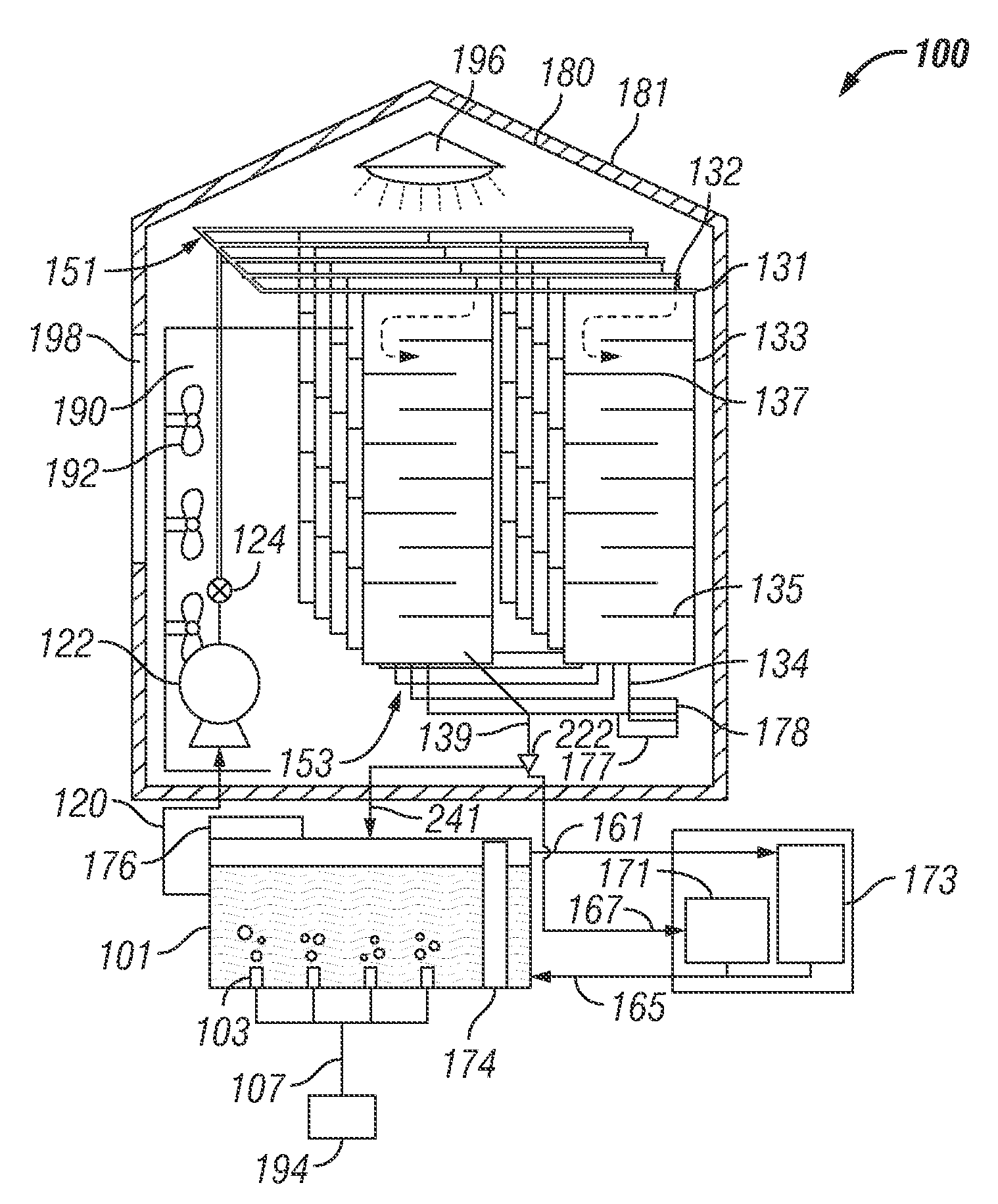

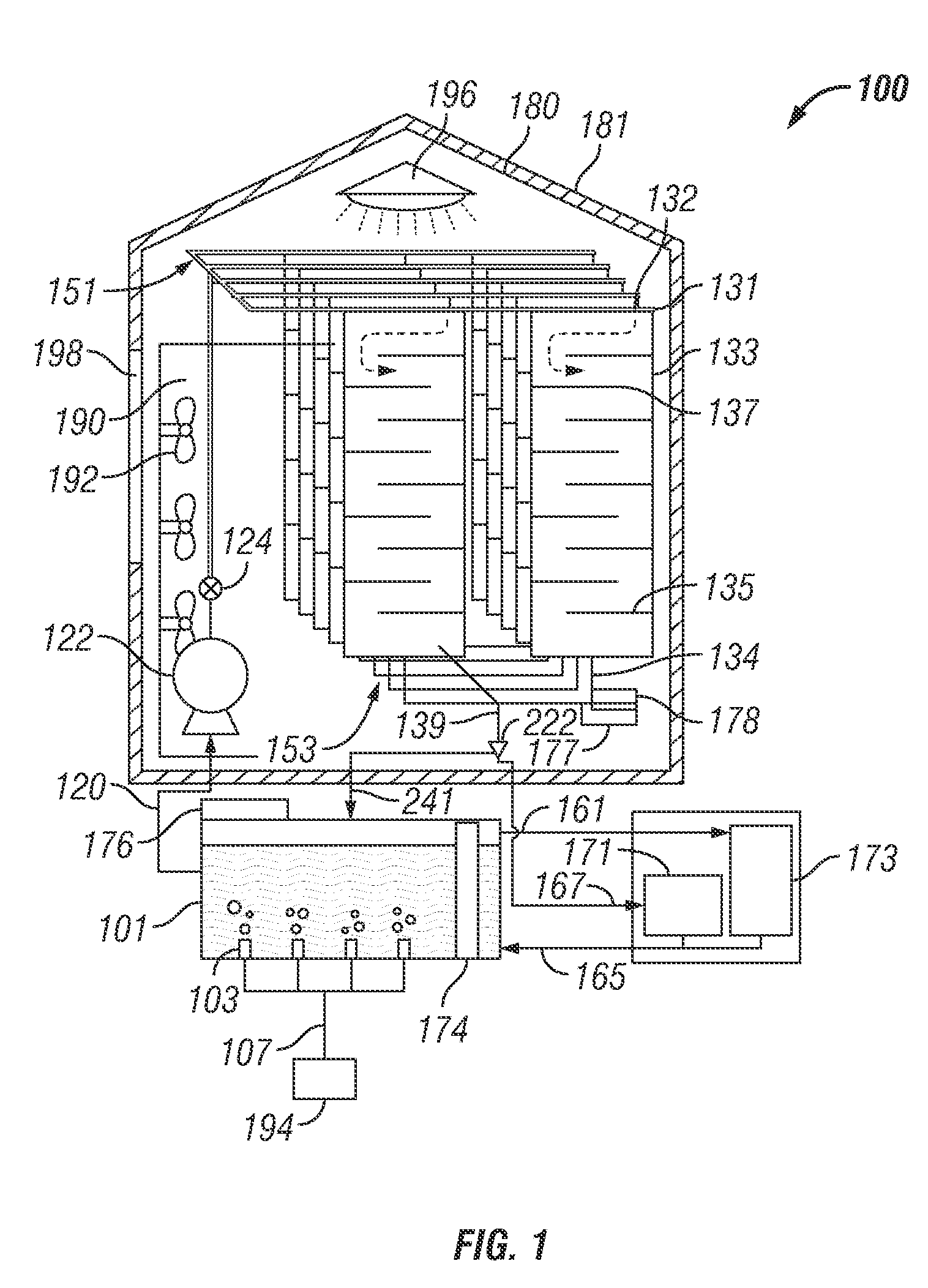

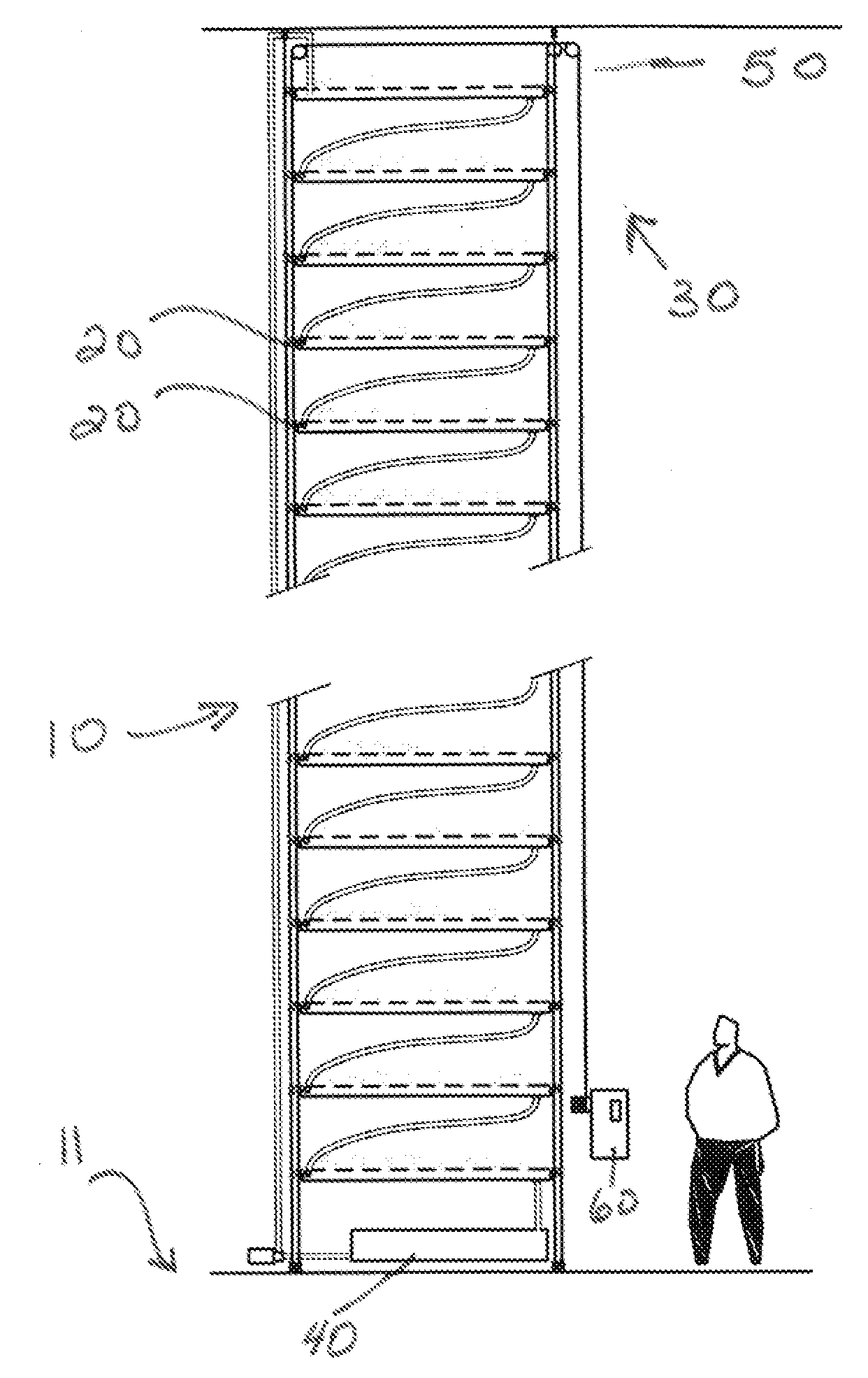

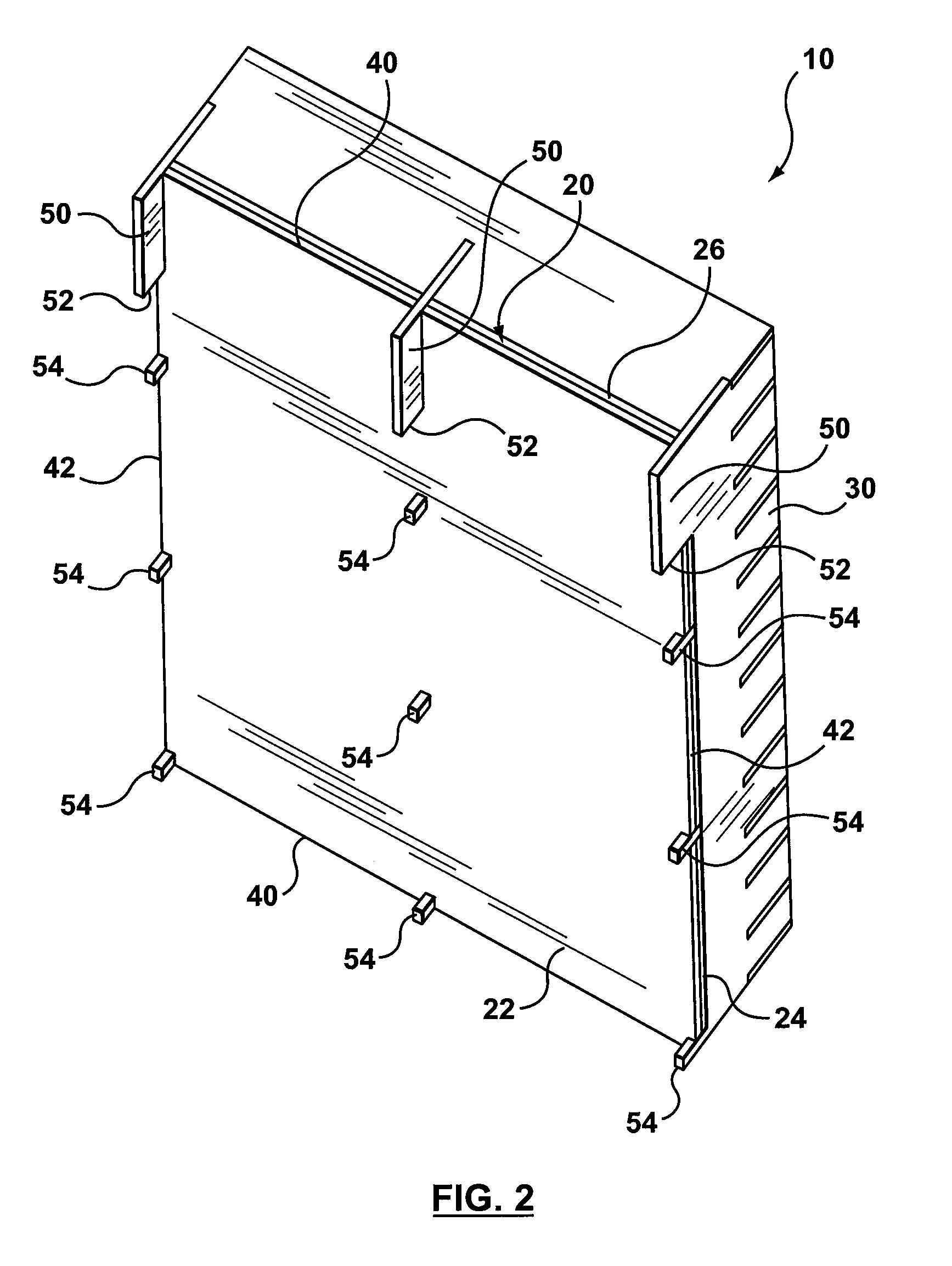

Self-sustaining artificially controllable environment within a storage container or other enclosed space

InactiveUS20140115958A1Readily apparentSeed and root treatmentClimate change adaptationEngineeringActuator

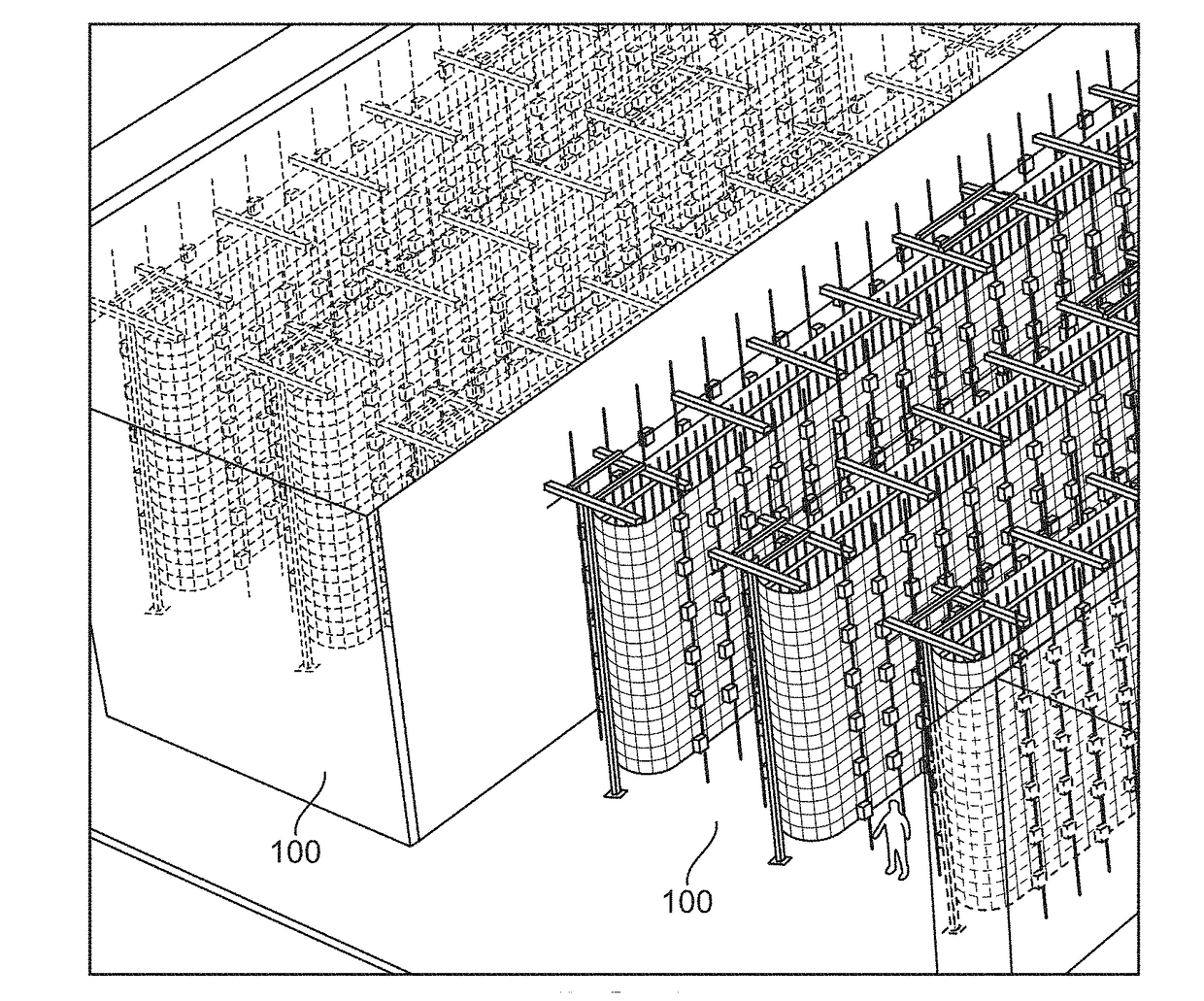

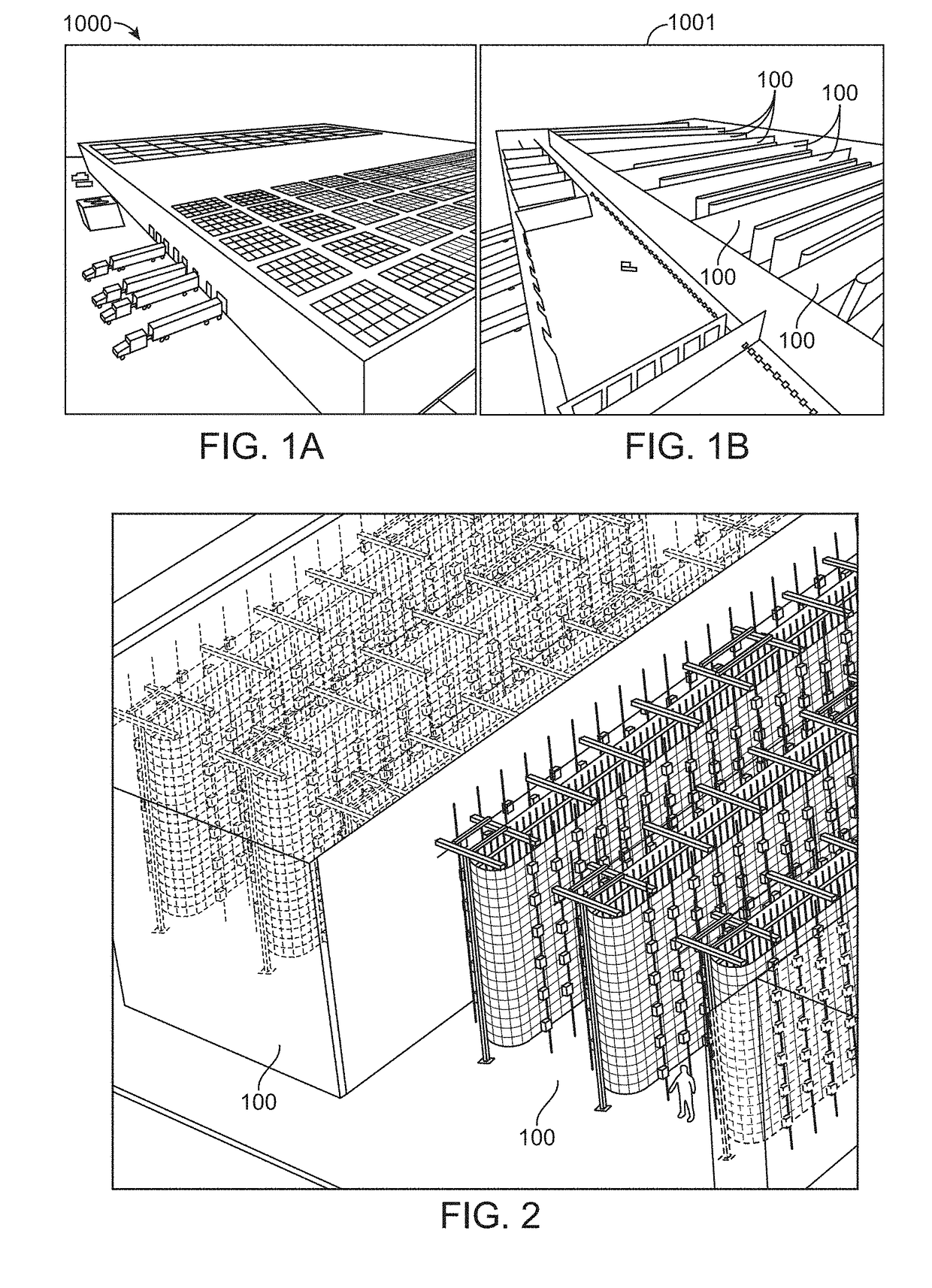

A system includes an enclosed space defining a controllable environment chamber. The system also includes at least one monitoring device configured to measure multiple characteristics of an environment within the chamber. The system further includes multiple actuators configured to alter the characteristics of the environment within the chamber. The enclosed space includes at least one rack system configured to be placed within the enclosed space. Each rack system includes multiple layers configured to receive multiple plants to be grown in the chamber. The actuators are configured to adjust the characteristics of the environment within the chamber to condition the environment based on the plants to be grown in the chamber.

Owner:GREENTECH AGRO

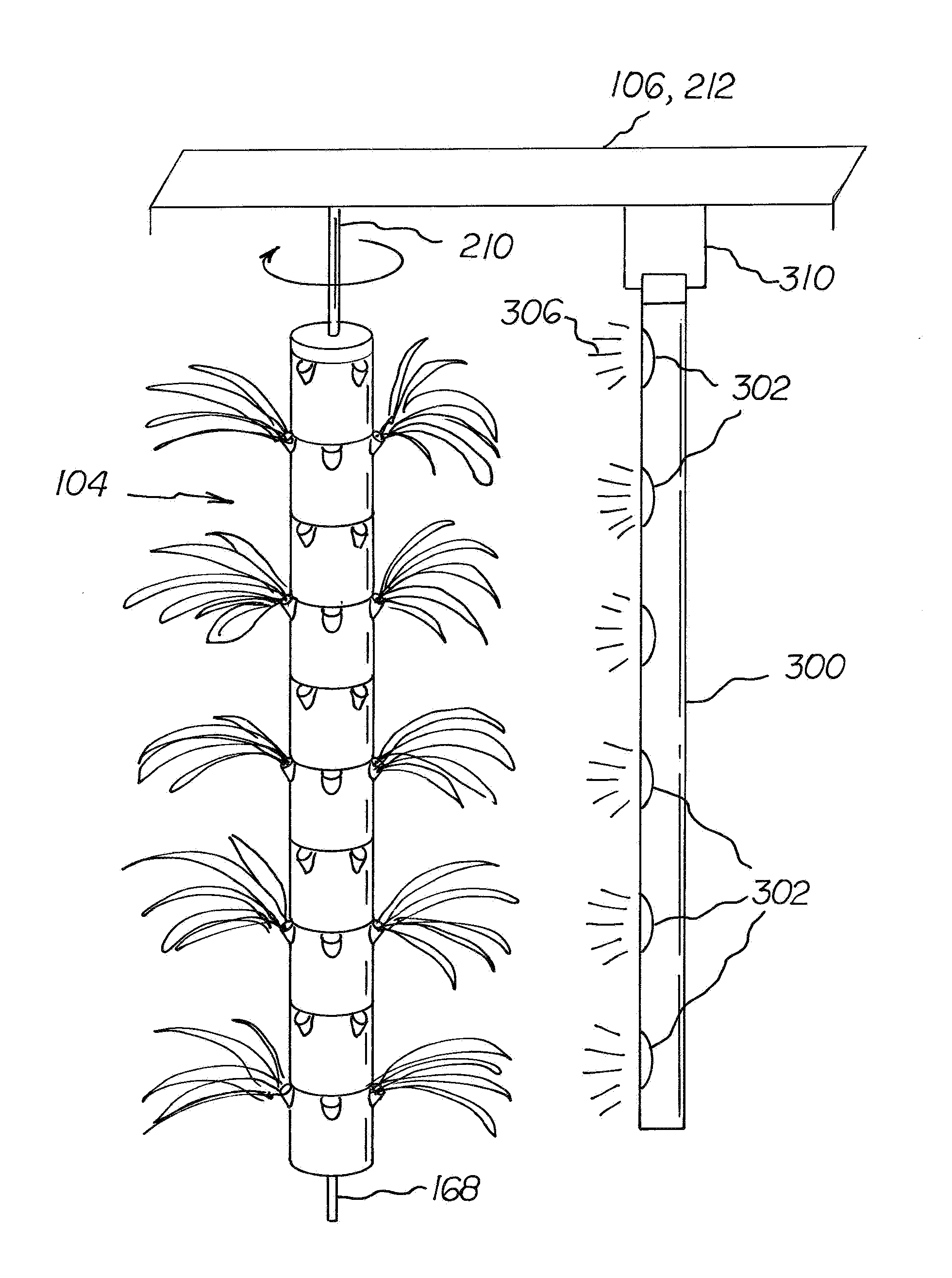

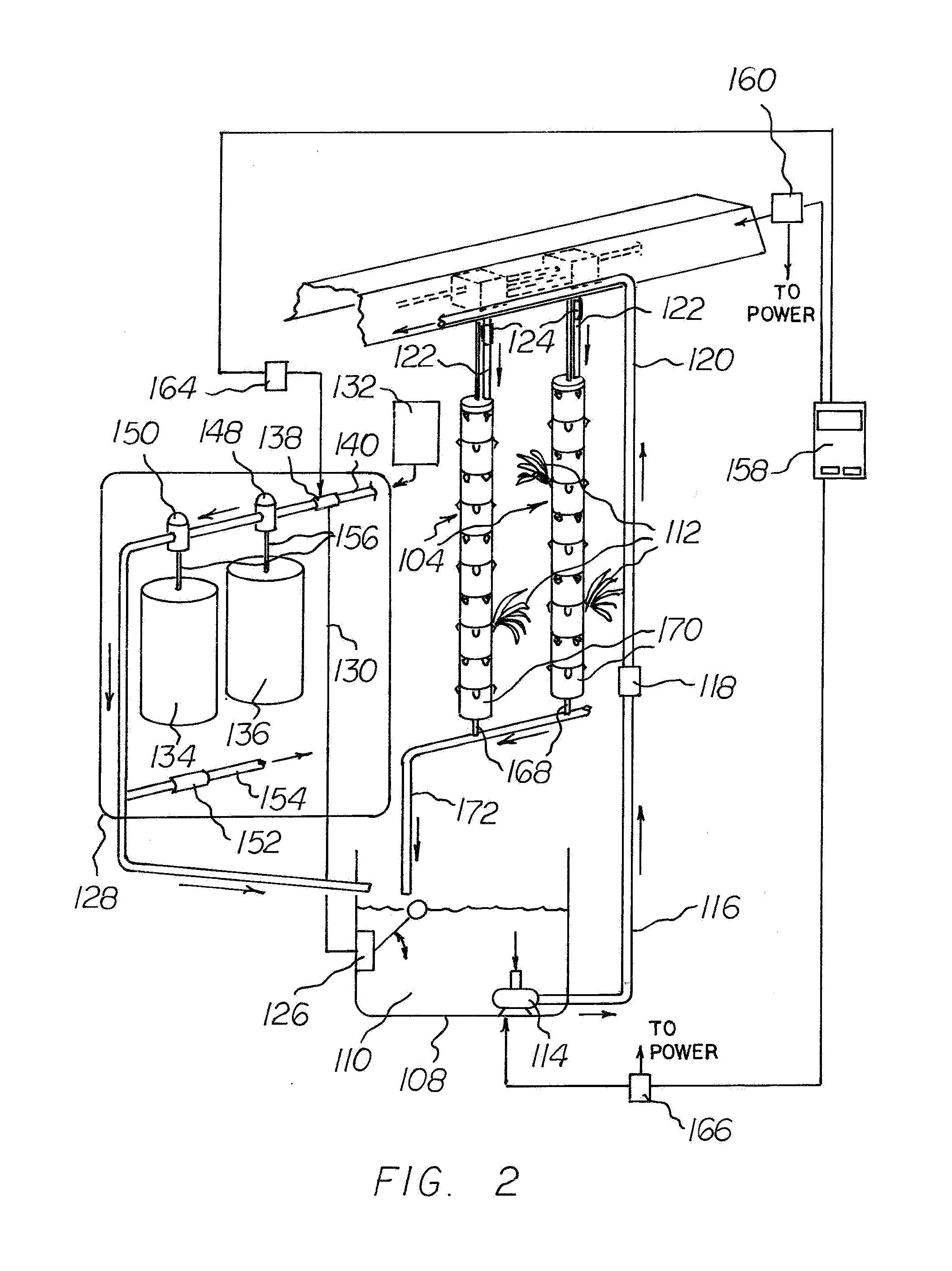

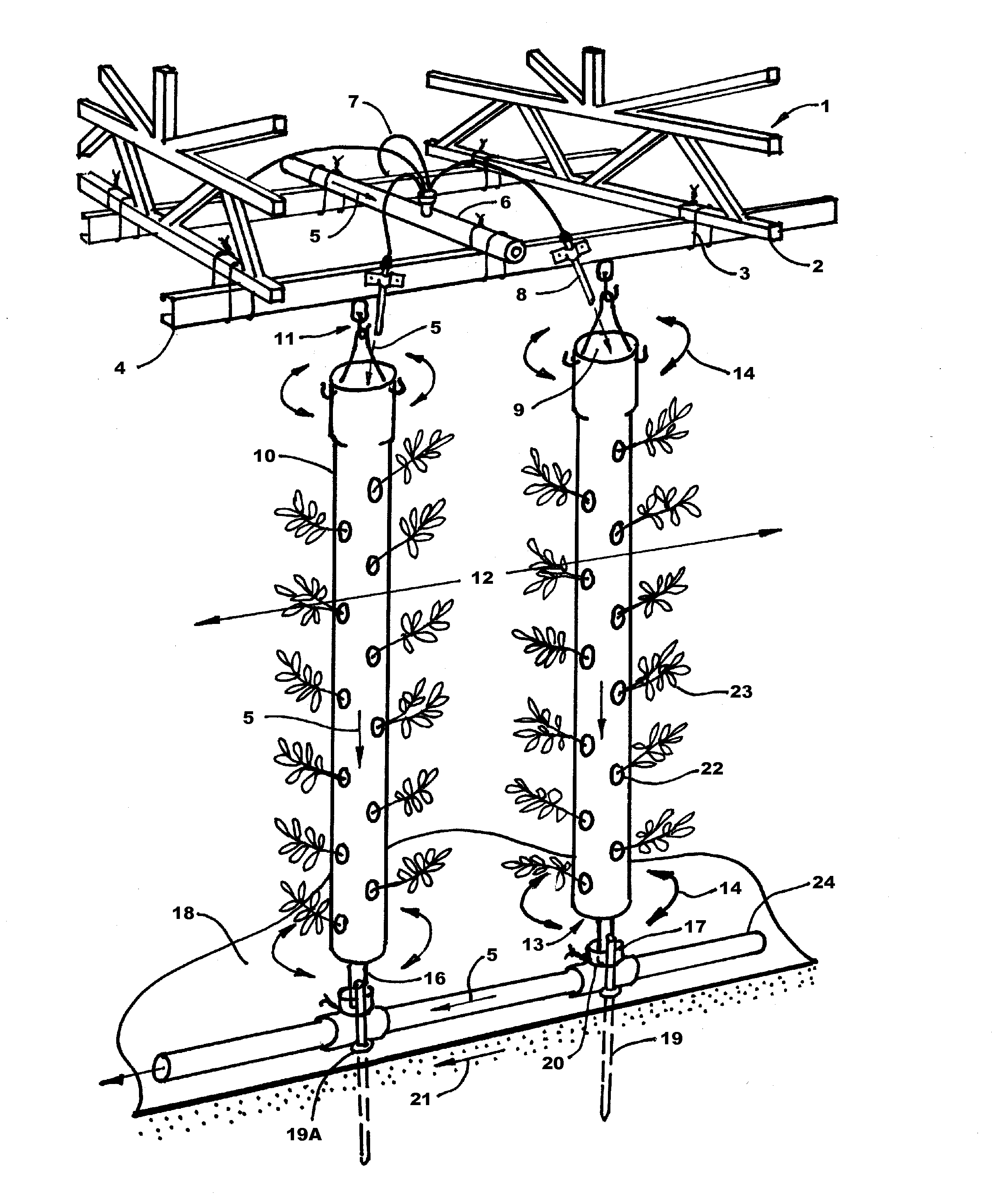

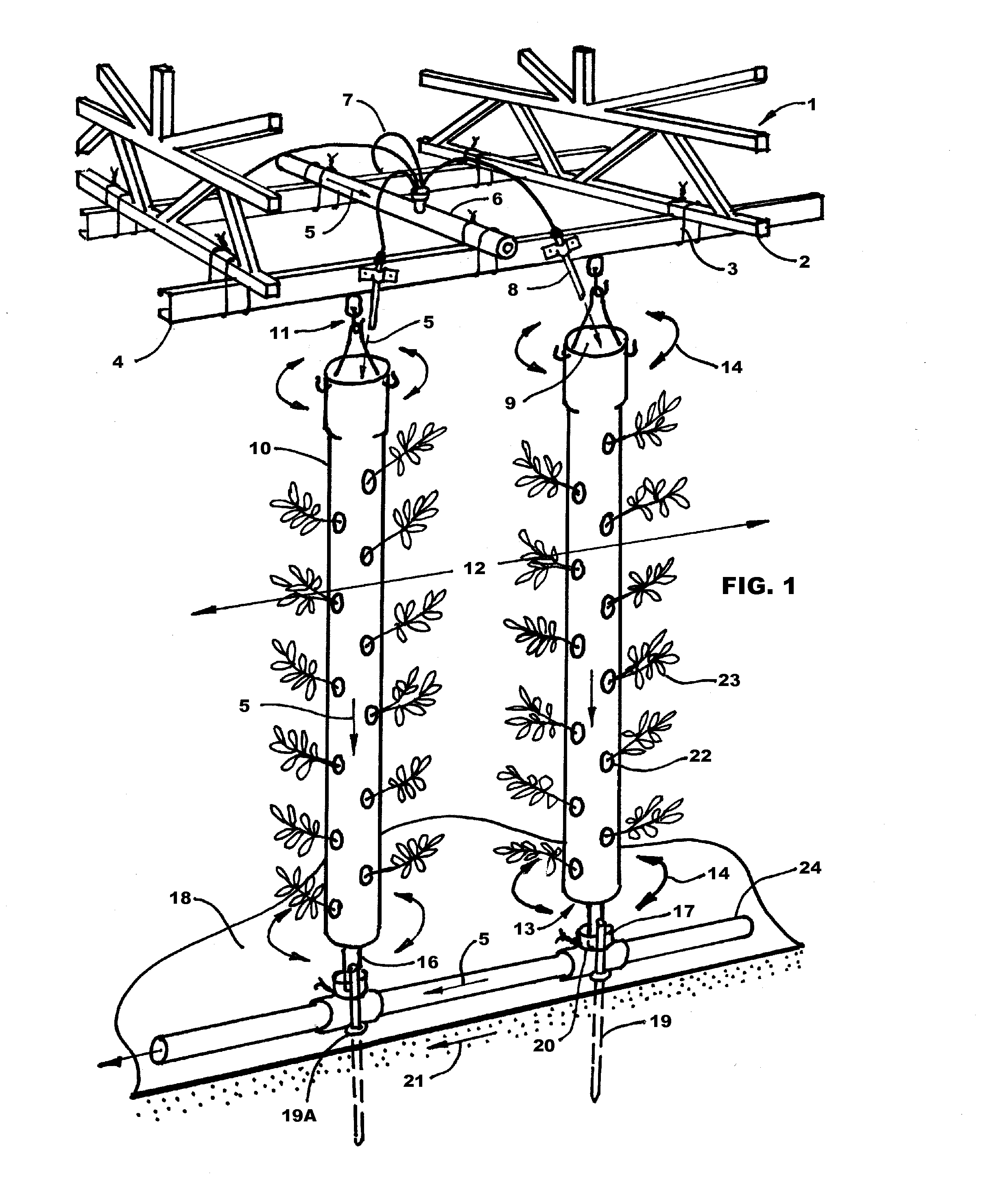

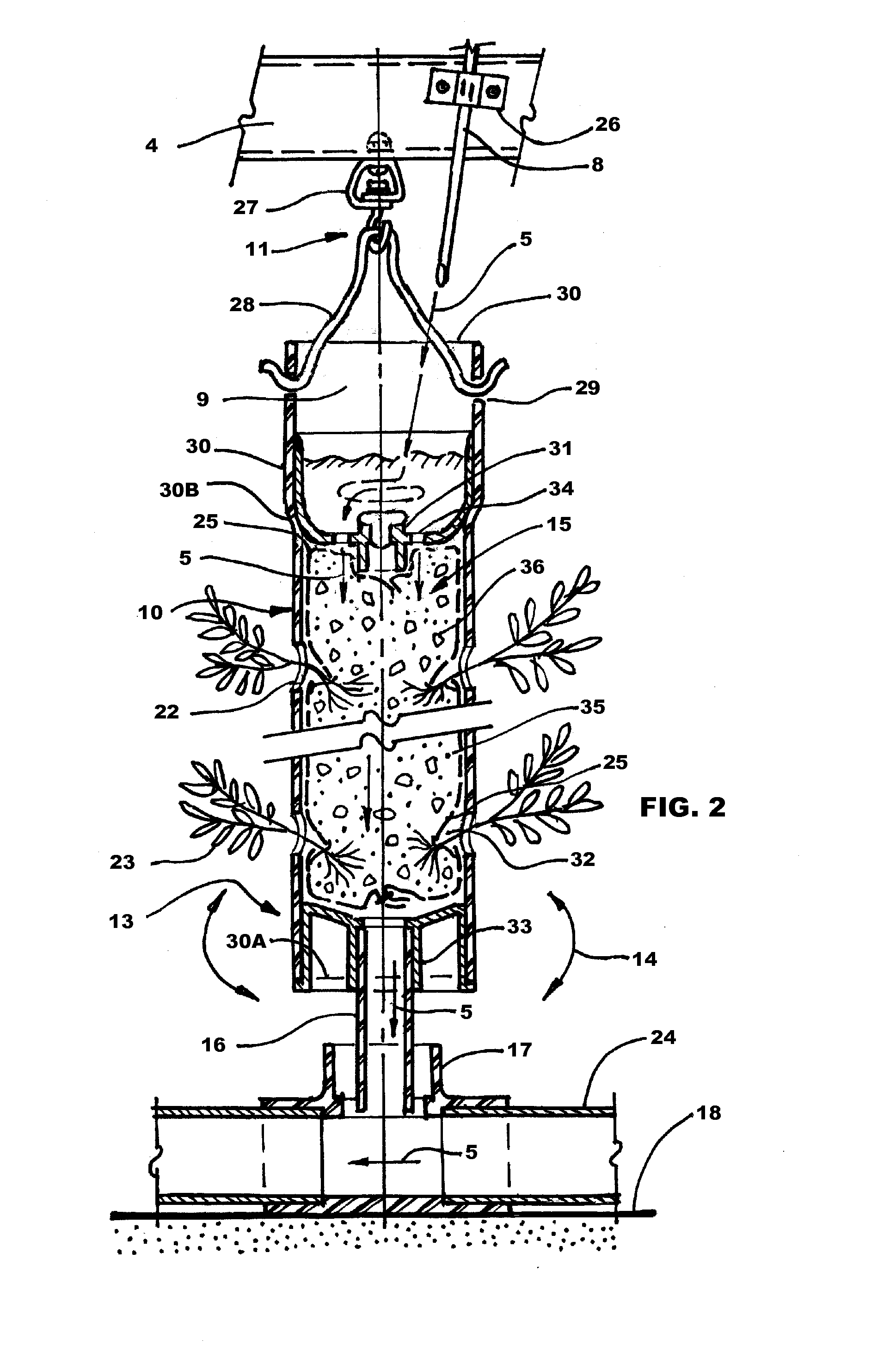

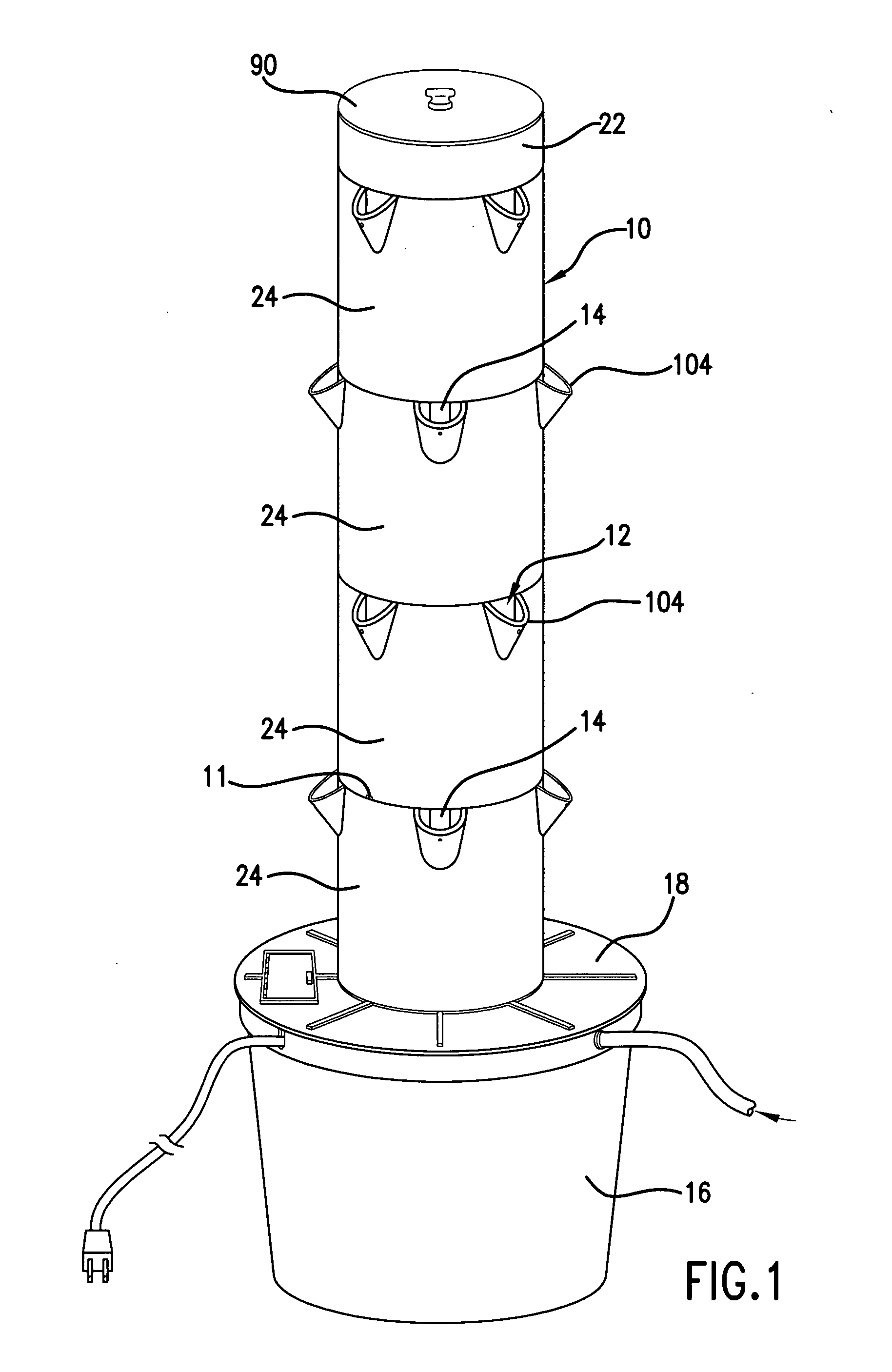

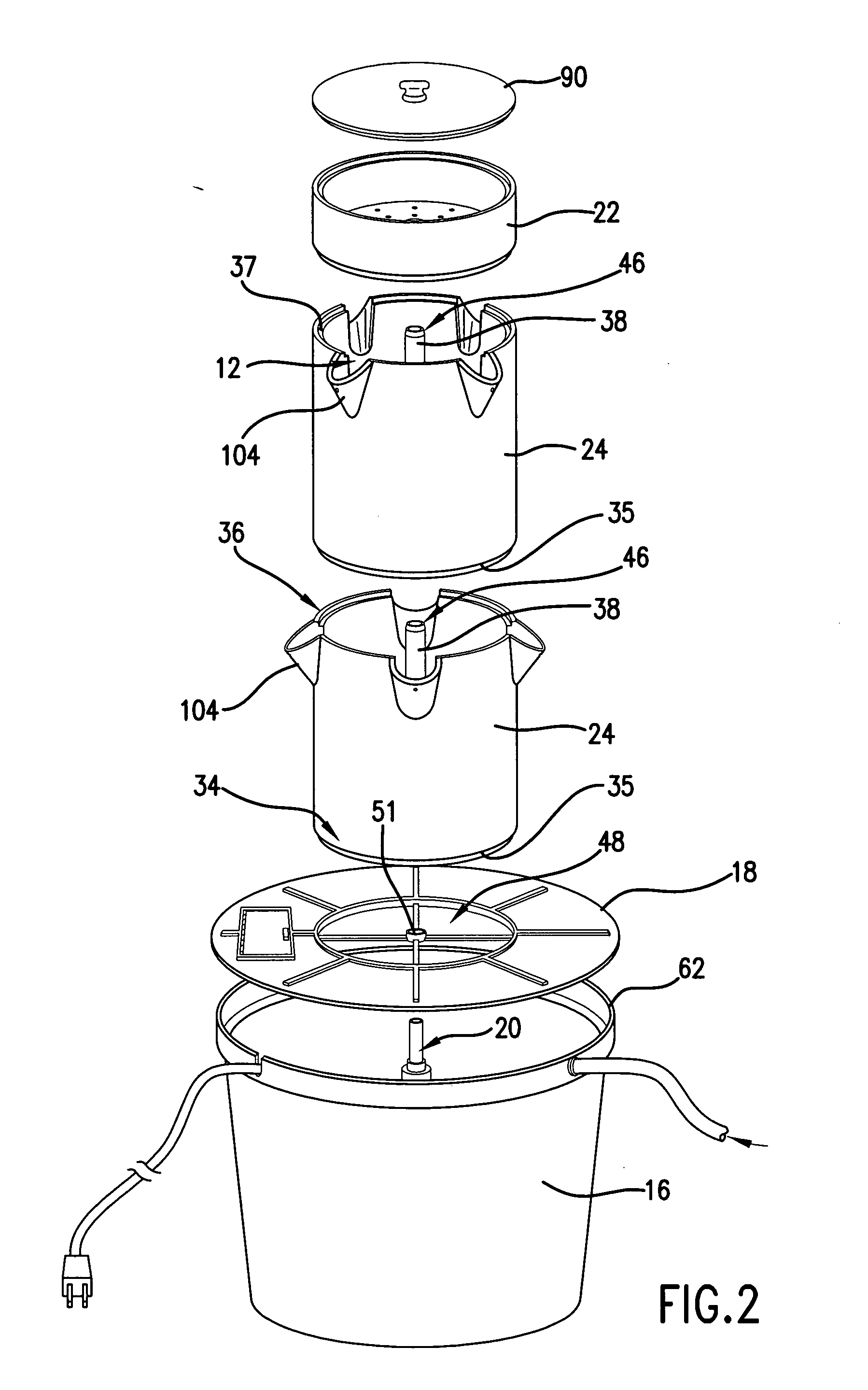

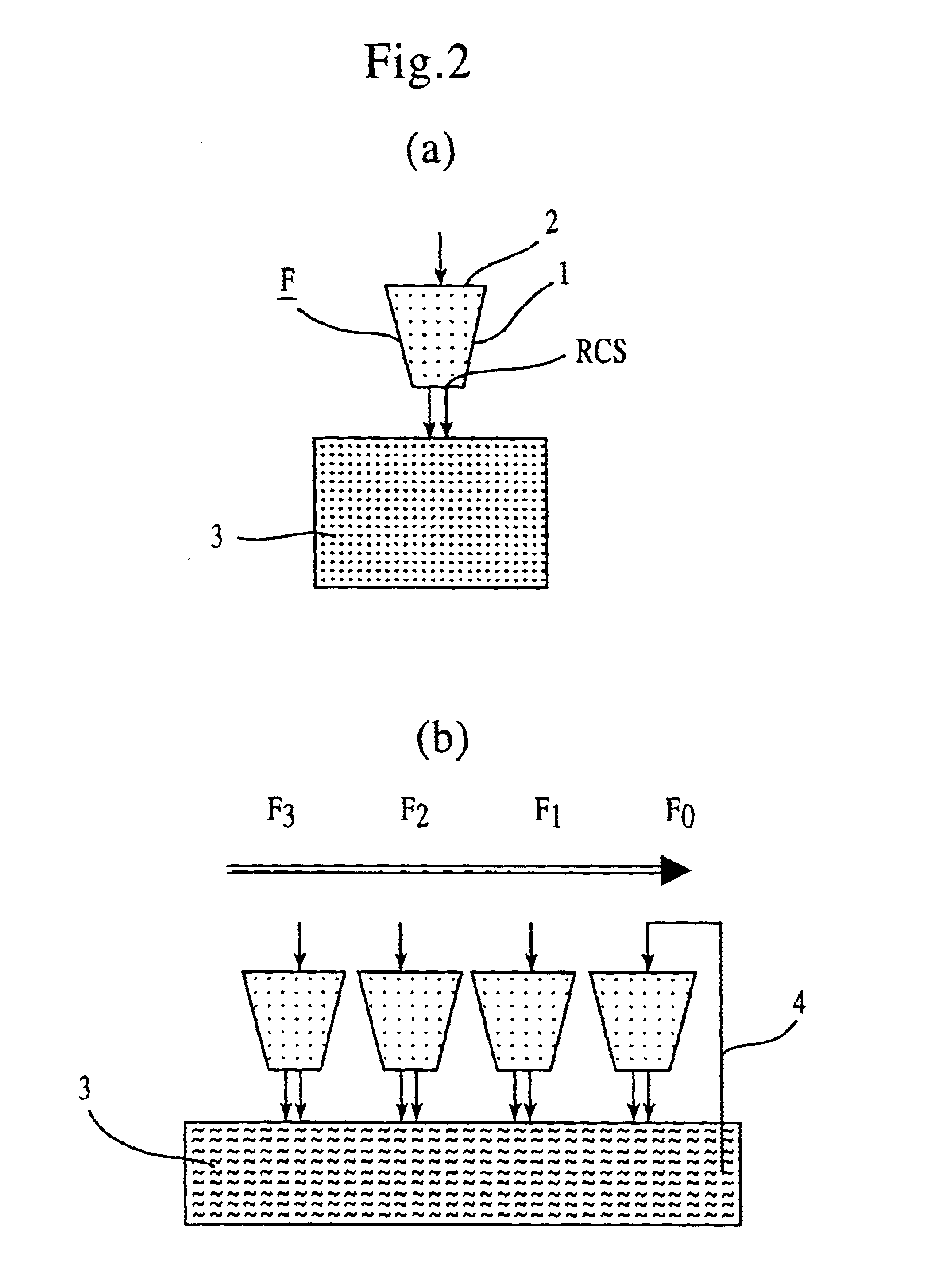

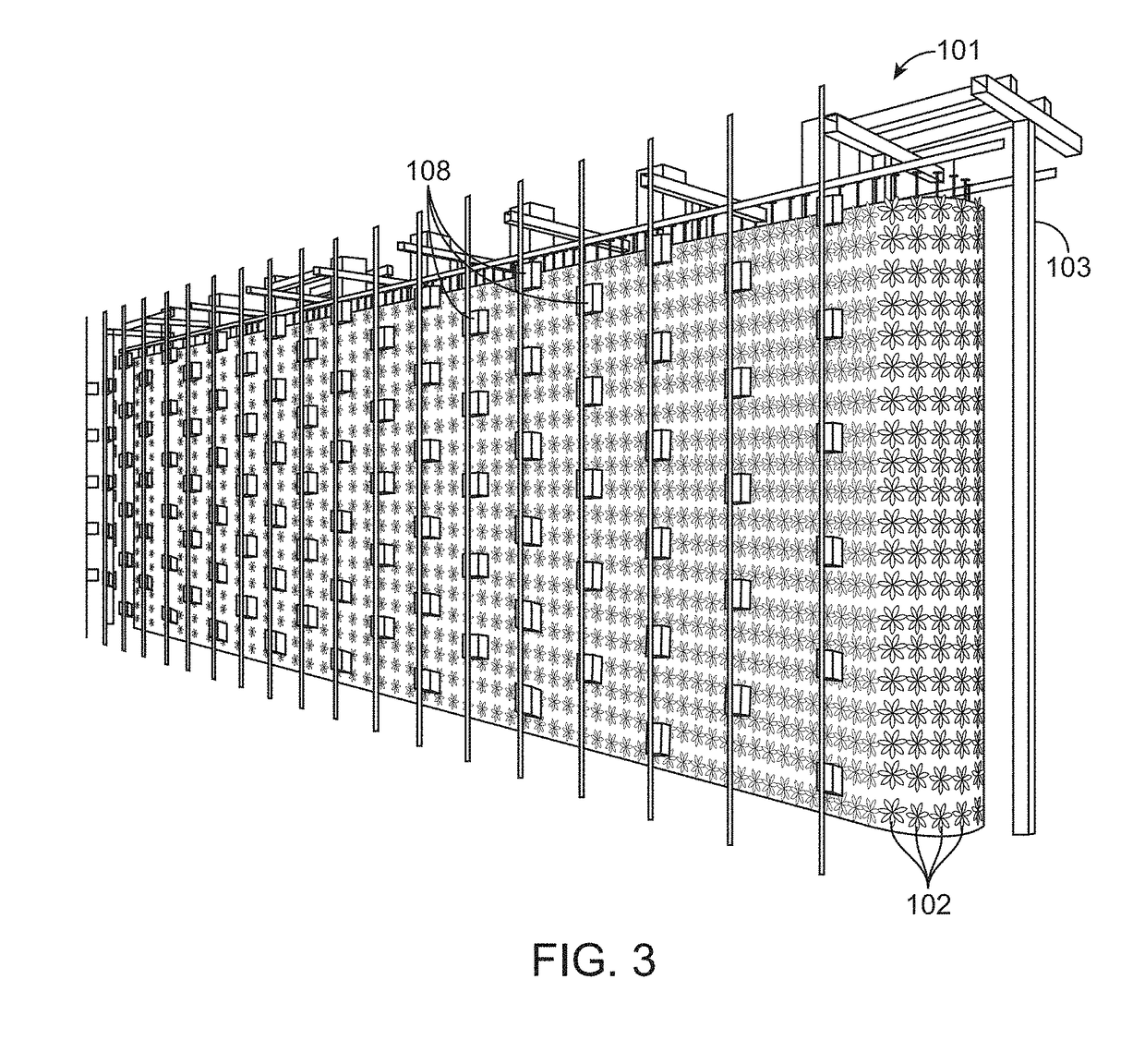

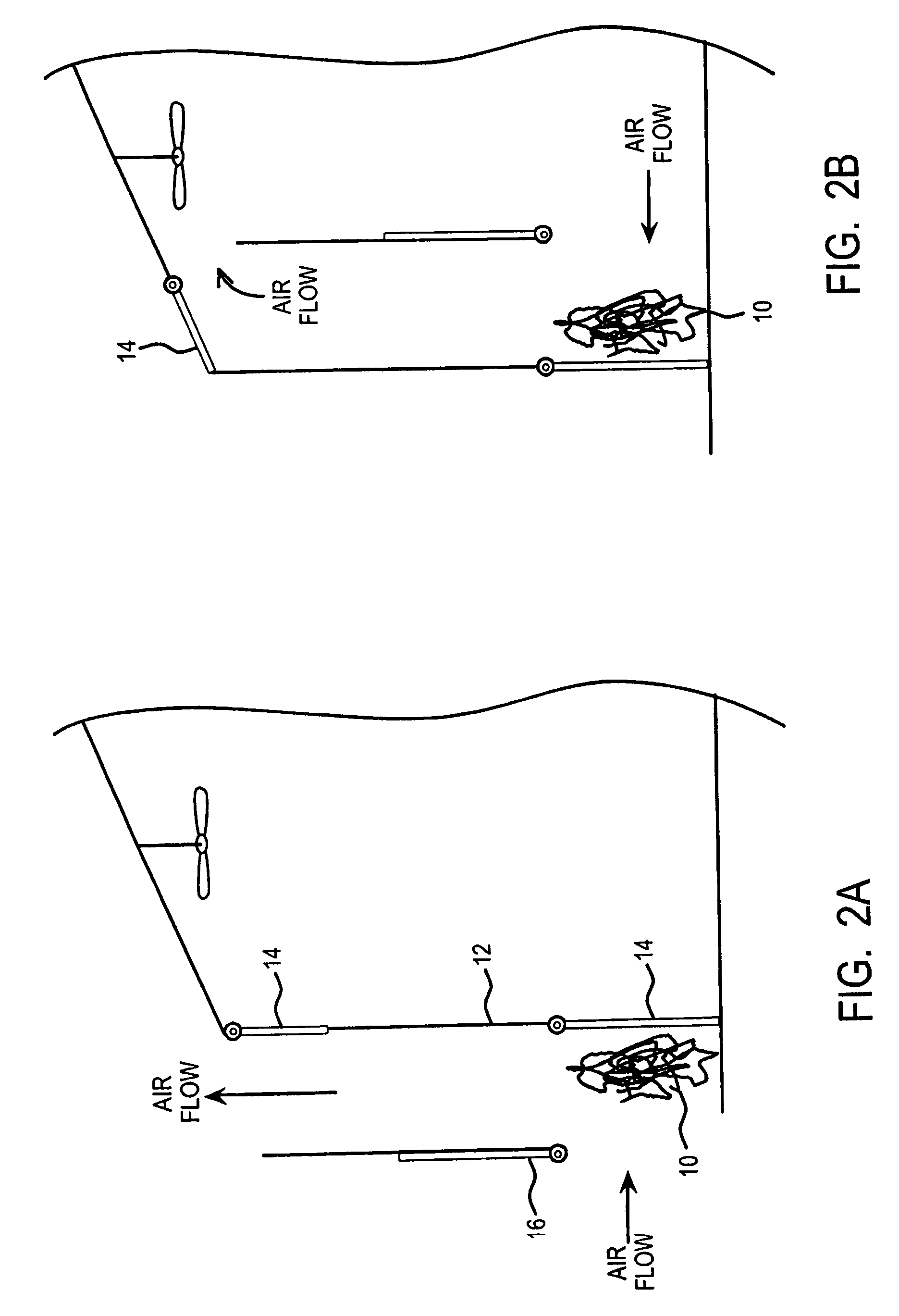

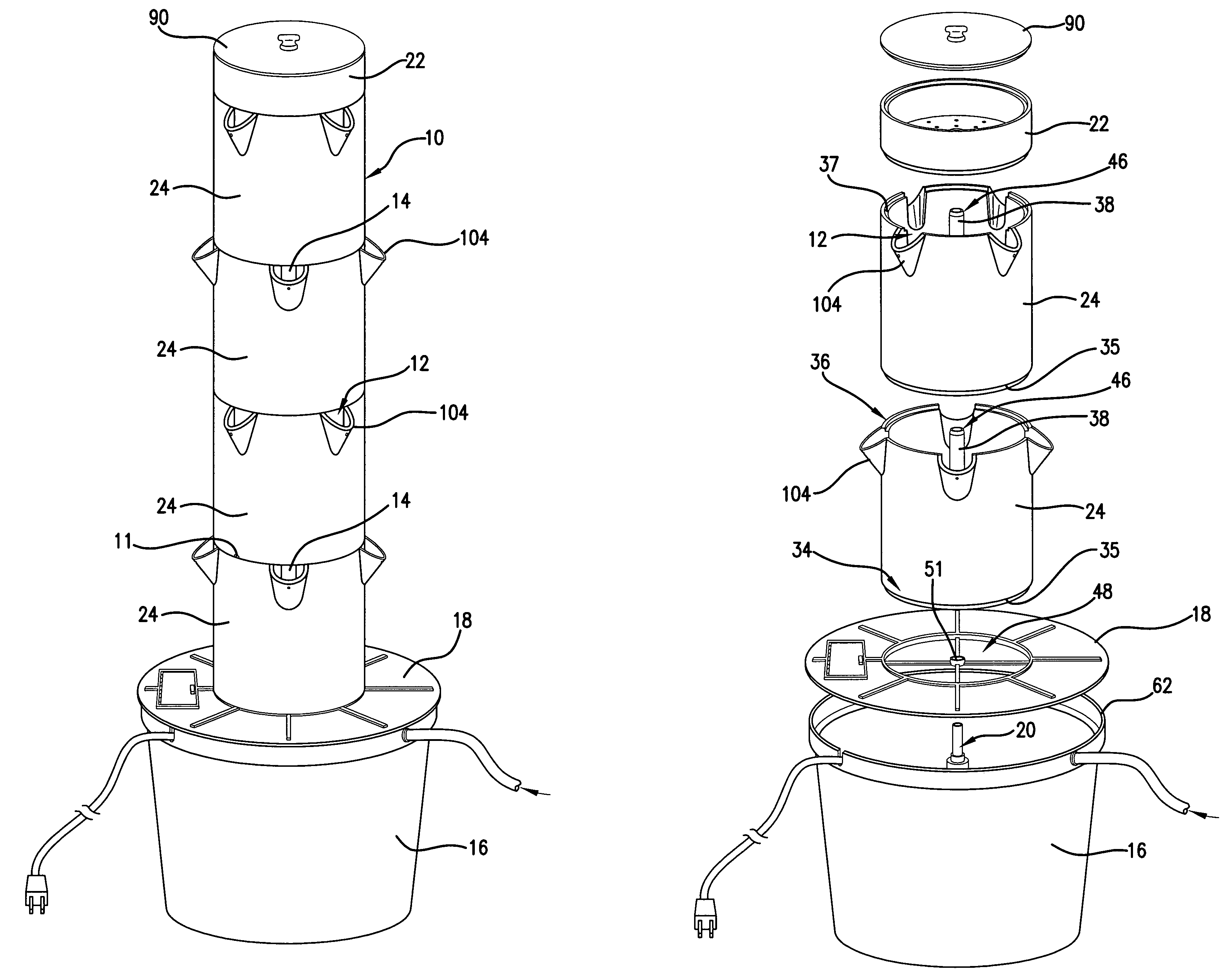

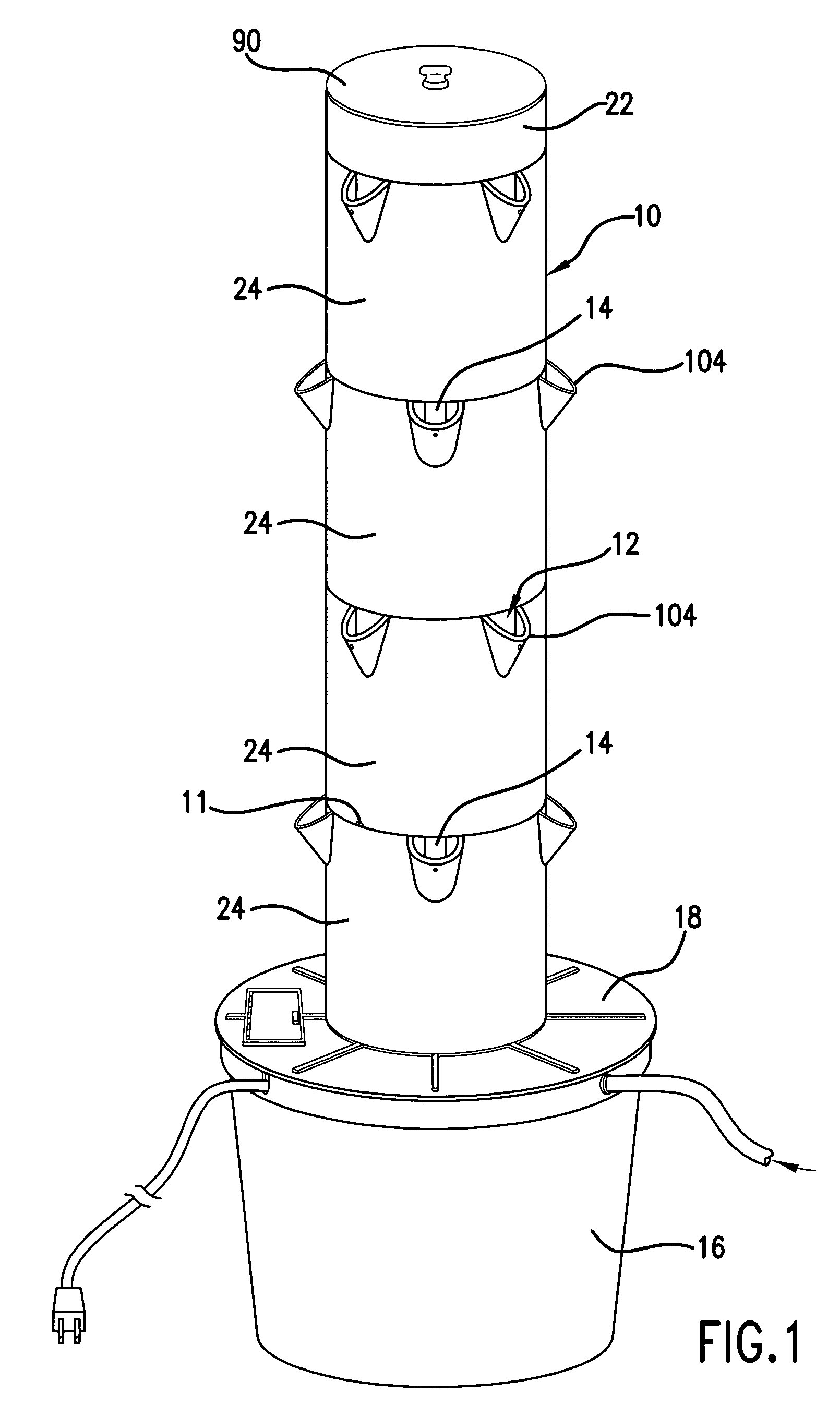

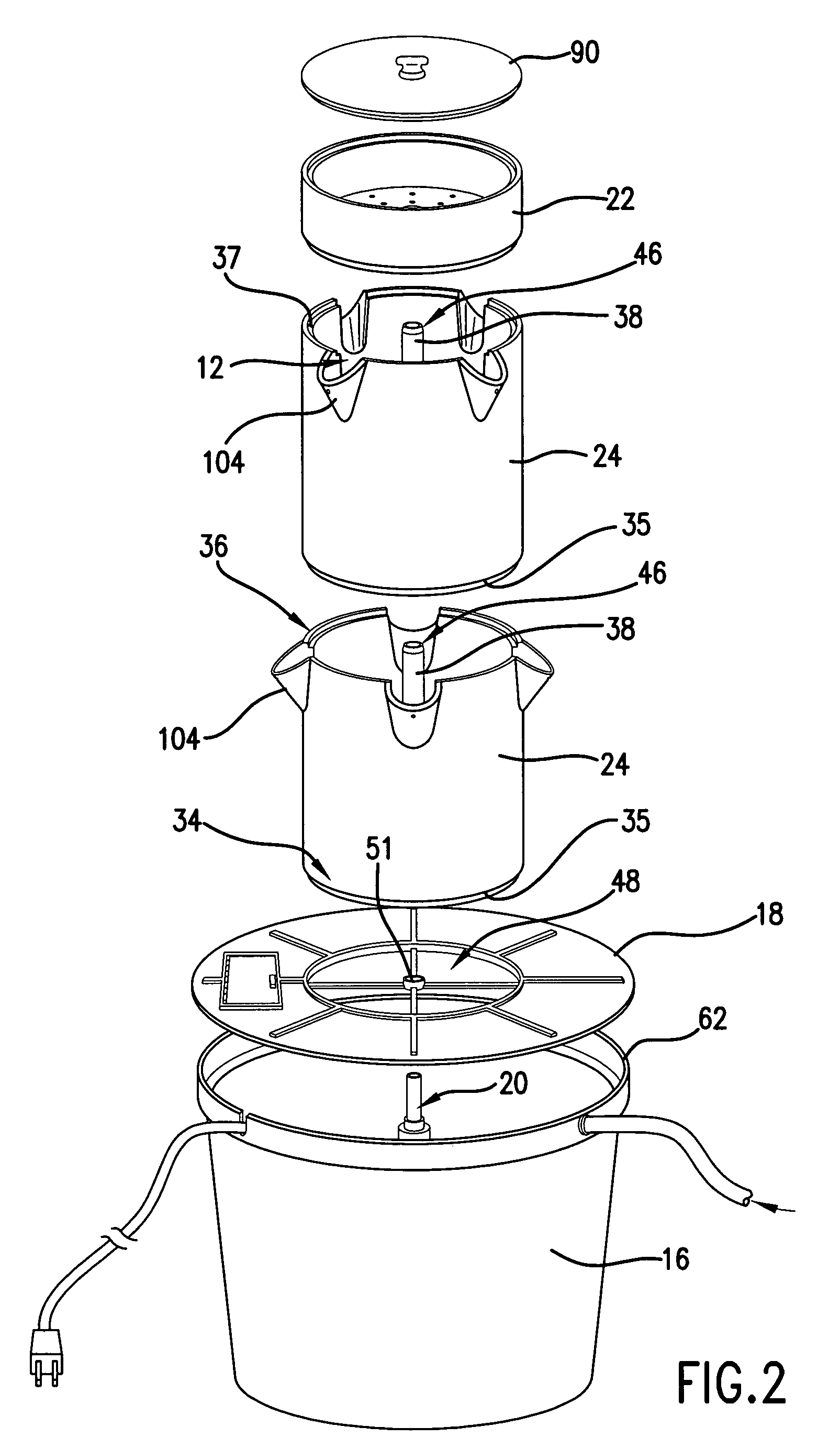

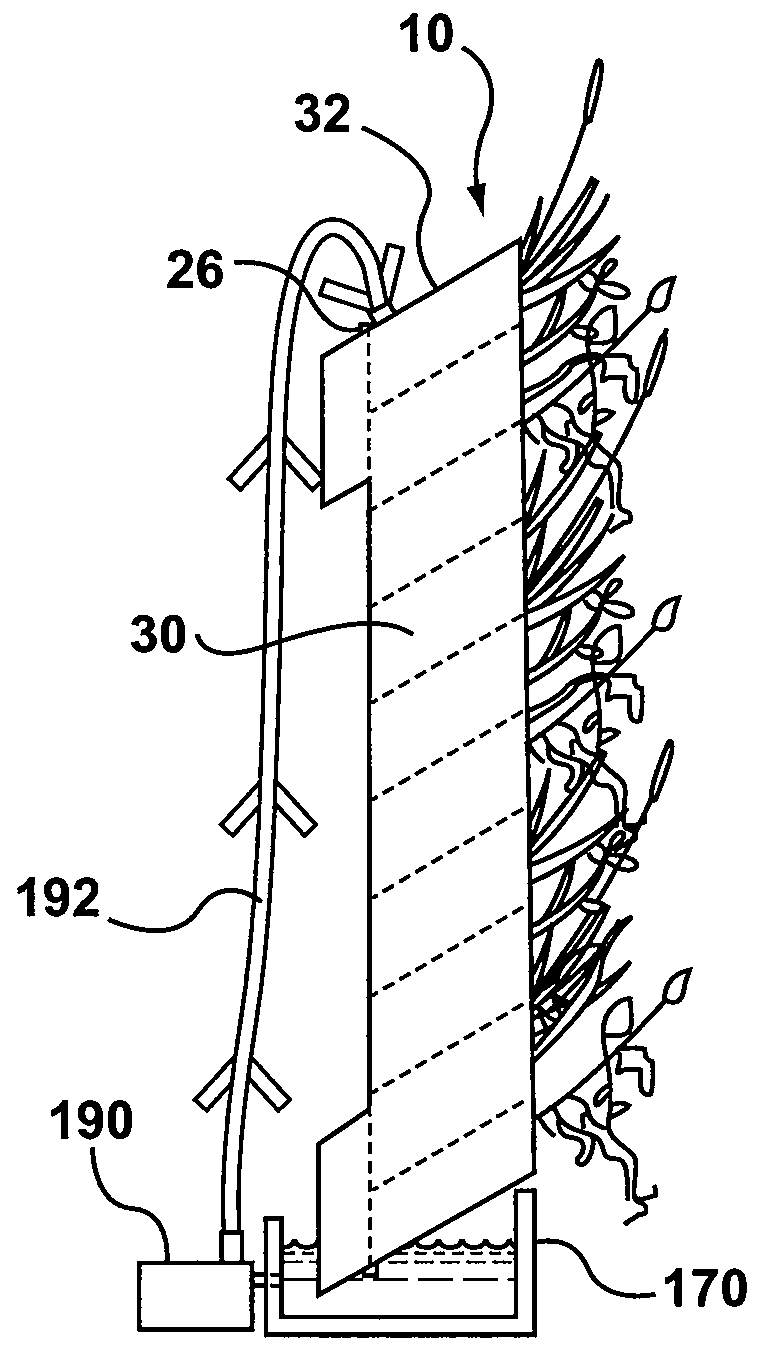

Aeroponic growing system and method

An aeroponic growing system and method is disclosed. In a particular embodiment, the system includes at least one vertical column of interconnected growing pots and an overhead support to suspend the vertical column of interconnected growing pots. The system also includes a supply conduit that is in fluid communication with a top of the vertical column of interconnected growing pots and a return conduit in fluid communication with a bottom of the vertical column of interconnected growing pots. In addition, the system includes a reservoir in fluid communication with the supply conduit and the return conduit. A turning mechanism may also be used for rotating the column to achieve uniformity of illumination.

Owner:TOWER GARDEN

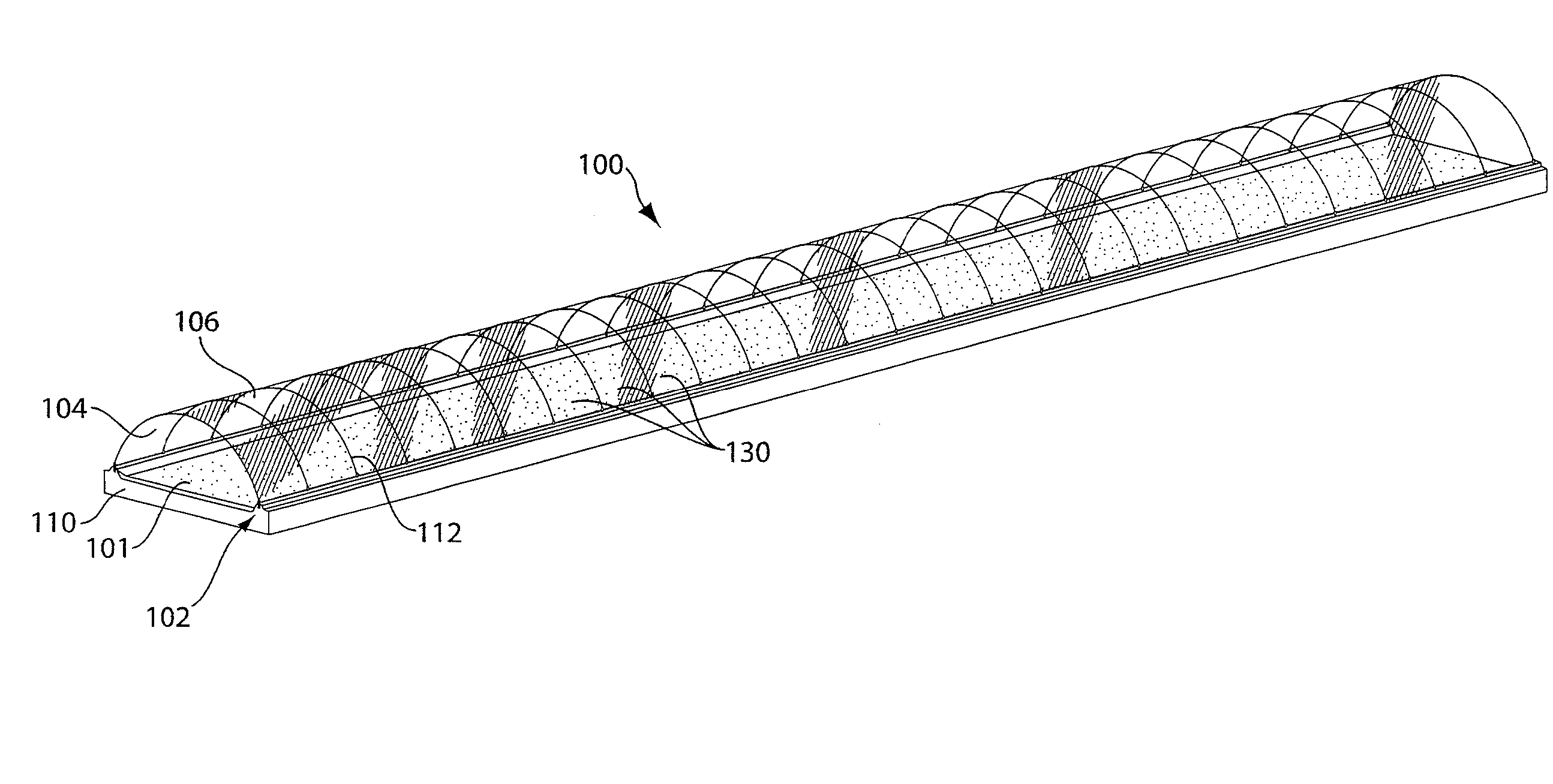

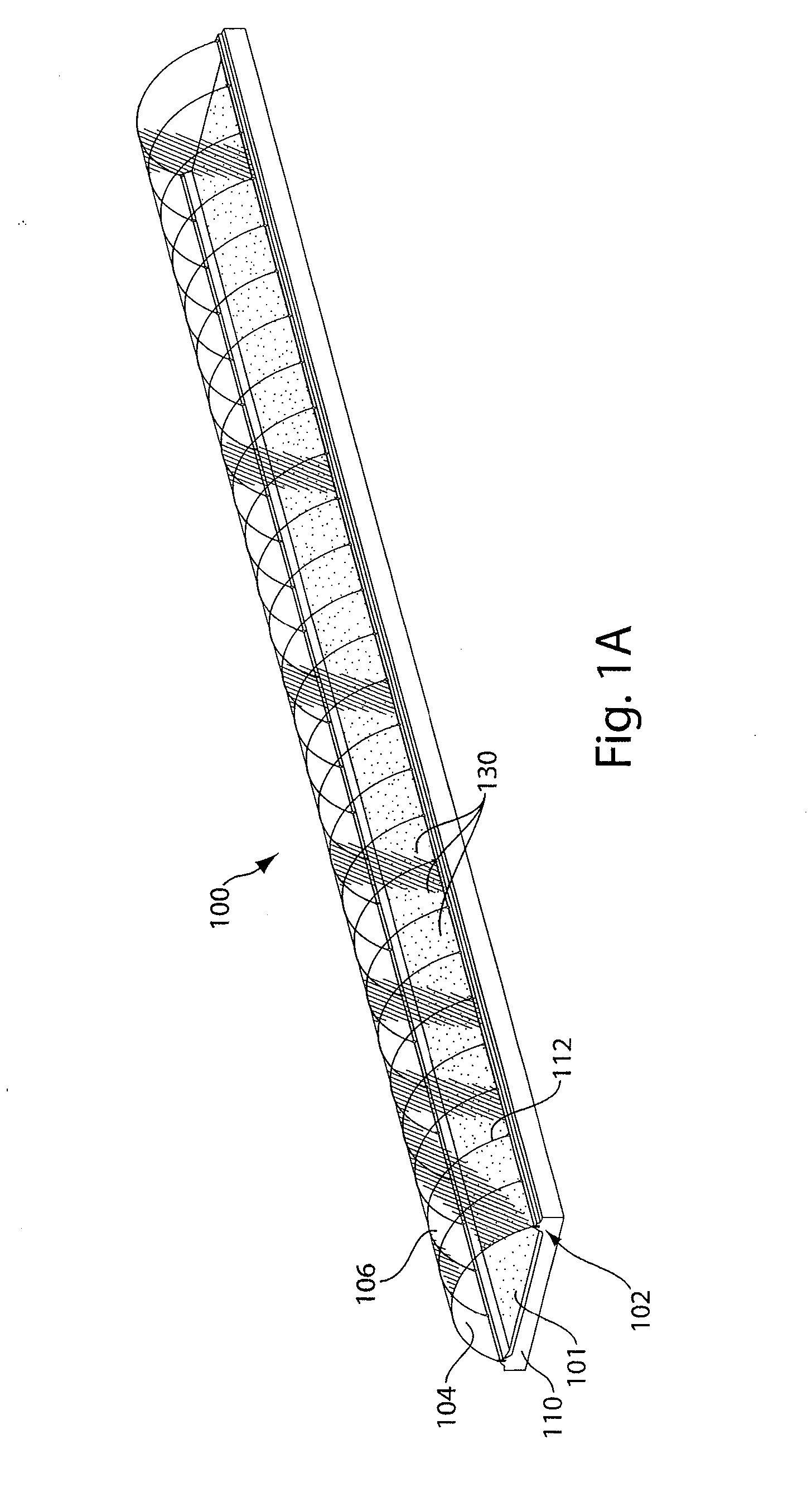

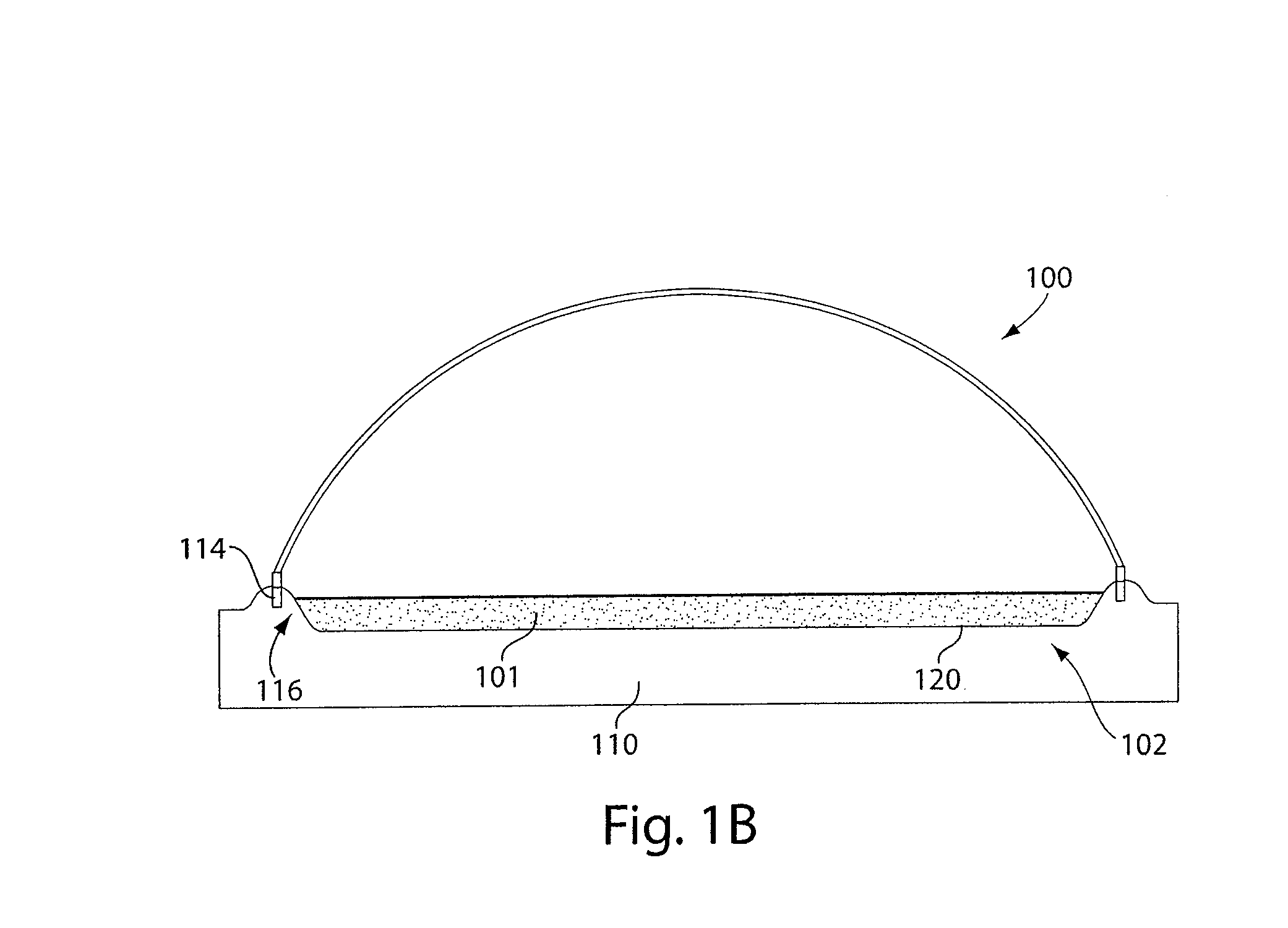

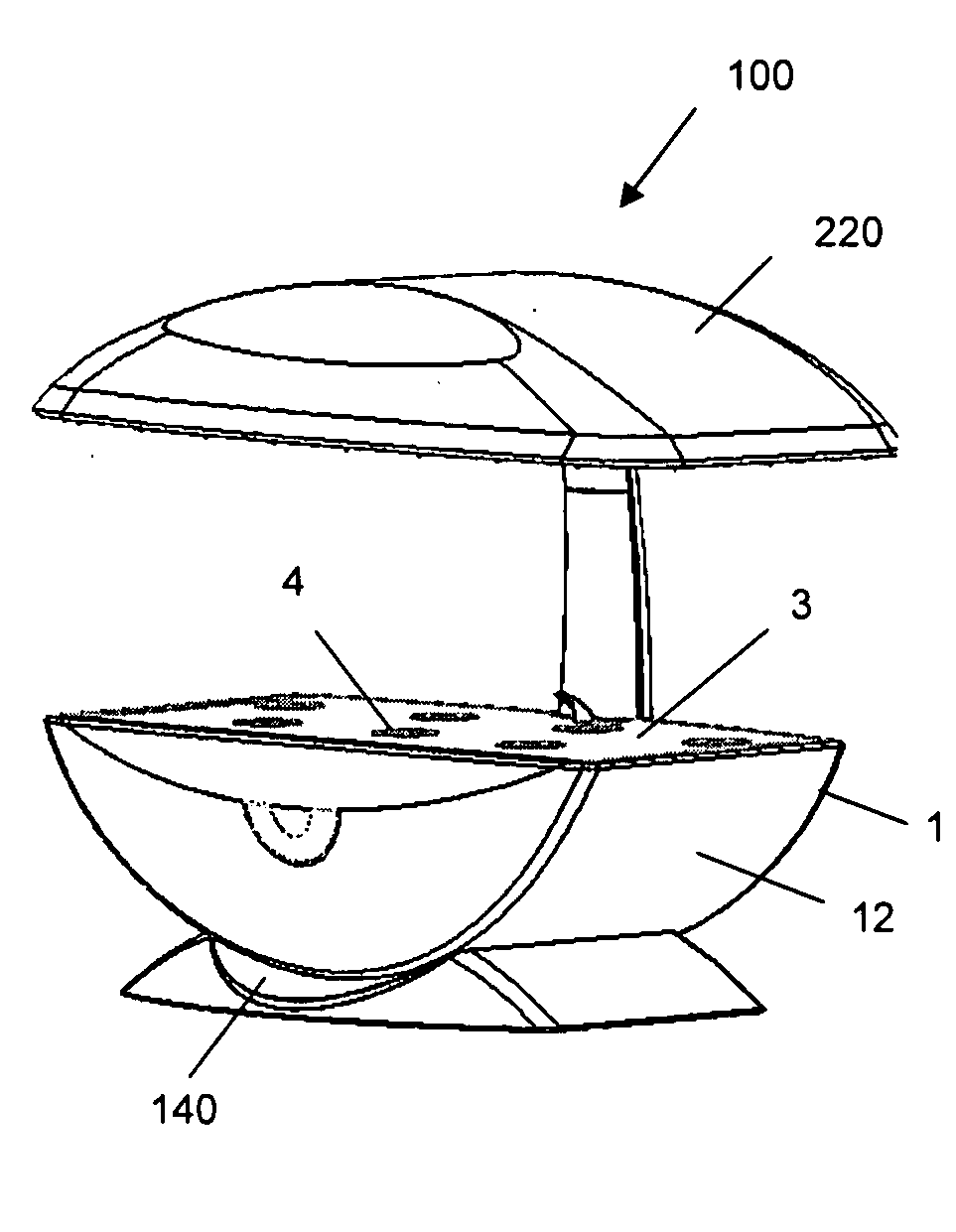

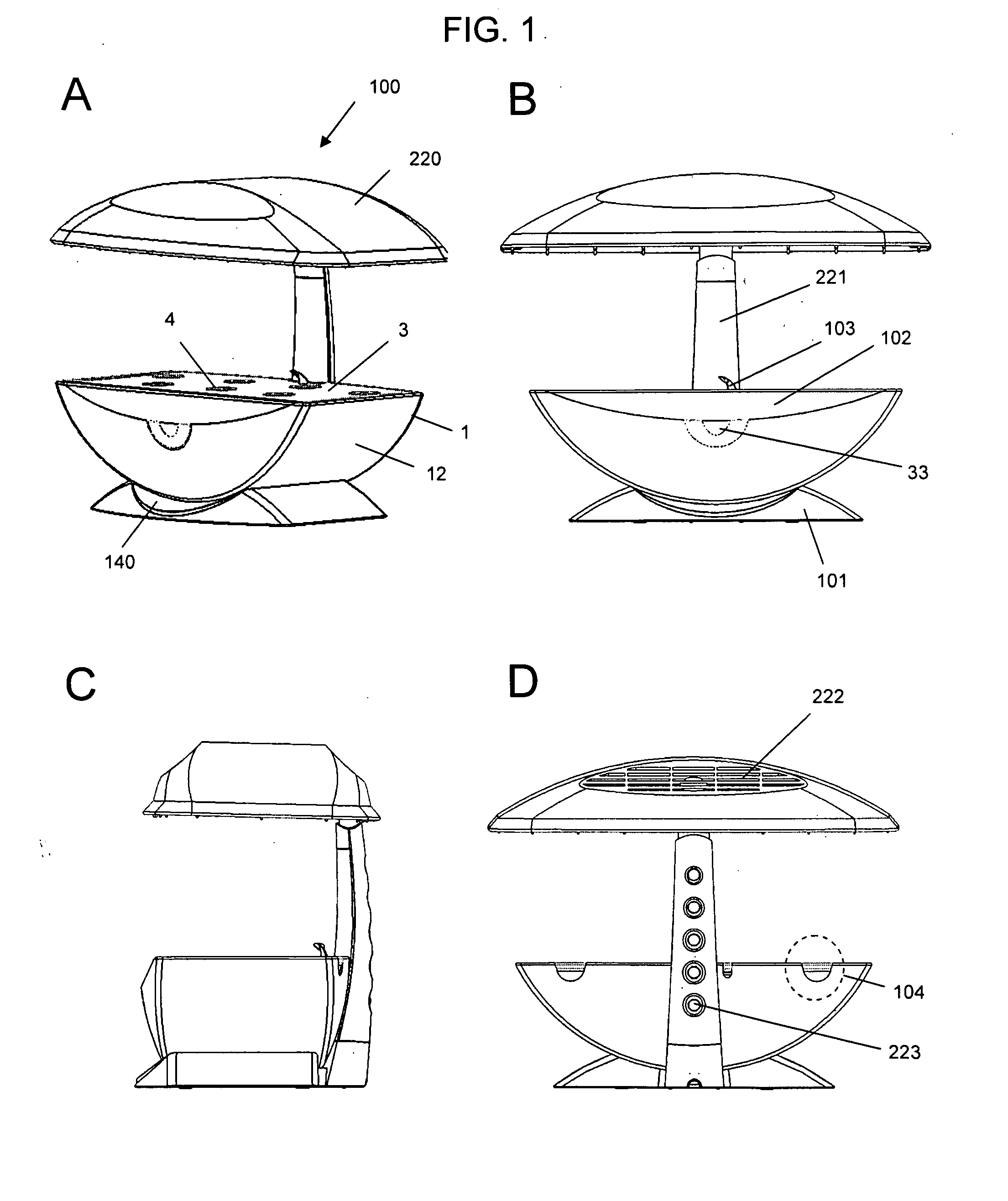

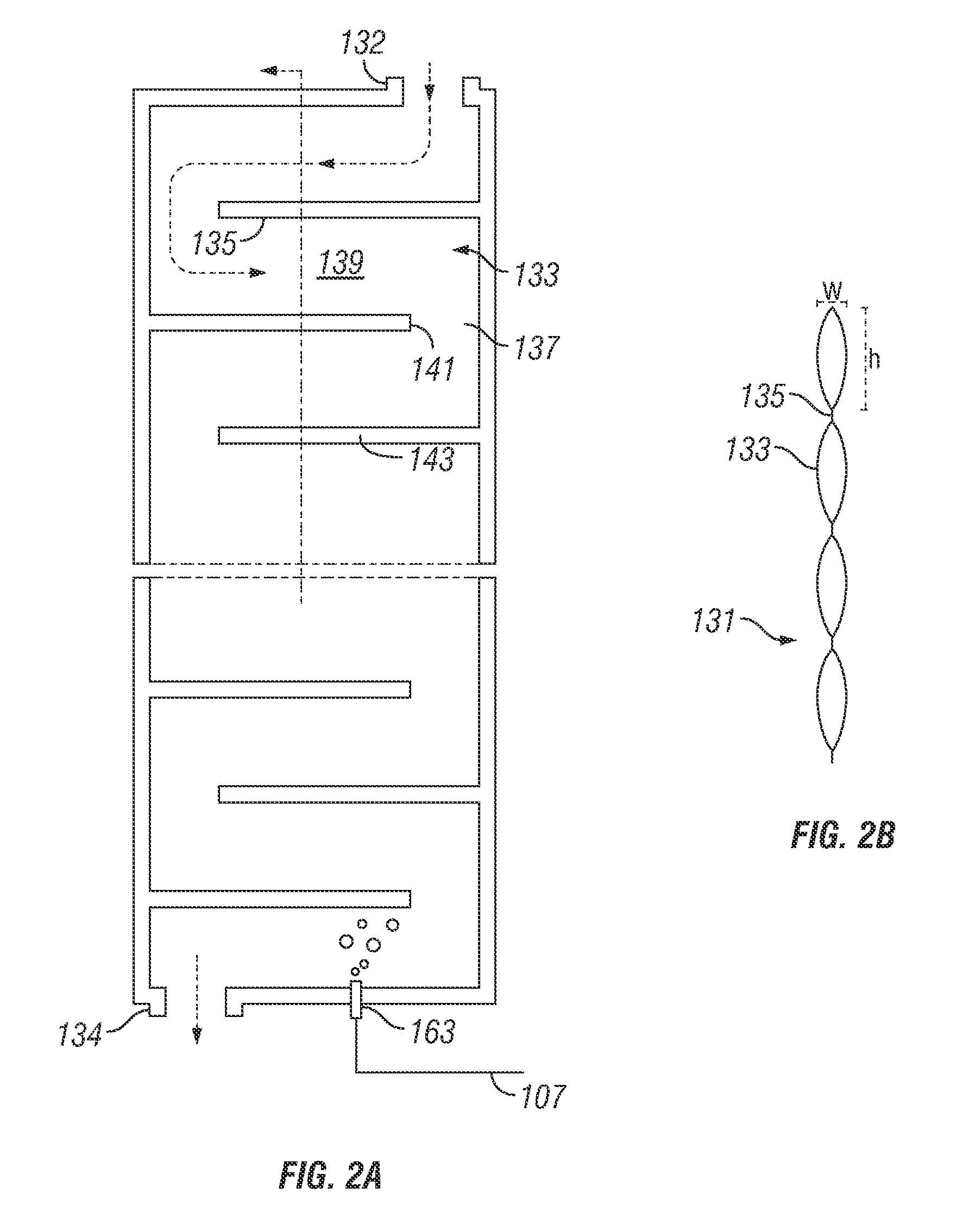

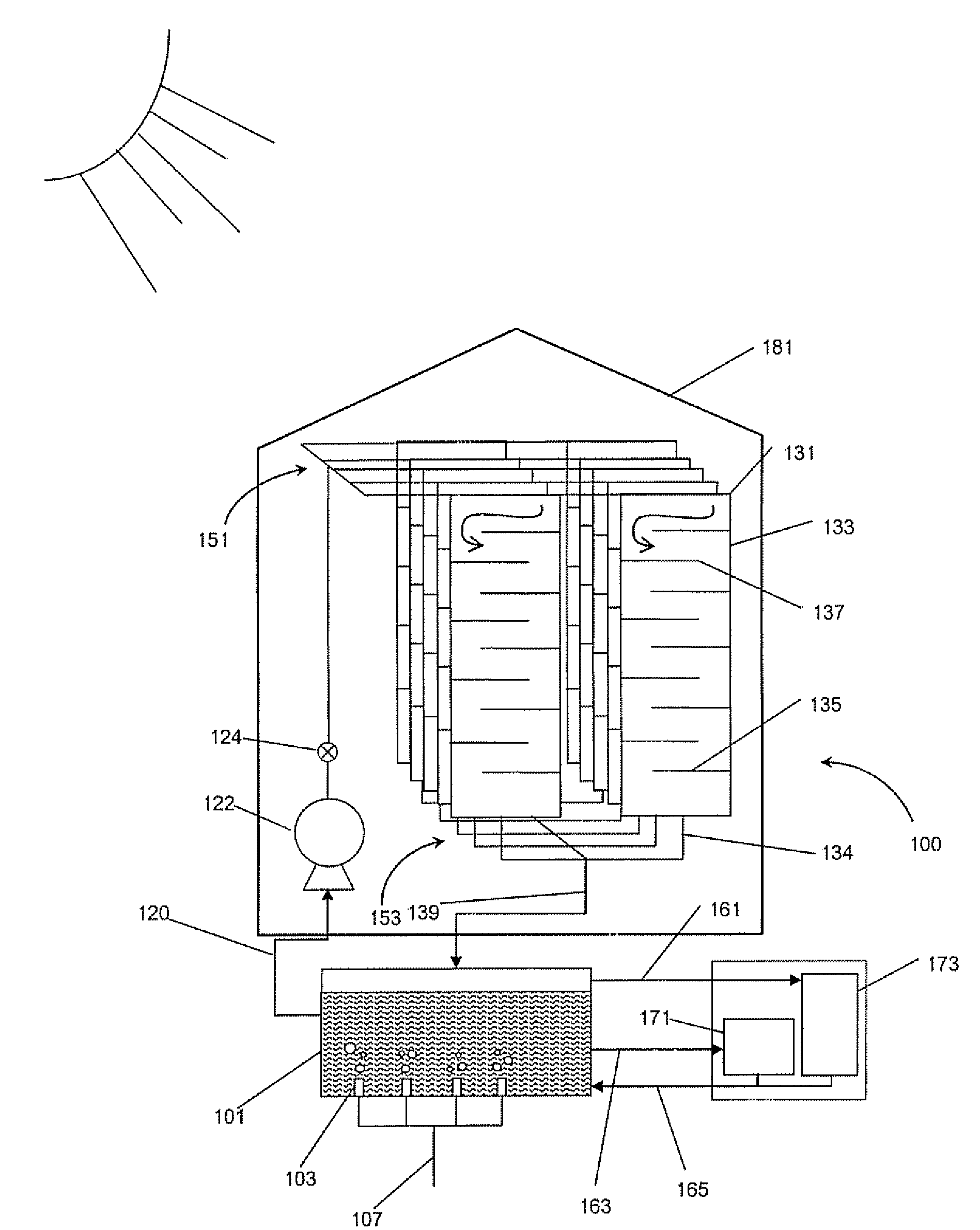

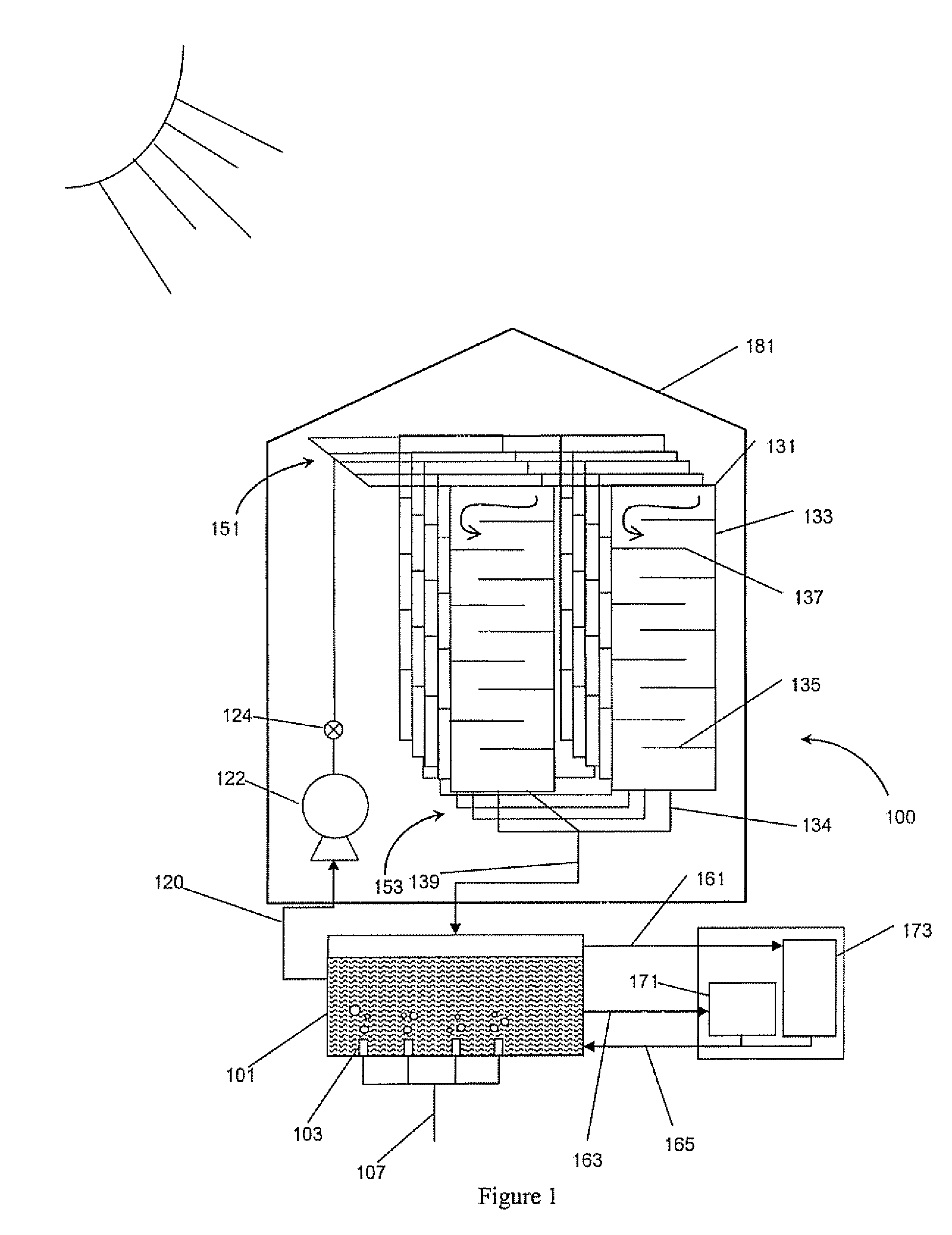

Photobioreactor systems and methods for treating CO2-enriched gas and producing biomass

InactiveUS20080178739A1Facilitate evaporative coolingSupport growthBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumStream flow

Certain embodiments and aspects of the present invention relate to a photobioreactor including covered photobioreactor units through which a liquid medium stream and a gas stream flow. The liquid medium comprises at least one species of phototrophic organism therein. Certain methods of using the photobioreactor system as part of fuel generation system and / or a gas-treatment process or system at least partially remove certain undesirable pollutants from a gas stream. In certain embodiments, a portion of the liquid medium is diverted from a photobioreactor unit and reintroduced upstream of the diversion position. In certain embodiments, the disclosed photobioreactor system, methods of using such systems, and / or gas treatment apparatus and methods provided herein can be used as part of an integrated combustion method and system, wherein photosynthetic organisms used within the photobioreactor are harvested from the photobioreactor, processed, and used as a fuel source for a combustion system such as an electric power plant.

Owner:THE TRON GRP

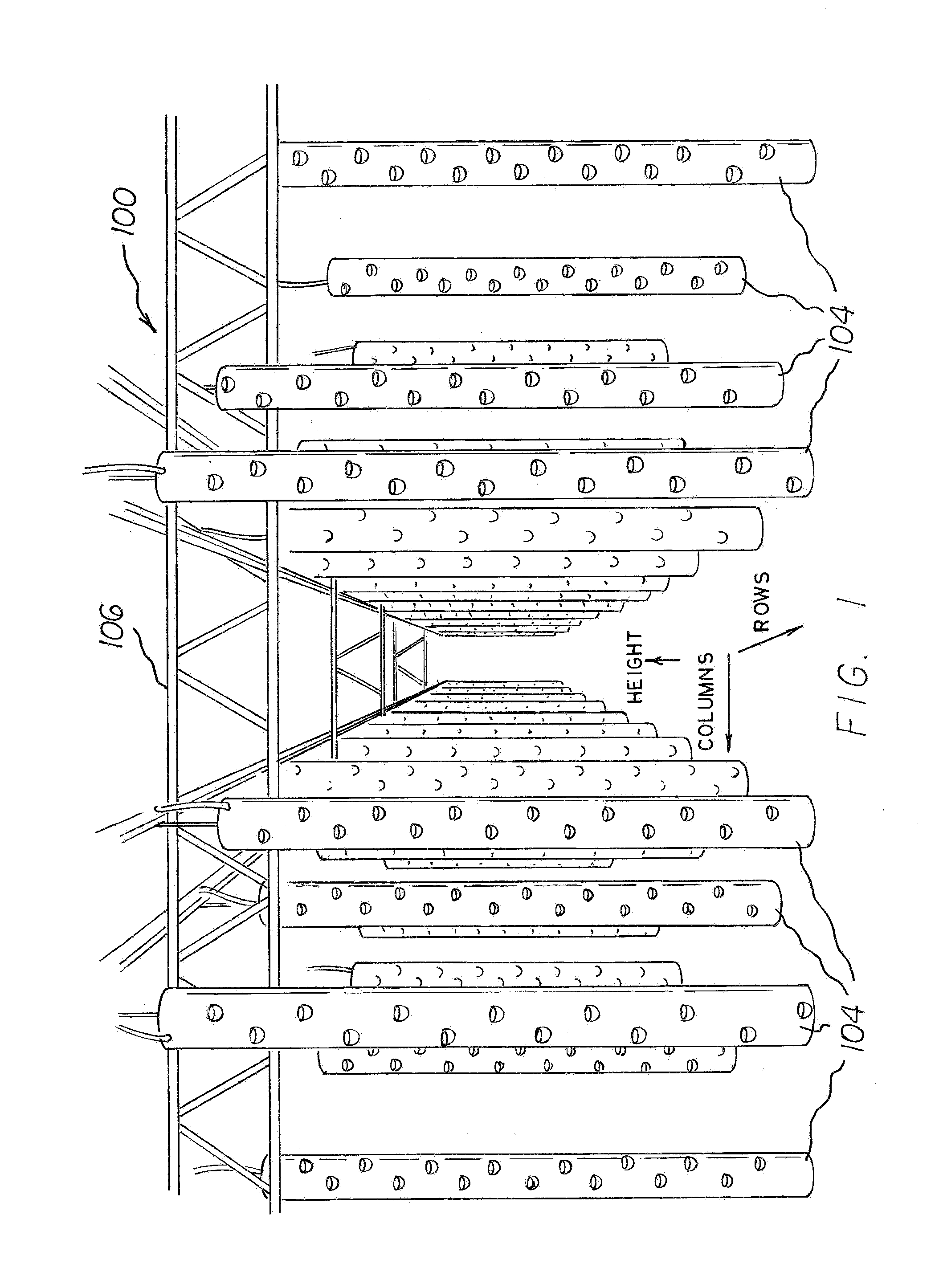

Light-weight modular adjustable vertical hydroponic growing system and method

A light-weight, modular, adjustable vertical hydroponic growing system and method of Native American design for cultivation plants and beneficial soil organisms (BSO's) in symbiotic combination. Forest-like arrays of fully rotatable and demountable grow tubes are suspended within climate-moderating greenhouses, optionally from conveyor tracks. The tubes are filled with light-weight, porous 100% in-organic grow media predominately comprised of expanded volcanic or recycled glass granules. The grow tube arrays are provided with an insulated, overhead-mounted fertigation distribution system delivering metered intermittent flows from insulated mixing and holding tanks. The flows are recycled via an insulated return piping system to maintain cool fertigation temperatures near those of natural ground water. Fertigation supply mains provided with vortex flow induction devices impart rotational momentum to flows for delivery of uniform aerated fertigation to plants and BSO's via a combination of open-tube emitters and gravity flows within grow tubes.

Owner:COLLINS FRED +1

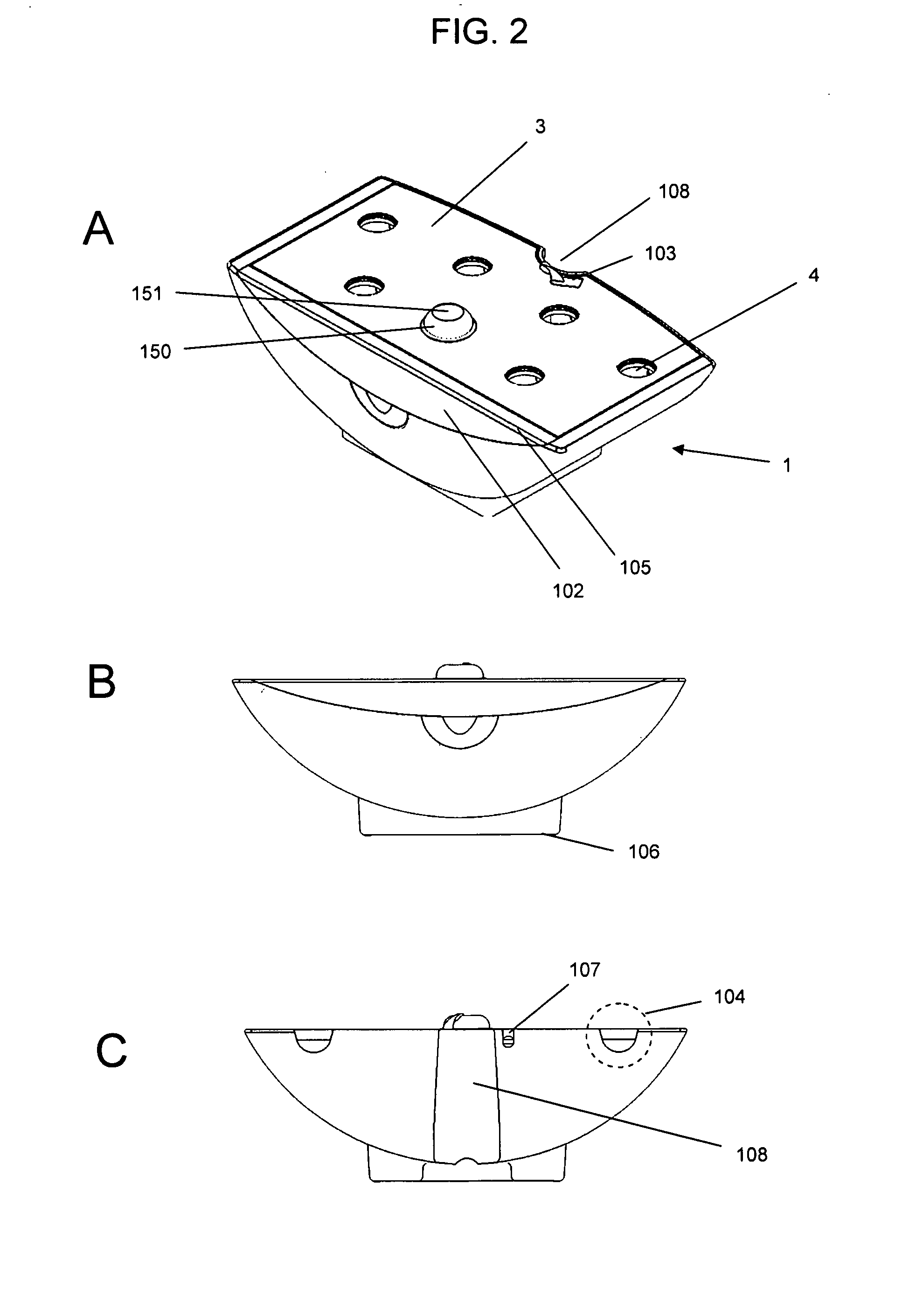

Hydroponic plant cultivating apparatus

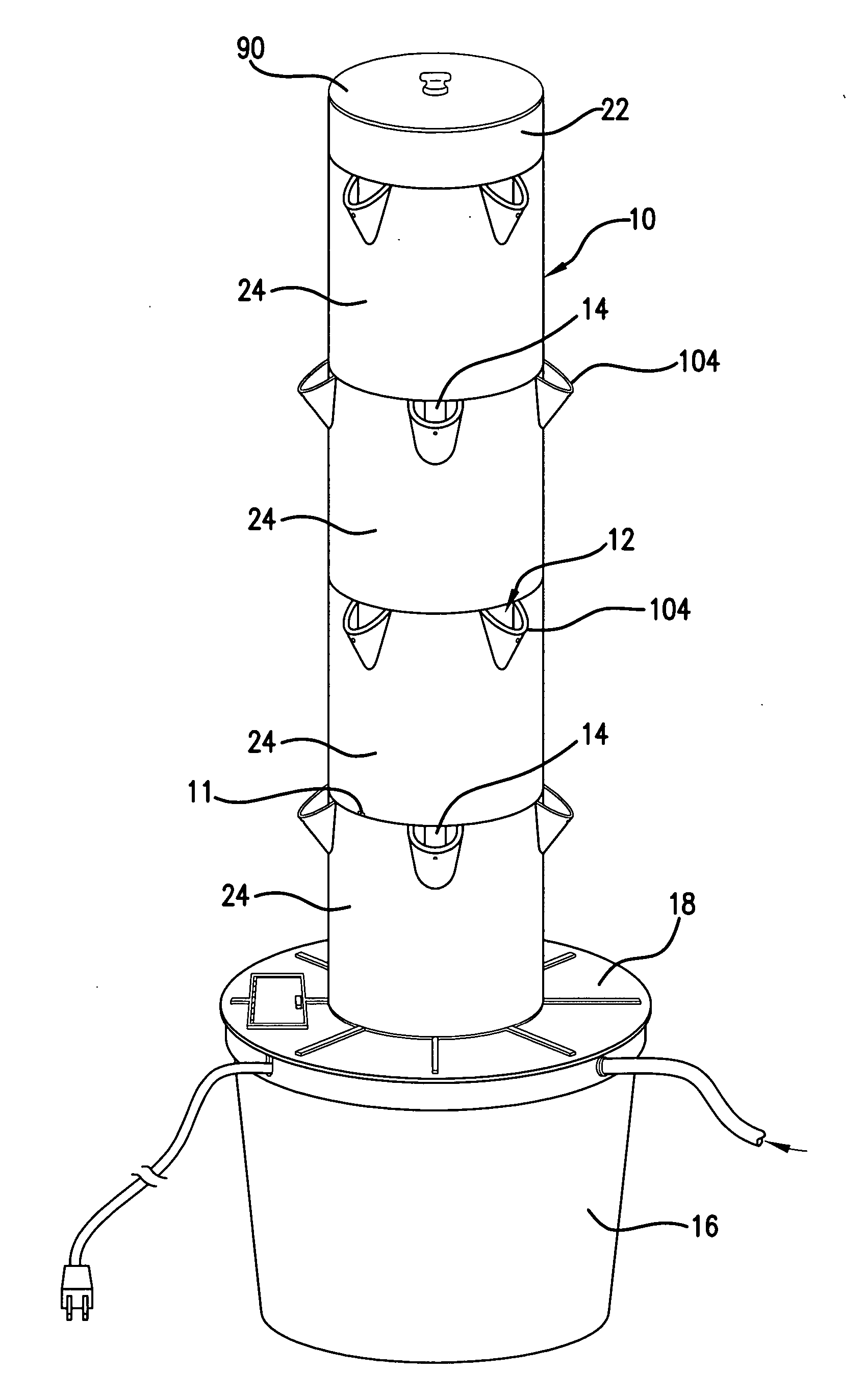

A hydroponic system with modules having a hollow interior, a bottom wall with drain holes, and an open top end. A module conduit in each module carried by the bottom wall for channeling fluid through the hollow interior. The bottom wall of each the module adapted to engage a top end of an adjacent module for stacking the modules in an end-to-end arrangement to form a planting column. A conduit receiving slot formed in the bottom wall of each module to engage a top portion of a conduit from an adjacent lower module when the modules are stacked end-to-end to provide a continuous fluid passageway through the planting column. A platform vertically carrying the planting column atop a fluid reservoir. A supply line connecting the reservoir to the fluid passageway. A fluid distributor atop the column in fluid communication with the fluid passageway for distributing fluid into the planting column.

Owner:TOWER GARDEN

Devices and methods for growing plants

InactiveUS20080222949A1Suppress soundIncrease oxygen contentSaving energy measuresAgriculture gas emission reductionCell culture mediaEngineering

A gardening system includes a modular seed cartridge including a rigid, cup-shaped receptacle including an upper portion having an outer rim, a soilless growth medium located in the rigid, cup-shaped receptacle, and at least one seed in contact with the soilless growth medium. The gardening system also includes an aeroponic or hydroponic garden including a chamber including a lower portion for storing a liquid nutrient solution, a cover located above the chamber, the cover including a plant opening adapted to removably support the modular seed cartridge by the outer rim, and a pump located in the chamber and adapted to circulate the liquid nutrient solution from the lower portion of the chamber to the modular seed cartridge supported by the plant opening.

Owner:AEROGROW INT

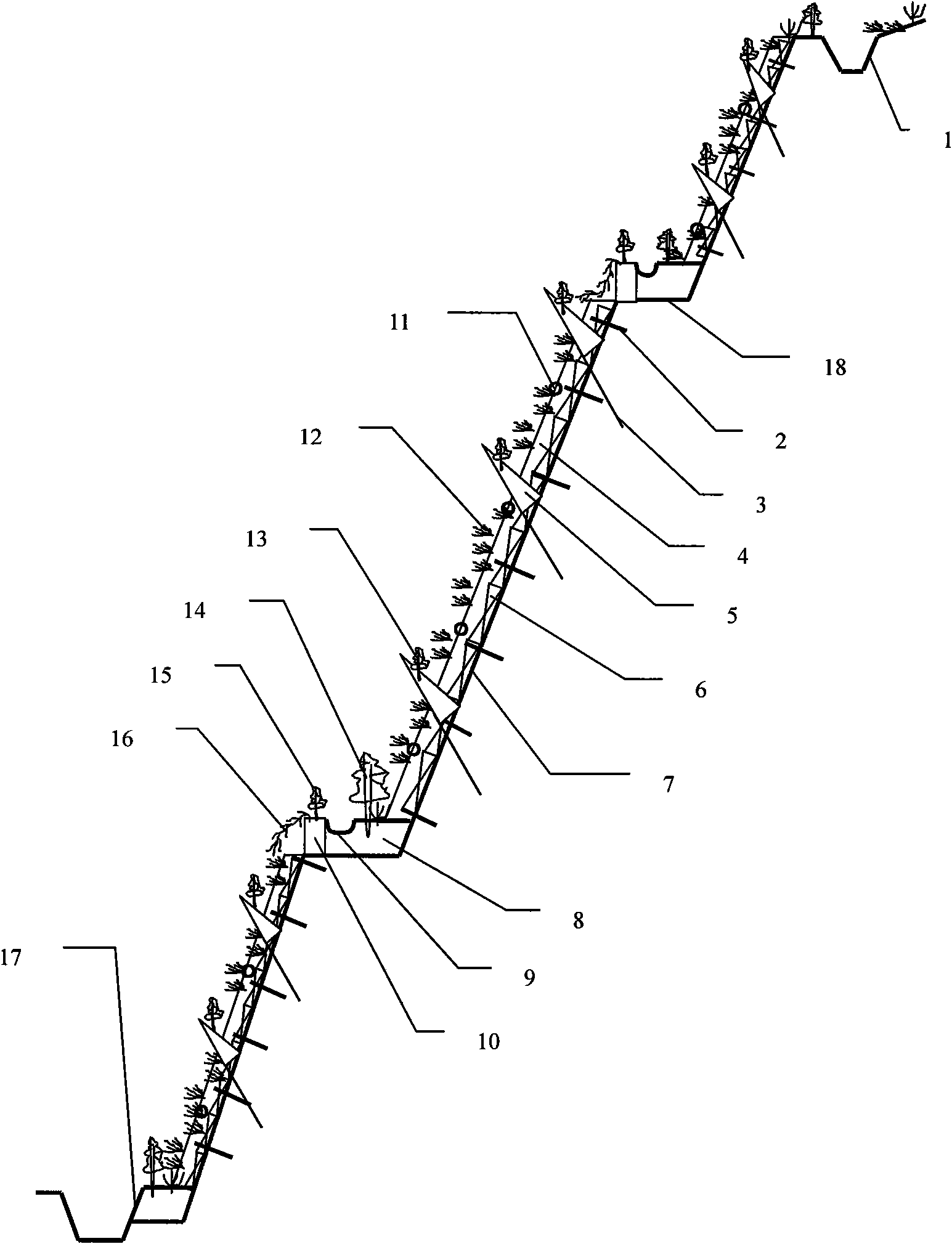

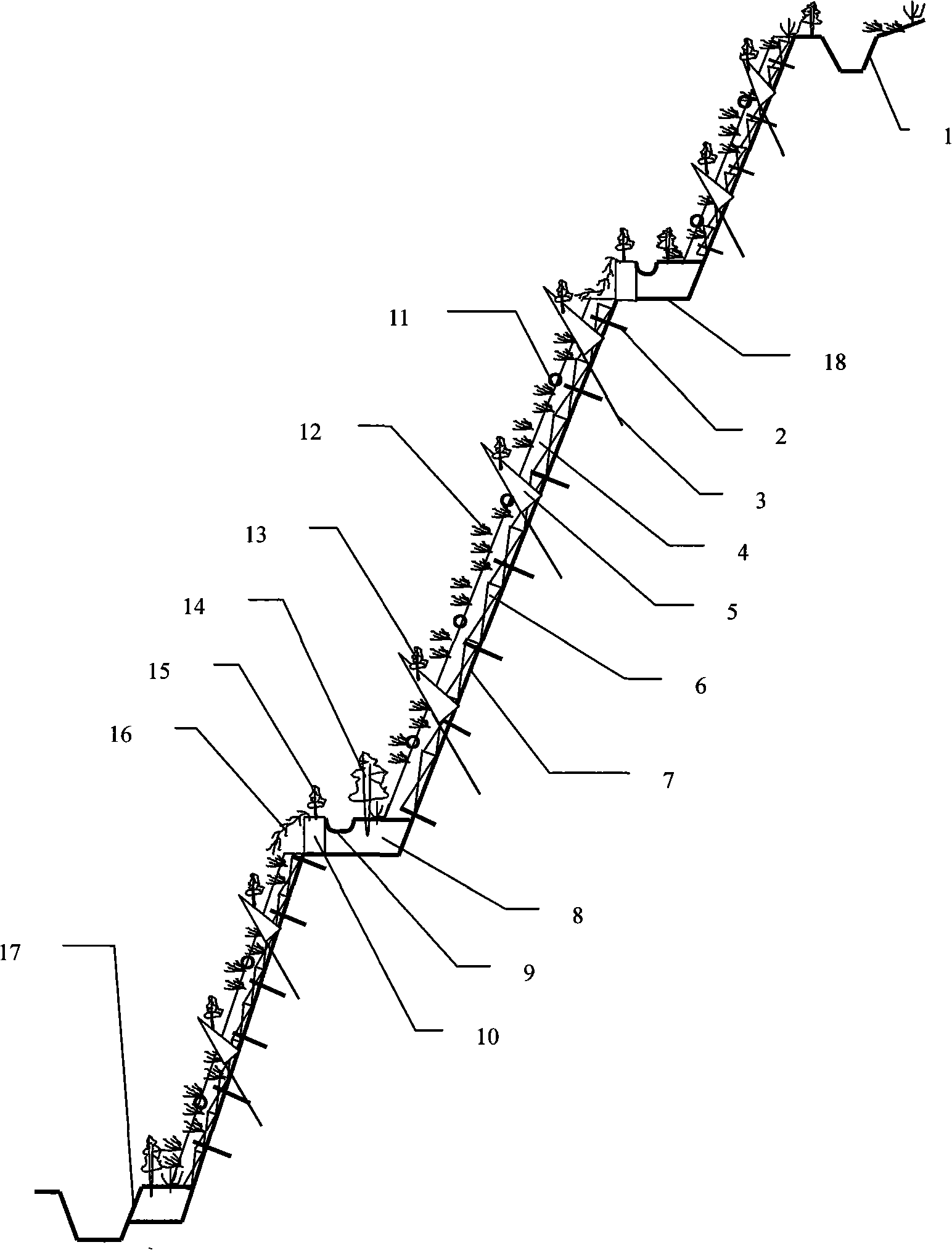

Revegetation system on steep rocky slopes and implementing method thereof

The invention discloses a revegetation system on steep rocky slopes and an implementing method thereof, which are suitable for surface vegetalization of steep rocky uncover slopes with the gradient of 60 degrees above. A slope drainage system is arranged in the system to prevent the vegetalization layer from being flushed by rainwater and reduce water loss and soil erosion; a mix-sprayed vegetalization layer plastic-covered with iron wire corrugated meshes and consisting of continuous fiber is arranged on the slopes and has stable structure, rich nutrition and functions of water conservation and ventilation. The casting separator prevents the mix-sprayed vegetalization layer from sliding downwards; and a drop irrigation facility is distributed to make sure that the vegetalization layer is moist. After maintenance of mix-sprayed construction on the slopes, the vegetable layer with herbaceous plants and shrubs can be effectively formed, thereby reconstructing the destructed vegetables on the slopes and recovering the natural landscapes on the uncover slopes.

Owner:深圳市如茵生态环境建设有限公司

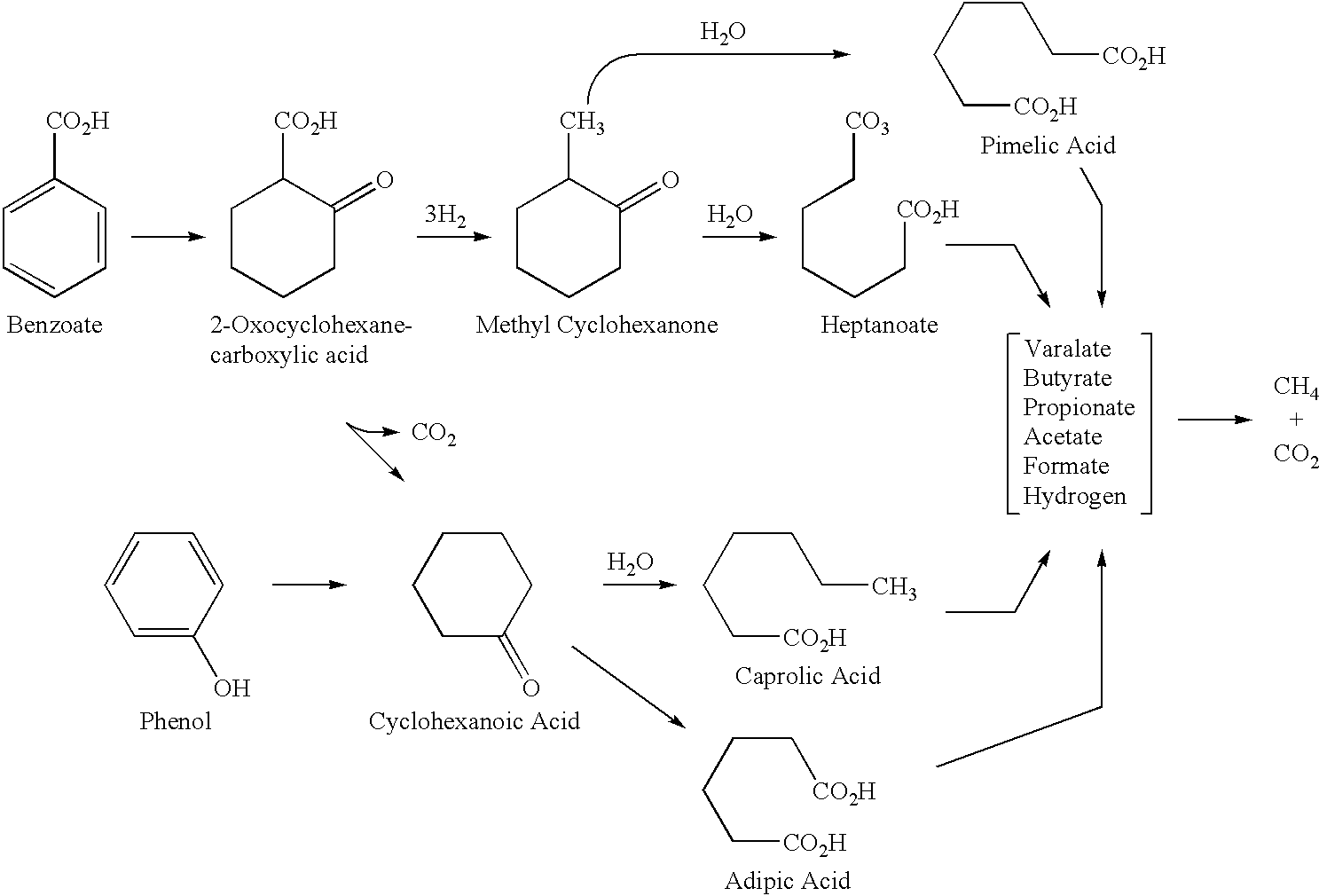

Method and apparatus for co2 sequestration

InactiveUS20080274494A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAlgaeBiological materials

A method and apparatus for growing algae for sequestering carbon dioxide and then harvesting the algae includes a container for a suspension of algae in a liquid and a bioreactor having a translucent channel in fluid communication with the container to absorb CO2 and grow the algae. A monitor determines the growth of the algae in the channel. A separator separates the grown algae from the suspension and an extractor extracts biomaterials from the grown algae.

Owner:KERTZ MALCOLM GLEN

Microbial culture liquors containing microorganisms differing in characteristics and living in symbiosis and metabolites thereof, carriers and adsorbents containing the active components of the culture liquors and utilization of the same

Solutions containing microorganisms differing in characteristics from each other and living in symbiosis with each other and enzymes characterized by containing aerobic microorganisms, anaerobic microorganisms and at least one basidiomycete belonging to the family Pleurotaceae living in symbiosis, metabolites thereof and enzymes; carriers obtained by adsorbing the components of the above solutions onto finely ground carbonaceous materials; and porous materials obtained by adsorbing the components of the above solutions onto porous materials. Because of having various effects of absorbing, adsorbing and decomposing harmful matters, deodorizing, decolorizing, etc., these materials are applicable to various uses in the fields of agriculture and environment.

Owner:ORIENT GREEN

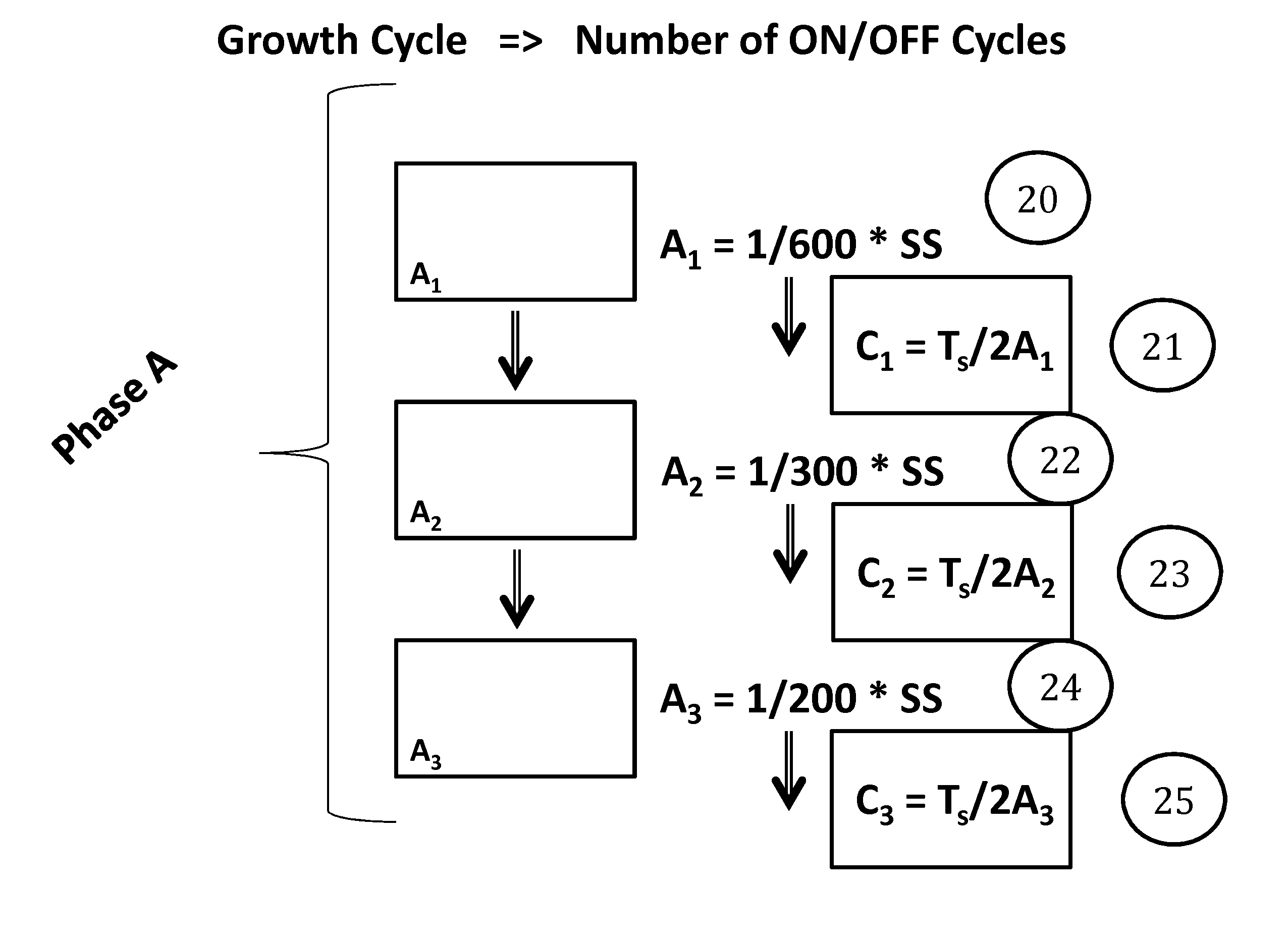

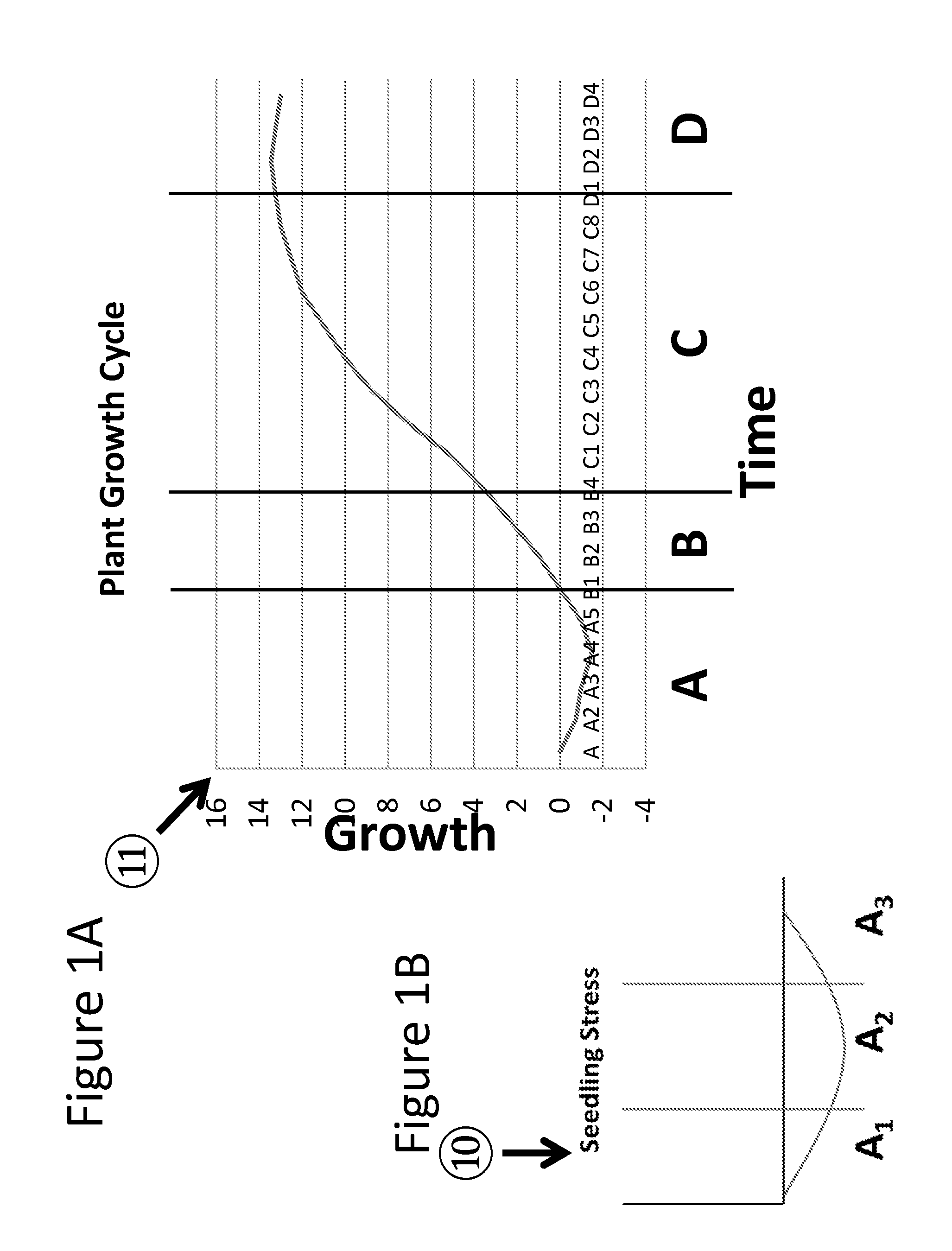

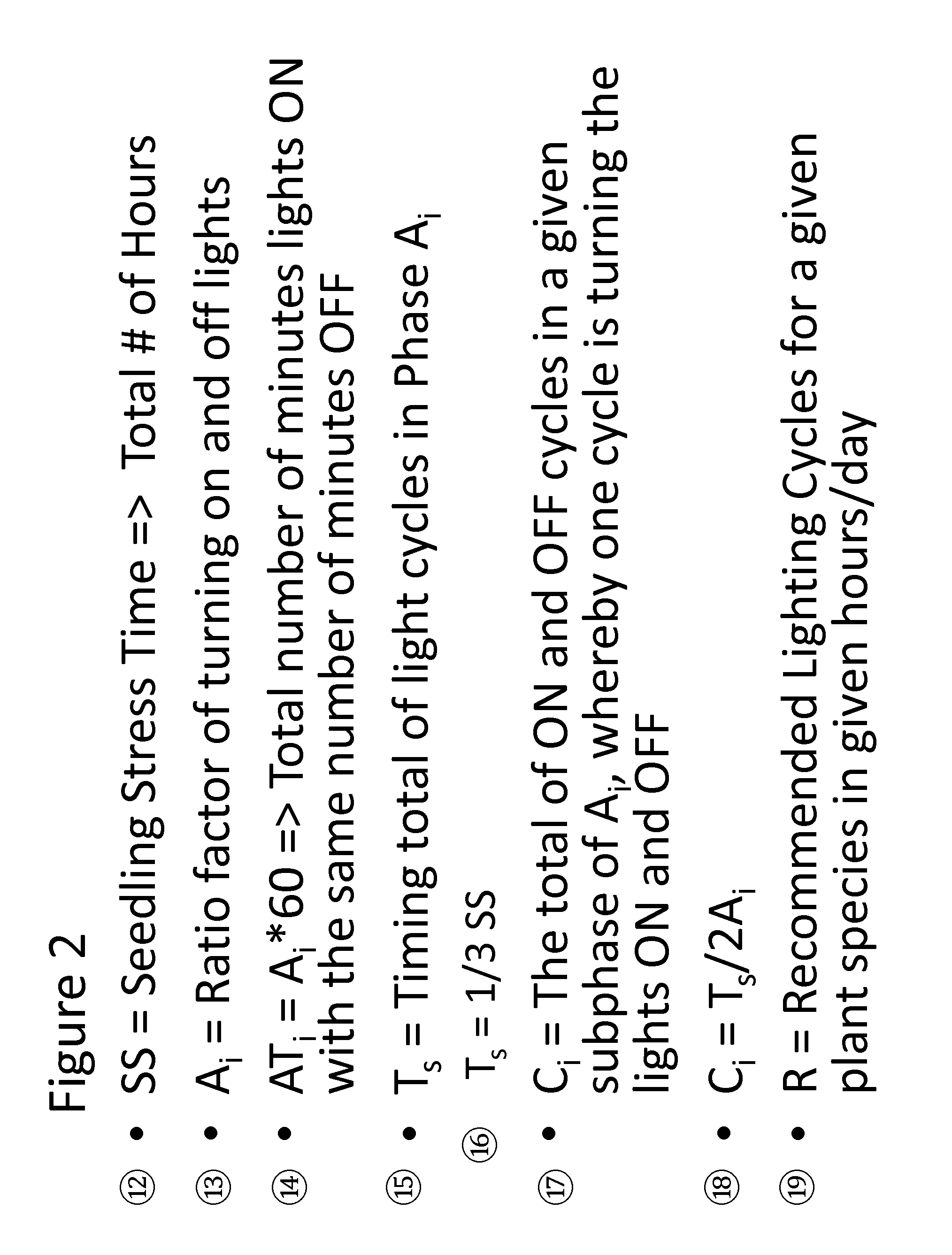

LED light timing in a high growth, high density, closed environment system

ActiveUS20140259920A1Reduce duplicationWell mixedSaving energy measuresGrowth substratesGrowth plantHigh density

Owner:CROP ONE HLDG

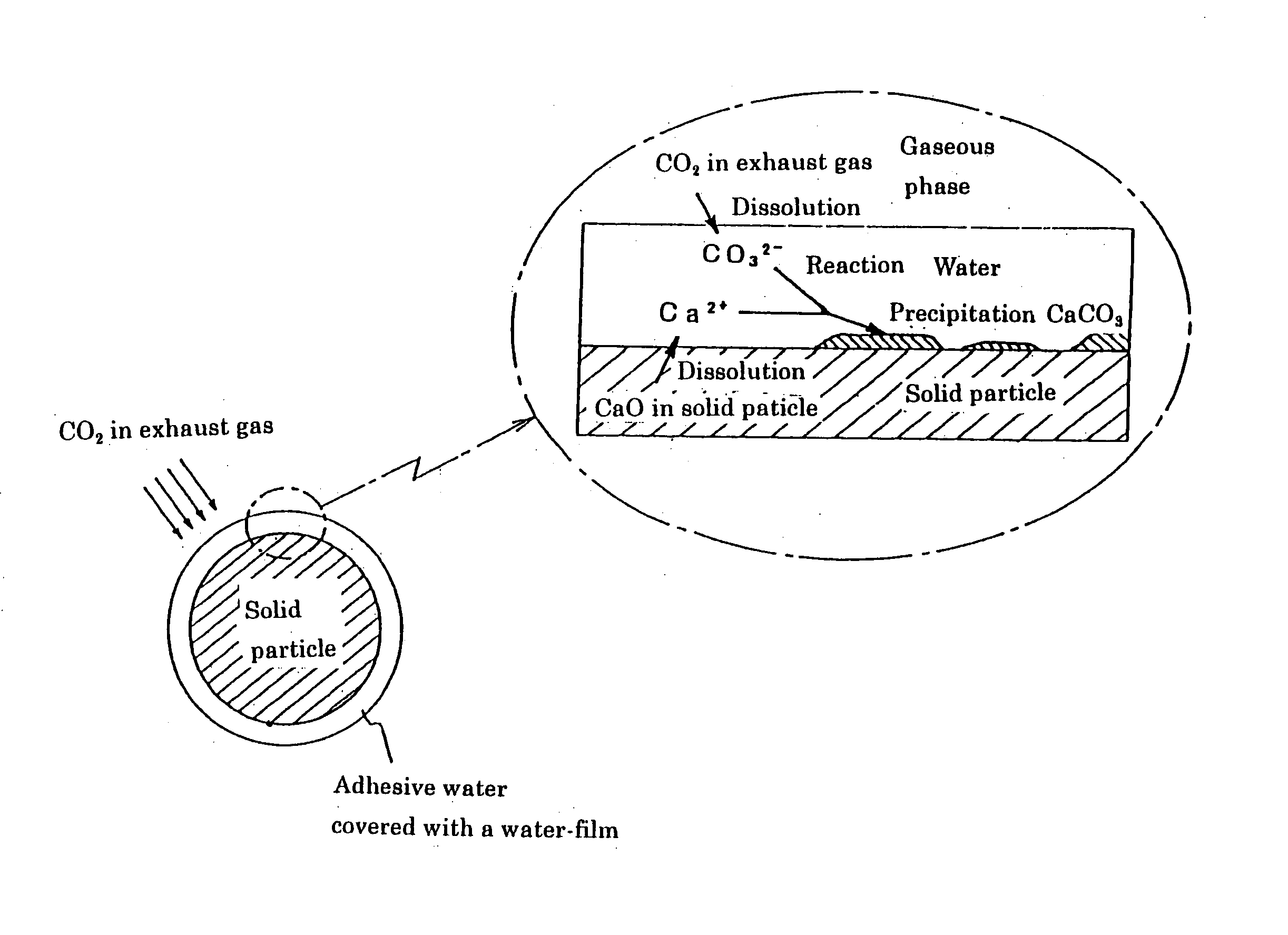

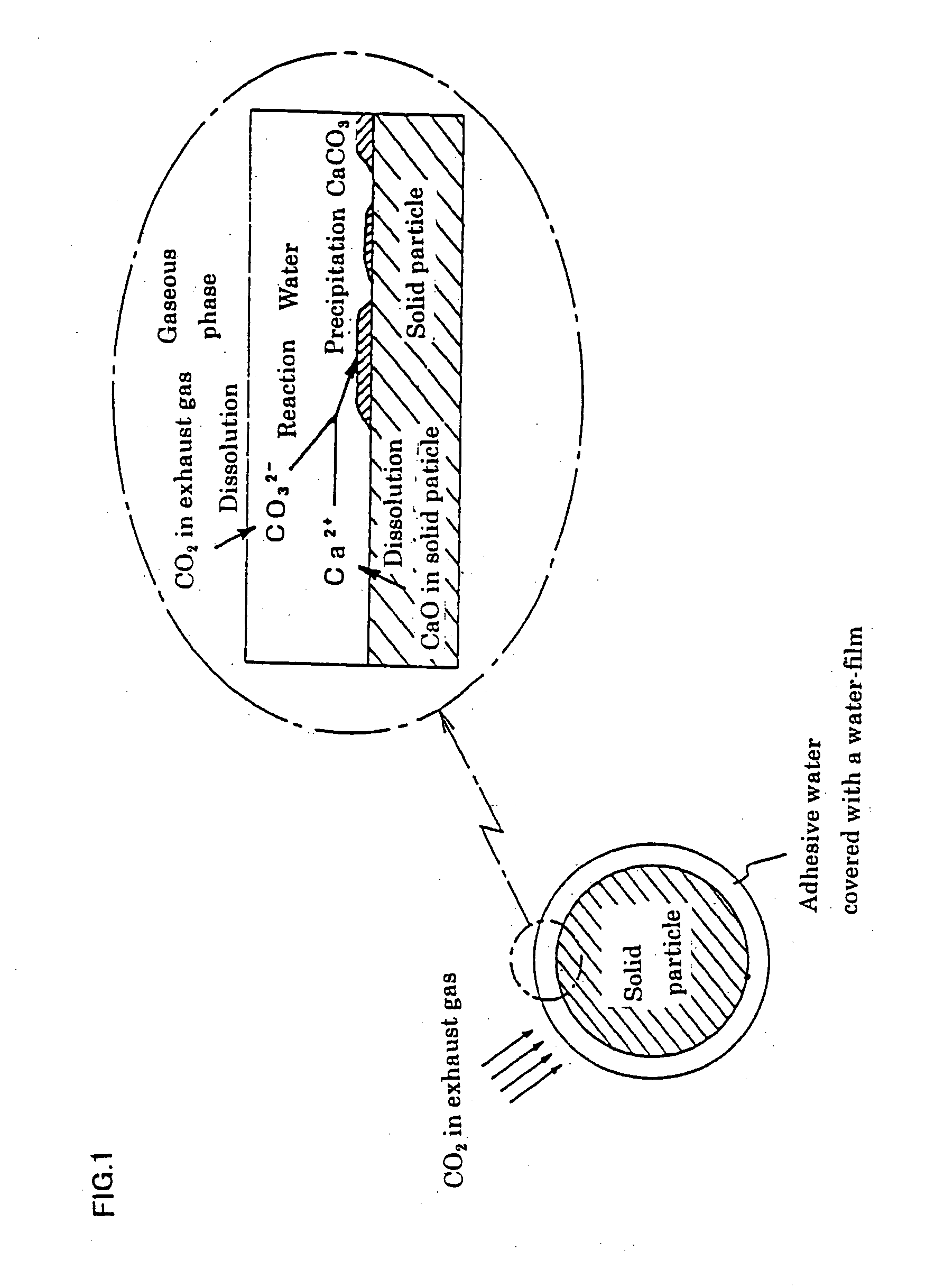

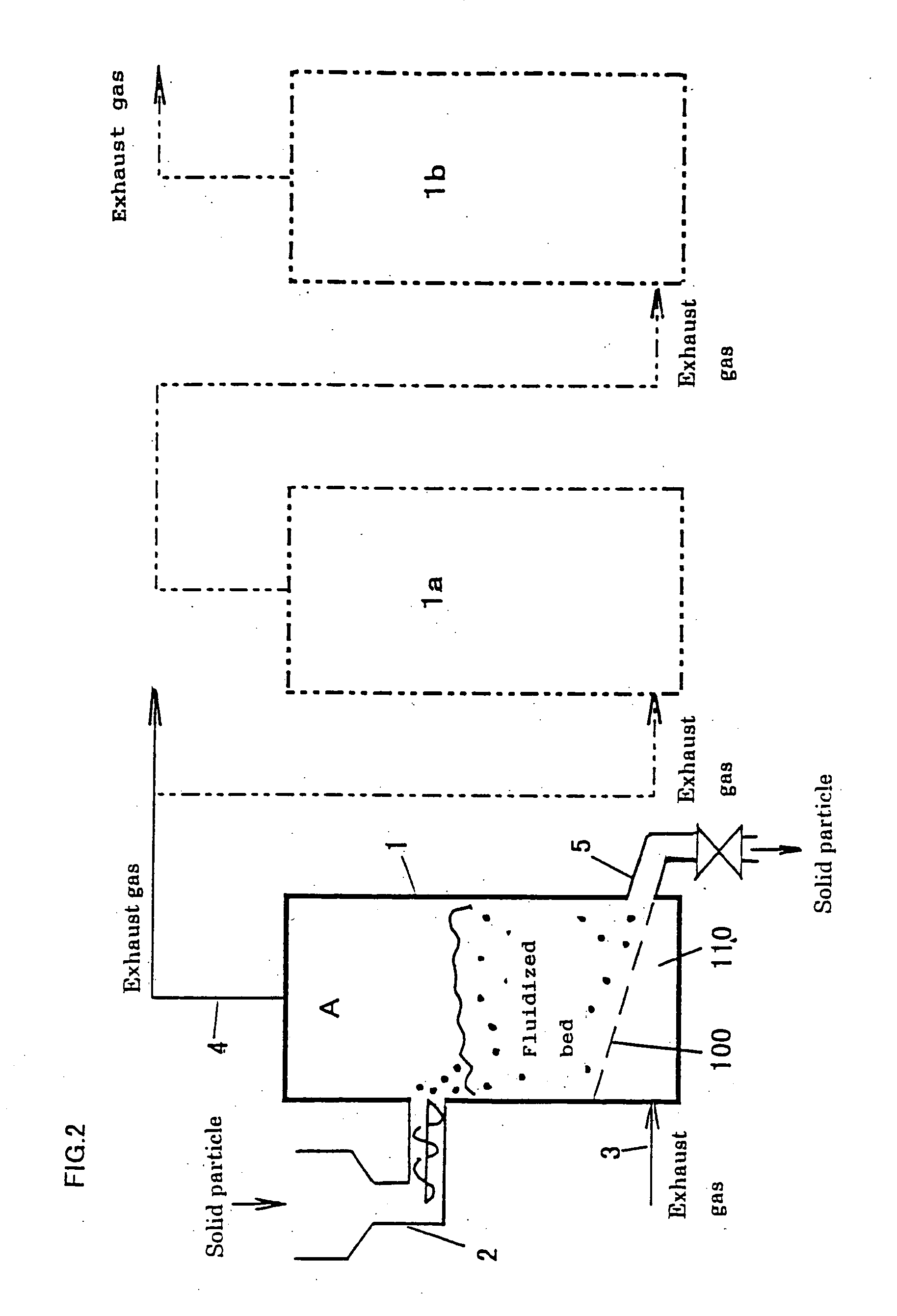

Method for reducing exhaust carbon dioxide

InactiveUS20050036932A1Efficient removalReduce exhaustCalcium/strontium/barium carbonatesWater resource protectionExhaust fumesEnvironmental engineering

A method for effectively absorbing and removing CO2 in an exhaust gas generated during an industrial process for reducing the amount of CO2 that is exhausted into the atmosphere. The exhaust gas containing CO2 is blown into an agglomerate of solid particles containing CaO and / or Ca(OH)2 so that the CO2 is in contact with the agglomerate for fixing the CO2 in the exhaust gas as CaCO3, thereby reducing the CO2 concentration in the exhaust gas. Preferably, the solid particles contain water, and more preferably, the solid particles contain surface adhesive water.

Owner:JFE STEEL CORP

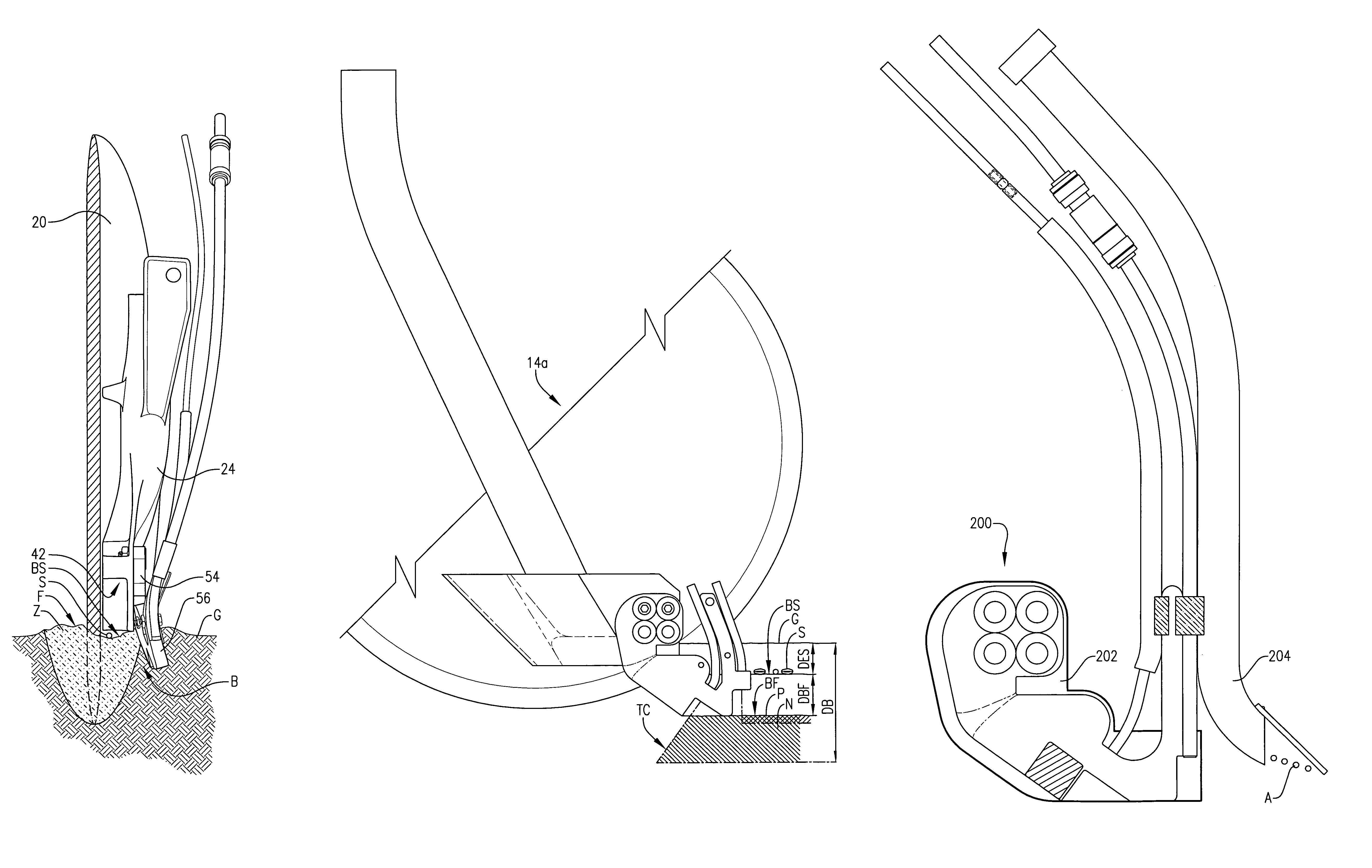

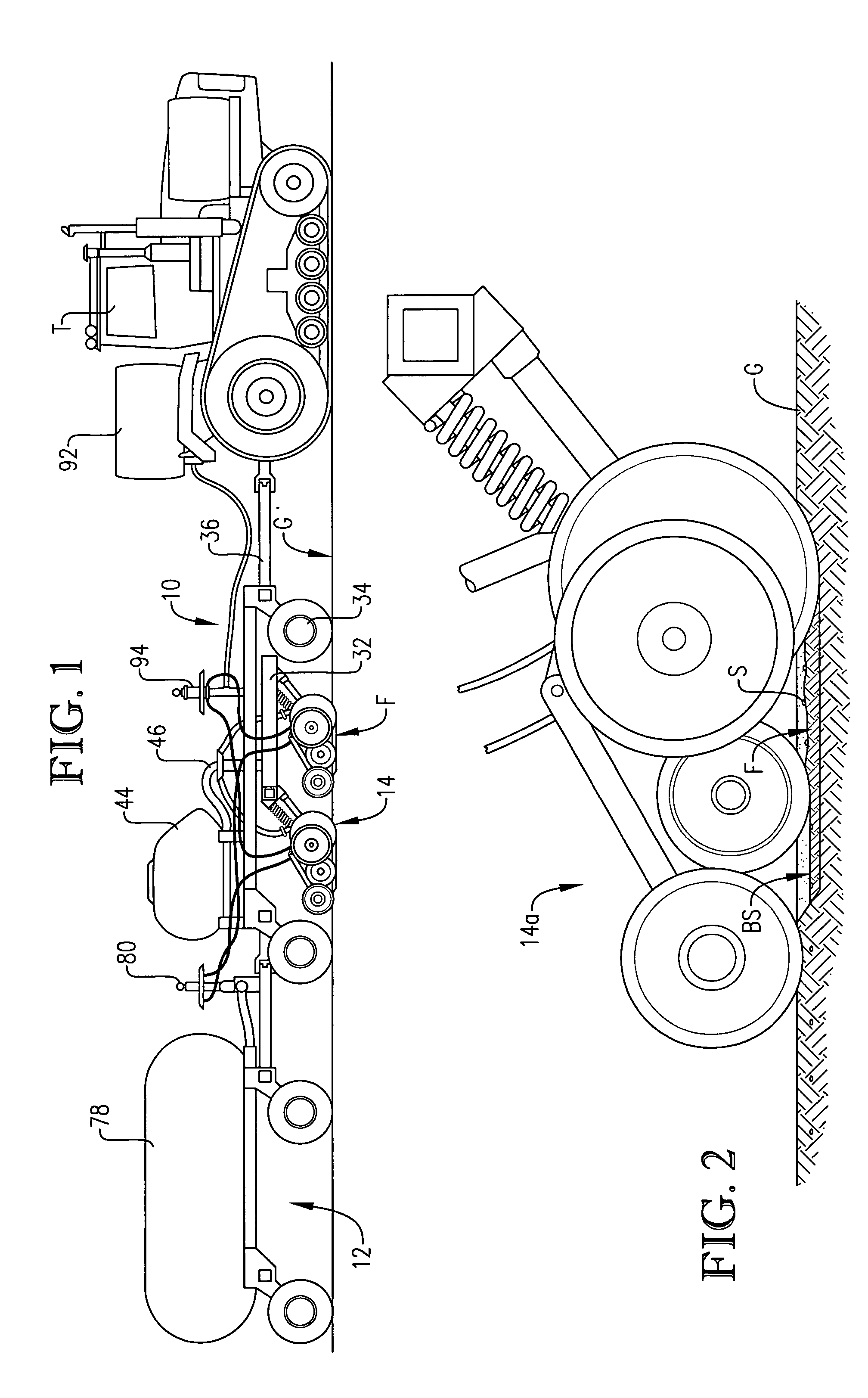

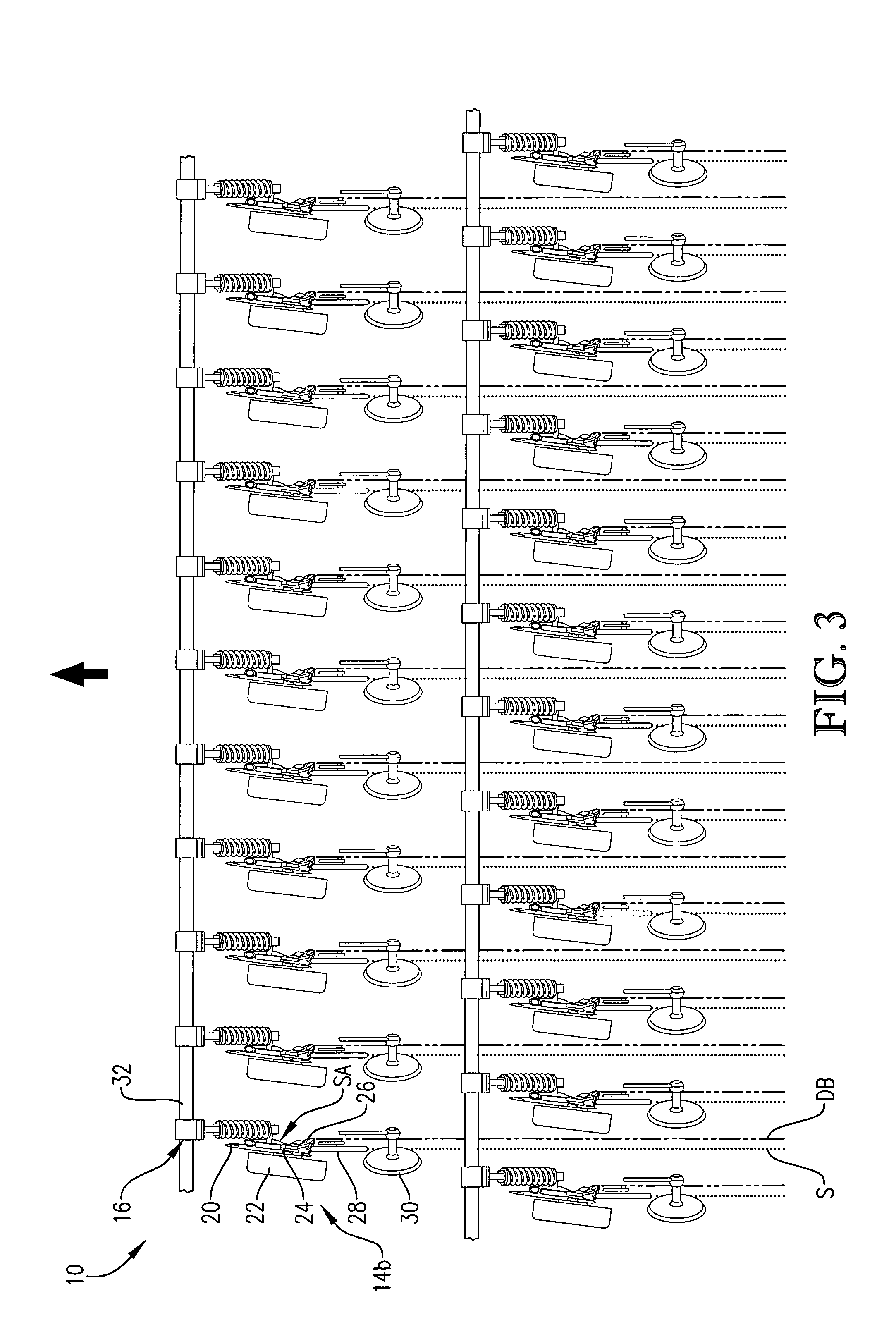

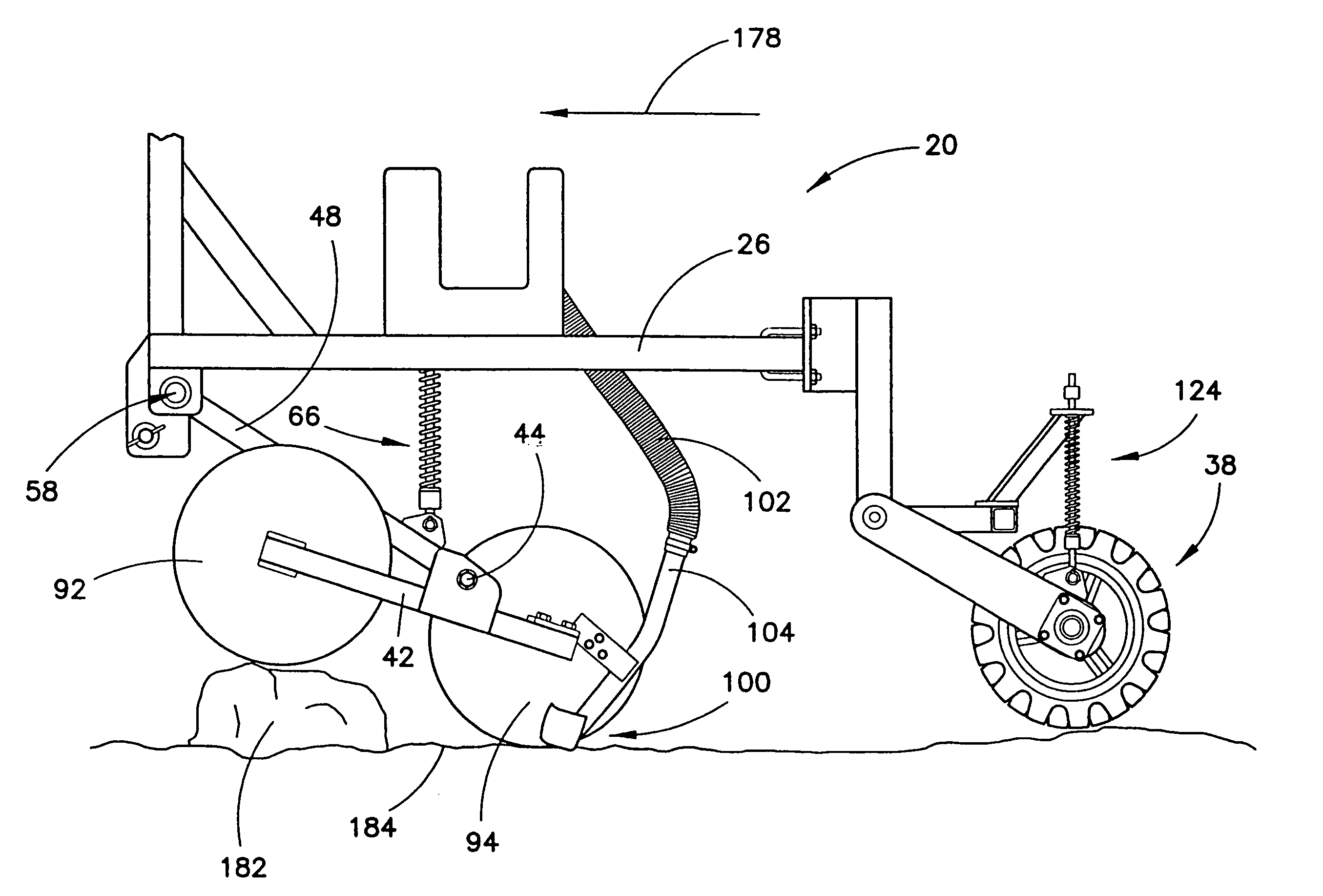

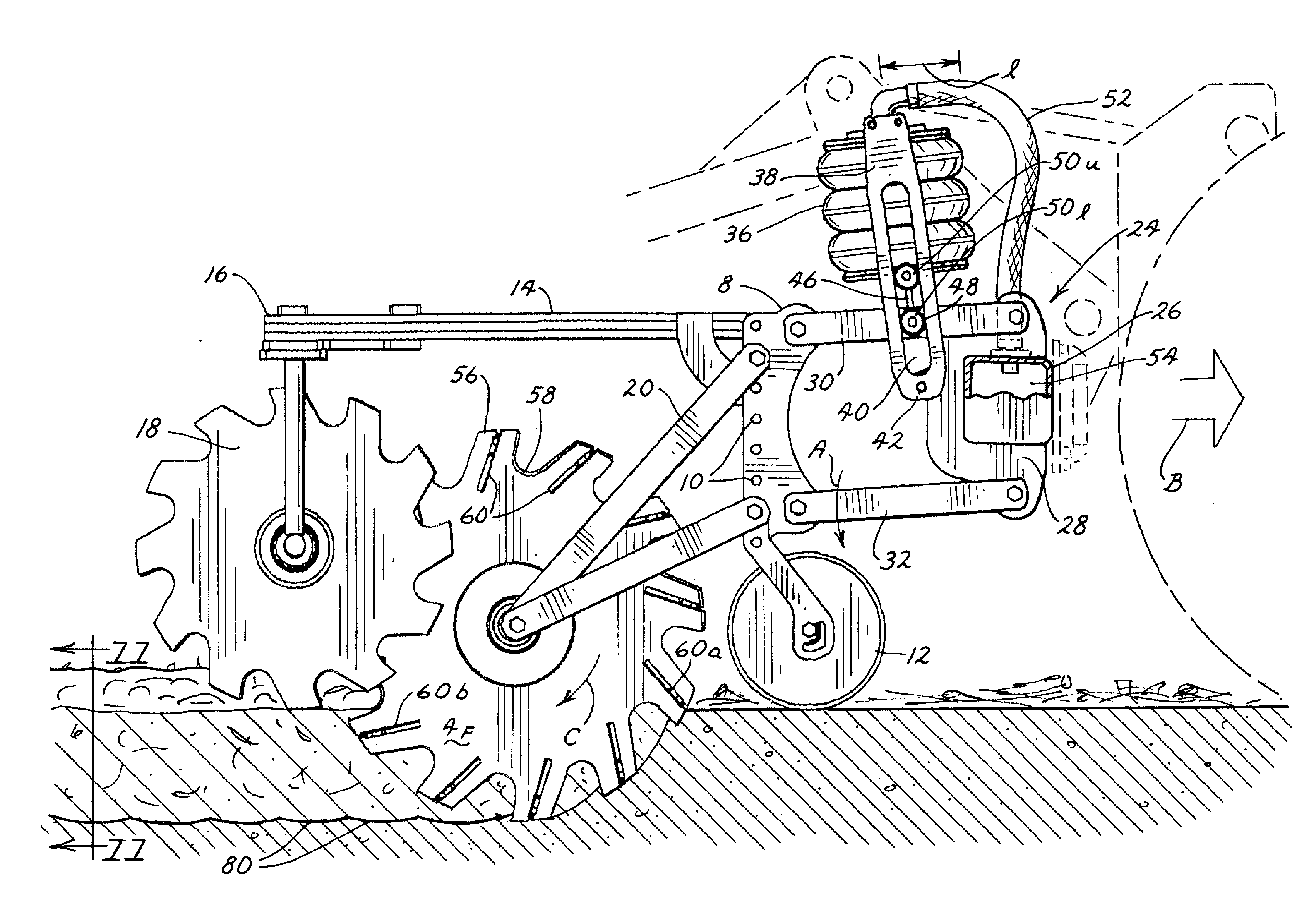

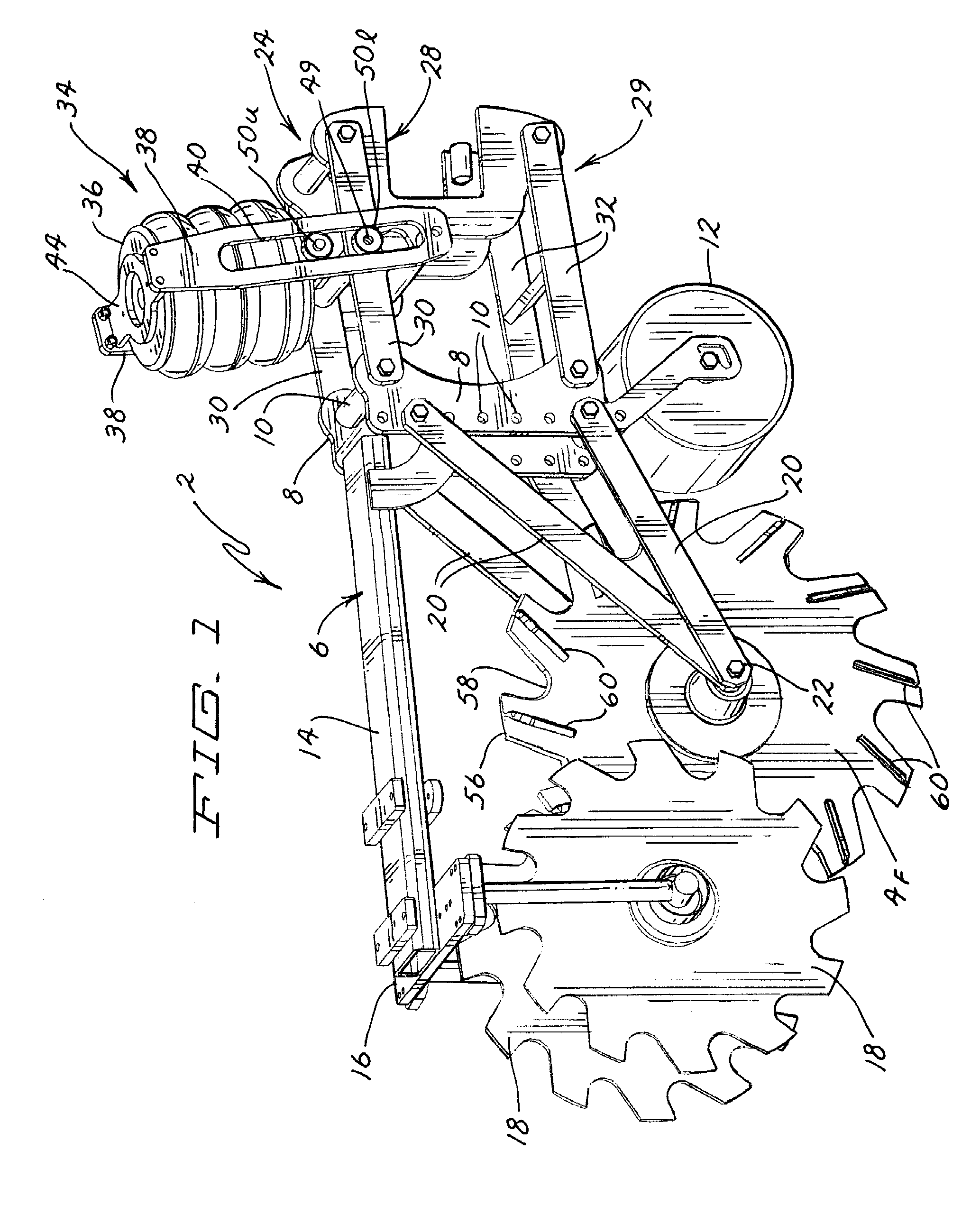

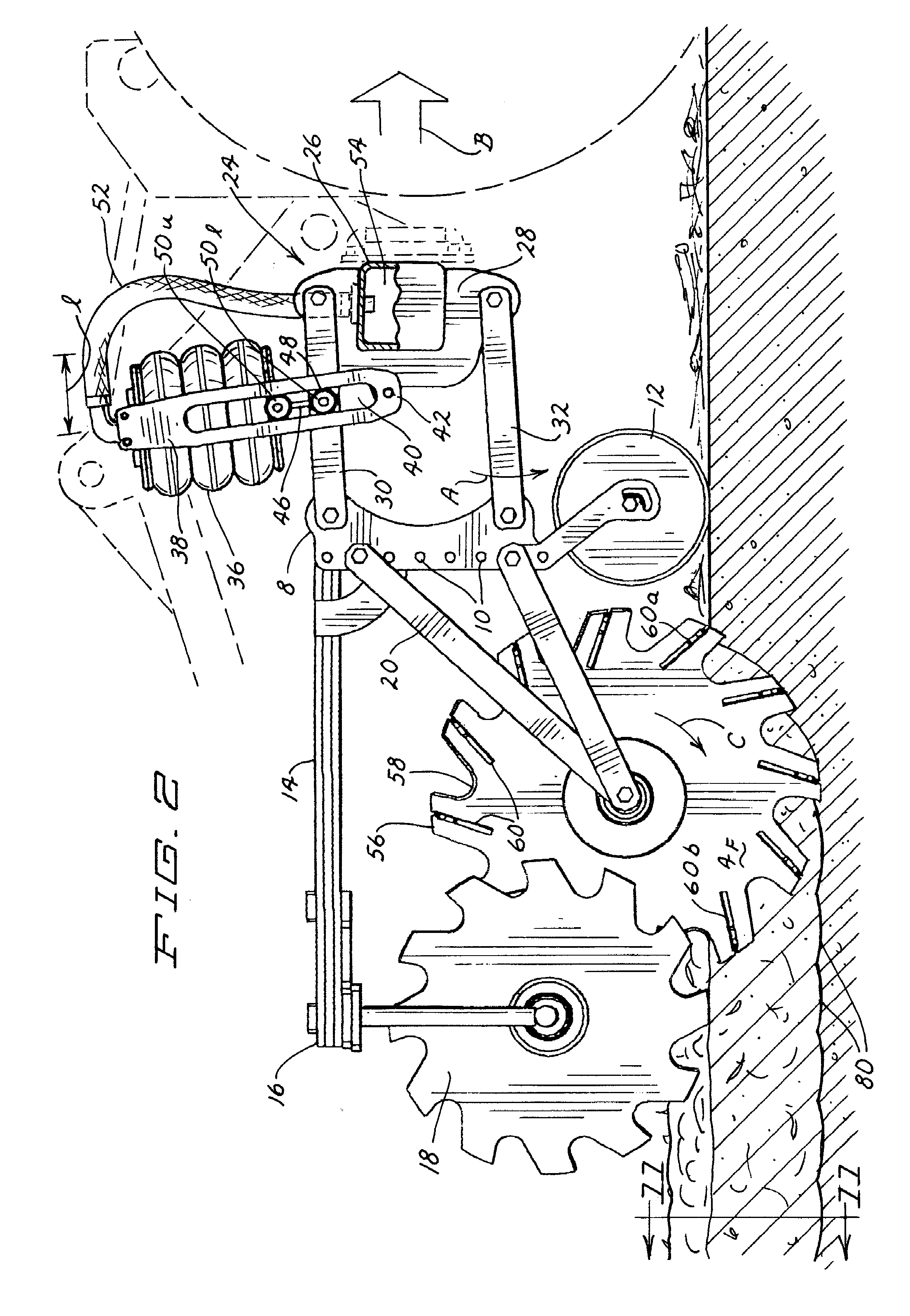

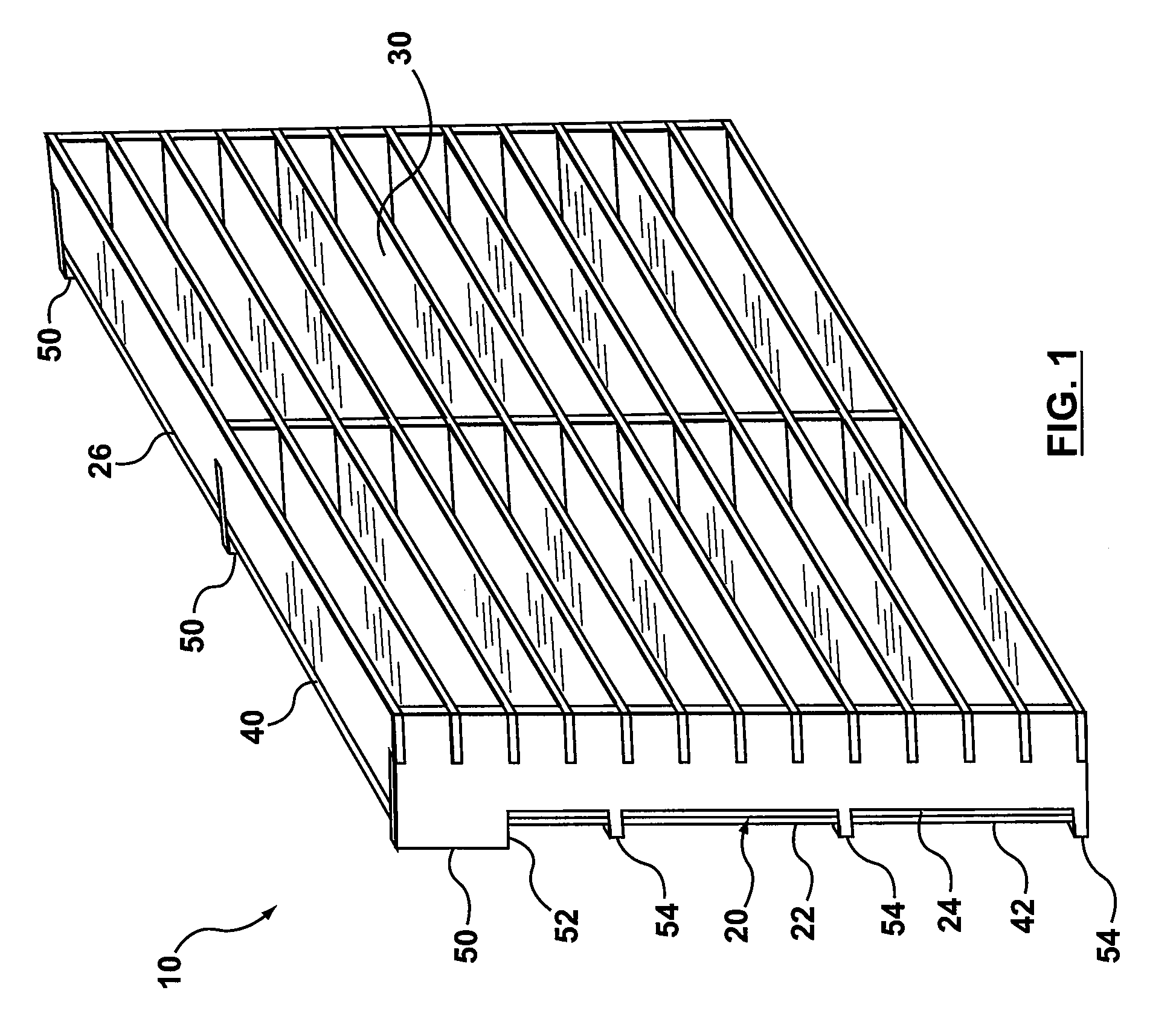

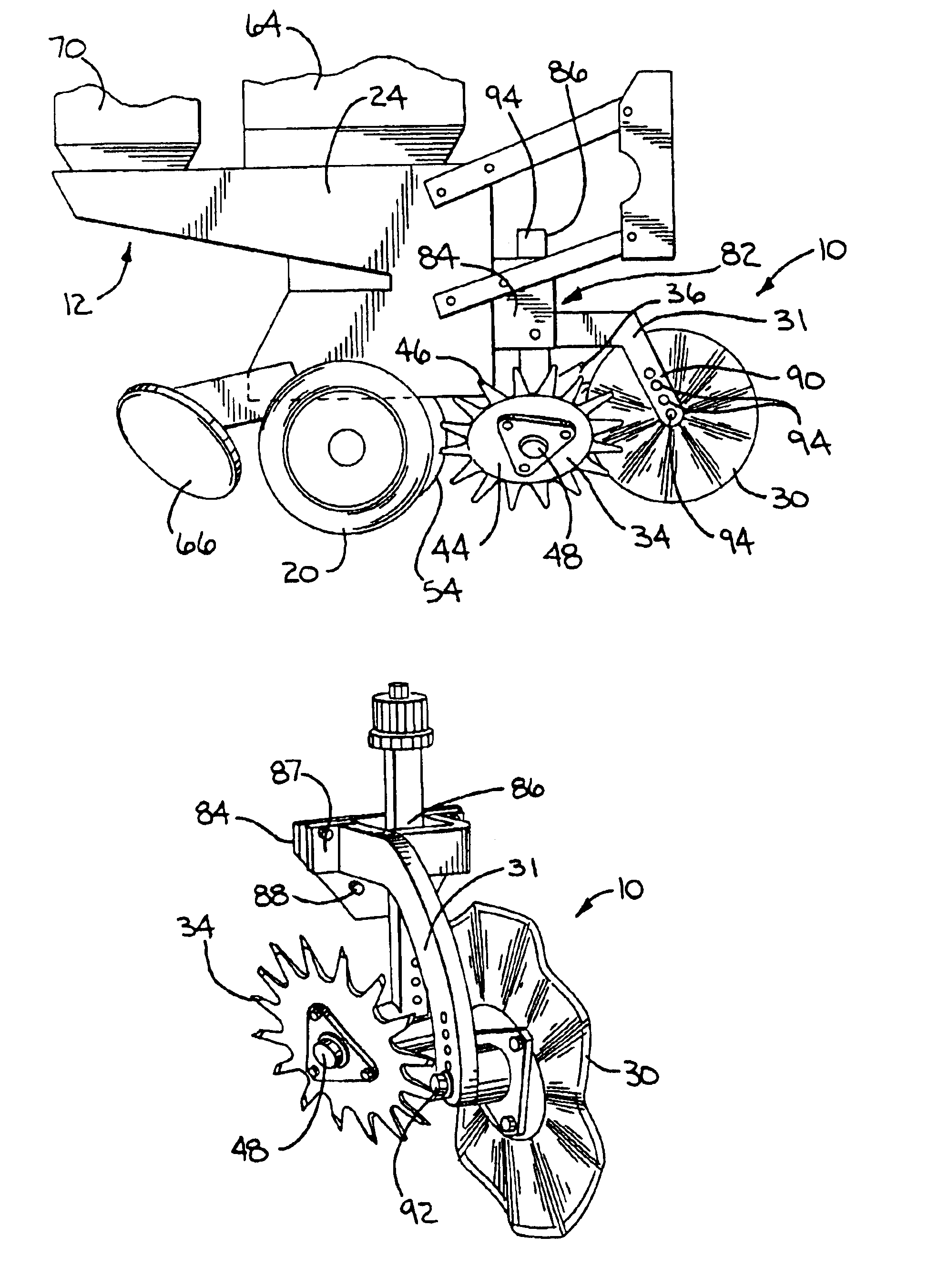

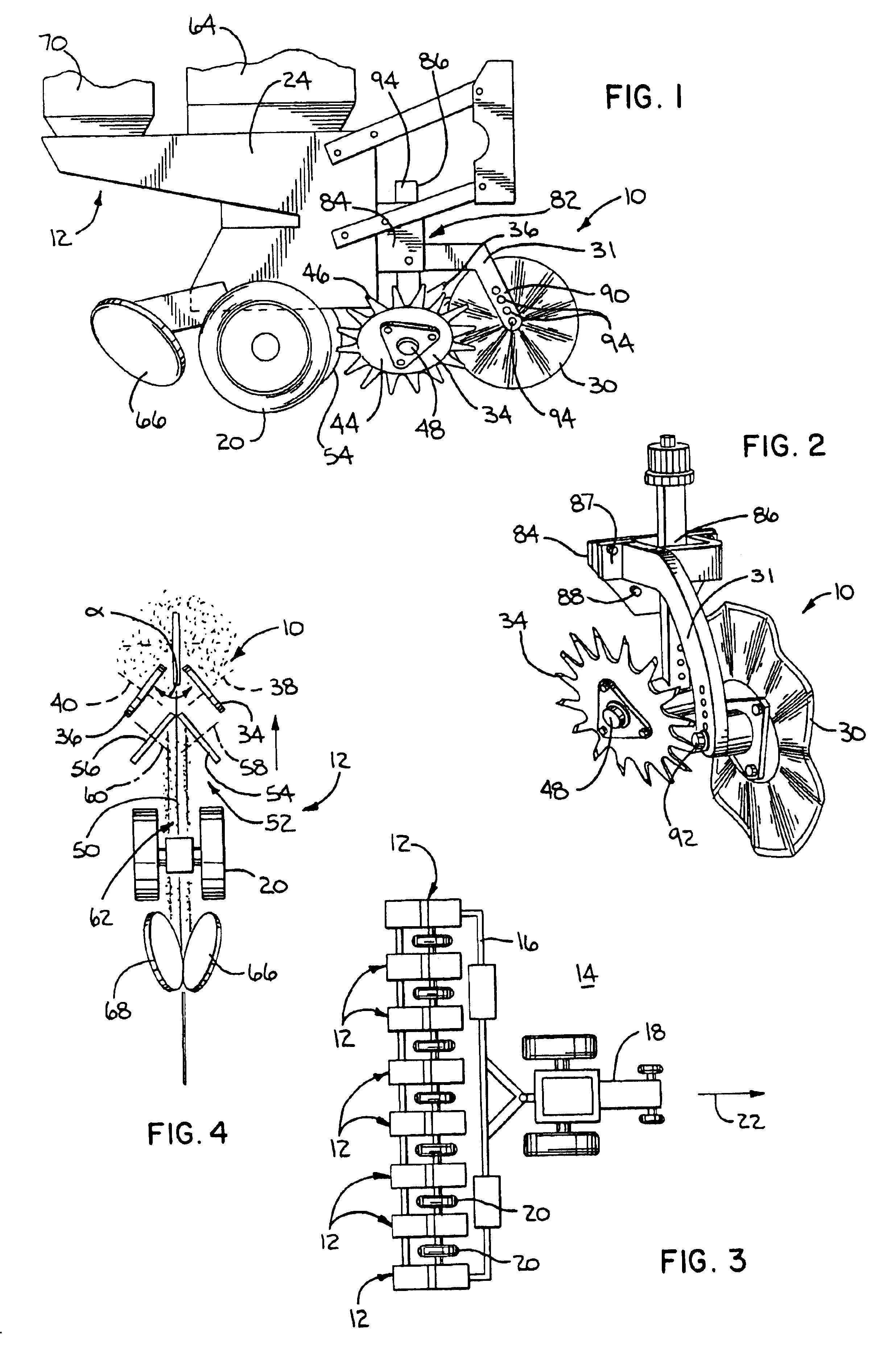

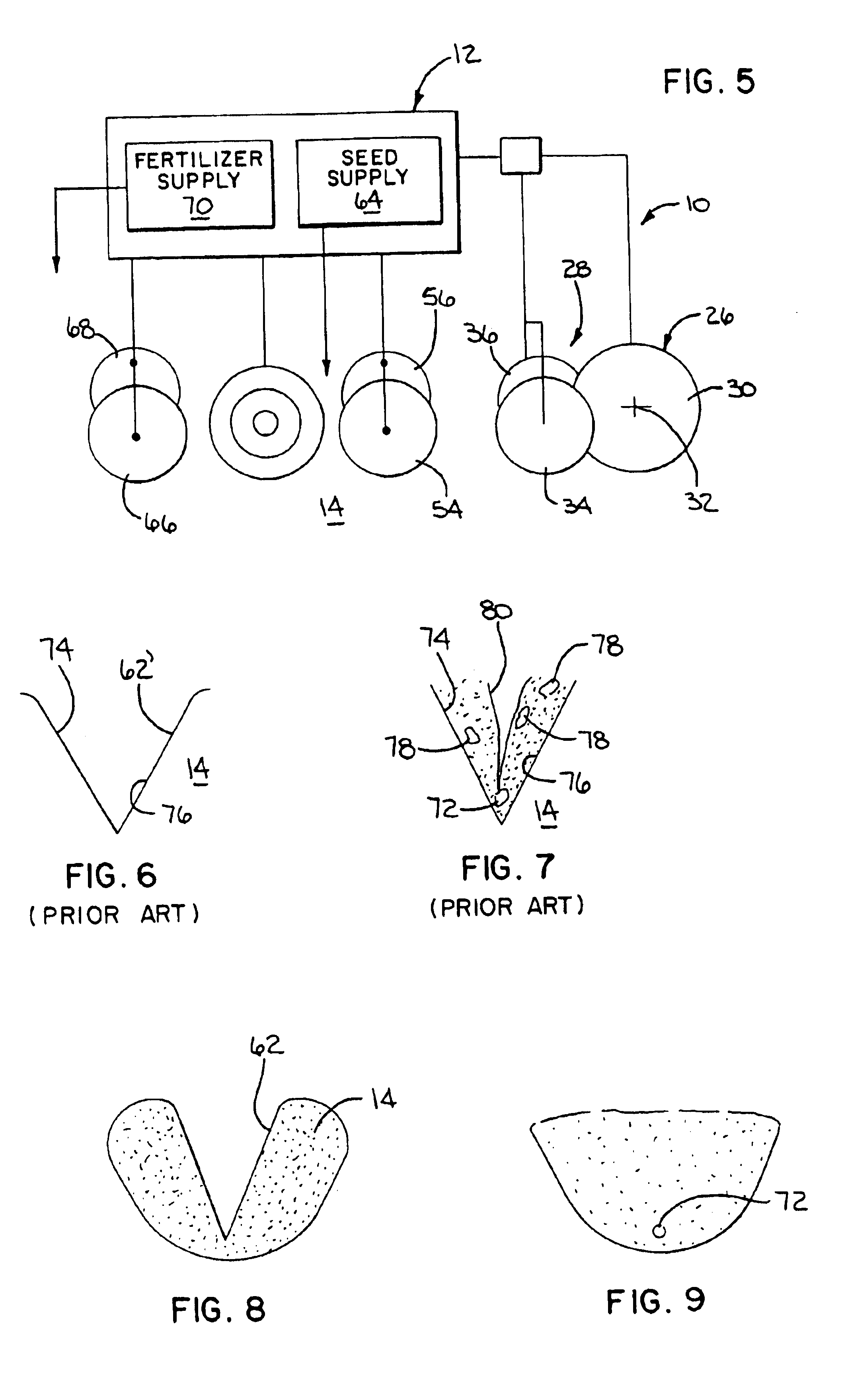

Fertilizer injector wing for disc openers

InactiveUS7004090B2High speed useReduce distractionsTill seedingDirect liquid fertiliser deliverySeederAgricultural engineering

Disc openers (14) for use with an air seeder (10), are configured for seeding and fertilizing a field (G). The opener (14b) broadly includes a drawbar assembly (16), a disc assembly (18) including a coulter disc (20) and a gauge wheel (22), a seed boot (24), a fertilizer injector wing (26), a firming wheel assembly (28), and a closing wheel assembly (30). The fertilizer injector wing (26) is configured for fixed attachment to the seed boot (24) and broadly includes a body (48), including an angled outboard portion (56), a toxic fertilizer injector (50), and a non-toxic fertilizer injector (52). The opener (14b) with the fertilizer injector wing (26) is configured to place the seed row (S) and the dedicated fertilizer band (DB) at an optimum geometric positional alignment relative to the seed row (S), in a single, low soil disturbing planting pass without disrupting the seed bed (BS).

Owner:EXACTRIX

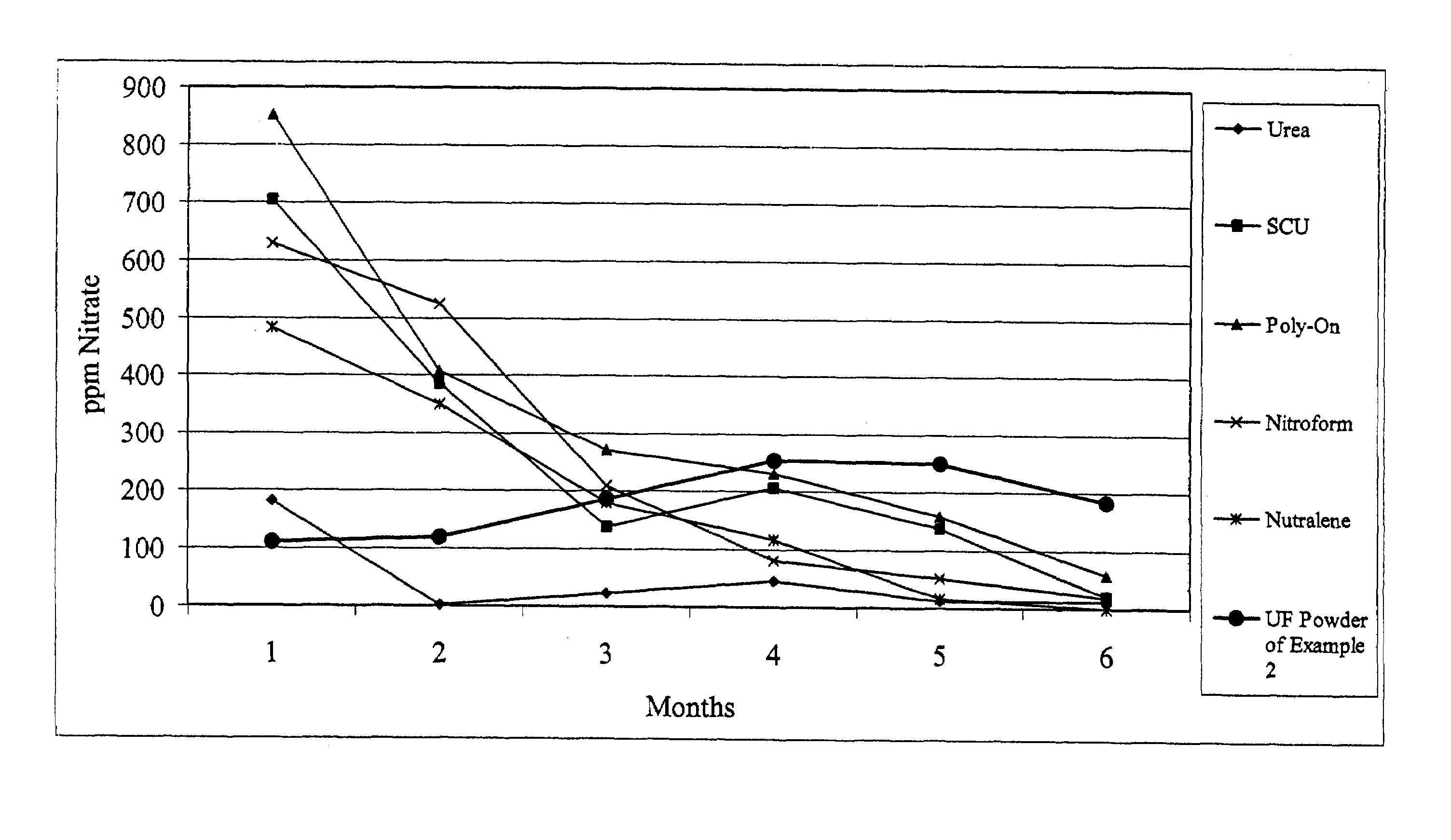

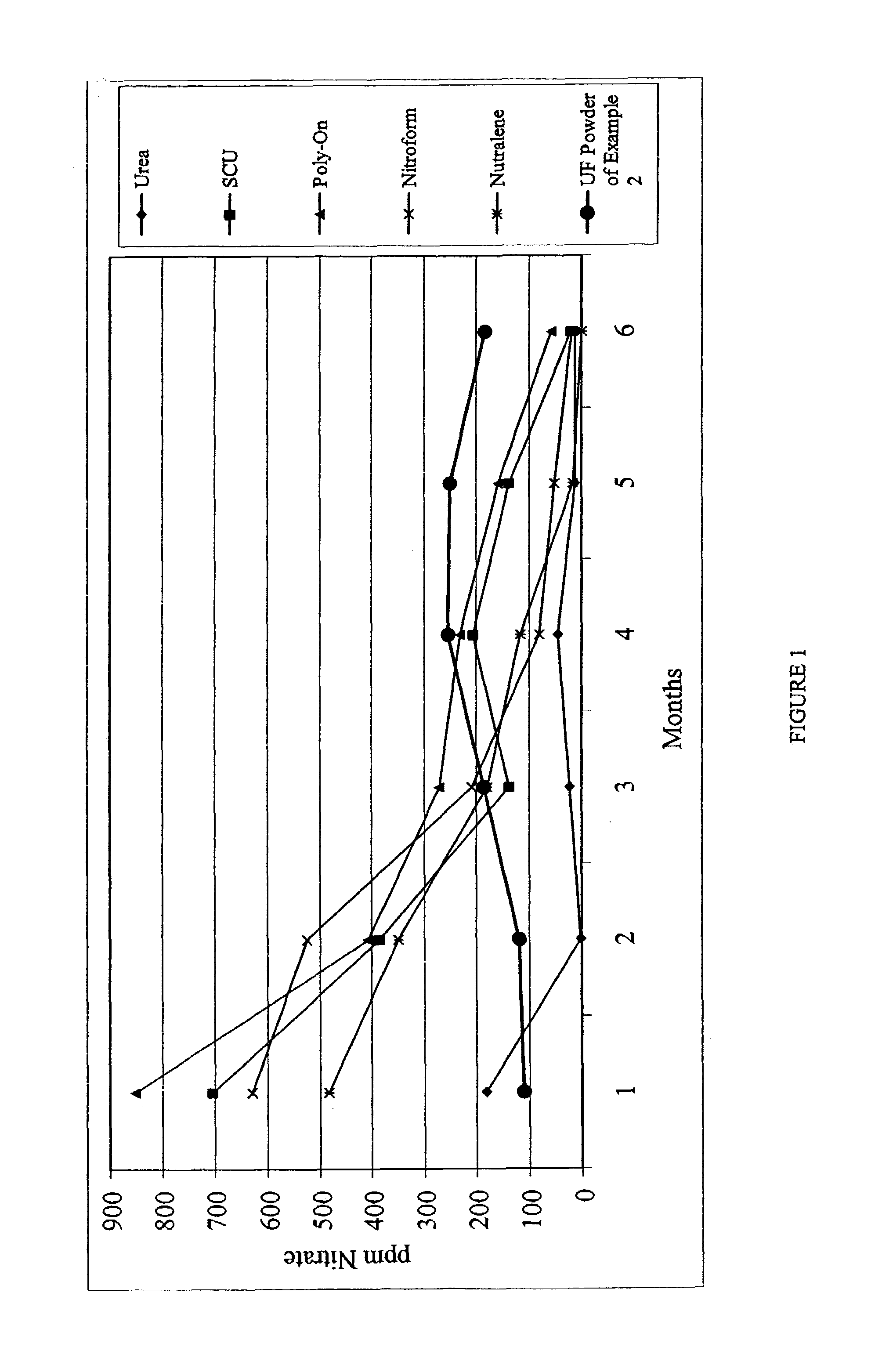

Slow release nitrogen seed coat

Owner:KOCH AGRONOMIC SERVICES LLC

Coal gangue lightweight through-hole ceramsite

The invention discloses coal gangue lightweight through-hole ceramsite. The technical scheme has the essentials that the coal gangue lightweight through-hole ceramsite is composed of coal gangues, attapulgite clay, a powdery coal gangue foaming agent, active carclazyte waste dreg, hollow microspheres, lightweight magnesium oxide, expanded perlite, expanded vermiculite, ferrous sulfate and quick lime. The materials of the coal gangue lightweight through-hole ceramsite are stirred and mixed, extruded and granulated, dried, roasted, subjected to heat insulation, sieved, sealed and packaged to prepare the coal gangue lightweight through-hole ceramsite. The coal gangue lightweight through-hole ceramsite has the characteristics of large specific surface area, small bulk density, high water absorption rate, excellent ventilation performance, beautiful appearance and shape and no odors, no harmful bacteria, good lightweight strength, and consistent micro-pores and macro-pores. When the coal gangue lightweight through-hole ceramsite is used for culturing or planting various types of nursery stocks, flowers and vegetables, the roots of the plants can absorb nutrition constituents of water or a liquid fertilizer from the coal gangue lightweight through-hole ceramsite, so that good growth and development and the survival rate of the plants are ensured and the coal gangue lightweight through-hole ceramsite is suitable for preparing a soilless culture substrate and nutrient soil.

Owner:平凉华晨非金属应用科技有限公司

Control and sensor systems for an environmentally controlled vertical farming system

ActiveUS20180014486A1High yieldCost per square footSelf-acting watering devicesLayeringControl systemSensor system

A computer implemented system for a vertical farming system comprising at least a first crop growth module and operating in an environmentally-controlled growing chamber, the control system comprising sensors for measuring environmental growing conditions in the environmentally-controlled growing chamber over time to generate environmental condition data, a device configured for measuring a crop characteristic of a crop grown in the crop growth module of the environmentally-controlled growing chamber to generate crop growth data and a processing device comprising software modules for receiving the environmental condition data and the crop growth data; applying an algorithm to the environmental condition data and the crop growth data to generate an improved environmental growing condition and generating instructions for adjustment of the environmental growing conditions in or around the growth module in the environmentally-controlled growing chamber to the improved environmental growing condition.

Owner:MJNN LLC

Method and apparatus for extracting carbon dioxide from air

A method and apparatus for extracting CO2 from air comprising an anion exchange material formed in a matrix exposed to a flow of the air, and for delivering that extracted CO2 to controlled environments. The present invention contemplates the extraction of CO2 from air using conventional extraction methods or by using one of the extraction methods disclosed; e.g., humidity swing or electro dialysis. The present invention also provides delivery of the CO2 to greenhouses where increased levels of CO2 will improve conditions for growth. Alternatively, the CO2 is fed to an algae culture.

Owner:CARBON SINK

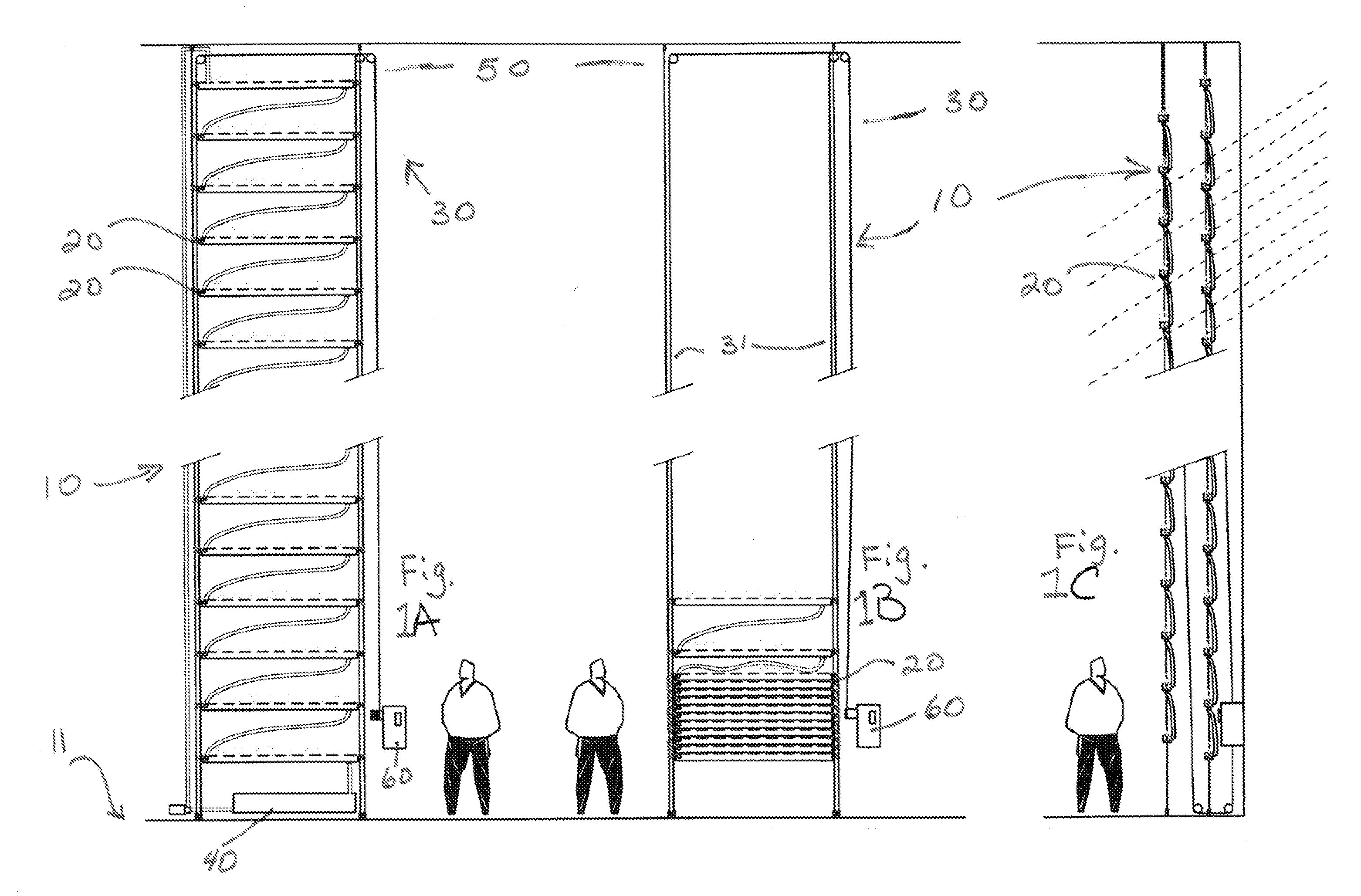

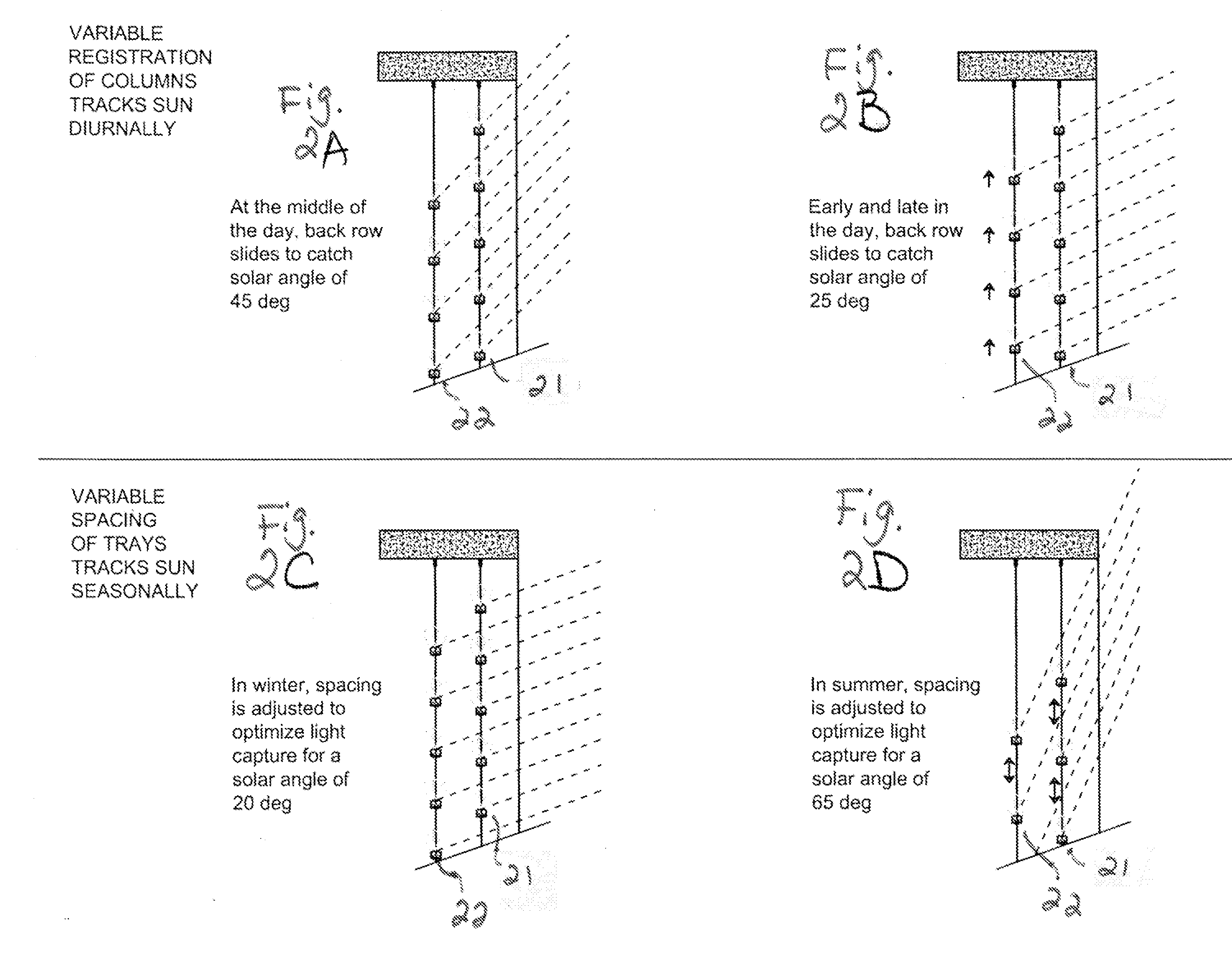

Vertically Integrated Greenhouse

ActiveUS20090307973A1High yieldTight spacingClimate change adaptationWatering devicesGreenhouseBuilding energy

A vertically-integrated greenhouse for growing plants in suspended trays. The design is particularly well-suited for installation in a double-skin façade of a building, or in an interior atrium, lobby, or similar structure. In addition to producing food, plants can reduce building maintenance costs by providing shade, air treatment, and evaporative cooling to building occupants. The vertically-integrated greenhouse involves the use of a dynamic movable array of plant trays as a mechanical shading device. The spacings and arrangements of the trays in the tray suspension system can be adjusted on both a diurnal basis and a seasonal basis to maximize plant light capture and building shading, thereby maximizing crop yield and building energy savings, or for esthetic considerations.

Owner:NEW YORK SUN WORKS

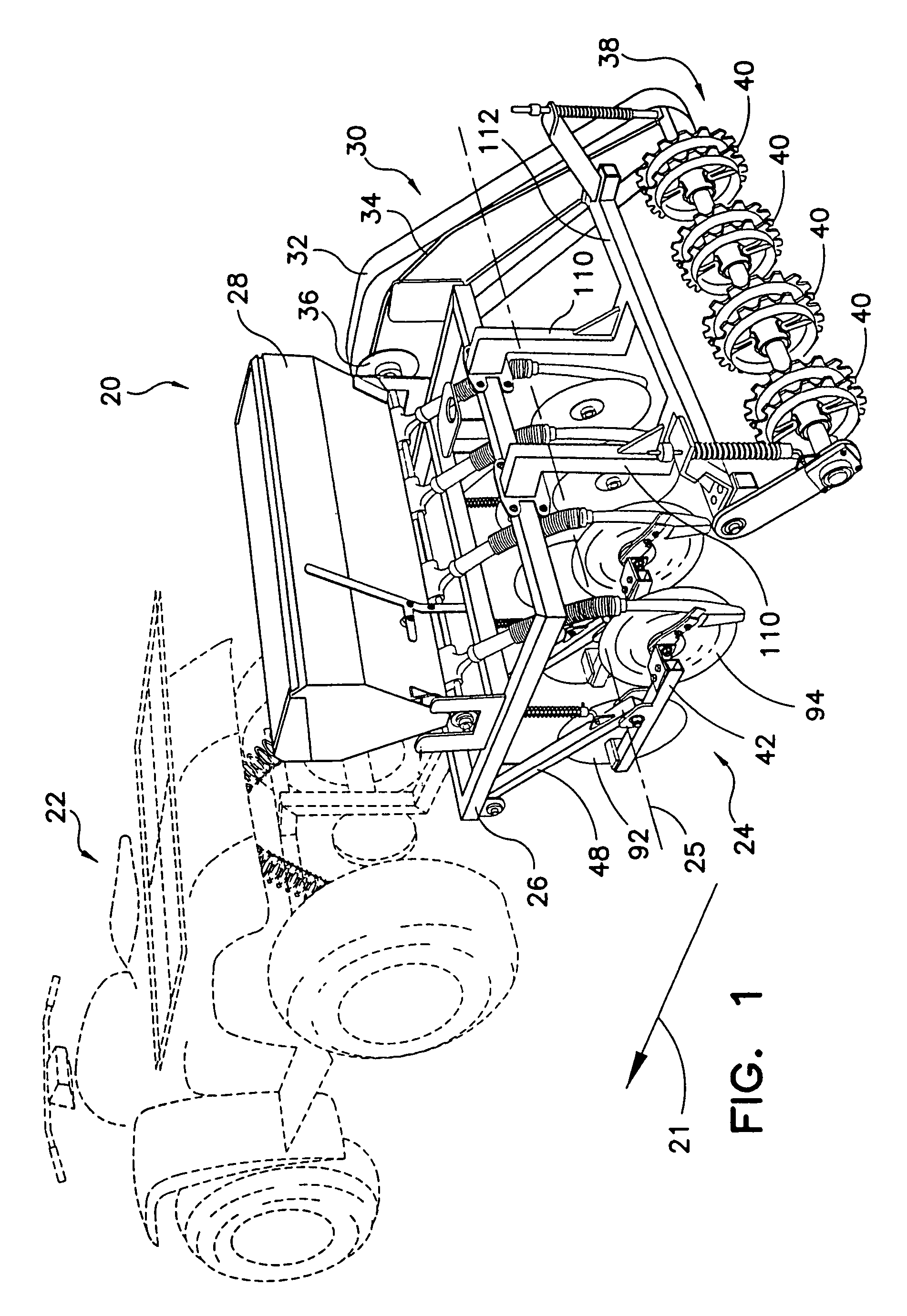

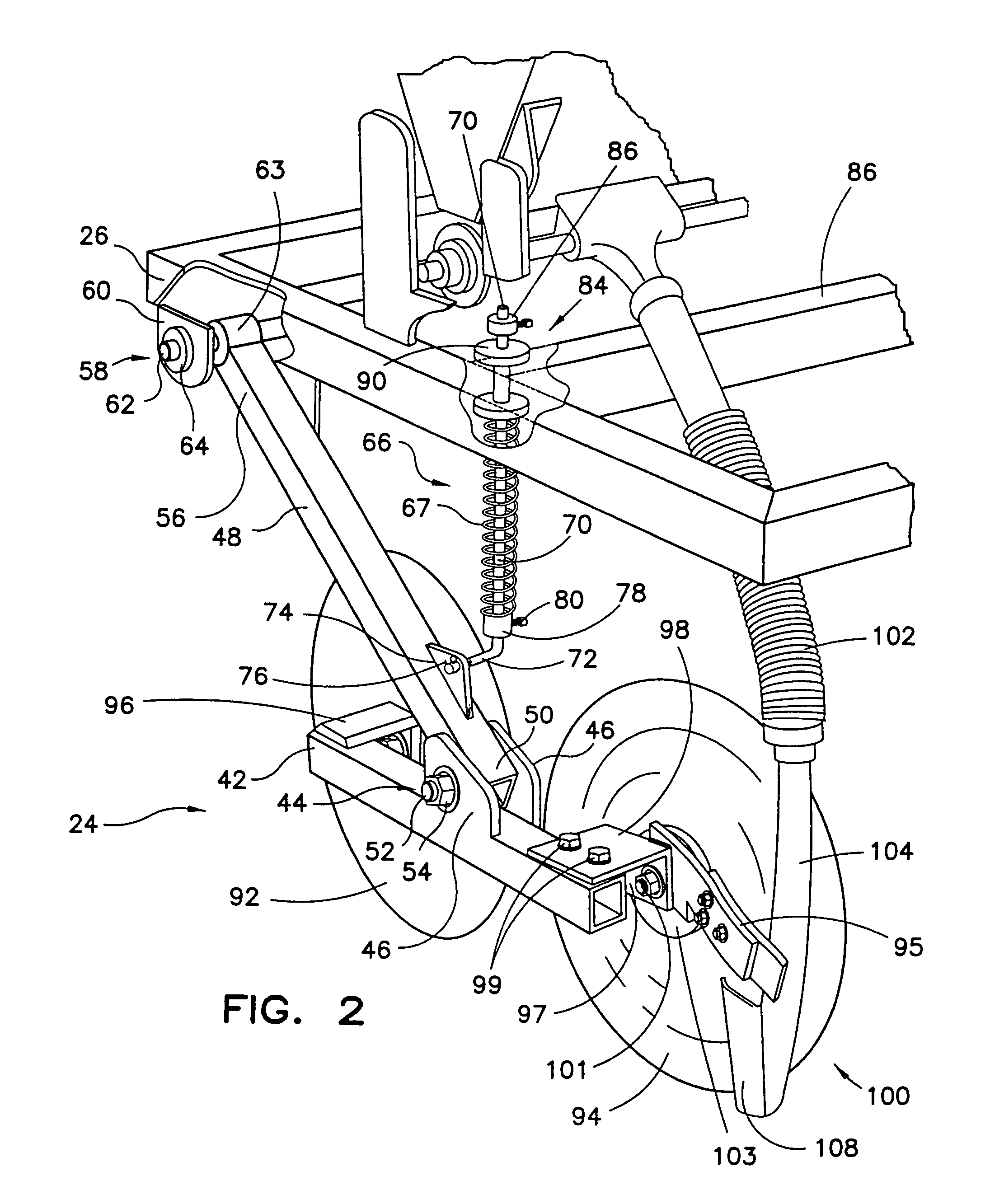

Seed drill with walking beam assembly

A no-till drill with a novel walking beam assembly that allows the drill to be pulled over severe terrain conditions that include large rocks, fallen limbs and other large obstructions. The inventive walking beam assembly includes two independent pivot points that allow the cutting and opening disks to maintain substantially constant or continuous contact with the ground, such that the length of the furrow formed and seed deposited therein are maximized. A closing disk assembly is suspended from the rear of the drill independently from the walking beam assembly. This independent suspension allows the walking beam assembly to function without interference from the closing disks.

Owner:KASCO MFG

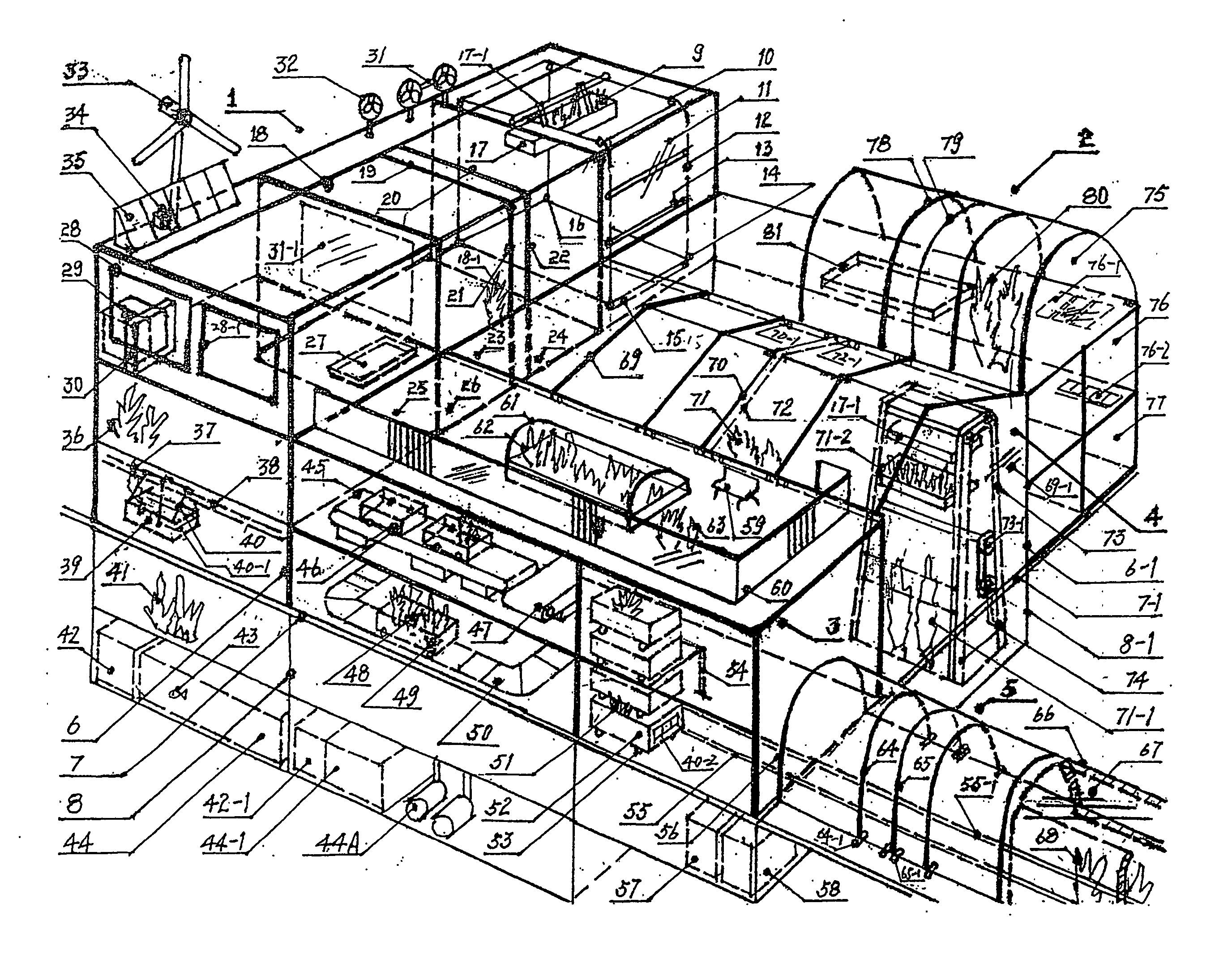

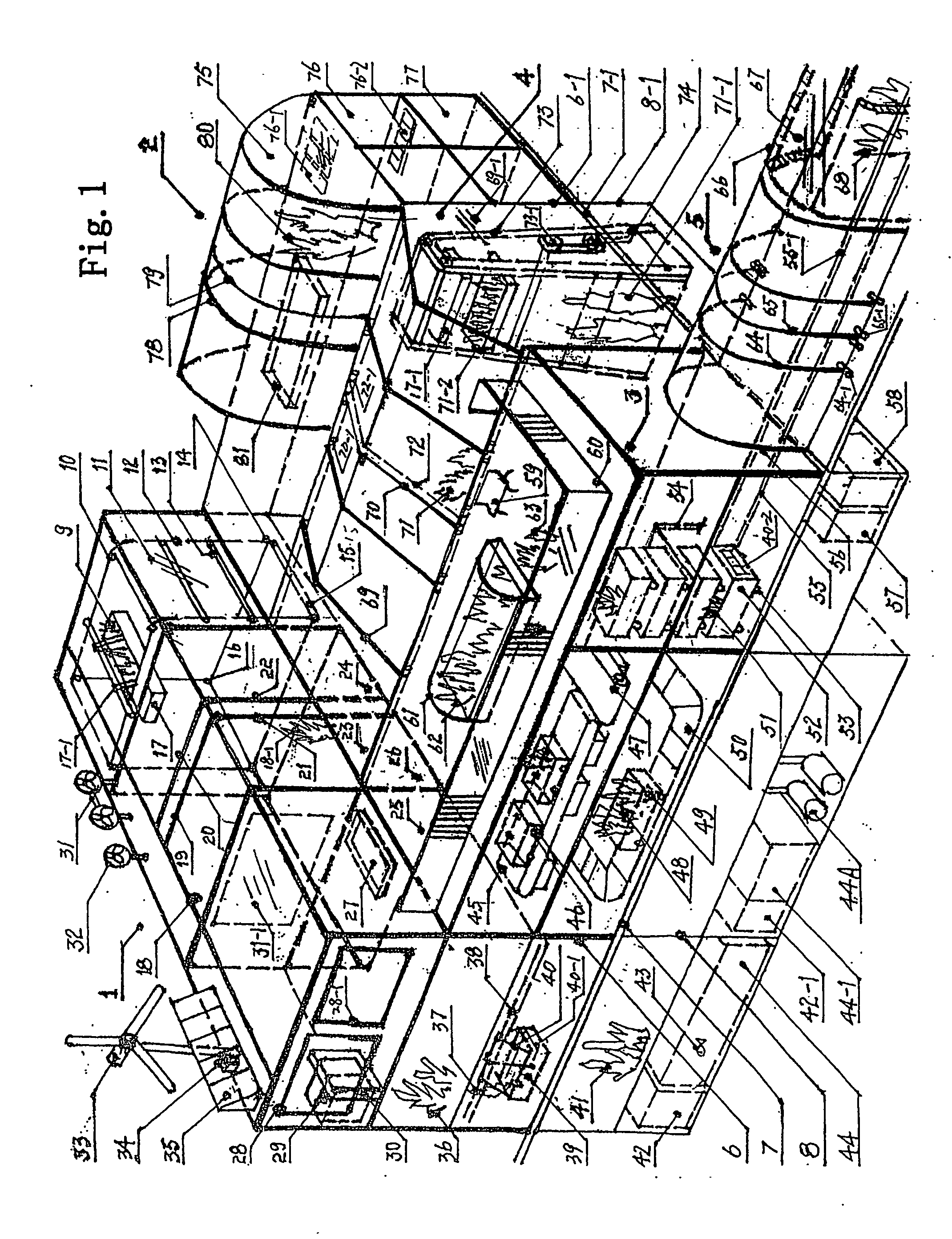

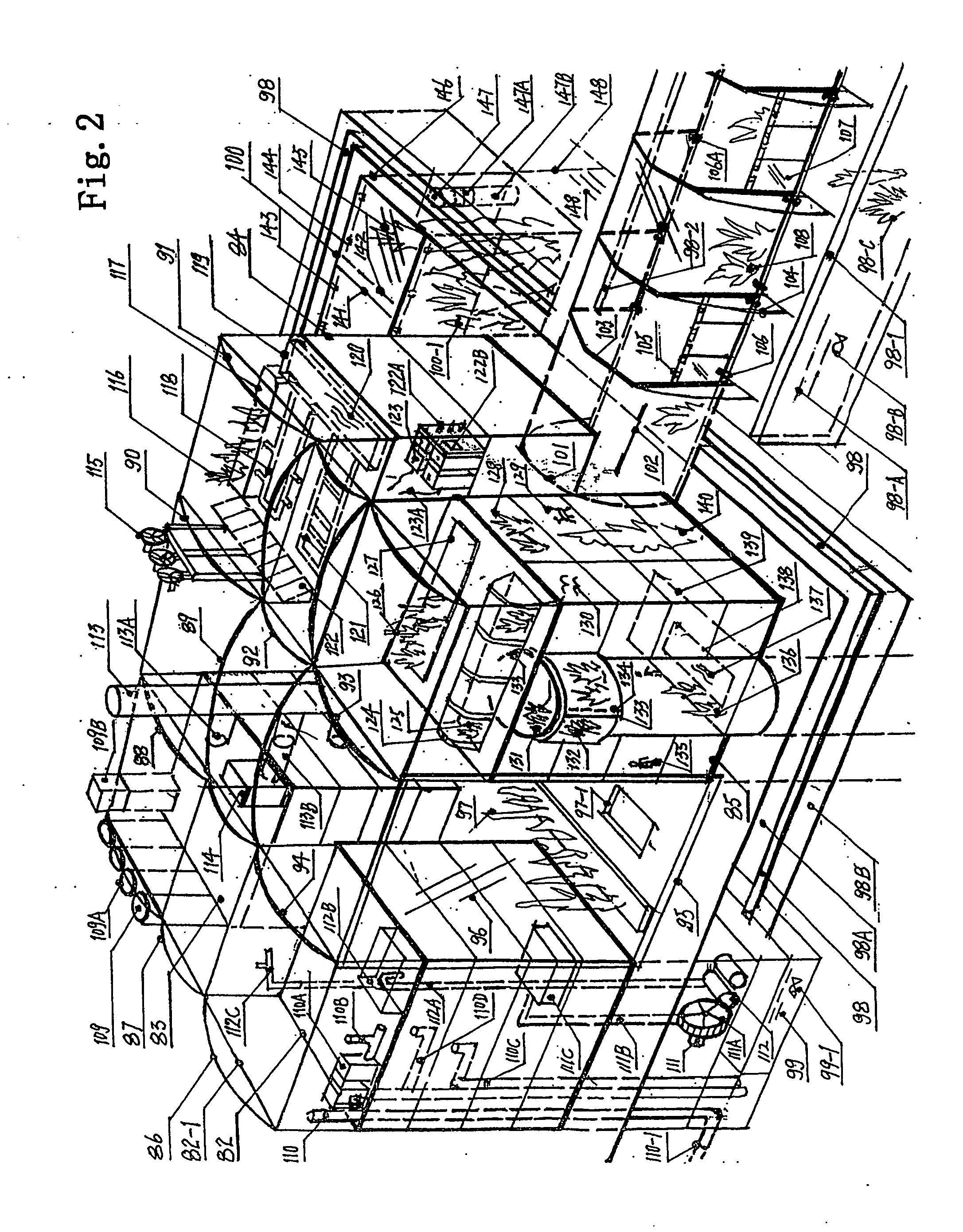

Multifunctional tridimensional combined green building

The present invention is related to a tridimensional combined green building which is constituted with plant, biologic ecosystem, physical environment ecosystem, habitation environment and the combination thereof. Said tridimensional combined green-building may comprises green villages, green areas and green scientific town, such as tridimensional wall, tridimensional river and tridimensional bridge etc., and they can be divided into variety of green building.

Owner:ZHAO BING

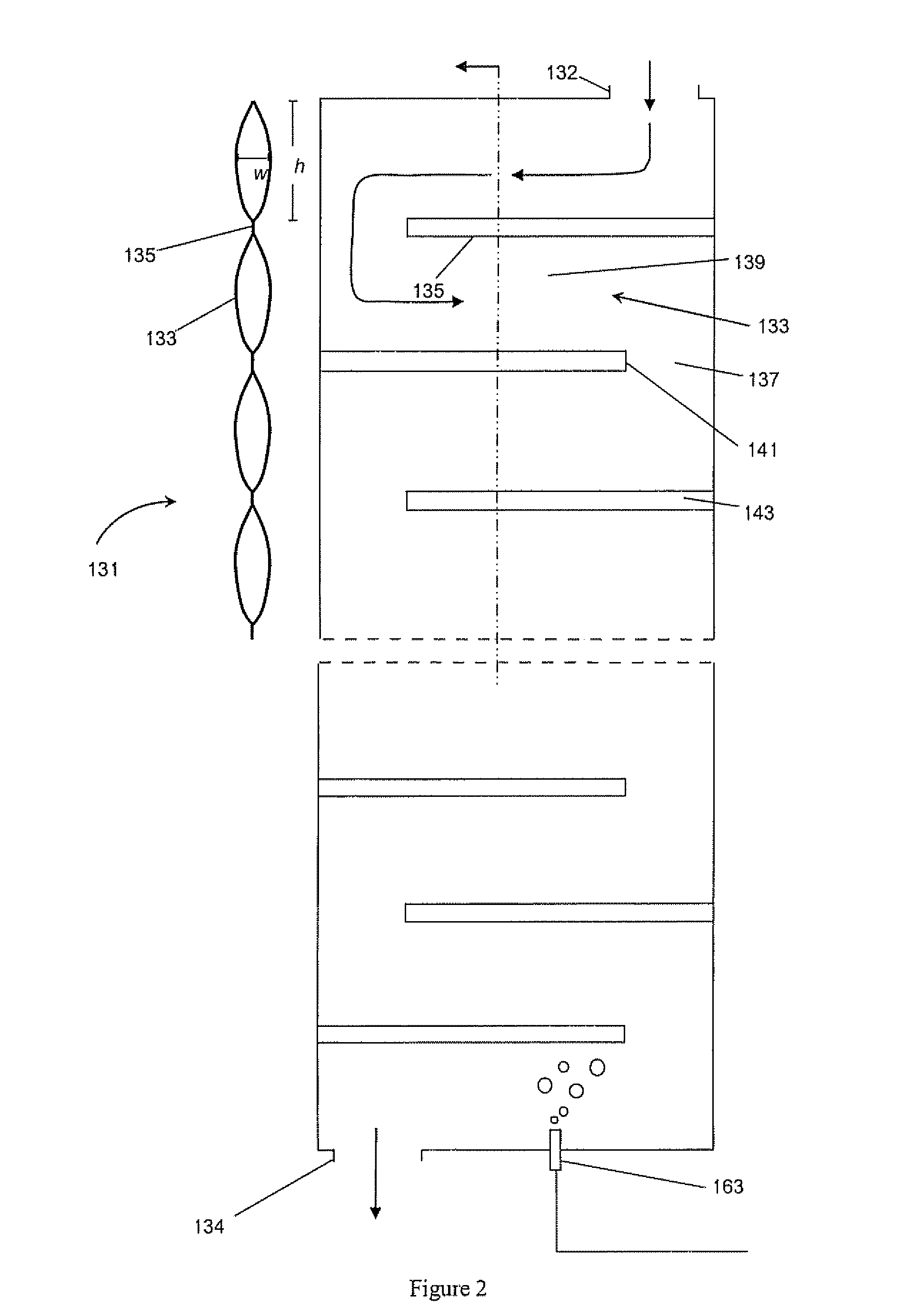

Method and apparatus for co2 sequestration

InactiveUS20070289206A1Easy to manufactureIncrease surface areaBioreactor/fermenter combinationsBiological substance pretreatmentsAlgaeBioreactor

A method and apparatus for sequestering CO2 using algae comprises a plurality of vertically suspended bioreactors, each bioreactor being translucent and including a flow channel formed by a plurality of baffles. A culture tank contains a suspension of water and at least one algae and includes a plurality of gas jets for introducing a CO2-containing gas into the suspension. The culture tank is in fluid communication with an inlet in each channel for flowing the suspension through the channel in the presence of light. A pump pumps the suspension into the channel inlet.

Owner:KERTZ MALCOLM GLEN

Zone tillage tool and method

A zone tillage tool comprises a tool frame connected by a parallel lift linkage to a tool bar. A fall tillage coulter or dual spring tillage coulters can be carried on the tool frame in advance of a pair of containment coulters. The fall tillage coulter tills soil in a zone that is approximately 7 to 9 inches deep while the spring tillage coulters till 2 to 3 inches deep. The fall tillage coulter includes a plurality of shovel bits located around the circumference thereof at a forward rake angle. The tip of each shovel bit has a generally vertical entry position into the ground due to the forward rake angle. As the fall tillage coulter rotates, the shovel bits rotate around and exit the soil in a generally horizontal position, thereby lifting and loosening the soil without compacting the soil through a series of rearwardly and upwardly directed soil scooping actions.

Owner:ENVIRONMENTAL TILLAGE SYST

Hydroponic plant cultivating apparatus

A hydroponic system with modules having a hollow interior, a bottom wall with drain holes, and an open top end. A module conduit in each module carried by the bottom wall for channeling fluid through the hollow interior. The bottom wall of each module adapted to engage a top end of an adjacent module for stacking the modules in an end-to-end arrangement to form a planting column. A conduit receiving slot formed in the bottom wall of each module to engage a top portion of a conduit from an adjacent lower module when the modules are stacked end-to-end to provide a continuous fluid passageway through the planting column. A platform vertically carrying the planting column atop a fluid reservoir. A supply line connecting the reservoir to the fluid passageway. A fluid distributor atop the column in fluid communication with the fluid passageway for distributing fluid into the planting column.

Owner:TOWER GARDEN

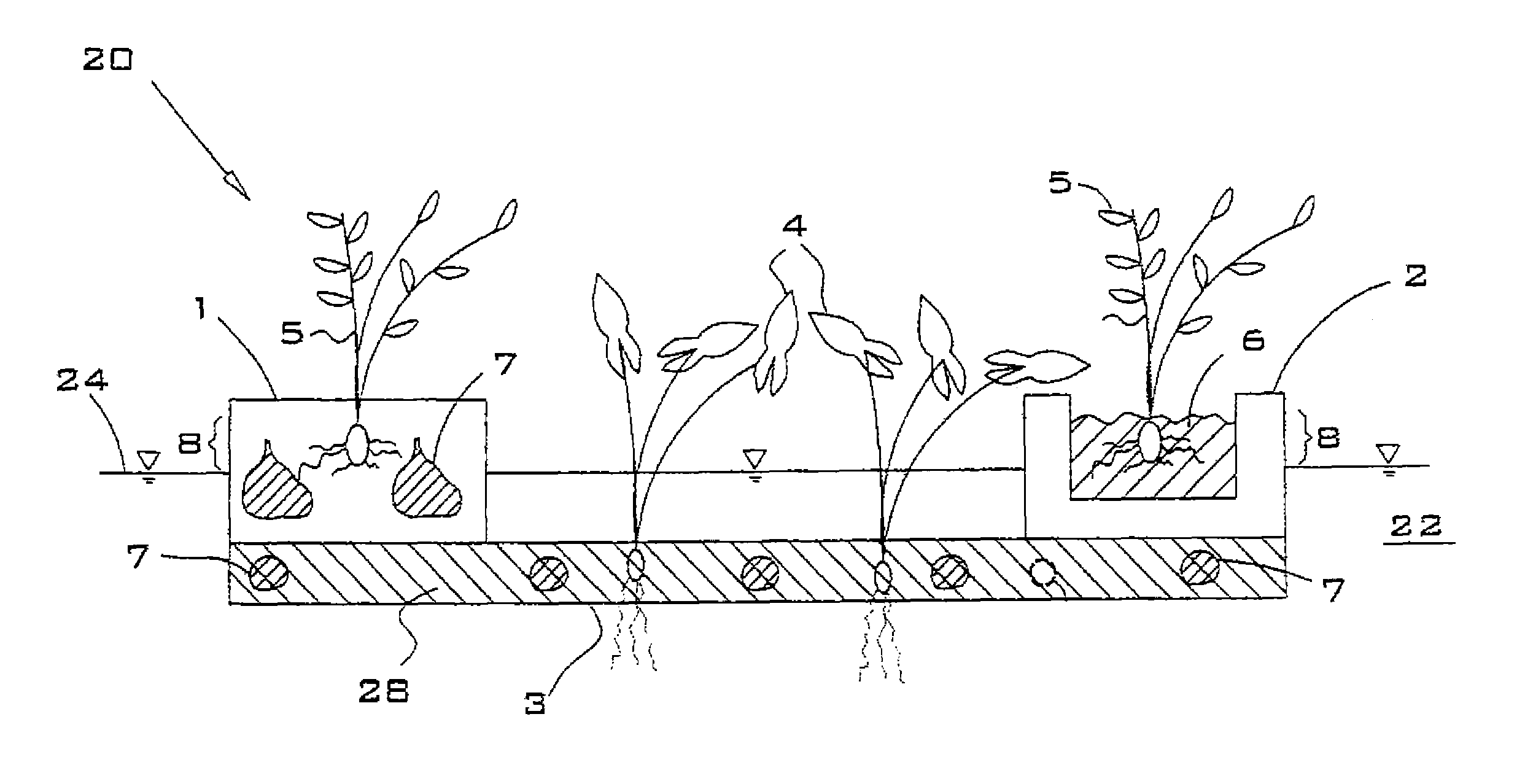

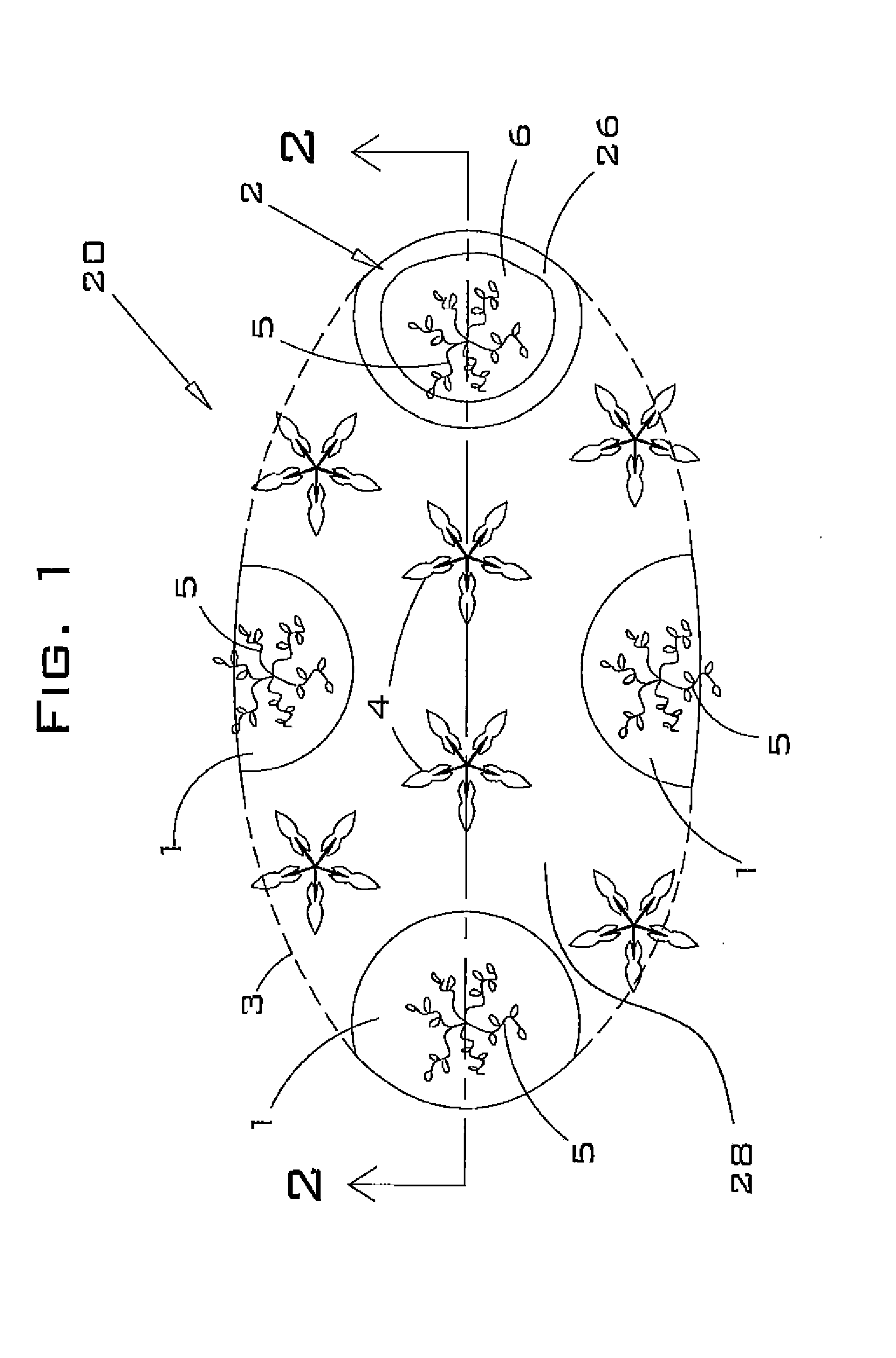

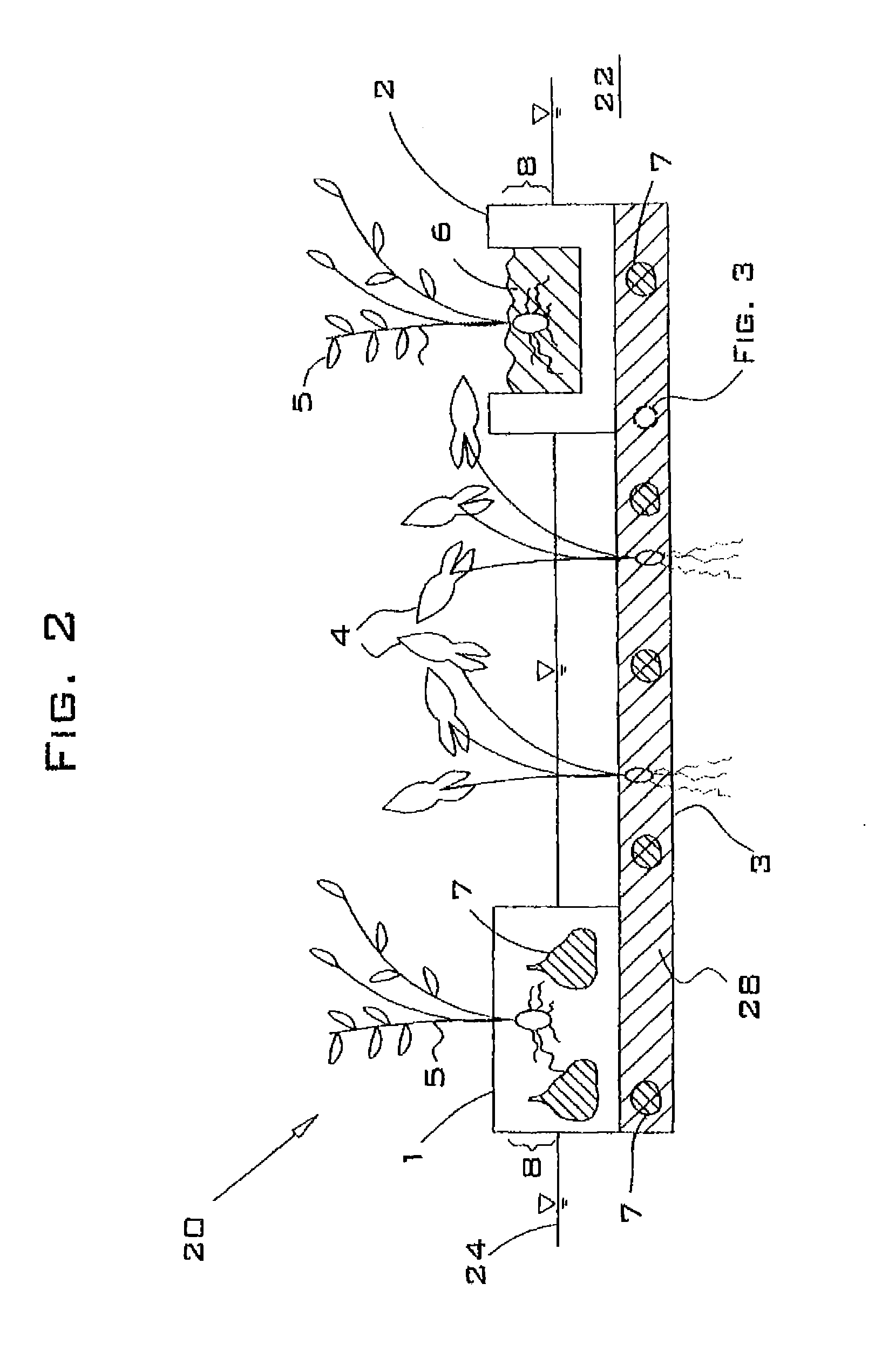

Buoyant wetland system

InactiveUS7810279B2Low costEasy constructionPlanting bedsAgriculture gas emission reductionCell culture mediaBiology

Owner:FOUNTAINHEAD

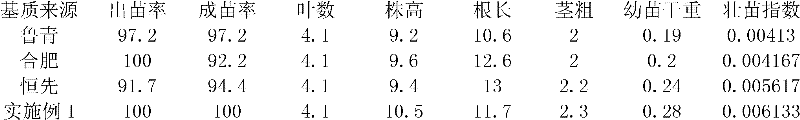

Seedling substrate for soilless culture for vegetables

ActiveCN102432394AHigh in potassiumRich in trace elementsBio-organic fraction processingAgriculture gas emission reductionPorosityBiology

The invention discloses a seedling substrate for vegetables, belonging to the technical field of soilless culture. The substrate formula comprises the following components based on volume ratios: 10-40% of fermented vinegar dreg, 5-30% of fermented cassava dreg, 5-30% of plant ash, 5-30% of perlite, 5-30% of vermiculite and 10-25% of turf. The water content of the substrate is not bigger than 50%, and the total porosity of the substrate is 65-95%, and the total nutrient content of the substrate (N+P2O5+K2O) is 3-5%, and the grain diameter of the substrate is 0.1-4.9 mm, and the volume weight of the substrate is 0.2-0.8 g / cm3, and the gas-water ratio of the substrate is 1: 2-4, and the EC (elastic coefficient) value of the substrate is 1-3 and the pH value of the substrate is 5.8-7.5. The seedling substrate for soilless culture for vegetables mainly uses organic wastes as raw materials, and produces seedling substrate by high temperature fermentation treatment, and changes wastes into wealth, and turns harm into good. The invention has a low production cost, a light weight and complete nutrients such that it is suitable for growth and development for vegetable seedlings, and is a good substrate for soilless culture industrialized tray seedling for vegetables.

Owner:江苏培蕾基质科技发展有限公司

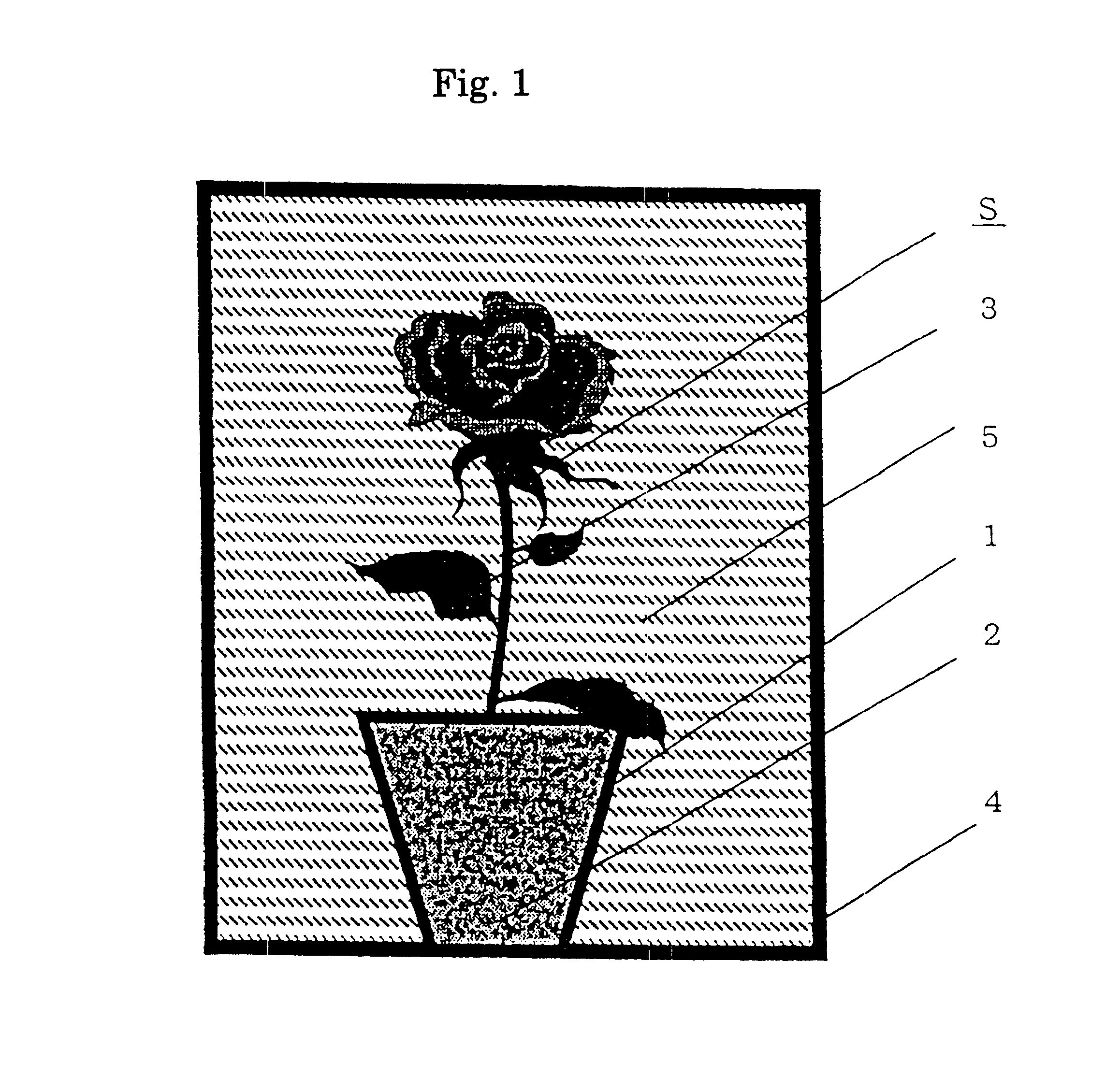

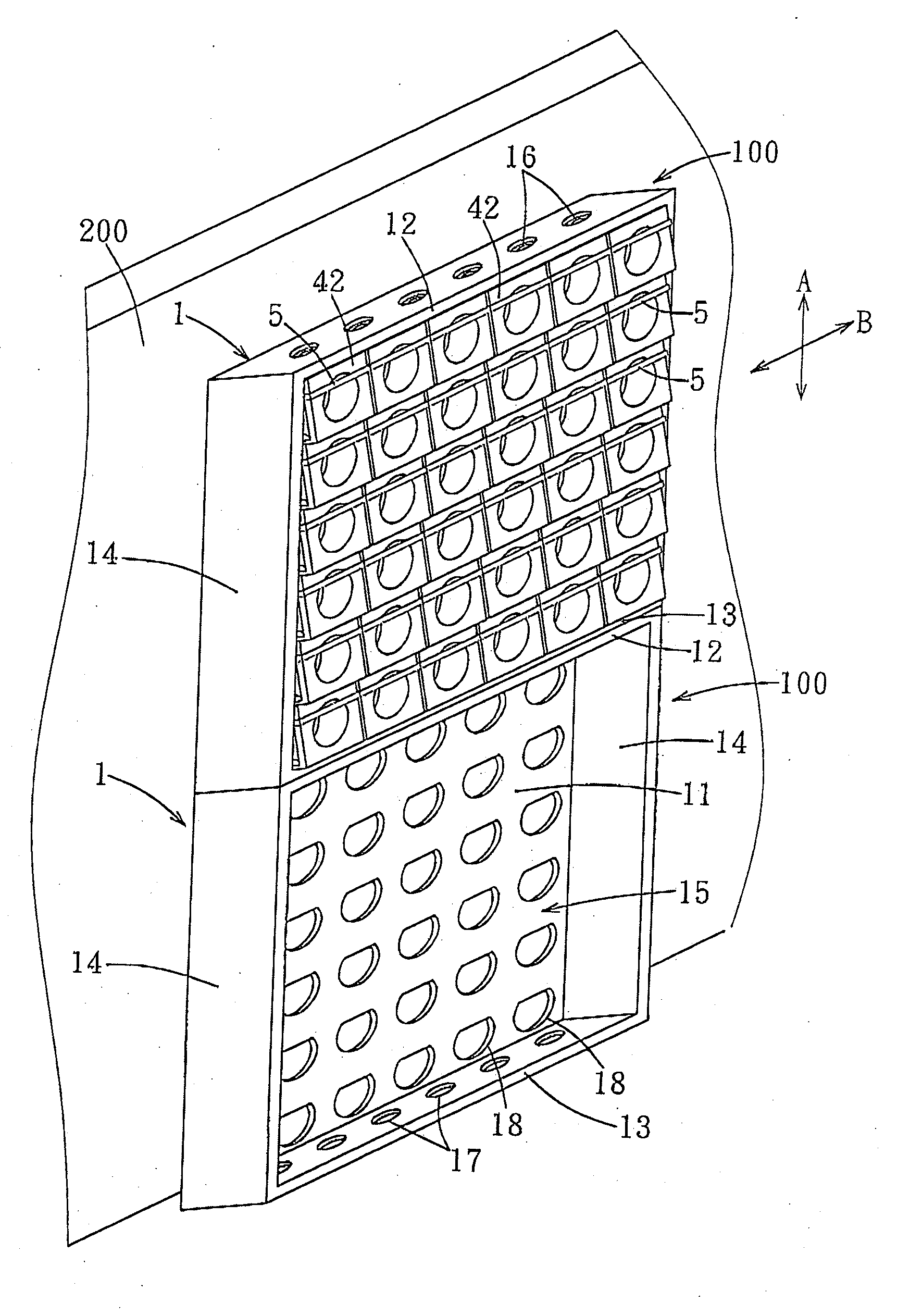

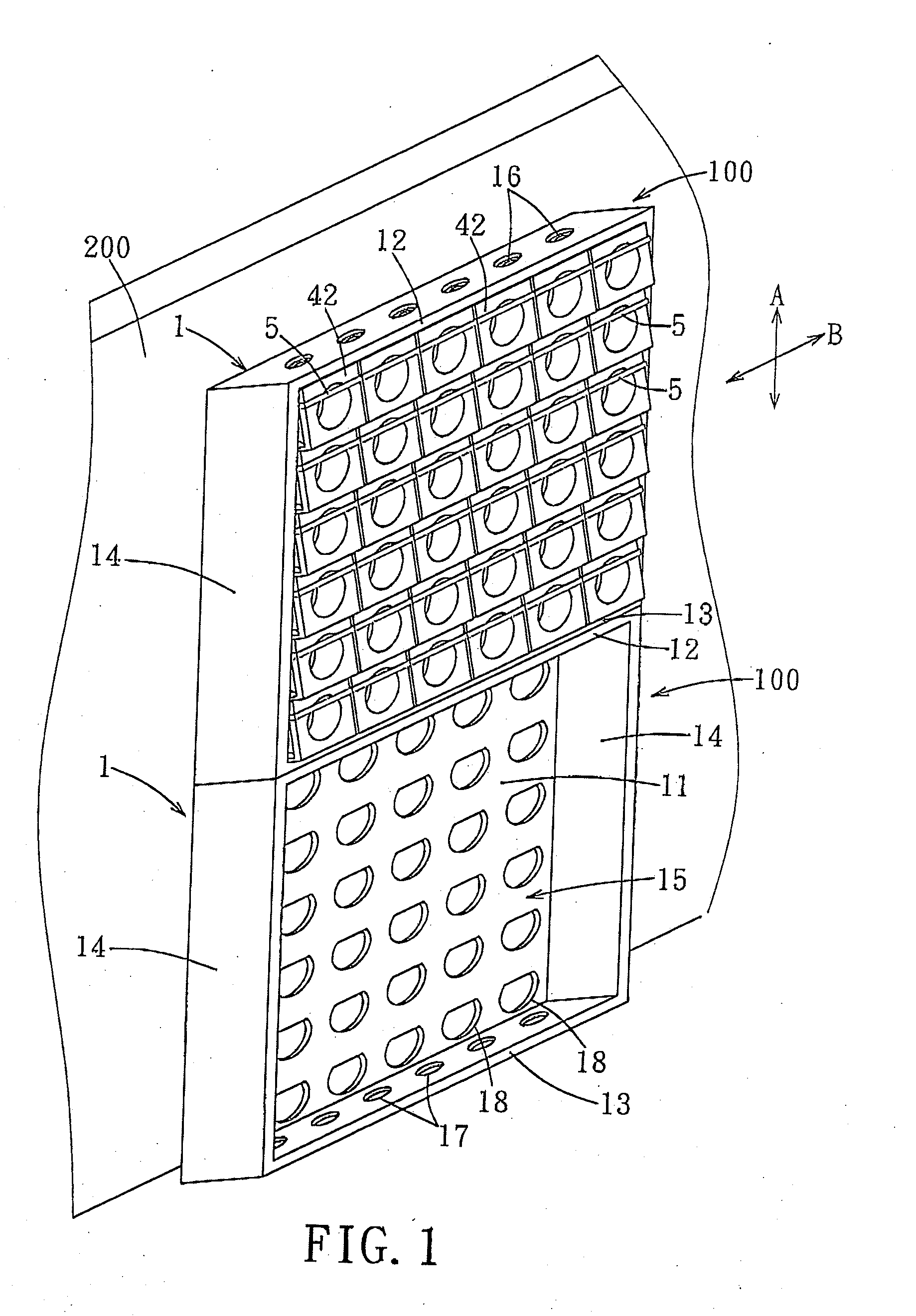

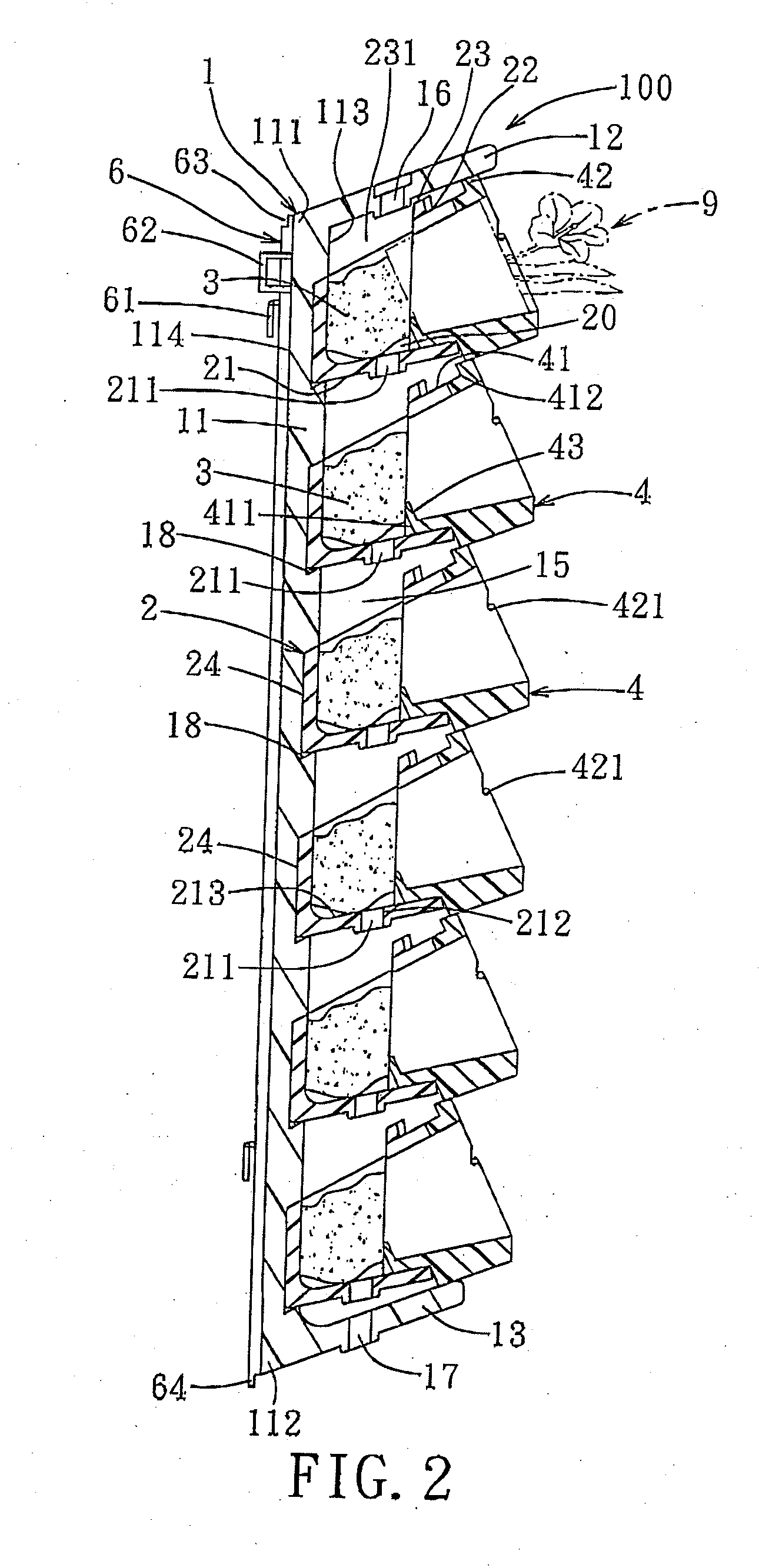

Modular Plant Growing Device

A modular plant growing device includes a main frame mounted on an upright supporting surface. The main frame is configured with an accommodating space defined by an upright rear plate, an inclined top plate extending gradually and upwardly from an upper end of the rear plate, an inclined bottom plate extending gradually and upwardly from a lower end of the rear plate, and opposite lateral plates for receiving a plant unit. The top plate is formed with an inlet unit permitting flow of liquid for plant growth into the accommodating space therethrough. The bottom plate is formed with an outlet unit disposed adjacent to the lower end of the rear plate and permitting leakage of the liquid from the accommodating space therethrough.

Owner:MA KE TEN

Vertical plant supporting system

A vertical plant support includes a wall having a panel and an anchor layer, and a matrix of tubes being connected to the wall. The anchor layer is located intermediate the panel and the matrix of tubes. The panel can be liquid impermeable and the anchor layer can be liquid permeable.

Owner:ELEVATED LANDSCAPE TECH

Domestic full-automatic vegetable planting machine

ActiveCN103416292ASecure carbon dioxideEnsure demandAgriculture gas emission reductionCultivating equipmentsControl systemEngineering

Owner:WUXI IGROWTHS TECH CO LTD

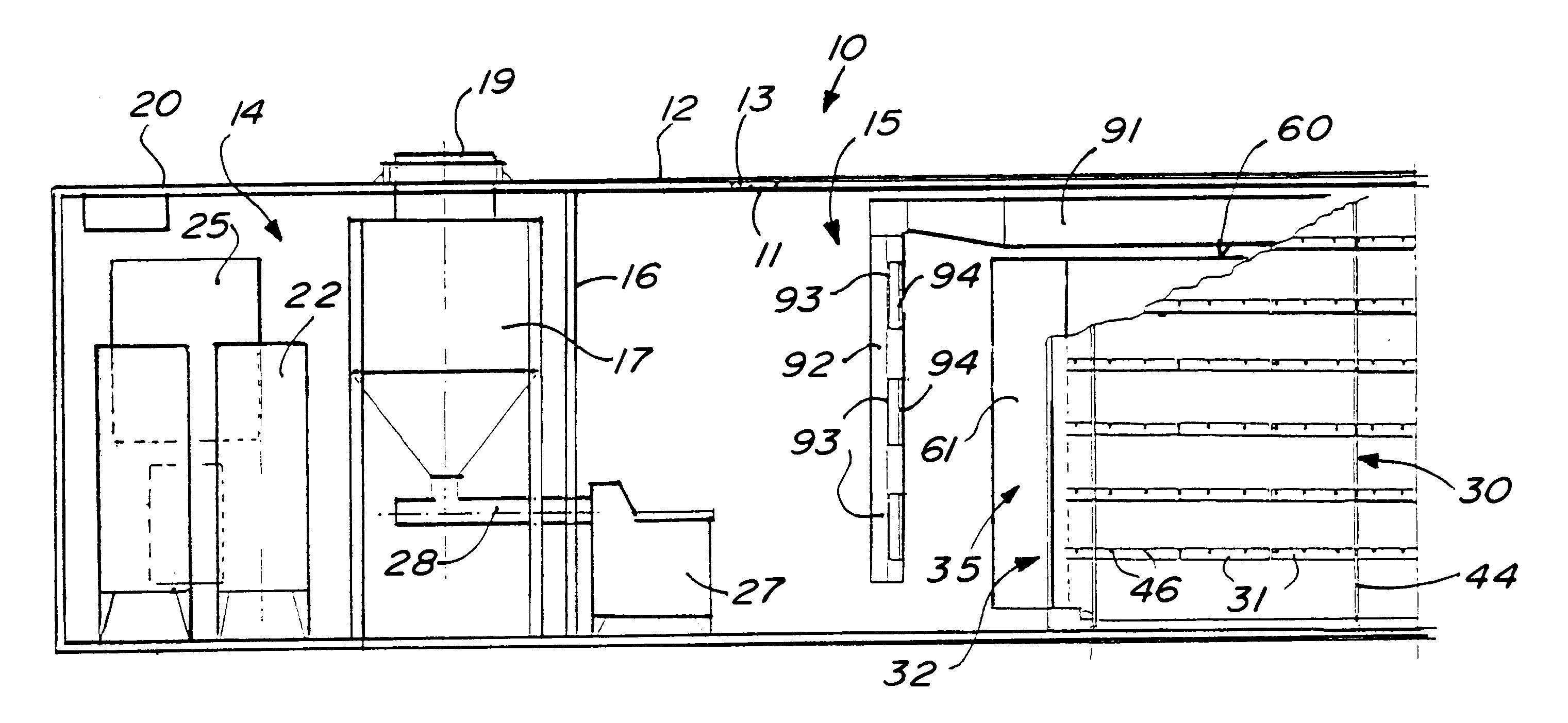

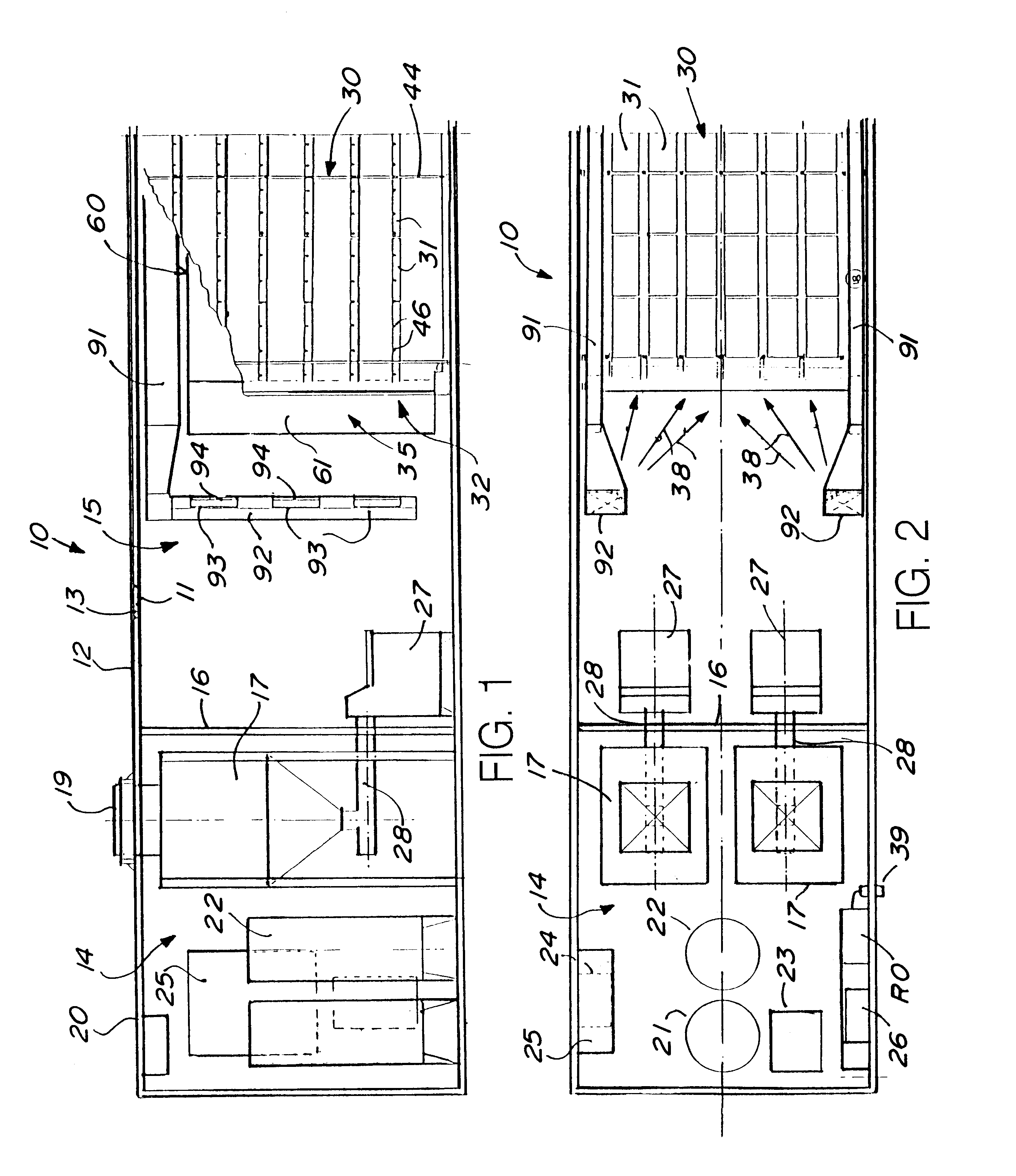

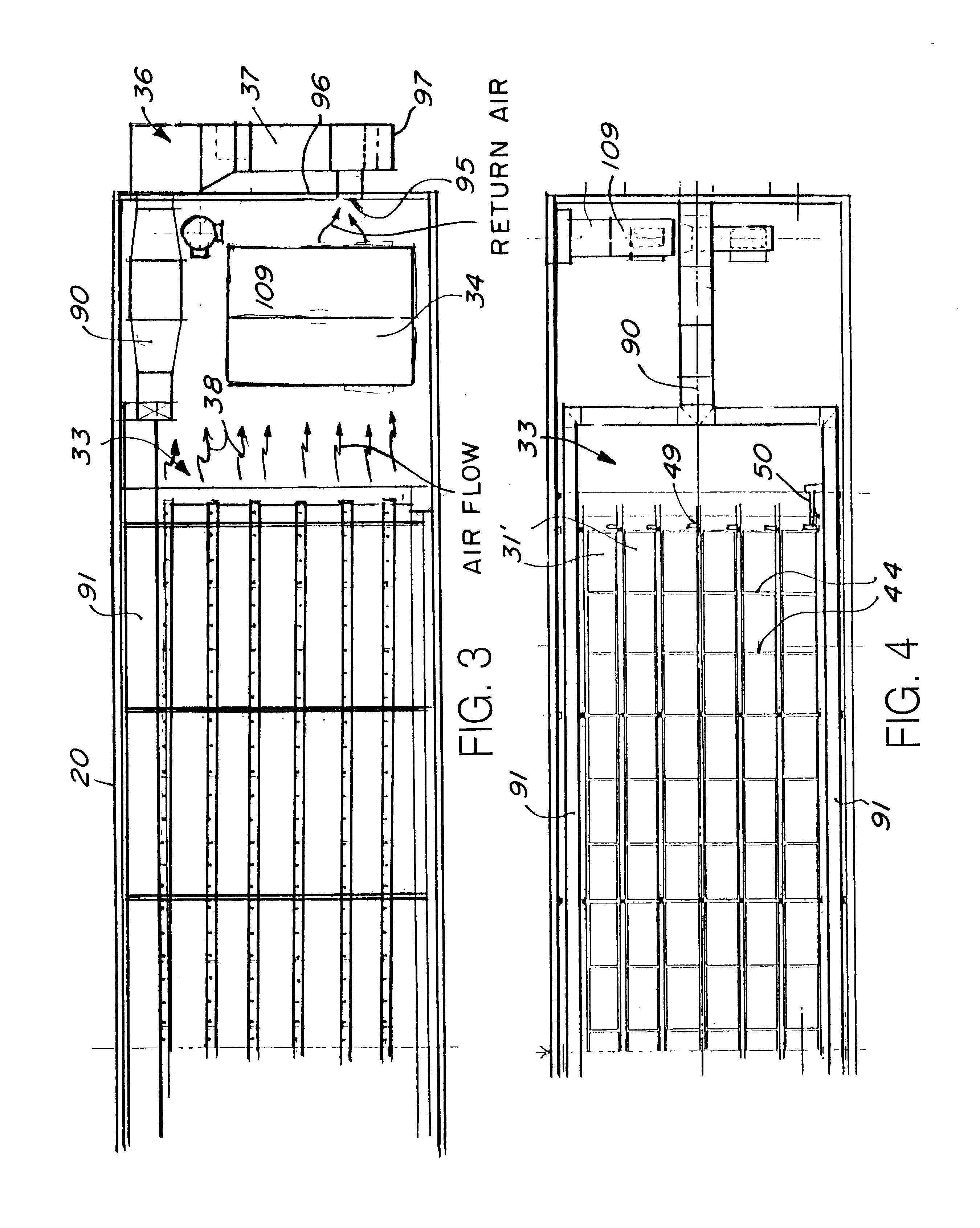

Hydroponic growing enclosure and method for the fabrication of animal feed grass from seed

InactiveUS6578319B1Easy to useAgriculture gas emission reductionCultivating equipmentsSprouted SeedsEngineering

Owner:COLE ROBERT +1

Apparatus for preparing soil for the placement of seed and additive

An apparatus for preparing soil for the placement therein of at least one of seed and fertilizer. A frame is provided with there being first structure on the frame for penetrating the soil to create an opening for at least one of seed and fertilizer as the frame is advanced in a travel direction. A second structure is provided on the frame at least partially downstream of the first structure for at least one of a) stripping soil clods from the first structure and b) loosening soil downstream of the first structure.

Owner:BASSETT JAMES H

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com