Patents

Literature

2106results about "Public buildings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

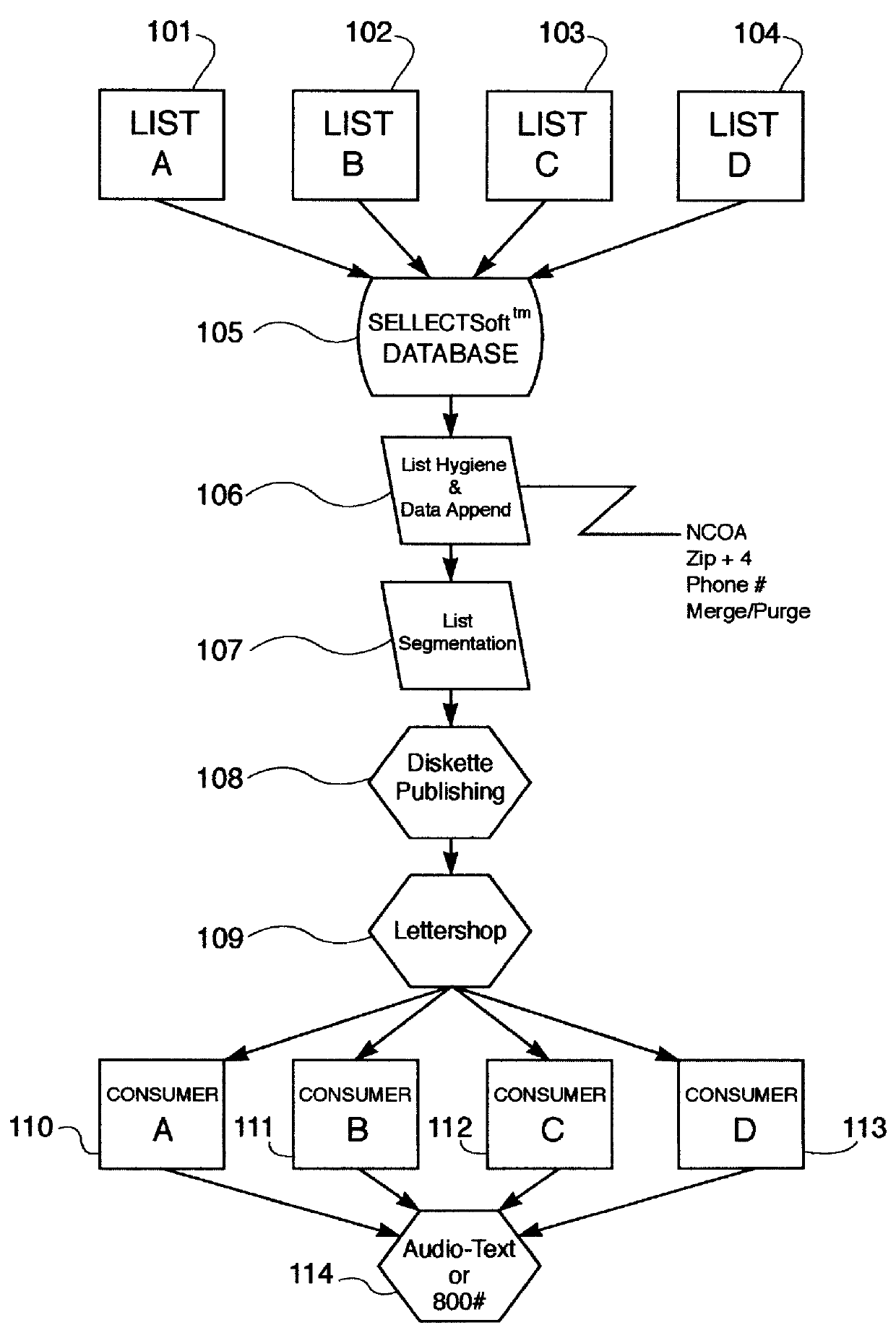

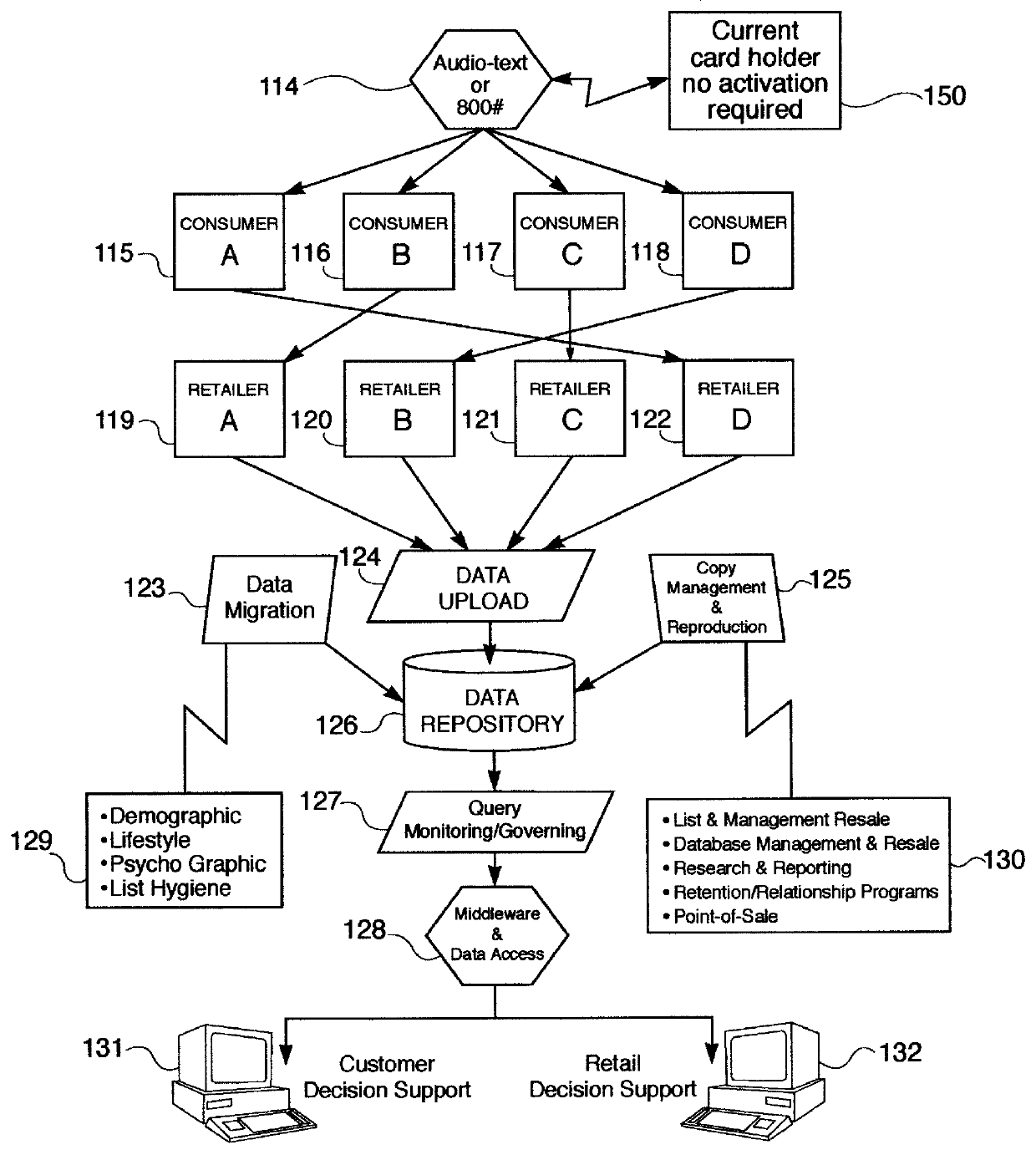

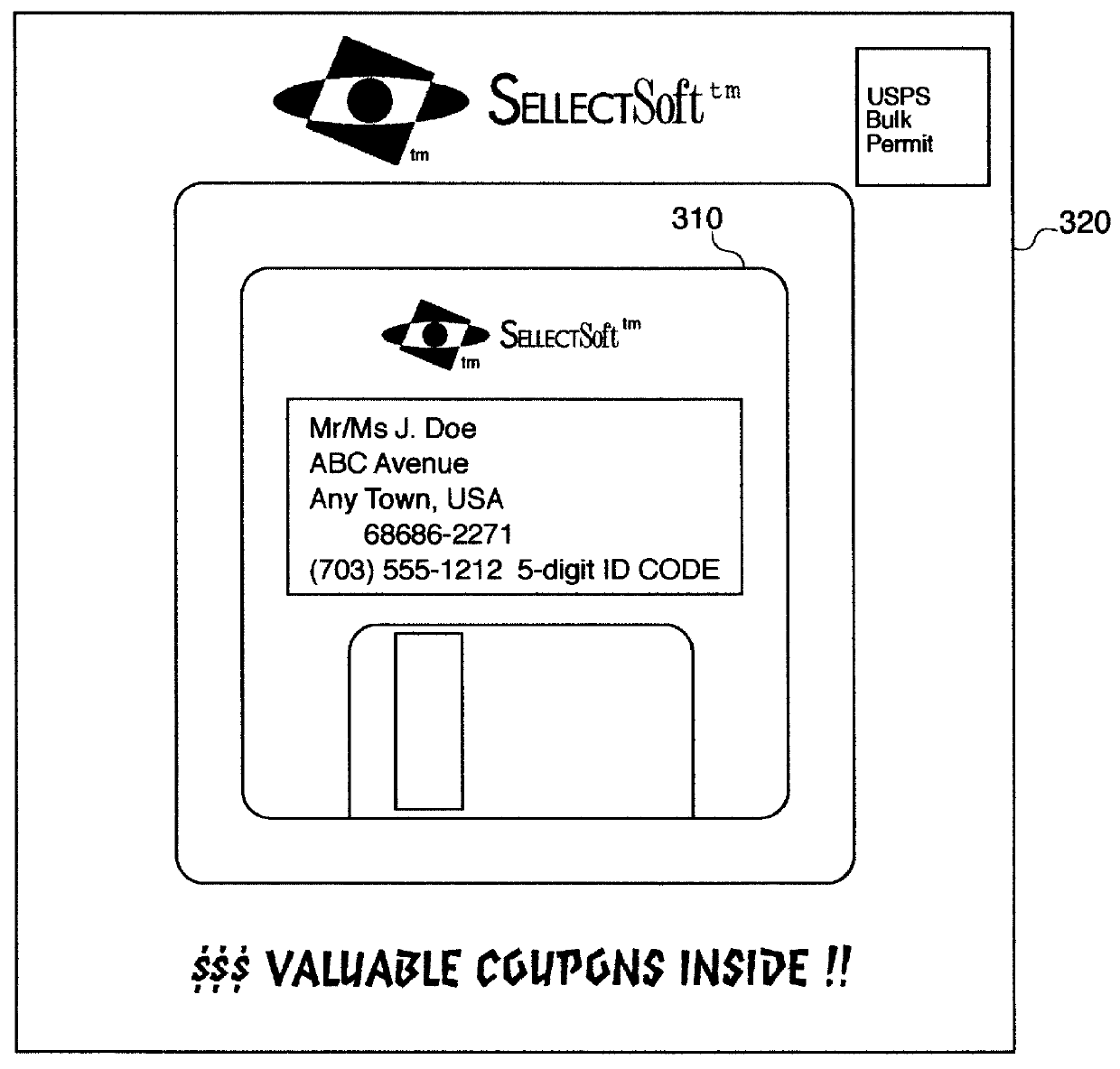

Electronic discount couponing method and apparatus for generating an electronic list of coupons

InactiveUS6035280AReduce the possibilityEliminate needPublic buildingsDigital computer detailsGraphicsGraphical user interface

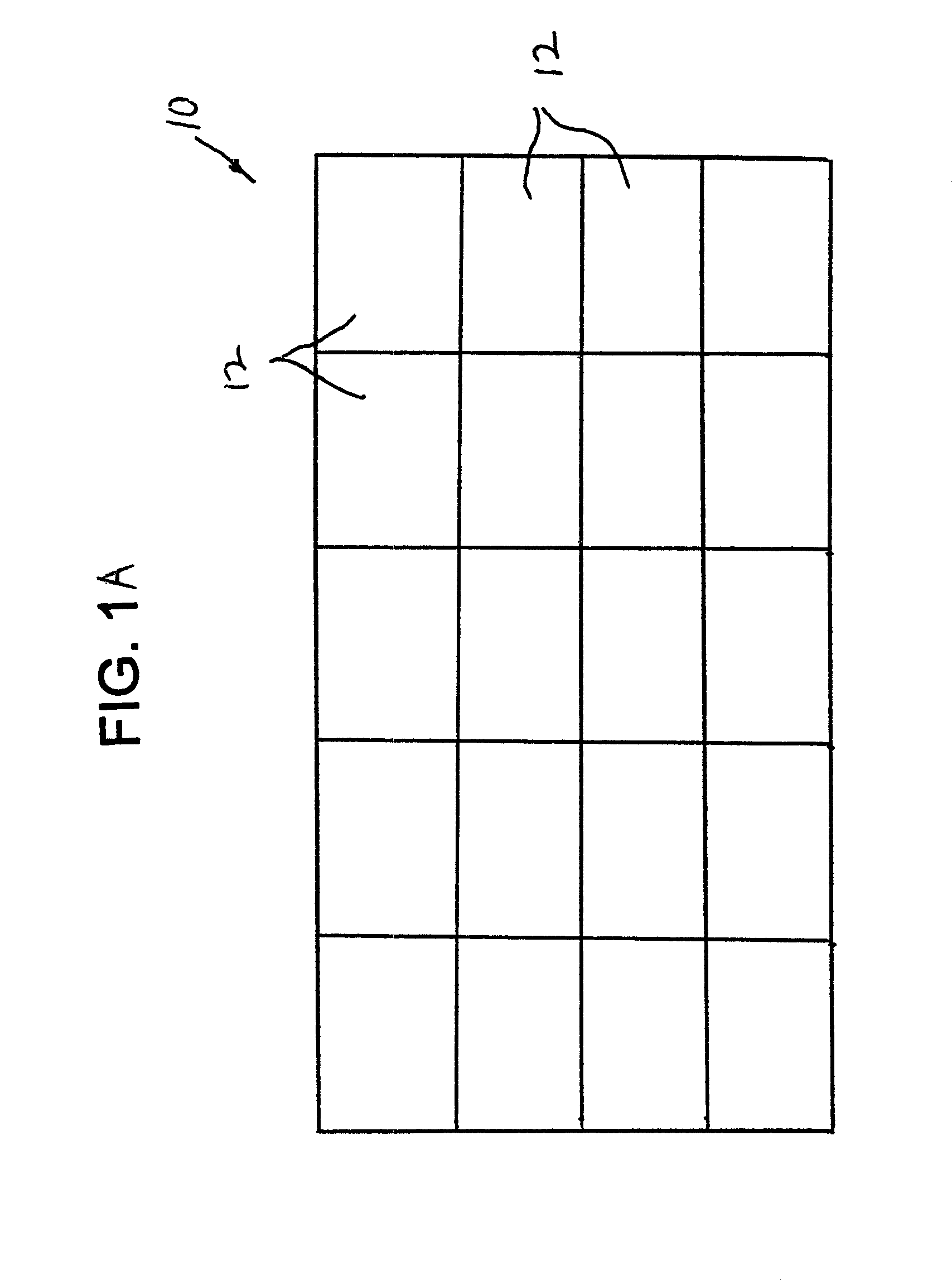

A method and apparatus for distributing, generating, and redeeming discount Virtual Coupons TM , rebate or gift certificates or the like which may be used on conjunction with a frequency card program or the like. Virtual Coupons TM may be distributed electronically, for example, in the form of a diskette or CD-ROM software. Software on the diskette or CD-ROM may prompt a consumer to call a 1-800 number for a validation number or code. During the phone call, telemarketing personnel may request consumer demographic and or identification information which may be entered into a centralized database. Once the software is validated, a consumer may print out a list selected Virtual Coupons TM displayed on a Graphical User Interface (GUI). When a product is purchased, the UPC code of the product may be compared electronically with a list of Virtual Coupons TM authorized for a particular consumer. An appropriate coupon discount may then be applied and the Virtual Coupon TM may be considered "redeemed". Once redeemed, consumer ID information and Virtual Coupon TM information may be retrieved electronically and used to update a central database. Accurate data may then be produced illustrating which consumers or groups of consumers are redeeming which Virtual Coupons TM . Such data may be used for marketing purposes or to generated further diskettes for distribution targeting specific consumers or groups of consumers with specific classes of Virtual Coupon TM offerings. The use of Virtual Coupons TM eliminates or reduces fraud, and allows a frequency card discount to be applied only a limited number of times.

Owner:CATALINA MARKETING CORP

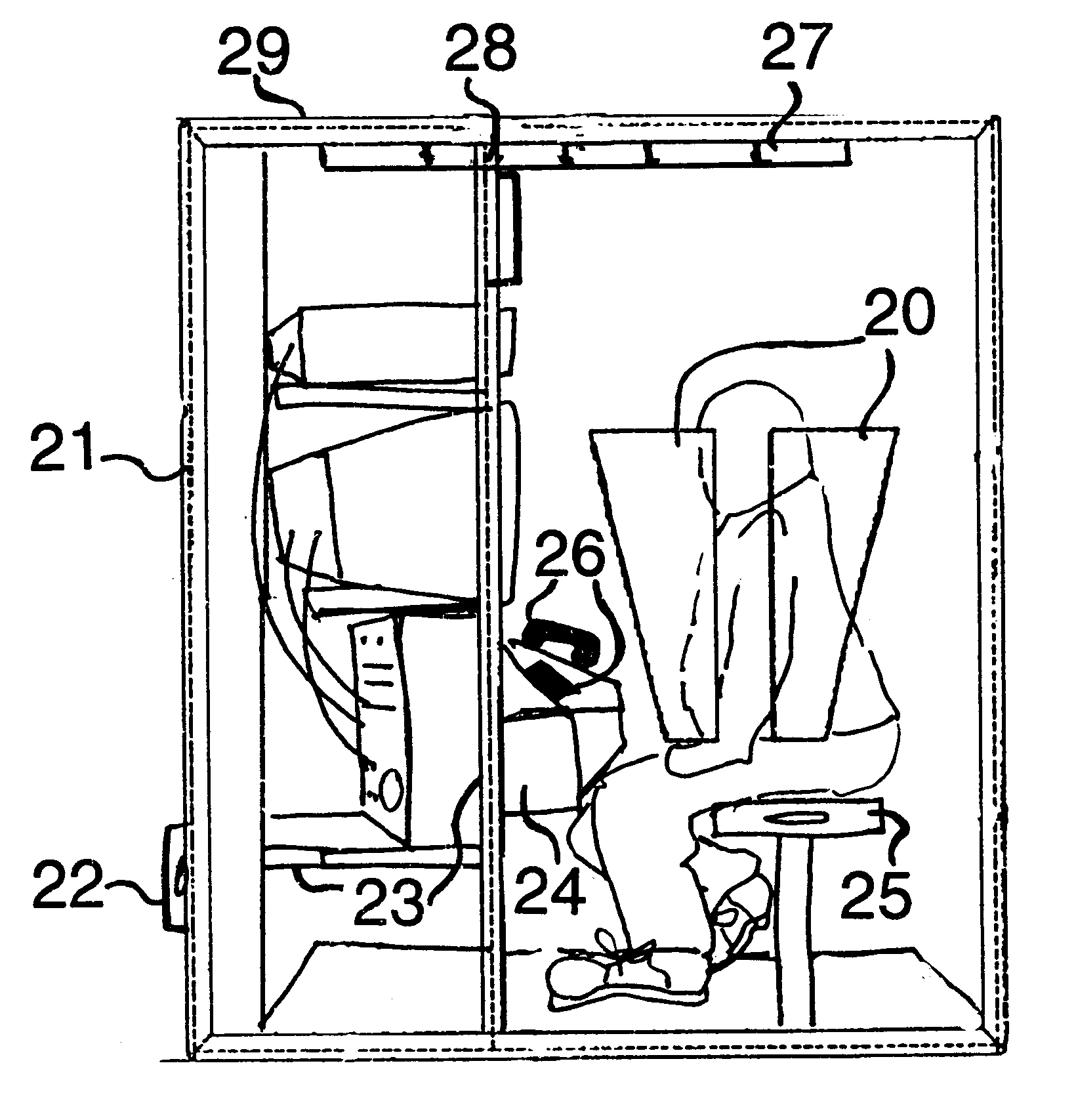

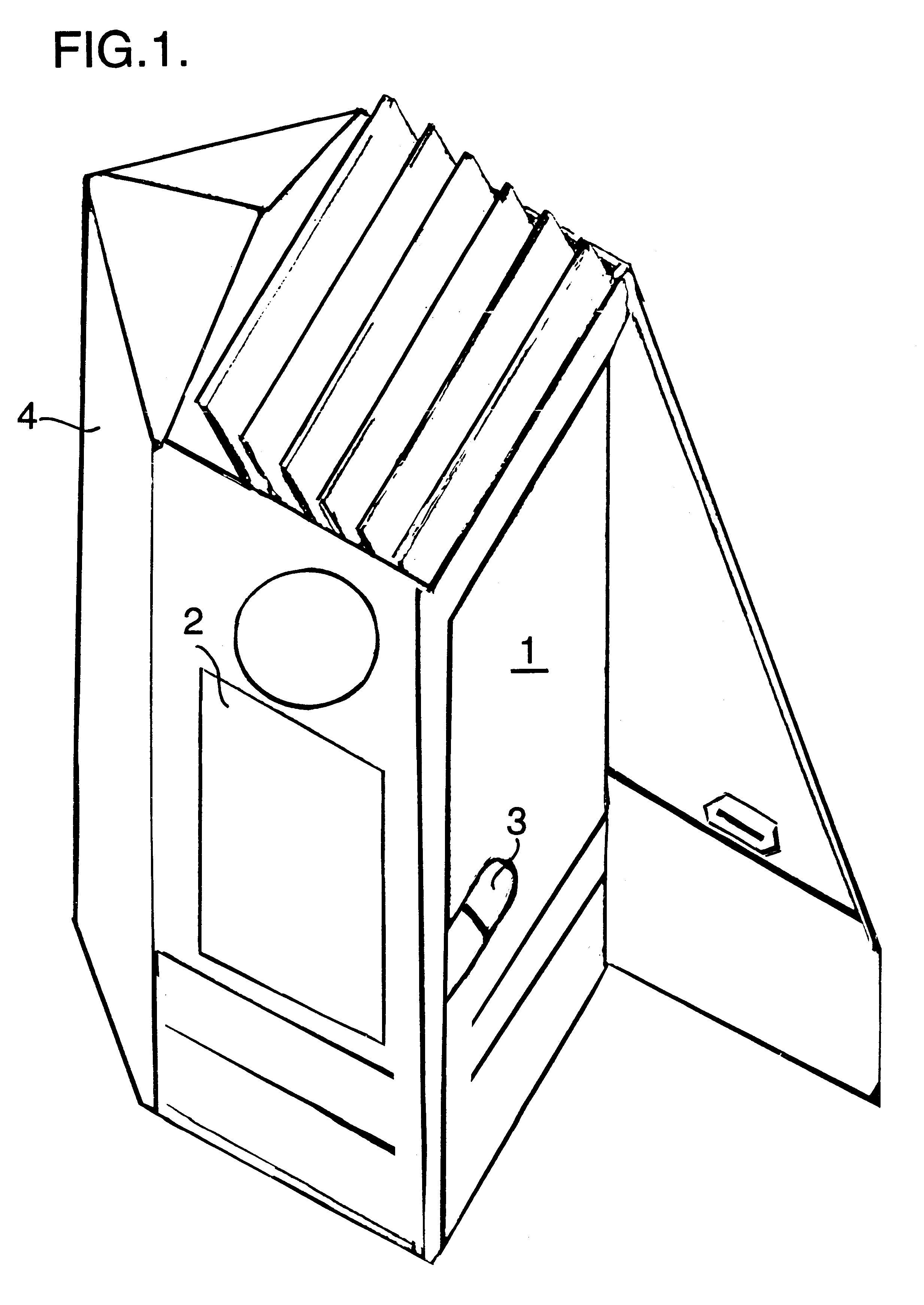

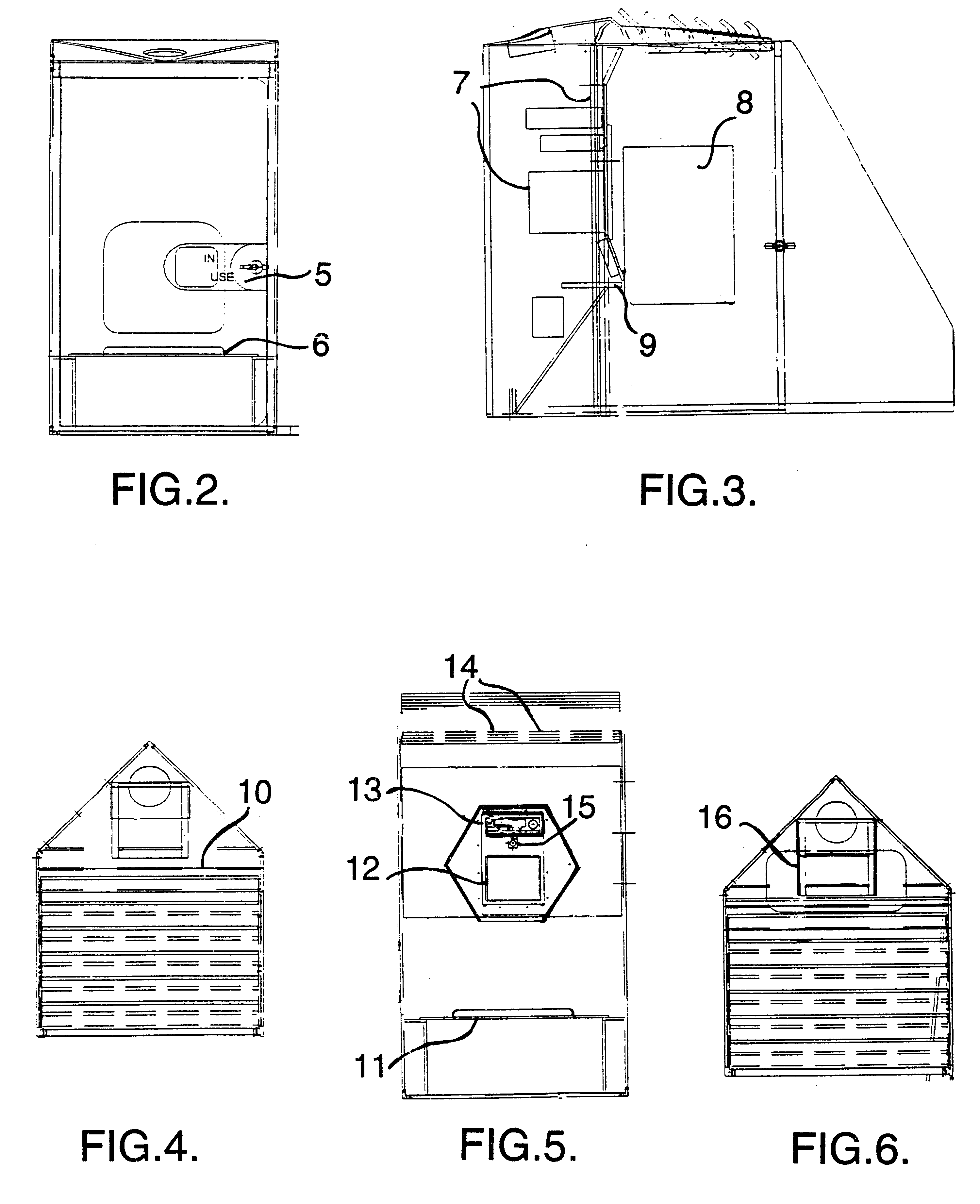

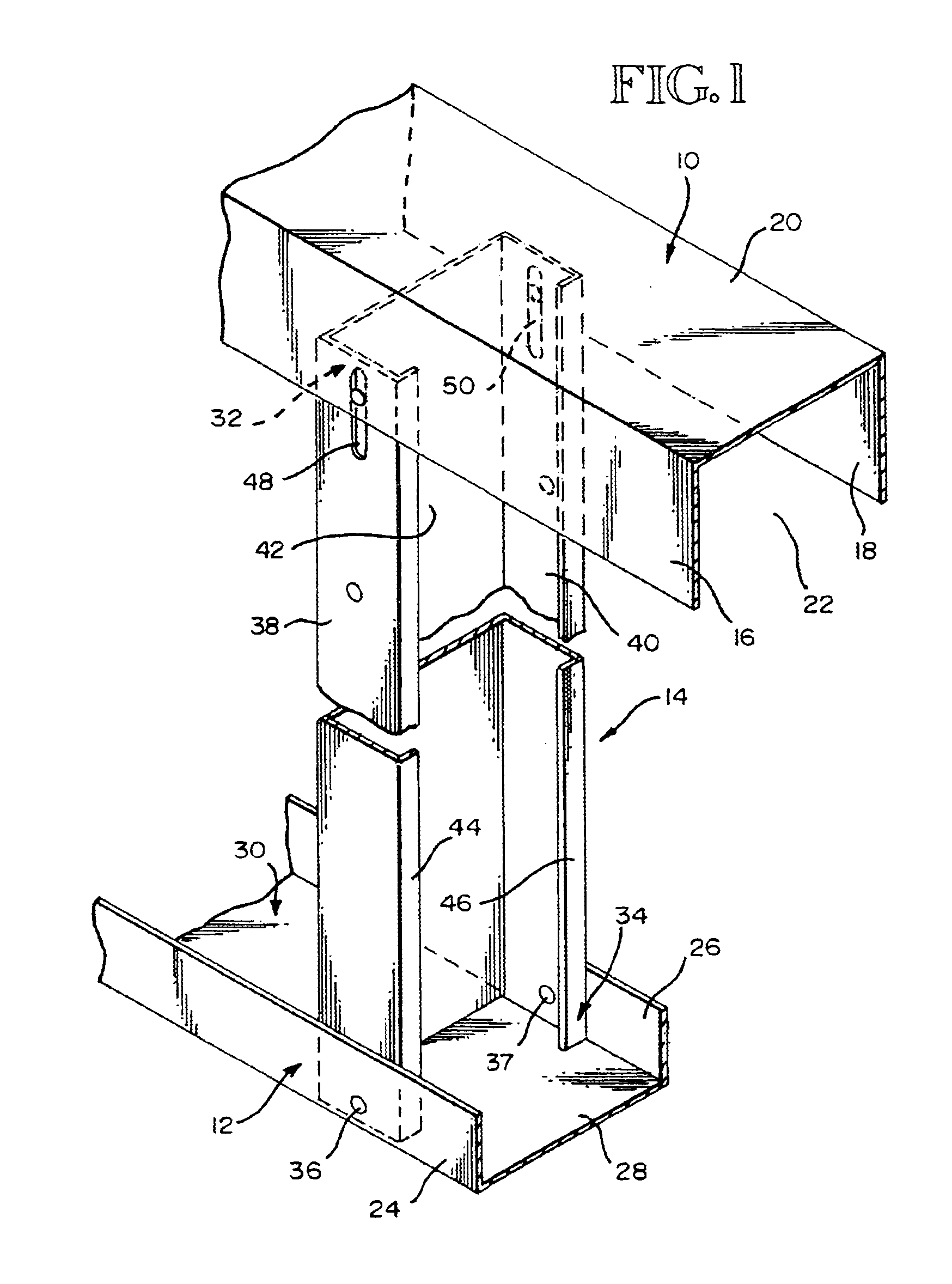

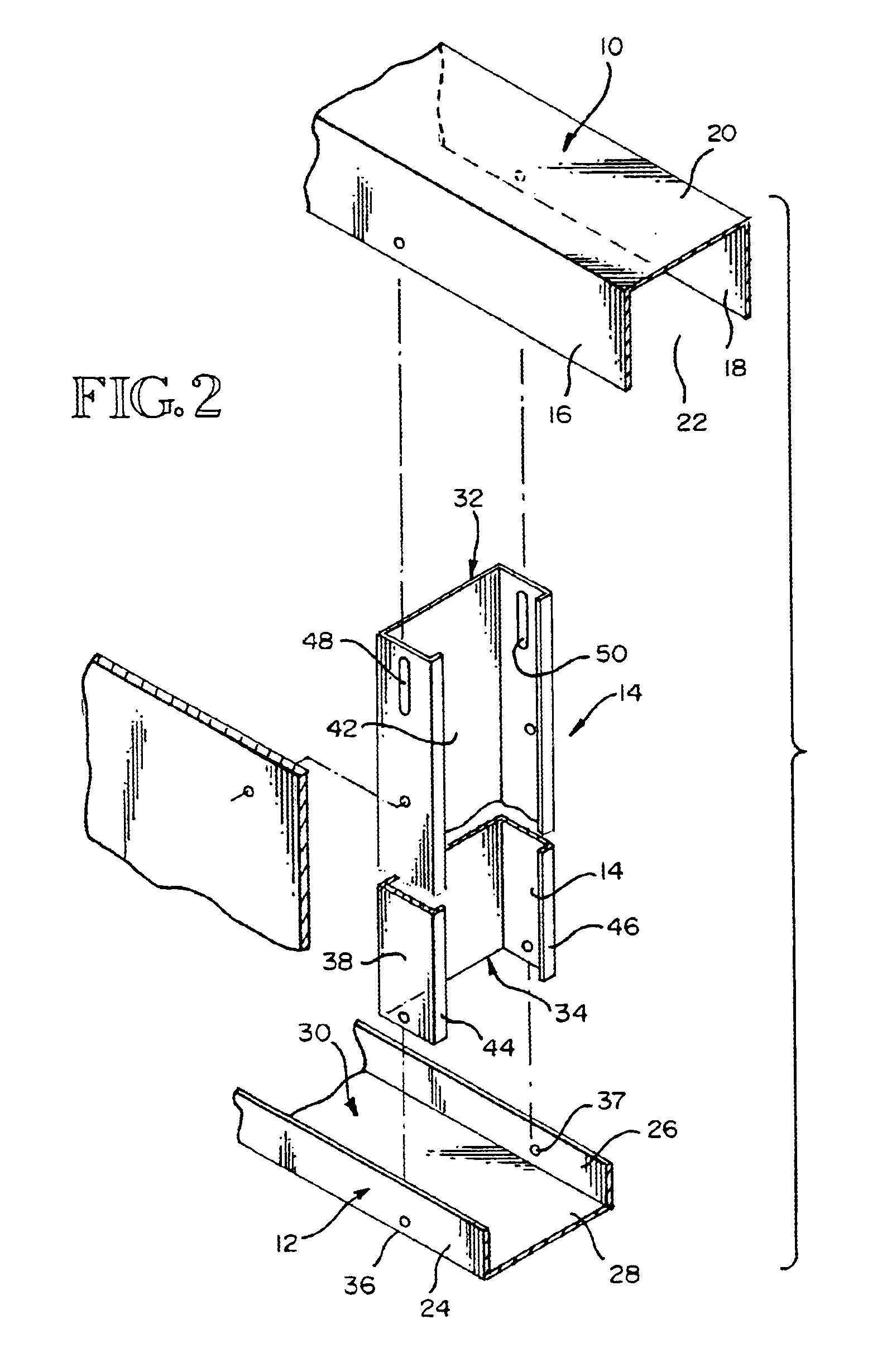

Modular video conference enclosure

InactiveUS6205716B1Easily broken down into transportable pieceTelevision system detailsTelevision conference systemsModularityDistance collaboration

A secure, modular and movable interactive two-way telecollaborative video conferencing and imaging enclosure for conducting business or privileged medical, legal, or other confidential matters in private, being particularly equipped for remote monitoring of physiological attributes of one or more users by medical specialists and remote interaction between users and medical specialists.

Owner:PELTZ DIANE P

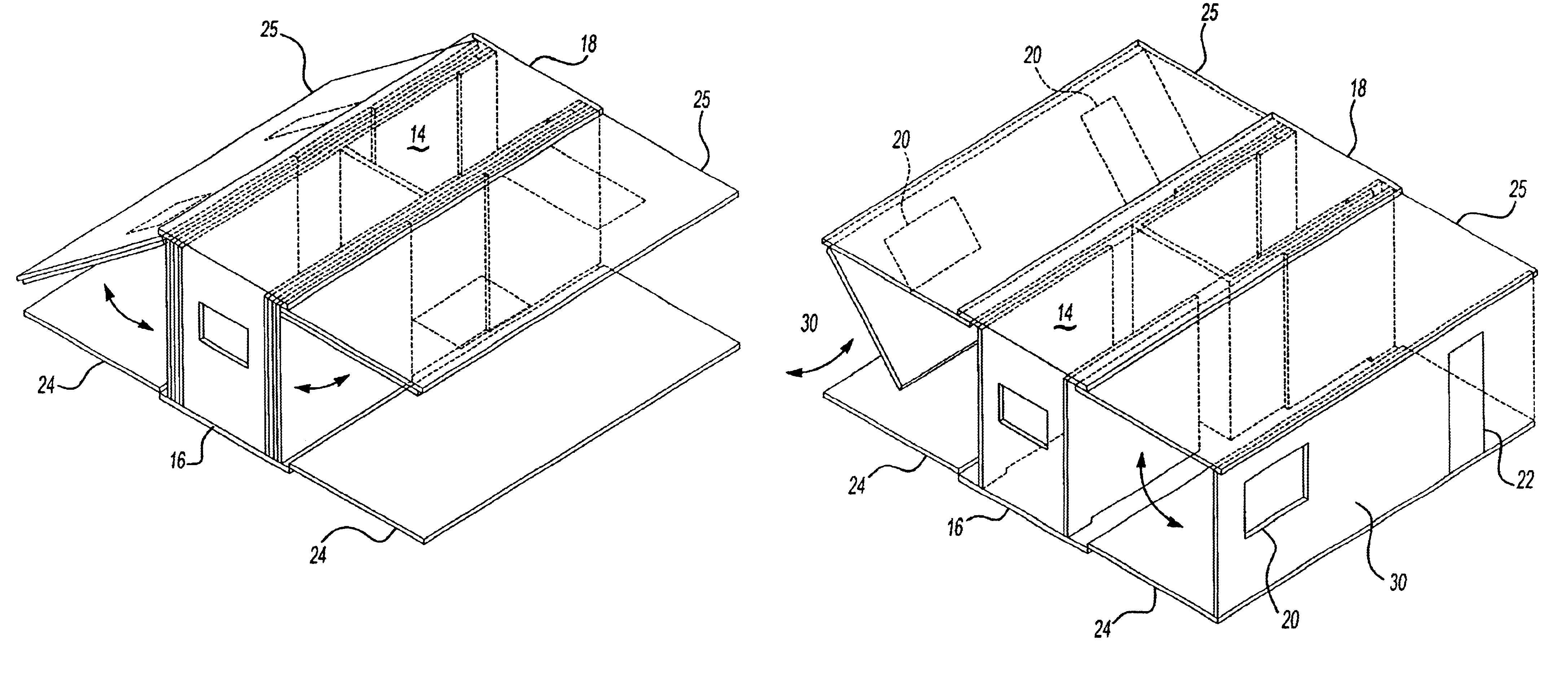

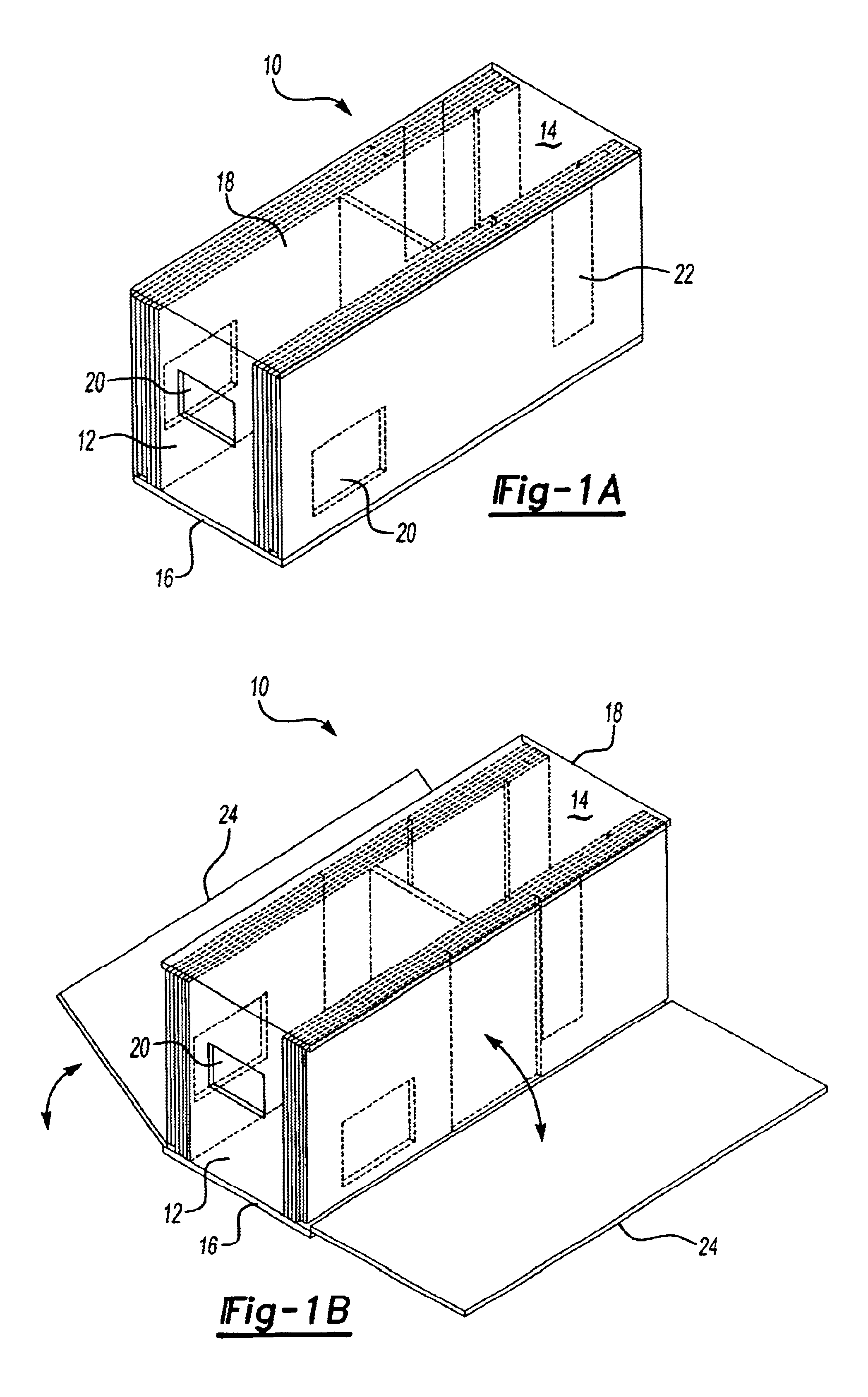

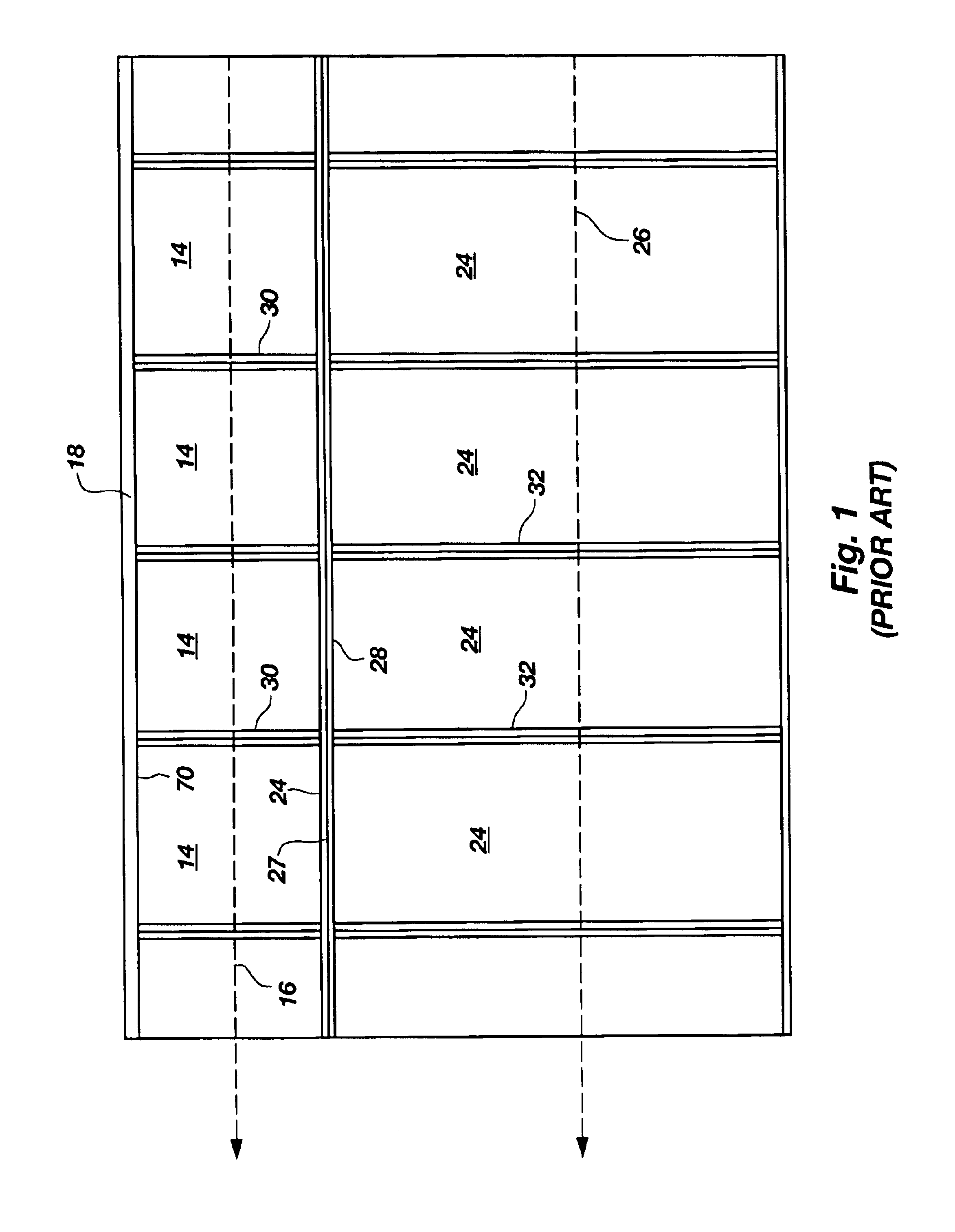

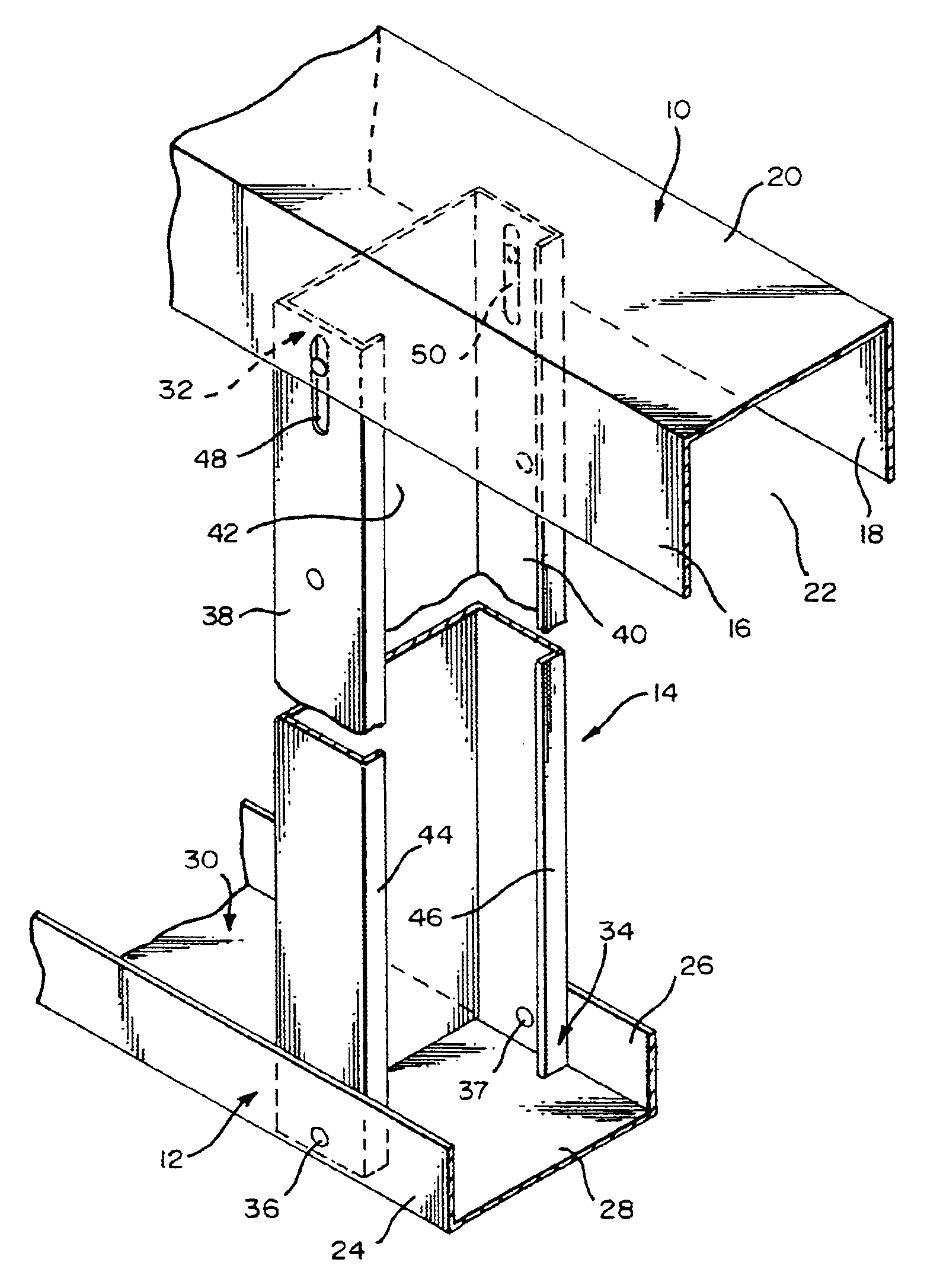

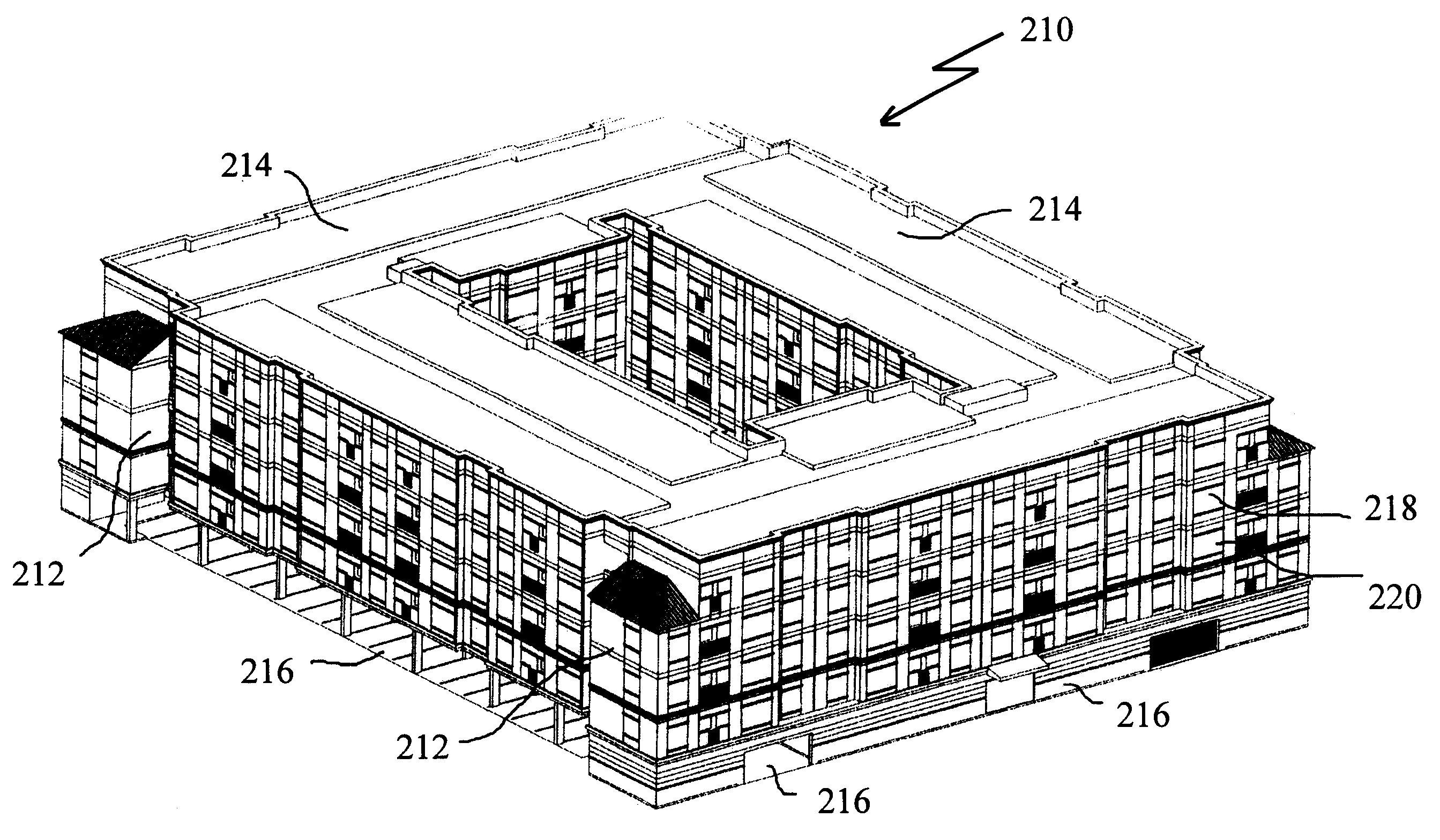

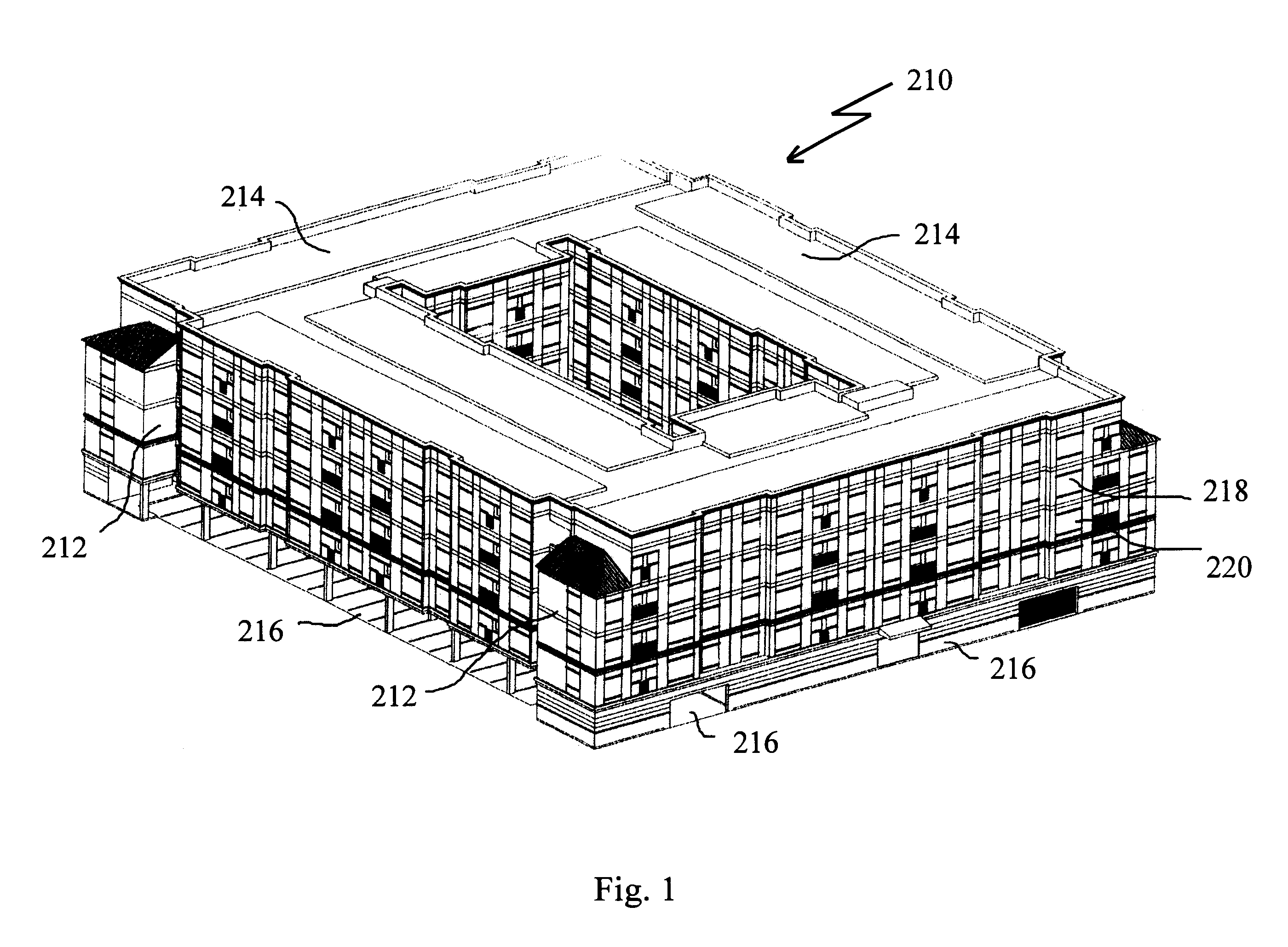

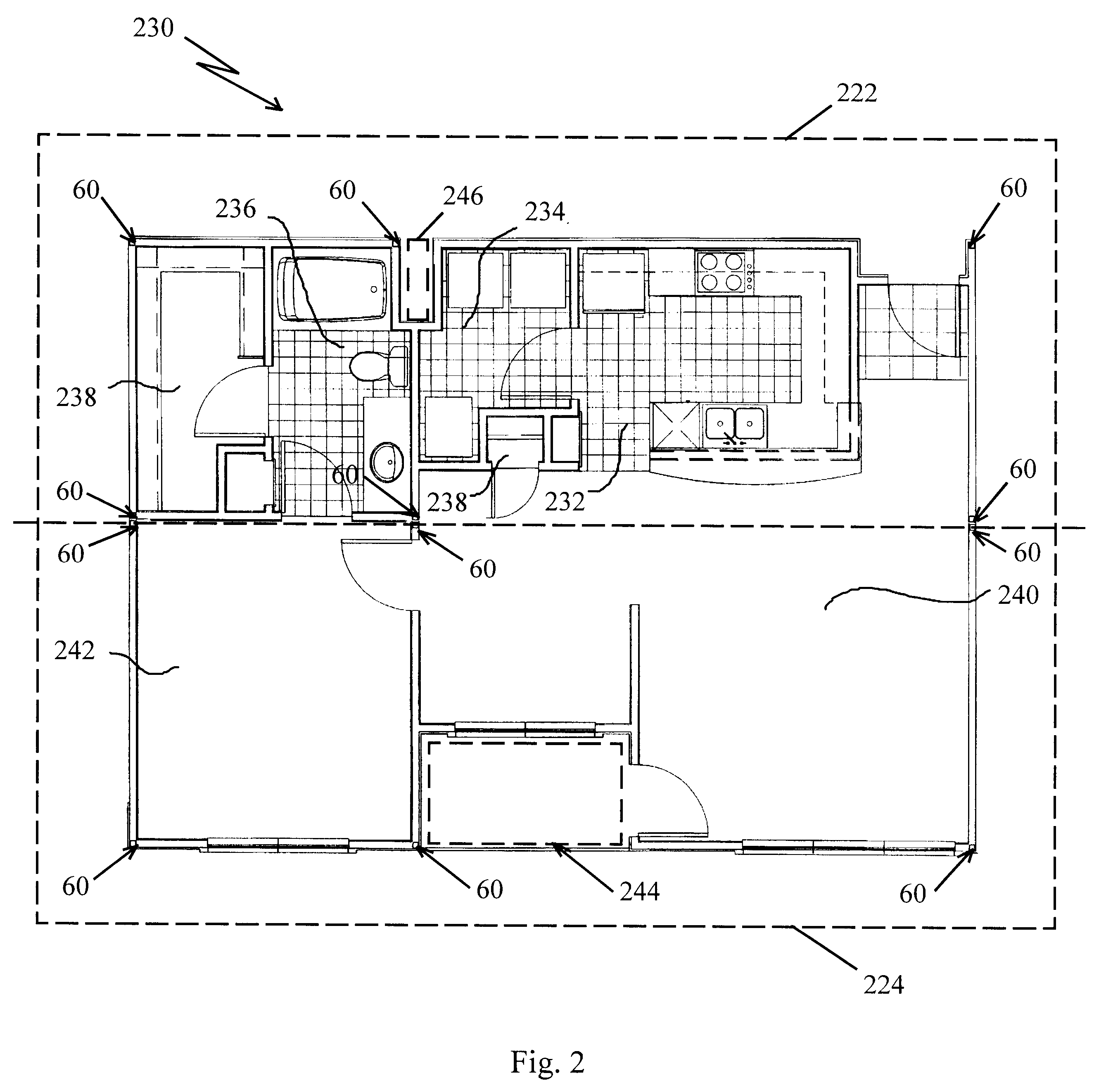

System for modular building construction

InactiveUS20080134589A1Facilitating selective interconnectionGood choiceConstruction materialLighting and heating apparatusEnvironmental systemsModular unit

Construction systems for erecting building structures comprise a plurality of prefabricated interconnectable modular building units, each unit not meeting at least one of the ISO certification criteria for transport of cargo but each unit comprising a frame shaped as a rectangular parallelopiped and comprised of framing members and a plurality of nodes, each node situated at a corner of said frame for selective interconnection with other units, the nodes and the exterior dimensions of the frame conforming to ISO shipping standards such that each unit is transportable using the ISO intermodal transportation system, and such that when the units are aggregated horizontally and vertically and adjacent units are interconnected, a building structure comprising at least one habitable space is formed. The modular units are assembled in a factory remote from the job site, and are there constructed to a semi-finished state, including installation of one or more of interior fit-out systems and finishes, exterior envelope systems, plumbing systems, electrical systems, environmental systems, and fire protection systems, following which the semi-finished modular units are transported from the factory to the job site, where they are craned into place and secured to form the structure being erected, a plurality of adjacent pairs of semi-finished modular units also being “stitched” together, and the semi-finished modular units are thereafter constructed to a finished state.

Owner:GLOBAL BUILDING MODULES

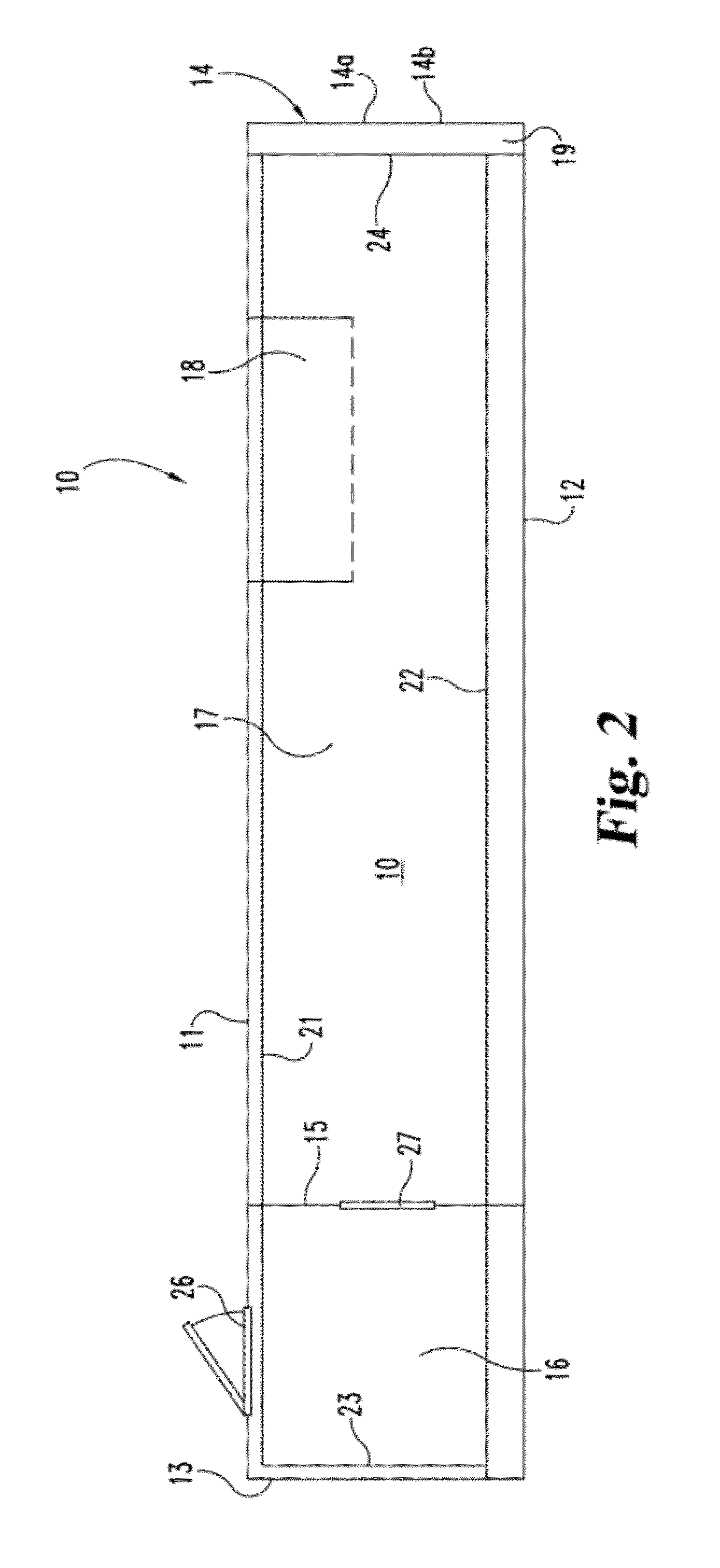

Mobile, modular cleanroom facility

ActiveUS20120077429A1Mechanical apparatusLighting and heating apparatusAir filtrationComputer module

A mobile, modular, cleanroom facility is made from one or more pre-assembled modules, transportable in their pre-assembled form. Each pre-assembled module includes an air filtration system including a ceiling plenum for providing clean air to the interior of the module. The air filtration system provides air cleaned to at least an ISO 8 classification. When the mobile, modular cleanroom facility is made of two or more modules, each of the modules is pre-assembled, and is transportable in its pre-assembled form. Each of the modules also includes an air filtrations system having a ceiling plenum for providing clean air to the interior of the module. Most preferably, the modules are connected by a connection assembly effective for providing a seamless transition from one module to the other while maintaining the appropriate clean air classification in the transition space.

Owner:BIOLOGICS MODULAR

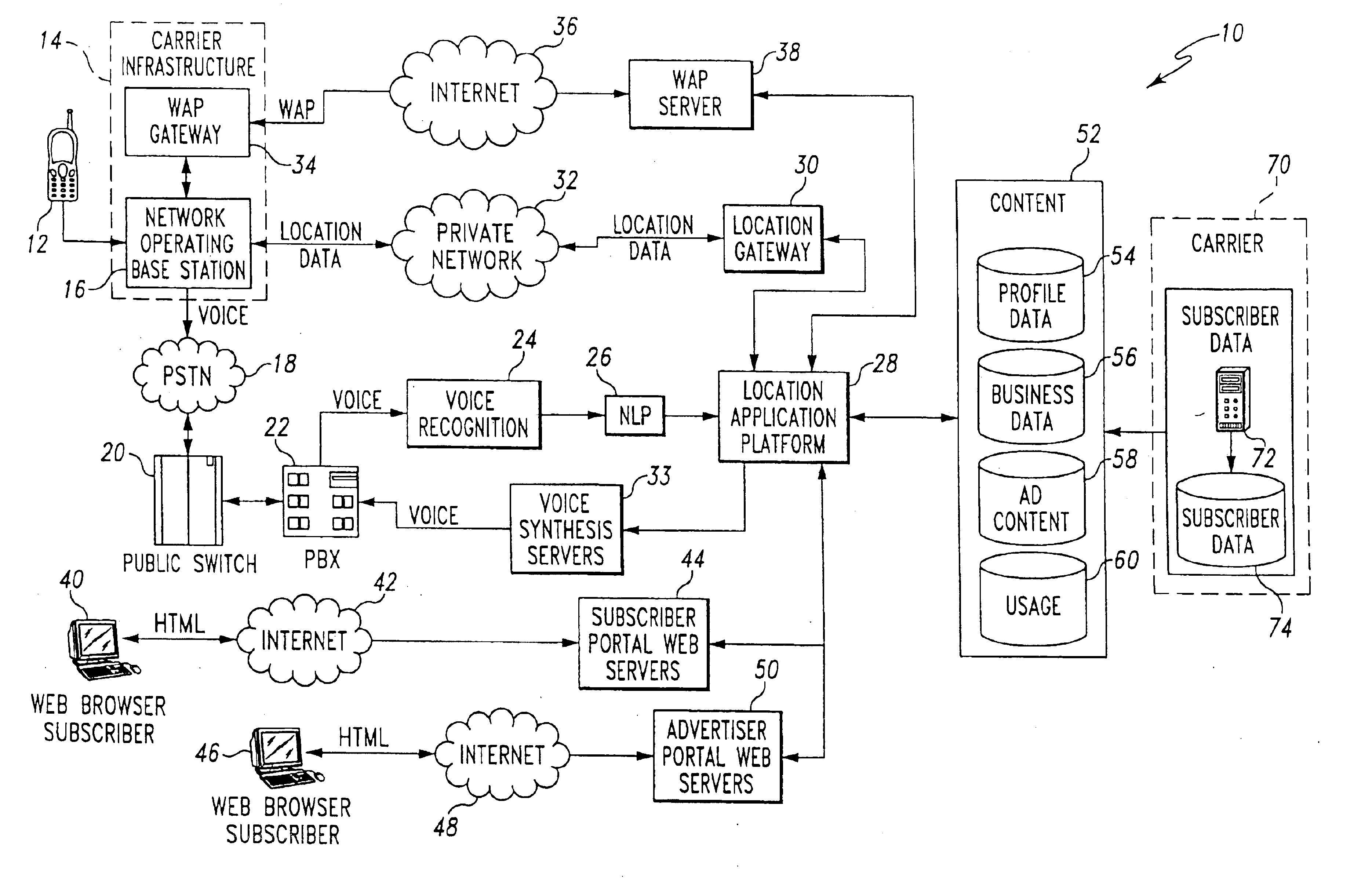

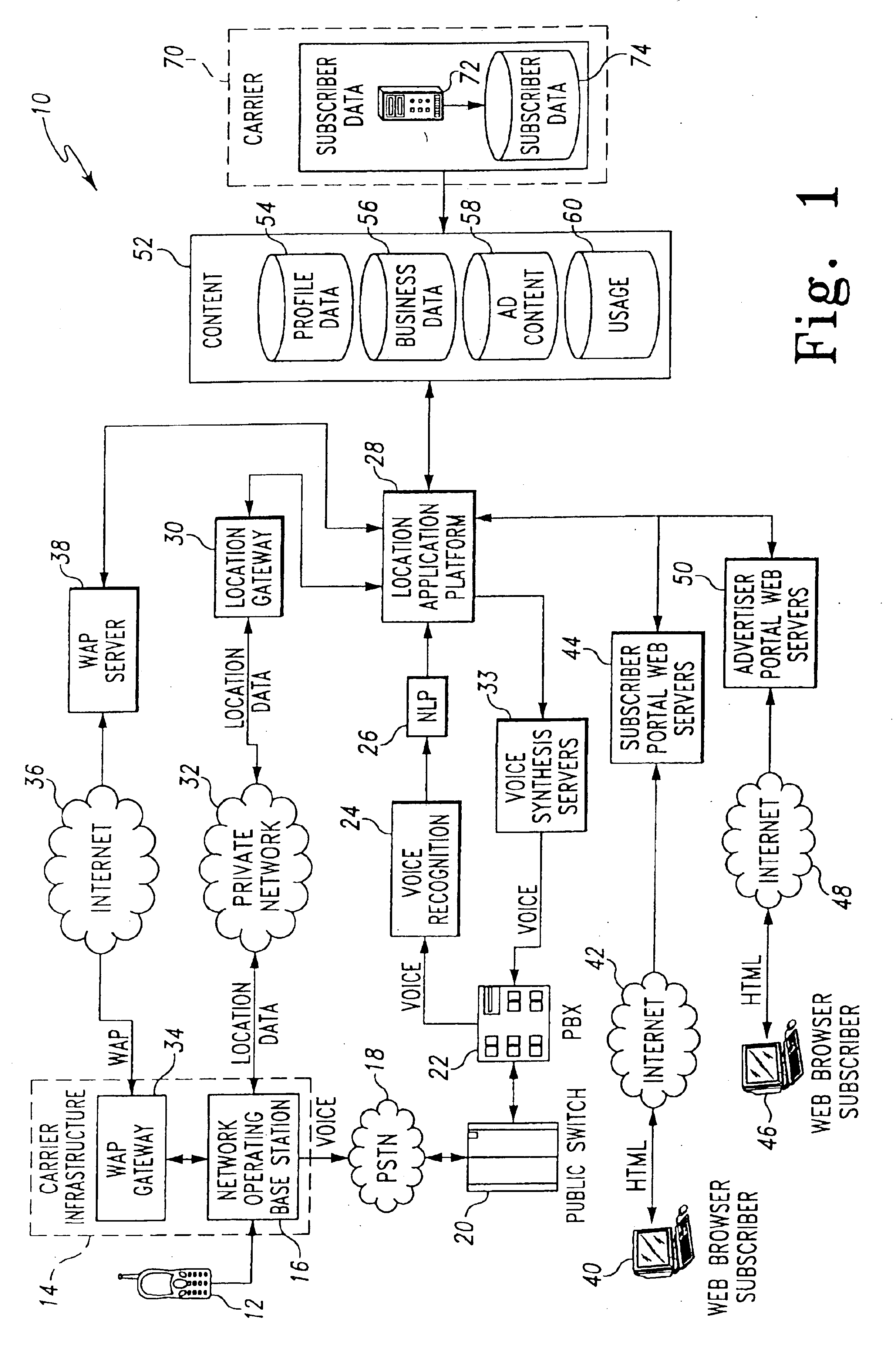

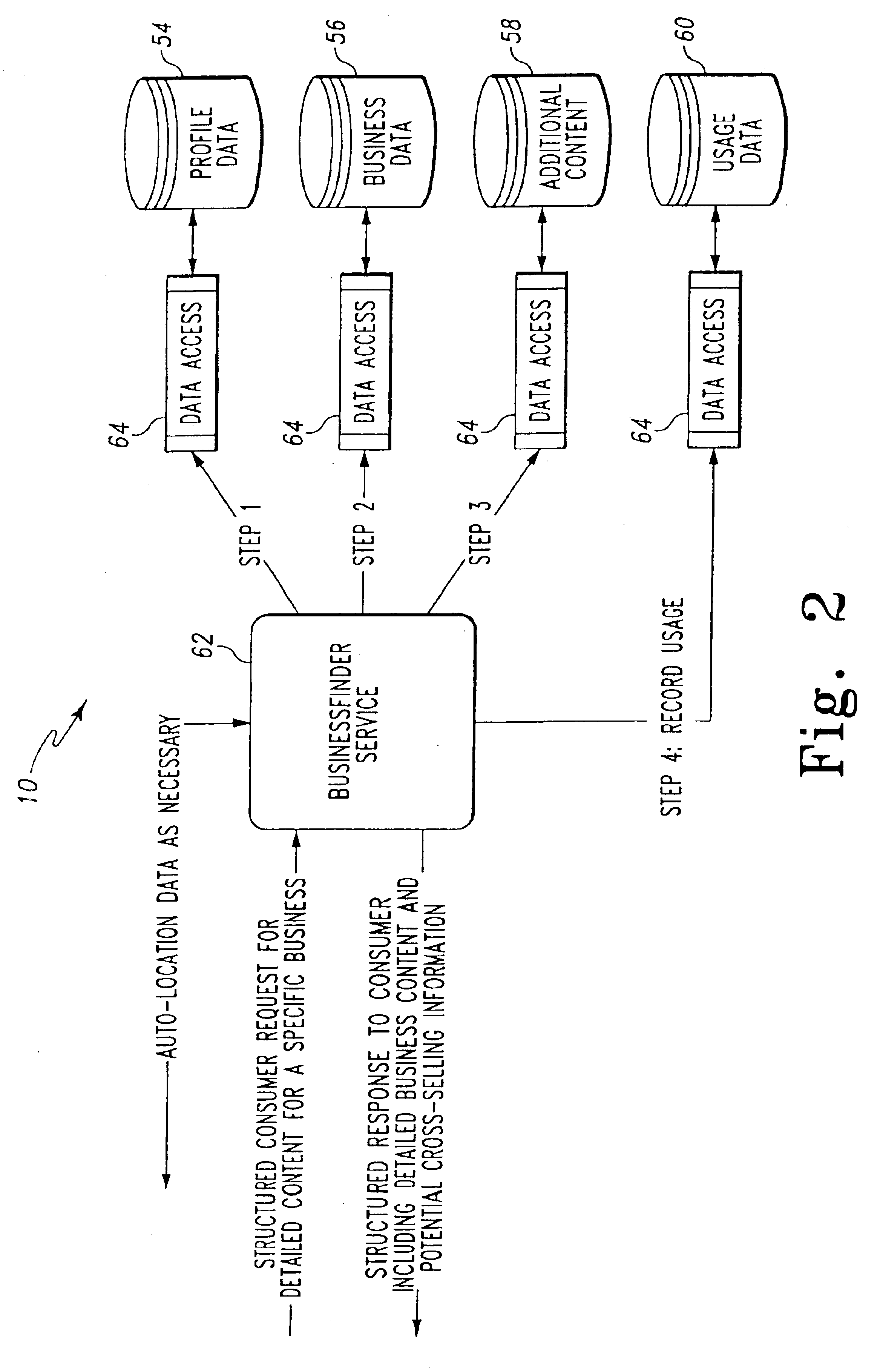

Method for passive mining of usage information in a location-based services system

InactiveUS6848542B2Discounts/incentivesRadio/inductive link selection arrangementsComputer terminalApplication software

A method and system for providing advertising effectiveness searching capabilities, predictive modeling capabilities and usage mining in a location-based services system is disclosed. During operation of the location-based services system, usage information for advertising campaigns placed on the location-based services system is stored. Advertisers are provided with the ability to enter a search request form on a remote terminal to mine the usage information. The search request is then transmitted to an application that searches usage information to generate a response to said search request.

Owner:ACCENTURE GLOBAL SERVICES LTD

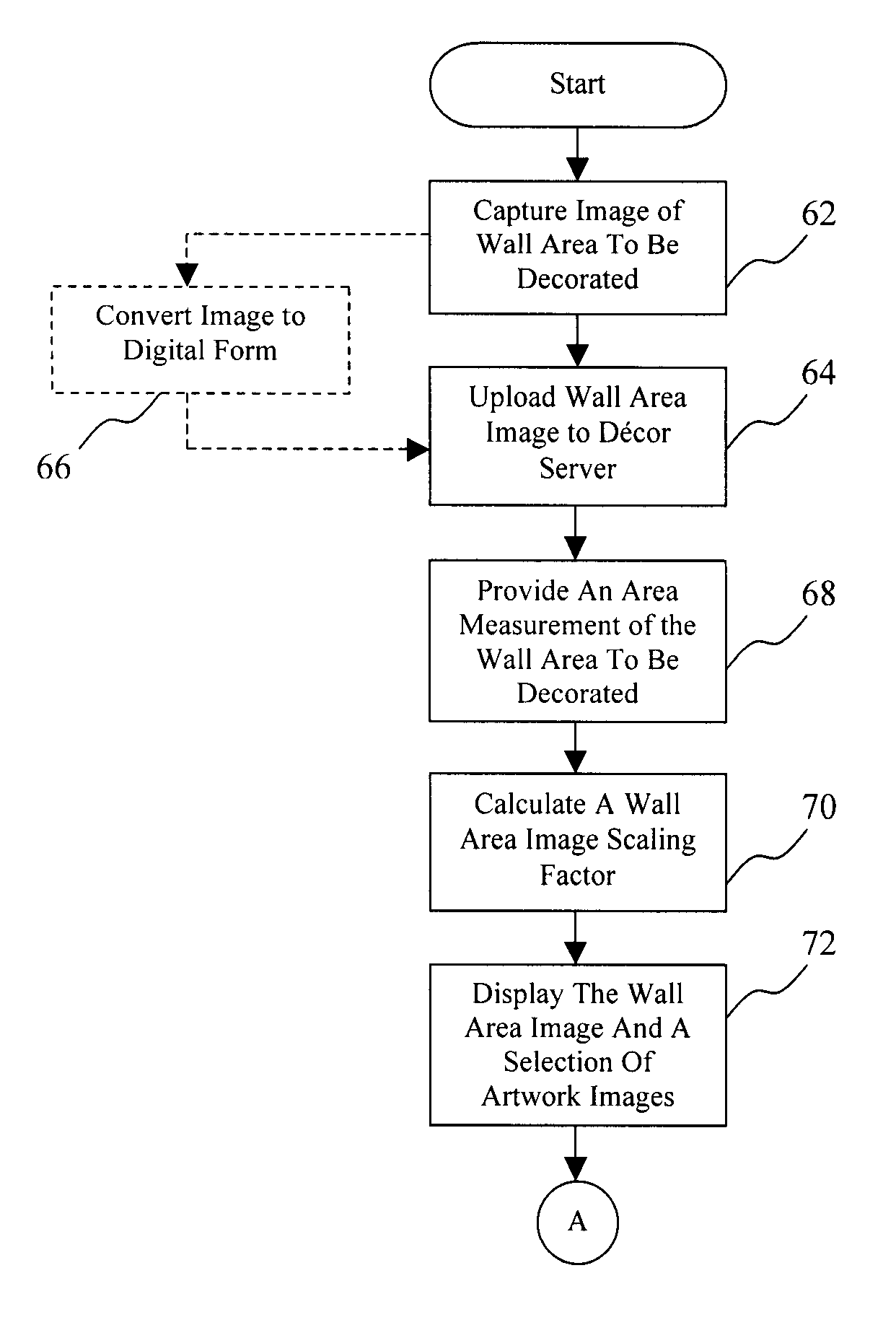

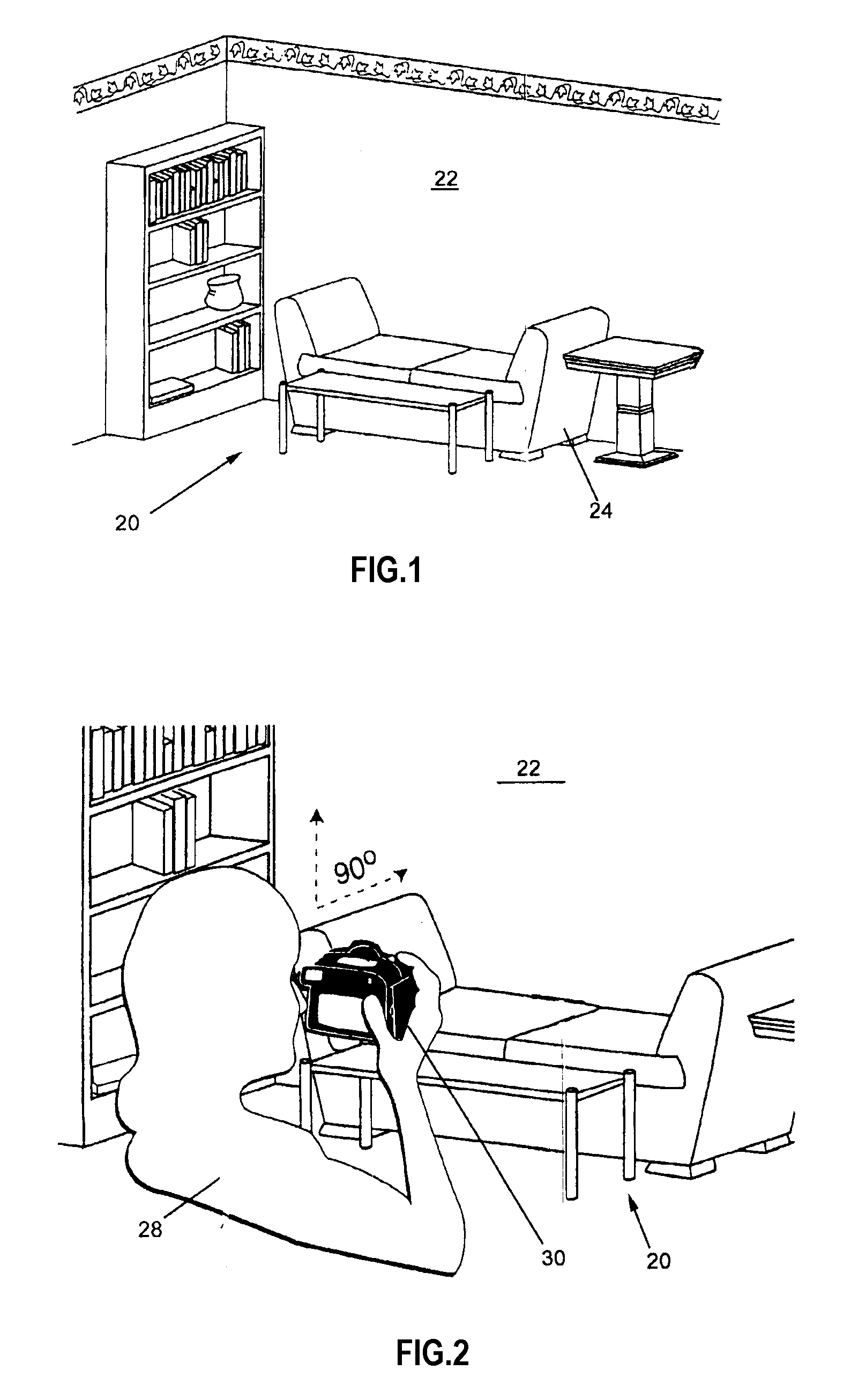

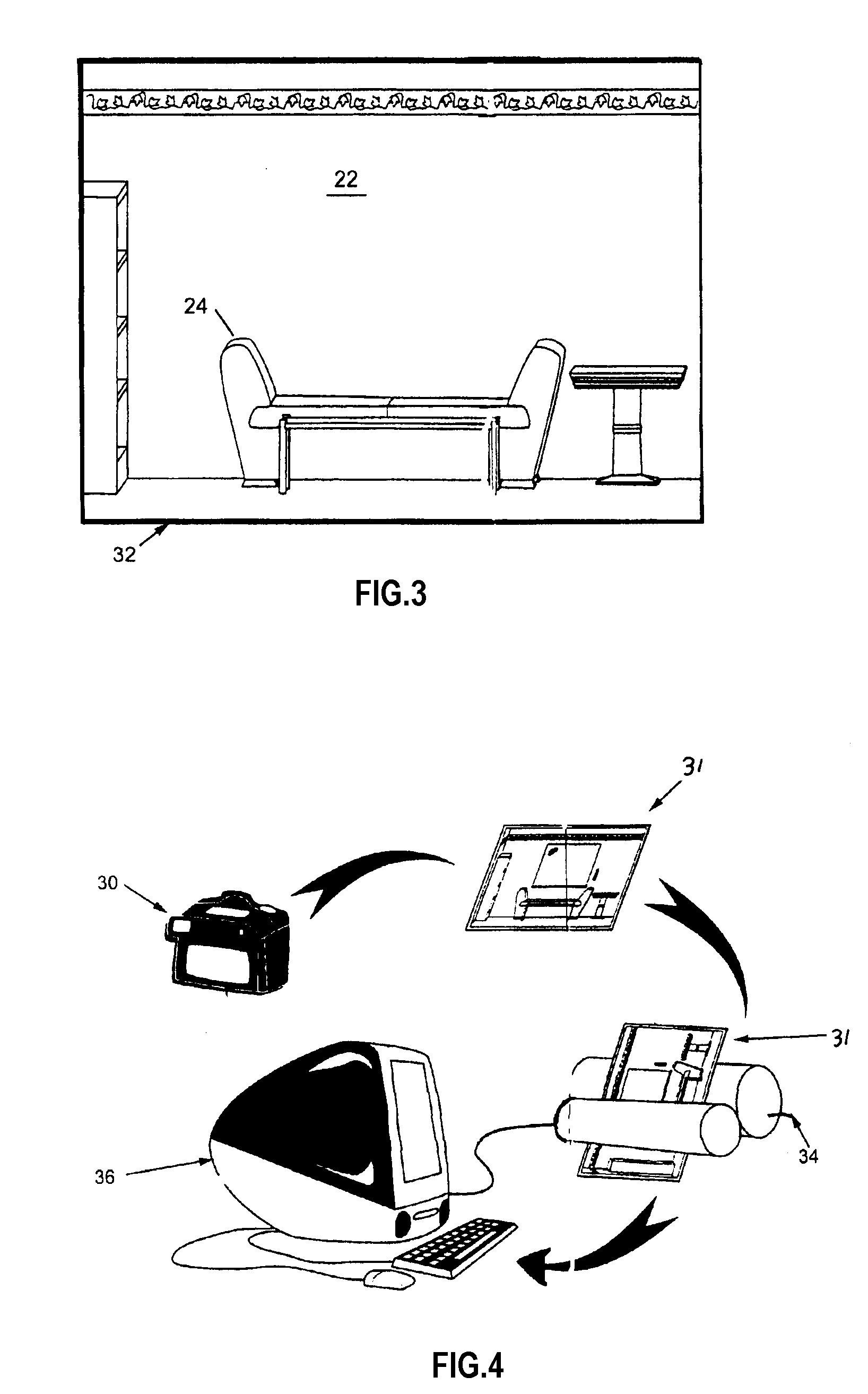

Method and System for Virtual Decoration

InactiveUS20070143082A1Simulation is accuratePublic buildingsService system furnitureComputer graphics (images)

Systems and methods for facilitating the decoration of an area, and particularly a surface such as a wall in a room, are provided. A user may view a virtual impression of the placement of selected artwork on a particular wall. The user provides an image of the area to be decorated, along with a reference scale associated with the area, to a server. The user views and selects an image of an artwork object from an available selection of artwork images, the artwork image having a corresponding size of the artwork object. The image of the artwork is scaled such that the ratio of the size of the artwork object and the size of the artwork image substantially corresponds to the ratio of the size of the area to be decorated and the size of the area image. The scaled artwork image is then overlayed on the area image and may be viewed by the user to provide a simulated image of the area and artwork.

Owner:DEGNAN DONALD A

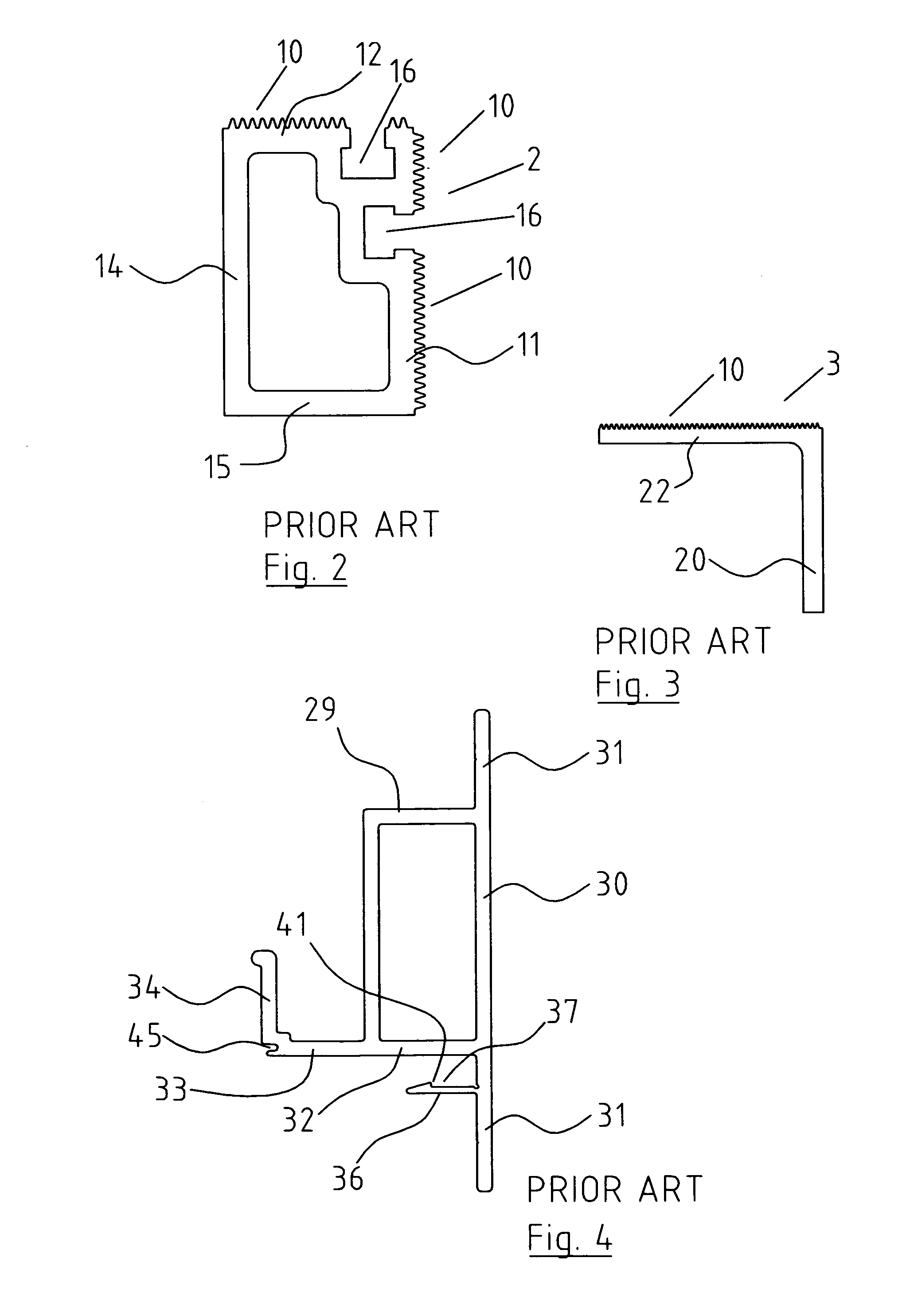

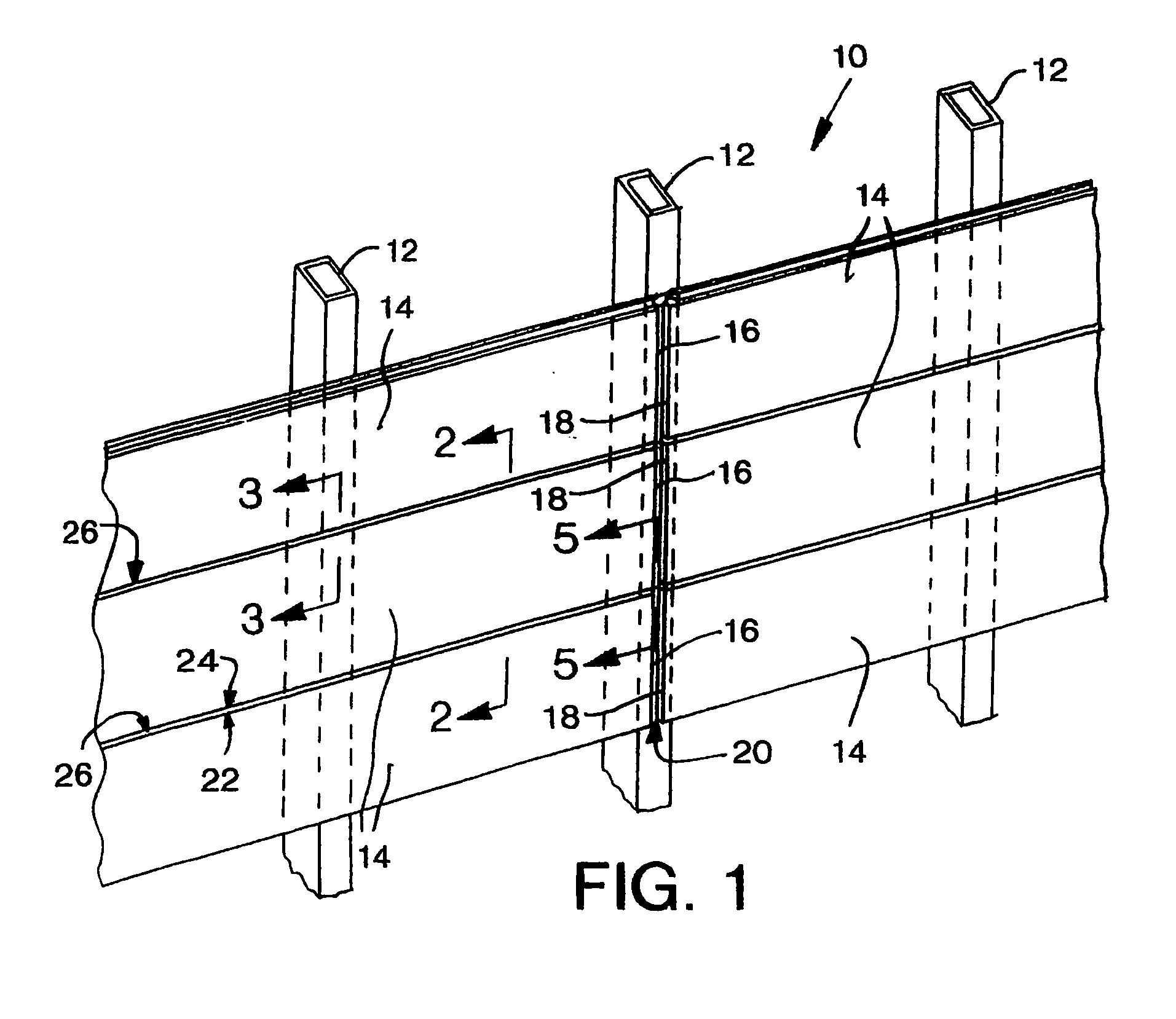

Cladding system

InactiveUS7043884B2Readily and easily and quickly mounted on and removedEasy constructionCeilingsCovering/liningsBraced frameArchitectural engineering

A stone cladding system for building has a support frame formed by a plurality of spaced-apart upright mullions fixed to an exterior of a building by anchor bracket's with a number of horizontal cladding panel support rails mounted in vertically spaced apart rows on the mullions. Each stone cladding panel is mounted between at adjacent pair of vertically spaced-apart rails with a bottom of the cladding panel seated on the lowermost rail and a top of the cladding panel secured to the uppermost rail by a pair of retaining clips. A bottom of each stone cladding panel is fully supported along its length by the lowermost rail.

Owner:CRONOS 2000

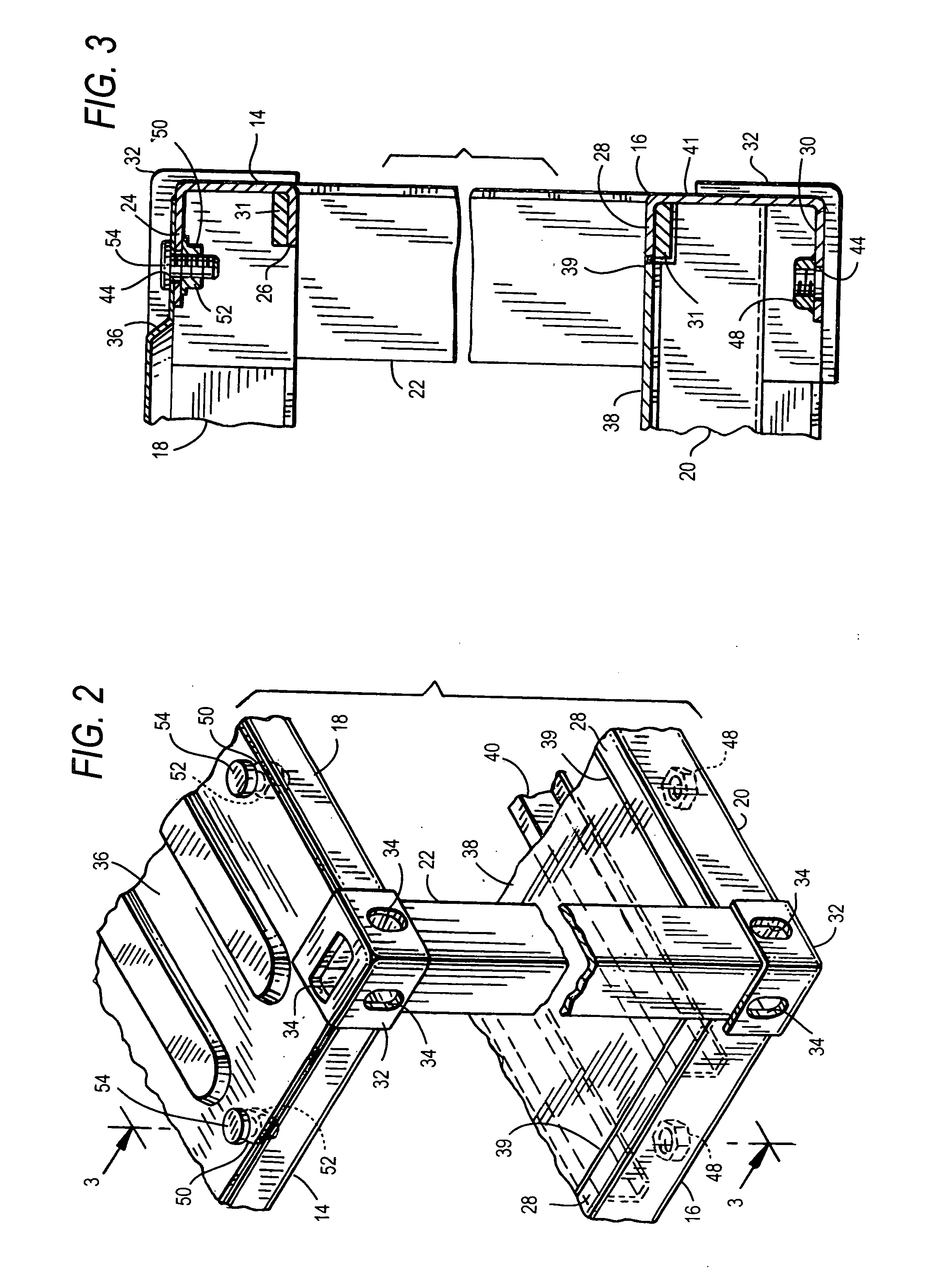

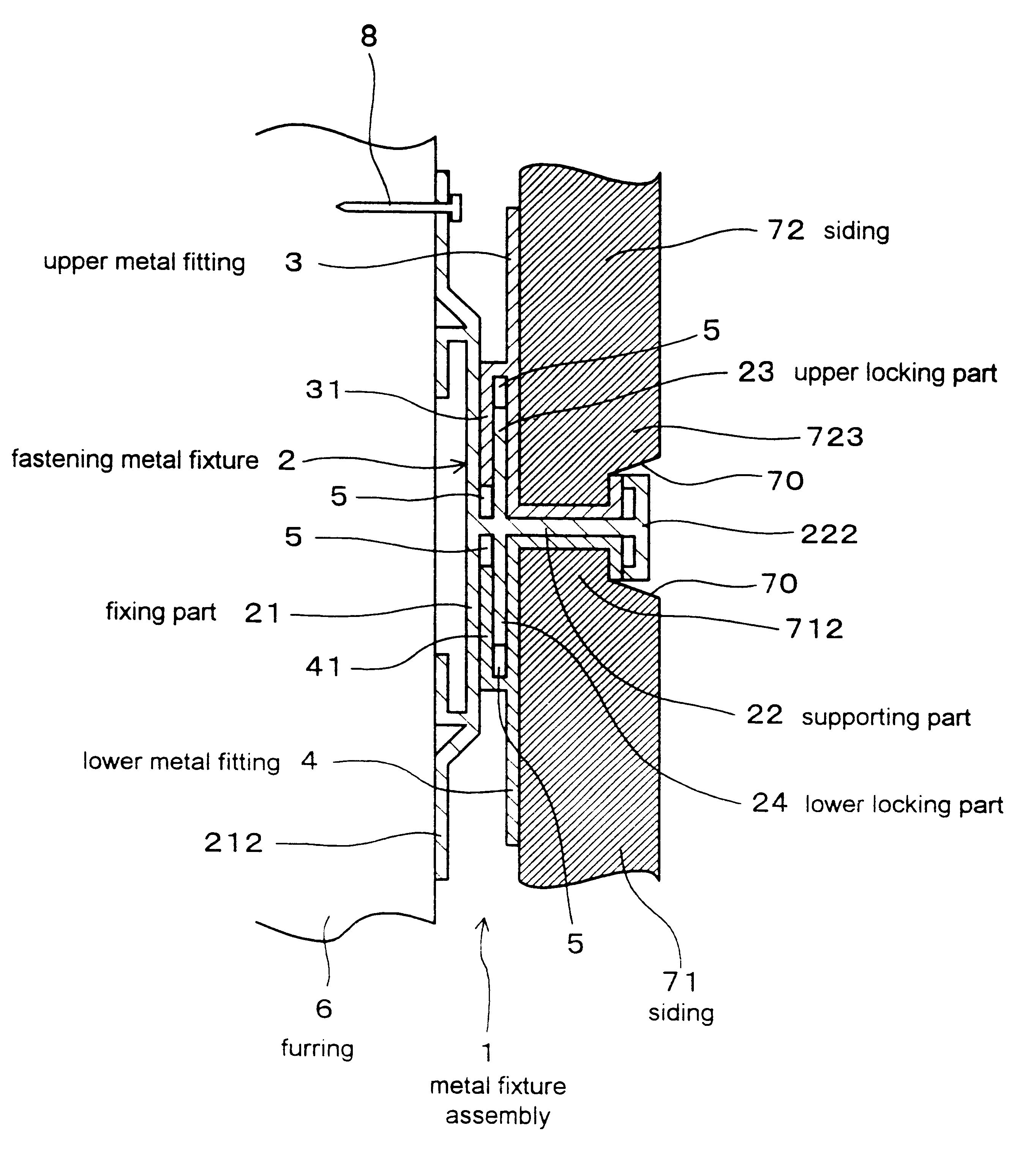

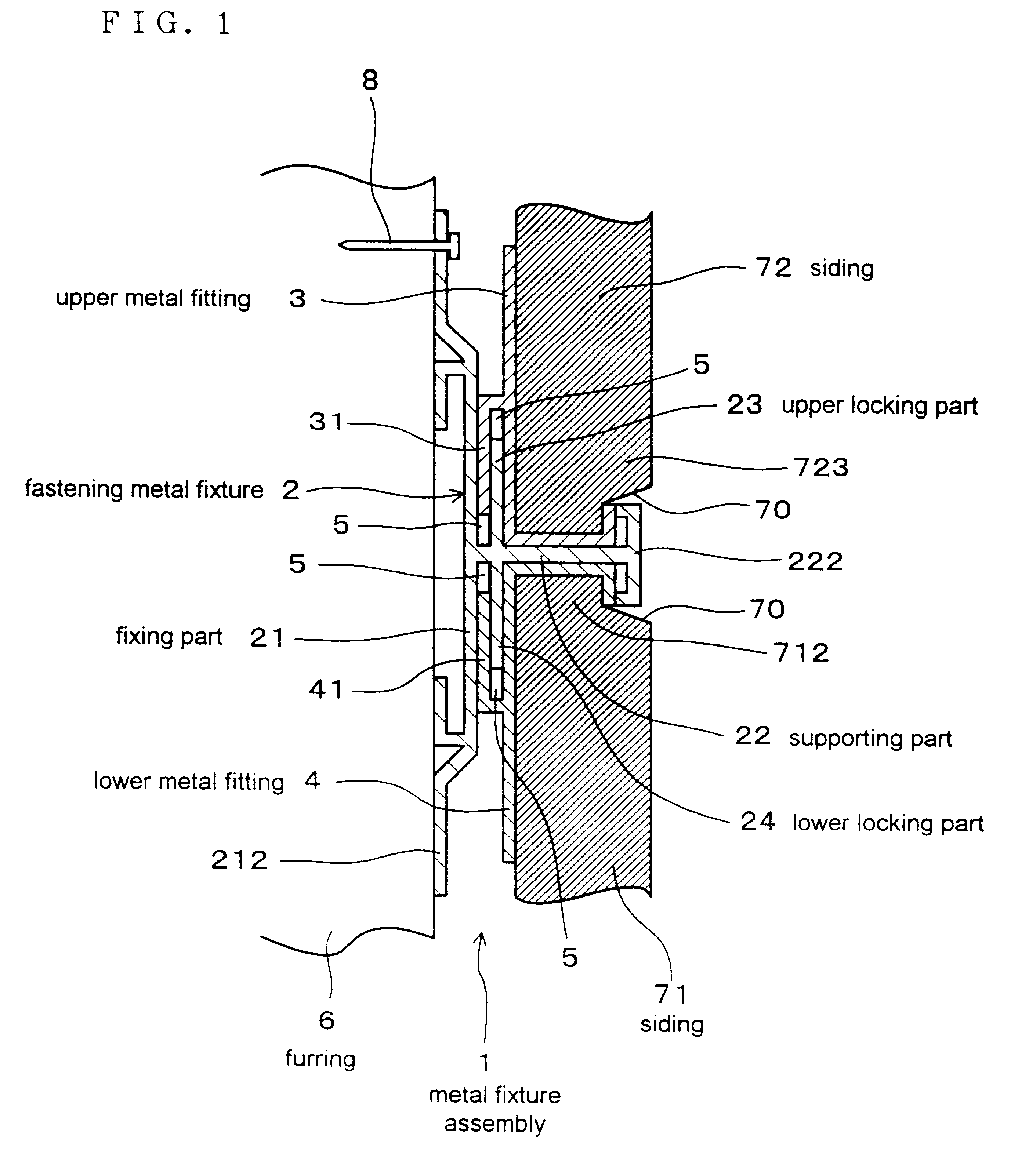

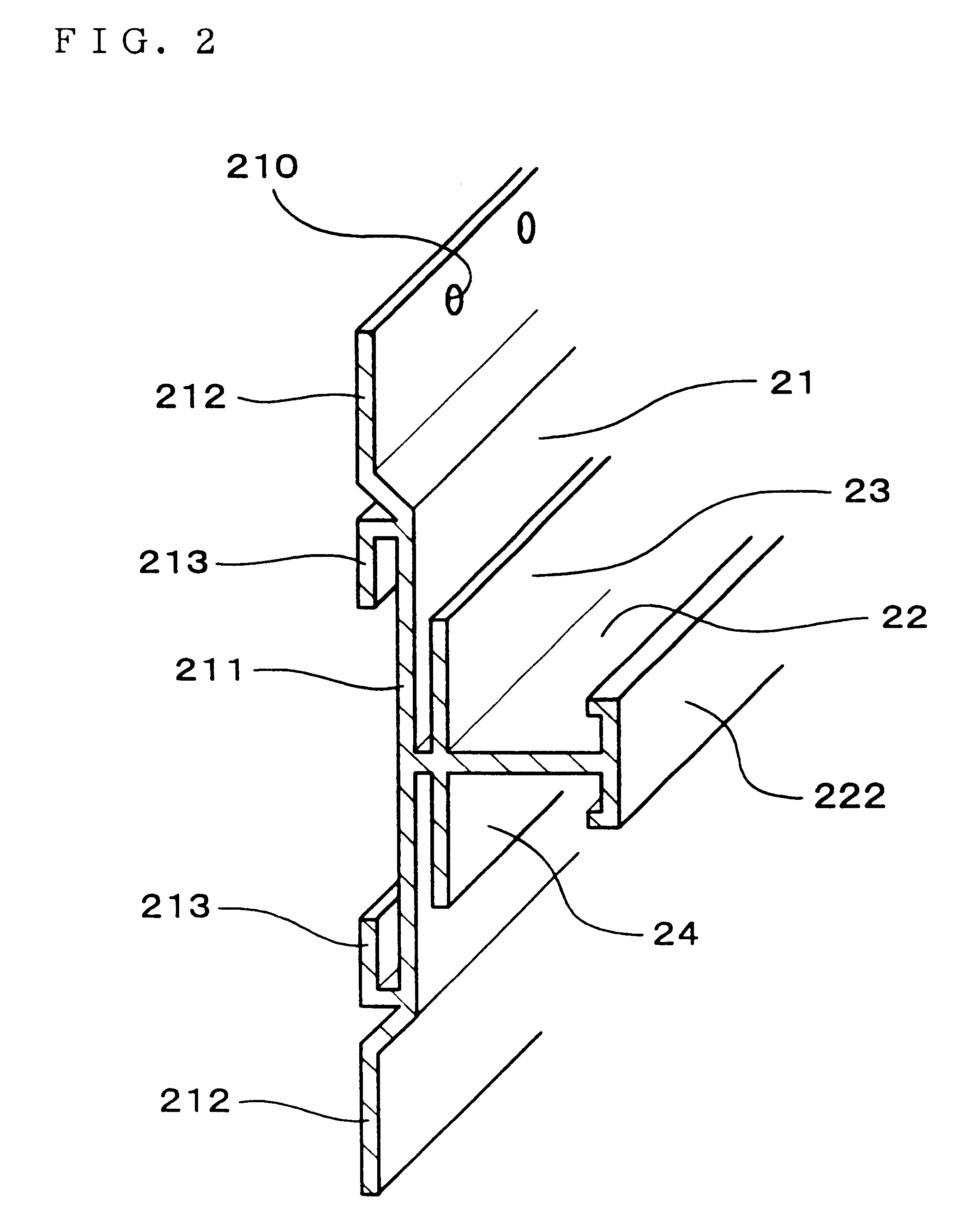

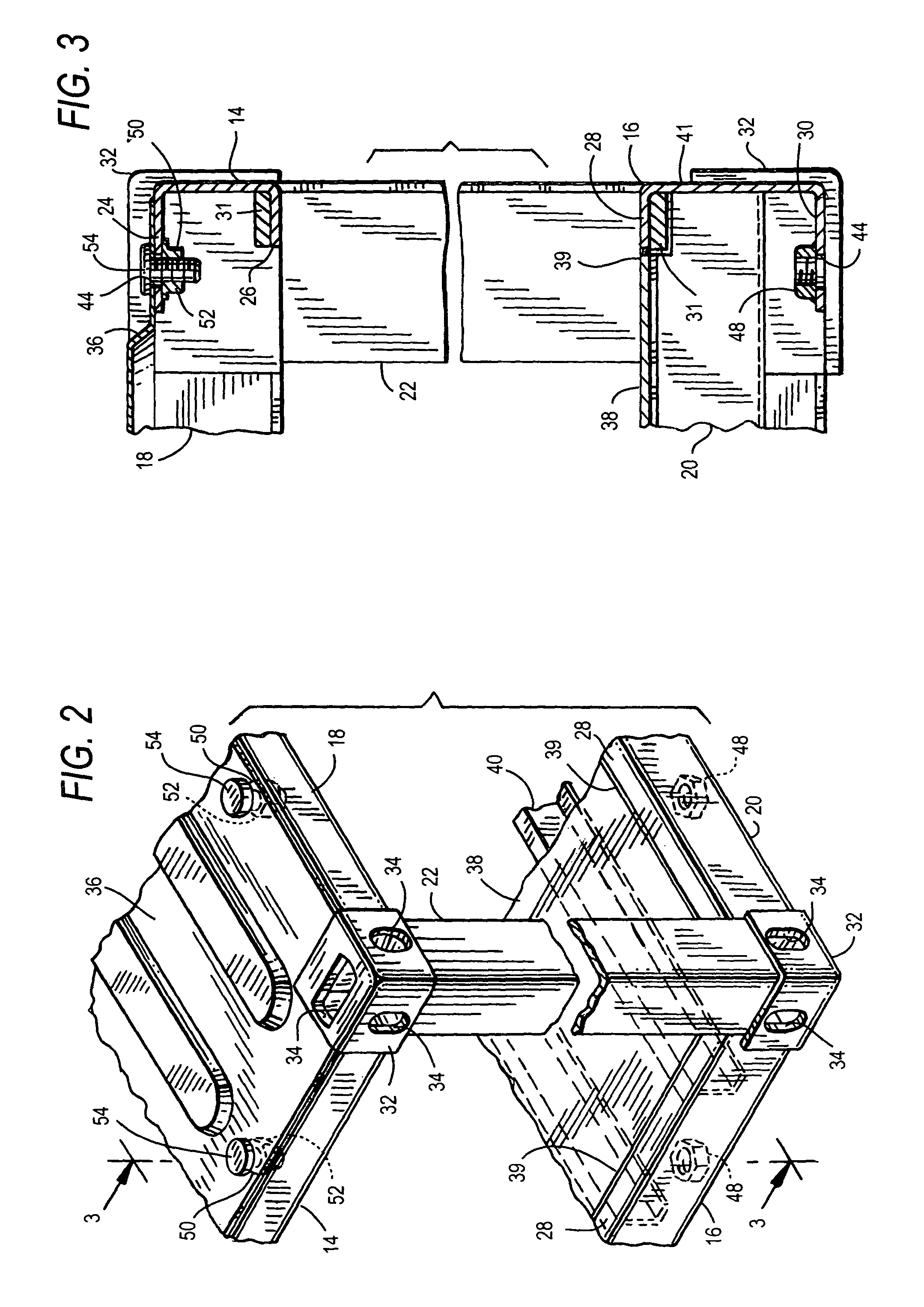

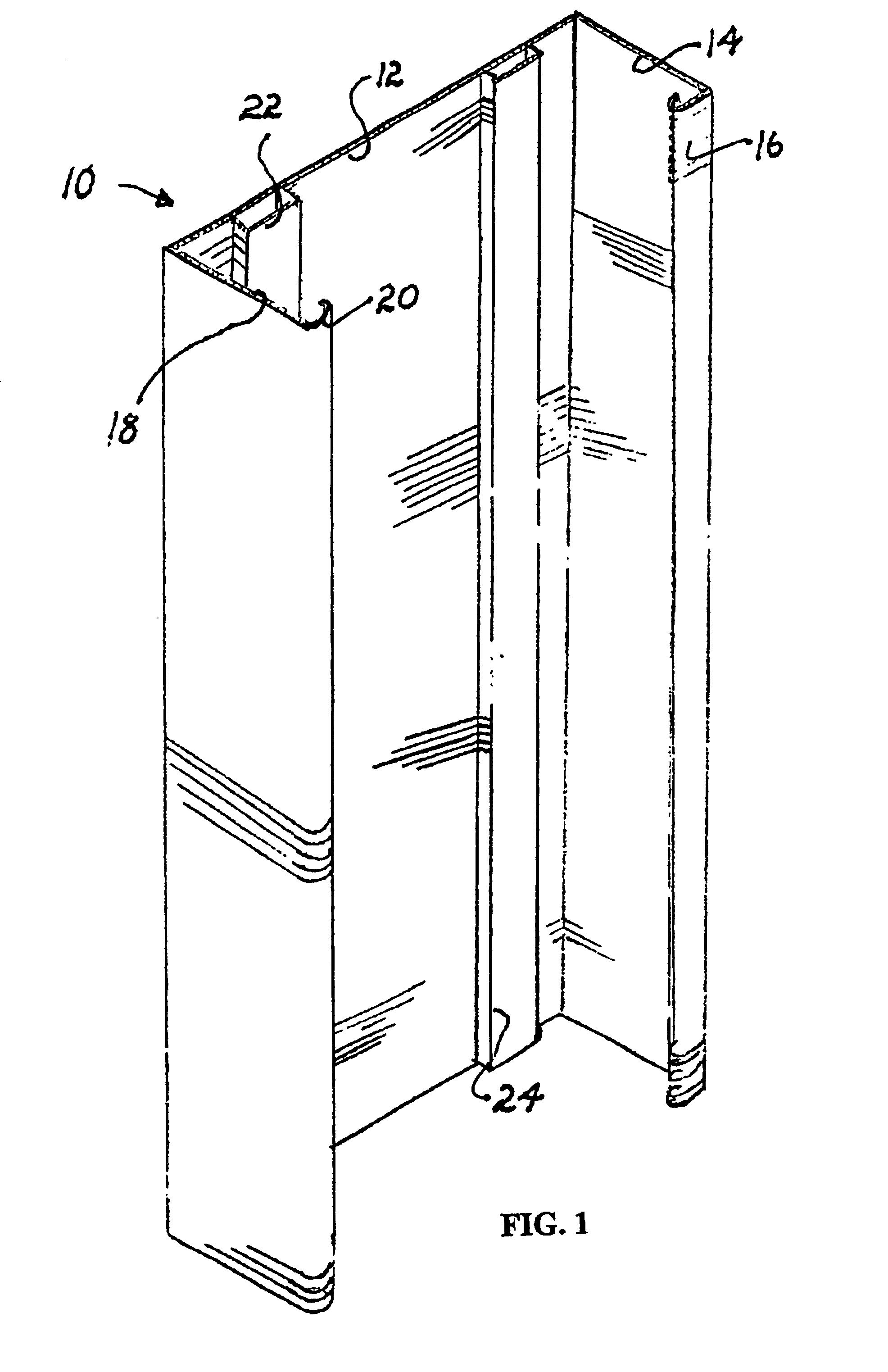

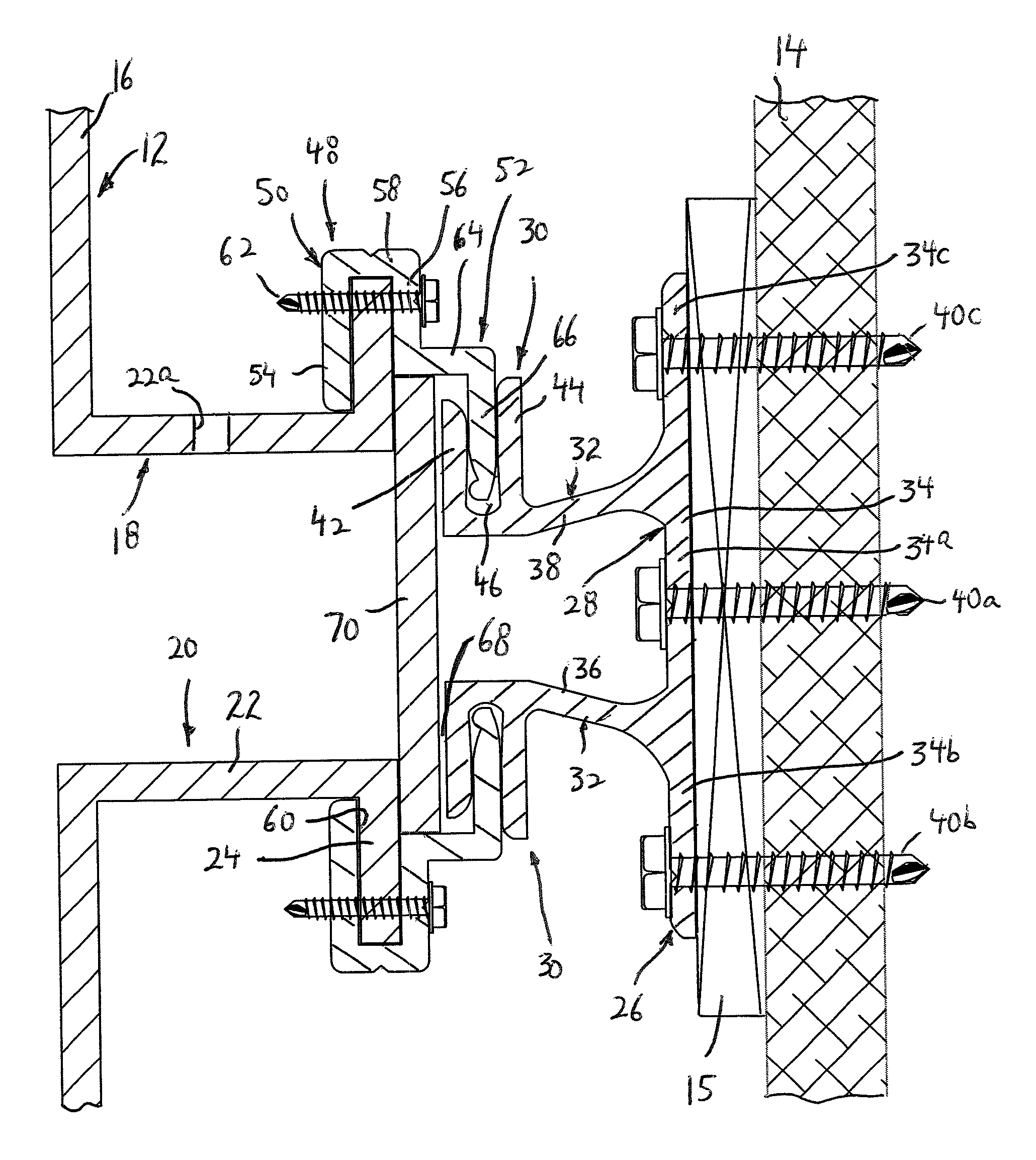

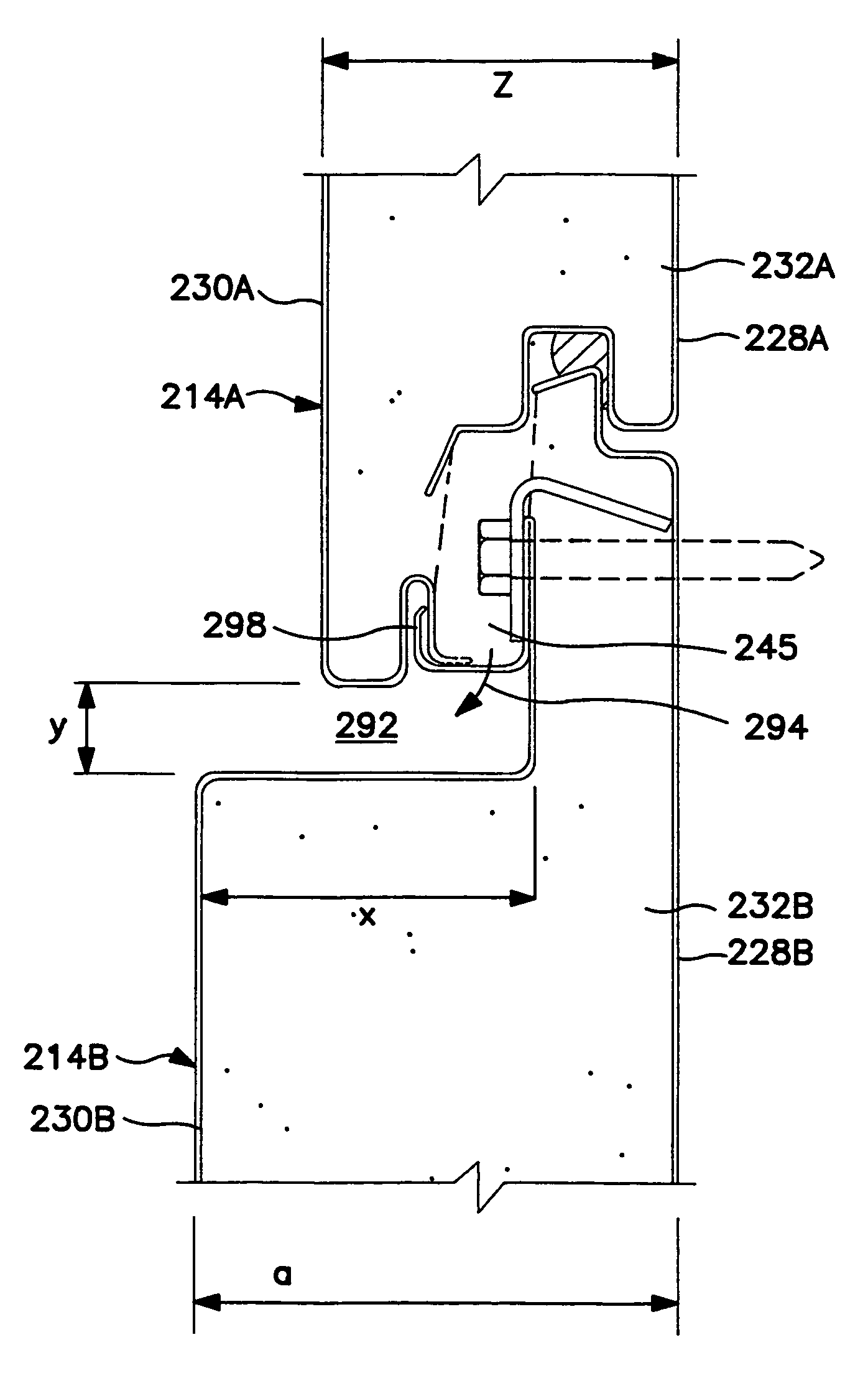

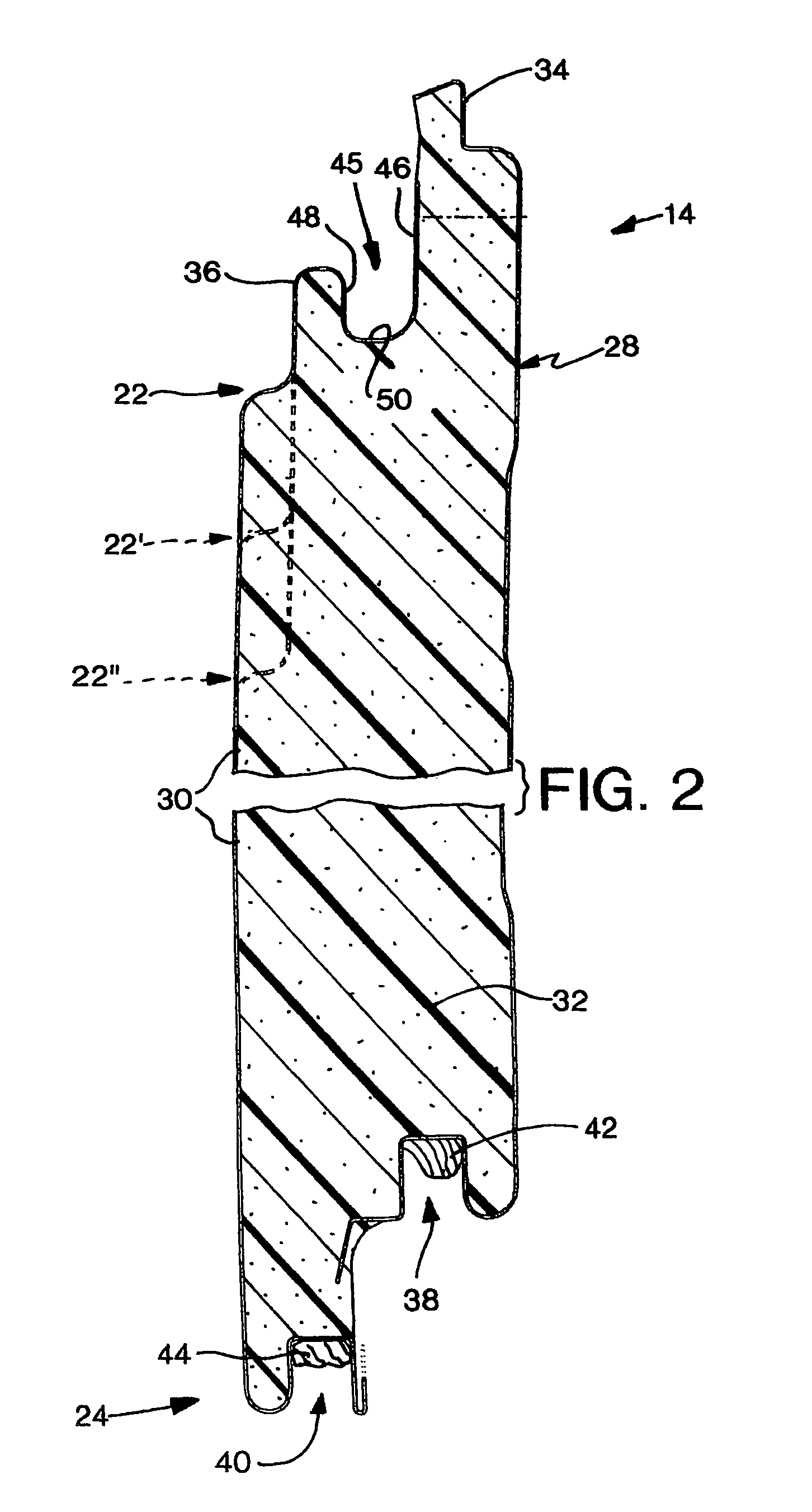

Metal fixture assembly for installation of vertical sidings, construction and method of installation

InactiveUS6289646B1Safe installationGood lookingCeilingsRoof covering using tiles/slatesArchitectural engineeringFurring

A metal fixture assembly for installation of vertical sidings to fix the siding to a furring, which is capable of providing a construction of the installation having excellent appearance and weathering, and a method using the metal fixture assembly to facilitate the installation. A metal fixture assembly for installation of a vertical lower siding and a vertical upper siding vertically adjacent to each other on a furring is positioned therebetween. The metal fixture assembly includes a fastening metal fixture to be fixed to the furring, an upper metal fitting provided between the fastening metal fixture and the upper siding and fittingly fixed on a bottom portion thereof, and a lower metal fitting provided between the fastening metal fixture and the lower siding and fittingly fixed on a top portion thereof. The fastening metal fixture has a fixing part to be fixed to the furring, a supporting part projecting from the fixing part to support the lower and upper sidings, an upper locking part provided between the fixing part and the supporting part and locking the upper metal fitting thereto, and a lower locking part provided between the fixing part and the supporting part and locking the lower metal fitting thereto.

Owner:NICHIHA CORP

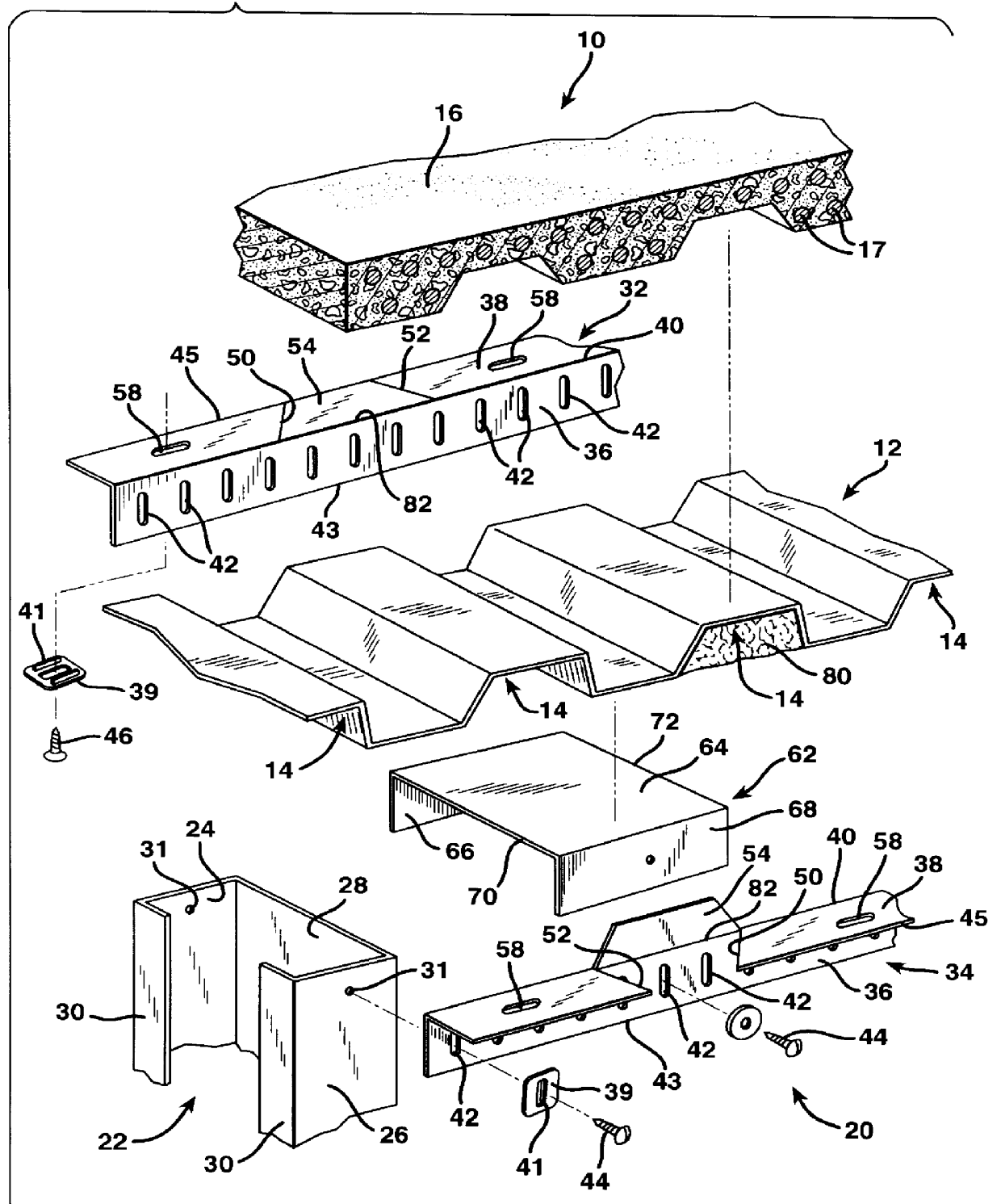

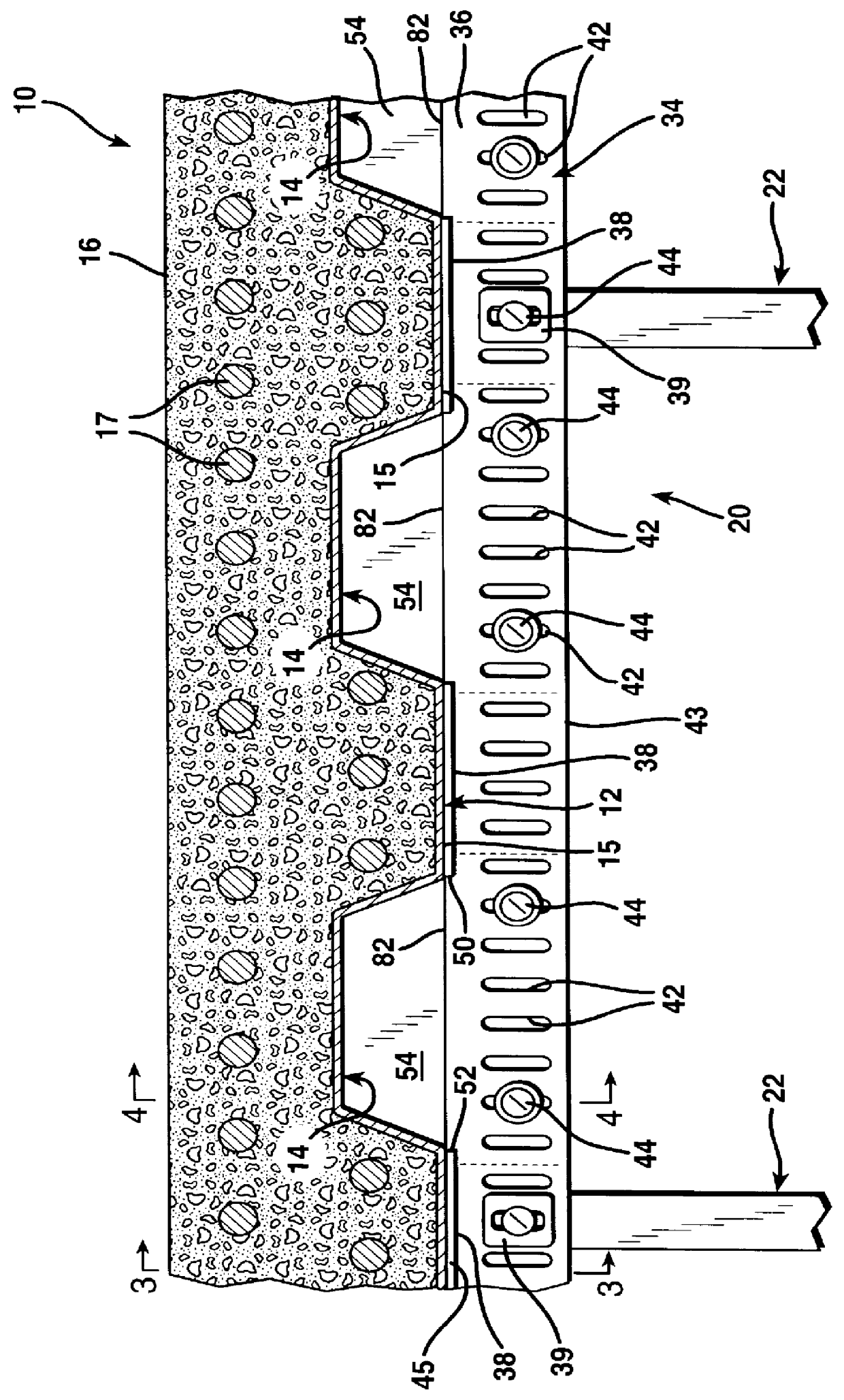

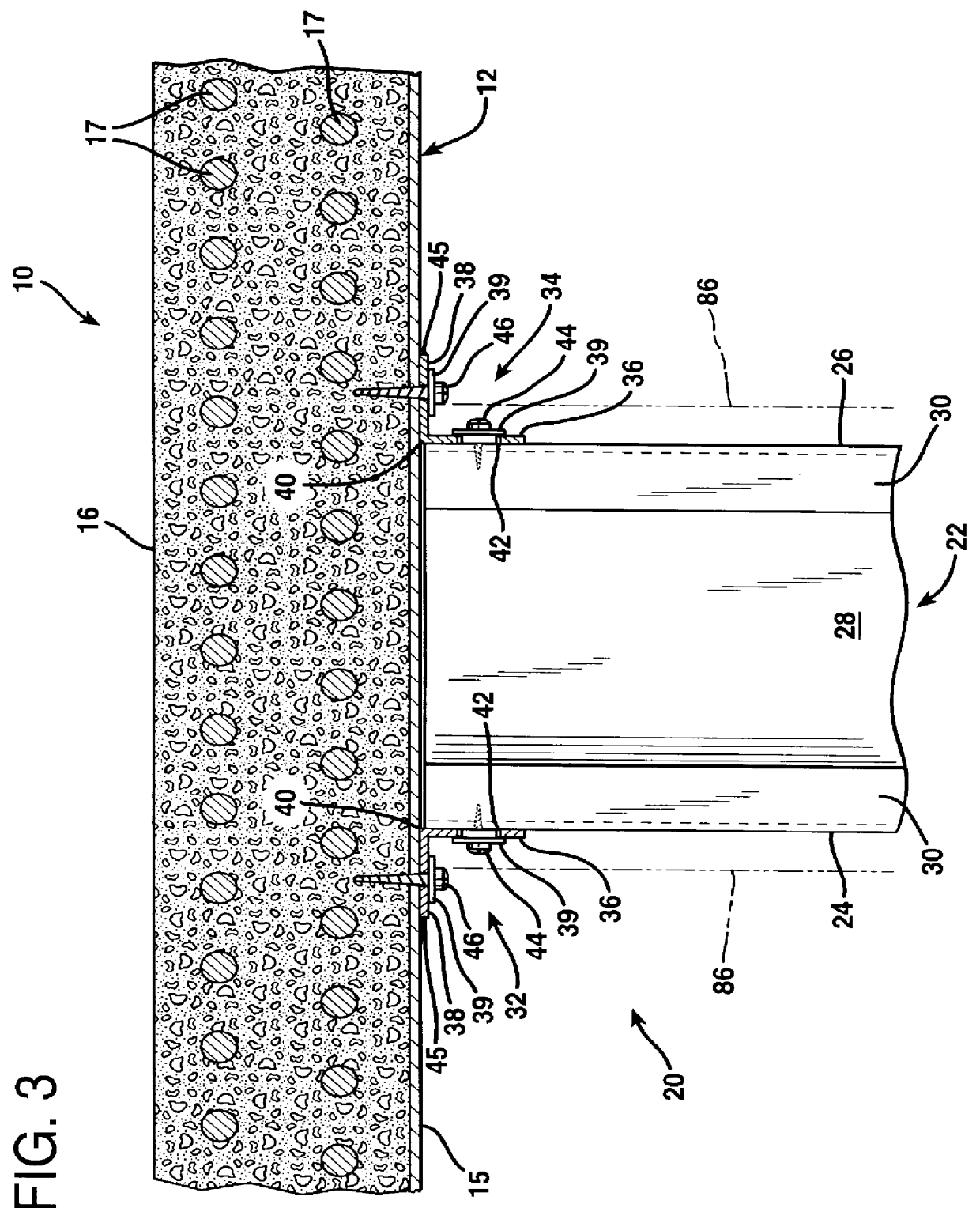

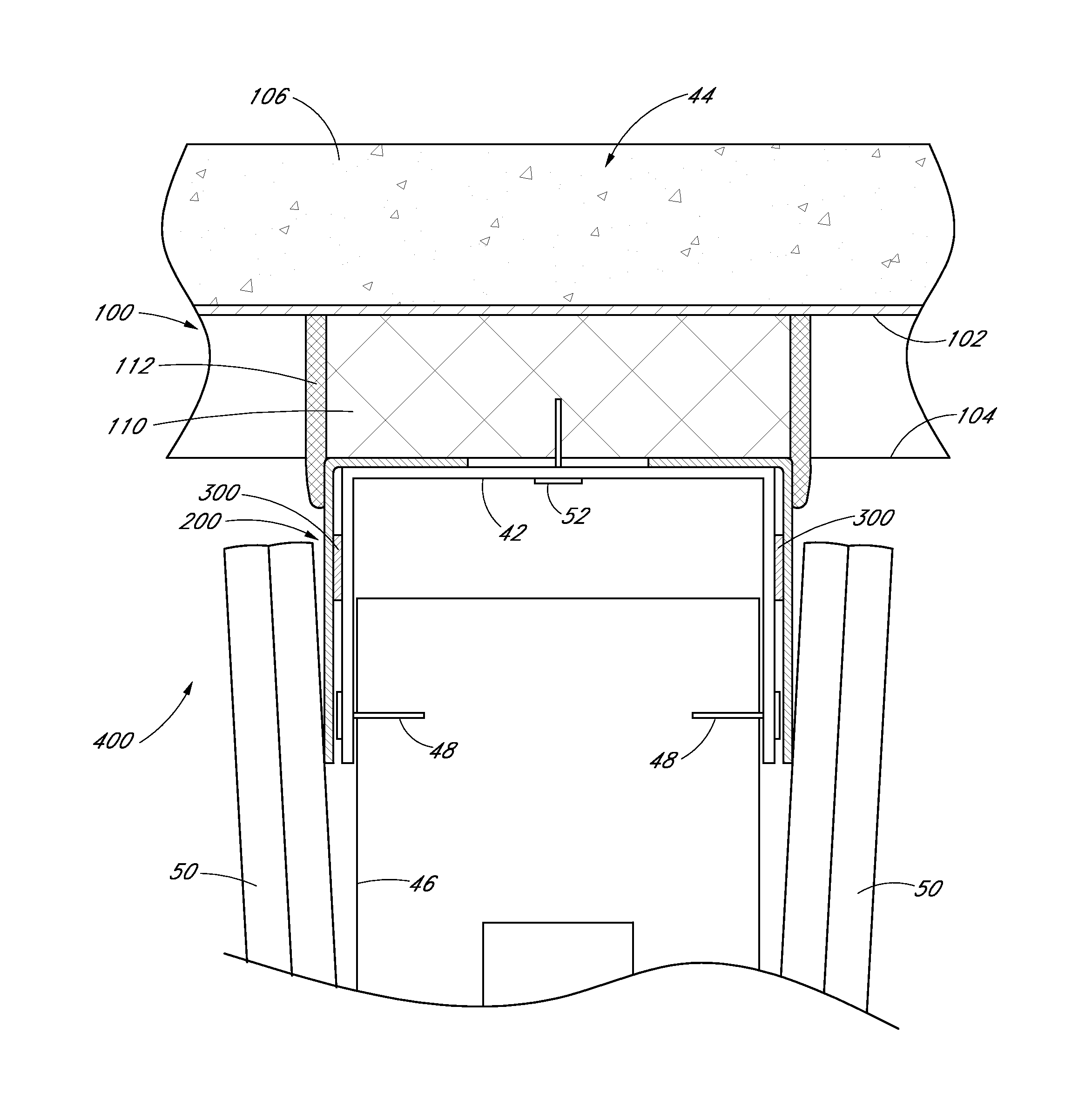

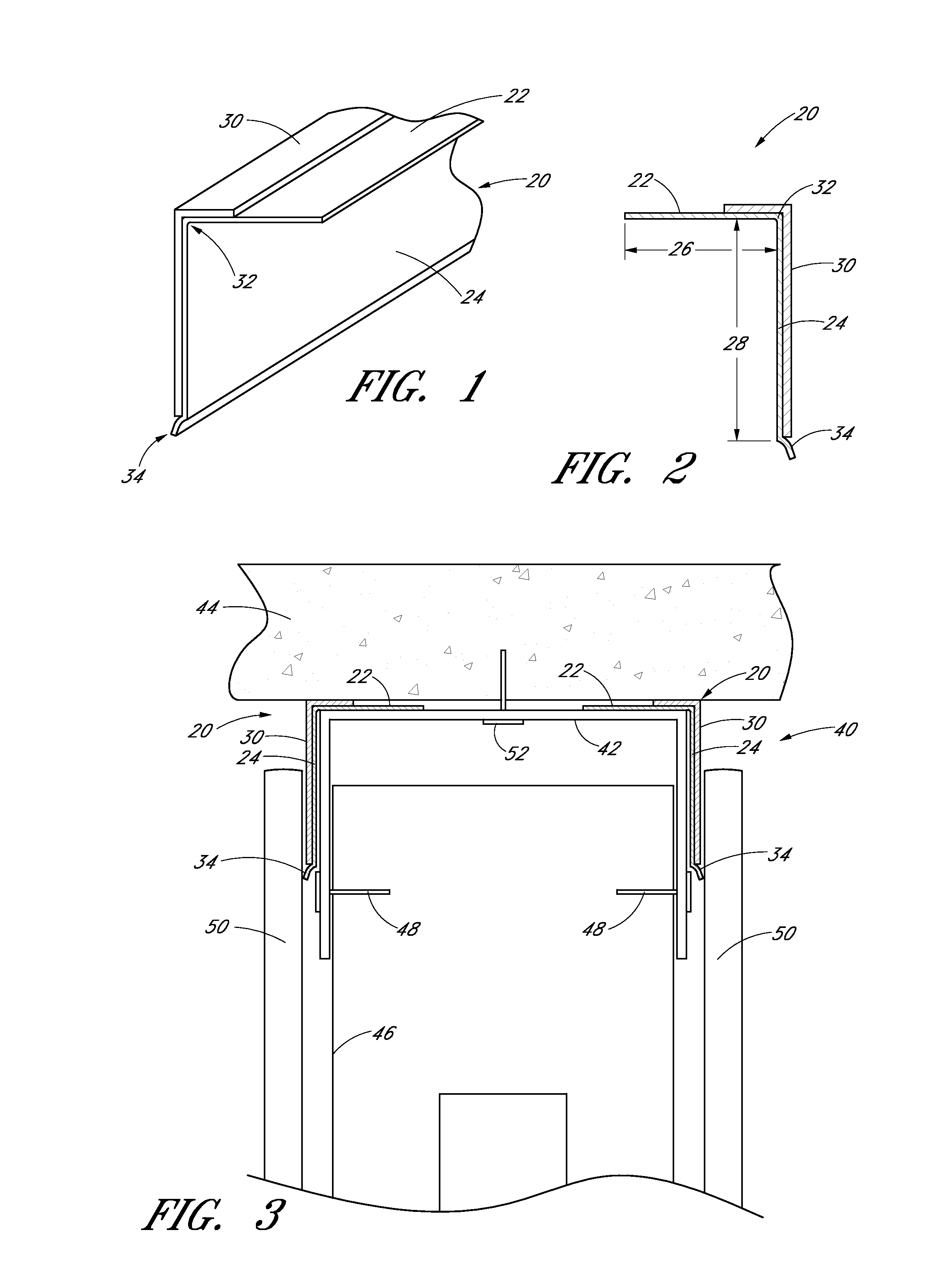

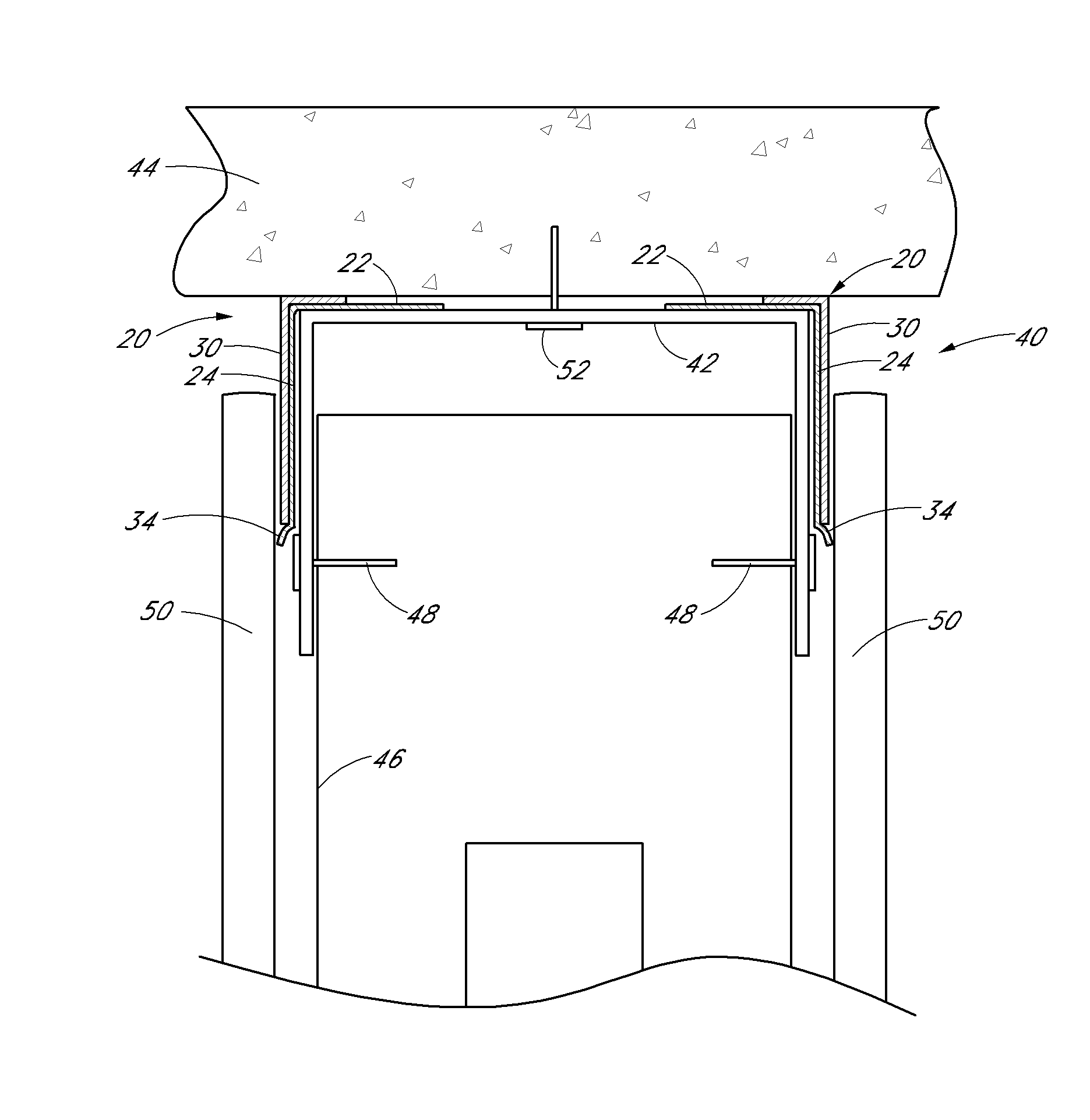

Seismic and fire-resistant head-of-wall structure

An improved head-of-wall structure for an interior, nonload-bearing building wall is provided in which a pair of elongated angle strips are employed to connect the upper ends of to the upright metal studs fluted metal decking above in a seismic and fire-resistant manner. A plurality of uniformly spaced pop-up tabs are defined in the horizontal legs of the angle strips directly beneath the open flutes or channels of the metal decking above. Insulation supports are located beneath the ceiling flutes to span the distance between the angle strips. The insulation supports are connected to the vertical legs of the angle strips to form flat, horizontal platforms directly beneath the portions of the flutes that cross the line of studs. Batts of fire-proofing insulation are located atop the insulation supports and are held in position by bending up the pop-up tabs from their original horizontal disposition into a generally vertical orientation.

Owner:HERREN THOMAS R

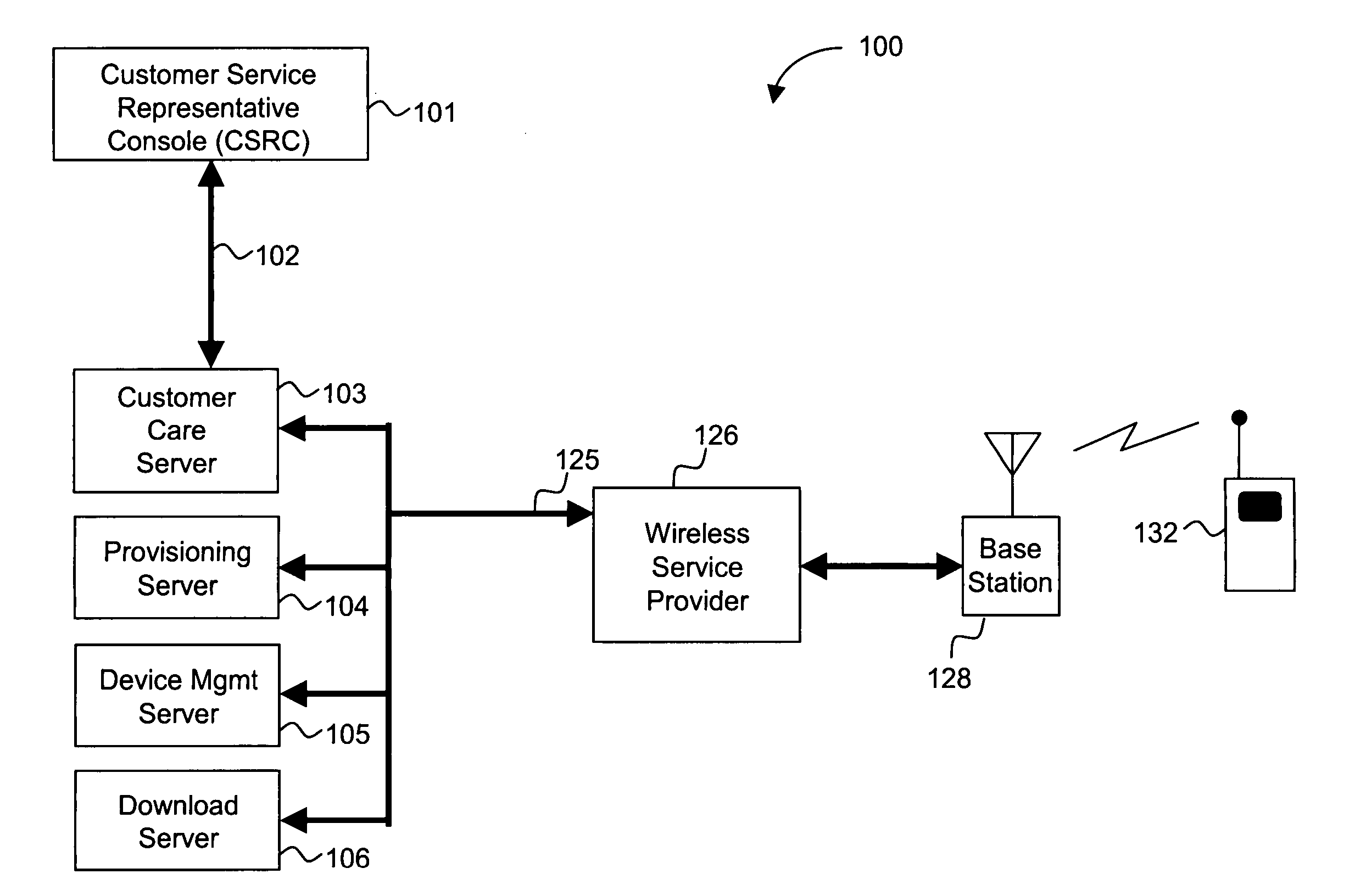

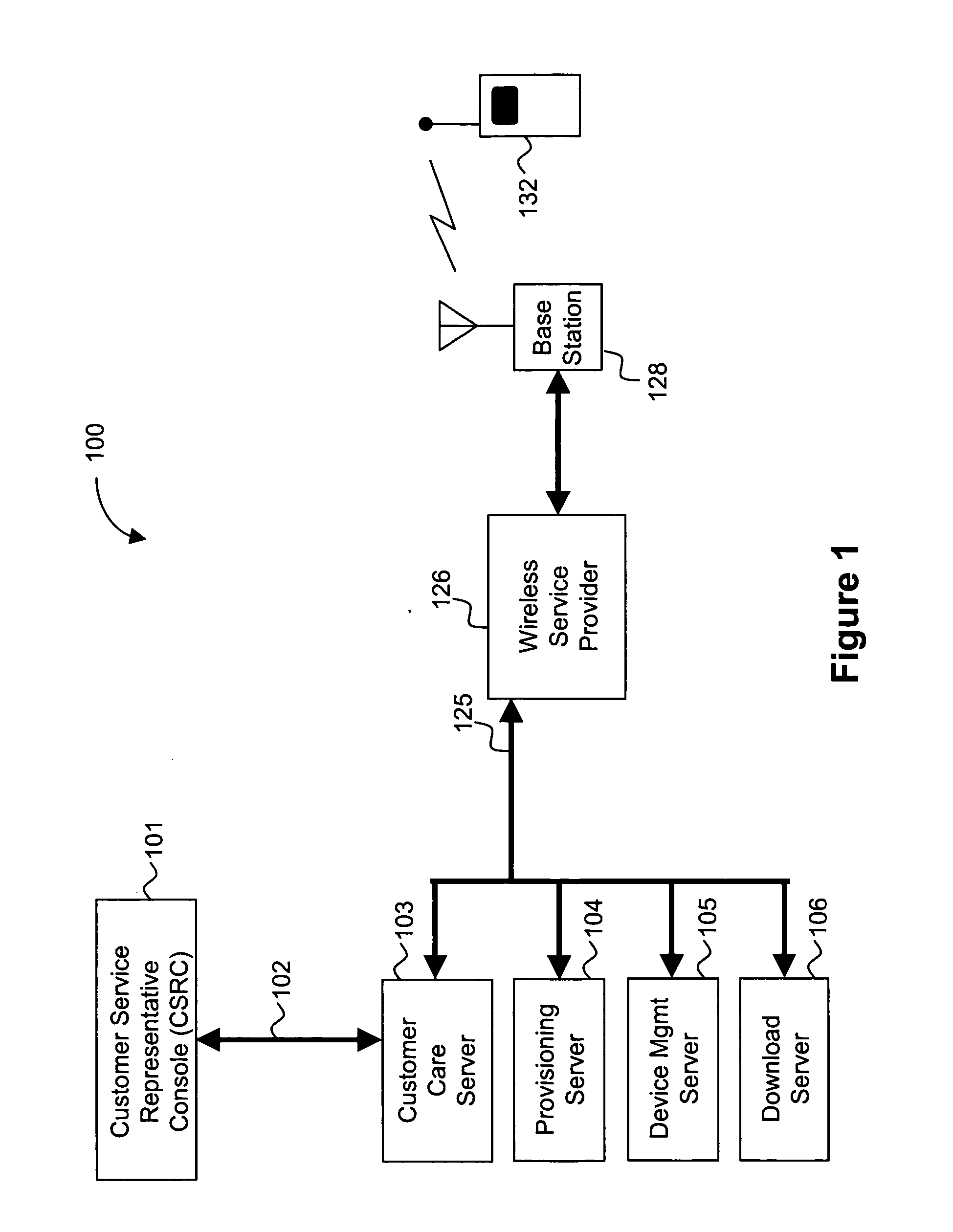

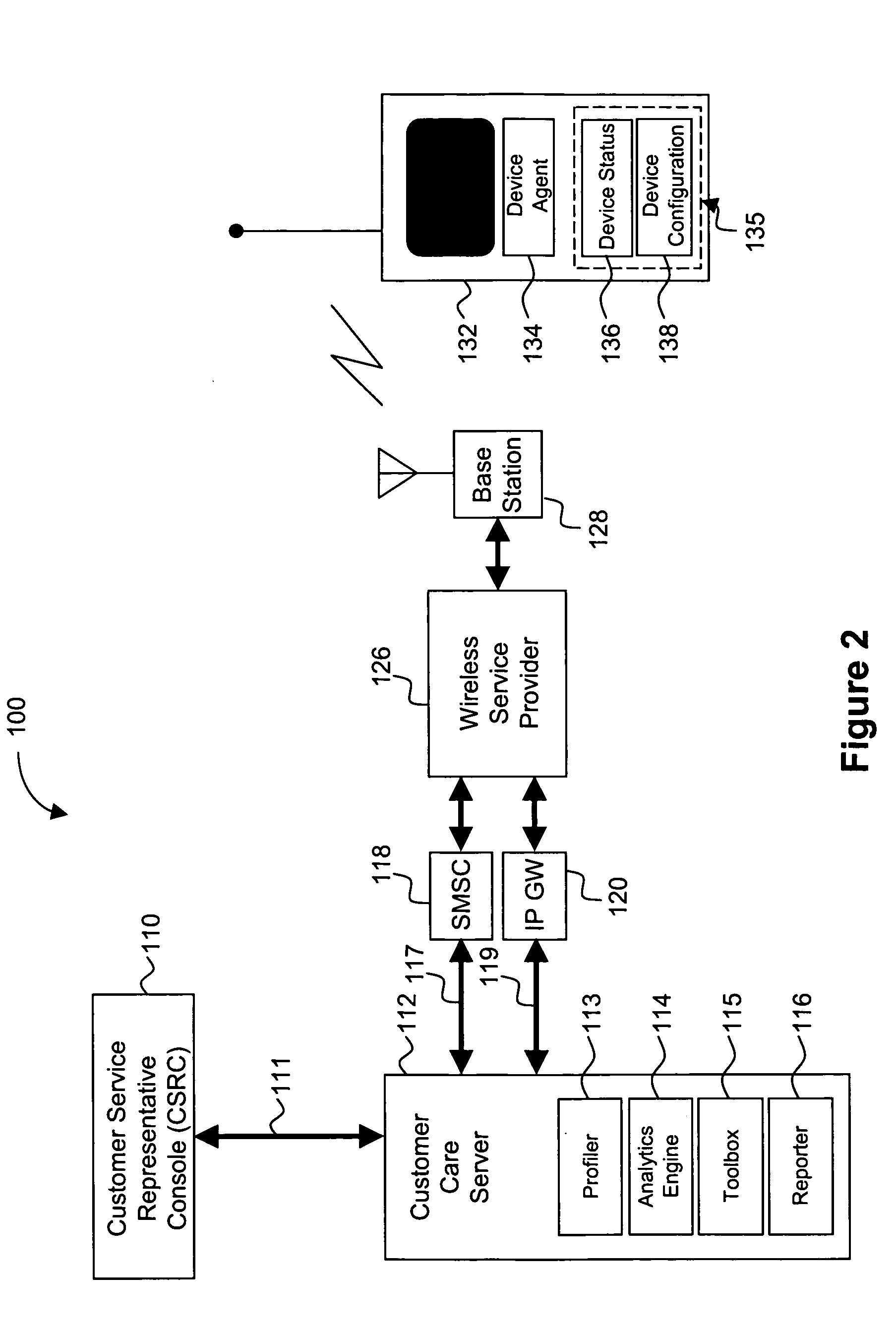

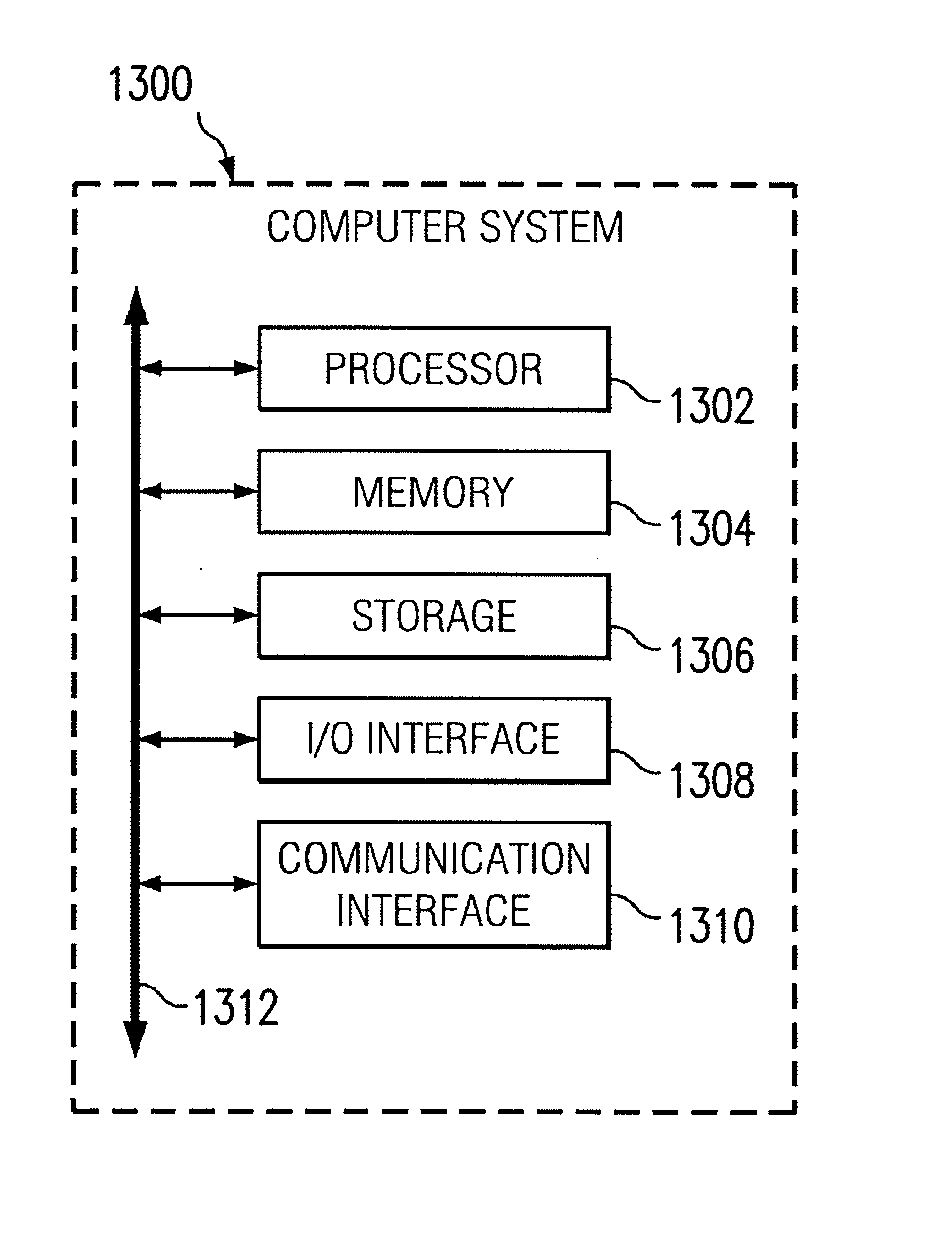

Network for customer care and distribution of firmware and software updates

InactiveUS20060217111A1Public buildingsRadio/inductive link selection arrangementsSoftware updateClient-side

A network for customer care and distribution of update packages to electronic devices makes it possible to efficiently manage and update firmware and software in devices. A provisioning server in the network employs provisioning means to update configuration, provision devices and manage devices. An electronic device capable of receiving these update packages comprises a update client that is capable of updating the device.

Owner:HEWLETT PACKARD DEV CO LP

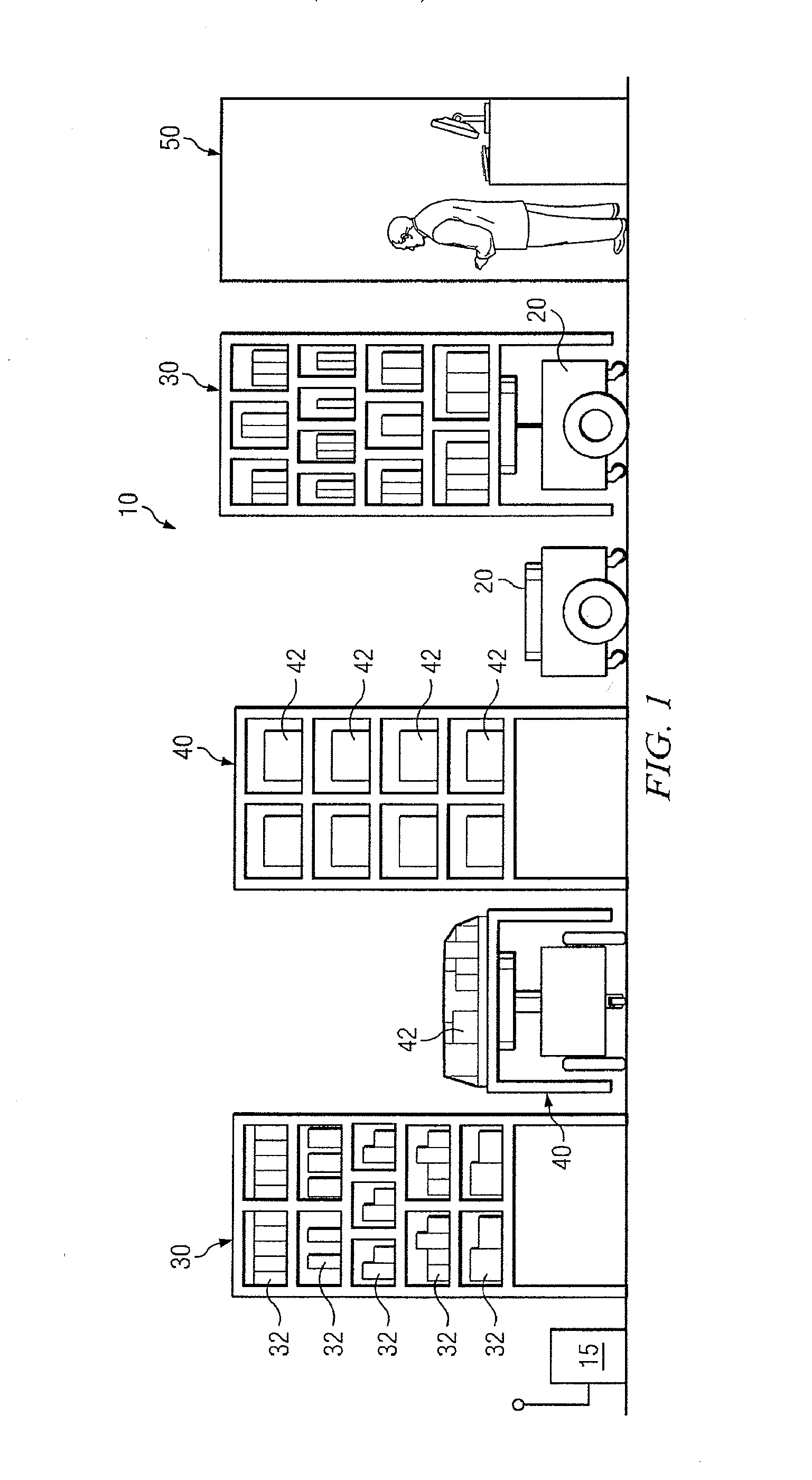

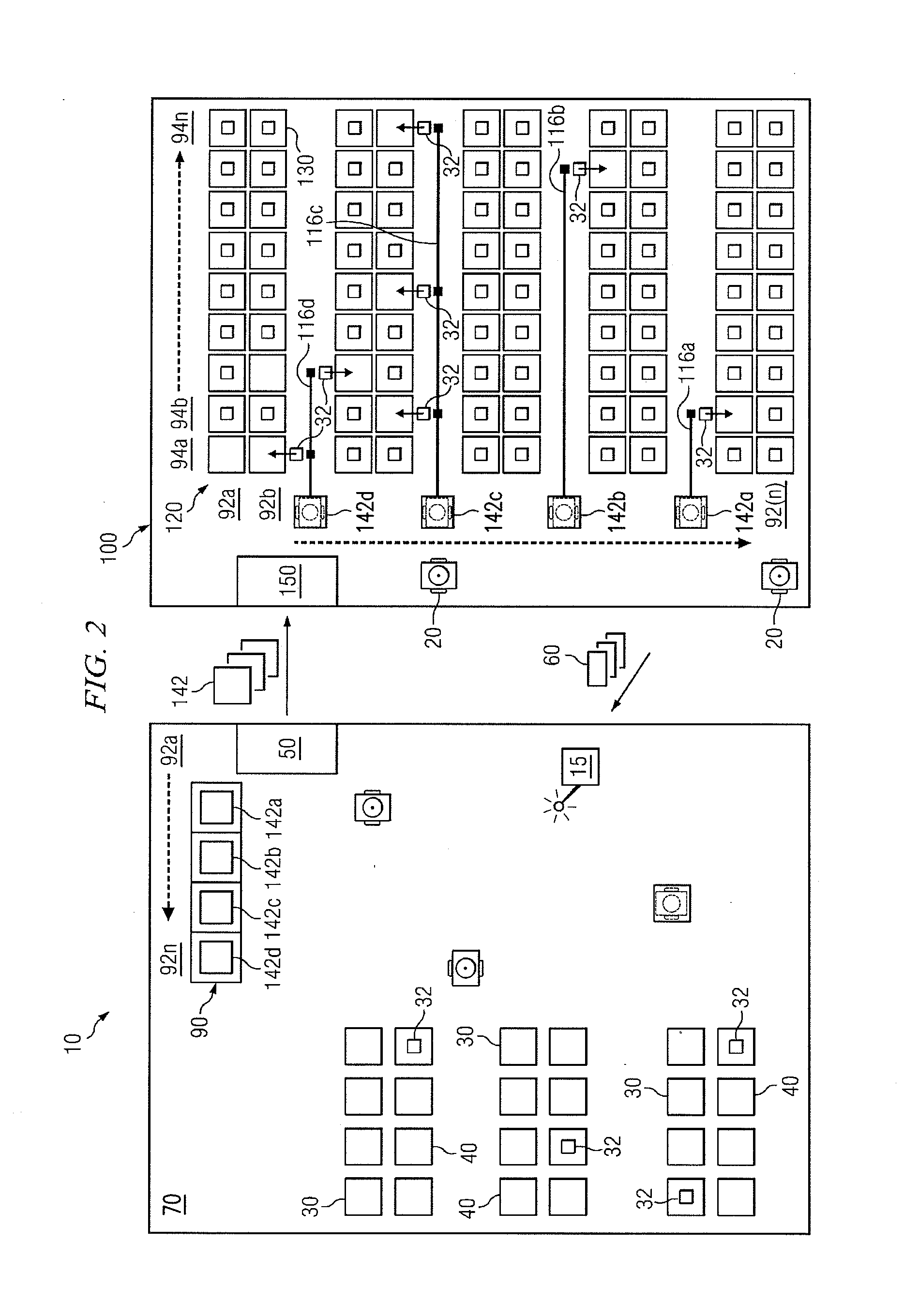

Replenishing a retail facility

ActiveUS20140100769A1Hand manipulated computer devicesPublic buildingsComputer moduleTransport engineering

A system includes storage shelves and display shelves at a retail facility. The system also includes a management module operable to determine to replenish a display shelf with an inventory item stored by a storage shelf. The management module is also operable to coordinate movement of mobile drive units to replenish the display shelf with the inventory item at an inventory restocking station. The system also includes a first mobile drive unit and a second mobile drive unit. The first mobile drive unit is operable to receive first instructions from the management module to transport the display shelf to the inventory restocking station. The second mobile drive unit is operable to receive second instructions from the management module to transport the storage shelf to the inventory restocking station. At the inventory restocking station, the display shelf receives the inventory item.

Owner:AMAZON TECH INC

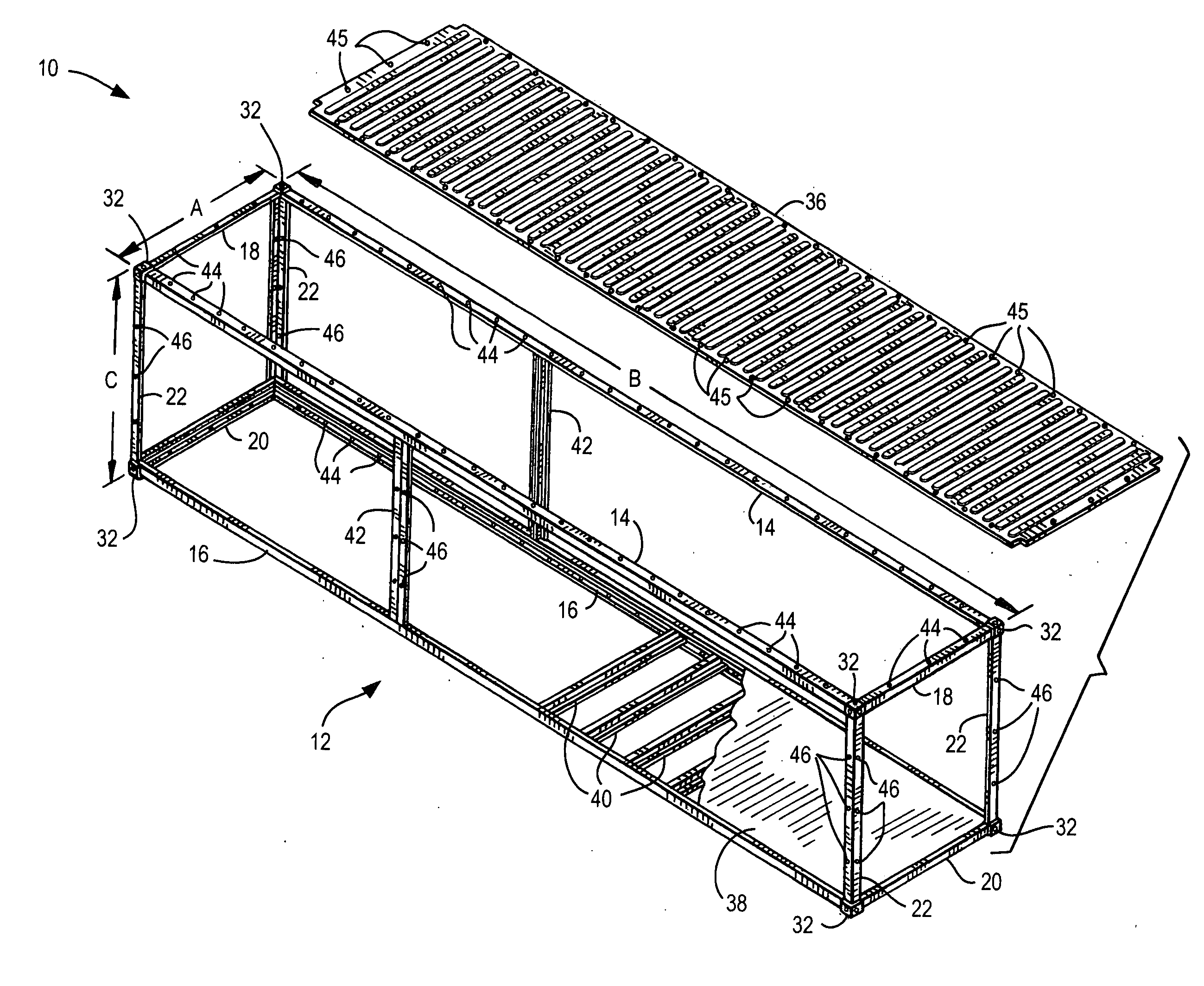

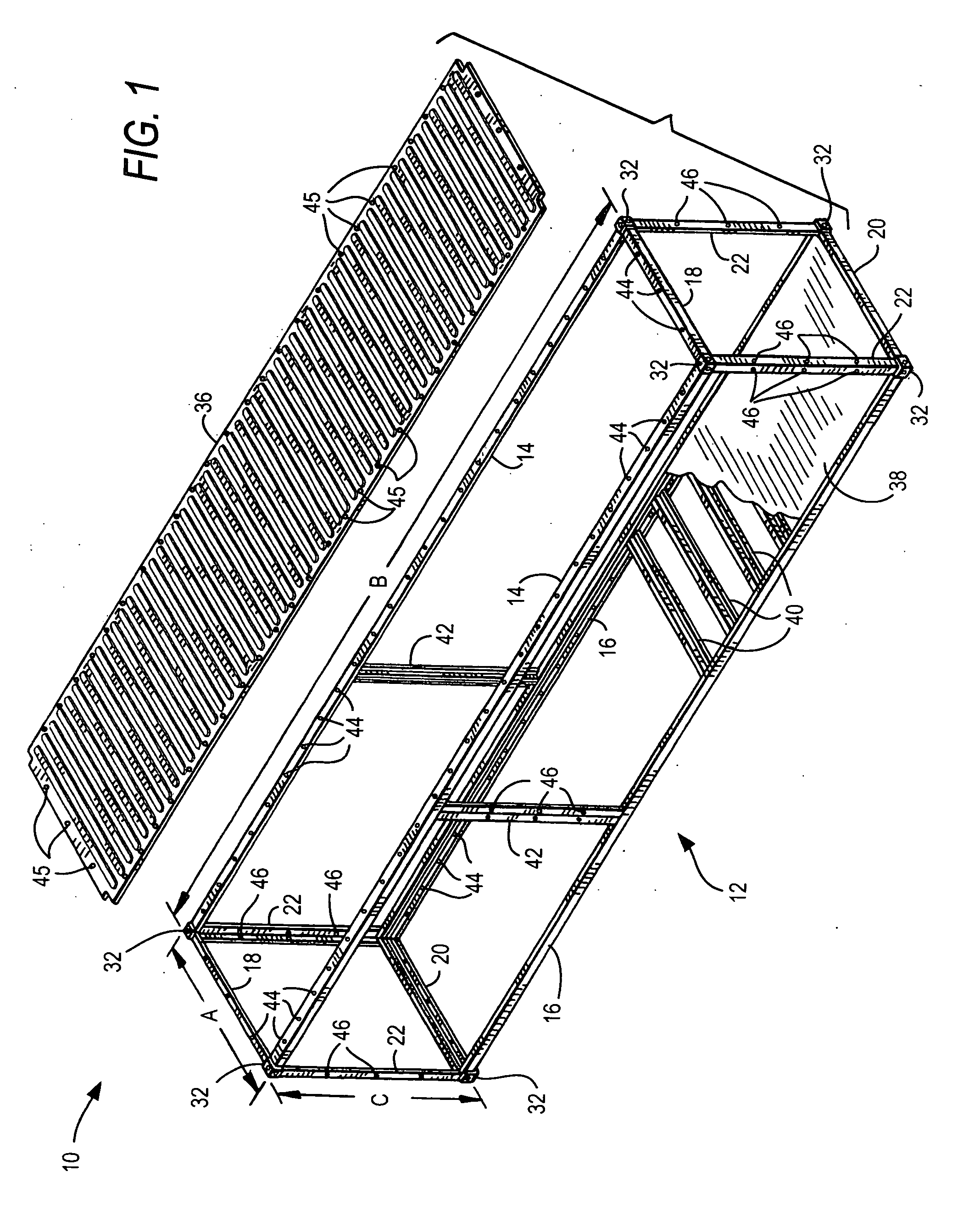

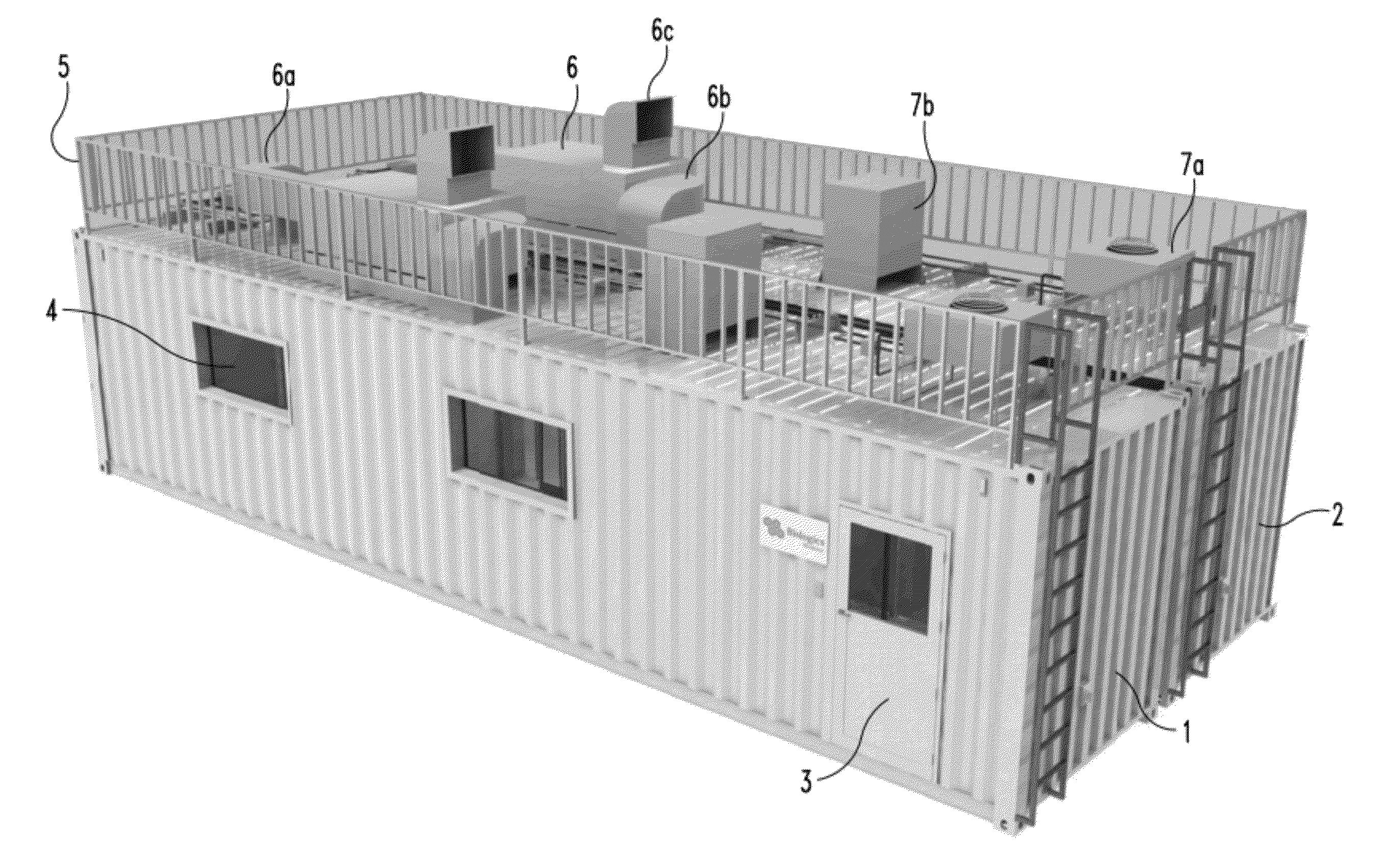

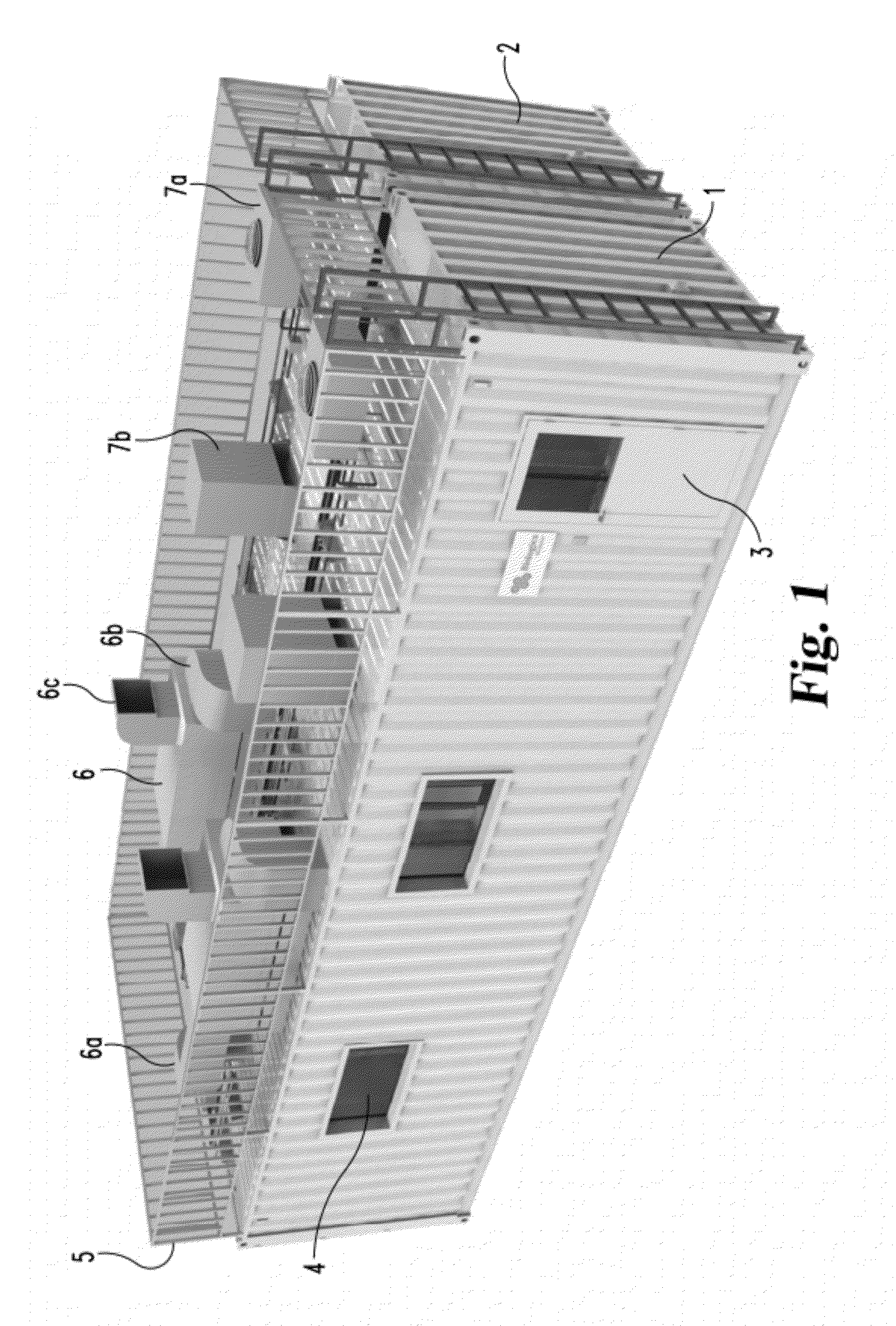

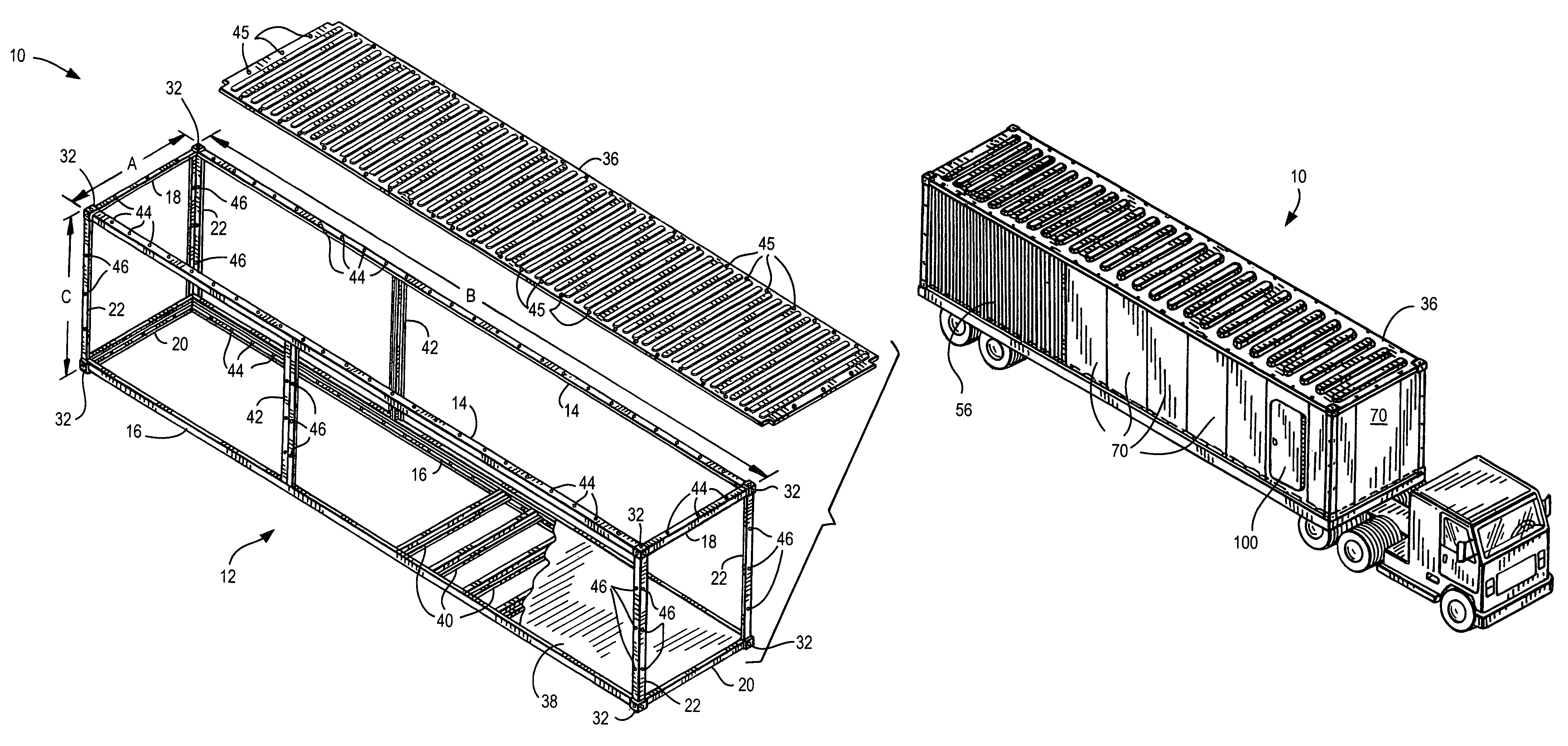

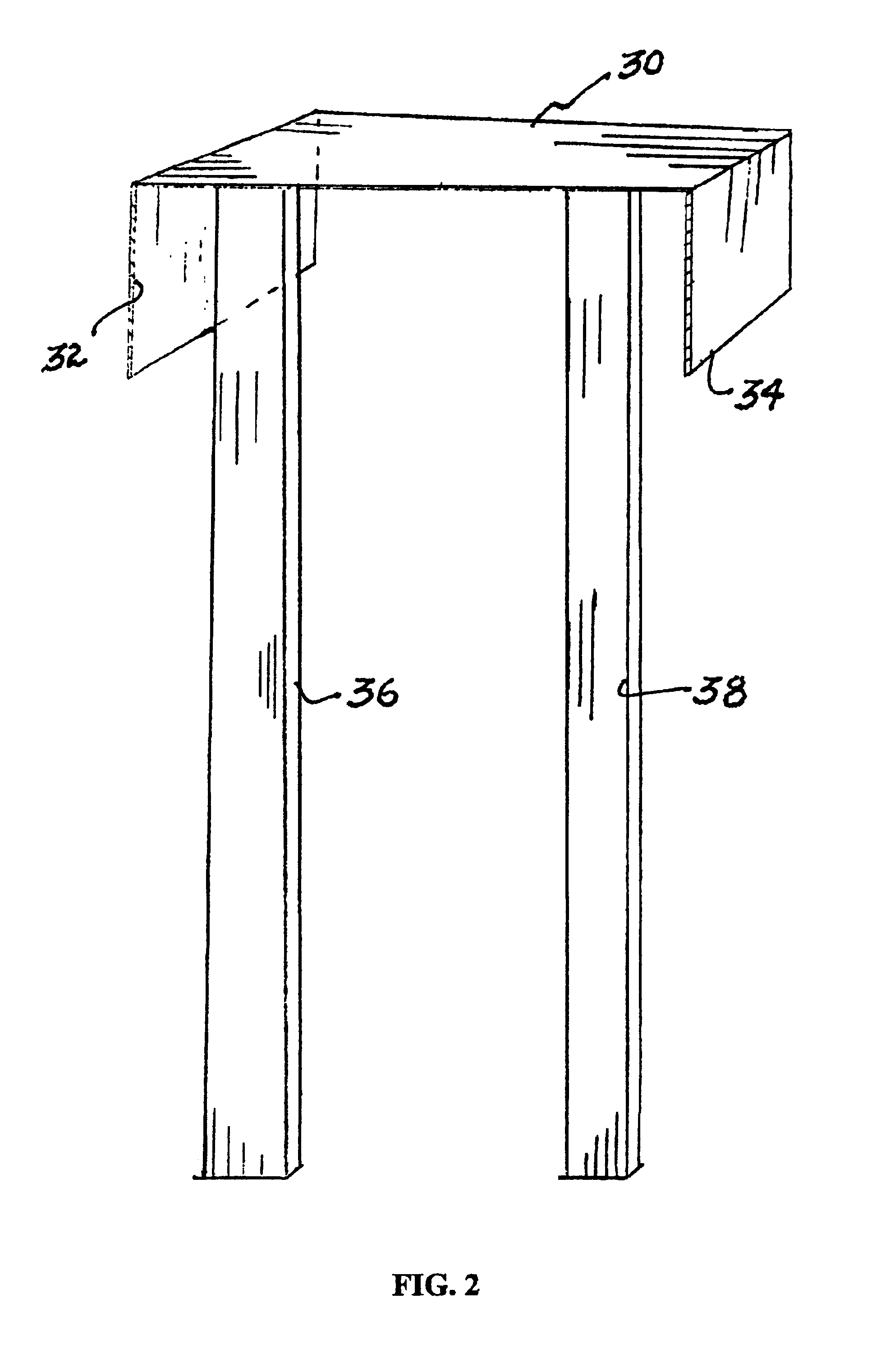

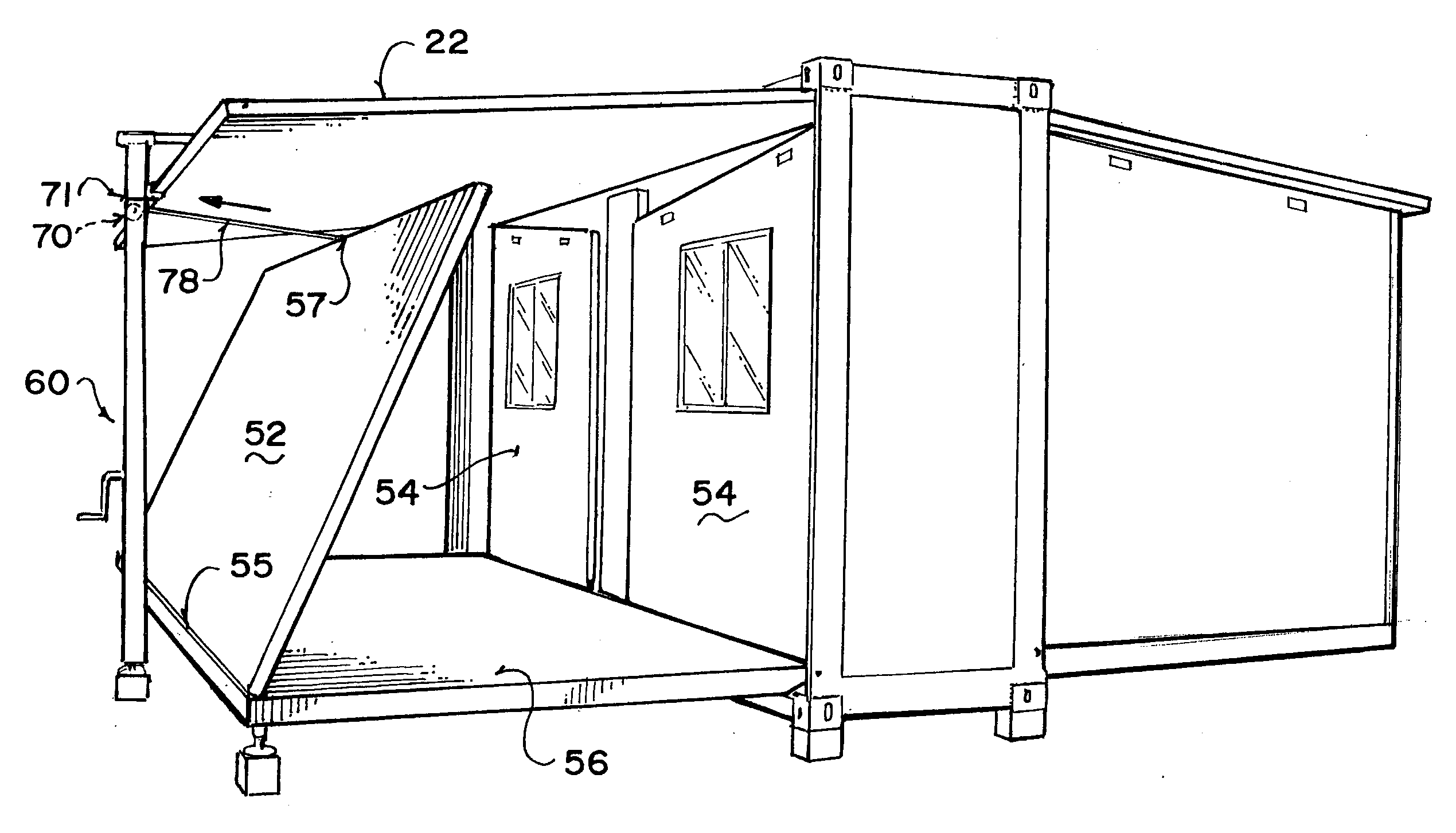

System for modular building construction

InactiveUS7827738B2Good choiceFacilitating selective interconnectionConstruction materialLighting and heating apparatusBuilding unitBuilding construction

Construction systems for erecting building structures comprise a plurality of prefabricated interconnectable modular building units, each unit not meeting at least one of the ISO certification criteria for transport of cargo, but each unit comprising a frame shaped as a rectangular parallelopiped and comprised of framing members and a plurality of nodes, each node situated at a corner of said frame for selective interconnection with other units, the nodes and the exterior dimensions of the frame conforming to ISO shipping standards such that each unit is transportable using the ISO intermodal transportation system, and such that when the units are aggregated horizontally and vertically and adjacent units are interconnected, a building structure comprising at least one habitable space is formed. The modular units are assembled in a factory remote from the job site, and are there constructed to a semi-finished state, including installation of one or more of interior fit-out systems and finishes, exterior envelope systems, plumbing systems, electrical systems, environmental systems, and fire protection systems, following which the semi-finished modular units are transported from the factory to the job site, where they are craned into place and secured to form the structure being erected, a plurality of adjacent pairs of semi-finished modular units also being “stitched” together, and the semi-finished modular units are thereafter constructed to a finished state.

Owner:GLOBAL BUILDING MODULES

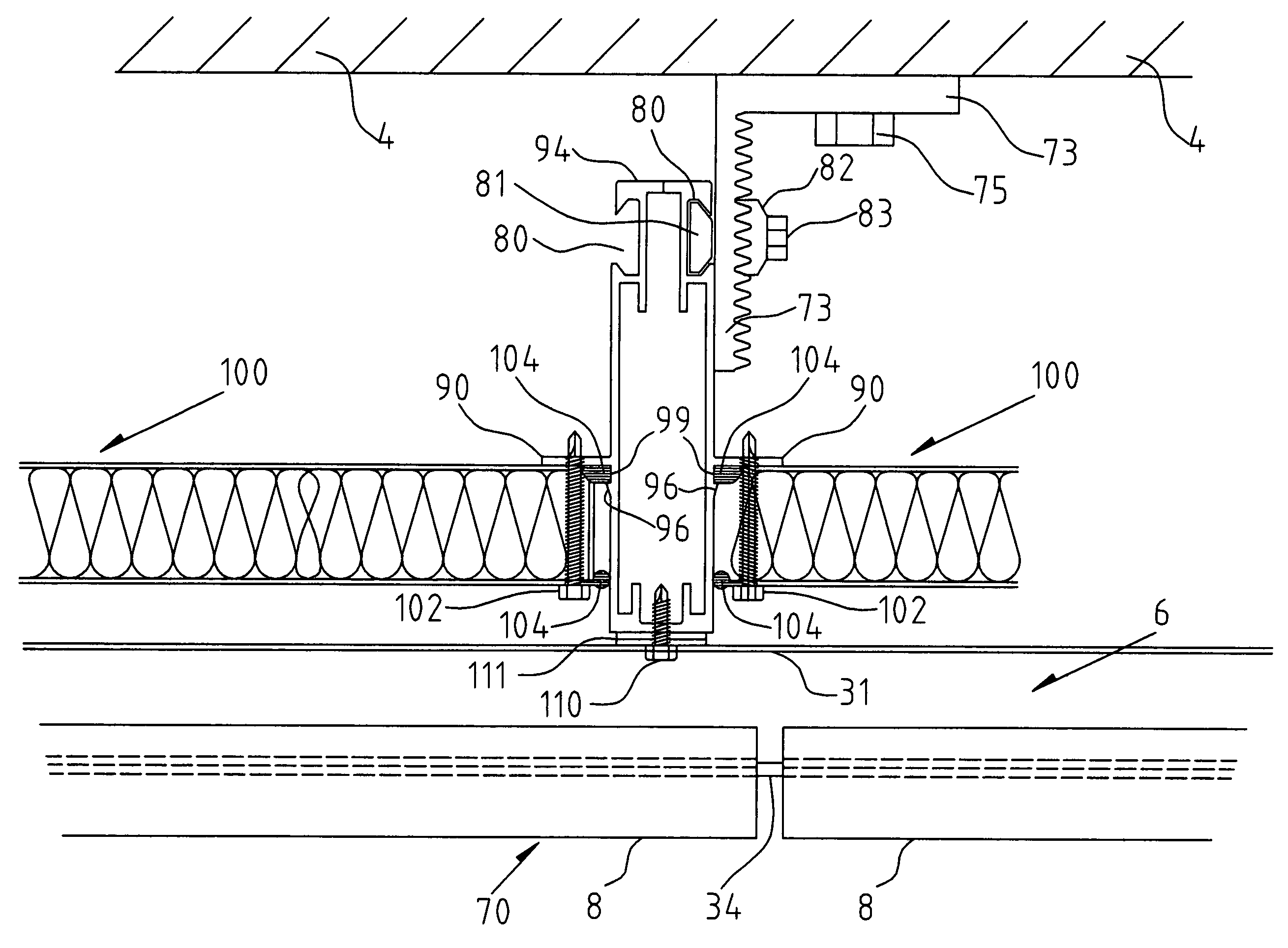

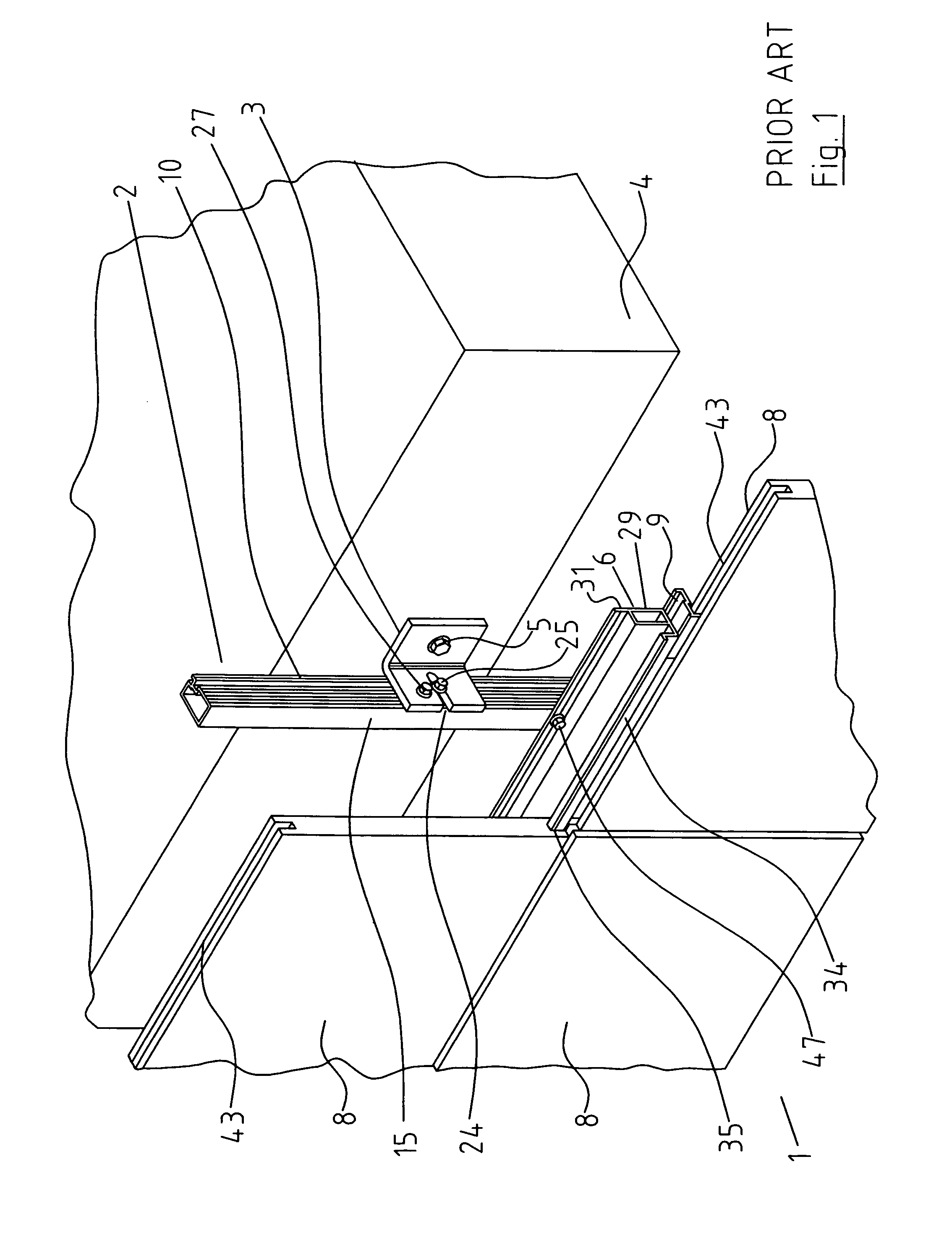

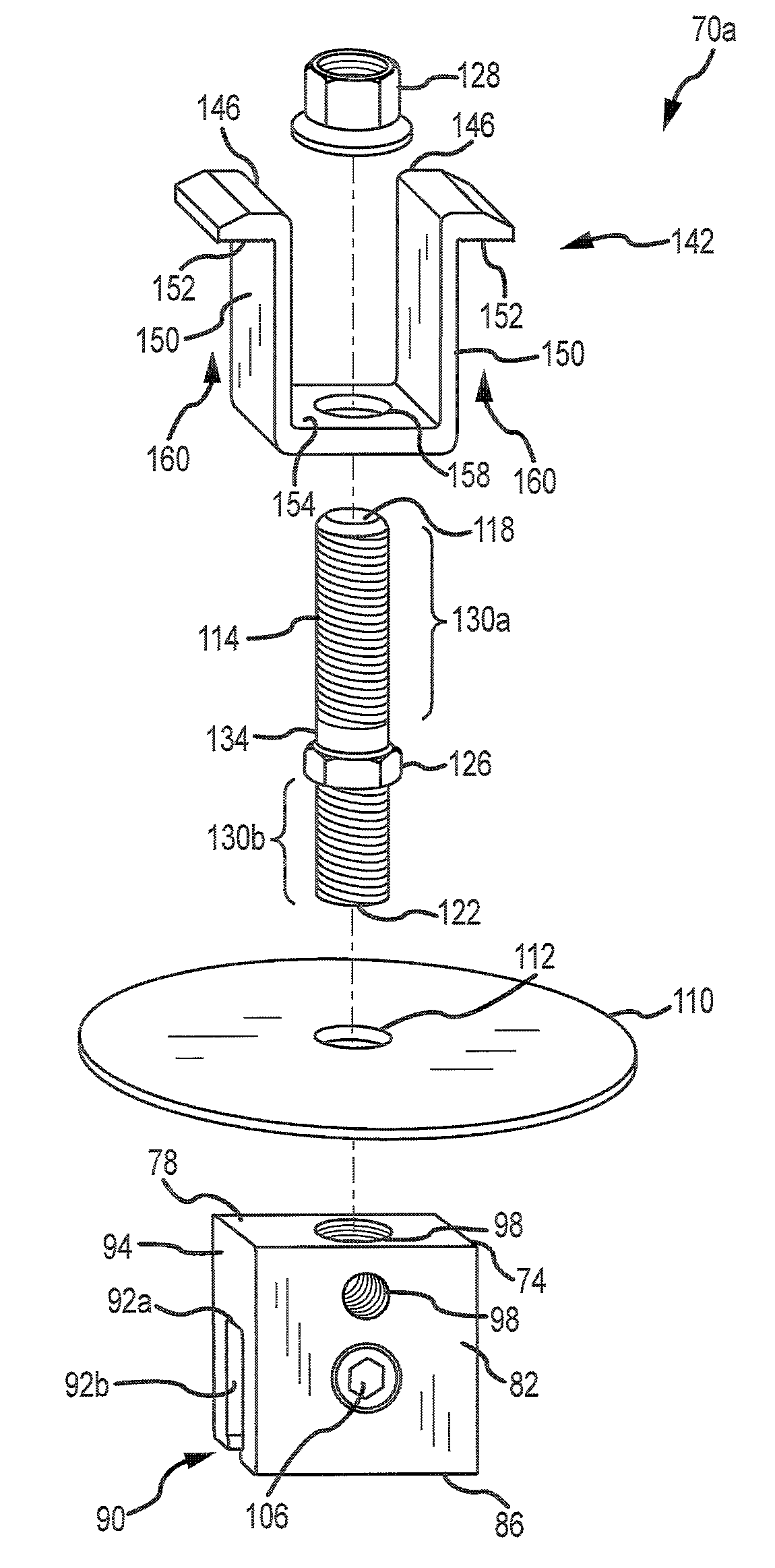

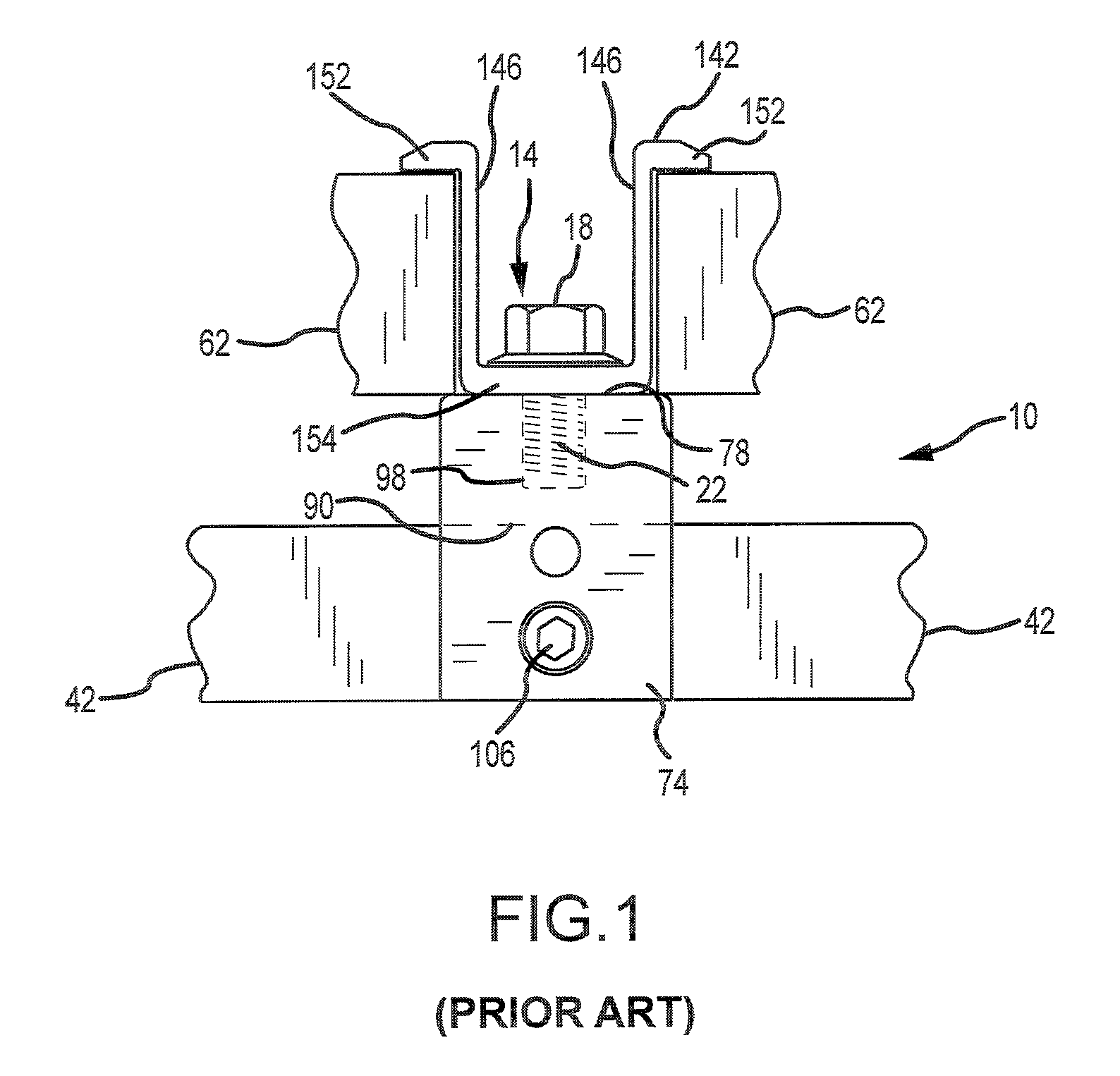

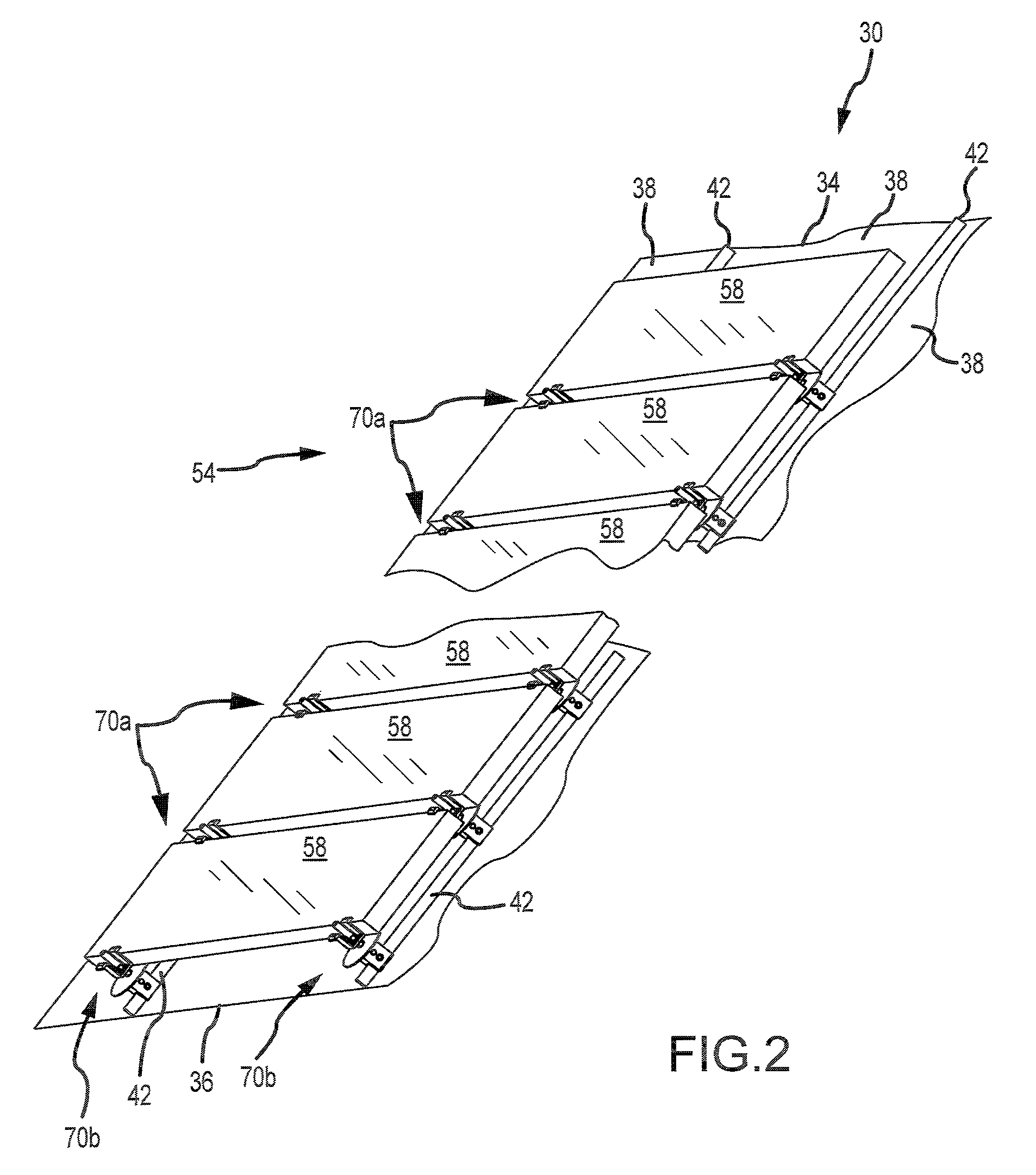

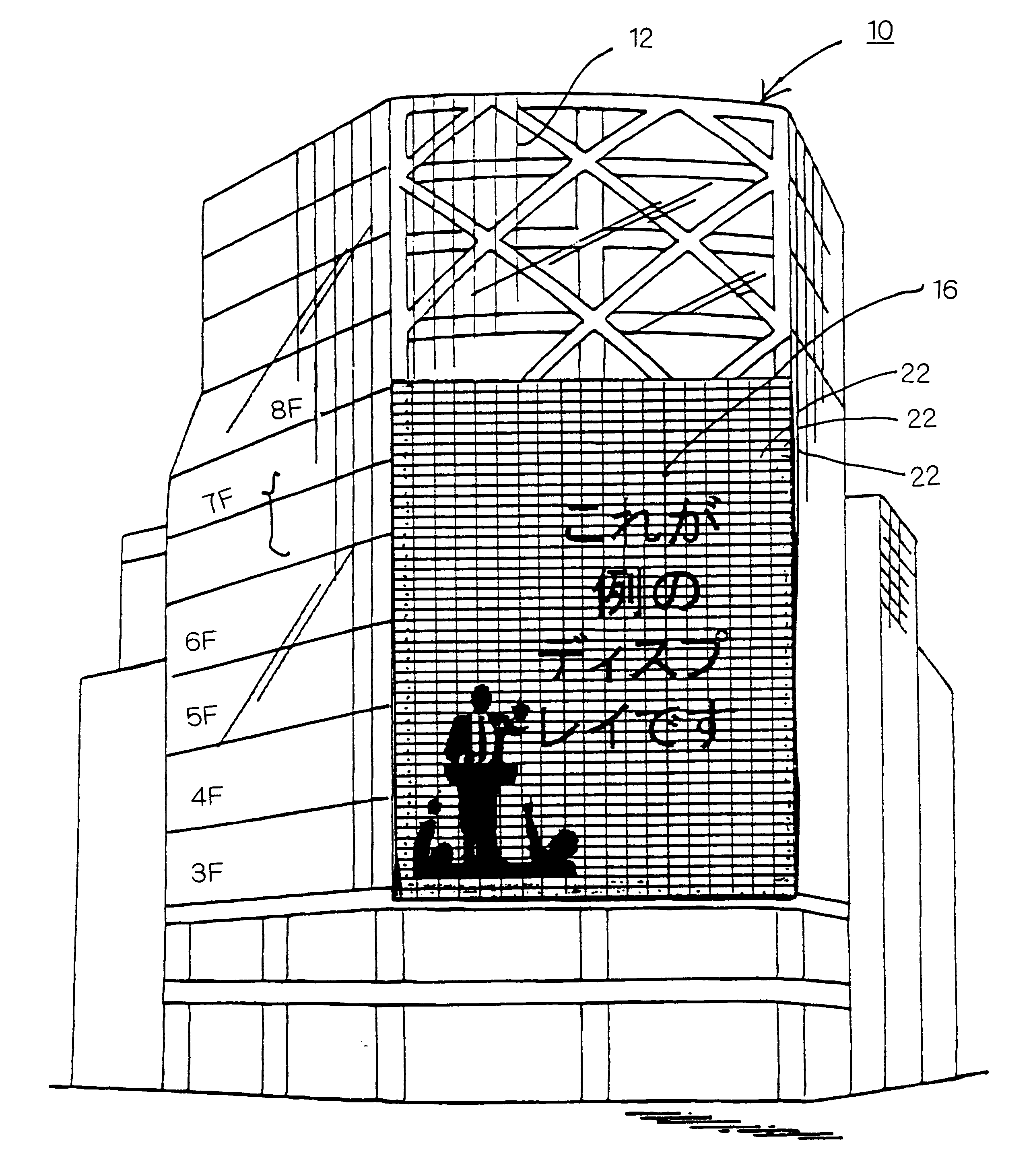

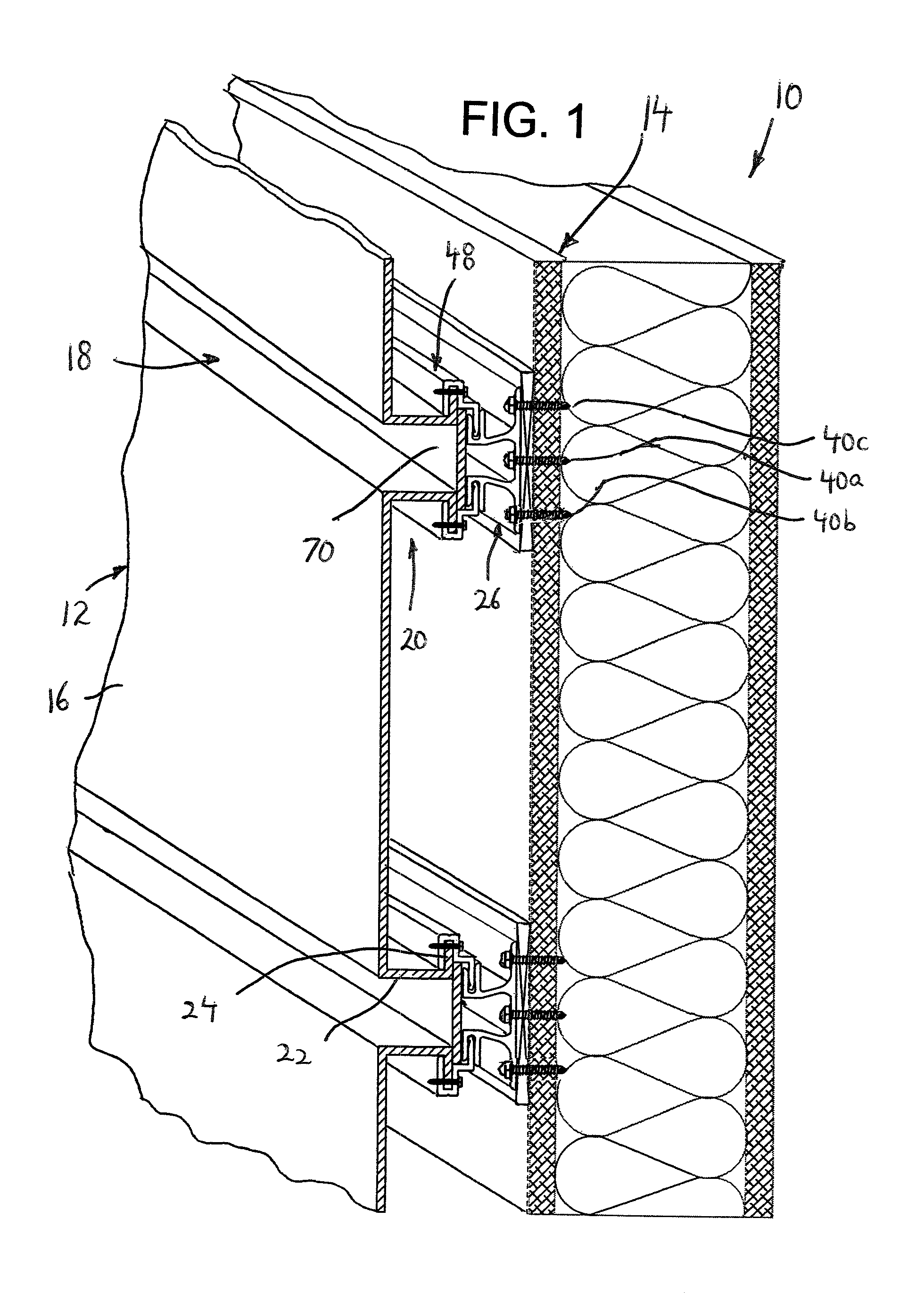

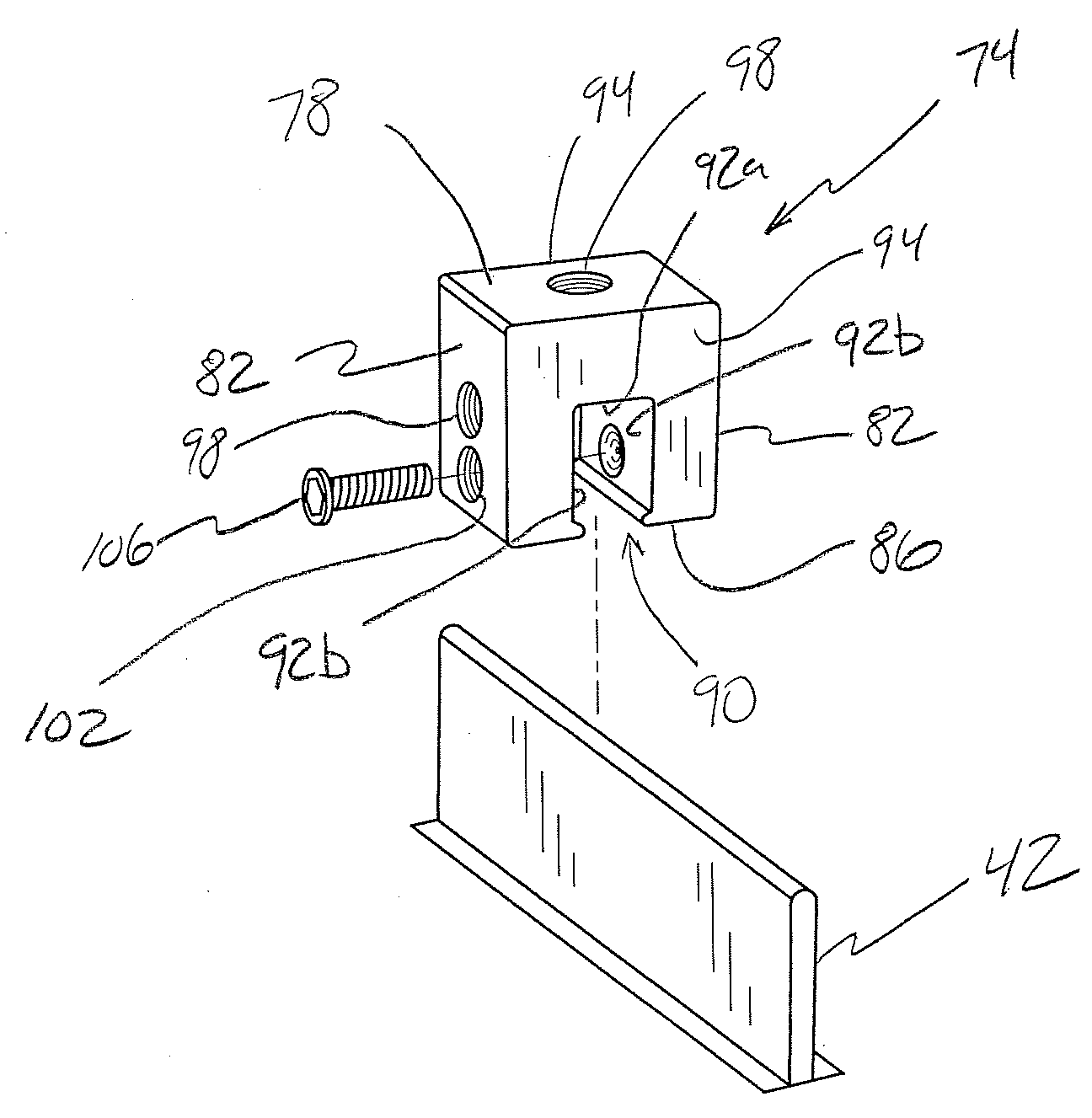

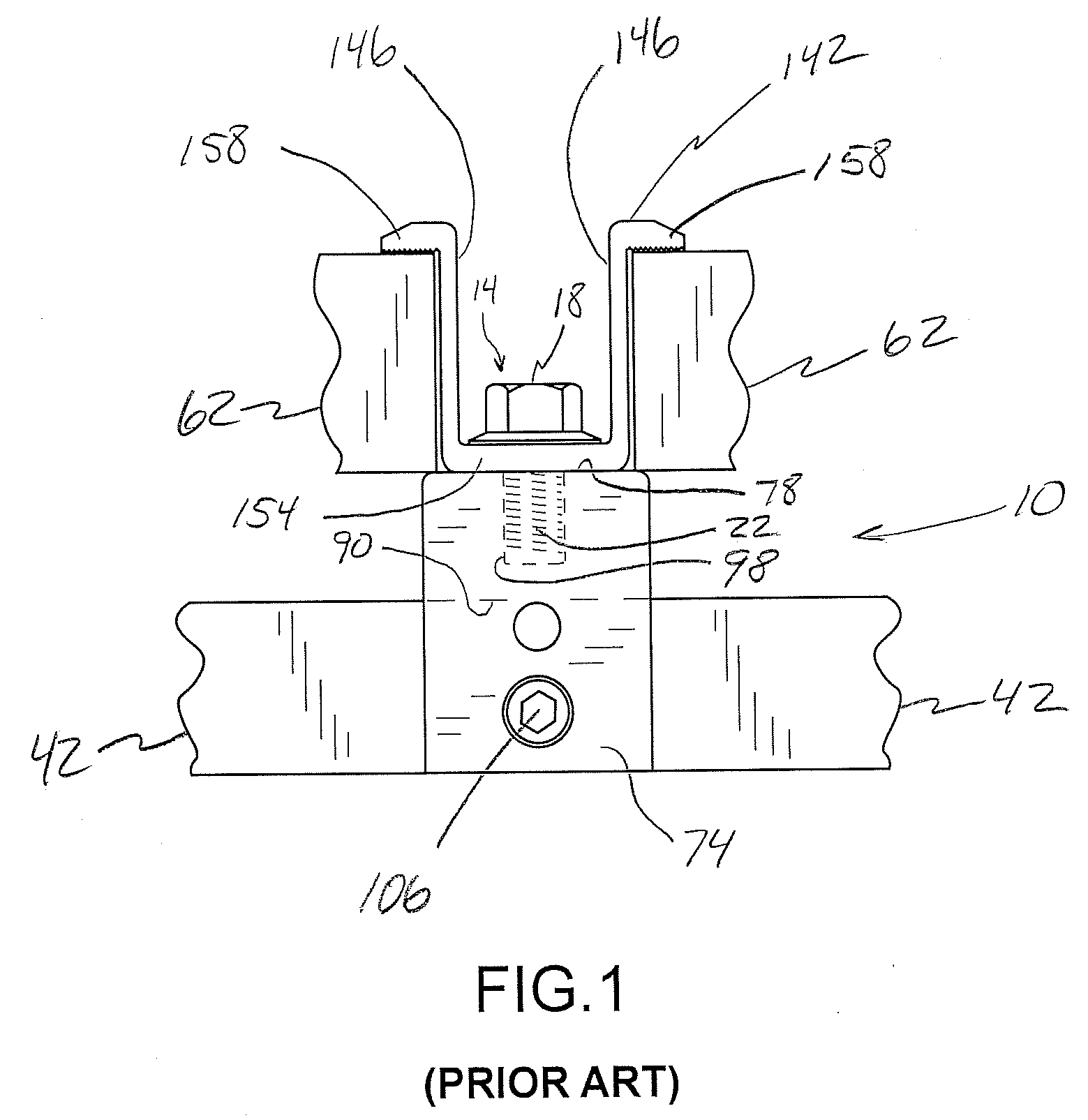

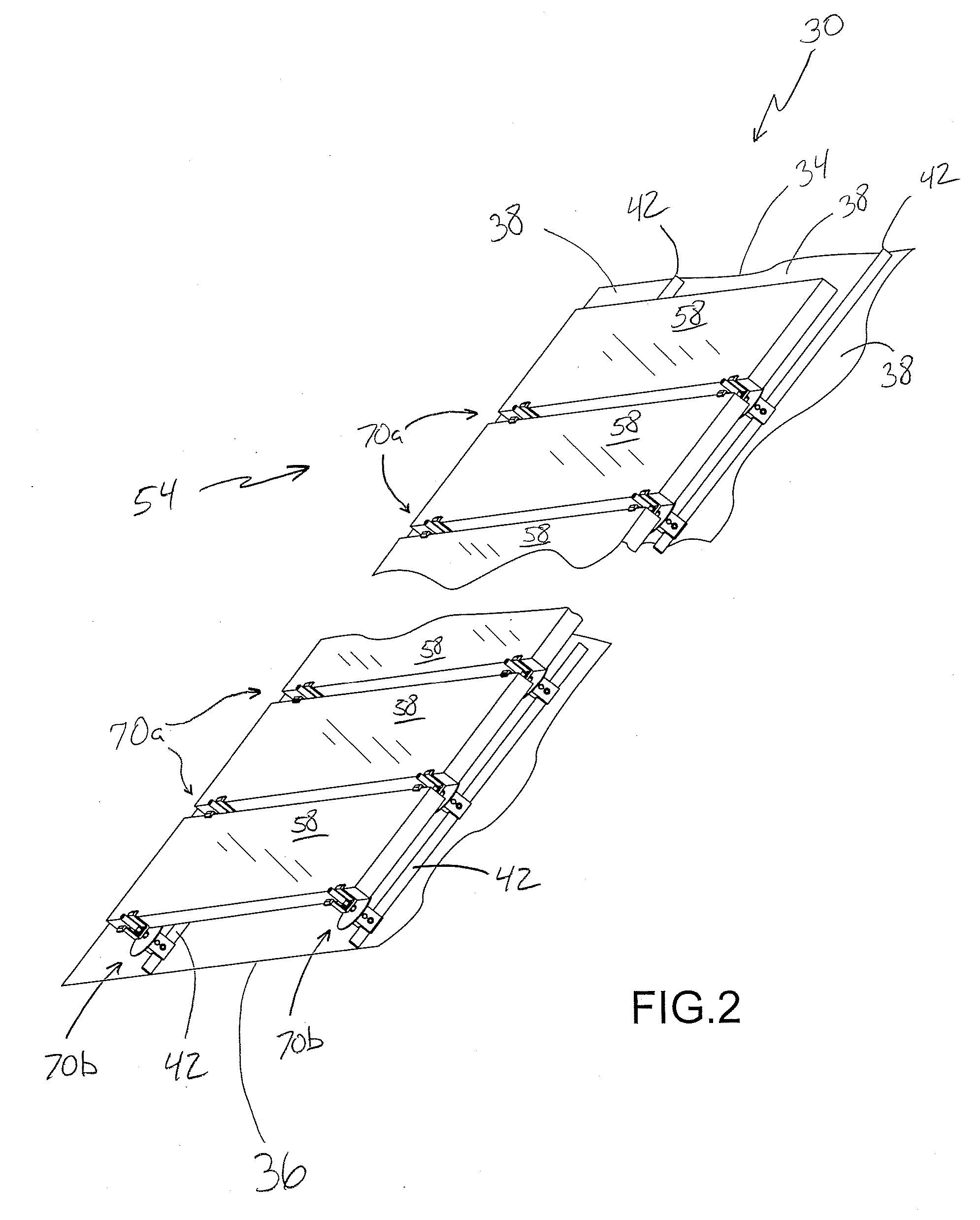

Adjustable mounting assembly for standing seam panels

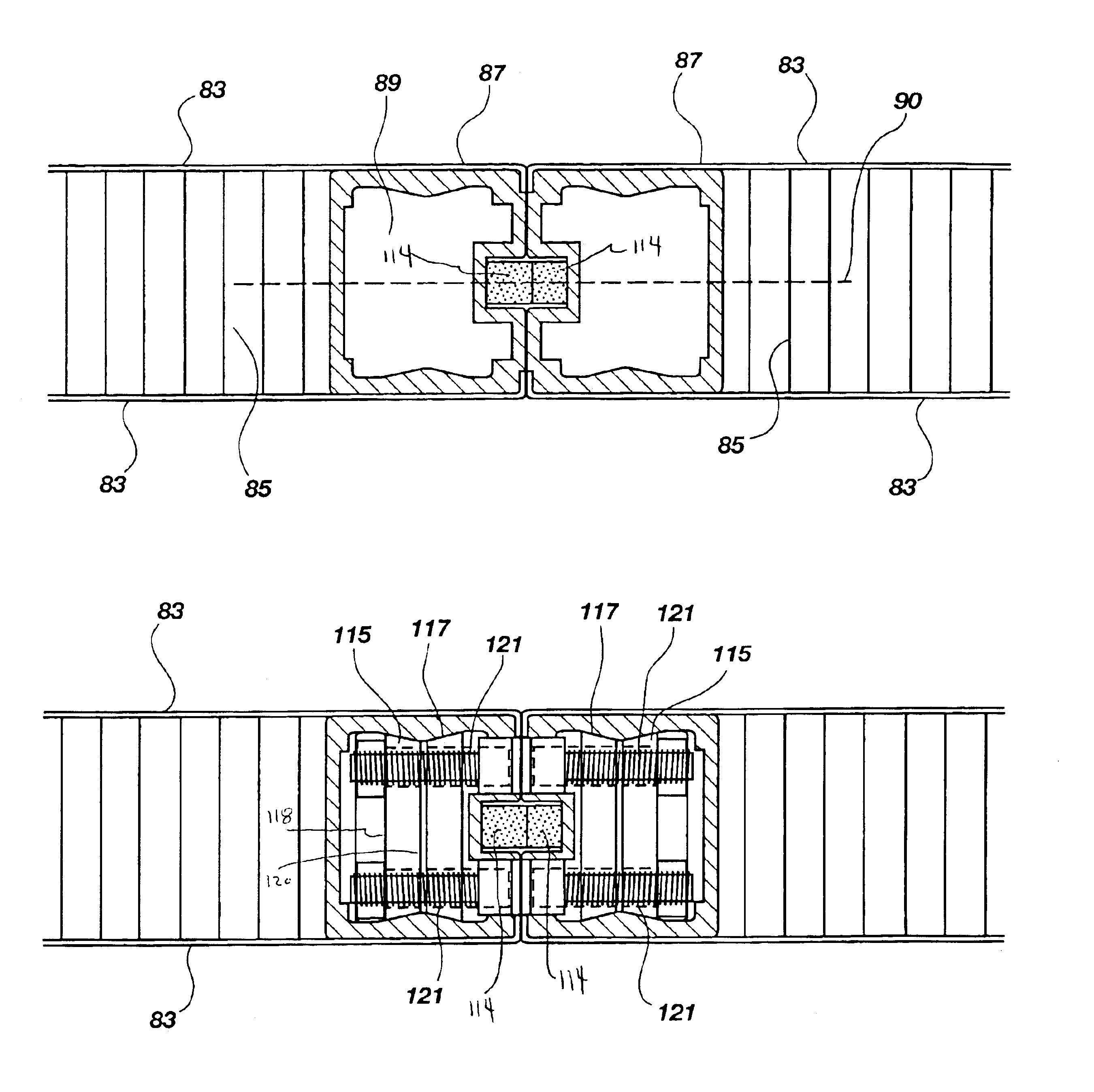

An adjustable mounting assembly (70a / 70b) for installing solar cell modules (58) on a building surface (34) is disclosed. The mounting assembly (70a / 70b) includes a mounting device (74), a stud (114) that may be threaded to the mounting device (74), a clamping member (142) that may be positioned on the stud (114), and a nut (128) that may be threaded onto the stud (114) to secure the clamping member (142) to the mounting device (74). A nut (126) is fixed to the stud (114) at an intermediate location along its length. This fixed nut (126) may be used to tighten the stud (114) to a mounting device (74), and furthermore may be positioned such that the stud (114) does not extend into a slot (90) of the mounting device (74).

Owner:RMH TECH LLC

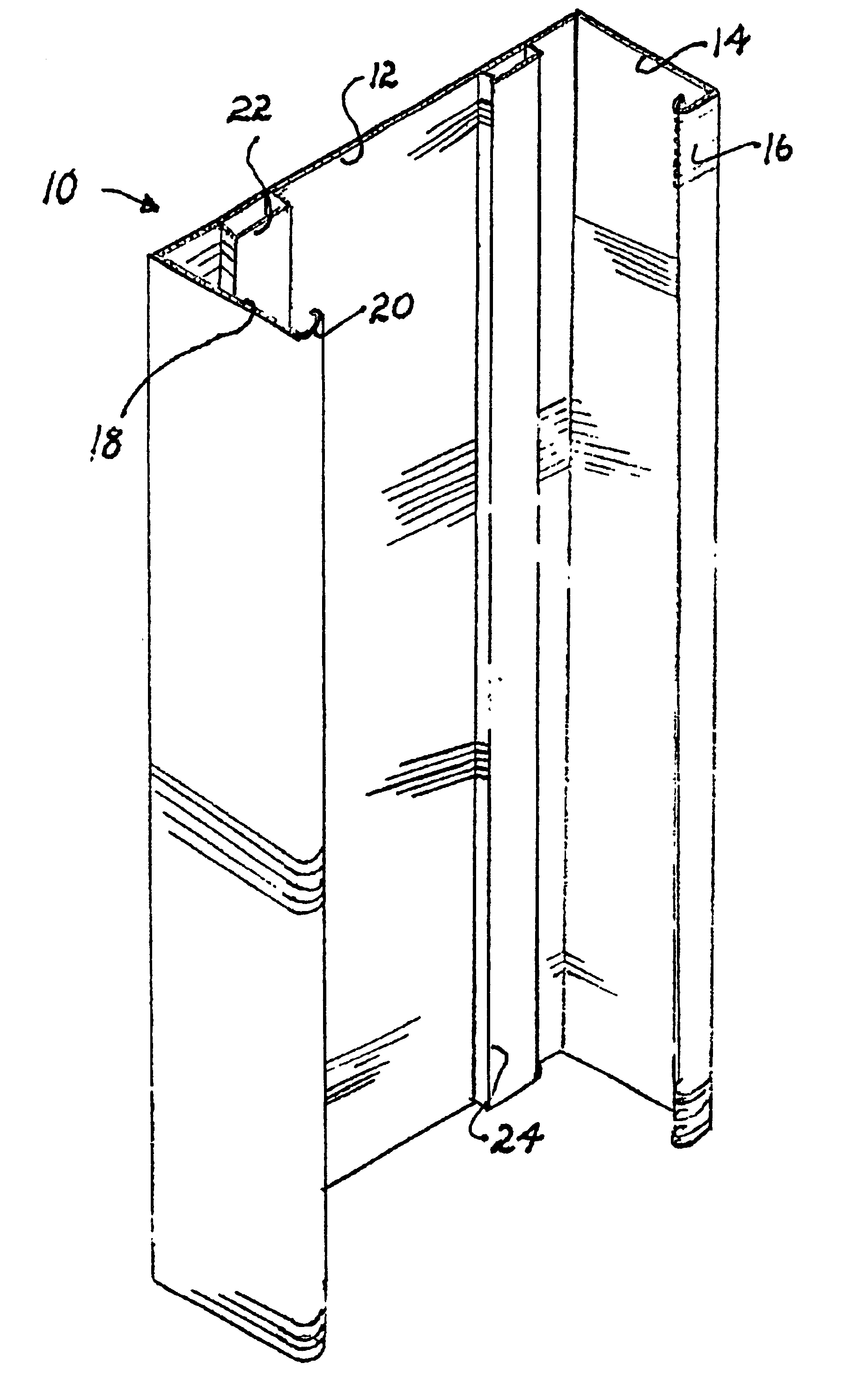

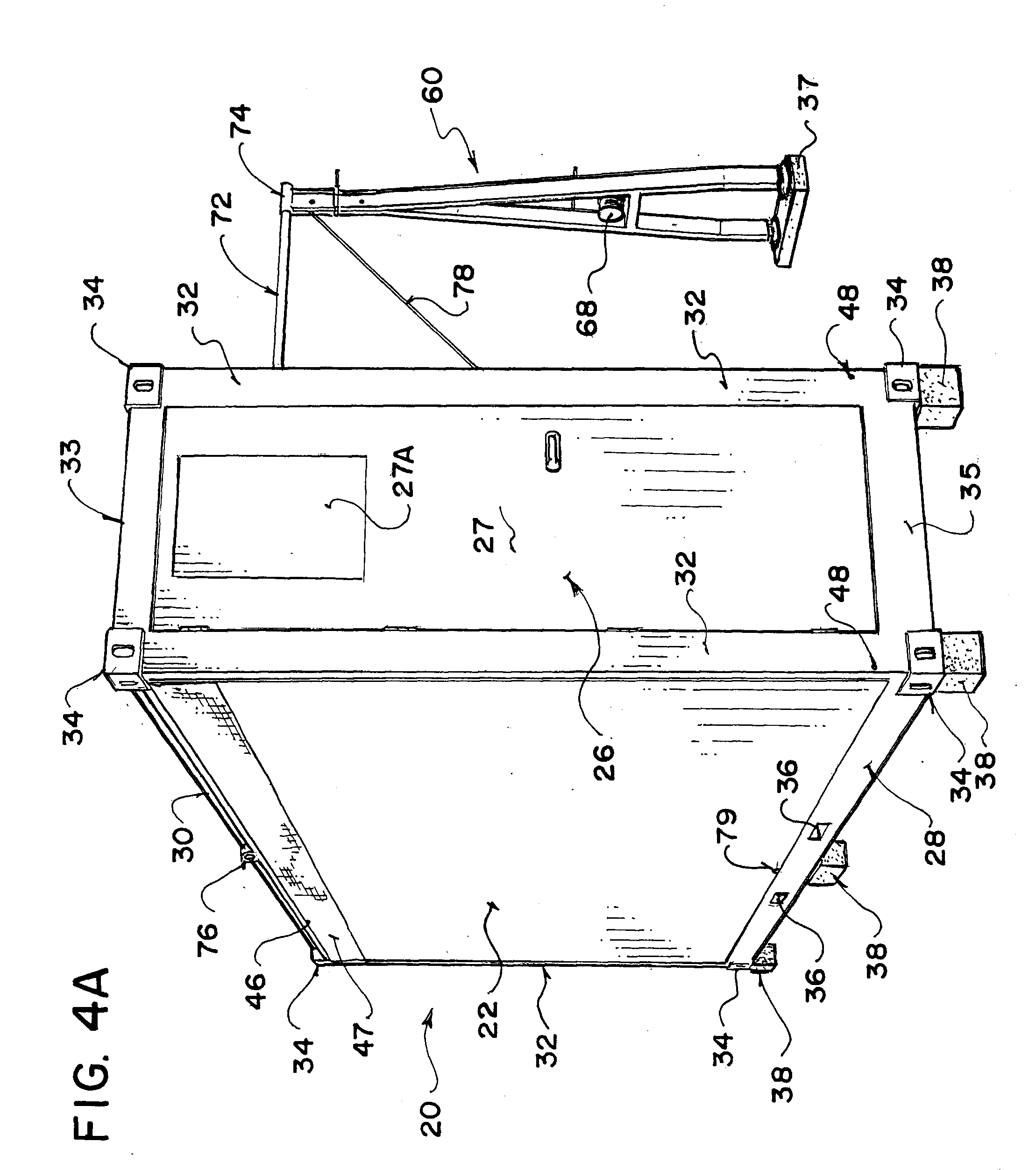

Containerized habitable structures

An engineered purpose-built portable habitable structure formed of a transformable rectangular enclosure that includes a base shell having hingedly attached exterior and interior walls that fold out to form a habitable structure. The walls of the structure are pre-wired and pre-plumbed and are adapted to connect to appropriate supply sources exterior to the structure.

Owner:CIOTTI THEODORE T

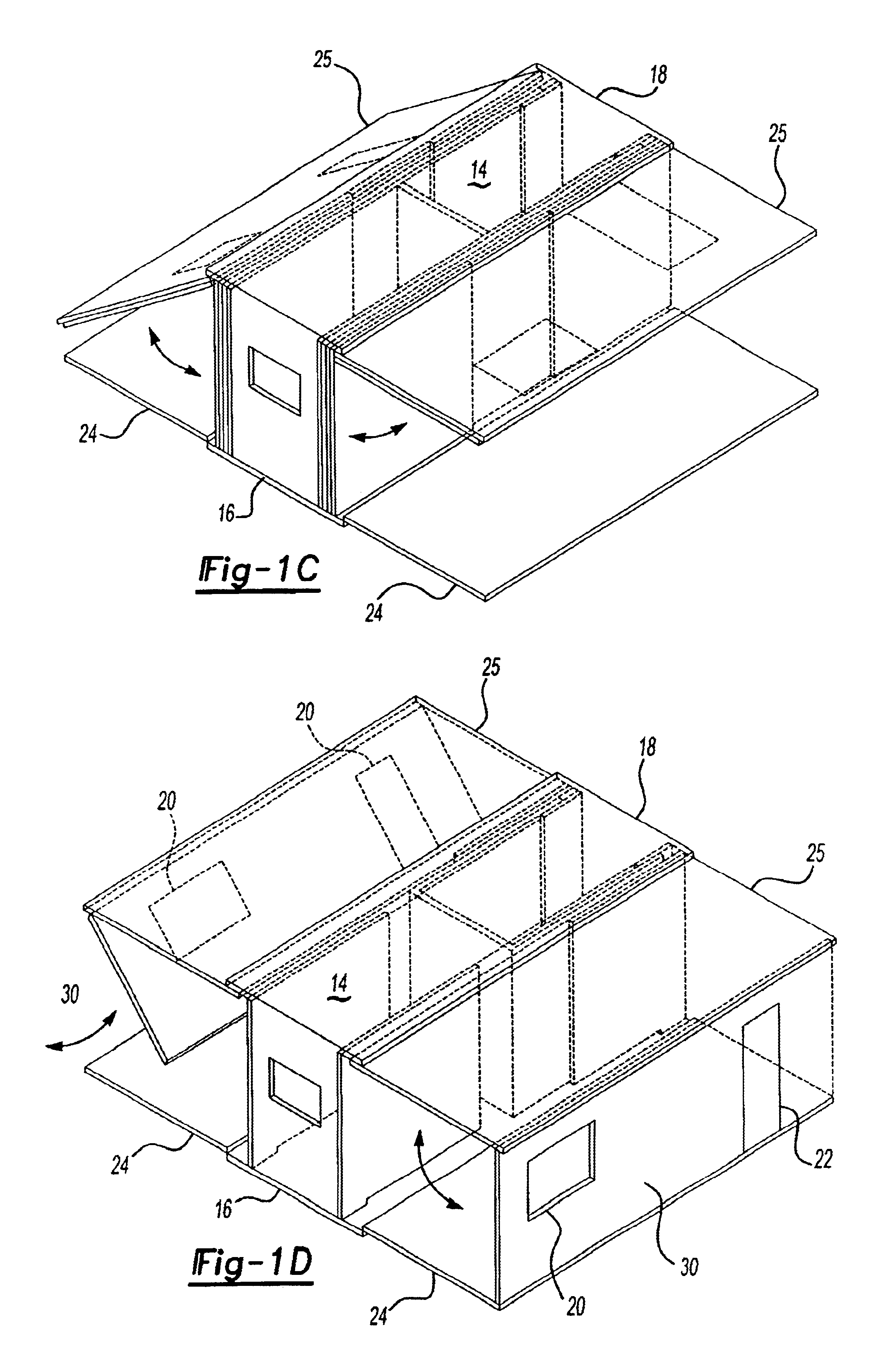

High-rise building with large scale display device inside transparent glass exterior

InactiveUS6237290B1Easy to carryImprove device performanceStampsPublic buildingsFloor slabWindow shutter

A high-rise building with a large scale dot-matrix display device is disclosed. The glass panels arranged in rows and columns form a curtain wall structured transparent outer wall 12 extending over an exterior of a building 10. Each panel is installed apart from end portions of floor slabs to form a void space therebetween. A plurality of louver structured modules 22 are arranged within the void space in rows and columns to form a large scale display area. Each module 22 has a louver-like structure formed of a plurality of posts 24 arranged in substantially parallel relationship and a plurality of parallel, uniformly spaced beams 26 connecting said adjacent posts 24. A plurality of LED combination lamps 28 are mounted on each beam 26 at uniform pitches as those between the adjacent beams 26. The LEDs are driven by drive circuits disposed in each beam 26. The vertical guide members 44 are fixed to the end portions of the floor slabs 20. The guide members 44 are arranged substantially in parallel relationship so that the modules 22 are supported between the adjacent guides 44 at the both lateral sides thereof. A plurality of vertical mullion members 48 fixed to the vertical guide members 44 as spaced apart from each of the vertical guides 44, so that the glass panels 12 are supported therebetween.

Owner:AVIX

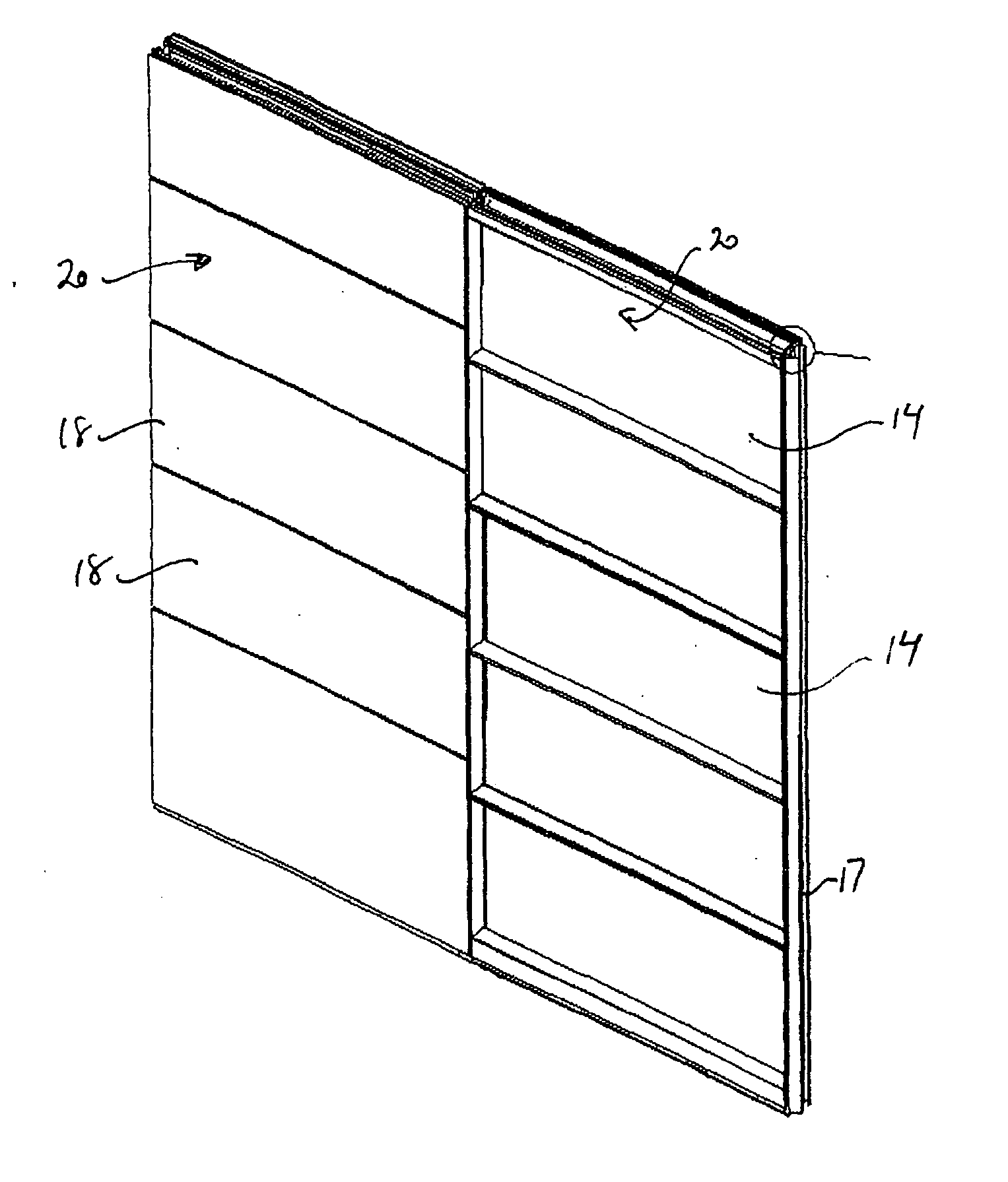

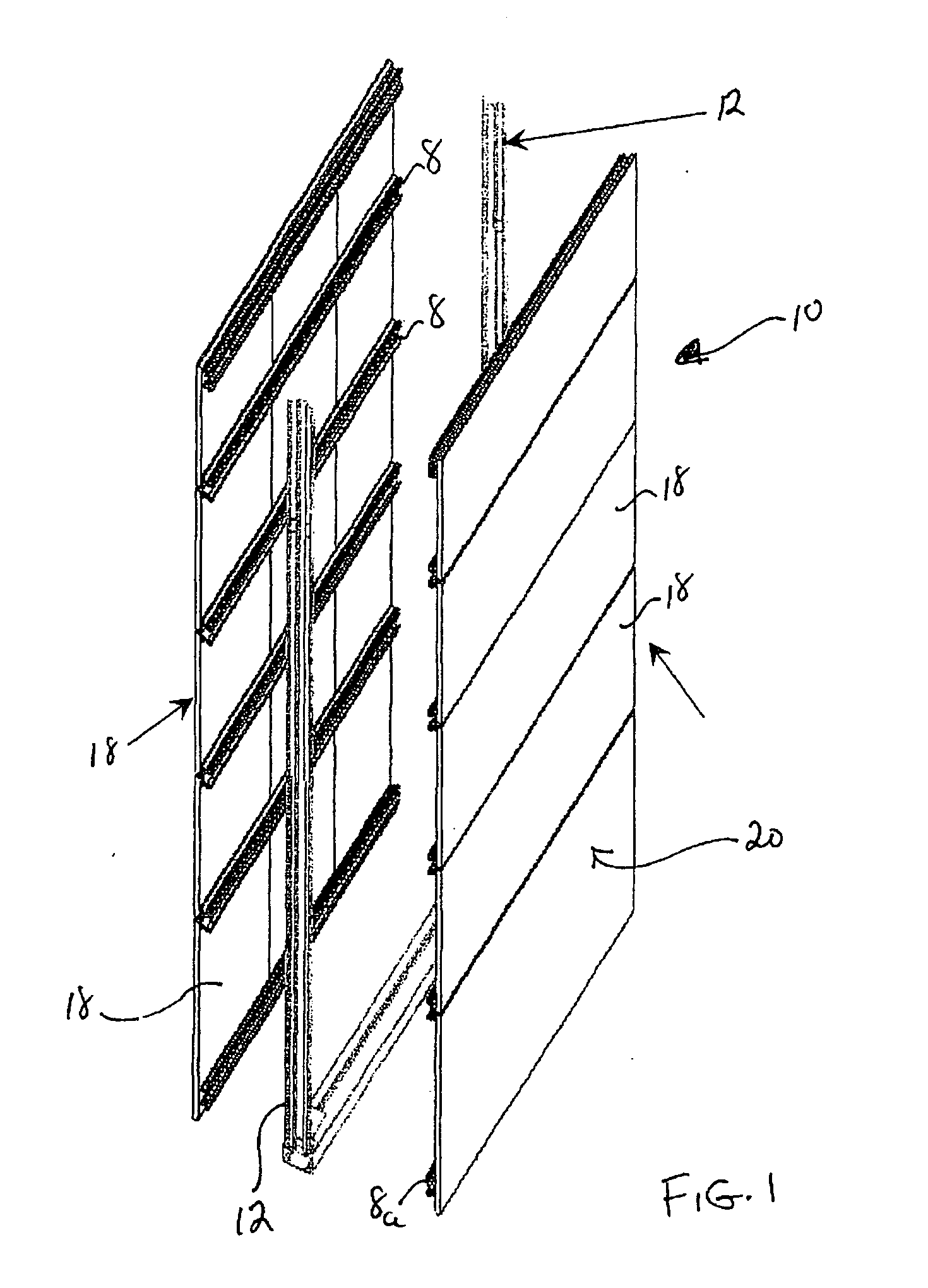

Wall panel assembly and method of assembly

A wall assembly includes at least two panel elements which are configured for contiguous placement adjacent to one another. Each of the panel elements defines a hollow internal passageway. The panels are configured to permit a contiguous placement whereby the respective passageways of the panels are brought into registration with one another. A connection element is positioned within one of the passageways. The connection element is accessible through a slot defined within the sidewall of the panel wherein the connection element resides. The connection element is slidable whereby it may be displaced partially into the second panel element. The connection element is thereafter actuatable whereby its lateral dimension is decreased to form a pressure fit union with the interior sidewalls of the two passageways. In its spatially decreased configuration, the connection element provides a means of interconnecting the two panel elements together.

Owner:AIRTEX MFG LLLP

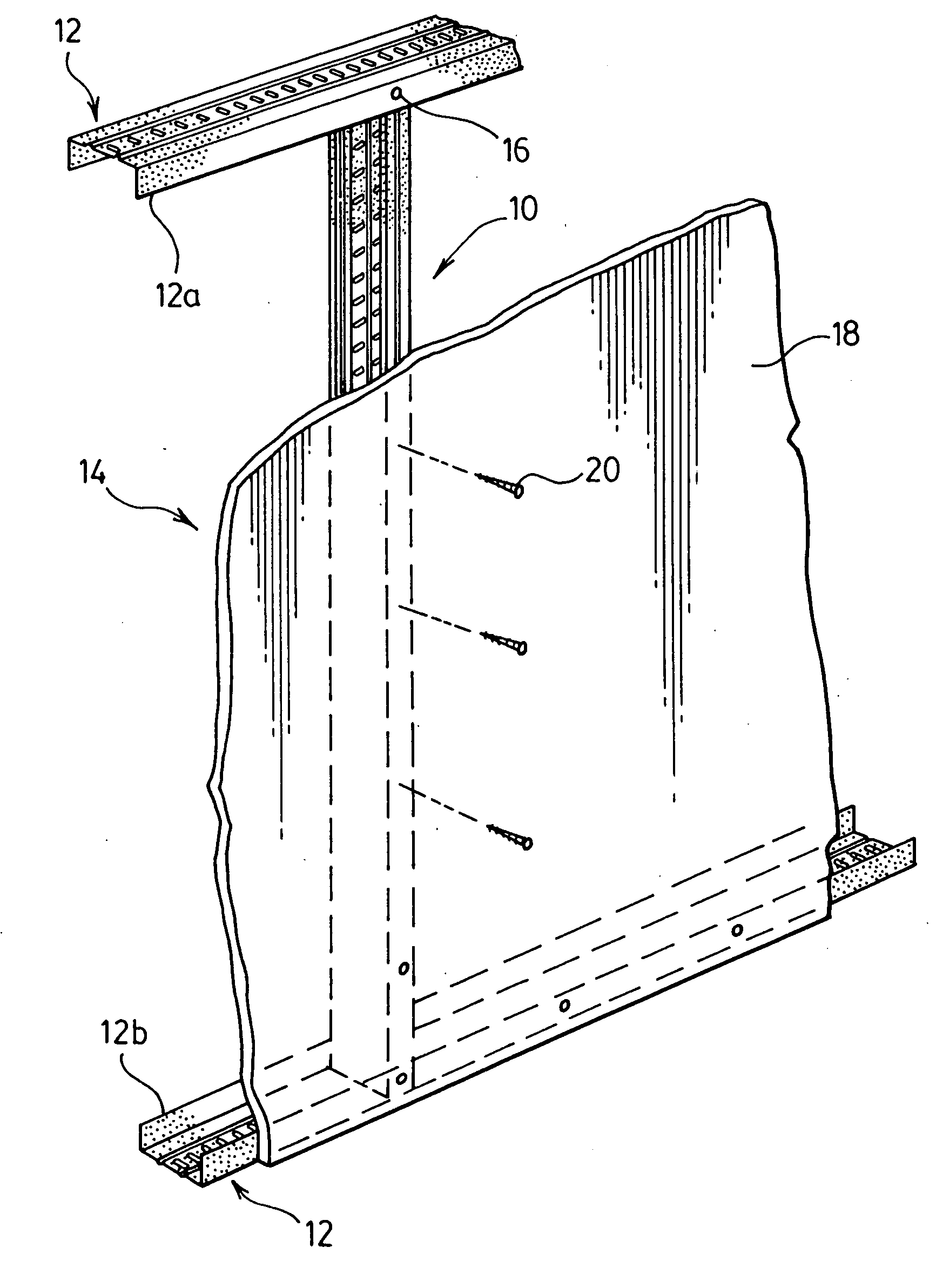

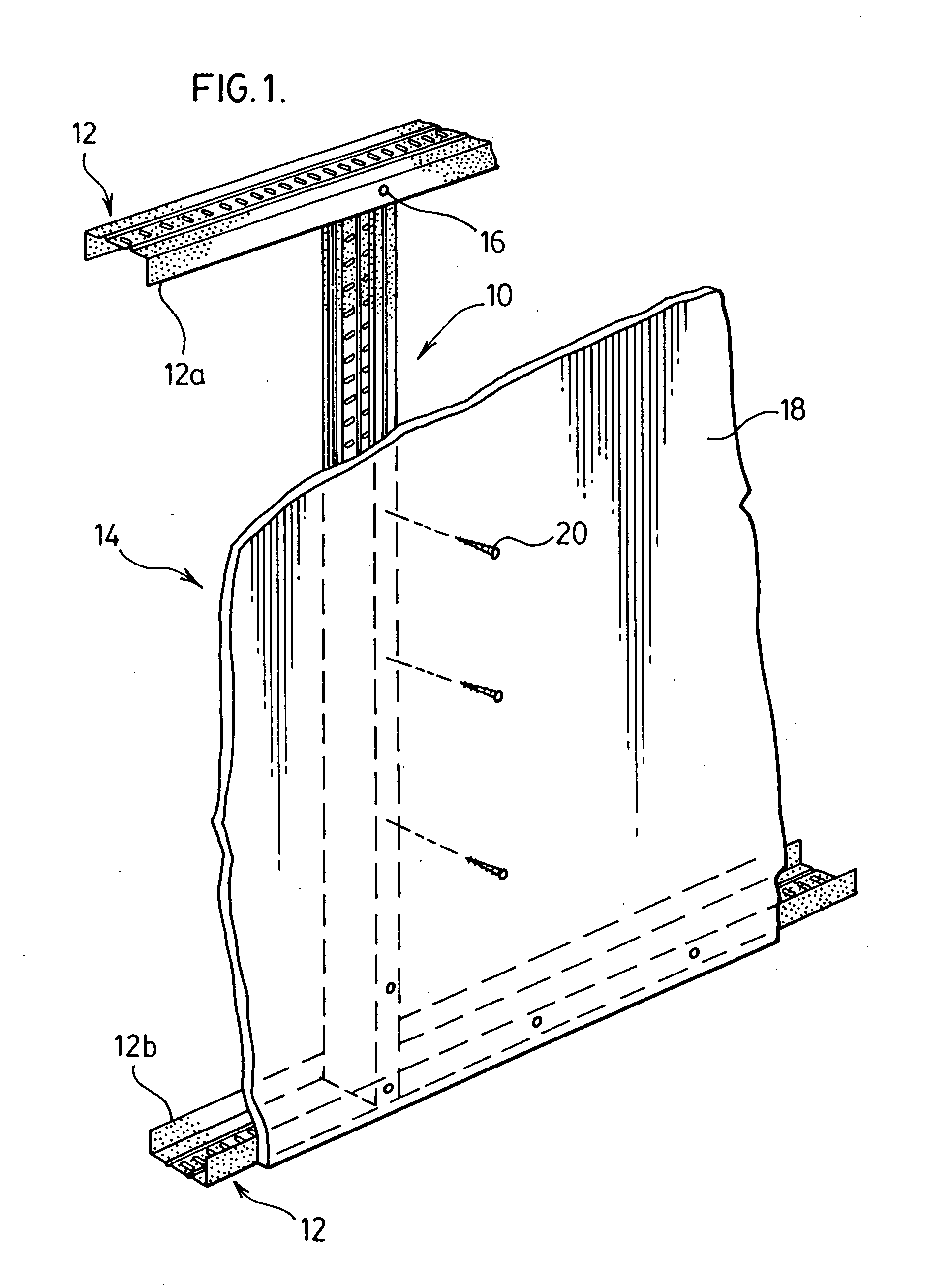

Metal stud building system and method

A metal stud and clip assembly is designed for use in a non-load-bearing wall to allow a horizontal ceiling to vertically float thereon. This is accomplished by an elongated receiving channel on the stud spaced inwardly from its edges. A clip member has an elongated stabilizing bar slidably inserted into the channel, and the stabilizing bar itself then is secured to a horizontal ceiling or a track system mounted to the ceiling. Thus, relative movement of the ceiling with respect to the wall allows the stabilizing bar to move up and down in the receiving channel on the stud member.

Owner:STOVER DONIE

System for mounting wall panels to a wall structure

A system for mounting wall panels to an existing wall structure, includes wall panels, each having a main panel section and hook walls at edges thereof which define a U-shaped configuration therewith; fastening extrusions, each including a securing section for securing the fastening extrusion to the existing wall structure, and a female connecting section including a recess and connected with the securing section; a frame extrusion connected to each hook wall, each including a securing section connecting the frame extrusion to a hook wall, a male connecting wall engaging within a recess of one female connecting section, and a spacer wall connecting the male connecting wall to the securing section so as to define a gap between the female connecting section and the hook wall when the male connecting wall is engaged within the recess; and a cover panel inserted in the gap.

Owner:BILGE HENRY H

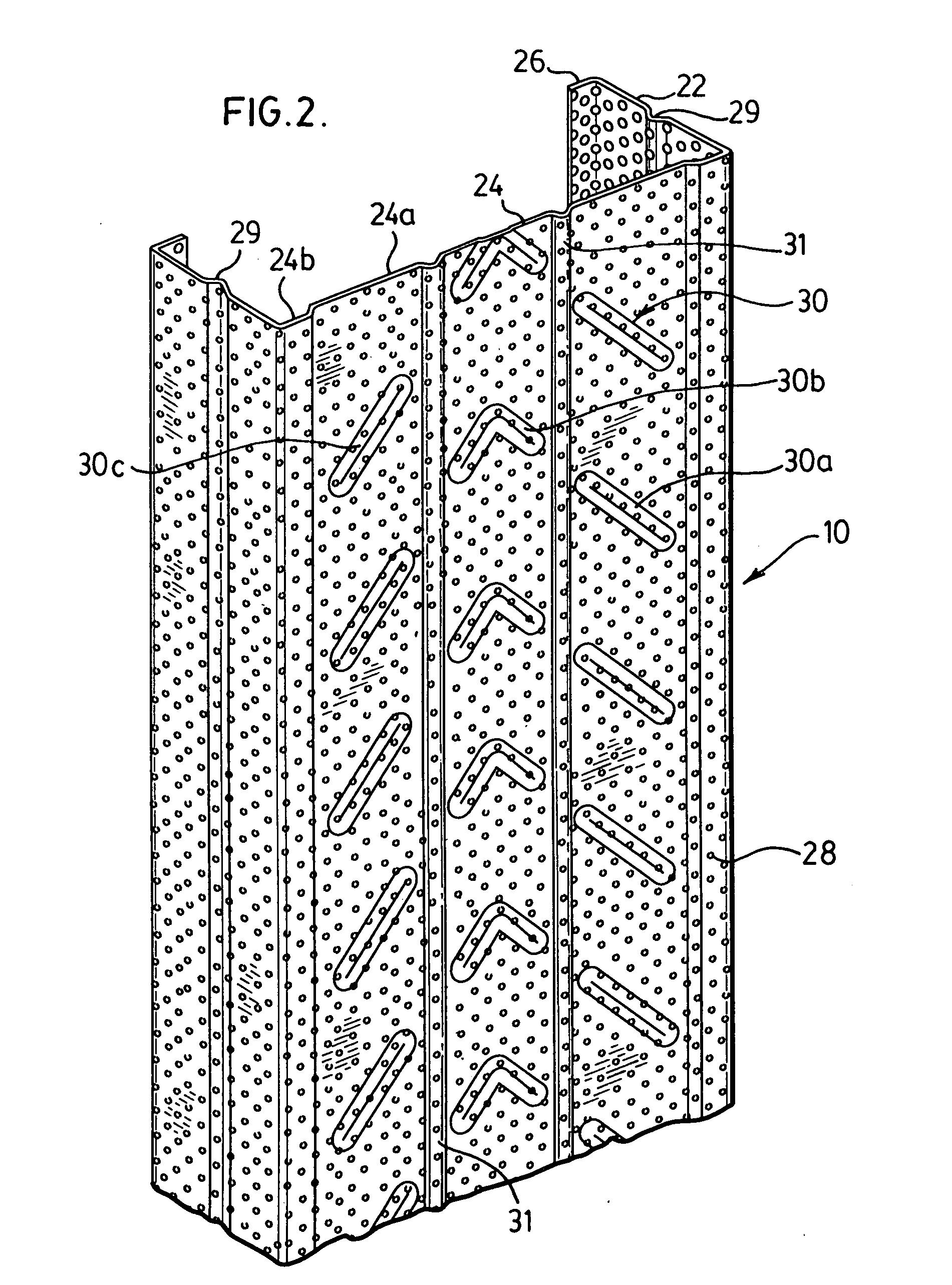

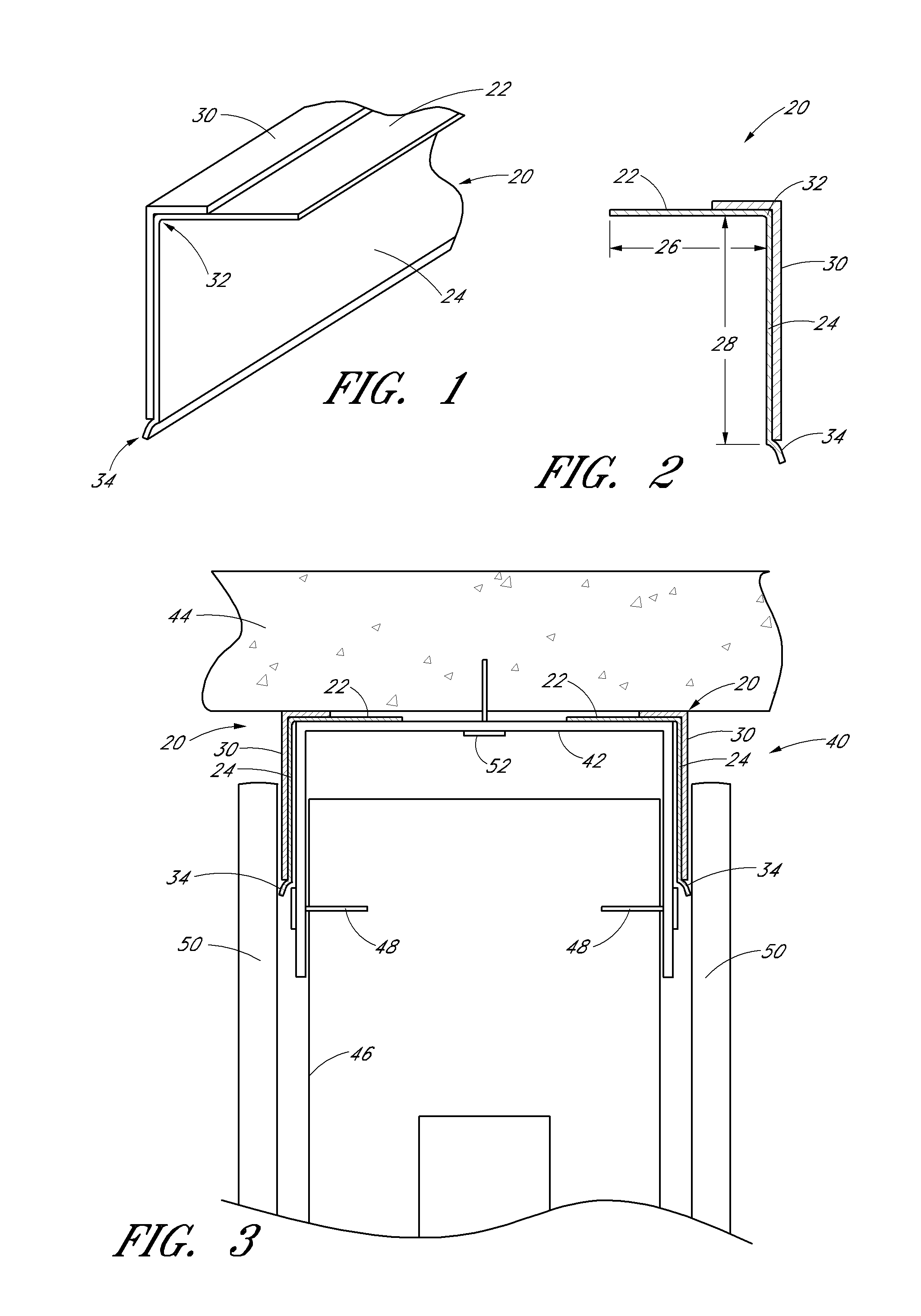

Light weight metal framing member

InactiveUS20080250738A1Low shrinkageReduce twistWallsPublic buildingsEngineeringMechanical engineering

The present invention provides for a lightweight metal framing member having a central web and two parallel spaced apart side walls extending upwardly from the sides of the web. The framing member has at least one longitudinally oriented rib extending the length of the web of the framing member to aid in reducing shrinkage and twisting of the framing member when non-symmetrical reinforcing structures are found in the framing member.

Owner:BAILEY METAL PROD

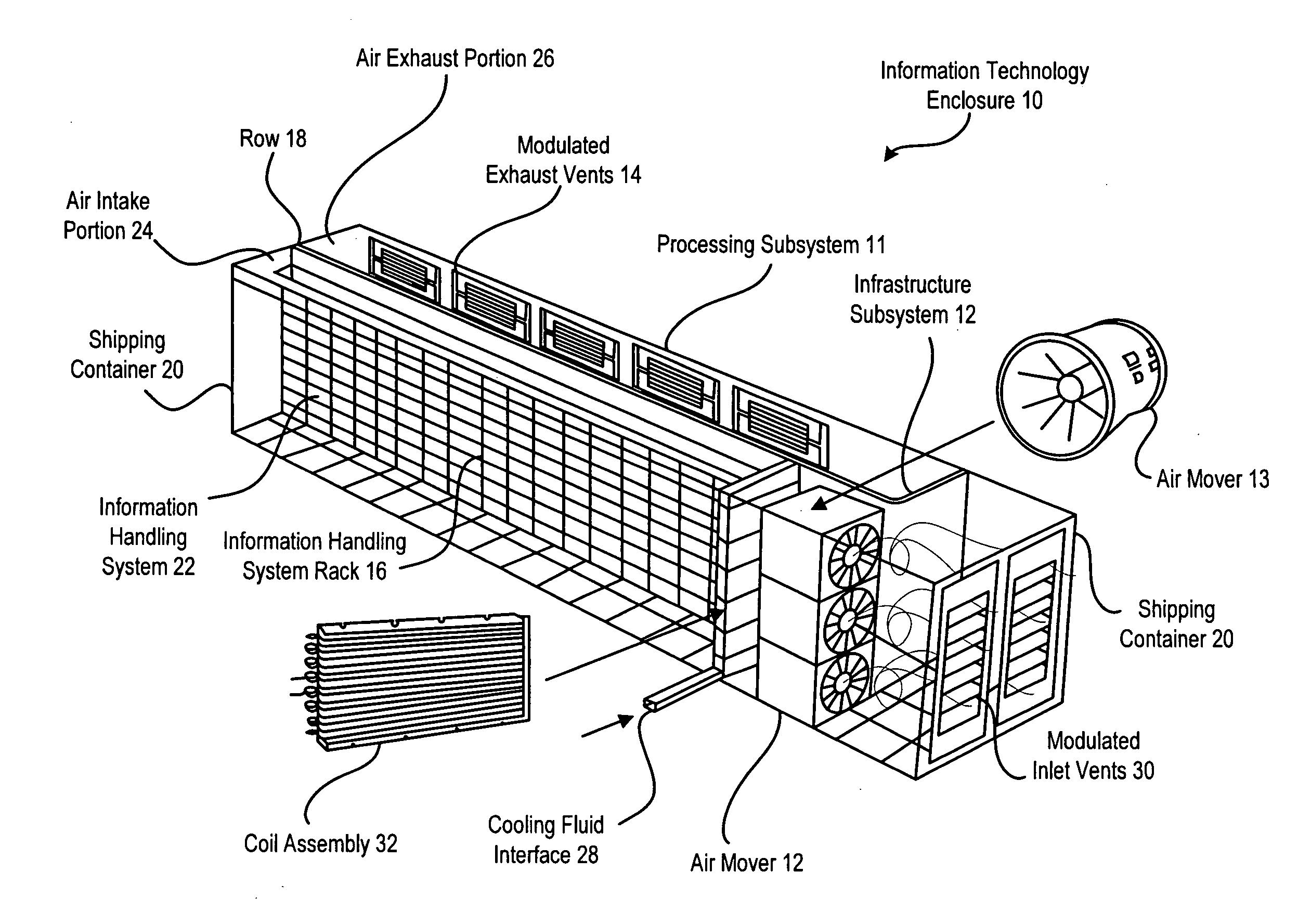

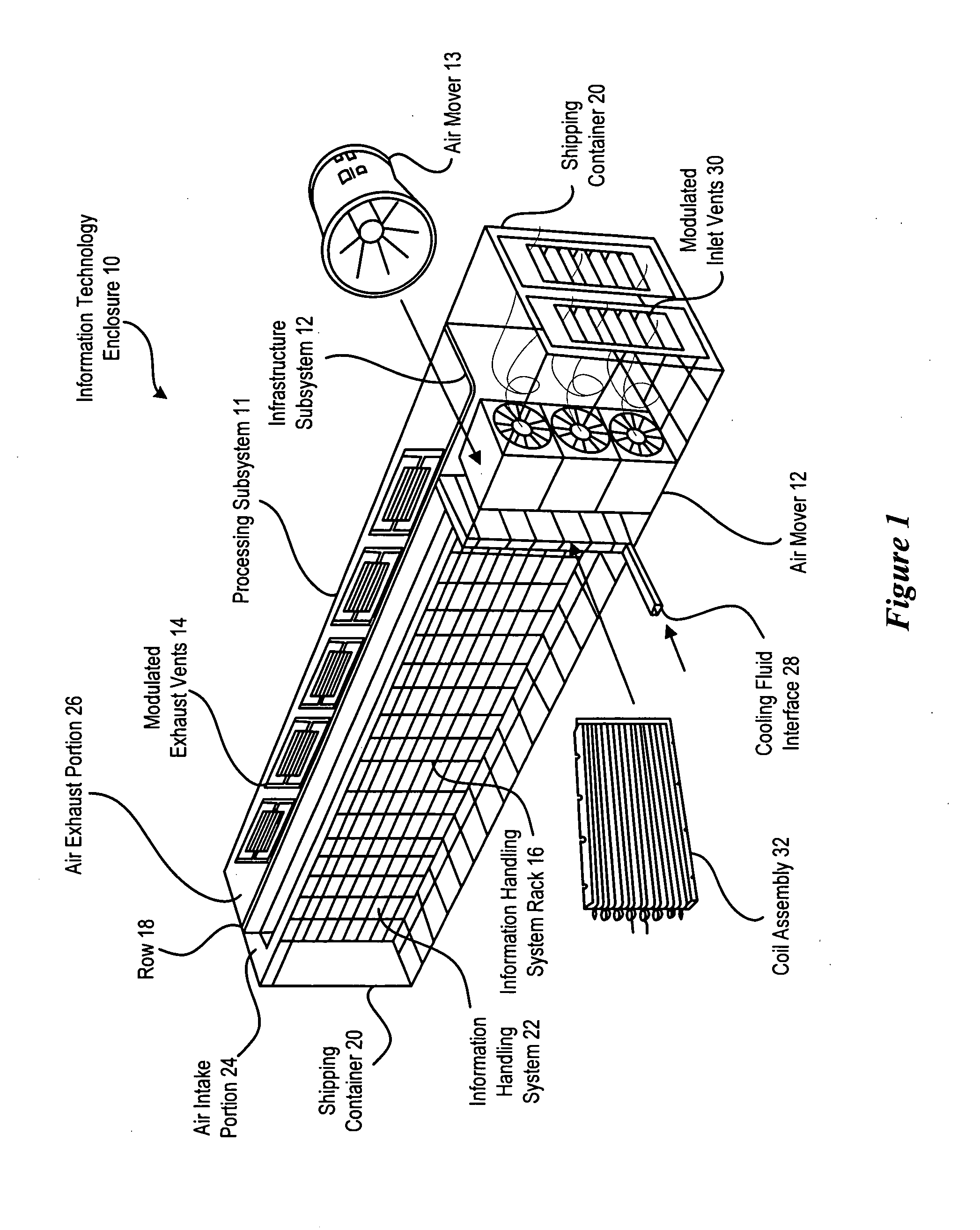

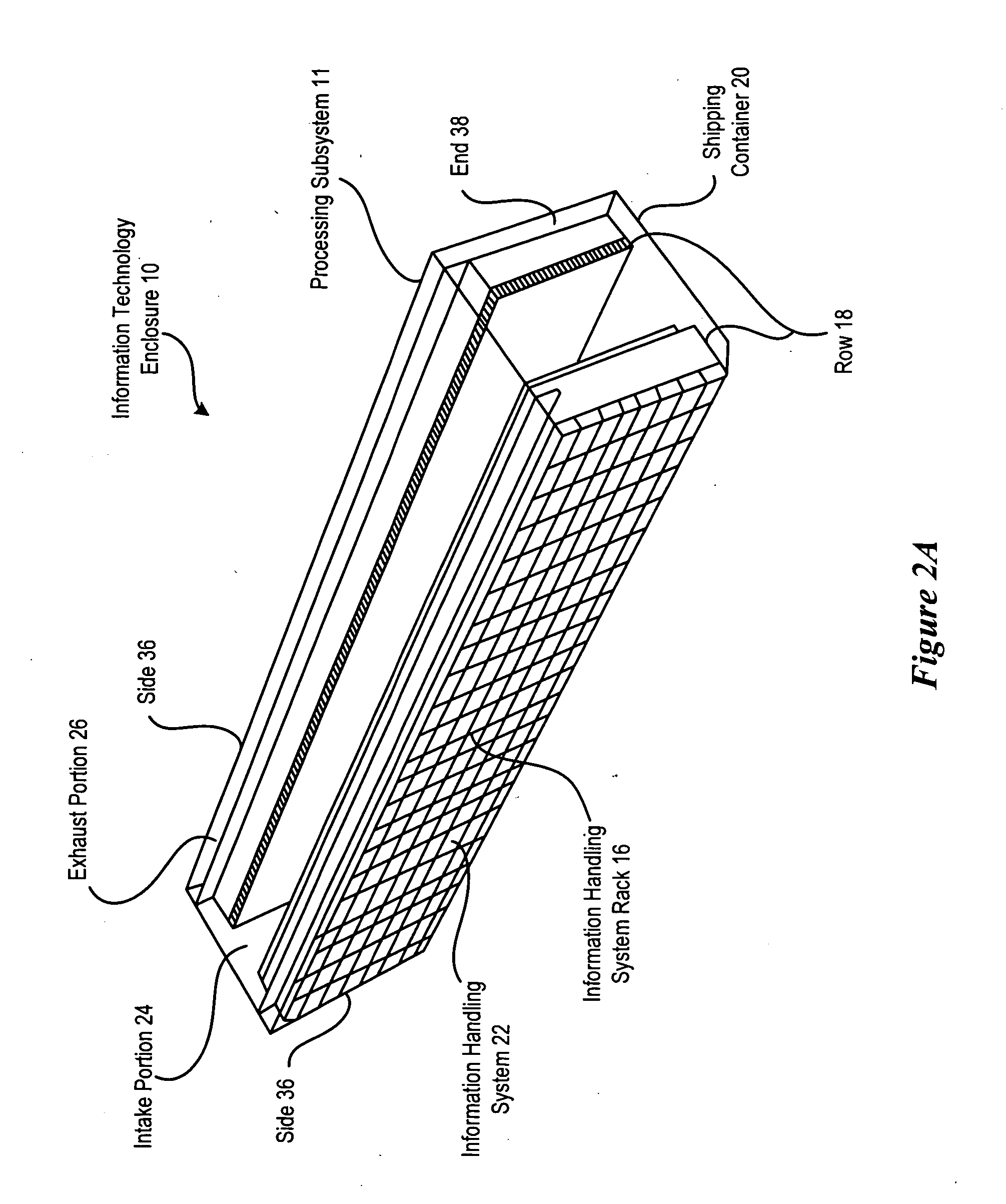

System and Method For Vertically Stacked Information Handling System and Infrastructure Enclosures

ActiveUS20100170277A1Improve processing densityEffective distributionDomestic cooling apparatusIndirect heat exchangersInformation processingVolumetric Mass Density

An information technology enclosure has a processing subsystem and infrastructure subsystem in separate shipping containers that cooperate to process information. The processing subsystem has increased information processing density by concentrating information handling systems in a first processing shipping container that is supported with infrastructure equipment in a second infrastructure shipping container. In one embodiment, the shipping containers are arranged in a stacked configuration so that cooled air and exhausted air are exchanged through aligned vents formed in the ceiling and floor of stacked shipping containers.

Owner:DELL PROD LP

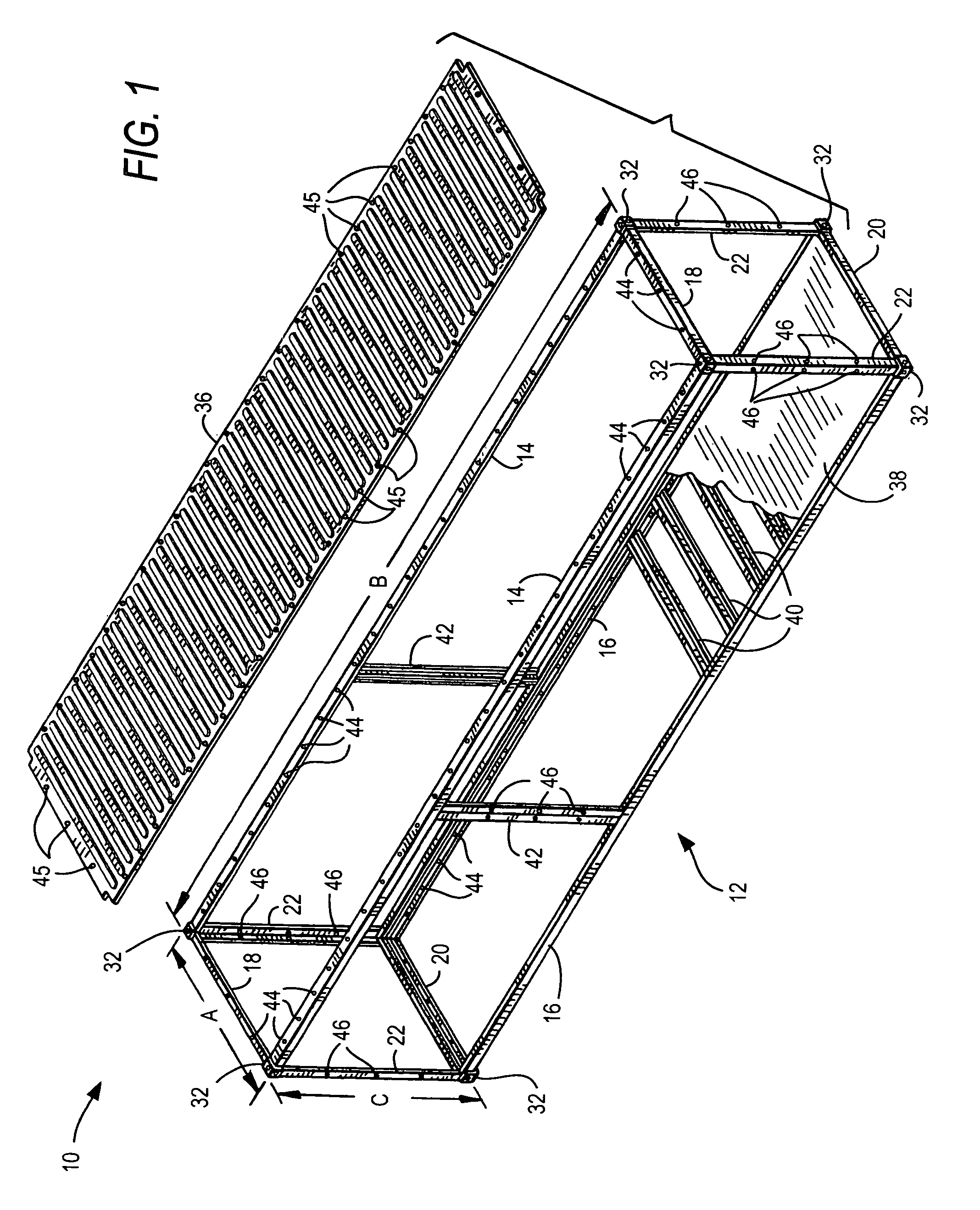

Adjustable mounting assembly for standing seam panels

ActiveUS20080302928A1Not to damagePhotovoltaic supportsSolar heating energySolar cellMechanical engineering

An adjustable mounting assembly (70a / 70b) for installing solar cell modules (58) on a building surface (34) is disclosed. The mounting assembly (70a / 70b) includes a mounting device (74), a stud (114) that may be threaded to the mounting device (74), a clamping member (142) that may be positioned on the stud (114), and a nut (128) that may be threaded onto the stud (114) to secure the clamping member (142) to the mounting device (74). A nut (126) is fixed to the stud (114) at an intermediate location along its length. This fixed nut (126) may be used to tighten the stud (114) to a mounting device (74), and furthermore may be positioned such that the stud (114) does not extend into a slot (90) of the mounting device (74).

Owner:RMH TECH LLC

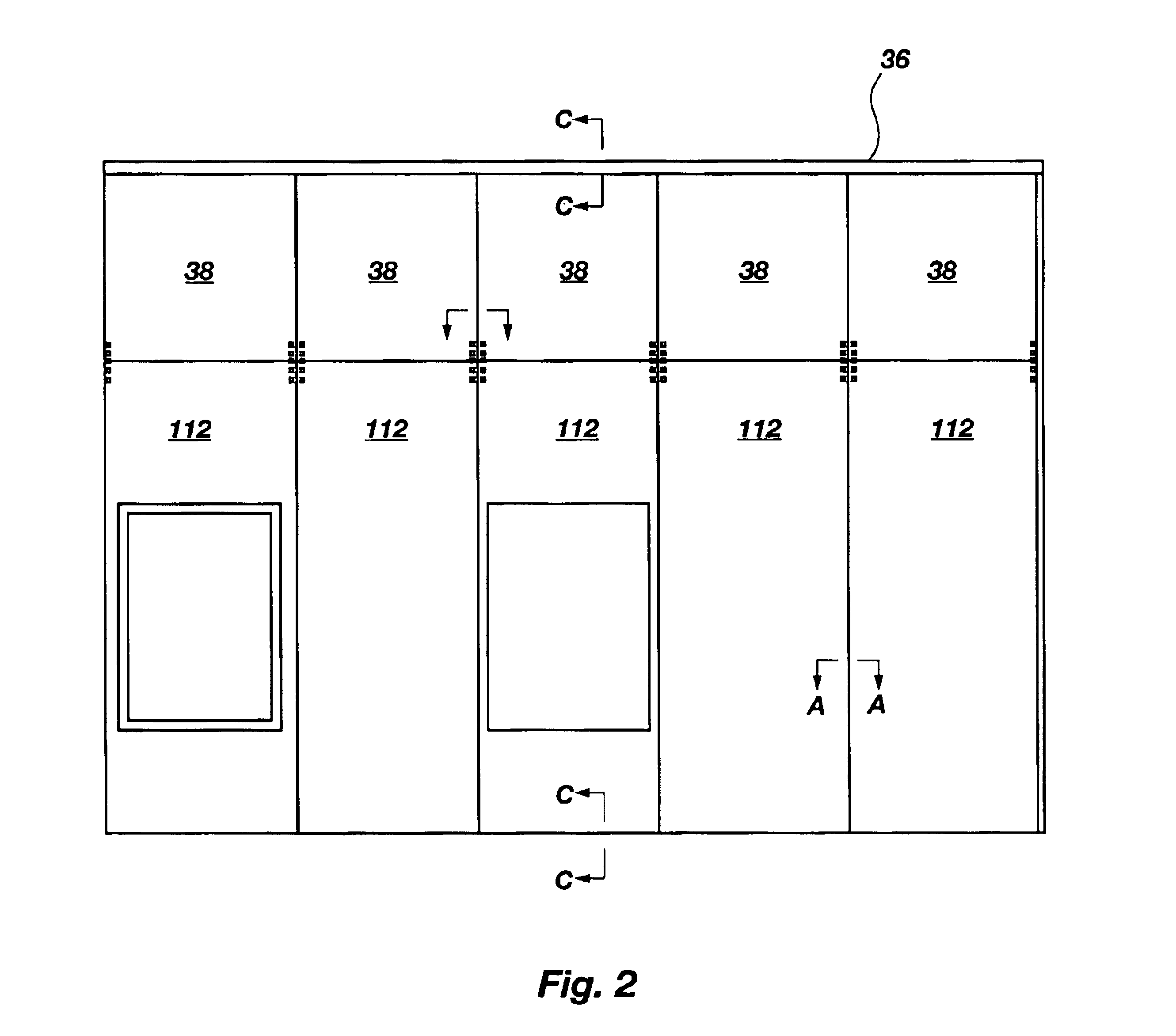

Integrated reconfigurable wall system

ActiveUS20060059806A1Increase heightConvenient framingWallsPublic buildingsComputer moduleEngineering

A movable reconfigurable wall system having at least one module having a front and rear surface, the at least one module having: vertical end frames disposed at least at its side edges, each the vertical end frame having a vertically extending flange directed toward the front surface and a vertically extending flange directed toward the rear surface; a plurality of horizontal stringers affixed between the pair of vertical end frames; and an aesthetic surface affixed to the stringers; and a removable connecting strip, the connecting strip adapted to affix about one of the two flanges on one of the vertical end frames and join the one of the two flanges to a corresponding flange on one of a second module, a wall bracket, a finishing trim or a connection post.

Owner:DIRTT ENVIRONMENTAL SOLUTIONS

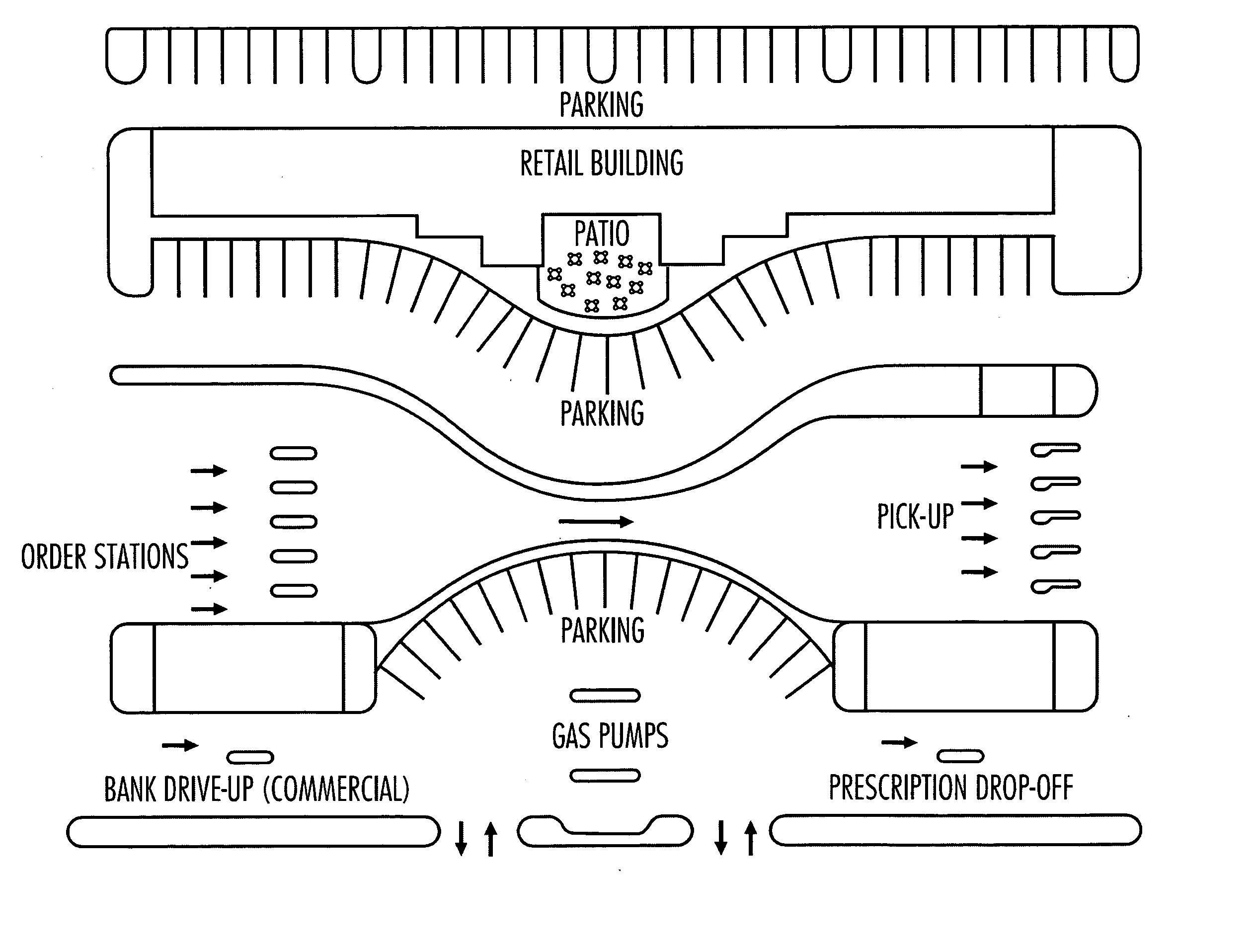

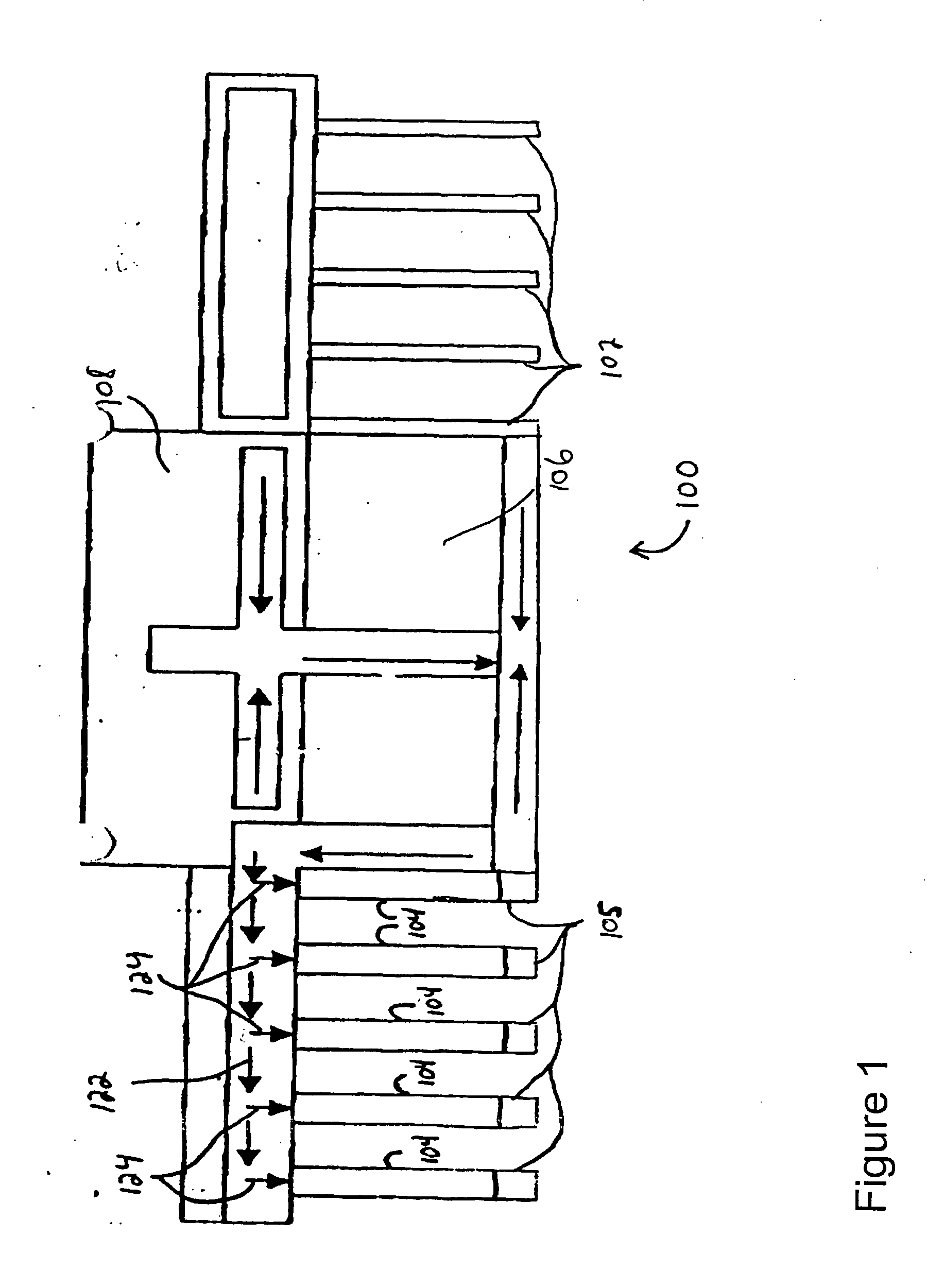

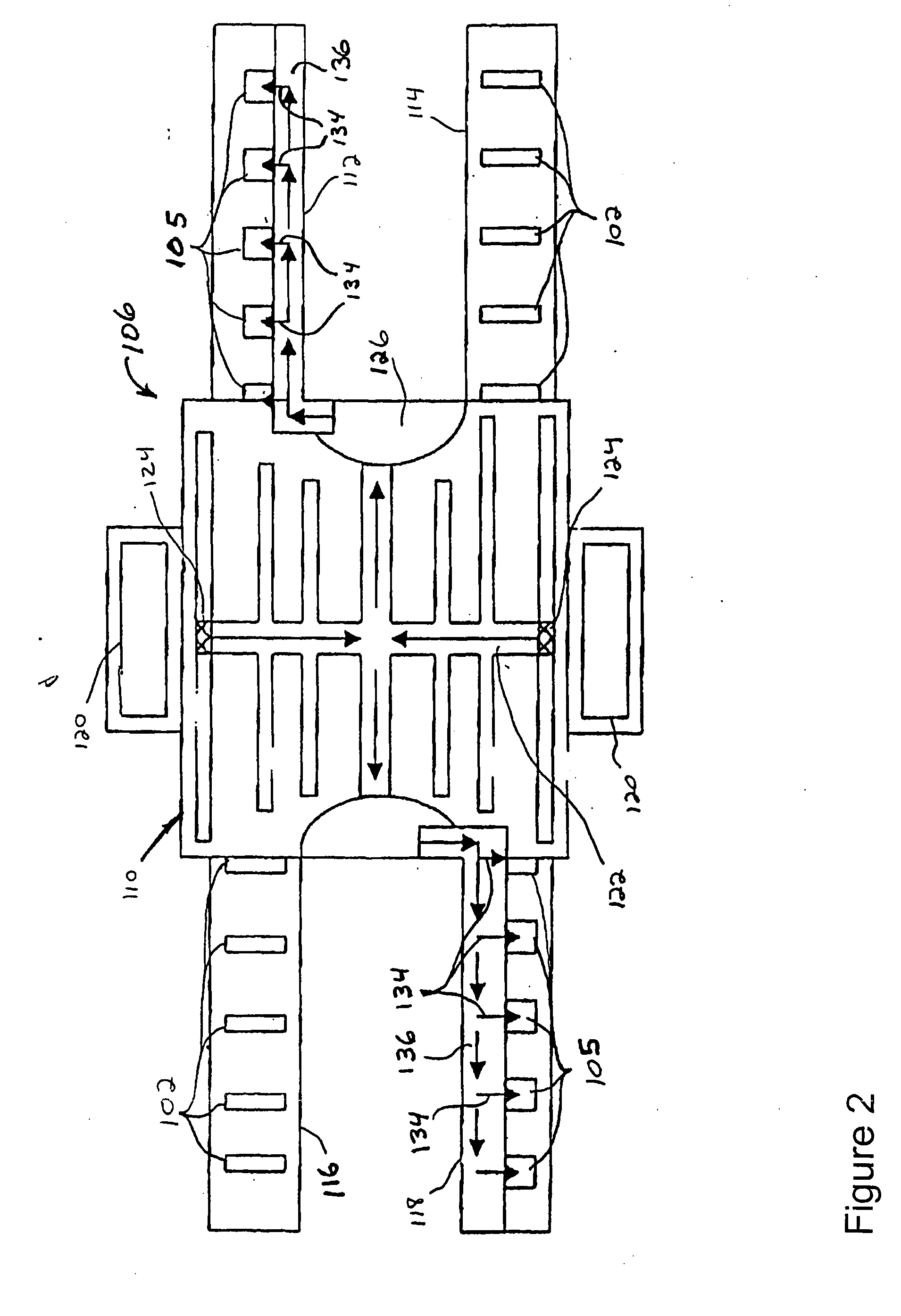

System, method and process for computer controlled delivery of classified goods and services through an amalgamated drive-thru complex

InactiveUS20070187183A1Easy to understandPublic buildingsService system furnitureTransport systemSystems approaches

The present invention comprises, in one embodiment, a system, method and process for delivery of classified goods and serviced items through a vehicle drive-thru facility, the facility having a plurality of vehicle drive-thru pick-up portals for goods or services orderable via an electronic or computer medium. The present invention comprises, in another embodiment, a computer controlled transport system for the variable or high speed retrieval and delivery of amalgamated classified goods or services at any location within the facility or adjacent to the facility.

Owner:SAIGH & SON

Structural walls

Owner:STEELER

Composite joinery

Owner:NCI GROUP

Construction system for manufactured housing units

Owner:LORWOOD PROPERTIES

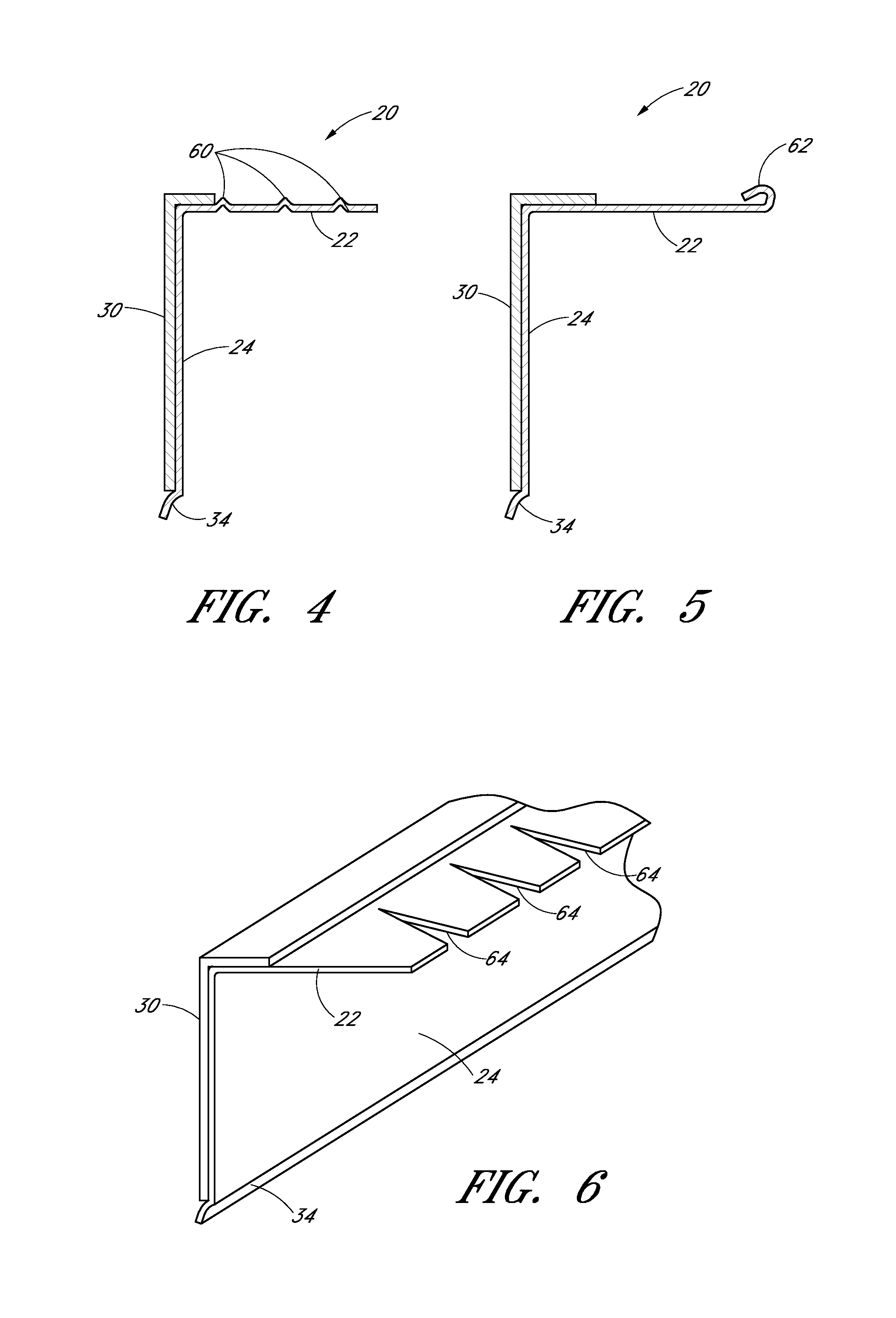

Fire-rated joint system

ActiveUS8595999B1Efficient and cost-effectiveAvoid the needWallsPublic buildingsSill plateEngineering

A fire-rated angle piece and wall assemblies or other assemblies that incorporate the fire-rated angle piece, in which the angle piece can include an intumescent or other fire-resistant material strip. The angle can be attached adjacent to a corner of a framing member, such as metal tracks, headers, header tracks, sill plates, bottom tracks, metal studs, wood studs or wall partitions, and placed between the framing member and a wall board member at a perimeter of a wall assembly to create a fire block arrangement. A fire spray material can be applied over a portion of the angle piece.

Owner:CEMCO LLC

Fire-rated joint system

ActiveUS8590231B2Without damaging the intumescent material more easilyEfficient and cost-effectiveWallsPublic buildingsSill plateMechanical engineering

A fire-rated angle piece and wall assemblies or other assemblies that incorporate the fire-rated angle piece, in which the angle piece includes an intumescent or other fire-resistant material strip. The angle can be attached adjacent to a corner of a framing member, such as metal tracks, headers, header tracks, sill plates, bottom tracks, metal studs, wood studs or wall partitions, and placed between the framing member and a wall board member at a perimeter of a wall assembly to create a fire block arrangement.

Owner:CEMCO LLC

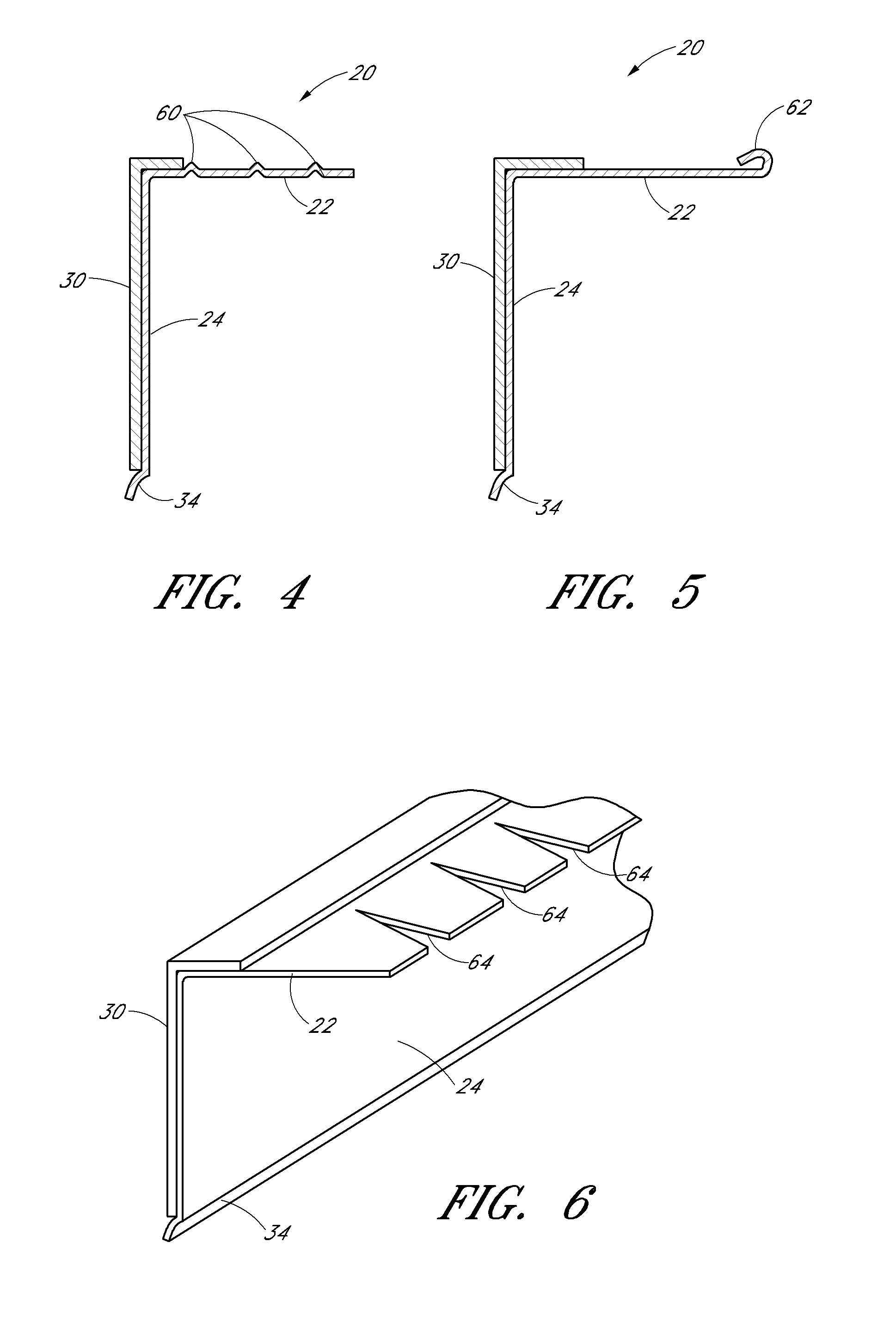

Collapsible modular shelter for containerized transportation

ActiveUS20090217600A1Facilitate raising of the roof sections and sidesLow floorPublic buildingsLarge containersModular unitModularity

A containerized portable shelter which is small and light enough for helicopter transport but which can also travel through container channels and has increased expandability of the floorspace is provided. It has a fraction (e.g. one-half) the standard ISO width, so that a plurality of modular units can be joined to form a standard ISO container. Two or more modular units can be joined side-by-side and / or end-to-end to form a compound shipping container preferably having ISO freight container characteristics.

Owner:WEATHERHAVEN GLOBAL RESOURCES

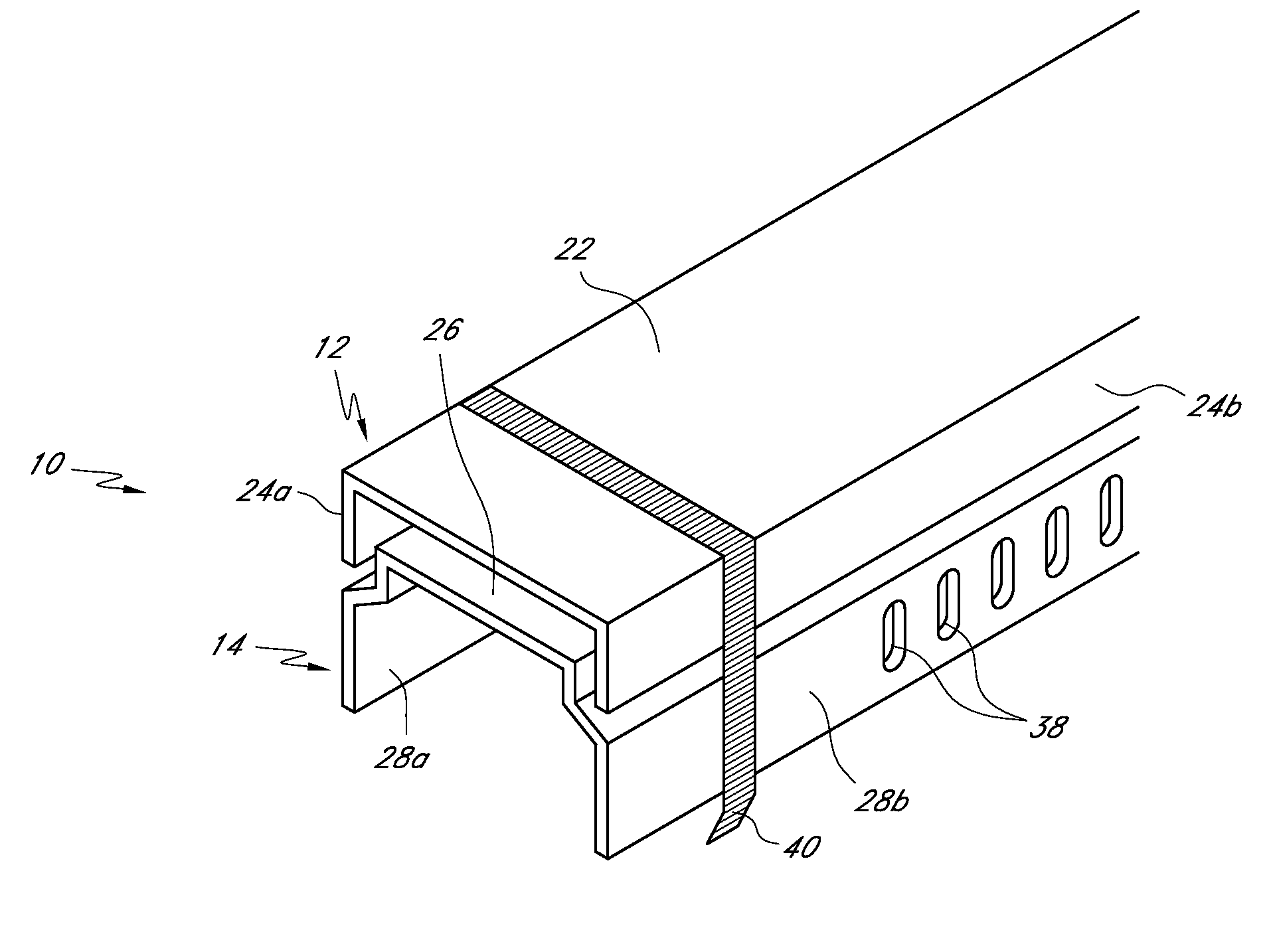

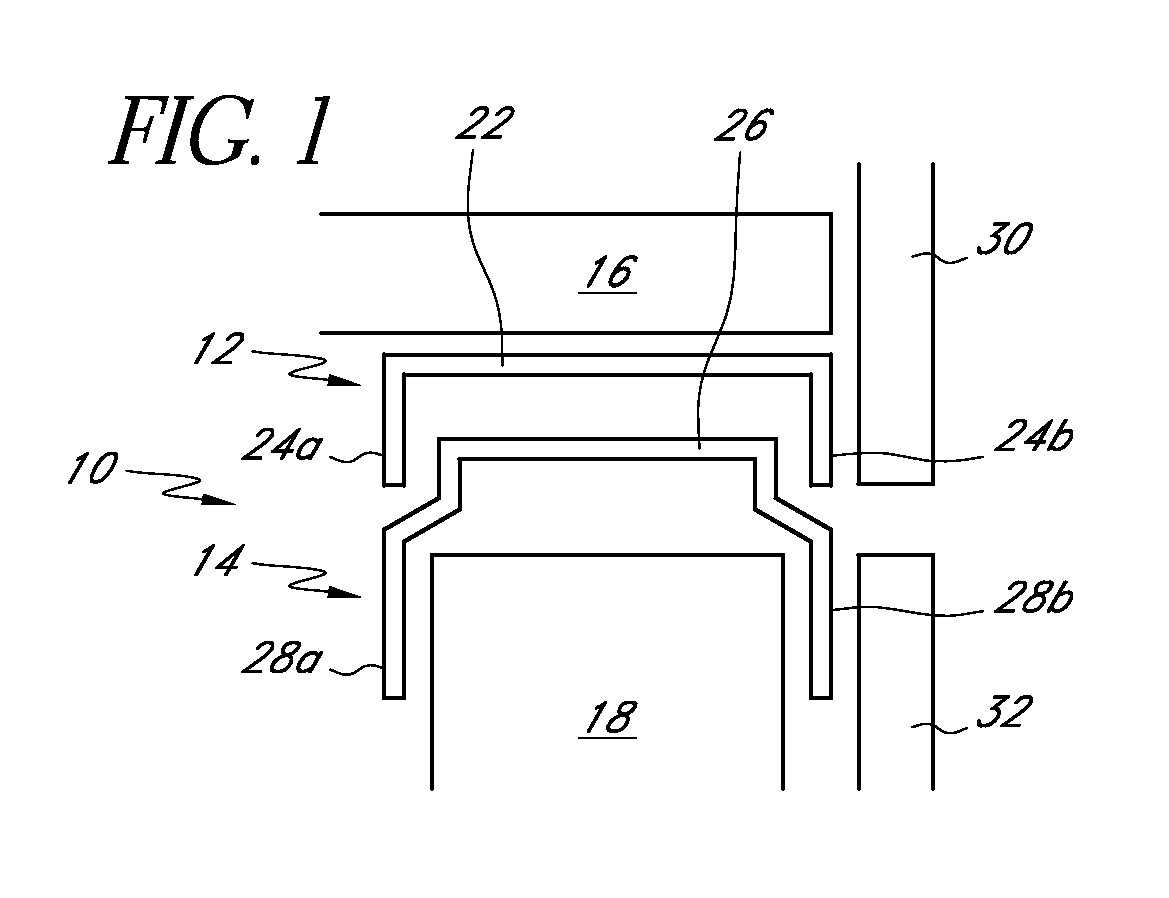

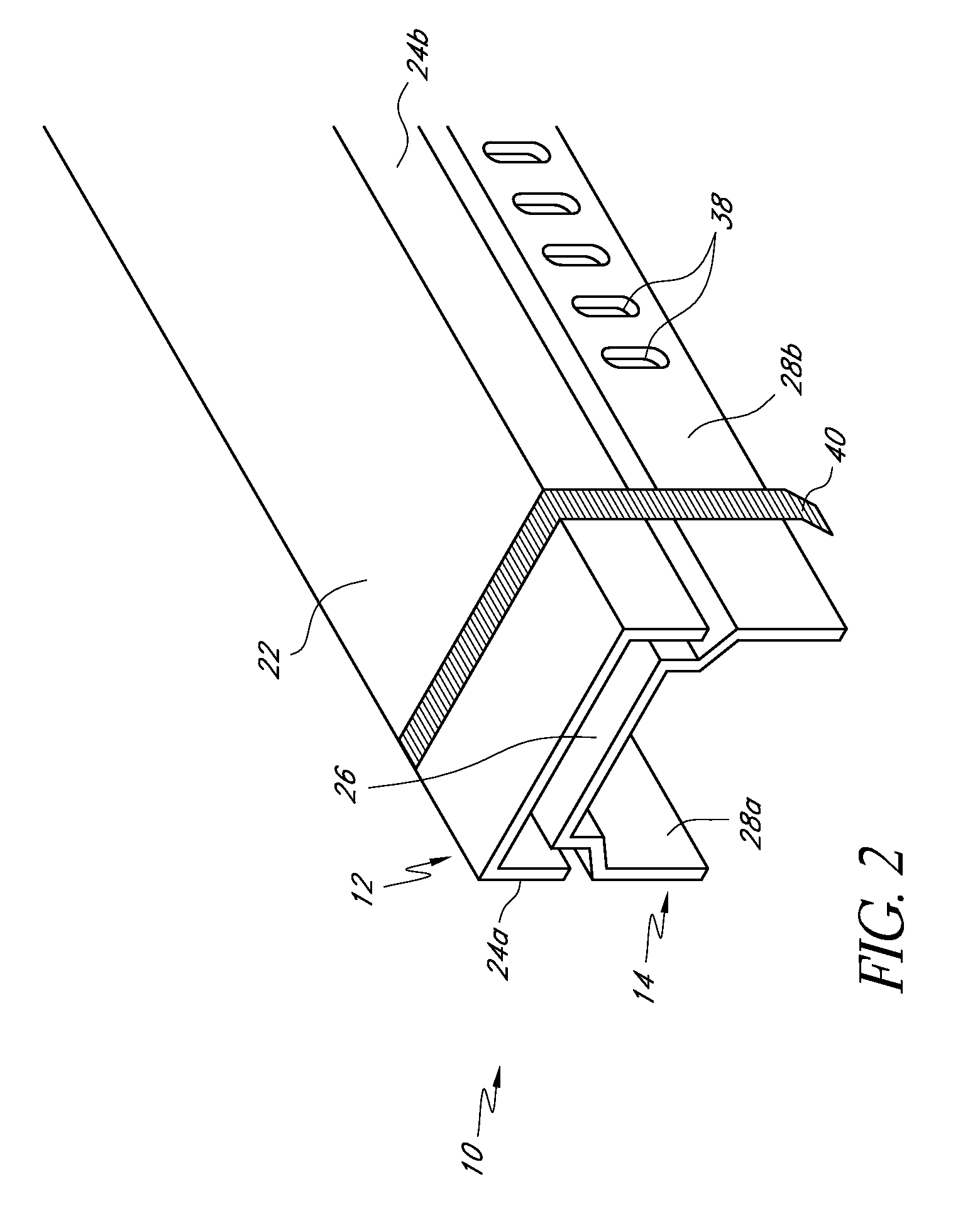

Two-piece track system

The present invention is directed toward a track assembly comprising two nested tracks, an inner track and outer track. The assembly is designed so that the outside width of the outer track is equal to or less than the outside width of the inner track to present a substantially flush external surface for attachment of exterior sheathing elements when the assembly is used in an external wall. The system may further comprise a strap or series of engaging surfaces on the inner and outer tracks that generally restrain the inner track relative to the outer track.

Owner:CALIFORNIA EXPANDED METAL PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com