Patents

Literature

274 results about "Panelling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Panelling (or paneling in the U.S.) is a millwork wall covering constructed from rigid or semi-rigid components. These are traditionally interlocking wood, but could be plastic or other materials. Panelling was developed in antiquity to make rooms in stone buildings more comfortable. The panels served to insulate the room from the cold stone. In more modern buildings, such panelling is often installed for decorative purposes. Panelling, such as wainscoting and boiserie in particular, may be extremely ornate and is particularly associated with seventeenth and eighteenth century interior design, Victorian architecture in Britain, and its international contemporaries.

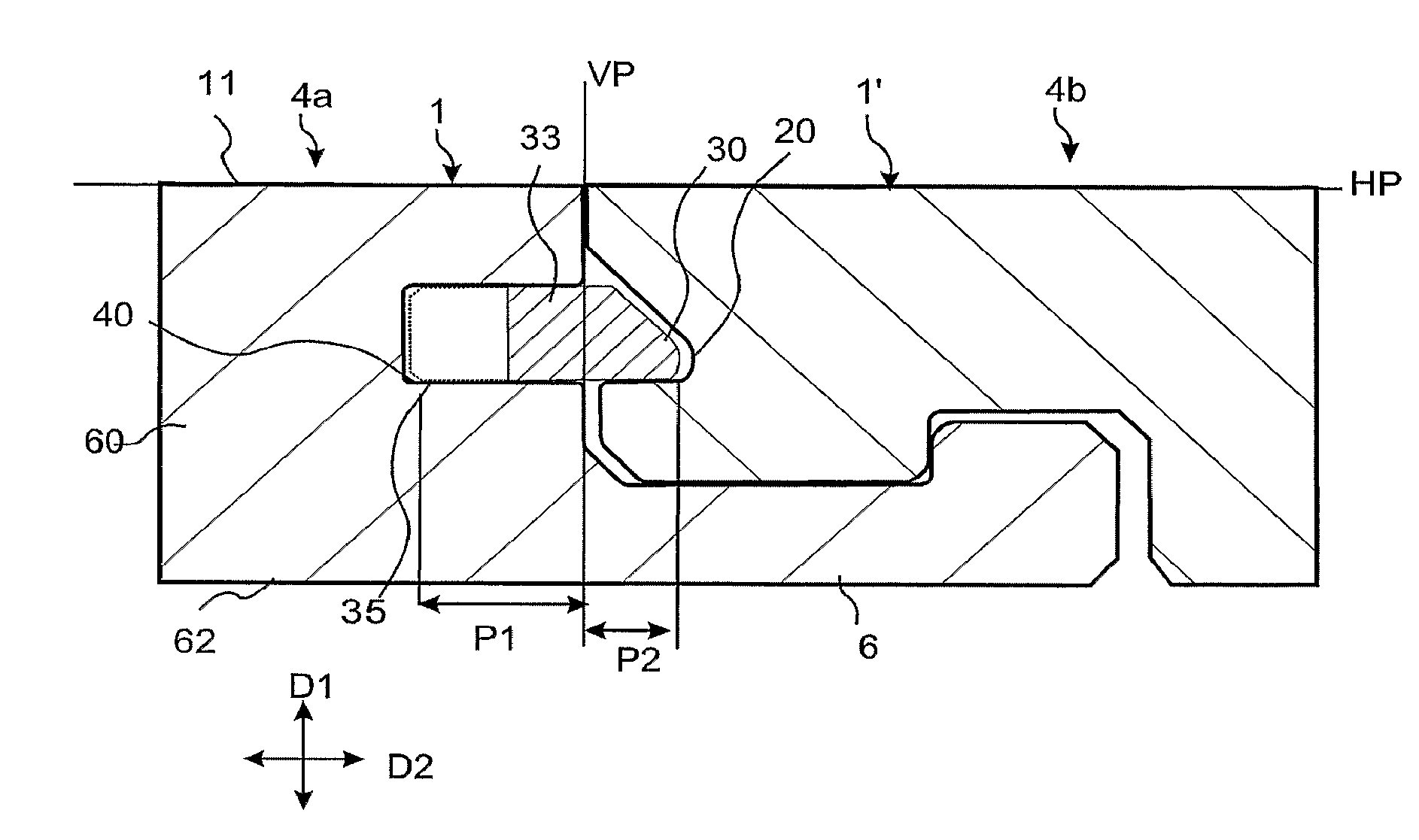

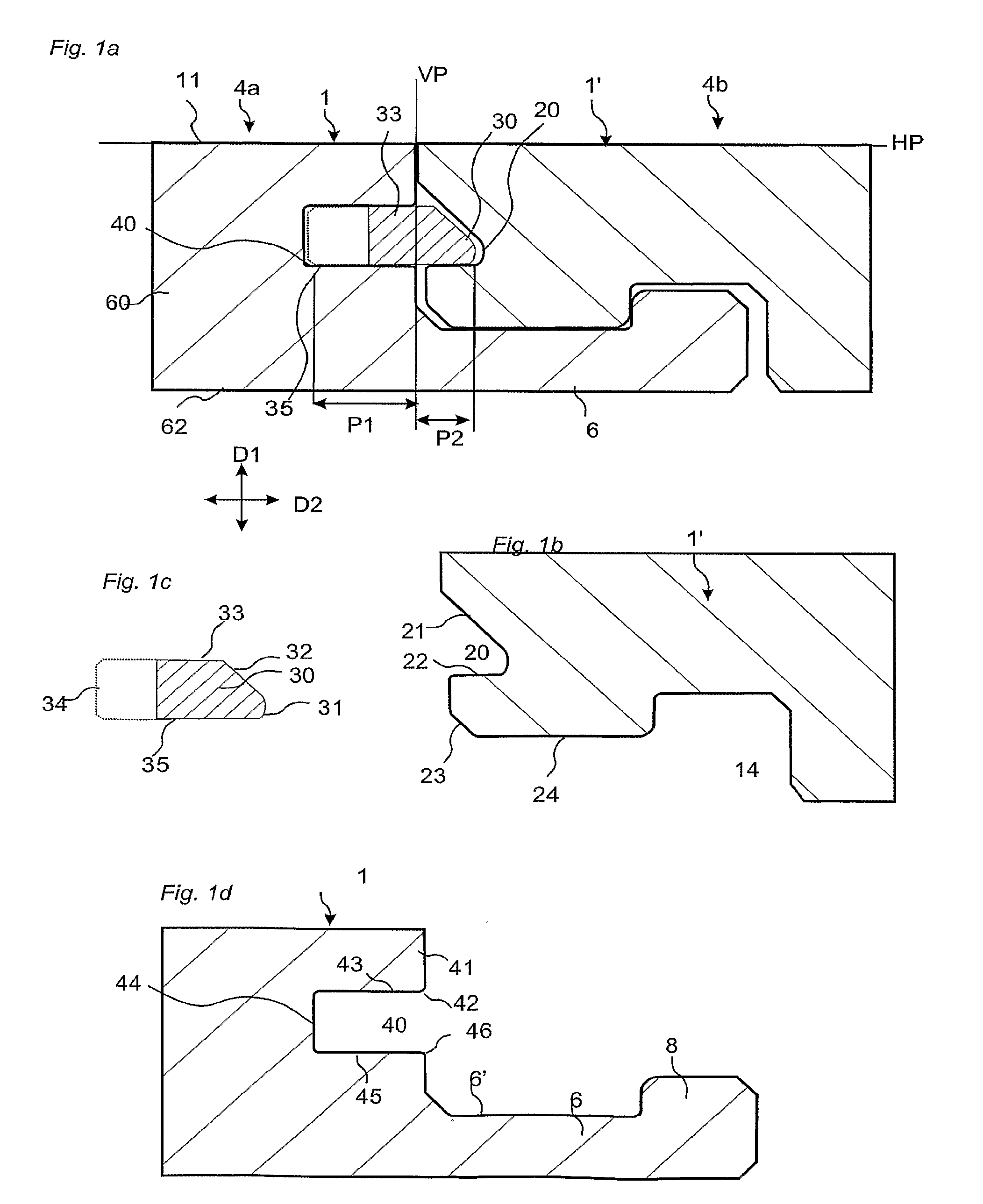

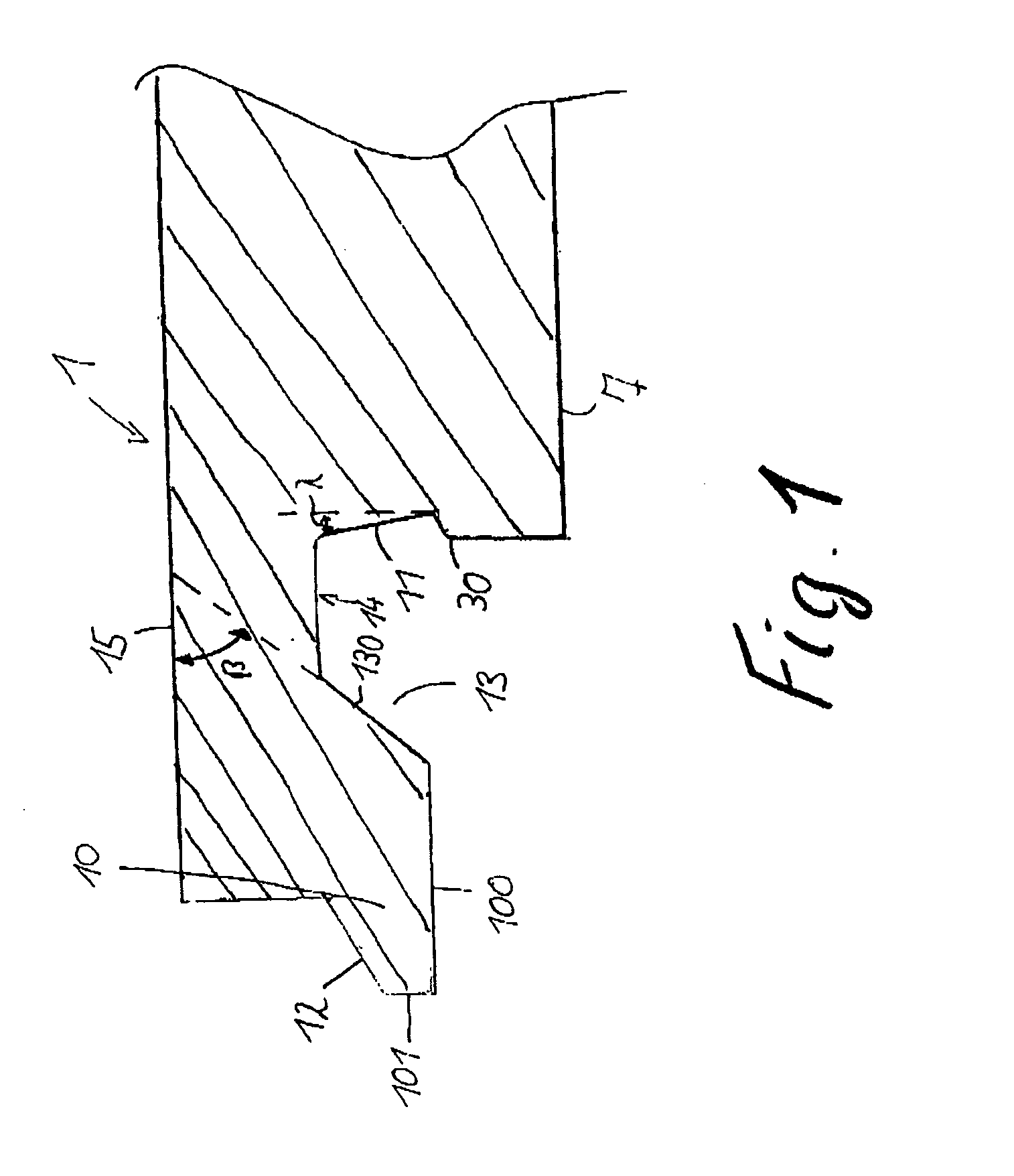

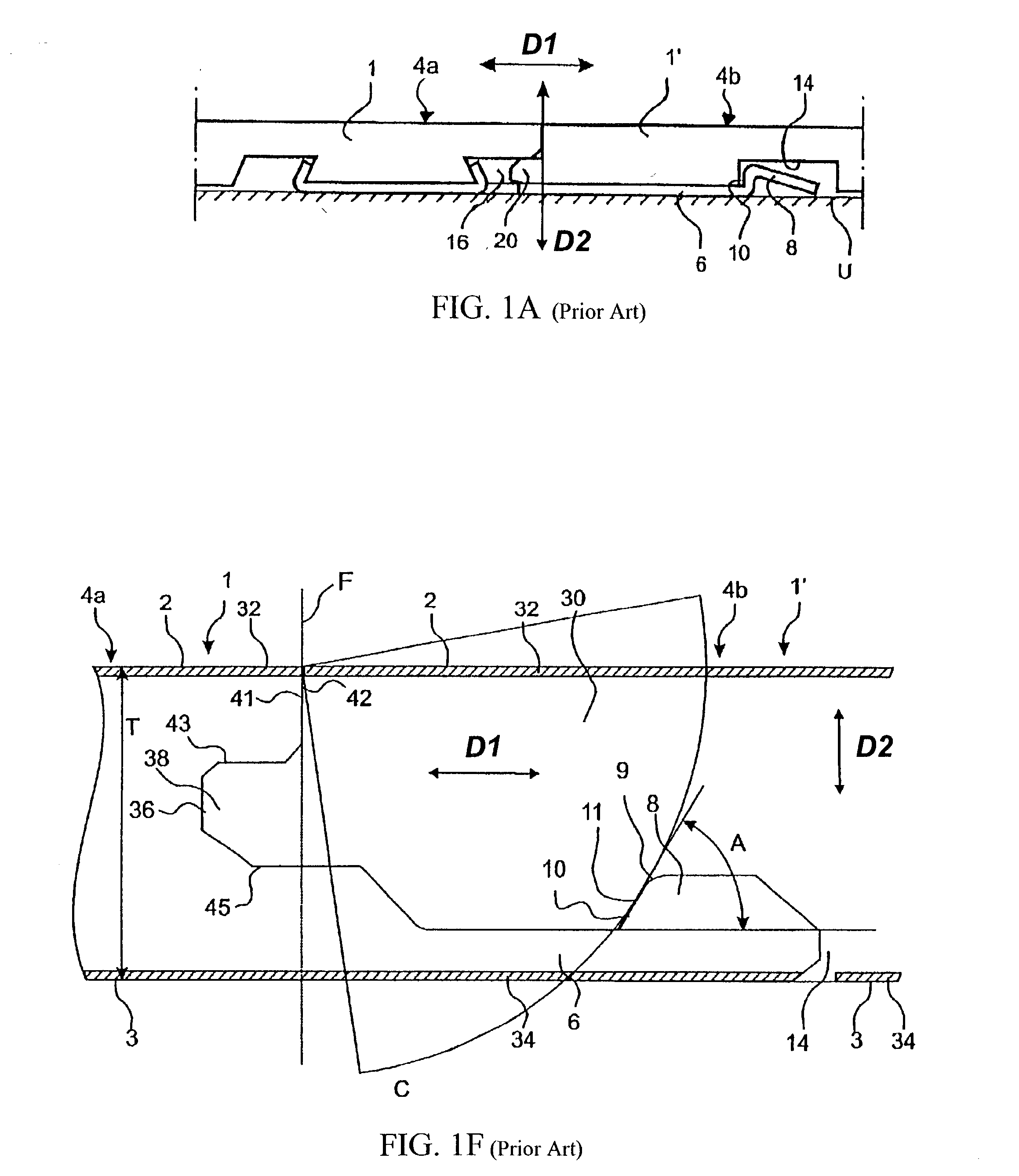

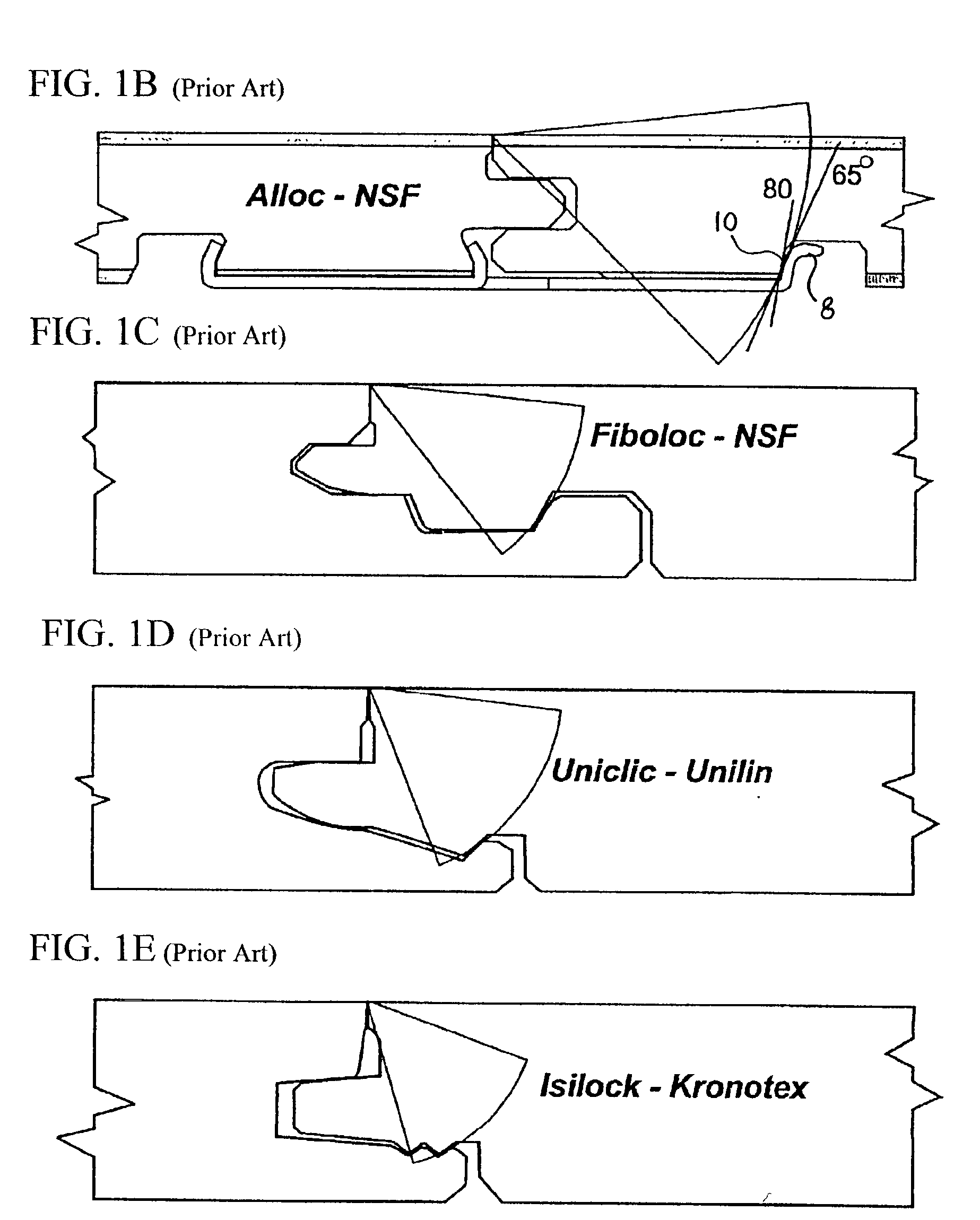

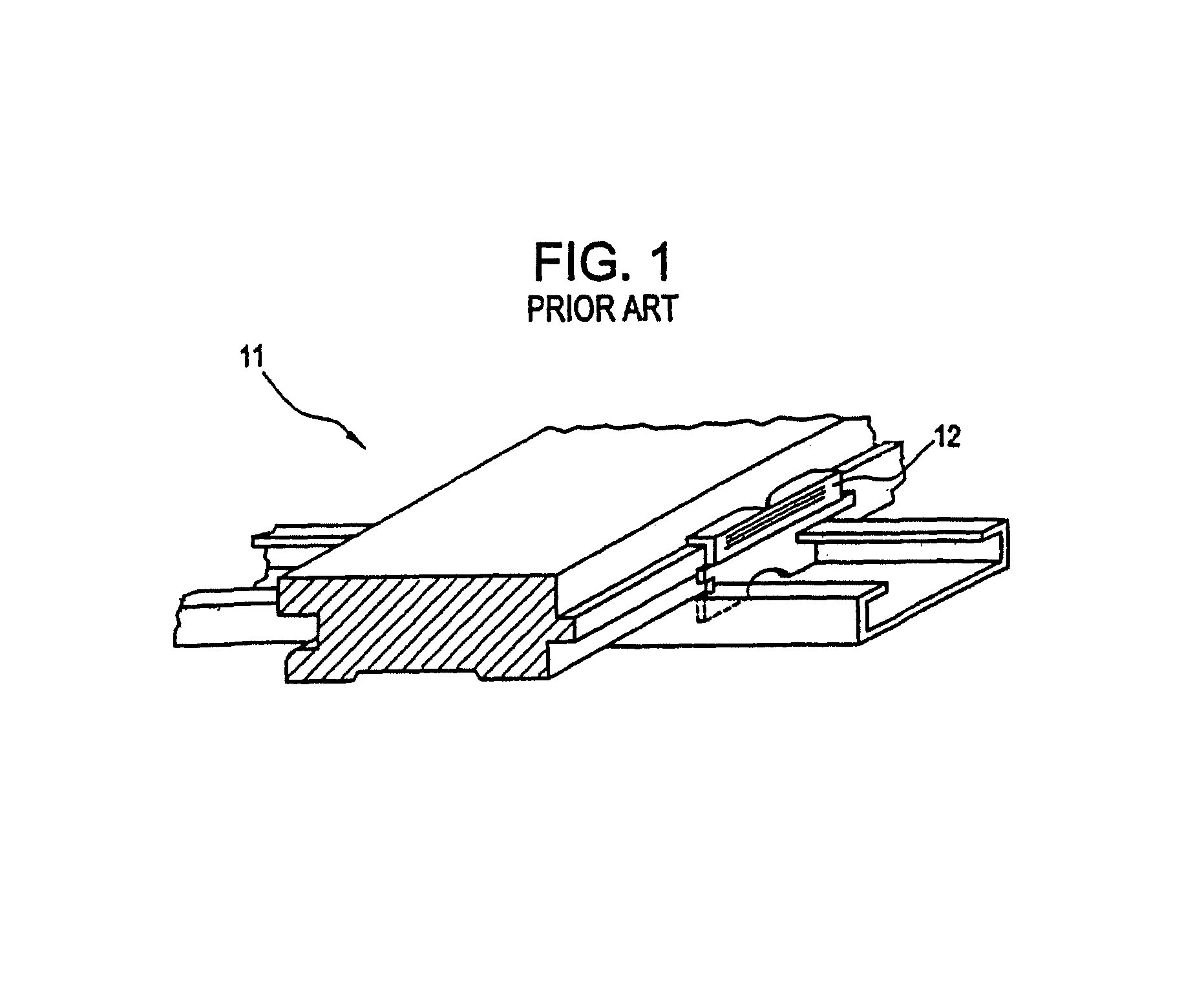

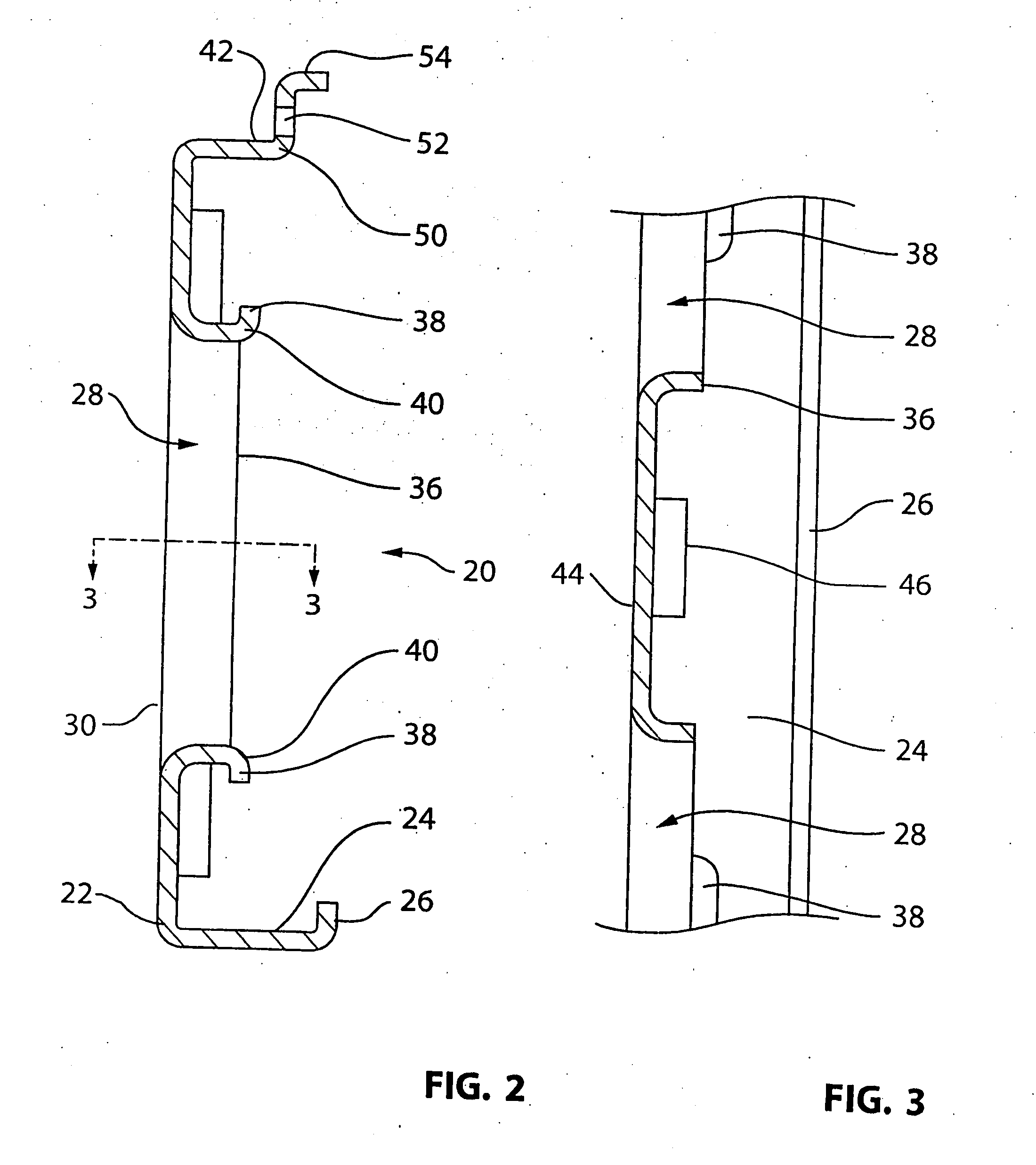

Mechanical Locking of Floor Panels With a Flexible Tongue

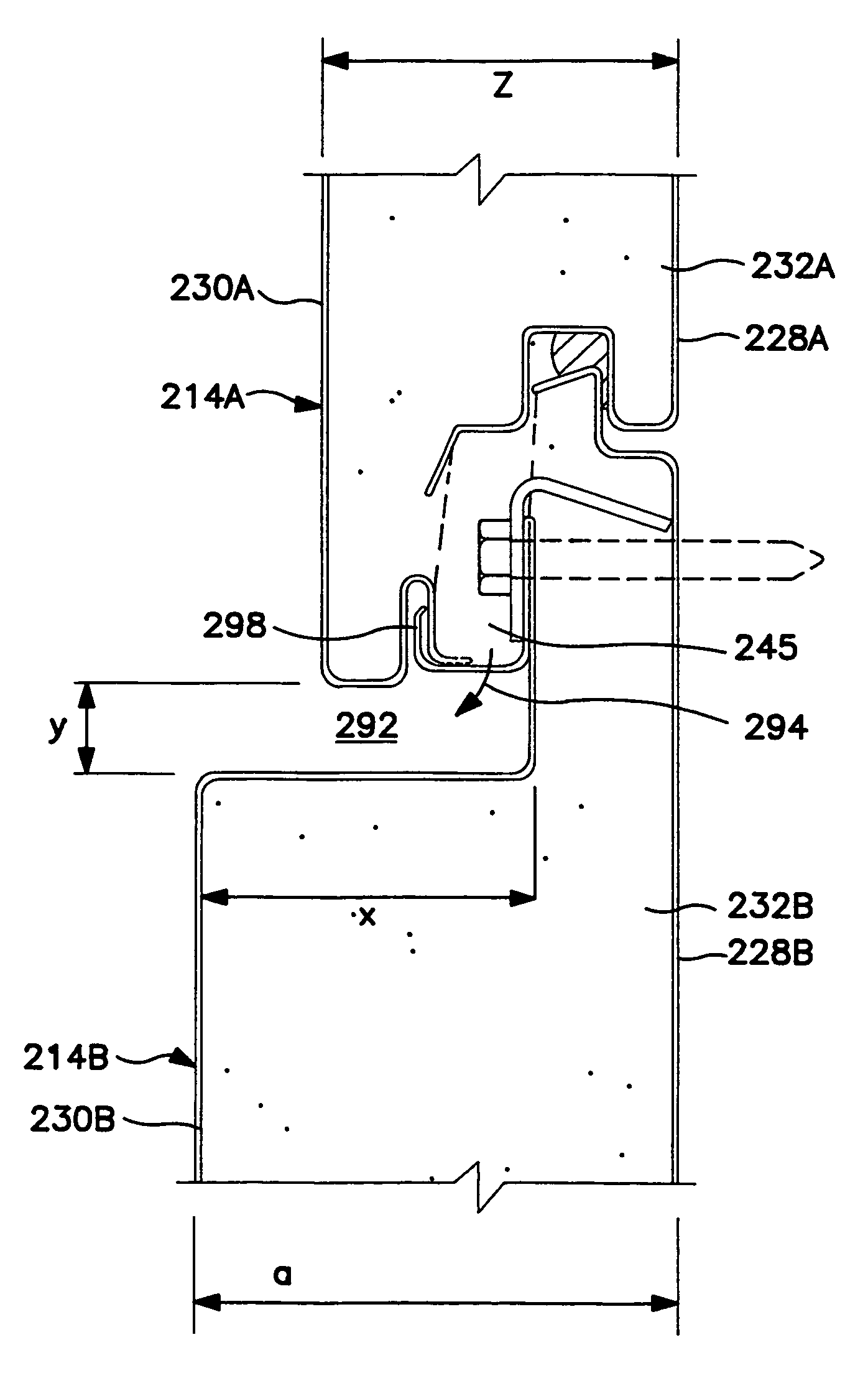

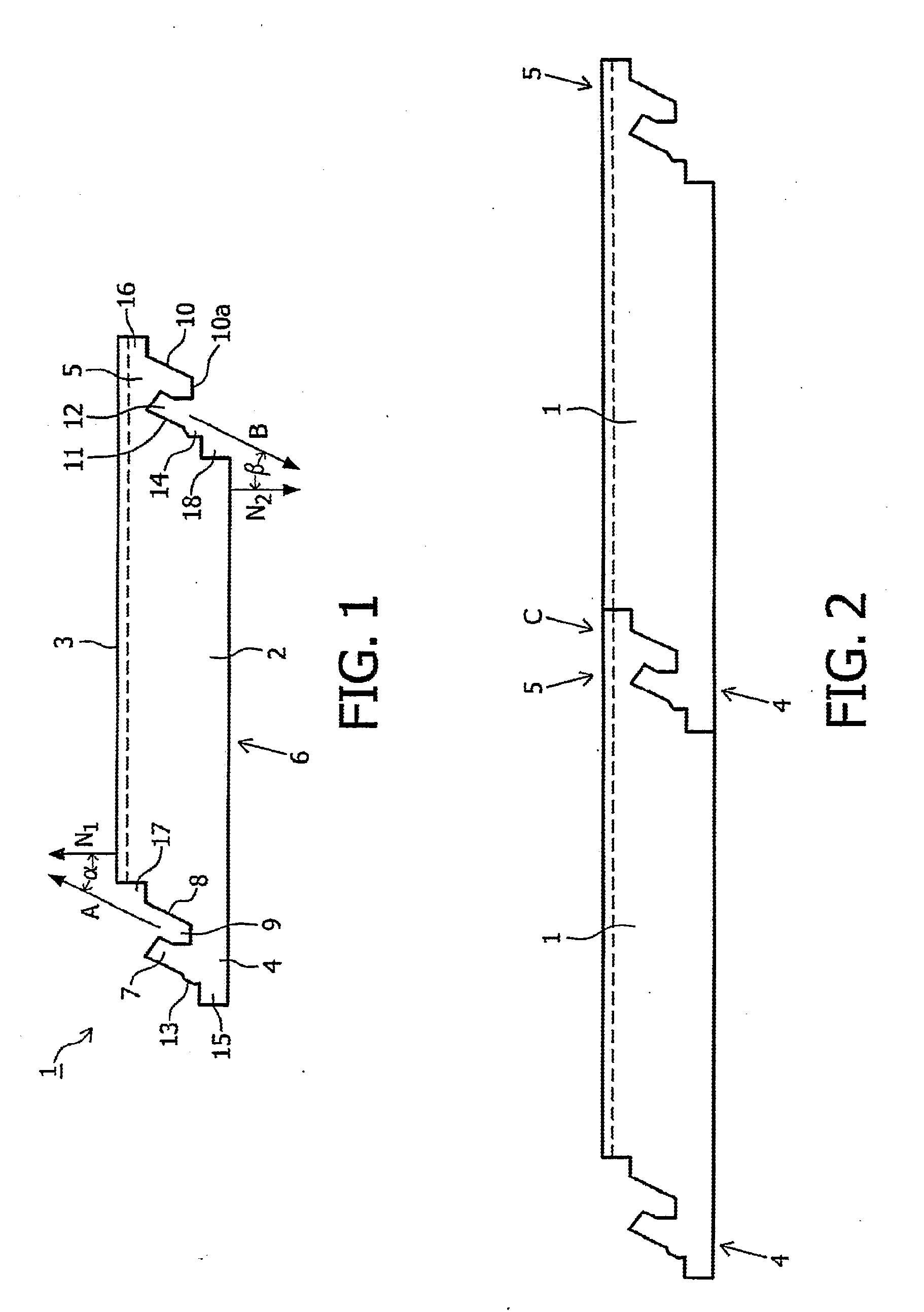

Floor panels (1, 1′) are shown, which are provided with a mechanical locking system having a flexible tongue (30) in a displacement groove (40), which during a vertical folding motion is displaced. Moreover, a tongue blank (50), a production method and an installation method are shown.

Owner:VÄLINGE INNOVATION AB

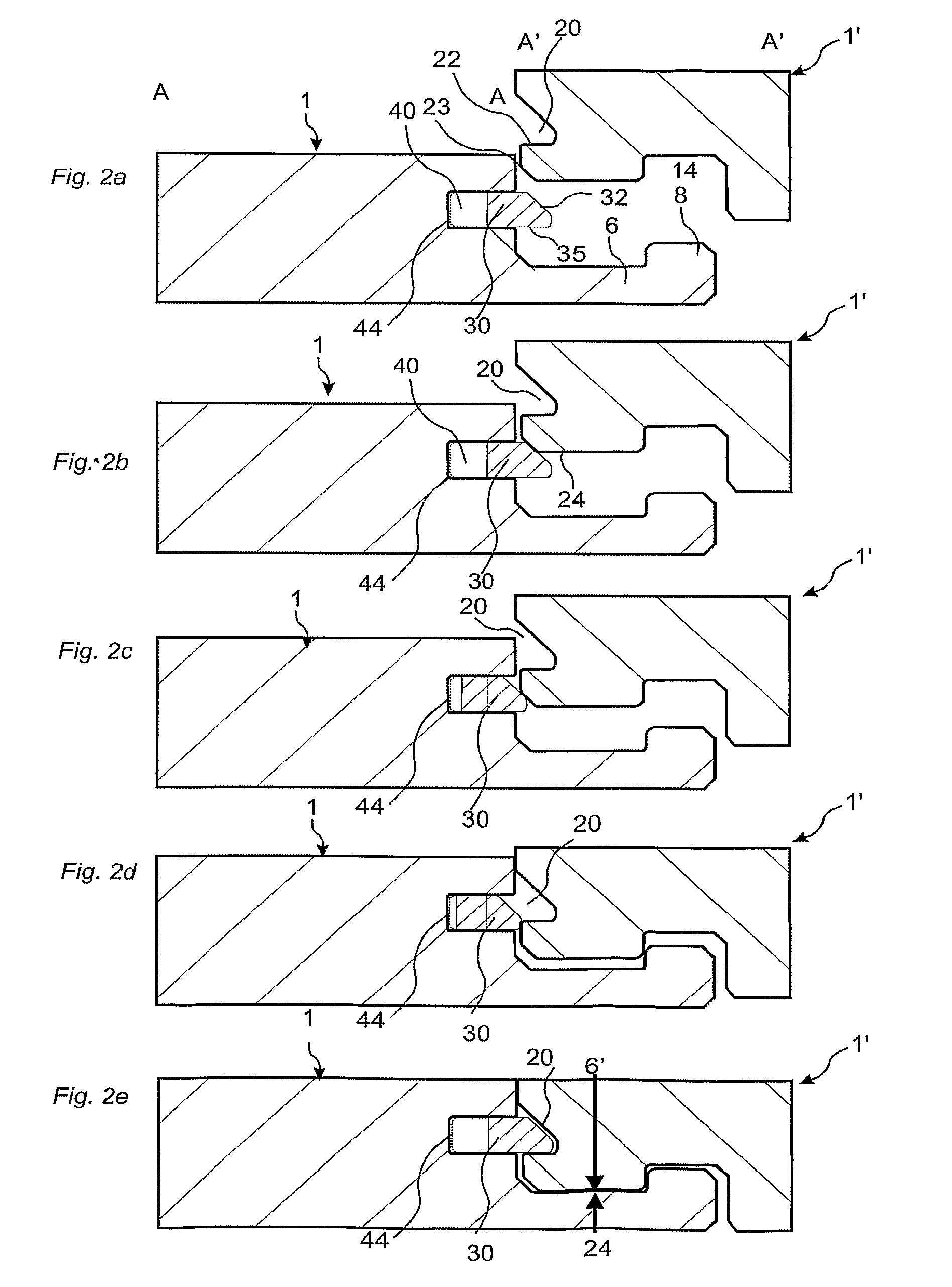

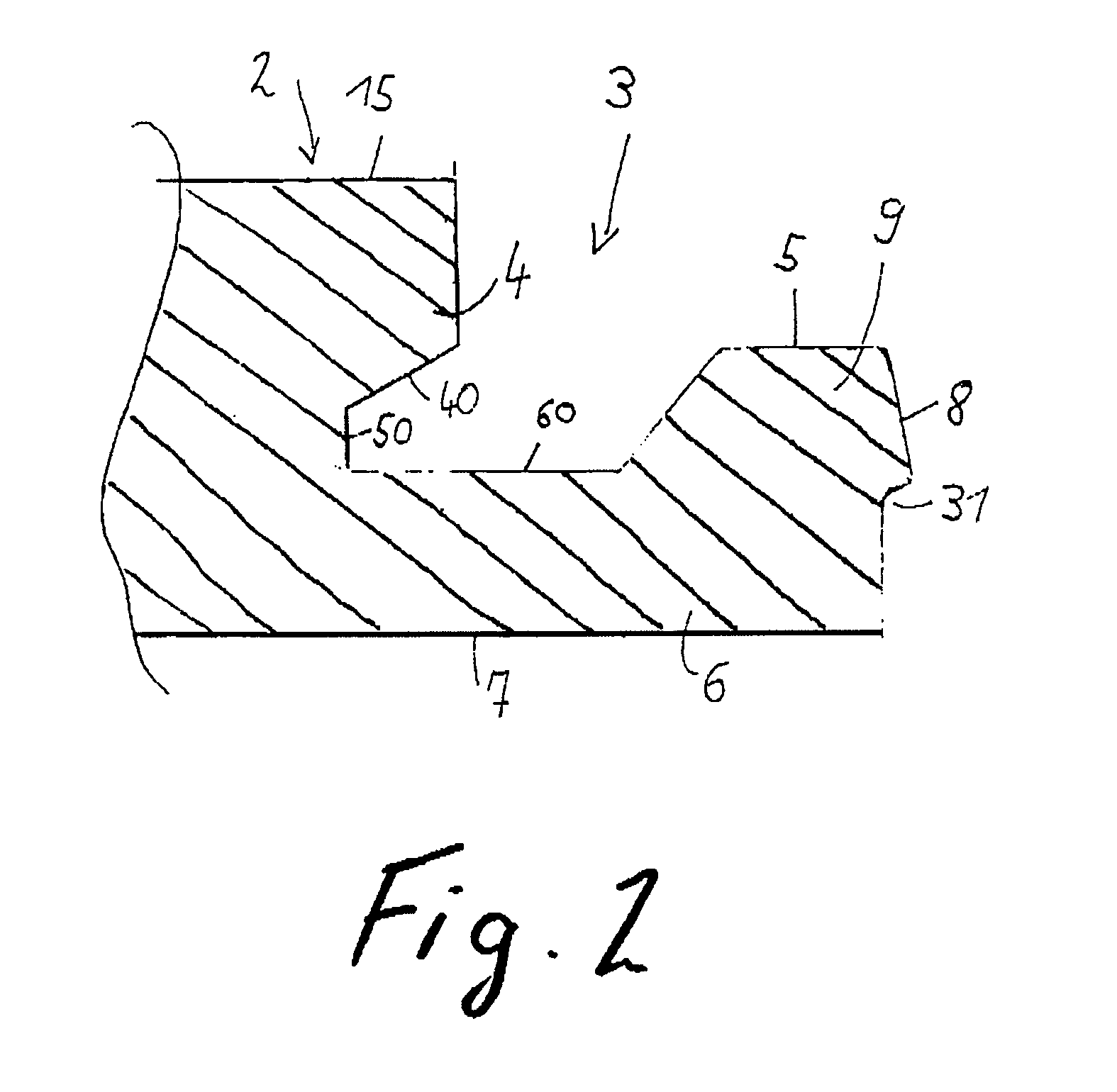

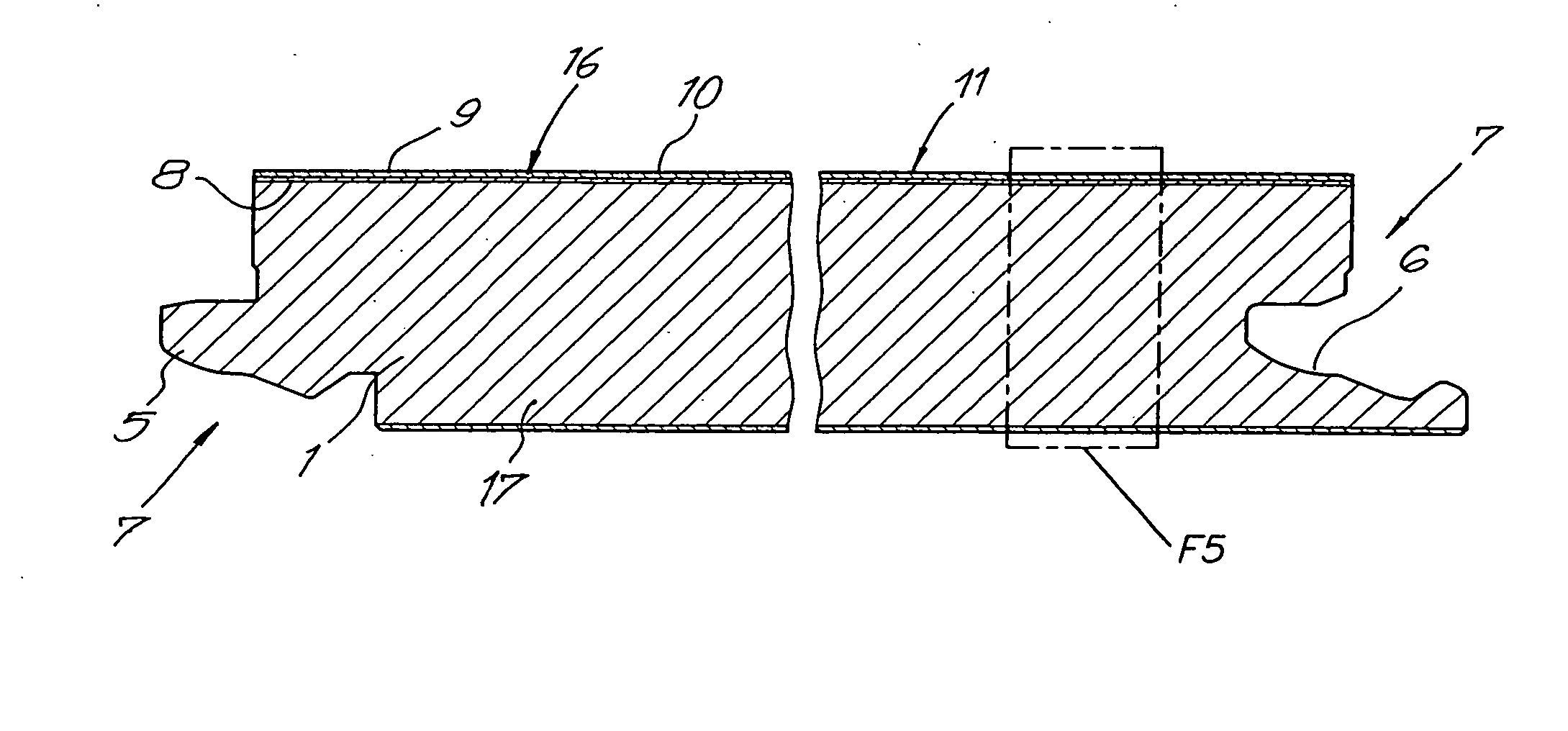

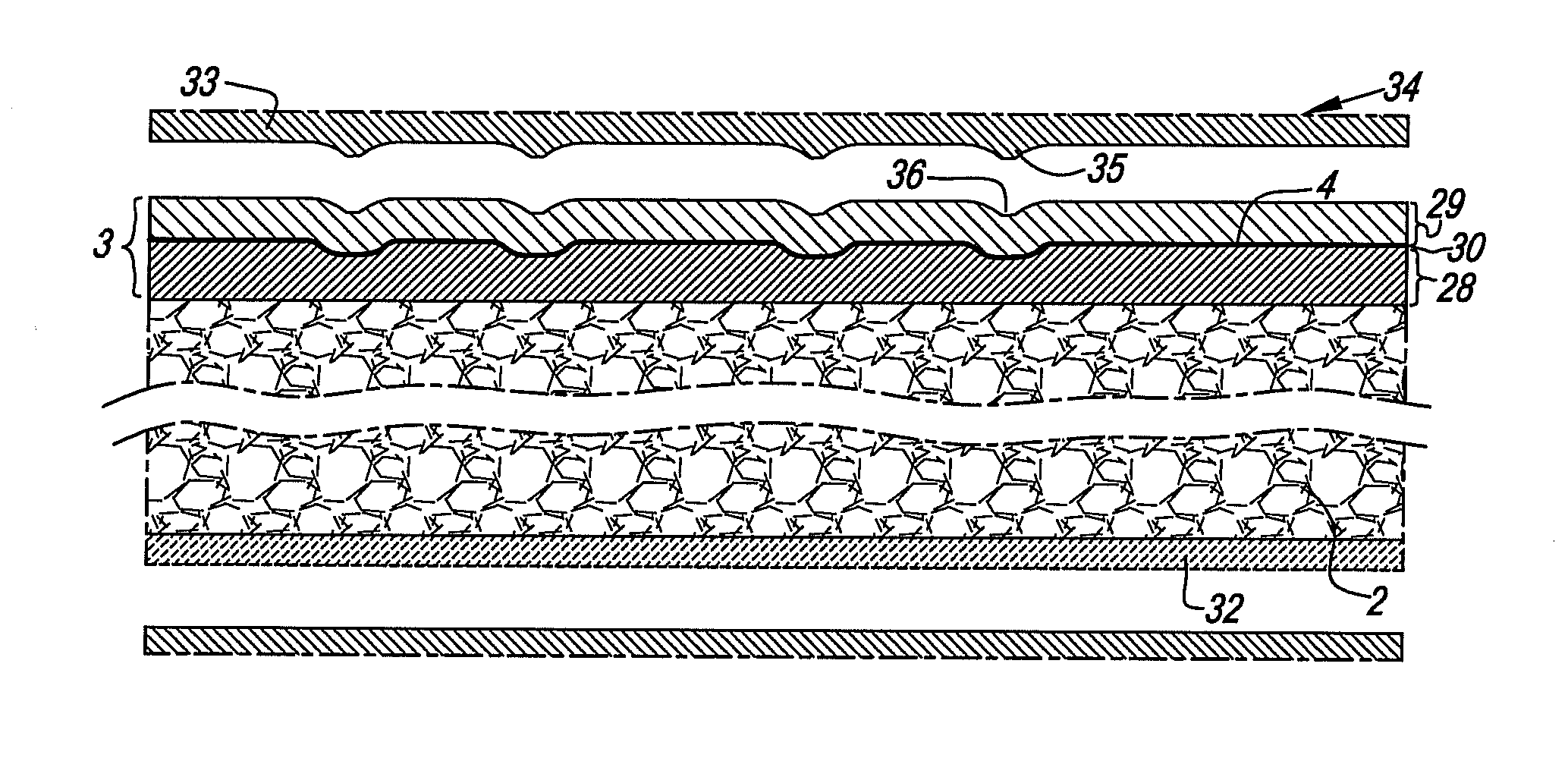

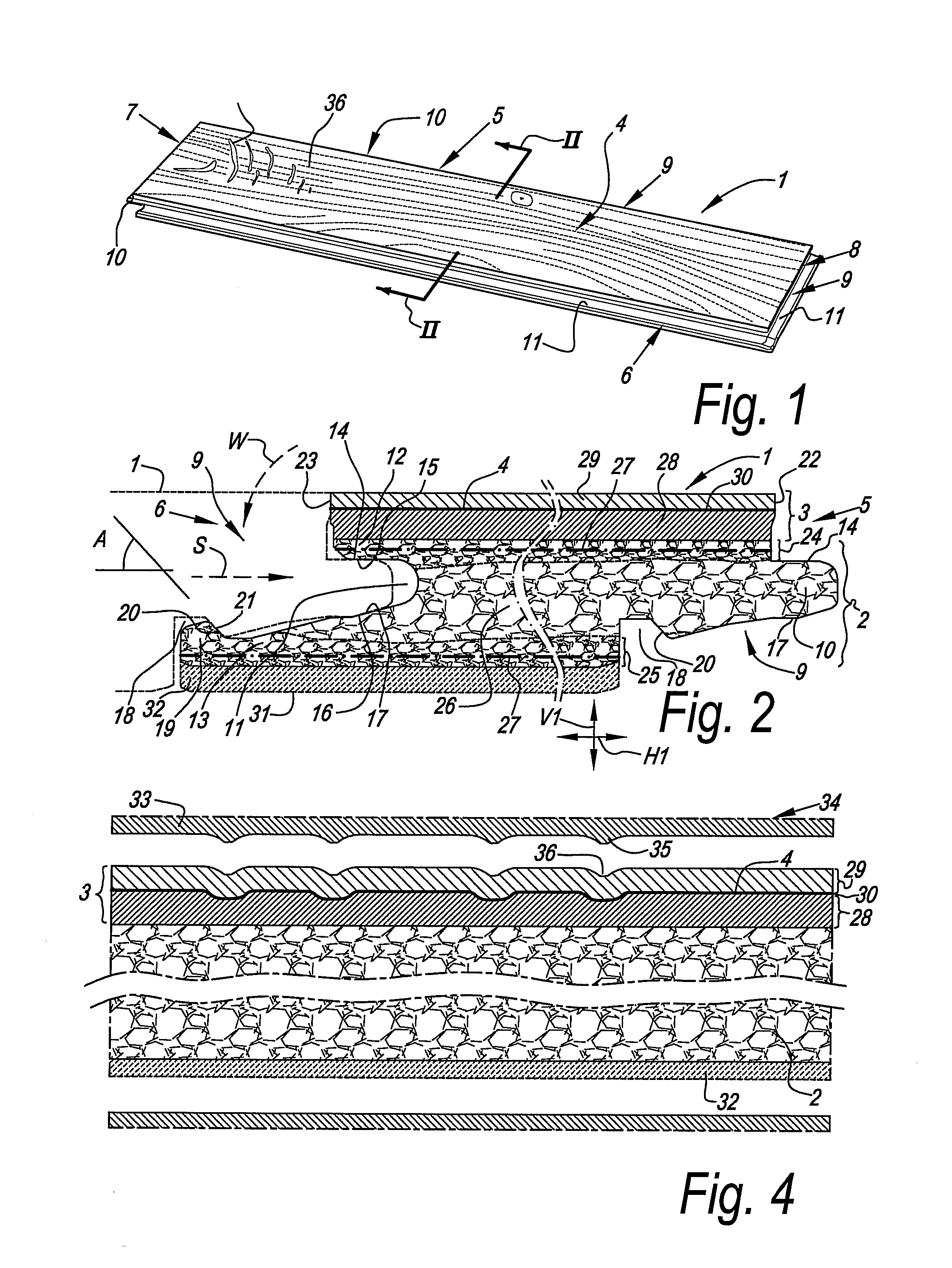

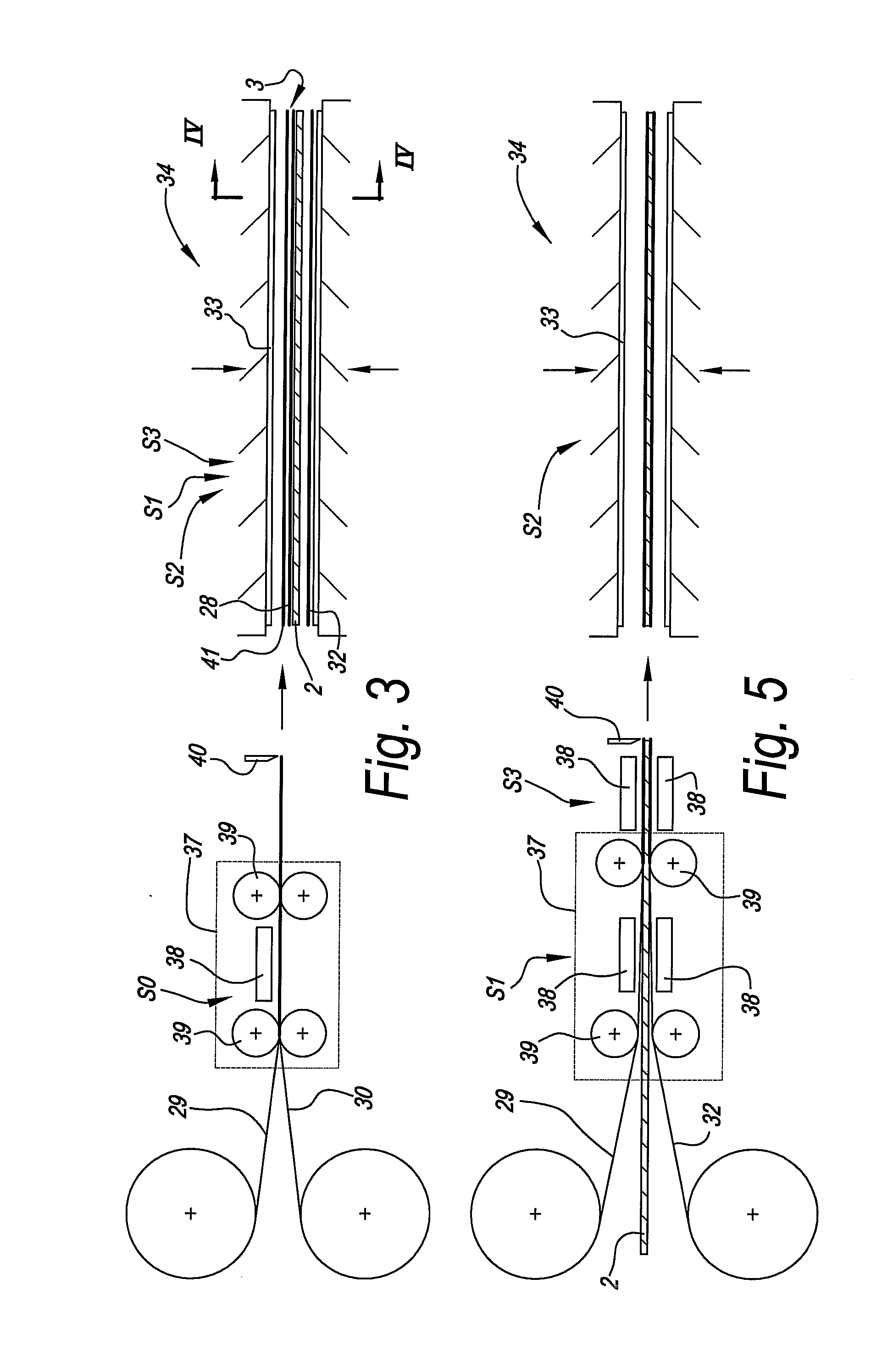

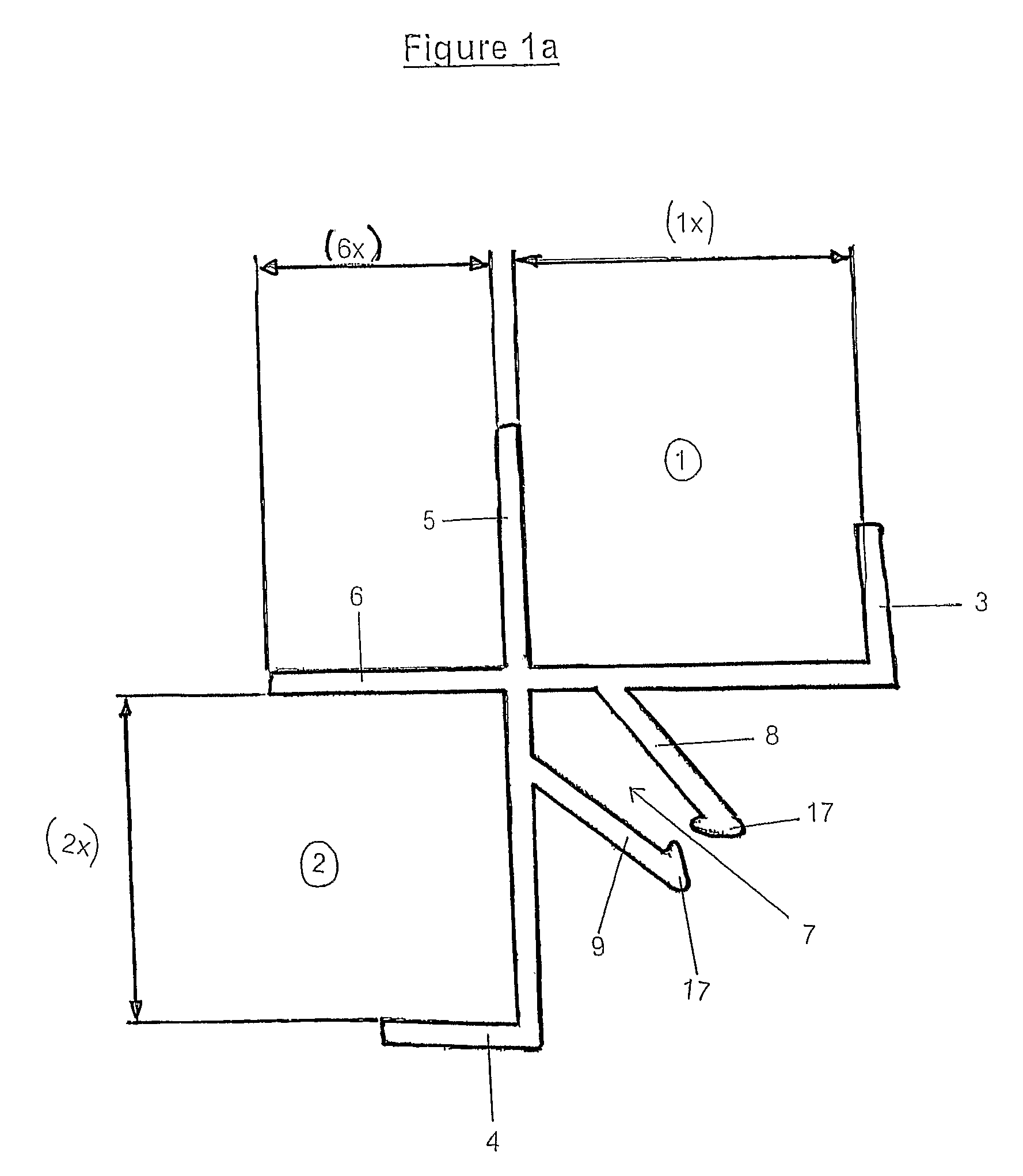

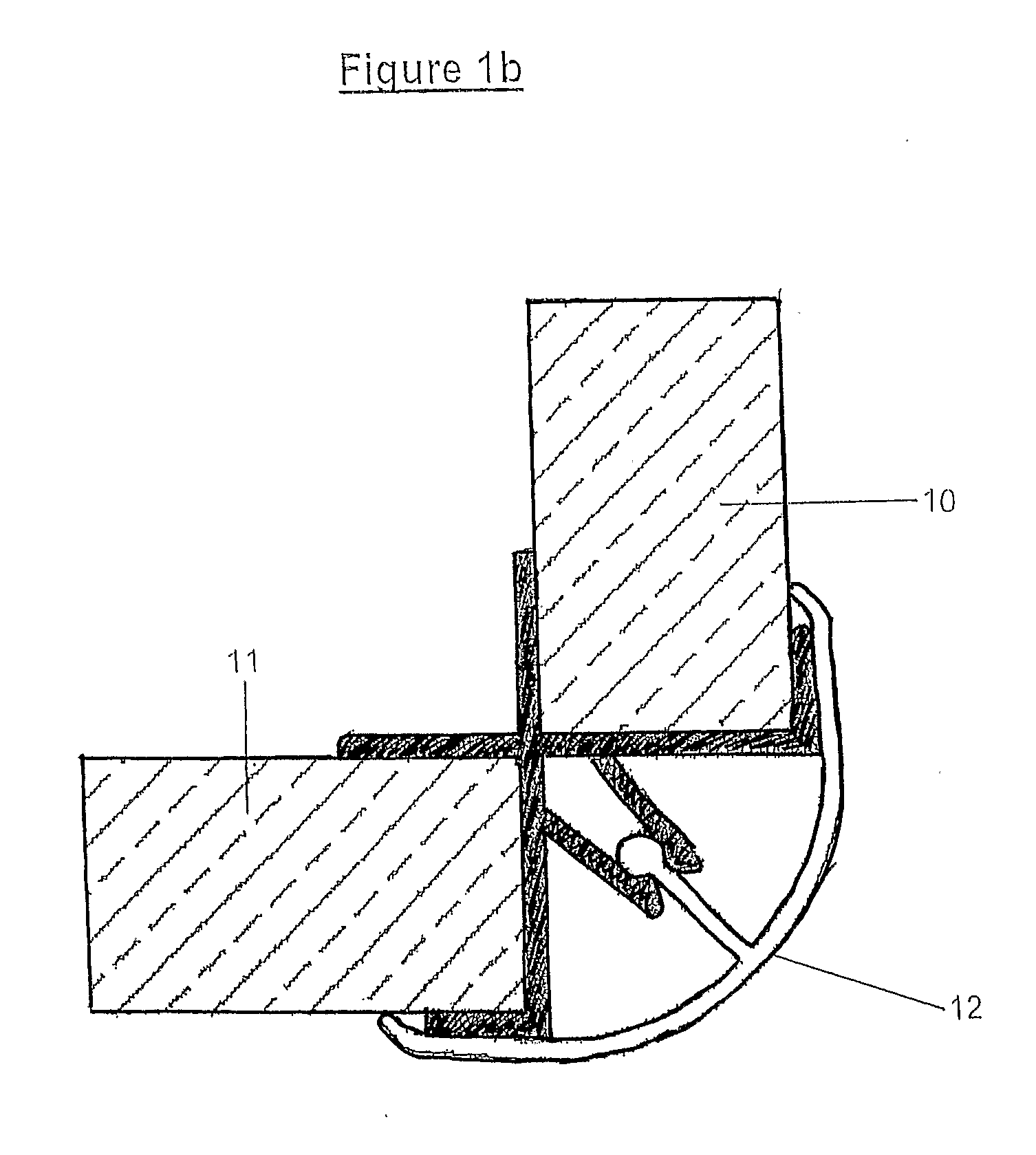

Floor panel and method of laying a floor panel

ActiveUS20040128934A1Quick and straightforward layingReliably latchStrutsCovering/liningsEngineeringMechanical engineering

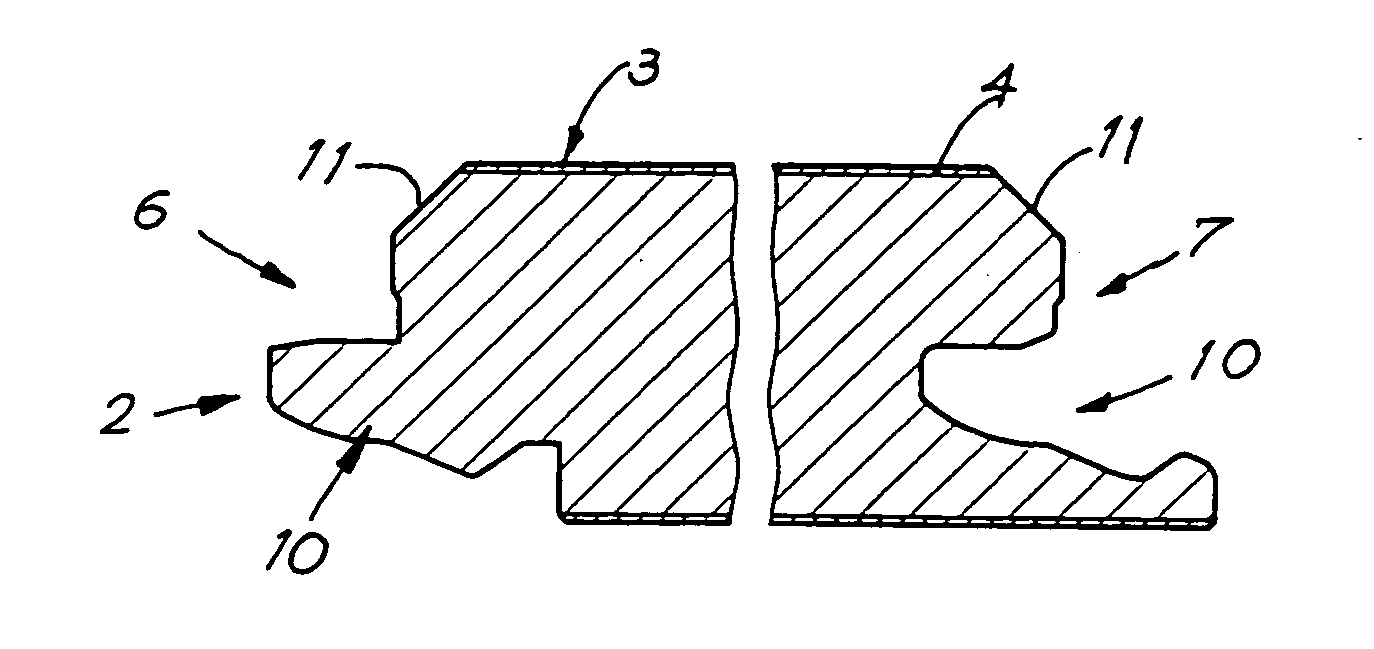

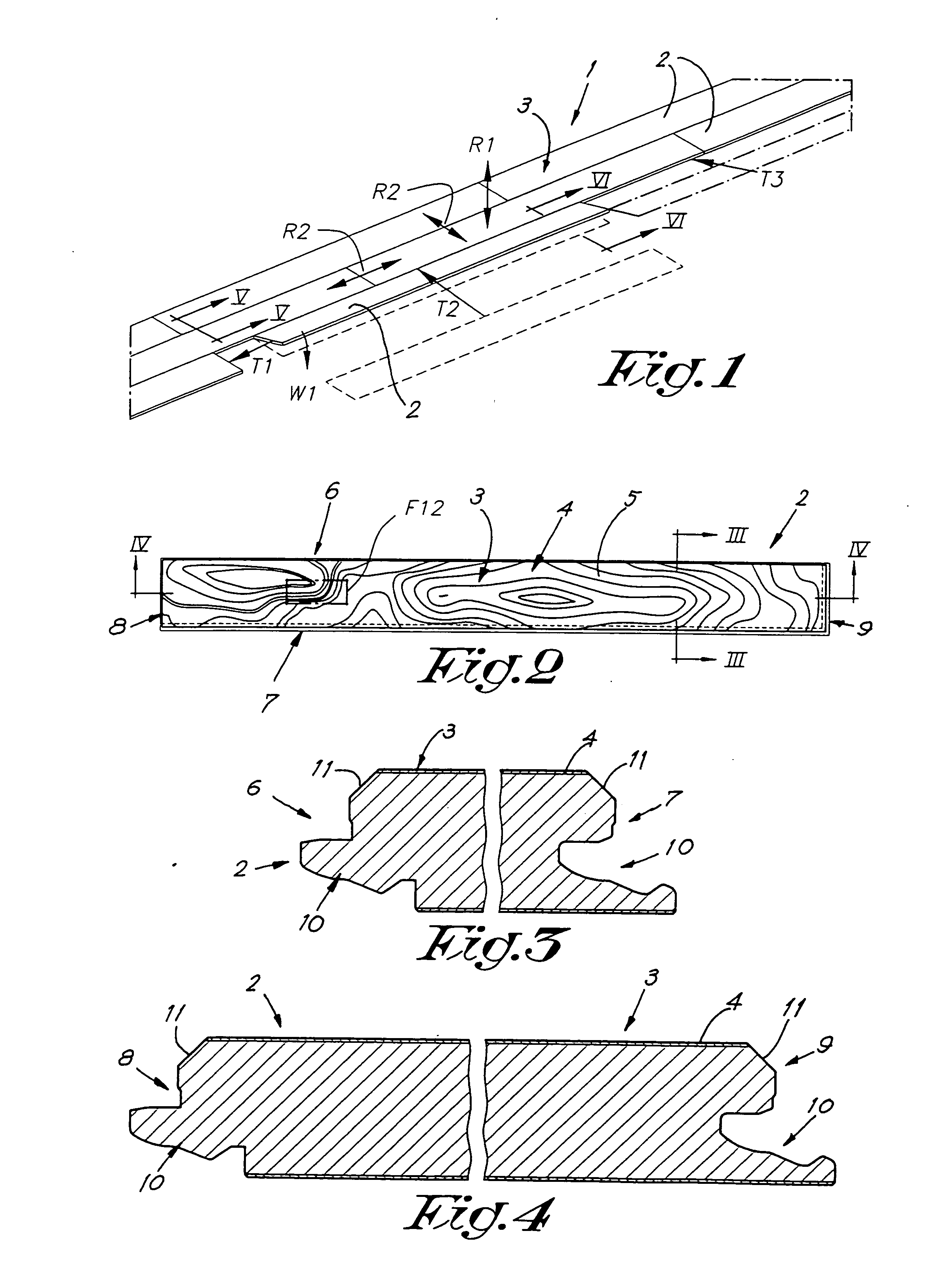

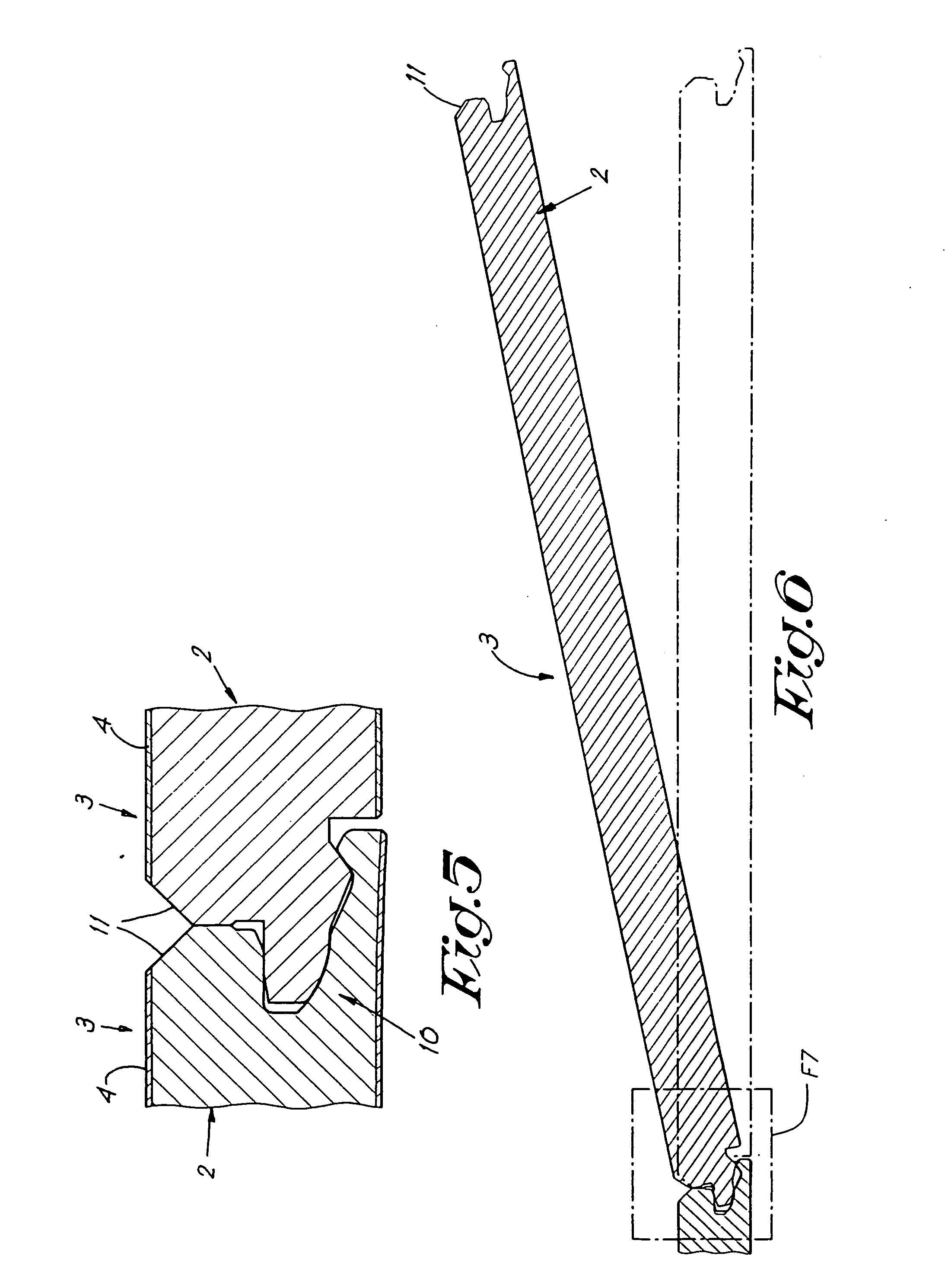

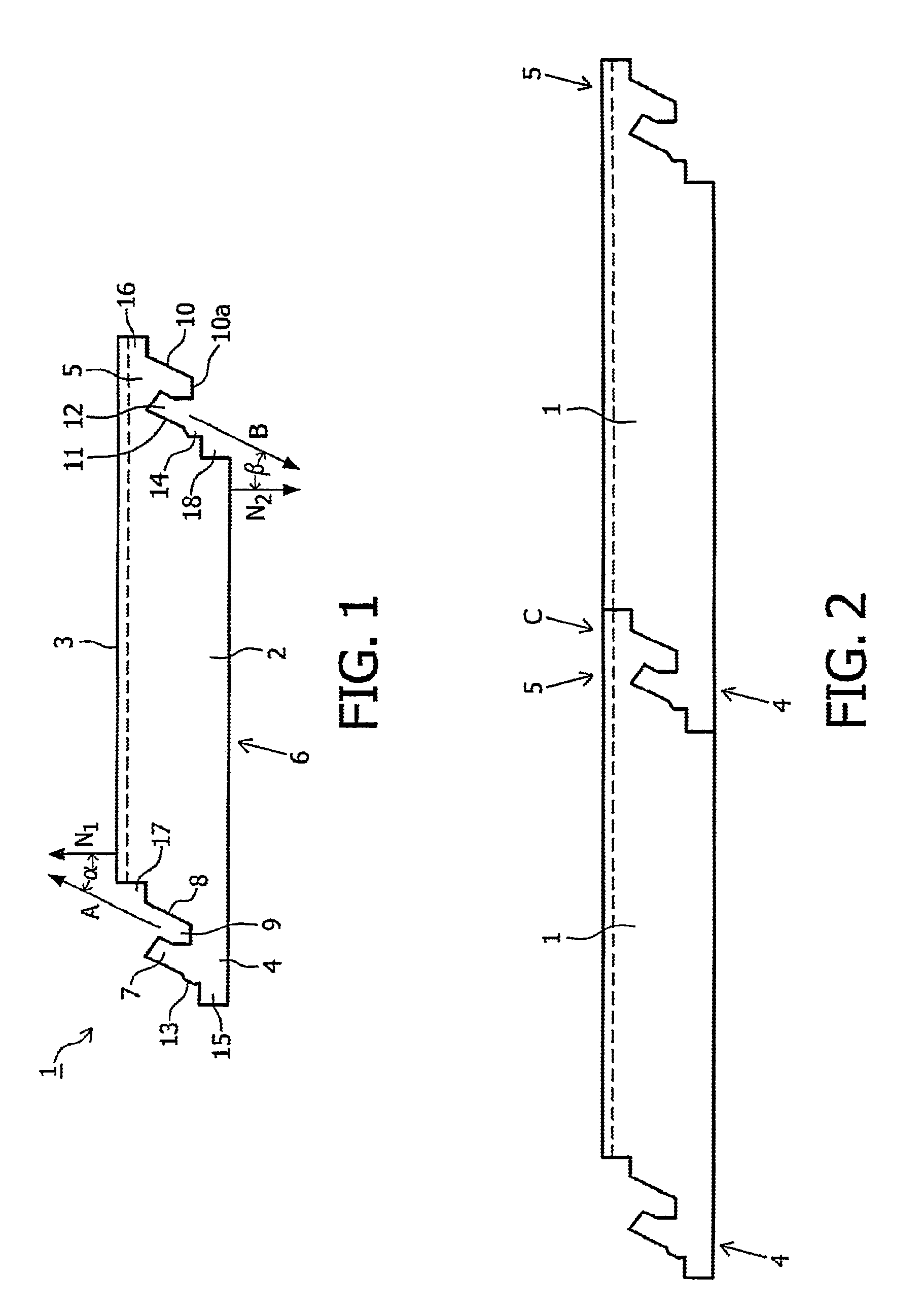

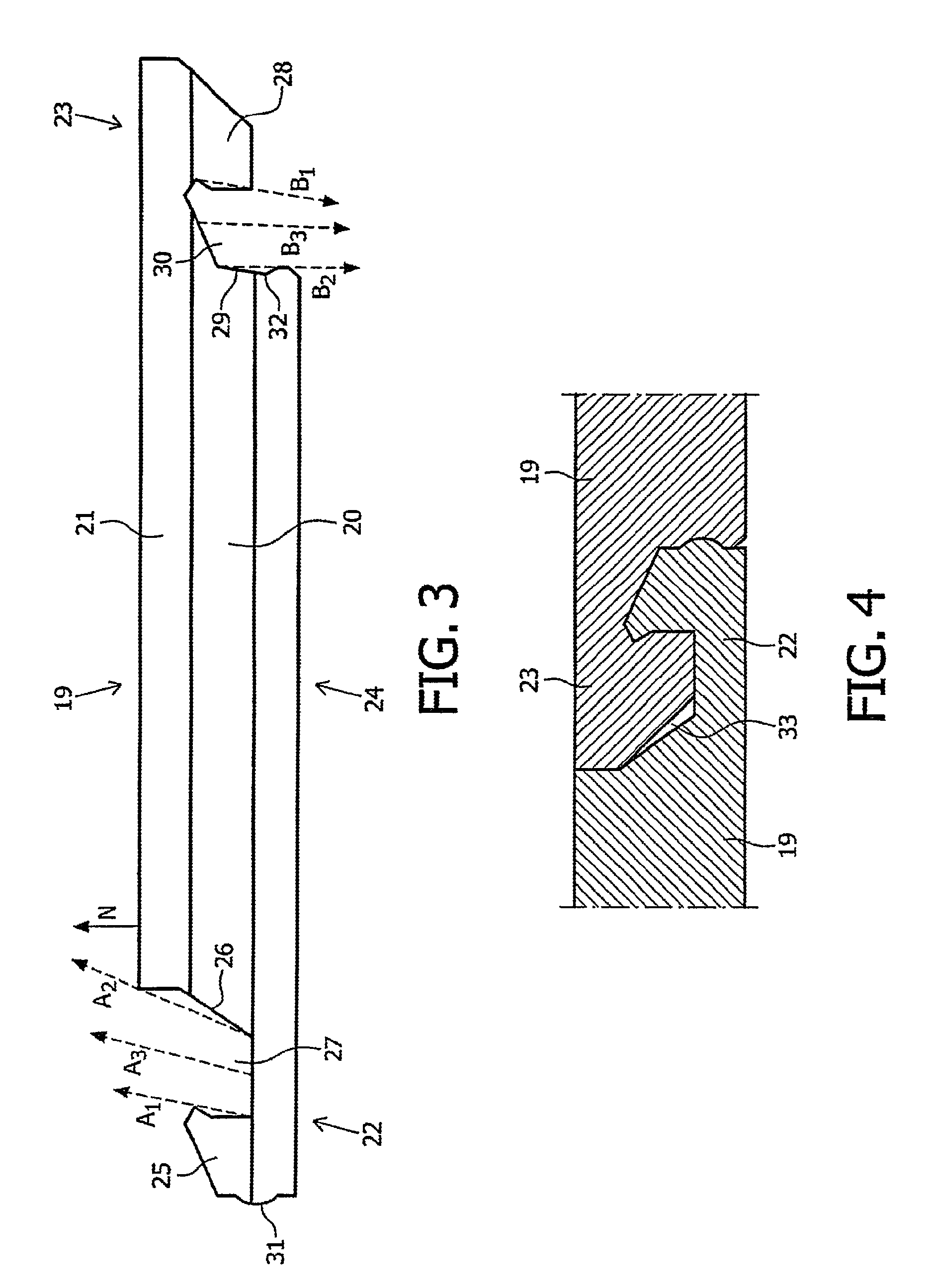

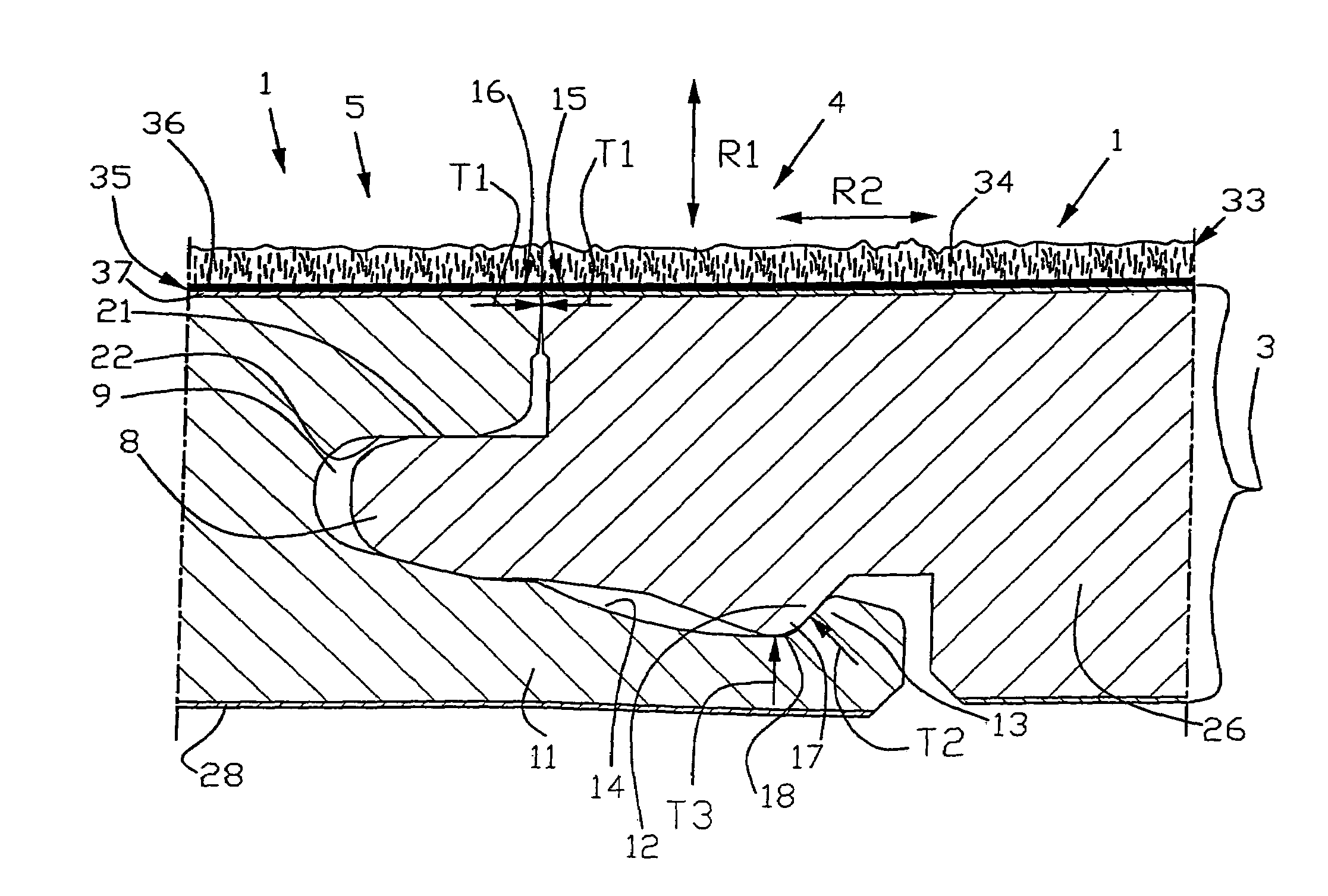

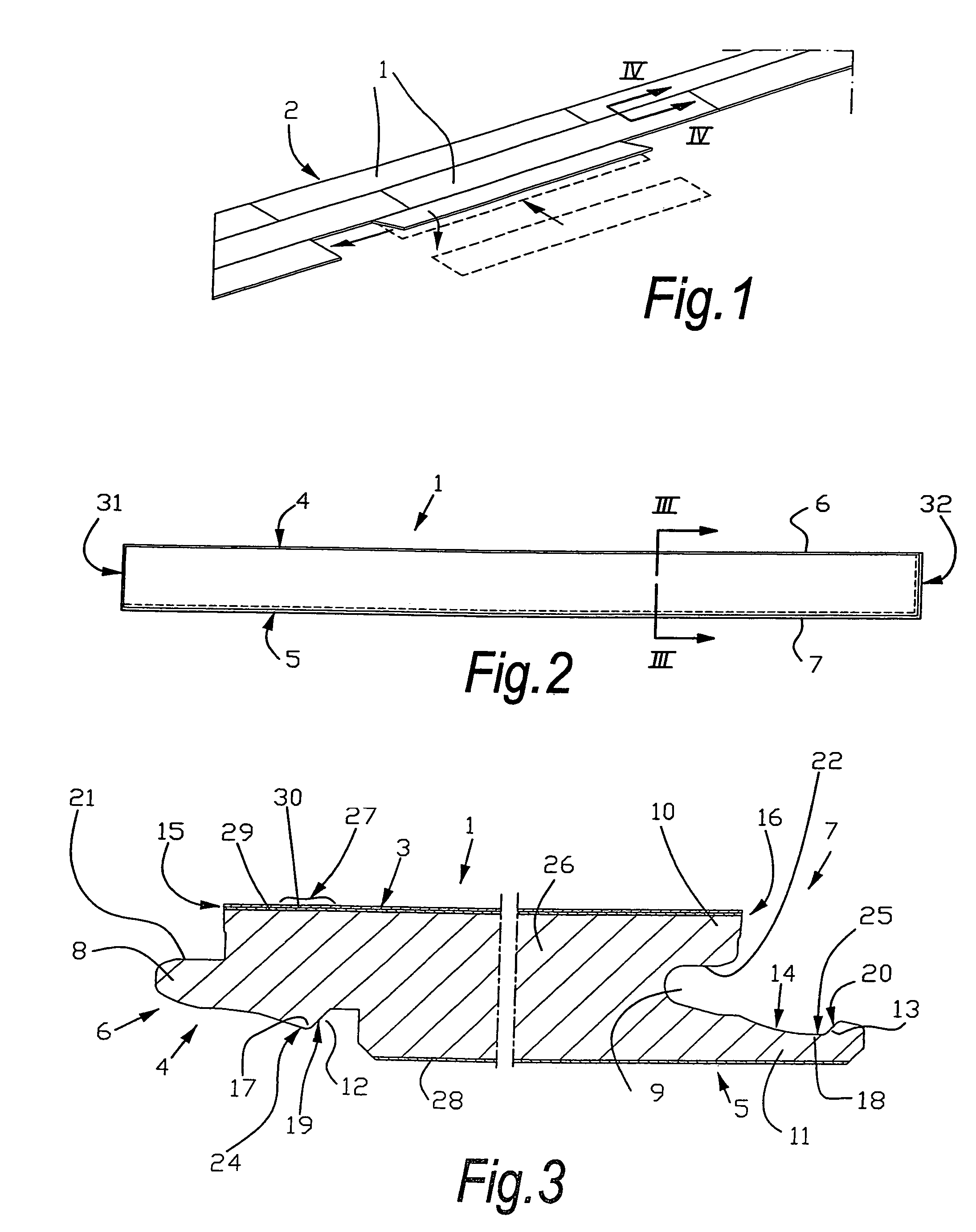

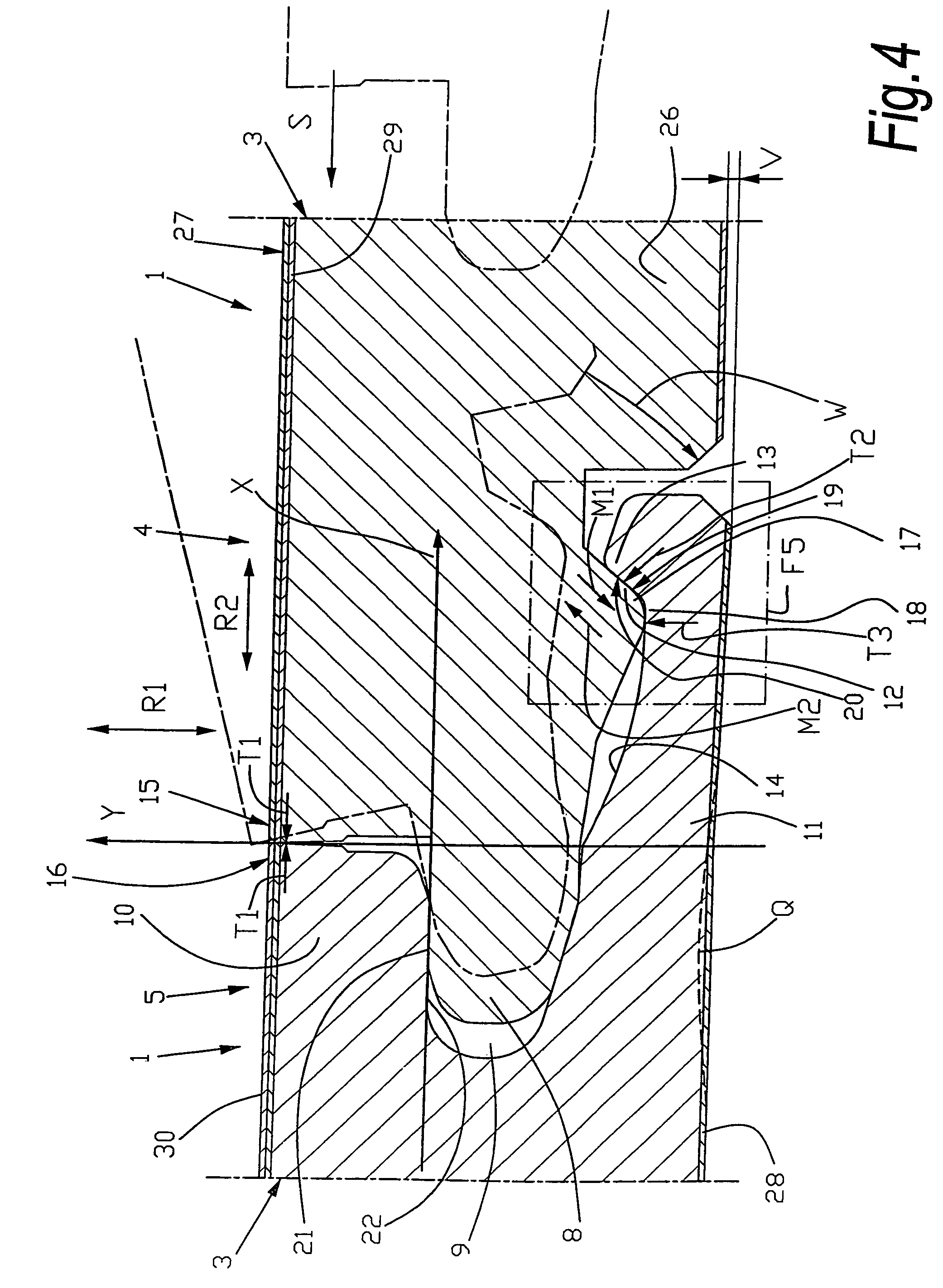

Floor panel which is provided with means for releasably connecting at least two panels, it being the case that a tongue is formed to extend in the longitudinal direction of the side edge and corresponding recess is formed opposite it, that the recess comprises a top lip and a bottom lip, and the bottom lip forms a shoulder with a front shoulder side, said shoulder blocking the panels in the transverse direction (Q), that an undercut is adjoined by a recess, with a bearing region which corresponds to the shoulder, and a wall, which, with the front shoulder side in the installed state, is located opposite the latter, and that corresponding form-fitting elements are formed on the wall and the front shoulder side, said form-fitting elements, in the installed state, engaging one inside the other and bringing about locking in the vertical direction (V), and an underside of the tongue and a top side of the bottom lip runs parallel to the top side.

Owner:VÄLINGE INNOVATION AB

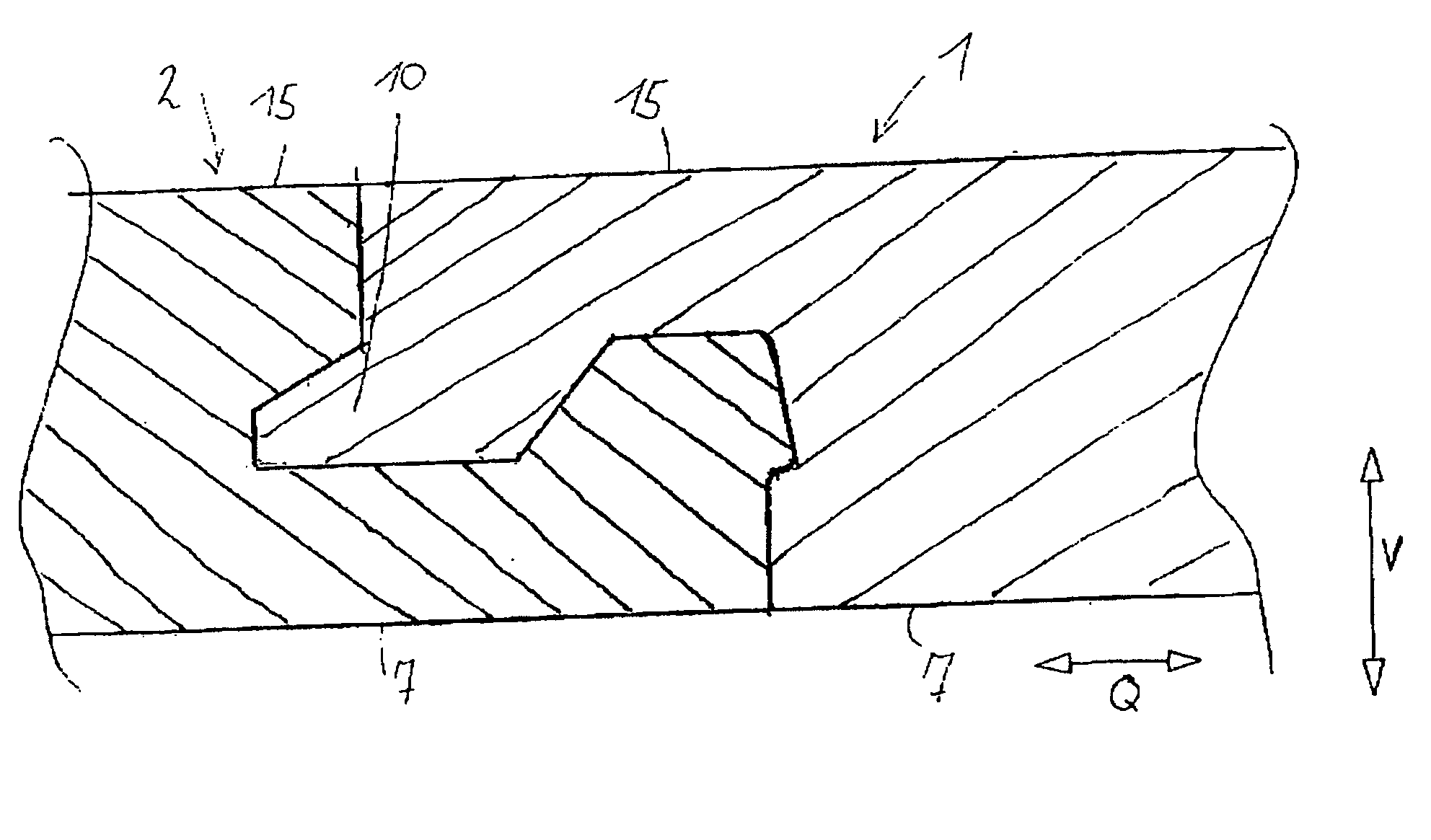

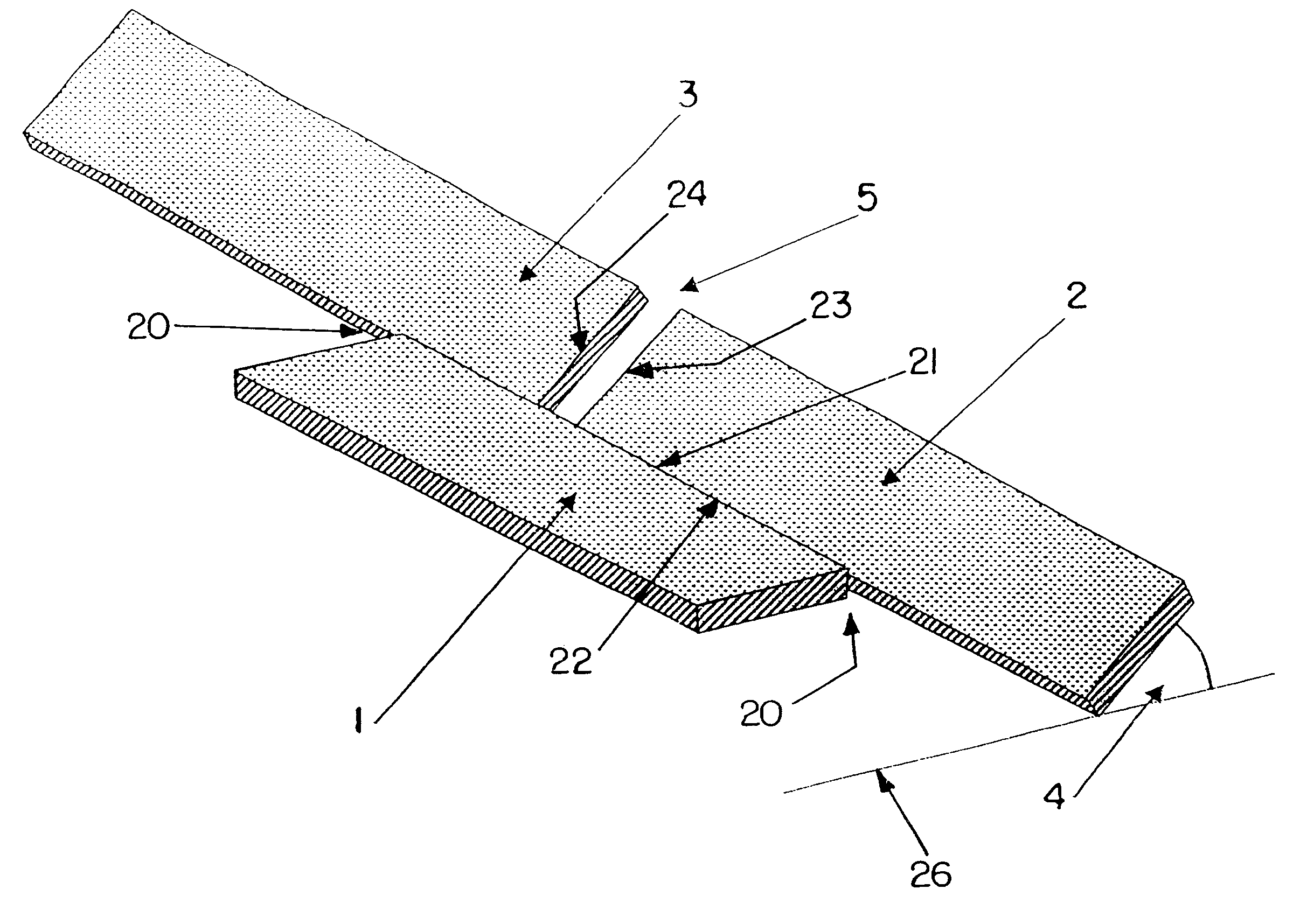

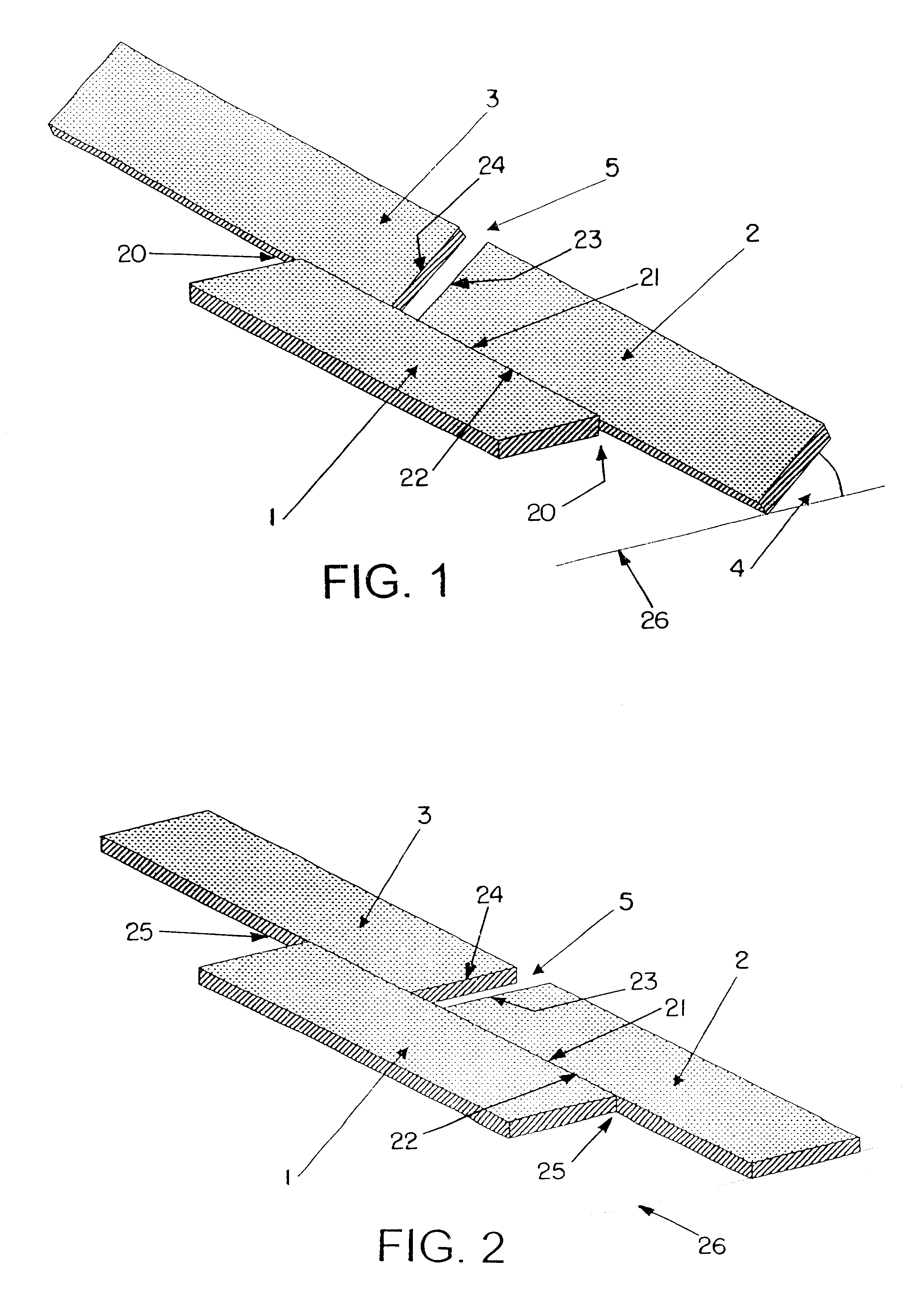

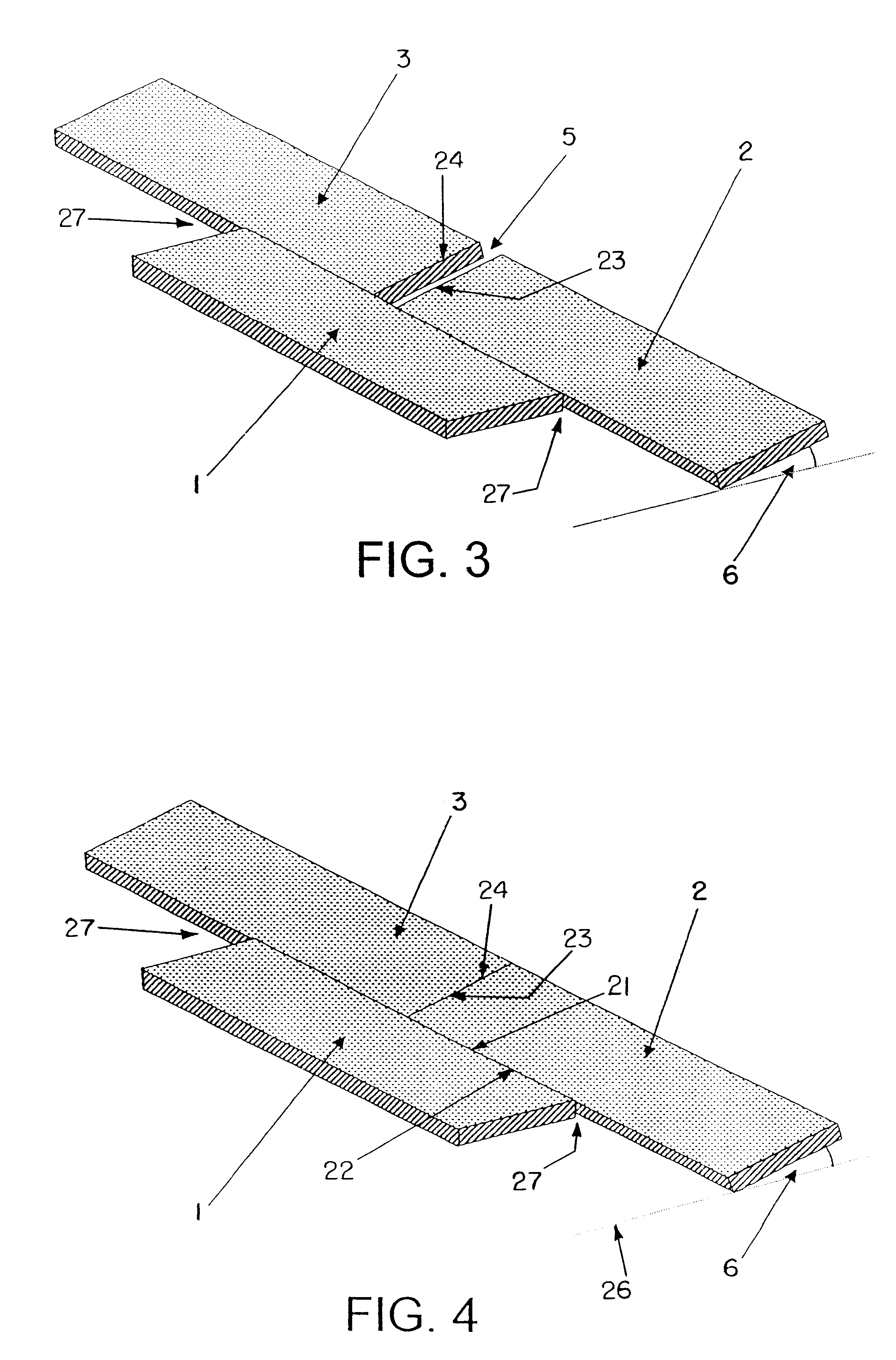

Method of laying panels

InactiveUS6546691B2Increase displacementAvoid the needRoof covering using tiles/slatesWallsEngineeringMutual position

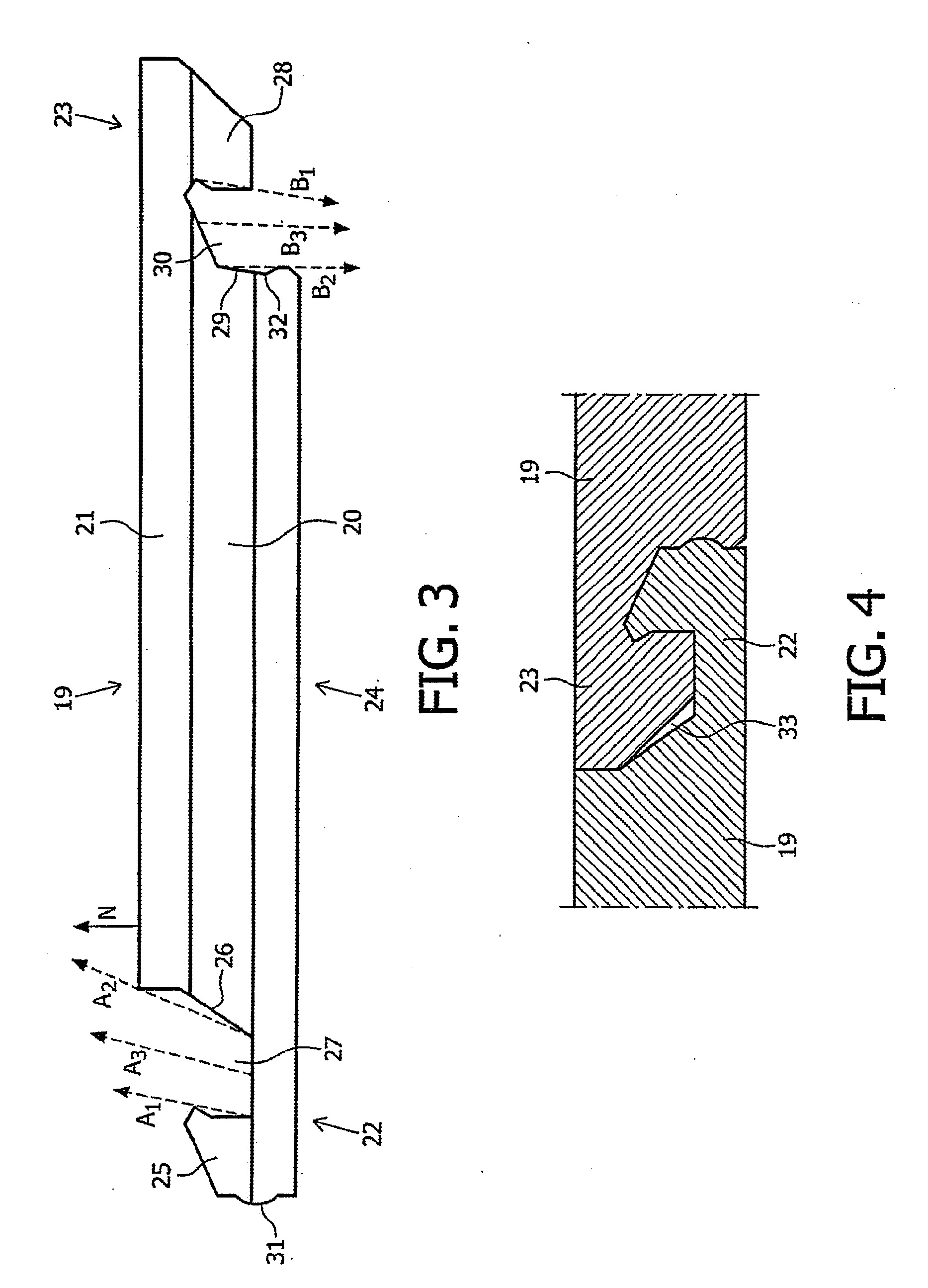

The present invention provides a method of laying and mechanically joining panels, especially floor panels. In a first step a first panel is already located in a first row. A second panel is positioned in a second row in a first position in relation to the first panel. A third panel is now brought into the second row and into the first position in relation to the first panel. In this position, there is a mutual distance between the adjacent edges of the second and third panel. In a second step the second and third panel are angled into the third mutual position in relation to the first panel. Thereby, the second and third panel each achieve the possibility of easy displacement in the third direction in relation to the first panel. In a third step one or both of the second and third panel are moved in relation to the first panel. By this displacement the second and third panel get in a second position in relation to each other. An additional intermediate step may be employed between the first and the second step. In this intermediate step the second and third panel are angled down into the second mutual position in relation to the first panel.

Owner:KRONOSPAN TECHN

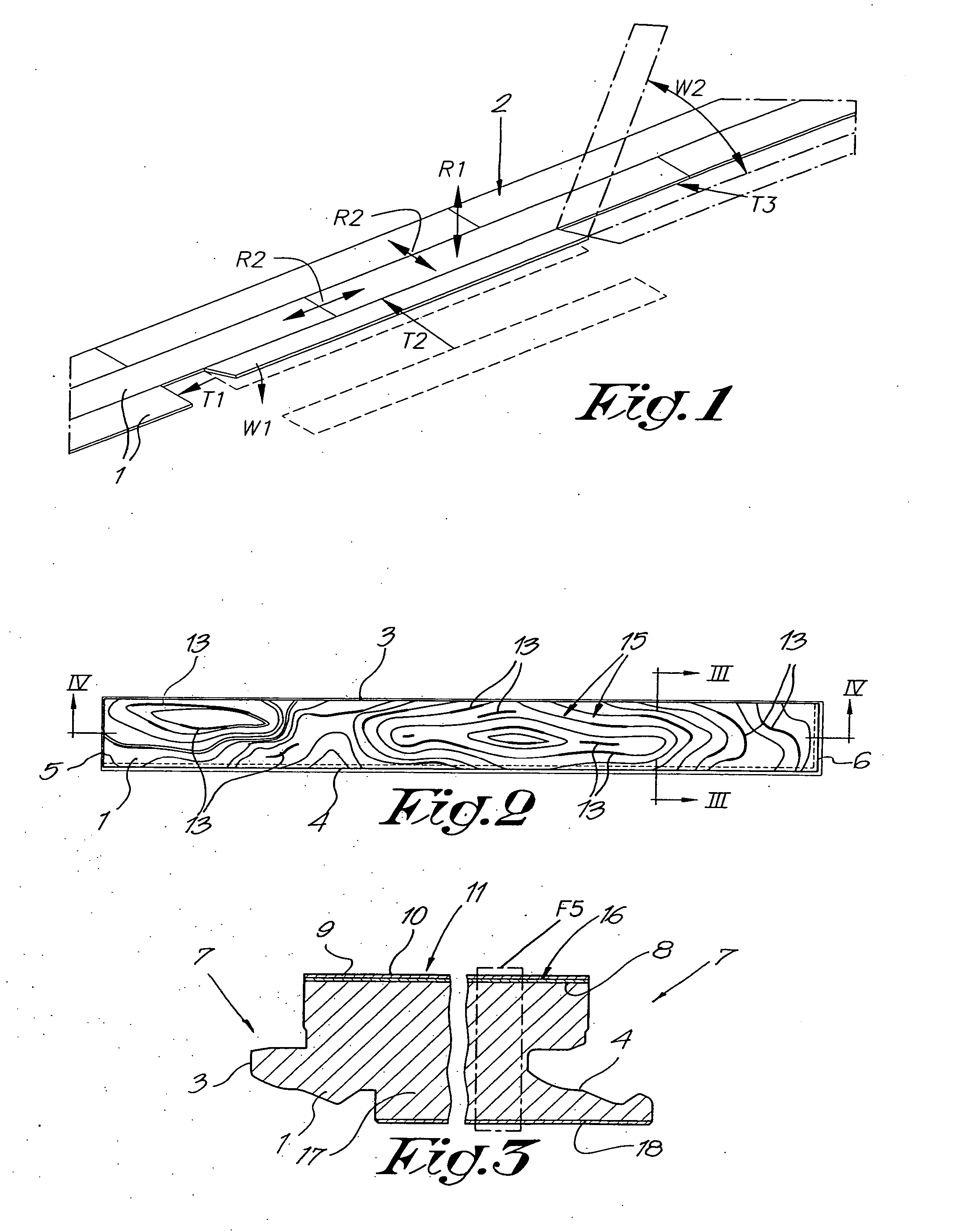

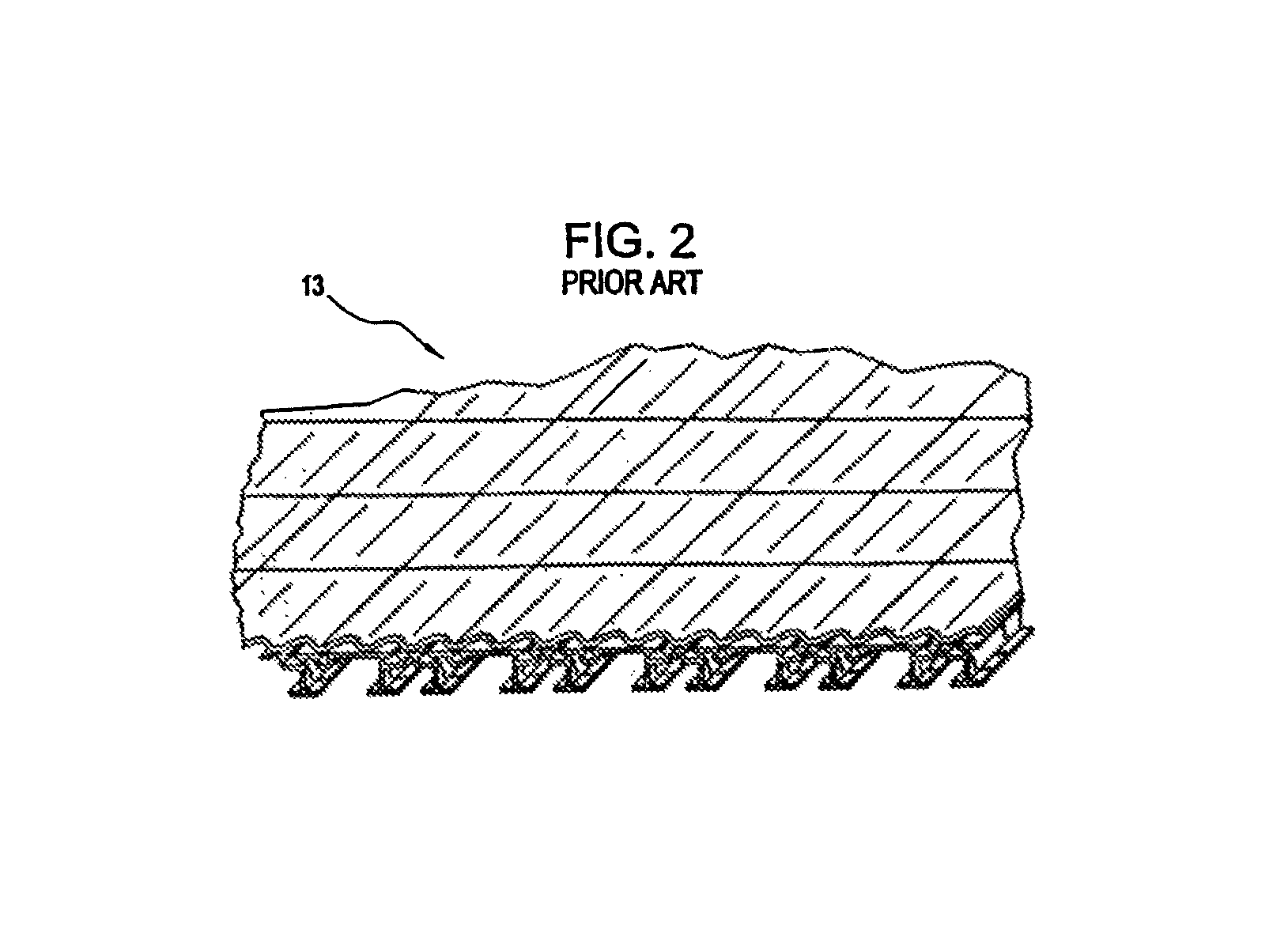

Floor panel and method for manufacturing such floor panels

Floor panel, of the type consisting of a laminate panel which comprises at least a printed decorative layer (8) and a top layer (9) forming the upper surface (10) of the floor panel (1), more particularly a so-called overlay, whereby this top layer (9), or, thus, overlay, is realized on the basis of a thermosetting resin, characterized in that in the upper side (11) of the floor panel (1), indentations (12) are formed and in that at last in a number of these indentations (12), a component (13) is provided, which is obtained in that it has been provided in those indentations (12) after the provision of the indentations (12).

Owner:FLOORING IND LTD

Floor covering, floor panels for forming such floor covering, and method for realizing such floor panels

InactiveUS20050025934A1Improvement of imitationReduce disadvantagesCovering/liningsNatural patternsSynthetic materialsPanelling

Floor covering, consisting of hard panels, with a laminated structure, whereby at least at the upper surface a printed decorative layer with a wood pattern is present, with thereupon a transparent layer of synthetic material in which impressions are formed, wherein the impressions substantially follow the wood pattern.

Owner:FLOORING IND LTD

Composite joinery

Owner:NCI GROUP

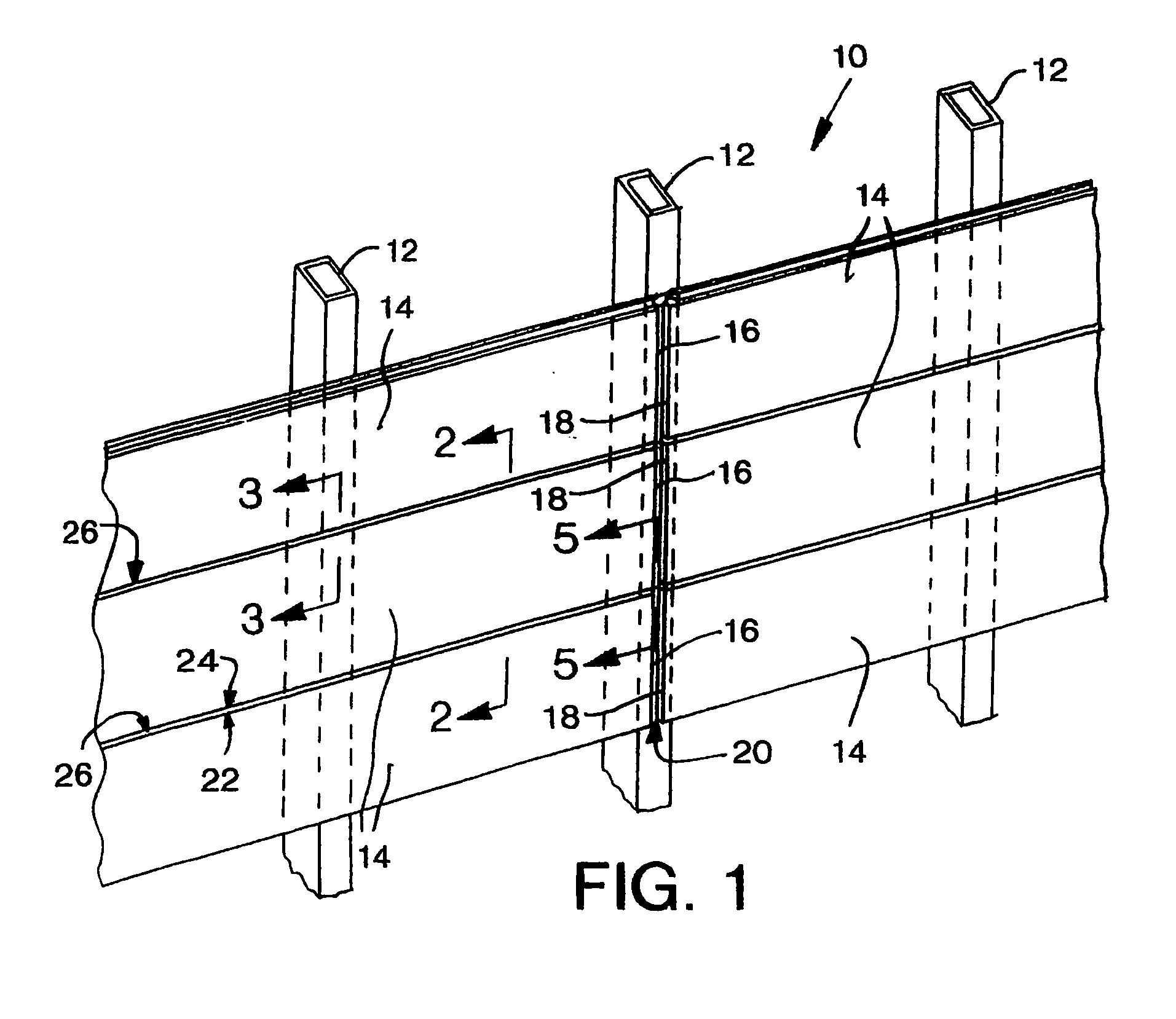

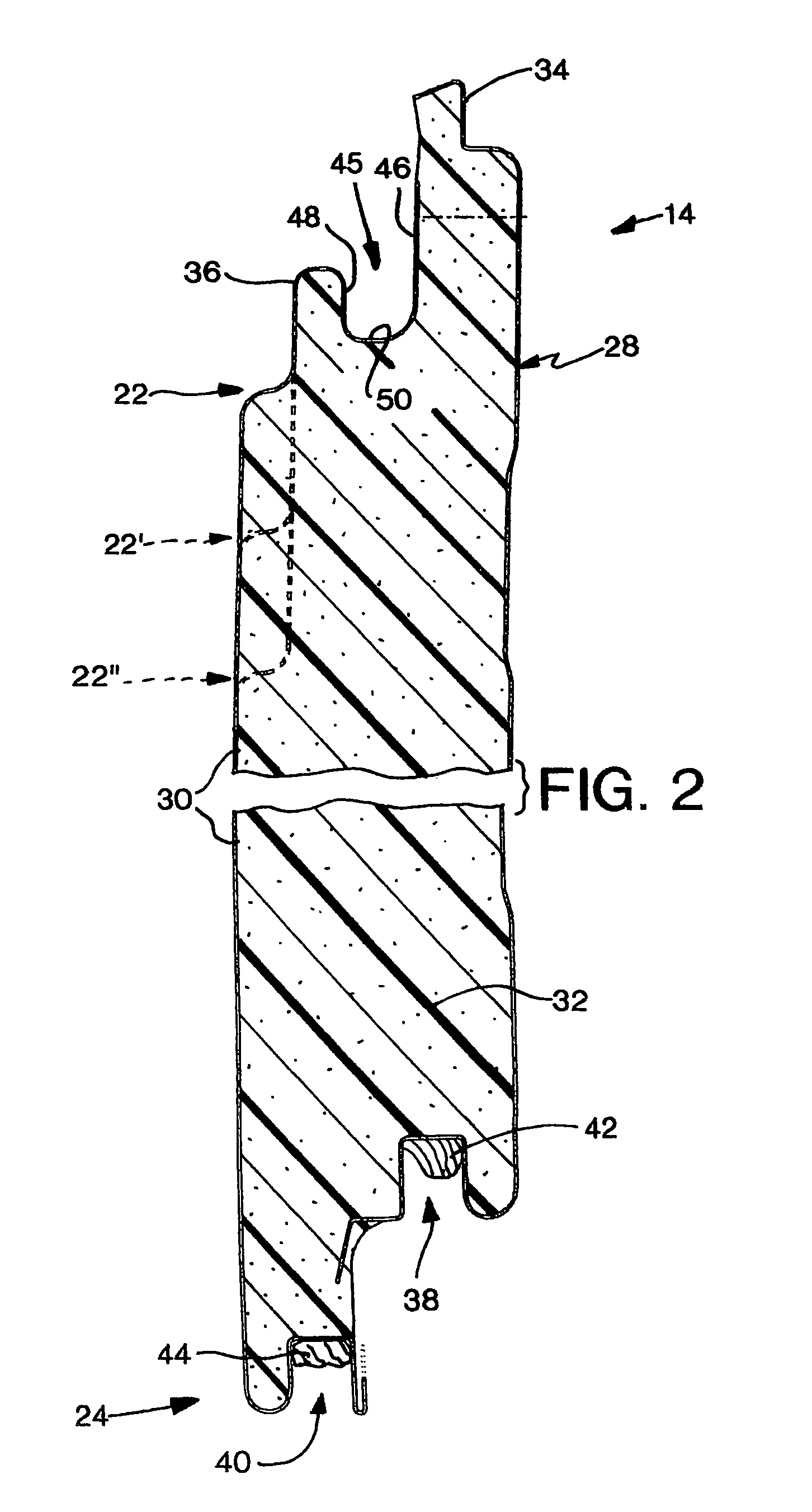

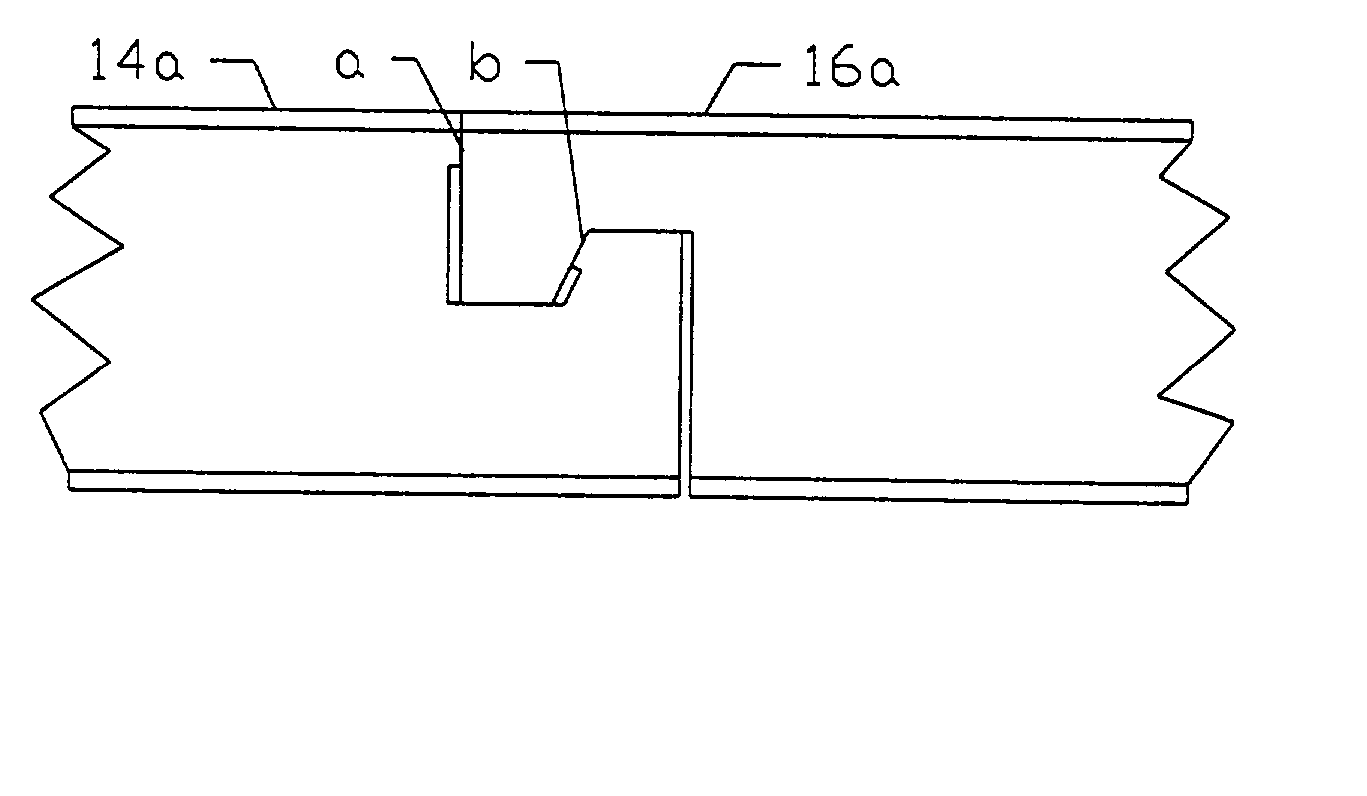

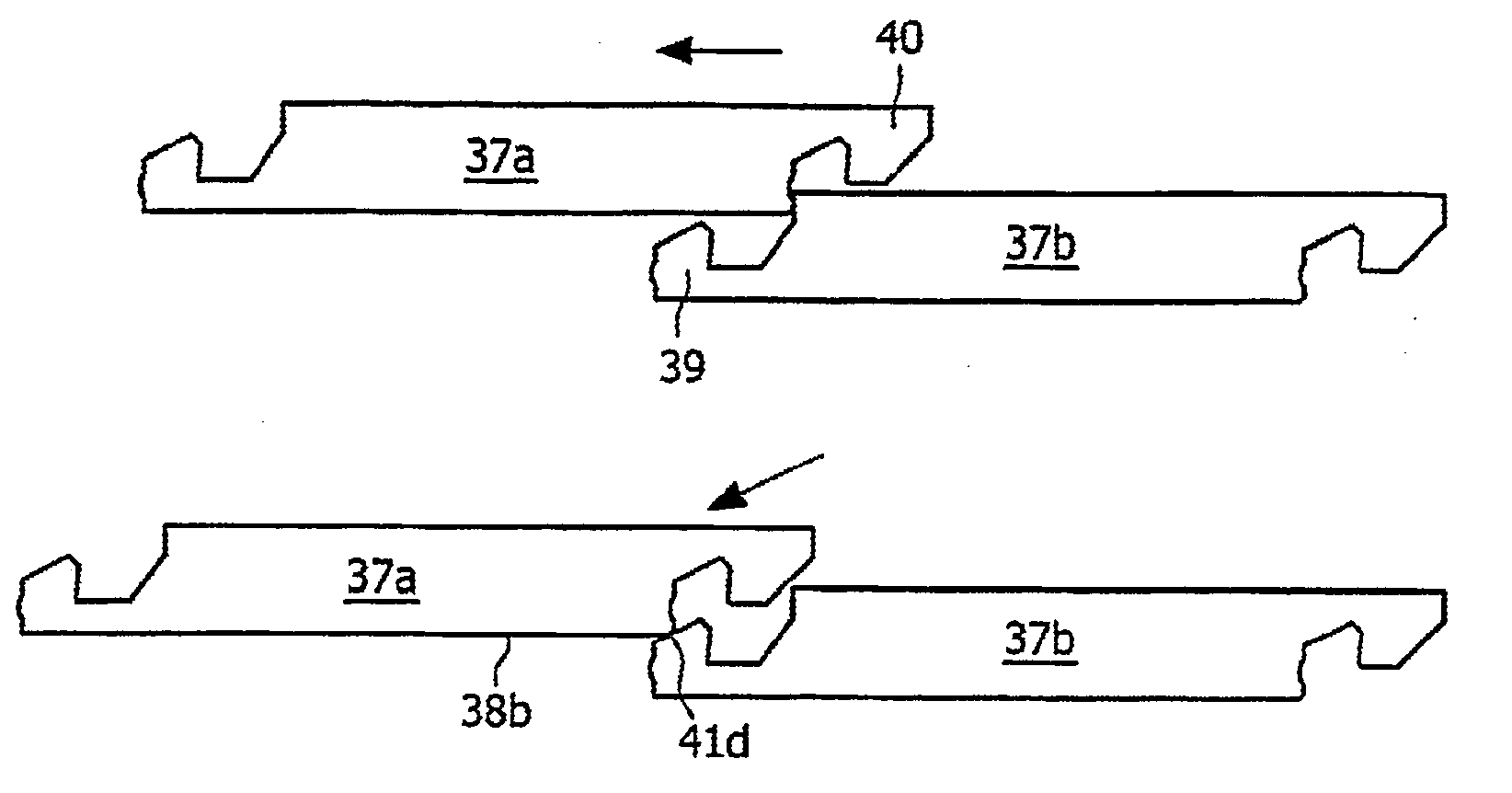

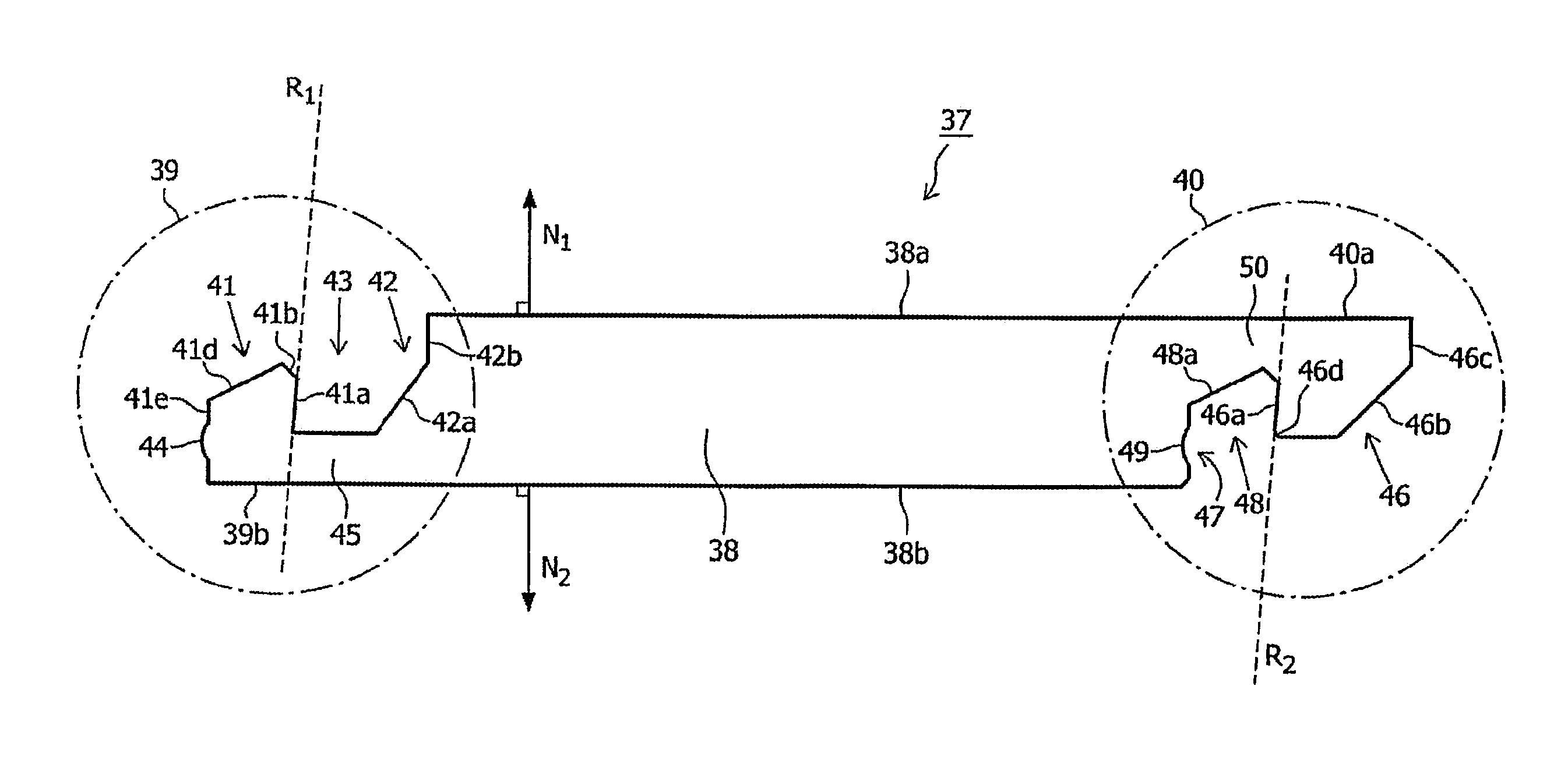

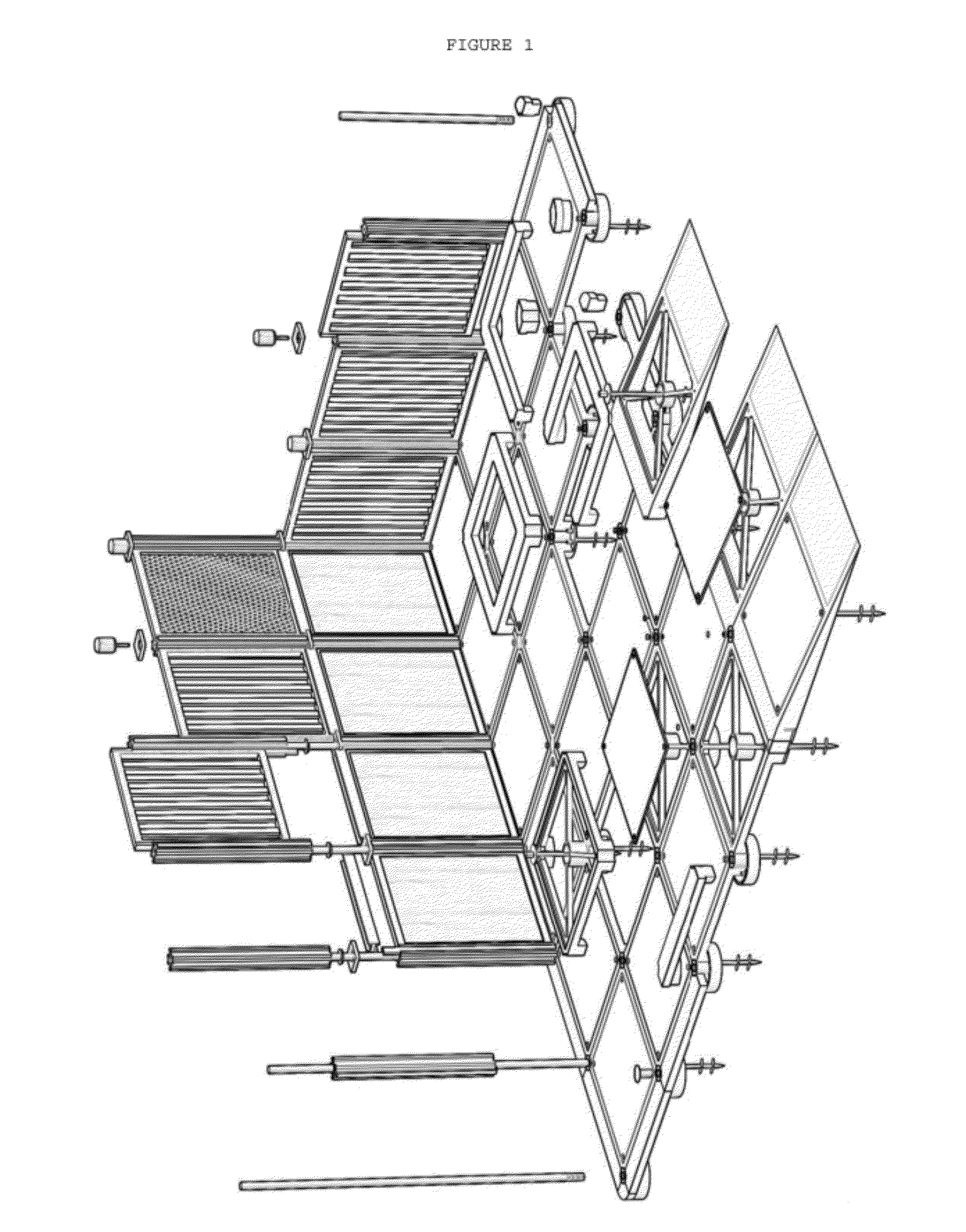

Method and apparatus for interconnecting paneling

A paneling system is provided herein that concerns interconnecting panels with opposite connecting sides of substantially tongue in groove joint couplings and opposing adjacent connecting sides that are of substantially hook-joint coupling. The hook joint hinders lateral motion while permitting movement in a direction perpendicular to the plane of the interconnected panels to provide ease of installment and removal. The hook joints also provide proper alignment and spacing between panels.

Owner:EVJEN JOHN M

Floor panel and methods for manufacturing floor panels

ActiveUS20130067842A1High densityHigh sensitivityCovering/liningsDecorative surface effectsPanellingEngineering

In a method for manufacturing floor panels that have at least a substrate and a top layer provided on the substrate, the top layer including a thermoplastic layer that is translucent or transparent, the method may involve providing the top layer, including the thermoplastic layer, on the substrate. The method may also involve heating at least the thermoplastic layer, and structuring the thermoplastic layer using a mechanical press element.

Owner:FLOORING IND LTD

Floor Panel and Floor Covering Consisting of a Plurality of Such Floor Panels

ActiveUS20120180416A1Increased durabilityEnhanced couplingConstruction materialFloorsPanellingEngineering

The invention relates to a floor panel; in particular a laminated floor panel. The invention also relates to a floor covering consisting of a plurality of mutually coupled floor panels according to the invention. The invention further relates to a method for mutually coupling two floor panels, in particular laminated floor panels, according to the invention.

Owner:I4F LICENSING NV

Floor panel and floor covering consisting of a plurality of such floor panels

ActiveUS8745952B2CouplingEnhanced couplingRoof covering using tiles/slatesBuilding repairsEngineeringFloor covering

The invention relates to a floor panel; in particular a laminated floor panel. The invention also relates to a floor covering consisting of a plurality of mutually coupled floor panels according to the invention. The invention further relates to a method for mutually coupling two floor panels, in particular laminated floor panels, according to the invention.

Owner:I4F LICENSING NV

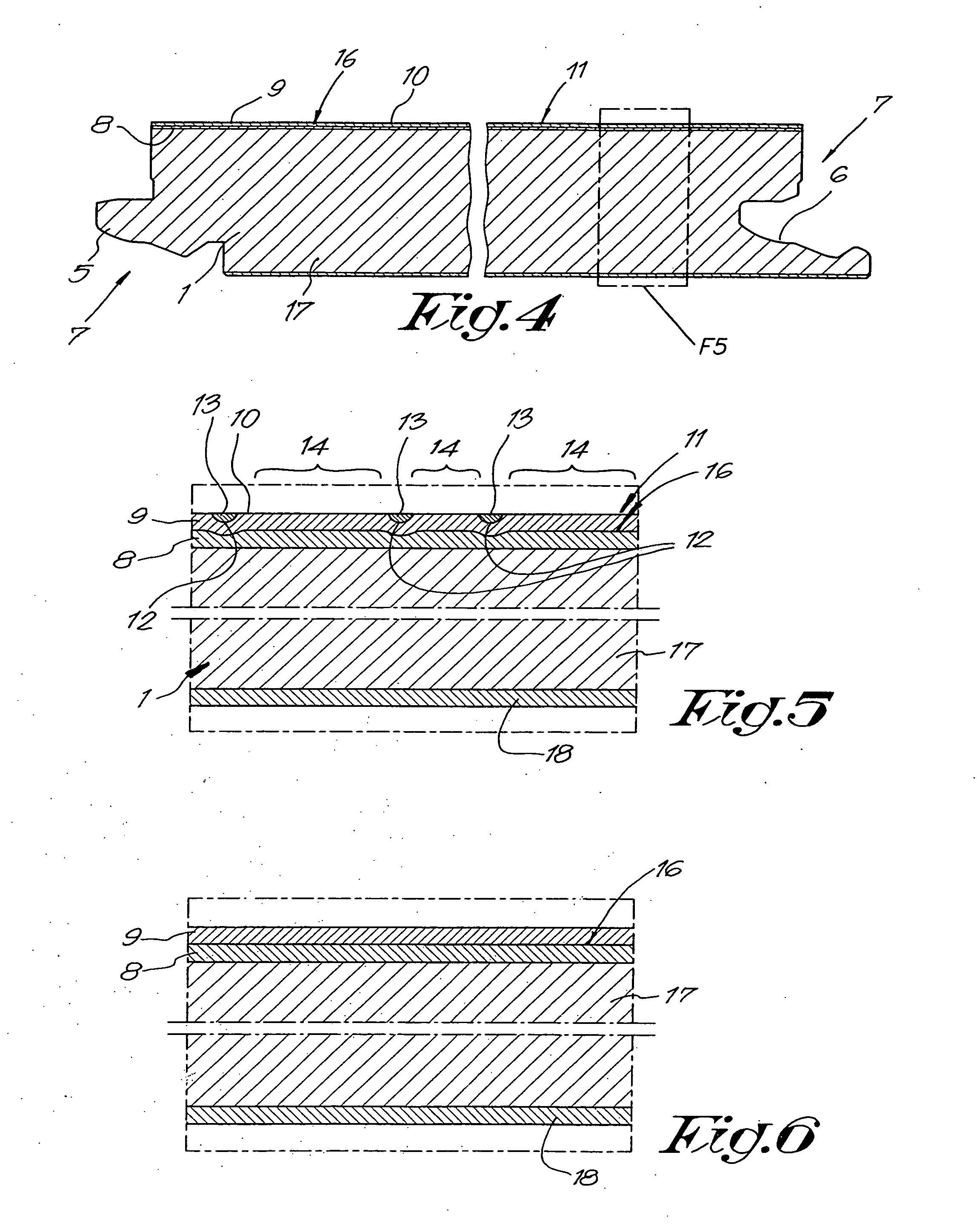

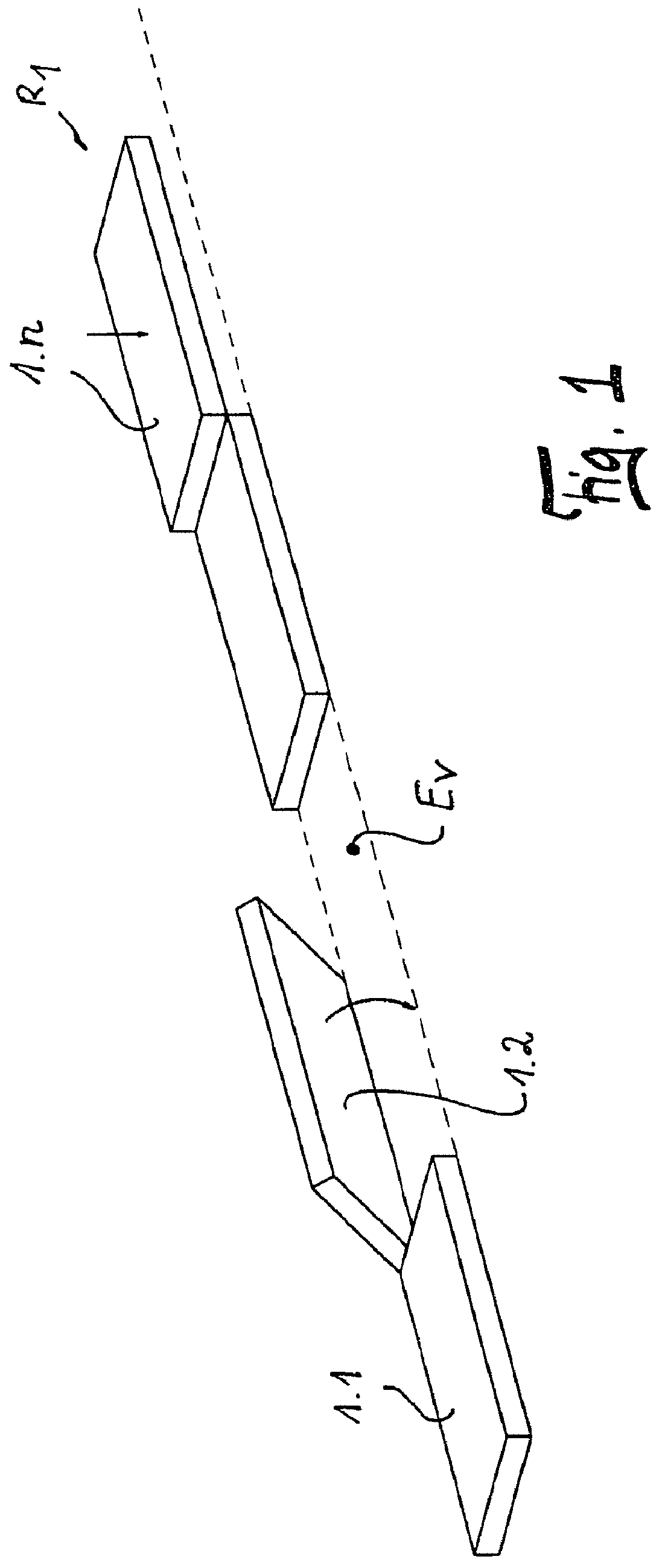

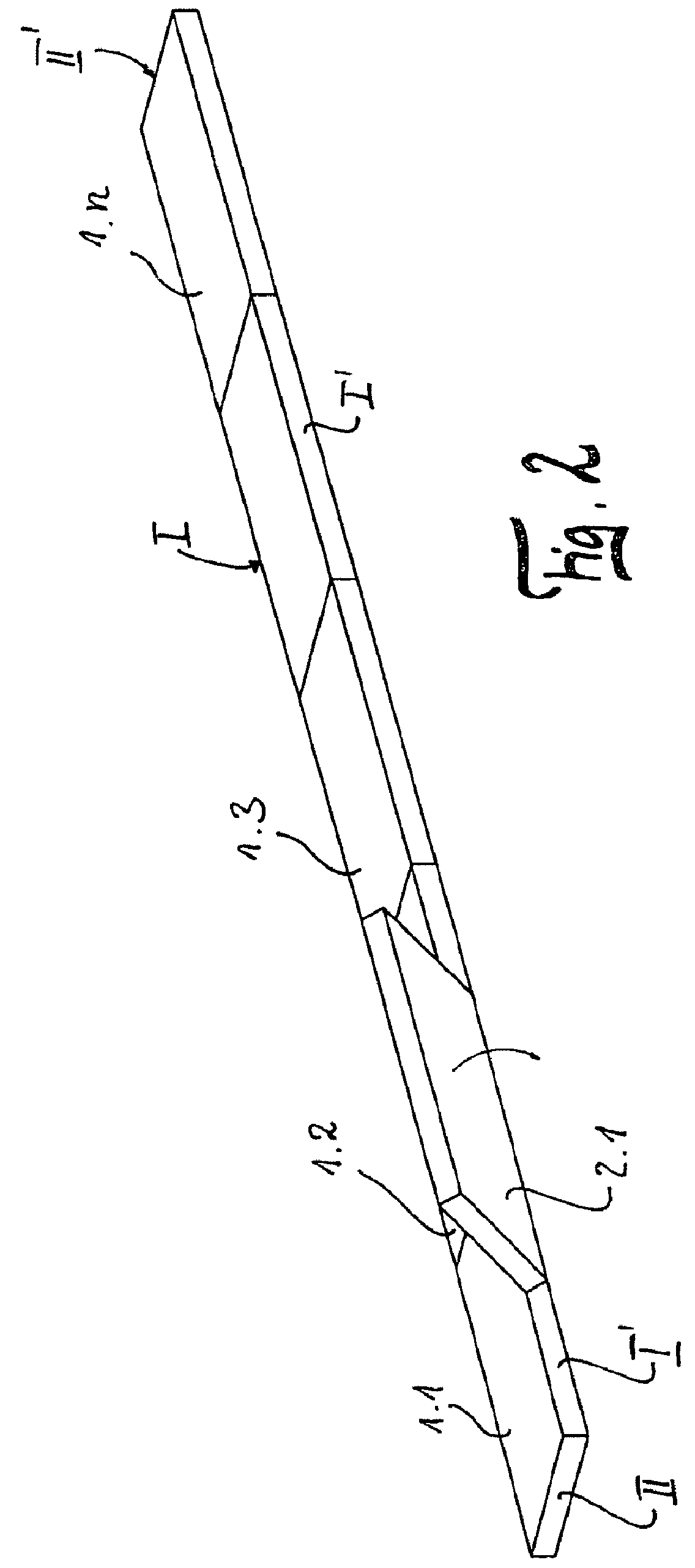

Method for laying floor panels

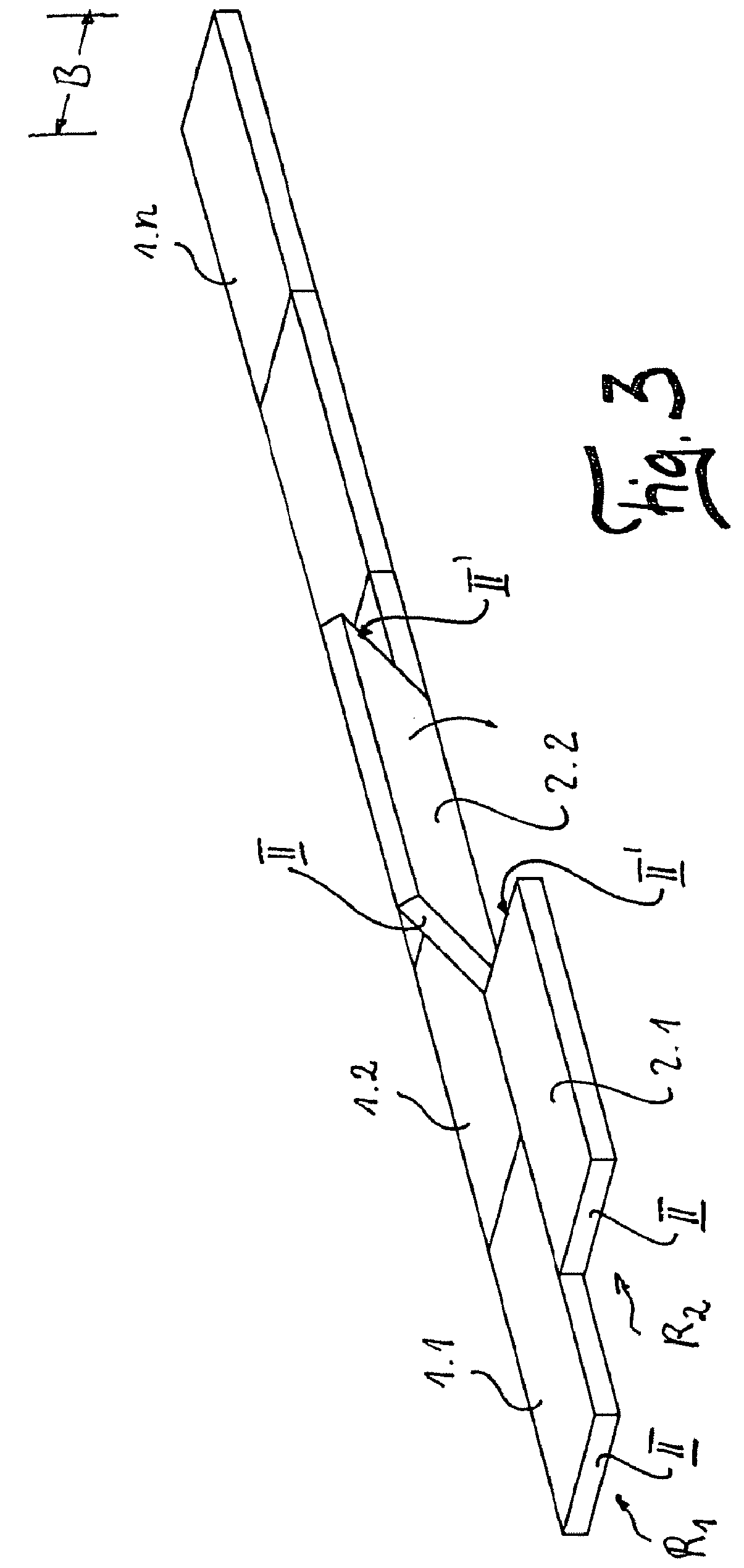

A method for laying floor panels in a room to form a closed floor area on a laying plane (R) without using an adhesive. The floor panels especially comprising a wood material, such as MDF or HDF, and having matching corresponding profiles on opposite longitudinal edges (I, I′) and transverse edges (II, II′). The closed floor area is obtained by interconnecting a plurality of panels on their transverse edges (II, II′) to give a row (R1) and on their longitudinal edges (I,I′) to give a plurality of rows (Rn) and then locking them in relation to each other.

Owner:FLOORING TECH

Floor panel and floor covering composed of such floor panels

ActiveUS7762035B2Counteract riskReduce riskRoof covering using tiles/slatesCovering/liningsPanellingMechanical engineering

Floor panel in a board shape having at least at two opposite edges coupling parts enabling several of the panels to be coupled to each other, wherein the coupling parts have contact portions forcing the floor panels in the coupled condition with a tension force at least laterally towards each other. The coupling parts also include support portions, which, in the coupled condition of floor panels, create a fixation in the mutual position of the contact portions cooperating under tension.

Owner:FLOORING IND LTD

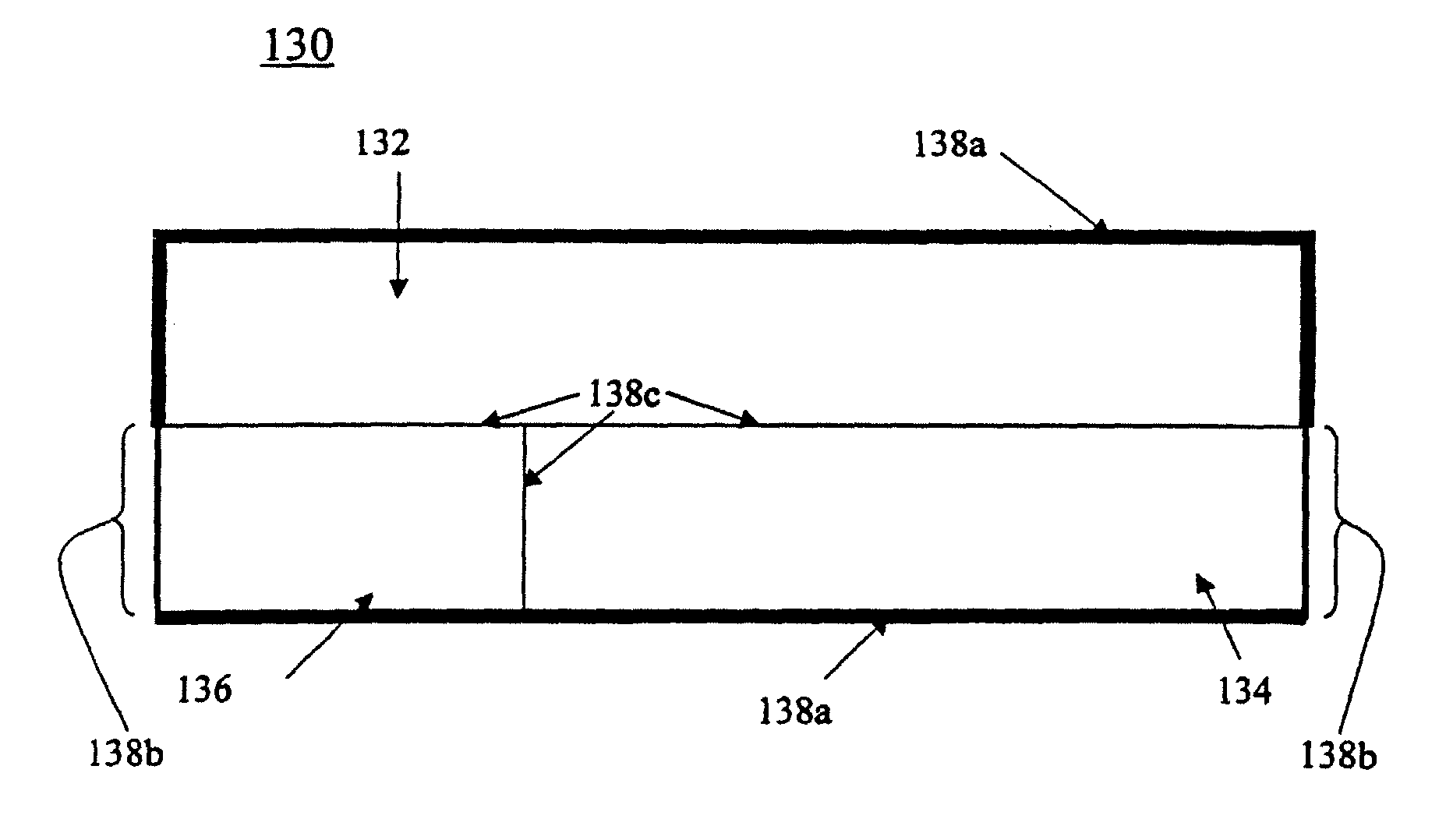

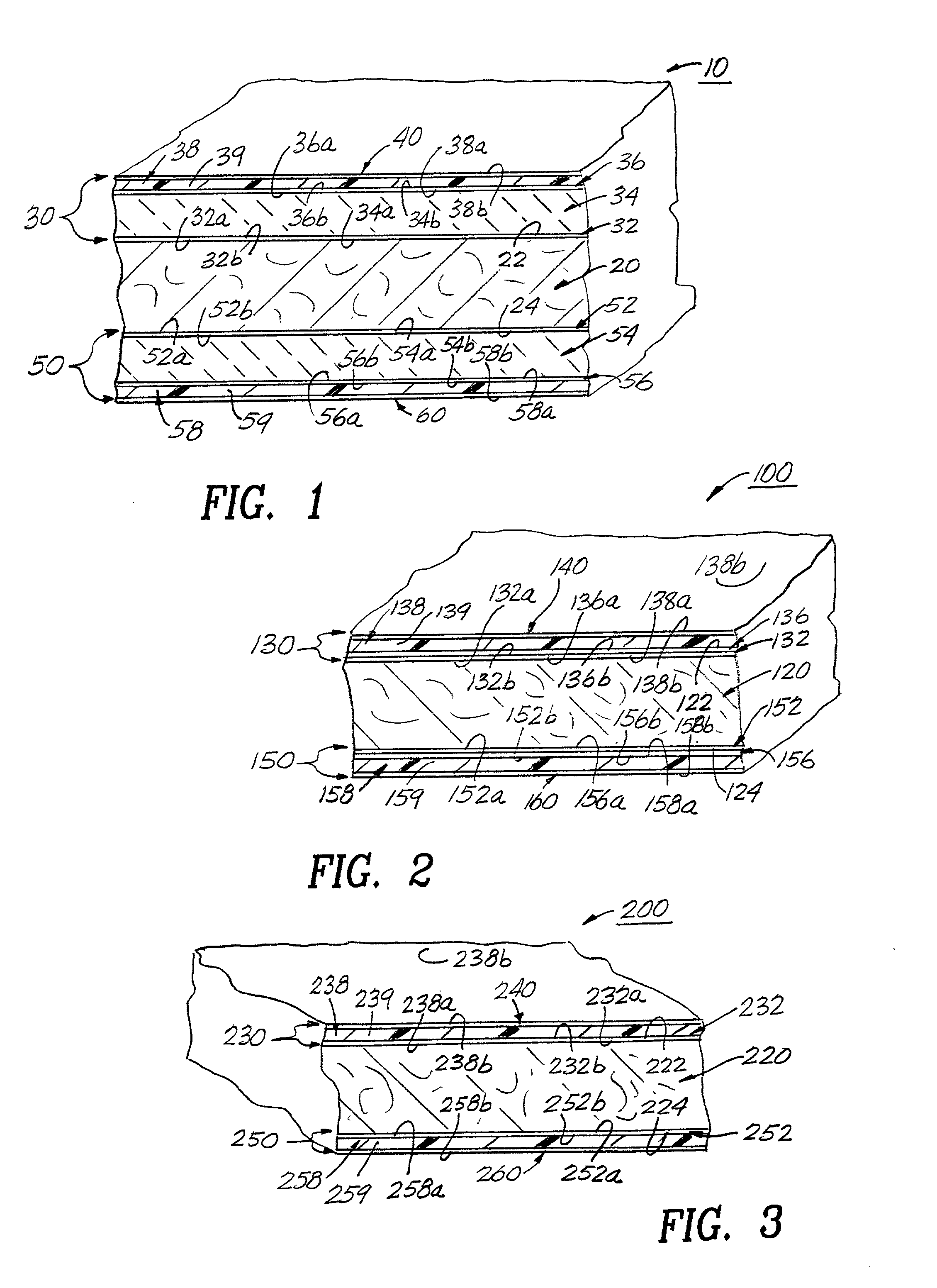

Integrally damped composite aircraft floor panels

Owner:THE BOEING CO

Flooring system having microbevels

Laminated flooring panels include decorative motifs, mechanically embossed-in-registration surface textures, recessed perimeters, and locking mechanisms. The locking mechanisms facilitate the alignment of adjacent flooring panels. Adjacent flooring panels substantially aligned allow embossed-in-registration patterns to be substantially continuous across adjacent flooring panels. The recessed perimeter prevents the edges of the flooring panel from prematurely wearing. Individual flooring panels within the flooring system may comprise at least one partial sub-panel having a decorative motif and / or embossed surface texture that is complementary with a decorative motif and / or embossed surface texture of a neighboring partial sub-panel.

Owner:FAUS GRP INC

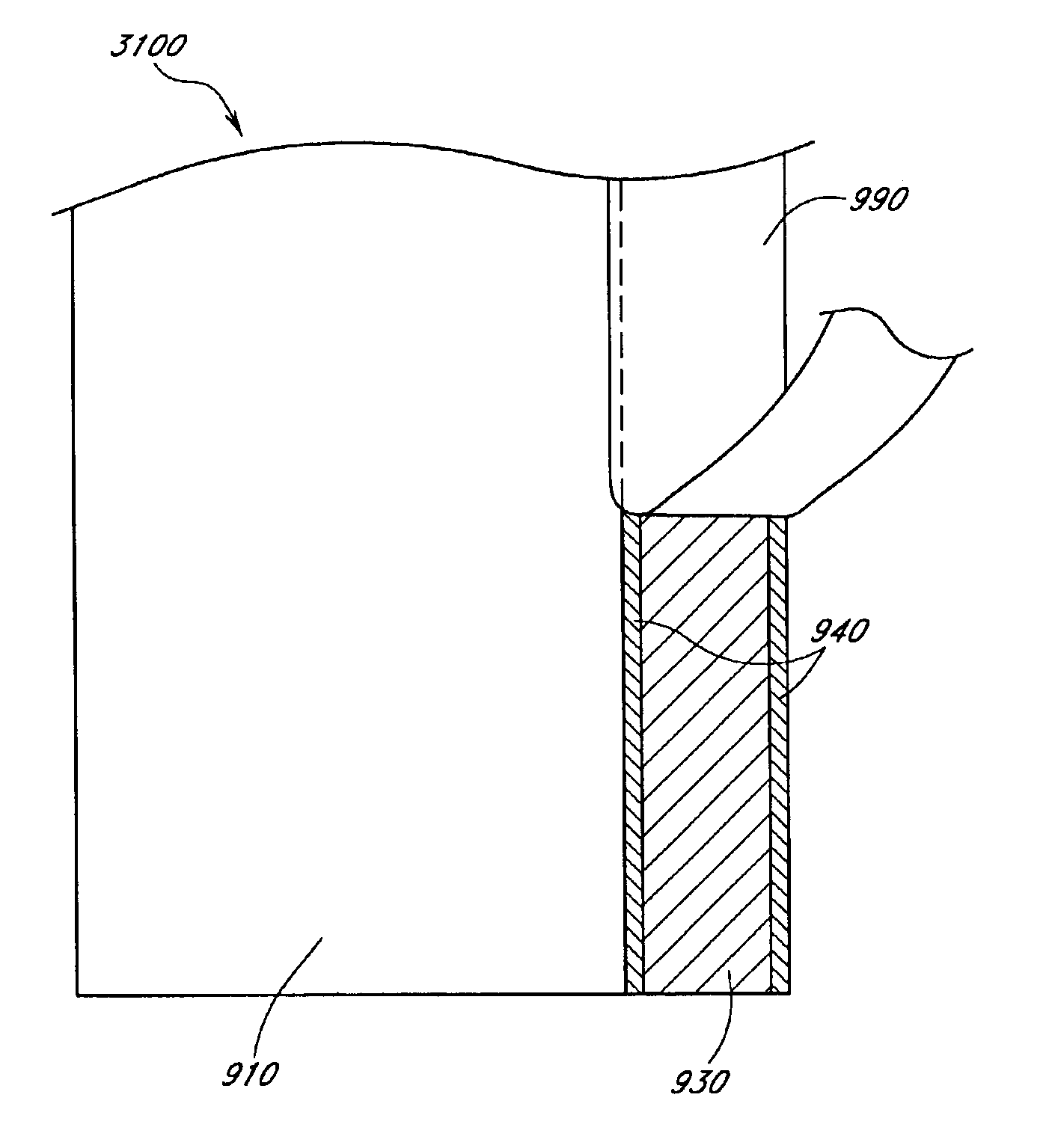

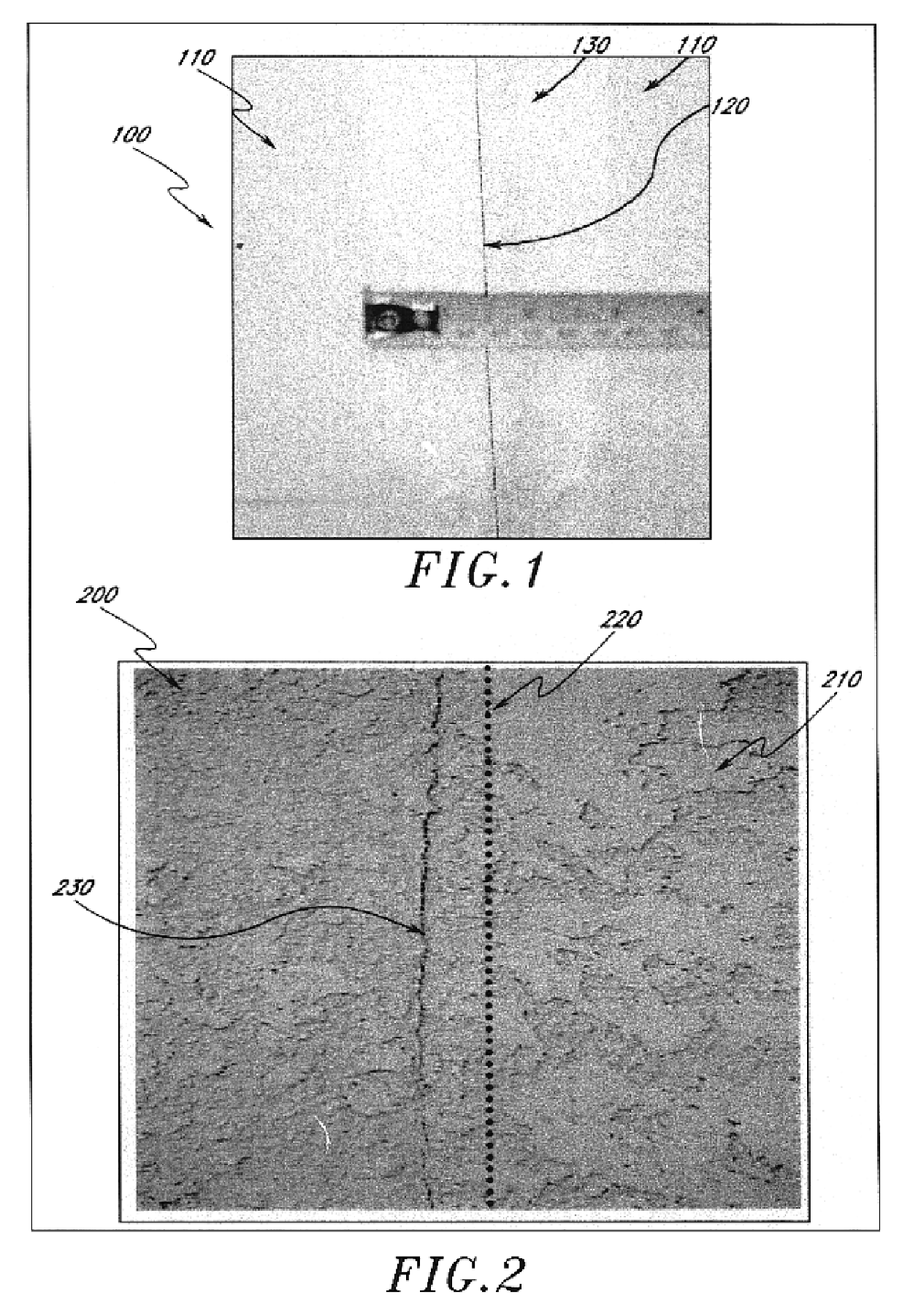

Panelized wall system utilizing adhesive-edge building panels

Disclosed herein are panelized wall systems and methods for their construction, wherein the wall systems have elastomeric joints that are resistant to cracking. The walls are constructed with adhesive-edge building panels. The adhesive-edge building panels are preferably fiber cement. The front surface of each panel has an adhesive preapplied to an edge of the panel. Panels are fastened to a frame with the adhesive-edges adjacent to each other. A joint tape is applied to the seam between the panels such that the edges of the joint tape adhere to the adhesive-edges of the adjacent panels. The wall is then finished with an elastomeric finish.

Owner:JAMES HARDIE INT FINANCE BV

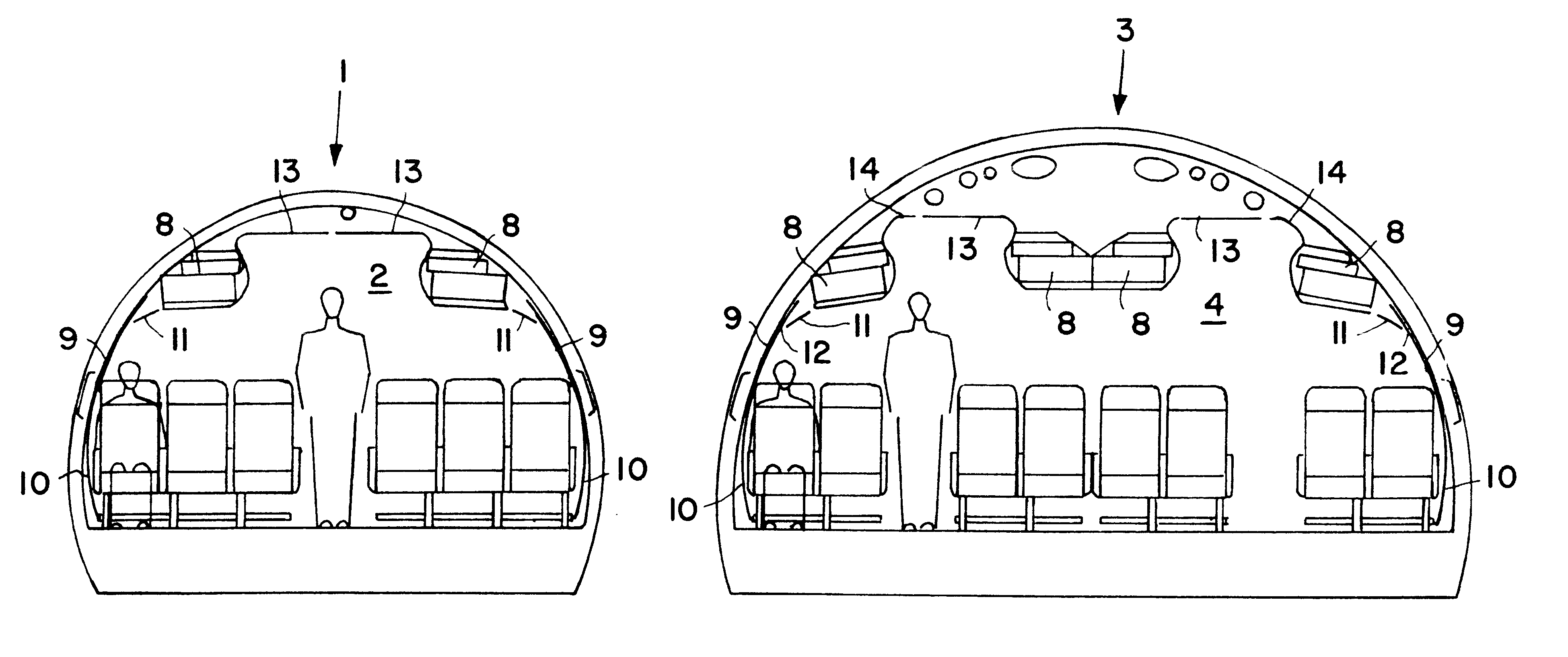

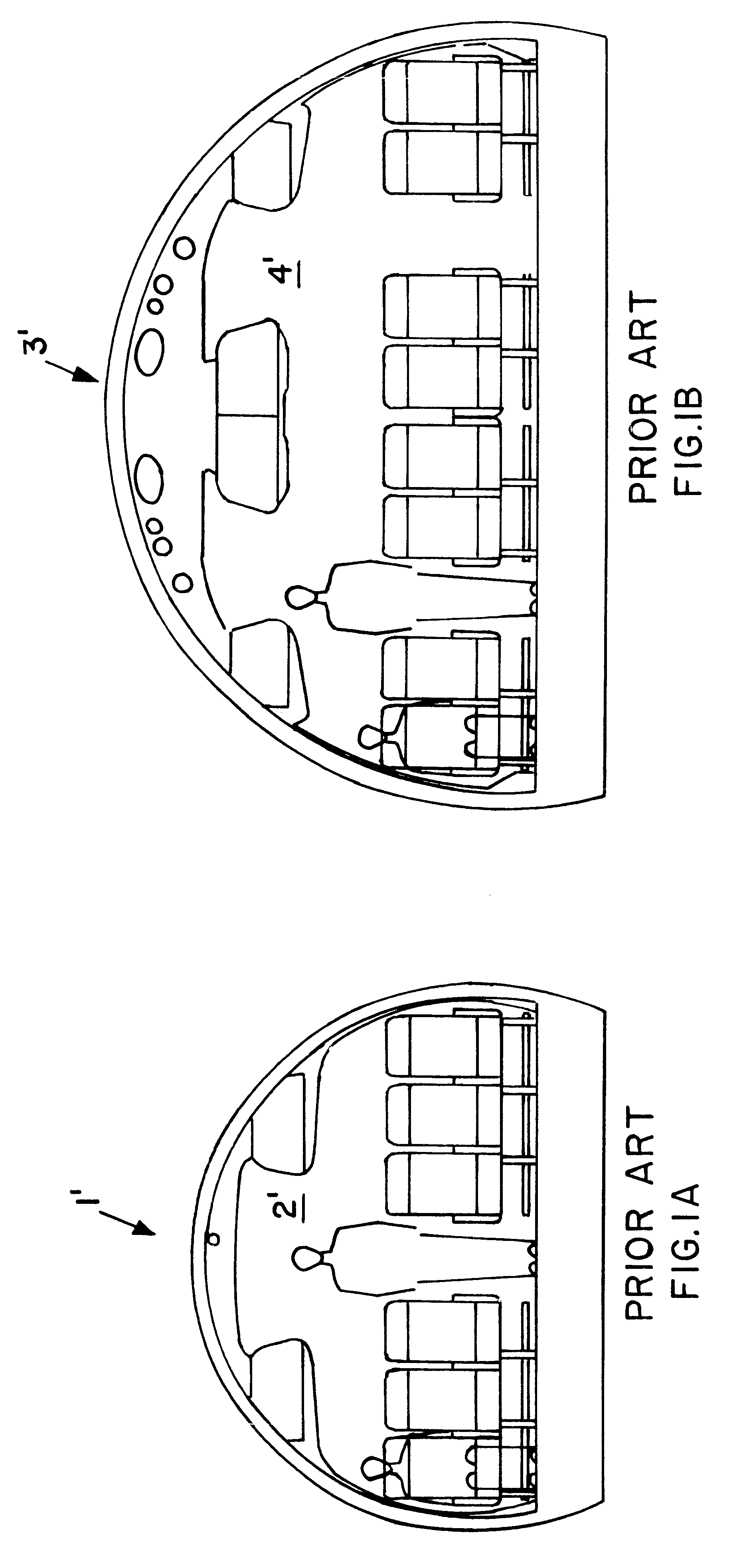

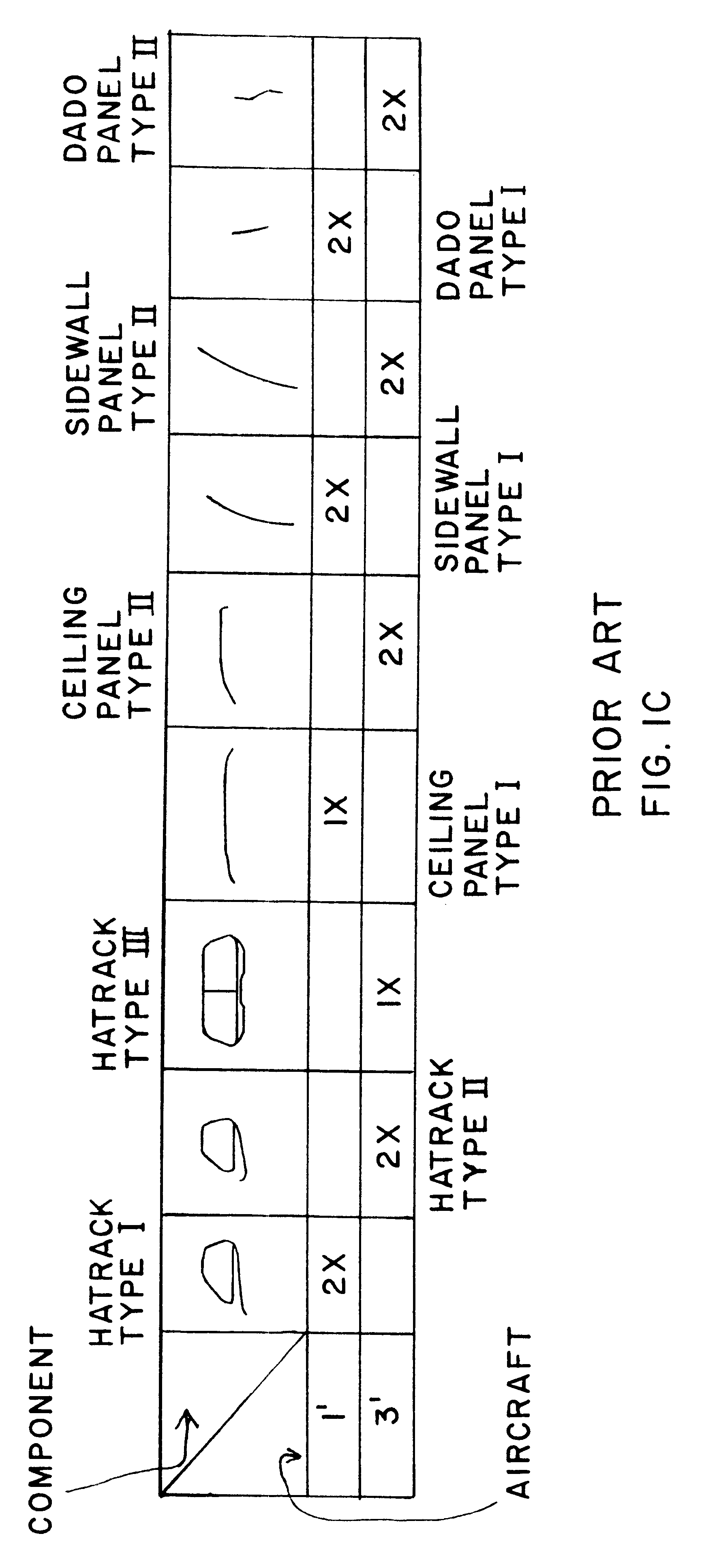

Modular trim paneling and outfitting system for an aircraft passenger cabin interior

An aircraft passenger cabin includes modular interior components selected from ceiling panels, wall panels, dado panels, window funnels, light covers, and baggage compartments or hat racks. At least one interior component is a standardized modular building block that can be used uniformly and interchangeably in different cabin configurations and sizes, in different aircraft types having different fuselage cross-sectional sizes and configurations. The interior components are modularly combined so as to be adapted to different passenger cabins in the various aircraft types. The multiplicity of distinct interior components among all aircraft types in the entire product range of an aircraft manufacturer is reduced, so that the piece count of each particular type of component is increased, and the manufacturing, installation, maintenance, replacement and inventorying costs are reduced. The time and cost for a new cabin design are reduced.

Owner:AIRBUS OPERATIONS GMBH

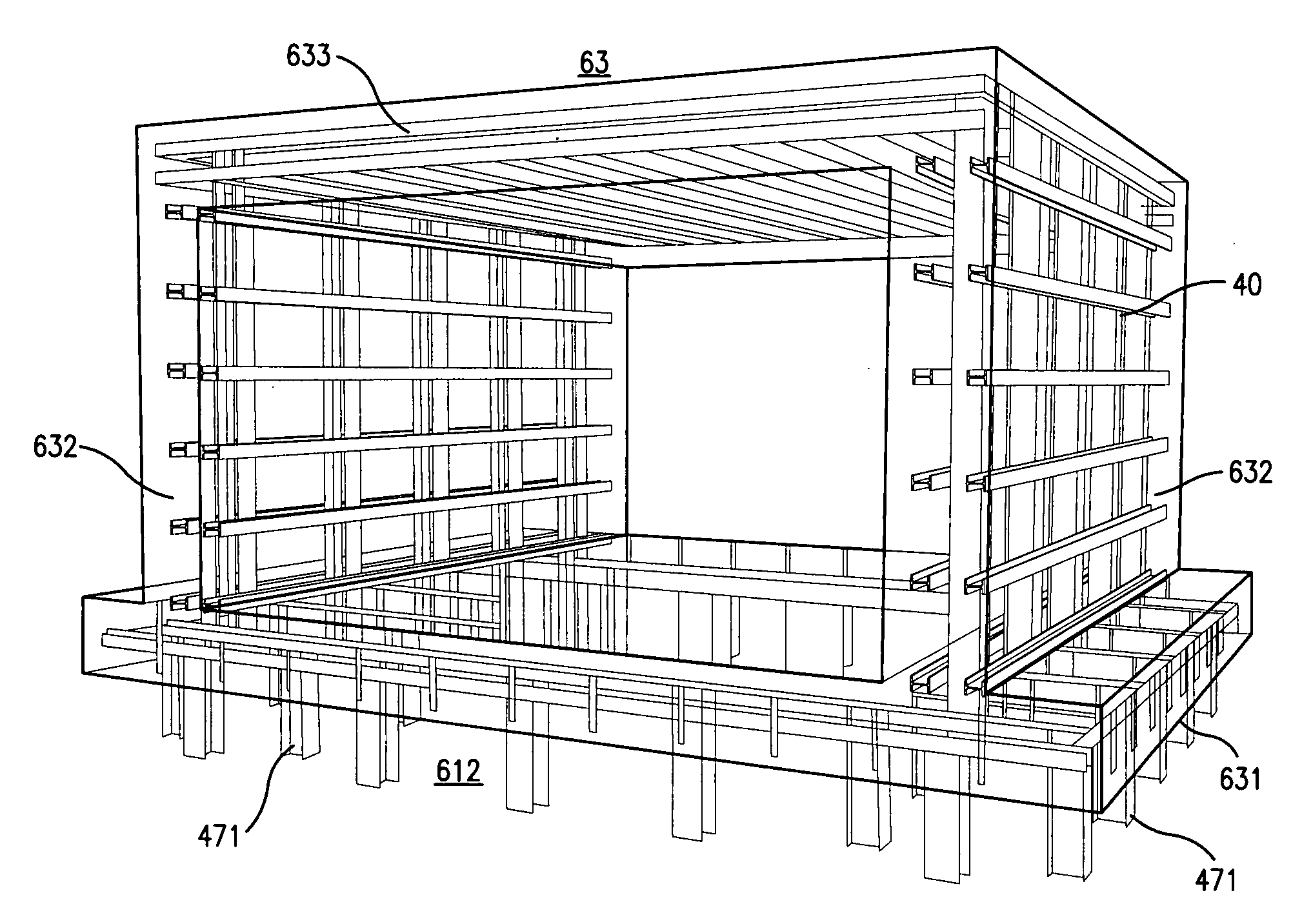

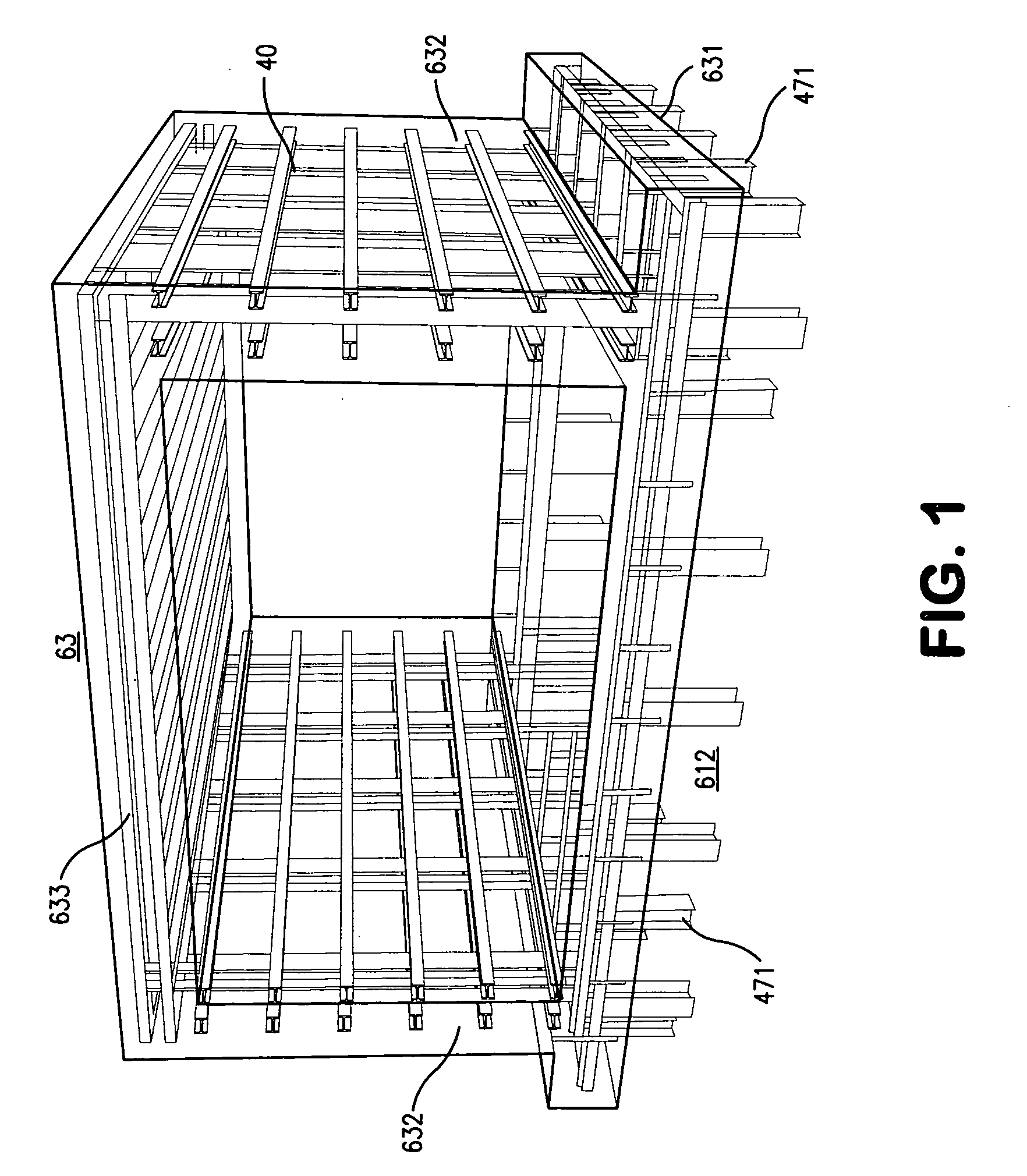

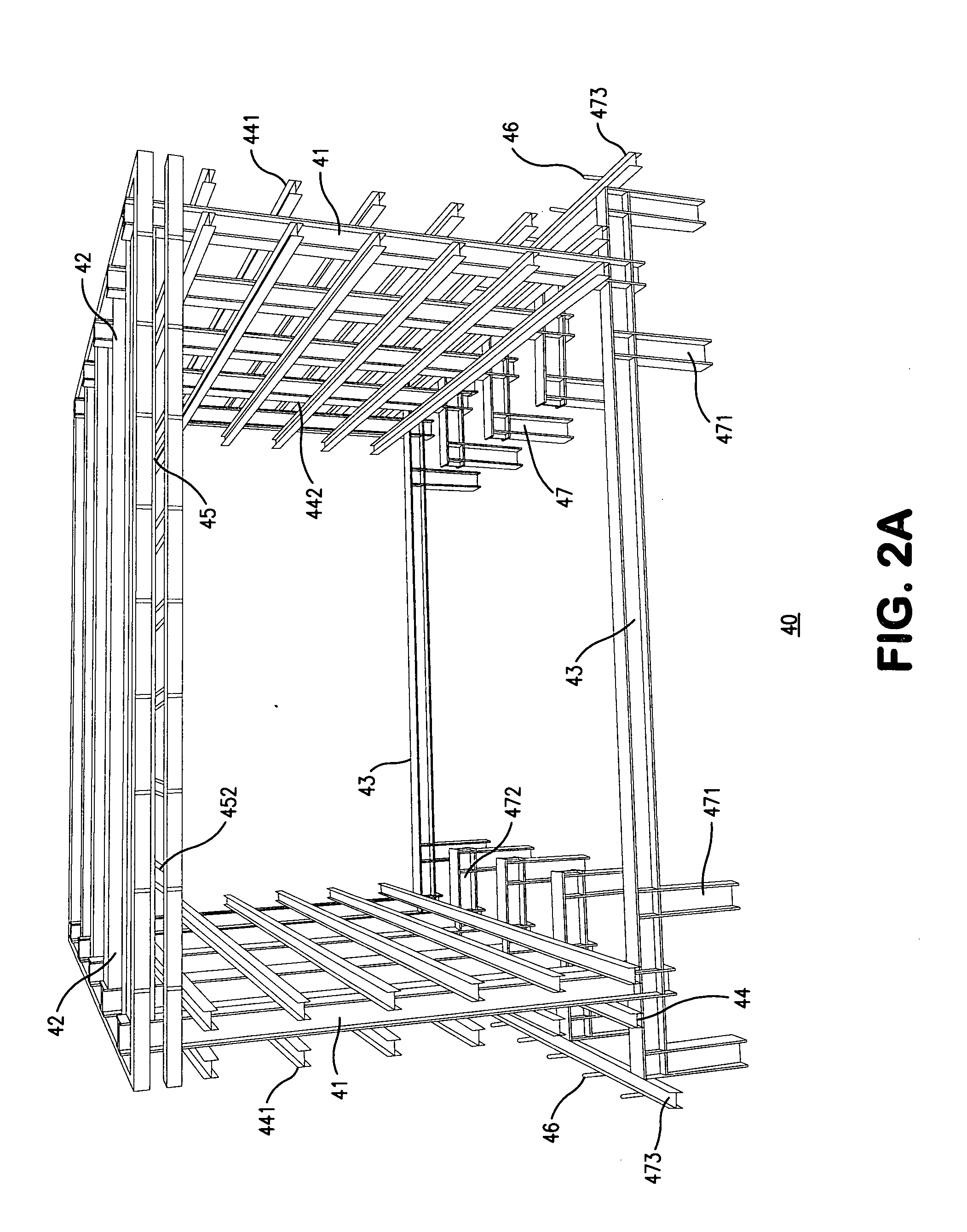

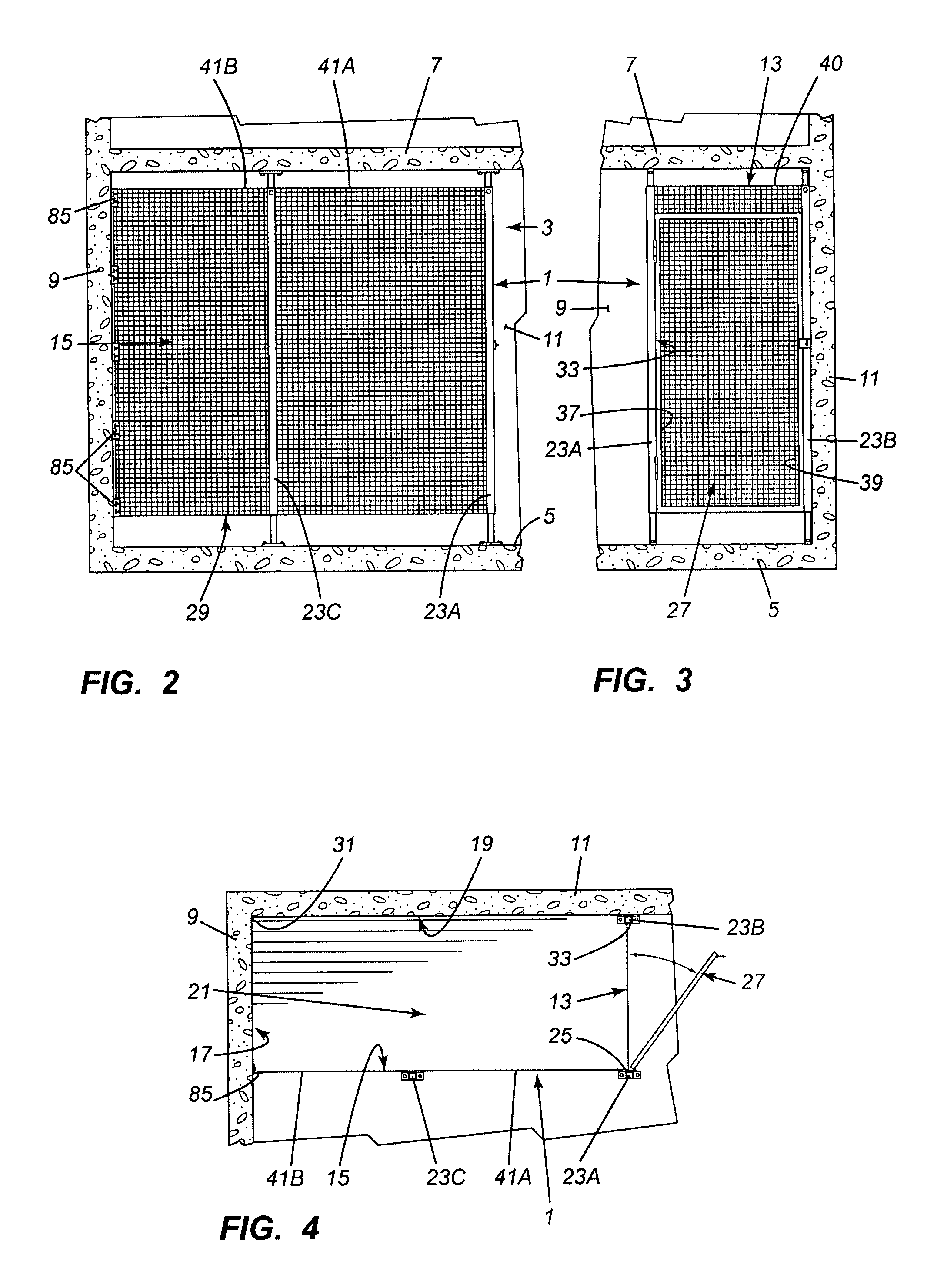

Modular construction mold apparatus and method for constructing concrete buildings and structures

ActiveUS20110011018A1Easy constructionSimpler and safer and economicalConstruction materialWallsSteel frameCompressive strength

A modular steel-framed construction mold apparatus comprised of a plurality of contiguous foundation, cavity wall and roof deck void spaces defined and formed by assemblies of interlocking encasement panels and connectors integrally attached to a structural steel grillage for accepting, containing, and shaping wet concrete fill, a method for forming, casting, and encasing monolithic composite concrete and steel buildings and structures in situ using said mold apparatus, and a permanently encased monolithic composite concrete and steel structure constructed by employing the foregoing modular mold apparatus and method of concrete construction. The structural steel grillage supports the encasement assemblies before and during the casting process, becoming fully embedded within the cast concrete, and provides tensile strength complementing the compressive strength of concrete fill. The panelized encasement assemblies remain in place following casting protecting and insulating the resulting composite concrete and steel buildings and structures.

Owner:JOHNSON FR +1

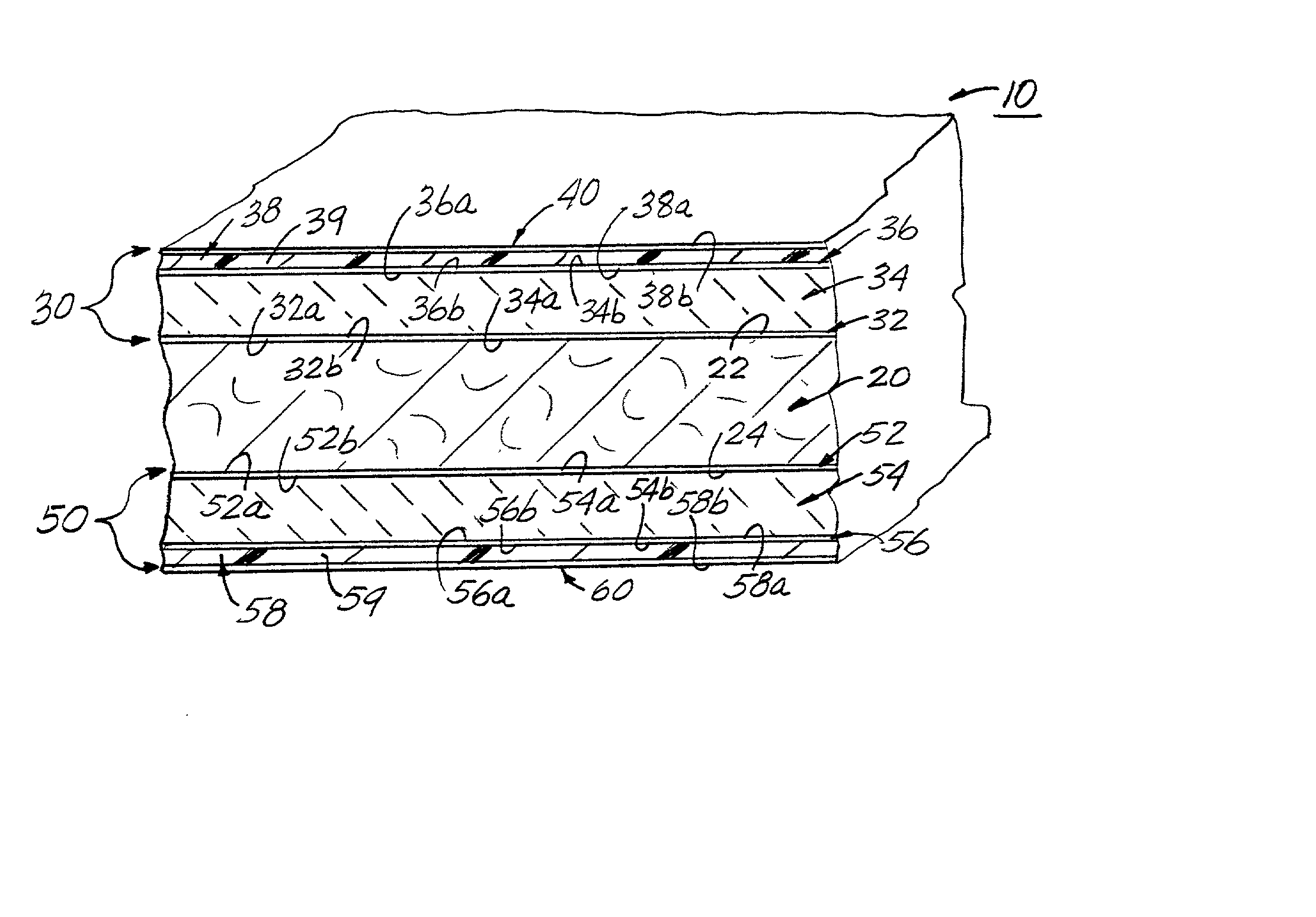

Pre-fabricated fireproof bulkhead with special interlocking joints for a ship

A prefabricated fireproof bulkhead section for a ship. The fireproof bulkhead section includes an inner core layer made of an incombustible fiber material and having a first side for receiving a first composite and a second side for receiving a second composite for forming a fireproof bulkhead section. The first composite includes a first metal layer formed of a metal sheet, a first ceramic layer formed of ceramic fibers, a first foil layer formed of a metal foil sheet and a first outer layer formed of an intumescent, fire-retardant coating on a fiberglass sheet; and the second composite includes a second metal layer formed of a metal sheet, a second ceramic layer formed of ceramic fibers, a second foil layer formed of a metal foil sheet and a second outer layer formed of an intumescent, fire-retardant coating on a fiberglass sheet. The fireproof bulkhead section further includes connecting means in the form of section locking joints for connecting and interlocking two or more of fireproof bulkhead sections together. The fireproof bulkhead section provides protection for at least 60 minutes at a temperature of up to 1700° F.; and has a weight of less than 4.5 lbs per square foot. An interlocking fireproof bulkhead paneling system for supporting a plurality of fireproof bulkhead sections for a ship's bulkhead. The interlocking fireproof paneling bulkhead system includes a plurality of fireproof bulkhead sections each having an upper edge and a lower edge; a plurality of connected ceiling track members for slidably receiving the upper edges of the plurality of fireproof bulkhead sections; and a plurality of connected floor track members for slidably receiving the lower edges of the plurality of fireproof bulkhead sections. Each of the fireproof sections includes connecting means in the form of section locking joints for connecting and interlocking two or more of the fireproof bulkhead sections together. Each of the fireproof bulkhead sections includes an inner core layer made of an incombustible fiber material and having a first side for receiving a first composite and a second side for receiving a second composite for forming said fireproof bulkhead section. The first composite includes a first metal layer formed of a metal sheet, a first ceramic layer formed of ceramic fibers, a first foil layer formed of a metal foil sheet and a first outer layer formed of an intumescent, fire-retardant coating on a fiberglass sheet; and the second composite includes a second metal layer formed of a metal sheet, a second ceramic layer formed of ceramic fibers, a second foil layer formed of a metal foil sheet and a second outer layer formed of an intumescent, fire-retardant coating on a fiberglass sheet. The interlocking fireproof bulkhead paneling system provides protection for at least 60 minutes at a temperature of up to 1700° F; and has a weight of less than 4.5 lbs per square foot.

Owner:NO FIRE ENG

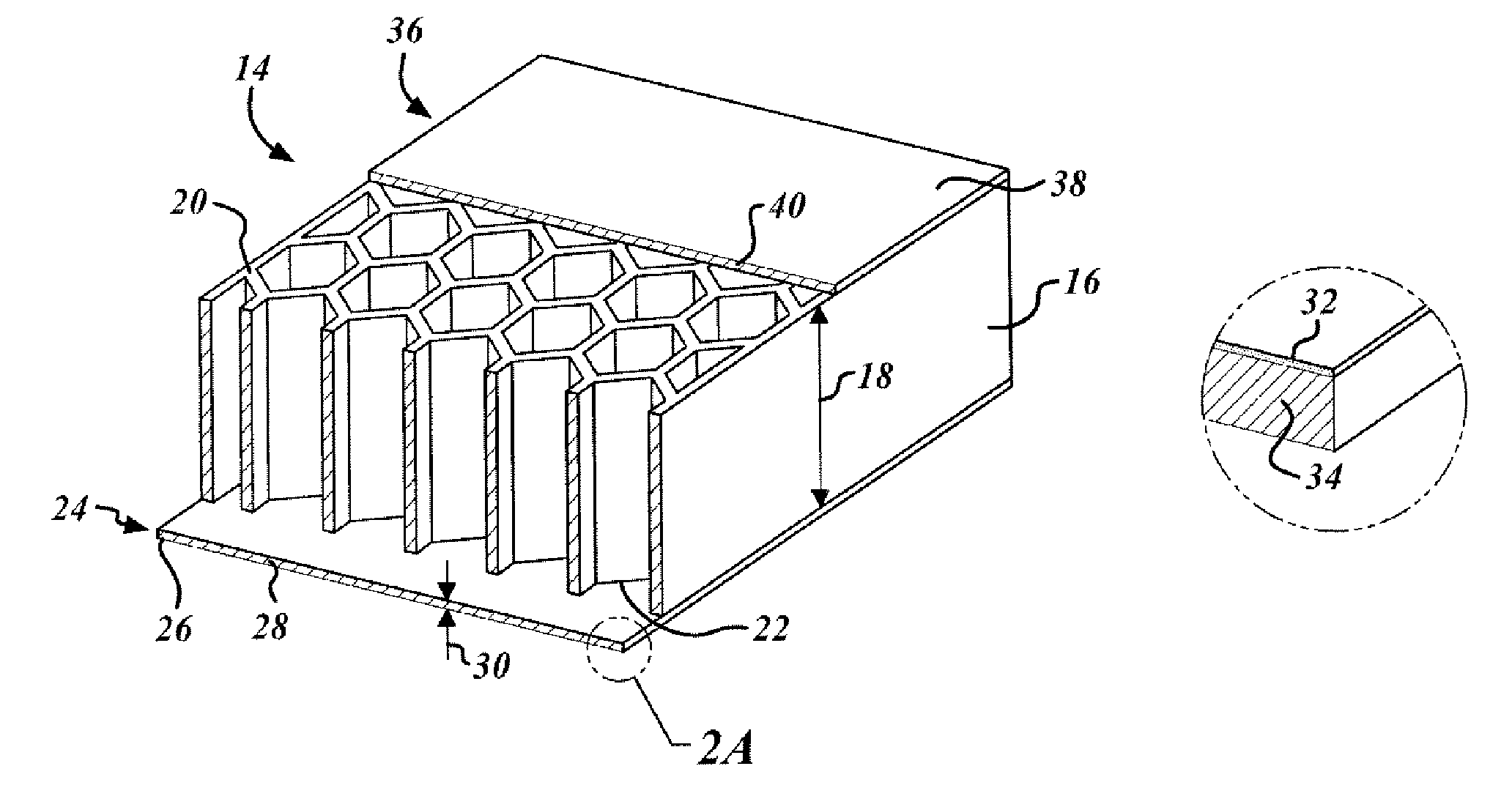

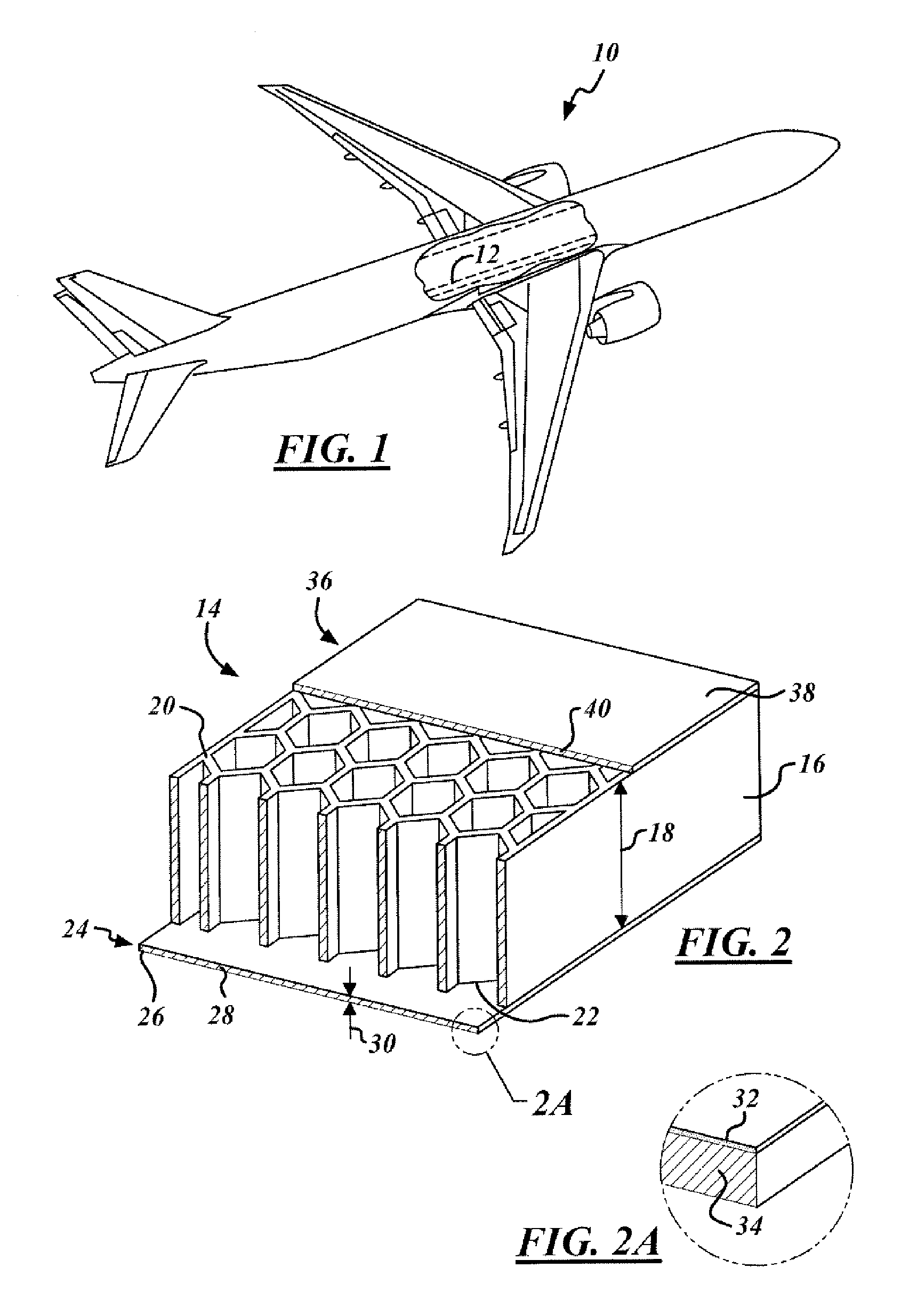

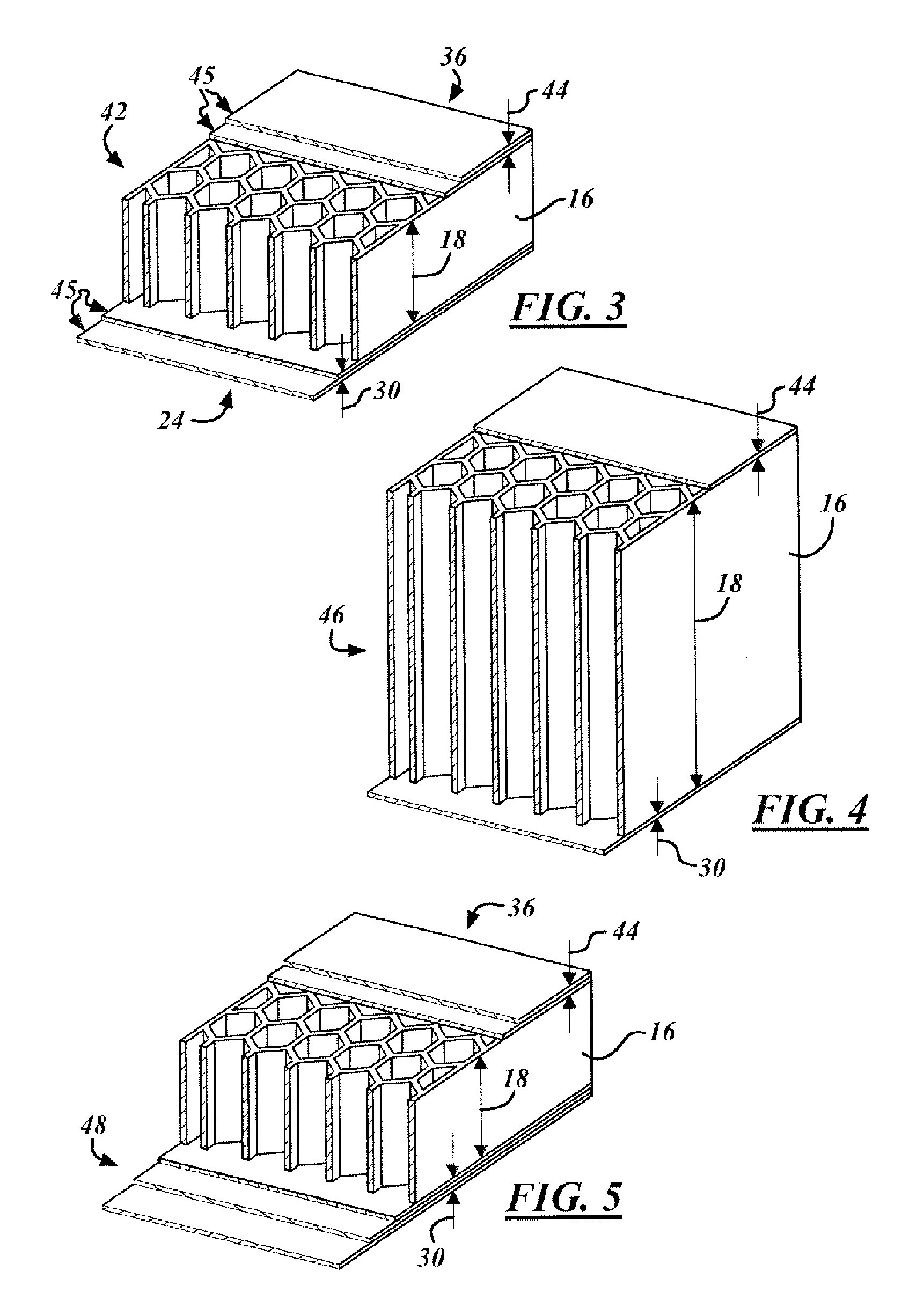

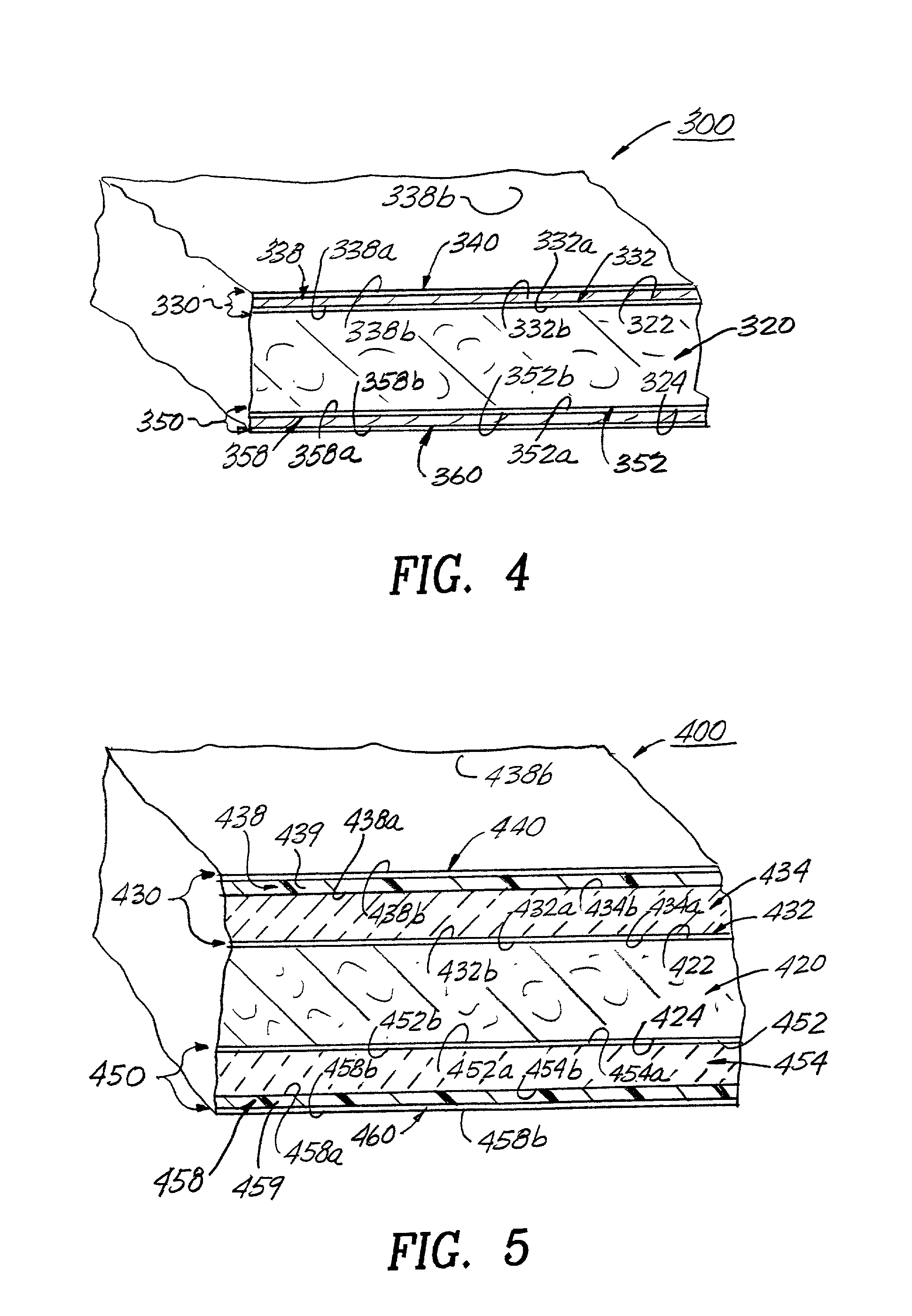

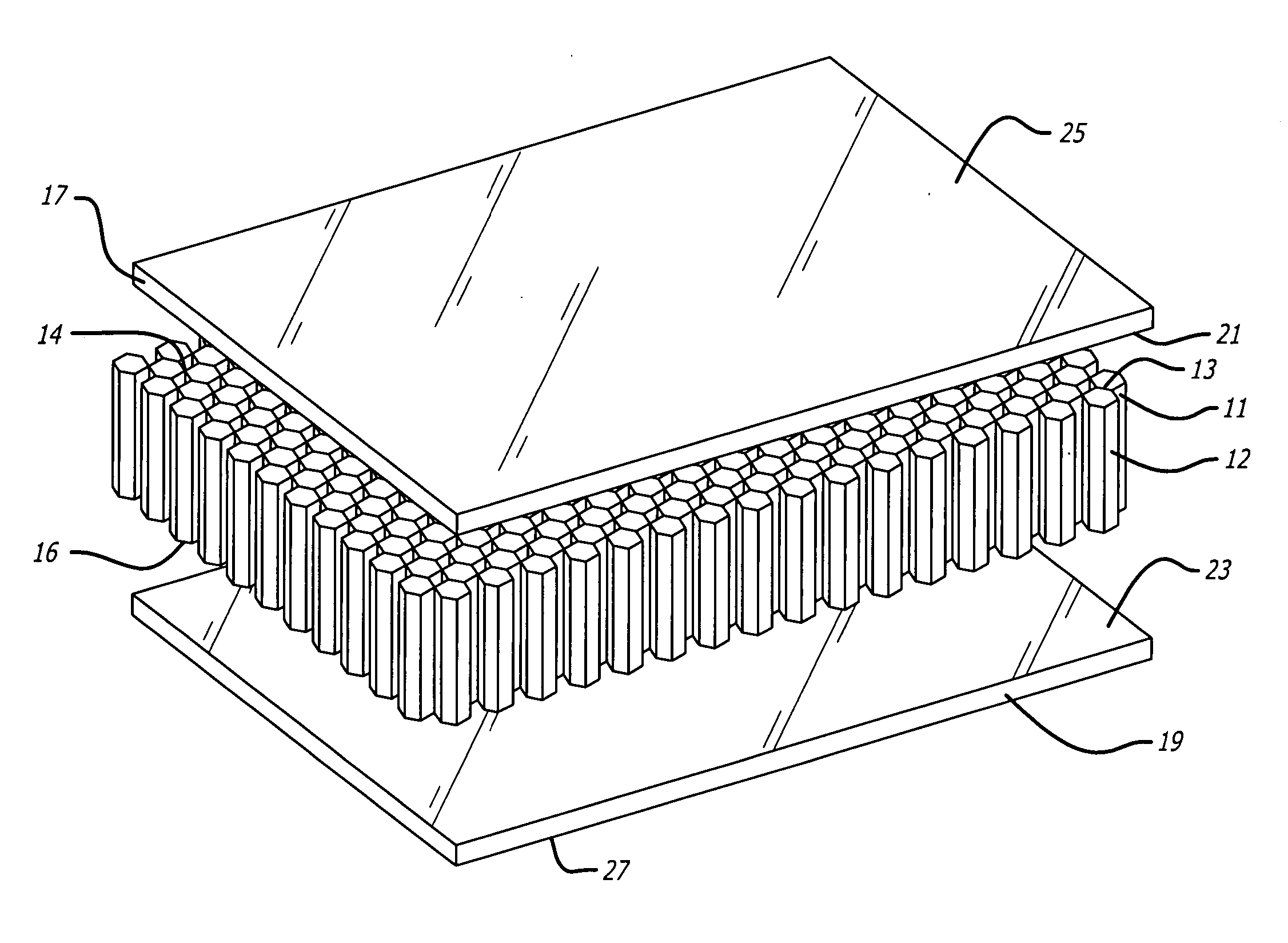

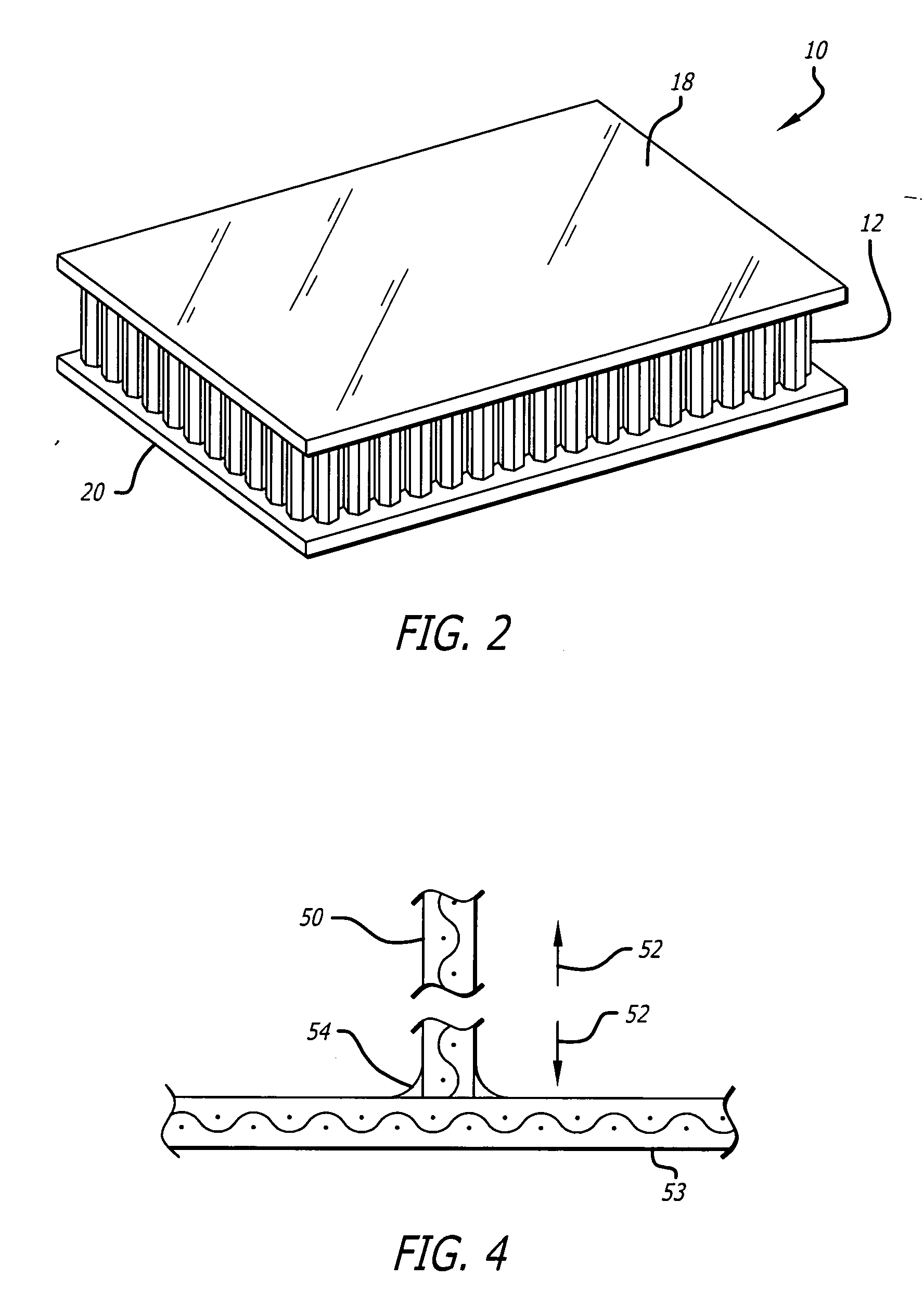

Aircraft floor panels using edge coated honeycomb

InactiveUS20070054087A1High bonding strengthGood adhesionSynthetic resin layered productsLaminationPanellingPolyamide

Aircraft floor panels where core-skin bonding is improved between honeycomb and composite face sheets (skins) by applying a nylon-based (polyamide) adhesive to the edge of the honeycomb prior to bonding. Edge coating of the honeycomb allows one to reduce panel weight without reducing the performance parameters that are required for different types of aircraft floor panels.

Owner:HEXCEL

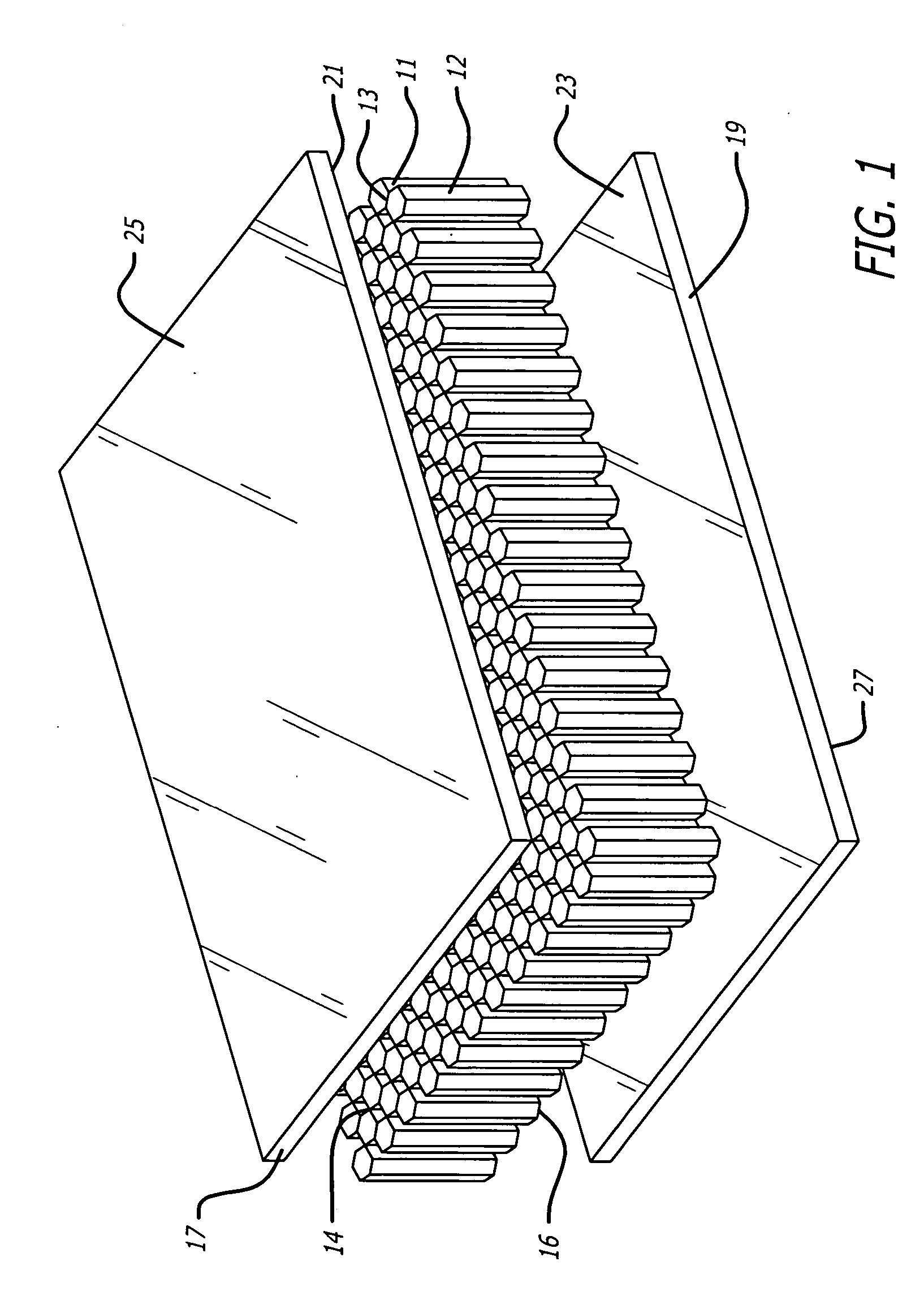

Floor panel for a vehicle

InactiveUS20090230729A1Reduce sound transmissionBlock sound transmissionVehicle seatsSuperstructure subunitsVehicle framePanelling

A structural shear panel for forming a floor panel for support by a vehicle frame is formed by a composite of top and bottom sheets and a core with a vacuum infused resin. The core is formed of top and bottom layers each formed from a honeycomb panel defining an array of hexagonal tubular cells with walls which extend in the thickness direction filled with a foam material. A third layer is located between the first and second layers and is formed of a material such as foam, rubber or cork which is free from tubular cells in the thickness direction and free from rigid structural members in the thickness direction to reduce communication of sound through the panel.

Owner:FAROEX

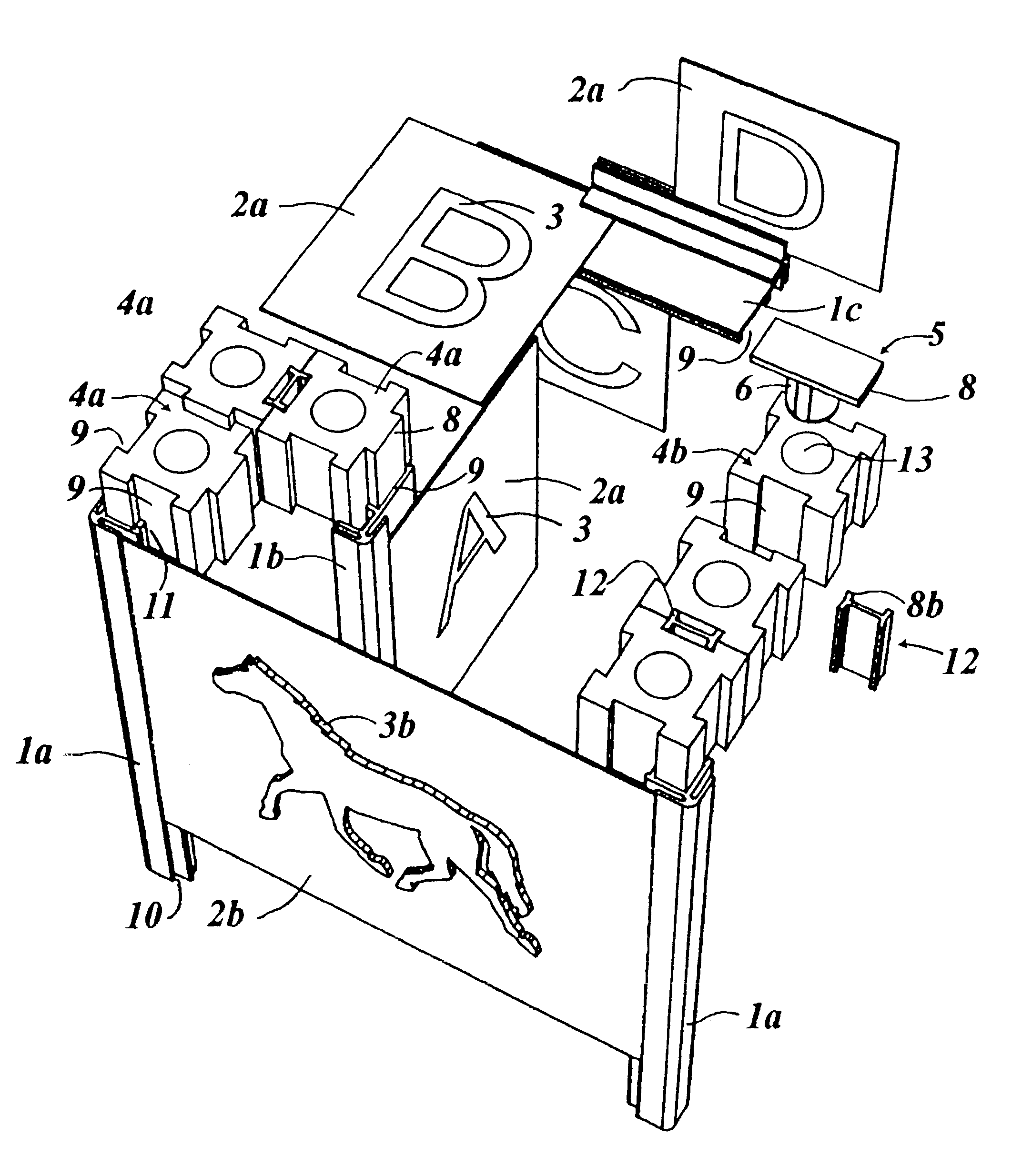

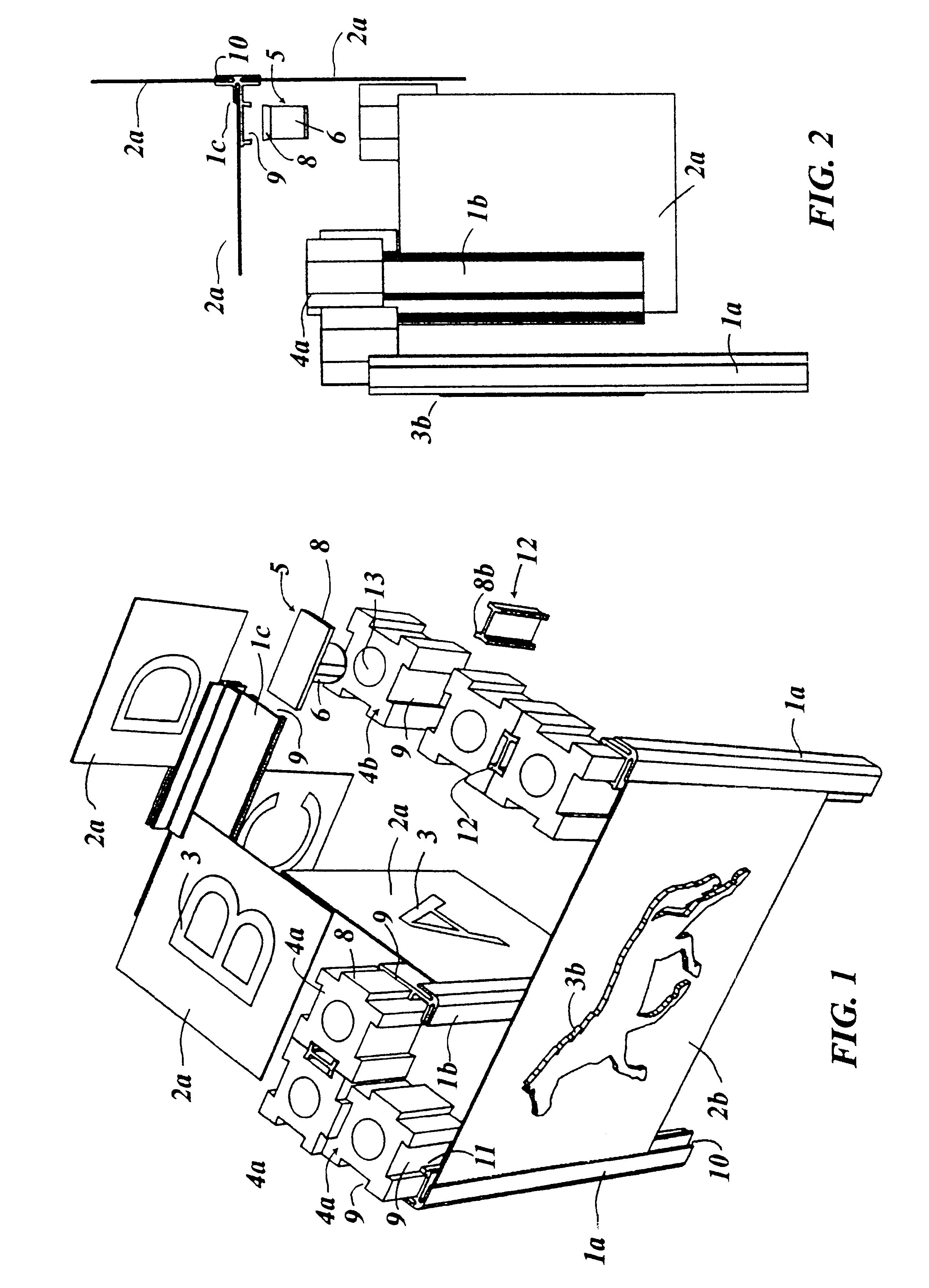

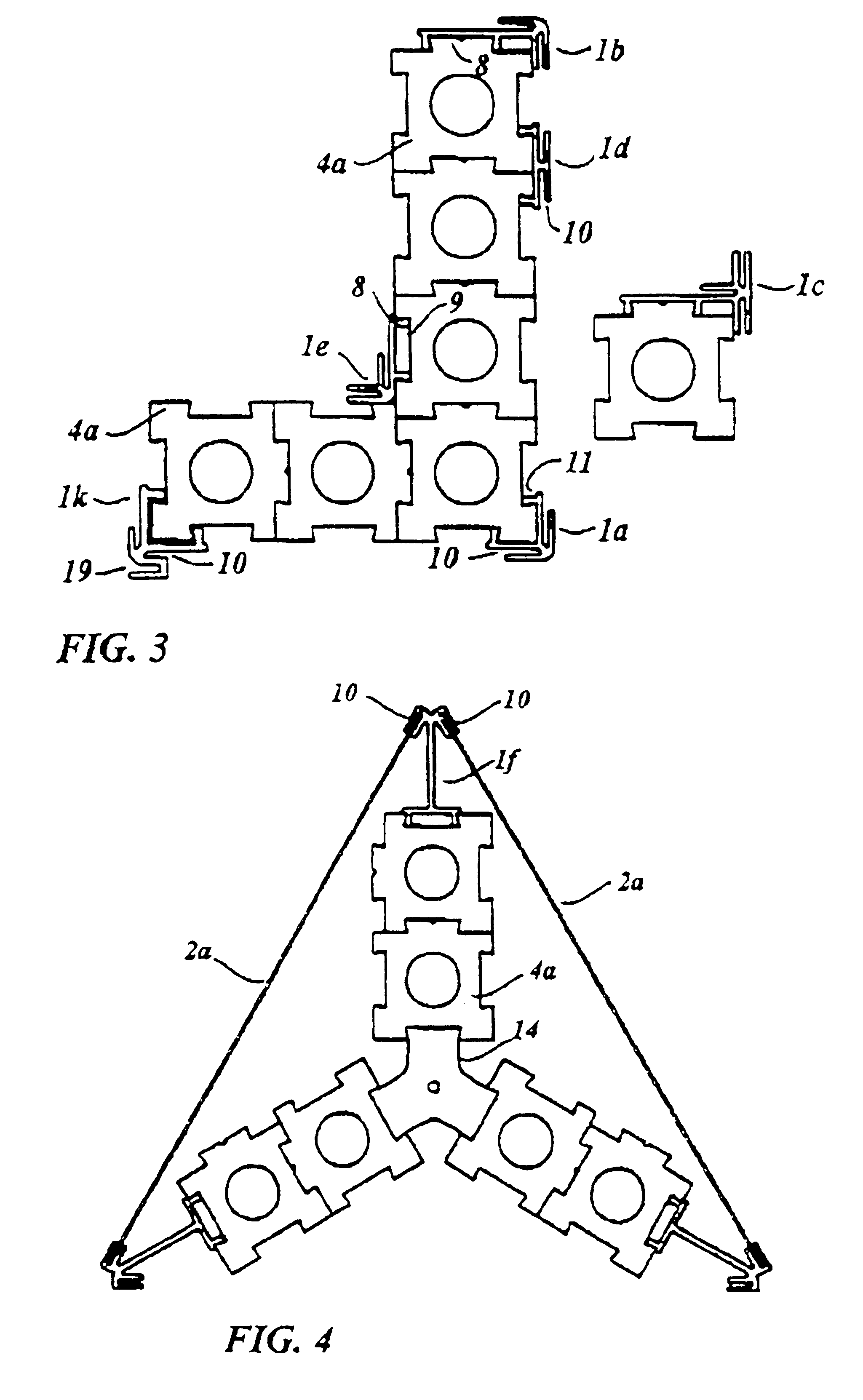

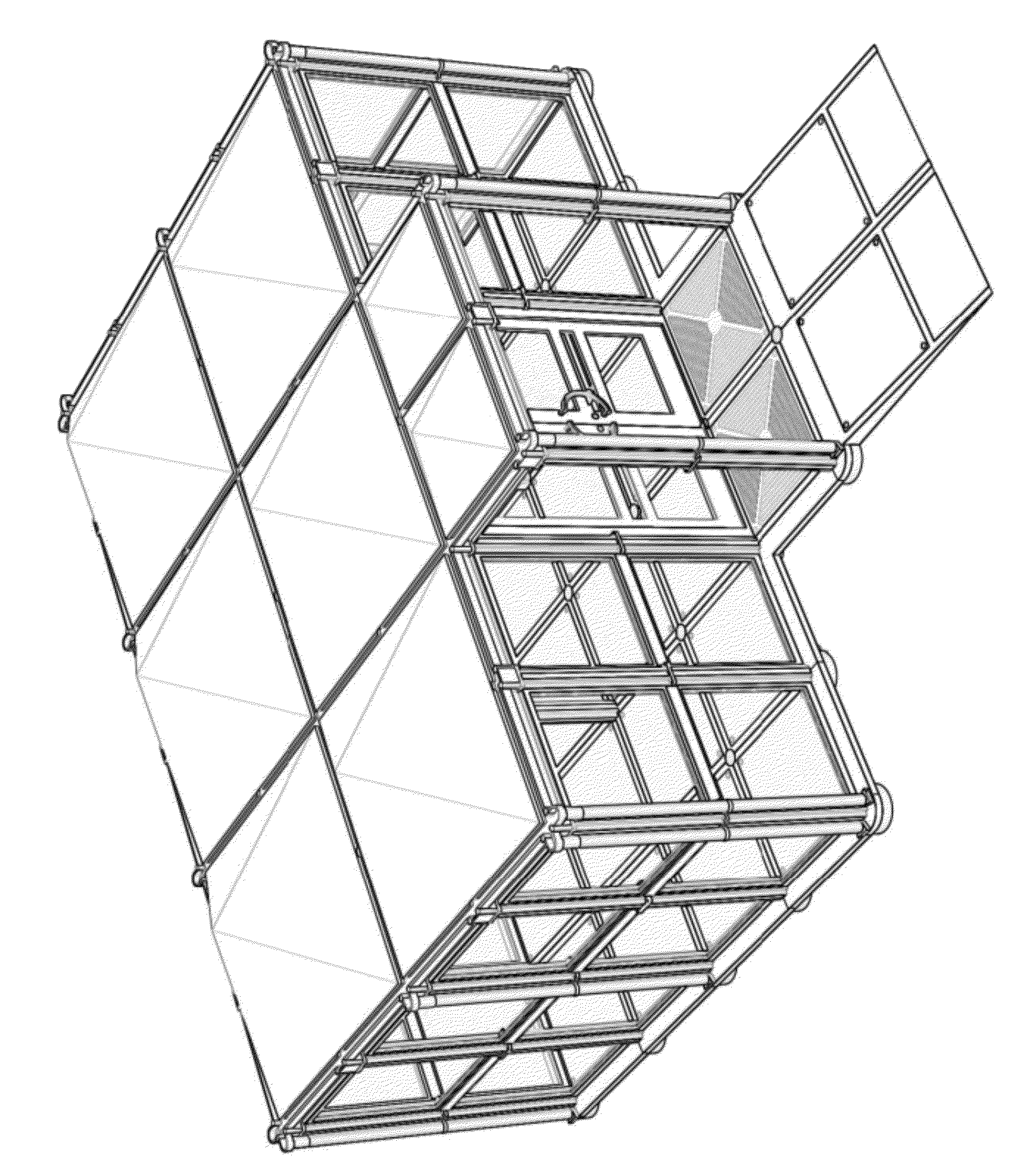

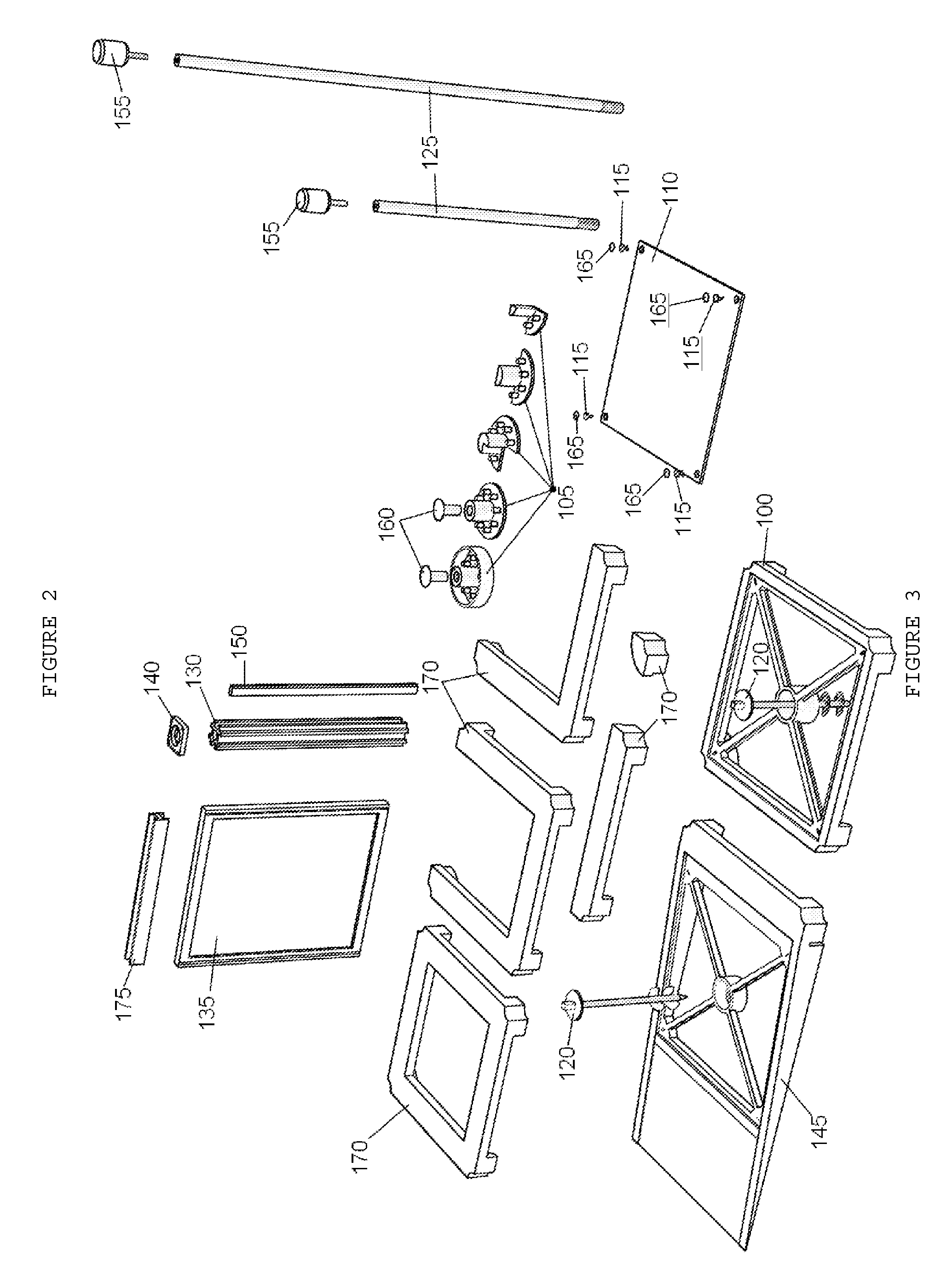

Panelling and supports for interconnected toy blocks

Spaced-apart blocks are interconnected by planar sheets. Thus, different configurations for the toy building blocks can be obtained. A simple geometric shape can be provided which is capable of interlocking in different directions and is capable of a choice of framing pieces. Retrofit interconnecting elements can be provided which facilitate the addition of planar members to the construction.

Owner:MADDOCK PAUL THOMAS

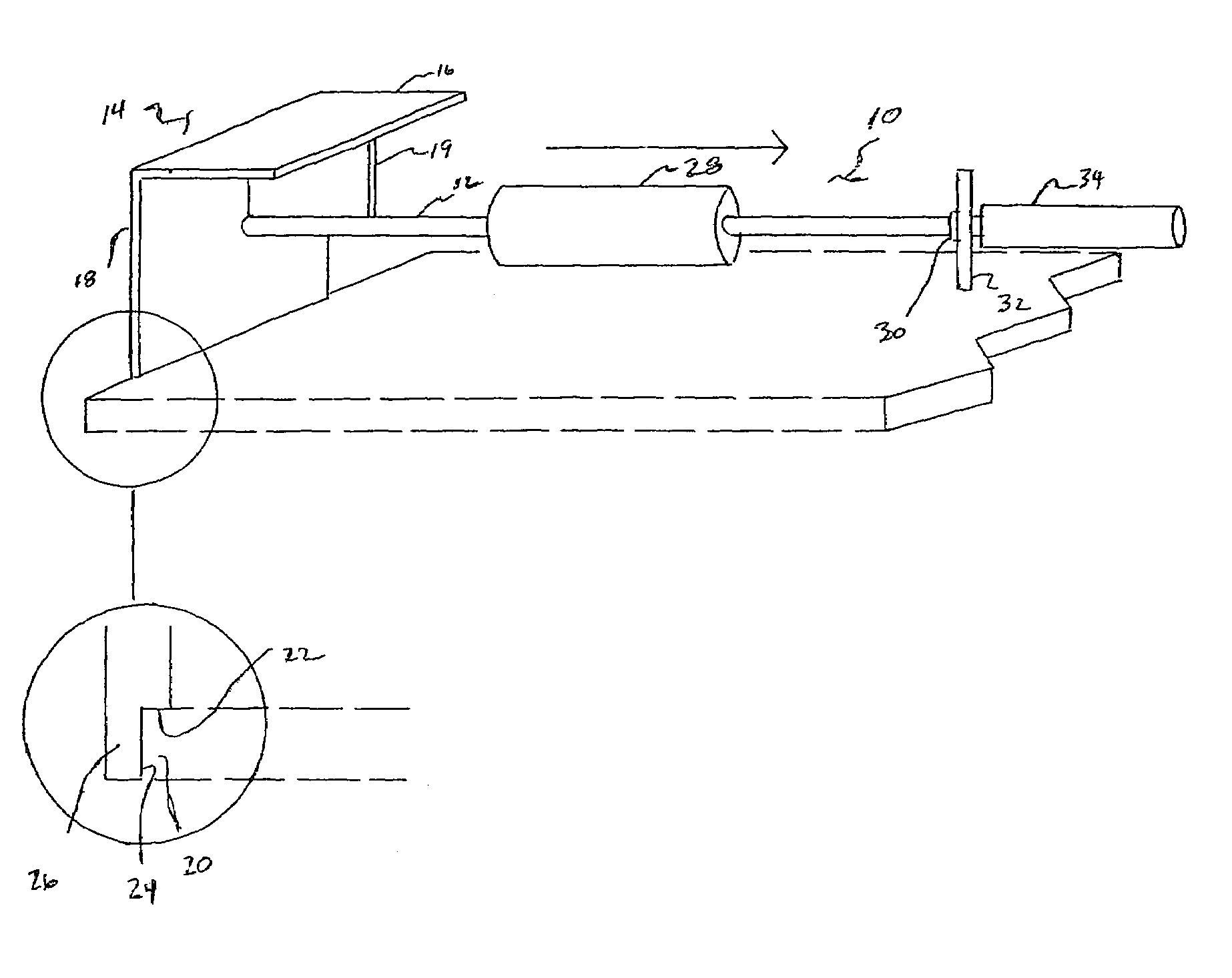

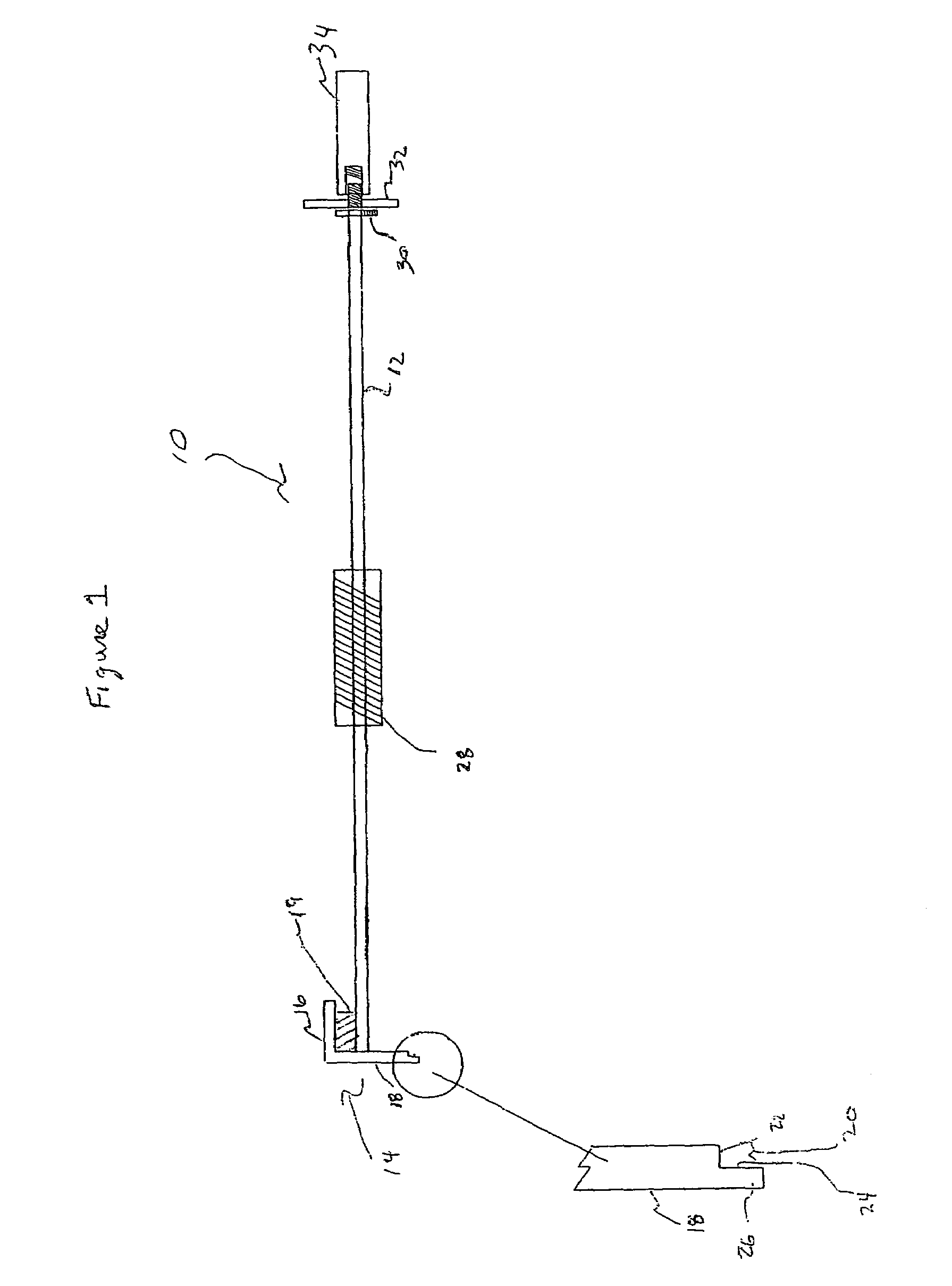

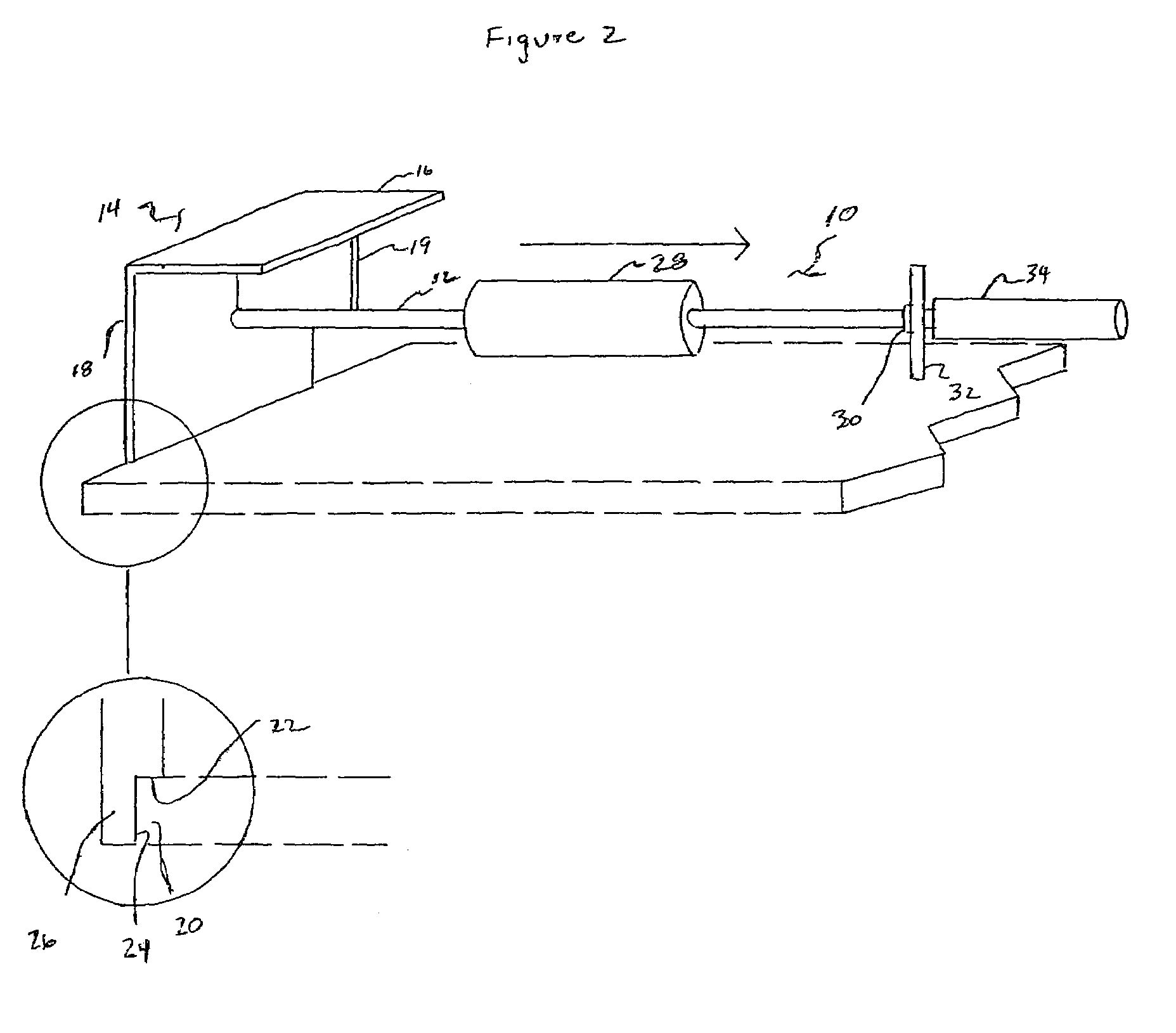

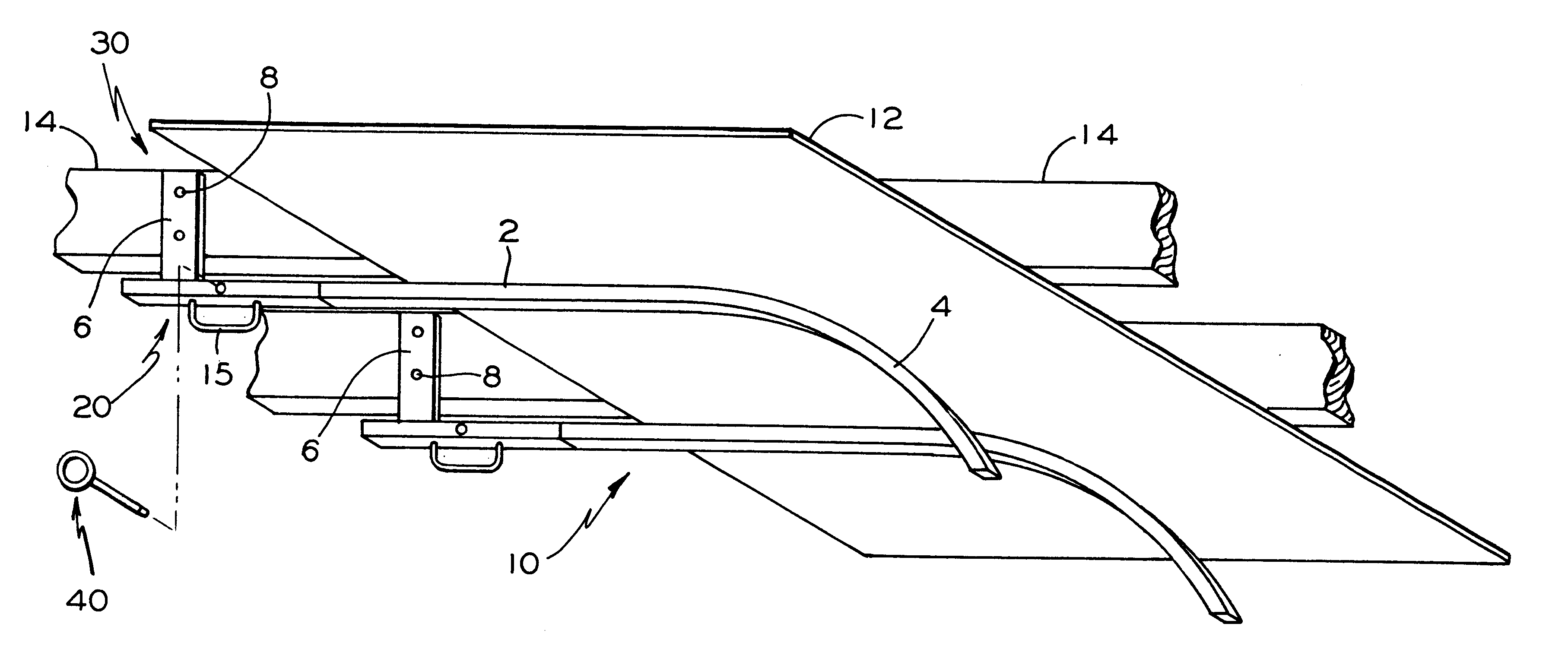

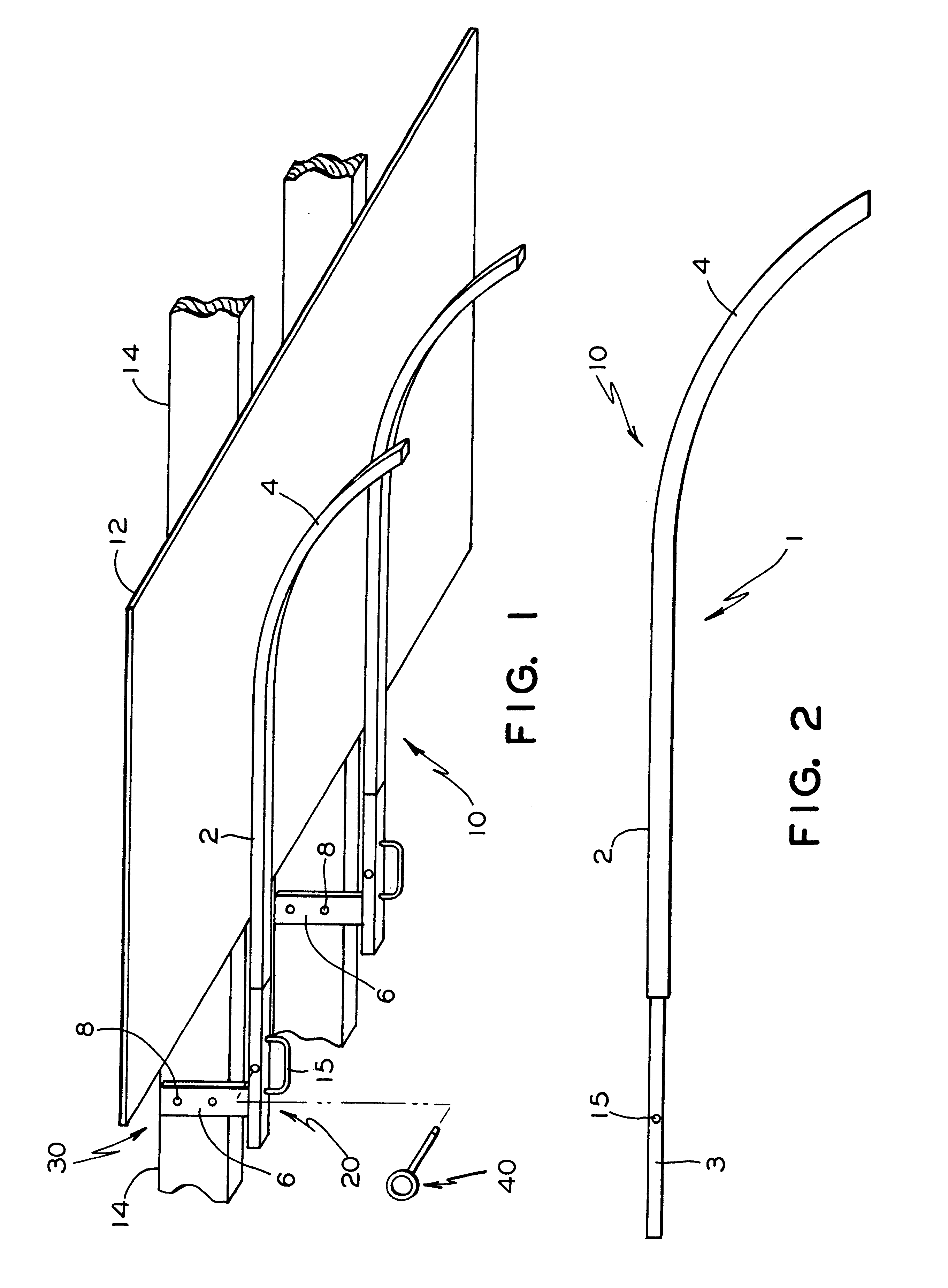

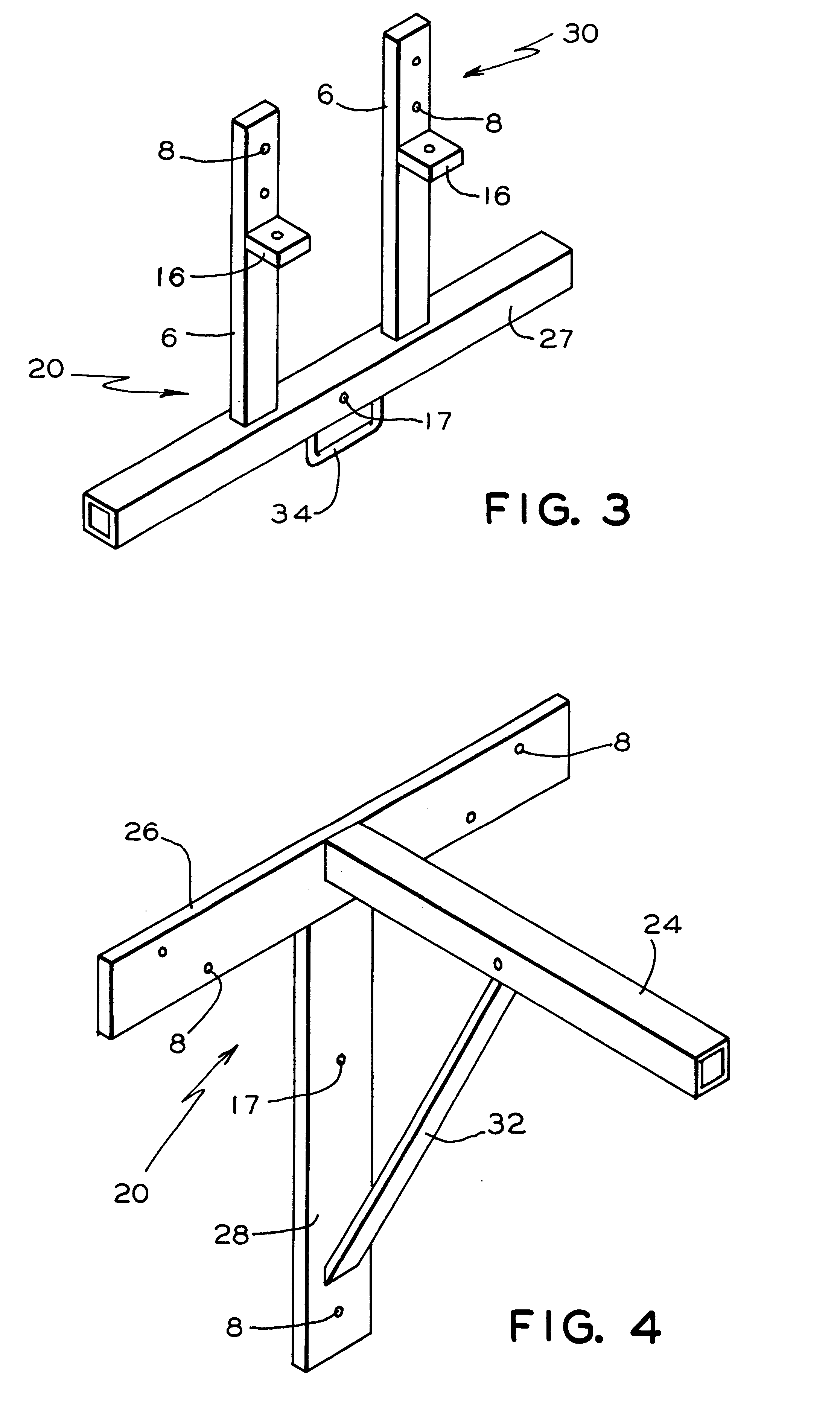

Method and apparatus for laying floors

ActiveUS7398628B2Avoid liftingThe equipment is easy to operateLifting devicesRoof toolsHorizontal forceEngineering

A tool and method for abutting an individual floor panel which is near an obstruction, such as a wall, to the assembled floor. The tool and method provide a rod having a flanged member at one end. The flanged member has a notch in its vertical flange which contacts the floorboard to be abutted, requiring a minimal amount of space between the obstruction and floorboard to be set. A sliding weight mounted on a rod can then be slid toward an impact surface resulting in a horizontal force being applied to the individual floorboard thereby abutting or setting that floorboard with respect to the assembled floor. An especially useful application for the device and method is in the installation of a tongue-in-groove laminate floor in which the individual floorboards have a tongue and groove connection on their ends.

Owner:VAN HORNE JR JEFFERSON

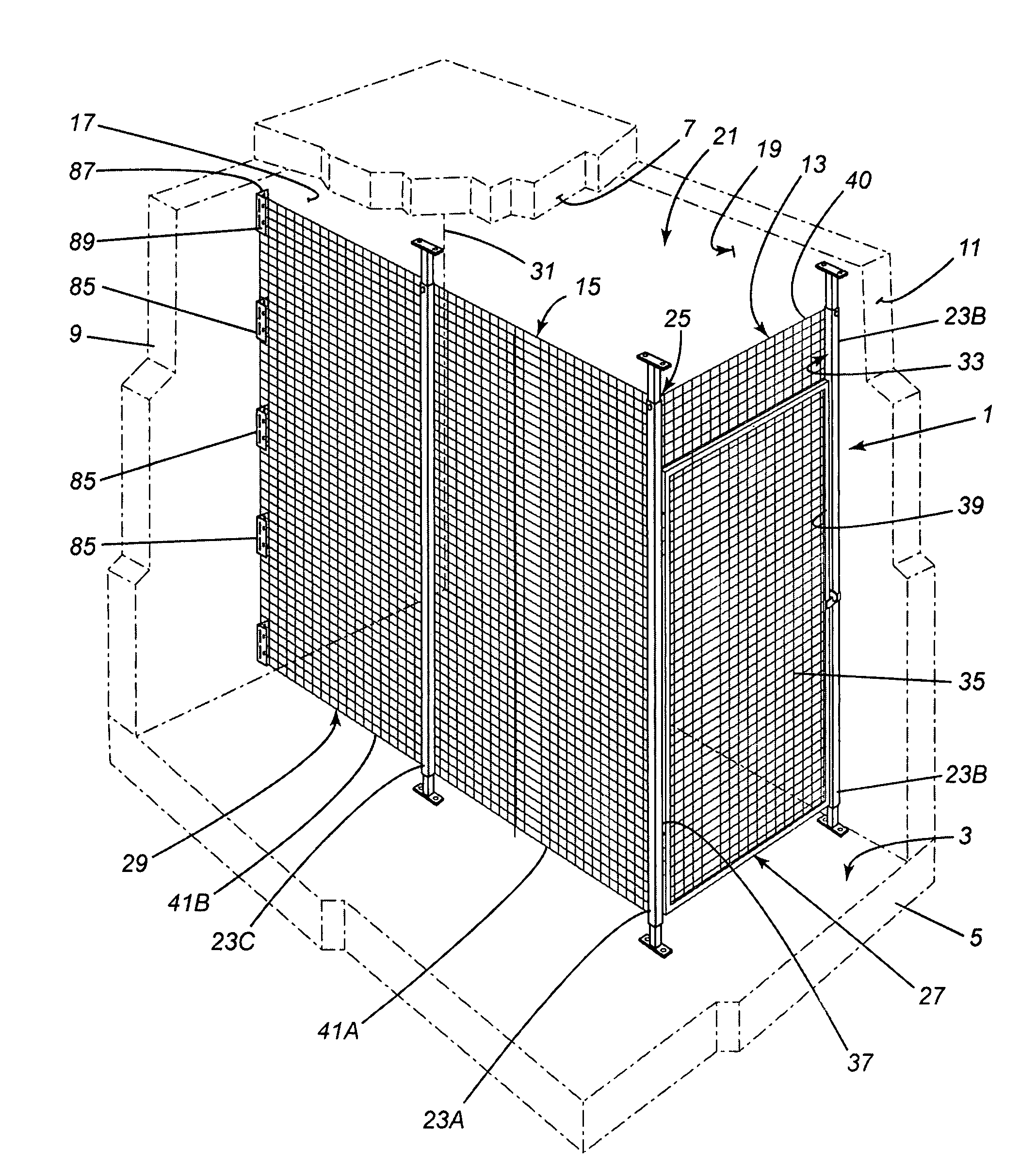

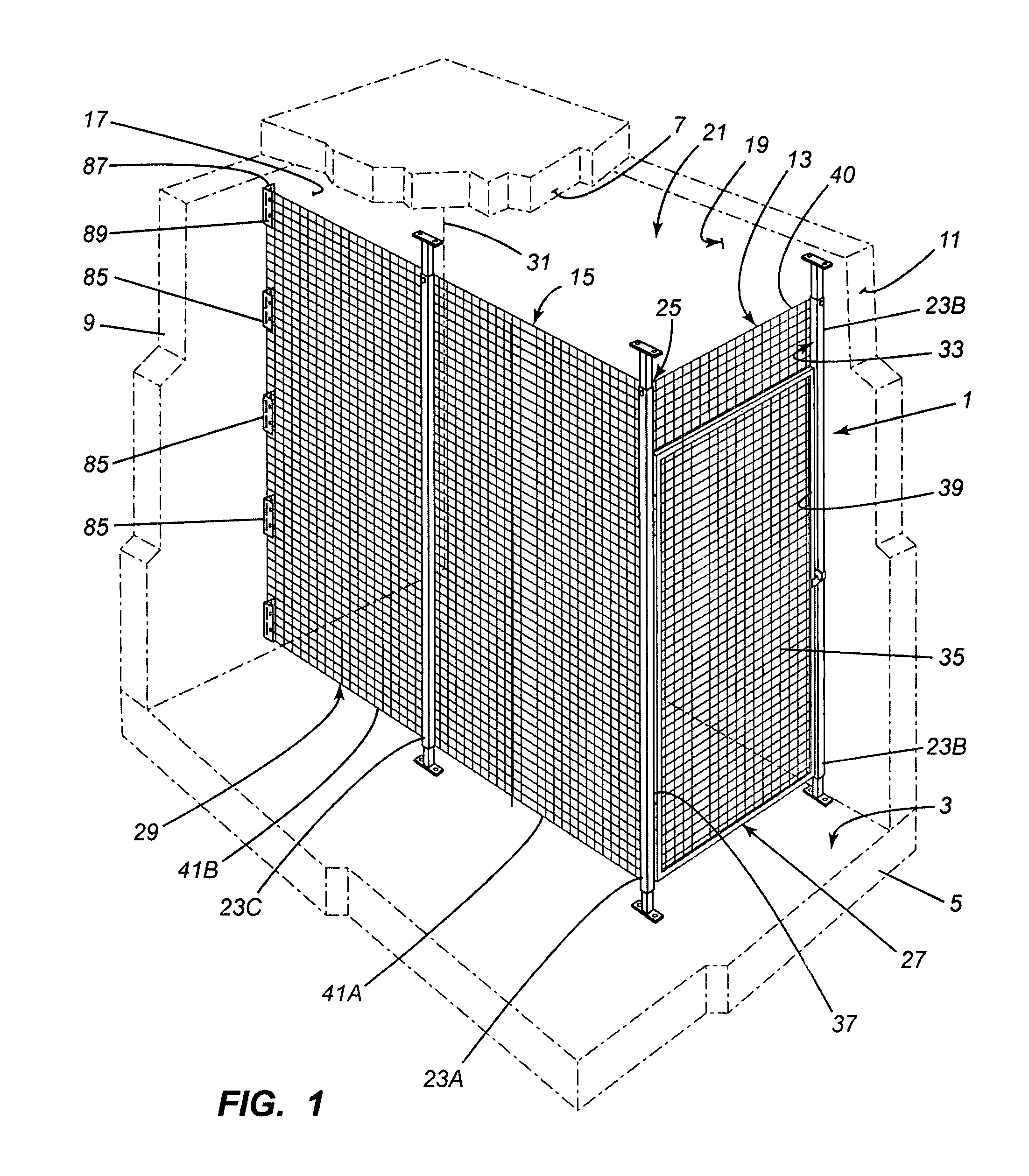

Storage locker

InactiveUS20080229678A1Easy constructionLess-expensive to manufactureWallsTents/canopiesPanellingEngineering

A storage locker in a building space, the building space having a floor, a ceiling and walls bounding the space between the ceiling and floor. The storage locker has at least four walls defining a storage space in the building space, first and second walls forming a first corner. At least the first and second walls each have spaced-apart posts extending between, and mounted to, the floor and ceiling, one of the posts at the first corner and common to the first and second walls. One of the first and second walls has a closure therein mounted between two of the posts forming the wall. At least the other wall has self-supporting wire mesh panelling extending over the length of the wall and mounted on the posts including the corner post to close the wall.

Owner:COGAN WIRE & METAL PRODS

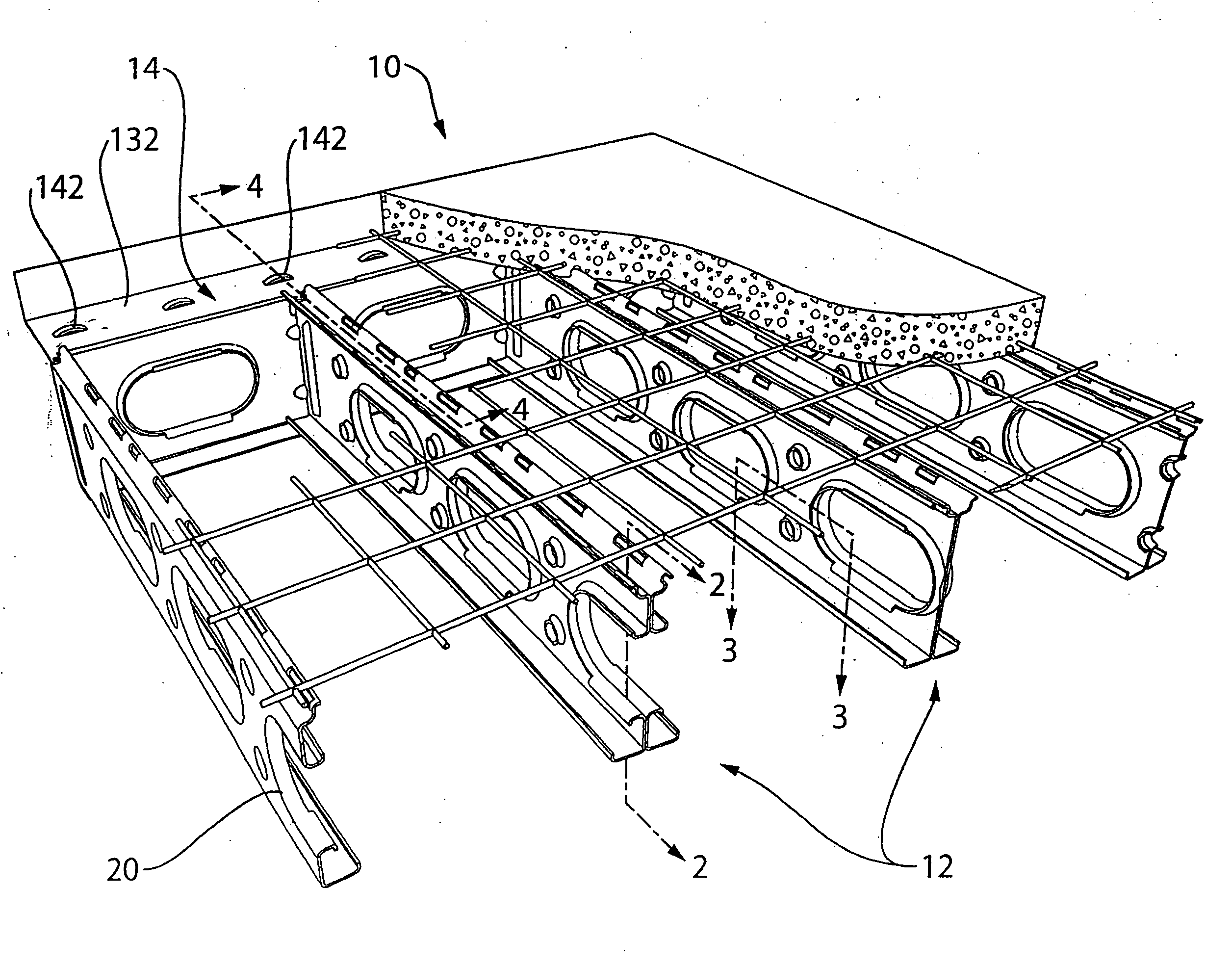

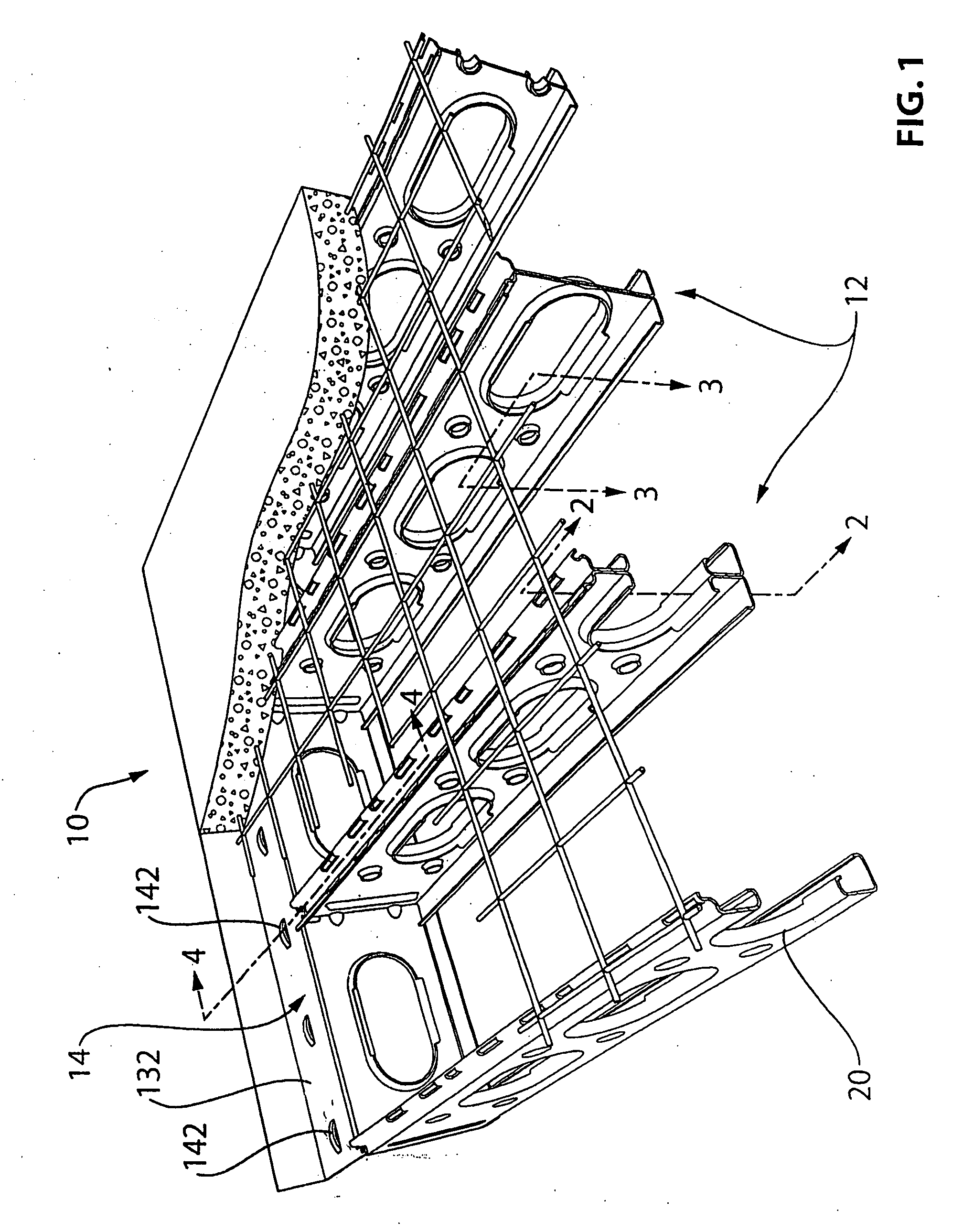

Floor system with steel joists having openings with edge reinforcements and method

InactiveUS20100037551A1High strengthReduce heat transferFloorsMetal-working apparatusOperating energyPanelling

A steel joist member for use in supporting floor structures giving great strength and convenience and improved acoustical performance having a web defining edges, first and second side surfaces and an axis, a edge wall on at least one edge, main openings through the web at spaced intervals therealong, with rounded ends and parallel linear sides, channel portions of the web displaced from the main openings remaining attached integrally to the web by right angle bend lines formed on the first side surface of the main opening along axes parallel to the web axis, and forming reinforcing channels alongside the opposite sides of the main opening.Also disclosed is a composite joist member made up of two such joist members joined together back to back with their openings in registration.Also disclosed is a rim member for supporting the composite joists to form a floor structure.Also disclosed is a method of making such a floor joist member.Also disclosed is a floor panel system by which floor panels can be prefabricated in a factory and transported to a construction site ready for installation in a building.

Owner:UNKNOWN

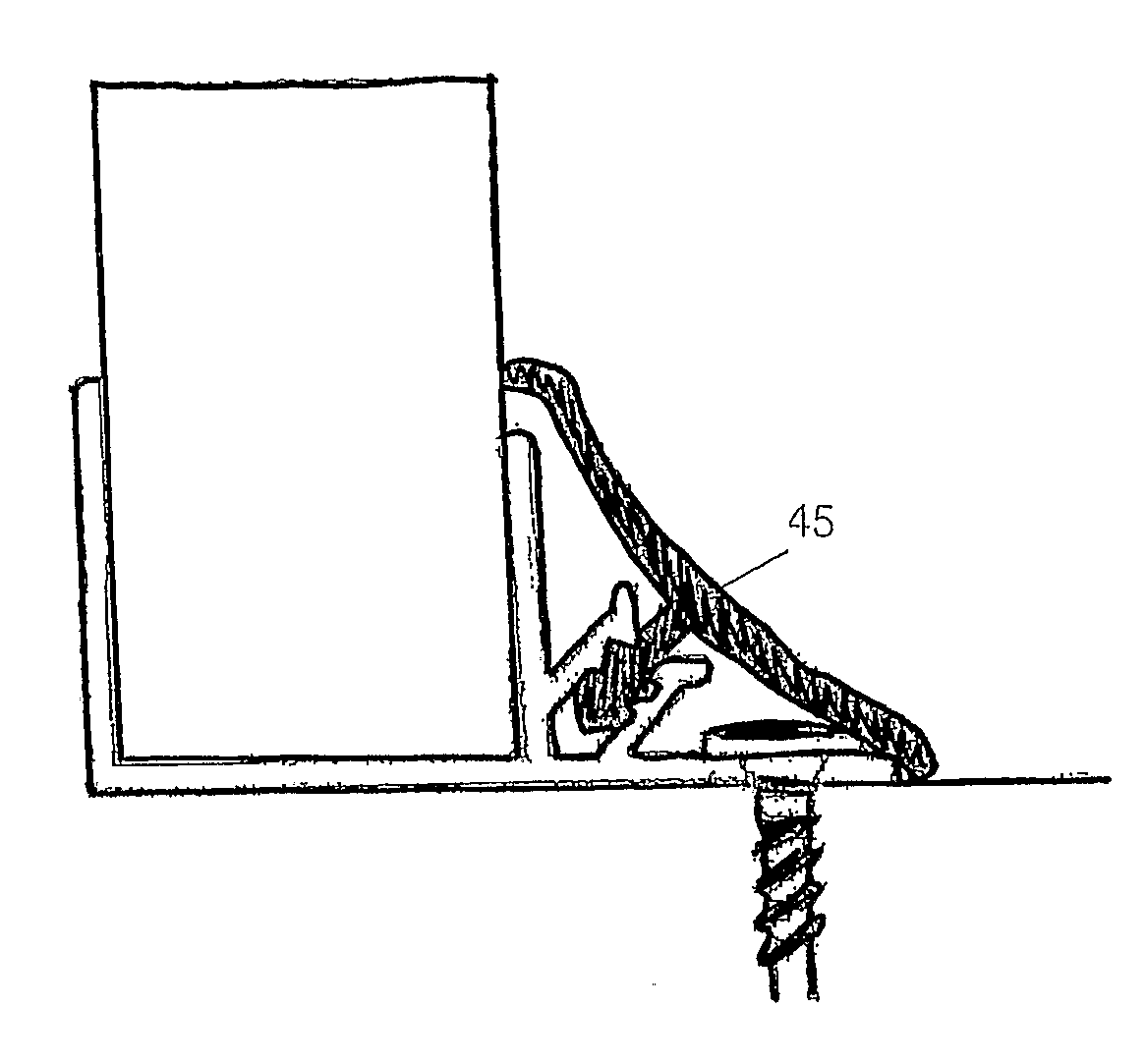

Connector for panelling

InactiveUS20090139167A1Easy to produceEasy to manipulateBuilding roofsYielding couplingPanellingElectrical and Electronics engineering

Owner:DONALDSON GLEN MURRAY +1

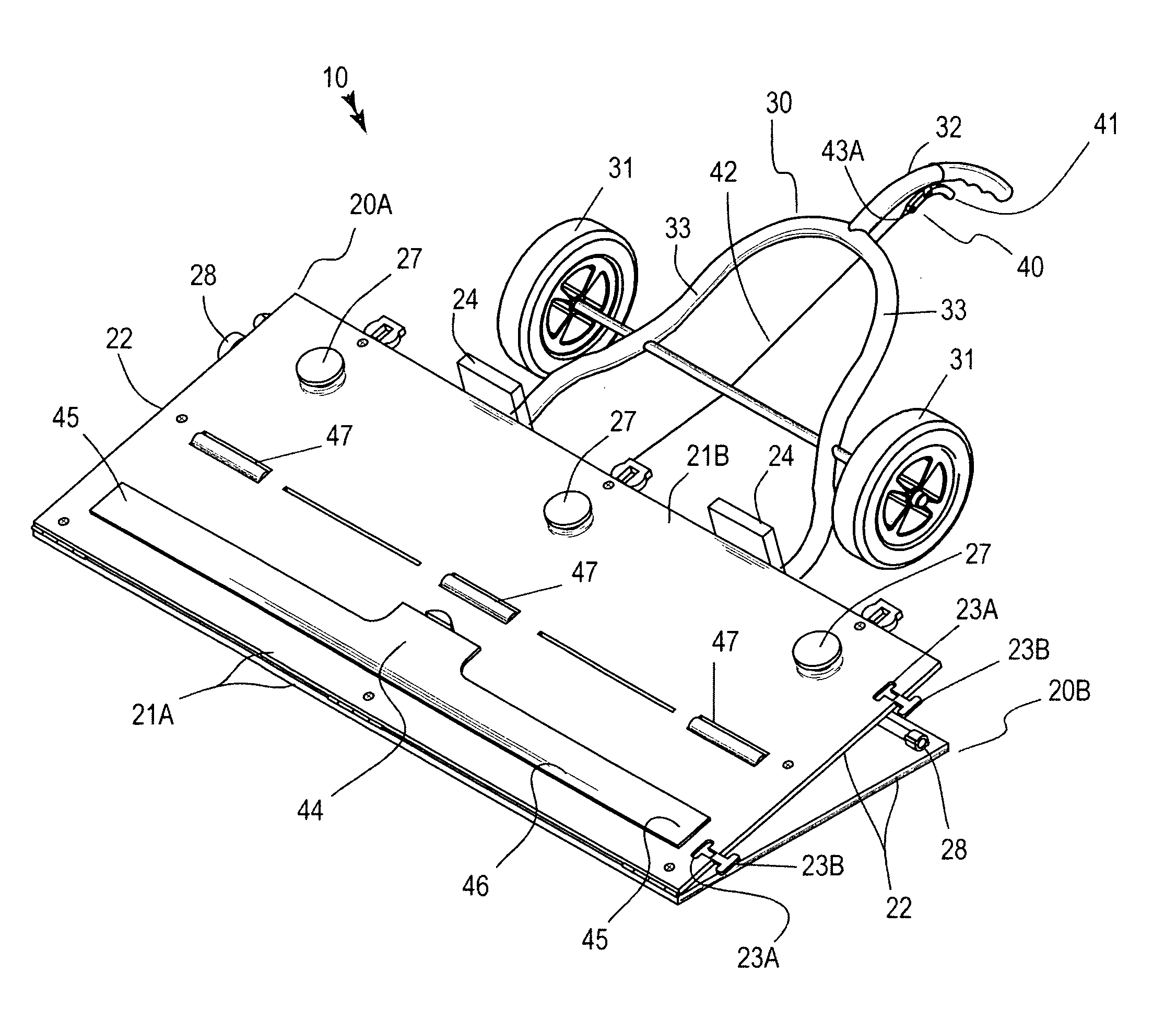

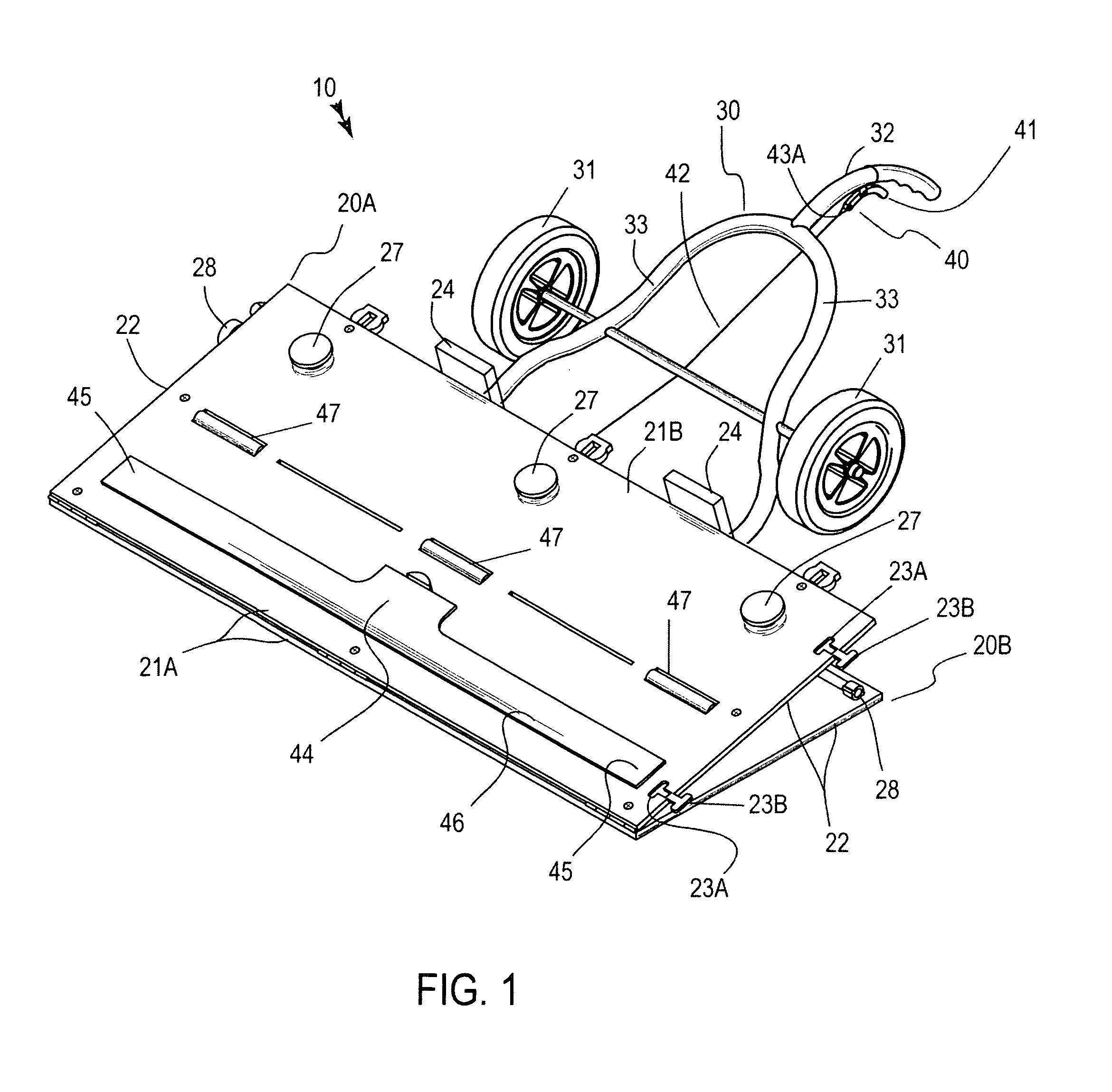

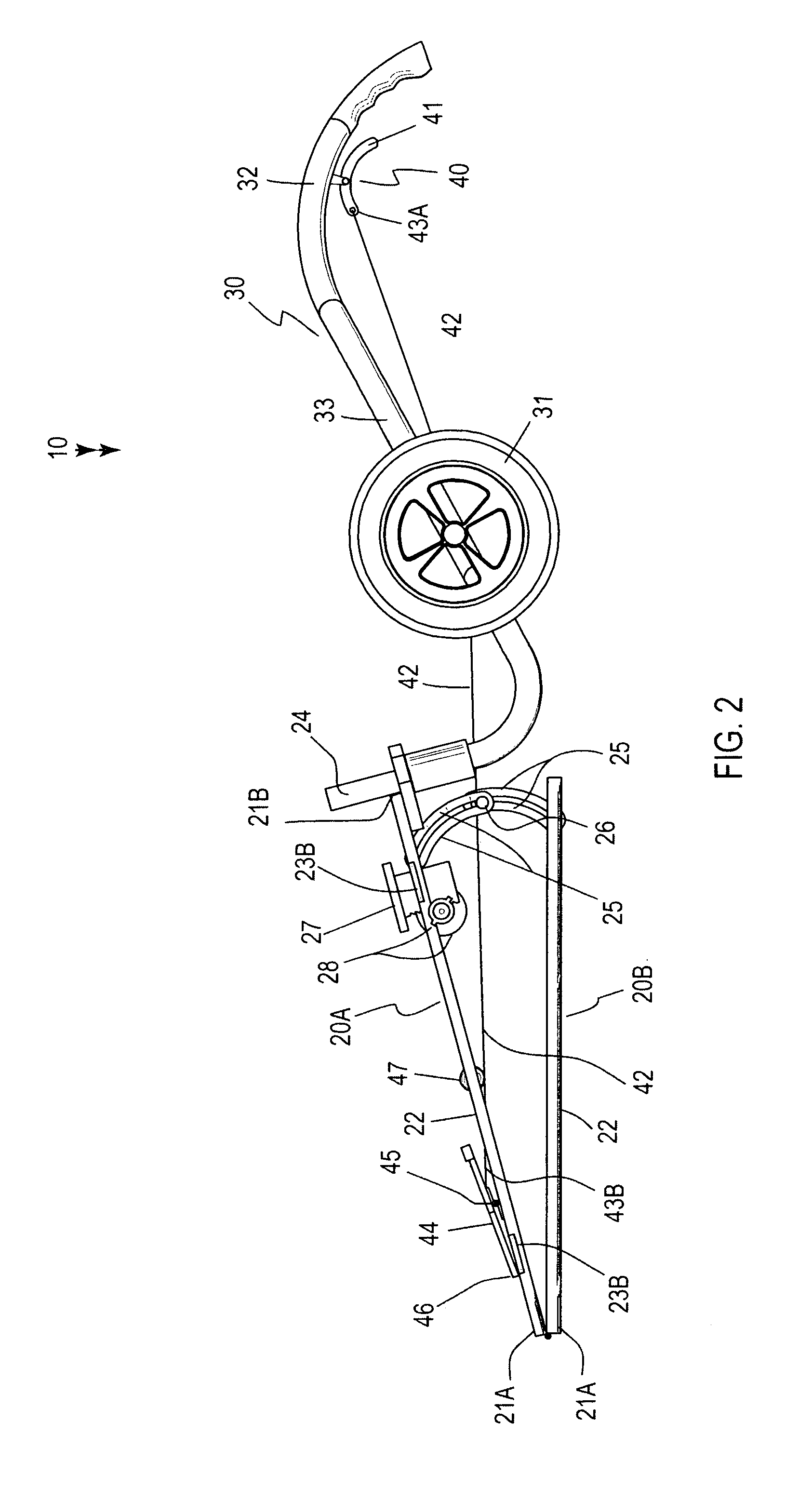

Installation tool for interlocking grooved flooring panels

InactiveUS7156383B1Quickly and securely interlockConveniently and effectively raiseLifting devicesRoof toolsPanellingEngineering

A tool includes pivotally conjoined top and bottom planar bodies being coupled along their distal edges and having opposed linear ends. The bottom body is statically registered while the top body is dynamically articulatable. Slotted brackets are coupled to one linear end of the bodies, and are slidably interlocked and repeatedly moveable between compressed and engaged positions. Knobs traverse through the top body and are engaged therewith. The knobs are adaptable between raised and lowered positions. A turn wheel is connected to the knobs for raising and lowering the knobs in sync. A handle assembly includes wheels that are seated proximal to the bodies. A lever protrudes proximally from the wheels. A mechanism is included for preventing laminate planks from sliding downwardly along the top body. Rotatable and equidistantly spaced rollers are axially oriented along the top body and are registered with corresponding ones of the knobs.

Owner:JACOBS CHARLES A

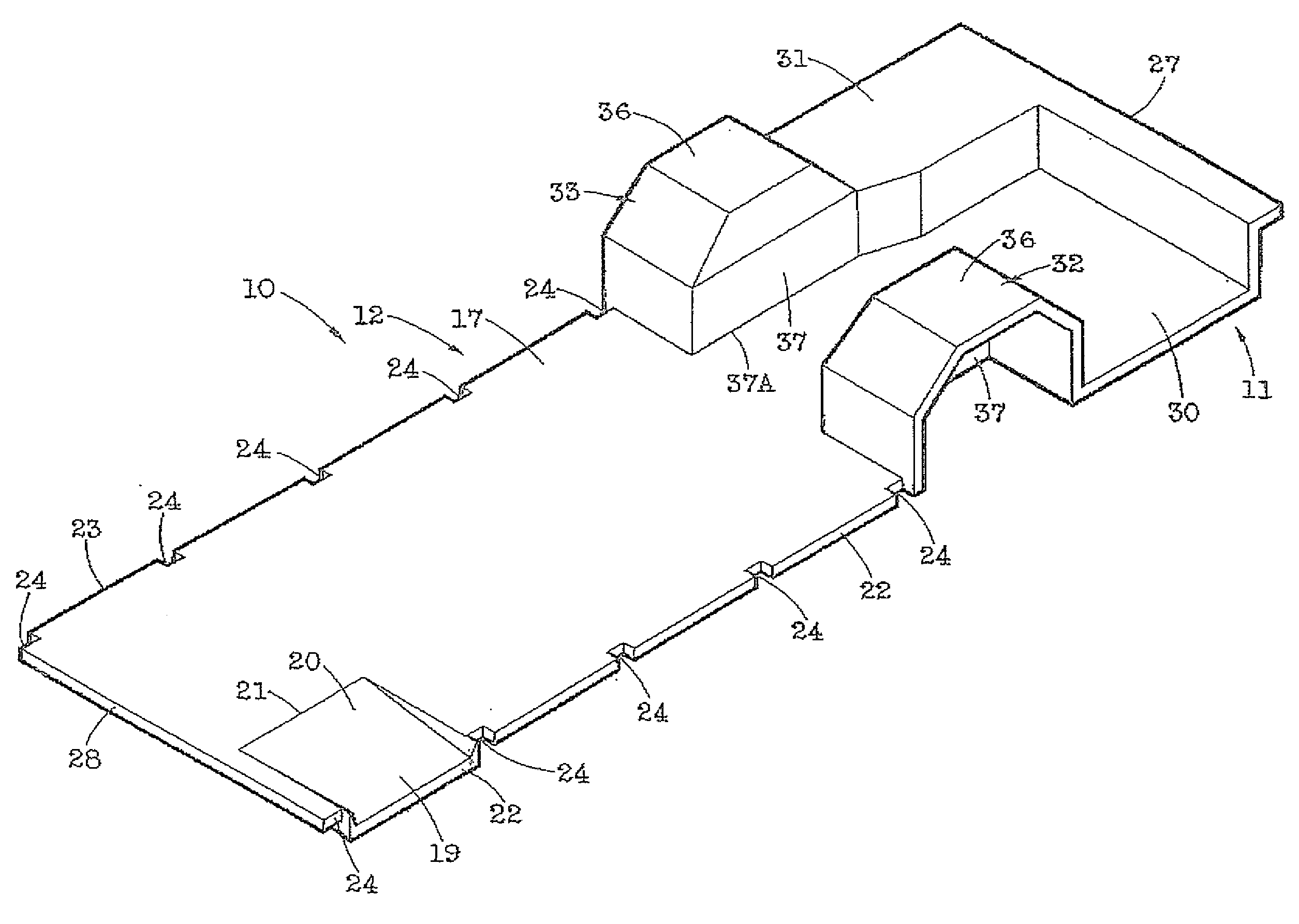

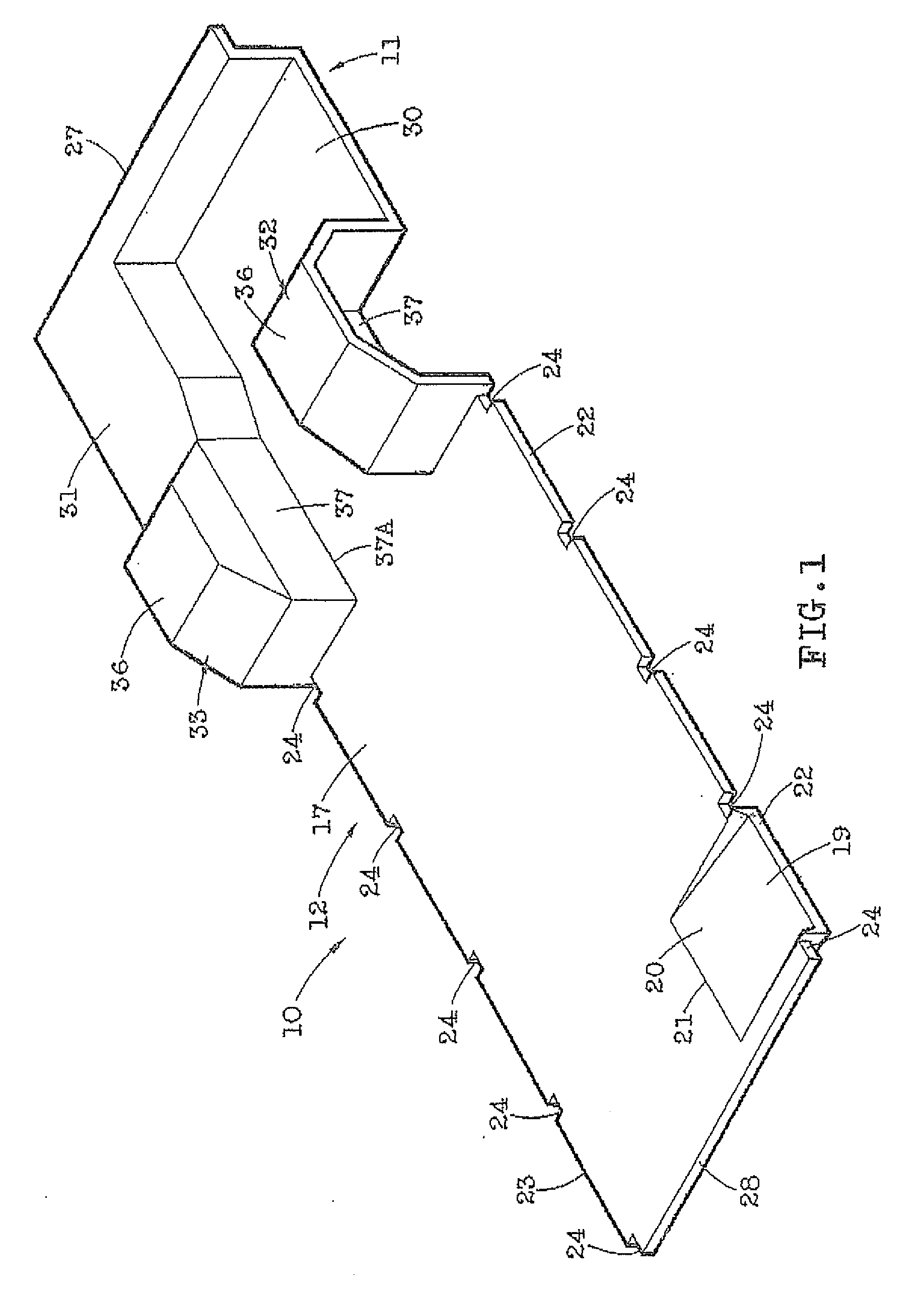

Handmade Structure System

A system of prefabricated modular components, designed to fit and connect together using no tools other than human hands, allowing persons with little or no construction experience to assemble floored / partitioned / roofed structures of variable shape and surface area. Flooring panels are inserted and secured into flooring frames that have been inserted and secured into frame connectors. Flooring frames may be anchored into an outdoor installation surface for long term use. Certain configurations of the frame connector allow for the installation of variable height partition supports, as well as partition panels. A special configuration of the flooring frame allows for wheeled implement / conveyance access to the floored surface from the surrounding surface. Open, unfloored areas may be created within the periphery of a structure. Roof Panels are installed onto and supported by Roof Brackets, Roof Beams and Integrated Gutter Sections. Precipitation is conveyed to Downspout Pipes and Fittings via Downspouts.

Owner:RUTLEDGE RICHARD BRUCE

Ballistic paneling for bullet traps

InactiveUS20110233869A1Reduce the amount requiredReduce chanceArmourLaminationPanellingBiomedical engineering

Owner:ACTION TARGET

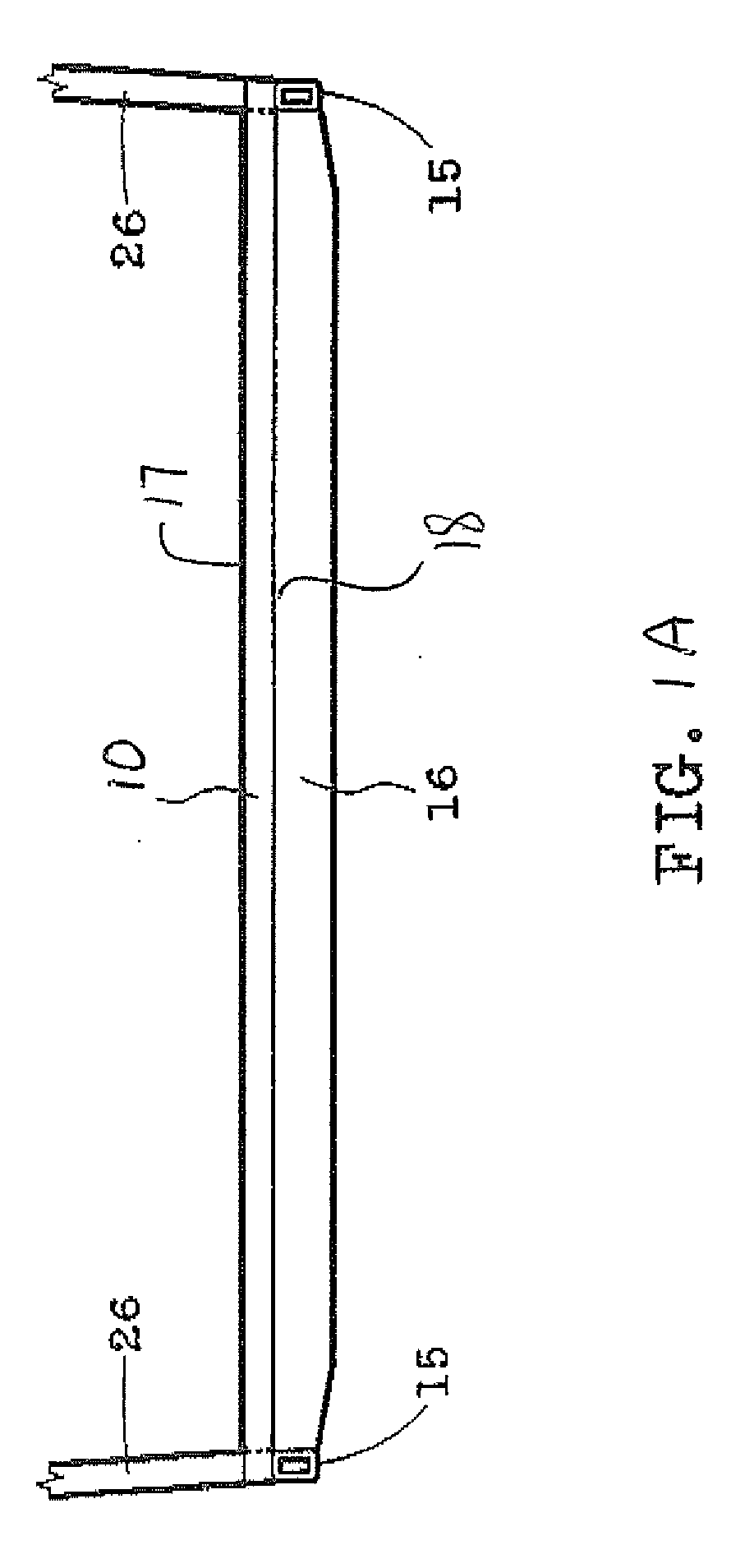

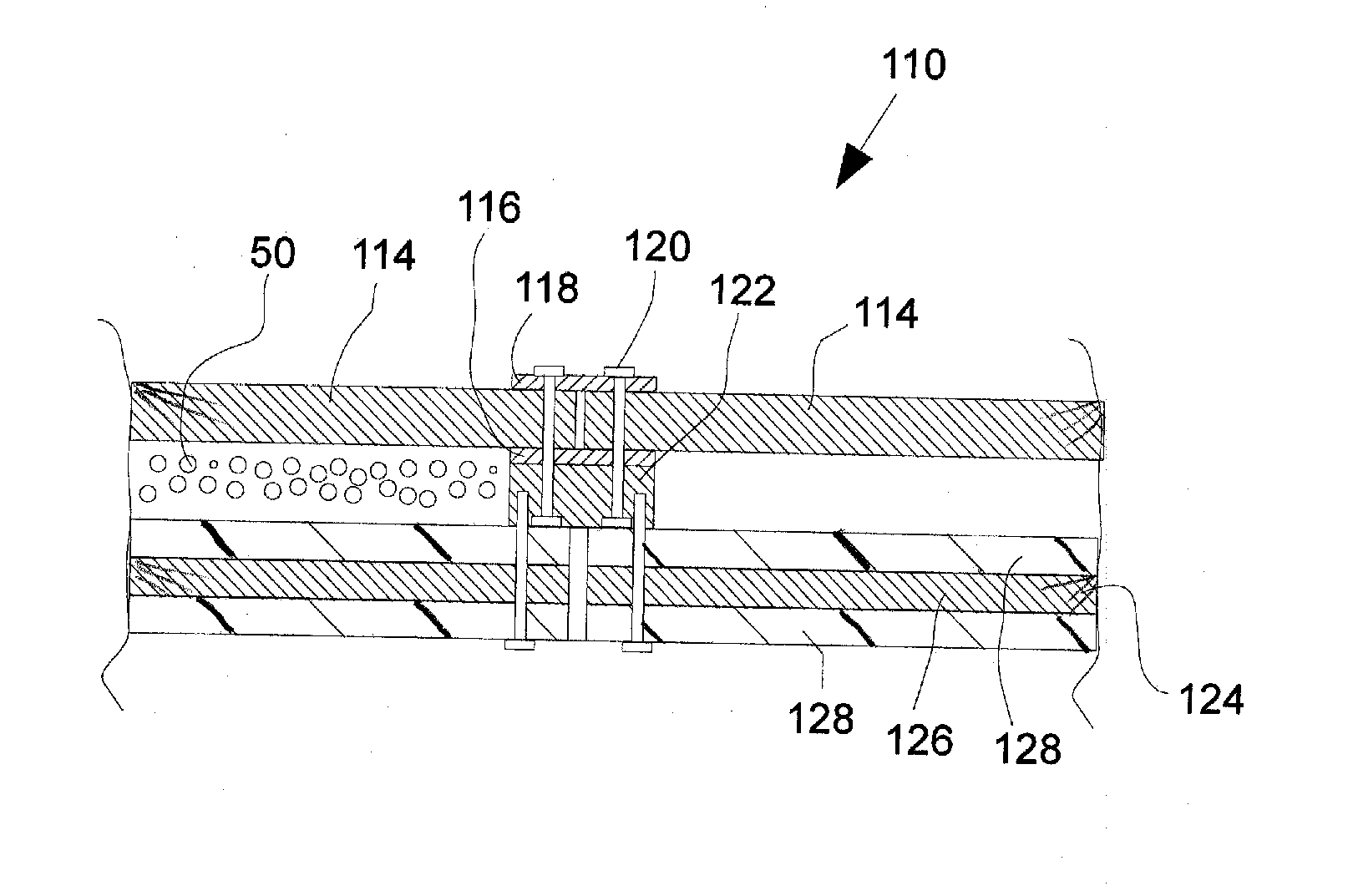

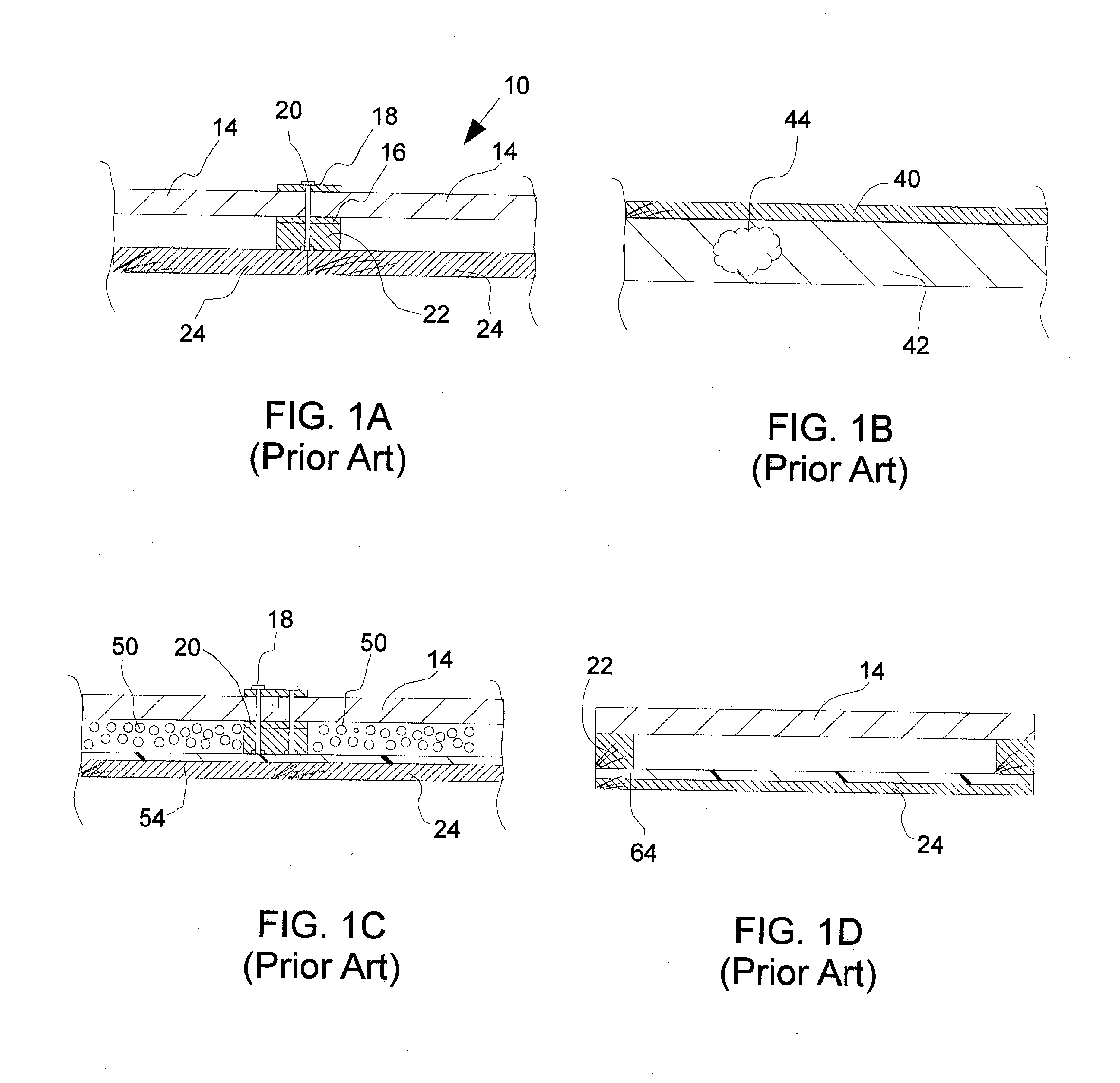

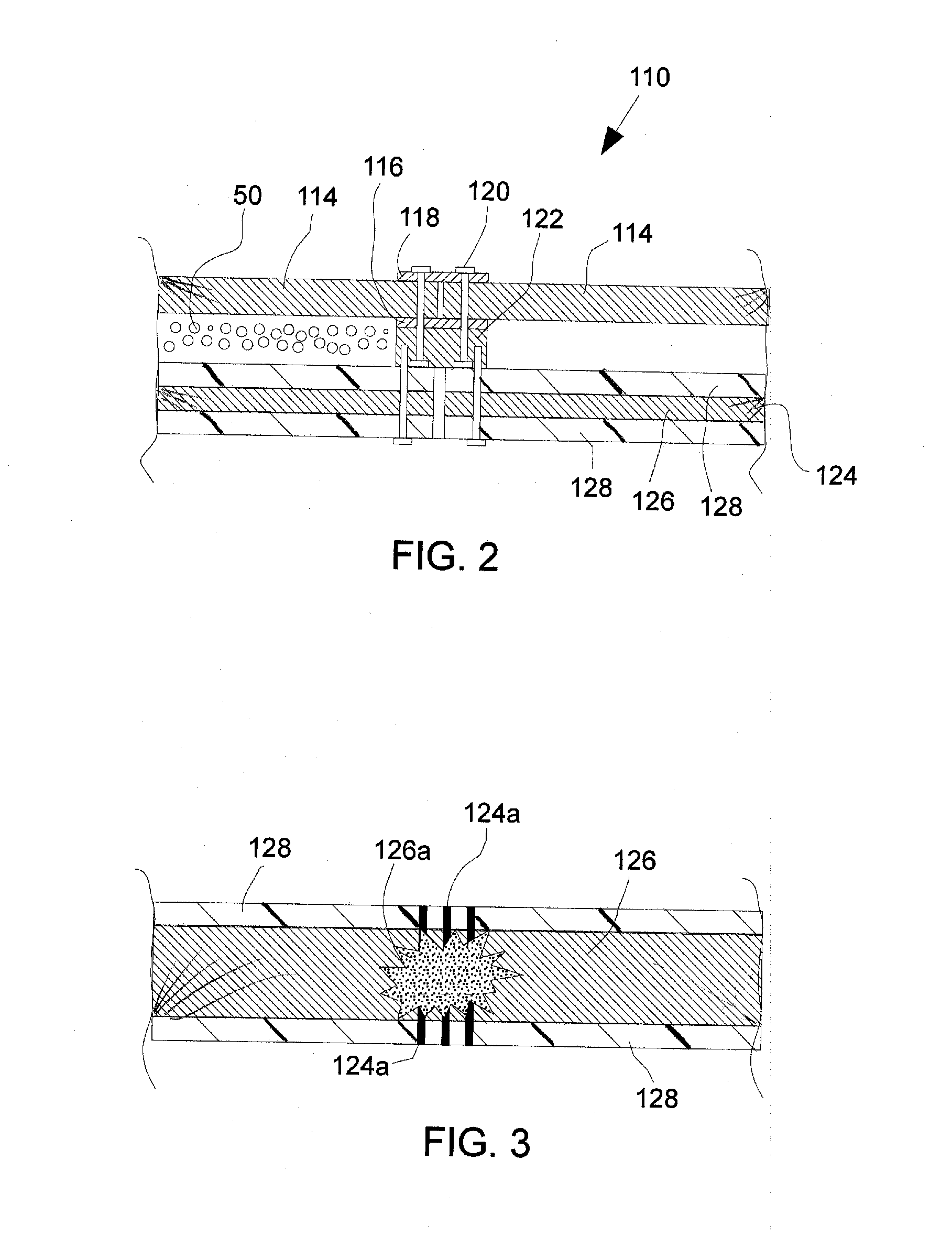

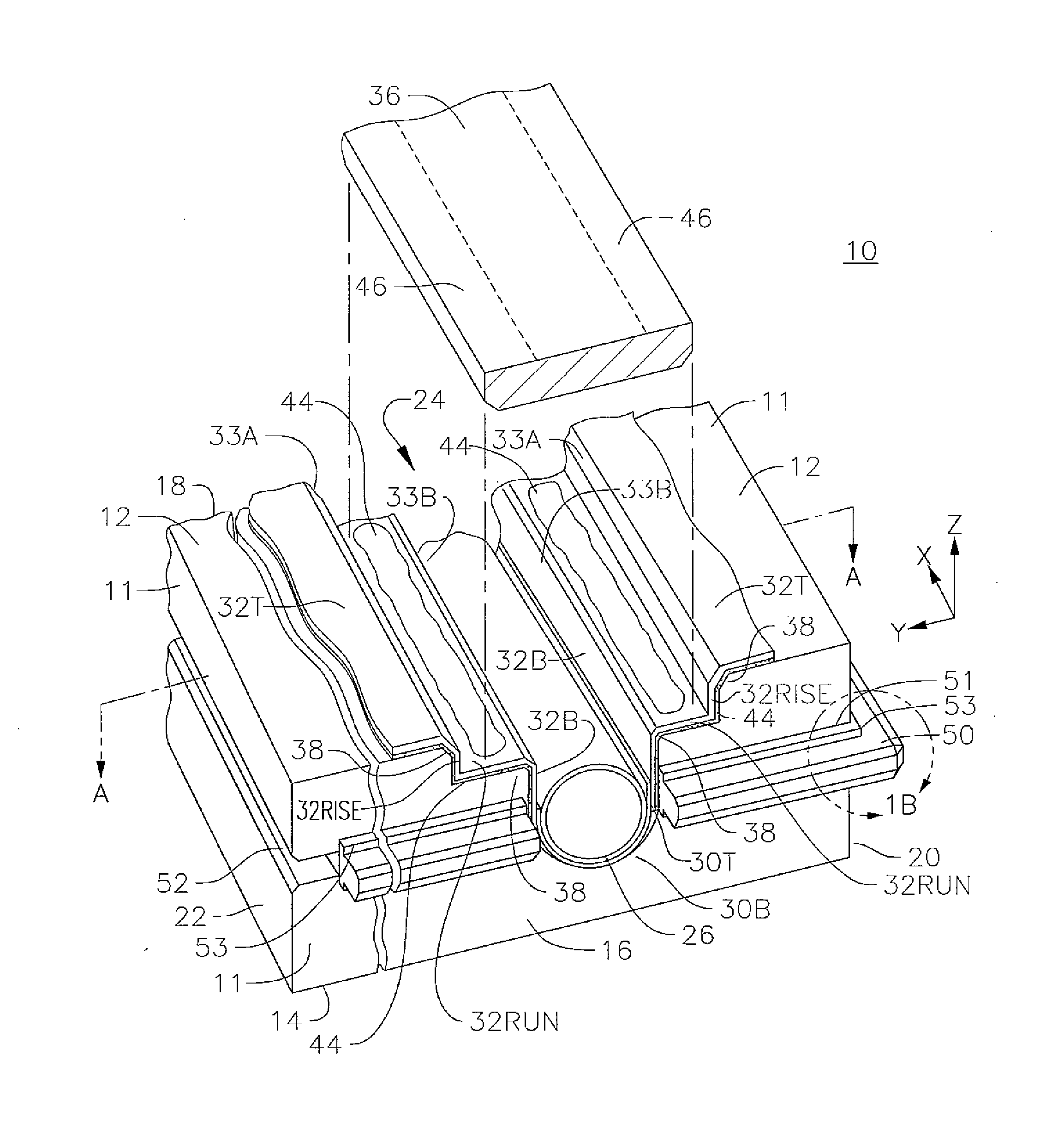

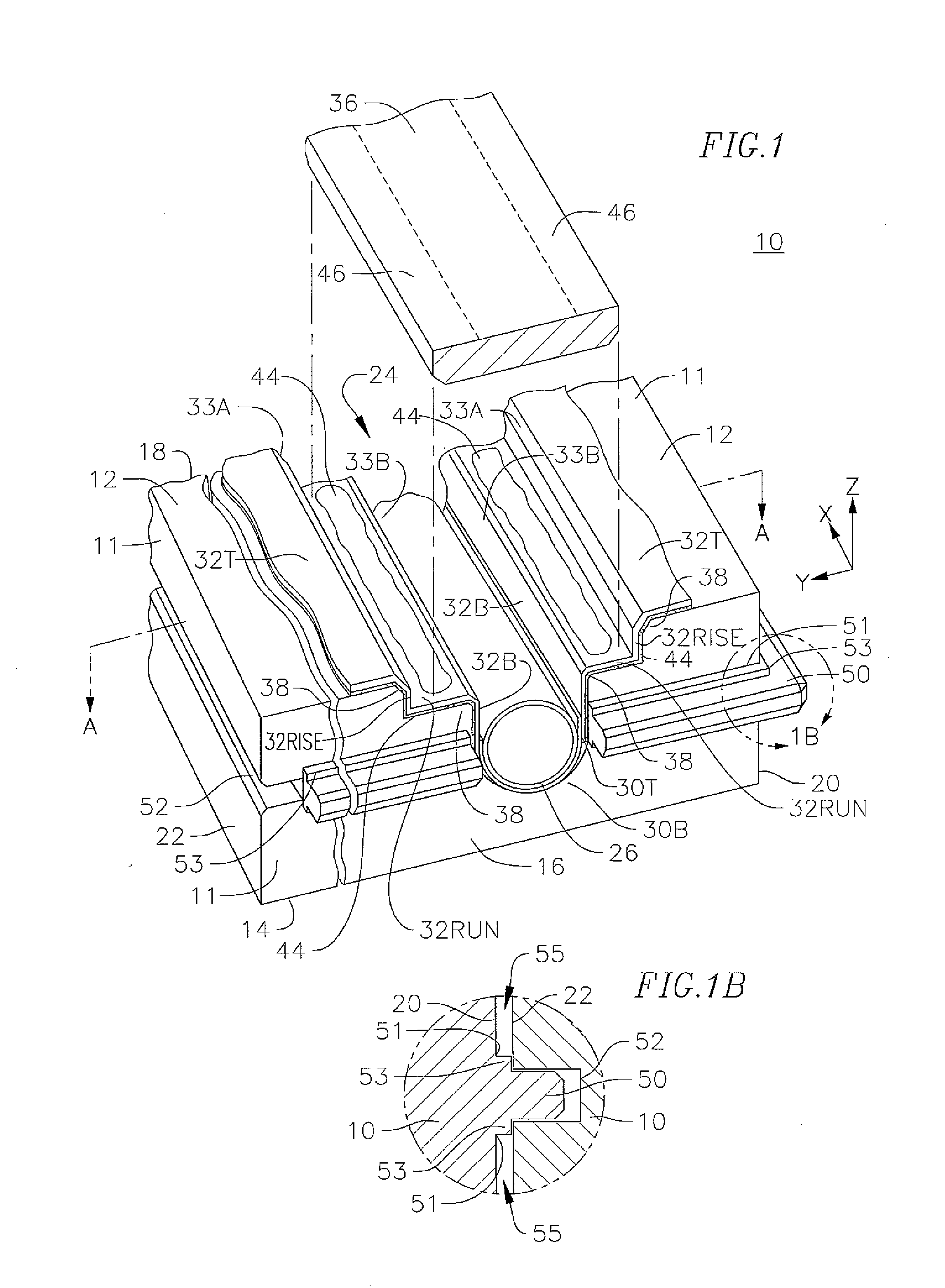

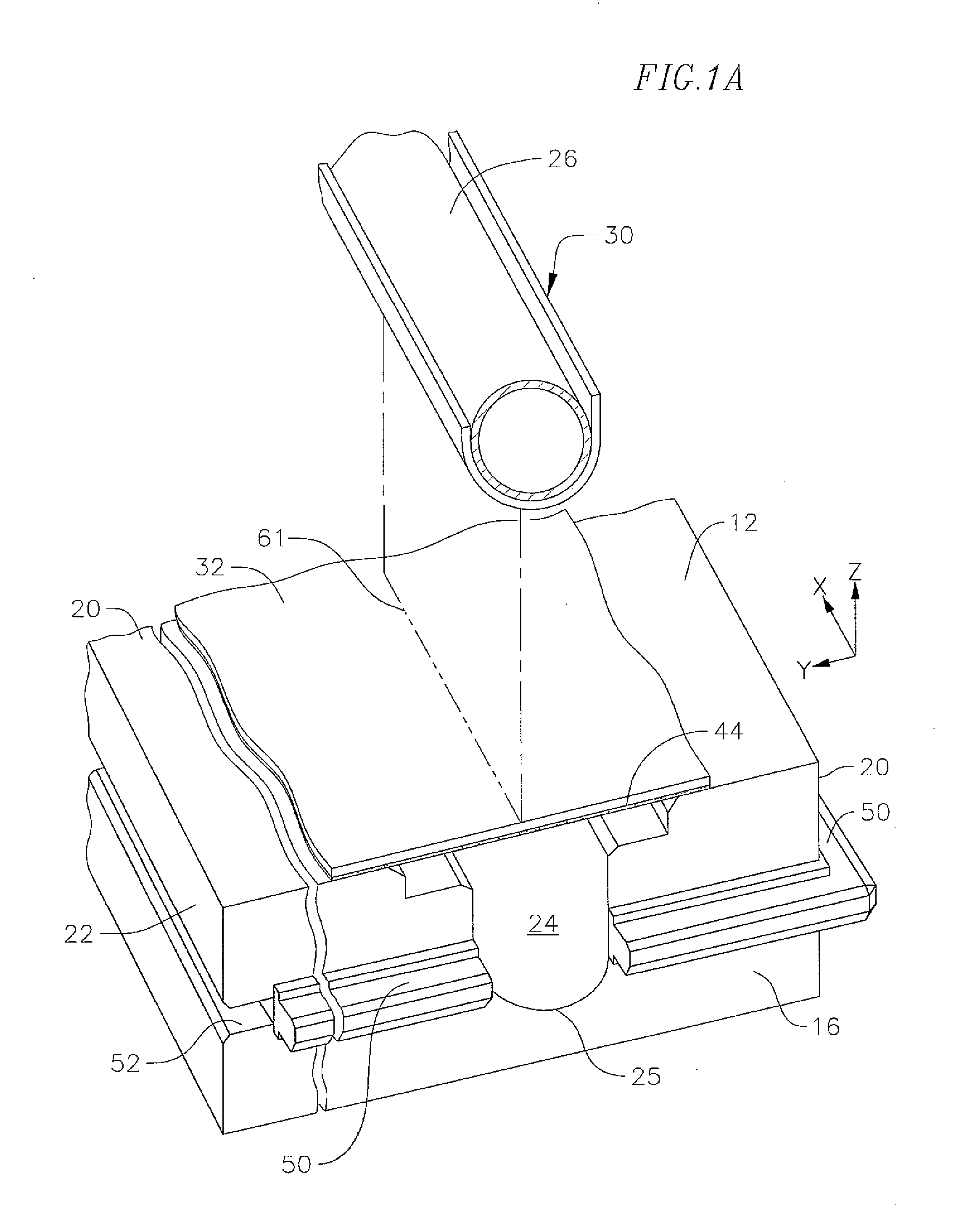

Impact and/or sound deadening hydronic sub-flooring panel and related system and method

A sub-flooring panel with improved impact and / or sound deadening (ISD) properties that is adapted to adjoin other sub-flooring panels to form a sub-flooring panel assembly, includes a base body having an upper surface formed with a groove for receiving a heating / cooling element, such as hydronic piping. A sub-flooring system with significantly improved ISD properties includes the panel assembly and an underlayment assembly which comprises a plurality of stabilizing supports, each support being adjustable in height, to support at least a generally rigid board and a fiberboard on which finishing flooring or laminate may be installed.

Owner:CODI GRP

Apparatus to assist in installation of drywall

Owner:SCHLEGEL GARY R

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com