Patents

Literature

1693 results about "Wood grain" patented technology

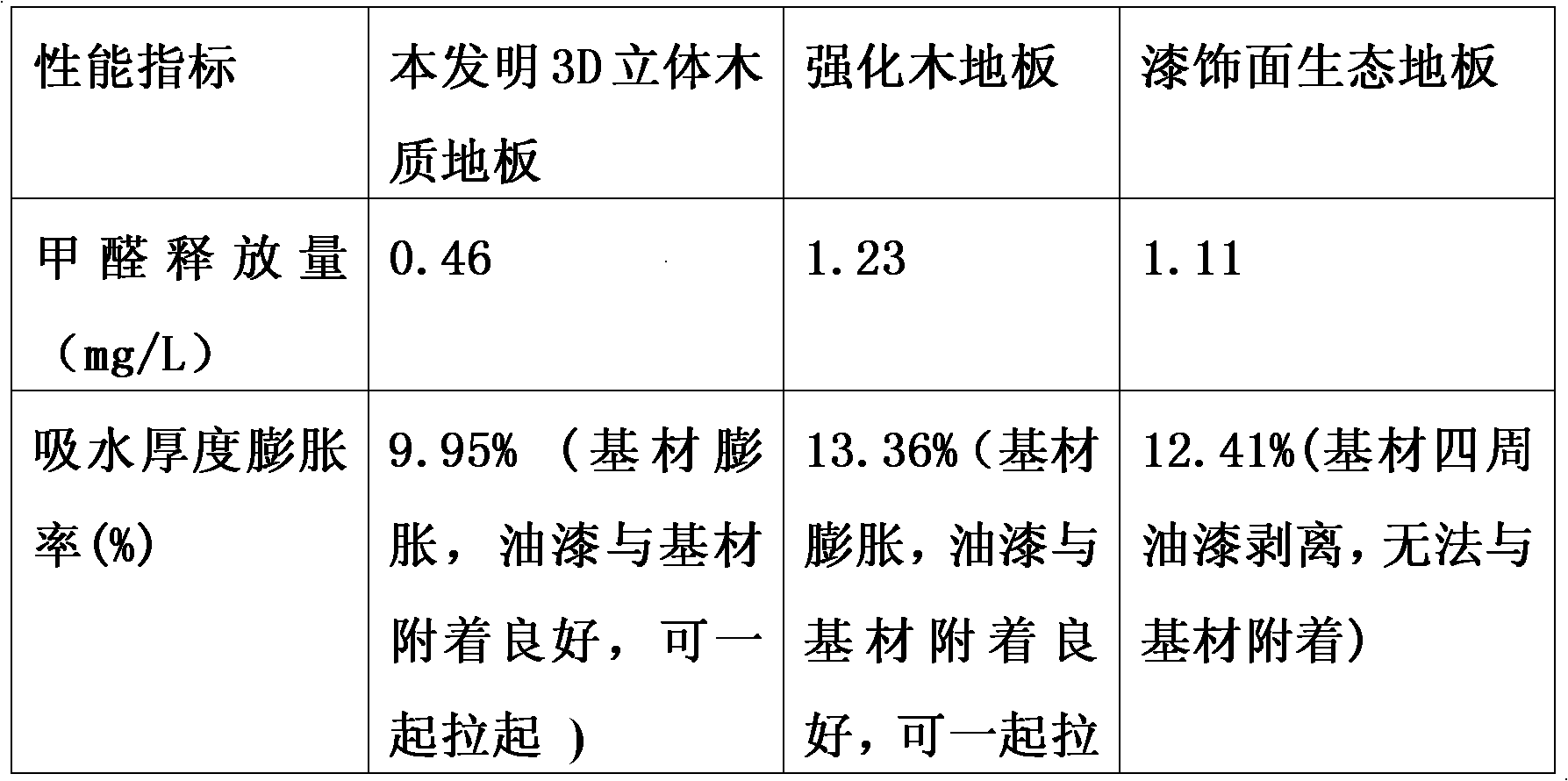

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood grain is the longitudinal arrangement of wood fibers or the pattern resulting from this.

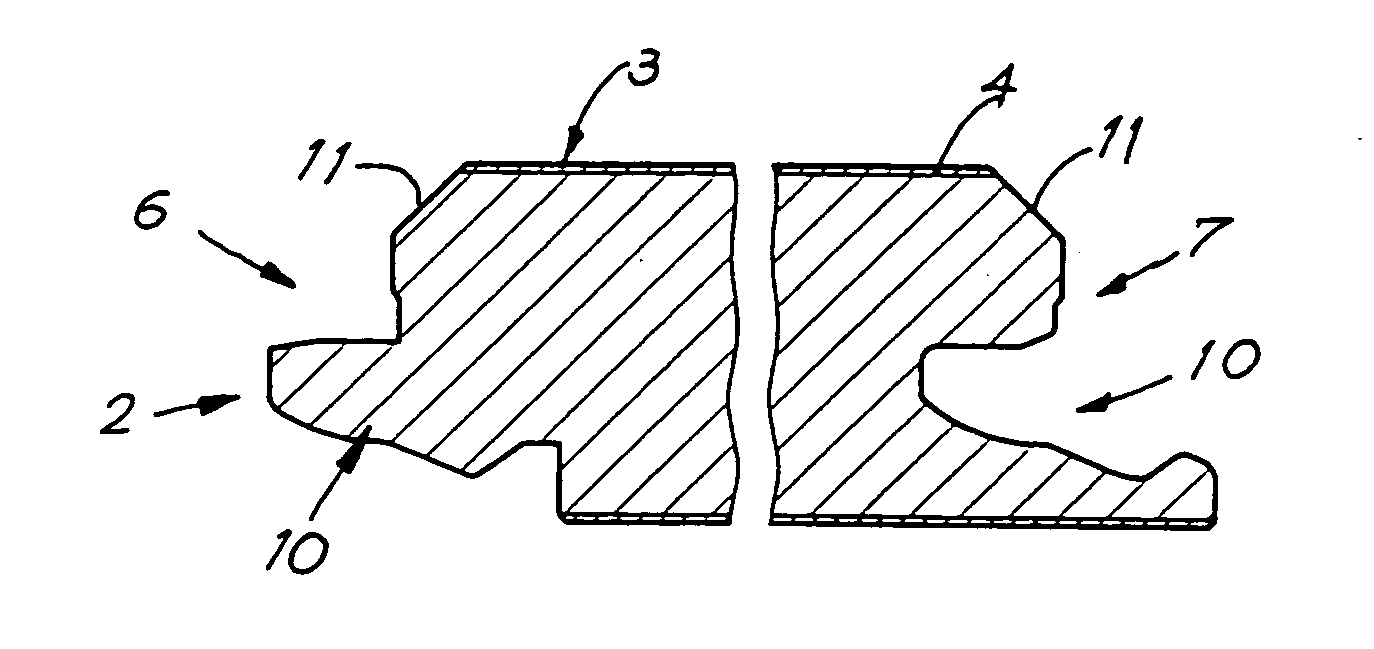

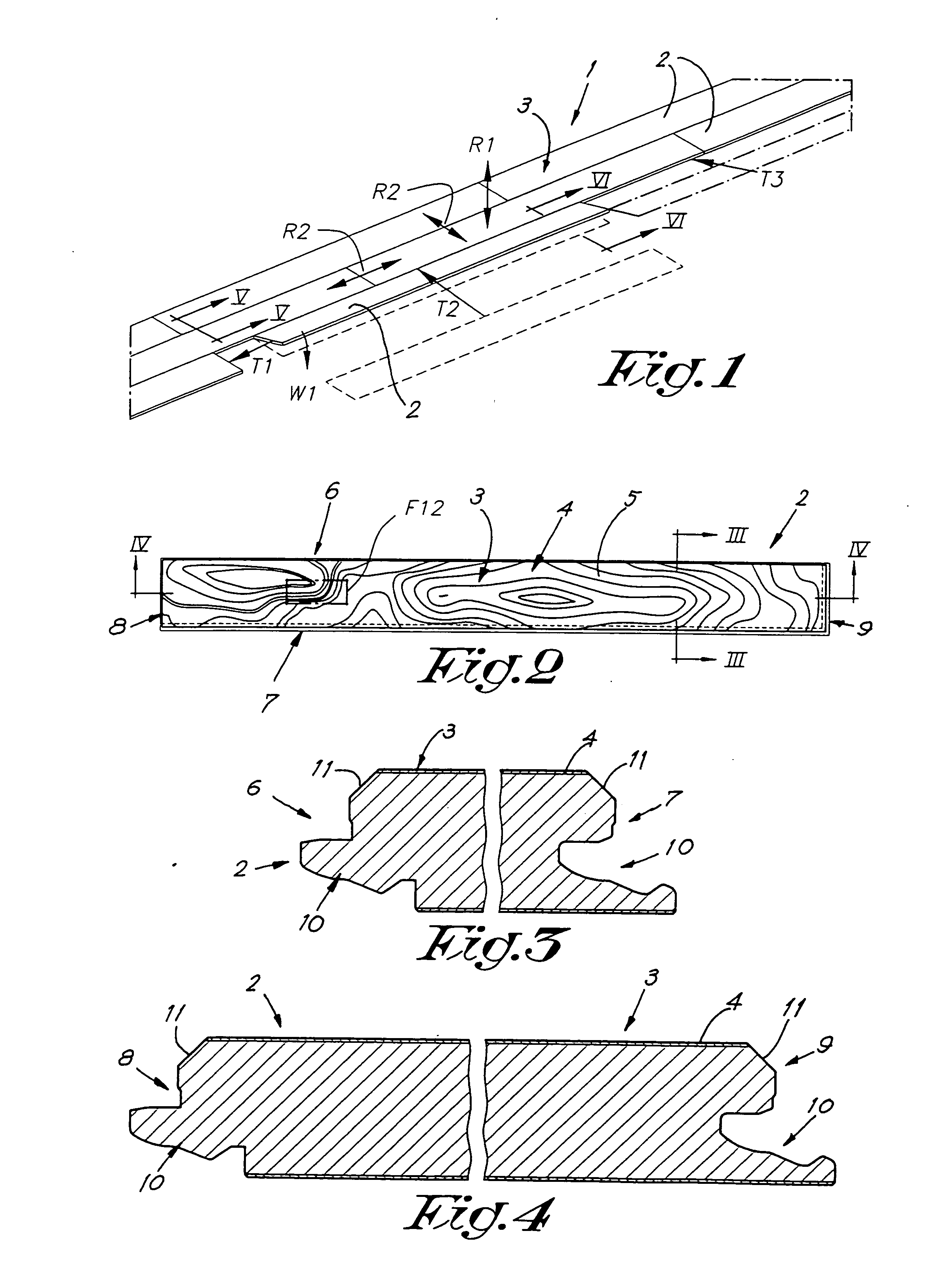

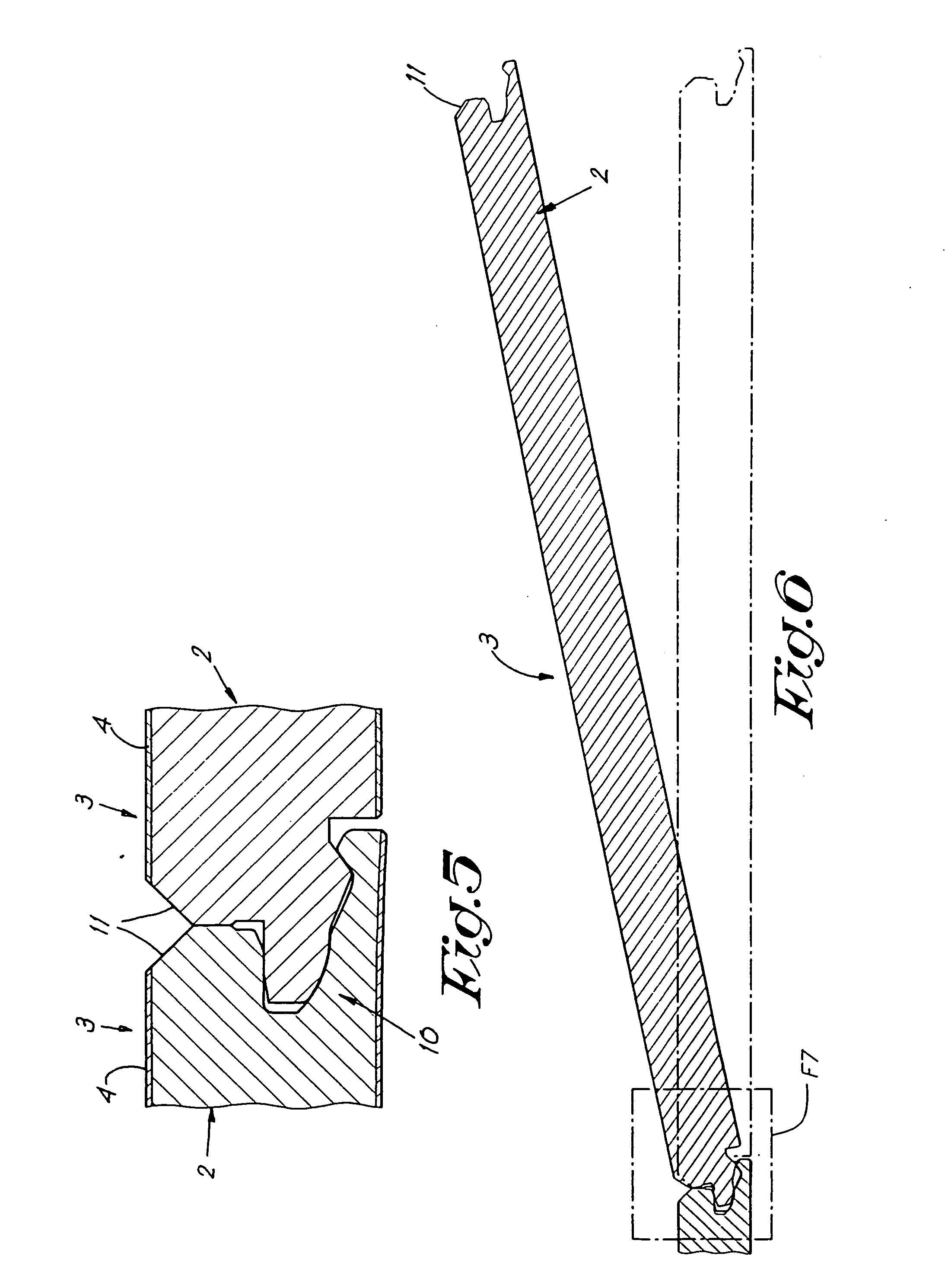

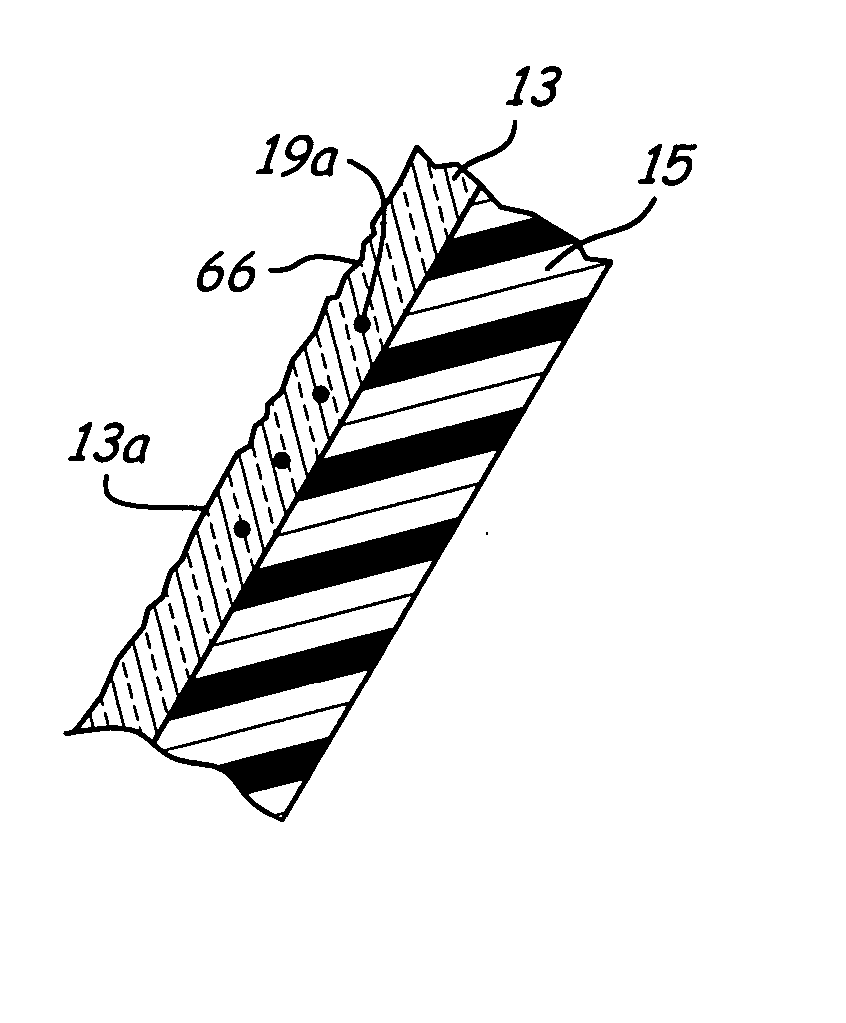

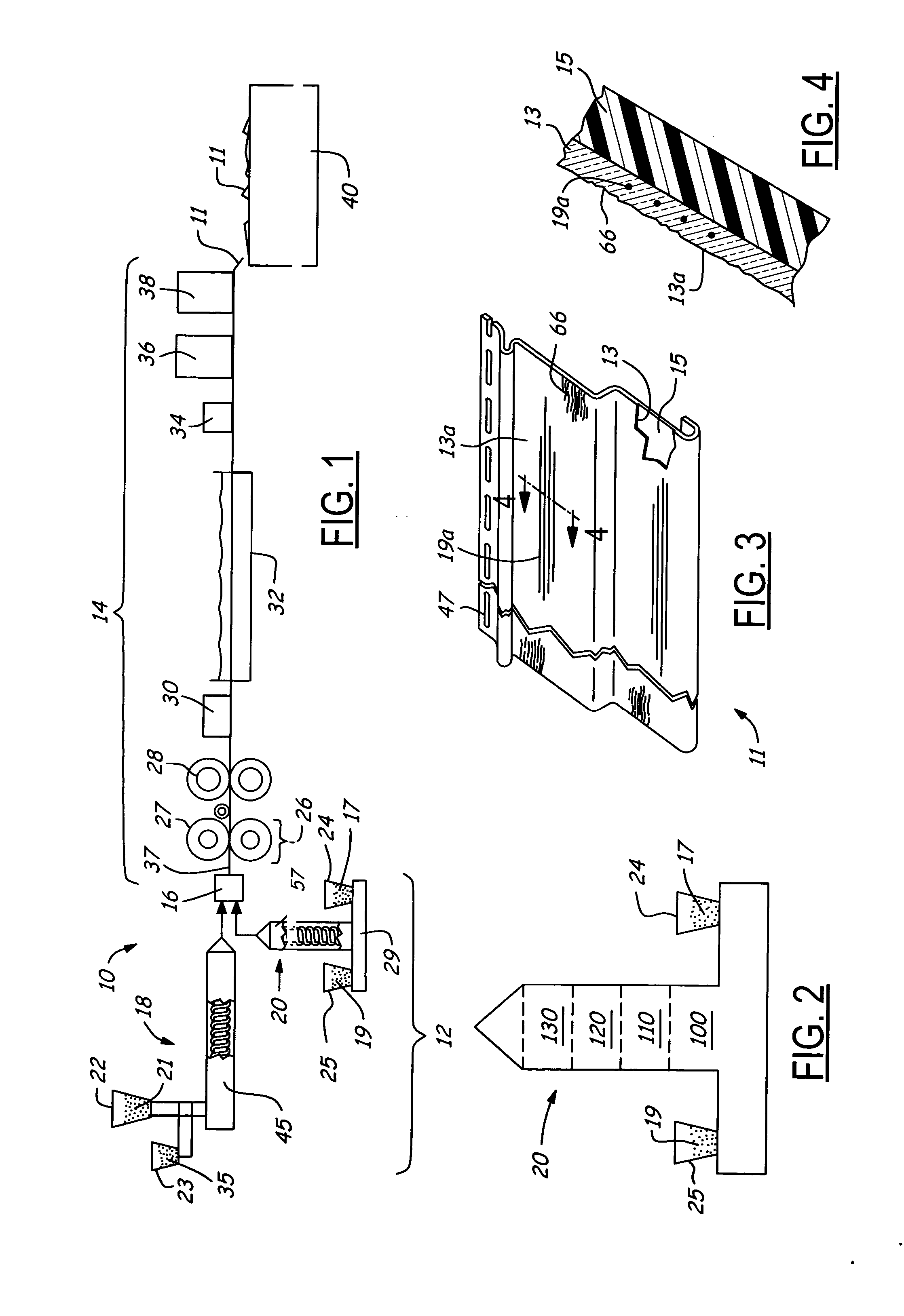

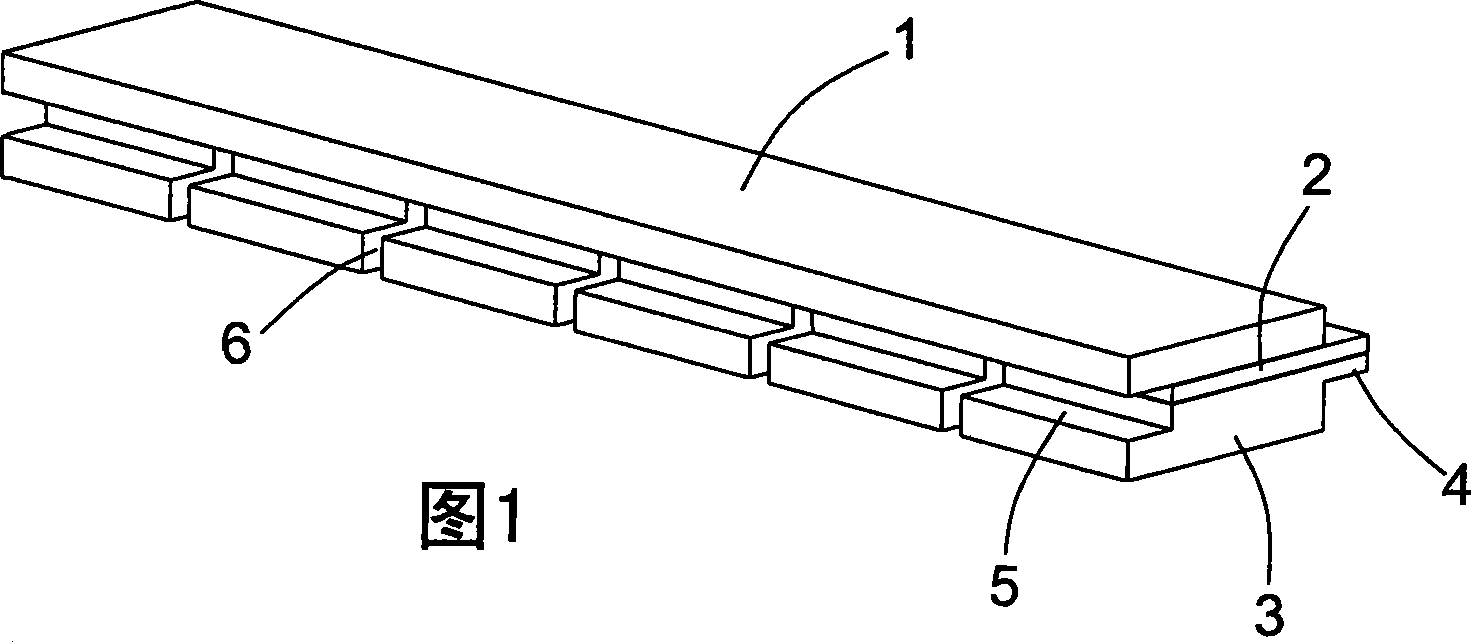

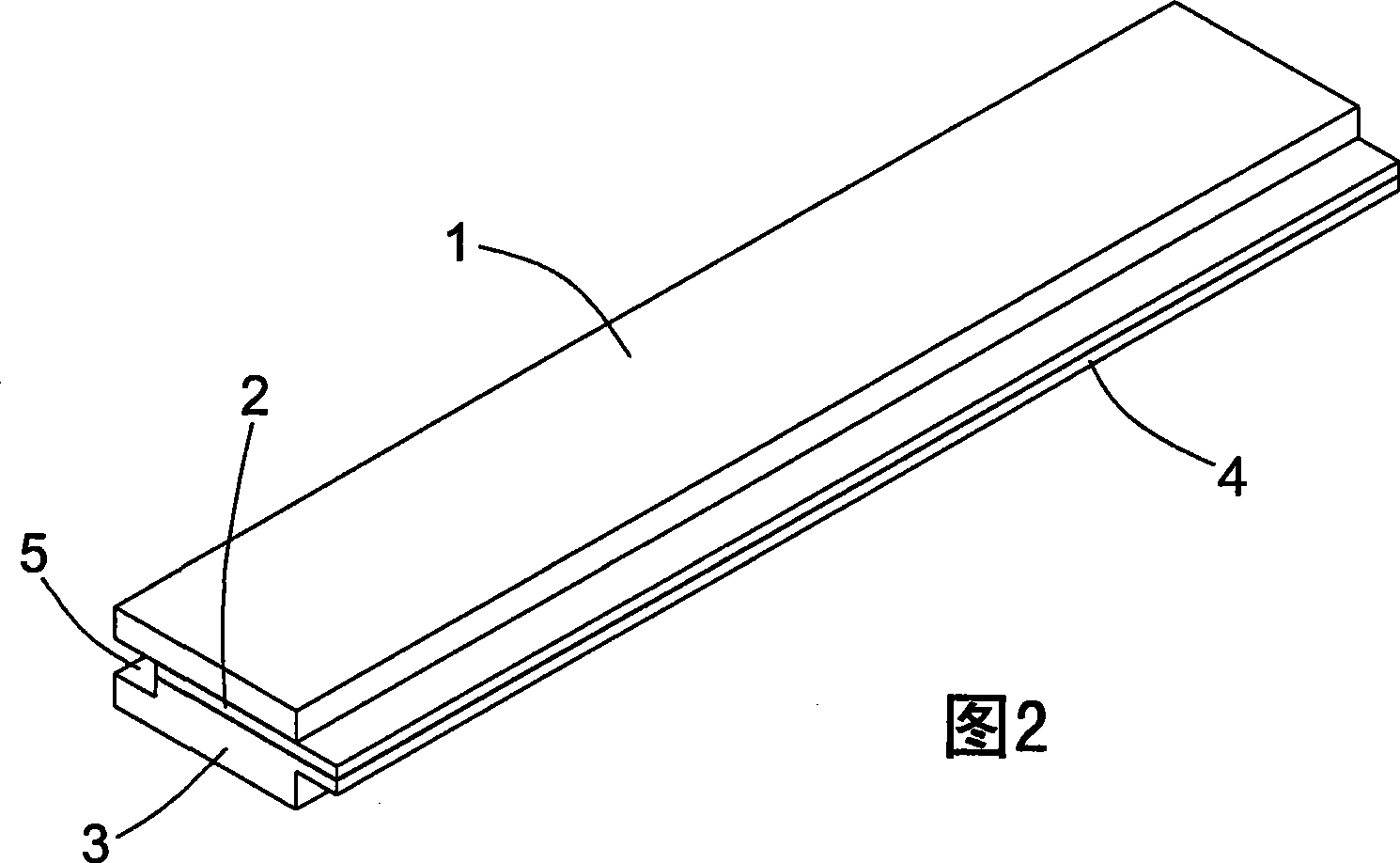

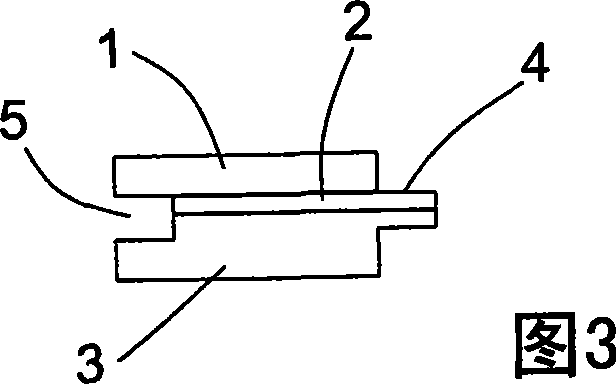

Floor covering, floor panels for forming such floor covering, and method for realizing such floor panels

InactiveUS20050025934A1Improvement of imitationReduce disadvantagesCovering/liningsNatural patternsSynthetic materialsPanelling

Floor covering, consisting of hard panels, with a laminated structure, whereby at least at the upper surface a printed decorative layer with a wood pattern is present, with thereupon a transparent layer of synthetic material in which impressions are formed, wherein the impressions substantially follow the wood pattern.

Owner:FLOORING IND LTD

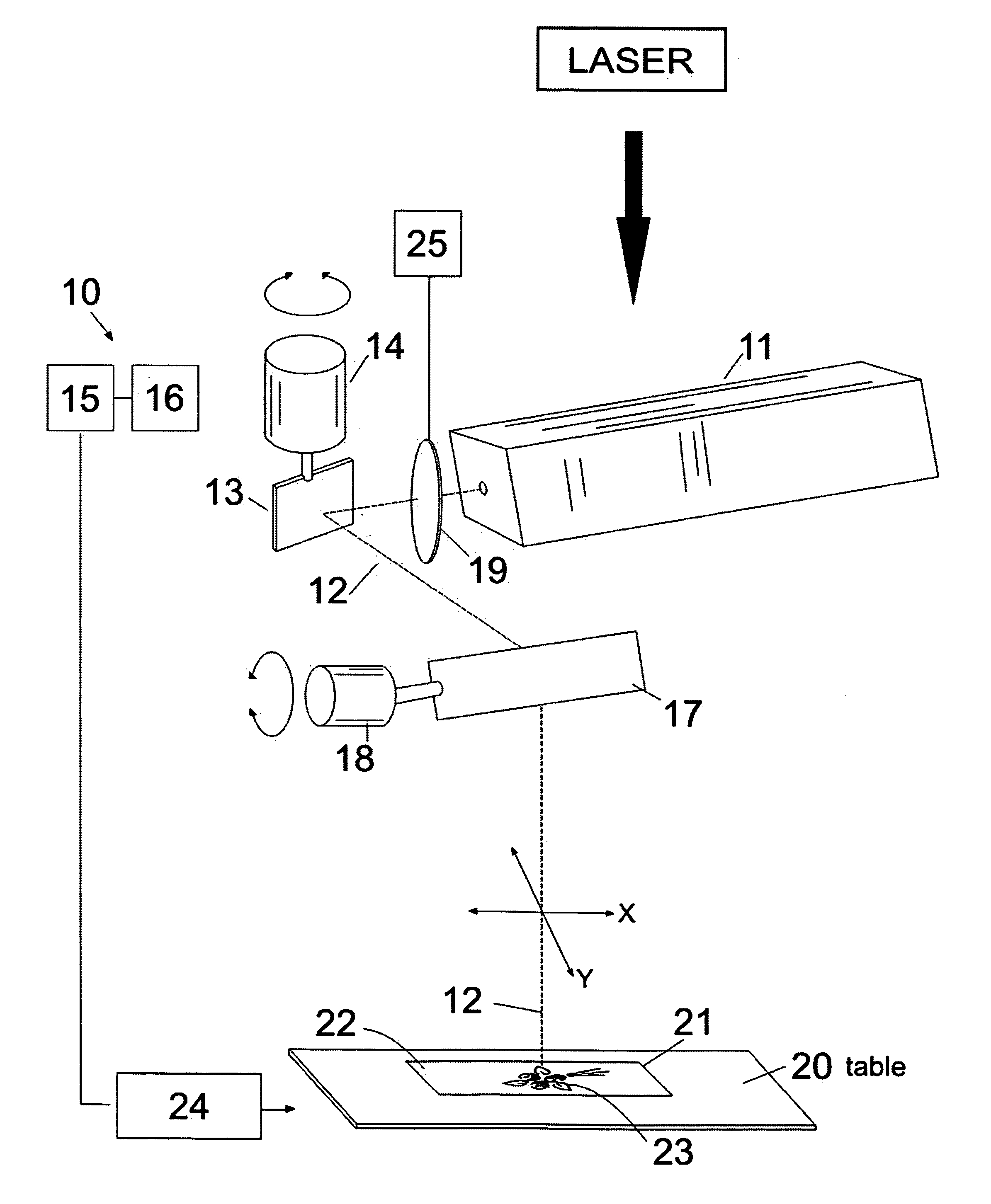

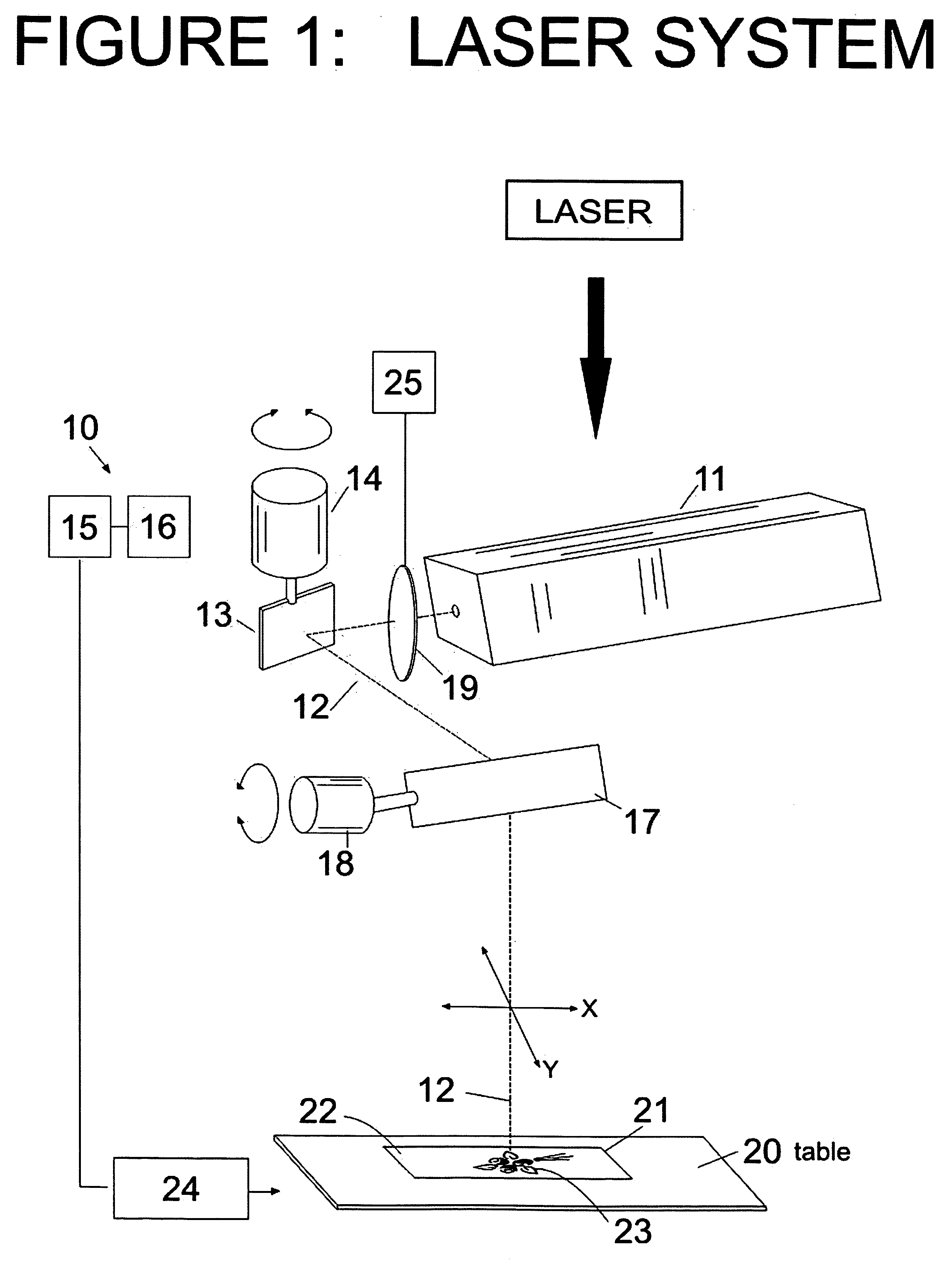

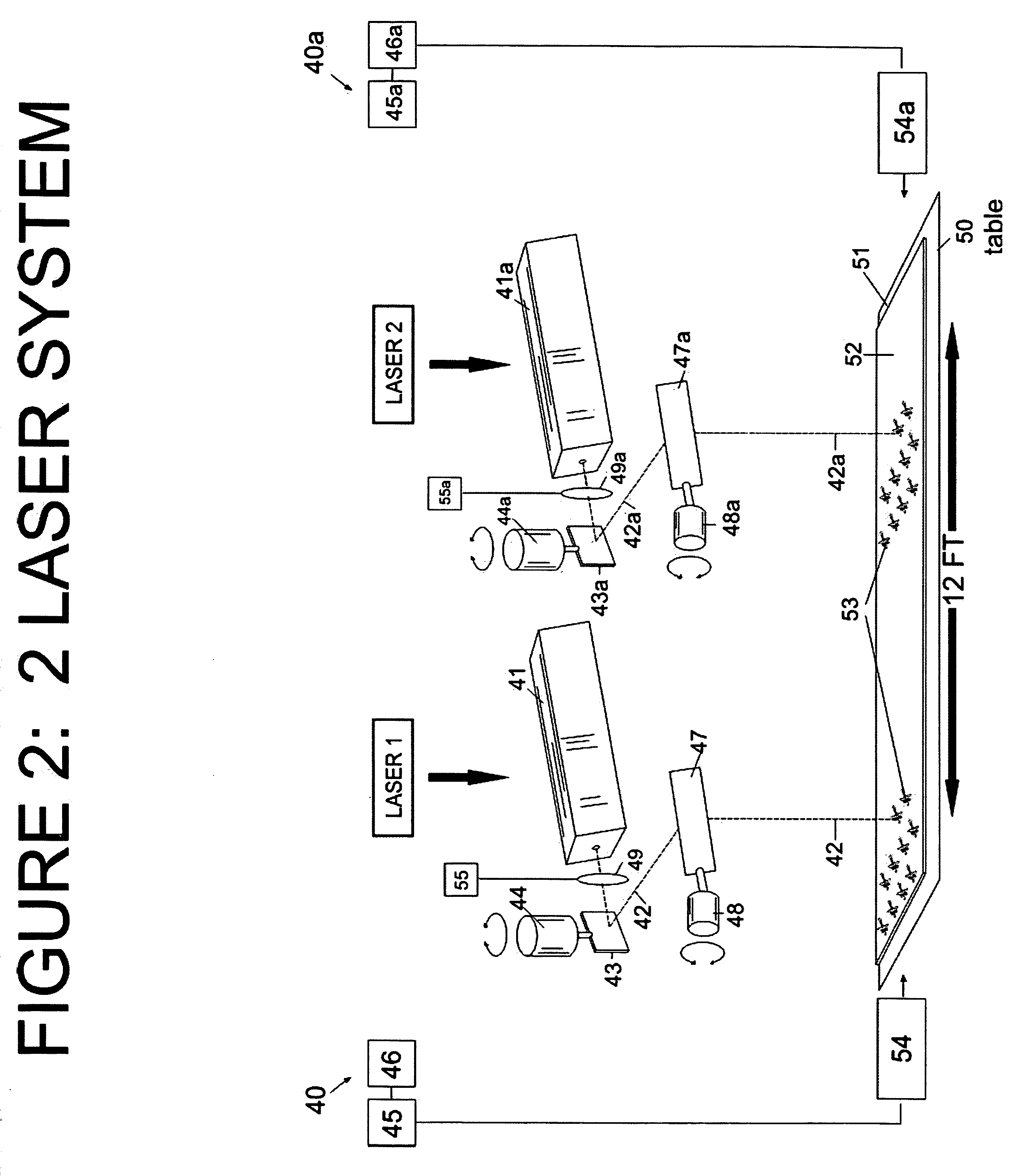

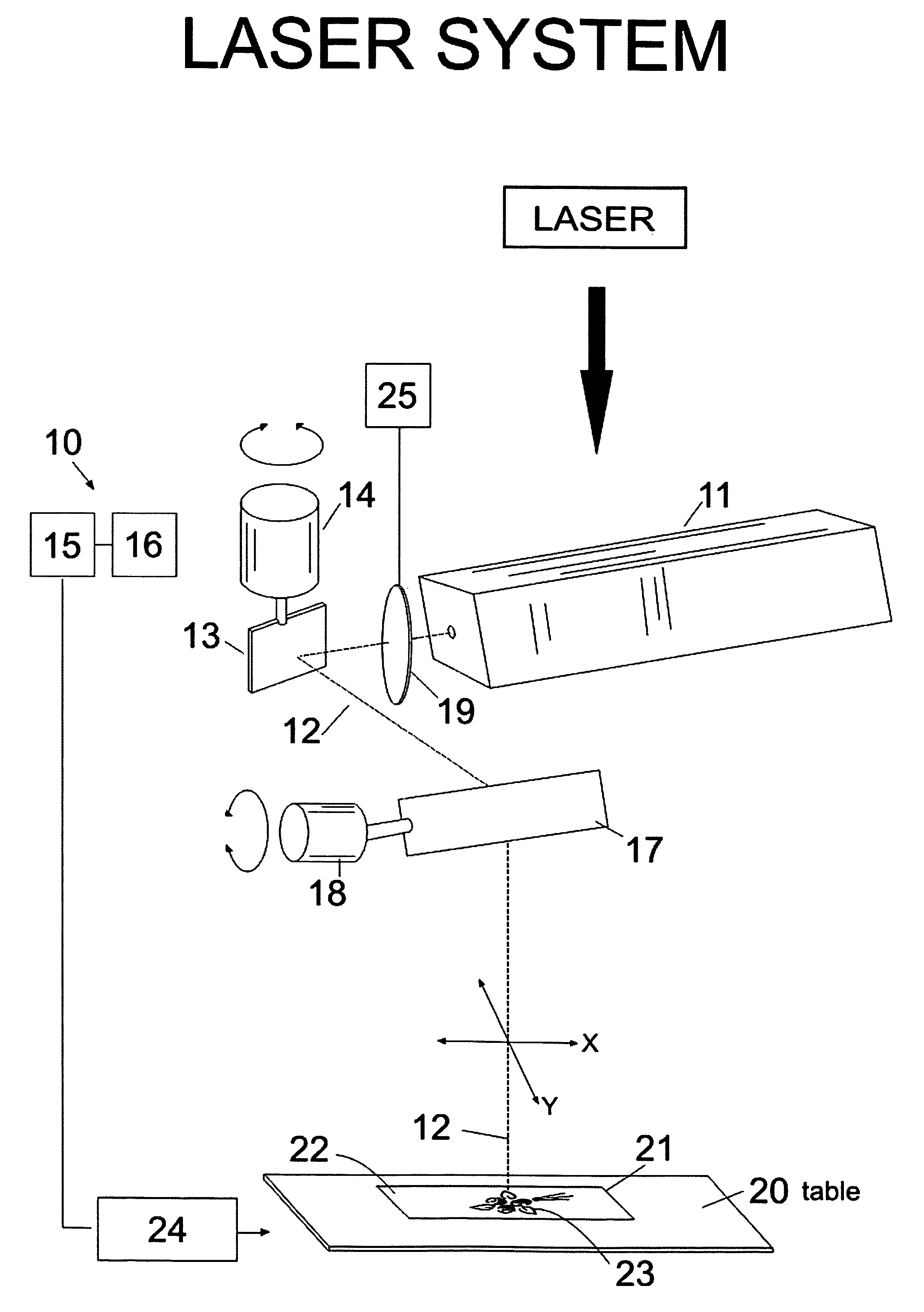

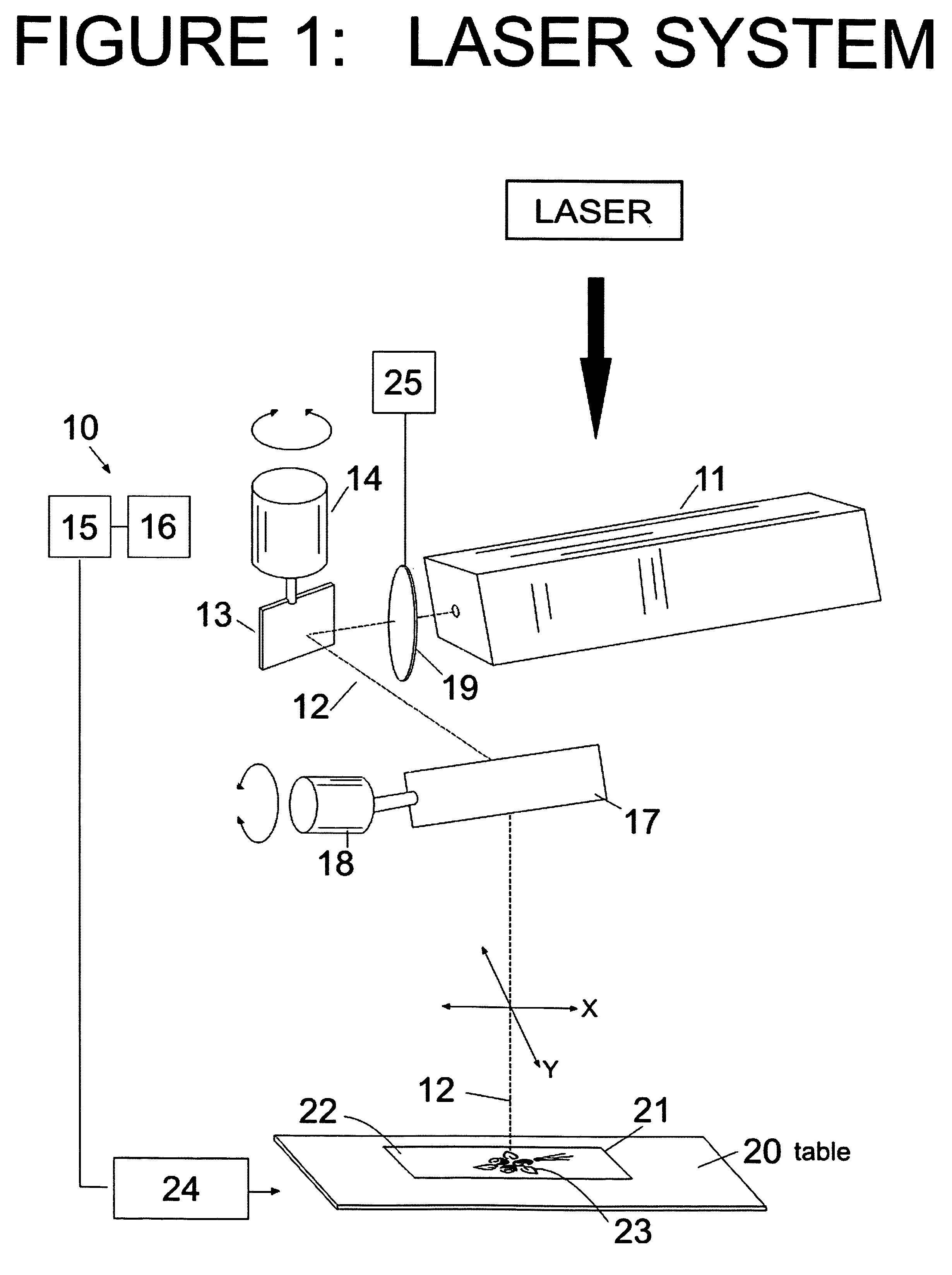

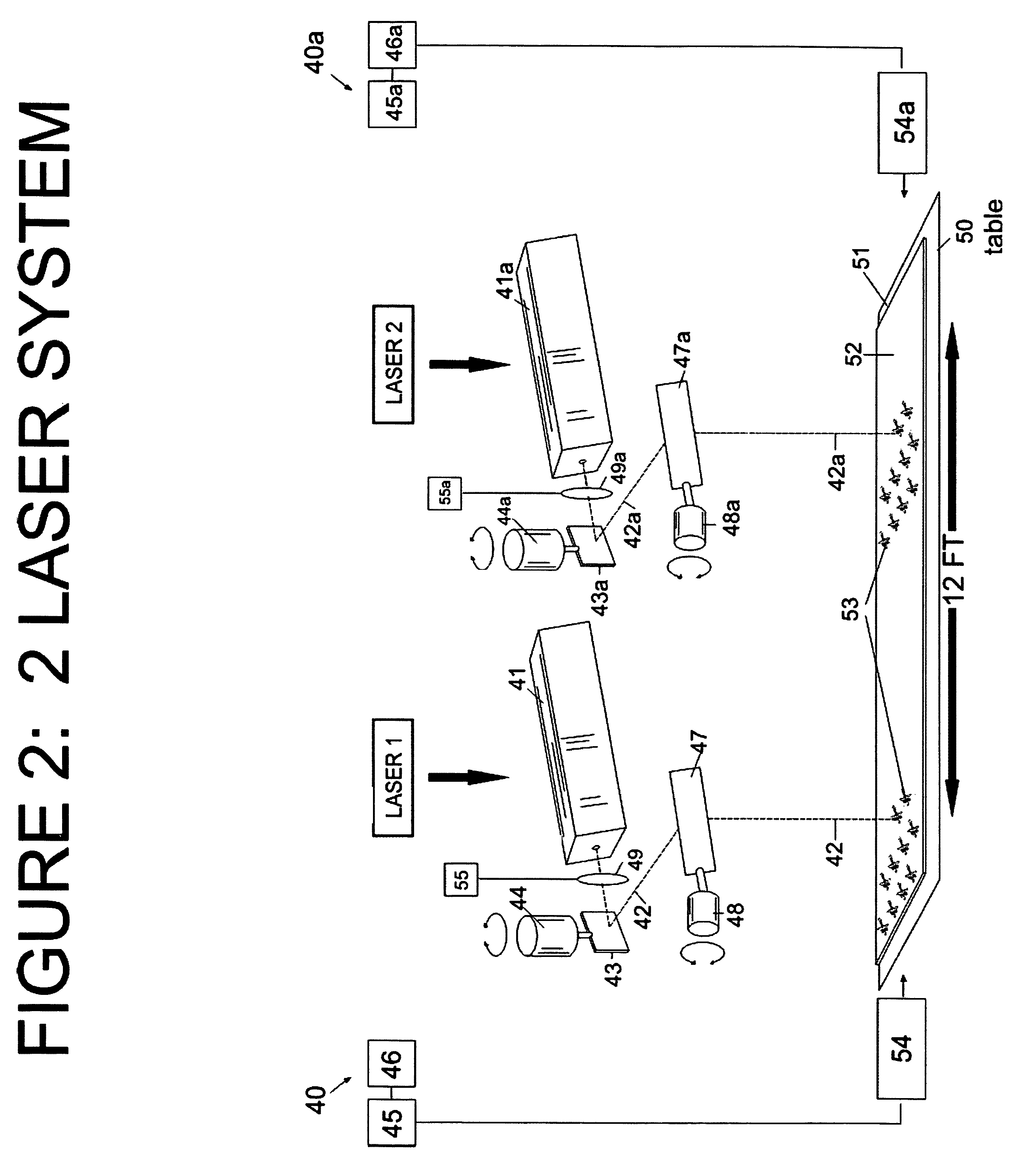

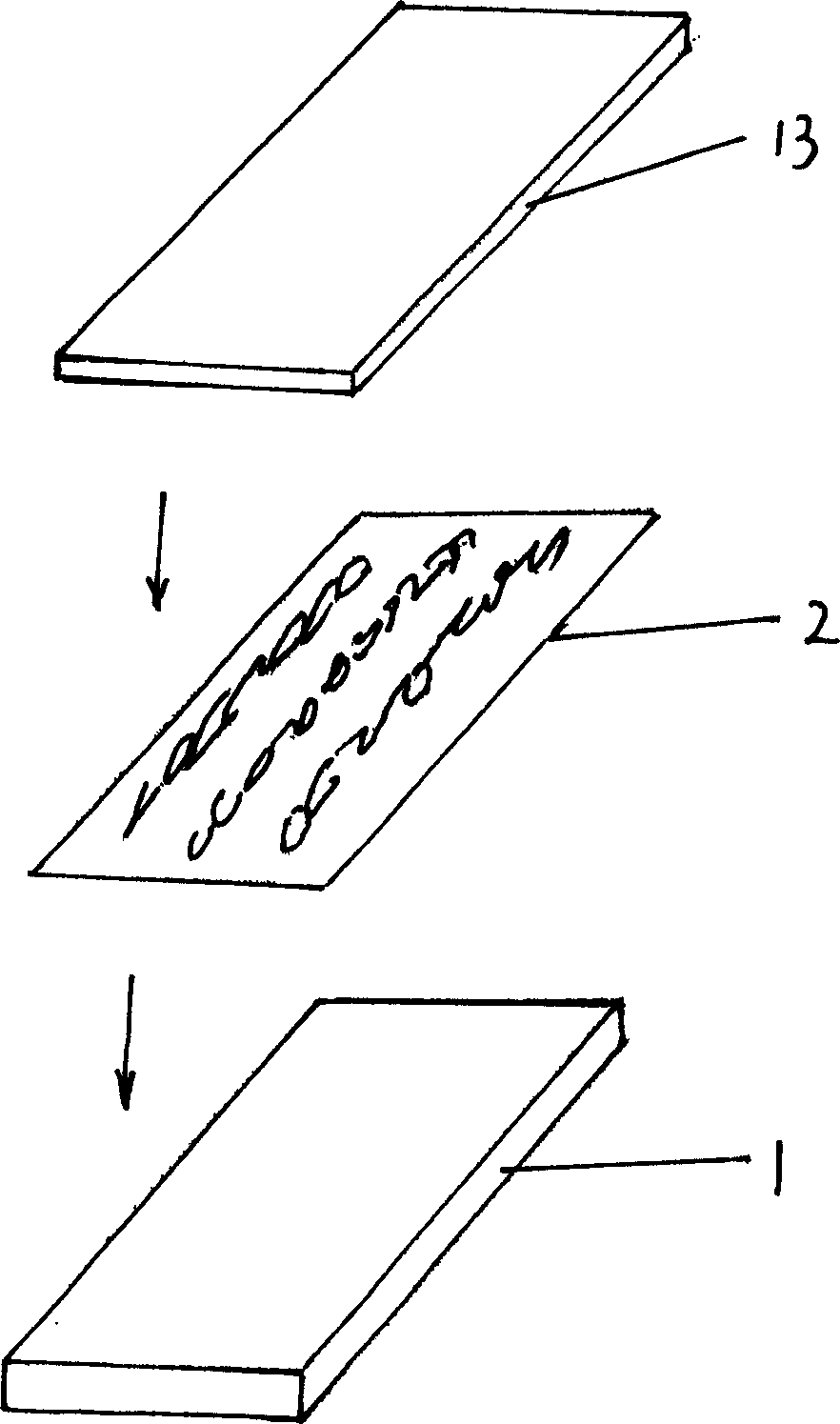

Engineered wood fiber product substrates and their formation by laser processing

InactiveUS20070108170A1Improve realismLow costNatural patternsDecorative surface effectsFiberLaser processing

A laser is used to a form information indicative of a pattern on a surface of a support piece formed from a compressed wood fiber product substrate. The pattern can be a wood grain. The field of the laser is increased, to allow lazing more of the material at once. According to an embodiment, the field is increased in a way that does not reduce the resolution of the lasing.

Owner:REVOLAZE LLC

Digitally printed surface covering

InactiveUS20050249929A1Finite shelf lifeAvoid necessityNatural patternsLayered productsEngineeringDigital printing

Owner:ARMSTRONG WORLD INDUSTRIES

Extruded variegated plastic siding panels

InactiveUS20050003221A1Reduces startup and changeover scrap associatedEliminate needSpecial ornamental structuresGlass/slag layered productsPolyvinyl chlorideUltraviolet lights

A variegated polymeric article such as a variegated siding panel having improved depth of color and a three-dimensional appearance is formed having a substantially clear, methacrylic acid based capstock coextruded to a tinted polyvinyl chloride based substrate material. A specially formulated streaker pellet provides accent color streaks within the capstock to simulate a wood grain appearance. The use of a clear capstock material eliminates the need for capstock tinting necessary in the prior art to color match the capstock to the substrate material in post formed variegated vinyl sidings. Titanium dioxide may also be introduced in small amounts to the capstock to provide further ultraviolet light protection to the underlying tinted polyvinyl chloride based substrate material.

Owner:CERTAINTEED CORP

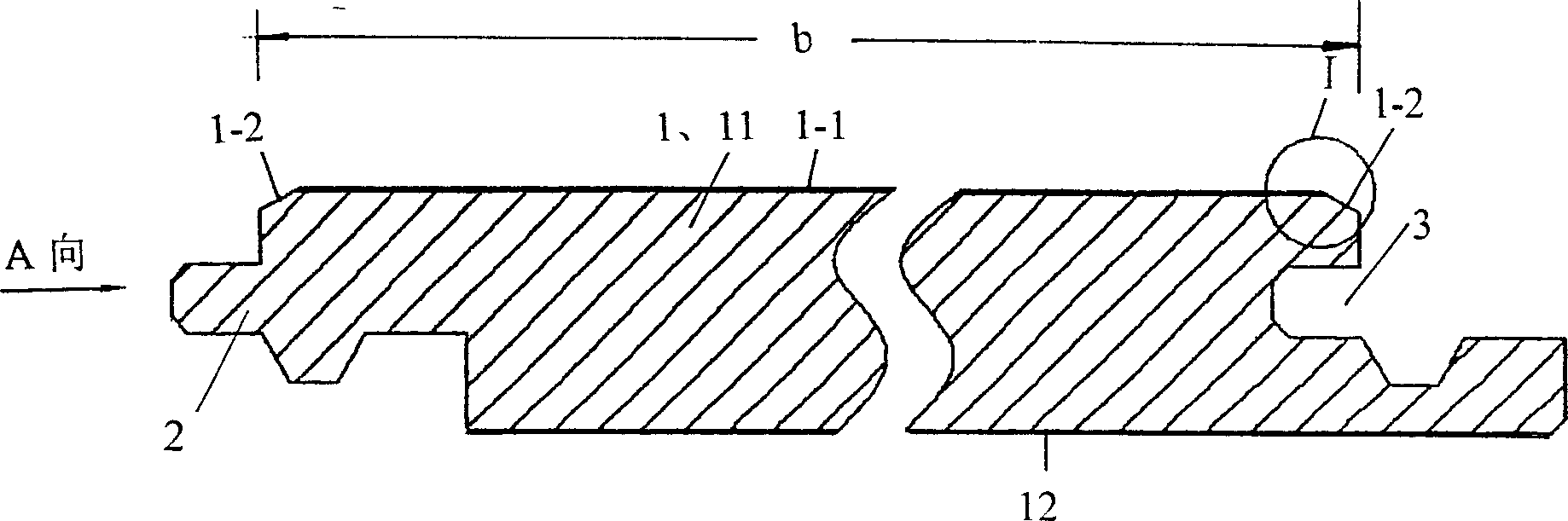

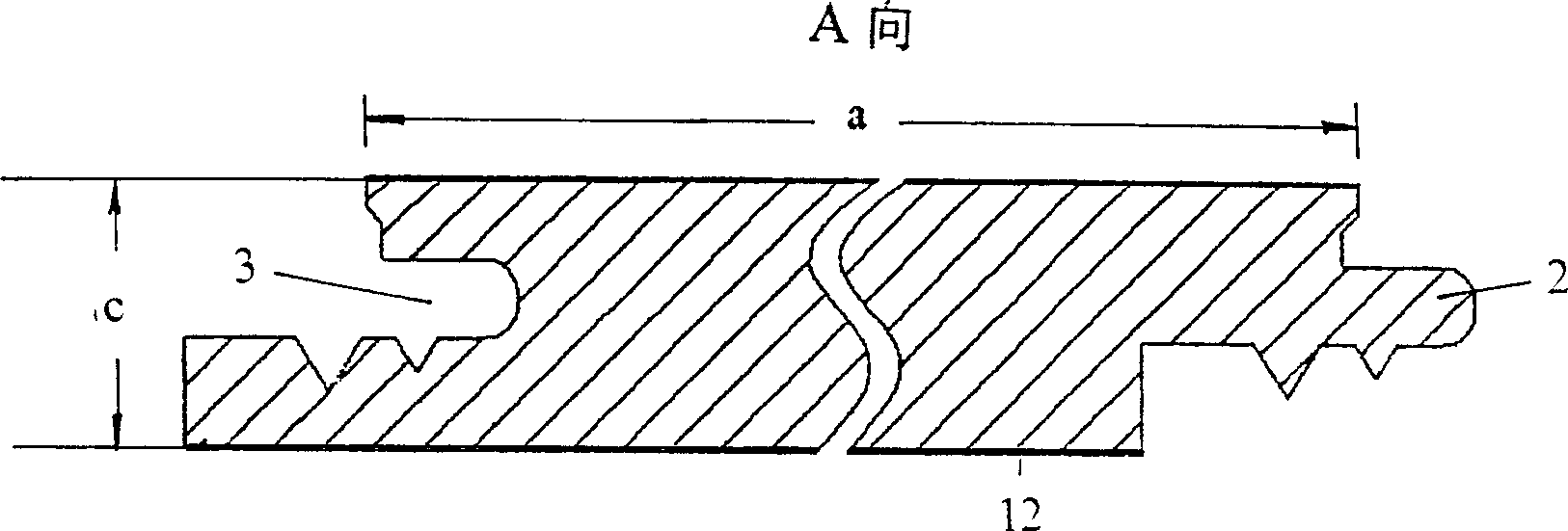

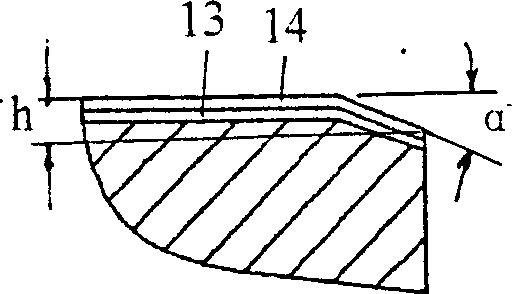

Stiffened timber floor and the manufacturing method thereof

InactiveCN1485184ALow priceExtended service lifeWood working apparatusWood layered productsSolid woodPulp and paper industry

An intensified wood floor board and its manufacturing method. One measure is, the upper surface of the floor mainbody is composed of the walking plane and inclined planes of the two sides of the walking plane; the upper surface of fiberboard has a paper layer with wood texture and a durable paper layer in sequence; by pressing mold, balanced paper layer, fiberboard, the paper layer with wood texture and a durable paper layer are adhered with each other. The second measure is, the upper surface of the floor mainbody is composed of the walking plane parallel to the base surface and inclined planes of the two sides of the walking plane, the upper surface of the upper surface of the fiberboard has a paper layer with wood texture and a durable paper layer in sequence; by bonding, the inclinedplanes on two sides are adhered with the paper layers with wood texture; resin varnish is coated on the paper layers with wood texture. due to inclined planes of two sides of the upper surface of floor mainbody, it is convenient to pave floor board. The floor board is durable, inexpensive and could use for a long time.

Owner:葛跃进

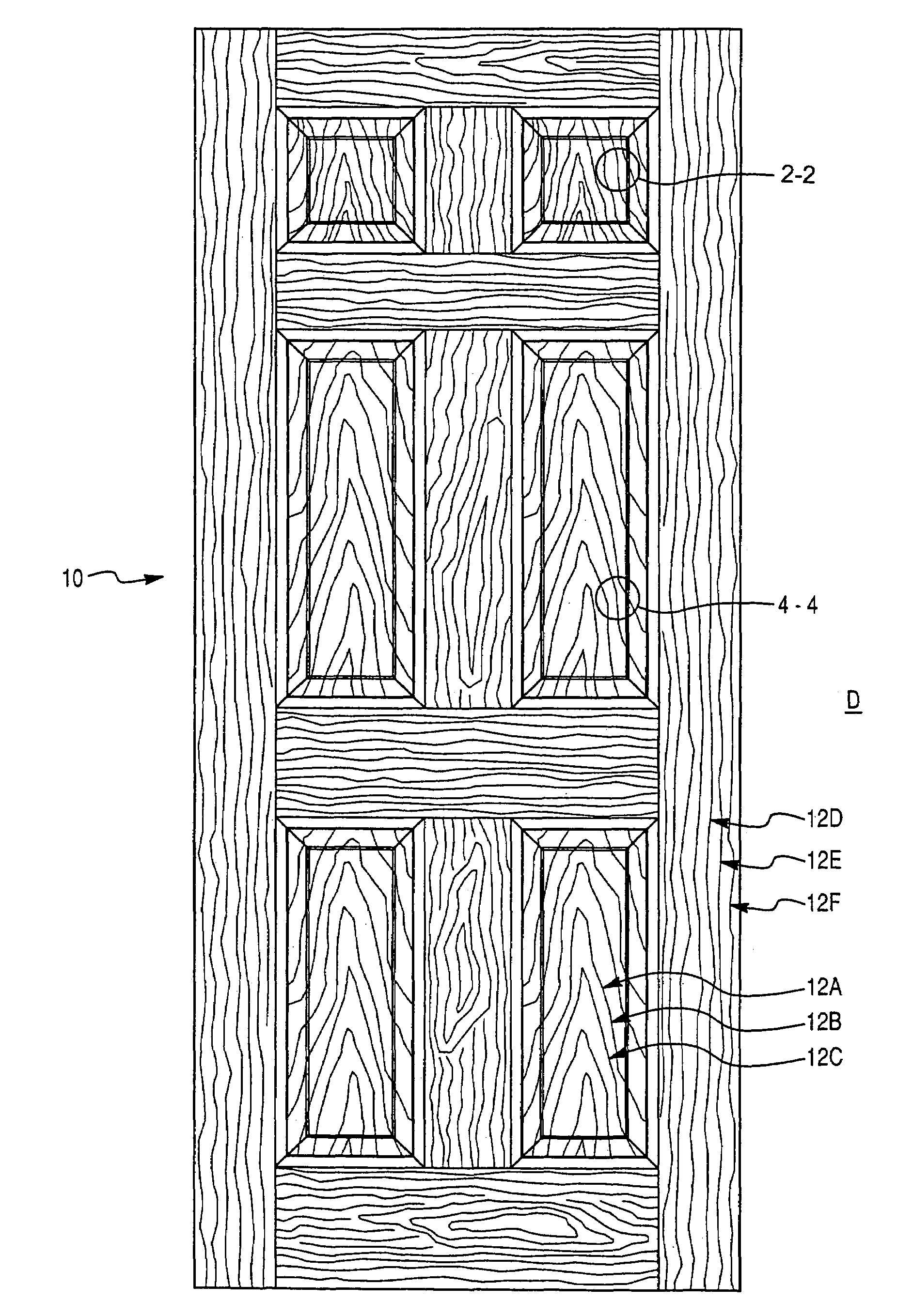

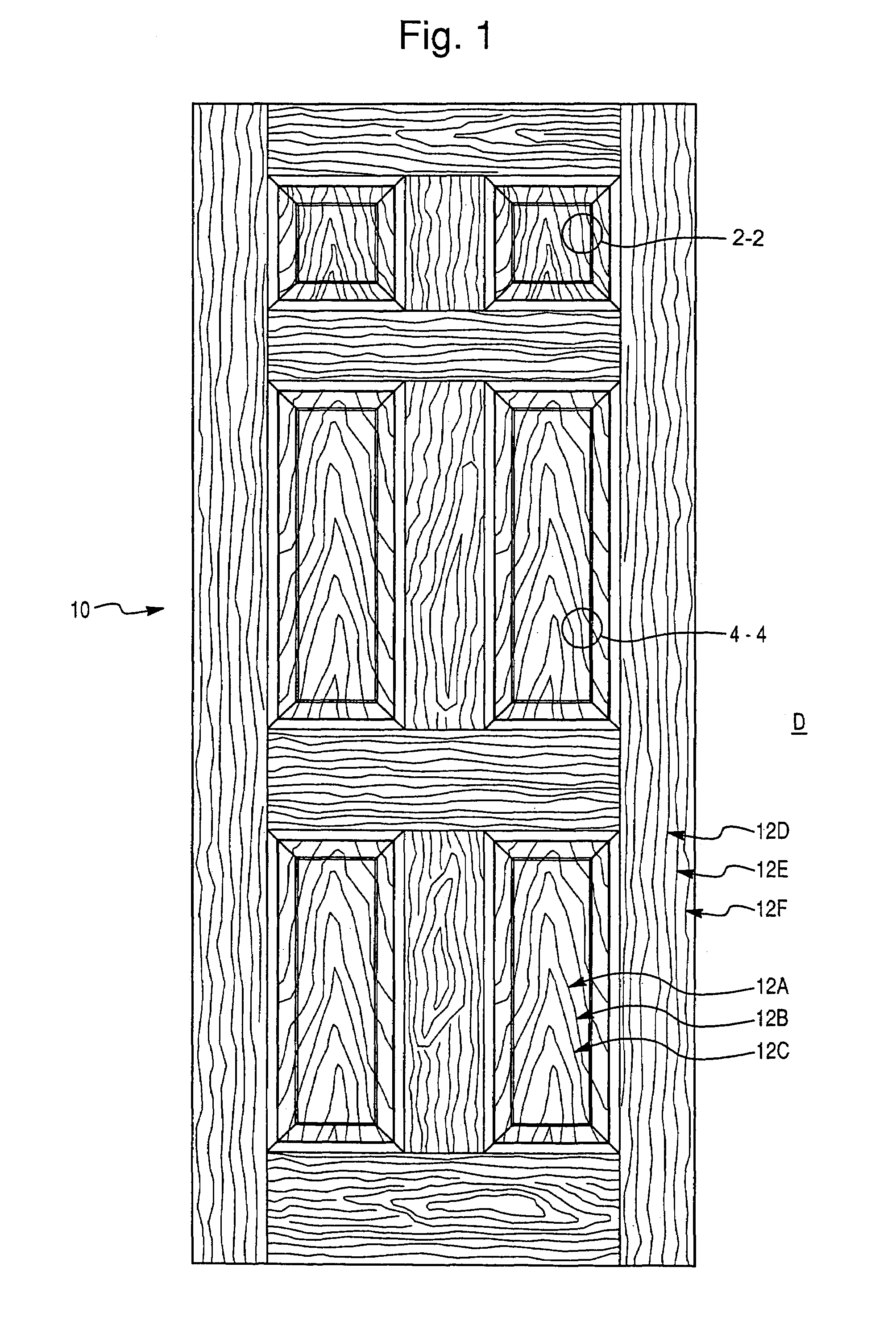

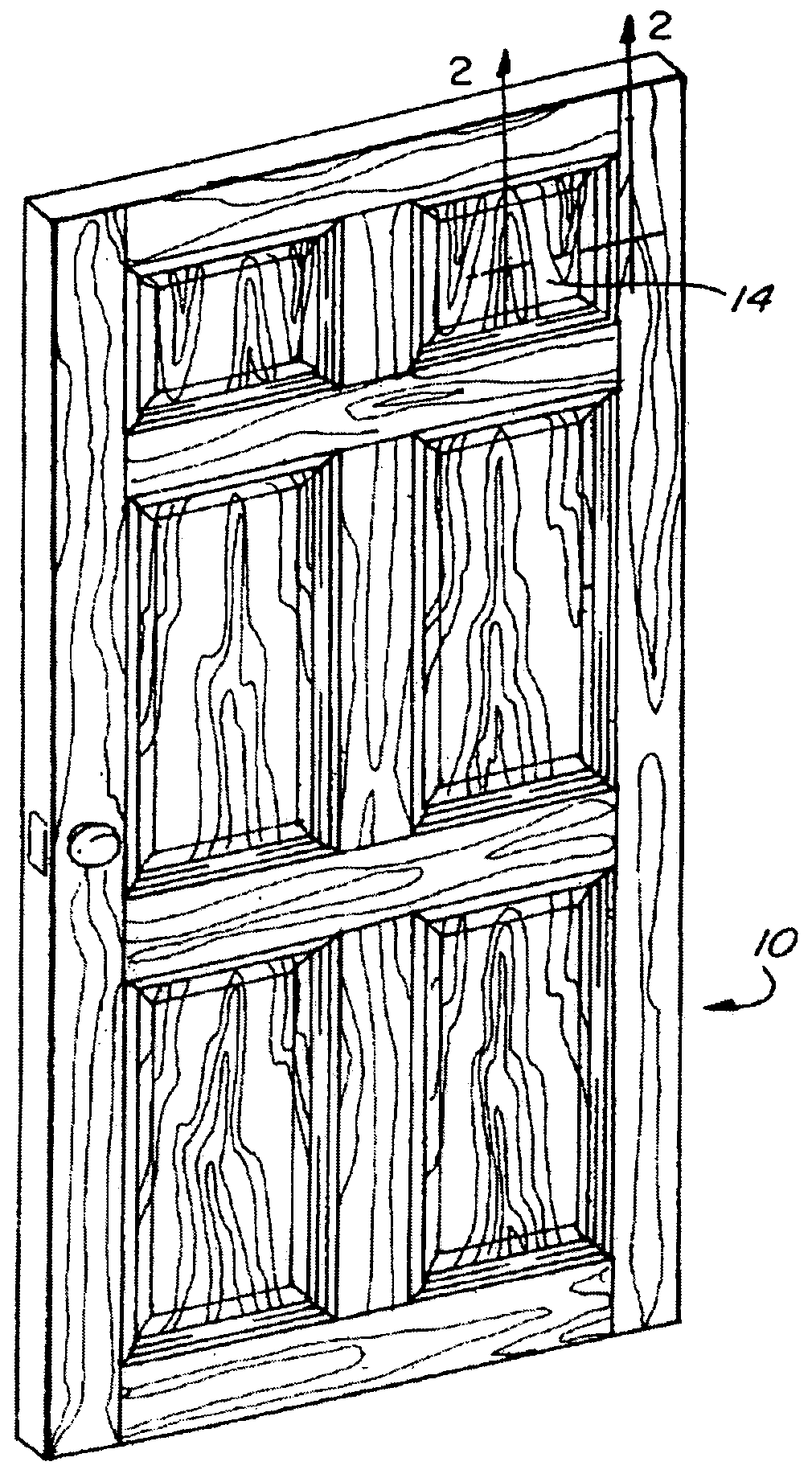

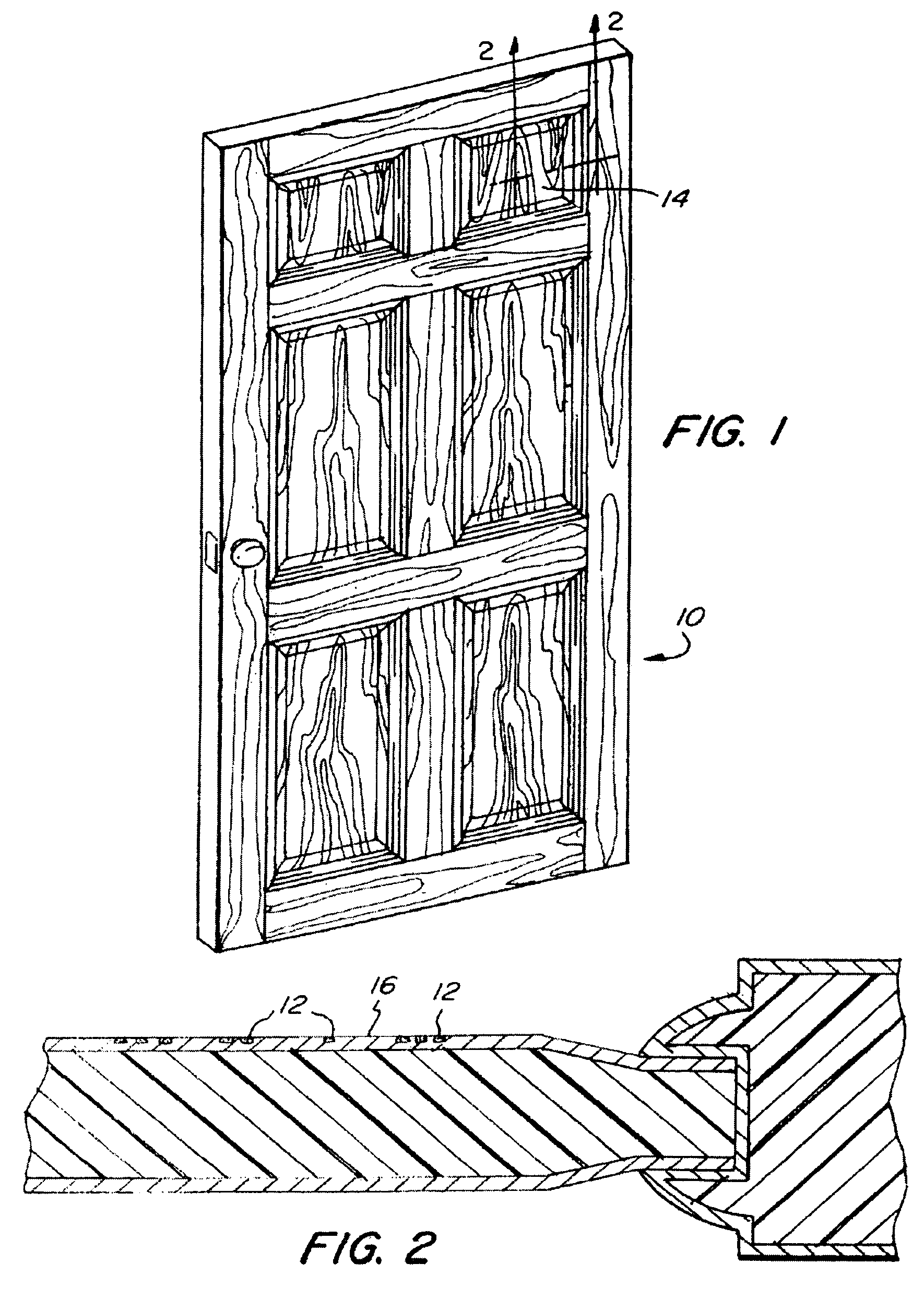

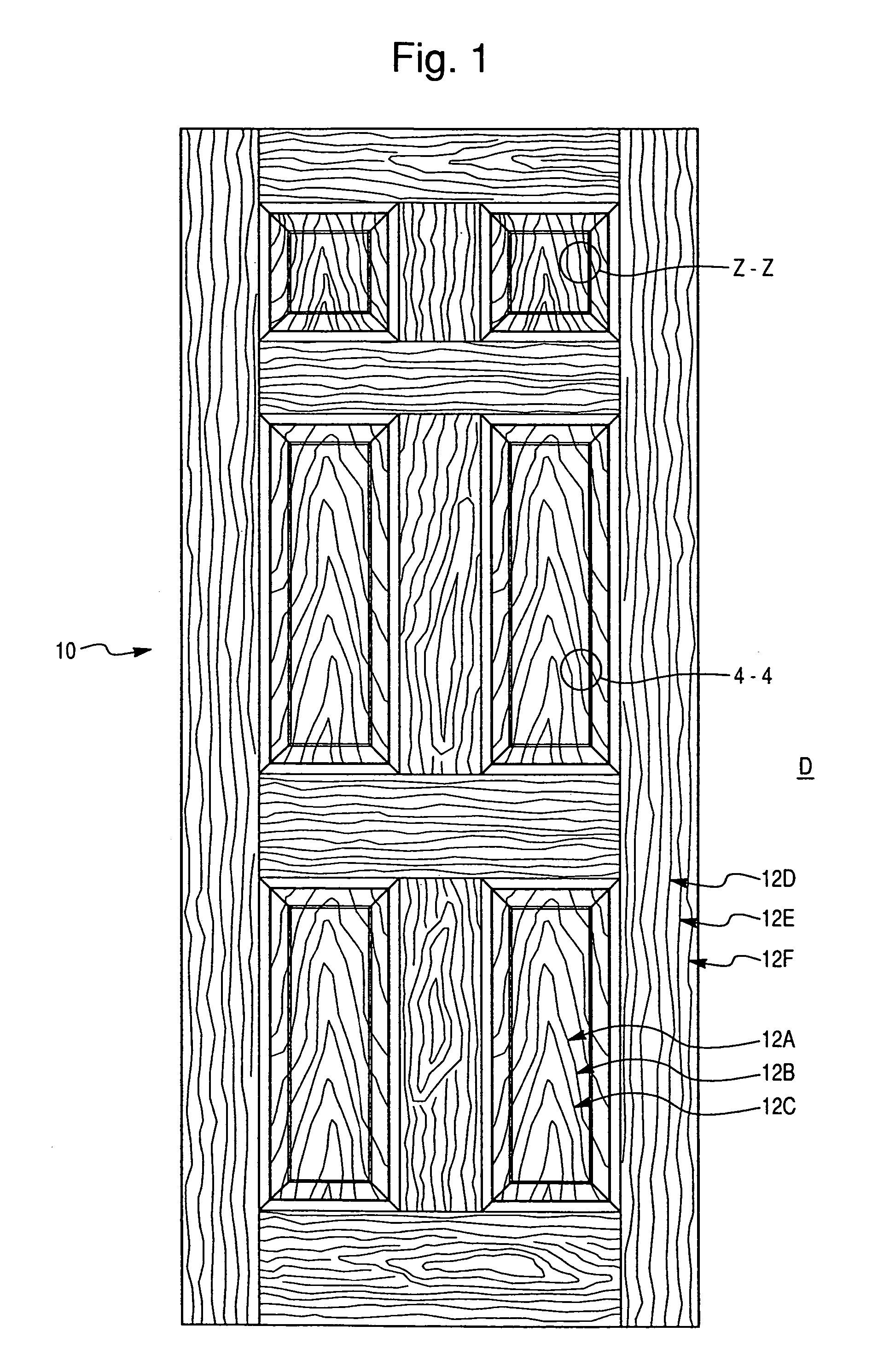

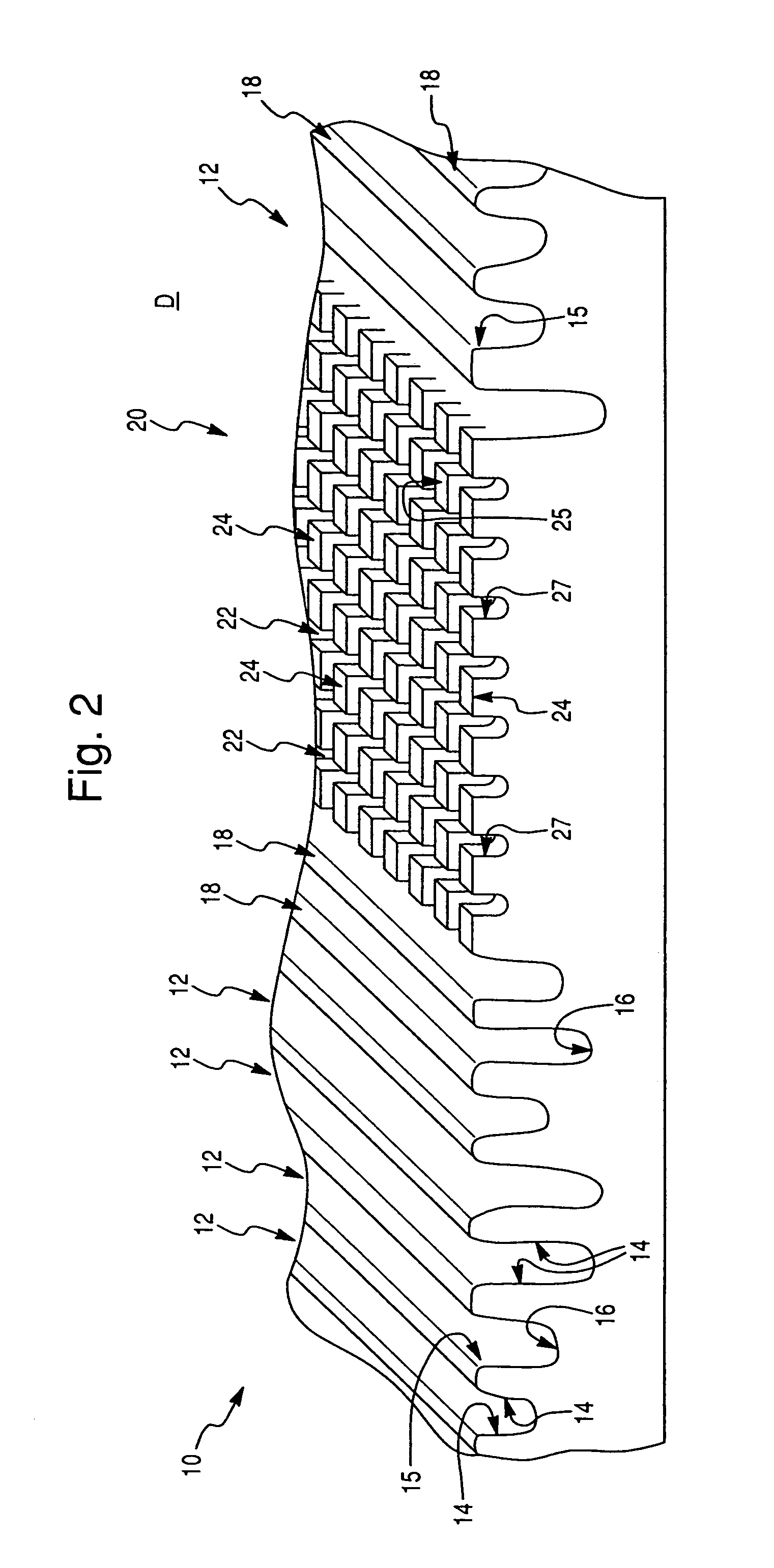

Articles of composite structure having appearance of wood

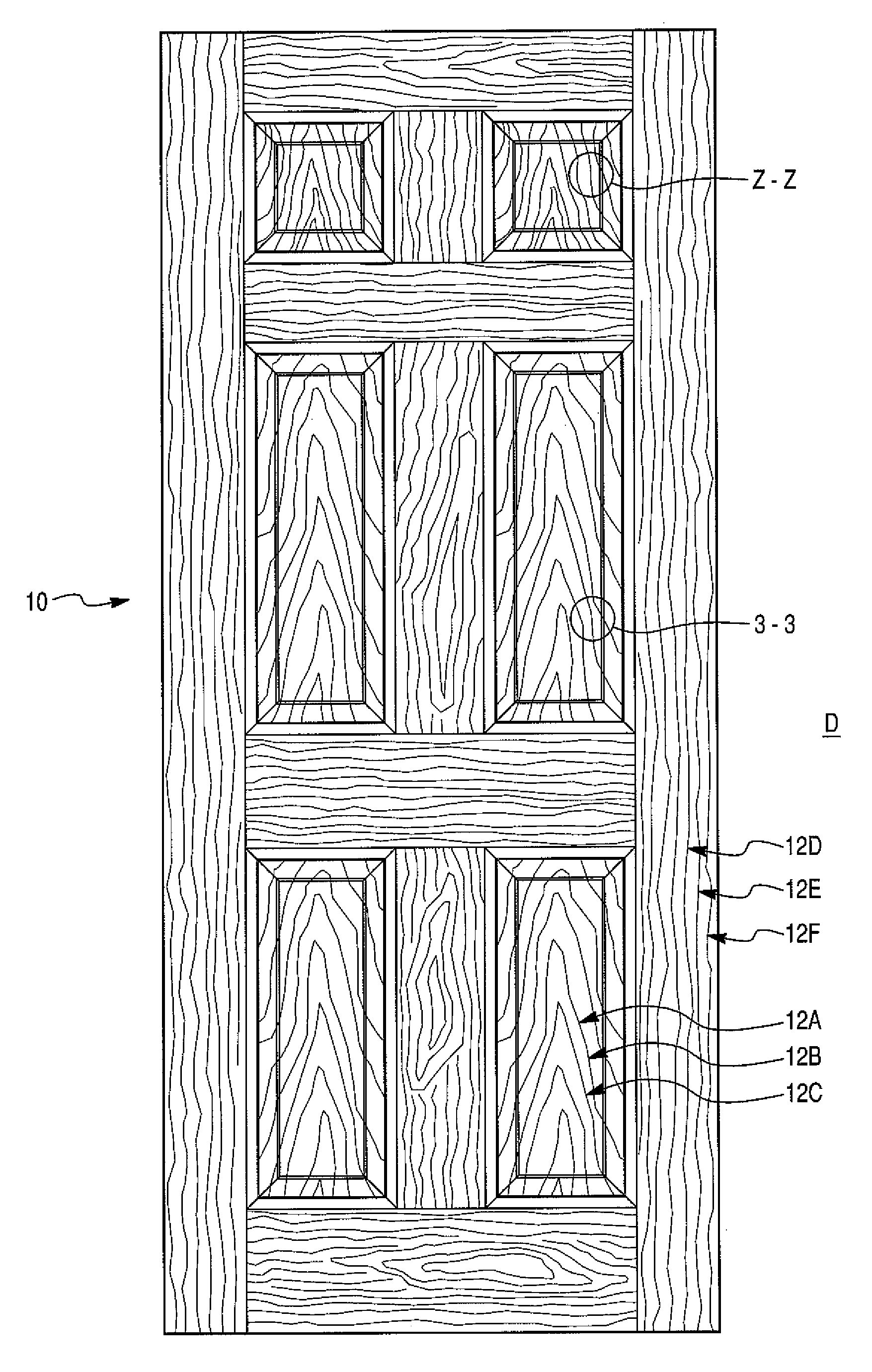

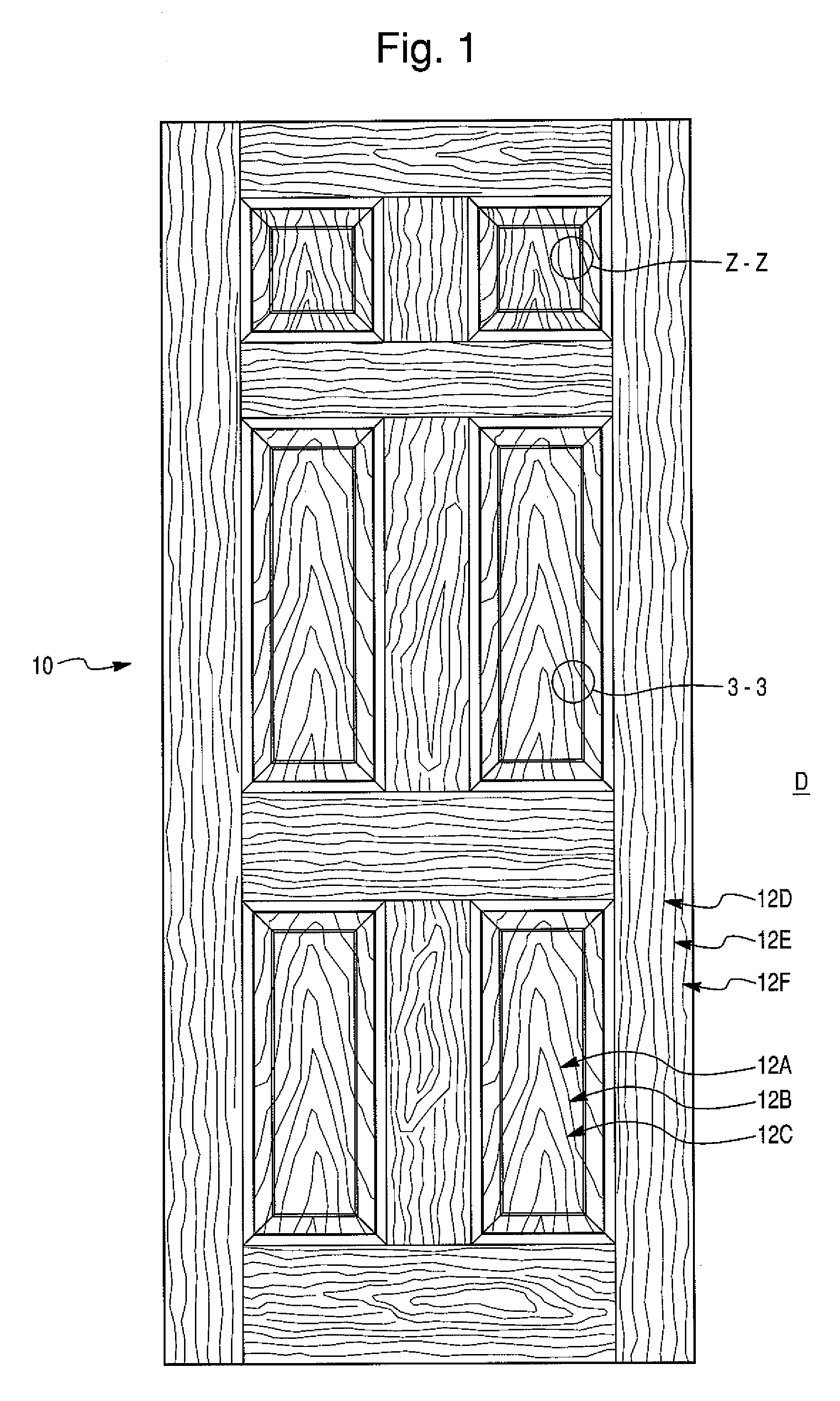

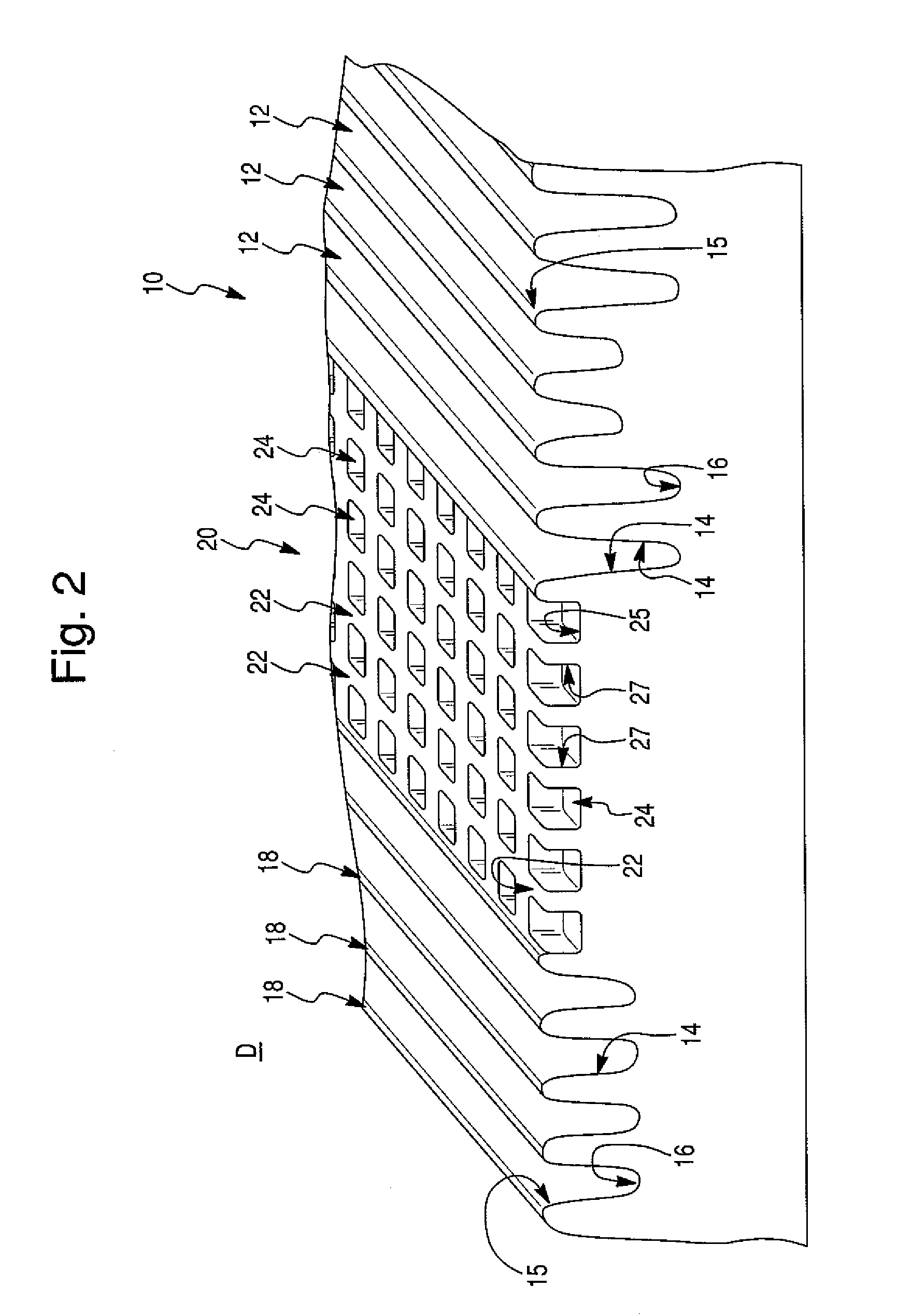

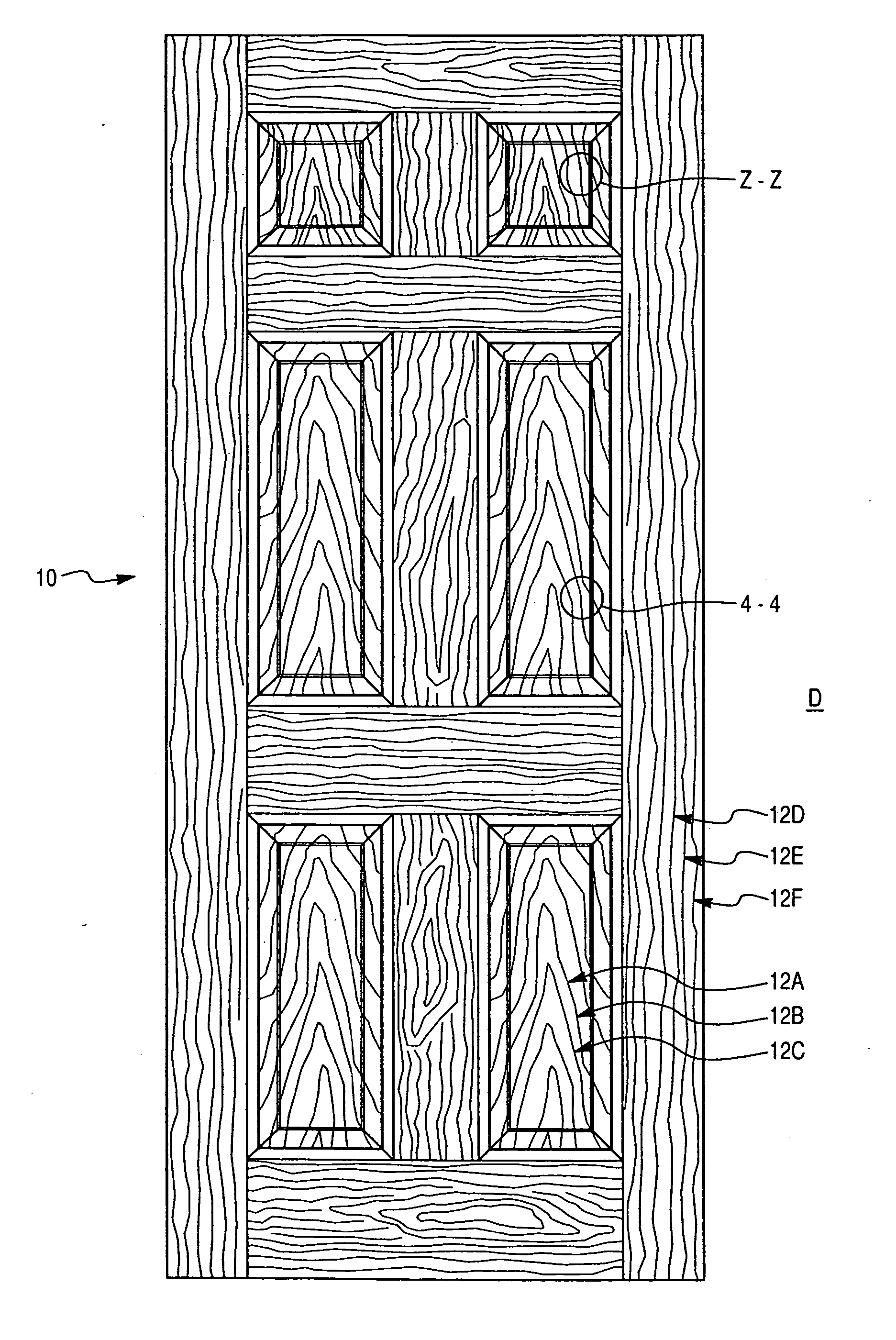

A door or other entryway component of synthetic resin composite construction and closely resembling the appearance of stained real wood. Skin portions of doors and other structures have a surface layer of clear gel coat resin molded to include the texture of a wood grain surface. A subsurface layer adjacent the clear gel coat layer is of pigmented gel coat resin. A structural support layer of the skin is of reinforced resin. Skins of a door or similar article are mounted on frames, and dense micro porous resin foam is provided between the skins to form a solid structure such as a door. Moldings retaining glass panels in openings defined in the door or similar structure are attached to the skins by adhesively fastening the moldings to the skins. Fasteners mounted in the moldings so that there are no plugged holes in the exterior surfaces of the moldings are used to locate the moldings properly with respect to the skins by inserting the fasteners into predrilled holes in the skins. The assembled doors and other structures can be finished by staining and coating with a finish system such as a urethane varnish to provide an appearance closely resembling real wood.

Owner:JELD-WEN

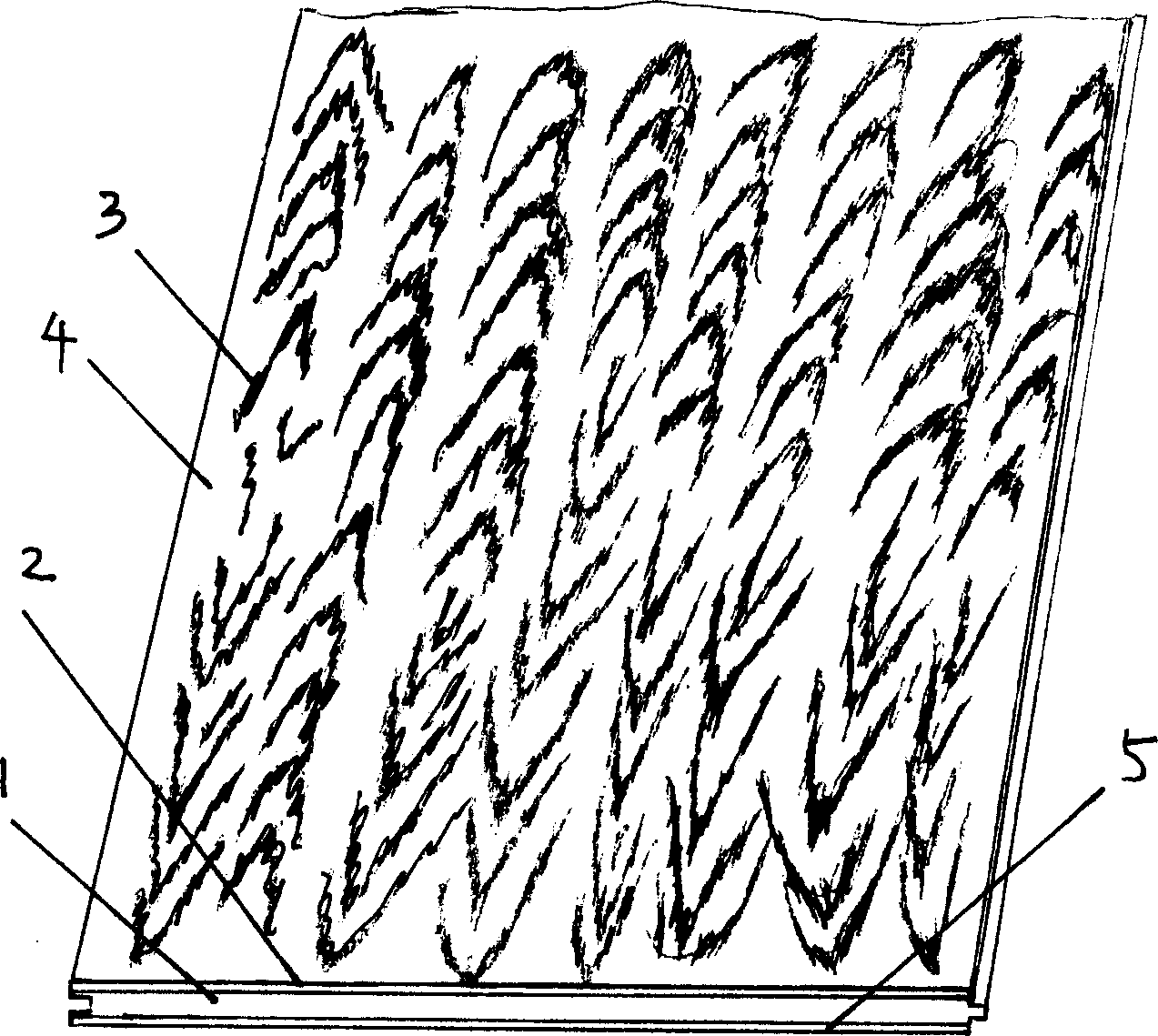

Method for producing high-emulation three-dimensional (3D) wood floor and high-emulation 3D wood floor

ActiveCN101885200AThree-dimensionalUnique wood grain printing effectWood treatment detailsWood dampingPulp and paper industrySubstrate surface

The invention discloses a method for producing a high-emulation 3D wood floor and the high-emulation 3D wood floor. The method comprises the following steps of: processing the surface of a base material to form a convex-concave three-dimensional surface; transferring wood grain on a rubber covered roller by using a steel roller with the wood grain, printing the wood grain on a substrate for 2 to 3 times by using the rubber covered roller, and coating finish on the substrate surface for 1 to 2 times; and printing the wood grain on the substrate for 2 to 3 times; and finally, coating finish on the substrate surface for 2 to 5 times. The wood floor produced by the method has high-emulation 3D wood grain layering and visual effects; the wood grain is clear and very vivid; and the produced floor voids repeated wood grain and has a good footfeel and the smooth and soft surface.

Owner:ZHEJIANG SHIYOU TIMBER

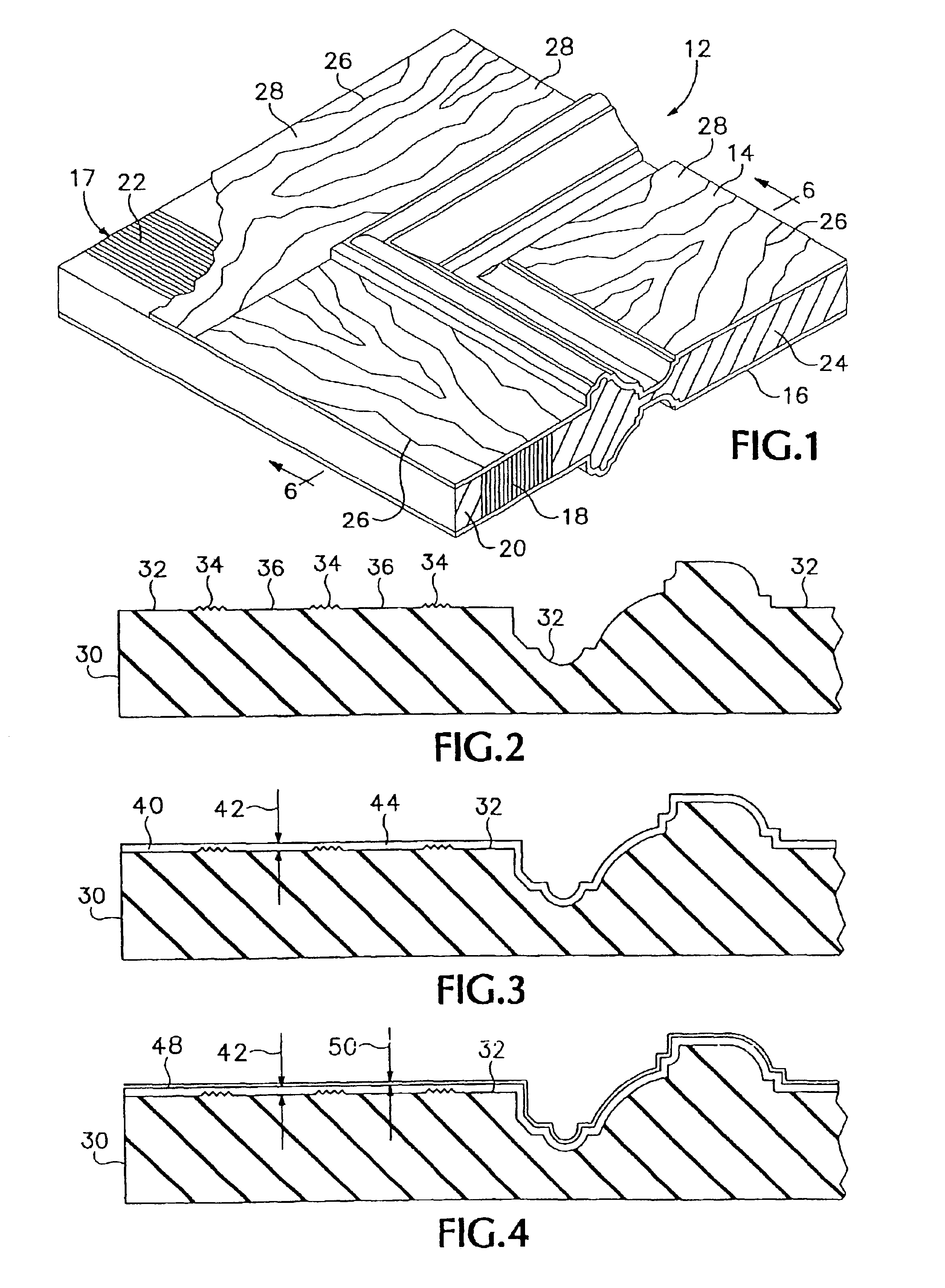

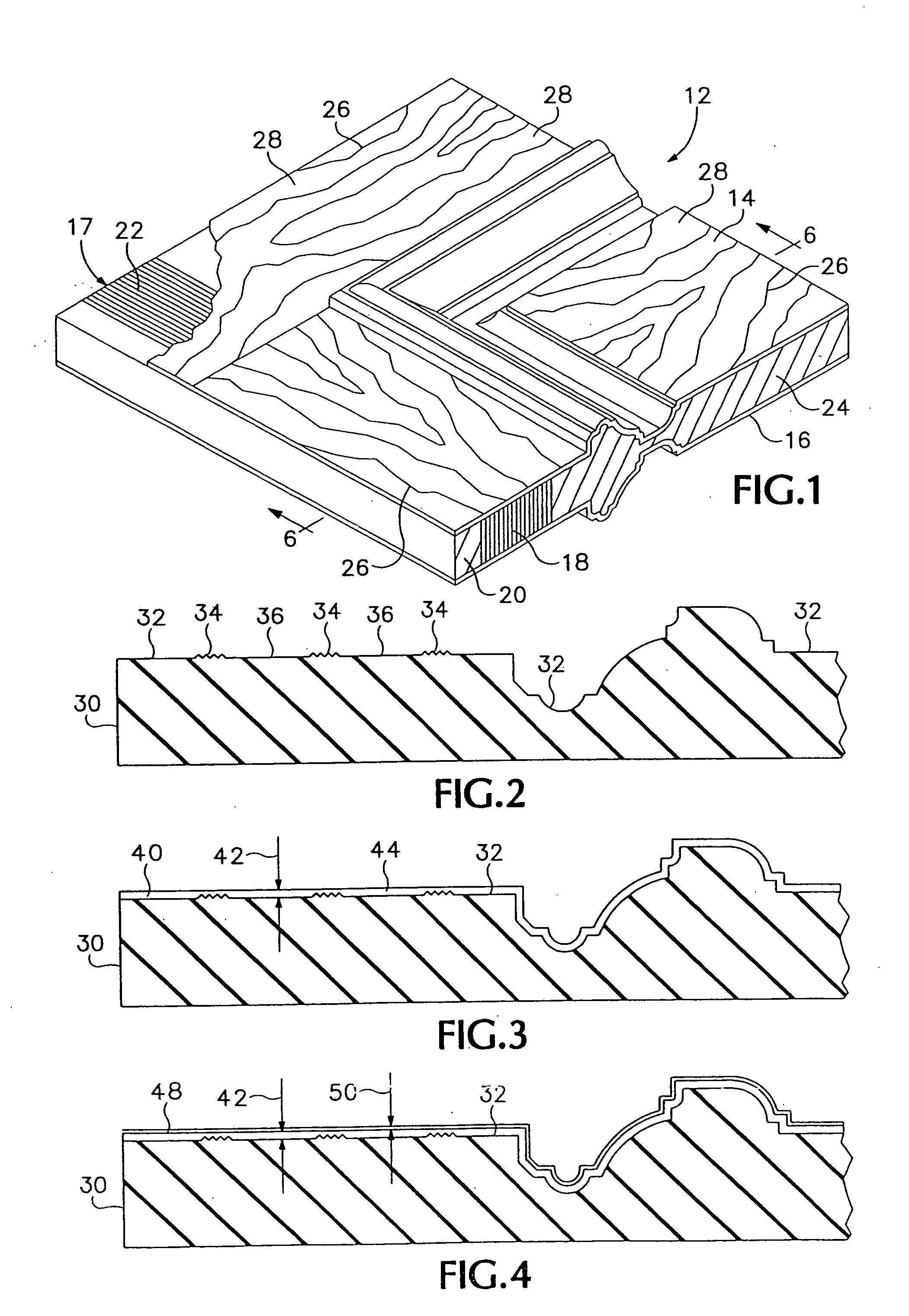

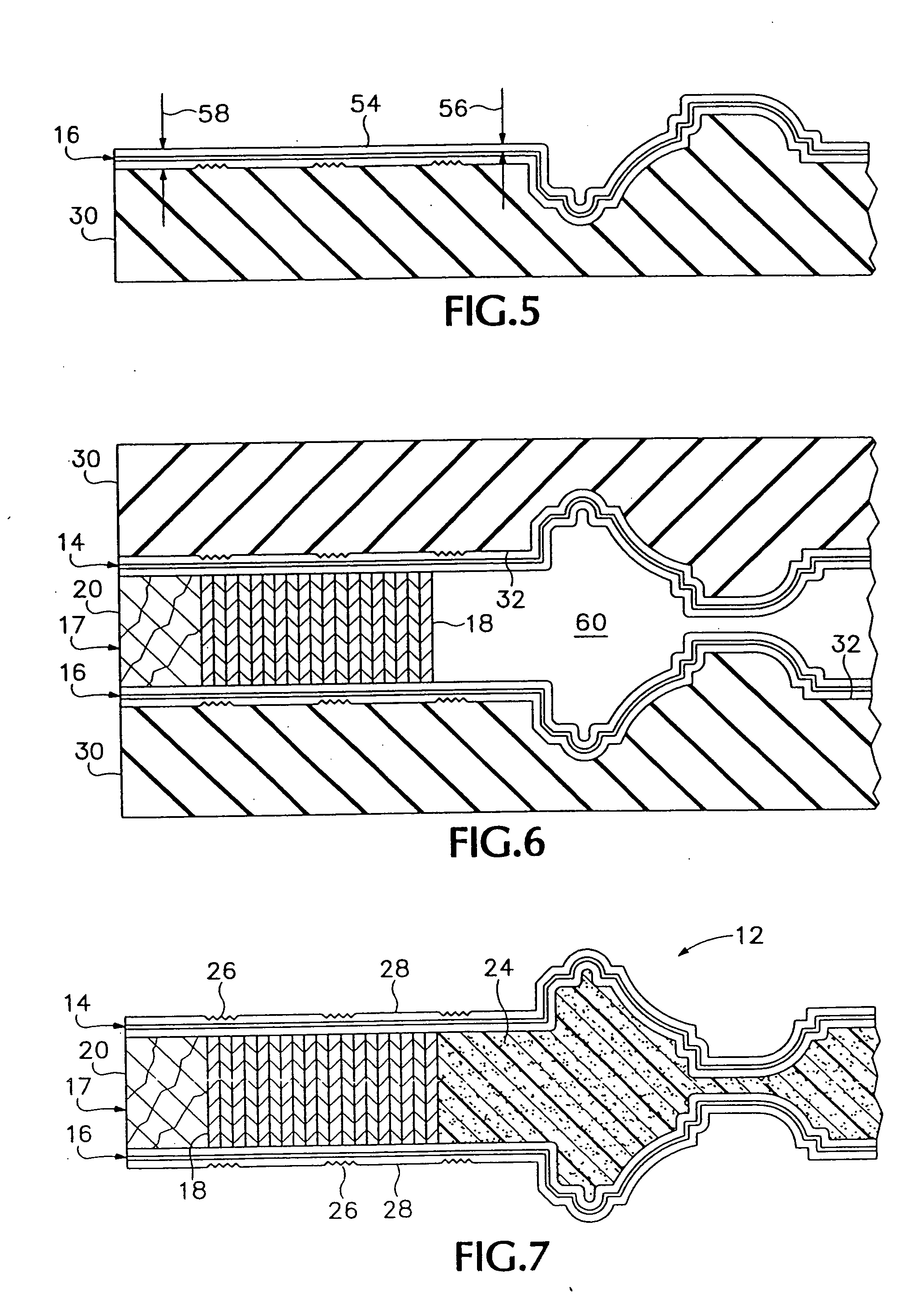

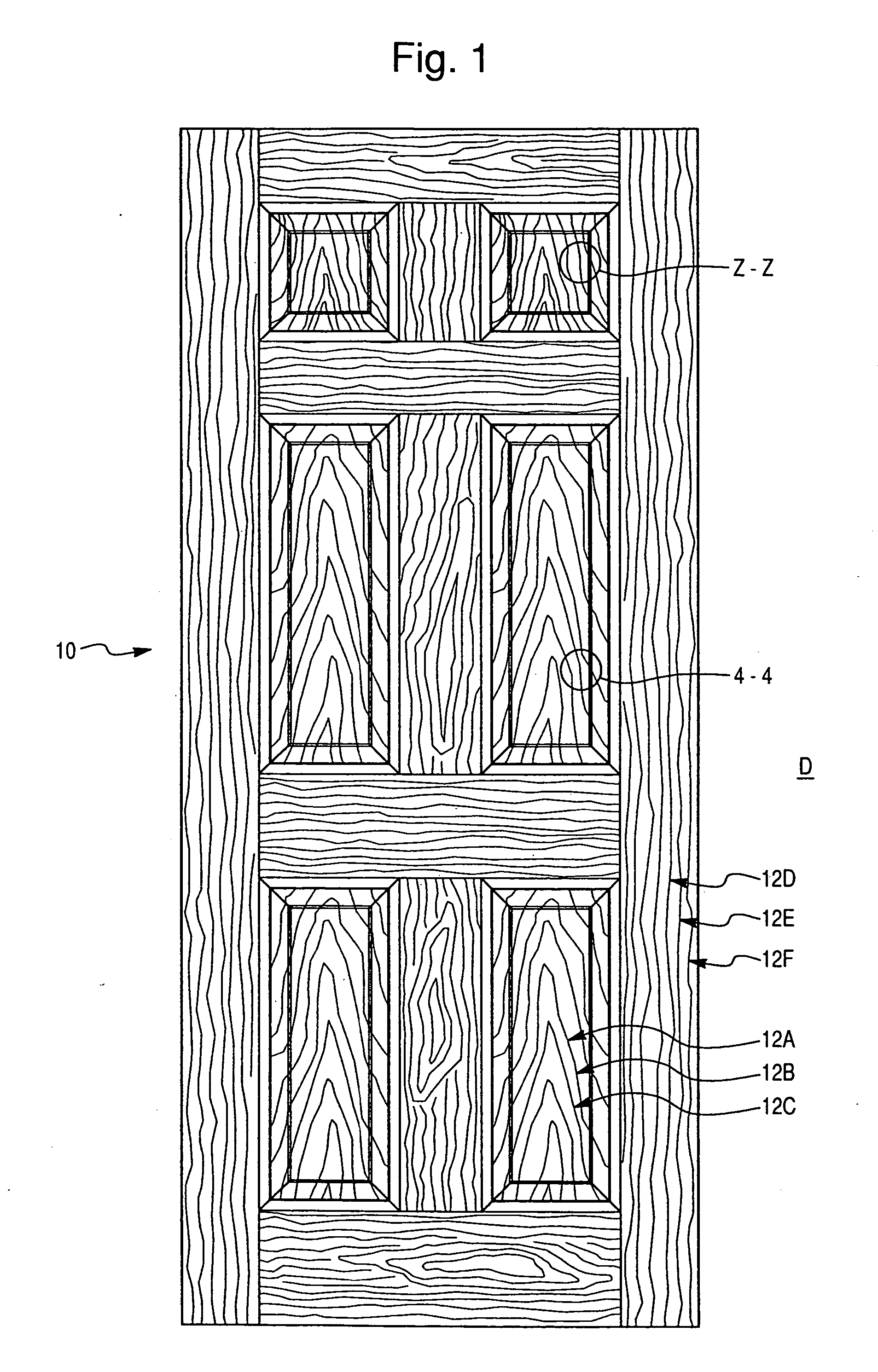

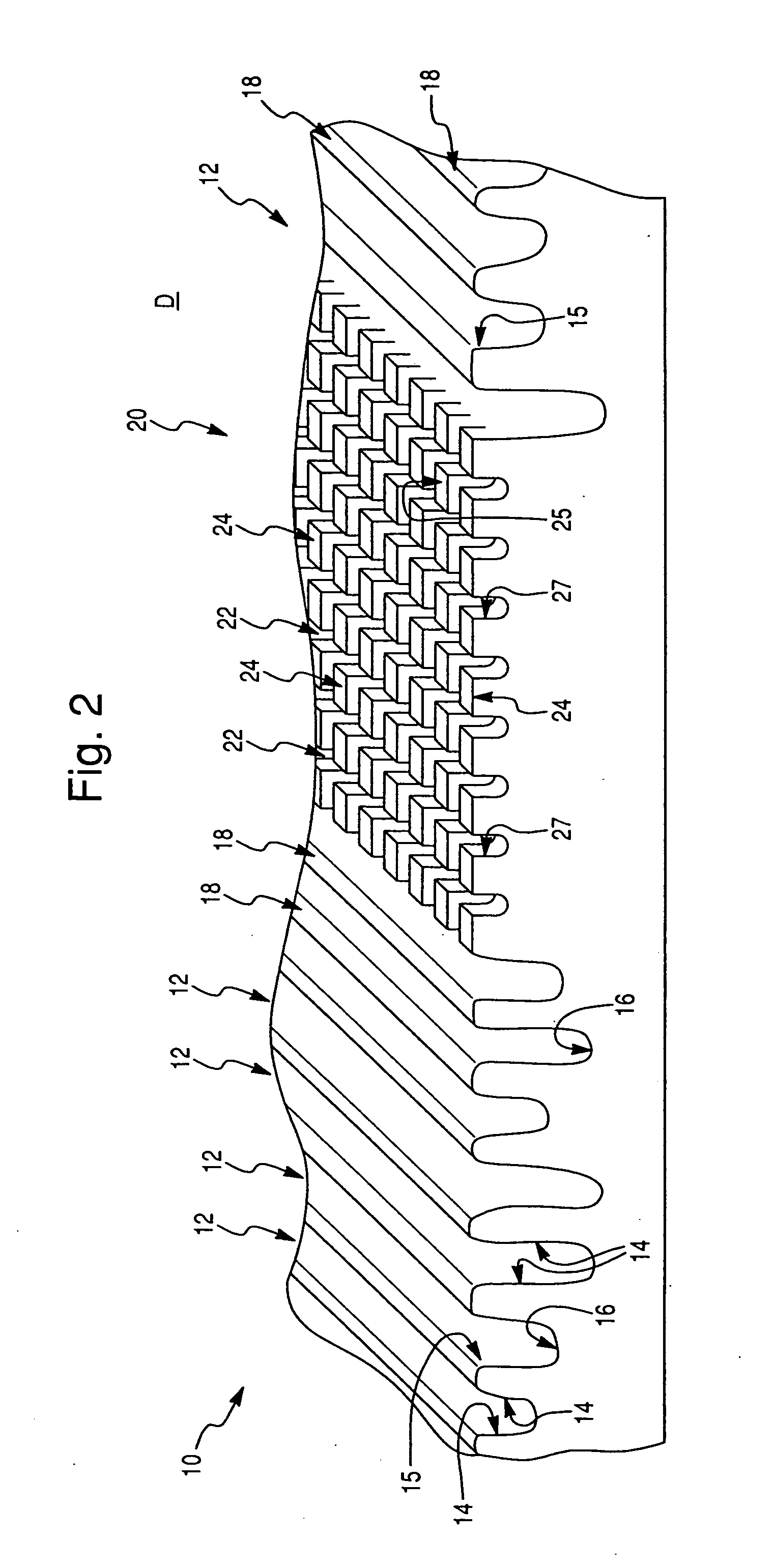

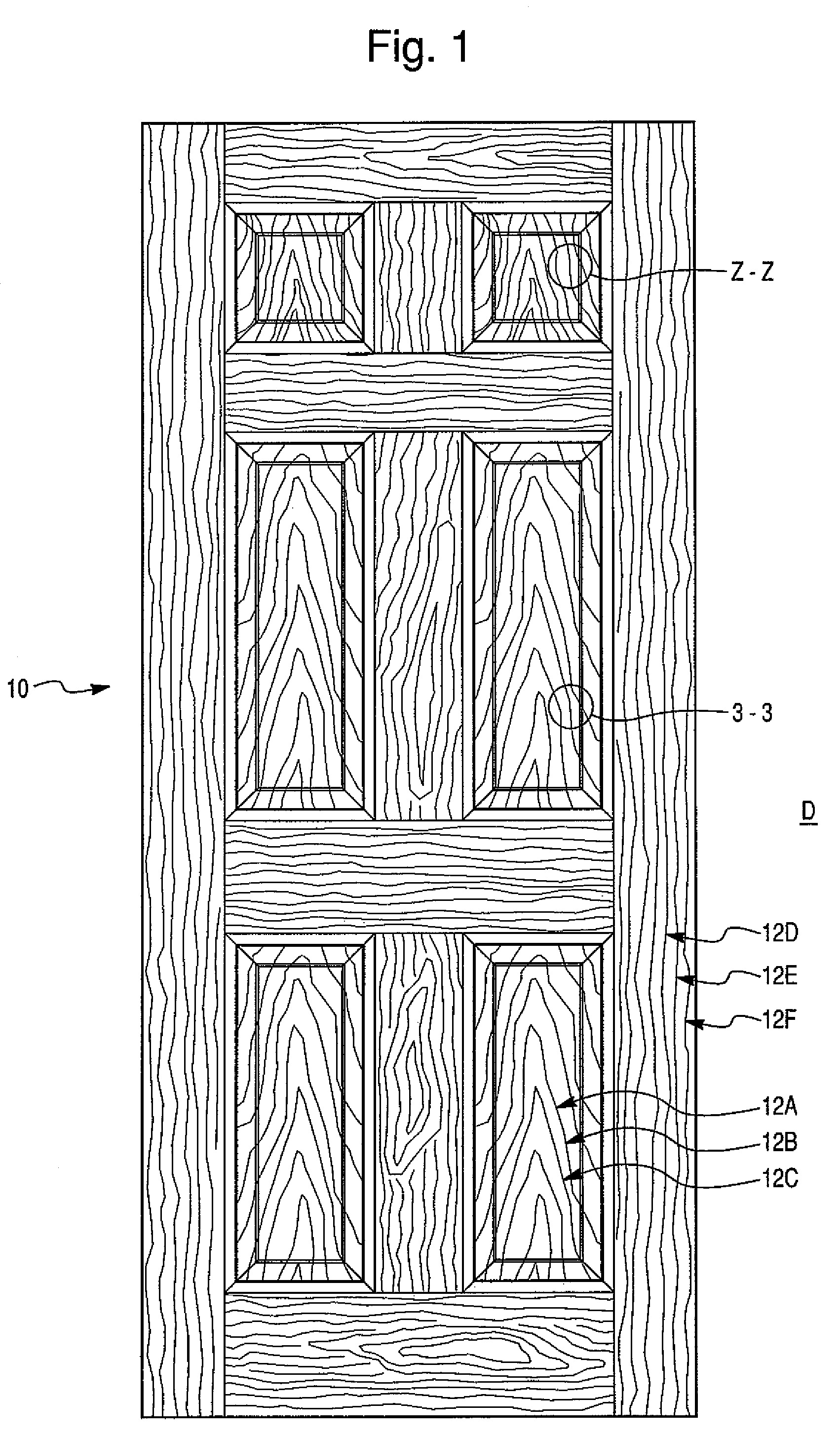

Door skin, a method of etching a plate, and an etched plate formed therefrom

The present invention relates to a door skin comprising an exterior surface having outer portions lying on a first plane, spaced grooves recessed from the plane of the outer portions, and tonal portions having a planar area and a plurality of spaced depressions recessed from the plane of said planar area. The present invention is also directed to a method of etching a plate, for use with a molded die set, for embossing a wood grain pattern in the door skin, and the etched plate formed therefrom.

Owner:MASONITE CORP

Engineered wood fiber product substrates and their formation by laser processing

InactiveUS8071912B2Improve realismLow costNatural patternsDecorative surface effectsFiberLaser processing

A laser is used to a form information indicative of a pattern on a surface of a support piece formed from a compressed wood fiber product substrate. The pattern can be a wood grain. The field of the laser is increased, to allow lazing more of the material at once. According to an embodiment, the field is increased in a way that does not reduce the resolution of the lasing.

Owner:REVOLAZE LLC

Articles of composite structure having appearance of wood

InactiveUS20050166402A1Metal rolling stand detailsSpecial ornamental structuresSolid woodSurface layer

A door or other entryway component of synthetic resin composite construction and closely resembling the appearance of stained real wood. Skin portions of doors and other structures have a surface layer of clear gel coat resin molded to include the texture of a wood grain surface. A subsurface layer adjacent the clear gel coat layer is of pigmented gel coat resin. A structural support layer of the skin is of reinforced resin. Skins of a door or similar article are mounted on frames, and dense micro porous resin foam is provided between the skins to form a solid structure such as a door. Moldings retaining glass panels in openings defined in the door or similar structure are attached to the skins by adhesively fastening the moldings to the skins. Fasteners mounted in the moldings so that there are no plugged holes in the exterior surfaces of the moldings are used to locate the moldings properly with respect to the skins by inserting the fasteners into predrilled holes in the skins. The assembled doors and other structures can be finished by staining and coating with a finish system such as a urethane varnish to provide an appearance closely resembling real wood.

Owner:JELD-WEN

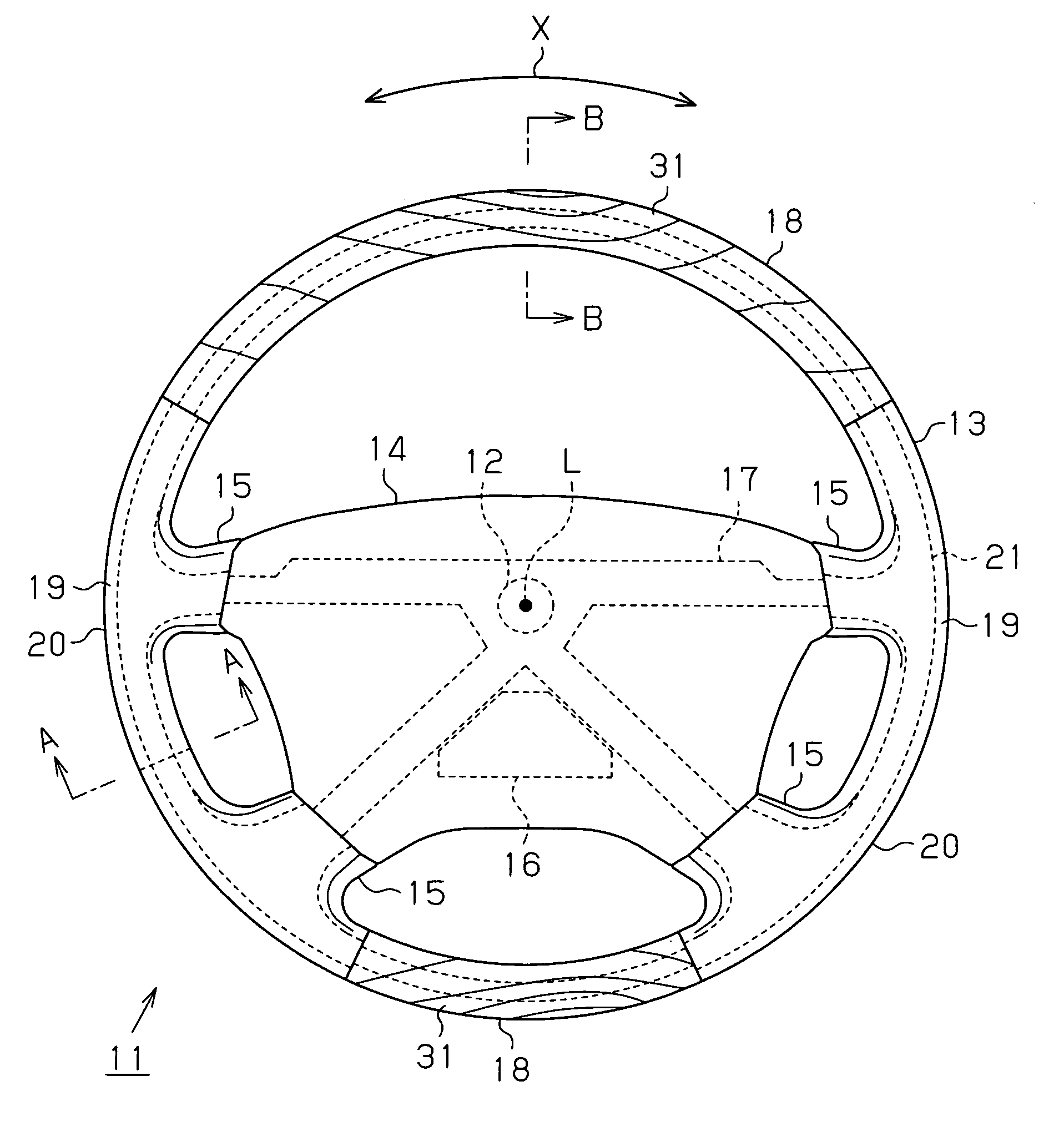

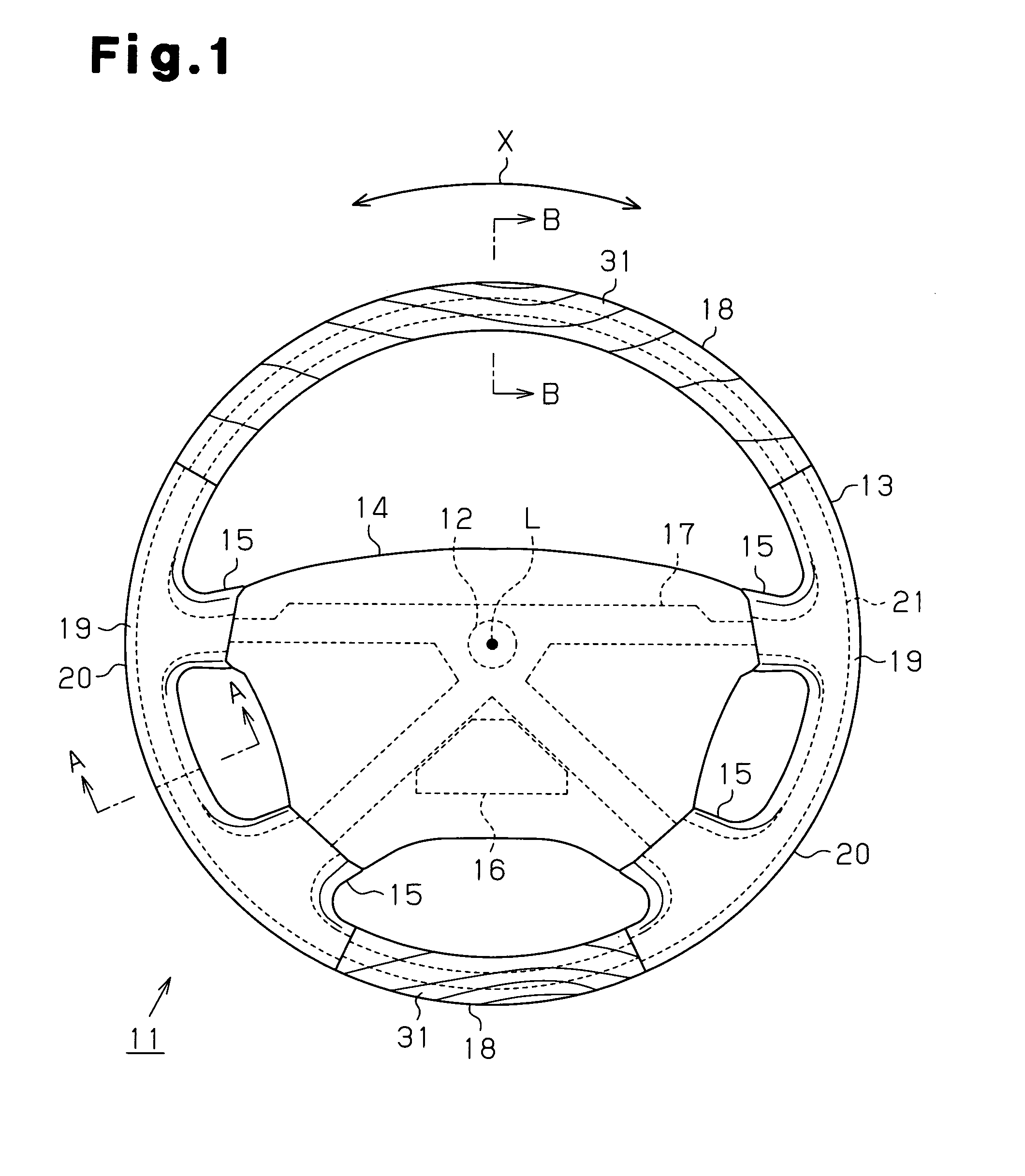

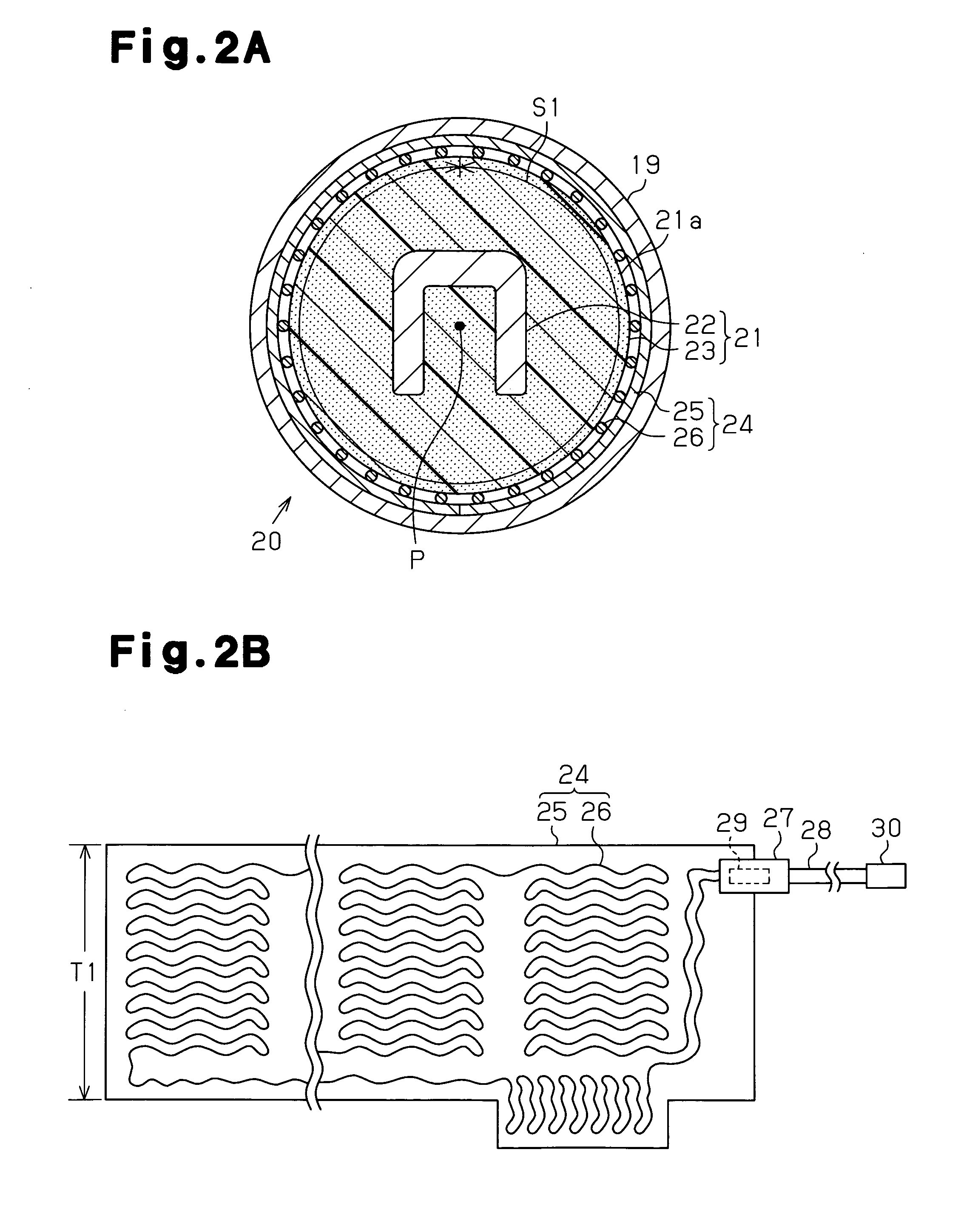

Steering wheel

ActiveUS20100071502A1Reducing thermal discomfortControlling membersMechanical apparatusSteering wheelEngineering

A steering wheel including a rim, first heating members, second heating members, and a control section is provided. The rim has leather-covered portions and wood-grain portions. The surface of the leather-covered portions has a thermal conductivity different from the thermal conductivity of the surface of the wood-grain portions. Each first heating member is provided inside of the surface of the corresponding leather-covered portion. When being energized, each first heating member adjusts the surface temperature of the corresponding leather-covered portion. Each second heating member is provided inside of the surface of the corresponding wood-grain portion. When being energized, each second heating member adjusts the surface temperature of the corresponding wood-grain portion. The control section controls the energization of the first heating members and the energization of the second heating members independently from each other.

Owner:TOYODA GOSEI CO LTD

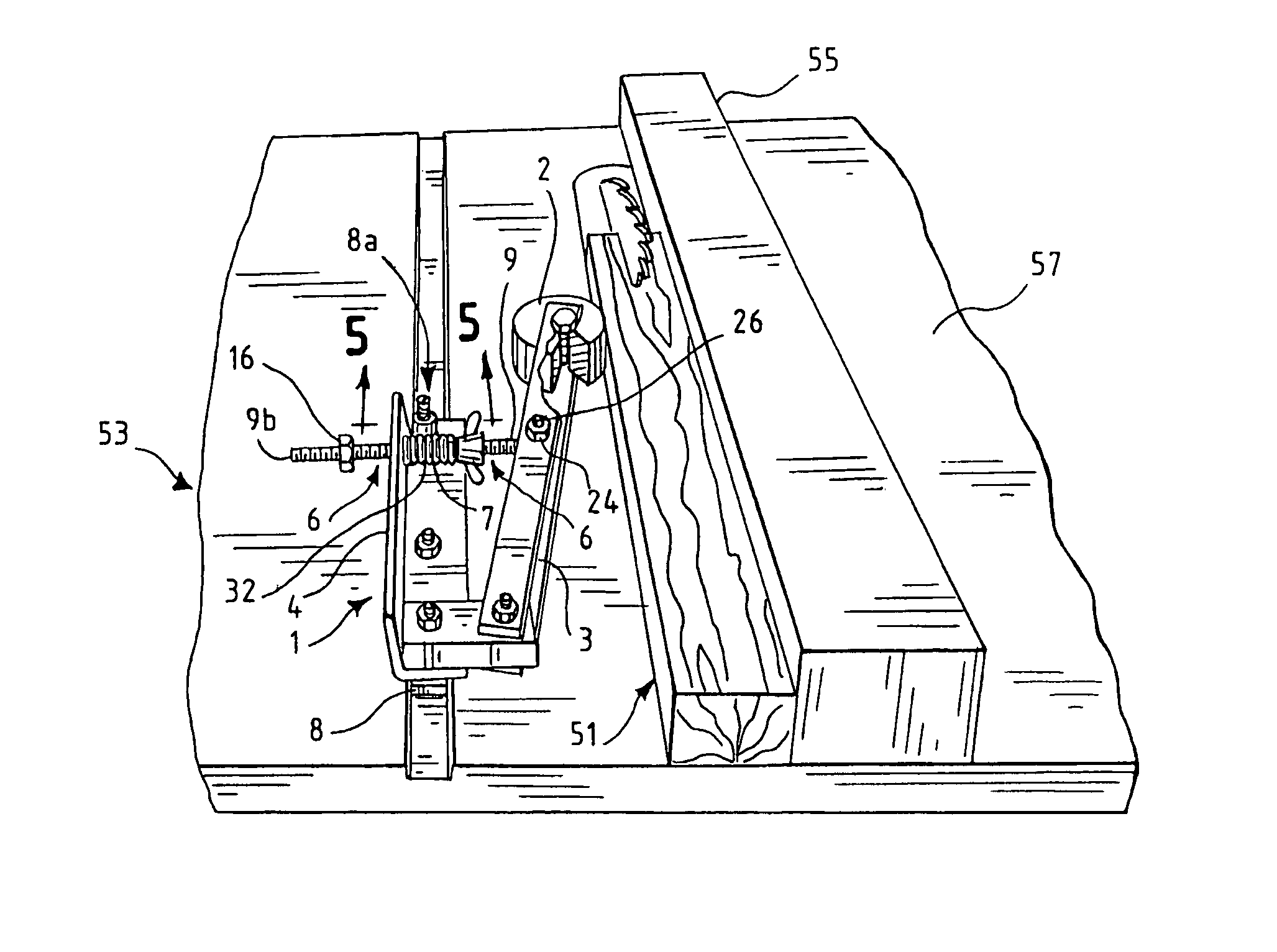

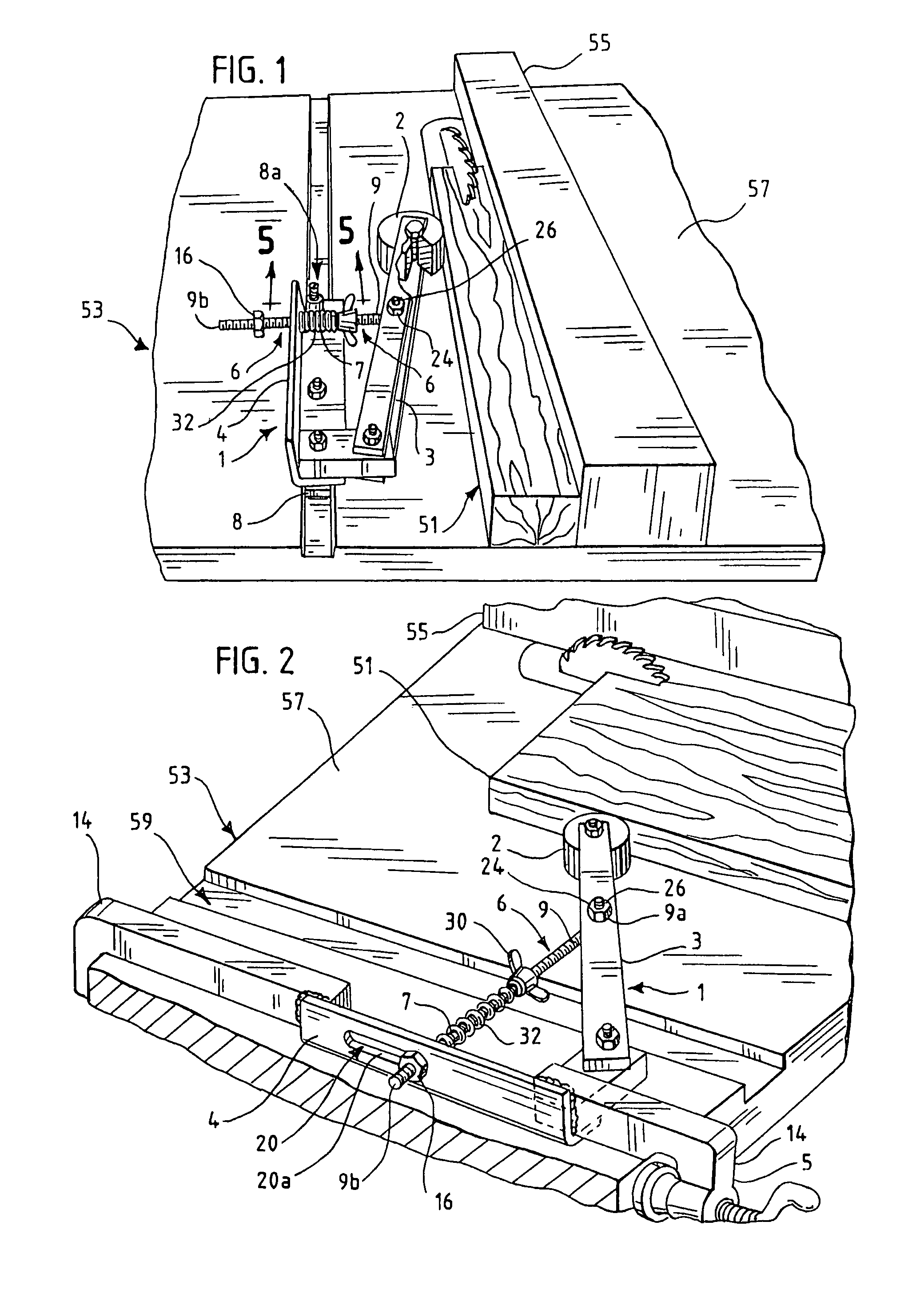

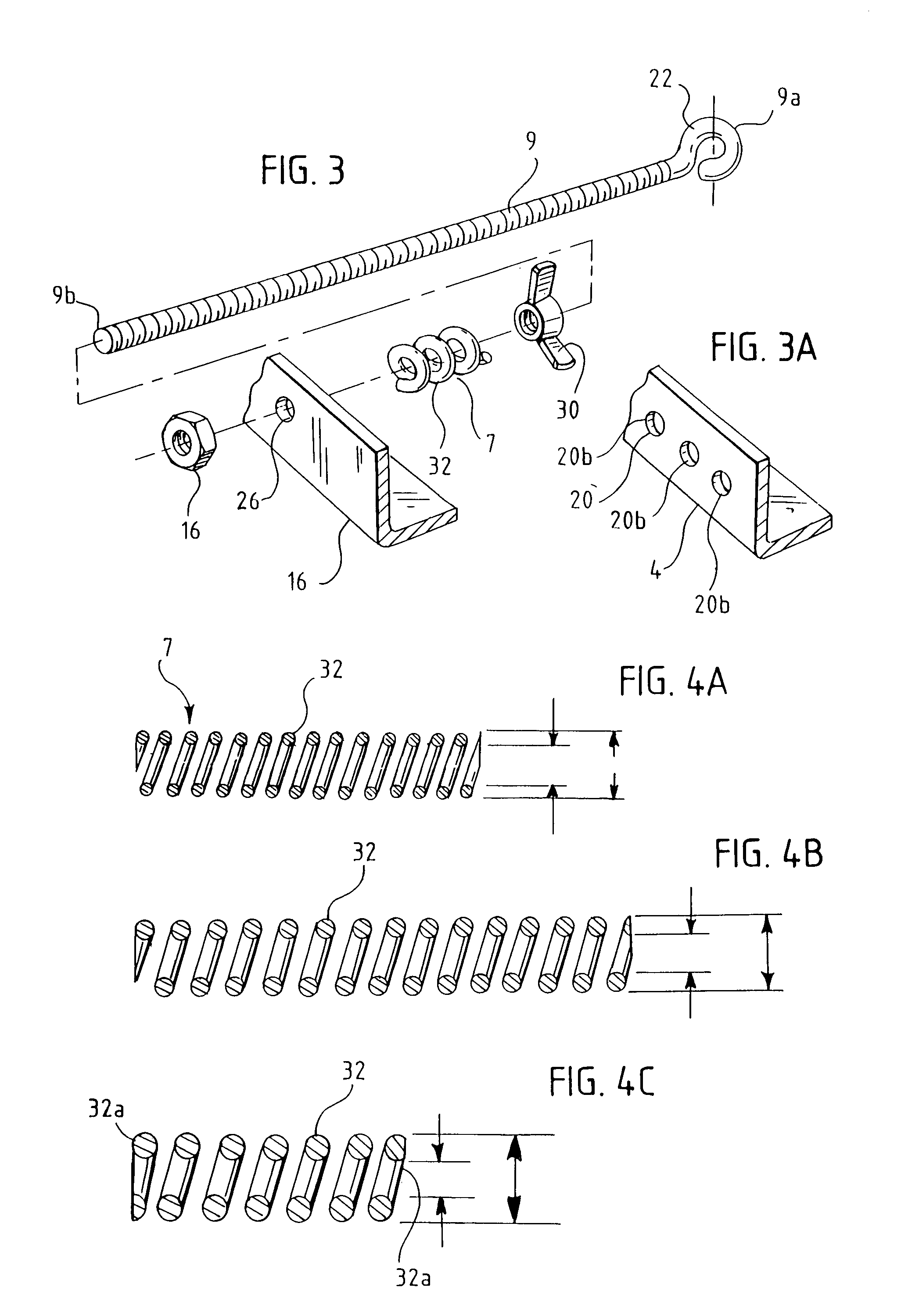

Horizontal hold down jig

InactiveUS7341081B1Uniform pressureEasy to useWood feeding arangementsFeeding devicesCompressive strengthMechanical engineering

A horizontal rotary hold down jig for use in horizontally guiding a piece of wood to be cut on one of a portable table saw and a portable router table comprising a spring biased rotatable wheel that can be secured to the table. The spring biasing can be adjusted to provide uniform or enhanced pressure through use of a plurality of substitutable compression springs of varying compressive strength characteristics to laterally stabilize a piece of wood of varying consistency, wood grain angle, feed cutting speed, width, and thickness or depth of cut.

Owner:VILLIGER ERIC J

Bamboo wood-grain plate and the preparing method

InactiveCN101036999AShun goodIncreased shear strengthWood treatment detailsCane mechanical workingSolid woodEngineering

The invention discloses a wood grain board made of bamboo and manufacturing method, the wood grain board made of bamboo includes a faceplate made by bonding and pressing the bamboo pieces arrangement, the bamboo pieces are arranged with inclination less than 90 degrees to the board plane, the inclination is adjusted and set based on the grain of required boards. The bamboo boards made by the invention technique project, because the faceplate is pressed by form of inclined arrangement of the bamboo, so the grain of faceplate has solid wood grain of top grade; because the core plate and base plate use interlaced in length and breadth arrangement form of bamboo mat, bamboo curtain, bamboo filament and piece plate, the multiple indexes of shear strength, bending intensity and elastic modulus for long and cross grain of the whole boards are better.

Owner:张世庆

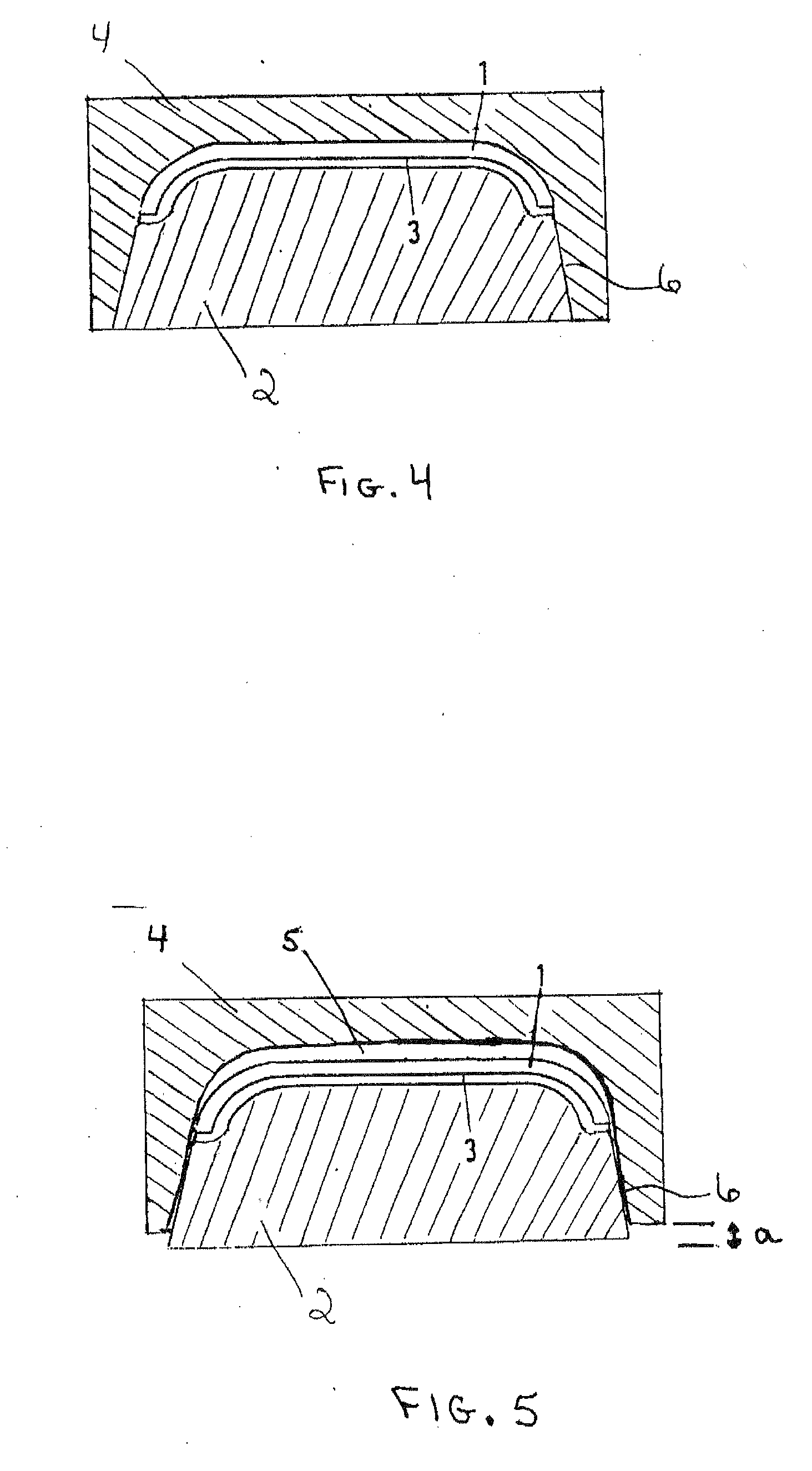

Insulated door assembly with low thermal deflection

InactiveUS6226958B1Increase and decrease viscosityViscosity modifierNatural patternsThree-dimensional effectsCompression moldingShell molding

Compression molded pigmented door skins fabricated by compression molding a pigmented, curable, unsaturated polyester sheet molding compound containing a co-curable unsaturated monomer, a low profile additive, and a microvoid-reducing thermoplastic polymer, exhibit uniform stainability while maintaining a low linear thermal coefficient of expansion. Such door skins are suitable for preparing wood grain textured exterior insulated doors which exhibit minimal thermal deflection when exposed to interior / exterior temperature differentials, even at eight foot door heights. The doors may be stained without first applying a seal coat.

Owner:THERMA TRU HLDG

Terrestrial heat composite floor and manufacturing method thereof

ActiveCN101412238AEasy constructionDoes not affect strengthWood working apparatusFlooringHardnessWear resistance

The invention relates to a terrestrial heat composite floor board and a method for manufacturing the same. The method comprises the following processing steps: step A, preparation of face veneer, which is to process face veneer raw materials into sheets, and dry and balance the sheets; step B, preparation of middle veneer, which is to process middle veneer raw materials into sheets, and dry and balance the sheets; step C, preparation of bottom veneer, which is to process bottom veneer raw material into sheets, and dry and balance the sheets; step D, glue spreading; step E, blank assembling, which is to arrange the face veneer, the middle veneer, and the bottom veneer longitudinally, transversely, and longitudinally respectively according to wood grains; step F, hot pressing, which is to put the face veneer, the middle veneer, and the bottom veneer into a hot press to perform hot pressing; step G, conditioning, which is to put the floor board after the hot pressing and gluing into a balancing storeroom with constant temperature and humidity to keep stand and perform balance conditioning; step H, securing thickness and sanding; step I, mortice opening; step J, back trough opening; and step K, surface finishing, which is to adopt a roll painting process to lacquer the glued floor board. The composite floor board manufactured by the method has the characteristics of beautiful surface, hardness, wear resistance, good heat conductivity, high flexibility, and humiture change resistance.

Owner:FUSONG JINQIU WOOD CO LTD

Door skin, a method of etching a plate for forming a wood grain pattern in the door skin, and an etched plate formed therefrom

The present invention is directed to a door skin having an exterior surface with an woodgrain pattern formed therein, and an etched plate for use as an embossing plate or with a molded die set, for forming the woodgrain pattern in the door skin. The exterior surface has outer portions lying on a first plane, spaced grooves recessed from the plane of the outer portions, and halftone portions. The halftone portions have spaced protrusions defined by channels, wherein the channels are recessed from the plane of the outer portions.

Owner:MASONITE CORP

Artificial wood grain floor and its press-paste technique and equipment

InactiveCN1737295ASimple structureStable structureDecorative surface effectsOrnamental structuresHydraulic cylinderSheet steel

This invention relates to a simulate wood card, in addition to a plaster technique and device, characterized in that it based on a hot press, and the lower of the bay has a working bench, and the upper of the bay is connected with a press hydraulic cylinder and a connecting board which can be moved up and down; the work bench can be a transforming bench which can be shifted outside; on the connecting board upon the bay it sets at least one wood sheet steel form with inner heating system and wood grain in the lower surface; the bay also has at least two infrared generators; the method of using the device comprises the following steps: fixing the wood sheet steel form on the top of the hot press, aligning the impregnated wood paper according to the interior wiring of the flooring base material, laying it on the transforming working bench and aligning with the upper wood sheet steel form, plastering with the hot press to get the base material, which has a wood paper with at least one wood pattern, and on the surface of the wood paper it has warp wood grain.

Owner:SENJIA WOOD IND MFG PLANT HANGZHOU +1

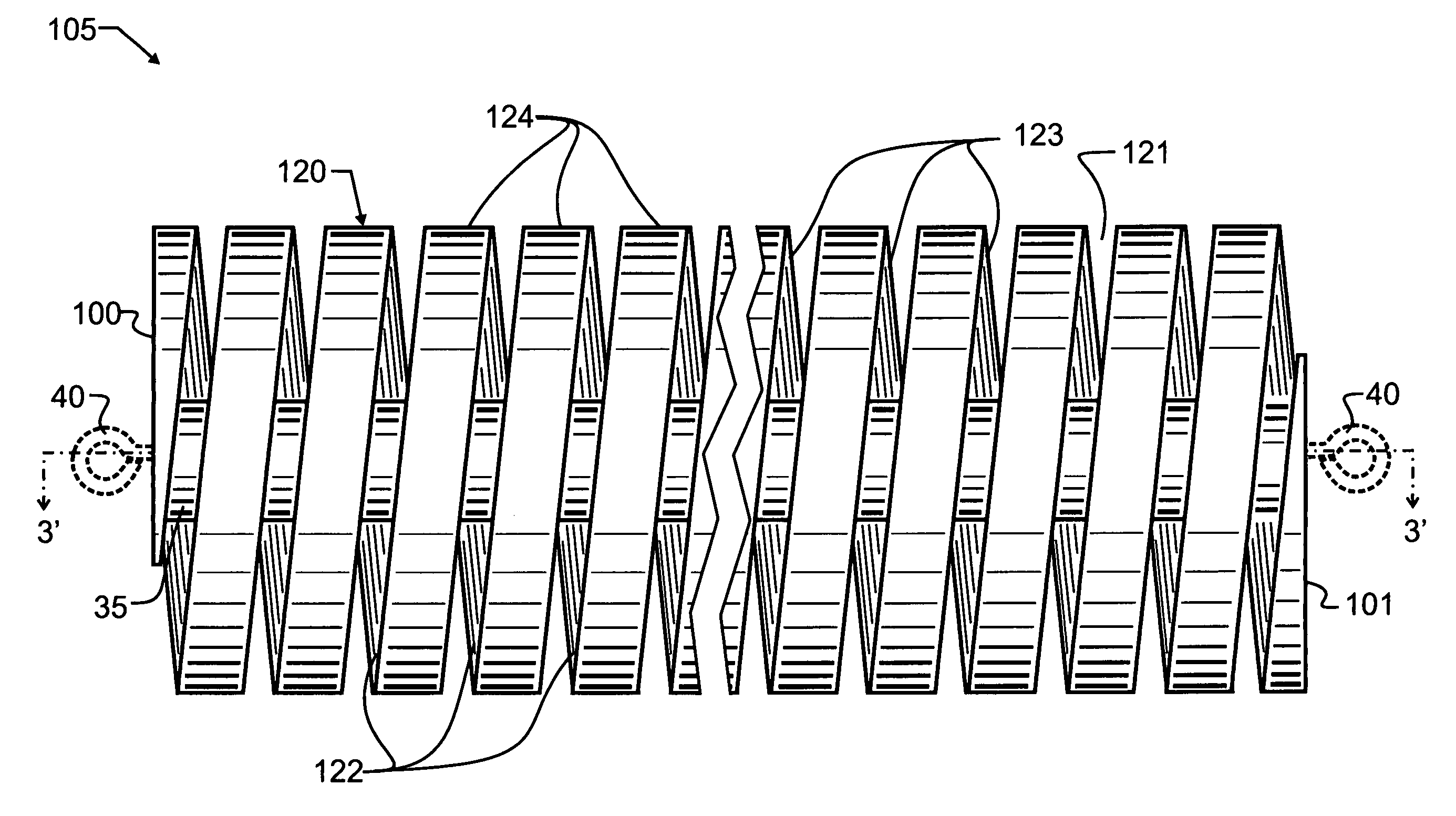

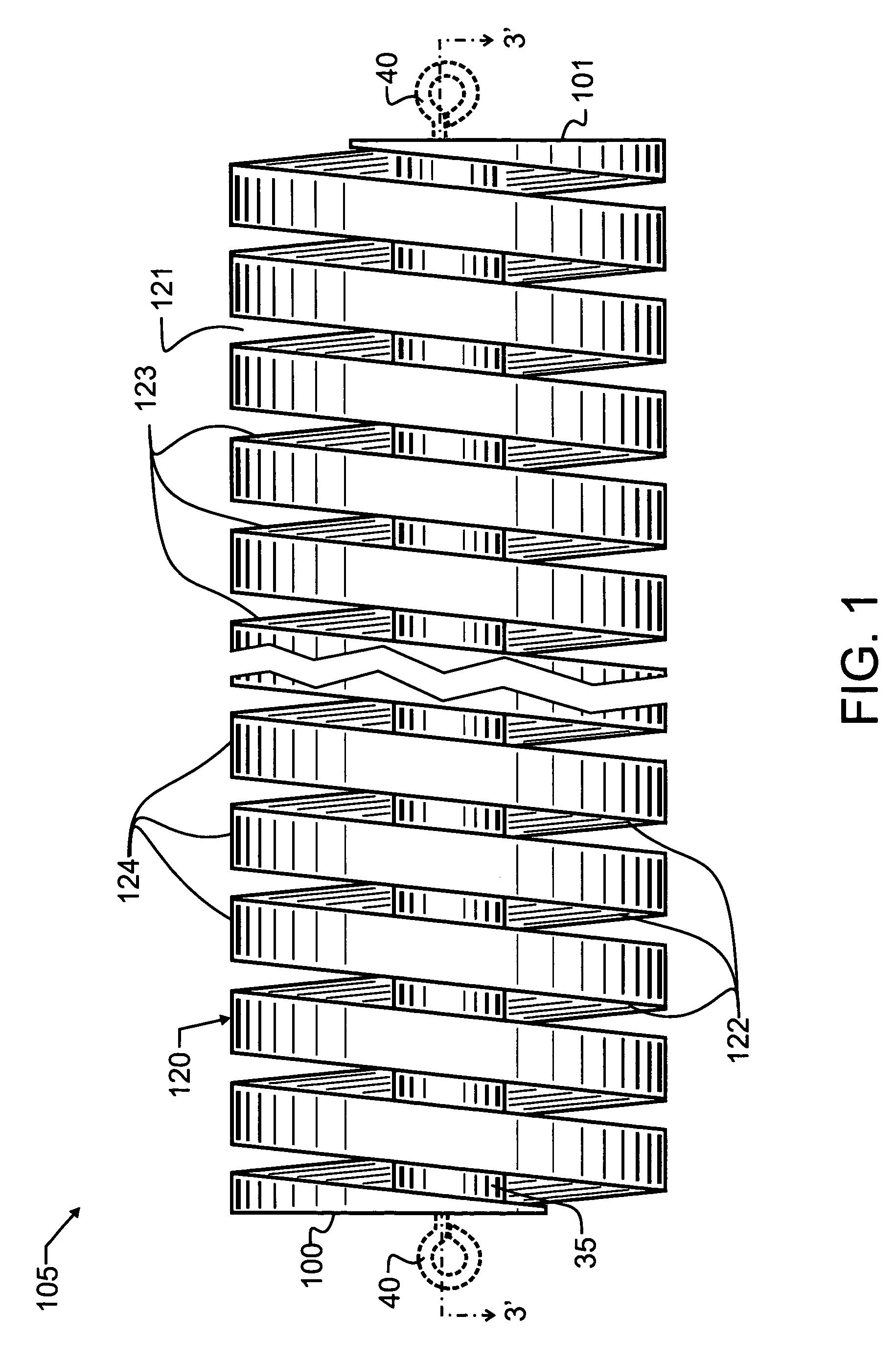

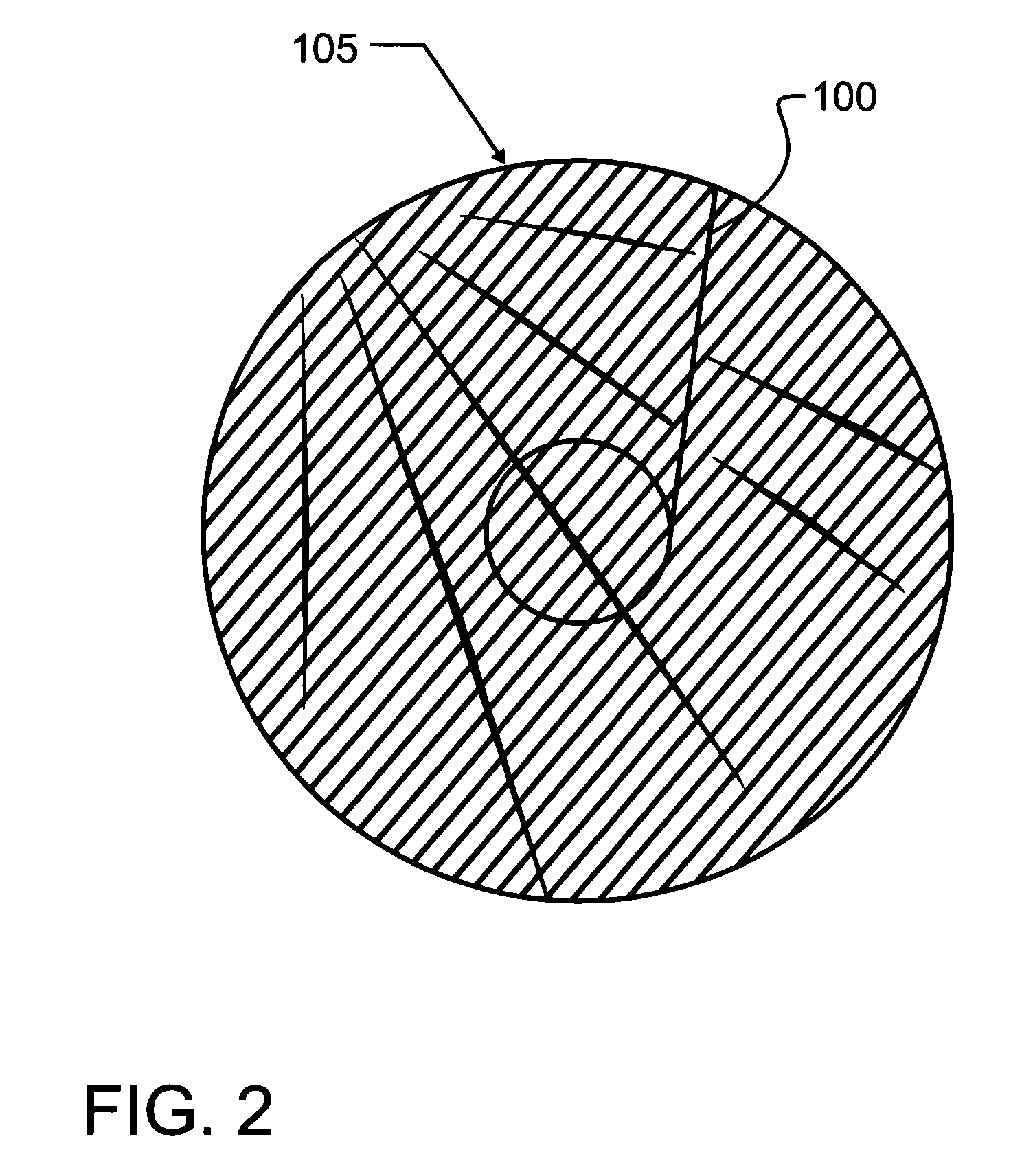

Beverage infusion spiral and methods of making and using the same

A liquid may be aged and infused using a wooden infusion apparatus having grain oriented along a longitudinal axis of a rod. One preferred infusion apparatus comprises machining a grain oriented wooden cylinder into the shape of a spiral having a longitudinal central axis. A preferred method is disclosed for continuously machining wooden rods into spirals, and subsequently toasting them. Another infusion apparatus comprises a plurality of wooden discs connected by a longitudinal central axis in the form of a rod, the wooden discs which are toasted. The present invention allows for more control over the time required to properly age the wine and to impart the wood flavor by giving the producer more control over the amount of wood surface area that is exposed to the wine. The rate of infusion is increased substantially when the wood grain extends along the longitudinal axis of the infusion apparatus. The shape and size of the infusion apparatus may be customized to fit any container from a huge wine barrel to a small liquor bottle. Additionally, the infusion spiral may be connected to a lid or bung of a container, and may thereby be removed when desired by merely opening the lid or bung. The infusion spiral can be replaced, by this same manner, with a different type of wood infusion spiral or a fresher infusion spiral to enhance the flavor imparted to the wine without having to fish around in the container for the infusion spiral.

Owner:RIVERSIDE ROCKETAB

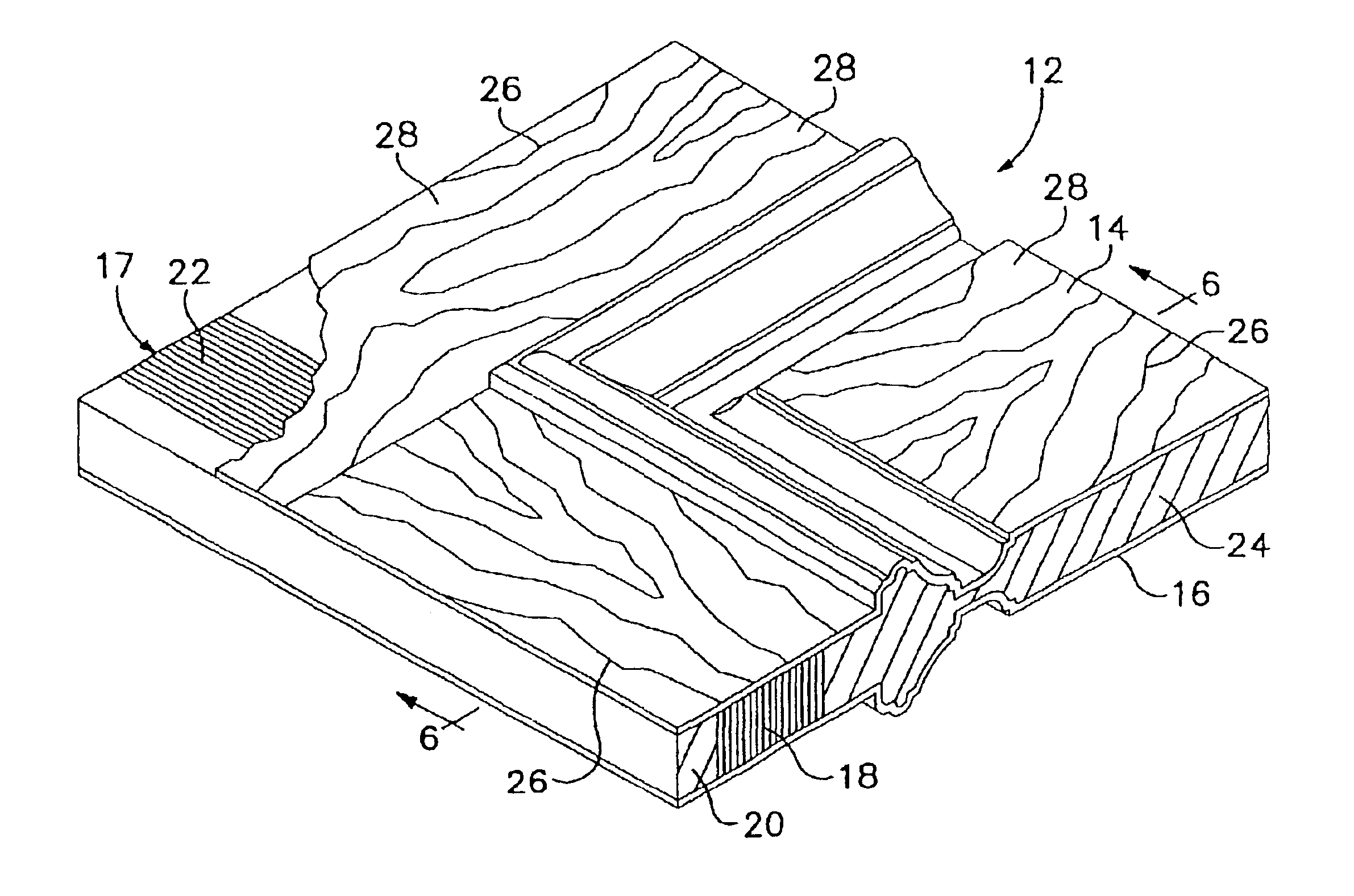

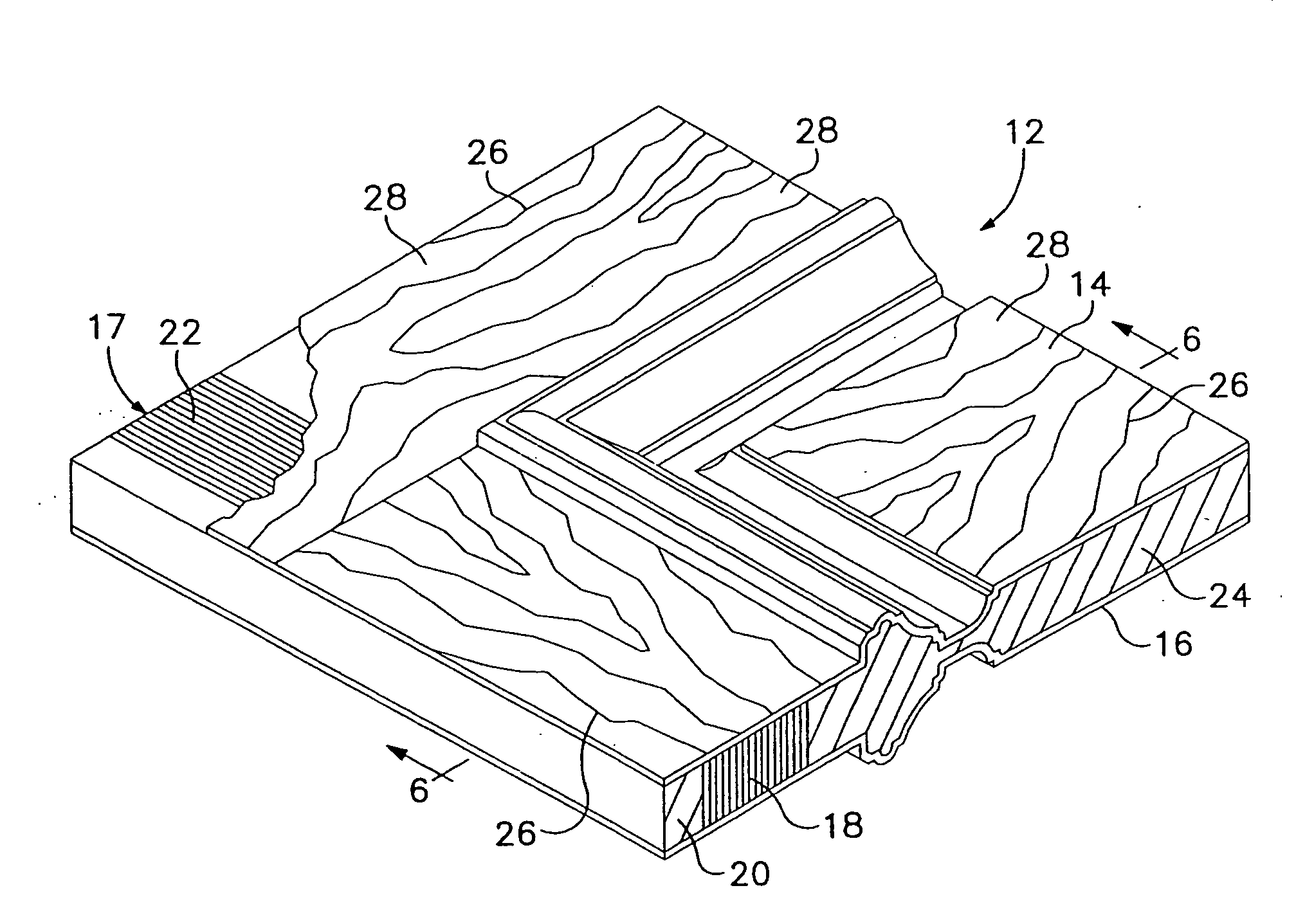

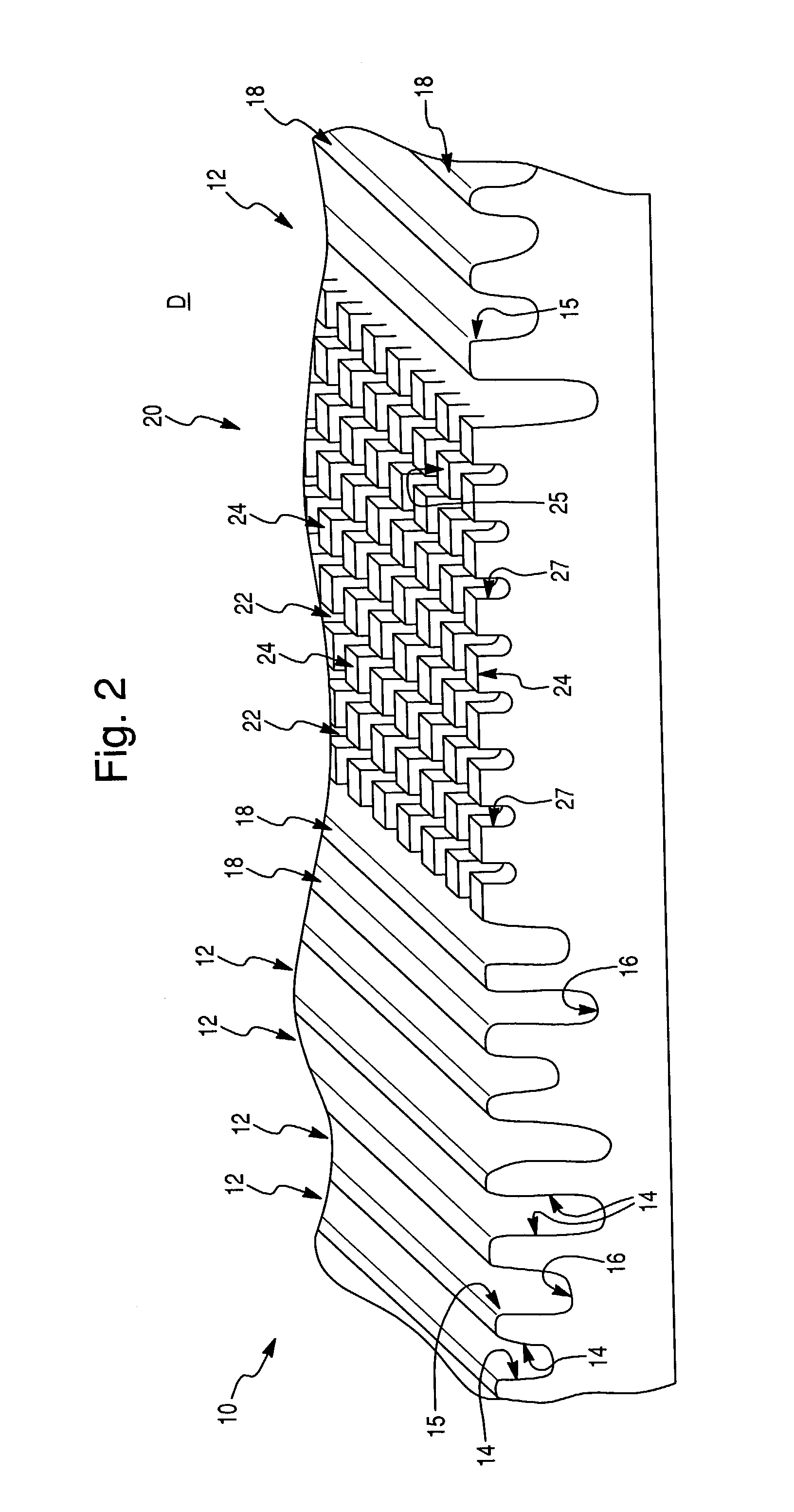

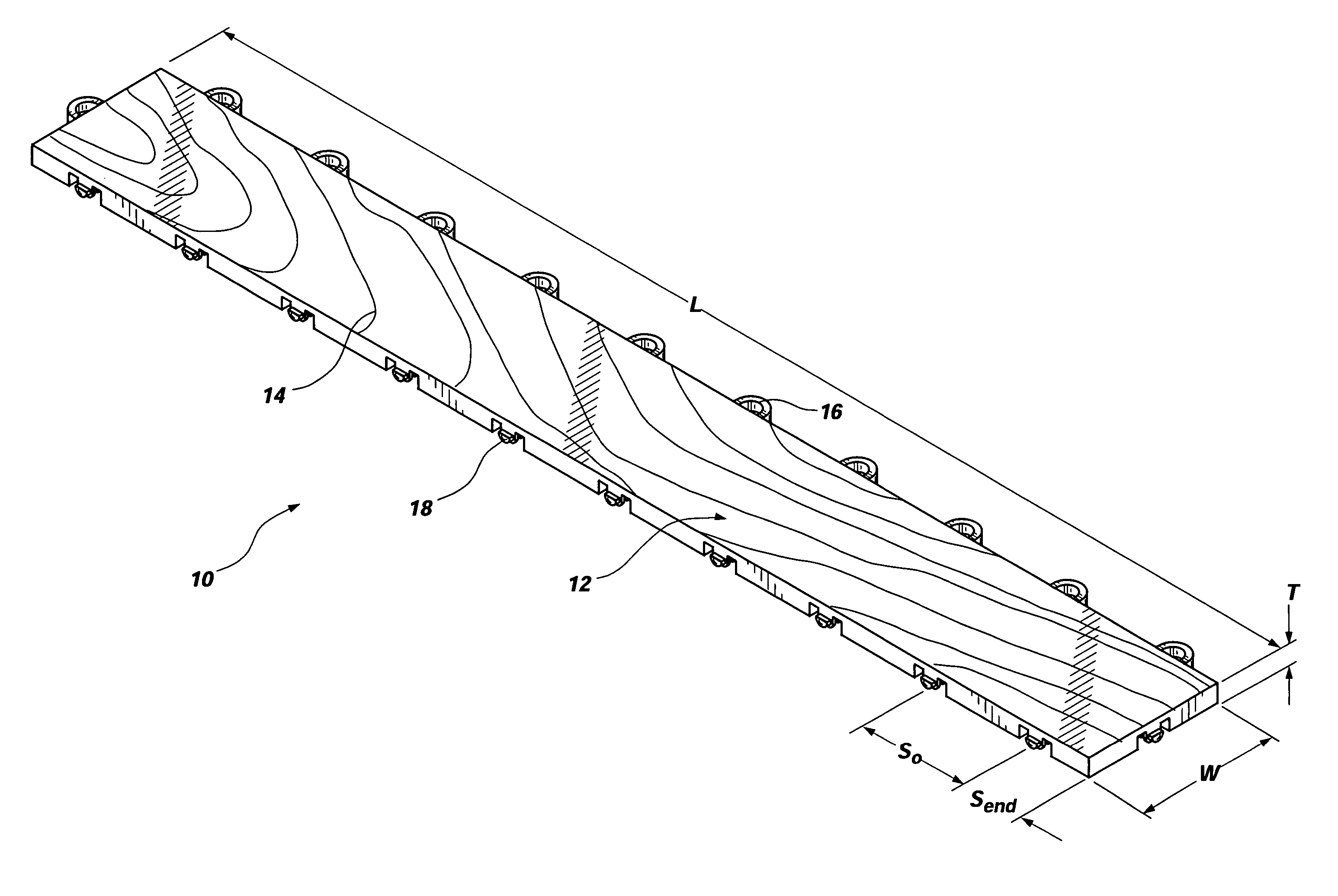

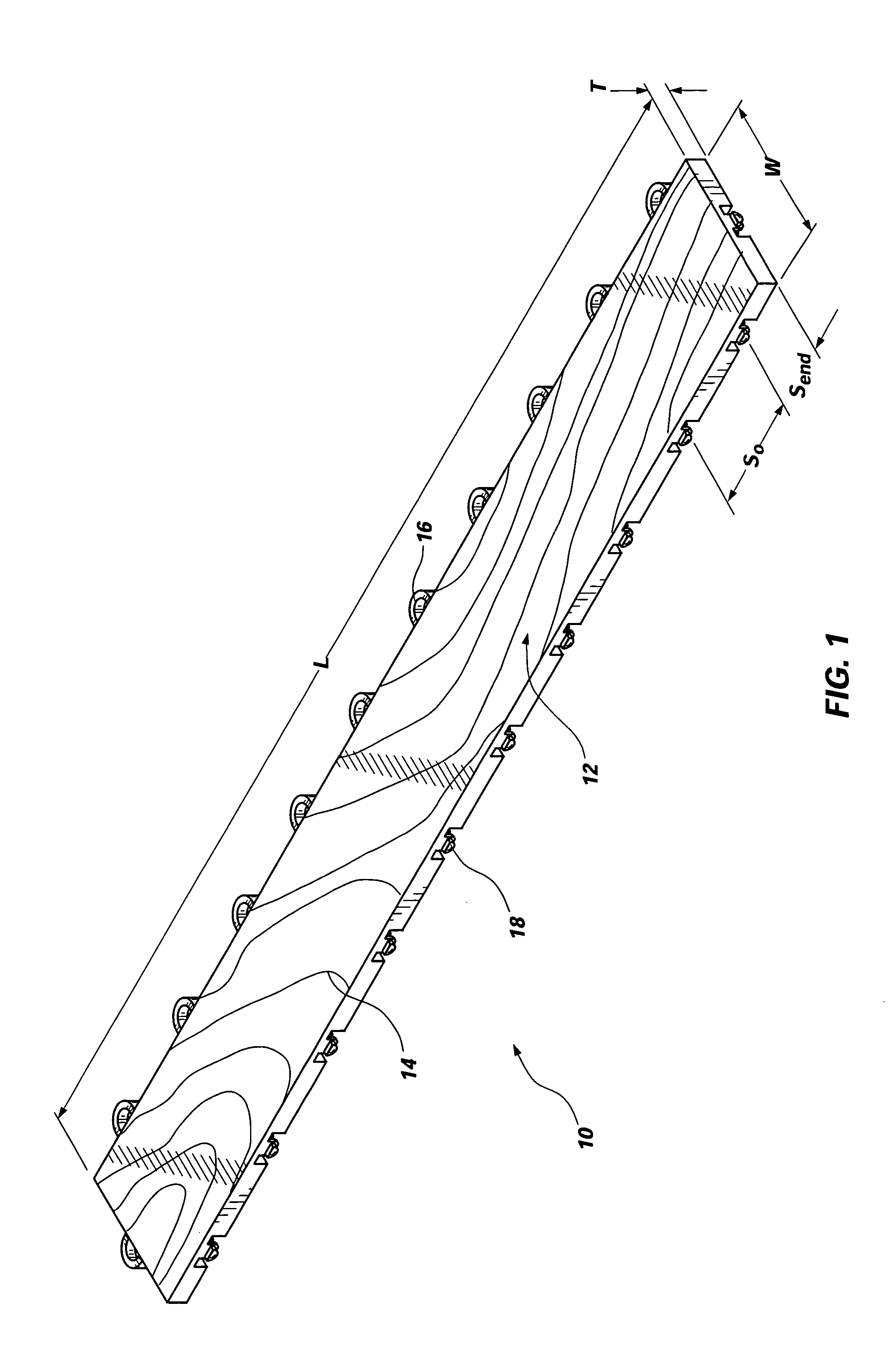

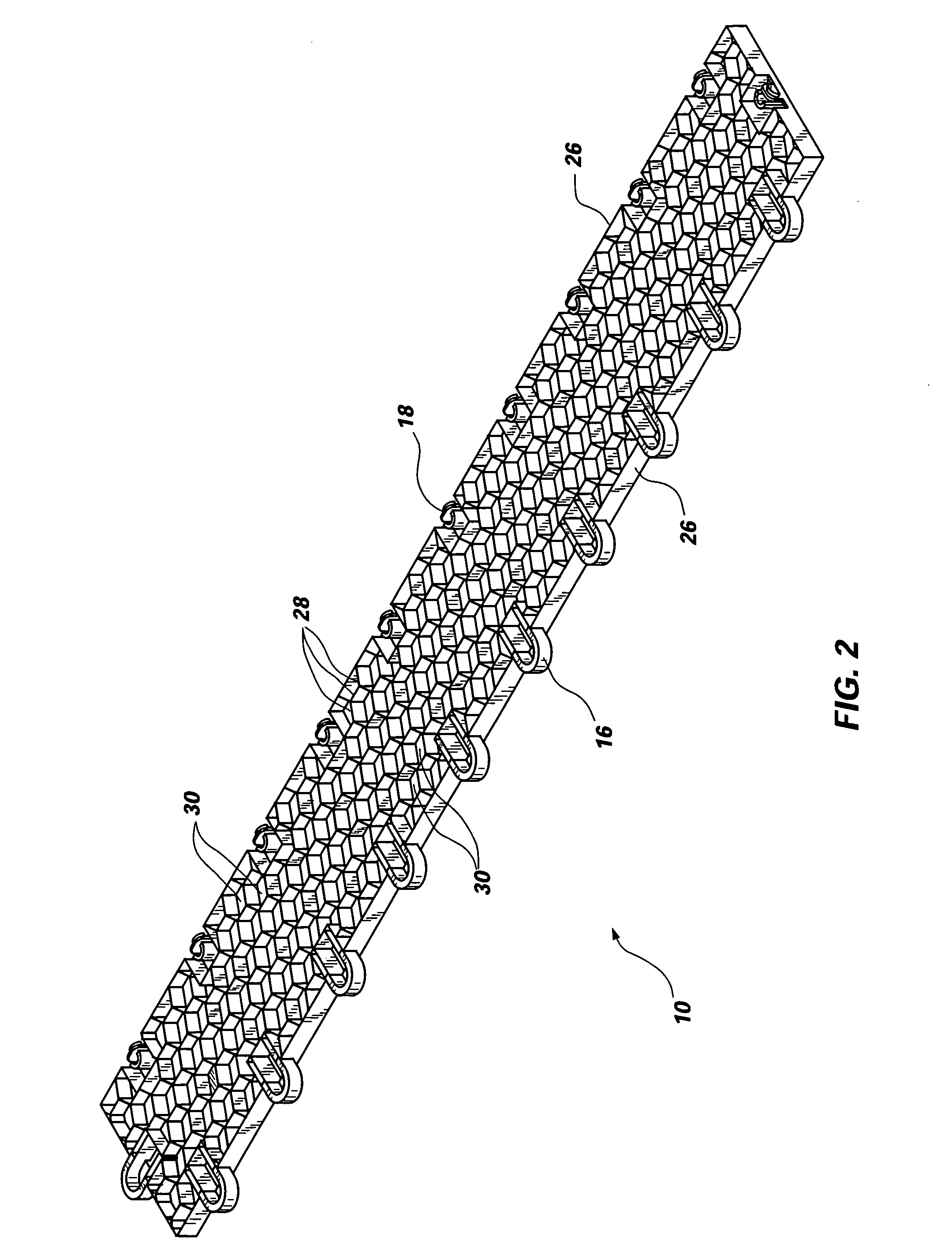

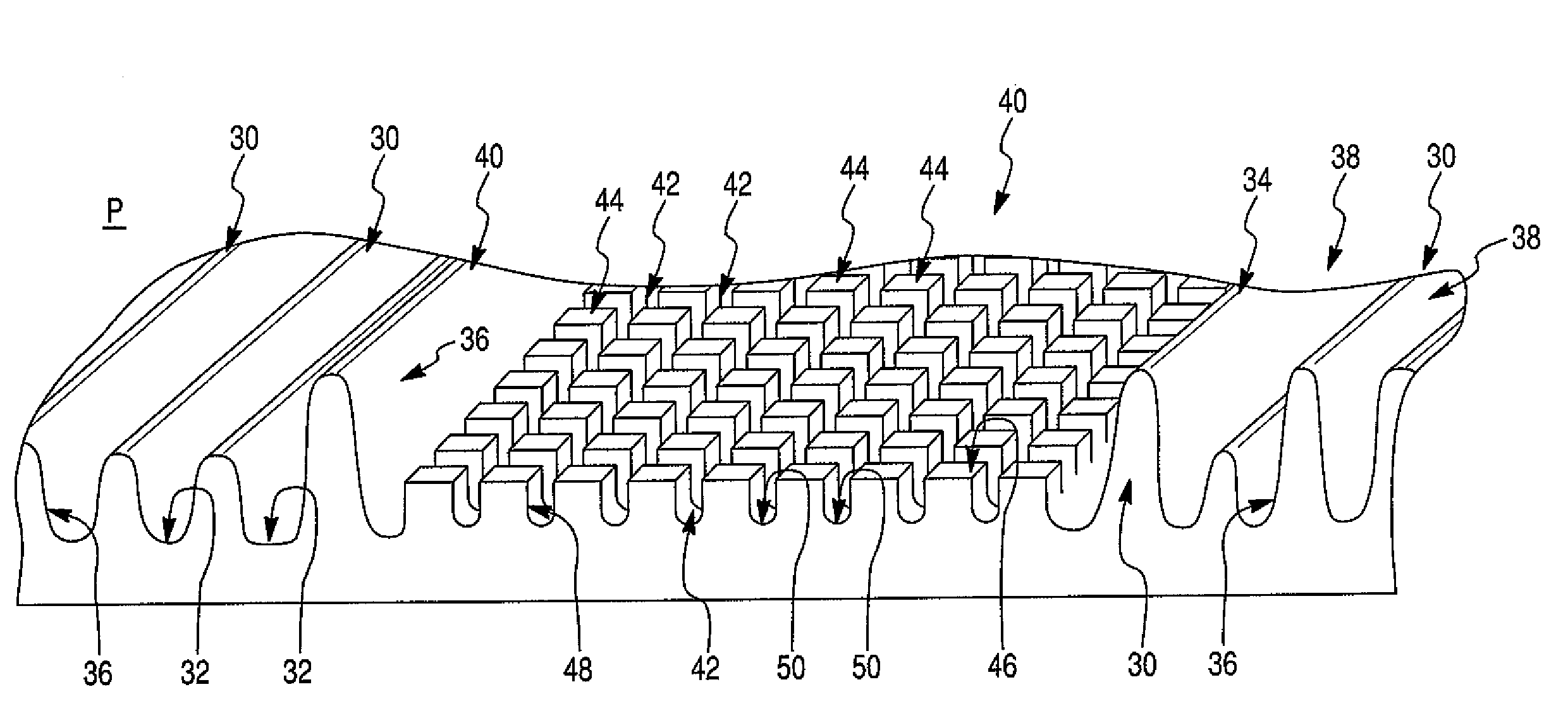

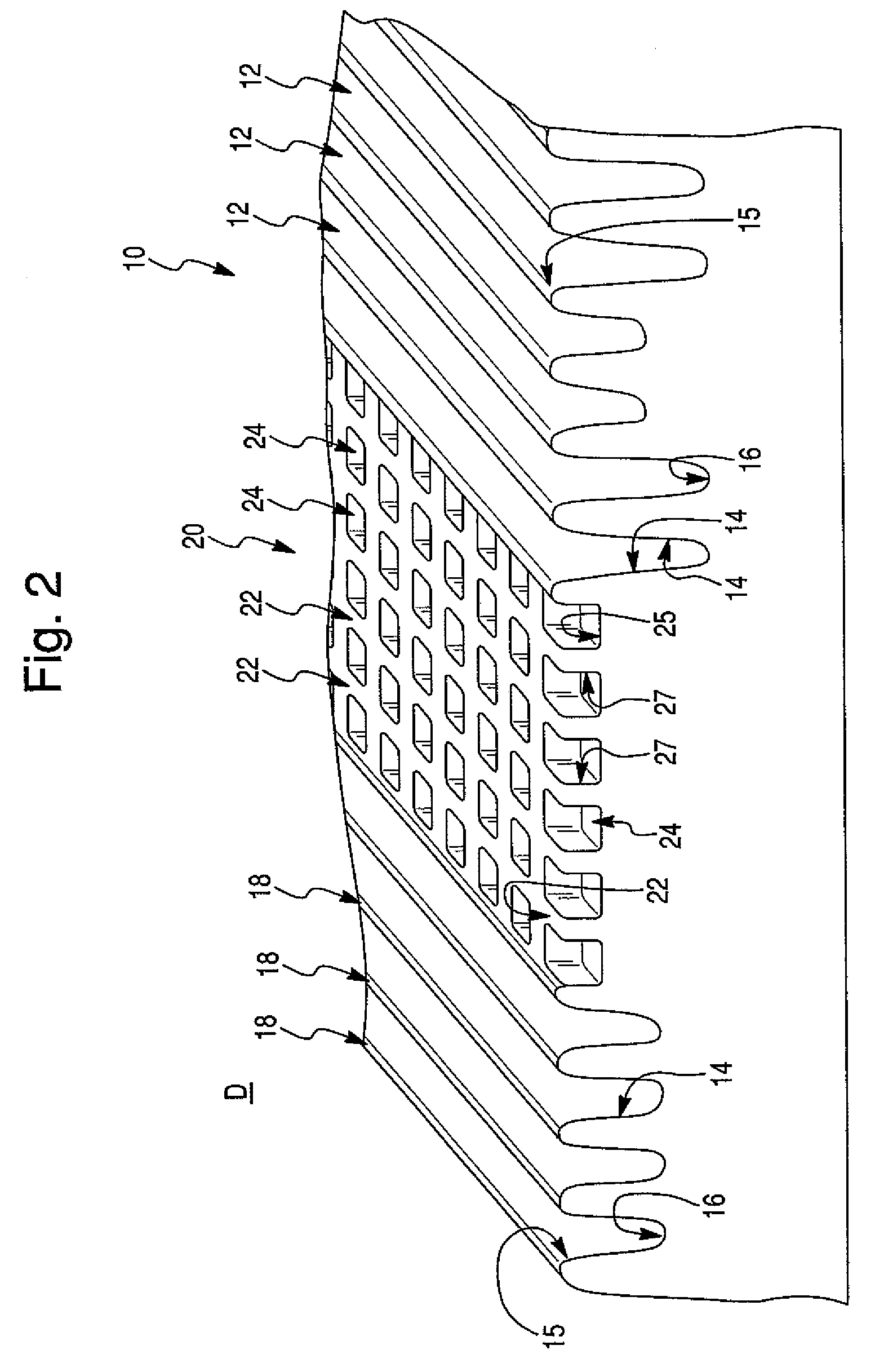

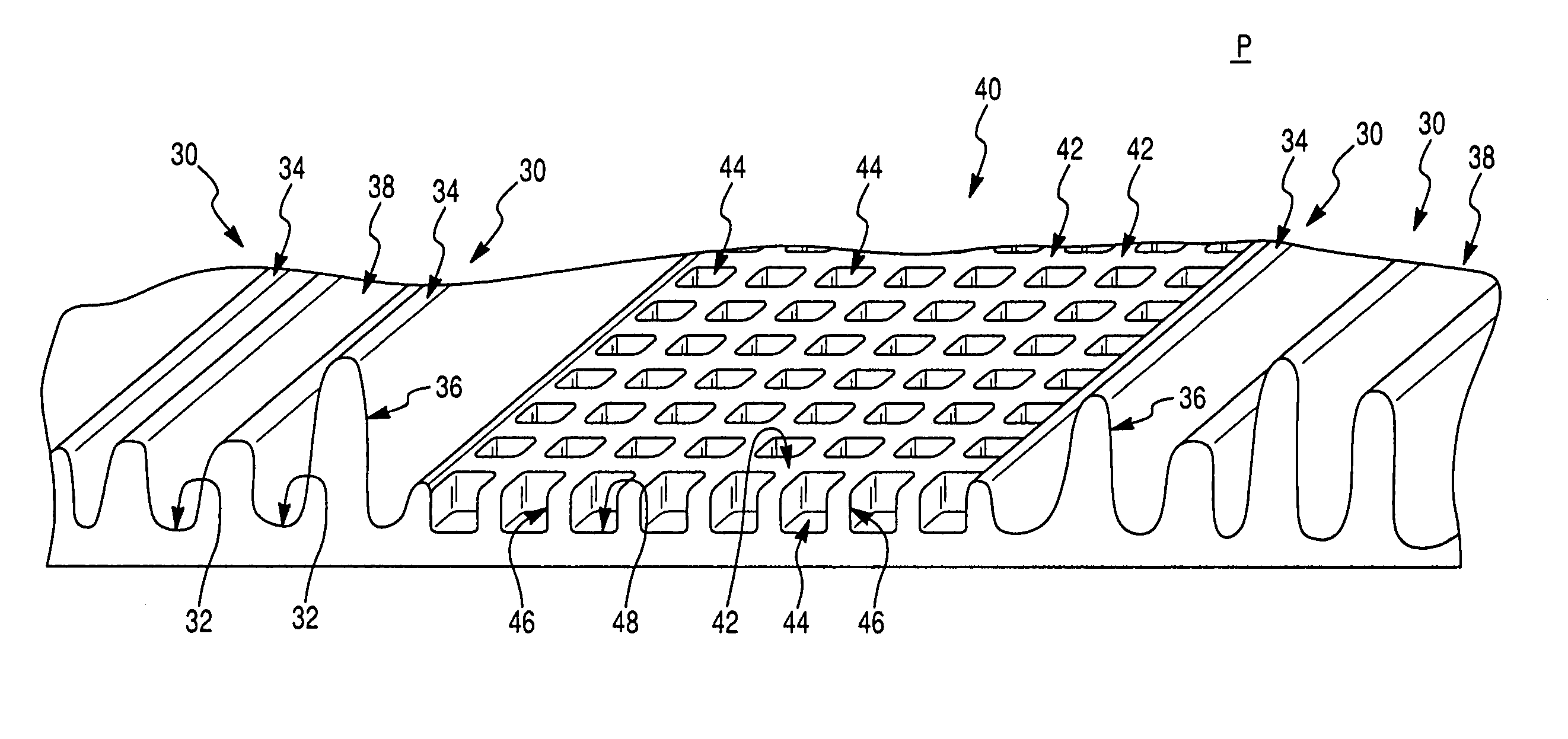

Interlocking floorboard tile system and method of manufacture

An interlocking polymer floorboard tile (10) comprises an elongate rectangular plank having a length (L) that is at least four times its width (w). The elongate tile includes a top surface (12), a perimeter wall (26) and lattice-type support structure (28) supporting the top surface, and interlocking structure of loops (16) and pins (18) configured to mate and interlock with pins of adjacent similar tiles to form a floor covering resembling a natural wood plank floor. The top surface (12) may include a wood grain pattern imprinted thereon, to enhance the appearance of a natural wood plank.

Owner:CONNOR SPORT COURT INT

Door skin, a method of etching a plate for forming a wood grain pattern in the door skin, and an etched plate formed therefrom

The present invention is directed to a door skin having an exterior surface with an woodgrain pattern formed therein, and an etched plate for use as an embossing plate or with a molded die sets for forming the woodgrain pattern in the door skin. The exterior surface has outer portions lying on a first plane, spaced grooves recessed from the plane of the outer portions, and halftone portions. The halftone portions have spaced protrusions defined by channels, wherein the channels are recessed from the plane of the outer portions.

Owner:MASONITE CORP

Process for printing and doping solid wood and wood composite floor boards

InactiveCN101591969ASatisfy the pursuitSave resourcesPretreated surfacesWood working apparatusSolid woodPulp and paper industry

The invention relates to the field of floor boards, in particular to a process for printing and doping solid wood and wood composite floor boards. The method comprises the following steps: material preparing; the material processing; wood grain preparing; special adhesive agent printing; UV drying; oil sands doping; bouncing putty doping; UV drying; the oil sand doping; printing special adhesive agent for the substrate board surface; printing mask primer; UV drying; printing special ink varnish; wood grain transfer printing; wearable primer printing; UV drying; sanding primer printing; UV drying; roller paint doping; curtain coating of finishing coat; and four lamp drying. The process can print various natural wood grains according to client requirement, and greatly save wood resources which are reduced day by day.

Owner:史海龙

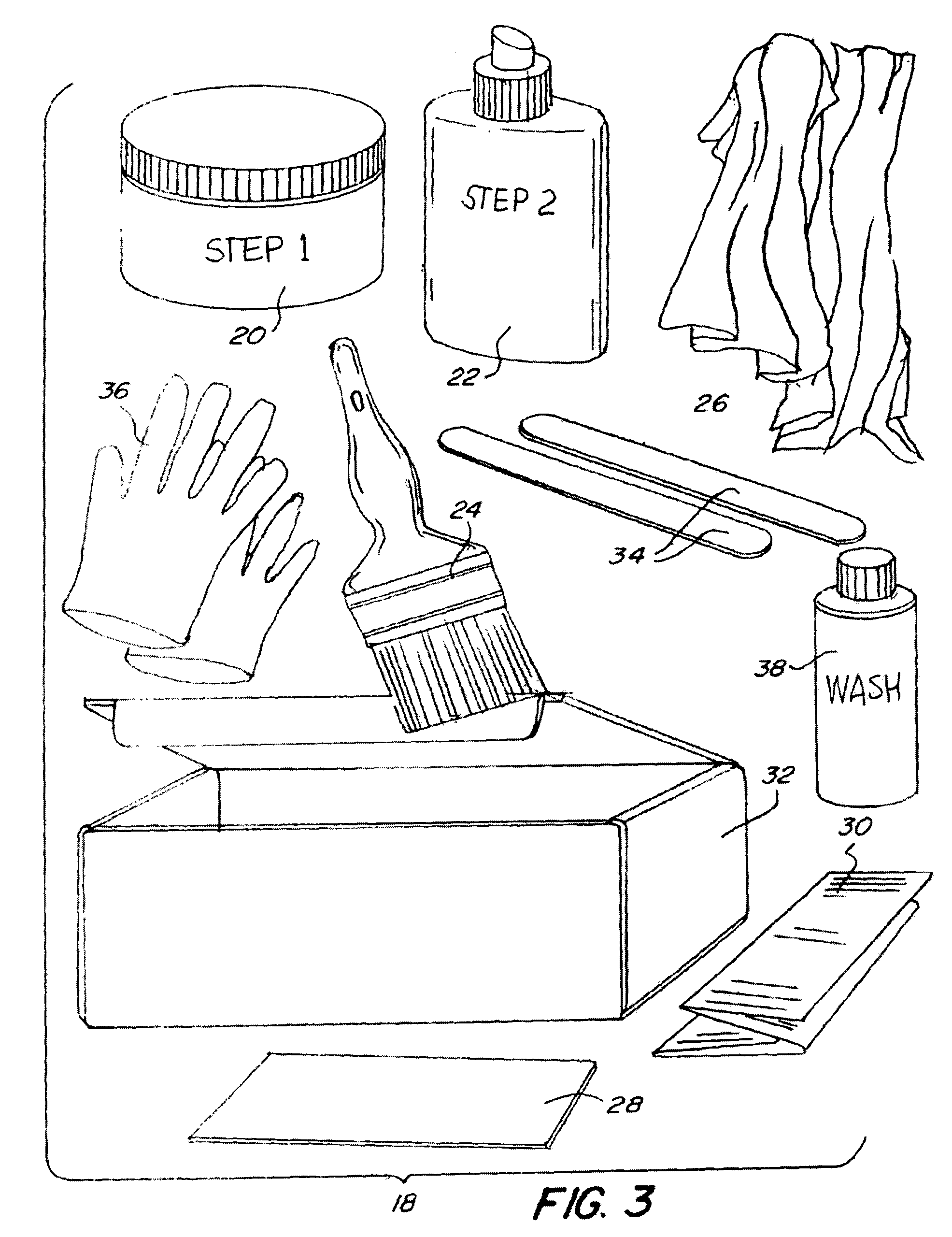

Wood graining process

A kit and a process for using it to impart wood grain appearances are provided. According to the method, an opaque, pigmented, water-based paint / stain emulsion is applied to a wood-grain textured substrate and dried. Then, a pigmented, water-based graining coat water-based graining coat (most preferably a self-crosslinked urethane / acrylic) is applied sparingly, preferably by spraying from a small bottle, in an amount sufficient to color at least a majority of texture recesses in the substrate and drying. According to the kit aspect of the invention, the kit will comprise: an opaque, pigmented, water-based paint / stain emulsion; a pigmented, water-based graining coat emulsion, packaged in a spray bottle. Optionally, the kit can include a surface cleaner, a scraper, brush and / or cloth.

Owner:GRAFTED COATINGS

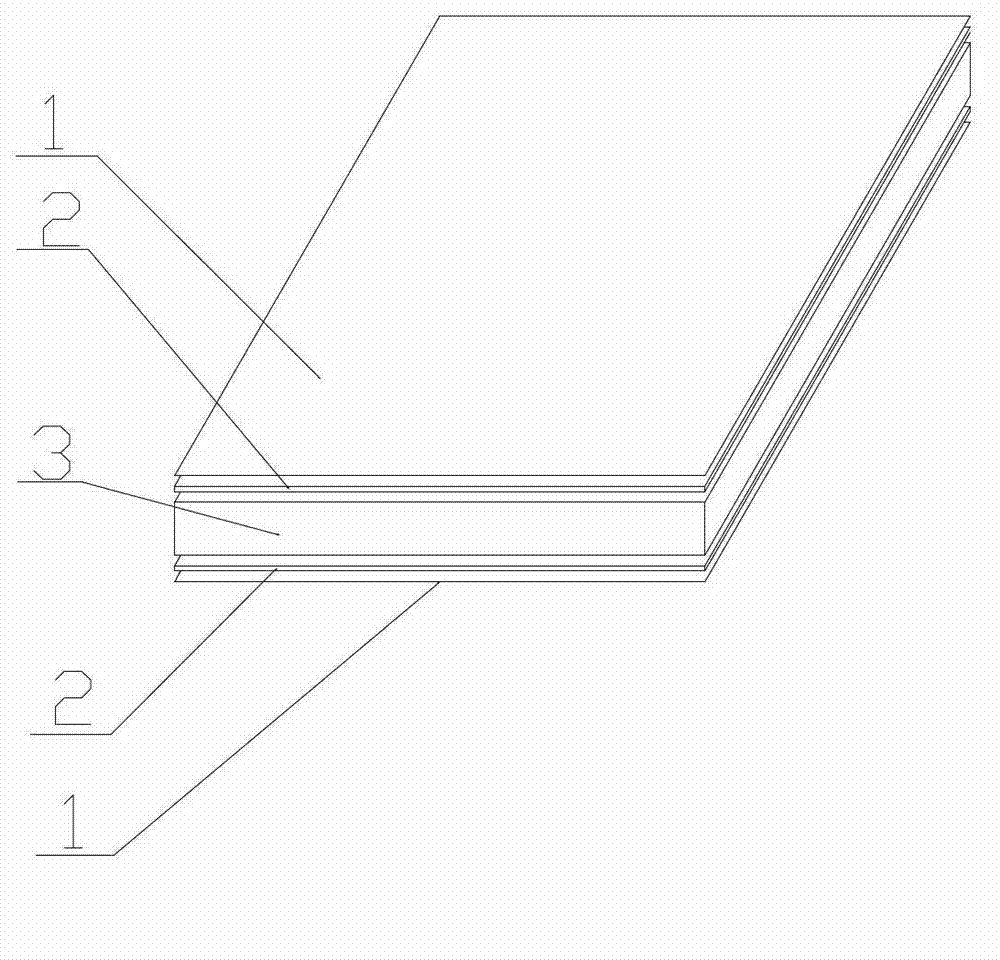

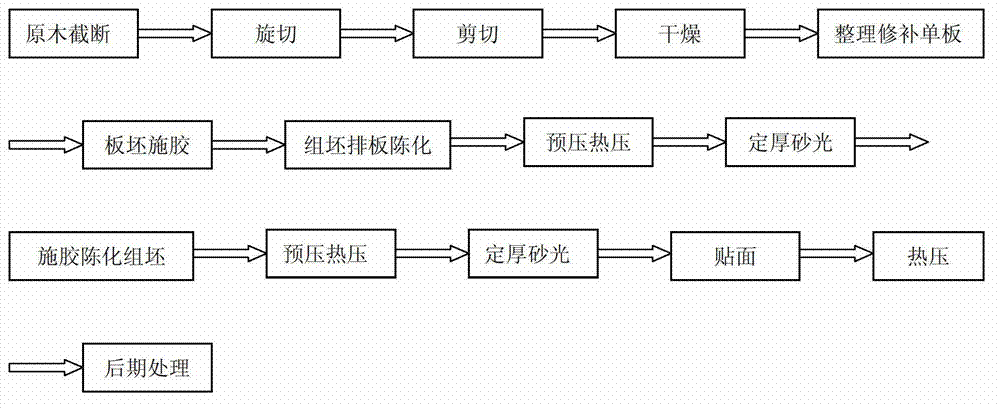

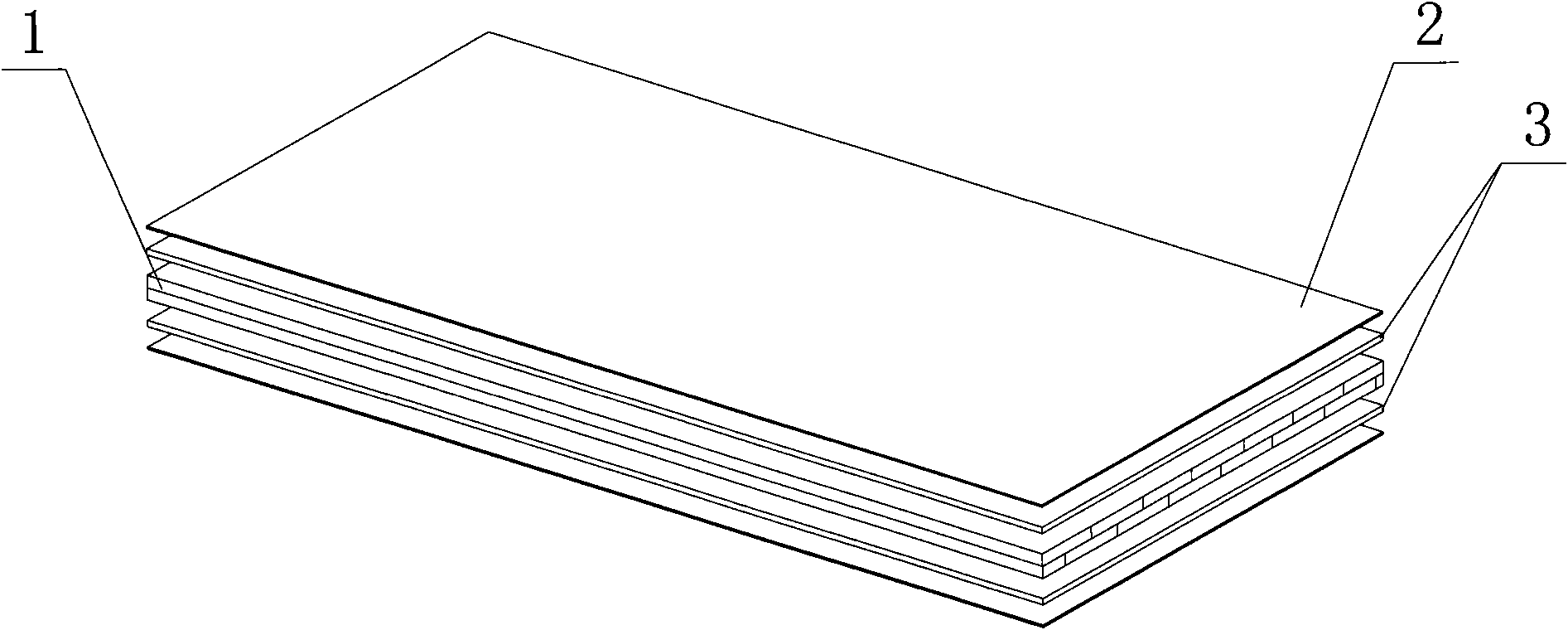

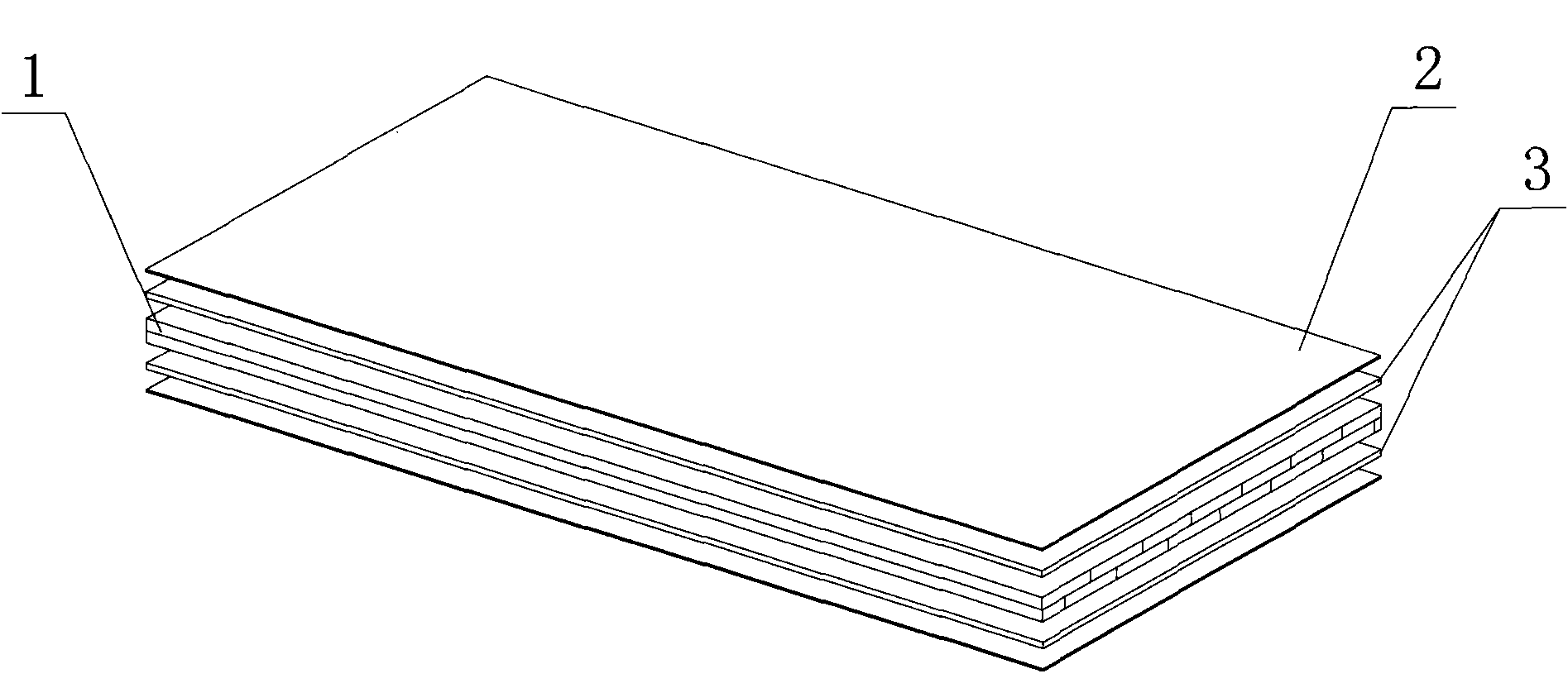

Three-hot-pressing and two-sanding eucalyptus poplar composite artificial board and method for manufacturing same

InactiveCN102785273ALow costReduce usageWood veneer joiningWood layered productsPolymer resinOptoelectronics

The invention discloses a three-hot-pressing and two-sanding eucalyptus poplar composite artificial board and a method for manufacturing the same. The composite artificial board is composed of a core layer, a poplar thin veneer layer and a grainy paper layer soaked with melamine polymer resins. The core layer is eucalyptus poplar plywood which is formed by assembly pressing of a plurality of layers of eucalyptus poplar veneers according to mutual vertical textures, a layer of eucalyptus poplar veneers is arranged on the upper and lower surfaces of the core layer respectively, the fiber direction of the eucalyptus poplar veneers is perpendicular to the fiber direction of the surface of the core layer, and a layer of grainy paper soaked with melamine polymer resins is arranged on outer surfaces of two layers of eucalyptus poplar veneers respectively. The method for manufacturing the artificial board includes log trim, rotary cut, shear, drying, veneer settling and repairing, veneer sizing, assembly row veneer aging, pre-pressing and hot pressing, thickness determination sanding, sizing to age the assembly, pre-pressing and hot pressing, thickness determination sanding, veneering, hot pressing and post processing. According to the three-hot-pressing and two-sanding eucalyptus poplar composite artificial board and the method for manufacturing the same, furniture cost can be reduced, harmful gas releasing of furniture is reduced, and indoor air is guaranteed to be clean.

Owner:广西南宁绿园北林木业有限公司

Composite slab with symmetric structure and manufacturing method thereof

InactiveCN101890739ASimple structureHigh strengthWood veneer joiningWood layered productsSurface layerAdhesive

The invention discloses a composite slab with a symmetric structure and a manufacturing method thereof. The composite slab with the symmetric structure comprises two surface layers and core layers inside the two surface layers, wherein the core layers are formed by overlapping a plurality of layers of saw cutting plates, and each layer of saw cutting plates is adhered with each other by using an adhesive. The core layers are formed by overlapping the saw cutting plates with the thickness of 5 to 1.5 mm; a middle layer is arranged between each surface layer and each core layer and is a single plate with the thickness of 1.5-2.5 mm; the surfaces of the saw cutting plates are provided with a plurality of dot-line shaped crackles along a direction of wood grain; and the average length of the cracks is between 2.5 mm and 4.8 mm, the width is between 0.5 mm and 2.5 mm, the depth is 40 to 60 percent of the thickness of the saw cutting plates of the core layers, and the distance between the crackles is between 1 cm and 4.8 cm. The invention has the advantages of simple structure, firmness, durability, concise procedures of the manufacturing method, wide application range and easy popularization, can be used as raw materials of any panel-type furniture, and is suitable for processing and manufacturing various kinds of fast-growing tree timber composite plates.

Owner:成都市双虎实业有限公司

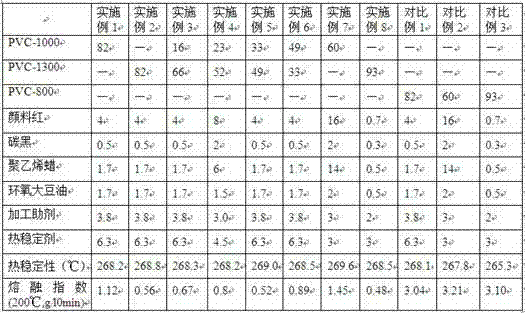

Wood-grain-like color master batch, and preparation method and application thereof

The invention discloses a wood-grain-like color master batch which comprises the following components in percentage by weight: 60-93% of PVC (polyvinyl chloride) resin, 1-18% of pigment, 0.5-14% of dispersant and 3-15% of other assistant. The preparation method comprises the following steps: a) proportionally mixing the components in a high-speed mixer; and b) carrying out melt blending extrusion on the mixture with a single screw extruder at the screw bolt speed of 14-27RPM at the melting temperature of 120-170 DEG C, uniformly dispersing the pigment in the carrier resin through the shearing and compounding of the screw bolt, naturally cooling, granulating, and airing to obtain the wood-grain-like color master batch. The wood-grain-like color master batch has the advantages of low toner consumption, favorable temperature tolerance and excellent dispersibility; when being used for preparing a wood-grain-like wood-plastic composite material, the wood-grain-like color master batch is easy to operate and control and has favorable compatibility with the PVC-based base material; the wood-grain-like wood-plastic composite material has highly simulated wood appearance, natural and clear grains, bright surface color and favorable wood-grain-like effect, and thus, is an ideal wood-like wood-plastic product.

Owner:KINGFA SCI & TECH CO LTD +2

Insulated door assembly with low thermal deflection

InactiveUS6740279B2Improve insulation performanceImprove rigidityNatural patternsSpecial ornamental structuresCompression moldingShell molding

Owner:TTTECH

Door skin, a method of etching a plate, and an etched plate formed therefrom

The present invention relates to a door skin comprising an exterior surface having outer portions lying on a first plane, spaced grooves recessed from the plane of the outer portions, and tonal portions having a planar area and a plurality of spaced depressions recessed from the plane of said planar area. The present invention is also directed to a method of etching a plate, for use with a molded die set, for embossing a wood grain pattern in the door skin, and the etched plate formed therefrom.

Owner:MASONITE CORP

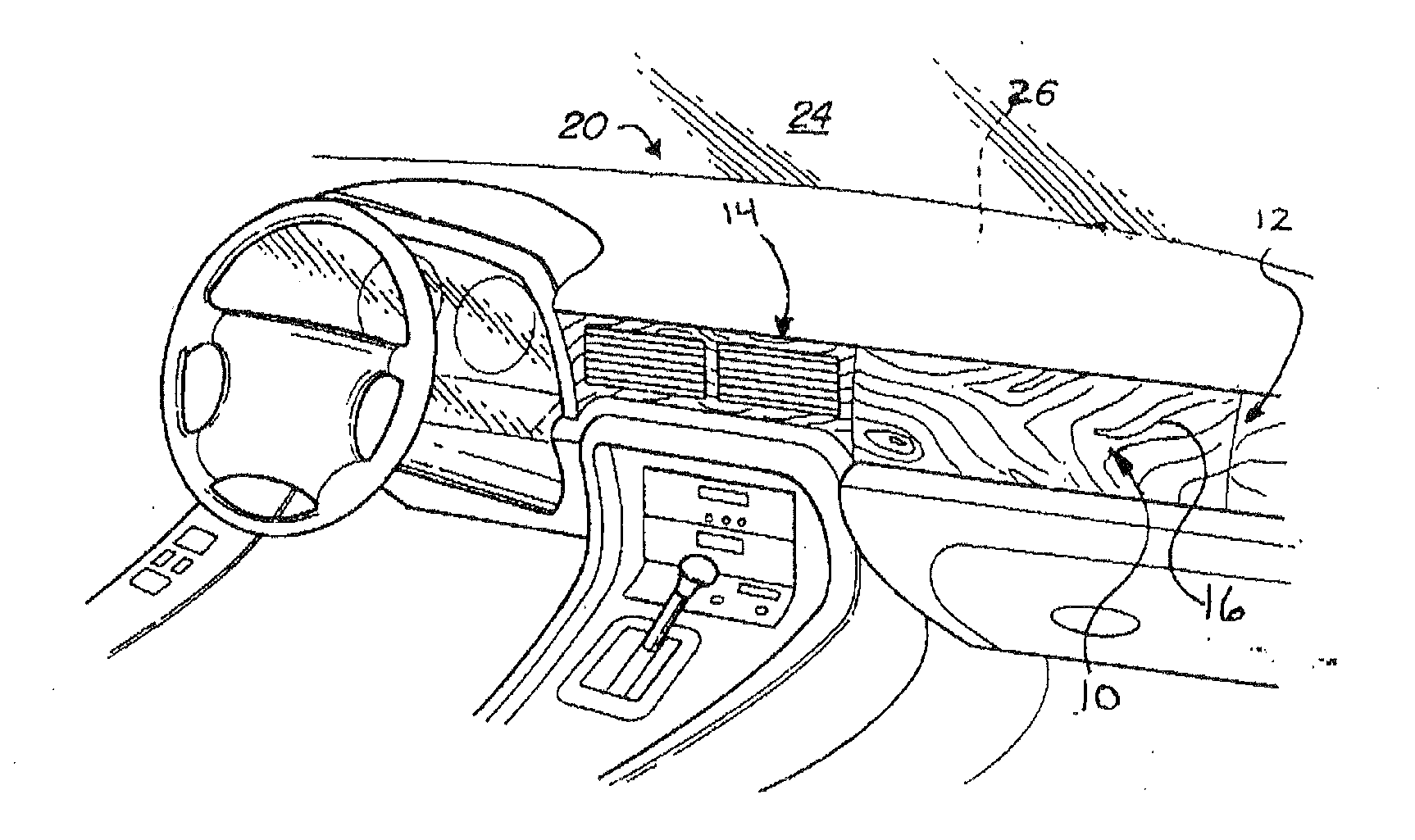

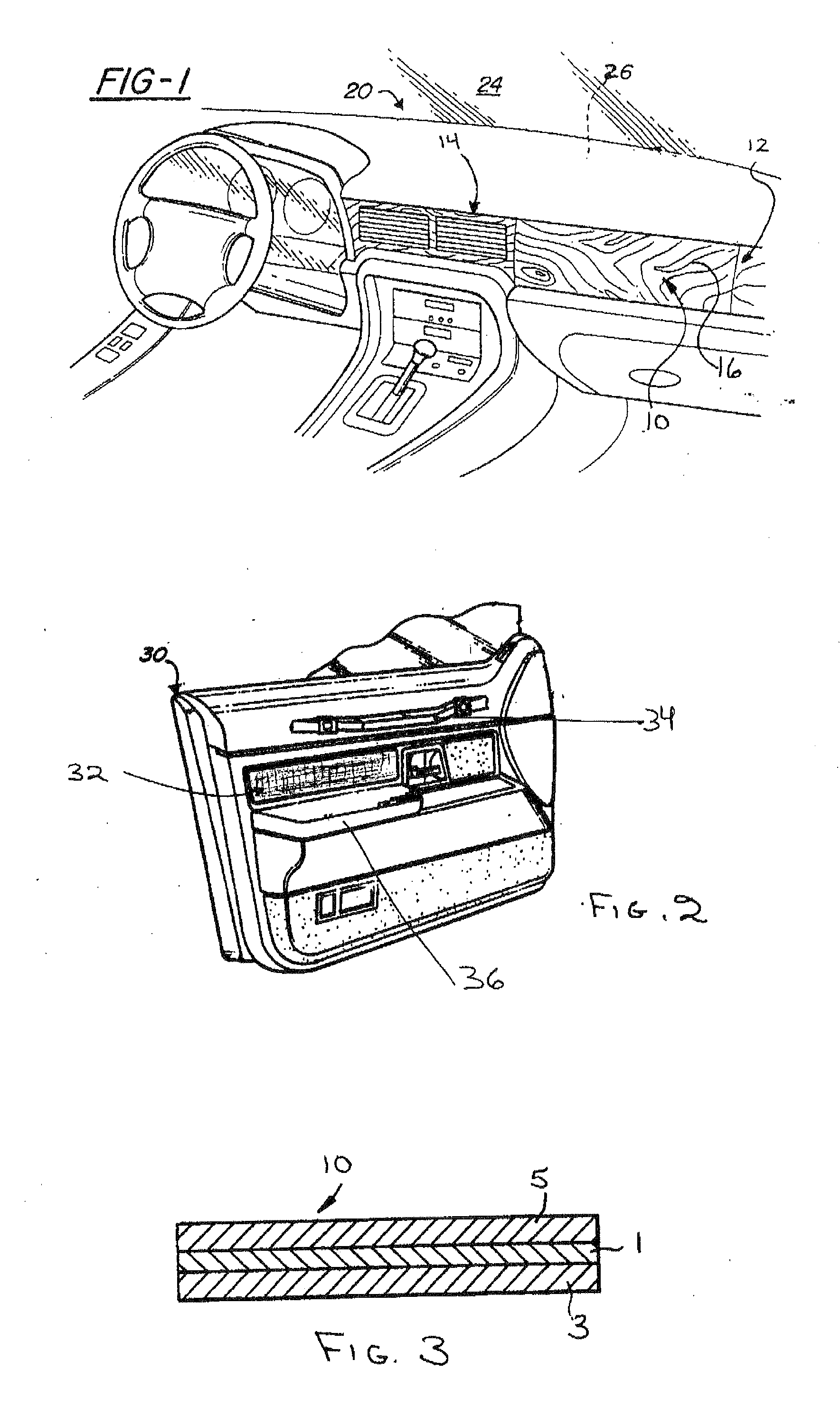

In mold lamination of decorative products

A method of manufacturing decorative plastic composites having a decorative layer, a backing layer and a clear outer layer which provides exceptional “depth of image” is disclosed. Decorative or protective appliqués' having a wide range of decorative patterns may be formed by injection molding a backing layer behind and a clear outer layer on the top surface of a decorative layer, the decorative layer comprising a relatively thin metal foil, film, fabric, veneer or sheet of paper having a digital image from an inkjet printer deposited on a front surface thereof. In one exemplary embodiment, the appearance of a wood veneer may be modified by digitally printing a burl pattern over the wood grain surface of the veneer prior to injection molding.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

Door skin, a method of etching a plate for forming a wood grain pattern in the door skin, and an etched plate formed therefrom

The present invention is directed to a door skin having an exterior surface with an woodgrain pattern formed therein, and an etched plate for use as an embossing plate or with a molded die sets for forming the woodgrain pattern in the door skin. The exterior surface has outer portions lying on a first plane, spaced grooves recessed from the plane of the outer portions, and halftone portions. The halftone portions have spaced protrusions defined by channels, wherein the channels are recessed from the plane of the outer portions.

Owner:MASONITE CORP

Insulated door assembly with low theraml deflection

InactiveUS20010001356A1Improve insulation performanceImprove rigidityNatural patternsSpecial ornamental structuresCompression moldingShell molding

Compression molded pigmented door skins fabricated by compression molding a pigmented, curable, unsaturated polyester sheet molding compound containing a co-curable unsaturated monomer, a low profile additive, and a microvoid-reducing thermoplastic polymer, exhibit uniform stainability while maintaining a low linear thermal coefficient of expansion. Such door skins are suitable for preparing wood grain textured exterior insulated doors which exhibit minimal thermal deflection when exposed to interior / exterior temperature differentials, even at eight foot door heights. The doors may be stained without first applying a seal coat.

Owner:TTTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com