Patents

Literature

47 results about "Crackles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crackles are the clicking, rattling, or crackling noises that may be made by one or both lungs of a human with a respiratory disease during inhalation. They are usually heard only with a stethoscope ("on auscultation").

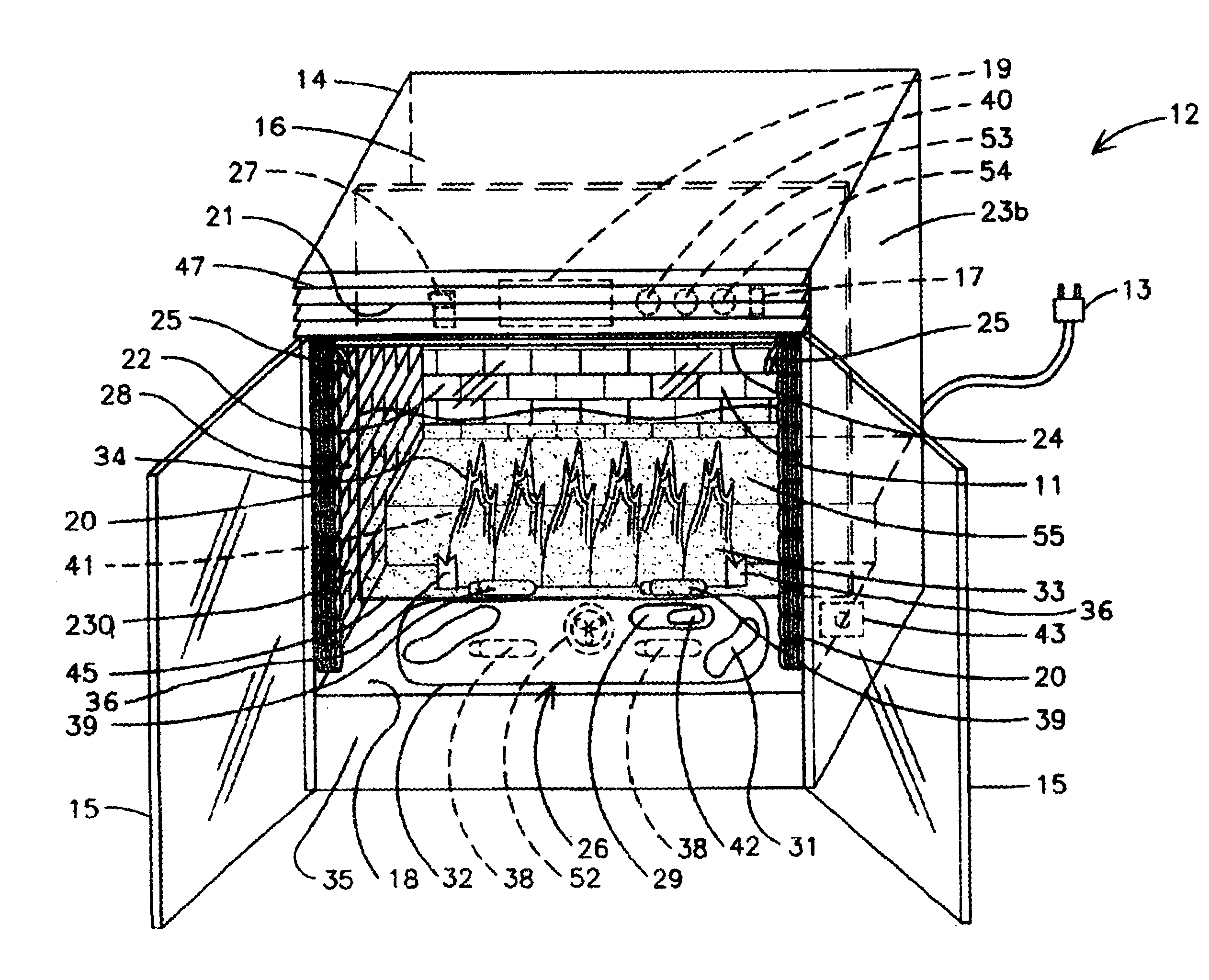

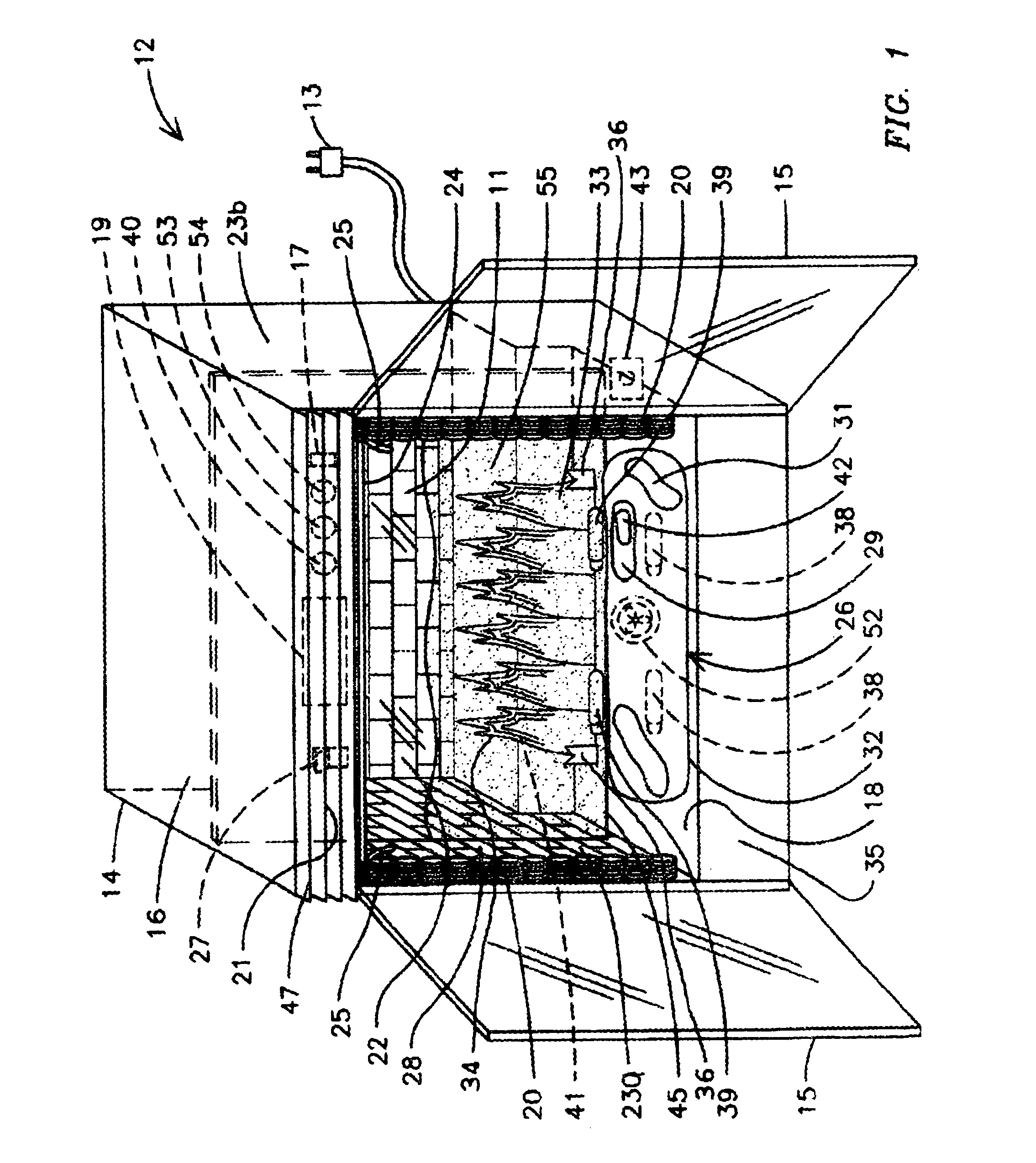

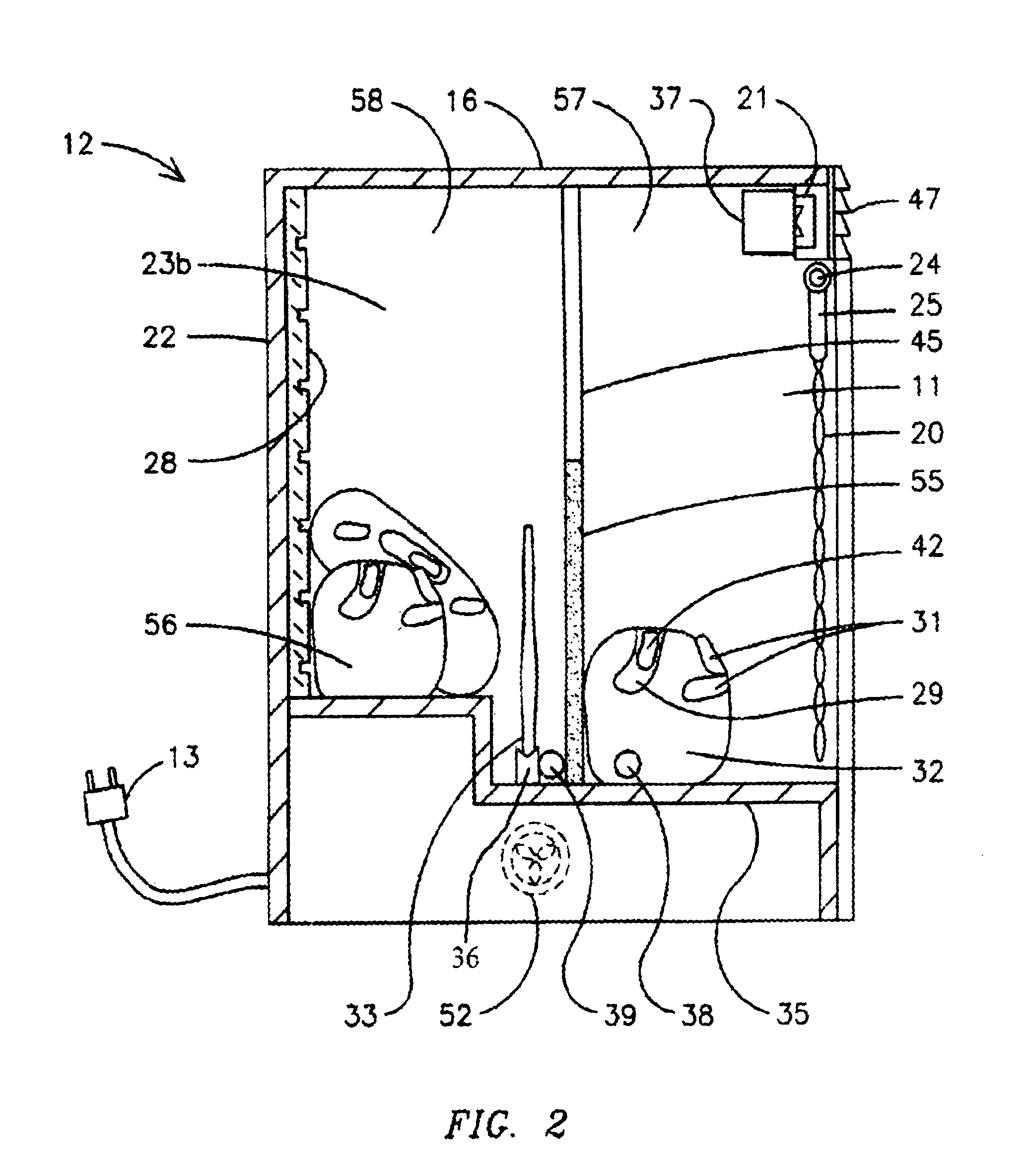

Simulated log burning fireplace apparatus

InactiveUS7111421B2Enhanced RealityDomestic stoves or rangesLighting and heating apparatusEmberBrick

The simulated log fireplace apparatus housing forming a fire box having back, bottom, top wall, two side walls, and an open front containing at least one artificial log and simulated flame sheet. A blower directs air on to the flame sheet to simulate real flame movement. A colored light source provides color of real flames. The light source and blower are adjustable from a control panel under a top louver panel. The artificial log may include a translucent base log and ember bed with a light source beneath the translucent log. A window log having an aperture simulate a burning core. A transparent partition has a partially opaque area just above the simulated flame sheet provides the full depth of real fireplace. The apparatus may include electric blower heater, a crackle box, decorative simulated brick panels placed on back and side walls, metal screen, glass doors, vents and louvers.

Owner:CORRY ARTHUR A +1

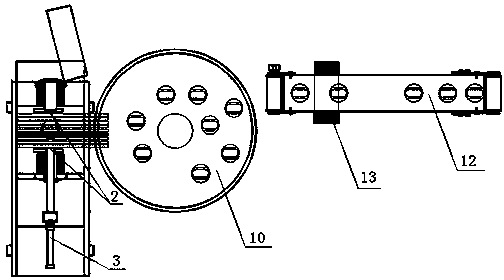

Method for growing non-crack III family nitride on silicon substrate

InactiveCN1825539AEliminate cracksSimple processSemiconductor/solid-state device manufacturingBoron nitrideGallium nitride

The invention is a method for growing crackles family-III nitride on a silicon substrate, using stress compensating buffer layer to grow crackles a family-III nitride film on the silicon substrate, and comprising the steps of: 1) firstly depositing an about 20 nanometer thick aluminized high-temperature aluminum nitride buffer layer on a monocrystalline silicon substrate and then depositing a layer of hexagonal-phase matter (such as low-temperature aluminum nitride, gallium aluminum nitride or boron nitride) whose lattice constant is far less than that of the family-III nitride and thus forming a buffer layer with stress compensating function; and 2) adding in an activating agent to make a stress compensating layer easy to form at low temperature and simultaneously the surface smooth and the crystal quality high; 3) because the lattice constant of the predeposited hexagonal-phase matter is less than that of the family-III nitride, able to introduce pressure stress into the family-III nitride film grown on the predeposited hexagonal-phase matter so as to compensate drawing stress caused by mismatching with the silicon substrate.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Preparation method of vale control lead-acid accumulator green plate without crackles

The invention discloses a preparation method of a vale control lead-acid accumulator green plate without crackles, for the purpose of removing crackles of plates. The improvement of the invention is characterized in that: a pasted green plate is processed by rolling and acid treatment, in which dilute sulphuric acid of 1.150 g / cm is sprinkled on a compression roller; the green plate is rolled under the compression roller; and the dilute sulphuric acid is attached uniformly to the green plate. Relatively high-density dilute sulphuric acid is used for sprinkling on the green plate by rolling, which leads to thicker lead sulfate coating; water loss of the plate is decreased due to quick drying; uncombined lead existing as active substance during solidifying and drying process reacts sufficiently with oxygen, thus producing better solidifying effect and enhancing the bonding force between the active substance and a slab lattice. The vale control lead-acid accumulator green plate made by the method has smooth plate surface without crackles. Therefore, the quality of the plate is significantly improved.

Owner:FENGFAN

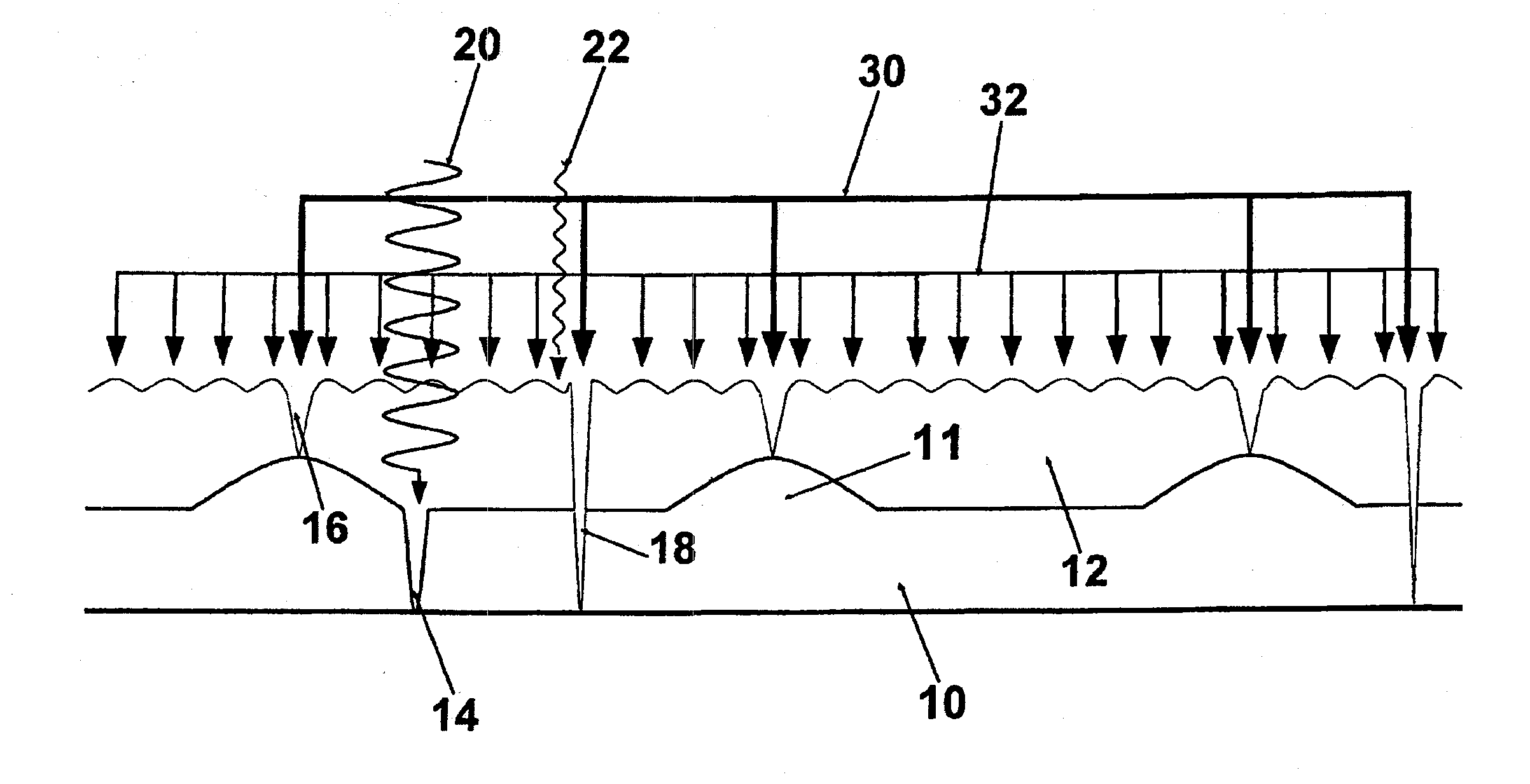

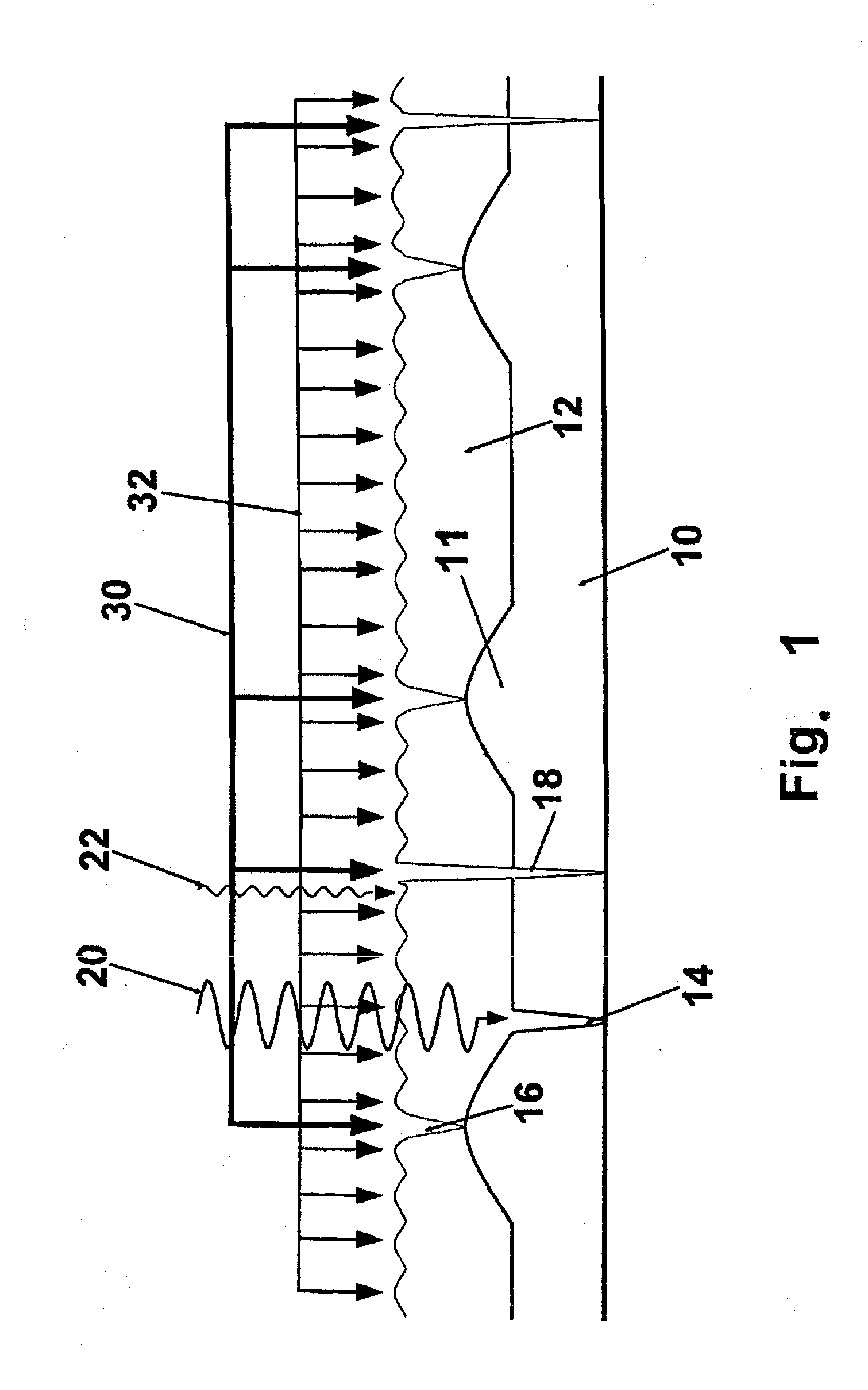

Security element for marking or identifying objects and living beings

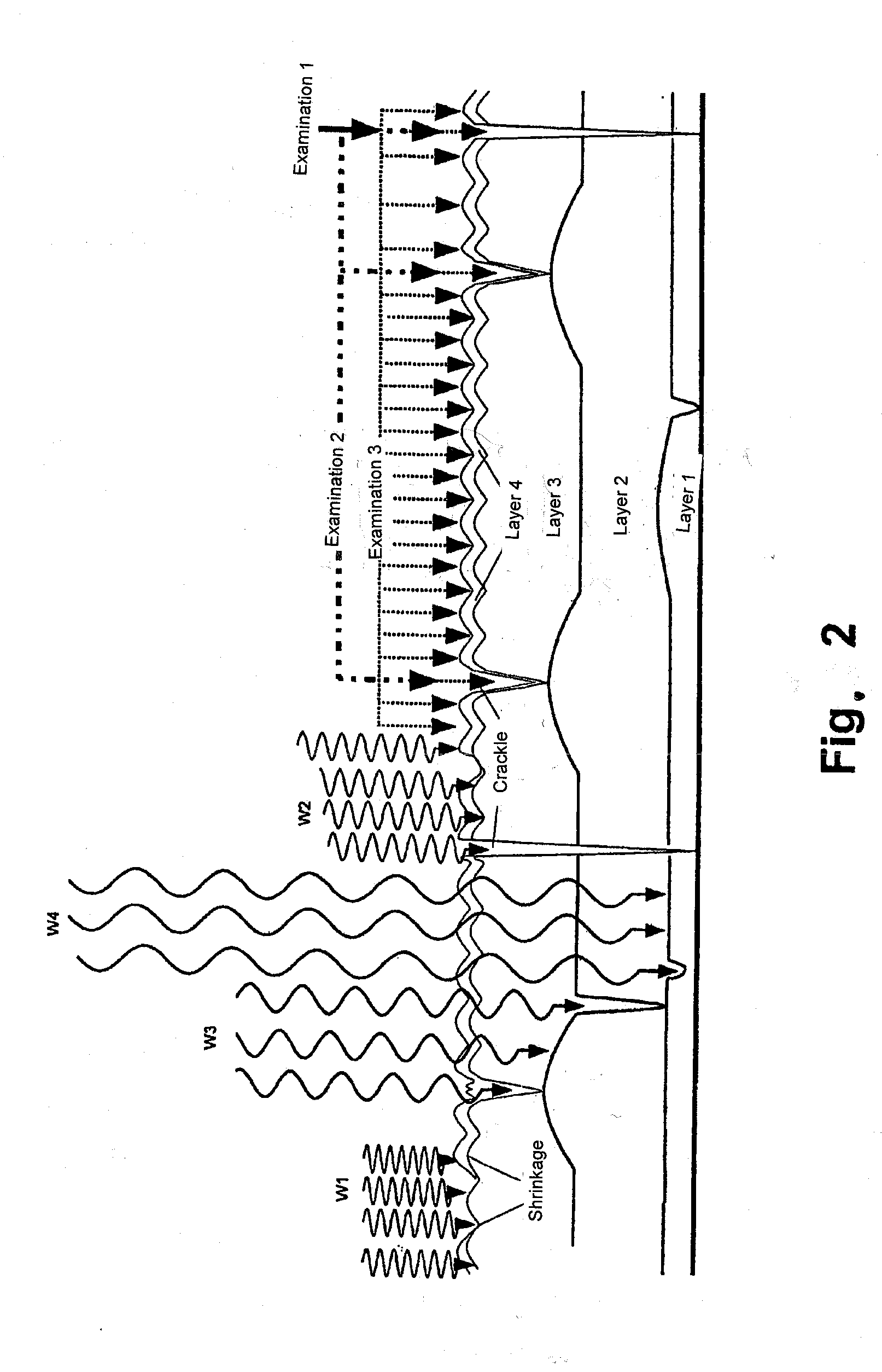

InactiveUS20120175866A1Increased formationImprove securityOther printing matterChecking apparatusInternet privacyImpurity

A security element for marking, authenticating or identifying objects or living beings, such as people, animals or plants is provided that includes one or more layers of materials that are arranged next to or on top of each other or that overlap, which have security markings. At least one layer of the security element has, at least regionally, a crackle pattern in form of tears or cracks, nicks, wear areas or shrinkages and possible impurities, which can be scanned and detected together or separately as security features. A method for producing such a security element and to a use thereof for authenticating a person or an object, or for authorizing, triggering, continuing, carrying out and ending an action is also provided.

Owner:KISTERS FRIEDRICH

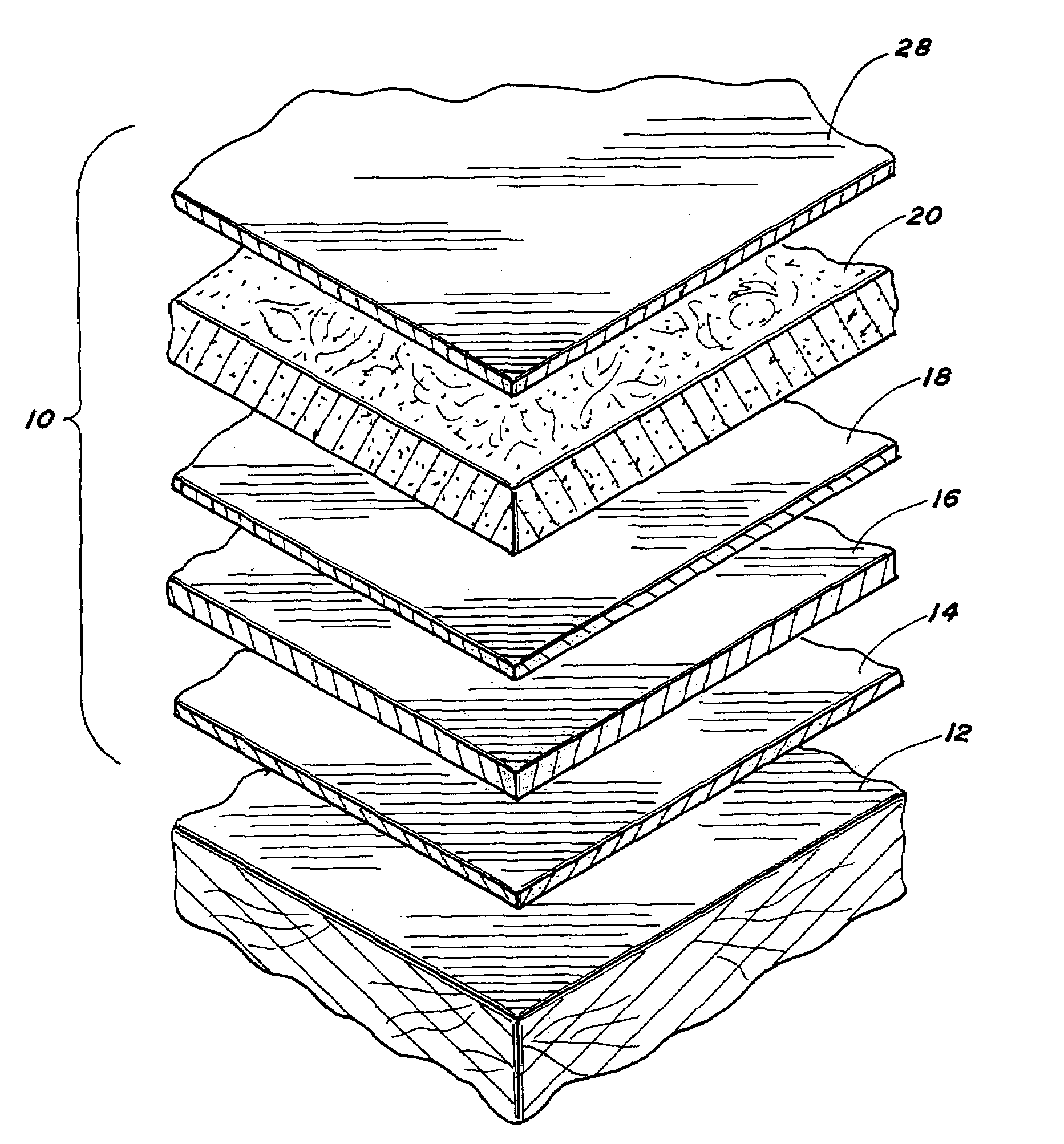

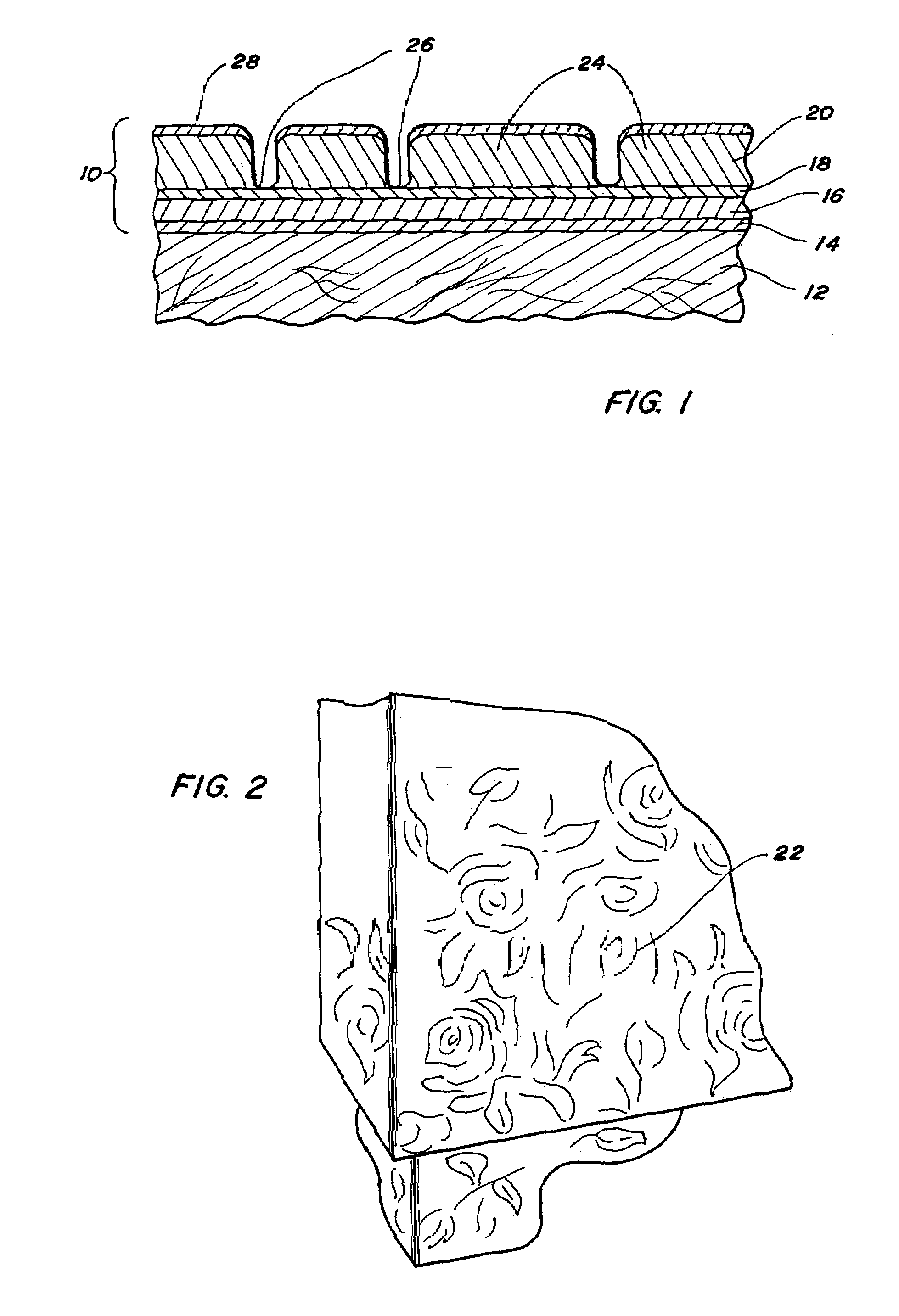

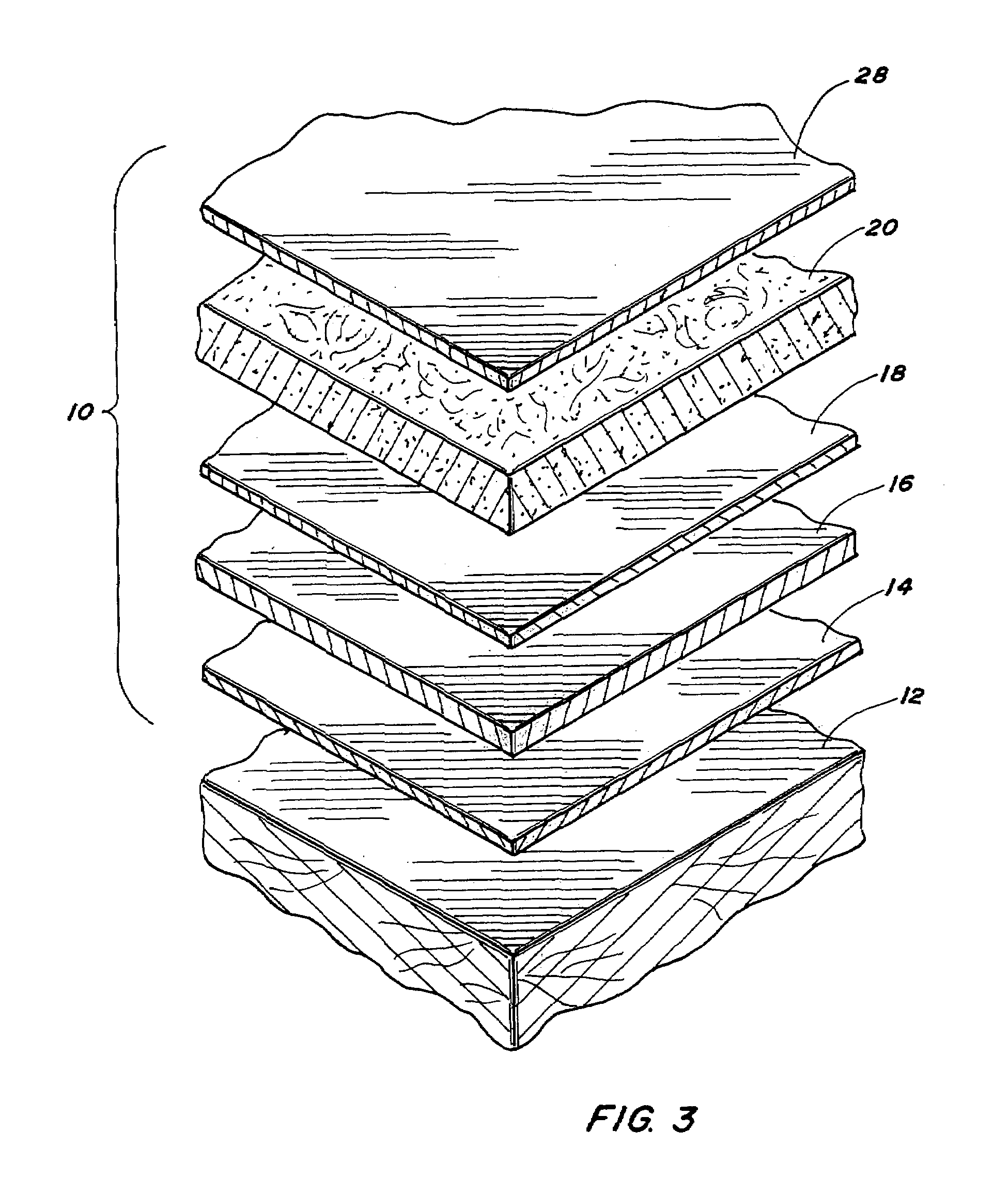

Crackle finish

A crackle finish, method of forming a crackle finish and a kit for forming a crackle finish. The crackle finish includes a base coat of latex paint or stain on a surface to be treated. A crackle coating is applied over the base coat and dried to tack dry or completely dried. A latex wood filler is applied over the crackle medium. As the latex wood filler dries, it forms islands or domains separated by cracks or valleys revealing glimpses of the underlaying base coat.

Owner:WILDE ROSE Z

Method and device for measuring dynamic fracture property of laser shock loading material

InactiveCN101975703AHigh loading rateObservation spreadStrength propertiesShock waveStrength of materials

The invention relates to a method for testing mechanical property of a material under the action of stress wave, in particular to a method and a device for measuring dynamic fracture property of a laser shock loading material. The method comprises the following steps of: loading a three-point bent sample (4) with preformed crackles (1) by using shock wave induced by nanosecond-scale laser pulse (8), and detecting the propagation property of the stress wave (17) in the three-point bent sample (4) and the expansion property of the crackles by adopting a method of combining photo-elasticity and moire. The device acquires a high-speed transient photo-elastic image of interaction of the material and the stress wave under the condition of a high loading rate by using a multi-spark camera optical system (13), can clearly observe the propagation of the laser-induced short pulse stress wave (17), and can accurately and reliably acquire the fracture property of the material by processing.

Owner:JIANGSU UNIV

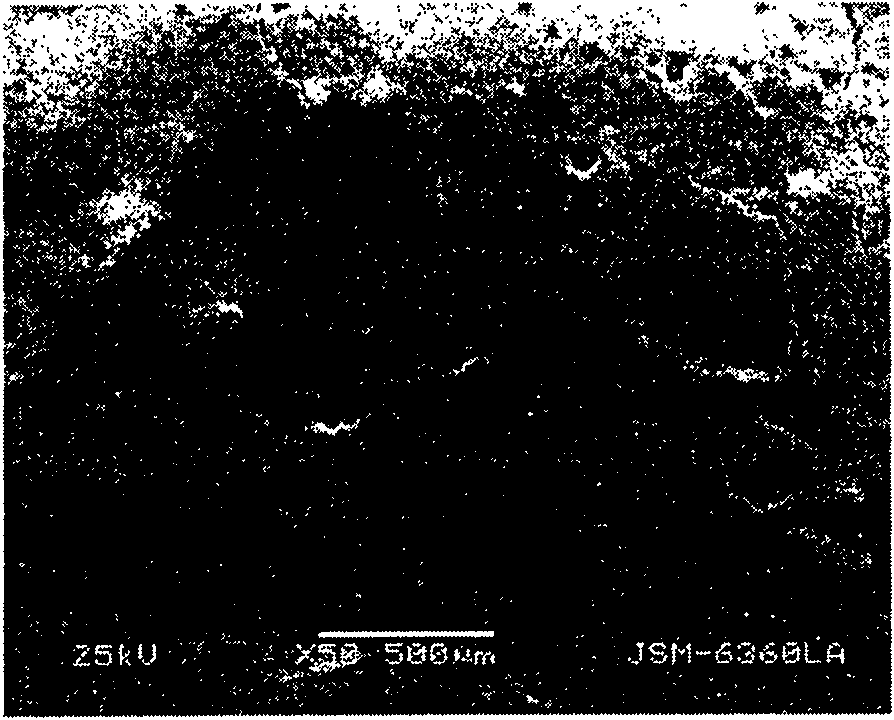

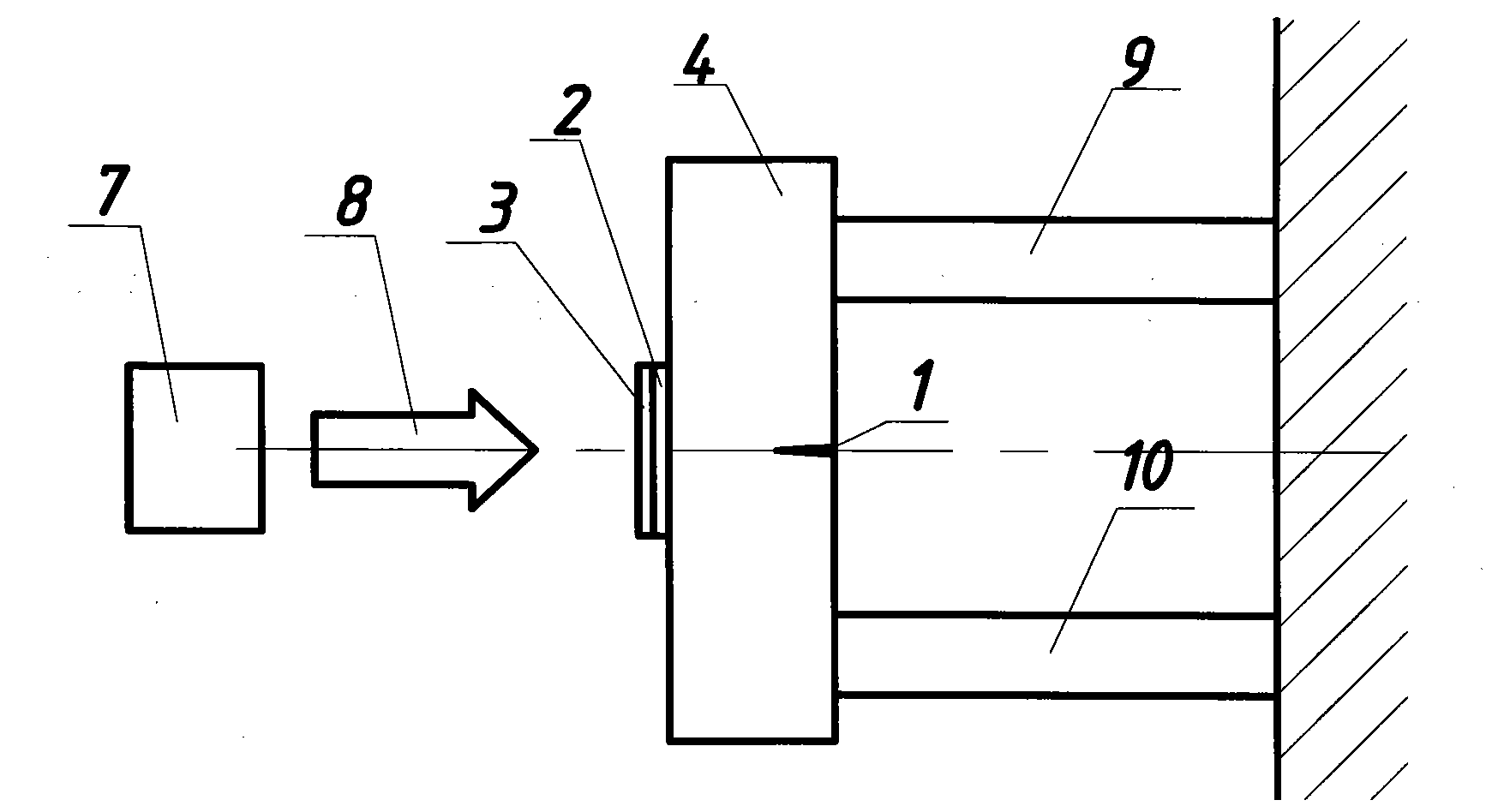

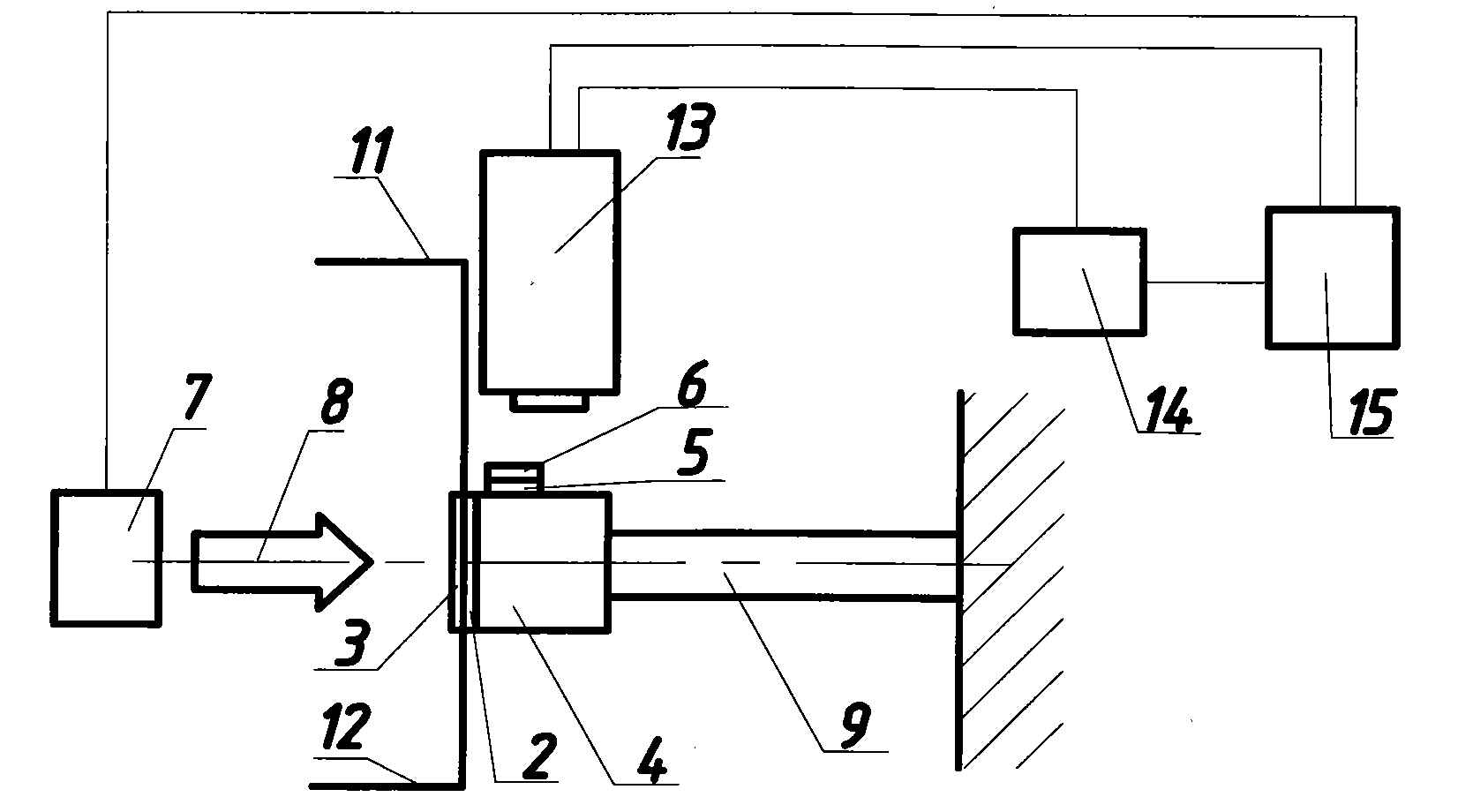

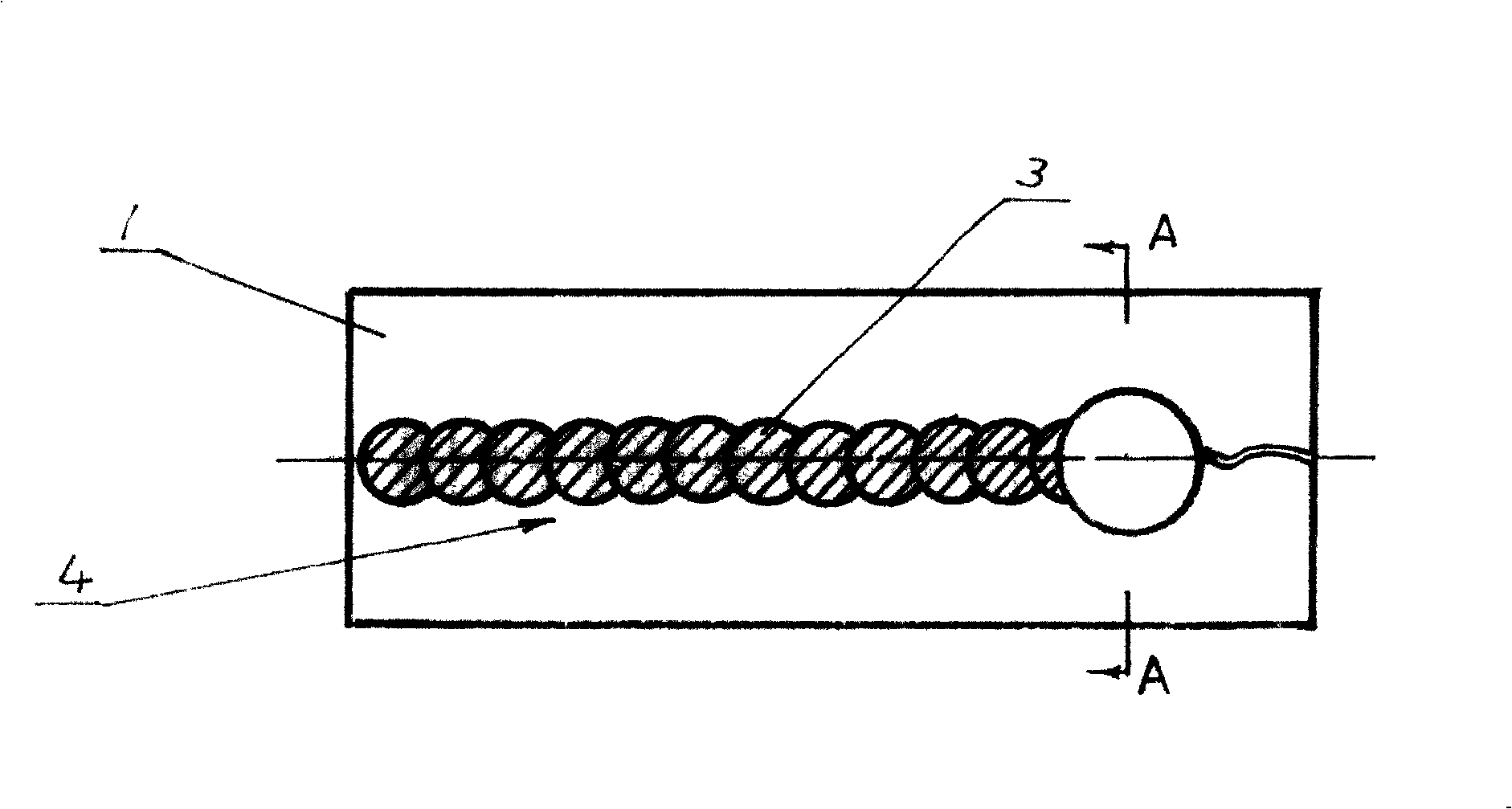

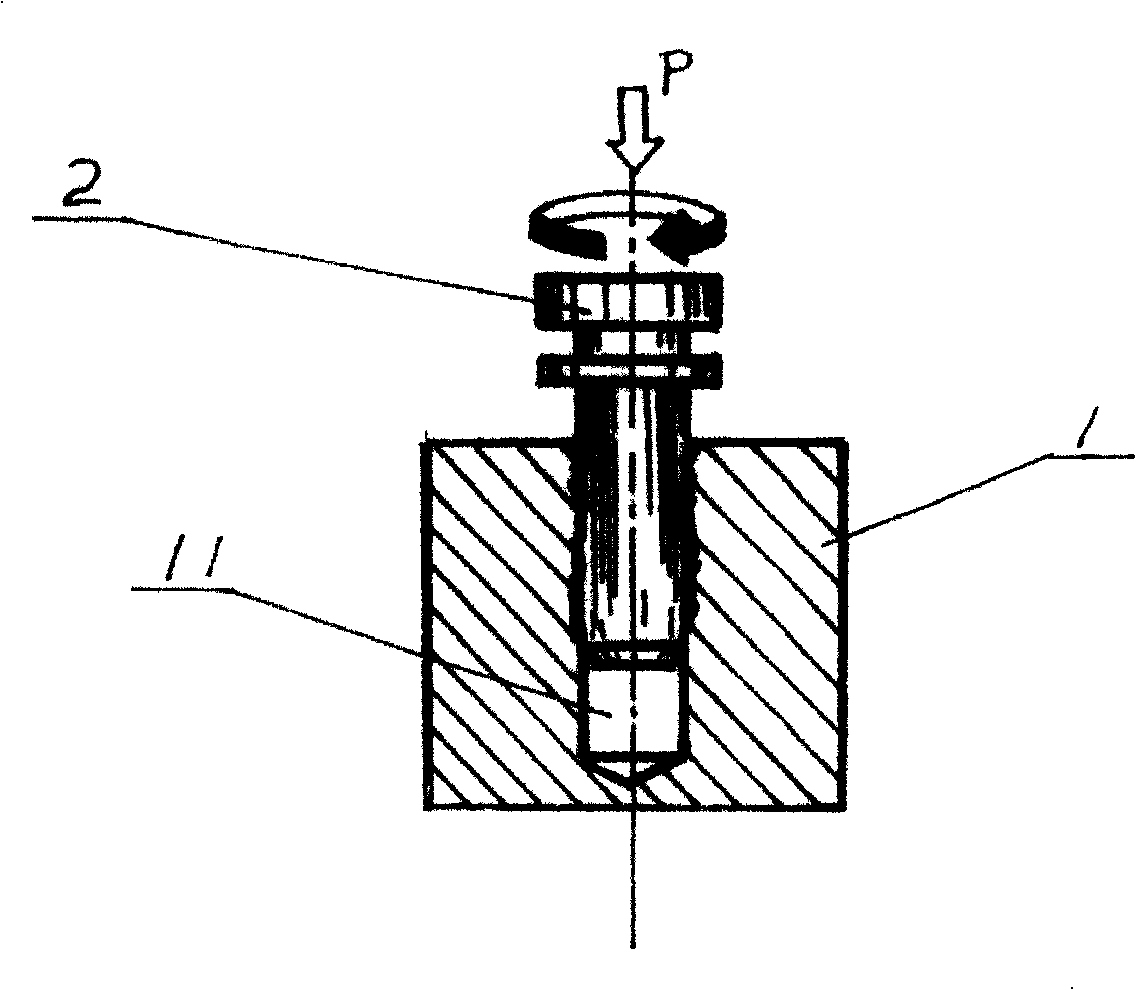

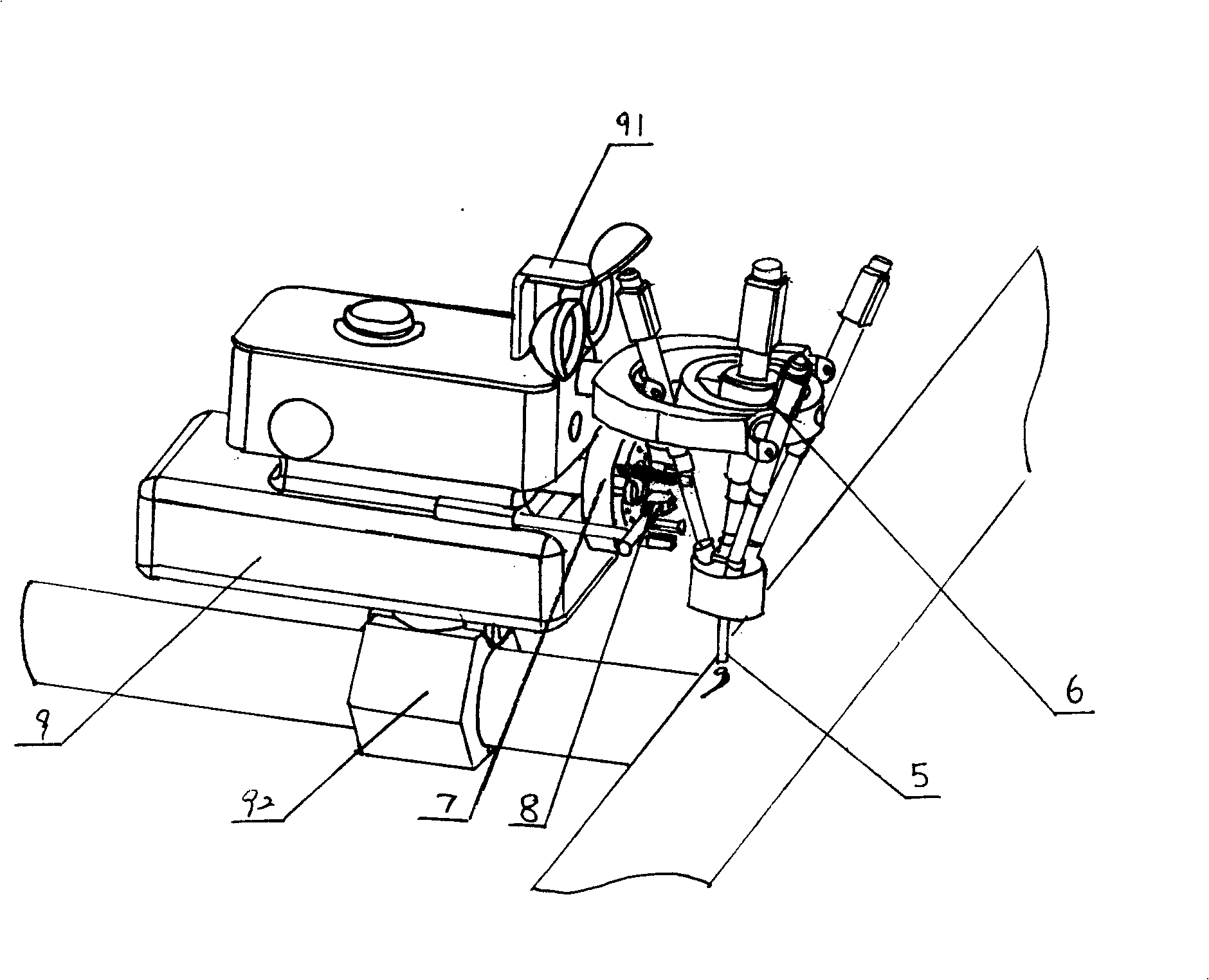

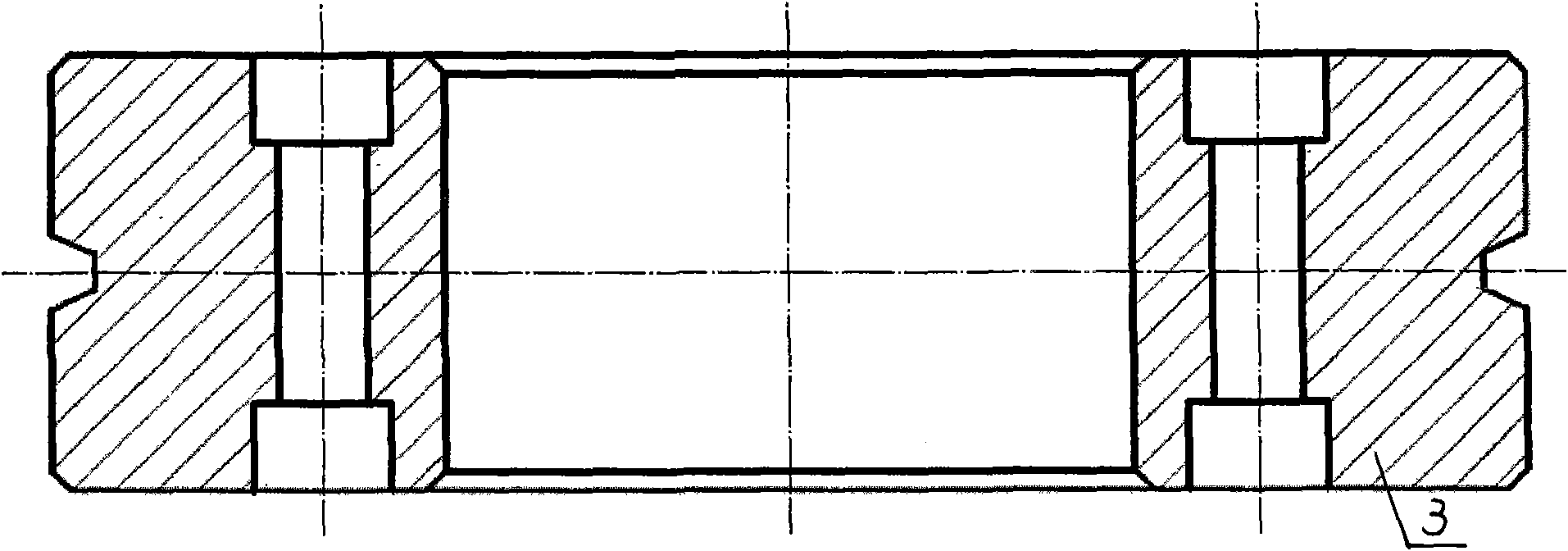

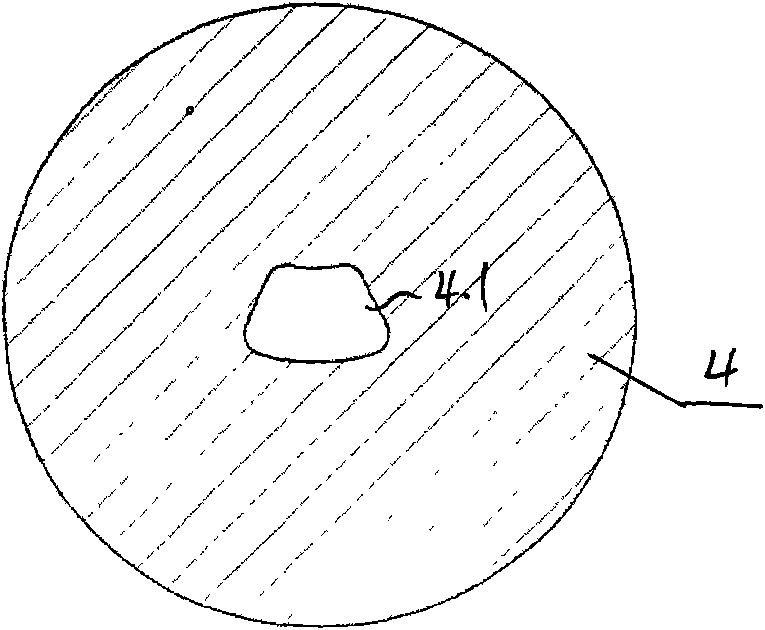

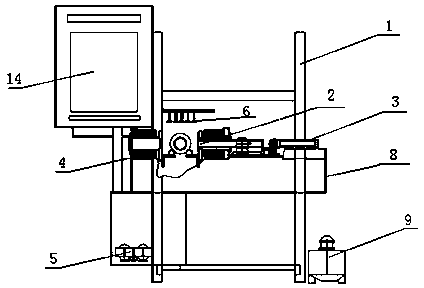

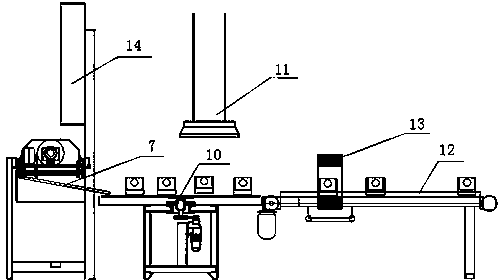

Underwater steel construction crackle friction stitch welding renovation method and equipment

InactiveCN101244485AImprove welding qualityImprove welding efficiencyNon-electric welding apparatusAxial pressureMarine engineering

The invention relates to a friction stitch welding repairing method for the underwater steel structure cracks and the device, wherein, the friction stitch welding method is as follow: a stopper (2) rotating at high speed is inserted in the preboring welded hole (11) and is applied with axial pressure; the contacting interface of the welded hole (11) and the stopper (2) is heated and melted to form a plurality of welding units (3) through crystallization and metallurgical reaction; the welding units (3) are overlapped with each other to form a complete stitch welding seam (4). The repairing device for the underwater steel structure cracks adopts the friction stitch welding method and comprises a plurality of underwater components and a plurality of above-water components, wherein, the underwater components comprise a friction spindle head (5), an underwater operational manipulator (6), an automatic tool magazine (7), a tool changer (8) and an underwater teleoperator (9); the above-water components comprise a hydraulic power system, an electric control system and a data acquisition system. The device adopting the friction stitch welding method has the advantages of excellent welding quality, simple structure, reliability and easy operation, low cost and easy use, maintenance and repair.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

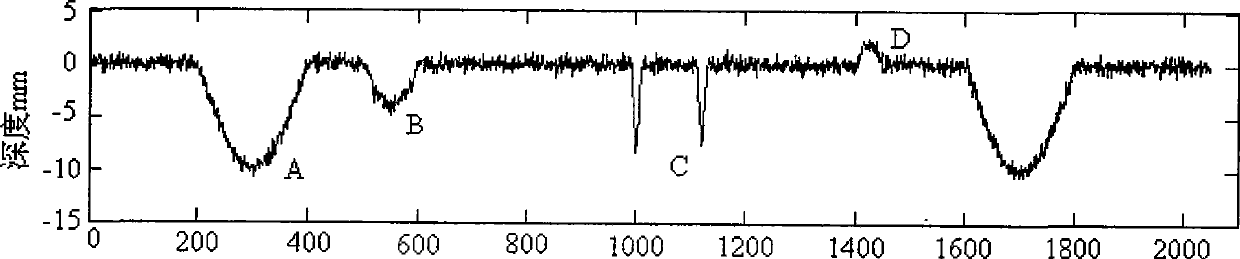

Highway pavement diseases characteristic extracting method based on sparse resolution theory

InactiveCN101510261AFlexible structureAccurate extractionMeasurement devicesCharacter and pattern recognitionDecompositionRoad surface

The invention discloses a method for extracting road surface disease features based on the sparse decomposition theory and relates to the road surface disease detection technique, which solves the problems that the contour signal analysis technique based on structured light has insufficient feature extraction and unsatisfactory actual application effect and the like. The method comprises the following steps of: firstly, establishing different disease feature atom dictionary according to different disease features, taking position and scale as parameters which change in a different ranges, and normalizing the atoms, thus obtaining a complete disease feature atom dictionary; secondly, according to the signal spreading theory, selecting K atom pair signals from the complete disease feature atom dictionary to carry out K approximations, and then selecting an atom combination with a most sparse decomposition coefficient from the K atom combinations according to the sparse decomposition theory. The selection of the coefficient Ck of the disease feature should satisfy a sparse constraint condition which is as follows:* C 0 s. t f =*Ck Phi k; the disease feature can be expressed as: f (t) = fk + Sigma = Sigma Ck Phi k (t)+ Sigma, wherein k = 0, 1, 2, and other integers; and Sigma is an approximate error. The method for extracting road surface disease features is used for detecting road surface disease features, such as crackles, tracing ruts, pits or earth bulges, and the like.

Owner:HARBIN INST OF TECH

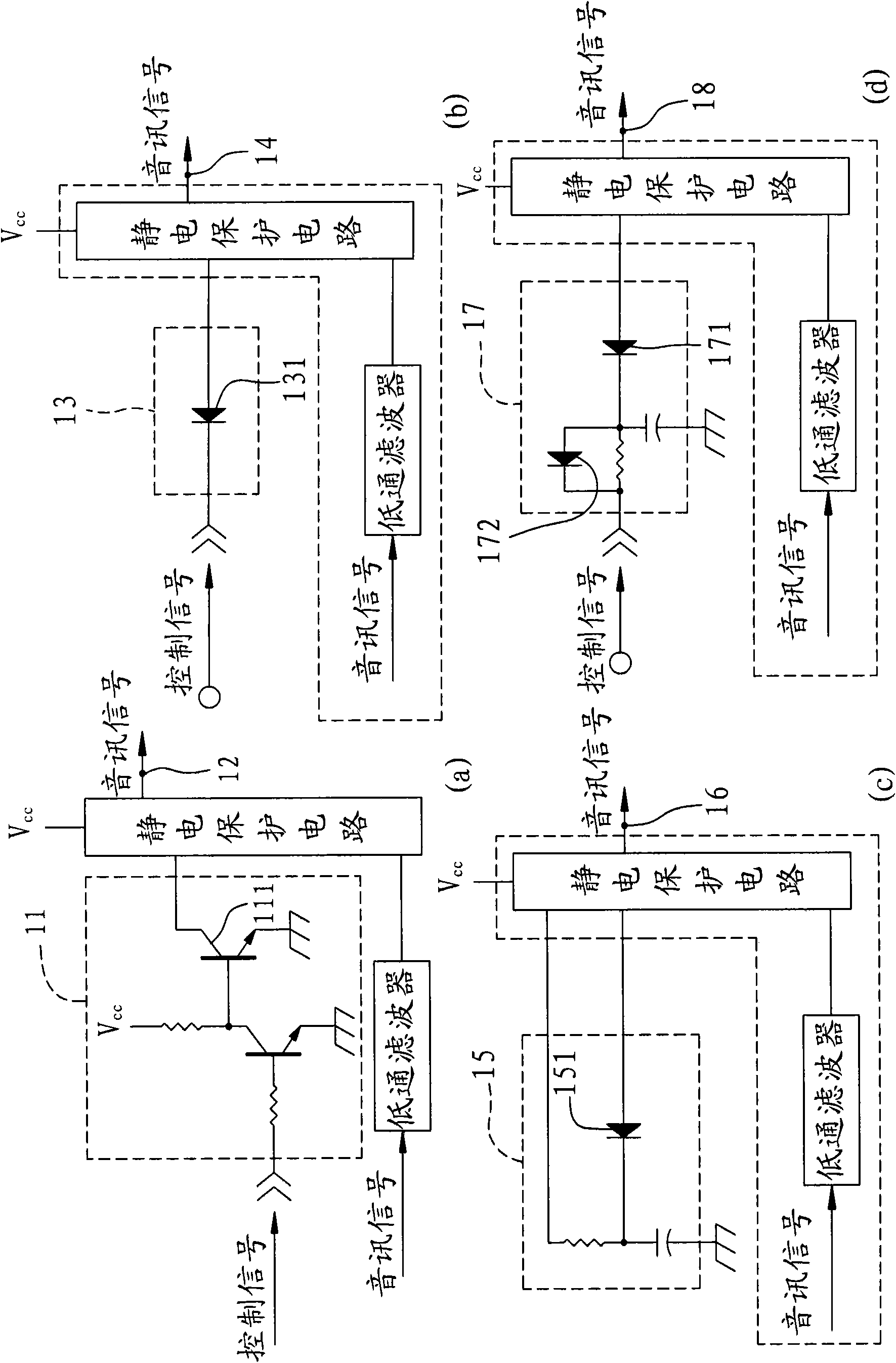

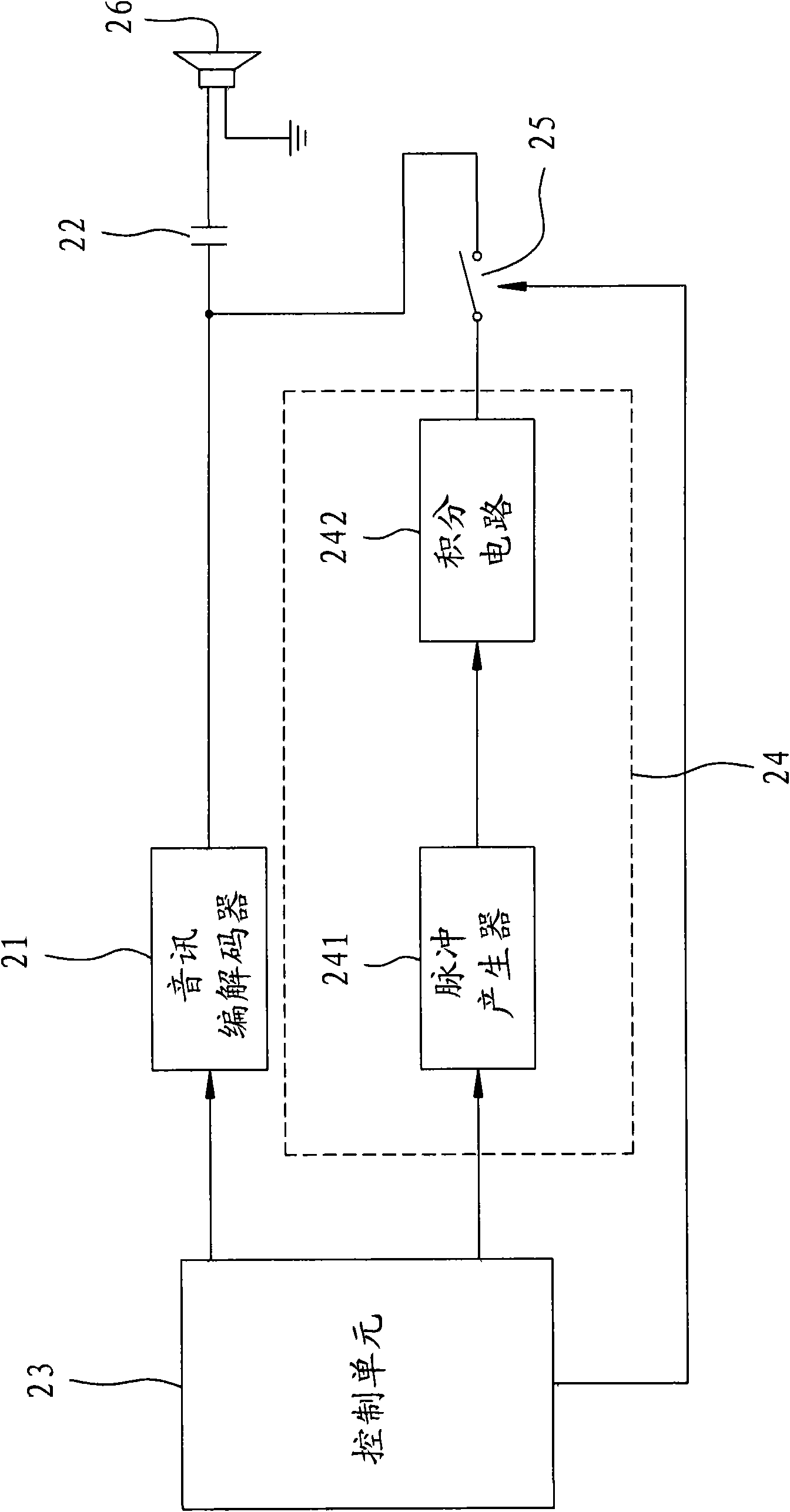

Audio output device for preventing crackle

InactiveCN101621280AAvoid chargingAvoid dischargeAmplifier modifications to reduce temperature/voltage variationGain controlControl signalOutput device

The invention relates to an audio output device for preventing crackle, comprising a system controller for outputting a digital audio data; an audio codec for generating a corresponding stimulation audio signal according to the digital audio data; a capacitor, one end of which is connected with an audio output end of the audio codec; a switch, comprising a first end electrically connected with the other end of the capacitor and a second end electrically connected with the ground, and being controlled by a control signal to determine whether the first end and the second end are in two-way conduction; a switch controller for generating a control signal; and a power circuit for supplying electric power. When crackle possibly happens, at least one of the system controller, the audio codec and the power circuit triggers the switch controller to conduct the switch for a while through the control signal. The audio output device provided by the invention can operate in various crackling-possible situations and prevent the crackle caused by surge of positive voltage and negative voltage.

Owner:TWINHEAD INT

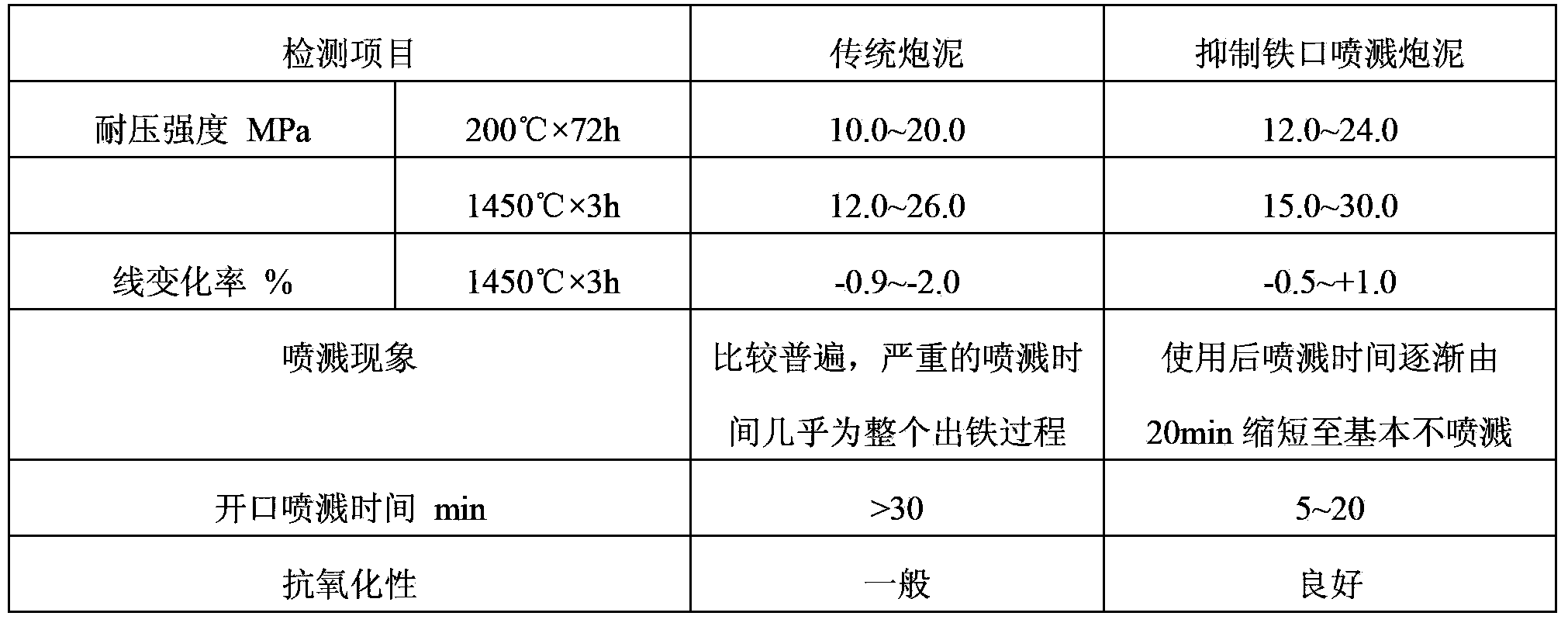

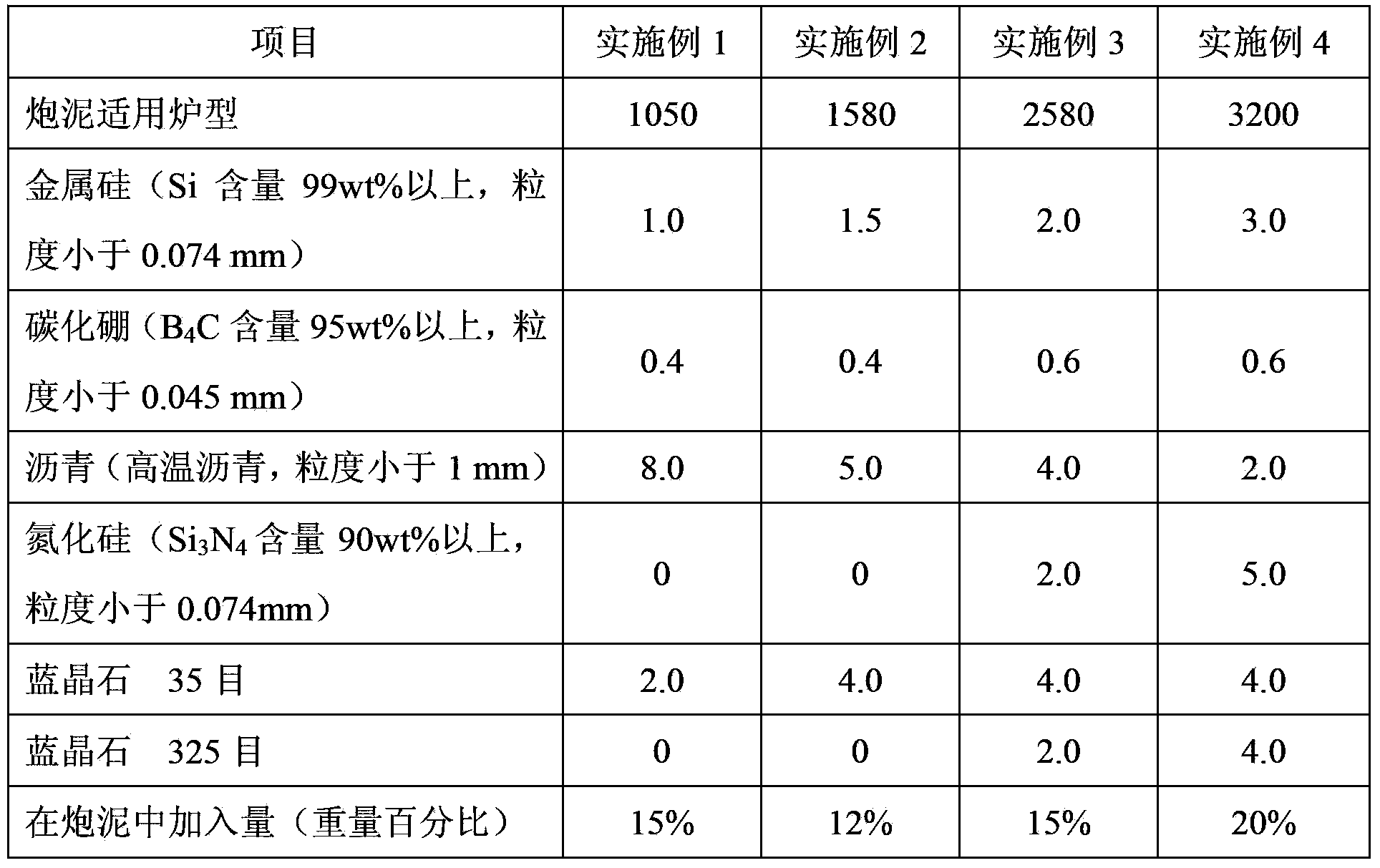

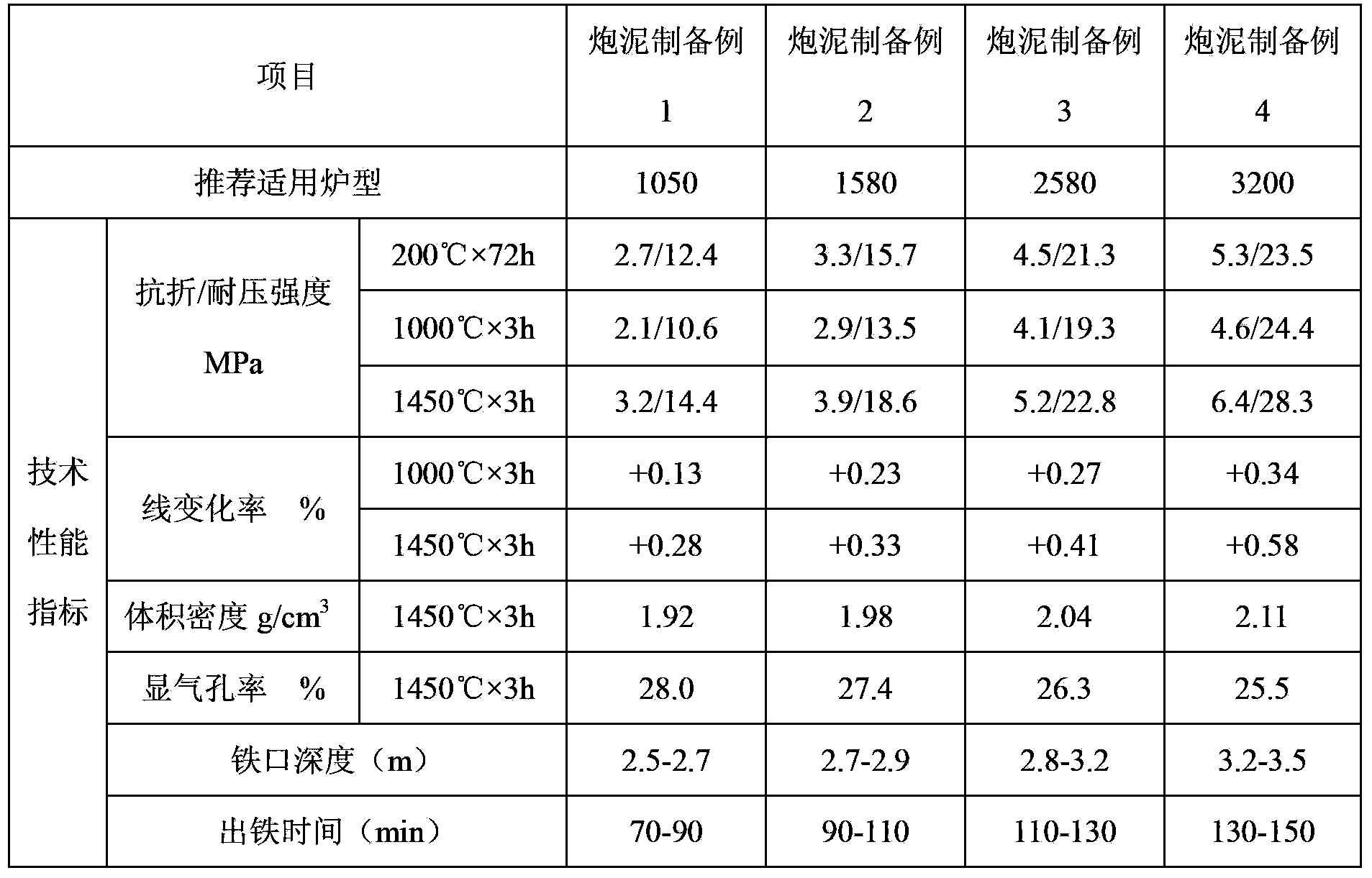

Stemming for inhibiting splashing of iron notch

The invention relates to stemming for inhibiting the splashing of an iron notch. The stemming comprises the following components in parts by weight: 15-25 parts of high-aluminum granules, 10-15 parts of alumina powder, 10-25 parts of silicon carbide, 13-20 parts of coke, 2-7 parts of quartz sand, 10-18 parts of clay, 12-20 parts of additives, 7-14 parts of tar and 2-7 parts of phenolic resin, wherein the additives comprise the following components in parts by weight: 1-3 parts of metallic silicon, 0.4-0.6 part of boron carbide, 2-8 parts of asphalt, 0-5 parts of silicon nitride and 2-8 parts of kyanite. The stemming disclosed by the invention is capable of generating a proper quantity of glass phase components at a high temperature; under the precondition that high temperature property is not influenced, the layer of glass phase in contact with molten iron can effectively plug various crackles of an iron notch channel and thus can prevent the splashing caused by gas moving; in addition, the stemming has the advantages of proper microdilatancy effect and medium-high temperature intensity.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

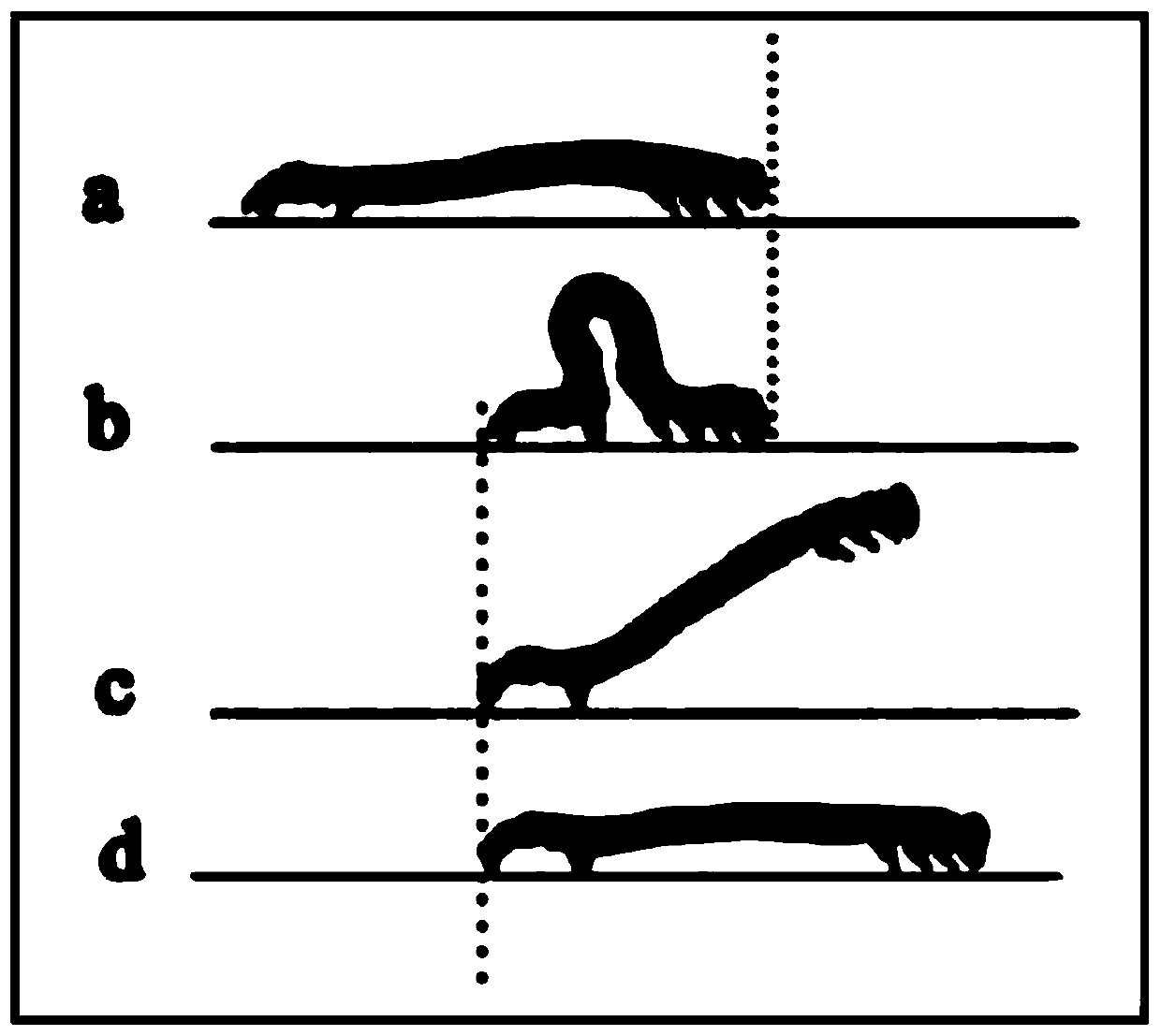

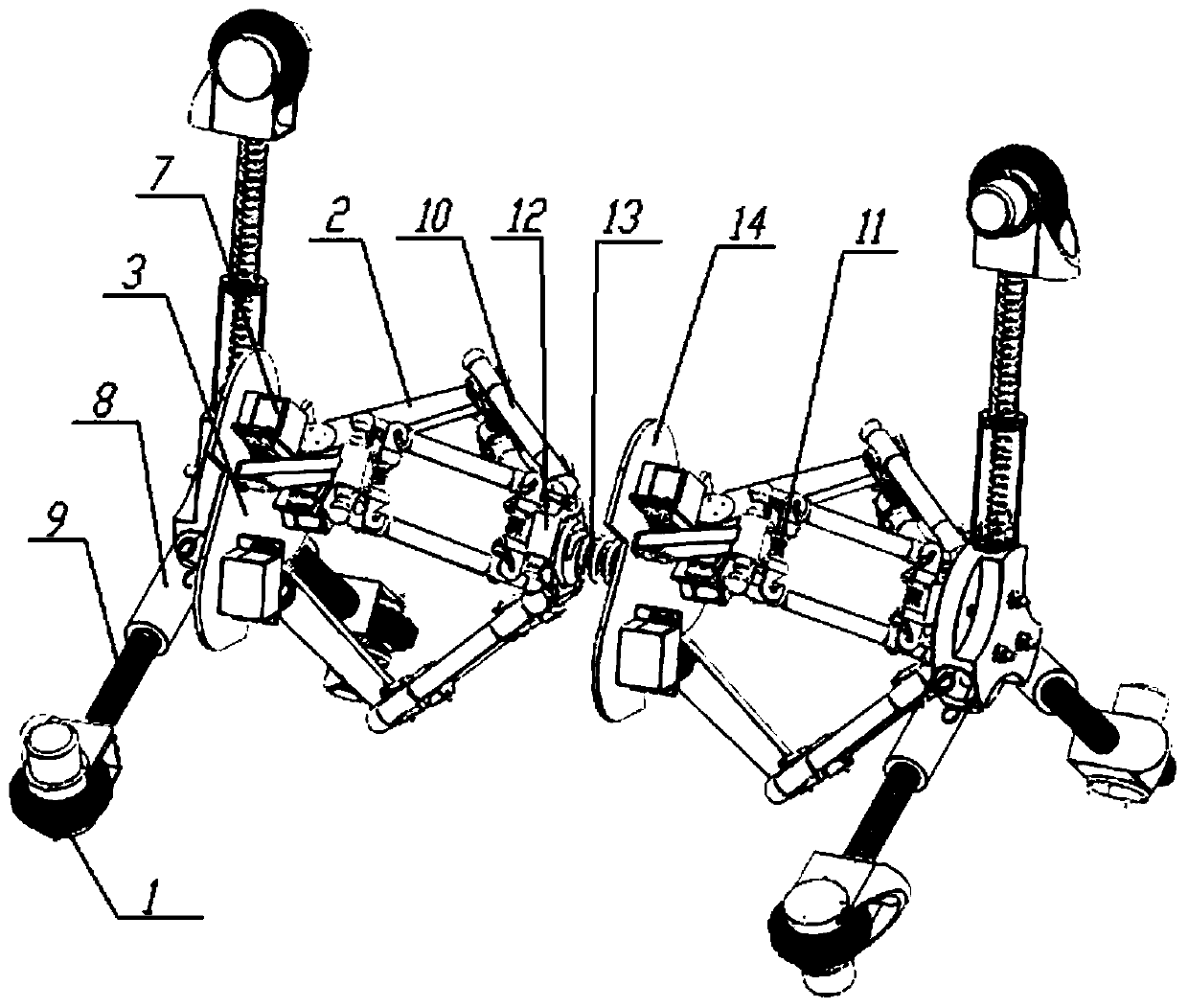

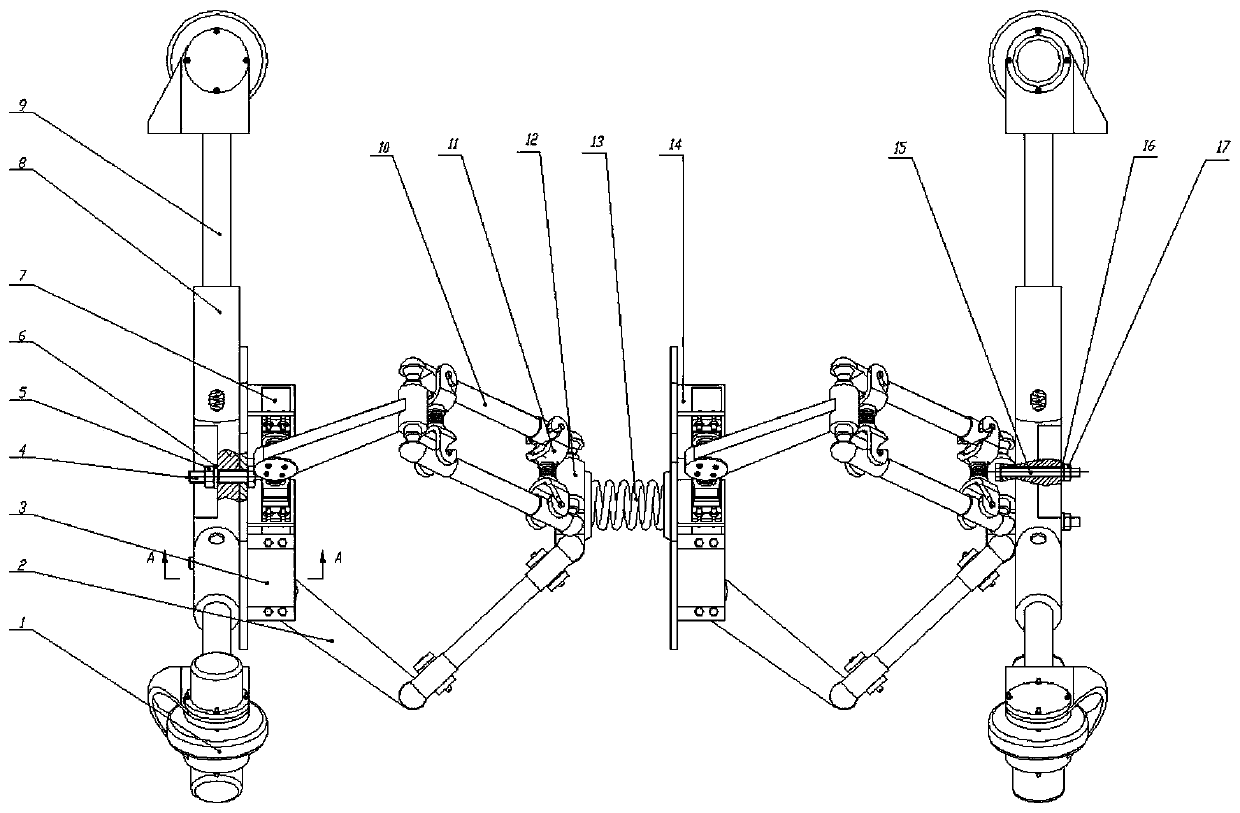

Bionic pipeline crawling robot

ActiveCN110486570AEfficient monitoring of corrosivityEffective monitoring of cracksPigs/molesEngineeringGait

The invention discloses a bionic pipeline crawling robot. The bionic pipeline crawling robot consists of two fundamental expanding and contracting modules, wherein each fundamental expanding and contracting module consists of a supporting structure which is in contact with a pipe wall and a three-freedom-degree parallel connection structure; the three-freedom-degree parallel connection structuresare respectively connected with a moving platform and a static platform; and the fundamental expanding and contracting modules are flexibly connected through springs. According to the bionic pipelinecrawling robot disclosed by the invention, based on simulating gait characteristics of crawling of geometers and earthworms, the bionic robot capable of crawling in a pipeline is developed; the bionicpipeline crawling robot is used as a carrying platform to pick up all kinds of equipment, so that functions of performing flaw detection and periodical scanning in a pipeline, dredging the pipeline and the like can be realized; and solutions are provided for the problems of corrosion, crackles, wear, plugging and the like in the pipeline, so that the situations of the corrosion, the crackles, thewear and the plugging of the pipeline are effectively monitored, and accidents caused by this type of problems are avoided.

Owner:GUIZHOU UNIV

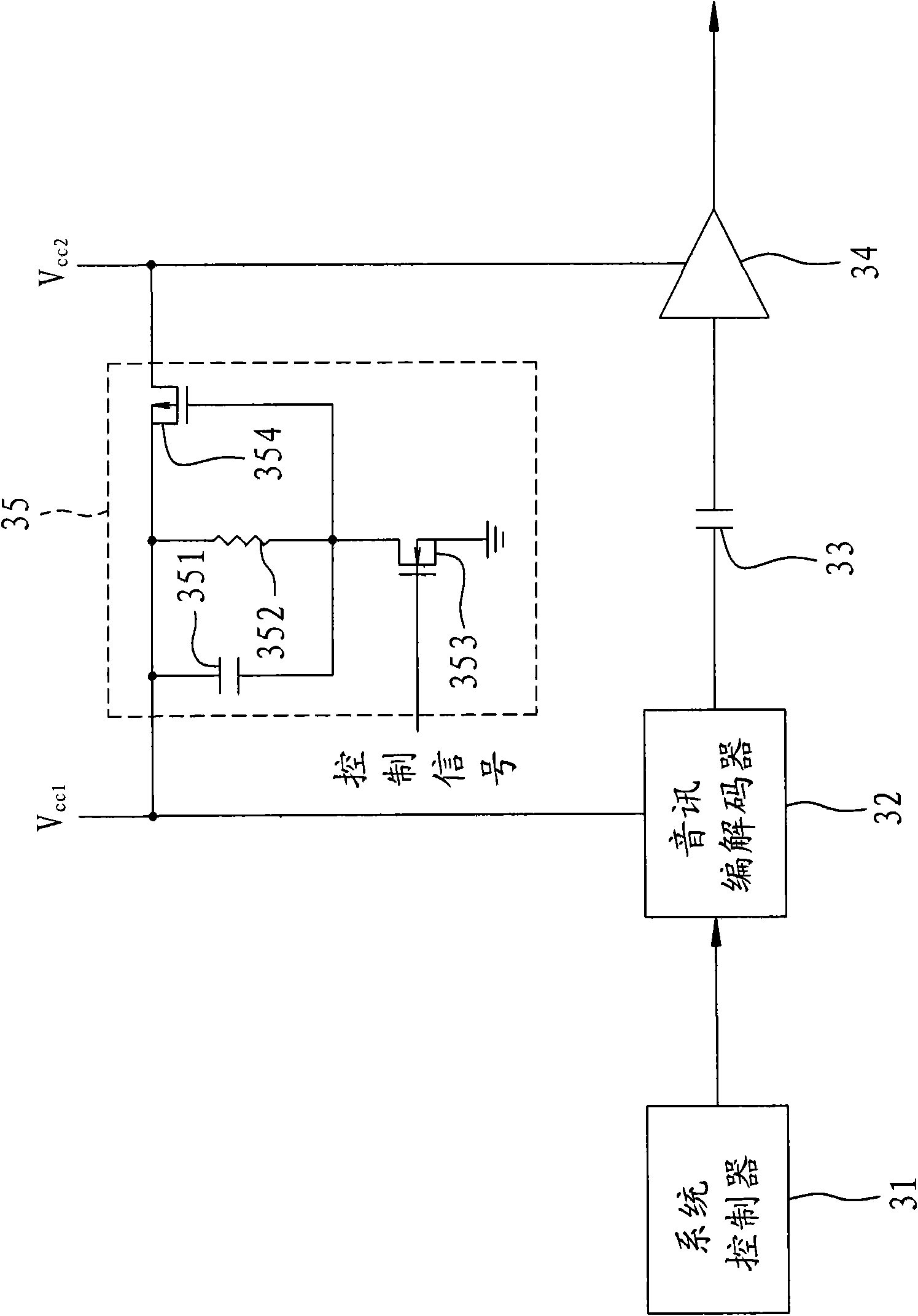

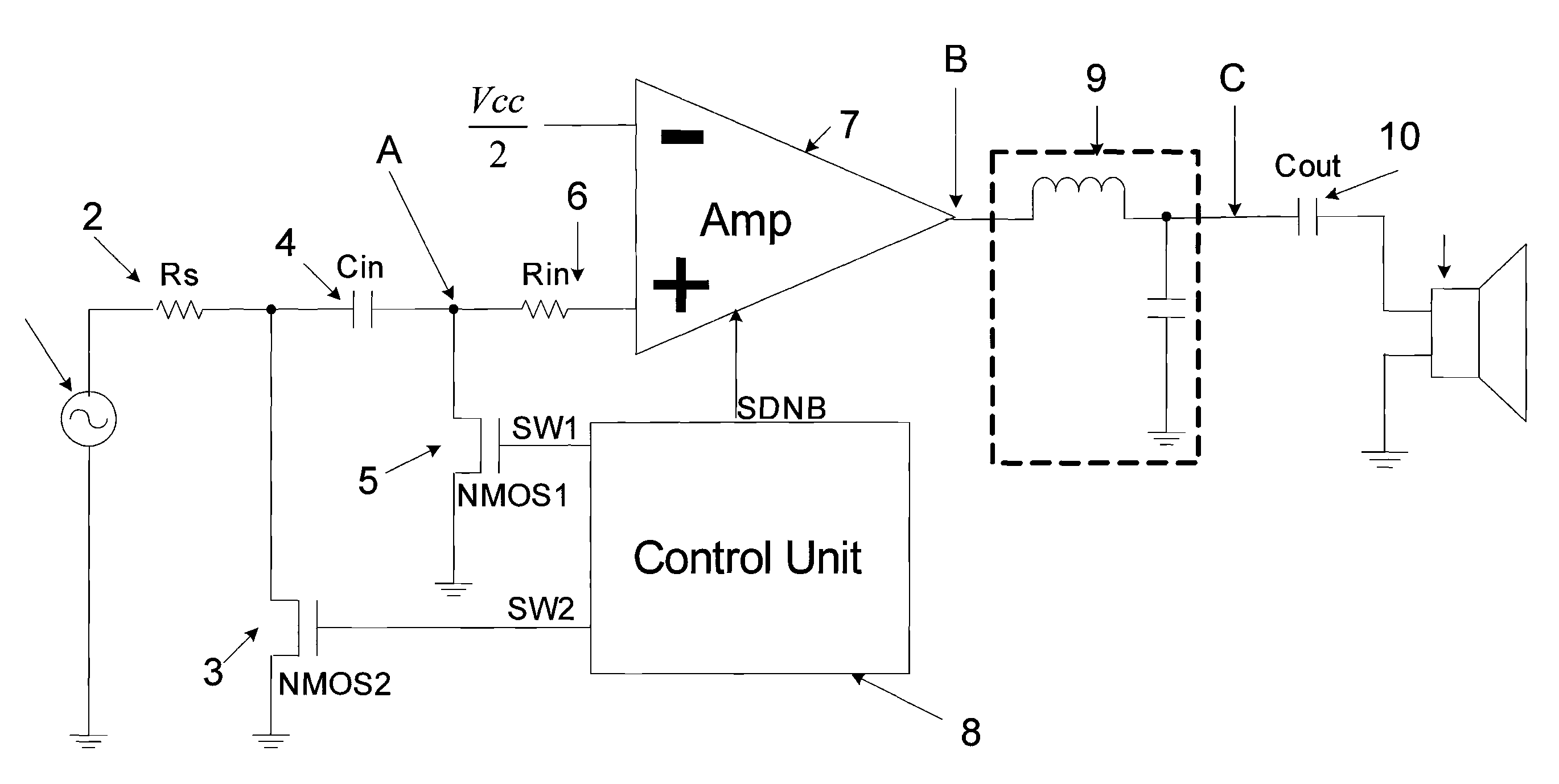

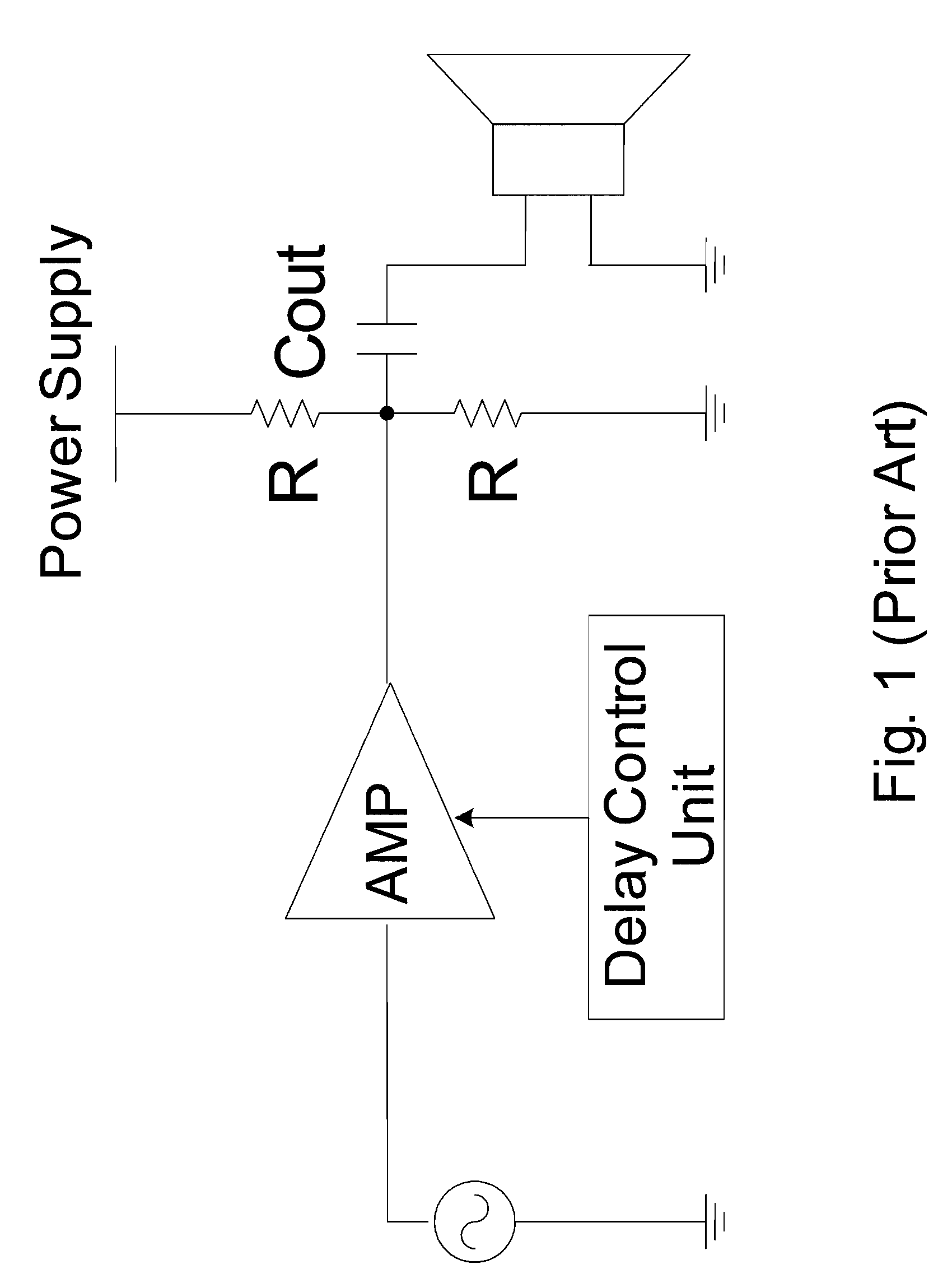

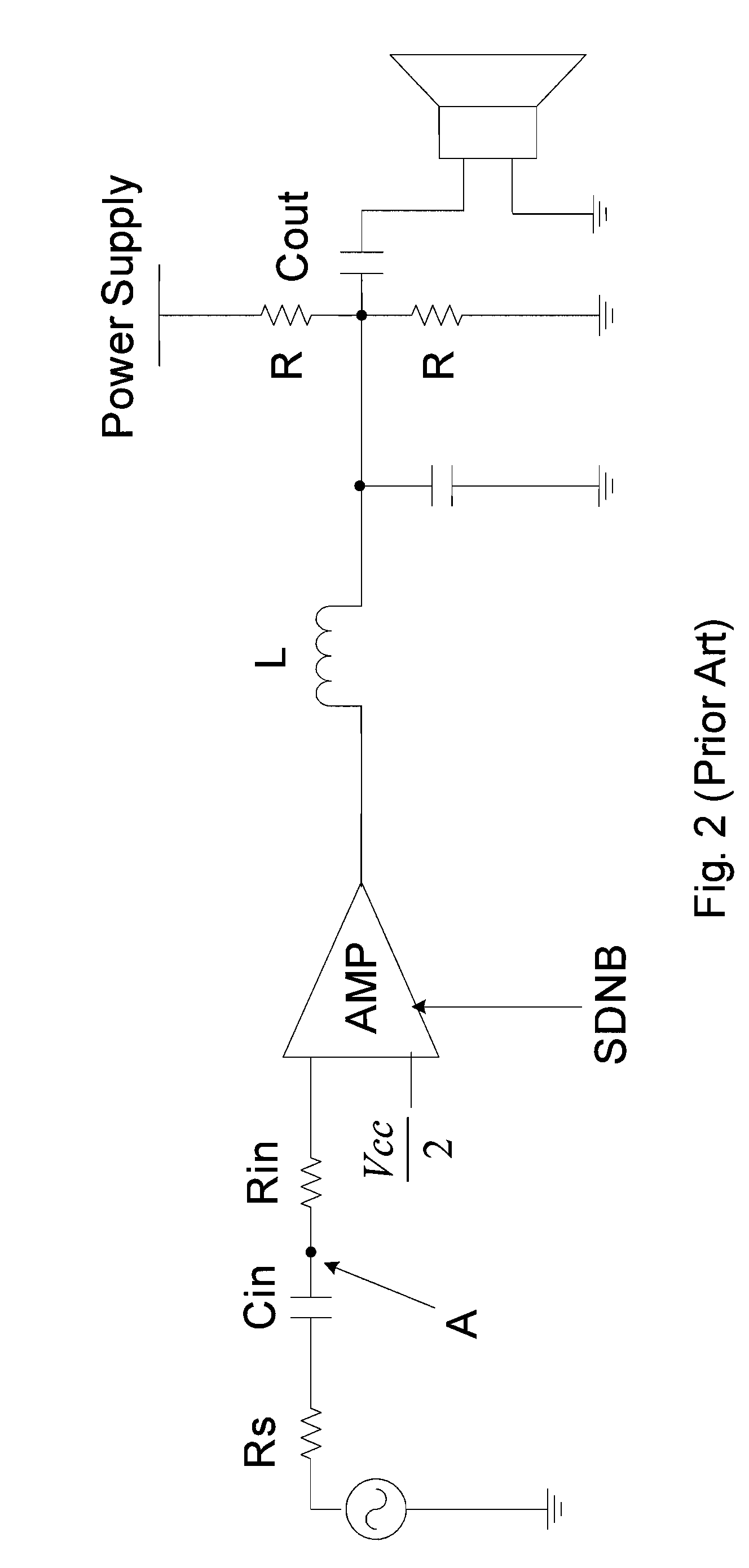

Circuit and method for eliminating speaker crackle during turning on or off power amplifier

InactiveUS20080310651A1Eliminate cracksReduce speaker crackleAudio amplifierTransmission noise suppressionAudio power amplifierPre-charge

The present invention discloses a circuit for eliminating speaker crackle during turning on or off a power amplifier and a method for the same, particularly to a circuit and method, wherein an input capacitor is used to pre-charge an output capacitor to reduce speaker crackle to an inaudible level during turning on or off a power amplifier. The present invention has a low cost and a simplified design without the penalty of bandwidth.

Owner:TAI 1 MICROELECTRONICS CORP

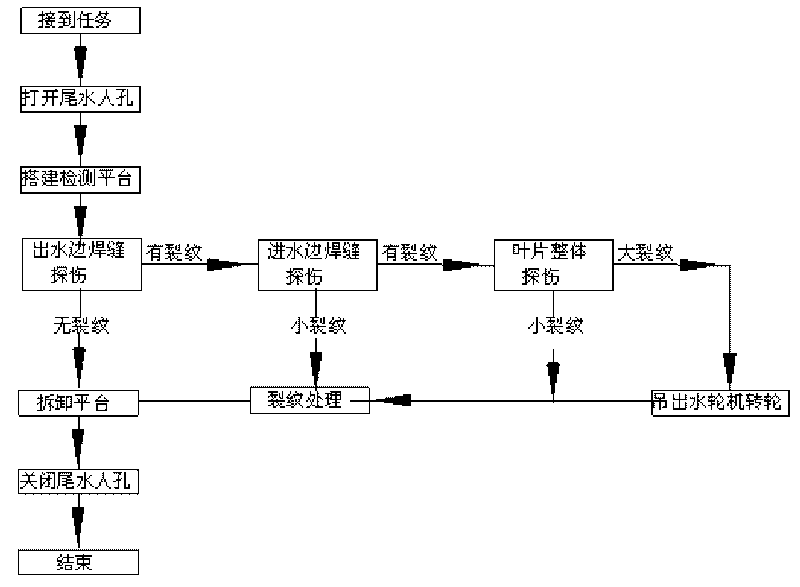

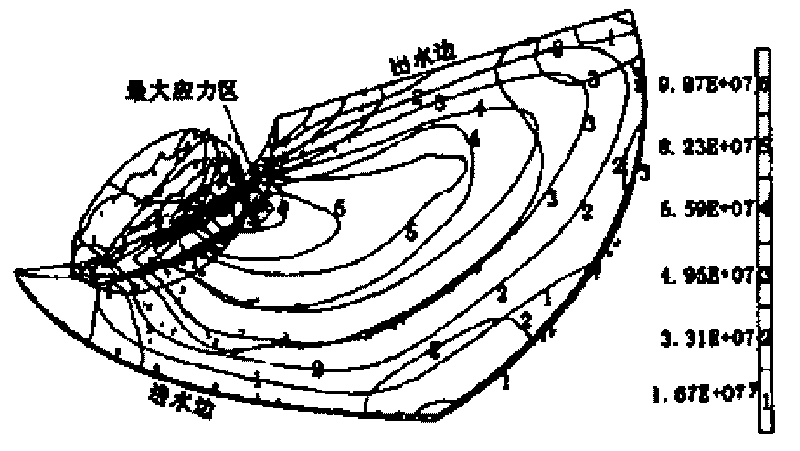

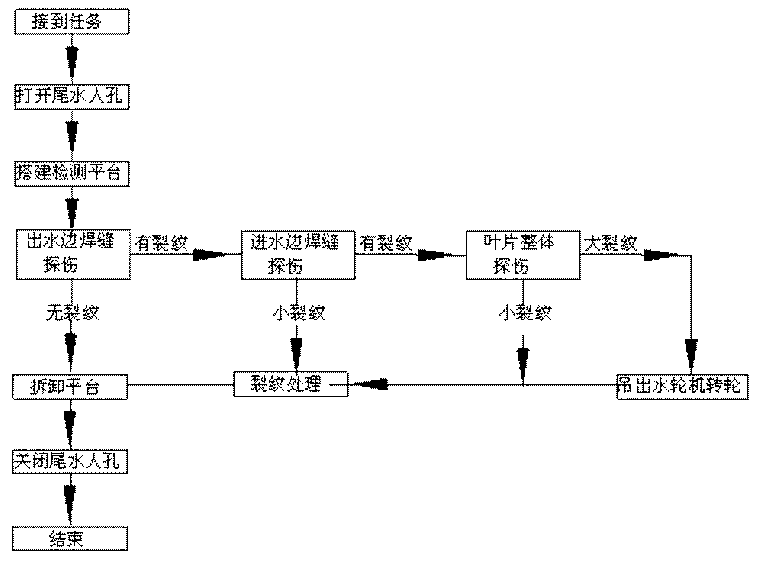

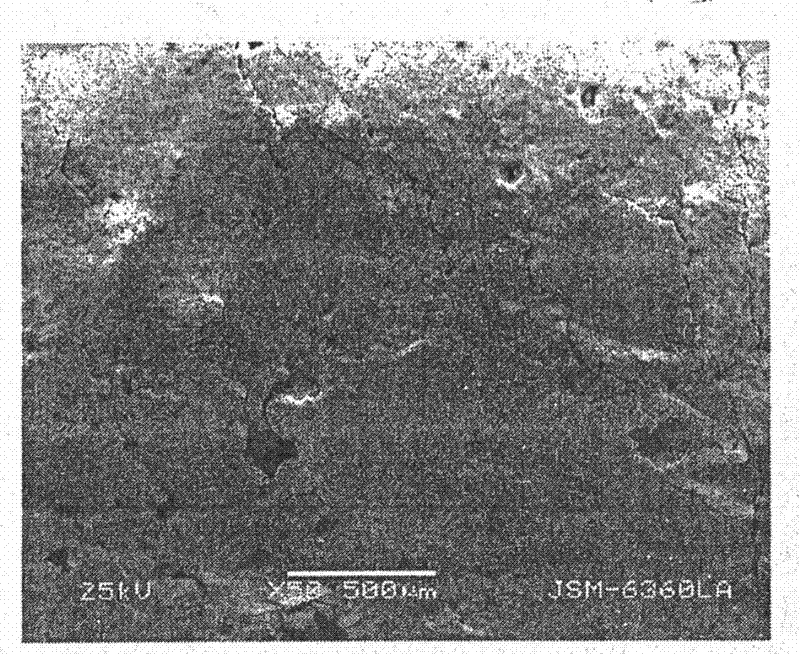

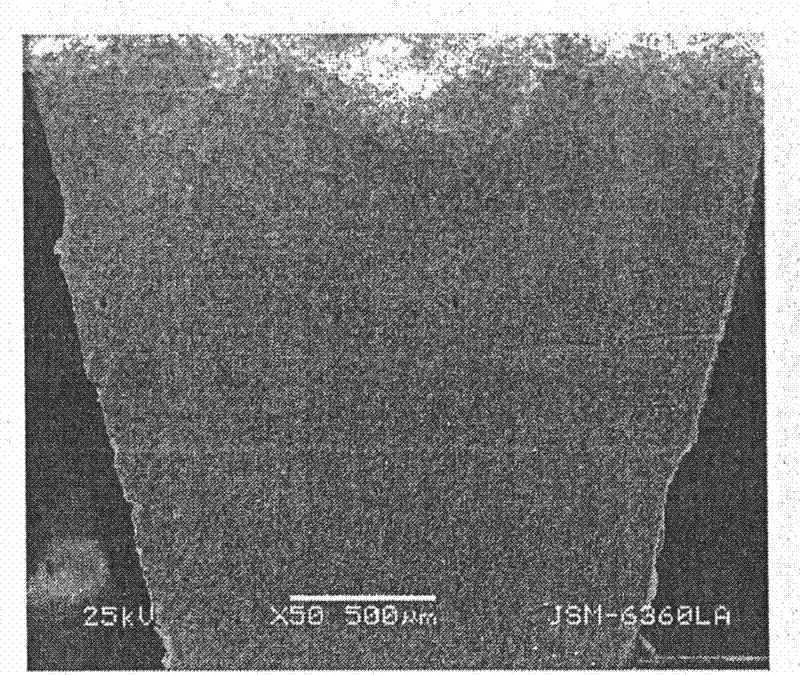

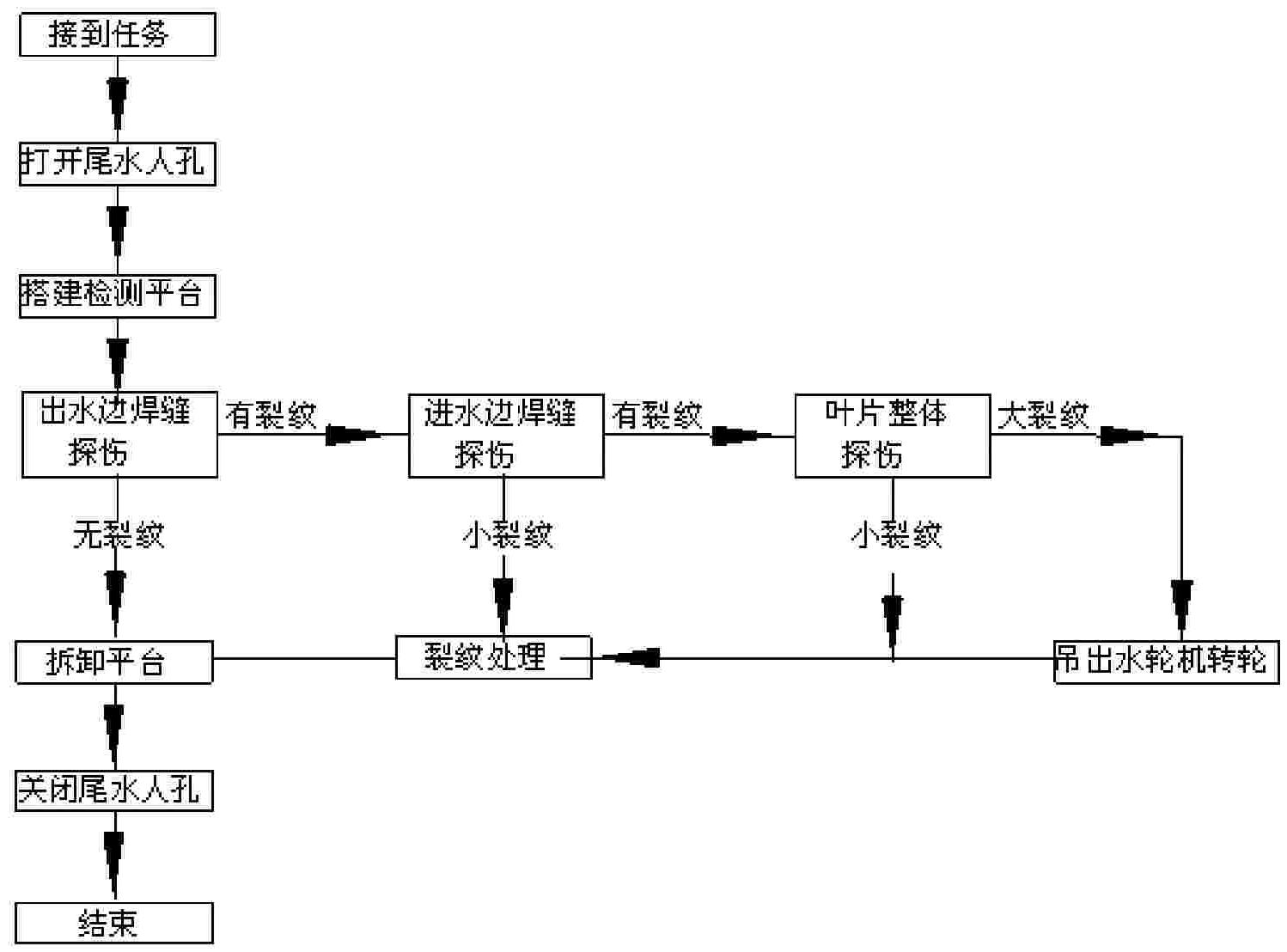

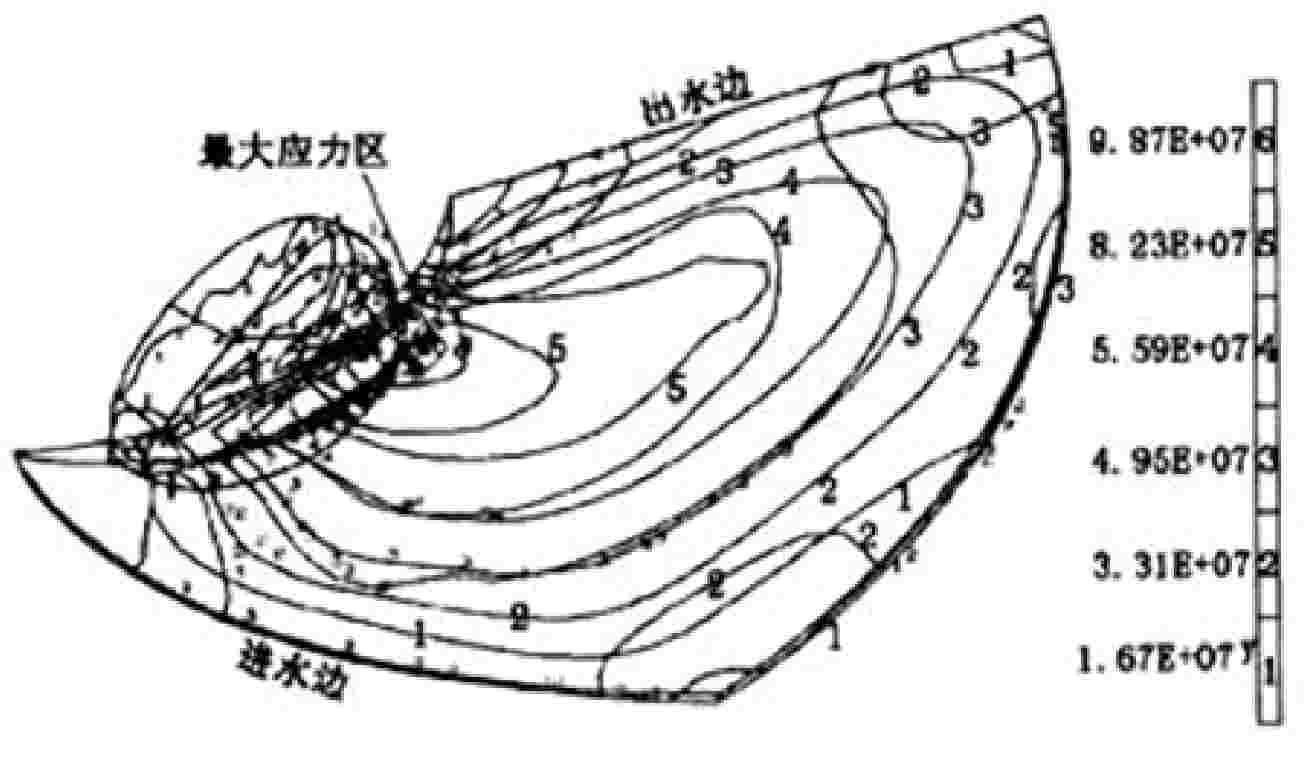

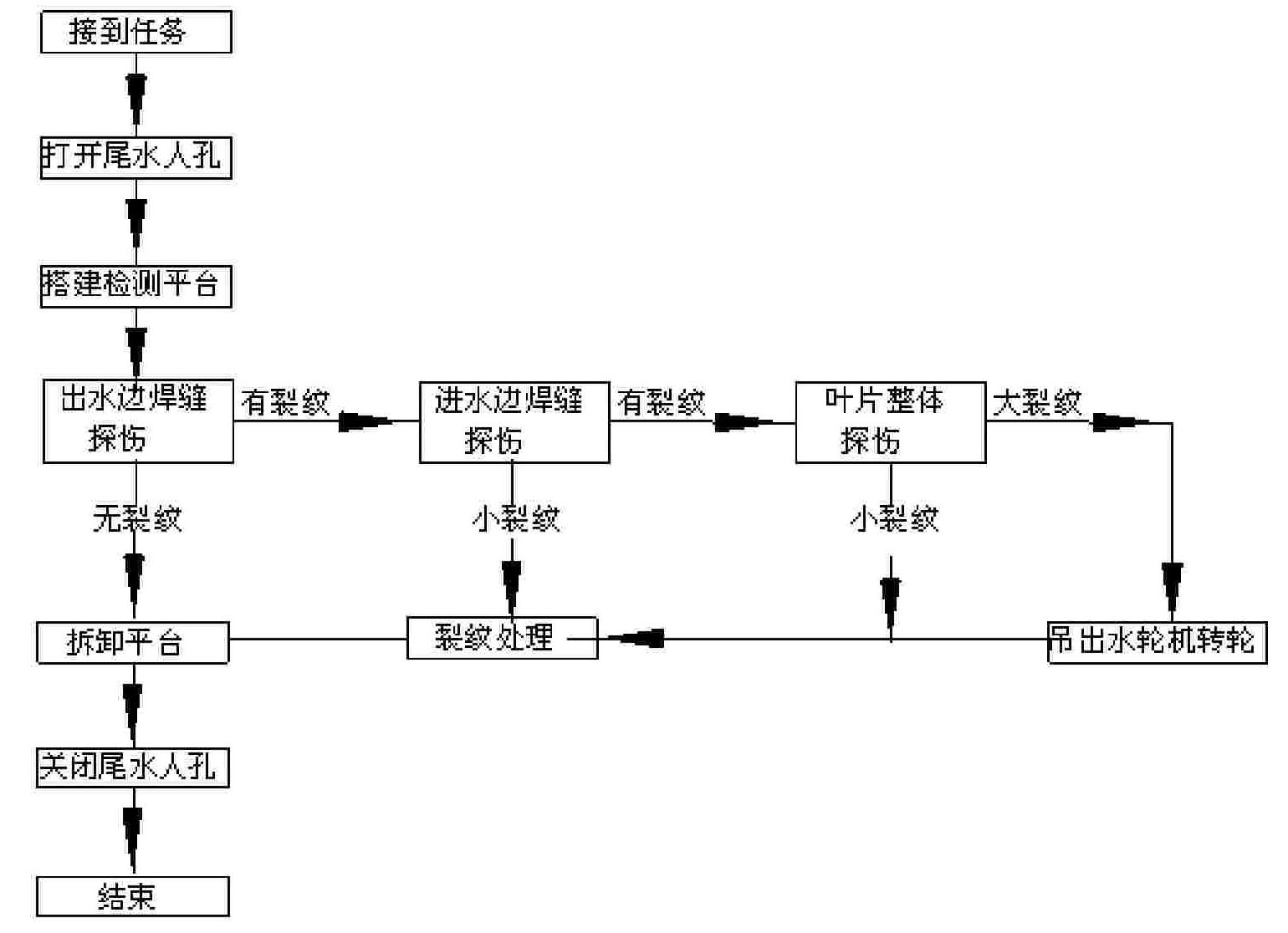

Decision method for testing in-service water turbine runner crackle

The invention discloses a decision method for testing in-service water turbine runner crackles, comprising the following steps of: opening a manhole of a draft tube to set up a testing platform, and then testing outlet and inlet edges of a runner blade and the ends of upper and lower ring fillet welds by adopting a penetrant testing method. For testing of the in-service water turbine runner crackles, the decision method tests the outlet and inlet edges of the runner blade and the ends of the upper and lower ring fillet welds, so the false dismissal probability can be greatly reduced in testing, and the testing time can be greatly shortened and the use level of a penetrant check agent is reduced. Penetrant testing (PT) can be screened out from the conventional four testing methods. The testing method can be implemented after a runner is lifted out of a volute and the manhole of the draft tube is opened to set up the platform without disassembling a generator set when testing the in-service water turbine runner, thereby satisfying the economical efficiency of the overhauling work.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

Method for high-temperature firing of underglaze color crackle ceramic

The invention discloses a method for high-temperature firing of underglaze color crackle ceramic. The method comprises steps as follows: 92-95 parts of zirconia, 1-3 parts of silicon oxide, 1-2 parts of feldspar, 0.5-1.5 parts of kaolin, 1.5-2.5 parts of zirconium silicate and 0.5-5 parts of a fluorine-containing additive are weighed out for ball milling and then mixed with an inorganic nano-particle dispersion liquid, and a ceramic clay body is prepared; 30-35 parts of feldspar powder, 5-10 parts of calcium magnesium powder, 3-8 parts of melilite, 5-10 parts of calcite, 3-8 parts of dolomite, 5-10 parts of kaolin, 20-25 parts of silicon oxide, 5-10 parts of zinc oxide, 3-6 parts of calcium carbonate, 3-6 parts of a heat-resistant agent and 5-15 parts of water are weighed out for ball milling, and then transparent feldspar glaze slurry is prepared; the obtained ceramic clay body is placed in the slurry for soaking and placed in a kiln for firing after being dried. The prepared finished product has the concave-and-convex stereoscopic crackle effect and the good shock resistance and heat stability.

Owner:PINGDINGSHAN UNIVERSITY

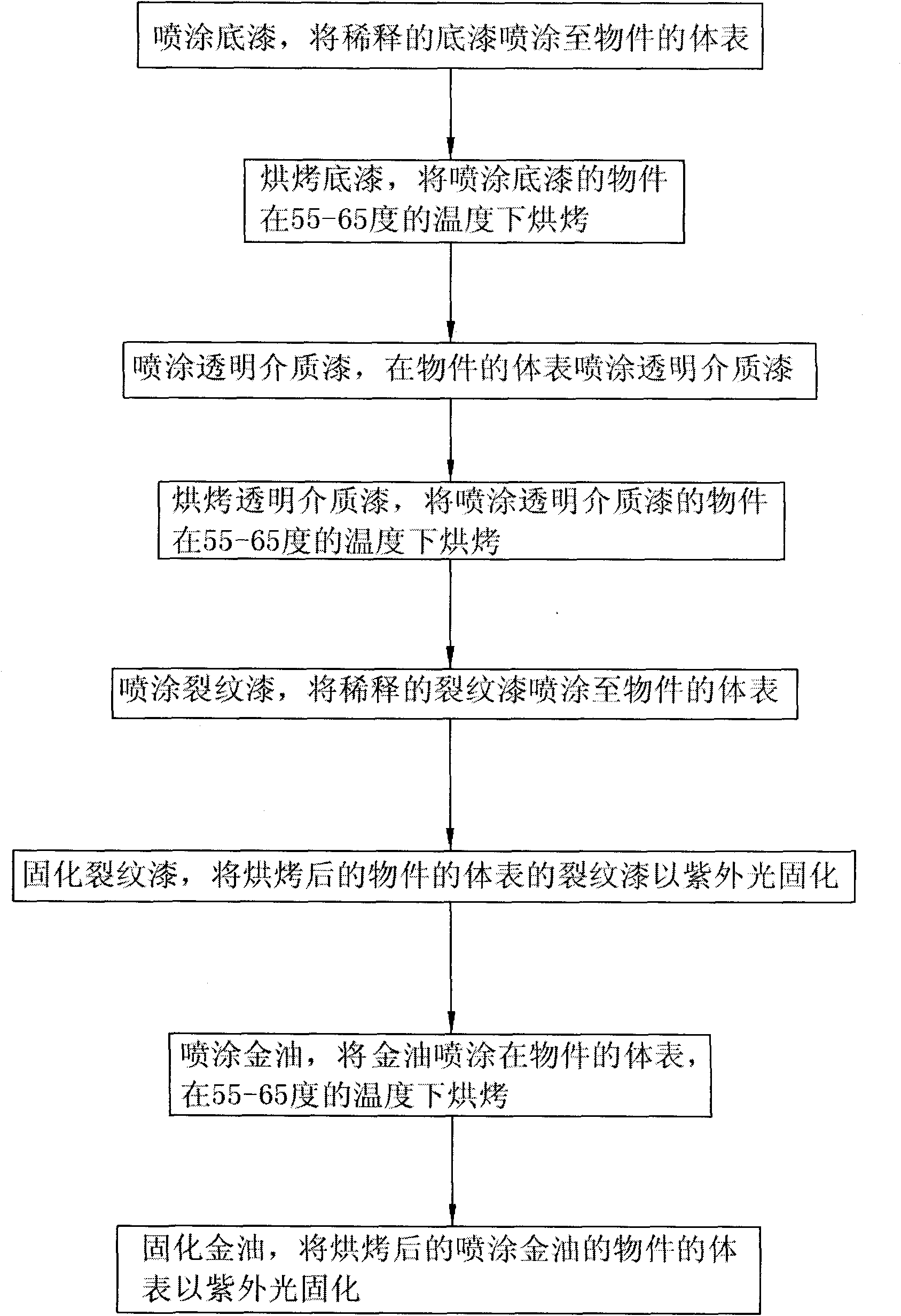

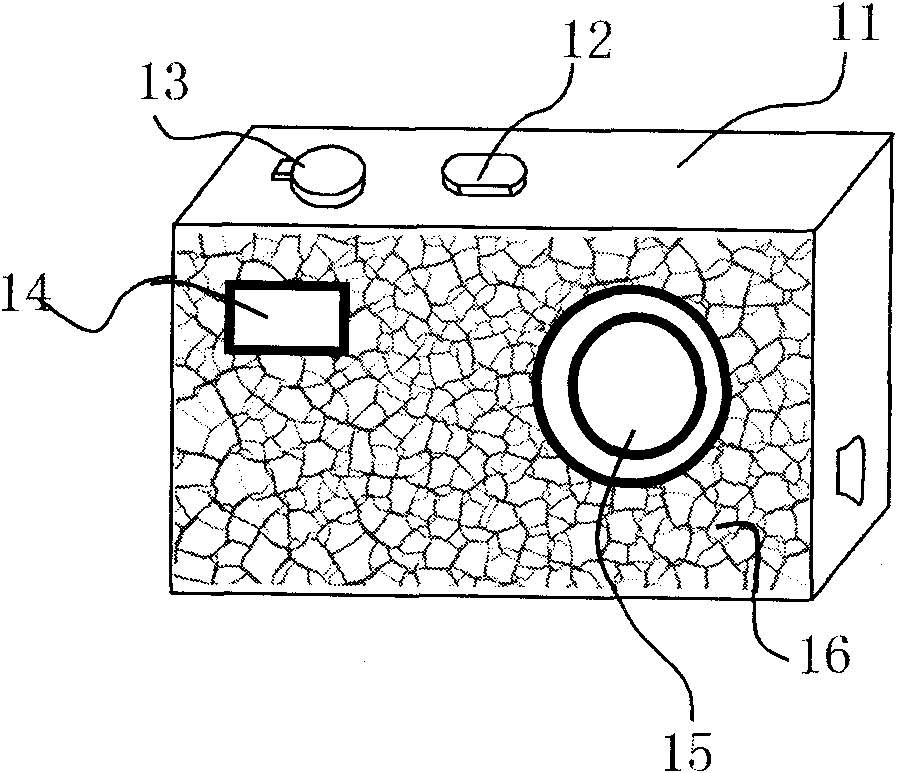

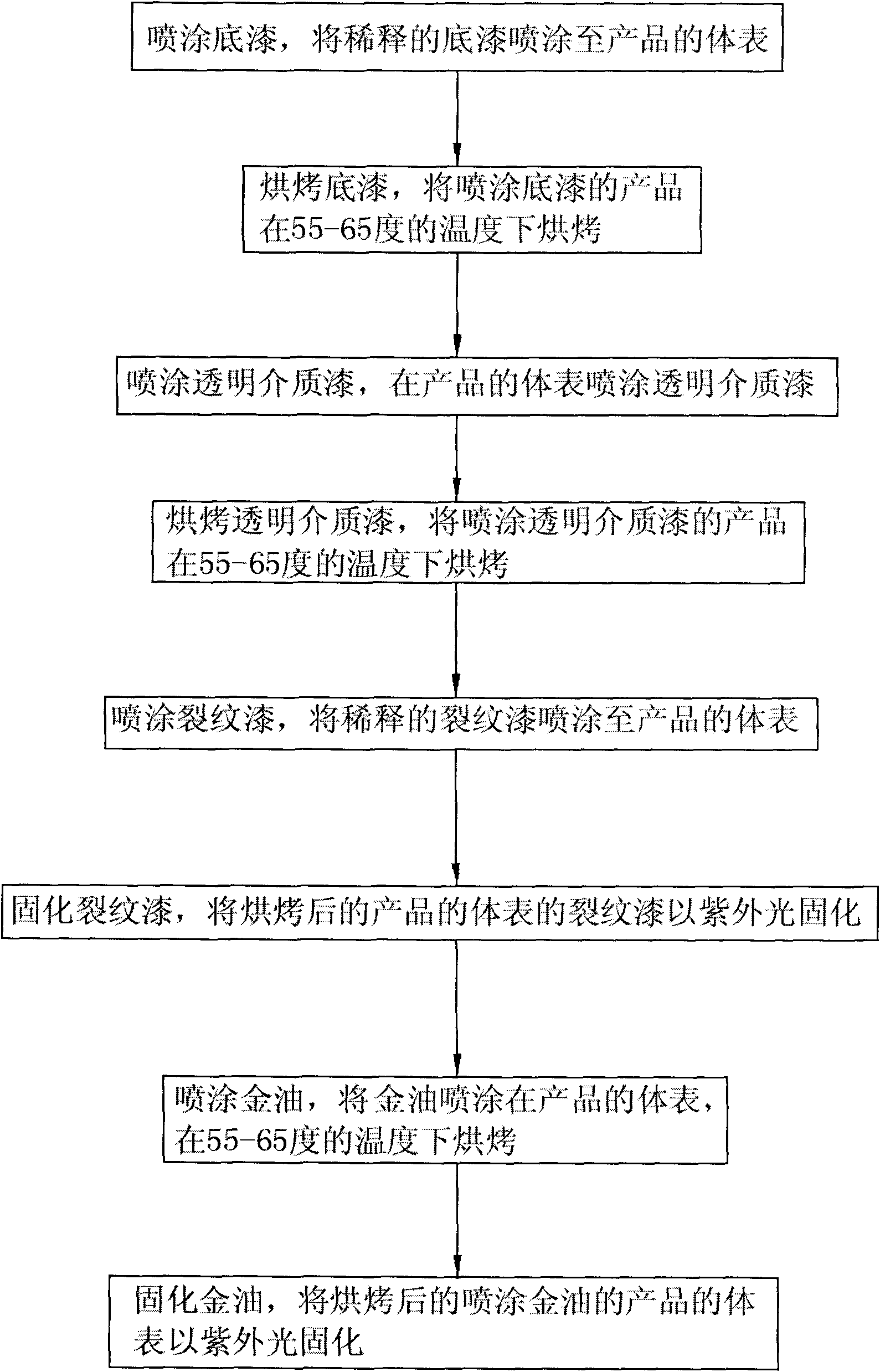

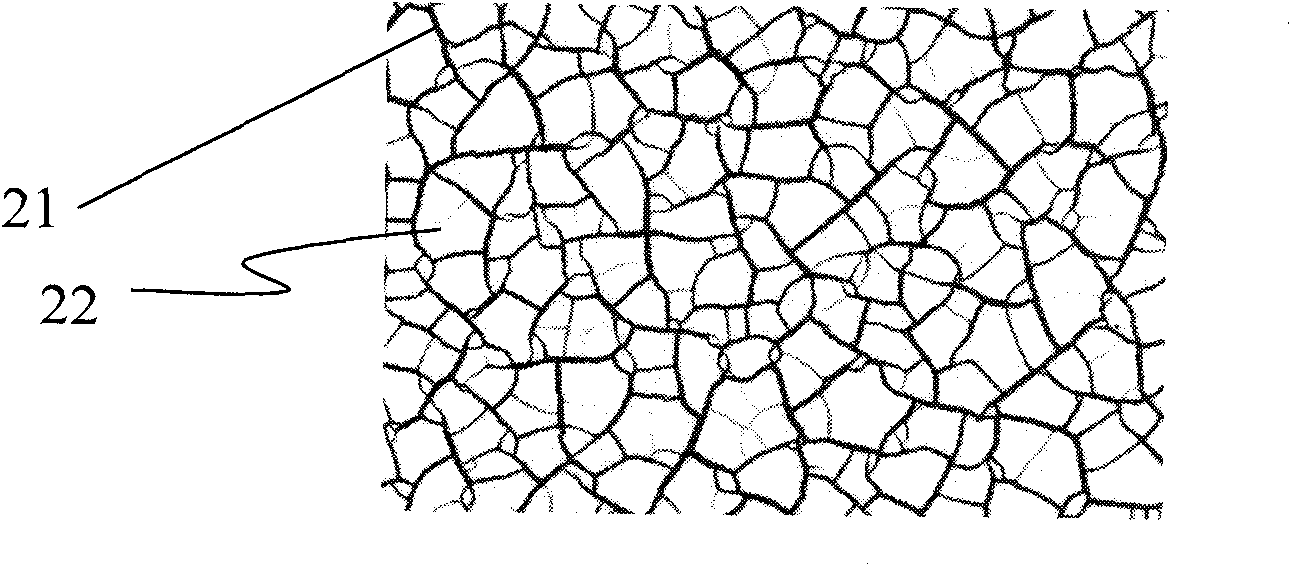

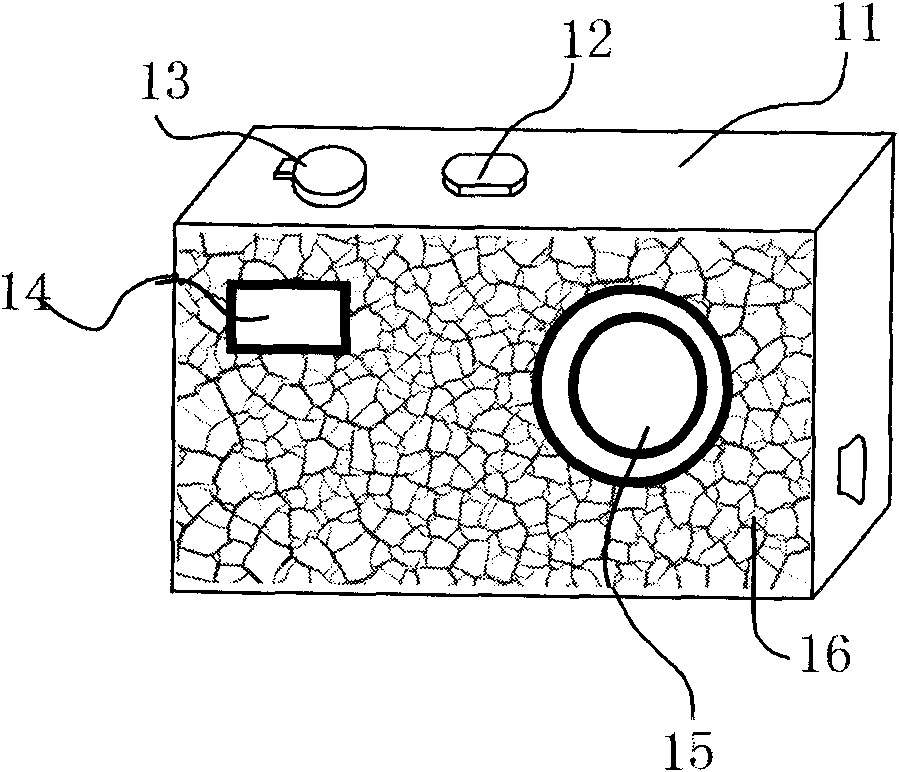

Method for manufacturing crackle ornamentations on articles and digital camera with ornamentations

InactiveCN102211082AEasy to manufactureBeautifiedTelevision system detailsDecorative surface effectsCooking & bakingLacquer

The invention discloses a method for manufacturing crackle ornamentations on articles. The method comprises the following steps: spraying a base paint; baking the base paint; spraying a transparent medium paint; baking the transparent medium paint; spraying a crackle paint, baking the crackle paint and solidifying the crackle paint, wherein the baking processes are performed at 55-65 DEG C.; and the crackle paint is solidified by ultraviolet lights. Therefore the line ornamentations manufactured in an object can be used for increasing the aesthetic sense; the ornamentations are manufactured in a digital camera according to the method, so the aesthetic sense of the digital camera is increased; and the method is convenient for the facilitation and simplification for manufacturing the ornamentations on the digital camera, and beneficial to the diversity of digital cameras.

Owner:AIGO DIGITAL TECHNOLOGY CO LTD

Process for making tortoise shell medicinal slices by adopting sand heating and vinegar quenching method

InactiveCN104224843AEasy to decoct medicinal ingredientsGood curative effectUnknown materialsComing outCurative effect

The invention discloses a process for making tortoise shell medicinal slices by adopting a sand heating and vinegar quenching method. The raw materials comprise the following components in parts by weight. The process comprises the following steps: (1) washing and drying; (2) performing continuous stir-fry on a tortoise shell; (3) continuously heating, when the temperature rises to 180 DEG C, crackle can be heard, the color is slightly yellow, micro smoke comes out, then pouring out the tortoise shell, screening river sand, pouring the tortoise shell into a container filled with 200 parts of table vinegar while heating, and performing continuous stir-fry; and (4) adding small blocks in the step (3) into a medicine frying machine, roasting the vinegar at the temperature of 50-80 DEG C, taking out the blocks, cooling, thereby obtaining the product. According to the tortoise shell medicinal slices made by the method disclosed by the invention, medicinal components are easily decocted, and the curative effect is increased.

Owner:TONGREN FANJINGSHAN CHINESE HERBAL PIECES

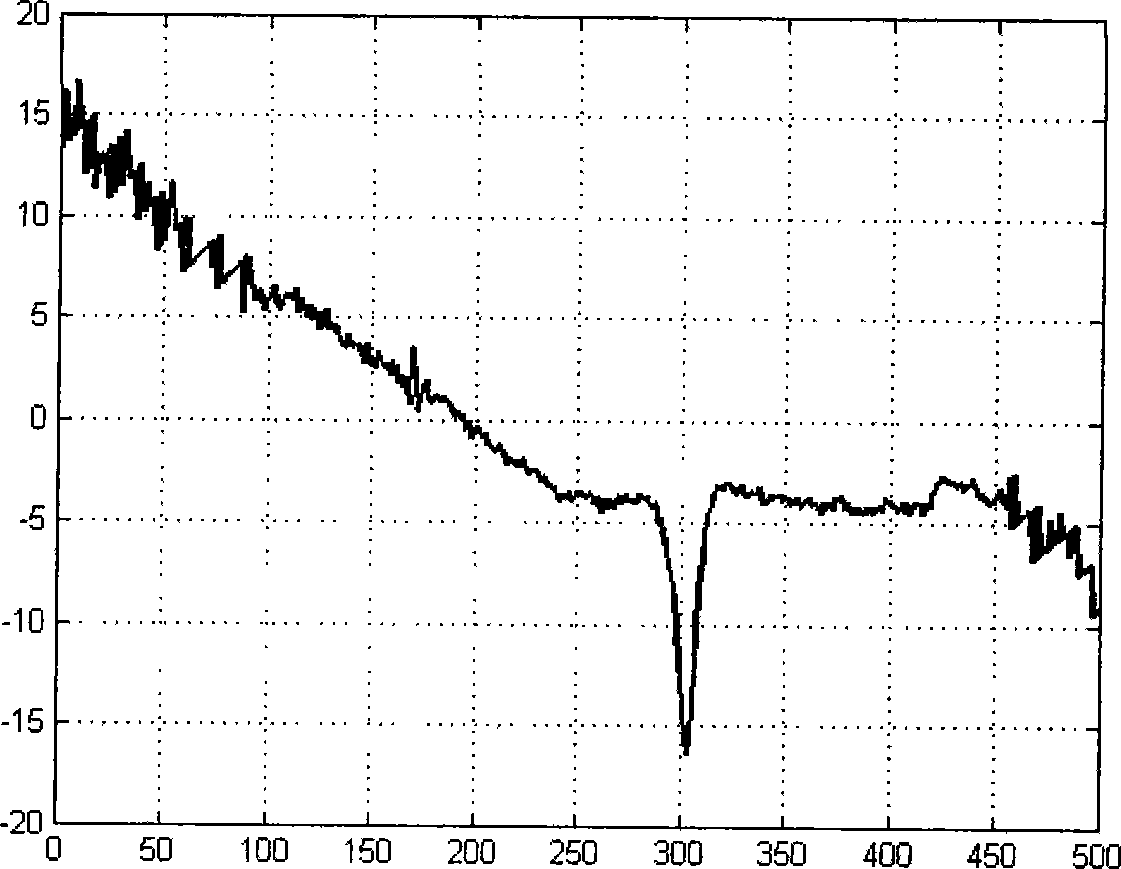

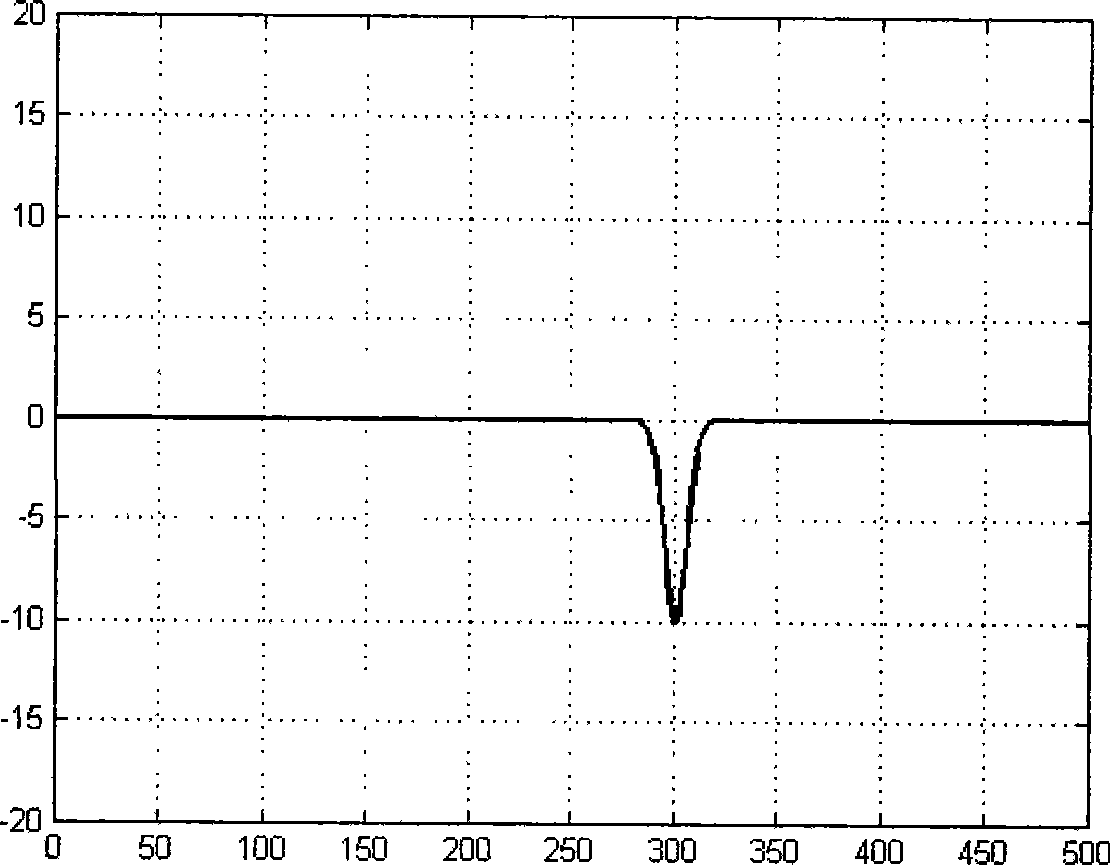

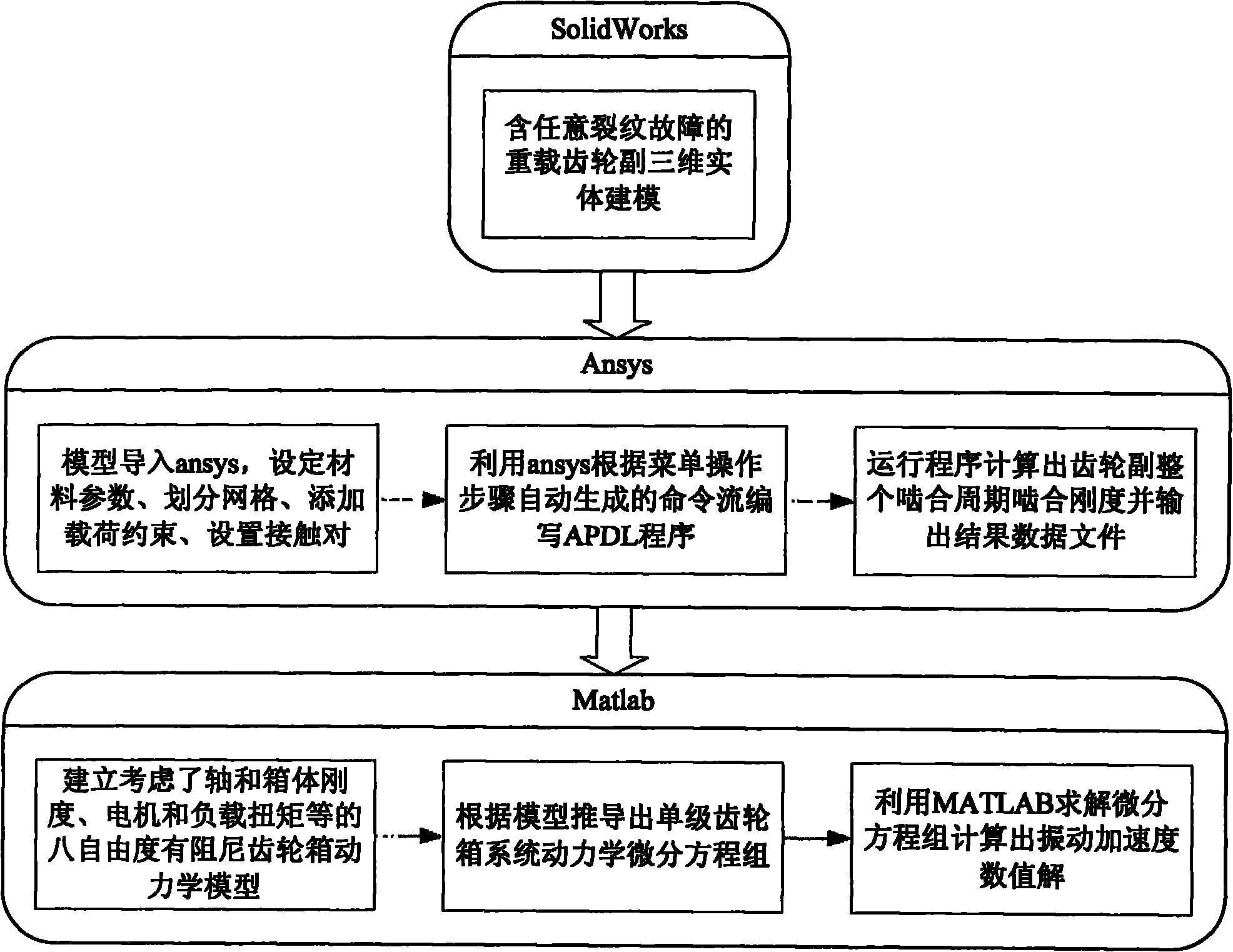

Simulation analysis method of vibratory response of variable working condition single-stage heavy gear case containing crackle fault

InactiveCN101625710BAvoid pitfalls when modeling abnormal gearsReliable theoretical basisMachine gearing/transmission testingSpecial data processing applicationsLoad torqueSystem dynamics model

The invention relates to a simulation analysis method of the vibratory response of a variable working condition single-stage heavy gear case containing a crackle fault, which comprises the following steps: establishing a gear pair 3D solid model containing a crackle fault on the basis of 3D design software SolidWorks; leading the model into finite element analysis software ansys, programming a program capable of calculating the gear meshing rigidity of any meshing positions by combining menu operations of the ansys and APDL languages and outputting a result data file of the meshing rigidity; establishing a damping gear case system kinetic model of 8 degrees-of-freedom and kinetic simultaneous differential equations considering factors of the rigidity and the damping of a shaft and the case, an input torque and a load torque of a motor, and the like and utilizing MATLAB to solve the equations so as to simulate the system vibratory response of the single-stage heavy gear case containinga crackle fault. The invention integrates the advantages of the SolidWorks, the ansys and the MATLAB and can quickly and accurately simulate the vibratory responses of variable working condition heavy single-stage heavy gear cases containing various different forms of crackle faults.

Owner:BEIJING UNIV OF TECH

Method for testing environmental stress cracking resistance (ESCR) of drip tape

InactiveCN101900652ATest environmental stress cracking resistanceGuaranteed reasonablenessMaterial strength using tensile/compressive forcesChinese charactersRoom temperature

The invention relates to a method for testing the environmental stress cracking resistance (ESCR) of a drip tape, which comprises the following steps of: (1) sampling; (2) cleaning, drying, cooling to be room temperature, and keeping the drying status for later use after adjusting the status of a plurality of samples; (3) preparing active solution with volume concentration of 20%; (4) evenly coating active solution on the two sides of each sample, and folding each sample to be four layers in a shape like Chinese character 'ZHI'; (5) putting the five folded samples into a sample clamp in parallel and screwing; (6) putting the sample clamp with the samples into an oven with the temperature of 60+ / -20 DEG C and timing; (7) drying under constant temperature for 8h, withdrawing the clamp, naturally cooling to the room temperature, withdrawing the samples, wiping solvent, and visually observing whether the side edge of each sample has crackle under natural light; and (8) judging a result. The method is easy to operate, practical and convenient, and is an effective method for testing the environmental stress cracking resistance (ESCR) of the drip tape currently after being verified with repeated experiments.

Owner:GANSU DAYU WATER SAVING

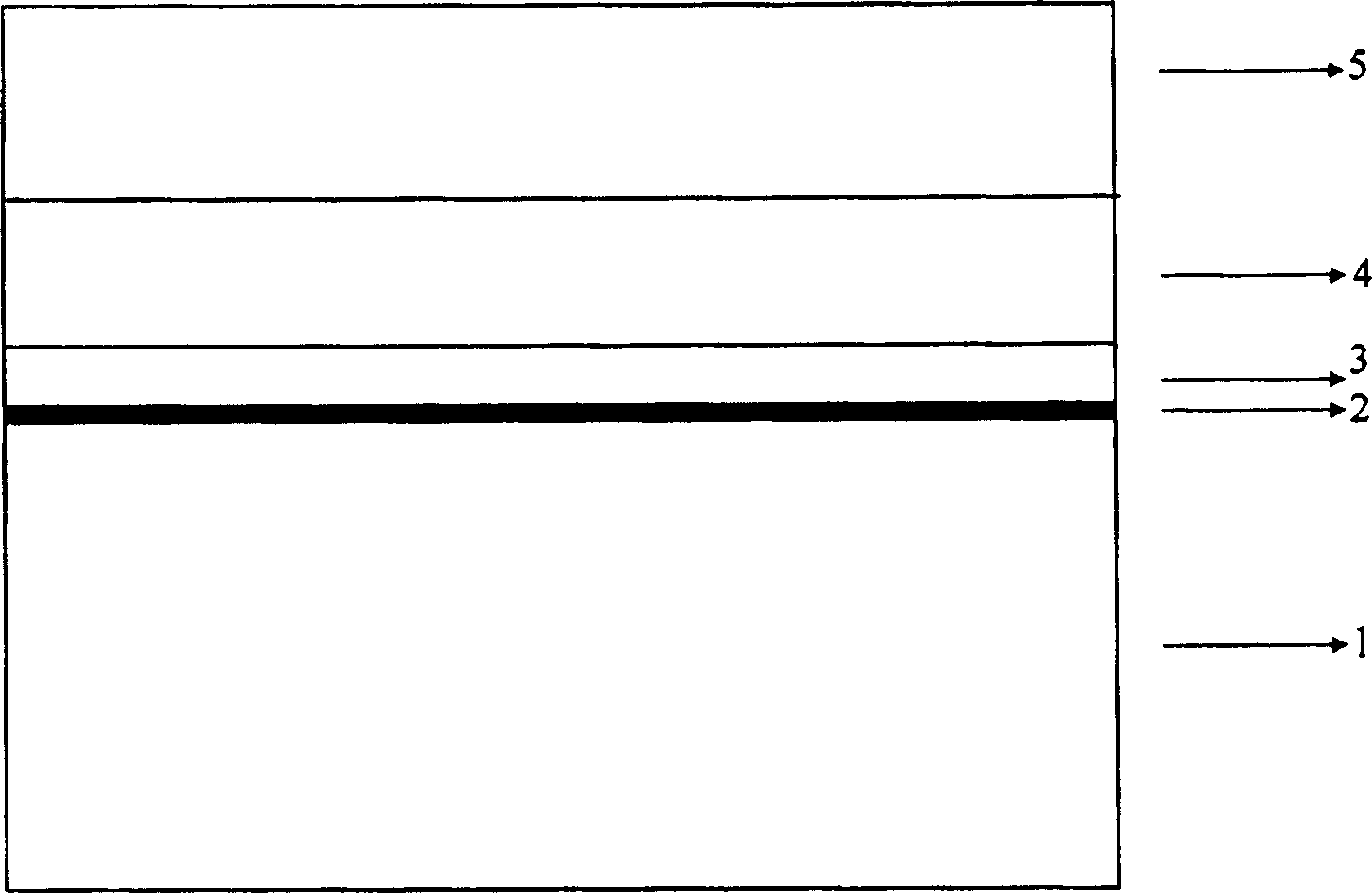

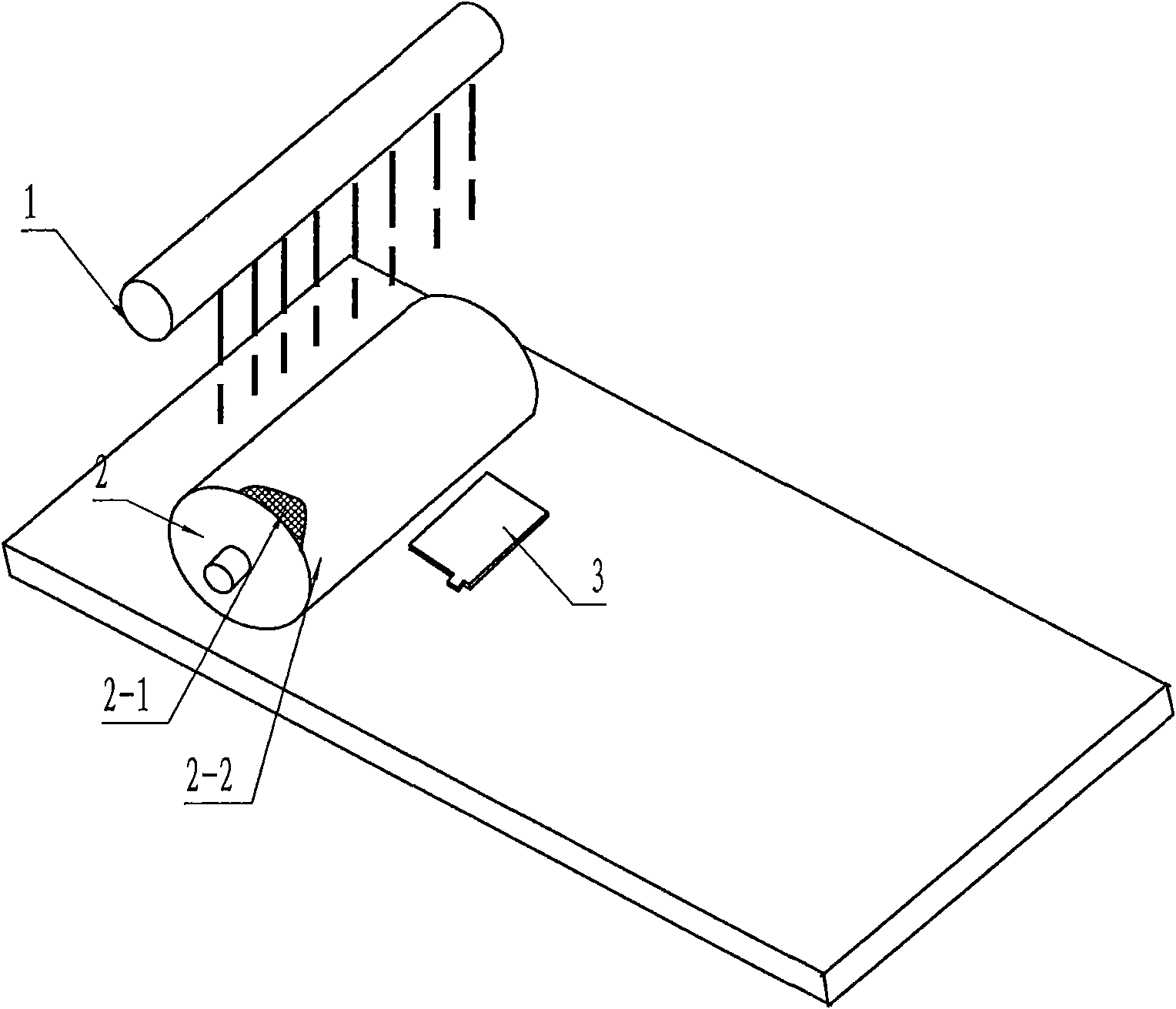

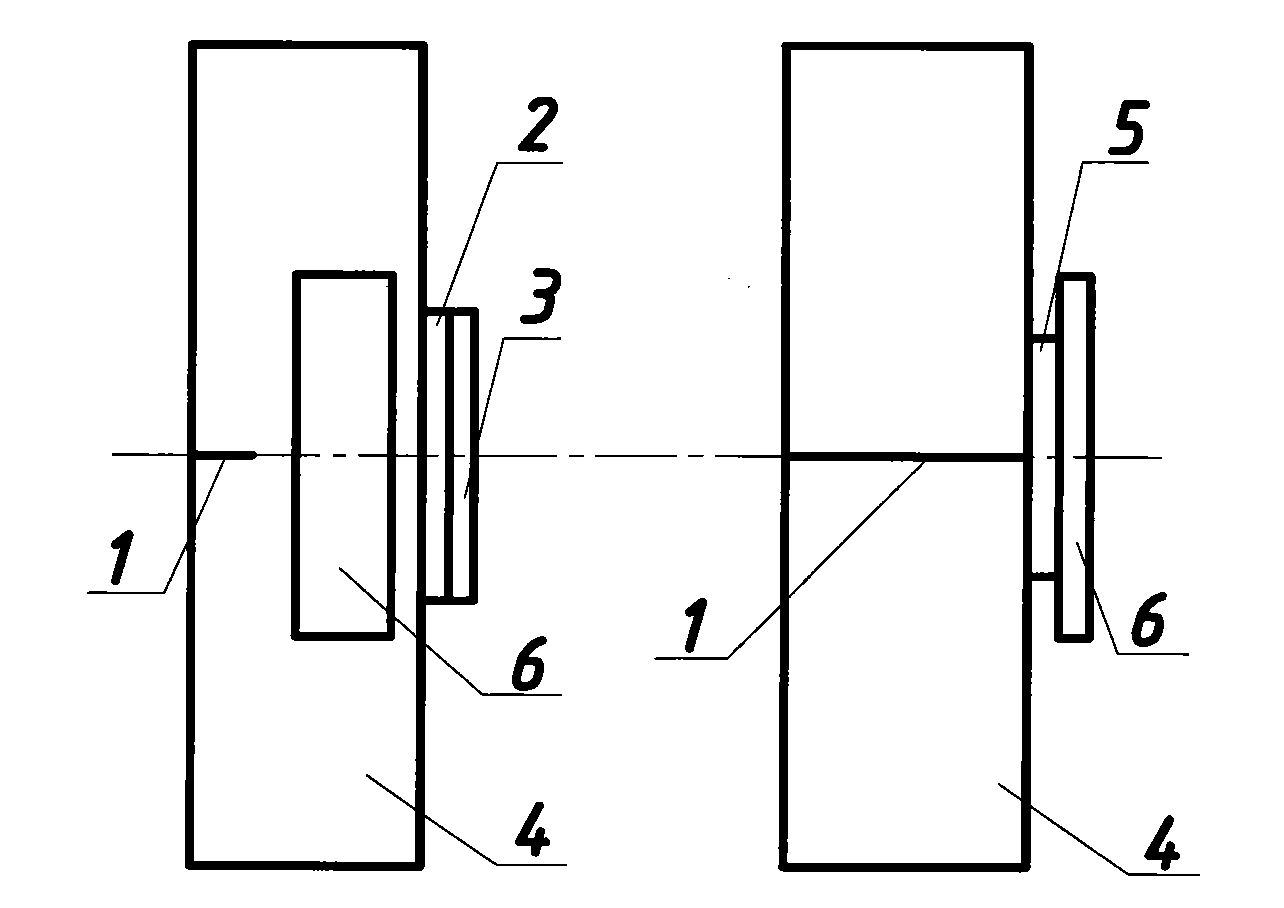

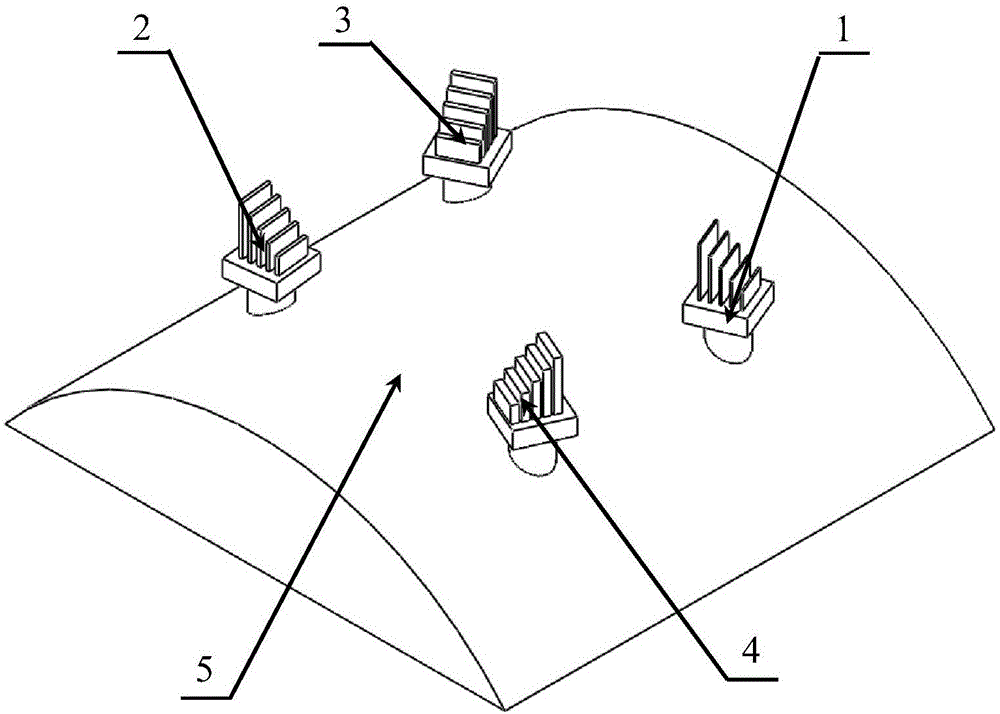

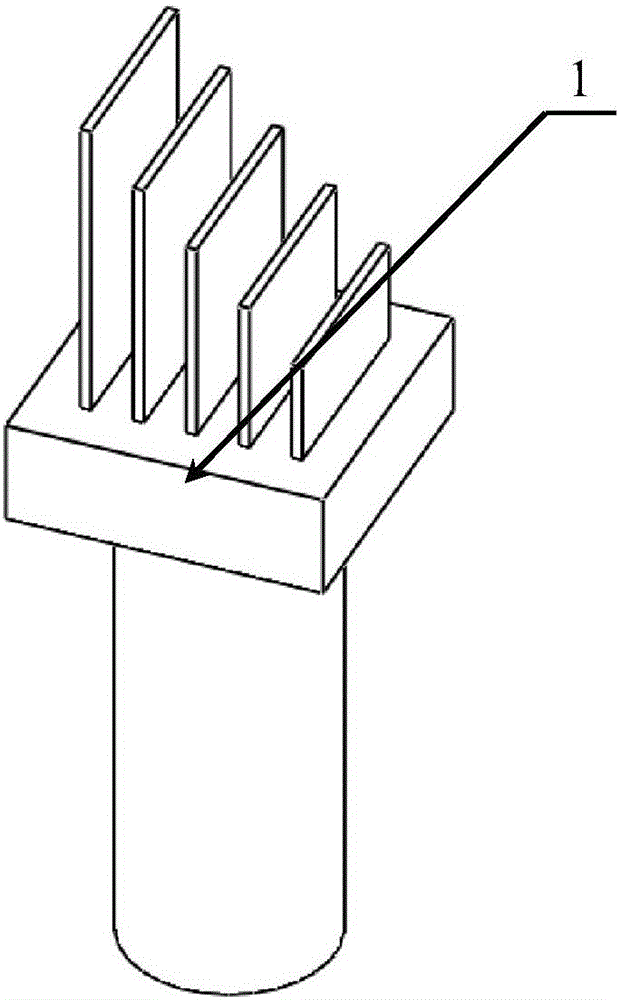

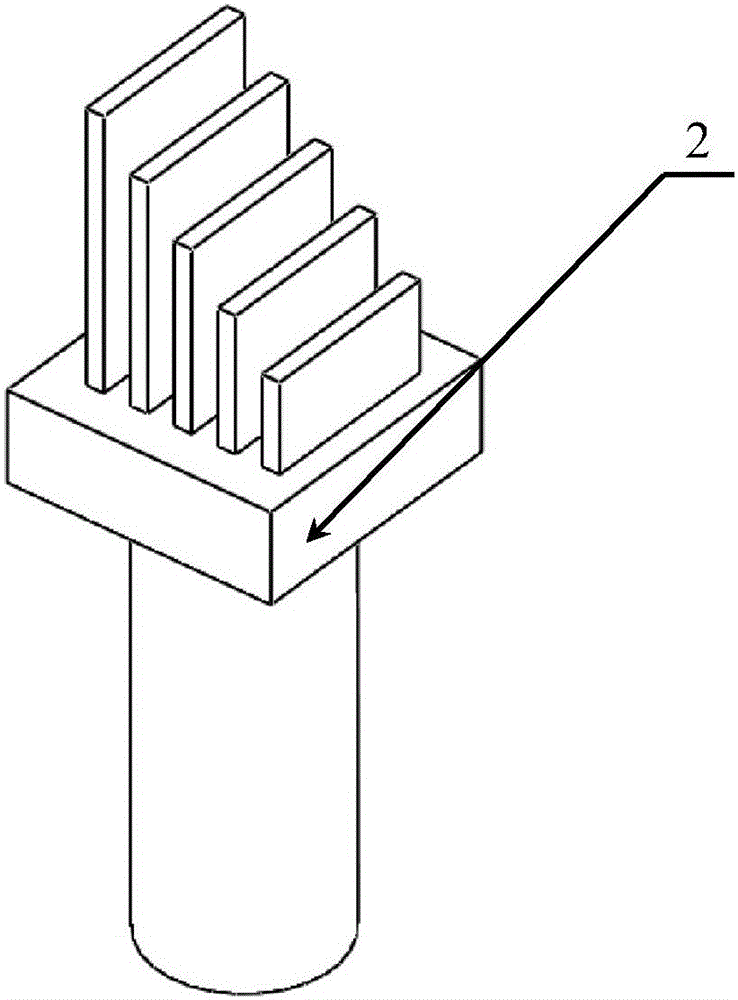

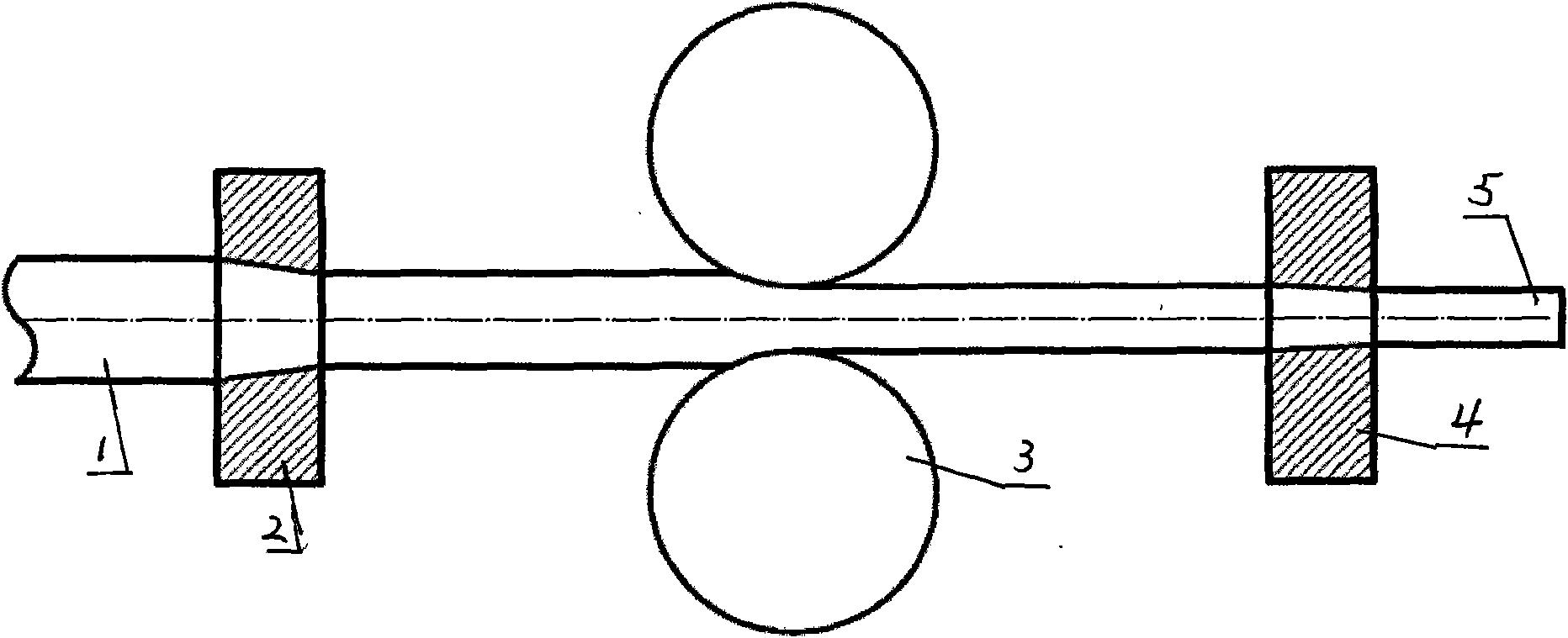

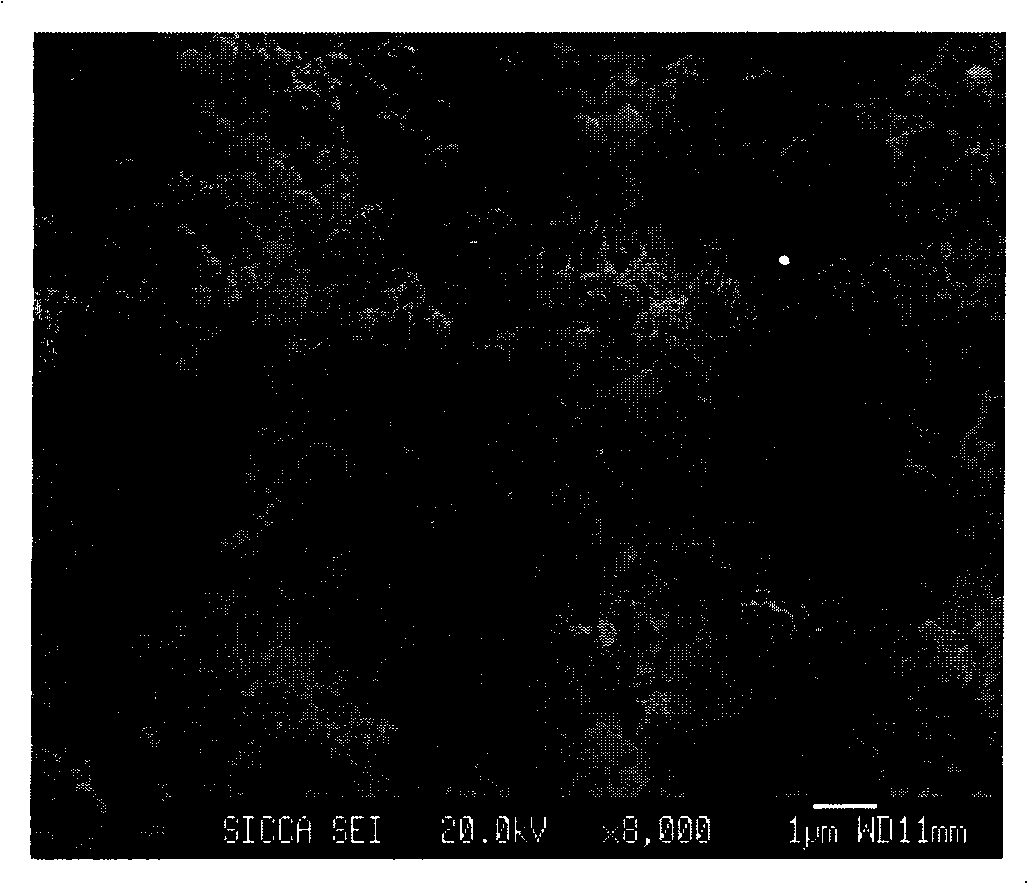

Multiscale flexibility verification target of vehicle-mounted pavement crackle detecting system based on active vision

The invention discloses a multiscale flexibility verification target of a vehicle-mounted pavement crackle detecting system based on active vision, and aims to solve the problem existing in the test of the illumination influence of the vehicle-mounted pavement crackle detecting system based on the active vision. The system comprises a No.1 target (1), a No.2 target (2), a No.3 target (3), a No.4 target (4) and a base (5), wherein the lower surface of the base (5) is put on flat ground, the No.1 target (1), the No.2 target (2), the No.3 target (3), and the No.4 target (4) are in fixed and threaded connection with four threaded holes processed in the upper surface of the base (5). The system provides the multiscale flexibility verification target of the vehicle-mounted pavement crackle detecting system based on active vision, which is small in space usage, simple in structure, high in detection precision, simple and convenient to operate, easy to mount, low in cost and reliable in performance.

Owner:JILIN UNIV

Cataplasm used for inner electrode and laminated ceramic electronic part using the same

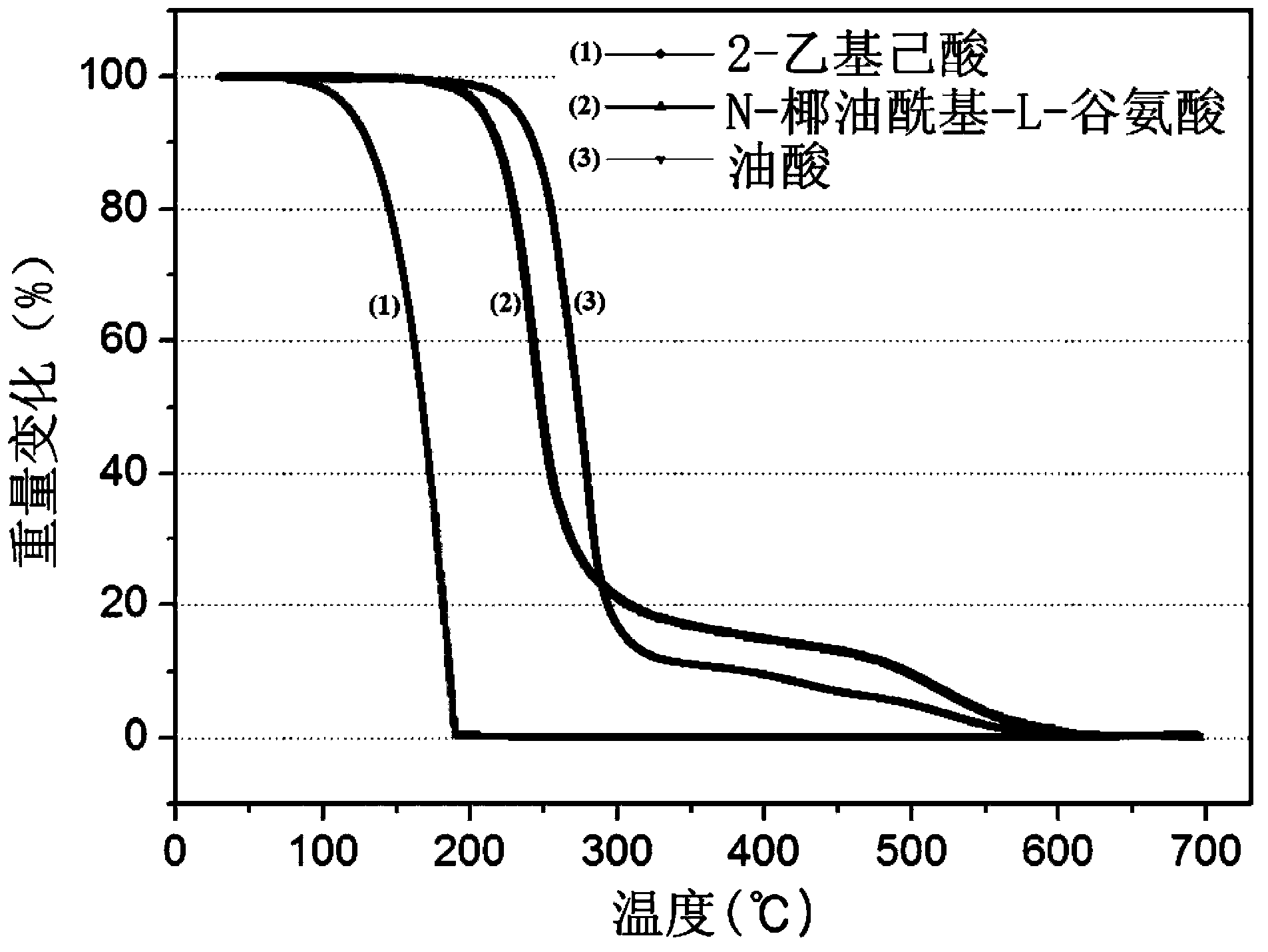

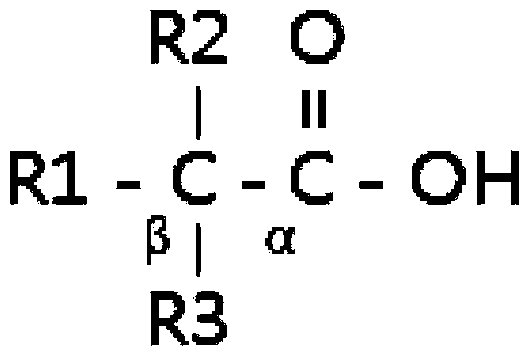

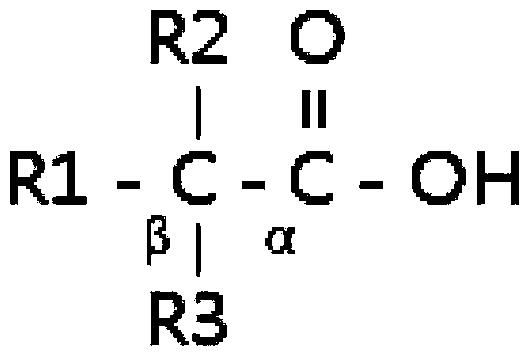

ActiveCN103903676ASolve the phenomenon of gelationSolve viscosityFixed capacitor electrodesStacked capacitorsCrazingSolvent

The invention relates to a cataplasm used for an inner electrode and a laminated ceramic electronic part using the same, and to be specific, relates to the cataplasm used for the inner electrode comprising dispersant having specific structure, and therefore the compatibility of the solvent is high, and the problem of the gelation phenomenon and the rising of the viscosity of the cataplasm can be solved. The thermal decomposition performance is good, and therefore the cataplasm used for the inner electrode does not generate crackles during the plastification, and in addition, the laminated ceramic electronic part using the cataplasm used for the inner electrode is provided.

Owner:NURI VISTA

Technique for repairing crackle lacquer of historical building wood product

ActiveCN101468580ASolve problems that are not refined enoughPretreated surfacesArtistic surface treatmentWater basedLacquer

The invention relates to repair technology, in particular to technology for repairing historical building woodwork, and in particular relates to technology for repairing crack lacquer of the historical building woodwork. The technology for repairing the crack lacquer of the historical building woodwork is characterized by comprising the following steps: firstly, spraying or coating a layer of water-based paint which is taken as a water-based base on positions required to be repaired of the historical building woodwork; secondly, spraying or coating a layer of liquid arabia gum or dextrin on the water-based base, and drying the water-based base in the atmosphere without moisture to form an arabia gum or dextrin layer; thirdly, spraying or coating a layer of water-based paint on the arabia gum or dextrin layer; fourthly, drying the arabia gum or dextrin layer in the air; fifthly, using water to wipe positions required to be made antique, making moisture impregnated into the lower side of the water-based paint layer, and wiping off dried water-based paint fragments; and sixthly, spraying or coating at least one layer of water-based paint again. The technology solves the problem that the prior crack lacquer painting made by arabia gum is not exquisite enough.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

Making method of natural crackle on surface of red stoneware ware

The invention discloses a making method of natural crackle on surface of red stoneware ware, including the following steps: three red stoneware green-ore materials are selected, wherein the shrinkageof material (A) is 8-10%, the shrinkage of material (B) is 15-20%, and the shrinkage of material (C) is 20-25%; complexing the three materials together in inside-to-outside sequence and making original blank according to conventional manufacturing method, wherein the thickness of the inner layer material (A) is 60-70% of the total thickness of the blank body, the thickness of the immediate layer material (B) is 5-10% of the total thickness of the blank body, and the thickness of the outer layer material (C) is 20-30% of the total thickness of the blank body; carrying out three times of sintering on the made original blank, wherein the temperature of a primary sintering is 1120-1160 DEG C, the temperature of a secondary sintering is 1140-1170 DEG C, and the temperature of a third sinteringis 1170-1190 DEG C. the invention realizes crackle on surface of red stoneware ware, so that the surface of the ware forms 'spun gold iron wire' beautiful texture.

Owner:马俊华

Preparation method of molded line used for stranded conductor

InactiveCN101834035AImprove surface qualityAvoid Surface Quality IssuesCable/conductor manufactureProduction rateElectrical conductor

The invention relates to the improvement of the preparation method of the molded line used for a transmission stranded conductor, and is characterized by comprising the following steps: firstly reducing deformation by multiple round broaching; carrying out normal temperature roll to form a molded line with a needed shape when approximating to the area of the needed molded line; and finally carrying out one molded line mold reforming. The invention realizes the optimal process combination of preparing molded line conductor in batch, the wire breaking frequency is greatly reduced, fundamentally no broken wire exists in the experiment, the production rate is high, and the efficiency is high, the production efficiency can be increased by at least more than 20%. In the same way, when aluminum ladder-shaped or Z-shaped molded lines are prepared, the production rates can respectively reach 11 m / s and 9-10 m / s; the prepared molded line has good surface quality, no burr, bright and clean large-length surface and no defects of hemmed edge, crackle, rag, delamination and the like, not only can save equipment investment, but also can save preparation energy consumption.

Owner:FAR EAST COMPOSITE TECH

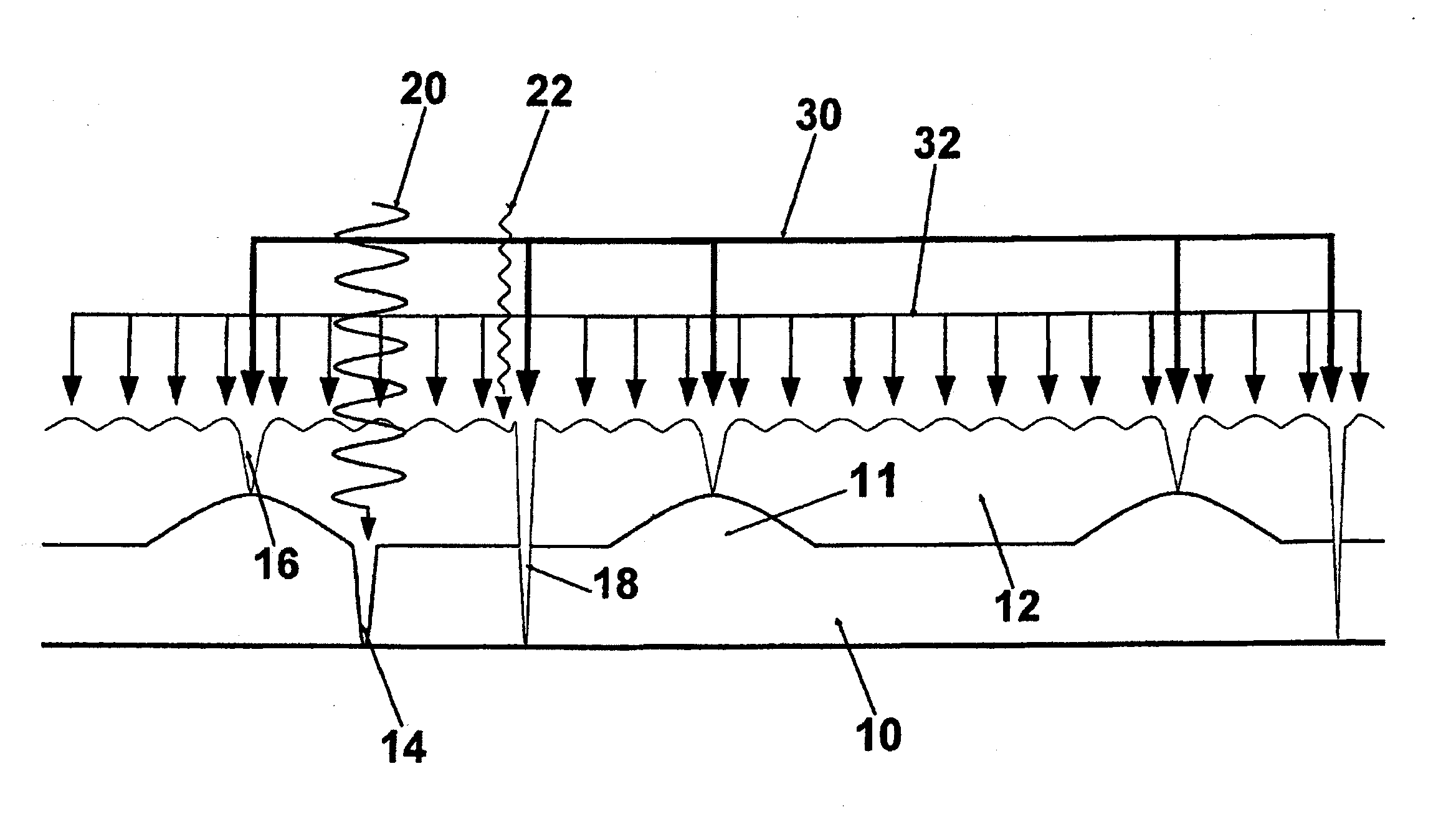

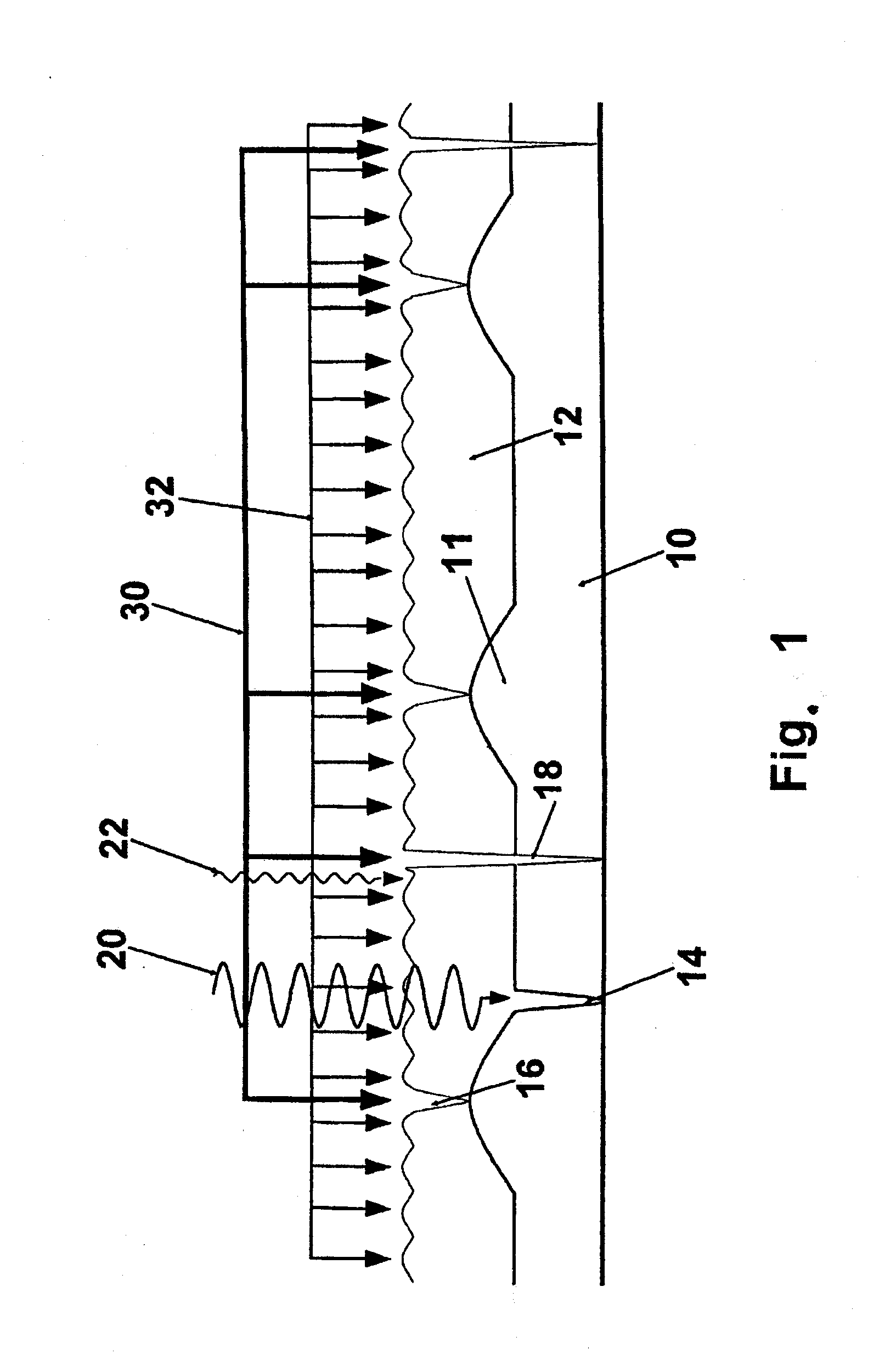

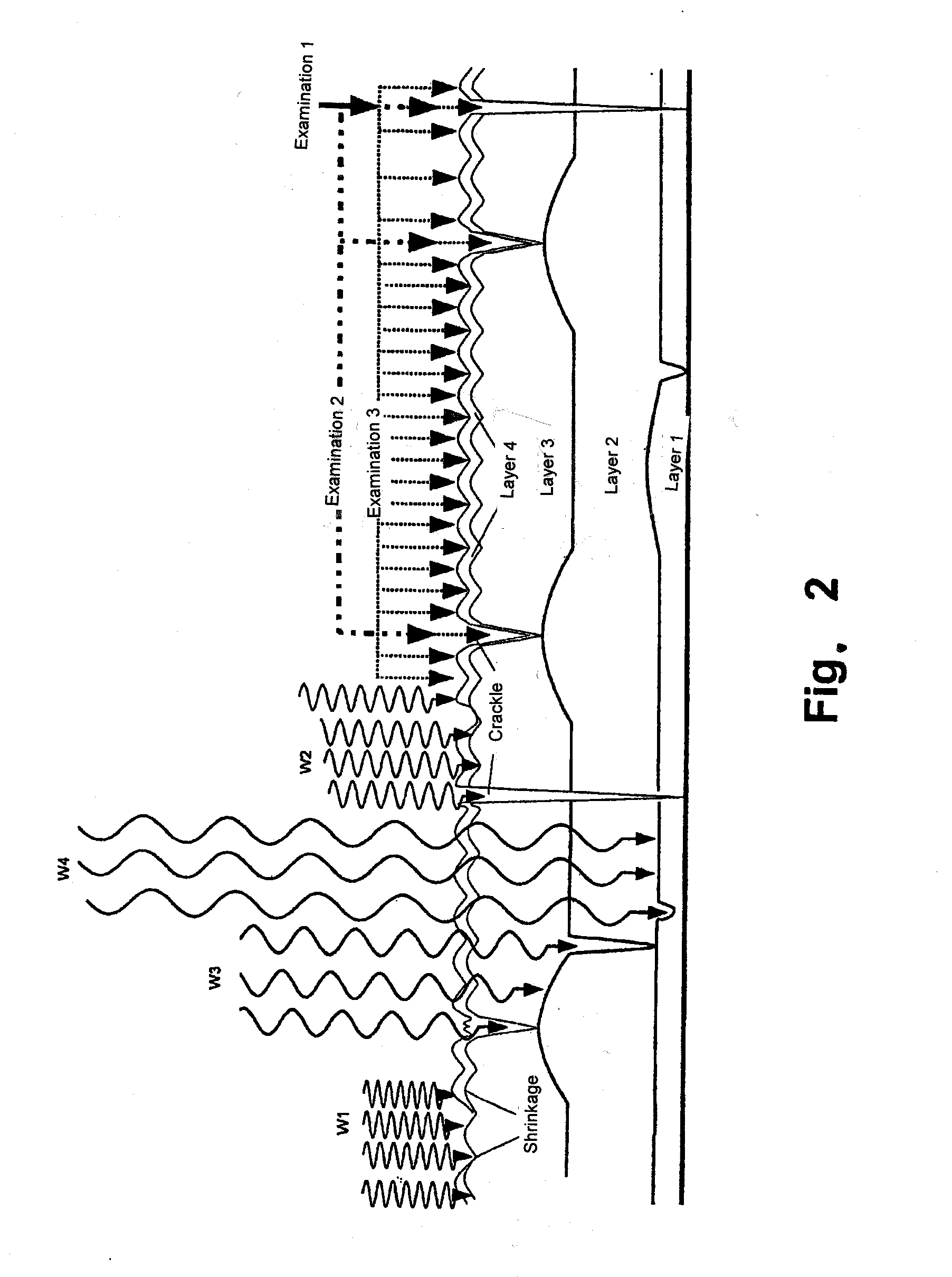

Security element for marking or identifying objects and living beings

ActiveUS20140231511A1Crackle can be more intenseLess strongOther printing matterChecking apparatusInternet privacyImpurity

A security element for marking, authenticating or identifying objects or living beings, such as people, animals or plants is provided that includes one or more layers of materials that are arranged next to or on top of each other or that overlap, which have security markings. At least one layer of the security element has, at least regionally, a crackle pattern in form of tears or cracks, nicks, wear areas or shrinkages and possible impurities, which can be scanned and detected together or separately as security features. A method for producing such a security element and to a use thereof for authenticating a person or an object, or for authorizing, triggering, continuing, carrying out and ending an action is also provided.

Owner:KISTERS FRIEDRICH

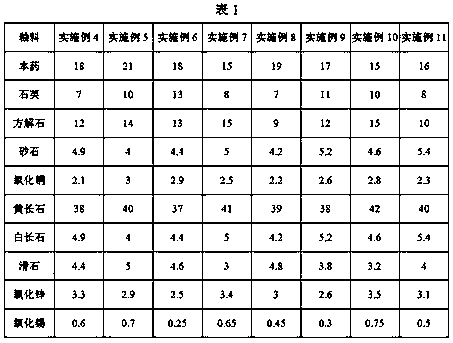

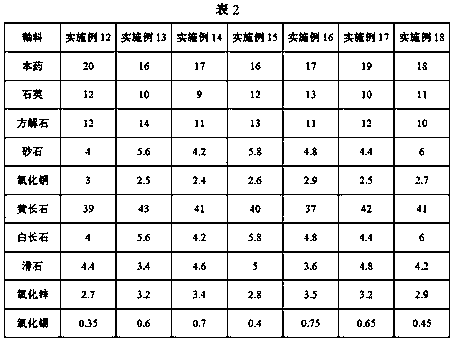

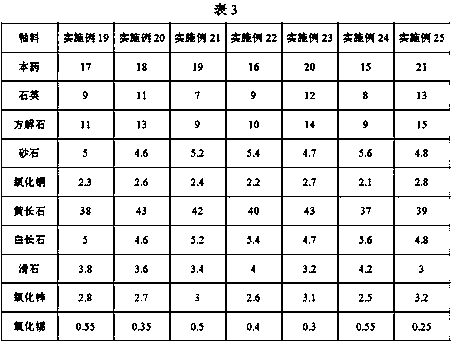

Cracked lujun glaze

The invention provides a cracked lujun glaze. The cracked lujun glaze is characterized by being prepared from the following raw materials in parts by weight: 15 to 21 parts of local feldspar from Yuzhou, Henan, China, 7 to 13 parts of quartz, 9 to 15 parts of calcite, 4 to 6 parts of gravel, 2 to 3 parts of copper oxide, 37 to 43 parts of melilite, 4 to 6 parts of white feldspar, 3 to 5 parts of talcum, 2.5 to 3.5 parts of zinc oxide and 0.25 to 0.75 parts of stannic oxide. Compared with the prior art, by scientifically and reasonably proportioning the raw materials and controlling a sinteringprocess, the sintered cracked lujun glaze disclosed by the invention has the advantages of natural color, has crackle, high jade texture, high rate of a finished product and rare floating light; in addition, a large kiln is adopted for firing, a firing method adopts a gas firing mode, and the rate of the finished product can reach 90 percent or above.

Owner:禹州市锦丰源瓷业有限公司

Method for manufacturing grains and patterns on product and digital camera with grains and patterns

InactiveCN102211081AEasy to manufactureWith aesthetic effectTelevision system detailsDecorative surface effectsCooking & bakingUltraviolet lights

The invention discloses a method for manufacturing grains and patterns on a product, comprising the following steps of: spraying priming paint; baking the priming paint; spraying transparent medium paint; baking the transparent medium paint; spraying crackle paint; baking and solidifying the crackle paint, wherein baking is carried out at the temperature of 55-65 DEG C in a baking process, and the solidification of the crackle paint is carried out through ultraviolet light. In the invention, beauty is increased according to the grains and the patterns which are manufactured through the steps of the method; the grains and the patterns are manufactured on a digital camera according to the method disclosed by the invention, and therefore, the beauty of the digital camera is increased, the convenience and the simplification of the digital camera are conveniently achieved and the diversification of the digital camera is facilitated.

Owner:AIGO DIGITAL TECHNOLOGY CO LTD

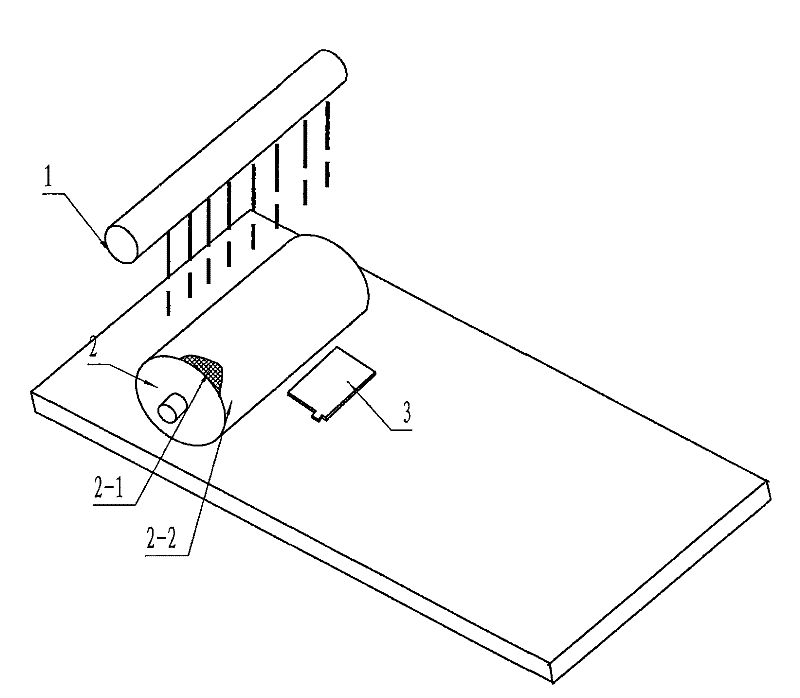

Non-destructive inspection unit of cup-shaped forge piece

InactiveCN103412041AImprove the magnetization effectThe secondary induced current is largeMaterial magnetic variablesNon destructiveFluorescence

The invention discloses a non-destructive inspection unit of a cup-shaped forge piece. The non-destructive inspection unit comprises primary non-destructive inspection equipment and secondary non-destructive inspection equipment which are sequentially arranged, wherein the primary non-destructive inspection equipment and the secondary non-destructive inspection equipment both comprise magnetization fixtures, fluorescence detection platforms, demagnetization delivery devices and electric control cabinets; the magnetization fixtures, the fluorescence detection platforms and the demagnetization delivery devices are sequentially arranged; the electric control cabinets are connected with the magnetization fixtures, the fluorescence detection devices and the demagnetization delivery devices. The non-destructive inspection unit disclosed by the invention can be used for overcoming the defects of the prior art, realizing the non-destructive inspection of the cup-shaped forge piece and early discovering the product defects of forging folds, quenching cracks, material crackles, and the like of the cup-shaped forge piece; the equipment disclosed by the invention can be used for saving energy and manpower and greatly reducing the rejection rate and safety risk of the cup-shaped forge piece.

Owner:ANHUI ANHUANG MACHINERY

Method for promoting healing of crackles in gelatin casting molding biscuit

Aiming at the shortcoming that crackles easily appear in gelatin casting wet biscuit, the invention provides an improved curing and drying proposal which can effectively heal the micro crackles appeared owing to demoulding, moving and too fast volatilization of surface solvent of the wet biscuit and ensures that complete and flawless biscuit is obtained after drying. The crackle healing proposal provided by the invention mainly comprises two steps which are curing and drying. In the curing stage, the gelation process of the monomers in the slurry is controlled by regulating a controlling curing temperature and curing time so as to ensure that part of cured monomers form gelatin in a bond crossing way and the other part of monomer are still preserved in the form of the monomers. In the subsequent drying process, the constant temperature and humidity drying proposal is adopted for causing the remained monomers in the biscuit to continously be cured and form bridging among sides of crackles, thus promoting the healing of the crackles. The crackle healing proposal provided by the invention has simple and reliable technique and is suitable for the preparation of blocks or porous ceramics.

Owner:中国科学院上海硅酸盐研究所苏州研究院

Decision method for testing in-service water turbine runner crackle

The invention discloses a decision method for testing in-service water turbine runner crackles, comprising the following steps of: opening a manhole of a draft tube to set up a testing platform, and then testing outlet and inlet edges of a runner blade and the ends of upper and lower ring fillet welds by adopting a penetrant testing method. For testing of the in-service water turbine runner crackles, the decision method tests the outlet and inlet edges of the runner blade and the ends of the upper and lower ring fillet welds, so the false dismissal probability can be greatly reduced in testing, and the testing time can be greatly shortened and the use level of a penetrant check agent is reduced. Penetrant testing (PT) can be screened out from the conventional four testing methods. The testing method can be implemented after a runner is lifted out of a volute and the manhole of the draft tube is opened to set up the platform without disassembling a generator set when testing the in-service water turbine runner, thereby satisfying the economical efficiency of the overhauling work.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com