Method for manufacturing grains and patterns on product and digital camera with grains and patterns

A technology for digital cameras and products, which is applied in the process of producing decorative surface effects, cameras, camera bodies, etc., to achieve the effect of simplifying production and increasing aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

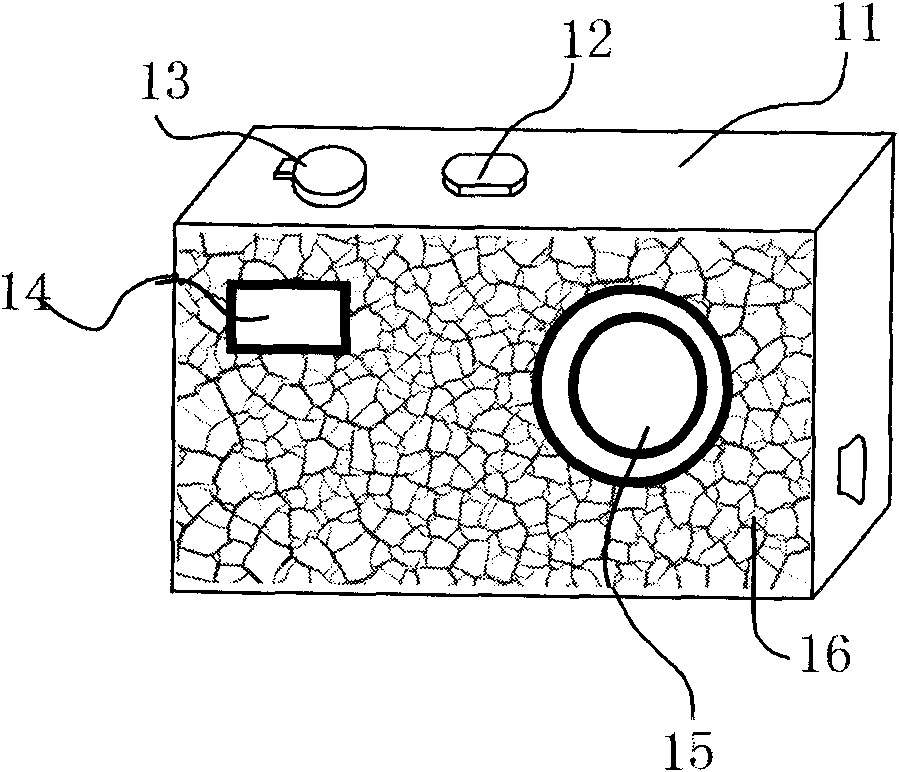

[0036] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose, the following is a detailed implementation of the method for making textures on products of the present invention and the digital camera with textures formed according to the method in conjunction with the accompanying drawings and embodiments. The methods, structural features and effects are described in detail as follows.

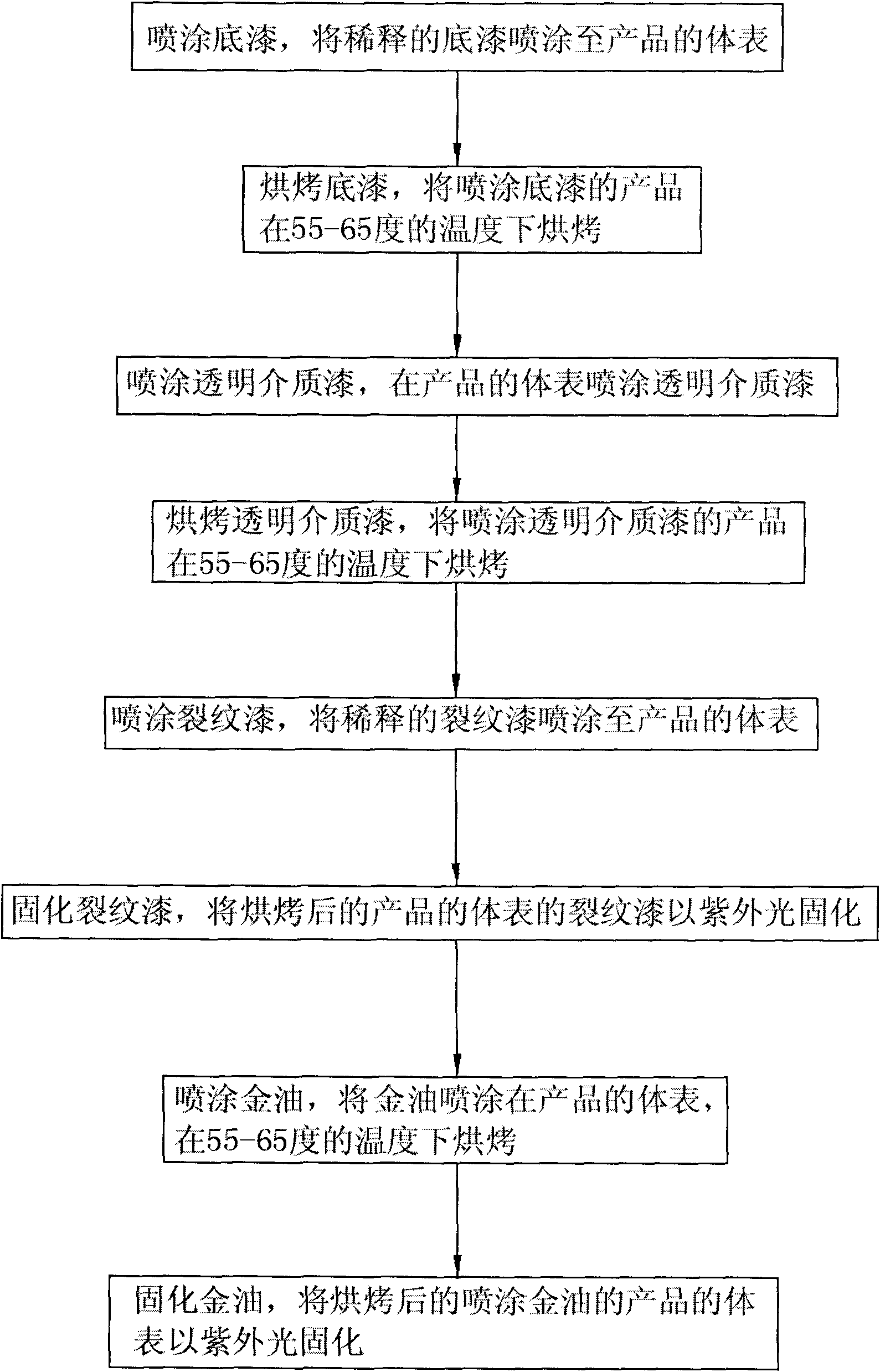

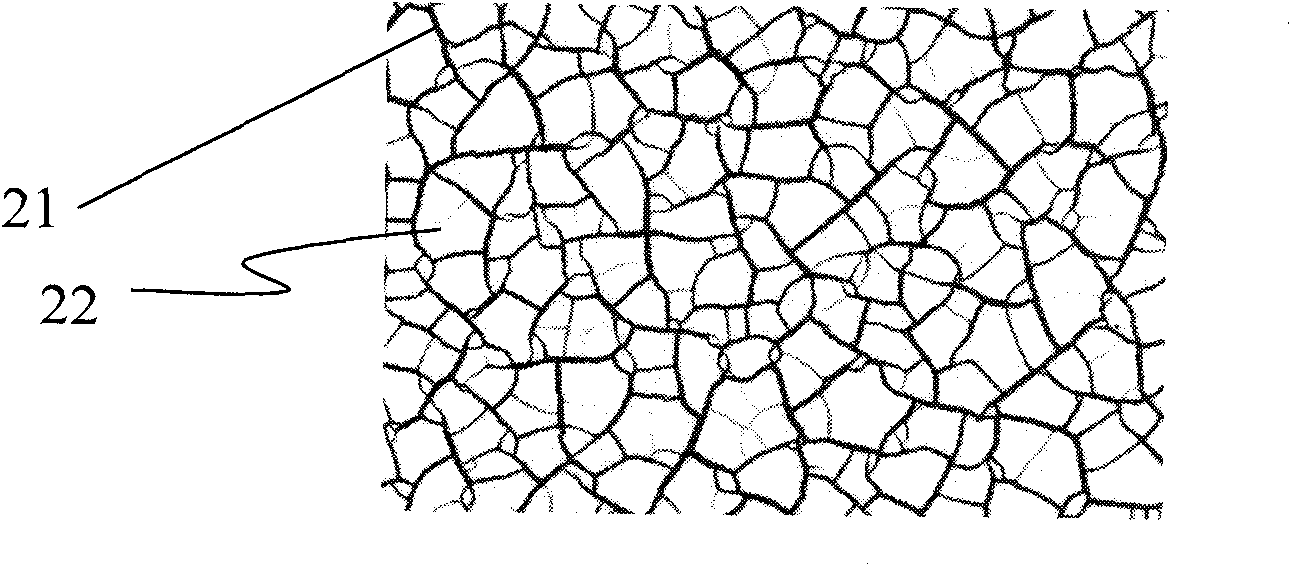

[0037] Such as figure 1 Shown here is the method for making textures on products of the present invention. The textures are formed on the surface of products such as plastic or metal, which increases the aesthetics of electronic products and facilitates the richness and diversification of products. According to the method for producing a grain decoration on a product of the present invention, the grain decoration includes a grain line and a region block, and the grain line divides the body surface of the product into a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com