Patents

Literature

10267 results about "Cooking & baking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Baking is a method of cooking food that uses prolonged dry heat, normally in an oven, but also in hot ashes, or on hot stones. The most common baked item is bread but many other types of foods are baked. Heat is gradually transferred "from the surface of cakes, cookies, and breads to their centre.

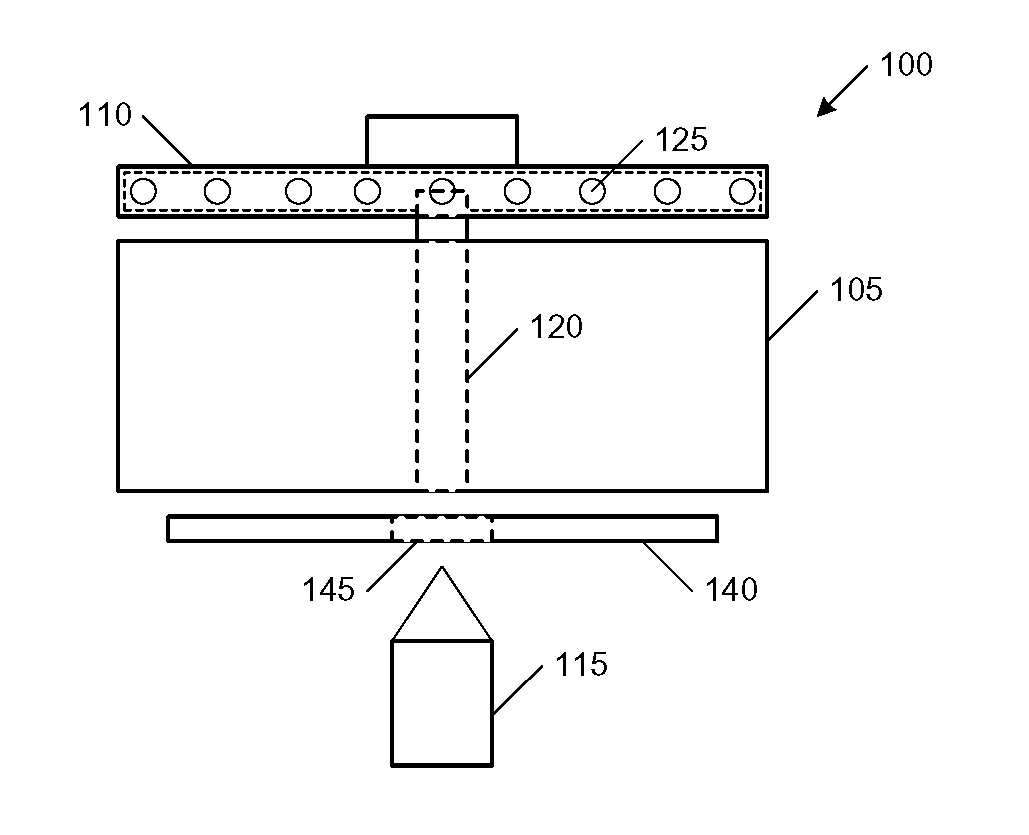

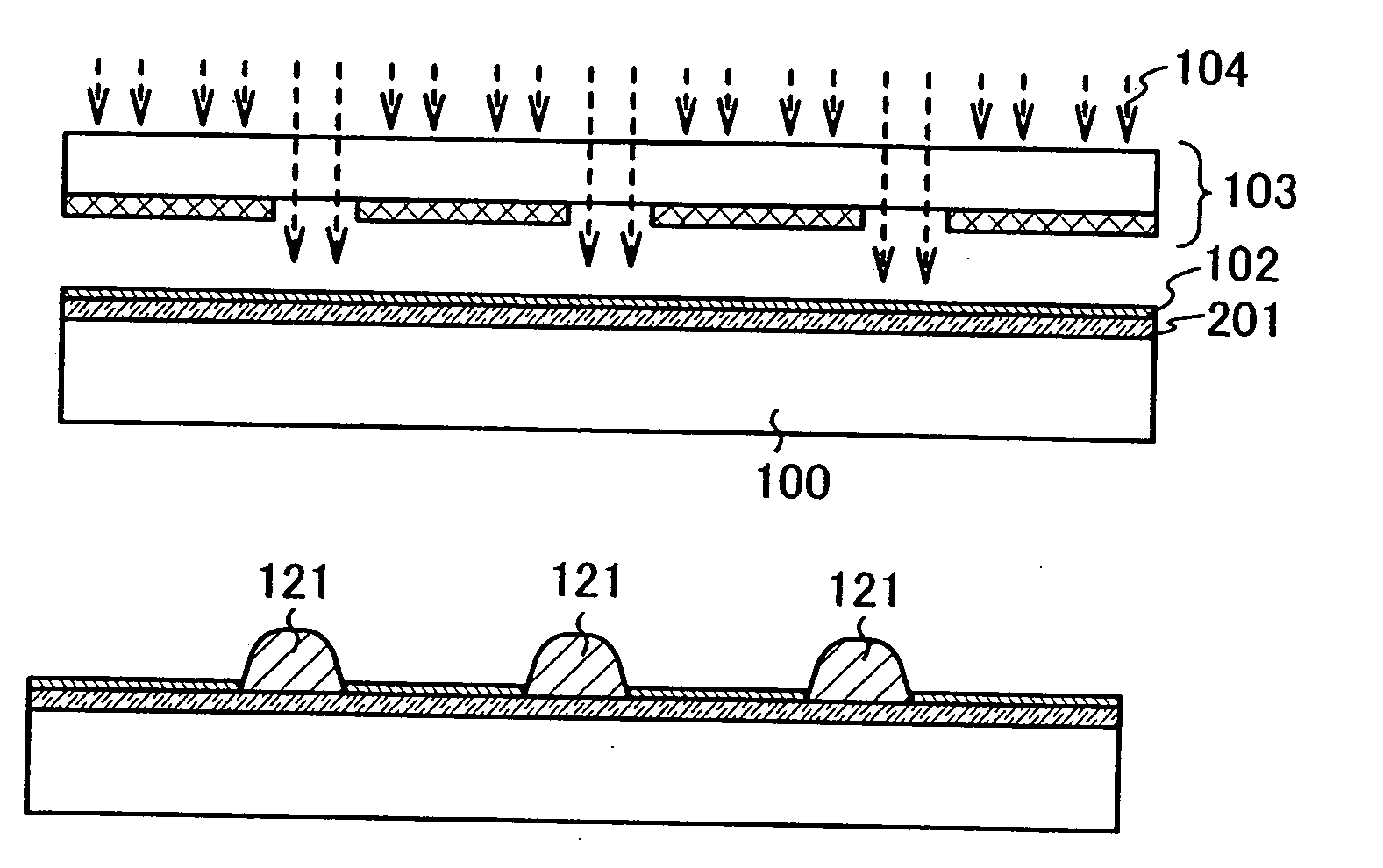

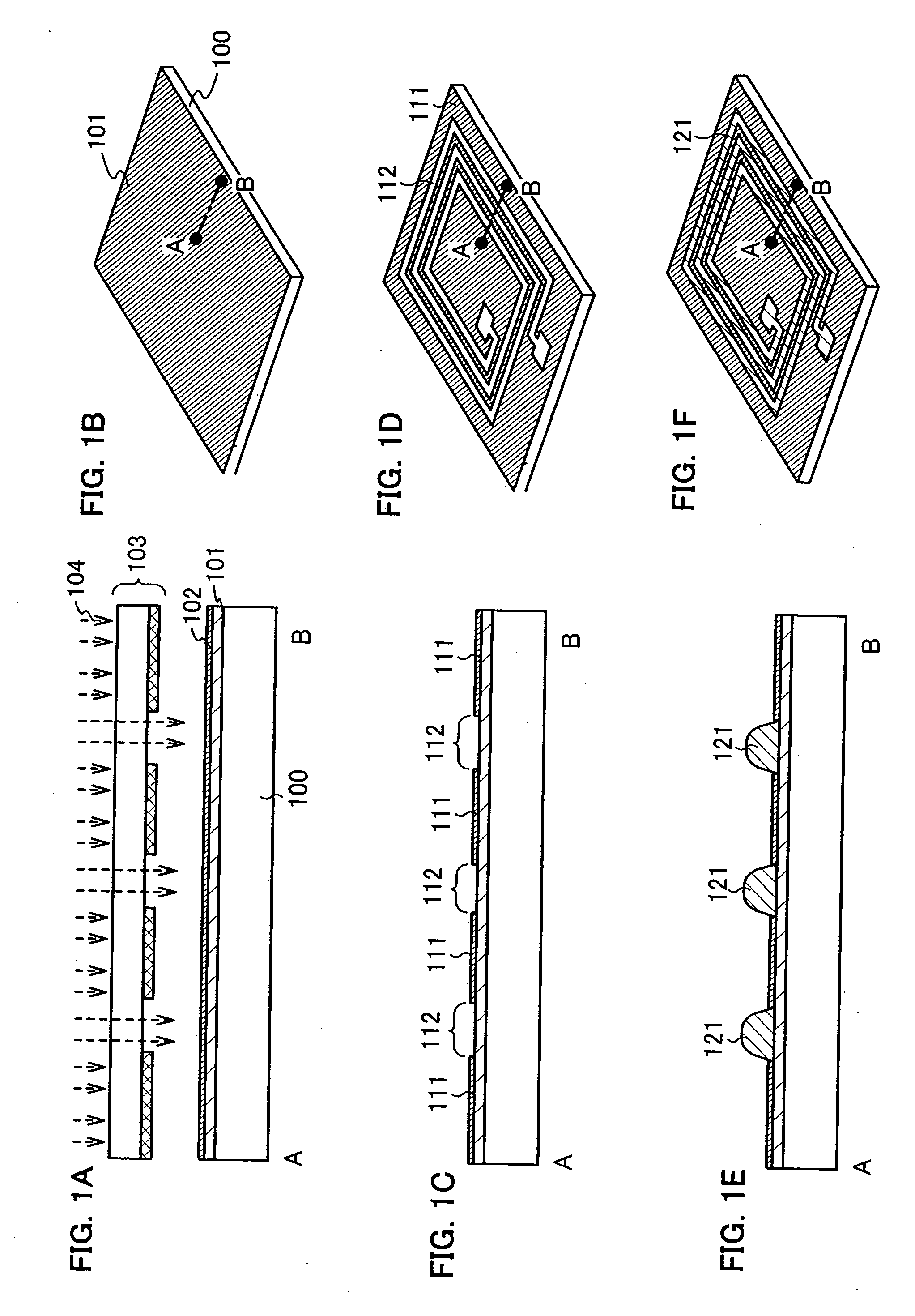

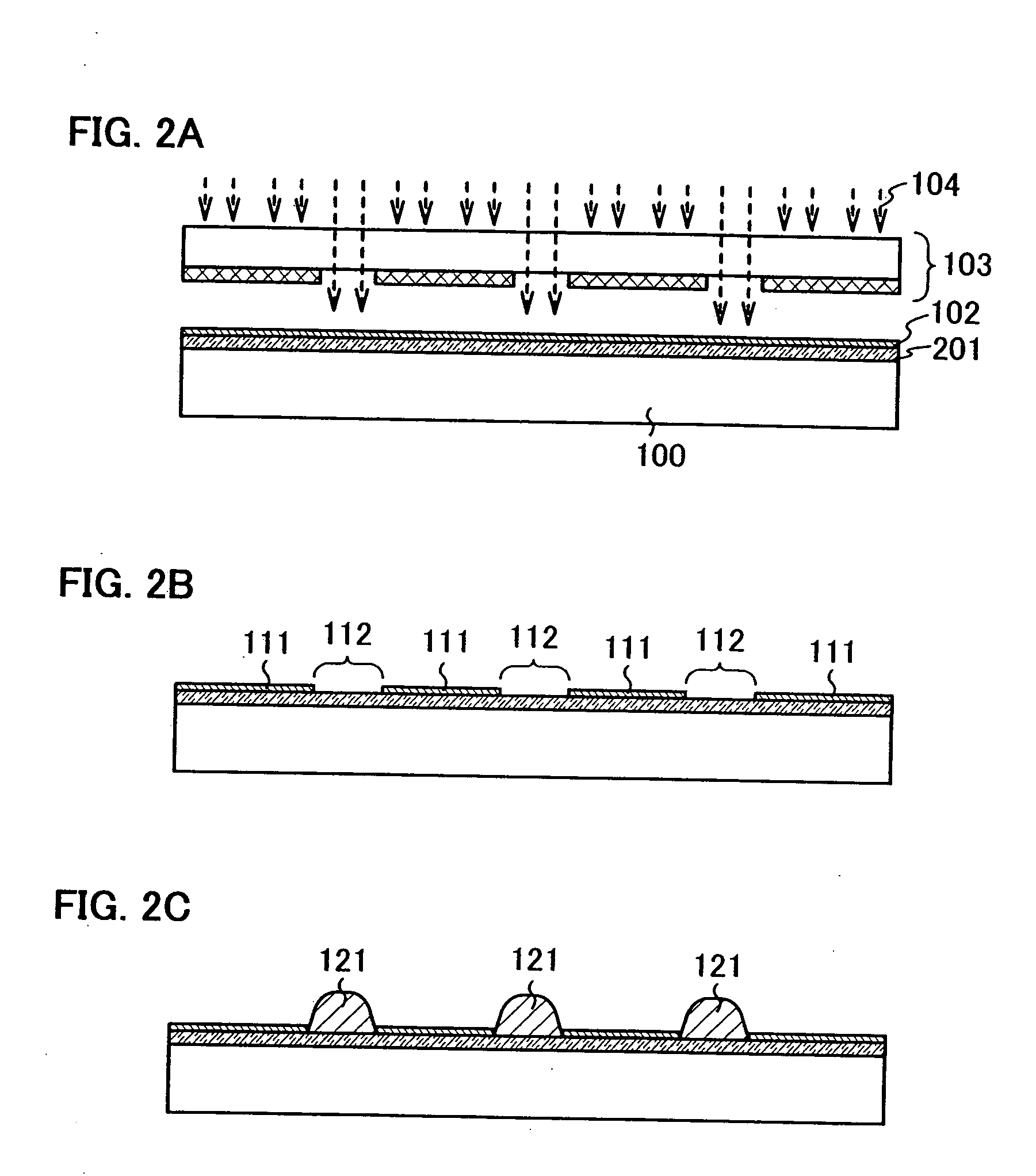

Method and system for drying a substrate

ActiveUS20050046934A1Good pattern uniformityImprove uniformityMicroscopesPhotomechanical exposure apparatusCooking & bakingThin membrane

A method and system is described for drying a thin film on a substrate following liquid immersion lithography. Drying the thin film to remove immersion fluid from the thin film is performed prior to baking the thin film, thereby reducing the likely hood for interaction of immersion fluid with the baking process. This interaction has been shown to cause non-uniformity in critical dimension for the pattern formed in the thin film following the developing process.

Owner:TOKYO ELECTRON LTD

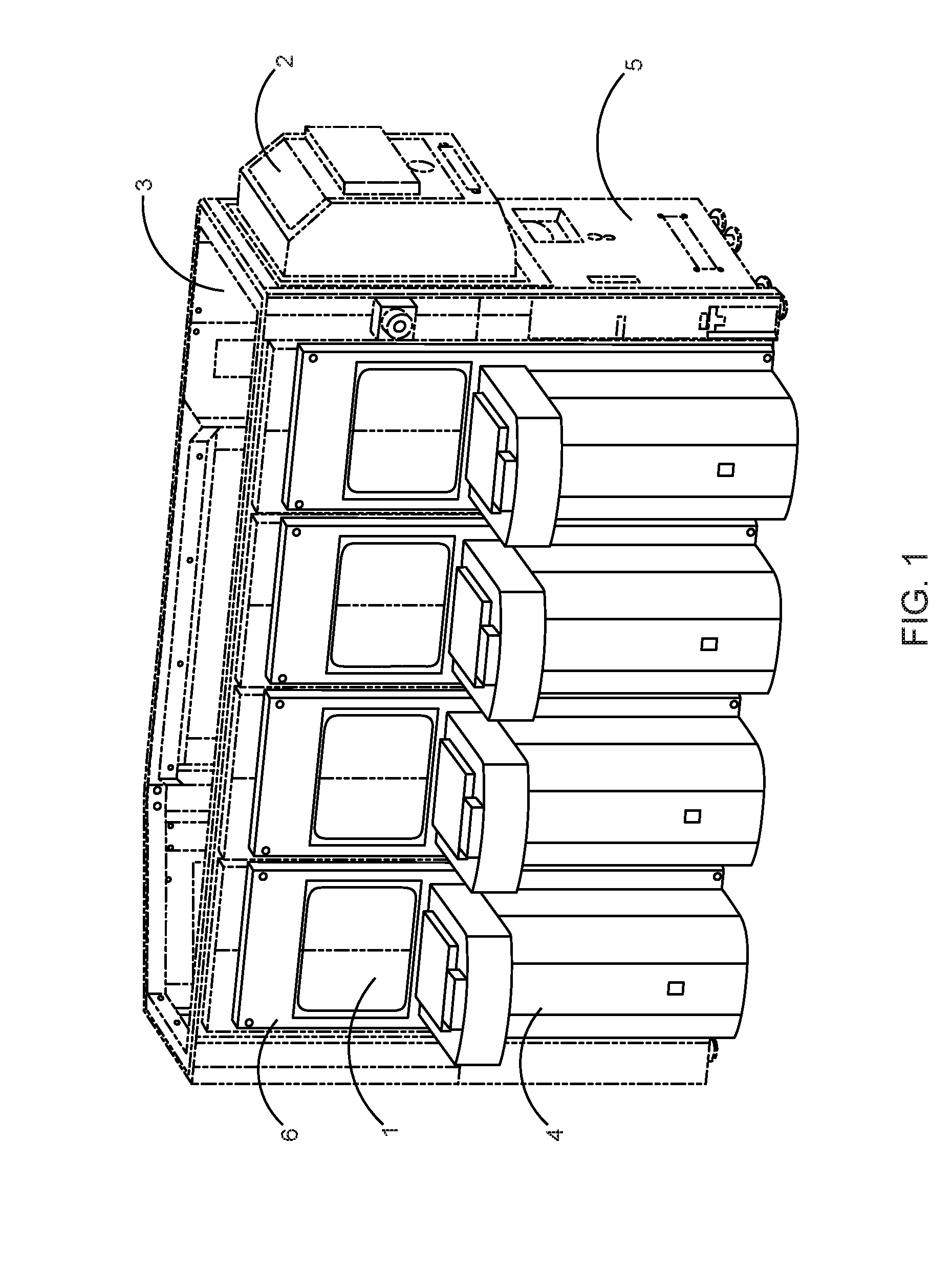

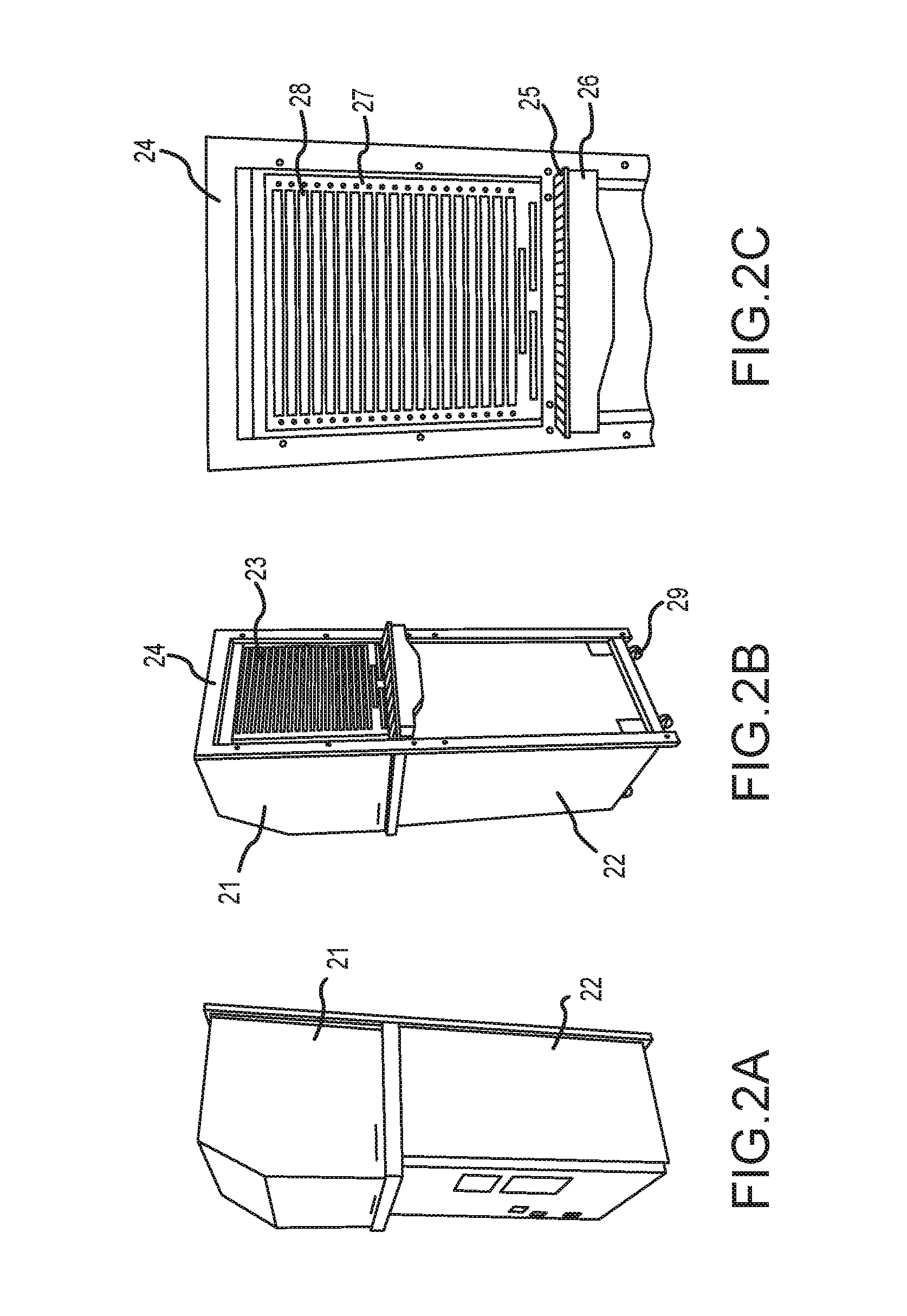

Apparatus and method for pre-baking substrate upstream of process chamber

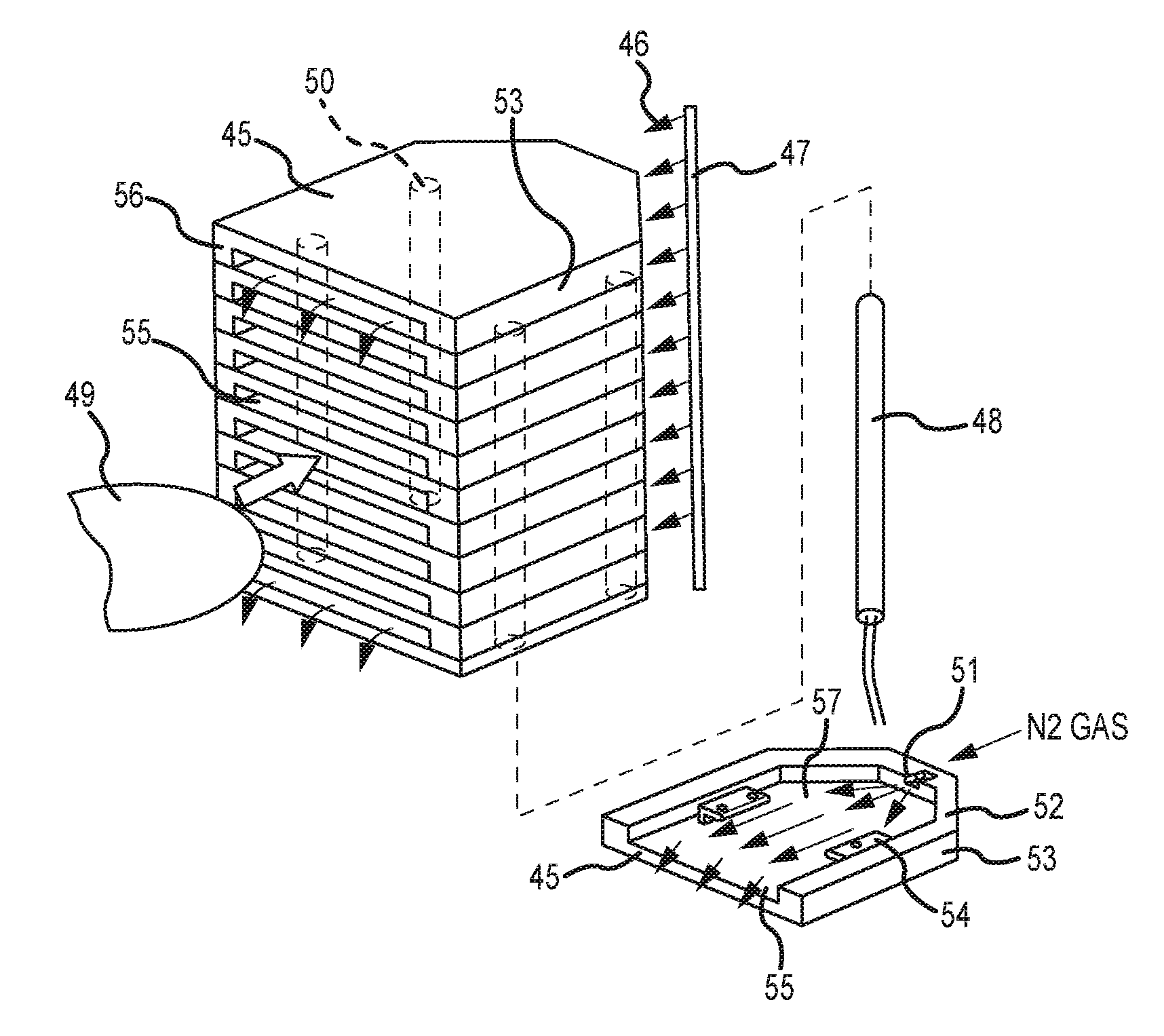

ActiveUS9349620B2Efficient heatingGuaranteed uptimeSemiconductor/solid-state device manufacturingFurnace typesCooking & bakingInjection port

A pre-baking apparatus for heating a substrate upstream of a process tool is adapted to be connected to an EFEM (equipment front end module) and includes: a chamber which has a front face with multiple slots arranged in a height direction of the chamber, and which is divided into multiple compartments extending from the multiple slots, respectively, toward a rear end of the chamber for loading and unloading substrates; and a connecting frame for connecting the chamber to the process tool. The multiple compartments are separated from each other by a divider plate and provided with heaters for heating the multiple compartments, and each compartment has a gas injection port for blowing a hot inert gas over the substrate placed therein toward the slot.

Owner:ASM IP HLDG BV

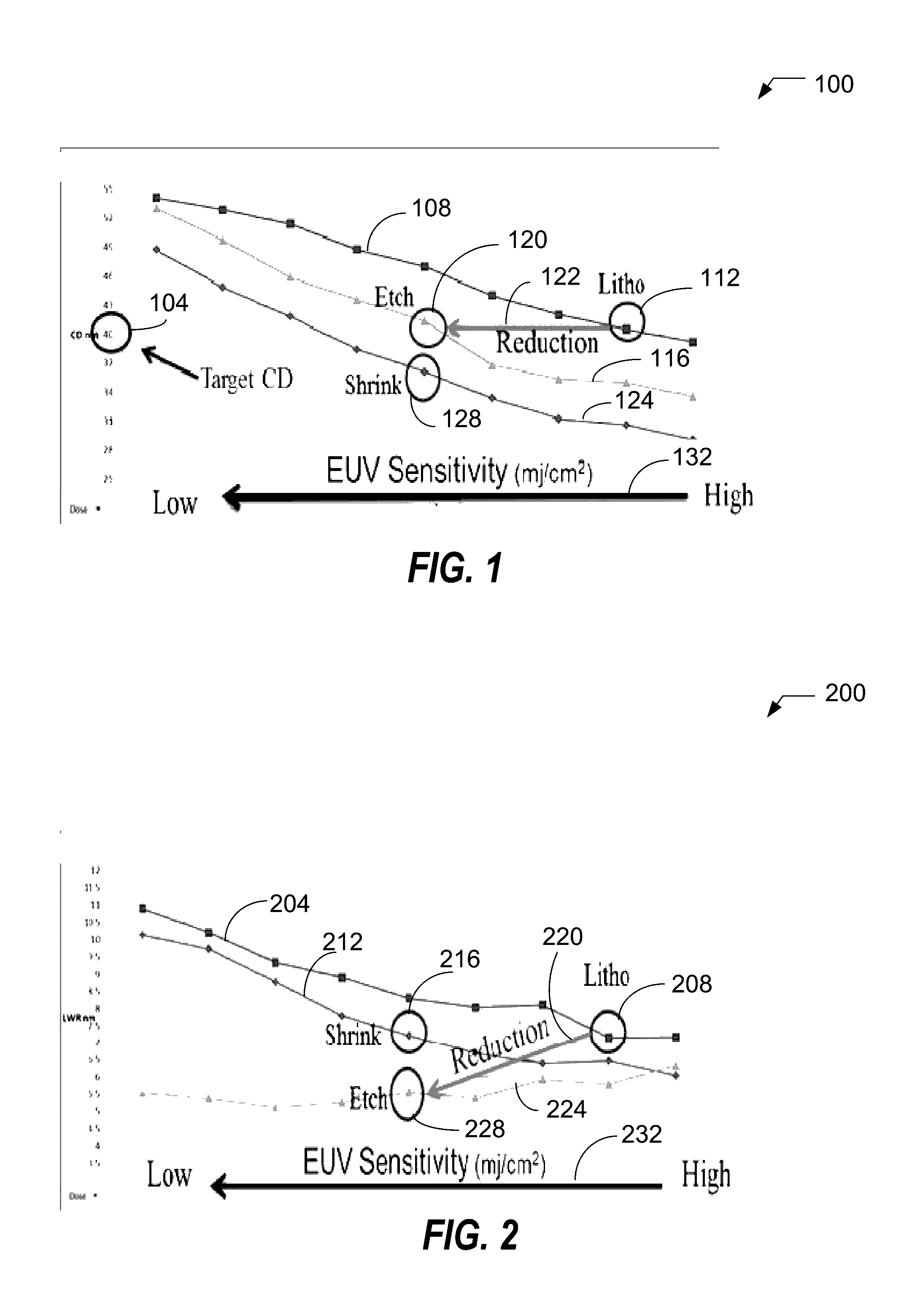

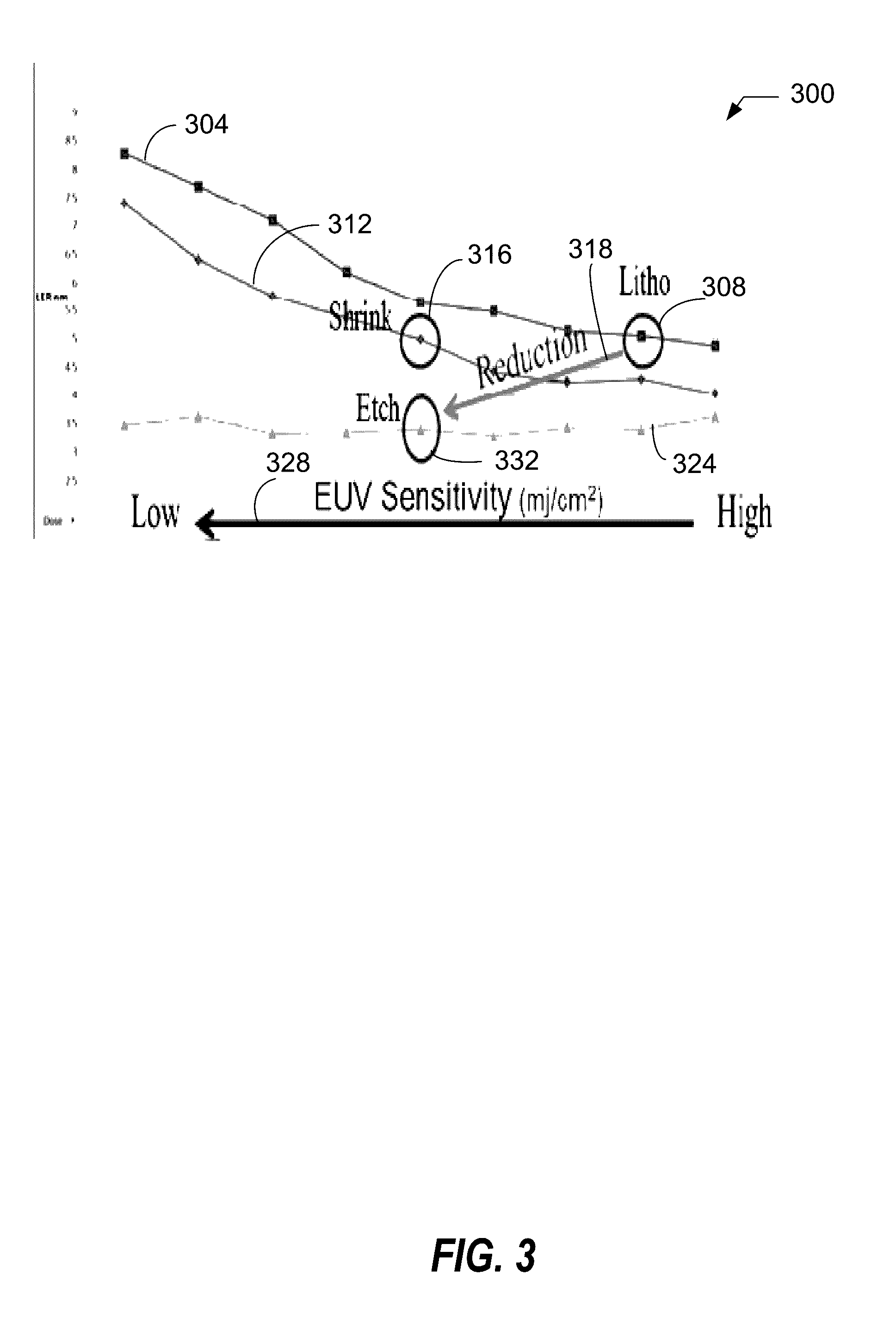

Extreme ultra-violet sensitivity reduction using shrink and growth method

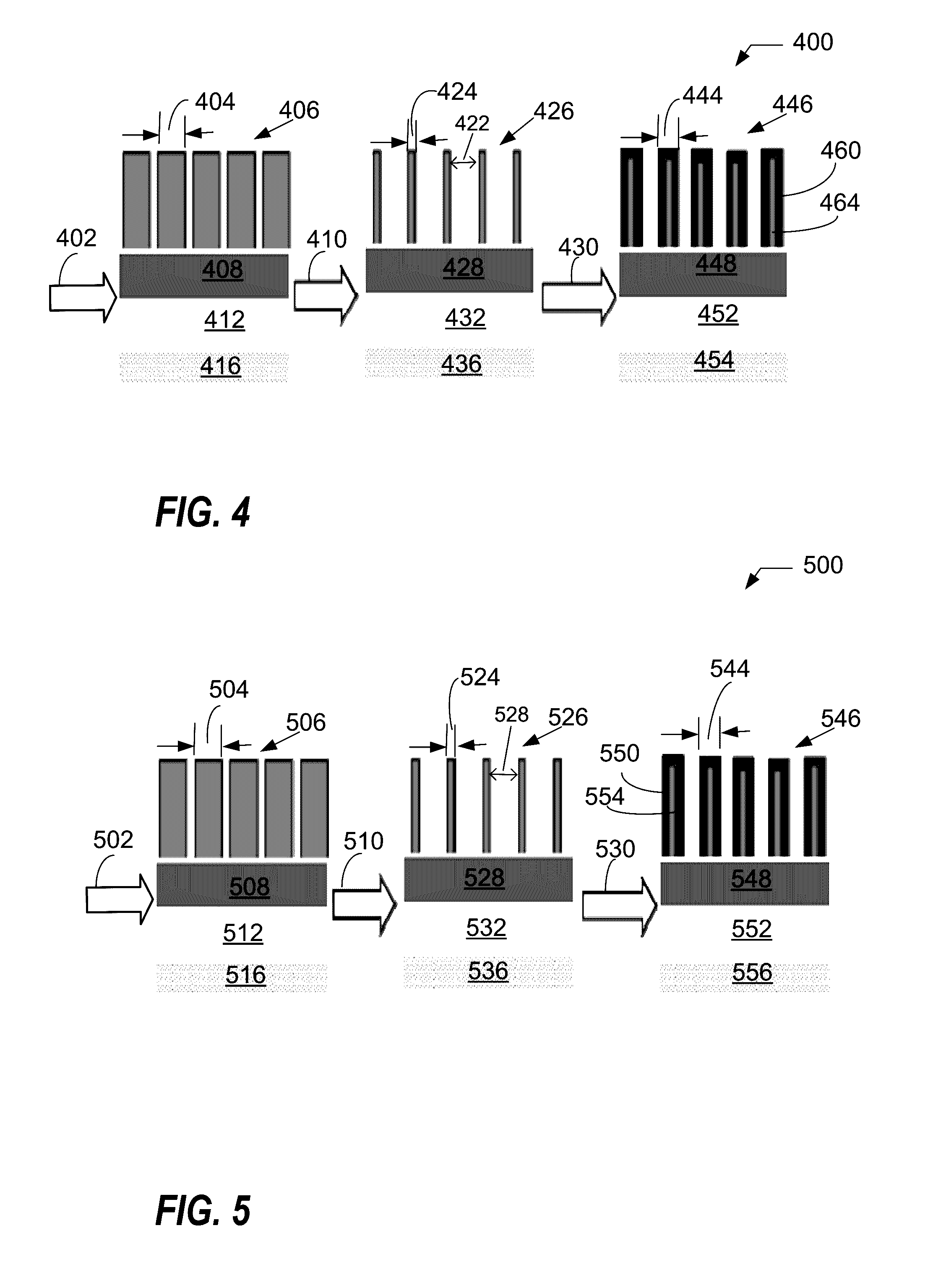

ActiveUS20160334709A1Substrate throughput can be increasedImprove throughputPhotomechanical exposure apparatusPhotosensitive material processingCooking & bakingLine width

Provided is a method for patterning a substrate, comprising: forming a layer of radiation-sensitive material on a substrate; preparing a pattern in the layer of radiation-sensitive material using a lithographic process, the pattern being characterized by a critical dimension (CD) and a roughness; following the preparing the pattern, performing a CD shrink process to reduce the CD to a reduced CD; and performing a growth process to grow the reduced CD to a target CD. Roughness includes a line edge roughness (LER), a line width roughness (LWR), or both LER and LWR. Performing the CD shrink process comprises: coating the pattern with a hard mask, the coating generating a hard mask coated resist; baking the hard mask coated resist in a temperature range for a time period, the baking generating a baked coated resist; and developing the baked coated resist in deionized water.

Owner:TOKYO ELECTRON LTD

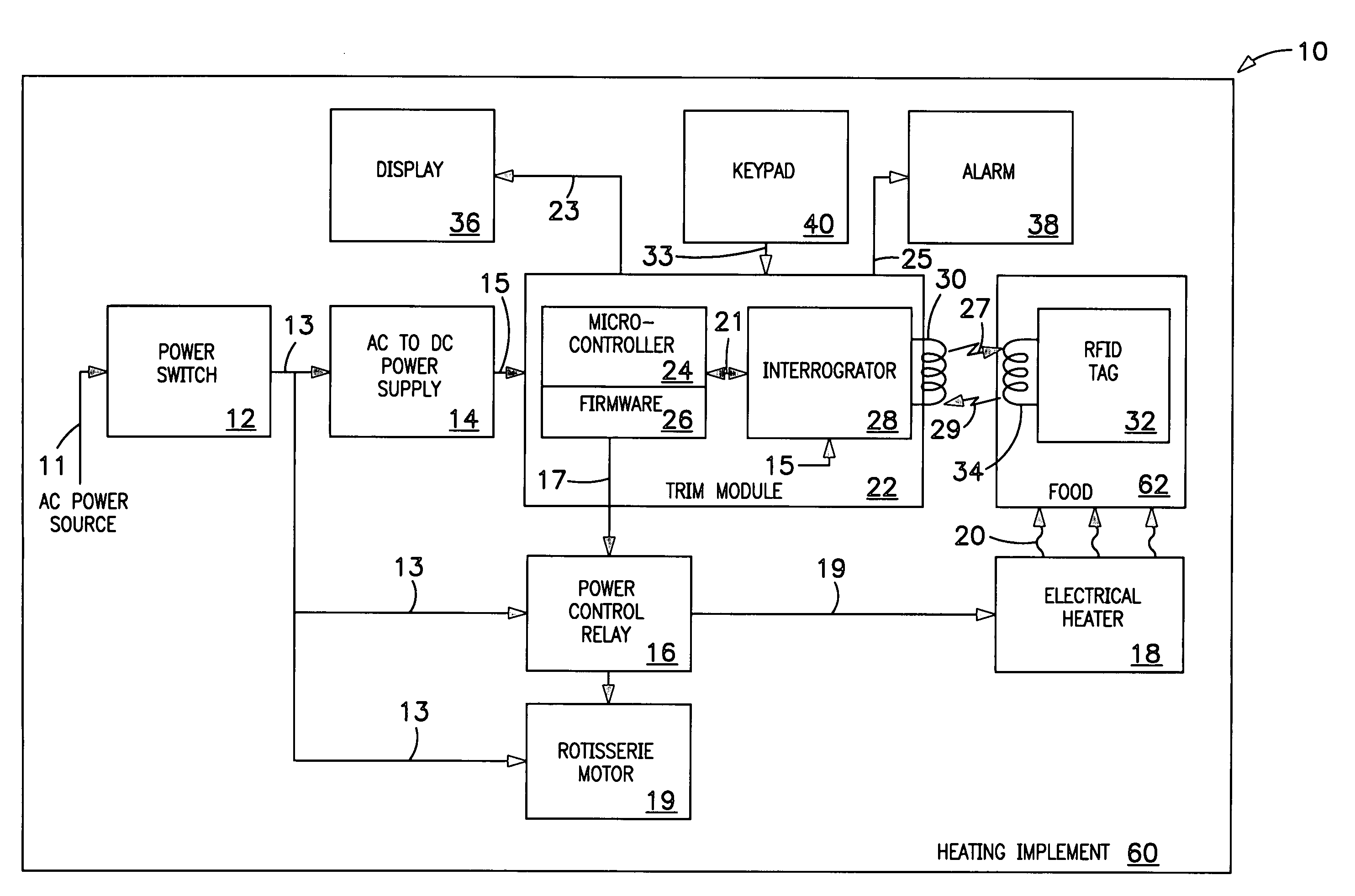

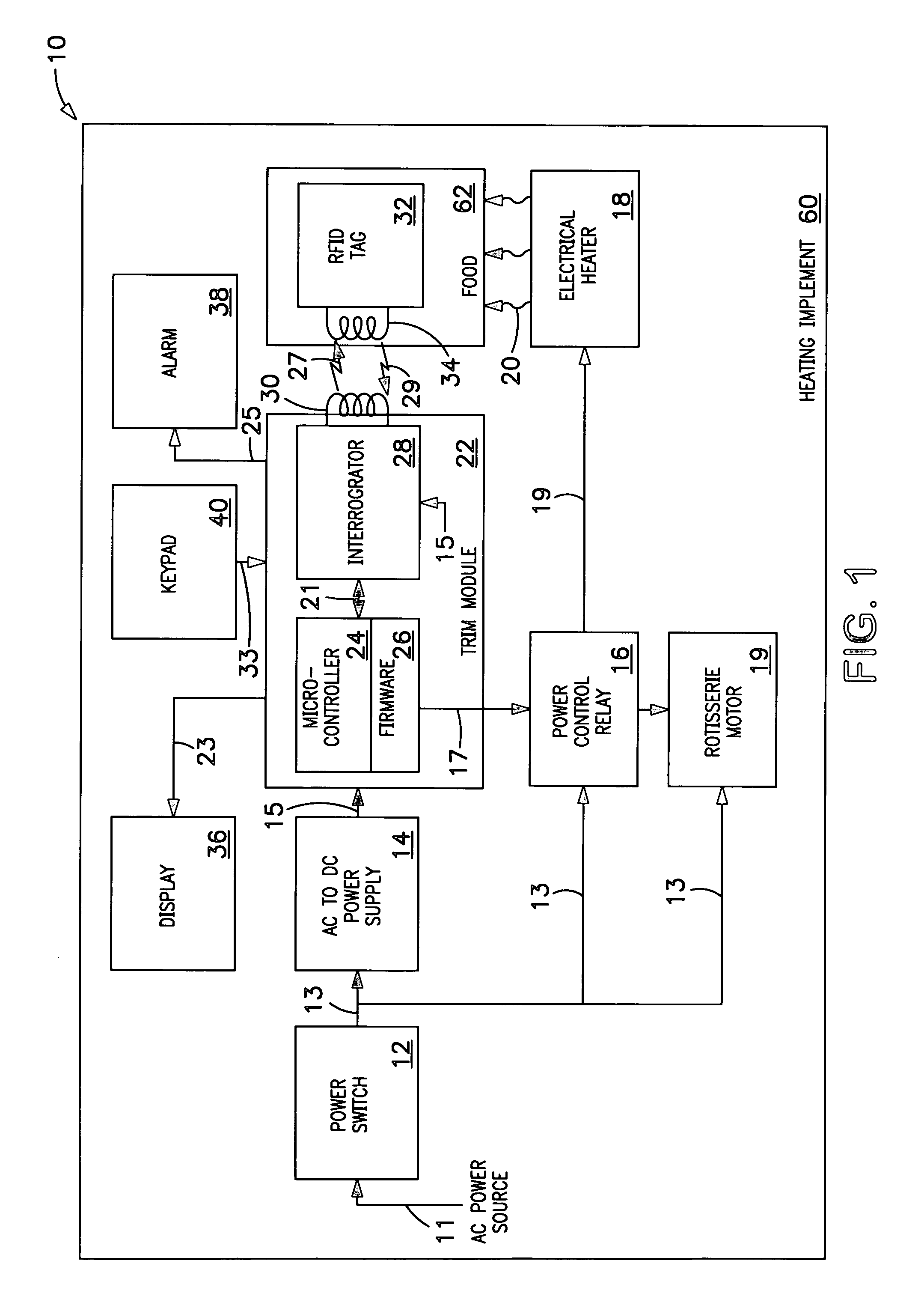

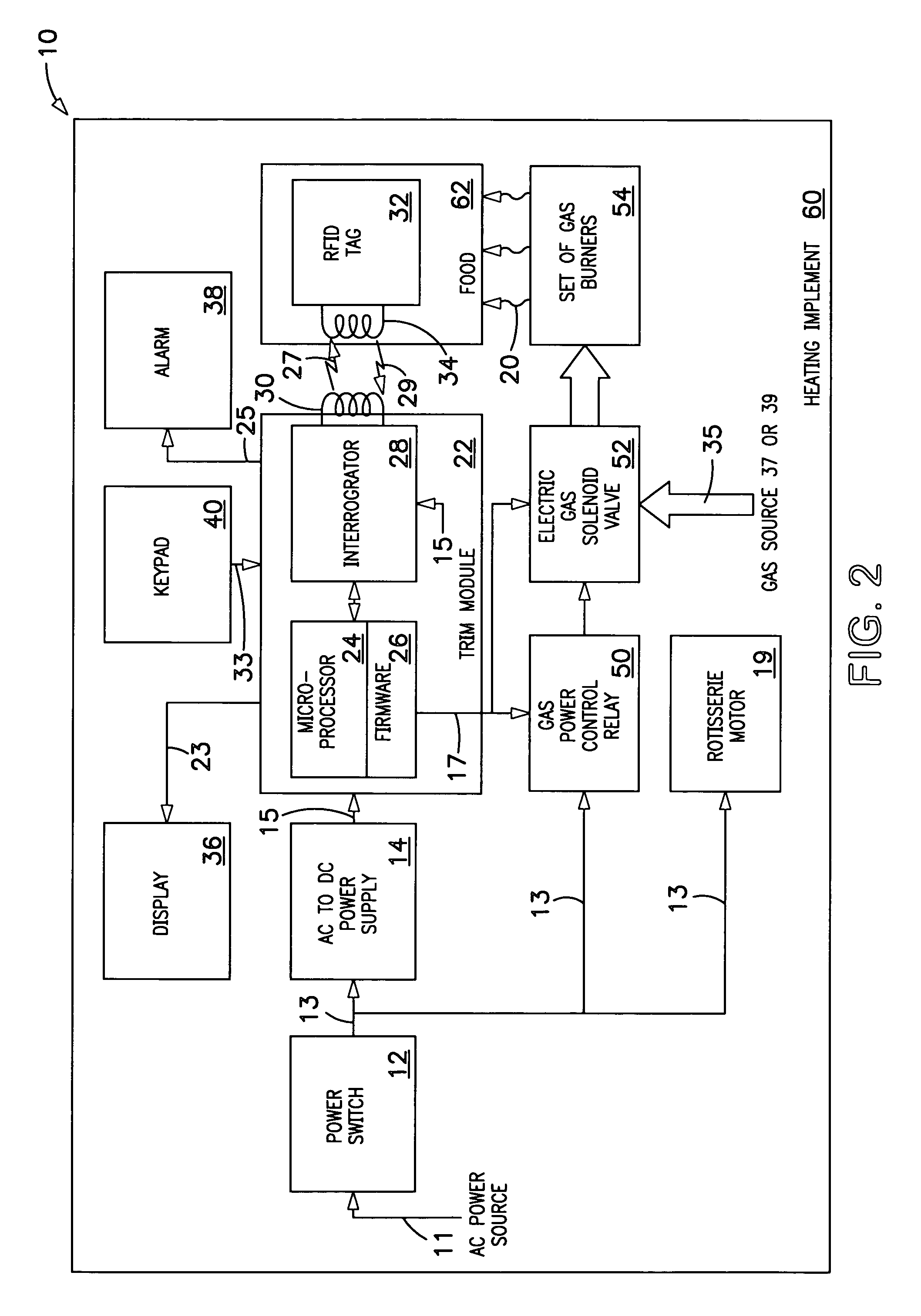

Controlled cooking system

InactiveUS7080593B1Inherent temperature sensitivityPrevents or minimizes salmonella and other food borne diseasesElectric signal transmission systemsBoiling over preventionCooking & bakingComputer module

A controlled cooking system (CCS) that monitors, measures, and controls the internal temperature of foods placed in an oven having a Radio Frequency Identification (RFID) antenna(s), a transmitter / receiver / interrogator / reader / microprocessor (TRIRM) module and an RFID tag with built-in temperature sensor. The RFID tag is buried in the food being cooked and is energized and enabled by an RF signal of pre-determined frequency. The tag output is an RF “backscatter signal” having encoded temperature data indicative of the internal temperature of the food that the tag is buried in. The backscatter signal is received and decoded by the antenna(s) and the TRIRM module incorporating a programmed cooking / baking temperatures for various foods. If the decoded temperature is below a user-set temperature, the TRIRM module allows the oven to remain on. Conversely, if the decoded temperature is at or exceeds the user-set temperature, the TRIRM module shuts off the oven and produces a signal that activates an alarm indicating that the cooking has been terminated.

Owner:FRANKEL DAVID

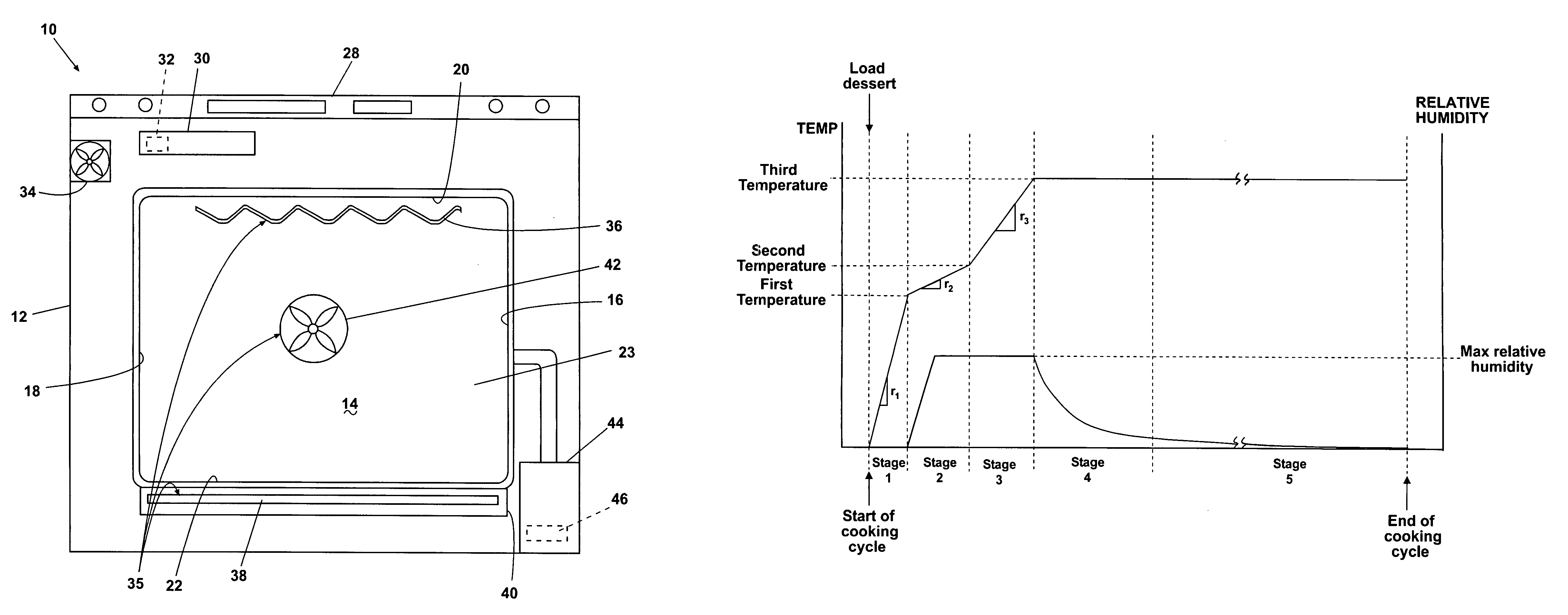

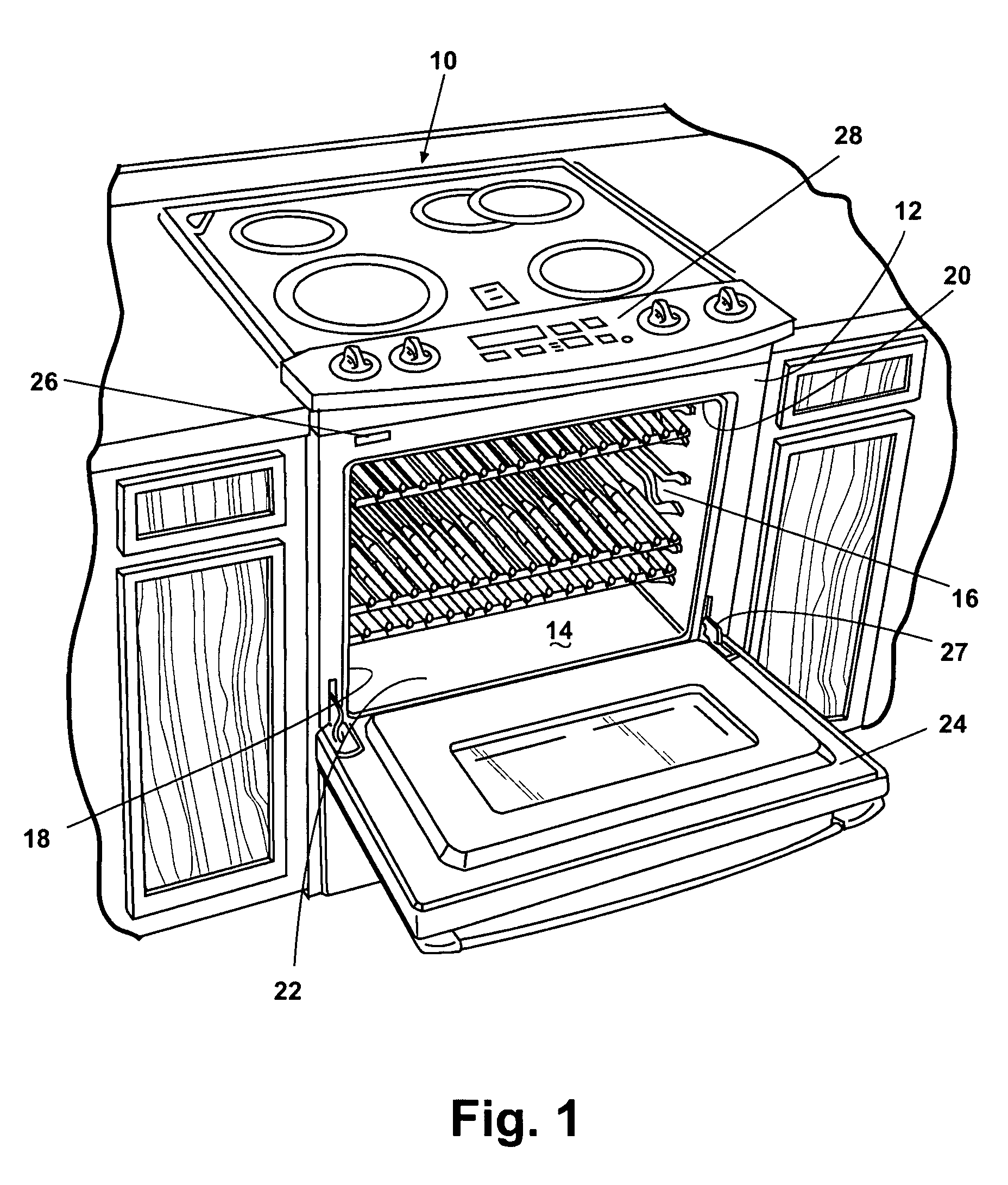

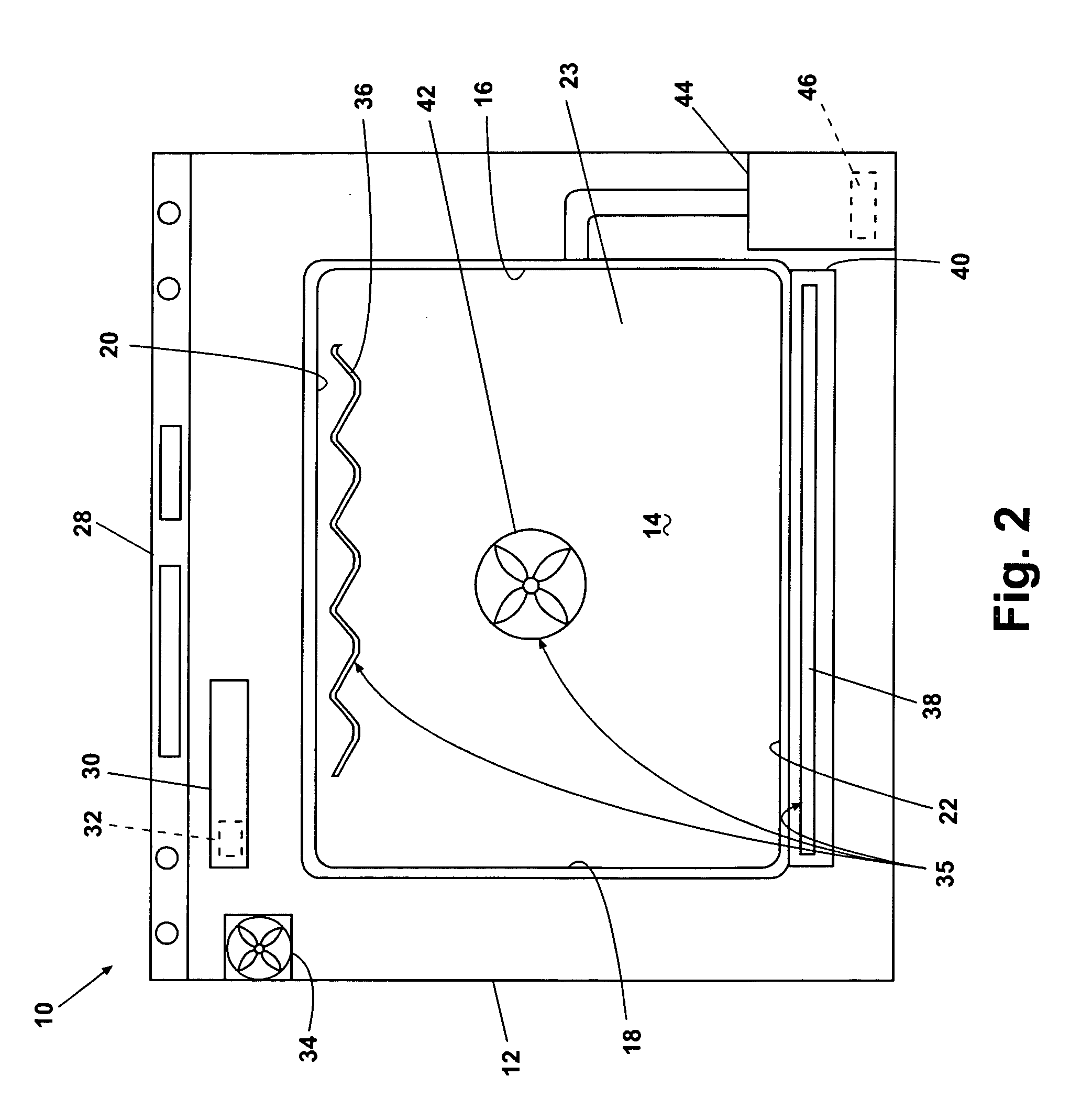

Method for baking a dessert using steam

A method of baking a dessert using steam in an automated household oven comprises a first heating step where a heating system preheats a cooking cavity to a first temperature at a first heating rate and a second heating step where the heating system preheats the cooking cavity from the first temperature to a second temperature at a second heating rate less than the first heating rate. The first temperature is preferably about the boiling point of water, and a steam system introduces steam into the cooking cavity to facilitate baking of the dessert after the cooking cavity reaches the first temperature. A convection fan of the heating system is active during the first and second heating steps to help circulate air and steam in the cooking cavity and becomes inactive later in the baking method.

Owner:WHIRLPOOL CORP

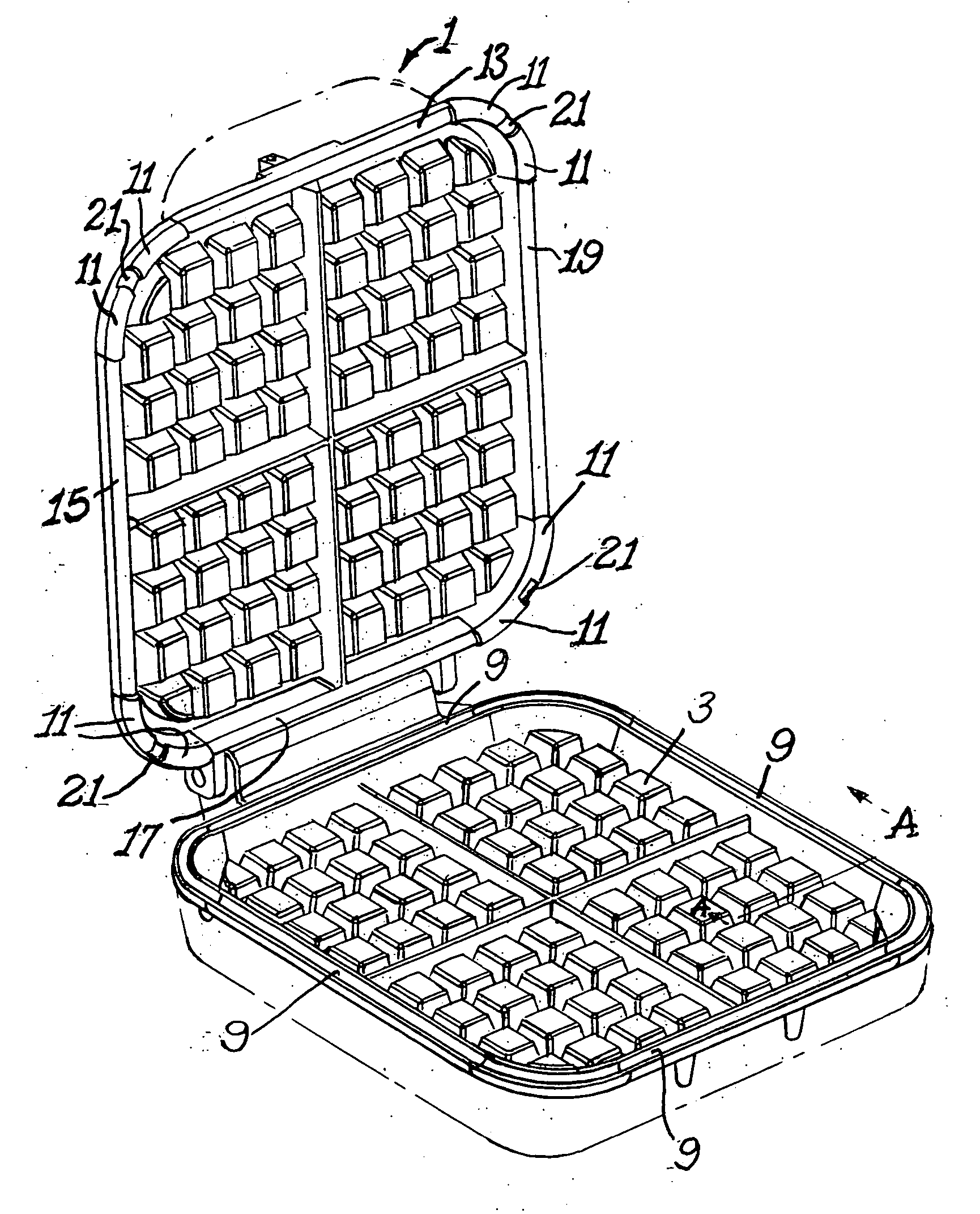

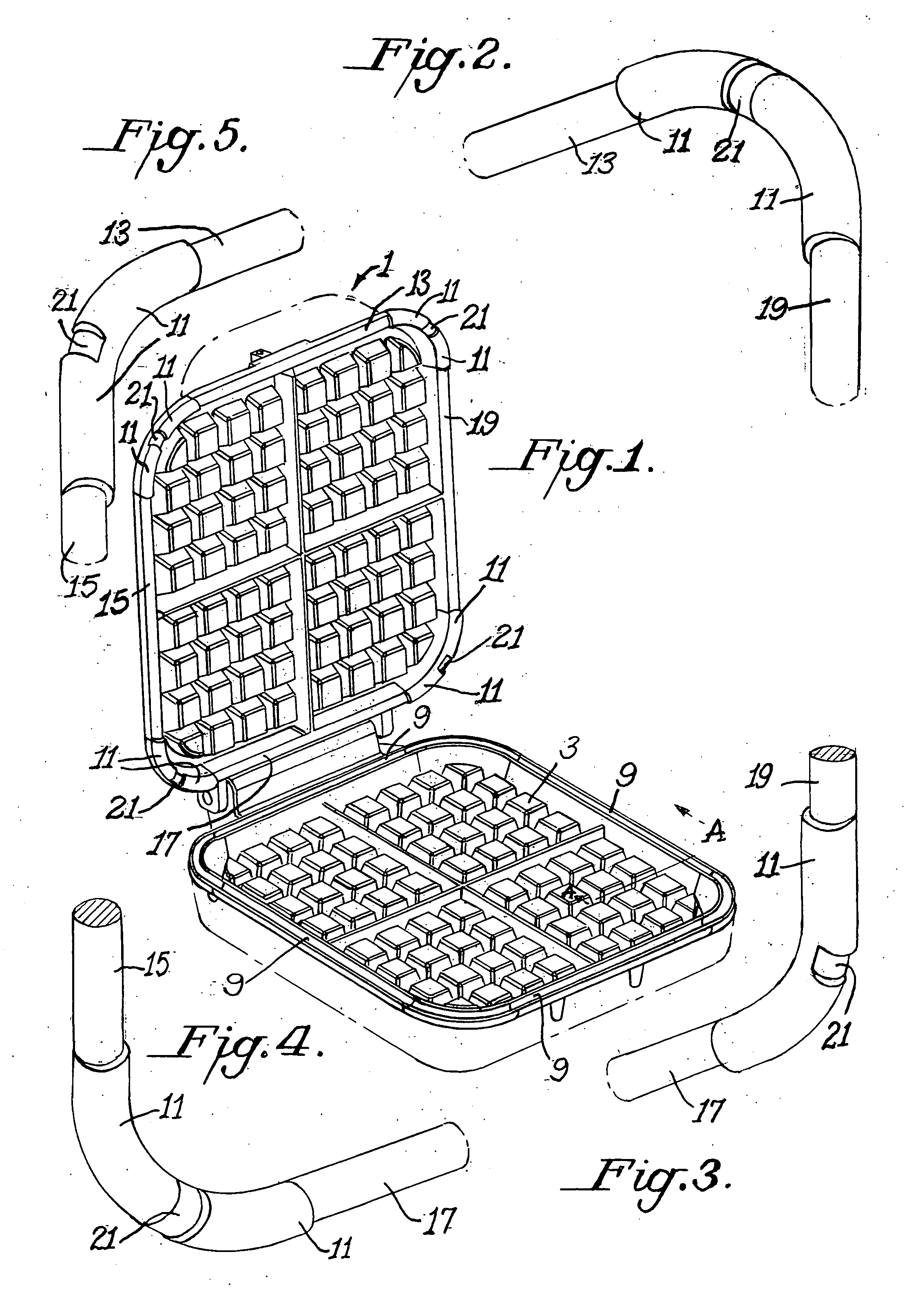

Waffle maker

A waffle maker has upper and lower baking plates each of which is powered with at lease one heating element for baking waffle. A power control unit responds to a temperature sensing unit to control power applied to the heaters and to maintain the heating plates both before and after each baking cycle at a manually pre-selected temperature. A manually adjustable timer controls the duration of the baking cycle.

Owner:EDGECRAFT

Copper bismuth catalyst and preparation method thereof

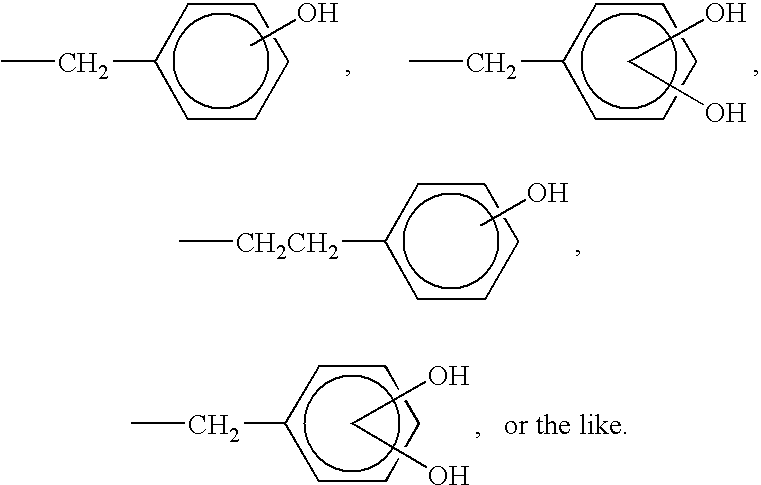

ActiveCN102658158AImprove wear performanceExtended service lifeOrganic compound preparationHydroxy compound preparationCooking & bakingAlcohol

The invention relates to a copper bismuth catalyst for combining chemically into 1, 4-butynediol with formaldehyde and ethyne and a preparation method thereof. The preparation method comprises the following steps of: preparing mixed solution which contains copper salt, bismuth salt, magnesium salt and dispersant; dropping alcoholic solution with an organic silicon source into the mixed solution; adjusting a pH value of the mixed solution with alkaline solution to obtain mixed precipitate; and further aging, washing, drying and baking in inert atmosphere to obtain the copper bismuth catalyst with C-MgO-SiO2 a carrier, in the catalyst, the content of CuO accounts for 25-50 weight percent, and the content of Bi2O3 accounts for 2-6 weight percent. The catalyst is applied in a reaction of combining chemically into 1, 4-butynediol with formaldehyde and ethyne, and has high catalytic activity and high selectivity.

Owner:SHANXI UNIV

Semiconductor device and method of manufacturing the semiconductor device

InactiveUS20030193090A1The process steps are simpleRun at high speedSemiconductor/solid-state device detailsSolid-state devicesCapacitanceCooking & baking

A semiconductor device capable of high speed operation with a substantially small interlayer capacitance is produced by steps of using an insulating film comprising an organic insulating film and an insulating film composed of an organometallic polymer material as an interlayer insulating film formed by coating, patterning the insulating film in a semi-thermosetting state, etching the organic insulating film as the lower layer by means of the organometallic polymer as a mask, using a plasma gas containing oxygen as the main component, and then conducting ultimate baking treatment of these insulating films.

Owner:RENESAS ELECTRONICS CORP

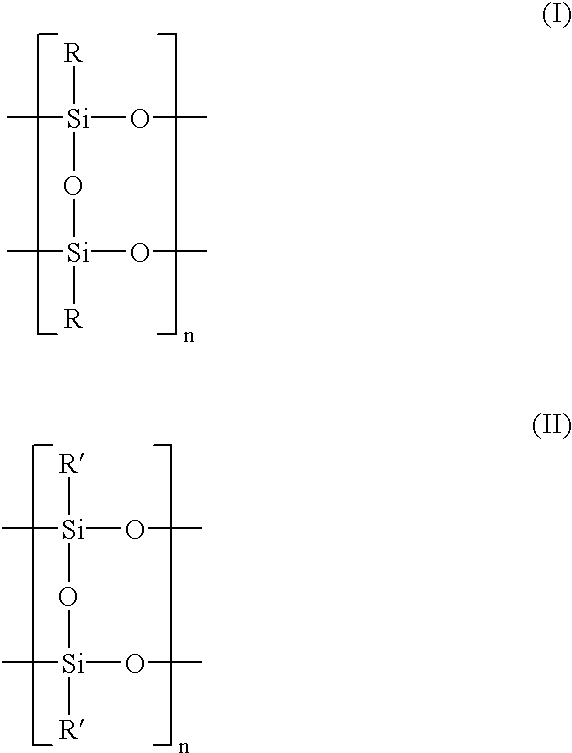

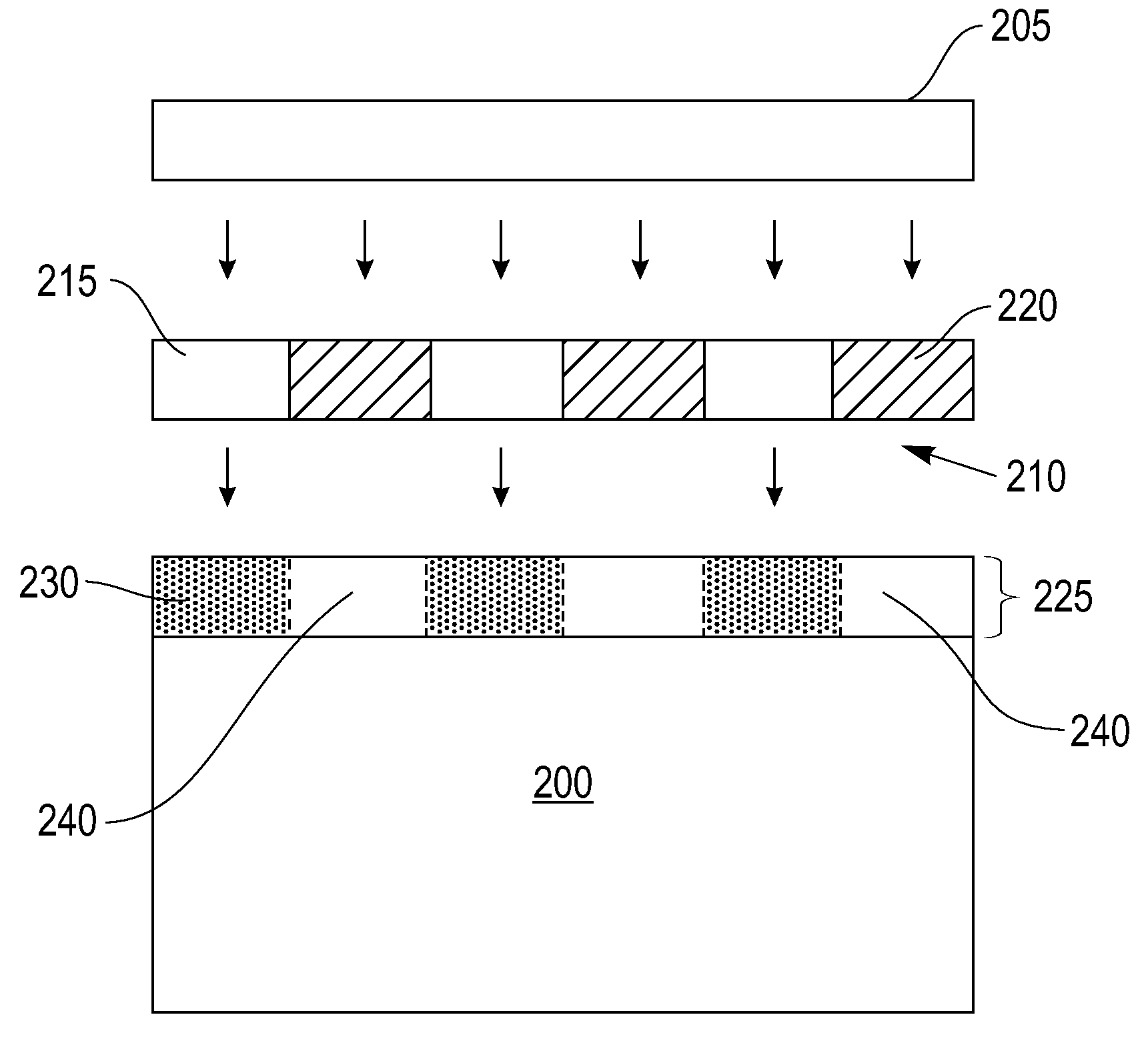

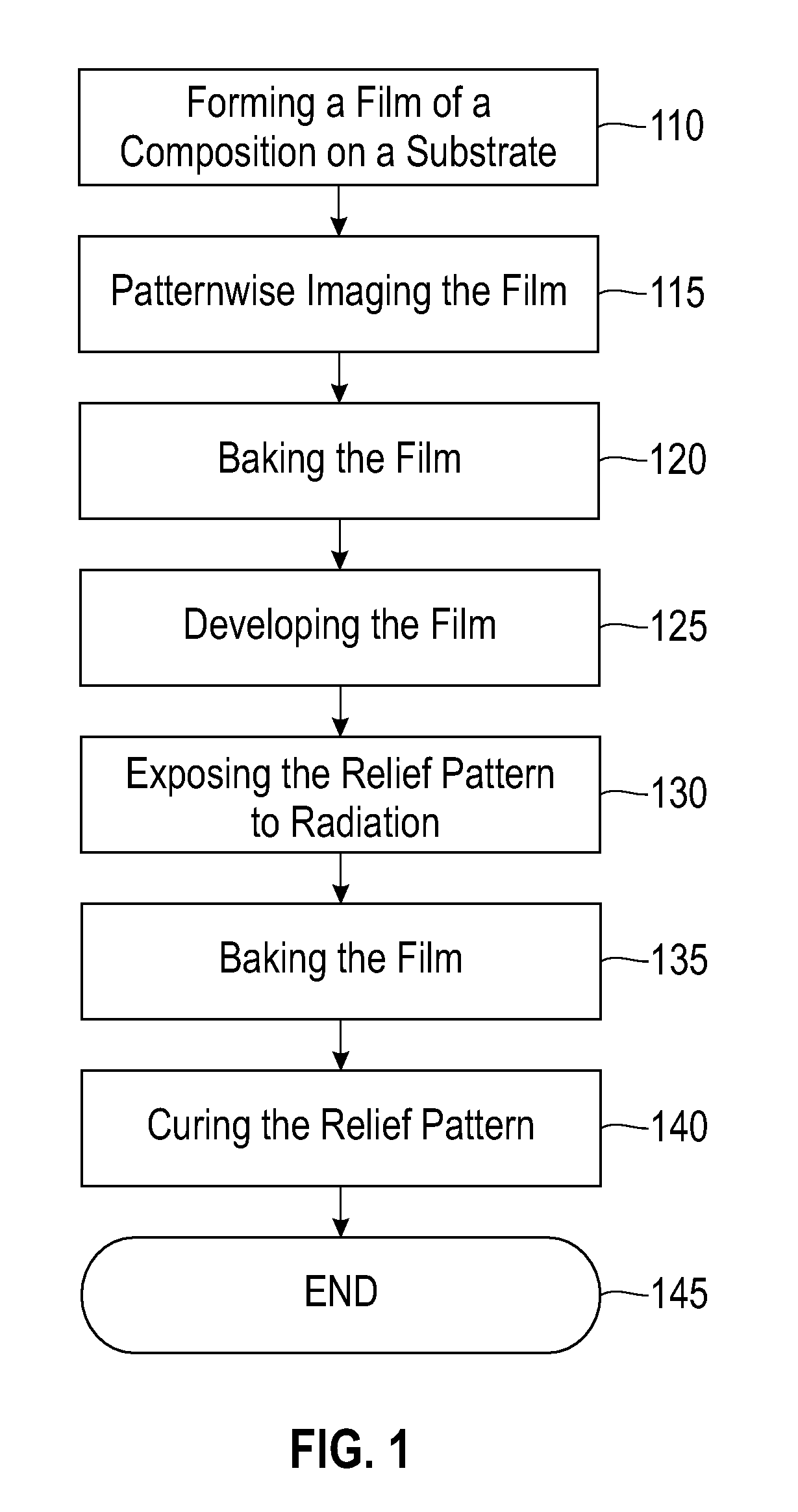

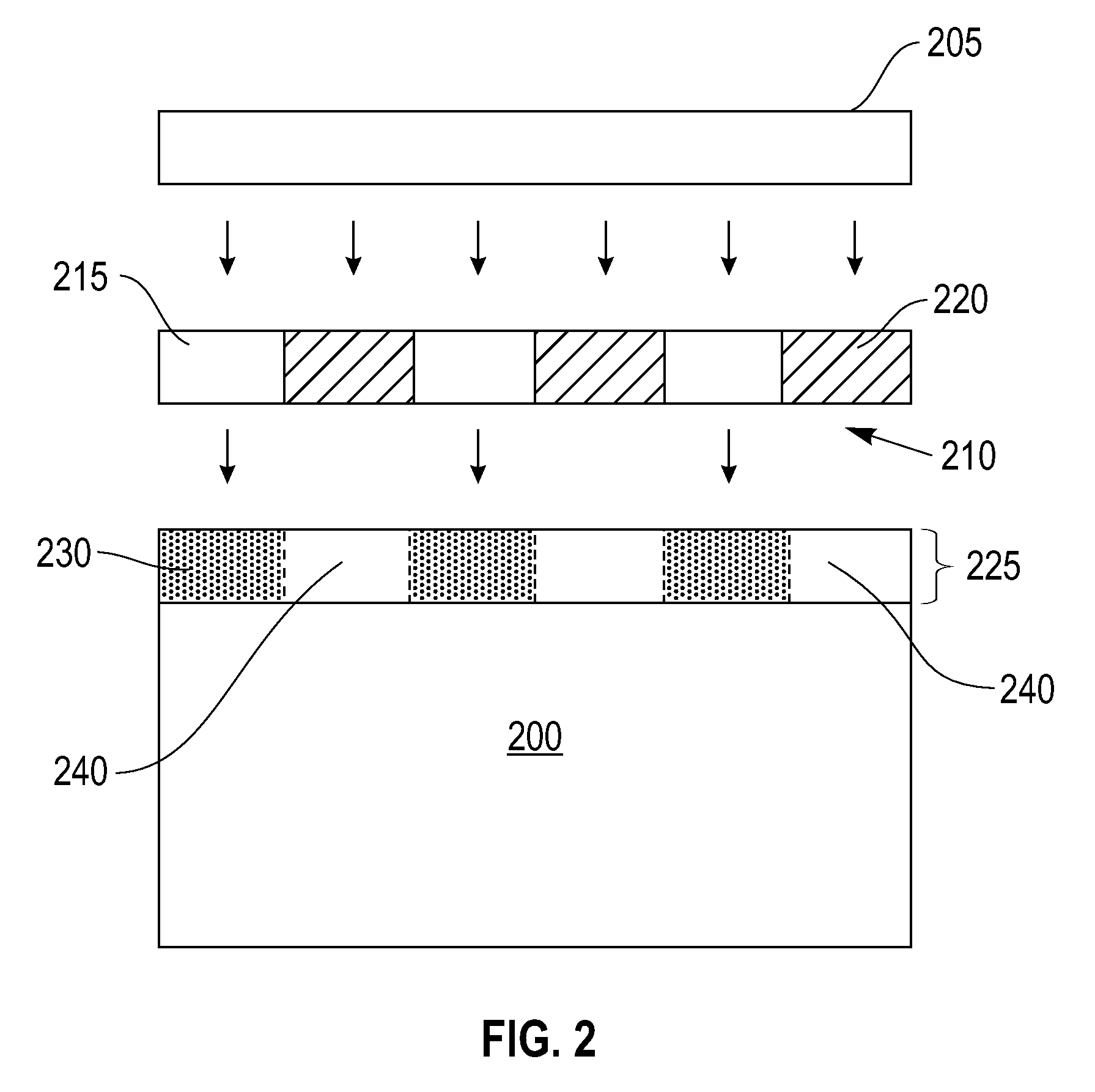

Photopatternable dielectric materials for beol applications and methods for use

InactiveUS20090233226A1Electric discharge tubesPhotosensitive materialsThermal energyCooking & baking

Compositions, a method, and a photopatternable blend. The compositions include a blend of a first and a second polymer. The first polymer is a substituted silsesquioxane copolymer. The second polymer is a substituted silsesquioxane polymer. The second polymer is configured to undergo chemical crosslinking with the first polymer, the second polymer, or a combination thereof, upon exposure to light, thermal energy, or a combination thereof. The compositions include a photosensitive acid generator. The method includes forming a film. The film is patternwise imaged, and at least one region is exposed to radiation. After the imaging, the film is baked, wherein at least one exposed region is rendered substantially soluble. After the baking, the film is developed, wherein a relief pattern remains. The relief pattern is exposed to radiation. The relief pattern is baked. The relief pattern is cured. A chemically amplified positive-tone photopatternable blend is also described.

Owner:GLOBALFOUNDRIES INC

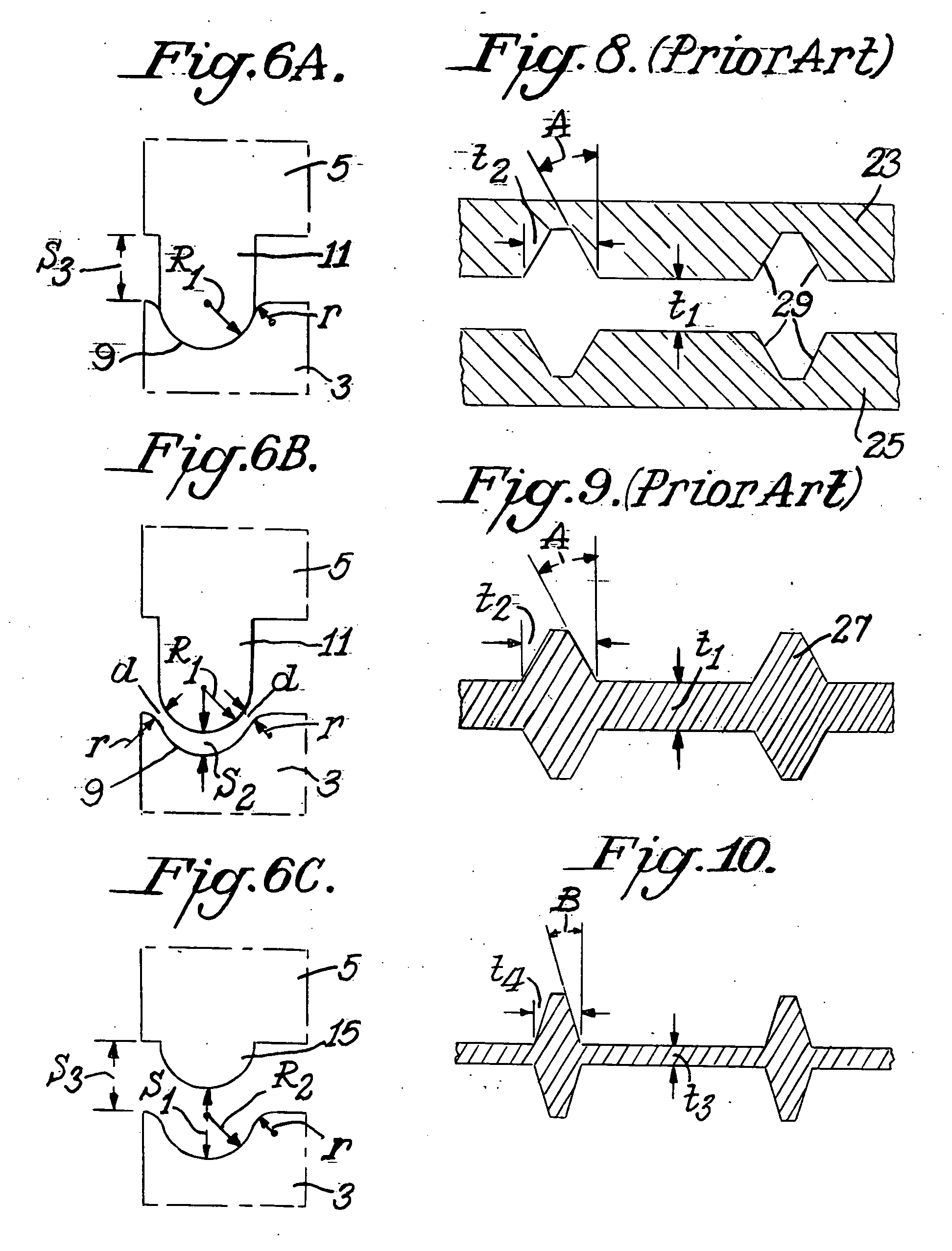

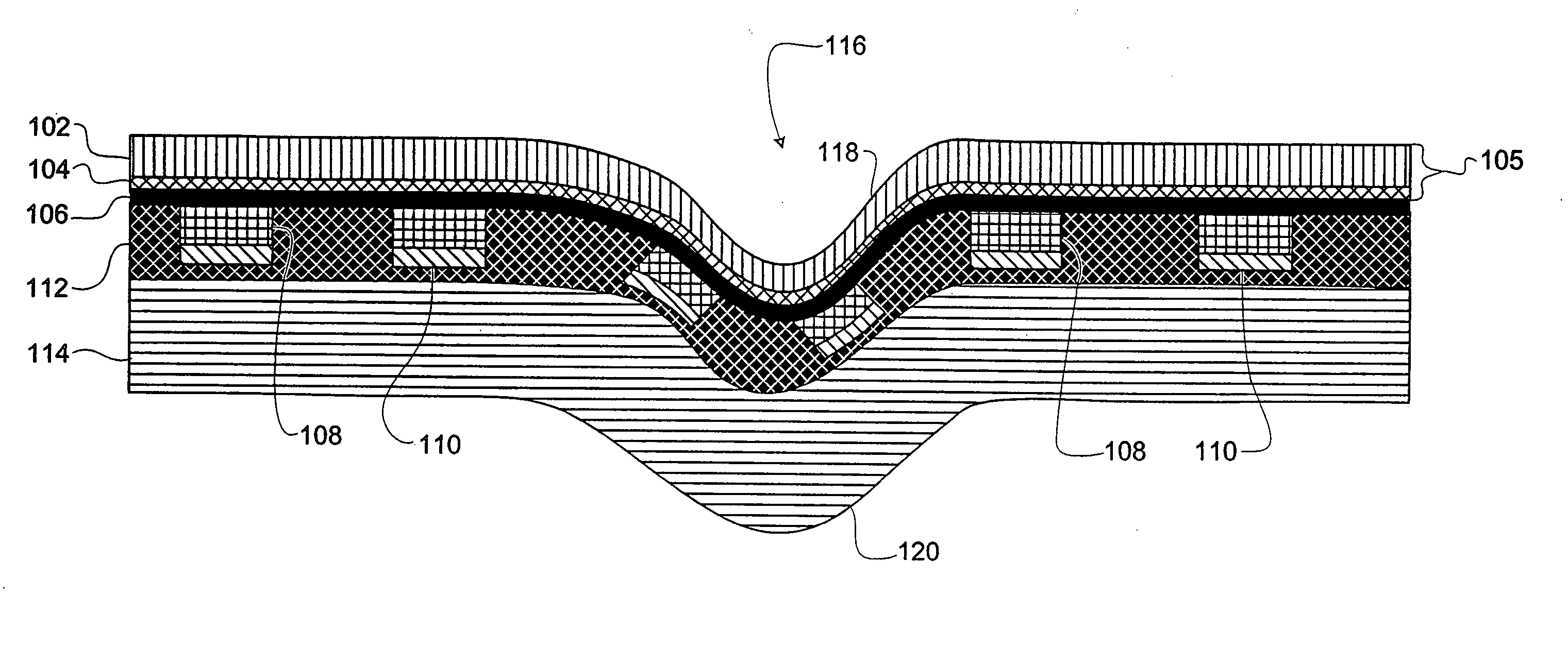

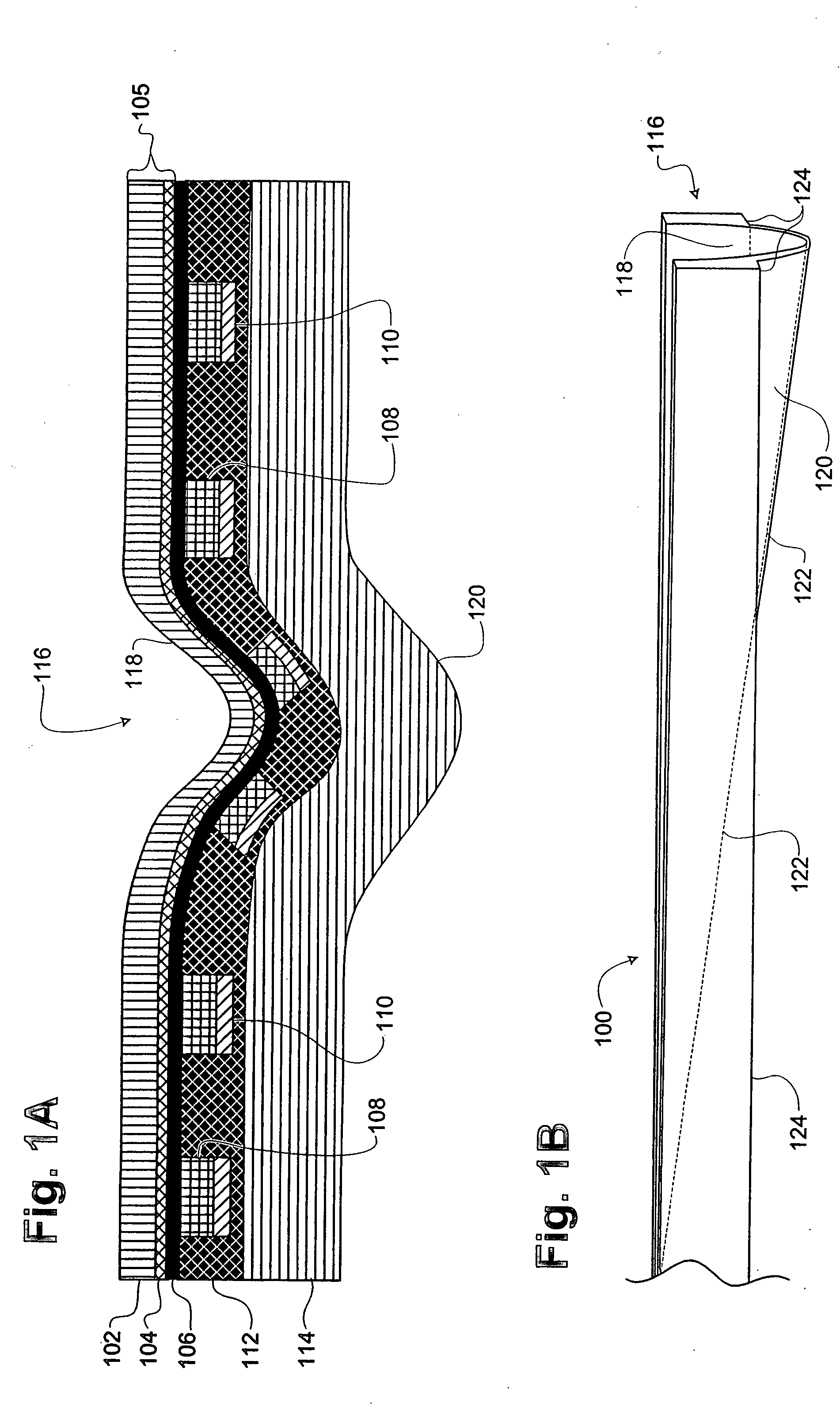

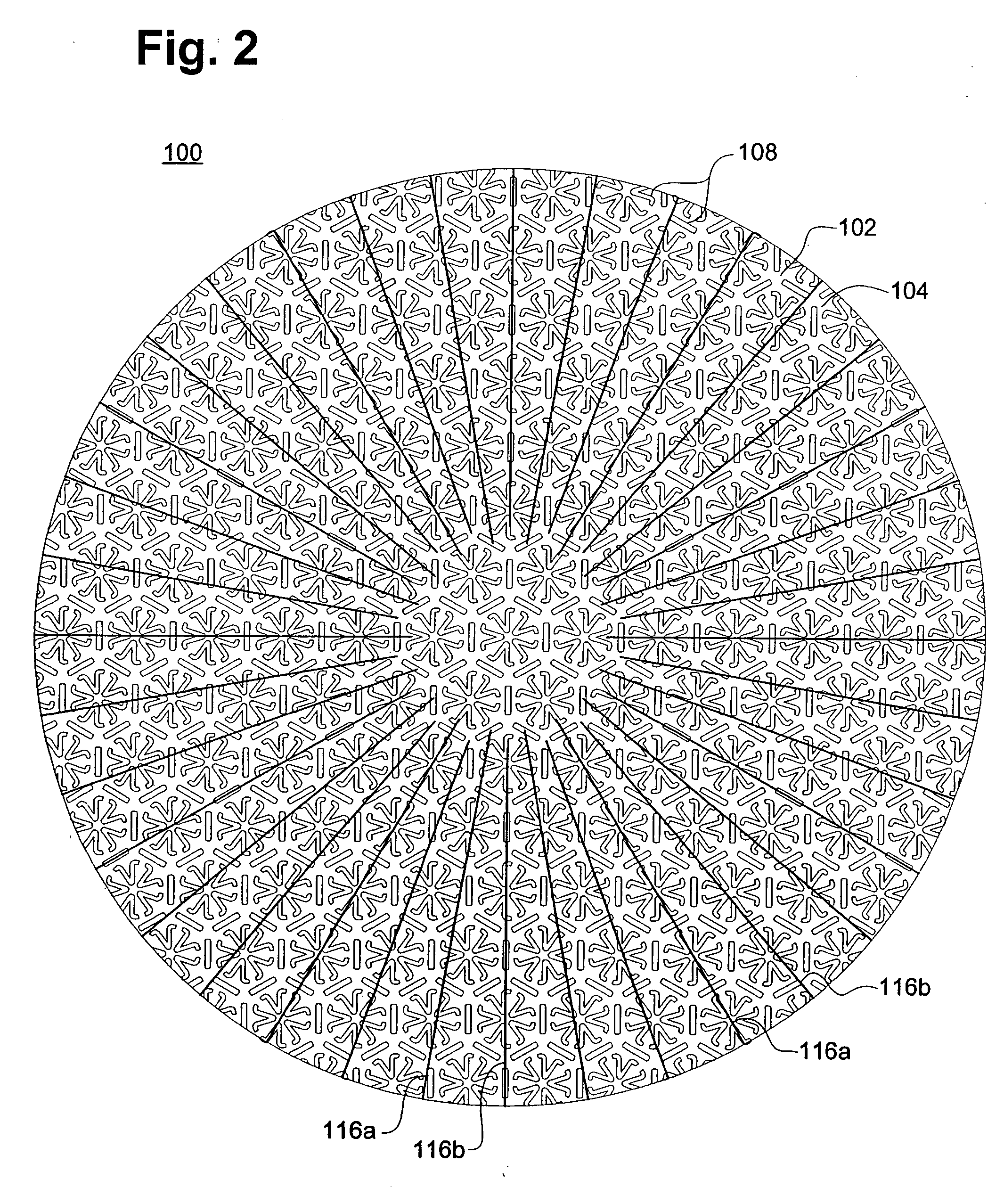

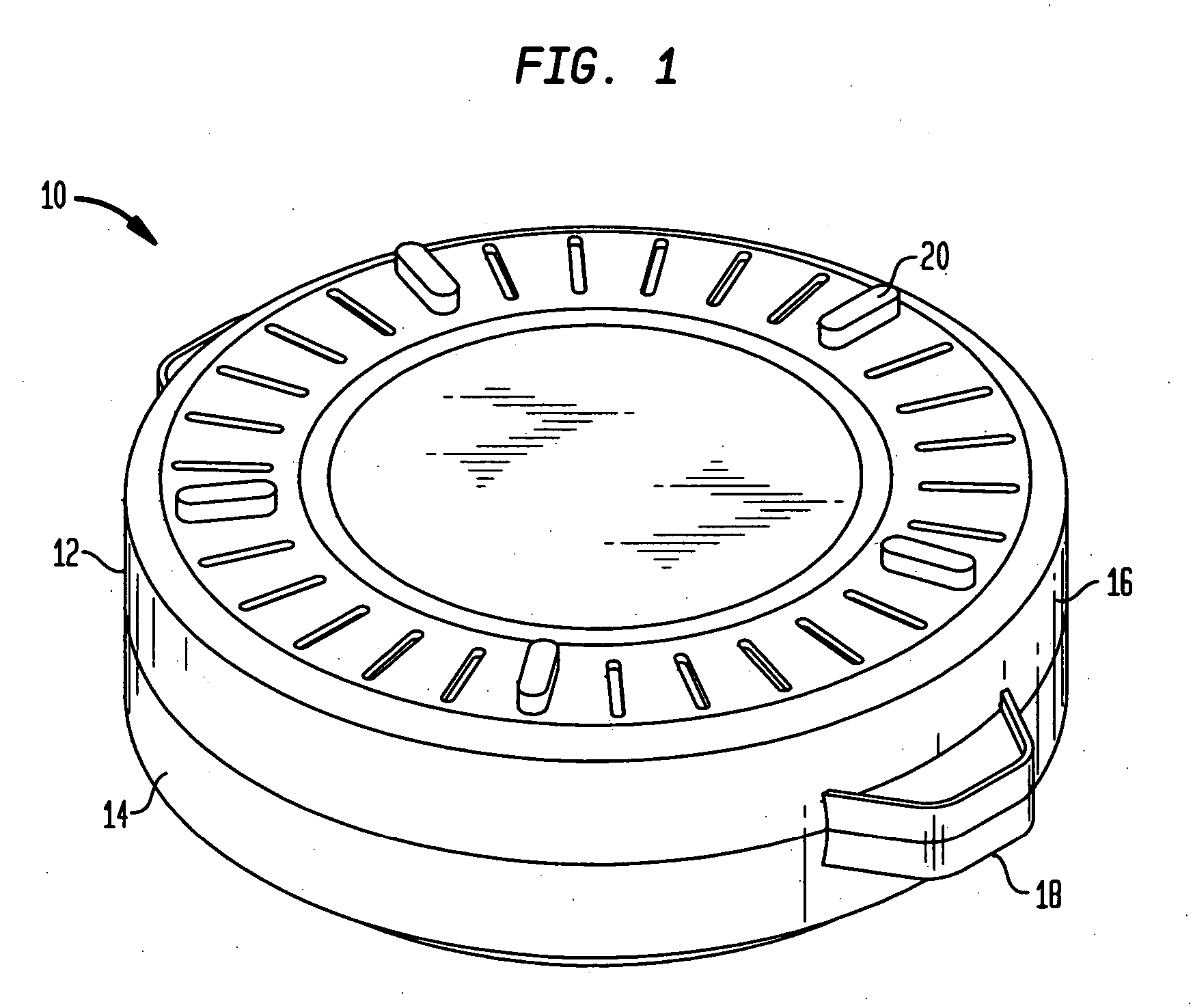

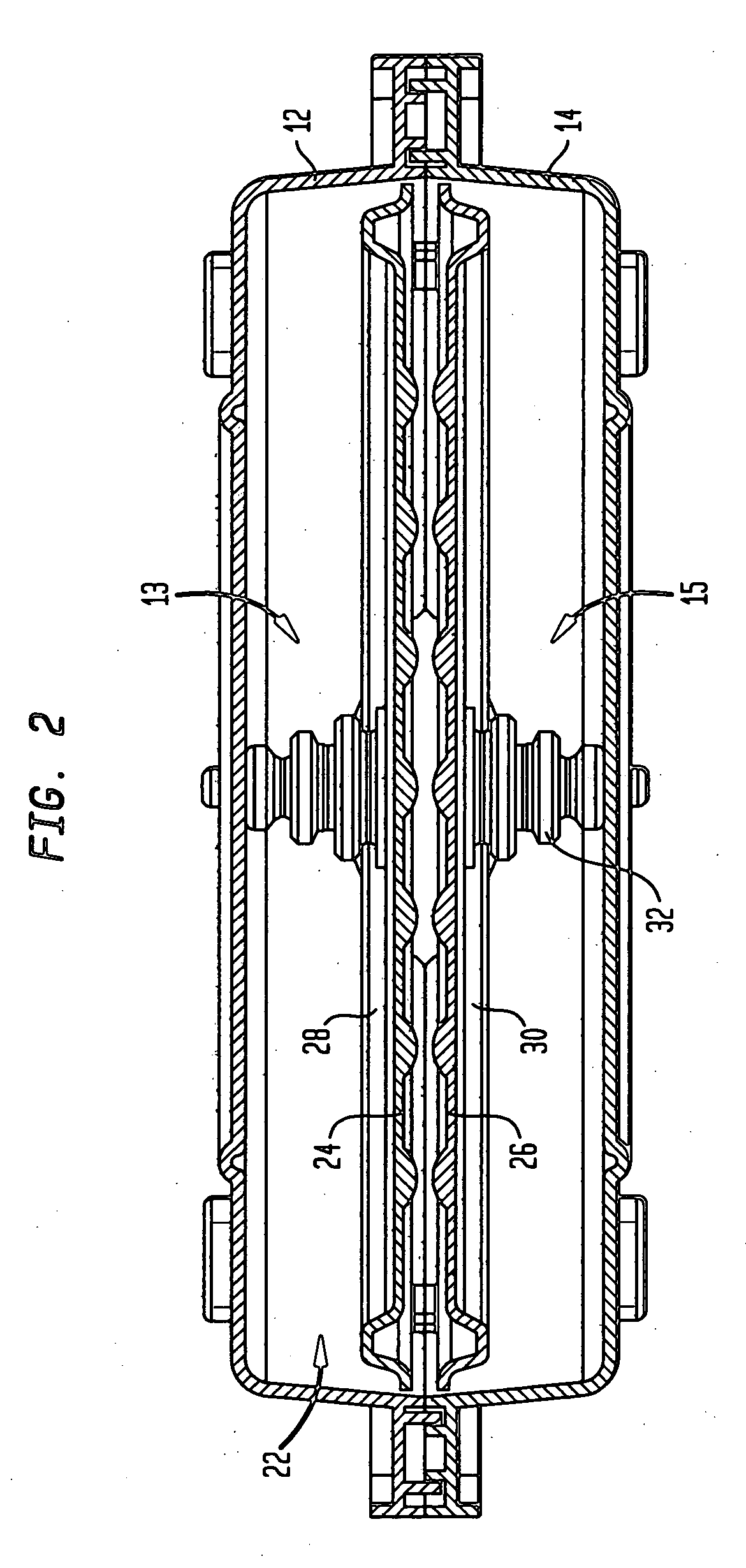

Microwave packaging with indentation patterns

InactiveUS20060011620A1Improve cooking resultsGood cooking effectMilk preparationReady-for-oven doughsCooking & bakingEngineering

Indentation patterns in microwave packaging materials can enhance the baking and browning effects of the microwave packaging materials on food. The indentation patterns can provide venting to either channel moisture from one area of the food product to another, trap moisture in a certain area to prevent it from escaping, or channel the moisture completely away from the food product. The indentation patterns can cause the microwave packaging material underneath a food product to be slightly elevated above the cooking platform in the base of a microwave. The indentation patterns can lessen the heat sinking effect of the cooking platform by providing an air gap for insulation. Elevating the base of the microwave packaging material further allows more incident microwave radiation to propagate underneath the microwave packaging material to be absorbed by the food product or by microwave interactive materials in the microwave packaging material that augment the heating process.

Owner:GRAPHIC PACKAGING INT

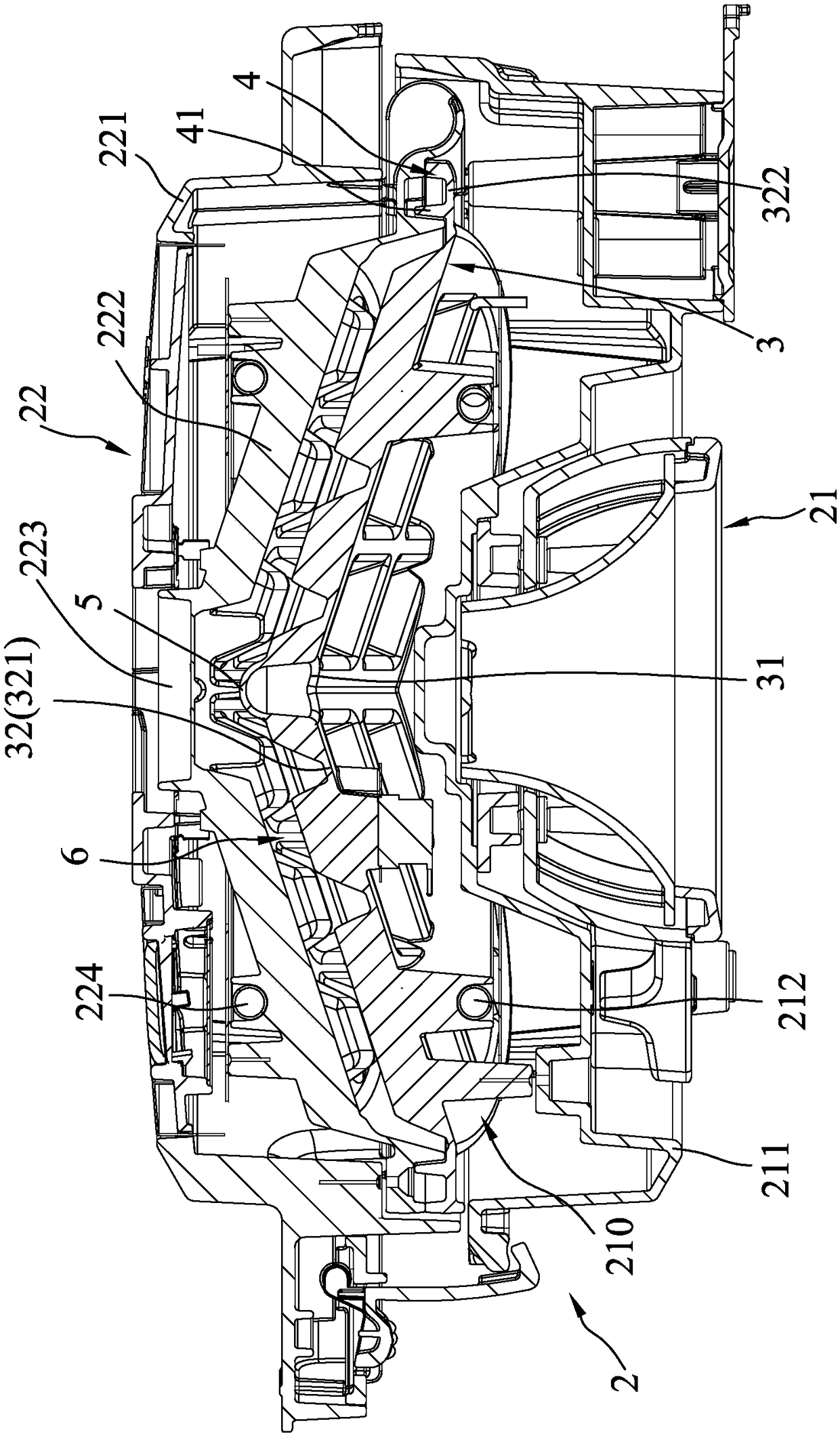

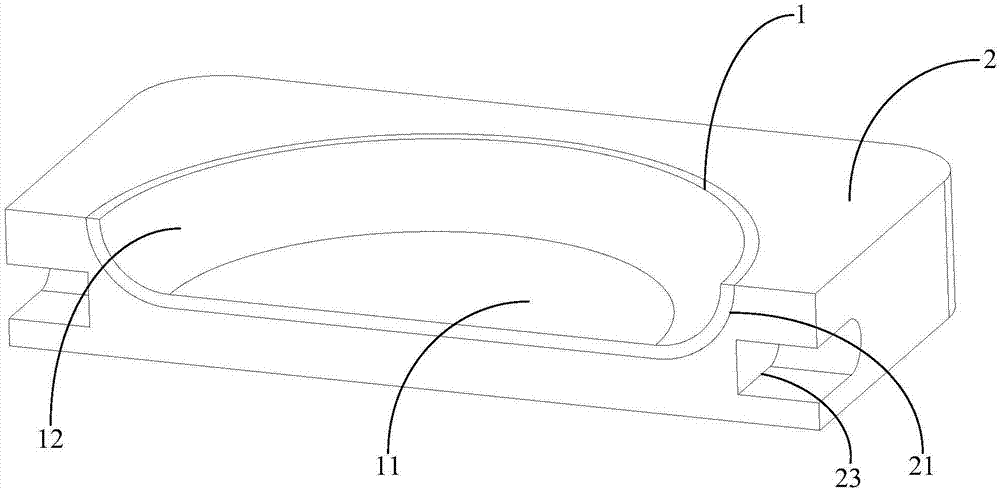

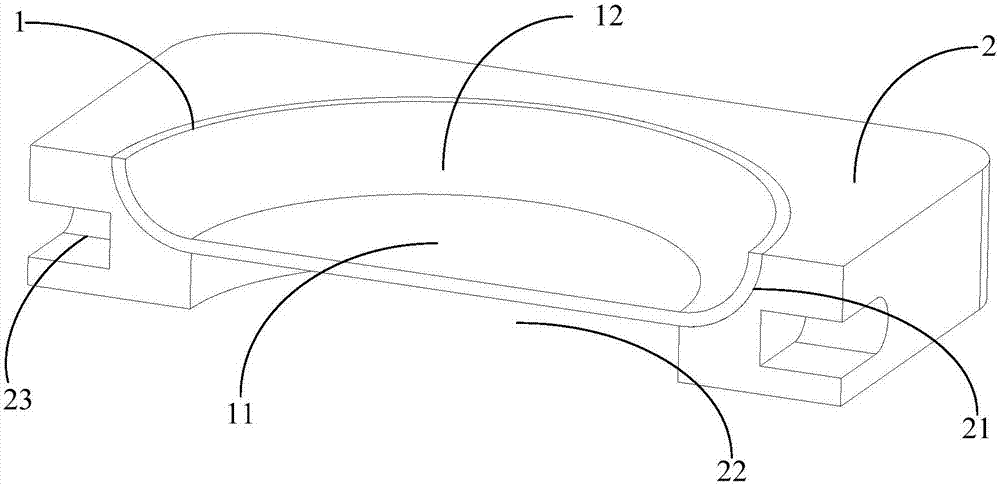

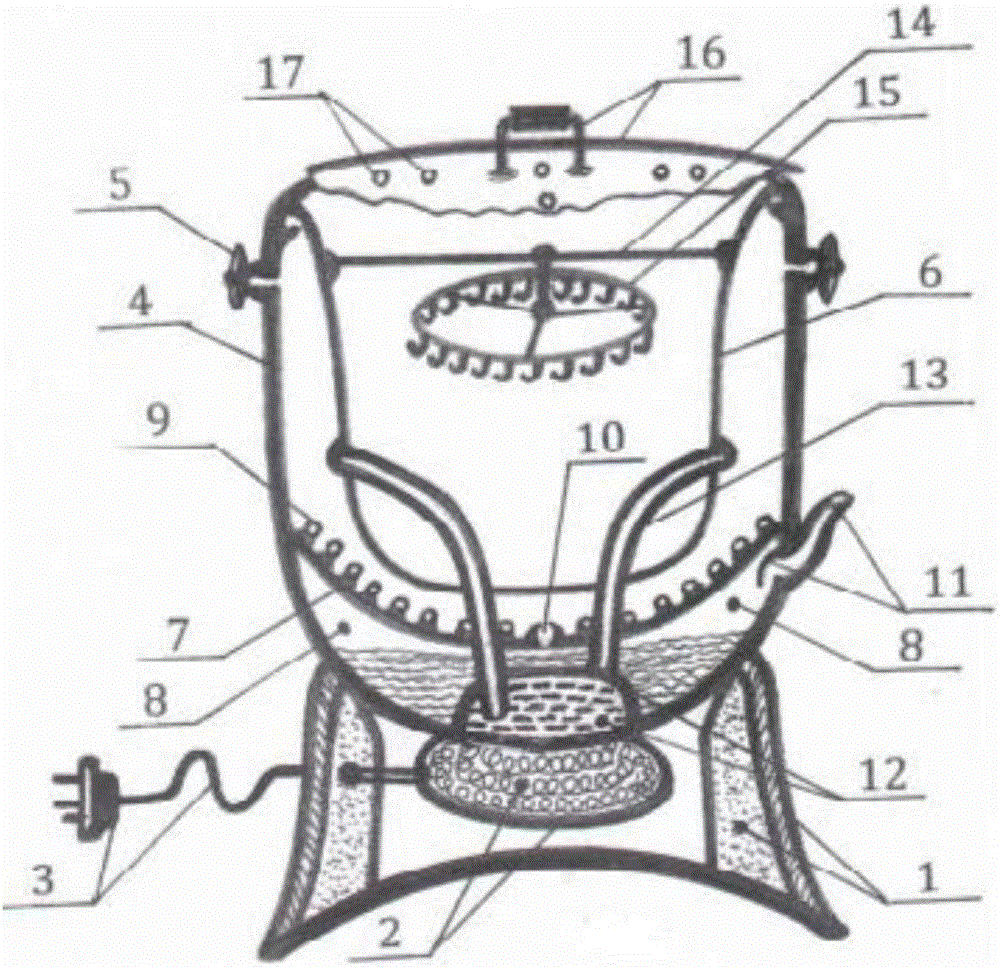

Food frying and baking device

ActiveCN108720633ARapid and uniform diffusionImprove qualityBaking vesselsRoasters/grillsCooking & bakingFluid - substance

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

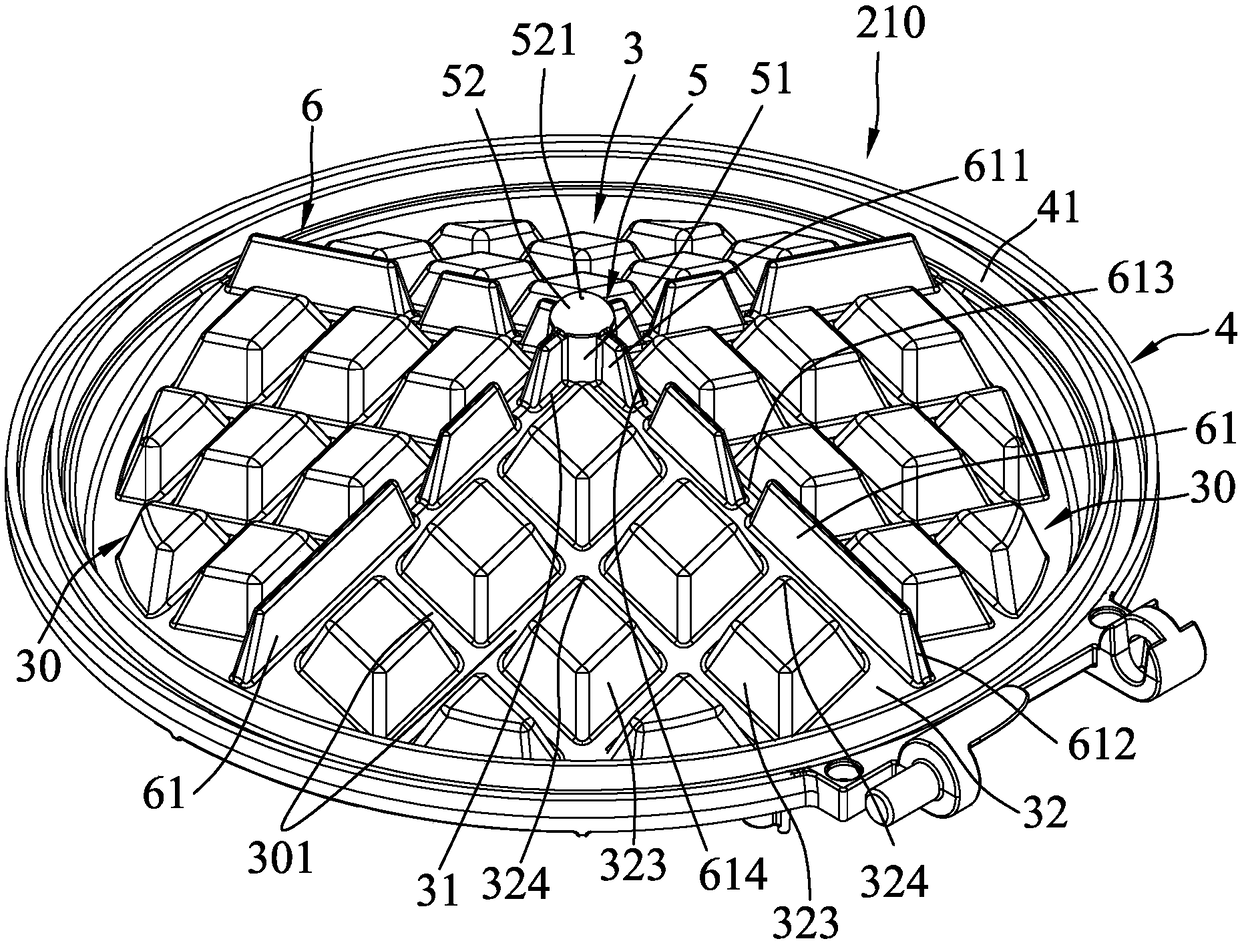

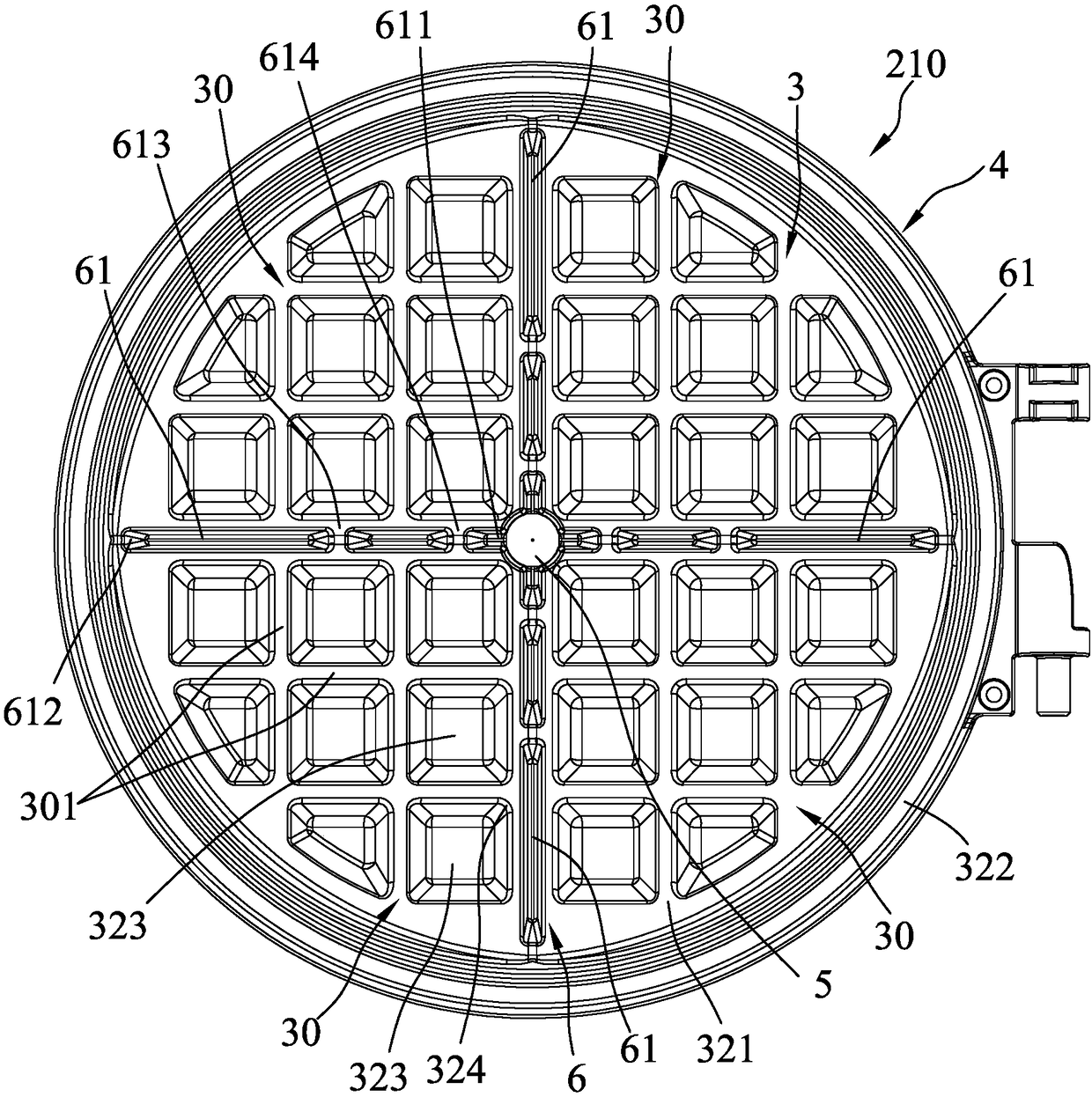

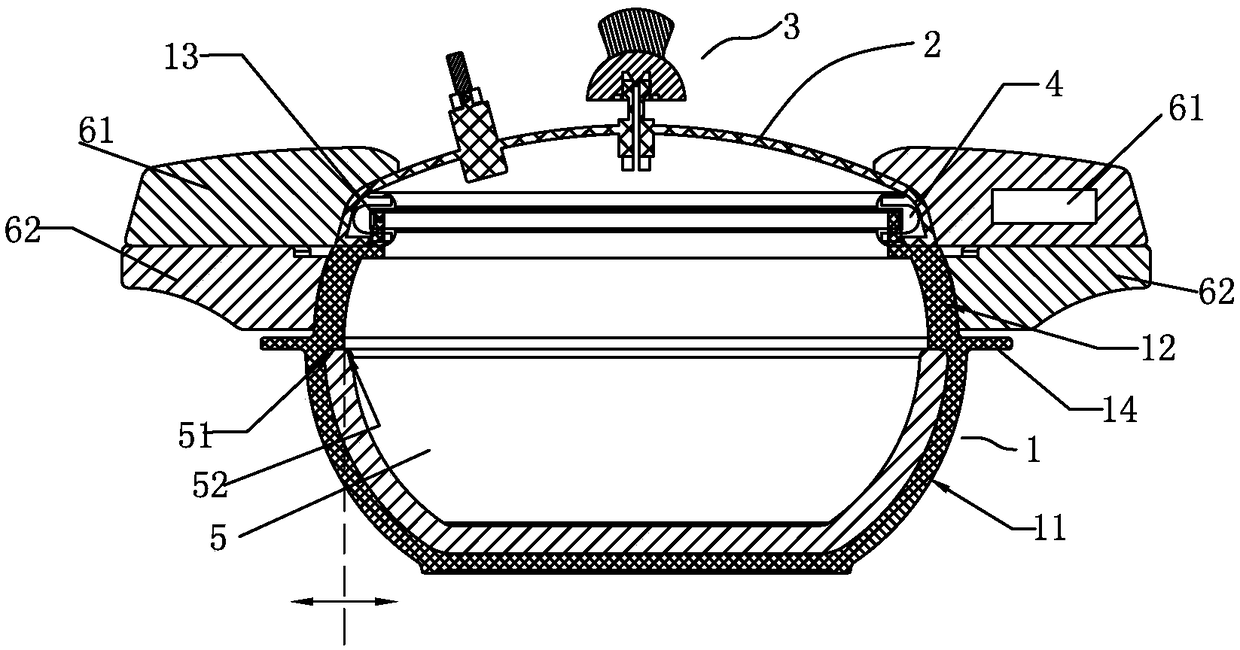

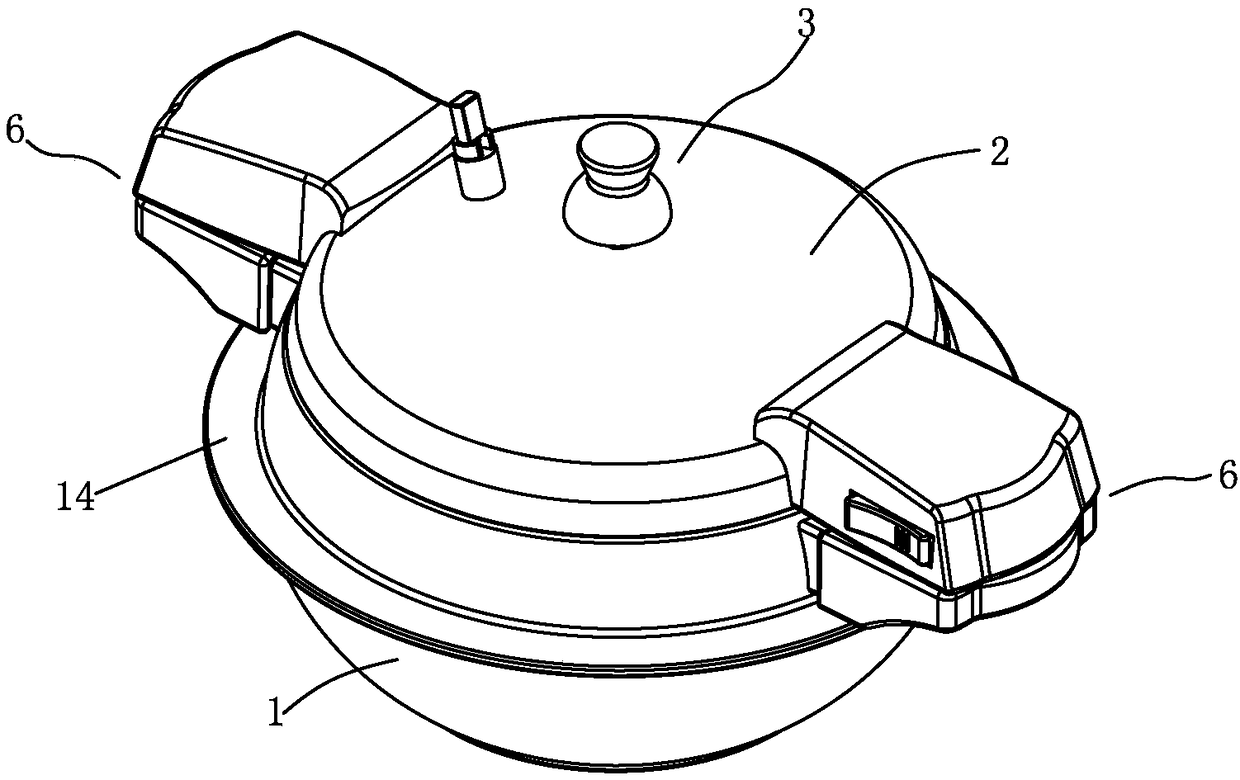

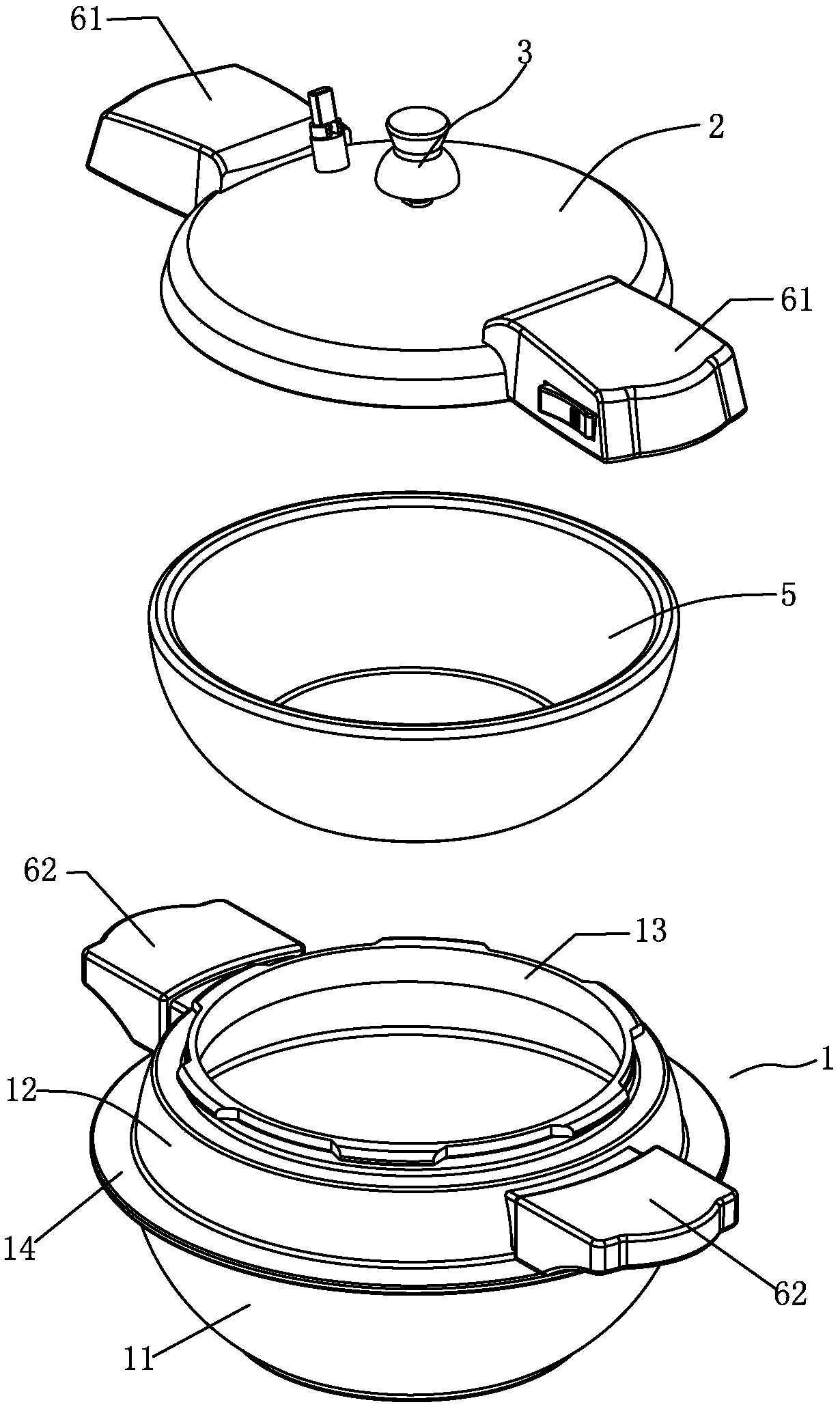

Pressure cooker

PendingCN108652431AKeep the smellPlay a role in breaking the wallCooking-vessel materialsPressure-cookersCooking & bakingMetallic materials

A pressure cooker comprises a body, a lid, a pressure relief valve arranged on the lid and a sealing ring arranged on the lid. Upper fastening threads of the lid are in screw fit with lower fasteningthreads on an opening in the body. The cooker further comprises an inner pot opening up and made of a non-metallic material and a heat conductive material. The body is made of aluminum or aluminum alloy with certain ductility, and comprises a lower wrapping portion, a steam chamber portion and an upper interface portion. The upper interface portion is provided with the lower fastening threads. Theinner pot is embedded in the lower wrapping portion. During use, a food material is located in the inner pot, a high temperature cooking area is formed in the inner pot, a high pressure high temperature heat source area is formed in the steam chamber portion, and a secondary high pressure and high temperature area is formed in the lid. During use, the high temperature cooking area is formed in the inner pot, a high temperature high pressure hot baking area is formed in a steam chamber, and a secondary high temperature high pressure hot baking area is formed in the lid. The inner pot is heatedto emit infrared rays, and the infrared rays break the long starch protein in the food material and achieve a wall-breaking effect. The original flavor of the food material can be effectively maintained, and the taste is effectively improved.

Owner:中山市家冠电气有限公司

Dual Baking/Cooking Camping Appliance

InactiveUS20070199557A1Efficiently enableDomestic stoves or rangesLighting and heating apparatusCooking & bakingHeat conducting

Owner:VON KAENEL WILLIAM E JR

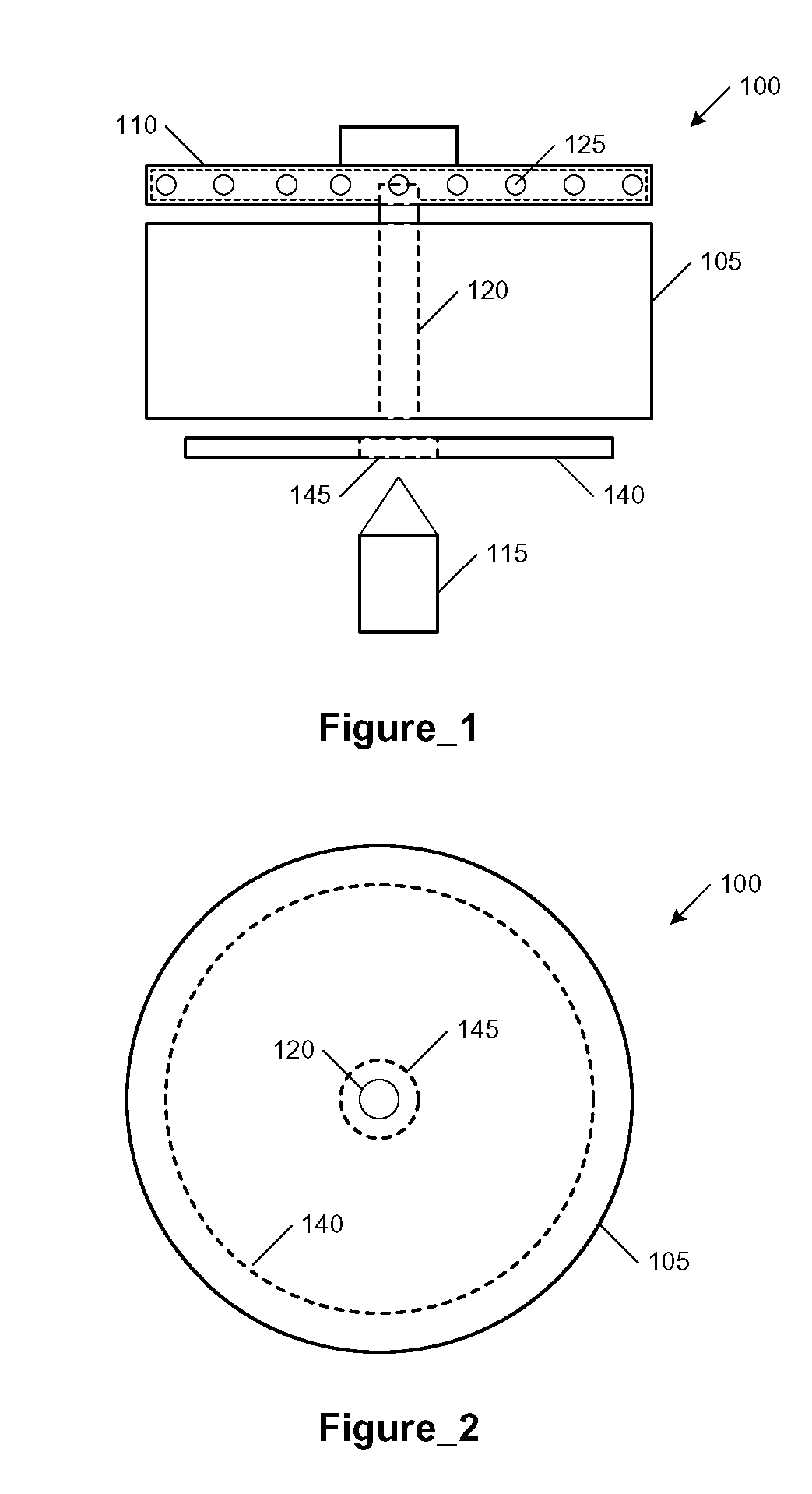

Baking tray and baking oven

ActiveCN107495849AAchieve heatingAchieve rapid heat conductionBaking vesselsRoasters/grillsCooking & bakingFood material

The invention discloses a baking tray and a baking oven, wherein the baking tray comprises a metal article carrying body and a heat storage body; the upper surface of the metal article carrying body is used for carrying food materials to be baked, so that the heat of a heating device of the baking oven can be conducted to the food materials to be baked; and the heat storage body is made of heat storage materials and is in heat conduction connection with the metal article carrying body. According to the technical scheme provided by the invention, the heat is transferred to the food materials through the metal article carrying body; the heating on the food materials is realized, so that the fast heat conduction on the food materials can be realized; the heat storage body can store heat; when the heating device of the baking oven stops heating, the heat stored by the heat storage body is used for continuously conducting heat to the metal article carrying body to realize the heating on the food materials; on one hand, the mouthfeel of the food materials is improved; and on the other hand, the utilization rate of the heat of the baking oven is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Manufacturing method of substrate having conductive layer and manufacturing method of semiconductor device

InactiveUS20060134918A1Uniform thicknessLarge electromotive forceTransistorSemiconductor/solid-state device detailsCooking & bakingDevice material

The manufacturing method of a substrate having a conductive layer has the steps of: forming an inorganic insulating layer over a substrate; forming an organic resin layer with a desired shape over the inorganic insulating layer, forming a low wettability layer with respect to a composition containing conductive particles on a first exposed portion of the inorganic insulating layer; removing the organic resin layer; and coating a second exposed portion of the inorganic insulating layer with a composition containing conductive particles and baking, thereby forming a conductive layer.

Owner:SEMICON ENERGY LAB CO LTD

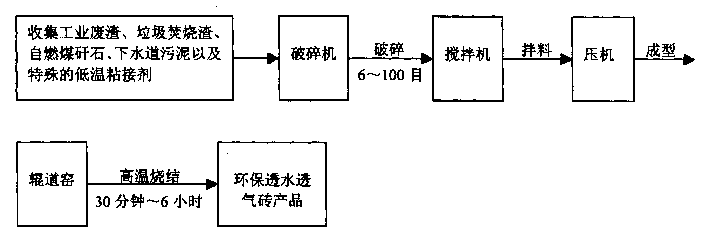

Fast baking process of environment protecting water and air permeable brick in roller kiln

InactiveCN1436750AReduce the temperatureStable water tableSolid waste managementSolid waste disposalEnvironmental resistanceCooking & baking

Owner:广东唯美新技术实业有限公司

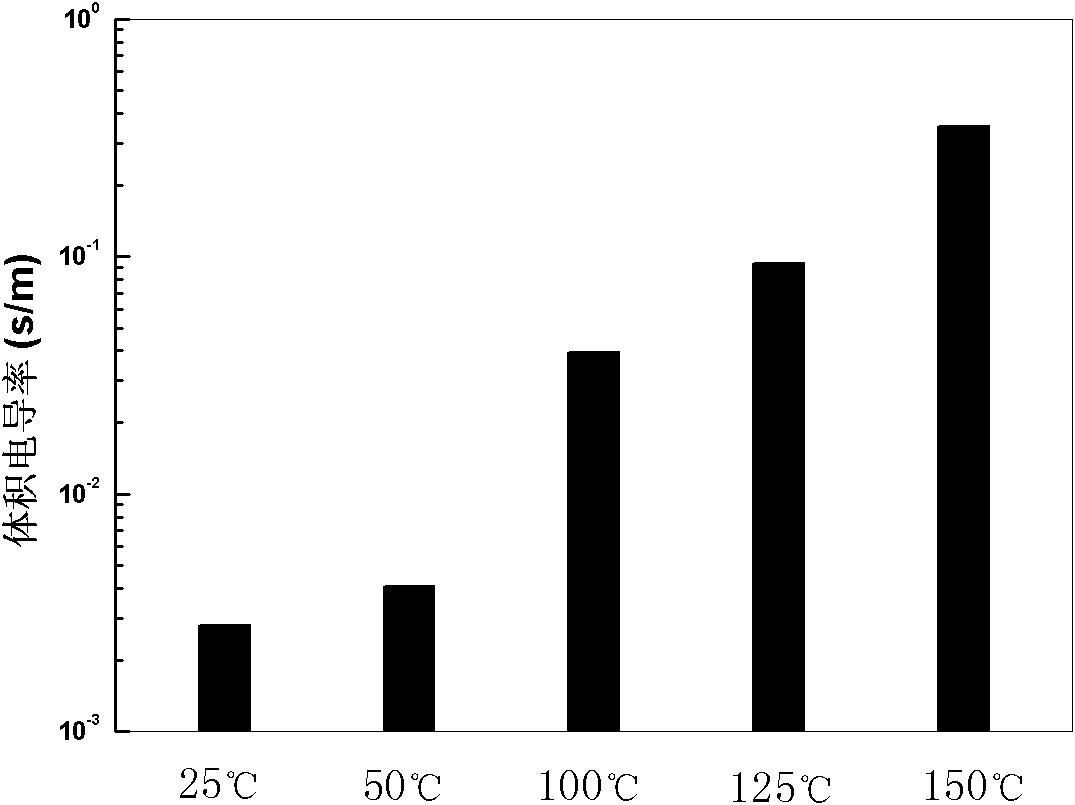

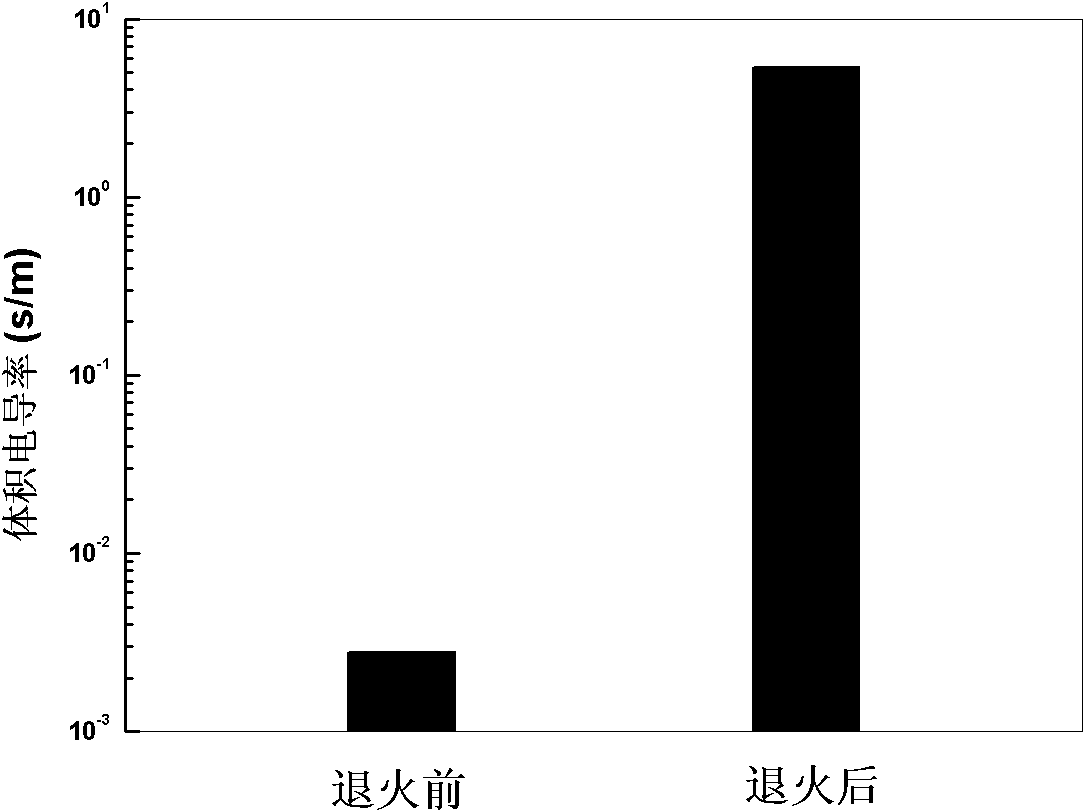

High-conductivity polymer carbon nanotube composite material and micro-processing method thereof

InactiveCN102115558AImprove dispersion stabilityImprove conductivityLiquid crystal compositionsSurgeryCooking & bakingBiomedical sensors

The invention discloses a high-conductivity polymer carbon nanotube composite material and a micro-processing method thereof. The invention is characterized in that the method comprises the following steps: adding 50-99.95 parts of polymer grain or powder, 0.05-20 parts of carbon nanotube, 0-15 parts of antioxidant and 0-15 parts of dispersant into a micro-extruder, a double-screw extruder or a double-screw extruder / micro-extruder combined facility, extruding at a screw rotation speed of 20-500rpm at a polymer melting or softening temperature of Tm+10 DEG C-Tm+80 DEG C for 1-3 times to obtainuniformly dispersed composite material grains, and carrying out micro extrusion, micro injection or micro compaction on the grains to prepare a high-conductivity micro product; or carrying out isothermal or non-isothermal heat treatment on the product in a baking oven with a temperature of Tm-80 DEG C-Tm+20 DEG C for 5 seconds to 1.5 hours; or carrying out after-treatment on the sample in microwaves, infrared rays or plasma. The high-conductivity polymer carbon nanotube composite material disclosed by the invention is used for preparing micro biomedical devices in minimally invasive operations, and used in the field of micro biomedical sensors, micro electronics, micro electro-mechanics or micro-robots.

Owner:SICHUAN UNIV

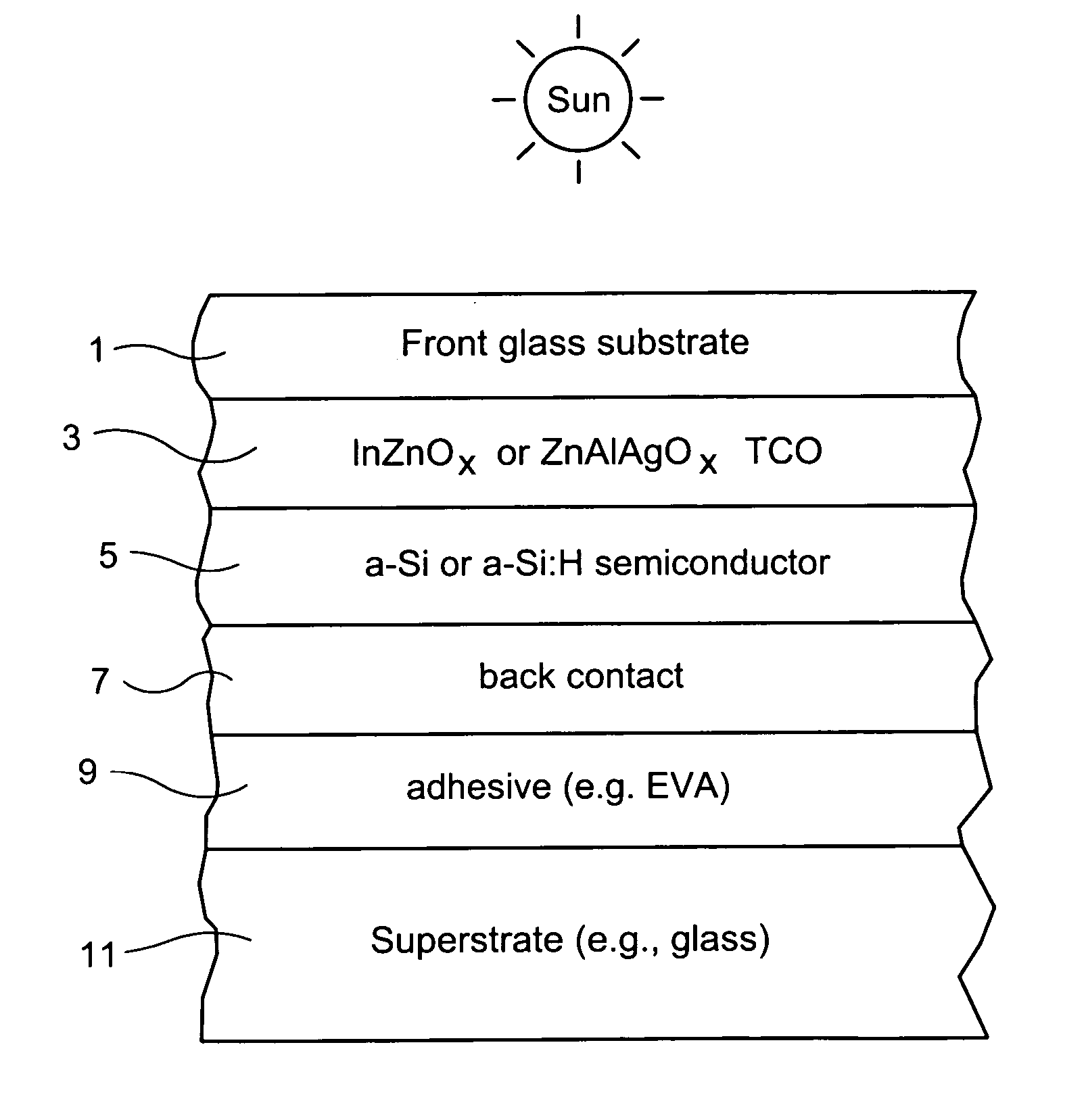

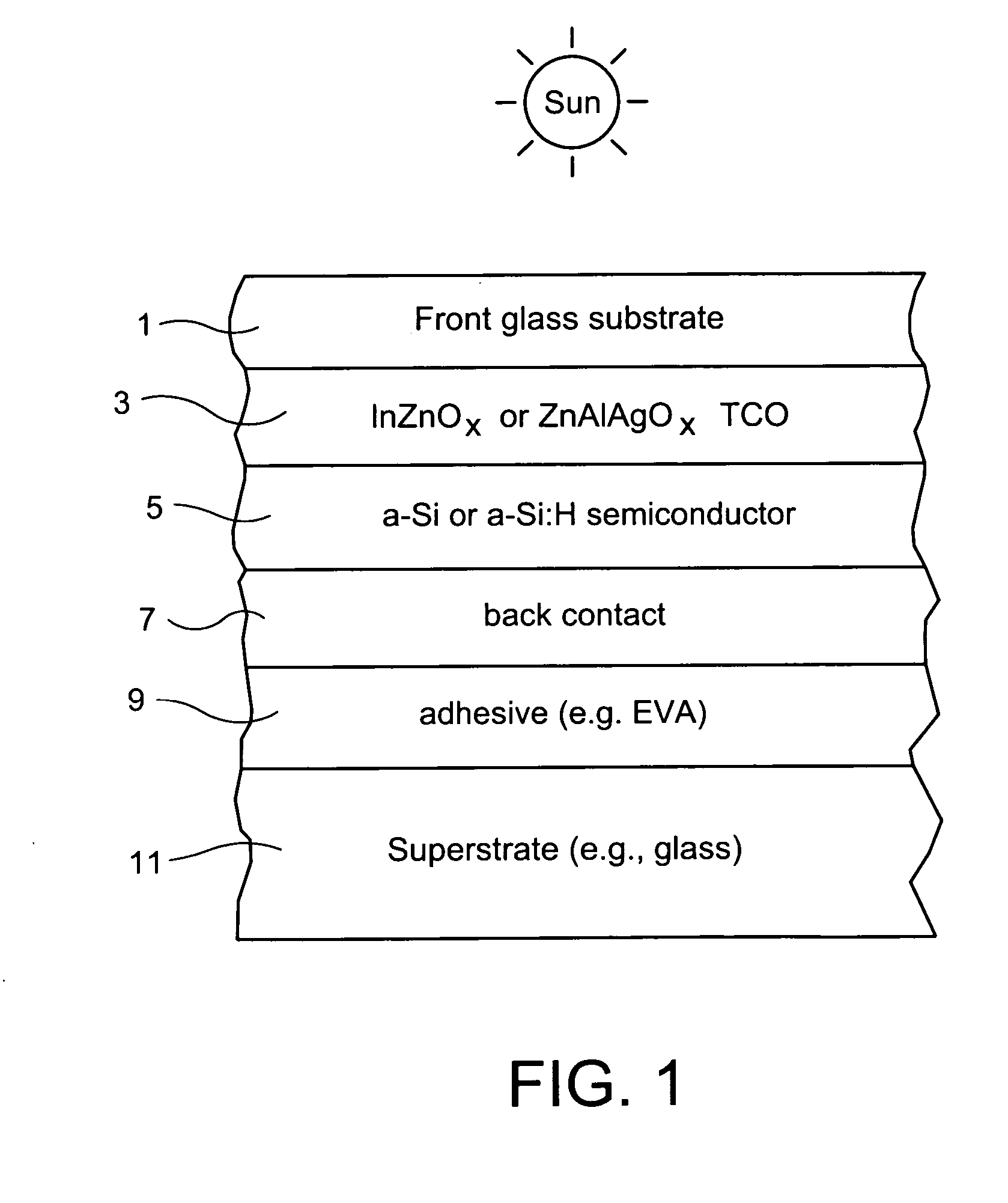

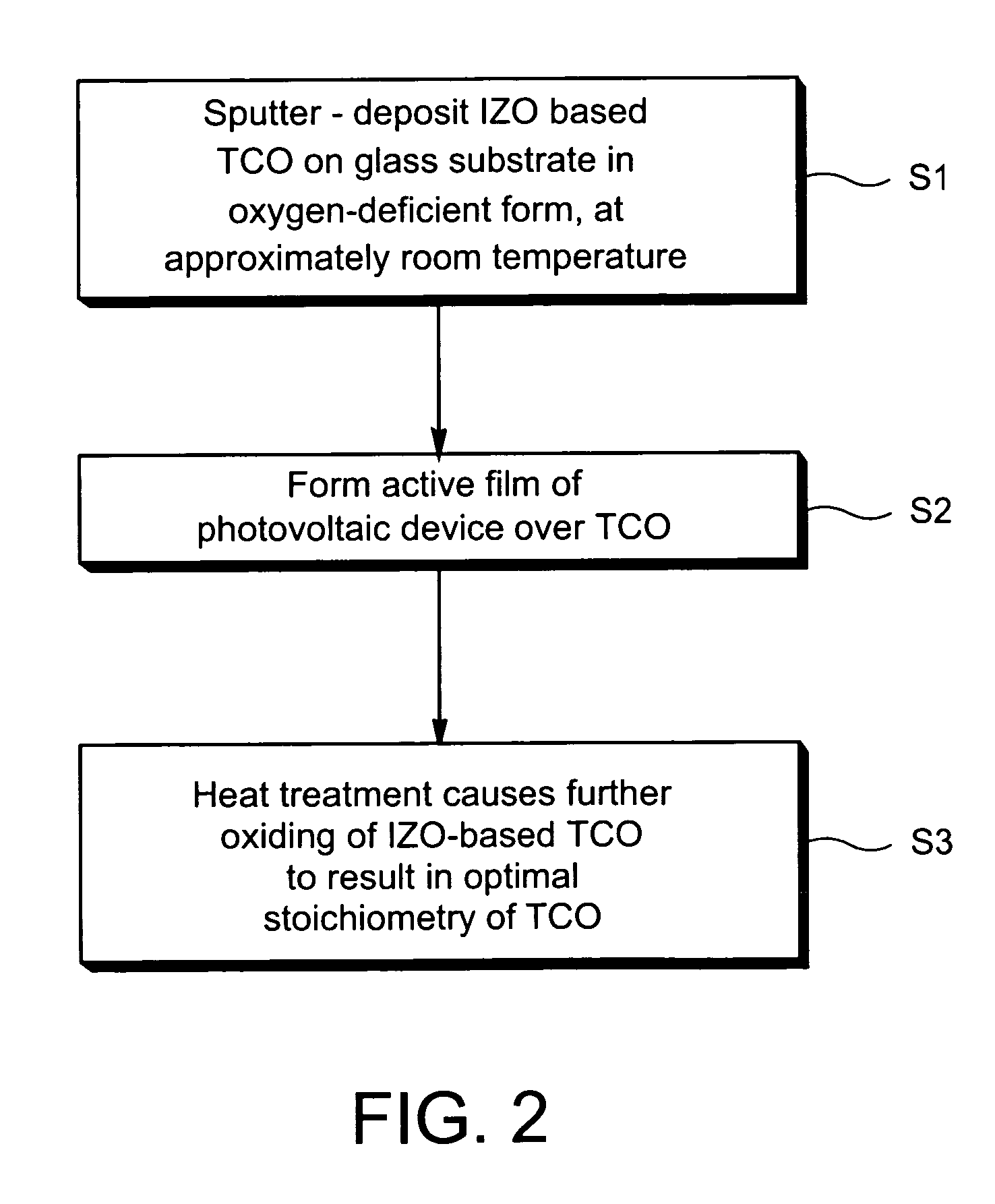

Indium zinc oxide based front contact for photovoltaic device and method of making same

InactiveUS20070193624A1Low resistivityPhotovoltaic energy generationSemiconductor devicesCooking & bakingIndium zinc oxide

This invention relates to a photovoltaic device including a front contact and / or a method of making the same. In certain example embodiments, the transparent conductive oxide (TCO) front contact is of indium zinc oxide (IZO). In other example embodiments, the IZO may have other element(s) such as silver (Ag) added thereto so that the front contact may be of or include zinc aluminum silver oxide (ZnAlAgO) for example. Moreover, in certain example embodiments the front contact (e.g., IZO or ZnAlAgO) may be sputter-deposited in an oxygen deficient form (substoichiometric); so that subsequent heat treatment or baking used in the photovoltaic device manufacturing (e.g., for subsequent layer formation) results in an optimal stoichiometry which may or may not be substoichiometric in the final product.

Owner:GUARDIAN GLASS LLC

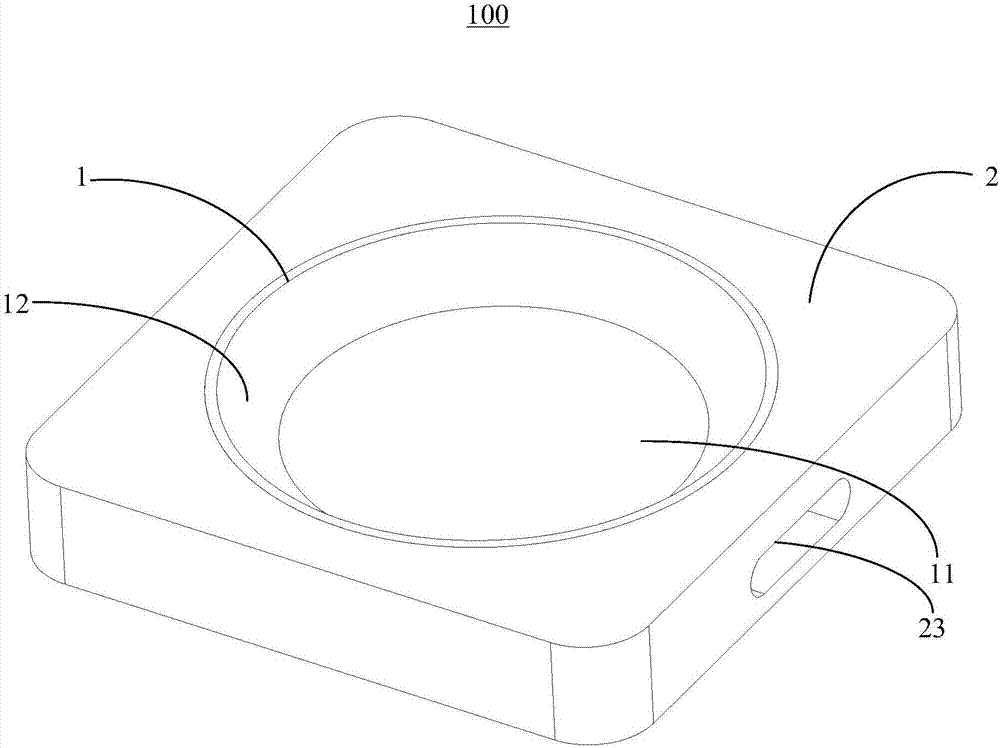

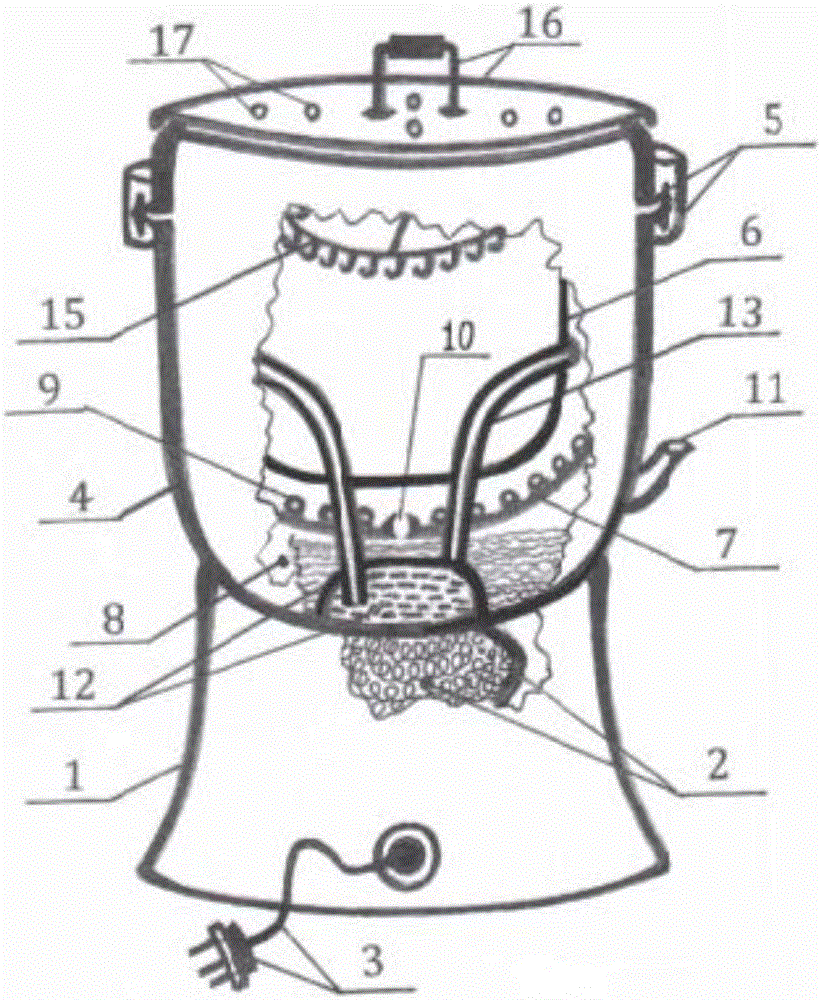

Double-heat-source steaming type barbecue grill

A double-heat-source steaming type barbecue grill comprises a base, a shell and an inner container. The bottom of the shell is arranged on the base. A heating disc is arranged at the position, close to the bottom of the shell, of the base. The inner container is arranged in the shell. A cavity is formed between the inner wall of the shell and the outer wall of the inner container. A steam pressure reducing plate is arranged between the position, above the bottom of the shell, in the cavity and the position, below the bottom of the inner container, in the cavity, a steam water tank is formed by the steam pressure reducing plate and the bottom of the shell, and steam nozzles are evenly distributed on the steam pressure reducing plate. A steam accumulated water circulating hole is formed in the middle of the steam pressure reducing plate, and a secondary heat source heat conducting oil tank is arranged at the position, in the middle of the bottom of the shell, of the steam water tank. A circulating oil pipe penetrates through the steam pressure reducing pipe and is wound around the outer wall of the inner container, and the two ends of the circulating oil pipe are connected with the secondary heat source heat conducting oil tank. According to the double-heat-source steaming type barbecue grill, it is unnecessary that open fires are used for directly baking food, double indirect heat sources are adopted for baking, and therefore the baked food contains no harmful matter, and is healthy to eat.

Owner:定远县创新科技服务园

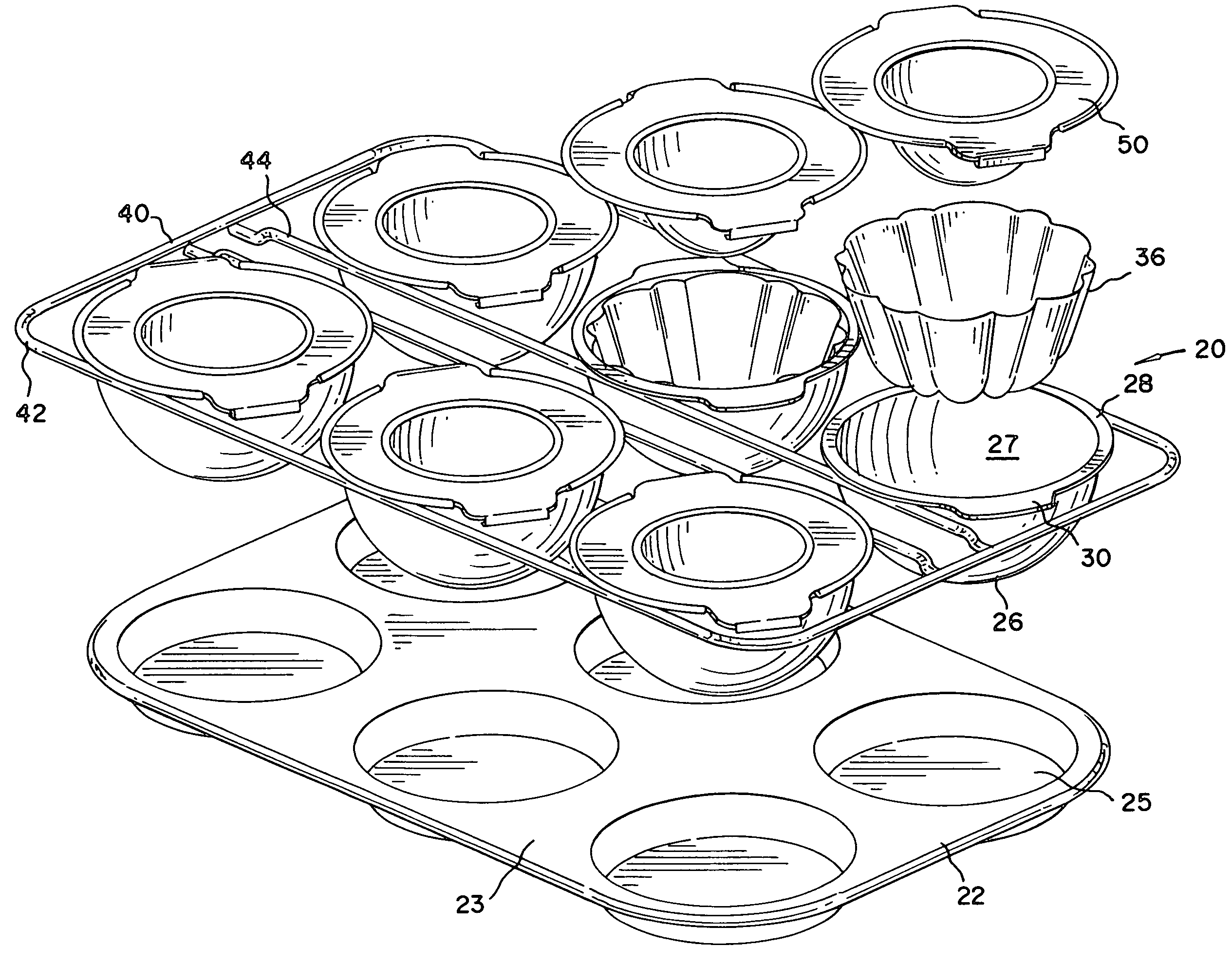

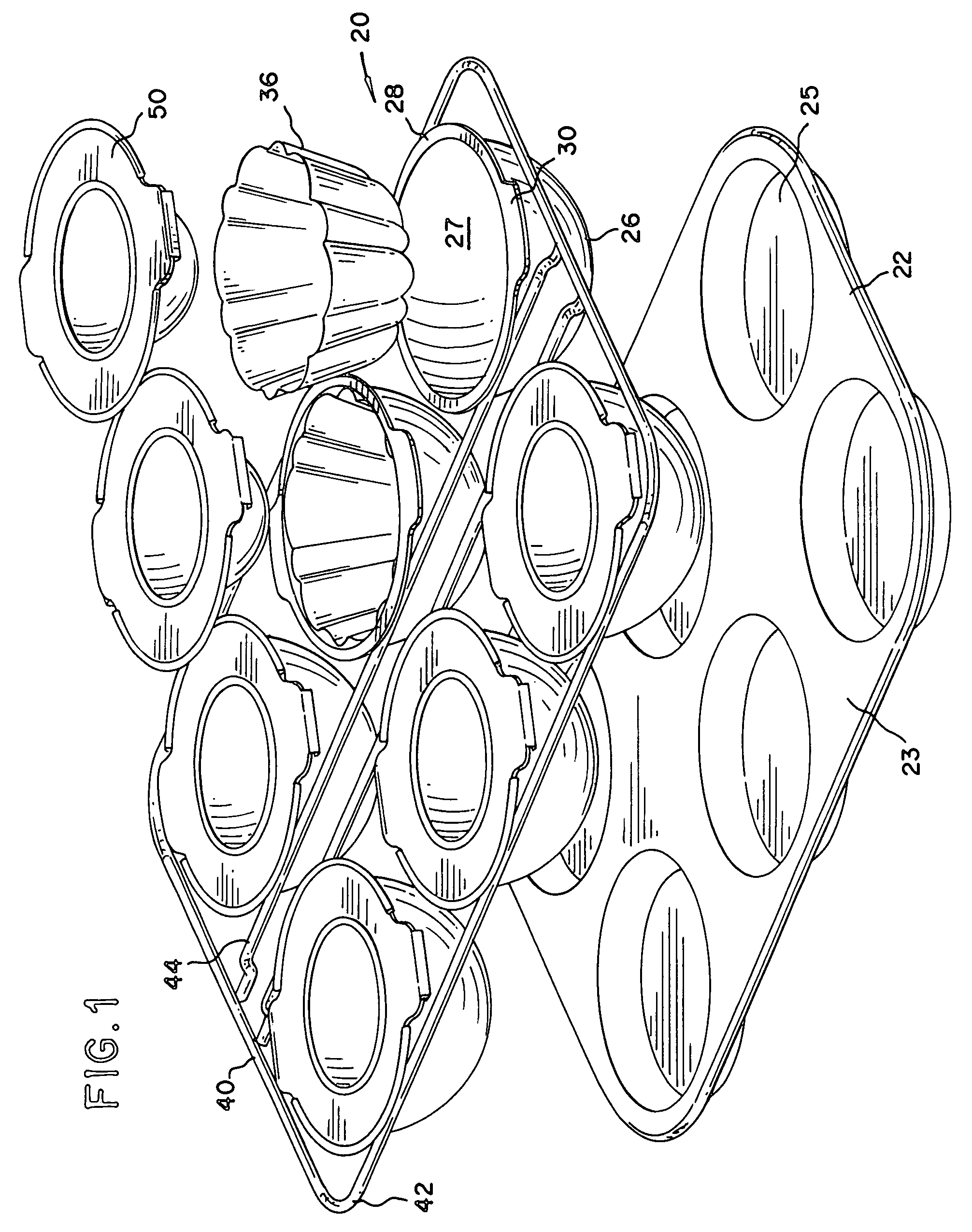

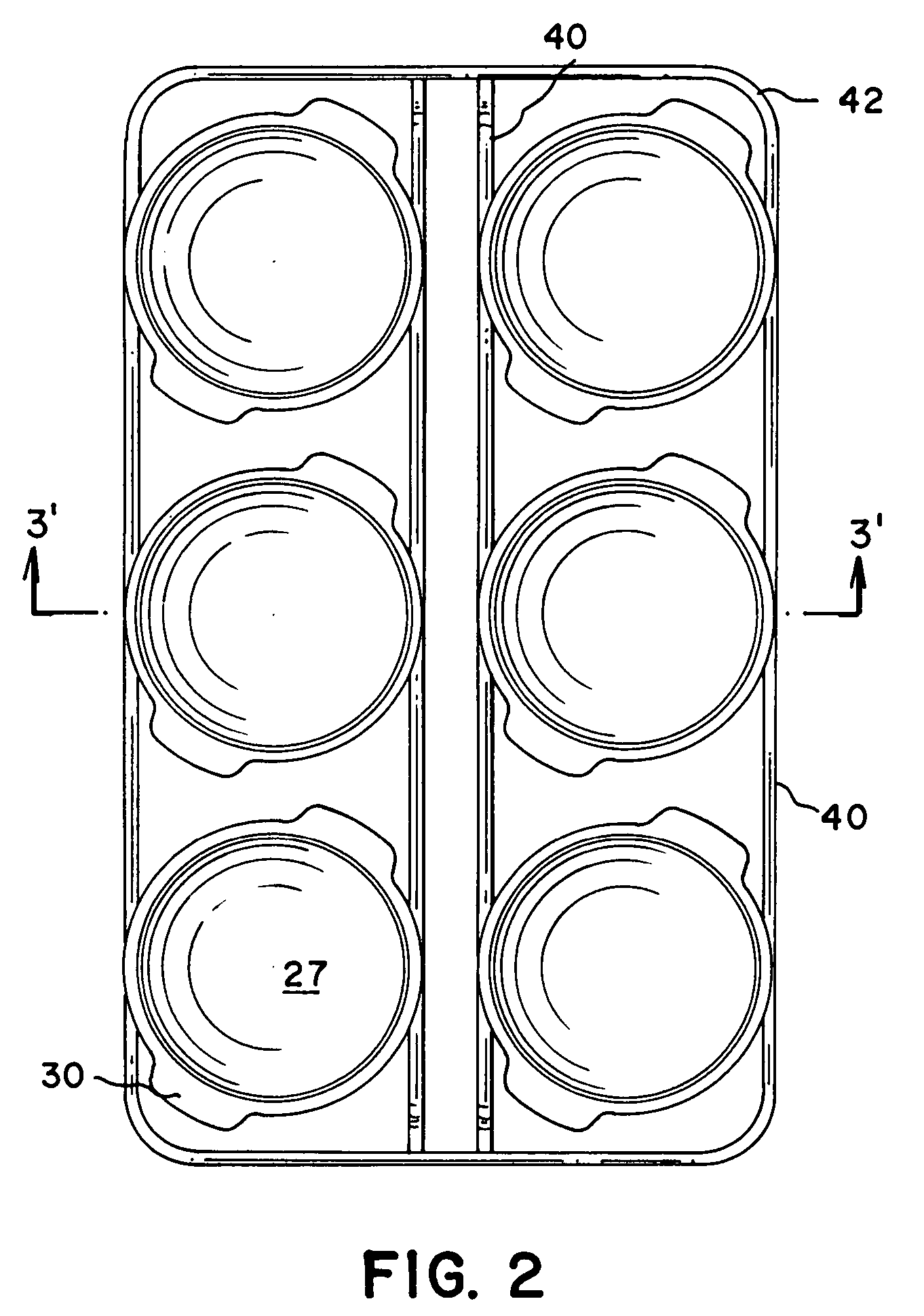

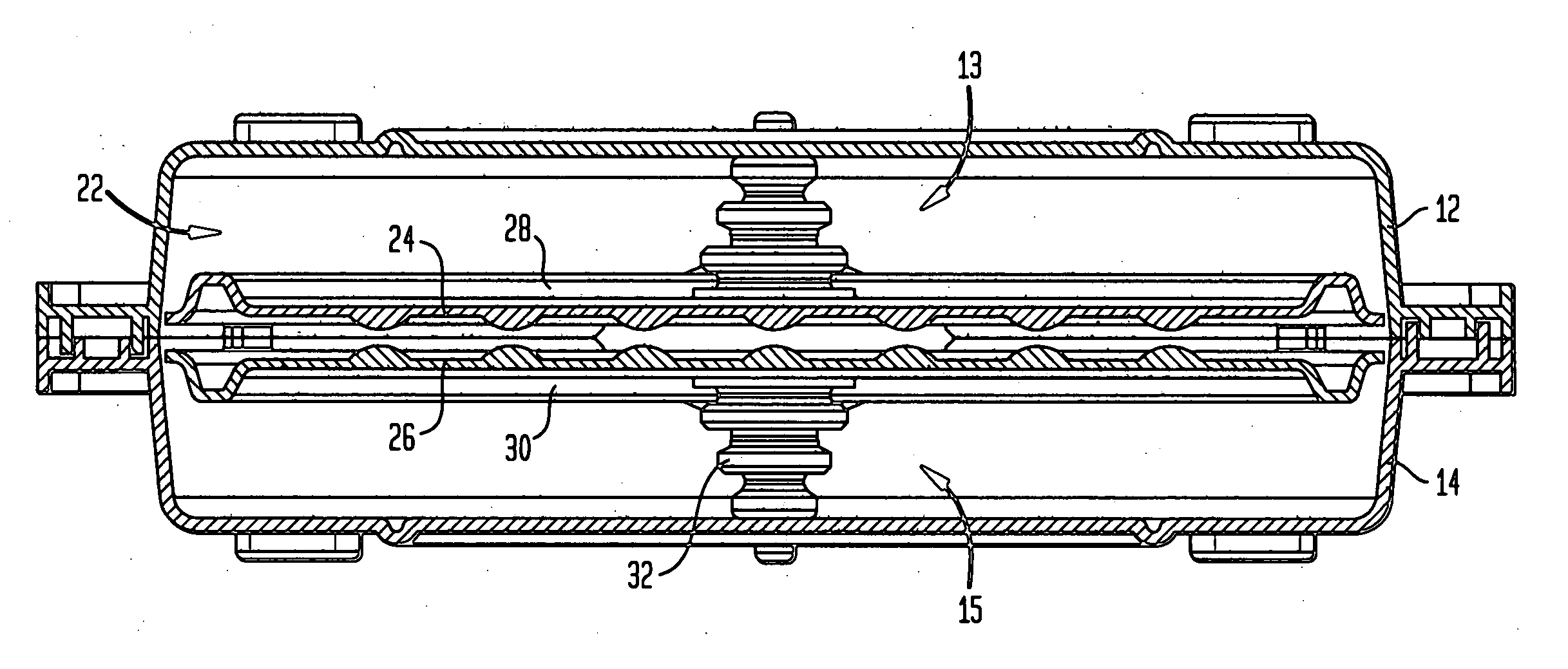

Multiple cake baking assembly

InactiveUS7150221B2Easy to useMinimum of cooking skillMeat processingKitchen equipmentCooking & bakingFixed position

An assembly for forming multiple individual compound desserts in a predetermined dome shape including a base tray having a plurality of recessed cavities to form a base for said compound dessert. A rack and a plurality of dome shaped bowl assemblies secured in a fixed position to said rack. Each bowl assembly is formed with a closed semi-spherical end and an open end forming a cavity, and a cover member which is mounted over said open end, the cover member having an inner bowl extending therefrom which extends into the cavity.

Owner:MORGAN FLETCHER

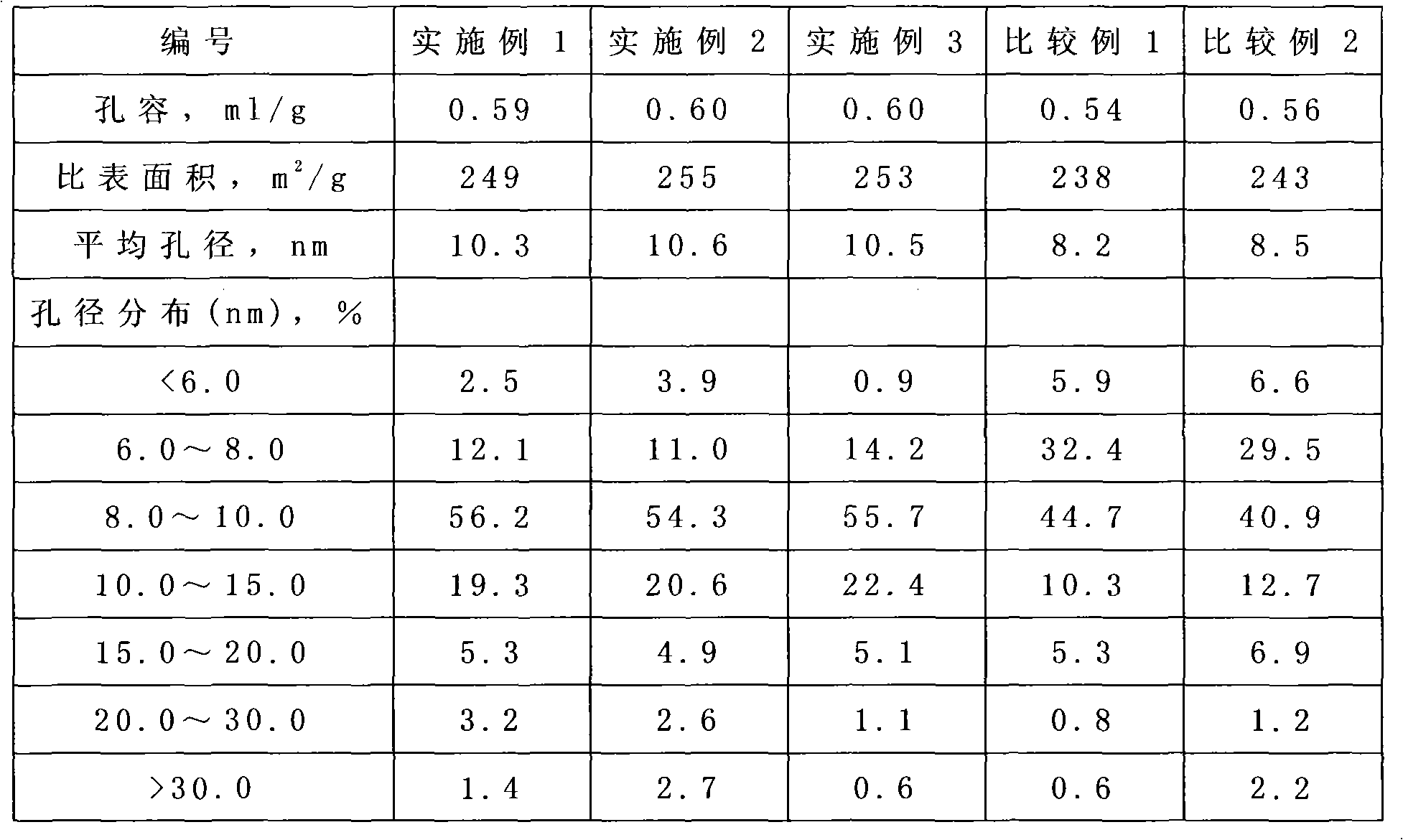

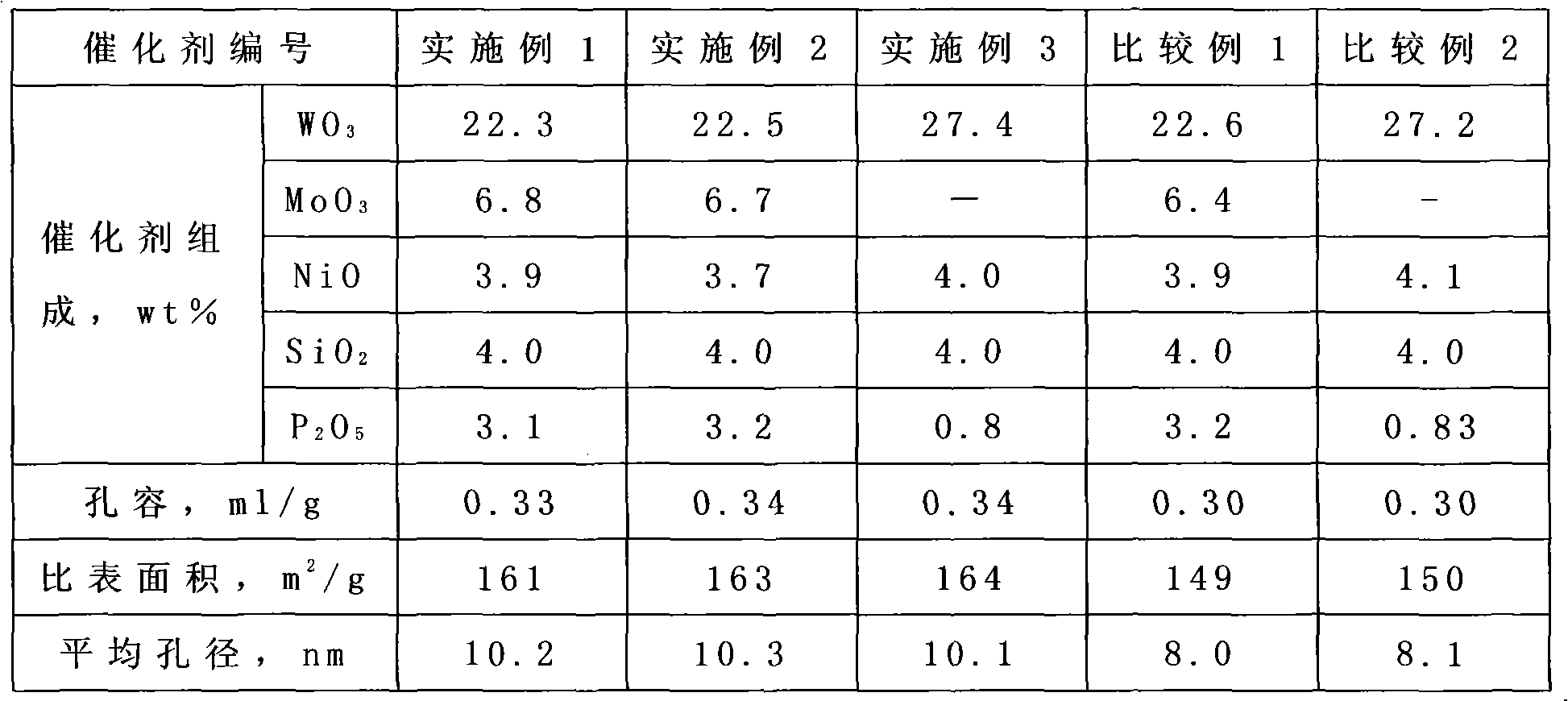

Method for preparing petroleum wax hydrofining catalyst

ActiveCN102039148AIncreased dispersionPore Structure ModulationCatalyst carriersPetroleum wax refiningCooking & bakingWax

The invention relates to a method for preparing a petroleum wax hydrofining catalyst. The method comprises the following steps of: weighing boehmite, adding a silicon-containing compound in an amount which is 6 to 17 percent based on the weight of the boehmite and phosphorus-containing organic compound solution in an amount which is 2 to 20 percent based on the weight of the boehmite, and extruding and forming on an extruder; drying at the temperature of between 100 and 120 DEG C; baking at the temperature of between 500 and 700 DEG C to obtain a gamma-Al2O3 carrier containing silicon and phosphorus, wherein the silicon-containing compound is silica solution of which SiO2 accounts for 30 percent based on the weight of the silica solution, or nano-silica; the active ingredients are one or two of NiO and Moo3, and WO3; NiO accounts for 2 to 7 percent based on the total mass of the catalyst, and MoO3 and / or WO3 account for 28 to 32 percent based on the total mass of the catalyst; the prepared catalyst has intensively distributed pores and appropriate surface acidity and still has high hydrogenation activity at a low reaction temperature and under a low reaction pressure.

Owner:PETROCHINA CO LTD

Resistance welding superposition technology for PCB thick copper lines

ActiveCN101534612AIncreasing the thicknessInhibit sheddingNon-metallic protective coating applicationProduction scheduleCooking & baking

The invention discloses a resistance welding superposition technology for PCB thick copper lines, comprising the steps of: at first, printing resistance welding ink on the surface of a PCB and forming a first resistance welding layer via screen printing resistance welding; and pre-drying while remaining 75 DEG C and semi-hardening the first resistance welding layer after cooling; then printing the resistance welding on the first resistance welding layer once again in order to form a second resistance welding layer; pre-drying once again while remaining 75 DEG C and semi-hardening the first resistance welding layer and the second resistance welding layer after cooling; eventually, hardening the resistance welding layer and the second resistance welding layer completely subsequent to the segmented baking of the semi-hardened PCB. The invention requires only one-time resistance welding pattern transfer and high-temperature baking by the superposition printing on the thickness of the resistance welding, which increases the thickness of the resistance welding layer, thickens, in particular, the thickness of the resistance welding layer at corners of the lines, and avoids the problems of resistance welding blistering and falling in thermal impact procedures of post-processing procedure, and meanwhile, using the inventive technology shortens production procedure dramatically, speeds up production schedule and lowers production cost.

Owner:SHENZHEN BOMIN ELECTRONICS

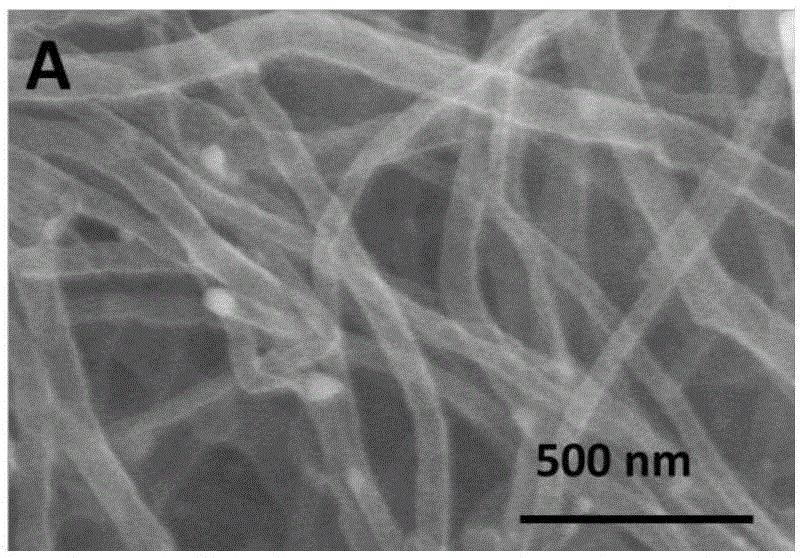

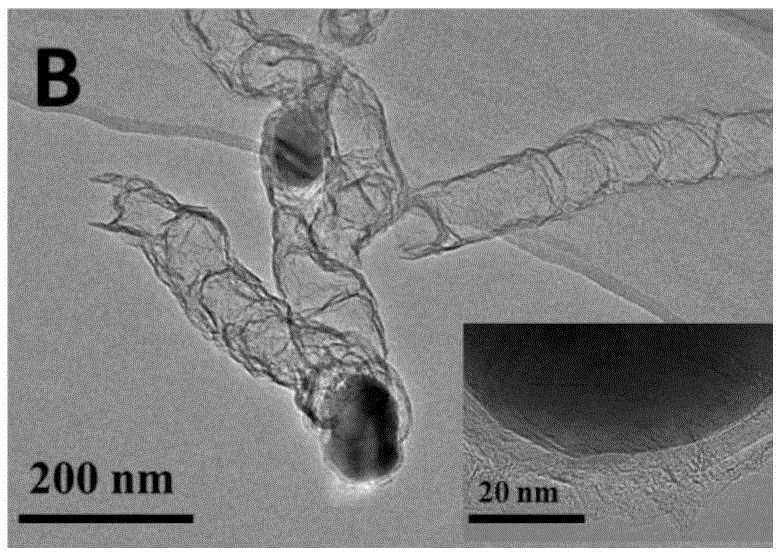

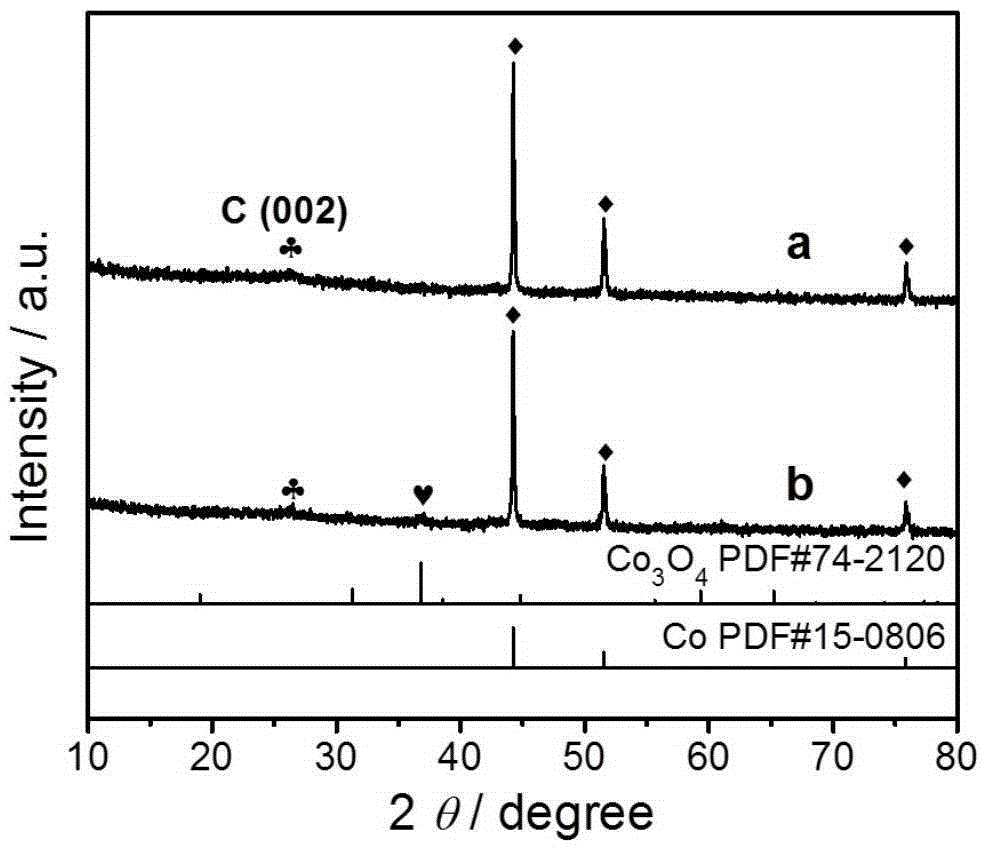

Preparation method of cobalt electro-catalysis oxygen reduction material wrapping nitrogen-doped carbon nanotube

ActiveCN105413730AOrderly arrangement and assemblyImprove performancePhysical/chemical process catalystsCell electrodesCooking & bakingOxygen

The invention discloses a preparation method of a cobalt electro-catalysis oxygen reduction material wrapping a nitrogen-doped carbon nanotube. The method includes the following steps of making melamine, cobalt nitrate hexahydrate and glucose react to obtain a self-assembled melamine precursor, and baking the self-assembled melamine precursor to obtain a cobalt nanoparticle hybrid material electro-catalysis oxygen reduction agent wrapping the nitrogen-doped carbon nanotube. In preparation of the precursor, a self-assembled body can be formed through the electrostatic interaction and the hydrogen-bond interaction by means of nitrate radicals and melamine under the acid condition, cobalt ions are adsorbed into the self-assembled body, ordered arrangement and assembly of materials in the high-temperature baking process are facilitated by the pre-assembled precursor, and therefore more catalysis active sites are exposed, and the improvement of the performance of a catalyst is facilitated.

Owner:QINGDAO UNIV

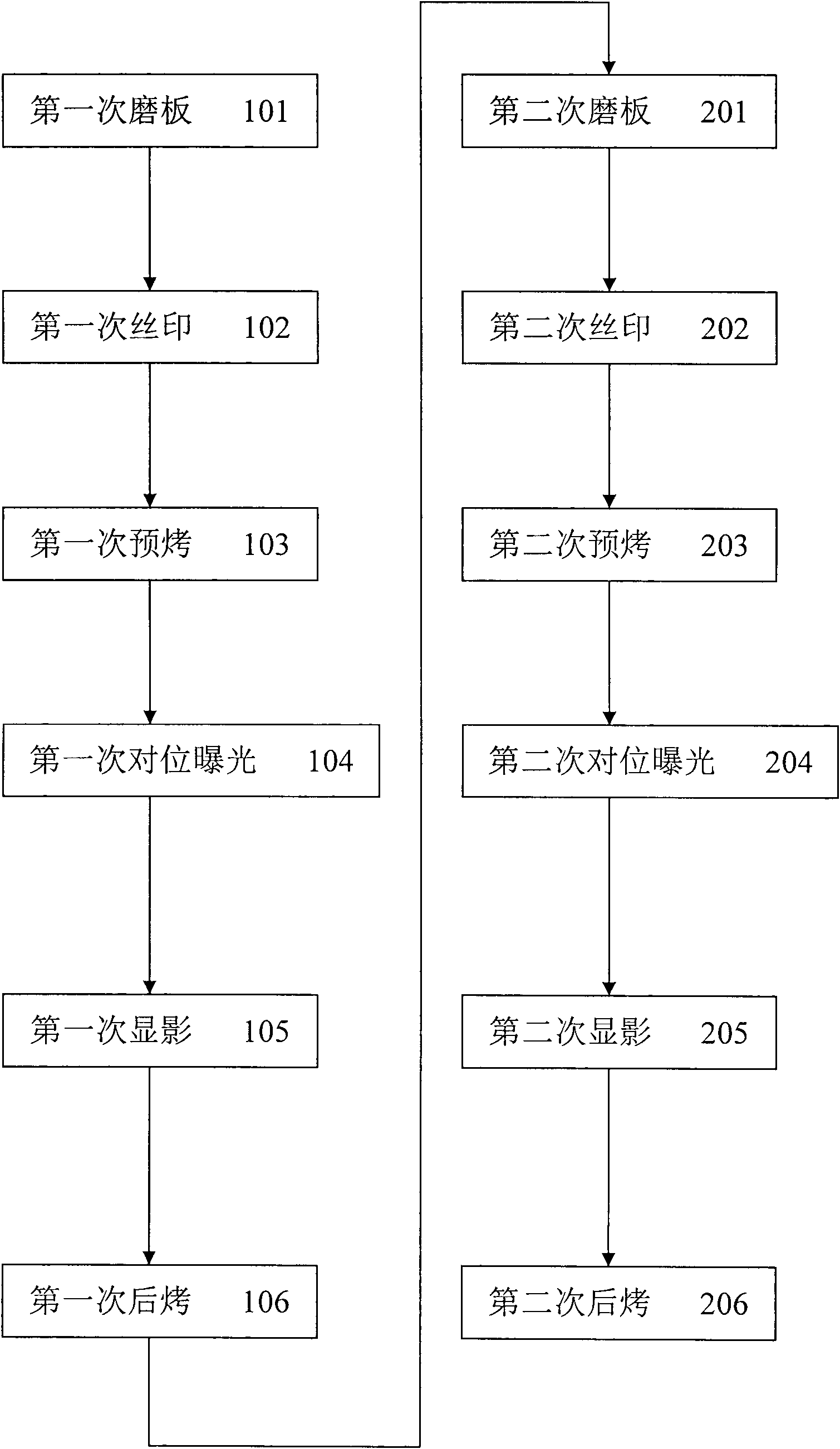

Production technology of PCB (Printed Circuit Board) solder mask

ActiveCN101668390AIncrease productivityImprove product qualityNon-metallic protective coating applicationCooking & bakingProduction schedule

The invention relates to a production technology of a PCB (Printed Circuit Board) solder mask, which comprises the following steps of: a first board grinding, a first silk screen, a first pre-braking,a first contraposition exposure, a first development, a first post-baking, a second board grinding, a second silk screen, a second pre-braking, a second contraposition exposure, a second developmentand a second post-baking, wherein the mesh number of the first silk screen is larger than that of the second silk screen, and the windowing size of the first contraposition exposure is larger than that of the second contraposition exposure. The production technology of the PCB solder mask better eliminates the harmful defects in the solder mask production process that green oil and the like easilysolders an oil plughole, the developing is dirty, the circuit becomes red, and the lateral erosion of a film printing and development is large and the like, thereby improving the production efficiency and the production quality, speeding up the production schedule and reducing the production cost.

Owner:大连崇达电子有限公司

Method for finishing wool fabric by compositing chitosan/TiO2

ActiveCN103981694AImprove the efficiency of grafting reactionGood antibacterialLiquid/gas/vapor removalUltrasonic/sonic fibre treatmentCooking & bakingPollution

The invention provides a method for finishing wool fabric by compositing chitosan / TiO2, which comprises the following steps: A)pretreating fabric; B)preparing composite finishing liquor, taking butyl titanate and dissolving in ethanol, adding diethanolamine, uniformly stirring and adding mixed liquor mixed by ethanol and water, heating, stirring under a backflow state to form nano TiO2 sol; adding chitosan, citric acid and sodium hypophosphate in the nano TiO2 sol, uniformly stirring to obtain the composite finishing liquor; C)finishing wool fabric, placing wool fabric in the composite finishing liquor, dipping and padding twice, wherein mangle expression is 85% and padding temperature is 50-65%; D)predrying; E)baking; F)washing; and G)drying. According to the finishing method, chitosan and nano TiO2 sol are employed as the composite finishing liquor, the finished wool fabric has good antibiosis, shrinkproof, ultraviolet resistance and anti-insolation performances; the finishing method generates no pollution on human body and environment, and the finished wool fabric has good hand feeling.

Owner:ZHEJIANG ZHONGXIN DYEING & FINISHING CO LTD

Technique for producing Jinhuaqianliang tea (flower coil tea)

ActiveCN101352191AQuality improvementUniform qualityPre-extraction tea treatmentCooking & bakingThirst

The technology for producing golden flower Qianliang tea (Hua-juan tea) is characterized in that the technology comprises the process steps as follow: plucking criteria-water removing in high temperature-rolling and shaping-pile-fermentation-dry and adding incense-stems picking and sieving-matching and pile-classificaition and weighting-steam softening-moisture detection-adpressing and sizing-premilary test and baking-cultivating golden flower-aerationagitation. The technology is an improved deep processing technology. The processes of the pile-fermentation and the cultivating golden flower ensure that the appearance of the products is ooiu colour, the interior is brown, and even distributed beneficial organism (namely, golden flower)-eurotium cristatum is clearly saw, the shangse is bright red, the taste is pure and aromatic, and the flower is aromatic, and has the health care functions of promoting sleeping, invigorating stomach and promoting digestion, relaxing bowel, slaking thirst and helping produce saliva, antidiabetics, lowering blood pressure, curing bloated, cuing laxness, etc. The technology fully actives microelements such as vitamins contained in tea, mineral composition, 18 amino acid, protein, glucide, folic acid, catchol which are beneficial to human health and easily absorbed, and the cultivation of golden flower has substantial transformation on tea polyphenols, caffeine, and theophylline that are transferred into elements that are beneficial to human health, all ages, expand market, have high cultural value, provide collection opportunity for black tea lovers.

Owner:湖南省安化县晋丰厚茶行有限公司

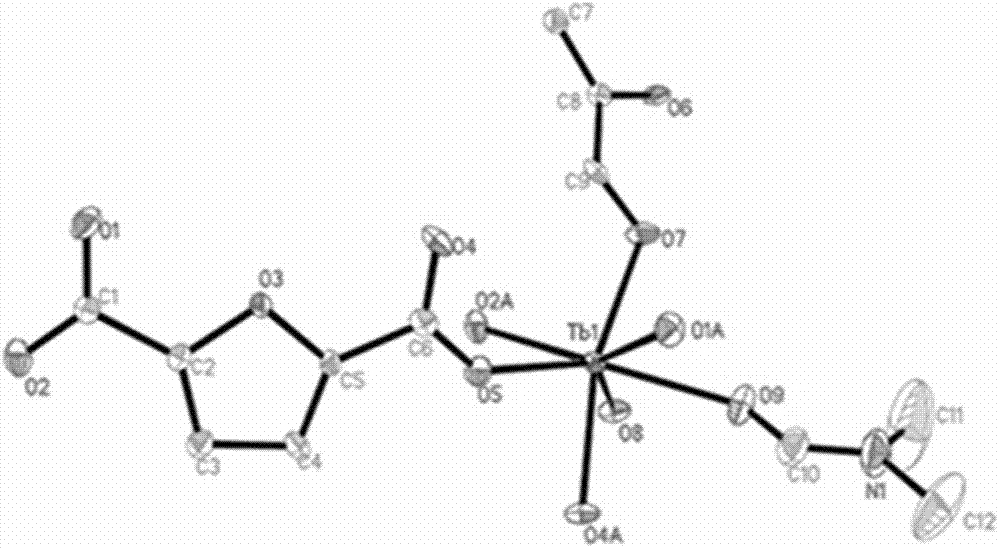

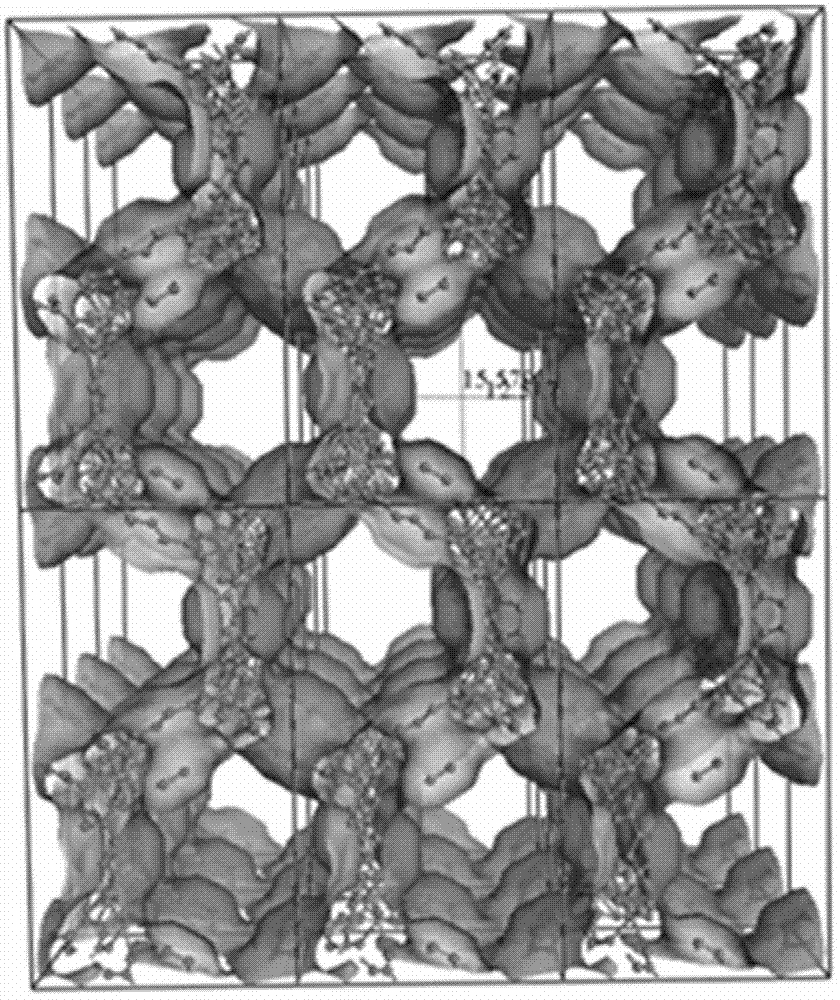

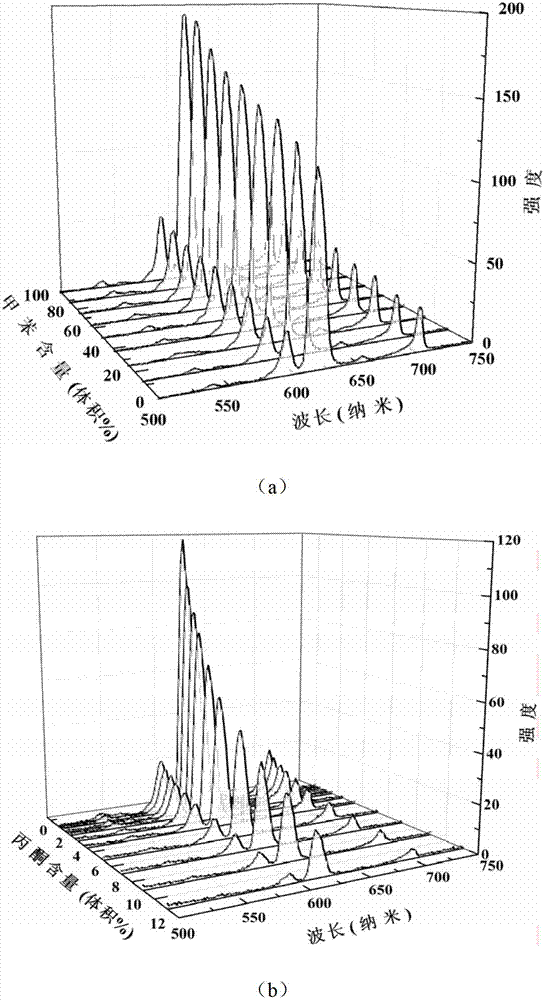

Multifunctional rare earth metal-organic framework and preparation method thereof

InactiveCN102757453ANovel structureSensitive recognitionCarbon compoundsOther chemical processesCooking & bakingN dimethylformamide

The invention relates to a multifunctional rare earth metal-organic framework of which the chemical formula is {[Ln(FDA)1.5(DMF)].DMF}n, wherein Ln is Eu or Tb, the FDA is furyl-2,5-dicarboxylic acid, and the DMF is N,N-dimethylformamide; and the rare earth metal framework structure has an Eu<3+> / Tb<3+> ion in a coordination environment, and forms a three-dimensional framework structure containing one-dimensional honeycomb channels. The preparation method comprises the following steps: by using europium nitrate hexahydrate or terbium nitrate hexahydrate as a metal salt, H2FDA as a ligand and DMF as a solvent, stirring the mixed solution, baking, separating and washing the solid to obtain the multifunctional rare earth metal-organic framework. The multifunctional rare earth metal-organic framework provided by the invention has an fluorescent identification function on cancerigenic organic solvents, such as methylbenzene, benzene and acetone, has excellent selective adsorptivity for gas and high acting force with H2, contains high adsorptive enthalpy, and thus, is a multifunctional novel-structure microporous MOF (metal-organic framework) material.

Owner:NANKAI UNIV

Microwavable grill

InactiveUS20070029316A1Efficient preparationIncrease contactCooking vesselsMicrowave heatingCooking & bakingMicrowave oven

A microwavable cooking apparatus is disclosed. The apparatus may contain one or more cooking surfaces to, among other functions, cook foodstuffs in a microwave oven in a variety of ways, including grilling, griddling, baking, browning, crisping, and steaming. The cooking surfaces may be composed of any one of a variety of cooking plates, each having different surface profiles. for different modes of cooking. Such cooking plates may be detachable and interchangeable. Springs may be included, which permit movement of the cooking plates. The apparatus may also be utilized while being situated in both horizontal and vertical orientations. In addition, the apparatus may include features to facilitate these various uses. Furthermore, several attachments may be operable with the apparatus in order to offer even more functionality.

Owner:PRODS OF TOMORROW

Process for the production of articles covered with silica-base coats

InactiveUS6465108B1Reduce the degree of polymerizationImprove responsePretreated surfacesLiquid/solution decomposition chemical coatingCooking & bakingAlcohol

Coating liquid prepared by dissolving an acid and a silicon alkoxide into alcohol, containing at least one of either a silicon alkoxide or a hydrolyzate thereof (including a partial hydrolyzate) in an amount of 0.010 to 3% by weight (in terms of silica), an acid in terms of 0.0010 to 1.0 normality, and water in terms of 0 to 10% by weight is coated on a substrate to produce an article coated with a silica-based film. By this method for producing a silica-based film coated article, an excellent silica-based film coated article can be obtained without requiring baking and pretreatment. Furthermore, a functional film coated article excellent in durability can be produced in a short period of time and safely by using the abovementioned silica-based film as a primer film and applying thereon an organosilane having a hydrolyzable group and a functional group having a specific function or a hydrolyzate thereof.

Owner:NIPPON SHEET GLASS CO LTD

Processing process for anhua black raw tea

InactiveCN102972541ASoup color orange redSoup color orange red translucentPre-extraction tea treatmentCooking & bakingBlack tea

The invention relates to a processing process for anhua black raw tea, and in particular relates to the processing process for the anhua black raw tea. The processing process comprises the following steps of: picking fresh leaves, removing water, primarily rubbing, piling, secondarily rubbing, drying, naturally storing and pre-pressing. According to the processing process provided by the invention, the material selecting is particular, and all black tea raw materials adopt the raw materials in the producing area of liudong tea in jiangnan town; in the process of removing water, the firewood is used as fuel, so that air pollution caused by using coal as fuel is avoided and the tea is prevented from absorbing peculiar smell of sulfur dioxide released by coal combustion, and the original flavor of the tea is greatly ensured. The tea can be kept black and oily through the baking of pine firewood, and the tea color is orange red and bright. After being baked, the tea is naturally stored for over one year before being pressed, fermented in an oxidative manner, and primarily processed; no crushing process is needed before the pressing process; as space inside the tea is bigger due to raw tea-leaf pressing, oxygen needed for microbial activities is provided, and so golden flowers can be seen inside the black tea finished product.

Owner:湖南三十九铺茶业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com