Patents

Literature

2499 results about "N dimethylformamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

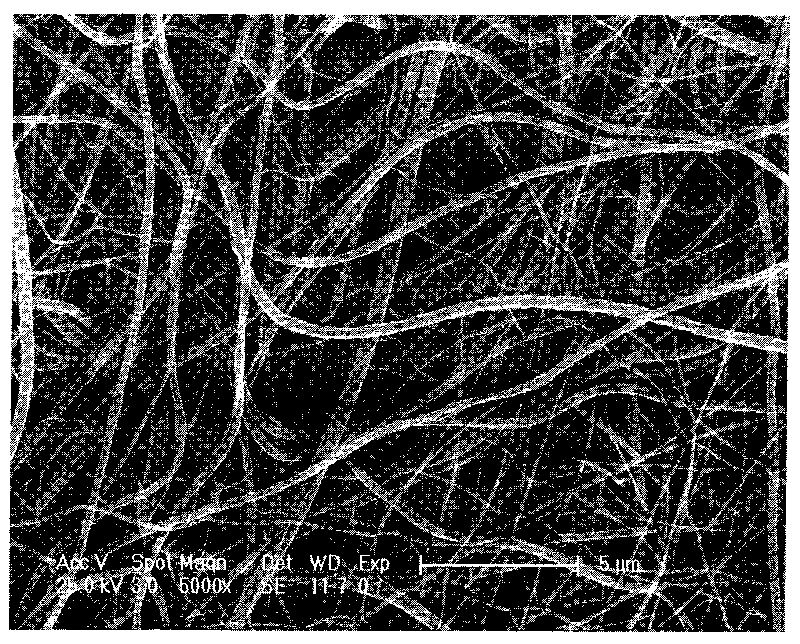

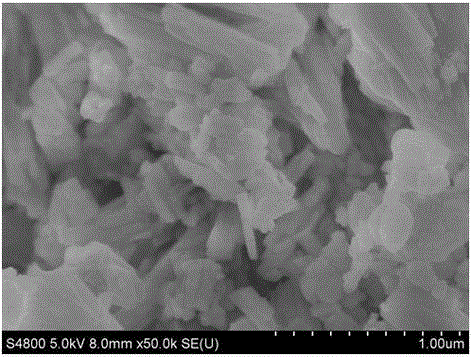

Process for preparing titanium dioxide nano-belts

The invention provides a method for preparing a titanium dioxide nano belt, belonging to the nano material technical field. The prior methods for preparing the titanium dioxide nano belt comprise the hydro-thermal method and the combination method of the sol-gel method and the hydro-thermal method. The prior electrostatic spinning method is applied to the preparation of nano fibers. The invention comprises three steps that: 1. a spinning solution is prepared; the mixture of polymethylmethacrylate and vinylpyrrolidone is used as a macromolecule template, and the mixture of chloroform and N,N-dimethylformamide is used as a solvent; 2. a titanium alkoxide / macromolecule template compound nano belt is prepared; the electrostatic spinning method is used, and the technical parameters are as follows: the voltage is between 15 and 25kV and the curing distance is between 15 and 30cm; 3. a TiO2 nano belt is prepared; the heat treatment method is used, and the technical parameters are as follows: the rate of temperature rise is between 0.5 and 2 DEG C / min and the heat preservation time at the temperature of between 500 and 900 DEG C is between 10 and 15h; for the TiO2 nano belt prepared, the width is between 5 and 15mu m, the thickness is between 30 and 60nm and the length is more than 200mu m; the TiO2 nano belt comprises a pure phase anatase type TiO2 nano belt and a pure phase rutile type TiO2 nano belt.

Owner:CHANGCHUN UNIV OF SCI & TECH

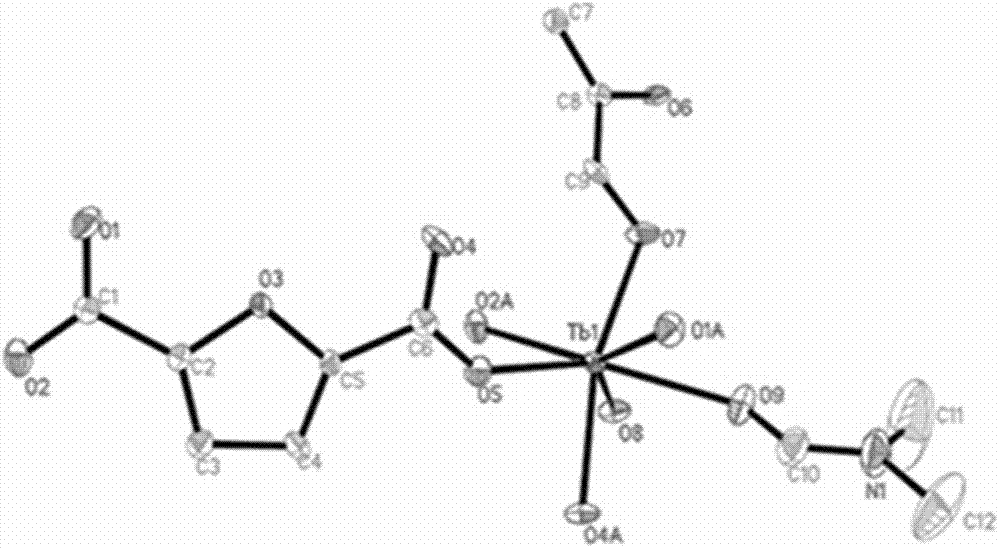

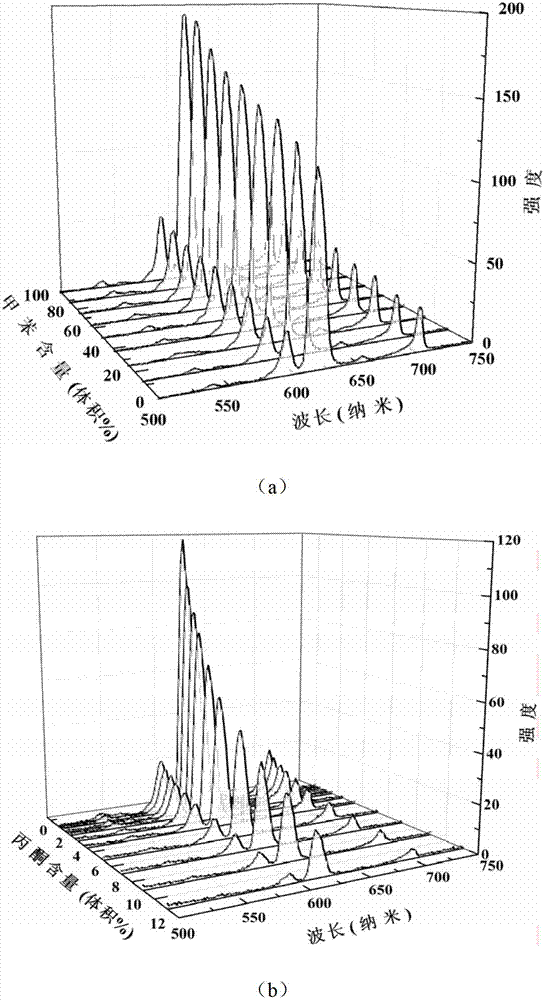

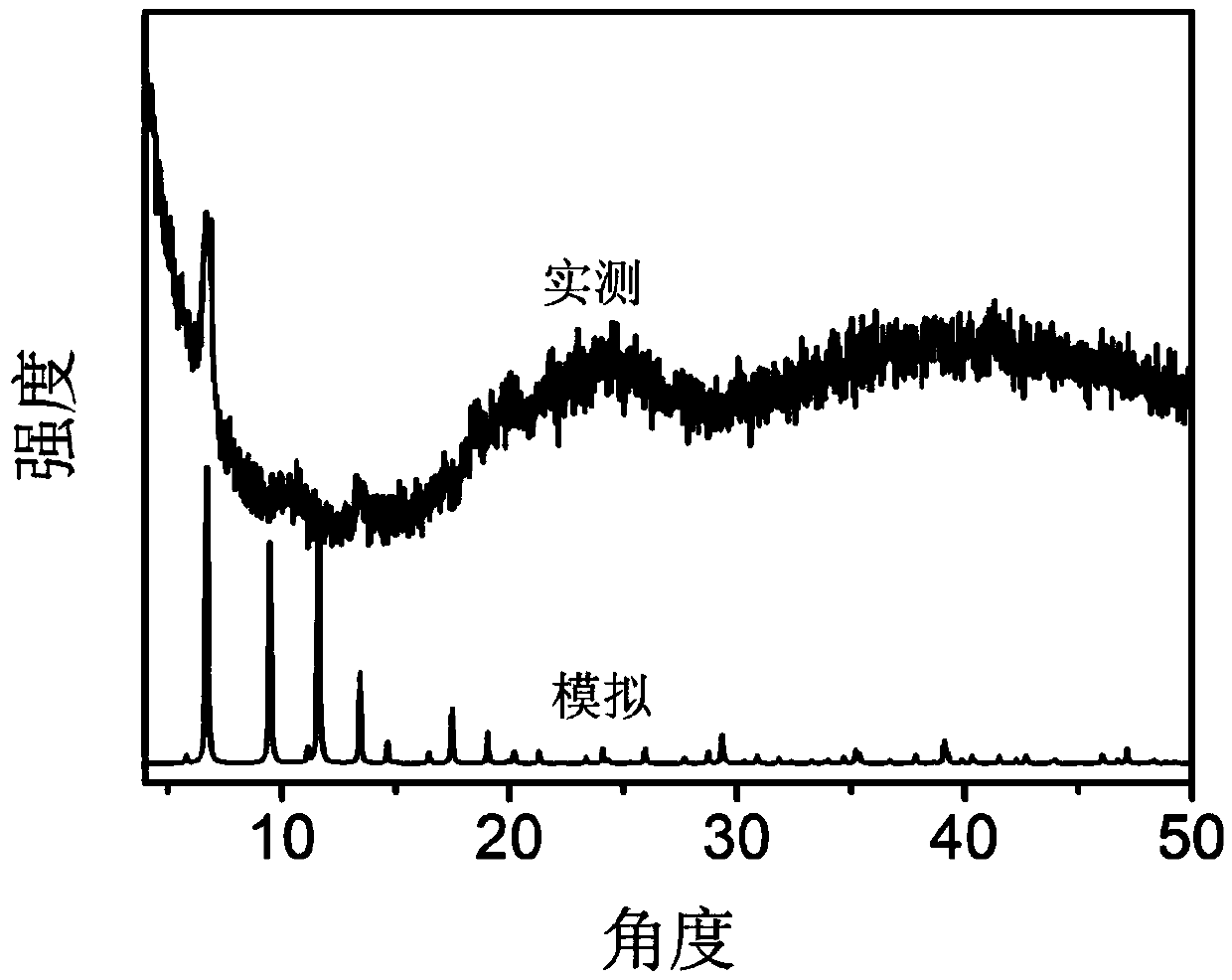

Multifunctional rare earth metal-organic framework and preparation method thereof

InactiveCN102757453ANovel structureSensitive recognitionCarbon compoundsOther chemical processesCooking & bakingN dimethylformamide

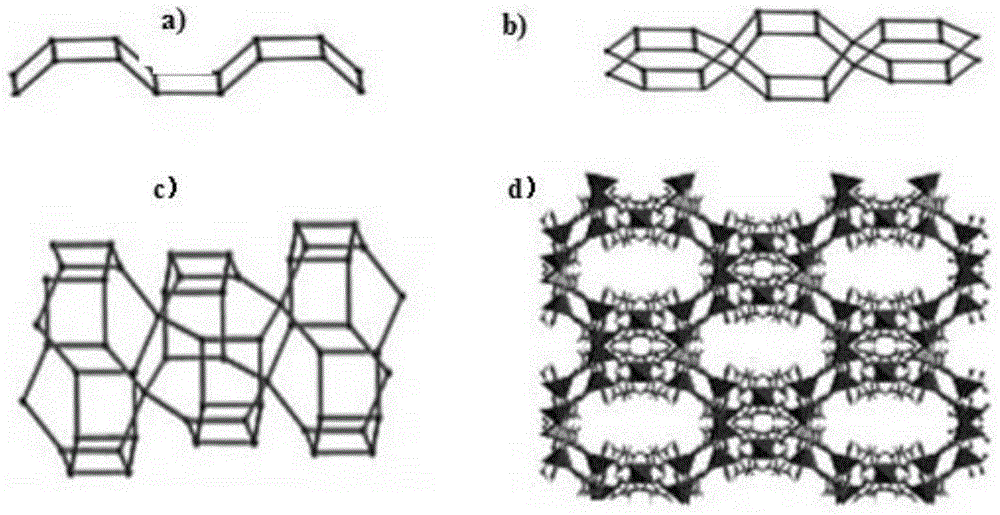

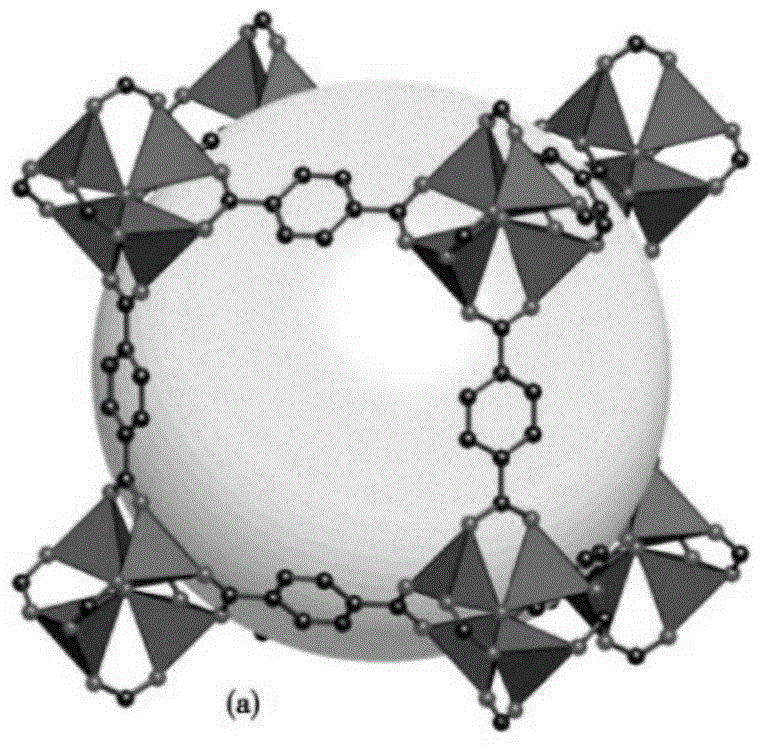

The invention relates to a multifunctional rare earth metal-organic framework of which the chemical formula is {[Ln(FDA)1.5(DMF)].DMF}n, wherein Ln is Eu or Tb, the FDA is furyl-2,5-dicarboxylic acid, and the DMF is N,N-dimethylformamide; and the rare earth metal framework structure has an Eu<3+> / Tb<3+> ion in a coordination environment, and forms a three-dimensional framework structure containing one-dimensional honeycomb channels. The preparation method comprises the following steps: by using europium nitrate hexahydrate or terbium nitrate hexahydrate as a metal salt, H2FDA as a ligand and DMF as a solvent, stirring the mixed solution, baking, separating and washing the solid to obtain the multifunctional rare earth metal-organic framework. The multifunctional rare earth metal-organic framework provided by the invention has an fluorescent identification function on cancerigenic organic solvents, such as methylbenzene, benzene and acetone, has excellent selective adsorptivity for gas and high acting force with H2, contains high adsorptive enthalpy, and thus, is a multifunctional novel-structure microporous MOF (metal-organic framework) material.

Owner:NANKAI UNIV

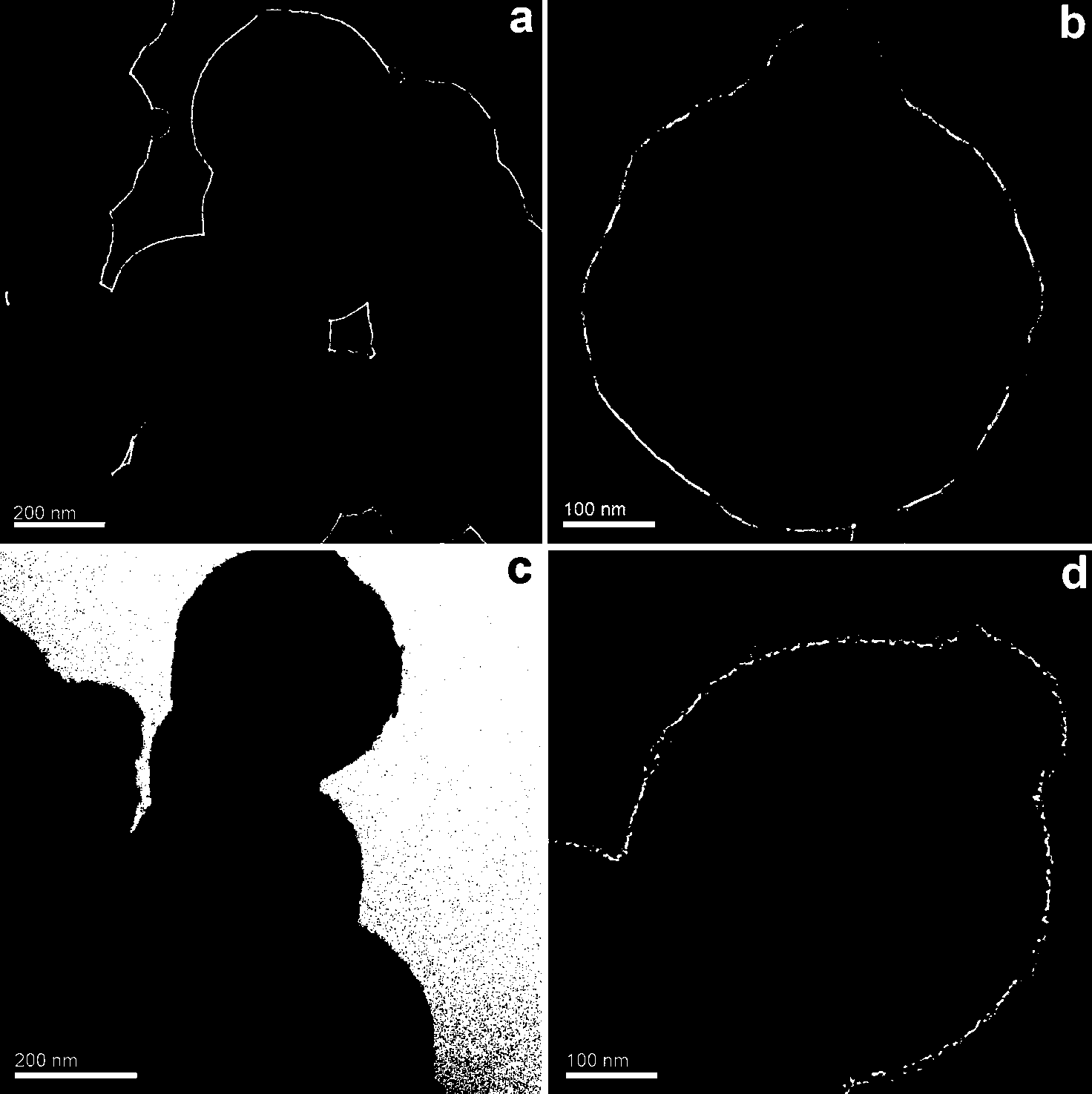

Synthesis method of magnetic metal organic framework composite material and application of material

InactiveCN103894161AGood magnetic responseImprove hydrophilicityOther chemical processesPreparing sample for investigationN dimethylformamideSynthesis methods

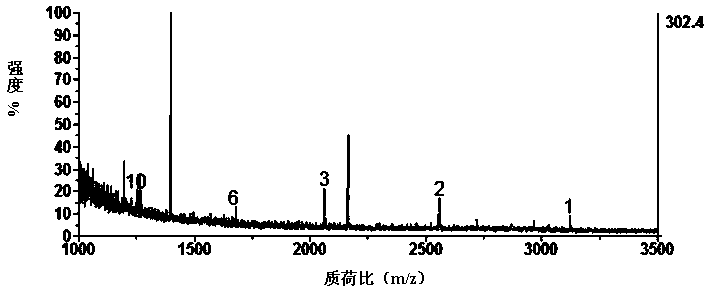

The invention discloses a synthesis method of a metal organic framework composite material which has a sandwich structure, comprises magnetic microsphere ferroferric oxide surface coating polydopamine and takes zirconium ion as central metal ion and application of the material. The synthesis method comprises the following steps: firstly synthesizing ferroferric oxide magnetic microspheres by using a hydrothermal synthesis method; dispersing the magnetic microspheres in an aqueous solution of polydopamine hydrochloride to coat the surfaces of the magnetic microspheres with polydopamine layers; dispersing the magnetic microspheres coated with the polydopamine in an N,N-dimethylformamide mixed solution of zirconium chloride and terephthalic acid to prepare the magnetic metal organic framework composite material with a sandwich structure. The synthesis method is simple and quick; the magnetic metal organic framework composite material obtained by synthesizing is high in specific surface area, good in biocompatibility and applicable to selective enrichment of phosphorylated peptide and MALDI-TOFMS detection in biological samples.

Owner:FUDAN UNIV

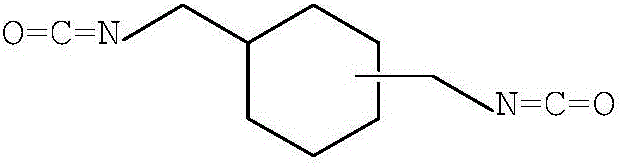

Preparation method of hydrogenated xylylene diisocynate

ActiveCN106674056AGood dispersionImprove liquidityOrganic compound preparationIsocyanic acid derivatives purification/separationXylyleneN dimethylformamide

The invention discloses a preparation method of hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate comprises the following steps: (1) performing salt forming reaction on 1,3-cyclohexanol dimethylamine and concentrated hydrochloric acid in a two-phase reaction solvent to obtain amine salt, wherein the two-phase reaction solvent consists of water and an inert organic solvent insoluble in water ; (2) performing photochemical reaction on the ammonium salt obtained in the step (1) and phosgene in an inert solvent by taking N,N-dimethylformamide or N,N-dimethylacetamide as a catalyst to obtain reaction liquid, and performing aftertreatment on the reaction liquid to obtain the hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate has the advantages of complete ammonium salt formation, small grain size of the ammonium salt, low viscosity of the ammonium salt, high space-time conversion rate of photochemical reaction, simple process, low cost and the like.

Owner:HUNAN HAILI CHEM IND

Method for modifying epoxy resin through amino-terminated hyperbranched polymer-grafted graphene oxide

The invention discloses a method for modifying epoxy resin through amino-terminated hyperbranched polymer-grafted graphene oxide. The method comprises the following steps: preparing graphite oxide from flake graphite utilized as a raw material by adopting a Hummers oxidation method, adding the graphite oxide into a beaker, adding distilled water and forming a graphene oxide mixed solution by virtue of ultrasonic waves; stirring for dissolving triethylene tetramine in N,N-dimethylformamide, raising the temperature to 55-65 DEG C, dropwise adding a mixed solution of methyl methacrylate and methanol, continuously raising the temperature to 80-120 DEG C and reacting for 6-10 hours to get an amino-terminated hyperbranched polymer; further adding the graphene oxide mixed solution and NaOH, regulating the PH value to be 5-10, performing ultrasonic dispersion for 2-8 hours at the temperature of 80-120 DEG C, evaporating the methanol, cooling to room temperature, adding water to precipitate a product, drying to get the amino-terminated hyperbranched polymer-grafted graphene oxide capable of toughening and modifying the epoxy resin. The method disclosed by the invention is wide in raw material source, simple in preparation process, pollution-free, lower in cost and beneficial to industrial large-scale production.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

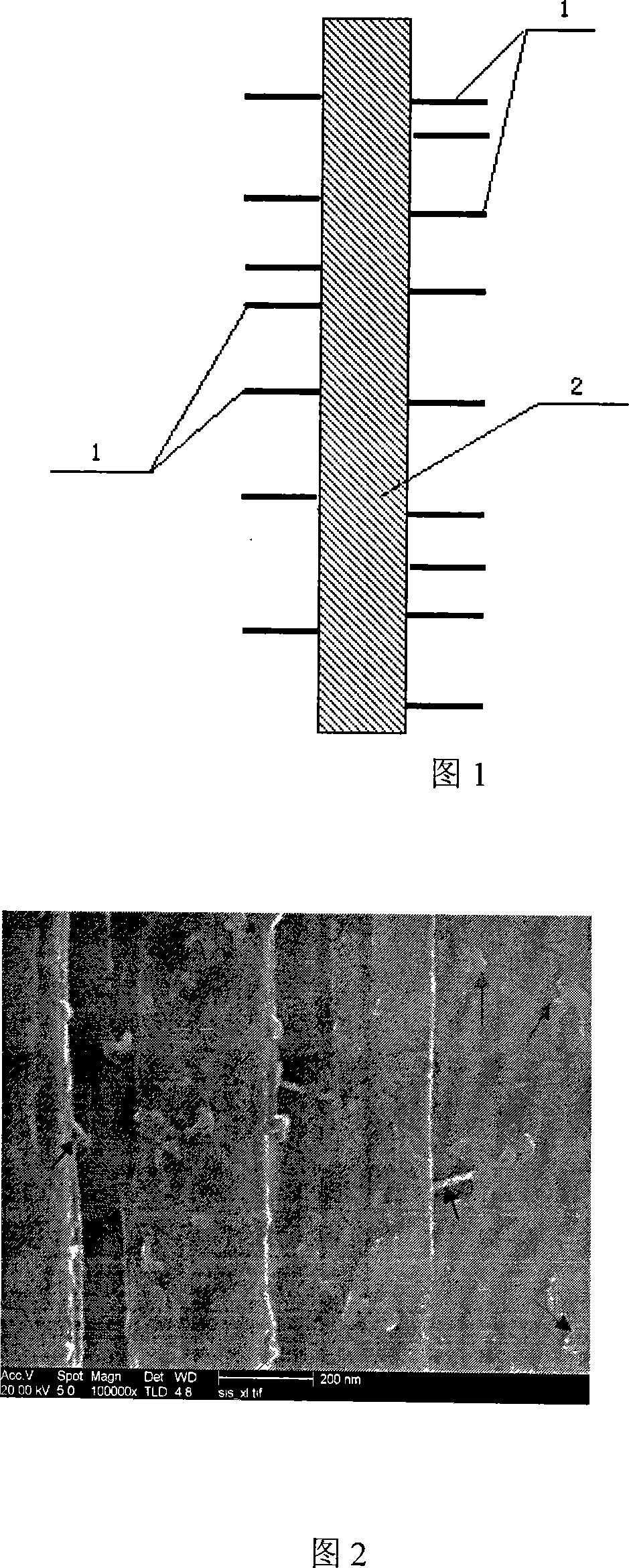

Carbon nano-tube connecting carbon fiber multi-scale reinforcing body and method for producing the same

InactiveCN101173386ATake full advantage of mechanical propertiesRealize chemical bond connectionFibre treatmentArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a multi-scale reinforcement body that carbon nano-tube is connected with carbon fiber and a preparation method aiming at solving the drawbacks of increasing rigidity at the interface, lowering toughness of material and not improving performance of resin base between the fibers and between carbon fiber plywoods after prior carbon fiber treatment is made. The multi-scale reinforcement body of carbon nano-tube connecting carbon fiber is made through combining between a carbon nano-tube decorated by 1, 6 hexamethylenediamine and carbon fiber with acyl chloride functional group on the surface. The preparation method comprises: the carbon nano-tube decorated by 1, 6 hexamethylenediamine and the carbon fiber with acyl chloride functional group on the surface are prepared before put into N,N-dimethylformamide for reaction, thereby getting the multi-scale reinforcement body of carbon nano-tube connecting carbon fiber. The invention has the advantages of big activity on the surface, a plurality of chemical activated functional groups, strong reactive activity, good cohesiveness with the base, improving shearing intensity at the interface for composite material by 127.5% to 144.7% and improving toughness for the base by 34.43% to 48.67%.

Owner:HARBIN INST OF TECH

Preparation method of inorganic/organic hybridization antibacterial film

The invention relates to a preparation method of an inorganic / organic hybridization antibacterial film. The preparation method mainly comprises the steps of: (1) preparing a nano-silver-loaded molecular sieve germicide with stronger stability by ion exchange and a chemical reduction method; and preparing a molecular sieve / polymer hybridization antibacterial film loaded with nano-silver particles by a phase transformation film preparation process; and (2) taking N,N-dimethylformamide as a solvent and a reducing agent simultaneously, reducing silver ions to nano-silver serving as an antibacterial function body in a film casting liquid system in situ, and firmly loading the nano-silver in a polymer porous matrix material by a dispersion action and a coupling action of a coupling agent so as to form a nano-silver-loaded polymer porous film. The hybridization antibacterial film, provided by the invention, keeps excellent water flux, high retention rate and tough mechanical intensity, and has excellent antibacterial function, and can effectively solve the problems of loss of the silver ions of the silver-ion-loaded molecular sieve in the membrane filtration, loss of the nanometer inorganic particles in the polymer porous matrix, easy pollution of a separation film by microorganisms, and the like.

Owner:天津鼎芯膜科技有限公司

Organic metal framework supported palladium, preparation method and application thereof

InactiveCN101733162AImprove stabilityHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryN dimethylformamide

The invention discloses an organic metal framework supported palladium in the technical field of chemical industry, a preparation method and application thereof. The organic metal framework supported palladium is prepared by the method comprising the steps of: dissolving terephthalic acid and zinc nitrate hexahydrate into N, N-dimethylformamide, dripping triethylamine with the stirring, continuing stirring the obtained solution, filtering the obtained solution, and washing a precipitate to obtain a solid, namely MOF-5; and dissolving Na2PdC14 into the N, N-dimethylformamide to obtain solution, adding the MOF-5 into the solution, and then dripping hydrazine hydrate to obtain Pd@MOF-5 through stirring, filtration, washing and vacuum drying. The invention also relates to the method for preparing the organic metal framework supported palladium, application thereof taken as a catalyst in a Sonogashira reaction, and the method for preparing diaryl acetylene. The organic metal framework supported palladium in the invention has good stability, can catalyze the reaction with high selectivity and high efficiency under rather low loading of the catalyst, and can be repeatedly used.

Owner:SHANGHAI JIAO TONG UNIV

Immobilized carrier of nano-attapulgite clay compounded hydrophilic urethane foam microorganisms

InactiveCN101619310AHigh affinityImprove mass transfer effectImmobilised enzymesSustainable biological treatmentN dimethylformamideRaw material

The invention relates to an immobilized carrier of nano-attapulgite clay compounded hydrophilic urethane foam microorganisms, which consists of the following raw materials in parts by weight: 100 polyether, 36-55 toluene di-isocyanate, 3.1-3.9 polyisocyanate, 0.5-5 nano-attapulgite clay, 0.45-1.2 silicon oil, 0.14-0.25 tertiary amine, 0.14-0.20 organotin, 1.0-2.7 water, 1.6-4.5 methylene dichloride and 0-80 N, N-dimethylformamide. The polyisocyanate and the nano-attapulgite clay are added in the foaming process of common polyether urethane, thereby the common polyether urethane has a water absorbing surface with crosslinked network structure and strong polarity, meanwhile has great adsorption capacity and hydrophilicity of nanomaterials, improves the compatibility and the mass transfer performance of a foam carrier to the microorganism, and simultaneously strengthens the physicochemical performance and the stability of the materials, thereby improving the sewage treatment efficiency.

Owner:LANZHOU JIAOTONG UNIV

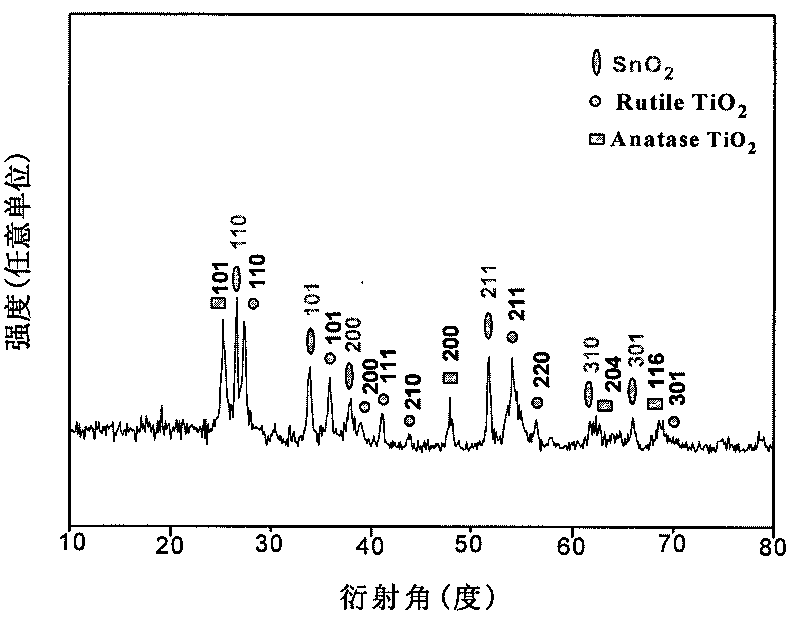

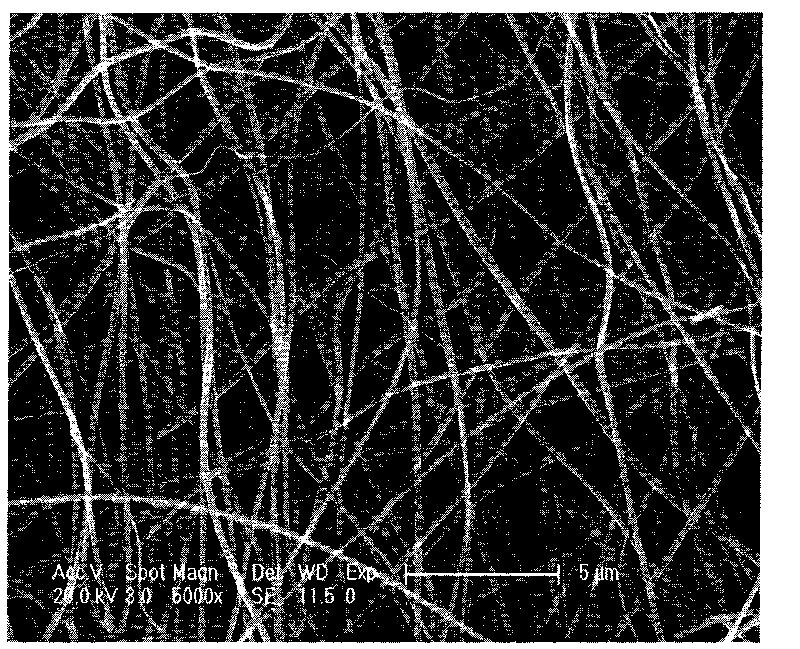

Method for preparing tin dioxide and titanium dioxide nano cable

The invention relates to a method for preparing a tin dioxide and titanium dioxide nano cable, which belongs to the technical field of nano material preparation. The method comprises the following three steps of: (1) preparation of spinning solution, adding stannic chloride and polyvinylpyrrolidone (PVP) into a mixed solvent of N, N-dimethylformamide and glycerin so as to prepare a core layer of the spinning solution, and adding PVP into a mixed liquid of butyl titanate and absolute ethyl alcohol so as to prepare a shell layer of the spinning solution; (2) preparation of (PVP+SnC14) and [PVP+Ti(OC4H9)] composite nano fiber by a coaxial electrostatic spinning technology under the condition that the voltage is 11.5-15 kV, the curing distance is 10-15 cm, the room temperature is 20-25 DEG C and the relative humidity is 45-50 percent; (3) preparation of SnO2 an TiO2 nano cable: carrying out heat treatment on the composite nano fiber to obtain the cable with cable diameter of 300-340 nm, core layer diameter of 200-220 nm, the shell layer thickness of 50-60 nm and length of more than 300 mu m.

Owner:CHANGCHUN UNIV OF SCI & TECH

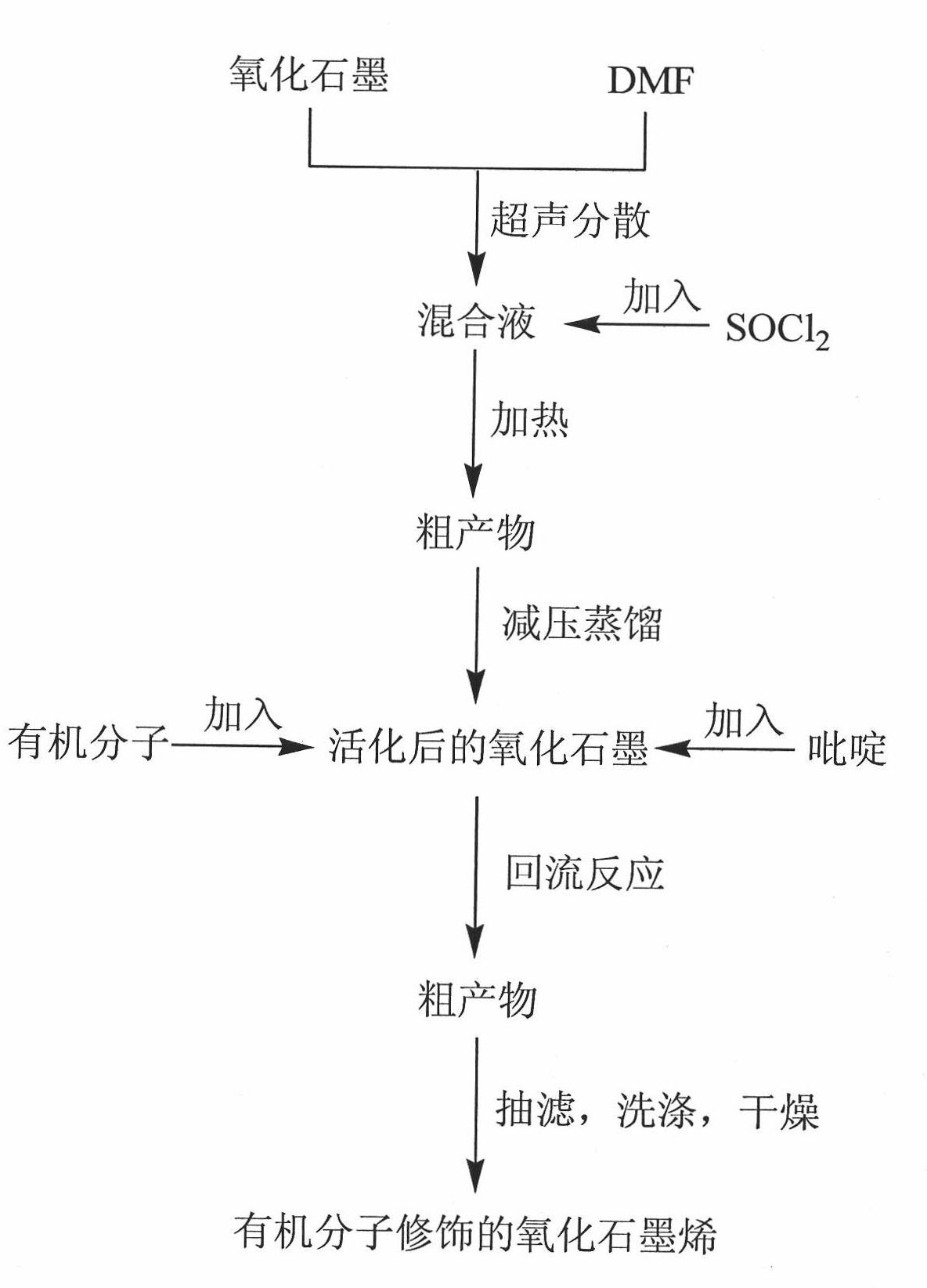

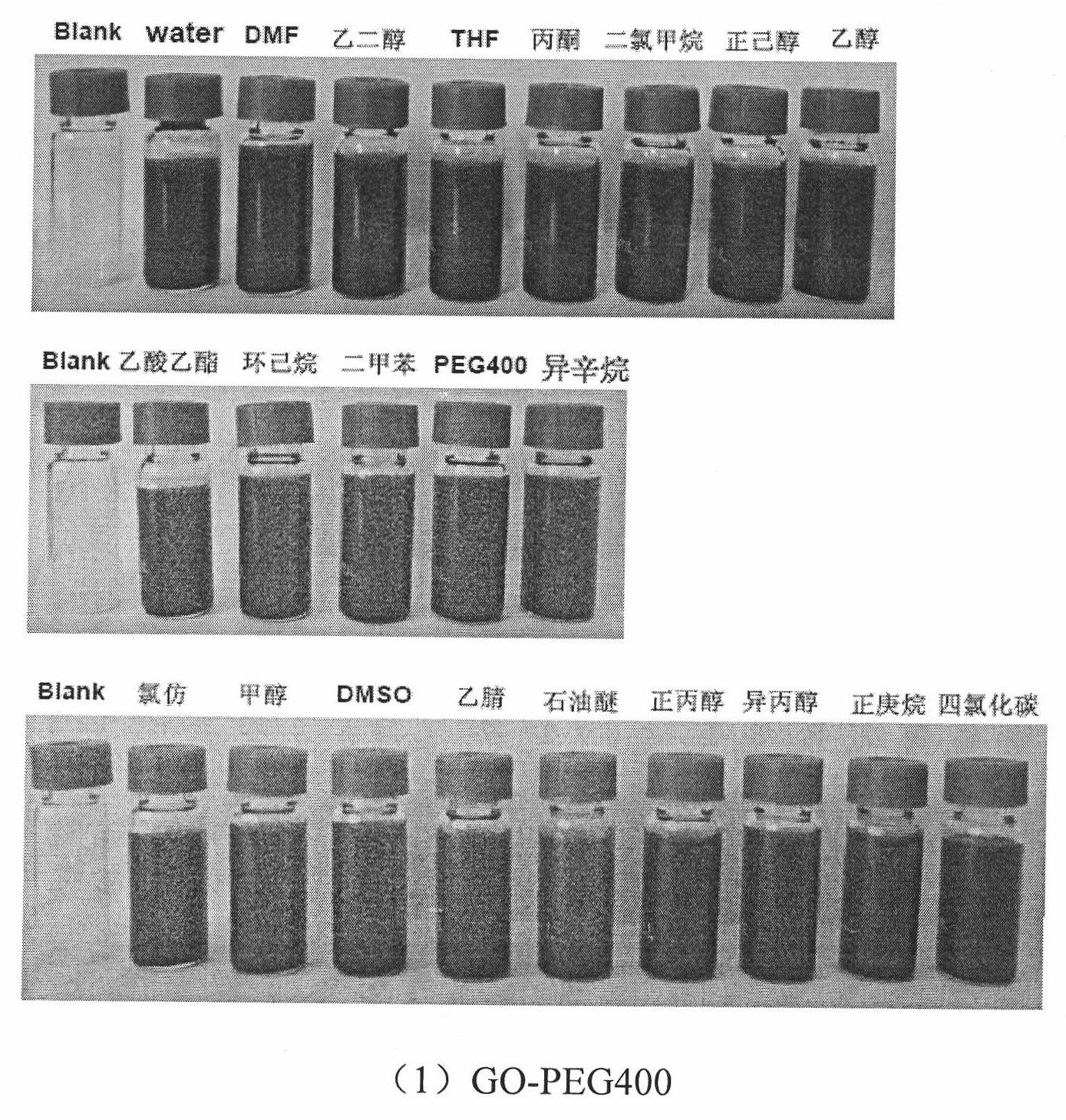

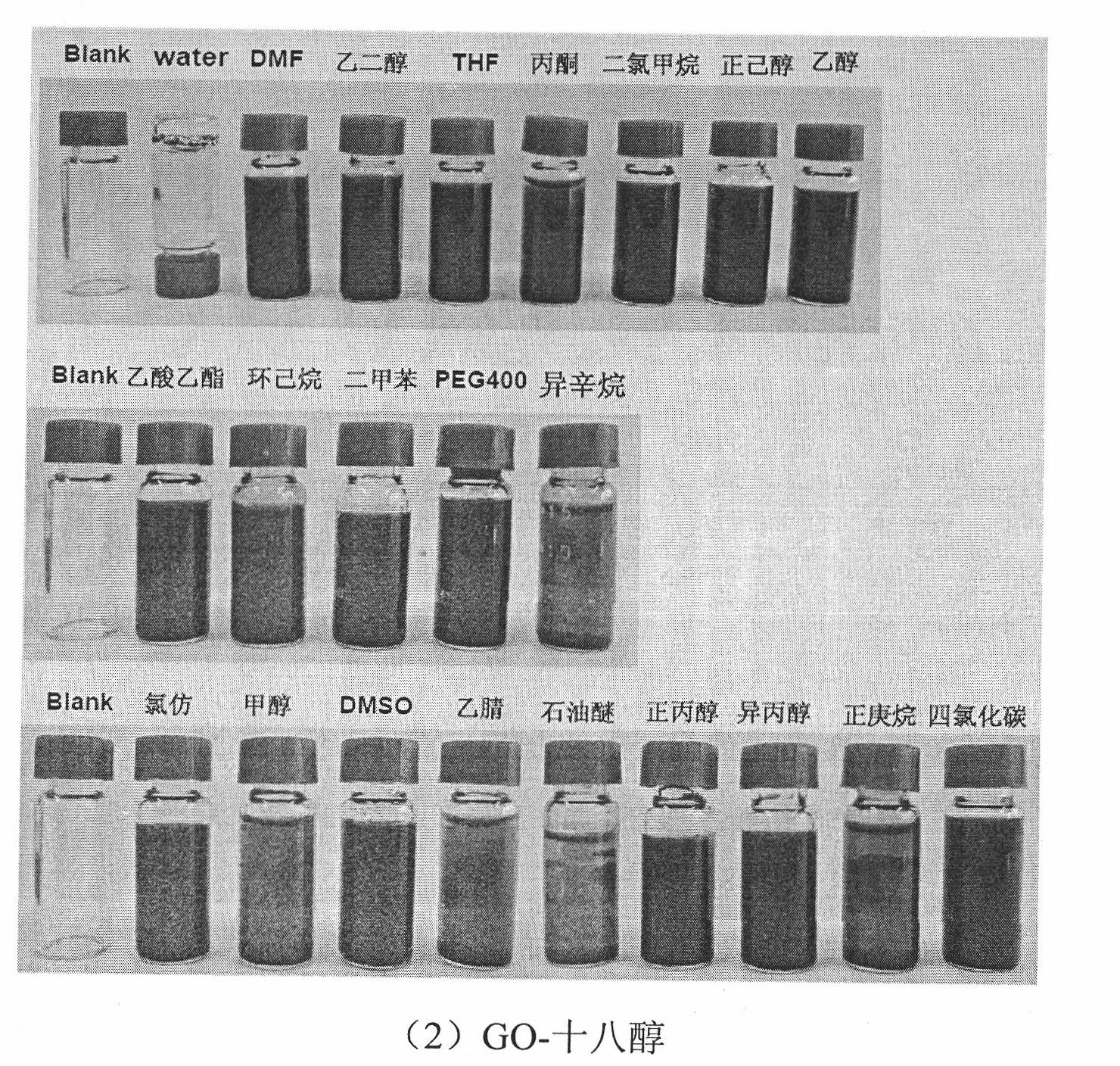

Functional graphene oxide for adjusting and controlling dispersibility of solvent by using organic chain segment as well as preparation method thereof

The invention discloses a functional graphene oxide for adjusting and controlling the dispersibility of a solvent by using an organic chain segment as well as a preparation method thereof. The structural formula of the functional graphene oxide is shown in specification, wherein R is equal to R1, R2 and R3. The preparation method comprises the following steps: 1, dispersing graphite oxide prepared by a Hummers method in N, N-dimethylformamide to form uniform dispersion liquid; 2, adding a thionyl chloride agent into the product obtained in step 1 to perform reflux reaction to synthesize an intermediate product of graphite oxide activated by acyl chloride; 3, distilling the mixed liquor obtained in step 2 under reduced pressure to remove excessive thionyl chloride; 4, adding pyridine and graft organic molecules into the product obtained in step 3, and heating and stirring the mixture; and 5, filtering, washing and then drying the mixed liquor obtained in step 4. The functional grapheneoxide can disperse well in different solvents, particularly solvents with low polarity and low boiling point, can be preferably compatible with multiple polymer molecules, leads the preparation of nano particles / polymer nano composite materials to be possible, and has good application prospects and economic benefits.

Owner:NANJING UNIV OF SCI & TECH

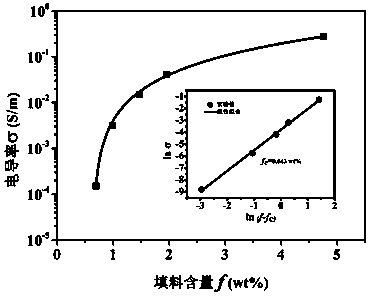

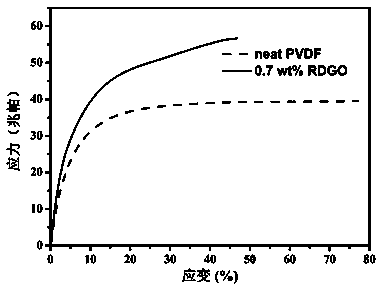

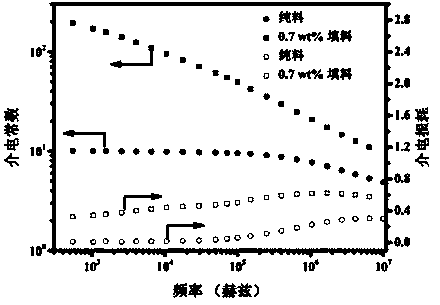

Preparation method for polyvinylidene fluoride/poly-dopamine-coated graphene nanocomposite

The invention discloses a preparation method for a high-dielectricity polyvinylidene fluoride / poly-dopamine-coated graphene nanocomposite. The method comprises the following steps: graphene oxide is prepared through a Hummers oxidation method, dopamine is automatically polymerized under the alkaline condition to coat the surface of the graphene oxide, reduction is performed on the poly-dopamine graphene oxide through hydrazine hydrate, centrifugal washing is performed repeatedly for removing impurities, the obtained poly-dopamine-coated grapheme can disperse in N, N-dimethylformamide well after being subjected to ultrasonic treatment, the polyvinylidene difluoride and the poly-dopamine-coated graphene are mixed through a solution method, and hot press molding is performed on the mixture, so that the nanocomposite is obtained. The preparation process is simple and easy to operate, the repeatability is good, the composite is good in flexibility and machinability, and has high potential for being applied to dielectric materials of energy storage parts such as capacitors.

Owner:SICHUAN UNIV +1

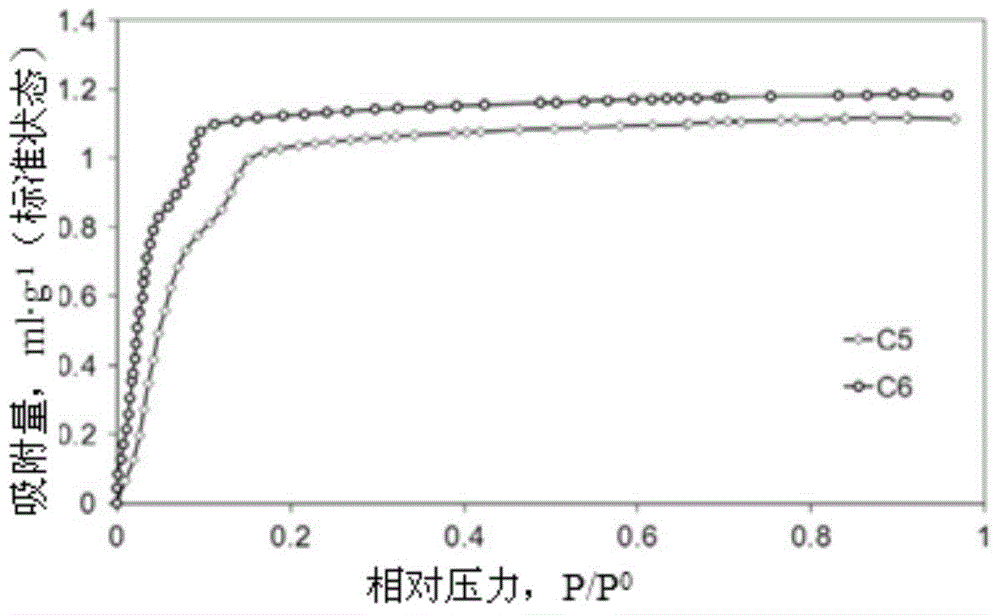

Preparation method of metal-organic framework porous adsorption material for normal paraffin and isoparaffin adsorption separation

InactiveCN104549160AHigh purityReduce transition timeOther chemical processesAdsorption purification/separationN dimethylformamideReaction temperature

The invention relates to a preparation process of a metal-organic framework porous adsorption material for C4-C8 normal paraffin and isoparaffin adsorption separation. According to the preparation method of the synthesized metal-organic framework porous adsorption material, metal ion nitrate and an organic ligand are dissolved according to the mass ratio of 1:1-15 in a mixed solution of N,N-dimethylformamide and N,N-diethyl formamide; stirring is carried out for 0.5-12 h; reaction temperature is controlled to 80-250 DEG C, and reaction time is 12-120 h; and by a hydrothermal synthesis method, the metal-organic framework porous adsorption material is prepared. The material has characteristics as follows: specific surface area is large; pore structure height is ordered; pore size is controllable; surface potential energy is controllable; and adsorption capacity of normal paraffin is large. The material can selectively adsorb normal paraffin from mixed materials of normal paraffin and isoparaffin, has high selectivity and has a wide practical application prospect in normal paraffin and isoparaffin separation.

Owner:CHINA PETROLEUM & CHEM CORP +1

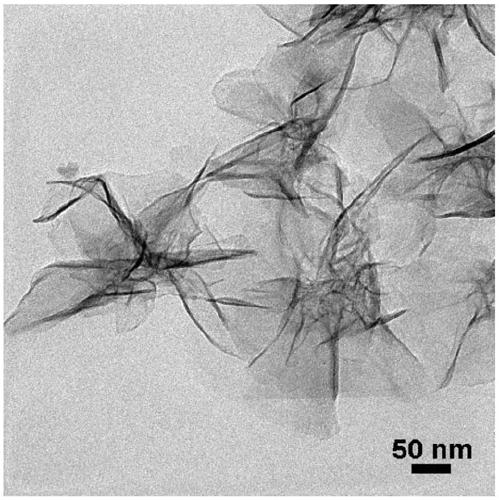

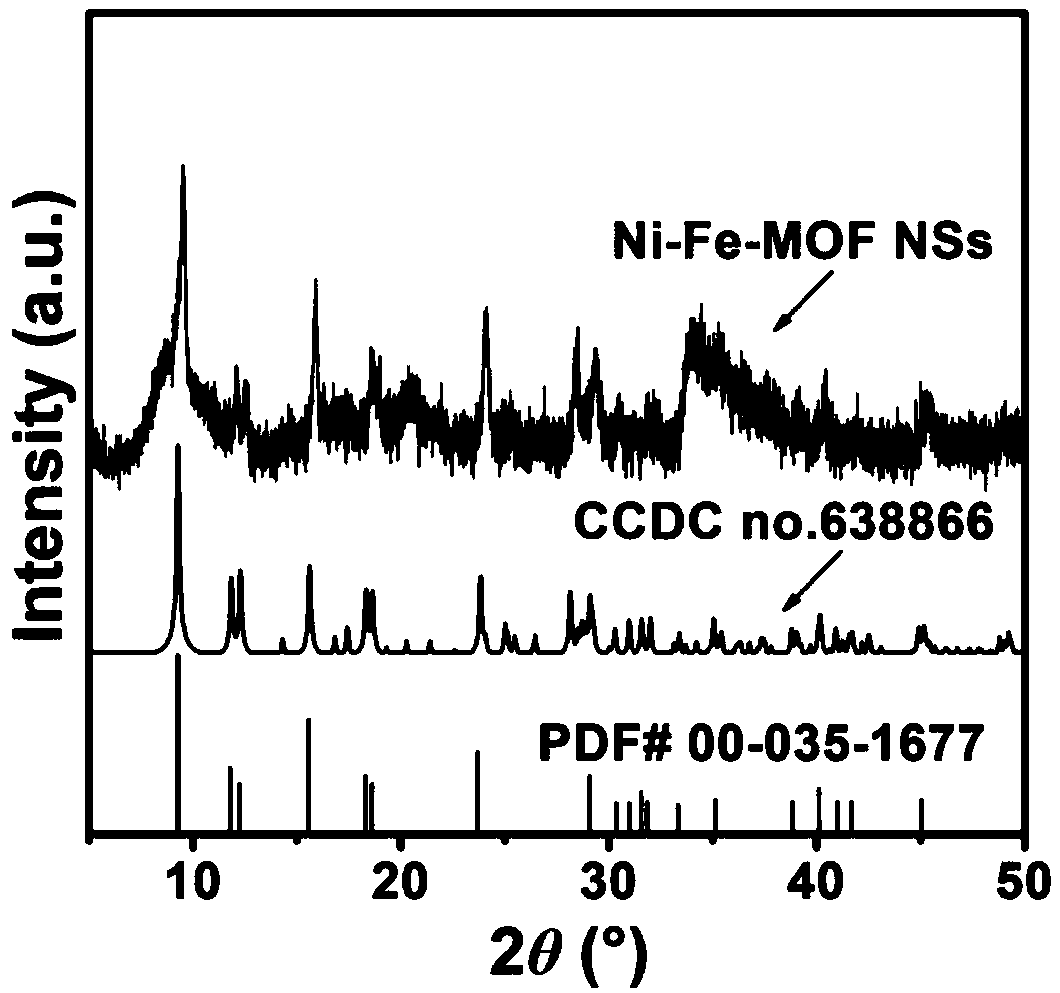

Ultrathin Ni-Fe-MOF nanosheet, preparation method and application thereof

ActiveCN109267093AEasy to operateShort reaction timeNickel organic compoundsNanotechnologyN dimethylformamideIron salts

The invention discloses a preparation method of an ultrathin Ni-Fe-MOF nanosheet. The preparation method comprises the following steps of dissolving an organic ligand in an organic solvent, dripping the obtained solution into a water solution with nickel and iron salts dissolved, mixing uniformly, then reacting for 3-6 hours at 140-160 DEG C, so as to obtain the ultrathin Ni-Fe-MOF nanosheet, wherein the organic ligand is p-phthalic acid and / or disodium terephthalate, and the organic solvent is N,N-dimethylacetamide and / or N,N-dimethylformamide. The invention further discloses the ultrathin Ni-Fe-MOF nanosheet and application thereof. The preparation method needs no surfactant, and can synthesize a large quantity of 2D ultrathin MOF material. The product has a clean surface and is easy toclean.

Owner:SUZHOU UNIV

Magnetic particle with hydrophilic polymer coating, preparation and water-base magnetic flowing deformating liquid therefrom

InactiveCN1613919AOvercome stabilityOvercome the shortcomings of easy oxidation, deterioration and agglomerationAdditivesPigment treatment with macromolecular organic compoundsWater basedN dimethylformamide

Magnetic particles packed by the hydrophilic polymer of inorganic oxidate are prepared by: putting the 100 portion of compound particle, 0.1-5.0 portion of alkoxy metallic compound and 0.05-5.0 portion of hydrophilic macromolecular having an alkoxy-Si in the end into 50-10000 portion of N-N-dimethylformamide solvent, then dropping the alkalily to abjust the pH when mixing the solution, purifying and collecting the solid by magnetic separating and water scrubbing to obtain solid products after drying. The products have good oxidation resistance and soft magnetism, and the process is very easy to do.

Owner:WUHAN UNIV OF TECH

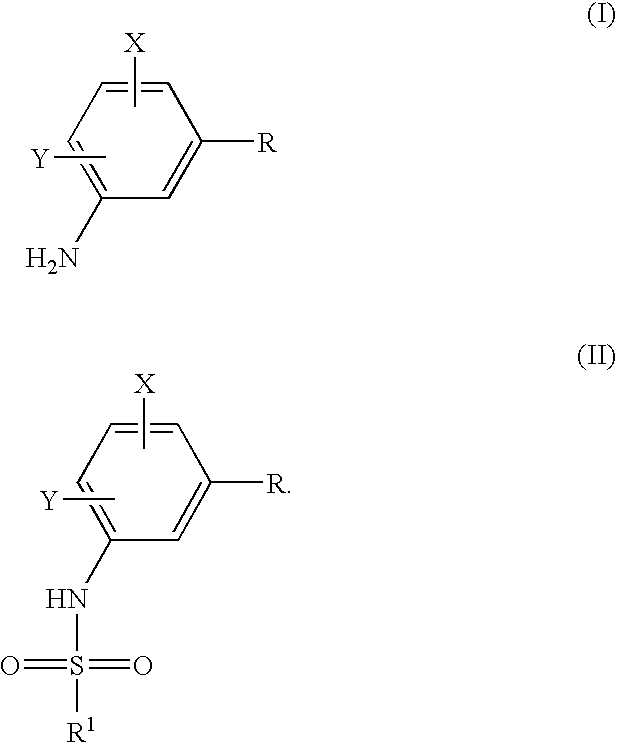

Process to prepare sulfonamides

InactiveUS7169952B2Organic compound preparationSulfonic acid amide preparationN dimethylformamideAniline

A process for the preparation of a sulfonamide of formula (II), comprising reacting at elevated temperature an aniline of formula (I), with a sulfonating agent A of the formula R1—SO2-Z in the presence of a catalytic amount of either: (i) an amide B-1, other than N,N-dimethylformamide, or (ii) a high boiling tertiary amine B-2. Also provided in accordance with the present invention are processes for preparing sulfonamides of formula (II) by reacting an aniline of formula (I) with sulfanating agent A of the formula R1—SO2-Z in the presence of N,N-dimethylformamide, at a temperature in the range of about 120° C. to about 160° C. for about three to about seven hours. X, Y, Z, R and R1 are defined herein

Owner:FMC CORP

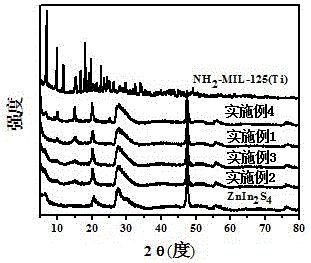

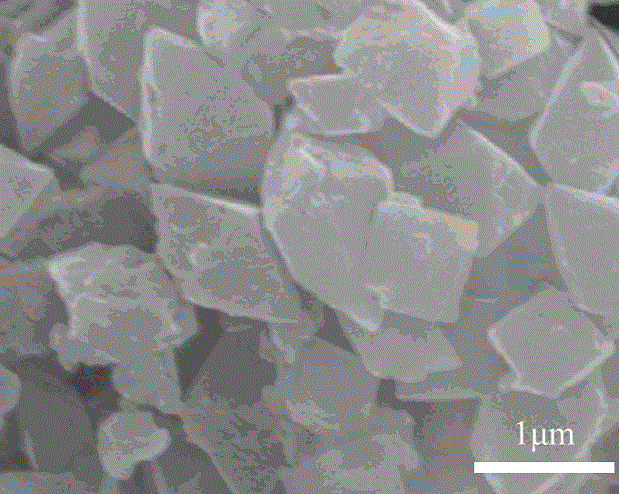

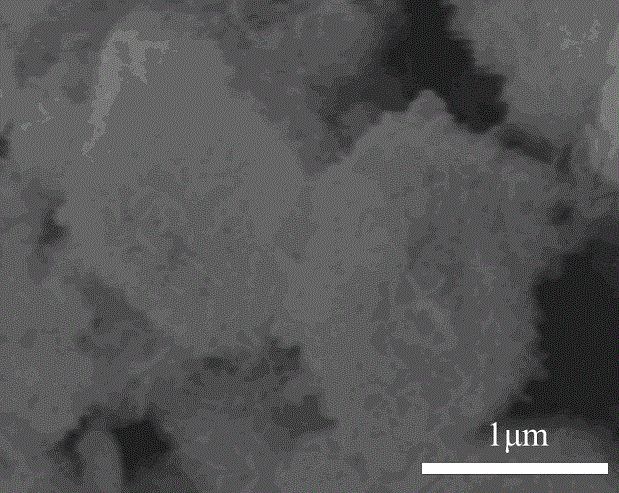

ZnIn2S4/NH2-MIL-125(Ti) composite visible-light catalyst and preparation method thereof

InactiveCN105964305AOrganic-compounds/hydrides/coordination-complexes catalystsN dimethylformamideUltrasonic dispersion

The invention relates to a novel ZnIn2S4 / NH2-MIL-125(Ti) composite visible-light catalyst and belongs to the technical field of photocatalysis. The novel ZnIn2S4 / NH2-MIL-125(Ti) composite visible-light catalyst is characterized in that ZnIn2S4 is nanosheet-shaped and is uniformly distributed on the surface of lumpy NH2-MIL-125(Ti), and the mass percent of the NH2-MIL-125(Ti) is 20.0% to 6.0%. A preparation method comprises the steps: (1) dissolving a certain amount of tetrabutyl titanate and 2-amino terephthalic acid in a mixture solution of N,N-dimethylformamide and methanol, and carrying out a crystallizing reaction for 48 hours in an autoclave at the temperature of 150 DEG C, so as to obtain the NH2-MIL-125(Ti); (2) dispersing the synthesized NH2-MIL-125(Ti) into a certain volume of ethanol in an ultrasonic dispersion manner, then, sequentially adding a certain amount of propanetriol, indium chloride, zinc chloride and thioacetamide into the dispersion while carrying out stirring, carrying out a crystallizing reaction for 10 hours in an autoclave at the temperature of 180 DEG C to 200 DEG C so as to obtain a solid product, and subjecting the obtained solid product to filtrating, washing and drying, thereby obtaining the ZnIn2S4 / NH2-MIL-125(Ti) composite visible-light catalyst. The preparation method of the composite visible-light catalyst is environmentally-friendly and is simple in process. The prepared composite catalyst has very high visible-light catalytic activity and has a potential application value in photocatalytic hydrogen production using solar energy.

Owner:SHANGHAI UNIV

Nanofiber vascular prostheses and preparation method

ActiveCN101708344AImprove bindingCombine firmly and evenlyFilament/thread formingProsthesisFiberN dimethylformamide

The invention discloses a nanofiber vascular prostheses and a preparation method. The preparation method is as follows: mixing the solution of gelatin and glacial acetic acid with the aqueous solution of a crosslinker evenly to pre-crosslink the solution of gelatin and glacial acetic acid, adding heparin sodium aqueous solution to prepare spinning dope and collecting the formed fibers on a collecting roll by using the electrospinning process to form a nanofiber nonwoven membrane tube; dissolving polyurethane into the mixed solvent of tetrahydrofuran and N,N-dimethylformamide to prepare polyurethane spinning dope and continuously collecting the formed fibers on the collecting roll which has collected the nanofiber nonwoven membrane tube by using the electrospinning process; and taking off the nanofiber nonwoven membrane tube covered by the polyurethane fiber nonwoven membrane tube structure from the collecting roll and then soaking the nanofiber nonwoven membrane tube into the aqueous solution of a post-crosslinker to carry out post-crosslinking treatment, thus preparing the nanofiber vascular prostheses. The inner layer of the vascular prostheses of the invention can improve the blood compatibility and the outer layer has biological stability and can improve the physical and mechanical properties.

Owner:南通双辉医疗器械科技有限公司

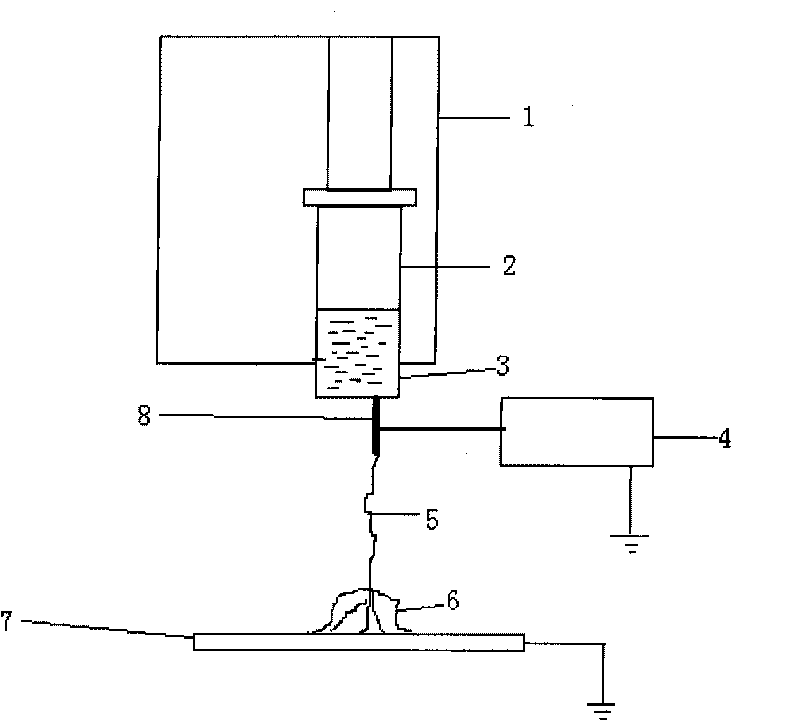

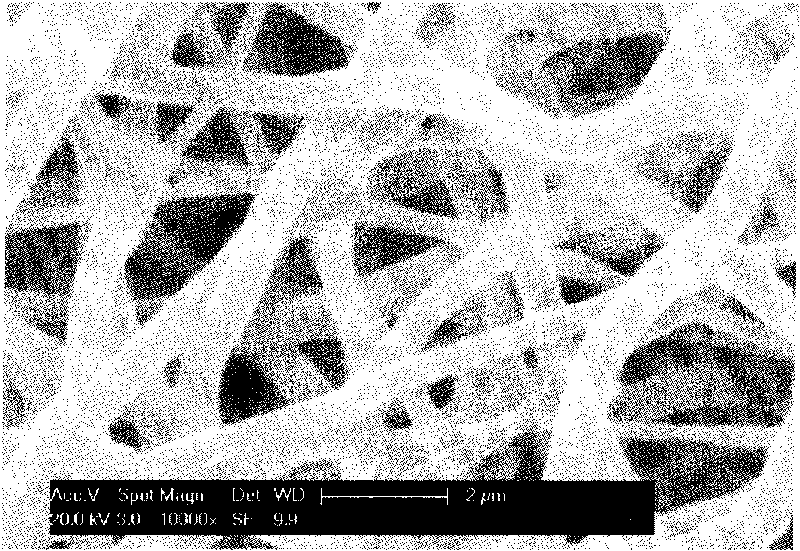

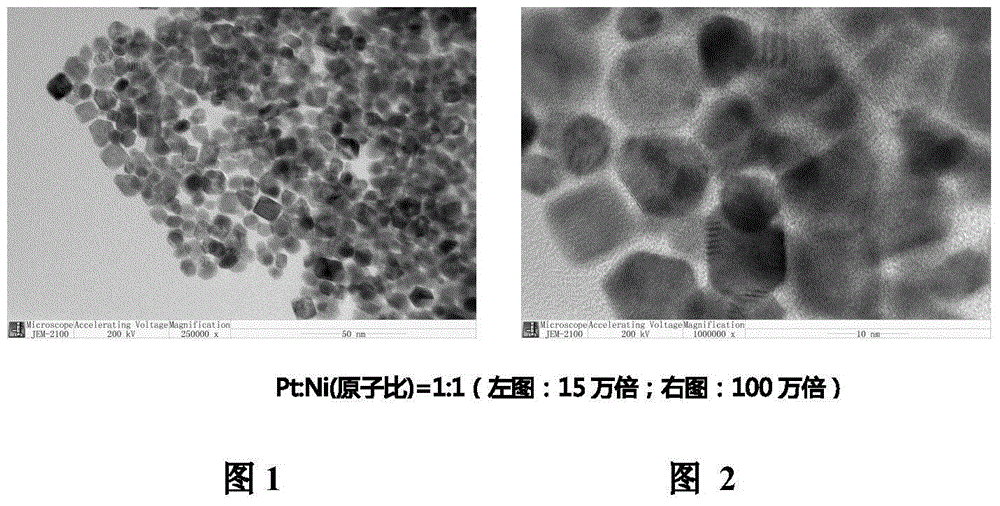

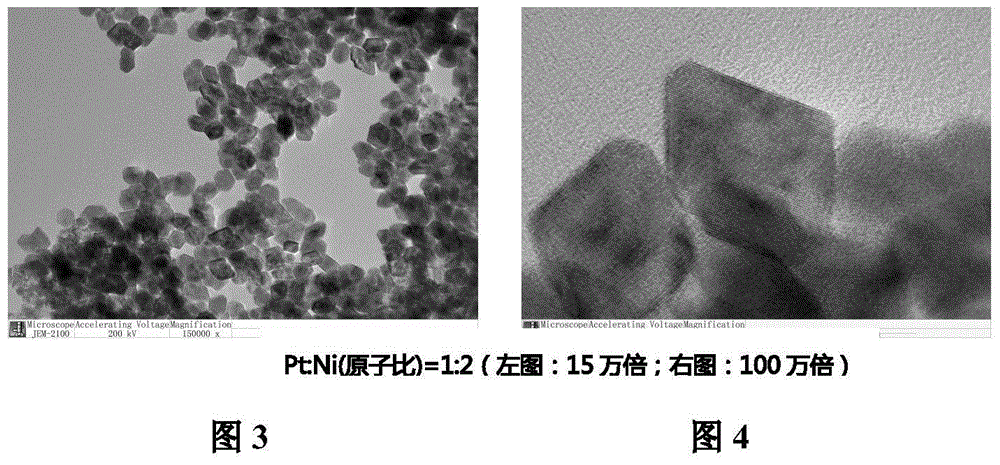

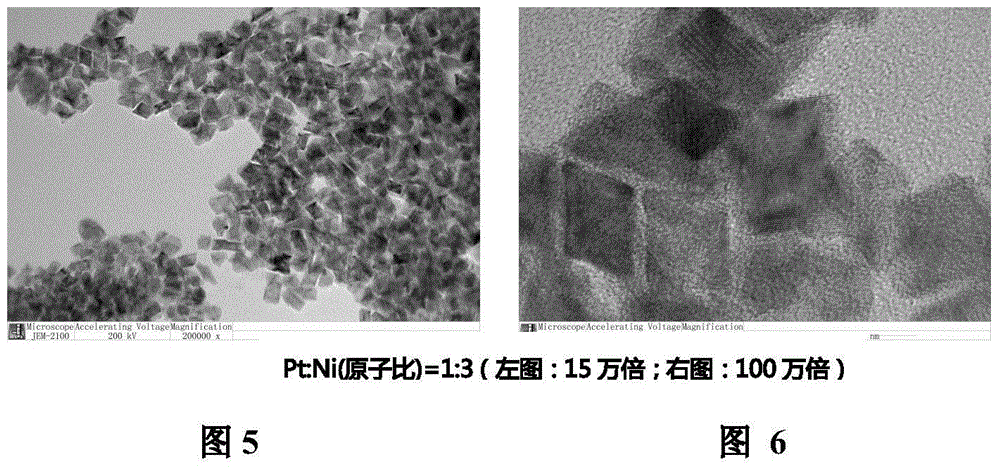

Method for preparing proton-exchange membrane fuel cell oxygen reduction catalyst based on PtNi (111) octahedral single crystal nanoparticles

InactiveCN104998658AHigh catalytic activity for oxygen reductionPt content decreasedCell electrodesMetal/metal-oxides/metal-hydroxide catalystsN dimethylformamideSingle crystal

Owner:昆明贵研催化剂有限责任公司

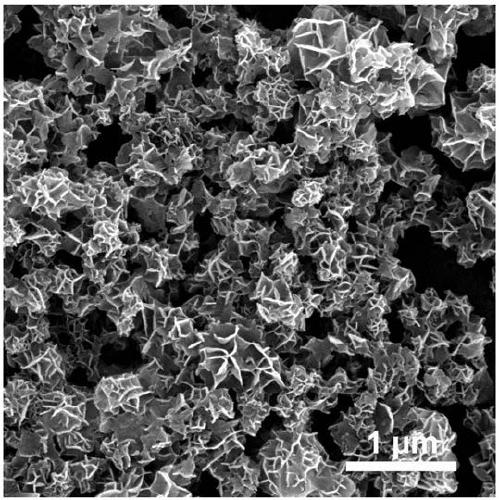

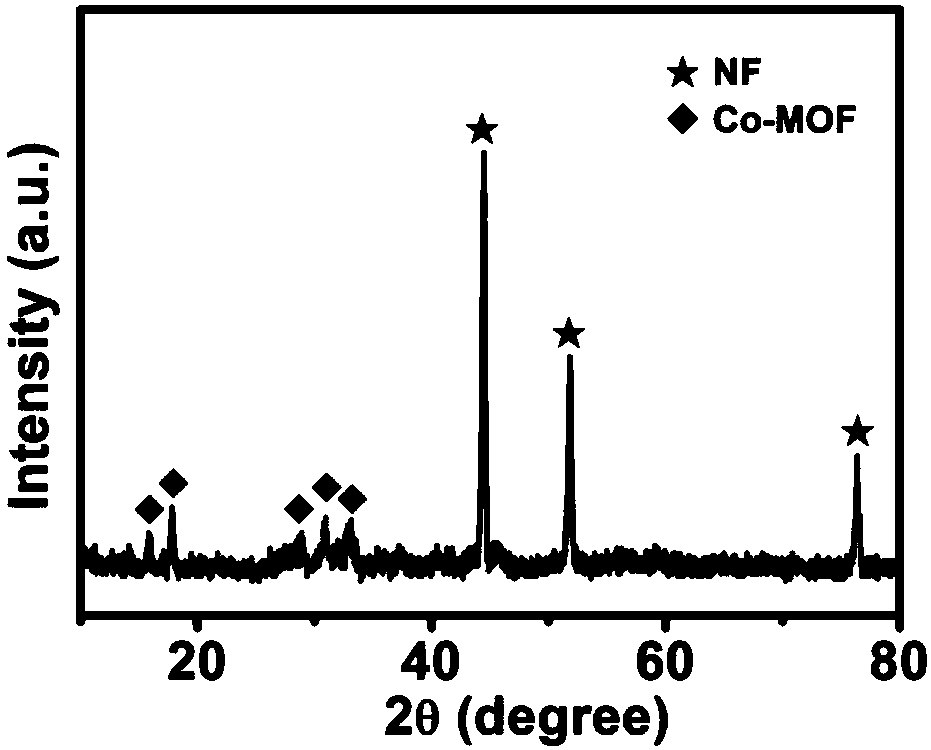

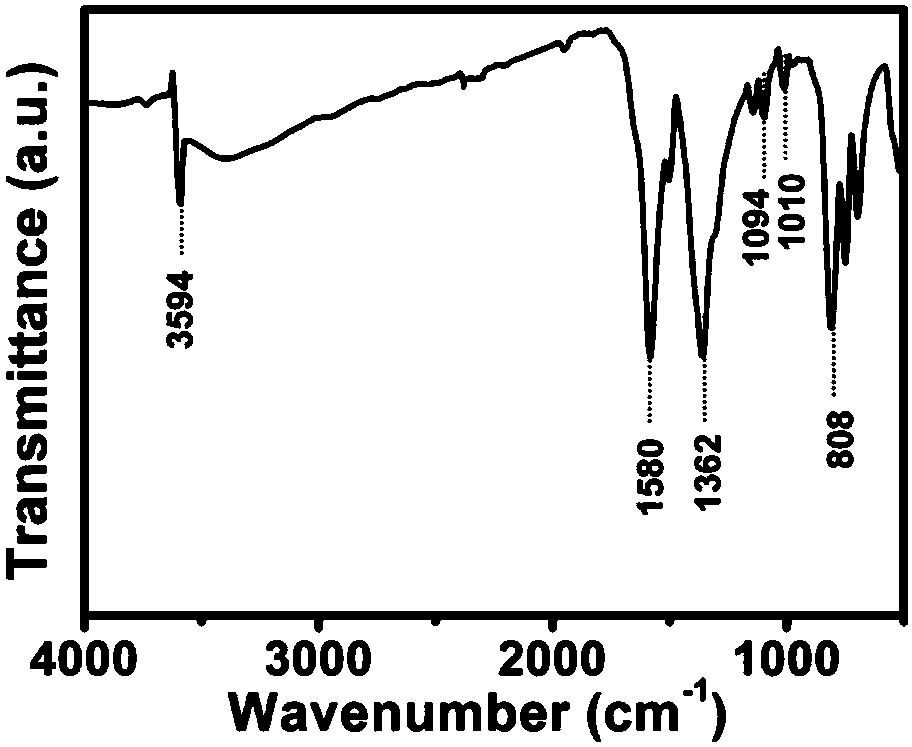

Method for preparing three-dimensional structure Co-MOF/NF supercapacitor electrode material in situ based on foamed nickel

InactiveCN108492999ANo generationEasy to makeHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceN dimethylformamide

The invention discloses a simple, easy-to-operate and environmentally friendly method for synthesizing a three-dimensional structure Co-MOF / NF material in situ. With a cobalt nitrate hexahydrate adopted as a cobalt source, terephthalic acid as an organic ligand, N,N-dimethylformamide as a solvent, absolute ethyl alcohol as an additive, and foamed nickel as a substrate, a one-step solvothermal method is adopted to obtain Co-MOF / NF; when being used as supercapacitor self-supporting electrode material, the Co-MOF / NF exhibits ultra-high area ratio capacitance (13.6 F cm<-2>), the performance of the Co-MOF / NF is far superior to the performance of previously reported MOF-based materials. With the method of the invention adopted, problems such as large contact resistance, insufficient applicationof active materials, and complex electrode preparation processes which are caused by the application of powder electrode materials can be solved. The Co-MOF / NF material is a novel energy storage material which has the advantages of ultra-high area specific capacitance, excellent rate performance and low cost.

Owner:SICHUAN UNIV

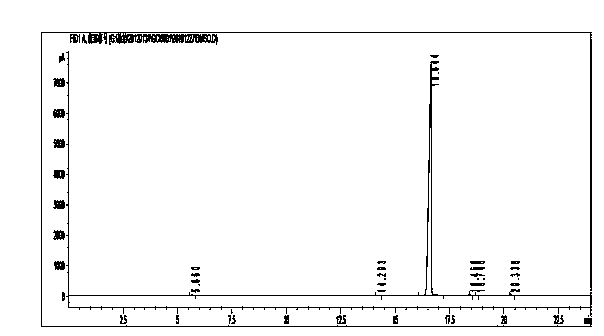

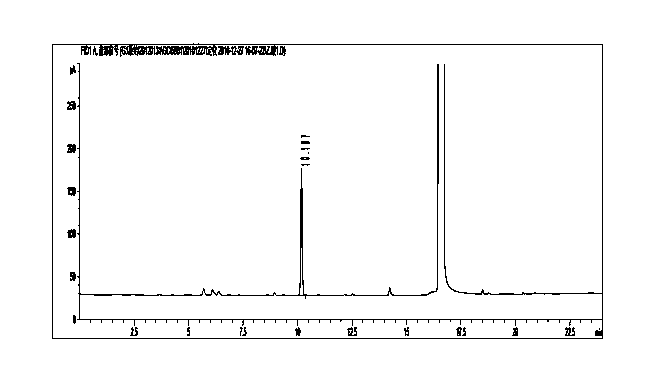

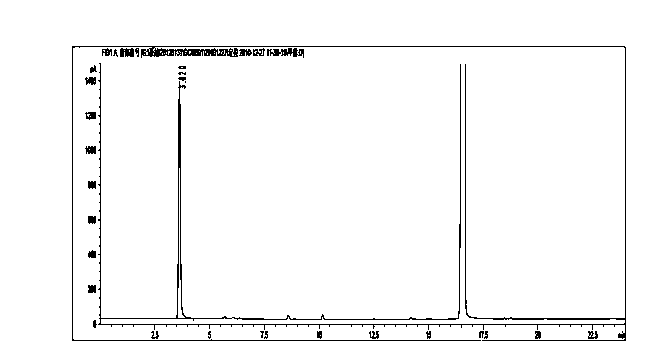

GC method for detecting residual quantity of solvent in compound

ActiveCN103728402ALong operating timeCumbersome operationComponent separationCapillary gas chromatographyN dimethylformamide

The invention discloses a method for analyzing a residual quantity of a solvent in a compound by GC (Gas Chromatograph). The method comprises the step of carrying out separation by adopting the following chromatographic conditions: a detector is a hydrogen flame ionization detector, the temperature of the detector is 200 DEG C to 300 DEG C and is preferably 300 DEG C, and the temperature of an injection opening is 180 DEG C to 250 DEG C and is preferably 220 DEG C; a chromatographic column is a medium-polarity capillary gas chromatography column and adopts a programmed temperature process of keeping the temperature of 40 to 60 DEG C for 3 to 10min, then heating to the temperature of 100 to 140 DEG C at a speed of 5 to 15 DEG C / min, keeping the temperature of 100 to 140 DEG C for 1 to 10min, heating to the temperature of 200 to 230 DEG C at a speed of 15 to 25 DEG C / min and keeping the temperature of 200 to 230 DEG C for 1 to 20min; carrier gas is nitrogen, hydrogen or argon and is preferably nitrogen, and the flow rate of the carrier gas is 1ml / min to 10ml / min and is preferably 3ml / min; the solvent is selected from one or more of C1 to C6 carboxylic acid, methanol, ethanol, acetonitrile, ethyl acetate, tetrahydrofuran, methylbenzene and N,N-dimethylformamide; the C1 to C6 carboxylic acid is preferably C1 to C4 carboxylic acid and is more preferably acetic acid. When the method is adopted to detect the residual quantity of the solvent, the operation is simplified, time is saved and cost is saved.

Owner:NEW FOUNDER HLDG DEV LLC +2

Method for preparing electrocatalytic water-splitting oxygen production electrode

ActiveCN105369306AHigh activityImprove oxygen production efficiencyFuel and primary cellsCell electrodesN dimethylformamideMetal-organic framework

The invention particularly relates to a method for preparing an electrocatalytic water-splitting oxygen production electrode, with Fe / Ni duplex metal coordinating with trimesic acid, of a metal organic framework material and belongs to the field of electrodeposition / electrocatalysis. The method comprises the steps that (1) Ni(NO3)2.6H2O, Fe(NO3)3.9H2O and the trimesic acid are all dissolved in N,N-dimethylformamide, then tributylmethylammonium methyl sulfate is added, and sufficient stirring is conduced till all the components are completely dissolved, so that electrolyte, with the Fe / Ni duplex metal coordinating with the trimesic acid, for the metal organic framework material is obtained; (2) a standard three-electrode system is assembled by using foamed nickel as a working electrode, a silver / silver chloride saturated electrode as a reference electrode, a platinum sheet as a counter electrode and the solution prepared in the step (1) as the electrolyte; and (3) the standard three-electrode system assembled in the step (2) is connected to an electrochemical workstation, and the working electrode is taken out of the electrolyte, cleaned and dried after constant-potential electrodeposition is conducted, so that the electrocatalytic water-splitting oxygen production electrode is obtained.

Owner:理工清科(北京)科技有限公司

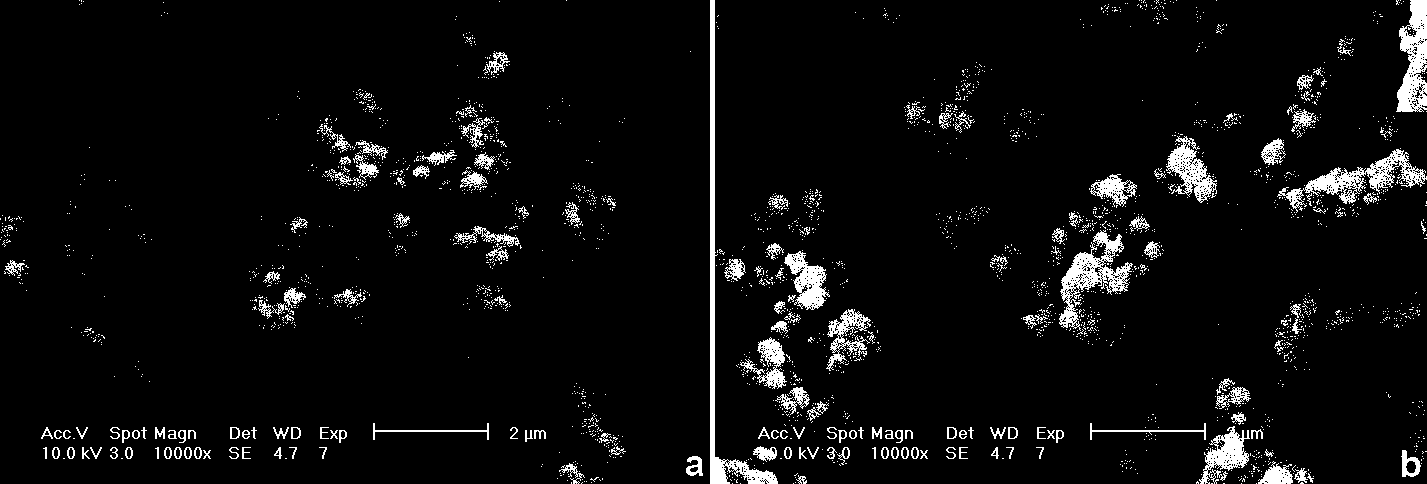

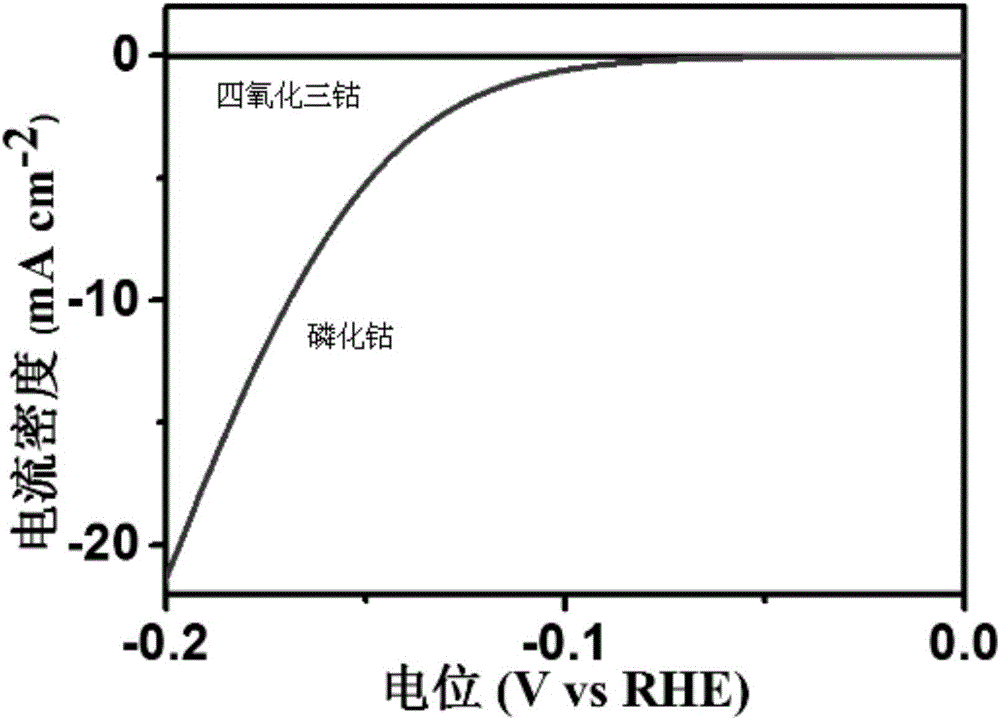

Preparation method of cobalt phosphide hollow nano-fiber material

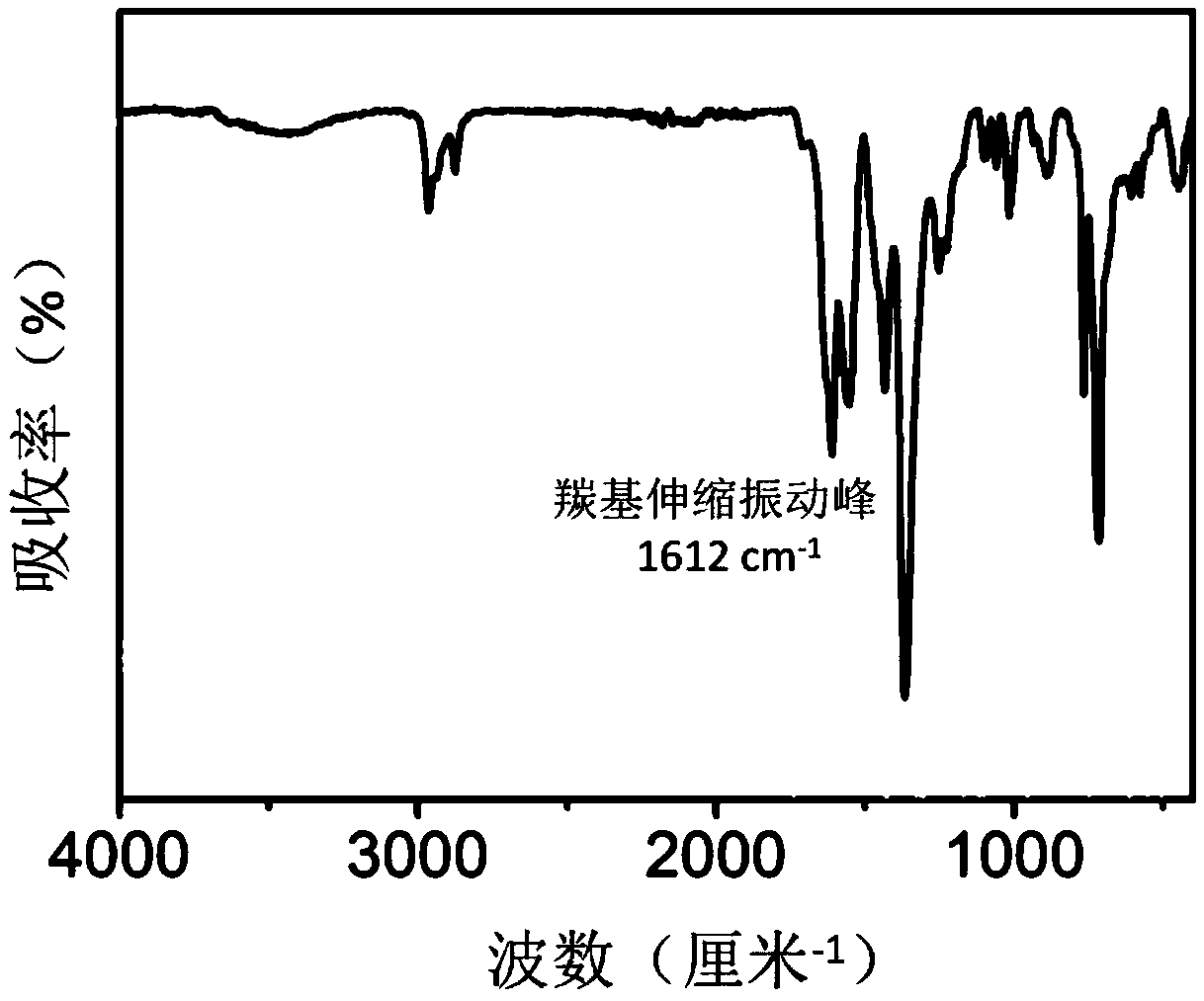

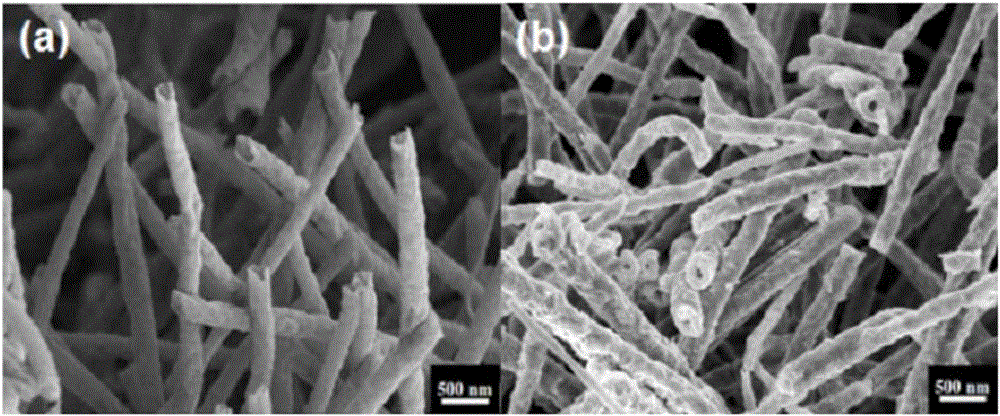

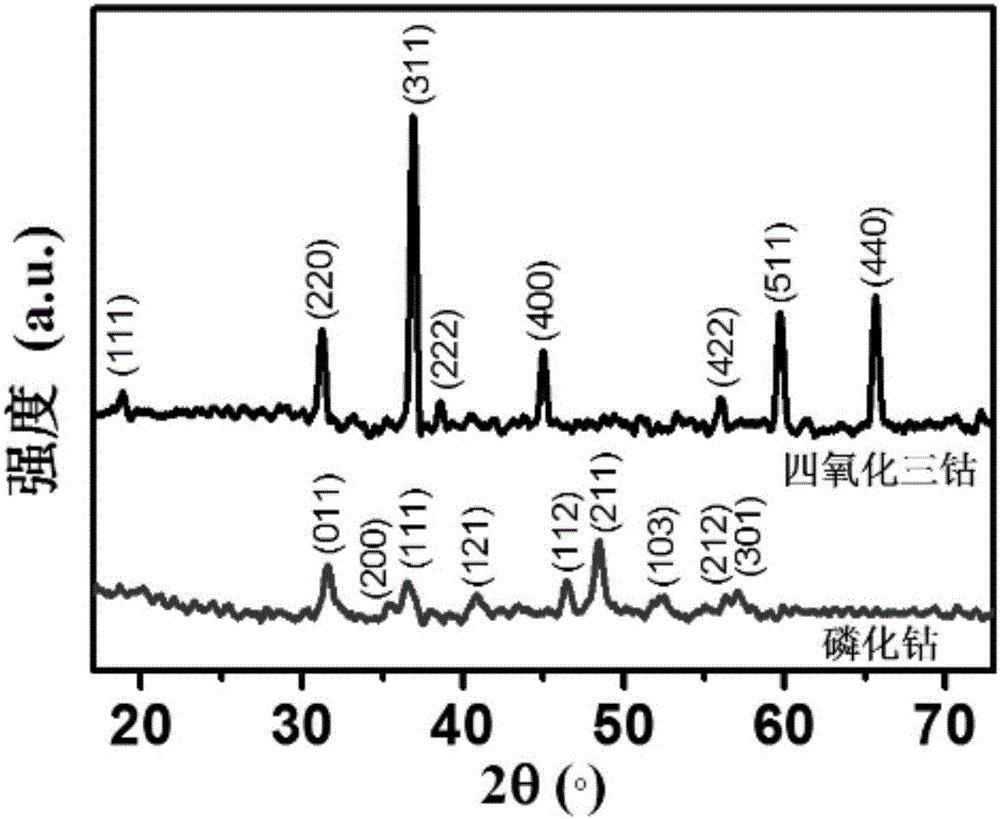

InactiveCN105803580AIncrease the areaHigh activityInorganic material artificial filamentsNanotechnologyFiberN dimethylformamide

The invention relates to a preparation method of a cobalt phosphide hollow nano-fiber material.The preparation method comprises the steps of adding cobalt salt to N, N-dimethylformamide, after the cobalt salt is dissolved, adding polyvinylpyrrolidone, conducting stirring, so that a precursor spinning solution is obtained, and conducting electrostatic spinning, so that a polyvinylpyrrolidone nanofiber membrane doped with cobalt ions is obtained; conducting pre-oxidation, and then conducting calcination at the temperature of 400-700 DEG C, so that a hollow tubular cobaltosic oxide nano-fiber is obtained; then mixing the hollow tubular cobaltosic oxide nano-fiber with sodium hypophosphite monohydrate, conducting a phosphorization reaction, and conducting cleaning and drying, so that the cobalt phosphide hollow nano-fiber material is obtained.The method is environmentally friendly in process and low in cost; the obtained cobalt phosphide hollow nano-fiber material is stable in chemical property and high in activity of electro-catalysis hydrogen evolution and expected to serve as an ideal high-performance electrochemical hydrogen evolution catalytic material.

Owner:DONGHUA UNIV

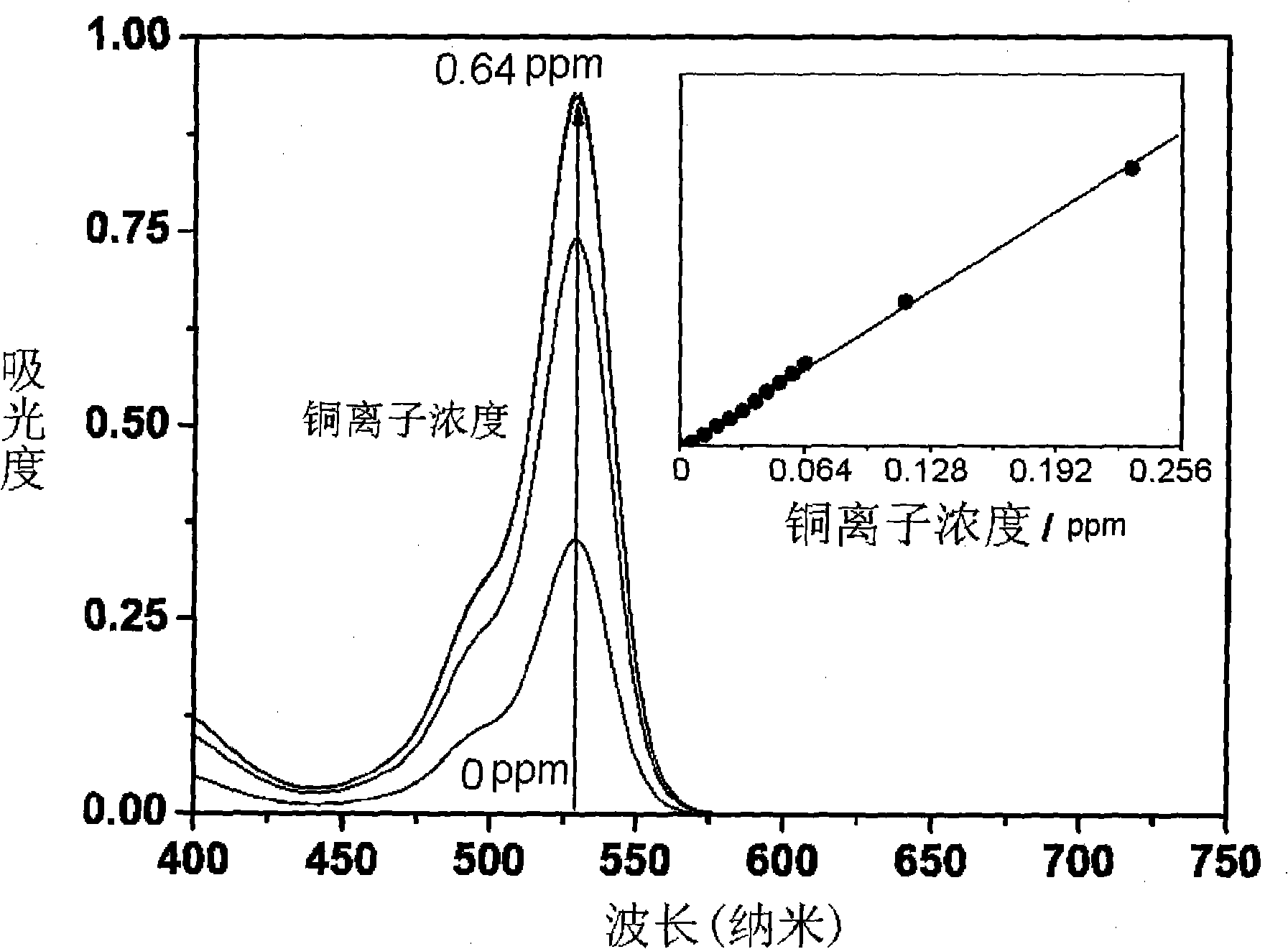

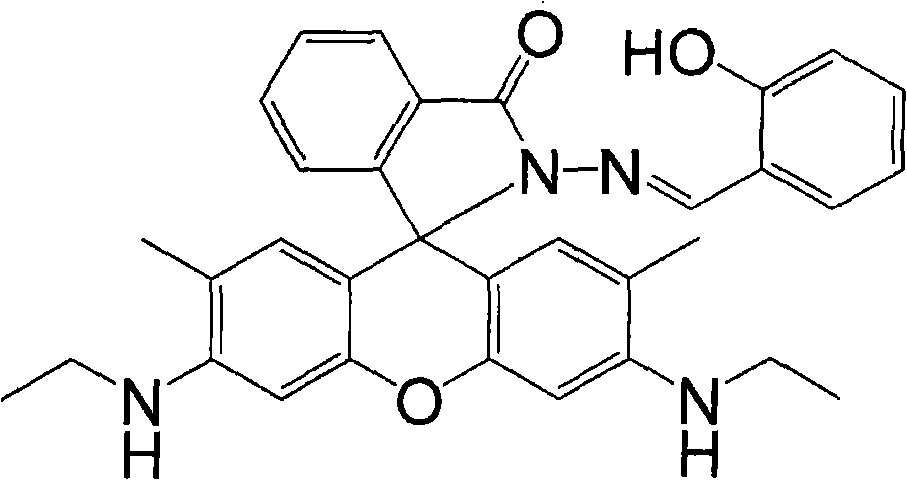

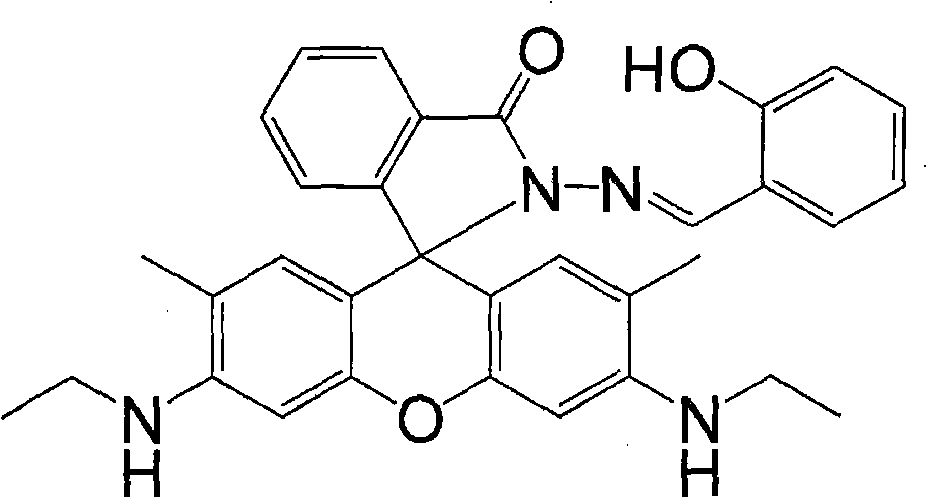

Rhodamine 6G hydrazide salicylaldehyde azomethine, synthesizing process and application in measuring content of copper ion

InactiveCN101270121AAccurate quantitative analysisHigh sensitivityAnalysis using chemical indicatorsOrganic chemistrySodium acetateSodium acetrizoate

The present invention relates to rhodamine 6G hydrazide salicylal azomethine, a synthesization method and an application in the content determination of cupric ions, which belong to the field of the analysis and determination of cupric ions in water sample. The molecular structural formula of the rhodamine 6G hydrazide salicylal azomethine is shown on the right, and the present invention discloses the synthesization method of the rhodamine 6G hydrazide salicylal azomethine and rhodamine 6G hydrazide salicylal azomethine solution used for the content determination of a small amount of cupric ions in water sample: 0 percent to 98.99 percent of ethanol, 99.99 percent to 1 percent of acetic acid / sodium acetate buffer solution with the pH value of 5 to 9, in which the total concentration of acetic acid is 1 to 100 millimoles per litre, 0.01 percent of N, N-dimethylformamide and 1ppm to 100ppm of rhodamine 6G hydrazide salicylal azomethine, all measured in mass percentage. By a spectrophotometer, the solution can be used for the accurate quantitative determination of 0.005ppm to 0.256ppm of cupric ions in water sample as well as the semiquantitative determination of no less than 0.075ppm of cupric ions in water sample by direct naked-eye observation on the change of colors.

Owner:TSINGHUA UNIV

Cellulose-polyacrylonitrile composite fiber and its production process

ActiveCN101240467AReduce lossLow costFilament/thread formingConjugated cellulose/protein artificial filamentsCelluloseOrganic solvent

The invention relates to a cellulose-polyacrylonitrile composite fiber and a manufacturing method of the same, the inventive method is characterized in that the composite fiber is a bending type or sheath-core type, the mass ratio of cellulose and polyacrylonitrile is 1:99 to 80:20 in the cortex of bending type or sheath-core type, the core layer of sheath-core type is made of the cellulose or polyacrylonitrile; the manufacturing method is that a ionic liquid is a solvent, also the organic solvent is a cosolvent, the organic solvent includes one or more N-N-dimethylacetamide, N-N-dimethylformamide or dimethyl sulfoxide. The bending type or sheath-core type composite fiber is formed after deairing, filtering, spinning, freezing, drawing, washing, drying and other steps, the fiber has a microporous structure which endows the characteristic of moisture absorption, breathable, coloring, good health, and other because of the moisture absorption of cellulose and the semi-compatibility of polyacrylonitrile; the ionic liquid is used in the production process being more green environmental protection.

Owner:CHINESE TEXTILE ACAD

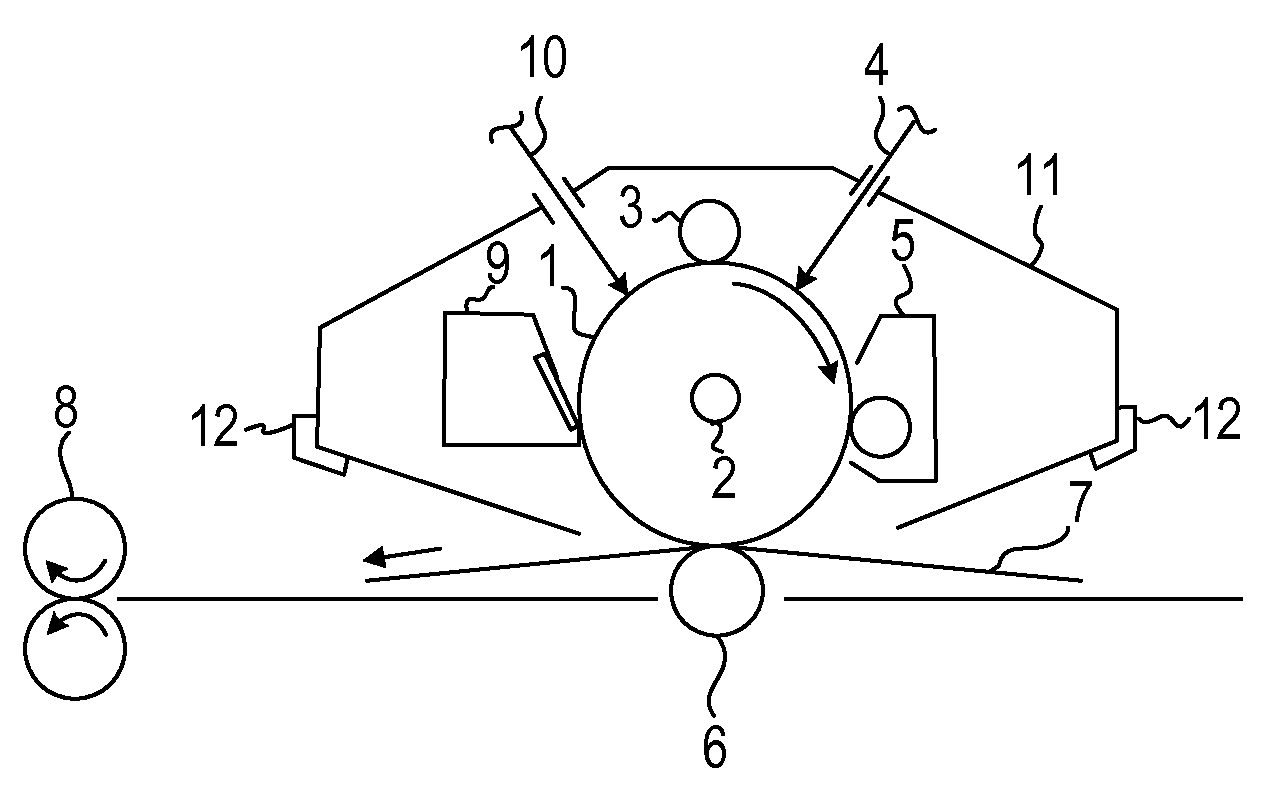

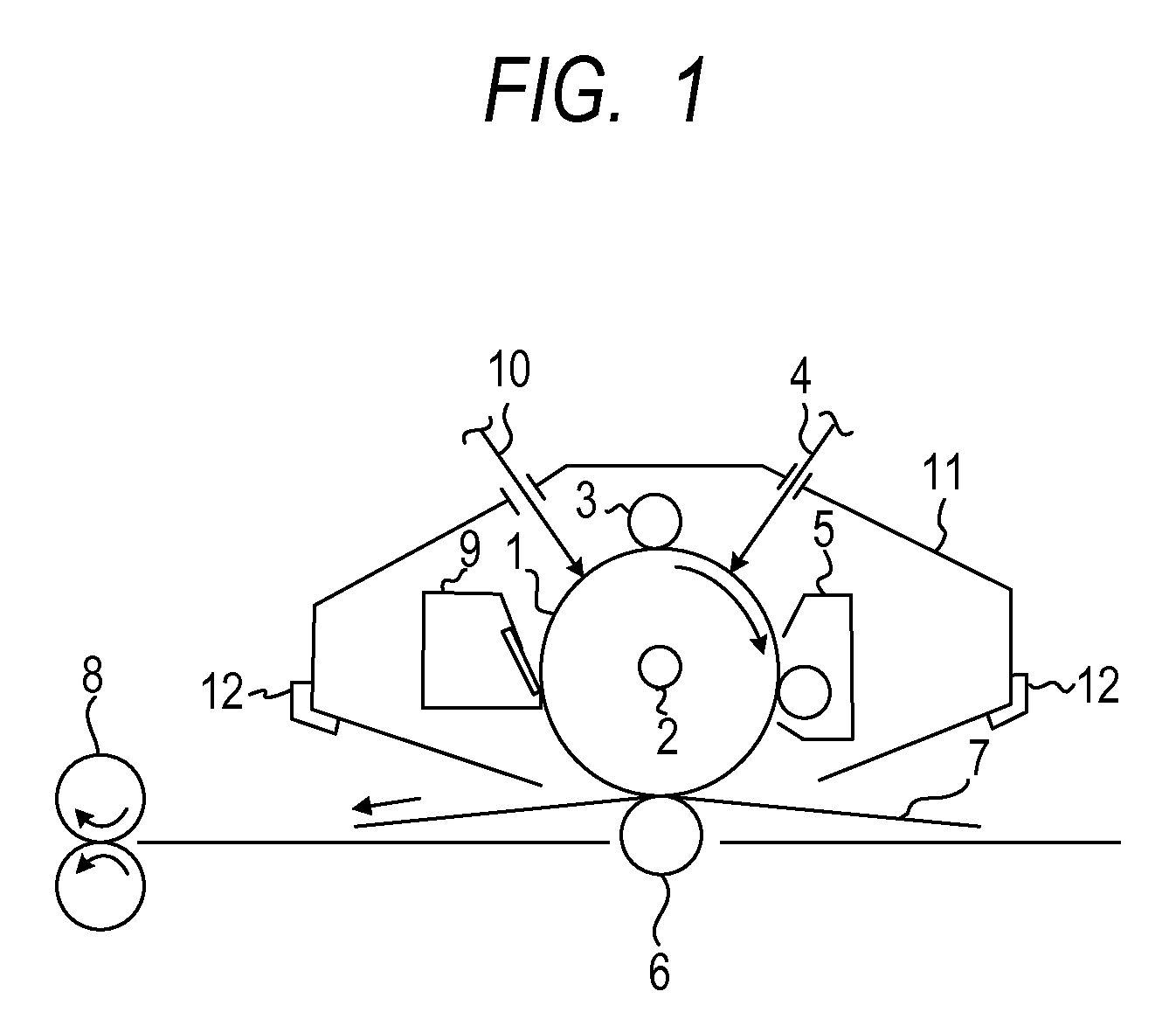

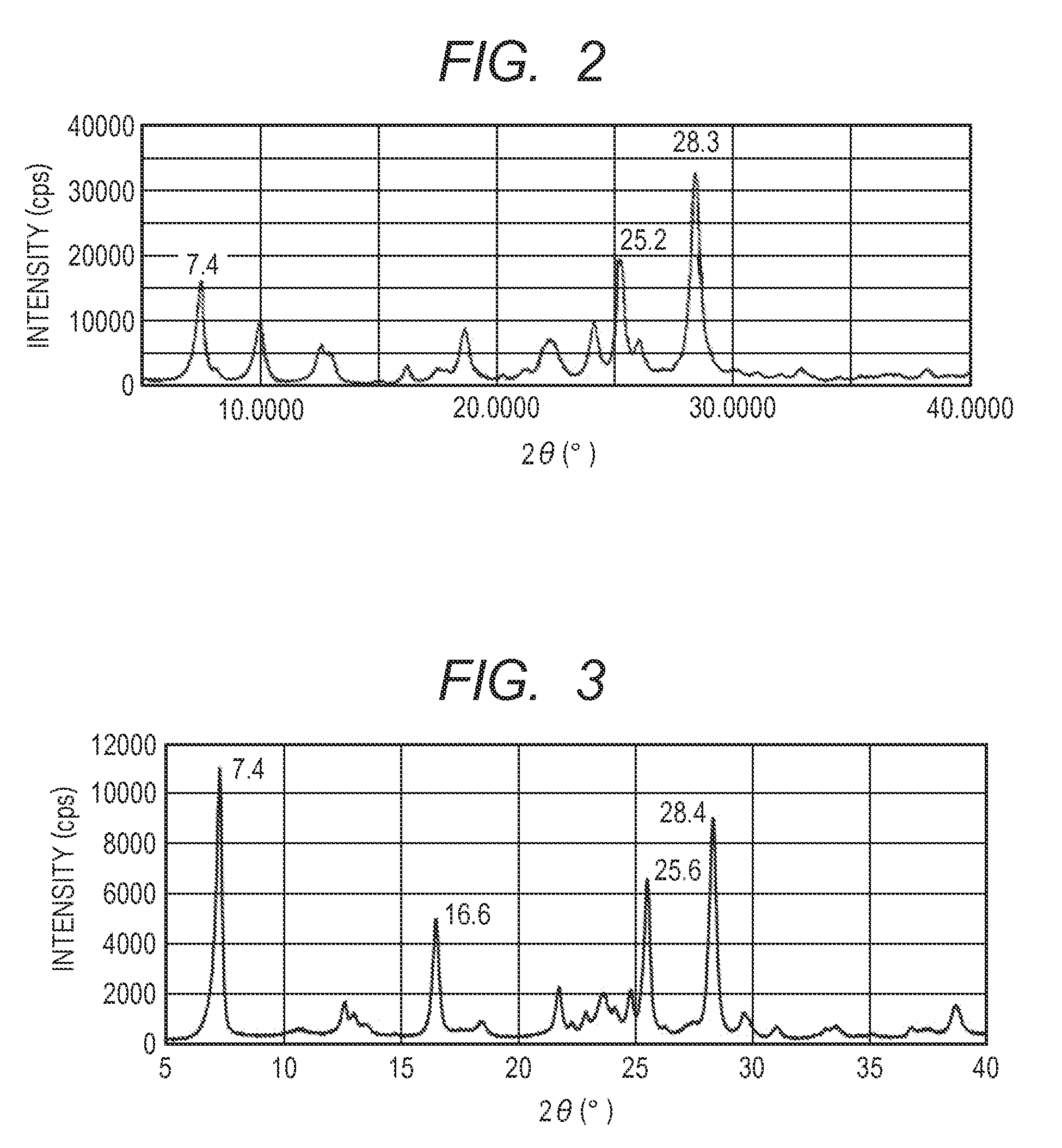

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

ActiveUS9563139B2Simple materialEnhance layeringElectrography/magnetographyN dimethylformamideTransport layer

An electrophotographic photosensitive member wherein a charge generating layer of the electrophotographic photosensitive member includes a gallium phthalocyanine crystal in which an organic compound is contained, wherein the organic compound is at least one compound selected from the group consisting of dimethylsulfoxide, N,N-dimethylformamide, N-methylformamide, N-propylformamide, N-vinylformamide and N-methylpyrrolidone, the content of the organic compound is 0.1% by mass or more and 2.0% by mass or less based on a gallium phthalocyanine in the gallium phthalocyanine crystal, and a charge transporting layer of the electrophotographic photosensitive member includes a polycarbonate resin having structural units represented by formulae (1) and (2).

Owner:CANON KK

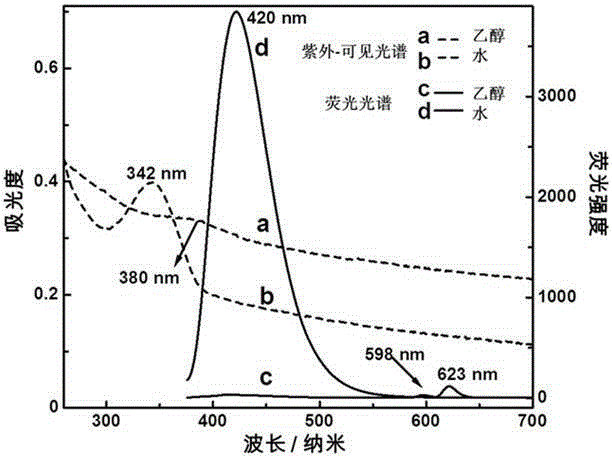

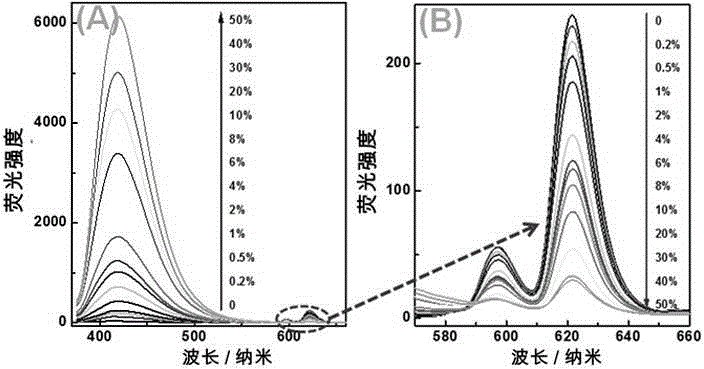

Bicolor Eu-MOFs/CDs fluorescent material as well as preparation and application thereof

InactiveCN105219376AThe synthetic route is simpleReduce cost inputFluorescence/phosphorescenceLuminescent compositionsN dimethylformamideUltraviolet

The invention discloses a bicolor Eu-MOFs / CDs fluorescent material as well as preparation and an application thereof. Europium ions, trimesic acid and carbon quantum dots are used as raw materials, and the bicolor fluorescent material is prepared through heat treatment in a solvent prepared by mixing N,N-dimethylformamide, distilled water and cyclohexanol. Under irradiation of ultraviolet lamps, the material can emit red fluorescence when dispersed in organic solvents and can emit blue fluorescent when dispersed in water, so that fluorescent colorimetric sensors for measuring water content in organic solvents can be prepared from the material, the prepared sensors are high in sensitivity, good in stability and low in cost and have higher population value and brighter application prospect.

Owner:FUZHOU UNIV

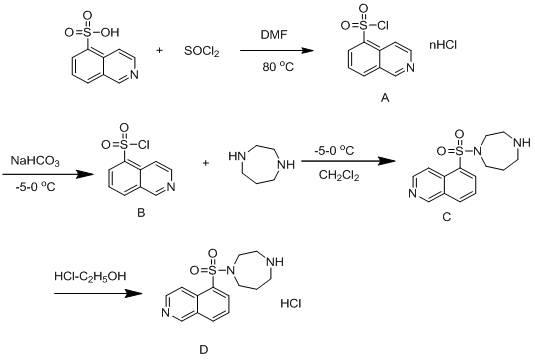

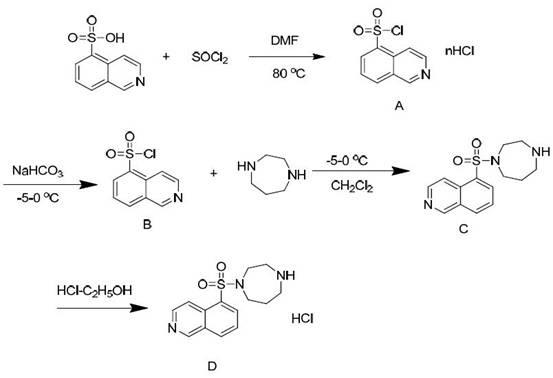

Method for synthesizing and purifying Fasudil hydrochloride

InactiveCN102020636AReduce generationSolve excessive residualOrganic chemistryBenzodiazepineSodium bicarbonate

The invention relates to a method for synthesizing and purifying Fasudil hydrochloride, comprising the following steps of: adding N,N-dimethylformamide and thionyl dichloride to 5-isoquinoline sulfonic acid to obtain a 5-isoquinoline sulfonyl chloride hydrochloride; adding the 5-isoquinoline sulfonyl chloride hydrochloride, water and sodium bicarbonate to dichloroethene to obtain a 5-isoquinoline sulfonyl chloride solution; dripping the 5-isoquinoline sulfonyl chloride solution to homopiperazine at zero DEG C to obtain a hexahydro-1-(5-sulfonyl isoquinoline)-1(H)-1,4-benzodiazepine solution; removing impurities in three steps; adjusting the pH value to be 4.5-5.5 with an acidizing fluid, extracting, and discarding an organic phase dissolved with a dipolymer impurity; adjusting the pH value to be 9.5-10.5 with alkali, extracting and discarding a water phase dissolved with homopiperazine impurities and a majority of pigments; removing the residue pigment by passing through silica gel; and finally, washing, drying, filtering, then dripping a hydrochloric acid-ethanol solution at 0 DEG C, and crystallizing while stirring to prepare the Fasudil hydrochloride. The invention has the advantages that the three kinds of impurities are effectively removed through the three-step purification process, and the purity of a product reaches more than 99.9%.

Owner:JIANGSU WANBANG BIOPHARMLS +1

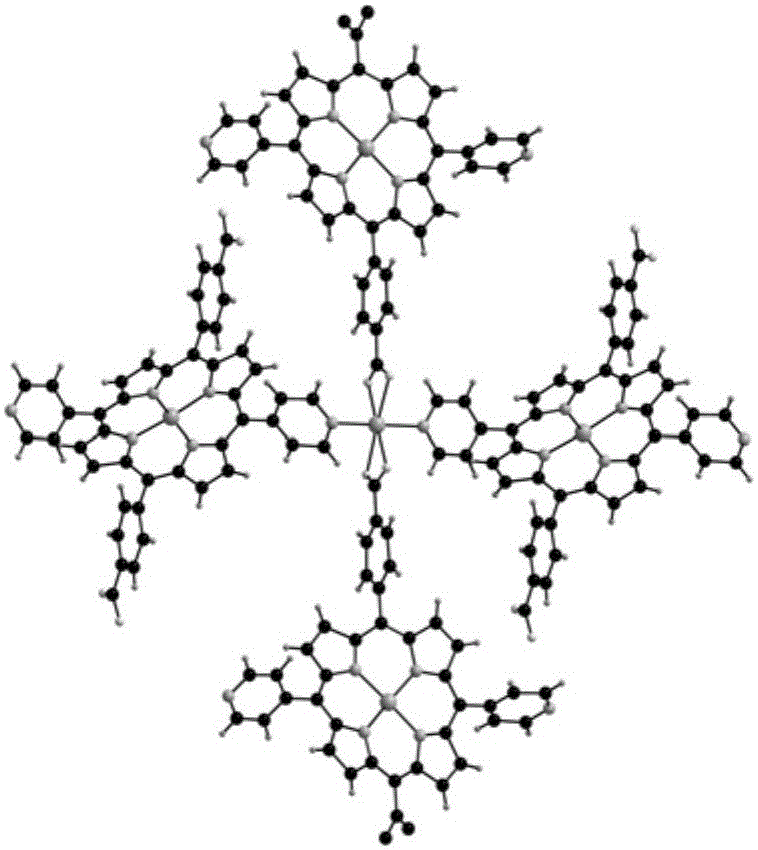

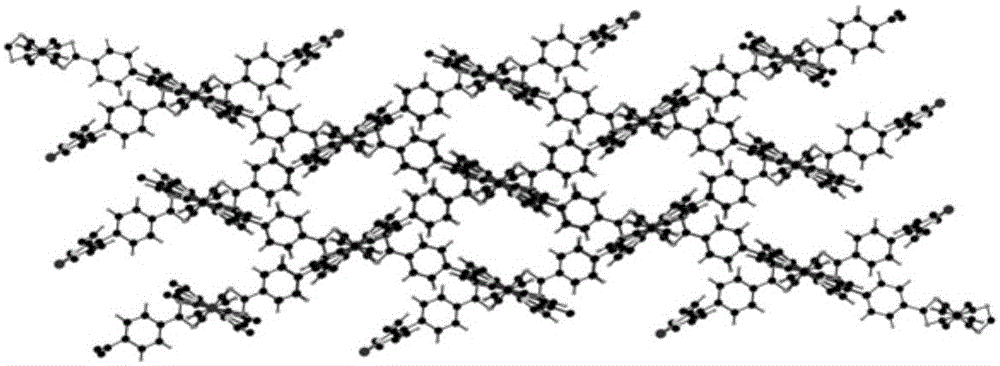

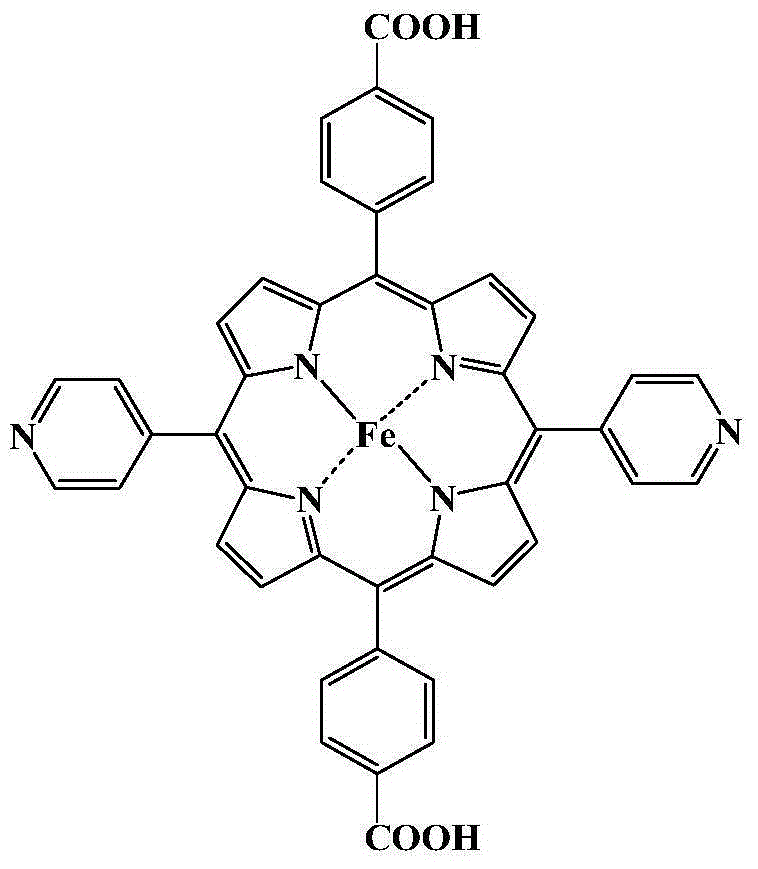

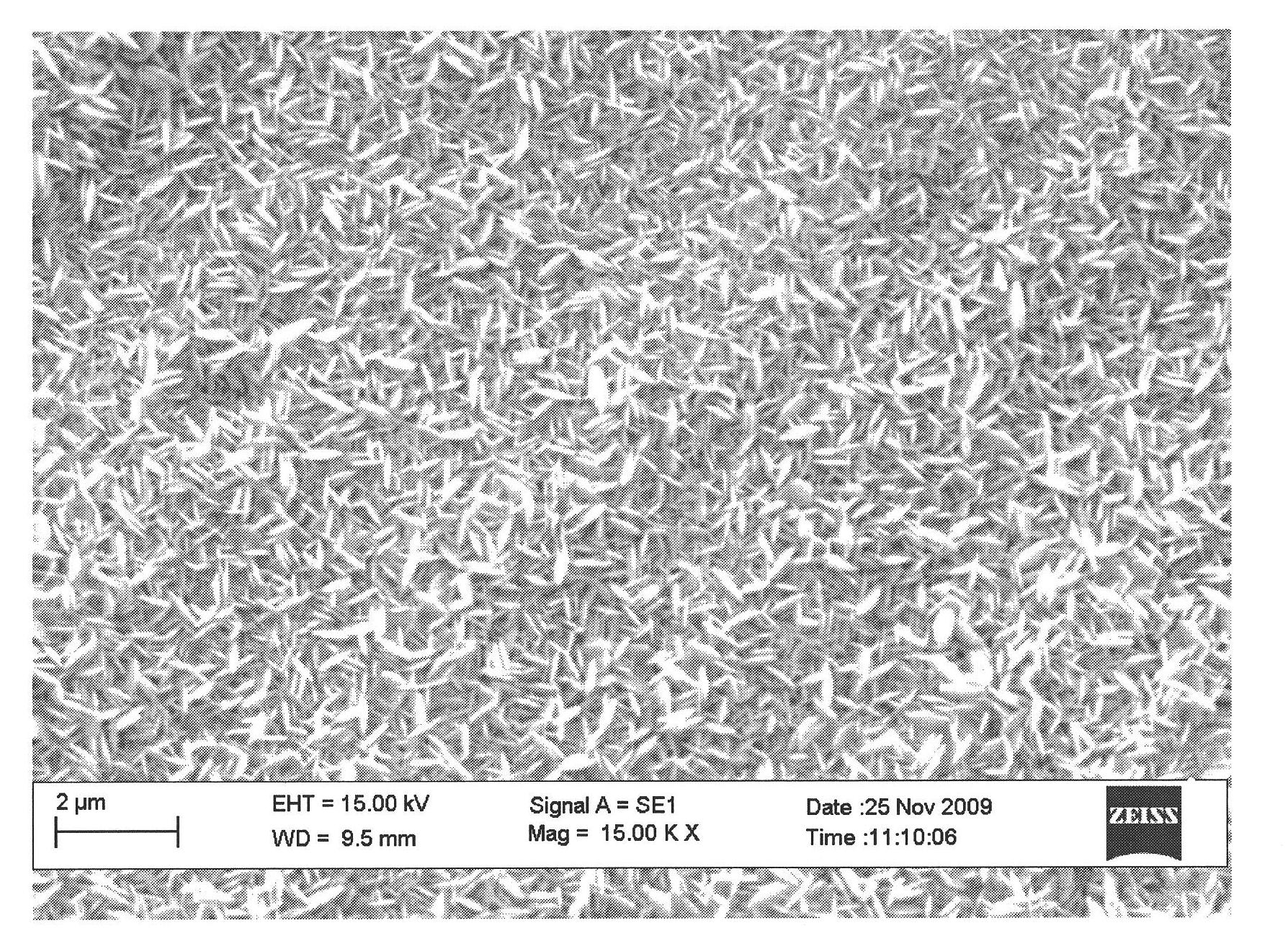

Metal organic framework material of Fe porphyrin ligand, preparation method therefor and application thereof

InactiveCN105061776ANovel structureImprove catalytic performancePreparation by oxidation reactionsOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidN dimethylformamide

The invention discloses a metal organic framework material of a Fe porphyrin ligand, a preparation method therefor and an application thereof, and belongs to the technical field of crystalline materials. A chemical formula of the Fe porphyrin ligand is FeL, wherein L is am organic ligand, namely 5, 15-bipyridine-10 and 20-dicarboxyphenyl ironporphyrin. In a closing condition, a crystal of the metal organic framework material is obtained by the organic ligand, namely 5, 15-bipyridine-10, 20-dicarboxyphenyl ironporphyrin and iron nitrate nonahydrate by virtue of thermal reaction in a solution of N,N-dimethylformamide and acetic acid. The metal organic framework material has an iron porphyrin catalytic property, and can be used for selective catalysis of cycloalkane.

Owner:BEIJING UNIV OF TECH

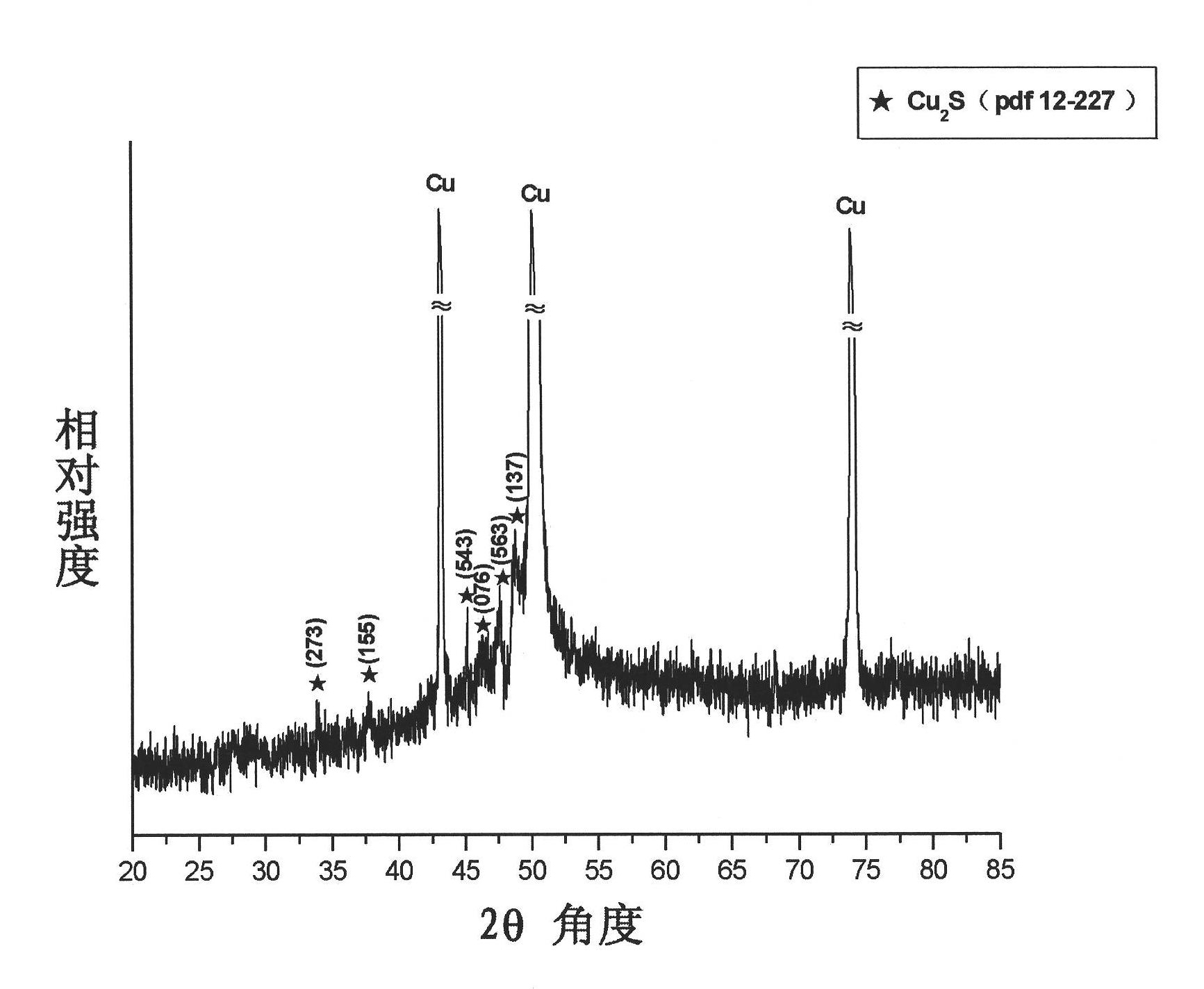

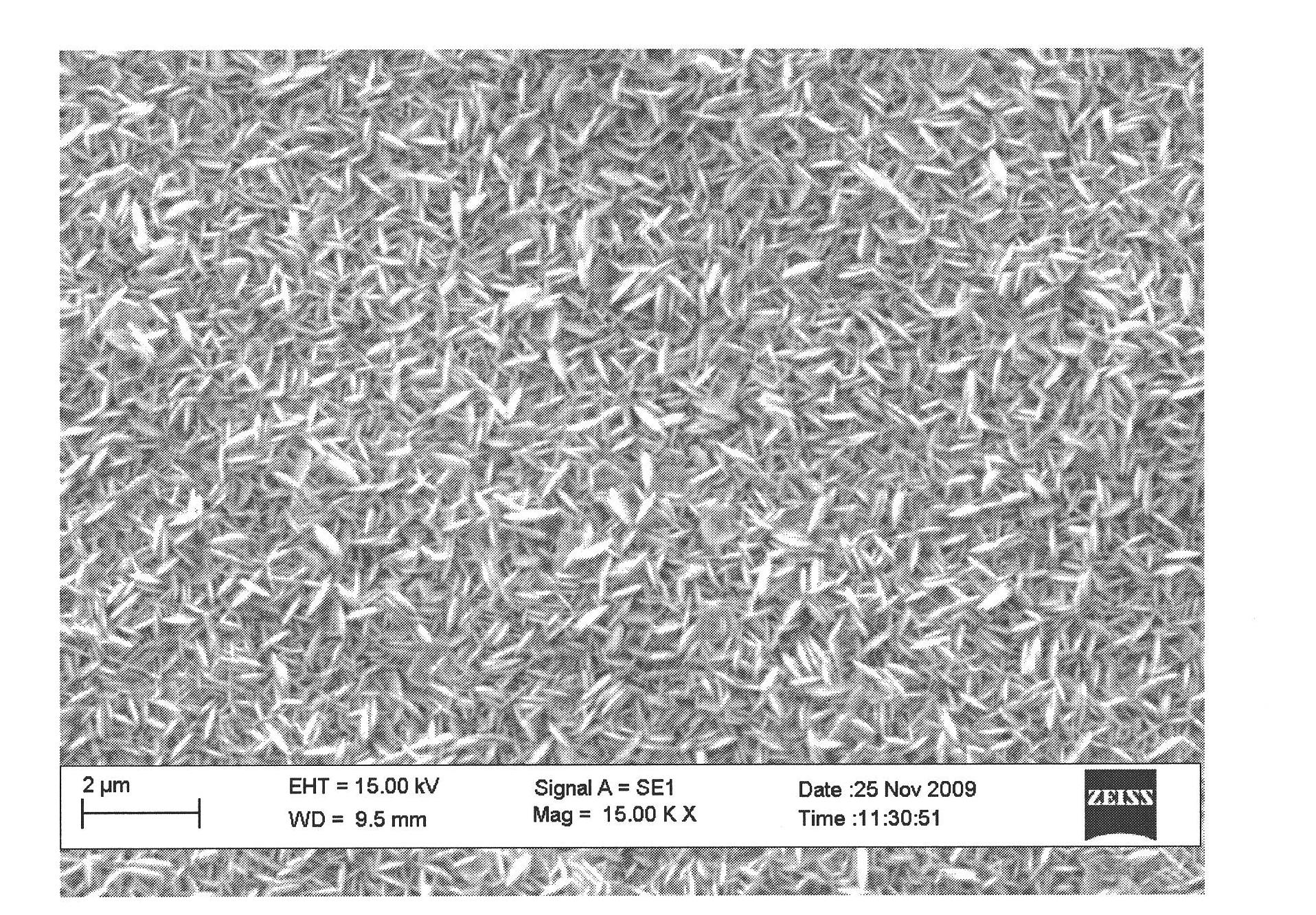

Chemical method for synthesizing flaky CuxSy nanocrystalline optoelectronic film controllably at low temperature

InactiveCN101792173ALow reaction temperatureReduce energy consumptionNanostructure manufactureCopper sulfidesN dimethylformamideFilm material

The invention provides a chemical method for synthesizing flaky CuxSy nanocrystalline optoelectronic film controllably at a low temperature. The method comprises the following steps: firstly adding sulfur powder in a container, secondly adding organic solvent N,N-dimethylformamide or absolute alcohol, wherein the volume of organic solvent is more than a half of the capacity of the container; standing at 0-60 DEG C for 1h to ensure that the sulfur powder dissolved in organic solvent is saturated, horizontally placing substrate material with a new and clean metal copper surface on the bottom of the container to avoid directly contacting with sulfur powder, reacting at 0-60 DEG C for 5-24h, cleaning the product with absolute alcohol, drying at room temperature to in-situ prepare the big area film material composed of flaky CuxSy nanocrystalline on the metal copper surface of the substrate material, wherein x:y=1-2. The method of the invention adopts low temperature, has low energy consumption, is simple, green and environmentally friendly and particularly applicable to large-area industrial production, and does not use any template, add any surfactant and perform complicated post-processing operations such as purification.

Owner:XUCHANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com