Method for preparing electrocatalytic water-splitting oxygen production electrode

An electrocatalysis and electrode technology, which is applied in the field of preparation of electrocatalytic water splitting oxygen production electrodes, can solve the problems of no electrocatalytic activity, MOFs membrane can not be applied to the field of electrocatalysis, etc., and achieve low raw material cost, low overpotential, high active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

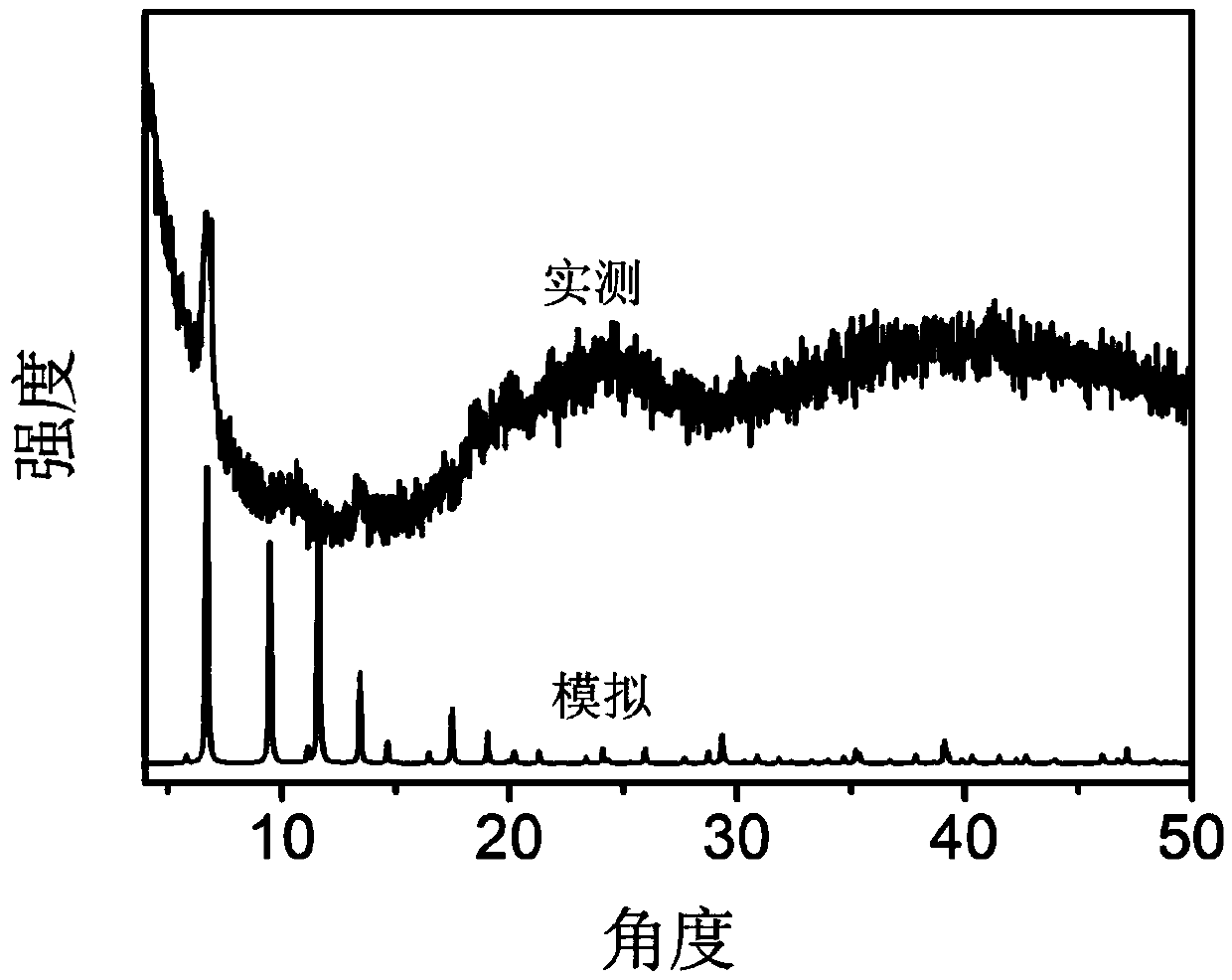

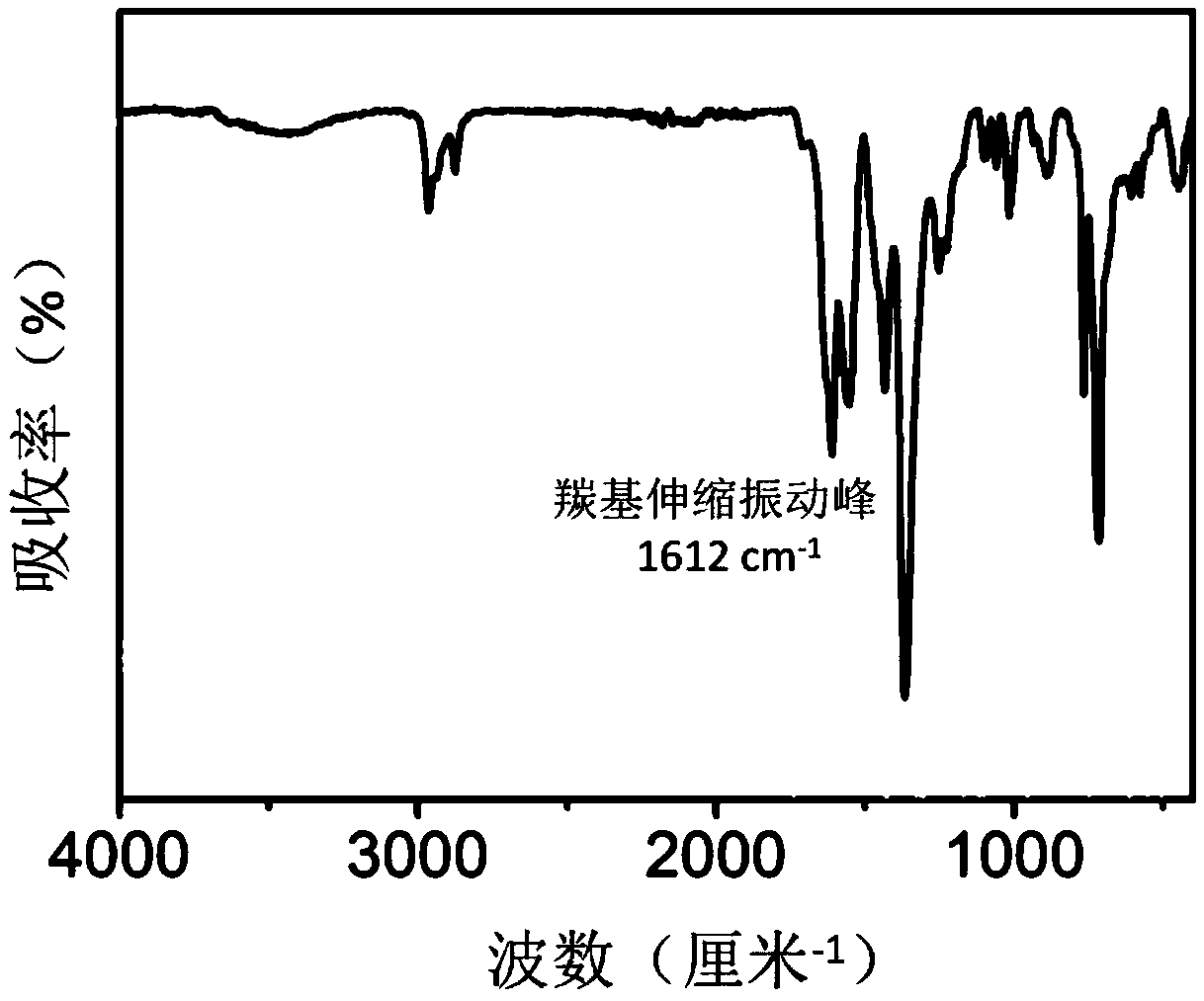

[0029] Preparation of Fe / Ni-BTC powder samples: From the prepared Fe / Ni-BTC electrocatalytic water-splitting oxygen production electrode, carefully scrape the Fe / Ni-BTC powder with a scraper. The foamed nickel was scraped off, and the obtained powder was collected with filter paper for subsequent use;

[0030] Reagents used in the examples of Table 1

[0031]

[0032] Instruments used in the embodiment of table 2

[0033]

[0034] Linear voltammetry test: the prepared electrocatalytic water splitting oxygen production electrode was used as the working electrode, the silver / silver chloride saturated electrode was used as the reference electrode, the platinum sheet was used as the counter electrode, and the KOH solution of 0.1 mol / L was used as the reference electrode. Electrolyte, use the linear voltammetry scanning test mode of the electrochemical workstation, set the potential window to 0~0.8V, the scanning speed is 2mV / s, and apply 95% iR compensation to test;

[003...

Embodiment 1

[0039] (1) Preparation of electrolyte: 0.6543g Ni (NO 3 ) 2 ·6H 2 O, 0.1010g Fe (NO 3 ) 3 ·9H 2O and 1.0507g of trimesic acid were dissolved in 50mL of N,N-dimethylformamide, and then 1.5574g of methyltributylammonium sulfate was added as the supporting electrolyte, and after fully stirring until completely dissolved, the Fe / Ni bilayer was obtained. Electrolyte of metal-organic framework material (Fe / Ni-BTC) coordinated by metal and trimesic acid;

[0040] (2) Assembling a standard three-electrode system: take the nickel foam as the working electrode, take the silver / silver chloride saturated electrode as the reference electrode, take the platinum sheet as the counter electrode, and take the solution prepared in step (1) as the electrolyte, Assembled into a standard three-electrode system;

[0041] (3) Preparation of oxygen-producing electrode: connect the standard three-electrode system in step (2) to an electrochemical workstation, carry out potentiostatic electrodepos...

Embodiment 2

[0045] (1) Preparation of electrolyte: 0.3272g Ni (NO 3 ) 2 ·6H 2 O, 0.0505g Fe (NO 3 ) 3 ·9H 2 O and 0.5254g of trimesic acid were dissolved in 25mL of N,N-dimethylformamide, and 0.7787g of methyltributylammonium sulfate was added as the supporting electrolyte. After fully stirring, the Fe / Ni bilayer was obtained. Electrolyte of metal-organic framework material (Fe / Ni-BTC) coordinated by metal and trimesic acid;

[0046] (2) Assembling a standard three-electrode system: take the nickel foam as the working electrode, take the silver / silver chloride saturated electrode as the reference electrode, take the platinum sheet as the counter electrode, and take the solution prepared in step (1) as the electrolyte, Assembled into a standard three-electrode system;

[0047] (3) Preparation of oxygen-producing electrode: connect the standard three-electrode system in step (2) to an electrochemical workstation, carry out potentiostatic electrodeposition at -1.0V, and after depositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com