Preparation method of cobalt phosphide hollow nano-fiber material

A technology of nanofibers and nanofiber membranes, which is applied in the field of preparation of cobalt phosphide hollow nanofiber materials, can solve the problems of difficult cobalt phosphide nanomaterials, and achieve the effect of cheap and easy-to-obtain materials, good conductivity, and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

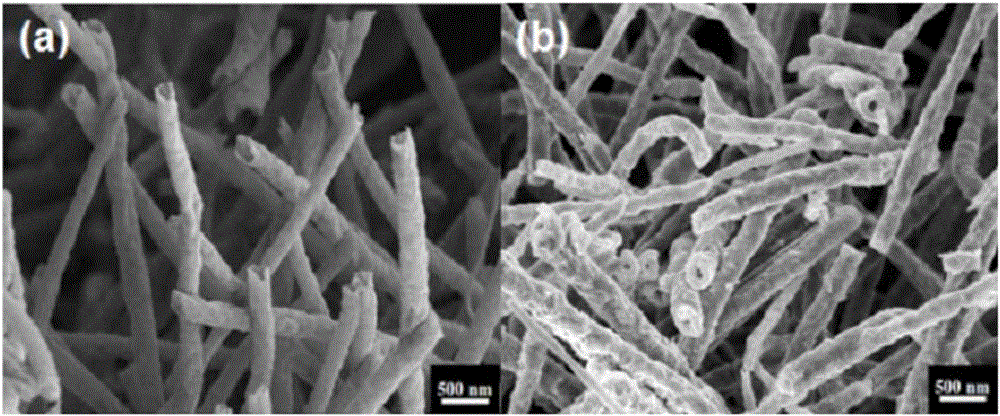

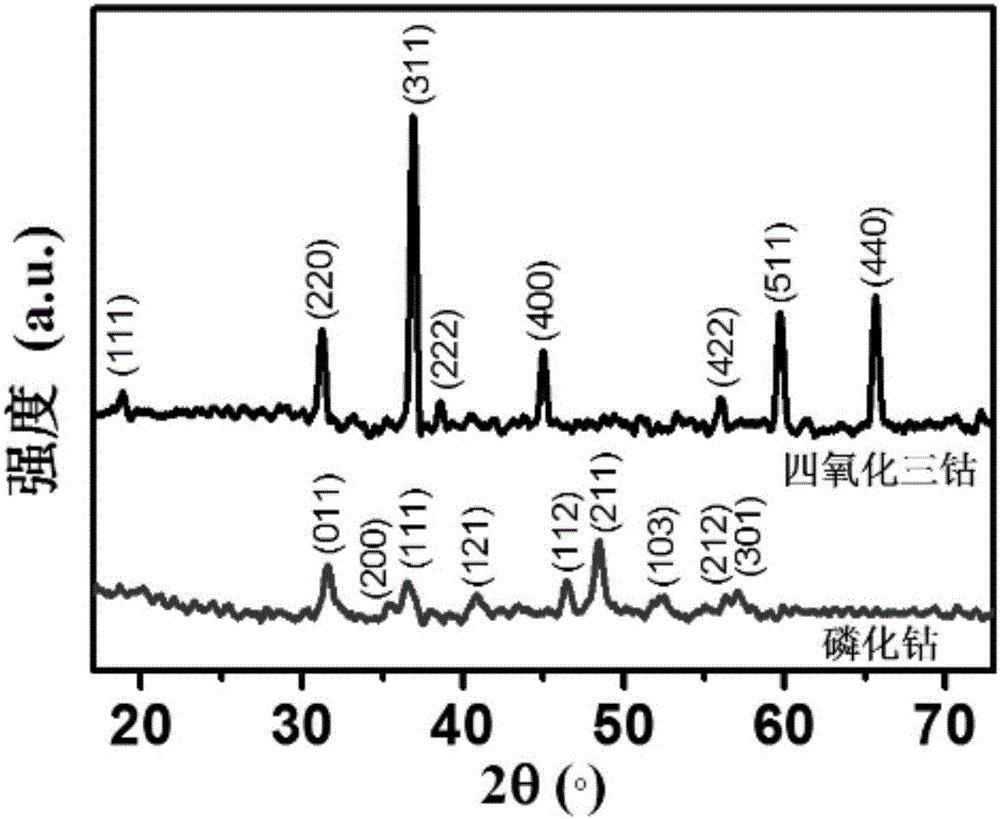

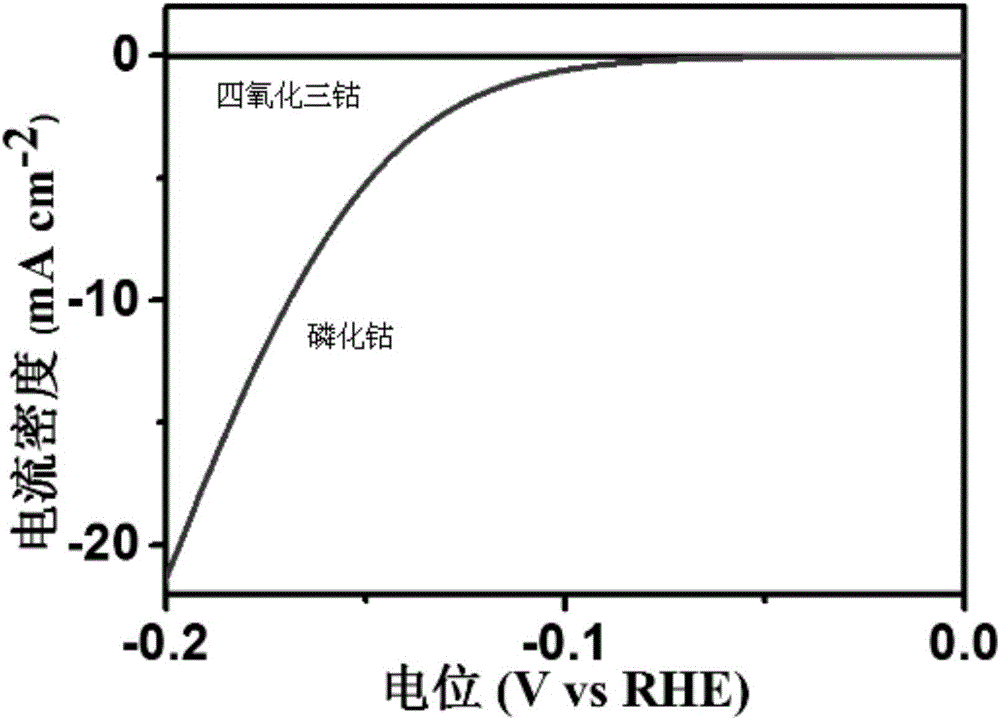

[0035] (1) Add 2g of cobalt acetate tetrahydrate to 9g of N,N-dimethylformamide, and use an ultrasonic cleaner to ultrasonically disperse it for 10 minutes to dissolve it quickly, then add 1.5g of polyvinylpyrrolidone powder, and continue stirring for 6 hours to obtain a uniform viscosity Thick precursor spinning solution.

[0036] (2) The polyvinylpyrrolidone spinning solution (precursor spinning solution) that is dissolved with cobalt salt is carried out electrospinning, and its process parameter is: electrostatic field voltage 15kV, spinning speed 0.2mm / min, receiving distance 20cm, A polyvinylpyrrolidone nanofiber membrane doped with cobalt ions was prepared.

[0037] (3) Pre-oxidize the polyvinylpyrrolidone nanofiber membrane doped with cobalt ions in an air atmosphere, the pre-oxidation temperature is 200 °C, and the heating rate is 2 °C min -1 , the pre-oxidation time is 1h.

[0038] (4) Calcining the polyvinylpyrrolidone nanofiber membrane doped with cobalt ions obta...

Embodiment 2

[0047] (1) Add 2g of cobalt acetate tetrahydrate to 9g of N,N-dimethylformamide, and use an ultrasonic cleaner to ultrasonically disperse it for 10 minutes to dissolve it quickly, then add 1.5g of polyvinylpyrrolidone powder, and continue stirring for 6 hours to obtain a uniform viscosity Thick precursor spinning solution.

[0048] (2) The polyvinylpyrrolidone spinning solution (precursor spinning solution) that is dissolved with cobalt salt is carried out electrospinning, and its process parameter is: electrostatic field voltage 15kV, spinning speed 0.2mm / min, receiving distance 20cm, A polyvinylpyrrolidone nanofiber membrane doped with cobalt ions was prepared.

[0049] (3) Pre-oxidize the polyvinylpyrrolidone nanofiber membrane doped with cobalt ions in an air atmosphere, the pre-oxidation temperature is 200 °C, and the heating rate is 2 °C min -1 , the pre-oxidation time is 1h.

[0050] (4) Calcining the polyvinylpyrrolidone nanofiber membrane doped with cobalt ions obta...

Embodiment 3

[0055] (1) Add 2g of cobalt acetate tetrahydrate to 9g of N,N-dimethylformamide, and use an ultrasonic cleaner to ultrasonically disperse it for 10 minutes to dissolve it quickly, then add 1.5g of polyvinylpyrrolidone powder, and continue stirring for 6 hours to obtain a uniform viscosity Thick precursor spinning solution.

[0056] (2) The polyvinylpyrrolidone spinning solution (precursor spinning solution) that is dissolved with cobalt salt is carried out electrospinning, and its process parameter is: electrostatic field voltage 15kV, spinning speed 0.2mm / min, receiving distance 20cm, A polyvinylpyrrolidone nanofiber membrane doped with cobalt ions was prepared.

[0057] (3) Pre-oxidize the polyvinylpyrrolidone nanofiber membrane doped with cobalt ions in an air atmosphere, the pre-oxidation temperature is 200 °C, and the heating rate is 2 °C min -1 , the pre-oxidation time is 1h.

[0058] (4) Calcining the polyvinylpyrrolidone nanofiber membrane doped with cobalt ions obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com