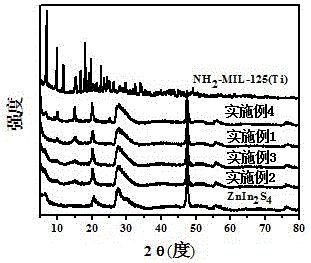

ZnIn2S4/NH2-MIL-125(Ti) composite visible-light catalyst and preparation method thereof

A NH2-MIL-125, znin2s4 technology, applied in the field of photocatalysis, can solve the problems of low quantum efficiency, less research on photocatalytic performance of MOF-based composites, and low photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

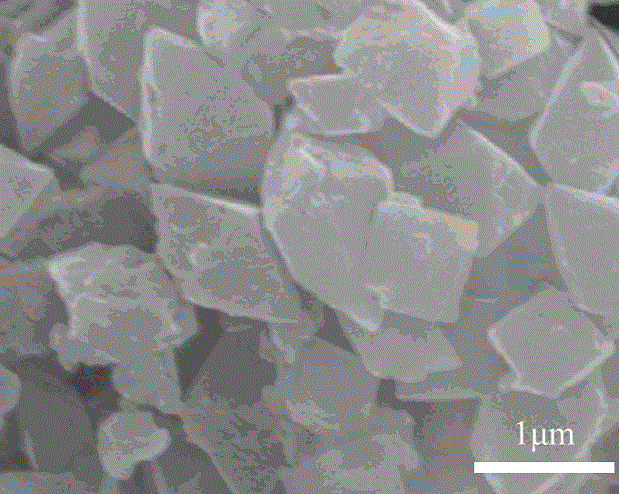

[0029] A. NH 2 - Preparation of MIL-125(Ti)

[0030] (1) Dissolve 2.201 g of 2-aminoterephthalic acid in a mixed solution of 36 ml of N, N-dimethylformamide and 4 ml of methanol at room temperature;

[0031] (2) Add 2.4 ml tetrabutyl titanate dropwise to the above solution;

[0032] (3) After stirring the above solution for 0.5 h, move it to a 100ml polytetrafluoroethylene-lined autoclave, and conduct a crystallization reaction at 150°C for 48 h;

[0033] (4) The obtained solid product was filtered, washed three times with N, N-dimethylformamide and ethanol, and dried under vacuum for 24 h to obtain NH 2 - MIL-125(Ti) catalyst.

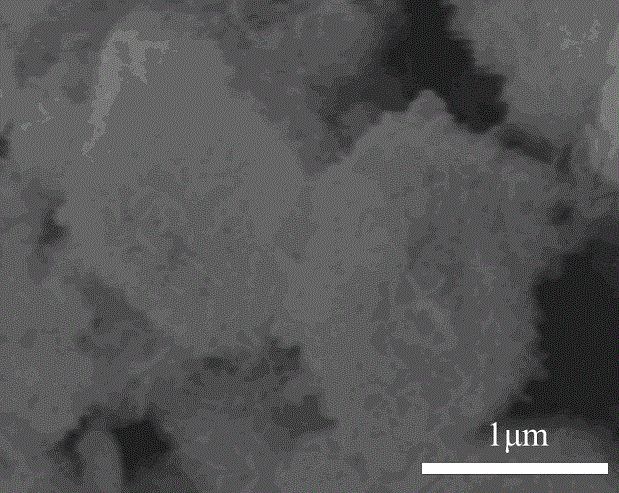

[0034] B. ZnIn 2 S 4 / 40%NH 2 - Preparation of MIL-125(Ti) Composite Visible Light Catalyst

[0035] (1) The NH synthesized above 2 -MIL-125 (Ti) catalyst 0.169 g, ultrasonic dispersion in the mixed solution of 15 ml ethanol and 5 ml glycerol;

[0036] (2) Add 0.136 g ZnCl to the above mixture 2 and 0.586 gInCl 3 .4H 2 O, stirred for 1 h; ...

Embodiment 2

[0041] A. NH 2 - Preparation of MIL-125(Ti)

[0042] Operation process is like embodiment 1

[0043] B. ZnIn 2 S 4 / 20%NH 2 - Preparation of MIL-125(Ti) Composite Visible Light Catalyst

[0044] Operation process is except following difference, all the other are with embodiment 1

[0045] The above synthesized NH 2 - 0.085 g of MIL-125 (Ti) catalyst, ultrasonically dispersed in a mixed solution of 15 ml of ethanol and 5 ml of glycerol.

Embodiment 3

[0047] A. NH 2 - Preparation of MIL-125(Ti)

[0048] Operation process is like embodiment 1

[0049] B. ZnIn 2 S 4 / 30%NH 2 - Preparation of MIL-125(Ti) Composite Visible Light Catalyst

[0050] Operation process is except following difference, all the other are with embodiment 1

[0051] The above synthesized NH 2 - 0.127 g of MIL-125 (Ti) catalyst, ultrasonically dispersed in a mixed solution of 15 ml of ethanol and 5 ml of glycerol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com